PRIMARY

2.8 million tons OF PRIMARY ALUMINIUM PRODUCED ANNUALLY

Lowest carbon footprint IN THE WORLD

7,500 HIGHQUALITY JOBS

EQUIPMENT SUPPLIERS

1,734 BUSINESSES

29,800 HIGH-QUALITY JOBS

$11.5B TURNOVER PROCESSING

+50 EQUIPMENT AND SPECIALIZED SUPPLIERS SPREAD ACROSS THE WORLD

We had grands plans to host this Future Aluminium Forum in Québec City back in 2020, but as we all know by now, 2020 didn’t quite turn out as we’d expected.

With plans disrupted and lives changed forever, we have now finally been able to make our return to this beautiful city and engage with the vast aluminium supply chain that encompasses the region.

The timing couldn’t be better. The world is back open for business and with global aluminium demand projected to increase by almost 40 per cent by 2030, the aluminium sector will need to produce an additional 33.3 Mt to meet demand growth in all industrial sectors.

This will only be possible through the inception of streamlined technologies, digital manufacturing and sustainable solutions across the production process.

Originally launched in 2018, the Future Aluminium Forum has focused on the challenges of implementing digitalisation and technologies associated with Industry 4.0 such as Big Data, the Industrial Internet of Things, Artificial Intelligence and Machine Learning.

Today, we are already seeing the industry take huge steps towards digital manufacturing and this goes hand in hand with some of the exciting sustainable solutions we are poised to hear more about over the coming days.

By finally being able to host this Forum in Québec City, I am excited to visit a region where the aluminium industry has existed for more than a century and is now seeing rapid change and collaboration between manufacturers, processors, suppliers and OEMs.

With a dynamic industrial cluster and a number of research centres occupying a special place at the heart of this aluminium sector, Québec City is perfectly positioned to welcome discussions and presentations about what the future of aluminium production looks like.

I hope you have an enjoyable few days, hearing from industry experts and meeting with other colleagues, clients and friends.

Thank you to all of our speakers, sponsors and supporting associations who have helped make this event possible.

Nadine Bloxsome Content Director

Hydro is entering a new development stage for its HalZero production technology. The company will invest in a test facility supported by the Norwegian government. With this step, Hydro claims they are on track to deliver pilot production of zero-carbon primary aluminium by 2030.

HalZero is a brand new process for production of primary aluminium. Instead of carbon dioxide, only oxygen is emitted from the process. If Hydro succeeds in this development, it could revolutionize the aluminium industry.

“The development of HalZero is our most groundbreaking technology initiative ever. This could be the first industrial production of primary aluminum without greenhouse gas emissions in the world. The plan is ambitious, and there is considerable risk. Therefore, we depend on the authorities to join us on the road to make a major investment,” says Eivind Kallevik, Executive Vice President for Hydro Aluminium Metal.

Decarbonizing industrial sectors is one of the most important contributions to reducing global greenhouse gas emissions. Hydro has been working on early phase development of the HalZero technology at Hydro’s Technology Center in Porsgrunn, Norway for seven years. The Norwegian government, via state

enterprise Enova, has granted NOK 141 million for the construction of a test facility. The total investment is expected to be approximately NOK 400 million.

“The technology that Hydro is developing here can contribute to significant emission reductions for the aluminium industry both in Norway and in other countries. Enova supports companies that take a lead in decarbonizing industry, and we believe that HalZero can contribute strongly to reducing emissions from the aluminium industry,” says Kristian Nakstad, CEO in Enova.

Zero-carbon aluminium has properties that are essential in the green shift. The metal is light and is weather resistant, which is significant for, among other things, electric cars, building facades and solar panels.

“We know that demand for aluminium will increase, and aluminium without CO2 emissions will mean a lot for the climate goals. Today, the aluminium industry accounts for 2 percent of the world’s CO2 emissions. We are aware of our responsibility and we want to take the lead in developing zero-emission technology for aluminium production,” says Kallevik.

Development of HalZero is part of Hydro’s technology roadmap to reduce the emissions associated with aluminum production. HalZero is primarily suited for new production capacity.

Hydro is working in parallel to develop carbon capture and storage for its existing aluminum smelters while increasing the use of renewable electricity and testing green hydrogen in the value chain.

“The aluminium industry needs optionality to increase our chances of reaching net zero by 2050. Working on several decarbonization routes in parallel increases our chances of success and the speed at which we will be able to reach our ambitious climate targets,” says Kallevik

Facts about the HalZero project

� HalZero is a new production process for primary aluminum that emits oxygen instead of carbon dioxide (CO2)

� In the HalZero process, alumina is chlorinated and becomes aluminum chloride in a process that also produces carbon dioxide. Instead of releasing the CO2 to the atmosphere, it is sent back into the process and reused in the chemical reaction in a closed loop. This makes the electrolysis process completely greenhouse gas emission free.

� The HalZero process differs significantly from the current production of primary aluminum and is being developed for use in new production facilities.

Gone are the days when premium car buyers simply looked for speed, style, and luxury. Today, there’s increasing interest in the origin, sustainability and emissions profile of the materials used to build their cars.

The new mantra for the high-end auto industry is “green is the new black.” From the leather used for upholstery to the metals used for engine parts, premium car buyers are increasingly demanding vehicles made from responsibly sourced materials.

This fundamental shift in the automotive market has led to the creation of a new, innovative partnership between Rio Tinto and the BMW Group, leaders in their respective industries who share a common goal of developing more responsible, sustainable, traceable and secure supply chains.

Under this new partnership, Rio Tinto plans to provide responsibly sourced aluminium to the BMW Group’s vehicle production plant in Spartanburg, South Carolina, for use in body components from 2024.

Low-carbon primary aluminium from Rio Tinto’s hydro-powered operations in Canada, combined with recycled content, could generate a reduction of up to 70 percent in CO2 emissions compared to the BMW Group’s benchmark for aluminium.

The two companies have signed a Memorandum of Understanding (MoU) which

will see technical experts working together on how to embed these low-carbon solutions into the BMW Group’s supply chain while ensuring the highest standards of vehicle quality are maintained. The partnership provides for the use of aluminium produced using ELYSIS™ on BMW production vehicles. ELYSIS™ is the world’s first carbon free smelting technology for aluminium as it enables the production of aluminium metal without direct carbon dioxide emissions during the smelting process, instead emitting pure oxygen.

Rio Tinto and the BMW Group will also work to deploy START from Rio Tinto. START provides supply chain traceability to customers and consumers with information about provenance and ESG standards.

Rio Tinto Chief Commercial Officer Alf Barrios said: “Rio Tinto’s world-leading position in responsible aluminium production means we can offer innovative solutions to our customers on their decarbonisation journey toward net zero. As global demand for responsibly sourced materials continues to grow, automakers are increasingly looking to partner with suppliers who share their commitment to traceability and sustainability. Rio Tinto is proud to play a role in helping to drive a greener future in the premium car industry through this partnership with the BMW Group and we look forward to deepening our ties with the

automotive industry in the years ahead.”

BMW AG member of the Board of Management, responsible for Purchasing and Supplier Network, Joachim Post, said: “We have clear goals for lowering CO2 emissions in the supply chain. By using innovative materials, we can reduce our vehicles’ carbon footprint – even before handing them over to customers. The agreement to supply low-carbon aluminium is based on several pillars: in addition to hydroelectric power and secondary material, we also want to lead the automotive industry by ramping up our use of aluminium with no direct CO2 emissions from the smelting process.”

The Honourable François-Philippe Champagne, Canada’s Minister of Innovation, Science and Industry, said: “Canada is a global destination of choice for low-carbon investment. This exciting partnership between BMW and Rio Tinto is proof that Canada is well positioned to seize the economic benefits of the clean economy. I am proud to see that low carbon Canadian aluminum will be going into BMW’s vehicles. Canada will continue to enhance our competitive advantages— abundance of critical minerals, skilled labour, clean energy, proximity to markets—to grow our economy and to support made-in-Canada innovation.”

TOMRA Recycling Sorting opened a second test facility at its headquarters in Germany to meet growing demand for material trials. The company now operates one test center each for waste and metal sorting applications at the same location.

From February 28 to March 2, TOMRA welcomed industry partners, customers and media representatives to celebrate the opening of a second test center at its headquarters in Mülheim-Kärlich, Germany. The event took place within the framework of the company’s Integrator’s Conference. More than 200 participants from 26 countries joined the twoday event and enjoyed a diverse conference and event program. On the first conference day, participants listened to numerous presentations detailing the company’s strategic direction, including one held by TOMRA CEO, Tove Andersen. The second day focused on the extension of the test facilities that marked another milestone in TOMRA Recycling Sorting’s long-term goals.

“With more stringent legislation and higher recycling targets, the demand to recover recyclables from waste is at a record high and so is the demand for our sorting solutions and material tests. We’ve observed this situation over the last few years and came close to our test capacity limits in Germany. We had to act to ensure the best service for customers and partners”, states Fabrizio Radice, VP and Head of Global Sales and Marketing at TOMRA Recycling Sorting.

Previously, TOMRA’s test center incorporated both its waste and metal sorting solutions and is one of 8 facilities operated at 7 locations worldwide that give recyclers and plant operators the unique opportunity to test their materials on TOMRA’s advanced sorting machines before making an investment. “Apart from the increasing demand for tests, we are continuously developing new sorting systems that are all installed in our test center. In the last few years, we have introduced multiple new

products into the market and will roll out more in the future. Thus, we needed to make sure that we have sufficient space for our growing portfolio and decided to invest in an additional building”, adds Radice. TOMRA itself will use the extra space for the development of innovations that can be extensively tested and optimised by specialised teams on-site. The company conducts approximately 650

TOMRA’s metal sorting systems recover recyclable metals from mixed metal streams and enable plant operators to create the purest material fractions, such as furnaceready aluminum. As the industry strives for sustainable production and a reduction of CO2 emissions, the global demand for recycled metals continues to surge and so does the need for accurate material recovery

customer and internal trials each year and anticipates the demand to grow in the future. The decision to extend capacities entailed another important change. Ralph Uepping, VP, Head of Technology at TOMRA Recycling Sorting explains: “Until recently, we’ve combined both metal and waste sorting machines in one area. Now, each test hall will be dedicated to one segment only. While waste sorting trials are done in the first established facility, the focus of the new facility is on metal sorting.” TOMRA’s new X-TRACT®, FINDER®, and COMBISENSE®, as well as a soon-to-be release machine for advanced aluminum sorting, have been installed in the new facility measuring 1.000 m2 Equipped with state-of-the-art technology

and processing. “We have a long legacy in the metal industry but given current market trends and our customer’s requirements we will concentrate even more on this area in the future. With our expanded test capacities and the most advanced technology, we are wellequipped to support the industry in processing higher volumes and reaching the required qualities”, explains Radice.

While the new facility allows the company to place a stronger emphasis on the metals segment, waste applications continue to play an equally important role. The original test center started as a mobile test station in Andernach, Germany, moved to MülheimKärlich in 2009, and steadily grew in sophistication. Today, it offers 1.500 m2 for

waste sorting trials. The test possibilities range from the recovery of recyclable polymers from mixed and source-separated waste streams, to flake sorting, the separation of wood by material type, and many more.

Also, deep learning technologies, as a

subset of AI, are part of TOMRA’s product portfolio and can be tested in different sorting tasks. Available as a complementary solution to its core technologies, deep learning is a future-forward tool that helps improve sorting performance by detecting previously hard or impossible-to-detect materials. Summarising the advantages of the new test center setup, Ralph Uepping stresses: “All our products are installed and can be tested in a complete circuit. Together with our expert teams, we can simulate the entire sorting process with eddy currents, magnets, screens and a ballistic separator. This allows us to demonstrate the importance of material pre-treatment and define processes that are stable and economically viable even with changing input streams.”

The rationale behind the expansion was extensively explained during the three-day conference that took place both at TOMRA’s German headquarters as well as in a hotel nearby to combine theory and practice. On the first conference day, participants listened to numerous presentations to learn more about

TOMRA’s strategy, new ventures, its digital offerings including deep learning, as well as its approach to customer service. On the second day, it got more practical on-site. After a presentation held by Tom Eng, SVP and Head of TOMRA Recycling Sorting, to explain the evolution of the site in Mülheim-Kärlich, the management team guided the participants to the new facility to cut the ribbon an declare the new building opened. Divided into different groups, the conference attendees were guided through the plant and saw live demonstrations for numerous applications. The tour was rounded off by presentations that emphasised how TOMRA and its technology support maximising resource circularity in the plastic, metal and wood industries.

The opening of a new trial hall as well as the conference set the stage for TOMRA’s growth ambition, its commitment toward stakeholders and its mission to enable a world without waste. Customers and partners are invited to take the opportunity to work with TOMRA’s experts to specify the most suitable sorting solution for their requirements.

During the Future Minerals Forum 2023, the Saudi Arabian Mining Company (Ma’aden) announced a major new venture with the Public Investment Fund (PIF). A new, jointly owned company will make significant investments internationally into upstream strategic minerals opportunities, securing value chains critical to industrial development and energy transition in the Kingdom.

Ma’aden has also signed strategic partnerships with leading mining companies, Ivanhoe Electric (IE) and Barrick Gold Corporation (Barrick) to develop globally significant strategic mineral resources in the Kingdom to fuel the development of the sector internationally. These agreements will play an important role in unlocking value from Ma’aden’s extensive exploration and development portfolio, expanding Ma’aden’s international reach and bringing new skills and technology into the sector in Saudi Arabia.

Ma’aden has also signed more than 20 agreements and MOUs with globally leading organizations to increase exploration and technical capabilities in mining operations.

Improving exploration capability through world-leading technology and expertise

Ma’aden also announced that it has entered into an agreement with Ivanhoe Electric that will give Ma’aden an increased international presence and access to cutting edge exploration technology.

IE is a NYSE-listed technology and mineral exploration company that combines advanced mineral exploration technologies, renewable energy storage solutions and electric metals projects. The agreement with IE will see Ma’aden subscribing to new shares in IE resulting in a 9.9% equity interest for $126 million. Ma’aden will obtain the right to appoint one independent director to the Ivanhoe Electric Board of Directors and will be issued with approximately 10.2 million new common shares in IE at a price of US$12.38 per share.

As part of the agreement, Ma’aden and IE will also establish a 50:50 joint venture to explore for copper, gold, nickel and silver in Saudi Arabia. Ma’aden and Ivanhoe

will explore approximately 48,500 km2 of selected licenses areas that demonstrate excellent potential. The joint venture will provide Ma’aden with access to IE’s proprietary Typhoon™ technology, which conducts geophysical surveys using high powered transmitters to detect the presence of sulfide minerals containing copper, nickel, gold and silver. This will help accelerate, de-risk and advance exploration and development activities, enabling Ma’aden to realize value from its exploration assets.

This is a significant investment for Ma’aden giving it strategic presence in a leading international mining company with its own proprietary technology and increasing its

Ad Damar license areas. The close proximity of the new license areas to Jabal Sayid and the associated mine infrastructure will enable the partners to capture synergies between the three areas.

This agreement will strengthen Ma’aden’s copper production and advance its strategic drive for job creation and economic development in remote areas of the country.

A pipeline of agreements to transform the capabilities of the Saudi mining industry

Ma’aden is also entered into more than 20 agreements and memorandums of understanding with a number of high-profile market leading organizations to integrate new

international exposure to critical minerals.

Robert Wilt, CEO of Ma’aden commented:

“Ma’aden’s strategic investment in Ivanhoe Electric is a critically important moment in our journey to becoming a leading supplier of strategic minerals, which will fuel global economic growth over the coming decade. Through Ma’aden Saudi Arabia is making an invaluable contribution to fast-developing new industries across the world characterized by technological advancement.”

Unlocking value from highly prospective copper licenses Barrick Gold Corporation, a world leader in discovering and developing large-scale gold and copper mines, is strengthening its relationship with Ma’aden through two new joint venture agreements to explore and develop the Jabal Sayid South and Umm

technologies and innovation into its exploration and mining operations. These will further reduce energy consumption, improve water and environmental management, advance decarbonization and improved health and safety. Partners include companies such as Nokia, Shell, Bechtel and Eurasian Resources Group (ERG) S.à r.l.

Robert Wilt, CEO of Ma’aden, commented:

“By attracting new partners to Saudi Arabia and increasing the commitment of our existing partners, we are introducing new technologies into our operations, diversifying our upstream product mix and accelerating the development of our exploration portfolio. This will create opportunities for knowledge and technology transfer that will deepen the talent pool in Saudi Arabia and open up new opportunities to develop the Kingdom’s abundant mineral resources.”

Emirates Global Aluminium (EGA) have announced that they are to collaborate on Industry 4.0 and broader digital transformation, aiming to set global best practice for the aluminium industry while improving the sustainability of EGA’s computing operations.

Both Microsoft and EGA are members of the UAE Ministry of Industry and Advanced Technology’s Industry 4.0 Champions Network, which aims to accelerate Industry 4.0 adoption across UAE industry.

Under the new agreement, the two companies will work together to progress EGA’s Digital Roadmap, which is already transforming EGA’s operations through digital capabilities such as artificial intelligence and big data.

EGA and Microsoft will leverage the power of cloud computing to accelerate and scale the development of new digital solutions, shifting a third of EGA’s server infrastructure and applications to Microsoft Azure Cloud.

Through digital transformation and by driving increased efficiencies, Microsoft’s cloud will empower EGA to make substantial energy savings. EGA is estimating to reduce the energy consumption of its overall computing operations by up to 65 per cent and CO2 emissions by more than 80 per cent.

EGA will also develop a private Microsoft

Azure Cloud at its sites, shifting a further third of its computing to this system, unlocking opportunities to deploy data-heavy and timesensitive artificial intelligence and automation solutions within the company’s industrial operations.

EGA will use virtual desktop cloud computers to create a more efficient, flexible, and secure workplace computing experience for employees.

Abdulnasser Bin Kalban (Right), Chief Executive Officer of Emirates Global Aluminium, said: “We are already transforming EGA’s operations, business and employee experience through Industry 4.0 and ourbroader digital transformation. Our collaboration with Microsoft will enable us to further accelerate, scale and sustain this work as a digital lighthouse for the region and our industry.”

Carlo K. Nizam, Chief Digital Officer of Emirates Global Aluminium, said: “Deploying EGA’s and Microsoft’s talent, muscle and technology together will allow us to develop the most advanced digital capabilities and hybrid cloud platform in the aluminium industry. At the same time, we will improve the environmental sustainability of EGA’s computing infrastructure and benefit from seamless security and operations of both our

public and private cloud assets.

Naim Yazbeck, General Manager at Microsoft UAE, said: “We are proud to partner with EGA... to accelerate their Industry 4.0 transformation while also pioneering further improvements in Microsoft’s own cloud for manufacturing services. I look forward to further collaborations between EGA and Microsoft in the future, both locally and globally.”

EGA will provide input to Microsoft on innovations and improvements to the technology company’s products and services. Microsoft will help upskill EGA staff on relevant Microsoft technologies to accelerate adoption within the aluminium giant’s operations. EGA has a bold aspiration to innovate the future of aluminium production. For the decades ahead, the company intends to act as technology pathfinder for the aluminium industry, expanding its position as technology supplier of choice, and establishing a thriving manufacturing innovation ecosystem in the UAE.

EGA has developed technology in the UAE for more than 25 years and is focused on improving the efficiency of the aluminium smelting process. EGA’s latest home-grown technology is among the most efficient and competitive in the global aluminium industry.

GNA specializes in the design and supply of for the primary and secondary aluminum industries...

cast house equipment, technical services and operation strategies

Que votre mission soit de recycler des rebuts d’aluminium ou la production de métal primaire, pour votre opération.

9am WELCOME

Nadine Bloxsome, Editor, Aluminium International Today

9.05am

OPENING ADDRESS

M. Pierre Fitzgibbon, Ministre de l’Économie, de l’Innovation et de l’Énergie

9.15am – 11am

KEYNOTE SESSION: THE FUTURE OF ALUMINIUM

Reinventing the Aluminium Industry for a Sustainable Future

Gaby Poirier, Vice-president of Operations – North America, Alcoa

Partnering for a Responsible and Sustainable Future

Marie-Eve Pomerleau, Specialist Product Advancement, Rio Tinto

Hydro’s Way to Make Aluminium in the Coming Decades

Pierre Rény, Chief Engineer, Primary Metal, Technology and Operational Support

Hydro Aluminium Canada

11am – 11.30am Coffee & Networking Break

11.30am – 12.30pm

SESSION ONE

STATUS, STRATEGY AND CAPABILITIES

Using Digital Modelling to Optimize Business Outcomes

Jean-Denis Carrier, Global Director – Aluminium, HATCH

How to Transform Predictive Intelligence into Valuable Actions

Hilbrand Kuiken, CEO, Quantillion

12.30pm – 2pm Lunch & Networking Break

2pm – 3.30pm

SESSION THREE

SUSTAINABILITY & TECHNOLOGY: A PERFECT MATCH?

Design and Implementation of a CCUS Project Dedicated to a Primary Aluminium Smelter: Focus on Partnerships

Guillaume de Goÿs, CEO, Aluminium Dunkerque

Technology Roadmap – Maximizing the use of Bauxite Residue in Cement

Linlin Wu, Manager Statistical Analysis, International Aluminium Institute

How Becoming Future Ready Means Optimizing Efficient Energy Scheduling to Energy Availability

Gunther Schober, Sales Manager, PSI Metals Non-Ferrous GmbH

3.30pm – 4pm Coffee & Networking Break

4pm – 5.30pm

SESSION FOUR

THE ADVANCE OF AUTOMATION

Digital Transformation Approaches Aluminium Industry

Simone Tadiello, Automation Project Enginee, POLYTEC

The Foundation of a Smart Plant

Mileidy Hernandez, CPI en systèmes automatisés - Informatique industrielle chez WSP au Canada (CPI in Automated Systems - Industrial Computing at WSP in Canada

Haulers’ evolution: From Diesel to Electrification, Autonomous or Semi-Autonomous Solution

Malcolm Caron-Boivin, International Business Development Manager, EPIQ Machinery

5.30pm DAY ONE CLOSE

7.30pm

GALA DINNER HOSTED IN BALLROOM A+B

9.15am – 10am

BREAKFAST BRIEFING:

Aluminium from the Amazon: Lessons for Sustainability

Simon Lobach, Researcher, Geneva Graduate Institute

10am – 11.30am

SESSION FIVE

THE ADVANCE OF AUTOMATION

Waste and CO2 Reductions with Automated Scrap Charging and Skimming

David Roth, Americas Business Representative, Ria Casthouse

Alulibs - Effortless Automated Molten Metal Sampling

Andrew Sauerwald, Product Leader - LIBS at Tecnar

On the way to the Automation of Refractory Maintenance Works for the Aluminium Producers

Jean-Benoit Pineault, CEO, Refraco

11.30am DAY TWO CLOSE

Andrew Sauerwald is an electrical engineer from Drexel University with over 15 years of experience in automation and design. He is the technology and product leader at Tecnar Automation, a company specialising in turning cutting-edge science into industrial products. His role is to oversee and help bring these innovative products to market.

For an aluminium alloy manufacturer to be competitive they rely on recycled aluminium in which the elemental composition may or may not be known. To utilise this material successfully requires constant monitoring through continuous and frequent sampling of the melt to ensure it meets specifications. The sampling process is time-consuming, labour intensive, and a safety risk due to the amount of interaction with the melt.

The Alulibs streamlines the aluminium alloy production by automating sampling by providing 24/7 real-time multi-element chemistry readings in molten aluminium. It enables operations to react faster with additions by understanding how the melt is changing and without the need for sampling it will provide a safer work environment and increased man hours.

The Alulibs will benefit facilities by enabling them to produce the same high-quality aluminium alloys more efficiently and safely, helping to meet customer demands and remain competitive.

Jean-Benoît Pineault is involved in the company since 1997. During his studies, he started as a specialized laborer for the furnace repairs. He learned about the production stages of various products. In 2003, he became project manager, while pursuing his university studies (2nd cycle in metallurgical engineering -specializing in refractories and ceramics). In 2005, he was appointed Director of Product Development, where he assumed R&D responsibilities. Two years later, he managed in addition the department of the works in the customer plants. In 2009, his expertise led him to take on the position of Director of Sales and Operations and in 2012, Jean-Benoît became Vice President and General Manager. He is now the CEO of the company since 2022.

Jean-Benoît has an excellent understanding of the manufacturing processes of different refractory products as well as the various metallurgical processes in the market. In 2003, he patented three refractory processes. In 2004, he jointly published two scientific articles: one at “The Minerals, Metals, & Materials Society” and the other at the “Canadian Institute of Mining, Metallurgy and Petroleum”. Jean-Benoît obtained a Bachelor’s degree in Computer Science - Mathematics in 2004 and a MBA, both at the University of Quebec in Chicoutimi.

We will share the reasons we have started to work on the automation of refractory maintenance work four years ago. We will then present a first industrial unit operating in Canada for six months, materialising an important milestone on our way to fully automated processes. We will finally share our next steps of innovation, including the short term developments we are working on, as well as the global vision we have for a complete automation of refractory maintenance in an aluminium producer.

Gunther Schober, born November 21, 1970 in Leoben, Austria graduated in 1994 as Metallurgical Engineer with focus on industrial and energy economics at the Mining University of Leoben.

After his first experience as sales engineer and sales manager he took over management responsibility as head of sales & marketing for AVL DiTEST an international automotive company.

2007 he joined PSI Metals. As Senior Consultant, Project Manager and Sales Manager his expertise in metals and international experience in process development and Supply Chain Management is much sought-after.

With more than 10 years of experience in the area of Production Management Solutions comprising Supply Chain Management and Planning, Product Design, Quality Management, Production Execution and Logistics he became an acknowledged cognoscente in these fields. PSI Metals known as a very innovative company became metals industries’ partner for Industry 4.0. Gunther Schober’s expertise together with the innovative approach of PSI metals make him a demanded contact for future solutions.

Aluminium has been described as a “miracle-metal” but we also need to admit that with around 1.1 billion metric tons of CO2, aluminium accounts for 2 percent of global man-made emissions. A precious metal that requires a vast amount of energy for production. The abrupt change of the geopolitical situation last year showed us dramatically the fragility of our resources and our energy supply. In Europe, the aluminium industry had to cope with major gas crisis leading also to energy prices skyrocketing. However, that is not all. Global industrial sectors are on a race to achieve green transformation, which entails replacing coal and gas with green and non-fossil energy in the future. One of the consequences would be that energy availability will remain the problem, and increase, as manufacturers strive to get green hydrogen and electricity, creating high demand. To overlook these factors will affect competitiveness. A solution to this current and in-coming challenge is a proactive measure that prepares steelmakers today to forecast and efficiently manage their energy consumption and production scheduling. Our presentation reveals how we can reliably determine energy consumption and successfully adapt production schedules to energy availability. Smart Planning and scheduling supports our customers on their transformation path to green and sustainable production management by significantly increasing energy efficiency, and therefore reducing CO2 emissions.

Hilbrand Kuiken is the CEO of Quantillion. He is an entrepreneur focusing on data intelligence that enables real time autonomous decision making in complex environments. Hilbrand loves working with passionate people in creating real value for the clients. He believes data is not about analytics but about doing!

After working in industrial asset management for several years, Hilbrand started his own company. For the past 5 years he and his team have been developing new solutions for the core processes in the aluminium and steel industry making sure they are able to adapt to changing environments and successfully making the bridge between operators and autonomous equipment.

With Quantillion, Hilbrand is enabling the heavy industry with the usage of dynamic multi-agent planning power by AI-algorithms. With the combined integration of separate workflows and agents, Hilbrand aims to support the industry in its transition towards “Collaborative Intelligence”.

Industries are starting to collect more information and create complex models to forecast their supply, production and demand. With these indepth analysis companies gain in-depth knowledge, but only one question remains. How do we act on it? By combining these insights with the current state of the factory, Quantillion transforms predictive models into real-time tangible actions.

4.0

Collaborative Intelligence focusses on the improvements when humans and AI work together.

Based on a study published in Harvard Business Review in 2018, organizations that use machines to displace workers through automation, will miss the full potential of AI. Collaborative intelligence has already proven itself and is now becoming an essential contributor to solving a number of issues that are critical for metal production.

The heavy industry has flexibility at the top of their agenda!

Flexibility provides the industry with the ability to adjust to unforseen events and increase profitibility by optimizing costs.

Improved Quality

Flexible automation and processes enables the industry to achieve increased consistency and the ability to capitalize on opportunities.

Adaptable

Flexible manufacturing increases adaptability, making it easy to react to changes, whether predictable or unpredictable

At Quantillion, we are putting fast and powerful decision-making algorithms at the heart of production processes. Our products make it easy for operators and machines to make smart decisions, fast.

Hilbrand is the CEO of Quantillion. He is an entrepreneur focusing on data intelligence that enables real time autonomous decision making in complex environments. Hilbrand loves working with passionate people in creating real value for the clients. He believes data is not about analytics but about doing!

FAST. SMART. SUSTAINABLE.

At Quantillion we use AI systems and digital twins to optimize smelter operations in the production process. We consider the production environment as a cyber-physical space where humans, machines and equipment need to work together in the most optimal way. By increasing this collaborative intelligence within the process we allow companies to create actions upon valuable data analytics.

We believe that new technology enables world leading industries to increase their flexibility. Translating predictions into real-time actions opens industries up to act on outer change as well as the changes they face in their day-to-day operations. Therefore, we are putting fast and powerful decision-making algorithms at the heart of production processes.

Industry 4.0 is currently one of the most talked about topics in the aluminium industry, with such elements as automation, robotics, IIoT, ML, AI and AR leading the way towards the ‘smelters of the future’. All these smart implementations have provided an increased understanding of current operations and allowed for complex models to forecast supply, production and demand. Identifying trends, risks and opportunities is only the first step, transforming this knowledge into actions is the next!

By making use of our platform, we can combine the power of predictive models with a cyber-physical space and translate insights into executable actions. By doing so we can capitalize on predictions in your core process.

Industry increases human-machine interactions Linlin Wu

MSc from London School of Economy and Political Science, 2007

Joined the Institute in 2009, is responsible for statistical analysis and environmental impact information; manages the Life Cycle Assessment data collection and analysis; also focuses on sustainable development of the industry.

Primary Aluminium demand is expected to increase over the next 20 years, consequently, the increase of metallurgical alumina production, and the generated bauxite residue. This roadmap provides information and support by addressing technical, legislative and prejudicial barriers. It facilitates bauxite residue valorisation actions of the alumina sector and engages other stakeholders who can help deliver success. Developing standards, frameworks and promoting bauxite residue is critical to all stakeholders in increasing the use of BR in cement and concrete products.

Malcolm Caron-Boivin

Malcolm Caron-Boivin

Malcolm Caron-Boivin holds a bachelor’s degree in Mechanical Engineering from Laval University. Owning a private pilot licence, he began his career at CAE in Montreal as a Test Engineer on full flight simulators dedicated to pilot training. He later worked in a paper mill as a Reliability Engineer for Produits forestiers Résolu where he acquired industrial experience and knowledge. Malcolm joined EPIQ Machinery in May of 2021 as a Product Manager for AGV solutions. More recently, he was assigned to the International Business Development Manager position. He will provide frontline support for new MECFOR vehicle opportunities to our international customers. Malcolm shows passion for new technologies and innovation. The industrial haulers’ electrification process, for which is gets highly involved, is a great source of motivation.

Conventional. Electric. Auto guided (AGV). Technological breakthroughs open the door to a range of options for industrial equipment. In this presentation, EPIQ MECFOR will share its experience in designing haulers and its vision of what they could look like in the future. These days, two buzz words are drawn on everyone’s lips: Industry 4.0 and net-zero emissions. How can these be concretely integrated to mobile equipment? What technologies are available to aluminium producers? What type of transition is possible if they want to switch from conventional to semi-autonomous or even full autonomous (aka AGV) haulers equipment? All these questions pop multifaceted challenges across all levels.

The task haulers perform is rather repetitive, but essential to the operation of a smelter. Hauling may seem simple. However, when we take a closer look at the operating environment of aluminium producers, we quickly come to understand the complex challenges that comes with operating haulers in this environment. It requires extreme vigilance.

What ever changes are to be made, the leap centres on two key aspects:

1. Analysis of vehicle usage: Type of driving, accelerations/decelerations, speed management, duty cycle, etc.

2. Analysis of work processes and practices: Defining a transition strategy

The two major challenges of the industry are: net-zero emissions and system optimisation by data management.

On the same token, Aluminium production managers aim to adopt a holistic approach of their operations and processes. The concept of Industry 4.0 implies gathering data that, once managed and processed through proper algorithms, will predict a behaviour and populate an order. Adding software layers with artificial intelligence (AI) will help us grow towards an optimised ecosystem.

EPIQ Machinery strives to be a strong link in this constantly evolving aluminium production ecosystem. Our goal: delivering ‘green’ intelligent equipment.

15 years at Alouette aluminium smelter, Quebec, Canada

1991-1996 Senior process engineer, reduction

1996-2000 Potrooms superintendant, reduction

2000-2006 Reduction manager

17 years for Hydro, Norway

2006-2009 Process and projects manager Kurri Kurri, Australia

2009-2017 Principal engineer, HAL4e Ultra project Årdal, Norway

2017-2018 KTP start-up manager Karmøy, Norway

2018-2020 KTP head of controller team Karmøy, Norway

2020- Chief engineer, Techology and Operational Support, Aluminium Metal

Under the multiple social and political pressures for acceptability, decarbonisation, transparency and sustainability, corporations must keep increasing profitability and returns. Following its mission, Norway’s Hydro has a been engaged in developing renewable and clean energy sources while providing low carbon, high quality aluminium products to its customers for many years.

But in today’s fast changing world, companies like Hydro must compete not only for markets shares, but also for resources, the most important yet volatile being their workforce. In this context, Hydro’s Industry 4.0 initiatives will help making aluminium production safer and easier through robotics and automation, while improving the productivity and the workplace quality for the active force. Furthermore, innovation in Information and Operation Technology convergence, connectivity, remote operations and digitalisation of processes and equipment will help Hydro improve the quality and efficiency of its activities to meet society’s demands in the coming years.

This presentation gives some examples of Hydro’s ambitions and progress in better serving society by improving production and sustainability through decarbonisation and in digitalisation. through decarbonisation and in digitalisation.

Senior figure with over 25 years of experience in the world of Automation and Industrial Machinery in various sectors (Steel, Paper, Plastics, Automatic warehouses, food & beverage, Heavy lifting, motion control). Managerial and Technical Management, combined with solid training in the field of Hydraulic and Pneumatic Controls with a strong aptitude for continuous learning. Able to manage and collaborate with a work team to pursue the objectives and finalise the project focuses. Coordinator of multi-ethnic teams, with good organisational, interpersonal and time management skills as well as solid technical skills. Maximum seriousness and use of the working method for objectives. Problem solving, decisionmaking autonomy, multidisciplinary skills, resilience and profitable interpersonal relationships in the professional field.

The aluminium Industry today is deeply involved in the Green and Digital transitions. The integration of environmental and digital technologies in industrial processes allows us today to achieve not only competitive goals in terms of production efficiency, product quality and sustainability, but also social ones, placing the health and well-being of workers at the centre of the process .

Digital technologies such as artificial intelligence (AI) and intelligent robotics allow to reimage workplaces, safer and less burdensome, optimising human-machine interactions with an added value acquired: the worker’s empowerment. Furthermore, the digitalisation path makes factory work more attractive for new generations.

Innovation always comes at the same time as a cultural renewal. Developing innovation more effectively and quickly is only possible through the synergy between specialisations and with the involvement of all stakeholders.

How can we upgrade traditional aluminium production process?

Through the integration of different digital technologies connected simultaneously to computer systems equipped with artificial intelligence and learning algorithms. Robots can automatically perfect their operations and operators are able to quickly intervene on the production efficiency, making decisions based on objective data, in a path of continuous improvement. The presentation offers an overview on latest technological innovations that turn an aluminium production plant into a “smart” one.

David has over forty years of experience in the aluminium industry. Originally employed by ALCOA and the ARCO Aluminum, David has held various positions within both companies. These positions included Process Metallurgical Engineer, Cast House Metallurgical Engineer, Chief Metallurgical Engineer, Senior Process Engineer, Engineering and Maintenance Manager and Director of Technical Services. David has also been involved in major projects, including plant installations of propriety processes, development of recovery devices for reclamation of aluminium from dross, established technical services for organisations and project engineering on complete recycling facility projects.

Mr. Roth was a founder and with ALTEK for twenty-five years. He was involved in dross handling projects, casting projects and furnace installations. He developed patents in these areas. As a principle and President of the company, David oversaw all aspects of ALTEK dross handling systems and engineering services.

Currently as Americas Business Representative – RiA & President of GPS Global Solutions, he is focused on providing automated scrap and patented dross processing systems to make the scrap melting operations a safer and more efficient working environment.

David has a B.S. in Metallurgical Engineering from the University of Missouri – Rolla, USA.

Automation of the scrap charging and skimming operations gives a set of advantages that are unique, especially in an environment where keeping well trained operators in the cast house can prove difficult in today’s labour market.

This presentation will review the utilisation modern scrap charging systems with In-Furnace cameras, that can optimise scrap loading systems. This can reduce cycle times by up to 50%, while saving up to 30% in energy consumption and subsequently reduce CO2 generation. Automated skimming with video optimisation, has a significant impact on melt yield. Taking the skimming out of the hands of the operator, makes total dross removal a thorough practice every time. Automation of the process allows for no dross to remain in the furnace between cycles, eliminating the generation of more dross and lowering recoveries. Precise skimming operations keeps the free and alloyed aluminium in the furnace where it belongs and not removed due to untrained operators or uneven floors. Automated skimming also shortens skim cycles, further reducing door open time and wasted energy.

Advantages of these areas will be discussed in detail in this presentation.

Mileidy Hernandez is a recent graduate with a bachelor’s degree in engineering who is passionate about the field of automation, specifically in relation to industry 4.0. She is currently working at WSP, where she specialises in working with EDA, a technology developed by the company used in a variety of industries to optimise production processes and efficiency.

During her studies, she completed internships in the automation industry, providing her with a solid foundation in the field and sparked her interest in pursuing a career in automation. She is fascinated about discovering new ways to improve both production processes and efficiency using the latest technologies. At WSP, she has participated in several commissioning projects working with EDA which brought her valuable reallife experience. She is constantly seeking to expand her knowledge and skillset in this area.

Ms. Hernandez’ experience working with EDA will bring valuable insight as speaker at the Future Aluminium Forum 2023 in sharing how automation technology can optimise production and enhance bottom line across a range of industries. She looks forward to sharing her enthusiasm to the audience as well as exchanging on these topics with other experts and learning from their experiences.

Industry 4.0 is quickly changing the way production and maintenance teams operate, and WSP has recognised the need to facilitate this transition. To help with the shift to Industry 4.0, WSP has developed a tool, called ADE, that brings autonomy and insights to all of its users. This tool has two primary goals: from a production standpoint, it aims to minimise alarms during production, provides autonomy to the operation team and centralizes all systems in the same interface. From a maintenance standpoint, it standardises and simplifies controller and HMI programming, reduces programming interventions, gives access to failure analysis tools, reduces calls for minor issues and helps track faulty equipment. We have successfully implemented ADE at ABI aluminum smelter and in various factories across Québec, such as Rio Tinto. where it has enabled more efficient production and maintenance processes, allowing the company to stay competitive in the ever-evolving Industry 4.0 landscape.

With the help of ADE and the modernisation of the equipment in the factories, we can build a solid foundation to continue revolutionising production and maintenance in line with Industry 4.0 principles. ADE is the foundation of a smart plant.

Guillaume de Goÿs is the CEO of Aluminium Dunkerque, the largest primary aluminium smelter in the EU and one of the largest industrial consumers of electricity in France. He chairs the board of Aluminium Duffel, a rolling mill located in Belgium. He has held several management positions in France and abroad, as a senior executive and project manager for various global aluminium, graphite, and tyre companies. He is also President of the French Association of Aluminium Producers and chairs the primary division of European Aluminium where he actively defends the interests of the profession and contributes to decarbonisation and the circular economy.

With less than 4.5 tons of CO2 per ton of aluminium produced (Scope 1, 2 and 3), Aluminium Dunkerque is one of the best performing primary aluminium smelters in the world. AD has reduced its CO2 emissions by 40% over the last 15 years and has developed a roadmap to near zero by 2050.

Carbon Capture, Utilisation and Storage (CCUS) is a key technology to achieve this roadmap and to halve its emissions by 2030. CCUS is a well-known technology, but it is yet not suitable for primary aluminium smelting because the CO2 in the flue gases is not concentrated enough to be economically viable. Therefore, Aluminium Dunkerque has developed several partnerships in order to: i/ adapt carbon capture to primary aluminium smelting ii/ transport and store the CO2 captured in the smelter iii/ offer the CO2 to partners for reuse.

Mr. Jean-Denis Carrier is a chartered Civil Engineer holding an Executive MBA whom has been working for the growth of the aluminium industry in North America, Europe and the Middle East for the past 20 years. He combines his passion for projects and business value creation to support the aluminium industry identify growth opportunities.

Mr. Carrier is currently the Global Director, Aluminium & Alliances at Hatch

In this digital era, data-based decision making is an efficient way to improve business outcomes. Over the past years, Hatch has been developing technical and techno-economic models to improve operational performance and business outcomes across the aluminium.

Marie-Eve Pomerleau is a product specialist in the metals and minerals marketing team at Rio Tinto. In her role, she aims at finding solutions to future market demand and supporting asset investment to meet these needs. She joined Rio Tinto in 2006 after graduating with a bachelor’s degree in Metallurgical Engineering from the University of British Columbia. Her career begun as a metallurgist in aluminum casting operations where she held various roles optimizing processes, monitoring product quality, and enhancing customer satisfaction. She believes in partnership with customers and suppliers to build a better more sustainable world.

Aluminium is a critical material in a decarbonizing world and we expect that demand will continue to grow while supply is more challenged. As an industry leader in responsible aluminium, we’re committed to pioneering responsible and sustainable aluminium. Partnering to provide recycling solutions is key to be ready and able to address the needs and demands of end users and consumers we work for. To be successful, we’ll leverage local scrap availability, our dilution capabilities, and our diverse portfolio advantage.

Simon Lobach is a doctoral researcher and a consultant in the fields of sustainability and environment. After a career within the United Nations advising governments on green economy policies, Simon is currently working as a researcher for the Geneva Graduate Institute, where he is obtaining a PhD on his multiple-year research project regarding the aluminium industry in the Amazonian region in South America. Countries where bauxite, alumina and aluminium are produced in Amazonia include Brazil, Guyana, Suriname and Venezuela. In the context of this research, Simon evaluates cutting-edge technologies applied in the aluminium industry in the context of the very particular demands and opportunities of this highly diverse, rich, yet vulnerable region. Elements of this research were funded by the European Research Council (grant 950672).

The Amazon region in South America contains operations of some of the main aluminium producers worldwide, including Alcoa and Norsk Hydro. These companies are among the avant-garde in terms of sustainability, as certified by the Aluminium Stewardship Initiative. They have earned their green reputation thanks to cutting-edge technologies applied in mining as well as in alumina and aluminium production. Examples include the management of bauxite tailings, measures for safer disposal of red mud, the greening of the energy mix used, carbon capture and sequestration, and reforestation programmes at the impacted sites.

Bringing an academic perspective, Simon Lobach has studied the environmental performance of aluminium producers in the Amazon. Besides the actions of the aluminium producers, he has also taken the fragility and global importance of this unique ecological biome into account. Based on a several-year research project on aluminium production in the Amazon, he presents his findings in the form of lessons that can be learned from the aluminium producers in the Amazon in terms of sustainability, but also the lessons that the sector can learn from a wide array of academic and societal actors in the region that were consulted in the context of this project regarding responsible operations in this highly diverse, rich, yet vulnerable biome.

Gaby Poirier is Alcoa’s Vice President of Operations for North America, overseeing the company’s operational facilities in the United States and Canada.

Poirier has deep operational background in diverse industries such as aluminum, iron ore, and copper and has worked in senior leadership roles in the United States, Canada, Europe, and Australia.

Prior to joining Alcoa in 2022, Poirier worked for Rio Tinto for 20 years. Between 2020 and 2022, he was Managing Director of Kennecott copper mining and smelting complex in Salt Lake City, USA. From 2017 to 2020, he served as General Manager of the Greater Hope Downs joint venture in Perth, Australia, part of Rio Tinto’s Iron Ore Product Group. He also served as General Manager of the Dunkerque smelter in France, from 2016 to 2017, as well as General Manager of the Kitimat smelter in British Columbia, between 2013 and 2016. Previously, Gaby occupied management roles at Kentucky’s Sebree smelter, as well as Alma and Arvida smelters in Quebec’s Saguenay region.

He was a member of the Board of Directors of the Salt Lake Chamber, as well as the Copper Development Association and the Copper Club, until 2022.

He holds a bachelor’s and master’s degrees in Chemical Engineering and an MBA in Finance.

Aluminum is essential for modern life, and the metal will play an even larger role in the low-carbon future. It is lightweight, strong, and – most importantly – infinitely recyclable. It is being used to replace plastics and heavier metals in a wide range of applications, and it is vital for the ongoing transition to electric vehicles and renewable energy infrastructure.

Alcoa is working to meet the needs of a more sustainable world, improving its environmental footprint, delivering sustainable products that support its customers’ own sustainability ambitions, and creating shared value in our communities. Alcoa has a rich legacy of innovation, and is leveraging that history with a technology roadmap that has the potential to decarbonize the upstream aluminum value chain.

Alcoa (NYSE: AA) is a global industry leader in bauxite, alumina and aluminum products with a vision to rein-vent the aluminum industry for a sustainable future. With a values-based approach that encompasses integrity, operating excellence, care for people and courageous leadership, our purpose is to Turn Raw Potential into Real Progress. Since developing the process that made aluminum an affordable and vital part of modern life, our talented Alcoans have developed breakthrough innovations and best practices that have led to greater ef-ficiency, safety, sustainability and stronger communities wherever we operate.

Website: www.alcoa.com/global/en/home/

Located in the north of France, Aluminium Dunkerque (AD) started its activity in 1991. Today, with an annual production of 290,000t, it is the largest primary aluminium smelter in the EU. Employing 650 people and located on 65ha, AD is one of the main sites of the Dunkirk industrial port platform.

The electrolysis process which transform alumina into molten aluminium requires significant electrical power. AD consumes an average of nearly 4TWh/year, making it the leading industrial site in France for electricity consumption.

AD uses the AP40 technology, with a consumption of 13,120 kWh per ton of aluminium, AD is among the most efficient in the world. The site manufacture of aluminium rolling plates and ingots with a purity of over 99% for value-added applications in the transportation, automotive, packaging, building and construction sectors. Aluminium Dunkerque’s historical customers include major players in the European manufacturing industry such as Constellium and Stellantis.

With more than 30 years of operations, AD is recognised by its customers as a robust supplier, with a satisfaction level of over 98%. Recently certified to IATF standards, AD is a key supplier to its automotive customers.

Website: www.aluminiumdunkerque.fr

Australia’s leading innovator of technical textile solutions. Bruck is the major manufacturer in Australia of value added, high performance and protective clothing fabric’s, used in end applications such as Metal Smelting, Military, Mining, Oil and Gas, Fire Fighting and General Industrial.

Bruck has proven design capability and integrated product development processes. Our PR97 brand is globally recognised and renowned for its superior protective and comfort benefits. Bruck is committed to product innovation and development of new technologies.

Website: www.brucktextiles.com.au

EPIQ Machinery is a world class equipment designer with the mission to manufacture innovative and effective solutions for the global heavy duty material handling and mobile systems market. The EPIQ team blurs the lines between being a technology company and a machinery manufacturer by bringing new technologies onto its equipment portfolio. The synergies found in the equipment brands; AD, MECFOR, BROCHOT, HYDROMET and EPIQ DTA enable the EPIQ Machinery to take on both large- and small-scale projects while keeping the flexibility and agility to design custom made to order equipment.

The EPIQ team has the ability to analyse current systems and make recommendations of upgrades, equipment additions or the addition of new technologies to a process.

As leaders in their respective primary and secondary aluminium markets, the founding companies, Advanced Dynamics (AD) and MECFOR, make EPIQ Machinery a company capable of supplying and improving processes in all sectors of aluminium production: from the smelter to the finished good area.

With EPIQ Machinery; there is more than meets the eyes.

Website: www.epiqmachinery.com

Equibras is an equipment supplier for the aluminium industry since more than 20 years. With over 5000 equipment distributed worldwide, Equibras is the world leader in Equipment for the potlining of the electrolysis cells.

Our focus is to provide the best products and services to our clients to increase efficiency, safety, profitability as well as reducing operation costs. Our solutions include advanced technologies for operation in potroom and worshops.

At Equibras, client needs are at the center of the design process of the equipment / service. Thanks to its collaborative approach, Equibras is able to offer turnkey products, perfectly adapted to the needs of the aluminium plants. This approach also allows Equibras to be flexible in its offers. Thus, the company is able to meet the needs of various industries. Whether it is for an equipment or consultant need.

Website: www.equibras.com

The Geneva Graduate Institute is an institution for research and higher education situated within the top-50 globally in the field of international affairs. Located in the heart of International Geneva, it produces and shares academic knowledge and expertise on international relations, development issues, global challenges and governance. Within the Geneva Graduate Institute, the Centre for International Environmental Studies is a top academic institution for the assessment and development of environmental policies for the public and the private sector.

Website: www.graduateinstitute.ch

GNA specializes in the design and supply of equipment, technical services and operating strategies for the pot room and cast house in both primary and secondary aluminium industries. Our Cathode Sealing Systems are in operation world-wide and

recognized as industry-leading designs. Different pot room technologies are being processed in our systems daily and they include, AP, DX+, Mitsubishi, Montecatini, and others. Our cathode sealing systems are supported by three decades of experience in designing, fabrication, testing and a continuous improvement program driven by Client needs.

For the cast house, we cover design and technical support services from scrap yard layout through all major process steps to get product to the shipping door. GNA will assist you with raw material segregation, material flow and process management. Furnace charging equipment, melting and holding furnaces, bath skimming and alloying, metal treatment, filtration and casting lines can all be integrated into an autonomous operation. GNA is the leading innovator in modern cast house hands-free technologies. Whether you are melting/casting prime metal, clean or contaminated scrap, GNA can help you to improve metal quality and yield while decreasing energy consumption, melt losses, emissions and operating costs.

Our casting capabilities include technologies for slab, extrusion ingot (continuous and vertical) and continuous casting for sheet, plate and coil using Hazelett Corporation’s Twin-Belt Casting Machine. Hazelett joined the EBNER Group in 2021.

Our heat treatment capabilities include batch and continuous homogenizing, annealing and more using fully integrated and automated production lines.

Website: www.gna.ca/en

Our organisation is passionately committed to the pursuit of a better world through positive change. We embrace your visions as our own and partner with you to develop better ideas that are smarter, more efficient, and innovative. Our global network of 9,000 professionals work on the world’s toughest challenges. Our experience spans over 150 countries around the world in the metals, energy, and infrastructure sectors.

We are employee-owned and independent—free to bring our best thinking to your business. Our exceptional, diverse teams combine vast engineering and business knowledge, working in partnership with our clients to develop market strategies, manage and optimise production, develop new game-changing technologies, and design and deliver complex capital projects.

We work closely with the communities in which we serve to ensure that our solutions optimise environmental protection, economic prosperity, social justice, and cultural vibrancy. We want their businesses, ecosystems, and communities to thrive, both now and into the future.

Our people are passionate about our corporate purpose and values. We believe in long-term relationships with our partners, and are committed to our clients’ lasting success.

We are “entrepreneurs with a technical soul.”

Website: www.hatch.com

Funded in 1905 in Norway by Sam Eyde, Hydro is one of the largest aluminium companies worldwide. It has operations in some 40 countries at 140 locations around the world and is active on all continents. The Norwegian state owns 34.3% of the company. Hydro employs approximately 31,000 people.

First a synthetic fertiliser and power producer, Hydro entered oil and gas production in 1965. The fertiliser business was spun off in 2004 as Yara, while the oil part of the company was sold in 2007. Hydro entered aluminium production in 1986 when it acquired the Årdal aluminium plant from the Norwegian state.

Today Hydro is a fully integrated company with

- High quality bauxite and alumina production in Brazil,

- Primary aluminium production in Norway, Qatar, Slovakia, Germany, Brazil, Canada and Australia

- Production of 13.4TWh of renewable power

- A world leading position in aluminium extrusion ingots, extruded profiles solutions and precision tubing

- Remelting operations in America and a large European recycling network

- Efficient Technology and R&D organisation

In line with its mission of creating a more viable society by developing natural resources into products and solutions in innovative and efficient ways, Hydro aims at lifting productivity drive sustainability - creating value for all stakeholders. Pursuing that goal, the Company is strengthening its position in low-carbon aluminium and recycling, along with diversifying and growing renewable energy.

Website: www.hydro.com

The International Aluminium Institute (IAI) is the only body representing the global primary aluminium industry, aim to promote the sustainable development of the aluminium industry and to increase demand for aluminium products by raising awareness of their unique and valuable properties. Established in 1972, IAI member companies are engaged in the production of bauxite, alumina, aluminium, the recycling of aluminium, or fabrication of aluminium or as joint venture partners in such.

Website: www.international-aluminium.org

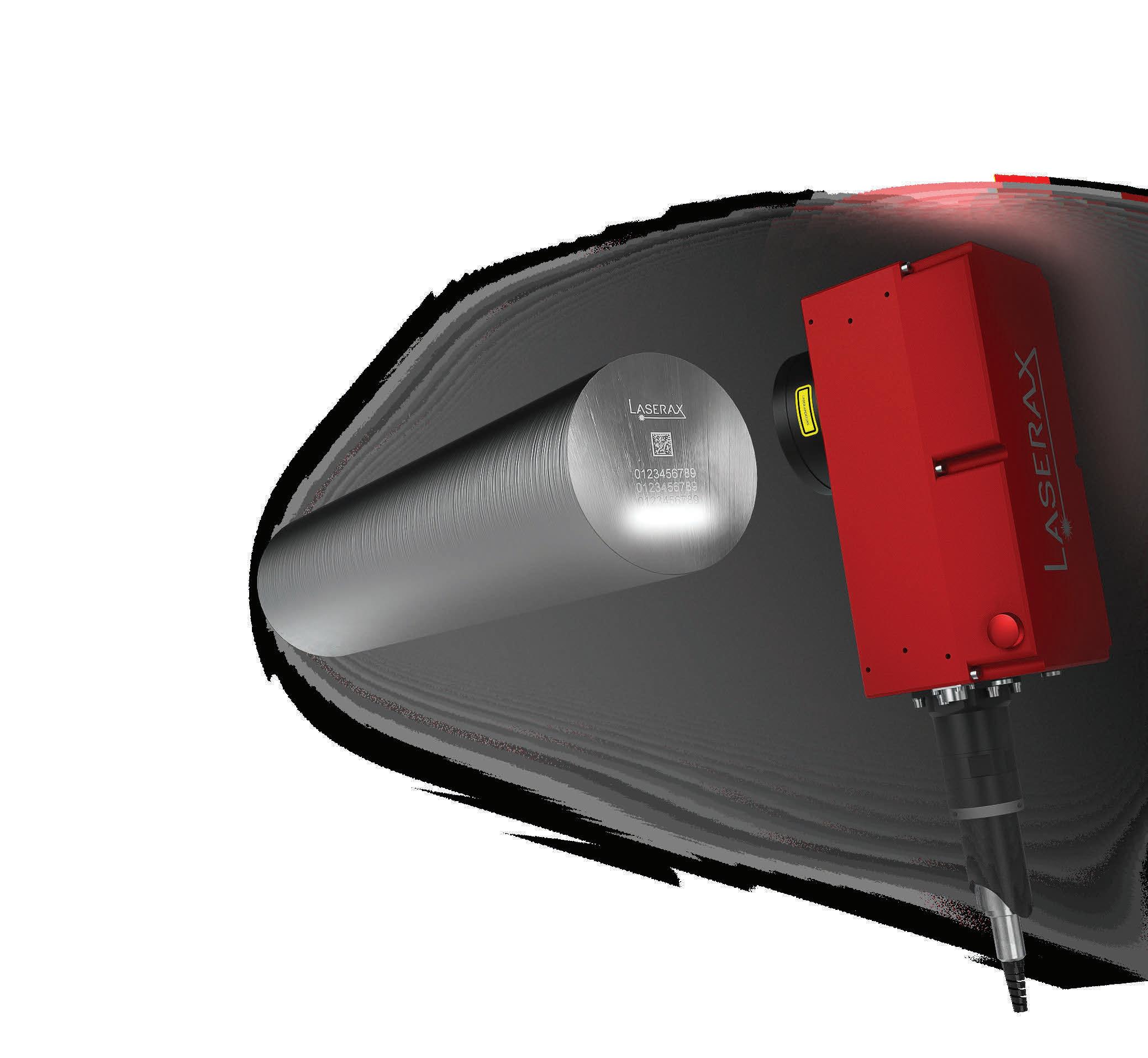

Laserax works with the world’s leading manufacturers to implement automated laser marking, cleaning, texturing, and welding solutions. Providing turnkey machines and OEM systems, the driving force behind Laserax is the desire to push the limits of laser technology and establish new standards in the industry.

Founded in 2010, Laserax first developed inline laser solutions for major smelting plants. Building on our reputation, we moved on to conquer casting plants and automotive parts suppliers all over the world.

Laserax is a manufacturer of laser systems that provide fast, reliable, and safe solutions for the most demanding industrial applications. Laserax relies on laser technology experts to offer a complete range of products for leading-edge marking and cleaning applications in the primary metals industry, automotive industry and battery and fuel cell industry.

Website: www.laserax.com

Maestria Solutions’ expertise is recognized by users worldwide. Our tools are used on a daily basis by different teams to detect and improve the performance of their cells, track crucibles for the transfer of molten metal over the road, or manage and deliver status and alarm messages through hall PAS, SMS, or email while creating a history of all the events. Instrumental in increasing Current Efficiency, Better Energy Consommation with proven results.

The mVa Profito solution for anode drop measurement allows quicker incident detection on your cell in order to limit the process degradation or speed up the crisis recovery, limiting the incident cost. Combined with our software, it’s proven to improve the Current Efficiency or get better Energy Consumption. Allow quick detection of problematic anode and cell, watch for potline drift, and help to locate the probable cause. Use big data strategy on measurement. We expect 0.1% CE increase for most smelters and 1% reachable in some cases. No modification on your potline is needed.

CICERO covers the security and plant operation field. This solution meets the needs of communication and transmission of messages, of any event requiring the attention of the staff with an objective to ensure efficiency and safety. This intelligent system, coupled with the pot control systems, pushes their messages to the right staff and location and with efficiency, using multilingual messages, and diffusing them by many means through the hall via PAS (speakers), SMS, or email.

In the primary aluminum business, part traceability protects manufacturers, buyers and sellers by providing a set of authentic and valid data.

By tracking each individual product, the information can be narrowed down to a specific batch or production process.

Laserax’s laser technology is the most widely used marking method to identify and guarantee the origin of sustainable aluminum.

We are proud to work with leading primary aluminium producers around the world to drive a meaningful change for product transparency and sustainability.

APPLICATIONS FOR THE ALUMINUM INDUSTRY

ALUMINUM BILLETS

Serialize products and accurately identify billets to automate extrusion process and meet new extrusion requirements from major automotive OEMs.

ALUMINUM SOWS

Stop spending on expensive labels that fall off. Laser etch a high-definition identifier label directly on the sow’s surface to obtain foolproof traceability and inventory management.

ALUMINUM INGOTS

Ensure heat resistant traceability with laser marking and unlock industry 4.0 features with individual ingot serialisation and bundle automated labeling.

LASERAX.COM

ProMETO is a solution for casting to track crucibles for the transfer of molten aluminium over the road. This solution precisely tracks logistically and geographically molten aluminium move in cradles by trucks for optimal planning and increases risk management, and updates it lives over private internet access with proper mapping. Enable tracking within the plant site access road by easily customizing the mapping.

Website: alu.maestria.ca/en/home

Mössner develops and builds special solutions in the fields of mechanical engineering, automation technology and robotics. With our 140 employees we can handle even larger projectswithout losing the necessary flexibility for your special solutions. At our location in Eschach, Germany we develop, manufacture and assemble your system and commission it for our customers worldwide.

Aluminium Technology

In the field of aluminium technology, we offer precise sawing and milling systems for primary and secondary aluminium production. These enable the processing of rolling ingots, T-bars, blanks, contours, round blanks, samples, ingots and plates.

Foundry Technology

Whether system components or turnkey casting and finishing lines - our special machines stand for reliable and automated system technology. This includes core handling, automation of casting machines, cooling and industrial marking, decoring, sawing, milling and deburring, as well as all necessary sub-processes of your casting production.

Band Saw Machines

For more than 130 years our band saws have been known for their durability, robustness and precise cutting performance on a wide range of materials. The saws are manufactured and assembled exclusively at our location in Eschach. Spare parts supply is guaranteed even decades after the purchase.

Special Machinery

In addition to handling tasks, our machines take over the processing steps of drilling, milling and sawing. As a complete supplier, we supply systems for all areas of quality control, conveyor technology and nuclear decommissioning.

Engineering

Our engineering department supports you in all questions of planning, optimisation, simulation and programming of robot applications. We offer automation in the field of robotics and control engineering as well as image processing for automated inspection stations and the digitisation of workpieces by 3D scanning.

Website: www.moessner-kg.de/en

Polytec is the merger of two leading companies in automation, robotics, renewable energy and plant engineering, an internationally renowned company operating in the field of system integration, specialising in solutions and platforms that combine robotics, artificial intelligence, process automation and software to help manufacturing companies achieve the technological transformation they need to become smart factories.

Polytec provides digital technologies, to allow aluminum producers a significant leap in productivity, while offering a better control over the production process and customer reach. This also provides better safety and environmental sustainability.

Our expertise in plant upgrading and retrofitting:

Automation and Process Control, Electrical Engineering, Distribution Systems HV/MV/LV, MCC and Drive Panels, Safety Management, PLCs & Drives, DCSs, HMIs & SCADA, Data Management, Cloud & IIoT

We design and supply tailor-made robotic solutions for:

� Plate removal and replacement in the ceramic foam filter

� Coil waste removal from the rolling mill unwinder

� Strap cutting and removal

� Machine tending for aluminum components

� Ingots handling and palletising

� Coils and products marking and tagging Website: www.Polytec.bmgroup.com

PRECIMETER specialise in premium products and technology for molten metal level and flow control solutions. We have been active within the molten metal industry for more than 25 years. Our products are specifically designed to withstand the harsh conditions in a casthouse environment.

We continuously improve and develop both current and new technology in order to offer our customers intelligent and modern solutions to safely make casthouse operations automatic for quality assurance. Our extensive industry expertise and knowledge lays the foundation of our continued work and product development. We work with the major corporations in the business and value a longlasting cooperation together with our customers for a definite future success.

We are fully committed to our customers worldwide and are able to offer our onsite assistance and support for service and support requirements in any of our installations. A hands-free casting process enables various advantages such

Mössner

Vertical saws

Horizontal saws

Saws for the aerospace industry

Saws for T-bars, rolling ingots, slabs, billets

Contour saws

Automation technology

Conductivity measurement

www.moessner-kg.de

Aluminium technology

Aluminium technology

as increased productivity due to automation, optimised safety for casthouse personnel, by a repeatable and traceable production the sustainability of the process as a whole is enhanced due to less scrap and remelting procedures.

Webiste: www.precimeter.com

WORLD-CLASS TECHNOLOGIES FOR ALUMINIUM ROLLING

Primetals Technologies provides metals producers with cutting-edge, custom-tailored plant equipment and services.

With over 90 years’ experience in the aluminum industry, Primetals Technologies is your single source supplier for aluminum rolling solutions;

� Fully integrated hot and cold rolling mills

� Mill modernisation projects and equipment upgrades

� Specialist shape measuring and process control technology

� Comprehensive spares and servicing support

� Extensive process knowhow to ensure your plant is fully optimised