partnership providing innovative mining products and services

A partnership providing innovative mining products and services

A partnership providing innovative mining products and services

FOR INCREASED ASSET PRODUCTIVITY

collaborative delivery model value-added products and services, including:

A collaborative delivery model of value-added products and services, including:

A collaborative delivery model of value-added products and services, including:

Mill linings

Mill linings

Mill linings

Wear resistant liners

Wear resistant liners

Wear resistant liners

Conveyor components

Conveyor components

Conveyor components

Screening and filtering solutions

Screening and filtering solutions

Screening and filtering solutions

Trommels

Trommels

Trommels

Hydrocyclones

Hydrocyclones

Hydrocyclones

Water cutting services

Water cutting services

Water cutting services

DYNAPRIME® IS IDEAL FOR HIGH ASPECT MILLS

The DYNAMAX range of mill liners offers optimum mill lining endurance and reliability

The DYNAMAX range of mill liners offers optimum mill lining endurance and reliability

The DYNAMAX range of mill liners offers optimum mill lining endurance and reliability

SPILLEX

SPILLEX

SPILLEX

Conveyor for environmental

Conveyor for the environmental

Conveyor skirt for the ultimate environmental

VOLUME 123 NO. 6 JUNE 2023

info@tegaindustries.co.za www.tegaindustries.com

Mill Linings

Dynamic innovation maximum durability

A partnership providing innovative mining products and services

partnership providing innovative mining products and services

A partnership providing innovative mining products and services

collaborative delivery model value-added products and services, including:

A collaborative delivery model of value-added products and services, including:

A collaborative delivery model of value-added products and services, including:

Mill linings

Mill linings

Mill linings

Wear resistant liners

Wear resistant liners

Wear resistant liners

Conveyor components

Conveyor components

Conveyor components

Screening and filtering solutions

Screening and filtering solutions

Screening and filtering solutions

Trommels

Trommels

Trommels

Hydrocyclones

Hydrocyclones

Hydrocyclones

Water cutting services

Water cutting services

Water cutting services

The DYNAMAX range of mill liners offers optimum mill lining endurance and reliability

The DYNAMAX range of mill liners offers optimum mill lining endurance and reliability

The DYNAMAX range of mill liners offers optimum mill lining endurance and reliability

SPILLEX

SPILLEX

SPILLEX

Conveyor for the environmental

Conveyor for the environmental

Conveyor skirt for the ultimate environmental

www.tegaindustries.com

The Southern African Institute of Mining and Metallurgy

OFFICE BEARERS AND COUNCIL FOR THE 2022/2023 SESSION

Honorary President

Nolitha Fakude

President, Minerals Council South Africa

Honorary Vice Presidents

Gwede Mantashe

Minister of Mineral Resources and Energy, South Africa

Ebrahim Patel

Minister of Trade, Industry and Competition, South Africa

Blade Nzimande

Minister of Higher Education, Science and Technology, South Africa

President

Z. Botha

President Elect

W.C. Joughin

Senior Vice President

E. Matinde

Junior Vice President

G.R. Lane

Incoming Junior Vice President

T.M. Mmola

Immediate Past President

I.J. Geldenhuys

Honorary Treasurer

W.C. Joughin

Ordinary Members on Council

W. Broodryk G. Njowa

Z. Fakhraei S.J. Ntsoelengoe

R.M.S. Falcon (by invitation) S.M. Rupprecht

B. Genc M.H. Solomon

K.M. Letsoalo A.J.S. Spearing

S.B. Madolo A.T. van Zyl

F.T. Manyanga E.J. Walls

M.C. Munroe

Co-opted to Members

K. Mosebi

A.S. Nhleko

Past Presidents Serving on Council

N.A. Barcza C. Musingwini

R.D. Beck S. Ndlovu

J.R. Dixon J.L. Porter

V.G. Duke M.H. Rogers

R.T. Jones D.A.J. Ross-Watt

A.S. Macfarlane G.L. Smith

M.I. Mthenjane W.H. van Niekerk

G.R. Lane–TPC Mining Chairperson

Z. Botha–TPC Metallurgy Chairperson

M.A. Mello–YPC Chairperson

K.W. Banda–YPC Vice Chairperson

Branch Chairpersons

Botswana Being established

DRC Not active

Johannesburg N. Rampersad

Namibia Vacant

Northern Cape I. Tlhapi

North West I. Tshabalala

Pretoria Vacant

Western Cape A.B. Nesbitt

Zambia J.P.C. Mutambo (Interim Chairperson)

Zimbabwe A.T. Chinhava

Zululand C.W. Mienie

PAST PRESIDENTS

* W. Bettel (1894–1895)

* A.F. Crosse (1895–1896)

* W.R. Feldtmann (1896–1897)

* C. Butters (1897–1898)

* J. Loevy (1898–1899)

* J.R. Williams (1899–1903)

* S.H. Pearce (1903–1904)

* W.A. Caldecott (1904–1905)

* W. Cullen (1905–1906)

* E.H. Johnson (1906–1907)

* J. Yates (1907–1908)

* R.G. Bevington (1908–1909)

* A. McA. Johnston (1909–1910)

* J. Moir (1910–1911)

* C.B. Saner (1911–1912)

* W.R. Dowling (1912–1913)

* A. Richardson (1913–1914)

* G.H. Stanley (1914–1915)

* J.E. Thomas (1915–1916)

* J.A. Wilkinson (1916–1917)

* G. Hildick-Smith (1917–1918)

* H.S. Meyer (1918–1919)

* J. Gray (1919–1920)

* J. Chilton (1920–1921)

* F. Wartenweiler (1921–1922)

* G.A. Watermeyer (1922–1923)

* F.W. Watson (1923–1924)

* C.J. Gray (1924–1925)

* H.A. White (1925–1926)

* H.R. Adam (1926–1927)

* Sir Robert Kotze (1927–1928)

* J.A. Woodburn (1928–1929)

* H. Pirow (1929–1930)

* J. Henderson (1930–1931)

* A. King (1931–1932)

* V. Nimmo-Dewar (1932–1933)

* P.N. Lategan (1933–1934)

* E.C. Ranson (1934–1935)

* R.A. Flugge-De-Smidt (1935–1936)

* T.K. Prentice (1936–1937)

* R.S.G. Stokes (1937–1938)

* P.E. Hall (1938–1939)

* E.H.A. Joseph (1939–1940)

* J.H. Dobson (1940–1941)

* Theo Meyer (1941–1942)

* John V. Muller (1942–1943)

* C. Biccard Jeppe (1943–1944)

* P.J. Louis Bok (1944–1945)

* J.T. McIntyre (1945–1946)

* M. Falcon (1946–1947)

* A. Clemens (1947–1948)

* F.G. Hill (1948–1949)

* O.A.E. Jackson (1949–1950)

* W.E. Gooday (1950–1951)

* C.J. Irving (1951–1952)

* D.D. Stitt (1952–1953)

* M.C.G. Meyer (1953–1954)

* L.A. Bushell (1954–1955)

* H. Britten (1955–1956)

* Wm. Bleloch (1956–1957)

* H. Simon (1957–1958)

* M. Barcza (1958–1959)

* R.J. Adamson (1959–1960)

* W.S. Findlay (1960–1961)

* D.G. Maxwell (1961–1962)

* J. de V. Lambrechts (1962–1963)

* J.F. Reid (1963–1964)

* D.M. Jamieson (1964–1965)

* H.E. Cross (1965–1966)

* D. Gordon Jones (1966–1967)

* P. Lambooy (1967–1968)

* R.C.J. Goode (1968–1969)

* J.K.E. Douglas (1969–1970)

* V.C. Robinson (1970–1971)

* D.D. Howat (1971–1972)

* J.P. Hugo (1972–1973)

* P.W.J. van Rensburg (1973–1974)

* R.P. Plewman (1974–1975)

* R.E. Robinson (1975–1976)

* M.D.G. Salamon (1976–1977)

* P.A. Von Wielligh (1977–1978)

* M.G. Atmore (1978–1979)

* D.A. Viljoen (1979–1980)

* P.R. Jochens (1980–1981)

* G.Y. Nisbet (1981–1982)

A.N. Brown (1982–1983)

* R.P. King (1983–1984)

J.D. Austin (1984–1985)

* H.E. James (1985–1986)

H. Wagner (1986–1987)

* B.C. Alberts (1987–1988)

* C.E. Fivaz (1988–1989)

* O.K.H. Steffen (1989–1990)

* H.G. Mosenthal (1990–1991)

R.D. Beck (1991–1992)

* J.P. Hoffman (1992–1993)

* H. Scott-Russell (1993–1994)

J.A. Cruise (1994–1995)

D.A.J. Ross-Watt (1995–1996)

N.A. Barcza (1996–1997)

* R.P. Mohring (1997–1998)

J.R. Dixon (1998–1999)

M.H. Rogers (1999–2000)

L.A. Cramer (2000–2001)

* A.A.B. Douglas (2001–2002)

S.J. Ramokgopa (2002-2003)

T.R. Stacey (2003–2004)

F.M.G. Egerton (2004–2005)

W.H. van Niekerk (2005–2006)

R.P.H. Willis (2006–2007)

R.G.B. Pickering (2007–2008)

A.M. Garbers-Craig (2008–2009)

J.C. Ngoma (2009–2010)

G.V.R. Landman (2010–2011)

J.N. van der Merwe (2011–2012)

G.L. Smith (2012–2013)

M. Dworzanowski (2013–2014)

J.L. Porter (2014–2015)

R.T. Jones (2015–2016)

C. Musingwini (2016–2017)

S. Ndlovu (2017–2018)

A.S. Macfarlane (2018–2019)

M.I. Mthenjane (2019–2020)

V.G. Duke (2020–2021)

I.J. Geldenhuys (2021–2022)

Honorary Legal Advisers M H Attorneys Auditors Genesis Chartered Accountants Secretaries The Southern African Institute of Mining and Metallurgy 7th Floor, Rosebank Towers, 19 Biermann Avenue, Rosebank, 2196 PostNet Suite #212,

2132 E-mail: journal@saimm.co.za

*Deceased

Private Bag X31, Saxonwold,

Editorial Board

S.O. Bada

R.D. Beck

P. den Hoed

I.M. Dikgwatlhe

R. Dimitrakopolous*

L. Falcon

B. Genc

R.T. Jones

W.C. Joughin

A.J. Kinghorn

D.E.P. Klenam

H.M. Lodewijks

D.F. Malan

R. Mitra*

H. Möller

C. Musingwini

S. Ndlovu

P.N. Neingo

M. Nicol*

S.S. Nyoni

M. Phasha

P. Pistorius

P. Radcliffe

N. Rampersad

Q.G. Reynolds

I. Robinson

S.M. Rupprecht

K.C. Sole

A.J.S. Spearing*

T.R. Stacey

E. Topal*

D. Tudor*

F.D.L. Uahengo

D. Vogt*

*International Advisory Board members

Editor /Chairman of the Editorial Board

R.M.S. Falcon

Typeset and Published by

The Southern African Institute of Mining and Metallurgy

PostNet Suite #212

Private Bag X31

Saxonwold, 2132

E-mail: journal@saimm.co.za

Printed by Camera Press, Johannesburg

Advertising Representative

Barbara Spence

Avenue Advertising

Telephone (011) 463-7940

E-mail: barbara@avenue.co.za

ISSN 2225-6253 (print)

ISSN 2411-9717 (online)

Directory of Open Access Journals

Contents

Journal Comment: The Value of Variety by W.C. Joughin iv President’s Corner: The neuroscience of high-performing teams by Z. Botha .................................................................

PROFESSIONAL TECHNICAL AND SCIENTIFIC PAPERS

In this study the flat jack method was used to measure pillar stresses in three underground rock salt mines from the Eastern, Central and Western Salt Ranges, in Punjab, Pakistan. It was found that the measured pillar stresses in the Salt Range are proportional to the overburden stress values with their magnitude ranging from 4.38 MPa to 11.97 MPa. Pillars were found to be stable. A guideline chart was developed to find out the suitable length of pillar for safety.

Dependence of solar reflector soiling on location relative to a ferromanganese smelter

287

M.A. Swart, L. Hockaday, Q. Reynolds, and K. Craig

299 This paper presents the results from a solar reflector soiling study at Transalloys, a ferromanganese smelter in South Africa. Several meteorological parameters were monitored to establish the conditions that lead to increased soiling. The reflector set’s proximity to the dust source was the primary driver for increased soiling. The study revealed that, while there are periods of intense soiling at this particular site, proper planning of reflector location relative to the smelter dust sources can have a significant positive impact on soiling rate.

THE INSTITUTE, AS A BODY, IS NOT RESPONSIBLE FOR THE STATEMENTS AND OPINIONS ADVANCED IN ANY OF ITS PUBLICATIONS.

Copyright© 2023 by The Southern African Institute of Mining and Metallurgy. All rights reserved. Multiple copying of the contents of this publication or parts thereof without permission is in breach of copyright, but permission is hereby given for the copying of titles and abstracts of papers and names of authors. Permission to copy illustrations and short extracts from the text of individual contributions is usually given upon written application to the Institute, provided that the source (and where appropriate, the copyright) is acknowledged. Apart from any fair dealing for the purposes of review or criticism under The Copyright Act no. 98, 1978, Section 12, of the Republic of South Africa, a single copy of an article may be supplied by a library for the purposes of research or private study. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means without the prior permission of the publishers. Multiple copying of the contents of the publication without permission is always illegal.

U.S. Copyright Law applicable to users In the U.S.A. The appearance of the statement of copyright at the bottom of the first page of an article appearing in this journal indicates that the copyright holder consents to the making of copies of the article for personal or internal use. This consent is given on condition that the copier pays the stated fee for each copy of a paper beyond that permitted by Section 107 or 108 of the U.S. Copyright Law. The fee is to be paid through the Copyright Clearance Center, Inc., Operations Center, P.O. Box 765, Schenectady, New York 12301, U.S.A. This consent does not extend to other kinds of copying, such as copying for general distribution, for advertising or promotional purposes, for creating new collective works, or for resale.

▶ ii JUNE 2023 VOLUME 123 The Journal of the Southern African Institute of Mining and Metallurgy

VOLUME 123 NO. 6 JUNE 2023

v-viii

of

salt

a

–

case

Y. Majeed, N. Abbas, and M.Z. Emad

Stability evaluation

room-and-pillar rock

mines by using

flat jack technique

A

study

Predicting open stope performance at an octree resolution using multivariate models

B. McFadyen, M. Grenon, K. Woodward, and Y. Potvin

This article presents a step towards a new stope design approach, where stope OB and UB is measured and georeferenced at an approximately cubic metrer resolution (octrees) and predicted using statistical multivariate models. Results showed that OB and UB location as well as their magnitude is predicted with good precision. The resolution of the data and the use of multivariate analysis has enabled the prediction of the variation of stope performance along the design surface.

Spontaneous combustion of carbonaceous shale at an iron ore mine, South Africa

The SPONCOM liability and properties of samples of black carbonaceous shales in an iron mine were examined and compared with results of studies conducted on Witbank coal-field samples. The Wits-Ehac Index classification results show that the samples displayed between medium and high risk. The linear regression analysis showed very poor correlations between the Wits-Ehac Index results and the XRF and proximate and ultimate results. The most valuable relationship was between the presence of relatively high sulphur (greater than 3%) and ground reactivity with nitrate-bearing explosive emulsion.

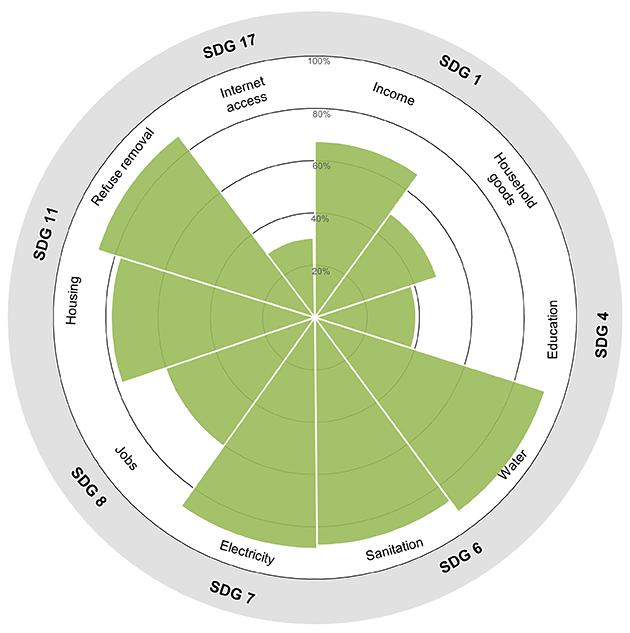

Assessing coal mine closures and mining community profiles for the ‘just transition’ in South Africa

This paper provides an in-depth view of the coal mining industry in South Africa, and it questions the narrative that premature mine closure is inevitable. Our research shows that the shift to cleaner energy will likely occur without the premature closure implied by the ‘just transition’. The South African approach to the ‘just transition’ needs to take local realities into account. The narrative needs to support an effective transition that does not undermine energy security and economic growth.

309

321

The Journal of the Southern African Institute of Mining and Metallurgy VOLUME 123 JUNE 2023 iii ◀

C. Gous and B. Genc ........................................................................

Cole, M. Mthenjane, and A. van Zyl ........................................................

M.

329

Journal Comment

The Value of Variety

This edition of the Journal contains five general papers on a variety of topics. Three of the papers deal with rock engineering issues, one deals with spontaneous combustion, and another with soiling of solar reflectors or heliostats. The three rock engineering papers each cover very different challenges faced by the mining industry.

Squeezing rock conditions occur when tunnels located in weak, ductile rock masses are overstressed. Unlike the strong, brittle rock masses typically encountered in deep South African gold mines, which fracture and burst when overstressed, these weaker rock masses deform excessively, resulting in gradual closure of the tunnels until they are no longer serviceable. Support needs to be designed to manage squeezing rock conditions without rockfall incidents, and to keep the tunnels serviceable. The paper on this topic represents an update of an earlier benchmarking exercise on squeezing ground management in Australian and Canadian mines, taking into account advancements in deformation monitoring technologies and the increased availability of yielding ground support elements. The authors provide practical guidelines for predicting the level of squeezing, selecting appropriate support systems, and rehabilitation.

Another rock engineering paper deals with pillar design in Himalayan rock salt mines. The authors describe a comprehensive field testing exercise using flat jacks to determine pillar stress.

Monitoring and predicting the performance (overbreak and underbreak) of open stopes is essential for minimizing dilution, ore loss, and disruptions to the mining cycle to ensure profitability. Most open stoping operations perform cavity monitoring surveys of all stopes. The paper on open stope performance describes an improvement on the classic empirical methods for predicting overbreak that includes prediction of underbreak. The method was developed using machine learning techniques.

Spontaneous combustion is a common problem in coal mines, which causes environmental and safety and health problem risks. Another paper deals with the potential for spontaneous combustion and ground reactivity in carbonaceous shales at an opencast iron ore mine, and highlights the importance of determining the properties of the carbonaceous shale.

The soiling of solar reflectors (heliostats) is perhaps an unusual topic for inclusion in the Journal. However, concentrating solar power (CSP) technology is likely to play an important role in the energy transition, particularly for energy-intensive industries such as smelting. This paper addresses the soiling rate due to dust from a ferromanganese smelter, and its effect on heliostat performance.

W.C. Joughin

▶ iv JUNE 2023 VOLUME 123 The Journal of the Southern African Institute of Mining and Metallurgy

President’s Corner

The neuroscience of highperforming teams

Iam going to be honest … I have a little bit of an obsession with neuroscience research and how that can be utilized to create highperforming teams. I have been exposed to this by a fantastic project manager and a brilliant industrial psychologist. Neuroscience can show us how we build relationships, react to our environment, respond to learning, and learn to work collaboratively. How do multiple, unique, and different individuals, each with their own perspective, ideas, thoughts, skills, and abilities, contribute to the success of a working, whole unit? I believe, for the most part, that a large sum of that success is how the team enables each member to feel included, valued, heard, and safe. Neuroscience can show us how to do this.

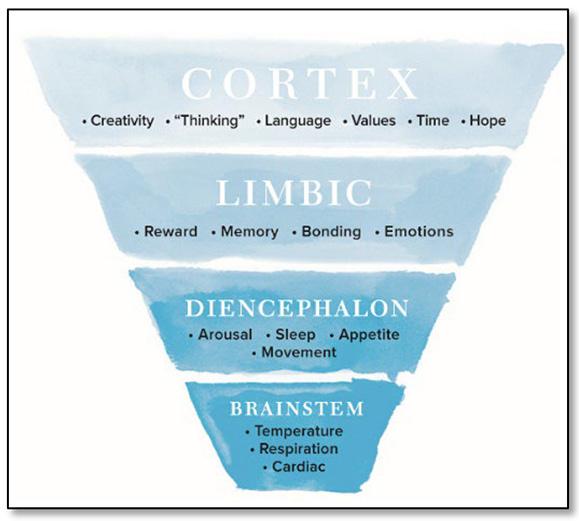

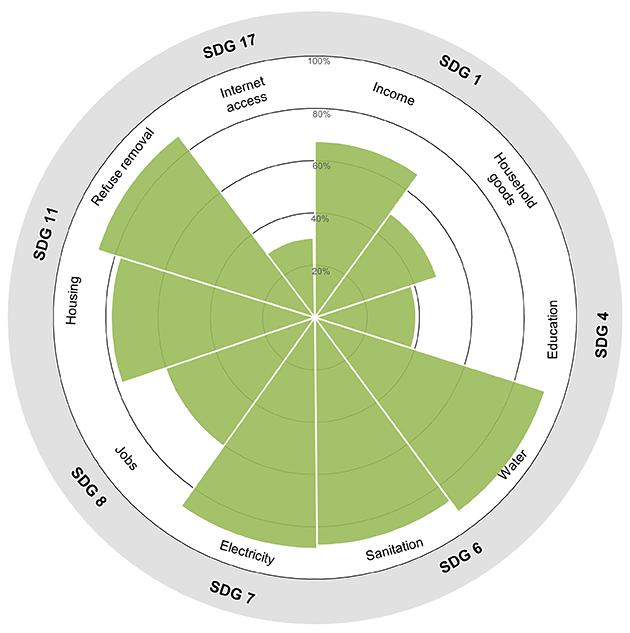

Knowing a little bit more about how neuroscience influences your own performance can help you contribute to the wellbeing of the whole team. Through scrutinizing neuroscientific research, Neurozone has identified all the drivers (outer sphere) and conditions (inner sphere) for optimal performance (Figure 1).

The Journal of the Southern African Institute of Mining and Metallurgy VOLUME 123 JUNE 2023 v ◀

Figure 1–An example of a Neurozone Model, taken from a Neurozone report, April 2019. Since 2019 the Neurozone model has been updated. It now refers to high performance rhythms, not foundational drivers. When operating from a regulated state of being (the four high performing rhythms), social interaction will be easier to engage in

President’s Corner (continued)

This ‘model’ shows granular responses of the internal system; small, nuanced behaviours that make up our complex response to our environments. This refers to the following: types of exercise and mobility, the components of sleep and mindfulness training, our emotional-energy-releasing responses (such as optimism, gratitude, enthusiasm, and humour), ways in which we learn and solve problems, as well as the ways that we ensure collective creativity through belonging, bonding, and mining diversity. This complexity and adaptability in response allow us to have many ways to solve a problem.

External changes require internal adaptations. If you know the ‘reprioritizing code’, then you can assign the most energy to the right behaviour, leading you to act in the best interest of not only yourself, but the group.

This is a very good description of building resilience. Resilience, of course, refers to adaptability and capacity to respond appropriately in changing situations. Resilience is not about personality; rather, it’s about behaviour. That’s why it is so important to continually assess and monitor behaviour so that you can ensure you get the highest yield for the energy ascribed to the tasks of living, surviving, and thriving.

Neuroscience, and more specifically the Neurozone model, supports the development of our capacity to maximize personal optimization so that we maximize other higher-order entities that we form, such as teams and organizations, by shining a light on the complex connections between the brain, nervous system, and immune system (This is taken from CEO and Co-Founder of Neurozone, Dr Etienne van der Walt, neurologist and a subject matter expert in clinical neurology, 5 July 2023).

I believe we desperately need to remember, and understand, that we are wired for connection and empathy. There is power and healing in relationships and community. Dr Bruce Perry, a renowned brain development and trauma expert, child psychiatrist, neuroscientist, and principal of the neurosequential model of brain-based therapy, has proven this in his book What Happened to You? (Perry, B.D. and Winfrey, O. 2021. Flatiron Books).

He says: ‘Marginalized people — excluded, minimized, shamed — are traumatized people, because as we’ve discussed, humans are fundamentally relational creatures. To be excluded from an organization, community, or society you are exposed to prolonged uncontrollable stress that is sensitizing.’

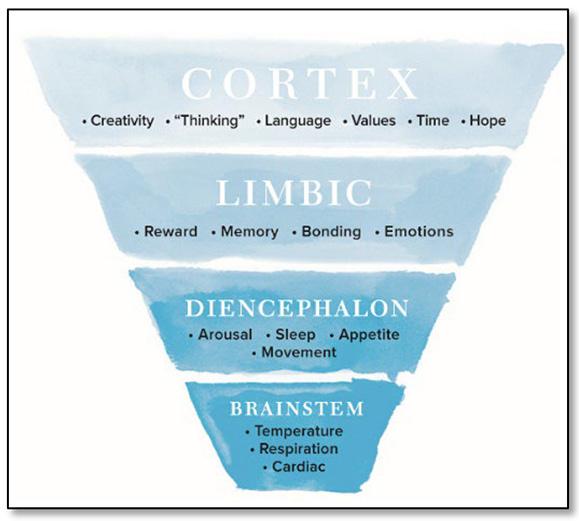

The key difference between team members NOT affected by trauma and those affected by trauma is that members ‘sensitized’ by trauma can escalate more quickly into states of dysregulation. In Figure 2 you can see how a sensitized person can easily end up in a state of fear or terror daily. As we move

▶ vi JUNE 2023 VOLUME 123 The Journal of the Southern African Institute of Mining and Metallurgy

Figure 2–Stress-reactive curve, taken from What Happened to You?, Perry, B.D.and Winfrey, O. 2021, Flatiron Books

President’s Corner (continued)

between different emotional states, from ‘Calm’ to ‘Terror’, the amount and type of access we have to our cognitive abilities changes. This is also confirmed in the book by Malcolm Gladwell, ‘Talking to Strangers’. We lose our ability to do creative problem-solving, with our prefrontal cortex, when we perceive ourselves to be under threat and we consequently move back into amygdala regulation, where we resort to freeze, flight, or fight, which not only leads to destructive conflict, but also complete disengagement (Figure 3).

How do we combat exclusion in a team? How do we ensure that one of our team members are not exposed to chronic stress?

Psychologist Kelly McGonigal (health psychologist and lecturer at Stanford University), with her TED talk ranking under the 25 most popular TED Talks of all time (updated January 2023), shows that while stress has been made into a public health enemy, new research suggests that stress may only be bad for you if you believe that to be the case. She urges us to see stress as a positive and introduces us to an unsung mechanism for stress reduction: reaching out to others. Again, connection plays a crucial role in resilience. When any individual perceives the stress response to be chronic, their whole brain-body system will continually be in fight mode, which will lead to burnout, ill health, and ultimately, death. From a neurobiological perspective, the best protection against this is resilience. This capacity of the brain-body system to prevent implosion under severe stress is underpinned by the ability to belong and contribute to the group. To solve a problem or

The Journal of the Southern African Institute of Mining and Metallurgy VOLUME 123 JUNE 2023 vii ◀

Figure 3–Accessing the Cortex, taken from What Happened to You?, Perry, B.D.and Winfrey, O. 2021. Flatiron Books

President’s Corner (continued)

fashion novel products that are adapted for the group, promoting group survival and thrivability. We need forces that will foster a cohesive whole so that we can surpass the sum of its parts. According to Neurozone, there are four themes that could combat exclusion in a team and ensure that one of our team members are not exposed to chronic stress.

Are you practising this in your teams?

Table

I

Four themes to ensure connection, inclusion, and resilience for high-performing teams. This is my own representation of work done by Dr Etienne van der Walt and his team at Neurozone

Z. Botha President, SAIMM

Z. Botha President, SAIMM

▶ viii JUNE 2023 VOLUME 123 The Journal of the Southern African Institute of Mining and Metallurgy

Stability evaluation of room-and-pillar rock salt mines by using a flat jack technique – A case study

Y. Majeed1, N. Abbas1, and M.Z. Emad1

Affiliation:

Mining Engineering Department, University of Engineering and Technology, Lahore, Pakistan.

Correspondence to:

M.Z. Emad

Email: zaka@uet.edu.pk

Dates:

Received: 25 Oct. 2021

Revised: 17 Oct. 2022

Accepted: 17 Oct. 2022

Published: June 2023

How to cite:

Majeed, Y., Abbas, N., and Emad, M.Z. 2023

Stability evaluation of room-and-pillar rock salt mines by using a flat jack technique – A case study.

Journal of the Southern African Institute of Mining and Metallurgy, vol. 123, no. 6. pp. 287–298

DOI ID:

http://dx.doi.org/10.17159/24119717/1872/2023

Synopsis

Room-and-pillar mining is commonly employed for the extraction of rock salt in underground mines. Pillar stress is a major concern in these mines as it is directly related to stability and mineral recovery. In this study a flat jack method was used to measure pillar stresses in three underground rock salt mines in Pakistan. The field work included determination of in-situ stress, in-situ elastic modulus, recording of field variables (pillar length and width, height and width of opening, opening width to height ratio, extraction ratio, and overburden height) and collection of salt block samples. The geomechanical properties of rock salt (uniaxial compressive strength, Young’s modulus, Brazilian tensile strength, and density) were also determined to estimate overburden stress, pillar strength, and factor of safety (both estimated and actual). It was found that the measured pillar stresses are proportional to the overburden stress values, with their magnitude ranging from 6.05 MPa to 11.97 Mpa, and the pillars were found to be stable. Regression analysis was performed to develop statistical models for in-situ stress and in-situ elastic modulus. Finally a quick guideline chart was developed to determine the suitable length of pillar for a given span and required level of safety.

Keywords

flat jack, room-and-pillar mining, in-situ stress, factor of safety, regression analysis.

Introduction

The global practice for excavating massive underground rock salt deposits is by adopting stope-and-pillar or chamber-and-pillar mining techniques, which can be applied with both regular and irregular layouts depending upon the deposit characteristics. In this method almost 40% of the material is excavated forming the rooms, whereas around 60% is left in place as structural pillars in order to support the overlying burden (Hustrulid, 2001).

Pakistan has vast deposits of Himalayan rock salt in a Precambrian sequence known as the Salt Range Formation of the Salt Range, Punjab (Shah, 2009; Baloch et al., 2012). Mining of rock salt and allied industries plays an important role in the local economy. Salt Range is located in the northern part of the province of The Punjab, extending from Tilla Jogian in the east to Warcha in the central and Kalabagh in the western portion. The Salt Range Formation is associated with a dynamic frontal thrust zone of the Himalayan mountain range. The present name of ‘Salt Range Formation’ was suggested by Asrarullah (1967). The same rock unit was previously called the ‘Saline Series’ or ‘Punjab Saline Series’ (Wynne, 1878; Gee, 1945). The Salt Range Formation is further classified into three units, namely the Sahwal Marl unit, Bhandar Kas Gypsum unit, and Billianwala Salt unit. The Billianwala Salt unit consists of red ferruginous marl and massive layers of rock salt having a thickness more than 650 m. This unit is exposed along the southern escarpment of the Salt Range, where underground mining of rock salt is conducted at Khewra, Warcha, and Kalabagh (Shah, 2009). The rock salt deposits are categorized as massive, with only Khewra mine containing more than 82 Mt of rock salt (Asrarullah, 1967). Khewra salt mine is the second largest in the world and the largest underground room-and-pillar mining operation in Pakistan (Baloch et al., 2012). When underground excavations are made the original in-situ stresses are disturbed, since stresses cannot pass through the excavated voids, hence they are transferred to the adjacent rock pillars. This results in an increase in the pillar stresses due to the load of overburden above the pillars and the excavations (Brady and Brown, 2005). The stability of a pillar depends on its strength and the level of stress generated in it. Many researchers have considered pillar stress as an important parameter in room-and-pillar mine design. According to Deng et al. (2003) a good pillar design can be obtained by accurate estimation of strength to stress ratio. Salamon and Munro (1967) studied 125 pillar failure cases to estimate pillar safety factor (ratio of pillar strength to pillar stress). Similarly, Bieniawski (1968) formulated equations for pillar strength calculations by performing tests on samples of various sizes ranging from 0.75 in. to 2 m. The pillar strength can be estimated by employing Equation [1]:

287 The Journal of the Southern African Institute of Mining and Metallurgy VOLUME 123 JUNE 2023

Stability evaluation of room-and-pillar rock salt mines by using a flat jack technique

where Sp = strength of pillar, Si = strength of a specimen measured in the laboratory, and w h is the width to height ratio.

The in-situ pillar stresses can be quantified by using two approaches, namely a theoretical approach and on-site experimentation. It is noteworthy that unlike many other uniform materials, rocks and earth materials contain a lot of natural complexities like joints, faults, groundwater etc. These complexities offer many challenges in the correct estimation of pillar stresses (Sebastiani et al., 2015). Generally a theoretical approach to estimate the in-situ stress considers it as unit weight of the rock (γ) times the depth of overburden (Z). Many researchers (Hoek, Kaiser, and Bawden, 1995; Salamon and Munro 1967; Hedley and Grant, 1972; Krauland and Soder 1987) have used the tributary area method to determine the expected average pillar stress. According to the tributary area theory the pillar stress is not only a function of the rock above it, but also the load over the excavated area. As per Brady and Brown (2005) the load of overburden material above an excavation is shared by the pillars on the either side of excavation. Brady and Brown (2005) formulated the following equation based on the tributary area theory.

➤ Measurement of average stress orthogonal to the surface of the test slot

➤ For jack tests the rock mass is assumed to be isotropic and homogenous

➤ In highly cracked or shattered rock materials the relief of stress may not be completely reversed (ASTM, 2008)

➤ The flat jack is only useful at the excavation's surface where the rock is close to being overstressed (Lin et al., 2018). Flat jack is one of the reliable technologies that have been used by many researchers in measuring in-situ stresses in mining and civil structures. Comprehensive information on flat jack testing can be found in the relevant literature (Bieniaweki, 1981; ISRM, 1986; Binda and Tiraboschi, 1999; Gregorczyk and Lourenco, 2000; Fedele and Marier, 2007; ASTM, 2008; Verstricht et al., 2010; Lamas, Muralha, and Figueiredo, 2010; Figueiredo, Lamas, and Muralha, 2010, 2011; Simoes et al., 2012; Dhawan, 2012; Sabri, Ulybin, and Zubkov, 2015; He and Hatzor, 2015; Cescatti et al., 2016; Latka and Matysek, 2017; Mendola, Giudice, and Minafo, 2019; Selen et al., 2020; Corkum, 2020; Armanasco and Foppoli, 2020; Rios and O’dwayer, 2020; Medeiros, Soriani, and Parsekian, 2020, amongst others)

where σP denotes the in-situ stress acting on the pillar, γ is the unit weight; Z is the depth below surface, and e is the extraction ratio. For real-time on-site stress measurements in mines, various techniques have been developed including hydraulic fracturing, overcoring, and flat jack. Hydraulic fracturing is particularly employed in the petroleum engineering industry for the measurement of ground stresses. In 1960, this method was used for stress assessment in productivity stimulation. There are now two major categories of this technique, namely conventional hydraulic fracturing and hydraulic tests on pre-existing fractures (HTPF). Bell and Gough (1979) proposed the traditional concept of borehole breakout stress orientation by interpreting the stress field around the borehole using Kirsch's solution. Overcoring is another common stress measurement technique, especially utilized in the geotechnical industry (Feng, Harrison, and Bozorgzadeh, 2020). The calculation is based on the deformation of a pilot hole. This technique delivers high-accuracy stress measurements and can be used in a variety of geological situations (Lin et al., 2018). Details regarding hydraulic fracturing and overcoring techniques can be found in the literature (Obert and Duvall 1967; Jumikis, 1983; Goodman, 1989; Hoek and Brown, 2005; Brady and Brown, 2005; Lamas, Muralha, and Figueiredo, 2010; Eberhardt and Stead, 2011).

The flat jack technique of in-situ stress measurment is particularly employed in the mining industry. The idea is to use the pressurization of a flat jack in a slot to calculate stress. Strain gauges are used to continually measure two points A and B, and a slot is cut adjacent to the measurement points. A flat jack is then put into the slot and compressed until the distance between A and B is restored to its previous value. The cancellation pressure at this point is believed to represent the average normal stress over the slot, and the stress field can then be evaluated. According to Gregorczyk and Lourenco (2000) the stress test results are interpreted converting jack pressure to the in-situ compressive stress. This method is simple, inexpensive, and straightforward to implement, and it does not require an elastic modulus for calculation. On the other hand there are some limitations of this method:

Pakistan produces around 3,193,791 Mt of rock salt per annum (Mines and Minerals Department, 2020). Due to the massive nature of the deposits, mines have mostly multi-level operations developed using the stope-and-pillar method with regular layouts. For example, the Khewra salt mine, rated as second largest mine in the world, has 17 working levels. The annual production is about 465,000 t and the expected mine life is around 350 years (Baloch et al., 2012). Due to the multi-level underground operations the in-situ pillar stresses are important for the stability and integrity of mine structure.

This research study is focused on determining vertical stress levels in rock salt pillars at three selected salt mines located in the Salt Range, Punjab. Stress measurements were performed in pillars with the help of the flat jack method, and on-site challenges associated with its use are also discussed. The stability of selected rock salt mines was evaluated by using actually measured stresses as well as empirically estimated pillar stress and strength values. Moreover, the effect of pillar dimensions on mine stability was investigated based on the factor of safety approach.

Research methodology

The research work consisted of field work and laboratory investigations along with computations of pillar strength and in-situ stress using an empirical approach.

Field work

The field studies included real-time in-situ stress measurements using the flat jack technique, study of underground mine plans, and collection of representative blocks of rock salt for subsequent laboratory studies. Three rock salt mining projects operated by M/s. Pakistan Mineral Development Corporation (PMDC), namely Khewra, Warcha, and Kalabagh, located in the eastern, central, and western regions of the Salt Range, were selected (Figure 1). Table I lists the selected projects along with their locations, geological environment, and age (Shah, 2009). At each mine suitable pillars for flat jack testing were selected based on the underground mine plans, pillar geometry, rock salt type, overburden height, and distance from the mine portal. Figures 2, 3, and 4 show the mine plans of PMDC Warcha, Khewra, and Kalabagh projects respectively, illustrating the test pillars selected for performing flat jack tests

288 JUNE 2023 VOLUME 123 The Journal of the Southern African Institute of Mining and Metallurgy [1]

[2]

Stability evaluation of room-and-pillar rock salt mines by using a flat jack technique

along with mine geometry and extraction ratio. At PMDC Warcha project (Figure 2) the pillar width varies from 4.5 m to 10 m and the width of the chambers ranges from 12 m to 16 m. The height of chambers varies from 4 m to 16.5 m, with an average mining height of 12.2 m. The PMDC Khewra project has two mine plan configurations, comprising 10.5 m (Figure 3, left) and 15.5 m (Figure 3, right) wide rooms and pillars. The height of openings varies from 3.65 m to 12.50 m. It is worth mentioning here that Khewra has adopted the layout with 15.5 m wide rooms and pillars for its current and future workings. The mine layout at PMDC Kalabagh project (Figure 4) comprises 14 m wide pillars and rooms with 8.5 m width and 7 m height. Before proceeding with the flat jack tests, the specific locations on selected pillar ribs were checked for material competence and the presence of any micro- and macro-

flaws by visual inspection and sonic testing using blows with a geological hammer.

Field experimental set-up

The in-situ stress measurement set-up comprised a flat jack, hydraulic pump, and deformometer (a device to measure length variation). A locally manufactured flat jack (length 40 cm; width 20 cm; thickness 1.5 mm) with maximum operating pressure of 400 bars was used (Figure 5a). It consisted of two steel plates (20/10 plate thickness) welded together along the edges using high-strength acetylene-assisted welding. Two steel tubes with 6 mm outer diameter and 3 mm inner diameters were introduced to pressurize the flat jack with hydraulic oil, one tube for the attachment with the hydraulic pump and the other to connect an extra flat jack if used, otherwise plugged. The hydraulic pump was a single-stage hand pump with reservoir with a pressure gauge of 700 bar range

Selected rock salt mining projects for flat jack testing

1 Khewra Salt PMDC Khewra Project, White, pink, red, Room and Salt Range

Precambrian Mines Khewra, District Jhelum, Punjab, Pakistan and industrial pillar Formation

2 Warcha Salt PMDC Warcha Project, Rukhla Mandi, Pure white, pink, Room and Salt Range

Precambrian Mines Tehsil Qaidabad, District Khushab, and industrial pillar Formation

Punjab, Pakistan

3 Kalabagh Salt PMDC Kalabagh Project, Kalabagh, White, pin.k and Room and Salt Range

Precambrian Mines District Mianwali, Punjab, Pakistan industrial pillar Formation

PMDC – Pakistan Mineral Development Corporation

289 The Journal of the Southern African Institute of Mining and Metallurgy VOLUME 123 JUNE 2023

Figure 1—Map of Pakistan showing locations of PMDC rock salt projects (Khewra, Warcha, and Kalabagh) included in this research work (adapted from Khan and Shah, 2019)

Table I

Sr No. Project Location Salt seams Mining method Formation/Group Geological horizon

Figure 2—Selected location for testing in main mine at PMDC Warcha. Pillar no. 22, extraction ratio 73%

Stability evaluation of room-and-pillar rock salt mines by using a flat jack technique

290 JUNE 2023 VOLUME 123 The Journal of the Southern African Institute of Mining and Metallurgy

Figure 3—Selected pillars for testing in PMDC Khewra. (a) Main level pillar no. 25-26; extraction ratio 73%, (b) main level pillar no. 51-52, extraction ratio 72%

Figure 4—Selected locations for in-situ testing at PMDC Kalabagh. (a) Mine no. KB-14, extraction ratio 66.20% ,(b) mine no. WK-16, extraction ratio 37.88%

Figure 5— (a) Flat jack equipment, (b) hydraulic pump with pressure gauge

Stability evaluation of room-and-pillar rock salt mines by using a flat jack technique

and flexible hose for connection with the flat jack (Figure 5b). A mechanical dial gauge deformometer was used to measure the rock deformation as shown in Figure 6. It consists of three components, namely the dial gauge, moveable limb, and static limb or scale. The static limb is fixed while the moveable limb gives a measuring range of 5.00 mm. The instrument can be used to measure deformations in rock with an accuracy of 0.001 mm.

On-site challenges

Site selection was a major challenge as pillar stress was determined in the middle of the mine instead of a test gallery. The testing required an undisturbed rock surface with an electrical connection nearby. In addition, the site had to be safe and away from operational activities. The flat jack testing requires a lateral slot to be cut in the rock, which is a challenging task. Generally, the slot can be developed using overlapping or contiguous drill-holes, a disc cutter, or chainsaw. In this work the slot was cut using contiguous drill-holes due to the relatively soft rock conditions. The other two methods of slot creation (disc cutter and chainsaw cutter) are usually preferred in hard rock. The disc cutter can be used on site with an appropriate mounting assembly, which enables lateral movement of the cutter, thus creating a slot. The cutter must have a large enough diameter to cut a deeper slot. If a chainsaw is employed for slot cutting, the cutting tips must be customized for use in softer and corrosive rocks such as rock salt. Overall, the locally manufactured flat jack equipment used in this research work was handy in terms of flexibility, with specifications making it robust for site conditions. It was also cheaper than the commercial solution available. The only catch was its calibration and validation of the tests performed. The calibration was performed in the laboratory as suggested by Mendola, Giudice, and Minafo (2019).

Flat jack calibration

The pressure exerted by the flat jack on the walls of the slot is

indicated by the pressure gauge of the hydraulic pump. Therefore in order to perform precise in-situ stress measurements the pressure gauge was calibrated using the pre-calibrated read-out gauge/ unit of the laboratory 200 t Schimadzu universal testing machine (UTM). For this purpose the flat jack was placed between the platens of the UTM under a known applied force. Then the pressure in the flat jack was increased in increments of 11 kg/cm2 and at each increment the dial gauge reading of the hydraulic pump and corresponding reading of the UTM gauge were noted. Finally, a relationship was developed (Figure 7) to calculate the calibrated stress value using the stress value indicated by the pressure gauge of the flat jack hydraulic pump.

In-situ stress measurement

The in-situ flat jack tests were performed according to the test procedure provided in Brady and Brown (2005). In the selected pillar rib, the location for evaluating rock deformation was prepared by installing three sets of measuring pins (Figure 8a) on each side along the centreline orthogonal to the axis of the pre-marked flat jack slot. The distance between the measuring points was accurately measured by using a highly sensitive dial-gauge deformometer with an accuracy of 0.001 mm. A slot approximately 48 cm wide was cut (Figure 8b) using a hand-held rock-drill machine to drill contiguous holes of 25 mm diameter. After cutting the slot, the distance between the installed pins was measured again in order to determine the amount of slot closure (Figure 9). The difference between the measured distances before and after slot cutting is the deformation of rock around the slot. Finally, the flat jack was

291 The Journal of the Southern African Institute of Mining and Metallurgy VOLUME 123 JUNE 2023

Figure 6—Mechanical dial gauge for deformation measurement

Figure 7—Relationship for the calibration of stress values indicated by the hydraulic pump of the flat jack

Figure 8—(a) Marking and installing the measuring points, (b) cutting of slot and its dimensions

Stability evaluation of room-and-pillar rock salt mines by using a flat jack technique

fully inserted into the slot and hydraulic pressure was applied in increments of 20 kgf/cm2 utilizing a manual hydraulic pump capable of exerting a pressure of up to 700 bar. The cancellation pressure at which the measurment points shifted to their original positions was noted from the pressure gauge on the hydraulic pump. Figure 10 illustrates an integrated view of in-situ stress measurement carried out at PMDC Khewra (pillar no. 51-52). During experimentation reversals of axial deformations were also noted after every 20 kg/cm2 increment of hydraulic pressure. This data was utilized to plot axial stress versus axial strain and ultimately in-situ moduli of elasticity were determined for all the selected pillars.

Computation of pillar strength and stress

The average pillar strength and stress were determined by employing the tributary area method (Brady and Brown (2005) for rectangular room-and pillar-layout. According to this approach the load of the overlying strata is equally distributed among the pillars. The pillar strength for rock salt mines was computed by using Equation [3] (Mao, 2015). It is pertinent to highlight here that Equation [3] is a modified version of Bieniawski (1968, Equation 1) which was originally developed for coal pillars only. Similarly the pillar stress was computed by using Equation [4] (Brady and Brown, 2005). Finally, the factor of safety (FOS) was computed both for actual in-situ pillar stress (measured in the field) and estimated stress scenarios.

from all three selected mining projects according to the ASTM D2113 (2014) standards. In this regard, representative salt blocks of appropriate size (at least 12 inches edge dimensions) and free from any noticeable flaws were selected.

Laboratory testing

As per the research plan a comprehensive suite of laboratory experiments including uniaxial compressive strength (UCS), Young’s modulus (E), Brazilian tensile strength (BTS), and density (ρ) tests were performed. Rock salt cores were obtained by drilling the collected blocks using standard NX size (54 mm) core cutting bits and cylindrical specimens were prepared according to the guidelines in the ASTM D4543 (2008) standards.

Compressive strength and elastic modulus

The UCS and uniaxial deformability tests were performed on prepared cylindrical rock salt core samples utilizing a 200 t universal testing machine. To compute the elastic moduli, axial as well as lateral strains were determined at fixed loading intervals until the sample failed. Two mechanical dial gauges having a least count of 0.01 mm were used for this purpose. The tests were carried out according to the recommendations in ASTM D7012 (2010).

Brazilian tensile strength

where Sp = strength of pillar. Si = strength of specimen measured in the laboratory, and w h is pillar width to height ratio.

The BTS tests were carried out in accordance with the recommendations in ASTM D3967 (2016). Prepared discs of rock salt with thickness or height approximately equal to 0.5 times the diameter were loaded diametrically and failure loads were noted.

Density

where Pzz = vertical component of pre-mining stress field, r is the extraction ratio, Wo is the span of the opening or room, Wp is the span of the pillar, and a and b are the pillar dimensions in plan view for a rectangular pillar.

Collection of rock salt blocks

To carry out laboratory scale testing, rock salt blocks were collected

The density of rock salt was determined from the weight to volume ratio of prepared core samples. The volume of each core specimen was determined by taking the average of height and diameter values with a Vernier caliper. A weighing balance with a least count of 0.01 g was used to determine the weight of the specimen.

Results and discussion

Table II lists the field variables along with actual and estimated parameters including pillar width (W), pillar length (L), width of opening (Wop), height of opening (Hop), opening width to height

292 JUNE 2023 VOLUME 123 The Journal of the Southern African Institute of Mining and Metallurgy

[3]

[4]

Figure 9—Deformation measurement after cutting the slot

Figure 10—In-situ stress measurement test being carried out at PMDC Khewra (pillar 51-52)

Stability evaluation

Table II

Field

of room-and-pillar rock salt mines by using a flat jack technique

Results of laboratory testing

ratio (W/H(op)), extraction ratio (ER), overburden height (OB), insitu pillar stress (σ(Measured)), estimated pillar stress (σ(EST)), estimated pillar strength (ST(EST)), factor of safety based on in-situ pillar stress (FOS(Actual)), factor of safety based on estimated pillar stress (FOS(EST)), and in-situ Young’s modulus (E(Measured)). Similarly, Table III lists the data acquired from laboratory investigations comprising uniaxial compressive strength (UCS), Young’s modulus E(Lab)), Brazilian tensile strength (BTS), and density (ρ). The discussion of results is chiefly focused on performing a comprehensive pillar stability analysis for the selected rock salt projects by considering stress (in-situ versus estimated) and factor of safety (actual against measured) approaches. Moreover, statistical relationships including in-situ and laboratory elastic modulus, in-situ pillar stress versus width to height ratio of opening, as well as overburden height are also developed specifically for room-and-pillar rock salt mines. Finally, the pillar optimization analysis was performed to suggest the effective pillar length based on factor of safety for a given pillar width.

Pillar stability analysis

To investigate the stability of the mine layout, analysis was performed based on pillar stress and pillar factor of safety (FOS) by considering both in-situ and estimated values. It is worth mentioning here that Salamon and Munro (1967) and Bieniawski (1981) initially recommended the factor of safety (FOS) approach to evaluate the stability of underground room-and-pillar mines. A close look at Table II shows that estimated stresses for pillars KH_25-26; KH_51-52, and WR-22 are an order of magnitude higher than expected. This is attributed to deviations from the designed mine plans, especially around the test locations or pillars selected for in-situ testing. Due to over-extraction of pillars (i.e increased width of crosscuts and high chambers) the resulting extraction ratios in respect of pillars KH_25-26; KH_51-52, and WR-22 are 73, 72%, and 73% respectively. This fact is also evident from the actual measured stress values (σ(Measured)) (Table II), which

remain in a closer range to the estimated stress values([σ(EST)) and demonstrate the accuracy of field measurements. Similarly, in the case of pillars KB_14 and WK_16 (Table II) the measured stress values (σ(Measured)) are somewhat higher in comparison to the estimated stress values (σ(EST)), which may be ascribed to the complex tectonosedimentary framework of the western Salt Range (Ghazi et al., 2015). Moreover, inclined chambers are forming ramps around the test pillar, incorporating ground stresses leading to higher in-situ stresses. Figure 11 shows the relationship (R2 = 0.93) between the in-situ stresses measured in the field and those estimated using Equation [4], where an increasing linear trend can be observed. The developed relationship (Figure 11) can be applied for the estimation of in-situ stress in rock salt pillars from empirically estimated stress values.

An attempt was also made to establish a possible correlation (Figure 12) between the FOS(Actual) and FOS(EST) and a power function of moderate strength (R2 = 0.96) was found. According to Jeremic (1994) FOS values of 1.0, 1.3, and 1.6 must be maintained for temporary, intermediate, and long-term underground roomand-pillar rock salt mines in order to carry out safe mining operations. The FOS(Actual) and FOS(EST) values determined in this

293 The Journal of the Southern African Institute of Mining and Metallurgy VOLUME 123 JUNE 2023

Project Test W L Wop Hop W/H ER OB σ(Measured) σ(EST) ST(EST) FOS(Actual) FOS(EST) E(Measured) ID (m) (m) (m) (m) (op) (%) (m) (MPa) (MPa) [Eq. 4] (MPa) [Eq. 3] (GPa) Khewra KH_25-26 10.50 45.00 10.50 8.20 1.28 73.00 139 11.23 10.81 28.71 2.56 2.66 0.68 KH_51-52 15.50 45.00 15.50 5.00 3.10 72.00 142 11.97 10.57 60.88 5.09 5.76 10.70 Warcha WR_22 10.00 31.00 13.00 7.33 1.77 73.00 65 7.53 5.18 46.87 6.22 9.05 1.63 Kalabhagh KB_14 11.66 16.00 8.00 7.00 1.14 66.20 52 6.05 3.25 64.26 10.62 19.77 1.21 WK_16 14.00 21.00 8.54 6.50 1.31 37.88 56 7.52 3.13 65.53 8.71 20.94 3.50

parameters of the selected rock salt projects

Table III

Project Test ID UCS (MPa) E(Lab) (GPa) BTS (MPa) Density (ρ) (kg/m3) Khewra KH_25-26 20.13 0.73 2.14 2143.99 KH_51-528 21.03 2.41 1.19 2130.10 Warcha WR_22 31.37 1.41 2.08 2161.01 Kalabhagh KB_14 36.99 0.97 2.37 2113.31 WK_16 30.75 1.51 2.81 2198.91

Figure 11—Correlation between in-situ and estimated pillar stresses

Stability evaluation of room-and-pillar rock salt mines by using a flat jack technique

work (Table II) are well above the recommended value of 1.6 for long-term underground mines, which indicates the stability of the layouts and allowance for pillar optimization, which will enable the extraction ratio to be increased without compromising stability.

Relationship between in-situ and static elastic modulus

Elastic modulus (Young’s modulus) is a fundamental property that represents the stiffness of a material, i.e. how the material deforms under applied load. In underground room-and-pillar mines it is an important design parameter which indicates the likelihood of pillar failure as well as providing an evaluation of the stability of the overall layout. In this work, the elastic moduli were determined both in the field and in the laboratory. Table II shows the in-situ modulus of elasticity (E(Measured)) measured for the selected projects, whereas Table III includes the static Young’s modulus (E(Lab)) measured in laboratory tests. A significant correlation (R2 = 0.95) was established between E(Measured) and E(Lab) (Figure 13). Since it is both costly and laborious to measure in-situ stress and elastic modulus, the developed conversion equation in Figure 13 can be utilized to estimate the in-situ modulus for underground roomand-pillar rock salt mines based on the laboratory-measured static Young’s modulus.

Correlation of in-situ stress with room width to height ratio and overburden height

In underground room-and-pillar mining layouts, the vertical stress on pillars (due to overburden material) is dependent on the width of rooms and pillars as well as height of rooms. The opening width to height ratio [W/H(op)] is an important parameter in studying the combined effect of these factors on the pillar stress (Hartman and Mutmansky, 2002). In the current work efforts have been made to establish a relationship between width to height ratio of the opening and actual or in-situ stress measured in the field. Figure 14 displays a linear positive correlation of moderate power (R2 = 0.41) illustrating the effect of increasing room span on pillar stress. The results are in full conformity with past investigations (Hartman and Mutmansky, 2002; Lau, 2010).

The effect of height of overburden material on in-situ pillar stress was also investigated. Room-and-pillar mining in a massive orebody like rock salt causes redistribution of the load, which results in an increase of stress concentration on the supporting pillars (Brady and Brown, 2005). A plot of overburden height (OB) against the actual in-situ stress measured in the pillar ribs for the selected mine sites yields a positive increasing trend with a high coefficient of determination (R2 = 0.96, Figure 15). The correlation so developed is specific to rock salt mines of the Salt Range, and

can be used for the estimation of in-situ pillar stress by using the overburden height.

Effect of pillar dimensions on mine stability

The influence of pillar dimensions on factor of safety (FOS) was investigated for the selected rock salt mines based on the average values of rock salt properties [σ(Measured), UCS] for the calculations of FOS included in Tables II and III. This pillar optimization analysis was performed by keeping the height of pillars the same as those in the actual field situations (3.65 m) and varying the width and length of pillars. In the case of rectangular pillars, equivalent pillar length was determined by using Equation [5] as suggested by Wagner 1974).

294 JUNE 2023 VOLUME 123 The Journal of the Southern African Institute of Mining and Metallurgy

[5]

Figure 12—Correlation between FOS(Actual) and FOS(EST)

Figure 13— Correlation of in-situ elastic modulus and laboratory Young’s modulus for selected rock salt projects

Figure 14 Correlation of in-situ stress with room width to height ratio (W/H(op))

Figure 15 Correlation of in-situ stress with overburden height (OB)

Stability evaluation of room-and-pillar rock salt mines by using a flat jack technique

Table IV

Example calculation of equivalent length and FOS for a fixed pillar width of 5 m and height of 3.65 m

where; WE = equivalent length, A = area of pillar, and C = perimeter of the pillar.

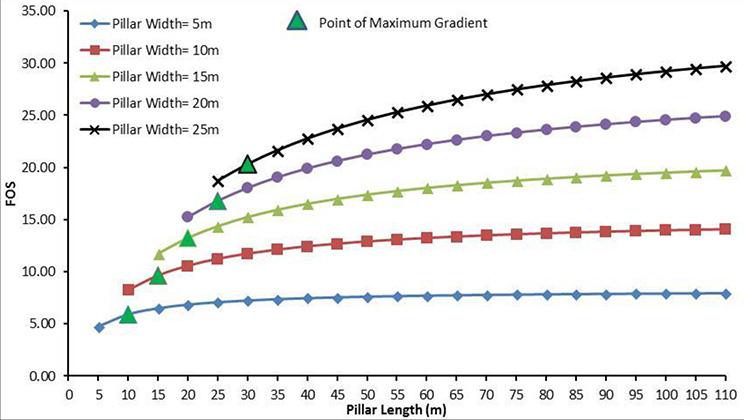

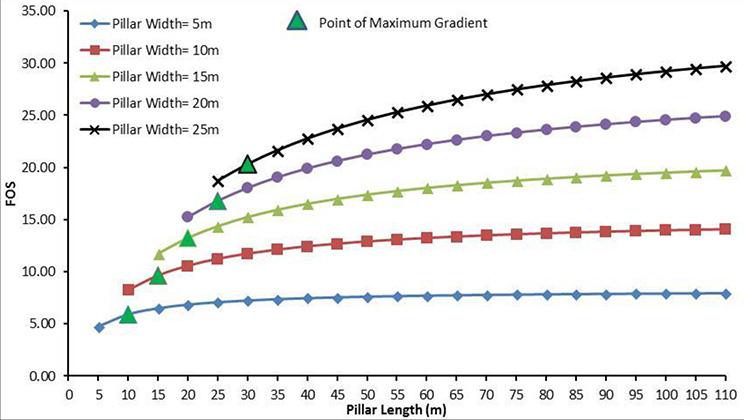

Table IV shows an example calculation for a pillar width fixed at 5 m and various pillar lengths from 5 m to 110 m. In a similar way, equivalent lengths and FOS calculations were performed for pillar widths of 10, 15, 20, and 25 m. Figure 16 shows the relationship between pillar effective length and FOS for selected pillar widths.

It is interesting to note from Figure 16 that initially the FOS increases with increasing in pillar length, but the influence on FOS becomes negligible when the length of pillar is increased beyond a certain limit. This limit is termed here the maximum effective length (MEL). It is evident from Figure 16 that a pillar length beyond MEL is responsible only for lowering the extraction ratio and sterilizing mineral resources. Similarly, optimum length (Figure 16) is that which falls at the point of maximum gradient on the FOS versus pillar length curves for the selected pillar widths and is the

most suitable length in terms of obtaining the maximum extraction ratio. Keeping these facts in view, the generic chart (Figure 16) can be used to determine the most efficient layout of rock salt pillars without compromising the extraction ratio and stability of the mine for a planned pillar width. As can be seen in Figure 16, a pillar of 5 m width should not be longer than 20 m in order to obtain maximum extraction and safety. All other layouts are conservative designs and can be amended for maximum extraction. The curves proposed in Figure 16 are applicable for rock salt mines in the Salt Range with similar rock and mine conditions.

In order to find the maximum effective length (MEL) of a pillar the percentage FOS difference (computed for each increment of 5 m in pillar length) is adopted by setting the cut-off value at 1.00. For example, in Table IV for a pillar width of 5 m, the values of pillar length and FOS at predetermined cut-off grade are 45 m and 7.54 respectively. In addition to the generic chart (Figure 16), a

295 The Journal of the Southern African Institute of Mining and Metallurgy VOLUME 123 JUNE 2023

Pillar width (m) Length (m) WE (m) W/H Strength (MPa) (Equation [3]) FOS % change in FOS 5.00 5.00 1.37 42.03 4.74 10.00 6.67 1.83 52.37 5.91 21.899 15.00 7.50 2.05 57.54 6.49 9.405 20.00 8.00 2.19 60.64 6.84 5.248 25.00 8.33 2.28 62.70 7.08 3.352 30.00 8.57 2.35 64.18 7.24 2.327 35.00 8.75 2.40 65.29 7.37 1.711 40.00 8.89 2.44 66.15 7.47 1.311 45.00 9.00 2.47 66.84 7.54 1.036 50.00 9.09 2.49 67.40 7.61 0.840 55.00 9.17 2.51 67.87 7.66 0.695 5.00 60.00 9.23 2.53 68.27 7.71 0.584 65.00 9.29 2.54 68.61 7.74 0.498 70.00 9.33 2.56 68.91 7.78 0.430 75.00 9.38 2.57 69.16 7.81 0.374 80.00 9.41 2.58 69.39 7.83 0.329 85.00 9.44 2.59 69.60 7.86 0.292 90.00 9.47 2.60 69.78 7.88 0.260 95.00 9.50 2.60 69.94 7.89 0.234 100.00 9.52 2.61 70.09 7.91 0.211 105.00 9.55 2.62 70.22 7.93 0.191 110.00 9.57 2.62 70.34 7.94 0.174

Figure 16— Relationship between FOS and effective pillar length

Stability evaluation of room-and-pillar rock salt mines by using a flat jack technique

Table V

Maximum effective length and FOS for selected pillar widths

and WK_16, Table II) were greater than the estimated stresses (σ(EST)) due to the complex regional tectonic setting of the western Salt Range and the development of ramps around the test pillar that impart lateral stresses.

➤ The actual and estimated values of FOS determined (Table II) for the three mines lie above the recommended value of 1.6, which indicates their long-term structural stability. Moreover, a strong linear correlation (R2 = 0.93, Figure 11) was established between the actual and estimated pillar stresses. Similarly, a power function correlation of moderate significance (R2 = 0.96) was also established (Figure 12) between the FOS(Actual) and FOS(EST).

➤ In view of the cost and laborious work involved in the determination of in-situ stress and elastic modulus, efforts have been made to suggest a correlation between E(Measured) and E(Lab). The application of this proposed relationship (R2 = 0.95, Figure 13) is specific for the estimation of the in-situ modulus for underground chamber-and-pillar rock salt mines based on the laboratory-measured static Young’s modulus.

regression equation is proposed to predict MEL based on the pillar width. Table V lists down the data values (FOS and maximum effective pillar length) corresponding to the cut-off value of 1.00 for the selected pillar widths of 5, 10, 15, 20, and 25 m. Figure 17 shows the regression plot and correlation between MEL and pillar width.

Conclusions

Pillar stability was investigated at three underground rock salt mining projects operated by Pakistan Mineral Development Corporation (PMDC) in the Salt Range of Punjab, Pakistan. The first part of this study comprised field work and included actual in-situ pillar stress (σ(Measured)) measurements conducted on suitable pillar locations using a flat jack, determination of in-situ modulus of elasticity (E(Measured)), and recording of mine geometry parameters. This data was further utilized to estimate empirically the pillar stress (σ(EST), Equation [4]). The second part of the study consisted of rock mechanics laboratory testing in order to estimate pillar strength (ST(EST), Equation [3]). The physico-mechanical properties of rock salt considered were uniaxial compression strength (UCS), Brazilian tensile strength (BTS), Young’s modulus [E(Lab)), and density (ρ). Finally, safety factors of pillars for both actual and estimated scenarios were calculated. The following conclusions can be drawn from the results.

➤ The pillar stabilities for the selected mines were checked based on pillar stress and pillar factor of safety (FOS) by considering both in-situ and estimated values. The in-situ pillar stresses (Table II) were found to be 11.60 MPa, 7.53 Mpa, and 6.78MPa at Khewra, Kalabagh, and Warcha salt mining projects respectively. The estimated stresses in the pillars at Khewra (KH_25-26; KH_51-52) and Warcha (WR-22) were somewhat higher than expected. This is mainly due to the deviations from the mine design and pillar robbing to increase the extraction ratios. The same result was reflected from field measurements (σ(Measured)) (Table II) having values close to the estimated stresses (σ(EST)). However, the measured stress values (σ(Measured)) at test pillars at Kalabagh mine (KB_14

➤ In order to demonstrate the effect of opening width to height ratio (W/H(op)) and overburden height (OB) on actual in-situ pillar stress in underground conditions, two linearly increasing correlations have been developed (Figures 14 and 15) that can be used for the estimation of in-situ pillar stress for the rock salt mines of Salt Range by employing the room width to height ratio and overburden height.

➤ In addition, the influence of pillar dimensions on FOS (pillar optimization analysis) was investigared for the selected mines by keeping the height of pillars the same as in the actual field situations (3.65 m) and varying the width and length. It was noticed that a greater pillar length does not contribute significantly to FOS beyond a certain length, termed the maximum effective length (MEL). Therefore, it is recommended to reduce pillar length to improve the extraction ratio without compromising mine stability. Finally a generic chart (Figure 16) was developed for different pillar widths from 5 m to 25 m to determine the effective length and FOS of rock salt pillars. Furthermore, a correlation (Figure 17) was also proposed to predict MEL based on pillar width. The generic chart so developed can be used to establish a suitable length of pillar for a given span and required level of safety.

➤ For future work it is recommended that three-dimensional geomechanical modelling and simulation be performed using the data from this research project in order to enhancethe recovery ratio of rock salt through optimization of pillar dimensions for the rock salt mines of the Salt Range, Punjab.

Funding information

This study was funded by the Higher Education Commission (HEC), Pakistan with Grant No.9545.

Acknowledgements

The authors would like to acknowledge the support provided by the management of Pakistan Mineral Development Corporation (PMDC) at their Khewra, Kalabagh, and Warcha salt mines. Especial appreciations goes to Engr. Rana Tanveer (Project Manager) and Engr. Umer Pervaiz (Assistant Manager) at PMDC Khewra Project, Engr. Irfan Chaudhry (Project Manager), Engr. Mohsin Aziz (Assistant Manager) and Engr. Shoaib (Assistant Manager) at PMDC Kalabagh Project and Engr. Malik Naeem (Project Manager), and Engr. Imran Khan at PMDC Warcha

296 JUNE 2023 VOLUME 123 The Journal of the Southern African Institute of Mining and Metallurgy

Figure 17—Correlation between MEL and pillar width

Pillar width (m) Maximum effective length (MEL) (m) FOS 5.00 45.00 7.54 10.00 65.00 13.38 15.00 80.00 18.93 20.00 90.00 24.15 25.00 105.00 29.51

Stability evaluation of room-and-pillar rock salt mines by using a flat jack technique

Project. Many thanks are also due to the Department of Mining Engineering, Faculty of Earth Sciences and Engineering, of University of Engineering and Technology (UET), Lahore, for facilitating this research work.

References

Armanasco, A. and Foppoli, D. 2020. A flat jacks’ method for in situ testing of brick masonry shear characteristics. Construction and Building Materials, vol. 262.119840.

Asrarullah, P. 1967. Geology of the Khewra Dome. Proceedings of 18th and 19th Combined Session of all Pakistan Science Conference Part III, Hyderabad, Pakistan.

ASTM D4729. 2008. Standard test method for in-situ stress and modulus of deformation using flatjack method. American Society for Testing and Materials. doi: 10.1520/D4729-08

ASTM D2113. 2014. Standard practice for rock core drilling and sampling of rock for site exploration. American Society for Testing and Materials. https:// standards.globalspec.com/std/ 9885092/ASTM D211.

ASTM D4543. 2008. Standard practices for preparing rock core as cylindrical test specimens and verifying conformance to dimensional and shape tolerances. American Society for Testing and Materials. https://www.astm.org/ DATABASE. CART/HISTORICAL/ D4543-08.htm

ASTM D7012. 2010. Standard test method for compressive strength and elastic moduli of intact rock core specimens under varying states of stress and temperatures. American Society for Testing and Materials. https://www.astm. org/DATABASE.CART/HISTORICAL/D7012-10.htm

ASTM D3967 2016. Standard test method for splitting tensile strength of intact rock core specimens. American Society for Testing and Materials. https://www.astm. org/Standards/D3967.htm

Baloch, M., Qureshi, A., Waheed, A., Ali, M., Ali, N., Tufail, M., and Khan, H 2012. A study on natural radioactivity in Khewra Salt Mines, Pakistan. Journal of Radiation Research, vol. 53, no. 3. pp. 411–421.

Bell, J.S. and Gough, D.I. 1979. Northeast-southwest compressive stress in Alberta evidence from oil wells. Earth and Planetary Sciences Letters, vol. 45, no. 2. pp. 475–482.

Bieniawski, Z.T. 1968. The effect of specimen size on compressive strength of coal. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, vol. 5, no. 4. pp.c325–335, doi: 10.1016/0148-9062(68)90004-1

Bieniawski, Z.T. 1981. Experience with in situ measuremment of deformability. Geophysical Research Letters, vol. 8, no. 7. pp. 675–677.

Binda, L. and Tiraboschi, C. 1999. Flat-Jack Test: A slightly destructive technique for the diagnosis of brick and stone masonry structures. International Journal for Restoration of Buildings and Monuments, vol. 5, no. 5. pp. 449–472.

Brady, B.H.G. and Brown, E.T. 2005 Rock Mechanics for Underground Mining.3ed edn. Springer, Dordrecht.

Brady, B. and Brown, E. 2007. Pillar supported mining methods. Rock Mechanics for Underground Mining. Springer, Dordrecht. https://doi.org/10.1007/978-14020-2116-9_13

Cescatti, E., Benetta, M.D., Modena, C., and Casarin, F. 2016. Analysis and evaluations of flat jack test on a wide existing masonry buildings sample. Proceedings of the 16th International Brick and Block Masonry Conference, Padova, Italy. Routledge. pp. 26–30.

Corkum, A.M.M.A.G. 2020 Experimental evaluation of rapid flat jack testing with various shaped saw cut slots. Rock Mechanics and Rock Engineering, vol. 53, no. 1. pp. 455–466.

Deng, J., Yue, Z., Tham, L., and Zhum, H.H. 2003. Pillar design by combining finite element methods, neural networks and reliability: A case study of the Feng Huangshan copper mine. China. International Journal of Rock Mechanics and Mining Sciences, vol. 40. pp. 585-599.

Dhawan, K.R. 2012. Flat jack method for measuring design parameters for hydraulic structures of the Koyna hydro-electric project in India. ISSMGE International Journal of Geo-engineering Case Histories, vol. 2, no. 3. pp. 182–195.

Eberhardt, E. and Stead, D. 2011. Geotechnical Instrumentation. Mining Engineering Handbook. 3rd edn, Darling, P. (ed.). Society for Mining, Metallurgy & Exploration, Littleton, CO. pp 551–571.

Fedele, R. and Maier, G. 2007. Flat-jack tests and inverse analysis for the identification of stress states and elastic properties in concrete dams. Meccanica, vol. 42, no. 4. pp. 387–402.

Figueiredo, B., Lamas, L., and Muralha, J. 2010. Determination of in situ stresses using large flat jack tests. Proceedings of the 6th Asian Rock Mech.Symposium - Advances in Rock Engineering, New Delhi, India,, 23-27 October 2010. doi: 10.13140/2.1.3118.9762

Figueiredo, B., Lamas, L., and Muralha, J. 2011. Numerical simulation of a large flat jack test with cyclic loading. Proceedings of the 6th International Conference on Dam Engineering, Lisbon, Portugal, 15-17 February. Pina, C., Portela, E., and Gomes, J. (eds). CI-Premier, Singapore. http://repositorio.lnec.pt:8080/ jspui/h,andle/123456789/1002718

Feng, Y., Harrison, J.P., and Bozorgzadeh, N. 2020. A Bayesian approach for uncertainty quantification in overcoring stress estimation. Rock Mechanics and Rock Engineering, vol. 54, no. 2. pp. 627–645. doi: 10.1007/S00603-020-02295W

Gee, E.R. 1945. The age of the Saline Series of the Punjab and of Kohat. National Academy of Sciences, India, Section B, vol. 14. pp. 269-310.

Ghazi, S., Ali, S.H., Sahraeyan, M., and Hanif. T. 2014. An overview of tectonosedimentary framework of the Salt Range, northwestern Himalayan fold and thrust belt, Pakistan. Arabian Journal of Geoscience. doi: 10.1007/s12517014-1284-3

Goodman, R.E. 1989. Introduction to Rock Mechanics. 2nd edn. Wiley & Sons.

Gregorczyk, P. and Lourenço, P.B. 2000. A review on flat-jack testing. Revista Engenharia Civil, vol. 9. pp. 39-50. https://citeseerx.ist.psu.edu/ document?repid=rep1&type=pdf&doi=093cbc7d06f40d24b02fc849eb50cb14c78629a5

Hartman, H.L. and Mutmansky, J.M. 2002. Introductory Mining Engineering. 2nd edn. Wiley.

He, B.G. and Hatzor, Y.H. 2015. An analytical solution for recovering the complete in-situ stress tensor fpp. rom flat jack tests. International Journal of Rock Mechanics and Mining Sciences, vol. 100, no. 78. pp. 118–126.

Hedley, D.G.F. and Grant, F. 1972. Stope-and-pillar design for Elliot Lake Uranium Mines. CIM Bulletin, vol. 65. pp. 37–44.

Hoek, E., Kaiser, P.K., and Bawden, W.F. 1995. Support of Underground Excavations in Hard Rock. Balkema, Rotterdam, 215 pp.

Hoek, E. and Brown, E.T. 2005. Underground Excavations in Rock. Revised 1st edn. Taylor & Francis.

ISRM. 1986. Suggested method for deformability determination using a large flat jack technique. vol. 23, no. 2. pp. 133–140.

Jeremic, M.L. 1994 Rock Mechanics in Salt Mining. Ist edn. CRC Press. 544 pp.

Jumikis, A.R. 1983. Rock Mechanics. 2nd edn. Vol. 7. Trans Tech.

Khan, S. and Shah, M.M. 2019. Multiphase dolomitization in the Jutana Formation (Cambrian), Salt Range (Pakistan): Evidences from field observations, microscopic studies and isotopic analysis. Geologica Acta, vol. 17. pp. 1–18.

Krauland, N. and Soder, P. 1987. Determining pillar strength from pillar failure observation. Engineering and Mining Journal, vol. 8. pp. 34–40.

Łątka, D. and Matysek, P. 2017. The estimation of compressive stress level in brick masonry using the flat-jack method. Procedia Engineering, vol. 193. pp. 266–272.

297 The Journal of the Southern African Institute of Mining and Metallurgy VOLUME 123 JUNE 2023

Stability evaluation of room-and-pillar rock salt mines by using a flat jack technique

Lamas, L., Muralha, J., and Figueiredo, B. 2010. Application of Global Interpretation Model for Assessment of the Stress Field for Engineering Purposes. Taylor and Francis, London.

Lin, H., Oh, J., Masoumi, H., Canbulat, I., and Zhang, C. 2018. A review of insitu stress measurement techniques. Proceedings of the Coal Operators Conference 2018. Australasian Institute of Mining and Metallurgy, Melbourne. pp 95–102.

Medeiros, W.A., Soriani, M. de O., and Parsekian, G.A. 2020. Innovation in flat-jack application to evaluate modern high-strength hollow concrete block masonry. Construction and Building Materials, vol. 255. 119341. doi: 10.1016/J. CONBUILDMAT.2020.119341

Mendola, L.L., Giudice, E.L., and Minafo, G. 2019. Experimental calibration of flat jacks for in-situ testing of masonry. International Journal of Architectural Heritage: Conservation, Analysis and Restoration, vol. 13, no. 5. pp. 619–629.

Mines and Minerals Department, Government of The Punjab. 2020. Mineral production 2019-20. https://mnm.punjab.gov.pk/system/files/2019-20

Obert, L. and Duvall, W.I. 1967. Rock Mechanics and the Design of Structures in Rock. Wiley.

Rios, A.J. and O’Dwyer, D. 2020. Adaptations of the flat jack test for its application in cob walls. MethodsX. doi:10.1016/j.mex.2020.101003

Sabri, M.M., Ulybin, A.V., and Zubkov, S.V. 2015. A review on different destructive methods to determine the compressive strength of an existing masonry. International Journal of Engineering Research and Development, vol. 11, no. 4. pp. 19–26.

Salamon, M.D.G. and Munro, A.H. 1967. A study of the strength of coal pillars. Journal of the Southern African Institute of Mining and Metallurgy, vol. 68. pp. 55–67.

Sebastiani, M., Johanns, K.E., Herbert, E.G., and Pharr, G.M. 2015. Measurement of fracture toughness by nanoindentation methods: Recent advances and future challenges. Current Opinion in Solid State and Materials Science, vol. 19, no. 6. pp. 324–333. doi: 10.1016/J.COSSMS.2015.04.003