Custom Bricks showcases 47 projects that use bricks with special formats, colours or glazes. We hope they will inspire you.

03 Introduction

21 Public institutions

22 Maitland Riverlink, New South Wales, Australia

26 Kannikegården, parish hall, Ribe Cathedral, Denmark

30 Goel Center for Theater and Dance, Massachusetts, USA

34 After-school club, Allenmoos, Switzerland

38 Gothenburg City Library, extension, Sweden

42 City Circle Line (M3), Copenhagen, Denmark

46 Andlinger Center for Energy and the Environment, Princeton University, New Jersey, USA

50 Christian IV’s Brewhouse, Copenhagen, Denmark (R)

53 Commercial

54 Konvert, headquarters, Kortrijk, Belgium

58 1A Page Street, Victoria, London, England

62 Astoria House, Stockholm, Sweden

66 Turnmill offic building, Clerkenwell, London, England

74 Tivoli Corner, Tivoli Gardens, Copenhagen, Denmark

78 Kville Saluhall, Gothenburg, Sweden

80 Design studio, Rancate, Switzerland

84 Petrol station, Skovshoved, Denmark (R)

90 Arcade building, Nordre Toldbod, Copenhagen, Denmark (R)

93 Culture

94 Kunstmuseum Basel, new extension, Basel, Switzerland

98 Z33, House for Contemporary Art, Hasselt, Belgium

104 Tobias Mayer Museum, Marbach am Neckar, Germany

108 CLAY Museum of Ceramic Art, Middelfart, Denmark

112 Museum of the Bible, Washington DC, USA

116 European Hansemuseum, Lübeck, Germany

122 LAM Lisser Art Museum, Lisse, The Netherlands

126 Museum de Lakenhal, Leiden, The Netherlands

134 Brooklyn Botanic Garden ticket pavilion, New York, USA

138 The main entrance to Tivoli Gardens, Copenhagen, Denmark (R)

144 The Round Tower, Copenhagen, Denmark (R)

149 Housing

150 Villa Platan, Aarhus, Denmark

154 Private home in Groenekan, The Netherlands

158 Private home in Utrecht, The Netherlands

162 Cabin in Hvaler, Norway

166 Holiday home in Tisvilde, Denmark

170 Private home, Prinsen Bolwerk, Haarlem, The Netherlands

174 Houttuinen townhouse, Dordrecht, The Netherlands

178 Paper Island, housing project on Christiansholm, Copenhagen, Denmark

182 Residential block on Jagtvej 2/Ågade 110, Copenhagen, Denmark (R)

187 Churches

188 Don Bosco Church, Maribor, Slovenia

190 Ordrup Church, Ordrup, Denmark (R)

192 Grundtvig’s Church, Copenhagen, Denmark (R)

194 Underground chapel, Grundtvig’s Church, Copenhagen, Denmark

198 St Paul’s Church, Copenhagen, Denmark (R)

203 Art

204 Bibliotheca – Archaeological Library, Kivik, Sweden

208 Yu‘un, private gallery, Tokyo, Japan

212 Trekroner Church, Roskilde, Denmark

216 ‘Interspecies Campus’, artwork at Roskilde University, Roskilde, Denmark

220 Traffi Tower East, Copenhagen, Denmark

224 Index by technique

(R) = Restoration Projects

Contents Introduction Public institutions Art Commercial Culture Housing Churches

2

Introduction

3

Photo: Anders Sune Berg

4

Petersen Tegl employees in 1951.

Photo: Broagerlands Lokalarkiv

In 1791, King Christian Vll granted permission to the founder of the family-owned company, the smallholder Peter Andresen, to open the brickworks. The officia document is in the possession of the Petersen family.

Timeless craft, endless possibilities

Brick has a great many qualities. Made from the purest elements imaginable – clay, water and fie – it has an almost infinit lifespan and requires no maintenance. Bricks laid in lime mortar can be taken down and reused. Or they can be crushed, and the grains used to make new bricks or to build roads, squares and other facilities.

As a building material, brick also has another almost unique quality. It can be produced in exactly the shape you need. All it takes is a brickworks capable of making them by hand. Like Petersen Tegl.

When the company was founded at the present address at Nybølnor in Broager in 1791, handmade bricks were the norm. The Industrial Revolution changed all that, and by the early 20th century, the entire Western world was using machines to produce bricks. They looked mass-produced – uniform, smooth, very few colours.

But not at Petersen Tegl. It was one of the few brickworks to return to its roots.

5

Petersen Tegl employees in 2022 – with the owner Christian A. Petersen in the centre.

Photo: Annette Petersen

66

Petersen Tegl in Nybølnor, 1957. Photo: Sylvest Jensen, www.kb.dk/danmarksetfraluften (Denmark seen from the air)

7

Petersen Tegl in Nybølnor, 2021. Photo: Erhorn Hummerston

In the early 1980s, Petersen invented and built machines designed to imitate manual processes, endow the water-brushed bricks with their original, uniformly uneven look and provide four equally presentable surfaces. Ever since then, those same machines have accounted for a significan proportion of the company’s production.

Tivoli in Copenhagen, the second oldest amusement park in the world, celebrated its centenary in 1990. To mark the occasion, it commissioned Petersen Tegl to produce new terracotta ornamentation for the original main entrance. Christian A. Petersen immediately threw himself into the project, and the Custom Brick Department was born.

In the late 1990s, when the architect Peter Zumthor won a competition to design the Kolumba Museum in Cologne, he asked Petersen Tegl to develop a special brick for the project. The Custom Brick Department had the requisite expertise, and the museum was built in the new, handmade Kolumba brick and inaugurated in 2007. Handmade standard bricks have been a hallmark of Petersen Tegl ever since.

8

Petersen Tegl recreated the ornamented terracotta elements for the main entrance to Tivoli Gardens in 1991. Photo: Anders Sune Berg

Architect Peter Zumthor developed the Kolumba brick for the Kolumba Museum in Cologne, which was inaugurated in 2007. Photo: Anders Sune Berg

A large part of the company’s production now consists of the standard bricks Kolumba and Cover. They are produced 100% by hand in wooden moulds. However, custom bricks for special projects also account for an ever-increasing proportion of turnover.

9

Architects Min2 developed Petersen Cover in 2009 for their home in Bergen aan Zee in the Netherlands. Photo: Paul Kozlowski

Architects Lundgaard & Tranberg refine Kolumba for The Royal Playhouse in Copenhagen, which opened in 2008. Photo: Anders Sune Berg

Special formats

The fact that so much of Petersen’s standard production is by hand makes it easy to comply with requests for special formats. The processes and equipment are all there. The customer and brickworks discuss the specificaions for orders. Then a wooden mould is made. An order can range from a single brick for a restoration project to large-scale new construction.

Demand for special formats has been increasing in recent years. It gives an obvious freedom to architects and designers during the creative process that brick can be custom made.

In some cases, special formats are used for ornamentation and complicated detailing. In others, they make the brickwork look as harmonious as possible, for example by using angled bricks on corners. Or bricks can be produced in exactly the lengths needed in order to fi the planned length of the row in the most elegant way.

10

Bricks with customised angles are used to form seamless, harmonious brickwork corners.

11

Preparation of clay

Petersen Tegl adapts the production methods according to the actual type of brick. At Petersen Tegl, the clay is pugged, formed and pressed by means of techniques imitating the procedures used when also this part of the work was done by hand. The method gives the clay its optimum texture with capillars and air pores allowing the water to expand when it freezes to ice without spoiling the brick. The fact that the brick may absorb water does not entail risks of frost damage, and Petersen Tegl’s bricks are 100% frost resistant.

12

The owner of the brickworks, Christian A. Petersen, at the machine that processes the clay.

Photo: Anders Sune Berg

Methods of formatting

Three methods of formatting are used to produce the special formats, wooden moulds, templates or plaster moulds.

Wooden moulds: Bricks have been produced in wooden moulds for thousands of years. They are hand struck by pressing a lump of clay into a wet form. The clay is then compressed and any surplus material struck off. Water or slurry is used as a lubricant to slide the lump out of the mould and onto a plate to dry. It is then fied in a kiln.

Photos: Anders Sune Berg

13

Wooden mould and finishe brick.

Templates: A lump of clay bigger than the fina product is pressed into a wooden mould and left to dry for a few days. It is then clamped between two pieces of indented wood and cut with a wire. The excess clay is removed, and the brick is rubbed down. After the wooden template is removed, the clay is dried and fied.

14

Photo: Martin Schubert

Examples of bricks produced using templates.

Plaster moulds:

Mainly used in restoration projects to recreate the original bricks. Based on a 3D drawing, a plastic or wooden model is produced, 8-10% larger than the original. This is then used to make a plaster mould. High-quality clay is pressed carefully into the mould to avoid air pockets forming. Once the mould has been filed, a cavity is carved out to ensure that the clay dries evenly. The plaster draws water out of the clay for a few hours, and then the mould is removed. The brick is left to dry before firing Photo:

15

Martin Schubert

Examples of bricks produced using plaster moulds.

16

Highly detailed terracotta elements made in a plaster mould for a restoration project on a church spire.

Photo: Anders Sune Berg

The artist Vibeke Fonnesbech designed the portrait reliefs in tile that are built into the façades of a housing block.

Photo: Anders Sune Berg

Custom bricks made in wooden moulds create the illusion that the façade is made of pine logs.

Semi-circular bricks positioned in a pattern were recreated to replace existing ones when the wall around a 19th-century property was restored.

17

Photo: Martin Schubert

Photo: Anders Sune Berg

Special colours

To meet the rising demand for custom shades and tones, the brickworks has its own dedicated colour department, which constantly conducts experiments. As a result, several specially coloured bricks originally developed for specifi projects have later been added to Petersen’s standard range.

Two factors determine a brick’s colour –the type of clay and the firin process. Petersen uses Danish, German and English clay, either in pure or mixed form. When clients request particularly unusual hues, small amounts of natural clay minerals are added to the mixture.

The bricks are fied at 1,000-1,150°C. Different temperatures influenc the fina colours and appearance. The firin process can also be adjusted by adding to or reducing the amount of oxygen in the kilns. These processes – known as ‘reducing’ and ‘oxidising’ – provide extra colour options.

The variations in clay type and firin processes can be combined in various ways to produce an almost infinit array of colours in the fina product.

For Petersen Tegl, the colouring process can be part of fulfiling a major order for bricks that all have the same tone and play of colour. However, and just as often, it can also be for a project that calls for a batch of bricks all of which have different colour variations.

18

The colours in tile are produced by combining different types of clay and using different firin processes.

Photos: Anders Sune Berg

Kim Reinecker, head of the Department for Colour and Product Development.

Special glazes

Glazed brick has been around for millennia. For example, remains have been unearthed in Mesopotamia of buildings with glazed brick façades built hundreds of years BCE.

Architects have loved the glazed look ever since. It catches and reflect light and can be used to emphasise certain details, sections or colours on the façade.

Petersen Tegl has a special glazing department, which – like the colour department – is constantly experimenting to meet clients’ requirements.

Glazed bricks are produced by applying a liquid glaze after the firs firing The bricks are then fied in electric or gas kilns at varying temperatures so that the glaze melts without affecting the character of the brick. Sometimes, an underglaze is necessary, in which case the brick needs to be fied several times.

19

Bricks can be glazed in an endless variation of nuances.

Public institutions

21

Photo: Julie Vöge Hansen

Maitland Riverlink, New South Wales, Australia

Client: Maitland City Council

Architect: CHROFI Architects

Brick: D71 DNF + 1,180 bricks in custom formats in the same clay

Completed: 2018

Photos: Justin Alexander

Sharp looking soft corners

Custom bricks with sharp corners create a precise profile in a multi-purpose house along a river in New South Wales.

CHROFI knew early on that Riverlink would be brick-built, and that very special materials would be required to achieve the desired effect.

“When you get close to the building and touch it, it conveys a clear sense of something human and recognisable,” explains Joshua Zoeller, architect and senior associate partner at CHROFI.

The surrounding old houses’ brick façades alternate between soft yellow and cream, with some fin sandstone buildings in between.

“Petersen D71 proved to be the perfect match in every respect. It has just the right powdery tone, and there’s even something sandstone-like about it,” Zoeller says.

The Riverlink building is characterised by its sharp, tapered wall corners, which required custom solutions.

“At two of the corners, the walls meet at angles of 18 and 22 degrees, respectively,” says Zoeller. “We had to specially commission a number of bricks from Petersen, including some with rounded corners. While the corners look razor-sharp from a distance, up close, you see they are rounded. This changes the look in a quite unique way.”

22 A2 B2 A1 60° 60° 60° 54° 18° 40° 118° 60° 60° 60° 22° 118° 108° 108° C1. C2. C3. C4. C5. C6. C7. C8. C9. C12. C13. C11. C15. C10. C14. 10040mm 9960mm 8710mm - 8710mm 3570mm 3570mm 2740mm 2730mm 2730mm 2730mm 840mm - 850mm 2785mm 2755mm 9100mm 9040mm 8725mm - 8730mm 2625mm 2625mm 2630mm - 2625mm 2715mm - 2635mm 5090mm 6255mm 9070mm - 9030mm 156 Bricks tall 136 Bricks tall 56 Bricks tall 43 Bricks tall 43 Bricks tall 13 Bricks tall 44 Bricks tall 142 Bricks tall 137 Bricks tall 41 Bricks tall 41 Bricks tall 43 Bricks tall 98 Bricks tall 142 Bricks tall 2730mm - 2730mm 43 Bricks tall A B B1 108°

205 108 186 81 98 203 83 155 228 R25 R25 120° 40° 140° 40º SPECIAL 60º SPECIAL 60°

Ground floo

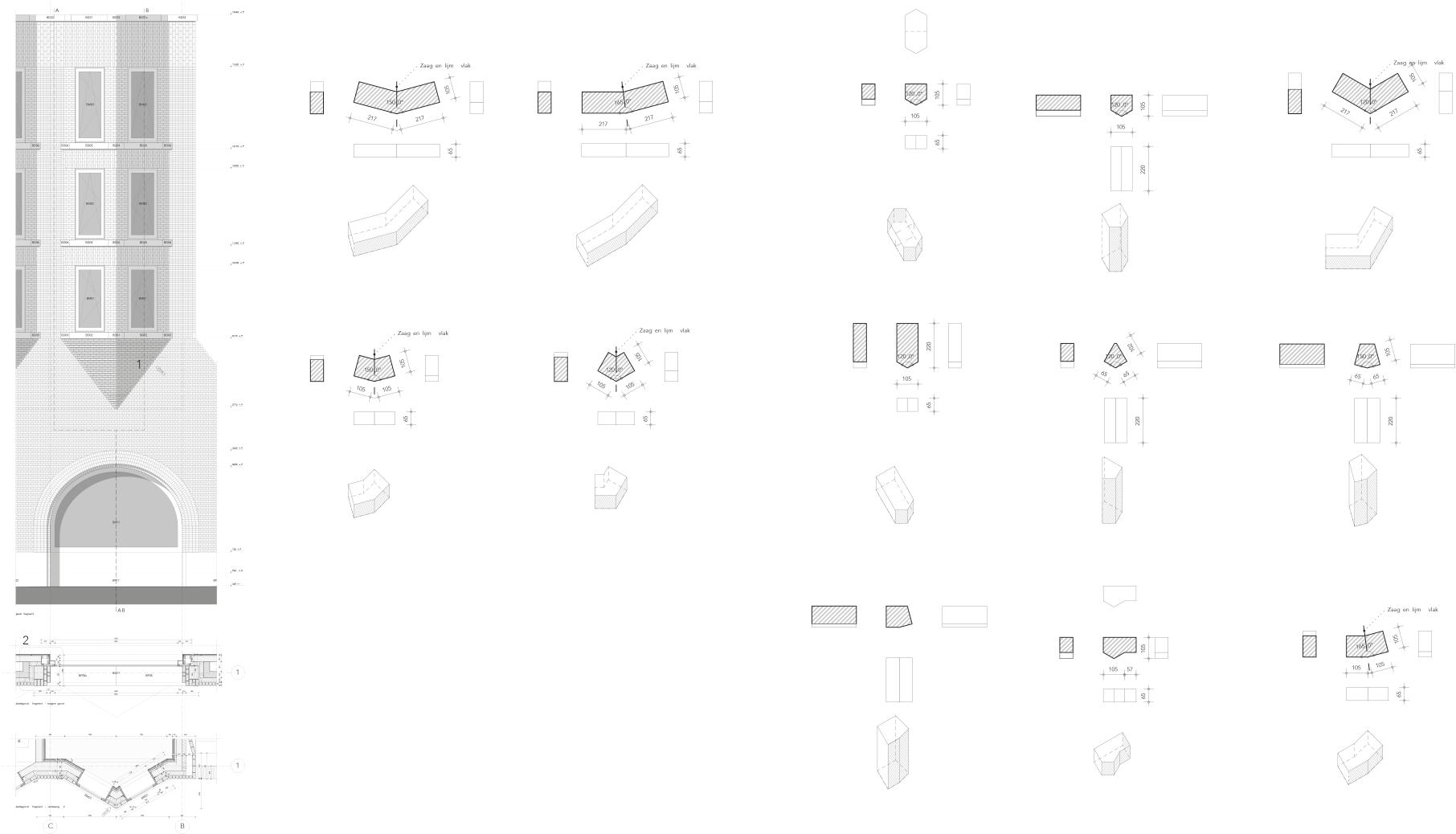

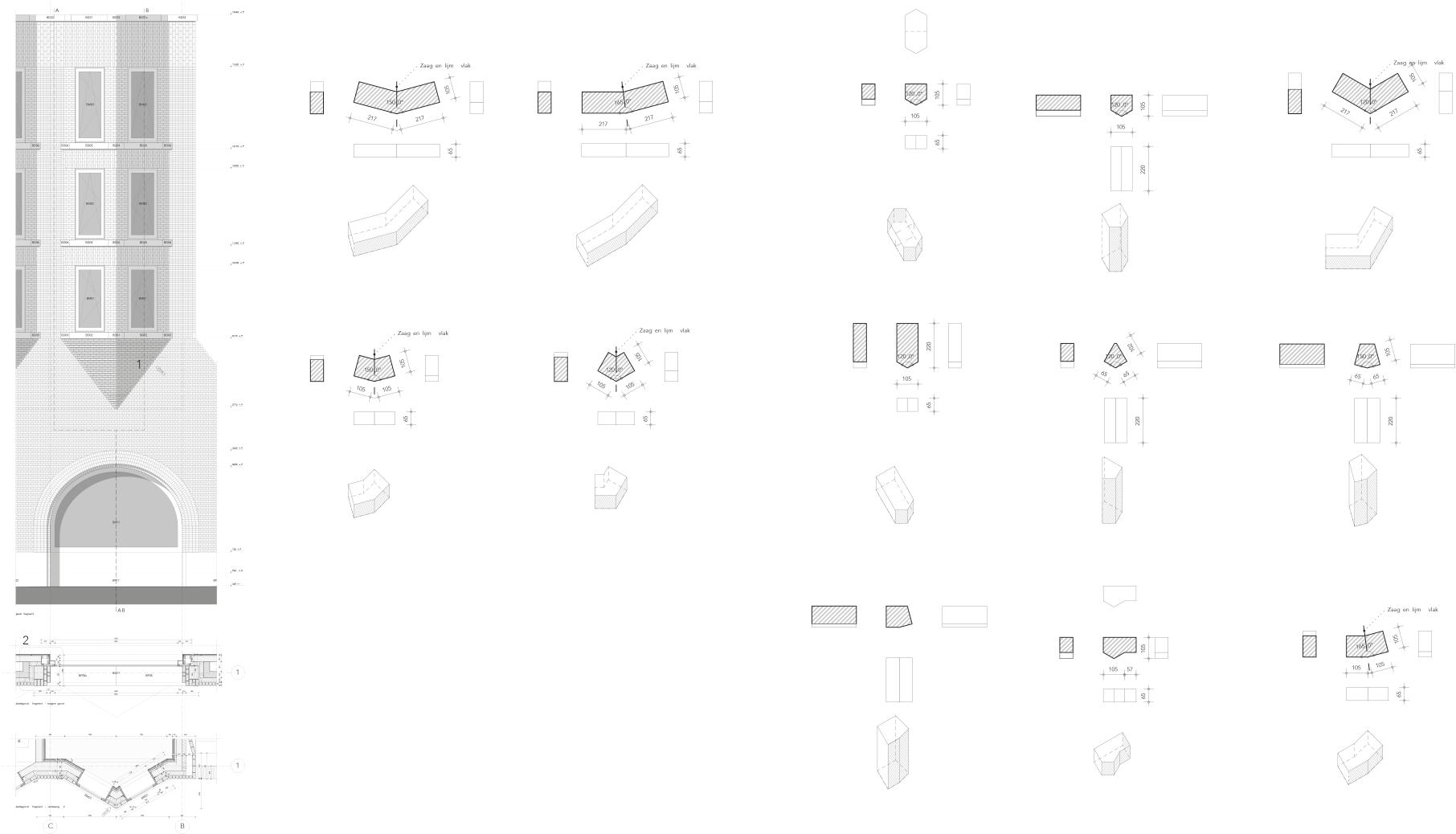

186 25 154 70 81 200 108 217 49 260 188 25 161 68 175 108 55 81 44 205 108 212 254 215 R40 R25 R 40 R40 R25 133° 18° 119° 118° 90° 152° 129° 54° 126° 108° 54º SPECIAL 22º SPECIAL 118º SPECIAL 108º SPECIAL 18º SPECIAL 22° 119° Drawings of the various special format bricks for the project.

24

About Maitland Riverlink

The town of Maitland in New South Wales, on the banks of the Hunter River, has been a thriving trading town for centuries. About 80 years ago, the river began to overflo its banks, and between 1949 and 1955, Maitland repeatedly endured heavy and devastating floods The town stagnated, and the new houses built on the High Street were positioned facing away from the river.

The flooing has since abated, and a project to revitalise the city was launched around 12 years ago. This resulted in the construction of Riverlink, an architectural landmark that re-establishes physical and visual contact between Maitland’s city centre and the Hunter River.

The building is designed as an open gateway between the High Street and the river, and its café and restaurant quickly made it a focal point for the townspeople. Maitland Riverlink also houses office for citizen services and functions as an attractive covered urban space that hosts various outdoor events.

25

Kannikegården, parish hall, Ribe Cathedral, Denmark

Client: Ribe Domsogns Menighedsråd

Architect: Lundgaard & Tranberg Arkitekter

Archaeology: South-west Jutland Museums

Funding for landscape project: Realdania

Completed: 2016

Brick: C48 customised by Lundgaard & Tranberg, 630 x 350 x 50 mm

Photos: Anders Sune Berg

Medieval associations

A special edition of Cover fosters kinship between a new parish hall and the surrounding 12th-century architecture.

It was crucial that the materials used in Kannikegården harmonised with the cathedral and surrounding buildings on the main square, all of which are brick with tiled roofs. At the same time, the parish hall needed its own distinct identity.

The architects and Petersen Tegl developed a special edition of Cover, which was firs used at the Sorø Art Museum in 2011. The custom Cover measures 350 x 630 mm and weighs over 15 kg. From a distance, the clinker-clad surface appears light

compared to the surrounding brick buildings. Up close, the irregularities of the granular brick become obvious, echoing the crooked medieval buildings, for which tolerances were measured in inches.

Its proximity to the buildings to the south dictated that the hall had to be tapered slightly towards the west, leaving a diagonal incision in the roof. The crooked look is common in Ribe, where many buildings have had to adapt to their neighbours over time. This determined the size of the new Cover, as the bricks had to be relatively large to ‘sew’ them together in an elegant manner along the roof edge.

27

The 630 x 350 x 50 mm C48 custom brick is shown next to a 228 x 108 x 54 mm Danish standard brick to indicate the measurements.

Carsten Jørgensen of Petersen Tegl, moulding the special format Cover brick by hand.

About Kannikegården

Kannikegården in Ribe is a long building on the south of the square, opposite the cathedral. It houses facilities for the parish council and cathedral staff, as well as a 100-seat lecture theatre. In the course of the project, an exhibition space was also added, as the excavation work on the site in 2012 uncovered archaeological remains of the cloisters built in 1100 – possibly the earliest brick building in Denmark. Believed to have been part of the refectory wall, the ruins of the old monastery were immediately subjected to a preservation order. They were integrated into the new building and are now on display to the public. An open glass façade stretches the entire length of the ground floo, while the rest of the façades, gables and roofs are covered with brick shells.

Kannikegården was one of fiv finaists in the Mies van der Rohe Award 2017 due to its “exceptional interaction with both the cathedral and the wider urban space. At the same time, it is also a genuine architectural expression of today, providing a functional space and, in particular, underscoring and contextualising the cultural, historical significanc of its setting.”

“Firing bricks is a kind of alchemy. Using mock-ups, the brickworkers were able to make decisions about colour on the site. Tiny adjustments to the oxygen supply in the ovens eventually resulted in just the right mix of rustic red hues to enable the new building to blend in with its surroundings.”

Erik Frandsen, architect, partner, Lundgaard & Tranberg

Erik Frandsen, architect, partner, Lundgaard & Tranberg

28

29

Architects and partners Erik Frandsen and Lene Tranberg, Lundgaard & Tranberg Arkitekter.

Goel Center for Theater and Dance, Massachusetts, USA

Client: Phillips Exeter Academy

Architect: Tod Williams Billie Tsien Architects

Completed: 2019

Brick: K92 + five ifferent formats of handmade, glazed bricks

Photos: Michael Moran, Tom Eckerle

30

Erich Mick, head of the Custom Brick Department.

Bricks in special formats were glazed in three different shades of red and yellow.

Theatre curtain in fiery bric

A flaming ed and orange curtain in glazed, moulded brick welcomes visitors when arriving to a theatre building.

Tod Williams Billie Tsien Architects and their client wanted the Goel Center for Theater and Dance to have a distinctive entrance area, the texture and colour of which would provide a stark contrast to the rustic, grey façades. The vision was for an undulating surface in strong, red hues, resembling a theatre curtain that is pulled aside to let the performance begin. A glass entrance is drawn back from the façade, alluding to the large space behind it.

The vision was realised by the brickworks in Broager, which produced fiv different curved and rectangular bricks, the largest measuring 489 x 511 mm.

The bricks were glazed at the brickworks in red, orange and light brown. To achieve exactly the right shade, the thickness of the glaze had to be precisely measured. Careful consideration was also given to the bricks’ rounded and angular forms in order to achieve the illusion of folds in a hanging curtain. The fact that the brick is made by hand and therefore has a rustic surface means that the colour pigments are distributed somewhat unevenly, which gives the beautiful surface a flame-ike appearance.

31

32

About the Goel Center for Theater and Dance

The square 5,200-m2 building includes an auditorium housing the main stage, a blackbox studio, several rehearsal rooms and dance studios, as well as a whole range of ancillary services. The building has almost no internal symmetries. Instead, it consists of a network of corridors, stairways, and rooms connected in an irregular but extremely functional manner within a square floo plan.

The architectural concept was inspired by a geode – a stone with a rough, uneven outside but a glittering inside. The client wanted the theatre building to contrast a natural, rustic exterior and a radiant and active interior.

Irregular, hard-fied bricks would add precisely the raw simplicity that architects and clients sought. They alighted on a handmade Kolumba, the diverse, greyish hues of which are at once muted and distinctive.

After-school club, Allenmoos, Switzerland

Client: Stadt Zürich

Architect: Boltshauser Architekten AG

Completed: 2013

Brick: K43, custom format 20 x 110 x 530 mm

Photos: Paul Kozlowski

Clinker façades with brick quality

Custom-made, hard-fied clinkers add warmth and rusticity to an after-school club in a Swiss suburb.

When commissioned to transform a school pavilion into an after-school facility in Allenmoos, Boltshauser Architekten originally wanted a brick façade in Kolumba, similar to the facing wall in their own Zurich studio. However, the authorities placed strict limits on the amount of energy used to produce the materials for the pavilion, which precluded using a 37-mm thick brick – the standard Kolumba measurement.

Instead Boltshauser asked Petersen Tegl to produce a custom clinker that was only 20 mm thick, 110 mm wide and 530 mm long. It is directly attached to the underlying 250-mm insulation and pointed with a cement mortar compressed to a couple of millimetres. To ensure the façade was durable, the studio built a 1:1 mock-up that coped admirably with all kinds of weather conditions.

The expansion joints are carefully positioned in all of the outward- and inward-facing corners but deliberately avoided in the middle of the long, north-facing façade. The handmade Kolumba clinker is not completely flat which endows the façade with a welcoming, textured character, avoiding the clinical, bathroom-like feel of many façades clad with tiles or facing bricks. The clinkers’ horizontal format emphasises the building’s resting form, while the vertical joints dispel any association with a massive wall.

A special format of Kolumba was mounted directly onto the façades.

35

36

About the after-school club in Allenmoos

Boltshauser Architekten were commissioned to extend a 1958 school pavilion and convert it into an after-school club for children aged 4-13. The basement and a few concrete walls from the original pavilion turned out to be reusable and have been integrated into the new building. The resulting structure greatly resembles the aesthetic of the original modernist pavilion but has a warmer, more empathetic feel.

The same plot that previously housed six south-facing rooms now hosts five with a connecting corridor along the back. The fla roof is fited with skylight boxes running the length of the building like a backbone.

To the north-west, the building has stairs running down to the basement, toilets and a kitchen with the same proportions and window placement as the

fiv rooms. In the west gable, the main offices large window directly echoes the front door – the only opening presenting itself in the east-facing gable.

One new element is the loggia, which connects the building to the park. From the inside, the loggia feels protective. From the outside, it conveys permeability and transparency.

37

Gothenburg City Library, extension, Sweden

Client: Higab

Architect: Erséus Arkitekter

Completed: 2016

Brick: D32 + customised bricks in three formats

Photos: Ulf Celander

Conic-shaped tile columns

Narrow columns made from custom bricks frame the glass façade of Gothenburg City Library’s extension, elegantly preserving the brick motif on the original building.

Gothenburg City Library has a new three-sided glass extension. It was important to make it blend in with the surrounding cultural institutions, all of which are in yellow brick. The solution was to suspend slender pillars in grey-yellow brick in front of the glass façades.

Viewed head-on, the library looks open and transparent, but from more oblique angles, the exterior is gradually transformed and the brick becomes more prominent. The effect is achieved by the relatively close spacing of the pillars, each of which is two brick lengths deep.

Erséus Arkitekter designed three different moulded bricks, including a conical one that endows the pillars with their tapered shape. The 37-mm-high moulded bricks are made of the same Danish blue clay as D32. The yellow brick has a partially whitish surface, derived from the white, slurried clay used as a lubricant when the lump of clay is pressed out of the mould.

The massive columns in the façade are made of yellow cone-shaped custom bricks.

The massive columns in the façade are made of yellow cone-shaped custom bricks.

Drawings of the special format bricks for the project. Below, detail, horizontal section.

39

40

The initial Gothenburg City Library, inaugurated 1967, designed by Lund & Valentin Architects.

About Gothenburg City Library

Gothenburg City Library is on Götapladsen in Sweden’s second-largest city and is surrounded by several large, historic cultural institutions, all in yellow brick. In order to adapt to its monumental neighbours, the library has its own yellow-brick façades, albeit in a form and idiom reflecing its era.

The building is the third structure to house the city library. The firs was constructed in 1897, and the current one was designed by Lund & Valentin Arkitekter and opened by the author Astrid Lindgren in 1967.

Erséus Architects refurbished and extended the library in 2012-14. The largest section of the extension is north-facing and houses conference facilities, a large café, a new main entrance and a foyer. To increase the library’s footprint and retain the link with the nearby park, the architects wrapped an extension around the existing building on three sides.

41

Floorplan, 2nd floo. Extension marked.

City Circle Line (M3), Copenhagen, Denmark

Client: Metroselskabet (Copenhagen Metro)

Architect and engineer: COWI, Arup Systra JV

Main contractor: Copenhagen MetroTeam CMT, a Salini Impregilo Group Company

Completed: 2019

Brick: Custom format Kolumba in various colours

Brick suspension system: Fischer

Photos: Anders Sune Berg

“We asked Petersen to produce the bricks because we know they welcome challenges and are happy to develop new products. And we weren’t disappointed. It was an eye-opener to meet artisans willing to experiment tirelessly throughout the development process, with minor variations during the firing process, until the bricks had exactly the look we wanted.”

Nille Juul-Sørensen, architect and associate, Arup

Underground textures

Each of the 17 new stations on the recently completed City Circle Line has its distinct look. Four have wall panels made of handmade brick.

Aksel Møllers Have Station

Located in Frederiksberg, home to many fine ornate buildings. Many of the local façades are decorated with glazed brick, which inspired the decision to glaze the station bricks diagonally, creating a beautiful play of light. Brick: K21 with glaze.

Nørrebros Runddel Station

Located right by Assistens Cemetery, where the surrounding buildings are made of brick. Using a single type of light-coloured brick and a single overhead light source underscores the sense of a sacred place. The golden hue also references the yellow-washed walls around the cemetery. Brick: K71.

Nuuks Plads Station

Three bricks in three different shades of grey reference a neighbouring building from 1964, clad in black slate – the National Archives’ storage facility, designed by architect Nils Koppel. A powerful, natural material was needed to complement this iconic Copenhagen building, and a greyish hue was an obvious choice. Brick: K91, K51, K50.

Enghave Plads Station

The neighbourhood around the station is dominated by heavy, dark, brick buildings that stretch all the way back to Copenhagen Central Station. The combination of three types of red bricks creates a surface that evokes most of the red nuances that meet the eye above ground. Brick: K23, K33, K36.

Aksel Møllers Have Station

43

About the City Circle Line

The City Circle Line has a consistent design language both above and below ground. At street level, the stations are easily identifiabl by their glass lift towers and daylight-channelling prisms.

The stations are hugely important structures and have to stand out in the urban space – many Copenhageners have an emotional attachment to the station nearest their home. Each station has a distinct look due to its wall cladding, which varies in the different parts of the city.

For example, the wall panels in the Marmorkirken (Marble Church) station are clad in Gotland limestone, referencing the architecture of the Frederiksstaden area, which is characterised by natural stone.

Brick was chosen for the four stations as a recognisable, very Danish and particularly tactile material. The wall panels – a modifie version of Kolumba – are mounted on a lightweight steel construction supplied by Fischer, behind which is a space for cables. As Kolumba is handmade, it has a certain amount of tolerance in terms of measurements.

All the bricks were calibrated to within a few millimetres on the short side to achieve a precise measurement, allowing them almost to touch. The largest surface of the bricks faces outwards, creating a uniform but distinctly rustic idiom.

44

Nuuks Plads Station

45

Nørrebros Runddel Station

Enghave Plads Station

Andlinger Center for Energy and the Environment, Princeton University, New Jersey, USA

Client: Princeton University

Architect: Tod Williams & Billie Tsien Architects

Associated architect: Ballinger

Completed: 2016

Brick: K92 + 18 different custom format bricks in the same clay

Photos: ©Michael Moran/OTTO

Idiom humanised by brick

The brickwork in a recently built Princeton building blend in with the surrounding brick architecture and expresses at the same time the look of natural stone.

Most of the buildings at Princeton University are built in grey stone and red brick. For the Andlinger Center for Energy and the Environment, architects Tod Williams & Billie Tsien and their client chose the light-coloured K92. The wild bond gives the building a handmade structure and texture but with shades reminiscent of light-coloured natural stone.

The Andlinger Center is composed of precise and minimal shapes and completely smooth façades, with recessed windows and doors. The architects insisted that every edge and corner in the building should merge seamlessly and without dissonance. To achieve the harmonious façades, they used 18 customised bricks made of K92 clay, which blends into the brickwork without making a fuss. One of the custom products is a brick measuring 483 x 483 mm, which gives a beautiful finis on the walls around the large multi-level terraces.

“Engineering is a bridge discipline, no longer a pure study of chemistry, mathematics or biology. There is now much greater recognition of the need for engineering and the humanities to work side-by-side. The desire to convey this coming together of the two disciplines determined the choice of material for the Andlinger Center, and the use of Petersen brick humanised the overall expression.”

Billie Tsien, architect

Export manager Stig Sørensen, architects Billie Tsien and Tod Williams, brickworks owner Christian A. Petersen.

47

Various custom bricks were designed for the project. A brick, 483 x 483 mm, height sloping from 57 to 37 mm, finishe the walls around the large terraces. The custom brick is shown next to a 228 x 108 x 54 mm Danish standard brick to indicate the measurements.

About Andlinger Center for Energy and the Environment

Princeton University was founded in the New Jersey town of the same name in 1746 and is the fourth-oldest institution of higher education in the United States. An Ivy League university alongside Harvard and Yale, Princeton consists of more than 200 buildings, including Nassau Hall from 1756, which served as the original United States Capitol building.

Tod Williams & Billie Tsien Architects were commissioned to design one of the most recent additions to the Princeton campus. Called the Andlinger Center for Energy and the Environment, the facility is devoted to research into sustainable energy production.

Some of the labs in the Center conduct research into materials at the atomic level, which requires an ultra-low-vibration environment. To achieve that level of stability, the labs had to be built directly on bedrock – i.e. below ground level. The 12,000-m2 building is divided into three pavilions – two containing laboratories and one a lecture theatre. The sunken gardens allow plenty of daylight to reach the subterranean rooms.

48

In terms of colour, the masonry in Andlinger Hall matches the greyish, sedimentary stone called argillite used, for example, in Princeton University’s Blair Hall, built in 1897.

49

Christian IV’s Brewhouse, Copenhagen, Denmark

Builder: King Christian IV

Completed: 1608-1762

Repairs to the brickwork on the façade, 1996

Brick: Medieval format bricks, 285 x 140 x 85 mm made in custom colours of red and blue clay

Architect: Bornebusch

Photos: Anders Sune Berg

New bricks with 17th-century patina

As part of the façade repair, new bricks replaced ones that were 400 years old – and the difference is imperceptible.

The façades on the Brewhouse, parts of which are almost 415 years old, occasionally need an overhaul. The last time bricks were replaced was about 25 years ago. Bornebusch have been associated with Christian IV’s Brewhouse for many years.

In 1996, following a survey of the state of the building and options for the interior, Bornebusch undertook repairs to the façades. At that time, the brickwork looked mottled, with an age difference of up to 200 years between the oldest bricks, dating from 1608, and the sections rebuilt after two major fies.

Brickwork is well suited to repairs, as individual bricks can easily be replaced. The challenge is to fin bricks that are a good fi for the existing look. For the restoration of the façades of Christian IV’s Brewhouse, Bornebusch and Petersen Tegl developed a custom brick measuring 285 x 140 x 85 mm. With their rich play of reddish, greenish and yellowish shades, the new bricks blend in beautifully with the surrounding medieval ones.

50

About Christian IV’s Brewhouse

With its enormous roof surfaces and huge, flame-ed medieval brick façades, Christian IV’s Brewhouse is one of Copenhagen’s most spectacular historic buildings. Built by King Christian IV more than 400 years ago, it was designed as a strong bastion and formed part of Copenhagen’s defences. To this day, the aloof, enigmatic, approximately 8,000-m2 building overlooks the waterfront and Frederiksholms Canal.

After the construction of the fortress town of Christianshavn, the bastion lost its military importance, and in 1618 it was converted into a brewery for the military. After fies in 1632 and 1767, the brewery was moved to a new address in the town. It was rebuilt in its current form and spent two centuries as a warehouse for the Royal Arsenal Museum, among others.

With its angled floo plan, up to 2.5-metre-thick exterior walls, and numerous cross vaults and cylinder vaults, the building’s sturdy, brick-built ground floo clearly resembles a military fortificaion. The ground floo consists of one vast room called ‘The Brick Ceiling’. It is built in a style reminiscent of older warehouses, with a timber roof structure that rises to a height of six storeys.

51

Commercial

53

Photo: Anders Sune Berg

Konvert, headquarters, Kortrijk, Belgium

Client: Konvert NV

Architect: Bureau Goddeeris Architecten

Completed: 2019

Brick: Kolumba in custom colour, F261, F264, F287 various formats bricks in the same types of clay

Photos: Luuk Kramer

Blue brick echoes branding

The addition of minerals to the clay conjures up blue tones in the finished brick hat match the company’s logo.

The client and architect wanted Konvert’s new headquarters to look architecturally straightforward, which made materials of the highest quality an obvious prerequisite. They also wanted the building to be as flexibl as possible.

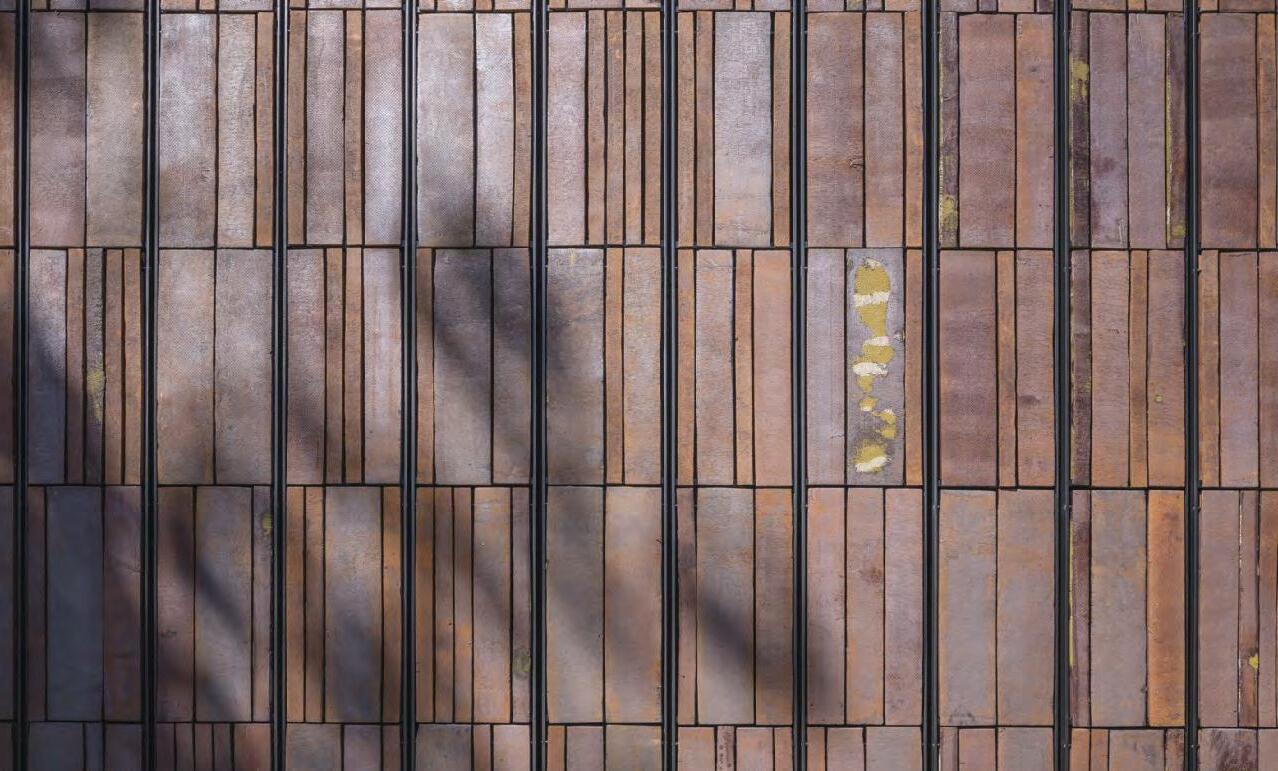

Load-bearing concrete columns are incorporated into the façades, which makes some storeys column-free and affords the maximum interior flexibiity. The façades are rhythmic and minimal, with rectangular window sections without parapets, pulled back from the façade. Closed sections around the service cores enclose two of the gables. The brick borders that frame the window sections are cut at oblique angles, which makes the surfaces visible from all directions and creates a fascinating depth effect.

Kolumba was chosen for the façade to emphasise the building’s horizontal lines. Konvert wanted a distinctive look that would echo the company’s visual identity. Along with Petersen brickworks, they designed three custom bricks that use minerals to create the same delicate blue shades as Konvert’s logo.

To achieve brickwork that perfectly and silently wraps around the building, the architects designed a total of 43,500 custom bricks. These are deployed around the windows, doors, corners, crowning walls and on the undersides of lintels.

At firs glance, you might not notice the custom bricks. But that is the point – the impression is of a beautifully tailored wall surface that does not instantly give up the secret of how it was achieved.

Kolumba in three custom colours.

55 90 20 doorsnede aanzicht 15.5 15 25 grondplan 25 12 15.2 25 99.75 21x4.75=99.75 98.7 98.7 60.7 60.7 60.7 45 45 64 64 18 33 14 33 18 aanzicht 60.7 25 15.2 98.7 45 45 64 25 15.2 45 45 64 33 18 25 15.2 98.7 45 45 64 B' B' C D D B' A E' E F B B C D B A C G G B' B B B B B B B' B' B' B' B' B' B' A A A A A A A A A A A B B B B B B B' B' B' B' B' B' A A A A A A A A A A A E E' B' A E B E' B' A E B B' A E B E' B' A E B E' E' E' E E E E E E H H H E' A E B E' B' A E B E' B' A E B E' B' A E B E' B' A E B 630 18 18 18 18 laag 1 laag 2 E' B' A E B laag 1 laag 2 laag 1 laag 2 B B' B' B B' B' B B B laag 1 laag 2 grondplan grondplan grondplan 361 D E F B A B' C E' dorpel lateien 7 56 25 56 25 56 25 56 25 10.8 107° 107° 11.75 10.8 22.2 47.75 10.8 10.8 4.58 17.81 52.8 30.75 12.75 12.75 30.75 36.5 3.7 56.25 61.44 66.76 67.81 5 107° 11.75 90° 163° 66.76 71.15 163° 107° 10.8 10.8 10.8 10.8 10.8 53.3 7.2 10.8 5.5 4.51.2 66.76 0.4 steenstrips 10.8 17 56 17 17 56 17 17 56 17 17 56 17 10.8 10.8 11.75 12.75 12.75 30.75 4.58 53.71 163° 9.91 60.8 90 20 doorsnede aanzicht 15.5 15 25 grondplan 25 12 15.2 25 99.75 21x4.75=99.75 98.7 98.7 60.7 60.7 60.7 45 45 64 64 18 33 14 33 18 aanzicht 60.7 25 15.2 98.7 45 45 64 25 15.2 45 45 64 33 18 25 15.2 98.7 45 45 64 B' B' C D D B' A E' E F B B C D B A C G G B' B B B B B B B' B' B' B' B' B' B' A A A A A A A A A A A B B B B B B B' B' B' B' B' B' A A A A A A A A A A A E E' B' A E B E' B' A E B E' B' A E B E' B' A E B E' E' E' E E E E E E H H H E' A E B E' A E B E' B' A E B E' B' A E B E' B' A E B 630 18 18 18 18 laag 1 laag 2 E' B' A E B laag 1 laag 2 laag 1 laag 2 B B' B' B B' B' B B B laag 1 laag 2 grondplan grondplan grondplan 361 D E F B A B' C E' dorpel lateien 7 56 25 56 25 56 25 56 25 47.75 10.8 107° 107° 11.75 10.8 22.2 0 10.8 10.8 4.58 17.81 30.75 12.75 12.75 30.75 36.5 3.7 56.25 61.44 66.76 67.81 5 107° 11.75 90° 163° 66.76 71.15 163° 107° 10.8 10.8 10.8 10.8 10.8 53.3 7.2 10.8 5.5 4.51.2 66.76 0.4 steenstrips 10.8 17 56 17 17 56 17 17 56 17 17 56 17 10.8 10.8 11.75 12.75 12.75 30.75 4.58 163° 10.8 9.91 60.8 90 20 doorsnede aanzicht 15.5 15 25 grondplan 25 12 15.2 25 99.75 21x4.75=99.75 98.7 98.7 60.7 60.7 60.7 45 45 64 64 18 33 14 33 18 aanzicht 60.7 25 15.2 98.7 45 45 64 25 15.2 45 45 64 33 18 25 15.2 98.7 45 45 64 B' B' C D D B' A E' E F B B C D B A C G G B' B B B B B B B' B' B' B' B' B' B' A A A A A A A A A A A B B B B B B B' B' B' B' B' B' A A A A A A A A A A A E E' B' A E B E' B' A E B E' B' A E B E' B' A E B E' E' E' E E E E E E H H H E' A E B E' A E B E' B' A E B E' B' A E B E' B' A E B 630 18 18 18 18 laag 1 laag 2 E' B' A E B laag 1 laag 2 laag 1 laag 2 B B' B' B B' B' B B B laag 1 laag 2 grondplan grondplan grondplan 361 D E F B A B' C E' dorpel lateien 7 56 25 56 25 56 25 56 25 47.75 10.8 107° 107° 11.75 10.8 22.2 0 10.8 10.8 4.58 17.81 30.75 12.75 12.75 30.75 36.5 3.7 56.25 61.44 66.76 67.81 5 107° 11.75 90° 163° 66.76 71.15 163° 107° 10.8 10.8 10.8 10.8 10.8 53.3 7.2 10.8 5.5 4.51.2 66.76 0.4 steenstrips 10.8 17 56 17 17 56 17 17 56 17 17 56 17 10.8 10.8 11.75 12.75 12.75 30.75 4.58 163° 10.8 9.91 60.8 Elevation, window section Horizontal section Drawings of various special format bricks produced for the project.

56

About Konvert HQ

Konvert is a company based in West Flanders. Its portfolio spans a wide range of industries and includes service companies, employment agencies, offic administration, waste management and security services. In Kortrijk alone, Konvert employs 2,275 people.

In 2019, the company inaugurated a new headquarters in Kortrijk covering a total of approximately 6,000 m2 spread over six floors A figue that includes a partially subterranean ground floo and an underground car park the size of the whole building.

The new building is in a prominent spot on Kennedylaan, a broad avenue that runs through central Kortrijk. The building is designed as a wing located parallel to the avenue, with two smaller buildings on each side, forming a double L-shape. The side wing facing away from the avenue incorporates a large terrace overlooking surrounding green areas.

The various floor inside the building are designed as large, flexibl work areas, with service cores located at the front of the two wings. At the top of the building is a large terrace where staff gather for informal meetings and to enjoy unobstructed scenic views.

57

1A Page Street, Victoria, London, England

Client: Derwent London

Architect: PLP Architecture

Completed: 2014

Brick: D45 DNF custom colour + three bricks in custom format in the same clay

Photos: Philip Vile

“The people at the brickworks are just as passionate as we are. They don’t rest until the right brick is found for each building – and everything is possible in terms of colours and custom formats.” Simon Silver, director, retired, Derwent London

Glass converted to brick

Custom formats made it possible to clad the building in brick and to match the heritage building across the street.

The beautifully proportioned façades of 1 Page Street, in London’s prestigious Victoria district, give little indication of the enormous amounts of planning involved. The previous glass and steel cladding dated from 1999 and looked out of place in the area. As part of a complete renovation a decade ago, PLP Architecture proposed new brick façades.

“Normally, a building’s size is based on the dimensions of the bricks. In this case, the façade would have to be adapted to fi the existing concrete construction behind it. We had three extra formats specially made, and each brick was laid vertically to make the bond work. The John Islip Street corner is not a right angle, which is reflecte in the architecture, so Petersen produced a custom brick with an angle of 115°. Since the ceiling height varies throughout the building, we also had to intervene on the vertical plane – not that it’s visible in the finishe façade – to get the bonds to work,” explains Ron Bakker, architect and partner at PLP.

59

Architect, director, Amy Holtz Mathy and architect, founding partner, Ron Bakker.

Elevation, window section.

The position of the special format bricks in the façade.

60

About 1A Page Street

After purchasing 1A Page Street, Victoria, owner and operator Derwent London decided to restore the approximately 16,000-m2 building so it more closely reflecte its upscale neighbour, Horseferry House in Dean Ryle Street, also owned by Derwent. Architecturally, brick and sandstone façades were the obvious choice for Page Street. Burberry, which leases both buildings, also expressed a desire for a more coherent look.

“Finding the right brick was crucial. We knew from working with Petersen Tegl in the past that they are just as passionate as we are,” says Simon Silver, former Derwent director.

“The tolerance of the bricks is also hugely important. All Petersen bricks are slightly different sizes, which results in an irregular and rich façade. The coal firin also gives each brick a crystalline surface that reflect light and enhances the

effect,” adds architect Amy Holtz, CEO of PLP Architecture.

“At first we intended to use a mixture of bricks,” Bakker continues, “but during a visit to Broager, we spotted a brick that was not only red but also had the hints of purple and blue present in Horseferry House. It had been discontinued a decade ago, but Petersen was, of course, willing to resume production specificaly for our project.”

61

The building was previously covered with glass and steel. The extensive renovation included new brick façades.

Horseferry House across the road, rightmost, inspired the look of 1A Page Street.

Astoria House, Stockholm, Sweden

Client: Humlegården

Architect: 3XN

Completed: 2020

Brick: F154, custom format

Photos: Rasmus Hjortshøj, Ulf Celander

Unifying tiles

Innovative use of brick on the roof and façade adds a unique and modern twist to a new building complex.

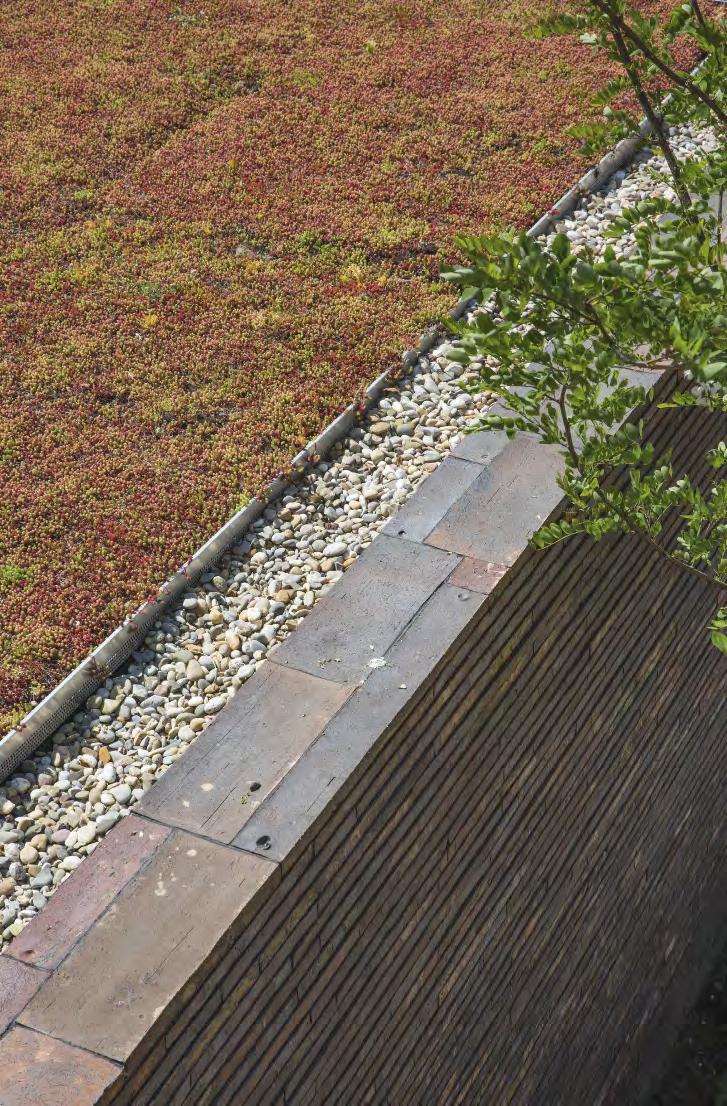

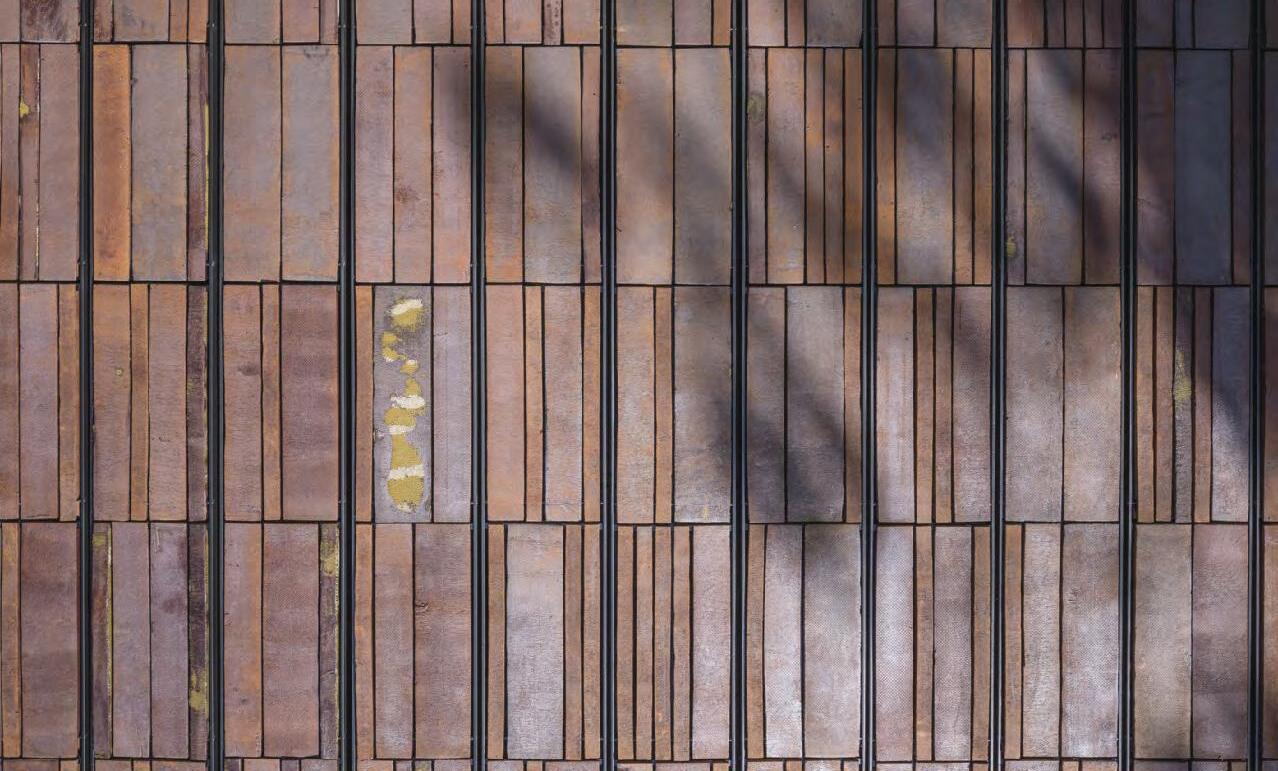

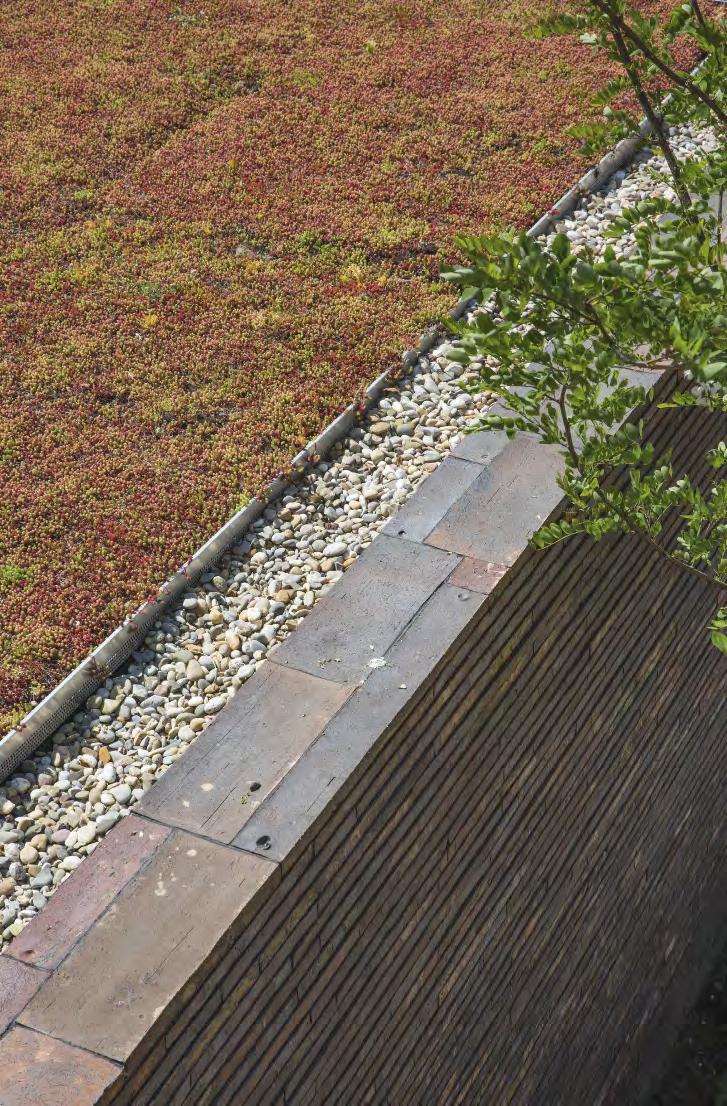

To unify the whole complex, the big new roof covering both the restored Astoria House and the newly built adjacent offic building was to be clad in one material.

“It was only natural to go in the direction of brick, which is used in older buildings in the area,” says architect Audun Opdal of 3XN. “It was crucial for us that the new building would look weathered right from the very beginning as if it had been there for years and years, and at the same time it should be contemporary. We felt that bricks from Petersen could be the element that tied the two buildings together, particularly if we bypassed traditional, joint-based masonry and instead developed a new way to lay the bricks.”

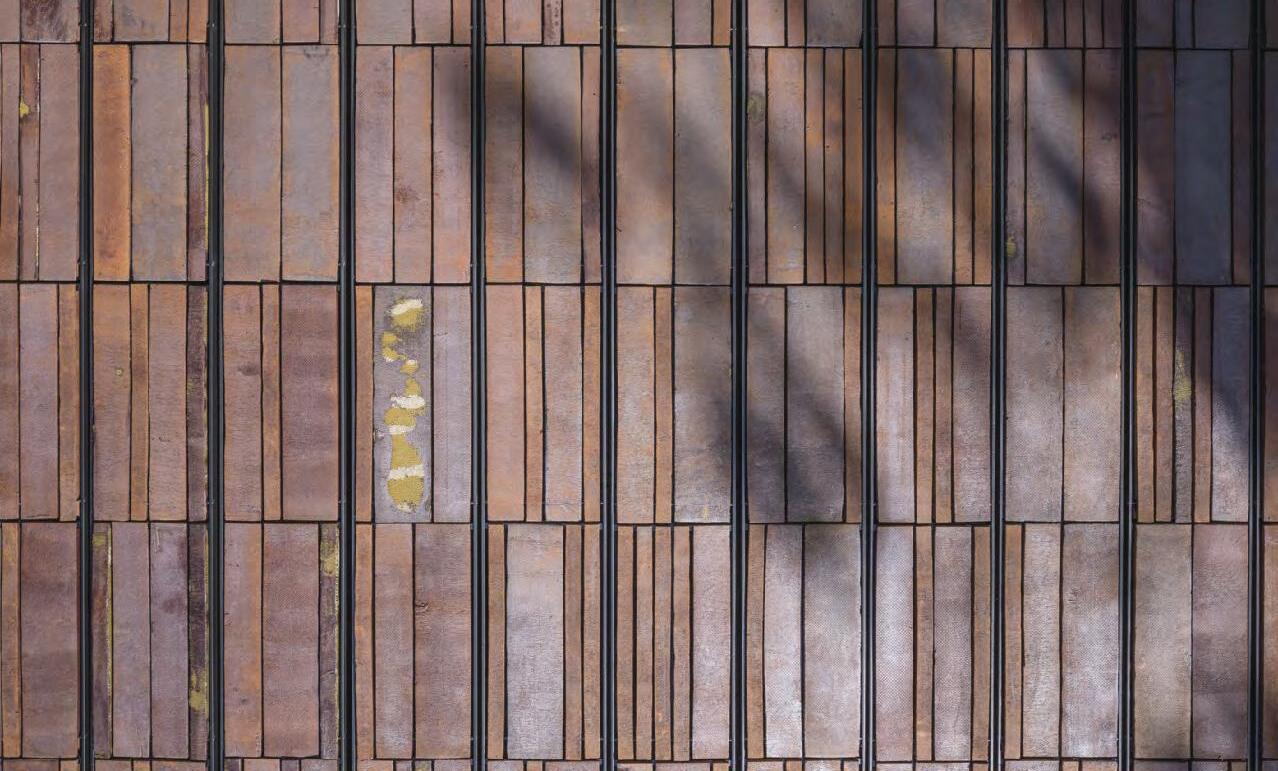

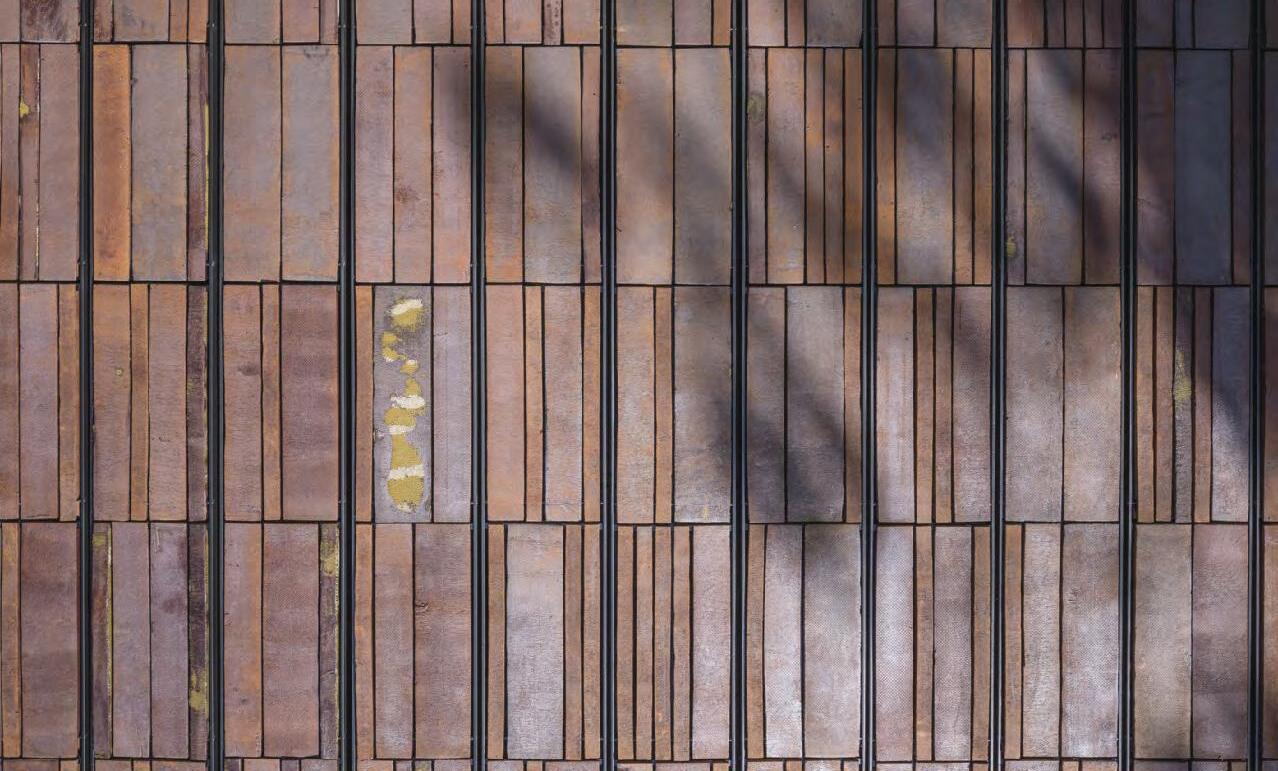

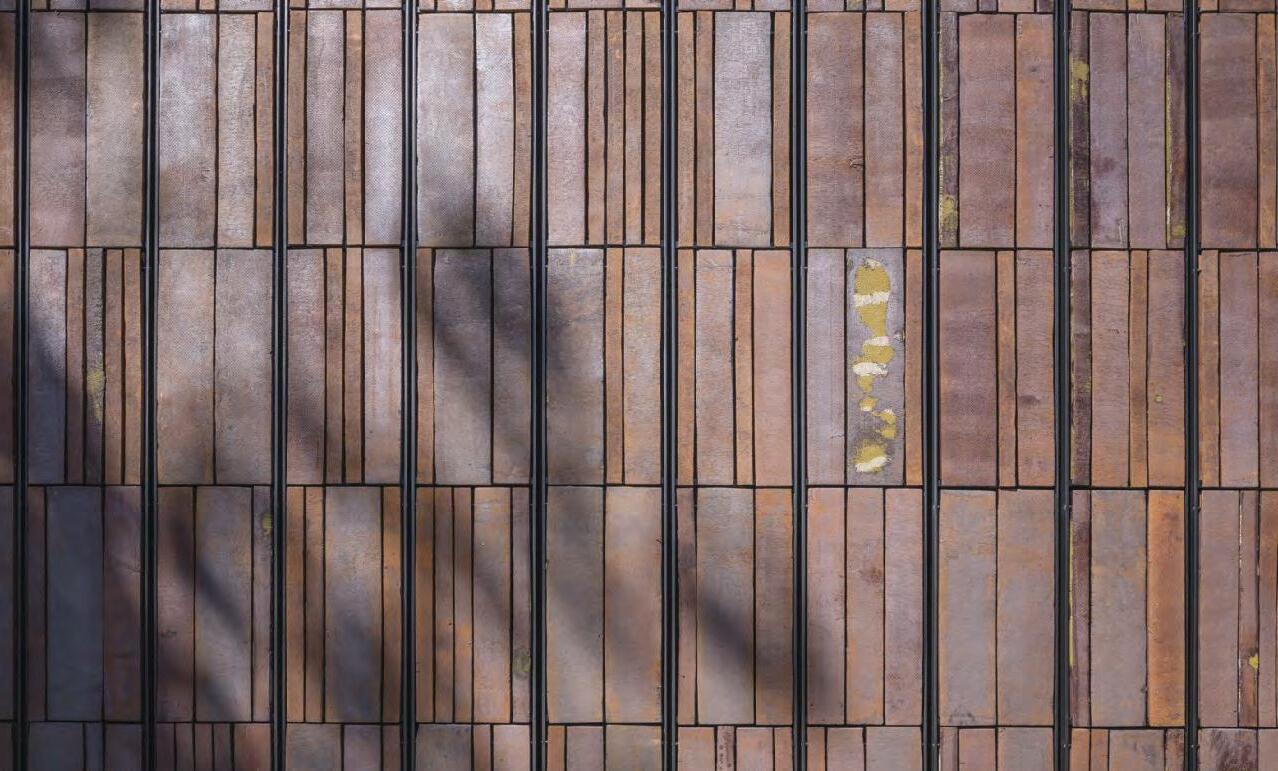

The brickworks and the architects experimented to fin the right brick and a suitable mounting technique. The result was a special edition of Kolumba, 800 mm long, in a deep, rusty red. To get the most out of the hand-moulded bricks’ rich play of colours and uneven texture, the architects decided to mount them on the façade vertically, with the broad, more rustic underside facing outwards. This resulted in a completely new brickwork effect.

62

The cinema in Nybrogatan opened in 1928 and closed in 2007.

64

About Astoria House

Before it closed in 2007, the Astoria on Nybrogatan, Östermalm, Stockholm, was one of the Swedish capital’s oldest and best-known cinemas. The property that housed the cinema was known as Astoria House. Originally home to luxury apartments, the upper storeys were later converted into offices

An extensive and very successful restoration of the property was combined with the construction of a new 6,000-m2 offic building next door, replacing a former outbuilding. The preserved part of the complex, including the façade and the entrance to the former cinema on Nybrogatan, has been superbly and sensitively returned to its original residential use.

The overall project, handled by 3XN, has re-established the address as a contemporary landmark in Östermalm.

The complex’s roof is its most striking feature. The unique, two-storey construction starts as a pitched roof atop the preserved Astoria House and from here rises in a twisting movement over the new building volume, ending in a right angle - as a greeting to the neighbouring fie walls. In the process, the two storeys inside the pitched roof are transformed into more conventional offic space.

65

Turnmill office builing, Clerkenwell, London, England

Client: Derwent London

Architect: Piercy&Company

Executive architect: Veretec

Completed: 2015

Brick: Three custom colours in Kolumba, F56, F58, F59. 27 custom format bricks made of the same clay

Photos: Allan Crow, Philip Vile

Adapting 18th-century colours

85,890 handmade bricks in 27 formats and three special colours make an office block in Clerkenwel simultaneously stand out and fit in

Brick was always going to be used to clad the building. It is the classic Clerkenwell material – unlike the City of London to the east, which is all about glass and steel. Machine-made bricks were also out of the question. At first the architects Piercy&Company and client Derwent London envisaged dark shades to reflec the building’s kinship with the nearby railway buildings. Along the way, however, they looked to the listed Session House across the road, which was built as a courthouse in 1780 using sandstone in various shades of warm grey.

The architects and client chose the handmade, 528-mm-long Kolumba due to the vertical profil of the building. However, the colours they wanted were not in the standard Kolumba range, which was either too grey or too golden compared to the sandstone of Session House. Instead, they developed three subtle, special colours at the brickworks in Broager. One complicating factor that emerged from the development work was that the light in London differs from that in Denmark.

The architects could not make fina decisions about shades until the bricks were mocked-up in situ with the right mortar. The three colours were mixed so that bricks of the same tone do not appear beside each other.

As well as producing three special colours, Piercy&Company designed 27 different custom bricks to accommodate a range of architectural details.

The colours for the new version of Kolumba were inspired by the sandstone façades on the 18th-century Session House next door.

67

Architects Henry Humpfreys and Stuart Piercy, Piercy&Company and Simon Silver, Derwent London, in the lobby at Turnmill.

Architects, client and the brickworks experimented for months with colours for the new Kolumba bricks.

The three new Turnmill colours which are now to be found in the standard range of Kolumba.

Architects Henry Humpfreys and Stuart Piercy, Piercy&Company and Simon Silver, Derwent London, in the lobby at Turnmill.

Architects, client and the brickworks experimented for months with colours for the new Kolumba bricks.

The three new Turnmill colours which are now to be found in the standard range of Kolumba.

69

Standard Brick

Brick Special Type F

Brick Special Type A

Brick Special Type Ch

Brick Special Type B

Brick Special Type Dh

Brick Special Type C

Brick Special Type Eh

Brick Special Type D

Brick Special Type Fh

Brick Special Type E

Brick Special Type G1

Brick Special Type F

Brick Special Type G2

Brick Special Type Ch

Brick Special Type G2h

Brick Special Type Dh

Brick Special Type H1

Brick Special Type Eh

Brick Special Type H2

Brick Special Type Fh

Brick Special Type H2h

Brick Special Type G1

Brick Special Type I

Brick Special Type G2

Brick Special Type G2h

Brick Special Type H1

Brick Special Type H2

Brick Special Type H2h

Brick Special Type I

70

Drawings of some the many custom bricks designed by the architects.

71 03 04 02 Brick Special Type FH

Dogleg Brick Special Type E Cill Brick Special Type B Reconstituted

Perforated

03 04 02 Brick Special Type FH

Dogleg Brick Special Type E Cill Brick Special Type B

Perforated

Extent

of

brick-faced precast lintels dashed red

Stone Coping

Masonry Parapet

Extent of brick-faced precast lintels dashed red

Reconstituted Stone Coping

Masonry Parapet

Elevation, façade section. Plan, horizontal section.

About Turnmill

The delicate, light and shimmering colours and the bricks’ handmade structure give the façade of the six-storey offic building the appearance of a refined woven piece of cloth, while the edifices volume and solidity invoke associations with the centuries-old warehouses that have played a key role in the local area’s colourful history.

The Great Northern Railway Company constructed the original building in 1886 as a multi-storey stable for the horses that used to pull the carriages on the underground. The local authority was very keen to preserve the building, even though all the original interior details had disappeared over the years.

Piercy&Company analysed all the options for the building but ultimately decided that it would not be suitable for either housing or offices In consultation with the London Borough of Islington, a decision was finaly made to demolish and rebuild, on condition that the new building would make a more positive contribution than the old building in both architectural and material terms –and it does.

72

Lukas Thomsen, part of the 9th generation of the Petersen family, designing the street number for Turnmill.

73

Tivoli Corner, Tivoli Gardens, Copenhagen, Denmark

Client: Tivoli

Architect: Pei Cobb Freed & Partners

Completed: 2017

Brick: Custom colours and formats of Petersen Cover developed by Pei Cobb Freed & Partners in cooperation with Tivoli

Photos: Anders Sune Berg

Inspired by local heritage

Handmade bricks forge a connection between Tivoli’s most recent addition and the 180-year-old amusement park.

The rear façade of Tivoli Corner, facing the gardens, comprises undulating terraces with green outdoor spaces. Although the surfaces are sub-divided and spread over different levels, the building has a unifie feel – not least thanks to the brick cladding chosen by Tivoli and Pei Cobb Freed & Partners, which has a natural look that complements the greenery of the Gardens. Denmark’s wonderful brick heritage, including the Church of the Holy Trinity, was a source of great inspiration for the architects so using natural Danish materials to pay homage to the history of Tivoli was an obvious choice.

The new building stands between the ceramic-tiled main entrance to Tivoli Gardens from 1890, and Hotel Nimb, with its Moorish-inspired façade in Venetian marble. As they wanted to establish a dialogue with the two older buildings, the architects commissioned Petersen Tegl to develop a special edition of Cover for the new brick façade. The result is a Danish blue-clay brick made in wooden moulds, using a greyish-white slurry as lubricant. Its white and yellow shades reflec the colours of the neighbouring buildings.

As well as the unique colour, the architects and client chose a special format that results in slightly less relief in the clinker-built construction. Another custom format is used on the façade facing Bernstorffsgade, where the bricks are flus with the façade.

According to the architects, the history of Copenhagen is reflecte in the layers of materials used on its façades over the centuries, for example, this wall in Fiolstræde in the old city centre. These materials served as a source of inspiration for the work on the façades at Tivoli Corner.

Cover samples in various colours and with various level of slurry were inspected at the brickworks.

The architects wanted façades with a limited profil and shadow effects, a look achieved by using this L-shaped custom version of Cover.

About Tivoli Corner

Tivoli Corner is the name of the latest attraction built as part of Tivoli’s mission to connect with the surrounding city. The 8,500m2, four-storey building on the corner of Bernstorffsgade and Vesterbrogade was designed by the American architects Pei Cobb Freed & Partners. Architect and partner Ian Bader has been the designer on the project since its initial conception 15 years ago. Accessible from both the Gardens and the street, Tivoli Corner houses restaurants, cafes, shops and a modern food hall with takeaway outlets and sit-in dining, all under one roof.

Facing the street, the exterior is decidedly urban, comprising two dynamic, undulating glass bands with vertically integrated rotating slats that provide shade and alter the view between the interior and the street. The two floor behind the glass house a restaurant and 21 new rooms of the five-sta Nimb Hotel. By day, the glass façade reflect the surrounding buildings and absorbs the colours of the city. By night, it sparkles and twinkles, enticing visitors to experience the fairy-tale adventures within.

76

77

A flat custom version of Cover, used as a smooth cladding on the façades facing out to the city.

Kville Saluhall, Gothenburg, Sweden

Client: Älvstranden Utveckling

Architect: Gustav Appell Arkitektkontor

Completed: 2016

Brick: D71 FF + custom brick in the same clay with clear glaze

Photos: Ulf Celander

Shimmering brick

Glazing selected bricks reveals a surprising, illuminated pattern in a certain light.

Architect Gustav Appell’s vision for Kville Saluhall was for an architecturally simple structure, which required a brick with a strong idiom.

“The brick had to be handmade to bring the façade to life,” he explains. “We chose a yellow one that derives its light tones and unusual play of colours from the white porcelain clay used to ease the lump of clay out of the mould after the firin process. In the end, we decided on Flensburg Format, which is very elegant and works well with the other building components.”

Seeking a distinctive aesthetic for the façades, the architects decided that selected bricks would glisten when they caught the sunlight at certain angles. So they asked Petersen Tegl to glaze a number of bricks before firing

“The effect was just as refine and understated as we had hoped,” says Appell. “Once the building work was completed, we had the pleasure of the client and partners telling us that the brick had been worth the money and that they were glad we had insisted upon it. In 2014, the hall was named the best building project in Gothenburg – the fines accolade we could wish for because it didn’t come from architects!”

6,000 bricks were glazed in order to create a shimmering effect in the façade.

About Kville Saluhall

Southern European-style market halls have gained a foothold in Scandinavia in recent years and are now found at several locations around Sweden. The aim of the saluhaller (as they are called in Swedish) is to support small traders and producers in a consumer-friendly way.

Located in the Gothenburg suburb of Kvillebäcken, Kville Saluhall looks like a three-storey building that tapers off into a lantern-like structure at the top. This tapering of the main body allows the afternoon sun to reach the small, neighbouring square.

On the ground floo, one enters a double-height hall with shops side by side, creating a bustling, intimate atmosphere. A firs floo balcony has various restaurants that open onto a large terrace. Large windows provide plenty of light and open up the market hall to its surroundings.

The design called for materials that would correspond to the functional and architectural robustness of the hall, which made hardwearing, timeless and maintenance-free brick the obvious choice.

79

Design studio, Rancate, Switzerland

Client: Stocker Lee Architetti

Architect: Stocker Lee Architetti

Completed: 2019

Brick: C48, K49 + C48 custom format

Photos: Paul Kozlowski

Seamless integration of Kolumba and Cover

An architectural office in Switzerland uses a special version of Cover allowing for simple, elegant corners.

A few years ago, Stocker Lee Architetti designed and consummately executed a building that houses a design studio for their own use. The building is a sharply define brick volume with no overhanging eaves. Recessed glass façades at ground level make the upper storeys look as if they are floaing in the air. The studio feels straightforward in its appearance and entirely convincing in its hierarchy – a testament to both Stocker Lee’s natural incorporation of nature into the design, and the building’s striking precision and veneration for detail.

The upper gables are clad in Kolumba with a wild bond, while the roof and façades on the long sides of the building are clad in Cover fied in the same way and with the same colours. Two-thirds of the way up, the roof breaks sharply to make room for fla skylights.

The meeting of Kolumba on the gables and Cover on the long façades required a custom solution designed by Stocker Lee. Every Cover brick at the corners of the building has a side section that borders the gable end, giving the bricks a closed look. The Kolumba bricks, which also go all the way out to the corners, are cut to

The architects developed a U-shaped version of Cover to merge the roof seamlessly with the Kolumba façade.

81

About Stocker Lee design studio

The building in Rancate is on an elongated plot measuring 12.70 x 22.60 m and facing the imposing mountain Monte Generoso, between Lake Lugano and Lake Como. The shape of the plot is due to the shape of the old village, which is surrounded by vineyards, forests, small-scale industry and housing. Close to the forest, the design studio is semi-submerged to take up less space and leave more room for nature.

The floo plan measures 6.6 x 17.6 m, and the compact structure is based on 29 tightly packed load-bearing wooden

beams rooted in the in-situ-cast concrete walls surrounding the partially submerged ground floo. Above this are the windows on the lower façade, which is slightly retracted from the deep reddish-brown solid Cover brick monolith of the upper volume. Cover was chosen as a nod to cottage architecture and blends in naturally with the colours of the landscape. Equally, the bricks emphasise the shape of the building without dominating the surroundings.

Architects and partners Dong Joon Lee and Melanie Stocker, Stocker Lee Architetti.

83

Petrol station, Skovshoved, Denmark

Builder: Texaco

Architect: Arne Jacobsen

Completed: 1938

Restoration project: 2001-2003

Client: Gentofte Kommune

Architect: Dissing+Weitling

Brick: Various custom format glazed ceramic tiles

Photos: Anders Sune Berg

Recreating iconic ceramics

Following a successful restoration almost two decades ago, a world-famous petrol station looks just as it did when completed in 1938.

Arne Jacobsen’s petrol station was restored in 2002 and 2003 to mark the centenary of the architect’s birth. The project was subject to close scrutiny by the conservation authorities and involved recasting the elliptical roof and resurfacing and cleaning up the site. The service building’s ceramic tile cladding – a key element in the overall aesthetic – was in poor condition and needed to be replaced.

According to Teit Weylandt, former partner at Dissing+Weitling and the architect who oversaw the restoration project, the texture, colour, finis and format of the replacement tiles were crucial.

“We didn’t manage to track down the original manufacturer, which we think may have been in Bohemia. We approached several others, only to fin tiles with smooth, uniform and lifeless surfaces with a bathroom-like feel. Luckily, Petersen Tegl offered what we were looking for.”

The original standard tile measures 150 x 300 mm, but the project also used 130 custom formats, including curved and double-curved tiles, which required specially produced plaster moulds. After shaping and drying the tiles, they were glazed.

“The brickworks came up with special methods to produce a rustic, raw, vibrant glaze and surface, with a slight variation in colouring as close to the original as possible,” Weylandt explains. The successful result on Kystvejen has been admired for the last two decades.

The original standard tile measuring 150 x 300 mm was recreated by hand for large sections of the façade. In addition, 130 custom formats, including curved and double-curved tiles, were produced with plaster moulds.

85

“The brickworks came up with special methods to land on a rustic, raw, vibrant glaze and surface, with a slight variation in colouring as close as possible to the original.”

Teit Weylandt, architect

86

87

The tiles around the windows and doors were recreated 1:1 like the originals, including the rounding of the edges.

“The seemingly simple tiles present myriad variants, corners and edges that manufacturers today aren’t equipped to accommodate to this degree of individual fiting. We were thrilled by Petersen Tegl’s commitment to our collaboration and achieving the desired result.”

Teit Weylandt, architect

Teit Weylandt, architect

About Arne Jacobsen’s petrol station

Located on Kystvejen in Skovshoved, north of Copenhagen, Arne Jacobsen’s famous petrol station was part of his modernist plan for the area around Bellevue: ‘The White City on the Sound’. In 1938, Texaco commissioned him to design a new type of petrol and service station. The result was a light and elegant construction that went on to be world famous and is today a listed building. Architecturally, Jacobsen had an experimental approach to materials and structures.

A distinctive roof construction provides shelter and acts like a giant lamp – the ellipse is illuminated from below by specially designed fixtues that reflec off the shiny underside. The roof’s distinctive contour is echoed in Jacobsen’s furniture design – most clearly in the classic Ant Chair from 1952.

The building measures just 9 x 15 m and consists of a car wash, office storage room, boiler room and two toilets. It is cast in reinforced concrete and clad in white ceramic tiles, reflecing Jacobsen’s preference for pure, minimalist design.

The petrol station is a fin example of free form and reflect Jacobsen’s openness to influence from peers in other countries such as Gunnar Asplund, Alvar Aalto, Mies van der Rohe and Le Corbusier.

The restoration of the petrol station was awarded the prestigious Europa Nostra Prize 2006.

Architectural drawings and Arne Jacobsen’s original watercolour for the petrol station from 1936.

Copyright: Arne Jacobsen

® Design, Photo: Danish National Art Library

89

Arcade building, Nordre Toldbod, Copenhagen, Denmark

Architect: Gustav Friedrich Hetsch

Completed: 1850

Client: A.P. Møller Mærsk

Restoration project: 2010

Architect: Fogh & Følner Arkitekter

Brick: custom format and custom colour brick in Danish blue clay

Photos: Anders Sune Berg

Golden bricks on historic port buildings

Restored a decade ago, the brickwork on the listed arcade buildings in this historic Copenhagen district looks as harmonious as ever.

From the mid-1850s, access to Nordre Toldbodplads in the Port of Copenhagen was via a lattice gate, on the pillars of which sat two lions who still guard the spot to this day. Inside the gate, visitors pass two low arcade buildings, built in 1856 by the architect Gustav Friedrich Hetsch. The listed and partially preserved arcades bear witness to a historic era and are today owned by the shipping company A.P. Møller and the development company By & Havn. A decade ago, as part of a renovation project, the Fogh & Følner studio was commissioned to restore the brickwork in the southern arcade’s pillars.

Petersen Tegl supplied golden-hued bricks to replace the damaged ones. These custom bricks are fied from Danish blue clay and laid with an extruded joint that allows them to blend in with the 165-yearold brickwork.

About the Arcade building

Københavns Toldbod (Copenhagen’s Customs House) was the name given to a large area in the north-east of inner Copenhagen in 1630. From here, customs officer controlled the seaward approach to the city, and the name stuck for centuries. Heads of state and other dignitaries would disembark there when they landed in the capital, including the world-renowned Danish sculptor Bertel Thorvaldsen when he arrived back from Rome in 1838.

As trade grew in the 18th and 19th centuries, the Customs Service erected a number of buildings in the area, several of which were later demolished. The abandoned warehouses came down in the mid-1970s when changes in the law meant that goods no longer had to be stored for physical inspection. Two arcade buildings from 1856 have been preserved and listed.

Part of the oil painting Toldbodvejen by Peter Ølsted (1860), featuring the lions and arcades. From the book: Hundrede år under Dannebrog (100 Years under the Danish Flag), Bo Bramsen, 1983.

91

Culture

93

Photo: Anders Sune Berg

Kunstmuseum Basel, new extension, Basel, Switzerland

Owner: City of Basel, Immobilien Basel-Stadt

Client: Construction and Transport Department of the Canton of Basel-Stadt, Städtebau & Architektur, Hochbauamt

User: Department of Presidential Affairs of the Canton of Basel-Stadt, Kunstmuseum Basel

Architect: Christ & Gantenbein

Completed: 2016

Brick: D91 and D11 in custom formats

Photos: Anders Sune Berg

Concealed lighting effect

Integration of light frieze into the façade of a Swiss art museum.

Two-thirds of the way up the front of the Kunstmuseum Basel is a broad band that serves not only as a decorative frieze but also as a communicative element.

Architects Christ & Gantenbein worked with Petersen Tegl to produce custom, concave-moulded bricks that form a horizontal band in which LED lights have been mounted. The lighting is adjusted to make parts of the frieze appear flus with the rest of the façade. When selected lights are turned on, letters appear on the façade, seemingly formed by protruding bricks. However, they are, in fact, created by the contrast between illuminated and non-illuminated areas.

The lighting is digitally controlled so the text can be modifie to advertise special exhibitions, etc. The custom bricks are handmade from the same type of clay as the facing brick (K11).

The customized concave-moulded bricks form an underlying horizontal band in which LED lights are mounted in order to achieve flexibl lighting effects.

96

About Kunstmuseum Basel

Kunstmuseum Basel, on the boulevard St. Alban-Graben, houses the world’s oldest city council-owned art collection, which includes several Renaissance masterpieces. The original museum was built in 1936 and clad with decorative limestone bands. Christ & Gantenbein won the competition to design the extension, which was inaugurated in 2016.

The new building spans fiv storeys, two of which are underground where a passage connects the new and old parts of the museum. The three storeys above ground correspond to the height of the older main building.

The extension comprises a large volume divided into horizontal strata as if formed by geological deposits over millennia. The brick façade has no expansion joints, creating the appearance of one continuous surface. Every other brick course protrudes, producing a subtle relief effect.

The hand-made bricks of the façade vary in shades ranging from dark to light grey. This smooth shading effect is broken near the roof, where large letters appear to have been carved out of the façade in a band encircling the building. The darkest bricks are at the bottom and appears to provide a solid base supporting the lighter layers toward the top.

“The beauty is that you can’t see the LEDs – just the light on the bricks. In traditional architecture, a frieze was usually decorated with sculptures, and sculpture is, of course, all about how light and shadow fall on three-dimensional objects. Here, we explore these principles in a highly technological and adaptable way. It is a pragmatic, modern building that reflect contemporary textual modes of communication.”

Architect Christoph Gantenbein, Christ & Gantenbein

Z33, House for Contemporary Art, Hasselt, Belgium

Client: Provincie Limburg, Z33

Architect: Francesca Torzo

Completed: 2019

Brick: Custom format tiles for facades, made of German and Danish clay

Photos: Gion von Albertini

Allusion to damask linen

The custom colour in façade tile was achieved by mixing red wine, water and milk

Architect Francesca Torzo started developing a brick for the façades on Z33 by devising a colour palette for each of the remaining Beguine buildings on the site. The aim was to explore ways the new building could harmonise with its historic surroundings.

The result was a purplish-reddish hue, which Torzo recreated at Petersen Tegl by mixing red wine, water and milk. Using this colour as a reference, the brickworks combined German and Danish clay to produce a custom brick. The new façade’s bricks are rhombus-shaped, 370 mm high, 130 mm wide and 37 mm thick.

The cladding on the street-facing wall, which is solid, was carried out so that expansion joints were unnecessary. Coloured mortar creates a coherent look – almost like a damask pattern, monochrome, but with a hint of zigzag due to the rhombus-shaped bricks.

Architect Francesca Torzo mixing wine, water and milk to arrive at the exact purple-red hue she wanted.

Architect Francesca Torzo mixing wine, water and milk to arrive at the exact purple-red hue she wanted.

Three formats of tiles were produced in order to create the façade exactly as the architect had envisioned it.

99

100

101

About Z33

Z33 is in the heart of Hasselt, on a triangular plot of land surrounded by streets on all sides. In the 18th century, a semi-monastic lay order called the Beguines established a community here, and most of the buildings still survive today. Their closed external façades line the edge of the plot, while the more open façades, heavily punctuated with windows, face the large garden. Later, a gin distillery was built on part of the site and has since been turned into a gin museum. In 1958, the art museum Vleugel ’58 was built at Zuivelmarkt 33, the address from which the new gallery derives its name.

The extension to Z33, designed by Francesca Torzo, is built in brick and follows the same principle as the Beguine buildings: closed toward the street, open toward the garden. A 60-metre-long, 12-metre-high wall almost surrounds the site. The wall is interrupted only by a ridge in the middle and two openings, one of which leads into a small courtyard and continues into Z33.

The new building has two floor of exhibition space, between which is a floo housing offices It also has classrooms, a space for handling museum objects and an apartment for artists in residence.

Z33, House for Contemporary Art has been nominated for the Mies van der Rohe Award 2022

102

“Minor variations in the handmade bricks create a shimmering effect, and the façade will age well with few, fine wrinkles –which I love because absolutely nothing is perfect in life.”

Francesca Torzo, architect

Francesca Torzo, architect

103

Tobias Mayer Museum, Marbach am Neckar, Germany

Client: Hermann and Erika Püttmer, Tobias Mayer Association

Architect: Webler + Geissler Architekten BDA (planning and supervision)

Knappe Innenarchitekten (competition winners)

Completed: 2018

Brick: K11 + nine custom format bricks made of K11 clay

Photos: Lukas Roth

Seamless corners

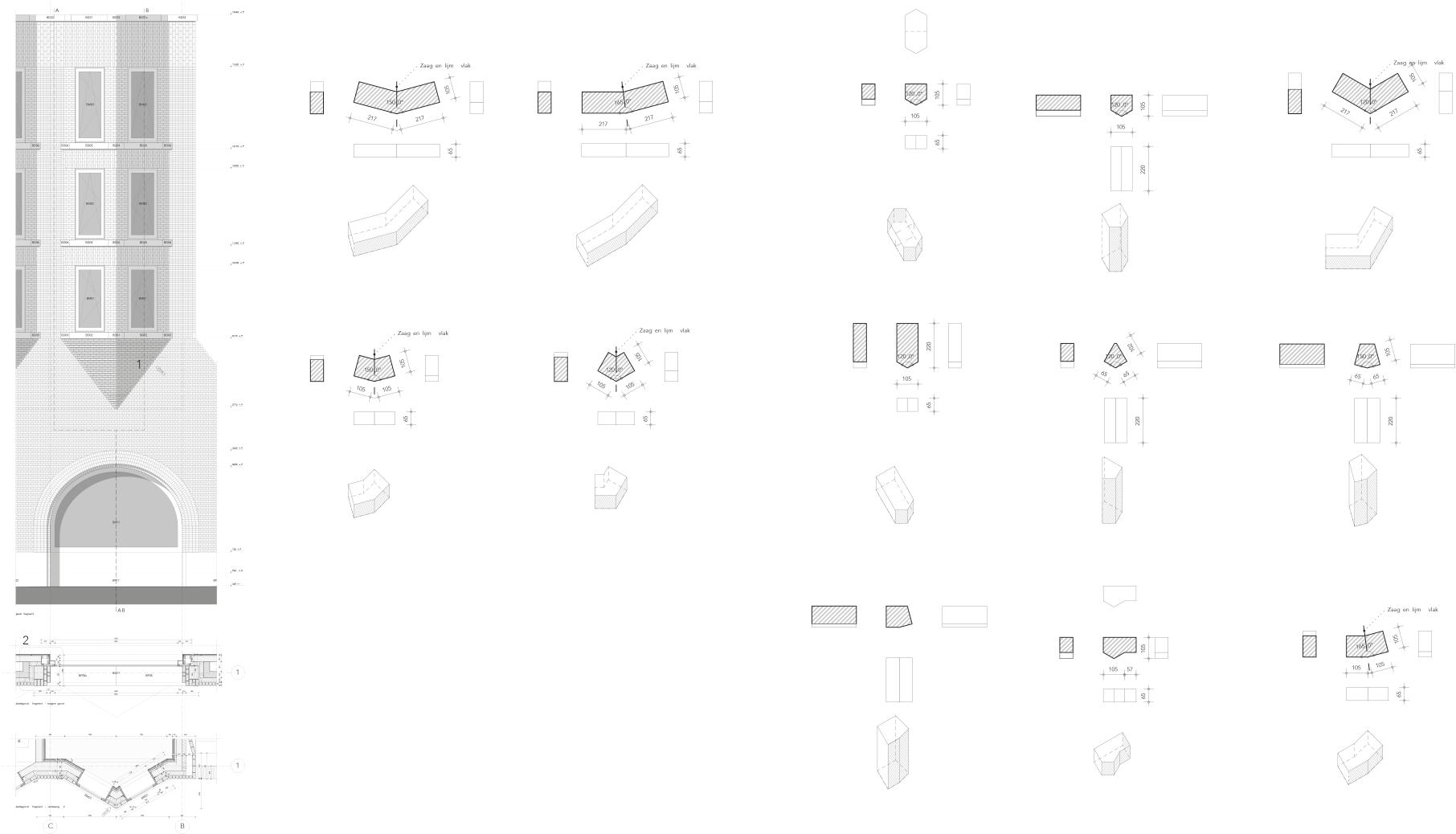

Meticulously planned custom brickwork endows the unusual pentagonal building with the appearance of a precisely constructed block.

The museum extension is reminiscent of both the fortress towers that fascinated Tobias Mayer and the observatories in which the scientist and astronomer spent so much of his life. The extension’s irregular pentagonal footprint closely follows the construction site’s outer boundary. Due to the varied profile it was an obvious choice to use specially moulded, handmade bricks with exactly the angles required to achieve the building’s distinctive shape. Webler + Geissler Architekten designed nine different custom bricks and drew up the façade brickwork at 1:1 scale.