Washington's Fall Agenda

Hot Runner Troubleshooting Tips

Mold Builders Offer Sales and Marketing Strategies

Maximizing Website Impact

Washington's Fall Agenda

Hot Runner Troubleshooting Tips

Mold Builders Offer Sales and Marketing Strategies

Maximizing Website Impact

Kenny

Kenny

By calling on Progressive for components for hundreds of mold bases each year, Kenny Skar has gotten to know Pro’s team over the years:

“The dimensional consistency of critical components is spot on, and Pro’s Customer Service team is like family. And, we appreciate that Progressive steps up and gives back to strengthen our industry.”

Whether as your default BOM source or spec’ing exclusive innovations, Progressive delivers the service and performance your company deserves. Call 1-800-269-6653 to discuss putting these advantages to work for you.

AMERICAN MOLD BUILDERS ASSOCIATION 7321 Shadeland Station Way, #285 Indianapolis, IN 46256 P: 317.436.3102 • F: 317.913.2445 info@amba.org • www.amba.org

AMBA TEAM

Troy Nix, Executive Director

Kym Conis, Managing Director

Susan Denzio, Business Manager

Rachael Pfenninger, Director of Strategic Execution

Brittany Stratmann, Public Relations and Marketing Manager

Advising Editor: Kym Conis

Advertising/Sales: Susan Denzio

PUBLISHED BY:

2150 SW Westport Dr., Suite #101

Topeka, KS 66614 P: 785.271.5801

Vice President, Editorial: Dianna Brodine

Editor: Lindsey Munson

Vice President, Design: Becky Arensdorf

Graphic Designer: Hailey Mann

Opinions expressed in this publication may or may not reflect the views of the Association and do not necessarily represent official positions or policies of the Association or its members.

Dear AMBA family, I hope everyone has been enjoying the summer! As Labor Day is upon us, we enter one of my favorite seasons of the year – fall.

Looking back on AMBA summer events, a BIG thank you goes out to Wepco Plastics and Westminster Tool for hosting two very informative plant tours. These two companies were kind enough to open their doors and share best practices. These plant tours allow AMBA members and partners an opportunity to learn and help one another grow. The networking opportunity with industry partners and peers from these tours was worth it alone. There were many laughs during those two days, as so many in the trade can relate to what we each go through daily.

Even though I am writing this message before the Dynamic Group facility tour, I also would like to thank the Dynamic team. It’s a lot of work to put a tour together, but everyone always walks away creating memories and gaining something new that they learned.

Now that a few months have passed since the AMBA Conference in May, it’s important to be reminded about each of the sessions that were attended. As the industry knows, the US economy is struggling – and it’s important to stick together. The positive side is that manufacturing typically is the first to experience the recession, but also the first one out of it. As an industry, it is crucial to stay strong and support each other. As a reminder, please take advantage of and utilize the Work Capacity Tool on AMBA’s website by visiting www.amba.org/member-resources/work-capacity-tool. Whether looking for help on a project or needing to fill capacity, this tool is a significant resource and should be kept at the forefront.

The Emerging Leaders recently launched a weekly series on Management Fundamentals. If you haven’t signed your future leaders up, take advantage of the program. It’s been a game changer for my team! AMBA also is adding a CNC Machinist forum. The goal is to help each other out with specific CNC best practices. I know my CNC team is excited about this opportunity to learn and share with their peers.

I also would like to welcome our new board members, including Mike Hetherington from Franchino Mold & Engineering, Troy Roberts from Tolerance Tool, Camille Sackett from Accede Mold & Tool and Kyle Klouda from MSI Mold Builders. Thank you to Charles Daniels from Wepco Plastics and Chad LaMance from United Tool and Mold for their second terms on the board. Also, a big shout out to AMBA’s board members who continue to serve for their continued dedication and commitment to the organization.

Finally, I ask that every AMBA member consider digging deeper to include the Emerging Leaders in our companies, as well as the current leaders, in these AMBA events! When we grow the AMBA together, we become a powerful presence in the industry. All the best!

David Bowers, II, JMMS, Inc.

OFFICERS

National President

Tom Barr, TK Mold & Engineering

Immediate Past-President

Jim Sperber, Master Tool & Mold

Vice President Tyler VanRee, Legacy Precision Molds

Secretary and Legal Counsel

Alan Rothenbuecher, Benesch, Friedlander, Coplan & Aronoff LLP

Treasurer

Andy Peterson, Industrial Molds Group

Charles Daniels, Wepco Plastics

Ed Francis, Crystallume Engineered Diamond Products

Mike Hetherington, Franchino Mold & Engineering

Eric Karaman, Michiana Global Mold

Kyle Klouda, MSI Mold Builders

Chad LaMance, United Tool and Mold

Troy Roberts, Tolerance Tool

Camille Sackett, Accede Mold & Tool

John Stocker, Swiss Steel USA, Inc.

Hillary Thomas, Westminster Tool, Inc.

By Omar S. Nashashibi, co-founder, The Franklin Partnership, LLC

By Omar S. Nashashibi, co-founder, The Franklin Partnership, LLC

In July, I marked my 25th year living and working in Washington, D.C. – Bill Clinton still occupied the Oval Office; Newt Gingrich was in his final months as House Speaker; and northern Republicans and southern Democrats still were a regular sight on Capitol Hill. Those were not the good old days by any stretch of the imagination, as we were in the midst of the Ken Starr investigations and fierce partisan battles. Back then, those in opposing parties often still found a way to legislate, whereas today, the infighting within the Republican party is so intense that Democrats are happy to sit back and watch as they are five seats away from retaking control of the US House next November.

That infighting has the potential to hold up important tax legislation, cause the federal government to shut down on October 1, and possibly hand the House back to Democrats

by forcing vulnerable moderate GOP lawmakers to take tough votes on cultural issues that never will clear the Senate. This dysfunction is wreaking havoc on Washington’s agenda for the second half of 2023.

In July, House Republicans had planned on moving major tax legislation that cleared committee only to run into intraparty opposition to the GOP-only drafted plan. The legislation includes a reversal of the Tax Cuts and Jobs Act Section 174 requirement to amortize and capitalize Research and Development expenditures and reinstates the ability to fully deduct those R&D expenses. In an April 2023 survey, AMBA members reported having a $290,013 tax liability for 2022 due to the tax law. That is a significant tax bill that will continue to grow without congressional action this year.

If Republicans do come to an internal agreement in the coming month, there still is enough time to negotiate a solution with Senate Democrats – meaning, once the GOP resolves its infighting, they still must battle with Senate Democrats and a Biden White House on a package of largely business tax cuts. The message is that AMBA members certainly can spend $290,013 more wisely than bureaucrats in Washington, but Congress needs to act to give the industry a chance. Agenda item number one – put money back into the pockets of America’s mold, tool and die builders.

Stalled agenda item number two is funding the federal government beyond October 1. Congress last passed all 12 of the required bills to fund the federal government in 1996, and this year is not the one in which lawmakers break their winless streak. Senators cleared all 12 bills from their committee, while the House failed to pass two and did not move any through that lower chamber prior to leaving for the August summer break on July 28. Should lawmakers fail to pass a bill, government agencies will begin to shut down –and GOP lawmakers in the House are miles apart from their Senate counterparts on spending levels.

The House Republican bill proposes to eliminate or reduce funding for roughly 100 programs, including those for workforce development and training, and to help with recruiting the youth, underserved and remote communities into careers. The bipartisan Senate bill increases funding for these programs by $147 million, setting up yet another showdown for lawmakers and causing further disruption to the congressional agenda this fall.

Congress this fall also must pass the National Defense Authorization Act, the Pentagon policy bill lawmakers have completed each year since 1961. House Republicans inserted a number of untenable cultural provisions into their bill that largely passed along party lines, compared to an overwhelmingly bipartisan Senate bill that passed by a vote of 86 to 11. Of note, language to codify President Biden’s increased Buy America domestic content requirements to require purchases of domestically manufactured goods likely will survive in a final bill – if Congress can pass one.

Bills to renew programs for the nation’s airports and farmers also are among the top ticket items left on the congressional agenda for this fall. These all are must-pass bills, from defense to farming to career development, the pending legislation impacts all aspects of the industry.

On the Senate’s agenda is a possible bill focused on China and US supply chains. Senate Majority Leader Charles Schumer (D-NY) has tasked nine Senate committees with

builders.

piecing together parts of a bill focused on controlling exports to China, increasing transparency of imports and restricting investments from China into key US industries and companies. AMBA is working with lawmakers on language to address transshipment and third-party subsidization. China often creates hub zones in different countries and then provides subsidized loans, directs investments or pays employees directly, creating a network of government-backed manufacturing companies around the world competing with American mold, tool and die makers.

Bipartisan legislation some hope to attach to this broader China bill will increase resources for US Customs to crack down on Chinese shipments coming in from other countries as importers seek to avoid the 25% import tariff still in place.

All of this represents a calendar of uncertainty on Capitol Hill for American manufacturers. What is certain, however, is when Washington cannot legislate, it will regulate. This summer, the Biden administration released its regulatory agenda for the remainder of 2023 and the first half of the coming year. The regulatory agenda includes 1,472 proposed federal rules, much of which impact American industry. The most immediate AMBA members can expect to see include an increase in the overtime exemption threshold, making millions more workers eligible for time and a half; rules that increase the OSHA reporting requirements for manufacturers; and an aim to increase industrial decarbonization by limiting process heating in manufacturing and reducing emissions.

Of particular concern, and certainty, is a potential OSHA rule in development regulating indoor and outdoor workspaces when the heat index exceeds 80o F. This could require manufacturers to impose additional PPE and engineering-control requirements, along with designated cool-down stations and specified rest breaks.

While manufacturers can count on uncertainty on Capitol Hill, it is the certainty when Congress does not act, and regulators do, that should raise the most concern.

Omar Nashashibi is a founding partner at The Franklin Partnership, LLC, a bipartisan government relations and lobbying firm retained by the American Mold Builders Association in Washington, D.C.

Agenda item number one – put money back into the pockets of America’s mold, tool and die

An interview with Jim Bott, business development manager of mobility/automotive/heavy truck, INCOE

Hot runner technology has been around for decades. However, it’s piquing plastics processors’ interest, and sales have been increasing over the past 10 years. The technology has made encouraging advancements and manufacturers are capitalizing on its benefits. Known for efficiently and precisely delivering molten plastics to the mold cavity, hot runners offer a number of advantages, including design flexibility with no limitations, quicker production cycles, waste reduction and improved part quality output.

The American Mold Builder reached out to Jim Bott, business development manager of mobility/automotive/heavy truck at INCOE and an industry veteran, for his perspective on hot runner technology.

HOT RUNNER TECHNOLOGY IS UTILIZED IN MARKETS INCLUDING AUTOMOTIVE, MEDICAL, PACKAGING, ELECTRONICS AND MORE. WHERE IS THE MARKET GROWTH, AND HOW ARE HOT RUNNERS ENABLING THOSE APPLICATIONS?

Yes, certainly “more” markets (in alphabetical order) such as appliance, caps/closures, cosmetics, defense, lawn and garden and recreation can be added to the question.

Each one of these markets then is subdivided into numerous categories. Not taking the easy way out, the belief is market growth opportunity hits “across the board” for the various applications. The exception may be non-critical, singleuse parts where recycling is not commonly practiced. Organizations, namely PLASTICS, are lobbying and educating both with the government and the public regarding proper human care of recycling as the solution rather than banning certain single-use plastic products. This important message, turned into practice, will delete the noted listed exception to market growth.

Hot runner technology, in many cases, is the only approach to meet the final product demand(s). These needs include, but are not exclusive to, part quality, weight reduction, production volume and material scrap reduction.

Interesting references to “hot topics” and “hot runner!” Hot runner melt delivery technology always has contributed to the reduction of CO₂ emissions. However, rarely was it or was it not mentioned just five years ago. Now, it has become a topic of higher recognition. Some global governments “reward” the pursuit of reducing carbon emissions – as an example, giving grants to those that demonstrate investments in technology that lowers CO₂ emissions over the currently used technology(ies).

Other governments “penalize” those that do not provide proof of CO₂ reduction. As an example, the governments may impose higher taxes for those businesses that do not demonstrate the implementation of emission-reduction technology. Hot runner technology when directly comparing gating on the part to cold runner technology – and, more so, parts that must be processed with zero regrind – reduce CO₂ emissions.

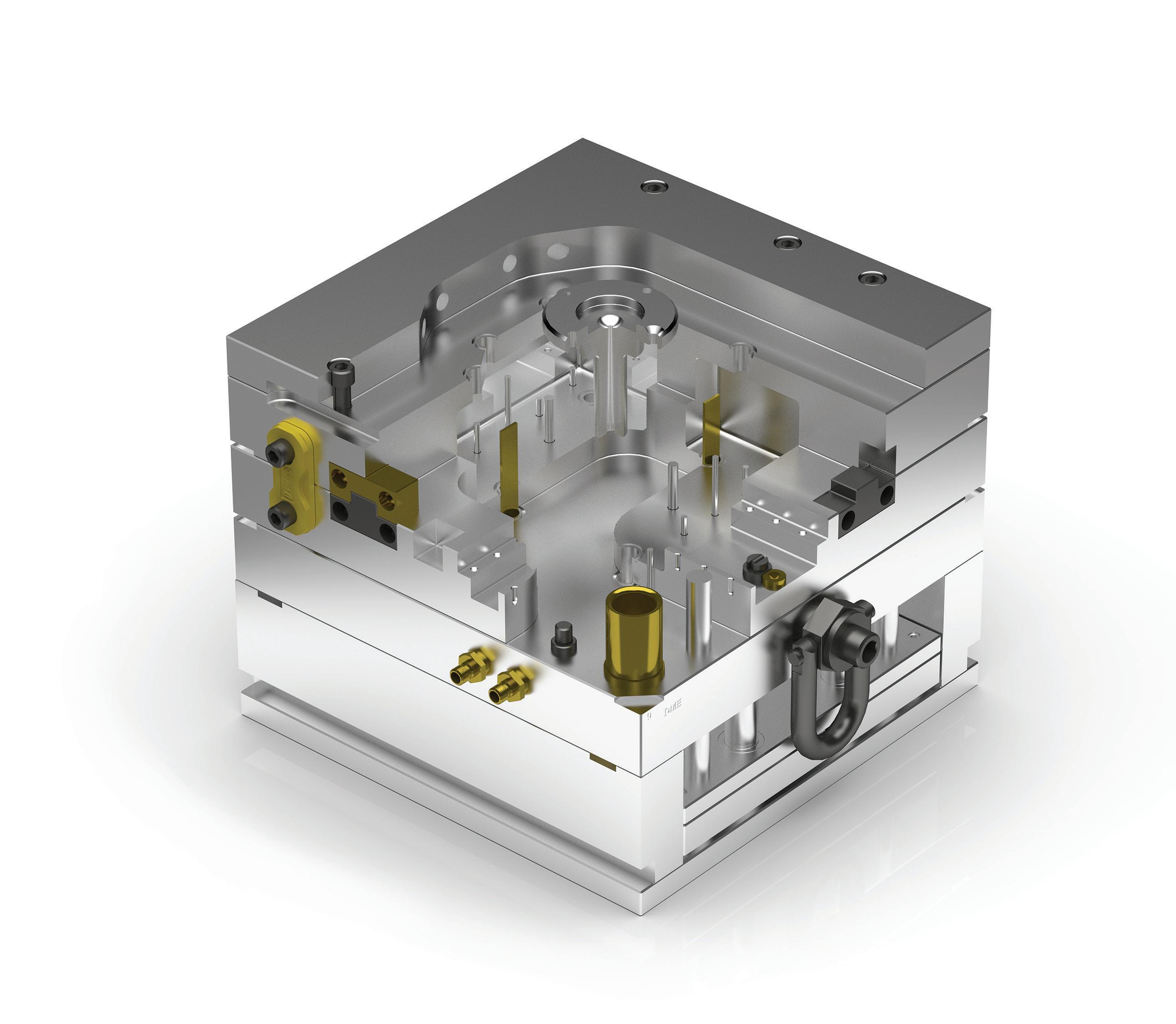

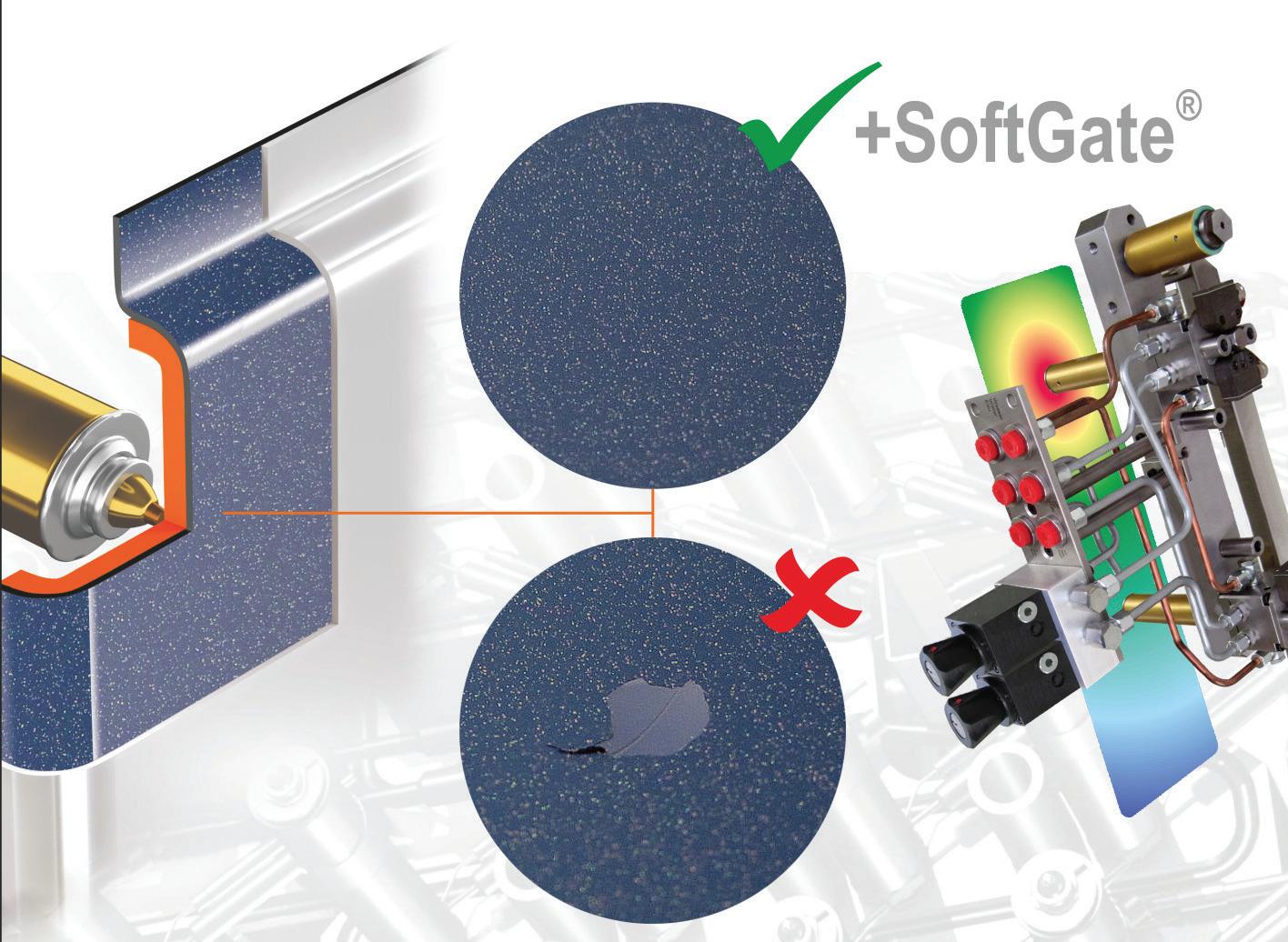

Opti-Flo® Balanced Hot Runner Systems Advanced Manifold Technology – a Beaumont Technologies implemented science, is designed for performance that often reduces part scrap rate and increases productivity.

Photo courtesy of INCOE.

INCOE’s most impactful CO₂ reduction hot runner technology is Opti-Flo® – a Beaumont Technologies implemented science, that often reduces part scrap rate and increases productivity when compared to using conventional hot runner melt delivery technology. This is accomplished by managing the melt to ensure the homogeneous distribution

For parts with shot sizes from a fraction of a gram to multiple kilograms, INCOE provides Hot Runner Technology solutions throughout the entire process — from engineering mold review and filling simulation to on-site technical support.

Our global commitment is to be your Melt Logistics® partner — producing value in your process — and ultimately delivering satisfaction where it counts.

Hot runner melt delivery technology always has contributed to the reduction of CO2 emissions.

of plastic laminates, both part to part and within the part. Using the before and after, molded parts per hour results then can be entered into a provided presentation to get quantified data on the CO₂ emissions reductions. The results now are documentation of the advancement of sustainability.

Further, energy savings are realized with the use of thermal blankets on the injection molding machine barrel and hot runner system.

Since the markets and sub-categories of each market are broad, there must be a vast offering of hot runner auxiliary technologies to enhance profitability. Not all these technologies necessarily are the lowest price/performance ratio for certain applications. Bott’s slang is, “There are different horses for different courses.” Some run best in dry course conditions, whereas others outperform the field in muddy conditions. Selecting the proper “horse” for the application is critically important.

First, the design and construction of hot runner heaters, thermocouples, manifolds and nozzles now optimize insulation/isolation. In addition, PIDD temperature controllers and valve-gate sequence controllers, combined with (and/or) FEA thermal, filling and warp analysis technologies, have advanced over the years.

Second, there exists hot runner melt management technologies for thermal-gated and valve-gated applications. The latter, valve-gate, can be live-monitored with valve gate sequence controller technology. Pressure transducers can be added to the injection molding machine and/or the mold cavity(ies). Thermocouples can be added to the mold cavity(ies). These sensors will provide live (every shot) data that is graphed – pressure vs. time – on the valve gate sequencer monitor. INCOE uses RJG architecture and sensors.

If required (i.e., parts that require multiple valvegated nozzles to properly fill the part), valve-gate pin retraction speed technology can be included with the hot runner to improve part aesthetics and reduce maximum injection pressures. This improves the process window while reducing scrap.

Progressive Components has live monitoring cycle counter technology that is added to the mold parting line. Software that collects and displays data is very useful for the molder. Hot runner parameter data can be entered, such as preventive maintenance when a certain number of cycles is reached.

Lastly, sensors can be used to collect data and share that data with other equipment within a molding cell for monitoring or to trigger an action. Additional sensors for measuring various parameters can be installed on the hot runner system or on the corresponding supply lines. Examples are plastic leakage, water temperature, valve gate media monitoring and/or valve gate function monitoring. This sensor data is connected to a data logger with output and control software to display the measured data, so the process can be monitored and/or acted on.

In conclusion, Bott shared, “The auxiliaries add cost to a very price-competitive mold-building market. Everybody wants technology – until the price tag is seen. But the addition of the technology only is profitable to the molder and/or OEM when properly selected.”

Over the past 38 years, Jim Bott has been employed at INCOE Corporation, a world-class global supplier of hot runner systems as the business development manager of automotive and heavy truck for North America. Bott has held past positions as draftsman, designer, checker, applications engineer, engineering manager and North America sales manager.

More information: www.incoe.com

HEIDENHAIN, Schaumburg, Illinois, a developer and manufacturer of linear and angle encoders, rotary encoders, digital readouts and CNC controls, has introduced the KCI 120 Dplus dual encoder. It allows a single device to provide position feedback from both the motor shaft and gearbox output shaft of a robot joint. Using robust inductive scanning technology, the encoder’s scanning head reads two separate circular scales for dual feedback. The KCI 120 Dplus can counteract design-induced inaccuracy on highly articulated and dynamic robots by measuring the gearbox output shaft. The dual encoder comes in three variants, featuring different hollow-shaft sizes and mounting dimensions for the scanning unit and two disk/hub assemblies. For more information, visit www.robotics.heidenhain.com

PCS Company, Fraser, Michigan, provides solutions and innovative products for the plastic injection molding, moldmaking and die casting industries, and has launched its M-2 ejector pins. The pins are constructed from wearresistant high-speed steel, ranging in diameter from 1/32" to 1/4" with lengths of 6" and 10", are through hardened to 6063 RC, eliminate chipping from form work and can be used for the ejector pin or core pin. For more information, visit www.pcs-company.com.

Mastercam, Tolland, Connecticut, a leading CAD/CAM software company, has announced the release of Mastercam 2024. The program has dozens of enhancements, including mill-turn additions, process hole and holemaking, milling and general system features and updates. Manufacturers test-drove Mastercam 2024 during the public beta program, providing valuable feedback to help shape the final product. Additionally, Mastercam partnered with Sandvik to integrate the CoroPlus® Tool Library, which makes tool recommendations based on material, operation and tool type. The ability to import tool assemblies directly into Mastercam 2024 saves time and effort since users quickly and easily can find and use the right tools. For more information, visit www.mastercam.com

Sandvik Coromant, Mebane, North Carolina, a supplier of tools and know-how to the metalworking industry, has launched the Silent Tools™ Plus boring bar. It’s a vibrationdamped sensor boring bar with control integration. The sensors provide data on utilization, temperature, deflection and surface quality, and they adaptively intervene in the machining process if the limit parameters are exceeded. The process transparency gained allows the machining process to be optimized. The Silent Tools™ Plus boring bar has many advantages, including sensors in the boring bar to give protection for the workpiece, tool and machine; reduced workload for operators; greater process reliability during machining; early detection of overloads and vibrations during the machining process; integration in WFL iControl Advanced+; and documentation of the force curve during the process. For more information, visit www.sandvik.coromant.com

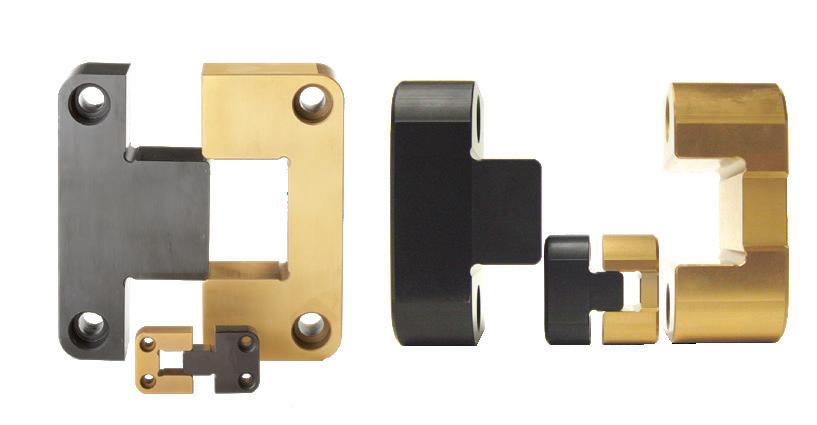

Meusburger, Mint Hill, North Carolina, a provider of highprecision standard parts, has offered a solution for optimizing set-up times with its multi couplers. Through the central connection, customers benefit from optimized set-up times of the temperature regulation components; for example, 20 minutes down to 20 seconds. Meusburger offers the multi coupler in the systems EU (E 2861/E 2871), US (E 2862/E 2872) and RMI-Stäubli (E 2830/E 2833). Additionally, Meusburger offers custom-made components in various dimensions with just a few clicks, including guiding elements, inclined pins, support pillars, ejectors, insulation boards, locating rings and high-temperature hoses. For more information, visit www.meusburger.com

Dormer Pramet, Czech Republic, a global manufacturer and supplier of tools for the metal cutting industry, has released the LNEX 12 insert designed for shoulder milling and the SLN12X cutter. The LNEX 12 has a maximum depth of cut up to 10 mm and features a positive rake angle and narrow T-land to provide a smooth cutting action, with lower demands on spindle torque. This ground insert offers improved wall accuracy and straightness, creating a true

90° corner. The insert comes in two different geometries: F for machining various workpiece materials in light and medium applications, and M for medium to semi-roughing in steels and cast irons. In addition, the SLN12X cutter series is available in cylindrical, weldon and shell styles, featuring internal coolant systems. For more information, visit www.dormerpramet.com.

Oerlikon HRSflow, San Polo di Piave, Italy, a specialist in hot runners, has developed the HRScool Evo system. The system eliminates the need for active water cooling of the hydraulic cylinder that positions the pin. Depending on the system size and application, this can reduce energy consumption at the drops by up to 10%. In addition, the low number of components reduces the assembly and maintenance time. This technology, which contributes to more sustainability in injection molding, can replace conventionally cooled designs in a variety of applications across a wide temperature range. For more information, visit www.hrsflow.com.

EMUGE-FRANKEN USA, West Boylston, Massachusetts, a manufacturer of high-performance taps, thread mills, end mills, drills and other rotary tools, has introduced its CeraCut end mills. These mills feature a high-hardness cutting ceramic head brazed to a carbide shank for optimal vibration dampening and longer tool life. With a high-feed duplex cutting-edge geometry, Cera-Cut produces high metal removal rates in challenging nickel-based alloys, resulting in machining parts 200% to 400% faster than conventional carbide end mills. Cera-Cut end mills are suitable for face milling, slot milling, helical milling, contour milling and pocket milling. Mills are offered in different diameters from .24" to .79" (six to 20 mm). Also available are corner radius, modular and special designs. For more information, visit www.emuge-franken-group.com/us/en/

Regardless of what type of business, a website should bring in and convert prospective customers and attract new employees. In a world where nearly everything is going digital, a website is more critical than ever. It acts as the hub for all marketing and communications efforts, so it needs to succinctly and effectively tell audiences why they want to work with and for the company. However, before adding troves of content to the website, a business needs to analyze the various steps of its sales funnel and recruiting processes.

In a typical sales funnel, prospective customers enter the funnel by learning about products or services and then slowly move through the qualification and nurturing phases before making a purchase.

1Awareness: This first step of the funnel is initiated when someone learns about a business through advertisements, social media, visiting a booth, online search results or word of mouth.

2Engagement: This is considered to be the true start of the funnel. Awareness is nothing more than someone acknowledging that a business exists. Engagement is that same person interacting and showing signs of interest.

In this phase, a business begins to see the value of a prospect and the prospect begins to see value in the business. The goal is to have these interested prospects exit this stage by submitting a contact form, following a social media account, subscribing to a newsletter or contacting the business.

We define performance. For nearly 30 years, we’ve helped our customers to produce more e ciently, with lower cycle times and lower per unit costs.

Our new compact stainless steel, modular unitized system features exible heaters that can be utilized o n multiple designs, so you don’t have to stock custom bent heaters Our new drop heaters provide more uniform heating and feature smaller pockets and no clamps They have in-line ow restrictors

for better process repeatability, and no over-pressurizing the cylinders. It all adds up to a reduced sized hot runner system, shorter heating times and better tool performance

We deliver value. We complement our hardware with leading-edge analytical tools, including Mold ow® and MOLDEX3D so ware. We’ll work with you on design issues and optional gating solutions before the mold or hot runner manifold system is ever built. Use us for the mold ow analysis and the manifold build, and we’ll do whatever it takes to make your hot runner/manifold system work to your complete satisfaction.

We’re committed to your success. Find out more. Call us today at 248.373.0800 or visit us at www.petsinc.net.

Photos courtesy of Jimmy Renallo, Creative Technology Corp.

Photos courtesy of Jimmy Renallo, Creative Technology Corp.

During this phase, consider how to categorize prospects who engage. Will a business note how they first engaged (e.g., tradeshow, website, social media or newsletter)? Will a business categorize them with others based on similar interests? A business also should consider the best way to return the interaction. Do sales representatives personally reach out, visit their facilities or call them? Do marketing managers enter contact information into a newsletter campaign or customer relationship manager (CRM)? Does the marketing team target digital advertisements to the companies or industries?

Once the initial engagement begins, the prospect sees potential for a partnership. The contact hopefully will interact more frequently, at which time the contact can be moved further into the funnel, as either a Marketing Qualified Lead (MQL) or a Sales Qualified Lead (SQL).

3MQL: A Marketing Qualified Lead is a contact who repeatedly is engaged, shows interest and has been reviewed by the marketing team. This may be a contact who repeatedly opens and engages with a newsletter, submits a contact form or engages on social media. An MQL often is watched more closely as the level of purchasing interest increases.

Closed: After a customer accepts a proposal or quote, the lead moves into the “Closed” phase.

4SQL: A Sales Qualified Lead is a contact who was an MQL and shows growing interest in the business. SQLs are reviewed by the sales team and identified to be true, potential customers – meaning the business’ capabilities align with their needs. In this stage, the sales team will provide quotes and negotiate. If an SQL becomes uninterested, it makes the most sense to hand it back to the marketing team for more nurturing with content. This allows the marketing team to further analyze interest so the sales team can focus its time on more valuable prospects. 5

A website should be structured and filled with content that delivers value to all visitors – regardless of where they fall within the sales funnel. Gone are the days when a business could control the buyer’s journey and push a prospect through the steps of the sales process. Prospects think differently now and control their buyer journey. A business can, however, supply content so that wherever or however prospects move through the funnel, information they want and need is provided. This will keep them engaged and coming back to the site until they decide to make a purchase.

1

Awareness: When someone first discovers a business, it’s important to present information about the product and services, business overview, mission and value statements and leadership summaries. Display this information so it is easy to find and understand. Website visitors in this phase haven’t engaged yet, so they won’t hesitate to quickly leave the site if they can’t find or understand what a company does.

2Engagement: Once prospects see value in a business, they will begin to engage with the content. This is a great phase of the funnel to introduce a content strategy full of thought-leadership material that is relevant and intriguing – informational-type resources, such as how-to guides, videos, audio/podcast files and answers to frequently asked questions. It’s important to show a company has the answers and expertise, but not push its solution. Successful thought leadership provides a safe place to find answers, not push a product or service. Remember, a trusting relationship still is being built with the prospective customer.

3MQL: Once prospects engage with a business, it can implement more technical marketing techniques so they keep coming back. Depending on their behavior on the site and the resources they accessed, a business can launch a retargeting campaign to keep the business in front of them. A business can send them specific, personalized emails with links to more content that is similar to what they previously

viewed. The purpose of content in this phase is to capture data and keep visitors engaged.

SQL: By this point, a prospect is interested, so it’s up to the sales team to take it from here with quoting, negotiating and closing the deal. The marketing team supports sales efforts, perhaps with an online resource center of case studies, client testimonials or technical sheets for the sales team to reference.

Closed: The prospect now is a customer. But that doesn’t mean the website’s job is done. It can house a portal where customers access the onboarding documents, projectspecific files and communications. Also, the prospect's business logo can be added to a “Customer” section of the website and maybe a testimonial can be provided about working with the business. This would showcase the breadth of experience to a new round of prospects.

Beyond supporting the sales processes, a website also should support recruiting activities. Potential employees look at a company’s website for information prior to applying for an open position. They want to know the history of the company,

leadership team, company culture and values, employee benefits, testimonials and more. Applicants even may look for pictures that showcase the facilities and staff. If possible, don’t use stock photos. Use pictures of staff, team gatherings and production facilities to give a true representation of the company and help fulfill the applicants’ need to trust the business. They want to begin building a relationship with the company – even before the business knows they want a career. A website can accomplish all these goals with a “Career” or “About Us” page.

Additionally, applicants should be able to access job opportunities at the facility and apply via the website. The application process should be streamlined and not require significant steps or complicated forms. Once applicants realize they can trust the business, they research open jobs and, hopefully, begin applying.

A website has the potential to be a powerhouse for attracting new customers and employees. It’s the place that houses all strategic activities through a diverse library of resources. It should track visitor behavior and data, store and report contact or subscription forms, attract new employees,

repeatedly engage prospects until they become customers and, perhaps, house a customer portal.

When a company fills its website with content that covers the sales and recruiting processes and structures it so information easily is accessible, the company will begin to see the value. There is a reason many manufacturers are investing in strategic, well-rounded websites – they realize that without them, they won’t remain competitive and can’t capture the attention of modern-day customers.

Sara Melefsky is the digital marketing director at WayPoint Marketing Communications, a marketing agency that partners with small- to medium-sized businesses to help them reach their goals through strategic marketing and communications programs. Melefsky boasts a background with over 20 years of B2B digital and traditional marketing experience. Her diverse skill set includes campaign strategy, project management and execution, graphic design, print and digital marketing, community relations and advertising. A firm believer that a solid marketing approach is the cornerstone of any successful business, Melefsky emphasizes

the importance of constant evaluation and tweaking to adapt to the ever-changing industry environment.

More information: www.waypointmc.com

● Organization’s “Why”

● Vision, mission and values

● Leadership bios and images

● Recent news and information about the business

● Job openings

● Employee testimonials

● Pictures of the facility and employees

● Capabilities and services

● Facility equipment (software and hardware)

● Tonnage range/capability

● Quality and other certifications

● Customer case studies and/or testimonials

● Images of the products produced and their end use

● Easy way to contact the company

The iWarriors mission is to honor severely injured soldiers from all branches of the Armed Forces by providing personalized tablets and technology to aid in their rehabilitation and recovery. Support is from the American Mold Builders Association, MoldMaking Technology, and suppliers.

2023 GOLF OUTING FRIDAY, SEPTEMBER 22

2023 GOLF OUTING FRIDAY, OCTOBER 27

2024 GOLF OUTING FRIDAY, FEBRUARY 9

We offer mold finishing, laser welding, laser engraving, mold maintenance, and hot runner manifold repair all under one roof. We also manufacture and sell the only fully American made laser welding and laser engraving systems, custom built specifically for your toolroom. Let Alliance make a difference for you.

THIS WORKSTATION IS A PURE, HANDS-ON, COMPACT, FLEXIBLE LASER WELDING MACHINE. IT’S EASILY ADJUSTABLE TO ALLOW USERS THE VERSATILITY AND FLEXIBILITY NEEDED TO MEET THE DEMANDS OF SMALLER JOBS.

•NO MAINTENANCE NEEDS

CONTACT US TODAY ABOUT AN IN-HOUSE DEMO, TO SEE THE ALLIANCE DIFFERENCE.

August 30, September 6, September 13 and September 20 | 12-1 p.m. (EST)

The AMBA Emerging Leaders Network is inviting 40-andunder emerging leaders (and/or those in emerging leadership roles) to sharpen their skills in a four-part virtual series designed to help participants motivate their workforce, strengthen communication and coach employees toward continuous improvement.

Leadership development expert Kelly McDaniel, DeLisa Group and 360 Recruiting, will lead three one-hour sessions providing participants with tools, strategies and advice to enhance their leadership styles. Attendees also will have the opportunity to share challenges and experiences with their peers in a fourth session led by AMBA staff. For more information and to register, visit www.amba.org/events/ management-fundamentals-session-1.

Member cost: $99

Conference room rate: $250 (for three or more attendees)

Save the date, March 19-21, 2024, for AMBA Conference 2024 – Engage. Elevate. Evolve., which will be held in Grand Rapids, Michigan, at the Amway Grand Plaza Hotel. This annual conference brings together best-in-class mold manufacturers to discuss the industry’s challenges and share best practices in business management, leadership, operations, sales and marketing and more. For more information, visit www.amba.org/conference

Now in an interactive format, the report includes charge rates specific to services supplied by US mold manufacturers in engineering, moldmaking and specialty services, as well as details regarding company demographics, mold size and

type production, average overhead cost, gross margin ranges by annual sales revenue and current vs. anticipated capacity utilization. Additionally, this year’s report contains a variety of expert insights to support survey data.

Due to the sensitive nature of this report, its contents are available for purchase only to AMBA members in good standing with the association for $399 at www.amba.org/ publications/browse. Non-AMBA members interested in joining the organization and accessing this report can email info@amba.org

This report represents a first-time collection of operational efficiency strategies and measures reported by US mold manufacturing facilities. Gathered results focused on member strategies and investments intended to enhance profitability, increase throughput, improve workforce utilization and effectively implement new technologies. Additionally, respondents described whether they had won business from China and other foreign competitors and the key differentiators that allowed them to do so. Members can purchase the report for $99 at www.amba.org/publications/ browse.

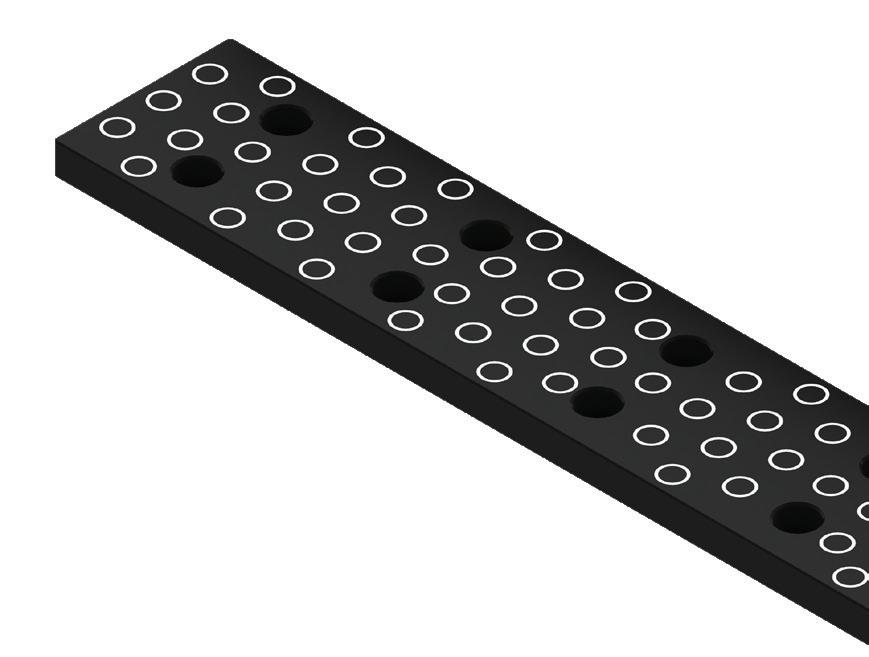

The AMBA Work Capacity Tool is an innovative resource available to AMBA members designed to help mold manufacturers share and fill capacity when needed. The user-friendly tool allows mold builders to log open capacity over a 90-day period in over 50 areas of operation, including Special Machines and Additional Services. Members are encouraged to update capacity every 30 days, with automatic reminders sent to help keep the information current. With a simple click of a button, the Work Capacity Tool connects members with shops that meet their needs providing direct links to email for quick communication and rapid results. For more information and to view a short video on how to best use this resource, visit www.amba.org/member-resources/ work-capacity-tool/.

iWarriors Alliance Charity Golf Outing

September 22 | Mundelein, Illinois

Alliance Specialties and Laser Sales once again will partner with the iWarriors organization during its annual golf outing, Mundelein, Illinois, at Countryside Golf Club. The annual event supports the iWarriors mission, to assist severely injured members of all branches of the Armed Forces by providing them with personalized tablets to aid in their return, recovery and reintegration. The golf outing will kick off with an open house at the Alliance facility, followed by registration, lunch and a shotgun start at noon (CST). Event information, including sponsorships, registration and more, is available at www.Alliance-Charity-Golf-Outing.eventlify. com

October 27 | Fountain Inn, South Carolina

Registration now is open for the 2023 United Tool and Mold Golf Outing, Fountain Inn, South Carolina, at Carolina Spring Golf Club in support of the iWarriors organization. Lunch will be provided prior to the 18-hole “Captain’s Choice” tournament and refreshments will be available throughout the event. Event information, including sponsorships, registration and more, can be found at www.2023-UTMgolf. eventbrite.com

Mike Hetherington is the president of Franchino Mold & Engineering, Lansing, Michigan, an industry leader in the design, engineering and manufacturing of die cast dies and plastic injection molds. He is focused on building a teambased culture that drives continuous improvement of people, processes and technology while assuring that the company exceeds the expectations of its employees and customers. “During my tenure on the board,” stated Hetherington, “I look forward to working with fellow AMBA colleagues to identify the needs of the members and develop tools and strategies to help them improve.”

Kyle Klouda is the third-generation owner and president of MSI Mold Builders (MSI) located in Cedar Rapids, Iowa, and Greenville, South Carolina. Ensuring MSI continues to be its customers’ competitive advantage, and growing manufacturing in America is what motivates Klouda continually to push the company to be an industry leader in the manufacture of plastic injection molds. “For my time on the board,” stated Klouda, “I desire to continue to grow American mold building. American manufacturers no longer can continue to be victims – we must grow and evolve to be healthy businesses even in the face of changing regulations.”

Troy Roberts is the CEO of Tolerance Tool, LLC, North St. Paul, Minnesota, a designer and manufacturer of complex bridge and multi-cavity high-volume production thermoplastic and silicone injection molds. Additionally, Roberts is the CEO and co-founder of Beanstalk Collaborative Community Wealth, LLC, a holding company dedicated to providing attractive financial and legacyprotecting opportunities to transitioning manufacturing business owners. Roberts said, “I look forward to working with other board members and AMBA staff in identifying and implementing pragmatic solutions that support AMBA’s mission. I think industry promotion should be at the forefront of mission objectives, considering the current economic environment and international competitive landscape for North American mold requirements.”

Camille Sackett is vice president of sales and marketing at Accede Mold & Tool, Rochester, New York, an injection mold builder specializing in high-cavitation, stack molds and in-mold actions with servo-solutions for consumer packaging, healthcare and other industries. Sackett grew up in the manufacturing industry and began her career in the moldmaking industry as a college co-op and apprentice injection mold designer at Accede Mold & Tool. She has served in a variety of roles over the past 30 years. Sackett holds degrees in mechanical engineering technology and mechanical engineering and is working toward an MBA in business management. “I’m looking forward to working with AMBA’s board and strengthening relationships,” stated Sackett. “I look forward to sharing knowledge, learning and collaborating with the team to bring value to AMBA and its members.”

G&W Electric Company

305 W. Crossroads Pkwy.

Bolingbrook, Illinois 60440

Steven Bucaro, lead tooling engineer

Phone: 708.388.5010

Email: sbucaro@gwelec.com

Founded in 1905 in a small Chicago machine shop, G&W Electric has grown into a global leader in electric power equipment. The company provides reliable distribution and transmission products that can be custom-configured and incorporated into industry-leading power grid solutions for its customers.

On July 19-20, 2023, AMBA convened its first plant tour workshop run entirely by emerging leadership. Sponsored by the AMBA Emerging Leaders Network, this dual plant tour workshop provided all AMBA members with an opportunity to tour two facilities renowned for their workforce development efforts – Wepco Plastics Inc. (Middlefield, Connecticut) and Westminster Tool, Inc. (Plainfield, Connecticut).

As active community participants, vocal supporters of workforce development and previous winners of the AMBA Tooling Trailblazer of the Year Award, both companies represent the gold standard in employee recruitment, training and elevation.

During the two-day event, these efforts were illustrated as emerging leaders from both facilities highlighted the ways in which operations have been impacted, improved and driven by the empowerment of next-generation leadership and the provision of executive-level guidance.

At Wepco Plastics, attendees experienced a hands-on plant tour, where Wepco Plastics employees established how the company empowers its workforce and works across departments to collaborate for success within the manufacturing environment. Attendees then were provided with an opportunity for informal crosstalk, where best practices and opportunities were shared with the host facility.

The following day, Westminster Tool guided attendees through several areas of operation, including areas dedicated to 5-axis machining, EDM robotic cell, 3D printing and more. Each station highlighted how culture has played a role in achieving operational efficiency and managing everyday tasks through an individual-based challenge/solution format. Attendees again had the opportunity to share insights with the host company during an end-of-event lunch at Westminster Tool’s second facility in Sterling, Connecticut.

Both facilities represent members of the Emerging Leaders Advisory Board, including its Chair, Amanda Wiriya, Wepco Plastics. The Emerging Leaders Advisory Board, originally convened in 2018, features six mold manufacturers intent on developing emerging leadership within the industry, as well as two industry partners.

“Since its inception in 2018, the AMBA Emerging Leaders Network has grown in membership and engagement beyond our wildest expectations,” explained Wiriya, who is an inaugural member of the committee and remains at its head today. “Our mission is dedicated to elevating emerging leadership, which has led to impactful, year-over-year

programming designed for that very specific demographic. While we’re proud of the community that we’ve built to date, it made this event particularly special in that it took our intentions one step further. For the first time, we were able to engage both emerging and executive leadership, allowing the best practices shared to impact an entire organization rather than a single individual.”

During AMBA’s tours at Westminster Tool and Wepco Plastics, attendees agreed that each facility’s culture and employee management strategies represented some of the best in the business.

Although the takeaways at each facility were wide-ranging, touching on everything from operations and technology to employee accountability and training, each highlighted the company-wide impact of three key areas of focus –accountability, empowerment and partnership.

At Wepco Plastics, these themes emerged in the facility’s emphasis on continuous improvement, its flexible shift structures and the way its workforce lives and breathes the company’s core values. At Westminster Tool, the workforce development theme continued, touching on employee accountability, crosstraining strategies, the cultural elements that enhance the team environment and the community partnerships and financial resources that have generated new business opportunities.

“The culture at Westminster Tool and Wepco Plastics is special, but neither happened overnight,” explained Hillary Thomas, Westminster Tool’s vice president and AMBA board member. “What we really wanted attendees of this tour to understand is that adapting your culture and investing in your workforce can make a true impact on your bottom line. But building that will require time, investment and patience… as well as a willingness to try doing business a little differently than it may have been done in the past.”

The AMBA Emerging Leaders Network offers a variety of events throughout the year – in-person and virtual –for 40-and-under emerging leaders at AMBA member companies. To get involved with the Network, its Advisory Board and to see what opportunities are upcoming, visit www.amba.org/Events or email Rachael Pfenninger at rpfenninger@amba.org

More information: www.westminstertool.com. and www.wepcoplastics.com

amba members saved an average of $6K in mro spend in 2022 -

$4,800 more than average member dues.

Get involved to start saving today. AMBA.org.

At the end of 2022, American Mold Builders Association (AMBA) members indicated that wages for their employee workforces continue to rise, despite continuing challenges related to inflation and the current economic environment. These mold manufacturers are hoping that, by offering competitive wages, they will be able to attract new employees from an increasingly limited talent pool.

Although inflation has slowed in 2023, the mold manufacturing industry continues to identify this element –alongside increasing competition and decreasing profitability – as top challenges in 2023 (as cited in AMBA’s 2023 Business Forecast Report).

For these reasons, US mold manufacturers must focus more than ever on driving profitability for their businesses. This is why the AMBA, again, surveyed US mold builders on charge rates across over 20 moldmaking, engineering and specialty services.

To complement its findings and provide a competitive edge to survey participants, the AMBA benchmarking team also added business insights and trending data that will help guide executives in their use of this year’s report.

To provide these insights, the AMBA team relied heavily on the provided charge rates, as well as other key data points, such as capacity utilization, gross margin percentages and overhead. This year’s report also highlighted the variation between attended and unattended rates (as applicable), reviewed the delta between 2022 and 2023 charge rates by individual service and featured industry insights from AMBA partners.

The final report includes survey responses from 70 US mold manufacturers, the majority of which are in the Midwest region, followed by the Eastern region of the United States. The industries served most frequently by this year’s respondents include the automotive, consumer products and medical/optical/dental industries.

For the second time, respondents indicated not just which markets they primarily served, but what percentage of work that industry accounted for over the last 12 months. Of the respondents represented in this data set, approximately threequarters serve the medical/optical/dental market in some capacity, followed by over half that serve the automotive market (Chart 1).

Overwhelmingly, respondents – 87% – identified new mold/ die builds as their primary revenue generator. To expound on revenue sources, this year’s survey also asked respondents to identify their secondlargest revenue source (only identifiable if it generated 20% or more of total annual revenue over the last 12 months). Of the provided options, mold/die repairs and engineering changes were identified by 56% of respondents as the second-largest revenue

source (a drop of 7% from 2022 data); another 11% identified this option as their primary source of revenue.

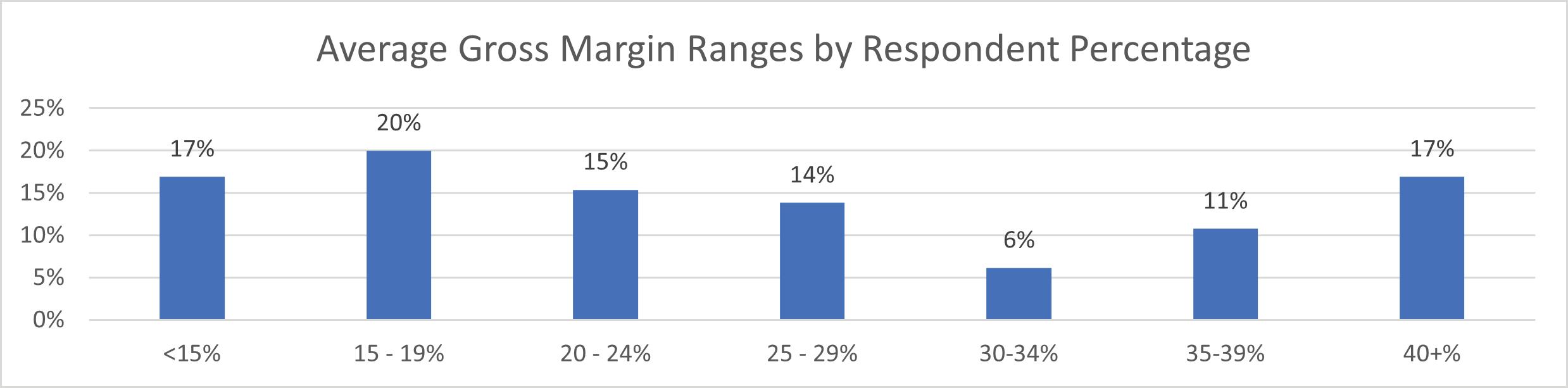

Respondents also were asked to provide their approximate gross margin percentage – calculated as ((Revenue – Cost of Goods Sold) / Revenue) x 100). This year, only 17% of respondents indicated that their average gross margin was relatively thin (under 15%) – a drop of nearly 50% from the previous year. In contrast, one-in-three respondents reported gross margin percentages of 30% or above (Chart 2).

Once again, respondents were able to add both attended and unattended rates for the following services: 5-axis machining, 3D printing steel core and cavities for conformal cooling, CNC milling, EDM drilling, gun drill operation, high-speed milling (30k plus RPM), sinker EDM, surface grinding and wire EDM.

Because this survey now is in its third year, this year’s report was better able to compare changing conditions across all services by tracking 2022 vs. 2023 data than in past reports.

The full 2023 report illustrates additional information on over 20 individual charge rates, as well as further charge rate breakdown by annual sales revenue and other features.

On average, mold manufacturers reported a current utilization of 73%, with companies in the $1 million to $2.5 million range reporting the most positive outlook. Overall anticipated capacity utilization is expected to rise only 1% through the end of the year; however, companies in the $10 million to $19.9 million reported the most negative outlook.

Respondents also provided insight into the approximate percentage their shop’s overhead costs represent compared to total annual expenses. When including all survey responses, this percentage equaled 32%.

Of the service charge rates studied, statistics provided included the average and median rates, as well as the mode, minimum and maximum rates charged for each service. To best illustrate this year’s data, it was presented in a “boxand-whisker” format, as well as via scatterplot graphs, to better demonstrate the frequency and distribution of charge rates for each service area.

To protect the interests of its members and the competitive advantage of the US mold manufacturing industry, the final report is available at no cost only to AMBA members who participated in this survey process. AMBA members who did not participate are able to purchase the report for $399. This report will be unavailable to any non-member (regardless of participation). Eligible parties interested in purchasing the report can visit the AMBA publications page.

More information: www.amba.org

Further information was provided to survey participants in AMBA’s first-time Shop Rate Webinar, where participants gained access to business best practices and insights from legal counsel Alan Rothenbeucher, Benesch Law, an overview of trending data from AMBA's benchmarking team and a Q&A panel with three noted manufacturing executives facilitated by AMBA Executive Director Troy Nix. Access to the webinar is included with purchase of the 2023 Shop Rate Report.

On average, mold manufacturers reported a current utilization of 73%, with companies in the $1 million to $2.5 million range reporting the most positive outlook.

After a six-year absence, North America’s biggest plastics event is back, and NPE is coming to Orlando, Florida, from May 6-10, 2024. If you are one of the more than 2,000 companies exhibiting at the show, the booth space has already been chosen. Now what? How will your company be presented at NPE? And, how will your company’s success be measured?

One thing is for sure: Exhibiting at NPE is a major investment. It’s an investment in terms of what it’s going to cost, but it’s also an investment in your company. If done right, companies will come out of this show with a better image, better prospects and better sales. Therefore, it is important – critically important – that you do all you can to make NPE2024 the best show ever done.

‘NPE Season’ for exhibitors starts now and runs through May 2024. There are two parts of NPE Season: Marketing Season and Sales Season. From now until May 5, 2024, it is Marketing Season. On the morning of May 6, it’s Sales

Season (more about that later). Read on for some tried and true tips for getting the most out of exhibiting at NPE.

Marketing Season starts with NPE booth planning. If you haven’t started already, it’s time to get moving on designing the booth. How should it look? What will be displayed in it? Pay attention to the ‘selling areas’ in the booth: How will guests enter the booth? How will booth staff lead guests through the booth to show them displays, etc.? How will your company’s branding (logo, brand names, messaging, etc.) be presented in signage?

There are plenty of excellent, professional tradeshow houses that can help design and produce great-looking displays. Seek them out, get a few quotes and design options, choose one and move forward. Having a strong tradeshow display partner is a major step, and once they’ve been engaged, you can be confident the ‘look’ is covered.

Next, it’s important to hone your message and then get that message out to the masses in as many ways as possible over the next eight months. To do this, companies need an integrated marketing strategy. This is essential to getting the best results. Remember, there are over 2,000 companies trying to do the same thing. Cut through the clutter and ‘cover your bases’ by addressing the following parameters:

1. PR and Social Media. For PR, write and distribute press releases promoting what will be presented at the show. Most of the plastics industry publications – including this one! – will be doing NPE previews, features, etc. For social media, post regularly on LinkedIn, Twitter and any other platforms that make sense.

2. Website. Keep the company website updated and populated with news about what will be shown at NPE. All the marketing efforts made for NPE will drive traffic to your site, so make sure it’s current and provides good information.

3. Email marketing. Send out regular eblasts to your customer base with news on what the company will be doing at NPE, and invite them to visit the booth at the show. Exhibitors can access assets on the NPE2024 site that can be used to help with this, including free passes that can be offered guests who plan to attend the show.

4. Advertising. Produce a print and/or digital ad campaign promoting your NPE presence. Tell people what the company will be showing, explain why it’s important and invite them to visit the booth. Try to match the ad placements with the editorial issues of each publication that match the plastics industry sector your company is in (injection molding, extrusion, etc.).

5. Collateral. Produce digital and/or print brochures and flyers about any new products that will be introduced at the show and put them on your website. Also, consider producing a flyer that shows a schematic of the booth, pointing out the highlights so visitors will know in advance what they’ll be seeing.

These five key marketing parameters are all important for spreading the word about your company’s NPE plans. So, how do you get it all done?

Again, there are plenty of excellent, professional marketing firms out there that can help with some or all of these functions. The same advice is offered here that was offered in the booth planning paragraph above: Seek these firms out, get quotes, choose and move forward. Having a strong marketing partner, especially one that knows your business

and is familiar with the plastics industry, will go a long way in helping to achieve your objectives.

One word on the power of PR: Consider inviting industry editors who will be at the NPE to stop by your booth. If an editor visits and produces an article that mentions your company, you have scored in a big way. Think about it: You may see a few hundred to a thousand attendees during the five days of NPE, but an article in an industry publication will be seen by thousands more.

It’s the morning of Monday, May 6, 2024. The booth is ready, and you’ve done all you can up to this point to prepare for the show. Hopefully, those marketing efforts will pay off. Now, it’s time for marketing to take a back seat, and turn it over to the sales team. But first…

Leading up to the show, it’s important to gather the team and train them on best practices on the show floor. Sales activities at a tradeshow are very different from a typical sales call. Instead of 15, 30 or 60 minutes visiting a customer, the sales team may have a few minutes. It’s important to make the most out of that limited time.

This convenient, all-in-one mold repair & polishing kit includes a variety of our most popular products to get you from start to final finish. Item # 90800

By now, the sales team staffing the booth should all be on the same page… meaning, they’ve been briefed on how to work the booth over the next five days. This can include:

1. Asking the right questions. To pull visitors in from aisles, have a qualifying question specific to your business. Examples include: Does your company do injection molding? Does your company use purging compounds in your machinery? Does your company do maintenance on injection molds? When talking with visitors in the booth, ask other questions, such as: What’s new for you? How is business?

2. Booth etiquette (ground rules while working in the booth). What fits your company’s culture? Is it okay or not okay to sit or be seen on a cellphone? Remind the team they are there to sell and not to be sold to, so be careful not to get caught up in conversations with non-customers. Train for it, and have someone in charge of watching and preventing this from happening. Make a booth staffing schedule and include breaks.

3. What’s the pitch? Make sure everyone has it down, so they know what to say about the products on display, what their benefits are, how your company can help, etc.

4. Capture leads. Don’t let your visitors get away without getting their contact information. Consider producing a lead sheet for the team to fill out on each visitor – something easy to use, with checkboxes that capture the information needed after the show. Include a way to prioritize lead follow up, such as rating visitors with an A, B or C. If possible, schedule follow-up meetings immediately with guests by saying, “Let’s get something in our calendars now.”

5. Encourage teamwork. Make sure staff is trained to hand off guests to the best person in the booth for their needs. For instance, “I handle the East Coast, so let me introduce you to John, who covers the Midwest for us,” or “I’m the product manager for purging compounds, so let me introduce you to Bryan, who’s in charge of our mold maintenance products.”

If the sales staff is properly trained in advance of the show, you’ll be getting their best efforts over the five days of NPE. Making the best use of their time will result in getting the best leads and potential future new business for your company. During the show, schedule time with the team to review how things are going and make adjustments, if necessary. A good time to do this is in the morning at the booth, before the show opens each day. Ask the staff how things are going, what’s working and what’s not.

After the show closes on Friday, May 10, take some time to celebrate! The team has all worked hard, and it’s important to enjoy and acknowledge those achievements. Then, once NPE2024 is done, NPE2027 starts on Monday, May 13. Don’t miss this step. Call a meeting with all stakeholders, and document what went well and what could have been better. Put those notes into a time capsule, and pull them out when it’s time to get serious about planning for the next NPE!

Greg Hannoosh and Mark Malloy are partners in Next Step Communications, Inc., a marketing firm specializing in serving clients in the plastics industry. Hannoosh has supported clients at every NPE show since 1988, and Malloy since 1994. As president of Next Step, Hannoosh manages day-to-day operations and client relationships and guides marketing program strategy to ensure all deliverables exceed expectations. Malloy has spent his entire career in the plastics industry and joined Next Step as a partner and equity stake holder in April 2021.

More information: www.next-step.com

Greater process reliability

Maximum efficiency

As the next level in CNC control, the TNC7 offers professional machinists completely new possibilities at every stage, from initial design to the finished workpiece. Graphical programming developed from scratch, individual customization of the user interface, perfect visualization of machined parts and the work

envelope, and numerous smart functions all make your workday immensely easier.

The TNC7 assists you throughout the entire production process. It will advance your operations and add reliability to your processes. So take your manufacturing to a new level. It’s the future of machining.

www.heidenhain.com/tnc7

During an AMBA sales and marketing strategies virtual roundtable conducted August 9, 2023, member companies and affiliates shared experiences, proven tactics and suggestions on a handful of important marketing and sales topics. Whether the issue was eliciting crucial feedback from customers and prospective customers, or how to drum up new sales opportunities, the roundtable participants were generous in offering solid advice to their peer mold builders. Here are a few of the topics covered and the suggestions shared.

For any moldmaker with a web presence, the company’s website can be put to work as a silent salesperson, often at minimal cost. Roundtable participants suggested three smart ways to attract the attention of more customers.

First, include a contact form on the website so that prospective customers easily can ping the company for a callback. Another winning way to let a website draw interested parties is to feature a blog with regularly refreshed content that is of value to potential clients. A third suggestion, for moldmakers with an international clientele, is to add a language translator to the company website so that foreign visitors can understand what the company offers as described in its own language.

The days of traveling salespeople doggedly knocking on strange doors in strange cities are in the past, especially post-pandemic and in light of today’s communications technology. The roundtable members had suggestions regarding choosing locations for cold calling, qualifying the list of companies to approach, taking the chill off cold calls

with some pre-call “warming,” and including a freebie in cold call drop-off packets.

The roundtable offered several ideas for choosing a location for cold calling. The quickest, easiest and cheapest cold calls take place locally, especially in areas where prospects might be concentrated such as industrial parks. Another time- and money-saving option is to plan a cold call blitz as an add-on when paying a visit to an existing customer in another locale. Do research to find a handful of prospects in a radius around the existing customer’s site and make the rounds before or after visiting the customer.

Another way to piggyback cold calling onto another activity is to use cold calls to make new contacts at industry events and tradeshows. The initial contact available in the booth at an event or show might be a salesperson, but those folks generally are happy to answer initial questions about a business and suggest the most appropriate person at their company for further contact.

Narrowing down the list of companies to approach cold makes the calls much more likely to be fruitful. The roundtable participants suggested characterizing how one’s company stands out as exemplary in the industry or what one’s company has to offer that is most valuable to clients; with that info in mind, one can scan for prospective companies that are simpatico with their own standout qualities and closely held values.

To take the chill off cold calls, take a pre-call step or two to warm things up. If one launches cold email campaigns, tracking the engagement rate of the campaigns can point to the recipients whose engagement indicates that they already are intrigued and open to learning more.

Every mold builder has seasonal slowdowns or unexpected idle stretches. Some of them fill the gaps with peripheral services and expertise, such as making spare parts or producing components for inventory. It’s also good to be diversified, especially with some low-stress work that can be the occasional welcome change for the production team. Some moldmakers use the lag time to finetune their “ideal target list” of prospects and then focus on cultivating the top ten.

The roundtable participants also suggested using a slow spell to reach out to the company’s top 10 customers – the ones that truly value the company’s best qualities – and ask for a little more of their business. During pitches to the top 10, be sure to reiterate how the customer benefits from the mold builder’s strengths, whether that means saving money, saving time or having complete confidence to hand over a complicated, squirrelly job.

The moldmakers in the roundtable all lamented the tight labor market and the wildly fluctuating costs of doing business

with labor costs that only seem to rise, and rise, and then rise some more. The best advice offered by the roundtable was to institute a variable pay program for everyone in the company, built on the premise that if the company is extra profitable, the team receives a quarterly bonus. If, on the other hand, spiking costs cut into the company’s profits, the team gets its regular pay but not the quarterly bonus.

One of the roundtable moldmakers noted that the bonustied-to-profitability scenario helped everyone on the team understand the bottom line in business. It even spurred employees to take the initiative and volunteer to work additional hours when the situation required it, in order to keep the company profitable.

More information: www.amba.org/members/archivedwebinars/ or www.amba.org/events/

Take a fresh approach to

As

AMBA members can receive discounted shipping rates on eligible services. Sign up for the FedEx Advantage® discounts program for free to start saving on eligible services.

With the FedEx Advantage program, you’ll get:*

It’s free to sign up using your FedEx account number, and there are no quotas or commitments. Typically, your FedEx discounts will be available 7 to 10 business days after you join the FedEx Advantage program. To

HASCO, Fletcher, North Carolina, a manufacturer of modular high-quality standard mold units and individually designed hot runner systems, has launched an optimized website in a responsive design, offering customers one of the most modern online shops. The website offers worldwide access to smart product navigation, CAD and digital services and a usable platform for all digital services. Information, innovations and services easily can be called up in 16 languages. Molds can be calculated, configured and directly ordered around the clock with just a few clicks. The mold base assistant offers innovative possibilities to simplify and speed up processes. For more information, visit www.hasco. com.

PCS Company, Fraser, Michigan, a provider of solutions and innovative products for the plastic injection molding, moldmaking and die casting industries, will host its First Annual Golf Outing benefiting St. Jude Children’s Research Hospital. The golf outing is scheduled for September 22, 2023, at the Cracklewood Golf Club, Macomb, Michigan, with check-in at 9 a.m. and a shotgun start at 10 a.m. The golf event includes 18 holes of fun-filled golf, free range balls before the golf outing, three drink tickets per golfer, a hot dog lunch at the turn and a meat buffet dinner following the golf round. The deadline to register is September 8, 2023. For more information, visit www.pcs-company.com/ pcs-company-golf-outing or email sales@pcs-company.com

Ford Motor Co., Dearborn, Michigan, has hired Liz Door, a sourcing executive at appliance maker Whirlpool, to be the company’s chief supply chain officer. The move comes nine months after Ford warned Wall Street about surging parts costs and put its CFO in charge of supply chain efforts, on an interim basis, while it searched for someone to take on the newly created role. Door has served as Whirlpool’s executive vice president of global strategic sourcing since 2017. Before, she led North America procurement at Whirpool for more than six years. Door started her career as a resident quality engineer with Prince Corp., working at a Chrysler assembly plant in St. Louis, Missouri. For more information, visit www.ford.com

Seco Tool, Troy, Michigan, a provider of metal cutting solutions for indexable milling, solid milling, turning, holemaking, threading and tooling systems, has appointed Andrew Hunter as vice president of global sales, effective July 1, 2023. In his new position, Hunter is responsible for securing the company’s growth, along with developing and implementing sales strategies to gain market share. He also is responsible for global sales activities and setting the scene for the sales organization. For more information, visit www.secotools.com.

The Plastics Industry Association (PLASTICS), Washington, D.C., has released the updated 2023 Customs and Practices of the Moldmaking Industry Guide. The Guide has been prepared by the Moldmakers Division of Plastics Industry Association, as part of a continuing effort to improve practices benefiting the industry. The updated guide offers information intended to assist buyers when seeking guidance regarding plastic injection mold procurement, and benefits moldmakers by providing descriptions and terminology to help standardize and streamline the process with customers. The Guide is complimentary for PLASTICS members and can be purchased by non-members. For more information, visit www.plasticsindustry.org.

Okuma America Corporation, Charlotte, North Carolina, a global builder of computer numeric control (CNC) machine tools, controls and automation systems, has announced appointments within its sales organization to direct and support sales growth in the US. Brandon Glenn was appointed as the newly created director of sales, responsible for leading day-to-day sales programs and partnerships with distributors throughout the US and Canada. Luke Lofland was promoted to regional sales manager for US eastern territories, overseeing day-to-day business activities with the Morris Group. Mike Hampton was promoted to business development manager and is responsible for managing Okuma’s partners in Technology and Tech Center facilities. For more information, visit www.okuma.com.

Adding decoration to injection-molded parts not only increases the attractiveness of plastic products, but also functionality and value. The inherent durable nature of appliques or ink transfer process, coupled with the ever-expanding decorative options and addition of functional electrical circuits, provides original equipment manufacturers with a multitude of product options with a long service life.

Automotive interiors, large appliances, medical devices and consumer products are just some of the potential markets for durable in-mold decorated components. But properly designing an injection-molded part and the resulting tooling can be complex, as modifications to traditional molded part design and additional in-mold specific considerations are required for the project to be successful.

Before this article gets into the details of how to design a durable part for in-mold decoration, let’s talk first about some definitions used to describe the various decoration processes.

In the durable goods arena, the term in-mold labeling (IML) often is used interchangeably with film insert molding (FIM). This process consists of a screen or digitally printed film that is thermoformed, diecut and placed into a cavity to be molded. The decorated film stays with the molded part when delivered to the customer.

In-mold decorated (IMD) parts use a roll-to-roll heat transfer process. A gravure-printed roll of film passes through the parting line of a specially designed mold, is indexed and located using a specialized film feeder mounted to the platen of the molding machine. The carrier film with decoration is formed to the cavity geometry using vacuum. Only the decoration ink layers are transferred from the carrier film to the resin during the molding process, and the carrier film is no longer present on the part after molding.

For all the various in-mold decoration processes, the design process starts with reviewing the part geometry and product specifications in detail. Typical molded part design principles still apply, including consistent wall thickness, potential weld line locations, minimum draft, maximum rib-to-wall ratio to prevent sink marks and minimum radii to reduce stress concentrations.

Confirming all customer specifications is critical to ensuring the delivered product meets expectations. Chemical resistance, environmental exposure (humidity, temperature cycling, heat aging and UV resistance), scratch resistance, finish requirements, color and mechanical requirements, such as flex modulus or impact strength, must be established to identify a material set that will meet the specifications. Overlooking a specification at the beginning of the project