3 minute read

02 fine natural plasters

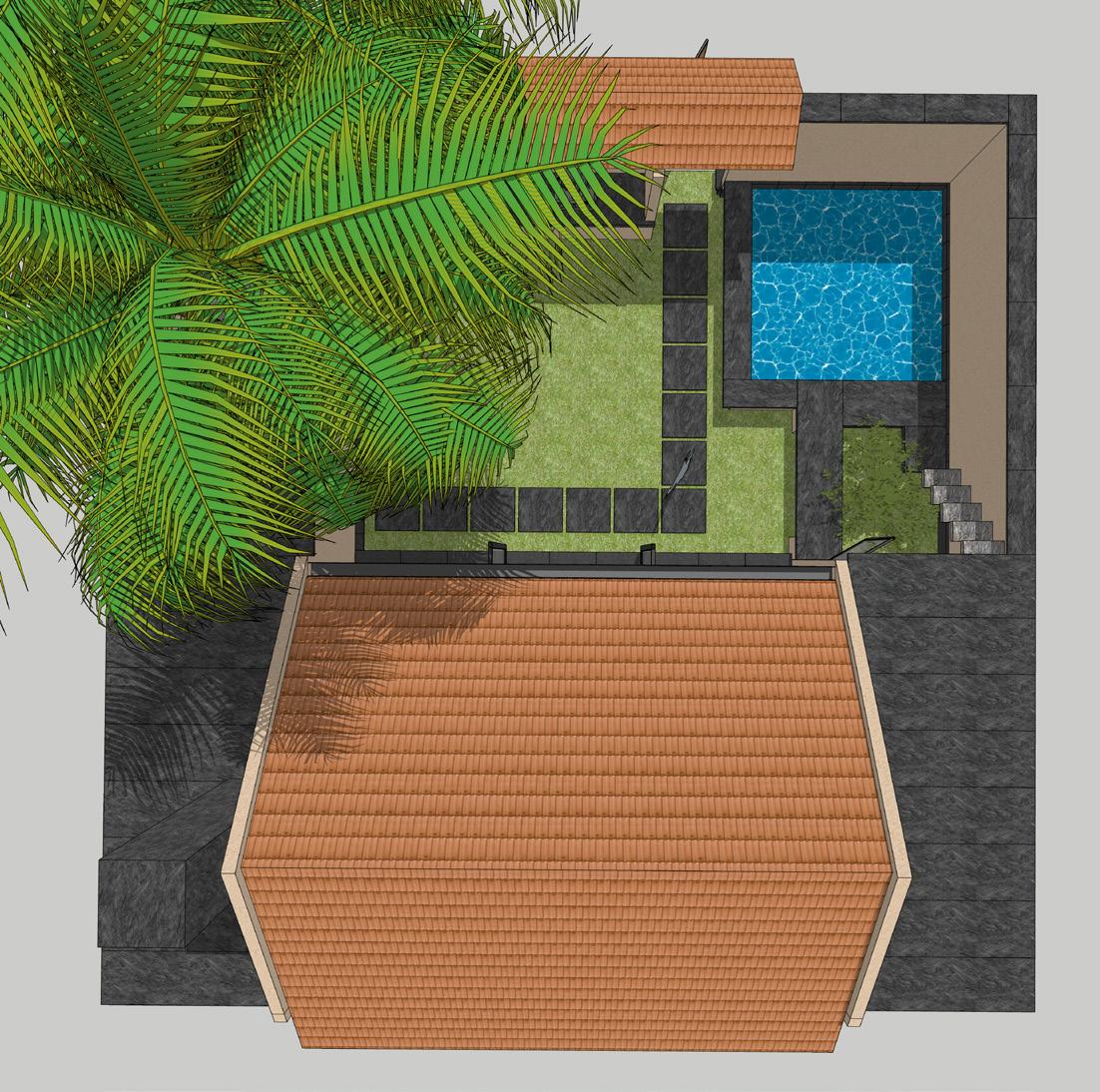

Vanamu | Bengaluru

About The Workshop

Advertisement

The workshop focused predominantly on the traditional plasters that were practised centuries ago by natural means. Any earthen material’s primary attribute is the aesthetic value it upholds that is indegenious in nature. Natural plasters are easy to use and provides one with scopes of eperimentation with divergent colors & textures. These natural finishes deny the need of any chemicals in finishes as they provide us with a variety of finishing options such as smooth trovel finish, sponge finish, rough brush finish, matte finish, grainy and glossy finishes, etc.

about the primary material - lime

Lime is a material which gains most of its strength in the first few weeks after application, before which it is delicate. Once this curve crosses the setting time, while its still gaining strength, becomes scratch resistant when compared too any finished plasters.

dawood muval - a master artisan from rajasthan Dawood muval is a master artisan who predominatly works with lime, from Sardarshahar, Rajasthan. As we called him humbly as ‘Dawoodji’, has a hands on working experience for more tthan half a century. He takes pride in sharing his craft with eager students and in doing so hopes too raise awareness of and appreciation for these ancient techniques.

We were fortunate to get an opportunity to work and more over observe him two workshops and during his consultancy over a month. His ways of work are more inclined towards intuitve approaches rather than rational methods, which makes it more observation centric. The rational part of the process which is important for us to understand the process, method and the art was decoded and covered by Varun sir in simplified manner.

Lime Processing

Lime has to go thorugh a slaking process inorder to be used as a primary component of a plaster.

Types of slaking: lohi

• First - lime was added in a big barrel which filled about 1/20 of volume. To this about hallf a barrel of water is added iin a continuous heavy flow. Water and lime reacts in an exothermic way and hence was left untouched until it slaked on its own.

• Second - normal temperature water was added to a small lime sample slowly, batch by batch and was continuously stirred.

• Third - It involved hot water addition in small batches with stirring. In both these methods it was made sure that lime doesn’t boil, else it will produce undesirable powder and not paste.

This is a type of a final coat and can be directly applied on the top layer. Seiving of lime is ensured here to avoid lumps and a finer grade of surkhi is used. This is a trovel finished plaster and is very thin. But, since lime is hardens over time, it becomes durable over time. The result is a hard, slightly shinny reddish brown smooth finish.

Applications

Lime plasters were mostly applied in 3 coats soo as to obtain a fine finish. For an undulated surface, even one coat is acceptable and many places only have lime washes as the final finish. In the 3 layer coat: thappi araish

• First layer is applied with coarse aggregattes to allow carbonation.

• Second layer witnesses a mix of finer aggregates which generally is followed by soft compression for minimising cracks.

• The final layer acts as a hydraulic mortar and has the finest components.

It is also sensible not to apply any sort of alien coat on a surface, because if anything like that happens then the structural bond between the material weakens.

It is an indegenious lime application process where a wooden tool caleld thappi is used to apply pressure on the plaster. The mortar preperation starts with slaking lime atleast a day prior, which is then added to coarse surkhi or brick powder and MSand. In order to make it more workable, jaggery and fenugreek water is added. It facilitates the setting of lime, while anchoring it to the previous layer. The lightness and levels of a ‘thappi’ stick is an important consideration to maintain consistency.

It is also a finish coat plaster that is only 2-3mm thick. It involves seiving of slaked lime to get rid of lumps and addition of ‘sangjeera’ powder or a type of marble dust to the mix and grinded well. The traits of araish is in its glossy shine and velvety touch which is achieved by a trovel finish at an angle.

Tadelakt

Tadelakt is a mexican cum morooccan based plaster. It primarily consists of two coats. First one being a trovel finish, followed by a soap and alum water coat. The final coat has wooden trovelling and burnishing the surface with a semi prcious stone such as a ‘black tourmaline’ or ‘red jasper’. we get a glossy, waterproof finish.

Intent

Mayamandalam was concieved as a communal meditation space for the village, Mayavadi. It was buillt for a social cause and was ececuted through a workshop inorder to emphazise the communal approach towards building it.

Mayavadi | Nandi Hills