VOL. 115, NO. 6

Print ISSN # 0033-9016, Digital ISSN # 2160-2514

EDITORIAL OFFICES

20 South Clark Street, Suite 1910 Chicago, Ill. 60603

Vol. 118, No. 12 1025 Rose Creek Drive Suite 620-121 Woodstock, GA 30189 Telephone (470) 865-0933

Telephone (312) 683-0130 Fax (312) 683-0131 Website www.rtands.com

BILL WILSON

Editor-in-Chief wwilson@sbpub.com

DAVID C. LESTER dlester@sbpub.com

Perusing the December 1905 edition, one finds articles such as “Evolution of the T-Rail,” “Track Elevation Through Cities,” “The New Pennsylvania Passenger Station at Wilmington,” “Tie Preservation of the A.T. & S. F. Railway,” and many others. Interestingly, many of the infrastructure issues at the beginning of the 20th century are still with us today, despite the explo sion of technology the industry has seen over the past 100+ years.

KYRA SENESE

CORPORATE OFFICES

Managing Editor ksenese@sbpub.com

1809 Capitol Avenue Omaha, NE 68102 Telephone (212) 620-7200 Fax (212) 633-1165

BOB TUZIK Consulting Editor btuzik@sbpub.com

ARTHUR J. MCGINNIS, JR. President and Chairman

CORPORATE OFFICES

JONATHAN CHALON Publisher

55 Broad St 26th Fl. New York, N.Y. 10004 Telephone (212) 620-7200 Fax (212) 633-1165

MARY CONYERS Production Director

ARTHUR J. MCGINNIS, JR. President and Chairman

NICOLE D’ANTONA Art Director

JONATHAN CHALON Publisher

HILLARY COLEMAN Graphic Designer

MARY CONYERS Production Director

JO ANN BINZ Circulation Director MICHELLE ZOLKOS Conference Director

NICOLE D’ANTONA Art Director

ALEZA LEINWAND Graphic Designer

CUSTOMER SERVICE: 402-346-4740

It’s very humbling to take the reins of a publication that’s been around since 1905. After more than three years as Managing Editor of RT&S , I’m very grateful for the opportunity to serve this venerable magazine as Editor-inChief. I am standing on the shoulders of thousands of people, including editors, writers, railroaders, MOW equipment vendors, consulting engineers, engineer ing professors, and many more. And, of course, today’s “magazine” is much more than that. RT&S Media also includes important digital content, newsletters, conferences, webinars, and an active presence on social media. All our work seeks to inform, enlighten, and support the Rail Engineering and Maintenanceof-Way sectors.

Our mission at RT&S has always been and will continue to be, focused on our readers and clients. We aim to produce print and digital content that will be useful to practicing railway civil and other engineers, professors, and students in university engineering programs. Our content is useful for railroad executives and association leaders as it provides a forum for discussing and evaluating existing and emerging technologies.

In 2023, more content will focus on railway structures, such as passen ger stations and freight terminals. And wayside communications and signaling systems, including positive train control. Our ball game is infrastructure, which covers a wide berth, and is critical to the success of the railroad industry.

I also want to shout out to my colleagues at Simmons-Boardman Publishing, publisher of RT&S, and our sister maga zines, Railway Age and International Railway Journal .

MAUREEN COONEY Circulation Director

Reprints: PARS International Corp. 253 West 35th Street 7th Floor New York, NY 10001 212-221-9595; fax 212-221-9195 curt.ciesinski@parsintl.com

MICHELLE ZOLKOS Conference Director

CUSTOMER SERVICE: 800-895-4389

Reprints: PARS International Corp. 253 West 35th Street 7th Floor New York, NY 10001 212-221-9595; fax 212-221-9195 curt.ciesinski@parsintl.com

The longevity of RT&S is evident not only in digital and paper copies but in conversations with railroaders of various ages. I’ve had railroaders tell me they first learned about RT&S because one of their parents or grandparents was a railroader and regular reader. The magazine began as Railway Engineering and Maintenance of Way and eventually changed to Railway Track & Structures.

I have never worked with a more collaborative and supportive group of professionals during my stint as Manag ing Editor and my transition to Editor-inChief. Several appear on our masthead, and some do not, but each has a vital role in preparing our print and digital content each month. Our work is undoubtedly a team effort.

DAVID C. LESTER Editor-in-ChiefCOPYRIGHT © Simmons-Boardman Publishing Corporation 2022. All rights reserved. Contents may not be reproduced without permission. For reprint information contact: PARS International Corp., 102 W 38th St., 6th Floor, New York, N.Y. 10018 Phone (212) 221-9595 Fax (212) 221-9195. For subscriptions and address changes , Please call +1 (402) 346-4740, Fax +1 (847) 291-4816, e-mail rtands@omeda.com or write to:

Railway Track & Structures, Simmons-Boardman Publ. Corp, PO Box 239, Lincolnshire IL 60069-0239 USA.

POSTMASTER: Send address changes to Railway Track & Structures, PO Box 239, Lincolnshire IL 60069-0239 USA.

inhibit gage corner shell initiation. The same strategy for preventive grinding at periodic intervals was implemented on this test.

In the two previous IS rail tests conducted by MxV Rail at FAST, rail manufacturers were contacted for donations of their latest rails.

the provided IS rails belonged to carbon IS rail or low alloy IS rail categories.

Ananyo

Banerjee, Ph.D., Principal InvestigatorMxV

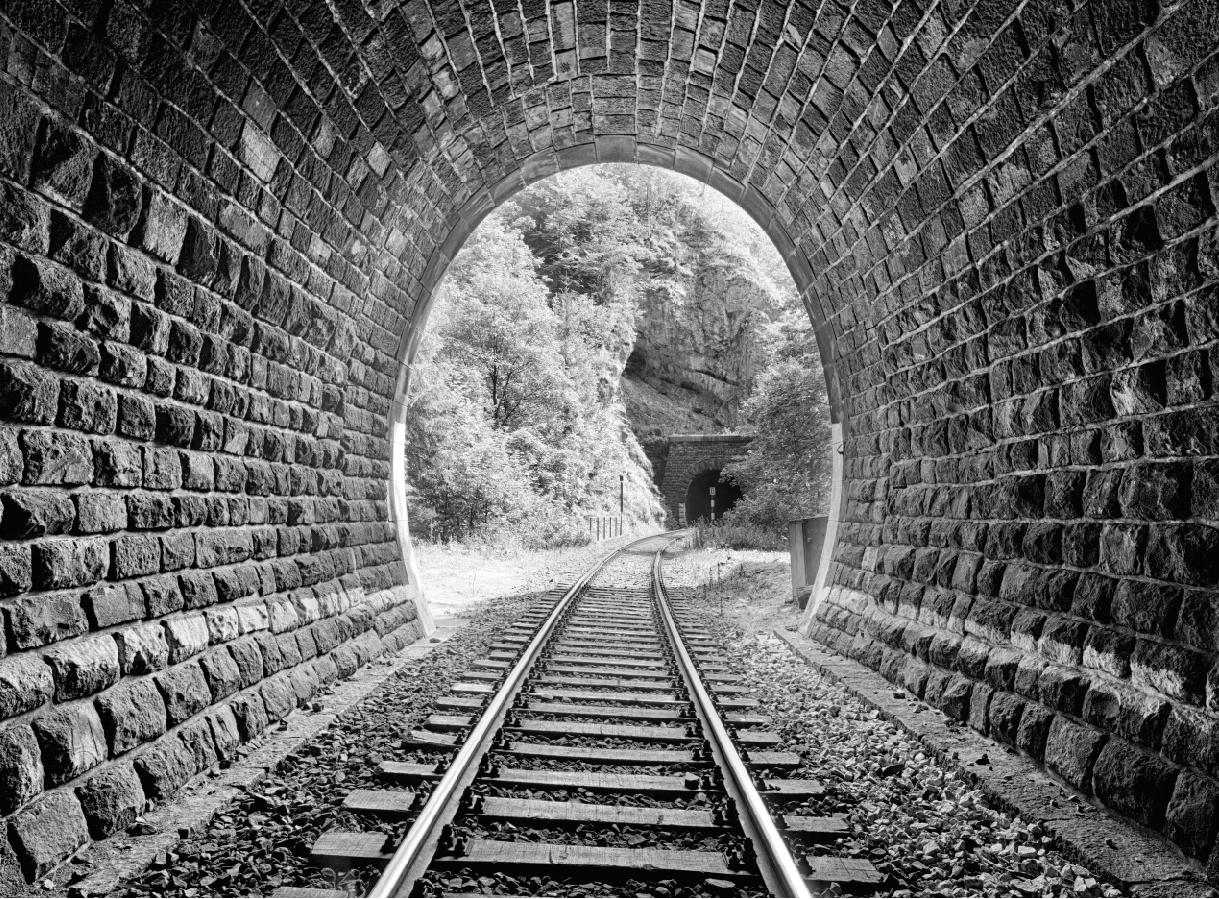

Rail | Pueblo, COMxV Rail (formerly TTCI) started testing three intermediate strength (IS) rail types and a standard strength (SS) rail type on a 5-degree curve of the High Tonnage Loop (HTL) located at the Facility for Accel erated Service Testing (FAST) in Pueblo, Colo. The rails were installed in January 2021 and accumulated 141 million gross tons (MGT) of service through June 2021. The 5-degree curve in Section 3 of the HTL is equipped with gage face (GF) lubrication on the high rail and oil as top-of-rail lubrication on the low rail. MxV Rail is monitoring rail wear, internal rail defects, and electric flash butt (EFB) weld fail ures as parts of the test. There were no internal defects or weld failures in this test through 141 MGT. Preventive grinding was done twice, at 56.5 MGT and at 127 MGT, to remove surface rolling contact fatigue (RCF). The two previ ous IS rail tests lasted until 390 MGT (2010–2012)(1) and until 598 MGT (2012–2016)(2); the increase in tonnage accumulation was due to preventive grinding cycles used in the second test to remove surface cracks and to

For the current test, members of the Associa tion of American Railroads (AAR) rail Tech nical Advisory Group (TAG) volunteered to donate the latest IS rails being used in revenue service. Getting new IS rails from railroads instead of from manufacturers provided the ability to select rails as a part of random sampling from large inventories of rails sched uled to be used in revenue service. Once the selection process was complete, the rails were installed by an external contractor on the HTL using EFB welding.

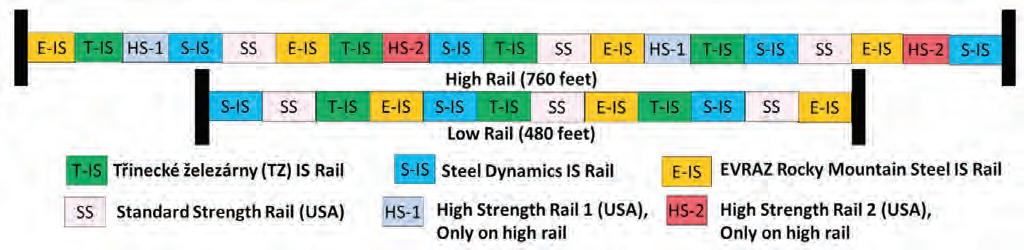

As shown in Figure 1, the high rail layout was chosen to monitor the wear performance of one SS, three IS, and two high-strength (HS) rail types in similar track conditions. These HS rails, manufactured in 2018, were chosen from the existing stock of rails at FAST. The high rail had four rails of each IS rail type while the low rail had three rails of each IS rail type. The 40-foot SS rails, donated by BNSF Railway, were placed on the high rails and on the low rails (three on each). The participating IS rail types were donated by the following: Třinecké železárny (TZ)–Norfolk Southern Railway, Steel Dynamics–CSX Transporta tion, and EVRAZ Rocky Mountain Steel–Union Pacific Railroad (UP). Since the rails came from the railroads and were randomly selected, mill certificates showing test results were not obtained. It was not known whether

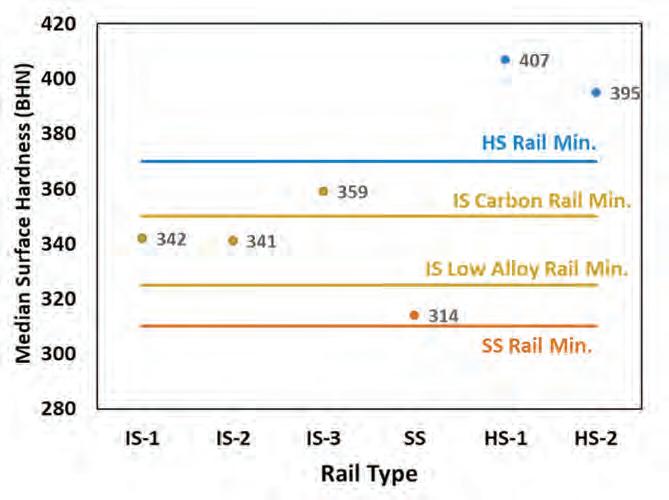

Figure 2 shows the median surface hardness values of all participating rail types. The hard ness values of all rails were compared to the minimum surface hardness recommended values mentioned in Tables 4.2.1.3.2a and 2b in Chapter 4: “Rail,” of the American Railway Engineering and Maintenance-of-Way Asso ciation (AREMA) 2021 Manual for Railway Engineering (MRE).(3) Hardness was deter mined at ~0.03-inch depth by grinding to remove the decarburized surface layer at the testing locations on the rail heads. As Figure 2 shows, all IS rail types were above the recom mended minimum value of the IS low alloy rail. All SS and HS rail types exceeded the minimum AREMA recommended values for their respective rail types.

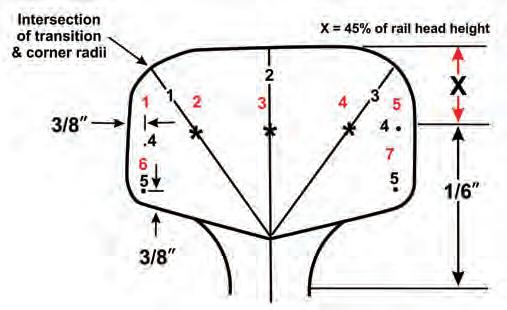

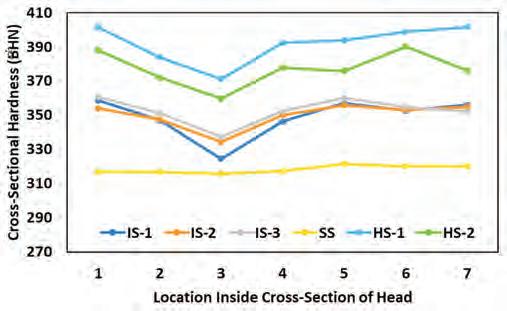

The internal cross-sectional hardness of the head of the eight rail types was measured at seven locations using a Rockwell C indenter. The measurements were converted to Brinell scale per the conversion equation in Table 4.2.1.3.3a of the AREMA MRE Chapter 4.3. Figure 3a shows the seven locations labeled in red font on the original Figure 4-2-1 of the AREMA MRE Chapter 4.3.

The three IS rail types have hardness values similar to each other, lower than the two HS rail types, and higher than the SS rail types (Figure 3b). In all three IS rail types and in the HS rail types, location Numbers 1, 2, and 4 through 7 were all higher in hardness than location Number 3—the location farthest from the rail surface. The lower hardness in location 3 can be due to the head hardening

treatments done to the IS and HS rails to provide a hardness gradient that is highest near the surface. In comparison, the SS rail type has similar hardness values in all seven locations inside the rail head and indicates the absence of any head hardening treatment.

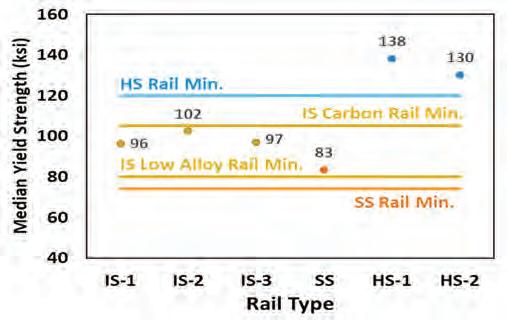

Six-inch-long samples were cut from all the 40-foot rails installed on the high rail. Tensile bars were machined from one gage corner of the head and center of the base for all rail types per Article 2.1.3.4 of AREMA MRE Chapter 4.3. These bars were tested for yield strength and tensile strength by an independent labora tory. Figures 4a and 4b show the median ulti mate tensile strength (UTS) values and median yield strength (YS) values, respectively.

Figure 4a shows that all three IS rail types have UTS values well above the minimum recommended values for IS rail types. The median UTS value of the SS rail type was above the recommended minimum for IS rail types. Figure 4b shows that the YS values of all three IS rail types are higher than the recom mended minimum YS for IS low alloy rails. The YS value of the SS rail is higher than the recommended minimum value for SS rails.

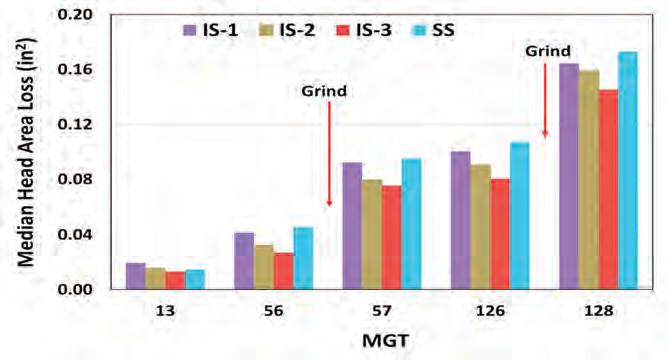

No initial grinding was done to remove the mill scale from the new rails. All the test rails were EFB welded both to one another and to the non-test rails in track. Initially, the rail

profiles were measured at zero tonnage for baseline measurements. Measurements were taken at 13 MGT and then at every pre-grind and post-grind tonnage interval. The pre-grind and post-grind measurement intervals were at 56 MGT and at 57 MGT for the first grind and at 126 MGT and at 128 MGT for the second grind. Preventive grinding was done twice in 2021, and the test has accumulated 141 MGT. The 2010 to 2012 IS rail test lasted for 390 MGT (1) and concluded due to the excessive shelling of the rails. No preventive maintenance grind ing was done during the test, and the test ended with 18 shells. One of the goals of the second IS rail test done between 2012 and 2016 was to monitor the defect formation and longev ity of the rail performance by doing preventive maintenance grinding at regular intervals (2). Although preventive grinding was not done at equally spaced time and traffic intervals, eight grinding cycles at an average interval of 60 MGT were completed. Both the grind ing cycles and the gage face lubrication led to longer rail life and delayed initiation of shells. Since the new IS rail test is in the same curve and at approximately the same location as the previous two IS rail tests, grinding is planned at every 60 to 70 MGT interval to delay shell formations. Figure 5 shows the overall median head area loss due to wear and grinding on the high rail.

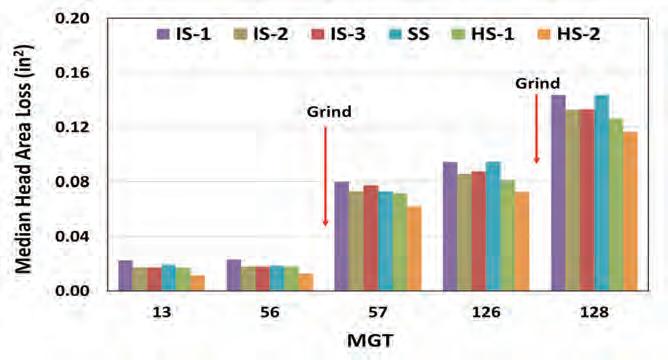

Figure 6 shows the overall median head area loss of all the rail types in the low rail. Since there are no HS rails installed in the low rail per the layout in Figure 1, a direct comparison can be made only between the SS and the three IS rail types.

Note that the train operations have led to differences in RCF damage and wear between the high and low rails. The difference in head area loss between 126 MGT and 128 MGT is lower for the high rail, as shown in Figure 5,

and comparatively higher for the low rail, as shown in Figure 6. These results can be attrib uted to the higher number of grinding passes on the low rail to remove surface RCF.

MxV Rail initiated a new IS rail test on the HTL at FAST in early 2021 and accumulated 141 MGT before the end of FAST operations in 2021. Four Class I railroads donated rails belonging to three IS rail types and one SS rail type for this test. Two HS rail types were included in the high rail of the test. Tests for hardness and mechanical properties indicated all three IS rail types had surface hardness, YS, and UTS values above the AREMA recom mended minimum values for IS low alloy rail. Similarly, the SS rail type had surface hard ness and mechanical properties above the AREMA recommended minimum for SS rails. Grinding was done at 56.5 MGT and at 127 MGT with pre-grind and post-grind rail profile measurements. No internal rail or weld defects were observed until the end of 141 MGT, and continued testing is planned.

1. Szablewski, Daniel and Joseph LoPresti. “Intermediate Strength Rail Testing at FAST: Wear, RCF, and Deep-Seated Shell ing Analysis.” Technology Digest TD14-010. AAR/TTCI, Pueblo, CO. May 2014.

2. Banerjee, Ananyo and Joseph LoPresti. “Intermediate Strength Rail Test: Wear and Defect Analysis” Technology Digest TD17-005. AAR/TTCI, Pueblo, CO. March 2017.

3. American Railway Engineering and Main tenance-of-Way Association. Chapter 4: Rail, Manual for Railway Engineering. Lanham, MD. 2021.

While the pandemic has eased, inflation and worker shortages persist

By David C. Lester, Editor-in-Chief

By David C. Lester, Editor-in-Chief

To keep track in proper shape to host high-speed intermodal and passenger trains, excellent Maintenance-of-Way (MOW), and constant monitoring of everything that contributes to the stability of the right-of-way is required. Whether it’s an intermodal train hitting a broken rail at 70 m.p.h. or a passenger train coming upon a washout at 79 m.p.h., a highspeed derailment is a catastrophe, and results in property damage; lost revenue; clean-up costs; and, worst of all, human injury or death. Those responsible for MOW have a heavy responsibility and depend upon the railroad supply indus try for materials and equipment to keep the roadway in top shape.

Maintaining the railroad to these high standards is expensive. Therefore, it’s essential for Class Is and short lines alike to maintain strong financials, so they don’t have to defer maintenance. While short lines don’t run 79 m.p.h. trains, their thinner margins may require spending a smaller percentage of their revenue on MOW than Class Is, and keeping track in good enough shape to keep the track safe.

The phrase “cautiously optimistic” sounds like an old, tired description, but it accurately describes the overall outlook of the railroad industry and railroad MOW sectors for 2023. Indeed, the outlook for the North American economy is cautiously optimistic. The pandemic has abated significantly but continuous monitoring is required. While an increase in COVID cases does not seem imminent in North America, the number of cases has spiked in other

parts of the world. The waning of the pandemic also resulted in a signifi cant increase in economic activity and, combined with government stimulus spending, kicked off a round of infla tion that has taken a toll on businesses and consumers alike. Higher diesel prices have hit the railroads’ bottom lines, but the same is true for the truck ing industry.

The National Unemployment Rate spiked at the beginning of the pandemic, but has almost returned to the pre-pandemic levels of 2019. However, the labor force participation rate has remained relatively flat for the past year, supporting the notion that part of the American workforce has not yet returned to work. Even though the worker shortage has improved some what, keeping trains running with the available number of qualified employ ees is still a challenge. Indeed, the American Public Transportation Asso ciation (APTA) recently reported that the worker shortage for some transit agencies is such that they struggle to maintain their regular schedules.

The supply chain has not fully recov ered from the disruptions of the past couple of years. One example is freight embargoes on Union Pacific have increased significantly over the past several months because of network congestion aggravated by worker short ages. The Surface Transportation Board is asking Union Pacific to explain why the embargoes have risen so much over the past few months.

There is concern over the extent to which inflation will increase in 2023. Growing inflationary pressure will moti vate banks to raise interest rates, which

should theoretically slow inflation but also the economy. There is debate over whether the inflation rate will reach a point where interest rates will increase significantly, possibly resulting in a recession.

Against that macroeconomic backdrop, we recently completed our annual “State of the Industry” survey and learned that planned spending patterns closely matched those of last year’s survey. For example, when we asked companies about overall MOW spending for the coming year, the 2021 survey reported that 42% said spend ing would be flat in 2022 compared with 2021, while the 2022 survey reported 50% said spending would be flat in 2023. In addi tion, 38% of 2022 respondents said they would be spending more on MOW in 2023, while 42% of 2021 respondents planned more spending in 2022.

The financial health of a business drives the degree of MOW planned for 2023, so this was one of the first issues our survey addressed.

Barring any disruptive or catastrophic events in 2023, MOW spending appears that

How Do You Think 2023 Will Compare To 2022 As A Business Year For Your Company?

55.98% 2023 better than 2022 32.94% Flat 11.08%

2022 will be better than 2023

it will be strong. According to our survey, business has either been excellent or good for most respondents in 2022, and most carriers say their dollar spend on MOW will be greater than or equal to that in 2022. The table on page 14 shows, according to our survey, how carriers will spend their MOW dollars in 2023.

To gain further insight into the state of the industry, RT&S reached out to Chuck Baker, President of the American Short Line and Regional Railroad Association. Baker said, “The effects of the pandemic are pretty much

are the big story for the short line indus try in 2022. “I believe our Class I friends would agree that the network did not operate at full tilt in 2022. This has been frustrating for the short lines—they work hard, scrap for business, and hustle to get every carload. They work to grow existing market share, and some significant deals were left on the table this year due to lack of mainline capacity.”

“However, the short line industry continues to collectively push ahead and has held up OK. We believe things will continue to get better in 2023. We see some green shoots around Class I service getting better, and short lines say that some service is improving. Big picture: There is some positive outlook for 2023.”

Ba ker told RT&S , too, that while there has been some labor shortage for short lines, it has not been nearly as bad as it has been for the Class Is. “We used not to hear about short line problems around worker availability. Short lines offer well-paying jobs, and you can sleep in your own bed every night.” Baker added that while there is not a nationwide short line labor crisis,

“We do see situations where, say, the local warehouse in a community used to pay $18 per hour, while the short line paid $30 per hour; with wage inflation, the warehouse now pays $26 per hour, and the short line may still pay $30 per hour, but there is pres sure on short lines to raise wages.”

In addition, Baker said, “there is no ques tion that inflation is a challenge. The cost of track, people, really anything you buy has risen. Short lines don’t have much pricing power, so if their costs go up, they can’t usually recoup them. It’s up to the Class Is to pass on some additional revenue to the short lines. Diesel prices are growing, and short lines cannot levy fuel surcharges. Nor are they able to recoup fuel surcharges from the Class Is. There are two sides to the rise in diesel costs, though. Trucks use diesel, and railroads are more efficient with fuel, so the trucks take a harder hit.”

Baker pointed out the industry has a couple of regulatory concerns that are looming large. “The first is the federal effort to

regulate crew size—i.e., the Federal Railroad Administration’s push to have two-man crews in the locomotive cab.” This impacts short lines differently from the Class Is in that most short lines use oneperson crews. Short lines have some true one-person crews, like the ones they run on the Indiana Rail Road, along with crews where there is one person in the cab while another crew member is following along in a truck to address any problems that may arise, including throwing switches when making customer pick-ups and deliveries.

“We believe this is masquerading as a safety issue,” Baker said. When asked if there were any special considerations given to short lines in the pending rules, Baker said that there were numerous rules and special conditions to be met that would benefit the short lines, but working through all of these would be onerous. “It’s important to note, too, that Class Is currently have the two-man crew rule because of labor agree ments and not because of a federal rule,” he said. If this rule were enacted, current short line operations would be impacted, where

the two-person crew operations on Class Is would remain the same.

The other big regulatory concern is that California is keeping its powder dry through the California Air Resources Board for another potential showdown with the short line industry. Baker said, “California has proposed a locomo tive emissions reduction rule that says if you’re running locomotives that produce any emissions at all—in other words, any

MAINTENANCE TYPE

more than zero emissions—the state will start forcibly taking money from the short line and put it in a spending account, and release it to you only when you can afford to buy emission-free locomotives.” Baker said this would be financially cata strophic for short lines, and if the rule were approved, several short lines would face bankruptcy.

“And of course,” Baker added, “the short lines can remain financially viable

because they use older locomotives with Tier 0, Tier 1, and Tier 3 emissions ratings, which are the dirtiest locomotives around.” In addition, starting in 2030, California would ban any locomotive you’re running that’s older than 23 years. Baker and the ASLRRA worry that if Cali fornia successfully implements this rule, other states may pick it up and even the Environmental Protection Agency (EPA) may adopt similar regulations.

How Will You Spend MOW Dollars In 2023?

More than 2022 Less than 2022 Same as 2022

17.85% 17.23% 14.09% 19.04% 25.50% 21.40% 14.14% 21.89% 17.45% 30.69% 21.28% 21.02% 26.16% 9.09%

5.72% 9.46% 8.72% 9.70% 8.72% 10.70% 10.77% 13.80% 9.40% 7.26% 8.45% 10.51% 6.95% 10.10%

34.68% 39.86% 28.86% 37.12% 28.19% 34.45% 42.09% 29.63% 33.22% 43.56% 40.54% 38.64% 43.38% 33.67%

Railway Age, Railway Track & Structures and International Railway Journal have teamed to offer our Rail Group On Air podcast series. The podcasts, available on Apple Music, Google Play and SoundCloud, tackle the latest issues and important projects in the rail industry. Listen to the railway leaders who make the news.

William C. Vantuono Railway Age

David C. Lester Railway Track & Structures

Kevin Smith International Railway Journal

Podcasts are available on Apple Music, Google Play and SoundCloud

William C. Vantuono Railway Age

David C. Lester Railway Track & Structures

Kevin Smith International Railway Journal

Podcasts are available on Apple Music, Google Play and SoundCloud

Loram designs top-of-rail friction modifiers for wayside applications that help reduce noise, extend rail and wheel life and contribute to fuel savings.

David C. Lester, Editor In Chief

David C. Lester, Editor In Chief

While watching several locomotives struggle upgrade with a heavy train, often with sanders activated, it’s counterintuitive that the wheel/rail interface requires lubrica tion. However, lubrication is critical to preventing premature rail and wheel wear. Lubrication is essential after grinding has occurred. According to Allan Zarembski’s The Art and Science of Rail Grinding , “. . . rail grinding leaves behind a relatively rough surface finish with distinct grind ing that requires the passage of a number of trains before they fold and dissipate. Another feature of this immediate postgrind surface condition is a high coeffi cient of friction. The coefficient can be in the range of 0.4 to 0.5-plus immediately behind the grinder since the grinding process generally eliminates any resid ual rail lubrication that is present in the portion of the rail head being ground. This high coefficient of friction can

increase the magnitude of lateral loads generated during curving and can also increase the potential for wheel climb on curves.” And wheel climb can result in significant derailments.

This month, three vendors share their latest lubrication products and services to help maximize wheel and rail life and maintain a safe railroad.

Adverse wheel and rail interaction poses one of the greatest threats to the life and performance of rail and rolling assets. Loram Technologies offers both gauge face and top-of-rail consumables in biodegradable, synthetic, and waterbased versions.

Loram Technologies designs gauge face lubricants for transit or heavy haul appli cations, which are pumpable in extremely low temperatures, and are biodegradable. EcoCurve Heavy Haul is readily biode gradable, carries the European Ecolabel,

and is suitable for use near bodies of water. EcoCurve Trackside is also readily biodegradable and has found wide accep tance in the transit market worldwide. Rail King HL is inherently biodegradable and has high load-carrying additives, best suited for heavy haul applications.

The company designs top-of-rail fric tion modifiers for wayside applications that help reduce noise, extend rail and wheel life and contribute to fuel savings. TOR-Extend is a clean synthetic fric tion modifier with a low evaporation rate, uses less material per application versus competitive products, and has a carry distance of more than six miles in most applications. TORFM technology continues to evolve and remains a focus of Loram Technologies’ product develop ment efforts.

In 2022, Loram Technologies intro duced a family of modular tank sizes from 25-gallon/200 lbs. to 200-gallon/1600 lbs. in carbon steel or stainless steel

configurations. These units are avail able for TOR or gauge-face applications and can be solar or AC-powered. Easy to maintain and install, the 25/200 tank size is the solution for low-traffic areas like switching yards and industrial spurs and can also manage lower tonnage Class I mainlines and transit systems. The larger tank sizes are most appropriate for Class

I mainline applications. Remote moni toring of wayside friction management systems continues to be of strong interest to most of the company’s customers.

L.B. Foster

and solutions for every challenge faced by train or track operators looking to improve performance, reduce costs, and lower their carbon footprint. L.B. Foster’s full-scale offerings include designing, installing, and applying end-to-end friction management solutions and services anywhere they are required – on board a train, in a tunnel, or a remote trackside location.

L.B. Foster has introduced its nextgeneration Top-Of-Rail (TOR) Friction Modifier spray product to the market – the KELTRACK® On-Board (KOB) System. KOB is the culmination of years of research and development and expands the use of its industry-leading trackside TOR technology directly to the vehicle. The advantages of a train-mounting system include ease and safety of main tenance, system coverage, and direct application to the critical location on the wheel-rail interface. Essentially, the product goes where the vehicle goes.

L.B. Foster is committed to Total Fric tion Management, shaping its business offering to include the latest products

Track Safety Standards, contains the Track Safety Standards, Subparts A-F, for Classes of track 1-5. The standards cover general information, Roadbed, Track Geometry, Track Structure, Track Appliances and Track-Related Devices, and Inspection. Includes Defect Codes. Updated March 21, 2022.

BKTSSAF Track Safety Standards, Subparts A-F $11.95 Only $10.75 for orders of 50 or more!

FRA Part 237 establishes Federal safety requirements for railroad bridges. This rule requires track owners to implement bridge management programs, which include annual inspections of railroad bridges, and to audit the programs. Part 237 also requires track owners to know the safe load capacity of bridges and to conduct special inspections if the weather or other conditions warrant such inspections. Updated March 21, 2022.

BKBRIDGE

Bridge Safety Standards $8.95 Only $8.00 for orders of 50 or more!

www.RailwayEducationalBureau.com

This reprint includes the FRA's Railroad Workplace Safety Standards addressing roadway workers and their work environments. These laws cover such things as: personal protective equipment, fall protection, and scaffolding for bridgeworkers; and training issues. Also includes safety standards for on-track roadway vehicles. Updated March 21, 2022

BKWRK

Railroad Workplace Safety $11.50

Only $10.35 for orders of 50 or more!

The Track Safety Standards Calculator is a must for anyone who works on track. This slide rule type calculator contains many of the details for Classes of track 1- 5. Deviation from uniform profile and from zero cross level. Difference in cross level. Compliant with part 213.

BKTCAL

Track Calculator $11.50

Only $10.75 for orders of 50 or more!

Updates from the Federal Register may be supplied in supplement form.

U.S.A. CAN

KOB also provides a residual benefit. Operators do not have to fulfill a 100% fleet outfit for 100% of the fleet to receive The Railway Educational Bureau 1809 Capitol Ave., Omaha NE, 68102

UP TO $10.00 $5.25 $10.15 10.01 - 25.00 9.70 16.90 25.01 - 50.00 13.20 22.06 50.01 - 75.00 14.85 27.55

the benefit – saving on capital expense and ongoing running costs.

With the launch of KOB comes a new consumable, KELTRACK® AP EX all-season sprayable TOR modifier. KELTRACK® AP EX is formulated with premium raw materials to increase film durability and optimize spray quality for an operating temperature range of -4°F to 104°F (-20°C to +40°C) without the need to heat the product.

The KELTRACK® AP EX formulation leverages the latest technology in environ mentally friendly and health-conscious raw materials. Field testing has shown traction and braking are uncompro mised, while the same trackside benefits of KELTRACK® (lateral force reduction, fuel saving, noise abatement, wear reduc tion, etc.) exist.

Shell & Whitmore Reliability Solu tions serves Class I, II, and III rail roads throughout North America. The combined strengths of Shell and

Whitmore offer the rail market multisector expertise, advanced equipment and services, and an integrated product port folio, including lubricants, friction modi fiers, and rail equipment.

The company’s comprehensive friction management provides year-round, supe rior top-of-rail friction modifiers. Shell Gadus (TOR Armor) is ideal for hot to moderate climates, and Shell Gadus (TOR Armor Arctic) works when temperatures dip below -10°F (-23°C) for extended periods. Both grades are fully compatible and can mix with trackside applicators without changes to the performance char acteristics other than the low-tempera ture usage. Shell Gadus (TOR Armor) and Shell Gadus (TOR Armor Arctic) provide optimum friction at the wheel-rail inter face, substantially reducing noise, wear, and lateral forces. High lateral forces lead to loosened tie plates and fasteners and can result in low rail rollover. These fric tion modifiers significantly reduce lateral creep, and when wheel creep occurs, it immediately increases positive friction,

reducing the creep condition and return ing the wheels to a healthy rolling motion. The result is a substantial reduction in vibrations, corrugations, and highfrequency squealing. When wheel creep is not occurring, the coefficient of friction drops during normal rolling resulting in less fuel consumption. With the success of reduced rolling friction and fuel consumption, fuel savings programs in tangent track are now being implemented with the company’s friction modifier by Class I railroads.

Pair these friction modifiers with Shell & Whitmore Reliability Solutions’ PolyTOR top-of-rail wiping bars for maximum friction control. These bars offer strong protection and resistance to impact. Whitmore PolyTOR bars are 36 inches long and designed explicitly for friction modifiers. They have proprietary and patented technology that allows the friction modifier to be placed into the contact patch of the wheel-rail interface, resulting in less splash to the field side and less product used.

In the vernacular of railroading, “safety” is arguably the most ubiq uitous yet crucial term. According to the Association of American Railroads (AAR), “U.S. freight railroads have lower employee injury rates than most other major industries. Between 2000 and 2021, the train accident rate was down 33%, and between 2000 and 2020, the hazmat accident rate was down 60%. The rail employee injury rate in 2020 was an all-time low” (a possibly skewed number because fewer trains were running, with fewer employees on duty, during the pandemic).

“Through a multifaceted strategy of continued investment, innovative part nerships, technology deployment, and operational improvement, railroads have continued to improve safety over the past decade,” AAR notes. “Rail roads’ annual investments are central to this safety mission, but the ability to more broadly deploy technology target ing the underlying causes of accidents is critical to ushering in the next era of safety gains. A tech-enabled workforce drives safety. Today’s highly skilled rail workforce uses technology—from new design specifications for railcars and track components to smart sensors to big data and drones—to monitor network and equipment health in real time. These technologies help guide maintenance planning, which has led to greater safety, accuracy, and produc tivity than ever before. Automated technologies will allow further prog ress in challenging areas like reduc ing human error and improving grade crossing safety.”

The railway supply community is central to this broad application of technology, developing—in coopera tion with customers—equipment and systems designed to drive accident and incident rates down continuously. Among numerous companies provid ing safety gear ranging from fall and roadway worker protection to portable physical barriers are David Clark Co.,

DMF, Focused Technology Solutions, HySafe, ILLUMAGEAR, Koppers, L.B. Foster, Miller Ingenuity, Orgo-Ther mit®, SafeRack LLC and Tech Prod ucts, Inc. Following are examples from suppliers that responded to RT&S’s inquiry on safety technology.

L.B.

“While running trains with empty cars may not be an uncommon occurrence in the rail industry, it can at times pose serious hazards,” L.B. Foster Company tells RT&S. “Empty railcars in the middle of a train may experience ‘floating’ (heavy tension), which decreases the bearing load the car exerts on the track and increases the risk of derailment, especially in curves. Bulk trains, or trains whose railcars are uniform in weight, are particularly suscep tible to empty railcar issues.”

threshold configuration for bulk train and empty-car detection that suit any user’s needs,” L.B. Foster says. “This system is part of our overall Total Track Monitoring solutions suite that helps customers improve safety, prevent disruption and protect reputation.”

With safety as “the number one prior ity for everyone working on the rail roads,” Orgo-Thermit®, a Goldschmidt company, offers the Tracksafe Barrier, a product the company says “[is] built to guarantee the safety of railroad track workers while working utilizing a physi cal barrier.”

The Tracksafe Barrier attaches to the rail using a magnet, “allowing speedy installation and removal,” the company explains. “Unlike other barrier systems, there is no need to work with the ballast for installation. So no digging the ballast during installation or tamping following removal is required. Further more, the ease of attachment and removal can allow it to be moved from one site to another quickly and effi ciently. The system comes with custom ized cradles for efficient transportation and storage.”

L.B. Foster recently partnered with a Class I railroad in a joint effort to identify empty railcars and reduce the hazards that may present. Utilizing L.B. Foster’s Wheel Impact Load Detector (WILD) and Wheel Data Management System (WDMS), passing trains are automatically analyzed to determine if they are bulk trains. If they are, the railroad inspects the entire consist for empty cars, and upon finding one, a report automatically generates and is routed to designated railroad person nel. The report identifies the train and the empty car’s position in the consist, “allowing railroad operators to take appropriate corrective action to reduce hazardous conditions,” the company notes.

Empty-car monitoring “allows

Orgo-Thermit® says that since its introduction to the North Ameri can market, “an increasing number of customers have chosen this method over other ways to protect their workers, with some requiring Tracksafe Barrier for working on their properties, as it complies with FRA adjacent-track protection requirements. It increases safety at the job site and enhances productivity and efficiency. With a fixed inter-track barrier erected, rail road workers can continue their duties when trains are operating on adjacent tracks. Moving to a predetermined place of safety is no longer necessary. This allows for continuous construction and a reduction in brief work stoppages.”

Tracksafe Barrier is available for ener gized third-rail on an electrified transit system and standard applications. “The design of this version is to protect railway workers from the hazards of working on tracks with energized third rails,” the company notes. “Its unique design does not interfere with signaling or shunt, so it does not affect any other railroad operation.”

“

AUTOMATED TECHNOLOGIES WILL ALLOW FURTHER PROGRESS IN CHALLENGING AREAS LIKE REDUCING HUMAN ERROR AND IMPROVING GRADE CROSSING SAFETY.

Safe railroading is good business for suppliers and railroads alike.

events will occur in the future and your feedback is appreciated.

TRENT M. HUDAK AREMA President 2022-23As 2022 comes to a close, life gets busy with year-end tasks, completing construction projects, making winter preparations, and, of course, celebrating holiday events. I hope that you can fully enjoy all that is most impor tant to you this holiday season.

As I reflect on the past year, I think about all the changes AREMA has made, as well as all the efforts under way to keep AREMA relevant and growing in value. “In any moment of decision, the best thing you can do is the right thing, the next best thing is the wrong thing, and the worst thing you can do is nothing.” - Theodore Roosevelt (www.theodorerooseveltcenter.org) I think this is very applicable to AREMA as we continuously work to keep the associa tion relevant and try new things. AREMA has been very focused on meeting the pres ent-day needs of our membership and the railway industry. Some changes we have made have been more effective than others, but we will continue to try new things and improve AREMA as our industry continues to evolve.

Some of the enhancements and changes in recent years include:

1. Mo dernizing the Annual Confer ence. This is an ongoing process as we respond to our members’ evolving needs. Some old traditions have been retired and others have been added. One example is providing the presen tations On Demand after the Confer ence. We relied on the Mobile App allowing us to go totally paperless in 2022. More changes with in-person

2. Of fering Symposiums. In recent years, we have held two Symposiums – the Railway Roadbed & Ballast Symposium in 2020 and the Communications & Signals Symposium in 2022. A second Railway Roadbed & Ballast Symposium is scheduled for February 6-8, 2023 in Kansas City, Mo., and a Sustainability and Resiliency Symposium is planned for 2024. The plan is to hold a sympo sium every year. This will provide an opportunity to dive deeper into tech nical areas that can’t be accomplished with Seminars, Webinars, or at the Annual Conference.

3. Ex panding Student Chapters. The first AREMA Student Chapter was created in 2006 and many have been established since. Reenergizing the chapters that have been impacted by the pandemic is an active effort as mentioned in my October message.

4. En hancing member recruitment and increasing student and young profes sional participation. This has been a goal for several years. Our efforts can be seen with some of the improvements at the Annual Conference. Committee 24 – Education & Training develops the Student Program and modifies it annu ally to provide students with a myriad of activities to introduce the railway industry. The Young Profession als’ event has been very popular with participation increasing every year.

5. Of fering Electronic Publications. For several years the electronic publica tion platform has been available and very successful. As this becomes the norm, hard copy versions will be avail able upon request only and printed On Demand. Due to the high demand for digital publications, 2022 will be the last year we will offer binders/slipcase sets for hardcopy versions of the Commu nications & Signals Manual and the Manual for Railway Engineering.

6. Providing On Demand learning. AREMA successfully launched our Learning Management System, which allows On Demand learning, not only from content retrieved from the Annual Conference, but other educa tional opportunities, such as Webinars

and Symposiums. The library of topics continues to grow and PDH hours can be earned.

7. Es tablishing a Member Forum. One last area that I would like to highlight was the launch of AREMA’s Member Forum and the various online Communities for Committees and the Annual Conference.

The initiatives we have in progress include:

1. En suring the manuals are in good health. This project was initiated several years ago and focuses on measuring the frequency of updates, removal of out-of-date material, and adding new material.

2. Updating the AREMA Strategic Plan. This includes a review of the AREMA Bylaws, Regulations Governing AREMA Committees and the individ ual Committee Bylaws.

3. Re freshing the AREMA website in 2023. Headquarters is excited to intro duce an eye-catching and user-friendly site to accommodate member needs.

4. Re viewing AREMA membership demographics. This effort will help staff align value and support to ensure AREMA remains inclusive to all.

As you can see, AREMA has made many changes and improvements in recent years. We have much in progress that will keep us relevant and increase our value in the coming years. Our hope is that all these items will ensure AREMA keeps pace with the industry and generational changes in the railway engineering workforce. This cannot be done without all the volunteers that make recommendations and help implement these initiatives. Progressing all these initiatives and running the dayto-day operations of the Association is a huge job for the AREMA staff and I thank them for keeping everything moving forward efficiently. If you have ideas on how AREMA can improve and provide more value to its membership, please reach out to me or the staff. Happy holidays to you and your family!

Enjoy your journey until next year.

TRENT M. HUDAK AREMA President

Register now for the AREMA Railway Roadbed & Ballast Symposium, February 6-8, in Kansas City, Mo. To check the latest information about hotel reservations, speakers, presentations, sponsorship, and more, visit www.arema.org.

Did you know we have a wide variety of On Demand education for learning on your time? Browse our most popular Webinars, Seminars, and Annual Conferences to earn your PDH credits on the go. Visit www.arema.org to start your On Demand learning today.

Don’t miss out on the conversation happening in AREMA’s Member Forum. The Member Forum connects you with other Members allowing you to send messages, start conversations, and more. See what everyone is talking about today: https://community.arema.org/home.

If you’re looking for a new podcast to binge, listen to AREMA’s Platform Chats. They feature guests from every aspect of the railway industry. Come “roll with AREMA” available on all of your favorite listening services.

Do you want to generate leads, promote your company and reach a target audience? Sign up for sponsorship at the AREMA 2023 Annual Conference to be held October 1-4 in Indianapolis, Ind. Please visit www. arema.org or contact lmcnicholas@ arema.org for more information on sponsorship investment opportunities.

Order the NEW, 2022 edition of the Portfolio of Trackwork Plans. This edition features new plans and specifications that relate to the design, details, materials and workmanship for switches, frogs,

turnouts & crossovers, crossings, rails and other special trackwork. Order online now at www.arema.org or contact publications@arema.org for more details.

NOT AN AREMA MEMBER? JOIN TODAY AT WWW.AREMA.ORG

CONNECT WITH AREMA ON SOCIAL MEDIA:

DEC. 5-6

Committee 6Rail Facilities, Utilities and Buildings Orlando, Fla.

JAN. 19

Committee 16Economics of Railway Engineering & Operations Virtual Meeting

FEB. 22-23

Committee 7Timber Structures Russellville, Ariz.

DEC. 8

Committee 16Economics of Railway Engineering & Operations Virtual Meeting

JAN. 19-20 Committee 8Concrete Structures & Foundations Orlando, Fla.

MAY 16-17

Committee 15Steel Structures Pueblo, Colo.

JAN. 31-FEB. 1 Committee 15Steel Structures Atlanta, Ga.

FEB. 22-23 Committee 9Seismic Design for Railway Structures Las Vegas, Nev.

JUNE 15-16 Committee 8Concrete Structures & Foundations Washington, D.C.

Joining a technical committee is the starting point for involvement in the Association and an opportunity for lifelong growth in the industry. AREMA has 30 technical committees covering a broad spectrum of railway engineering specialties. Build your network of contacts, sharpen your leadership skills, learn from other members and maximize your membership investment. If you’re interested in joining a technical committee or sitting in on a meeting as a guest, please contact Alayne Bell at abell@arema.org.

For a complete list of all committee meetings, visit www.arema.org.

Access to important professional development content is just a few clicks away with AREMA Education.

Our On Demand content spans many disciplines of PDH accredited courses that allow you to get your PDHs by learning from experts online without leaving your office.

1.

Studies show that participants learn more while taking On Demand courses as you can skim through the material you understand and take more time in the more challenging areas.

2.

With AREMA On Demand courses, you don’t have to wait to learn and get your PDHs as they’re available instantly after purchase.

3.

Above all things, On Demand education is meant to take at your own pace and on your time. Study from anywhere in the world, whether from your office or the convenience of your sofa.

AREMA On Demand education offers a wide variety of topics for all studies of the railway engineering community.

BECOME A MEMBER AND SAVE Register today and start learning at www.arema.org

Not an AREMA member?

Join today and get discounts on all AREMA Educational Offerings.

of students, they were passionate and eager to share the potential for career opportunities in the railroad industry. I always had an inter est in railroads when I was young, but never really considered the railroad industry as a career choice. I was intrigued, so I decided to join the chapter as a student member and learn more about the industry and AREMA.

Over the years, the AREMA Educational Foundation, through the generosity of its donors, has provided hundreds of thousands of dollars in scholarships funds to students interested in a career in railway engineering. Over the next few months, we’ll be checking in with a few of these recipients to see how these have funds have helped them and where they are in their careers now. This month we’re checking in with Aaron Dean.

AREMA: Aaron, you started your rail career as an AREMA Student Chapter Member at Michigan Technological University (Michi gan Tech), how did this participation guide you to your career goals?

DEAN: When I first began my education, I knew I wanted to be a mechanical engineer, but I didn’t know what I wanted to do in my professional career. As an aspiring engi neer with a mechanical focus, you have all of these “flashy” choices or specializations, such as working in the aerospace or automotive industries, for example. I considered many alternate paths at first, but I really wanted something “different.”

I came across the Michigan Tech AREMA Student Chapter, or as it is known on campus, the Railroad Engineering & Activities Club (REAC), during the annual Michigan Tech student organization fair. An energetic group

Through my early involvement with the AREMA Student Chapter at Michigan Tech, I had the opportunity to attend various railfocused speaker events and participate in field trips to many rail industry sites. I also began to volunteer more within the chapter, and during my third year in college I was nominated to be the president of the chapter. During my tenure, I was honored to have received the Michigan Tech Alumni Scholar ship from AREMA. Through my new connec tions within the student chapter, I was also able to hold various internships and co-ops within the rail industry, such as Undergradu ate Research Assistant for the Michigan Tech Rail Transportation Program, Mechanical Intern for CN Railroad, and Design Engineer Intern for my current employer, Pettibone/ Traverse Lift, LLC.

AREMA: You mentioned you were the recipi ent of the Michigan Tech Alumni Scholarship (2017). How did this impact you while you were at Michigan Tech?

DEAN: Being awarded this scholarship had an immense impact on my development as a student and now young professional in the railroad industry. Often, students are faced with the harsh reality of trying to figure out how to fund their education. As one of those students, receiving this scholarship was a significant relief, as it allowed me to focus on my education, rather than how to pay for it. Being awarded the scholarship also provided a slight sense of validation; that I was on a good path towards my career.

AREMA: What is the biggest accomplishment during your career at Pettibone/ Traverse Lift, LLC?

DEAN: I would say my biggest accomplish ment over the course of my career is the

many incredible relationships I have devel oped along the way. I quickly discovered that the railroad industry is a small, tight-knit community - founded on great working rela tionships. Over the years, I have made many great connections in the industry and have found mentorship in colleagues who I would have never considered.

As a professional in the Maintenance-ofWay (MOW) supplier space, I always tell people that I have the unique opportunity to work for not just one single railroad, but all of them, including the major rail construc tion contractors and equipment lessors. When I first began my career at Pettibone, I took it upon myself to make sure that I was getting out into the field, connecting with the rail and section gangs, and meeting with the operators and mechanics who use our equipment daily. I have also established regular meetings with most of the Class 1 work equipment supervisors to gather useful feedback from the field, so I can work with our team at Pettibone to ensure our products are the most efficient, reliable, and safest examples of work equipment in the railroad MOW industry.

AREMA: Outside of your career, what do you do with your spare time?

DEAN: Not surprisingly, my rail industry involvement does not stop outside the office. I continue to be involved with AREMA, Committee 24 – Education & Training, and Committee 27 – Maintenance-of-Way Work Equipment. I currently serve on Committee 24 as the AREMA Student Chapters Coordi nator. My responsibility in this role is to be a liaison between the AREMA Student Chap ters, Committee 24, and AREMA Staff. We hold quarterly coordination calls with the Student Chapter leadership, to check in on their chapter activities throughout the year and address any operational challenges they might be faced with.

Additionally, I remain connected with my alma mater, Michigan Tech, where I recently joined the Civil, Environmental, a Geospa tial Engineering (CEGE) Department as a part-time instructor, teaching a multi-disci plinary Railroad Engineering course to both undergraduate and graduate students. I also currently sit on the Rail Transportation Advi sory Board (RTAB) for the Michigan Tech Rail Transportation Program (RTP). RTAB’s mission is to provide guidance to improve student recruitment to the rail industry professions, garner consistent and active participation from the industry in projects/ research opportunities and increase the

visibility of the RTP as a leading rail-focused university, capable of providing both students and research as future assets to the industry.

Anyone who has traveled to Michigan’s beautiful Upper Peninsula knows that it is indeed an outdoor paradise. As a resident of Upper Michigan, any extra time that I have left I spend most of it outdoors with my family. An avid outdoorsman and conser vationist, I thoroughly enjoy the superior hunting & fishing opportunities that the U.P. of Michigan has to offer. I happen to have the world’s largest freshwater lake (by surface area) right in my backyard, so it’s safe to say that I spend a majority of my spare time fishing (or trying to). Especially ice fishing in the winter when the mighty Lake Superior freezes over.

AREMA: If you could tell your younger self one thing, what would it be?

DEAN: If I could go back in time and give my younger self any useful advice, I would say to learn more about business operations or take more business classes. That is one thing that I struggled with a lot when I first embarked on my professional career - understanding the ins and outs of how a company operates in general. You can a learn a lot on the job (which I sure did and still do) but having the additional knowledge of business operations or business finance before leaving college would have been a tremendous benefit.

AREMA: What advice would you give to a student contemplating a career in the rail industry?

DEAN: I don’t feel that I am qualified to give such advice, as I am still early in my career and am learning new things every day! But if asked, I would say just say: Don’t stop learning and growing. As you enter the industry, you may have a nice, shiny fouryear degree (or five-year, if you’re like me), but that does not mean you immediately have a grasp on everything there is to know about this great industry. There is a wealth of knowledge in the industry, many things that can’t be taught from a textbook. Be humble. Ask questions. Learn. Also, don’t be afraid to mess up; capitalize on your mistakes and learn from them.

A last bit of advice; find something you’re good at and passionate about. Don’t make work, work. As for myself, working in the railroad industry is my passion. There are ups and downs, but for the most part, I enjoy coming into work every day. The task at hand is challenging but rewarding, and I couldn’t imagine doing anything else.

Notice to all members of AREMA The 2022-2023 Nominating Committee, under the Chairmanship of Immediate Past President Michael P. Freeman, hereby solicits suggestions and recommendations of candidates to serve on the AREMA Functional Group Board of Directors in the following positions:

All must be members of AREMA in good standing

• One (1) Senior Vice President – one-year term Must be a current or past member of the AREMA Board of Directors, and must be employed by a railway or transit company.

• Two (2) Functional Group Vice Presidents – threeyear terms (Maintenanceof-Way, Structures) Must be current or past member of the AREMA Board of Directors.

• Four (4) Functional Groups will have a vacancy to be filled in the Functional Group Director positions – three-year terms (Communications, Signals & Information Technology, Engineering Services, Passenger & Transit, Track)

Nominating recommendation should be submitted via mailed letter or email and should include all documentation to substantiate the recommendation. This must be signed by the member making the recommendation.

Deadline for Receipt of Recommendations is January 31, 2023.

The Nominating Committee will consider all recommendations. Submission of a recommendation should not be construed as affir mative Committee action on that recommendation.

AREMA Marketing Department

Danella Rental Systems

Hougen Manufacturing, Inc.

L B Foster Company

Loram

Nordco

Railway Educational Bureau

RELAM

Western Cukken-Hayes

WVCO Railroad Solutions

PHONE #

301-459-3200 561-743-7373 866-245-3745 412-928-3506 763-478-6014 414-766-2180 402-346-4300 770-335-9273 773-254-9600 541-484-9621

marketing@arema.org SBolte@danelle.com info@trak-star.com glippard@lbfoster.com sales@loram.com tiny.cumbridge@wabtec.com bbrundige@sb-reb.com jroberts@relaminc.com jm@wch.com wvcorailroadsolutions@wilvaco.com

JONATHAN CHALON

Publisher (212) 620-7224

jchalon@sbpub.com AL, KY, TN, CHINA JONATHAN CHALON (212) 620-7224

jchalon@sbpub.com

CT, DE, DC, FL, GA, ME,MD, MA, NH, NJ, NY, NC, OH, PA,RI, SC, VT, VA, WV, CANADA: QUEBEC AND EAST, ONTARIO JEROME MARULLO (212) 620-7260 jmarullo@sbpub.com

AMERICAS, EUROPE, ASIA, AFRICA, AUS TRAL ASIA NORTH AMERICA - CT, DE, DC, FL, GA, ME, MD, MA, NH, NJ, NY, NC, OH, PA, RI, SC, VT, VA, WV, AND EASTERN CANADA. EUROPE EXCEPT GERMANY, AUSTRIA, GER MAN SPEAKING SWITZERLAND, EASTERN EUROPE, ITALY, AND ITALIAN-SPEAKING SWITZERLAND. ASIA EXCEPT JAPAN AND CHINA.

ITALY, ITALIAN-SPEAKING SWITZERLAND

DR. FABIO POTESTA

Media Point & Communications SRL Corte Lambruschini

AR, AK, AZ, CA, CO, IA, ID, IL, IN, KS, LA, MI, MN, MO, MS, MT, NE, NM, ND, NV, OK, OR, SD, TX, UT, WA, WI, WY, CANADA: ALBERTA, BRITISH COLUMBIA, MANI TOBA, SASKATCHEWAN HEATHER DISABATO(CHICAGO OFFICE) (312) 683-5026 hdisabato@sbpub.com

JEROME MARULLO (212) 620-7260 jmarullo@sbpub.com

GERMANY, AUSTRIA, GERMAN-SPEAKING SWITZERLAND, LATVIA, LITHUANIA, ESTO NIA, POLAND, CZECH REPUBLIC, SLOVAKIA, HUNGARY, SLOVENIA, CROATIA AND SERBIA Simone and Simon Fahr Breitenbergstr. 17 Füssen 87629 Germany Tel: +49 8362 5074996 sfahr@railjournal.com

Corso Buenos Aires 8 V Piano, Genoa, Italy 16129 +39-10-570-4948 Fax: +39-10-553-0088 info@mediapointsrl.it

JAPAN KATSUHIRO ISHII

Ace Media Service, Inc. 12-6 4-Chome, Nishiiko, Adachi-Ku Tokyo 121-0824

Japan +81-3-5691-3335 Fax: +81-3-5691-3336 amkatsu@dream.com

IRJ PRO AND CLASSIFIED ADVER TISING SALES

JEROME MARULLO (212) 620-7260 jmarullo@sbpub.com

This section has been created solely for the convenience of our readers to facilitate immediate contact with the RAILWAY TRACK & STRUCTURES advertisers in this issue.

The Advertisers Index is an editorial feature maintained for the convenience of readers. It is not part of the advertiser contract and RTS assumes no responsibility for the correctness.

Business travel can be fun, or it can be miserable. And take it from me, after 12 straight years of trav eling for consulting work every week (fly out Monday morning, fly home Thursday, and back out again on Monday morning), business travel can be stress ful, especially if one must visit more than one location during the week. Things are much easier if you have smooth trips to and from, decent food, and a proper place to stay. Remember, too, that after enduring all the travel logistics, you must still focus on job expectations at a client or work site. That’s what the client cares about, and they rarely, if ever, think about your travel expe riences. Fortunately, except for one or two occasions, I never had to put up with substandard accommodations.

The New York Times published a story in late October written by Peter S. Goodman that focused on the pending rail strike and discussed conditions on the road for rail road track gangs which are often horrible. Goodman wrote, “The men were part of a traveling maintenance gang, a largely unseen force that plays a crucial role in keeping rail freight rolling. They had driven from 5 to 13 hours to [reach the work site in Texas], from homes as far away as Louisi ana, Mississippi, and Oklahoma.”

Goodman wrote, “They were accustomed to the gnawing regrets of life on the road, regularly missing wedding anniversaries, children’s birthday parties, and even the deaths of parents.” To this point, Goodman discussed aspects of railroad maintenance gang life on the road, which workers learn about when they hire on. It’s a difficult life, but the pay and benefits are pretty good, and most workers are hard-working, teamoriented individuals. However, the next part of Goodman’s article was surprising even to me – “[The workers] were used to cram ming in hotel rooms infested with bedbugs and rodents, working through bone-cold blizzards and punishing summer heat.”

This article discussed the sick leave debate between the unions and the railroads, but that’s not the point of my editorial. Nor is the challenge of working through “bonecold blizzards and punishing summer heat.” Those things impact most railroaders

in the field – that’s “just” part of working for the railroad or any profession that requires field work year-round. The part that infu riated me was Goodman’s statement about “cramming into hotel rooms infested with bedbugs and rodents.” Bedbugs and rodents? Really? I’m sorry, but that’s beyond the pale. No one should have to endure those conditions.

After reading this article, I turned to some friends working in the field in various jobs on Class I railroads, who corroborated this story. While this doesn’t occur at every hotel, having it happen at all is unaccept able. I know that railroads, like all compa nies, must keep costs down. However, it seems possible for carriers to negotiate rates

or cooperative hotel. And, if that’s too far away, it seems reasonable to ask the carriers to refurbish some rail cars to provide clean overnight places. If decent food isn’t nearby, install a small kitchen to enable the crews to be adequately fed.

This magazine provides news and insight into the latest maintenance-of-way methods and equipment. Many do not require track gangs in the field. Many do. We frequently write about, and the industry stresses, how well-maintained physical plants are criti cal to keeping trains running smoothly and on time. Those responsible for performing this challenging work and any human being deserve to comfortably rest after a hard day on the line without worrying about bug infestations or greeting rodents if they get up at night to go to the bathroom.

Traditionally, railroad leaders have come up through the ranks and likely spent at least some time working in the field as part of training or a first assignment. So, they must be aware that these problematic conditions exist. Do they think that “well, I had to endure some rough conditions, so today’s field personnel should be able to, as well?” I hope that’s not the case.

with decent hotel chains where guests will have clean rooms free of insects and crit ters. With the number of guests these hotels would see from the railroad, I expect them to offer very reasonable rates.

What if a relatively inexpensive but decent hotel is not in the area where rail work is taking place, and only fleabag hotels are available? Then the railroads should tell these establishments to clean up their acts, offer clean rooms, and be subject to regular inspection by rail supervisors to ensure continuous cleanliness. After all, depending on the length of the projects, these establishments are likely getting more revenue from the railroad than from any other customer.

If the sub-standard hotels don’t coop erate, the next option would be to bus workers to the nearest town with a good

Regardless of how many years of service a field railroader has, they should expect good conditions in hotels on the road. However, whether it’s appropriate or not, we see those who are younger and now entering the workforce reflecting a cultural change regarding work/life balance and willingness to tolerate onerous conditions in the work place. There are no signs that this cultural change will reverse and it’s likely to become more pronounced in the next several years.

As we all know, railroading is a tough job. Although worker shortages have gotten a little better, they are still an issue with most carriers, both freight and passenger. Railroaders in the field sign up for a differ ent type of work than those who work in an office or at headquarters. However, those at headquarters having access to specialized cafes and fitness classes is not right when you have workers in the field dealing with bedbugs and rodents. And I imagine today’s railroad executive does not stay in hotels where they expect non-human roommates.

“

BEDBUGS AND RODENTS? REALLY? I’M SORRY, BUT THAT’S BEYOND THE PALE. NO ONE SHOULD HAVE TO ENDURE THOSE CONDITIONS.