3 minute read

Forming: Siemens & Sklostroj

Pulling out all the stops

When it comes to electrification, automation, and digitalisation, Siemens has been Sklostroj’s technology partner of choice for more than 15 years, states Radek Novotny* and Mark Ziegler**.

When people talk about energy efficiency in glass manufacturing, they generally mean potential savings from the glass melting furnace.

But plant engineering and machine building companies like Sklostroj know that they also need to look at the forming process. “In the current energy policy situation – which will continue to challenge us all for some time to come – any process improvement is worthwhile,” says Mark Ziegler, Manager of Business Development and Marketing for the Czech manufacturer of IS machines and hot-end equipment.

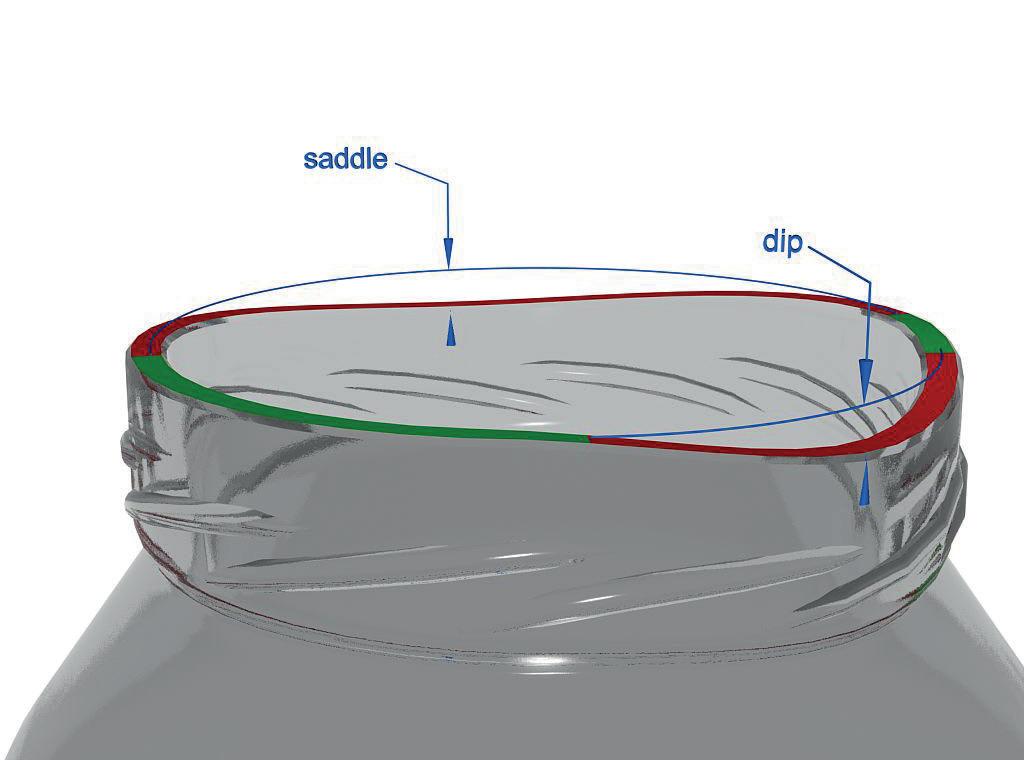

As an engineer, Ziegler understands that in most glass factories, almost 10% of melting energy goes unused because the “pack-to-melt ratio” – the ratio of final packed glassware to the initial glass melt – is most 90%. “Everyone who works in the industry knows that the process is highly complex and that workers are increasingly difficult to attract,” says Ziegler. “So it’s important we realise the remaining 10%.”

Reduced downtime

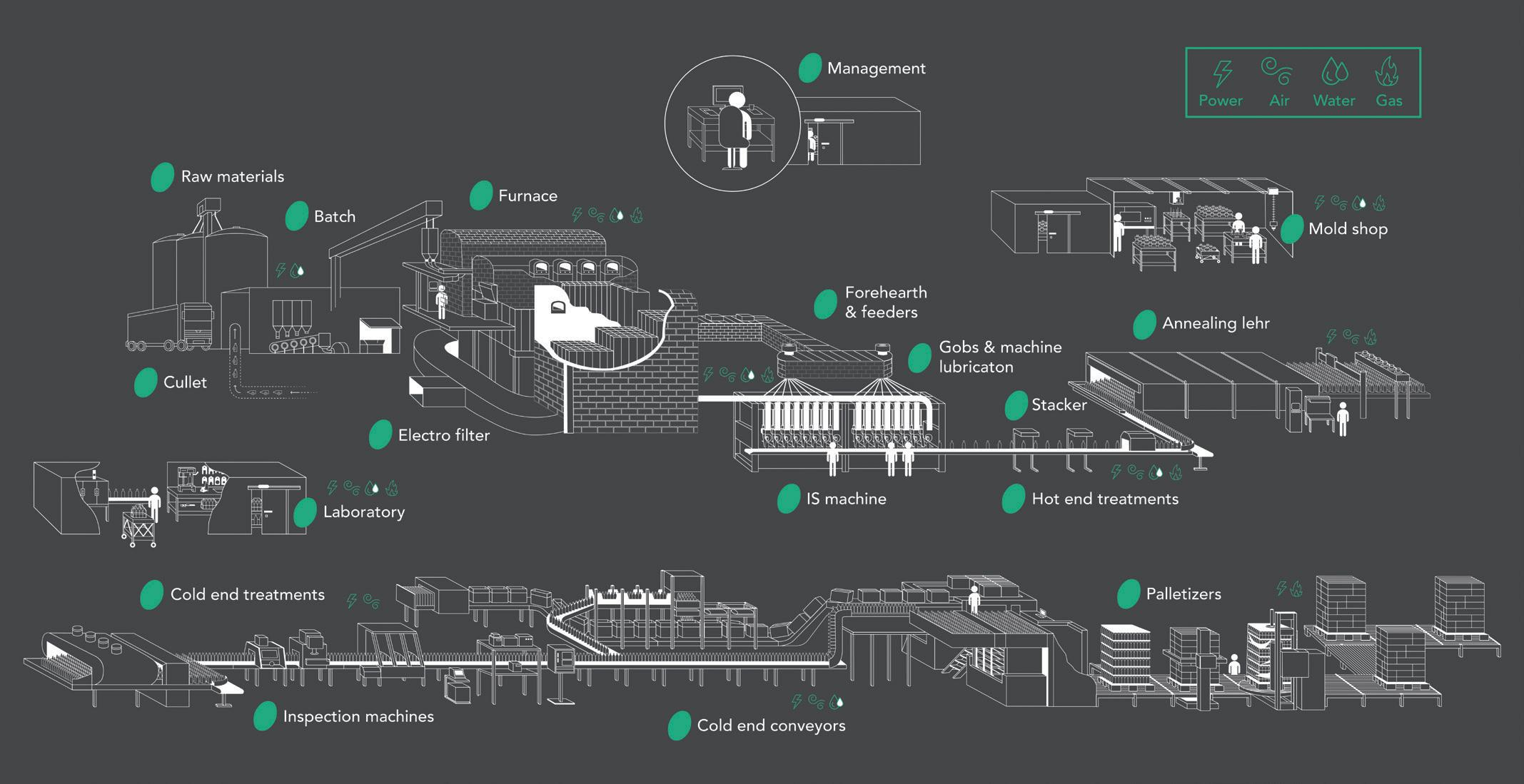

With its 200 employees, the company is forging new paths in the field that it knows best, container-glass forming, which it has practiced for more than 70 years. Sklostroj (sklo = glass, stroj = machine), with headquarters in the Czech city of Turnov, exports about 95% of its precision machines.

The engineering company supplies complete hot-end lines and plant components like IS machines, timing and drive systems, standalone systems including pushers, stackers, feeders, shears, and gob distributors, and much more.

“The downtime of IS machines plays an important role in our approach to an energy-efficient forming process,” explains Ziegler. Preventive maintenance concepts have been a valuable part of the solution at Sklostroj. These concepts are based on the Drive and Timing Control System (SDT-10) automation platform jointly developed by Sklostroj and Siemens.

Servo motors like the Simotics S immediately report deviations, such as higher torques caused by increased friction. With the added help of IoT platforms and at the customer’s request, the machines are becoming “smarter” thanks to AI, which makes them better and better at identifying data patterns. “At this point, glass manufacturers often become extremely concerned about data security, which is why we simultaneously developed appropriate security concepts,” says Ziegler.

Along with preventive maintenance,

Sklostroj believes that keeping production changeovers and maintenance activities as brief as possible is another way to reduce downtime. With the SDT-10, for example, it’s possible to load all the parameters from an article database in a matter of seconds when a new job has to be programmed.

� In many of its machines and plants, the Czech company consistently relies on control and drive technology from Siemens.

Energy-efficient actuators

The second component in the energyefficiency concept involves traditional drive issues. An estimated 80% of the actuators in IS machines in glass factories are still operated by pneumatic cylinders. “Servo technology would be more energy efficient, and compressed air is also extremely expensive,” says Ziegler. About every other IS machine from Sklostroj is delivered complete with servo technology. With the help of the Sinamics S120 converter, braking energy at the axes can be used to accelerate other axes at other stations. “In this context, we’re talking about DC or DC link couplings,” says Ziegler. Excess energy can also be transferred from machine to machine, thanks to regenerative AC/DC infeeds. A distributed Simatic fail-safe CPU with a fail-safe ET 200SP distributed I/O system controls higher-level and safety-oriented processes at the sections.

The versatile digital twin

A third strategic approach for achieving a sustainable forming process is the use of digital twins in engineering. “By simulating everything virtually in the development phase and commissioning the machines digitally on the computer, we shorten the conversion time, reduce downtime once again, and can prevent errors during ongoing operation,” says Ziegler. A good example is an upgrade to a new type of CPU that can be simulated without real hardware. “Operators can also be trained on the computer even before the machine is built.”

Side by side

“These are just three cornerstones among many in Sklostroj’s comprehensive strategy for making a substantial contribution to efficient and climateneutral glass production,” Ziegler affirms. “That’s why it’s all the more important to us that Siemens has stood by our side as a technology partner for over 15 years, providing consulting services and worldwide support in the areas of electrification, automation, and digitalisation,” he concludes. �

** Sklostroj, Turnov, Czech Republic www.sklostroj.cz/en *Business Development Manager for Production Machines, Siemens, www.siemens.com