2 minute read

timbrel vaulting

Advertisement

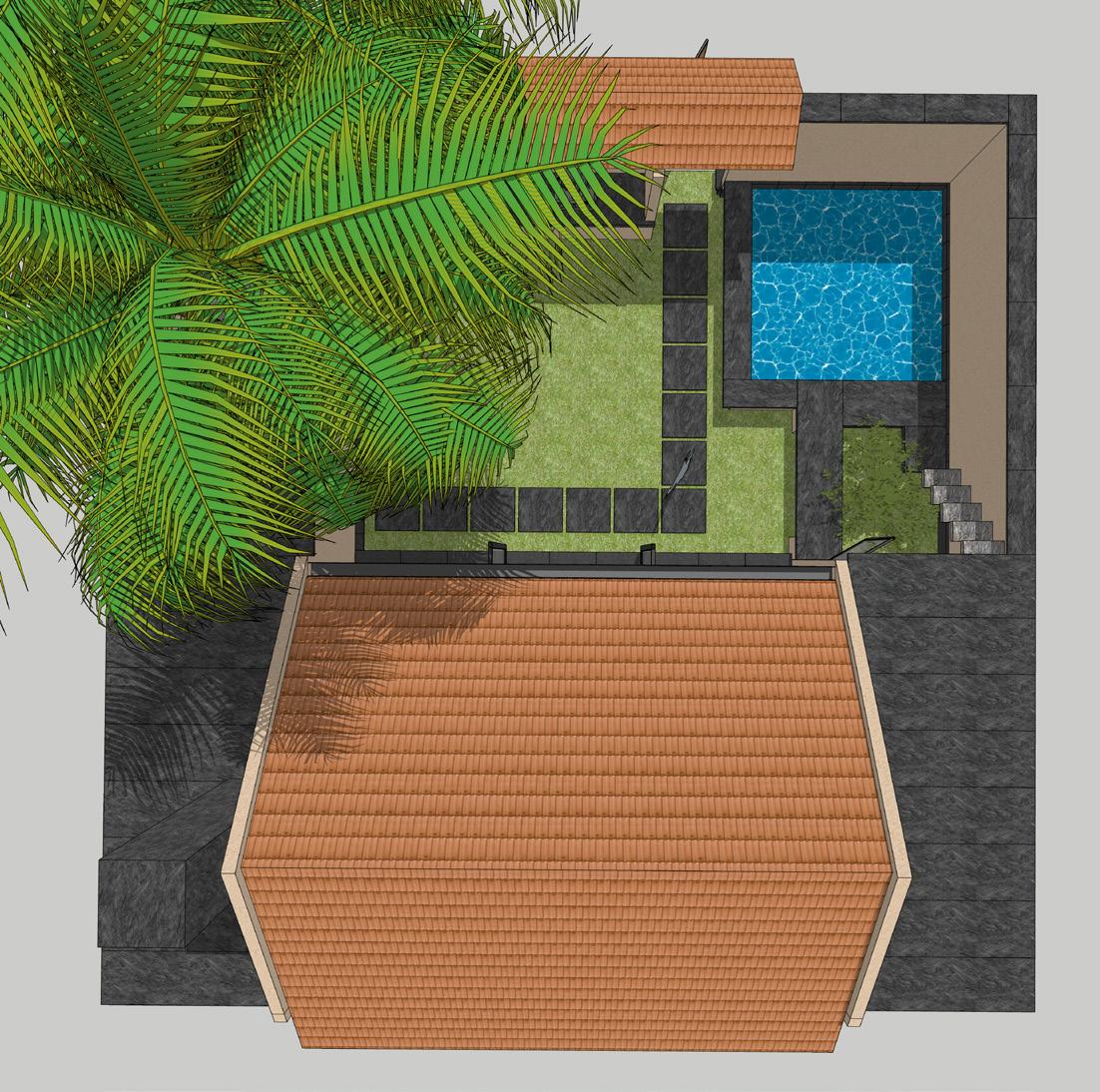

Suratkal | Mangalore approach

About The Workshop

This was a collaborative workshop based on ‘Gustavino Vaults’ or ‘Timbrel Vaults’ organised by a Mangalore based practice called as ‘Maya Space Monkey’. We were invited to conduct the workshop where we had to teach the art of building gustavino vaults. The workshop was organized on one of their sites in an ongoing projects in Suratkal, Mangalore. Every hands on workshop was about something that is integral in the building process and this was about patience.

The vault was planned by them as a roofing system for which we had a meeting a month prior to the workshop. We decided we would design the formwork out of steel which would eventuually be their clerestory windows to allow light in the space. The beam was used to mount the formwork and rollers were welded to it to move it along the beam.

The initial step of the process was to set up a track and trail system along the already cast RCC beams. The scafoldings were setup to reach the desired height and rollers were welded to the form work to be installed.

The 3 day workshop focused mainly on the building techniques and stratergies that are taken while executing such a construction. Timbrel vaults are generally delicate to handle whe they are being built, compared to when after. Few take aways from this workshop are listed below:

• The building should have a concrete strategy of execution and a well prepared site for its execution for a smooth construction. We had utilised a lot of our time on the installation of the track and trail for the formwork. Scaffoldings have to be erected hours prior to construction.

• It is also advised to procure and process the materials atleast 24 hours prior to the commencement of construction, such as ‘slaking lime’ or soaking brick tiles in water.

• The mortar used here is a gypsum lime mortar, which means one of the primary contents is ‘P.O.P’ a.k.a ‘Plaster Of Paris’. This means the motar has a tendency to settle or dry up faster, hence has to be mixed in small batches while building.

• The process of placing bricks or the primary construction process is a patience driven activity. Because it is just lime and pop, with lime being the major content, it doesnt set as quickly as a cement mortar. Hence, the mason is required to have that ppatience to keep holding the brick until the mortar hardens before moving on to the next brick.

The vault involved 3 layersthe first being a herringbone pattern. This helped the vault to be stable as we were using 1” thick brick tiles. It was made more stable by having 2 additional layers of 45º tilts such that the net thickness of the vault was 5”.

For the track & trail, 3” MS L-angles were pinned into the concrete beam. After construction, they are either left as it is or can be removed upon the design and client’s opinions because the vault is ultimately attached to the beam and not to the track and trail or the formwork.