February 2018 // Railway Track & Structures ALSO: DYNAMIC WHEEL FORCE MEASUREMENT: PART ONE GRADE CROSSINGS MXV RAIL FEATURING TEN OF THE INDUSTRY’S MOST IMPRESSIVE RAIL INFRASTRUCTURE PROJECTS PROJECTS TOP 2024 JUNE 2024 | WWW.RTANDS.COM

YOUR TRUSTED CHOICE FOR 25 YEARS AND COUNTING WVCORAILROAD.COM | 541-484-9621 | SALES@WVCORAILROAD.COM COMPLETE SERVICE THAT KNOWS NO END. CELEBRATING 25 YEARS Celebrating a quarter century of groundbreaking innovation and dedication to American-made quality, service and our unwavering commitment to providing the best solutions for the railroad industry.

June 2024 // Railway Track & Structures 1 rtands.com CONTENTS June 2024 10 DEPARTMENTS COLUMNS 4 34 Editor’s Notebook WRI 29 Is In The Books Just For Fun An Image Gallery From The Dome 3 30 Cover Story: RT&S Top Projects 2024 For story, see p. 10 MxV Rail Laboratory Testing of Tie Plugging Materials AREMA Message from the President 8 40 FEATURES Follow Us On Social Media @RTSMag 10 RT&S Top Projects Top 10 rail infrastructure projects of 2024 24 Dynamic Wheel Force Measurement Part One of a Two-Part Series 30 Vendor-Product Spotlight Grade Crossings

A New Way Forward In Maintenance of Way Safety Engineered | Speed Delivered | Budget Optimized +1-717-DAV-RAIL | contact@davrail.net DavRail Incorporated | 6300 Ridglea Place, Suite 1208 | Fort Worth, Texas 76116 Connect with Us Providing focused equipment and technology solutions for the North and South American markets.

Vol. 120, No. 6

Print ISSN # 0033-9016, Digital ISSN # 2160-2514

EDITORIAL OFFICES 1025 Rose Creek Drive Suite 620-121 Woodstock, GA 30189

Telephone (470) 865-0933 Website www.rtands.com

DAVID C. LESTER Editor-in-Chief dlester@sbpub.com

JENNIFER M c LAWHORN Managing Editor jmclawhorn@sbpub.com

EDITORIAL BOARD

David Clarke, University of Tennessee

Brad Kerchof, formerly Norfolk Southern William Riehl, Genesee & Wyoming/AREMA

Scott Sandoval, Genesee & Wyoming

Robert Tuzik, Talus Associates Gary Wolf, Wolf Railway Consulting

CORPORATE OFFICES

1809 Capitol Avenue Omaha, NE 68102

Telephone (212) 620-7200 Fax (212) 633-1165

ARTHUR J. MCGINNIS, JR. President and Chairman

JONATHAN CHALON Publisher

MARY CONYERS Production Director

NICOLE D’ANTONA Art Director

HILLARY COLEMAN Graphic Designer

JO ANN BINZ Circulation Director

MICHELLE ZOLKOS Conference Director

CUSTOMER SERVICE: 847-559-7372

Reprints: PARS International Corp. 253 West 35th Street 7th Floor New York, NY 10001

212-221-9595; fax 212-221-9195 curt.ciesinski@parsintl.com

WRI 29 Is In The Books

As I write this, I have just returned from the 29th annual Wheel/Rail Interaction Conference in Chicago, and the event exceeded my expectations. Although I had attended the conference in 2015 as a journalist, it was great to see that the quality of presentations and other aspects of the meeting were as well maintained and executed as in 2015, and perhaps even better. And as most readers know, Railway Track & Structures was the presenting sponsor for the Heavy Haul section of the conference, which took place on May 23-24. e two previous days were devoted to Mass Transit (Tuesday, May 21) and the Principles Course (Wednesday, May 22).

During the two days of Heavy Haul, there were een presentations to an audience of around 225 attendees on a variety of rail engineering topics, each made by an expert in the discipline. For example, Fabian Hansmann, Head of Marketing at Plasser & eurer presented “Track Geometry: Quality vs. Performance?” Corina Moore, Executive Vice President of Transportation and Infrastructure at WSP in Canada made a somewhat di erent presentation, “ e Intersection of Culture and Technology Implementation.”

Brad Kerchof, Senior Track Engineer at Global Rail, NA (formerly ARM) and long-time Director of Research and Tests at Norfolk Southern, went through a derailment investigation exercise that

focused on the diligent and careful work required to nd the correct cause of a derailment. His presentation was entitled “Case Study: A Derailment Investigation –– Was the Right Cause Found?” Gary Wolf also presented on derailment investigations with his “Current Status and Trends in Track Caused Derailments with Emphasis on Causes Related to the Wheel/ Rail Interface.”

In addition to the presentations, the Heavy Haul section featured three “InfoZone” sessions. Each InfoZone session lasts approximately 30 minutes, and during three InfoZone breaks over the two days, two sessions were o ered during each. ese sessions take place in private rooms and allow vendors to engage in in-depth discussions with attendees to learn more about the technical aspects of products and services available now or on the horizon. e vendors participating in InfoZones this year were BOSSPAC, LORAM, Plasser American, FTS Tools, and Global Rail NA. Each InfoZone session is followed by a thirty-minute “ExpoZone” session where attendees can spend time with vendors with booths in an open area of one of the larger meeting rooms. In addition to these thirty-minute sessions, the ExpoZone is open throughout the conference.

Railway Track and Structures is proud to be the presenting sponsor of the Heavy Haul session at WRI, and we look forward to continuing our partnership with this organization in the coming years. Please note, too, that at least one of our stories in the magazine each month will be a detailed written presentation originating from a conference, prepared by the team of Bob and Je Tuzik at Interface: e Journal ofWheel/Rail Interaction

DAVID C. LESTER Editor-in-Chief

DAVID C. LESTER Editor-in-Chief

EDITOR’S NOTEBOOK June 2024 // Railway Track & Structures 3 Railway Track & Structures (Print ISSN 0033-9016, Digital ISSN 2160-2514), (USPS 860-560), (Canada Post Cust. #7204564; Agreement #40612608; IMEX P.O. Box 25542, London, ON N6C 6B2, Canada) is published monthly by Simmons-Boardman Publ. Corp, 1809 Capitol Avenue, Omaha, NE 68102. Printed in the U.S.A. Periodicals postage paid at Omaha, NE, and additional mailing offices. Pricing: Qualified individual and railroad employees may request a free subscription. Printed and/or digital version: 1 year Railroad Employees (US/Canada/Mexico) $16.00; all others $46.00; foreign $80.00; foreign, air mail $180.00. 2 years Railroad Employees US/Canada/Mexico $30.00; all others $85.00; foreign $140.00; foreign, air mail $340.00. Single Copies are $10.00 ea. Subscriptions must be paid for in U.S. funds only. COPYRIGHT © Simmons-Boardman Publishing Corporation 2024. All rights reserved. Contents may not be reproduced without permission. For reprint information contact: PARS International Corp., 102 W 38th St., 6th Floor, New York, N.Y. 10018 Phone (212) 221-9595 Fax (212) 221-9195. For subscriptions and address changes, Please call 847-559-7372, Fax +1 (847) 291-4816, e-mail rtands@omeda.com or write to: Railway Track & Structures, Simmons-Boardman Publ. Corp, PO Box 239, Lincolnshire IL 60069-0239 USA. POSTMASTER: Send address changes to Railway Track & Structures PO Box 239, Lincolnshire IL 60069-0239 USA.

Laboratory Testing of Tie Plugging Materials

Examining Spike Pullout Forces

Yin Gao, Principal Investigator I, MxV Rail

Silvia

Galvan-Nunez,

Senior Data Analyst IV, MxV Rail

Sirius Roybal, Senior Instrumentation Engineer II, MxV Rail

Traditionally, North American railroads use wood plugs to ll the holes le a er removing spikes from wooden ties. Liquid-based synthetic tie plugging materials have been used as an alternative to wood plugs since the early 2000s.1 More recently, a powderbased tie plugging material has become available. MxV Rail performed laboratory tests on di erent tie plugging materials to evaluate their ability to hold cut spikes in wood ties. is study, part of the Association of American Railroads’ (AAR) Strategic Research Program, focused on comparing 1) the spike pull-out forces needed for wood plugs, 2) three liquid-based synthetic tie plugging materials, and 3) a powder-based tie plugging material in controlled laboratory conditions.

Spike pull-out forces can be extremely inconsistent in different wood ties due to the wide variation in wood properties (e.g., grain, density, moisture). Past field experience 1 shows that the pull-out forces between various wood tie types could vary by as much as a factor of three. Therefore, only wood ties of the same species and similar surface conditions were selected for the spike pullout tests. To ensure the appropriate ties generated consistent results during the plugging test, the preliminary tests were first conducted on a group of candidate ties to evaluate the consistency of spike pull-out forces.

To simulate the degraded condition of the ties, all tested spike holes were prepared to be a square hole with 3/4-inch inside length (longer than the nominal side length of a cut spike). e tie plugging materials were applied in both dry and wet conditions. A di erent cure time was also considered during testing. e spike pull-out tests (Test

3A) recommended by the American Railway Engineering and Maintenance-of-Way Association (AREMA) Manual for Railway Engineering were conducted.1 A er achieving acceptable laboratory results, future work will focus on evaluating the in-track performance of the tie plugging materials.

Test Preparation

To simulate the spike-kill holes, 3/4-inchwide spike holes were prepared using the following process. First, a 5 1/2-inch-deep round hole was drilled using a 5/8-inch

drill bit (Figure 1, le ). en, a 3/4-inchsquare steel bar was driven into the same hole to create a square hole with a side length of 3/4 inch (Figure 1, right). An eight-hole AREMA 14-inch tie plate was used to determine the spacing and pattern of the spike holes.

e tie plugging materials were tested under both dry and wet conditions. To simulate wet revenue service track conditions, the spike holes were pre-soaked with water overnight and lled with 10 milliliters of water prior to the application of the

4 Railway Track & Structures // June 2024 rtands.com MxV RAIL

Figure 1. Pilot hole preparation

Table 1. Average pull-out forces for each test case

(a)

(b)

plugging material.

e three liquid-based materials were applied with a hand-operated gun using two di erent cure times prior to spike insertion: 30 minutes (standard), as recommended by the manufacturer, or 10 to 15 minutes (less cure time). A er the spikes were inserted, all three liquid-based materials required a 60-minute wait time before the spikes could be extracted.

e powder-based material was poured into the spike holes using a paper cup. Wood plugs and powder-based materials did not require cure time prior to spike insertion or wait time before spike pull-out.

e insertion and pull-out speeds were 1 inch per minute, and the insertion and pullout forces were recorded as a function of displacement.

Test Results

Each test case contained eight spike pullout tests; a total of 128 spike pull-out tests were conducted using the various plugging materials. Table 1 summarizes the results of the average pull-out forces.

Although the AREMA Manual provides no test criterion, an average pull-out force over 2,000 pounds is generally considered acceptable. Based on the information in Table 1, all the tested materials met that requirement. e following subsections use statistical analysis to discuss the material performance in detail.

Comparison to Wood Plugs

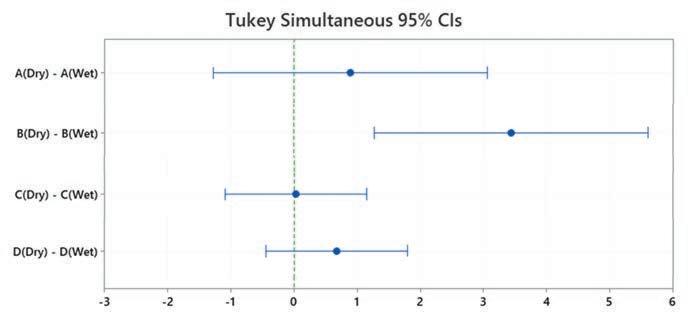

A statistical analysis was conducted to compare the performance of all tested materials. Wood plugs, a traditional way to plug ties a er spike pull-out, were used as the baseline reference in this comparison. Tukey’s honest signi cance test was used to determine if there was a signi cant di erence between the mean values of the pull-out forces for the tie plugging materials. As shown in Figure 2, the blue dot represents the mean di erence between pairs, and the extended lines show the 95 percent con dence intervals. If the condence interval crosses zero, the di erence is not statistically signi cant. As the plots indicate, all four tested materials (A, B, C, D) had higher average pull-out forces (mean value) than those for wood plugs under dry conditions. Out of the materials used, the pull-out forces of A and B were signi cantly higher than wood plugs; C and D were not signi cantly di erent. Under wet conditions, the four materials showed no signi cant di erences in the

pull-out forces when compared to wood plugs. Results from the standard cure time for the liquid materials were considered in this analysis.

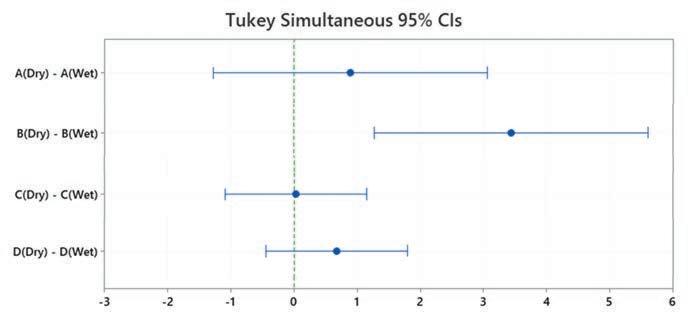

Wet and Dry Conditions

A similar analysis was performed to compare the results of wet and dry conditions. e average pull-out forces were higher under dry conditions than under wet conditions for all four non-wood plug materials, but only material B showed signi cant di erences in the average pull-out forces (Figure 3). e wood plugs were the only tested materials to exhibit higher average

pull-out forces under wet conditions compared to dry conditions. Again, results from the standard cure time for the liquid materials were considered in this analysis.

Material Cure Time

Two different cure times, one standard (30 minutes) as recommended by manufacturers and one shorter period (10–15 minutes), were applied. None of the three liquid-based materials showed significant differences in pull-out forces. Therefore, a reduced cure time (10–15 minutes) did not significantly affect the tie plugging performance in this test.

June 2024 // Railway Track & Structures 5 rtands.com MxV RAIL

Figure 2. Comparison of other materials to wood plugs

Figure 3. Comparison of wet and dry conditions

Characterization of Force-Displacement Curve

Figure 4 plots the typical pull-out force versus displacement curves for all ve tie plugging materials used in this study. e peak pull-out forces occurred during the rst 0.2 inch of the spike pull-out indicating that once the spikes are li ed more than 0.2 inch, the rail hold-down force could be past its peak. Materials B, C, and the wood plugs showed a signi cant drop (more than 50 percent) in the pull-out force a er reaching the peak force, while materials A and D generally showed a smoother decreasing trend as the spikes were extracted. e spikes did not provide much holddown force a er 2 1/2 inches of pull-out displacement.

Conclusions

In this study, spike pull-out tests were conducted using ve tie plugging materials to evaluate the pull-out force of each material on wood ties. Main conclusions for the study include:

• All tested materials generated acceptable pull-out forces, qualifying the

HowDiesel&Electric LocomotivesWork

ByJeffWilson

Thecombinationofthedieselengineandelectrictraction motorrevolutionizedrailroading.Inthepastcentury,the dieselanditscompanionelectriclocomotivehave advancedfromnewtechnologytosomeofthemosthightechvehiclesonsteelwheels.Findingoutwhatgoesonunderthehood,inthe electricalcabinet,andbehindthecontrolstandto maketheseunitsworkisjust asfascinatingaswatchingone(orseveral)haulfreightormovepassengers. Wilson’snewbooktracesthehistoryanddevelopmentofthedieseland examineseachmajorsystemthatispartofalocomotive.Thebookiswrittenin easy-to-understandlanguageprovidingjusttherightamountoftechnicaldetail withoutburdeningthereader.

Railroads&EconomicRegulationtracesthe development,failuresandsuccessesofrailroad economicregulationbyaninsiderwhowasaWhiteHouse appointedchiefofstaffattheSurfaceTransportationBoard andaseniorofficerattheAssociationofAmericanRailroads.

"ThequalityanddepthofWilner'sresearchprovidesaneededroadmap throughthelabyrinthofrailroadregulation.Itisavaluableresourceforfuture policydecisionmaking."

Dr.HarveyA.Levine Retired,VicePresident,Economics&FinanceAssociationofAmericanRailroads

6 Railway Track & Structures // June 2024 rtands.com MxV RAIL

(a)

Figure 4. Pull-out force vs. displacement: (a) full pull-out

AddShipping&Handlingifyourmerchandisesubtotalis: Ordersover$300,callforshipping.Pricesaresubjecttochange. U.S.A.CAN U.S.A.CAN TheRailwayEducationalBureau RailroadResources Thefiftheditionof TheRailroad:WhatItIs,WhatitDoes is evenmorevaluablethanbefore.Insideyou’llfinda comprehensivelookathowtoday’srailroadsfunction—from equipmenttoproceduresandmarketingtomaintenance. BKRRNN WhatitisWhatitdoes $49.95 TheRailroad Whatitis,Whatitdoes 1809CapitolAve.,OmahaNE,68102 800-228-9670 www.RailwayEducationalBureau.com Railroads&Economic Regulation (AnInsidersAccount) ByFrankN.Wilner

BKRER Railroads&EconomicRegulation(AnInsidersAccount) $69.00 NEW! 25.01-50.0015.0025.50 50.01-75.0016.8531.85 75.01-100.0020.0541.60 100.01-150.0022.8554.05 150.01-200.0026.7572.20 200.01-300.0032.4589.50

BKFCAB GuidetoFreightCarAirBrakes $74.50

GuidetoFreightCarAirBrakes presentsawealthof informationpertainingtoairbrakemaintenance.Theproceduresandmethodspresentedinthisbookaredesignedto keepyourfreightcarairbrakesystemsintopcondition.

GuidetoFreightCarAir Brakes

BKHDELW HowDiesel&ElectricLocomotivesWork $27.99 NEW!

materials for in-track testing.

• e liquid-based and powder-based materials had similar or signi cantly higher average pull-out forces than wood plugs under dry conditions and had similar pull-out forces to wood plugs under wet conditions.

• Compared to the results under dry conditions, the liquid- and powderbased materials showed similar or lower average pull-out forces under wet conditions.

• Less cure time (10–15 minutes) did not show a signi cant di erence in the pull-out force for all liquid-based materials.

References

1. R. Jimenez, J. LoPresti, L. Maal, J. Rzonca, and D. Davis. 2003, “Laboratory Testing of Synthetic Tie-Plugging Materials,” Technology Digest TD03007, AAR/Transportation Technology Center, Inc., Pueblo, CO.

2. American Railway Engineering and Maintenance-of-Way Association, 2022, Manual for Railway Engineering, Volume 1, Chapter 30, Ties. Lanham, MD.

(b)

June 2024 // Railway Track & Structures 7 rtands.com MxV RAIL

Figure 4. (b) first 0.3-inch pull-out displacement

THE RIGHT MOW TOOLS K1270 II Rail Saw 866-245-3745 www.trak-star.com Hydraulic & Gas Rail Drills • Hydraulic & Gas Rail Saws • Twister Bits ™ Rail Accessories RB2SPD Rail Drill The right tools make all the difference. Start here and everything else, will fit into place. Hou-762 RTS.indd 1 5/22/24 11:11 AM

Just for Fun

A few glimpses of Big Boy 4014

DBy David C. Lester, Editor-in-Chief

uring the time Canadian Paci c 2816 has journeyed from Calgary on its way to Mexico in celebration of CPKC’s First Spike Anniversary, the spotlight has moved o of Union Paci c’s 4-8-8-4 Big Boy steam locomotive that has garnered a large amount of attention during the past couple of years. However, beginning in July, 4014 will embark on its 2024 Westward Bound Tour from Wyoming to California. Here, we o er a few glimpses of this massive locomotive that will soon return to the rails.

of

so impressed by

Side view of a 4-8-8-4 Big Boy’s running

8 Railway Track & Structures // June 2024 rtands.com IMAGE GALLERY

During building

the Big Boy, a worker was

its size that he wrote “Big Boy” in chalk on the front of the boiler.

gear.

Photo Credit: Shutterstock.com/ Philip Arno Photography (Top), Shutterstock/ Wirestock Creators (Bottom)

June 2024 // Railway Track & Structures 9 rtands.com IMAGE GALLERY

Photo Credit: Shutterstock/ Rexjaymes To learn more, visit brandt.ca/Divisions/Road-Rail Looking for the most powerful railcar hauler on the planet? You found it: the Brandt R5 Power Unit. THE MOST POWERFUL. PERIOD.

Who is the little fellow sitting in the cab window with the engineer’s hat?

South Kansas & Oklahoma Railroad’s (SKOL) Cow Creek Bridge

South Kansas & Oklahoma Railroad’s (SKOL) Cow Creek Bridge

One of the top rewards working on Railway Track & Structures is exposure to the myriad of railroad infrastructure projects going on at any one time. One of the top challenges of working on the magazine is choosing ten of the many projects nominated for our annual Top Projects program as honorees. Capital budgets along with dollars from the federal infrastructure stimulus program resulted in more projects underway than usual this year, generating more nominations and making the selection process more di cult.

UP Global II Capacity Expansion

Union Paci c Railroad set out to simplify their Chicago intermodal operations and nd ways to optimize the global supply chain. As part of this e ort, the railroad invested heavily in upgrades to its Global II terminal located in Northlake, Illinois, while aiming to consolidate Chicago intermodal tra c from the Global I, Global III, and Canal Street facilities to Global II over a 4-year period from design to completion of construction.

PROJECTS TOP 2024

Rail infrastructure projects are our industry sector’s core business - here are ten of the most impressive

By David C. Lester, Editor-in-Chief and Jennifer McLawhorn, Managing Editor

Global II is in a heavily developed area where open spaces for terminal expansion were non-existent. is presented a unique challenge for Union Paci c to redevelop the site while limiting impacts to existing terminal operations. Design teams from TranSystems and Olsson were selected to help strategically redevelop the site, increasing the terminal’s capacity and allowing intermodal consolidation. e e ort saw existing warehouses turned into paved parking lots, runaround tracks relocated and grade separated, receiving and departure tracks turned into ramp tracks, portions of the hump yard turned into paved parking lots, relocation of maintenance facilities, and a new signalized intersection and out-gate to promote better tra c ow through the site. e transformation of Union Paci c’s Global II terminal embodies strategic planning, innovative solutions, and adaptability. Despite unique challenges, the collaboration between Union Paci c, the design teams, construction teams, and K-Five ensured these projects were completed allowing Union Paci c to reach their goal of simplifying Chicago intermodal operations and optimizing the global supply chain.

Vista Canyon Multi-Modal Center

e City of Santa Clarita is the project sponsor and lead agency that built this new

June 2024 // Railway Track & Structures 11 rtands.com

TOP PROJECTS

Photo Credit: Watco

SCRRA/Metrolink Station. Project work on the City of Santa Clarita’s new Vista Canyon Multi-Modal Transit Center included the development of a new passenger rail station, a center platform, and a grade-separated pedestrian access under main track to the platform. RailPros, Inc. served as the prime designer, while Icon West was the prime contractor. e installation of the transit center involved the relocation of the existing Via Princessa Metrolink Station, and the new construction included new main track and extended and realigned siding track, extensive grading, a new rail bridge, large soil nail wall, retaining walls, soundwalls, and a new control point.

Teams e ectively handled challenges like live operating track, which required the phasing of work at an existing control point, to deliver the project on time and within budget. CP Humphreys Signal house and PTC cutover and movement of the existing control point to a new location was nished in a weekend while also shi ing train tra c from siding to main track to complete the work. e project required close collaboration to plan and perform work concurrently during the weekend shutdown to successfully complete Metrolink’s Cutover, while also allowing the contractor to install platform footings, communications conduits, remove track and install new track underlaid with HMA.

PATH C-Yard Reconfiguration and Vehicle Storage Facility

e Port Authority of New York New Jersey PATH rail line provides daily commuters access between Jersey City, NJ and Manhattan, NY. e project is located at PATH ’s Yard C maintenance facility, which is responsible for maintaining continuous operation of their railcars. is HUB is active 24 hours a day, 7 days a week and poses one of the most signi cant challenges for the project.

is rail line is an electri ed line which means there are no diesel-powered locomotives to pull these passenger cars around. All the cars are powered and propelled by high voltage electricity fed through a 3rd rail mounted alongside the running rail. is poses the biggest challenge and safety concern as the crews are working in around live high voltage 3rd rail the entire time. All work must be coordinated with this in mind to ensure the safety of crews working, as well as PATH employee around. Access to the facility is required to be kept for PATH MOW forces and other contractors. e

yard is also situated near residential homes, requiring special consideration to equipment and construction sequencing was required to minimize the noise impact on the public.

Tracks Unlimited , as the general contractor, has the responsibility for recon guring the rail yard and constructing a new maintenance facility at PATH’s Yard C for the Port Authority of New York & New Jersey (PANYNJ). Tracks is responsible for planning, scheduling, and executing all work tasks throughout the project safely, and coordinating all communication with the Port Authority.

B-115.19 Conneaut Viaduct Bridge Replacement

In 2023, Norfolk Southern completed a bridge replacement in Conneaut, Ohio for one of its busiest bridges. e existing bridge was a 100+ year old, 1,320-footlong, 28 span open-deck bridge which had reached the end of its useful service life and needed to be replaced in order to maintain safe, continuous service along this busy rail corridor.

Norfolk Southern worked closely with project designer HDR , construction manager Michael Baker, and contractor Mascaro to navigate several complex challenges throughout the project. Among these challenges were minimizing impacts to rail operations and the public. e bridge is approximately 60-feet high and access was restricted near the bridge ends, in Conneaut Creek, and around another railroad.

Norfolk Southern worked with HDR to assess various options to replace the century-old bridge. HDR designed the new, 1,296-foot-long, 15-span ballast-deck bridge and provided geotechnical, hydraulic and environmental permitting services. e bridge design allowed for construction phasing to minimize track outages and operational downtime during construction. e superstructure consists of four welded girders with a steel deck. It’s supported by cast-in-place concrete caps and pairs of cast-in-place concrete columns founded on drilled sha s. e main span of the bridge weighed over one million pounds alone, and 4.7 million pounds of structural steel was used in the bridge’s construction. e new substructure was installed prior to the superstructure without impacts to train operations and was located such that interferences with the existing foundation were eliminated to the extent practical. e superstructure was replaced incrementally

BNSF constructed a new second main track and bridges to increase rail capacity while listening to the needs of the community.

in a series of short track curfews.

Mosaic Bone Valley Track 50 & 51

As part of the scope of work with Mosaic and CSX in New Wales Florida, Road & Rail Services was tasked with replacing two

12 Railway Track & Structures // June 2024 rtands.com TOP PROJECTS

Photo Credit: BNSF

sections of track which are used to clean empty railcars. e track was in extremely bad shape. Years of product buildup had covered the ties, to such an extent that CSX would no longer put trains on it. Because these sections of track typically

accommodated 80 railcars a day, six days a week at normal capacity, this was signicantly increasing dwell time and the costs associated with it. e project involved the removal and replacement of 11,615 track feet on Track 50 and Track 51, with two

switches to be designed, built, and cut in at each end. e project was scheduled for spring, when demand for the fertilizer produced at this Mosaic plant is at its peak, with a very tight time frame for completion; work was performed in two phases to

June 2024 // Railway Track & Structures 13 rtands.com TOP PROJECTS

minimize impact to the plant’s production, each with its own deadline, so that the other half of this track could still be used during the project. With a detailed plan of work prepared in advance and a seasoned track crew onsite, Phase I was safely completed on time with Phase II ahead of schedule.

e result was a signi cant reduction in dwell time for Mosaic and CSX railcars at the Mosaic site. As a result of the design work of Hatch Engineering and contracting services from Road & Rail Services, CSX will be able to set out trains on these two tracks, whereas the poor operating condition had previously prevented this e ciency.

Construction of Anaheim Canyon Metrolink Station Improvements

e Anaheim Canyon Metrolink Station Improvements improves the passenger experience for Metrolink riders in Orange County. e project included the installation of two new control points on the Olive Subdivision, construction of new siding and main track, construction of a new second platform, extension of the exiting main platform, installation of two new at-grade

crossings, and other associated improvements. All work was completed while maintaining freight and commuter rail service through the area, requiring close coordination with stakeholders and careful planning.

e project required coordinating with a variety of stakeholders including project owner, OCTA and project designer, HNTB. e success of the project required not only coordination with each stakeholder but also an understanding of each stakeholder’s priorities and needs for the project.

e project was constructed around live train (freight and passenger), vehicle, and pedestrian tra c. Minimizing the impact of construction was identi ed as a priority for several stakeholder groups including SCRRA and the City of Anaheim. Stacy Witbeck was allowed four planned All-Work-Window (AWW) outages for installation of insulated joints (IJs), turnouts, and transition track. is project was constructed within the existing OCTA/ SCRRA/City of Anaheim right-of-way and bordered on both sides by developed private property. e access through these properties was limited and restricted access to the

project to the existing at-grade roadway crossings and one temporary access point. is created a linear project that required detailed planning and coordination to ensure that access for critical work was not obstructed by concurrent activities. To help avoid con icts, Stacy Witbeck subdivided the project into four zones and all project schedules used these zones to help coordinate activities and ensure accesslimiting activities were identi ed early to avoid con icts.

“Stacy Witbeck was a great partner for OCTA. ey have shown their ability to meet critical timelines and work throughout challenging supply chain issues, whilst maintaining a high workmanship standards on site, look forward to working with them in the future.” Salvador Munoz, Rail Program Manager said.

CN Mile 90.3 Aberdeen Bridge

With the e orts of prime contractor PCL and prime designer AECOM, work on CN ’s Mile 90.3 Aberdeen Bridge involved the rehabilitation of an active railway bridge over the North Saskatchewan River. e

14 Railway Track & Structures // June 2024 rtands.com

Union Pacific worked to simplify its intermodal operations in Northlake, Illinois by investing in its Global II terminal.

Photo Credit: Olsson

CONGRATULATIONS

to the BNSF Sandpoint Junction Connector bridge project team on the project’s selection as an RT&S TOP PROJECT.

bnsf.com

scope of work included the addition of eight new concrete piers founded on driven H-piles built in between existing piers which were originally constructed in the early 1900’s. Gravel roads were built on both sides

of the river through private land to provide access to the project. Clay co erdams were installed in the river over the course of two seasons during the time frames approved by regulation. ese co erdams provided

access to complete the in-river bridge rehabilitation work.

Seven existing piers were modi ed with the addition of concrete extensions to support new deck plate girders which replaced the existing structural steel deck and through truss spans. Roughly 3m of concrete was cut o the top of the existing piers and hoisted down to the berm level elevation for three of the existing piers (two of which were redundant piers). is work occurred during speci ed track closure windows to facilitate the installation of the new deck plate girder spans, precast deck slabs and track panels. e bridge approaches were also rehabilitated on both sides of the river with the addition of new steel H-piles, structural steel bracing and new concrete box girder spans complete with track panels that replaced the original timber structure.

All construction work was completed on May 30, 2023, without interfering with the continued safe movement of rail tra c, except for the major span replacement work that was scheduled and planned for months

16 Railway Track & Structures // June 2024 rtands.com TOP PROJECTS

Material for the SKOL Cow Creek Bridge began to arrive in June 2023.

Visit RailPros.com/Career Follow Us On Congratulations to the City of Santa Clarita, Metrolink, and all the contractors who played a role in the new Vista Canyon Station! What an accomplishment for all. RailPros was honored to be part of the project and cannot wait to see its impact on the city of Santa Clarita unfold. Want to work on projects like this nationwide? Team RailPros has openings!

Photo Credit: Watco

in advance of the required track closures.

BNSF Sandpoint Connector

In an era when supply chain issues and logistical challenges are commonplace, the Sandpoint Junction Connector project is a positive example of how Class I railroad BNSF took the initiative to construct a new second main track and bridges to increase its rail capacity while listening to the community’s needs and concerns, as well as protecting the environment. With prime contractor Ames Construction and prime designer Hanson Engineering , the project’s primary goal was to improve rail traffic in the region. This was accomplished with the design and construction of a 2.7-mile stretch of second main track, including a 4,875-foot-long bridge over the beautiful and popular Lake Pend Oreille. The new bridge runs parallel to the original, early 1900s mainline structure, which was repaired and updated to continue its operations and increase the rail network’s resiliency.

During construction, the team used

innovative bridge-monitoring technology to detect track movement on the nearby original, operating bridge and gathered ongoing drone footage to monitor construction and progress. Because of Lake Pend Oreille’s

WE WOULD LIKE TO THANK OUR PARTNERS AND EMPLOYEES WHO WORK DILIGENTLY TO ENSURE THE SAFE AND SUCCESSFUL

COMPLETION OF OUR PROJECTS.

environmental importance to the area and its recreational impact, the team focused on identifying regional best management practices and conducted extensive permitting to protect the lake, sh and other

June 2024 // Railway Track & Structures 17 rtands.com TOP PROJECTS

Photo Credit: Watco

Upgrades to the SKOL Cow Creek Bridge were necessary to provide adequate rail service.

team focused on identifying regional best management practices and conducted extensive permitting to protect the lake, sh and other aquatic species. is included transporting construction equipment and materials on barges instead of building a temporary work trestle across the lake.

e soil conditions in the lake also presented challenges and complexities. e soil was so so and sensitive that installing a pile caused a short-term reduction in soil strength. e project team completed additional analysis and extended the pile length to nearly 240 feet in many locations, solving the pile capacity challenge. Hanson also limited the amount of castin-place concrete to avoid spills in the lake and lowered the number of strikes per pile to reduce vibrations and sounds to protect the sh in the lake.

e new bridge was completed ahead of schedule in November 2022. Train tra c was shi ed onto the new bridge as singletrack operation in order to execute the maintenance project. Following a successful replacement of all 1903 superstructure

18 Railway Track & Structures // June 2024 rtands.com TOP PROJECTS

Humatics Focus automatically collected and analyzed track geometry scans spanning a cumulative 6000 track miles over the course of more than 600 revenue service trips.

We are honored to be a part of the team behind the Union Pacific Global II Capacity Expansion. Congratulations to all of the 2024 RT&S Top Project winners.

Photo Credit: Humatics

was installed near the Amtrak station, and BNSF now has two continuous mainlines through the area.

SKOL Cow Creek Bridge Rehabilitation

Upgrading the South Kansas & Oklahoma Railroad ’s (SKOL) Cow Creek Bridge was a pivotal part of necessary infrastructure improvements to provide adequate rail service for a new soybean processing facility on the line. e Kansas weather refused to cooperate with the plan, but the coordination of the Watco team and contractors ensured the bridge replacement was completed on time and without incident.

e bridge, located just southwest of Pittsburg at milepost 59.6 on the SKOL’s Gorilla Subdivision, measures 385 feet across 12 spans. e original structure was mostly timber with steel spans over the river. Most components were over 100 years old. American Rail Engineers provided a design to eliminate the timber sections and ensure the bridge could safely handle 286,000-lb. tra c for years to come. e timber spans were replaced in phases, with

Rapid prototyping and digital collaborative tools were used to instantly incorporate design feedback from NJT vehicle engineers to create mechanical bracketry for proper installation.

CONGRATULATIONS

to the BNSF Sandpoint Junction Connector team on the RT&S Top Projects award!

June 2024 // Railway Track & Structures 19 rtands.com TOP PROJECTS

Photo Credit: Humatics

sections and ensure the bridge could safely handle 286,000-lb. tra c for years to come. e timber spans were replaced in phases, with the smaller, 3-span section being rst. But only a er access agreements with

neighboring landowners were made, roads and staging areas built, and equipment and materials delivered.

Material began arriving on June 6, 2023. Kraemer North America then started

driving steel H-pile, cutting it to the correct length, welding cross bracing, and installing precast concrete pier encasements below the existing timber structure. Demolition and reconstruction of the south section took place on July 11 within a 16-hour window. A er completion, the equipment and remaining materials were transported to the north side of Cow Creek, and the process began again. During this time, rehabilitation and improvements of the center steel deck and concrete piers continued at night, when SKOL trains weren’t running. e demolition and reconstruction of the north end began August 22, which coincided with one of the hottest days Kansas had seen in years. e temperature was 104 degrees, with the heat index reaching 125. is, combined with the surrounding trees and low-lying area near the creek turned the work site into an oven. e team responded by bringing in temporary shades, large fans, lling coolers with drinks and snacks, and shi ing schedules so the most demanding work could be done at night when temperatures dropped to 90 degrees. is

20 Railway Track & Structures // June 2024 rtands.com TOP PROJECTS

The

Vista

Canyon Multi-Modal Center Project included developing a new passenger rail station, a center platform, and a gradeseparated pedestrian access.

– RT&S Top Projects 2024 –South Kansas & Oklahoma Railroad

Creek Bridge Rehabilitation Watco is proud of those involved in the restoration of an important railroad bridge in southeast Kansas watco.com

Photo

Credit: RailPros, Inc.

Cow

36-hour window. Kelly-Hill laid the ballast and surfaced the new track. B&L Trenching hauled and loaded the ballast and helped with dirt work. Martinus Bottom Line provided agging services.

“I was really impressed with the lead contractor, Kraemer, in their ability to exibly plan around all the challenges by using all 24 hours in the day and safely completing the project in the heat,” said Mike McDermott, Watco senior bridge manager.

e SKOL didn’t miss a single Class I interchange or customer switch. e new bridge ensures a vital connection for existing customers and the new tra c that will come from the soybean facility and other large economic projects currently in the works.

“I was very impressed by the organization and safety coordination between Kraemer and their subcontractors during bridge construction and changeouts,” said Cameron Ginther, Watco director of rail infrastructure. “The professionalism and timeliness by Kraemer to work through project hurdles made it easy for us to continue safe and reliable service

to our customers and Class I partners in southeast Kansas.”

Innovative Track Condition Monitoring Trial

New Jersey Transit and Humatics engaged

in an accelerated 8-week Proof of Concept (POC) through in May through July 2023 to prove that sensor solutions can be quickly installed on revenue service vehicles and that arti cial intelligence so ware can be

The condition of your track sets the velocity of your operations. Getting you up to speed is what the Road & Rail Services Track Division does best. How? Deep track expertise, with a focus on prevention. A seasoned, wellequipped team. A reputation for staying on or ahead of schedule. And an emphasis on safety, first and always.

Site Assessments

FRA Compliance Inspections

Track Repairs

Road Grade Crossings

New Track Construction (our design or yours)

June 2024 // Railway Track & Structures 21 rtands.com TOP PROJECTS

Photo Credit: Road & Rail Services

For the Mosaic Bone Valley Track 50 & 51 Project, Road & Rail Services was tasked with replacing two sections of track.

www.roadandrail.com Jon Branton 859.489.2393 Conrad McMillan 314.308.1999 MOW • Vegetation Control

Ditching & Drainage

Surface Work

Thermite Welding

Bridge Work SEE OUR TRACK SERVICES PROJECT SPOTLIGHT IN THIS ISSUE! Let’s

speed.

•

•

•

•

get your track back up to

installed on revenue service vehicles and that arti cial intelligence so ware can be used to detect, determine and precisely locate track geometry anomalies, defects and other track conditions of interest in real-time.

e initial trial out tted two Kinkosharyo light rail vehicles with the Humatics Focus system consisting of an Edge Computing platform, an inertial measurement sensor, and a GNSS receiver, returning each vehicle to service in under an hour. Rapid prototyping and digital collaborative tools were used to instantly incorporate design feedback from NJT vehicle engineers to create mechanical bracketry for proper installation. e design and installation were both completed within a week. Track condition monitoring was provided for over 10 miles of the Newark Light Rail Line.

Humatics Focus automatically collected and analyzed track geometry scans spanning a cumulative 6000 track miles over the course of more than 600 revenue service trips - collecting and processing over 1.9 terabytes of data. New Jersey Transit has

22 Railway Track & Structures // June 2024 rtands.com TOP PROJECTS

The Mosaic Bone Valley Track 50 & 51 project involved the removal of 11,615 track feet.

Supplier Spotlight Find the right vendors for your business in the RT&S Buyer's Guide. Search for products, research vendors, connect with suppliers and make confident purchasing decisions all in one place. RTandSDirectory.com

STRUCTURES Get listed in the Directory, visit RTandSDirectory.com/AddYourCompany RT&S Buyer's Guide is powered by MediaBrains Inc. ©2023.

Photo Credit: Mosaic

RAILWAY TRACK AND

invested in wi connectivity along the majority of the line, allowing Humatics to leverage existing wireless infrastructure saving additional costs, setup/con guration time and allowing rich data streams to be sent to the cloud.

e aggressive schedule required signicant collaboration and coordination between NJT, Humatics and other thirdparty stakeholders which was successfully provided by the NJT innovation team who broke down barriers, coordinated meetings with the right people and moved quickly to make decisions and get the appropriate approvals. e POC showed speci c track geometry measurements and monitoring capabilities in real-time with precise geopositioning (within 2 feet) that led to the awarding of a 1-year pilot contract between Humatics and New Jersey Transit in January 2024. During this 1-year pilot, Humatics will be installing Focus systems on 4 additional trains this summer and monitoring over 100 miles of track while providing a modern intuitive user interface for maintenance management.

Congratulations

Being recognized as an RT&S Top Rail Project for 2024 is a testament to collaboration on Norfolk Southern’s Conneaut, Ohio, Viaduct Bridge Replacement project.

hdrinc.com

June 2024 // Railway Track & Structures 23 rtands.com TOP PROJECTS

Photo Credit: Jackson Spalding

Norfolk Southern replaced an existing 100+ year old, 28 span open-deck bridge in Conneaut, Ohio.

When evaluating wheel/rail interaction, the wheel is as important as the rail

By Je Tuzik

NEW APPROACHES TO DYNAMIC WHEEL FORCE MEASUREMENT

24 Railway Track & Structures // June 2024 rtands.com

DYNAMIC WHEEL FORCE

Photo Credit: Mike Yuhas

PART 1

The mechanics of wheel/rail interaction are in many ways at the core of railroading and the de ning characteristic of how a train gets from here to there. Because rail typically represents a railroad’s largest nancial asset, track-related issues are o en front and center, even when it comes to wheel/rail interaction. But the wheel is just as important. Advances in wheel impact load detectors and in continuous wheelcondition monitoring are beginning to change the way railroads monitor and

maintain their wheels.

In the context of the railroad industry, the wheel/rail pair is de ned by two basic characteristics:

• Quasi-rigid rolling contact with low rolling resistance

• Wheelset(s) with an approximately conical tread that promotes self-alignment and self-steering.

“These characteristics make railroads a very efficient mode of transportation, and from a theoretical perspective, present a system that is simple to manipulate and to optimize,” Yuqing Zeng, Principal Investigator at MxV Rail, told participants at the 2023 Wheel/Rail Interaction conference. Of course, theory and practice rarely align perfectly.

Defects on the wheel or rail surface can have a signi cant impact on the wheel/rail system, damaging both vehicle and track. Mismatched wheel/rail pro les can cause excessive wear and rolling contact fatigue, poor vehicle performance, and can lead to potential safety hazards. For these reasons, it’s important to be able to accurately measure forces at the wheel/rail interface from the perspective of wheel, truck, and rail interaction. is is typically done using onboard measurement devices like continuous output instrumented wheelsets (IWSs), or via wayside devices like strain gauges and wheel impact load detectors (WILDs).

“Wheel/rail force measurements allow you to make many fast and e ective measurements to identify practical problems and solutions,” Zeng said. IWSs have also been

used to validate and improve the accuracy of various models and simulations like those used in MxV Rail’s NUCARS modeling so ware.

Wheel impact load detectors are used extensively in the North American heavyhaul environment. ese systems detect the impact or loading force of each wheel passing through the test site and ag wheels that are approaching (or exceed) a threshold that requires intervention. “While the network of WILDs in use today has helped to improve industry safety and maintenance practices, there remains room for improvement in wheel condition monitoring,” Zeng said. One such area for improvement is in the uni cation of wayside and onboard vehicle safety threshold/evaluation. Another is the further development of simulations that can better model real-world vehicle behaviors. “ ose [simulations] require consistent and accurate wheel/rail force information as input,” he said.

Discontinuous and Continuous Measurement

From a technological standpoint, there are a number of ways to measure wheel-force discontinuously — measurements that are taken at certain discrete intervals. e most commonly-used rail strain gauge is based on the shear-force method, also called the di erential shear method, Zeng said. is method is easy to implement and generates output data that is independent of the status of tie and fastener. is is the basis for the typical wheel impact load detector.

June 2024 // Railway Track & Structures 25 rtands.com

DYNAMIC WHEEL FORCE

Figure 1. A diagram of an early version of China Railway’s Train performance Detection System (TPDS).

Yuqing Zeng, Principal Investigator at MxV Rail.

“ e weakness of this system is that the e ective zone of measurement is relatively small, and only accurate near the middle of the crib— typically, the length of the 95% e ective measurement zone is less than 200 mm,” he said.

Some of the weaknesses inherent in discontinuous wheel/rail force measurement can be countered by the use of continuous measurement devices based on load pads or instrumented tie plates. However, there are weaknesses inherent in this method, too. “For example, the output for a given wheel would be a ected by the forces generated by the adjacent wheels,” Zeng said. To counter this, the rail can be cut at both ends of the measurement zone. is isolates the wheel(s) from those adjacent,

26 Railway Track & Structures // June 2024 rtands.com DYNAMIC WHEEL FORCE

Figure 2. The overlap revision of the Train performance Detection System (TPDS) places another strain gage in the “dead zone.”

Figure 3. Various wheel surface defects and their Composite Unit Method signatures.

4. A continuous measurement system can measure the circumference of a wheel in a single pass.

but it also creates a discontinuity in the rail that is prone to generating high impact loads. “For this reason, such con gurations are typically found only in static or lowspeed settings like weighbridges and track scales,” he said.

An early breakthrough (circa 1980) in continuous measurement techniques proposed the pairing of discontinuous shear-force strain gauge measurement with load pad technology. “ is e ectively extends the e ective zone of the shear-force measurement and maintains better wheel force isolation without necessitating a physical cut in the rail,” Zeng said. A further re nement of this technique positioned the strain gauges so that the distance between the sensors was less than the wheelbase. “ is means there will never be more than one wheel on the shear force and the load pad unit at a time and means you can obtain the wheel/rail force for each wheel,” he said.

“In the early 1990s, the China Academy of Rail Sciences used this technique to improve the accuracy of high-speed track scales and to develop a train performance detection system (TPDS) to monitor vehicle

hunting on the lines operated by China Railway (CR),” Zeng said.

Figure 1 illustrates the basic design of CR’s earlier-model TPDS. In the case of this design, however, there are regions (circled in red) in which wheels pass through a transition zone that can’t properly measure rail shear force. “ ese ‘dead zones’ made up approximately 11% of the TPDS when it was rst implemented,” Zeng said, making it a “quasi-continuous” measurement system. “Full continuous measurement remained the goal for several reasons; rst, it would allow for accurate measurement of vehicles with di erent wheel diameters, and second, it would allow the TPDS to reliably measure wheel circumference,” he said. In this case, the solution was fairly simple: the addition of a strain gauge inside the dead zone to e ectively make the valid areas overlap (see gure 2).

ese overlapping full-continuous measurement systems have proven to be e ective and able to measure a wide range of wheel/rail / vehicle dynamics, such as weight in motion (WIM), overload, imbalance, hunting, wheel surface defects, and

preventing bearing failure. But they are also quite costly and di cult to maintain. “As a result, their use is typically limited to specialized test tracks, like the Siemens Test and Validation Center in Germany,” Zeng said.

e success of these systems inspired Yuqing Zeng, prior to his work with MxV Rail, to develop an approach to solve the “dead zones” issue (as shown in gure 1) without requiring additional hardware. “ is approach, dubbed the Composite Unit Method, uses algorithms to infer ‘dead zone’ data based on adjacent strain gauge, and underlying load pad data,” Zeng said. Data generated by this composite unit method can, like in overlap-type TPDS systems, also be used to detect speci c wheel surface defects like skid ats, shells, and out of roundness based on their measured characteristics. Figure 3 shows some of these defects and their respective composite unit signatures.

Another bene t of continuous measurement technologies versus discontinuous systems (like WILDs) is that the entire circumference of each wheel can be

June 2024 // Railway Track & Structures 27 rtands.com DYNAMIC WHEEL FORCE

Figure

MAXIMIZE UPTIME & MINIMIZE REPAIR COSTS WITH DATA-DRIVEN MAINTENANCE PLANNING

measured in a shorter test site (see gure 4). “Continuous measurement technologies give you 100% coverage of the wheel, enhancing the e ectiveness of wheel and vehicle monitoring,” Zeng said. ese systems also provide constant and consistent data that can be integrated with

other condition-monitoring data for more in-depth analyses. One example of the kind of in-depth analysis that this data makes possible is assessment of wheel-break risk.

Figure 5 shows the relationship between rim thickness, dynamic vertical forces and wheel-break risk compared to a

representative population. Continuous measurement systems can be used to determine wheel circumference, and thus rim thickness, in addition to providing data on dynamic forces — giving a full snapshot of wheel-break risk in this example. Similar methods can be used to assess the severity

Symbol of Innovation in

Maintenance of Way Equipment

Racine Railroad Products’ cutting edge operator control interface and computerized automation not only increases production, it also improves safety while making our machines easier to operate and maintain the equipment. We offer a wide-range of innovative powered portable hand tools.

28 Railway Track & Structures // June 2024 rtands.com DYNAMIC WHEEL FORCE

Visit us at racinerailroad.com Follow us on LinkedIn: linkedin.com/company/racine-railroad-products See our machines and operator controlled screens at youtube.com/@racinerailroad1986 Contact us on how we can assist you with your MOW needs (262) 637-9681 Racine Railroad Products, Inc. 1955 Norwood Court, Racine, WI 53403

Figure 5. A chart showing the relationship between rim thickness, dynamic vertical forces and wheel-break risk.

The

Figure 6. A chart showing wheel/rail force data of a polygonal wheel. of polygonal wheels (out-of-roundness) and their associated hazards (see gure 6). “Discontinuous measurement technologies like traditional WILDs may detect a polygonal wheel, but depending on the frequency/ order of the rotating out-of-round (OOR) wheel, it’s very likely to miss it instead,”

Zeng said.

Part 2 of this article will look at some of the other technologies that have been developed to collect continuous dynamic wheel and truck performance data and will cover some of the early ndings on research into bearing-based wheel impact load detectors.

Je Tuzik is Managing Editor of Interface Journal

This article is based on a presentation made at the WRI 2023 Heavy Haul conference.

The Model 10 Signal

Since 1936, the Model 10 Signal has set the standard for railroad crossing warning devices.

TheModel 10 can be configured to your specifications with a 3590 seriesgate mechanism, plus a gate arm up to forty feetlong. Then, either LEDorincandescent light units, along with either a mechanical oran electronic warningbell,andthe proper signage completethe signal assembly.

Please contact Western-Cullen-Hayes, for Model 10 details.

WESTERN-CULLEN-HAYES, INC. 2700W. 36th Place • Chicago, IL 60632 (773)254-9600 • Fax (773) 254-1110

Web Site: www.wch.com E-mail:wch@wch.com

June 2024 // Railway Track & Structures 29 rtands.com DYNAMIC WHEEL FORCE

Engineering News: The Weekly RT&S Email Newsletter SUBSCRIBE AT: www.rtands.com/engineeringnews Get The Inside Scoop ON AND OFF THE TRACK

Anti-Trespass Panels are a simple but e ective deterrent to pedestrian trespass.

RIDE A SMOOTH

RProtecting both the vehicle and the infrastructure

By Jennifer McLawhorn, Managing Editor

By Jennifer McLawhorn, Managing Editor

ecognized by those both inside and outside of the rail and track maintenance sphere, grade crossings are essential to ensuring a smooth ow of tra c for trains and emergency and civilian vehicles. Proper upkeep is important, and what follows is a smorgasbord of grade crossing products and services to ful ll those needs.

L.B. Foster grade crossing safety solutions include a variety of smart obstacle detection and anti-trespass deterrent systems. L.B. Foster markets and sells its innovative AntiTrespass Panels (ATPs) throughout North America as a proven environmentally friendly deterrent system to pedestrian trespass. AntiTrespass Panels (ATPs) have been shown to be a simple but e ective deterrent to pedestrian trespass on highway-rail grade crossings, rail yard entrances and in speci c areas such as transit terminal platforms. Applicable in many situations, ATPs work best around xed structures such as end of station platforms, walls,

fencing or dense vegetation to prevent pedestrians from walking around the panels.

“Since being introduced in 2017, initial acceptance has been among passenger rail systems with several transit agencies installing ATPs on various sites along their lines. Interest has also been growing among NA transits and state DOTs,” comments Sheen Fong, Director of Technical Sales.

In mid-2019, the FRA published results of a study done to determine the e ectiveness of deploying ATPs to reduce pedestrian trespass. eir researchers collected and analyzed video data for a total of 60 days (30 days before and 30 days a er the ATPs were installed) to better understand the e ectiveness of the ATPs on changing pedestrian behavior. eir analysis demonstrated that the ATPs successfully reduced the amount of pedestrian trespass onto the railroad right-of-way, observing that pedestrian trespass was reduced by 38%, indicating that use of the ATPs were e ective

in improving pedestrian behavior. Developed and engineered to minimize installation time, the anti-trespass panel system provides an innovative solution to meet the safety requirements of railroads worldwide. Made from 100% recycled rubber, the ATPs are environmentally friendly and come with a 15-year warranty.

Jim Overfelt, Director of Sales and Marketing, told RT&S that HiRail has received requests for specialized products to t a variety of fastening systems and track con gurations. He went on to say that “the market remains strong for grade crossings and we are cautiously optimistic that this will continue for the forseeable future.” Indeed, HiRail provides products for new transit start-ups and those extending their current systems.

HiRail o ers a line of rubber grade crossing surfaces. Among these are its HiRail, PedeRail, and HiRail Rail Seal. e HiRail Rail Seal is a rubber product that works with concrete

30 Railway Track & Structures // June 2024 rtands.com

Photo Credit: L.B. Foster

GRADE CROSSINGS

crossings or asphalt. It ts most timber or concrete ties using any type of rail fastener. HiRail’s PedeRail is a speci c crossing surface manufactured with a raised diamond surface designed with pedestrians in mind. It meets Americans with Disabilities Act (ADA) requirements. eir namesake HiRail fulldepth rubber crossing systems come in lagged and lagless designs, with lagless lessening crosstie degradation over time and allowing for installation on both concrete and steel ties. ese HiRail products can also be recycled.

Hitachi Rail’s Model 95 Highway-Crossing Gate Mechanism is the industry standard for simplicity, reliability, durability, ease of maintenance, and value. Its design culminates in innovation, meeting or exceeding the specications set by the American Railway Engineering and Maintenance of Way Association (AREMA) and the American Association of Highway O cials. With a focus on safety and value, the Model 95 series incorporates modern techniques and materials, featuring a modular design that simpli es service and maintenance. is commitment to quality ensures that Hitachi Rail’s gate mechanisms

are not just industry standards but also a critical component in maintaining the safety and e ciency of railroad crossings.

e SIL-2 solid-state motor controller o ers dependable performance and enhanced safety features. Its innovative design e ectively eliminates dust, thereby increasing the reliability and longevity of the system for the customer.

e Model 95-E Gate Mechanism, renowned for its robustness, is supported by Hitachi Rail’s eld support and product engineering services, ensuring the product performs optimally throughout its lifecycle.

Moreover, the Model 95-E Highway Gate Crossing Mechanism’s versatility is evident in its availability in various con gurations, making it an ideal solution for diverse crossing requirements. Whether it’s a standard highway crossing, a combined highway and pedestrian gate, pedestrian sidewalk or a sophisticated “Four-Quadrant Gate” system, the Model 95-E meets the speci c needs of each unique crossing situation, providing a tailored and e cient solution for tra c management and safety.

OMNI Rail’s 2024 priorities have focused on supply chain and inventory management

to ensure short and predictable lead times for its US and Canadian customers. Rob Greenside at Omni Rail told RT&S, “Building on a strong 2023 year-end, we also expanded our engineering sta and technical support resources to deliver new rubber and concrete products that include ‘design and build’ projects requiring complex panel structures (concrete, rubber, steel, composite combinations).” OMNI o ers concrete/rubber ange and full depth virgin rubber panel products for every load condition, tie size, rail size and fastener type installed in the US and Canada track system base. All OMNI products are ‘Buy America Compliant’.

OMNI is vertically integrated to manufacture both virgin rubber, concrete, and steel products serviced from 4 convenient factory locations. Production and custom panels are o ered less than 8’, 8.125, 9’ and 10’ and 12’, including custom fastener design modi cations for easy install clearance. Greenside says, “We typically manage multiple project deliveries scaling to greater than 1,000 track feet per month.” With manufacturing locations in McHenry, Ill., Lincolnton, N.C., and

GRADE CROSSINGS

Weatherford, Texas, OMNI supports combination concrete gauge installations, coupled with low-cost eld side solutions that use its molded virgin rubber products.

Its ‘solid cross section molded virgin rubber’ panel anges are embedded for continuous full-length support or installed as a separate load bearing angeway ller. Both carry a 6-year, no-tear warranty. OMNI’s core

product design rules incorporate rubber as a load bearing component to provide extreme rail head protection, ADA and/or customer speci ed dimensional control, avoiding tears or separation of the rubber ange for the design life of the panel. Some new product additions for this year include: VRA/2 molded rubber product, spike or clamp to rail install for asphalt or concrete road interface; A

reduced cross section version of OMNI’s VRA product with a 20-year eld history; Combinations of concrete grade panels with several rubber eld panel or angeway rubber con gurations to match customer cost and performance objectives; Molded ‘yellow rubber’ safety tread surfaces on full depth rubber panels or steel reinforced panels; Expanded concrete tub crossing products that include 11’ wide heavy load application tubs (Tra-Cast lll). is product expands the capabilities of our Tra-cast I and Tra-cast II products that have more than a decade of eld service (curves to 30 degrees).

Special application products include steel reinforced heavy load crossings that are a unique product relying on custom rubber surfaces bonded to steel structures. Steel reinforced panels are available for a wide range of rail sizes and easily extend performance for non- standard wide or extreme narrow-gauge applications. With AARM-1003 certi ed factories, all OMNI products are backed by a six-year limited factory warranty from the date of installation.

rtands.com GRADE CROSSINGS

Photo Credit: HiRail

STAY IN GEAR WITH RAIL GROUP NEWS ROUND-UP of NEWS STORIES RAILWAY A RAIL GROUP NEWS From Railway Age, RT&S and IRJ https://railwayage.com/newsletters RA_RailGroupNews_1-6Vertical_InGear_2022.indd 1 1/10/22 12:55 PM

Among its grade crossing portfolio, HiRail o ers HiRail, PedeRail, and HiRail Rail Seal.

PERFORMANCE ON TRACK®

Innovative System Solutions for Future-Proof Networks

Nortrak is more than special trackwork. We offer in-house design and manufacture of 100% Buy America compliant integrated railway system solutions featuring:

»

• special trackwork

• switch machines

• zentrak monitoring systems

• premium rail

• concrete ties

• direct fixation fasteners

• resilient clips, pads and insulators

• engineering design services

Are you planning to upgrade your rail infrastructure or start a new project?

Get in touch with your Nortrak Sales Professional to learn how we can assist you.

voestalpineRailwaySystemsNortrak

ww w.v oe st alpi ne.c om/ n ort rak

» »

» » » »

»

Message From The President

RAY VERRELLE

AREMA President 2023-2024

The Railway Engineering Education Symposium (REES) is a testament to the power of collaboration. Developed by the AREMA Educational Foundation in partnership with the American Public Transportation Association (APTA), it has been a vehicle to expose academia to the railway industry for over 15 years. REES is not just about knowledge delivery but also about fostering relationships and helping colleges and universities develop rail curriculums for their engineering programs.

REES was first held in 2008 with a clear mission: to engage universities, drive interest, and help graduate more engineering students with knowledge of the railway industry. It was a response to the need for a healthy supply of rail engineering candidates, aiming to balance the rate of attrition. The primary goal was to introduce railroad engineering content to professors and engineering students, with the hope of expanding the number of universities that offer railway engineering in their curriculum. Since then, REES has been held biannually, continuing its crucial role in the industry:

* 2008 – University of Illinois at Urbana-Champaign (UIUC)

* 2010 – Johnson County Community College (JCCC)/BNSF Technical Training Center (BNSF TTC), Overland Park, KS

* 2012 – JCCC/BNSF TTC

* 2014 – JCCC/BNSF TTC

* 2016 – UIUC

* 2018 – University of South Carolina

* 2020 – cancelled - COVID

* 2022 – University of Illinois Chicago

* 2024 – Utah Transit Authority, Salt Lake City

The first five symposiums were centered on the presentation of modules that could be inserted into a college course. Since then, REES has transitioned to more of a user’s group event. However, new professors are still invited to attend a section to introduce the Introduction to Rail Engineering modules. AREMA Member Michael A. Pochop, PE, Vice President of Hanson Professional Services, Inc. serves as the REES Committee Chair and has been running point on REES for AREMA since 2010. We are very grateful for his ongoing dedication to this educational program.

With REES being focused on the heavy freight rail side of the industry, APTA wanted to have a REES event focused on passenger rail and transit. Based on AREMA’s REES, the first APTA Passenger Rail Engineering Education Symposium (pREES) was held in 2015. REES was held on even-numbered years, and pREES was held on odd-numbered years. I had the honor of hosting pREES in 2023 in Washington, D.C. There was a great exchange of engineering topics, technical discussions, and project presentations. We finished with field visits hosted by Amtrak and Washington Metropolitan Area Transit Authority (WMATA). It was great to interact with the various faculty staff and see firsthand the interest in our industry.

Late last year, AREMA and APTA agreed to co-produce REES 2024, with funding and content from both organizations. REES 2024 is being expanded to a full three days to deliver both freight rail and passenger/transit rail content and tours. REES 2024 will be held in Salt Lake City, Utah from June 18th to 20th hosted by the Utah Transit Authority. Moving forward REES will be combined with freight and passenger railway engineering topics and be held every other year on even years as a joint effort. At the time of writing

this article, the team is working hard to finalize the agenda for REES 2024. After talking with Mike, the agenda looks to be filling up nicely.

Day one of the symposium will be focused on the needs of the industry from our Universities. There will be a vast array of speakers from contractors, equipment suppliers, Transit Agencies, Class 1 Railroads, Short Lines, and Engineering Consultants, all putting their perspectives on what they are seeking out in terms of knowledge from potential engineering graduate candidates. The day concludes with a reception and dinner with a freight railroad keynote presentation.

Day two is usually the most exciting and exhausting of the three-day symposium with the site tours. Utah Transit Authority is hosting a tour of their Warmsprings Commuter Rail Facility, then off to Stadler to tour their facility, and the day will wrap up with a tour of Union Pacific’s Salt Lake City Intermodal Terminal. There will also be a reception and dinner following the tours.

Day three will delve into research programs and research opportunities with a panel discussion that includes panelists from FRA, FTA, AAR, ENSCO, and DOT. There will be an opportunity to hear from academia on current programs and additional technical presentations.

While this year’s REES program has already been established, it is never too early to start thinking about REES 2026. AREMA & APTA are looking for volunteers to present, host, or sponsor our next REES event. This is a great opportunity to engage with the future of our industry. If you think this is something you would like to get more involved with to support the growth of our industry, feel free to reach out to info@arema.org

More information can be found on www.aremafoundation.org , where professors apply to attend. We would like to thank the sponsors making this event possible: APTA, Association of American Railroads (AAR), CSX, Stadler, TranSystems, Union Pacific, and Utah Transit Authority (UTA).

34 Railway Track & Structures // June 2024 rtands.com

FYI

Register now for the AREMA 2024 Annual Conference & Expo in Louisville, KY, September 15-18. Save your seat for the best education, speakers, networking events, Expo, and more online at www. conference.arema.org.

Is your Library up to date? Order the 2024 Communications & Signals Manual today. With over 95 new, revised, reaffirmed, or extended Manual Parts, including over 800 pages of updates, it’s the perfect time to get your copy of the 2024 Manual. Order online now at www.arema.org.

Did you know we offer a wide variety of on demand education for learning on your time? Browse our most popular webinars, seminars, and Annual

2024 MEETINGS

JUNE 11

Committee 28 - Clearances Savannah, GA

JUNE 21-22

Committee 24 - Education & Training Pueblo, CO

JULY 31 - AUGUST 1

Committee 7 - Timber Structures Kansas City, MO

SEPTEMBER 14-15

Committee 05 - Track

Committee 24 - Education & Professional Development

SEPTEMBER 15

Committee 10 - Structures

Maintenance & Construction

Committee 11 - Commuter & Intercity Rail Systems

Committees 11/17 - Joint Meeting

Committee 12 - Rail Transit

Committee 13 - Environmental

Committee 14 - Yards & Terminals

Conferences to earn your PDH credits on the go. Visit www.arema.org to start your On Demand education today.

Download the AREMA 365 App for essential rail resources and networking opportunities. Easy access to news, events, and educational materials lets you stay informed and connected to the industry. Download it today by searching for AREMA in your phone’s app store.

Don’t miss out on the conversation in AREMA’s Member Forum. The Member Forum connects you with other Members, allowing you to send messages, start conversations, and more. See what everyone is talking about today: https:// community.arema.org/home.

If you’re looking for a podcast to binge, listen to AREMA’s Platform Chats. It features guests from every aspect of the railway industry. Catch up on all four seasons available on all your favorite listening services today.

Leverage the power of your trusted association’s Railway Careers Network to tap into a talent pool of job candidates with the training and education needed for long-term success. Visit www.arema. org/careers to post your job today.

CONNECT WITH AREMA ON SOCIAL MEDIA: NOT AN AREMA MEMBER? JOIN TODAY AT WWW.AREMA.ORG

UPCOMING COMMITTEE MEETINGS

Committee 16 - Economics of Railway Engineering Operations Committee 17 - High Speed Rail Systems Committee 18 - Light Density & Short Line Railways Committee 33 - Electric Energy Utilization

Committee 40 - Engineering Safety & Training Committee 41 - Track Maintenance

SEPTEMBER 16-17

Committee 35 - Information Technology

SEPTEMBER 17-19

Committee 04 - Rail

Join a technical committee

SEPTEMBER 18-19

Committee 38 - Information, Defect Detection & Energy Systems Committee 39 - Positive Train Control

SEPTEMBER 19

Committee 27 - Maintenance of Way Work Equipment

OCTOBER 24-25

Committee 2 - Track Measurement and Assessment Systems San Francisco, CA

SEPTEMBER 15

Committee 17 - High Speed Rail Systems Louisville, KY

Joining a technical committee is the starting point for involvement in the Association and an opportunity for lifelong growth in the industry. AREMA has 30 technical committees covering a broad spectrum of railway engineering specialties. Build your network of contacts, sharpen your leadership skills, learn from other members and maximize your membership investment. If you’re interested in joining a technical committee or sitting in on a meeting as a guest, please contact Alayne Bell at abell@arema.org.

For a complete list of all committee meetings, visit www.arema.org.

June 2024 // Railway Track & Structures 35 rtands.com

PROFESSIONAL DEVELOPMENT

AREMA is committed to your education and advancement in the railway industry by providing Professional Development Hours (PDH) through our Seminars. These Seminars serve your educational needs and offer an opportunity to network with peers in the industry. Attendees can gain valuable insights into railway engineering and maintenance, featuring cutting-edge technologies, best practices, and industry trends. Whether a seasoned professional or newcomer, participants will leave equipped with practical tools and strategies for success and a network of industry professionals to support their journey.

INTRODUCTION TO PRACTICAL RAILWAY ENGINEERING SEMINAR

Date: Saturday, September 14Sunday, September 15

L ocation : Louisville, KY - in conjunction with the AREMA 2024 Annual Conference & Expo PDH: 16

TRACK ALIGNMENT DESIGN, PART I SEMINAR

Date: Wednesday, September 18 - Friday, September 20 Track Alignment Design, Part I Seminar

L ocation : Louisville, KY - in conjunction with the AREMA 2024 Annual Conference & Expo PDH: 16

TRACK ALIGNMENT DESIGN, PART II SEMINAR

Date: Wednesday, September 18 - Friday, September 20

L ocation : Louisville, KY - in conjunction with the AREMA 2024 Annual Conference & Expo PDH: 16

These courses comprise recommended practices and relevant accumulated knowledge from subject matter experts in the railroad industry. They are not intended as a regulatory qualification.

To register for these Seminars, please visit www.conference. arema.org.

36 Railway Track & Structures // June 2024 rtands.com

Kate O’Connor, PE

Announcement of AREMA Board of Governors 2024 Election

The Governance Nominating Committee, Chaired by Past President Trent M. Hudak, PE has completed its task and the following nominee has been officially elected: Ms. Kate O’Connor, PE – Board of Governor She will begin her Board of Governors position at the conclusion of the AREMA 2024 Annual Conference & Expo which is being held in Louisville, Kentucky, September 15-18, 2024.

Kate O’Connor, PE