Intertex Tunisia

Dates: October 6th to 8th 2022. Venue: Tunisia.

IGATEX Pakistan 2022, Lahore

Dates: December 1st to 4th 2022. Venue: Expo Centre, Lahore.

FESPA 2023

Dates: May 23rd to 26th 2023. Venue: Munich, Germany.

Textile Asia 2022, Faisalabad

Dates: October 29th to 31th 2022. Venue: Quilim Marquee, Canal Road Faisalabad, Pakistan

Textile Asia 2023, Karachi

Dates: March 11th to 13th 2023. Venue: Expo Centre, Karachi.

ITME INDIA 2022

Dates: December 8th to 13th 2022. Venue: India Expo Centre & Mart. Noida, India.

Index 2023

Dates: April 18th to 21th, 2023. Venue: Palexpo, Geneva, Switzerland.

Heimtextil 2023, Frankfurt

Dates: January 10th, to 13th, 2023 Venue: Frankfurt am Main.

JIAM 2022 OSAKA

Dates: Nov. 30th to Dec. 3nd 2022. Venue: Osaka, Japan.

INTEX SOUTH ASIA 2022

Dates: December 8th to 10rd 2022. Venue: New Delhi, India.

DOMOTEX Hannover 2023

Dates: January 12th to 15th 2023. Venue: Hannover, Germany.

ITMA 2023

Dates: June 8th to 14th, 2023. Venue: Milan, Italy.

ITMA ASIA + CITME 2023

Dates: November 19th to 23th, 2023. Venue: NECC, Shanghai, China.

iCADEX Pakistan 2022, Lahore

Dates: December 1st to 4th 2022. Venue: Expo Centre, Lahore.

Istanbul Yarn Fair

Dates: February 16th to 18th 2023. Venue: Istanbul, Turkey.

ITM 2024

Dates: June 4th to 8th, 2024. Venue: Istanbul, Turkey.

DOMOTEX asiaCHINAFLOOR 2023

Dates: May 29th to Sep. 31st 2023. Venue: NECC, Shanghai, China.

HIGHTEX 2024

Dates: June 4th to 8th, 2024. Venue: Istanbul, Turkey.

2 Calendar of Events

PAKISTAN TEXTILE JOURNAL - October 2022

Founded in 1951 by Mazhar Yusuf (1924-2009)

Publisher

Nadeem Mazhar

Editor in Chief Amina Baqai

Associate Editor

Dr. Noor Ahmed Memon

Associate Editor

Nimrah Nadeem

Associate Editor

Shahnawaz Khan

Production Manager Mazhar Ali

Hony-Editorial Board

Dr. Hafizur Rehman Sheikh Ph.D (UK) F.T.I. (UK)

Syed Mahfooz Qutab C.TEX, F.T.I (U.K), B.Sc. Fellow I.C.T.T Atlanta, GA; (USA)

Mian Iftkhar Afzal B.S.N.C State, M.Sc. (Leeds) C.TEXT.F.T.I (UK)

Dr. Zubair Bandukda PhD (Textiles), CText ATI

Editorial & Advertising Office B-4, 2nd Floor, 64/21, M.A.C.H, Miran M. Shah Road, Karachi - Pakistan Tel: +92-21-34311674-5 Fax: +92-21-34533616 Email: info@ptj.com.pk URL: http://www.ptj.com.pk

PTJ Europe Ltd.

Correspondence & Mailing address: 93 Fleming Place, Bracknell, RG12 2GN, United Kingdom Tel: +44 792 2228 721

Registered Office: Dairy House, Money Row Green, Holyport, Maidenhead, Berkshire, SL6 2ND, UK

Registered no. 09141989

Available on Gale and Factiva affiliated international databases through Asianet Pakistan

Printed at: Color Plus Korangi, Karachi.

Published by Nadeem Mazhar from D-16, K.D.A. Scheme No.1. Karachi.

Vol. LXXI No. 10 October 2022 Rs. 565.00

EDITOR’S PAGE . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Higher costs of doing business and uncertainty are not conducive to the textile industry

TEXTILE BRIEFS . . . . . . . . . . . . . . . . . . . . . . . . . . .8

NEWS & VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . .10

AROUND THE WORLD . . . . . . . . . . . . . . . . . . . . . .14

CORPORATE NEWS

Hong Kong Polytechnic University announces the establishment of the school of Fashion and Textiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

James Heal celebrates its 150th anniversary . . . . . . . . . . . . . . . . . . . . . . . . .20

Rieter expands service footprint in Kahramanmaraş, Turkey . . . . . . . . . . . . . .22

ExxonMobil expands product portfolio to advance healthcare solutions . . . . . . . .24

Dysin Group inaugurates new plant for Specialty Polymer in Gazipur . . . . . . . .26

20 18

28 FAIRS AND EXHIBITIONS ITMA ASIA + CITME 2022 rescheduled to November 2023 . . . . . . . . . . . . . . . . . . . . .28 India ITME 2022 at new world class Venue – IEML, Greater Noida . . . . . . . . . . . . . . .29 PERSONALIA Trützschler Group SE expands Board of Directors . . . . . . . . . . . . . . . . . . . . . .27

FEATURES

INTERVIEW

DYEING, PRINTING AND FINISHING

30 32 36 50

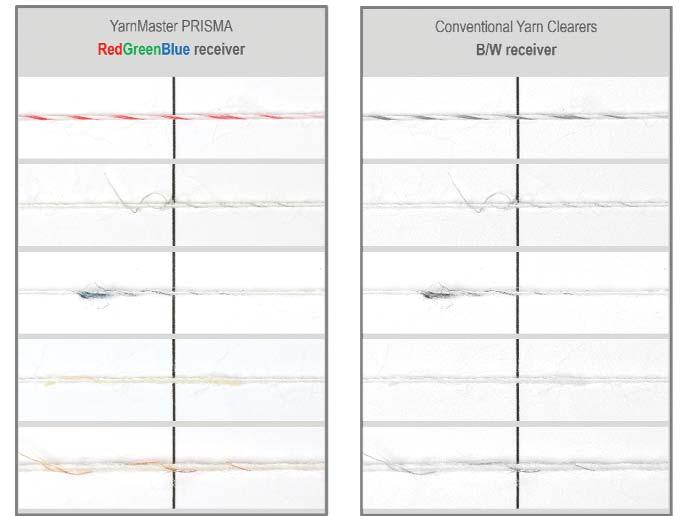

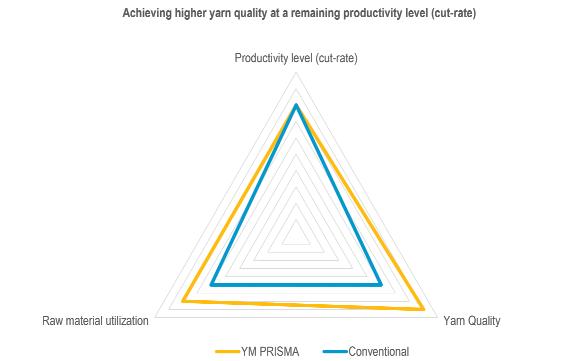

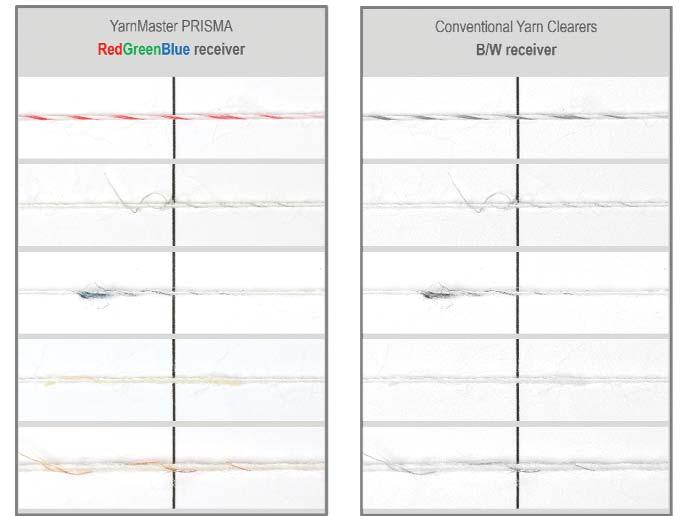

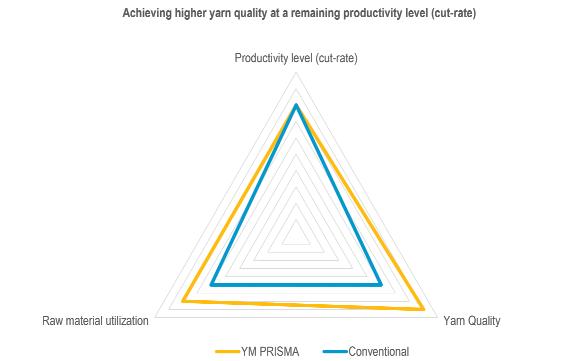

Accotex: Field tests confirm high performance of new Accotex aprons . . . . . . . . .30 LYCRA announces collaboration with Qore® to use QIRA® for Bio-Derived LYCRA® .32 World Cotton Day: Challenges for Pakistan’s cotton industry . . . . . . . . . . . . . .34 Suessen: Economical Compact-Spinning using state-of-the-art technology . . . . . . .36 Loepfe YarnMaster® PRISMA100% color monitoring leads the way! . . . . . . . . . . . .38 38 46 42

Swiss Textile Manufacturing – 30 years of sustainable progress . . . . . . . . . . . . .40 Cotton Council International celebrates its third Cotton Day in Mumbai . . . . .42 A World without odors, Fight or Flight? . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

SPECIAL REPORTS

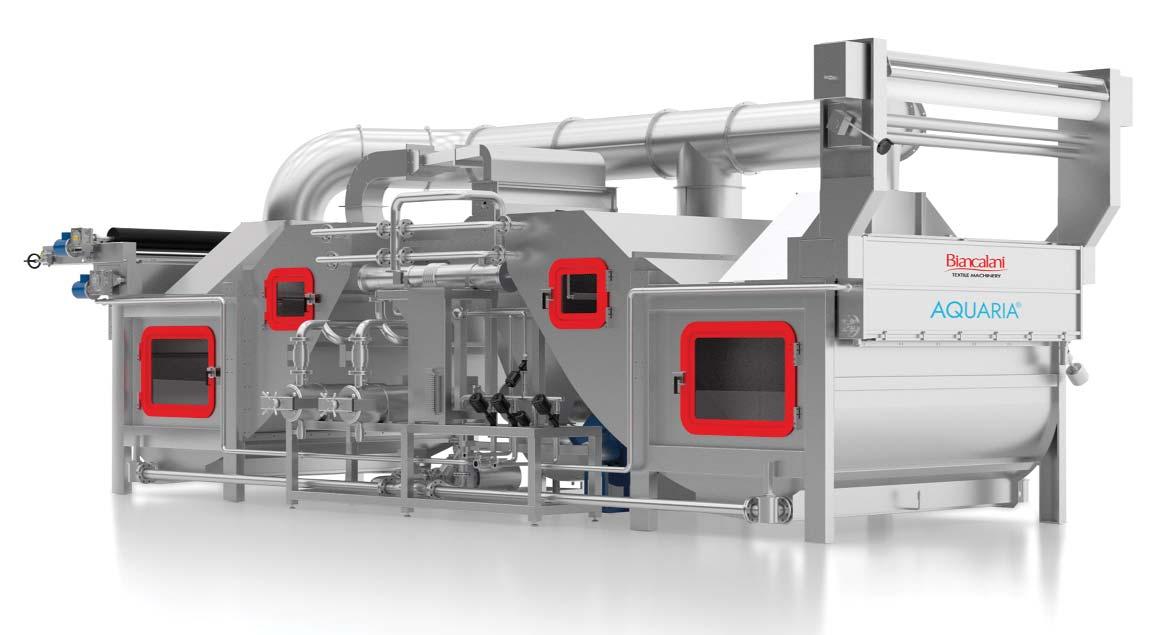

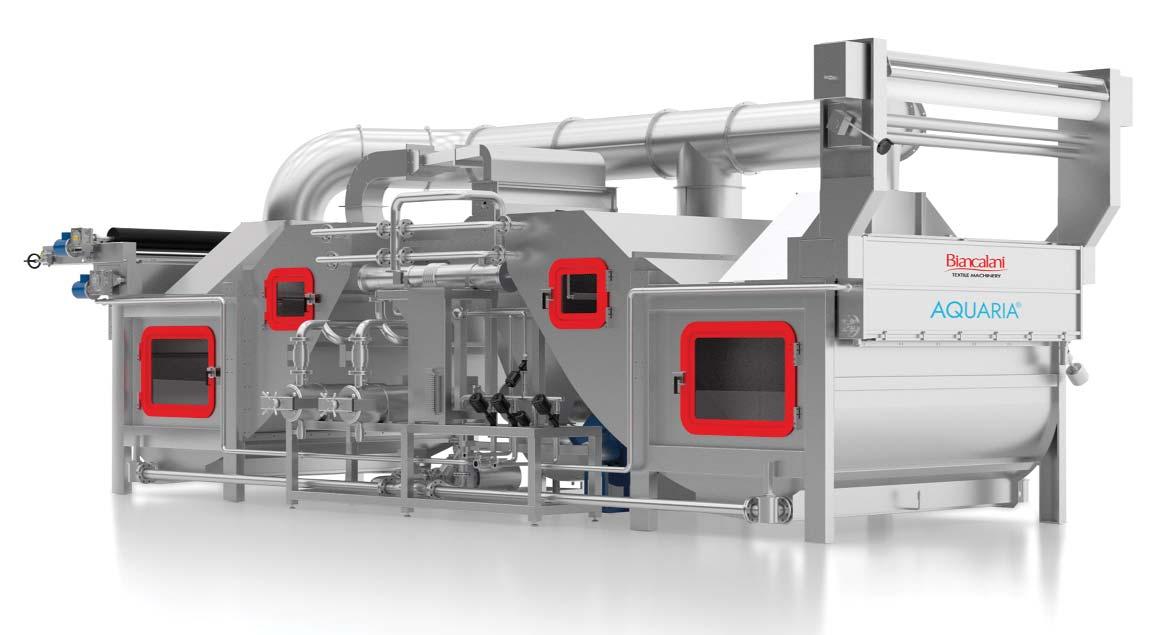

Unique waxed cotton finishing with new Monforts line . . . . . . . . . . . . . . . . . .50 AQUARIA® offers limitless potential for after-printing washing process . . . . . . .52 BRÜCKNER Textile Technologies & HEATHCOAT FABRICS – the journey continues . .54 Demsan - Leading manufacturer of textile machine . . . . . . . . . . . . . . . . . . . .56 Jeanologia empowers a new generation of tech artisans at DenimandJeans Japan . .58 Makroser Tekstil’s carpet production soars with a Mimaki TS300P-1800 . . . . . .60 Tonello: New O-Zone cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62 58

Stäubli creates new benchmarks with high-performance textile machinery . . . .46

Mr. Fritz Legler – Division Marketing Officer, Stäubli Textile

Interview:

Higher costs of doing business and uncertainty are not conducive to the textile industry

The Pakistani rupee witnessed a record decline in July 2020 when PKR traded above 240 to the dollar. This was over 35% depreciation of the Rupee against the USD since November 2021. While the PKR has witnessed a slight recovery since then, Pakistan is facing unemployment, high-interest rates and record inflation as a result of political and economic uncertainty due to internal and global factors including the war in Ukraine. As Pakistan is a net importer of fertilizers, oil, food items, machinery, and many raw materials, under the current scenario, the prices of commodities are increasing at a high pace due to the increase in the prices of imported goods.

The PKR depreciation has significantly increased the cost of doing business and will adversely affect Pakistan’s competitiveness in the international market. The first consequence of a depreciated Rupee logically would be an expected increase in exports. That expected surge in exports is not forthcoming due to the global recession and the highest inflation Pakistan has witnessed in decades.

The PKR depreciation is forcing Pakistan’s Gross Domestic Product (GDP) towards a downfall due to the higher cost of imported goods and increased exports at lower prices. The economy is suffering due to the imbalance between imports and exports.

Pakistan’s textiles had fared extremely well compared to other countries when dealing with the Covid19. During that period 2020 to 2021, Pakistan’s exports witnessed record growth and the industry buoyed by the great performance made good use of the favourable financial incentives by investing more than $5 billion (Rs1 trillion) in setting up new factories to meet their export commitments.

According to Mr. Shahid Sattar, Secretary General APTMA, some of these installations were now complete while the others are in the process. Due to the extraordinary decline in the foreign exchange reserves, some of the machinery of new plants/expansions was still stuck at ports, as letters of credit were being delayed. Also, electricity and gas are not being provided to these new units.

“If remedial action is not taken on non-functionality of this new investment; then instead of increasing exports by $5 billion per annum, it will likely lead to massive banking defaults, and complete loss of investor confidence in future for any investment in Pakistan with many other negative consequences,” Sattar said.

SBP has now stated that imports under Chapters 84-85 would be released. However, only direct exporters, whereas indirect exporters were neglected, these exporters keep the industry running. The intermediate goods exports are now suffering and will drop over time as this will result in the shutting down of mills due to lack of maintenance and availability of vital spare parts.

Pakistan also needs to import at least 5 million cotton bales this fiscal as well due to recent flood damages to the cotton crop. Flood-related losses to the cotton crop are currently estimated at 3.5 million bales, or 36 per cent of the anticipated harvest this year amounting to a total loss of over $1 billion.

Urgent policy measures by the government are required to arrest the decline in the industrial sector due to a multitude of economic issues faced by the country.

7 EDITOR’S PAGE

1951 October 2022 Dyeing, Printing and Finishing II

Established

October 2022

1The clothing and textile sector in Pakistan is anticipating a drop of at least 30% in the value of exports after the recent floods wiped out much of the country’s usually plentiful cotton crop, and the sector is seeking out strategies to buy cheaper cotton abroad.

2Effective from October 2022, the government has decided to discontinue the concessional tariff given to consumers of export oriented sectors. According to an official memorandum issued by the ministry of energy, the concessional tariff scheme to consumers of the export-oriented sector will be discontinued with effect from October 1, 2022.

3Pakistan’s textile exports have increased 6.37 per cent to $1.57 billion in August 2022 compared to last month’s $1.48 billion exports, with all major components – cotton cloth, knitwear, bedwear, towels, and readymade garments –showing growth. Textile exports were up 7.7 per cent over August 2021 exports of $1.46 billion, the Pakistan Bureau of Statistics (PBS).

4The Pakistan Hosiery Manufacturers and Exporters Association (PHMA) North Zone has elected Naseer Butt as its new zonal chairman for the period of one year 2022-23.

5Pakistan's Finance Minister has said that the country's textile sector had demanded the lifting of a ban on the import of cotton from India, but the government has so far not taken any decision on the issue.

6Asif Inam, Chairman, APTMA – Southern Zone urges the government for allowing the immediate release of textile machinery and spare parts that were stuck up due to restrictions on the import of items covered under Chapters 84 and 85 of the Customs Tariff.

7The Ministry of Finance and the Federal Board of Revenue (FBR) have

agreed to clear Rs 36 billion in deferred sales tax refunds of the textile sector in 32,000 cases pending since 2019. The decision to this effect was taken during a meeting of the Finance Minister with a delegation of the All Pakistan Textile Exporters Association (PTEA).

8Irfan Iqbal Sheikh, President, Federation of Pakistan Chambers of Commerce and Industry (FPCCI), the apex trade body of Pakistan urged the government has urged that the government to reintroduce the regime of fixed exchange rate and stop latest cycle of devaluation of the Pakistani Rupee (PKR) against the US dollar.

1The BGMEA recently urged investment in the country’s readymade garment sector as it gears up for graduation from its status as a least developed country (LDC). The country is expected to graduate from LDC status in 2024.

2Textile companies in China with an annual primary business revenue of at least 20 million yuan (about 2.89 million U.S. dollars) raked in 2.96 trillion yuan in revenue in the period, up 4.6 percent year on year. In this way the industry posted stable revenue growth in the first seven months of the year.

3Tajikistan's cotton exports to Uzbekistan vastly increased from January through June 2022. According to the statistics, cotton exports from Tajikistan to Uzbekistan in the reporting period amounted to $17.3 million.

4Bangladesh is an emerging star in the global textile industry as it has succeeded in converting itself into a global factory for textile products. Bangladesh apparel exports touched $42.61 billion during last fiscal 2021-22 (July-June).

5The 2022 revenue of the Italian fashion and luxury industry as a whole, including textiles, leather goods, apparel,

footwear, jewelry, beauty products and eyewear, is expected to reach Euro 92 billion, up 10.5% over 2021

6Japan’s imports of clothing and accessories increased by 47.3 per cent year-on-year to 400,348 million yen (approximately $2,791 million) in August 2022.

7The India International Textile Machinery Exhibition Society (ITME) has signed a Memorandum of Understanding (MoU) with Kenya National Chamber of Commerce and Industry (KNCCI), aimed at building new opportunities for growth in the industry.

8According to reports, the exports of the Turkish textile and raw materials sector increased by 7.5% in the January-August 2022 period compared to the same period of the previous year and reached 8,8 billion dollars.

9

Cotton exports from the US witnessed a steep fall to $28.362 million in July 2022 from $1,062.592 million in June 2022.

10Many textile and garment enterprises in Vietnam are seeing a sharp drop in export orders, mainly in the US and EU, because inflation pressure in these nations is large, forcing consumers to tighten spending.

8 PAKISTAN TEXTILE JOURNAL - October 2022

Textile Briefs National

Textile Briefs International

The clothing and textile sector in Pakistan is anticipating a drop of at least 30% in the value of exports after the recent floods wiped much of the country’s usually plentiful cotton crop, and the sector is seeking out strategies to buy cheaper cotton abroad.

Textile and garment exports from Pakistan amounted to US$21bn in the fiscal year 2021-22, said the All Pakistan Textile Mills Association (APTMA), but now, due to the devastation caused by flooding, industry experts fear a probable cancellation of many export orders by international brands.

With more than 40% cotton production in Sindh province, southern parts of the Punjab province and parts of Balochistan inundated, the APTMA and other industries fear the textile and garment exports may fall from shrinking production and increased costs, with APTMA noting this will hit “the government’s vision to achieve the export volume of US$50bn in the coming years”.

With the view to fostering exports and boosting the economy of the country, last month (August) APTMA unveiled a plan to launch a road map to achieve US$50bn in exports by increasing the country’s stitching-focused clothing manufacturing sector to process an additional US$3bn worth of yarn and

fabrics. In this way, it would boost Pakistan’s value-added garments for export, generating an additional income of US$10bn.

The Pakistan Textile Exporters Association has suggested to the country’s federal minister for finance and revenue to allow cotton imports from neighbouring India as it would be cheaper compared to cotton imports from Central Asia countries and other locations. However, the government has yet to take a decision in this direction.

Pakistan urged to add value to textile goods

The US Cotton Council International (CCI) has urged Pakistan to manufacture and export textile goods to America after enormous value-addition. The advice came at a meeting held between the All Pakistan Textile Mills Association (Aptma) and the CCI, with the objective of apprising the body about cotton quality, challenges, and possible solutions vis a vis challenges being faced by Pakistani cotton growers.

“Mutual cooperation between the American cotton growers and Pakistan’s textile industry offers a win-win situation for both countries where raw cotton imported from the US is converted into manufactured textile products and exported back to the US after enormous value addition,” said Kathleen Gibilisco, the Head of the Economic Wing of the US Consulate.

She was accompanying the US’s CCI delegation that called on the Aptma office bearers, emphasised the need for growth and sustainability in trade and economic relations between Pakistan and the US. She expressed hope that the current trend of growth in trade and economic ties would continue in the future as well.

The demand for improved product quality comes at a time when Pakistan is facing a severe shortage of approximately nine million bales this year due to various factors, including the devastation of the agriculture fields largely by floods.

It may be mentioned that Pakistan’s cotton demand continues to rise, as it needs 15m bales this year. The Aptma and CCI representatives resolved to boost bilateral cooperation in the area of cotton and explore investment opportunities in Pakistan.

Dealing with the cotton needs of Pakistan’s textile industry

More than 15 percent of Pakistan’s current cotton crop has been destroyed by severe rains and flooding, introducing a high level of uncertainty about the nation’s plans for export shipments. The All-Pakistan Textile Mills Association (APTMA) and the International Cotton Association (ICA) have agreed to strengthen their collaboration on the cotton needs of Pakistan’s textile industry.

Speaking at the event, APTMA chairman Rahim Nasir offered the

Pakistan garment exports could decline by 35% due to flooding

PAKISTAN TEXTILE JOURNAL - October 2022 10

APTMA facilities for the ICA training session. He also requested the ICA to establish an office on the APTMA grounds for better coordination, with the soaring need for cotton in the coming years.

Cotton, he added, is an important cash crop for Pakistan and a major raw material for its textile sector, accounting for 75 percent of the fiber mix in textile industry products, which provide a living for 25 million Pakistanis.

Chairman APTMA stated that cotton production in Pakistan has plummeted to less than 8 million bales this year, compared to a projected consumption of 13 million bales, due to water shortages, fake pesticides, and poor insect management. He noted that, when combined with other fundamental issues, the cotton import bill in FY022 has risen to roughly $1.8 billion.

He stated that Pakistan is becoming a cotton importing country, but importers are unaware of the ICA rules and their rights as buyers.

Textiles exports increase 6.37pc in Aug 2022

Pakistan’s textiles exports have increased 6.37 percent to $1.57 billion in August 2022 compared to last month’s $1.48 billion exports, with all major components – cotton cloth, knitwear, bedwear, towels, and readymade garments – showing growth.

Textile exports were up 7.7 percent over August 2021 exports of $1.46 billion, the Pakistan Bureau of Statistics (PBS). From July to August, the textile sector’s total exports increased by 4.2 percent to $3.056 billion from $2.93 billion the same period last year.

In August 2022, cotton cloth exports increased 7.37 percent to $195.4 million compared to $182 million in July 2022, while compared with August 2021, exports rose 3.8 percent from $188.2 million.

Over the previous month, knitwear exports increased 3.4 percent to $450 million; bedwear 1.7 percent to $258 million; towels were almost stagnant at $75 million; exports of readymade garments went up 8.35 percent to $330 million, whereas cotton yarn sales abroad increased 24.8 percent to $89.1 million.

Likewise, over the corresponding month of last year, cotton cloth exports were up 3.8 percent, knitwear 23.6 percent, and readymade garments 16.3 percent. However, over August 2021, exports of bedwear slashed 2.44 percent, towels 9.4 percent, and cotton yarn exports declined 14 percent.

In FY22, total textile exports were at a historic high of $19.35 billion, with an increase of over a quarter over FY21’s exports of $15.4 billion. Textiles is the top foreign exchange earner for Pakistan and occupies over 60 percent of the country’s total exports.

In August 2022, the economy imported 6.5 percent more machinery and it stood at $668.4 million against $627.6 million in July. In August 2021, its imports were

984.8 million. Textile machinery imports increased 49 percent to $55.86 million, power generation machinery went up 21.9 percent to $54.6 million, and telecom sector machinery increased by 49.5 percent to $101.5 million. However, electrical machinery imports were down 19.6 percent to $195.2 million and construction machinery imports declined 14 percent to $6.5 million.

It is to be noted that in August 2022, the country’s total exports were $2.482 billion as compared to $2.254 billion in July 2022, showing an increase of 10.12 percent and 10.46 percent as compared to $2.247 billion in August 2021. In JulyAugust 2022, exports totalled $4.737 billion against $4.587 billion during the corresponding period of last year showing an increase of 3.27 percent.

Total imports in August 2022 were recorded at $6.07 billion as compared to $4.993 billion in July 2022 showing an increase of 21.59 percent but a decrease of 7.69 percent as compared to $6.577 billion in August 2021. During JulyAugust 2022, total imports were $11.064 billion as against $12.152 billion during the corresponding period of last year showing a decrease of 8.95 percent.

Factories making towels and Bedsheets are facing difficult times

Pakistan’s small textile mills, which make products ranging from bedsheets to towels mainly for consumers in the US and Europe, are starting to shut after devastating floods wiped out its cotton crop.

As many as 100 smaller mills have suspended operations due to a shortage of good quality cotton, high fuel costs, and poor recovery of payments from buyers in flood-hit areas, said Khurram Mukhtar, patron-in-chief of the Pakistan Textile Exporters Association. Larger firms, which supply to global companies like Nike Inc., Adidas AG, Puma SE, Target Corp., are less affected as they are well stocked, he said.

The mill closures underscore challenges for the sector that employs about 10 million people, accounts for 8% of the economy and adds more than half to the nation’s export earnings. Their hardships have become acute due to

recent floods, which submerged a third of Pakistan, killed more than 1,600 people, and damaged about 35% of the cotton crop.

The latest blow comes at a difficult time for the South Asian nation that is already struggling with high inflation and falling currency reserves. The closure of firms, such as AN Textile Mills Ltd., Shams Textile Mills Ltd., J.A. Textile Mills Ltd. and Asim Textile Mills Ltd., could worsen the country’s employment situation and hit its export earnings. Larger companies are also facing rough weather, with demand for their products seen falling about 10% by December from now due to a slowdown in Europe and the US, Mukhtar said.

Due to an “unforeseen downturn in the market and unavailability of good quality cotton” following heavy rains and floods, the company’s mills have been temporarily closed.

Cotton production in Pakistan could slump to 6.5 million bales (of 170 kilograms each) in the year that started in July, compared with a target of 11 million, Mukhtar said.

That could force the nation to spend about $3 billion to import cotton from countries such as Brazil, Turkey, the US, East and West Africa and Afghanistan, said Gohar Ejaz, patron-in-chief of All Pakistan Textile Mills Association. About 30% of Pakistan’s textile production capacity for exports has been hampered because of cotton and energy shortages, Ejaz concluded.

Pakistan yet to decide on lifting of ban on cotton import from India

Pakistan's Finance Minister has said that the country's textile sector had demanded lifting of a ban on the import of cotton from India, but the government has so far not taken any decision on the issue.

Addressing a press conference along with Defence Minister Khawaja Asif, the Finance Minister talked about the damage caused to the cotton crop due to devastating floods that have affected more than 33 million people, inundated a third of the country and caused losses of more than USD 10 billion.

Replying to a question with respect to trade with India, the minister said that the All Pakistan Textile Mills Association (APTMA) was asking the federal government to allow import of cotton from India.

"The government has not taken any decision yet," he said, without elaborating when such a decision could be taken.

Pakistan suspended trade with India after the latter revoked the special status of Jammu and Kashmir in August 2019. But the ban is hurting the crisis-hit country in the wake of floods which caused scarcity of commodities and pushed up prices.

PAKISTAN TEXTILE JOURNAL - October 2022 12 News & Views

Pakistan cotton prices surge due to flood devastation

Cotton prices in Pakistan have surged sharply over the past few days as major floods destroyed the cotton crop. According to analysis, local cotton prices have traded up over the past month, increased by 24 per cent to Rs22,506 per 40-kg, having reached a recent high of as much as Rs24,649/40-kg on August 27, 2022.

The sharp uptick in prices was driven by expectations of supply-side constraints in the cotton market in the aftermath of the floods that left one-third of the country submerged in water.

According to latest estimates from the UN, about 3.6 million acres of crop land has been destroyed in the floods, with the majority of the devastation concentrated in Sindh (2.9 million acres affected).

In a recent address, Finance Minister Miftah Ismail pointed towards all of the cotton crop in the province of Sindh having been damaged by the floods –indicating that about 30 per cent of the national cotton crop has been lost. Resultantly, Pakistan is expected to meet the supply shortfall by importing cotton of $1.5-2 billion,

Latest data released by Pakistan Cotton Ginners Association (PCGA) showed that cotton arrivals in the ginners were down by 0.25 million bales when compared to the same period last year, with 1.54 million bales having reached by September 2022. The slump was largely driven by a shortfall in Sindh, where 0.84

million bales arrived at the ginners, lower by 0.4 million bales or 33 per cent year on year.

The prices have, however, eased from a high of USc173/lb reached in May 2022. Higher prices in the international arena are being driven by adverse climate conditions across the globe, with India suffering from heavy rains and pest attacks, while the US has experienced a drought in the cotton-growing region of Texas (the state has experienced the second driest year in 128 years so far this year).

To note, the US accounted for 33 per cent of total cotton shipments in FY22, and the US Department of Agriculture estimates 66 per cent of the cotton producing area has been experiencing a drought.

Moreover, the US has downward revised the global output for FY23 by around 3 million bales in recent WASDE reports, with the output now expected at 117 million bales.

PHMA elects its Zonal Chief

The Pakistan Hosiery Manufacturers and Exporters Association (PHMA) North Zone has elected Naseer Butt as its new zonal chairman for the period of one year 2022-23.

The newly-elected zonal chairman, addressing the annual general meeting held recently, said that it was an honour for them to lead the zonal office of the hosiery association for the year 2022-23, paying tributes to the outgoing chairman, saying the outgoing body has been

actively promoting the interests of the value-added textile industry throughout the year. He vowed to continue with their efforts for the promotion and protection of the value-added textile industry.

The PHMA new zonal chairman expressed the confidence that he would make all efforts to work selflessly in resolving issues and problems faced by the industry in the best interests of PHMA members and in further enhancing and boosting the exports.

Butt added that he would accord top priority in respect to reduction in cost of inputs, resolution of refund related issues, and a favourable environment for the promotion of hosiery industry in Pakistan. Growth of value-added textile industry was a must to steer the industry out of worse situation and contribute to the exports of the country. If conducive environment is provided by the government the exports of knitwear sector alone will be enhanced significantly in coming years, he pledged.

Naseer Butt said that the knitwear apparel maintains the highest exports share, remaining at top of exports statistics every year despite adverse factors such as liquidity crunch and high costs of doing business.

He suggested the new body to accord top priority in reduction of input cost, resolution of refund issues and a favourable environment for the promotion of hosiery industry. He said that growth of value-added textile industry was a must to steer the overall economic growth of the country.

13 News & Views

BANGLADESH

Bangladesh’s RMG industry preparing for next phase of growth

The RMG industry of Bangladesh has “immense potential for growth”, Shahidullah Azim, vice president of the Bangladesh Garment Manufacturers Exporters Association (BGMEA) has said, playing a crucial role in propelling the economic development of the country.

Speaking at an event in Dhaka last week, organised by the National Security Intelligence Training Institute (NSITI), Azim said, as a mainstay of Bangladesh’s economic success story, the apparel sector has continued its endeavours to seize every opportunity that lies ahead and contributes to the development of the country.

“The industry is increasingly focusing on product diversification, innovation, technology upgradation and skill development in a bid to enhance its capabilities and competitiveness in the global market in the coming days,” he added.

The BGMEA recently urged investment in the country’s readymade garment sector as it gears up for graduation from its status as a least developed country (LDC). The country is expected to graduate from LDC status in 2024, however, it will continue to benefit from duty-free access to the European Union, Canada, and Japan until 2027.

The country’s growth in recent years has resulted in a decline in poverty levels, stable inflation, moderate public debt, and greater resilience to external shocks.

In his keynote speech last week, Azim gave an overview of Bangladesh’s RMG industry, including its challenges, opportunities, and preparedness to realize its potential. He also briefed the audience about the RMG industry’s future priorities, including upgrading business capabilities and embracing innovation to address future challenges of the RMG industry, especially after LDC graduation. The industry is focusing on diversifying products, especially man-made fibrebased products as part of its strategy of shifting from volume to value and quantity to quality, he said.

CHINA

China's textile sector show growth in first seven months

China's textile industry posted stable revenue growth in the first seven months of the year, official data showed. Textile companies with an annual primary business revenue of at least 20 million yuan (about 2.89 million U.S. dollars) raked in 2.96 trillion yuan in revenue in the period, up 4.6 percent year on year, according to the Ministry of Industry and Information Technology.

The total value-added output of these companies rose 0.3 percent year on year during the period. The combined sales of primary retailers amounted to 9.48 trillion yuan in the January-July period, up 1.7 percent from a year earlier. The country's garment exports reached 189.4 billion U.S. dollars, an increase of 12.4 percent year on year.

China's textiles & apparel exports at $220 bn in Jan-Aug 2022

China’s exports of textiles, apparel and clothing accessories increased to $220.302 billion in the first eight months of the current year, registering a growth of 11.11 per cent year-on-year. The latest monthly data released by the General Administration of Customs of China shows that the country’s garment exports grew 11.6 per cent in the same period.

Around the World 14 PAKISTAN TEXTILE JOURNAL - October 2022

Garments and clothing accessories exports reached $118.034 billion in the first eight months, which was 11.6 per cent higher than the same period of last year. China’s textile exports, including yarn, fabrics and others, registered a growth of 10.2 per cent year-on-year and the shipment reached $102.268 billion in January-August 2022.

Textile and apparel exports during August 2022 amounted to $30.975 billion. Out of this, textile, yarn and articles exports earned $12.490 billion, while garments and clothing accessories fetched $18.485 billion in August this year, as per the data.

INDIA

CEPA may change India-Bangladesh textile trade equation

The recent visit of Bangladesh Prime Minister Sheikh Hasina to India is likely to expedite Comprehensive Economic Partnership Agreement (CEPA) as both nations showed interest in deepening trade ties. Currently, Bangladesh imports more yarn and fabric from India and exports finished products like apparel. The CEPA may change this equation.

Hasina and her Indian counterpart Narendra Modi welcomed the recent finalisation of a joint feasibility study which recommended that CEPA will be beneficial for both countries. Leaders of both nations directed trade officials to start negotiations within the current year and to complete them at the earliest. The joint statement issued at the end of Hasina’s state visit to India also highlighted the proposed agreement prominently.

According to statistics, Bangladesh is an emerging star in the global textile industry as it has succeeded in converting itself into a global factory for textile products. Bangladesh apparel exports touched $42.61 billion during last fiscal 2021-22 (July-June), registering an increase of 35.67 per cent over the previous fiscal. On the other hand, India’s apparel exports increased 33 per cent to $16.023 billion in the last fiscal 2021-22 (April-March) from $12.287 billion in the previous year.

Trade data explains the picture and implications of mutual trade between the two nations. As per reports, India imported apparel worth $474.522 million from Bangladesh in 2021, but it could manage to export apparel valued at $28.717 million to the neighbouring country. Similarly, India imported home textiles of $133.008 million and exported products of value $2.473 million.

The trend reverses in terms of raw materials. Bangladesh imports rawer materials from India. According to the data, India exported fibre earning $1430.146 million, while it imported the product spending $72.848 million. Similarly, its export of yarn

and fabrics were $1968.735 million and $812.234 million respectively during the last year, while imports of yarn and fabrics were $52.274 million and $78.735 million in the same period.

Textile stakeholders in India are against the idea of exporting cotton and yarn from the country as it would enable competing countries including Bangladesh to offer tough competition to Indian exporters after getting cheaper raw materials. It shows that the Indian textile industry needs to develop its strength and formulate an effective strategy when CEPA comes into effect. However, some experts feel that both countries can identify their strengths and be supplementary rather than competing with each other.

ITALY

Italian fashion industry expects record results in 2022

“In 2022, we are going to reach and even exceed the level of sales generated before the 2008 crisis, recording the [Italian] fashion industry’s highest revenue in the last 20 years,” said Carlo Capasa, president of the Italian Fashion Chamber, speaking at the presentation of the forthcoming Milan Fashion Week Women. Of course, Capasa could not avoid underlining the critical issues currently affecting the sector, above all the rise in energy costs which is severely penalizing Italy’s supply chain, manufacturers especially. Still, the outlook for the final part of 2022 remains optimistic.

The 2022 revenue of the Italian fashion and luxury industry as a whole, including textiles, leather goods, apparel, footwear, jewelry, beauty products and eyewear, is expected to reach €92 billion, up 10.5% over 2021. A forecast that is justified by an “extraordinary” performance in H1, which closed with a 25% rise in revenue. “Even if the sector was to stop growing in H2, thanks to the record-breaking first six months of the year we can predict a rise in sales in the region of 10-11% for 2022 as a whole,” said Capasa.

These positive results are partly explained by the price hikes introduced to compensate for the increase in energy

and raw material costs. As noted in the report published by CNMI, “excluding the [consumer] price increase effect, what we might call ‘real’ revenue has grown by over 18% above the level recorded before the 2008 financial crisis.”

Italian companies are currently reaping sizeable benefits from the depreciation of the euro against the US dollar, and their exports have grown significantly towards all countries, with the notable exception of Russia and Hong Kong.

Between January and May 2022, Italian fashion exports increased by 21.9% compared to the same period a year earlier. For 2022 as a whole, the value of exports by the Italian fashion industry is expected to reach Euro 79.4 billion.

In the first five months of 2022, Italian fashion sales have been booming especially in the USA (up by 59.7%), South Korea (up by 34.1%), Spain (up by 31.5%), France (up by 25.1%) and Germany (up by 20.2%). As well as in the UK (up by 22.3%), where sales showed a strong recovery after slumping in Brexit's aftermath.

8,061,925 million yen from Japan during August 2022.

Moreover, Japan exported textile machinery worth 25,223 million yen, which was 13.1 per cent higher than August 2021. It contributed 0.3 per cent to the total exports.

TURKEY

Turkish textile exports end the first 8 months with an increase

The exports of the Turkish textile and raw materials sector increased by 7.5% in the January-August 2022 period compared to the same period of the previous year and reached 8,8 billion dollars, according to the August 2022 Export Performance Report published by ITHIB (Istanbul Textile and Raw Materials Exporters’ Association). The share in Türkiye’s general exports decreased from 5.8% to 5.3% in the same period, while the percentage in August 2022 was announced as 5.0%.

JAPAN

Japan's clothing imports increase 47.3% YoY in August 2022

Japan’s imports of clothing and accessories increased by 47.3 per cent year-on-year to 400,348 million yen (approximately $2,791 million) in August 2022. Clothing imports accounted for 3.7 per cent of the country’s total imports of 10,879,249 million yen during the month under review, as per the provisional trade statistics by Japan’s Ministry of Finance.

The imports of textile yarn and fabrics were valued at 118,233 million yen in August 2022, which is 43.1 per cent higher than the same month of last year. Textile yarn and fabric imports were 1.1 per cent of the total imports of Japan, according to the data.

Japan exported textile yarn and fabrics worth 62,810 million yen, an increase of 19 per cent year-on-year. The textile yarn and fabric exports accounted for 0.8 per cent of the total exports of

Exports of Türkiye’s textile and raw materials sector increased by 1.5% in August 2022 and amounted to 1.1 billion dollars, increasing by 17% compared to July 2022. Türkiye’s general exports increased by 13.1% and reached a value of 21.3 billion dollars, while exports of industrial products decreased by 0.2% and amounted to 11.1 billion dollars in the same period.

USA US Cotton exports take drastic hit in July 2022

Cotton exports from the US witnessed a steep fall to $28.362 million in July 2022 from $1,062.592 million in June 2022. The new cotton marketing season begins in the country from August and exports had reduced drastically in the last month of the previous year 2021-22. However, the country had exported a large volume of cotton during the earlier months.

The country had exported large quantities of cotton till June 2022 due to a scarcity of the natural fibre and skyrocketing prices. Therefore, cotton

Around the World 16 PAKISTAN TEXTILE JOURNAL - October 2022

exports dried up in the last month of the previous season. Cotton exports amounted to $1,162.222 million in May, $1,104.972 million in April, $1,112.802 million in March and $919.778 million in February 2022, according to statistics.

On a quarterly basis, cotton shipment from the US rose to $3.328 billion in the second quarter of this year from $2.820 billion in the first quarter. Exports had declined to $1.002 billion in the fourth quarter of last year from $1.254 billion in the third quarter of 2021. Cotton exports amounted to $1.972 billion in the second quarter of last year.

The world’s largest economy earns $6-7 billion on an annual basis from cotton exports. The country had fetched $5.156 billion in 2021, $6.321 billion in 2020, $6.608 billion in 2019 and $7.088 billion in 2018 from cotton shipments.

VIETNAM

Garment, textile, footwear industries face declining trend in orders

Enterprises in the textile, garment and footwear industries are facing a decrease

in orders through the rest of this year and possibly into the next year.

Pham Xuân Hong, chairman of HCM City Textile and Embroidery Association, said in the eight months of 2022, Viet Nam's textile and garment export value reached US$30.1 billion, but this value mainly came from the first months of the year. Since July, textile and garment industry enterprises have been facing many difficulties, including the reduction in export orders.

Many textile and garment enterprises in HCM City are seeing a sharp drop in export orders, mainly in the US and EU, because inflation pressure in these nations is large, forcing consumers to tighten spending. Furthermore, textiles are not essential goods, Hong said.

An analysis report on the textile industry published by VNDirect Research has also commented that the demand for high-end clothing items such as shirts and t-shirts made from recycled cotton fibres would slow down in the second half of 2022.

According to this report, garment companies said that US customers had shortened the period of ordering exports

to three months before the deadline for goods delivery instead of six months due to high inventories and inflationary pressures.

At present, only a few large enterprises, such as Thanh Cong (TCM), Century Yarn (STK), and Damsan Joint Stock Company (ADS), have enough export orders for the third quarter of 2022. Still, some customers have cancelled the orders due to high inventory, while fourth-quarter orders have also slowed due to inflation concerns.

In the EU market, Pham Van Viet, chairman of Viet Thang Jean Co, Ltd, has also admitted that the orders of his firm have decreased by over 30 per cent and they have been forced to cut working hours to maintain jobs.

In the US and Europe, although the world fuel prices have decreased, inflation in these markets is still high to make people tighten their spending. This has negatively impacted the textile and garment exports of Vietnamese enterprises because the two markets account for a large proportion of Việt Nam's textile, garment and footwear exports.

Around the World

Hong Kong Polytechnic University announces the establishment of the

school of Fashion and Textiles

On the 25th anniversary of the establishment of the Hong Kong Special Administrative Region, The Hong Kong Polytechnic University (PolyU) announced the official upgrade of the Institute of Textiles and Clothing (ITC) and the establishment of the School of Fashion and Textiles (SFT), the third flagship and independent school within PolyU. The opening ceremony was held at the University's Jockey Club Innovation Tower on 2nd September 2022.

The School is an international institution integrating fashion and textile education, and innovative technology research. It will comprehensively enhance the competitive advantage of SFT graduates and Hong Kong's fashion and textile industry while also aligning it with the market development of the Greater Bay Area. The School's vision is to lead the fashion industry and create societal impact while offering solutions that leverage the research and innovative excellence of the School.

The School is renowned for its worldclass teaching and academic achievements. Its academics come from around the world, specialising and leading the way in a variety of academic and research areas including wearable and smart textiles, medical textiles and functional clothing, social fashion design, sustainable fashion, digital fashion marketing, and fashion supply chain management.

According to a report by Stanford University in 2021, 13 ITC Scholars are ranked among the world's top 2% scientists. Furthermore, according to CEOWORLD magazine, SFT was ranked the second in Asia and 43rd in the world of the World's Best Fashion Schools in 2022.

The School has reached significant milestones in its pursuit of research excellence for societal impact. Last year, SFT was appraised in the Hong Kong University Grants Committee (UGC) "2020 Research Review Exercise", and its research in the creative arts, performing arts and design was the best among the eight UGC-funded institutions.

School of Fashion and Textiles

Formerly known as the Institute of Textiles and Clothing (ITC), the School of Fashion and Textiles (SFT) is the pioneer of fashion and textiles education in Hong Kong. Since its inception in 1957, SFT has developed into a world-class institution in fashion and textile education, research and services. SFT offers a wide range of academic programmes embracing such disciplines as fashion and textiles technology, design, retail and marketing, intimate apparel and activewear, and knitwear design and technology. Its extensive ground-breaking research and innovations have advanced the development of the global textiles and fashion industry and helped transform Hong Kong from a manufacturing and merchandising base in the 1950s and 60s to an international fashion design, creative and branding hub today.

Corporate News 18 PAKISTAN TEXTILE JOURNAL - October 2022

James Heal celebrates its 150th anniversary

James Heal is celebrating its 150th anniversary this year, the company’s formation dating back to 1872, when it was listed as an oil and tallow merchant and mill furnisher in Yorkshire, UK.

“Remarkably, this was seven years before Thomas Edison’s successful invention of the lightbulb, which itself can be considered something of a textile innovation,” says Neil Pryke, UK MD of James Heal’s parent company since 2014, PPT Group. “Its world-changing introduction centred around an uncoated cotton thread that when carbonized to become the filament, could last 14.5 hours.”

Needless to say, on its journey to becoming the leading testing equipment manufacturer for textiles and nonwovens it is today, there have been many internal lightbulb moments within the James Heal organisation over the years – as early as 1899 there are records of the delivery of the first twist tester by the company to a local mill.

Fast forward to 2022 and James Heal continues to expand its range, with a focus on making testing simple, fast and intuitive – most notably with the introduction of its Performance Testing collection of instruments, most recently the AirPro and HydroView systems.

AirPro

The new James Heal AirPro air permeability tester is used to test the resistance of the flow of air through woven, knitted and nonwoven textiles. Its software offers flexibility with standards and comprehensive reporting options and different test head sizes are available, making it suitable for a range of applications and standards

“The way clothing interacts with the body, particularly in respect of the dissipation of heat and moisture, plays a major role in the wearer’s perceived comfort,” says James Heal technical specialist Peter Goodwin. “Today, textile fabrics used for clothing have new functional properties to improve the wearer’s sensory and thermal comfort, meaning that air and water vapour permeability is crucial to achieving clothing comfort – particularly for performance apparel such as sportswear and outdoor clothing.

HydroView

The HydroView hydrostatic head tester is meanwhile designed to measure the penetration of water in materials which have an end use that requires water resistance, such as those in the medical, geotextiles and nonwovens sectors. It is also proving essential in the testing of end-use applications for technical textiles, such as in protective gloves, diving dry suits and winter sports apparel, to fishing waders, roofing, tenting, ground sheets and more.

“As more and more brands are investing in new materials and making performance claims on water resistance and waterproofing, the hydrostatic head test is one of the most common ways to test,” says James Heal’s technical specialist Lisa Keeling. “An example of where hydrostatic pressure might be important, is in testing the groundsheet of a

tent, for example. This needs a high resistance to water penetration, especially when placed on saturated ground. When pressure is applied to the ground sheet by people standing, sitting or sleeping on it, water could then be forced through. Failure in this area would mean anything in contact with the groundsheet will become wet.”

This is also the case with a performance garment claiming waterproof properties, she adds.

“You need a high hydrostatic head value to demonstrate its defence ability against driving wind, rain and other physical factors. Water pemetration testing is key to understanding the performance of a garment in adverse weather conditions.

“HydroView was developed following extensive user research from which James Heal’s innovation team discovered that users were looking for a more flexible and user friendly instrument than was available on the market. With its manual droplet data-capture, combined with ‘pinch & zoom’ hi-res camera analysis, HydroView was designed for the user.”

“James Heal’s testing instruments are trusted and valued by thousands of manufacturers of textiles and nonwovens around the world,” adds Jason Kent, CEO of the British Textile Machinery Association. “The company has made a solid contribution over many decades to the quality and performance properties of today’s textile products, and just as importantly, enabled its customers to prove their claims.”

Corporate News 20 PAKISTAN TEXTILE JOURNAL - October 2022

The James Heal AirPro air permeability tester.

Rieter expands service footprint in Kahramanmaraş, Turkey

Rieter is moving its Kahramanmara service station to a larger location covering 2 000 m2 in a bid to broaden its offering and strengthen its market position in Turkey. The station will house one of the region’s largest testspinning facilities and provide know-how in sustainable yarn manufacturing.

The comprehensive portfolio covers both mechanical and electronic services, including the revision of gear units, servomotor adjustments, and suction drums. The station will also offer preventive maintenance and mill optimization. The service offering spans the entire Rieter product portfolio, including the automatic winding machine Autoconer X6. In addition, highly trained experts will help customers unlock the full potential of Rieter technology so they can better capture opportunities in the fastmoving textile markets.

Highlights of the Kahramanmara Service Station include the setup of a fully automatic rotor spinning machine R 70 and the winding machine Autoconer X6. Threequarters of the 2 000 m2 service space is reserved for functional activities,

which will feature one of the region’s largest test-spinning facilities. Customers can run yarn comparison tests and analyze the impact of different technology parts so they can optimize machine setups. In-depth yarn trials and access to Rieter textile technology expertise will allow customers to cater more effectively to the dynamic demands of textile brands regarding performance, quality and sustainability, such as recycling applications.

The Kahramanmara service station is strategically located at the heart of the region’s textile industry, with a large proportion of Rieter’s installed base located within a radius of around 200 kilometers. Turkey is a textile powerhouse, currently ranking fifth in

global exports and poised for additional growth. The country’s industry is also implementing a green action plan to help it meet the growing demand for sustainable textiles, especially from Europe.

Rico Randegger, Head of Business Group After Sales, says: “Customer centricity is a priority for us and the opening of the Kahramanmaraş service station is an important milestone. We are moving closer to our customers so we can help them seize growth opportunities faster and more effectively.”

Ali Özsamsun, Managing Director Rieter in Turkey, says: “The sole measure of success is the competitiveness of our customers. We support customers throughout the lifetime of their products and systems so they can unlock the full potential of Rieter technology and win in the market.”

The new service station starts operations in September 2022 and will accelerate the growth of the company’s three stations in Turkey. Rieter has been operating service stations in Turkey since 2005 with a presence in the country dating back to the 1990s.

Corporate News 22 PAKISTAN TEXTILE JOURNAL - October 2022

Rico Randegger, Head of Business Group After Sales

Ali Özsamsun, Managing Director Rieter in Turkey

The new 2 000 m2 Kahramanmaraş service station includes one of the region’s largest testing facilities and gives access to Rieter textile expertise.

Ribbon Cutting Ceremony (from left to right): Ali Özsamsun, Managing Director Rieter in Turkey, Erkan Ateşler, Member of the Board of Erbel Mümessillik, Hanefi Mahfiçiçek, City Mayor, Hanefi Öksüz, Chairman of Kipas Holding, Arif Sirikci, Chairman of Sirikcioglu, Rico Randegger, Head of Business Group After Sales, Haluk Erbel, Board Chairman of Erbel Mümessillik

ExxonMobil expands product portfolio to advance healthcare solutions

ExxonMobil has expanded its portfolio of healthcare solutions to meet changing medical market needs for healthy, safe material options.

Adhering to industry requirements for testing, quality assurance and traceability, the portfolio unites a wide range of highperformance products that are produced using Good Manufacturing Practices (GMP) for batch-to-batch product consistency that customers can rely on. Maximizing performance and longevity for a range of medical supplies

Delivering high-purity products for laboratory components and pharmaceutical packaging to meet the toughest standards Innovating to improve cleanliness and safety for better infection protection The portfolio provides the building

blocks to engineer a range of applications including medical supplies, infection protection products, and pharmaceutical and laboratory supplies. The portfolio includes Achieve™ Advanced PP, ExxonMobil™ PP, Vistamaxx™ performance polymers, Exact™ polyolefin elastomers, ExxonMobil™ butyl polymers, Exxpro™ specialty elastomers and ExxonMobil™ Isopropyl Alcohol (IPA).

“The decision to create a portfolio of healthcare solutions, supported by a dedicated team of trusted industry application experts, was cemented by a combination of market factors, including the COVID-19 pandemic,” said Market Development Manager Gertrud Masure. “With a legacy of innovation that spans over 100 years, ExxonMobil is well placed to meet demand from customers for a broader selection of alternative solutions

that promote healthy and safe patient care.”

The COVID-19 pandemic, which required rapid production of face masks and other products to help combat virus transmission, was a major factor in ExxonMobil’s decision to create a portfolio of healthcare solutions.

The healthcare industry’s desire for a polyvinyl chloride (PVC) replacement was another market driver which led ExxonMobil to develop suitable alternatives. While another motivating factor was customers’ preference to do business with a single-source materials supplier.

ExxonMobil’s high-quality, compliantsafe material solutions enable tailored innovation for:

Optimized performance and longevity of medical supplies, includ-

Corporate News 24 PAKISTAN TEXTILE JOURNAL - October 2022

ing drug/medical fluid delivery. Applications include syringes, infusion bags, IV/saline containers, ostomy bags, inhaling systems, drug and vitamin tubes, bottles, vials, containers, caps, seals, closures, briefs, and absorbent pads.

Purity required to meet the toughest standards for laboratory components and pharmaceutical packaging solutions, including labware, sanitizers, bio reactor bags, and pharmaceutical stoppers/seals.

Cleanliness and safety for protective products, such as face masks, gowns, gloves and alcohol wipes that help prevent infection.

Softness, loft, strength, improved barrier performance and ease of processing for spunbond or meltblown nonwoven products. Typical applications include absorbent articles, medical PPE, bandages, masks, gowns and wipes, surgical drapes and gowns, medical protective gowns, shoe covers, disposable bedding and

hospital apparel, pads, wraps, and filtration media.

“It really is the sum of the parts that makes our healthcare portfolio so attractive to customers,” said Americas Market Development Manager Abigail Agentis. “We seek to meet industry needs with a trusted portfolio of performance products that adhere to strict industry requirements for testing, quality assurance and traceability. Our collective motivation is to deliver innovative healthcare and pharmaceutical products that help enable patients to receive best-in-class, safe treatment.”

To support its commitment to the healthcare industry, ExxonMobil is dedicated to fulfilling the future business needs of its customers by continuing to invest in production capacity and comprehensive supply chains. For example, ExxonMobil’s Polypropylene Growth Project in Baton Rouge is nearing completion, and the company continues to make good progress in support of a 2023 startup of the $2 billion investment

to expand its Baytown chemical plant with a new Vistamaxx unit and worldscale, full range Linear Alpha Olefins unit. Products from both are expected to be used for a broad range of applications.

ExxonMobil has expanded its portfolio of healthcare solutions to meet changing medical market needs for healthy, safe material options.

About ExxonMobil

ExxonMobil, one of the largest publicly traded international energy companies, uses technology and innovation to help meet the world’s growing energy needs. ExxonMobil holds an industry-leading inventory of resources, is one of the largest refiners and marketers of petroleum products, and its chemical company is one of the largest in the world. To learn more, visit exxonmobil.com and the Energy Factor.

* Recyclable in communities with programs and facilities in place that collect and recycle plastic film

Corporate News

25

DYSIN GROUP inaugurates its new plant for Specialty Polymer manufacturing in Gazipur

Dysin Group, one of the pioneers to introduce new technologies for the knitdyeing, garments washing, and garments printing industries in Bangladesh since 1984, has set up a new plant for Specialty Polymer Manufacturing under the name of Dysin-Chem Industries (Pvt.) Ltd. at BCSIC Industrial Area, Konabari, Gazipur. The new plant was inaugurated on 16th of September, 2022.

“We have been working in the textile industry since 1984, providing Dyestuff and Chemicals with technical services. Now Dysin is recognized as a trusted leader in delivering innovative and sustainable chemical solutions across multiple industries. The setup of a specialty Polymer Manufacturing Plant is an important part of our vision to grow in local manufacturing capability. This plant will serve to produce the intermediate chemicals used as raw materials in our textile auxiliaries manufacturing, in turn reducing the cost.” Managing Director of DYSIN Group, Mr. Md. Amanur Rahman

said. He also added, “Our first manufacturing unit for Textile Auxiliaries was established in 1990. Now Dysin has three chemical manufacturing units under two companies, including a 100% export-oriented unit that serves the Export factories having a bond license.”

Mr. Rahman pointed out that instead of importing chemicals from abroad, textile mills can save valuable foreign currency, reduce their inventory, and reduce the lead time of garments export if they buy from local Textile Auxiliaries manufacturing companies like those of the DYSIN group.

Recently, Dysin Group’s Textile Auxiliaries manufacturing unit under the name of NAM Trading & Manufacturing Co., Ltd., became the first company in Bangladesh to receive ZDHC Confidence Level 3 certification (Zero Discharge of Hazardous Chemicals) – the highest ZDHC certification level currently available. In this regard, Mr. Rahman said, “Working to be certified as ZDHC level 3 was a key achievement in our

commitment to drive the Bangladesh textile industry to be more environmentally friendly and reduce its impact on the environment”.

Mr. Rahman, who is also the convener of Bangladesh Chemical & Dyestuff Manufacturers’ & Exporters’ Association, said, “We believe Bangladesh is at a turning point of Industrialization with huge potentials for growth in Chemical Industry, which can bring the second wave of industrial and export growth after the textile industry. However, we need Government’s policy support for this sector very much.”

Dysin is continuously investing to expand its R&D and manufacturing capabilities of Chemicals for Textile & other industries. We want to provide maximum benefit through “specialized” high-performance chemicals, for our customers to win in the marketplace, save our environment and contribute to making the world a better place, the company said in a media statement.

26 Corporate News 26 PAKISTAN TEXTILE JOURNAL - October 2022

Trützschler Group SE expands Board of Directors

The Trützschler Group SE has appointed Dr. Ulrich Schwenken and Heinrich Krull to its Board of Directors with effect from July 1, 2022. Dr. Schwenken will serve as Chief Executive Officer (CEO). Heinrich Krull will serve as Chief Operations Officer (COO).

Dr. Schwenken will assume responsibility for Development, Digitalization, IT and Corporate Communications. As a doctoral graduate specialized in engineering, he has many years of experience in automotive and mechanical applications. Since 2008, he has held various management positions in the areas of Service, Sales and Development at companies including Porsche AG and Volkswagen AG, where his responsibility covered a range of key topics such as digital transformation. Most recently, Dr. Schwenken served as CSO, CTO and CDO at Leistritz AG, and

was responsible for the strategic focus on innovative growth areas.

Mr. Krull joined Trützschler Group SE in September 2020. As a graduate engineer for production engineering and management with international experience in mechanical and production site engineering, he has comprehensive expertise related to operations. He also has extensive experience of production technologies, including in-depth knowledge of Lean Management methods and expertise in post-merger integration. As COO, he will be responsible for the areas of Production, Purchasing and Logistics, Quality Assurance as well as Supply Chain.

“We are delighted to welcome Dr. Schwenken and Mr. Krull to the Board of Directors. Both will bring diverse expertise to strengthen the development of the company for future growth. We wish them great success in their new tasks,”

says Dr. Roland Münch, Chairman of the Supervisory Board of Trützschler Group SE.

Until his scheduled retirement at the end of 2022, Dr. Dirk Burger will act as Co-CEO to Dr. Schwenken.

The responsibilities of the Board of Directors of Trützschler Group SE as of July 1, 2022 are as follows: Dr. Ulrich Schwenken (CEO) is responsible for Development, Digitalization, IT and Corporate Communications; Dr. Dirk Burger will take over the role of Co-CEO to Dr. Schwenken until the end of 2022; Dr. Ralf Napiwotzki (CFO) is responsible for Finance and Controlling, Human Resources, Legal and Compliance; Alexander Stampfer (CSO) is responsible for Sales, Marketing and Service; Heinrich Krull (COO) is responsible for Production, Purchasing and Logistics, Quality Assurance as well as Supply Chain.

27 Personalia

The new members of the Board of Directors of Trützschler Group SE: Dr. Ulrich Schwenken, CEO Trützschler Group SE (left); Heinrich Krull, COO Trützschler Group SE (right).

ITMA ASIA + CITME 2022

rescheduled to November 2023

ITMA ASIA + CITME 2022 has been rescheduled to November 2023 due to the uncertain pandemic situation in China.

Show owners CEMATEX and Chinese partners, the Sub-Council of the Textile Industry, CCPIT (CCPIT-Tex), China Textile Machinery Association (CTMA) and China Exhibition Centre Group Corporation (CIEC) advised that the new show dates will be announced shortly.

Mr Ernesto Maurer, President of CEMATEX, stated: “Due to the present circumstances in China, we have decided to reschedule the combined show to next year when the pandemic situation is expected to stabilise. As the exhibition features the participation of overseas exhibitors and visitors, we believe it is in the interest of the industry that we postpone the exhibition to allow greater participation at the most important textile machinery exhibition in Asia.“

Mr Gu Ping, President of China Textile Machinery Association (CTMA), said: “We are very grateful to our exhibitors, media and industry partners for their support. Although the preparatory work has been going smoothly and we are looking forward to the exhibition opening, we must also ensure the health and safety of all our participants.”

ITMA ASIA + CITME 2022 is organised by Beijing Textile Machinery International Exhibition Co., Ltd and coorganised by ITMA Services. Japan Textile Machinery Association is a special partner of the show.

Originally scheduled to take place from 20 to 24 November 2022, the 2023 exhibition will continue to be held at the National Exhibition and Convention Centre (NECC).

28 PAKISTAN TEXTILE JOURNAL - October 2022

Mr Ernesto Maurer, President of CEMATEX.

Fairs and Exhibitions

Mr Gu Ping, President of CTMA.

India ITME 2022 at new world class Venue – IEML, Greater Noida

The 11th edition of India ITME will be held from 8th – 13th December 2022 at India Exposition Mart Ltd (IEML), Greater Noida.

This event is being held in welldesigned Exhibition Venue in the National Capital Region and one of the largest in India, with lovely weather in December. It is an opportunity to combine business with travel, experience and also explore Delhi and capital region of India.

The only event in India which brings together 73 countries and 97 domestic regions Pan India under one roof; of this 52% of visitor’s belong to top management and decision makers enabling to close business deals decisively. India ITME-2022 is going to be very exciting business event for Textile and Textile Engineering Industry after a long gap.

India being home to the world’s second largest textile industry, India is also a very important sourcing hub for textile machinery, Technology, Components and Allied Services.

There are 22 chapters as listed below from fibre to finished products providing complete sourcing solutions, competitive pricing and latest technology:

Spinning machines and spare parts. Weaving.

Processing.

Digital Printing. Garments.

Knitting & Hosiery. Embroidery & Braiding. Non-woven & technical textiles. Dyestuffs and chemical products. Laboratory testing and measuring. Integrated Textile Parks. Fibers and Yarns. Software and Design. Recycling & Waste Management.

Visitors will be pleased with a large range of textile technologies. The price competitive high quality textile machinery in all sectors will be on display at India ITME 2022.

This is the only event in India which brings together 73 Countries & 97 domestic regions Pan India.

India ITME Society jointly with EEPC is organizing Reverser Buyer Seller Meet & B2B meetings concurrent to India ITME 2022.

This Event would be an excellent platform for textile industry business visitor to meet and network for new business opportunity both with Indian industry as well as other countries.

As an event organizer, India ITME Society is a globally trusted name for quality, excellence and has successfully served the industry with commitment. We hope and strive to provide a spectacular event which shall also coincide with the completion of 43 years of the Society.

29 Fairs and Exhibitions

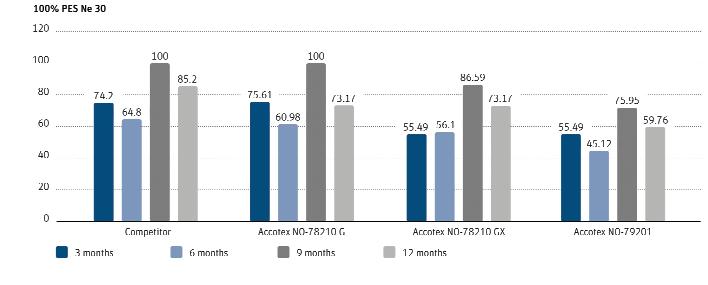

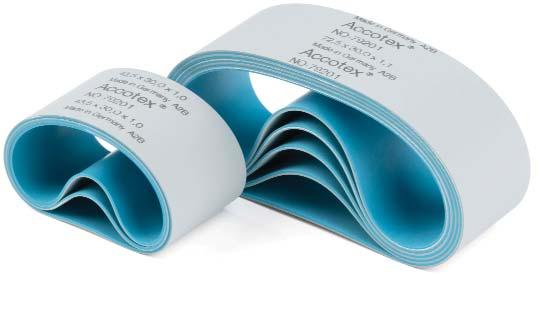

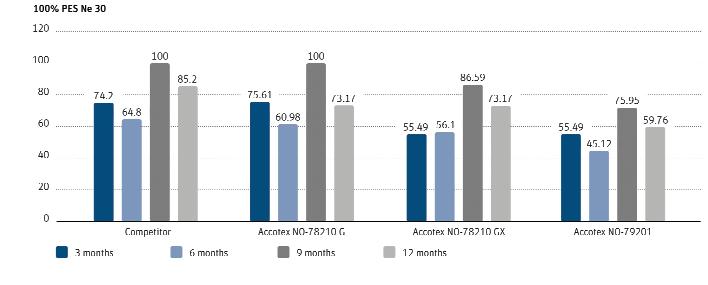

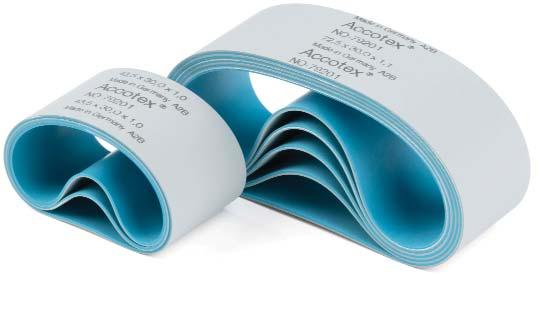

Field tests confirm high performance of new Accotex aprons

The latest Accotex apron NO-79201 is made from new compounds that deliver longer life and better performance. Flexible enough to work with all fiber types across ring and compact-spinning machines, field trials show better resistance throughout a 12-month spinning cycle. The NO-79201 is available in a wide range of dimensions as top and bottom aprons for all kinds of applications.

The Accotex NO-79201 (Fig.1) is a new generation of aprons for ring and compact spinning machines. It is made of two aligned rubber compounds which deliver a high abrasion and crack resistant spinning apron. The mechanical robustness of the rubber compounds allows effective use on all ring and compact-spinning machines, working with all fiber types and within the whole spectrum of yarn counts. The excellent friction properties of the compound contribute to a smooth and even running over the whole service life of the apron, especially at the start-up of machines.

Superior friction behavior

The new Accotex NO-79201 was tested for 12 months at a customer in the USA, alongside the already existing NO78210GX, the NO-78210G and a competitor’s apron (Fig. 2). The friction value of the different aprons was measured over the whole apron life in regular frequencies. Each column reflects the individual friction value of the inner layer evaluated on representative apron

samples from the field test at 3, 6, 9 and 12 months. After 12 months running, the inner layer friction of the new NO-79201 is nearly unchanged, confirming the smooth and even running over the whole service life of the apron. This superior friction behavior has also been reported from other Accotex customers across the world, processing different fiber types, blends and yarn counts. Besides, these trial customers have noticed far fewer broken bottom aprons than they would normally expect.

Different versions for flexible use

The Accotex apron NO-79201 is available in a wide range of dimensions as top and bottom aprons for all kinds of applications. It comes as closed apron, skived bottom apron or skived and preglued bottom apron. The NO-79201 can be supplied with a plain inside or a

specially configured inner layer pattern, known as a knurled version (Fig 3).

The main benefit of the knurled apron is to provide less contact area to the nose bar, which enables lower torque, and thus less stress on the bottom roller bearings. This also allows the inside structured apron to run clean on so-called “dirty” fibers and to work efficiently in demanding environmental conditions in terms of fiber cleanliness. The knurled apron is available with diameters of 72.5, 76.3 and 79.0 mm.

Overall, the new Accotex NO-79201 spinning apron provides improved performance for ring and compactspinning with less machine downtime. Its flexible application may also reduce stocking levels and simplify servicing regimes.

Features 30 PAKISTAN TEXTILE JOURNAL - October 2022

Fig.1: Accotex NO-79201 is available in a wide range of dimensions as top and bottom apron for all kinds of applications.

Fig. 3: Accotex NO-79201 can also be supplied with a knurled inner layer, for increased service life.

Fig. 2: The new apron NO-79201 shows nearly unchanged inner layer friction, confirming unmatched performance over time.

The LYCRA Company Announces Collaboration with Qore® to use QIRA® for next Generation BioDerived LYCRA® Fiber at Scale

The LYCRA Company, a global leader in developing innovative fiber and technology solutions for the textile and apparel industry, today announced it has entered into an agreement with Qore® to enable the world’s first large-scale commercial production of bio-derived spandex using QIRA®, the next generation 1,4-butanediol (BDO), as one of its main ingredients. This will result in 70% of the LYCRA® fiber content being derived from annually renewable feedstock. This change could potentially reduce the carbon footprint of LYCRA® fiber by up to 44%* versus equivalent product made from fossil-based resources, while maintaining the same high-quality performance parameters of traditional LYCRA® fiber.

QIRA® will be produced at Cargill’s biotechnology campus and corn refining operation in Eddyville, Iowa. The facility, which is currently being built, will commence operations in 2024. The first renewable LYCRA® fiber made with QIRA® will be produced at The LYCRA Company’s Tuas, Singapore

manufacturing site in 2024. The LYCRA Company is currently seeking commitments with brand and retail customers who are pursuing bio-derived solutions for their apparel.

“As part of our sustainability goals, we are committed to delivering products that support a more circular economy while helping our apparel and personal care customers reduce their footprint,” said Julien Born, CEO of The LYCRA Company. “We are especially pleased to collaborate with Qore®, a company that shares our vision for innovative, sustainable solutions. Their expertise in operating fermentation processes and understanding of the chemical value chains makes them the ideal partner to help develop a bio-derived LYCRA® fiber at commercial scale.”

“We are proud to partner with The LYCRA Company on bringing this sustainable material solution to the market. This collaboration demonstrates that QIRA® directly replaces conventional BDO and thus significantly improves the fiber’s sustainability profile,” said Jon

Veldhouse, CEO of Qore®. “QIRA® is an innovative platform chemical that can be used in various applications across industries.”

The first generation of renewable LYCRA® fiber made with QIRA® will use feedstock from field corn grown by Iowa farmers and will enable a significant reduction in CO2 footprint. In addition to replacing a finite resource with an annually renewable one, another benefit for mills, brands and retailers is that there is no change in fiber performance, eliminating the need for any reengineering of fabrics, patterns, or processes. Equivalent performance was demonstrated in 2014 when the world’s first bio-derived spandex was launched under the LYCRA® brand. The LYCRA Company has since been granted a patent for the process used to make renewable elastane from bio-derived BDO.

LYCRA® is a trademark of The LYCRA Company.

Qore® and QIRA® are trademarks of Qore® LLC.

32 PAKISTAN TEXTILE JOURNAL - October 2022

Features

The LYCRA Company signs an agreement with Qore® LLC to enable large-scale production of bio-derived spandex. Pictured – Julien Born, CEO of The LYCRA Company (left), and Jon Veldhouse, CEO of Qore® LLC (right), at The LYCRA Company’s headquarters in Wilmington, DE, USA.

World Cotton Day: Challenges for Pakistan’s cotton industry

Dr. Muhammad Qasim Siddiqui

Dr. Muhammad Qasim Siddiqui

The World Trade Organization (WTO) in collaboration with United Nations (UN) celebrates the World Cotton Day (WCD). Cotton is the most widespread profitable non-food crop in the world which provides income for more than 250 million people worldwide across 75 countries. Today, the world is using more cotton fiber than any other natural textile fibers specially in apparel and home textiles. Despite the fact of being expensive, cotton remain preferred in many minds due to its natural and comfort properties.

Devastated by recent rains and floods, cotton producing belt in Sindh and southern Punjab, the production is forecast down 700,000 bales to 5.5 million bales (1 bale = 218 kg), the second lowest production level in nearly 40 years. World cotton production is forecast at 118 million bales for 2022/23 (USDA cotton outlook September 2022). Globally, cotton has been grown on around 33 million hectares, with an average yield of 793 Kilograms/hectare.

In year 2021, with the production of 7 million bales (218 kg/ bale), Pakistan has inherent advantage of being 5th largest producer of cotton fiber after India, China, USA and Brazil. China is the largest cotton importers followed by Vietnam and Bangladesh. Pakistan spinning mill consumes/ demands more than 10 million bales. The yield of cotton in Pakistan is around 600 kg/hectare, while China and Brazil produce per hectare yield above 1500kg. This difference in yield underpins fatal negligence as a nation.

Every single part of cotton plant has its own value; clean cotton fiber lint is the most important segment used to produce home textiles and apparels. Linter, the short fuzz on cotton seed is source of pure cellulose for many products, like plastics and papers. Finally, the remaining cotton seed has to be crushed and separated into three items, that are oil, meal and hulls. These sub products are used as livestock feed, that makes cotton crop overall a cash crop.