A Publication of FRSA – Florida’s Association of Roofing Professionals

A Publication of FRSA – Florida’s Association of Roofing Professionals

A Publication of FRSA – Florida’s Association of Roofing Professionals

A Publication of FRSA – Florida’s Association of Roofing Professionals

NEW FOR 2023! MFM introduces IB-3™ StormStopper Plus, designed specifically for the Florida roofing market. Stop storm damage in its tracks and offer your customers a qualified FORTIFIED PROGRAM product for years of worry-free service. This 50-mil, self-adhering roofing underlayment features a granulated surface and a non-removable selvedge edge for a secure seal on overlaps for whole roof protection.

IB-3 StormStopper Plus meets ASTM D 1970 and Florida Building Code FL# 41919.1. Request a sample today at www.mfmbp.com or by calling

FRSA-Florida Roofing Magazine Contacts:

For advertising inquiries, contact: Skip Heymann at: skip@floridaroof.com (800) 767-3772 ext. 127

All feedback and reprint permission requests (please include your full name and address) contact: Lisa Pate, Editor lisapate@floridaroof.com (800) 767-3772 ext. 157 Florida Roofing Magazine PO Box 4850 Winter Park, FL 32793-4850

View media kit at: www.floridaroof.com/ florida-roofing-magazine/ #FRSA #roofingprotects

View the case study

Equally strong and attractive, these metal roofing panels are available in Florida in our full line of PAC-CLAD painted steel, aluminum and Galvalume Plus coatings, ensuring that your roof will endure whatever comes its way. All panels are Miami-Dade County and Florida Building Code approved.

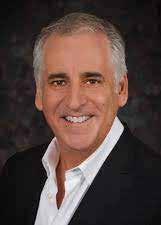

Furman Insurance is Now Acrisure

FRSA member and insurance advisor to the roofing industry, formerly known as Frank H. Furman, is now a part of Acrisure, LLC. Rob Foote continues to lead the Acrisure roofing team. Foote stated, “The transition to Acrisure six years ago has enabled our agency to further harness and deliver roofing-centric risk management resources to our roofing clients.” Acrisure serves 235 roofing contractors on a state and national level, many of whom are FRSA and NRCA members. Acrisure is the leading roofing-focused broker in the country, servicing roofing professionals generating annual revenues from $5-to-$425 million annually and an employee count ranging from 20 to 1,500.

Foote stated that the Acrisure roofing division is further investing industry-specific resources to enhance roofing clients’ operating results while carefully protecting the equity for each of the firms. Acrisure assists established roofing professionals in crafting and adopting industry-leading and innovative risk management resources to achieve their financial objectives. Additionally, for emerging roofing professionals, Acrisure provides industry-specific resources to help build a risk management infrastructure to meet growth objectives.

Acrisure serves the majority of the top 20 roofing contractors in Florida and many top 100 roofing contractors nationally. Rob Foote added, “We are humbled by the opportunities Florida’s roofing community provides for us to serve as a trusted service provider and stakeholder in our roofing clients’ operations. In the seventh year as Acrisure, our roofing team further strengthens risk-reduction and mitigation strategies to support better-in-class roofing professionals that seek to convert their insurance programs into a profit center.” Acrisure was the number one privately held national insurance brokerage firm in 2023, as published in the Insurance Journal's Top 100 Independent Property/Casualty Agencies report.

Best Roofing, Ft. Lauderdale, announced a new partnership with Harkness Capital Partners. Terms of the deal were not disclosed, but officials said it culminated six months of negotiations at a time when the company continues to experience rapid expansion.

Gregg Wallick, President and CEO of Best Roofing has built one of the most successful roofing companies in South Florida by consistently working on the

Continued on page 28

In the early hours of Tuesday morning, March 26, a 985-foot container ship issued a Mayday call before striking a pillar of the Francis Scott Key Bridge, which spans the Patapsco River and part of Baltimore Harbor. The bridge collapsed from the impact.

Due to the Mayday warning and the time of day, the loss of life was not as large as it might have been. However, late Tuesday night, the Coast Guard called

off its search for the six construction workers who had been repairing potholes when the accident occurred and were unaccounted for. Two others had been rescued.

The incident was sudden and horrific and the cause will likely take some time to determine. Meanwhile, the destruction of the bridge will necessitate traffic diversions and lead to supply chain disruptions for many months to come.

Named for Francis Scott Key, a Maryland-born lawyer who wrote the 1814 poem that later became our national anthem, the bridge was used by approximately 30,000 people each day. It carried both the Baltimore Beltway and I-695. With the 1.6-mile bridge destroyed, the shipping lane into the Port of Baltimore is now closed as the waters are cleared of debris and, presumably, plans are made to rebuild it. The port is off-limits to all vessel traffic for now; however, trucks can still access its terminals.

The Port of Baltimore is not one of the biggest U.S. ports, but it is a significant shipping hub. With twelve private terminals and five public ones, it services container ships, bulk carriers and passengers. It is the busiest U.S. port for automobiles, importing and exporting more than 800,000 vehicles each year. About 20 percent of the nation’s coal also passes through the port. In 2023, the port handled more than 52 million tons of foreign cargo worth more than $80 billion.

The port closure will result in an East Coast shipping disruption for vehicles and coal, as well as for “roll-on/ roll-off” machinery used in farmwork and construction. According to the Census Bureau, the Port of Baltimore accepted imports of some $9 billion in such machinery in 2023, making it the top “roll-on/roll-off” port. In 2023, it also managed $2 billion of aluminum, $1 billion of iron and steel and $1 billion of wood.

There are more than 3,000 distribution centers, warehouses and factories in a 30-mile radius of the Port of Baltimore, facilities that likely rely on the port.

Its closure will affect deliveries across the nation and around the world.

Although the supply chain has recovered since the worst of the COVID-19 pandemic, parts of it are still strained. For example, the Panama Canal has had to reduce traffic due to low water levels and shipping companies have been avoiding the Suez Canal due to Houthis attacks on vessels in the Red Sea. The closure of this port will add to that strain. In addition, this closure will impact other ports as ships destined for Baltimore must be diverted elsewhere.

When the Francis Scott Key Bridge opened in 1977, it provided a much-needed route for the city. It completed the I-695 circle and offered a bypass for transporting hazardous materials prohibited in tunnels. Without that bridge, so many vehicles will have to use a slower, longer route to get where they need to go.

Any disruption to the supply chain, no matter how large or small, has ripple effects. Individuals and companies should prepare for delays and slow-downs just in case as the system adjusts and materials are rerouted. As always, it is important for businesses to communicate with their customers and their vendors, working together to anticipate and plan for late deliveries. Make sure your contracts have material

availability provisions that discuss extensions of time associated with material delays.

The information contained in this article is for general educational information only. This information does not constitute legal advice, is not intended to constitute legal advice, nor should it be relied upon as legal advice for your specific factual pattern or situation.

Trent Cotney is a partner and Construction Practice Group Leader at the law firm of Adams and Reese LLP and FRSA General Counsel. You can contact him at 813-227-5501 or trent.cotney@arlaw.com.

Adams and Reese LLP is a full-service law firm dedicated to serving the roofing industry. FRSA members can contact Trent Cotney to discuss and identify legal issues and to ask general questions through access to specialized counsel. They offer free advice (up to 15 minutes) for members. If additional legal work is required, members will receive discounted rates. This is a pro bono benefit provided to FRSA members only. Contact Trent at 813-227-5501.

The 2024 Florida Legislative Session adjourned on March 8. Since leaving Tallahassee, legislators returned to their corners of the state to share with communities and constituents the product of their efforts. The presiding officers, in the last year of their terms, pushed through priorities ranging from social media restrictions to healthcare workforce development. Meanwhile, their successors started to assert their own influence, setting the stage for new leadership and new priorities in 2025 and 2026. With a total of 1,902 bills filed this year, legislators deliberated on many pieces of legislation, of which 325 were successfully passed. Below is an analysis of a handful of the key issues addressed during this session.

The Florida Legislature is constitutionally required to pass just one bill – the budget. The current year’s budget (passed in the 2023 Florida Legislative Session) totals $116.5 billion. With revenues far surpassing estimates, many expected legislative leaders to pass a budget somewhere north of $120 billion. However, at the behest of the Florida House leadership, the Legislature took a more measured approach with the budget, opting to put over $10 billion in reserves. The final product passed was a budget that increased spending less than one percent from the year before. The following is a breakdown of the budget’s key silos.

■ $46.5 billion (41%): Health and Human Services

■ $30.1 billion (26%): Education

■ $20.4 billion (18%): Transportation, Tourism and Economic Development

■ $9.9 billion (9%): Agriculture, Environment and General Government

■ $7.3 billion (6%): Criminal and Civil Justice

A top priority of Governor Ron DeSantis was property insurance tax relief. HB 7073 and SB 7074 provides a one-year exemption on taxes, fees and assessments for residential property insurance policyholders with homes valued up to $750,000. Effective on policies written between July 1, 2024 and June 30, 2025, the exemption will include the Insurance Premium Tax, the State Fire Marshal Assessment and the Florida Insurance Guarantee Association (FIGA) Assessment. The bill also includes a one-year insurance premium tax exemption on flood insurance policies and reduces

the cost of flood insurance policies. Estimates place the average savings per Florida policyholder around $100, though calls remain for the Governor and legislators to take additional actions to afford relief.

House Speaker Paul Renner’s (R-Palm Coast) top priority, originally bill (HB 1), would have prevented children under 16 from creating new social media accounts while simultaneously deleting all preexisting accounts for youth under the age of sixteen. The bill also required verification of the age of new account holders by using either anonymous or standard third-party age verification methods and allowed for private causes of action on behalf of or by minor account holders, with specified damages and filing periods. Concerns on the lack of parental consent options for fourteen and fifteen-year-olds ultimately led the Governor to veto HB 1 during session. The House and Senate reworked the bill and packaged it within HB 3 in the final week of session to include a delayed effective date, parental opt-in for ages 14 and 15 and other minor changes. Effective January 1, 2025, the bill may be challenged in court.

Chris Dawson is an Attorney and professional Lobbyist for GrayRobinson’s Orlando office and is licensed to practice law in both Florida and Alabama. He primarily focuses on lobbying and government relations for public and private sector clients at the executive and legislative levels of state government. He is credentialed as a Designated Professional Lobbyist by the Florida Association of Professional Lobbyists. Chris also holds two degrees in Civil Engineering and has experience in construction litigation and design professional malpractice defense.

Many roofing companies strive to achieve world-class safety standards but what does this mean? A worldclass safety system focuses on balancing people, equipment and technology, ensuring exceptional performance across all these areas. This vision must permeate every aspect of the organization, supported by all employees and leadership.

To achieve world-class safety, you need a clear vision outlining achievable targets. This vision should translate into SMART goals: specific, measurable, achievable, realistic and time-bound. Achieving these goals requires dedicated efforts from all employees, subcontractors and leaders, emphasizing the importance of a strong safety culture that recognizes safety as a core value.

World-class safety standards are industry specific. Roofing is a high-risk industry that necessitates substantial capital investment and technological adoption. Lowering the inherent risks requires reducing reliance on manual processes and embracing advanced safety technology, moving away from error-prone procedures and work practices.

A company’s safety vision must align with its larger corporate goals, setting the direction for the organization. This vision remains a long-term, attainable goal, while the mission represents the path to get there. The mission should adapt to changing business environments and circumstances and be executed by strategic leaders, managers and frontline supervisors.

A compelling vision can energize and inspire employees to pursue the highest safety standards, yielding improved performance and increased returns on investment. A strong safety vision and consistent mission steps promote continuous improvement in safety performance, benefiting employees and subcontractors year after year.

A Safety Management System (SMS) is a critical framework for protecting workers, assets and the environment. It offers direct benefits by reducing injuries and indirectly by improving profitability and sustainability. An effective SMS provides a roadmap for continuous improvement and ensures consistent

organizational safety performance.

An SMS typically consists of several key elements: Management leadership and employee involvement: Leaders must commit resources and employees must engage.

Planning: Set clear safety goals and outline steps to achieve them.

Implementation and operation: Ensure systems, processes and training are in place.

Checking and corrective action: Continuously monitor performance and implement corrective actions. Management review: Regularly assess and refine the SMS for continuous improvement.

Leadership commitment is essential for a successful SMS, as well as for providing resources and fostering employee participation. An effective SMS includes: Hazard identification and assessment: Regularly identify and evaluate risks.

Hazard control: Implement measures to control and mitigate risks.

Work site inspections: Conduct frequent inspections to ensure safety compliance.

Worker competency and training: Ensure all personnel are trained and competent.

Incident reporting and investigation: Report and investigate incidents promptly.

Emergency response planning: Develop and implement emergency response plans.

Implementing an SMS requires a “plan-do-check-act” cycle:

Plan: Define goals and standards and allocate resources.

Do: Execute the plan, train personnel and document activities.

Check: Monitor progress, perform audits and evaluate effectiveness.

Act: Make necessary changes for continuous improvement.

Safety culture vision: Communicate a clear vision supported by leadership actions and messaging. Standard Elements: Define clear, practical standards that meet or exceed regulatory requirements.

Allocate Responsibilities and Resources: Involve passionate team members, including a senior manager. Training: Provide training at various levels to ensure all personnel understand and follow standards. Document Activities: Maintain records for compliance, due diligence and continuous improvement.

A successful SMS needs robust internal controls to ensure compliance with standards, procedures, policies and codes of practice. These controls should provide simple tools for users to implement and comply with the SMS’s requirements. Internal controls should also alert leadership to non-compliance and suggest corrective measures to promote compliance. Recording and trending near misses are crucial for preventing accidents or incidents.

SMART reports – specific, measurable, achievable, realistic and time-bound – can include leading and lagging indicators to track progress further. For instance, personnel training records might show the amount of training completed over a fixed period, which can be easily conveyed through a training matrix. This matrix provides a snapshot of all groups at the project site, their required training and the status of each individual’s progress.

A good business practice is conducting regular audits, typically every one to three years, to identify opportunities for improvement. These audits help identify gaps and propose actions for closure, ensuring continuous enhancement of the SMS’s internal controls.

Once the SMS is rolled out and functioning, a maintenance and continuous improvement process is necessary to transition from regulatory compliance to world-class safety performance. This can be achieved by establishing a team to ensure sustained progress. The team should include a management representative, safety-motivated employees and a subject matter expert. Their agenda should outline members, expertise, management representation, deliverables, authority, resources, timelines, meeting frequencies and documentation needs.

Performance management is critical to the SMS, as leading indicators help improve overall safety performance. The impact of lagging indicators, such as injury frequencies, workers’ compensation claims and

insurance cost, provides accurate measures of performance improvements needed.

Transforming raw data into actionable information enhances performance management. One example is an incident management system that captures annual injury data gains value through internal trends analysis and industry benchmarking. Reviewing this data transparently with the team helps motivate the workforce towards enhanced safety focus and improvements.

If your company already has an SMS, upgrading it is essential for transitioning from compliance to worldclass safety performance. This process mirrors the implementation steps, with additional focus on:

Gap analysis: Compare current standards with new requirements to identify gaps.

Gap closure strategies: Develop strategies to address gaps, involving stakeholders to ensure ownership. Execution and rollout: Manage the rollout as a project with clear timelines, resources, leadership and internal controls.

Gap analysis identifies differences and prioritizes closing them, determining the necessary resources and time. The gap closure strategies should be simple, easy to follow and developed with stakeholders to ensure ownership. Finally, execution and rollout must include a schedule, key deliverables, a strong leader and internal controls to ensure on-budget and on-schedule delivery.

In this guide, we’ve explored vital aspects of an effective SMS for enhancing safety in the roofing industry. By implementing or upgrading an SMS, roofing contractors can protect workers, assets and the environment, fostering continuous improvement and transforming into industry leaders. Further articles will delve deeper into specific elements of workplace safety, providing additional insights for roofing contractor safety programs.

John Kenney, CPRC has over 50 years of experience in the roofing industry. He started his career by working as a roofing apprentice at a family business in the Northeast and worked his way up to operating multiple Top 100 Roofing Contractors. As CEO, John is intimately familiar with all aspects of roofing production, estimating and operations. During his tenure in the industry, John ran business units associated with delivering excellent workmanship and unparalleled customer service while ensuring his company’s strong net profits before joining Cotney Consulting Group. If you would like any further information on this or another subject, you can contact John at jkenney@cotneyconsulting.com.

While attending FRSA’s Board of Directors meetings in April, I listened time and again as our impressive financial condition was reviewed in several meetings. My thoughts wandered back to another meeting more than 30 years ago. It was during my time on the Executive Committee. FRSA was in a much different position. Staff was going through some major changes. Financial statements were confusing at best. Money was tight primarily due to the many different departments that were being supported and the lack of good financial information that would allow leadership to effect solutions. At that meeting, the Executive Committee chipped in by writing checks to cover expenses and payroll while waiting for incoming receivables. We’ve come a long way!

So, I decided (at my editor's urging) to review just how far we have come and to share some of those thoughts with you. Currently, our financial condition has improved dramatically. With several million dollars in liquid assets, we are much more than financially stable. Getting here has not been easy: it has taken the steadfast dedication of current and past members, leadership and staff.

Besides these liquid assets, we also own (debt-free) our impressive headquarters building in Orlando. It is the hub of Florida’s roofing industry and will continue to be for many decades into the future. The Training Center provides a facility that is used not only during FRSA’s many training efforts but by many other industry groups and companies.

The Education and Research Foundation and Endowment have combined assets that are approaching two million dollars. This has been accomplished by the generosity of our industry through donations, endowments, program proceeds and fundraisers. The Foundation is paramount in our efforts to share industry-specific knowledge and to help our contractors meet their licensure requirements through continuing education credits. It is also a source of funding for important research projects. Each year, the Foundation awards many scholarships to qualified applicants. I’m proud to announce that this year the Foundation will award $65,000 in scholarships – the largest amount ever. The financial strength of the Foundation and endowments, combined with generous donations from member companies, will ensure that we can continue to provide these services for our future leaders.

FRSA’s Convention and Expo have often been referred to as the second largest (after IRE) roofingspecific trade show in the country. This year, we will feature 246 exhibiting companies occupying a sold out show floor of 120,000 square feet. We're offering 41 roofing-related educational seminars and opportunities to network and socialize will be numerous.

Our Convention brings the entire industry together in an impressive scope but still keeps it intimate. We've secured over 1,200 hotel rooms on our peak night for a total of 3,582 room nights. The Convention is also a very important source of current and future revenue, which allows us to offer member services and add to the Association’s financial stability.

Although the FRSA Self Insurers Fund is a separate entity, it has, since its inception, been a major part of the FRSA family. The SIF has been a consistent source of workers’ compensation coverage and premiums. It provides invaluable information for regulators as well as offering unequaled roofing-specific safety training for its members. It has returned more than $190 million to its members in the form of dividends. The Fund is very strong financially with substantial assets of its own.

Florida Roofing Magazine is the voice of the Association and an important source of information not only for our contractor and associate members but also for building officials and others. Through advertising sales, it provides a consistent stream of revenue for the Association.

FRSA’s staff members and other professional representatives have always demonstrated outstanding dedication and professionalism. Some have served the membership for just a few years while others have served for many more. Our Executive Director has done so at an extremely high level, consistently for almost four decades now. Staff works together moving the positions taken by our leadership forward while assisting with making all the aforementioned activities possible. A lot is done each year with a very small and efficient group of professionals. They strive to meet the needs of our membership daily through their hard work and enthusiasm.

FRSA’s Members, volunteers, Directors and Officers have been the lifeblood of FRSA for 102 years. They are the reason we exist. To our founders and many early participants, we owe our gratitude for establishing a very well-constructed foundation through adoption of our bylaws, code of ethics and articles of incorporation. These documents and our traditions have been well thought out and have provided a path for new leaders to follow. As good as these founding principles are, they would be nothing

FRSA President Mike Silvers, CPRC, in the early 1990s.

without volunteers to carry those ideas forward. We are blessed to have so many dedicated individuals who serve our trade by the gracious expenditure of their time and energy working on the industry’s behalf. They serve on our many boards and committees; some also serve on the State of Florida’s commissions, boards and committees, further volunteering their time. They and our staff address our government representatives and regulators in Washington, Tallahassee and nearer to home. Volunteers step up to offer instruction for classes and seminars and, just as importantly, to offer support and advice to industry participants who seek it. This is all fueled by the overall professionalism of their member companies. In turn, our Association and all it offers, fuels higher levels of professionalism within those companies.

As important as all the assets above are, there is something that in the big picture is even more valuable to our future endeavors. It is something that all of us, who are involved in representing FRSA, draw on regularly. It is our Association’s reputation. FRSA has always held the improvement of our trades and our industry's reputation and image as our most important goal. That reputation took a big hit recently by what I refer to as the free roof syndrome. Media coverage and discussions within government portrayed roofers as crooked scammers praying on homeowners and their insurance companies. We pushed back on those misconceptions and changed the narrative by being part of the solution to an expanding problem that was limiting availability

of property insurance. The legislative and code proposals we supported and helped pass added significant substance to needed reforms and have helped to further our cause. Our ability to lean on the Associations’ long-term reputation allowed us to speak with authority on the subject and have a consequential impact. We’ve succeeded in retaking the high ground in defending our industry's reputation. There is still much work to be done.

All of this leads me to consider that our most valuable asset has been and should always continue to be, our integrity. It has been hard earned by so many for over a century and it deserves to be respected, protected and carried forward.

FRMMike Silvers, CPRC, is owner of Silvers Systems Inc. and is consulting with FRSA as Director of Technical Services. Mike is an FRSA Past President, Life Member, and Campanella Award recipient and brings over 50 years of industry knowledge and experience to FRSA’s team.

Editor’s note: It’s the unwavering passion of members like Mike that continue to grow and improve FRSA and the services we offer. We’ve been told time and again by new members that the reason they joined was to take advantage of the many services we offer and specifically for access to Mike. His code and technical expertise, knowledge and experience benefit so many. We’re extremely proud to have him on our team!

With the 2026 code modification process gearing up, there are already prevailing areas of focus that will affect the roofing industry in Florida. In the beginning stages, the modification process for the Florida Building Code (FBC) considers the recent changes and trends from the International Building Code (IBC) revision cycle. The IBC is the code in effect for most of the United States, as well as some smaller countries and territories that don’t publish their own building codes. As a part of the IBC code change process, natural events are analyzed to better understand their affects on building performance with an eye on life safety. Recent events include tornados, earthquakes, wildfires and hurricanes. Studying building performance and, in particular, building failures, helps us to see more clearly what is working and what needs to change in building codes. First response teams evaluate how the events affected these buildings. This knowledge is then taken back to the engineers, product manufacturers and industry associations to improve standards, codes, life safety and building performance for subsequent code cycles. The changes in code affect the features and designs of new construction as well as existing building modifications. Based on what we’ve seen with the IBC, three areas that we can expect to be focused on in the coming FBC modification process are fire rated assemblies, photovoltaic system design and design loads.

Fire is a topic that is gaining attention in Florida. More and more populated areas of the state are susceptible to wildfires as urban sprawl advances. The other consideration is that buildings are being built closer to each other, increasing the danger of fire jumping from one building to another. It is one thing to have a building loss because of a fire started from an electrical failure, a gas leak or a deep-fried turkey gone wrong. It is another tragedy when the building next to the fire is damaged because its roof assembly was vulnerable to ignition. The coming developments will impact roofers, as considerations and common sense will need to be applied to roofing projects to help reduce the likelihood of fires spreading even as buildings are built closer and closer to each other. Roofing products will also be affected. Product manufacturers need to keep on top of fire testing and fire ratings because this information is more frequently being included in event damage reports and building code development. Some municipalities in Florida are incorporating fire rated assemblies and fire test results into their permitting requirements without waiting for the code to catch up.

Solar panels or photovoltaics (PV) are also growing in application and code development. Not only are more PVs being used on residential homes and commercial buildings, it’s even becoming a part of the public utility power supply. We are accustomed to seeing rooftop solar installations and, now, public utility solar farms are being installed on the sides of Florida highways and interstates. The increasing popularity of PV has been fruitful to code development as we learn lessons in the real world. Widespread use is also providing valuable learning opportunities to make PV more economical, more efficient and more robust for design considerations. The idea of a building becoming energy independent is an end goal that is gaining momentum because of this development. In addition to using PV, this goal will also be aided by energy conservation efforts such as better insulation and moisture control for interior comfort, window and glazing designs with energy management and more energy efficient options for features like lighting, water heating, refrigeration and cooking.

New design loads are also emerging to be included in building codes. Hurricanes are an established consideration for wind loads in the FBC but tornado design considerations will be incorporated into the code as well. This change will have an impact on roof design. If you are in an area where tornados are a concern, the development of these codes and changes will be an important topic to pay attention to. As these code changes come into effect, permitting changes will also occur. Product selection will need to comply with the new requirements and roofs will need to meet or exceed the new codes.

Fire, PV and design loads are just some of the themes coming to the forefront of the 2026 code modification process. These and other code changes will have a profound impact on the roofing industry and will change the way we roof in the future. Firsthand knowledge and experience of these topics will be important to the process of code development and sharing the information will make the code stronger in the end. If you have concerns or information you would like to share, FRSA looks forward to hearing from you at frsa@floridaroof.com.

FRM

Riku Ylipelkonen, Owner, Standard Building Advisors has been in the roofing industry for 15 years. He is an engineer and is working as a consultant with FRSA. He is a member on FRSA’s Codes Committee, Codes Subcommittee, Tile Committee and on the FRSA-TRI Manual Rewrite Committee. Riku is also a member of the American Society of Civil Engineers (ASCE).

When I first began working for FRSA in 1985, we had 63 employees who worked for FRSA Services Corporation, our for-profit division. Much has changed over the years as we evolved from an association offering services outside the scope of our founding documents to an association focusing on the needs of our members. What originally consisted of ten different entities has been whittled in half and provides more specialized services for member companies.

Today, between the Association and the Credit Union, we’re a small staff of eight full-time employees, three consultants and one retired part-timer, each with a specific skill set that enables the whole organization to run smoothly.

“Teamwork Makes the Dream Work” is one of my favorite sayings and it embodies the spirit of our small but hardworking staff. I’m often told what a great job our team does on certain projects, events and publications and know that it takes all of us to accomplish these goals.

FRSA is the largest regional roofing association in the country, offering membership benefits, industry-specific educational programs, code and technical support, human resources and legal services, a convention and expo and media publications. Through the Credit Union, we offer equipment and vehicle loans, project financing, mortgage lending shared branching and in-person and online banking services. The SIF offers workers’ comp insurance to members who meet their underwriting guidelines and, together, FRSA is a one-stop-shop for the services and support contractors need to successfully run their businesses.

So, who makes up your FRSA team?

Mike officially retired from FRSA last May after 31 years. Although he trained his replacement, she ended up leaving us. Mike came back in October to help us through the yearend audit and continues to work part-time as our Accountant. He prepares and oversees all aspects of the financials for the Association, Services Corp. (our for-profit entity for Florida Roofing magazine), Educational and Research Foundation, Foundation Endowment and the Political Action

Committee. About 18 months ago, Mike convinced the Executive Committee to consider investing in U.S. Treasury Bills and, by doing so, all three of FRSA’s entities have earned considerable, consistent returns. Mike is an FRSA Honorary Member and Florida CPA. He has a wonderful sense of humor and is quick witted. He has been a great friend over the years and when he finally does retire, I will miss him dearly.

John Hellein, Director of Educational & Research Foundation

John has been with FRSA for 12 years and serves as the Educational Foundation Director. His duties include staff liaison for the Foundation, Endowment Board of Governors and the Worker Training Subcommittee. He also assists with the Codes Committee and Codes Subcommittee and works closely with Mike Silvers on many projects. John’s part-time job at FRSA? IT guru and photographer. He is also the graphic designer for the magazine and many of FRSA publications. And, although he won’t admit it, he’s also a continuous source of entertainment for the staff. His wonderful and outgoing personality is contagious.

Anna Torres, Convention Director

Anna has been with us for three years, starting as our Office Manager and then quickly moving into the Membership Director position. While Membership Director, she set an Association record for the highest number of members in her first year and exceeded that number in her second year. Obviously, she needed a challenge and in January (after numerous requests) accepted the position of Convention Director. Anna’s degree is in Event Management and taking over the Convention was a natural fit. She is also the staff liaison for the Convention and Ladies Committees.

Rachel Zehnal, Expo Director

Rachel has been working for FRSA three years, originally as the Administrative Assistant for the Convention and Expo department. Last year, I split the Convention and Expo into two different positions to accommodate the growth we’ve experienced in this area. Rachel works mainly with our exhibitors but also sells sponsorships for the events, hitting an alltime record this year for both profit centers. She is an incredibly talented artist and created the graphic for the 2023 Convention poster.

website. She’s ambitious and helpful and I haven’t found a project yet that she can’t handle.

Kelly Sealander, Membership Director

Kelly’s been with us since October, when she started as our Office Manager. When Anna moved from Membership, Kelly was eager to take over the Membership position. She’s done a wonderful job bringing in new members and is on track for pushing us to the 1,000-member mark by September. Kelly is also staff liaison to the Membership Committee and the Affiliate Council. She has a great sense of humor and an outgoing personality. And she bakes!

Alison Thalacker, Office Manager

Alison began working with us at the end of March as our Office Manager and Receptionist. She oversees all areas of our office from supplies to equipment maintenance and database updates. Alison also assists with the Auction, Training Center and Foundation duties as well as working on the Convention registration platform and the FRSA

After working with Mike as a contractor member for 30-plus years, it was a pleasant surprise when he agreed to work with FRSA as a consultant. I have worked with Mike in just about every facet of the Association, not only as a member, but when he served as FRSA President in 1994. There are very few people who know the roofing-related sections of the Florida Building Code as well as Mike does and I was elated when he came on board as our Technical Director. Mike is a Life Member, Certified Professional Roofing Contractor (CPRC) and a Campanella Award recipient. He is staff liaison to the Codes Committee, Codes Subcommittee and Worker Training Subcommittee. Mike is an easy-going mentor and friend who helps me to see the other side of issues.

Skip Heymann, Ad Sales Manager

Skip started with FRSA in October selling advertising for Florida Roofing magazine. His background includes experience in convention, expo, logistics, advertising and sponsorship, so he was a natural fit as Ad Sales Manager. Although he’s had little training from me, his experience has adapted well to roofing. He lives in New Jersey and vacations in Florida. He’s been working remotely but has become a vital part of our team. Our staff looks forward to meeting him in-person at the Convention.

Lisa Pate, CEM, Executive Director

I have the honor of serving as the Executive Director overseeing all FRSA programs and services. I’ve been with the Association for 39 years, starting in the accounting department while I was in college. Over the years, I’ve had the good fortune to work in every department and with every FRSA committee. Our members are like a second family to me. I’ve watched many of them grow up and take over their family businesses where I knew their fathers and grandfathers. I serve as staff liaison to the Executive, Advisory and Governmental Committees and the Board of Directors.

A big part of Adrienne’s job is assisting members who are applying for loans and then processing their applications. She has been with the Credit Union for almost 12 years and is one of two staff people who run a successful small financial institution. She works closely with the Credit Union Board of Directors and Supervisory Committee, who review all loan

documents. If you haven’t utilized the Credit Union, give Adrienne a call and let her bring you up to speed on all they have to offer you, your family, your employees and even your customers.

Alisha Bazin, FRSA Credit Union Member Service Representative

Alisha Bazin, FRSA Credit Union Member Service Representative

Alisha began working part-time for the Credit Union at the end of last year and serves as a teller, receptionist and customer service representative for the walk-up members who visit the Credit Union. She also assists Adrienne with the day-to-day activities of the Credit Union.

FRM

With over three decades of experience in the tile roofing industry, I have watched concrete and clay roof tile manufacturers come and go. In retrospect, I have seen far more go or be absorbed by market-driven changes.

On the contrary, the overall metal roofing space has expanded its offerings through low entry barriers and various products, from chicken coop grade panels sold by box retailers to high-end beautiful copper standing seam panels typically marketed by quality-focused vendors. Due to this, the metal roof segment has had greater opportunities to position its products as market competitors against other roofing materials. While I do not personally consider metal roofs a direct competitor of concrete and clay tile roof systems because of their longer life cycle performance, I welcome it as a competitor.

The popularity of concrete and clay tile roofing was first realized in the 70s and 80s, largely due to fire concerns in the West. This gave birth to the National Tile Roofing Manufacturers Association (NTRMA), originally established in 1971, now the Tile Roofing Industry Alliance (TRIA), which worked closely with the Committee for Firesafe Dwellings to create legislation to ban combustible roofing materials in California. With the support of the Fire Marshal, the industry began to restrict the use of wood shakes around the state after learning of the lack of fire-resistance issues posed by the material.

Over the next decade, the concrete and clay tile industry grew tenfold throughout the United States as builders ceased installing flammable wood shake roofs and homeowners searched for safe and sustainable alternatives. During the surge of fire-driven demand, the ascent of Mediterranean architecture that was once limited to pockets throughout Florida and Southern California gained popularity across the Sunbelt and

stimulated the demand for concrete and clay tile roofing.

During the 90s and early 2000s, flat concrete and clay tile roofs represented less than 25 percent of the industry’s shipments. Architectural trends shifted between 2010 and 2013 in search of new consumer appeal. A renowned leader in residential design declared, “Med is dead.” His not-so-thinly veiled reference to the death of Old-World design, known for its round windows, stucco facades and round “S” tile roofs, proved prophetic. New trends like modern, contemporary and farmhouse exteriors have become the norm over the last decade; in response, concrete and clay tile manufacturers have invested in new technology, molds and innovative products conducive to this dramatic market shift. Today, Eagle’s flat tile sales represent 61 percent of our total shipments nationwide. While Mediterranean architecture is far from departed, it is no longer a significant driver of our industry’s success. The threat of fires, hail, wind and the prevalence of Mediterranean architecture coupled with unmatched permanence and superior curb appeal has driven demand for the concrete and clay tile industry for nearly 50 years.

While we cannot predict the advent of another external demand driver, we can develop strategies to

strengthen our market as an industry. Under the umbrella of the Tile Roofing Industry Alliance, major manufacturers of concrete and clay roofing tiles in the U.S. have commenced a long-term field study to validate the energy-saving attributes of tile systems compared to other products. The research project, titled Tile Roofing Energy Cost Savings (TRECS), includes the construction of 41 uniform roof stations

placed in the ten code-defined climate zones across the country.

Using revolutionary sensors strategically placed in layers of the roofing assembly, we will gather real-time data every ten minutes over a three-year period. This will allow the industry to publish and post live temperature deltas for roof tiles, shingles and metal, which occur at the roof surface, as well as heat flux through the roof deck, the attic and inside the living space. Our benchmark will be temporary asphalt shingle roofs versus concrete and clay tile roofs in different installation configurations. In addition to measuring temperature deltas, we can convert the data into cumulative energy usage to maintain a constant temperature for both products. This will also validate roofing tiles’ ability to reduce energy through thermal mass and airspace, which will be a far greater benefit than the surface color of

other materials. In regions with tiered electricity, it can help move the expensive peak demand times in hot regions and reduce heat loss in the winter months for colder climates. In the end, the TRECS study will justify and validate the longterm benefits of spending a little more upfront costs to save ongoing energy costs. Together, we will create and market a new purchase driver to drive demand for concrete and clay tile roofing – energy savings.

FRMJohn Campbell is Vice President of Sales and Marketing for Eagle Roofing Products. After a brief stint working for a small independent specialty roofing materials supplier, John spent approximately 16 years at Lifetile, Monier, then the combined entity MonierLifetile. In 2005, John started Roof Component Solutions (RCS), a specialty distributor of roof tile and roof tile components.

In 2012, he joined the Burlingame family and Eagle Roofing Products as the National Sales and Marketing Director and later assumed the role of Vice President of Sales and Marketing as well as the General Manager for the Florida operation, Eagle Roofing Products Florida LLC.

I always find it distasteful to use the slogan “Safety First.” I cringe every time I hear someone say it. It’s a phrase that some contractors often fall back on concerning their safety policies. We must do more than simply give our workers equipment and tell them to “be safe” every day.

OSHA has been extremely busy during the first quarter of 2024. There have been record site inspections completed on both residential and commercial jobsites. Since the Orlando office opened two years ago, there are increasingly more Compliance Officers present and more are being hired. With that initiative, every contractor is encouraged to ensure their documentation and records are up to date regarding their safety policies and procedures.

In the roofing industry, OSHA’s primary focus is always fall protection. Falls continue to be the leading cause of work-related injuries and fatalities and currently OSHA has a special emphasis directive focusing on fall protection. Although fall protection is the primary safety concern, OSHA looks beyond fall protection policies and procedures and has begun to scrutinize

every aspect of the company’s exposures and liabilities during the course of an investigation.

Let’s review what documents OSHA has typically requested of a contractor immediately following a site inspection by a Compliance Officer. They include:

■ training records

■ company safety program

■ safety meetings and trainings

■ site inspections

■ disciplinary action policy and records of action taken

■ OSHA 300, OSHA 300A log and OSHA 301 forms for the past three years

■ fall protection plan for the jobsite

■ list of employees by position and any certifications.

In reviewing many safety and loss control programs, OSHA will note that the document should be reviewed and updated accordingly on an annual basis. Many of the programs also clearly identify the topics (fall protection, ladder safety, hazard communication,

GHS/SDS, PPE, electrical) that all employees must be trained on, annually, as well as new hires before being sent into the field to work.

I cannot stress this enough – ALL TRAINING MUST BE DOCUMENTED – otherwise, OSHA does not consider it to have been completed. Review your programs and coordinate training or establish a schedule for the year to have the training completed.

Document annual harness inspections by field personnel. There are many forms available online to download and print at no cost which will help you document training. Harnesses are identified by the serial number printed on the label of the harness, not the user.

In roofing we use a lot of equipment, ladders and machinery. All equipment should be inspected on an annual basis (or more frequently) and that inspection also documented. Damaged equipment must be either repaired by a competent person or properly disposed of or destroyed.

Companies need to take safety seriously – safety shouldn’t be just another slogan or a sign on the wall. Safety is a constant necessity and should be taken into consideration in all work activities. OSHA compliance should not be the primary goal for updating policies or training workers. The goal of safety is to make the company and workforce better and to ensure that the potential for accidents or injuries on the job is decreased or eliminated.

FRSA members have access to over 250 free Toolbox Talk documents in the Members Login section of the website, www.floridaroof.com. Download and incorporate them into your own safety program.

FRM

Access to workers’ comp coverage is available to all FRSA members. To find out if you qualify for FRSA-SIF workers’ comp insurance, please contact Alexis at 800-767-3772, ext. 206 or email alexis@frsasif.com. To learn more about the FRSA Self Insurers Fund, please visit www.frsasif.com.

During FRSA’s Convention, we’re offering 41 hours of continuing education seminars that feature the bestof-the-best industry instructors. Many of the seminars focus on changes in the Florida Building Code presented by instructors who possess strong insight into the code and its application. They provide real-world examples and can respond to specific questions that you face in your day-to-day operations. We’re also offering 10 hours of non-CE seminars that focus on business operations, sales and management taught by experts in these fields.

FRSA Self Insurers Fund

Alexis has over 10 years of insurance industry experience with the last six years exclusively in workers’ compensation. Along with her underwriting duties at FRSA-SIF, she is responsible for the Premium Audit Department and issues with the state rating organization (NCCI).

Adams and Reese LLP

Tray represents clients in all aspects of construction law, including liens, bonds, construction defect litigation, OSHA defense and licensing. Previously, he worked in construction as an estimator for a multi-million-dollar structural contracting company.

Brauner Safety Services

With more than 40 years of experience in the roofing industry, Jim understands the importance of education; he offers a hands-on approach that prepares crews for potential hazards and unexpected situations. He offers OSHA 10/30, CERTA torch and a full range of safety training.

Adams and Reese LLP

Ben represents clients in all aspects of labor and employment law, including wage and hour, discrimination and retaliation claims, drafting employment contracts, restrictive covenants and more. Ben has been recognized by Florida Super Lawyers for his work.

FRSA Self Insurers Fund

Jorge has been with the FRSA-SIF Safety and Loss Control Department since 2005 and has over 30 years experience in occupational health and safety. He is a master trainer for medic first aid training and CPR, automated external defibrillation, oxygen supplement and infant CPR.

Adams and Reese LLP

Trent, a Campanella Award recipient, FRSA Honorary Member and is a Partner and National Construction Practice Group Leader at Adams and Reese LLP. Trent is FRSA’s and NRCA’s General Counsel. He routinely represents contractors on construction-related matters.

Adams and Reese LLP

Jacqueline is an attorney with a general contractor’s license, Master of Laws degree in taxation and sale associate license. Her unique experience has earned her a name as a middle-market mergers and acquisitions attorney with a niche in the construction industry.

Brian Chamberlain

Carlisle Construction Materials

Brian has been with CCM since 1987 and has a Bachelor of Science in Architectural Design from the University of Wisconsin. He assists architects, consultants and specifiers on assemblies focusing on performance, sustainability and resilience.

Bo Copeland Integrity Metals

Bo is the Business Development Manager at Integrity Metals where he manages new product development, the product approval process and oversees the Gainesville manufacturing facility. He holds a general contractor’s license and a Bachelor of Science from the University of Florida.

Greg Keeler

Owens Corning

Greg is the Technical Services Leader for OC Roofing and Asphalt with decades of experience in architecture and as a building official. He serves on or chairs several ASTM D08 task groups and is a member of FRSA’s Codes Committee and Codes Subcommittee.

John Kenney, CPRC

Cotney Consulting Group

John has over 50 years of experience in the roofing industry. He started his career by working as a roofing apprentice at a family business in the Northeast and worked his way up to operating multiple Top 100 roofing companies.

Debbie Guidry, CPCU

FRSA Self Insurers Fund

Debbie has been at the FRSA-SIF since 1993 and serves as Fund Administrator. She has earned the chartered property casualty underwriter credential, specializing in risk management and property casualty insurance.

Greg Hayne

Hayne Coaching Group

Greg helps contractors find and implement better, smarter and more innovative ways to work. His proven “Creating Great Service” training, support and implementation program helps commercial roofers grow their service departments.

Manny Oyola, Jr. Eagle Roofing Products

Manny is Technical Manager Eastern Region and holds a Florida roofing license. He is FRSA’s President Elect and teaches roof tile courses for FRSA and TRI. He serves on FRSA’s Codes Committee and is the Chair for FRSA’s Codes Subcommittee.

Kyle Rea

Adams and Reese LLP

Kyle worked as an Assistant State Attorney for Florida’s Sixth Judicial Circuit for five years prosecuting felony, misdemeanor and juvenile charges. He prosecuted cases of individuals contracting without a license, including instances of unlicensed contracting during a state of emergency.

Kevin Lindley

FRSA Self Insurers Fund

Kevin is part of the Safety and Loss Control Department with 20 years of experience in the roofing industry, focused primarily on safety compliance. Kevin has a Bachelor of Architectural Design. He is an authorized CERTA Program Trainer.

Paul Oleksak

Westlake Royal Roofing Solutions

Paul serves as the Technical Trainer and has worked in the roof tile industry since 1990. He holds a Florida roofing contractor license and has been active on FRSA’s Codes Committee and the FRSATRI Roof Tile Committee for over 20 years.

Mike Silvers, CPRC

FRSA Technical Director

Mike is the owner of Silvers Systems, Inc. and a licensed roofing contractor with more than 50 years of industry knowledge. He is an FRSA Past President, Life Member and Campanella Award recipient.

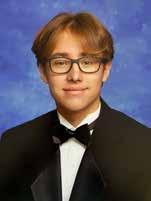

Industry Updates, continued from page 5

business, trying to maximize its reputation and public image in a very saturated roofing market. The partnership is an opportunity to enhance Best Roofing’s competitive edge in South Florida’s robust roofing market and achieve long-term stability for employees.

“We are thrilled to embark on this partnership with Harkness Capital Partners,” stated Wallick. “Their expertise and resources will be invaluable as we negotiate the next phase of our growth strategy.” Wallick and son, Ian, company COO, will push forward with plans to build new corporate headquarters, expand

Scott Siegal Certified Contractors Network

Scott is the owner of Maggio Roofing in Washington DC. Since 2009, he has served as President of CCN. Through in-person and virtual training, CCN helps small and mid-sized contractors develop a plan to increase the size and profitability of their business.

Dan Shurtz Aletheia Digital

Dan is Executive Vice President with roofing clients across North America, Aletheia Digital has a strong knowledge of the roofing business and understands the challenges contractors face in growing their business in an ever changing and highly competitive industry.

Gregg Wallick

Best Roofing

Gregg is President and CEO and a second-generation roofing contractor. His knowledge and passion for the industry is the driving force behind Best Roofing’s outstanding reputation, growth and success. He graduated from the University of Miami in Business and holds an MBA.

into the northern Palm Beach market and integrate critical new technology to enhance Best Roofing’s growth.

"We are excited about what the future holds with this strategic partnership and look forward to continuing to serve our customers with the highest standards of quality and professionalism,” Ian Wallick commented.

The FRSA Educational and Research Foundation is awarding $65,000 in industry scholarships to 27 students. FRSA President Les Sims, CPRC selected the Foundation scholarships as the 2024 Charity of Choice. Through the generosity of many, including matching funds from Trent Cotney, a historic number of donations were raised, enabling the Foundation Trustees to grant many applicants generous scholarships. Named scholarships originating from either Endowment earnings or Foundation donations

Olivia LaMotta

Trent Cotney Scholarship

Olivia graduated from Lake Howell High School and plans to attend Florida Atlantic University in the fall. She will study Biology with a goal of a Masters degree in Microbiology. She is a National Honor Society (NHS) member and swims competitively. Olivia’s grandmother is Debbie Guidry.

Tyler Sims

James Harrison Jenkins Memorial Scholarship

Tyler graduated from Palatka High School and will attend St. John’s River State College to pursue a Business degree. works at Armstrong Roofing. His father is Les Sims, CPRC, Armstrong Roofing, San Mateo, and his mother is Gina Sims.

Simon Scott

E.H. Engelmeier Family Scholarship

Simon attends EmbryRiddle, studying Aeronautical Science. He plans to become a commercial drone pilot. He also intends to use the construction skills he has learned in his family’s business. His parents are Shannon and Steven Scott, Advanced Roof Technology, Melbourne.

designated for scholarships, were awarded to 10 of this year’s recipients.

For more information about opportunities to support the FRSA Foundation, contact John Hellein, Foundation Director, at 800-767-3772 ext. 123 or by email at john@floridaroof.com.

Congratulations to the 2024 scholarship recipients and thank you to the generous donors who make these significant awards possible.

Erin Williams

Steve Steele Memorial Scholarship

Erin is a sophomore at the University of North Florida pursuing a Business Acounting degree. She volunteers in the recovery community, helping people to learn life skills. She is the Office Manager at Recovery Roofing, Jacksonville, where she hopes to serve as CFO.

Hope Garrett

Bob & Elaine Purdy Scholarship

Hope will attend the University of Florida to study Veterinary Medicine and Business. She graduated from Strawberry Crest High School, is an NHS member and a barrel racer. Her long-term goal is to suceed her parents, Richard and Traci Garrett, at Garrett Roofing Inc., Tampa.

Marcela Giampaolo

NEFRSA Scholarship

Marcela attended Cypress Bay High School where she was an AICE Cambridge Diploma recipient. She plans to pursue Marketing and Business at the University of Central Florida. Her father is Gilberto Giampaolo, Giampri Corp., Weston, and her mother is Marianne Rivas.

Kaylee Murray NEFRSA Scholarship

Kaylee is studying Business Marketing at Pensacola Christian College. She plans to operate her own Chick-fil-A franchise after graduating. Her parents are Mark and Julie Murra, Jacksonville.

Owen Johnson

Adam & Tracy Purdy Scholarship

Owen attends Daytona State College and plans to transfer to Florida State University to study Business. He looks forward to being the third generation to build the familiy roofing company. His parents are Ian and Caroline Johnson, R/J Group Inc, Port Orange.

Hayley Casey

Carlos Perez Memorial Scholarship

Hayley graduated from Cornerstone Charter Academy and will attend Florida State University to study Political Science. Her father is Royal Casey, Petersen | PAC-CLAD, Orlando, and her mother is Michelle Casey.

Ajay Sastri

Austin Ebersold Memorial Scholarship

Ajay is attending the University of Florida in pursuit of a Masters degree in Engineering. He plans to use his skills to further innovation. His father, Venki Sastri, Sabre Metals of Florida, Longwood, and his mother is Damyanti Sastri.

Kaiya Parent

FRSA Self Insurers Fund Scholarship

Kaiya graduated from The King’s Academy and hopes to attend the University of Alabama to study Sports Performance and Athletic Training. Her father is Joey Parent, State Pride Roofing of Florida, West Palm Beach, and her mother is Penny Parent.

Rylee Rauktis

Edwards Roofing Inc. Scholarship

Rylee attends the University of Florida's School of Construction seeking a Construction Management degree. She plans to become a general contractor. Her father is Todd Rauktis, Commercial Roofing Specialties, Orlando, and her mother is Michelle Rauktis.

Brooke Wilson

Bowen, Hilson and Turner Scholarship

Brooke graduated from Durant High School and will study Marine Sciences at the University of Central Florida. She played varsity lacrosse and is an NHS member. Her mother is Bridget Wilson, Cardinal Roofing, Brandon, and her father is Brian Wilson.

Hannah Garrett

Mason Liftig Scholarship

Hope graduated from Strawberry Crest High School as a Florida Medallion Scholar. She will attend the University of South Florida to study Biomedical Ethics. She plans to become a Dermatology Physician’s Assistant. Her parents are Richard and Traci Garrett, Garrett Roofing Inc., Tampa.

Makena Johnson

Makena graduated from Spruce Creek High School and is an NHS member. She plans to attend Tallahassee Community College and Florida State University to study Biology and Business. Her goal is to become a veterinarian. Her parents are Ian and Caroline Johnson, R/J Group Inc, Port Orange.

Mason Swetz

Mason attends Georgia Southern University studying Civil and Structural Engineering. During the summer and school breaks, he works with lead engineers at Mills, Short & Associates. Mason is an avid golfer and also enjoys fishing. His parents are Andrew and Melinda Swetz, Jacksonville.

Quinton Swetz

Quinton attended Vero Beach High School and will attend Indian River State College to earn a Bachelor of Science degree. He plans to become a commercial pilot. He played on his high school lacrosse team and is an NHS member. Quinton’s parents are Andrew and Melinda Swetz, Jacksonville.

Jessica Borowski

Jessica attends the University of Florida, majoring in Information Systems and minoring in Economics. She served in the Business Undergraduate Mentorship Program and intends to pursue post-graduate work in finance. Her mother is Rosita Borowski, Allied Services of Florida, Ft. Lauderdale.

Leslie Sims

Leslie is a post-graduate student at the University of Florida studying law. She is a member of the UF Law Women’s Association, UF Federalist Society and John Marshall Bar Association. Leslie’s father is Les Sims, CPRC, Armstrong Roofing, San Mateo, and her mother is Gina Sims.

Caroline Belcher

Caroline attends Tallahassee Community College studying Radiologic Technology. She is working toward becoming a Diagnostic Medical Sonographer. She volunteers in support of cancer fundraising and works as a nanny. Caroline’s parents are Jon Belcher, Marion Service Roofing and Sheet Metal Co., Ocala, and Tracy Belcher.

Ashley Rountree

Ashley graduated from Jupiter High School and will be attending Tallahassee Community College and then Florida State University for a degree in Business Finance. Ashley played on her high school golf and soccer teams. Her father is Christopher Rountree, Bitumar, and her mother is Alisha Rountree.

Jolee Andrews

Jolee graduated from Durant High School and plans to study Animal Science at Berry College. After completing her degree, she hopes to intern at an environmental lab. She is an ASL Honors Society member and active in lacrosse and weightlifting. Her mother, Rachael Andrews, Cardinal Roofing, Brandon, and her father is Joseph Andrews.

FRSA Self Insurers Fund is the best Workers’ Compensation carrier for Roofing Contractors in Florida.

The Fund’s exceptional service and dividend returns are unmatched in the industry.

In 2023, Fund members received $3.5 million in Dividends in July and another $1.5 million in December based on 2022 performance.

• SIF Safety Rep Monthly Safety Training

• Employee Documentation for OSHA Recordkeeping

• Drug-Free Workplace Discounts

Call FRSA’s Self Insurers Fund today to see if your company qualifies. 800-767-3772 ext. 206 | alexis@frsasif.com

William Kemp

William attends Florida State University studying Mechanical Engineering. Upon graduating in 2026, he hopes to become a U.S. Navy Pilot. He is an NHS and Catholic Student Union member. William enjoys cross country, fishing and surfing and plays guitar. His parents are Chris and Amy Kemp, Gulf Breeze.

Sarah Kemp

Sarah graduated from Gulf Breeze High School and will pursue a degree in Nursing. After completing college, her goal is to work in Pediatric Healthcare. She is a member of the Academy for Health and Medical Professionals. Her parents are Chris and Amy Kemp, Gulf Breeze.

Paige Bankston

Paige is pursuing a Health Sciences Associate’s degree and, after graduating, plans to enroll in a Radiology program. She playes softball at St. Petersburg College where she is on the President’s List for a 4.0 GPA. Paige's parents are Chad and Cynthia Bankston, Newberry.

Peyton Henry

Nicole Borowski

Nicole will complete her senior year at the University of Florida, where she is studying Applied Physiology and Kinesiology and plans to pursue a Master’s Degree in Human Performance Exercise Science. Nicole’s mother is Rosita Borowski, Allied Services of Florida, Ft. Lauderdale.

Peyton graduated from Boone High School and will attend the University of Central Florida to obtain her Bachelor’s of Science in Nursing. She is an NHS member and participated in varsity cheerleading. Peyton volunteers her time coaching cheerleading. Her parents are Scott and Bridget Henry, Orlando. The deadline for 2025 scholarship applications is March 15, 2025. floridaroof.com/scholarships

ProVia barrel tile metal roofing combines the timeless beauty of Spanish clay tile with the unrivaled strength of metal roofing. This 26-gauge galvanized metal roofing system is engineered to withstand 130-mph winds, damaging hail, torrential rain, and intense UV rays, and is backed by a limited lifetime transferable warranty. Give your customers the best of both worlds: style and substance.

It’s the right thing to do.

Learn More provia.com/metalroofing/barrel-tile/

As the largest wholesale distributor of roofing and other select exterior and interior building products in North America, ABC Supply delivers the products and services Florida builders and contractors need to be successful and grow their businesses.

ABC Supply’s local teams and national scale are here every day to help keep your projects on track and your business growing. From roofing and siding to windows, doors and renewable energy – with additional interior and weather support from L&W Supply and Town & Country Industries – your local ABC Supply is the one-stop product supply shop to manage your material needs.

The ABC Supply team includes over 20,000 associates who are highly trained and dedicated to helping you tackle the most challenging jobs with proven solutions. Our skilled associates handle building material selection, order placement and delivery for customers, consistently providing accurate, seamless service from start to finish.

We know you need to save time and money at every turn, so we’ve created unique programs and tools that help you do just that – quickly and easily.

■ MyABCsupply helps you run your business and do more on the go. Conveniently order materials, confirm order details and check the status of upcoming deliveries in real time, whether you’re working from an office, at home or from the jobsite. Any customer can access this easy-to-use tool from the convenience of a phone, tablet or computer.

■ Our automated Manufacturer Rewards Support Program helps you get rewards from manufacturers faster, putting more dollars in your pocket.

■ Freedom Programs provide value-added marketing services that allow you to get the word out about your business through targeted mail, websites, marketing starter kits and jobsite signs.

■ Solution Centers inside our ABC Supply locations feature comprehensive product displays, making them an ideal place to review projects and samples with your customers.

At ABC Supply, where we work is more than just a place of business: it’s a home. We give back to our communities through two very important partnerships.

For the third year in a row, we’re teaming up with AJ Foyt Racing during the Indy 500 to raise $4 million for Homes For Our Troops, a nonprofit that builds and donates specially adapted custom homes nationwide for severely injured post-9/11 Veterans, enabling them to rebuild their lives. Supporters can donate through the end of May at hfotusa.org/donate, with ABC Supply matching up to $1 million.

We’re honored to help make life brighter for some kids with critical illnesses across the country through our multimillion-dollar Make-A-Wish Champion Sponsorship, as well as by donating building materials and volunteering our time to help make their wishes come true.

With nearly 60 locations across Florida alone, ABC Supply provides easy access to support, products and expertise that contractors and builders can’t find anywhere else. For more information about ABC Supply or to find a location near you, visit www.abcsupply.com. You can also visit us during FRSA's Expo at booth 603. FRM

There aren’t many markets in the country where good roofers and good roofing materials are as important as Florida. Th`e sun may help give Florida its beautiful landscape and tourist appeal but it also wreaks havoc on roofs statewide. In this article, we will look at the science behind PM Silicone roof coatings and identify why they are the ideal solution for failing roofs throughout the Sunshine State.

As many Florida roofers know, white silicone roof coatings are highly UV resistant. Much of the UV reflectivity comes from the coating’s white color. A darker silicone will not reflect nearly the same amount of UV rays and dark colored or black coatings will actually absorb UV rays. White coating, however, does an excellent job reflecting the sun’s rays and keeping the roof and the internal building temperature cooler.

It’s not just about color, though. The UV reflectivity in PM Silicone is strengthened by the tight bond of the elements in the material form when cured. Because they are so tightly bonded, they are capable of resisting UV rays without rapidly deteriorating. The molecules that make up PM Silicone roof coatings are also highly thermal and light stable. Combining these two elements makes PM Silicone the perfect roof substrate to combat the hot Florida sun.

that they become brittle. PM Silicone is also flexible and elastic. The material can flex with different pressures, be it shifting in the building or new forces being applied to the roof surface. Despite possessing a very tight link between the molecules, the chemistry of silicone roof coatings allows them to remain elastic, which adds more years to the coating.

Silicone coatings have been formulated with hydrophobic properties to make them extremely water resistant. Because of the way the elements bond together, the surface of a silicone roof coating – when examined under a microscope – has tiny protrusions smaller than a drop of water. These protrusions make it very difficult for water to grab onto anything and work its way past the surface of the coating. Since PM Silicone is liquid-applied to the roof, it creates a seamless, waterproof membrane on the roof that can last decades.

Although the chemical bonds of silicone coatings are extremely strong and tight, they are not so strong

Silicone roof coatings are manufactured by mixing many chemicals, beginning with resins that are 100 percent solids. Most other roof coatings start with a lower solids base and include filler in the formula, which disallows their solids content to get much past 50-55 percent. These higher solids content allows PM Silicone roof coatings to be installed thicker, in fewer coats, with more precision and with a smoother surface. Florida roofers can enjoy time and money savings when using PM Silicone as they can typically get proper milage in just one coat.

Again, thanks to the extremely tight and strong bond of the molecules in silicone roof coatings, they are impermeable. Rather than just resisting water and allowing water to run off them, their molecules are so tightly bonded and so complexly organized that they cannot be permeated. This ponding water resistance is a significant advantage of PM Silicone roof coatings. PM Silicone also resists many chemicals that could spill onto the roof, offering even more protection.

As you can see, PM Silicone roof coatings are ideal for the Florida market. They are scientifically created specifically to resist the rain and UV rays even in heavier sunny and rainy areas like Florida. To find out more about PM Silicone, please visit pmsilicone.com or come see us at FRSA's Expo in booth 523. FRM

Sika is the world’s most trusted commercial roofing manufacturer. With over 60 years of proven performance history, our roofing systems perform for local and global customers “Beyond the Expected!”

Sika’s unique combination of proven materials, unmatched technical expertise and the best approved installers result in unparalleled performance and sets us apart from the competition. With technologies in PVC membranes, liquid-applied membranes and hot-rubberized asphalt, Sika Roofing can meet the needs of any building owner, in any climate imaginable, all over the world.

Sika Corporation manufactures thermoplastic (PVC) and liquid-applied membranes (LAM) for the commercial roofing and waterproofing markets. Whether your roof is a large distribution warehouse or a small downtown high rise, Sika roofing systems can provide long-term, watertight protection no matter what your project’s specific needs are.

From the performance leading Sarnafil membrane to the insulation board securement plate, Sarnaplate, you can rest easy knowing that all products offered from Sika Roofing for our roofing and waterproofing systems meet the strict quality standards that you come to expect from the leader in thermoplastic technology.

■ Innovation

■ Sustainability

■ Resiliency Technologies

■ PVC Membranes

■ Liquid-Applied Membranes

■ Hot Rubberized Asphalt

Designed for the use in multi-ply low-slope roofing systems, Modifleece sets a new standard in roofing technology, offering unparalleled performance and versatility. superior technology MADE FOR YOU

polyglass.us

33 Fully stocked locations throughout Florida to service your building material needs.

Homestead, FL 33032 (786) 829-2761

Ocala, FL 34470 (352) 210-6246

Jacksonville, FL 32209 (904) 503-9400

Tallahassee, FL 32304 (850) 574-7600

Odessa, FL 33556 (813) 749-5354

Orlando, FL 32804 (407) 291-7244

Tampa, FL 33619 (813) 740-8790

Fort Myers, FL 33916 (239) 935-5077

Deerfield Beach, FL 33442 (954) 969-8000

Miami FL, 33142 (305) 635-7177

Orlando, FL 32809 (407) 367-6246

Ocala, FL 34474 (352) 622-3933

Melbourne, FL 32904 (321) 369-7892