COMPANY PROFILE DECARBONISATION EVENT REVIEW INDUSTRY UPDATES www.furnaces-international.com - MARCH 2023 www.furnaces-international.com - MARCH 2023

Editor: Nadine Bloxsome nadinebloxsome@quartzltd.com Tel: +44 (0) 1737 855115

Editorial Assistant: Zahra Awan Tel: +44 (0) 1737 855038 zahraawan@quartltd.com

Production Editor: Annie Baker

Sales Manager/Advertisement

production: Esme Horn esmehorn@quartzltd.com

Tel: +44 (0) 1737 855136

Subscriptions: Jack Homewood subscriptions@quartzltd.com

Managing Director: Tony Crinnion

Furnaces International March 2023 www.furnaces-international.com 30 30

Published by: Quartz Business Media Ltd, Quartz House, 20 Clarendon Road, Redhill, Surrey RH1 1QX, UK. Tel: +44 (0)1737 855000. Email: furnaces@quartzltd.com www.furnaces-international.com Furnaces International is published quarterly and distributed worldwide digitally © Quartz Business Media Ltd, 2023 C FRONT COVER: SMS Group 6 25

GLOBAL FURNACES

2 Global Furnaces News

6 Phoenix: From the flames... monitoring innovations

25 Event review: Glassman Europe 2023 Making the Furnace of the Future

30 Ametek Global: How combining IMAGEPro Glass with NIR-B-2K thermal imaging and Lancom 4 can improve carbon footprint and reduce emissions

LIFE OF A FURNACE

34 Life of a Furnace News

36 Heat Treat Today: Radiant Tubes: Exploring your options

44 The rise and fall of a blast furnace

GREENER FURNACES

50 Greener Furnaces News

54 Decarbonising regenerative glass furnaces

64 Decarbonisation of secondary aluminium melting

As I’m writing this, the weather here in the UK can’t seem to make up its mind as to whether it is officially spring yet, but with the clocks poised to go forward at the end of this month, longer days and lighter evenings are on the horizon again.

We are always a few steps ahead in publishing and looking towards the next few months, so the months can fly by, but it seems the furnaces industry is also not standing still at the moment.

After a lively Glassman Event was recently held in Istanbul, Turkey, this issue features a host of articles featuring the efforts going into decarbonising glass furnaces.

There is also a fascinating historical look at an iconic UK landmark, Redcar furnace, which after close to five decades of service, was demolished in late 2022.

I hope you enjoy this issue!

Nadine Bloxsome,

Editor,

Furnaces International, nadinebloxsome@quartzltd.com

1 Furnaces International March 2023 www.furnaces-international.com

© Quartz Business Media Ltd, 2022

Welcome to the March issue of Furnaces International.

CONTENTS AND COMMENT

French glassmaker makes furnace investment

French glass manufacturer Waltersperger is to expand production as part of a furnace investment. The company based in Blangy-sur-Bresle, Normandy is to move to modern, expanded facilities on the outskirts of the town later this year.

Its current production facility is outdated and located in the centre of town, which was caused difficulties with truck movements.

As part of the move it has invested in a new 4 tonne furnace from Italian group Falorni Tech as well as two new production lines. It currently operates seven 500kg furnaces working in parallel with four production lines.

Waltersperger President, Stephanie Tourres, told Glass International, that the move to the new facility will enable it to make glass continuously in an automatic process.

“The current semi-automatic process we have to load the glass to enable us to work for seven hours a day. Once we move to an automatic process we will have a continuous flow of glass which means we can work for 24 hours a day. This will enable us to expand the process and to touch upon new markets and allow us to propose to clients an in-between service where we can serve medium sized runs.”

The structure of the new building is already in place, with the next move to work on the interior of the building. The aim is to open the building by the end of the year.

NEWS GLOBAL FURNACE 2 Furnaces International March 2023 www.furnaces-international.com

Danieli

Danieli to supply patented tech to Japanese EAF

Japanese flat-steel producer Shinkansai Steel Co., Ltd has announced plans to implement Italian plant supplier Danieli’s Q-One technology on the 74-ton tapping capacity electric arc furnace in operation at its Sakai plant.

Designed by Danieli Automation, Q-One uses the latest digital power electronics technology to maintain the EAF power-factor values close to unity.

The power-feeding system, that will be installed at Sakai, will have a five-unit configuration with a total maximum power of 54,6 MVA.

By controlling electrical current, voltage and frequency during melting to maintain optimal levels according to changes within the electric furnace, the consumption of electricity and electrodes will be reduced, says Danieli, leading to energy and operating cost savings in the steelmaking process.

The project is expected to be completed by the fall of 2024.

Furnace professionals form Mexican alliance

Furnace specialists M-Glass Factory Services (MGFS) and Excelsius have formed an alliance for the Mexican and South American glass production markets.

The two companies, which specialise in furnace draining, drilling, controlled cooling down, controlled heating up, cullet fill and thermal cleaning of regenerators.

The Excelsius-MGFS team is capable of heating up a furnace, with expansion control, bolt adjustment, cullet fill and furnace operation until glass reaches the machines, all in one hand.

The partnership has equipment domestically in Mexico as well as

qualified staff based in the country.

It has recently installed a new warehouse and offices in San Juan Del Rio Business Park in the state of Queretaro, located centrally for the Mexican glass industry.

NEWS GLOBAL FURNACE 3 Furnaces International March 2023 www.furnaces-international.com

UK manufacturing firm acquires major global

A UK manufacturing company’s growth plans have taken an exciting leap forward with the acquisition of a state-of-the-art product line from Europe.

A range of Variable Area (VA) Flowmeters will now be manufactured in Workington, Cumbria, after McMenon Engineering Services Ltd was chosen by global technology company ABB to make the VA flowmeter product portfolio that had been produced by ABB in Germany.

Following the acquisition, McMenon, under a supply partnership agreement, will continue to supply VA meters carrying the ABB brand and the meters remain part of ABB’s product offering.

McMenon, a worldwide manufacturer and supplier of quality flow and temperature measurement instrumentation, and ABB have a long-standing partnership.

McMenon CEO Anand Puthran said: “I take great pride in the fact that McMenon have been considered by ABB as a reliable new home for the VA flowmeter product portfolio.

(Image right: McMenon CEO Anand Puthran)

“The fact that we were chosen over other global competitors is testament to the quality of our product engineering and manufacturing capabilities and reputation for innovation.”

Complimenting the workforce, Chief Operations Officer Shiby Bernard said: “In the span of a few weeks, McMenon’s brilliant team successfully transferred the entire product line to Workington, UK.

“This acquisition will create stability, growth and more opportunities for our workforce and new jobs.”

She added: “Through proactive endeavours and the brilliant support of its team, McMenon is helping to secure its own future as we emerge from the after-effects of the pandemic and Brexit.”

The overall deal is set to create new jobs, increasing McMenon’s global workforce by almost a third.

With this acquisition, McMenon, already a highly recognised name in the global flowmeter and temperature instrumentation market, will now be placed among the top global manufacturers of VA flowmeters. ABB customers will see no difference and can expect the same product quality they are used to.

NEWS GLOBAL FURNACE 4 Furnaces International March 2023 www.furnaces-international.com

global product line

Mr Puthran added: “This win for McMenon is also a win for UK manufacturing. Not often do we see manufacturing operations being transferred into the UK, especially from countries like Germany which are the best in the business.

“We have recently celebrated 75 years of manufacturing heritage in West Cumbria and we are proud to keep flying the flag for UK manufacturing.”

NEWS GLOBAL FURNACE 5 Furnaces International March 2023 www.furnaces-international.com

FROM THE FLAMES ... MONITORING INNOVATION

Zahra Awan* Spoke with Dr Steve Offley** on the past, present and futures of the PhoenixTM company. With the introduction of new technology, the transition to Industry 4.0, for the furnaces industry, becomes one of many possibilities.

1.Can you give a brief history of the PhoenixTM company –how was it founded and why?

PhoenixTM “Phoenix Temperature Measurement” was founded in 2010 by a small, experienced team of individuals who had previously worked together for a well-known temperature monitoring company which had been acquired by a large American corporation providing industrial handheld measurement systems. From humble beginnings PhoenixTM has grown over the last 13 years with its team being strengthened by other experienced personnel from the same original company including myself (over 20 years), extending market and technology knowledge further.

*Editorial Assistant

**Product Marketing Manager at PhoenixTM

As you can see by the name chosen for the company the vision of PhoenixTM was to bring back new life to an important industrial technology. It seemed also fitting as the image of the phoenix rising from the flames/ashes is comparable to the PhoenixTM system emerging from the flames of a heat treat

GLOBAL FURNACES 6

Furnaces International March 2023 www.furnaces-international.com

furnace.

The company prides itself on a strong ethos to innovate and provide added value in terms of performance, and extended application suitability. We offer a value solution with informed market knowledge and quick efficient responsive service and support globally. Small enough to care, yet large enough to support the customer base. We strive to exceed customer expectations, offering that personal touch that makes a difference, often missing from larger corporate operations. As our tag line states……..where experience counts!

2. What is the technical principle of Thru-process temperature monitoring solutions offered by PhoenixTM and how do they benefit over traditional methodology?

In any thermal processing there is a need to monitor the temperature of the product being processed in the furnace. The product temperature is often critical to important metallurgical transitions to give material specific properties essential for its intended use. Traditional temperature monitoring methods don’t always give the desired information.

Furnace control Thermocouples provide only a snapshot of the furnace temperature at a specific location but not the product temperature. IR sensors or cameras are generally fixed point also, need line of sight, and only offer approximate average

GLOBAL FURNACES 7 Furnaces International March 2023 www.furnaces-international.com

surface temperature measurement. Trailing thermocouples can give product temperature measurement continuously through a furnace but use is difficult, if not impossible, and unsafe in many applications. The method is not feasible if the heat treat process is modular and generally impossible during production flow.

Thru-process temperature profiling is a simple concept but gives you product temperature information through the complete furnace with efficiency and safety. The data logger measuring product and or environment temperature is sent through the entire furnace process measuring temperature continuously during the journey. The data logger is protected from the potentially harmful process conditions (Heat, Gases, Pressure, Water Quench, Oil Quench) with a process specific thermal barrier design. The shape, form , material and protection technology is matched to the specific application challenges.

At the end of the process a temperature profile is obtained which is basically a thermal fingerprint of what temperature

GLOBAL FURNACES 8 Furnaces International March 2023 www.furnaces-international.com

Data Logger

GLASS SERVICE Tying Technology Together Help the planet existing chnology educe CO2 with: l Boost l More boost l Electric forehearth l Superboost l Hybrid ur naces ble future from Glass Service and FIC The World,s Number One in Fur nace Technology FIC (UK) Limited Long Rock Industrial Estate, Penzance, Cornwall TR20 8HX, United Kingdom www.fic-uk.com +44 (0) 1736 366 962

changes the product experienced during it’s processing. Such information allows full understanding of the process performance to guarantee quality, allow control and optimisation of the process and provide evidence to satisfy accreditation demands such as AMS2750 and CQI-9.

GLOBAL FURNACES 10 Furnaces International March 2023 www.furnaces-international.com

In the current global energy crisis optimisation of any thermal process is critical to manage energy usage costs and carbon emissions. The PhoenixTM system provides an accurate profile of the product temperature, allowing confident optimisation of the furnace program (Set-points and Line speed) to make a signifi-

GLOBAL FURNACES 11 Furnaces International March 2023 www.furnaces-international.com

Oil Quench

cant impact on the running costs of the production line without risk of compromising product quality. Consider the cost saving potential of reducing the furnace set-point by 10-20 °C over an entire annual production cycle.

3. Where is the PhoenixTM solution applied and what specific benefits does it bring to specific industries?

The PhoenixTM system is beneficial in any manufacturing process where the temperature of the process is critical to final properties of the product being processed. The scope and reach of the system is vast, crossing industry boundaries including heat treatment of primary raw metals and finished products, coating of products with thermally cured paint or powder coatings, kiln firing of ceramics and building products even processing of ready

GLOBAL FURNACES 12 Furnaces International March 2022 www.furnaces-international.com

Slab

Go efficiency.

Emerson’s combustion technology provides superior quality and flow performance, enabling you to meet the highest standards of safety and energy efficiency in your industrial burner application.

Learn more at Emerson.com/Combustion

Go Boldly-Go Efficiency_combustion ENGB_185x265mm.indd 1 2/20/2023 1:46:38 PM

to eat foods “cooking”.

The principle is the same but the solution may look very different in size design and complexity.

An excellent example of how thru-process monitoring can help optimise the operation of a process is that of the demanding reheat processing of Steel Slabs prior to rolling.

GLOBAL FURNACES 14 Furnaces International March 2023 www.furnaces-international.com

Steel Slab Reheat System

The PhoenixTM ‘thru-process’ temperature profiling system has been designed specifically to allow comprehensive monitoring of the slab/ billet, through the entire furnace pre-heat and soak processes to validate mathematical models used to control the furnace programs.

GLOBAL FURNACES 15 Furnaces International March 2023 www.furnaces-international.com

Optic

The TS07 system allows temperature monitoring both along the slab length and at different core depths within the slab. The water filled phased evaporation thermal barrier provides protection at up to 1300°C, is mounted in a cut-out within the slab allowing heavy duty MI thermocouples to be run along the slab to where measurement is required.

By applying accurate profile data to mathematical models, targeted roughing mill exit temperatures can be set to obtain a desired furnace drop out temperature throughout the product thickness. Accurate control of such variables allows a successful rolling operation with minimal scale build up maximising mill yields, saving significant energy and maximising production throughput. By accurate optimisation and reduction of the furnace operating temperature, the furnace life can be extended. At the same time under temperature products can be prevented, further protecting down-stream processing machinery.

GLOBAL FURNACES 16 Furnaces International March 2023 www.furnaces-international.com

TUS

4. What are the major innovations introduced by PhoenixTM in Temperature profiling?

The following section describes innovations to improve the monitoring of very different heat treating applications.

Oil Quench system

PhoenixTM are proud to have developed the first system, to not only allow monitoring of steel in a sealed gas carburizing furnace, but also allow safe monitoring of the critical integral oil quench and transfer through the final wash. The fully sealed thermal barrier is protected by an outer skin of sacrificial insulation blocks contained within a robust structural frame. Historically the monitoring system would need to bypass the oil quench completely which often created a physical and safety challenge retrieving the monitoring unit from the furnace exit where access may be very limited. Allowing passage through the oil quench allows monitoring of the product quench rate which is critical to not only the metallurgical phase transitions within the steel but identifying potential for part distortion / warpage and quench cracking.

Contamination free Controlled Atmosphere Brazing system

In Controlled Atmosphere Brazing, control of the product temperature is critical to achieve selective melting of the filler alloy

580°C -620°C to allow it to flow and fill the joints between the parent metal substrate without risk of melting the substrate itself.

Critical to the process is surface preparation and removal of any oxide layer with the use of a cleaning flux. The flux used is aggressive and can generate HF gas which is damaging to traditional glass cloth used in the construction of thermal barriers.

GLOBAL FURNACES 17 Furnaces International March 2023 www.furnaces-international.com

To eliminate the damage to barriers, extend operational life expectancy, and minimise process contamination outgassing of air (O2(g)) or moisture, PhoenixTM developed a unique TS08 thermal barrier specifically for the demands of Controlled Atmosphere Brazing.

The barrier design significantly reduces the amount of insulation cloth that is exposed to the aggressive flux. To eliminate outgassing contamination of the furnace environment prior to supply, the insulation block is preheated in a high vacuum and back flushed with nitrogen (N2(g)) to drive out any air trapped in the porous insulation structure. For processes where any air outgassing is a significant contamination risk, it is possible, with specific barrier configurations, for customers to purge the small barrier cavity of any remaining air with a supply of low-pressure Nitrogen (N2(g)).

GLOBAL FURNACES 18 Furnaces International March 2022 www.furnaces-international.com

TUS SW

Intrinsic safety ATEX system

With an ever increasing drive to improve health and safety on the processing floor, many areas are now classified as having an explosion risk, with a designated ATEX zone grading. In such areas instrumentation should be certified as ATEX approved to allow safe operation. To extend monitoring in such areas PhoenixTM complemented its data logger range with the PTM1500 Epsilon-x temperature data logger offering a unique intrinsically safe 10/20 channel profiling system. The PTM1500 data logger is certified against the ATEX European and cMETus USA standards as Group II category for safe operation in gaseous and dust environments (ATEX Zone 2 and 22 respectively).

5. What other areas of process monitoring is PhoenixTM looking to offer?

Optical profiling “Optic System”

Optical profiling is a new complementary technique to that of ‘thru-process’ temperature profiling. The new technology developed by PhoenixTM allows for the first-time process engineers to view the inner workings of the furnace under normal production conditions. Travelling through the furnace, with the products being processed, the Optic system gives a product’s eye view of the entire heat treatment journey. Employing similar thermal protection technology ‘thermal barrier’ used in temperature profiling, in place of the temperature data logger a compact video camera and Torch (flashlight) are used to record a video of what a product would see travelling through the furnace. The principle is just like your car’s dash cam, the only difference being that your journey is being performed in a furnace at up to 600 °C. The resulting video “Optical Furnace Profile” shows process engi-

GLOBAL FURNACES 19 Furnaces International March 2022 www.furnaces-international.com

neers so much about how their process is operating without any need to stop, cool and dismantle the furnace. This allows safe routine furnace inspection without any of the problems of costly lost production. The technique allows identification of the true root cause of furnace problems not only effecting the thermal processing of the product but also general furnace operation.

6. What future challenges do you see in temperature monitoring of Industrial heat treating market and how are you addressing them?

Industry is increasingly driven by pressures to comply with quality standards, to which they need accreditation to industry standards such as CQI-9 and AMS2750. Such standards and TUS monitoring requirements are constantly being updated with a need for customers to adapt their monitoring surveying SOPs,

GLOBAL FURNACES 20 Furnaces International March 2023 www.furnaces-international.com

RF

reporting protocols and deliverables.

PhoenixTM works diligently to keep abreast of legislative changes and adapt the system solutions to match the exact requirements of pyrometry standards so that heat treaters can maintain accreditation without extensive inhouse complimentary processing and reporting. As a dynamic team we have the flexibility to address customer requirements whether it be a customised thermal barrier design to match processing criteria or addition of new software features to address new specific analysis or reporting demands.

As a testimony to this fact the following is a direct quote from Safran Landing Systems’ site in Mirabel, Quebec, using the PhoenixTM Thermal View Survey software.

“We can definitely say that by using the PhoenixTM Survey software to produce our TUS has improved the process. Before, we had to debug our VBA code a couple of time per year, not counting the headaches when an up-revision of the AMS2750 occurred. We now have the peace of mind that our TUS are backed by a software from a company which has the right level of expertise and that we will be supported in the future. Also, the ease of use of the software helps a lot.”

We at PhoenixTM are constantly working with customers to specifically adapt the operating software Thermal View particularly Thermal View Survey to comply fully to the demands of the pyrometry standards and allow accurate, quick, efficient and traceable TUS reporting both from a monitoring hardware and data review, calculation and reporting perspective.

In industry automation and a move to real time monitoring and control of processes is becoming a major desire. Although thru-process monitoring is a transient point in time operation,

GLOBAL FURNACES 21

Furnaces International March 2023 www.furnaces-international.com

significant steps have been made to enhance the efficiency and value of the technique. One such innovation is that of RF Telemetry, allowing live monitoring of product temperature during the processing run. Not continuous monitoring but the next step to possible 24/7 product temperature collection. Phoenix TM has a flexible two way system allowing live data transfer from the data logger in the furnace to a monitoring PC, also allowing communication and control of the data logger live in-process.

Portable RF receivers known as repeaters can be positioned/ moved to where they need to be to act as a virtual data chain transferring the RF signal from the data logger back to the monitoring PC with master RF receiver called the Coordinator. No external power supply is needed or cumbersome communication cable between receivers. The receivers can be located exactly where they need to be allowing transfer of temperature data over hundreds of meters. Such operation allows you to identify process problems when they happen allowing possible immediate corrective action , reducing risk of waste and excessive process downtime. �

In memory of David Plester one of the original founders of PhoenixTM.

ABOUT THE AUTHOR:

Dr Steve Offley aka “Dr O” is Product Marketing Manager at PhoenixTM

Joined April 2018

25 years experience in the industrial temperature profiling market Company Website: www.phoenixtm.com

GLOBAL FURNACES 22 Furnaces International March 2023 www.furnaces-international.com

WE ARE USING ALL OUR ENERGY DESIGNING YOUR FURNACE, SO YOU DON'T WASTE YOURS! INNOVATION AS STANDARD ® TOLEDO ENGINEERING / TECOGLAS / ZEDTEC / KTG ENGINEERING / KTG SYSTEMS / EAE TECH www.teco.com

Making the Furnace of the Future

By Zahra Awan*

With thanks to Glassman

Events by Glass International

Furnaces International hosted a session on ‘Making the Sustainable Furnace of the Future’ at the Glassman Events Europe event.

*Editorial Assistant, Furnaces International

*Editorial Assistant, Furnaces International

On behalf of Quartz Business Media, Furnaces International, and Glass International, we would like to extend our sincerest condolences and best wishes to all those who have been affected by the Turkish earthquakes.

GLOBAL FURNACES 24 Furnaces International March 2023 www.furnaces-international.com

Furnaces and heat treatment is infamously demanding of energy; throughout the session, speakers from across Europe discussed the possible solutions that could tackle the issues faced in the industry. Taking place between the 8th – 9th February 2023 in Istanbul, the Glassman Europe event provided key players with the chance to connect, discuss and learn of the latest developments in the industry.

Following geopolitical tensions, the energy crisis has impacted almost, if not all, heavy industries. On top of this, we are facing the threats of recession with inflation. The push for industries to decarbonise by 2050 is one of our kinder tasks, and one that should be seen as opportunity rather than a challenge.

This being said, the challenge of decarbonising is a greater challenge for the Furnaces Industry, however, without furnaces, there is no glass.

The ‘Making the furnace of the future’ session, co-hosted by

GLOBAL FURNACES 25 Furnaces International March 2023 www.furnaces-international.com

Speaking next on behalf of Furnace International was Phillippe Kerbois, Global Industry Manager – Glass, AMETEK Land. In his presentation, ‘Combining IMAGEPro Glass with NIR-B-2K Thermal imaging to Improve Your Carbon Footprint and Reduce NOx Emissions in Glass Furnace Applications’ he continued on a similar theme to Mr Hakes. Mr Kerbois noted the importance of data collection in the name of technological advancement and development. He has elaborated on his presentation in a follow up editorial which can be read on page ….

Speaking next was Neil Simpson, Consultant and Managing Director, Simpson Combustion Ltd. Further elaborating on the importance of data measurements, his presentation ‘How much CO2 are glass furnaces producing and why you may want to measure?’ began with a short anecdote on “the cost of the analyser [in the 1990s, which] was the same price as a Vauxhall Astra!”. The message that “CO2 measurement [must be a] part of operation and decarbonisation strategy” was grounded from the beginning. Despite the challenges of 2023 namely the Ukrainian crisis, the energy crisis and living crisis (to name a few), the targets for decarbonising the glass furnaces industry by 2050 is still the goal. Claiming that the industry has somewhat regressed from the times where furnaces were fuelled on biofuels, i.e., wood, he notes his hope for biofuels or hybrid furnaces. Closing his presentation, Mr Simpson concluded that “Only when you know where you really are can you plan efficient path for decarbonisation. Only by measuring and recording CO2 will you make operators and stakeholders aware.”

Closing the day and session were CelSian speakers, Andries Habraken, Segment Leader Process Optimisation and Oscar Verheijen, Segment Leader R&D and GlassTrend Chairman. List-

GLOBAL FURNACES 26

Furnaces International March 2023 www.furnaces-international.com

Greg Morris. Editor Glass International

Furnaces International, aimed to target new innovations, challenge opinions and theorise solutions. Below is a summery of the Furnaces International Sessions.

Opening the session was Stuart Hakes, Chief Executive, F.I.C. In his presentation on ‘The Future of Glass Furnaces in a Decarbonised World’, he discussed the dilemmas faced with alternative fuel sources. Optimism in the face of realism only becomes a hindrance; this is highlighted by Mr Hakes. One reality check given by Stuart Hakes was on the positive outlook on biofuels. Usually praised as a carbon neutral alternative to fossil fuels, it is easy to dismiss the reality that it can “take a tree over 40 years to grow, therefore 40 years to replace the fuel we have just taken… can this be considered as sustainable?” Hydrogen and electric alternative fuels were also placed under interrogation as it came to light that the industry simply does not have the knowledge and means for the ideal furnace of the future. Maintaining the trend of ‘realism’, Hakes went onto state “the industry should consider the benefits of investing in a cheaper furnace, designed to last 10 years, in comparison to an expensive furnace that only lasts 20 years [and whose technology is outdated].” As the industry is rapidly changing, technology in 20 years will be vastly outdated. Therefore, a cheaper, short-term investment makes way for a second investment in a more efficient and technologically advanced machine, designed to last long term.

Short Term Solutions

• Boosting share increase

• Improve process efficiency

• Increased use of recycling glass

• Use of alternative raw materials

• Advanced process control (APC)

• Batch and/or cullet preheating

• Heat recovery systems

Mid-Long-Term Solutions

• Fuel switching (hydrogen, biogas)

• New furnace concepts

• Carbon capture technologies

• Alternative glass compositions

GLOBAL FURNACES 27 Furnaces International March 2023 www.furnaces-international.com

ing the mid-long- and short-term CO2 emission strategies, it is apparent that although there are options for the industry, we are restricted in options:

Once again, investing in research and data is the key to progress. The speakers provided us with CeSian’s “Stepwise approach to reduce energy and CO2,” which fell in line with what previous speakers had already noted:

� Evaluate furnaces in the energy benchmark database

� Full on-site energy and CO2 audit

� Generation of energy balance, visualising all energy flows

� Overview of technological options

� Select the best option

� Detailed simulation to analyse the impact of the chosen option(s) on glass quality, furnace lifetime, and emissions

� Final decision on the action(s)

The overall conclusion to the event was the importance of data collection and monitoring of current technology. It is also important to note that the industry is now in a place where investments on technology must be considered in ways that we would not have done so in the past. The benefits of short and long term investments is now its own challenge, with this, we all look forward to seeing how the furnaces industry will develop in 2023. �

GLOBAL FURNACES 28

ST. LOUIS, MISSOURI, USA 800 325 7075 | www.gillespiepowers.com | 314 423 9460 ✓SINGLE CHAMBER / MULTI CHAMBER FURNACES ✓SCRAP DECOATING SYSTEMS ✓TILTING ROTARY MELTING FURNACES ✓SCRAP CHARGING MACHINES ✓LAUNDER SYSTEMS ✓CASTING / HOLDING FURNACES ✓HOMOGENIZING OVENS ✓COOLERS ✓SOW PRE-HEATERS ✓REPAIR & ALTERATIONS

Glass manufacturing is an energy-intensive process. When I first joined AMETEK Land and began promoting high-temperature instruments in 2014, the NIR-B camera in particular, I was always surprised to see the number of furnace operation teams, using TCs and handheld pyrometers, such as Cyclops to build up the thermal profiles and hot spots of glass furnaces. This was the standard for decades, but it was clear to all that a process for optimization needed to be put into place.

In 2016, I started promoting thermal surveys, based on transportable NIR-B. At first, it was to provide a demonstration or just to gauge interest. From this, we were able to ascertain many case studies, which were presented at conferences such as GPC and DGG together with Neil Simpson, of Simpson Combustion and Energy Ltd. The glass market then decided to consider the value of NIR-B as a tool to start decarbonisation which pushed to ensure compliance with air pollution emissions regulations.

Optimising the combustion conditions is essential to minimise energy costs and combining AMETEK Land’s golden four – the NIR-B-2K, IMAGEPro-Glass Software, Cyclops, and our gas analyser, the Lancom 4, became the way to go.

The first requirement for combustion optimisation is to set the correct fuel:air ratio. In general, the requirement is to minimize the amount of excess air whilst still allowing complete combustion of the fuel. This requires a knowledge of the oxygen (O2) and carbon monoxide (CO) concentrations in the flue gases. A high oxygen concentration is an indication that heat is being wasted by venting hot air through the stack, whereas excess carbon monoxide is an indication of incomplete combustion. In most cases, the CO concentration is below 100 ppm but, on furnaces with failing regenerators, CO values more than 70,000ppm

How combining

How combining

2K thermal carbon footprint

2K thermal carbon footprint

Image

By Philippe Kerbois*

GLOBAL FURNACES: GLASSMAN 30 Furnaces International March 2023 www.furnaces-international.com

NIR-B-2K

combining IMAGEPro Glass with NIR-Bimaging and Lancom 4 can improve footprint and reduce emissions

combining IMAGEPro Glass with NIR-Bimaging and Lancom 4 can improve footprint and reduce emissions

* Global Industry Manager

Glass – AMETEK Land

are possible, so wide measurement ranges are essential. The Lancom 4 can accommodate both a low and a high-range CO sensor. Where the CO concentration exceeds the maximum range of the low CO sensor, the sensor is automatically purged with ambient air, and the instrument switches to the high-range sensor.

The next requirement is to minimise emissions of oxides of nitrogen (NOx). There is a direct correlation between peak flame intensity and the formation of NOx. Any parts of a flame that are

GLOBAL FURNACES: GLASSMAN 31 Furnaces International March 2023 www.furnaces-international.com

above 1600 °C will form thermal NOx.

AMETEK Land’s Lancom 4 is a portable flue gas analyser that is integrated into a compact battery-powered unit and can measure up to eight gases simultaneously with nine separate sensors (high and low CO).

Simple to set up and easy to operate, Lancom

4 enables highly accurate spot and semi-continuous gas testing. It wide variety of applications compliance with safety and emissions requirements. Cus- tomisable to specific gas measurements and process stream conditions, a resilient stainless steel probe extracts the gas sample, while advanced real-time processing techniques produce the highly accurate combustion and emissions calculations needed. A ceramic probe is available for high-temperature applications such as those in the glass industry.

Generally, the higher the temperature, the greater the risk of dissociating oxygen and forming thermal NOx, which is dominant in glass-melting furnaces. While a flue gas analyser such as AMETEK Land’s Lancom 4 can show which exhaust ports have the highest NOx, it may not indicate which of the burners is generating the most NOx.

This is where the use of thermal imaging NIR-B-2K cameras, to see the flames based on fixed locations and reinforced with portable AMETEK Land NIR-B infrared borescope imagers come in handy.

Since the indicated temperatures when the burners are firing are not real, we do not know the emissivity of the flames, but the application of relative isotherms within the image offers the

GLOBAL FURNACES: GLASSMAN 32

Furnaces International March 2023 www.furnaces-international.com

Lancom 4

ability to see which flames are typically hotter and give an indication of the flame length.

Additionally, the NIR-B-2K can support the batch line determination and location (batch coverage function) and build the hot spot locations on thermal profiles.

The tool provides much more value with the new IPV2 software, where ROIs can be measured, and accurate and repeatable measurements of refractories and glass surfaces.

This way, the hottest port can be determined easily when producing the most emissions and particularly NOx.

When working on an oxy-fuel furnace, it is important to consider that at stoichiometric conditions, there is, in theory, 66% water. The reality is that it will be less than this but still a significant potential to literally flood the instrument. When measuring the emissions from an oxy furnace, getting as close to the furnace as possible is key since there can be strange flows in the flue system, specifically when more than one port is used. The benefit of oxy-fuel is that conditions are typically steady state and there is no need to wait for a full firing cycle on a regener ative furnace. The exhaust port is typically under negative pres sure, so you should always seal the probe with fibre to reduce parasitic air ingress.

On an end-fired furnace, the port neck is the best location to test, from an emissions perspective but is likely more difficult from a health and safety perspec tive. The target wall is often used since there is almost always access platforms available. This point is close the potential location of a Lambda or sensor. It is important to remember that an in-situ oxygen sen-

sor measures on a wet basis, because of the sample conditioning, and the oxygen in a Lancom 4 is a percentage on a dry basis.

In conclusion, combining these three technologies, gaining a comprehensive understanding of the glass melting process and make targeted improvements to reduce energy consumption and emissions becomes possible. This can help to improve the sustainability of industrial processes and reduce their impact on the environment. �

GLOBAL FURNACES: GLASSMAN 33 Furnaces International March 2023 www.furnaces-international.com

NIR-Borescope

Thyssenkrupp Steel’s Black Giant blast furnace turns 50!

A blast furnace in operation at thyssenkrupp Steel’s Schwelgern steel mill in Germany, turned 50 years old on 6 February.

Known officially as Schwelgern 1 – the Black Giant – the blast furnace is 110 metres in height and has a daily capacity of 10kt of pig iron; it is regarded as one of the biggest blast furnaces in the western world.

Back in February 1973, a team of over 50 chemists and designers worked towards the goal of a ‘blue sky over Hamborn’ – proving that even 50 years ago, the German steel giant was conscious of environmental protection. Since then, of course, there have been massive investments, claims thyssenkrupp Steel, in environmental protection

measures, especially dust removal.

Today thyssenkrupp Steel claims it is well on the way to climate-neutral steel production. Coal-based pig iron production in the blast furnace is being replaced by direct reduction plants which can operate in a climate-friendly way using hydrogen. Eventually, the “black giant” will be retired.

Verallia relights French furnace

Verallia France relit furnace number three at its Chalon-sur-Saône site.

After 49 days of work, furnace number three was relit at the Verallia Group’s ‘most important site’ during a traditional match ceremony.

The furnace, which has been operating continuously since 2016, will be relit for the next seven years.

The oven is dedicated to the production of glass in the ‘dead leaf’ green colour traditionally associated with the wine bottles produced in Burgundy.

During the 49 days of repair, optimisations were made to the furnace improve its performance.

As per Verallia’s tradition, the godmother and godfather had the honour of

NEWS LIFE OF A FURNACE 34 Furnaces International March 2023 www.furnaces-international.com

restarting the oven in the match ceremony.

Godmother of the oven was site employee Myriam Allaoui, and godfather was Guillaume Valdenaire, Purchasing Director of Boisset.

New Tenova EAF for Valbruna ASW Inc.

Italian plant builder Tenova, a Techint company and a prominent force in sustainable solutions for the green transition of the metals industry, recently completed the successful start-up of a new 70t EAF at the Valbruna ASW Inc at a plant in Welland, Ontario, Canada.

Valbruna is a specialty steel producer that manufacturers high quality steel and stainless steel.

Tenova’s latest generation EAF unit has replaced an older EAF. The spout shape of the new furnace, says the company, will provide an increase in melt shop productivity as well as an improvement in production reliability.

The scope of supply included associated auxiliary equipment, the TDRH 4.0 (Tenova Digital Regulator and Harmonics) electrode regulation system, the KT (Koester Technologies) chemical injection system, a ladle-charging material handling system and complete EAF automation.

“It is through our important and long-term relationship with the Valbruna Group that this project was made possible. We have increased the plant’s production, sustainability and safety.”

Aldo Savioli, project manager operations at Tenova Upstream. The KT chemical injection system, says Tenova, is designed to fit the wide range of process needs, balancing energy distribution and increasing the efficiency and

productivity. The automation system is claimed to offer several advantages designed to increase plant efficiency. The system will guarantee the correct execution of the working cycle in relation to the production of different steel grades, while optimizing the parameters and storage of production data. The system is also designed to comply with all safety standards.

“We are proud of the innovative and state-of-the-art EAF design achieved for Valbruna ASW. It is through our important and long-term relationship with the Valbruna Group that this project was made possible. We have increased the plant’s production, sustainability and safety. We expect the plant to become a landmark for the production of high quality steel and stainless steel in the North American market”, said Aldo Savioli, project manager operations at Tenova Upstream.

NEWS LIFE OF A FURNACE 35 Furnaces International March 2023 www.furnaces-international.com

H

EAT REAT

There are many radiant tube options on the market, so which one is best for your furnace and your budget? In this column that compares radiant tubes in carburizing and continuous annealing furnaces, discover how two major types of radiant tubes stack up.

LIFE OF A FURNACE 36 Furnaces International March 2023 www.furnaces-international.com

ODAY

T T

Radiant Tubes: Exploring Your Options

By Marc Glasser*

Introduction

Radiant tubes are used in many types of heat treating furnaces from carburizing furnaces to continuous annealing of steel strip. Generally, a heat treater has three options for radiant tubes: cast tubes, wrought tubes, and ceramic silicon carbide tubes. Silicon carbide tubes are rarely used by heat treaters, so this article will not delve too deeply into this option. Suffice it to say, ceramic materials can often handle much higher temperatures at the expense of ductility; ceramics are more brittle than metals, making them prone to failure from the small impacts, so metal cages are sometimes fabricated to protect them. Most of the tubes being used today are cast radiant tubes. With new casting technology — primarily centrifugal casting — thinner tubes are being cast at a lower cost, which then results in a shorter life.

The primary factors for choosing radiant tube material are tube temperature and carbon potential of the furnace atmosphere. Cost-benefit analysis should also be considered. There are multiple applications for radiant tubes, including carburizing furnaces, continuous annealing furnaces for steel sheet galvanising, steel reheat furnaces, and aluminum heat treating. This article will explore two of the aforementioned radiant tube options, specifically for carburizing and continuous annealing furnaces.

* Director of Metallurgical Services, Rolled Alloys

* Director of Metallurgical Services, Rolled Alloys

LIFE OF A FURNACE 37

Furnaces International March 2023 www.furnaces-international.com

Radiant Tubes for Carburizing Furnaces

Gas carburization is traditionally performed between 1650°F and 1700°F at a carbon potential of 0.8% approximating the eutectoid composition. In today’s competitive environment, more heat treaters are increasing temperatures to 1750°F and pushing carbon potentials as high as 1.6% to get faster diffusion of carbon while spending less time at temperature. INCONEL® HX (66% Ni, 17% Cr) has been a common cast alloy seen in carburizing furnaces. This alloy is regularly selected for its resistance to oxidation and carburization up to 2100°F. Super 22H is more heavily alloyed than HX and is seeing more use as carbon potentials increase but at a premium price. With advances in centrifugal castings, cast tube wall thicknesses have decreased from 3/8-inch to 1/4-inch. Some heat treaters have shared that this decrease in wall thickness has also led to shorter tube life.

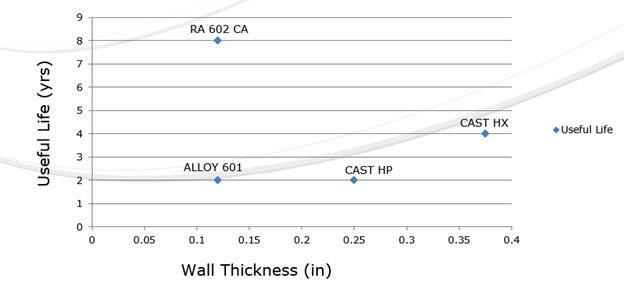

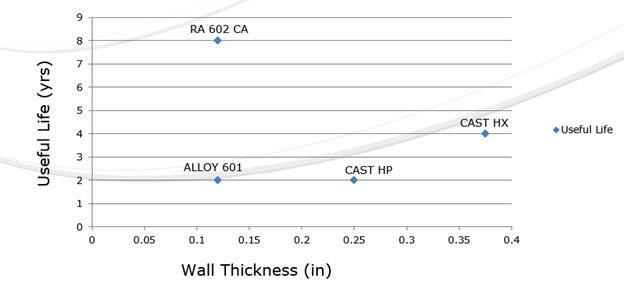

Fabricated and welded radiant tubes in alloys 601 and RA 602 CA® have been tested in industry. When tested, these wrought alloys were fabricated to have a wall thickness of 1/8 inch. At the extremes, tubes fabricated from 601 only lasted 50% as long as cast HX. Historically, HX tubes have been approximately 33%

LIFE OF A FURNACE 38 Furnaces International March 2023 www.furnaces-international.com

Figure 1

higher in cost than that of 601 and utilise heavier 3/8-inch walls. A little-known fact is that by switching to a thinner wall cast tube, the life drops by 50%. By switching to 1/8 -wall RA 602 CA, tube life has been extended to eight years or more, while running at 1750°F and up to 1.6% carbon potential, at just a 33% premium over cast HX.

Life cycle data are presented in Figure 1

Radiant Tubes for Continuous Annealing Furnaces

In the area of continuous annealing, the cast alloy of choice is HP/HT (35% Ni, 17% Cr, 1.7% Si, 0.5% C). Here again, this casting has been compared to 601 and RA 602 CA, with the same results. The total life data from these trials are also incorporated into Figure 1. During the collection of this data, there has been no effort to measure the actual tube temperature, so the effect of tube temperature is not clearly defined. In these continuous annealing furnaces, it has been reported that the tubes at the entry end are subject to more heat absorption as burners are firing more due to the continuous introduction of cold material; but in trials, the operators have not kept adequate documentation of specific tubes, making justification more difficult.

Justification for the higher cost wrought alloy needs to take into consideration initial fabricated tube cost, actual tube life, AND the lost production of each anticipated downtime cycle as these downtime costs are often much more than material costs. Only individual fabricators can determine these costs.

LIFE OF A FURNACE 39 Furnaces International March 2023 www.furnaces-international.com

LIFE OF A FURNACE 40 Furnaces International March 2023 www.furnaces-international.com

“

Cost-benefit analysis should also be considered.”

The Economics

Table 1 shows the economics of metal alloy choice. To properly interpret, understand that the costs are not actual, but rather relative to 601, so a round number of 1000 was used. With a 30% greater cost of cast tubes, that translates to a relative cost of $1300. The annual cost is the amortised cost over the life of the tube. The total eight-year cost is the relative cost times the number of tubes that would have to be purchased to obtain the life cycle of one tube of the longest-lasting material over its full life cycle.

Missing in this analysis is the additional cost of downtime and lost production. For the replacement of radiant tubes in a carburizing furnace, this typically entails a full week to turn a furnace off, allow it to cool, replace the tubes, and then heat it up again. Many heat treaters do not consider this, and therefore it is a hidden cost. Even without the downtime being considered, by examining the total cost of materials (including replacements) compared to the longest-lasting tube, it turns out that the most expensive tube is the cheapest tube. The obstacle to overcome is whether the heat treater is willing to wait eight years to realise these cost savings.

There can be additional factors to consider. With improvements in the efficiency of casting, the actual costs of the thinner wall casting may be somewhat less, but to match the overall cost of the longest-life material, it would have to be less than half the

LIFE OF A FURNACE 41 Furnaces International March 2023 www.furnaces-international.com

Table 1

expected cost. As better, more expensive cast alloys become accepted and actual life data becomes available, these more costly alloys can be added to this table for comparative analysis, too. This same method of analysis can be applied to radiant tubes for continuous annealing furnaces, but more details will need to be added including furnace position. Different alloy candidates will have to be put to the test in actual operations, carefully document what alloy is in what position or location, and when it gets changed out. This becomes quite cumbersome when annealing furnaces (depending on design and manufacture) can have over 200 radiant tubes.

Conclusion

Currently, cast alloy tubes dominate the market. The concept of total life cycle cost has been introduced as a means of more accurately justifying one’s choice of radiant tube. This comes into play more as processes are pushed beyond traditional process conditions. Cost-benefit analysis must be balanced over acceptable amortisation time, of course. However, performing the full analysis as well as the costs saved from downtime may lead some heat treaters to some alternate materials. �

ABOUT THE AUTHOR:

Marc Glasser is the director of Metallurgical Services at Rolled Alloys and is an expert in process metallurgy, heat treatment, materials of construction, and materials science and testing.

Marc received his bachelor’s degree in materials engineering from Rensselaer Polytechnic Institute and a Master of Science in material science from Polytechnic University, now known as the NYU School of Engineering.

For more information: Contact mglasser@rolledalloys.com.

LIFE OF A FURNACE 42 Furnaces International March 2023 www.furnaces-international.com

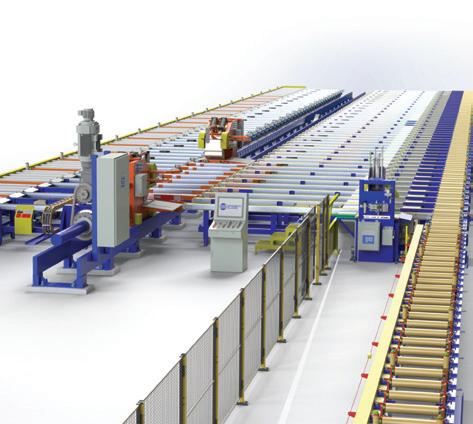

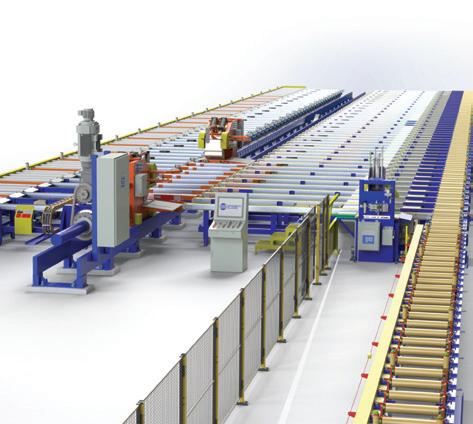

Scan: Impact quench data Engineering. Manufacturing. Global Support. Excellence is our standard. Precision Saw System The industries most productive offline-saw Infrared Die Oven Heat the die, not the air High Impact Spray Quench The leading profile quench in the industry Profile Handling System Fully automatic profile handling system Flying

The industries best

system Hot-Jet

Furnace The industries most energy efficient, flameimpingement log/billet furnace Performance Driven We engineer and manufacture high-performance heating, handling, and quenching systems. We service and support the globe. Contact us to discuss your next project. +1-800-918-2600 | gcinfo@grancoclark.com We are 100% employee-owned www.grancoclark.com

Cut Double Puller

puller

Log/Billet

The rise and fall of a blast furnace

Tim Smith* chronicles the history of an iconic UK landmark, Redcar furnace, which after close to five decades of service, was demolished in late 2022.

AT 9am, local time, on Wednesday 23 November 2022, the most significant destruction of the iron industry of Teesside, Middlesborough, North Yorkshire, UK, took place with the demolition of the Redcar blast furnace. Demolition specialists, Thompsons of Prudhoe based in Northumberland, UK, used 175 tonnes of explosives to bring down the largest blast furnace in the British Isles and once, the second largest in Europe. The BOS shop had already been demolished by them in October along with much of the former works infrastructure to make way for a £113m regeneration of the 600 acre (243 hectare) site, at the mouth of the River Tees, as a ‘Freeport’.

The blast furnace was commissioned in 1979 under the ownership of the then nationalised British Steel Corporation as part of a £400m investment, with a further £100m to upgrade the nearby Lackenby steelmaking complex.

The new blast furnace had a design capacity of 10kt/day (3.25Mt/yr) and, at the time, was planned as one of two identical furnaces to be built on the site to accommodate an annual output close to 6.5Mt. In the event, the second furnace was never built.

Open hearth furnaces

Furnaces were first built at Redcar in 1874 by Robson, Maynard

*Consulting editor, Steel Times International and a member of the Historical Metallurgy Society

LIFE OF A FURNACE 44

Furnaces International March 2023 www.furnaces-international.com

& Co which become Walker, Maynard & Co nine years later when four furnaces were in blast. Dorman Long & Co Ltd took over the site in 1915 when assets included two furnaces in operation and an ironstone mine at nearby Kilton. Dorman Long had earned a reputation for bridge building, ship plate manufacture and steel construction activities, at home and abroad. Steelmaking was by basic open hearth furnaces. In 1929, they acquired the one-time world’s largest ironworks, Bolckow-Vaughan & Co, which itself had taken over the Clay Lane ironworks at Eston, Redcar in 1900. The number of furnaces peaked at 40 in 1929 but had fallen to just two by 1957, both located at the Clay Lane works. In 1958, Dorman Long commissioned a Universal Beam

LIFE OF A FURNACE 45 Furnaces International March 2023 www.furnaces-international.com

The moment of demolition the Redcar blast furnace was demolished Picture courtesy Teesside Live Reach PLC)

mill 4km to the south-west of Redcar at Lackenby.

In 1967, the company became part of British Steel and Tube Ltd – a consortium including the steelmakers, Stewarts and Lloyd’s at Corby, Northants, and South Durham Steel & Iron, Middlesbrough. However, this merger was short lived as the UK government nationalised the UK’s steel industry in July of that year, with the works becoming part of British Steel Northern and Tubes Group.

In 1974, under the management of the British Steel Corporation, plans were put into action to build a new modern iron and steel plant at South Gare, Redcar which saw the opening of Britain’s largest ironmaking complex on 12 October 1979; the furnace being lit with fire from Clay Lane’s BF No 1.

In 1988, Britain’s iron and steel industry was once again privatised, and the Teesside complex became part of privatised British Steel. In 1999, British Steel merged with Dutch steelmaker, Koninklijke Hoogovens to form the Corus Group. Corus was sold to Tata Steel of India in 2007 but retained the Corus name and logo on Teesside until September 2010. With sufficient steel capacity supplied by Port Talbot and Scunthorpe works, the Redcar complex sought to supply steel to external customers. However, a 10-year agreement with Marcegaglia of Italy ended prematurely and, with no alternative demand, the furnace was blown out in December 2009 and mothballed. A short reprieve occurred in 2011 when the Thai Steel company, Sahaviriya Steel Industries (SSI) bought the iron and steel works to supply slab to its rolling mill in Thailand. Modernisation of the furnace was completed and it was re-lit in April 2012. In 2015 SSI UK went into liquidation and the furnace was blown out once again, never to be reprieved.

LIFE OF A FURNACE 46 Furnaces International March 2023 www.furnaces-international.com

The Redcar 14m hearth diameter blast furnace had a working volume of 4246m3 a PCI rate of 240kg/t and reached an output of 11kt/day of iron

(Picture copyright J Aylen)

A heritage task force was established to document the 170year history of iron and steel on Teesside with the aim of recording the cultural and economic industrial heritage of the area. From a public response of just 200 people, of which only one third commented on the blast furnace, just over half called for its demolition. Consequently, the task force recommendation was not to preserve the furnace as a public attraction but rather to retain various artifacts from it to be put on display near the entrance to the site and also to enhance existing nearby industrial heritage resources including the ‘Steel Stories’ exhibition at Kirkleatham Museum, Teesside Archives British Steel Collection and the Cleveland Ironstone Mining Museum in Skinningrove, which has undergone capital development.

LIFE OF A FURNACE 47 Furnaces International March 2023 www.furnaces-international.com

They did recommend considering preservation of the Dorman Long Tower, originally a coal bunker, and finding a new use for it. However, this was demolished in September 2021.

Lack of preservation

Sadly the destruction of the UK’s 20th century heritage is all too common and contrasts with that found elsewhere. Only the Magna Science Adventure Centre in Rotherham, the former Templeborough open hearth steel shop, later converted to electric arc steelmaking, has been preserved. Here, one of the electric arc furnaces has been retained, its light and sound reproduced periodically.

In Europe, the European Route of Industrial Heritage (ERIH) lists numerous preserved sites country by country. If one selects the ‘Iron & Steel’ filter details of iron related sites, including those with preserved furnaces, are revealed: https://www.erih.net/. Germany is particularly rich in sites including one of two blast furnaces at Neunkirchen decommissioned in 1982. This was the first blast furnace worldwide to be actively refurbished for the purpose of opening to the public. More recently, BF No 5 of Thyssen Krupp, Duisburg has been preserved in-situ within what is now the Duisburg Landscape Park. Further afield, we have the Carrie Furnaces in Homestead, Pennsylvania USA (decommissioned in 1978) open for special occasions and in Japan, the Yahata Steel Works in Yahatahigashi-ku, Kitakyushu, decommissioned in 1972.

Future of the site

In addition to becoming the UK’s largest Freeport, the site is already earmarked for the Net Zero Teesside Power carbon

LIFE OF A FURNACE 48 Furnaces International March 2023 www.furnaces-international.com

capture, utilisation and storage, power plant, and GE Renewable

Energy’s mammoth wind turbine blade manufacturing facility. Development of the site will be Europe’s largest brownfield undertaking, planned to create 18,000 jobs over the next five years. � On the internet

1) Demolition videos

https://news.sky.com/video/teessides-iconic-redcar-steelworks-blast-furnace-demolished-12754292

(Source: Sky News)

https://www.youtube.com/watch?v=_mmxJtvStWo

(Source: Thompsons of Prudhoe)

https://www.youtube.com/watch?v=8zZ02VSwyc8

(Source: Fat Egg Media)

2) Teesworks Heritage Task Force

https://www.teesworks.co.uk/about/teesworks-heritage-task-force

3) Kirkleatham Museum Steel Stories

https://redcarcleveland.co.uk/enjoy/steel-stories-2/

4) Cleveland Ironstone Mining Museum

https://landofiron.org.uk/

5) Teesside Archives British Steel Collection

https://teessidearchives.wordpress.com/tag/british-steel/

LIFE OF A FURNACE 49 Furnaces International March 2023 www.furnaces-international.com

AGC and Saint-Gobain partner for decarbonised

Borosil Renewables starts third solar glass production

India’s Borosil Renewables has started trial production of its third solar glass furnace, which has increased its capacity in India to 1,000 tons per day.

This is the equivalent to 6GW solar module production a year.

The company’s other two furnaces in India have production capacities of 240 tons per day and 210 tons per day.

The manufacturer now has a total solar glass capacity of 1,300 tons per day in India and Germany.

Its capacity includes includes 300 tons per day in Germany after it acquired Europe’s largest solar glass manufacturer, Interfloat Group.

NEWS GREENER FURNACES 50 Furnaces International March 2023 www.furnaces-international.com

decarbonised flat glass line

AGC and Saint-Gobain will collaborate on the design of a pilot flat glass line that is expected to reduce the companies’ direct CO2 emissions. AGC’s patterned glass production line in Barevka, Czech Republic, will be entirely refurbished into a high performing and modernised line. The line aims to be 50% electrified and 50% fired by a combination of oxygen and gas.

This is a technical breakthrough compared to current technology used in flat glass furnaces fired by natural gas.

It will be the most sustainable flat glass line design contributing to both companies’ paths towards carbon neutrality and to the necessary acceleration of the flat glass industry decarbonisation.

This development could pave the way for the conversion of industrial flat glass lines that are mainly powered by low carbon electricity, more efficient than any gas solution, and have reduced carbon emissions for the customers’ benefit.

The technology is expected to be implemented on the patterned glass line for operational success by the second half of 2024.

Davide Cappellino, President Architectural Glass Europe & Americas of AGC, said: “This hybrid design melter is another important milestone in our Net Zero Trajectory to become carbon neutral as a company by 2050.

“The breakthrough design will be done jointly with Saint-Gobain, combining the best technology knowledge of both companies.”

Joana Arreguy, Industrial Director Glass, Saint-Gobain, said: “We are delighted to co-develop with AGC [the] new, most advanced technology for flat glass production in the world.”

The news comes a few months after Saint-Gobain became the first company in the world to achieve zero carbon production of flat glass last May.

NEWS GREENER FURNACES 51 Furnaces International March 2023 www.furnaces-international.com

production furnace

Glass Futures: sustainable fuels could reduce glassmaking carbon emissions by 80%

While the results of less commercially available and technically unproven options like biofuels and hydrogen were positive, the report concludes that options to decarbonise the industry won’t be restricted to one single solution due to geographic drivers such as localised hydrogen networks and electrical grid capacity.

It found that no single low-carbon route will be suitable for the 21 largest glass manufacturing sites in the UK.

A report suggests sustainable fuels in the use of glass manufacturing could reduce carbon emissions by up to 80%

UK research organisation Glass Futures published its report for the Department of Business, Energy and Industrial Strategy (BEIS) which answers some of the fundamental questions surrounding low carbon fuels within the UK glass industry, with learnings applicable to the global industry.

Glass Futures is building a £54 million 165,000ft2 Global Centre of Glass Excellence in St Helens, UK. It is due for completion in 2023 to pioneer research into decarbonising glass and other industries, has established:

Biofuels: The use of 100% liquid sustainable biofuels resulted in carbon savings of between 70-80% when compared with high carbon natural gas.

Hydrogen: The potential for replacing natural gas with hydrogen has been demonstrated on an industrial scale and appears promising but the solution varied across the different sub sectors (float, container, etc). Further research is required to understand the effects of hydrogen combustion on glass melting and forming processes, glass quality, Nitrogen Oxide (NOx) emissions and refractory corrosion.

Electric melting: Some manufacturers are using increasing amounts of electric ‘boost’, with electricity supplying around 20-40% of melting energy. Increasing beyond this amount of boost requires significant changes to furnace design and other barriers exist including uncertainty around the rising cost of energy.

Economic modelling: Alongside a series of pilot scale tests, economic modelling and research into hybrid solutions from present day to 2100 found that payback on net zero investment is possible by 2060, based on retrofitting solutions and given a positive policy framework co-created by industry and government.

Dr Palma González García, Combustion Technical Lead at Glass Futures said: “Our research indicates that future investigation is warranted and that options to decarbonise the glass industry won’t be restricted to a single solution... A complex landscape exists around the many fuel switching solutions, and a number of key technical questions still remain regarding the long-term impacts of fuel switching choices.”

She added: “It’s clear there must be additional research to de-risk alternative technologies to enable the transition required.”

The BEIS IFS project has attracted critical global acclaim and it’s hoped the outputs of the report will provide a platform for discussions by policymakers as a blueprint to enable the uptake of key fuel switching options.

NEWS GREENER FURNACES 52 Furnaces International March 2023 www.furnaces-international.com

THE HYDROGEN HYBRID SOLUTION

Safe. Flexible. Clean. Efficient. Plug’n’play. What else? A European loyal customer has been the first to trust into our eco-breathly solution for a new mill project to be installed in 2023.

Do you wanna be the next partner adopting SMSZEROFLAMEHY2 solution?

We continue on our pathway of innovation for delivering excellent performances to our customers for the years to come! We start to breathe again.

Our expertise covers:

> From 100% natural gas to 100% hydrogen H2

> Down to 40 ppm @ 3% O2 NOx emissions.

> Up to +5% emissivity compared to a traditional natural gas burner.

> Substantial CO2 reduction compared to a traditional natural gas burner.

> From 500 kW to 3,500 kW power size availability.

> Overboost mode (extra power in quasi-flameless combustion).

www.sms-group.com

GREENER FURNACE 54 Furnaces International March 2023 www.furnaces-international.com Decarbonising

Ernesto Cattaneo* and Annick Lachance Nyiringango** investigate how operating conditions affect the amount of CO2 emitted by a regenerative glass furnace, while observing operating costs.

*Head of Innovation Department,

**R&D engineer for SGRPRO, a Stara Glass affiliate, Stara Glass, Genova, Italy

https://www.staraglass.it/

Decarbonising regenerative glass furnaces

The glass industry contributes significantly to CO2 emissions - 5% of European production according to European Union Emissions Trading System (EU ETS). Therefore, the industry is committed to participating in the global initiative to reduce them.

ecarbonising Furnaces

CO2 emissions during glass production originate from two sources and only a small portion comes from batch chemical reactions. The remainder, easily more than 80%, is caused by fossil fuels. They are burned to heat furnaces, due to the high temperatures

GREENER FURNACE

Furnaces International March 2023 www.furnaces-international.com 55

D

required to melt the raw materials used to make glass.

Though, in the process of designing a glass furnace, there are many unchangeable boundaries set by production needs which deeply affect the furnace performance, the designer has few but powerful operative leverages.

Several years ago, Stara Glass published an article describing how the process parameters impact the furnace consumption. In the light of the decarbonisation movement, we propose a similar evaluation, focused on the CO2 emission.

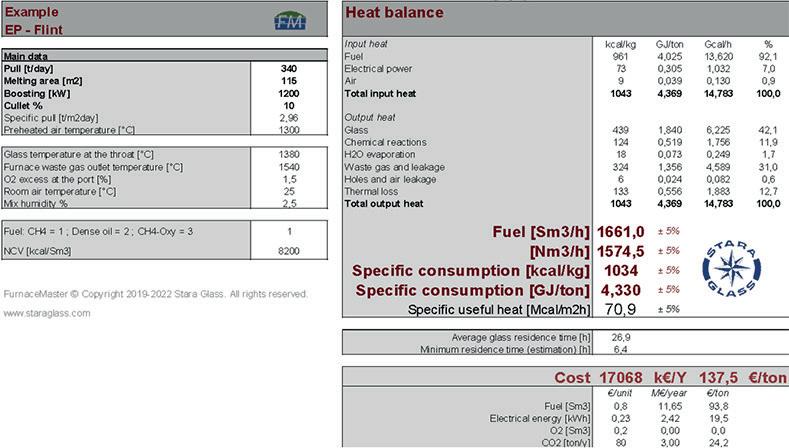

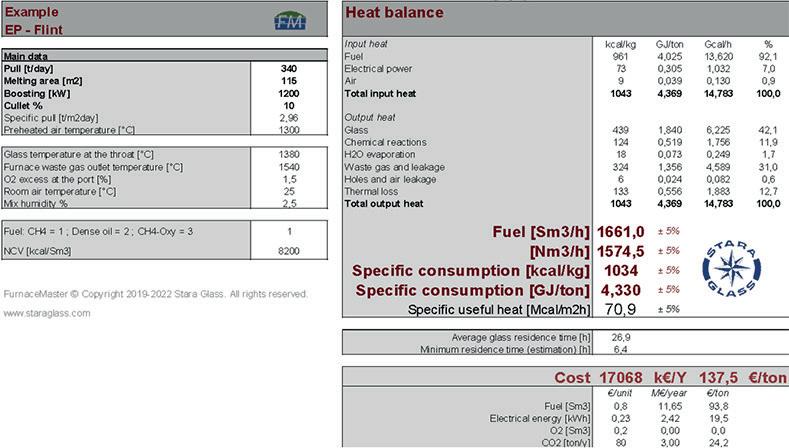

In this article, we will explore the influence of operating parameters on the CO2 emissions, consumption, and operating costs. The parameters will be measured through FurnaceMaster, a software designed by Stara Glass. It allows the designer to precisely define all computing input and collect all the significant output.

GREENER FURNACE 56

Furnaces International March 2023 www.furnaces-international.com

Input

Parameter Driver Notes

Pull [t/day] Set by the glassmaker based on production needs. The more stable it is, the more efficient the furnace will be.

O2 excess at the port [%] Environment, materials, consumption, and quality. It is used for balancing undesired productions of CO and NOx.

Boosting [kW] Investment

It is always useful for quality and capacity but it also increases the production cost

Cullet % Production and colour. Remarkably impacts consumption.

Mix humidity % Production, geographical position, storage method. Remarkably impacts consumption.

Preheated air temperature [°C] Available space / design The higher, the better.

Output

Parameter Notes

CO2 Emission [Ton/Year] It increases with energy consumption.

Gas consumption [Sm3] It increases with the pull.

Specific consumption [kcal/kg] It decreases when the pull increases and with the usage of electrical power.

Production cost [€] It decreases with a larger utilisation of electrical boosting.

Assumptions

For our study, the following consumption costs are assumed:

Fuel cost [€/Sm3] 0.8 Electric energy cost [€/kWh] 0.23 CO2 [€/ton] 80 GREENER FURNACE 57 Furnaces International March 2023 www.furnaces-international.com

Figure 1. Inputted nominal data in FurnaceMaster from a regenerative furnace producing container glass.

Table 1

Table 2

Nominal data

Figure 1 shows inputted nominal data in FurnaceMaster, given a state-of-the-art regenerative furnace producing container glass. Since the glass is white, the cullet is considered to be 10 to 60%.

Studied Parameters

The parameters below (table 1) will be individually varied in the analysis; their impact on CO2 emissions will be evaluated. We will also look at the fuel consumption, specific consumption, and production cost in table 2

Results

Pull

Figures 2 and 3 have been obtained by changing the pull while keeping the rest of the input parameters constant. We assumed the nominal point at 340 tpd and, for the purpose of this article, we did not change the electrical energy utilisation. Such param-

GREENER FURNACE 58 Furnaces International March 2023 www.furnaces-international.com

Figure 2. The table shows what happens to the parameters when the pull is changed.

Figure 3. Results in the graph show that the more the pull increases, the more CO2 is emitted.

eters would have been changed in common furnace operational practice.

Results show that the more the pull increases, the more CO2 is emitted and the more the consumption and operating costs are. Though, at the same time, specific consumption decreases together with quality expectations, which is connected to the minimum residence time rather than to the average, which is steadily defined by pull and furnace geometry.

We therefore observe that, to limit specific CO2 emissions, we need to use large furnaces at their highest pull.

GREENER FURNACE 59 Furnaces International March 2023 www.furnaces-international.com

Figure 4. The table shows that the higher the oxygen excess at the port, the higher the CO2 emitted.

Figure 5. The table shows that increasing boosting corresponds to decreasing CO2 emissions.

Figure 6. The results show that using glass cullet reduces CO2 emissions significantly.

TEMPERATURE AND HUMIDITY

Oxygen content

Figure 4 considers the oxygen content in waste gas at the port. It shows that the higher the oxygen excess at the port, the higher the CO2 emitted. Higher oxygen excess also means more consumption and operating costs.

However, the theoretical curve does not consider the following:

� At very low O2 level, combustion is not complete, and a certain quantity of CO is formed.

� Different levels of O2 correspond to different waste gas and air volumes.

� The higher the volumes are in the chambers, the higher the heat efficiency will be, but the lower the temperature efficiency of the chambers.

Nowadays this parameter is more under the spotlight for its connection with NOx and CO production rather than for its energy implications, but energy implications are important as well. To contain consumption and CO2 emission, we have to burn as stoichiometric as possible.

Boosting

Figure 5 shows the effect of increasing boosting from 600 to 2000 kW on the parameters.

The heat coming from the boosting is directly transferred to the glass heating it up with a better efficiency. Therefore, increasing boosting corresponds to decreasing the specific consumption, fuel consumption, and CO2 emissions.

Some barrier boosting is usually beneficial for the right formation of two opposing convective cells in the glass batch. Nevertheless, overuse of boosting may compromise the correct thermal profile of the superstructure and production itself. Also, an

GREENER FURNACE 60 Furnaces International March 2023 www.furnaces-international.com

increase in boosting means extra production costs.

While a high boosting decreases a furnace’s CO2 emissions, it has to be kept in account that the average fuel efficiency of a regenerative furnace is about 65%, while an average fossil power plant is 45%. Therefore, unless the electricity used in the furnace comes from renewable sources, more boosting means more CO2 in the environment.

Cullet

Using glass cullet reduces CO2 emissions as it reduces furnace consumption considerably. Cullet represents a portion of the glass mix that does not require the heat needed to transform raw materials into glass.

According to Fig 6, using 90% cullet reduces CO2 emissions by more than half. Less CO2 is emitted because melting cullet requires less energy.

However, external cullet utilisation is not an option for high quality extra-white glass.

GREENER FURNACE 61 Furnaces International March 2023 www.furnaces-international.com

Figure 7. The table shows that increasing mix humidity increases CO2 emissions.

Figure 8. The results show that an increase in air temperature reduces CO2 emissions.

Overall, the higher the cullet, the lower the CO2 emission.

Mix Humidity

Figure 7 shows the effect of increasing mix humidity from 1.5 to 5% on the parameters.

Increasing mix humidity increases CO2 emissions caused by increased furnace consumption. This is because the batch mix water absorbs heat to become steam and reach waste gas temperature.

In fact, a covered storage area for raw materials can be a very beneficial investment. A low mix humidity, on the other hand, frequently promotes carry over problems.

Air Temperature

Fig 8 shows the effect of increasing air temperature from 1150 to 1350°C on the parameters.

An increase in air temperature means the reduction of consumption and CO2. This temperature can be increased at the highest level possible to increase furnace efficiency.

A contemporary melting glass furnace needs a performing heat recovery system.

Glass Temperature

Figure 9 shows the effect of increasing glass temperature at the throat from 1340-1420°C on the parameters.

Increasing glass temperature obviously means more consump-

GREENER FURNACE 62 Furnaces International March 2023 www.furnaces-international.com

Figure 9. The table shows that increasing glass temperature increases CO2 emissions.

tion and consequently more CO2 emissions.

To reduce the CO2 emitted, this parameter can be maintained at the lowest level possible depending on the type of production and glass colour desired.

Conclusions

Glass furnaces are complex systems. Their performance in terms of energy, environmental performance, and glass quality is dependent on a range of characteristics.

However, there is still room for the designer to affect the reduction of CO2 they emit. For this transformation to be effective, it is critical to examine the desired glass quality as well as the cost of production.

To achieve decarbonisation, less energy should be consumed. Among all the parameters that reduce energy consumption,

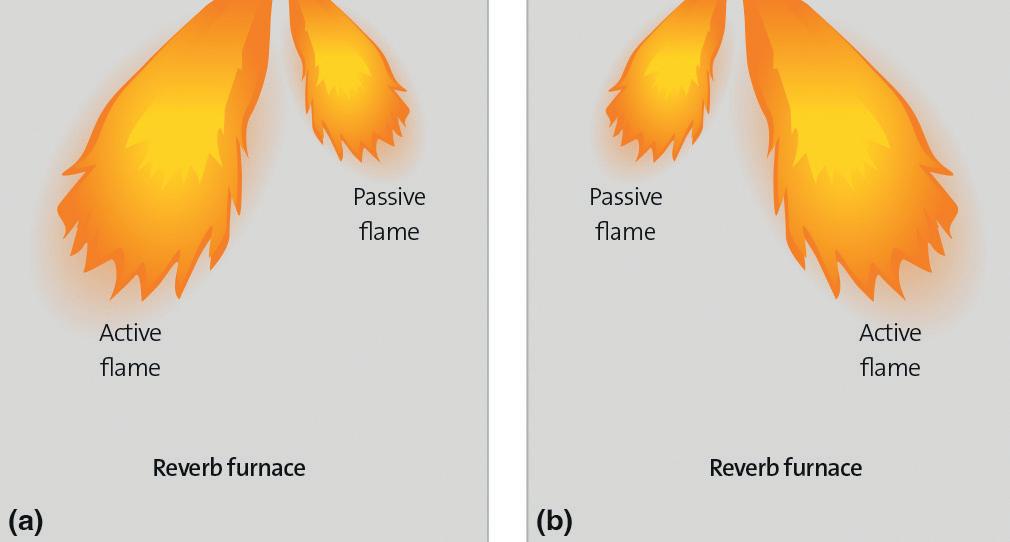

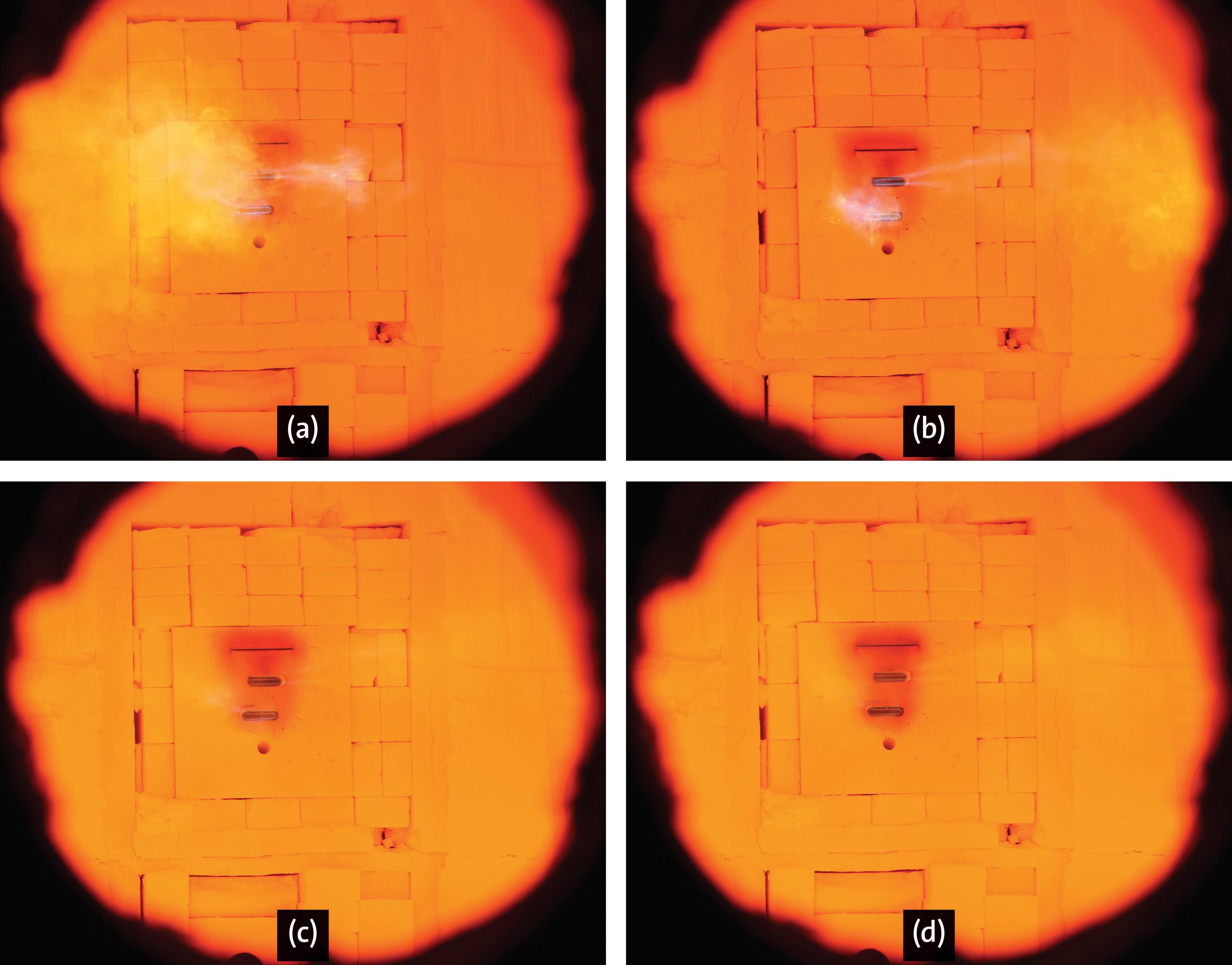

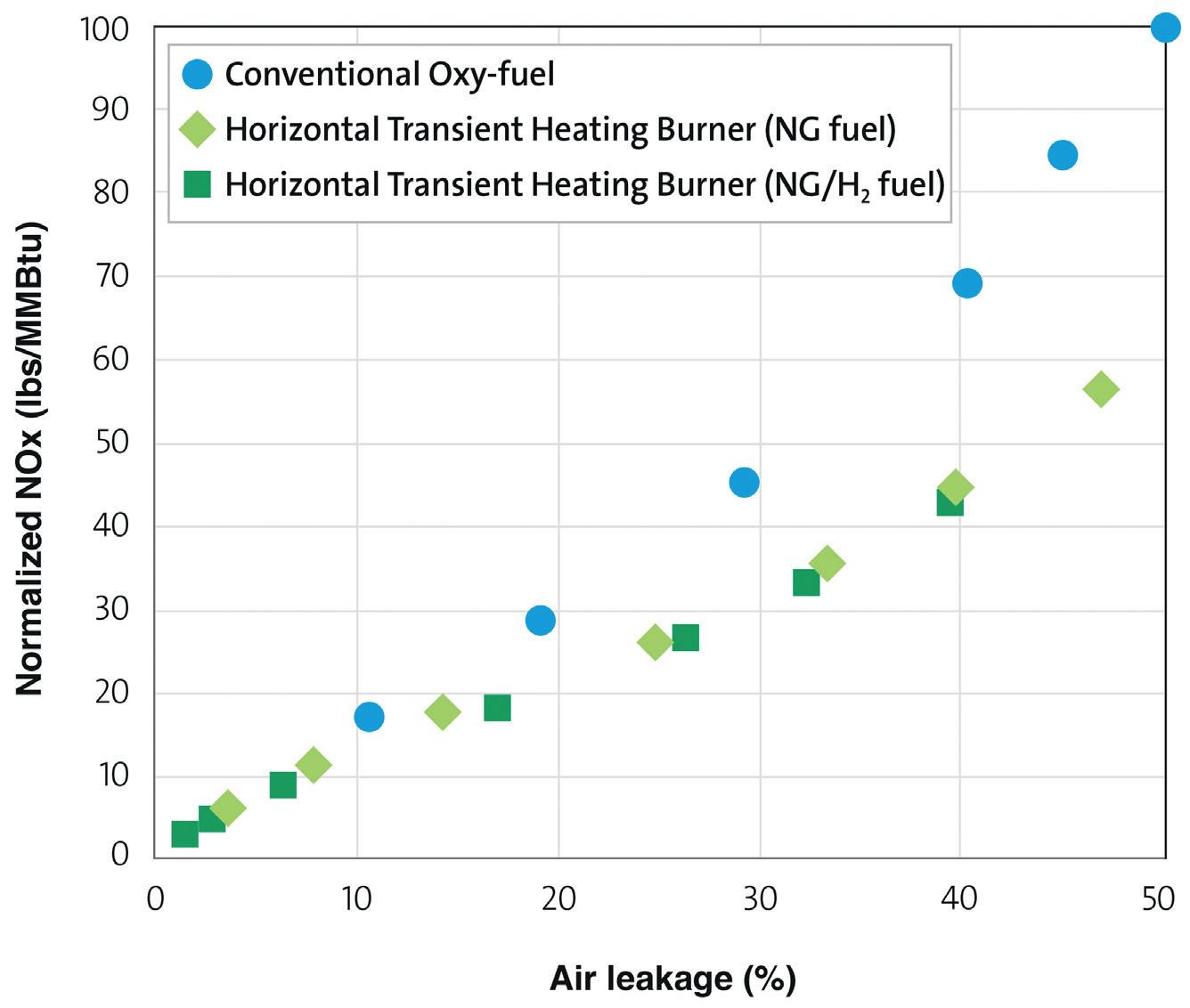

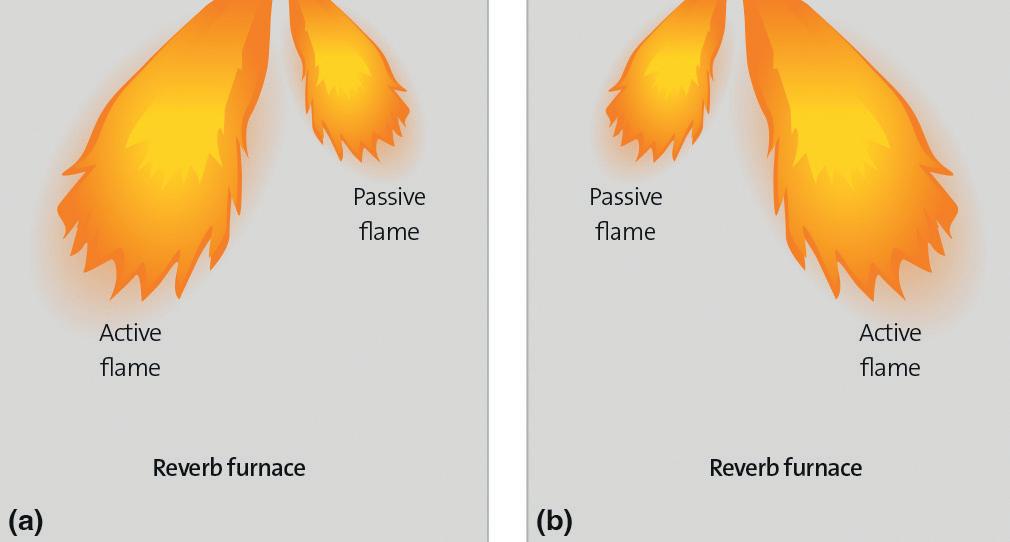

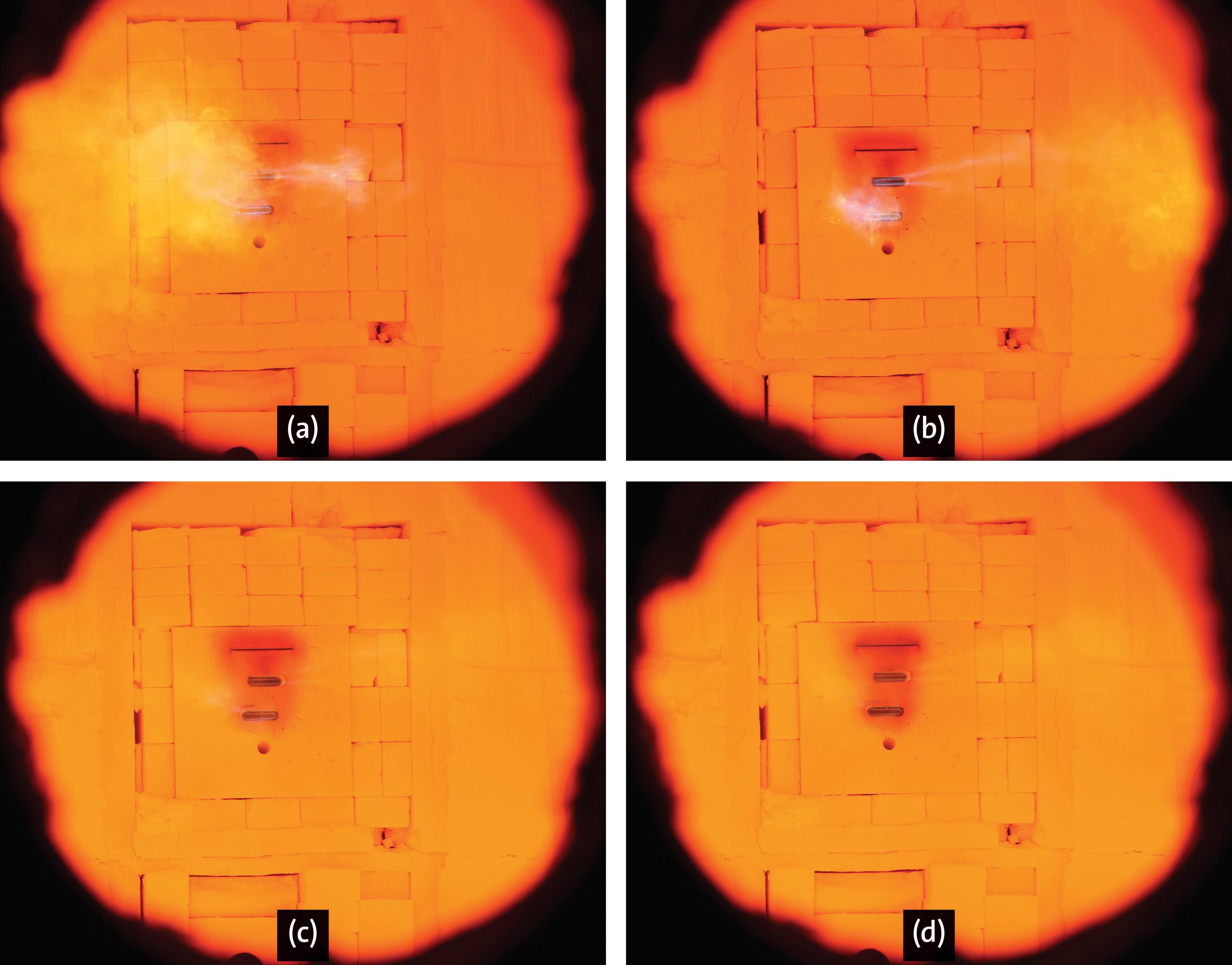

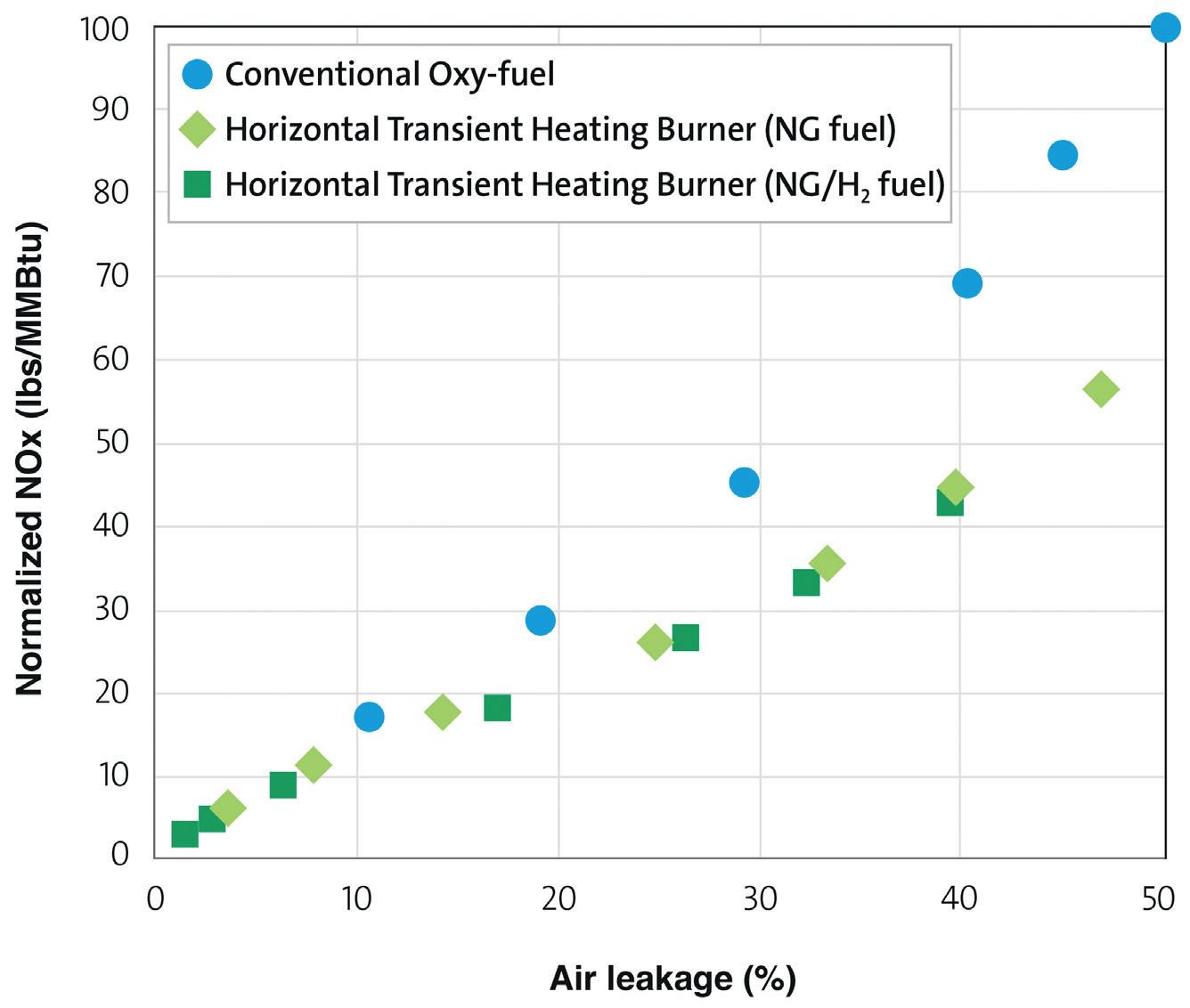

cullet stands out as a parameter that can have a significant impact on the amount of CO2 released by the furnace; the more glass that is recycled and used in the furnace, the more efficient the furnace is, and less CO2 is emitted.