MAGAZINE

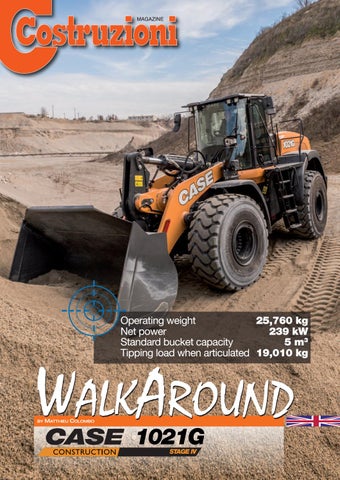

Operating weight 25,760 kg Net power 239 kW Standard bucket capacity 5 m3 Tipping load when articulated 19,010 kg

WALKAROUND BY

MATTHIEU COLOMBO

1021G STAGE IV

MAGAZINE

Operating weight 25,760 kg Net power 239 kW Standard bucket capacity 5 m3 Tipping load when articulated 19,010 kg

WALKAROUND BY

MATTHIEU COLOMBO

1021G STAGE IV