Powering Growth and Unity at the 2023 AMBA Conference

Progressive continues to develop exclusive tooling standards, and our new v15 Catalog delivers advancements that will assist mold builders and molders for years ahead:

• New standards for greaseless and cleanroom molding.

• Innovations expand alignment, undercut release, and side action wear strips, gibs, and center guides.

• Advantages for mold monitoring and asset tracking.

Contact us to receive our new Catalog or our CADalog ® , to optimize the design, build, and running of your molds.

We define performance. For nearly 30 years, we’ve helped our customers to produce more e ciently, with lower cycle times and lower per unit costs

Our new compact stainless steel, modular unitized system features exible heaters that can be utilized o n multiple designs, so you don’t have to stock custom bent heaters Our new drop heaters provide more uniform heating and feature smaller pockets and no clamps They have in-line ow restrictors

for better process repeatability, and no over-pressurizing the cylinders. It all adds up to a reduced sized hot runner system, shorter heating times and better tool performance

We deliver value. We complement our hardware with leading-edge analytical tools, including Mold ow® and MOLDEX3D so ware. We’ll work with you on design issues and optional gating solutions before the mold or hot runner manifold system is ever built. Use us for the mold ow analysis and the manifold build, and we’ll do whatever it takes to make your hot runner/manifold system work to your complete satisfaction.

We’re committed to your success. Find out more. Call us today at 248.373.0800 or visit us at www.petsinc.net.

AMERICAN MOLD BUILDERS ASSOCIATION 7321 Shadeland Station Way, #285 Indianapolis, IN 46256 P: 317.436.3102 • F: 317.913.2445

info@amba.org • www.amba.org

AMBA TEAM

Troy Nix, Executive Director

Kym Conis, Managing Director

Susan Denzio, Business Manager

Rachael Pfenninger, Director of Strategic Execution

Brittany Stratmann, Public Relations and Marketing Manager

Advising Editor: Kym Conis

Advertising/Sales: Susan Denzio

PUBLISHED BY:

2150 SW Westport Dr., Suite #101

Topeka, KS 66614 P: 785.271.5801

Vice President, Editorial: Dianna Brodine

Editor: Lindsey Munson

Vice President, Design: Becky Arensdorf

Graphic Designer: Hailey Mann

Opinions expressed in this publication may or may not reflect the views of the Association and do not necessarily represent official positions or policies of the Association or its members.

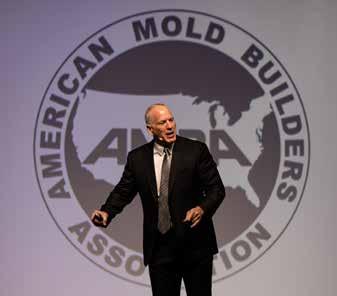

Hello, AMBA family. AMBA just celebrated its 50th anniversary in style as it kicked off the 2023 AMBA Conference with a clear message of unity from Executive Director Troy Nix. The message was spot on – in these challenging times, we need to unify our efforts. When moldmakers and business partners come together, we are stronger!

There were so many conference takeaways for my team and me. We made a promise that we would each work on one personal and one professional idea. Think about that for a minute. We had nine people there, so that means we will have nine improvements, personally and professionally.

There were 41 Emerging Leaders at the Conference – nearly 25% of the total attendance. The speaker for the Wednesday afternoon session delivered a message about how to delegate, empower and grow. Sounds simple, but I remember learning all that the hard way as I grew through the ranks. Keep your eye out for upcoming Emerging Leaders events, and get your young leaders involved!

Keynote speaker, Ricky Kalmon talked about changing your mindset to overcome some of the negative thoughts that enter your mind. I was cynical about hypnosis but witnessing some of my peers do something completely out of character was awesome! Paul Krismer talked about building a culture that thrives, with an emphasis on how important positive team interactions are to company culture. How many times do we have the “Eeyore” complex? More times than I would like to admit. We have the power to control how we act, and we need to focus on the positives in our work and lives.

Laurie Harbour informed members about using data to drive performance and strategies on how to compete in the global marketplace. Omar Nashashibi from The Franklin Partnership provided the latest from Washington D.C., and Mike Devereux was on hand to share expertise on the R&D Tax Credit situation. The breakout sessions were meaningful, and the topics were spot on with many great ideas, processes and philosophies shared. Also, the Peer-to-Peer sessions never disappoint! The chance to sit down with peers is incredible, and many of these profound conversations hit close to home.

Congratulations to Justin McPhee on winning the 2023 Mold Builder of the Year Award. I’ve known McPhee for a long time, and he deserves every accolade. Congratulations to the TK Mold & Engineering team on winning 2023 Tooling Trailblazer of the Year Award – and a HUGE thank you to Progressive Components for sponsoring the two awards!

Thank you to the awesome business partners who continue to support AMBA’s mission by setting up their booths to show off the latest and greatest technology. And last, but not least, on behalf of the Board of Directors and myself, thank you to Troy Nix, Kym Conis and the entire AMBA team for the hard work that went into making this year’s conference amazing.

At the AMBA Conference, we spent three days with some of the best partners and peers in the industry, and we walk away energized. Let’s not let the message of “unity” slip away. If you are ever in southeast Michigan, I welcome a visit from you. Likewise, if I am traveling near your facility, I would love to do the same. All the best to you, your families and your teams.

OFFICERS

National President

Tom Barr, TK Mold & Engineering

Immediate Past-President

Jim Sperber, Master Tool & Mold

Vice President Tyler VanRee, Legacy Precision Molds

Secretary and Legal Counsel

Alan Rothenbuecher, Benesch, Friedlander, Coplan & Aronoff LLP

Treasurer

Andy Peterson, Industrial Molds Group

BOARD OF DIRECTORS

David Bowers II, JMMS, Inc.

Charles Daniels, Wepco Plastics

Ed Francis, Crystallume

Eric Karaman, Michiana Global Mold

Chad LaMance, United Tool & Mold

John Stocker, Swiss Steel USA

Hillary Thomas, Westminster Tool

•MOLD FINISHING

•LASER WELDING

•LASER ENGRAVING

•HOT RUNNER REPAIR

•MOLD MAINTENANCE

•LASER MACHINE SALES

We offer mold finishing, laser welding, laser engraving, mold maintenance, and hot runner manifold repair all under one roof. We also manufacture and sell the only fully American made laser welding and laser engraving systems, custom built specifically for your toolroom. Let Alliance make a difference for you.

When Justin McPhee, general manager at Mold Craft, Inc. (dba Westfall Technik), took the microphone to accept the 2023 AMBA Mold Builder of the Year, he said, “Go big or go home! I’m speechless – what a ride it has been! I am blown away by this awesome organization, friends and mentors. But most importantly, I am here receiving this award because of the amazing team at Mold Craft that every day pushes our mission throughout the industry. I hope to continue to pay it forward wherever and whenever I can.”

The AMBA Mold Builder of the Year Award was created to recognize outstanding contributions as an industry leader and as an active AMBA member. The award recipient receives a $5,000 scholarship grant, sponsored by Progressive Components, to be donated to the industry-related educational program of choice. “Justin is a true ambassador of mold manufacturing, taking it to an extreme level as he does through all things in his life,” said Tom Barr, president and owner of TK Mold & Engineering, Inc. and the newly appointed board president for AMBA.

Recognized by his peers and the Association, he’s given so much over the course of his career, McPhee still was shocked when he realized he was this year’s award winner. “The whole thing was an absolute surprise from top to bottom… it may have been obvious with all the tears shed! I saw my wife making her way through the crowd and was absolutely beside myself,” he said.

Since 1964, a 59-year run, Willernie, Minnesota’s Mold Craft has been serving the mold industry as a custom injection mold manufacturer specializing in high-cavitation, interchangeable molds. McPhee has been with Mold Craft for 24 years, starting in 1999 as a mold designer immediately

after graduation from North Dakota State University. He quickly advanced to an engineering manager position in 2002 and became an owner in 2007, alongside Tim Bartz. He said, “The progression of my career from the mold design side is a little more unique than the traditional path of working your way up through the shop and toolmaker side of the business.”

From his earliest years in the industry, McPhee made an impact on mold building. He organized, crafted and developed the Mold Craft Design Handbook, which guided the company’s design group to design molds consistently, standardizing the mold building process. Ultimately, this handbook brought Mold Craft and the industry together with this ‘best practice’ – designing all fits and clearances up front rather than depending on custom mold fittings in the shop, there by eliminating unnecessary time spent sending molds back for repair and adjustments. McPhee said, “When I was developing the Mold Craft design standards, I was building a crutch for myself so I didn’t have to reinvent the wheel on every mold design. I didn’t realize I was changing a company and an industry.”

Furthermore, McPhee simplified the complexities of mold engineering and operations by inserting interchangeable components with full tolerance prints and models so customers theoretically could take Mold Craft’s prints to their own mold and tool shops, as well as send out spares – because if the design was built to print, it would fit in the mold. For the company and McPhee, staying on the cutting edge of innovation in the industry is imperative.

Creating opportunities for mold building and advocating for the manufacturing sector are big pieces of the impact

McPhee wants to leave on the industry and this world. From the education system to the government, there’s an opportunity for change, and McPhee believes reaching the next generation is instrumental in the growth of the industry.

As part of this outreach, he supports local colleges including serving on the advisory board of St. Paul College and assisting in developing a Machine Tool Program; serving on the advisory board and as a keynote speaker for events at Hennepin Technical College; and donating equipment and supplies to Dunwoody Institute. He also has shared his time and expertise with seven area high schools.

“I had great mentors who helped me understand the value of paying it forward, the value of helping others and the fact that you can’t complain about not having good employees if you aren’t helping the schools,” McPhee said.

A key annual outreach program for Mold Craft is Manufacturing (MFG) Day, where local high school and technical college students are invited to tour the facility. Each year, 100 visitors arrive at Mold Craft’s facility to see presentations at organized stations, including design, safety, operations, quality and tech center. This day is about students taking in a ton of information but, most importantly, walking away with a clear direction of what it takes to enter the mold industry and find a career path.

Additionally, Mold Craft takes part in White Bear Lake High School’s Gen Z Connection apprenticeship program, which started in May 2015 and is supported by the Vadnais Heights Economic Development Corporation (VHEDC) and others. The nature of the program is to hire high school students and expose them to several different cultures, industries and companies in the manufacturing industry in the Twin Cities area. The focus of the program is to show students that manufacturing is a solid career path that can be entered into with a two-year program after high school vs. a four-year post-secondary education. Students work 90 hours and are paid $10 per hour over the course of four weeks, rotating to a new manufacturer every week.

McPhee reflected on the introductory speech that was given prior to the reveal of the Mold Builder of the Year award winner. “When the Mold Craft Team did the high school and technical college tours and hosted the first ever AMBA Shop Tour, people thought we were crazy, but I said we were giving back to the industry,” he said. “When this happens a piece at a time, over many years, it doesn’t feel like a lot, but when you hear all these accomplishments read in one presentation… It was so special. I have become a little more emotional in my old age, but I don’t think I’ve had those types of tears of joy [during the awards ceremony] since Emily (19) and Connor (15) were born!”

McPhee continues to carry the advocacy and involvement torch as the longest-sitting board member in AMBA history, serving as a board member from 2010 to 2020, president from 2016 to 2018 and a participating member since 2001. In addition, he is part of the AMBA Minnesota Chapter, having served as treasurer and president from 2010 to the present time, while also supporting the AMBA Minnesota Chapter Golf Tournament fundraiser. McPhee shared, “This golf tournament is where funds are raised for local technical college kids and provides four $2,500 scholarships to help students complete their courses with less financial burden. It is so important and worth every ounce of energy.”

Always open to sharing innovations and ideas with other AMBA members, McPhee can be found traveling to other mold shops close to home or across the country. “The AMBA has supported me as a business leader – facilitating events that put leaders in the same room at the same time, producing events where professional and personal friendships are built (It feels like family every time we are together!) and organizing top-notch conferences where the bigger picture is seen,” said McPhee.

McPhee exemplifies the “American Mold Builder,” committing his life’s work and talent to Mold Craft, AMBA and the mold industry. From sitting in on customer meetings, design reviews and prospect presentations to attending tradeshow events and OEM mold design training sessions, McPhee loves being in on the action. He also is known for his infamous karaoke “Ice Ice Baby” moment(s), serving as boat captain for his son’s high school bass fishing team and cheering on his daughter, who plays volleyball at Moorhead State.

During his acceptance speech, McPhee thanked many for the career he’s been blessed with, but he wanted to mention a few things he missed on the night he received the award: “My mom and dad, who gave everything to raise three boys; to my wife for all the sacrifices she has made as a working mom and accountant, who ‘supported’ the decision and signed purchase papers with a three-year-old and a one-month-old; to the AMBA team for the support provided during my 10 or so years on the Board of Directors; and to Progressive Components, for the monetary commitment to continue the work with the future of mold manufacturing.

“This is a lifetime award that I am very proud to receive, honoring the drive and motivation to make a difference but also rewarding all of those who helped execute the plan,” said McPhee. “It’s about continuously filling the pipeline of opportunity, mentorship and support to our future generation.”

By Lindsey Munson, editor, The American Mold Builder

By Lindsey Munson, editor, The American Mold Builder

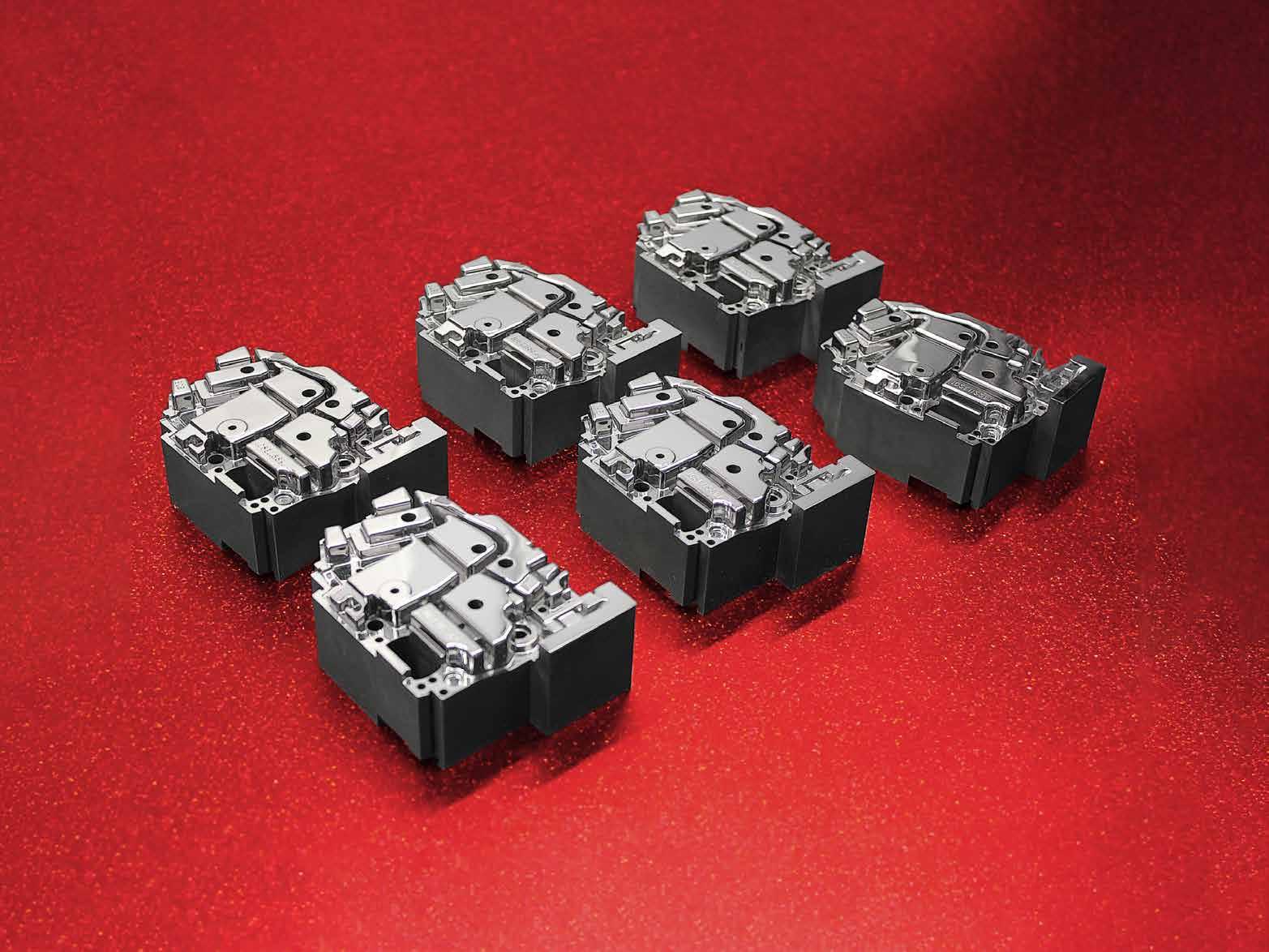

“TK Mold and its employees are a select few who talk the talk and then actually step up, doing exactly what they say they are going to do,” whispered a local business owner to Krista Barr at a community event a few weeks ago. That whisper became a roar when AMBA’s Tooling Trailblazer of the Year Award winner was announced in May.

The Tooling Trailblazer Award was established to recognize the accomplishments of an AMBA member company that have resulted in a notable impact in the area of education and is sponsored by Progressive Components. This year’s award recipient is a company known to the industry for its leadership and ability to respond where action is needed. For owners Tom and Krista Barr, their family-oriented business mentality has led to company engagement through educational development and training for the next generation of mold builders.

Barr sat alongside his wife, Krista; his daughter, Ashley; and a team of TK Mold employees during the awards ceremony, held during the 2023 AMBA Conference in Grand Rapids, Michigan. The room was buzzing when the company’s name was announced, and Barr stepped up to the microphone. “Tonight is about friendship and camaraderie” he said. “We are very fortunate at TK Mold, and by sharing our stories, we can expand the reach and touch many in and outside the industry, inspiring and showing what can be possible to those who will listen. I am very humbled by this award.”

Located in Romeo, Michigan, TK Mold has 24 employees and specializes in plastic injection molds, serving industries such as aerospace, automotive, consumer goods, defense,

medical and low-volume production runs. In 2017, Barr invested over $3 million in expanding his building and shop floor with new equipment – a new generation of moldmakers. More than half of the company is younger than 30, creating a balance between young and mature machinists. TK Mold has actively sought opportunities to be involved in the community, education system and related projects to promote workforce development, training and secondary degrees in manufacturing.

Barr said, “The day-in and day-out of what we do is not easy. It would not be possible to be who we are without all of us working together as a team.”

Parents and teachers often are the first to impact a student’s path, whether it be day-to-day, future educational endeavors or a career choice. That’s why TK Mold and its employees are dedicated to reaching students early to put the mold industry in their minds. From attending career days, speaking on panels and participating in advisory board meetings, TK Mold is in constant motion. The employees’ actions create awareness and deliver knowledge about an industry that many know about – all in an effort to find its next generation of moldmakers.

Especially meaningful for TK Mold was in 2021 when Romeo High School students developed an iPad holder with TK Mold’s influence and design assistance. When COVID-19 was hitting a peak, the CTE program at the high school was hitting a low. Barr knew the students needed engagement, and the school needed TK Mold’s resources.

With that, TK Mold chose to be a difference-maker, hosting live webinars and bringing students in to visit the facility, where they worked with TK Mold employees to make more than 2,000 iPad holders that then were distributed at an elementary school. The project's impact was two-fold: a fun project with purpose and accomplishment for the high school students and beneficial for the elementary students.

The company’s influence doesn’t stop there. In working with Macomb Community College, TK Mold developed a curriculum geared specifically to moldmaking, including applied trigonometry, drafting, electricity and electronics, CNC and EDM programming and machining, fluid power, robotics and welding. Then, TK Mold energized the newer generation of employees and the company’s seasoned team by restructuring the shop into new roles and beginning an apprenticeship program, which was officially registered in 2017. The program is completed in four years, with apprentices receiving recognition and certifications from the US Department of Labor, TK Mold and the college. Putting people in roles in which they can thrive and implementing cultural changes to attract youth in manufacturing have paid off for TK Mold. The program has had seven graduates over the past six years and three active apprentices will graduate within the next two years.

Barr shared his advice to the next generation: “Everything we use today is in existence because someone had the guts to have an idea to create. Be innovative, take chances and build the career you wish for yourself. Be proud of the fact that you are a part of this. Without you, people would not have things to make our world co-exist.”

In the fall of 2021, Barr was recognized by the government leaders of Macomb County with the Best Business Award, “Trailblazer of Future Talent.” Barr also has made a commitment to serving the industry, joining AMBA in 2014 and then the AMBA Board of Directors in 2017. He recently accepted a new role as the board president. Barr shared, “Having the support of the AMBA helps us remember that moldmakers are not alone in their journey. Moldmakers ‘get each other’ and truly understand the rewards and challenges of the trade.”

Barr also sits on local and national panels and has been instrumental in revitalizing the Southeast Michigan Chapter of the AMBA, working to rally AMBA member shops in the greater Detroit area. His ability to link businesses and networks, pulling them together on workforce development

and other pressing issues within the industry, is another example of his life’s purpose. And, Barr is a leader who walks the talk. In 2022, TK Mold employees and apprentices attended their first AMBA conference to help them grow professionally and personally.

TK Mold is in excellent hands with Barr at the helm, where he continues to mentor, bring awareness to career opportunities in the industry and offer hands-on learning at the local community college and high schools. Barr’s passion for growing the next generation of moldmakers lights a fire for all TK Mold employees, becoming an extension of the company’s culture and family mentality. As Krista Barr said, “It’s in our blood.”

Barr said, “It’s every moldmaker’s dream to be recognized for all the hard work that he achieves. We are grateful that at this year’s conference there were nine of us to witness this award. It would not have been the same if I were there with just Krista, and being together in a group made this acknowledgment more meaningful. I only wish I could have had the whole shop there in person with me. To win two AMBA awards back-to-back and be recognized amongst our peers was very humbling.”

Every mold building company operates with a set of metrics guiding its decision-making process. Is it time to hire? Purchase new equipment? Find a new market or customer set? … Close the doors?

Whether simple to calculate or incredibly complex, metrics often are the determining factor … but what if the metrics aren’t pointing in the right direction? Two mold manufacturing companies – Tolerance Tool and Westminster Tool – are approaching revenue, utilization and pricing metrics in a different way.

Troy Roberts is the CEO and co-owner of Beanstalk Collaborative Community Wealth, a holding company with an emphasis on preserving and growing manufacturing businesses in their communities. The Beanstalk team brings experience to its acquisitions that includes operating systems, strategic planning, and production and financial metrics. Roberts himself has more than 35 years of experience in manufacturing, including the plastics and metal industries. A page on the company website contains the following question, “Wouldn’t it be great if no privately held US manufacturing business was ever sold outside of its community again?”

In 2021, Beanstalk made its first acquisition with Tolerance Tool, located in North St. Paul, Minnesota. Tolerance Tool designs and manufactures complex, bridge and multi-cavity, high-volume production, thermoplastic and liquid silicone rubber injection mold tooling up to 500 tons. The company also designs and manufactures micro molds, multi-shot rotational molds, insert molds and over-molds.

Tolerance Tool had a strong, successful history, a wealth of knowledge and a veteran leadership team, but opportunities existed to strengthen the company. Data collection and increasing financial literacy was a priority, so an accounting/ office manager was hired who had previous experience with MRP/ERP implementations. A gap analysis was done, and the quoting and accounting policies and procedures were

restructured to address a disconnect in how the company was pricing its services. A strategic business relationship was developed with a sales representative agency, and the website was redesigned.

Senior management, while skilled and dedicated, never had exposure to the company’s financials, so Roberts introduced the senior leaders to value-add and gross margin concepts. The MRP/ERP system was brought online, giving the company the infrastructure to truly start analyzing what was happening within the company, and key benchmarks and financial metrics were identified using actual data from 2022. The stage was set for real change.

Roberts approaches revenue differently. Traditionally, manufacturing companies see high points where high volumes and throughputs drive revenue up, followed by low points where the shop floor isn’t used to its normal capacity. “When we were doing our due diligence on Tolerance Tool, we saw an accordion effect in the revenue record charts,” he said. “Sales efforts drove up revenue numbers and backlog, then revenue shrinks as backlog is worked off to the point that sales effort and sales orders are ramped up again. This up-and-down sales order cycle is not good for efficiency or utilization of resources.”

Roberts and the Tolerance management team established an order booking plan, with the goal of logging $300,000 in bookings every month – and they performed a weekly review to see if month-to-date orders were meeting the plan. If order volumes weren’t at the monthly goal, that told the general manager and the sales team that they needed to spend extra time focusing on key prospects to make sure that open capacity was communicated to prospects, which led to more stable order bookings.

“Favorable work efficiency, utilization and quality are directly related to a healthy backlog of orders,” Roberts said. “Looking at it this way makes companies proactive in

driving their sales teams to maintain a steady flow of sales orders and order backlog. Once achieved, it’s time to look at utilization, efficiency and quality metrics. A company may have the work coming in, a skilled work force and the equipment to do the job, but are those things working together efficiently and making quality product?”

The Tolerance Team uses a simple metric: The percent of direct labor absorbed into production jobs (i.e., utilization). “All companies should be able to evaluate this simple metric, regardless of the type of accounting systems they have available,” noted Roberts.

“If I am paying people on the floor – direct labor – how much of their time is spent actively working on a job?” he asked. “How much of their time is charged to a job? That leads us to ask if we’re spending too much time on activities that aren’t creating revenue. Are we effectively utilizing our direct labor

and fixed costs to generate revenue? These are numbers we measure and that our employees see every month.”

Thirteen-hundred miles to the east, Westminster Tool also focuses on its utilization metrics. With a 25-year history in the industry, Westminster Tool is a family-owned and -operated business started in 1997 by President Ray Coombs. Today, his three children have grown into significant roles within the company their father started: Colby Coombs is chief financial officer, Hannah Coombs is the talent development and marketing manager, and Hillary Thomas is the vice president leading sales and account management.

The company specializes in manufacturing complex injection mold systems, composite tooling and highperformance component production for the aerospace, medical and consumer packaging industries. Colby Coombs

knows the standards for those industries demand excellence. “As mold builders, we have the best and brightest people and machines,” he said. “When we are at a slow point, we avoid laying people off like Google or Amazon. We need to retain that experience and knowledge for the future.”

Coombs believes revenue is the result of when a company’s people are being utilized, but he pointed out that not all new tooling jobs utilize his team in the same way. “At Westminster Tool, we do machine modeling to see when our machines are working and when they’re not,” he said. “We have fixed resources, and we have great engineers, so the inclination is to fill their time with work, but it’s important that Hilary is bringing in the right type of work to keep our machines working consistently.”

As an example, Coombs said there may be certain components of a tool build that Westminster Tool sends to a partner company that specializes in those areas. Rather than a predictable and controllable progression from one department to another, engineering resources are used initially in the design of the mold and then other resources –machinery and team members – at Westminster Tool sit idle while waiting for the partner to complete its step.

“Understanding the progression of work and analyzing machine usage keyed a new way to look at revenue in our business, without an ERP system,” he said.

Ultimately, profitability at any mold shop is driven by pricing. “You want to have a plan to make sure you’re getting work into your shop, so you can have an opportunity to use your resources well,” said Roberts. “But not all work is profitable, so where should you be deploying those resources?” This is where employing velocity pricing serves as an additional check on a company’s preferred method for determining a price.

Velocity pricing is a system developed by Dr. Lisa Lang, CEO of Job Shop and Machine Shop Scheduling. “The traditional pricing method is to add materials, overhead and direct labor to come up with a base price, and then add margin,” said Roberts. “Instead, velocity pricing says to look at material and outside processing costs, and then decide what margin needs to be added. That margin is there to cover all of the company’s other costs and, hopefully, profit.”

To determine that margin – the value-add margin – Roberts uses this formula: sales – (cost of materials + outside processing).

This value-add margin is the residual margin to cover factory labor, selling activities, administrative functions and profit, Roberts and Coombs explained. In this pricing model, all operating expenses are treated as fixed costs. Once the cumulative value-add margin from all work is equal to the company’s fixed costs (the breakeven point), all additional value-add margin from future work adds to the bottom line.

“If the fixed costs are defined and the business prospects have been analyzed, you can understand clearly what company sales need to be to cover those fixed costs, along with the additional sales to generate the return (profit) you want,” Roberts said. “This analysis helps you regulate sales activity to avoid the accordion effect that makes it difficult for everyone to perform. Companies become more proactive rather than reactive when they focus on level loading of sales, which in turn improves utilization, efficiency and quality.”

Coombs added, “It’s important to look at what type of work you’re bringing in, whether your customers value what you’re doing, and whether that work complements your capabilities. At Westminster Tool, these metrics focused our efforts on customers that feed the equipment and investments we already have, rather than having to outsource components that don’t utilize the resources (people and equipment) that are fixed costs.”

What are fellow mold builders doing right now that can be implemented in other mold shops? Take a look through these information bursts for ideas on process efficiency, new business and the bottom line.

According to Laurie Harbour, president of Harbour Results, Inc., the edict from OEMs like Ford, GE Healthcare and John Deere is a 30% reduction in lead time. For mold builders looking to compete and reshore tooling, reducing waste and improving throughput are critical.

Standardized training is key. Instead of calling individuals out for performing job functions in a way that isn’t efficient, bring the entire team together to teach them the correct process.

Develop a sequence of events that is reviewed at the kickoff meeting so that each stage of the tool build is outlined, equipment and supplies are ready before the in-process tool reaches each station and employees know what they need to do to complete their portion of the job.

Track material waste. Is it specific to a particular machine or work station? If so, bring together a team to review the process and make recommendations.

When a tool builder is awarded a new program, the job rarely comes into the shop the next day. In fact, 12- to 18-month lead times aren’t uncommon. The sales pipeline has to stay full so the shop can maintain a consistent flow of business.

Create an annual plan with existing customers. Are they planning to buy new molds? Kick off new programs? Undertake repair or maintenance activities?

Follow engineers when they change jobs. What opportunities are available with the new company?

Exhibit at tradeshows where target customers are in attendance.

Cultivate international business (a California-based tool builder has more foreign customers than domestic at the current time).

Send email blasts to current customers and prospects to remind them of capabilities and current capacity levels. Customers’ needs change constantly – what they didn’t need three months ago may be exactly what they need today.

Small steps can allow businesses to keep more of the cash they’re earning.

Watch for “scope creeps” by being aware in real time (not after project completion) when the original scope of business changes. Don’t be afraid to go back to the customer to propose new terms based on the increased workload.

Audit existing banking relationships. Ask for better interest rates, and move the book of business if the request isn’t honored.

Do a credit check on customers to make sure they are able to meet financial obligations.

Call customers with a reminder a week or two before a payment due date.

CNC specialists who join the TNC Club enjoy exclusive benefits, including news updates, free software options, and in-depth support with questions about all aspects of HEIDENHAIN controls. In addition, premium members receive regional training courses, special invites to HEIDENHAIN events, and on-site consultations tailored to

Become

their applications. And one unique benefit is the TNC Specialist certification program, which trains lateral entrants to become skilled CNC operators. Stay in dialogue with HEIDENHAIN and other TNC experts. At the TNC Club, we care about your opinion and invite you to shape our offerings.

Gathering on May 10-12 in Grand Rapids, Michigan, AMBA members created an environment at the Amway Grand Plaza Hotel that was buzzing with energy as attendees united to learn and grow as a mold building community. Adding to the excitement, the Association recognized its 50th anniversary with a throwback celebration during the Welcome Reception (including everyone’s favorite childhood games and some epic costumes!) and celebratory desserts.

As the lights dimmed and spotlights lit up the stage, the theme of AMBA Conference 2023 – “Powering Growth” –kept its promise by delivering a conference unlike any other, challenging attendees to absorb new strategies, technologies and best practices. From inspiring keynote presentations and breakout sessions to leadership development and networking, the conference encouraged, motivated and empowered every attendee.

AMBA also hosted its annual awards dinner to announce and honor the 2023 Mold Builder of the Year and 2023 Tooling Trailblazer of the Year winners. Justin McPhee, general manager, Mold Craft (dba Westfall Technik), was recognized with the 2023 Mold Builder of the Year Award, and TK Mold, led by owner and president Tom Barr, was the recipient of the 2023 Tooling Trailblazer of the Year Award. Sponsored by Progressive Components, these Award recipients received a $5,000 scholarship grant to be given to the educational institution of their choice. Read more about the award recipients on pages 8 and 10 in this issue.

“The success of mold manufacturing relies on our people,” said Troy Nix. “It’s my personal belief that unity is important today more than ever before. People were meant to be together.” Nix took to the stage with a message about the importance of showing up. “Everything that has ever happened to you has led you here!” said Nix.” It’s the people sitting in a chair next to you – the person across the table – who impacts you to be a better leader, manager and person. When we are moved to be better, to grow and to learn from others –that’s called ‘unity.’”

Unity began for the mold building industry 50 years ago in the basement of a bar where a few colleagues gathered. Those founders created a path that grew into the American Mold Builders Association. Five decades later, the association is serving more than 200 member companies and over 50 partner companies.

Taking the time to connect – to be away from the business – isn’t always easy. Nix related his own recent experience in accepting an invitation from The Mission Continues, a local Indiana veterans’ organization. He was reluctant to go, but he honored his commitment to work with an organization whose mission is to bring military veterans together to continue service and transform communities. The leader of the group, who fought alongside seven of his friends only to ultimately lose them to suicide upon their return home. Nix walked away with a deep conviction that everyone needs purpose and connectivity.

“People make people better,” Nix said, “As a business leader, start visiting one another, open your shops – be part of the tide, so that when it rises, everyone rises.”

Ricky Kalmon jumped on the stage to the song

“I’ve Got a Feeling,” and immediately started his presentation, Leverage Your Mindset, by showing attendees how their mind controls every aspect of life. By changing the ways they think, individuals can reduce stress, overcome challenges, adapt to change, tap into the unrealized potential and ignite purpose and prosperity.

Kalmon walked the audience through exercises and examples to embrace awareness and gain clarity. Then he asked everyone to slowly stand and repeat the words, “I am amazing!” His message was that it’s time to embrace the world and change how the brain responds. By leveraging the power in each person’s mind, individuals have the power to:

● turn best intentions into greatest accomplishments;

● embrace change, growth and opportunities with purpose; and

● be the best version of self.

Omar Nashashibi, AMBA’s lobbyist in Washington, D.C., provided insights into what the Biden administration is considering on Section 301 tariff action on Chinese imports and how that will affect the mold manufacturing industry. Pending regulations on Capitol Hill also were discussed, and he urged the mold builders in the audience to advocate for themselves and the industry on a local, state and national level. Nashashibi also co-hosted a breakfast with Michael Devereux, Wipfli, where attendees had the opportunity to discuss pressing issues, such as R&D tax credits, over coffee. The AMBA is focused on fighting for the rights of US mold manufacturers, and Omar’s contributions to the conference ensured attendees were up to date on the latest developments.

Attendees joined in on a live, open forum to discuss ways in which improved business operations, better metrics and the latest technology can lead to stronger customer relationships, better products and, ultimately, re-shored work. This marked the first time live benchmarking occurred at the conference in an effort to focus on sharing with a wide audience the strategies that will allow those present to become more competitive in all areas of the mold manufacturing operation.

Facilitated by Harbour Results, Inc. President and CEO Laurie Harbour and AMBA Executive Director Troy Nix, attendees learned what strategies can be employed to improve OEM and processor relationships, draw business back to the domestic doorstep and how to advocate on the global stage.

Straight out of the gate, mold manufacturers dove into discussions on improving throughput and production time with strategies on analyzing company performance, software and equipment upgrades, workflow inspection and more. From quote turnaround time, design time and machine programming to the cutting of steel, mold manufacturers shared how they are making successful moves to improve time management – beginning with training and standardized practices.

Sales strategies also were covered, and mold manufacturers spoke to one another about the tactics currently used in their strategic sales processes. Conversation centered on customer quality and interaction, including assessing customer characteristics and classifications, vetting new customers, expanding existing customer lists and actively implementing a customer strategy with tracked data. Generating new business is a long-term game, demanding diversified approaches and a commitment to keep filling the pipeline for the future, even in moments when it looks like a shop is near capacity.

Lastly, mold manufacturers delivered insights on how to leverage cost-reduction opportunities and manage cash flow. These “best practices” ranged from bank audits, closely monitoring expenditures and rebates, performing annual (or more frequent) forecasting activities and instigating credit checks on new customers to avoid pitfalls.

The session focused on opening conversations among mold manufacturers who are facing the same hardships, concerns and overall industry highs and lows. A report gathering the best practices from this session and the pre-conference survey will be available in June.

LAURIE HARBOUR, HARBOUR RESULTS, INC., AND TROY NIX, EXECUTIVE DIRECTOR, AMBA

LAURIE HARBOUR, HARBOUR RESULTS, INC., AND TROY NIX, EXECUTIVE DIRECTOR, AMBA

Success and happiness are correlated; if you find success, you’ll find happiness. “The formula is actually quite opposite of what many expect – it’s happy first, then success,” Krismer said. Fundamental to workplace culture, employers are not responsible for “making” an employee happy, but rather for creating a culture of positivity, belonging, autonomy, appreciation and meaning.

Krismer elaborated on the cultural and emotional needs connecting the employee to the employer, showing the connection between forming the value-added emotional bond and the company’s retention rate. Creating a bridge of meaning between the organization and employee offers a career, rather than just a job.

To top the great resignation, Krismer kept it simple: As leaders, we have the power to shift or alter the cultural balance and it starts with positive energizers, creating impactful events within a company. By doing this small but mighty task every day, resilience is built throughout the organization.

The AMBA Conference offers many opportunities to share best practices and discuss solutions to shared challenges –the hallmark of the conference and of the AMBA network. These included an Emerging Leaders Pre-Con Workshop, a chance to meet industry mentors over breakfast, peer-topeer exchanges on Friday morning and live benchmarking with Troy Nix and Laurie Harbour. All of this sharing underlines the conference theme of “powering growth” –mold builders came together to unite, compete and grow!

Federated Insurance

INCOE

PCS Company

PLATINUM GOLD

Alliance Laser Sales

Cimatron

Crystallume

GROB Systems

HEIDENHAIN

BRONZE

Belmont BICO STEEL

CAM-TOOL

Creative Technology

Custom Etching

DME

EROWA

FCS

Gesswein

Progressive Components

SelfLube

Oerlikon HRSFlow

Plastic Engineering & Technical Services

Synventive

Wipfli

One of the most popular components of the AMBA Conference is the opportunity to attend Peer-to-Peer breakout sessions. Attendees sit with peers in their same job categories to ask questions and learn new ways of addressing challenges from colleagues who have had similar experiences. Four roundtable areas were offered: Operations, Owners/Presidents/CEOs, Sales and Marketing, and Workforce Development.

Hexagon Mantle

Mastip

MoldMaking Technology

PUNCH INDUSTRY

R.E.R. Software

Standex Engraving

Swiss Steel

DMS Harbour Results

Tebis

The American Mold Builder

UNISIG

Vincent Tool

Wisconsin Engraving

YCM Alliance

YT Solutions

The Emerging Leaders Pre-Conference Session, a halfday workshop designed for leaders under 40, was led by leadership coach and author Matt Lesser. The workshop focused on two important components of leadership –delegation and performance optimization. Peer-to-peer exchanges continued throughout the conference as leaders in mold building businesses shared best practices from their own organizations, from the implementation of Entrepreneurial Operating Systems and ways of improving OEM and processor relationships to simple metrics to evaluate profitability. Those in attendance walked away with a hot list of tools to grow and enhance their businesses.

The American subsidiary of the Swiss Oerlikon Group, Oerlikon Textile Inc., has moved into a new location near its previous location in Charlotte, North Carolina. A new service center for the polymer processing industry will be created by the middle of this year. The relocation of the commercial departments of Oerlikon Textile has been completed, and customer support is being provided in the 4,500 square meters of office and commercial space. Oerikon’s mechanical repair workshop and the electronic repair workshop will follow in the coming months. In addition, the company published its Sustainability Report 2022. Rated among the top 10% of the best-rated companies in the industrial sector in terms of sustainability following rating upgrades, the company improved on all of its environmental targets –from increasing the implementation of energy management systems and share of renewable electricity to decreasing emission intensity and share of waste disposed, according to Georg Stausberg, chief sustainability officer and CEO of Oerlikon’s Polymer Processing Solutions Division. For more information, visit www.oerlikon.com

Rollomatic, Inc., Mundelein, Illinois, a subsidiary of Rollomatic Holding Switzerland and a builder of CNC tool/ cutters, peel grinding machines and laser cutting machines, announced Joe Kane as CEO. Kane will continue his position as CEO of Strausak, Inc., overseeing operations for both companies and leading four senior managers supervising sales and operations. For more information, visit www.rollomatic.ch/

SyBridge Technologies, Southfield, Michigan, a provider of value-added design and manufacturing solutions across multiple industries, announced its acquisition of Cavaform, Inc., St. Petersburg, Florida, a tight-tolerance precision tooling and molding market manufacturer. Cavaform’s customers range across many end markets, but the company is known for its solutions in the medical disposables, personal care and intravenous (IV) catheter tipping tool industries. In 2008, Cavaform started MTM&D as a testing and qualifications business and quickly expanded into full “art to part” molding offerings. New York-based private equity firm

Crestview Partners established SyBridge Technologies in 2019 to create and build a value-added manufacturing solutions provider spanning end markets, geographies and advanced technological capabilities. For more information, visit www.sybridgetech.com

The Plastics Industry Association announced that exhibit space at NPE2024: The Plastics Show, the global platform for innovation in plastics, has sold out to more than 2,000 exhibitors. With more than 1.1 million net sq. ft. of exhibit space, this is a significant achievement 12 months ahead of the triennial trade show. With over 55,000 attendees expected, NPE2024 will be the largest plastics event in the Western Hemisphere showcasing the latest advancements in products and services highlighting six sold-out technology zones: advanced manufacturing, bottle, materials science, moldmaking, recycling and sustainability, and packaging. Registration will open on Tuesday, Sept. 12, 2023. For more information, visit www.NPE.org

SME’s Additive Manufacturing Start-Up Technology Award recognizes businesses with unique technologies that solve existing manufacturing problems with a unique technical approach. Mantle, San Francisco, California, was selected as the winner of the award for its groundbreaking TrueShape 3D printing technology, which significantly reduces the cost and lead times to produce precision tooling while allowing for better tool designs and solving skilled labor shortages. For more information, visit www.mantle3d.com

HS Inc., Grand Rapids, Michigan, a provider of turnkey automation solutions to the manufacturing industry, announced its strategic intent to focus on its automation integration business. HS Inc. offers comprehensive automation technology solutions, including automated and manual assembly, material handling, plastic processing and robot and vision integration. From design through installation and support, HS Inc. collaborates with customers to create a tailored automation application that delivers results. For more information, visit www.hsinc.us.

Gaining traction in the mold industry is the implementation of the Entrepreneurial Operating System (EOS), a system that integrates a set of simple, effective tools and a proven process to produce powerful business results.

At the 2023 AMBA Conference, one of the breakout sessions offered to mold manufacturers was Driving Successful Business Operations – The EOS Framework, led by presenter Dave Feidner, EOS Worldwide and certified EOS implementer. Panelists Tom Barr, president of TK Mold & Engineering, and Charles Daniels, chief financial officer of Wepco Plastics, contributed to the discussion.

Feidner kicked off the presentation with three key points that manufacturers and their leadership teams need to process, plan and take action on, including solving problematic areas, leading efficiently and effectively, and gaining focus in all areas within the company. To start the process, manufacturers must understand and actively implement the EOS framework:

● Get Real – Getting real in life and in business, sharing insights that are “real” – whether good or bad – so that a deeper dive can be taken into what works well and what doesn’t work well, and outlining pain points to redirect the company in the right direction.

● Keep It Simple – There’s no one-size-fits-all, no big theory or strategy, but rather a simple set of tools to assist in redirecting a company’s framework to meet its vision and create overall success.

● Get Results – Start acting today! Begin the process of creating a framework that is centered on the “real” and keep it “simple.”

In the EOS Model® strategy from EOS Worldwide, there are six components that should be looked at when building a strong foundation for an EOS platform within a business: vision, people, data, issues, process and traction.

Once the framework is accepted and implemented across all channels of the organization, companies can begin the “real” work, with the goal of accomplishing three key drivers: vision, traction and health. It is critical that the leadership team be 100% on board and on the same page with the company’s vision and goals, both short- and long-term, and

its future direction. From there and over a period of time, the point of traction happens when clarity, discipline and accountability are set, driving leadership and employees in their daily work. By putting in the work to make changes, a company begins the process of creating a healthy, successful operation.

A company’s pain points often are the impetus to redirect its vision and goals. These pain points may be centered on the following:

● Control – The inability to control the steering wheel (the business).

● Profit – It’s not always worth the squeeze – working hard, only to see that the ROI doesn’t match the effort.

● People – Employees who aren’t accountable and disciplined.

● Hitting the ceiling – All aspects of the business are going well until a certain point, and then the company suddenly hits a plateau.

● Nothing’s working – As a leader, there is never a shortage of books, organizations to join, training and more that can provide guidance. It’s not always about grabbing a hold of every resource, but instead finding the resources that make the most sense for the business.

Barr said, “When TK Mold started building out its EOS model on its own, immediately we came to grips with the fact that there was no structure or accountability. We saw our frustrations piling up and hit the ceiling. I knew, as a leader, I was too far into the company. I was too close to it and couldn’t be the lone person trying to fix our processes and operations. So, we chose to introduce other professionals to come in and hit the reset button.”

As for Daniels, he said, “I came across the book "Traction®" and shared it with internal leadership. We immediately jumped at the opportunity to bring the EOS model in-house. The book changed Wepco operations!”

The strategy is to simplify and streamline, focusing on the six areas – vision, people, data, issues, process and traction. This gives employees and leadership the ability to lean in and be a part of the changes, creating accountability, discipline, structure and clarity. In turn, a company maximizes

transparency across all employee channels and drives its long-term goals with the outcome of “real” results.

Once each area is defined, based on the model metrics, companies are presented with an opportunity to break the cycle of working on the same issues and problems over and over. Leadership and employees now have the tools and techniques to problem solve and create value-driven results that positively affect all areas of the operation.

One of the six components – vision – is key in strategically aligning a company’s operations. To create vision, there must be traction… and for a company to meet those key drivers, core values, core focus and long-term goals must be outlined. Barr and Daniels participated in this exercise when TK Mold and Wepco Plastics implemented EOS.

Wepco Plastics’ Daniels said, “Our values are to always do the right thing, never stop improving, impact our community and do more.” The company’s core focus sits on the pillars of purpose, cause and passion – to take on challenges that other manufacturers do not choose to value or focus on. Wepco’s long-term goal is simple, Daniels said: “To produce seven million parts per year.”

As for TK Mold, Barr said, “TK’s core values are to be passionate about the industry and work, seek curiosity and try new things, always work hard and be trustworthy. Our core focus is defined by what fits best in the TK Mold model, and every employee acknowledges it. Our long-term intent is to position TK to be consistently profitable and that any partner, employee and customer who touches TK Mold will be positively affected.”

In addition, the session touched on the second component of the six – traction - as part of driving business operations to reach maximum results. This component includes the development of a one-year plan and defining company “rocks” – a list of what stands in the way of the shortand long-term plans. TK Mold’s biggest “rock” was accountability, so a self-accountability chart was created that started with leadership and now is used company-wide. Barr said, “As a leader, it’s about ingraining discipline and being intentional.”

The EOS Model® is another tool readily available to strengthen tool builders’ internal operations. Daniels said, “For Wepco, it’s about staying focused on the implementation and pushing EOS with purpose every day.”

Learn more about the EOS Model® and Dave Feidner, EOS Worldwide, at www.eosworldwide.com or by contacting him at dave.feidner@eosworldwide.com

The AMBA has launched its 2023 Shop Rate Survey, which includes charge rates specific to services supplied by US mold manufacturers in engineering, moldmaking and specialty services. This survey also will gather related information including company demographics, mold size and type production, average overhead cost, gross margin ranges by annual sales revenue and current vs. anticipated capacity utilization. Due to the sensitive nature of this report, the final report will be available only to AMBA members for $399; participating AMBA members will receive the final report at no cost.

Additionally, the AMBA 2023 Business Forecast Report now is available for purchase. This report showcases industry trends and data specific to sales, profit levels, capital expenditures, shop and design employment levels and challenges faced in the industry. Now in an interactive version, this report is available to members for $299 and to non-members for $499.

For more information and to purchase these and other reports, visit www.amba.org/publications.

On July 19 and 20, AMBA members have the opportunity to attend a two-day dual plant tour workshop at Westminster Tool, Inc., (Plainfield, Connecticut), and Wepco Plastics, (Middlefield, Connecticut), where members will see workforce development efforts in action. Run by AMBA’s Emerging Leadership, the tour will highlight how operations can be impacted, improved and driven by the empowerment of next-generation leadership and the provision of executivelevel guidance. Hosts will highlight their facility’s operations, as well as the training and team development necessary to attract and retain the employees needed to drive continuous improvement efforts and profitability. For more information and to register, visit www.amba.org/events.

On Tuesday, June 6, and Tuesday, June 13 (11:30 a.m.-1

p.m. EST), AMBA members will participate in a workforceoriented, two-part “mini-series.” Each virtual session is an hour and a half and will begin with a presentation by a topic expert who will provide guidance on recruitment and retention strategies, tactics and best practices. Each presentation will be followed by a brainstorming session and will conclude with a roundtable discussion, where attendees will share related challenges and best practices during a facilitated peer-to-peer dialogue. For more information and to register for the two-part virtual series, visit www.amba. org/events.

Recently, during AMBA Conference 2023 in Grand Rapids, Michigan, AMBA members joined forces to package meals for children in the greater Grand Rapids area. Companies from across the US made short order of 311 lbs of food to produce over 400 meals in just 20 minutes. Tony Demakis with Alliance Specialties and Laser Sales, organize of the fundraiser commented, “When we all come together with a purpose and a common goal, we can make a real difference.”

The AMBA is excited to announce a new Executive Committee at the helm of the AMBA Board of Directors. The new AMBA Executive Committee features AMBA Board President Tom Barr, TK Mold & Engineering (Romeo, Michigan), Vice President Tyler VanRee, Legacy Precision Molds (Grandville, Michigan); Treasurer Andy Peterson, Industrial Molds (Rockford, Illinois); Immediate Past President Jim Sperber, Master Tool & Mold (Grafton, Wisconsin) and Alan Rothenbuecher, Benesch Law (Cleveland, Ohio), the board’s secretary and legal counsel. The AMBA Board of Directors, led by its Executive Committee, represents experience across all facets of the US mold manufacturing industry. As a governing body, these directors supervise, drive and support the strategic initiatives and priorities of the Association, as well as oversee disbursement of Association funds. Open positions now are available, if interested contact AMBA Managing Director Kym Conis at kconis@amba.org.

For parts with shot sizes from a fraction of a gram to multiple kilograms, INCOE provides Hot Runner Technology solutions throughout the entire process — from engineering mold review and filling simulation to on-site technical support.

Our global commitment is to be your Melt Logistics® partner — producing value in your process — and ultimately delivering satisfaction where it counts.

amba members saved an average of $6K in mro spend in 2022 -

$4,800 more than average member dues.

Get involved to start saving today. AMBA.org.

MES vs. ERP Software – What’s the Difference (to the Bottom Line)?

June 22 | 12-1 p.m. (EST)

To be competitive, shops need to focus on flexibility and efficiency – and the way to do that is to focus on the right management tools that can deliver measurable improvements. Join Martin “Marty” Chaput, project manager and manufacturing execution systems implementation expert, Tebis America, as he explains how MES and ERP can help shop owners better manage various aspects of their manufacturing processes. During this presentation, Chaput will review the aspects, benefits and functionality of each, how they differ and how they can work together to help manufacturers improve their bottom line and power growth.

August 9 | 12-1 p.m. (EST)

The AMBA has opened registration for its next roundtable discussion on current sales and marketing challenges, where peers will meet on camera to discuss topics such as management of current and new customer relationships, sales tactics/techniques, continuing business, use of new technologies and more.

AMBA members can register at no cost for both opportunities at www.amba.org/events.

The Work Capacity Tool is a members-only resource that allows AMBA members to share the capacity they have related to certain services. The objective of this tool is to facilitate connection between AMBA members who have open capacity with other members and who are over capacity and looking to share work. To learn more about the AMBA’s Work Capacity Tool and how it can be used to leverage business opportunities, visit www.amba.org/member-resources

Mantz Automation

1630 Innovation Way

Hartford, Wisconsin 53027

Rebecca Ohser, technical sales

Phone: 262.673.7560

Email: rosher@mantzautomation.com

From its humble beginnings, Mantz Automation has grown into an industry leader by heavily investing in state-of-the-art equipment and its people. With over 30 years of experience, the team is set to handle large or small projects, with single or multiple molds, and is ready to work with its customers to develop successful solutions regardless of the project.

Hytech Tool & Mold

2202 Washington St.

Jamestown, New York 14701

Bill Swanson, general manager

Phone: 716.488.2796

Email: bswanson@hytechmold.com

Hytech Tool & Mold started in 1988 and is staffed with the finest toolmakers, designers and programmers, with a total of over 200 years of mold building experience. With an 11,000 sq. ft. climate-controlled facility, the company provides a full range of tooling services and is an exclusive user of Catia V-5 products for modeling, design and cutter path. Hytech’s team takes pride in delivering top quality tooling that is production capable on the first sample.

Plastek Industries, Inc.

2425 West 23rd St.

Erie, Pennsylvania 16506

Doug Prischak, vice president of global tool and engineering

Phone: 814.878.4400

Email: dougp@plastekgroup.com

The Plastek Group, founded in 1956 as a toolmaking company and based in Erie, Pennsylvania, is a world-class

manufacturer of plastics packaging for the personal care, home care, food and beverage, cosmetics and pharmaceutical packaging industries. The company, with manufacturing sites in the US, UK, Brazil and Mexico, specializes in industrial design, product and package development, mold design and build, injection, injection blow and injection stretch blow molding, as well as value-added assembly and decorating.

Tessy Tooling

4962 Pittsburg Ave.

Erie, Pennsylvania 16509

Scott Smith, managing director

Phone: 814.838.9777

Email: ssmith@tessytooling.com

Tessy Tooling builds world-class injection molds, servicing many of the world’s top medical OEMs. By utilizing more than 45 years of experience to design and build highvolume plastic injection molds in the consumer products and medical markets, Tessy Tooling has become the go-to source for projects across the globe. The company prides itself on innovation, education and quality while taking a proactive approach toward the future of the mold building industry.

Mantle

1950 Cesar Chavez St. San Francisco, California 94124

Ethan Rejto, director of marketing

Phone: 415.655.3555

Email: ethan.rejto@mantle3d.com

Mantle accelerates product development by simplifying how mold tool components are made. Mantle’s TrueShape™ metal 3D printing technology delivers the accuracy, surface finish and tool steel properties required for demanding tooling applications. Tools made with Mantle’s technology have produced millions of parts while reducing tooling lead times and costs.

To learn more or apply for partnership, contact the AMBA office at info@amba.org. Visit www.amba.org/partners to see a complete list of the current AMBA partners.

The iWarriors mission is to honor severely injured soldiers from all branches of the Armed Forces by providing personalized tablets and technology to aid in their rehabilitation and recovery. Support is from the American Mold Builders Association, MoldMaking Technology, and suppliers.

These days, when there is reference to the Big 3 on Capitol Hill, it’s not about the Detroit OEMs. Instead, it’s about lobbying on the Big 3 tax provisions that are having an overwhelming impact on AMBA members: reinstating R&D expensing while eliminating capitalization and amortization requirements, restoring 100% Bonus Depreciation and including the full EBITDA standard for interest deductibility on business loans.

The Tax Cuts and Jobs Act signed by former President Trump in 2017 phased out or eliminated several key tax provisions used by AMBA members. Key among them is Section 174, which eliminates the ability to immediately expense a company’s R&D activities and requires manufacturers to capitalize their R&D and amortize those expenses over five years starting on Jan. 1, 2022. The change in law has caught many by surprise, leading AMBA to activate its membership and lobbying team to press lawmakers to reinstate full expensing and eliminate the capitalization and amortization requirements.

In a March 2023 survey, 77% of AMBA members reported conducting R&D activities in 2022, with the average dollar amount being $1.446 million for each company. Members report that the average increase in tax liability in 2022 for AMBA members due to having to pay tax on R&D as an asset and amortization of expenses is $290,013. AMBA’s message to lawmakers is that this is a direct tax on America’s small businesses; and will lead to the hiring of fewer manufacturers, decrease investments here in the US and increase China’s advantage over an industry critical for national and economic security.

This statement is borne out in the data from AMBA’s survey that is being sent to lawmakers on Capitol Hill. As a result of the requirement to capitalize and amortize R&D activities, 50% of AMBA members will reduce levels of R&D in 2023; 48% will have to reduce capital expenditures to pay the added tax liability; 25% will have to freeze hiring; 20% will have to borrow to pay the added tax liability; and roughly one in nine AMBA companies will have to lay off employees to pay the taxes due as a result of this law.

These are essential small businesses, averaging 56 employees as of April 1, 2023, according to the survey, placing an outsized impact of this tax hike on the shoulders of downstream manufacturers. This is why AMBA is lobbying Congress now. In the US House of Representatives, Reps.

Ron Estes (R-KS) and John Larson (D-CT) introduced the American Innovation and R&D Competitiveness Act (H.R. 2673) and Senators Maggie Hassan (D-NH) and Todd Young (R-IN) put forward the American Innovation and Jobs Act (S. 866), both of which permanently would repeal the harmful R&D amortization provision and reinstate R&D expensing retroactive to Jan. 1, 2022.

Making things worse for American businesses are other provisions in the TCJA that will reduce investments. The 2017 law provided manufacturers with the ability to immediately expense 100% of their capital expenditures, known as Bonus Depreciation. However, in a cost-saving measure similar to the R&D 174 provision, the law reduced 100% full expensing to 80% effective Jan. 1, 2023. While not unexpected, the reduction in 2023 to 80% and then to 60% in 2024 and down to 40% in 2025, before falling to just 20% in 2026 before the full elimination of expensing in 2027, will have a significant impact on spending by manufacturers on heavy equipment and machinery.

Bonus depreciation at 80% in 2023 means manufacturers may purchase smaller machines, buy less equipment and bid on fewer potential orders. AMBA is pressing lawmakers to reinstate full 100% bonus depreciation for two years to align with the looming tax fiscal cliff coming at the end of 2025 when individual and passthrough business tax rates will increase under the TCJA. Senator James Lankford (ROK) and Rep. Jodey Arrington (R-TX) recently introduced the Accelerate Long-Term Investment Growth Now (ALIGN) Act, which would restore full expensing for capital investments.

Another lesser-known provision in the TCJA also took effect on Jan. 1, 2023, this one eliminating the ability of companies to include Depreciation and Amortization when calculating their business loan interest deduction under Section 163(j). The law no longer allows companies to use the full EBITDA standard, which also impacts investment decisions by companies. The American Investment in Manufacturing (AIM) Act (H.R. 2788 in the House and S. 1232 in the Senate) is a bill supported by manufacturers that would reinstate the EBITDA standard for interest deductibility. The bill is led in the House by Reps. Adrian Smith (R-NE) and Joe Morelle (D-NY), and in the Senate by Sen. Shelly Moore Capito (R-WV) and Kyrsten Sinema (I-AZ).

These Big 3 tax provisions have varying levels of bipartisan support in Washington, D.C., and in the case of an R&D fix, overwhelming bipartisan support. The challenge is the same as always, Congress no longer regularly passes bills on its own. Rather, lawmakers bundle multiple pieces of legislation together on a must-pass vehicle, often a government spending bill or possibly this year, a debt ceiling package.

Lawmakers, in both parties, are assuring lobbyists that they will get an R&D fix done this calendar year but addressing both 100% expensing and business loan interest deduction

face a tougher path. Regardless, the Big 3, or even one on its own, likely needs a broader measure to which lawmakers ultimately will attach at least the R&D provision.

These assurances from members of Congress are of no use to manufacturers who are facing six-figure tax bills this year because of inaction on Capitol Hill last year. Sources indicate that a key House committee may start moving a bill with these and other tax provisions included in May or June, but a final solution likely is several months away still. There is a possibility of including R&D and other provisions on a bill to increase the debt ceiling that Republicans and Democrats will start to negotiate this summer, but more concrete action may not be seen until closer to September 30, or even after Thanksgiving.

This is why the continued pressure from AMBA members and the lobbying team in Washington to retroactively reinstate the Big 3 tax provisions is more critical than ever.

Omar Nashashibi is a founding partner at The Franklin Partnership, LLC, a bipartisan government relations and lobbying firm retained by the American Mold Builders Association in Washington, D.C.

Progressive Components, Wauconda, Illinois, a developer and supplier of components for the production tooling industry, expands its Z-Series Alignment Lock product line with five options for easier mold manufacturing. Designed to be machined from the top at the parting line, the Top Machine Style Bar Locks simplify machining steps and increase pocket accuracy. For multi-parting-line tools, Progressive added an X-Style Bar Lock configuration. To avoid water lines and other mold features, the Internal Top Locks mount inboard vs. at the mold base’s edge. As for the Counterbored Round Taper Lock, it provides counterbored mounting to allow for parting line installation. Finally, the Rectangular Taper Bar Locks extend performance with better materials and treatments utilized. For more information, visit www.procomps.com

HASCO, Fletcher, North Carolina, updated the CAD native data for the SolidWorks® database, providing customers with an exclusive tool with an estimated 100 products. The parametric data allows simple and precise working. Standard mold units in the CAD system can do more than just replicate the geometry. Parameter-controlled native standard mold units offer the designer numerous advantages. In addition to the geometry of the component, the standard elements also contain information about the cutting geometry. Through Boolean operations, the cutting elements can be removed from the mold plates. This facilitates the installation of the mold units in the mold. The fully parametric data also have decisive advantages if any changes are made since the relevant parts automatically adapt to the corrections. A new parts list then is generated, guaranteeing very high process reliability and eliminating the risk of incorrect orders. The largely automated ordering process ensures punctual delivery for the start of assembly and rounds off the overall process. For more information, visit www.hasco.com

Dormer Pramet, with global production facilities in Europe, Americas and Asia is a global supplier of metal cutting tools and related services. The company launched an economical

face milling family covering a wide range of applications with negative octagonal and square inserts, along with a variety of shell mills. The range includes three variants of a 16-edged ONMX insert for depths of cut up to 0.157 inches (4 mm). The eight-edged ONMX-W is a specific wiper insert for high-quality surface finish with large cutters and high feed rate. The portfolio also includes a range of eight-edged SNMX inserts for a higher metal removal rate. This includes an M chip breaker for medium machining and an R geometry for roughing, both for depths of cut up to 0.275 inches (7 mm) in various materials. For more information, visit www. dormerpramet.com.

GROB Systems, Inc., Bluffton, Ohio, a supplier in the development of manufacturing systems and machine tools, introduced its new, compact GRC-R12 robot cell. The robot cell offers a flexible, customizable and affordable automation solution for the GROB G150 5-Axis Universal Machining Center, the smallest horizontal machining center to date for the company in its modular G-series Universal line. The introduction of the GRC-R12 robot cell broadens GROB’s range of automation solutions for creating flexible manufacturing cells. The cell has a six-axis FANUC M-10iD/12 Robot with 4.7 ft. (1,441 mm) reach, capable of handling a maximum load of 26.5 lbs (12 kg). The GRC-R12 features a pneumatic single-or double-gripper system. The drawer feed system can have up to six drawers that can be unloaded and reloaded while the robot cell and machining center are in operation. For more information, visit www.grobgroup.com

Jergens, Inc., Cleveland, Ohio, a global manufacturer of work holding, lifting and specialty fastener products, combined key features of its SP2000™ and Shackle-Lok™ hoist rings for a new productive and secure solution to die flipping. The die-flipping hoist rings are available as standard or LiftCheck™ styles in both inch and metric dimensions and are made in the US. Die flipping is a standard process of rotating and inverting die plates for cleaning oils and metal chips. The hoist rings are manufactured to strict quality standards, proof tests for each one to 200% of the load and are certified. For more information, visit www.jergensinc.com

CNC Broach Tool LLC, Laguna Beach, California, a provider of inserted broaching tools and carbide broach inserts, launched sample Haas spline broaching programs and Haas keyway broaching programs on its website. With the carbide inserts, customers can create perfectly indexed broached features, which is useful when orientation is required for the broached spline or keyway as it can be machined in the same operation as other features. This reduces setup time and ensures that all the features are in perfect alignment, improving accuracy. A design advantage is that the inserts have two cutting edges so that when one edge dulls, the broaching insert can be rotated to bring a fresh edge into use, extending the life of the tool and reducing downtime for tool changes. The inserts are offered for various applications with 38 stock sizes ranging from .041" up to .752" wide. In addition, the company also offers a CNC Broach Gcode program generator to help customers with Haas CNC machines to hit the ground running. For more information, visit www.cncbroachtools.com.