Established 1951 February 2024 Spinning Review

Calendar of Events

Texworld Paris

Dates: February 5th to 7th, 2024.

Venue: Paris

GTex Global Expo 2024

Dates: Feruary 22nd to 24th 2024.

Venue: Expo Centre, Lahore.

Istanbul Yarn Fair

Dates: February 22nd to 24th, 2024.

Venue: Istanbul, Turkey.

Textile Asia 2024, Karachi

Dates: March 1st to 3th 2024.

Venue: Expo Centre, Karachi.

Textile Asia 2024, Faisalabad

Dates: March 07th to 09th 2024.

Venue: Faisalabad Quilim Marquee.

FESPA 2024

Dates: March 19th to 22nd 2024.

Venue: Amsterdam, The Netherlands.

Techtextil 2024

Dates: April 23rd to 26th, 2024

Venue: Frankfurt, Germany.

IGATEX Pakistan 2024, Lahore

Dates: May 1st to 4th 2024.

Venue: Expo Centre, Lahore.

iCADEX Pakistan 2024, Lahore

Dates: May 1st to 4th 2024.

Venue: Expo Centre, Lahore.

DOMOTEX asiaCHINAFLOOR 2024

Dates: May 28th to 30th 2024.

Venue: NECC, Shanghai, China.

ITM 2024

Dates: June 4th to 8th, 2024.

Venue: Istanbul, Turkey.

HIGHTEX 2024

Dates: June 4th to 8th, 2024.

Venue: Istanbul, Turkey.

INTEX SOUTH ASIA 2024

Dates: August7th to 9th 2024.

Venue: Colombo, SriLanka.

63rd DORNBIRN-GFC Call For Papers

Dates: September 11th to 13th 2024.

Venue: Dornbirn Austria.

ITMA ASIA + CITME 2024

Dates: October 14th to 18rd, 2024.

Venue: NECC, Shanghai, China.

JIAM 2024 OSAKA

Dates: November 27th to 30th 2024.

Venue: Osaka, Japan.

Heimtextil 2025, Frankfurt

Dates: January 14th, to 17th, 2025

Venue: Frankfurt am Main.

Index 2026

Dates: April 21st to 24th, 2026.

Venue: Palexpo, Geneva, Switzerland.

ITMA 2027

Dates: September 16th to 22nd, 2027.

Venue: Hanover, Germany.

2

PAKISTAN TEXTILE JOURNAL - February 2024

Tel: +92-21-34311674-5

Fax: +92-21-34533616

Email: info@ptj.com.pk

URL: http://www.ptj.com.pk

PTJ Europe Ltd.

Registered Office: Dairy House, Money Row Green, Holyport, Maidenhead, Berkshire, SL6 2ND, United Kingdom.

Registered no. 09141989

Tel: +44 792 2228 721

CORPORATE NEWS

ALLIED Feather + Down Ramps Up RENU:TRACE Program Through Partnership with NEMO Equipment

Navis TubeTex announces strategic partnership with Fibroline to revolutionize dry impregnation solutions in the U.S.

Vickers Oils secures OEM approval from Lonati S.p.A., Italy

A Swedish win-win partnership for ACG Kinna and Värnamo

22 21

DYES AND CHEMICALS

Archroma and Sanitized AG celebrate a decade-long partnership and align strategically for enhanced collaboration in marketing, sales and technology . . . . . . . .23

The search reopens for the SDC’s Global Colourist of the Year 2024 . . . . . . . . .24

PERSONALIA

Personnel changes at BRÜCKNER Textile Technologies . . . . . . . . . . . . . . . . . . . . . . .25

Karl Mayer Turkey appoints general manager;

FAIRS AND EXHIBITIONS

How digitalisation is driving growth: panel discussion on the future viability of the textile industry with reference to Techtextil and Texprocess 2024 . . . . . . . . . .26

Giltex LLC (Azerbaijan) joins ITMF as Corporate Member . . . . .

.28

63nd Dornbirn GFC Global Fiber Congress 11–13 Sep.2024, Dornbirn Austria . . . .29

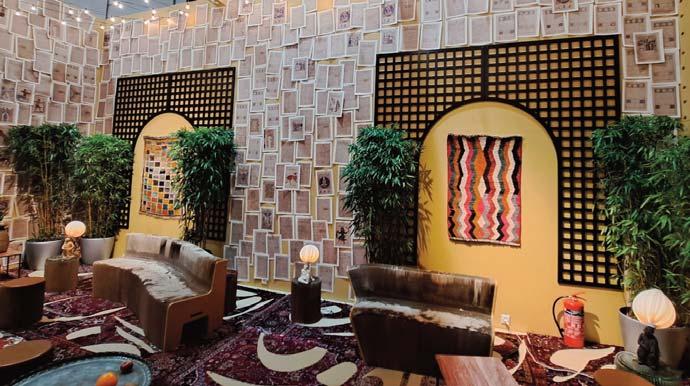

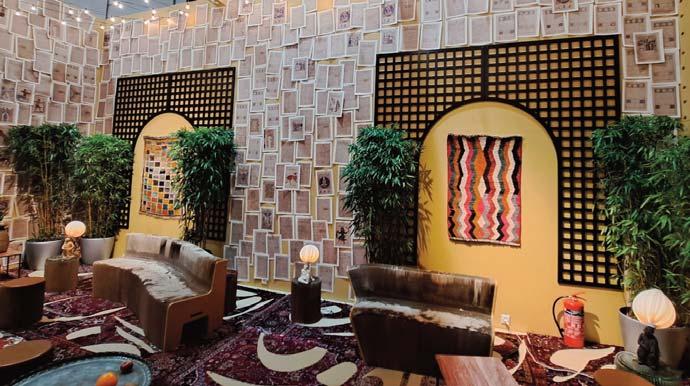

DOMOTEX 2024: A Gathering of Global Industry

AROUND THE WORLD . . . . . . . . . . . . . . . . . . . . . .14 NEWS & VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . .10 EDITOR’S PAGE . . . . . . . . . . . . . . . . . . . . . . . . . . .7 Impact of energy crisis on the textile industry, particularly spinning industry of Pakistan TEXTILE BRIEFS . . . . . . . . . . . . . . . . . . . . . . . . . . .8 Vol. LXXIII No. 02 February 2024 Rs. 565.00 Founded in 1951 by Mazhar Yusuf (1924-2009) Publisher / Nadeem Mazhar Editor in Chief Amina Baqai Associate Editor Nimrah Nadeem Production Manager Mazhar Ali Layout & Design Noor M. Jaan Website / Social Media Minhaj Ali Hony-Editorial Board Dr. Hafizur Rehman Sheikh Ph.D (UK) F.T.I. (UK) Syed Mahfooz

C.TEX, F.T.I (U.K), B.Sc. Fellow I.C.T.T Atlanta, GA; (USA) Dr. Zubair Bandukda PhD (Textiles), CText ATI Printed at: Color Plus Korangi, Karachi. Published by Nadeem Mazhar from D-16, K.D.A. Scheme No.1. Karachi. Available on Gale and Factiva affiliated international databases through Asianet Pakistan Editorial & Advertising Office B-4, 2nd Floor, 64/21, M.A.C.H, Miran

Road,

Qutab

M. Shah

Karachi - Pakistan

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

. . . . . . . . . . . . . . . .

.21

. . . . . . . . . . . . . . . . .22

. . . . . . . . . .

. . . . .

. . . . . . . . . . . . . .

. . . .30

. . . . .

. . .

. . . . . . . . . . . . . .

. . .

. . . .25

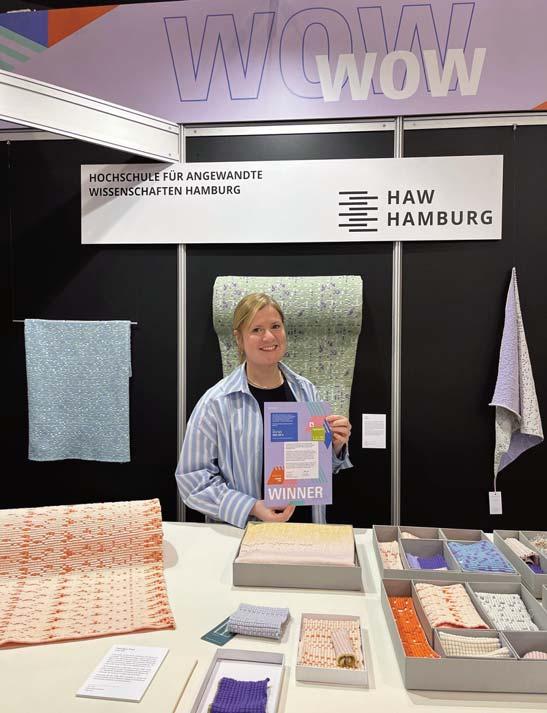

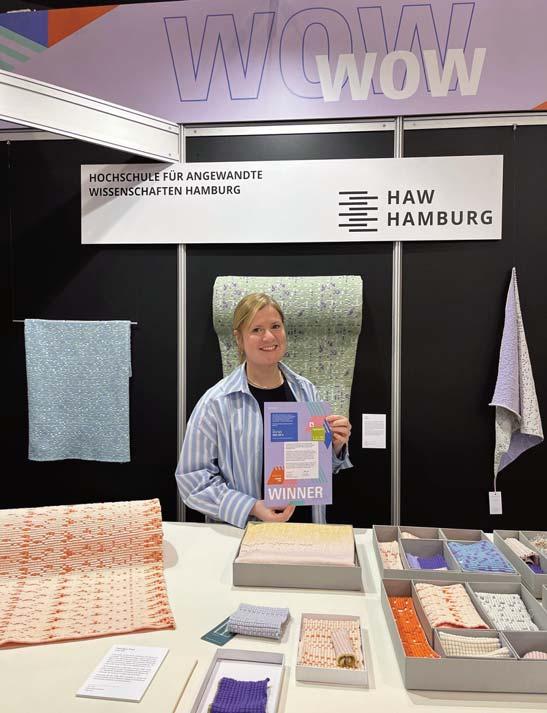

Heimtextil 2024

Heimtextil ends with an increase in exhibitors, a plus in visitors and sets new standards for a sustainable and AI-driven textile industry

Interview with Aamir Ansari, Head of Product Development & Innovation at Feroze1888 Mills Ltd., and Martin, Chief Technology Officer at Pond Global .

FESPA MIDDLE EAST 2024

Investment tops agenda for senior decision-makers at FESPA MIDDLE EAST 2024 . .46

Buyers with spending intentions worth $486mn+ gather at inaugural regional expo Interview with Marc Verbeem, Supervisor of Product Management at Mimaki Europe EMEA . . .

SPECIAL REPORT

Insight: Pakistan's cotton spinning sector during FY23

by Nadeem Mazhar, Managing Editor, Pakistan Textile Journal.

U.S. Cotton Trust Protocol now represents almost quarter of U.S. cotton acreage and reports continued improvements across all six sustainability metrics

Savio Winding and Air-Jet Spinning Innovations

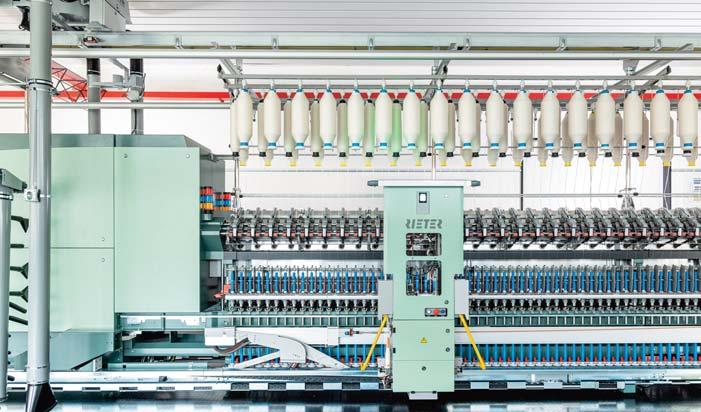

Major Win for Rieter in Patent Dispute in China

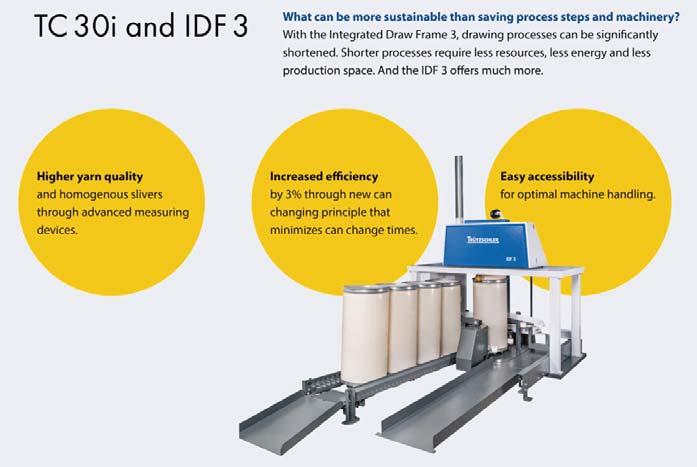

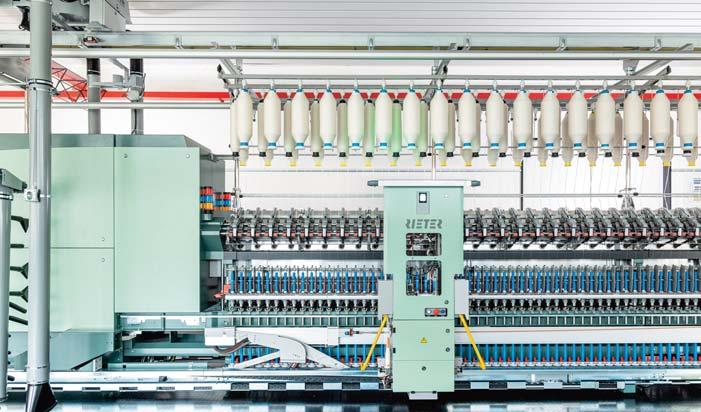

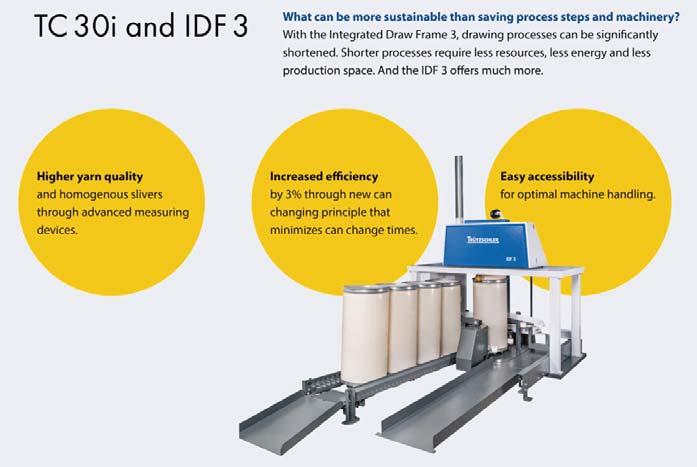

All eyes on the Trützschler’s TC 30i

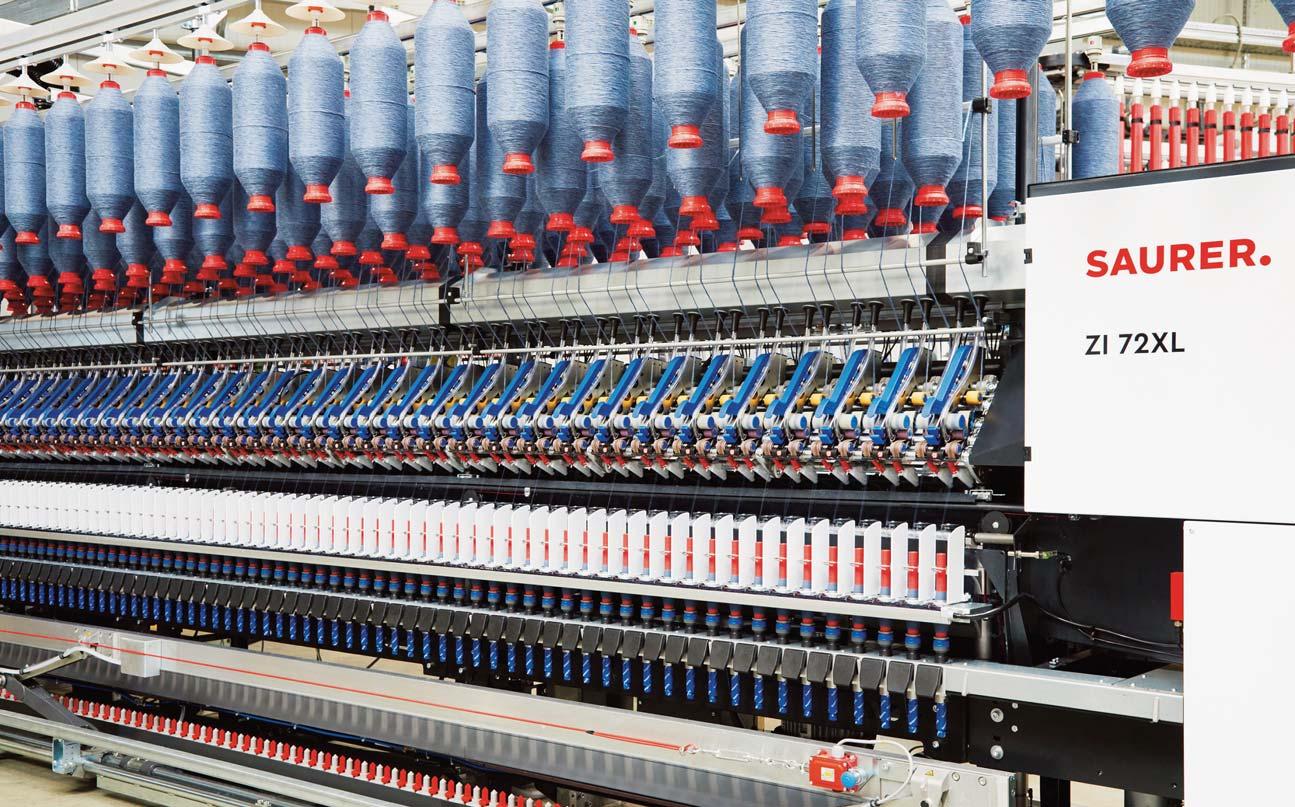

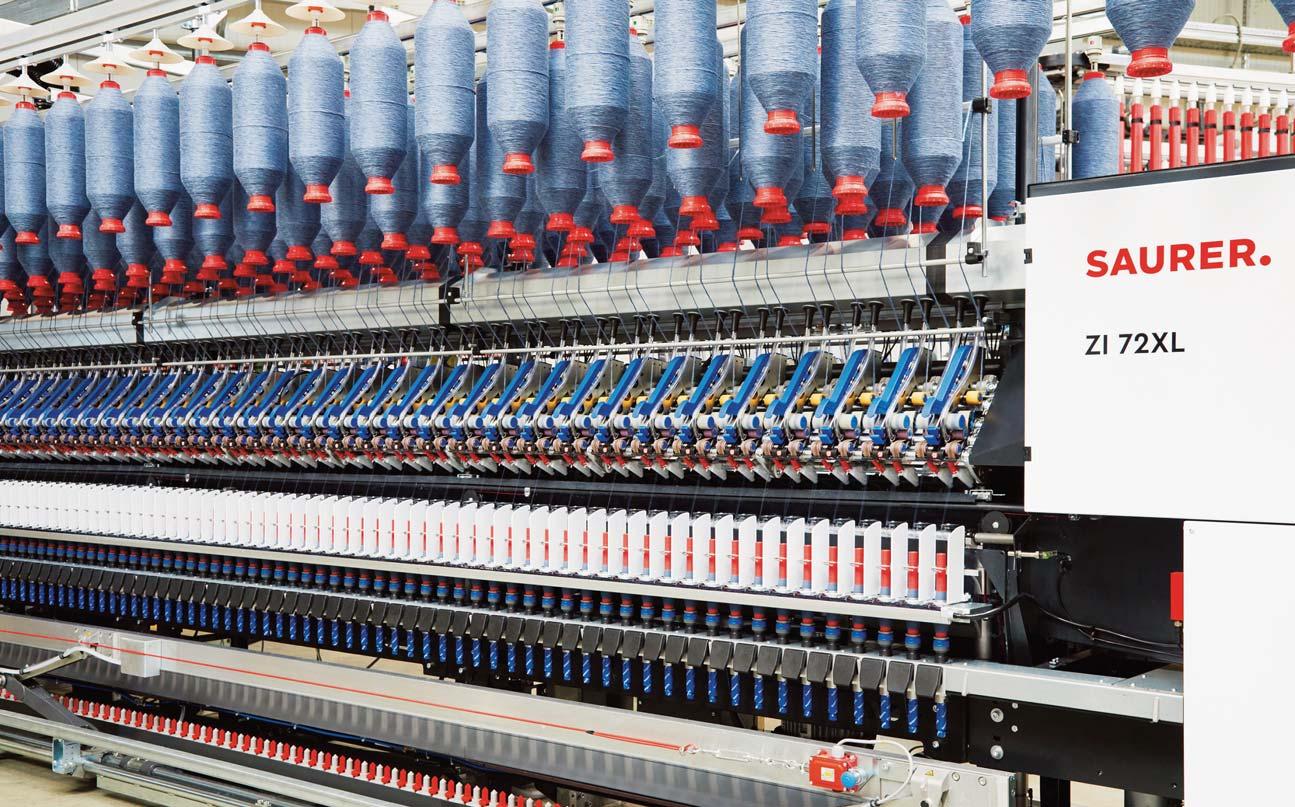

Saurer 72XL compact spinning machine first hand at Egy Stitch and Tex 2024

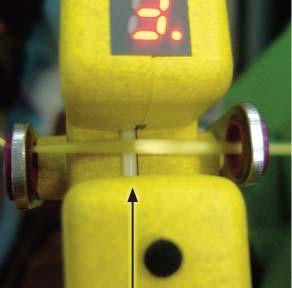

Uster: Right raw material, optimized production…

Uster solutions combine to deliver practical benefits in processes and profits

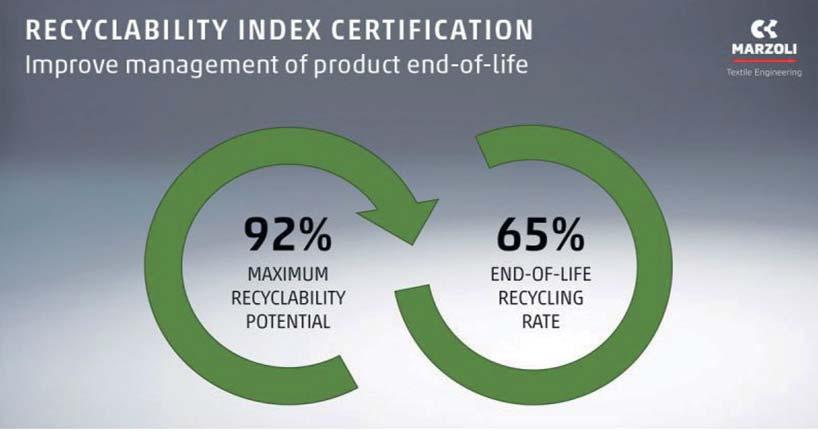

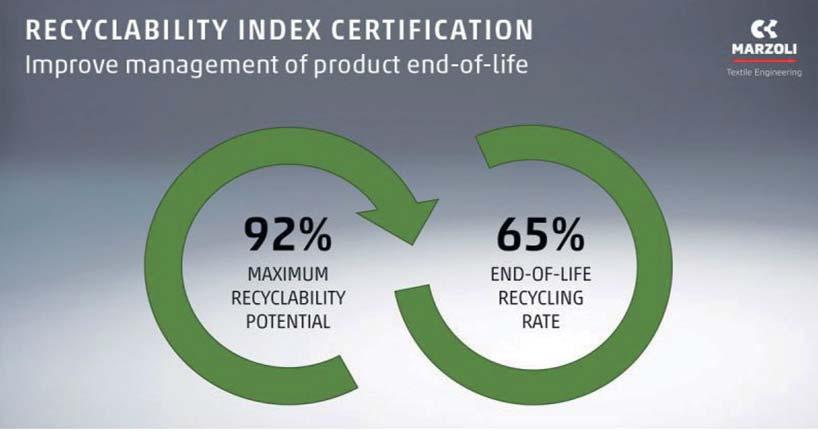

Marzoli obtains the Recyclability Index Certification

Mini-Spinning, new lab-scale Shredding machine & recycling in textiles

Weavers of carbon fabrics rely on Loepfe Weftmaster® FALCON-I

Oerlikon Barmag WINGS FDY Technology for a sustainable polyester yarn production at Garden Silk Mills in India

Yarn Quality at the Highest Level with Suessen Top Weighting Arms

34 32 36 48 54 53 30

. . . . . . . . . . . .32

. . . . . . . . . . . . . . . . . . .33 Uster

Finishing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34 Lenzing

. . . . . . . . . . . . . . . . . . .35

FEATURES Naia™ Renew receives Global Recycled Standard certification . . .

The third-party certification verifies recycled content in textiles. Know-how for a better world with recycled textiles . . .

Technologies issues practical guidance in its new Sustainability Bulletin

lines for carpets and textile floor coverings - Brückner offers the widest range of products in this field

once again on CDP’s prestigious Triple A List,

. . . .36

SPECIAL REPORT Saurer OpenHouse 2024: A platform for knowledge sharing and innovation

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

. . .

.

. . . . . . . . . . . . . . . . . .49

. . . . . . . . . .

.

.52

. . . . . . . . . . . . . . . . . . . . . . . . . . . .53

. . . . . . . . . . . . . . . . . . . . . . . . . . .54

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

. . . . . .56

. . . . . . . . . . . . . . . . . . . . . . . . .58

. . . . . . . . . . . . . . . . . . . .59

. . . . . .60

. . . . . . . . . . .61

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

. . . . . . . . .63

. . . . . . . . . . . . . . . . . . .38

. .44

Impact of energy crisis on the textile industry, particularly spinning industry of Pakistan

Spinners are demanding various concessions claiming that the increase in power and energy tariffs have made them non-competitive, yet the 33.5 percent increase in yarn exports in the first quarter of this fiscal speaks otherwise.

This is the period when power and energy rates were jacked up. Pakistan exported 114,818 metric tonnes of cotton yarn worth $315.40 million during the July-Sept 2023 quarter compared with exports of 73,209 metric tonnes of yarn worth $236.26 million.

Energy and power is a major input for the spinning sector. During the month of September, yarn exports increased by 49.8 percent to 41,563 metric tonnes compared with the yarn exports of 22,545 tonnes achieved during September 2022.

Yarn exports in fact were the highest among all manufactured textile items during the first quarter of this fiscal. Textile exports declined to $4.12 billion in Q1 from $4.58 billion achieved during the corresponding period of last fiscal. This depicts a decline of 9.95 percent.

In September, the textile and clothing exports declined by 10.88 percent to $1.36 billion from $1.52 billion in the same month last year. Caretaker Commerce Minister Gohar Ejaz last month announced to offer regionally competitive energy prices to textile exporters and resolve their cash flow issues by releasing pending sales tax refunds. Nothing has been done in this regard.

The most disturbing aspect of decline in exports is the decline in value-added exports.

The fact that there was an increase in volumes of both Knitwear and readymade garments showed that our exporters did get higher orders, but were forced to lower the rates due to global recession.

With the global situation improving the value-added sector might recover per unit value.

The Pakistan Bureau of Statistics data showed the exports of readymade garments shrank 11.21 percent in value in July-September, but grew by 8.24 percent in quantity; while knitwear dipped 15.83 percent in value, but grew 34.14 percent in quantity; and similarly, bedwear posted a negative growth of 10.02 percent in value, growing 1.39 percent in quantity.

The exports of textile and clothing contracted by 14.63 percent to $16.50 billion in FY23. However, the total merchandise exports dipped 12.71 percent to $27.54 billion from $31.78 billion in the preceding year.

Towel exports slightly increased by 2.89 percent in value and 16.24 percent in quantity, whereas those of cotton cloth dipped by 18.15 percent in value and 7.50 percent in quantity.

Textile millers are demanding regionally competitive power and gas tariff, as well as return to zero-rating regime to compete globally.

The increase in exports in volume of cotton yarn, cotton cloth, knitwear and readymade garments depicts that that export volume has increased meaning that the exporters obtained higher orders, but the value in dollars declined in line with the rates quoted by our competitors.

Another depressing news was the decline in the import of textile machinery by 75.38 percent in July-September. Pakistan lags behind its competing economies in technology and quality of textile machinery.

But it looks like expansion or modernisation projects are not the priority of our textile players. Most of the spinning industry is operating on outdated spindles that consume more power and more man power.

7

EDITOR’S PAGE

Established 1951 February 2024 Spinning Review February 2024

1

Pakistan's cotton production has soared by an impressive 75% in the current season, reaching a remarkable 8.35 million bales. This surge has not only buoyed the country's largest export earner, the textile industry but has also amplified its impact on overall economic activities.

2

Chairman Kamran Arshad of the All Pakistan Textile Mills Association North (APTMA) has fervently appealed to officials within the Ministry of Commerce to actively pursue foreign direct investment (FDI). Addressing a delegation of trade and investment officers selected for postings in Pakistan's missions abroad, Arshad emphasized the

immense potential for exporting a diverse range of textile products, including apparel, footwear, and related goods.

3Pakistan's textile exports faced a downturn of approximately 6.33 percent in the initial four months (July-October) of the current fiscal year, as reported by the Pakistan Bureau of Statistics (PBS). The sector recorded exports totaling $5.565 billion, compared to $5.940 billion in the corresponding period of the previous fiscal year.

4Pakistan's textile sector engaged in discussions with a US envoy during a recent visit by the US Consul General to the All Pakistan Textile Mills

Textile Briefs International

1

Tanya Plibersek, the Australian Environment Minister, is contemplating the imposition of a mandatory 4 cent clothing levy on the fashion industry, a decision slated for July pending industry compliance with a voluntary green levy initiative. The move comes in response to the alarming environmental impact of discarded clothing, with the majority ending up in landfills, according to the Australian Fashion Council.

2The once-thriving home textile sector of Bangladesh is facing tumultuous times in the global export market, grappling with a confluence of challenges ranging from a persistent gas crisis to volatile exchange rates and soaring production costs. The sector,

Association (APTMA) in Lahore. Sharing mutual optimism, both parties acknowledged Pakistan's promising potential in the textile and allied sectors, highlighting the untapped opportunities for joint endeavors to amplify trade and investment prospects, as conveyed through a press release from APTMA.

5

The All Pakistan Textile Mills Association (APTMA), representing Pakistan's largest industrial sector, has urgently called for the elimination of cross-subsidies from power tariffs for industrial consumers, advocating for a reduction to 9 cents/kWh. In a statement issued on earlier this month, APTMA emphasized that

implementing a tariff of 9 cents/kWh for industrial consumers is a vital structural reform necessary for Pakistan to regain competitiveness in international markets.

6

The Sindh Community Foundation (SCF) has recently signed a Letter of Understanding with the Directorate of Literacy and Non-Formal Education, part of the Education and Literacy department of the Government of Sindh to enhance female literacy and empowerment in rural Sindh. The collaboration aims to provide essential training to 3000 women cotton workers across the Matiari and Sanghar districts.

which witnessed a promising trajectory in previous fiscal years, has now encountered a sharp downturn, compelling several factories to shutter their operations.

3Despite facing a 10 percent decline in cotton production last year, Brazil maintained its position as the world's second-largest cotton exporter in 2023, a testament to its resilience in the face of challenging circumstances.

Figures released by the Brazilian Cotton Growers Association (Abrapa) reveal that Brazil exported 1.617 million tons of cotton, generating export revenues of US $3.06 billion.

4

China's export figures for refined cotton and specialty cotton linter pulp in 2023 offer insights

into the delicate balance between growth and challenges. Despite a marginal 0.74 percent yearly increase, reaching a total of 82,292 tons, the significance lies not just in the numbers, but in the nuanced fluctuations throughout the year.

5China's spandex imports witnessed a remarkable surge in 2023, underscoring the nation's pivotal role in the textile industry. Import figures surged by 22,112 tons, marking an unprecedented 85.6 percent increase over the previous year, with total imports reaching an impressive 47,900 tons.

6The European Union has forged a provisional political agreement aimed at overhauling its economic governance frame-

work, with far-reaching implications for member states. Spearheaded by Belgian finance minister Vincent Van Peteghem, the agreement marks a significant stride towards fostering sound and sustainable public finances while promoting inclusive growth and investment.

7The Indian cotton spinning sector is set to embark on a trajectory of robust growth, with projections indicating a substantial expansion of 12-14 percent in fiscal 2024-25, commencing from April 1. A key driver of this growth is the anticipated surge in cotton yarn exports, expected to skyrocket by 8590 percent, propelled primarily by the "China Plus One" strategy.

8 PAKISTAN TEXTILE JOURNAL - February 2024

Textile Briefs National

Pakistan’s cotton production witnessed a 75% increase during the current season

Pakistan's cotton production has soared by an impressive 75% in the current season, reaching a remarkable 8.35 million bales. This surge has not only buoyed the country's largest export earner, the textile industry but has also amplified its impact on overall economic activities.

The remarkable growth in cotton output can be attributed to favourable weather conditions and the government's announcement of a higher commodity support price at Rs8,500 per 40kg for the ongoing season. This policy shift has played a pivotal role in driving this unprecedented growth.

According to the Pakistan Cotton Ginner's Association, production, as reported in February, stands at 4.76 million bales in the same period (Jul-Jan) of the fiscal year 2022-23.

Breaking down the latest production data, the major boost in commodity output is attributed to Sindh, where harvesting increased by 120% to 4.11 million bales in the current season compared to the previous one. The remaining production, totaling 4.24 million bales, came from Punjab, marking a 47% rise in the first seven months of the season compared to the same period

last year. The PCGA estimates the fullseason output to be in the range of 8-9 million bales this year, while Naseem Usman, Chairman of the Karachi Cotton Brokers Forum, projects the total commodity production to reach 8.45 million bales by the end of the current season.

The government's decision to announce a minimum purchasing price of Rs8,500 per 40kg has incentivized farmers to cultivate the commodity over a larger area of agricultural land, according to industry officials.

However, despite stability in cotton prices internationally, local textile and spinning mills are facing challenges, notes Ahsanul Haq, Chairman of Pakistan Cotton Ginners' Forum. The industry is grappling with the rising cost of production due to increased energy prices, prompting discussions of potential protests.

Chairman Kamran Arshad of APTMA Urges Ministry of Commerce Officials to Prioritize FDI for Textile Sector

Chairman Kamran Arshad of the All Pakistan Textile Mills Association North (APTMA) has fervently appealed to officials within the Ministry of Commerce to actively pursue foreign direct

investment (FDI). Addressing a delegation of trade and investment officers selected for postings in Pakistan's missions abroad, Arshad emphasized the immense potential for exporting a diverse range of textile products, including apparel, footwear, and related goods.

During a recent gathering at the APTMA Lahore office, attended by senior officials including Senior Vice Chairman Asad Shafi, Executive Members Haroon Elahi and Ismail Fayyaz, Energy Consultant Tahir Basharat Cheema, and Secretary General Raza Baqir, Arshad underscored the critical need to prioritize duty-free access, identify investment opportunities, and foster strong industry linkages. He stressed the significance of initiatives such as organizing road shows, facilitating joint ventures, and transferring technology to bolster the domestic textile sector.

Arshad outlined the ambitious vision of the APTMA, which includes a USD 50 billion export plan aimed at establishing 1000 garment plants. This plan, with an expected investment of USD 7 billion, is projected to generate annual exports totaling USD 20 billion and provide employment opportunities for over 700,000 workers.

Highlighting the pivotal role of trade and investment officers stationed in over 50 countries, Arshad urged them to actively engage in exhibitions, prepare comprehensive reports for trade

News & Views 10 PAKISTAN TEXTILE JOURNAL - February 2024

associations and exporters, and explore new markets to expand Pakistan's export footprint. Additionally, he addressed key challenges facing the textile industry, advocating for the removal of cross subsidies, the introduction of export-oriented industry tariffs, and the streamlining of tax refund processes.

Asad Shafi, emphasizing Arshad's sentiments said, the importance of brand development and the promotion of Pakistani products on the global stage. Meanwhile, in a separate engagement, a delegation of Trade and Investment Officers from the Trade Development Authority of Pakistan (TDAP) visited the Lahore Chamber of Commerce and Industry (LCCI).

Led by Director General Shahzad Rana, the delegation engaged in discussions aimed at addressing hurdles in external trade, streamlining taxation systems, and diversifying markets to enhance Pakistan's export competitiveness.

The collective efforts of industry stakeholders, alongside proactive measures by government officials and trade bodies, underscore a concerted push to revitalize Pakistan's textile industry and position it as a key player in the global market.

Textile Sector Sees Decline of 6.33% during 1st quarter FY24 Despite Month-onMonth Growth

Pakistan's textile exports faced a downturn of approximately 6.33 percent in the initial four months (July-October) of the current fiscal year, as reported by the Pakistan Bureau of Statistics (PBS). The sector recorded exports totaling $5.565 billion, compared to $5.940 billion in the corresponding period of the previous fiscal year.

Despite this setback, the overall exports for the country during the July-October fiscal year 2023-24 amounted to $9.6 billion (provisional), showcasing a marginal decrease of 0.48 percent from the previous year's $9.554 billion.

Data analysis from the PBS reveals a month-on-month (MoM) growth of 5.61 percent in textile exports for October 2023, reaching $1.437 billion, compared to $1.360 billion in September 2023. Furthermore, textile exports witnessed a year-on-year (YoY) increase of 5.92 percent in October 2023, up from $1.356 billion in October 2022.

October 2023 saw total exports amounting to $2.690 billion (provisional), marking an 8.64 percent rise from $2.476 billion in September 2023 and a notable 12.84 percent increase from $2.384 billion in October 2022.

Noteworthy growth was observed in cotton yarn exports, surging by 42.85 percent during the initial four months of the current fiscal year, reaching $407.564 million compared to $285.315 million in the same period of the previous fiscal year. However, on a month-onmonth basis, there was an 18.85 percent negative growth.

Major commodities in exports for October 2023 included knitwear, readymade garments, bed wear, rice, cotton cloth, oil seeds, nuts, kernels, towels, cotton yarn, rice basmati, and made-up articles (excluding towels and bedwear).

The decline in the textile and clothing sector's exports is primarily attributed to rising production costs and a liquidity crunch. The Caretaker Commerce Minister, Gohar Ejaz, recently announced plans to address these challenges by offering regionally competitive energy prices to textile exporters and resolving cash flow issues through the release of pending sales tax refunds. However, the implementation of these measures remains pending.

Pakistan-US Partnership Aims to Leverage Trade Opportunities in Textile Industry

Pakistan's textile sector engaged in discussions with a US envoy during a recent visit by the US Consul General to the All Pakistan Textile Mills Association (APTMA) in Lahore.

Sharing mutual optimism, both parties acknowledged Pakistan's promising potential in the textile and allied sectors, highlighting the untapped opportunities for joint endeavors to amplify trade and investment prospects, as conveyed through a press release from APTMA.

Underlining their steadfast commitment to fostering collaboration, APTMA's leadership reiterated its

dedication to nurturing robust partnerships with their American counterparts, with a focus on expanding trade horizons and harnessing the full potential of the economic alliance between the two nations.

During the discourse, Kamran Arshad, Chairman of APTMA North, drew attention to the gradual decline in Pakistan's domestic cotton production, emphasizing the necessity of importing over three million bales this fiscal year. Notably, Arshad underscored the pivotal role of the USA as a primary supplier of cotton to Pakistan, emphasizing that the imported cotton would fuel the production of textile goods worth $8 billion, predominantly destined for the US market.

Proposing an innovative strategy, Arshad suggested leveraging the proceeds from Pakistan's textile exports

to the US as collateral via an escrow account mechanism, thereby offsetting the liabilities associated with cotton imports into the US.

In advocating for strengthened ties, APTMA's Chairman emphasized the importance of fostering closer USPakistan cotton linkages within the textile industry and advocated for the expansion of toll manufacturing opportunities in Pakistan by US textile enterprises. Additionally, Arshad emphasized the critical need for technology transfer to Pakistan, particularly concerning highyielding cotton seed, and proposed collaborative efforts with US cotton research institutions to enhance cotton quality.

The All Pakistan Textile Mills Association appeals for the urgent removal of the crosssubsidy from power tariffs

The All Pakistan Textile Mills Association (APTMA), representing Pakistan's largest industrial sector, has urgently called for the elimination of cross-subsidies from power tariffs for industrial consumers, advocating for a reduction to 9 cents/kWh. In a statement issued on earlier this month, APTMA emphasized that implementing a tariff of 9 cents/kWh for industrial consumers is a vital structural reform necessary for Pakistan to regain competitiveness in international markets.

"Reducing power tariffs to 9 cents/kWh will not only reverse the

News & Views 12 PAKISTAN TEXTILE JOURNAL - February 2024

declining power consumption among industrial consumers but also stimulate increased consumption, thereby offsetting any potential revenue losses with a positive volumetric effect," the statement asserted. Furthermore, APTMA highlighted the importance of such a move in addressing the escalating circular debt issue, which continues to grow despite significant energy price hikes over the past year.

The association underscored the detrimental impact of inflated energy costs, noting that many firms have been compelled to reduce production, resulting in job losses and decreased economic activity. Expressing concern over Pakistan's rapid deindustrialization, particularly evidenced by declining power generation and consumption among large industrial consumers, APTMA emphasized the urgent need to break the cycle of increasing power tariffs leading to decreased consumption and vice versa.

Looking ahead, APTMA stressed that Pakistan's gross external financing requirements are projected to exceed $25 billion annually over the next five years, underscoring the imperative of boosting exports to bridge this financing gap. APTMA asserted that reducing tariffs to 9 cents/kWh would not only bolster exports across various sectors but also stimulate growth in associated industries and services.

Highlighting the fierce global competition, APTMA emphasized the necessity of creating an environment conducive to business growth, with rationalized energy costs being a crucial element.

Sindh Community Foundation Partners with Government to Empower 3000 Women Cotton Workers

The Sindh Community Foundation (SCF) has recently signed a Letter of Understanding with the Directorate of Literacy and Non-Formal Education, part of the Education and Literacy department of the Government of Sindh to enhance female literacy and empowerment in rural Sindh. The collaboration aims to provide essential training to 3000 women cotton workers across the Matiari and Sanghar districts.

Javed Hussain, the Executive Director of Sindh Community Foundation, emphasized the organization's unwavering commitment to bridging the gender literacy gap and bolstering literacy rates in rural Sindh. He highlighted the pivotal role of literacy and education in both human and national development, underscoring how improved literacy levels among women cotton workers can lead to fair wages and better working conditions.

Dr. Aftab Sheikh, Director of the Directorate of Literacy, commended the collaborative efforts aimed at promoting literacy programs in rural Sindh. He expressed optimism that such joint endeavours would significantly elevate the female literacy ratio within the province. As a token of recognition for their dedicated efforts in advancing women's literacy in rural areas, the Directorate of Literacy and Non-Formal Education presented SCF with a shield of appreciation.

The signing ceremony was attended by key stakeholders including Additional Director Manzoor Uqaili, Deputy Director Muhammad Waseem, and Niaz Muhammad from SCF. This LoU marks a pivotal step towards empowering women in the textile industry through education and skill development initiatives.

Textile Exports Surge in January Despite Tariff Hikes, and Gas Price Hike Looms

Pakistan's textile sector witnessed a remarkable surge in exports during January 2024, defying earlier increases in power and gas tariffs. The boost in

exports, fueled by robust international demand and favorable pricing, underscores the resilience of the industry amid challenging economic conditions.

Official data released by the Pakistan Bureau of Statistics (PBS) revealed a significant uptick in textile exports, recording a 10.1 percent increase to $1.455 billion in January 2024 compared to $1.32 billion in the same month the previous year. Despite this positive momentum, textile exports for the period of July-January 2023-24 experienced a modest decline of three percent to $9.74 billion, down from $10.04 billion in the corresponding period of the previous fiscal year.

Key components of the textile group witnessed notable growth in January 2024. Sales of bedwear, knitwear, towels, readymade garments, cotton cloth, and yarn all registered substantial increases. Knitwear exports surged by 8.4 percent to $365 million, bedwear by 19.3 percent to $252 million, readymade garments by 13.85 percent to $333.4 million, and towels by 5.4 percent to $96.1 million.

Similarly, cotton yarn exports saw a significant increase of 19.8 percent to $81.3 million, while cotton cloth exports edged up by 0.5 percent to $159.7 million compared to January 2023.

However, amidst the overall positive trend, exports of textile machinery experienced a decline of 34.8 percent to $11.1 million in January, signaling potential challenges in this segment.

While the sector celebrates its recent export success, concerns linger over the impact of the recent increase in gas tariffs on future exports.

News & Views 13

AUSTRALIA

Environment minister weighs mandatory clothing levy to tackle fashion industry's carbon footprint

Tanya Plibersek, the Australian Environment Minister, is contemplating the imposition of a mandatory 4 cent clothing levy on the fashion industry, a decision slated for July pending industry compliance with a voluntary green levy initiative. The move comes in response to the alarming environmental impact of discarded clothing, with the majority ending up in landfills, according to the Australian Fashion Council.

Addressing an industry event, Minister Plibersek emphasized the need for action, citing the fashion industry's significant contribution to carbon emissions, surpassing those of international flights and maritime shipping combined. While acknowledging personal accountability in her own consumption habits, she stressed the industry's responsibility in fostering sustainable practices, underscoring the necessity of systemic change beyond consumer preferences.

Last June, a government-funded consortium led by the Australian Fashion Council launched "Seamless," a program charting a course for the industry's

transition to a circular economy by 2030. Participants are required to contribute 4 cents per clothing item towards Seamless initiatives, focusing on collection, sorting, research, recycling projects, and educational campaigns.

Several prominent brands, including Big W, Cotton On, David Jones, Lorna Jane, R.M. Williams, Sussan Group, and The Iconic, have pledged support for Seamless, signaling a growing industry commitment to sustainability. The Fashion Council estimates the program could raise up to $60 million annually if made mandatory, with hopes of diverting up to 60 percent of clothing from landfills by 2027.

With Australians purchasing an average of 56 clothing items annually and over 200,000 tonnes of clothing finding its way to landfills each year, the minister is exploring interventions to bolster recycling and reuse efforts. Potential measures include enforcing minimum design standards and mandating fashion brands to contribute to a green fund for each clothing piece they produce or import.

Around the World 14 PAKISTAN TEXTILE JOURNAL - February 2024

Tanya Plibersek, Australian environment minister

BANGLADESH

Bangladesh's home textile sector struggles amidst gas crisis and exchange rate volatility

The once-thriving home textile sector of Bangladesh is facing tumultuous times in the global export market, grappling with a confluence of challenges ranging from a persistent gas crisis to volatile exchange rates and soaring production costs. The sector, which witnessed a promising trajectory in previous fiscal years, has now encountered a sharp downturn, compelling several factories to shutter their operations.

After crossing the significant milestone of $1 billion in exports during the fiscal year 2020-21, the sector experienced a formidable setback in 2022-23. The adverse impacts of the gas crisis and a notable depreciation of the taka against the US dollar contributed to a staggering 32.47 percent decline in exports, plunging to $1.09 billion. The situation further exacerbated in the subsequent fiscal year, with shipments plummeting by 34.37 percent to $454.74 million between July and January of 2023-24.

The dwindling export figures have triggered a notable decline in the number of active home textile mills, dwindling from 38 to a mere eight establishments. The instability in the foreign exchange market has exacerbated the sector's woes, with the taka depreciating by approximately 30 percent against the US dollar over the past two years, rendering exports less competitive and imports costlier.

The immediate aftermath of the government's decision to hike gas prices from Tk 16 to Tk 30 per unit in February last year dealt a severe blow to millers, escalating production costs significantly. Home textile production, heavily reliant on gas for steam boilers and dyeing processes, faced unprecedented challenges as international retailers turned to alternative markets like Pakistan, leveraging its abundant cotton resources and favorable exchange rates.

The repercussions of the gas crisis are palpable, with local home textile millers

witnessing a staggering surge in gas bills, exerting immense financial strain on businesses. Moreover, the withdrawal of the 9 percent lending rate ceiling by the central bank has escalated the cost of funds for entrepreneurs, further exacerbating the sector's financial woes.

Amidst these challenges, industry leaders like Monsoor Ahmed of the Bangladesh Textile Mills Association (BTMA) and BTMA President Mohammad Ali Khokon warn of dire consequences if the gas situation remains unresolved, fearing the imminent closure of more textile mills.

BRAZIL

Brazil holds ground as second-largest cotton exporter despite production setback

Despite facing a 10 percent decline in cotton production last year, Brazil maintained its position as the world's second-largest cotton exporter in 2023, a testament to its resilience in the face of challenging circumstances. Figures released by the Brazilian Cotton Growers Association (Abrapa) reveal that Brazil exported 1.617 million tons of cotton, generating export revenues of US $3.06 billion.

Abrapa President Alexandre Schenkel attributes the production drop to adverse weather conditions during the 2022/23

crop season, coupled with a challenging global cotton market. Schenkel highlights the impact of ongoing geopolitical conflicts, such as the Russia-Ukraine and Israel-Palestine conflicts, on the global economy, leading to market instability, inflationary pressures, and reduced demand for cotton.

The repercussions of these conflicts manifested in decreased demand from textile mills, operating at lower capacities throughout 2023 and importing lesser quantities of cotton. Despite these challenges, Brazil managed to export 74 percent of its cotton in the second half of 2023, exceeding the volume recorded in the previous year by 24 percent.

In addition to its export prowess, Brazil solidified its position as the thirdlargest cotton producer globally in the previous season, further underscoring its significance in the cotton market.

CHINA

China's cotton export landscape a delicate balance amidst global shifts

China's export figures for refined cotton and specialty cotton linter pulp in 2023 offer insights into the delicate balance between growth and challenges. Despite a marginal 0.74 percent yearly increase, reaching a total of 82,292 tons, the significance lies not just in the numbers, but in the nuanced fluctuations throughout the year.

Around the World 15

Around the World

Throughout 2023, export volumes experienced oscillations, ranging from a low of 5,403.5 tons in June to a peak of 7,740.8 tons in August, with an average monthly export volume settling at 6,857.7 tons. This pattern reflects the intricate interplay of market dynamics and seasonal demands.

The trajectory of these exports follows a notable surge in 2022, with a remarkable 22.3 percent increase from the previous year, signaling robust growth and reaching unprecedented heights.

Diving into the geographical distribution of exports, refined cotton and specialty cotton linter pulp found their way to 40 countries and regions. Impressively, the top five markets accounted for a substantial 74 percent of overall exports, underscoring China's diversified yet concentrated export strategy.

Among these markets, South Korea emerged as the frontrunner, absorbing 27,965 tons of the total exports in 2023, marking a notable 25.9 percent increase and claiming a significant 34 percent share of the total exports.

However, amidst these success stories, challenges loomed large. Exports to the United States witnessed a staggering decline of 90.3 percent, plummeting to a mere 346 tons. Similarly, shipments to Germany also experienced a notable downturn, plummeting by 82.5 percent to 722 tons. These shifts reflect

not only market dynamics but also geopolitical and economic factors influencing trade relations.

Delving deeper into pricing dynamics, exports to France commanded the highest export price, fetching an impressive US $2,378 per ton. In contrast, exports to South Korea secured the lowest price point, at $1,387 per ton, highlighting the variance in market demands and willingness to pay.

China's imports of spandex skyrocket amid global supply dynamics

China's spandex imports witnessed a remarkable surge in 2023, underscoring the nation's pivotal role in the textile industry. Import figures surged by 22,112 tons, marking an unprecedented 85.6 percent increase over the previous year, with total imports reaching an impressive 47,900 tons.

Despite the substantial increase in import volumes, the average import price experienced a noteworthy decline, plummeting by $3.36 per kg to settle at $5.36 per kg on a year-on-year basis. This juxtaposition of soaring volumes and declining prices highlights the complex interplay of demand, supply, and pricing mechanisms within the spandex market.

The dominance of a select few countries in China's spandex imports became evident, with imports from four

key nations comprising a staggering 97.5 percent of the total. Notably, Vietnam emerged as a frontrunner, with imports soaring to 36,600 tons, marking a phenomenal 173 percent increase and capturing an impressive 80 percent import share.

Within China, specific provinces emerged as focal points for spandex imports, with Zhejiang, Guangdong, and Jiangsu provinces collectively commanding a substantial 95.3 percent import share. Notably, Zhejiang Province emerged as a powerhouse, with import volumes skyrocketing to 31,200 tons in 2023, marking a staggering 166 percent increase over the previous year. With a commanding 65 percent import share, Zhejiang Province solidified its position as a key player in China's spandex market.

EUROPEAN UNION

EU reaches milestone Agreement on economic governance reform to boost sustainability

The European Union has forged a provisional political agreement aimed at overhauling its economic governance framework, with far-reaching implications for member states. Spearheaded by Belgian finance minister Vincent Van Peteghem, the agreement marks a significant stride towards fostering sound and sustainable public finances while promoting inclusive growth and investment.

Central to the reform is the commitment to fortify the existing framework, ensuring its efficacy and applicability across all EU nations. Emphasizing the need for balanced and sustainable public finances, the agreement places a premium on structural reforms and strategic investments, envisaging a landscape conducive to robust growth and job creation throughout the Union.

Crucially, the agreement underscores a steadfast commitment to reducing debt ratios and deficits in a gradual, pragmatic, and growth-oriented manner. By prioritizing investments in key sectors such as digital transformation, environmental sustainability, social

16 PAKISTAN TEXTILE JOURNAL - February 2024

welfare, and defense, the reform paves the way for a more resilient and forwardlooking economic landscape.

In addressing macroeconomic imbalances and facilitating countercyclical policies, the agreement introduces mechanisms to guide member states towards fiscal prudence and long-term sustainability. Notably, provisions for extending fiscal adjustment periods underscore a nuanced approach to balancing fiscal discipline with the imperative of fostering resilience and growth.

Moreover, the reform aligns with broader EU objectives, including the pursuit of a fair, green, and digital transition, bolstering energy security, and enhancing social and economic resilience. By prioritizing sustainability and flexibility, the agreement reflects a holistic approach to steering the Union towards a prosperous and resilient future.

However, the journey towards implementation entails rigorous scrutiny and democratic deliberation. Subject to approval by the Council and the Parliament economic affairs committee, the agreement will undergo meticulous review before a formal vote is cast. This rigorous process underscores the EU's commitment to transparency, accountability, and democratic decisionmaking.

INDIA

Indian cotton spinning sector poised for robust growth in 2024-25

The Indian cotton spinning sector is set to embark on a trajectory of robust growth, with projections indicating a substantial expansion of 12-14 percent in fiscal 2024-25, commencing from April 1. A key driver of this growth is the anticipated surge in cotton yarn exports, expected to skyrocket by 85-90 percent, propelled primarily by the "China Plus One" strategy.

An ICRA press release highlighted that the surge in Indian cotton yarn exports will be spearheaded by increased imports from the United States and the European Union, particularly during the spring-summer season. This uptick in

Around the World

overseas shipments marks a significant turnaround following a sharp decline of 53 percent observed in the 2022-23 fiscal year.

Despite the optimistic export outlook, ICRA foresees a deceleration in cotton prices, which is likely to impact yarn realizations, consequently leading to a decline of 9-10 percent in sector revenues compared to the previous fiscal year.

The rebound in yarn exports is underscored by a remarkable 142 percent increase in total export volumes, albeit from a low base in the previous fiscal year. This growth trajectory has resulted in the share of yarn exports in overall production surging to 33 percent in the seven months leading up to October 2023, from 19 percent in the corresponding period of the previous fiscal year.

KENYA Kenyan cotton and textile industry stakeholders rally against duty-free fabric imports

The Kenyan cotton and textile industry is sounding the alarm over the government's decision to allow duty-free imports of fabrics, sparking concerns of dire consequences for local farmers and manufacturers. Stakeholders vehemently oppose the move, citing its potential to devastate cotton farming and cripple already struggling textile industries.

According to media reports, the decision threatens to undermine the gradual revival of cotton farming across several regions of Kenya and jeopardize the efforts to modernize key textile mills like Rivatex. Industry leaders warn that such a policy shift not only undermines the livelihoods of cotton farmers but also undermines the availability of locally sourced cotton.

Highlighting the commitment of farmers to meet domestic demand for cotton, stakeholders emphasize the need for government support to sustain this crucial sector. The importation of dutyfree fabrics is seen as a severe blow to the efforts aimed at revitalizing the cotton farming landscape.

Tejal Dodhia, Managing Director at Thika Cloth Mills, raises concerns about the adverse impact of duty-free fabric imports on domestic industries, warning of potential job losses. Dodhia stresses the importance of upholding the "Buy Kenya, Build Kenya" ethos to safeguard local businesses and livelihoods.

Rivatex Managing Director Thomas Kipkurgat underscores the significance of ongoing modernization efforts in enhancing the capacity and quality of Kenya's textile industry. Kipkurgat urges all stakeholders to unite in rejecting the proposal to import fabrics duty-free, emphasizing the need to prioritize the interests of local farmers and workers.

As the modernization of textile plants nears completion, stakeholders are calling for a united front against policies that threaten the progress achieved thus far.

17

ALLIED Feather + Down Ramps Up RENU:TRACE Program Through Partnership with NEMO Equipment

NEMO’s Endless Promise® circularity program is the first to utilize ALLIED’s one of a kind traceable down recycling program

ALLIED Feather + Down (AF+D), global leaders in high performance, ethically sourced, and recycled down, is proud to officially ramp up their one of a kind RENU:TRACE recycled down program with the help of NEMO’s Endless Promise® circular product collection. NEMO will be the first brand to utilize ALLIED’s industry leading recycling program to fuel the world’s first fully traceable recycled down insulation.

All ALLIED down is 100% ethically sourced and traceable back to the region where it was produced, and is therefore the ideal down material for their RENU:TRACE program. When NEMO’s Endless Promise down sleeping bags reach the end of their lifespan, ALLIED will fully recycle them and funnel the insulation into RENU:TRACE, the first and only fully circular and traceable recycled down insulation.

PFAS-free, RDS-certified ALLIED down fill. In addition to being made from recycled fabrics, each bag is 100% recyclable to stay out of the landfill at the end of its life.

While NEMO is the first to participate, the RENU:TRACE program is available to all of ALLIED’s partner brands.

“Recyclable and naturally biodegradable, down is one of the most sustainable insulations on the planet and plays an important role in a circular economy,” said Daniel Uretsky, President with ALLIED. “We launched our RENU:TRACE program in November, 2022, understanding the importance of ensuring animal welfare through traceable recycled down. We are excited to see the realization of RENU:TRACE’s potential within the NEMO Endless Promise program.”

Unless traceable down is both sourced and recycled in a closed loop, it is virtually impossible to ensure that any recycled down comes from purely ethical sources. Before RENU:TRACE, brands had to make a decision to either focus on post-consumer recycled material OR ethically treated animals.

For Spring 2024, NEMO’s top-selling down sleeping bags will be part of the fully recyclable Endless Promise Collection. The Disco™ and Riff™ Spoon™ shape sleeping bags, and the brand-new mummy-style Coda™ all incorporate technical features like next-generation Thermo Gill™ vents for fine-tuned temperature control; waterproof hood and footbox fabrics; and

About ALLIED Feather + Down

Founded in Vernon, Calif. in 1987, ALLIED has been responsibly sourcing and sustainably processing down while simultaneously driving innovation within the insulation market for over 30 years. The family owned and operated business has earned the reputation as the largest, most reliable and most responsible supplier of raw material in the industry. Through the creation of programs such as the Responsible Down Standard (RDS) and TrackMyDown, ALLIED is committed to safeguarding the welfare of animals while protecting the environment. ALLIED remains a family-owned company with facilities worldwide and is proud to produce the highest quality down technologies demanded by the most discerning brands in the outdoor, hospitality and fashion marketplaces.

About NEMO

NEMO is a New Hampshire-based outdoor gear company known for creating award-winning products that are built to last, comfortable, and fun to use. Named one of Outside Magazine’s and Business New Hampshire’s Best Places to Work, NEMO has also been recognized as a small business leader for the environment by New Hampshire Businesses for Social Responsibility. NEMO’s reputation for design innovation across its product lines—tents, sleeping bags, sleeping pads, camp accessories, and furniture—is an outgrowth of its design philosophy to never bring anything to market that doesn’t offer a meaningfully better experience. NEMO’s team of designers and engineers are motivated by a passion for outdoor adventure and sustainability.

18 PAKISTAN TEXTILE JOURNAL - February 2024 Corporate News

Navis TubeTex announces strategic partnership with Fibroline to revolutionize dry impregnation solutions in the U.S.

Navis TubeTex, a leading provider of advanced machinery solutions, is proud to announce its strategic partnership with Fibroline, a Lyon, France-based technology, and engineering company, which developed and patented revolutionary dry impregnation technologies. The Fibroline technology can impregnate powder form materials in a controlled manor throughout porous structures. Fibroline operates four business units including medical solutions, nonwovens & textiles, technical yarns, and composite materials.

Under the terms of the partnership, Navis TubeTex and Fibroline will launch “Fibroline USA”, a unique innovation Center dedicated to the promotion of Fibroline’s cutting-edge dry impregnation solutions for the U.S. market. Additionally, Navis TubeTex will be responsible for manufacturing and delivering the machinery required for U.S. customers, ensuring seamless access to Fibroline's groundbreaking technology.

"We are thrilled to announce this strategic partnership with Fibroline," said Will Motchar, President & CEO at Navis TubeTex. "Fibroline's expertise in dry impregnation technology aligns seamlessly with our commitment to delivering cutting-edge solutions to our customers.

This collaboration further demonstrates our strategic mission to provide sustainable solutions for coating, dyeing, and impregnation.

"We believe that this partnership with Navis TubeTex and the creation of Fibroline USA will significantly enhance our reach and impact in the U.S. market," said Jerome Ville, CEO at Fibroline.

"Navis TubeTex's reputation for excellence and commitment to innovation make them the ideal partner to introduce our dry impregnation solutions to a broader audience. We look forward to a successful collaboration that will revolutionize the industry landscape."

This partnership between Navis TubeTex and Fibroline represents a strategic alignment of expertise and resources, poised to elevate the standards of dry impregnation solutions in the U.S. market. The companies are committed to providing customers with unparalleled support, cutting-edge technology, and a seamless experience as they embark on this transformative journey together.

20 PAKISTAN TEXTILE JOURNAL - February 2024 Corporate News

Vickers Oils secures OEM approval from Lonati S.p.A., Italy

Vickers Oils is delighted to announce a significant milestone in our partnership with Lonati, as we have earned an Original Equipment Manufacturer (OEM) approval for our VICKERLUBE SOCK 46 needle oil.

Lonati, now officially recommends this product for use in their singlecylinder GOAL series, marking a successful collaboration that required dedicated efforts from Lonati, Lubrogamma, and Vickers Oils teams.

After rigorous testing and trials of VICKERLUBE SOCK 46 on Lonati singlecylinder machines, we received the much-anticipated approval earlier this year. This achievement is a testament to the dedication of our long-term Italian partners, Lubrogamma, who played a pivotal role in facilitating this partnership.

Lonati, a prominent name in the industry for over 70 years, is known for designing and manufacturing an impressive average of 8000 machines annually. They place a strong emphasis on delivering the highest quality textile machinery, underpinned by a commitment to research and development that ensures the use of cutting-edge products, technologies, and processes in their machines.

Vickers Oils shares these values, leading the industry in quality and assurance through our continuous focus

on research and development, technological leadership, quality control, and exceptional customer service.

About the product

Vickers Oils are committed to sustainable product development and

VICKERLUBE SOCK 46 meets the clearly defined criteria set out by the Global Organic Textile Standard (GOTS) and conforms to ZDHC MRSL Level 1 certification.

Sustainability for generations

VICKERLUBE SOCK 46 is a mineral based needle lubricant which is designed to meet the criteria for modern sock knitting machine technology.

VICKERLUBE SOCK 46 provides a high standard of lubrication as well as holding very good stability properties and having a high resistance to oxidation. The product is readily scourable and holds a well-balanced additive system meaning that it is fully compatible with all machine components. It can also be used with any yarn type including elastane, to produce the highest quality end product.

Vickers Oils is actively working towards several sustainability goals, with several already successfully realised. One standout achievement is a 39% reduction in gas consumption on site since 2020, despite a 40% increase in production output compared to previous years.

As part of Vickers’ ongoing sustainability journey, the company is determined to become net-zero for Scope 1 and 2 emissions by 2028, a goal coinciding with Vickers Oils’ 200th anniversary.

Corporate News 21

VICKERLUBE SOCK 46 now approved for Lonati single-cylinder machines

Team Lonati, Lubrogamma and Vickers Oils, at Airedale Mills, Leeds,

A Swedish win-win partnership for ACG Kinna and Värnamo

Continuous investment in the latest automation technologies – involving a long-standing and close cooperation with TMAS member ACG Kinna – has ensured family-owned Värnamo Sängkläder AB has retained its leading position in the production of high-quality bedding against heavy odds.

At the recent Heimtextil exhibition held in Frankfurt, Germany, from January 9-12, Martin Åhlander – the third generation CEO of Värnamo, which has specialised in high quality Nordic bedding since its foundation in 1951 – explained that his company is now the only producer of pillows, mattress protectors and quilts with manufacturing remaining in Sweden.

Investment

“Around fifteen years ago, our competition from Asia got very intense, as companies over there started exporting bedding products of very high quality at much lower prices than we could possibly produce conventionally in such a highcost country as Sweden,” he said. “Our solution was investment in the latest automated technologies, enabling us to be both flexible and to respond very quickly to the needs of our customers while cutting costs. This has proved to be a winning approach.”

Värnamo first started collaborating with ACG Kinna in the 1980s, initially with the installation of automated overlock stitching units for quilt production, followed by further moves such as bringing in-house polyester ball fibre filling technology into its plant with Nowo filling machines.

High volumes

In a more recent development, Värnamo became one of the very first companies to install an ACG Kinna robotic pillow line. With the ability to fill and finish some 3,840 pillows in an eighthour shift, this line configuration enables the completely seamless fibre handling, filling, sewing and packing of pillows.

“We needed big volumes to enable such an installation, and they were forthcoming,” Åhlander said. “We are now producing and supplying eight times more pillows than we did before the installation, so we’re pretty happy about this decision.”

“Since the Covid-19 pandemic there have also been increasing problems with the logistics and cost of international shipping, leading to very long lead times for products from Asia on occasions, which has worked in our favour too,” added Martin’s mother and Värnamo’s sales manager Berit Åhlander Nilsson.

Complete process

Nowo – a long-established name in fibre filling technologies – became part of ACG Kinna at the end of 2021 and most recently, EyeTech, a young, Swedish developer of machine vision solutions for manufacturing, warehouse and factory automation has also joined the company.

“EyeTech exploits 2D, 3D and deep learning techniques for inspection, measuring, and robot guidance and is further enabling us to fulfil our promise of ‘complete process – one supplier,” explained ACG Kinna marketing and sales manager Tomas Aspenskog. “We now provide complete customised automation for the entire production chain – from the opening and weighing of the fibre to the packaging of the final products.

“With one partner, one installation and one freight delivery, each customer’s needs are individually covered, eliminating the headaches that arise from trying to coordinate multiple suppliers during a new installation. Värnamo is the flagship showroom for our automation capabilities and because they are so close to us, we often take other potential customers on visits to them, in order to fully demonstrate what is possible.”

“Our relationship with ACG Kinna is beneficial to both companies and we’re constantly exchanging ideas on both new process and technology improvements,” concluded Martin Åhlander.

Heimtextil 2024

“ACG Kinna had a very successful Heimtextil 2024, along with another TMAS member, Automatex, which is developing further technologies for home textiles with the emphasis on fully automated and highly integrated production lines,” said TMAS Secretary General Therese Premler-Andersson. “These technologies enable significant resource savings to be achieved, while making production in high-cost countries once more profitable. Cost effective manufacturing closer to the customer is also more sustainable, while enabling companies like Värnamo to change their cost structures but also increase their capacities and flexibility.”

22 PAKISTAN TEXTILE JOURNAL - February 2024 Corporate News

Pictured at Heimtextil 2024: Martin Åhlander and Berit Åhlander Nilsson of Värnamo, with ACG Kinna’s Tomas Aspenskog.

Archroma and Sanitized AG celebrate

a decade-long partnership and align strategically for enhanced collaboration in marketing,

Archroma, a global leader in color and specialty chemicals, proudly announces the continuation of its longstanding partnership with SANITIZED AG, marking collaborative success in the textile industry. This enduring alliance has been a cornerstone in driving innovation and setting industry standards, particularly for odor and hygiene management within the home textiles and apparel industry.

The textile landscape has witnessed the transformative power of the partnership between SANITIZED AG and Archroma, resulting in cutting-edge solutions and unparalleled quality across diverse applications. Archroma, recognized as the number one chemical supplier in its markets, further solidifies its position through the acquisition of Huntsman’s Textile Effects division in February 2023. “The acquisition enabled Archroma to broaden its global reach and technical expertise. Paired with our strong expertise in freshness additives, we enhance our marketing teams for joint communication, enhance the salesforce in the regions and strengthen our innovation force to drive the industry towards more sustainable solutions,” says Michael Lüthi, CEO of SANITIZED AG.

The partnership is a testament to the commitment to excellence and shared values that have defined the collaboration since its establishment in 1989 (with the Textile Division of Sandoz AG). "Our

sales and technology

strategic partnership marks a pivotal moment for the global textile market. Both our company's commitment towards sustainability, innovation, and technical expertise is a perfect match," adds Dhirendra Gautam, Vice President Product Marketing and Strategy, Archroma Textile Effects.

With a focus on strategic development, Archroma and SANITIZED AG aim to reinforce mills and brands in elevating their products by adding the value of freshness to their products and providing high-quality effects. This

collaboration offers customers a flexible package, completed with application support through technical service and expertise, along with access to a strong product portfolio. Notably, the partners are ready to lead market trends and transformations, particularly in freshness finishes, ensuring their collective success in the dynamic landscape.

The commitment to this cooperation symbolizes the resilience and strength of this alliance, and it is poised for continued success in the years to come.

23

The search reopens for the SDC’s Global Colourist of the Year 2024

Long-time education provider Society of Dyers and Colourists (SDC) is delighted to announce that applications have now reopened for its Global Colourist Award.

The award recognises the professional achievements of those working across the wider coloration sector. Entries are open to colourists worldwide across the full gamut of specialisms including – but not limited to – textiles, dyes and pigments, leather, food and paint. Production dyers, shift dyers or printing colourists are all eligible.

A £1000 prize is on offer for the chosen recipient, with Advanced Colours and Chemicals Ltd in Rossendale UK kindly sponsoring the competition.

The winner will also be invited to the SDC’s all-expenses paid Day of Celebration and awards ceremony on 8 November 2024, where they will be presented with a certificate and their prize money.

Applications are welcomed up until the deadline of May and supervisors, managers or directors can also nominate

an employee. Alternatively, people can put themselves forward, on the proviso that a referee can confirm their suitability.

Ian Lewis, managing director of Advanced Colours and Chemicals Ltd, said: “This award represents recognition of outstanding achievement within the first decade of an individual’s career. There was an excellent array of nominations submitted for last year’s award, so the bar has been set very high!”

Dr Graham Clayton, chief executive officer of SDC, said: “The society is once again delighted to be reopening applications for the Global Colourist Award for a second year running. We’re looking for an outstanding individual who is able to demonstrate enthusiasm, commitment, excellent performance, competence, a contribution to team effort and strong general knowledge of the coloration industry.”

In addition to the event invitation and the prize money, the winner and their employer will be featured in the SDC’s quarterly members’ magazine, The

Colourist. Runners up and those who are highly commended will receive book vouchers to use for SDC’s books or nontextile coloration books, sponsored via other sources.

Highly commended winner for 2023, Hannah Rampley, teaching technician at the University of Manchester, said: “Being selected as last year's Global Colourist was completely unexpected and was a huge achievement for me, so thank you to the judges for selecting me as their winner and to the SDC for the award.

“It’s not often that technicians get recognised for the work that they do to educate and inspire students, so it was a huge honour to receive this accolade.

“I look forward to seeing how my future career in colour will develop and receiving this from the SDC has given me a huge confidence boost and made me really look forward to what will come next!”

Judging of the entries will take place in June, with interviews scheduled in early September. The winner will be notified in mid-September.

24 PAKISTAN TEXTILE JOURNAL - February 2024 Dyes and Chemicals

Personnel changes at BRÜCKNER Textile Technologies

Personnel changes in Production and Materials Management as well as in Sales of New Machines

Mr. Raghav Kuberan took over responsibility for production and materials management at Brückner Textile Technologies GmbH & Co. KG in Leonberg and Tittmoning as Vice President Operations. On April 1, 2024, he will also assume responsibility for IT at both locations and will manage these three areas as Managing Director in the future. He will take over from Mr. Rüdiger Gieske, who is retiring after more than 25 years as COO.

On January 1, 2024, Mr. Alexander Mandel succeeded Michael Tuschak as Sales Director at Brückner Textile Technologies GmbH & Co. KG in

Leonberg, Germany. He has been General Manager of Brückner Sales & Services Shanghai since January 1, 2020. He will continue in this role in the future. Mr.

Mandel

Karl Mayer Türkiye appoints Toros Greenhalgh as new general manager

The KARL MAYER GROUP established its own site in Bursa, Türkiye, thus increasing its presence in one of its most important markets. KARL MAYER TURKEY will meet increasing customer demands for after-sales service, spare parts (Care Solutions), and academy, in the sectors of warp knitting and warp preparation, while KARL MAYER’s longstanding regional representative ERKO focuses on machine sales.

Toros Greenhalgh was appointed General Manager of KARL MAYER TURKEY on February 1st of this year. Holding a degree in mechanical engineering and materials science from the University of Birmingham, he comes with vast global experience in the fields of industrial plant construction management, renewable energy technologies, and the distribution of medical devices. Now in his late thirties, for the past seven years he has been active in the sector of textile machinery

through ERKO with particular focus on KARL MAYER machine sales, service, and spare parts.

In his new position, he is focussing on enhancing the after-sales support experience for customers.”I plan to streamline and optimize our service processes, ensuring efficient response times and topnotch customer satisfaction. Additionally, I aim to foster a collaborative and motivated team to deliver excellent support and ultimately strengthening our customer relationships”, says the General Manager.

He will be able to build on his extensive professional experience and the support of the KARL MAYER GROUP for

the tasks ahead. In particular, ongoing training programs and clear communication from the corresponding departments at headquarters will provide effective assistance for Toros Greenhalgh and his team.

Personalia 25

previously worked in the company’s design and project management departments for over 15 years.

Raghav Kuberan (Vice Director Operations) and Alexander (Sales Director)

Toros Greenhalgh; Karl Mayer Turkey General Manager

How

digitalisation

is driving

growth:

panel discussion on the future viability of the textile industry with reference to Techtextil and Texprocess

How is digitalisation affecting the textile industry in terms of innovativeness?

How can digitalisation be used to meet the challenges currently facing the sector? What are the latest developments? What does the digital future of the textile industry look like? In a panel discussion ahead of this year’s editions of Techtextil and Texprocess, experts considered these and other questions and previewed the trade fairs from 23 to 26 April 2024.

Digitalisation has by no means carved out a place for itself in the work processes

2024

of many companies. A study conducted by the German Economic Institute in 2022 revealed that, for example, only 31 percent of companies in Germany are able to use data efficiently1. However, it is essential for companies to improve their digital infrastructure because legal regulations, such as the EU strategy for sustainable and circular textiles and the associated digital product passport, require a corresponding level of digitalisation. At the same time, digitalisation helps to meet the sustainability requirements of customers and partners, for example, by improving

supply chain transparency or resource calculation. Thus, companies wanting to remain competitive and produce efficiently and flexibly, can no longer avoid digital technologies. Digitalisation offers solutions to many of the challenges currently facing the industry.

Techtextil and Texprocess support companies on their journey into the digital future. At these leading international trade fairs, over 1,600 exhibitors from around 50 countries are showcasing their latest developments and innovations. There, participants can find the right business partners and digital

26 PAKISTAN TEXTILE JOURNAL - February 2024

solutions to suit their individual needs. The extensive programme creates the ideal setting for discussions with the industry and experts.

"The sectors have an enormous potential for innovation, especially in the field of digitalisation. We can only realise this through a joint international exchange of information. The global industry meets at Techtextil and Texprocess. Dialogue, knowledge transfer, unique innovations and multifaceted solutions strengthen companies on their journey into the future", said Olaf Schmidt, Vice President Textiles & Textile Technologies, Messe Frankfurt.

Panel talk: From yarn to smart textileshow digitalisation is driving growth

In the panel discussion, Prof. Thomas Gries, Director of the Institute of Textile Technology (ITA) at RWTH Aachen University, Elgar Straub, Managing Director of VDMA Textile Care, Fabric & Leather Technologies, and Olaf Schmidt, Vice President Textiles & Textile Technologies of Messe Frankfurt, offered insights into digitalisation in the textile industry from a variety of perspectives. The discussion was chaired by Zackes Brustik.

Meeting challenges with digitalisation

Digitalisation helps companies meet the challenges currently facing their industries and remain competitive. Companies can take advantage of digital developments to counter raw material and labour shortages, energy costs or increased sustainability requirements and produce more efficiently, faster, more flexibly, more transparently and more costeffectivel.

"Constantly changing consumer and legislative requirements, as well as labor shortages and more difficult trading conditions due to geopolitical changes, are constantly posing new challenges for garment manufacturers and processors of technical textiles. The manufacturers of machines, systems and processes for processing textile materials offer the necessary solutions. Through digitalisation and automation for increased flexibility, sustainability, quality and increased product potential, we help our customers in their production and at the same time ensure a boost in innovation," explained Elgar Straub.

Research and the industry are promoting innovativeness

Although many companies have already digitalised individual stages in their process chains, it is essential that the entire textile value chain be digitalised and all gaps closed if the industry is to realise its potential to the full.

“Resilient and sustainable value chains are vital for the viability of the textile industry in the future. And the

basis for this is the digitalisation of all process stages. To this end, researchers and the industry must work closely together. New forms of cooperation, such as Open Innovation guarantee speed and efficiency”, said Prof. Thomas Gries.

Digitalisation opens up new potential

Digitalisation offers numerous new opportunities for technologies and textile products. And the latest developments will be on show at Techtextil and Texprocess. There, international exhibitors present their latest products. The spectrum ranges from manufacturing technologies, via textile processing machines, fibres, yarns and nonwovens, to functional and smart textiles. The variety of industries in which the products are used is unique.

From the medical and mobility sectors to the construction industry, they are used in all areas of application. Moreover, digitalisation is significantly advancing the textile industry: not only can manufacturing and processing procedures be made more efficient, but smart products can also create new added value.

Techtextil and Texprocess 2024: Up-todate on the subject of digitalisation

The comprehensive programme gives visitors the chance to update their knowledge. For example, the lectures of the Techtextil and Texprocess Forum spotlight aspects of digitalisation and production technology, as well as intelligent textiles, digital textile printing and delivery chains.

The extraordinary degree of innovativeness is also reflected by the Techtextil and Texprocess Innovation Awards. The categories of New Technologies and Digitalisation and Digitalisation and AI focus specifically on the latest developments in the field of digitalisation.

The events Techtextil and Texprocess will be held from 23 to 26 April 2024.

Fairs and Exhibitions 27

Olaf Schmidt, Vice President Textiles & Textile Technologies, Messe Frankfurt.

Prof. Thomas Gries, Director of the Institute of Textile Technology (ITA) at RWTH Aachen University

Elgar Straub, Managing Director of VDMA Textile Care, Fabric & Leather Technologies,

Giltex LLC (Azerbaijan) joins ITMF as Corporate Member

GILTEX LLC is the only company built with a vertical integration system, not only in Azerbaijan but also in the entire South Caucasus region. The company covers the textile production flow and consists of a spinning factory, two weaving factories, two dyeing factories, a garment factory, and a medical masks factory.

Mr. Christian Schindler, Director General of ITMF, stated that “ITMF is delighted to welcome Giltex in ITMF. That for the first time a fully integrated company from this region of the world joins ITMF shows that the textile business is truly a global industry. The desire to join an international network like ITMF that represents the entire textile value chain is an indication that companies around the world are looking for relevant information and networks. To successfully navigate these challenging times and to prepare for the future it is indispensable to have access to relevant facts and figures about the industry and to identify potential partners to collaborate with. ITMF is offering such a platform.”

Mr. Kanan Budagov, Head of Procurement Dept. of Giltex LLC, pointed out that “ITMF is a unique global organisation that brings together likeminded industry people from around the world. It provides a special environment that allows to discuss pressing issues and

trends that help to better understand the ongoing and constantly changing dynamics in the global textile industry. In today’s world companies must develop long-term strategies based on reliable information. ITMF offers such information as well as provides access to a unique network of industry experts. To learn from the industry and to discuss with the entire textile value chain – from fibre producers to producers of home textiles and garments – how to overcome the challenges and turn them into opportunities is crucial.”

28 PAKISTAN TEXTILE JOURNAL - February 2024

63nd Dornbirn GFC Global Fiber Congress 11 – 13 September 2024, Dornbirn Austria