FEB2023 packworld.com 20 How to Scale Re llable, Reusable Packs 22 Bush Brothers’ Tiered CM/CP Approach 28 Alcohol Trend: Adult Ice Pops, RTD Pouches 32 Pneumatic Cannabis Oil Filling 44 Four Pack Design Trends For 2023 10 Coke Europe Rolls Out Tethered Caps Learn more about our automation solutions at www.westrock.com/ automation

xy o ou .

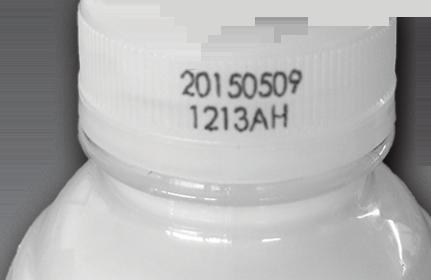

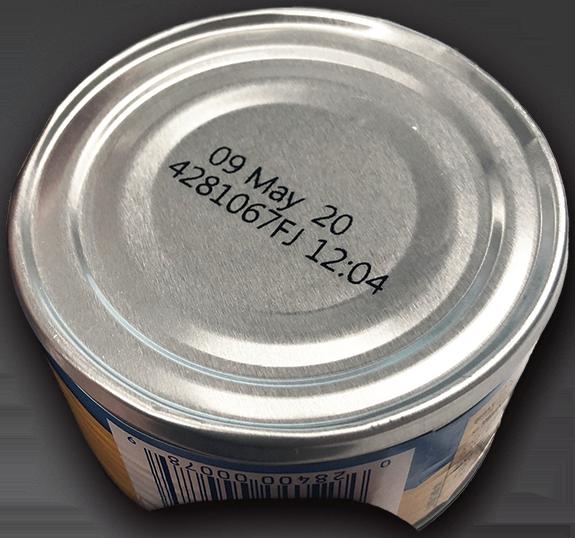

Following EU directives, this new tethered closure on Coca-Cola bottles makes the cap less likely to be littered and more likely to be recycled. This Proxima tethered closure format recently won a Technology Excellence Award for Sustainability from PMMI at PACK EXPO.

FEATURES

22

Bush’s Tiered Strategy for CM/CP Partnerships

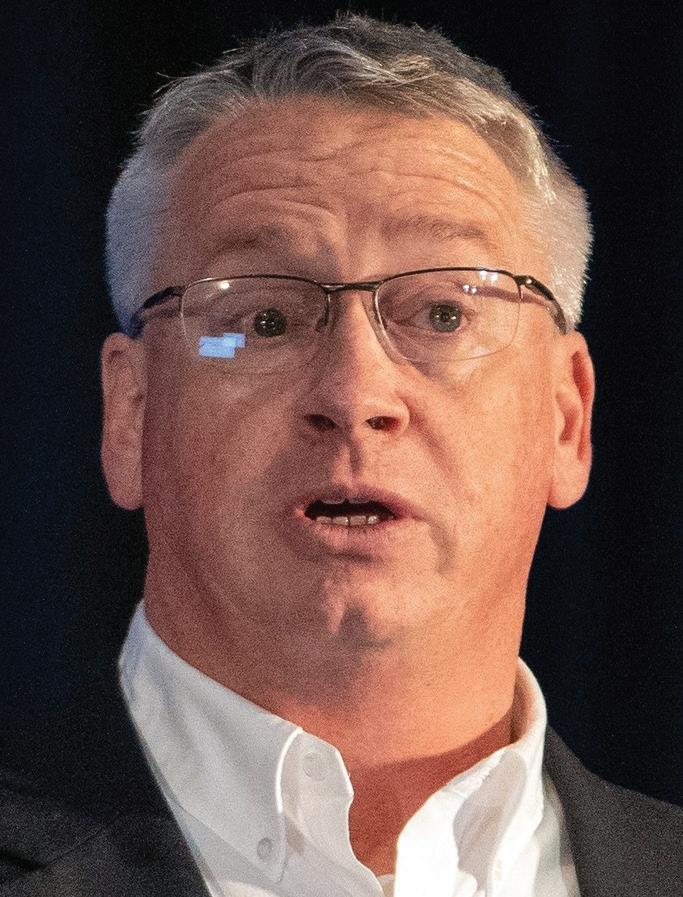

Robby Martin, senior packaging engineer at Bush Brothers & Co., is using a layered approach to contract packaging on a new multipack project. He explains navigating the testing and scaling phases of commercialization with several different CM/CP partners, and why up-front transparency is crucial.

28

CM/CP Rides the Wave of Adult Ice Pops, Pouched Alcohol

Adult beverage branding and marketing firm Iconic Brands merges with contract manufacturer/ packager TopPop Packaging to address the rapidly growing market for RTD cocktails and adult ice pops, as well as healthier options for wine and spirits.

32 AUTOMATION

Automation Lets Loud Labs’ Cannabis Oil Go National

A seemingly simple filling application shows that handling cannabis oils requires an understanding of their unique properties.

36

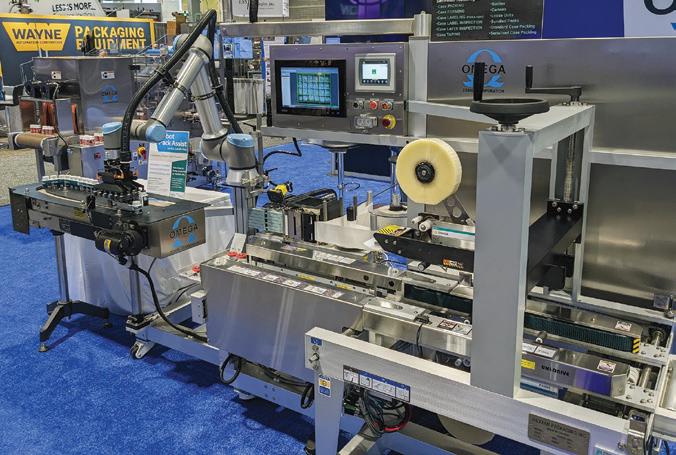

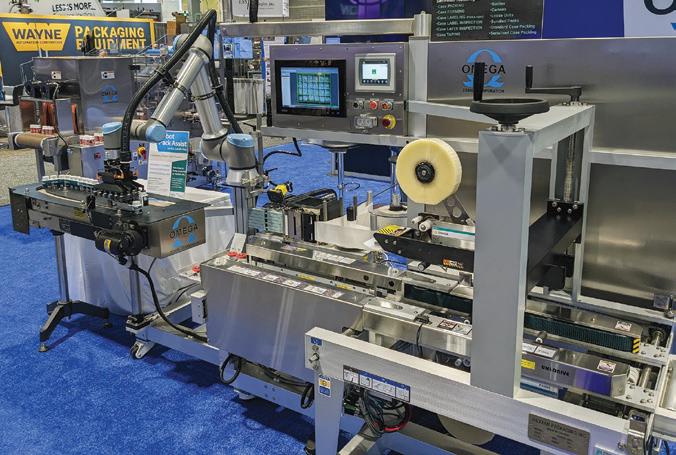

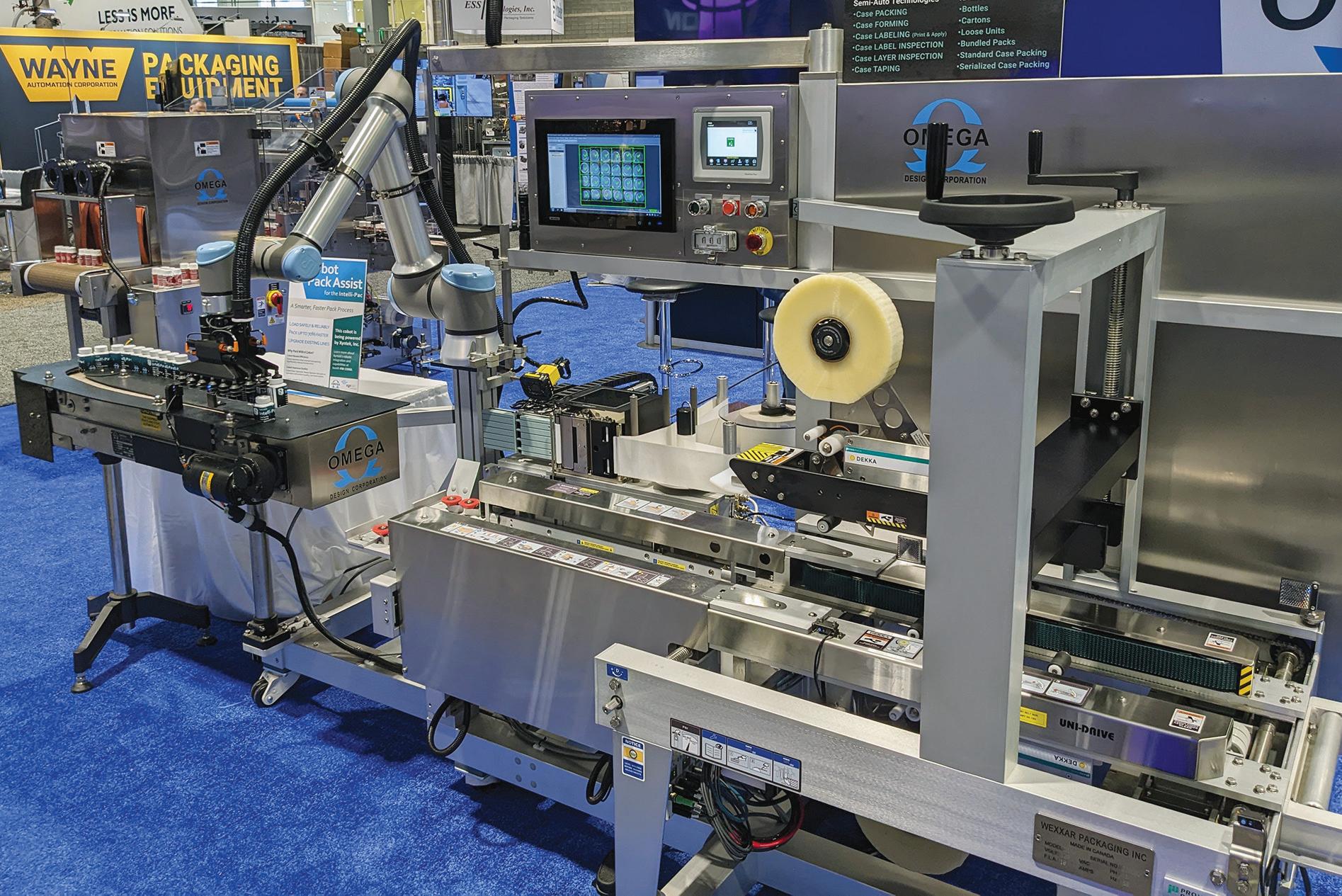

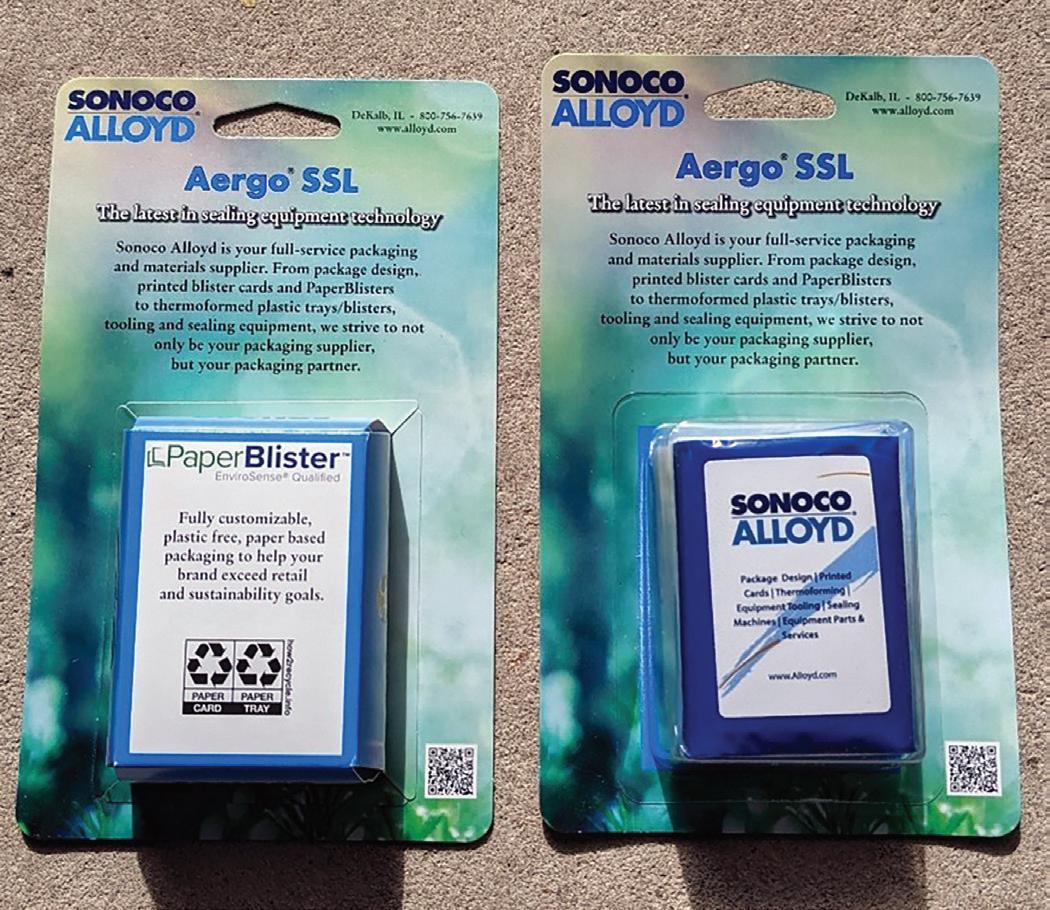

Packaging Automation Trends for Cosmetics and Beauty Care

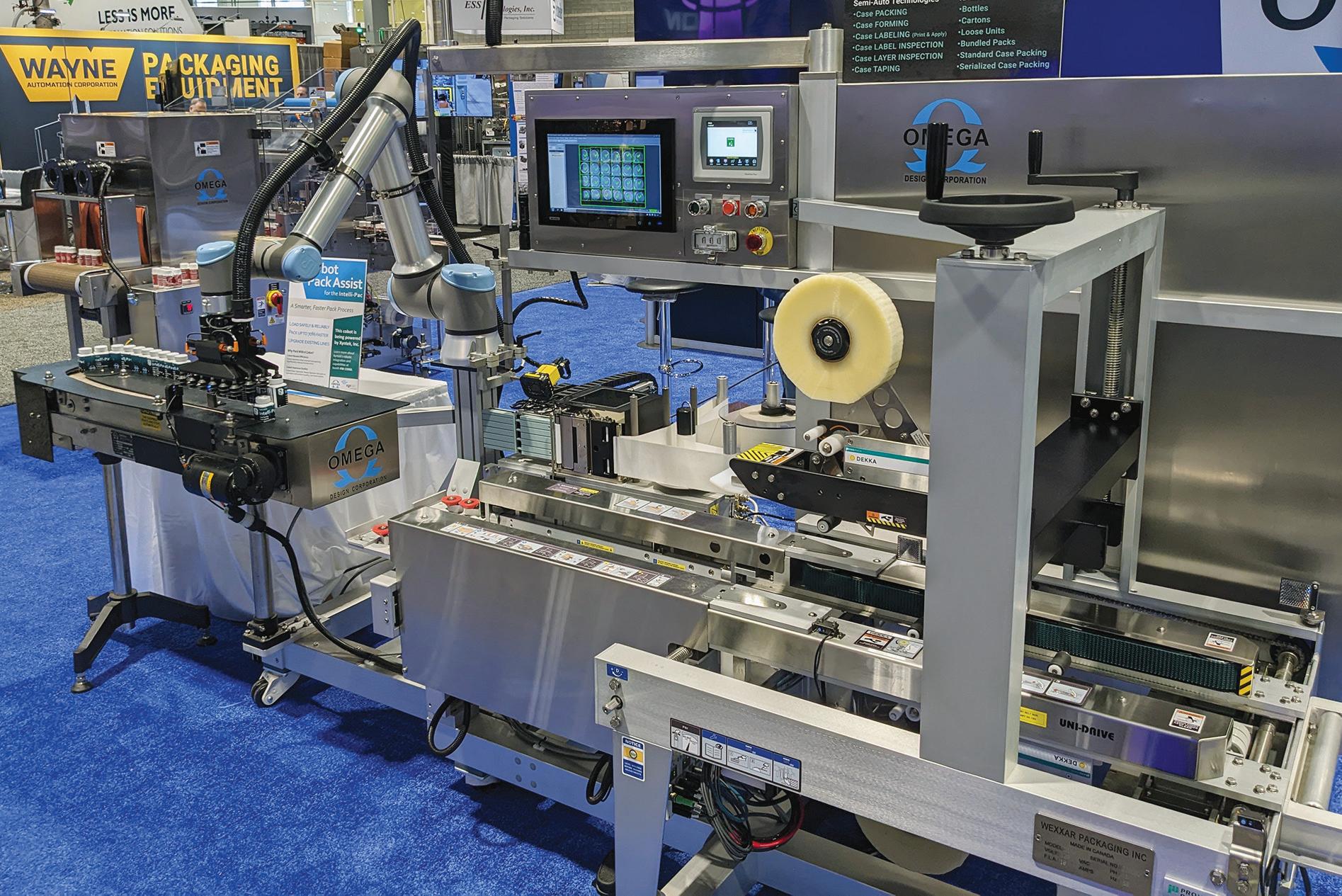

Packaging World asked C&BC packaging veteran David Hoenig to scour the aisles of PACK EXPO International to see what trends he felt were notable. Smart automation and cobots both stood out, as did improved late-stage customization capabilities.

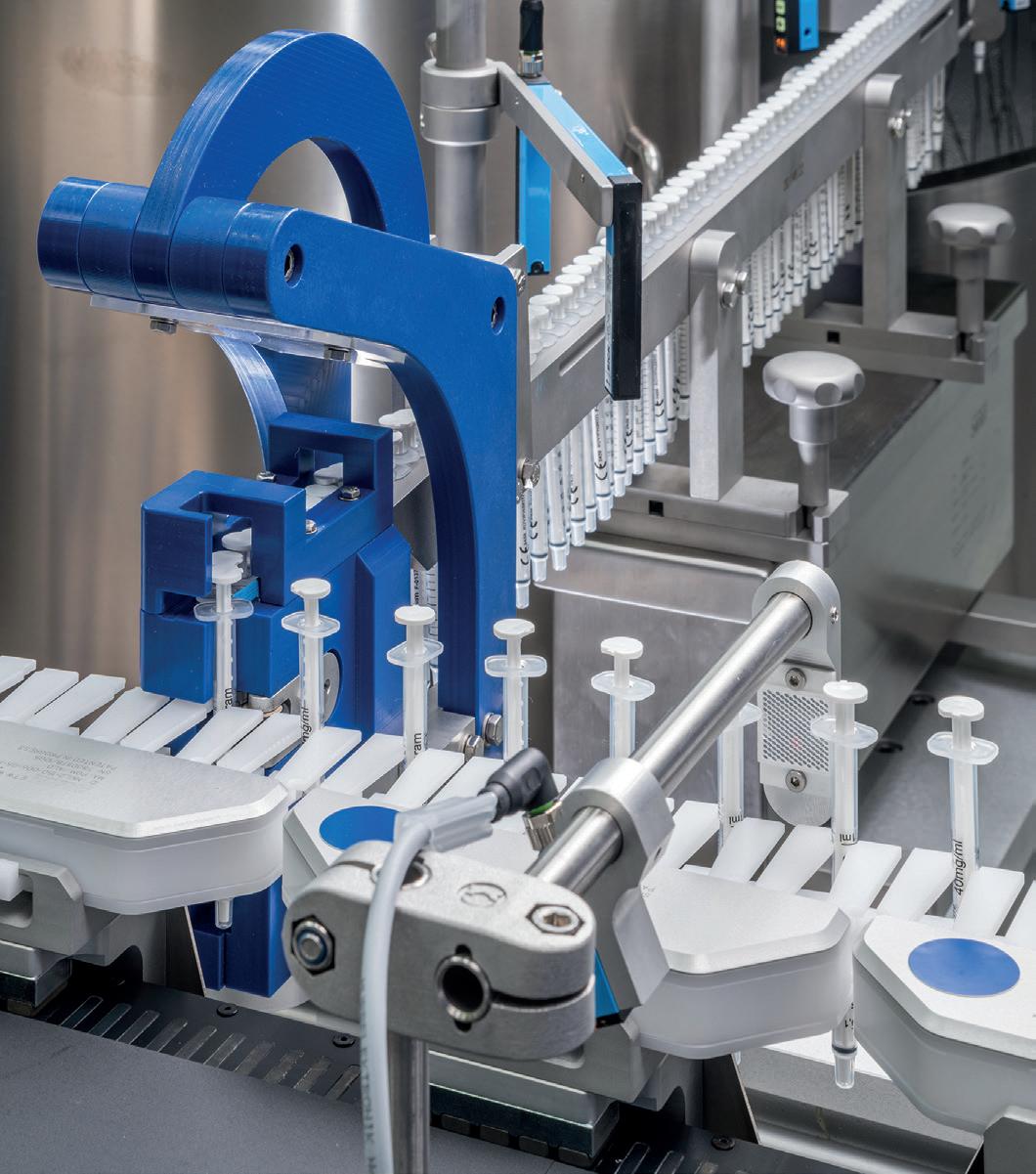

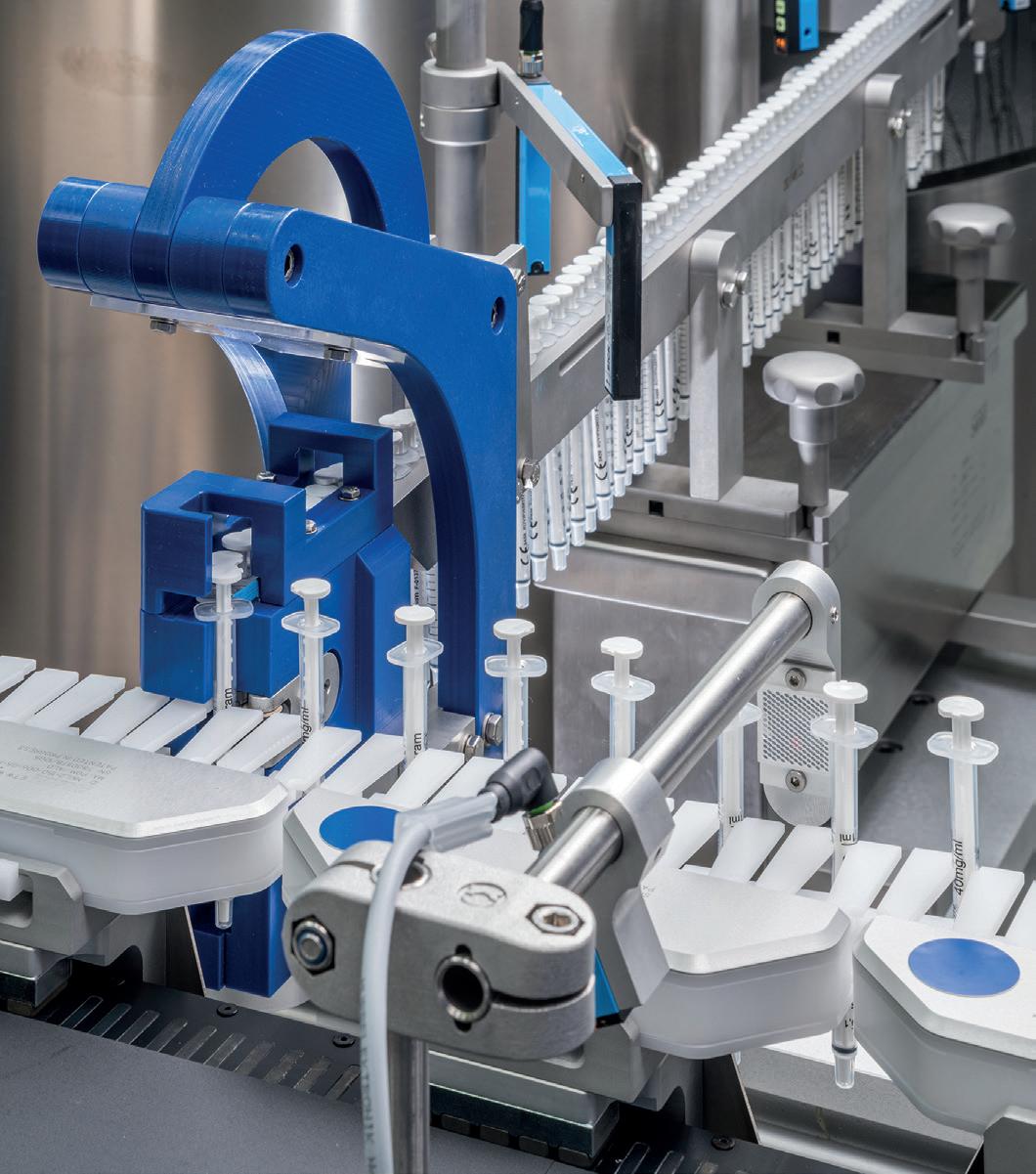

42 HEALTHCARE PACKAGING Turnkey Line Handles Ampules, Vials

This flexible system runs 17 formats with a 30-minute changeover.

2 PW FEB2023 VOL30 NO2

10

28 32 36 42

800.621.4170 | trianglepackage.com 100 YEARS OF KEEPING FOOD SAFE

4 PW FEB2023 Packaging World® (ISSN # 1073-7367) is a registered trademark of PMMI, The Association for Packaging and Processing Technologies. Packaging World® is published monthly by PMMI with its publishing office, PMMI Media Group, located at 401 N. Michigan Avenue, Suite 1700, Chicago, IL 60611; 312.222.1010; Fax: 312.222.1310. Periodicals postage paid at Chicago, IL, and additional mailing offices. Copyright 2023 by PMMI. All rights reserved. Materials in this publication must not be reproduced in any form without written permission of the publisher. Applications for a free subscription may be made online at www.packworld.com/subscribe. Paid subscription rates per year are $254 in the U.S., $363 Canada and Mexico by surface mail; $605 Europe and South America; $907 Far East, Australia, and other countries by air mail. Single copy price in U.S. is $20. To subscribe or manage your subscription to Packaging World, visit Packworld.com/subscribe. Free digital edition available to qualified individuals outside the United States. POSTMASTER; Send address changes to Packaging World®, 401 N. Michigan Avenue, Suite 1700, Chicago, IL 60611. PRINTED IN USA by Quad. The opinions expressed in articles are those of the authors and not necessarily those of PMMI. Comments, questions and letters to the editor are welcome and can be sent to: editors@packworld.com. Mailing List: We make a portion of our mailing list available to reputable firms. If you would prefer that we don’t include your name, please write us at the Chicago, IL address. DEPARTMENTS Connect with us: VIDEO How to Open an AdhesiveOnly Six Pack pwgo.to/7904 VIDEO Concentrated, Refillable Pack System pwgo.to/7905 PODCAST PepsiCo Empowers Next-Gen Workforce pwgo.to/7906 VIDEO Winter Fancy Foods Show Highlights pwgo.to/7907 packworld.com COLUMNS 7 Lead Off 18 The Big Picture 20 Sustainable Packaging 44 Shelf Impact! 48 The Insider NEWS/EVENTS 8 News 16 Quotables/By the Numbers 46 Industry Watch PRODUCTS 47 Technology ADVERTISING 47 Advertiser Index Connect with a Leaders in Packaging supplier and support packaging education! www.packworld.com/leaders 20 44

Aladin Alkhawam Director, Packaging Operations, Par Pharmaceutical Jan Brücklmeier Technical Application Group Packaging Technology Expert, Nestlé M. Shawn French Director – Innovation & Packaging Engineering (Beverage), Danone North America Patrick Keenan R&D Packaging Engineer, General Mills/Annie’s Organic Snacks Mike Marcinkowski Global R&D Officer, GPA Global & Hub Folding Box Co. Paul Schaum Chief Operations Officer, Pretzels Inc. David Smith, PhD Principal, David S. Smith & Associates Brian Stepowany Packaging R&D, Senior Manager, B&G Foods, Inc. Jasmine Sutherland President, Texas Food Solutions; Vice President, Perfect Fit Meals

EDITORIAL ADVISORY BOARD

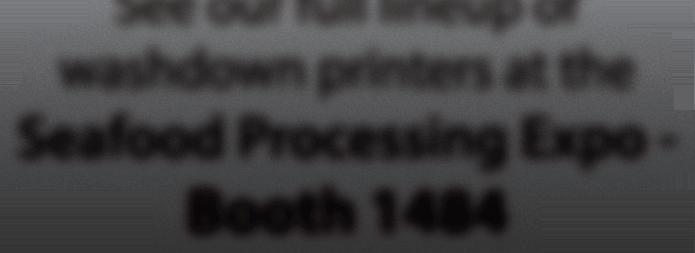

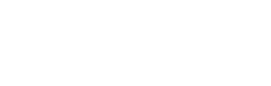

MORE THAN JUST LABELING & CODING EQUIPMENT

A leader in Labeling and Product Coding systems, ID Technology also produces labels for primary and secondary packaging. We’ve made major investments in prepress, flexo and digital print technology for printing prime product labels, RFID smart labels, and automated systems for making direct thermal and thermal transfer labels. With access to an extensive portfolio of materials and adhesives, there is an ID Technology label solution for even the most demanding applications.

• Multiple label converting facilities across North America to reduce shipping time and expenses.

• Innovative materials that give you more labels per roll while reducing waste.

• Capacity for high volume production of blank, preprinted, and specialty labels.

• Time saving added features, such as clear leaders and trailers and length-matched kits of thermal transfer labels and ribbons.

• Flexo, digital and hybrid printing technologies.

• Professional graphic artists that provide label design and construction expertise.

To find your local ID Technology sales and service contact, scan QR code or visit: idtechnology.com/online-sales-and-service-directory

UPGRADE YOUR PRIMARY & SECONDARY LABELS CONTACT US AT IDT@PROMACHBUILT.COM OR VISIT LABELS.IDTECHNOLOGY.COM IDTechnology@ProMachBuilt.com | Fort Worth, TX | 817-626-7779 | IDTechnology.com

© 2023 ProMach Inc.

CONTENT

Matt Reynolds Chief Editor

Anne Marie Mohan Senior Editor @PackagingTrends

Iris Zavala Managing Editor

Sean Riley Senior News Director

Pat Reynolds, Sterling Anthony,

Eric F. Greenberg, Ben Miyares Contributing Editors

David Bacho Creative Director

ADVERTISING

Wendy Sawtell Vice President, Sales wsawtell@pmmimediagroup.com

Lara Krieger Production Manager lkrieger@pmmimediagroup.com

Janet Fabiano Financial Services Manager jfabiano@pmmimediagroup.com

PMMI MEDIA GROUP

David Newcorn President

Elizabeth Kachoris Vice President, Digital

Kelly Greeby Senior Director, Client Success & Media Operations

Jen Krepelka Director, Digital Media

Mike Prokopeak Senior Director, Content & Brand Growth

Trey Smith Senior Director, Events

Sharon Taylor Director, Marketing

Joseph Angel Founding Partner and Executive Vice President, Industry Outreach, PMMI

Lloyd Ferguson Founding Partner

Questions about your subscription or wish to renew? Contact circulation@pmmimediagroup.com.

Packaging World • PMMI Media Group 401 N. Michigan Ave., Suite 1700, Chicago, IL 60611 Phone: 312/222-1010 • Fax: 312/222-1310

E-Mail: info@packworld.com • Web: www.packworld.com

PMMI The Association for Packaging and Processing Technologies 12930 Worldgate Dr., Suite 200, Herndon VA, 20170 Phone: 571/612-3200 • Fax: 703/243-8556 • Web: www.pmmi.org

Staff at PMMI Media Group can be contacted at info@pmmimediagroup.com

Follow us on twitter @PackagingWorld 6 PW FEB2023

How Will AI Shape Packaging’s Future?

As Artificial Intelligence (AI) technologies advance, they have the potential to revolutionize the way brands and CPGs approach packaging. One of the most significant impacts of AI on packaging operations is the ability to optimize and streamline the packaging process. AI algorithms can analyze vast amounts of data to determine the most efficient and cost-effective packaging solutions. This can result in faster and more accurate packaging, reducing waste, and increasing efficiency. Moreover, AI can help companies to quickly identify and resolve any issues that arise during the packaging process, such as missing or incorrect labels, reducing the risk of product recalls, and ensuring that consumers receive the right product.

In addition to optimizing the packaging process, AI can also help brands and CPGs to make more informed decisions about their packaging materials. AI algorithms can analyze environmental impact data, such as greenhouse gas emissions, water usage, and waste generated by different packaging materials, allowing companies to make informed choices about which materials are most sustainable and eco-friendly.

Moreover, AI can also be used to improve the design and labeling of packaging. For instance, AI algorithms can analyze consumer preferences and purchasing habits to determine the most effective and appealing packaging designs. AI can also be used to generate product labels, ensuring that they are accurate, legible, and comply with regulatory requirements.

Another significant impact of AI on packaging operations is the ability to personalize packaging. AI algorithms can analyze consumer data to create customized packaging and labeling solutions, helping brands and CPGs to stand out in a crowded marketplace. Customized packaging can also help companies to build stronger relationships with their customers, as well as increase brand recognition and loyalty.

Finally, AI can also play a crucial role in enhancing supply chain transparency and accountability. AI algorithms can be used to monitor and track products throughout the supply chain, ensuring that they are handled and stored correctly and that they reach their final destination on time and in good condition. This can help companies to reduce waste and improve the efficiency of their supply chains, as well as ensuring that consumers receive safe, high-quality products.

In conclusion, AI has the potential to transform the packaging operations of brands and CPGs, making the process more efficient, sustainable, and personalized. As AI technologies continue to evolve, it is likely that their impact on packaging operations will become even more pronounced, helping companies to remain competitive in a rapidly changing marketplace. Brands and CPGs that embrace AI and incorporate it into their packaging operations will be well-positioned to succeed in the future.

Editor’s note, coming clean. The above portion of this month’s column was brought to you by AI. Using ChatGPT, tech firm OpenAI’s latest AI application, I generated this text for free in a matter of about 90 seconds. The only input was the following prompt: Write an opinion column, in 500 words or less, that explains how Artificial Intelligence might impact brands’ and CPGs’ packaging operations.

How did the AI do? It’s a little formulaic and overly reliant on the word “moreover,” with all the charm of a high school essay. But it’s well-reasoned—I don’t have a bone to pick with any of the conclusions. It exhibits some lateral thinking, not confining itself to one subtopic.

But more importantly, it could easily pass for the work of a living, breathing human with access to Google and Wikipedia. Does that mean ChatGPT passes the Turing Test, an assessment first proposed by the godfather of computer science Alan Turing, to test a machine’s ability to exhibit intelligent behavior equivalent to, or indistinguishable from, that of a human?

In other words, had we just published it without telling you this column was AI-written, would you have known? Could you have spotted the machine in your midst?

The onset of the AI age is upon us, and it will precipitate a lot philosophical and ethical questions. This is just the tip of the iceberg, and questions like these will be keeping your columnist up late thinking. With the rise of AI, it’s time for packaging professionals to grapple with it, too. PW

mreynolds@pmmimediagroup.com

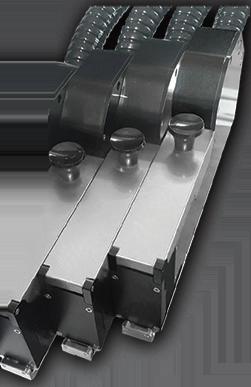

7 www.nerconconveyors.com 844-293-2814 SpirexTM Contact Us for Details New 18” Design CONVEYOR EQUIPMENT IN 6 - 8 WEEKS • Occupies minimal floor space • No changeover needed • Modular design for easy modifications • Configured for various in-feed and discharge height combinations

Options of multiple slope angles and chain widths

•

LEAD OFF

Image generated by the Lensa AI app after analyzing a dozen photos containing Matt Reynolds, Chief Editor

Japanese Brand’s Shower Cream Refill

Now in a 100% Recyclable Pouch

Japanese beauty care brand Shokubutsu Monogatari is hitting all of the three R’s—Reduce. Reuse. Recycle.—with a new 100% recyclable pouch construction for its shower cream refills in Thailand. Shokubutsu Monogatari is a brand of Lion Corp., a Japanese multinational manufacturer of detergent, soap, medications, oral hygiene products, and other toiletries, whose corporate commitment includes, “Supporting cleanliness, health, and comfort, while protecting our global environment.”

“Lion has always been committed to developing sustainable projects and packaging,” says Lion (Thailand) SPC Business Executive Manager Somsak Srisaardrak. “This is in line with the shifting needs of consumers, as they become increasingly interested in environmentally friendly products.”

In 2019/2020, Lion approached Dow Thailand Group “to not only address consumer needs but also reduce greenhouse gas emissions and advance a circular economy in Thailand” by developing a recyclable pouch for its shower cream refills, says Kodak Xiao, Asia Pacific marketing director for Packaging Health & Hygiene, global market segment director for Food & Specialty Packaging and Specialty Plastics at Dow.

Shokubutsu Monogatari had already entered the refillable/reusable packaging space with flexible refill pouches—a popular format in Thailand—but the packaging could not be recycled. According to Xiao, requirements for such a pouch include durability and high toughness to protect and ensure the quality of the product across its useful life as well as optics for shelf appeal. “Traditionally, such refill bags are made from multi-material packaging that typically involves different types of materials, such as PET, nylon, and polyethylene,” he explains. “PET and nylon are used for printing purposes, while nylon can further strengthen the toughness of the packaging, and PE provides the function of heat seal.”

Dow was able to create for the brand a recyclable refill pouch with the

required properties by using its Innate TF Polyethylene Resins for Tenter Frame Biaxial Orientation (TF-BOPE) to replace the PET and nylon, resulting in an all-PE structure. According to Xiao, Dow is first to launch the TF-BOPE solution globally, a material typically challenging to produce.

“Tenter frame biaxial orientation is a mature film fabrication technology widely used in producing BOPP [biaxially oriented polypropylene], BOPET, and BOPA [biaxially oriented polyamide] films,” says Xiao. “Traditionally, utilizing this technology to make BOPE is very difficult, as it is challenging to acquire a decent operation window on the industrial production lines due to the inherent property limitations of PE.”

To develop Innate TF PE resins, Dow employed its proprietary catalyst

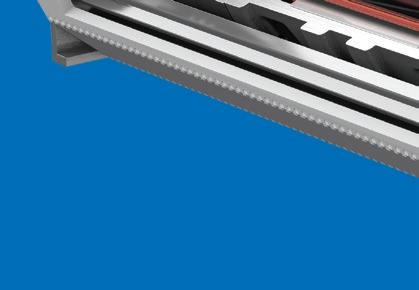

Estrella Galicia Replaces Paperboard with Adhesive-Only Multipacks

Spanish beer brewing heavyweight Estrella Galicia, a Corporación Hijos de Rivera brand, is rolling out a new adhesive-only multipack format it calls the “No Pack.” By using a line of glue dots where one can abuts another in a six-pack format, the company says can minimize packaging and improve its sustainability profile by completely doing away with paperboard can handles. The format is already rolling out on six-packs of 25-cL and 33-cL sizes of Estrella Galicia Especial and Estrella Galicia 00 beer varieties. It will eventually extend to 1906 Reserva Especial and Red Vintage varieties.

“Our ambition is to always do things better, looking

for new ways to generate a greater positive impact. We are constantly working to ensure that our products are increasingly respectful of the environment, innovating in different aspects that help us minimize waste and the carbon footprint linked to our activity. The No Pack is the perfect example that sums up our purpose of not conforming. We believe that the best packaging for the planet is the one that does not exist,” says Ignacio Rivera, chairman of Corporación Hijos de Rivera.

Under this format, paperboard multipacks are replaced with only a few glue dots that serve as a link between the six cans. The brand points out that it had never used plastic rings to begin with, only 100% recyclable paperboard multipacks. But

8 PW FEB2023 NEWS

and polymerization technologies as well as its experience in the orienta tion film market. Notes Xiao, due to its unique molecular architecture, BOPE films can be smoothly fabricated on existing BOPP lines with high quality consistency and gauge evenness.

“Meanwhile,” he adds, “the high orientation applied in MD [Machine Direction] and TD [Transverse Direction] during the tenter frame process endows films with excellent mechanical properties, high stiffness, and outstanding optical appearance, which represents a giant leap from the performance of traditional PE films and enables the substitution of tradi tional non-recyclable materials with all-PE designs for various packaging applications.

“The film also offers distinctive physical properties that can enable material substitution, film layer elimination, and downgauging to reduce overall packaging materials.”

Joining Lion Corp. and Dow Thailand Group in the development of the Shokubutsu Monogatari refill pouch were Dow’s Pack Studios Singa pore and the distribution network of Asian petrochemical company SCG Chemicals (SCGC). “The recyclable refill bag for Shokubutsu Monogatari shower creams is an example of how more sustainable packaging can help to close the loop, through collaboration from business alliances, Dow’s recyclable packaging solution, and support from SCGC,” says Lion Corp.’s Srisaardrak. “These made the development of Lion Thailand’s first recyclable refill bags possible while ensuring the quality of the product inside the packaging. This packaging also helps to reduce greenhouse gas emissions and advance a circular economy in the country.”

The Shokubutsu Monogatari shower cream refill pouch was intro duced in September 2022 in two sizes, 200 and 500 mL, across Thailand in department stores and supermarkets and, says the company, “will eventually replace the older bags.”

—Anne Marie Mohan

under the new format, the Galician brewery says it will further reduce the carbon footprint of each of its six-pack by 40%.

According to a release, “Along with this No Pack for the six-can packs, the company has announced other changes to minimize waste also in larger formats: the film that covers the packs of 12 and 24 cans will be replaced by 100% recyclable paper. With this, the company will eliminate all secondary plastic from all its canned formats.”

The No Pack format is implemented on equipment by KHS, which Estrella Galicia describes as “a company specialized in the manufacture of this type of packaging in packs of both cans and rPET bottles.” Recently, Danish multinational brewer Carlsberg has rolled out similar adhesive-only multipacks (read more at pwgo.to/7898), also using KHS technology.

This launch is part of the positive impact strategy of Hijos de Rivera. The brand owner says this is an ambitious plan that combines the regeneration of the planet, looking after people, pride in origin, and joint work with allies. —Matt

Reynolds

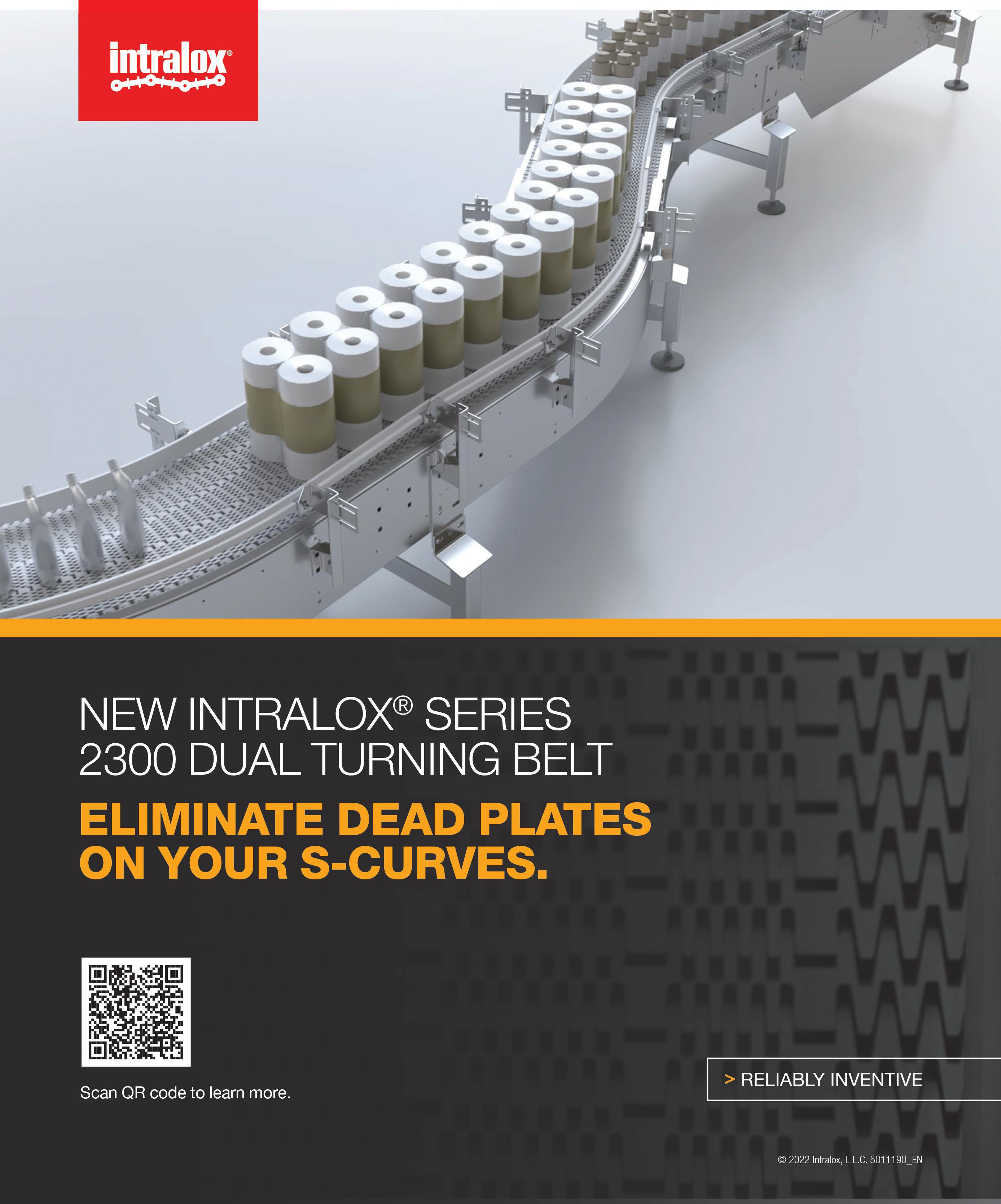

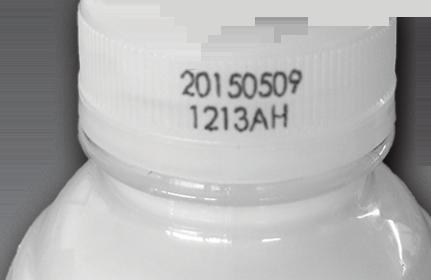

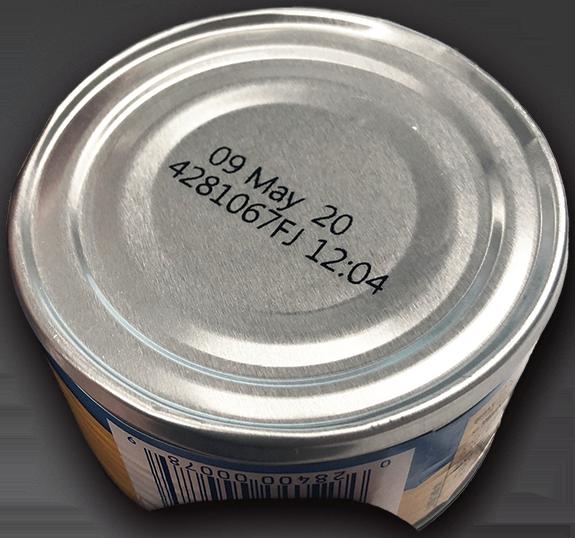

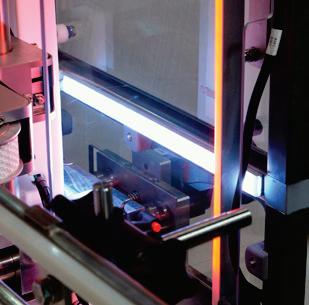

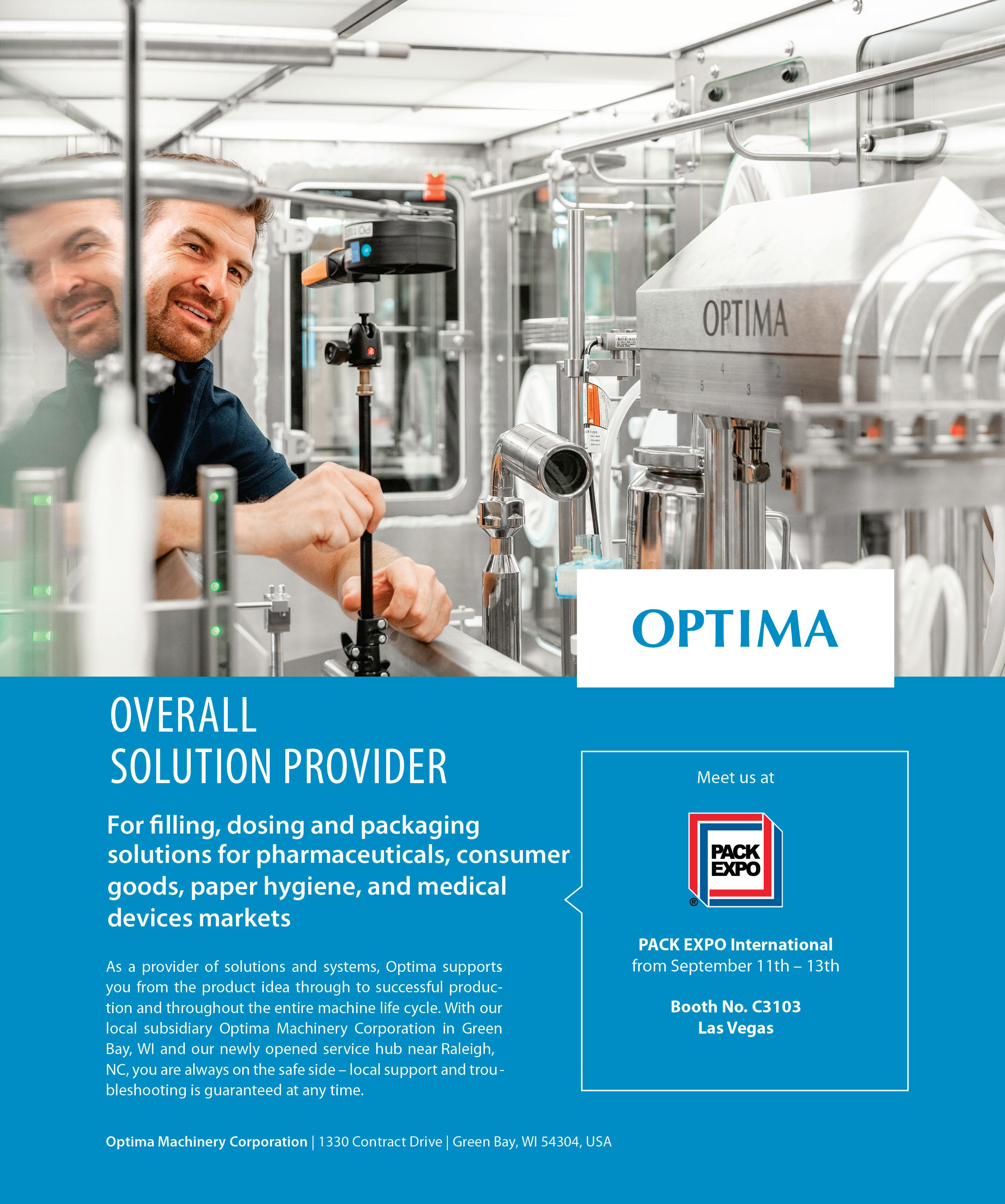

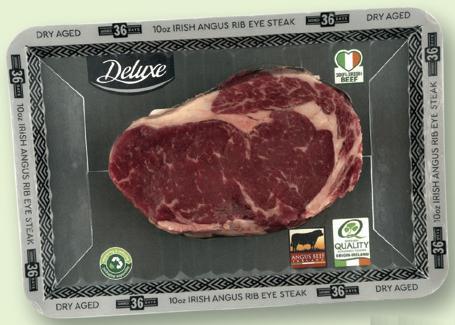

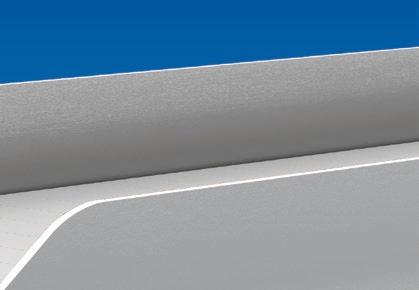

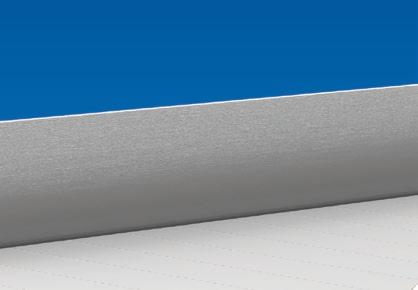

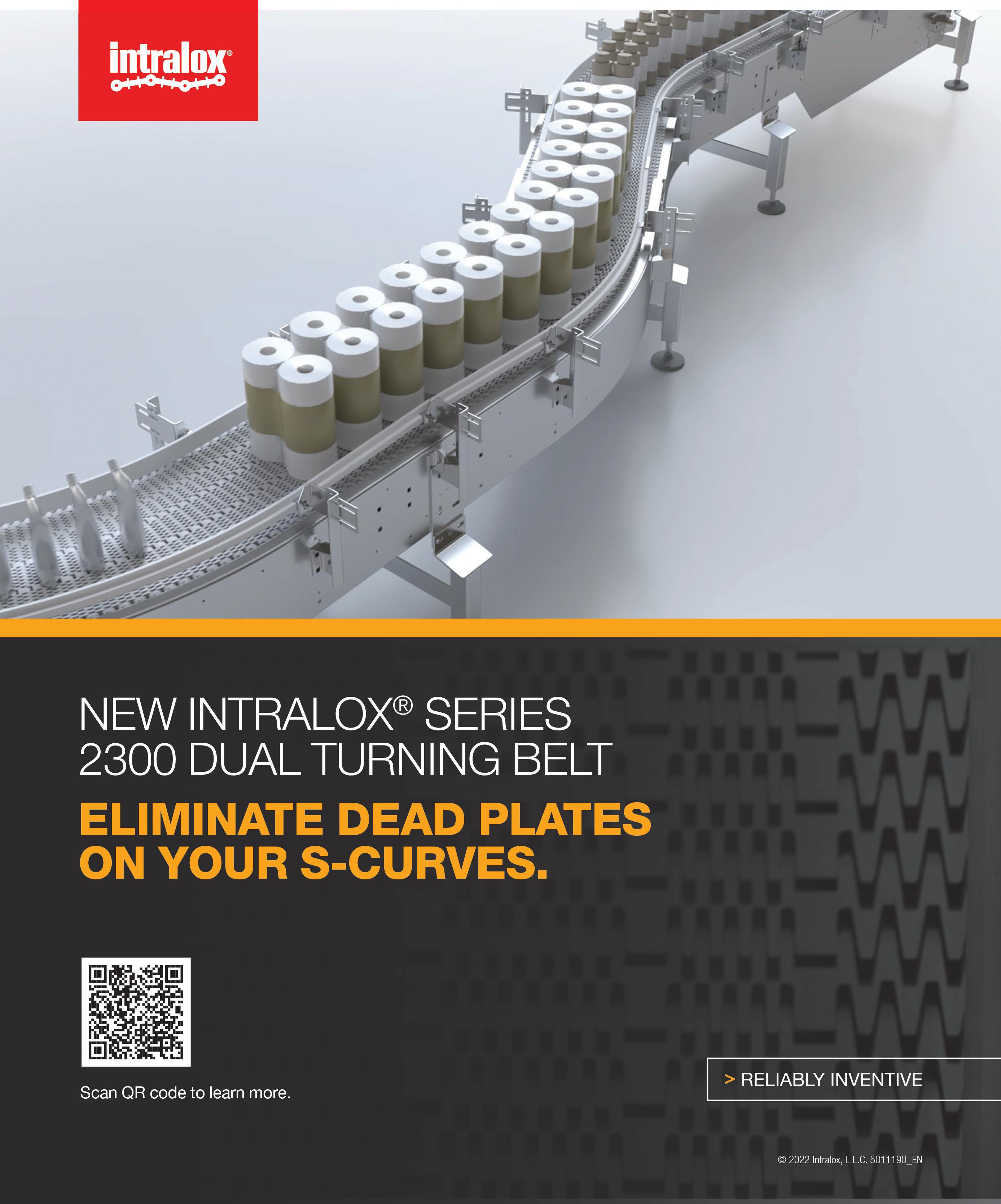

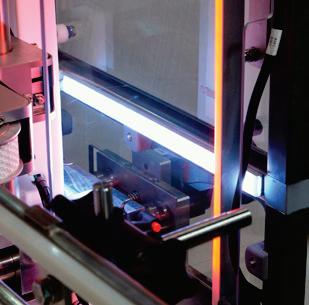

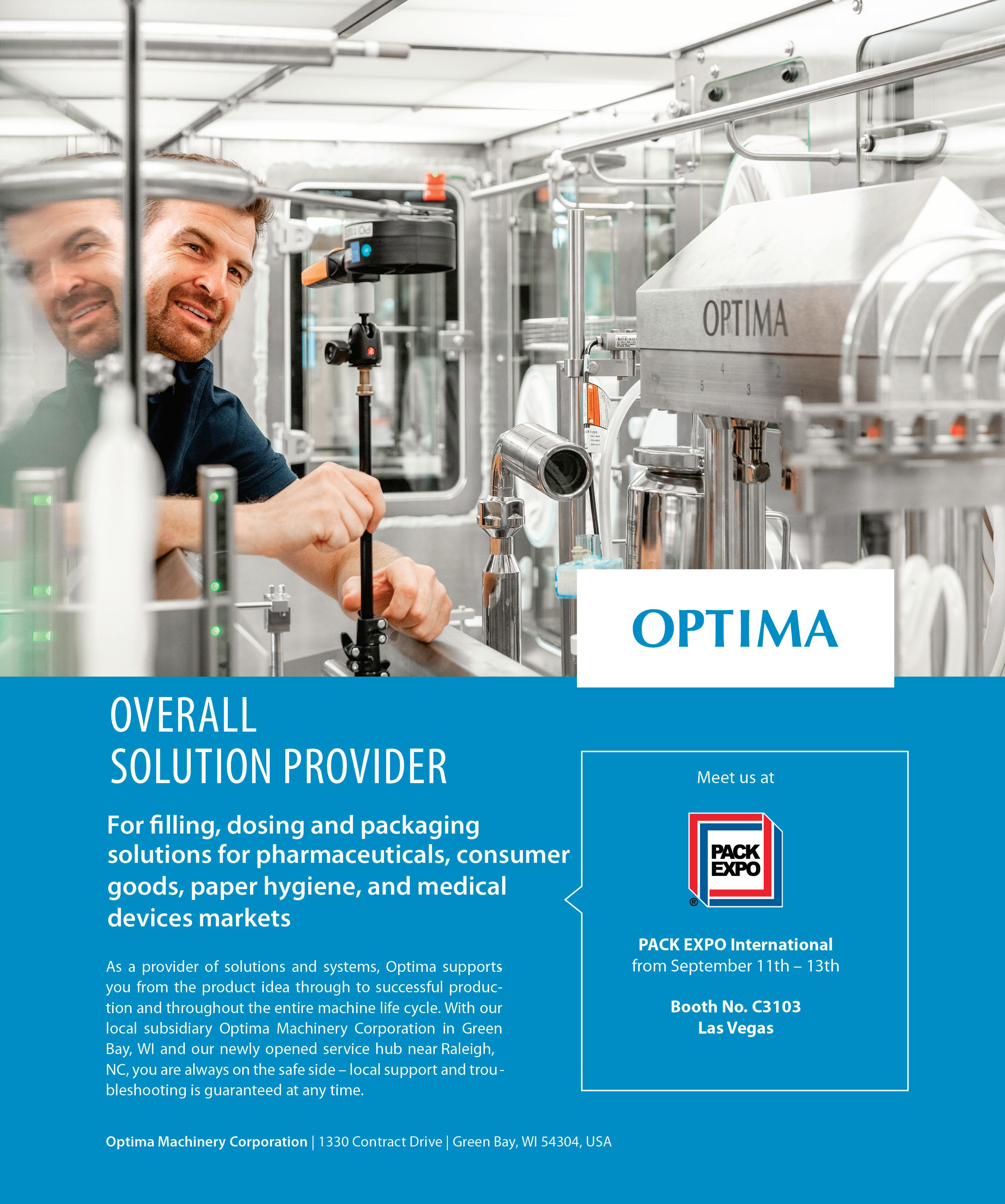

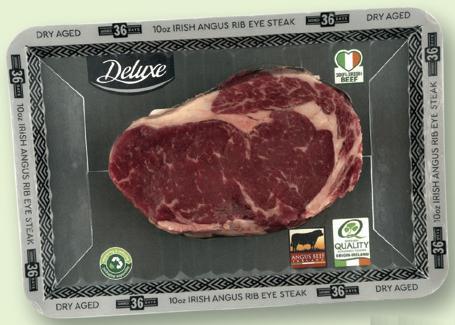

Coca-Cola Europe Adopts HDPE Tethered Closure, Follows EU Directive

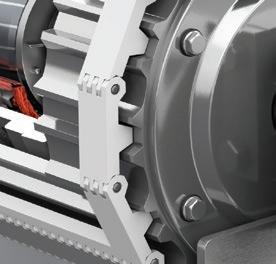

In Europe, the Coca-Cola Company announced that it is adopting a lightweight, HDPE tethered closure for its carbonated soft drinks in PET bottles. Bolstered by the European Union (EU) Single-Use Plastics Directive, this new tethered closure for Coca-Cola is designed to remain intact with the bottle, making it less likely to be littered and more likely to be recycled. Berry Global Group, Inc. is the rst plastic packaging manufacturer to supply Coca-Cola this tethered closure format. Berry’s Proxima tethered closure recently won a prestigious Technology Excellence Award from PMMI in the sustainability category at PACK EXPO International.

Over 400 million closures have been successfully applied to date on Coca-Cola bottling lines in Germany, Spain, and the UK, with the rollout to continue to the company’s other European plants. The EU Directive 2019/204 requires plastic beverage bottles up to 3 L in size to have closures that remain attached to the container throughout their intended use from July 2024. And this collaboration helps progress Coca-Cola’s goal to make 100% of its packaging recyclable globally by 2025.

Maintaining a convenient and comfortable user experience, in addition to product safety and security, Berry’s new tethered closure for CocaCola features a special tamper-evident band that, once broken, does not impact the closure’s ability to remain attached and is positioned out of the way for drinking but can easily be reclosed. When open, it provides a wide angle for easy access to the beverage and comfortable on-the-go drinking.

Berry’s closure for Coca-Cola is based on its patented CompactFlip hinge solution. It is the rst to be used in conjunction with the new lightweight 26-mm GME30.40 neck, developed by the Cetie (The International Technical Centre for Bottling) Single-Use Plastics Group, of which Berry is a member. The new neck nish delivers an over 1-g saving in PET compared to the current PCO-1881 neck. Combined with a 10% weight reduction from the Berry closure, the new pack is now around 20% lighter than the PCO-1881 version.

“Innovation in packaging design is key to helping our customers meet their ambitious sustainability goals while delivering attractive, functional solutions that meet and exceed constantly evolving market demands,”

says Thierry Bernet, VP circular economy & innovation at Berry Global. “Because PET bottles are the most recycled plastic package type, this collaboration has tremendous potential to help keep resources in use and out of our environment.” —Matt Reynolds

10 PW FEB2023 NEWS

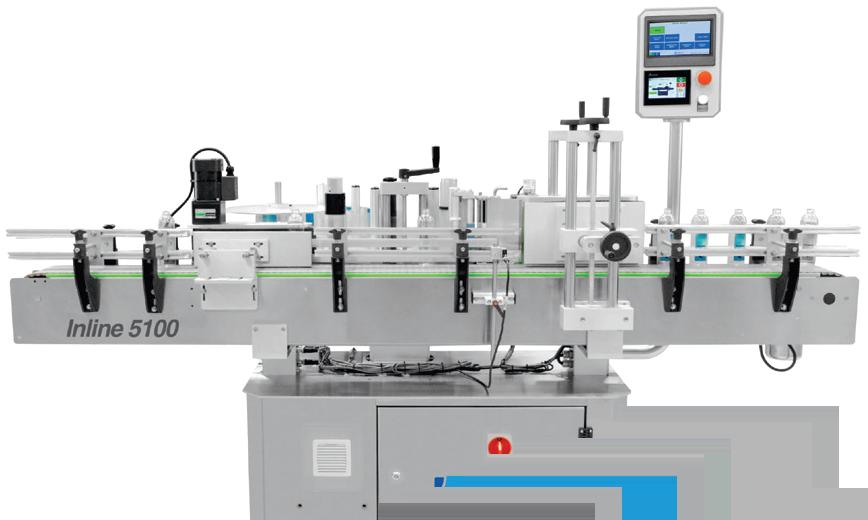

CONTACT US TODAY BellatRx.com | 514.630.0939 info@bellatrx.com Operator enters bottle and label dimensions and the recipe is automatically created Step-by-step video guides operator through the setup Arrows indicating the direction of the adjustments and green LED indicates when set point is reached Setup area is litup to drive operator attention Allows access to machine parameters from anywhere Servo Drives Setup Video Instructions Digital Set Point Setup Spot Light Mobile Screen View NOTARIS PLUS The Evolution in Labeling Automation Redefining the relationship between operator and machine to bridge the Skills Gap in Manufacturing

SIMPLY EFFICIENT SIMPLY RUGGED SimplyFillSM

Hennepin Technical College Students Awarded Packaging Scholarship

Five students at the Automation Robotics Engineering Technology program at Hennepin Technical College in Minnesota will split the $5,000 Future Leaders in Packaging Scholarship from Packaging World and PMMI.

The Future Leaders in Packaging Scholarship from Packaging World and the PMMI Foundation was established in 2011 in conjunction with Leaders in Packaging—a print and online marketing program that enables suppliers to promote their innovations and expertise to the packaging community.

PACKAGING WORLD’S Future leaders IN PACKAGING SCHOLARSHIP

The scholarship is awarded each year to an educational institution that prepares students for careers in packaging. The recipient school selects one or more students pursuing related degrees and distributes the funds to the student(s) to defray tuition and other education-related expenses.

Automatic Bottle Filling Machine

Specialty Equipment now has a full line of bottle filling and capping machines for the lubricants, oils, cleaning industries and personal healthcare/beauty. Available in up to 14 filling heads, fills up to 6,000 2oz to 2.5 gallon bottles an hour, both flowmeter and piston-based fillers. For more information, contact us at specialtyequipment.com

Benefits

» Runs 24/7 Without an Operator

» Accurate, Fast, Flexible and Silent

» Quick Product Changeover

» Clean In-place Functionality

» Increase Production & Maximize Uptime

» Add Savings to Your Bottom Line

Types of Bottles We Fill

We also provide installation, parts and field service. Learn more by calling 833-467-3432 www.specialtyequipment.com

“The Automation Robotics Engineering Technology program at Hennepin Technical College is one of the oldest Packaging Technician programs in the United States. The first set of students graduated in 1975 with under the original program name of Packaging Technician,” says Jeff Thorstad, faculty, Hennepin Technical College, Automation Robotics Engineering Technologies/Packaging. “Over time, as technology advanced and it was realized that the skill set provided to students focused on Packaging Systems could be applied to many different manufacturing industries, the program name evolved into the current name while keeping our unique focus on the Packaging Industry. We provide opportunities for both full-time and part-time students with schedules that are friendly to working both full-time and part-time jobs. Currently 60% of our students are part-time students.”

Hennepin Technical College has worked directly with many regional companies to help expand their workforces through developing apprenticeships, maintenance trainee, and earn-while-you-learn models of developing new maintenance personnel who are trained in mechatronics and can solve many different types of problems that arise in the manufacturing facility. This is helping companies to find and retain new maintenance technicians in a difficult job market.

“Our graduates have become true multi-skill technicians when they enter the workforce. We focus on the whole machine and not just specialty areas such as mechanical, electrical, or pneumatics,”

Thorstad says. “Our students have knowledge about all of these areas plus PLC programming, robotics, and troubleshooting. Through this our students are able to fix the majority of the problems that occur on the manufacturing floor.”

The Automation Robotics Engineering Technology program at Hennepin Technical College program is a stand-alone program that develops maintenance technicians. The program’s focus is packaging equipment and most of the equipment it uses has been donated to by PMMI member companies such as Delkor Systems and MGS Machinery Thorstad and the team and HTC train students on the packaging equipment as it has many different applications and shows different types of systems.

Hennepin will award five $1000 scholarships based on need and leadership. At press time, faculty are in the process of obtaining a list of all the program students who applied for the college scholarships with the standard application. Once this is in hand, the program faculty will review all the applicants and apply points for leadership in the classroom, participation in student-club activities, and participation in program tours and industry events. —Matt Reynolds

12 PW FEB2023

NEWS

CK G G

RENT OR BUY NEW EQUIPMENT IN THESE CATEGORIES

BAG SEALING EQUIPMENT

CAPPING EQUIPMENT

CARTONING EQUIPMENT

CASING EQUIPMENT

CONVEYORS

FRONT OF LINE EQUIPMENT

END OF LINE EQUIPMENT

INSPECTION EQUIPMENT

LABELERS

SHRINK EQUIPMENT

WRAPPING EQUIPMENT

COMPLETE PACKAGING LINES

VISIT OUR WEBSITE OR GIVE US A CALL US TO GET YOUR PROJECT STARTED TODAY!

build your best conveyor business

DISTRIBUTORS

Nestlé’s KitKat Wades Into Recyclable Paper Packs in Australia

Australia has of late been the epicenter of a spate of recent confectionery brand switches from traditional plastic flow wrapped packs, to recyclable, paper-based ones.

Shortly on the heels of Mars Wrigley’s launch of paper-based flow packs for Snickers, Milky Way, and Mars candy bars in Australia (read more at pwgo.to/7897), Nestlé Oceania today announced its first ever trial of what it says is innovative new paper packaging on four-finger, 45-g KitKat bars. The food grade recycled flexible wrapper for Nestle’s KitKat was supplied by Amcor, who also supplied the Mars Wrigley project.

In an exclusive trial with Coles Supermarkets across Western Australia, South Australia, and the Northern Territory, consumers can now buy KitKat bars featuring the paper wrapper for a limited time. More than a quarter of a million units will be wrapped in the new paper packaging across select stores for the trial.

The new paper packaging trial is a bid to innovate and explore every avenue to meet Nestlé’s goal of reducing its use of virgin plastics by a third by 2025, which includes using less plastic, recycled plastic, and alternatives to plastic packaging.

“We’re proud to be the first country globally to trial KitKat in paper packaging, as an important step towards reducing our use of virgin plastic. With all packaging innovations, our priority is to ensure we deliver the same delicious KitKat with creamy chocolate and crisp wafer,” says Chris O’Donnell, Nestlé Oceania general manager of confectionery and snacks. “Our partnership with Coles has made this packaging trial a possibility, where Aussie chocolate lovers can have their say on our innovative KitKat packaging. The feedback we receive on this trial will help shape the next step of giving Aussies their favorite break.”

According to a company release, each bar will feature a QR code which consumers in Western Australia, South Australia, and Northern Territory can scan to have their say by answering a series of questions about the new paper packaging. The 45-g KitKat milk [chocolate] wrapped in paper packaging has been available to purchase only from select Coles Supermarkets in those regions since January 2023 and can be recycled through curbside recycling bins that collect and process paper. The trial wrapper has a thin metal barrier film to keep the KitKat fresh and has a recyclable Australian Recycling Label.

Adds Leanne White, general manager of grocery at the partner retailer, “Coles is thrilled to partner with Nestlé on this important trial which will provide customers the opportunity to have a say on new packaging options and help the company lead the charge in innovative solutions. As part of Coles’ Together to Zero waste ambition, we are committed to reducing plastic packaging wherever possible in Coles supermarkets so we’re really proud to work with fantastic suppliers like Nestlé to trial a new packaging solution for one of Aussies’ favorite chocolate bar.” —Matt Reynolds

14 PW FEB2023

LOW PROFILE CONVEYOR modularconveyor.com 844.293.2816 • Product Flexibility: Quickly introduce new products into inventory • Process Flexibility: Modular conveyor systems with standard designs • Cost Flexibility: Quote solutions with options for every project blueprint represent Modular Conveyor Express and get your conveyor systems and equipment in 3-4 weeks!

designed

Nercon NEWS

Conveyors

by

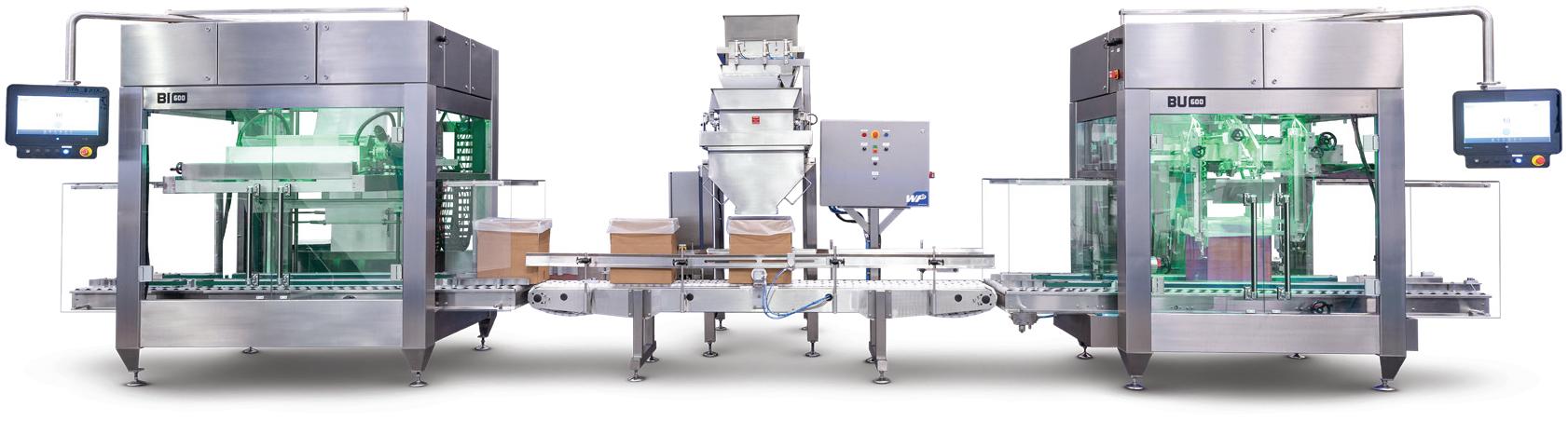

Multi-Head Combination Weighers

• Available in 10, 14, 16, 20 & 24 Head Models

• 10.4” Color Touch Screen

• Fully Enclosed Radial Feeder

• Wash-Down Models Available

• Easy Access to Breaker for –Lock Out Tag Out

• Achievable Speeds of up to 150 BPM

• Load Cell Technology for ln-Feed Detection

• Easy Removal of All Parts for Cleaning

• Optional Timing Hoppers & Diverting Hoppers

800.504.7120

Our MULTI-HEAD COMBINATION WEIGHERS deliver a high-quality build backed by our industry leading customer service. High Tek USA knows that the food industry needs the best performance, with the best options all in one reliable and lasting solution. .

BY THE NUMBERS 2 in 3

The number of Americans, according to a recent report from the American Bakers Assn. (ABA), who say sustainability matters to them; however, only 1 in 5 say it influences their purchases

9.4 million

The number of barrels of oil displaced annually by bio-based products, with the potential to reduce GHGs by an estimated 12.7 million metrics tons of CO2 equivalents per year, according to the U.S. Department of Agriculture

$996B

The current size of the global plastics packaging industry, which is expected to grow at a CAGR of 4.4% to $1,406 billion by 2030

5.6X

The average rate of sales growth for products marketed as sustainable versus non-sustainable versions, according to the Harvard Business Review

“Redefining value throughout the food and beverage industry will lead in 2023 as consumers seek brands that listen, understand, and respond to their core values. They want brands that provide quality, trust, and confidence via their product formulations, communications, and wider sustainability actions.”

–Lu Ann Williams, global insights director at Innova Market Insights, in an article from Prepared Foods, “Trend Predictions Provide New Insights to Consumer Thinking”

“Advanced recycling diverts plastics from landfills, reduces greenhouse gas emissions and use of natural resources to create new plastics compared to conventional manufacturing methods, and creates new jobs and revenue streams. This new legislation can showcase Michigan’s leadership in plastics recycling. Regulating advanced recycling technologies as manufacturing operations, as more and more states are doing, will encourage investments in new advanced recycling facilities and manufacturing careers in the state, while contributing to a more sustainable Michigan.”

–Joshua Baca, vice president of plastics for the American Chemistry Council (ACC), in an article from Plastics News, “Michigan adopts industry-backed chemical recycling rules”

“While it’s not feasible to make a unique product for every individual, brands have found clever ways to meet this desire for personalized products, including products designed for specific need states, tech-enabled tools, and online quizzes. Consumers are looking for elevation and premiumization across their beauty and personal care purchases, and a custom-made toothpaste could fit right into this unique need state.”

–Anna Mayo, thought leadership vice president of beauty and personal care at NielsenIQ, in an article from CosmeticsDesign.com, “‘Uniquely yours’: Colgate trials customization in mass-market oral care”

–Joseph Aquilina, senior director and associate general counsel for the Consumer Brands Association (CBA), as quoted in an article from the association, “Consumer Brands Supports FTC’s ‘Green Guides’ Review”

16 PW FEB2023 QUOTABLES

“We’re pleased the Commission [FTC] is taking action to provide much needed clarity for consumers and regulatory certainty for industry through long awaited updates to the [Green] Guides. Revising the Guides based on the changes to consumer expectations and stakeholder commitments around environmental claims that have emerged in the past decade will help ensure consumers, industry, and environment are better served.”

By Sterling Anthony, CPP, Contributing Editor

By Sterling Anthony, CPP, Contributing Editor

The Importance of Load Diagrams

A load diagram is a depiction of how a given shipment of pallet loads is to be positioned inside a trailer. The diagram is a pre-loading instruction, not a post-loading documentation. Load diagrams might not be necessary for repetitive shipments of the same composition, given a prior determination of the load pattern. When shipments vary by composition, however, load diagrams can provide multiple benefits, starting with the loading process and continuing throughout the supply chain. There are factors to be considered prior to the production of a load diagram.

Pallet loads arrive at the outgoing shipping dock via different routes, for example, from warehouse storage, directly from end-of-the-line operations, or by cross-docking. The best practice is to have the entire order collected and staged before loading commences. A load diagram is the preferred alternative to having to rely on the discretion of the loader (a forklift driver, for example).

Since a trailer is a three-dimensional enclosure, the challenge is to optimize the use of its cube. A twin challenge is compliance with state and federal regulations that set maximum combined weights (tractor, trailer, load). Loads, therefore, at most, can either “cube-out” or “weigh-out.” For any truckload (TL), the questions are how many pallet loads can there be, and how should they be positioned?

How much a pallet load should weigh can be estimated by dividing the maximum cargo weight allowed by regulations by the number of pallet loads. If the weight limit that the trailer can carry is 42,000 lb or thereabout, for example, dividing by 26 and by 30 yields a per-pallet-load weight of 1,615 lb and 1,400 lb, respectively. The optimal utilization of a trailer, therefore, requires the optimal number of pallet loads, each at the optimal per-pallet load weight.

But reality has a habit of imposing itself against theory. An example is products that are comparatively lightweight. Pallet loads can be stacked to better utilize cube and weight limits. It’s possible that the aforementioned per-pallet load weights will result in a pallet load height that’s too great for stacking. The needed tradeoff is a shorter pallet-load height and a lighter per-pallet-load weight, in exchange for the ability to stack the pallet loads.

Load diagrams might not be necessary for repetitive shipments of the same composition, given a prior determination of the load pattern. When shipments vary by composition, however, load diagrams can provide multiple benefits, starting with the loading process and continuing throughout the supply chain.

Assume a 53-ft trailer and 48-in x 40-in pallets. If the pallets are straight-loaded (length of pallet running parallel to length of trailer), 13 pallets can be aligned in a row, along the trailer’s length. Trailer width allows two such rows, for a total of 26. If the pallets are turnloaded (length of pallet running parallel to width of trailer), 15 pallets can be aligned in a row, along the trailer’s length. Trailer width allows two such rows, for a total of 30. When the additional four pallets can be had without exceeding weight limits, fewer trailers will be needed, yielding savings in transportation costs, along with sustainability/ environmental benefits. On the other hand, straight loading is faster, providing higher shipping dock productivity and efficiency.

Pinwheeling is a third way to load a trailer. There, too, pallets are arranged two-across. However, one is straight-loaded, the other turnloaded. The pairings alternate positions along the trailer’s length, yielding a pattern that accounts for the name. It is a more complicated loading, at times used when the trailer’s width is too narrow for turnloading (not the case with a 53-ft trailer and 48-in. x 40-in. pallets).

Another reality is that a trailer needs to have its load’s weight distributed evenly, with special attention afforded to the weight placed over the trailer’s axles. While in transit, trailers exit the highway, pulling into weigh stations to be checked for compliance with regulatory weight limits. Non-compliance must be corrected on the spot, before the trailer can leave the station. A variety of consequences can result. Among the worst is when the driver has to break the seal on the trailer’s doors to correct the weight distribution, and thereafter, the consignee rejects the shipment because the seal was broken.

Yet another reality is that loads must be blocked and braced so that they remain immobile during transit. How the pallet loads are positioned determines the size and location of the voids that have to be filled or otherwise accommodated. Take the example of a straight-loaded trailer, with each row of pallets placed against the adjacent wall, leaving a void down the center. Airbags and/or boards nailed into the trailer’s floor are popular methods. For back-of-trailer restraint, load bars are popular. Loads that move and shift within a trailer are not just a hazard for cargo damage. They also pose a safety hazard by interfering with the stability of and the steering of the trailer.

A final reality worth mentioning is that the loading process should take into consideration the unloading process. The latter simply is the reverse of the former. As a generality, therefore, methods that are the most productive and efficient for loading make for productivity and efficiency in unloading. PW

18 PW FEB2023

THE BIG PICTURE

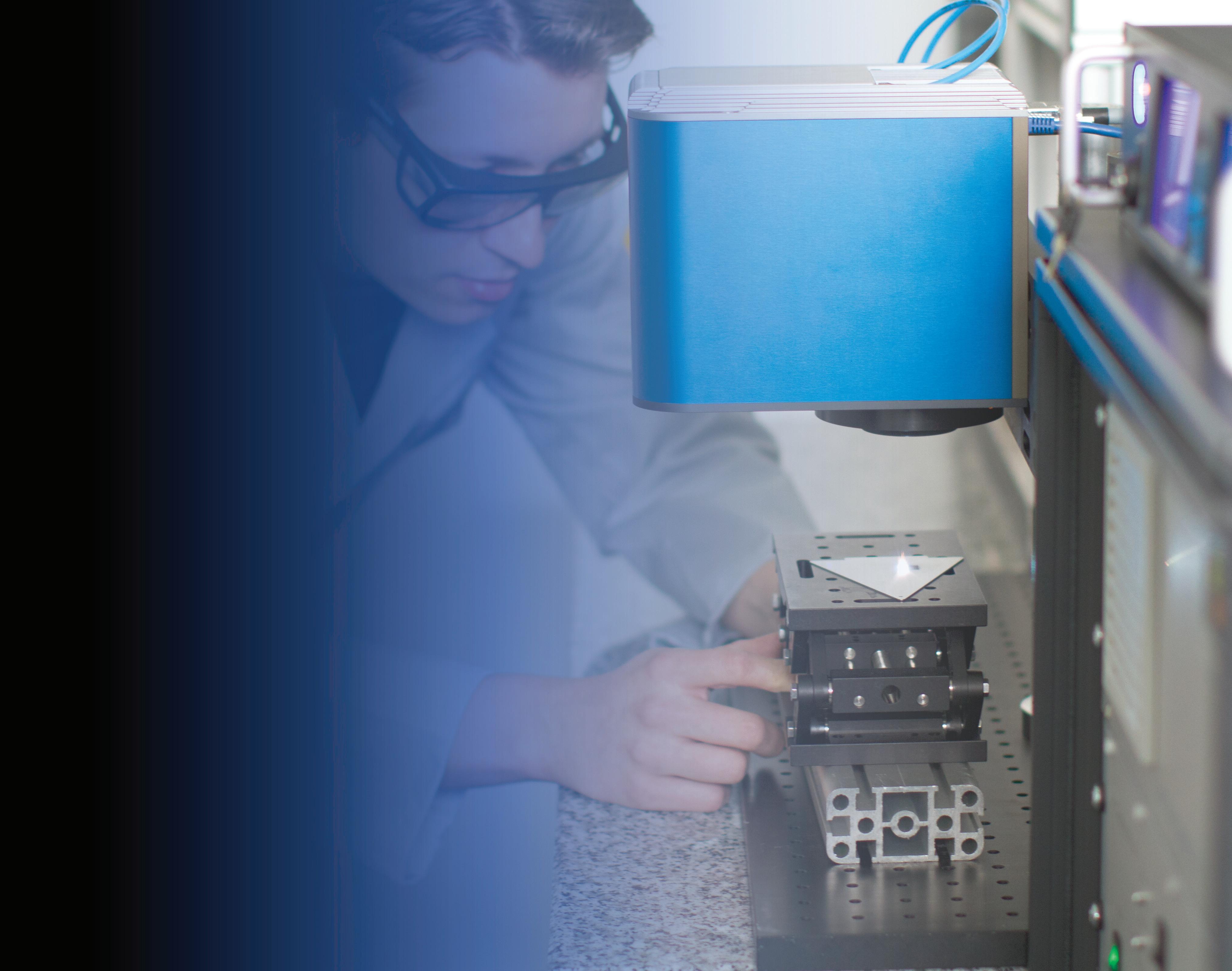

Keep pace with shifting market demands

If shorter runs, higher degrees of complexity, variations within a single run, and extreme tolerances are just some of the challenges you face today, then integrating a laser system may be the solution you are looking for. Build your next generation processing equipment with reliable laser system components and purpose-built laser processing sub-systems from a trusted technology partner.

novantaphotonics.com

By Tom Szaky, Contributor

What’s Needed to Scale Reuse?

The transition to reusable packaging is now being seen as a must in the consumer packaged goods industry. The pressure is on from the international community—take the United Nations treaty on plastic pollution and calls from organizations like Greenpeace, for example. And reuse legislation is on the way. As far back as 2020, French law 2020-105 called for 10% reusable packaging on the market by 2027. Recently, the European Commission issued a proposed revision to its Packaging and Packaging Waste Directive that includes reusable packaging mandates. Among the controversial targets: reusable packaging for 95% of cold and hot beverage cups by 2040.

Even the world’s biggest packaging creators have set specific commitments in response. In February 2022, Coca-Cola set a target of 25% reusables by 2030. PepsiCo recently followed suit, with a target of 20% by the same year.

The time to begin transitioning to reusables is now, and many companies are launching reuse pilots. But can they meaningfully implement at scale?

Reuse is scalable—it’s proven

Let’s start with the main methods for approaching a reusable packaging program. You could opt for a concentrate, refill, or prefill model—each of which boasts success stories.

With concentrate-based systems, companies remove the water from their products, delivering them in capsule, tablet, or other concentrate form. Shipping is inexpensive, and “just add water” is relatively easy for consumers. Look to the cleaning product company Blueland to see this model in action (see pwgo.to/7851).

Refill can be approached through in-store or at-home models, with consumers either refilling their own packaging at kiosks in stores or receiving refill packs directly at home. For the former, picture classic bulk bins full of cereals, pet food, and laundry powder, or more modern Algramo refill vending machines (see pwgo.to/7876). For the latter, consider Above & Beyond, which sells its lip balm in an aluminum case and then sends refills to users in compostable pods (see pwgo.to/7877).

Then we have the prefill model, in which consumers can pluck prefilled items off of shelves. They pay a deposit that they receive back when they return the empty container. Prefill has been proven time and again. Great examples are the German beverage system, The Beer Store in Canada, and our propane tanks in the U.S.

From a personal perspective at Loop, we’ve found our prefill strategy to be highly scalable (see pwgo.to/7878). It’s convenient for all stakeholders and, most importantly, it can be deployed in all product types (from ketchup to shampoo to tea), which isn’t true of concentrates or bulk bins. Consumers still get to grab a package right off the shelf, rather than having to fill a container.

Health drink brand Pocari Sweat in Japan approached the launch of its reusable packaging with a comprehensive public relations, social media, and POS marketing strategy.

When it comes to operations, Loop has successfully passed all quality and safety audits from our partners and has proved that it can reuse a wide variety of products—from baby food with Gerber to motor oil with Shell—in a wide range of materials, shapes, and forms. It has been operational across channels, from e-commerce to in-store, has become fully integrated into its retail and brand partners’ supply chains, and has successfully handled deposit reimbursement to consumers by leveraging its own online application as well as through the cashier or via smart bins.

20 PW FEB2023 SUSTAINABLE PACKAGING

With Loop, consumers can purchase a range of products in prefilled, reusable/returnable packaging, either online or at select retailers across three continents.

Tom Szaky is founder and CEO of TerraCycle and founder of the Loop global shopping platform.

Loop also has proven scalability. With successful pilots across three continents, Loop has shown that reuse can successfully be applied to any packaged good at large (see pwgo.to/7879). The consumer response has been very strong and consistently reconfirmed via both qualitative and quantitative research. In-market sales showed up to 4% conversion, and return rates were up to 80%. A McKinsey & Company study, commissioned by one of our partners, also proved that the model was as profitable as single-use for both brand and retailers.

All this is to say that prefill reuse works. The key now is focusing on scale.

What’s needed to scale?

As consumers are ready to adopt refillable options, the true roadblock to scalability is that reuse is often not made a commercial priority. Through our learnings from launching and growing Loop, we’ve identified four aspects needed to scale a reuse program.

1. Make it a commercial priority: To be successful, reuse has to be a priority across the entire corporate ecosystem, from commercial to supply chain to packaging suppliers to retailers. Too often, reuse is seen as simply a sustainability pilot (with no commercial ownership) versus a commercial priority. The key KPIs should not be learnings and publicity but objective volume shift from disposable to reusable.

2. Support it in market: It’s been shown that if a reusable version of a product is supported, it can outsell its disposable counterpart. For example, health drink brand Pocari Sweat in Japan approached the launch of its reusable packaging just like the launch of a brand-new product, with a comprehensive public relations, social media, and point-of-sale marketing strategy. Products were sold out every single day across 66 stores for the first weeks and continue to outsell the brand’s disposable products.

3. Create the right value equation: Approach reusable package design from a product innovation standpoint. What value can reuse help unlock? Durable packages have the opportunity to deliver extra benefits to the consumer. For instance, we found that reusable Häagen-Dazs containers had a number of new functional benefits as well as better aesthetics.

4. Pick scalable materials: We learned that stainless steel or aluminum, while durable materials, can be less scalable because they are more expensive than durable plastics and are not compatible with existing fill lines. A more scalable alternative for some companies could be to transition packaging that is single-use today into something durable enough to be reusable—for instance, by swapping PET to polypropylene or simply increasing wall thickness, which would mean existing production molds could still be used.

The reuse revolution is here

The world wants reusables, and legislation is coming. Organizations that start planning for reuse now will be ready for the inevitable mandates and gain a competitive advantage.

While shifting to reusables is an important and necessary step, it’s not the answer. As we always say, the only real solution to the waste crisis is for us all to buy less PW 92

PROCESSING AND PACKAGING SOLUTIONS

• Food processing systems

Helping you bring

Delivering Results. With Heat and Control, you have a partner with the scale to support your success, the innovation to advance your operations, and a commitment to quality that will help you offer better products for consumers.

• Conveying and product handling

• Multihead/combination scale weighing and filling

• Snack bagmaking and case packing

• Metal detection and x-ray

• Check weighing and seal checking

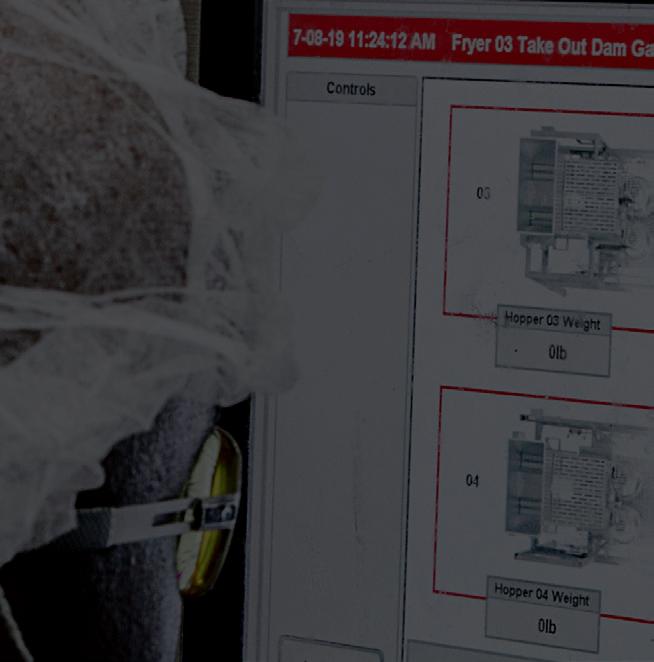

• Controls and information systems

91 97 98 34 108

• On-machine and process area seasoning application

94 116

We are successful when you are successful. That’s why we apply creativity, engineering excellence, and determined perseverance to every project to help our customers get the performance their business demands—whether measured by flavor, efficiencies, sustainability, improvement, or innovation.

107

17 20

32 99 36 42 0842 2 ~2~ ~2 26

your best products to market.

LOOKING BACK. PRESSING FORWARD. ALWAYS INNOVATING. info@heatandcontrol.com | heatandcontrol.com Apr.

Oregon

21

04-06, 2023 Booth 304 Portland,

USA

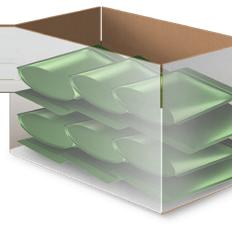

Bush’s Tiered Strategy for CM/CP Partnerships

Robby Martin, senior packaging engineer at Bush Brothers & Co., is using a layered approach to contract packaging on a new multipack project. He explains navigating the testing and scaling phases of commercialization with several different CM/CP partners, and why up-front transparency is crucial.

Packaging World:

Tell us about your traditional multipack approach, and what you wanted to change.

Robby Martin:

We’ve been in club stores with eight-packs and six-packs of 16 oz. cans, which represent the right purchase size in a club store situation. Those are bulk-packed and shipped at the pallet level all the way to the club store location. Whatever the club brand is, it goes all the way onto the floor in that bulk-stack pallet. We’ve been in that format for over 15 years, using a fully enclosed paperboard carton with beautiful graphics that creates a great visual in the store.

But those eight- and six-pack multipacks are a bit too large for more traditional grocery retail, no?

That’s right. While soup and some other categories have been doing some smaller multipacks in grocery retail for years, we never had much luck making that work for our products. Still, we think that there’s a market for multipacks that are more of an appropriate size for opportunities in regular grocery retail, and we just need to get the solution right to succeed.

Why haven’t you gotten these smaller multipacks to work?

When we get down below a certain size—generally a six-pack is the smallest we do—our high-speed cartoning equipment can’t always go down that small. Or, if we get down to a two-by-two four-pack of round cans in a carton, then we remove the opportunity for an interlocking pallet pattern. At that point, you are column-stacking with even smaller containers on a great big pallet for shipping. That’s a problem for us from a secure shipping standpoint, and it’s a problem for a retailer— not for club store, but regular grocery retailer—because they’re not going to put pallet loads of those on the floor the way a club store does.

So, we have both palletizing issues to consider on our end-of line, and post-delivery distribution issues by the retailers themselves within their system.

And your existing equipment isn’t up to the challenge anyhow, correct?

Yes, mostly. To date, we didn’t plan for our equipment to run those smaller packs. While our equipment can produce the smaller packs, that’s not the only issue. We’re casing the four-packs into six-packs of four-packs, which gives our retail partner a way to distribute them to their stores once they receive them. So, the goal is to be running cartons through a carton machine then putting them in cases, all automatically. But, we don’t have a line installed to do that today. So, for test purposes, and probably even for any initial rollout that could follow, we’re using contract packaging.

What does the vendor selection look like when it comes to contract packagers?

Obviously, they have to be capable of filling the need to begin with. They need to have capacity, and we need to be able to tolerate the cost. We get those big “C” words out of the way first.

And we certainly start with folks who we have worked with before. We know enough about them to consider why they would or wouldn’t be a good fit for an application. “Have they done work for us before? Do they do it well? Do we have a good relationship?” Those are pretty high on our list.

After that, it quickly gets into other, more complicated factors, like: How well do our systems work with each other? How do we maintain food safety? How do we maintain traceability? And how do we make sure we know how we’re flowing the cash and maintaining the inventory records that we need to?

22 PW FEB2023

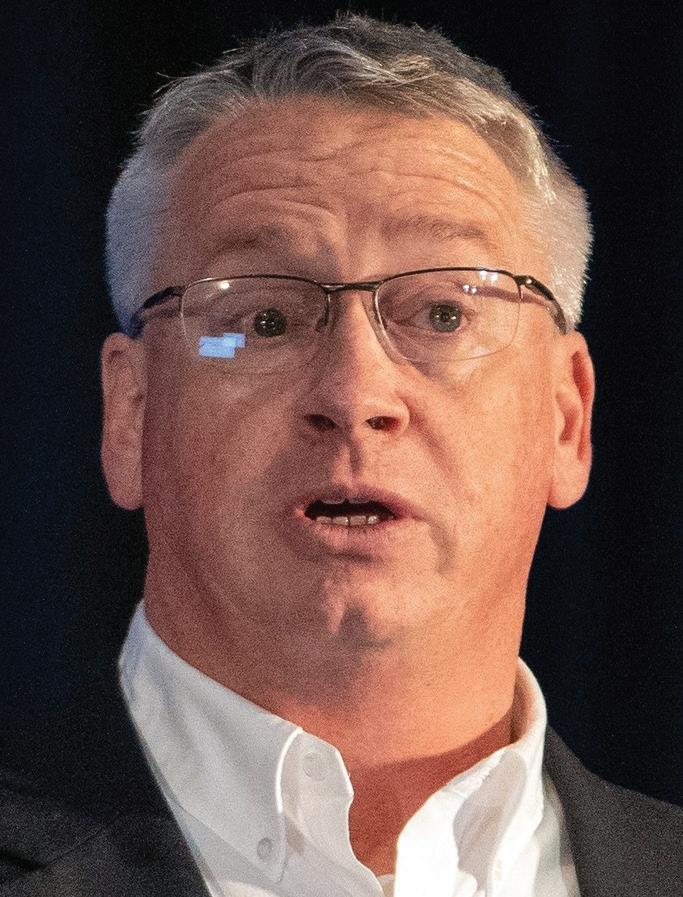

Robby Martin, senior packaging engineer at Bush Brothers & Co.

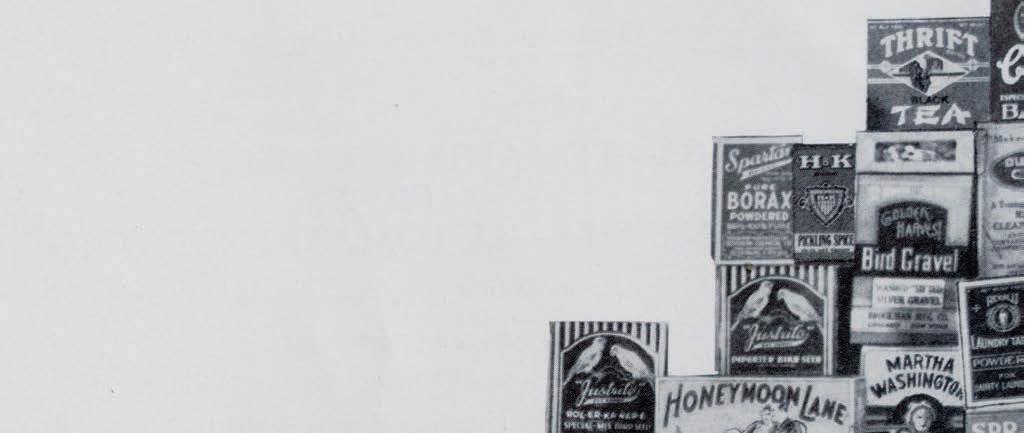

CPA’s Busiest Event Calendar Yet Unfolds on Heels of Record-Breaking Conference

The Contract Packaging Association kicked off the year with an early tradeshow in Las Vegas—the Winter Fancy Food show with two full towers of CPA member products and capabilities. The show was a success, and a booth was secured for the 2024 show. Trade shows continued with additional member towers into March with the Natural Products Expo West in Anaheim, Calif. and a return to SNAXPO in Orlando, Fla., this time with a large CPA branded contract manufacturer and packager CM/CP pavilion, increasing the association’s presence at the show. CPA will also attend the international Interpack show in Dusseldorf, Germany May 4-10. To see CPA’s 2023 event calendar visit pwgo.to/7900

CPA hosted its annual event: ENGAGE – The Contract Packaging and Manufacturing Experience in San Antonio, Texas in February, with a record number of registrations, attendees, and overall event participation. This annual event was joined by F4SS: The Foundation for Supply Chain

Solutions which brought more brand representation to the show. At the show, awards were announced for The Strategic Sourcing Award which recognized the most effective and innovative use of a CM/CP, along with a CPA Hall of Fame and two Outstanding Contribution Award winners.

CPA continued its support of the advancement of students who are pursuing a degree in packaging or a packagingrelated field through its scholarship program. The organization also helps individuals who are looking to improve their professional background and/or increase their skill set in the packaging world.

The CPA says it proudly offers the following scholarships: the Contract Packaging Association Collegiate Scholarship with three individual $1000 scholarships, and the Contract Packaging Association Professional-Certification/WorkplaceGrant Scholarship with a $2000 award. To apply, visit pwgo.to/7901. PW

23_000124_Packaging_World_FEB Mod: December 19, 2022 4:58 PM Print: 01/06/23 3:09:57 PM page 1 v7 π WE'RE WILD ABOUT PAC AGING ORDER B M FOR SAME DA SHIPPING COMPLETE CATALOG 1-800-295-5510 uline.com 24 PW FEB2023

Was there anything unique in vendor selection in this four-pack project?

In the case of a test like this one, where we’re re-handling finished product into a different configuration to conduct a test, and possibly even to initially launch, we’re having to then make decisions on some less obvious considerations. We also have to consider where they are located. Because if we’re going to have to move product to them, have it converted, and then get it back, then where they are in relation to our shipping points—which are our two facilities in Wisconsin and Tennessee—is important. And in many of these cases, most of the volume may ship from only one of our facilities. So, where the contract manufacturer is located can be a big factor. Even when they’re relatively close—say 200 to 250 miles—it’s very expensive moving that product back and forth.

Who foots that bill?

In test mode, we eat that cost. We live with the cost because it’s about being sure we execute the test correctly, so we get a good read of the market. But should we decide we’re going to stay in market, or expand that work, then we are far more likely to look harder at how we could do it internally. Or if not internally, we ask ourselves if we have a partner that could handle the greater scale, even if we had to provide some equipment for them to do so. This might be someone that already handles a lot of our outbound shipping, like a local 3PL to our plant. There’s a good chance that we could move it back there.

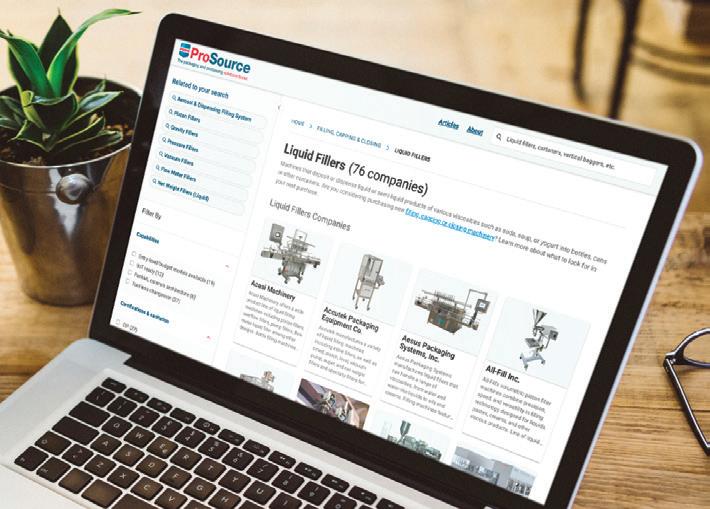

Connect with Suppliers Fast

PMMI ProSource is a free online directory with 900 categories of validated suppliers of packaging machinery, materials, and service solutions. With a powerful search engine and the ability to filter solutions by machine feature and package type, ProSource brings vetted suppliers to you. Visit www.prosource.org today.

It sounds like a tiered or graduated network of partners for different phases of product launch. How have you moved work around for this current four-pack project?

The partner supporting our test phase is about 200 miles from our producing plant. We have done some really successful projects with them. They operate manually—literally, they’re manually doing the cartoning—and they’re good at making fixtures to accomplish that. They like

For show information: Messe Düsseldorf North America Tel. (312) 781-5180 _ info@mdna.com www.mdna.com For hotel and travel arrangements: TTI Travel, Inc. Tel. (866) 674-3476 _ info@ttitravel.net interpack PROCESSING & PACKAGING GERMANY 4 – 10 MAY 2023 25

to say they supply labor to our problem. They have helped us by completing the initial inventory builds and replenishments for our test.

All manual seems fine for a test, but not to scale. What would be the next phase?

Even if we aren’t sure we have the space or the appetite to spend the capital in our plant to automate this function, we would need to address the over-and-back nature of how we are executing the test phase. With the contract packager, we ship them product in the original primary pack format, they convert it, and we bring it all the way back to our producing plant or a nearby 3PL provider we use for shipping orders. It just incurs too much transportation cost and risk to be a sustainable process in the long run.

One of the biggest factors that doesn’t keep us from testing with a partner—but often keeps us from fully commercializing with that same partner—is systems integration, electronic data interchange (EDI), and the like. A more local 3PL’s ability to actually ship our orders and maintain traceability is a must-have for full commercialization. More complete systems integration is crucial so that we can count on maintaining traceability, accurate inventory records, and keep as many transactional activities as automated as possible.

The 3PL has a lot of factors in their favor, but can they actually make the four-pack formats?

Not yet. Even if we have to get someone up to speed on the actual capability, we still might move to the 3PL where the systems integration pieces are already in place and they transact orders for us every day. But rather than make that investment in-house, or with a 3PL, just for a test up front, instead we take the hit on what it costs to run the tests at a more manual facility. We know it’s going to stay contained to a certain number of stores, or a certain constrained geography where you’re going to distribute the four-packs for the test. During that time, we are just taking the hit on cost, but crucially, we’re finding out what value we have in the marketplace.

Say you move packaging operations to your local 3PL, and the fourpack continues to do well over some time. At what point does a brand owner start to consider taking the project completely in-house?

This isn’t a very satisfying answer, but it really depends. Let’s say we rolled out these four-packs nationwide. That still doesn’t mean we’re going to be shipping entire truckloads of this format, because we’re probably not going to see retailers order full truckloads. So, it’s still going to be mixed product orders, right? Because if it was going to be full truckloads, then we would have spent our money getting our original partner’s systems upgraded to become EDI-capable and system-capable instead. Because they can make the product correctly already.

But since we’re not going to be able to just have them ship only that product, and we’re not going to be able to ship it in the quantities to make that make sense, we have reason to look at bringing it back to our plant, or back to a more localized 3PL even if it changes the investment from systems investments, to physical equipment or other capability investments.

Your contract packaging business moves around from partner to partner at different phases of commecialization. How do you manage taking business away from one partner in favor of another? Part of the key to making this work is transparency, both from us and from our partners. They tell us, “We may make fixtures, and we may even store a little bit of product, but what we really do is we provide labor. We sell you labor. We do, mostly manually, things you either can’t do, or don’t want to do yourself. That doesn’t mean that we want to grow to the entirety of your scale, because what we’re really good at is getting labor together to attack problems for our customers.”

Because they are transparent with their core competencies and what they do best, we’re able to say, “If this really takes off, we have to figure out another answer.” Up front openness on those conversations is a huge deal.

It’s just an important element to be continually talking about what is, or isn’t, helping this work. We all have to have some agreed-upon understanding of what our pain points look like. What does that trip point look like? What is that triggers you to say, “Hey, we have to make a change here?”

How’s this multipack project going for you so far?

We’re just now, after a few months of selling in this particular test, beginning to talk about how we are going to solve for next steps. Are we going to add more capital equipment on our own line, so we could at least build the pallet? Since we know that doesn’t work for a retailer, that answer is not the whole solution. Are we going to build pallets, then rehandle it to get it cased? Who is going to do the re-casing part? We’re just starting to think of questions like that now, what we could actually need to tackle as we talk about how we could go bigger, go larger, go more permanent with this, assuming we ultimately make the decision to do that.

It sounds like you have some big decisions on the horizon. How do you handle your vendor relationships as you make them?

It’s important that they [contract packagers] understand up-front what you need them for, what you’re contracting with them to do, and most literally, what you’re using them for. And it’s important for you [brands, CPGs] to understand that at some point, your scale may be out of their comfort zone. They need to have the right to say, “We’ve probably helped you much as we can really help you. We’re not going to dump you, but you’re paying this much, and there’s got to be better ways of doing this.”

We love being important to our partners, but if we’re too important to them, then we can start feeling constrained. If we’re a halfway decent customer—and it is important to us to be a good customer—we’re feeling constrained about how quickly we can pivot away from them. We don’t want a trail of used up, unfairly treated partners in our wake. Because the next one’s going to say, “I know what you did to so-and-so on that four-pack product Packaging World wrote about. I’m not sure I want to take a phone call from you guys.” We don’t want to become that, either. That’s why mutual, up-front transparency is one of the keys to good relationships between our contract packagers and us. —Matt Reynolds

26 PW FEB2023

It’s important that they [contract packagers] understand up-front what you need them for, what you’re contracting with them to do, and most literally, what you’re using them for.

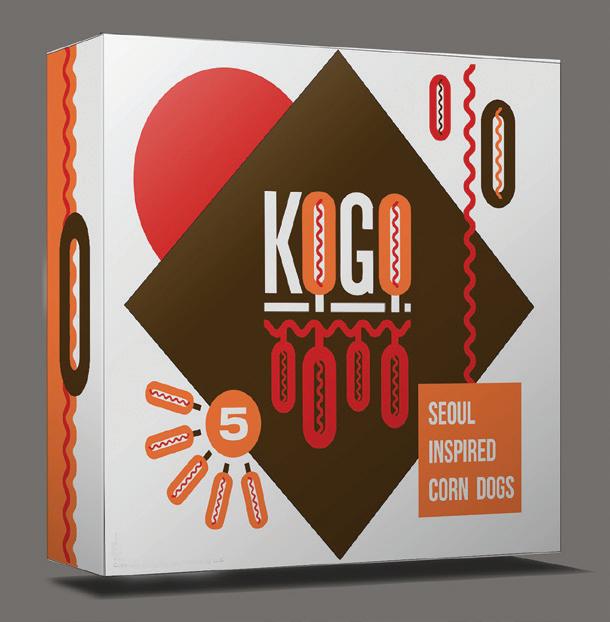

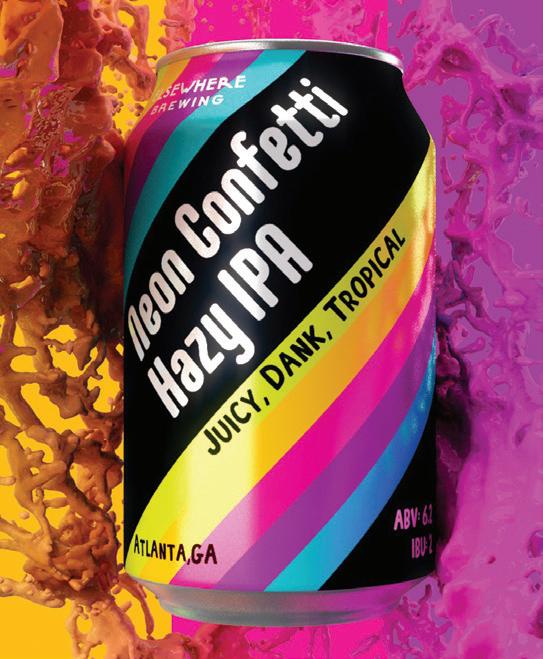

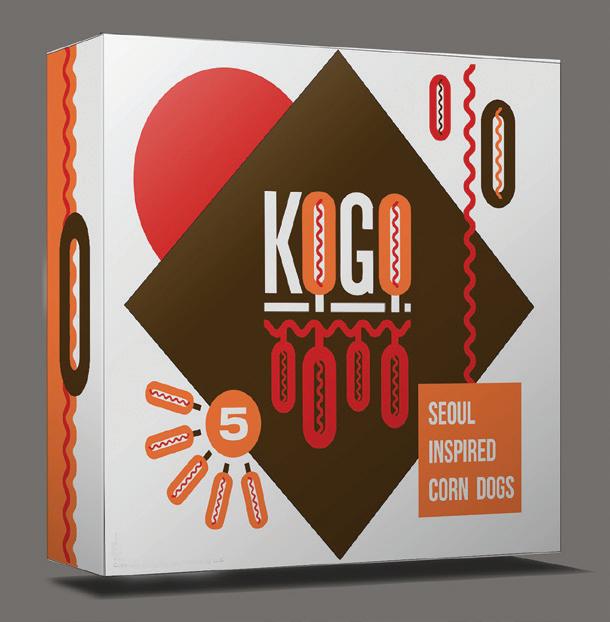

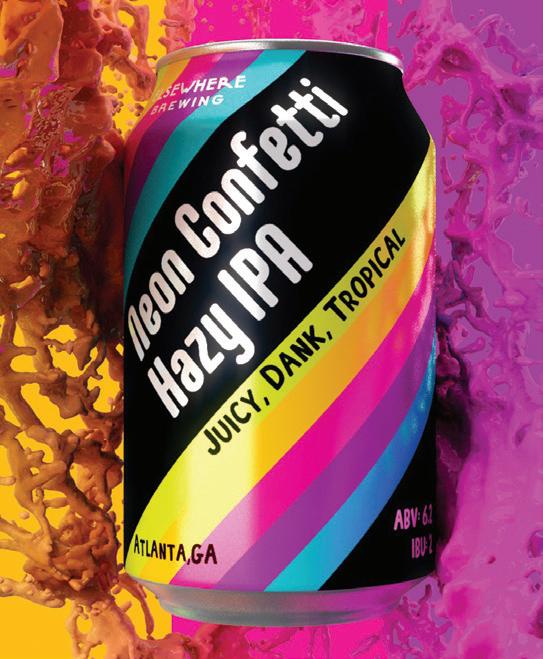

CM/CP Rides the Wave of Adult Ice Pops, Pouched Alcohol

Adult beverage branding and marketing firm Iconic Brands merges with contract manufacturer/packager TopPop Packaging to address the rapidly growing market for RTD cocktails and adult ice pops, as well as healthier options for wine and spirits.

RTD/RTF adult beverages

By Anne Marie Mohan, Senior Editor

Amityville, N.Y.-based Iconic Brands was founded as a lifestyle branding company with expertise in developing—from inception to completion—alcoholic beverages, with a focus on celebrity branding. TopPop Packaging, purchased by Iconic in July 2020, is a contract manufacturing and packaging company that specializes in malt-, spirits-, and wine-based products in singleserve exible packaging. Together, the two companies, soon to be renamed TopPop Innovative Brands, Inc., are delivering on some of today’s top trends in the alcoholic beverages market. Among them are ready-to-drink (RTD) and ready-to-freeze (RTF) cocktails in pouches and sachets and better-for-you, better-for-the planet adult beverages that are sustainable, ethical, and authentic.

Flexible pouch & stick-pack packaging

According to Grand View Research, the global RTD cocktail market, which includes RTF drinks in exible sachets or squeeze pouches, was valued at USD $782.8 million in 2021 and is expected to expand at a CAGR of 13.4% from 2022 to 2030. A number of factors are driving this expansion, including the growth of the at-home cocktail market resulting from COVID-19 lockdowns, greater health consciousness among consumers, with RTD beverages typically containing less alcohol by volume (ABV), a desire, especially among Gen Z consumers, for new avors and tastes, and the convenience of premixed, portable adult beverage options.

In 2021, a survey conducted by Public Opinion Strategies for the Distilled Spirits Council of the United States (DISCUS) found that premixed cocktails were the fastest growing spirits category in both revenue and volume. Nearly two-thirds of survey respondents said they considered themselves to be a regular or occasional consumer of RTD beverages.

Another market where consumers are turning to better-for-you and better-for-the-planet alcohol options is in the wine industry, which is experiencing tremendous growth in vegan organic products. These wines are made without the use of animal products or byproducts, from farming to vini cation. In mid-2022, one online retailer of wine products reported that sales of its vegan options had grown 51% since 2019—a trend that is expected to continue.

Iconic Brands’ agship product is Bellissima Prosecco and Sparkling Wines by Christie Brinkley, a vegan product made with organic grapes

28 PW FEB2023

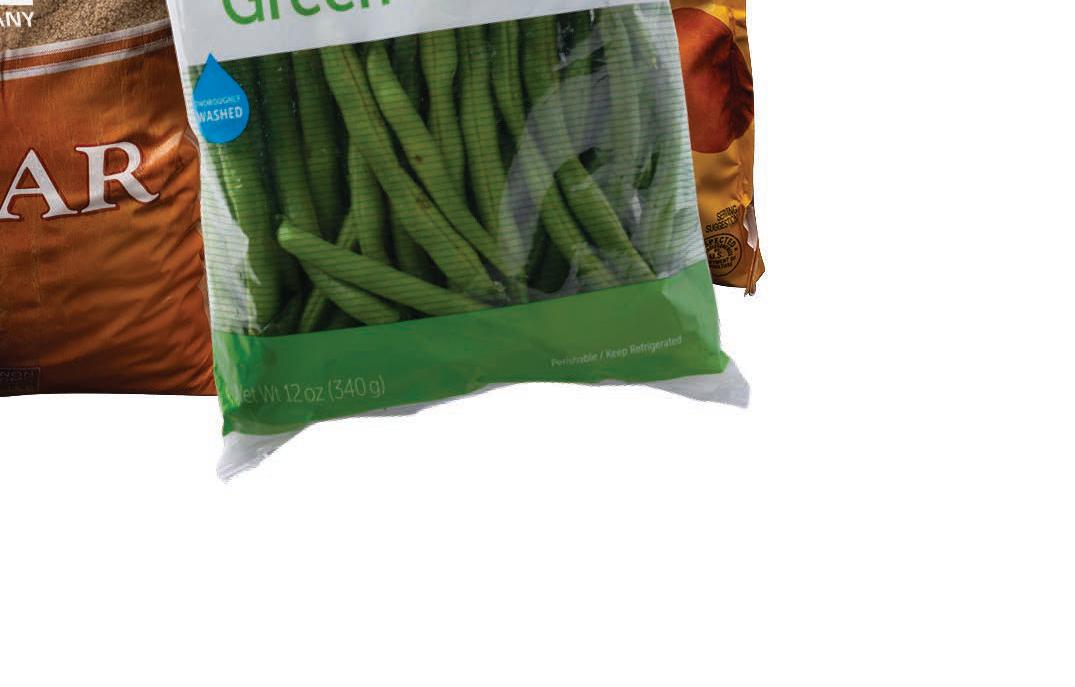

Among TopPop’s offerings are adult ice pops in exible sachets and juice and water products in stand-up pouch packaging.

WHAT YOU’LL LEARN

that also includes a new zero-sugar, still wine variety. “We bring to life brands that are honest, earth-friendly, and of premium quality,” says Iconic. “Our brands lead change in their category while committing to make a difference for a sustainable future.”

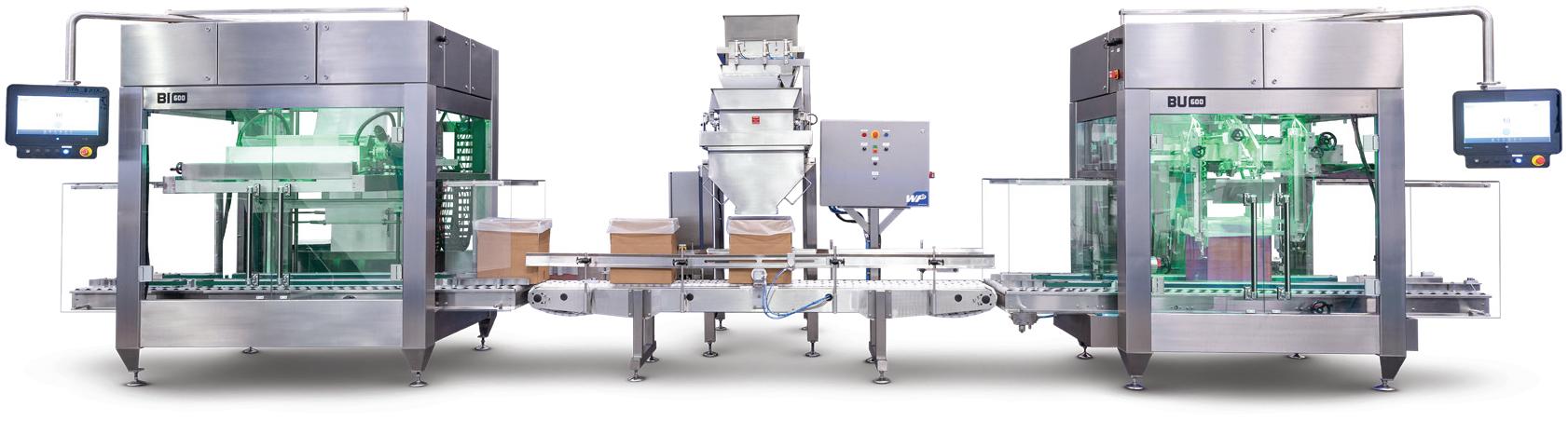

Following Iconic’s acquisition in 2021 of TopPop and its 30,000-sq-ft Marlton, N.J., manufacturing facility, the company quickly expanded, adding a second production facility in Pennsauken, N.J. The new facility, which covers 65,000 sq ft, reached full-scale production in March 2022. Says Tom Martin, co-founder and former president and chief operating officer of TopPop and now interim chief executive officer of TopPop Innovative Brands, the move to rename the company marks a milestone in its evolution from a focus on adult beverage/celebrity brand building to a focus on innovation, development, and delivery of alcohol and non-alcohol beverages, foods, and frozen treats.

Full turnkey services for adult beverage options

TopPop Beverages was founded in 2019 to capitalize on the growing trend of adult ice pops for retail in ambient shelf-stable form in an RTF flexible-film format, with the product made with either spirits, wine, or malt. In 2020, its Marlton facility produced 40 million ice pops, packaged in long-form form/fill/seal pouches (sachets with four-sided seals) and stand-up pouches (SUPs) for both multimillion-dollar Fortune 500 companies and medium-sized businesses.

Said TopPop co-founder and CMO Laurance Rassin when the formation of the company was announced, “With lower shipping costs per unit and a lower environmental footprint compared to cans and bottles, our pouch packaging solutions are the most economical and sustainable way to reach the ready-to-drink market and more specifically, the ready-to-freeze market.”

According to TopPop, it offers a “360-deg tailored approach to manufacturing and packaging”—in other words, full turnkey solutions, from

29

TopPop runs its ready-to-freeze cocktails on one of its 12 vertical f/f/s sachet machines.

formulation to fulfillment. In the initial stages of a project, the company can help customers with their product formulation, creating recipes that meet their needs and the current demands of the market, followed by sourcing of all the ingredients and product blending. TopPop’s brand design services can assist clients in designing custom packaging, which it can also procure. With its vast manufacturing capabilities, the company can also handle a range of run sizes and an array of pouch shapes and volumes for multiple SKUs. And, once the product is packaged, TopPop can ship it to distributors, logistics companies, or directly to retail. If the customer does not require turnkey services, TopPop can use customersupplied packaging, formulations, ingredients, and supplied liquids.

With the addition of the Pennsauken facility, TopPop’s capacity has grown to 150 million units per year, including 150,000 flexible SUPs a day. The plant not only runs alcohol-based products, including adult ice pops and 10-oz cocktails in a pouch, but it also produces 6-oz fortified flavored water in a pouch, non-alcohol fruit-based smoothie pops, ice pops for dogs, and 6-oz juice pouches for various retailers. Martin estimates that pops make up 80% of the company’s business and pouches 20%; that number is expected to change to 60% pops and 40% pouches next year as TopPop’s pouch production ramps up. The company can also produce Jell-O shots and flavored shot cups.

“The Marlton facility is 100 percent alcohol production, and the Pennsauken facility is 80 percent alcohol,” Martin explains. “We expect Pennsauken to be 60 to 70 percent alcohol next year.

“The blend of Iconic’s wine and spirits and TopPop’s RTD, RTF, water, and juice products gives us the ability to offer a wide range of branded alcohol and non-alcohol products and production expertise that is not available in the market today,” he adds.

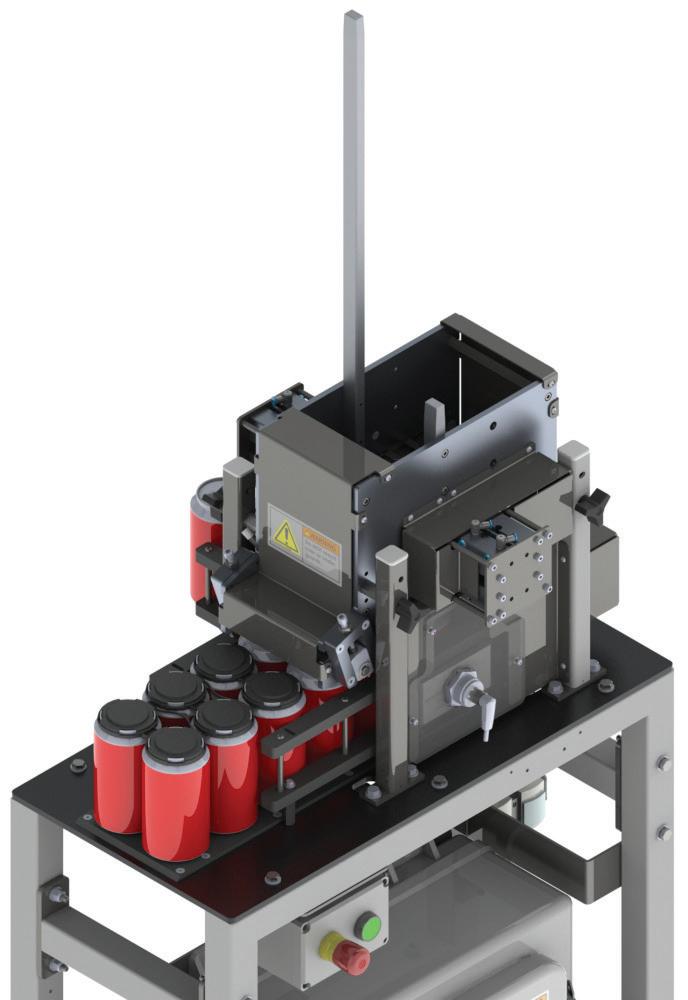

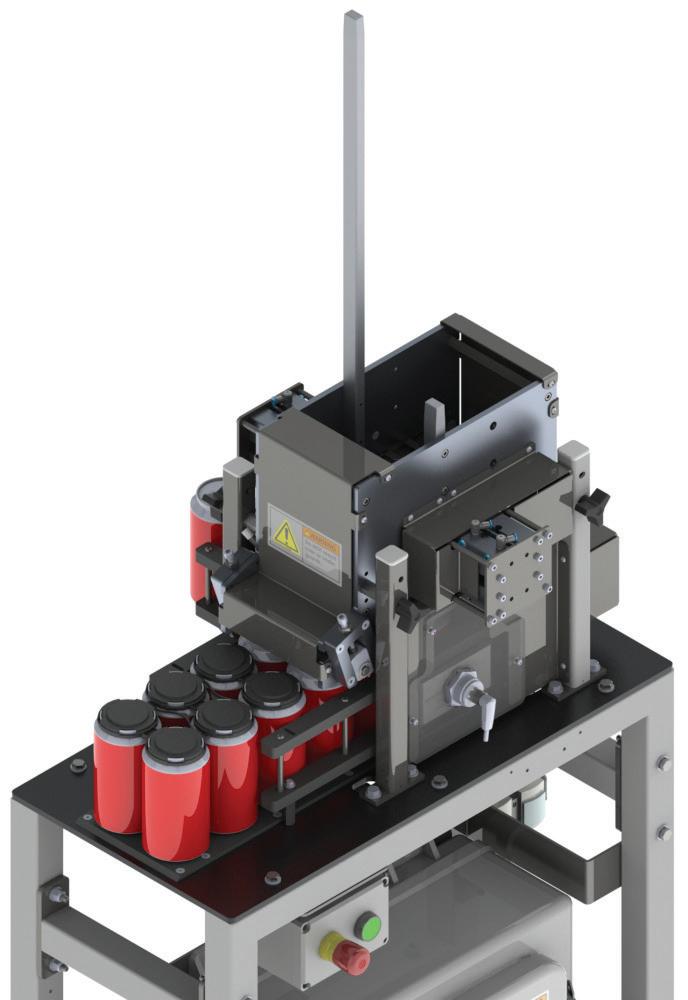

Well-equipped packaging operations

The increase in TopPop’s capacity from 40 million units to 150 million units in just three years has naturally entailed a large investment in equipment. TopPop began its packaging operations with two custombuilt, eight-lane vertical f/f/s machines for its 2-oz adult ice pops and then added three more eight-lane vertical f/f/s machines that could be easily changed over to run different sizes from 2 oz to 3.4 oz. It then added four four-lane machines that Martin says run faster, are easily changed over to run different sizes, and are more suited for smaller or larger runs, when combined side by side.

Most recently, it added three Sanko FR3 eight-lane continuous-motion liquid stick-pack machines, sold by T.H.E.M., that together can run approximately 5 million ice pops per week. “The high-speed Sanko machines took us to another level of speed and uptime, but they are not easily changed over to different sizes. They are more suited for larger runs,” says Martin. “We expect to add more Sanko machines as we grow.”

With the new facility, TopPop has also installed four new premade-pouch machines, with two more on the way. The equipment includes two rotary pouch machines from Viking Masek, two custom-built, single-head rotary machines, and two dual-head rotaries from an offshore supplier. All of the rotary systems are outfitted with Sneed Coding Solutions inkjet printing systems as well as secondary coding equipment.

For cartoning, TopPop recently enlisted EDM Machine & Tool to build four custom carouselstyle carton filling systems that present the cartons for filling, folding, gluing, and coding. “This has lowered our labor and increased our packout speed and uptime,” says Martin. “We have also added an overwrapping system to eliminate the shippers for our juice pouch products.”

30 PW FEB2023

A rotary pouch machine from Viking Masek fills premade pouches with RTD alcohol and non-alcohol products.

Operators case pack squeezable smoothie products for club-store distribution.

Pack-out options include cartons, SUPs, PET-labeled tubs, pop-up boxes, and larger-format display cartons. Case packing is done semi-automatically, due to the range of products produced by TopPop. Smallervolume jobs are case-packed manually.

According to Martin, the company plans to add a plastic bottling line, expected to be operational by summer 2023.

Sustainable packaging adds value

In addition to being on-trend with consumers’ growing taste for innovative cocktail options that are lower in calories and alcohol content, Iconic and TopPop also have the advantage of offering a packaging format that falls in line with the shift toward more sustainable packaging formats.

“The sustainable exible packaging business continues to grow rapidly, as brands and retailers are increasingly looking for U.S. packaging solutions that enhance their products and brand portfolios while also lowering packaging costs and reducing waste,” says Martin. “Our capabilities enable our customers to provide a healthier and more environmentally friendly end product to consumers.”

TopPop packages its ice pops and pouched beverages in PET and PET/aluminum formats. According to Martin, it’s also testing paper and polyethylene formats.

On the company’s website, it details the advantages of exible packaging versus glass and aluminum. One is that exible packaging requires signi cantly less water and energy per unit to produce. It’s also considerably lighter in weight and can be stored with much greater space ef ciency. “That means more units loaded onto each truck, which lowers not just the total cost of logistics, but also reduces the total carbon footprint of your product,” TopPop explains.

Another advantage it cites is product-to-packaging ratio. “A major component of sustainability is reducing the amount of source material required per unit of product,” says the company. “With signi cantly less material required compared to rigid packaging, exible packaging reduces the total waste throughout the entire product lifecycle.”

It also notes that exible packaging often includes added barriers to protect against product spoilage, extending the product’s shelf life and reducing the total food waste generated by traditional packaging.

Getting Started with Sustainable Packaging

Looking for information on how to get started with sustainable packaging? This Packaging World primer provides an overview on what sustainable packaging is, what’s driving the push for more sustainable packaging, and how to reduce the environmental impact of packaging. It also includes links to resources. Download this free PDF today at pwgo.to/7345

“The durability of exible materials also reduces the risk of punctures or damage to the package seal,” TopPop adds.

When asked if the company ever receives criticism due to the fact that its packaging is not recyclable, Martin says, “We do get some pushback, but the recycling avenues are growing, and the carbon footprint is four-times more favorable than plastic bottles.”

In addition to its healthier beverage options and more sustainable packaging, as part of its better-for-the-planet positioning, both of TopPop’s manufacturing facilities are 100% solar powered, ensuring the energy used to create its customers’ products are from renewable sources. In addition, Iconic has a history of supporting social and environmental causes, including Bellissima’s partnership in 2021 with NGO One Tree Planted, which resulted in the planting of 10,000 trees in California; its support of the Cleveland Clinic Lou Ruvo Center for brain health in 2021; and its donation of 30% of all Bellissima Prosecco’s DTC sales in April and May of 2021 to Direct Relief for the purchase of masks for doctors and nurses during COVID-19.

Plenty of room to grow

With its extensive lineup of packaging equipment and capabilities, soon-to-be TopPop Innovative Brands is well positioned to continue to take advantage of the RTF and RTD drinks market, as well as other pouched and bottled beverage opportunities.

Predicts Martin, “The alcohol pops market came into play around four years ago, but in a smaller way. It really grew in 2020 and has increased ever since. We expect it to continue to grow for the next three years.”

Of the pouched cocktail market, he says TopPop believes this will be a tremendous growth area over the next two years. “Cocktail pouches will be a staple for the on-the-go restaurant takeout business as well as in retail formats,” he notes.