SSV Sanitary Drum Motors Reduce Washdown Time & Water Consumption by 50%

MADE M ADE IIN N

USA

APRIL 2021

VDG_Page1_Onsert.indd 2

MADE IN

USA

(888) 326-1476 • vandergraaf.com/PF

4/1/21 1:48 PM

SSV Sanitary Drum Motors Reduce Washdown Time & Water Consumption by 50%

The most sanitary drive solution for your belt conveyor. Designed for 80,000 hours of operation before maintenance, and with all drive components enclosed inside the drum, the SSV Sanitary Series Drum Motor drives modular, wire mesh, and monolithic thermoplastic conveyor belts without the use of sprockets. The sprocketless SSV Drum Motor with belt profile machined directly onto the drum cuts washdown time by 50%, reducing water consumption and minimizing downtime.

ELIMINATE PRODUCT BUILD-UP ELIMINATE BACTERIAL HARBORAGE

ELIMINATE FOREIGN MATERIAL CONTAMINATION

(888) 326-1476 • info@vandergraaf.com • vandergraaf.com/PF

VDG_Page2_Onsert.indd 2

4/1/21 1:46 PM

April 2021

BUILDING A FOOD SAFETY CULTURE EMPOWERMENT TO THE PEOPLE

Automated Control Provides Insight Into Inventory Weigh Cell Technology Boosts Packaging Efficiency Focus on Dry Processing Solutions Tech Update: Motors and Drives 0421_Cover-FINAL.indd 2

4/9/21 1:15 PM

Reduce and Distance Plant Personnel while Boosting Output and Preventing Contamination with automated, enclosed bulk equipment and systems from Flexicon

Automated, sealed BULK-OUT® Discharger-Conveyor Systems replace multiple workers dumping hand-held bags manually, while preventing contamination.

Enclosed Bulk Bag Weigh Batch Systems feed a central weigh hopper mechanically, and remove weighed batches pneumatically, requiring labor only to attach/detach bulk bags.

Bulk Bag Discharging Systems can loosen solidified material and meter it into liquid streams (shown), screeners, size reduction equipment and continuous blenders—automatically.

Dual SWING-DOWN® Bulk Bag Fillers fed by weigh hoppers fill up to 40 bags per hour with only one operator connecting empty bags and one forklift removing full bags.

Flexicon Bulk Bag Filling Lines automatically dispense pallets, fill bulk bags, and disconnect/accumulate filled bags, minimizing operator involvement.

TIP-TITE® Drum/Box Dumpers seal, tip and mate a discharge cone to a gasketed hopper lid, open a slide gate and feed downstream processes— automatically and dust-free.

Flexicon automated equipment and systems can move your bulk materials at higher capacities with fewer personnel, cutting costs while distancing operators from one another. UK AUSTRALIA SOUTH AFRICA CHILE SPAIN FRANCE GERMANY SINGAPORE INDONESIA

+44 +61 +27 +51 +34 +33 +49 +65 +62

(0)1227 374710 (0)7 3879 4180 (0)41 453 1871 2 2415 1286 930 020 509 (0)7 61 36 56 12 173 900 78 76 6778 9225 81 1103 2400

II-0639

USA sales@flexicon.com 1 888 FLEXICON

See the full range of fast-payback equipment at flexicon.com: Flexible Screw Conveyors, Tubular Cable Conveyors, Pneumatic Conveying Systems, Bulk Bag Unloaders, Bulk Bag Conditioners, Bulk Bag Fillers, Bag Dump Stations, Drum/Box/Container Dumpers, Weigh Batching and Blending Systems, and Automated Plant-Wide Bulk Handling Systems ©2020 Flexicon Corporation. Flexicon Corporation has registrations and pending applications for the trademark FLEXICON throughout the world.

ProFood_AdTemplate.indd 1 ProFood_AdTemplate.indd 1

5/21/20 9:31 3/31/21 2:51 AM PM

— Unlock maximum energy savings

Motors operating in food processing facilities often run 24/7 even though the load can vary significantly during the day. Variable frequency drives (VFDs) provide precise speed control, so the motor is controlled to match the actual process demand. The speed of an electric motor is tied to the power it consumes so even a modest speed reduction yields significant energy savings. Cost-effective plant-wide condition monitoring and smart sensors can work together with the energy monitoring capabilities of VFDs to collect a wealth of data to help analyze energy use. Leverage an ABB VFD and motor solution to optimize energy savings for your facility. To discover how, visit new.abb.com/drives/energy-efficiency

ProFood_AdTemplate.indd 1 ABB PFW Energy Saving ad.indd 1

3/31/21 3/18/21 9:31 8:36AM PM

This is the Way

Gericke is the way to a uniform, homogeneous mix, and fast, easy, complete cleaning. 2QO\ 0XOWL X[® *06 PL[HUV IURP *HULFNH LQFOXGH D SURSULHWDU\ GRXEOH URWRU GHVLJQ WKDW GLUHFWV \RXU LQJUHGLHQWV LQWR D XLGL]HG VDIHW\ ]RQH IRU thorough - yet gentle - mixing and blending in as little as 30 seconds :KHQ LWȇV WLPH IRU FOHDQLQJ WKH HQWLUH IURQW GRRU RSHQV DQG WKH RSWLRQDO FDQWLOHYHUHG PL[LQJ PHFKDQLVP VOLGHV RXW RQ UDLOV IRU GHJUHH RSHQ DFFHVV )RU KLJK TXDOLW\ UHVXOWV HYHU\ WLPH WKLV LV WKH ZD\

6HH QHZ YLGHR GRZQORDG EURFKXUHV DW GerickeGroup.com!

Sifting • Size Reduction • Weighing • Feeding Conveying • Mixing • Bagging

*HULFNH 86$ ΖQF :RUOGV )DLU 'ULYH 6XLWH & 6RPHUVHW 1- ȏ [ ȏ VDOHV XV#JHULFNHJURXS FRP

ProFood_AdTemplate.indd ProFood_AdTemplate.indd 11

4/2/20 9:04 3/31/21 9:31 AM AM

APRIL 2021

CONTENTS 35

47 DEPARTMENTS 6 From the Editor Good news abounds for improving food safety.

9 In the News Measure the ‘size of the prize’ via asset reliability.

20 ON THE COVER Food Safety Culture: Empowerment to the People Commitment, collaboration, and communication are essential for building a successful food safety culture. But don’t forget that people at all company levels are the dominant factor in producing high-quality, safe food and beverages.

17 Packaging Technology Extended shelf life is key to Lidl’s latest ready-to-eat line.

41 Plant Floor New Products Take an inside look at the latest machinery and technologies for production facilities.

47 Case Study: GoldRiver Automated control delivers real-time insight into inventory.

50 Case Study: Tree Top Decanter helps optimize fruit juice concentrate process.

54 Tech Perspective Advanced weigh cell technology boosts efficiency in packaging applications.

FEATURES 12 OpX Intel: Manufacturing Health Being in the zone means balancing your technology investment with all the people and teams using that technology. The short-term benefits realized through accelerated performance can achieve a lasting impact by sustaining those gains.

28 Tech Today: Motors and Drives Beyond the advances made to both motors and drives in terms of energy efficiency, safety, cleanability, and more, suppliers emphasize the importance of how they work together in a complete motion system.

DRY PROCESSING SOLUTIONS 35 Case Study: Goya Foods Automated bulk bag dischargers help keep pace with high-speed packaging.

37 Dry Processing Products

www.profoodworld.com

0421-Contents.indd 1

| April 2021 | PROFOOD WORLD

3

3/31/21 7:29 AM

ProFood World ISSN 2476-0676

BLEND ROTARY BATCH MIXERS • 0.25 to 600 cu ft (0.01 to 17 cu m) • 100% uniformity in less than 3 minutes • Uniform liquid additions • Ultra-gentle • Complete discharge • Fast sanitizing

EDITORIAL

CONNECT WITH US

EDITOR-IN-CHIEF JOYCE FASSL Mobile: 610/547-9814 jfassl@pmmimediagroup.com

@ProFoodWorld

EXECUTIVE EDITOR AARON HAND ahand@pmmimediagroup.com

VEE-CONE BLENDERS

MANAGING EDITOR NATALIE CRAIG ncraig@pmmimediagroup.com

• 1 cup to 200 cu ft (0.5 to 5663 L) • Gentle, 5 to 15 minute cycles • Complete discharge • Ultra-fast sanitizing of smooth internal surfaces

@ProFoodWorld www.linkedin.com/ showcase/profoodworld

NEW PRODUCTS EDITOR MORGAN SMITH msmith@pmmimediagroup.com CONTRIBUTING EDITORS MELISSA GRIFFEN, STEPHEN PERRY, STEPHEN SCHLEGEL, JEFFREY BARACH

B U S I N E S S S TA F F PUBLISHER PATRICK YOUNG 610/251-2579 pyoung@pmmimediagroup.com

RIBBON BLENDERS • 1.0 to 1,150 cu ft (0.03 to 32.56 cu m) • Blends dry bulk to pastes • Shear reduces agglomerates • Low cost

BRAND OPERATIONS MANAGER CLAUDIA SMITH 312/222-1345 csmith@pmmimediagroup.com

ART CREATIVE DIRECTOR DAVID BACHO

REDUCE

ASSOCIATE ART DIRECTOR KATHY TRAVIS

AU D I E N C E A N D T E C H N O L O GY SENIOR VICE PRESIDENT, DIGITAL AND DATA

LUMP BREAKERS

DAVID NEWCORN

• Throat widths 12 to 48 in. (30.5 to 122 cm) • Bed screens 1/32 to 2 1/2 in. (0.79 to 64 mm) • Quick screen cleaning, inspection, removal

SENIOR DIRECTOR, DIGITAL AND DATA ELIZABETH KACHORIS DIRECTOR, WEBSITE PRODUCT MANAGEMENT JEN KREPELKA SENIOR DATA ANALYST LAUREN SANZ

PUBLISHING PRESIDENT JOSEPH ANGEL PUBLISHER PATRICK YOUNG VICE PRESIDENT, CONTENT AND BRAND STRATEGY JIM CHRZAN SENIOR CONTENT STRATEGIST KIM OVERSTREET DIRECTOR, MARKETING SHARON TAYLOR SENIOR MARKETING MANAGER AMBER MILLER EXECUTIVE ADMINISTRATOR JANET FABIANO

CLASSIFYING CUTTERS • Throat widths 10 to 72 in. (25 to 183 cm) • Bed screens 1/32 to 2 1/2 in. (0.79 to 64 mm) • Precise sizes with minimum fines

PIN MILLS

ADVE R TI S I N G PRODUCTION MANAGER GEORGE SHURTLEFF SENIOR DIRECTOR, CLIENT SUCCESS AND MEDIA OPERATIONS KELLY GREEBY DIRECTOR, MEDIA INNOVATION SARAH LOEFFLER SENIOR MANAGER, PRODUCT AND REVENUE STRATEGY ALICIA PETTIGREW

• Controlled sizing down to 400 mesh • No screens, hammers, knives or rolls • Coarse & fine grinding of friable materials • Conditioning of cellulose fibers

ADVE R TI S I N G SALE S PUBLISHER PATRICK YOUNG pyoung@pmmimediagroup.com • 610/251-2579 REGIONAL SALES MANAGER BRIAN J. GRONOWSKI bgronowski@pmmimediagroup.com • 440/564-5920 REGIONAL SALES MANAGER DANIEL SMITH dsmith@pmmimediagroup.com • 312/205-7935 VICE PRESIDENT, SALES WENDY SAWTELL wsawtell@pmmimediagroup.com • 847/784-0520 REGIONAL MANAGER RICKY ANGEL rangel@pmmimediagroup.com • 630/805-3892 REGIONAL MANAGER LEO GUENTHER guenther@packworld.com • 904/377-7865 REGIONAL MANAGER JIM POWERS jpowers@automationworld.com • 312/925-7793 REGIONAL MANAGER CHRISTINE J. SMALLWOOD csmallwood@pmmimediagroup.com • 770/664-4600 PUBLISHER, AUTOMATION WORLD KURT BELISLE kbelisle@pmmimediagroup.com • 815/549-1034 PUBLISHER, HEALTHCARE PACKAGING LIZ TIERNEY tierney@packworld.com • 815/861-2992 PUBLISHER, OEM MAGAZINE JIM CHRZAN jchrzan@pmmimediagroup.com • 847/830-2915

COMPARE Only at Munson can you test these and 14 other blending and size reduction machines side-by-side using your material—ensuring you of top efficiency at the lowest cost.

ProFood World • PMMI Media Group 401 N. Michigan Ave., Suite 300, Chicago, IL 60611 Phone: 312/222-1010 • Fax: 312/222-1310 Email: info@pmmimediagroup.com • Web: www.profoodworld.com

1-800-944-6644 info@munsonmachinery.com WWW.MUNSONMACHINERY.COM

PMMI, The Association for Packaging and Processing Technologies 12930 Worldgate Drive, Suite 200, Herndon, VA 20170 Phone: 571/612-3200 • Fax: 703/243-8556 • Web: www.pmmi.org Staff at PMMI Media Group can be contacted at info@pmmimediagroup.com.

0421_Masthead.indd 4

JJ-0551

©2021 Munson Machinery Co., Inc. MUNSON® is a registered trademark of Munson Machinery Co., Inc.

4

PROFOOD WORLD

| April 2021 | www.profoodworld.com

3/31/21 7:35 AM

kpfilms_ProFoodWorld_FullPageAd_MonoSeal_Pancetta.pdf

1

3/8/21

2:56 PM

C

M

Y

CM

MY

CY

CMY

K

kp MonoSeal

TM

Introducing our top of the range, sustainable PET base rigid film for form, fill and seal applications. kp MonoSealTM is a mono PET film that is fully recyclable, with the strongest sealing capability in the market and is 7% lighter than multi-layer films. Perfect for fresh food applications, from protein and cheese to pasta. Strongest sealing capability in the market Mono PET made with post-consumer recycled PET and fully recyclable 7% lighter, lower sealing temps and longer rolls for a reduced carbon footprint

3585 Klöckner Road, Gordonsville, VA 22942 T: +01.540.832.3600 | E: kpainfo@kpfilms.com | W: kpfilms.com

ProFood_AdTemplate.indd 1

3/31/21 9:32 AM

FROM THE EDITOR JOYCE FASSL | EDITOR-IN-CHIEF

Good News All Around on Food Safety There’s one caveat: A qualified and experienced workforce that has remained elusive over the past two decades is one of the greatest challenges in creating your food safety culture.

W

hile the pandemic has caused a lot of challenges and shifting priorities for the food and beverage industry, one front burner matter is constant, and that’s food safety. As the U.S. Food and Drug Administration (FDA) ushers in its New Era of Food Safety, some of its main intents are to increase digitalization of traceability and modernize and create food safety cultures within each processing plant. The food safety leaders I spoke with for this month’s cover story are committed to producing the highest quality and safe foods, while training and empowering their staffs to do the same. This is certainly not a new approach. The difference is now processors will be rated on how well they create a food safety culture. But here lies the rub. A qualified and experienced workforce has remained elusive over the past two decades. One bit of good news is that the Global Food Safety Initiative (GFSI) has become The Consumer Goods Forum’s (CGF) Coalition of Action on Food Safety. The coalition recently announced its goal to operate with more agility and increased transparency. It will be led by CGF board members Dirk Van de Put, chairman and CEO of Mondelēz International, and Danny Wegman, chairman of Wegmans Food Markets. The coalition’s aim is to address food safety systems in supply chains, help raise the bar on food safety globally, strengthen and harmonize food safety systems to feed a growing global population, and develop markets that can deliver food safely worldwide. As our industry unites to produce safe, high-quality food and beverages, here’s hoping 2021 will also be the year our entire planet becomes a safer place, free of COVID-19. Some additional good news is that PMMI is gearing up for the safe return of PACK EXPO Las Vegas on Sept. 27-29, including the return of The Processing Zone. Attendee registration opens in May. Visit packexpolasvegas.com for more information.

jfassl@pmmimediagroup.com

6

PROFOOD WORLD

0421_FromtheEditor.indd 6

EDITORIAL ADVISORY BOARD

CHRISTINE BENSE CHIEF OPERATING OFFICER Ventura Coastal HENDRIK EYSELEE DIRECTOR OF ENGINEERING, CHEESE AND DAIRY The Kraft Heinz Company GREG FLICKINGER SENIOR VP, OPERATIONS Green Thumb Industries Inc. JOHN HILKER DIRECTOR OF MANUFACTURING Blommer Chocolate Company VINCE NASTI VP, OPERATIONS Nation Pizza & Foods JIM PRUNESTI VP, ENGINEERING Conagra Brands LISA RATHBURN VP, ENGINEERING T. Marzetti MARK SHAYE VP, ENGINEERING Ken’s Foods TONY VANDENOEVER DIRECTOR, SUPPLY CHAIN ENGINEERING PepsiCo DIANE WOLF FORMER VP OF ENGINEERING AND OPERATIONS Kraft Foods BROOKE WYNN SENIOR DIRECTOR OF SUSTAINABILITY Smithfield Foods JOE ZEMBAS DIRECTOR, ENGINEERING AND TECHNICAL SERVICES The J.M. Smucker Company

| April 2021 | www.profoodworld.com

3/31/21 7:31 AM

YOUR RECIPE AUTOMATED TO PERFECTION. Global resources that deliver. shickesteve.com

ProFood_AdTemplate.indd 1

3/31/21 9:35 AM

Flexible Screw Conveyors

Vacuum Conveyors

Tubular Drag Conveyors

Bulk Bag Handling

Bag Dump Stations

SERVICEABILITY Get more uptime, faster turnarounds and better use of your staff time. Hapman equipment is built for fast, easy disassembly for cleaning and maintenance. Since 2012, we’ve made 22 design improvements to maximize serviceability, including 12

Feeders

design changes for tool-less access.

What can you do with the extra production time?

Full Systems

Serviceability

Expertise

Durability

That Extends Uptime

Confidence in

That Pays Dividends

Your Equipment

Get the equipment you can trust to last. Visit hapman.com/profood 269-421-2912

ProFood_AdTemplate.indd 1

3/31/21 9:36 AM

NEWS

IN THE

Measure the ‘Size of the Prize’ via Asset Reliability

A

SSET RELIABILITY is the focus on planned and unplanned downtime reduction—or, put another way, “Is the machine doing what it is supposed to do, when it is supposed to do it?” The OpX Leadership Network, in conjunction with PMMI, The Association for Packaging and Processing Technologies, and the FSO Institute, recently released a work product called “Asset Reliability Roadmap for the Consumer Products Industry,” created to assist with calculating asset reliability and improving communications between CPGs and OEMs during this process. The work product focuses on the relationship between overall equipment effectiveness (OEE) and three key performance indicators (KPIs)

for asset reliability: people, operating, and financial. It provides an asset reliability “roadmap,” as well as a calculator, to help quantify the total value of asset reliability to an organization by determining missed opportunities, in addition to the potential value gained by improving the reliability of a line and reducing unplanned downtime. As the report states, seeing maintenance as more than just a cost of doing business but rather a tool in meeting desired and expected performance in the asset and financial expectations is key to seeing positive and effective results in profitability and requires ownership from all levels in an organization. Download this free OpX work product at pfwgo.to/OpXAsset.

MWC, Kraft Heinz, CTI Foods Win Manufacturing Innovation Awards ProFood World will honor the winners of the fifth annual Manufacturing Innovation Awards at PACK EXPO Las Vegas in September 2021. The awards recognize outstanding food and beverage processing and packaging innovation projects involving greenfield plants, expansions and renovations, or line upgrades. The 2021 winners include MWC’s new cheese and whey facility in St. Johns, Mich.; an expansion and modernization project at Kraft Heinz’s Wausau, Wis., plant; and filled taco line robotic innovations for CTI Foods, based in Saginaw, Texas.

T. Marzetti to Expand Kentucky Plant Salad dressing and sauce producer T. Marzetti is investing $133 million to add 184,500 sq ft of manufacturing space to its Horse Cave, Ky., operation, purchase new equipment, add eight new processing kitchens, and create several packaging lines. Expected to be completed by July 2022, the expansion will create 220 full-time jobs.

Kraft Heinz Uses Recycled Packaging as Roofing Material

IMAGE COURTESY OF PMMI’S OPX LEADERSHIP NETWORK

This graphic provides a more traditional continuous improvement model regarding the asset reliability journey. It is important to note the critical value of engaging stakeholders from all relevant functions.

Kraft Heinz completed a pilot project, installing roofing material made from post-consumer flexible plastic at its plants in Beaver Dam, Wis., and Holland, Mich. Installed late last year, the recycled roofing materials were comprised of 4- by 8-ft boards, 94% of each made of post-consumer recycled plastic and fiber. If the recycled materials perform as well or better than standard building materials, the company will consider standardizing their use in the future.

www.profoodworld.com

0421_IntheNews.indd 9

| April 2021 | PROFOOD WORLD

9

3/31/21 7:41 AM

IN THE NEWS

The Processing Zone Returns to PACK EXPO

P

ACK EXPO LAS VEGAS 2021 (Sept. 27-29, 2021, Las Vegas Convention Center) will feature the return of the Processing Zone and solutions from food processing/systems, food safety, engineering, design and construction services, and more. Attendees from industries such as baking and snack, beverage, meat and poultry, dairy, and fruit and vegetable can once again start their search for front-of-the-line processing solutions—while continuing to solve their packaging challenges. The Processing Zone will showcase operationsimproving and newly unveiled technologies for attendees to assess and compare solutions for current projects while inspiring future projects, all in one trip. Walking the aisles, connecting with colleagues, and meeting new people offer attendees the opportunity to discover solutions they didn’t even know they needed. Manufacturing’s essential role during the pandemic shed a spotlight on new technological needs,

0421_IntheNews.indd 10

which the packaging and processing industry rose up to meet. These improvements and advancements in equipment and technology will continue to evolve. As the most comprehensive packaging and processing event in the world in 2021, PACK EXPO Las Vegas and Healthcare Packaging EXPO will lead the way in bringing the packaging and processing community together again at a safe and productive event for all participants. Attendee registration opens in May. In the meantime, visit packexpolasvegas.com for more information.

3/31/21 7:40 AM

Keep metal OUT of your product with BUNTING’S quickTRON™ 07 RH The quickTRON™ 07 RH High hygienic metal separator is for inspection of material in gravity free-fall applications. This metal detector detects and rejects all ferrous metals, non-ferrous metals, and stainless steels. Its reject mechanism minimizes the loss of good product while ensuring contamination is thoroughly removed without interrupting your process, keeping your operations timely and your product metal free. 7KH TXLFN7521v 5+ IHDWXUHV DQ LQWHJUDO VHQVLQJ WXEH IRU JUHDWHU VHQVLWLYLW\ DQG D UHPRYDEOH UHMHFW DQG ưDS IRU ease of cleaning without the use of tools. Protect your product and your equipment with BUNTING metal detectors.

800.835.2526 or 316-284-2020 Sales.Newton@BuntingMagnetics.com BUNTINGMAGNETICS.COM ProFood_AdTemplate.indd 1

3/31/21 9:37 AM

OPX INTEL: MANUFACTURING HEALTH STEPHEN C. SCHLEGEL

| CO-FOUNDER AND MANAGING PARTNER, FSO INSTITUTE

The Technology Balancing Act of Staying in the Zone Being in the zone means balancing your technology investment with all the people and teams using that technology. The short-term benefits realized through accelerated performance can achieve a lasting impact by sustaining those gains.

A

CCORDING TO SPORTS PSYCHOLOGY TODAY, being in the zone is a state of supreme focus that helps athletes in all sports perform at their peak potential. This widely accepted view for athletes is equally applicable to the food and beverage industry. A recent FSO Institute survey on technology in food and beverage manufacturing supports this notion. This survey sought to identify the correlation between a company’s level of technological maturity and the technology adoption rate of its users. As you will see in the charts below, a company can compare its results to the FSO industry average for each of the 12 Dimensions of Manufacturing Health. This data can be useful for developing appropriate improvement plans. A few observations of the FSO industry average include: • The level of technology in worker safety, product safety, and manufacturing performance reflects the reported investments in recent years.

• The use of the technology tools provided to the workforce generally reflects an alignment to the investments. • The upside opportunity for our industry is that most dimensions recorded to be midway on the scale. Achieving the desired state of being in the zone requires a significant balancing act of new technology investments with the worker skills required to use that technology. While the latest technology investments promise greater productivity and effectiveness, the adoption rate of technology relies on a workforce that is skilled enough to at least manage, let alone be aligned, with its predictive capabilities.

Level of Technology

Level of Use

12 Dimensions of Manufacturing Health To enable an entirely new perspective, consider how a company employs technology through the lens of FSO’s 12 Dimensions of Manufacturing Health. What follows are insights from industry leaders, sharing how they are using technology to accelerate performance at their companies.

Engagement

Engagement Quality

Packaging

Asset reliability

Worker safety

Current FSO industry average Company’s score

Quality

Performance

Technology

Facilities

CapEx

Product safety

Sustainability Supply chain

Performance

Packaging

Asset reliability

Technology

Worker safety

Facilities

CapEx

Product safety

Sustainability Supply chain CHARTS COURTESY OF FSO INSTITUTE

12

PROFOOD WORLD

0421_OpX.indd 12

| April 2021 | www.profoodworld.com

3/31/21 7:44 AM

FEATURED TOPIC AUTOMATION SYSTEMS PROMOTE SAFETY AND IMPROVED PERFORMANCE

F

ood processing plants, warehouses, and distribution centers see the value in robotics and automation and are expected to invest $14.3 billion by 2025 in automation and technology. Driving this spend is the need to address a shrinking labor force, accommodate safer working conditions in a postCOVID world, and a desire to decrease employees’ exposure to repetitive tasks and harsh environments. “Management teams have seen an overall attendance increase when an effort is made to invest in equipment that helps employees with the daily work at hand, by giving employees more control over the line performance, which in turn, increases output and performance,” says Mark Livesay, vice president, Automated Facilities for ESI Group USA. Below we’ve highlighted automation systems that plant and warehouse management may consider to reduce risks, decrease picking errors, and increase safety.

Automated Storage & Retrieval Systems

Storage solutions on the floor can be improved without human intervention with the addition of automated storage and retrieval systems (AS/RS). Food manufacturers, processors, and distributors are finding these systems critical for tracking a product’s status and improving turnaround times. When choosing an AS/RS, first a building type needs to be determined: Conventional (up to 50 ft. tall) or Rack Supported (up to 150 ft. tall). There are three types of AS/RS systems: • One-to three-pallet deep system with multiple storage

Courtesy of NM Photos.

retrieval machine (SRM) aisles; • Deep-lane system (stores up to 12 pallets deep on either side of the aisle); • Pallet shuttle system serviced by elevators located in the end of aisle run-out area. Facility managers also need to decide what type of order picking is desired: • Pick-to-belt or a pick to pallet/cart system: This involves the product being manually picked and the product transported to a palletizer. • Layer picking: A pallet is automatically brought down by the AS/RS and conveyed into a layer picking area where a gantry robot picks a layer off the pallet and builds a mixed pallet with different layers of product. • Case picking: Individual cases are stored in a mini-load AS/RS or a multi-shuttle (as seen in the photo) where individual cases are picked and conveyed to a palletizer.

Food automation market to reach $29.4 billion by 2027 60% of companies use technology to support workforce Tyson Foods invested $215 million in robotics and automation over 5 years ESI Front.indd 1

4/1/21 1:56 PM

There are approximately 13 major AS/RS equipment manufacturers in the US (see sidebar). The working environment and type of project defines which AS/RS company is the best fit for an operation. ESI Group USA lays out the general project parameters, lets the AS/RS supplier propose its solution, and reviews the options with the customer, discussing the pros and cons of the system design and equipment. Choices are narrowed down based on customer input and the supplier’s experience with the application.

Automated Guided Vehicle Systems

Many warehouses have replaced traditional forklifts with automated guided vehicle systems (AGVS) to perform tasks previously performed by multiple employees, such as unloading and loading trucks and transporting large items across warehouse floors. AGVS can also perform operations in harsh conditions. For these reasons, AGVS use is becoming more accepted. There are ba-

sically two types of AGVS: the forklift type that stores and retrieves product on multiple levels and pallet movers where the product is either conveyed onto or off the AGVS, or the pallet is placed onto a cart and the pallet is towed to the desired location.

Robotics

In an effort to reduce time spent on redundant tasks or address workforce shortages, robotics and automation are great options. Successful robotics implementation ensures that the workforce understands that the technology is working alongside them, not replacing them. As an example, autonomous scrubbers automatically clean and scrub floors, and are designed to work safely and efficiently alongside employees. “There is no question that more food processing facilities and distribution centers are incorporating automation to take advantage of all its benefits and still keep food safety at the forefront,” says Livesay.

LEADING AS/RS MANUFACTURERS: Automha Dematic Dambach Daifuku Wynright Electric 80 LTW Murata SSI Schaefer Stoecklin Swisslog System Logistics Via Store Westfalia

FEATURED PROJECT

THE ONLY PLACE TO GO IS UP

R

eyes Holdings, L.L.C., the parent company of Great Lakes Coca Cola, is expanding production and needs additional finished product storage at its existing distribution center in Alsip, Illinois. The only place to add storage space was on a parcel of land between two existing production and storage buildings. Based on the site constraints and storage requirements, it was determined to build “up” and implement an Automated Storage and Retrieval System (AS/RS). After considering a few options, the Automha AS/RS was chosen because it offered the most storage and throughput capacity using a deeplane pallet shuttle with full pallet pick, explains Mark Livesay, vice president, Automated Facilities for ESI Group USA. Constructing the AS/RS involves a 95-ft. tall rack-supported structure, roof decking, and insulated metal wall panels. The new beverage storage facility is approximately

CONTACT ESI Group: ESI Front.indd 1

65,000-70,000 sq. ft. The AS/RS will move 2-liter filled plastic bottles stacked on plastic pallets shrink wrapped on four sides with open gridded crates.

Curtis Waltz / aerialscapes.com

Find us at an event: esigroupusa.com/about-esi/events/

4/1/21 1:57 PM

1

Manufacturing Performance Dimension

FSO Institute: How are you using technology to manage production schedules and improve throughput performance? As leaders, we are obligated to enable our people and, as a result, our teams, with the capability to take true and meaningful action. Along with supporting the development of everyone’s skills, we must enable our teams with the authority to make decisions and address opportunities. Unfortunately, the combination of a comprehensive set of skills combined with the ability to make decisions is not enough. To make a meaningful impact on the organization, our teams must also have the resources to take action. The resources of today are centered in technology— technology in the form of tools, data, and analytics. Technology is the great enabler, accelerating results and cementing sustainment, when [it is] placed on a solid foundation of empowered and skilled teams. —Greg Flickinger, SVP Operations & Supply Chain, Green Thumb Industries

2

Quality Dimension

3

Workforce Engagement Dimension

FSO Institute: How do you accelerate the adoption and use of new technology? Adoption of technology requires workforce engagement. No project big or small happens without an engaged workforce, especially when it comes to technology. Some studies show a 60% failure rate when placing technology without an engaged workforce. If the end users are not well trained and do not understand the why behind the automation you have added to their day, they will simply revert to the way of doing work that they know. The company ends up spending time and money with no real benefit, because the technology will not get used. —Bob Gates, P.E., Sr. Director, GE Digital

4

Technology Dimension

FSO Institute: What observations can you share regarding the roles of OT and IT, and how are they changing?

IAF continues to refine and improve production to specification through technology. Recent additions of benchtop and production tools have driven our product quality to a new level. The introduction of a desktop refractometer in the production area has replaced handheld units to measure Brix, a key processing parameter, to a very precise and repeatable level. In addition, the routine use of a titrator to measure moisture percentages in all our products and the introduction of a water activity meter have improved our post-production quality checks and provide feedback for process improvements. In 2021, IAF plans to add a tensiometer to our sensory protocol for gummies to accurately measure mouthfeel in conjunction with actual taste and texture sampling.

I believe that OT and IT will be nondistinctions in a decade, as the two worlds continue to merge. For example, years ago, when you were developing a maintenance program, you instructed the owner to look at the ‘odometer’ and determine what PMs were appropriate to perform. You did the work of creating the maintenance plan in an IT system, because that’s where you could transcribe your thoughts and communicate them to others. The OT system tracked the odometer, but only communicated it or visualized it locally. With the convergence of the technologies with the OT and IT worlds, we continue to get more efficient, so that today, the machine communicates the ‘odometer’ to the maintenance planning system, and the maintenance system pushes the information to do the maintenance [parts, procedures, diagrams, etc.] to the plant floor. As the convergence of technologies [Ethernet communication, database management, switches, routers, and security] continues, the distinction of the two separate worlds will continue to disappear. It will become a distinction without a difference.

—Scott Spencer, President and COO, Island Abbey Food Science

—Joe Zembas, Sr. Manager, Reliability Engineering, J.M. Smucker

FSO Institute: How are you using technology in your quality functions to manage and verify specification compliance?

www.profoodworld.com

0421_OpX.indd 13

| April 2021 | PROFOOD WORLD

13

3/31/21 7:44 AM

OPX INTEL: MANUFACTURING HEALTH

5

Asset Reliability Dimension

FSO Institute: How are you using technology to automate the reporting of critical asset reliability issues in your plants? Using solid data collected from the operational conditions on an asset or set of connected assets to analyze opportunities allows us to make data-based decisions, which lead to high efficiencies and profitability. Our objective for each plant is to assemble a standardized technology package, which can collect the data from the plant floor network, aggregate the data for isolating key issues, engage the team to conduct root cause analysis, implement the corrective actions and track results, and report the outcomes into our care strategy network, so it can be shared across all plants. —Mark Hanley, CMRP, Sr. Corporate Asset Reliability Manager, Land O’Lakes

6

Supply Chain Dimension

FSO Institute: How are you using technology to inform those in the supply chain of replenishment requirements? We provide manufacturers with the ability to connect their supply chain end to end by leveraging data and analytics that enable visibility and data-driven decision-making. We use state-of-the-art technology and science to provide better planning and execution from demand forecasting, network, and inventory optimization to scheduling solutions that incorporate production and logistical constraints and rewards. —Dayana Cope, Director, Simulation and Data Science Practice, Engineering USA

7

Product Safety Dimension

FSO Institute: How are you using technology to enable your teams to do root cause tracking on product safety? At Blommer Chocolate, we have moved the production floor paperwork to an electronic database.

14

PROFOOD WORLD

0421_OpX.indd 14

Operators use a tablet to enter this data real time. When a critical result is outside criteria limits, an immediate alert is sent via text, email, and even to the monitors around the plant, to signal attention is needed now. A team converges on the location to assess what just happened and can take instant steps to address it. —John Hilker, Director of Manufacturing, Blommer Chocolate

8

Worker Safety Dimension

FSO Institute: How are you using technology to manage and report on worker safety compliance? We use EHS [environmental, health, and safety] software technology to track and trend performance companywide. We leverage that information to further focus on enhancements made to our sites that will decrease the possibility of incidents. As we move forward, we are looking at predictive-based safety analytics and wearable technology to help us better manage EHS and ergonomic compliance, in light of the COVID-19 pandemic. —Xavier Aguilera, Director of Corporate EHS, Bumble Bee Seafoods

9

Packaging Dimension

FSO Institute: From a technology provider perspective, how are CPGs using technology in packaging and new product introductions? Timely product introduction means first to market and addressing product cost erosions. CPG customers are utilizing automation to help their teams standardize new workflows for product setup and changeovers, allow faster time to market, and provide delivery to customer shelves in less time. When issues do occur, CPG companies are using the more timely and accurate reporting of the key metrics most critical to their operations. With this drilled-down ability, they are eliminating repeatable issues and developing more reliable supply for their customers. —Bob Gates, P.E., Sr. Director, GE Digital

| April 2021 | www.profoodworld.com

3/31/21 7:45 AM

10

scheduling decisions autonomously with the objective of maximizing a reward function.

CapEx and Facilities Dimension

FSO Institute: How are you using technology to enhance communication during capital projects? After creating an expectation about a virtual FAT during preliminary discussions with an OEM, we write it into the purchase order. Before fabrication is complete, we create a list of items to be tested or demonstrated, such as pictures, dimensions, HMI screens, interlocks, induced failure/ recovery, video clips of important machine actions, machine guarding, and hygienic design. All of this is uploaded to the cloud, so it can be reviewed in advance. Then, we have the virtual FAT by Zoom, and it goes very quickly; outstanding items are added to a punch list. —David Drum, Global Engineering, Kellogg

11

Sustainability Dimension

FSO Institute: How are you using technology to facilitate the automation of sustainability reports?

—Dayana Cope, Director, Simulation and Data Science Practice, Engineering USA Being in the zone means being in balance with your level of technology investment and all the people and teams using the technology. Think of your favorite athlete. What is his or her journey to prepare for the zone, perform while in it, and do it repeatedly? It is a journey, just as it is for food manufacturers. To begin your journey of getting into the zone, see the free technology survey for food and beverage manufacturers at pfwgo.to/FSOSurveys.

ABOUT THE OPX INTEL SERIES OF ARTICLES PMMI’s OpX Leadership Network has produced more than 20 manufacturing process-improvement documents for CPGs and OEMs. The FSO Institute has facilitated the adoption and implementation of these documents, especially for food and beverage manufacturers. This series of articles shows how CPGs are using OpX and FSO documents to improve their overall manufacturing health and collaboration with OEMs and other suppliers. Learn more at www.opxleadershipnetwork.org and www.fsoinstitute.com.

Technology for gathering sustainability data has advanced tremendously over the past few years. Automation and cloud solutions have made the collection and analysis of accurate data less challenging, allowing [us] time to work on advancing environmental progress. —Amber Brovak, Sr. Manager, Global Safety Operations, Church & Dwight

12

Manufacturing Performance Dimension

FSO Institute: From a technology provider perspective, how are CPGs using technology to manage production schedules and improve throughput performance? We utilize data and technology to help manufacturers become less reactive and more predictive to how their systems perform. By leveraging descriptive, predictive, and prescriptive analytics, we give manufacturers the tools they need to understand and manage their performance in real time. Using machine learning technology, we help them predict yield and quality, while providing indications of how they should intervene to make sure that their performance is within an acceptable standard. In addition, by leveraging reinforcement learning and discrete event simulation, we enable manufacturers to implement intelligent, effective production scheduling agents that can make www.profoodworld.com

0421_OpX.indd 15

| April 2021 | PROFOOD WORLD

15

3/31/21 8:18 AM

• Aluminum provides an absolute barrier at even a very low thickness with unique properties that provides an excellent source for heating and keeping cold. • Smooth Wall aluminum is suitable for Gas Flushing, MAP, CAP and Vacuum Packaging resulting in extended shelf life. • Smooth Wall aluminum also works well in a Freezer, Microwave, Oven, Broiler, Grill, Turbo-Chef, Cooktops, Toaster Oven, and is 100% infinitely recyclable.

FULLPAGE_CRB/COPPICE.indd 46 ProFood_AdTemplate.indd 1

3/31/21 8:10 AM 3/31/21 9:50 AM

PACKAGING TECHNOLOGY MATT REYNOLDS | EDITOR, PACKAGING WORLD

Extended Shelf Life Is Key to Lidl’s Latest RTE Line Using a process-in-pack technology, the German grocery giant added shelf life to ready-to-eat meals that will extend their market range.

G

ERMAN GROCERY GIANT Lidl recently launched three ready-to-eat (RTE) meals made with a refrigeration technology that provides a much longer shelf life. Released under its Chef’s Select brand into the Swedish market, the three meals—Meatballs with Mashed Potatoes, Sausage Stroganoff, and Pasta Pomodoro—are made by long-time Lidl partner Smålandskräftan, a Swedish cookery and private-label food producer. Smålandskräftan employed the Micvac method on the ready-made meal applications—a patented method that affords the products a far longer shelf life compared to other ready meals, without compromising on taste, nutrition, or consistency, according to Micvac. The meals are produced and chilled, not frozen, and only require warming by the consumer. “Our ready meals produced with the Micvac method taste as if they’re homemade. We have great faith in this launch, and are also planning to introduce the dishes abroad,” says Alexander Weiss, purchasing manager for food at Lidl. “We were very interested when Smålandskräftan told us about the technology, and the products have not let us down.”

The Micvac method The meals are produced with a microwave application that cooks food in its package. On the packaging and processing line, thermoformed polypropylene (PP) trays supplied by Faerch plast are denested and conveyed to a depositor that fills them with the raw ingredients. Next, the trays are lidded with a PP/PA laminate film. The lidding material is sealed to the tray in a sealing machine from G.Mondini. A specialized valve that allows steam to vent from the package is then applied to the lidding material of each sealed tray, but the mechanism only allows venting to occur after a pre-determined pressure is reached during the next process, which is a microwave cook. When the cooking process is finishing, and the pressure inside the sealed tray reduces, the valve recloses to maintain a barrier for the cooked food. The finished, cooked tray maintains a negative internal pressure. Secondary packaging involves a printed

PHOTO COURTESY OF LIDL

Lidl launched three ready-to-eat meals made with the Micvac method, which provides a much longer shelf life than other ready meals.

paperboard bellyband, which is automatically applied after the tray is sufficiently cooled. Compared with many other ways of making ready meals, Micvac says its method better preserves vitamins and flavor. This means that the artificial E-number additives can be minimized. “For me as a purchaser, it’s extremely important that the products have as long a shelf life as possible without affecting the quality, and the Micvac method makes sure they stay fresh for a very long time,” Weiss says. “Since they were only recently launched, we don’t have any statistics yet, but we believe they’ll reduce food waste.”

Plans for an international launch The products have been well-received on the market since their launch in November 2020, Lidl reports, and the ambition is to launch them on additional European markets moving forward. “I truly believe in the Micvac method, and in the longer term, I hope we can export these dishes to other Lidl countries,” Weiss says. “Taste is of course subjective, but many find that dishes made using the Micvac technology taste delicious—as if they were homemade, even. We have long been looking to develop the ready-meal segment, and with this method we can do so with products of high nutritional content, which also taste great and look appetizing.” Micvac www.micvac.com

Faerch plast www.faerch.com

G.Mondini www.gmondini.com

www.profoodworld.com

0421_PackagingTech.indd 17

| April 2021 | PROFOOD WORLD

17

3/31/21 7:51 AM

PACKAGING TECHOLOGY

Partnership Focuses on Replacing Single-Use Plastics

P

▲

ULPAC, PA CONSULTING, AND SEISMIC SOLUTIONS announced that they will be working together to replace single-use plastics with a sustainable, affordable alternative. The technology behind the global partnership comes from PulPac, which has created Dry Molded Fiber—using renewable pulp and cellulose resources to produce low-cost, high-performance, fiber-based packaging and single-use products. PulPac’s Dry Molded Fiber is a patented manufacturing technology

PHOTO COURTESY OF PULPAC

The PulPac Tech Center in Gothenburg, Sweden, shows off trays made from its Dry Molded Fiber technology.

that provides up to a 90% lower CO2 footprint at the same or lower cost as plastic. It enables high-speed manufacturing and can replace most packaging and single-use products presently made of plastics, including soda and coffee cup lids, meat trays, food carry-out containers, and bottles. The partnership will focus on accelerating the replacement of single-use plastics with packaging that is both sustainable and commercially competitive. The technology is licensed to packaging manufacturers and brands setting up their own production. Today, the partnership has cooperation and licensing agreements with a number of selected customers, including several large global brands operating in food and beverage, beauty, toys, healthcare, and other industries. PulPac www.pulpac.com

PA Consulting www.paconsulting.com

Seismic Solutions www.seismicoutcomes.com

PERFORMANCE, PACKAGED

GREAT PRODUCTS GREAT IDENTITIES LABELING AND SLEEVING SOLUTIONS As more and more brands and SKUs enter the market, how do you make your product stand out from the crowd? A great brand identity supported by great graphic designs is one way to create a competitive edge. P.E. Labellers and Axon, product brands of ProMach, offer labeling and sleeving systems that can accommodate a virtually unlimited range of container types, shapes and sizes. From P.E. Labellers' pressure sensitive, cold glue, hot melt and roll-fed labelers to Axon's shrink sleeve and stretch sleeve labeling systems, we offer the broadest range of labeling technologies in the industry. If you have a product that needs a label, a shrink sleeve or a stretch sleeve, give us a call to discuss your application.

800-598-8601

0421_PackagingTech.indd 18

PENorthAmerica.com

AxonCorp.com

4/1/21 1:00 PM

LADDER-TRACK

™

WIRE BELT’S NEW CONVEYOR BELT! • Easy belt assembly and disassembly due to simple open construction

• High tensile rods resist permanent distortion and reduce down-time

• Flat uniform surface for gentle product handling

• Positive drive to ensure there are no tracking issues

• Smooth edges for easy movement around transfers

154 Harvey Road, Londonderry, NH 03053 Tel: 603-644-2500 | sales@wirebelt.com | www.wirebelt.com

ProFood_AdTemplate.indd 1

3/31/21 9:38 AM

FOOD SAFETY CULTURE JOYCE FASSL |

EDITOR IN CHIEF

Commitment, collaboration, and communication are essential for building a successful food safety culture. But don’t forget that people at all company levels are the dominant factor in producing high-quality, safe food and beverages.

B

As a director of quality for Conagra Brands, Shawn Fear says a food safety culture is built upon a combination of employee engagement, effective training programs, adherence to documented policies and procedures, and a continuous improvement mentality. “We have a comprehensive, enterprise-wide approach that is measurable and enables us to make high-quality, safe food each and every day,” Fear states. “This requires a great deal of commitment and collaboration by teams across the enterprise that are involved with product development, sourcing, production, packaging, warehousing, distribution, and customer service.” Food safety and quality are foundational to the trust customers and consumers have in Smithfield Foods and its brands, according to Warren Dorsa, senior vice president of food safety and quality assurance at the company. “We employ rigorous systems and exacting procedures, including more than 40 internal policies, to ensure we continue to deliver consistently high-quality products,” he states. The meat processor’s quality-assurance plan is built on the Hazard Analysis and Critical Control Smithfield moved quickly at the outset of COVID-19 to implement protocols mitigating the risk of viral transmission by employing barriers, masks and shields, and enhanced air purification systems across its facilities.

▲

ACK IN THE 19TH CENTURY, author Alexander Dumas empowered “The Three Musketeers” with the famous mantra: “All for one and one for all, united we stand, divided we fall.” The same philosophy can be applied to building a food safety culture. Unless your facility has buy-in from all staff levels, you may have a tough time getting your food safety culture program off the drawing board. During a recent webinar, Liliana Casal-Wardle, senior director for food safety and supply chain risk management at The Acheson Group (TAG), discussed the 10-year strategy from the U.S. Food and Drug Administration (FDA) to enhance the capabilities of the Food Safety Modernization Act (FSMA) through its New Era of Smarter Food Safety program. Casal-Wardle reviewed the four core elements of the FDA’s new strategy: • Tech-enabled traceability • Smarter tools and approaches for prevention and outbreak response • New business models and retail modernization • Food safety culture “It’s a big group of people that have the same shared values, beliefs, and norms,” Casal-Wardle said about building a food safety culture. “People feed into those values and create a cohesive model that has a little bit of the input of each component, of each person, and of each individual as part of the culture.”

PHOTO COURTESY OF SMITHFIELD FOODS

20

PROFOOD WORLD

0221_F1-Food Safety.indd 20

| April 2021 | www.profoodworld.com

3/31/21 7:52 AM

0221_F1-Food Safety.indd 21

3/31/21 7:52 AM

FOOD SAFETY CULTURE

Point (HACCP) management framework and is a living document that is continually updated to adhere to best practices and industry innovations. Smithfield also continuously monitors U.S. Department of Agriculture (USDA) safety and quality regulations, and in-house labs inform and lead the implementation of any new test requirements. The company has Global Food Safety Initiative (GFSI) certification, which drives continuous improvement in food safety management systems internationally, adds Dorsa. GFSI certification also includes audits conducted by Safe Quality Food (SQF), Brand Reputation through Compliance Global Standards (BRCGS), International Food Standards (IFS), and ISO 22000. In addition, Smithfield enhances its food safety culture by relying on its suppliers to provide high-quality ingredients. All Smithfield vendors must comply with GFSI and HACCP requirements.

Empowerment, measurement, and recognition When employees have a voice, they become part of the solution, according to Joni Fagan, vice president of quality control at Ken’s Foods. “Food safety is everyone’s responsibility,” she says. “This is included in job descriptions, training, and specific job tasks. Expectations of food safety culture become behaviors.” Leadership buy-in and continuous support of the food safety culture is mandatory, Fagan PHOTO COURTESY OF GTI adds. Ken’s Foods fosters an environment of collaboration, where staff listens and enlists An automatic handwashing station and signage remind GTI staff the help and knowledge of the workforce. that a food safety culture is mandatory. In the cannabis edibles industry, it’s important to build a food safety culture that at a Florida facility, has implemented a quality and the leadership team embraces by showing and prefood safety presentation board, where the company senting expectations themselves before rolling out presents a new food safety topic each month. “Last the program to hourly workers, says Wendy Uhls, month, we refreshed the GMP [good manufacturing quality and compliance manager for Green Thumb practice] policy for the whole plant and put a copy of Industries (GTI). “We’ve actually implemented some the GMP policy up with the training that we had done new roles recently, where hourly workers own more in PowerPoint,” she explains. “Every month, we’ll do of the quality piece, are able to provide feedback up a different topic just to get the team involved.” through the chain, and own that space,” she says. Smithfield invites employees to “audit” the prodUhls’ facility also uses a “best buds” program. ucts they’ve helped produce. Cross-functional teams “Whenever we catch somebody doing an awesome of staff representing all levels of the organization job of complying or just being a supportive member are invited to appraise products daily. This program of the team, we provide coins that employees can colunderscores how critical safety and quality stanlect over time,” she says. Depending on the number dards are and instills a sense of employee ownership. of coins they acquire, employees can choose from an Through its “Raise Your Hand” campaign, array of goodies, such as hats, shirts, and GTI products. Smithfield empowers employees to stop production GTI’s Janet Sullivan, quality compliance manager 22

PROFOOD WORLD

0221_F1-Food Safety.indd 22

| April 2021 | www.profoodworld.com

3/31/21 7:53 AM

Dispersion Genius The ROSS Solid/Liquid Injection Manifold (SLIM) system saves time and money on your bottom line. Engineered to accelerate mixing in challenging applications, the SLIM instantly disperses hard-to-mix powders like xanthan gum, calcium carbonate and pectin into a liquid stream. Directly induct powders at rates up to 700 lbs/min and

Powder Inlet

cut processing times by 80% or more. By preventing the formation of agglomerates, the SLIM helps ensure the maximum yield of solids. No pump, eductor or clogging. In-line and batch models are portable to serve multiple process lines.

Liquid Inlet Completed Dispersion

Try our free online Knowledge Base & Product Selector web app at mixers.com/web-app.

www.mixers.com/SLIM • 1-800-243-ROSS

ProFood_AdTemplate.indd 1

3/31/21 9:38 AM

FOOD SAFETY CULTURE

The culture paradigm TASK-BASED

ROLE-BASED

Matrix driven by work Collaborative Equal visibility among all departments QA/QC is the gatekeeper Solutions-driven Findings seen as opportunities Equal ownership Empowered employees “It’s our problem”

Hierarchy/driven by title Conflicting agendas Unbalanced representations and diminished capacity QA/QC is the police officer Problem-focused Blame placed on findings No ownership of tasks Powerless employees “It’s not my problem”

IMAGE COURTESY OF THE ACHESON GROUP (TAG) AND SAFETYCHAIN. FSMA FRIDAYS, “BUILDING AN AUDITABLE, MEASURABLE FOOD SAFETY CULTURE.”

if they see anything throughout the day that affects food safety or quality. The company recognizes employees who identify potential product safety or quality hazards. At Smithfield, employees learn from day one that food safety is non-negotiable. The company’s

goal is zero product recalls, which it achieved in 2019. As a vertically integrated company, Smithfield is collaborating with FoodLogiQ’s Food Industry Blockchain Consortium and the IBM Food Trust to drive customer visibility into food safety and quality assurance, and to increase transparency. GTI measures customer complaints using key performance indicator (KPI) boards. “We’re looking at customer complaints, third-party audits, and our Department of Health inspections, so we’re taking all of those, and we try to present those every month,” says Sullivan. “We don’t want to have any findings from the Department of Health, and we don’t want to have any GMP findings. We want to make sure that our customers are happy, so we try to get customer complaints down to zero.” Currently, GTI facilities are preparing for SQF certification. Learn more about GTI’s food safety culture in the sidebar below. According to Casal-Wardle, measuring the culture is not about checking your critical control points and then thinking you’re finished. “That’s great,” she says,

Cannabis Food Safety Culture GREEN THUMB INDUSTRIES (GTI) is a consumer packaged goods company and retailer that manufactures and distributes a range of cannabis products. Headquartered in Chicago, the company owns and operates national retail cannabis stores called Rise. GTI has 13 manufacturing facilities, licenses for 97 retail locations, and operations across 12 U.S. markets. The food safety culture at its facilities is nearly identical to those at food and beverage plants, but is ramped up to meet cannabis regulations. “If one of us fails, we all fail, especially being a new industry,” says Wendy Uhls, quality and compliance manager. “Right now, it’s not federally legal. If one of us has any sort of major incident, that could take us down. We can’t risk that. We’re doing everything that we can to make sure that doesn’t happen on our end. We must have a very specific flow with traceability that’s probably a little more than what the food industry has.” Janet Sullivan, quality compliance manager for GTI, agrees. Even though GTI’s Homestead, Fla., facility does not currently produce edibles, it still follows all FDA, state, and local regulations. “We make sure that we have our asset plan, the allergen control, and all the regular GMPs that any food plant would have,” she states. At present, the Florida facility is producing oils and tinctures. Sullivan was hired by GTI for her broad range of food safety experience to handle edibles when her facility starts the production process. “I have the background to make sure we have the right controls and programs in place to be

24

PROFOOD WORLD

0221_F1-Food Safety.indd 24

able to handle those edibles when we do get them,” she says. Changing the culture has been a bit of a challenge, Sullivan says. “People have been here for several years, and here I am, the new person, coming in trying to change the culture. The biggest obstacle so far is just to get them onboard with the food safety piece, and how to develop that into the facility,” she states. “It’s just changing people’s mindset on what they had been doing before.” Uhls says one of her biggest challenges is training employees who come from outside the food industry. “We’ve got a lot of workers coming from textiles or other industries that may not necessarily have the same standards,” she states. The good news is that most of the workers are fairly young in their careers, so Uhls says she is able to embed the needed knowledge early, which is a definite benefit. As would be expected, the cannabis industry is heavily monitored. In Illinois, for example, the Department of Agriculture monitors all processes, has access to facility cameras, and performs weekly virtual inspections. In addition, Illinois State Police conduct monthly in-person surprise visits. In Florida, the Department of Health regulates production. “We have a whole book of regulations to follow, all the way from where the employees come in through the door, and all the way through our green waste being disposed of at the end of the day,” says Sullivan. Florida workers must be fingerprinted and undergo a check with the Department of Health to ensure potential employees have no past history of felonies or drug convictions, for example.

| April 2021 | www.profoodworld.com

3/31/21 7:53 AM

URSCHEL CUTS YOUR WORKLOAD DOWN TO SIZE

with 5 New Dynamic Models Affinity® CD-L Dicer 2-Dimensional Cuts; Newest in the Affinity Line

Affinity® Integra-D Dicer

TranSlicer® 2520 Cutter in standard and short models Next Generation Sanitation Fresh Cut Salad Industry

As The Global Leader in Food Cutting, Urschel is constantly exploring and improving on cutting methods. Depend on Urschel to overcome challenges to exceed your production goals. Contact Urschel to discover the many benefits of these new machine models.

U.S.D.A. Dairy Division Accepted High Performance Cheese Dicing

DiversaCut 2110A® Dicer with Conveyor Batch Processing & Controlled Discharge

® Set-up a free test-cut of your product: +1.844.URSCHEL (877.2435) | info@urschel.com

THE GLOBAL LEADER

IN FOOD CUTTING TECHNOLOGY NORTH AMERICA | EUROPE | SOUTH AMERICA | ASIA | AUSTRALIA | AFRICA

1

# Best Selling

www.urschel.com MADE IN THE U.S.A.

provider of industrial cutting machinery throughout the world.

®Urschel, Urschel logo symbol, Affinity, TranSlicer, DiversaCut 2110A and The Global Leader in Food Cutting Technology are registered trademarks of Urschel Laboratories, Inc. U.S.A.

2113_5NewMachines_USA_PFW.indd 1 ProFood_AdTemplate.indd 1

3/15/21 3:18 PM 3/31/21 9:39 AM

FOOD SAFETY CULTURE

Auditing Food Safety Culture What will the GFSI auditor look for? • Evidence of a plan with objectives and targets around food safety culture and evidence of the site completing the activities in its action plan • Senior management’s commitment and leadership that enable the development and continuous improvement of the culture • Management of communication related to food safety behaviors and programs • Empowerment of the workforce through education and training • Feedback from employees through interviews across all levels of personnel on an informal basis (The auditor will expect to find an awareness of food safety culture, how individuals can impact it, and the company’s objectives.) • Performance measurement on food safety-related activities • Evidence of a plan with objectives and evidence of the site completing the activities in its action plan • Rewards and recognition of employees Source: The Acheson Group (TAG) and Safetychain. FSMA Fridays, “Building an Auditable, Measurable Food Safety Culture.”

“but look at how the people are managing it. Look at how they’re doing it. Are they doing it on time? Is it something that is consistently being done? Because that shows you where you are in the culture model.”

Casal-Wardle also discussed the culture parodies of task-based and role-based programs during the FSMA Fridays webinar conducted by TAG and Safetychain on “Building an Auditable, Measurable Food Safety Culture.” “A task-based culture is a matrix driven by work,” she explained. “People are related in that culture through the work they do.” In contrast, she said, a role-based culture is driven by hierarchy and its chain of command. “A task-based culture is collaborative,” she continued. “And a role-based culture can have conflicting agendas, because the manager might want something different than what the operator is doing, or the director thinks that the manager is doing something different than what they’re doing.” In a task-based culture, employees have equal ownership and are empowered. To learn more about role-based and task-based cultures, see the box on page 24.

Sage advice Your food safety culture must be adaptable, Casal-Wardle says. She recommends having clear expectations of your current food safety state and adapting to the changes that come either internally or externally. “Change is creating a new habit. In creating a new habit, you have to create the tools for the people to understand why you are changing it, and how that is going to help them, and why it is important.” She says communication is a key factor in the success of the culture. “Explain the objectives, manage the objectives, be open to questions,” she declares. Uhls says food safety is an ongoing process. “Partner with everyone you can to find the best systems to implement any way you can,” she states. “Share what you can, and do the best you can.” Sullivan concurs, but adds, “Don’t give up. Reach out to companies, places, or people that can help you with what you’re struggling with.” Fear says it is critical that everyone understand the role they play in making food safety a top priority. He says Conagra Brands is committed to training and empowering people to identify potential issues and improvement opportunities, and then following through by taking the right actions. After all, Fear states, “the most discerning judges are customers and consumers.” FoodLogiQ www.foodlogiq.com

26

0221_F1-Food Safety.indd 26

Safetychain www.safetychain.com

PROFOOD WORLD

The Acheson Group (TAG) www.achesongroup.com

| April 2021 | www.profoodworld.com

4/9/21 1:03 PM

ONE SOURCE

David Roberts Lubriplate District Manager TN, AL, GA & Northern FL

FOR ALL OF THE LUBRICANTS AND SERVICES YOU NEED

WE HAVE THE EXPERIENCE Lubriplate has been helping industry meet its lubrication needs for more than 150 years. In that time, we have learned what works and what doesn’t. Put our experience and knowledge to work for you.

WE HAVE THE PRODUCTS Lubriplate offers a full range of ultra high-performance, NSF H1 registered, synthetic and USP mineral oil-based lubricants that have been engineered from the ground up to provide a number of cost saving benefits including; extended lubrication intervals, reduced friction, multiple application capability and lubricant inventory consolidation.

WE HAVE THE SERVICES Lubriplate offers its Complimentary ESP Extra Services Package to all of its customers at no additional charge. Services include; Complete Plant Surveys to help determine your exact lubrication needs, Color Coded Lube Charts and Machinery Tags which simplify maintenance procedures, Lubrication Training Programs and Follow-Up Oil Analysis.

Call 800-733-4755 to get started. INCLUDED AT NO ADDITIONAL CHARGE

Lubriplate’s

ESP

Complimentary Extra Services Package Newark, NJ 07105 / Toledo, OH 43605 / 800-733-4755 To learn more visit us at: www.lubriplate.com

ProFood_AdTemplate.indd 1

COLOR CODED LUBE CHARTS & MACHINERY TAGS PLANT SURVEYS / TECH SUPPORT / TRAINING LUBRICATION SOFTWARE / FOLLOW-UP OIL ANALYSIS

3/31/21 9:39 AM

TECH TODAY: MOTORS AND DRIVES AARON HAND | EXECUTIVE EDITOR

Come Together for Motion Efficiency, Performance, Reliability Beyond the advances made to both motors and drives in terms of energy efficiency, safety, cleanability, and more, suppliers emphasize the importance of how they work together in a complete motion system.

T

O CHOOSE THE RIGHT MOTOR for your application, you need to consider more than just horsepower, speed, and torque, of course. With electric motor systems accounting for about 70% of the electricity demand in industry, energy efficiency has long been a prerequisite that seemed, however, to be reaching its limits. Efficiency is being pushed further through full system optimization, but requirements are also increasing for improved hygiene, safety, connectivity, data availability…everything that will keep those motors and drives—and all the production equipment they keep in motion—from shutting down unexpectedly. Motor and drive suppliers are creating products for a food and beverage industry that is on the move. “It’s an industry which I think is really more of a laggard

▲

Coca-Cola HBC Austria saved 75% of the energy consumed with its previous drive and control technology by installing SEW-Eurodrive’s Movigear mechatronic drive system. 28

PROFOOD WORLD

0421_TechToday.indd 28

PHOTO COURTESY OF SEW-EURODRIVE

in terms of automation and technology,” says John Parrott, vice president of Siemens Industry’s U.S. food and beverage market. “Now we’re seeing a significant upswing in robotics, digitalization projects, and how to manage the business remotely.”

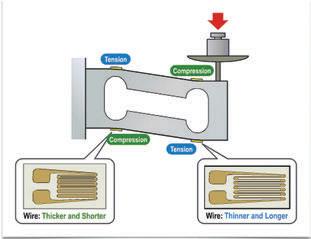

Finding new energy efficiencies In a recent international push urging greater adoption of high-efficiency motors and drives in industry and infrastructure, ABB Motion emphasizes the point that—despite rapid efficiency advances in the past decade—a significant number of automation systems in operation today consume much more power than required. Saving energy goes straight to the bottom line. There’s a limit to how efficient a standard induction motor can be made, which is why SEW and others have moved to permanent magnet technology instead. Permanent magnet motors are 25-30% more efficient than standard induction motors, according to Chris Wood, food and beverage industry account manager for SEW-Eurodrive. “They’re not only more efficient, but they also have higher starting torques and bigger speed ranges,” he adds. In the past several years, there has been an emphasis on improving the energy efficiency of motors through testing and classification standards, but more importance is being putting these days on understanding how the whole power drive system

| April 2021 | www.profoodworld.com

3/31/21 7:57 AM

PHOTO COURTESY OF SIEMENS INDUSTRY

can work together for improved efficiency. SEW’s Movigear mechatronic drive system comprises a permanent-field synchronous motor, gear unit, and integrated drive electronics. The system improves efficiency not only through the efficiency of the motor itself, but through the energy optimization of the overall system, with expected energy savings of up to 50%. Focused on reducing CO2 emissions as well as energy costs, Coca-Cola HBC Austria upgraded one of its bottle transport lines (from shrinkpacker to palletizer) with a Movigear system, ultimately saving 75% of the energy consumed over its previous drive and control technology.

Cleaning things up High-efficiency, compact, and hygienic solutions are increasingly becoming requirements in the food and beverage industry, says James Chandler, key markets manager for Nord Drivesystems. Nord’s new IE5+ synchronous motors combine all three—providing a compact, energy-efficient motor in a hygienic design. For areas where motors and drives are likely to

come in contact with food products, the industry has seen a push toward the use of more hygienic devices. Manufacturers are recognizing that standard motors often don’t cut it in food processing environments. These motors cannot stand up to high-temperature, high-pressure cleaning methods prevalent in those environments, nor the caustic chemicals often used. Standard motor and drive designs also provide plenty of food collection points, harboring bacteria and other contaminants. And the fans used in typical motors can spread those contaminants even further afield. One change ABB made to its NEMA motors a few years ago was to independently weld the feet on the bottom of the motors, enabling them to be cleaned more effectively and efficiently. “It helped to eliminate food collection points,” says Matt Rodebush, global food and beverage segment manager for ABB Motion’s NEMA motors division. He adds that the smooth contours of the motor, along with a rotatable, round conduit box, eliminates food collection points that are common to competing conduit boxes. Encapsulated windings are another feature. “One www.profoodworld.com

0421_TechToday.indd 29

| April 2021 |

Digital twins can be used to help optimize production lines, including motor and drive configurations.

PROFOOD WORLD

29

3/31/21 7:57 AM

TECH TODAY: MOTORS AND DRIVES

For its mobile craft brew canning lines, Wild Goose Canning wanted a solution in which the variable-frequency drive was mounted directly to the motor.

30

PROFOOD WORLD

0421_TechToday.indd 30

time to wash it down as conventional motors.” Also, they don’t use a fan to cool the motor the way conventional electric motors do—an important point in sanitation, particularly considering COVID-19 concerns of spreading germs. “As a joke, I took a picture masking an electric motor to prevent forced air flow carrying microbes to process food,” Kanaris says. “Now we are conducting a study to find out how serous that problem is, post-COVID. It is serous. That problem PHOTO COURTESY OF NORD DRIVESYSTEMS doesn’t exist with the use of the drum motor.” VDG set up a conveyor to conduct a simof the biggest failures for food-grade motors is when ple experiment, covering a piece of cardboard with condensation or water gets in,” Rodebush says. “We sticky material to see how much cinnamon would fully encapsulate our windings. The windings are be spread by the fan at the back of the motor. “The dipped into a solution that seals the winding from cinnamon went all over,” Kanaris says. “You can wash any water or contaminants.” down the conveyor all you want. It can still be sucked Neugart is seeing a trend toward more hygienic out of the motor and delivered to the food.” gearboxes. “From our perspective, food safety and There’s such a push for sanitary products that the non-corrosive material is the most major requireVDG plans to completely separate its stainless-steel ment we face when we get requests from customers production from its plants in Toronto and Michigan, or partners in the industry,” says Daniel Weis, area Kanaris notes. “We’ll have totally sanitary drive prosales manager for Neugart. “The challenge that our duction for food, somewhere in Florida,” he says. “Our customers have is to find hygienic components that sanitary products will all be produced in one place.” are truly hygienic. There are plenty of stainless-steel products out there, but they’re not truly food-grade.” Made with food-grade stainless steel, Neugart’s Keep it safe HLAE gearbox was designed for hygienic use in food, Though some might argue that safety has always pharmaceutical, and cosmetics industries, Weis notes. been priority No. 1, the push continues to improve It’s IP69K-rated, which makes it suitable for steam safety in food and beverage operations. “When we’re pressure washing and industrial chemical cleaners. looking at food, one of the biggest topics for sure “There are no corners, and no flat space that any would be safety—not only food safety, but the safety debris can sit on and dwell,” he says. “And the housing of the people who come in contact with the motors is electropolished, which makes it a non-stick surface. and drives,” Rodebush says. Water will always pearl off of it, and no bacteria can One safety measure is provided with ABB’s hang onto it. There are no indentations or manufacBluetooth-enabled drives, enabling maintenance turing grooves that microorganisms can grasp.” workers to troubleshoot a system without necesVan der Graaf (VDG), which has been making drum sarily having to open up the panels. “They can look motors for more than 35 years, has seen a bigger at parameters on their phone or laptop,” notes Jim push for sanitation in the past five years, according Neawedde, U.S. food and beverage segment manto Alex Kanaris, VDG’s president and CEO. A typical ager for the drives division of ABB Motion. “They can design has a square shaft where sprockets are mountkeep out of the arc flash area.” ed, and then the motor belt runs on top of the sprockThis also has the potential to keep workers out of ets. “The problem we saw is if you have a product like other types of dangerous areas, whether in high locaprotein debris falling in between the sprockets, it’s tions or otherwise just difficult to reach, Rodebush nearly impossible to fully sanitize it,” he explains. adds. “They can look on the screen of their phone and VDG has designed a drum motor that has a consee the health of the equipment without having to go tinuous profile, with no need for sprockets. “The out and put their hands on the product.” benefit is that you can clean it a lot easier, and the Siemens is seeing a lot more use of synchronous debris doesn’t stay on the motor as much as the servo motors in the food and beverage industry, says square shaft,” Kanaris says. “It takes a third of the Craig Nelson, senior product manager for digital | April 2021 | www.profoodworld.com

3/31/21 7:58 AM

Making our world more productive

CRYOLINE® CST CryoSaver Tunnel Freezer

CRYOLINE® CVT CryoVantage Tunnel Freezer

CRYOLINE® 837 Ultra Performance Tunnel Freezer

When it comes to improving freezing systems, we have tunnel vision Sometimes it takes single-minded focus to achieve the best result. That’s where Linde food experts come in. We’ll H[DPLQH \RXU SURGXFWLRQ SURFHVV DQG UHFRPPHQG WKH /LQGH IUHH]LQJ V\VWHP WKDW LV EHVW IRU \RXU VSHFLÀF QHHGV Our lineup of cryogenic tunnel freezers offers options for your product, process, and price point, to increase production WKURXJKSXW PD[LPL]H FU\RJHQ HIÀFLHQF\ DQG PDLQWDLQ SURGXFW TXDOLW\ /LQGH H[SHUWLVH ZLOO KHOS \RX SURGXFH DQG GHOLYHU WKH TXDOLW\ IUR]HQ SURGXFW \RX HQYLVLRQ

Contact us at lindefood.com/vision or 1-844-44LINDE for more information.

7KH /LQGH ORJR DQG WKH /LQGH ZRUGPDUN DUH WUDGHPDUNV RU UHJLVWHUHG WUDGHPDUNV RI /LQGH SOF RU LWV DIÀOLDWHV &RS\ULJKW /LQGH SOF 3