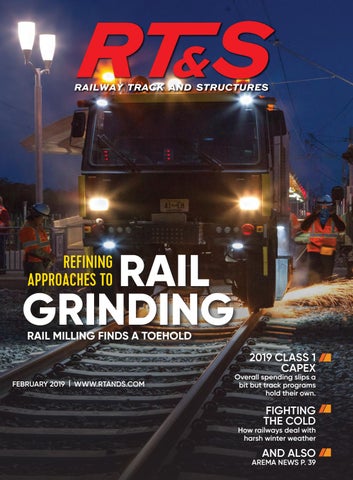

RAIL GRINDING refining approaches to

Rail Milling Finds a Toehold

2019 CLASS 1 CAPEX

February 2019 | www.rtands.com

Overall spending slips a bit but track programs hold their own.

FIGHTING THE COLD

How railways deal with harsh winter weather

AND ALSO

rtands.com

AREMA NEWS p. 39​

February 2018 // Railway Track & Structures 1