8 minute read

Company profi le: Fusion Y Formas

The evolution of Mexican glassmaker Fusion Y Formas has mirrored that of one of Mexico’s ““We have to most famous exports in recent years.

Both Fusion Y Formas and the tequila spirit are continuously located in the famous Jalisco state, Mexico and over the last 25 years the two brands have grown innovate, the considerably.

The rise in the popularity of tequila in recent industry is famously years has been spectacular and it is now the second most popular spirit in the USA, only behind vodka. rigid but within that

Fusion Y Formas’s success is linked to the increase in popularity of tequila. context we innovate

The glassmaker’s origins were founded upon the production of bottles for a single tequila brand local even if sometimes to Jalisco state. In the subsequent 25 years since its inception the company has grown to supply more it is by accident. than 200 customers around the world.

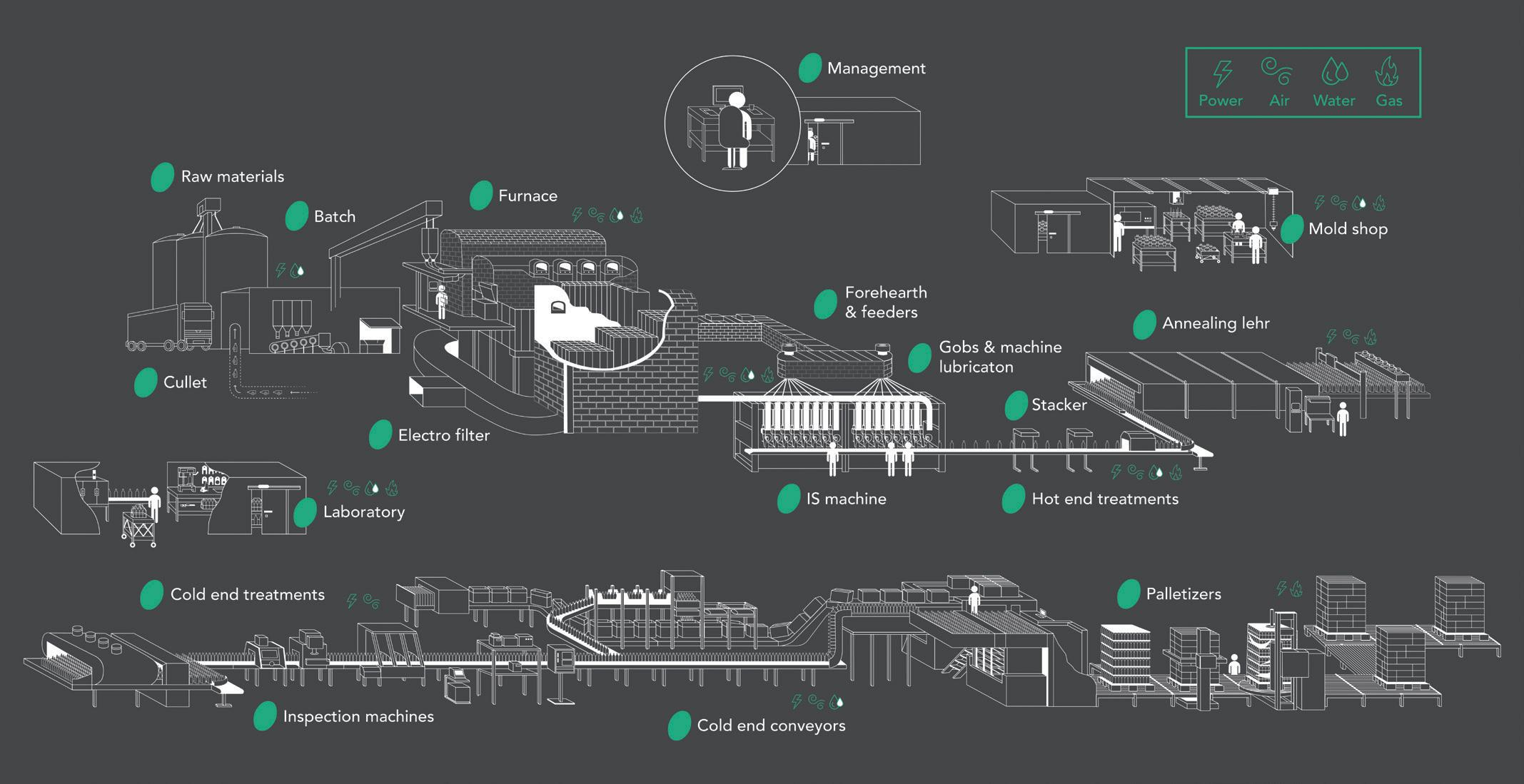

And this growth is set to continue. The company Innovation is one recently completed a furnace investment which has increased the daily capacity at its 3600m2 of those things that facility in Zapopan, Mexico.

The company is managed by the Hernandez you get to do when family, who have glassmaking in their DNA.

Father Cesar founded the company while alone, when no one working for his own father at the family’s handmade glass factory back in 1998. is telling us that it The company was formed when Cesar was working in his father’s handmade glass factory cannot be done.” when a customer requested a tequila bottle.

“This customer came in who wanted to make tequila a premium spirit, which was a new idea at the time. It took us 10 months to do it and as the Andres Hernandez tequila industry changed, the business grew.”

Cesar decided to form Fusion Y Formas which would focus exclusively on making tequila bottles using a semi-automatic process.

After 20 years he handed over the management to sons Andres and Pablo who changed to the production to an automatic glass manufacturing process.

The organisation’s focus lies in the craft of glassmaking. Rather than making lower cost, generic and mass-produced glass, it specialises in the production of small batches of approximately 10,000 bottles and upwards. It will work closely with customer to design a bottle with personality

Mexican glassmaker with a personal touch

Fusion y Formas is located in the same region of Mexico as tequila. Thanks to its strong customer focus, the family-run company thrives in building relationships and in crafting glass bottles that have personality.

and one which will maximise its impact on the shelf. Given its proximity to the tequila distilleries of Jalisco, it naturally specialises in the manufacture of bottles for the spirits sector but also caters for the food and olive oil markets. Its size of bottles range from 25ml to 3 litres.

As Managing Director Andres Hernandez says: “Our main market is Mexico, but our bottles are also in Europe, USA and South America - they are shipped all over the world.”

Recycled glass

One of its stand-out points is it manufactures from 100% recycled glass. While there is currently a strong trend on the environment, the company has used 100% recycled glass for as long as Andres can remember. Its furnaces also use an oxy combustion process to help prevent solid discharges into the atmosphere and to minimise the generation of CO2.

Andres says: “The main difference between us is we use 100% recycled glass to make our bottles and are the only factory in Mexico that produces this way.

“We have used recycled glass from the beginning. At the time it was not appreciated that using recycled glass could help the environment, we just did it. Today energy saving and helping the environment is a big subject, but we have been doing it since our grandad’s factory, it is in our bloodline if I can say that.”

The majority of its glass is in fl int but it has the adaptability to produce in other colours too.

The company is involved in the design phase of the bottle and aims to add personality to every brand it works with.

Andres said: “We work with customers from the design to the production phase and then afterwards we open the doors of the factory – we want customers to feel part of the product, it is their factory.”

Key to the design of the bottles is brother Pablo who is responsible for the engineering behind the design ideas. He will talk with a customer, take their idea and then add his own creativity to the design.

Andres says: “There are always guys that want to push the limits and try to do something crazy but Pablo is the guy who brings them down to Earth. We want to offer something more realistic and he will describe what can and cannot be done and the risks involved.

“We’re focused on the long-term relationship and we always say that if you want to do something with us then they should also discuss something with another factory to see if they can do it.”

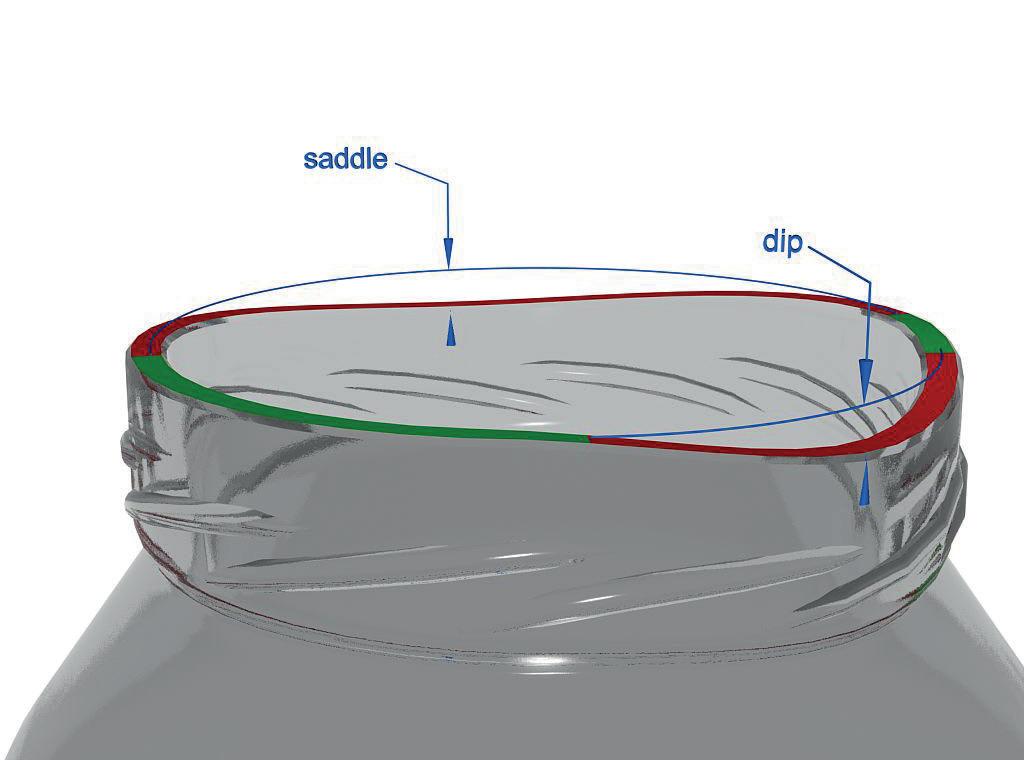

Its bottles and jars are shipped from Jalisco to all around the world so when Pablo is in discussions to design the bottle he has to consider the impact of transportation and of the temperature in its fi nal destination, for example.

Pablo has worked on more than 100 bottle and jar designs, working on elements such as engraving, holes in the bottle and asymmetric shapes. His favourite remains his fi rst design for that of a small Mezcal bottle.

“It was a diamond shape in a cylindrical bottle which was diffi cult to engineer. It also had an unusual texture which I liked about it.”

As a smaller, family run company it has to continuously be creative. In the past it has created water-based mould cooling technology and added seeds to glass.

Andres says: “We have to continuously innovate, the industry is famously rigid but within that context we innovate even if sometimes it is by accident. Innovation is one of those things that you get to do when alone, when no one is telling us that it cannot be done.”

Key to the development of the factory has been colleague Victor Pedraza, the company’s production director who Andres and Pablo both cite as a huge infl uence.

He has been with the group for 22 years and has worked in all areas of the business. Not only is he technically minded but has also consulted on the design of bottles.

Andres states: “In my opinion, he is an artist who can see things before everybody else. He plays a unique role and has been involved in many aspects of the factory.

“He has put a lot of sweat into the company and

puts the company before himself sometimes. He lives and breathes the company.”

It was Victor who developed the water-based mould cooling technology and who played a key role in the optimal layout of its production area.

Family company

The benefits of a smaller, family company means it is quick to respond to customer questions and make rapid decisions.

“Our biggest strength is our flexibility, we are a family-owned business and are always close to the customer. If we make a decision we don’t have several layers of people to go through. I’m in charge of the commercial area and it is always nice to form relationships and form friendships and build that close knit trust.”

It has forged strong links with several other companies which have a similar, family run profile. One of its strongest ties is with Spanish furnace designer and manufacturer Hornos Plamasso. The companies have worked together for 15 years and are now more like friends than suppliers.

“They are a family-owned company, are similar ages to us so we have a lot in common. It is a really human and easy-going relationship.”

Plamasso worked on Fusion’s recent 38t/ day furnace investment, which saw its capacity increase to 53 tonnes a day during a 30-day construction programme. The glassmaker has two furnaces and went through the furnace rebuild after the previous oven reached the end of its life. It has two semiautomatic forming machines with plans to possibly increase to three machines in future.

History

Both Andres and Cesar’s links to glass were forged at a young age, when both would spend weekend in the glass factory as youngsters.

Cesar said: “For me it was aged 10 or 11 when my father would take me to his factory on a Saturday to give my mum a break! I would help wrap the glass figurines but I never related it as a place of work, it was just somewhere where I would help out.”

Andres would spend the weekend at the factory as a teenager, just hanging out. It was only after finishing university aged 21 when he began to work for the company that he began to fully appreciate the magic of the glassmaking process.

“In Mexico there is saying that once you are in glass industry you make a crystal widow – you get fully absorbed in the industry! For me I started in moulds and have worked in maintenance, furnace production etc to see the whole factory. Lastly I worked in the administrative part such as accounting and HR and then took the commercial side of the company. It has allowed me to get a wider view of the company and to see every element of how the factory is run.”

While Cesar has handed over the management reigns to his sons, he still retains a consultancy role and is open to any questions his sons might have about the business and glassmaking. He is proud of what his family has achieved so far.

“I have seen the company grow with more machines and a larger oven. I thought it would stop at a second machine but once you’re in the glass industry you cannot stop. I hope my sons continue working here for as long as they want.” �

Fusion Y Formas, Zapopan, Jalisco, Mexico http://fusionyformas.com/en