With Loram’s Rail Pro ® Infinity, Loram’s best-in-class production rail grinders are now even more efficient and productive. Infinity allows for infinite grind patterns to achieve any transverse rail profile. New for 2023, Loram offers improved wear life and economic modeling to help our customers measure and visualize the impacts of their rail grinding programs. Learn more at Loram.com

Vol. 119, No. 2

Print ISSN # 0033-9016, Digital ISSN # 2160-2514

EDITORIAL OFFICES

1025 Rose Creek Drive Suite 620-121 Woodstock, GA 30189 Telephone (470) 865-0933

Website www.rtands.com

DAVID C. LESTER

Editor-in-Chief dlester@sbpub.com

KYRA SENESE Managing Editor ksenese@sbpub.com

CORPORATE OFFICES

1809 Capitol Avenue Omaha, NE 68102 Telephone (212) 620-7200

Fax (212) 633-1165

ARTHUR J. MCGINNIS, JR. President and Chairman

JONATHAN CHALON Publisher

MARY CONYERS

Production Director

NICOLE D’ANTONA Art Director

HILLARY COLEMAN

Graphic Designer

JO ANN BINZ Circulation Director

MICHELLE ZOLKOS Conference Director

CUSTOMER SERVICE: 402-346-4740

Reprints: PARS International Corp.

253 West 35th Street 7th Floor

New York, NY 10001

212-221-9595; fax 212-221-9195

curt.ciesinski@parsintl.com

Project stories are among the best tools for learning about rail maintenance-of-way and keeping infrastructure in top shape. This magazine has covered projects of all kinds for many years, but we’re going to focus on them even more. At the recent annual convention of the National Railroad Construction and Maintenance Association (NRC) in Boca Raton, Fla., I talked to several companies who would like to share their stories with a broader audience. I also spoke to people who said they enjoy reading about rail and rail-related construction and learning things they may be able to apply at their own companies.

We aim to have longer-form stories to give readers a detailed look at how a project was done, from conception to execution. A good story, in my view, should be built around the project plan. What is the goal and scope? What are the major milestones? What resources are involved? What are the timeline and budget?

Since some companies may not want to share this information, we would not have to identify the project client if a third party does it. Moreover, we’d

like to feature projects from small firms to Class I railroads. Again, we realize that some projects could be proprietary, but we can offer flexibility in covering those involved.

While maintenance-of-way and infrastructure efforts would likely be the key focus, we’d like to cover information technology projects, PTC, and other signal/communication activities. These types of projects are just as critical to the operation of the railroad as any others, and since RT&S added Communication & Signals to its lineup, these would be a perfect fit. We’ve also added stations to our coverage, so stories related to those are welcome.

I’ll contact many companies to ask about interest in presenting a project story in the coming months. I aim to have several feature-length stories each year. And one important note: this editorial focus will not have any bearing on our top projects feature in the June issue. Top Project entries will be separate from and unrelated to any long-form stories at other times of the year. Now, that’s not to say that submitting a long-form project story disqualifies that project from entering the Top Project competition. And obviously, since we will run a limited number of these stories each year, having worked with us on a long-form story is not a requirement, nor does it provide an advantage for selection as a Top Project.

Please call or write me if you’d like to work with us on a project story, regardless of the size of your firm.

DAVID C. LESTER Editor-in-ChiefMxV Rail (formerly TTCI) has developed an alternative method of projecting the degradation of track geometry and track components using foot-by-foot track inspection data. By using the 95th percentile of a track segment instead of a median or maximum, this method may be better-suited to identify when larger-scale track maintenance is required. e median value of a track segment o entimes does not represent problematic locations (e.g., if only 20 percent of locations are degrading) while the maximum number of degradation locations is o en addressed with spot maintenance. e 95th percentile (or some percentile between 75 and 99 depending on the situation) balances the two typical approaches and may better identify locations requiring production work. An example of the application of this method may be the prioritization of production tamping or determining when 10 percent of track components are nearing a maintenance threshold.

On North American railroads, regular track inspection is required to ensure both track geometry and component conditions meet railroad and regulatory standards. Technological innovations over the past few decades have allowed railroads to consolidate di erent types of track inspections into a single inspection vehicle with regular inspection intervals. Track-based inspection data generally provides the current track condition and typically identi es locations that exceed railroad and regulatory thresholds so they can be maintained. However, with frequent inspections and improved data analytics, railroads will have the ability to calculate degradation trends and project future track conditions, thereby creating the possibility for systematic proactive maintenance planning and the prioritization of track regions at risk of exceeding railroad internal and regulatory thresholds in the near future.

Several methods can be used to calculate track degradation trends, and each method emphasizes certain aspects of track health. For example, a median (50th percentile) may indicate average track roughness but may not be able to identify locations that surpass internal track geometry maintenance limits. Alternatively, track geometry exceptions may indicate a few locations that require frequent maintenance but may not be representative of the majority of track. Appropriate balancing between general track roughness (majority of track) and the

number of track geometry exceptions makes ballast maintenance planning challenging because, among other reasons, while there is a correlation between the roughness of the majority of the track and the number of high-degradation locations, the relationship is not always predictable.

Track degradation is typically calculated using trending analyses that use various statistical methods to “ t” historical data and project future degradation. (1) e track degradation method is well-suited for identifying locations that will require spot maintenance in the near future if problematic regions are isolated in the analysis and calculating the maximum. However, largerscale track maintenance typically involves larger track sections where the majority of track in that section (i.e., median) is performing well with multiple problematic locations within that section. Representing the degradation in these situations presents two challenges.

e rst challenge is to determine the length of track needed to represent as a single data point. Existing track geometry degradation analysis methods include footby-foot, 250-foot windows, and aggregated speci ed track distances (100 feet to 1 mile or even larger). Aggregating into 0.1- to 1-mile segments is a common practice because it balances the need for high-enough resolution data with identifying localized high-degradation regions while keeping

data quantities at a manageable level. High resolution methods are becoming more common with more powerful computing abilities, but a higher resolution requires a more accurate data location alignment and a better means of storing, analyzing, and making decisions with large amounts of data.

e second challenge is to select an appropriate metric to represent the desired parameter (e.g., surface pro le of the aggregated section). is metric may range from simple statistical values (e.g., maximum or median) to proprietary Track Quality Indices (TQIs).

e metric selection also presents a tradeo regarding whether to emphasize a representation of the entire track segment (percentile) or focus on the degraded locations (maximum surface pro le).

e “distributional analysis” method uses percentiles (e.g., 95th percentile) of larger track segments (e.g., mainline turnout to mainline turnout or single curve) to calculate degradation. is method is therefore less dependent on data alignment, and the analyzed segment, typically, has similar track structure, loading conditions, and production maintenance histories, allowing this method to reduce the in uence of the above factors. Percentiles can be a bit more di cult to calculate than the median or maximum in some so ware products, but there are available codes for these calculations.

e statistical distribution can be visualized by plotting the desired parameter (e.g., the absolute value of foot-by-foot, 62-foot surface pro le data) as an inverse cumulative distribution function. e y-axis is in logarithmic form ( ipped to match percentiles) because the statistical distribution of the track geometry/components tends to be exponential.

is visualization is an important rst step in exploring how the data is distributed and selecting appropriate percentiles. Figure 1 visualizes the distribution of (a) multiple track geometry runs and (b) a more generic track index.

These plots show the 50th percentile (median), the 75th percentile, and the 90th percentile with the plot separated between a majority of track (up to and including the 99th percentile) and the outliers (>99th percentile). The use of “outlier” is meant as “extreme” in a colloquial sense, not in the statistical sense of a data point that should be removed from a dataset. The left plot shows that the surface profile appears generally linear in this representation (“exponentially distributed”), and

the range in values increases significantly with increasing percentiles. The right plot shows a different trend where the distribution is more non-linear in this representation but is linear if the y-axis is in a linear scale.

e second step is to take the calculated percentile value over multiple runs, plot the degradation, and project future behavior. Two track segments (A, B) are presented as examples in this article. Both segments

Railgrindingsavesmillionsofdollarseveryyear!TheArt andScienceofRailGrindingisthefirstbookdedicated exclusivelytothesubject.

RailwayGeotechnics coverstrack,tracksubstructure,load environment,materials,mechanics,design,construction, measurements,andmanagement.Itiswrittenprimarilyfor professionalsandgraduatestudents.

are from the same subdivision of a western railroad. During the analysis time period, multiple track inspections and at least one surfacing event were conducted on each segment. Two considerations for this analysis are discussed.

e rst consideration is the percentile used to represent degradation. In the rst example, Segment A is used because it has low degradation and high inspection frequencies (due to being recently undercut and a single mainline track). Figure 2 shows the distribution and degradation trends for this segment. More speci cally, Figure 2a shows the overall distributional analysis and the general rightward movement with increasing accumulated tonnage measured in units of million gross tons (MGT) (green is low accumulated MGT a er surfacing; red is high accumulated MGT). A careful look shows this consistently rightward trend changes at about 99.5% with the red lines moving to the le of the orange lines, which suggests spot maintenance between those time intervals.

YourGuidetoRailwaySignals isanexcellentguidefor trainingsignalpersonnelespeciallyrailwaycross-function managers,supervisors,andsupportpersonnel.High-quality graphicsanddiagramshavebeenusedthroughout. Complieswithallstandardsandcommonlyusedpractices.

Themostcomprehensivecollectionofdefinitionsrelatingto track.Over1500termsfromantiquatedforgottenslangto today'sjargon.Clearlyillustratedlineartenhancesthetext.

Reprintedbypopulardemand,thisbookisavaluablereference forroadmasters,tracksupervisors,trackforeman,surveyors andothersinvolvedintheplanningandexecution oftrackmaintenanceandconstructionwork.

Fold-outdiagrams.Softcover.301pages.

Thefiftheditionof TheRailroad:WhatItIs,WhatitDoes is evenmorevaluablethanbefore.Insideyou’llfinda comprehensivelookathowtoday’srailroadsfunction—from equipmenttoproceduresandmarketingtomaintenance.

WhatitisWhatitdoes $46.95

Figure 2b indicates the 95th percentile degradation is generally linear with an obvious reset from the scheduled surfacing. is consistent increase in degradation matches the general rightward trend in Figure 2a (only rst surfacing cycle is shown). Figure 2c displays the 99.9th percentile where the initial trend is similar, but the value levels o around 50 MGT and uctuates in a small range until the reset from the scheduled surfacing. is small uctuation characteristic likely represents unscheduled spot maintenance, and, since the magnitude of the surface pro le is relatively low, it may be a non-track-geometry issue such as a rail break or a tie replacement. ese results show how spot maintenance is more common late in a surfacing cycle to maintain the degraded locations before scheduled maintenance resets the entire segment.

e appropriate percentile will vary by situation (analysis goal, output, output distribution). For this situation (Segment A, Surfacing Cycle 1), the 95th percentile would be recommended because spot maintenance was only performed in about 0.5 percent of

track. In other situations, the appropriate percentile may be much lower (75 to 95th percentile) and the data should be explored in manner presented in Figure 2a.

A second consideration for trending analyses is the inspection frequency required to capture an accurate trending t. is consideration is important because highdegradation locations require a higher inspection frequency to capture a trend due to high rates of degradation and unscheduled spot maintenance. Knowing the degradation rate will help forwardly project degradation and identify appropriate inspection intervals. e appropriate inspection interval will depend on multiple factors. However, since degradation occurs at di erent rates in di erent track segments, there is potential in optimizing track-based inspections in complicated networks and double mainline territories if the inspection frequency of these various segments can be reliably calculated.

Figure 3 shows the 95th percentile of Segment B. Segment B is a good example

of how a gap in inspection intervals can produce multiple interpretations of degradation trends. is phenomenon is known as “aliasing.” e 95th percentile can be interpreted with a non-linear stabilizing trend or an unknown production surfacing event. ese two situations are shown by the blue and red lines.

Final Remarks

Finding simple representations of track conditions is a di cult task because the conditions of track components are sometimes distributed in very non-linear manners. Appropriate representation in one situation may not be appropriate in another. Visualizing the distribution and then selecting an appropriate percentile to calculate the degradation may be a bene cial task in certain situations, such as planning largescale track maintenance.

References

1. Wilk, S. Y. Paudel, R. Alishio, and D. Li. 2022. “Distributional Analysis of Track Geometry.” Technology Digest TD22015. AAR/MxV Rail, Pueblo, CO.

OVER THE PAST COUPLE OF YEARS , ESG (Environmental, Social Governance, and Corporate Governance) has taken the business community by storm. Many organizations, including railroads, have stopped issuing Sustainability Reports, but have gone to full-fledged ESG Reports. Many believe the jury is still out as to whether these reports are worthwhile.

For example, the Harvard Business Review reported in 2022 that companies should want to achieve the goals of ESG

“of their own accord,” and that ESG funds generally do not perform well financially.

The HBR article went on to state that a study by Columbia University and the London School of Economics showed that companies invested in ESG funds had a “worse compliance record for both labor and environmental rules” than those invested in ESG funds.

Finally, Vanguard Funds recently pulled out of its ESG investing initiatives and exited the Net Zero Asset Managers

Initiative. While not everyone in the investment community is on board with moving away from ESG, some speculate that Vanguard’s departure could encourage other firms to do so.

While environmental stewardship, treating employees fairly and appropriately, and good corporate governance should be the goal of all organizations, observers and investors should keep a keen eye on how the ESG initiative evolves.

THE WALL STREET JOURNAL recently reported that the transit industry faces a couple of long-term threats that policy makers should note. First, with more people working remotely, the demand for daily transit has dropped, particularly on Mondays and Fridays. Even though many work in the office a couple of days a week, the WSJ notes, ridership on most large systems has not reached pre-pandemic levels. For example, the New York subway system ridership is about two-thirds of what it was before the pandemic started, and BART boards one-third of the passengers it did pre-pandemic.

The WSJ also points out that lower ridership results in increased crime, and that transit agencies are likely going to have to re-think their funding models if

this trend continues. The pandemic, along with other factors, have resulted in a major shift of cultural attitudes toward work and the workplace, and the funding transit systems received in federal relief, about

THE HAMMERING of the railroad industry over the past four years is no secret to readers of this magazine. Service problems galore, shipper dissatisfaction, worker shortages, weakened demand followed by an unexpected traffic rebound, and a single-minded focus on short-term shareholder value – the list goes on.

The industry has a long way to go to fully recover from the dark clouds hanging overhead. However, we were encouraged by many of the remarks of Alan Shaw, President and CEO of Norfolk Southern at Norfolk Southern’s Investor Day in December.

First, he repeatedly used the phrase long-term shareholder value, which is something we haven’t heard in a while. To make this point clearer was his statement that “reducing OR [Operating Ratio] is no longer the singular focus” of NS. The strategy, Shaw said, is a balanced mindset that strives for good service, productivity, and growth. He pointed out that these things balance each other out and will be the vehicles through which the company can create long-term shareholder value.

It will be interesting if other railroads adopt similar policies. Hopefully, the days of senior rail executives walking around with the words “Shareholder Value” splashed on their foreheads are behind us.

While the language is encouraging, we hope to see NS and the industry walk the

$69 billion, according to the WSJ is being used to support operations and make up for budget shortfalls. And this money will run out at some point in the future, and could change the yellow signals to red.

walk. As mentioned earlier, we have a long way to go.

Most companies spend a lot of time on projects of various kinds. Infrastructure projects, though, can be particularly challenging because most take place outside; they o en change the appearance of the built environment and are usually dangerous. Proper planning and management, though, can mitigate the safety risks. Moreover, when the project is complete, the planners and those who built the infrastructure enjoy a unique level of satisfaction.

While there are hundreds of projects to read about and feature, we’ve chosen two for this issue that we thought were especially interesting. We begin with a story from Progress Rail, which completed a set of switches that, as the company says, “looks like a puzzle.” Second, who is building railroad stations these days? Well, Brightline, for one. We’ll look at the company’s recent completion of the Aventura and Boca Raton stations and Brightline’s showcase station at the Orlando International Airport, which will be the temporary termination point for the line extension north from West Palm Beach. e Orlando line will open later this year, and passengers can enjoy higherspeed rail travel from Orlando to Miami and several points between the two.

When a railroad puzzle switch at the Port of Beaumont in Texas was identi ed as aged and unreliable, impeding car operations, and a cargo safety hazard, Progress Rail was contracted by Trans-Global Solutions Inc. (TGS) to supply a switch with optimized eciency and reliability.

e Caterpillar company redesigned a new, custom puzzle switch – consisting of a double crossover containing two #6 turnouts and two double slips with a crossing diamond in the center.

Progress Rail’s trackwork team in Decoursey, Ky., manufactured and assembled the complex in an enclosed transit assembly building. A er all components were assembled, they t within a 165-foot by 39-foot space. e puzzle switch was labeled and color-coded at the end of each section to ensure accurate and e cient reassembling of panels on site a er their 1,000-mile journey by truck from Kentucky to Texas.

“ e tight spatial constraints, along with its complex design, made this an ideal project for the Progress Rail Trackwork team,” said Patrick Jansen, Senior Vice President for Progress Rail. “From a site visit to con rm the geometry through the completion and

submission of the detailed drawings, our Engineering team ensured our work would meet the highest quality standards. All components were manufactured and assembled at our Decoursey Trackwork facility before nal inspection and shipment to the Port. We are proud of our team’s successful execution of this complex project to meet our customer’s requirements and provide their operation with increased e ciency and reliability.”

Upon arrival at the Port of Beaumont in December 2021, TGS staged and stocked the disassembled puzzle switch at an unoccupied, secure property and parking lot. is put the switch components near the installation area and provided security before installation. In March 2022, TGS began managing the installation, including two new switches at the leads to the puzzle switch and civil preparations.

August 2022 marked the completion of the engineering, fabrication, and installation of the replacement puzzle switch, which today expands the Port of Beaumont’s ability to set four routes, increases the volume of car

movement in a compact space and ensures maximum cargo handling for the Port by rail.

“ e Port of Beaumont is incredibly proud of this project,” commented Brandon Bergeron, P.E., Director of Engineering for the Port of Beaumont. “Although it was on the ‘small’ side in terms of nances, it is huge in terms of the e ciency and function of the Port.”

Operationally, the new switch design improves the e ciency and operability of cargo movements, ensures reliable cargo movement of two unit trains can continue and saves the Port annual switch maintenance costs. From a safety standpoint, the puzzle replaces a deteriorating switch with lower structural integrity and bearing loads than recommended, decreases the possibility for common derailments, and increases the safety for rail cargo handlers, who can handle two unit trains simultaneously.

“We studied various options for modernizing the switches in that area, but a completely rebuilt puzzle switch was the only option that allowed us to function within the

tight spatial constraints and demands of Port business,” Mr. Bergeron added. “We would gladly score our satisfaction with the project with the highest marks.”

Launched in October 2020, the project was completed within budget, without any recordable injuries, and ahead of schedule in the Fall of 2022, meeting the fabrication and installation objectives the Port and its engineering design team set forth.

Organizations involved in the project include Trans-Global Solutions Inc., Progress Rail, a Caterpillar Company, Port of Beaumont Board of Commissioners, Lanier & Associates Engineering, Railroad Infrastructure and Terminal Development, Kansas City Southern, Burlington Northern Santa Fe, Union Paci c, Southeast Texas Regional Planning Committee and Louis Dreyfus Company.

It’s not too o en that you hear about the opening of new railroad passenger stations. However, Brightline has completed three within the past few months, and two are

already open. e station at Orlando will open when the railroad begins service on its Orlando line from West Palm Beach later this year.

Orlando

e Orlando station spans three stories, featuring a new design and a synthesis of luxury amenities that meet the demand of today’s traveler. e journey begins at the main entrance, located o the airport’s expansive two-story glass atrium. Once inside the station, passengers can purchase tickets from guest services or one of several self-service kiosks and check luggage before proceeding through the touchless turnstiles into the security screening area. Brightline is currently the only rail system in America that screens all passengers and bags before boarding.

Patrick Goddard, president at Brightline, said, “ is world-class train station continues our mission of transforming train travel in America. We have carefully thought through each detail of this station to ensure that it exceeds the modern traveler’s expectations.”

Passengers will access trains by escalator or elevators to the rst level platform and board from one of two new track platforms. ese platforms are 1,000 feet long and will accommodate a train with four coaches and two locomotives that will transport passengers on the Orlando to Miami route in just over three hours.

e 37,350 square foot station is in the

heart of the Orlando International Airport’s new 80,000 sq. . Terminal C and connects directly to the airport’s parking deck C, which will have more than 350 parking spaces reserved for Brightline passengers. In under ve minutes, an automated people mover connects the terminal to the rest of the airport facilities, including Terminals A and B.

Aventura

Brightline’s Aventura station opened for revenue service on December 21, 2022. is station has 34,000 sq. . and was designed to LEED (Leadership in Energy & Environmental Design) Silver criteria as part of Brightline’s e ort to reduce its carbon footprint. e LEED Silver station design features include a solar canopy, installation of electric charging stations, a selection of materials to increase healthy indoor spaces, and smart technology to reduce water use.

e Aventura station opens one hour before the rst train departure and closes ten minutes a er the last train arrival. e initial schedule for trains operating in and out of the station is designed to optimize commuter patterns and will focus on peak morning and evening weekday service. During non-peak hours and weekends, Brightline will provide service approximately every other hour. Regular hourly service will continue in West Palm Beach, Fort Lauderdale, and MiamiCentral.

Miami-Dade County invested $76

million in the Aventura station and created more than 400 jobs during construction. Now that the station is open, it is expected to generate signi cant economic bene ts. e station will bring $90.8 million annually in economic impact and $2.7 billion over 30 years.

e Boca Raton station and platform occupy 22,000 sq. . on a 1.8-acre site. e station also opened for revenue service on December 21, 2022. As with the Aventura station, the Boca Raton station will open one hour before the rst train departure and close ten minutes a er the last train arrival. is station will also focus on peak morning and evening weekday services, and during non-peak hours and weekends, Brightline will provide service approximately every other hour. Regular hourly service will continue in West Palm Beach, Fort Lauderdale, and MiamiCentral.

e funding for the Boca Raton station began in 2021 when Brightline was awarded a $16.3 million Consolidated Rail Infrastructure and Safety Improvement (CRISI) Grant from the FRA to fund a portion of the construction of the Brightline train station, parking garage, and associated rail infrastructure. In addition to the CRISI grant, the City committed $9.9 million toward funding the parking garage. e balance of funding, approximately $30 million, was contributed by Brightline.

While watching a rail grinder round a curve, particularly at night, it’s hard to imagine the scientific and precise process that goes into this work, with sparks lighting up the sky and surrounding area and smoke from the process filling the air. Yet the grinding vehicles, carrying different numbers of grinding stones, are performing such exacting work that if the grinding plan contains movements that will not result in the optimal grind, the rail will not perform as expected. And the main “performance” of rail is minimizing wear. A grinding plan is generally developed based on where the problem areas on the rail are, such as rolling contact fatigue, along with the wear pattern as trains roll along the tracks. For example, wear can be excessive in some areas while too little in others. The goal of grinding is to maintain the balance of wear to extend the life of the rail, as well as to remove small surface cracks and other anomalies that could cause a rail to crack and break in two, possibly causing a major derailment.

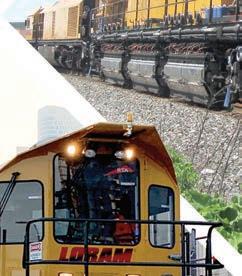

Software technology associated with rail grinding is becoming increasingly sophisticated. For example, Loram introduced Rail Pro® Infinity for production grinding. This software controls the position of grind stones used by Loram’s rail grinders, allowing for the precise removal of damaged or fatigued metal and shaping rails to desired profiles. Implementing the new software has improved conformity to desired rail profiles with less grinding effort, resulting in reduced energy and fuel consumption.

Loram also reports the company was recently recognized for these contributions to sustainability through recognition by the Norfolk Southern Thoroughbred Sustainability Partner Awards in January. Rail Pro Infinity enabled Loram to grind more miles for NS than ever before while achieving a 30% reduction in fuel consumption per finished mile. Moreover, in 2021, Loram customers using Rail Pro Infinity helped reduce over 225,000 gallons of fuel consumption, thereby reducing 2,530 tons of CO2 emissions.

Customers have also benefited from reduced rail head loss up to 15%.

Another way of maintaining track profiles is rail milling. While Europe uses milling, it’s a relative newcomer to the United States. The rail milling process is different from rail grinding. According to Interface , the Journal of Wheel/Rail Interaction, “rail milling is a non-abrasive cutting process where material is cut from the rail surface in the form of chips. A typical milling machine utilizes one to four cutting tools per rail, depending on the size of the machine. A subsequent polishing unit is used to create a smooth, high-quality surface. The removed chips are collected in the machine and can be recycled.”

Plasser American has recently introduced the rail milling machine Romill Urban 3 E3 (in collaboration with Robel) into the North American market. This globally first hybrid rail milling machine can operate for up to three hours on battery. The hybrid milling concept provides energy source flexibility – the batteries can be charged externally (if charging infrastructure is available) or can be quick-charged (<2h) through the integrated diesel generator (Tier 4 final) even while working.

The milling process is free of sparks and dust, and this Romill machine can operate completely emission-free. This is especially useful in closed environments like tunnels and stations. Operating

electrically also significantly reduces noise, and carriers can use the machine on transit and freight systems.

Considering the massive size of grinding operations, it’s impressive that handoperated machines can be used in certain situations. According to Robel, the operator’s experience is paramount when using these machines. The result should be a high-quality grind with the lowest possible material removal and a profile restored true to form.

Robel offers lightweight and compact 13.45 rail profile grinders with gas or electric motors that can be used for all common rail types and switches with tool-free spindle adjustment and quicklock cup wheel change. Battery operation is also available for emission-sensitive urban areas or tunnels.

Due to its hybrid electric drive solution, the modular 13.49 high-frequency grinder is easy to handle, has low hand/arm vibrations, and creates a top surface pattern while producing significantly less exhaust gas, heat, and noise.

The 13.63 modular grinder works builtup welds on switch blades, frogs, stock and check rails and removes burrs from rail heads on frogs and in switches. It just takes the base frame and one of the eight grinding modules, swapped without tools, to perfectly reprofile the rail.

Rolling contact fatigue can be difficult to spot. The arrival of Eddy Current, a relatively new technology that’s been in

testing for years, has made RCF easier to see, enabling grinding machines to grind just the right amount of rail to remove it.

Orgo-Thermit, a Goldshmidt company, uses a proprietary Eddy Current System and the Trackscan Mira with up to eight probes on each rail to provide a complete picture of the RCF in customer track optimize a grinding or milling program accordingly. The probes measure from the gauge corner, where most RCF originates, over the head of the rail to ensure a complete analysis.

This analysis enables the company to ensure that grinding focuses on the most affected areas of the railroad instead of a strategy where a complete system is ground. This saves the customer both

money and track time and ensures the area with the most need receives attention.

Orgo-Thermit can grind track with a 12-stone Hi-Rail vehicle which offers strong performance for embedded track with its unique ability to get on and off track in less than a minute at crossings. The company’s trucks are equipped with a profile measurement to support grinding operation and guarantee the work achieves the required rail profile.

PortaCo, also a Goldschmidt company, offers a range of grinders to support all Maintenance-of-Way activities and has developed both lightweight and heavyweight profile grinders. The lightweight grinder has an ergonomically designed halo handle that allows the user to quickly maneuver the grinder around the rail. For the heavyweight grinder, the operator does not have to apply as much downward force to grind the rail, and it has an adjustable handle, so the operator is always upright when using it. Both grinders share hydraulic components, so even if different people on the same railroad prefer a different grinder, the spare parts are the same across both.

Vossloh o ers several options for pro ling

rail. e VTM-compact is a highly exible, cost-e cient milling machine designed to t even the tightest of clearances. It will remove up to 2 mm in one pass, saving rails with serious defects and transverse pro le deviations from cost-intensive rail replacement. e technology is ideal for re-restricted areas with no re or dust hazards. e VTMcompact can be on track and ready for operation within a few minutes, maximizing even short track windows.

Vossloh also offers its proprietary High-Speed-Grinding technology that can prevent the onset of rolling contact fatigue, with operating speeds of over 40 mph without preparing the track.

Developing a maintenance strategy based on local conditions and individual circumstances of a specific network is very challenging. Vossloh has enhanced its rail maintenance machines into digital diagnostics vehicles to address this. Their SMART technology, which can be added to all existing machines, allows measurements to be taken during normal scheduled operations to determine the condition of rails and turnouts. This visually displays where, when, and which machining procedures are required.

“SOFTWARE TECHNOLOGY ASSOCIATED WITH RAIL GRINDING IS BECOMING INCREASINGLY SOPHISTICATED.Loram heavy-grind train. Photo Credit: Loram

By David C. Lester, Editor-in-Chief

By David C. Lester, Editor-in-Chief

The winter months, especially with the weather extremes the nation has experienced lately, are especially tough for anyone who works outside, particularly railroaders. While some industries do not work during frigid weather, railroaders must continue to move trains and maintain the infrastructure. Switches freeze, snow blocks train passage, and working on the railroad is more challenging when bundled up in a

heavy coat, hat, and gloves. Fortunately, the railway supply industry o ers some solutions for making the task of winter maintenance a bit easier.

For example, Pettibone told RT&S that its Speed Swing is thought by many to be the original, do-it-all rail crane for various maintenance-of-way and rail service tasks. is machine can have dozens of diverse attachments, including options to clear snow from railways and surrounding areas.

The Speed Swing is highly versatile and quickly transitions between jobs, traveling at 25 mph on hi-rail and 20 mph with all-terrain rubber tires. The tires also afford greater maneuverability off the rails, simplifying many winter maintenance tasks.

A standard Speed Swing unit can be equipped with snow blowers and adjustable V-plows for heavy-duty snow removal. In addition, a sweeper-broom attachment

Pettibone’s Speed Swing 445F is thought by many to be the original “do it all” rail crane.

can brush the snow o switches.

A specialized track-cleaning attachment – a large bucket designed for travel right on the rails – can also be employed in snow removal. is bucket cleans the snow o the tracks via built-in notches that slide over each rail as the bucket advances.

Pettibone o ers diesel heating systems for the Speed Swing for operation in colder northern climates. e operator can program the system to start the engine at a speci c time before work begins. is ensures the machine is ready to go – with the engine, hydraulics, and inside of the cab all properly heated – without needlessly idling overnight and burning costly fuel.

e use of cold-weather uids is another smart measure for winter preparedness. Less viscous gear oil and hydraulic uids

will perform better in cold temperatures. Customers can specify cold-weather packages for their Speed Swing when built at the factory. Alternatively, maintenance techs should change uids when servicing before winter.

Progress Rail, a Caterpillar company, points out to RT&S that winter operations require planning and positioning resources and assets and ensuring those assets are ready for the cold winter months by keeping them maintained and in topnotch condition. Progress Rail has a range of products to help customers remain productive during winter.

The company’s Kershaw® Model 60 is a multi-purpose machine platform that can be used as a heavy-duty snow fighter. It has benching snow wings, a

high-output snow auger, and a highspeed V plow or four-season plow with flanges. In warmer months, the Model 60 can be transformed into a ballast regulator or brush cutter to tackle a full range of maintenance-of-way jobs.

As Progress Rail looks ahead to 2023, they anticipate customers will continue to demand more value for their money and increased productivity and reliability. And the company continues to develop new products. For example, Progress Rail developed and delivered the first of their new high-output snow fighters. This machine sports a 415 HP Cat® C9.3B diesel engine coupled to upgraded drive train components, including a new power-shift transmission and variable displacement traction pump and motor. The machine

also incorporates all new heavy-duty axles and can transmit 30% more tractive effort than previous models. The machine can deal with the most severe winter climatic conditions and is equipped to keep operators comfortable and safe in the harshest conditions.

Thermon provides freight and transit railways throughout North America with a portfolio of products purpose-built to ensure wayside equipment functions as intended in even the harshest winter conditions. Products include Fastrax and SwitchBlade electric heating elements and controllers, Hellfire gas and electric hot air blowers for track switches, heated covers to keep hot box detectors functional, and crib and platform heaters for a variety of applications.

ermon told RT&S that the Hell re 905 gas- red hot air switch heater is the industry’s most powerful and reliable heater intended for locations with high wind and snowfall, such as in the mid-west and other harsh winter regions of the US and Canada. e improved performance eliminates the need for switch covers in

some applications, as seen in the photo of an installation in the Rocky Mountains.

e ve hp 3600 rpm motor, aerodynamic impeller, and inlet cone increase air ow by 50% to 3000 standard cubic feet per minute while maintaining the quiet operation of 62 decibels at 25 feet. e design provides burner e ciency of 95%, which is veried by testing emissions before shipment. Additionally, openings added to the burner pro le plate allow bypass air ow to maintain the ideal air velocity across the burner without compromising e ciency, ame signal strength, or reliability.

When con gured with Hell re track duct systems, increased air ow provides greater point nozzle and track duct vent exit velocities and uniform heat distribution over the switch from toe to heel.

e exhaust ange, gas supply pressure, burner, and many control components, are downward compatible with existing Hell re 900 or Mark 6 systems. e Variable Frequency Drive option allows the 905 to be installed in locations that otherwise can’t handle the in-rush current of the direct startup.

February is the month we remember and celebrate the presidents of the United States on President’s Day. e holiday was initially designated by congress to remember President George Washington’s birthday. In 1972 it was broadened to include President Abraham Lincoln and all the others. In my previous messages, I used two quotes from my favorite president – eodore Roosevelt. He is my favorite because of his progressive policies and conservation e orts that have le a large impression on the soul of the United States. He had a huge impact on the growth of the National Park System, a favorite of mine. One of my goals is to visit all 63 national parks, 19 down and 44 to go.

I want to highlight a progressive step within the railway construction industry that has developed over the past few years. I am speaking mostly from my own experience, in having led various construction projects and programs over the years, but I believe it re ects the whole industry to some extent. e concept of bringing the construction contractor into the project team during the design phase rather than at the point of bidding the work is an approach that was not utilized for most of my time in the industry. e Construction Manager/General Contractor (CM/GC) project delivery method does this, and I will summarize some of the advantages that make this an excellent approach for many larger construction projects.

CM/GC is one of many alternative delivery methods for construction projects. It has been around for many years, primarily with some State DOT’s for publicly funded

highway projects. It is exible and can be customized to accomplish speci c project goals. CM/GC o ers the greatest value with large and complex projects ($50M or more in my opinion). is is not a method for simple, small, or easily repeatable projects. ere is an added small up-front cost to cover preconstruction services, but when the project is large and complex, the savings generated will easily o set those costs. e basic CM/GC method is this – a er selecting a design/construction management (CM) rm with CM/GC experience, solicit interested contractors, request proposals from a selected short list, and through a quali cations-based selection process a contractor is brought into the team before the design reaches 30%. On a similar timeline you also select an Independent Cost Estimator (ICE) who validates the market rates the contractor provides in their cost proposals. e project team is then complete – a design/ CM rm, a contractor, and an ICE - all which would have a direct contract with the owner/railroad. Below are the key steps, value opportunities and pitfalls to avoid in the process.

There are several key steps in a successful CM/GC process:

• Initiate design

• Preconstruction phase - bring the contractor and ICE into the design process a er the 10% stage and before the 30% stage is completed

◊ Evaluate alternative design concepts to meet functionality

◊ Complete constructability reviews and evaluate alternative materials

◊ Schedule and price the work

◊ Develop a risk register and assign who will carry each risk item

◊ Complete the 30%, 60% and 90% design stages and repeat the steps above as the design, schedule, and pricing are re ned

• Owner and contractor negotiate the guaranteed maximum price (GMP) with ICE providing guidance to the owner

• Construction phase proceeds

◊ If negotiations fail to produce a competitive market-based price agreeable to the owner and contractor, then the owner can proceed with formally bidding the project to other contractors

◊ Execute early work packages prior to the GMP to accommodate longlead material/equipment and/or if starting certain work before all the design and pricing is complete benefits the schedule

Along the way, take note of the many value opportunities CM/GC can provide, such as:

• Schedule compression – with shared ownership

• Reduced risks – early identi cation and mitigation

• Upfront value engineering – drives out costs

• Improved constructability of designminimize railway operational impacts

• Improved cost certainty - a reduction of change orders

• Incorporate sustainability opportunities

– evaluate in both design and construction phases

• Environmental permits – incorporate contractor inputs

As with all projects, there are a few potential pitfalls to avoid:

• Failure to agree upon a GMP – resolve any large estimate di erences early and prepare to bid if not resolved

• Noncompetitive pricing through deceptive estimating techniques – a well-quali ed ICE will prevent this

• Contractor provides little value during preconstruction services – be sure to use a contractor with proven CM/GC experience

It is important to note that with the CM/ GC method, the owner remains in control of the entire process. is is one of the key reasons it can be a great method – the owner gets all the bene cial input from the contractor but retains control of the design process. I have provided a very simpli ed overview with the intent of raising awareness and highlighting the value CM/GC can bring to the rail industry. Much has been written about CM/GC and other alternative delivery methods, so if I have spurred your interest you may want to explore it further.

Enjoy your journey until next month.

Save the dates: October 1-4 as Railway Interchange is back after more than 3 years . The AREMA 2023 Annual Conference in conjunction with Railway Interchange will be held in Indianapolis, IN with registration set to open in April. For the latest information about Keynote Speakers, Technical Presentations, Sponsorship, and more, visit www.conference.arema.org.

Did you know we have a wide variety of On Demand education for learning on your time? Browse our most popular webinars, seminars, and Annual Conferences to earn your PDH credits on the go. Visit www.arema.org to start your On Demand learning today.

Is your Library up to date? Order the

NOT AN AREMA MEMBER?

JOIN TODAY AT WWW.AREMA.ORG

NEW 2023 Communications & Signals Manual today. With over 35 new, revised, reaffirmed, or extended Manual Parts, including over 500 pages of updates, it’s the perfect time to get your copy of the 2023 Manual. Order online now at www.arema.org.

Don’t miss out on the conversation happening in AREMA’s Member Forum. The Member Forum connects you with other Members allowing you to send messages, start conversations, and more. See what everyone is talking about today: https://community.arema.org/home.

If you’re looking for a podcast to binge, listen to AREMA’s Platform Chats. It features guests from every aspect of the railway industry. Come ‘roll with

CONNECT WITH AREMA ON SOCIAL MEDIA:

AREMA’ available on all of your favorite listening services.

Order the NEW, 2022 edition of the Portfolio of Trackwork Plans. This edition features new plans and specifications that relate to the design, details, materials and workmanship for switches, frogs, turnouts & crossovers, crossings, rails and other special trackwork. Order online now at www.arema.org or contact publications@arema.org for more details.

Leverage the power of your trusted association’s Railway Careers Network to tap into a talent pool of job candidates with the training and education needed for long-term success. Visit www.arema.org/careers to post your job today.

FEBRUARY 9

Committee 9 - Seismic Design for Railway Structures

Las Vegas, NV

MARCH 19

Committee 17 - High Speed Rail Systems

Los Angeles, CA

MAY 16-17

Committee 15 - Steel Structures

Pueblo, CO

FEBRUARY 9-10

Commitee 1 - Roadway & Ballast

Kansas City, MO

MARCH 19-21

Committee 11 - Commuter & Intercity Rail Systems

Los Angeles, CA

JUNE 15-16

Committee 8 - Concrete Structures & Foundations

Washington, D.C.

FEB. 22-23

Committee 7 - Timber Structures

Russellville, Ariz.

MAY 15-17

Committee 5 - Track

Dallas, TX

Joining a technical committee is the starting point for involvement in the association and an opportunity for lifelong growth in the industry. AREMA has 30 technical committees covering a broad spectrum of railway engineering specialties. Build your network of contacts, sharpen your leadership skills, learn from other members and maximize your membership investment. If you’re interested in joining a technical committee or sitting in on a meeting as a guest, please contact Alayne Bell at abell@arema.org.

For a complete list of all committee meetings, visit www.arema.org.

Metro Transit in St. Louis, in conjunction with its parent organization Bi-State Development, hosted a group of AREMA Committee 24 (Education and Training) members in June for a tour of the historic Eads Bridge in St. Louis, Mo. Originally completed in 1874, it was one of the first bridges in the United States to utilize steel for construction. It is the oldest bridge structure still in use over the Mississippi River and connects Illinois and Missouri. Early in the construction phase in the 1870’s, the contractor utilized new technology at the time in the form of pneumatic caissons to seat the foundation on bedrock more than 100’ below the surface water elevation. This historic bridge has two decks. The upper deck carries vehicles, pedestrian, and

cycling traffic and MetroLink light rail trains operate on the lower deck. A $48 million full-scale rehabilitation project was completed in 2016, restoring the steel truss and superstructure of the bridge.

During the June site visit, industry professionals saw the steel arch ribs, track, rail interlocking, as well as the overhead conductor rail for the MetroLink trains. The site visit was part of an overall Committee 24 meeting, which also included two days of in-office work on progressing tasks including: completing the new Advanced Track Alignment Design Seminar (TADS II), preparing for Student Activities for the Annual Conference, and debriefing from the Railway Engineering Education Symposium (REES) held in June 2022, among other things.

Coordinating a site tour like the Eads Bridge takes months of coordination to ensure a safe site visit. Special thanks to Matt Chrapek (Transit Asset QAQC PM – Civil/Structural for Metro Transit and Committee 24 Vice Chair – Education and Training), Joni Korte (Director of Engineering – Maintenance of Way for Metro Transit), K. Faith Long (Structural Engineer – Maintenance of Way for Metro Transit), and Greg Millender (Superintendent of Light Rail Operations for MetroLink).

Committee 24 meets in person three times a year and met in Denver, Colo. at the AREMA 2022 Annual Conference. If you’re interested in being a guest at that Committee meeting, please contact John Green at johngreen@mail.fresnostate.edu.

AREMA is focused on your education and helping you advance in the railway industry.

AREMA’s webinars provide Professional Development Hours (PDH) to serve your educational needs.

CULVERT AND STORM DRAIN INSPECTION WEBINAR

DATE: Wednesday, February 22 - Thursday, February 23

TIME: 2:00-4:00 PM ET Each Day

PDH HOURS: 4

AREMA also offers On Demand education available to watch at any time at your convenience. Find courses like the newly released AREMA 2022 Annual Conference, the Bridge Inspection Webinar series, FREE Webinars for Members, and soon to come, the Railway Roadbed & Ballast Symposium.

These courses are comprised of recommended practices and relevant accumulated knowledge from subject matter experts in the railroad industry. They are not intended as a regulatory qualification.

To register for these webinars and our other On Demand education, please visit www.arema.org.

MAIN OFFICE

JONATHAN CHALON Publisher (212) 620-7224 jchalon@sbpub.com

AL, KY, TN, CHINA

JONATHAN CHALON (212) 620-7224 jchalon@sbpub.com

CT, DE, DC, FL, GA, ME,MD, MA, NH, NJ, NY, NC, OH, PA,RI, SC, VT, VA, WV, CANADA: QUEBEC AND EAST, ONTARIO

JEROME MARULLO (212) 620-7260 jmarullo@sbpub.com

AR, AK, AZ, CA, CO, IA, ID, IL, IN, KS, LA, MI, MN, MO, MS, MT, NE, NM, ND, NV, OK, OR, SD, TX, UT, WA, WI, WY, CANADA: ALBERTA, BRITISH COLUMBIA, MANITOBA, SASKATCHEWAN HEATHER DISABATO (CHICAGO OFFICE) (312) 683-5026 hdisabato@sbpub.com

AMERICAS, EUROPE, ASIA, AFRICA, AUSTRAL ASIA NORTH AMERICA - CT, DE, DC, FL, GA, ME, MD, MA, NH, NJ, NY, NC, OH, PA, RI, SC, VT, VA, WV, AND EASTERN CANADA. EUROPE EXCEPT GERMANY, AUSTRIA, GERMAN SPEAKING SWITZERLAND, EASTERN EUROPE, ITALY, AND ITALIAN-SPEAKING SWITZERLAND. ASIA EXCEPT JAPAN AND CHINA. JEROME MARULLO (212) 620-7260 jmarullo@sbpub.com

GERMANY, AUSTRIA, GERMAN-SPEAKING SWITZERLAND, LATVIA, LITHUANIA, ESTONIA, POLAND, CZECH REPUBLIC, SLOVAKIA, HUNGARY, SLOVENIA, CROATIA AND SERBIA SIMONE AND SIMON FAHR Breitenbergstr. 17 Füssen 87629

Germany

Tel: +49 8362 5074996 sfahr@railjournal.com

ITALY, ITALIAN-SPEAKING

SWITZERLAND

DR. FABIO POTESTA

Media Point & Communications SRL

Corte Lambruschini

Corso Buenos Aires 8 V Piano, Genoa, Italy 16129

+39-10-570-4948

Fax: +39-10-553-0088 info@mediapointsrl.it

JAPAN

KATSUHIRO ISHII

Ace Media Service, Inc.

12-6 4-Chome, Nishiiko, Adachi-Ku Tokyo 121-0824

Japan

+81-3-5691-3335

Fax: +81-3-5691-3336

amkatsu@dream.com

IRJ PRO AND CLASSIFIED ADVERTISING SALES

JEROME MARULLO (212) 620-7260

jmarullo@sbpub.com

This section has been created solely for the convenience of our readers to facilitate immediate

advertisers in this issue. The Advertisers Index is an editorial feature maintained for the convenience of readers. It is not part of the advertiser contract and RTS assumes no responsibility for the correctness.

During the height of the pandemic, no one was sure how things would turn out. COVID19 was spreading rapidly, and it seemed the only way to avoid it was to stay home and not be around anyone other than family who lived with you. For those who could, working from home became the norm. Meanwhile, there were many people who could not work from home and many from both groups were hospitalized and died at an alarming rate. Then, the pandemic began to ease for whatever reasons, such as vaccines, wearing masks or maintaining distance from others when in public. The latter half of 2022 saw people gathering and meeting again, and COVID-19 ceased to be the lead news story each night.

We were le with what seems a permanent change in the way we work, however.

ose who work outside or cannot work from home continue to go to the o ce, factory, or other workplaces to do their jobs. ose who can work from home seem to have embraced a new “hybrid” lifestyle, where the average is two days in the o ce and three days at home. Moreover, I believe this change has occurred not because people are afraid of getting COVID-19 or some other respiratory disease but enjoy the balance of working at home and in

the o ce. And I think many workers and managers have been surprised by how e ectively people can work and collaborate when they’re not in the o ce.

The social implications of this change, if permanent, will be significant and beyond the scope of this discussion. However, the impact on commuter rail

it’s too early for transit leaders to assume this pattern will stick and begin making service and fare adjustments. Similarly, it’s too early for federal, state, and local governments to start making funding changes on the assumption that total prepandemic ridership will never return.

Nevertheless, as uncomfortable as it may be, it is time to begin planning for such a situation if ridership remains at. About one-third of a transit agency’s funding comes from the farebox, which means that to maintain transit systems as they are now, more government subsidies will be needed. I expect some preliminary planning is already underway, as some agencies have mentioned they may experiment with fare increases and reductions in service.

and public transit is what we’ll focus on here. You may have already noticed that we ran a small story on whether public transit is facing yellow signals in this issue’s edition of NewsWatch. It is disturbing to read that ridership on the New York subway is two-thirds of what it was before the pandemic, and BART has only onethird of its pre-pandemic ridership. Yet,

Hopefully, the scenario I’ve outlined here will not come to pass. Transit and commuter rail have been a huge part of American history and provide commuters with convenience and environmental bene ts. And they will continue to play a signi cant role in American urban life. Our nation cannot a ord to continue building and refurbishing highways and building life around personal automobiles. Of course, we’ll always have cars, but balancing their use with good public transit is the wisest course, even if a sizable percentage of our workforce is remote.

IT IS DISTURBING TO READ THAT RIDERSHIP ON THE NEW YORK SUBWAY IS TWOTHIRDS OF WHAT IT WAS BEFORE THE PANDEMICPhoto Credit: Shutterstock.com/Panimoni

Part 1: February 22 | 2:00 - 4:00 PM ET

Part 2: February 23 | 2:00 - 4:00 PM ET

4.0 PDH | Presenters: Matthew C. Richie & Shawn R. Coombs, PE

This two-part course presents methodology for rapid condition evaluation of culverts and buried bridges that establishes a rating system to prevent failure/ washout. The system also provides a framework for managing assets, reducing risk, and prioritizing maintenance and rehabilitation.

To REGISTER or for more information, visit www.arema.org

October 1- 4, 2023

P lasser American contracting s er vices will provide the next l evel of rail m a intenance through the innova ti ve Romill Urban 3 E ³ milling machine to Tr a n sit Systems as well as Frei ght Ra ilroads in North America. Th e in novative R omill Urban 3 E ³ high-performance milling m ac hin e in co rpo rates the next g e neration of electric rail mi lling. The Hybrid drive system wi th hi gh capacity batteries will provide hours of emission-free operations with th e in tegrated diesel engine. This provides th e ability to charge the batt er ies and operate the m a c hine continuously. Featuri ng the r evolutionary new cutter hea d desig n for l o nger tool life and extended o per ational capabilities along with s tate-of-thea rt measurement technology This compact layout fi t s int o the tightest s ubway tun nels and allows easy road tra nspo rta tion.