MED OIL & GAS

Winter Magazine 2021 1

A partner able to reduce your emissions Our customers need us to increase the profitability of their projects while also lowering the carbon footprint of production. We achieve these twin goals by taking ownership of the emissions challenge and working with our customers to comply with new regulations and seize new opportunities. Learn more at maerskdrilling.com

Contents Features Comments from Cyril Widdershoven.............................................................................................................................................5 Using Digital Twins to Support a Safer and More Sustainable Industry.........................................................................................6 LNG Market Development- Small Scale Plants, Environmental & Italian Permitting Solutions....................................................10 Underbalanced Coiled Tubing Drilling System uses Internet Technologies to Ensure Reliable Data Handling..............................16 Well Ageing Studies for the Safe Extension of a Well’s Life........................................................................................................23 A Case Study of Pipeline Integrity Management in Green Stream Natural Gas Pipeline Through Corrosion Mitigation and Inspection Strategy..............................................................................................................36 Innovative Field Development Solutions: Enabling Technologies for Long Subsea Oil Tiebacks................................................. 44 Reducing CO2 Emissions Through the Selection of an Energy Efficient Artificial Lift Method....................................................53 4D Gravity & Seafloor Subsidence Surveys for Cost-Effective Monitoring of Offshore Gas Reservoirs........................................67 Conferences.........................................................................................................................................................................43, 59 Companies in the news: ABS Consulting, Butting, Liebherr-MCCtec, NDT Global Press Releases....................................................................................................................................................61, 63, 65, 73, 74

Published by: OYOMEDIA18 Limited, (MED OIL & GAS MAGAZINE is a subsidiary of OYOMEDIA18 Limited), Malta & Dubai Printed & designed by: Stibo Complete, Denmark Cover photo courtesy of Shutterstock Inc. 3

Innovative insulation system for pipeline construction:

ELASTOSHORE® GS – our new subsea benchmark.

Top-performing under pressure: l High-performance solid polyurethane elastomer l Suitable for application areas such as

l l l l l

field joints, line coat and static structures like manifolds, jumpers or tiebacks Mould to subsea deployment in less than 5 minutes (field-joints) Fast and efficient application Single moulded operation Homogeneous system, excellent adhesion Low maintenance, reduced downtime

Constructing Tomorrow Functional, easy to process and globally available: Elastoshore® GS – the no. 1 thermal insulation solution.

Harsh Truth Behind Europe’s Energy Crisis EU member states, changing the narratives in Brussels and the respective European capitals.

Commentary by Cyril Widdershoven

Europe’s energy crunch is continuing, as gas storage volumes have shrunk to 10-year lows. A possible harsh winter could lead to severe energy shortages and possible shutdowns of large parts of the economy. While the main discussion is currently focused on the potential role of Russia in the energy crisis, a new narrative could soon make the headlines. In a surprise move, the Dutch government has indicated that in a severe supply crunch situation, the Groningen gas field, Europe’s largest onshore gas field, could partially and temporarily be reopened. It seems that the term Dutch Disease could get a new meaning, from being the paradox of a rentier state suffering from plentiful resources to a show of Europe’s lack of realism when it comes to energy transition risks and current market powers. Dutch Minister Stef Blok has indicated that he is considering the potential reopening of the Groningen field, in particular five wells, especially the one at Slochteren, as indicated by Johan Attema, director of the Nederlandse Aardolie Maatschappij (NAM), the operator of the Groningen field. The reopening of the field, even in the case of an emergency or an energy crisis, is politically controversial. Until recently, the plan was that Groningen would be closed completely by 2023, ending the large-scale gas production and export by the Netherlands with a bang. The Dutch media is speculating that minister Blok will be asking for a possible reopening of the Groningen field, a decision that must be made before October 1. If the Minister decides to change the current shutdown plans, the whole Groningen debacle, as some see it, will be prolonged. It is clear, looking at the current deplorable situation of the European energy sector, that Groningen is still needed. The ongoing energy crunch could have grave consequences for the economies and wellbeing of

The lack of supply of natural gas by Russia (or the political will to supply more), the difficulty of ramping up Norwegian gas or other gas imports quickly, is jeopardizing Europe’s energy situation. At the same time, a possible shutdown of several electricity-intensive industries in Europe, such as fertilizers, chemicals, and steel/aluminum production is on the table.

Political leaders will have to face the direct implications of higher energy bills or possible energy deficits for consumers and the industry. Both could lead to protests or political landslides during upcoming elections. Threats of an energy crisis are being discussed widely, but no real solutions except lower taxes are available. Due to higher energy costs, a possible record price level of $100 MMBtu or $250 per barrel of crude oil equivalent is very bad news for politicians, especially in the Netherlands, Germany, France, and the UK. It remains unclear, however, whether European politicians are aware of the role that their own policies have played in creating this crisis.Even with the partial restart of the Groningen field, which could relieve some of the pain in Western Europe, there is a larger problem that must be addressed. By opening up the gas market for liberalization, without giving the necessary tools to parties, and pushing for a spot market, instability was introduced into the system. Geopolitical powers are still at play, while utilities and European suppliers have seen little support from their governments. At the same time, when oil price-indexed longterm contracts with Russia were thrown out of the window, many did not understand that this could mean handing over full market powers to NOCs, such as Gazprom. Putin has been cele-

brating, knowing that he has been handed the key to European markets, with the option of manipulating fundamentals and prices at the same time. In the meantime, Europe has failed to sufficiently diversify supply.

European leaders desperately need to reconsider their position towards Russian gas supplies and the future role of NordStream 2, which is still being threatened by US sanctions and Eastern European opposition. It seems that Russia’s leader Vladimir Putin, however, is holding all the cards when it comes to natural gas in Europe. Without substantially more natural gas supply to Europe, consumers and industry may well be facing a winter of discontent. Europe’s gas supply diversification strategy has been a failure, not only due to EU tactics and regulations but also because of the ongoing one-sided emphasis on a rapid energy transition, hydrocarbon divestment, and full-scale investments in renewables, without realizing that the backbone of the European economic system is still hydrocarbon fueled. The current situation shows one main fact of life, the success of the energy transition is not based on a one-sided approach. By relying too much on renewables, the market became destabilized, but politicians and others didn’t want to admit it. Destabilization could and should be prevented, by acknowledging the fact that for the foreseeable future hydrocarbons, including coal, will be playing a significant role in the European energy market

At the same time, European politicians also should acknowledge that without hydrocarbons, not only does energy supply become threatened, but the hydrocarbon economy suffers. It is not yet fully understood by most, but without hydrocarbons, especially natural gas and oil, food and other primary sectors will be hit hard. The first shutdowns of fertilizer and steel companies have already been reported. Brussels, London, Berlin, and even The Hague, should start to change their approach to energy and the economy of the future. Politicians should start to listen to market analysts that have been warning of a disruption in energy markets. The European long-term energy strategy should acknowledge the position of hydrocarbons as a backbone while investing in renewable options at the same time. Investments in storage, diversified supply, and domestic production are crucial. Without these, supply giants such as Putin’s Russia are holding all the cards. 5

Using Digital Twins to Support a Safer and More Sustainable Industry Digital twins have in recent years received increasingly more attention as their value creation has become more apparent when utilised in an efficient manner. More are realizing that an efficient use of digital twins might be the key to not only a more optimised future, but also in supporting other important aspects in the industry. By Nadir Azam and Anders Andreasen, Ramboll

There are many understandings of what a digital twin is and what it is not. In this article, a digital twin is understood as a virtual representation of an object or system that potentially spans its lifecycle, can be updated from real-time data, and uses simulation, machine learning and reasoning to help decision-making. A digital twin consists of several facets and layers, which may separately or combined contribute to increased value in their own way within different disciplines. In this article, we will focus on showing how digital twins specific for structural integrity, referred to in this article as True Digital Twin, and process simulations, referred to as Process Digital Twin, have been used to create value and support a safer, more optimised, and sustainable industry.

Why use digital twins? There are several quantifiable and unquantifiable benefits of using a digital twin. The True Digital Twin technology, focusing on structural integrity of structures, has demonstrated its value throughout the past 25 years. It enables cost reduction, provides safer operation, and supports sustainability by allowing for optimisation of operational performance and life cycle management. These benefits are highly valuable in for example lifetime extension projects where the technology may be the differentiator between being able to reuse existing 6 | MED OIL & GAS

structures or having to decommission and build new ones. The technology may at the same time provide invaluable information in time of need, for example during expected or unexpected critical events such as storms, ship impacts, vibrations etc. The True Digital Twin technology allows for moving from costly and time-consuming experimental testing in the laboratory to cost-reducing full-scale testing in the field under real operational conditions, which enables safer and more cost-efficient operation of the asset. Utilising a digital twin for process simulations can enable optimisation and offers unparalleled insight and facilitates increase in revenue, reduction in OPEX and more importantly reduced greenhouse gas emission footprint. The methodology presented in this article can be applied for brownfield optimisation as well as for basic design of greenfield facilities. In the design phase, the method can assist in choosing the best process scheme and selecting favourable operating conditions for minimisation of both CAPEX and OPEX. Another interesting and increasingly important area is lifetime extension and maximising the usability of existing facilities for tie-backs through detailed bottleneck identification studies.

Structural integrity: True Digital Twin Ramboll combines digitalisation with innovative structural health monitoring to create the True Digital Twin for structures. The technology is a state-of-the-art methodology to facilitate coupling between the real physical conditions and their structural analysis models, which captures the real-life behaviour of structures in real-time. The True Digital Twin technology has several applications within optimised operational performance and life cycle management. Specific use cases include among others lifetime extension projects, root cause analyses, uncovering knowledge gaps, detection of changes, and predictive maintenance.

Methodology The value creation expected from a True Digital Twin starts already in the specification of a structural health monitoring system as illustrated in figure 1. It is critical that the sensors defined are up to the required task and placed at the right locations to fulfil the overall purpose and objectives. There are several parameters to consider and evaluate when specifying a structural health monitoring system with the purpose of utilising it within structural integrity assessments. These parameters for the sensors include

for example: type, frequency range, accuracy, sensitivity, resolution, location of sensors and which post-processing methods will be utilised.

Continuous monitoring hence allows for continuous assessment of the structural integrity of the structures.

When the system is up and running, the real conditions are continuously identified using the Structural Health Monitoring System (SHMS), which provides information about the actual environmental loads and the corresponding structural response before the data from the monitoring system are analysed through a cloud computing solution. The True Digital Twin technology combines a variety of sensing technologies with an embedded measurement controller to capture, log and analyse real-time data.

EXAMPLES OF USE

The real-time data from the Structural Health Monitoring System (SHMS) is used to compare the real-time behaviour with the analysis model, and the analysis model is updated by using several novel methods to create a True Digital Twin, i.e. a structural analysis model that simulates the real-life behaviour of the structure. Advanced analyses may now be performed using the True Digital Twin and assessment of the measured uncertainties associated with the analysis of structures, relating to elements such as quantification of model uncertainties and the direct link to Risk- and Reliability-Based Inspection planning (RBI).

Lifetime extension The technology has been used in several lifetime extension projects throughout the years. The use of True Digital Twins in lifetime extension projects have resulted in large savings and sustainable reuse of structures, since quantifying the actual uncertainties leads to a safer and usually more optimised predictive risk-based inspection program.

or flare tower. The technology has been used to monitor large structures to identify root causes of unexpected and unknown events, to provide an efficient mitigation strategy.

Process simulations: Process Digital Twin

Currently there are on-going projects where reusing oil & gas platforms as substations for offshore wind farms is being investigated and will also include this technology combined with advanced analyses.

The process digital twin is a process simulation representation of the chemical (and physical) processes taking place inside the plant process equipment. The process simulation invokes appropriate thermodynamic models of the fluid phase behaviour as well as correlations for transport properties etc. The process simulation combines several unit operations to make a digital representation of the real plant, which can be explored for several tasks such as for example: plant design, optimisation studies, diagnostics and troubleshooting, bottleneck identification and mitigation, training, safety studies, and what-if scenarios.

Root cause analyses In cases where unexpected and unknown events occur, it might be invaluable to have measurement data from the events and being able to utilise it within structural integrity when it comes to understanding the root causes and how to mitigate these events from occurring in the future. Such events could for example include vibrations of either entire platforms or parts of a platform such as a topside module

Process simulations have been used for decades as a representation of the real plant. However, extensive multi-parameter optimisation of complex process facilities is a more recent discipline, which has not yet achieved widespread foothold in the industry, especially where machine learning and multi-objective evolutionary algorithms are applied. In the following, we aim at describing the basic methodology and presenting some recent examples.

Figure 1: Workflow of a typical True Digital Twin project – from sensors to decision making 7

Methodology The starting point is a high-fidelity model of the real plant. While the highest fidelity can be provided by a detailed process simulation model, a surrogate model may be a better choice, provided the model is well trained via e.g. supervised machine learning. Using a surrogate, the insight of the model can be fully leveraged through massively parallel computations while minimising software license cost. The model is leveraged in combination with global optimisation methods. The number of variables of interest, which for example may include pressure, temperature, flow etc. from various places in the process, range from a few parameters up to hundreds of variables, with a typical range being 10-20 variables of interest. The objective of the optimisation may for example be maximisation of a product yield, improved product quality, minimisation of production cost/OPEX, minimisation of emission-footprint / energy optimisation or any combination of these objectives. However, not all variables can be set freely due to natural limitations such as design pressure limits, design temperature limits, cooling/heating medium constraints etc. Constraints may include product quality such as crude oil export RVP/TVP, gas export quality, equipment constraints etc. All these limitations and constraints must be handled while seeking the best solution for the objectives.

EXAMPLES OF USE Increased product yield In various optimisation studies considering both full process simulation as well as surrogate models, the process digital twin approach has identified a significant optimisation potential for increased stabilised oil production.

Figure 2: Pareto frontier for constrained and unconstrained multi-objective optimisation of an oil and gas separation plant

An increase of 0.1-1.3 % can be achieved, which over lifetime is a significant increase in revenue, and this is achieved without any hardware modifications, i.e. only obtained through changes in the operating parameters. The magnitude depends on for example the reservoir fluid and plant topology. Elucidating the optimisation potential requires a vast amount of simulation realisations, often 10,000-100,000 evaluations. A main challenge is competing forces of different objectives. Often an increase in recoverable stable oil comes with an expense of increased power demand, see figure 2. Thus, the challenge is to identify the sweet spot that gives the most value for money - either the highest increase in production (starting from operating point A) at the lowest increase in energy demand or the highest reduction in energy demand for the lowest penalty in oil

Authors

Nadir Azam

Anders Andreasen

is Business Development Manager, working with digitalisation and innovation within structural integrity management for offshore structures. He has 15 years of experience in working with complex lifetime extension projects.

is Technical Manager and chemical engineer, working with chemical process design for energy storage, carbon capture, utilisation & storage, Power-to-X, and gas production and utilisation.

8 | MED OIL & GAS

production (starting at point B). For processes not continuously optimised it may be possible to improve both parameters (starting at suboptimal point C). Reducing separation gas plant footprint for NGL rich fluids During recent years, several projects including various development phases for reservoirs rich in NGL (natural gas liquids) have been executed, such as for example the Hejre and the Solsort fields in the Danish sector of the North Sea and the Yme re-development on the Norwegian continental shelf. Such fluids are challenging since NGL may build up in the compression system and condensate recycle streams, increasing the power requirement substantially. For some fluids it may not be feasible to extract NGL offshore and it may be chosen to export excess NGL via either off-spec gas or off-spec crude. Using a process digital twin approach, it has been demonstrated that for a realistic hypothetical fluid, the topside energy requirement could be reduced by approx. 20% by choosing the gas export over the crude export for transport of NGL to shore for downstream extraction. This would translate into a significant downsizing of the entire compression system and gas treatment facilities with a significant concurrent reduction in CAPEX.

Final reflections We are still in the early days of digitalisation, but we believe it will be a vital part in creating an optimised transition from fossil fuels to renewables and support the green transition with accelerated technology-based knowledge.

Bright ideas. Sustainable change.

9

Regional Challenges

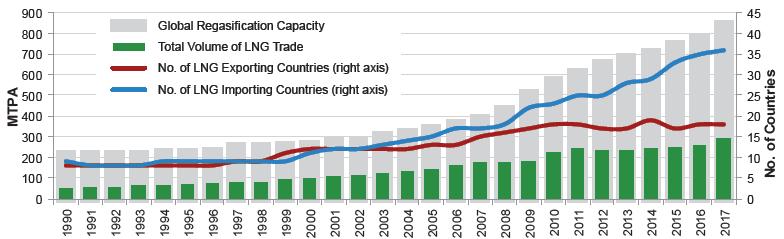

LNG Market Development - Small Scale Plants. Environmental & Italian Permitting Solutions Marco Compagnino, Alessandro Puppo, Maurizio Florio, Rina Consulting S.p.A Introduction Since the first tanker shipment of LNG took place in 1958 aboard the experimental vessel (the Methane Pioneer)1 the LNG global market has undergone an unprecedented expansion of production capacity. During the last 50 years, LNG started being imported from Pacific countries and later from the Atlantic Basin (Europe, North America), and the market developed in an exponential manner, averaging, in last decades, an annual growth of 7.5%2. Globally, in 2017 the LNG volumes traded set an historical annual record of 293.1 Mtpa (Million Tonnes Per Annum) with an increase of 35.2 MT (see Figure 1). For the same year, LNG demand across Mediterranean markets were enhanced by severe summer drought (resulting in low hydropower energy production) and heat waves (correlated with strong air conditioning demand) with an increase of LNG imports for France (+2.0 Mtpa), Italy (+1.5 Mtpa), Portugal (+1.5 Mtpa), and Spain (+2.3 Mtpa)3. Based on demand estimates, it is plausible that LNG trade will grow to 360-420 Mtpa by 2020 and the number of LNG importing countries will probably reach about 404. Nonetheless, even if these numbers are impressive, the LNG trade market has been in a state of overproduction since late 2014, with a plethora of suppliers competing with each other, resulting in prices fluctuations and investors insecurity, that it is likely to produce a ‘boom and bust cycle’. Also, investors were counting on higher prices to guarantee that their new LNG plants would be economical and remunerative5. This condition is the product of on historical element of the LNG trade: the idea that LNG plants must be supported by long-term contracts covering most of their capacity due to high capital costs. Anyway, 10 | MED OIL & GAS

this assumption is clearly conflicting with current saturated market conditions since the oversupply situation is challenging the future of long-term contracts as they stand today6,7. It is not surprising that LNG trade is already going through an interesting shifting from the traditional pattern of long-term contracts of distribution to one based on spot and shortterm contracts (contracts of less than four years)8. If in the early 2000 spot and shortterm contract accounted only for 5.4% of the LNG trade, in 2014 they rose up to 29% and they are expected to continue rising, potentially reaching 45% of global LNG trade by 2020. The rise in spot and short-term LNG trade will allow buyers to source more and more of their LNG from the oversupplied market rather than rely on long-term contracts, possibly leaving cargoes available at penurious prices, below long-term oil-indexed contracts9. In the present market condition, it seems unlikely that new greenfield LNG projects will move ahead. Brownfields expansion are probably standing better chances, but demand uncertainty is still a challenge10. This complex market condition, joint with new environmental emissions policies and the advancement of new technologies, are together leading the affirmation of a new trend in LNG project development: the LNG Small Scale business (SSLNG)11. This business is receiving growing attention form exporters, since allows the convenient distribution of LNG to several kind of end-users. Due to relatively novelty of SSLNG market, statistical figures are not yet available. Figures and volumes on SSLNG provided in this report are the result of thorough research of the study group, but may not be exhaustive.

Today, a total amount of approximately 100 small scale LNG production plants is found globally. In 2017 in Europe, the number of LNG import terminals offering SSLNG infrastructure was clearly on the rise, with hotspot concentrated in Spain and Northern Europe, Greece and Turkey12. As illustrated in Fig. 2, it must be noted that, to date, no Italian regasification terminal is able to provide SSLNG services yet; however, with appropriate technical modifications, it would be feasible to adapt present regasification terminals and make them capable to also offer LNG storage and refuelling services for both vessels and road-vehicles. In addition, at 2018 several projects exist in Italy for covering at least some SSLNG activities, especially in the field of LNG storage and refuelling services vessels13. But what exactly is SSLNG? While the traditional pattern of LNG market can be assimilated to a “straightforward chain” of activities, mainly consisting of a liquefaction plant, transport, regasification and end-users (power plant or domestic); the small-scale business can be defined as 3 a “network of activities” related to the transport, distribution and supply of LNG deriving directly from traditional large-scale LNG (hereafter LSLNG)14. The main nodes (activities) of SSLNG network can be summarised as follows (see also Fig. 3): • supply of LNG from break-bulk, (i.e. the distribution of LNG cargoes into smaller fractions and the loading of LNG from carriers or regasification terminals onto bunker vessels1 or coastal or land storage depots, by ship, truck or train); • transport of the LNG cargoes, by ships or tankers, to LNG storage depots possibly equipped with small regasification plants, also for the purpose of streaming natural gas into the distribution network;

Fig. 1: LNG Trade Volumes, 1990–2017 (source: IHS Markit, IEA, IGU)

•

•

secondary transport, mainly by road, to: i. tanks located in areas not connected to existing networks for the supply of gas to industrial and civil users (so-called off-grid users); ii. vehicle refuelling stations; end uses: production of electricity with LNG, industrial and civil (off-grid) consumption, fuel for direct transport in liquid form.

lThe activities listed above are possible through the provision of specific “SSLNG Services”15 (see also Figure 4) such as: • service of unloading LNG from carriers onto small scale vessels; • storage service, using LNG depots at regasification terminals (typically used only for regasification service), or other LNG depots; • LNG loading service on bunker vessels, (i.e. loading of ships with LNG stored in regasification terminal/coastal depots). Bunker vessels can, in turn, be used as refuelling stations for LNG-fuelled vessels (bunkering service) or for transporting LNG to other coastal depots; • LNG loading service on tankers/ISO-containers (only for onshore terminals), used for road/rail transport. Tankers and ISO-containers can, in turn, be used as refuelling stations for LNG-fuelled vehicles, local storage facilities, bunkers, industrial and civil uses, trains; • additional services (only for onshore terminals), such as supplying LNG through the use of infrastructures built near regasification terminals or LNG storage depots and directly connected to them (e.g. loading LNG onto bunker ships/tankers through a dedicated line connected to the terminal, or the refuelling service for road/ rail vehicles through a dedicated station connected directly to the terminal, etc.).

Fig. 2: SSLNG Facilities in Europe

Considering all of the above, it seems that the LNG business is entering in a new era, and has started dealing with present necessity and trends, embracing the future possibility offered by present technologies16. In synthesis, LNG business has begun the process of adapting to an ever-changing market development scenario, and to (partially) free itself from largescale dynamics. In this context, SSLNG seems to be “the next big thing” in the LNG world, capable to offer real possibility of LNG market enlargement, with all the benefits associated to the diffusion of the cleanest hydrocarbon of all, as well as at the same time maintaining acceptable costs. As always, during the affirmation of a new method/technology, the society is requested to understand it - in order to deal with possible unexpected issues, or criticalities - and to regulate it in order to allow a fair and sustainable use of it. In this context, the present article aims at providing an overview of, and gather

data on, two of the most important themes associated at SSLNG development: • health, safety, social and environmental issues of LNG; • the legislative framework of SSLNG installations, with a special focus on Italian permitting process.

Health, safety, social and environmental (hsse) issues of lng When talking of LNG, several elements are usually misunderstood by general public, leading to an erroneous understanding of LNG real dangers, thus reducing project acceptability, today one of the main issues during project development. In the following, is presented a brief analysis of LNG typical HSSE elements that must be put at the center of discussion with general public during the promotion of a project. First, it is necessary to highlight the lessons learned from the development of previous 11

LSLNG projects, suggesting that, in order to promote and boost the acceptance of projects, careful attention must be put on the following aspects: • site location: it is always preferable to propose projects development in brownfield and other underused areas that can be converted for “cleaner” productive uses, and can be associated to the revival of an abandoned and/or contaminated area, linking the project to immediate benefits for the local population both in terms of employment opportunities in the energy sector and from the point of view of improving the health and safety of the area; • identification of territorial constraints (land planning, natural protected areas, cultural goods, etc.): projects are better accepted when their interference with territorial constrains is minimized. In this manner, it is possible to avoid the typical drawbacks derived from the association of an “socio-emotional” value that any stakeholders detect in a given area, but also to minimize any problems that may arise in the authorization phase and that as a result could lengthen the time of implementation of a project; • adequate baseline data collection, to assess the status of the environment prior the commencement of the work, and to identify potential sensitiveness, that in a similar manner to the above mentioned identification of territorial constrains, will help the project proponent to avoid many of the problems that may arise in the authorization phase, but also to identify adequate actions in order to reduce the footprint of the project; • in depth impact assessment, resulting from the previous items, crossing the project actions vs the environmental sensitiveness; • identification of mitigation measures and definition of monitoring plan for construction and operation phases: these elements are very important not only to comply with typical Authorities requests, but also are needed in order to present to the general public the considerable and remarkable effort of the proponent to improve the project ensuring its presence will not negatively affect the area in which is developed. Of no minor importance, it is necessary to leverage on the understanding real proprieties of the LNG17: it is a high energetic fuel, clear,

Fig. 3: “Five different logistic LNG distribution methods in Small Scale LNG Wholesale”. Source: Shell (IGU edited version, 2014)

odorless, non-corrosive, non-toxic, cryogenic liquid at normal atmospheric pressure. If spilled on water, it floats on surface and vaporizes rapidly because it is two times lighter than water, if spilled in open air, it rapidly dilutes18.

the ignition hazard. In addition, the NG auto-ignition temperature at atmospheric pressure is above 540°C, an unlikely condition that requires strong source of thermal radiation, heat or hot surface19, 20.

In order to obtain LNG form natural gas (NG), the mixture of gasses must undergone to a liquefaction process. Such process is based on a pre-treatment of the natural gas stream to remove impurities such as water, nitrogen, carbon dioxide, hydrogen sulphide and other sulphur compounds. After that, the pre-treated gas is refrigerated to a temperature of approximately –160°C. At this temperature the gas liquefy and it is ready for storage and shipping. Liquefied gas occupies 1/600th of the original gas volume, clearly representing a very convenient way of moving GN around. Another advantage is that, since LNG is obtain through refrigeration, it can be stored at atmospheric pressure.

In the end, all of the potential hazards concerning LNG facilities operators and surrounding communities are direct consequences of physical and chemical properties of natural gas. Primary and secondary containment, safeguard systems as well as separation distance are measures applied across the entire LNG value chain, from production, liquefaction and shipping, to storage and re-gasification, providing effective and redundant layers of protection from LNG hazards. This explain why the LNG industry has an excellent safety record: up to 2012 more than 50,000 LNG carrier voyages were performed, without significant accidents or safety problems either in port or in the high seas. Data form 1986 to 2016 show that globally, only 19 LNG-related accidents happened, of those, only 5 are considered “notable” by the EU Major Accident Hazards Bureau and only one with fatalities (2 victims, in 1989). All considered, LNG is the safest hydrocarbon. For reference, ITOPF (Internationfal Tanker Owners Pollution Federation Limited) estimated that between 1970 and 2016 approximately 5.73 million tons of oil were lost as a result of about 460 tanker incidents21.

It can became flammable, but explosive only under certain (well-known) conditions. Anyways, in a closed, secure storage tank where the vapor concentration is approximately 100% methane, it cannot ignite because there is no oxygen to sustain the combustion. Methane gas will ignite only if the ratio gas/ air is within the limited flammability range (5 to 15%). An often-expected hazard is ignition from flames or sparks, therefore all LNG facilities are equipped with several fire detection and protection systems in order to eliminate

LNG is also the cleanest non-renewable energy source. In general, natural gas combus-

Among the SSLNG bunker vessels (vessels with a loading capacity of 500-30,000 m3), it is possible to distinguish between vessels used for bunkering services such as supplying other vessels (known as lighters), or shuttle vessels, used to transport LNG to other depots. On the other hand, traditional LNG carriers usually have a loading capacity of 30,000 and 270 000 m3. 1

12 | MED OIL & GAS

of natural gas, including LNG, and owned or operated by a company. Again, this definition does not match exactly the SSLNG since it excludes the part of the facility used for production operations and facilities reserved for transmission system. The much-needed clarification on the matter of SSLNG activities and services, expected with the Legislative Decree No. 257/2016, did not arrive. The Decree indeed regulates the administrative procedure, the so-called “Autorizzazione Unica” (on national, regional or communal scale according to the dimension of the activities), necessary to obtain authorisations for the construction of “storage and transport infrastructures” of LNG. In particular Art. 9 regulates the case of facilFig. 4: SSLNG services in wholesale and retail. Source: Shell (IGU edited version, 2014). ities that are connected or functional to the

tions products are cleaner than other fossil fuels: air emissions resulting from combustion of vaporized LNG as a fuel in vehicles or for electric power generation present significant lower concentration of carbon monoxide (CO), nitrogen oxides (NOx), non-methane volatile organic compounds (VOC), and fine particulates (less than 2.5 microns in size). In addition, as shown in Fig. 5, natural gas has lower emissions of carbon dioxide (CO2) and toxic, heavy metals. Since the liquefaction process requires removal of all impurities from the produced natural gas, LNG actually has lower air emissions than natural gas when it is produced (since sulfur content of LNG is near zero)22. The usage of LNG as a fuel for heavy-duty road transport, shipping and rail is the best alternative to diesel and heavy fuel oil. Indeed, due to recent stringent regulations on emissions in the marine sector (MARPOL 73/78 Annex VI)23, LNG is getting more and more attractive for ship builders. Up to 2017, LNG is used as a fuel in more than 100 vessels, and in 2019 LNG will fuel two of the world’s largest passenger cruise ships and the world’s first LNG-powered cruise ships. In the near future, a similar process is expected to involve also road and rail transport24. In this context, the affirmation of SSLNG may pose the foundation of a new beginning for the LNG market, contributing to a more sustainable usage of energy resources spurring further and in a capillary way the utilization of LNG among geographically isolated and infrastructure-poor regions and everywhere pipeline construction is not a viable investment.

SSLNG legislative framework – italian focus The Directive 2014/94/EU of the European Parliament and of the Council of 22 October 201425 constitutes the common framework of measures for the construction of infrastructure for alternative fuels in the European Union. In Italy, the Directive was implemented by the Legislative Decree No. 257 entered in force on 16 December 2016, the so-called DAFI Decree26, aimed at defining a set of rules for the establishment of an infrastructure for “alternative fuels”, and of course, LNG is one of them. However, it must be highlighted that the regulatory framework governing LNG-related activities and the relative construction of facilities is still a “work in progress”, quite far from being completed. Firstly, it must be noted that the current legislation (Article 2 of Legislative Decree No. 164/2000, the Italian implementation of Directive 98/30/EC concerning common rules for the internal market in natural gas)27 defines “LNG plant” as the terminal used for the liquefaction of natural gas or the import operations, and/or the unloading and regasification of LNG, including all the auxiliary services and temporary storage necessary for the regasification process and subsequent delivery to the transport system. It is immediately obvious that this definition does not correctly apply to SSLNG, since it excludes any tanks located in the plant that are not functional to the regasification cycle. On the other hand, the law qualifies a “storage facility” as a facility used for the storage

construction of/ the linkage to the national gas transmission network, or isolated parts thereof, and thus defining them as “works of public utility” and “strategic importance”. Therefore, according to a strict literal interpretation of the Art. 9, the qualification of infrastructure of “strategic importance” can be attributed only to storage facilities that could have a functional or systemic role in the construction of portions of the national network for the transmission of natural gas. A role which would necessarily require the performance of the activity of LNG regasification. However, it is self-evident that DAFI Decree does not regulate traditional regasification infrastructures and their possibility of providing SSLNG services, for which the Decree merely redirect to the single procedure referred to in Article 46 of Decree No. 15 of 1 October 2007, valid for the construction of any type of regasification plant, regardless of size, thus linking them to more complex permitting national procedure. In synthesis, it should be noted that the definitions referred in the DAFI do not succeed in resolving the complexity of the regulatory issues in relation to the variety of situations that arise in SSLNG practice. In particular, a grey area is left unsolved on the matter of which rules are applicable to mixed-purpose infrastructures under authorisation or design. Of those, some will be forced to mainly allocate their reception capacity to regasification activities, reserving a marginal share for the supply of so-called “SSLNG services”; while others, on the contrary, will have to act for the most part as storage depots not destined to supply natural gas transmission networks, but with the possibility of starting a regasification activity to the advantage of isolated network portions. 13

The above explains why, up 2018, all new Italian projects relating SSLNG are defined as “storage” depots of LNG that do not foresee the additional (and potentially remunerative) presence of small-scale sub-services28, 29. Anyways, it must be noted that other players are increasing their interest to SSLNG possibilities, with more projects being proposed every now and then (see Fig. 5)31. In addition to new projects, following the considerations on DAFI Decree, some LSLNG providers are imaging the possibility to modify their traditional regasification plants in order to propose SSLNG services. In this context of blurred boundaries, it is also necessary to highlight the existence of a possible inconsistency in the administrative procedures required to obtain authorisation to build LNG facilities or storage facilities.

Fig. 5: Carbon Dioxide Emissions Factor, kg CO2 per MWh

On one hand, Legislative Decree 257/2016 provides for the existence of three different procedures for the construction of storage facilities, each of which is calibrated on the basis of the size and function of the plant (Articles 9 to 11), while on the other hand, for the construction of traditional regasification infrastructure, the same Article 9 of the DAFI confirms the existence of the most burdensome procedure under Article 46 of Decree No. 15/2007, valid for the construction of any type of plant, regardless of size. The absence of administrative procedures proportionate and appropriate to the capacity and functioning of regasification/liquefaction plants (especially those with reduced capacity that also perform activities functional to SSLNG services), may be an obstacle to the construction and development of new project, in clear contradiction with the role assigned to LNG in the national energy strategy. Moreover, the lack, in the Italian normative, of a precise legal definition of the so-called “Small Scale LNG services”, generally recognised as the means by which liquefied natural gas is managed in small/medium quantities directly in liquid form, such as the loading, storage and subsequent unloading of part of the LNG not destined for the national natural gas transmission network (see Introduction), also weighs heavily on the regulatory level and exacerbate the complexity of the permitting processes. On top of that, SSLNG services, as confirmed by the Authority in its resolution No.

Fig. 6: SSLNG facilities in Italy. Source: Ref-e/ Interfax, 2018

141/2017/R/GAS of 16 March 2017, are not subject to tariff regulation but would be managed on a free market basis. With this in mind, the Authority, with the aforementioned resolution, initiated a procedure aimed at gathering the main information necessary for

the definition of an initial regulation of the technical and economic conditions of access to/supply of the services provided by the LNG storage facilities and infrastructures referred to in Article 9 of DAFI Decree, and for the exact qualification of SSLNG services. 15

Underbalanced Coiled Tubing Drilling System uses Internet Technologies to Ensure Reliable Data Handling Laptops on wellsites were once a rare sight, but a much-needed evolution in wellsite IT is providing the system capability, reliability and security needed to support today’s technically advanced, data-intensive drilling techniques. Toni Miszewski, Managing Director at AnTech Ltd

Despite the staggering volume of data required for Underbalanced Coiled Tubing drilling (UBCTD) applications, for a recent UBCTD job in Western Australia it would have been perfectly possible for a directional driller to have steered the directional drilling assembly from the comfort of an office in the UK via satellite internet. Whilst this might not always be desirable in practice, the mere fact that it is possible demonstrates the significant capability of modern communications and computing systems, and highlights the opportunities this can bring to the field. Just as Internet servers in data centres driving e-commerce and online banking are managed remotely using software specifically adapted to configure, monitor and control hardware from a distance, this same capability can be employed in the oilfield where the fundamental requirements are the same (namely to provide timely, reliable and secure data to users). To understand why UBCTD is so data intensive, it is worth considering the measurements being acquired. Downhole data from up to 200 sensors at a time is transferred at electric wireline speeds, rather than slow mud pulse speeds. This downhole data is then combined with surface data from the CT rig and the flowback equipment in real time. Throw in the complica16 | MED OIL & GAS

tion of these data points being controlled by different providers and you begin to get an idea of the processing power required. In short, traditional methods of data transfer are no longer viable for these applications.

The evolution of wellsite IT Before the advent of the PC, the most sophisticated piece of IT at the wellsite was the wireline logging truck. As PC technology became more widespread, it was harnessed by the industry and internet-enabled laptops were increasingly used on wellsites for reporting, email and data acquisition. However, this evolution has not been without its problems and, in many cases, the solution has been ad hoc fixes rather than long term strategy. Clearly, wellsites are rugged environments that require robust equipment. However, consumer

grade equipment is significantly cheaper and more readily available, thus it often tends to be the preferred choice. But dust and other contaminants inevitably shorten the useful life of consumer grade equipment, making this a flawed logic. Then there’s the connectivity issues. Back before equipment was WiFi enabled, cables were strung across the wellsite and many hours were frequently lost repairing communications cables damaged by trucks. When WiFi did become available, many of us will recall instances where the source of a slow-running communication link was tracked down to a crew member streaming video on their mobile phone. In addition, data stored on desktop computers is inaccessible from the time it’s packed up to the time it arrives back at base, resulting in the costly and inefficient loss of valuable post job processing and reporting time. These factors and the associated security

risks and performance issues are all common features of an IT system under limited control, but by adopting a new strategy using readily available technology, things can be improved dramatically.

How internet technologies help The speed, reliability and ubiquity of the internet has unquestionably made it an integral feature of modern life. Long gone are the days of dial-up and logging into a single server with static web pages. Nowadays it’s all about load balanced server farms, redundant databases that power e-commerce and network switches that efficiently and quickly connect users globally. Billions of dollars and man hours have been spent rigorously improving the technology necessary to enable companies to operate their businesses online. This has primarily included automating the IT tasks that keep the system running. A key feature of modern internet management is that the person doing the managing is very rarely anywhere near the physical hardware being used, and the end user (in oilfield terms: the wellsite crew) requires minimal understanding of the technology to be able to use it. This is made possible by running many applications directly online through a browser without having to download any additional software. These so-called web apps can be up-

dated centrally, and all updates are available to end users at the same time. This concept can be applied to the wellsite by installing a mini data center at the heart of the wellsite IT system and ensuring a reliable connection to it. This ensures on-site quality-of-service to local users is maintained, essentially becoming part of the ‘cloud’ for the purposes of management and remote data processing.

The WellVault™ mini data center The key to optimising the wellsite IT system is to treat it as an integral part of the wellsite, central to wellsite operation, rather than an added productivity tool. In a UBCTD setup, the time between rig up and rig down is relatively short, and there is usually no existing installation such as a rig communication system to plug into, and certainly not one configured for the data-intensive nature of a UBCTD operation. The essential features are: Environmental protection: Heat, cold, water, dust and vibration, all common wellsite features, are the enemies of delicate IT equipment. While these factors can be mitigated, measures can conflict with one another. For example, specifying fan-less computers may seem the obvious choice for minimising the impacts of

excess dust, but such computers have reduced computer clock speed impacting performance. Therefore it will be necessary to provide dust protection and filtering for fan cooled computers. In addition, protective cases can isolate equipment from shock and vibration in use and during shipping. Internet connection: Optimum connection type (e.g. satellite, mobile internet or microwave link) is location-dependent, but must always be planned and tested rather than being considered as an afterthought or nice-to-have feature as has often been the case. Data interfaces and displays: Individual data displays placed around the wellsite provide the communication required for integrated operations such as UBCTD. These also serve as a connection to third party data sources and drive the WiFi access points. Long range point-to-point WiFi: Specialist WiFi access points provide longer range than consumer items. The challenge here is to be able to offer a range of secure fixing methods in order to position them as required, preferably on the outside of cabins with reliable cable entry into cabins. Remotely configurable routers: Every device must be able to be configured, monitored and

The WellVault™ mini data center setup

17

maintained remotely to avoid costly downtime. Consumer products are cheap and readily available but, unlike enterprise-grade devices, don’t offer the control of configuration or feedback of data required for a remotely controlled industrial system. Redundancy: To ensure reliability, especially where there is limited IT knowledge on site, a

robust redundancy setup is required. At least two servers must operate concurrently so that in the event the first server goes down, operation can switch to the backup servers without a loss of data. Currently, the switch over requires intervention by a remote engineer, but newer technologies can enable an automated switch over, potentially removing server failure as a cause of downtime.

Encryption and access control: To ensure data security, end-to-end encryption is essential and each device must have its own firewall and anti-virus software. To prevent the system being used by crew members for non-operational reasons, access should be limited using IP address control.

the cloud-based ERP system to provide daily updates on cost and any pending spares or stock requirements.

Reliable, if slow, satellite internet connection meant that the wellsite database could be replicated in the UK for job support, troubleshooting and to create the RockSense® log for geosteering. Wellsite equipment needed to withstand extreme heat and pervasive dust. The value of a robust internet setup was proven during a server power supply failure on-site. Whereas a less sophisticated setup might have meant stopping operation for a few hours, and would have created data splicing problems later on, the new redundant setup allowed the backup server to be activated remotely, minimising downtime.

CASE STUDY: The advantages of the new WellVault™ mini data centre were demonstrated during a recent project in Australia. UBCTD was used to drill a multilateral well with RockSense® porosity log used for geosteering. The objective was to drill two laterals in the reservoir section. The remoteness of the operation, 1200km north of Perth, and the fact that the support locations were in the US and the UK meant a minimum 2 day travel time to bring in equipment and support staff if required. Therefore, it was essential that equipment was reliable and could be configured remotely. The requirement was to send real-time data and logs to the client’s office in Perth and to the UK for interpretation. Additionally, the equipment maintenance data and inventory usage needed to be recorded in

This was the first operation where it was deemed unnecessary to send a dedicated IT engineer to provide pre-job setup. A satellite link from the wellsite provided an internet connection and the WellVault™ data centre was configured to automatically provide a secure VPN connection to the UK, with any further setup tasks completed remotely. WiFi access points were setup around the wellsite by the local crew to provide connectivity to the underbalance equipment and the CT unit. Their data was provided in WITS format, with communication links having been tested before the job started.

Conclusion The era of ad-hoc IT systems at the wellsite that do not meet the requirements for functional capability, reliability, security or remote control required for advanced drilling applications has passed. Modern development of internet data storage and communications technologies means it is possible to place a portable, internet connected, mini data center at the wellsite that can match the data security and equipment uptime capability of larger systems. Suitable precautions must be taken to physically protect hardware from harsh wellsite environments but, with care, this is achievable with relative ease.

18 | MED OIL & GAS

While most operations are not as data intensive as UBCTD, the era of integrated wellsite IT systems drawing and streaming data from multiple sources is most definitely upon us. Implementation of cutting edge remote controlled internet technologies enables wellsite crews to focus on their primary roles without having to undergo training to support additional equipment, while reducing the need for additional specializations on site and placing control of IT hardware and data within the IT department, where it can be managed and kept secure. The evolution of internet technology relies on users adapting the way they interact with it. Oilfield IT needs to similarly adapt in order to fully benefit from the digital transformation.

Toni Miszewski

About the author Toni is founder and Managing Director at AnTech Ltd where he has led the company’s entry in the Underbalanced Coiled Tubing Drilling market. Before founding AnTech, Toni worked for Schlumberger both in the field and in engineering development. He has a Batchelor’s degree in Mechanical Engineering from Imperial College, London and is the holder of several patents for downhole technology.

We need to talk. Seriously. For decades we have been carrying out large projects with mechanically lined pipes in Brazil and globally – we have always had satisfied customers. Because the originals from BUTTING keep what we promise. 100 % Quality 100 % Fairness 100 % Reliability

Fairness, quality and reliability. This is BUTTING. Hermann Butting, President of BUTTING Group

www.butting.com – more than pipes –

20 | MED OIL & GAS

THE HEAVY TRANSPORT CHAMPIONS + Towed modules + Self-propelled modules + »ADDRIVE« the 3 in 1 solution

Find out more www.bolding.as

Well Ageing Studies for the Safe Extension of a Well’s Life Paolo D’Alesio, Livio Caramanico, Elisa Angelucci, Luigi Scalzitti, ProEnergy s.r.l., Norbert Jamot, Jérémy Sorhabil, TEREGA. Introduction Due to the ever more challenging, and thus “investment-intensive”, contexts in which new wells are to be drilled, together with uncertainties of the current market, existing oil & gas assets do not only ensure an important cash source for Operators, but they also represent a low-risk and maybe the easiest opportunity to sustain production and reserves with a relatively limited cost. Furthermore, the availability of effective secondary and tertiary enhanced recovery technologies allows today to2 achieve a longer productive life of mature fields. These factors put together, definitely suggest that the extension of the existing wells’ life is a more advisable option than the drilling of new wells. However, wells age and, if not properly maintained, may generate safety risks and environmental concerns, due to the degradation of the relevant Well Barrier Elements (WBEs). Similar considerations also apply to gas storage wells, for which the degradation of WBEs is even amplified compared to production wells, because of the alternating production and injection cycles at the original reservoir pressures every year. That said, a specific methodology and software for the proactive management of ageing wells have been developed. Such methodology is described herein, in terms of tasks involved and the related software functionalities to support them. Moreover, the results achieved from their implementation in two gas storage fields in France are also provided, namely the opportunity to keep wells ageing under control through a customized Workover Plan.

their current “health conditions”, but also to predict future critical WBEs in order to put in place suitable preventive measures. In other words, it is key to analyse the ageing mechanisms of specific WBEs and proactively maintain them.

Phases of the “well life extension methodology” A typical Well Life Extension Study consists of the following tasks: 1. Assessment of the current integrity status of well, along with the execution of a Failure Modes, Effects and Criticality Analysis (FMECA), to identify the potential failure modes of WBEs and assess the related risks. 2. Collection of well integrity failures experienced in the field, analysis of corrosion logs, and definition of possible corrosion scenarios and degradation mechanisms. 3. Estimation of WBEs degradation factors (tubing and casing corrosion/erosion factors and elastomers degradation factors). 4. Prediction of current and future criticalities and estimation of the residual well life (“well ageing”) of each well subject of the study. 5. Definition of various Workover Plan options for the specific field, based on the priority levels resulting from wells and asset integrity, ageing, safety and performance factors. 6. Execution of a cost-benefit analysis. Substantially, the Well Life Extension Methodology includes three main phases: • Well Integrity Assessment • Estimation of Wells Ageing • Definition of Workover Plan Options

Concept of “well life extension” The concept of Well Life Extension is to keep wells “young”; to this aim, it is necessary not only to get a comprehensive understanding of

Each phase is described below, along with the main results obtained for two gas storage fields in France.

A typical Well Life Extension Study consists of the following tasks: 1. Assessment of the current integrity status of well, along with the execution of a Failure Modes, Effects and Criticality Analysis (FMECA), to identify the potential failure modes of WBEs and assess the related risks. 2. Collection of well integrity failures experienced in the field, analysis of corrosion logs, and definition of possible corrosion scenarios and degradation mechanisms. 3. Estimation of WBEs degradation factors (tubing and casing corrosion/erosion factors and elastomers degradation factors). 4. Prediction of current and future criticalities and estimation of the residual well life (“well ageing”) of each well subject of the study. 5. Definition of various Workover Plan options for the specific field, based on the priority levels resulting from wells and asset integrity, ageing, safety and performance factors. 6. Execution of a cost-benefit analysis. Substantially, the Well Life Extension Methodology includes three main phases: • Well Integrity Assessment • Estimation of Wells Ageing • Definition of Workover Plan Options Each phase is described below, along with the main results obtained for two gas storage fields in France.

Phase 1 - well integrity assessment The first phase of any Well Life Extension Study is represented by the assessment of the current integrity status of wells, with the aim to evaluate whether the wells can be still operated safely. Previous papers Fig. 1. (1), (2) describe the applied well integrity assessment methodology, whose main steps are summarized in Fig. 1. 23

Fig. 1 Well Integrity Assessment Methodology

Fig. 2 Degradation of WBEs Over Time

In the specific case of the well integrity assessment performed for two gas storage fields in France, the main results achieved are as follows: • Field A: 10 wells have been identified as having a Medium Criticality Level • Field B: 6 wells have been identified as having a Medium Criticality Level. Within the assessment, calculation of MAASPs and the definition of the preliminary wells criticality level has been performed by using the well integrity software developed in accordance with the criteria established by the ISO/ TS 16530-2.

Phase 2 - estimation of wells ageing The future performance standards of WBEs, 24 | MED OIL & GAS

and consequently the “ageing mechanisms” of wells, are affected by degradation over time; from this point of view, the main “time-dependant factors” are: • corrosion/erosion factor, which has a progressively increasing impact on the resistance of WBEs due to possible corrosion/ erosion phenomena; • elastomer ageing factor, which has a progressively increasing impact on the sealing capability of WBEs, due to degradation of elastomers. The application of such degradation factors to the current WBEs’ performance standards allows to predict when the resistance of the weakest WBE(s) will become lower than the operational load it is exposed and, therefore, evaluate the residual well life and identify the

WBEs that are expected to become critical in the future. The residual well life has been estimated by using the previously mentioned well integrity software. Such software starts introducing “non-time dependant (safety) factors”: • Design safety factor, which is normally included in Operators’ well design standards, to take into account the uncertainty of the manufacturing process. • Hydrostatic factor, to take into account the differential pressures generated by fluids inside and outside tubing/casings, as a result of their different densities and the related uncertainties. • Wear factor, to take into consideration the possible erosion of casing internal diameter, caused by drill string during the drilling

of the subsequent well phase, to calculate the resistance of each WBE at the time of installation. Then, by applying the above mentioned time-dependant degradation factors, the software provides the graph shown in Fig. 2. Such graph, produced for each well included in the study, shows how the resistance of each WBE of the well decreases over time. As operation load, a Reference Operating Pressure (ROP) equal to the maximum Tubing Head Pressure (THP) of the well under study is used. THP is the maximum pressure value that can be potentially found in the tubing and affects the barrier elements of the A-Annulus. By drawing the horizontal line of ROP, the first declining line that is intersected defines the weakest WBE that is expected to become critical in the future (in the example of Figure 1, it is the Packer and Seal Assembly elastomers). The intersection point defines the well remaining life-time (in the example, 2049). It is worth pointing out that the residual well life is an estimation aimed at anticipating the WBEs which are more likely to fail in the future; as such, it should not be considered as an exact value, but rather as a range of years in which failure may occur.

Fig. 3 MFC/EMDS (tubing) ofof thethe reference gas storage gas well storage well Fig. 3 MFC/EMDS log log (tubing) reference

Calculation of Corrosion/Erosion Factors Corrosion/erosion factors are typically defined based on the analysis of the logs performed in the well of interest or in reference wells. In the performed gas storage fields applications, in addition to the extensive experience gained in similar works, the results of the Multifinger Caliper/Electro-Magnetic Defecto-Scope (MFC/EMDS) logs carried out on two reference wells of the fields (a gas storage well and a reservoir pressure monitoring well) have been used. Such logs had the objective of evaluating the extent of wear and corrosion on both the tubing and production casing: the combination of the two tools has allowed determining the reduction of wall thickness (WT) from inside and outside of both pipes. By deeply analysing, joint by joint, the values of the average and minimum remaining wall pipe thickness reported in the two logs, some “false” erosion/corrosion detections have been identified and excluded. In particular: • Fig. 3. The “PJ2” of the reference gas storage well’s tubing showed a very different thickness reduction compared to previous joint. By verifying the joint top and bot

Fig. 4 MFC/EMDS (tubing) of of the the reference pressure monitoring well Fig. 3 MFC/EMDS log log (tubing) reference gas storage well

Fig. 4 MFC/EMDS log (tubing) of the reference pressure monitoring well 5

25

SiH2CI2

CH2O

SiH4

C3H8

C2H2

CI2 O3

H2S

H2 (CH3)2O

H2O2 CH4

N2O

NH3

C7H8 CO2 O2

C4H8O C6H6

CO

YOUR ADVANTAGE IN FLAME AND GAS DETECTION Trusted by leading industries since more than 50 years. Omniguard’s products are available with a variety of certifications and approvals:

SIL2 For information on the certifications and approvals each product holds please visit our website. Omniguard by Firefly Stockholm, Sweden

Phone: +46 8 449 25 00 E-mail: omniguardsales@firefly.se

www.omniguardbyfirefly.com

26 | MED OIL & GAS

• Scenario the third from the average remaining wall pipe measured for each joint (low Reference Pressure scenario).Reference Gas Storage Well

Monitoring Well

Medium Corrosion

0,054

0,015

Low Corrosion

0,042

0,011

InHigh each scenario, the values factors are given by the average of th Corrosion 0,094 of resulting corrosion 0,041 calculated for each joint (Table 1). •

Tubing Corrosion Factors (mm/y) tom depths reported in the log, it has been Table 1 Corrosion/Erosion Factors of Reference Wells’ Tubings Scenario Reference Gas Reference Pressure found that the PJ2 includes the 7” pup Storage Well Monitoring Well joint, the crossover and the 5 ½” pup joint theupdecision to exclude the values of High theCorrosion “low corrosion scenario”, a sensitivity0,041 analysis has 0,094 located above the packer, as After per the been performed to assess the impact of the “high” and “medium” corrosion/erosion scenarios on Medium Corrosion 0,054 0,015 per completion tally. Therefore, since the wells residual life, and define the final tubing corrosion/erosion factor. depth at which the maximum measured inLow Corrosion 0,042 0,011 Tocrossover, carry out the sensitivity analysis, it has been decided to use the tubing corrosion/erosion factors side radius was at the top of the Table 1 Table Corrosion/Erosion Reference summarized 1 Corrosion/ErosionFactors Factors ofof Reference Wells’Wells’ Tubings Tubings it is possible that such measurement was in Table 2.