• Highly Automated Direct Drive Pulverizing Systems

• Silos

• Conveying Systems for Pellets and Powder

• Dry Blending High Intensity Mixers

• Lab Testing Equipment for Powder Analysis, Rotap Particle Testing and Dry Flow Testing

• New Disks for Pulverizing Systems

• Largest CNC Disk Sharpening Services for Pulverizers in the World

We also provide responsive technical assistance to customers or any inquiry into the pulverizing process of powder production. We are happy to assist you with knowledgeable and fast courteous services.

sales@powder-king.com

Powder King® LLC

41780 N Vision Way, Units 120-125, Bldg. 2

Anthem AZ 85086

www.powder-king.com

623.551.9897

Cover Photo is courtesy of Slide ®. The Rotomolded novelties featured on the cover of this issue include: AMANDA & AMBROGIO, designed by Favaretto & Partners; and OTTOCENTO LAMP, designed by Paola Navone OTTO Studio - for Slide ®

The ARMO Showcase is designed to educate the world about fantastic, innovative, attractive, practical, and economic rotationally moulded products.

42

Alvin Spence, Centro Incorporated

A close look at the last few years in the Rotational Molding industry.

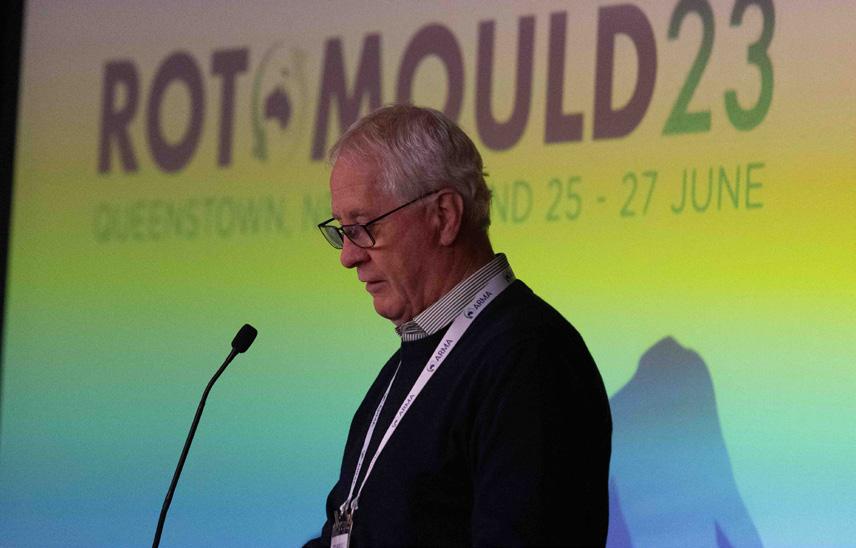

ROTOMOULD23 QUEENSTOWN

Michelle Rose, ARMA CEO ARMA gathers a large attendance in New Zealand.

8 From the Publisher

Susan Gibson, JSJ Productions, Inc. What’s Buzzing?

10 Credits

Global Contributors, Department Contributors, and Issue Contributors

15 Upfront Industry News, Trends, and Products

49 At Issue

Martin Coles, Matrix Polymers

Sustainability in Rotomoulding – What Does It Really Mean?

54 X-Factor

Tom Innis, Xcelerant Growth Partners

Tenjam’s pivot to rotomolding proved to be its turning point.

58 Leadership

Cutting Edge PR

What PR teams need to know about cybersecurity concerns

62 ARM Report Roto Recharge

70 Roto Around the World

Ian Hansen, RotaConsult

KSC-Plast is Market Leader in Central Asia

74 Practical Roto Tips

R. Dru Laws, Brigham Young University - Idaho

Should you reverse your rotations?

Since the 1940s when mass production of plastics products had their beginning, the market has grown exponentially. The global plastics market reached USD 593 billion by the end of 2021, is estimated to double by 2040, and increase by 2.5 times by 2050.

Plastics are the most common materials for producing end-use parts for a wide spectrum of uses. Plastics are a versatile category of materials, with many polymer options, each with their own specific mechanical properties.

A variety of plastic manufacturing processes have been developed to cover a wide range of applications, part geometries, and types of plastics. For any designer and engineer working in product development, it is critical to become familiar with the manufacturing options available today and the new developments that signal how parts will be manufactured in the future.

The global rotomolding market was reported to reach a revenue of 5 billion in the year 2022 and is estimated to reach a revenue of 9 billion by the end of 2033.

Welcome to RotoWorld® Issue 3, 2023. We are pleased to feature the 2023 ARMO Showcase Special Section inside this issue. This ARMO Showcase is also featured as a separate digital “ISSUU” publication online. We hope to return to the full ARMO Showcase print and online publication in 2024.

The ARMO Showcase is designed to educate the world about fantastic, innovative, attractive, practical, and economic rotationally molded products. In this special section you will see some great product examples of what can be achieved with this process. From an innovative hunting feeder to versatile event applications, end-users are finding rotational molding is the answer for a world of product applications.

When looking for a plastic manufacturing process that produces high-end, versatile, and functional parts, the rotational molding process is the one to look to. This is a process that involves heating a hollow mold filled with powdered thermoplastic and rotating it around two axes simultaneously to produce mainly large hollow objects.

Rotational molding requires less expensive tooling compared to other plastic processes as there in no pressure required to form the part. Molds can be fabricated, CNC machined, or cast from aluminum at a lower cost and shorter lead times compared to tooling for other molding processes, especially for large parts.

Rotational molding creates parts with nearly uniform wall thickness. Once the tooling and process are set up, the cost per part is very low relative to the size of the part. It is also possible to add prefinished pieces, like metal threads, internal pipes, and structures to the mold.

These factors make rotational molding ideal for short production runs or as an alternative to blow molding for lower volumes. Typical rotomolded products include tanks, buoys, large containers, toys, kayaks, and playgrounds just to name a few.

Rotomolding has some design constraints and finished products tend to have broader tolerances. As the entire mold must be heated and cooled down, the process also has long cycle times and is quite labor intensive, limiting its efficiency for higher volume applications. However, it is perfect for lower volumes.

The most common material for rotational molding is polyethylene (PE) which is used in more than 80% of applications, mainly because PE can be easily ground into a powder at room temperature. Commonly rotomolded plastics include:

• Polyethylene

• Crosslinked Polyethylene

• Polypropylene

• Polyvinyl chloride

• Nylons (6, 11 & 12)

• Polycarbonate

We hope you will enjoy this issue as it contains some great reading regarding current developments in the rotational molding industry. See “Adaptability...the Secret Sauce for Many Rotational Molder’s Success Stories”, authored by Alvin Spence, Centro Incorporated starting on page 42. Also, inside is a look at two successful 2023 rotomolding conferences, ARMA’s Rotomould23 Queenstown and the 2023 StAR Conference held in New Delhi. Congratulations to both!

I hope to see you in Poznan for what promises to be an excellent conference for our global industry!

Sincerely,

Susan Gibson Publisher & Editor

Jerico’s complete line of aesthetic compounded materials brings a bright and dazzling look to your rotational molded products. Our Stone Effect specialty color compounds are designed for many outdoor applications like hot tubs, lawn/garden accessories, flower pots, and patio furniture, and they’re now FDA compliant for use in coolers.

Stone Effect can be produced in any color and with varying color intensities by using our line of Stone Effect color concentrates. We work with you to acheive your optimum color and design expectations every time!

As we grow, we look for ways to exceed your expectations and help you achieve even greater success! Our mission is to be the go-to resource for resins and compounds that meet your precise specifications, arrive on time, and provide the consistent level of quality you’ve come to expect from Jerico! You’ll always receive the kind of personal service that we like to call the Jerico Effect!

Our commitment and flexibility show in everything we do!

info@jericoplastic.com

Publisher & Editor

Susan D. Gibson President - JSJ Productions, Inc. susan@jsjproductionsinc.com

Technical Editor

Alvin Spence PhD MEng aspence@centroinc.com

Process Editor

Paul Nugent PhD MEng paul@paulnugent.com

Design Editor

Michael Paloian President - Integrated Design Systems, Inc. paloian@idsys.com

Global Contributing Editors

Celal Beysel Chairman - Floteks Plastik beysel@superonline.com

Tom Innis Excelerant Growth Partners w@xcelerantgrowthpartners.com

Martin Coles Matrix Polymers martin.coles@matrixpolymers.com

Adam Covington Ferry Industries acovington@ferryindustries.com

Mark Kearns Moulding Research Manager m.kearns@qub.ac.uk

Ravi Mehra Managing Director - Norstar International LLC maramehra@aol.com

Advertising and Art Production

Marketing/Advertising Director Jennifer Gibson Hebert Vice President, JSJ Productions, Inc. jennifer@jsjproductionsinc.com

Chief Art Director Anya Wilcox JSJ Productions, Inc. awilcox@designintersection.com

Circulation & Distribution Administration

Sheryl Bjorn JSJ Productions, Inc. sheryl@jsjproductionsinc.com

Editing & Translations

Suzanne Ketron | Oliver Wandres | Sheryl Bjorn

Website & Online Technology

Jason Cooper JSJ Productions, Inc. jason@bound.by

RotoWorld ® is a JSJ Productions, Inc. Trade Publication JSJ Productions, Inc. 625 West Market Street, Salinas, CA 93901 Phone: (512) 894.4106; Fax (512) 858.0486

Email: rotoworldmag@rotoworldmag.com and Website: www.rotoworldmag.com

Subscriptions One-year subscription (six issues), print or digital, $80 US, $100 Canada/Mexico, $155 All Other Countries. To subscribe or to submit change of address information, call us at (512) 894.4106; fax us at (512) 858.0486; visit us online at www.rotoworldmag.com; or email us at sheryl@jsjproductionsinc.com. You may also write to RotoWorld ® Subscriptions, JSJ Productions, Inc., 625 West Market Street, Salinas, CA 93901

Advertising For information on advertising, please contact Advertising Director Jennifer Gibson Hebert, JSJ Productions, Inc.

Email Jennifer Gibson at jennifer@jsjproductionsinc.com

Letters We welcome letters about our contents. Write Letters to the Editor, JSJ Productions, Inc., 625 West Market Street, Salinas, CA 93901 512.894.4106 phone 512.858.0486 fax, or Email susan@jsjproductionsinc.com.

Editorial Queries We consider unsolicited contributions. Send manuscript submissions as email attachment to Susan Gibson at susan@jsjproductionsinc.com.

JSJ Productions, Inc. bears no responsibility for claim or factual data represented in contributed articles.

Postmaster Send changes of address to RotoWorld®, JSJ Productions, Inc., 625 West Market Street, Salinas, CA 93901

RotoWorld® is a JSJ Productions, Inc. independently owned, bi-monthly trade magazine for the international rotational molding and plastics design industries. JSJ Productions, Inc. owns all copyrights on articles published herein unless ownership is otherwise stated. Reproduction of this magazine, in whole or in part, without the express written permission of the publisher is not permitted.

Polyethylene Granules & Powders

Crosslink Polyethylene

Polypropylene Granules & Powders

Polyamide Powders

Ancillary Products

Designed

Dedicated Technical Services Support Team

Multi-lingual

NEW for 2023 our latest investment in a purpose-built compounding and grinding plant in Rayong, Thailand.

To learn more about our products & material solutions get in touch at:

Alvin Spence is Vice President Engineering at Centro, Inc., North Liberty, Iowa. He provides leadership for Centro’s product development team and quality resources. Alvin received his Bachelor’s degree in Mechanical & Industrial Engineering and PhD from Queen’s University Belfast. aspence@centroinc.com

Paul Nugent

Paul is a consultant who travels extensively across six continents assisting clients in many roles from training to expert witnessing. He received his Eng. degree in Aeronautical Engineering and Ph.D. in Mechanical Engineering from Queen’s University of Belfast. Paul developed the Rotolog system, the first complete computer simulation (RotoSim), and authored a book entitled Rotational Molding: A Practical Guide paul@paulnugent.com

Celal is Chairman of Floteks Plastik, the pioneer and innovative leader of the rotational molding industry in Turkey and a Global Contributing Editor for RotoWorld® magazine. Being an ARM member for more than 20 years, he has made many presentations at ARM meetings in various countries. He is also active in business and political organizations in his country. Celal has authored numerous articles published in various newspapers and magazines about politics, plastics, rotomolding, and innovation. beysel@superonline.com

Michael is President of Integrated Design Systems, Inc., Great Neck, New York. Over the past 25 years, Mike has developed a broad range of plastic products utilizing various processing methods including rotational molding. Mike’s B.S. degree in Plastics Engineering and Masters in Industrial Design, combined with his extensive experience, has formed the basis for his branded and unique insights into the field of plastics part design. paloian@idsys.com

Martin Coles, CEO of Matrix Polymers co-founded the business 30 years ago and is the company’s largest shareholder. Shortly after graduating from London University, he began his career in the plastics industry working for a major Italian petrochemical and soon became passionate about the unique world of rotomoulding. Matrix Polymers are experts in rotomoulding materials and have become a global supplier with compounding and grinding plants in the UK, Poland, Australia, New Zealand, and Malaysia. The company sells more than $150 million of rotomoulding materials each year and has 230 employees. martin.coles@matrixpolymers.com

Adam Covington is President of Ferry Industries, Inc. in Akron, Ohio U.S.A. Covington has been with Ferry Industries for over 11 years, advanced through the manufacturing, engineering, sales, and service positions within the company and was appointed President in 2019. Adam strives to find solutions for customer’s needs and advance machine technology for the rotomolding industry. He is a graduate of Ohio University’s Russ College of Engineering and Technology with a Bachelor’s degree in Industrial Technology. acovington@ferryindustries.com

Mark Kearns is the Rotational Moulding Research Manager of the Polymer Processing Research Centre at Queen’s University of Belfast. He is a Chartered Chemical Engineer with a M. Phil Degree in Rotational Moulding. Mark manages rotational moulding research and development projects for companies across Europe, Australasia, and North America. M.Kearns@qub.ac.uk

Tom Innis is owner and Principal CEO of Xcelerant Growth Partners, LLC (Madison, WI), a multi-discipline consulting firm with specific focus in the global plastics sector. Leveraging industry experience and relationships built over 25+ years in the international manufacturing realm, Xcelerant connects the links in the industry supply chain to accelerate speed-to-market and deliver turnkey personnel, product development and manufacturing solutions to an international audience. tinnis@xcelerantgrowthpartners.com

Ravi Mehra has been associated with the rotational molding industry since the early 1970’s. He is a Past President of ARM – Association of Rotational Molders, and has been inducted into the ARM Hall of Fame. He is the Founding Chairman of StAR – the rotational moulding Trade Association of India. He was the Chairman of ARMO – Affiliation of Rotational Moulding Organizations from 2012 to 2014. Ravi consults internationally with companies in the rotational moulding arena to help their global strategy, facilitate technology tie-ups, and business alliances. maramehra@aol.com

Ian Hansen has over 30 years of experience in the rotational moulding industry and has presented to conferences around the world on the subject of quality, safety, and tank design standards. Rotomoulders around the globe have problems from time to time. Rota Consult delivers production solutions so rotomoulders can improve productivity and profitability, without wasting more of their valuable time. ianhansenconsult@gmail.com, www.ianhansenconsult.com

R. Dru Laws, educator and rotomolding expert, graduated from Brigham Young University in 2003 with a BS in Mechanical Engineering and a minor in Mathematics. In 2005, he graduated top of his class with distinction (honors) from the Queens University Belfast in Northern Ireland with an MSc in Polymer Engineering from their school of Mechanical & Manufacturing Engineering. He has several rotomoulding-related patents. Laws is currently a full-time Manufacturing Engineering professor at BYU-Idaho, as well as CEO of Halltech Systems and High Pointe Plastics.

Kim Harrison, Founder and Principal of Cutting Edge PR, loves sharing actionable ideas and information about professional communication and business management. He has wide experience as a corporate affairs manager, consultant, author, lecturer, and CEO of a non-profit organization. Kim is a Fellow and former national board member of the Public Relations Institute of Australia, and he ran his State’s professional development program for 7 years, helping many practitioners to strengthen their communication skills.

S B Zaman has been an industry promotion professional in the Plastics sector for about two and a half decades; he has been executive head of StAR since inception of the association in 2004. As its Executive Director currently, he has played his role in the continuing success of StAR being a truly representative body of the Indian & South Asian rotomoulding industry, as well as proactive member of ARMO. Coming from a Media background he has been involved in several publication projects and frequent industry articles.

With a Degree in Hotel Management and a background in event organisation, Michelle started with the ARMA almost 15 years ago, in the role of Deputy Executive Officer. During her career so far, Michelle has organised conferences and study tours all over the world and gained extensive experience in membership management, stakeholder engagement, and administrative services, as well as business and project management. Due to her commitment, hard work, and wide range of expertise, as well as the value of her current industry relationships, Michelle was selected for the role of CEO starting January 2021.

BAXTER, MN, USA — a leading tooling manufacturer serving the global rotational molding industry, has announced the sale of its business to Self Group USA, a multi-national thermoforming tool manufacturer headquartered in Rivignano Teor, Udine, Italy. The strategic acquisition aligns and expands the capabilities of the two companies, creating a broader offering of tool building technologies and expertise to customers in the rotational molding and thermoforming manufacturing sectors.

Founded as Lakeland Mold Company in Brainerd, MN in 1988, and later acquired by Tom and Ellen Haglin in 2012, Avantech has leveraged significant investment in state-of-the-art facilities, CNC machining equipment, manufacturing systems, and exceptional people to deliver high-quality tooling and exemplary service to rotational molders throughout the global industry. As the company has expanded, it has become of a target of acquisition, but it was not until the dialog with Self Group began that this piqued the interest of the Haglins.

“Over the years, we’ve been approached numerous times (regarding selling the business),” commented Tom Haglin,

co-owner and CEO of the company, “but until now, none of the potential buyers fit the profile necessary to capture our interest: a company with similar values that is prepared to invest in the organization’s future while respecting its legacy.” Noting Self Group’s family-owned and -operated structure, its ability to diversify Avantech’s manufacturing capabilities, and its sole focus on tool-building, Haglin stated,“There was true alignment with Self Group - from both philosophical and business perspectivesthat drove both parties’ desire to make this happen.”

As Self Group USA assumes ownership, the Avantech management team will remain intact in moving the business forward. “As this transition takes place,” stated Haglin, “maintaining customers’ confidence in entrusting us with their tooling investments is absolutely critical, and we’re excited that the Avantech team will continue to provide the experience, expertise, and service to which our customers have become accustomed.”

Please visit avantech.com for more information, or contact Michael McConnell at (218) 828-0110.

CALGARY, AB CANADA NOVA Chemicals Corporation (“NOVA Chemicals”) and Plastic Energy have entered into an agreement to explore the feasibility of developing a pyrolysisdriven advanced recycling facility in the Sarnia, Ontario, region. If constructed, the facility would be the largest of its kind in Canada with a potential initial capacity of 66kt per annum.

“Post-use plastics offer tremendous value to furthering the circular economy, and our teams at NOVA Chemicals work daily to innovate new and collaborative ways to extend the lifecycle of our products and plastic packaging,” said Greg DeKunder, VP, NOVA Circular Solutions. “This agreement with Plastic Energy is a prime example of two companies working together to create timely, effective, and sustainable solutions that will help us make progress towards our 2030 recycled plastics ambitions, while diverting hardto-recycle segments of plastic waste away from landfills.”

Plastic Energy is one of the world’s leading advanced recycling technology companies through use of its patented TAC™ process to treat post-consumer plastic waste. Recycled polyethylene manufactured using Plastic Energy-produced feedstock, called TACOIL™, has identical properties to virgin polyethylene and can be used in food contact and high-performance applications, helping manufacturers and packagers achieve their recycled content goals. Plastic Energy has two commercial recycling plants in Spain that have been in operation for 7 years, alongside new projects in Europe and Asia.

“We are pleased to sign this agreement with NOVA Chemicals to explore the scope for our first advanced recycling project in Canada,” said Carlos Monreal, Founder and CEO of Plastic Energy. “Advanced recycling will continue to be important for the North American market by providing a solution for incorporating recycled content into food-grade packaging. Together with NOVA Chemicals, we aim to reduce the amount of plastic waste ending up in landfills, incineration, or as leakage into the environment, which is important for the circular economy in Canada.”

NOVA Chemicals recently announced its aspiration to reach 30 percent recycled content as a share of its total polyethylene sales by 2030 in its Roadmap to Sustainability Leadership, including its commitment to build a state of the art mechanical recycling business and continue exploring world-leading and proven advanced recycling technologies. If built, this new facility would see NOVA Chemicals build on its already CAD 2 billion investment into Ontario to inject additional new technology, jobs, and long-term viability into the local and Canadian economies.

NOVA Chemicals, headquartered in Calgary, Alberta, Canada, has nearly 2,500 employees worldwide and is wholly owned by Mubadala Investment Company of the Emirate of Abu Dhabi, United Arab Emirates. Learn more at www.novachem.com or follow us on LinkedIn.

GARLAND, TX, USA Cole Industries is pleased to announce the acquisition of Norstar Aluminum Molds, Inc., including the RotoMart business unit. Norstar, which operates out of two facilities in Cedarburg, WI and Middlefield, OH will strategically complement Cole’s facility in Garland, TX. Both companies are longstanding mold makers for the rotational molding market.

“We are thrilled to partner with Sandy and the entire Norstar and RotoMart team – from the back office to the shop floor. We are excited about the additional capabilities and the combined business, and we look forward to being better able to service our customers from 3 well-situated facilities. This is a win-win for our employees and our customers as we position our business for longterm success with strong foundries and meaningful CNC capacity. We look forward to continuing to find ways to grow and improve so that we can better support the rotational molding community,” said Austin Miller, President of Cole Industries.

“I am very pleased to have Norstar join the Cole Industries family who understands and supports not only the rotational mold making business but our markets and customers, as well. I see this as a strategic alliance which will provide opportunities for our employees and better service for our customers,” added Sandy Scaccia, President and Owner of Norstar.

Austin Miller is President and Owner of Cole Industries. Cole Industries designs and manufactures cast aluminum molds for the rotational molding industry.

Sandy Scaccia is President and Owner of Norstar Aluminum Molds, Inc. Norstar designs and manufactures cast aluminum, CNC machined aluminum, and fabricated molds for the rotational molding industry. RotoMart sells mold enhancement parts, replacements parts, and consumables.

For more information, contact Austin Miller at austin@coleindustries.com.

Centro, Inc.’s newest facility in Hampton, Iowa

NORTH LIBERTY, IA, USA — Centro, Inc. announces the addition of a 30,000 sq. ft. building to expand production capacity throughout the Midwest and accommodate the rapid growth of current demand and future business growth.

The new facility located at 1235 Imperial Road houses two rotational molding machines and employ over 40 Associates.

“This expansion represents continued confidence in our markets and our future business prospects. This, our 11th location, is an exciting opportunity in Hampton, IA, which is a terrific Midwest community,” said Brian Olesen, President & CEO of Centro, Inc. “I really couldn’t be prouder of all Centro Associates that create opportunities for our business to grow through execution in a very challenging time.”

“Centro would like to thank the Franklin County Development Association and City of Hampton for their partnership.” said Nick Hansen, Chief Financial Officer of Centro, Inc. “We have been very pleased with the local and community support and look forward to being a part of the Hampton community.”

Centro, Inc., headquartered in North Liberty, Iowa is the largest custom rotational molder in North America. The company designs and manufactures custom rotational molded product for industry leading Original Equipment Manufacturers in markets such as Agriculture, Construction, and Lawn & Garden.

Since 2021, Centro has added 8 rotational molding machines into their operations to support growing customer demand. The Hampton Business Unit will be the 11th Centro facility added to their global footprint, and falls on the heels of a successful startup in Cascade, IA nearly 1 year ago.

The company employees nearly 1,200 associates and operates domestic facilities in Iowa, Wisconsin, Illinois, North Carolina, North Dakota, and international facilities in Northern Ireland and Brazil.

For more information or to learn about employment opportunities, please visit centroinc.com.

Chevron Phillips Chemical has completed construction of the world’s largest on-purpose 1-hexene unit in Old Ocean, Texas, with operations set to begin at the plant by early September, company officials recently announced.

The company celebrated its new 1-hexene unit with a ribboncutting ceremony at the Old Ocean site, which included remarks by elected leaders and CPChem executives.

New unit increases CPChem’s 1-hexene capacity

CPChem’s investment in the new unit brings its total U.S. 1-hexene capacity up to 646 thousand tons per annum. The new unit’s location provides additional flexibility and production capacity to meet anticipated demand from our growing customer base.

CPChem has been operating two full-range alpha olefin units and one on-purpose 1-hexene unit at its Cedar Bayou plant in Baytown, Texas. CPChem’s new unit in Old Ocean will surpass Baytown as the world’s largest on-purpose 1-hexene unit. The new unit will use the latest iteration of CPChem’s proprietary, on-purpose technology to produce exceptional-purity 1-hexene, a component in the production of polyethylene.

“This represents an exciting step forward in our manufacturing

capabilities, and I am incredibly proud of the work it has taken to get us to this point,” said Bruce Chinn, President and CEO of CPChem.

The 1-hexene unit has become a major economic engine for the region, joining CPChem’s other assets in creating jobs and adding to the local economy. In addition to increased production capacity, this project created more than 600 construction jobs and 50-plus full-time positions.

In 2022, CPChem spent $31.5 million with more than 70 Brazoria County vendors and suppliers for operating materials, equipment, and services for the facility. CPChem spent an additional $1.4 million for catering, office supplies, and other indirect consumable items and services.

Investing in the community is also part of CPChem’s vision to serve as a neighbor of choice, said Jose Trevino, plant manager at the Sweeny, Clemens, and Old Ocean facilities.

“We take pride in investing time, talent, and resources to make a lasting impact in the surrounding communities,” Trevino said.

CPChem has invested in education like the CPChem Career

and Technical Education Center in Sweeny Independent School District and supported scholarships at Brazosport College and Wharton County Junior College. “These investments help prepare generations of local students for careers in our industry,” he said.

Other CPChem community investments include support of local healthcare options like the Sweeny Community Hospital and Matagorda County Medical Center and the Friends of the River San Bernard organization. “And we strive to increase economic prosperity by supporting non-profits like United Way, True to Life Ministries, and Communities in Schools,” Trevino said.

CPChem leverages advances in design to reduce emissions

CPChem leveraged the latest advances in process design to reduce emissions while maximizing production at the new unit. Resource efficiency and reduced emissions are both central to the company’s sustainability strategy.

“Aligning our investment strategy to our sustainability goals is a critical component to our business strategy, and this is a great example of balancing our sustainable commitments with manufacturing growth,” Chinn said. “The new asset harnesses the latest advances in process design to maximize production, optimize resource management, and reduce emissions.”

National survey respondents rated employers on benefits, working environment, work-life balance, training and career progression, company image, corporate culture, sustainability awareness, and proactive management of a diverse workforce. CPChem earned five out of five stars.

“This accolade reflects our ongoing commitment to fostering a workplace where our employees thrive, innovate, and grow,” said Maricela Caballero, Senior Vice President of Human Resources for CPChem.

“At CPChem, we believe that a supportive environment, coupled with a culture of empowerment, is the way to succeed,” she said. “This recognition energizes us to continue prioritizing employee well-being and nurturing a culture that celebrates diversity, encourages learning, and drives both personal and professional advancement.”

Newsweek and the data firm Plant-A Insights Group created the list by gathering public data and anonymous survey responses from around 62,000 American workers about their current or former employers, or the employers of people in their circle.

Plastics and Rubber events will cover Thailand, Indonesia, and Vietnam from 2024 Messe Düsseldorf Asia and Informa Markets. Two of the region’s leading international exhibition organisers have announced a landmark partnership that will see the consolidation of their plastics and rubber trade exhibitions in Southeast Asia.

From 2024, the new alliance will see the two parties jointly organise the Plastics and Rubber series of exhibitions, kick starting with Plastics and Rubber Thailand, which is scheduled to take place from 15 to 18 May 2024 at BITEC, Bangkok.

The strategic alignment of the plastics and rubber portfolio by Messe Düsseldorf Asia and Informa Markets will see them streamline their respective plastics and rubber exhibitions in the region into three anchor events. Starting in 2024, the partners will jointly organise Plastics and Rubber Thailand, and Plastics and Rubber Indonesia, in addition to Plastics and Rubber Vietnam, which has been a long-established collaboration since 2008.

Aimed at harnessing collective capabilities and expertise of both partners to deliver an enhanced business experience for the industry, Gernot Ringling, Managing Director, Messe Düsseldorf Asia, said: “Our alliance with Informa Markets builds upon a long history of successful partnerships in the region. By consolidating the plastics and rubber trade exhibitions to now include Thailand and Indonesia starting in 2024, we are poised to enhance our customer experience both locally and internationally, delivering even greater value for business growth, especially against the backdrop of industry sustainability and circularity goals.”

“This latest endeavour amplifies our regional presence and further streamlines both our efforts to serve the Southeast Asian markets effectively. Following in the successful footsteps of our joint partnership with Plastics and Rubber Vietnam in Ho Chi Minh City and Hanoi, with Plastics and Rubber Thailand and Plastics and Rubber Indonesia, we are paving the way for the absolute best local and regional platforms for international businesses in the most dynamic markets in Southeast Asia within the ever-evolving plastics and rubber landscape,” Ringling added.

The synergy will capitalise on Informa Markets’ deep regional insights and connections, complemented by Messe Düsseldorf Asia’s extensive global expertise in plastics and rubber and multisectorial competence, including their connection with K, the world’s leading plastics trade fair organised by Messe Düsseldorf.

Ian Roberts, Vice President, Informa Markets (Asia), expressed enthusiasm over this partnership and echoed similar sentiments. He said: “Our collaboration with Messe Düsseldorf is a continuation of our successful joint ventures, highlighting our shared commitment to deliver industry-leading experiences. By concentrating our efforts and consolidating the number of plastics and rubber events in the region, we aim to create an unparalleled experience for exhibitors and visitors, offering enhanced business opportunities and thus maximising the impact of each exhibition.”

Roberts added; “Together, we are ushering in a new era of innovation, collaboration, and mutual growth, which is testament to our shared commitment to advancing the industry and the region.”

The plastics and rubber industries in Thailand, Indonesia, and Vietnam play pivotal roles in the global market. Thailand has emerged as a leading manufacturer and exporter of plastic and rubber products, serving key markets such as China, Japan, India, and the ASEAN region. Similarly, Indonesia and Vietnam are crucial players in this sector, contributing significantly to the regional and global supply chains.

For more information on the first edition of Plastics and Rubber Thailand, go to: www.plasticsrubberthailand.com.

Over 1,400 Machines in Over 60 Countries

It is with great pleasure that we introduce the latest “Special Edition” of the ARMO Rotational Moulding Showcase publication, which focuses on showcasing innovative products in the rotational moulding industry.

This issue is dedicated to showcasing the many advantages of rotational moulding, as well as exploring future trends and promoting information sharing within the industry.

Rotational moulding is a versatile manufacturing process that has been used for decades to produce a wide range of products, from large tanks and containers to small toys and household items.

In recent years the global industry has continued to push the boundaries to further prove the capabilities of Rotational Moulding. While there has been great development within the area of specialised materials and improved technology there still seems to be an opportunity for growth and development in this area.

Looking to the future, we see exciting trends emerging in the rotational moulding industry, including the use of new materials and technologies, as well as a growing focus on sustainability and environmental responsibility.

ARMO is represented by 12 associations from all over the globe and prides itself in what has been achieved over the years.

As ARMO, we are committed to promoting information sharing and collaboration within the rotational moulding industry. We believe that by working together, we can continue to drive innovation and growth in this dynamic and important sector.

We hope that you find this publication informative and engaging, and we look forward to your feedback and contributions as we continue to explore the many opportunities and challenges facing the rotational moulding industry.

Sincerely,

Wayne Wiid ARMO Chairman wayne@pioneerplastics.co.za

Looking to the future, we see exciting trends emerging in the rotational moulding industry, including the use of new materials and technologies, as well as a growing focus on sustainability and environmental responsibility.

ARMO Rotational Moulding Showcase is an annual marketing publication by the Affiliation of Rotational Moulding Organizations (ARMO) and published by JSJ Productions, Inc.

ARMO Board of Directors

Past Chair & IT-RO Representative – Katia Zoppetti, DRAM S.r.l. katia.zoppetti@dramsrl.com

‘Rotopol’ Representative – Dr. Marek Szostak, Poznan University of Technology marek.szostak@put.poznan.pl

ARMSA Representative – Wayne Wiid, Pioneer Plastics wayne@pioneerplastics.co.za

Past Chairman & BPF Representative – Martin Spencer, Unique Roto Martin@UniqueRoto.com

ARM Representative – David Smith, H. Muehlstein DLSmith@Muehlstein.com

AFR Representative – Francois Kieffer francois.kieffer@bwt.fr

Anipac Representative – Eduardo Guizar, Spincraft eguizar@spincraft.onmicrosoft.com

ARMA Representative – Scott Magill, Plastic Tanks QLD scott@ptq.com.au

Past Chairman & ARM-CE Representative – Oliver Wandres, MAUS ow@maus-gmbh.de

Nordic ARM Representative – Ronny Ervik, Norner ronny.ervik@norner.no

RPC – CPPIA Representative – Jacky Wang, Zhejiang Rotoun Plastic Technology Co., Ltd. jacky@rotoun.cn

Past Chairman & StAR Representative – Ravi Mehra, International Consulting - Maramehra LLC maramehra@aol.com

Publisher

Publisher – JSJ Productions, Inc.

Chief Editor – Susan Gibson JSJ Productions, Inc. susan@jsjproductionsinc.com

Editor & Marketing Director – Jennifer Gibson JSJ Productions, Inc. jennifer@jsjproductionsinc.com

Designer – Anya Wilcox JSJ Productions, Inc. awilcox@designintersection.com

Internet & Digital – Jason Cooper JSJ Productions, Inc. jason@jsjproductionsinc.com

Distribution – Sheryl Bjorn JSJ Productions, Inc. sheryl@jsjproductionsinc.com

Legal – Joseph V. Gibson, IV JSJ Productions, Inc. jvg@jsjproductionsinc.com

Editorial Contributors

Alvin Spence, Centro Incorporated ASpence@centroinc.com

Susan Gibson, JSJ Productions, Inc. susan@jsjproductionsinc.com

Product Showcase / Photo Contributors

Remote Operated Water Rescue Craft - India

The Flex Box - South Africa

Foot Pedal Wheelie Bin - India

Tenjam Shayz™ In-Pool Lounger - USA

Recycled Bead Tank - Australia

Chubby - Italy

Ferrari Jumps & Trifectas - Australia

Uncle Dan’s USA T-Post Feeder - USA

Inquiries

info@armo-global.org / armo-global.org / rotoworld@rotoworld.com

Reproduction

All Copyrights belong to ARMO and in no part may this publication be reproduced or transferred through any digital or electronic means, photocopied, or otherwise without the written consent of ARMO and the Publisher, JSJ Productions, Inc.

ANIPAC THE MEXICAN PLASTIC ASSOCIATION

www.anipac.com

Herschel # 188, Col Anzures

Mexico, D.F.

Miguel Hidalgo, 11590

Eduardo Guizar

(55) 62 73 88 44 • +27 865682675

ARM - ASSOCIATION OF ROTATIONAL MOLDERS

www.rotomolding.org

North America

USA

3400 W Stonegate Blvd, Suite 2315 Arlington Heights, IL 60005 +1 630-942-6589

Adam Webb adamw@rotomolding.org

AFR - ASSOCIATION FRANCOPHONE DU ROTOMOULAGE

www.rotomoulage.org

French-language countries

France

Immeuble Danica B 21 Avenue Georges Pompidou, 69003 LYON, France +33 67 0452 117

Francois Kieffer, Chairman

Anne De Lansalut, Permanent Member of the Board a.delansalut@rotomoulage.org

ARMSA - ASSOCIATION OF ROTATIONAL MOULDERS SOUTHERN AFRICA

www.armsa.co.za

Southern Africa

Johannesburg South Africa

P.O. Box 8184, Centurion, 0046, South Africa

+27 72 245 5310

Gary Wiid - Chairman info@armsa.co.za

SOCIETY OF ASIAN ROTOMOULDERS (STAR) www.starasia.org

India and Asia

“ROTOPOL” ASSOCIATION

www.rotopol.put.poznan.pl

Poland

60-965 Poznan, Piotrowo 3 street +48-61-6652776 • +48-601785126

+48-61-6652202

Dr. Marek Szostak, President of, ROTOPOL, Association marek.szostak@put.poznan.pl

NORDIC ASSOCIATION OF ROTATIONAL MOULDERS (NORDIC ARM)

www.nordicarm.org

Scandinavia

Iceland

Gunnarsbraut 12, 620 Dalvk, Iceland

+354 863-5373

Ronny Ervik ronny.ervik@norner.no

IT-RO ITALIA ROTAZIONALE www.it-ro.it/it

Italy

E. Brigatti, 12 - 20152 - Milano (MI) +39 348 7652 560

Katia Zoppetti, President info@it-ro.it

3rd Floor, 36 Krishna Market, Kalkaji, New Delhi- 110019, India

+91 9810305356 • +91 11 41634952

Ravi Mehra, Founding Chairman StAR S.B.Zaman, Executive Director StAR sb.zaman@starasia.org

RPC-CPPIA

www.chinarotomoulding.com/

Greater China Region including Mainland China, Taiwan, Hong Kong and Macau

RPC-CPPIA

Room 202, Lon 72, No. 1501, Tong Pu Road, Pu Tou District, Shanghai, China 200333

86 21 6237 1991 • 5271 5002

86 21 6237 1991 • 5271 5002-8005

Mr. C.C Shi, Secretary-General, Jacky Wang, Foreign Affairs Officer – for foreign affairs (English communication) jacky@rotoun.cn

BPF ROTATIONAL MOULDERS GROUP

www.bpf.co.uk

United Kingdom

6 Bath Place, Rivington Street

London EC2A 3JE

+0044 (0)207 457 5013 • +44 20 7457 5045

Graeme Craig, BPF Rotational Moulding Group Executive gcraig@bpf.co.uk

ARM-CE -ASSOCIATION OF ROTATIONAL MOULDERS CENTRAL EUROPE

www.rotational-moulding.de

Central Europe Germany

Keltergrasse 6, D-76356 Weingarten +49 721 948 7412 • +49 721 948 7444 Oliver Wandres info@rotational-moulding.de

ARMA - ASSOCIATION OF ROTATIONAL MOULDERS AUSTRALASIA LTD

www.rotationalmoulding.com

Australasia

Australia

PO Box 237 Moonee Ponds VIC 3039 Australia

+61 (0)404 265 887 • +1 630 790 3095

Michelle Rose

michellerose@rotationalmoulding.com

This product can be operated from up to 1 km Line of Sight and Radio Communication up to 2 kms. This can be deployed from a helicopter, ship from a height of 10 meters near a drowning person and steered using a remote.

A drowning person can hold on to the antiskid handles and can be pulled to shore / boat / jetty.

Designed for Saif Marines Pvt Ltd. by Satish Gokhale and team Design

Directions Pvt. Ltd. and manufactured by Vinodrai Engineers – India

Drowning is the 2nd largest cause of deaths, and to save a person struck in this panic situation the golden time is only 3 minutes. There are cases when there are no lifeguards on the beaches or it is difficult to reach the person in distress using conventional lifebuoys.

Patented Remote Operated Water Rescue Craft, is a battery powered and jet propelled lifebuoy which is compact and fast (ability to travel at 7 m/sec on

water OR 14 Knots) and can be easily manoeuvred to reach the person in distress. A drowning person can hold on to the antiskid handles and can be pulled to shore / boat / jetty. In case it is observed that the person to be rescued is unconscious, a person is sent along with the craft to help the drowning person since the craft can pull up to 3 persons.

This craft is better in many ways than

its global competitors. The main pluses over the competition is the high speed, stability in choppy conditions, and its self-righting capability and good visibility of the craft in choppy sea conditions.

The Rotational Moulding process was used for a much better quality control and uniform hull. The product is manufactured utilising 100% UV stabilized, recyclable HDPE material, which is best suited for all types of waters.

Being a product deployed on water, water tightness is an integral part of the design, and very important to protect all the electronic and electrical components. This was specially taken care of in each and every stages of the design. End goal was to make it easy to manufacture in bulk using the CNC machined moulds and cooling fixtures to avoid and reduce unwanted distortions of the moulded parts.

The overall size considerations were based on how the craft was going to be thrown in the water. It had to be as compact as possible and as light as possible.

This product can be operated from up to 1 km Line of Sight and Radio Communication up to 2 kms. This can be deployed from a helicopter, ship from a height of 10 meters near a drowning person and steered using a remote. In case the craft turns turtle when deployed in choppy sea conditions, it self-rights or straightens itself by buoyant self-righting structure, which doubles as visibility block to spot the craft in sea - a unique feature amongst all global competition.

The designers are working on add-ons to transport, food, medicines, clothes, etc. during flood situations. 180 units have been successfully inducted in the Indian Navy.

A home gym station designed to be a personal home gym that looks like a modern piece of furniture when not in use.

Designed by Nick Swardt and manufactured by Pioneer Plastics – South Africa

The Flexbox is a Home Gym Station designed to be a personal home gym that looks like a modern piece of furniture when not in use. The product is manufactured by Pioneer Plastics with our client seeing the need for a functional, yet aesthetically pleasing, home gym station.

The box is designed as a home gym system with one of the main features being that the user can store his or her weights inside, while the lid acts as an incline bench to exercise the different muscle groups.

Due to its smart design, the home gym system doubles as an item of furniture which, when shut, will happily fit seamlessly into the average living room, but when the resident or guests wish to work out, all manner or gym exercises can be performed and in flash too.

The product consists of thirty-three individual parts, of which 5 are rotational moulded and polyurethane foamed for stiffness. The moulds are CNC machined moulds designed and manufactured in-house at Pioneer Plastics. The design intent was to develop a high-quality product aimed at fitness enthusiasts that is aesthetically appealing when not in use. The Flexbox also has numerous moulded inserts, and the design allows for an inserted Bluetooth speaker.

The product was designed together with a South African entrepreneur, now resident in the USA, coming up with the concept. Nick Swardt, Technical Manager at Pioneer Plastics, designed and developed the final product.

This is a brand new product launching this year with the first orders received to be supplied to the South African market as well as exported soon.

The user can store his or her weights inside, while the lid acts as an incline bench to exercise the different muscle groups.

Designed by Satish Gokhale and team Design Directions Pvt Ltd. and manufactured by Frontier Polymers Pvt Ltd. – India

In an era of increasing environmental awareness and sustainable practices, waste management solutions have become an integral part of every establishment’s operations. Catering to the needs of hotels, restaurants, airports, and similar high-traffic venues, we proudly present the revolutionary Foot Pedal Wheelie Bin – a game-changer in waste disposal efficiency and hygiene.

Key Features and Benefits

Hands-Free Operation: The hallmark of our Foot Pedal Wheelie Bin is its hands-

free design, allowing users to dispose of waste without the need for direct contact to the lid. In high-traffic areas like hotels, restaurants, and airports, where hygiene is paramount, this feature drastically reduces the risk of crosscontamination and the spread of germs. The strategically positioned foot pedal ensures that waste disposal is effortless and convenient. Users can easily open the bin’s lid using their foot, making it suitable for people of all ages and physical abilities. Full closure lid coupled with its sturdy built quality, helps contain

Crafted from highquality, eco-friendly materials, our wheelie bin is designed to withstand the rigors of heavy daily usage.

odours effectively. This is especially crucial in hospitality settings where guest satisfaction is paramount.

Crafted from high-quality, eco-friendly materials, the wheelie bin is designed to withstand the rigors of heavy daily usage. Its robust construction ensures longevity, minimizing the need for frequent replacements and reducing the overall environmental impact. Made from Hexene polymer and UV stabilised, non-fading colours, and utilising cast aluminium tooling, these bins can withstand harsh outdoor weather conditions for years to come.

We understand that different establishments have unique aesthetic preferences. Frontier Wheelie Bins are available in a range of three sizes of 70, 90, and 120 Liters. For waste separation, different colour lid options are available. Colour coded wheel caps adds to the overall aesthetic design appeal allowing seamless integration into your venue’s existing decor.

The most comfortable pool lounger in the world. Designed by Tenjam and manufactured by Tri-Ven – USA

Tenjam furniture created Shayz - the most comfortable in-pool lounger in world. Featuring a patent pending Speed Fill Ballast System and three heights of snap-in risers for various pool depths up to 17”. Armrests were added for easier entry and exit from the seat and a “social” backrest angle is a more comfortable position for talking, watching, reading, and sipping a refreshment. Designed to comfortably fit the entire family from children to adults. Tenjam’s focus on comfortable and easy to use rotomolded furniture is creating a splash in the pool market.

Rotomolding is used to optimize durability, functionality, comfort, aesthetic appeal, design-for manufacture, and integration of differentiating features:

• Cupholders.

• “Speed-Fill” ballast system.

• Speed emptying system.

• Flow-through seats.

• Seat drain.

• Integrated handles.

• Stackability.

Shayz™ is offered in 14 colors with high UV stability to ensure color vibrance in outdoor environments. It has optional risers (three optional heights: 9”, 13” & 17”) that snap into the bottom of the Shayz™ lounger to accommodate various water depths.

Tenjam’s focus on comfortable and easy to use rotomolded furniture is creating a splash in the pool market.

Designed and manufactured by Suncoast Waste Water Management – Australia

Rotomoulding is a sintering process traditionally done with micronised PE but, not essential as it is possible to sinter bead in the same process.

Suncoast Waste Water Management manufactures a multi-layered LLDPE tank incorporating three layers. The outer layer consists of a melt compounded virgin micronised powder. The middle layer consists of a recycled PE in a Bead form, this polymer is NataLab Batch tested to check conformity to our AS/NZS Standard. The inner layer consists of micronised PE to produce a smooth inner layer giving the tank the required impact resistance. Tanks are produced using a templogger for correct multilayer points and piat.

OzziKleen products can recycle water and waste water in a recycled tank. 75% of material in a tank can be recycled LLDPE.

Ozzi Kleen Sewerage Systems act as a digestive system using a unique cyclic

fully aerobic sewage treatment process. This means there is no septic process, so no septic smells, it’s environmentally friendly producing nutrient rich water to reuse on gardens and is cost efficient to run (only half the running cost of other aerobic sewerage systems).

The heavy-duty polyethylene Ozzi Kleen sewerage system tank is up to 20mm thick and is, weight for weight, 100 times stronger than concrete. The material has a 500-year half-life. As the Ozzi Kleen RP10 sewage treatment system tank is roto-moulded and completely seamless, there is no risk of seepage, leaking, or root intrusion.

The Ozzi Kleen RP10 sewerage system tank is not affected by the acidity of sewage. Polyethylene materials are often used to store hazardous chemicals. The mechanical components are all designed and constructed to ensure years of effect, trouble-free service, and are backed with a full manufacturer’s warranty.

OzziKleen products can recycle water and waste water in a recycled tank. 75% of material in a tank can be recycled LLDPE.

Chubby is a perfect mix between the beauty of the lines and the comfort of the seat.

Designed Marcel Wanders for SLIDE Srl – Italy

The armchair Chubby, created by the famous designer Marcel Wanders, is one of the best products of the whole Slide production. Chubby is a reinterpretation of Crochet Chair: it has got the same design but, it is made in polyethylene, suitable for every kind of people. The design armchair Chubby is suitable with every kind of settings, for contract, events, or private houses.

Thanks to its sinuous and linear design, Chubby is a perfect mix between the beauty of the lines and the comfort of the seat.

The Chubby Collection includes the Chubby, Chubby Low, and Chubby Side

Table. It began production in 2008. Its dimensions are 130 x 120h 56 cm (seat H 27 cm). Its packaging dimensions are 131 x 121 x 57 cm and packaging volume 0,903 m3. It comes in thirteen standard colors and 8 lacquered (glossy/matt) finishes. Its weight is 25 Kg.

The product is made from Polyethylene with the rotational moulding process. It is resistant to extreme temperatures (-600°C to +800°C). It is UV resistant and has high tensile strength. SLIDE® has a closed production cycle with no health prejudicial emissions and complies with ecological sustainability rules.

slidedesign.it

The design armchair Chubby is suitable with every kind of settings, for contract, events, or private houses. Thanks to its sinuous and linear design, Chubby is a perfect mix between the beauty of the lines and the comfort of the seat.

Designed and manufactured by NexGenRoto in conjunction with Massey Designs – Australia

NextGenRoto Jumpstarts are solid and versatile. They can be used at several different heights, are safe for the horse and rider, and have no sharp edges. The product is UV stabilised and made super strong. It can be filled with water for extra stability, is easy to stack or leave on the arena, takes standard wooden poles, and comes in a range of colors.

The Jump is a definite money saver because you can make multiple jumps with one set of jump wings. It is a complete all-rounder as it will do it all: Cavaletti’s, Single Jump Spreads, Boxers, and Oxers.

The Ultimate Jump has 9 different heights, ranging from 11cm to 110cm, and the best part is you don’t need cups (no more losing jump cups). The jumping heights are imprinted into the jump for easy setup. It is very stable at 8kgs each side, which makes it easy to move around but can be pegged down or filled with water for stability.

The NextGenRoto Trifecta is a saddle rack, grooming/tack tray, and mounting block. It is the most versatile product on the market. The saddle rack fits easily into the back seat, car boot, or float. The saddle will fit perfectly on top, and the shape is protected and cannot be compromised. The Grooming Tray is designed for packing tack into the grooming tray provide and slide tray in the caddy storage area. The Mounting Block is purpose designed to mount a horse. It reduces strain on the horse’s back and helps maintain the rider’s

balance. It stops stirrup leather being stretched, is used for a seat, and is perfect for quick saddle changes. It has hands on both ends and 2 anti-slip steps. Very stable and sturdy, the Trifectas are light weight, UV stabilized, and have no sharp edges. Their weight is 6kg, 45cm high x 43cm wide x 54cm long. The weight rate is 130Kg.

At NextGenRoto, we’re not just about water tanks. Our talent and expertise in rotational moulding means that if you’re looking to develop a customised product, we have the experience and commitment to get the job done to the highest of standards.

We take pride in our work, and we ensure that the concept you need manufactured is delivered on time, and of the highest quality. From the materials we use, to the experts who lead our custom design projects, we make certain that what we produce is right every time. Our quality control method is of the strictest standards, we don’t cut corners, they are industry-leading quality control procedures. An idea is all you need to get started. Our development process is simple and straightforward.

nextgenroto.com.au

The Jump is a definite money saver because you can make multiple jumps with one set of jump wings. It is a complete allrounder as it will do it all: Cavaletti’s, Single Jump Spreads, Boxers, and Oxers.

Designed by Dan Ross and manufactured by Ken Ross Rotational Molding – USA

The Uncle Dan’s T-Post wild game feeder was designed using an ordinary T-Post to secure the feeder outdoors. Using customer-supplied T-Posts keeps the retail price lower than competitors who rely on leg kits produced in China and supplied with their feeders. Using a T-Post driven into the ground provides an exceptionally secure system that is resilient against game or livestock destruction. The four individual feed ports are equipped with slide gate valves to regulate the flow of different types of feeds - corn, protein pellets, finely ground attractants, and feeds. This innovative game feeder system is designed with the hunter in mind and built to last in all weather conditions.

Dan Ross, aka “Uncle Dan,” has been manufacturing products for the hunting industry for over 30 years and, as an avid hunter for 60 years, he has the experience and knowledge to design products that work for the hunter. All Ken Ross products are designed by Uncle Dan and his team.

The feeder is rotationally molded of Jerico Plastics Stone Effect PE, using threaded inserts and graphics. All secondary operations are performed using CNC routers.

Ken Ross Incorporated, Rotational Molding manufactures the feeder. Jerico Plastic’s Stone Effect material formulated in uniquely specified colors bring the whole package together into a game feeder that is solidly constructed and very attractive to the hunter and the entire outdoor/hunting industry. All products are manufactured in-house using tooling that is produced in a Ken Ross in-house tooling shop.

This innovative game feeder system is designed with the hunter in mind and built to last in all weather conditions.

Much has happened since the last ARMO review of the industry published 4 years ago[1], approximately 9 months prior to COVID-19 taking a stranglehold of virtually every economy around the world. Prior to COVID, the rotational molding industry was in a strong position, with many sectors enjoying healthy growth. Material prices were reasonably stable, helping molders to be competitive with other processes. The industry was surging, and the future looked promising, with one major exception being the tight labor markets in established regions of the world making it exceptionally difficult to fill open positions. Also, the manufactured product value per labor hour ($/hr) was in decline in the US and there was much discussion about the need to automate to reduce labor content and improve productivity[2].

During the COVID years unemployment initially surged and many rotational molding market sectors took a sharp decline. Manufacturing companies came to terms with how to manufacture safely and avoid the spread of the virus. Rotational molders had to react quickly and develop new systems and procedures to protect their employees, which proved to be challenging for this labor-intensive process. Some of the industry’s most faithful employees, who were at or near the end of their careers, decided the risk of working outweighed the gain and opted for retirement. This was the case for many other industries at the time. Global economies went into decline initially and demand for manufactured products waned. It was a very worrying and uncertain time for many molders. The only good news at that particular moment in time was that labor was abundant…but that did not last for long!

Towards the end of 2020, approximately

6-9 months after COVID started, several rotational molding markets started to recover to unexpected high levels of demand. Markets that involved outdoor activities, such as kayaking, boating, camping, etc. remained largely unaffected by COVID and demand for rotationally molded products in these sectors soared. Before we knew it, the labor crisis was back again, and productivity was being greatly impacted by the health and safety measures put in place to prevent the spread of COVID. During this time the sale of rotational molding equipment surged, and many

businesses looked to add capacity. This was caused by increased demand, reduced productivity, and employees not wanting to work overtime, especially at the weekends. Also, mold builders experienced growth from new programs as well as molders needing additional cavities to meet the increase in demand. This was also a time when the lack of industry capacity led to several new companies emerging as they tried to overcome supply chain issues.

From late in 2020 through 2022, molders faced a variety of challenges as they tried to meet growing market demand. One of the greatest challenges came for the supply chain, with many suppliers

6-9 months after COVID started several rotational molding markets started to recover to unexpected high levels of demand.

struggling to obtain raw materials and provide on-time deliveries. As if that was not enough, prices started to escalate for supplied components and raw materials. Labor availability resurfaced again as a major constraint and labor costs increased as businesses competed for the locally available labor. This was a very challenging time for many businesses, but also an opportunity for those who could adapt quickly to grow market share and profitability. It was a time when businesses had to justifiably increase pricing in response to increasing costs, but part of the challenge was that purchased components and materials continue to rise, sometimes resulting in multiple price increases.

The ever-changing environment has resulted in no shortage of challenges for many molders. More recently, some market sectors that boomed during COVID are now in decline due to saturation, and so the cycle of change and the need for adaptability continues. For most businesses managing the decline of markets is much more difficult than managing a surge in business. This is especially true for those molders who added capacity to take advantage of the growth opportunities during COVID. This added capacity will no doubt bring concern to some, as a fall in demand will result in a very competitive marketplace.

Further challenges are now coming from the customer base, who absorbed significant price increases and now would like to see some relief and cost reductions. As molders look forward, one thing is for certain, they will need to have great adaptability to maximize the opportunities that lie ahead. Timely adjustments to business strategies will no doubt ensure competitiveness in an ever-changing environment.

For those trying to maintain a thriving, healthy business, the need for efficiency improvement and cost reduction is clear. It is imperative that molders find suitable technologies to either reduce the amount of labor or reduce the skills needed to manufacture high quality rotationally molded parts. Also, efficiency gains during processing need to be made to minimize machine downtime and maximize arm loading. This will drive technological developments to sustain a balance between the load/ unload cycle time and the other stages of the cycle. While automation is seldom easy, justification for investments is getting easier as labor costs increase and efficiencies decline. With the future likely bringing some harder and more competitive economic times, molders must work to improve these efficiency opportunities to sustain their businesses and be more competitive in the marketplace, which will in turn help to provide growth opportunities.

As molders look forward, one thing is for certain, they will need to have great adaptability to maximize the opportunities that lie ahead.

For those who are reading this article that are unfamiliar with the rotation molding process, the process is best suited to the manufacture of hollow plastic products of various sizes and shapes, with the ability to produce extremely complex geometries. The following information will highlight some of the industry’s most common applications, represented by several product categories. These products demonstrate why rotational molding competes favorably with all other manufacturing process. Here are several product families that are typical rotationally molded applications:

Perhaps one of the earliest and wellknown rotational molding applications is children’s toys. Toys, fitness equipment, and playground structures are extremely common rotomolded applications. For soft touch and flexible products, Poly Vinyl Chloride (PVC) is used. This material can replicate the most intricate of details, as seen in PVC dolls heads. Other toy products are manufactured from Linear Low Density Polyethylene (LLDPE) such as the Cozy Car, kitchen play sets, wagons, etc. These products tend to be brightly colored, thin-walled applications with rounded corners that are relatively easy to manufacture. However, to be competitive with other processes the cycle times for these products have to be very aggressive, requiring the application of automation and lean manufacturing methods. Playground structures are also a very common global rotational molding application because of the durability and weatherability of the Polyethylene (PE) material used.

Flotation of plastic has recently become a serious problem for the plastics industry, creating a negative perception regarding the use of plastics. However, PE’s buoyance, water resistance, weatherability, and toughness all help to make it an excellent choice for

rotationally molded flotation products. Fishing buoys, boat ramps, and floating docks are all common rotomolded products. Some floating docks incorporate either PE foam or Polyurethane (PU) foam to increase both strength and buoyance. Kayaks and canoes are also commonly rotationally molded, and often include PE foam. These types of products are typically molded using a rock and roll machine because of their geometry. Insulated coolers are also rotationally molded, and often include PU foam between the external and internal PE layer. This provides excellent insulation properties, allowing the contents of the cooler to remain chilled for several days.

Another very common rotationally molded product is chemical and water storage tanks, which come in a range of shapes and sizes and are globally manufactured using the rotational molding process. Tank volumes can be substantial, up to tens of thousands of gallons. Product design plays an important role to ensure the geometry has sufficient structure to support the tank contents load in the environment in which it operates. Quite often ribs are employed to enhance stiffness of the wall and/or wall thickness is targeted to areas of the tank that are subjected to the highest deflective loads. Typically, High Density Polyethylene (HDPE) materials are used for larger tanks with sufficient hoop strength to meet the functional requirements. Often carousel machines or rock and roll machines are used to manufacture these products. The applications for this type of product family include water storage or harvesting, static fuel storage, and chemical storage.

Products & Floor Cleaning

Containers, pallets, IBCs, totes, trash cans, dumpsters, etc. are all commonly rotationally molded products. Cases and containers can be highly sophisticated, for the purpose of carrying and protecting valuable goods. IBCs are commonly used for transportation of chemical products. Trash cans and dumpsters

The process is best suited to the manufacture of hollow plastic products of various sizes and shapes, with the ability to produce extremely complex geometries.

are also common applications for the process and can often incorporate recycled material. Single piece septic tanks can be manufactured using the rotational molding process. Floor cleaning equipment benefits from the process’s ability to mold highly complex geometries that are capable of holding cleaning fluids at elevated temperatures. The recent development of electrically heated molds has further enhanced the process’s ability to achieve uniform wall thickness for these types of applications.

Fuel tanks for tractors, construction equipment, trucks, marine engines, generators, compressors, lawn and garden equipment, etc. represents a significant rotomolding sector. Many of these products can be extremely complex in design and include an array of assembled components. For example, agricultural fuels tanks are typically one of the last components to be designed for the vehicle, which results in a very complex geometry to take advantage of any available space to maximize the tank’s volume. These types of applications can include several inserts, bosses, drain plugs, graphics, sending units, etc., all of which must be leak proof. The material of choice for these applications is crosslinked polyethylene because of its UV stability, low temperature impact strength, environment stress crack resistance, and its ability to pass various test requirements such as ECE 34. Crosslinked PE has also been used in combination with other materials that provide excellent resistant to hydrocarbon emission, to reduce fuel weight loss from gasoline tank applications. Many small off-road engines and marine fuel tanks benefit from this material combination to meet environmental regulations.

In addition to those previously mentioned, there are many other industries and applications that utilize the rotational molding process. These

include: air ducts, cargo beds, blower housings, hydraulic tanks (typically from Nylon 6 or 11), urea tanks, roofs, fenders, consoles, display cabinets, road barriers, traffic signs, laundry carts, furniture, plant pots, mannequins, hoppers, rickshaws, etc.

While the future of the rotational molding process is not in doubt, the challenges the industry has faced over the years have not significantly changed. The process remains unique, but heavily dependent on labor, which is becoming less available, less skilled, and more costly. To be competitive, molders must apply their entrepreneurial spirits to find creative solutions to reduce the cost to manufacture rotationally molded products. In order to do that, one of the most critical factors will be for molders to attract the right talent for these types of manufacturing positions. Staffing, managing the impact of rising labor costs, resin costs, and other inflationary costs are the real challenges that the industry faces today. Therefore, focusing on the work environment, production methods, training, equipment/tools, ergonomics, engagement, teamwork, career growth, and compensation needs to be a top priority to attract good employees and make them feel that manufacturing is a career worth pursuing. An energized and engaged team can do great things when pointed in the right direction. Another challenge for some molders will be the changing competitive landscape, especially in the US, as mergers and acquisitions have been extremely prevalent in recent years. It will be interesting to see if higher interest rates will cause a slowdown in the recent trend.

References:

To be competitive, molders must apply their entrepreneurial spirits to find creative solutions to reduce the cost to manufacture rotationally molded products.

Jerico is first in quality resins and compounds! We’ve made our name by providing vibrant colors, specialty blends, and recycled black, while focusing on being that one complete source for ALL your rotational molding compound needs. Now you can add natural PE to the list!

Time and again over the years, our team has responded to the changing times with resilience, ingenuity, resolve, and confidence. In true Jerico fashion, we developed sustainable and adhesion compounds, then

blended vibrant colors into both. Make no mistake, we are expanding and are focused on becoming your supplier of choice for rotational molding materials.

As we grow, we look for ways to improve so that we exceed your expectations and help you achieve success! Our mission is to be the go-to resource for resins and compounds that meet your precise specifications, arrive on time, and provide the consistent level of quality you have come to expect from Jerico!

In September, the ARMO rotomoulding conference in Poznan, Poland, will focus on the topic of “Sustainable Rotational Moulding”.

In our industry, the term sustainability is one of those buzzwords that is thrown around a lot and it is important for us to think about its meaning and how it applies to our business.

There are many definitions, but the one I like most is – “Sustainability is fulfilling the needs of the current generation without compromising future generations’ needs.”

There are many topics to discuss when it comes to sustainability, including change, carbon dioxide emissions, and NetZero.

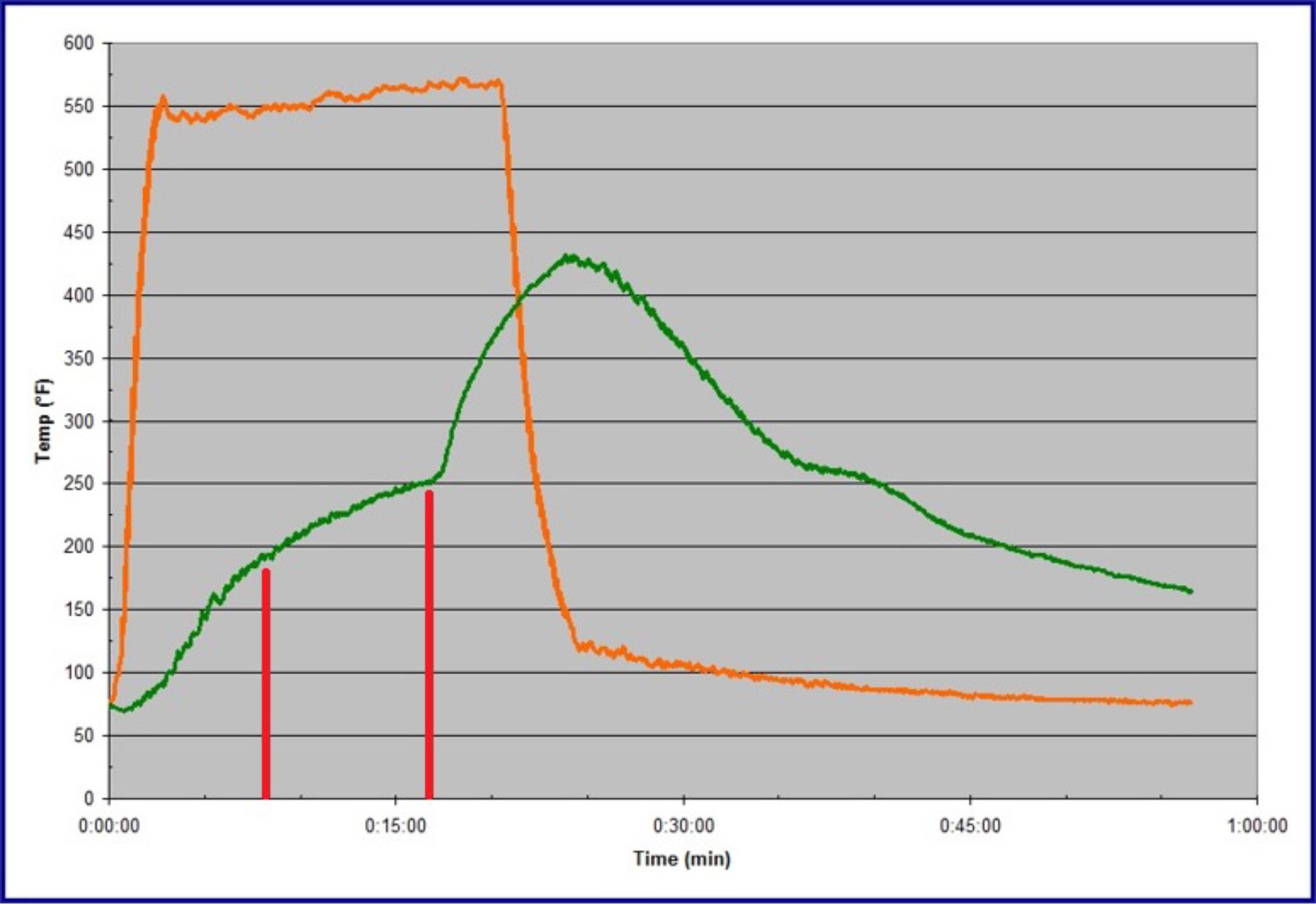

As most rotomoulders use natural gas, the efficiency of converting this non-renewable fossil fuel into rotomoulded parts is poor. In general, the actual production of the final product consumes only 5 - 8% of the energy used by conventional machinery.

This is why our industry’s recent focus on improving energy efficiency and heating molds directly is a welcomed development. Several rotomoulding companies are now exploring alternative energy sources, including biogas and renewable electricity, to reduce their carbon footprint.

As we begin to realize that resources are finite, the concept of reducing waste, using fewer resources, and recycling have become more and more common, and rotomoulders and their suppliers are now discussing what else can be done to reduce waste and improve resource efficiency.

In my view the third main area of focus when considering sustainability in the industry is plastic pollution. As plastic pollution in streams, rivers, and oceans continues to grow, it is evident that we are “compromising the needs of future generations” as a result. The plastic pellets and powder handlers have a major responsibility not to contribute to this problem, and everyone should take part in programs such as “Operation Clean Sweep” and do everything they can to prevent plastic from entering the environment.

Another issue that is being forced onto the agenda is the end of product life. While I was in New Zealand recently, I discovered

that some moulders had developed recycling programs for old rotomoulded junction boxes and water storage tanks.

As a company that specialises in materials for rotational moulding, we take this subject of sustainability very seriously and have several projects, mostly related to materials that we are working on in different regions of the world. Indeed, we are supporting one of our employees Jake Kelly-Walley in studying for a PhD titled “A Sustainable Approach to Materials for Advanced Rotational Moulding Applications” at the Polymer Processing Research Centre at Queen’s University in Belfast.

At the forthcoming conference in Poznan, we will be giving an update on some of the areas we’ve been working on to help reduce energy and material consumption, to develop bio-based polymers and to incorporate post-consumer and post-industrial waste into consistently performing rotomoulding materials.

We are very much looking forward to discussing and sharing ideas at this global event, which will be attended by rotomoulders from all over the world. See you in Poznan

Queenstown remains a consistently stunning destination, and it has once again proven to be the ideal host for Rotomould. Upon arrival, delegates were captivated by the majestic mountains embracing the pristine Lake Wakatipu, along with the welcoming and relaxed atmosphere that enveloped us all.

The location’s allure for Australians was expected, yet I was pleasantly surprised by the international and local New Zealand industry participants who also decided to join. With a substantial turnout of over 115 attendees at the Millennium Hotel, it promised to be a great event.

We were fortunate to have Professor Dru Laws as the presenter for the Sunday morning Introduction to Rotational Moulding Workshop. The workshop encompassed crucial aspects of the rotomoulding process, such as material options, primary equipment types, processing parameters, process control techniques for enhancing part properties, and essential design guidelines. Attendees had ample opportunity for questions and engagement, and as they departed the workshop, they were already praising the exceptional quality of the information provided by Dru.

Rotomould23 commenced with an official Mihi Whakatau, featuring a warm welcome from esteemed local Māori elder,

Darren Rewi, followed by Chris Glenn, the President of ARMA. Chris emphasised the conference’s valuable nature as a platform to reconnect with like-minded industry leaders and renew friendships with familiar faces.