ISSUE 4 2022

PUBLICATION OF THE AMERICAN MOLD BUILDERS ASSOCIATION MACHINE MONITORING: CAPTURE DATA AND TAKE ACTION Map Out a Recruitment Plan Are Workforce Woes Improving? Call to Action on the China Tariffs

THE OFFICIAL

Progressive’s roots are in mold design, and with the release of our new v14 CADalog®, we are delivering advanced tools to simplify and speed the design process:

• Geometry that is created and verified by Progressive engineers

• Complete CAD libraries (SolidWorks, NX, VISI, and neutral formats)

• Configurable files allow quick part selection and offer populated attributes for ordering cut-to-length parts for production

While the cost is free, the benefits are valuable. Receive your copy and begin putting this mold design advantage to work for you.

TIME SAVING

NEW CADALOG: PROCOMPS.COM/CAD NEW CATALOG: PROCOMPS.COM/v14

CADalog advancements

DESIGN SOLUTIONS

“Our

simplify and speed the mold design process. ”

Kevin Kelly, Project Engineer, Progressive Components

As the next level in CNC control, the TNC7 offers profes sional machinists completely new possibilities at every stage, from initial design to the finished workpiece. Graphical programming developed from scratch, individ ual customization of the user interface, perfect visual ization of machined parts and the work envelope, and

numerous smart functions all make your workday im mensely easier.

The TNC7 assists you throughout the entire production process. It will advance your operations and add reliabili ty to your processes. So take your manufacturing to a new level. It’s the future of machining.

The new

Task-focused Customizable HEIDENHAIN CORPORATION www.heidenhain.us Ask for HEIDENHAIN on your next machining center

TNC7 control Intuitive

www.heidenhain.com/tnc7

4 the american MOLD BUILDER | Issue 4 2022 Speak Out ................................................. 6 Association ............................................. 18 Industry ................................................... 21 Product .................................................... 28 Calendar .................................................. 46 Ad Index .................................................. 46 ISSUE 4 2022 THE OFFICIAL PUBLICATION OF THE AMERICAN MOLD BUILDERS ASSOCIATION MACHINE MONITORING: CAPTURE DATA AND TAKE ACTION Map Out a Recruitment Plan Are Workforce Woes Improving? Call to Action on the China Tariffs ISSUE 4 2022 8 OPERATIONS Machine Monitoring: Capture Data and Take Action 14 VIEW FROM 30 Raising the Bar on Recruitment and Retention 23 MANAGEMENT 5 Obstacles to Growth and How Businesses Can Overcome Them 26 BENCHMARKING Are Workforce Woes Improving? Data Points to Positive Indicators 30 FOCUS Employee Benefits: Rising Costs vs. Necessary Incentives

AMERICAN MOLD BUILDERS ASSOCIATION

7321 Shadeland Station Way, #285 Indianapolis, IN 46256

P: 317.436.3102 F: 317.913.2445 info@amba.org • www.amba.org

AMBA TEAM

Troy Nix, Executive Director Kym Conis, Managing Director Susan Denzio, Business Manager Rachael Pfenninger, Director of Strategic Execution

Advising Editor: Kym Conis Advertising/Sales: Susan Denzio

PUBLISHED BY: 2150 SW Westport Dr., Suite #101 Topeka, KS 66614 P: 785.271.5801

Vice President, Editorial: Dianna Brodine

Editor: Lindsey Munson

Vice President, Design: Becky Arensdorf

Graphic Designer: Hailey Mann

Opinions expressed in this publication may or may not reflect the views of the Association and do not necessarily represent official positions or policies of the Association or its members. Cover

5 www.americanmoldbuilder.com | AMBA.org 14 33 TALENT AMBA’s Emerging Leaders Explore Leadership Principles and Management Styles at Inaugural Retreat 36 STRATEGIES Shared Tips and Ideas for Approaching Everyday Sales and Prospecting 39 INSURANCE CORNER How Does Healthcare Delivery Differ from Pizza Delivery? 43 ADVOCACY Keeping the China Tariffs: A Numbers Game

33

image courtesy of HEIDENHAIN.

DON DUMOULIN AMBA President Precise Tooling Solutions

A MESSAGE FROM THE AMBA PRESIDENT

Welcome to November and the latest issue of The American Mold Builder! I hope you’ll find at least five things in this issue that you can apply immediately to your business. The team works hard to publish a quality magazine so please let us know anything you would like to see covered in 2023.

Special thanks to the members of your AMBA Board of Directors, who spent two days in August and multiple meetings since working through the three-year strategic plan for the association. The team has done a great job identifying three strategies that we all believe will help take your business to new heights. We are firm in our belief that by helping you strengthen your business, the AMBA will be a stronger organization; and when we help strengthen your business, more mold builders will join the AMBA. Everyone wants to hang around with the cool kids!

The Board is in the process of creating three powerful strategies: Advocate for US Competitiveness; Improve Business Operations; and Expand and Improve Resources and Educational Opportunities for AMBA members.

We’ll have more information to share about bringing these strategies to life in the coming months as tactics to deliver innovative programming, business-building ideas and profit-enhancing education will come to both the AMBA conference and to programs for you and your team.

We have an important call to action coming to you in a few weeks. Once again, we need to defend our critical need for tariffs on Chinese molds. The United States Trade Representative (USTR) will reopen the tariff issue for a national discussion in late November. It will be critical that all AMBA members voice their support for tariffs. The team is creating an easy way for you to communicate your support, and you will be hearing about it shortly! Our collective voice has been heard repeatedly and strongly, and we need to step up once again to ensure we have this strong, competitive barrier for our businesses.

As we wrap up 2022 and start to plan for 2023, please make sure that the 2023 AMBA Conference, May 10-12, in Grand Rapids, Michigan, is on your schedule and in your budget. This year’s meeting will be a terrific learning experience for you and your team. If you were with us last year, you saw how Board Member Tom Barr from TK Mold & Engineering brought eight of his youngest colleagues to the meeting. Tom will tell you the investment has paid huge dividends.

I’m planning on bringing my crew of young guns, and I hope you will, too. It would be great if we could get 100 colleagues under 30 at the 2023 conference. The contacts they would make, the information shared and the energy for our industry could set our entire association on a new course. Please join Tom and me in committing to bringing your youngest, most talented colleagues to the 2023 AMBA Conference. It’s an investment in their future and in your company!

As we head into the holiday season, I hope you, your family and colleagues have a wonderful Christmas and a safe New Year. Let’s hope that 2023 is the best year ever for American mold builders! All the best! DDD

OFFICERS

National President

Don Dumoulin, Precise Tooling Solutions

Immediate Past-President

Jim Sperber, Master Tool & Mold

Vice President

Tyler VanRee, Legacy Precision Molds

Secretary and Legal Counsel

Alan Rothenbuecher, Benesch, Friedlander, Coplan & Aronoff LLP

Treasurer

Tom Barr, TK Mold & Engineering

BOARD OF DIRECTORS

David Bowers II, JMMS, Inc.

Charles Daniels, Wepco Plastics

Ed Francis, Crystallume

Dan Glass, Strohwig Industries

Eric Karaman, Michiana Global Mold

Chad LaMance, United Tool & Mold

Andy Peterson, Industrial Molds Group

John Stocker, Swiss Steel USA

Hillary Thomas, Westminster Tool

6 the american MOLD BUILDER | Issue 4 2022

Molders

Components can be ground to a tolerance of ±0 000050 inches, with tips as small as 0.002 inches and lengths up to 14 inches. Custom details such as tapers, rings, vents, ribs and spirals can be shaped using wire EDM. In addition to standard tool steel, components can be made of powdered steels, stainless steel and copper alloys including M-2, A-2, H-13, S-7, PMM-4, PM10V420SS for greater control over thermal transfer, tensile strength, hardness and other physical properties. The molding surface can be polished, coated and/or plated.

Components Higher Standards for Molds and Dies Custom precision core pins, sleeves, ejectors, blades and punches

Regal

with non-standard requirements can

precision core pins,

ejectors,

800-760-5715

order custom

sleeves,

blades and punches from Regal Components. Custom components are used in molding a variety of medical, electronics and consumer products that require extreme precision, such as needles sheaves, closures, nipples, pipettes, IV connectors, shavers, electronic components and writing instruments.

10 Almeida Avenue, East Providence, RI 02914 (Q 727-299-0800 � 727 499-7109 @) sales@regalcomps.com @regalcomps.com

MACHINE MONITORING: CAPTURE DATA AND TAKE ACTION

by Liz Stevens, writer, The American Mold Builder

The range of data available from manufacturing machinery is wide, and different data gives insight into different aspects of operations. Fundamentally, there is production data (what the machine did or made, and whether the quality was acceptable or not) and there is condition data (the machine’s state of operational health).

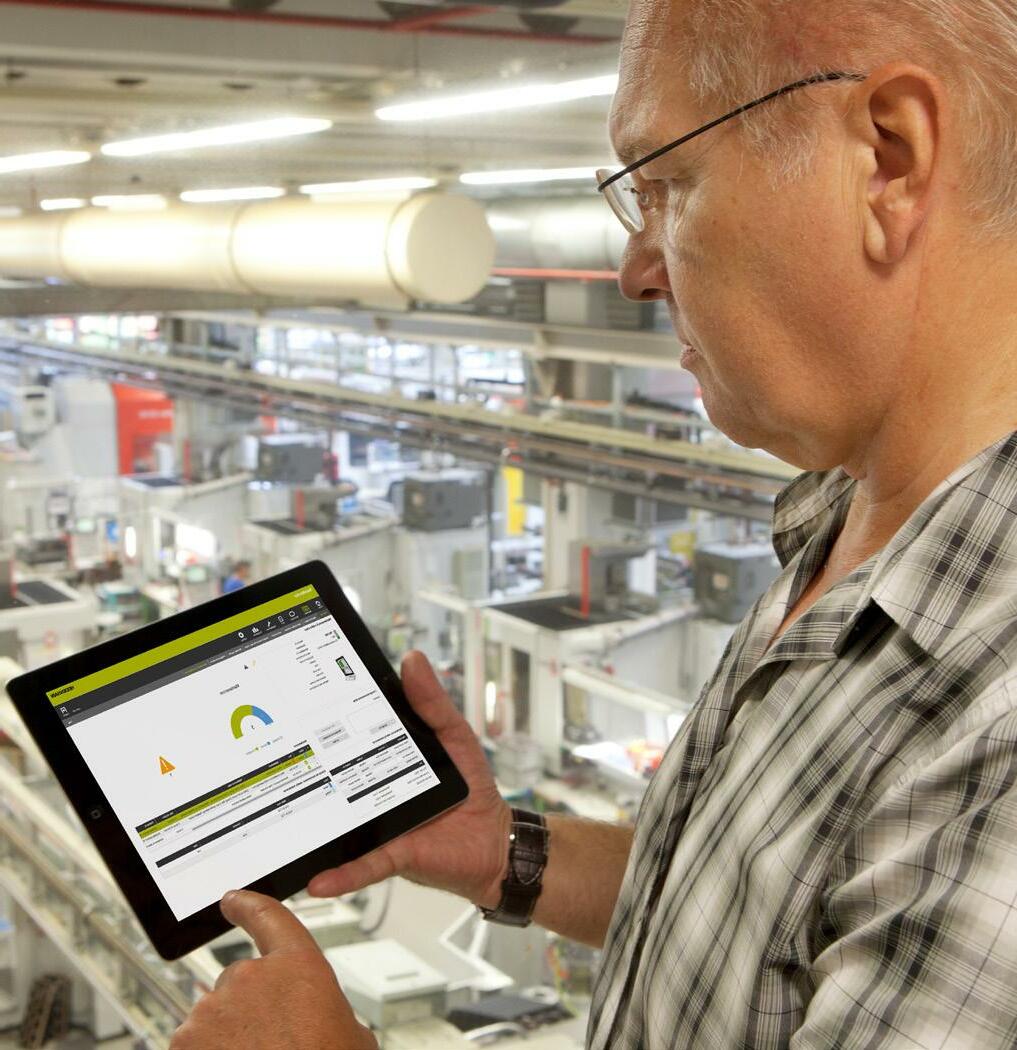

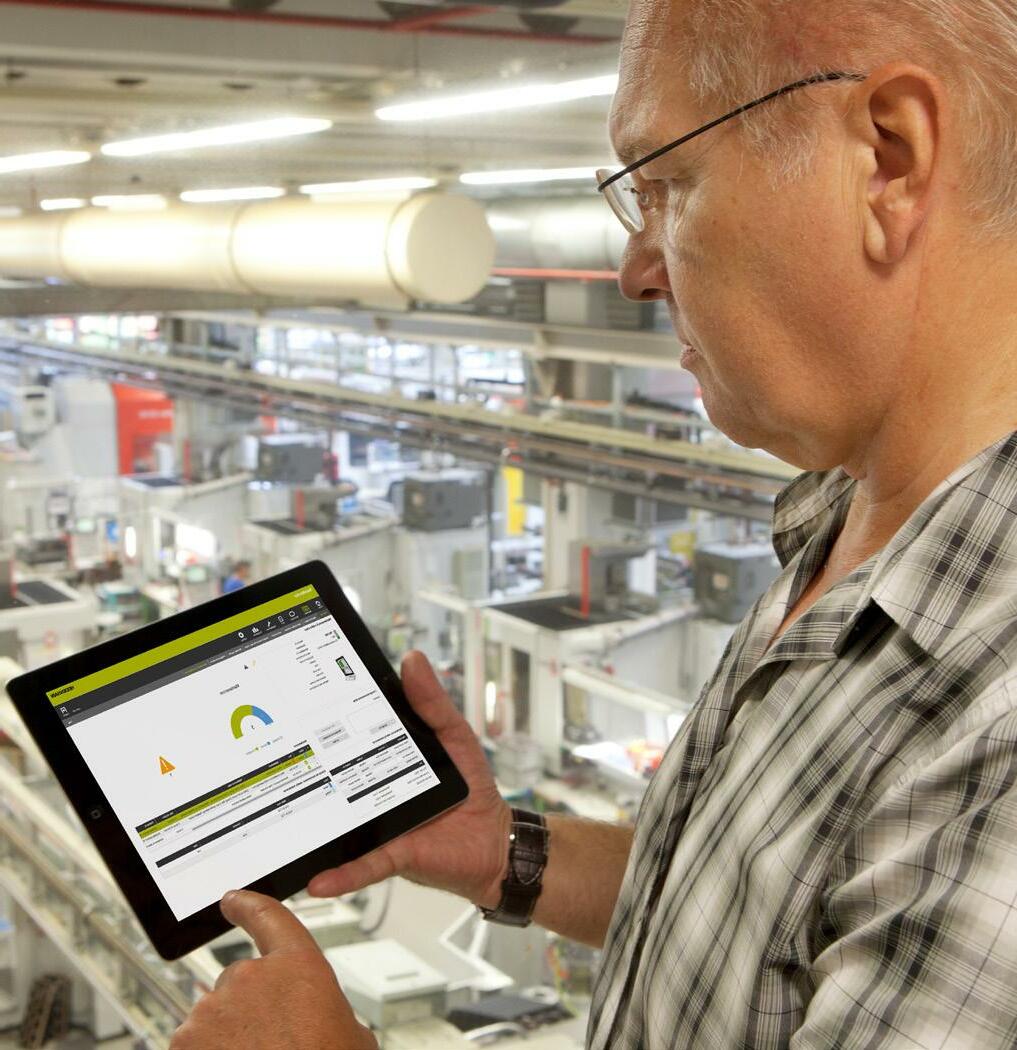

Software packages offer ways to slice, dice and present the big data captured, and also offer analysis tools for identifying trends and anomalies. Data presentation might include high-level views of single or multiple machines, graphics showing elapsed time (time in production, at idle, during maintenance) or a single job as it moves from workstation to workstation. Maintenance data likely will be available in some form that allows for scheduling regular maintenance tasks. A suite of standard reports will summarize data by time period or equipment type, and there may be drill-down features or query tools. There are many ways to share the data and analysis, including via plant floor-based displays/ workstations, through equipment-side terminals, and by PC-, tablet- and smartphone-based applications.

All of that data capture, transmission and reporting are useless unless the data leads to action. Many Industry 4.0 software packages include alerts that can be programmed to send a message automatically if a machine’s sensed characteristics fall below or rise above a certain level, giving operators a heads-up that production has stopped or that an equipment failure may be imminent. Maintenance-oriented alerts and maintenance task management can be found in many systems.

The American Mold Builder talked with four companies that address smart factory issues: Akshat Thirani, CEO of Amper, Chicago, Illinois; Gisbert Ledvon, director of business development, machine tool, Heidenhain Corporation, Schaumburg, Illinois; Sujit Sheth, monitoring systems manager, Progressive Components, Wauconda, Illinois; and Edward Bassous, management/optimization consultant, R.E.R. SOFTWARE, INC., Rochester, Michigan.

In this article, the companies present a high-level rundown on some of the data to be captured, the connectivity options, the analysis tools and the digital aids for taking action to optimize the plant floor.

AKSHAT THIRANI, AMPER

Amper offers hardware and software for machine monitoring of equipment status and for capturing machine production information. The company’s software system offers operational analytics tools, automatic alerts based on flexible criteria, an Andon-like communication app and digital tally sheets. Add-ons are available, including cycle counting features, a complete maintenance system and custom integration to ERP systems. Amper touts easy-to-deploy real-time shop floor data visibility and operational tools.

The core of Amper’s hardware and software is deviceindependent; that is, it can be used on any type of electrical manufacturing equipment, including mold building machines and injection molding machines. Amper monitors a machine’s electrical load via an interface device that attaches to the power cord. Additional data from machine operators can be added through other system interfaces to provide details, for instance, on downtime reasons or good vs. scrap parts. Amper recently expanded its ability to capture machine data by tapping into cycle times and piece counts from machine PLC outputs, and the company will add more types of PLC data capture in the future.

Amper’s hardware and software can be used on new and even relatively old equipment. “We started the design process wanting to be agnostic of the machine,” said Amper’s CEO Akshat Thirani. “We found that a lot of industrial equipment – whether it is a CNC or an injection molding machine –has digital outputs on the PLC. Even older machines have

8 the american MOLD BUILDER | Issue 4 2022

Amper Sensor clipped to a machine’s power supply delivers data.

that kind of signal.” The Amper software system is primarily cloud-based, although some processing is done locally on the IIoT sensors.

Amper’s machine state sensor hardware includes electrical sensors, sensor aggregators and telecommunications gateways that transmit data to the cloud via wi-fi or cellular connectivity. The sensors take only minutes to install and, when connected to the software system, the application goes through a self-calibration period. Amper maintains a database of machine characteristics and proprietary algorithms for interpreting each machine’s sensed data. “Let’s say a company has a CNC machine,” Thirani explained. “It installs a sensor onto the machine itself and then, in the app, describes the equipment as a CNC mill of this particular brand. Amper’s algorithms interpret the type of machine and perform a week-long calibration period, learning the machine’s patterns and building a baseline. Then data in real-time begins to be captured for display and reporting.”

The system captures machine state (without PLC integration) and also can capture some production data (via PLC outputs). Users can set up preventive maintenance schedules and the system also handles ad hoc maintenance requests. Machine status alerts can be sent automatically to targeted recipients. “Let’s say an operator is running a five-hour machining operation and has walked away from the machine, said Thirani. “There could be an alert set up for the machine so that if it is down for more than 10 minutes (with a broken tool or some other issue), the operator is notified by a text message immediately, instead of returning to the machine at the end of the shift to see that the machine is down and only 20% of the job was completed.”

The application gives management high-level views of the shop floor, including by machine, via scoreboards, on a KPI dashboard and through a downtime console. Reports are available for drilling down to the details or for watching trends that develop over time. System users can examine utilization, downtime, setup and call response information. And as an add-on, Amper offers customized integration with ERP systems.

GISBERT LEDVON, HEIDENHAIN CORPORATION

HEIDENHAIN, with headquarters in Traunreut, Germany, and US offices in Schaumburg, Illinois, manufactures linear encoders, angle encoders, rotary encoders, digital readouts and CNC controls. The company also offers a scalable suite of software solutions – namely, Digital Shop Floor. Digital Shop Floor includes options for collecting and monitoring individual machines and for managing data from combinations of machines, analyzing the different processes used to complete a job, managing machine maintenance and collecting and analyzing additional PLC data.

Heidenhain’s software is device-independent; it works with Heidenhain PLCs or other PLCs on CNC machines by tapping into the PLCs’ outputs via the existing Ethernet connections. Heidenhain’s software packages collect production data and maintenance data for CNC machines and can model the entire CNC process chain from job orders to machine maintenance.

Within the Digital Shop Floor package, mold builders can track five machines with StateMonitor’s basic option (up to 30 machine tools per seat) or track the whole plant with PlantMonitor. Optional modules include MaintenanceManager, for scheduling maintenance and issuing alerts; 5 Signals, for capturing additional machine data, such as coolant levels, spindle temperature and ball screw resistance; and 5 Machines, for expanding the number of machines tracked via StateMonitor.

StateMonitor covers machine status, maintenance plans, malfunction notices and KPI data. “Users can see the performance of the machines, spindle times and, for example, whether machines were manipulated by having their speed overridden by the operator,” explained Gisbert Ledvon, Heidenhain’s director of business development, machine tool. The company’s PlantMonitor module centralizes StateMonitor data.

MaintenanceManager is used to schedule and track scheduled maintenance, and also routes unscheduled maintenance problems to one or more recipients – for instance, maintenance, programming or operations personnel. “Plants don’t need to have one person receiving all kinds of messages and figuring out whom to send them to,” said Ledvon. “StateMonitor does that based on the error messages that come from the machine.”

9 www.americanmoldbuilder.com | AMBA.org page 10

HEIDENHAIN PlantMonitor

Ledvon stressed the scalability of Heidenhain’s software offerings, giving plant owners maximum flexibility in planning and implementing Industry 4.0 tools. “The beauty of Heidenhain’s solution is that customers can grow with it,” he said. “Customers can start out with maybe one or two machines, and then as a company learns from the data, it can decide what else to add to the StateMonitor. The concept is to start very small, to give customers enough initial data so that the analytics and statistics are very simply laid out for identifying the bottlenecks in the shop. Heidenhain’s goal is to ease customers into digital manufacturing by taking it one step at a time and not bombard them with a huge package that includes unneeded tools.”

SUJIT SHETH, PROGRESSIVE COMPONENTS

Progressive Components is a maker of mold monitoring devices and software, as well as mold maintenance software. While its hardware and software are geared toward manufacturing plants that use molds, mold builders can integrate Progressive Components’ technology into the molds made to give themselves and their clients added value. Progressive offers a range of mechanical counters as well as a digital counter/monitor that can be retrofitted into the mechanical counter pockets. Other hardware includes

press modules, QR asset tags and a device for transmitting data to the cloud.

Progressive Components counters and monitors are machineindependent. The CounterView series of seven-digit, nonresettable mechanical cycle counters include standard counters, insulator blocks and counters suitable for hightemperature tools, A- and B-side mounting options, retrofit brackets and attachment blocks for external mounting. CVe Monitor, the company’s digital counter/monitor, tracks tool activity including cycle count, cycle efficiency and mold temperature. With this hardware, some data can be viewed in person and additional data can be captured, aggregated and analyzed with Progressive’s software packages.

“There has been a switch over to the digital version,” said monitoring systems manager Sujit Sheth, “especially as the capabilities of data transmission and IIoT grow, but there still is a place for the mechanical counters.” Users of the CounterView mechanical counters have free access to Profile-System.com, Progressive’s cloud-based profile asset management system for storing data about each mold, as well as for handling preventive maintenance and work orders.

With CVe Monitors, users can view eight present-time data displays in person. By using the company’s free internetbased OnDemand software, a large volume of performance data can be accessed for performance info, uptime vs. downtime, preventive maintenance adherence, number of cycles and cycle time information. “By using OnDemand with CVe Monitors,” Sheth explained, “different parameters can be displayed on reports, presenting much more than the current values shown when someone cycles through the monitor’s screens.” The OnDemand system also features comprehensive, historical service records for tools.

Also available as a CVe Monitor option is the more advanced ProFile software. “Think of it as building blocks,” said Sheth. “A customer can use the hardware and software for as little or as much as needed.” By installing a CVe Monitor by itself, a customer can walk up to the device and get basic real-time counts. “As a next step,” Sheth said, “the customer can use the PC-based OnDemand software; plug into a CVe Monitor with a tablet computer, for instance, and get 52 weeks’ worth

10 the american MOLD BUILDER | Issue 4 2022 page 9 page 12

Lapping • Textured Surface Prep • Benching • Quoting from Drawings, Prints, Pictures and Parts • On-Site Support Capabilities • 50+ Polishers • 40 ton Capacity • 24 hours 7 days • Pick-up and Delivery • 3-D CAD File Capabilities Partnerships • Welding • Plating • Texturing Ph: 847-352-5249 Fx: 847-352-4052 1320 Holmes Rd., Elgin, Illinois sales@ultrapolishing.com www.ultrapolishing.com Gets you to market faster

Progressive CVe Monitor

Fewer setups. More productivity

Optimize your mold production and reduce lead times with powerful deep hole drilling machining centers from UNISIG. Combining advanced milling, BTA and gundrilling capabilities into a single machine for fewer setups, USC-M series machines are built for speed and reliability while tackling challenging materials, heavy workpieces and complex geometries.

SALES@UNISIG.COM

information

| (262) 252-5151 Visit UNISIG.COM/MOLD for more

FOR COMPLEX MOLDMAK �NG.

of data automatically populated to reports. The next step would be to use ProFile, which requires a couple pieces of hardware that push data in real-time to the cloud.” With ProFile, customers can access machine data from anywhere, and the software also includes an asset management system, a preventive maintenance system and a work order system.

Installing CVe Monitors on molds, said Sheth, can do more than provide the mold users with machine data. Info loaded into the monitor by the mold builder and the collected mold performance data can be valuable for mold builders. Sheth cited a possible scenario: “A mold builder delivers a brandnew mold with an uploaded PM schedule that says every 50,000 cycles the mold owner should do this PM and every 100,000 cycles the owner should perform that PM. If the mold builders, gets a mold back with a warranty issue, they can plug into the monitor and see, for instance, that this mold has run nonstop. Nobody has ever done a PM on it. There is a lot of data there that can help mold builders ensure against warranty claims that occur as a result of required maintenance not having been performed.”

Progressive Components offers choices for plants at any level of Industry 4.0 sophistication. “A lot depends on the simplicity or complexity that exists at the plant,” said Sheth.

5-AXIS UNIVERSAL MACHINING CENTERS

“CounterView is ideal for a plant where a manager walks around once a week, takes counts and enters that data into an Excel spreadsheet or another system. CVe Monitors and ProFile are a step toward an automated mold maintenance system.”

EDWARD BASSOUS, R.E.R. SOFTWARE, INC.

R.E.R.’s InFocus software suite is designed for improving shop floor operations efficiency, and for planning and oversight of work. The product suite includes three main solutions, two of which address machine monitoring: AutoTrack and SmartAlert. AutoTrack captures an unlimited amount of machine production data as well as quality data, presents real-time production data and historical information, and features reporting, job tracking and operations analysis. SmartAlert is a condition monitoring module that is capable of monitoring one or many conditions in real time.

R.E.R. is equipment-independent, locally based software that draws information from PLCs, electrical load sensors or via the company’s proprietary IIoT devices. “Priority is to go directly to the control of each machine, such as Fanuc or Heidenhain or Haas,” explained Edward Bassous, management/optimization consultant. “Most newer machines and controls provide connections to communicate with, which in turn provide access to the machine data. If the machine is older or doesn’t have an interface for communication, an IIoT device would be used.”

Tapping into InFocus data can be done in a variety of ways. “R.E.R. provides a Windows application,” said Bassous, “as well as scheduled reports, which can be emailed, raw-data-file-dropped or sent to TV displays on the plant floor over the network. Additionally, web interfaces for accessing the systems are available. One of the web tools is a powerful business intelligence tool in which R.E.R. built many dashboards. Each customer can create custom InFocus dashboards.” Customers also can use the tool to create dashboards for other internal systems, such as ERP systems.

12 the american MOLD BUILDER | Issue 4 2022

For the highest accuracy, dynamics & process reliability! WANT TO KNOW MORE? CONTACT US AND VISIT OUR WEBSITE! www.grobgroup.com GROB_Anzeige_2022_05_3,75x4,875inch.indd 1 13.05.2022 08:53:06 page 10

R.E.R software screenshot demonstrating real-time and job tracking.

AutoTrack is the company’s production and quality monitoring package. It can accept data points from machines and other digital systems (CAD, CAM, machine, ERP). The machine monitoring capabilities do not stop at machine uptime and job information; data such as coolant level, electric cabinet temperatures, oil levels, tools used, part count and material type can be tracked. To gather qualityoriented data, the InFocus system can tap electronic CMM reports from CAD and data from probing operations that are physically performed on machines.

InFocus has reporting tools that provide visibility into areas such as job machining durations, tool usage, job costing, and maintenance and machining methods. “On newer equipment, by virtue of the data available from PLCs along with some R.E.R. magic,” said Bassous, “users can track where a job is, what is being done to it and with which tools, people and machining strategies.” R.E.R. also offers AutoPlan, a manufacturing execution system which, when combined with AutoTrack, constantly communicates with all equipment in real time, logging hours to each task automatically.

SmartAlert is the InFocus framework for the automation of given criteria to dynamic response. This condition monitoring

software works via PLC data, sensors or R.E.R.’s IIoT device. It can be used as the basis for preventive maintenance or can be used to predict premature machine failure when an electrical overload is recorded consistently for a specific duration. “Once the criteria are met,” said Bassous, “the system will send a notification to the manufacturer, the maintenance team and/or the customer, informing them of the issue.” The system also can be used to send an alert when a task has reached 100% of its budgeted hours or to give the next department in a multi-step job a “heads up” that a job now is ready for its next step.

As shown by the variety of hardware and software options highlighted here, mold builders have many options for adding machine monitoring to their plants. By taking advantage of the big data captured and the operational analyses provided to create a smarter factory, and by taking action to improve their predictive maintenance, mold builders can join the IIoT and graduate to Industry 4.0.

More information: www.Amper.xyz, www.heidenhain.com, www.procomps.com and www.rersoftware.com.

13 www.americanmoldbuilder.com | AMBA.org THEY GAVE THEIR ALL. LET’S GIVE SOME BACK. The iWarriors mission is to honor severely injured soldiers from all branches of the Armed Forces by providing personalized tablets and technology to aid in their rehabilitation and recovery. Support is from the American Mold Builders Association, MoldMaking Technology, and suppliers. HAVE i WARRIORS BE THE BENEFICIARY OF YOUR COMPANY’S CHARITY OUTING. TO DISCUSS, CONTACT INFO@IWARRIORS.ORG THANK YOU! Raising $33,681 at your 2022 Golf Outing! Raising $27,000 at your 2022 Golf Outing!

RAISING THE BAR ON RECRUITMENT AND RETENTION

by

Business gurus often talk about the view from 30,000 feet – the big picture that provides a look at overall operations. Perhaps, however, the focus should be on the view from 30 feet – a close-up of specific processes and procedures that make an impact now.

A leading manufacturer is raising the bar when it comes to recruitment and retention, and its strategy is not complicated – focus on the employee journey straight out of the gate!

RESPONDING WITH ACTION

Pyramid Molding Group (PMG) a nimble and adaptive company in Rockford, Illinois, is independently owned and operates on the concept of “growing its own talent.” PMG is the parent company of Industrial Molds and Pyramid Plastics, combining the talent and expertise of toolmaker and molder with over 50 years in the plastics industry.

Brook

recruiter

THE BUILDING BLOCKS TO RECRUITMENT SUCCESS

With what once was a one-person human resources department, PMG leadership knew the company needed to adapt to the challenging times and hired a full-time recruiter. “We had a vision for the position,” Peterson said. “This talented individual would manage the full-cycle recruiting process, including posting job descriptions, initiating screening calls, scheduling interviews and facilitating offers and employment negotiations.”

Peterson elaborated, “The recruiter also builds a candidate pipeline of ‘active’ and ‘passive’ talent by finding and screening candidates and tracking them in PMG’s applicant tracking software. This person is public-facing, partnering with local high schools, colleges and technical schools to gain access to emerging students. This individual also needed to be able to sell the benefits of joining our team.”

In 2020, when the job market tightened due to the pandemic, PMG responded by evaluating employee compensation, restructuring benefits to deliver top-of-the-line options and making adjustments in its entry-level plastic machine operator roles. These smart, necessary and simple tactics were focused on investing and responding to employees’ hard work and skill development – building a strategy centered on attracting, recruiting and retaining in-demand, highly skilled talent in the industry.

PMG employees saw their pay increase on average by 18.1% in 2021; this created a competitive pay opportunity against industry competitors. Additionally, “We introduced an employee referral program of $1,500 per hired referral, paid out in three installments over six months,” said Becca Peterson, PMG director of sales. “According to Chris Paulson, our human resource specialist, we have hired 12 referrals so far, from skilled to entry-level positions.”

Pond joined the team in 2022. With her on board and Paulson in place for HR support, PMG now has its human resources department set up for success and the skills in place to manage the full-cycle recruiting process to deliver efficiently and effectively, from filtering applications to interviewing candidates and then onboarding top talent for the company. Sounds easy, right? Not so fast! A recruiter is challenged with locating the future of a company and is the pillar, Pond said, of PMG’s recruitment efforts. “When searching for new employees, it’s not a search for ‘talent,’ but rather for a candidate who will fit with the company culture and shows potential,” she said. “From there, the employee can be trained.”

When mapping out a recruitment plan, it is key to know what to do and what not to do – or what a company should stop doing. This requires evaluating the internal and external workings of the company and then taking actionable steps to adjust the plan. Peterson said, “We made decisions about what we’re not doing anymore: No more print ads, and no more job fairs. They have been non-existent over the last two years due to COVID-19 and still have not bounced back.”

14 the american MOLD BUILDER | Issue 4 2022

Pond, PMG corporate

said, “We believe in investing in our people!”

Lindsey Munson, editor, The American Mold Builder We don’t ever want to be forced to turn away a new customer due to staffing shortages.”

High school students tour PMG’s Industrial Molds facility.

PMG also restructured to better meet current and potential employees in the middle, offering them value-added positions and growth opportunities. Peterson elaborated: “Paulson helped us move from a temp-to-hire model at Pyramid Plastics to direct hire only about one year ago. We previously had staffed about eight to 12 temporary employees at any given time. Hiring direct allowed us to increase our entrylevel, starting wages and gain control over the messaging and value proposition being communicated to potential new hires. New hires also receive benefits upon hire in, instead of having to wait to complete the 90-day temp-to-hire period.”

By being intentional with its recruitment strategy, PMG and its parent companies now have the building blocks for success in hiring skilled talent and industry professionals who contribute to its positive company culture and deliver results.

CONNECTING AND COLLABORATING

Peterson credits social media efforts for some of PMG’s recruitment advancements. “We have tried to grow our social media following organically, including Facebook and LinkedIn,” she said. “We doubled our LinkedIn following from 551 followers in November of 2021 to 1,041 followers today. We encourage our employees to follow us and reshare our posts with their network.”

Beyond the internet, PMG knows the importance of connecting with a handshake and face-to-face conversations. Pond said, “We have focused a lot of energy on connecting with youth in our community. As manufacturing is not always the first career path for young adults, and students seem to be more encouraged to pursue other fields, we are trying to engage with local high school and community college students to show them the value of working in manufacturing.”

To aid in deepening that connection, PMG has thrown its doors wide open to expand its recruitment pool with the next generation of the industry. “If they are interested, we are happy to offer them tours and connect them with any open positions,” Pond explained.

The cornerstones of PMG’s evolution in its recruitment success are the collaborative efforts with its community partners and schools and its outreach to the next generation of potential manufacturers. Connecting these efforts for PMG starts in-house, with employees and leadership giving facetime to Rockford’s local high schools, technical schools and the college, creating partnerships and providing incentive offers, such as $5,000 per year tuition reimbursement. Company leadership works with Rockford Public Schools’ College and Career Academy to assist with student mock interviews; offer halfday job shadows for juniors and seniors with an interest in engineering; and open its doors for plant tours.

ACTIONS SPEAK LOUDER THAN WORDS

PMG deploys key retention actions, building its philosophy on a company culture that is evident and inclusive the moment a new employee walks through its doors. “We welcome our new hires with a gift bag of goodies and a handwritten note,” said Peterson.

The effort to make new employees feel an immediate connection with their new employer doesn’t stop there. “Our recruiter conducts a seven-day new employee check-in, and our recruiter and human resource specialist conduct a 30-day check with all new hires (hourly and salaried employees),” Peterson said. “This is a scheduled meeting with our new hires to find out how they’re liking the position so far, where they see themselves going with the company in terms of career goals and if there are any concerns that need to be addressed.”

Continuing, Peterson noted, “We want to not just say that we care, we want to show it and establish open lines of communication.”

When a company creates job roles that have specified advancement opportunities, coupled with leadership communication, employees have the potential to grow and prosper, which increases retention rates. Peterson shared, “We have an advancement program for entry-level machine operators at Pyramid Plastics. Once they reach certain levels

15 www.americanmoldbuilder.com | AMBA.org

page 16

of training, they receive an increase – it’s not just a yearly increase based on tenure; instead, the pay is for performance and there are three levels they can attain.”

She continued, “Beyond this, we always try to promote from within, whether it’s into our quality or logistics department. We look to train and promote dedicated employees who fit into our work culture, rather than hiring from outside.”

PMG sponsors employees at Industrial Molds who would like to get their Journeyman Tool and Die Certification through Rock Valley College, which entails night classes over a number of years. Peterson said, “The company pays for tuition and books, and the employee receives not only the certification but also its associate’s degree. We just had four employees start the program!” In addition, Pyramid Plastics offers employees an opportunity to increase their skills through online training offered through Paulson Training Programs, Inc.

Passionate not only about retaining its employees but also about growing and developing them, PMG has emphasized connection – both on the job and in the community. Peterson

said, “We have quarterly meetings for communication and hold holiday meals to get everyone together. Last year, we had our first companywide Christmas party in over 10 years. We also encourage employees to network and facilitate their involvement in outside organizations for their own personal and professional growth.”

THE WORK NEVER ENDS

PMG is far from done “growing its own” – a concept that is the driving force behind the company’s recruitment and retention success. “Our customers keep us motivated to consistently keep employee recruitment and retention front of mind,” Pond said. “We don’t ever want to be forced to turn away a new customer due to staffing shortages.”

With customers in the queue and job opportunities abundant, it’s important now more than ever to have a recruitment and retention strategy. PMG and its parent companies – Pyramid Plastics and Industrial Molds – have made the investment by creating internal positions focused on hiring; recognizing the importance of connecting with new and future employees; and rewarding the efforts of current employees.

Z2600 /... Highperformance grease, food-safe

The high-performance grease is approved to NSF H1 and is especially suitable for use at lubricating points in which direct food contact cannot be avoided.

Toll Free: 877-427-2662 www.hasco.com

16 the american MOLD BUILDER | Issue 4 2022 page 15

Program Listed H1 163920

WHO’S BRINGING NEW LEVELS OF PERFORMANCE TO COMPACT HOT RUNNER/MANIFOLD SYSTEMS?

At Plastic Engineering & Technical Services, we are.

We define performance. For nearly 30 years, we’ve helped our customers to produce more e ciently, with lower cycle times and lower per unit costs.

Our new compact stainless steel, modular unitized system features exible heaters that can be utilized o n multiple designs, so you don’t have to stock custom bent heaters Our new drop heaters provide more uniform heating and feature smaller pockets and no clamps They have in-line ow restrictors

for better process repeatability, and no over-pressurizing the cylinders. It all adds up to a reduced sized hot runner system, shorter heating times and better tool performance

We deliver value. We complement our hardware with leading-edge analytical tools, including Mold ow® and MOLDEX3D so ware. We’ll work with you on design issues and optional gating solutions before the mold or hot runner manifold system is ever built. Use us for the mold ow analysis and the manifold build, and we’ll do whatever it takes to make your hot runner/manifold system work to your complete satisfaction.

We’re committed to your success. Find out more. Call us today at 248.373.0800 or visit us at www.petsinc.net.

page 19

[1] NOW AVAILABLE – ANNUAL INDUSTRY-WIDE SHOP RATE AND WAGE BENCHMARKING REPORTS

AMBA has published two key industry-wide publications, including its second annual Shop Rate Report and the 2022 Wage and Salary Report. The 2022 Shop Rate Report features charge rates specific to services supplied by US mold manufacturers in engineering, moldmaking and specialty services; the average overhead cost; gross margin ranges by annual sales revenue and current vs. anticipated capacity utilization.

In contrast, the 2022 Wage and Salary Report gathered data related to high, low and average rates of pay across more than 50 job functions commonly found in mold building, and also included pay incentives and vacation policy data.

To purchase the reports, visit www.amba.org/publications.

OPEN FOR SUBMISSIONS – 2023 BUSINESS FORECAST SURVEY

The 2023 Business Forecast Survey now is available to US mold manufacturers. This annual survey gathers data on sales trends, profit levels, capital expenditures, shop and design employment levels and challenges faced in the industry. Data from this year’s report will be pulled from surveyed responses on 33 economic indicator questions that cover 2022 performance, fourthquarter performance and forecasts, and expectations for 2023. To participate, visit www.amba.org/events.

AMBA SOURCEBOOK COVER CONTEST UNDERWAY

AMBA is accepting submissions for its 2023 Sourcebook cover contest. Mold building members who advertise in the 2023 Sourcebook are eligible to apply by submitting an image(s) of a mold and a write-up on what makes the mold particularly unique or challenging. The winning company will have its mold featured on the front cover of the 2023 Sourcebook with a write-up inside the book, a notation on the directory listing page and a credit toward its 2024 Sourcebook ad. To do a submission, contact Susan Denzio at sdenzio@amba.org for an application form.

END-OF-YEAR LEARNING OPPORTUNITIES

To close the year, AMBA has worked with its partners and members to supply end-of-year learning opportunities so industry executives can better prepare for 2023.

On November 26, Benesch Law will present employer “dos and don’ts” regarding employee unionization efforts, as well as tactics to address unionization efforts.

This event will be followed by the final session in the “Perspectives from the Top” Emerging Leaders series, a set of virtual meetings where AMBA’s Emerging Leaders are able to meet with other young professionals from two other manufacturing associations (Manufacturers Association for Plastics Processors and Association for Rubber Products Manufacturers) to hear best practices and leadership stories from industry mentors and executives.

To wrap up the year, on December 6, AMBA’s advocacy partner, The Franklin Partnership, will provide a review of AMBA’s 2022 advocacy activity. This webinar also will include highlights from the 2022 midterms and anticipated topics of interest affecting the mold manufacturing industry moving into 2023.

To register for any of these events, visit www.amba.org/ events.

REGISTRATION OPEN FOR 2023 C-SUITE DIALOGUE (INTERNATIONAL QUOTING STRATEGY)

AMBA will host its final C-Suite Dialogue alongside Wipfli, AMBA partner and provider of industry-focused accounting, tax and consulting services. This meeting is an opportunity for executives to meet with one another and discuss a particular challenge faced by the mold manufacturing industry in an exclusive setting. To learn more and join the meeting, RSVP to Rachael Pfenninger at rpfenninger@amba.org.

[2] SAVE THE DATE FOR AMBA CONFERENCE 2023: POWERING GROWTH

May 10-12, 2023 | Grand Rapids, Michigan

Mark the calendar for AMBA Conference 2023, May 1012, Grand Rapids, Michigan, where the stage will be set with the conference theme, “Powering Growth.” During this two-and-a-half-day event, attendees will experience a shift in mindset as they explore never-before-considered strategies, technologies and best practices that will impact how they lead teams, drive team productivity and support company profitability. Set to take place at the Amway Grand Plaza Hotel, AMBA Conference 2023 will push the envelope as it forces attendees to think outside of the box

18 the american MOLD BUILDER | Issue 4 2022

Powering Growth 2023 1 2 3

with thought-provoking breakout sessions, inspiring keynote presentations and numerous opportunities to connect with mold building peers. For more information, visit www.ambaconference.com.

[3] ALLIANCE RAISES OVER $33,000 AT ANNUAL GOLF OUTING

On September 23, 2022, Alliance Specialties and Laser Sales hosted its annual Charity Golf Outing at Countryside Golf Course in Mundelein, Illinois. The event drew more than 150 registered golfers, 75 businesses and over 30 sponsors, all of whom came together for networking, fun and laughs on the greens. Together, this generous community raised a total of $33,681 to support the iWarriors organization. With these funds, iWarriors is able to assist severely injured members of all branches of the Armed Forces by providing them with personalized tablets to aid in their return, recovery and reintegration. Learn more at www.alliancelasersales.com.

TAP 2022 AWARD WINNERS ANNOUNCED

On Monday, November 7, 2022, the West Michigan Chapter AMBA held its quarterly business meeting and Tooling for Apprentices Program (TAP) Awards dinner at Boulder Creek Golf Club, Belmont, Michigan. This program recognizes chapter companies’ best apprentices and awards them a $500 gift card for purchasing tools and equipment for their apprenticeship training. Congratulations to the following winners: Austin Grabill – Deppe Mold & Tooling, David Hoekstra – Cedar Springs Tool Engineering, Inc., Donavan Hornak – Commercial Tool & Die, Inc., Josh Weinberg –Franchino Mold & Engineering and Trevor Mathews –Franchino Mold & Engineering

NEW MEMBERS

S&K Tool & Die Co., Inc. 4401 Environmental Dr. Portage, MI 49002 Philip Best, engineering Phone: 269.345.2174 Email: phil@sktool.com

Since 1972, S&K Tool & Die Co., Inc., has been a manufacturer of plastic injection molds. The company offers design and engineering services, along with on-time delivery. With its team of mold building specialists, S&K Tool & Die has established a foundation to produce quality molds for its customers.

DECATUR MOLD TOOL & ENGINEERING

3300 North State Hwy. 7 North Vernon, IN 47265

Teresa Kessler, sales manager Phone: 812.346.5188

Email: teresa.kessler@decaturmold.com

Decatur Mold Tool & Engineering is a family-owned business that specializes in injection mold manufacturing, offers contract machining services and conducts short-run plastic part production. The company is implementing highspeed optical 3D scanning via robotic automation to expand and streamline its metrology capabilities. Decatur Mold has built its reputation on delivering quality results for its customers.

NEW PARTNERS

Regal Components 10 Almeida Ave. East Providence, RI 02914

Derek Coelho, vice president Phone: 727.299.0800 Email: dcoelho@regalcomps.com

Regal Components welcomes the opportunity to be a source for standard and custom die and mold components, with a commitment to providing high-precision products at the lowest possible prices. The Regal team has over 30 years of experience helping guide its customers to the right component selection for each application.

Sandler Training

100 W. Big Beaver Rd., Suite 100 Troy, MI 48084

Ken Seawell, managing partner Phone: 248.688.9805 Email: ken.seawell@sandler.com

Sandler Training is a performance development company partnering with businesses and high-performing individuals to deliver training for sales, management and organizational excellence to grow top and bottom lines with locations in the Southeast, West and Central Michigan.

Slide Products

430 Wheeling Rd. Wheeling, IL 60090

Michael Muth, sales manager Phone: 847.541.7220 Email: mmuth@slideproducts.com

Slide Products has been offering support and products for the moldmaking and plastic processing markets for nearly 70 years. The Slide line includes mold cleaners, mold release agents, rust preventives, ejector pin greases and purging compounds. Slide’s factory experts schedule in-person site assessments to share field experience and solutions.

www.americanmoldbuilder.com

19

| AMBA.org

Powering Growth 2023 AMWAY GRAND PLAZA | GRAND RAPIDS, MI May 10 - MAY 12, 2023 Take it to the next level. Details coming soon | ambaconference.com

[1]

SYBRIDGE TECHNOLOGIES ACQUIRES

TOOL & MOULD

GALWAY

SyBridge Technologies (SyBridge), a global industrial technology company located in Southfield, Michigan, acquired Galway Tool & Mould Ltd, Galway, Ireland, a company that designs and manufactures precision molds for partners in the medical device and pharmaceutical markets. This acquisition expands SyBridge’s presence in the highprecision life sciences end-market and places it at the epicenter of Ireland’s medical technology manufacturers. For more information, visit www.sybridgetech.com

[2] SECO TOOLS OPENS PRODUCTION UNIT IN MEXICO

Seco Tools, Troy, Michigan, opened a new 2,500 sq. m. manufacturing facility known as Seco Tools Production Unit (PU) in Ramos Arizpe, Mexico, housing special tool manufacturing. Seco Tools is a provider of metal cutting solutions for milling, stationary tools, holemaking and tooling systems. The facility features Seco Tools’ unique architecture, design and production cell layout standards with education spaces and multifunctional rooms. The new PU is positioned strategically to serve the growing demand for carbide and diamond tools in Mexico, throughout North America and some countries in South America and Europe. For more information, visit www.secotools.com

[3] HEIDENHAIN UNVEILS NEW WEBSITE

HEIDENHAIN CORPORATION, Schaumburg, Illinois, a developer and manufacturer of linear and angle encoders, rotary encoders, digital readouts and CNC controls, has unveiled a redesigned North American website. The new website showcases up-to-date layouts, design elements and expanded content to assist customers in finding what they need faster and more efficiently. The portal brings a unified voice to the HEIDENHAIN brand worldwide with key website menu highlights, including products outlined by detailed information, industries and applications, and service and support. For more information, visit www.heidenhain.us.

NEWCO PLASTICS ACQUIRES PM MOLD

PM Mold, Schaumburg, Illinois, a vertically integrated manufacturer of custom plastic injection molded parts and custom molds, has been acquired by NewCo Plastics, a portfolio company of White Wolf Capital. Terms were not disclosed. PM Mold provides a comprehensive suite of manufacturing services from product design to final shipment to its customers, operating in industries such as automotive, appliances, military, aerospace, electrical, consumer goods and agriculture. NewCo Plastics is a plastics manufacturing platform formed by White Wolf Capital to acquire North American plastic injection molding and manufacturing companies. For more information, visit www.pmmold.com.

IN MEMORIAM: LEROY “ROY” D. LUTHER

LeRoy “Roy” D. Luther, the owner of Triangle Tool Corporation and AMBA member, passed away on September 5, 2022, at the age of 84. Throughout his lifetime, Luther was an avid fisherman, hunter, bowler, golfer and card player; and he loved the Green Bay Packers. Luther started his apprenticeship in 1955, as a tool and die maker at Flambeau Plastics. He and his wife, Lois, moved their family to Brookfield, Wisconsin, in 1968. At that time, Luther became president of Triangle Tool Corporation and, in 1981, owner. Throughout his career, Luther realized his dream of farming when, in 1975, he began Luther Farms. In 1985, Luther purchased 18 acres and built a new facility where Triangle Tool currently resides, serving a wide range of customers in a variety of industries, providing plastic injection molds and large machining services. Luther truly was a one-of-a-kind icon and leader. To read Luther’s full obituary, visit www.jsonline.com .

www.americanmoldbuilder.com

21

| AMBA.org

1 2 3

5 OBSTACLES TO GROWTH AND HOW BUSINESSES CAN OVERCOME THEM

by Kirk W. McLaren, author

by Kirk W. McLaren, author

With 2023 fast approaching, it could be time for business owners and CEOs to decide whether to accelerate the growth plans for their businesses in the coming year.

Growth doesn’t just happen though, and ambitious businesses typically face five obstacles that can thwart their efforts: winning new customers, keeping existing customers, gaining access to capital, overcoming low financial performance, and having the right people and capacity to deliver.

All five of those obstacles are connected, and the two involving customers especially are intertwined.

1. WINNING NEW CUSTOMERS.

There are effective ways to attract new customers and notso-effective ways. Unfortunately, businesses often pour time and resources into things that have little value, so scrutinize efforts carefully to see if they are paying off.

Let me give you one example: My firm once analyzed an inside-sales call center to see how efficient it was at getting new customers on board, as opposed to allowing customers to sign themselves up online. What we discovered was that the additional step of calling someone was a deterrent for the customer. Because of this finding, the company improved its web-based technology, making it even more efficient for customers to sign themselves up for services.

2. KEEPING EXISTING CUSTOMERS.

Although businesses need to bring in new customers to grow, they can risk alienating their most loyal customers if they take them for granted. This is where the 80/20 rule could help. That rule essentially states that 80% of a company’s revenue comes from 20% of its customers. It’s critical to

identify those 20% and focus retention efforts there, because not all revenue or all customers are equally worth chasing.

3. PROACTIVELY GAINING ACCESS TO WORKING CAPITAL.

Dealing with increased demand brought on by growth often requires gaining access to working capital. This is where positive cash flow can be crucial. The better a company’s financial picture, the more likely a lender is to evaluate it favorably. But how does a business that’s on wobbly financial ground establish positive cash flow?

A good first step is making a 12-week cash forecast, listing every payment that’s expected to come in and go out. If more is going out than is coming in, then it’s time to take action. One option might be to put off taking on new expenses. Another could be to control the payment of invoices; that is, where possible, delay paying bills until closer to their due date – or as long as possible.

If a business can find ways to tweak cash flow, it also may be able to avoid borrowing money, or at least borrow less.’ When cash gaps are forecasted, the best practice is to proactively source lines of credit, term loans and/or investment funding.

4. OVERCOMING LOW FINANCIAL PERFORMANCE.

Many CEOs tend to focus on topline revenue and fail to pay sufficient attention to net profit or loss. In a way, who can blame them? It’s easy to get excited by soaring sales numbers, but that joy isn’t justified if expenses are soaring even more. Clarity about financial performance always is important strategically, and this especially is so when a CEO is seeking a bank loan, doing succession planning or considering a merger or acquisition from the buyer side.

23 www.americanmoldbuilder.com | AMBA.org page 24

One way to measure whether a business is performing well is to compare it to others in its industry using benchmarks. Are sales weak for everyone right now, or is this particular business an outlier?

5. HAVING THE RIGHT PEOPLE AND CAPACITY.

As a business increases its customer base, it faces new challenges, but one question at the top of the list? Does the business have the staff and the capacity to serve everyone well? After all, it does little good to snag new contracts if the workload is more than the team and equipment can handle.

Unfortunately, many businesses fail to make wise decisions on managing capacity. The data and analysis that could help the CEO forecast demand either are nonexistent, erroneous, delayed or lost in the daily whirlwind. It’s important to have a good handle on capacity so that the business can plan what staffing, equipment, software, vehicles or other resources will be needed. Without the proper planning of a forwardthinking chief financial officer, the CEO, key employees –and everyone else – could become overwhelmed.

Although these obstacles are not insurmountable either individually or as a group, businesses intent on growing in 2023 should start working now to overcome them so that nothing impedes them from achieving their ambitious goals.

Kirk W. McLaren, author of The Growth CFO Void: The Guide to What’s Holding You Back from Being a 2% CEO, is the CEO of Foresight CFO and a graduate studies lecturer at Georgetown University School of Continuing Studies. His team at Foresight CFO develops selected financial talent into Growth CFOs who work side by side with CEOs across the full business journey, from foundation to succession options. McLaren served in the US Army as a behavioral scientist during the first Gulf War. He holds an MBA with a finance and accounting concentration, an MA in international relations and economics from Johns Hopkins SAIS, a graduate certificate in international business from Georgetown University and a BS from University of Maryland University College. For more information, visit www.linkedin.com/in/kirkwmclaren

24 the american MOLD BUILDER | Issue 4 2022 page 23 PCS_MinLube_HalfPgH_7_5_x_4_875_102522_Final.indd 1 10/25/22 11:37 AM

For parts with shot sizes from a fraction of a gram to multiple kilograms, INCOE provides Hot Runner Technology solutions throughout the entire process — from engineering mold review and filling simulation to on-site technical support.

Our global commitment is to be your Melt Logistics® partner — producing value in your process — and ultimately delivering satisfaction where it counts.

© 2022 INCOE® 10/22

Your Melt Logistics® partner for successful mold making www.incoe.com North America | Europe | Asia | South America February7-9,2023|Anaheim,CA VisitusatBooth#3838

ARE WORKFORCE WOES IMPROVING? DATA POINTS TO POSITIVE INDICATORS

by Rachael Pfenninger, director of strategic execution, AMBA

As Americans nationwide experience the pinch of inflation, wages continue to be an increasingly hot topic of conversation. Paired with the persistent labor issue (an industry-wide challenge made worse by the coronavirus pandemic), employers are scrambling to see how they can remain competitive in the war for qualified labor.

To help US mold manufacturers better understand the labor landscape and benchmark their wage standards against others in the industry, AMBA again has completed and published its annual Wage and Salary Report. The 2022 AMBA Wage and Salary Report (now in its 12th year of publication) is the nation’s most comprehensive study of wage data, analyzing starting and average salary and wage benchmarks for over 50 job classifications within mold manufacturing. Additionally, the report benchmarks information related to cost-ofliving increases (recent and forecasted), vacation benefits, employee incentives, salary adjustment opportunities, hiring expectations, employee demographics and more.

This year’s report is based on data provided by executives, human resource leaders and finance professionals in 107

US mold building facilities across 23 states. Of the four regions represented, the Midwest accounted for the largest percentage of respondents (80%), the bulk of which hail from Michigan, Wisconsin and Illinois.

Of these respondents, the majority (84%) intend to hire new employees over the next 12 months (See Chart 1). Although manufacturers reported the need to hire at least one administrative and management position each, technical vacancies were by far the highest priority. On average, companies reported the need to fill a minimum of three vacancies; this rises to five or more for companies producing $10 million or more in revenue.

Although the need to fill vacancies is not a new challenge, what is remarkable is that the number of companies seeking new hires has risen by four percentage points and now is at its highest point of the last five years. What makes this even more interesting is that, while hiring labor certainly continues to be a challenge, other data is pointing to some industry improvement. For example, although the number of companies needing to hire has risen, the average number of current employees per facility also has risen for the first time in several years, breaking a three-year decline (See Chart 2).

To further the good news, there also is a positive upward trend in employees aged 18 to 50. For the first time since the years before 2018, as shown in Chart 3, this age demographic makes up 64% of the survey’s reported workforce – three percentage points higher than data from 2020 and 2018 (the past two recent peaks) and within six percentage points of levels last seen in 2006.

To see an upward trend in overall employment and a fall in the average age points toward significant

26 the american MOLD BUILDER | Issue 4 2022

Chart 1 Chart 2

improvement within the industry in terms of workforce development. Because it is well-documented that employers are struggling to provide wages that mirror rising economic inflation1, workforce development improvements may be due instead to employers’ willingness to provide additional salary adjustment opportunities, cost-of-living increases and employee incentives. While nearly every mold manufacturer provides merit increases, eight out of 10 mold manufacturers surveyed reported providing salary adjustments across the board and/or cost-of-living adjustments (COLA) in 2022. When asked specifically for details regarding COLA for employees, companies reported an average increase of 3% in 2022 and an average planned increase of 2% in 2023.

Companies didn’t just focus on benefits for existing employees. Nearly three-quarters of respondents provided or currently provide a signing bonus (totaling anywhere from $160 to $3,000), while an even higher percentage of survey respondents enticed new hires with offerings of increased insurance coverage, expanded PTO policies and employee development opportunities.

For many years, fears of an aging workforce have been plaguing the mold manufacturing industry. With this reported data, however, it looks like the tide may be due to turn as employers look to new opportunities to attract labor and keep their existing workforce.

To learn more about wage fluctuations by position and market segment for the 50+ roles featured in the 2022 AMBA Wage and Salary Report, visit www.amba.org. The report is available for $299 to members and $499 to non-members.

References 1. https://www.weforum.org/agenda/2022/06/wages-why-are-theynot-keeping-up-with-inflation

Molded to Perfection

With over 160 years of steel production experience backing their brands, Swiss Steel Group is not only a pioneer, but also a market leader in specialty steels. Their comprehensive range of Formadur®, Thermodur®, Cryodur®, and Mold Die® grades allows you to choose the ideally suited mold material for your application. In addition, an extensive range of value added services provides you with more alternatives from one source, Swiss Steel USA.

www.swisssteel-international.us www.swisssteel-international.ca Phone: +1 800 323 1233

27

| AMBA.org

www.americanmoldbuilder.com

Chart 3

[1] HASCO EXTENDS COOLING RANGE AND LAUNCHES POSITIONING WEDGES

As a full-service provider for tool and moldmaking, HASCO America, Inc., Fletcher, North Carolina, extended its stainless-steel cooling range of more than 30 product groups, ensuring the reliable cooling of injection molds when using hot or cold water or heat-transfer oil. Manufactured from high-quality 1.4305 material, the robust, safe and easily coupled system guarantees reliable, leak-proof and durable temperature-control applications. In addition, HASCO launched new positioning wedges Z1855 – easy to assemble and disassemble with their extraction threads in the throughholes. The wedges offer good conditions for fast and precise fixing of mold inserts in injection molds and help to reduce set-up times. For more information, www.hasco.com

[2] HEIDENHAIN LAUNCHES THE TD 110

HEIDENHAIN, Schaumburg, Illinois, a developer and manufacturer of linear and angle encoders, rotary encoders, digital readouts and CNC controls, has launched its new TD 110 tool breakage detector. Providing contact-free inspection of drill bits and end mills, the TD 110 can determine if a tool is broken off by more than 2 mm as it passes within a machine tool, yielding significant time and money savings. Benefits of the TD 110 include a maintenance-free sensor for reducing non-productive time for breakage inspection, cooling lubricant and lightly contaminated tools that are tolerated and universally retrofittable. For more information, visit www.heidenhain.us

[4] PROGRESSIVE COMPONENTS INTRODUCES NEW MOLD STANDARDS AND PROFILE® V4

Progressive Components, Wauconda, Illinois, introduced new standards to improve mold performance, including plate sequencing (plate retainers and plate locks), undercut release (C-Series UniLifters®), mold handling (RhinoFeet™) and mold monitoring (high-temperature mold CounterViews®). Additionally, Progressive Components introduced ProFile® v4, a cloud-based tracking system designed for OEMs, molders and mold builders to organize and track tooling activity. For more information, visit www.procomps.com.

SECO LAUNCHES X-HEAD QUICK-CHANGE SYSTEM

Seco Tools LLC, Troy, Michigan, a provider of metal cutting solutions for milling, stationary tools, holemaking and tooling systems, has launched its new X-Head quick-change, replaceable milling head system. With this system, users quickly and easily can change between various solid-carbide milling geometries and types to optimize milling operations while reducing manufacturing costs and tooling inventories. For more information, visit www.secotools.com.

[5] MANTLE DELIVERS 3D PRINTING SYSTEM AND TRUE SHAPE TECHNOLOGY

[3]

PCS

RELEASES NEW

MOLD CLAMPS AND ANNOUNCES MIN-LUBE™ DISTRIBUTION

PCS Company, Fraser, Michigan, a provider of solutions and innovative products for plastic injection molding, moldmaking and die casting industries, has released the new Forged Quick Adjusting Arching Mold Clamps that provide faster, more reliable and accurate clamping of a mold or die. The clamps are an extra wide, closed-toe design with the pivoting action of one bolt and sliding washer to reduce mold change time. PCS also announced its distribution of MIN-LUBE™, an advanced universal lubrication product designed for extreme high-temperature, high-wear mold and die applications. For more information, visit www.pcs-company.com

Mantle, San Francisco, California, a metal 3D printing company, announced the commerical availability of its technology and production systems. Mantle’s system and patented TrueShape technology, include the P-200 printer, a hybrid system built on a CNC platform that integrates printing and machining; the F-200 furnace, which sinters parts from the printer and produces tooling components; two tool steel materials, H13 and P2X; and easy-to-use software that automates the printing process. For more information, visit www.mantle3d.com.

[6] ANCA DELIVERS MX7 ULTRA

ANCA, Melbourne, Victoria, Australia, a global manufacturer of precision tool-grinding machines, equipment and software, delivered its next-generation machine, the MX7 ULTRA. The ULTRA has the ability to manufacture large volumes of endmills and other cutting tools, delivering the highest accuracy and quality. For more information, visit www.machines.anca.com

28 the american MOLD BUILDER | Issue 4 2022

1 2 3 4

[7] OKUMA LAUNCHES 5-AXIS VERTICAL MACHINING CENTER

Okuma America Corporation, Charlotte, North Carolina, a manufacturer and supplier of CNC and machining technology, launched its 5-axis vertical machining center, the GENOS M560V-5AX. The GENOS M560V-5AX is a next-generation product built with a double-column machine design. With maximum structural integrity, it offers a working envelope with a 500 mm table and wideaxis travels (X: 1,050 mm, Y: 560 mm, Z: 460 mm), with a compact footprint of 2,515x3,750 mm. It comes standard with a 60 ATC magazine and can accommodate tools measuring up to 400 mm; and the machining center has Okuma’s Thermo-Friendly Concept, an onboard thermal and energy management technology. For more information, visit www.okuma.com

[8] PTI RELEASES UCAMS™ PLUS

Processing Technologies International, LLC (PTi), Aurora, Illinois, released its next-generation flat die servicing system – Universal Cleaning Assembly and Maintenance System™ Plus (uCAMS™). This enhanced design transforms the functionality of the flat die service system into a multipurpose “triple-play” for sheet extrusion-related critical component maintenance and service. For more information, visit www.ptiextruders.com

CNC OFFERS INDEXABLE SPLINE BROACHING INSERTS

CNC Broach Tool™ LLC, Laguna Beach, California, recently began offering indexable carbide spline cutting inserts. The spline inserts fit the existing line of tool holders and can be used to punch broach internal and external involute splines in a CNC lathe or mill broaching system. Each spline insert has two cutting edges, can be changed out quickly and is TiN-coated carbide. For more information, visit www.cncbroachtools.com

29 www.americanmoldbuilder.com | AMBA.org

5 6 7 8

EMPLOYEE BENEFITS: RISING COSTS VS. NECESSARY INCENTIVES

by Maggie Taylor, writer, Inside Rubber

by Maggie Taylor, writer, Inside Rubber

Employers in virtually every industry are struggling to attract and retain high-quality employees. Large and small businesses alike are scrambling to overhaul their wage and benefit structures to remain competitive in a highly volatile employment market. Many companies have found themselves locked in constant competition with other local businesses over a singular pool of employees and workers. Leaders and human resources professionals in the manufacturing industry are experimenting with a variety of solutions and changes to deal with these ongoing challenges.

A primary struggle for many companies is the challenge of offering a competitive rate. In the Detroit area, for example, multiple Amazon facilities and the “Big 3” automotive manufacturers are major competitors, especially for smaller companies and tier suppliers.

“Now that the larger companies are back in production, they’re making offers to our employees that we can’t compete with. One of the Big 3 has taken three of our people in the last two months,” said Audra Kimbel, human resource manager for PolyFlex Products, Inc., Farmington Hills, Michigan. “Those were key positions for us. We’ve been able to backfill them, but you’ve got to start the training all over again. A leadership change does bring a fresh perspective, but when it comes all at once, it doesn’t give you a whole lot of time to adapt.”

Most businesses have raised pay rates multiple times over the past two years in an attempt to remain competitive. Suzie Thomas, accounts payable, reported that Eclipse Mold, Inc., Chesterfield, Michigan, has implemented three substantial wage increases since 2019, anywhere from two to four dollars. And those changes have applied to longterm employees as well as new hires, though the exact rate – within a specified range – is determined by seniority and good standing. The company currently is exploring what a wage ceiling might look like for long-term employees. “It’s hard because there’s a point where they’ll cap out. We haven’t done that yet,” said Thomas.

PolyFlex Products also has changed its pay rates to $15 per hour for general labor and adjusted its policy for paying

temporary employees. The company paid a higher rate of $16.50 to temporary employees but offered a slightly lower rate of $15 for a full-time role, with the promise of a onedollar raise at the 90-day mark, pending good performance. PolyFlex Products tested this strategy on five employees from temp agencies and have retained all five. However, there’s risk involved when hiring temporary employees.

“Temp employees outshine regular employees until they get hired,” said Kimbel. “Suddenly, they’re missing days or being unsafe or having problems on the floor with other people. That’s always a risk you take. So, we’re trying to work out the kinks right now.”

Many companies are struggling to balance wage increases against the overall rising costs of doing business. “Obviously, with everything else going up, so are our costs,” said Thomas. “It’s been a struggle. The price of materials is going up. We’ve gotten quite a few new jobs in, which we’re quoting differently. And we’re negotiating new terms and new prices with long-term customers, but it’s a slow process.”

Businesses also are being forced to consider their employees’ expenses in their calculations. “I started tracking daycare expenses, fuel costs and food prices back in March,” said Kimbel. According to her research and records, the cost of sending a single three-year-old child to daycare in the Detroit area, the 14th largest metropolitan area in the United States, is around $340 per week. For some employees, childcare costs account for their entire paycheck – or more. “Their money is going to daycare,” said Kimbel. “They’re not earning anything. They’re losing more money. That has become more of a reality that we haven’t addressed yet.”

Recruitment professionals have experimented with a variety of additional benefits to incentivize new hires – with mixed results. “A lot of entry-level people have state benefits,” said Thomas. “Benefits are not a high priority for people in my area. More paid time off would be the only benefit that actually would attract people.”

Different types of cash incentives have proven to be slightly more effective, though the results are not dramatic. PolyFlex

30 the american MOLD BUILDER | Issue 4 2022

Products began offering a $500 bonus to any employee who referred a new hire who stayed on for at least 90 days. “We thought it would have more of an impact,” said Kimbel. But some employees have taken advantage of the program. “One guy has referred four people,” she said.

Some companies have implemented more flexible workfrom-home policies. But for some roles, that benefit is irrelevant. “People on the floor have to be here,” said Kimbel. “They can’t work from home.” Kimbel shared that PolyFlex Products is exploring the possibility of a program to help employees offset the rising costs of fuel. The program would award a weekly “appreciation allowance” to employees who worked their full schedule, at least until gas prices drop below four dollars per gallon.

The cost of sending a single three-year-old child to daycare in the Detroit area, the 14th largest metropolitan area in the United States, is around $340 per week. For some employees, childcare costs account for their entire paycheck – or more.

Gas prices are not the only transportation barrier affecting recruitment. Many major public transportation providers are experiencing similar hiring struggles and have cut back on routes due to a driver shortage. In the Detroit area in particular, this has led to a gap in the bus schedule that affects second-shift workers.

“That’s a huge issue for us right now,” said Thomas. “People are saying, ‘I can’t do second shift because I can’t get home.’” Thomas has been working directly with the local transit authority to add a bus stop that would accommodate second shift, but until more drivers are available, the problem remains. “If they don’t have anyone to drive a bus, they can’t get home,” she added.

PolyFlex Products has offered two solutions to the issue: a partially funded carpool program and flexible scheduling.

Commute with Enterprise is a program that groups employees by zip code or other criteria to share a vehicle for commuting purposes. Thanks to reimbursements from the Michigan Department of Transportation (MDOT), the cost of Commute with Enterprise is $120 per month for PolyFlex employees. That payment includes a vehicle, regularly scheduled vehicle

maintenance and a gas card. The employees in the pool can share the vehicle for regular errands as well, such as grocery shopping and healthcare appointments.

However, the program hasn’t attracted much interest. “So far, just one person has taken me up on it, and he wound up having to resign,” said Kimbel. “I brought it up in a meeting, asking people to compare it to their car payment. You could be making money by following through with this program. But people just didn’t want others to know where they lived.”