Established 1951 February 2023 Spinning Review

Textile Asia 2023, Karachi

Dates: March 11th to 13th 2023.

Venue: Expo Centre, Karachi.

Index 2023

Dates: April 18th to 21st, 2023.

Venue: Palexpo, Geneva, Switzerland.

Techtextil 2023 North America

Dates: May 10th to 12th, 2023

Venue: Georgia USA.

DOMOTEX asiaCHINAFLOOR 2023

Dates: May 29th to 31st 2023.

Venue: NECC, Shanghai, China.

FESPA 2023

Dates: May 23rd to 26th 2023.

Venue: Munich, Germany.

Istanbul Yarn Fair

Dates: June 1st to 3rd, 2023.

Venue: Istanbul, Turkey.

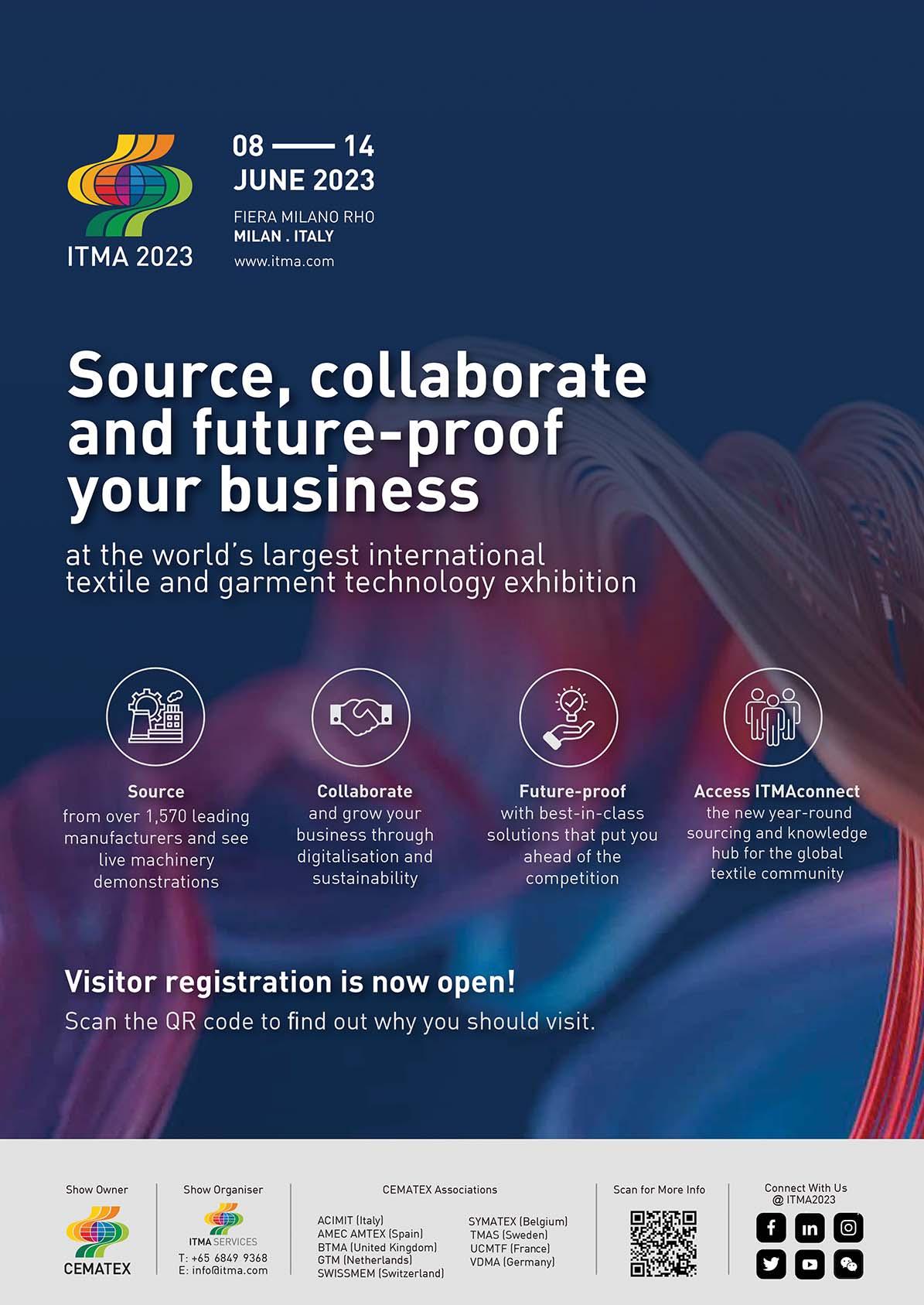

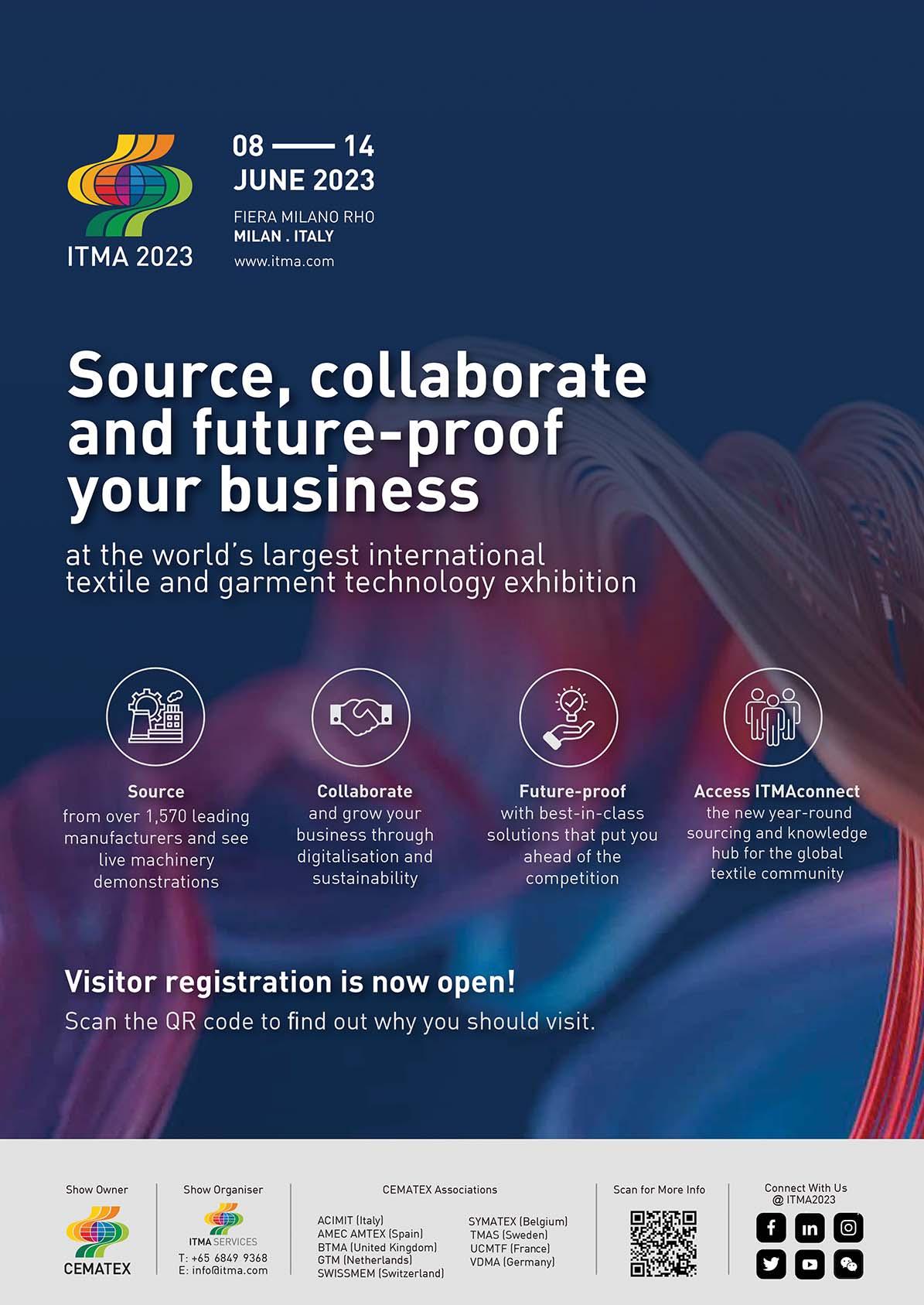

ITMA 2023

Dates: June 8th to 14th, 2023.

Venue: Milan, Italy.

Johannesburg, South Africa !

Dates: June 18th to 20th, 2023.

Venue: Gallager Convention Centre.

iCADEX Pakistan 2023, Karachi

Dates: September 7st to 9th 2023.

Venue: Expo Centre, Karachi.

IGATEX Pakistan 2023, Karachi

Dates: September 7st to 9th 2023.

Venue: Expo Centre, Karachi.

62th Dornbirn GFC Global Fiber Congress

Dates: September 13th to 15th 2023.

Venue: Dornbirn Austria.

ITMA ASIA + CITME 2023

Dates: November 19th to 23rd, 2023.

Venue: NECC, Shanghai, China.

Heimtextil 2024, Frankfurt

Dates: January 09th, to 12th, 2024

Venue: Frankfurt am Main.

DOMOTEX

Hannover 2024

Dates: January 11th to 14th 2024.

Venue: Hannover, Germany.

ITM 2024

Dates: June 4th to 8th, 2024.

Venue: Istanbul, Turkey.

HIGHTEX 2024

Dates: June 4th to 8th, 2024.

Venue: Istanbul, Turkey.

JIAM

2024 OSAKA

Dates: Nov. 27th to Nov. 30th 2024.

Venue: Osaka, Japan.

12th ITME INDIA 2024

Dates: December 2024.

Venue: India Expo Centre & Mart. Noida, India.

2

Calendar of Events

PAKISTAN TEXTILE JOURNAL - February 2023

Founded in 1951 by Mazhar Yusuf (1924-2009)

Publisher

Nadeem Mazhar

Editor in Chief

Amina Baqai

Associate Editor

Nimrah Nadeem

Production Manager

Mazhar Ali

Hony-Editorial Board

Dr. Hafizur Rehman Sheikh

Ph.D (UK) F.T.I. (UK)

Syed Mahfooz Qutab

C.TEX, F.T.I (U.K), B.Sc. Fellow I.C.T.T Atlanta, GA; (USA)

Mian Iftkhar Afzal

B.S.N.C State, M.Sc. (Leeds)

C.TEXT.F.T.I (UK)

Dr. Zubair Bandukda

PhD (Textiles), CText ATI

Editorial & Advertising Office

B-4, 2nd Floor, 64/21,

Miran M. Shah Road, Karachi - Pakistan

Tel: +92-21-34311674-5

Fax: +92-21-34533616

Email: info@ptj.com.pk

URL: http://www.ptj.com.pk

PTJ Europe Ltd.

Correspondence & Mailing address: 93 Fleming Place, Bracknell, RG12 2GN, United Kingdom

Tel: +44 792 2228 721

Registered Office: Dairy House, Money Row Green, Holyport, Maidenhead, Berkshire, SL6 2ND, UK

Registered no. 09141989

CORPORATE NEWS

Insights into Belgian textile industry

close acquisition of Huntsman Textile Effects

AROUND THE WORLD . . . . . . . . . . . . . . . . . . . . . .14 NEWS & VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . .10 EDITOR’S PAGE . . . . . . . . . . . . . . . . . . . . . . . . . . .7 Renewable energy transition for Pakistan’s textile industry TEXTILE BRIEFS . . . . . . . . . . . . . . . . . . . . . . . . . . .8 Vol. LXXII No. 02 February 2023 Rs. 565.00

Printed at: Color Plus Korangi, Karachi. Published by Nadeem Mazhar from D-16, K.D.A. Scheme No.1. Karachi. Available on Gale and Factiva affiliated international databases through Asianet Pakistan

M.A.C.H,

Biancalani:

. . . . . . . . . . . . . . . . . . . . . . . .19 Archroma

. . . . . . . . . . . . . . . . .20 Mahlo offers data-controlled production: The answer to today‘s challenges in textiles . .21 Navis TubeTex receives the North Carolina Governor’s award . . . . . . . . . . . . . .22 CCI: Sampling solution Everdu-O Maximizes efficiency . . . . . . . . . . . . . . . . . . . .22 Hohenstein standard for identifying the environmental impact of textiles . . . . .23 FEATURE Naia™ from Eastman is back at Première Vision Paris with a new brand image . . .29 CONFERENCES The 2nd International Conference on Knowledge-Based Textile . . . . . . . . . . . . .30 UET: 5th international conference on sustainable textile 2022 . . . . . . . . . . . . .34 21 20 PERSONALIA Change of Leadership at Rieter Board of Directors . . . . . . . . . . . . . . . . . . . . . . . . .24 Robert Reimann, CEO of Jakob Müller Group . . . . . . . . . . . . . . . . . . . . . . . . .25 FAIRS AND EXHIBITIONS ITMA 2023: Innovator Xchange to offer innovation insights from industry experts . . .26 Online application for ITMA ASIA + CITME 2022 exhibition . . . . . . . . . . . . . . . . . . . .28

to

INTERVIEWS

“Testa Group stands for innovation, efficiency and sustainability,” says Dr. Annalisa Testa, CEO . . . . . . . . . . . . . . .

“Highly concentrated aerogel fabric available by the meter is soft, easy to process, with unique processing of NASA insulation on a textile medium,” says Volker Schuster, Head of Research and Development at Outlast Technologies. . . . .

SPINNING REVIEW

SPECIAL REPORT

25 38 48 52 30

. . . . . . . . . . . . . . . . . . . .38

.

. .40 34 53

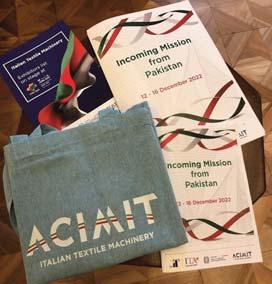

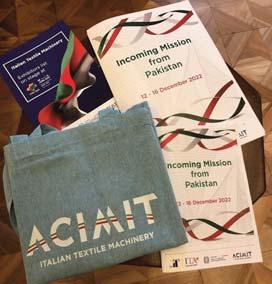

Trade Mission

Pakistan

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53 Italian textile machinery at the forefront of their customers in Pakistan. . . . . .56 53

from

to Italy

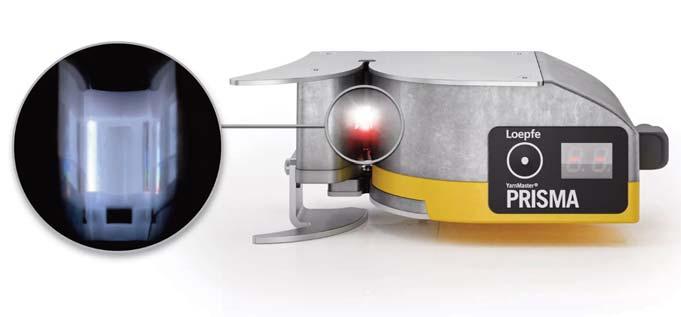

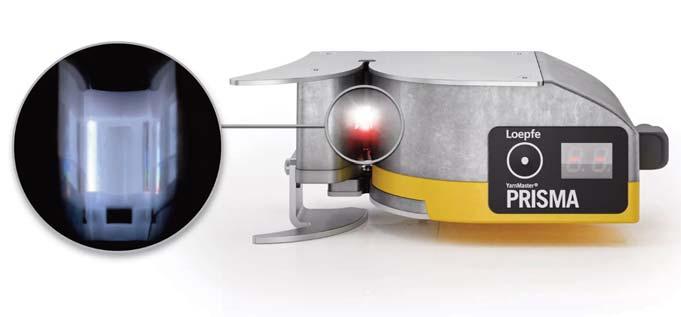

Cotton Trust Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42 Meridian adds Mercerized Merino Wool yarn to family of luxury wool products. .43 Uster Tester: Celebrating 75 years of the world’s most famous instrument . . . .44 Oerlikon: WINGS HD – superb efficiency and functionality . . . . . . . . . . . . . . . .46 Loepfe: PRISMA is the

choice for profitable yarn clearing . . . . . . . . . . . .47 SAVIO’S NEXT DESTINATION: PROXIMA Smartconer® . . . . . . . . . . . . . . . . . . . . .48 Rieter: Financial year 2022 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50 Customer Testimonial for SSM XENO-AC for high quality yarns . . . . . . . . . . . . .52

U.S.

right

Renewable energy transition for Pakistan’s textile industry

Pakistan's textile industry faces several barriers to transition to renewable energy sources, which has hindered the sector's efforts to adopt sustainable and low-carbon practices. One of the main barriers is the high upfront capital costs associated with renewable energy infrastructure. For instance, installing solar panels or wind turbines requires significant investment, which may be difficult for smaller textile businesses to bear. Additionally, the high cost of financing in Pakistan makes it challenging for businesses to secure affordable loans to finance renewable energy projects.

The Government of Pakistan must address the existing limitations of the net-metering scheme for solar, and wheeling charges and continue providing regionally competitive energy tariffs for the industry to regain sustainability progress and transition to renewable energy.

The energy sector is the largest GHG (Greenhouse Gas Emissions) producer in Pakistan. It is estimated that the energy demand in the country will reach 108 – 126 million tons of oil equivalent (TOE) by 2030. With the growing unsustainable management of energy demand, Pakistan’s continuous reliance on imported fossil fuels and outdated coal technology has affected the country’s energy security and its compliance with the global requirements on energy efficiency and decarbonization. However, the government’s recent inclination towards enhancing the country’s capacity for renewable energy (RE) consumption presents a major legislative and policy advancement.

The updated National Climate Change Policy, 2021 puts a major emphasis on achieving climate change mitigation goals via energy efficiency and reducing carbon emissions. It aims to seek technological breakthroughs to harness the country’s potential for renewable energy and declares that 60% of all energy produced in the country by 2030 will be clean through renewable resources and Pakistan will no longer pursue imported coal power plants.

Further, Pakistan’s updated Nationally Determined Contributions (NDCs), 2021 support government’s energy-related policy interventions and have determined integration of renewable energy sources in all major sectors a high-priority area. The updated Renewable Energy Policy 2019 focuses more on green energy and aims to reduce GHG emissions using Kyoto Protocol.

Pakistan has enormous potential for renewable energy, particularly solar and wind. The country's geography provides an abundance of solar radiation, with the potential to generate more than 2.3 million MW of electricity through solar energy. Moreover, the coastal areas of Pakistan have an average wind speed of 6-7 meters per second, which is ideal for wind energy production. Additionally, Pakistan has significant hydropower potential, estimated at more than 50,000 MW. The country has already developed several hydropower projects, such as the Tarbela Dam and Mangla Dam, which contribute a significant proportion of the country's electricity generation.

The annual global horizontal irradiance in the Himalayas and Karakorum is 2300 kWh/m2, which is the highest of any other region on Earth. Wind energy sources have the potential to generate 43,000 MW of electricity.

Moreover, the International Renewable Energy Agency (IRENA) estimates that Pakistan’s hydropower sector has a potential of 60 GW and it remains the cheapest source of power in the country. Biomass is estimated to generate 50,000 Gwh/ year in the country. Finally, geothermal energy resources are present in all the provinces, which can be used for power generation, heating and cooling of buildings and supply of hot water.

If Pakistan brings into play this untapped potential in all the major sectors by implementing exemplary policy reforms in spirit and expanding RE, a massive decoupling of growth from conventional energy resources such as fossil fuels can add to the existing efforts on climate resilience. RE expansion will make electricity cheaper, and enhance energy security and Pakistan can save up to $5 billion over the next 20 years, as per World Bank’s report.

7

1951 February 2023 Spinning Review

Established

February 2023.

1

Textile exports reached to $10,039.743 million during the first seven months of the current fiscal year (2022-23). The textile exports during the period showed a decline of 8.17 per cent as compared to the exports of $10,933.059 million during the same period of last year (July-January 2021-22). 2

The Pakistani textile sector suffered a financial loss of $70 million after the day-long countrywide power breakdown, following the major power outage, industries across the country came to halt as the electricity supply to three provinces was cut from the National Grid.

3

The latest increase in gas prices has created a rift between industrialists of Punjab and Sindh, as the former has to pay almost three times more than their counterparts in Sindh. The APTMA-North has urged the government to adopt a uniform price of $7 per million British thermal unit (mmBtu).

4Pakistan’s textile sector exports witnessed a significant decline of 12.4%, clocking in at $1.36 billion in January 2023 in comparison to $1.55 billion recorded in the same month of the previous year.

5

The shortage of raw materials, depreciation of the rupee against

Textile Briefs International

the dollar and energy crisis have badly affected exports of textile items from Pakistan to other countries during the last few months.

6

Pakistan’s textile industry is quickly slipping into a disastrous situation as it is losing credibility and market share among international buyers. The $19.3 billion export-focused industry is expecting a downward trend in global shipments in the current fiscal year 2022-23.

Pakistan, more than 1 million informal workers in the textile sector are likely to be impacted, according to National Trade Union Federation Pakistan (NTUF) Secretary General Nasir.

8

The industrial sector in Pakistan is preparing for more job cuts and a sharp decline in production. As a result of the economic uncertainty that has gripped

7

The Government of Pakistan must address the existing limitations of the net-metering scheme for solar charges and continue providing regionally competitive energy tariffs for the industry to regain sustainability progress and transition to Renewable Energy. Pakistan has potential for renewable energy, particularly solar & wind. The country has hydropower potential at more than 50,000 MW.

1

Australian wool prices dip due to abrupt supply increase. That significant and abrupt supply increase acted as the catalyst for sentiment to be turned on its head, hence part of the reasoning behind the price retractions on almost all types recently.

2

The sale of textile and garment machinery in Bangladesh worth more than $4 billion, and is growing by 20 per cent annually. The country has now turned a key hotspot for such machinery due to high demand by entrepreneurs to raise productivity and accept apparel orders shifting from other countries.

3

Brazilian cotton has gained a major market share in China, even though the latter is the largest cotton producer in the world. Trade data indicates that Brazil’s cotton exports have soared in value and volume over the last five years, with a sharp increase between 2017 and 2020.

4

China exported textiles, apparel and clothing accessories worth $323.344 billion in the entire 2022, registering a slight growth of 2.53 per cent compared to the previous year. The latest data shows that the country's garment exports grew by 3.2 per cent in the same period.

5India’s textile sector needs a Budget booster to face present challenges and headwinds, according to an industry expert. The industry is eagerly awaiting the government’s support in the form of incentives, programs and investments to help the sector overcome the obstacles and achieve sustainable growth in the future.

6

Italy’s textile machinery orders index for the fourth quarter (Q4) of 2022 showed a sharp 35 per cent year-on-year (YoY) decline, as per the Association of Italian Textile Machinery Manufacturers (ACIMIT). In absolute value, the index stood at 83.6 points.

7

The imports of clothing and accessories by Japan increased by 23.2 per cent to 3,494,110 million yen ($26,483.96 million) in January-December 2022, accounting for 3 per cent of the total imports of 118,164,219 million yen during the period under review

8

Türkiye’s textile and raw materials sector exports decreased by 17.3% to 991 million USD in December 2022, according to the ‘December 2022 Exports Performance Report’ published by (ITHIB). Its share in Türkiye’s overall exports, which increased by 3.1% in the same period and reached 22.9 billion dollars, was announced as 4.3%.

8 PAKISTAN TEXTILE JOURNAL - February 2023

Textile

Briefs National

Pakistan exported textile products worth $10 billion

Textile exports reached to $10,039.743 million during the first seven months of the current fiscal year (2022-23). The textile exports during the period showed a decline of 8.17 per cent as compared to the exports of $10,933.059 million during the same period of last year (July-January 202122).

The textile products that witnessed positive growth during July-January (2022-23) as compared to the corresponding period of last year included raw cotton, the exports of which grew by 134.77 percent, from $5.233 million to $12.286 million.

The exports of tents, canvas and tarpaulin also went up by 13.44 percent, from $65.339 million to $74.122 million.

The textile goods that witnessed negative growth in trade included cotton yarn, the exports of which declined by 34.66 per cent, from $ 687.857 million to $449.419 million.

Likewise, the exports of cotton cloth decreased by 9.34 percent, from $1,351.532 million to $1,225.348 million; cotton (carded or combed) by 41.18 per cent, from $1.610 million to $0.947 million, yarn (other than cotton yarn) by 23.15 per cent, from $34.031 million to $26.154 million, knit-wear by 2.93 per cent from $2,887.880 million to $2,803.298 million, bed wear by 14.81 percent, from $1,924.030 million to

$1,639.103 million and towels by 5.29 per cent, from $615.355- million to $582.833 million.

Likewise, exports of readymade garments decrease by 1.71 percent, from $2,162.627 million to $2,125.698 million; art, silk and synthetic textile by 8.88 percent, from $262.519 million to $239.208 million; made-up articles (excluding towels, bedwear) by 11.41 per cent, from $491.091 million to $435.050 million while the exports of all other textile materials went down by 3.98 per cent, from $443.955 million to $426.276 million.

Meanwhile, on a year-on-year (YoY) basis, the textile goods' exports declined by 14.83 per cent in January 2023 to $1,321.768 million against exports of $1,551.890 million in January 2022. On a month-on-month (MoM) basis the textile

goods' exports decreased by 2.53 per cent in January 2022 when compared to the exports of $21,356.061 million in December 2022, according to the PBS data.

Textile industry suffers financial loss amid power breakdown

The power outage in Pakistan had a significant impact on the textile sector, with a reported loss of $70 million. The overall financial loss for the country is estimated to be Rs100 billion, with the textile industry alone suffering a loss of $7 to $8 billion. The ineffective policies of the government have already put pressure on the industry, and the power outage has worsened the situation. If the government fails to provide

PAKISTAN TEXTILE JOURNAL - February 2023 10 News & Views

uninterrupted power supply, the financial damage to the textile sector could soar to billions of rupees.

Sources suggest that power generation was lower than 7,000 megawatts during the outage, with hydel power generation down to 90 percent and thermal power generation by 70 percent. Prime Minister Shehbaz Sharif has ordered a high-level probe into the power outage issue to determine the cause and prevent such incidents in the future.

Industrialists battle over gas prices as IMF pressure looms

The issue of differential gas prices between industrialists in Punjab and Sindh in Pakistan has caused a rift, with the All Pakistan Textile Mills AssociationNorth urging the government to adopt a uniform price of $7 per MMBtu. The policy of charging different rates has been criticized as it causes one group of industrialists to be pitted against another and is bad for investment.

Industrialists in Punjab have been demanding a gas tariff of $9/MMBtu to remain competitive in the international market. The closure of Punjab’s textile industry could result in massive unemployment in the country, leading to further deterioration of the balance of payment crisis.

The All Pakistan Textile Mills Association has argued that the country could lose $10 billion annually if the government withdraws the regionally competitive energy tariff (RCET). The textile sector has invested $5 billion over the last three years, and the sector has shown robust growth of 55% in exports in FY22. If the RCET is withdrawn, the closure of the textile industry in Punjab would be inevitable.

Furthermore, the export sector in Sindh enjoys a cost advantage of at least $575m per year due to the price difference of $5 per MMBtu with exportoriented units based in Punjab. This puts Punjab-based industrialists at a disadvantage, leading to unequal competition. The government’s decision to increase gas prices was expected to stop the fresh build-up of the circular debt within the gas sector, but it appears that the objective is not yet achieved.

The government has introduced the definition of “protected” consumers, which doesn’t take climate differences across major cities into account, potentially leaving affluent households in Karachi that consume less than 90 cubic meters in the four winter months shielded from the hike, while households in Quetta or Islamabad might not. This could lead to an unequal distribution of the burden of the gas price hike among consumers.

Pakistan’s textile exports significantly decline in January

Pakistan’s textile sector exports witnessed a significant decline of 12.4%, clocking in at $1.36 billion in January 2023 in comparison to $1.55 billion recorded in the same month of the previous year, showed provisional data released by the All Pakistan Textile Mills Association (APTMA) recently.

It added that the country’s textile exports in the first 7 months of FY23 decreased by 8% to $10.08 billion, declining from $10.93 billion recorded in 7MFY22. The decline in textile exports is concerning for the South Asian economy, which is already facing depleting foreign exchange reserves. Its central bank has reserves of just $3.7 billion remaining, barely enough for three weeks of essential imports.

Asif Inam, Chairman of the All Pakistan Textile Mills Association (APTMA), has stated that Pakistan's textile sector is facing significant challenges. As the largest manufacturing

sector in the country, it is being negatively affected by a combination of factors, including the ongoing Ukraine crisis and floods within Pakistan. These events have disrupted the country's already inefficient supply chains, causing further difficulties for the industry. In addition, the floods have destroyed significant amounts of agricultural land in dozens of districts across Pakistan, which will likely have long-lasting effects on the economy and the country's ability to produce goods.

According to Asif Inam, the APTMA Chairman, the textile industry in Pakistan is facing a significant shortage of cotton. The country's domestic production of cotton stands at 5 million bales, whereas the industry requires 14 million bales, creating a significant gap that needs to be filled by imports.

However, the shortage of foreign exchange (Forex) in the country is making it difficult to import the required amount of cotton and other essential inputs for exports.

The issue of clearance of raw materials from the ports has also remained unresolved due to the unavailability of Forex, leading to a shortage of raw materials for mills. As a result, mills are currently unable to obtain cash against documentation and are shutting down due to the shortage of raw materials.

In December, the All Pakistan Textile Mills Association (APTMA) wrote a letter to the Prime Minister of Pakistan, Shehbaz Sharif, warning that the country's textile exports could fall below $1 billion a month from 2023 onwards.

11 News & Views

The letter highlighted a range of issues facing the textile sector, which is currently operating at less than 50% capacity utilization. These issues include a shortage of cotton due to low domestic production and restrictions on imports, the unavailability of foreign exchange, and difficulties in clearing raw materials from ports.

The letter also noted that high electricity and gas prices, as well as the lack of government support for the industry, were contributing to the challenges faced by textile manufacturers in Pakistan. If these issues are not addressed, the country's textile exports could suffer significant losses in the coming years.

Textile exports hit hard by shortage of raw materials, depreciation of rupee

The shortage of raw materials, depreciation of the rupee against the dollar and energy crisis have badly affected exports of textile items from Pakistan to other countries during the last few months.

Pakistan’s textile exports declined by 12% in January, making it the fourth consecutive month of negative growth. The country’s textile exports also fell by 8% during the first seven months of the current fiscal.

Asad Naqvi, a senior analyst at the All Pakistan Textile Mills Association (APTMA), said that growth in textile exports remained below expectations due to various problems. He said that a shortage of raw materials, an increase in prices of petroleum products, currency devaluation, and the global financial crisis hindered Pakistan’s textile export. Nonavailability of cotton, closure of textile units, stranding of cotton consignments at ports and high-interest rates are also among the major problems.

He said that Pakistan’s cotton production dropped by 50% from 14 million bales to six million bales, inflicting annual losses of $2 billion on the textile industry. The analyst feared that textiles exports could further decline in the coming months if reliable and affordable energy supplies were not ensured.

APTMA has repeatedly said that the volume of Pakistan’s textile exports can

decline by $400 million to $500 million each month if the problem of energy shortage is not resolved. According to data released by the association, Pakistan’s textile exports dropped to $10.08 billion during the first seven months of the current fiscal year from $10.93 billion in the same period of the previous financial year. Exports in January also dropped to $1.33 billion in January 2023 from $1.55 billion during the same month of last year, showing a decline of 12%.

Pakistan exported textile items worth $19.329 billion, the highest-ever volume, during the last fiscal. However, the textile sector couldn’t sustain the trend of positive growth and exports started to decline in October after recording a growth of a single digit during the first three months of the current fiscal. According to the data, textile exports surged by only 1%, 8% and 9% in July, August and September, respectively. However, exports appallingly dropped by 15%, 18%, 15% and 12% in October, November, December and January, respectively.

Spinning into turmoil: Textile industry calls for help

Pakistan’s textile industry is quickly slipping into a disastrous situation as it is losing credibility and market share among international buyers. The $19.3 billion export-focused industry is expecting a downward trend in global shipments in the current fiscal year 2022-23.

Many exporters are also reluctant to book new orders as Pakistan is short of dollars and basic raw material including

cotton, dyes and chemicals. Different textile lobbies have warned that they will fail to meet the $25 billion export target, instead fearing a drop to around $16 billion in FY23.

In the first six months (Jul-Dec) of the current fiscal year, Pakistan’s textile exports dropped by $1 billion to $8.5 billion against $9.54 billion in the same period last year. In FY22, textile exports had gone up by a whopping 26%.

Babar Khan, Chairman of Pakistan Hosiery Manufacturers and Exporters Association said: “We have to import almost everything, starting from cotton to buttons and zips in order to manufacture one single product. As the government is reluctant to clear the imported cargo stuck at Karachi Port, one can imagine what the textile sector’s future will look like.”

According to exporters, the import raw cotton worth $1 translates into an export item worth $4 after value addition. The production of cotton crop, however, which is the key raw material for textile products, has dropped by 45% this year. The industry needs 15 million bales of cotton to translate into an annual export revenue of $20 billion.

Pakistan has only produced 4.5 million bales this year. To bridge the shortfall, the textile industry has ordered 1.7 million bales of cotton from the US, of which 0.531 million bales have already been dispatched.

Interestingly, around 100,000 bales worth $300 million have reached Karachi Port but are waiting for a go-head from the authorities.

News & Views 12 PAKISTAN TEXTILE JOURNAL - February 2023

“The textile industry is left with only 60 days of raw material and if the imported cotton is not released timely, then the industry will completely shut down by the end of March. This will result in massive unemployment as 25 million people are associated with the sector,” cautioned Hamid Zaman, Chairman North Zone of the All-Pakistan Textile Mills Association (Aptma).

Pakistan economic crisis results in big layoffs; 1 million textile workers to lose jobs

The industrial sector in Pakistan is facing a challenging economic environment, which has led to concerns about job cuts and declining production levels.

According to the National Trade Union Federation Pakistan (NTUF), more than 1 million informal workers in the textile sector are likely to be impacted by this uncertainty. The NTUF Secretary General Nasir Mansoor has expressed concern about the situation, noting that the textile sector is a major employer in the country and that any decline in production could have a significant impact on workers. The informal sector, in particular, is vulnerable to economic shocks and job losses, which could have long-term effects on workers' livelihoods. The NTUF has called on the government and employers to take steps to support workers and ensure that they are not left behind as the economy faces these challenges.

The NTUF Secretary General Nasir Mansoor has described the situation in Pakistan's industrial sector as "bleak," highlighting that many companies in the textile sector are hiring workers through third-party contracts, which makes all workers informal. He added that because these workers do not have formal contracts, they do not have the same legal protections as regular employees, making it easier for companies to terminate their contracts without facing legal consequences.

Mansoor also noted that because companies are required to offer different perks to employees under special laws for workers, hiring informal workers through third-party contracts becomes more convenient for them. This practice of hiring informal workers without proper legal protections can leave workers vulnerable to exploitation and can make it difficult for them to seek legal redress if they are unfairly dismissed.

Nasir Mansoor has also raised concerns about existing workers being expected to work longer hours to compensate for staff shortages and increasing operational costs in the textile sector. He stated that many companies ask informal workers to come to work for only 15 days in a month but require them to submit a month's worth of work, which means they are only paid for the days they come to the office. This practice can put additional strain on workers, who may already be facing challenging working conditions due to

long working hours and limited job security. It also highlights the need for companies to adopt fair labor practices and ensure that workers are paid for the work they do and are not expected to work for free or for fewer wages than they deserve.

Encouraging cotton growing helps excel textile industry’

The government of Pakistan is considering multiple options for economic revival, including boosting exports and generating employment opportunities to overcome growing poverty. The textile industry has been a key player in exports over the decades, and paying special attention to this sector by providing a congenial environment could pave the way to capture more international markets and earn revenue. However, cotton growing, which is vital for the sector, has diminished with the passage of time, and the Pakistan Cotton Ginners Association (PCGA) has reported a 35% decline in cotton production as of Feb 1, 2023, compared to last year. To strengthen this sector, the PCGA recommends measures such as announcing support price, declaring specific cotton zones, introducing highyielding, climate-smart, and pests resistant cotton varieties, and mechanized farming techniques. This sector provides employment to 40% of the total labor force and is 46% of Pakistan's total manufacturing sector, making it crucial for the country's economy.

News & Views 13

AUSTRALIA

Australian wool prices decrease due to abrupt increase in supply

Australian wool prices have recently decreased due to a sudden increase in supply. Previously, there was high demand for wool which led to an increase in price. However, when an additional 12,000 bales or 25% of wool was added to the auctions in response to the price rise, it caused the market sentiment to shift and prices to drop. The sudden increase in supply allowed the market to ease back to the buyer's favor, and the pressure on prompt shipments for delivery to overseas mills was satisfied.

As a result, the steady inquiry and new business opportunities from China and India dried up, and buyers anticipated the availability of cheaper wool this week. This is according to the Australian Wool Innovation Limited (AWI) commentary for sale week 33 of the current Australian wool marketing season.

“The spot markets for wool since the onset of the pandemic in 2020 have been very much influenced by the ruling sentiment of the day; both positive and negative. Any significant difference to basic trading circumstances or macroeconomics seems to have a greater bearing on those spot wool price setting factors. Additionally, the open cry auction system is a very emotive environment so over reactions to day-to-day positions have to be considered and recognised as a factor in prices offered.” AWI concluded.

BANGLADESH

Textile-garment machinery market growing by 20% annually

The textile and garment machinery market in Bangladesh is currently worth over $4 billion and is growing by 20% annually. The country has become a hotspot for such machinery due to high demand from entrepreneurs looking to increase productivity and accept apparel orders that have shifted from other

countries. Despite the current low demand for apparel due to the RussiaUkraine war, representatives of several European garment-textile machinery companies with operations in Bangladesh are optimistic about the market potential of the country. Even during the pandemic, many entrepreneurs in Bangladesh have imported machinery from Europe.

Moreover, there is a growing demand for machinery that uses man-made fibres (MMF) in the country as entrepreneurs are investing heavily in the MMF textile industry to capture a larger share of the global market, according to Bangladeshi media reports.

BRAZIL

Cotton exports to China grows significantly and not linked to US ban

Brazilian cotton has gained a major market share in China, even though the latter is the largest cotton producer in the world. Brazil’s cotton exports have soared in value and volume over the last five years, with a sharp increase between 2017 and 2020. The increase is not linked to the US ban on Xinjiang cotton.

Brazil exported 82.953 million kg of cotton in 2017, valued at $132.393 million. The value and volume of exports more than tripled to 302.981 million kg ($523.495 million) in 2018, and further grew to 501.725 million kg ($820.445 million) in 2019.

Despite COVID-related disruptions, Brazil exported 658.752 million kg of cotton to China in 2020, valued at $1,016.738 million. However, the volume and value of exports slightly fell to 582.985 million kg ($983.141 million) in 2021, and further eased to 521.499 million kg ($1,082.756 million) in 2022, as per research data. Despite the decline in shipments over the last two years, the exports still increased more than three times in terms of volume and value.

The data suggests that the surge in exports from Brazil to China was not solely due to Chinese importers seeking alternative sources of cotton after the US ban on cotton originating from the Xinjiang region of China. The US banned cotton from the region in June 2022.

CHINA

Textiles & apparel exports grow 2.53% to $323 bn in 2022

China exported textiles, apparel and clothing accessories worth $323.344 billion in the entire 2022, registering a slight growth of 2.53 per cent compared to the previous year. The latest monthly data released by the General Administration of Customs of China shows that the country's garment exports grew by 3.2 per cent in the same period.

Garment and clothing accessories exports reached $175.396 billion in 2022, which was 3.2 per cent higher than the same period of last year.

Around the World 14 PAKISTAN TEXTILE JOURNAL - February 2023

China's textile exports, including yarn, fabrics, and others, registered a growth of 2 per cent year-on-year to reach $145.079 billion in 2022. Textile and apparel exports during December 2022 amounted to $25.295 billion. Out of this, textile, yarn, and articles exports earned $11.002 billion, while garments and clothing accessories fetched $14.293 billion in December this year, as per the data.

INDIA

Indian textile industry needs budget booster to continue to boom

An industry expert has stated that India's textile sector requires a boost from the Budget to face current challenges and headwinds. The Finance Minister of India, Nirmala Sitharaman, is set to present the Budget for the financial year 2023-24.

The Joint President & Business Head - Spinning of Ginni Filaments Limited, Balkrishan Sharma, has expressed the industry's eagerness for the government's support in the form of incentives, programs, and investments to help the sector overcome obstacles and achieve sustainable growth in the future. Sharma cited a decline in global demand, lackluster domestic demand, and a cotton shortage as some of the challenges faced by India's textile industry in the past fiscal year.

The rising prices of cotton in India have had a significant impact on the profitability and margins of spinners, leading to sub-optimal capacity utilization, an accumulation of inventories, and a decline in merchandise exports. In addition, the volatility of currencies and uncertainty in the European market, combined with the ongoing Ukraine war, have presented a challenging situation for the industry. To address these challenges, the textile industry is looking to the annual Budget 2023-24 for measures that will provide further support to the sector. These measures could include additional incentives for exports, the extension of existing programs such as the Remission of State Levies and the Interest Equalization Scheme, and the introduction of new programs that support the textile industry. Furthermore, the industry is expecting the Budget to include measures that will reduce the cost of labor, raw materials, and other production costs, as well as promote innovation and technology in the sector.

In order to remain competitive, the textile industry in India is seeking immediate removal of the 11 per cent import duty on cotton and cotton waste. Furthermore, the industry is expecting the Budget to provide export incentives and additional credit support to facilitate easy liquidity at competitive costs for export-oriented units. These measures are expected to help the industry to overcome the challenges posed by rising cotton prices, volatile currencies, and uncertainty in the European market, and to maintain its competitiveness in the global market.

Around the World

yen, a 25.7% increase from the same period of last year, and accounted for 1.1% of the total imports.

Imports from China were 1,901,152 million yen, a 20.1% increase from the same period of 2021 and accounted for 7.7% of the total imports from China.

The exports of textile yarn and fabrics from Japan to the US increased by 10.8% to 77,404 million yen, and the exports of textile machinery to the US increased by 37.5% to 13,830 million yen in the same period.

TURKIYE

ITALY

Italian textile machinery orders index drops 35% YoY in Q4 2022

Italy’s textile machinery orders index for the fourth quarter (Q4) of 2022 showed a sharp 35% year-on-year (YoY) decline, as per the Association of Italian Textile Machinery Manufacturers (ACIMIT). In absolute value, the index stood at 83.6 points.

Orders took a 34% drop on the domestic market, while the foreign index was down fully 37%. In Italy, the index’s absolute value came in at 155.4 points, whereas on foreign markets the value stood at 75.8 points, ACIMIT said in a media release.

On an annual basis, the orders index marked an 18% decrease and an absolute value of 110.4 points. The drop in orders abroad was 17%, while orders collected in Italy were 28% lower than the figures drawn up in 2021.

“The orders index data for the fourth quarter confirms what had already been observed in the previous quarters in 2022. After a sharp increase in 2021, this decrease in orders for the past year is physiological. Furthermore, the ongoing war between Russia and Ukraine, with its related consequences on daily business and trade, and a macroeconomic framework in which uncertainty prevails, have further negatively affected the orders intake,” stated ACIMIT president Alessandro Zucchi.

Data for the last quarter does not suggest a reverse in the negative trend for the first months of 2023. Declining energy prices and inflation, although still high, also declining slightly are, however, signs of a light improvement in the business of companies in the sector as well.

“We need to look to the current year with optimism,” continued the ACIMIT president. “Our member companies are already focusing on ITMA, the upcoming global textile machinery industry trade fair that will be held from June 8–14 in Milan.”

“I am confident that ITMA Milan can represent an opportunity for further development of the Italian textile machinery sector,” concluded Zucchi. “The technological innovations that our manufacturers will bring to the trade show will meet the textile industry’s need to be increasingly sustainable, both environmentally and economically.”

JAPAN

Clothing imports up 23.2% to 3,494,110 million yen in 2022

According to provisional trade statistics released by Japan's Ministry of Finance, clothing and accessories imports by Japan increased by 23.2% to 3,494,110 million yen ($26,483.96 million) in January-December 2022, accounting for 3% of the total imports during the period. Textile yarn and fabric imports were valued at 1,261,222 million

Textile exports standstill in 2022

The Turkish textile and raw materials sector was able to achieve an increase in exports in 2022, despite the challenging economic conditions around the world. While the sector may not have met its initial export target, the 0.6% increase in exports to $12.9 billion is still a positive outcome.

As the 5th largest producer and exporter in the world, the Turkish textile industry is an important player in the global market and its continued growth is essential for the country's economy.

According to the December 2022 Exports Performance Report published by Istanbul Textile and Raw Materials Exporters Association (ITHIB), Turkey's textile and raw materials sector experienced a decrease in exports by 17.3% to USD 991 million in December 2022. However, Turkey's overall exports increased by 3.1% in the same period, reaching USD 22.9 billion, with the textile and raw materials sector contributing 4.3% to the total exports.

The report also shows that the textile and raw materials exports to the EU (27) countries, the largest export destination for Türkiye, decreased by 5% in 2022 to USD 5.6 billion, while exports to African countries increased by 7% to USD 1.4 billion.

The capacity utilization rate for textile product manufacturing increased by 1.3% in December 2022 compared to November 2022, reaching 71.3%, but it was down by 11.5% compared to December 2021.

PAKISTAN TEXTILE JOURNAL - February 2023 16

VIETNAM

Textile & garment exports down 37.6% to $2.25 billion in Jan 2023

The preliminary data from Vietnam's Ministry of Finance shows that the country's textile and garment exports declined by 37.6% to $2.25 billion in January 2023 compared to the same period in the previous year. The US, Japan, and South Korea were the major destinations for Vietnam's textile and garment exports during the month.

The US accounted for a major share (about 44 per cent) totalling $0.991 billion in the textile and garment exports of Vietnam during the first month of this year. Japan and South Korea were the other major destinations with exports of $0.248 billion and $0.244 billion, respectively.

Vietnam's yarn exports also decreased by 52.4% in January 2023 compared to the same period in the previous year. Of this, China imported around 38.22 per cent or $0.086 billion worth of yarn, followed by India that imported yarn worth $5.004 million. In volume terms, Vietnam exported 88,130 tons of yarn which was 38.9 per cent lower than the exports during the corresponding period of last year.

In 2022, Vietnam's textile and garment exports grew by 14.7% to $37.5 billion, while yarn exports increased by 50.1% to $5.609 billion.

The Vietnam Textile and Apparel Association (VITAS) has set a target of $48 billion for the country's textile, garment, and yarn exports in 2023, assuming a positive market scenario.

USA

US cotton industry faces a slowdown

Although modest economic growth is forecasted by National Cotton Council (NCC) economists for the next two years, the projected growth for the US cotton industry represents a slowdown from the prior two years. The past year can be characterised as a year with significant uncertainty and volatility in the global economy and the world cotton market.

The US cotton industry continues to navigate an environment characterised by increased production costs, slumping consumer demand, and supply chain disruptions. “The NCC projects 2023 US cotton acreage to be 11.4 million acres, 17.0 per cent less than 2022,” Dr. Jody Campiche, the NCC’s vice president, economics and policy analysis, said in her analysis of the NCC Annual Planting Intentions survey results.

While production costs remain elevated, cotton harvest-time futures prices are currently 16.5 per cent less than a year ago and the prices of most competing commodities are relatively unchanged. The current economic signals are reflected in the 2023 survey results as many growers indicated a shift away from cotton to other competing commodities.

Using five-year average abandonment rates along with a few state-level adjustments, Cotton Belt harvested area totals 8.8 million acres for 2023 with a US abandonment rate of 22.6 per cent. Using the five-year average state-level yield per harvested acre generates a cotton crop of 15.7

17 Around the World

Around the World

million bales, with 15.2 million upland bales and 466,000 extra-long staple (ELS) bales.

World cotton production is estimated to increase slightly to 115.9 million bales in 2023-24 due to an increase in harvested acreage. Overall, the outlook for world cotton demand for the 2023-24 marketing year takes on a more positive tone as compared to 2022-23 with the expectation of improving global economic conditions.

For the 2023-24 marketing year, world consumption is projected to increase by 4.7 per cent to 116.1 million bales. The removal of COVID-19 restrictions in China should provide a boost to cotton consumption in 2023. The International Monetary Fund has projected an increase in China’s growth rate from 3 per cent in 2022 to 5.2 per cent in 2023. With expanded consumption in key importing countries, world trade is projected to increase to 44.2 million bales in 2023-24.

Regarding domestic mill cotton use, the NCC is projecting an increase in US mill use to 2.3 million bales during the 2023-24 marketing year.

It is true that the US textile industry faces competition from Asian suppliers,

which has led to a decline in domestic textile production over the years. However, the industry has responded by investing in new technologies and adopting innovative practices to remain competitive.

Additionally, the US has been working to maintain and strengthen trading arrangements with Western Hemisphere

countries, which are important markets for US cotton and textiles. The US government has also implemented various trade policies and agreements aimed at supporting domestic textile production and exports. Overall, the US textile industry continues to play a significant role in the global cotton market, and efforts are being made to ensure its continued success.

PAKISTAN TEXTILE JOURNAL - February 2023 18

Insight: Belgian textile industry

Belgian textile industry has always been a reference point in the global textile industry. With upholstery and furniture fabrics as their assets and a centuries-spanning tradition, Belgian textile companies generate an annual turnover of more than EUR 4 billions and are massively investing in e-textiles and sustainable fibers, i.e. a whole innovative textile ecosystem. Not least – indeed essential – textile education, training and research are being strongly supported: therefore, nowadays Belgium is definitely a textile and fashion business cluster and incubator.

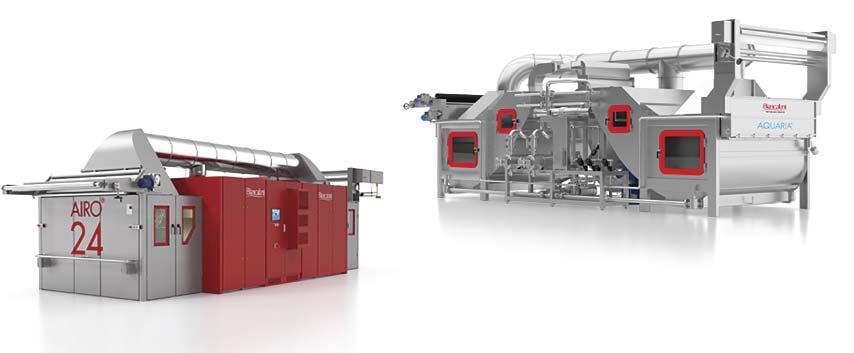

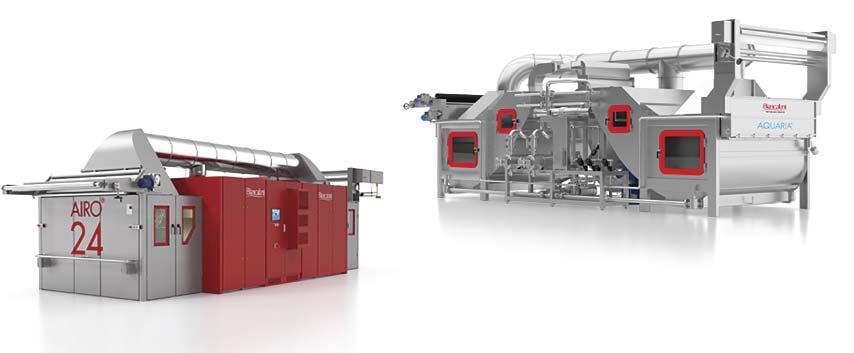

Jean Comhaire, the founder of Petrocom BV, has been working with Biancalani Textile Machinery since 1991. Petrocom operates in the textile, plastic, and chemical industries and has

expanded its business to Belgium, the Netherlands, and Luxembourg. Comhaire believes in building strong, long-lasting partnerships with textile machinery companies, which he views as the cornerstone of Petrocom's success.

Comhaire praises Biancalani for its innovative ideas, honest and professional approach, and ability to provide the best solutions for fabric finishing despite increasingly stiff competition.

Biancalani is viewed as one of the most innovative textile machinery manufacturers in Belgium, with a long tradition and experience in finishing textiles, which is highly valued in Belgian textile clusters. Biancalani is also known for providing high-tech solutions, which have been well received by its clients.

Comhaire notes that Biancalani's positive reputation among customers is

evident throughout the entire process of contacting, testing, quoting, and final negotiations. The company is able to work closely with its customers to find specific technical solutions or even develop brand new products that the customer may not yet have. The release of AIRO®24 and AQUARIA® open-width washing lines have further enhanced Biancalani's reputation as an innovator.

Looking to the future, Comhaire believes that the textile industry, particularly in Belgian textile clusters, will continue to demand innovation and new ideas. To remain one of the most qualified producers on the market, Biancalani must continue to provide the best machines to its customers and listen carefully to their needs. This approach aligns with Biancalani's style and will allow the company to thrive in an everchanging and healthy competition.

19

Corporate News

The AIRO®24 and AQUARIA® open-width washing lines by Biancalani for providing high-tech solutions.

Archroma to close acquisition of Huntsman Textile Effects

Archroma, a global leader in sustainable specialty chemicals and solutions for industries such as textiles, packaging & paper, paints and coatings, today announced that it has secured all regulatory approvals required to complete the acquisition of the Textile Effects business from Huntsman Corporation (Huntsman Textile Effects).

Both parties expect the transaction, which was first announced on 09 August 2022, to close on 28 February 2023.

Archroma is a portfolio company of US-based private investment firm SK Capital Partners. Since its formation in

2013, Archroma acquired and successfully integrated the global textile chemicals businesses of BASF as well as BASF’s stilbene-based OBA business for paper applications, and M. Dohmen, a specialist in coloration for automotive textiles.

Heike van de Kerkhof, Archroma Group Chief Executive Officer (CEO), commented: “We are very excited to see this acquisition nearing completion. I am deeply grateful to the project teams of Archroma and Huntsman who are preparing for a smooth transition for our employees and partners. After closing, we will be able to bring together our expert

teams and highly complementary product portfolios to offer our customers and brand partners the high performance they expect, whilst respecting natural resources and the planet.”

20 PAKISTAN TEXTILE JOURNAL - February 2023

Corporate News

Heike van de Kerkhof.

Mahlo offers data-controlled production: The answer to today‘s challenges in textiles

the textile machinery manufacturing companies face numerous challenges in the current market, and in order to remain competitive, they must increase the efficiency and flexibility of their production while minimizing manufacturing costs. One of the key solutions to these challenges is online quality control in textile production processes, which has become more important than ever before.

Mahlo, a German machine builder, has demonstrated how data-controlled production can solve the problems facing the textile industry.

According to Matthias Wulbeck, product manager for Quality Control Systems (QCS) at Mahlo, the correct collection, analysis, and treatment of the right data, as well as the seamless transition of data flows between machines, company divisions, and other companies, such as customers or suppliers, is crucial to successful implementation.

Leading industrial companies are already introducing automated processes and high-tech networked devices to perform live data analysis, and Mahlo

quality control systems, which are Industry 4.0 compliant, can be installed throughout a modern textile coating line.

The Qualiscan QMS system has a broad portfolio of intelligent scanners and sensors that record product and process parameters online at different stages of the production. The measured values are processed in real-time processors of the

sensors, and the finished measurement data is visualized internally in an intuitive control display or transmitted via interfaces to an external network.

The implemented automatic control algorithms interact directly with the suitable actuators of the textile coating line, reducing deviation from the target and leading to a more uniform endproduct.

This allows for optimized target value specifications, better product quality, and significant savings in raw materials and energy costs. Process reliability and production throughput also increase, allowing companies to react quickly and flexibly to changing market demands.

In addition to online control of the above-mentioned parameters, an important function of any quality control system is to provide detailed historical data. By a simplified and direct data exchange, the end user can keep track at any time where and how its product is fabricated. This not only guarantees a trouble-free value chain, but also ensures that the fabric is always produced with the right parameters. In these unsecure times, such security is of high value.

The measured values are visualized in real time

21 Corporate News

Web gauging with Qualiscan QMS

Navis TubeTex receives the North Carolina Governor’s award

The Governor of North Carolina, Mr. Roy Cooper, has recognized Navis TubeTex with the Governor’s Award for Excellence. This award is given each year to recognize one North Carolina company that has made significant contributions in the effort to increase North Carolina exports. Navis TubeTex has worked with

North Carolina for over 10 years with exhibition cooperation in many of the world's textile centers with Senior International Trade Manager, Mr. Glenn Jackman.

The Award was presented at the Governor’s Mansion in Raleigh. President and CEO, Mr. William Motchar and Senior Director – International Sales, Mr. Jeffrey Dixon were present to receive the award on behalf of Navis TubeTex.

Navis TubeTex is a leader in finishing machinery for the global

textile industry. Based in Lexington, North Carolina, Navis TubeTex designs, engineers, and manufactures the world’s leading machinery for the global knit, woven, nonwoven, technical and geotextile industries. Navis TubeTex has customers in over 65 countries.

CCI: Sampling solution Everdu-O Maximizes efficiency

CCI announces a release plan for its latest sampling solution, Everdu-O. The machine innovatively combines Weaving, Warping, and even Drawingin functions together with the new concept of Integrated Design.

And that means, the user can effortlessly complete a piece of fabric sample just on One Machine without additional cost! With the brand new sampling solution, one can enjoy a streamlined experience from Easy installation and operation to responding quickly to changing markets.

Effective and fast sampling shouldn’t be limited to huge budget and dedicated weaver team. The Everdu-O is designed

to make fabric sample production simpler and give customers more flexibility in their production planning. One machine can efficiently finish Warping, Weaving, and even Drawing-in jobs. CCI offers the quickest way to see the result of your design or produce the samples that your customers request urgently.

In addition, Everdu-O comes with a weaving width of 400 mm and warping length up to 2.2 m which is ideal for quick production of woven sample any time within studio, office or factory floor. Designed with the mindset of reduced machine dimensions, the machine can blend perfectly into any working environment without space concern. More features include Minimum Cost

Required for making a piece of sample, Easy to maintain with the easy-to-access doors, Plug n Play without the cost of installation service.

22 PAKISTAN TEXTILE JOURNAL - February 2023 Corporate News

Economic Development Partnership of

The Governor of North Carolina, Mr. Roy Cooper.

Will Mothar, Jeff Dixon, and Glenn Jackman, Senior International Trade Manager for Economic Development Partnership of North Carolina.

Everdu-O is latest sampling solution by CCI.

Hohenstein sets new standard for identifying the environmental impact of textiles during washing, including fiber release, biodegradability and ecotoxicity

Testing service provider Hohenstein has worked with partners to create a new standardized test method for detecting and classifying the environmental effects of textiles during washing. DIN SPEC 4872 combines analysis of fiber release, biodegradability and ecotoxicity.

The test method according to DIN SPEC 4872 shows how many fibers are released during textile laundering, how well these fibers degrade in waste water and how harmful the fiber residues are to the environment.

Studies have shown that washing textiles releases microfibers into the wash water, which cannot be sufficiently retained by wastewater treatment plants. Synthetic fibers pose the greatest risk to the environment because of their longevity and inability to biodegrade. However, Hohenstein project manager Juliane Alberts does not give the all-clear

for biodegradable fibers and natural fibers: "Biodegradability alone does not mean that pure natural fibers, for example, are completely harmless to the environment. They, too, remain in ecosystems until they completely degrade and can also have a negative impact. In addition, additives, auxiliaries or finishes used in textile production can further slow the degradation process and leach into the environment."

The new standard enables textile producers and suppliers to test, evaluate and compare products for fiber release during washing and environmental impact. Juliane Alberts sees this systematic evaluation as an opportunity for the textile industry to take the initiative on environmental

Ecotoxicity – Duckweed is a particularly sensitive organism used as a model for higher aquatic plants. Its green color and healthy development prove the ecotoxicological harmlessness of its environment.

impact: "Our reliable data can be used as a basis for more targeted product development. This is a way to actively and consciously control further environmental pollution."

About Hohenstein

With more than 40 offices and laboratories, Hohenstein is an international partner for independent testing, certification and applied research around the human-textile-environment interaction.

They develop science-based methods and standards that consider the user in real life, not just in the lab. Through standard or customized testing, and interpretation of the results, Hohenstein experts solve problems, verify claims and help partners bring better, safer products to market – more sustainably.

Hohenstein is a founding member and leading provider of the OEKO-TEX® portfolio of services, and is certified by the U.S. Consumer Products Safety Commission (CPSC ID #1058) as a thirdparty, independent laboratory for CPSIA compliance verification.

23 Corporate News

Microplastics – micro sized with global environmental risk. The DIN SPEC 4872 test method classifies how many fibers are released during textile laundering, how well these fibers degrade in wastewater and how harmful the fiber residues are to the environment. With systematic analysis, textiles are classified in terms of fiber release during the washing process.

Regarding environmental impact, biodegradability of fibers in wastewater plays a decisive role. The biodegradability is determined after a defined period, by measuring fiber residues in the wastewater.

Change of Leadership at Rieter Board of Directors - Thomas Oetterli as New CEO

Norbert Klapper, who has led Rieter as CEO for nine years, has informed the Board of Directors that he wishes to take on new professional challenges. The Board of Directors of Rieter Holding Ltd. has taken note of Norbert Klapper’s resignation, expressing its gratitude for his service to Rieter. The Board of Directors has appointed Thomas Oetterli as his successor as CEO of Rieter.

Thomas Oetterli (53) has made a significant contribution to the successful development of the world-leading Schindler Group, starting in 2006 as CEO Switzerland, later as a member of the Group Executive Committee responsible for Europe and China, and from 2016 until 2022 as CEO of the Group. With his comprehensive leadership skills and many years of industrial and international experience, Thomas Oetterli brings ideal prerequisites to lead Rieter as a global market leader through the current challenges and successfully develop it further in the long term. He will take over the function of CEO from Norbert Klapper on March 13, 2023.

The Board of Directors would like to thank Norbert Klapper for his many years of hard work for Rieter and his lasting contribution to the company, particularly in terms of further strengthening its technology leadership, developing the components and service business, completing the systems offering, and wishes him all the best for the future, both professionally and personally. Following his departure as CEO, he will be available to the Chairman of the Board of Directors as Senior Advisor until the end of September 2023.

Thomas Oetterli also proposed as member of the Board of Directors

In the course of the intensive talks with Thomas Oetterli that led to his appointment as CEO of Rieter, the Board

of Directors came to the conclusion that, with his proven strategic competencies, extensive industrial experience and international network of contacts, he would also make important contributions to Rieter’s Board of Directors and strengthen its overall profile. As Chairman of the Board of Directors of SFS, an industrial company in Switzerland, he is also familiar with the international industrial environment from the perspective of another globally active Swiss industrial company.

In view of the current challenges Rieter is facing in the current economic and market situation, which require close cooperation between the Board of Directors and the Group Executive Committee, the Board of Directors considers a dual function of Thomas Oetterli as CEO and member of the Board of Directors to be advantageous and in the interest of all stakeholders. It will therefore propose Thomas Oetterli for election as a member of the Board of Directors at the upcoming Annual General Meeting on April 20, 2023.

24 PAKISTAN TEXTILE JOURNAL - February 2023 Personalia

Norbert Klapper

Robert Reimann, CEO of Jakob Müller Group (Frick), announces his resignation

Robert Reimann, long-term CEO of Jakob Müller Group (JMG) in Frick/AG, is stepping down from his position. He has decided to leave the company by midyear. The search for a successor has been initiated. JMG develops innovative and sustainable systems and solutions for tape and narrow fabrics. It operates at 11 locations worldwide. The company's headquarters are in Frick, in the canton of Aargau. Jakob Müller Group is part of Jakob Müller Holding AG

Robert Reimann, long-term CEO of Jakob Müller Group, is stepping down from his position. He has decided to leave the company by mid-year. Stephan Bühler, Chairman of the Board of Directors, regrets his departure on many levels: "He was particularly distinguished by his great commitment to the good of the company and exemplary loyalty. We warmest thank Robert Reimann for his exceptional performance and loyalty over the past 30 years." The search for a

successor has already been initiated. Robert Reimann will be available to the company until mid of the year, and a smooth handover will be ensured by internal resources.

Exceptional career

Robert Reimann has been with the company for over 30 years, during which time he has had an unparalleled career. He started his career as a commercial apprentice, later managed the German branch and then became Head of Global Sales. In 2014, he took over as CEO of the Jakob Müller Group. It has developed very successfully under his leadership.

Convincing through innovation

JMG stands on a solid foundation, its market position is leading worldwide. The machinery building company with systems and solutions for tape and narrow fabrics has coped well with the

challenges of the recent past. Stephan Bühler: "The key word for our success is and remains innovation - we must remain fast and agile and continuously evolve." Among other things, this means driving digitalization forward and significantly shortening the "time-to-market".

Jakob Müller Group develops innovative and sustainable systems and solutions for tape and narrow fabrics. "Müller machines" set standards in quality, Swiss precision and state-of-theart technology. Founded in 1887, the company has grown from a small Swiss business to a global player through constant innovation. The Jakob Müller Group operates at 11 locations worldwide. The company's headquarters are in Frick, in the canton of Aargau. The company's primary field of activity is the global fashion industry. Jakob Müller Group is part of Jakob Müller Holding AG.

25 Personalia

Robert Reimann, long-term CEO of Jakob Müller Group,

ITMA 2023: Innovator Xchange to offer innovation insights from industry experts

The stage is set for ITMA 2023 to host a highly anticipated showcase of trendsetting textile and garment technologies when it opens in Milan on 8 June. Exhibition space grossing 220,000 square metres of the Fiera Milano Rho exhibition centre is fully booked.

Mr Charles Beauduin, Chairman of ITMA Services, said: “Since the last ITMA exhibition in Barcelona in 2019, the world has changed drastically due to the coronavirus pandemic and geopolitical situation. Despite various disruptions, we are glad that space in ITMA 2023 is

fully booked. Companies are buoyant about the outlook of the market with most borders now fully open.”

The upcoming exhibition will feature over 1,600 exhibitors from 44 countries and a list of 100 companies are still waiting to be allocated space in their preferred sectors. There is a total of 20 product sectors covering the entire textile and garment manufacturing value chain, including textile composites.

Mr Ernesto Maurer, President of CEMATEX, said: “Sustainability is no longer just a buzzword; the industry has to move faster to adopt the sustainability agenda to secure the future of their business. During the pandemic, many of our members channelled their resources into R & D activities. ITMA 2023 is perfectly timed to offer our exhibitors an opportunity to showcase these new products and cutting-edge technology. If and when R & D is paired with sustainability efforts, this will be the

formula for success.’

“Our visitors can look forward to ITMA 2023 to preview the latest innovation. We hope that textile and garment manufacturers, brands and retailers will take this opportunity to meet at ITMA to source and collaborate with leading members of the textile industry. In addition, they can also gain insights into industry trends and developments at various complementary events.”

Innovator Xchange

ITMA 2023 will be accompanied by several activities spotlighting industry

26 PAKISTAN TEXTILE JOURNAL - February 2023 Fairs and Exhibitions

Mr Charles Beauduin, Chairman of ITMA Services.

Mr Ernesto Maurer, President of CEMATEX

innovation. Among the highlights is the Innovator Xchange which offers participants unique opportunities to gain insights from the winners and finalists of the ITMA Award, as well as exhibitors and industry experts.

An industry expert has been invited for each of the four featured topics: automation and digital future, advanced materials, sustainability and circularity, and innovative technologies. The invited speakers are:

Mr German Garcia Ibañez, Head of Sustainable Raw Materials Circularity, Inditex. (Sustainability & Circularity)

Dr Jesse S. Jur, Director of Ecosystem Technology, Advanced Functional Fabrics of America. (Innovative Technologies)

Mr Kevin McCoy, Vice President made, New Balance Athletics.

(Automation & Digital Future)

Professor Parikshit Goswami, Professor of Technical Textiles, The University of Huddersfield.

(Advanced Materials)

The Innovator Xchange will be held from 9 to 13 June. Other highlights held alongside ITMA 2023, are the ITMA Sustainable Innovation Award, Innovation Video Showcase, ITMA forums and partner events.

For more information on the above events, please visit www.itma.com/events.

Online ITMA 2023 visitor registration

Visitors can enjoy early bird badge rates until 7 May 2023 when they register online. With the badge, they will be able to access the ITMAconnect platform from 8 March 2023 to plan their exhibition visit. Visitors can explore exhibitors’ digital spaces, chat and make appointments for stand visits. For enquiries, please email visitor@itma.com

About CEMATEX & ITMA

The European Committee of Textile Machinery Manufacturers (CEMATEX) comprises national textile machinery associations from Belgium, France, Germany, Italy, Netherlands, Spain, Sweden, Switzerland and the United

Kingdom. It is the owner of ITMA and ITMA ASIA. Considered the ‘Olympics’ of textile machinery exhibitions, ITMA has a 73-year history of displaying the latest technology for every single work process of textile and garment making. It is held every four years in Europe.

ITMA Services

Headquartered in Brussels with a subsidiary in Singapore, ITMA Services is the appointed organiser of ITMA 2023 and future ITMA branded exhibitions. It is managed by professionals with extensive experience in organising ITMA and other major trade exhibitions around the world. It aims to maintain and expand ITMA’s unique selling proposition and relevance to a global audience.

Fairs and Exhibitions 27

Online application for ITMA ASIA + CITME 2022 exhibition

Leading textile machinery manufacturers from around the world are invited to apply for space at the 8th combined ITMA ASIA + CITME exhibition to be held at the National Exhibition and Convention Centre, Shanghai from 19 to 23 November 2023.

The Combined show is the trendsetter textile and garment machinery technology platform where the industry converges every two years to explore fresh ideas, effective solutions and collaborative partnerships for business growth.

ITMA ASIA + CITME 2020 Facts

Live machinery demonstrations160,000 sqm platform of advances technologies.

1,237 exhibitors from all over the world.

65,000 visitorship from over 30 countries/regions.

More than 80% of the exhibitors were satisfied with the exhibition.

99% of the buyers will visit ITMA ASIA + CITME 2022 again. Strong support from all major trade associations around the world. China's GDP is projected to increase 5.2 percent in 2023, according to the

International Monetary Fund. With reopening of China, business communities are looking forward to face-to-face interactions at trade exhibitions - the ideal platforms to meet, greet and conclude deals.

28 PAKISTAN TEXTILE JOURNAL - February 2023

Fairs and Exhibitions

Naia™ from Eastman is back at Première Vision Paris with a new brand image

Attendees at this year’s Première Vision Paris witnessed debut of an updated Naia™ from Eastman that showcases a variety of possibilities for uncompromising, sustainable style for everyone.

“Sustainable style your way is the vision of Naia™ at its core,” said Carolina Sister Cohn, Eastman global marketing leader for textiles. “Naia™ has a unique, sustainable approach that results in topquality, innovative cellulosic acetate materials, including staple fibers and filament yarns. They aren’t just from nature but are for nature. And they are as sustainable as they are versatile and adaptable - to everyone everywhere in the world.”

With a portfolio of fibers that doesn’t compromise on luxury, comfort or ease of care, Naia™ circular materials provide a sustainable solution for tops, dresses, Tshirts, sweaters, comfy pants and more.

Show attendees experienced, touch and feel how Naia™ fibers enhance more than 250 fashion fabrics in many applications: ready-to-wear, casual wear, knitwear and sweaters.

The Eastman team was also available to discuss the results of an in-depth study Eastman conducted in January 2023 about professional womenswear among consumers in Europe and the U.S. The research includes perspectives on various topics, including insights on the versatility that women expect from professionalwear pieces, opportunities to differentiate clothing performance, and the need for more sustainable materials.

With Naia™, Eastman strives to create a fashion future where sustainable textiles are the best and easiest option. Naia™ Renew offers an innovative solution to one of the most pressing fashion issues: developing large-scale circularity.

Produced from 60% sustainably sourced wood pulp and 40% certified* recycled waste materials, Naia™ Renew creates the same top-quality fabrics as traditional Naia™ fibers, but with a reduced carbon footprint of around 35% and it’s available at scale.

All Naia™ products are produced in a safe and circular way, with solvents redirected back into the production process with a low tree-to-fiber carbon and water footprint.

With full traceability from tree to fiber, the wood used to produce Naia™ products is responsibly sourced from sustainably managed pine and eucalyptus forests. Naia™ is also TÜV AUSTRIAcertified as biodegradable and compostable.

Sustainable style your way

Naia™ stands out with the ideal ecoconscious ingredients for fashion and ready-to-wear brands all over the world. And because Naia™ fibers can be used alone or blended with other yarns, they offer almost unlimited possibilities for textural variety.

Naia™ filament yarns deliver excellent drape and silky-soft hand feel, are Hypoallergenic, and ensure natural breathability and a cool sensation on the skin; other benefits include technical performance as in dimensional stability as well as easy stain removal and odor management.

Naia™ staple fibers deliver enduring softness in fabrics for longer-lasting comfort. They are smooth and guarantee reduced pilling and a fuzz-free look — the ideal solution to deliver supreme softness and ease of care to perfectly blended knitwear.

*Mass balance approach

29 Feature

Innovative and versatile Naia™ fibers make sustainable style accessible to brands and inclusive for everyone.

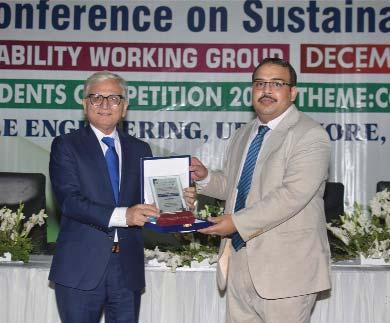

The 2nd International Conference on Knowledge-Based Textile

The 2nd International Conference on Knowledge-Based Textile took place at the National Textile University, Faisalabad on 14th-15th February 2023. The conference was organized by the School of Engineering and Technology under the Grand Challenge Fund Project (KnowTex) and co-organized by seven institutes and universities, including three national and four international co-organizers: Donghua University, China, University Technology Malaysia, Malaysia, Northumbria University, UK, and Taxonomy, UK, and at national level NED University, Karachi, BUITEMS Quetta, and Pakistan Circular Fashion Council.

This conference was fully sponsored by several industries. Including Interloop Limited (Platinum Sponsor), Gold sponsors were Nizam Sons, US Denim, iTextiles (pvt) Ltd., and Sapphire Textile Mills Ltd., while WWF Pakistan, Mahmood Group and ELEVATE global were the Silver Sponsors. Media partners of this conference were TEXtalks and

Pakistan Textile Journal. There were also several supporting bodies like Pakistan Hosiery Manufacturers and Exporter Association (PHMA), Pakistan Readymade Garments Manufacturer and Exporters Association (PRGMEA), Faisalabad Chamber of Commerce and Industries (FCCI), Feroze 1888 and Artistic Apparels who contributed in the success of this conference.

The opening session of this conference was attended by a large gathering of professionals from all fields of life. Dr. Yasir Nawab, the Chairman of the conference, delivered the opening speech and welcomed all the attendees, including distinguished guests and speakers from around the globe. He also shared the current progress of KnowTex with the participants. Mr. Mujeeb Ullah Khan from i-Textiles delivered his talk about the industry perspective of Grand Challenge Fund (GCF).