OFFICE BEARERS AND COUNCIL FOR THE 2024/2025 SESSION

Honorary President

N. Tsengwa

President, Minerals Council South Africa

Honorary Vice Presidents

Gwede Mantashe

Minister of Mineral Resources and Energy, South Africa

P. Tau

Minister of Trade, Industry and Competition, South Africa

Blade Nzimande

Minister of Higher Education, Science and Technology, South Africa

President E. Matinde

President Elect

G.R. Lane

Senior Vice President

T.M. Mmola

Junior Vice President

M.H. Solomon

Incoming Junior Vice President

S.J. Ntsoelengoe

Immediate Past President

W.C. Joughin

Honorary Treasurer

W.C. Joughin

Ordinary Members on Council

W. Broodryk

Z. Fakhraei

B. Genc

K.M. Letsoalo

S.B. Madolo

M.A. Mello

K. Mosebi

Co-opted Council Members

A.D. Coetzee

L.T. Masutha

M.C. Munroe

S.M. Naik

G. Njowa

S.M. Rupprecht

A.T. van Zyl

E.J. Walls

Past Presidents Serving on Council

N.A. Barcza C. Musingwini

R.D. Beck S. Ndlovu

Z. Botha J.L. Porter

V.G. Duke M.H. Rogers

I.J. Geldenhuys G.L. Smith

R.T. Jones

G.R. Lane – TP Mining Chairperson

Z. Botha – TP Metallurgy Chairperson

K.W. Banda – YPC Chairperson

C.T. Chijara – YPC Vice Chairperson

Branch Chairpersons

Botswana K. Mosebi

DRC K.T. Kekana (Interim Chairperson)

Johannesburg N. Rampersad

Limpopo M.S. Zulu

Namibia T. Aipanda

Northern Cape Vacant

North West Vacant

Pretoria P.G.H. Pistorius

Western Cape Vacant

Zambia N.M. Kazembe

Zimbabwe L. Shamu

Zululand Vacant

*Deceased

* W. Bettel (1894–1895)

* A.F. Crosse (1895–1896)

* W.R. Feldtmann (1896–1897)

* C. Butters (1897–1898)

* J. Loevy (1898–1899)

* J.R. Williams (1899–1903)

* S.H. Pearce (1903–1904)

* W.A. Caldecott (1904–1905)

* W. Cullen (1905–1906)

* E.H. Johnson (1906–1907)

* J. Yates (1907–1908)

* R.G. Bevington (1908–1909)

* A. McA. Johnston (1909–1910)

* J. Moir (1910–1911)

* C.B. Saner (1911–1912)

* W.R. Dowling (1912–1913)

* A. Richardson (1913–1914)

* G.H. Stanley (1914–1915)

* J.E. Thomas (1915–1916)

* J.A. Wilkinson (1916–1917)

* G. Hildick-Smith (1917–1918)

* H.S. Meyer (1918–1919)

* J. Gray (1919–1920)

* J. Chilton (1920–1921)

* F. Wartenweiler (1921–1922)

* G.A. Watermeyer (1922–1923)

* F.W. Watson (1923–1924)

* C.J. Gray (1924–1925)

* H.A. White (1925–1926)

* H.R. Adam (1926–1927)

* Sir Robert Kotze (1927–1928)

* J.A. Woodburn (1928–1929)

* H. Pirow (1929–1930)

* J. Henderson (1930–1931)

* A. King (1931–1932)

* V. Nimmo-Dewar (1932–1933)

* P.N. Lategan (1933–1934)

* E.C. Ranson (1934–1935)

* R .A. Flugge-De-Smidt (1935–1936)

* T.K. Prentice (1936–1937)

* R.S.G. Stokes (1937–1938)

* P.E. Hall (1938–1939)

* E.H.A. Joseph (1939–1940)

* J.H. Dobson (1940–1941)

* Theo Meyer (1941–1942)

* John V. Muller (1942–1943)

* C. Biccard Jeppe (1943–1944)

* P.J. Louis Bok (1944–1945)

* J.T. McIntyre (1945–1946)

* M. Falcon (1946–1947)

* A. Clemens (1947–1948)

* F.G. Hill (1948–1949)

* O.A.E. Jackson (1949–1950)

* W.E. Gooday (1950–1951)

* C.J. Irving (1951–1952)

* D.D. Stitt (1952–1953)

* M.C.G. Meyer (1953–1954)

* L.A. Bushell (1954–1955)

* H. Britten (1955–1956)

* Wm. Bleloch (1956–1957)

* H. Simon (1957–1958)

* M. Barcza (1958–1959)

* R.J. Adamson (1959–1960)

* W.S. Findlay (1960–1961)

* D.G. Maxwell (1961–1962)

* J. de V. Lambrechts (1962–1963)

* J.F. Reid (1963–1964)

* D.M. Jamieson (1964–1965)

* H.E. Cross (1965–1966)

* D. Gordon Jones (1966–1967)

* P. Lambooy (1967–1968)

* R.C.J. Goode (1968–1969)

* J.K.E. Douglas (1969–1970)

* V.C. Robinson (1970–1971)

* D.D. Howat (1971–1972)

* J.P. Hugo (1972–1973)

* P.W.J. van Rensburg (1973–1974)

* R.P. Plewman (1974–1975)

* R.E. Robinson (1975–1976)

* M.D.G. Salamon (1976–1977)

* P.A. Von Wielligh (1977–1978)

* M.G. Atmore (1978–1979)

* D.A. Viljoen (1979–1980)

* P.R. Jochens (1980–1981)

* G.Y. Nisbet (1981–1982)

A.N. Brown (1982–1983)

* R.P. King (1983–1984)

J.D. Austin (1984–1985)

* H.E. James (1985–1986)

H. Wagner (1986–1987)

* B.C. Alberts (1987–1988)

* C.E. Fivaz (1988–1989)

* O.K.H. Steffen (1989–1990)

* H.G. Mosenthal (1990–1991)

R.D. Beck (1991–1992)

* J.P. Hoffman (1992–1993)

* H. Scott-Russell (1993–1994)

J.A. Cruise (1994–1995)

D.A.J. Ross-Watt (1995–1996)

N.A. Barcza (1996–1997)

* R.P. Mohring (1997–1998)

J.R. Dixon (1998–1999)

M.H. Rogers (1999–2000)

L.A. Cramer (2000–2001)

* A.A.B. Douglas (2001–2002)

* S.J. Ramokgopa (2002-2003)

T.R. Stacey (2003–2004)

F.M.G. Egerton (2004–2005)

W.H. van Niekerk (2005–2006)

R.P.H. Willis (2006–2007)

R.G.B. Pickering (2007–2008)

A.M. Garbers-Craig (2008–2009)

J.C. Ngoma (2009–2010)

G.V.R. Landman (2010–2011)

J.N. van der Merwe (2011–2012)

G.L. Smith (2012–2013)

M. Dworzanowski (2013–2014)

J.L. Porter (2014–2015)

R.T. Jones (2015–2016)

C. Musingwini (2016–2017)

S. Ndlovu (2017–2018)

A.S. Macfarlane (2018–2019)

M.I. Mthenjane (2019–2020)

V.G. Duke (2020–2021)

I.J. Geldenhuys (2021–2022)

Z. Botha (2022-2023)

W.C. Joughin (2023-2024)

Editorial Board

S.O. Bada

R.D. Beck

P. den Hoed

I.M. Dikgwatlhe

M. Erwee

B. Genc

R Hassanalizadeh

R.T. Jones

W.C. Joughin

A.J. Kinghorn

D.E.P. Klenam

D.F. Malan

D. Morris

C. Musingwini

S. Ndlovu

P.N. Neingo

A. Nengovhela

S.S. Nyoni

M. Phasha

P. Pistorius

P. Radcliffe

N. Rampersad

Q.G. Reynolds

I. Robinson

S.M. Rupprecht

K.C. Sole

T.R. Stacey

D. Vogt

F. Uahengo

International Advisory Board members

R. Dimitrakopolous

R. Mitra

A.J.S. Spearing

E. Topal

D. Tudor

Editor /Chairperson of the Editorial Board

R.M.S. Falcon

Typeset and Published by

The Southern African Institute of Mining and Metallurgy

PostNet Suite #212 Private Bag X31

Saxonwold, 2132

E-mail: journal@saimm.co.za

Printed by Camera Press, Johannesburg

Advertising Representative

Barbara Spence

Avenue Advertising

Journal Comment: Special Edition of the Southern African Rare Earths Conference 2024 by E. Matinde

President’s Corner: Critical raw materials result in substantive technological and economic catch-up for the global south: Setting the scene for a deeper Socratic dialogue by E.

Matinde

THE INSTITUTE, AS A BODY, IS NOT RESPONSIBLE FOR THE STATEMENTS AND OPINIONS ADVANCED IN ANY OF ITS PUBLICATIONS.

Copyright© 2024 by The Southern African Institute of Mining and Metallurgy. All rights reserved. Multiple copying of the contents of this publication or parts thereof without permission is in breach of copyright, but permission is hereby given for the copying of titles and abstracts of papers and names of authors. Permission to copy illustrations and short extracts from the text of individual contributions is usually given upon written application to the Institute, provided that the source (and where appropriate, the copyright) is acknowledged. Apart from any fair dealing for the purposes of review or criticism under The Copyright Act no. 98, 1978, Section 12, of the Republic of South Africa, a single copy of an article may be supplied by a library for the purposes of research or private study. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means without the prior permission of the publishers. Multiple copying of the contents of the publication without permission is always illegal. U.S. Copyright Law applicable to users In the U.S.A. The appearance of the statement of copyright at the bottom of the first page of an article appearing in this journal indicates that the copyright holder consents to the making of copies of the article for personal or internal use. This consent is given on condition that the copier pays the stated fee for each copy of a paper beyond that permitted by Section 107 or 108 of the U.S. Copyright Law. The fee is to be paid through the Copyright Clearance Center, Inc., Operations Center, P.O. Box 765, Schenectady, New York 12301, U.S.A. This consent does not extend to other kinds of copying, such as copying for general distribution, for advertising or promotional purposes, for creating new collective works, or for resale.

Honorary Legal Advisers

M H Attorneys Auditors

Genesis Chartered Accountants Secretaries

The Southern African Institute of Mining and Metallurgy 7th Floor, Rosebank Towers, 19 Biermann Avenue, Rosebank, 2196

PostNet Suite #212, Private Bag X31, Saxonwold, 2132 E-mail: journal@saimm.co.za

Telephone (011) 463-7940 . E-mail: barbara@avenue.co.za ISSN 2225-6253 (print) . ISSN 2411-9717 (online)

Rare Earth Extraction with Ionquest® 801 initial modelling development by C.F. Carrozza, F. Dutoy, and M.B. Stella 555

This study explored approaches to rare earth element extraction using IONQUEST® 801 and it integrated predictive modelling to enhance process understanding and optimization. A screening test to evaluate the best extraction efficiency was conducted. The data obtained were used to develop empirical and mechanistic models to predict rare earth extraction yields and flowsheets. The experimental results demonstrated the effectiveness of the proposed extraction methods, highlighting improvements in both yield and selectivity.

An assessment of Rare Earth Elements in borehole cores from the Ermelo, Witbank and Waterberg Coalfields, South Africa: Focus on mode of occurrence by D.G. Modiba and N.J. Wagner

This project aimed to determine the concentration of REE, including yttrium and scandium (REY+Sc) in various coal seams and adjacent sediments in borehole cores from the Ermelo, Witbank, and Waterberg coalfields in South Africa. The ICP-MS results following SCEP indicated that both coal and the associated sediments were light REY+Sc dominant. The Waterberg samples had the lowest REY+Sc from both the coal and associated sediments. MLA determined that monazite and xenotime in all the coal samples were the REY+Sc-bearing mineral.

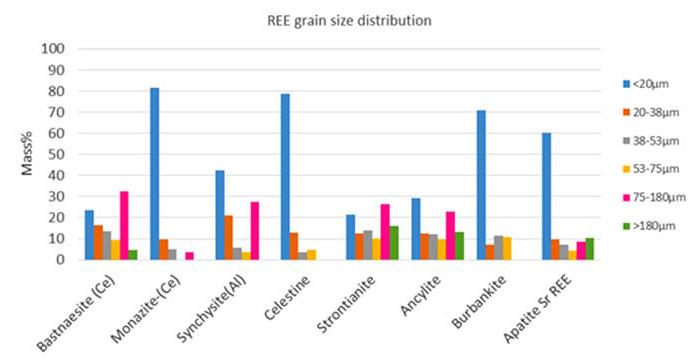

Development of a physical separation pre-concentration process for the extraction of Rare Earth bearing ore by T. Mokgomola, G. Marape, A. Singh, and K. Bisaka

This paper investigated the pre-concentration amenability of sovite (carbonatite) ore to enhance the grade of rare earth elements (REE) bearing minerals by rejecting calcite, and to improve total rare earth elements (TREE) recovery using gravity and magnetic separation. Mineralogy liberation data at 2 mm top size indicated poor liberation of TREE. Grain size distribution data showed that the majority of REE minerals are fine grained and report to the <20 µm size class. A combination of a single-stage shaking table with a wet high intensity magnetic separator at a magnetic intensity of 7520 Gauss was found to be the optimum flowsheet. Due to the fine-grained nature of TREE, no flowsheet improved their grade.

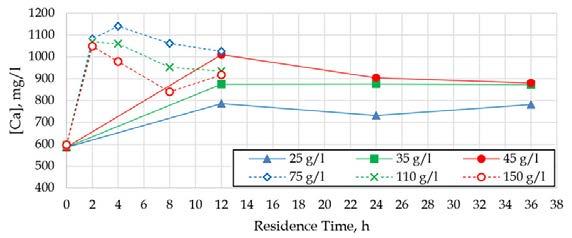

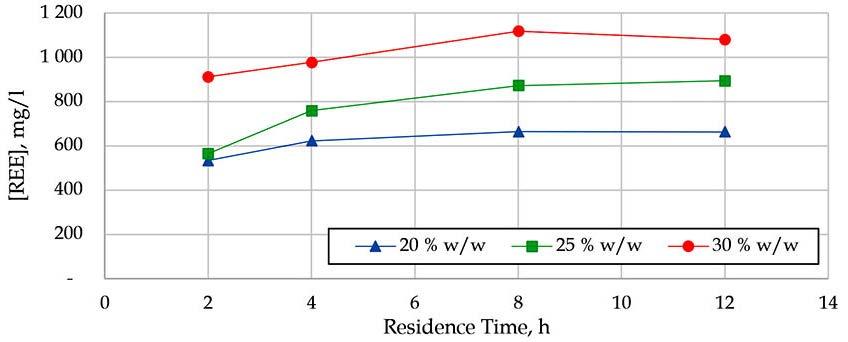

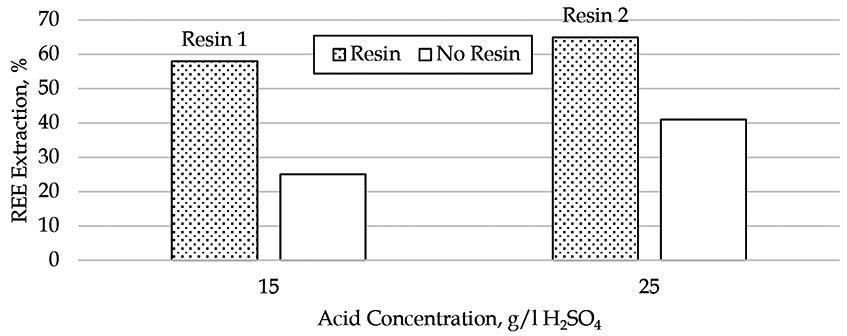

Extraction of Rare Earth Elements from Phalaborwa phosphogypsum by R.A. Wildenboer and R.F. Sandenbergh

This paper presents the results of investigations into the leaching behaviour of rare earth elements and other impurities from phosphogypsum using aqueous sulfuric acid. The effects of acid concentration, temperature, residence time, and the influence of impurities were evaluated for their impact on the solubility of rare earth elements in a sulfate medium. It was found that a significant fraction of the REE can be leached from the phosphogypsum in a range of conditions much less severe than traditional hard rock rare earth processing conditions.

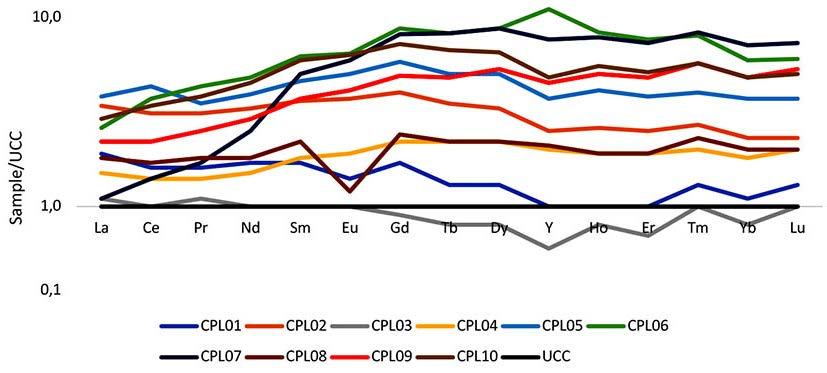

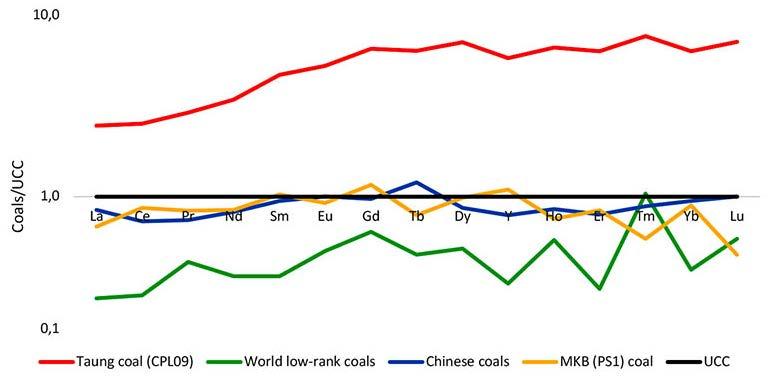

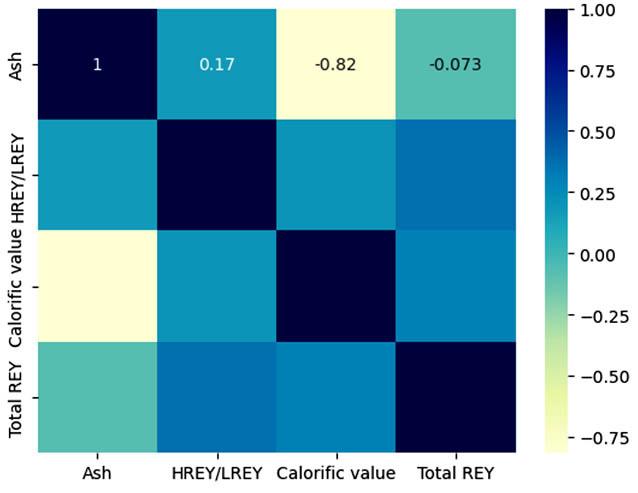

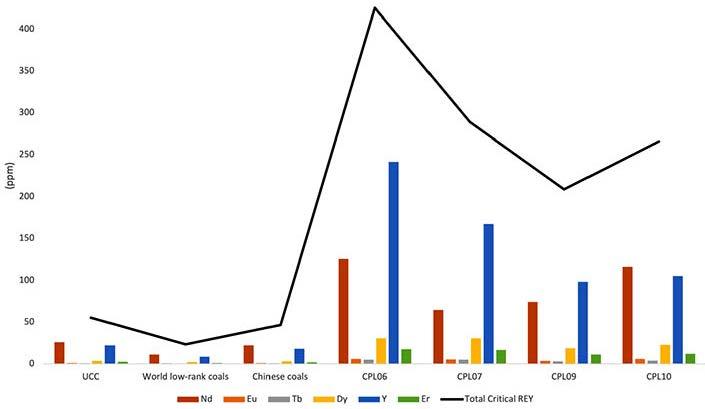

Rare Earth Elements enrichment in Triassic coals deposits and associated argillaceous rocks in Lesotho by S. Hlajoane and L.S. Mokhahlane

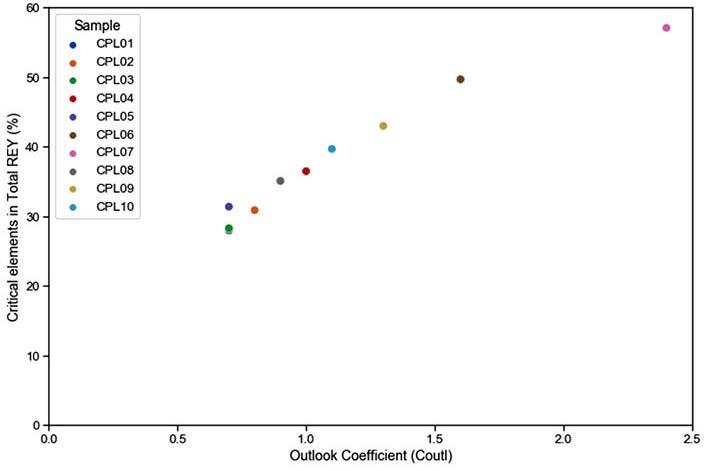

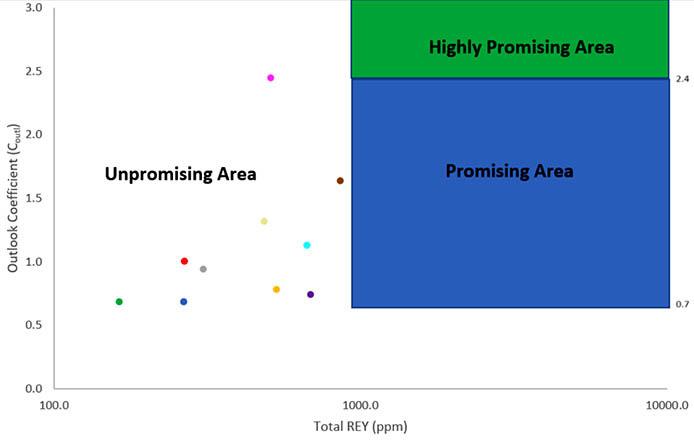

This study aims to characterize and evaluate the potential of rare earth elements and yttrium in the Taung coal deposit, southwest of Lesotho. Coal and associated argillaceous samples from the Taung coal deposit were analysed using microscopic petrography and an inductively coupled plasma mass spectrometry. The average critical rare earth elements and yttrium concentration of samples from the Taung coal deposit is 189.4 ppm, which is three times higher than that of the Chinese Bayan Obo deposit. Samples classified as very promising and promising because of their outlook coefficients, are found to contain up to 77% of critical rare earth elements and yttrium. It is envisioned that the area could be a prime deposit for these rare earth elements and yttrium.

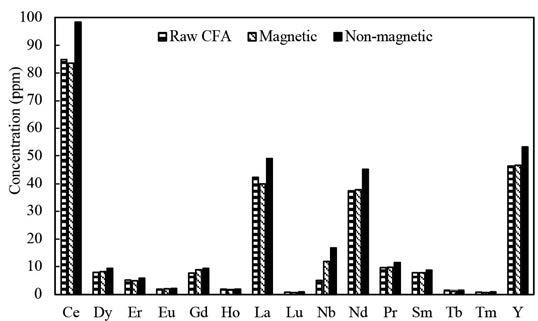

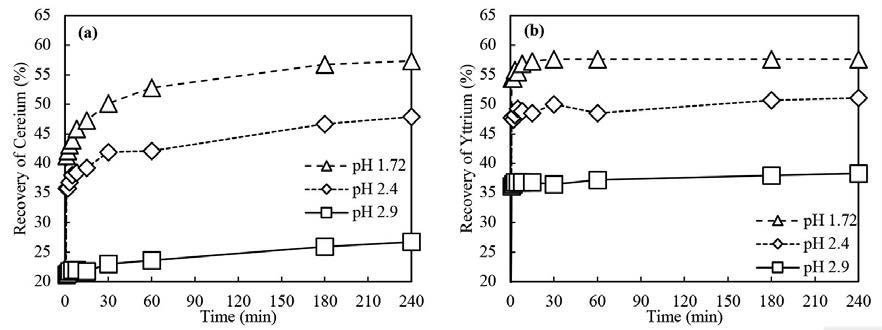

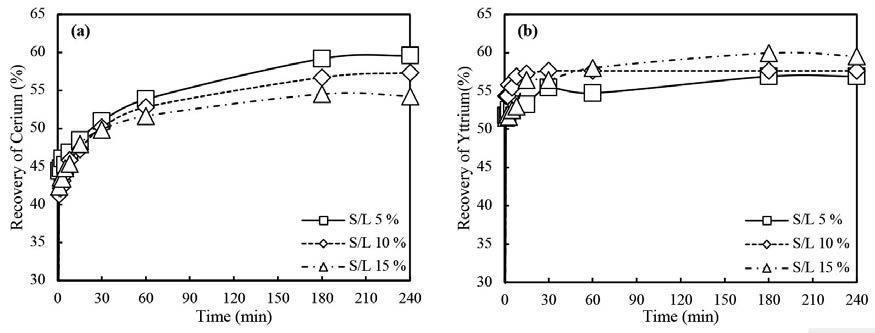

Leaching characteristics of cerium and yttrium from non-magnetic coal fly ash after silicate digestion using acetic acid by H. Manurung, I.M. Bendiayasa, F. Anggara, K.C. Wanta, W. Astuti, and H.T.B.M. Petrus

The leaching kinetics of cerium (Ce) and yttrium (Y) in sodium-hydroxide-digested non-magnetic coal fly ash using acetic acid were investigated. The variables analysed were pH, solid-to-liquid ratio (S/L), and temperature. The results show that cerium and yttrium’s maximum recovery was 57.33% and 58.36%, respectively. The kinetic leaching models of cerium and yttrium all fit Dickinson’s new shrinking core model. The calculation results show that the leaching reaction is controlled by combining interface transfer and diffusion across the product layer.

567

575

583

595

Rare earths elements (REE), often dubbed the ‘vitamins driving the 21st century industrial epoch and clean energy transitions’, have been a subject of debate and are at the centre of the geopolitical and supply-side tensions between China and the West. With everyone scrambling for de-risk of their supply chains, the attention is now increasingly being focused on seeking alternative sources of these critical raw materials. This is where Southern Africa, as a geopolitically neutral region rich in these irreplaceable raw materials, comes in to ensure the sustainable supply of the critical raw materials needed to drive the clean energy transition.

Although the Institute is historically known for its acumen for organizing thought provoking and interesting conferences, nothing would have prepared any reader for the perfect timing to release the special October edition. The special edition of the Journal is unique in that it showcases the Institute’s contribution to the global conundrum on the debate about these critical and strategic raw materials. This special edition contains seven papers that were selected from the 2nd International Conference on Southern African Rare Earths 2024 held in Swakopmund, Namibia. With the theme ‘Global Impact and Sustainable Supply’, the conference focused on fostering dialogue, leveraging on global diversity and innovation in the rare earths sector. The selected papers enhance an understanding of the occurrence and extraction of these vital elements from both conventional, and non-conventional resources, ranging from exploration and geology, characterization and concentration, right up to leaching behaviour, extraction, and recovery from solutions. The diverse nature and scope of the topical issues discussed in the papers included in this special edition highlights both the challenges and opportunities in harnessing the feasibility and economies of scale associated with the recovery of REEs from such complex, and low-grade resources.

E. Matinde President, SAIMM

TCritical raw materials result in substantive technological and economic catch-up for the global south: Setting the scene for a deeper Socratic dialogue

he debate on sustainable economic development is increasingly focused on the widescale deployment of carbon neutral energy sources to drive the future energy systems. Renewable energy technologies such as hydropower, solar, wind, geothermal, fuel cells and bioenergy, among others, are indispensable to mitigating the impact of anthropogenic global warming while concurrently addressing the energy poverty faced by many countries in the global south. The transition to clean energy generation and storage systems is metal and mineral intensive and will require a substantive but sustainable supply of many of these critical metals and minerals. For example, metals and minerals such as lithium (Li), nickel (Ni), cobalt (Co), manganese (Mn), and graphite are irreplaceable in battery energy storage systems while rare earth metals are critical in the manufacture of high-performance magnets needed for wind turbines and electric vehicles. Likewise, industrial metals such as aluminium (Al) and copper (Cu) are irreplaceable in electricity generation and distribution systems. According to the International Energy Association (2021), electric vehicles require approximately 53 kg Cu, 9 kg Li, 40 kg, 25 kg Mn, 13k g Co, and 66 kg graphite per vehicle, compared to 22 kg Cu and 11 kg Mn in conventional vehicles. In the Minerals for Climate Action report (Hund et al. 2020) compiled by the World Bank Group, it is estimated that the production of critical raw materials (CRMs), such as graphite, lithium and cobalt, will increase by 500% by 2050 to meet the growing demand for clean energy technologies. This giganteum increase in demand in CRMs will create unprecedent opportunities for industrialization to resource-rich countries through exports and localization of value-added manufacturing activities.

Similar to a lot of other countries in the global south, Southern African states are either least developed or middle-income countries with ambitions to escape the poverty trap and catch up with more advanced economies. Contrary to these long-held ambitions to upgrade their economies, the GDP for most countries in sub-Saharan Africa has contracted over a protracted period of time and continue to face unprecedented challenges in transitioning from an economy driven by the exports of low value mineral commodities to manufacturing and knowledge driven economies. Being high value and high impact, clean energy technologies naturally present windows of opportunity for technological and economic upgrading to resource-rich countries such as South Africa. Although often associated with high risk and a high degree of uncertainty, clean energy technologies are characterized by high radical novelty, fast growth, and relatively high economic impact, with significant potential in creating new industries and/or transforming existing ones (Rotolo et al. 2015). There is indisputable evidence that, if managed properly, emerging technologies can indeed result in sustained technological and economic growth, and ultimately, lead to economic catch-up by the countries in the global south.

Economic scholars define ‘catch-up’ as a process by which a developing country narrows the income gap (‘economic catch-up’) and increases its technological capabilities (‘technological catch-up’) relative to frontier countries (Lee, 2013; Lee, 2019). When combined, technological and economic catch-up thus refers to the ability of a developing economy to grow faster compared to frontier economies and eventually reaching similar levels of technological capabilities and per capita income. Thus, in order to reduce the technological and income gaps relative to frontier economies, developing economies must attain and sustain both technological capabilities and income growth more rapidly than the advanced economies. Technological catch-up, which itself is a function of the specific technological strategies adopted as part of the growth strategy, logically precedes economic catch-up. Although ‘technological catch-up’ and ‘economic catch-up’ are not identical, they are closely related to each other in such a way that technological catch-up precedes or leads to market or economic catch-up (Lee, 2013).

Two main models have been proposed to explain catch-up trajectories, namely, path-following (also known as flying geese) catch-up, and leapfrogging catch-up, with the latter form occurring following a stage-skipping or path-creating strategy (Lee, 2013; Lee, 2019). The path following catch-up is a linear and cumulative process whereby the latecomer follows the same technological trajectories taken by frontrunners. In this case, the latecomer moves along the same path, but faster by taking advantage of historical factors such as the maturity, declining costs, and ubiquity of technologies and technical knowledge (Lee, 2013). The leapfrogging model is more complex and occurs when a latecomer bypasses traditional stages of development to either jump directly to the latest technologies (stage-skipping) or explore an alternative path of technological development involving emerging technologies with new benefits and opportunities (path-creating) (Lee, 2019; Yayboke et al. 2020). This form of catch-up often occurs when technologies are shifting towards new technological trajectories, which allow the latecomers to reduce the technological gaps by skipping the older generations to adopt the next generation and cost-efficient technologies. This may, however, depend on a number of factors, such as market availability, cost of next generation of technologies, and/or the willingness of incumbents to share their proprietary technologies (Lee, 2013; Lee, 2019; Yayboke et al. 2020).

Regardless of the leapfrogging model adopted, the ability to catch up is dependent on the windows of opportunity arising from the emergence of new technoeconomic paradigms (Perez and Soete, 1988; Lee and Malerba, 2017). The emergence of radically new technologies, for example, offers latecomers the window of opportunity to leapfrog the incumbents whose technological capabilities and investments are locked into older technologies, limiting their agility to mitigate against the destructive potential of new technologies and products. In contrast, latecomers are able to leapfrog older technologies, bypass sunk investments in previous technology systems, and adapt new and emerging technologies to assume control of markets and thus outcompete the incumbents (Lee and Malerba, 2017). Shorter cycle technologies also present windows of opportunity to latecomers by reducing reliance on old and existing knowledge bases characteristic of longer cycle, often capital-intensive technologies, often dominated by incumbents (Lee, 2013). Complimentary to emerging and shorter cycle technologies, radical changes in demand conditions, business cycles, and/or abrupt changes in markets, such as those presented by the clean energy transition, also increase the ability of agile latecomers to enter new markets, catch up, and leapfrog the incumbents (Lee and Malerba, 2017). The success to catch-up by leapfrogging also depends on the regulatory and institutional framework. Most importantly, deliberate government policies through strategic mission-oriented industrial policies and R&D programs can shape the rate of innovations and accumulation of technological capabilities by domestic firms (Mazzucato, 2018).

Obviously, the ability to catch up is not a free ride, but rather, depends on a number of deliberate efforts and strategic interventions. The answer to sustained catch-up and growth lies in the ability to build technological capabilities, which in this context, can be defined as the ability to effectively assimilate, use new and existing knowledge to create new technologies, products and processes, and to acquire and commercially exploit new knowledge and skills (Lee, 2013). Purposive efforts to build technological capabilities at macroscale can thus significantly increase the national absorptive capacity to assimilate technologies and knowledge developed by frontier economies (Kinoshita, 2000). Although the importance of national absorptive capacity in technology transfer is widely accepted, very few case studies are available to demonstrate its linkage to sustained technological and economic upgrading in most resource-based economies.

To conclude, the vast majority of literature and policy statements clearly articulate the high technological and economic importance of critical raw materials to the clean energy transition. Most notably, the emerging discourse on net zero transition has mostly focused on the critical roles of resource-rich countries from the global south derisking supply chains for these critical raw materials, which in my view, would only function to exacerbate the current ‘pit to port extractivist’ strategies being employed by most developing economies. In my mind, there is no doubt that the clean energy transition presents windows of opportunity for technological upgrading and industrialization through localization of value-added manufacturing activities. These issues definitely warrant further debate, and it is prudent to explore the macro-level linkages and challenges, and most importantly, the potential industrial policy tools available to increase the localization of manufacturing capabilities by resource-rich countries.

References

Hund, K., La Porta, D., Fabregas, T.P., Laing, T., Drexhage J. 2020. Minerals for Climate Action: The Mineral Intensity of the Clean Energy Transition. The World Bank. https://pubdocs.worldbank.org/ en/961711588875536384/Minerals-for-Climate-Action-The-Mineral-Intensity-of-the-Clean-Energy-Transition.pdf

International Energy Association. 2021. The Role of Critical Minerals in Clean Energy Transition. https://www.iea. org/reports/the-role-of-critical-minerals-in-clean-energy-transitions/executive-summary

Kinoshita, Y. 2000. R&D and technology spillovers via FDI: Innovation and absorptive capacity. CERGE-EI Working Paper Series No. 163. https://papers.ssrn.com/sol3/papers.cfm?abstract_id=258194

Lee, K. 2013. Schumpeterian analysis of economic catch-up: Knowledge, path-creation, and the middle-income trap. Cambridge University Press, UK, pp 3-37.

Lee, K., Malerba, F. 2017. Catch-up cycles and changes in industrial leadership: Windows of opportunity and responses of firms and countries in the evolution of sectoral systems. Research Policy, vol. 46, no. 2, pp. 338-351.

Lee, K. 2019. The economics of technological leapfrogging. UNIDO Department of Policy Research and Statistics Working Paper Series WP 17/2019, United Nations Industrial Development Organisation. https://papers.ssrn.com/ sol3/papers.cfm?abstract_id=3549420

Mazzucato, M. 2018. Mission-oriented innovation policies: Challenges and opportunities. Industrial and Corporate Change, vol. 27, no.5, pp. 803-815.

Perez, C., Soete, L. 1988. Catching up in technology: entry barriers and windows of opportunity. Dosi, G., Freeman, C., Nelson, R., Silverberg, G. & Soete, L. (Editors), Technical Change and Economic Theory, Pinter Publishers, London, pp 458-479.

Rotolo, D., Hicks, D., Martin B.R. 2015. What is an emerging technology? Research Policy vol. 44, no. 10, pp. 1827-1843.

Yayboke, E., Crumpler, W., Carter, W.A. 2020. The promise of leapfrogging. Center for Strategic and International Studies https://www.csis.org/analysis/need-leapfrog-strategy

E.Matinde President, SAIMM

Affiliation:

1Italmatch Chemicals Spa, Italy

2Italmatch Belgium Sprl, Belgium

Correspondence to: C.F. Carrozza

Email: c.carrozza@italmatch.com

Dates:

Received: 29 May 2024

Published: October 2024

How to cite:

Carrozza, C.F., Dutoy, F., Stella, M.B. 2024. Rare Earth Extraction with Ionquest® 801 initial modelling development. Journal of the Southern African Institute of Mining and Metallurgy, vol. 124, no.10 pp. 555–558

DOI ID:

http://dx.doi.org/10.17159/24119717/689/2024

ORCID:

C.F. Carrozza http://orcid.org/ 0000-0002-4692-3332

This paper is based on a presentation given at the Southern African Rare Earths 2nd International Conference 2024, 19-20 June 2024, Swakopmund Hotel and Entertainment Centre, Swakopmund, Namibia

by C.F. Carrozza1, F. Dutoy2, and M.B. Stella1

Abstract

Rare earth elements (REEs) are indispensable components in the manufacturing of high-tech devices, renewable energy technologies, and defence applications. As global demand for these elements continues to rise, there is a pressing need to optimize extraction processes for both efficiency and environmental sustainability. This study explores approaches to rare earth extraction using Ionquest® 801 and integrates a predictive modelling to enhance process understanding and optimization.

We conducted a screening test varying pH process to evaluate the best extraction efficiency. Starting pregnant leach solution (PLS), solution was prepared in the lab with the following rare earth elements: La, Ce, Gd, Dy, and Υ, at 0.02 M for each element. The data obtained were used to develop empirical and mechanistic models to predict rare earth extraction yields and flowsheet. Further tests were performed by mixing specific concentrations of different extractant and/ or phase modifier. Our experimental results demonstrated the effectiveness of the proposed extraction methods, highlighting improvements in both yield and selectivity. The developed models successfully captured the complex relationships between process parameters and extraction efficiency, providing valuable insights for process optimization.

Keywords rare earth elements, phosphinic acid-SX, distribution ratio, modeling development

Introduction

Rare earth elements (REEs) constitute a family of 15 elements crucial for various high-tech applications, including wind turbines, electric motors, catalysts, and batteries. The surge in REE prices in 2010, triggered by China's decision to reduce exports, underscored the need for countries to secure their own REE supplies. As a result, there has been a growing interest in exploiting REE resources domestically and through recycling.

The majority of REE production comes from mining ore bodies, where the elements are clustered in minerals like bastnasite and monazite. Extracting REE from these ores requires separating and precipitating them into individual rare earths, a process typically accomplished through solvent extraction (SX) in mixersettlers.

Unlike the more commonly used SX processes for metals like copper or uranium, REE extraction poses unique challenges due to the chemical similarities among the elements and the need for extensive separation steps. While conventional SX circuits may involve fewer than 10 units, REE separation circuits can require over 1 000 mixer-settlers, making piloting and plant design exceptionally complex.

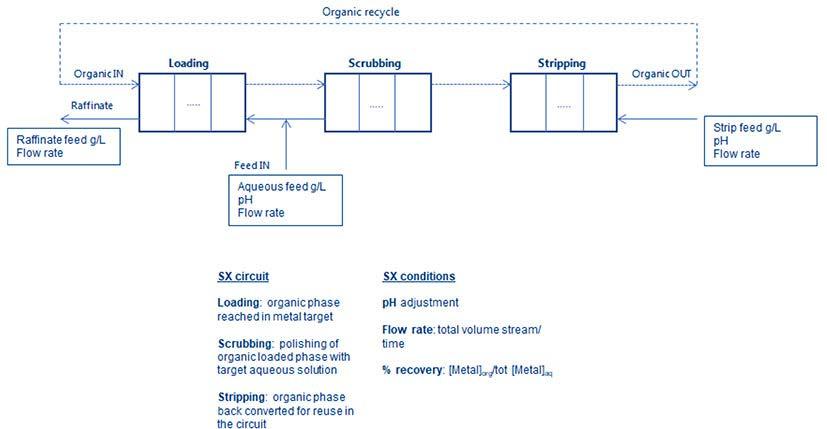

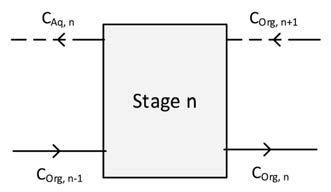

For a common multi-component feed, the process configuration consists of sequentially arranged units, each of them well defined by specific inputs e.g., composition in g/L, pH, and mass balance between inlet and outlet. The outcomes should be able to solve the requirements of stage extraction efficiencies, considering all the experimental variables. The complexity of the system increases from bench to pilot scale and as a result, the output profile requires a large data set for obtaining an accurate representation. In addition, this challenge is directly linked to the optimization of design flowsheet, especially for industrial applications (Figure 1).

To improve the description of the extraction performances related to different scenarios, the experimental data need to be coupled with computing strategy. The simpler idea is starting from equilibrium parameters collected during the lab screening as input to develop a steady state model. The

equilibrium concentrations of the target REE are calculated under fixed conditions of temperature and pH. Those data are used to construct a curve fitting based on distribution ratio, this being the best choice to estimate the mass transfer between the phases and evaluate how the extraction profile is affected by pH.

The next level consists of extending this approach on a countercurrent separation model to include the description of multi-stage extraction. The D-ratios can be included in a set of equations, which define the mass balance for each REE in the mixer unit. The goal is to calculate the metal amount in every stage by setting some known parameters, such as the total number of stages, the organic and aqueous flow rate, and the selected equilibrium pH. This approach works under the assumption that the steady-state variables are reasonable for a good representation of reactions that rapidly proceed, not including kinetic or interfacial phenomenon.

A mid/heavy REE solution was chosen to evaluate Ionquest® 801 performance: 2-ethylhexyl phosphonic acid mono-2-ethylhexyl ester and 0.3 M in aliphatic diluent ESCAID 110 provided by Exxon Mobil. The primary purpose was to find the operating conditions in terms of pH, as REE recovery occurs at remarkable acidic range. The pregnant leach solution (PLS, Table I) was prepared in HCl media (0.02 M REE as chloride). The aqueous and organic phases were kept in contact at room temperature under magnetic stirring for 15 min. HCl 20% wt and NaOH 13% wt were used for pH adjustment. Ratio A/O was 1 for all the lab work. The Ionquest® 801 profile was compared published data obtained from commercial phosphonic acid-SX.

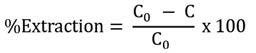

The metal ion concentration was determined by ICP-OES. The extraction efficiency can be calculated according to Equation [1]:

The distribution ratio and the separation factor are introduced to evaluate and quantify the performance of extractant. For the metals A and B, they are respectively expressed as Equations [2] and [3]:

Results

Solvent extraction results

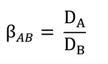

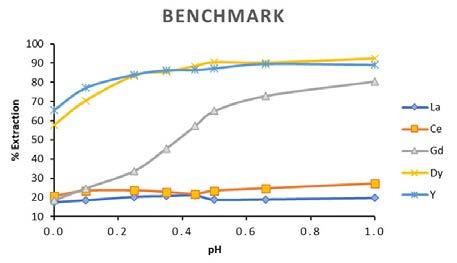

The plots in Figure 2 exhibit a good trend of extraction for Ionquest® 801. As expected for Dy and Υ, the percentage of extraction is high already at low pH. For Gd the recovery gradually increases as pH increases. The light REE grouping La and Ce needs less acidic conditions to overcome the issue of co-extraction of other rare earth elements, but Ionquest® 801 can achieve far better results when compared with those obtained from a commercial phosphonic acid reagent, as demonstrated in Figure 3.

The good trend is evident when distribution ratios are calculated for each REE. Three values of pH are selected to achieve a description of extraction capability. As depicted in Figures 4 and 5, the Ionquest® 801 distributions are more efficient for Gd, Dy, and Υ when compared with commercial phosphonic acid extractants. Typically, it implies a high extractability of metal ions from the aqueous phase, in addition to separation factors (β) that reflect how selectively metal can be extracted. In Table II separation factors are listed for Ionquest® 801 and a commercial phosphonic

acid extractant. ionquest® 801 shows a remarkable selectivity for the heavy REE (Gd, Dy, Υ) at the investigated pH interval. For La and Ce Ionquest® 801 offers the same separation performances as commercial extractant but increases the percentage of extraction under the same conditions.

The distribution ratios that were experimentally determined were used to validate the fitting curves resulting from the simulations. The approach was to functionalize empirical correlations with parameters known to affect equilibrium distribution. An intuitive strategy is proposed in the Equations [4] and [5]: D-ratios can be expressed as a function of pH and then predicted from a polynomial fitting. Note that the polynomial grade is directly related to stoichiometric coefficients of proton in the equilibrium reaction and, consequently, to ionic state of metal in the aqueous phase.

5—Distribution ratio experimentally calculated for commercial phosphonic acid SX at three different pH values (0.00, 0.33, 1.00)

A programming tool was developed to estimate how the extraction profile was affected by pH. The objective was to fit the experimental D-ratio by minimizing the sum of the squares of the deviations of the data from the model (least-squares fit). The results are demonstrated in Table III. The correlations reveal a good agreement between the two data sets for the selected range of pH.

Separation factors experimentally calculated for Ionquest® 801 (left side) and a commercial phosphonic acid (right side) at three different pH values (0.00, 0.33, 1.00)

pH 0.00

pH 0.35

801

801

phosphonic acid

The threshold for the error estimation is below 5%, but some small discrepancies can be corrected by changing the grade of polynomial fitting. In other words, the model provides a good representation of which are the best conditions to achieve a target REE extraction.

Future development

The next challenge is to successfully implement the D-ratio model into a model for a counter-current extraction flowsheet. The first step consists of including the experimental data in the species mass balance equations (Equation [6] and [7]). In accordance with mass transfer, as schematized in Figure 6, the objective is determining the REE composition at stage n for each unit as present in the entire flowsheet.

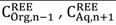

The programming key will be simultaneously solving a set of equations to achieve the organic and aqueous metal profile in terms of percentage of extraction (Figure 7). Inlet and outlet flow are characterized by some input parameters, such as flow rates, volumetric ratios, and pH of the feed (See Table IV).

Acknowledegements

This work, in particular related to the modelling development, is supported by the IPCEI Eu-Batin project. We thank all people included for their hard work and collaboration.

References

Aguilar, M., Cortina, J.S. 2008 eds. Solvent extraction and liquid membranes: Fundamentals and applications in new materials CRC Press.

Iloeje, C.O. 2020. Modeling Liquid–Liquid Extraction for Critical Elements Separations: An Overview Multidisciplinary Advances

III

Figure 6—Mass balance diagram illustration for a single unit in a currentcurrent extraction process

Table IV

Parameters set up for counter-current simulation flowsheet

Input

Output

Experiment pH feed Distribution ratio for batch scale

Model

PLS composition Efficiency for single stage

Distribution ratio for (mass balance) flowsheet process

Flow rate Efficiency for n stages

in Efficient Separation Processes. ACS Symposium Series American Chemical Society. pp 335–365.

Lyon, K.L., Utgikar, V.P., Greenhalgh, M.R. 2017. Dynamic Modeling for the Separation of Rare Earth Elements Using Solvent Extraction: Predicting Separation Performance Using Laboratory Equilibrium Data Industrial & Engineering Chemistry Research.,vol. 56, no. 4, pp. 1048–1056 American Chemical Society.

Omelchuk, K., Chagnes, A. 2018. New cationic exchangers for the recovery of cobalt (II), nickel (II) and manganese (II) from acidic chloride solutions: Modelling of extraction curves. Hydrometallurgy vol. 180, pp. 96–103. u

Laboratory data and model predictions for REE distribution with Ionquest® 801

Affiliation:

1University of the Witwatersrand, South Africa

2DSI-NRF CIMERA, University of Johannesburg, South Africa

Correspondence to: D.G. Modiba

Email: Duduzile.Modiba@wits.ac.za

Dates:

Received: 29 May 2024

Accepted: 12 Jun. 2024

Published: October 2024

How to cite:

Modiba, D.G. and Wagner, N.J.

2024. An assessment of Rare Earth Elements in borehole cores from the Ermelo, Witbank and Waterberg Coalfields, South Africa: Focus on mode of cccurrence. Journal of the Southern African Institute of Mining and Metallurgy, vol. 124, no.10, pp. 559–566

DOI ID:

http://dx.doi.org/10.17159/24119717/692/2024

ORCID:

D.G. Modiba

http://orcid.org/0000-0002-2135-0769

N.J. Wagner

http://orcid.org/0000-0002-4046-4788

This paper is based on a presentation given at the Southern African Rare Earths 2nd International Conference 2024, 19-20 June 2024, Swakopmund Hotel and Entertainment Centre, Swakopmund, Namibia

by D.G. Modiba1,2 and N.J. Wagner2

Abstract

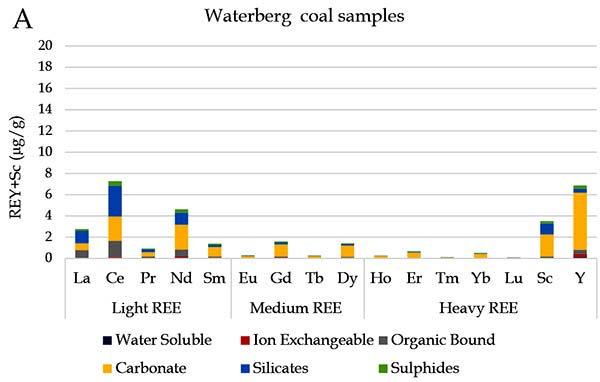

There is currently limited knowledge concerning South African coal deposits as hosts for rare earth elements (REE). This project aims to determine the concentration of REE, including yttrium and scandium (REY+Sc) in various coal seams and adjacent sediments in borehole cores from the Ermelo, Witbank, and Waterberg coalfields in South Africa. Coal petrography (maceral count and vitrinite reflectance), XRD, XRF, sequential chemical extraction procedure (SCEP) before ICPMS, and mineral liberation analysis (MLA) were conducted on the coal and associated sediment samples. The coals were inertinite-rich, medium-rank bituminous coal, with moderate to high ash content. The two dominant minerals in all the coalfields are kaolinite and quartz, except for sample ZBS2M, where dolomite was dominant. The dominant major oxides are Al2O3, SiO2, Fe2O3, and CaO, which concur with the XRD results. The ICP-MS results following SCEP indicated that both coal and the associated sediments were light REY+Sc dominant. There was also an elevation of medium REY+Sc in the Witbank coal’s associated sediment samples. Notably, the samples with the highest REY+Sc results were the sediment samples. The Waterberg samples had the lowest REY+Sc from both the coal (less than 2 µg/g to 7 µg/g) and associated sediments (2 µg/g to 15 µg/g). While the highest REY+Sc was yielded from the Witbank-associated sediments (500 µg/g to 2,500 µg/g). The carbonate fraction step proved to be the most successful leaching step, as most REY+Sc was recovered in that step for all coalfields. In addition to the carbonate fraction, the silicates and sulfide fraction in the Witbank samples, and the ion-exchangeable fraction for the Waterbergassociated sediments samples proved successful in leaching out the REY+Sc. MLA determined that monazite and xenotime in all the coal samples were the REY+Sc-bearing minerals.

Keywords REY+Sc, coal, South Africa, sequential chemical extraction procedure, ICP-MS

Introduction

There is an increase in the demand for critical elements such as lithium and rare earth elements globally with the advent of the fourth industrial revolution, green energy, and the need to reduce global greenhouse gas emissions (Bauer et al., 2022; Dai and Finkelman, 2018; Hower et al., 2018). Rare earth elements (REE) Sc, Y, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, and Yb, including yttrium and scandium (REY+Sc), are relatively abundant in the upper continental crust, despite being referred to as rare, which is a misnomer. The challenge is the separation of the elements from each other. According to the International Union for Pure and Applied Chemistry (IUPAC), the REE are 17 elements found on the periodic table, comprising 15 elements in the lanthanide group, plus two transitions metal elements, namely yttrium and scandium, collectively referred to as REY+Sc for the purpose of this paper.

According to Zhou et al. (2017), there are 178 REY+Sc deposits globally and as of the year 2017, they were reported to amount to 478Mt REY+Sc, either from primary or secondary sources. Balaram (2019) further elaborated that the primary sources of REY+Sc are from magmatic, hydrothermal, and metamorphic processes, while the secondary source is from weathering and erosion of the primary sources. The global demand has led to a need to broaden extraction from both primary mineable ore deposits, and to expand extraction from alternative, non-conventional sources, such as coal and combustion ash (Dai and Finkelman, 2018; Seredin and Dai, 2012). The increased interest in investigating REY+Sc in coal bears its challenges, such as gaining a clear understanding of the element’s host minerals and potential extraction techniques.

To determine the best technique for REY+Sc extraction in coal, there needs to be an understanding of the modes of occurrence in which these elements occur. Internationally, many studies have been dedicated to this topic, including work conducted by Arnold (2023), Balaram (2019), Borzykowski (2019), Dai et al.

(2004), Dai et al. (2017), Fu et al. (2022), Hower et al. (2018), Li et al. (2008), Li et al. (2023), Serendin and Dai (2012), and Yang et al. (2023). These studies proposed that REY+Sc may be associated with either the organic or inorganic component of coal material. A stronger organic association is mainly observed in low-rank coals. REY+Sc may be associated with the inorganic i.e., mineral fractions of coal in authigenic and clastic minerals, for example, in phosphate minerals such as monazite and xenotime, carbonate minerals like bastnaesite, and accessory minerals such as zircon and apatite (Arnold, 2023; Bauer et al., 2022; Seredin and Dai, 2012). There are two classifications of REY+Sc associated with coal, according to Seredin and Dai (2012). In the first classification, the elements are classified geochemically into Light REE (La, Ce, Pr, Nd, Pm, Sm), Medium REE (Eu, Gd, Tb, Dy), and Heavy REE (Ho, Er, Tm, Tb, Lu). The second classification is based on their market or economic importance and is classified into whether they are critical (Nd, Eu, Tb, Dy, Y, Er), not critical (La, Pr, Sm, Gd), or excessive (Ce, Ho, Tb, Yb, Lu).

Despite the traction globally, there is limited knowledge regarding REY+Sc in South African coals. Wagner and Matiane (2018) focused on coal and coal ash from 3 power stations EterighoIkelegbe et al. (2021) reviewed the enrichment and mode of occurrence of REY+Sc in coal and coal discards. Mokoena et al. (2022) investigated the effects of acid concentration on the recovery of REE from coal fly ash. More recently, Chitlango et al. (2023) reported on REE in density-fractionated coal samples from the Waterberg coalfield. The knowledge gap in South Africa brought about the inception of the current research, intending to determine the concentration of REY+ Sc in a variety of South African coals and their associated sediments in borehole cores from the Ermelo, Witbank, and Waterberg coalfields. In this paper, we discuss coal characterization and the sequential analytical technique used for leaching, prior to the inductively coupled plasma mass spectrometry

Table I

Coal sample names per coalfield

Coalfield Sample name

Ermelo UNI2 A, UNI2 B, UNI2 C, UNI2 D, UNI2 E, UNI2 F, UNI2 G,UNI2 H, UNI2 I, UNI2 J, UNI2 K, UNI2 L, UNI2 M, UNI2 N, UNI2 O

Witbank ZBSDR1, ZBS5T, ZBS5M, ZBS5B, ZBSHF1,ZBSDR2, ZBS4T, ZBS4M, ZBS4B, ZBSYF1, ZBSDR3, ZBS3, ZBSYF2, ZBSDR4, ZBS2Y, ZBS2M, ZBS2B, ZBDIF

Waterberg 12A, 11A, 10A, 9B, 8A, 8B, 8H, 8J, 8K, 7B, 6A,5A,4A, 4B, 3A, 3B, 3C, 2A,2B

(ICP-MS) analysis to determine the association and concentration of REY+Sc in coal and associated sediment samples

Methodology

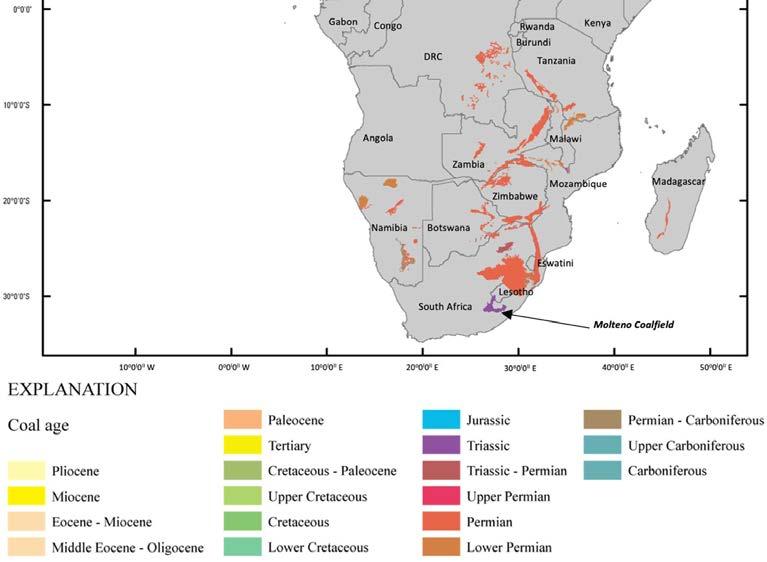

Sample collection

The Ermelo and Witbank coalfields are situated within the Mpumalanga province, over 200 km and 130 km east of Johannesburg, respectively. The Waterberg coalfield is in the Limpopo province, 297 km north of Johannesburg (Figure 1). We logged full borehole cores from the study areas and sampled both coal and lithologies found immediately above and below the coal seams. We obtained fifteen, eighteen and twenty coal and associated sediment samples from the Ermelo, Witbank, and Waterberg cores, respectively (Table I).

Sample preparation and characterization

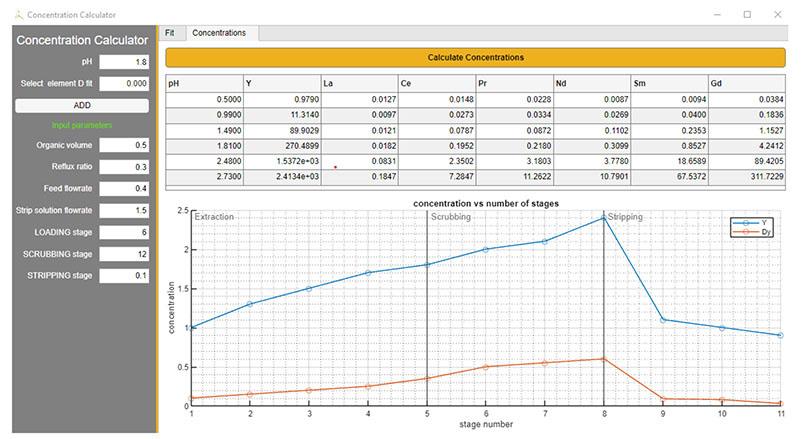

All coal samples and associated sediments were crushed and milled at the University of Johannesburg (UJ), using the Retsch ZM200

ultra-centrifugal mill to achieve homogenous -1 mm samples. A riffler was used to split each sample into three sub-samples. Sub-sample one (-1 mm) was retained for petrography. Coal petrographic analysis is based on 500-point counts per sample, categorizing the components observed as either vitrinite, liptinite, inertinite, or one of five mineral groups (i.e., clay, quartz, sulfides, carbonates, and other minerals). This is based on the South African National Standard/International Organization for Standardization (SANS/ ISO) 7404-3 (2016).

Sub-sample 2 was milled to -212 μm for X-ray diffraction (XRD), X-ray fluorescence (XRF), proximate and total sulfur analyses. The proximate analysis was conducted following SANS/ ISO standard number 17246 (2011). The mineral content was determined using XRD and the bulk chemistry (as major element oxides) in the samples were determined using whole rock analysis by XRF. Sub-sample 3 was further milled, using a pestle and mortar, and passing a screen of 106 µm in preparation for the sequential chemical extraction procedure (SCEP), a chemical leaching process, prior to inductively coupled lasma mass spectrometry (ICP-MS) analysis. All the coal samples used in the SCEP and subsequently analysed using ICP-MS are fresh coal samples. Samples with the highest REY+Sc values, following ICP-MS analysis, were resampled and ashed for further analysis using elemental mapping measurement mode on the mineral liberation analyser (MLA).

X-ray diffraction analysis

XRD analysis was outsourced to XRD Analytical and Consulting, Pretoria, South Africa. Samples were prepared for XRD analysis using a backloading preparation method. Diffractograms were obtained using a Malvern Panalytical Aeris diffractometer with a PIXcel detector and fixed slits with Fe-filtered Co-Kα radiation. The phases were identified using X’Pert Highscore Plus software. The Rietveld refinement method estimated the relative phase amounts (weight %).

Whole rock geochemistry - X-ray Fluorescence (XRF)

XRF analysis was outsourced to Bureau Veritas Testing and Inspection South Africa, Centurion, South Africa. A 0.7 g of a pulverized sample was added to 7.0 g of 66:33 LiT, LiM (LiI) flux and fused using a Claisse M4 fusion instrument. The resulting fusion discs were measured on a PANalytical Epsilon 3-XL EDXRF spectrometer equipped with a 50 kW 3mA Ag-tube, 10 sample carousel, He-purge chamber, and silicon drift detector.

Sequential chemical extraction procedures (SCEP) and ICP-MS

SCEP was conducted at UJ, Spectra labs. This procedure has been adapted from Dai et al. (2004). SCEP entails the chemical leaching of samples by different lixiviants. One sample is leached in six steps depending on which lixiviant is used. The steps are watersoluble, ion-exchangeable, carbonates, organically bound, silicates, and sulfides. Each sample derived from the respective step is analysed in the ICP-MS to determine the REY+Sc concentration. A PerkinElmer NexION 300X ICP-MS, housed at UJ was used for element determination in the coal and associated rock samples. Mineral liberation analysis (MLA)

For MLA analysis, coal samples with the highest REY+Sc content were selected from each coalfield (UNI2M, ZBS2B, and 11A). The sample preparation for MLA was outsourced to SJT MetMin Services, South Africa. These samples were ashed at 450⁰C for eight hours, to remove all volatile matter, and then mounted in

30 mm diameter epoxy resin blocks and cured. The prepared resin blocks were analysed at the Spectrum MLA laboratory, UJ. A scanning electron microscope FEI QUANTA 650 FEG instrument was operated under a vacuum to ensure no interactions with air particles occurred. A back-scattered electron detector (BSE) was used at 25 kilovolts so that the elemental contrast could be used to locate the rare earth-containing carriers of interest. The BSE images were captured using MLA processing software. The results presented in this paper indicate which minerals host the respective REY+Sc. The results are presented as BSE images with their respective spectral plots.

General characterization

The coal samples consist mainly of coaly-shales, dull-banded coal, and bright coal. The associated sediments are mainly clastic material consisting of carbonaceous shale, mudstone, sandstone, siltstone, and diamictite. All coal samples have moderate to high ash content. Samples from the Witbank coalfield have the highest average volatile matter of 25%. All samples have low sulfur content, the highest value is from the Witbank coalfields, sample ZBS4T, with 5.9% sulfur content.

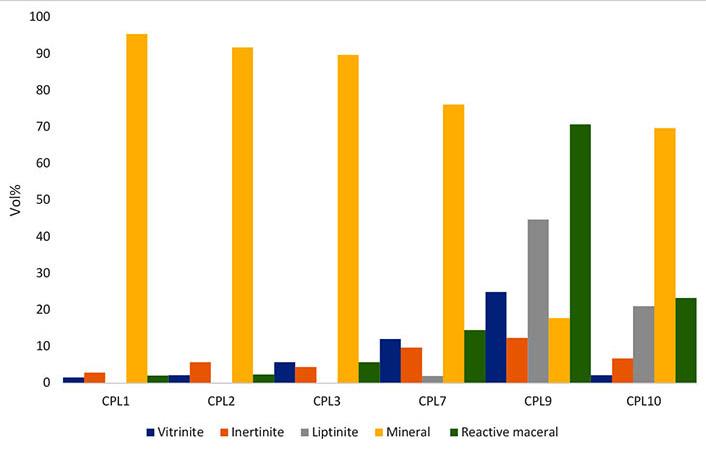

Petrographic results are shown in Figure 2 and Figure 3. Ermelo coal samples are classified as high inertinite, medium-rank D/C bituminous coal, while the Witbank and Waterberg coal samples are also high inertinite, medium-rank C bituminous coal. The dominant minerals, according to the petrographic analysis, are clay, quartz, calcite, and pyrite. These results agree with studies conducted by Mahooana (2022), Moroeng et al. (2024), and Wagner and Matiane (2018). Figure 3 illustrates the presence of calcite and clay in photomicrographs.

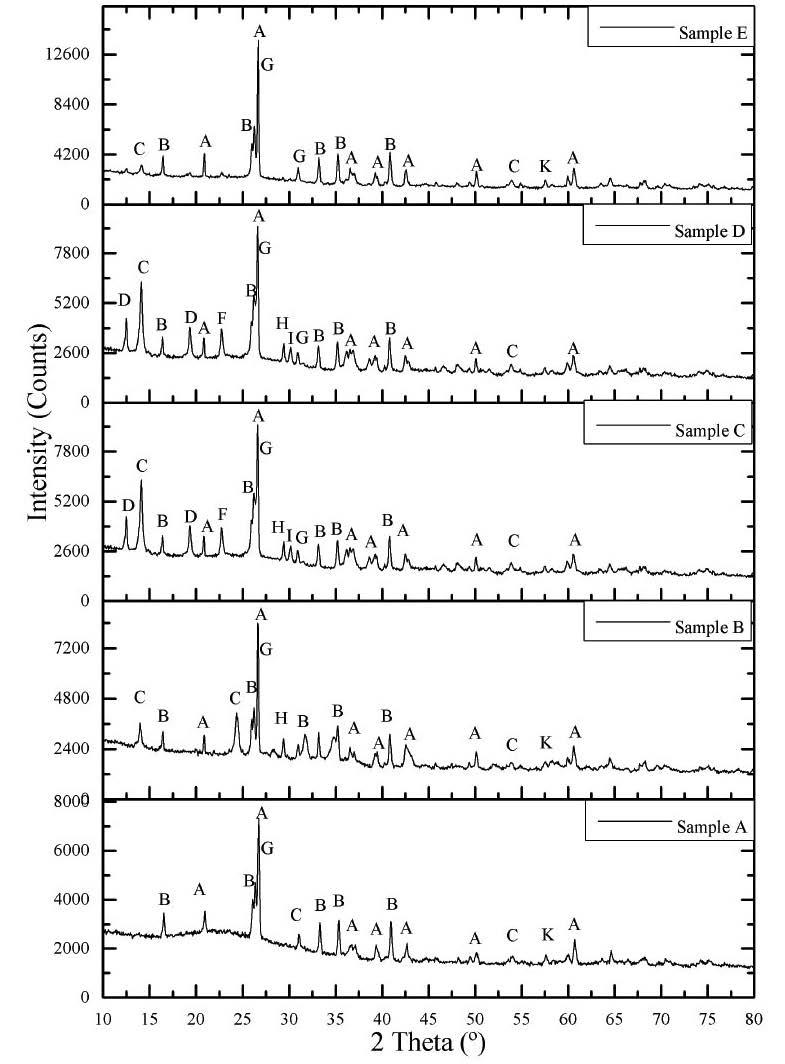

Mineralogy: XRD

The mineralogy results are represented in Figure 4a-c per coalfield. The two dominant minerals in all the coalfields are kaolinite and quartz, except sample ZBS2M where dolomite was dominant. These are followed by muscovite and microcline in the Ermelo and Witbank samples. Trace to minor amounts of calcite and pyrite were detected in samples from all three coalfields, while dolomite was only detected in samples from the Witbank and Waterberg coalfields. These findings were corroborated by the petrography results.

Whole rock geochemistry - X-ray Fluorescence (XRF)

The dominant major element oxides are Al2O3, SiO2, Fe2O3 and CaO, as indicated in Table II. These values reconcile with the mineralogy results discussed above and with work published by Bauer et al. (2022), Dai and Finkelman (2018), and Moroeng et al. (2024).

SCEP and ICP-MS analysis results

The SCEP results are indicated in Figures 5 to 7 a for the coal samples and b for the associated sediment samples). All the coal and associated sediment samples indicate that there is an enrichment in LREY+Sc. There is also an elevation of MREY+Sc for the Witbankassociated sediments (Figure 6b). Both coal and associated sediment samples display an affinity for the carbonate fraction. This agrees with the findings discussed by Moroeng et al. (2024). There is more REY+Sc recovered from the associated sentiments compared to the coal samples for all the study areas.

REY+Sc for the carbonate fraction in the Ermelo coal samples range from below 2 µg/g for the medium and heavy REE to ~16 µg/g and 7 µg/g for Ce and La, respectively (Figure 5a). While the associated sediments, indicated by Figure 5b, range from

~3 µg/g on average for the medium and heavy REE. Up to a maximum of ~35 µg/g and 18 µg/g for Ce and Nd, respectively. A similar pattern is observed in the Witbank coal samples, as indicated in Figure 6a. The medium and heavy REE are below 2 µg/g The light

Table II

Average major oxides per coalfield (Weight %)

REE displayed Ce amounting to 16 µg/g, followed by Nd and La at ~7 µg/g. The carbonates fraction yielded the most results in the Witbank coal samples. The carbonate, silicates, and sulfide fraction results from the Witbank coalfield-associated sediments yielded the highest REY+Sc from the SCEP process, ranging from ~200 µg/g to 600µg/g for HREE. Followed by ~500 µg/g to over ~1,000 µg/g for MREE. The LREE values ranged from ~500 µg/g to over ~2,500 µg/g for Ce, La, being the highest. Research conducted by Dai et al. (2004), Li et al. (2008), and Yang et al. (2023) also discussed REY+Sc associated with silicates and alumino-sillicates and clays.

The Waterberg coal and associated samples yielded the lowest concentration for all fractions and compared to the samples from the other two coalfields. The coal samples have the highest concentrations in the carbonates and silicates fractions. This ranges from less than ~ 2 µg/g to ~ 7 µg/g, indicated by Figure 7a. The Waterberg-associated samples indicated by Figure 7B have the highest concentration in both carbonates and ion-exchangeable fractions. This ranges from less than ~ 2 µg/g to ~ 15 µg/g. The REY+Sc associated with the ion-exchangeable fraction are also

discussed in the work conducted by Bauer et al. (2023). The SCEP results also imply that the highest concentrations of REY+Sc in a particular fraction indicate the highest leaching potential of the lixiviant used in that step.

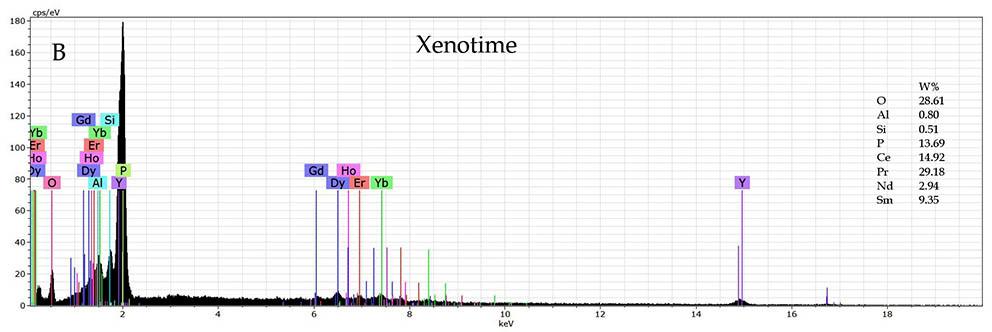

MLA

Monazite and xenotime particles were detected in all three samples (Figures 8a and 9a). In one example, monazite is locked in kaolinite (Figure 8a). Figure 8b indicates that the main rare earth elements present are La, Ce, Pr, Nd and Gd. Figure 9a depicts a xenotime grain attached to kaolinite. The main rare earth elements detected in the xenotime grain are Y, Gd, Tb, Dy, Ho and Er.

The borehole core samples examined are medium-rank C bituminous coals with moderately high ash content, low volatile matter and low sulfur content. The minerals present in all coal samples were mainly kaolinite and quartz, followed by muscovite, microcline, dolomite and trace amounts of calcite and pyrite. Both coal and associated sediment samples are enriched with LREY+Sc, with an elevation of MREY+Sc in the Witbank associated sediment

samples. There is more REY+Sc recovered from the associated sediments compared to coals following the SCEP. The Waterberg has the lowest REY+Sc in both the coal and associated sediment samples, while the highest REY+Sc was yielded from the Witbank associated sediments. The carbonate fraction step proved to be the most successful leaching step, as most REY+Sc were recovered on that step. This may also indicate an affinity for the carbonate minerals present, indicated by dolomite and calcite. However, there is also an affinity for silicates, sulfide fraction in the Witbank samples, and the ion-exchangeable fraction for the Waterberg associated sediments samples. MLA determined that monazite and xenotime in all the coal samples were the REY+Sc-bearing minerals and most are locked in kaolinite.

The authors are grateful for the support from the Centre of Excellence for Integrated Mineral and Energy Resources Analysis (DSI-NRF CIMERA) at the University of Johannesburg and the University of Johannesburg Spectrum Analysis Facility. This work is based on research financially supported by the National Research Foundation (NRF) of South Africa under Grant Number 118564. Any opinion, findings, conclusions, or recommendations expressed in this material are those of the author(s) and therefore, the NRF does not accept any liability in regard thereto. The authors also thank Dr TV Makhubela for his support in conducting the study.

References

Arnold B.J. 2023. A review of element partitioning in coal preparation. International Journal of Coal Geology, issue 104296, https://doi.org/10.1016/j.coal.2023.104296

Balaram, V. 2019. Rare earth elements: A review of the application, occurrence, exploration, analysis, recycling and environmental impact. Geoscience Frontiers, vol. 10, pp. 1285–1303.

Bauer, S., Yang, J., Stuckman, M., Verba, C. 2022. Rare Earth Element (REE) and Critical Mineral Fractions of Central Appalachian Coal-Related Strata Determined by 7-Step Sequential. Minerals, vol. 12, no. 1350, pp. 1–17.

Borzykowski, B. 2019. Wyoming may hold the key to the rare earth minerals trade war with China. [Online] Available at: https://www.cnbc.com/2019/07/10/wyoming-may-hold-key-tothe-rare-earth-minerals-trade-war-with-china.html

Chitlango, Z.F., Wagner, N.J., Moroeng, O.M. 2023. Characterization and pre-concentration of rare earth elements in density fractionated samples from the Waterberg Coalfield, South. International Journal of Coal Geology, vol. 275, pp. 1–16

Dai, S., Li, D., Ren, D., Tang, Y., Shao, L., Song, H. 2004. Geochemistry of the late Permian No.30 coal seam, Zhijin Coalfield of Southwest China: influence of a siliceous lowtemperature hydrothermal fluid. Applied Geochemistry, vol. 19, pp. 1315–1330.

Dai, S., Xie, P., Ward, C.R., Yan, X., Guo, W., French, D., Graham, I.T. 2017. Anomalies of rare metals in Loping Ian super-highorganic-sulfur coals from the Yishan Coalfield, Guangxi, China. Ore Geology Reviews, vol. 88, pp. 235–250.

Dai, S., Finkelman, R.B. 2018. Coal as a promising source of critical elements: Progress and future prospects. International Journal of Coal Geology, vol. 186, pp. 155–164.

Eterigho-Ikelegbe, O., Harrar, H., Bada, S. 2021. Rare earth elements from coal and coal discard – A review. Minerals Engineering, vol. 173, pp. 17–187.

Fu, B., Hower, J.C., Zhang, W., Luo, G., Hu, H., Yao, H. 2022. A review of rare earth elements and yttrium in coal ash: Content, modes of occurrences, combustion behaviour, and extraction methods. Progress in Energy and Combustion Science, vol. 88, pp. 1–47.

Hancox, J.P., Götz, A.E. 2014. South Africa's Coalfields — A 2014 perspective. International Journal of Coal Geology, vol. 132, pp. 170–254.

Hower, J.C., Qian, D., Briot, N.J., Henke, K.R., Hood, M.M., Taggart, R.K., Hsu-Kim, H. 2018. Rare earth element associations in the Kentucky State University stoker ash. International Journal of Coal Geology, vol. 189, pp. 75–82.

Li, D., Tang, Y., Deng, T., Chen, K., Liu, D. 2008. Geochemistry of rare earth elements in coal—A case study from Chongqing, southwestern China. Energy Exploration & Exploitation, vol. 26, no. 6, pp. 355–362.

Li, X., Qiao, W., Chen, D.,Wu, P., Xie, P., Chen, X. 2023. Anomalous concentrations of rare earth elements in acid mine drainage and implications for rare earth resources from late Permian coal seams in northern Guizhou. Science of the Total Environment, vol. 879, pp. 1–10.

Mahooana, P.E. 2022. Assessment of the possible occurrence of torbanite in the Ermelo Coalfield, South Africa, MSc. Johannesburg: University of Johannesburg.

Mokoena, K., Mokhahlane, L.S., Clarke, S. 2022. Effects of acid concentration on the recovery of rare earth elements from coal fly ash. International Journal of Coal Geology, vol. 259, pp. 1–9.

Moroeng, O.M., Bridgette, M., Wagner, N.J. 2024. Enrichment of rare earth elements in epigenetic dolomite occurring in contact metamorphosed Witbank coals (South Africa). International Journal of Coal Geology, 282(104405), pp. 1–18.

Serendin, V.V., Dai, S. 2012. Coal deposits as potential alternative sources for lanthanides and yttrium. International Journal of Coal Geology, vol. 94, pp. 67–93.

South African National Standard (SANS) 11760, 2018. Coal Classification. ISO 11760:2005

South African National Standard (SANS) 17246, 2011. Coal –Proximate Analysis. ISO 17246:2010.

South African National Standard (SANS) 7404-3, 2016. Methods

for the Petrographic Analysis of Coals - Part 3: Method of Determining Maceral Group Composition. ISO 7404–3:2009.

Wagner, N.J., Matiane, A. 2018. Rare earth elements in select Main Karoo Basin (South Africa) coal and coal ash samples. International Journal of Coal Geology, vol. 196, pp. 82–92.

Yang, P., Dai, S., Nechaev, V.P., Song, X., Chekryzhov, I.Y., Tarasenko, I.A., Tian, X., Yao, M., Kang, S., Zheng, J. 2023. Modes of occurrence of critical metals (Nb-Ta-Zr-Hf-REY-Ga) in altered volcanic ashes in the Xuanwei Formation, eastern Yunnan Province, SW China: A quantitative evaluation based on sequential chemical extraction. Ore Geology Reviews, 160(105617), pp. 1–22.

Zhou, B., Li, Z., Chen, C. 2017. Global potential of rare earth resources and rare earth demand from clean technologies. Minerals, vol. 7(203), pp. 1–14. u

26 MAY 2025 - WORKSHOP

Sulfuric Acid Catalysis - Key Parameters to Increase Efficiency and Lower Costs

27-28 MAY 2025 - CONFERENCE

29 MAY 2025 - TECHNICAL VISIT

PROTEA HOTEL STELLENBOSCH AND CONFERENCE CENTRE, STELLENBOSCH

OBJECTIVES

•

• To expose delegates to issues relating to the generation and handling of sulphur, sulphuric acid, and SO2 abatement in the metallurgical and other industries

•

• Provide an opportunity to producers and consumers of sulphur and sulphuric acid and related products to be introduced to new technologies and equipment in the field

EXHIBITION AND SPONSORSHIP

• •

• Enable participants to share information about and experience in the application of such technologies

• Provide an opportunity for role players in the industry to discuss common problems and their solutions.

There are a number of sponsorship opportunities available. Companies wishing to sponsor or exhibit should contact the Conferences and Events Co- Ordinator.

ECSA Validated CPD Activity, Credits = 0.1 points per hour attended

FOR FURTHER INFORMATION, CONTACT: Gugu Charlie, Conferences and Events Co-Ordinator, E-mail: gugu@saimm.co.za

Affiliation:

1Mintek, Randburg, South Africa

2Broadmind Mining Pty Ltd, South Africa

Correspondence to:

T. Mokgomola

Email:

TebogoMo@mintek.co.za

Dates:

Received: 29 May 2024

Accepted: 2 July 2024

Published: October 2024

How to cite:

Mokgomola, T., Marape, G., Singh, A., and Bisaka, K. 2024. Development of a physical separation pre-concentration process for the extraction of Rare Earth bearing ore. Journal of the Southern African Institute of Mining and Metallurgy, vol. 124, no.10, pp. 567–574

DOI ID:

http://dx.doi.org/10.17159/24119717/695/2024

ORCID: T. Mokgomola http://orcid.org/0000-0002-4446-5390

This paper is based on a presentation given at the Southern African Rare Earths 2nd International Conference 2024, 19-20 June 2024, Swakopmund Hotel and Entertainment Centre, Swakopmund, Namibia

by T. Mokgomola1, G. Marape1, A. Singh1, and K. Bisaka2

Abstract

This paper investigated the pre-concentration amenability of sovite (carbonatite) ore to enhance the grade of rare earth elements (REE) bearing minerals by rejecting calcite, and to improve total rare earth elements (TREE) recovery using gravity and magnetic separation. A high proportion of calcite affects downstream processes like leaching due to high acid consumption. Multiple flowsheets combining gravity and magnetic separation were employed to target > 60% TREEs recovery to the final concentrate and > 60% calcite rejection to the tailings. Head analysis of the feed showed the sample’s main constituents as Fe (15.61%), Ca (16.04%), SiO2 (7.13%), and lastly TREEs (1.12%). Mineralogy liberation data at 2mm top size indicated poor liberation of TREEs, with the majority of minerals displaying < 30% mass greater than 80% liberated. Grain size distribution data showed that the majority of REE minerals are fine grained and report to the < 20 µm size class. Calcite liberation mineralogy showed < 60% mass greater than 80% liberation.A combination of a single-stage shaking table with a wet high intensity magnetic separator at a magnetic intensity of 7520 G was found to be the optimum flowsheet. For a shaking table feed with P80 of 150 μm followed by tails regrind to P80 of 45 μm as feed to wet high intensity magnetic separator, the overall mass balance results showed that 60.5% TREEs are recovered to the concentrate while 63.0% calcite is rejected to the tails. However, due to the fine-grained nature of TREEs, no flowsheet improved their grade.

Keywords

Sovite, total rare earth elements (TREEs), calcite, wet high intensity magnetic separation (WHIMS), low intensity magnetic separation (LIMS), shaking table (ST)

Introduction

In recent years, worldwide investment in the recovery of rare earth elements (REE) has been financed due to their increasing use in modern high technology industries. REEs are included in a growing list of critical raw materials (Berger et al., 2014; Sager and Wiche, 2024). REE’s primary recovery from value bearing ores is costly due to low concentrations within the ore. According to Sager and Wiche (2024), the concentration of REEs in the earth’s crust ranges from 66 mg/kg (Ce) to 0.3 mg/kg (Lu). For the extraction of REEs minerals for valuable and raw material to be feasible, various REEs beneficiation processes have been established and others are currently being explored to upgrade and recover REEs at optimum costs.

Rare earth elements (REEs) are comprised of seventeen chemical elements in the periodic table. Among the seventeen, fifteen of them are lanthanides and the other two are yttrium and scandium, which occur in the same ore deposits as lanthanides and exhibit the same chemical properties (Hoshino, et al., 2016; Sager and Wiche, 2024). Yttrium was the first REE discovered by chemist Johan Gadolin in 1794 and promethium was the last REE discovered approximately 150 years later in 1947. REEs are found within other minerals in the earth’s crust, as they do not occur individually (Hoshino et al., 2016). REEs are critical raw materials for modern technologies ranging from cellphones, magnets, and LED lights to wind turbines due to their properties like magnetic, catalytic, and phosphorescent properties (Frances, 2021).

In this paper, the mineral of interest is sovite ore originating from Southern Africa. The ore is carbonatite or calcite rich, thus making calcite the main gangue mineral. According to Frances (2021), the majority of operational REEs mines are carbonatite-related deposits. This paper thus focuses on the rejection of calcite to improve the recovery of REEs, which is important in the mining industry.

This paper aims to provide an economically viable route to recover REEs and reject calcite from sovite ore using gravity and magnetic separation techniques according to the properties of the valuable and the gangue minerals within the ore. To achieve this, ore characterization using elemental chemical analysis followed by bulk modal mineralogy using AutoSEM technology was conducted.

Gravity separation methods are the most commonly used beneficiation methods employed to exploit the density differences between valuable minerals and the gangue within a given ore. The method uses the differential settling velocity between particles. This settling velocity is governed by particle weight, buoyancy and drag force (Roy, 2009; Murthy and Tripathy, 2020). It is the oldest beneficiation technique and is widely used due to the associated low costs, simple operating procedures, and its eco-friendly nature. The most popular gravity separation units used for wet processes are shaking tables, jig, and spirals (Roy, 2009).

Gravity separation units are selected based on particle size and the capacity of the unit. Gravity separators provide peak performance when operated in optimum conditions and the right feed particle size range for a given material. The biggest challenge for most gravity separation methods has been fine and ultrafine particles (Murthy and Tripathy, 2020). For this paper, due to limitations in feed mass, a flowing film gravity concentrator such as the Wilfley shaking table was utilized. Tabling of ores is efficient when the differences in specific gravity between the minerals is high (Roy, 2009).

Magnetic separation methods are employed to exploit the differences in magnetic properties of minerals within a given ore. This technique uses magnetism to separate materials that respond more strongly to a magnetic force from materials that exhibit a weak response. It is a newer process when compared with gravity separation but old when compared with froth floatation methods. Selection of a magnetic separation unit or mechanism is based on the magnetic properties of the given mineral. Some materials are ferromagnetic, paramagnetic and others diamagnetic. Ferromagnetic materials require a low magnetic intensity for separation, whilst paramagnetic materials require a high magnetic intensity to be susceptible to the magnetic forces. According to Cohen (1986), only four elements namely cobalt, iron, gadolinium, and nickel are ferromagnetic but seven REEs are strongly paramagnetic.

Most minerals are weakly paramagnetic or diamagnetic and their magnetic susceptibilities are constant and show straightline relationships to the strength of the magnetic field exerted on them. Paramagnetic minerals have a higher magnetic permeability compared to their surrounding media making it easier for the particle to move in the direction of the field strength due to high field density within the particle. On the other hand, diamagnetic minerals have lower magnetic permeability than the surrounding

Head

mineralogy

media (Cohen, 1986). In this research, both low and high magnetic intensity (LIMS and WHIMS) separators were used to determine the optimum flowsheet for REE recovery whilst rejecting calcite.

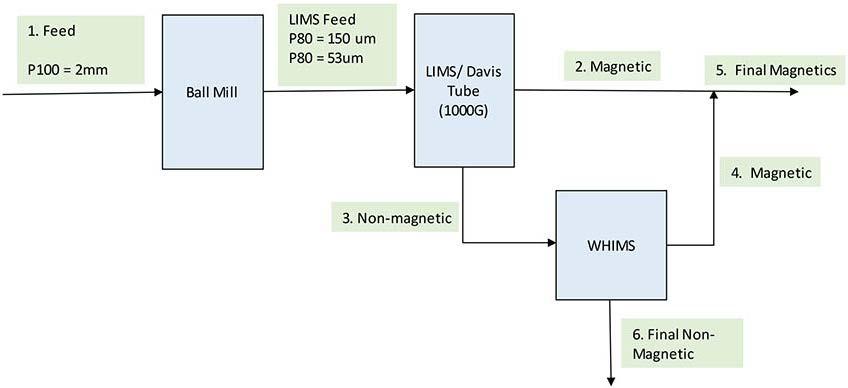

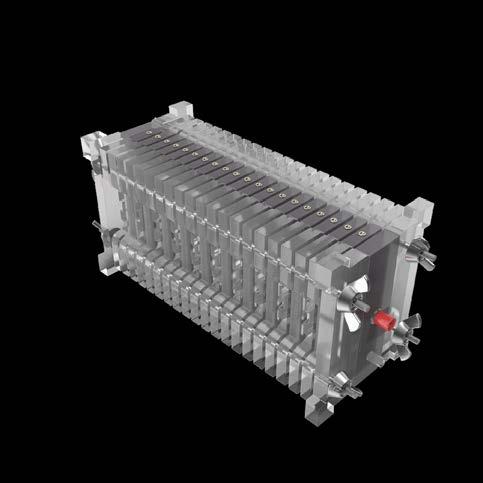

Figures 1 to Figure 3 shows the schematic diagrams of flowsheets used for the procedures of characterization and the different possible combinations of magnetic and gravity separation flowsheets.

Sample receipt and preparation

Approximately 280kg of sovite feed sample was delivered for testwork purposes. The sample was at a top size of 1/4 core pieces, so roughly 10 mm x 10 cm pieces and dry upon receipt. The sample was weighed, blended, stage crushed using Jaw and cone to 100% passing 20 mm, and then subsampled using cross-cut method for coarser sizes for various tests according to the scope of the testwork. The subsamples were stage crushed to 100% passing 2 mm for mineralogy, 100% passing 1mm for particle size distribution and head analysis and 2 mm for ball milling to P80 = 300 µm, 150 µm, 106 µm, 53 µm and 45 µm. The finer fractions, that is, -2 mm, samples, were subsampled using the rotary splitter.

Elemental chemical analysis on the sovite ore was done using ICP base metal, and REE solid digestion methods to determine the grade of calcite, REE, and Fe. Mineralogical analysis on the sample was carried out using quantitative X-ray diffraction (qXRD), scanning electron microscopy (SEM), and automated scanning electron microscope (AutoSEM) analysis. The purpose of the

investigation was to establish the presence, identity, and relative abundance of minerals as well as to obtain information on REE minerals in terms of their mode of occurrence, relative abundance, REE deportment, and grain size, liberation at a top size of 100% passing 1.18 mm, mineral associations and bulk modal mineralogy.

Magnetic separation

Figure 2 shows a typical magnetic separation flowsheet comprising of Ball mill, LIMS and WHIMS.

Davis tube testwork

To determine the percentage of ferromagnetic material in the sample, magnetic separation was conducted using an electromagnet Davis tube as depicted in Figure 2. The separation occurs by exploiting the high susceptibility of ferrous material in the sample to magnetic forces. The sample was fed at P80 of 53 µm and tested at a magnetic field intensity of 1000 G. The non-magnetic products were sent to the WHIMS equipment.

Laboratory Wet LIMS and WHIMS Testwork

As per Figure 2, laboratory wet LIMS testwork, using a permanent magnet at a magnetic field intensity of 1000 G, was conducted on the feed at P80 of 150µm to recover ferrous material in the feed before WHIMS testwork.

The non-magnetic material was subjected to WHIMS at four intensities (2000 G, 4000 G, 6000 G, and 7520 G) to determine the intensity that will reject calcite and improve the grade of REE. This testwork was conducted five (5) times across multiple flowsheet combinations with shaking table tails and slimes as feed (Figure 3), and the Davis tube and LIMS non-magnetic streams as feed (Figure 2).

The roasted feed at a P80 of 150 µm was subjected to dry magnetic

Shaking Table Feed

Ball Mill

Rougher Shaking table

separation using laboratory high-intensity induced-roll lift type magnetic separator at seven magnetic intensities (800 G, 850 G, 870 G, 900 G, 920 G, 950 G, and 1000 G). The sample contained hematite, thus roasting of the sample at 1000°C increased the magnetic susceptibility for low intensity dry magnetic separation.

Combined gravity separation and magnetic separation testwork

Figure 3 shows the schematic diagram used for the combination of shaking table with magnetic separation.

Shaking table testwork

The shaking table test was conducted six times across multiple flowsheets for calcite rejection using the density difference between REE, Fe, and Ca. The shaking table consists of a slightly inclined deck that exposes particles to gravitational, vibrational, and flow water forces allowing the particles to separate due to their difference in density, shape, and size. The shaking table produced nine (9) products namely four concentrates, two middlings, two tails, and one slimes stream. Shaking table was conducted at P100 of 1.18 mm, P80 of 300 µm, 150 µm (three times) and 106µm (Scavenger in a flowsheet). The tails from shaking table at P100 = 1.18 mm, were subjected to WHIMS to form flowsheet 7 as shown in Table II. The slimes and tails of these tests were milled to P80 of 45 µm for magnetic separation using WHIMS, with the exception of WHIMS on shaking table tests tails at P100 = 1.18 mm.

Results and discussion

Head analysis and mineralogical evaluation

Table I shows the chemical composition of the sovite ore. It is observed that the REE collectively constitutes 1.12% of the sovite ore. The %Fe was higher than expected at 15.61% with %Ca at

Ball Mill

WHIMS Feed

P100 = 1.18 mm

P80 = 150 mm

P80 = 45 mm

Ball Mill Scavenger Shaking table WHIMS

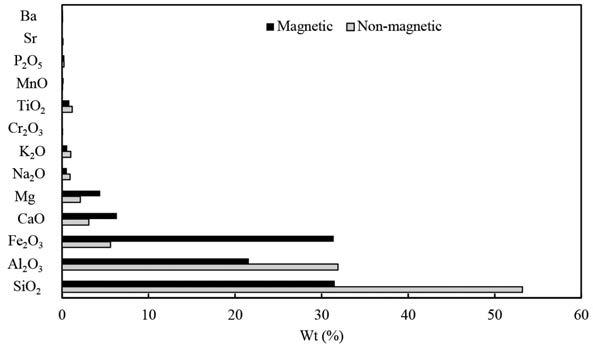

16.04% (40.10% CaCO3). Bulk mineralogy of the samples (Figure 4) shows that the ore predominantly consists of ferruginous clay, calcite and kutnohorite.

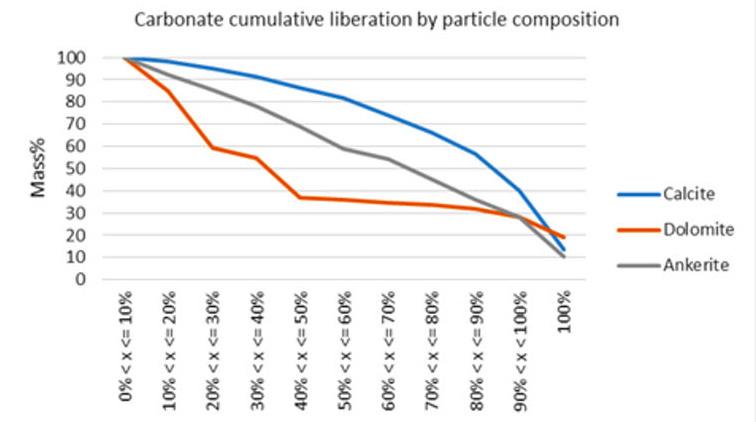

REEs and calcite minerals liberation and grain size distribution

Liberation characteristics of cumulative REE and calcite minerals by free surface and particle composition are presented in Figure 5 to Figure 8. Liberation classification by particle composition is based on area percent of the mineral of interest (e.g., TREE) over the total area of a particle. Liberation classification by free surface is based on the degree to which valuable minerals within the ore have a free

surface after crushing, making them accessible for separation and concentration processes. Liberation classes are defined in 12 groups ranging from 0% to 100% area, in 10% intervals and reported by cumulative liberation by area. Results in each class are cumulated from 100% liberated to 0 % liberated.

With the exception of burbankite, the majority of REE minerals display poor liberation by both particle composition and free surface liberation with the majority of minerals displaying <30% mass greater than 80% liberated.