Seismic/ Wind INSIDE: Seismic Rehab of Oregon Capitol 26 Preserving a 1960s-era Arena 30 Oakland's Tapscott Building 36 Brooklyn Powerhouse 42 STRUCTURE MARCH 2024 NCSEA | CASE | SEI

YOUR NMB Splice Sleeve System RebarSplicing MechanicalCouplers CAST-IN-PLACERebarSplicing MechanicalCouplers

subscriptions@structuremag.org

EDITORIAL BOARD

Chair John A. Dal Pino, S.E.

Claremont Engineers Inc., Oakland, CA chair@STRUCTUREmag.org

Marshall Carman, P.E., S.E. Schaefer, Cincinnati, Ohio

Erin Conaway, P.E. AISC, Littleton, CO

Linda M. Kaplan, P.E. Pennoni, Pittsburgh, PA

Nicholas Lang, P.E.

Vice President Engineering & Advocacy, Masonry

Concrete Masonry and Hardscapes Association (CMHA)

Jessica Mandrick, P.E., S.E., LEED AP

Gilsanz Murray Steficek, LLP, New York, NY

Jason McCool, P.E.

Robbins Engineering Consultants, Little Rock, AR

Brian W. Miller

Cast Connex Corporation, Davis, CA

Evans Mountzouris, P.E. Retired, Milford, CT

Kenneth Ogorzalek, P.E., S.E.

KPFF Consulting Engineers, San Francisco, CA (WI)

John “Buddy” Showalter, P.E. International Code Council, Washington, DC

Eytan Solomon, P.E., LEED AP Silman, New York, NY

Jeannette M. Torrents, P.E., S.E., LEED AP JVA, Inc., Boulder, CO

EDITORIAL STAFF

Executive Editor Alfred Spada aspada@ncsea.com

Managing Editor Shannon Wetzel swetzel@structuremag.org

Production production@structuremag.org MARKETING

Director for Sales, Marketing & Business Development

Monica Shripka

Tel: 773-974-6561 monica.shripka@STRUCTUREmag.org

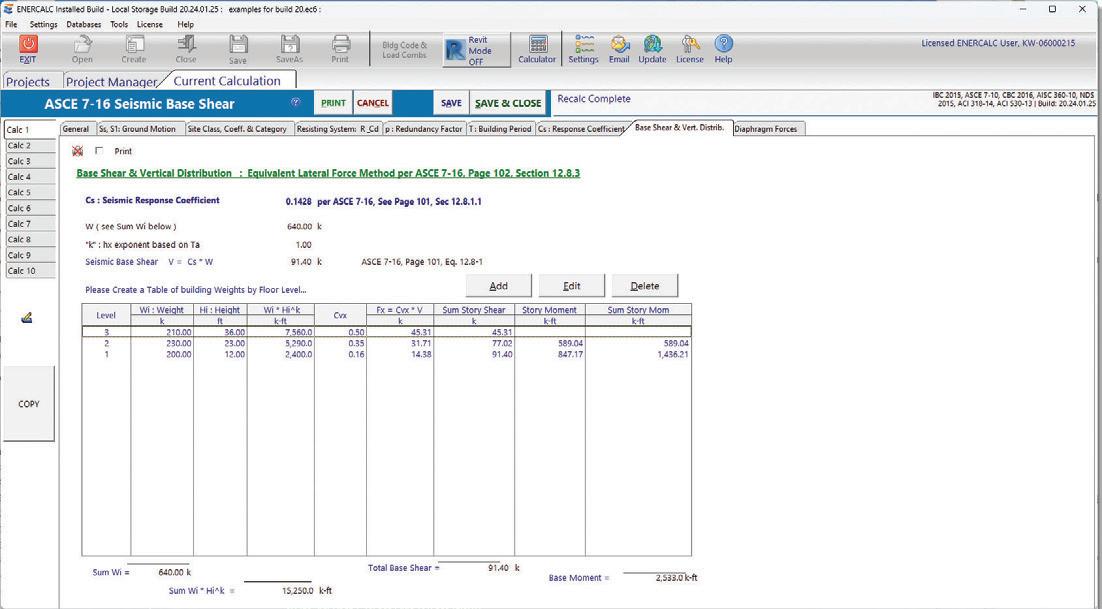

3 MARCH 2024 ADVERTISER index Please support these advertisers Allplan 4 Anthony Forest Products | Canfor 23 ASDIP Structural Software ..................................... 7 Computers & Structures, Inc. Back Cover DEWALT-Stanley Black & Decker ...................... 40 DuraFuse Frames 3 Enercalc 8 ICC-ES .......................................................................... 41 Keller Inside Back Cover NCEES ......................................................................... 53 Nucor 10-11 Nucor-Vulcraft/Verco Decking 25 RISA ............................................................................. 15 Simpson Strong-Tie 6 Splice Sleeve ........................... Inside Front Cover Subsurface Constructors, Inc. 19

® CIRCULATION

STRUCTURE

& ADVERTISING

SALES

STRUCTURE magazine (ISSN 1536 4283) is published monthly by The National Council of Structural Engineers Associations (a nonprofit Association), 20 N. Wacker Drive, Suite 750, Chicago, IL 60606 312.649.4600. Periodical postage paid at Chicago, Il, and at additional mailing offices. STRUCTURE magazine, Volume 31, Number 1, © 2024 by The National Council of Structural Engineers Associations, all rights reserved. Subscription services, back issues and subscription information tel: 312-649-4600, or write to STRUCTURE magazine Circulation, 20 N. Wacker Drive, Suite 750, Chicago, IL 60606.The publication is distributed to members of The National Council of Structural Engineers Associations through a resolution to its bylaws, and to members of CASE and SEI paid by each organization as nominal price subscription for its members as a benefit of their membership. Yearly Subscription in USA $75; $40 For Students; Canada $90; $60 for Canadian Students; Foreign $135, $90 for foreign students. Editorial Office: Send editorial mail to: STRUCTURE magazine, Attn: Editorial, 20 N. Wacker Drive, Suite 750, Chicago, IL 60606. POSTMASTER: Send Address changes to STRUCTURE magazine, 20 N. Wacker Drive, Suite 750, Chicago, IL 60606. STRUCTURE is a registered trademark of the National Council of Structural Engineers Associations (NCSEA). Articles may not be reproduced in whole or in part without the written permission of the publisher. Digital Issue Available Only at STRUCTUREmag.org March 2024 ADVERTISEMENT–For Advertiser Information, visit STRUCTUREmag.org

Buildable steel connections for smarter structures.

SDS2 steel detailing software offers unparalleled intelligence when it comes to steel connection design, delivering fabricationand erection-ready connections automatically to ensure smart, cost-effective structures you can deliver with speed and accuracy.

SDS2 2024 AVAILABLE NOW WITH AISC 16TH EDITION & CISC 12TH EDITION UPDATES

Model by Mold-Tek Technologies

SEE IT FOR YOURSELF REQUEST A DEMO TODAY sds2.com

\ Gillette Stadium North Endzone Renovation

MARCH 2024

SEISMIC REHAB OF THE OREGON STATE CAPITOL

By John McDonald, S.E., Stefanie Chamorro, P.E., and Geoff Bomba, S.E.

The Oregon State Capitol Renovation project seismically retrofits and renovates multiple structures utilizing ASCE 41. Cover photo courtesy of PngStudio.

PRESERVING A LANDMARK

By

30

Brian MacRae, P.E., S.E.,Kerem Gulec, Ph.D., P.E., S.E.

Using performance-based seismic design, the structural engineering team retrofitted the existing venue while maintaining the original 1960s feel.

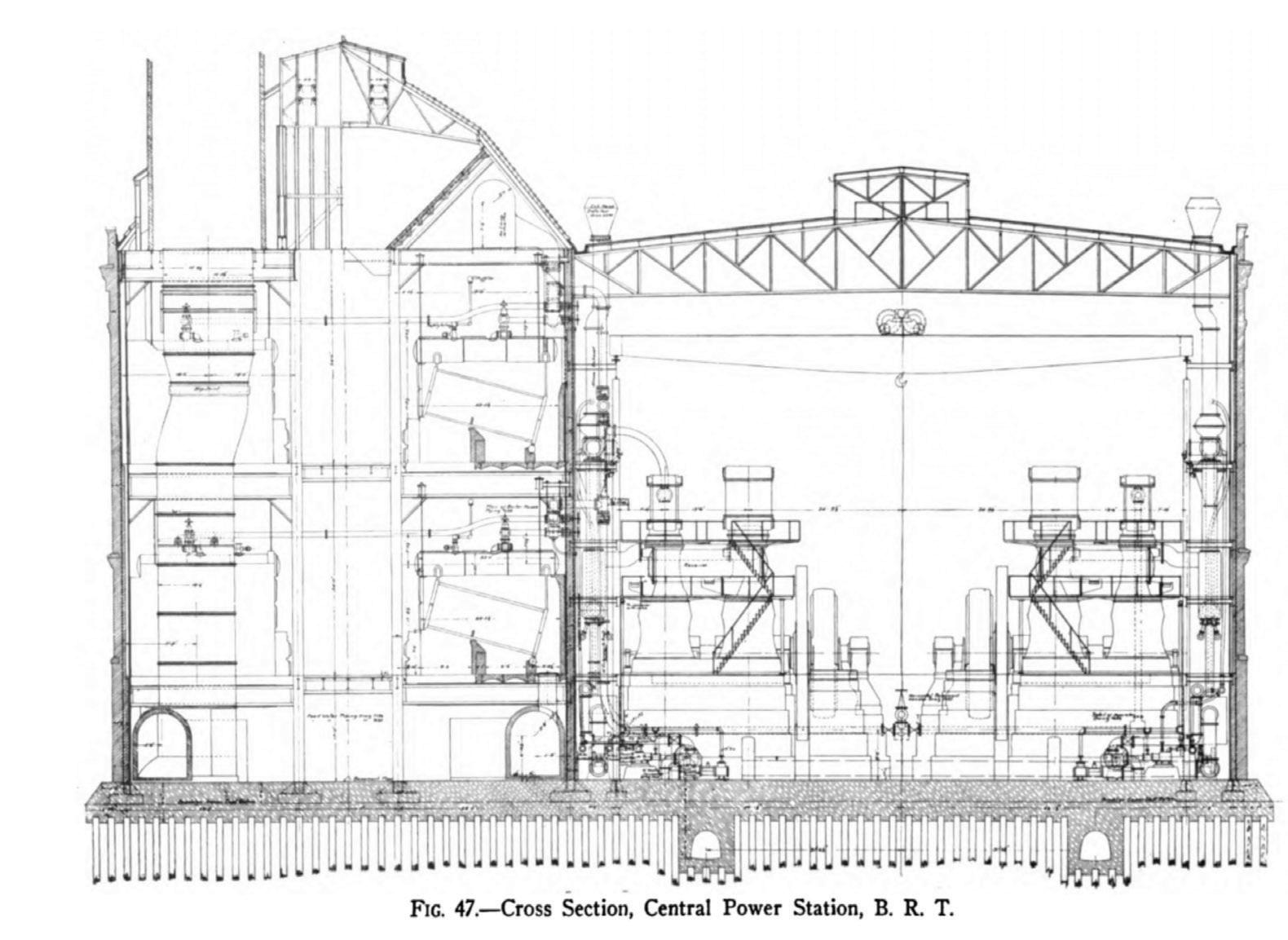

BROOKLYN POWERHOUSE

By Eytan Solomon P. E., LEED AP, and Richard Lo P. E

42

Powerhouse Arts in Brooklyn, New York is a $180 million adaptive reuse project that included extensive renovation and new construction—culminating in 170,000 square feet for fabrication shops, educational facilities, community programs, and multi-functional event space.

36

REVITALIZING OAKLAND’S BEAUX-ARTS TAPSCOTT BUILDING

By Zack Kardon P.E. and Viral Vithalani, AIA

A vacant structure returns as a functional portion of downtown while maintaining its historic appeal.

48

BEHIND THE SCENES OF STRUCTURAL ENGINEERING RECONNAISSANCE EFFORTS

By Robert K. Dowell, Gulen Ozkula, Jui-Liang Lin, Tunc Deniz Uludag, and Ayse Hortacsu

A team of structural engineers investigated the aftermath of the for the Mw 7.8 and Mw 7.5 Türkiye (Turkey) Earthquakes of February 6, 2023.

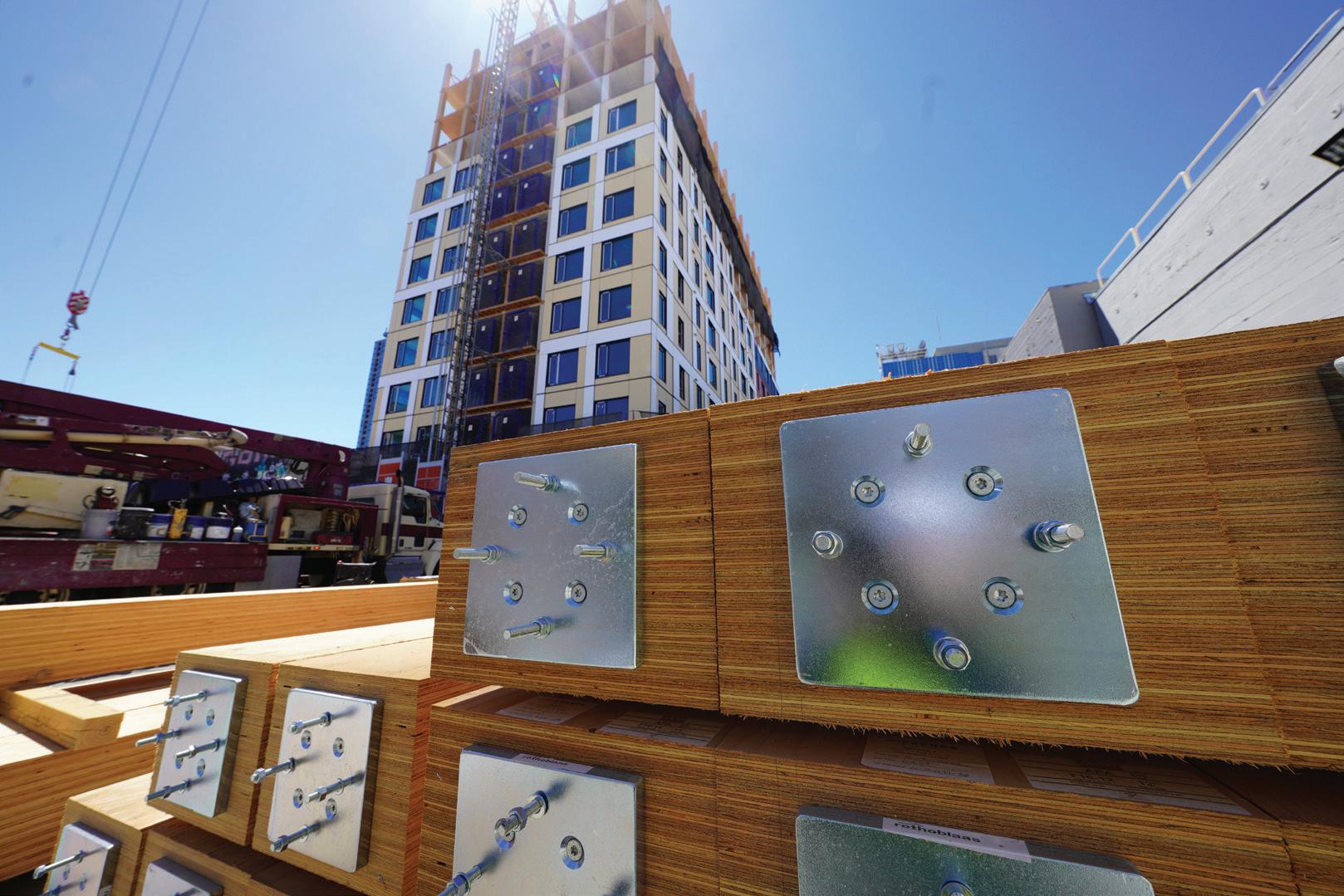

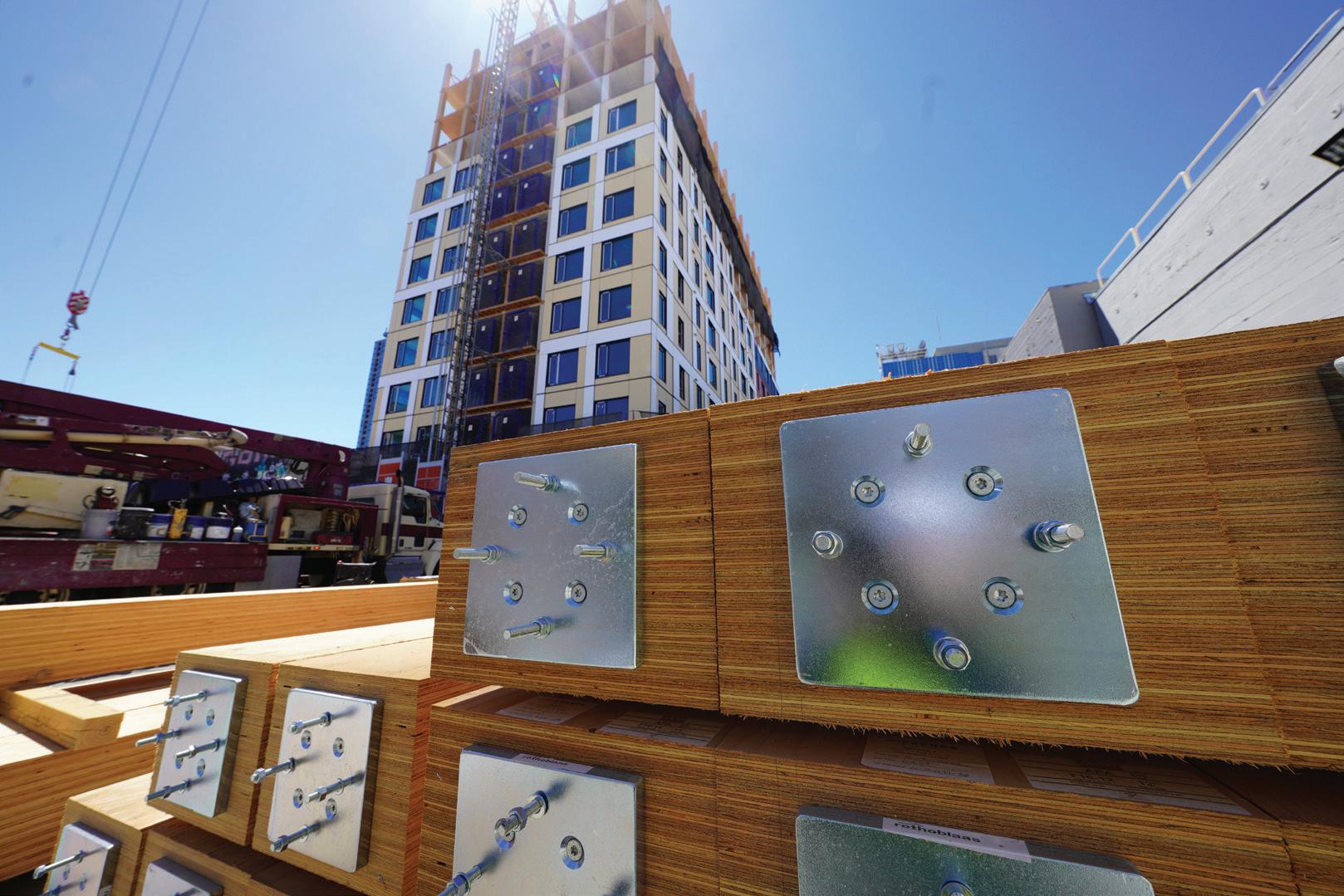

Tall mass timber shows its potential in 1510 Webster Street. 54

A NEW HOPE FOR HOUSING

By Jeff Brink and Michael Bauer

FEATURES Contents

26 Cover Feature

Slide a smarter cladding system into place.

Specify cladding and curtain-wall connections with the new Edge-Tie™ system from Simpson Strong-Tie. Designed with a unique, extruded shape and pour stop, it provides two times the load capacity of traditional bent plates. This innovative solution utilizes bolts that allow installers to easily position and adjust anchors along a continuous slot. By eliminating field welding, the Edge-Tie system speeds up building enclosure while saving time and labor costs. It’s simply a smarter, faster way to get the job done.

Engineer your next project with all of our structural steel solutions. To learn more, visit go.strongtie.com/edgetiesystem or call (800) 999-5099.

The Edge-Tie™ System

© 2024 Simpson Strong-Tie Company Inc. M-LS-ETS22-S Structural Steel Solutions | Products, Software and Service for Smarter Building

MARCH 2024 7 Publication of any article, image, or advertisement in STRUCTURE® magazine does not constitute endorsement by NCSEA, CASE, SEI, the Publisher, or the Editorial Board. Authors, contributors, and advertisers retain sole responsibility for the content of their submissions. STRUCTURE magazine is not a peer-reviewed publication. Readers are encouraged to do their due diligence through personal research on topics. COLUMNS and DEPARTMENTS In Every Issue 3 Advertiser Index 64 SEI Update 66 CASE in Point 68 NCSEA News 71 Resource Guide – Concrete 22 59 12 72 Structural Forum Understanding Developing Issues in Access to Design Data Part 2 By Joan Malana Kennedy 74 Structural Forum Shaking News! Myths in Seismic Design By Matt Barnard 70 Engineer's Notebook Finding Fun in Structural Engineering By John A. Dal Pino 59 Code Updates 2024 IBC Significant Structural Changes By John “Buddy” Showalter, P. E., M. ASCE, M. NCSEA, and Sandra Hyde P. E., M. ASCE, M. NCSEA 22 Structural Analysis Special Wind Zones in Washington and Oregon By Seth Thomas 20 Structural Design Watch Out for Unevenly Loaded Welds Part 2 By Duane K. Miller 16 Structural Design Declaring Independence By Kyle A. Karschner P.E., S.E., Jacob Sun, P.E., and Michael F. Hughes, P.E., S.E. 14 Structural Design Seismic Response Factor in ColdFormed Steel Flat Strapped Lateral Systems By Timothy R. Donahue, P.E. 12 Structural Design Residual Drift—The Ignored Outcome By John Worley, S.E. and Pierre Quenneville, Ph.D 9 Editorial Leading the Way in Sustainability and Resilience in Structural Engineering By Jerome F. Hajjar, Ph.D., P.E., NAE, F.SEI, F.ASCE ADVERTISEMENT–For Advertiser Information, visit STRUCTUREmag.org

Leading the Way in Sustainability and Resilience in Structural Engineering

By Jerome F. Hajjar, Ph.D., P.E., NAE, F.SEI, F.ASCE

Theconstruction and operation of the built environment accounts for a large portion of global greenhouse gas emissions. Governments, owners, occupants, architects, and engineers increasingly recognize the centrality of the structural engineering profession in our collective efforts to mitigate climate change. The United Nations (UN), through the Conference of Parties (COP) yearly intergovernmental summit aimed at creating global cooperation on issues of mitigating climate change, met in December 2023 in Dubai for COP28, at which they continued development of a Breakthrough Agenda

According to the UN Environment Program, the Breakthrough Agenda “provides a framework for countries, businesses and civil society to join up and strengthen their actions every year in key emitting sectors, through a coalition of leading public, private and public-private global initiatives.” The Breakthrough Agenda is focused heavily on areas central to structural and civil engineering, including Power, Road Transport, Steel, Buildings, and Cement & Concrete, with the latter two recently adopted following COP28.

COP28 and the Breakthrough Agenda

The Breakthrough Agenda goals are ambitious, and our structural engineering expertise is indispensable in achieving them. The world’s leading carbon producing countries are committing to netzero greenhouse gas emissions, with the United States and the European Union pledging to reach the goal by 2050, China following a decade later, and India committing by 2070. In addition, the United States has committed to reducing U.S. greenhouse gas emissions by over 50% from 2005 levels by 2030 and achieving carbon pollutionfree electricity by 2035. The White House has highlighted major U.S. steel and cement companies’ commitments to net-zero emissions no later than 2050.

Structural engineers are increasingly taking a lead in achieving these goals through research and design innovations that:

• Reduce the quantities of materials needed for construction.

• Enable the reuse of components at the end of the life of a structure.

• Utilize recycled materials made with electricity obtained from renewable resources.

• Adopt fabrication and construction practices that use electricity instead of fossil fuel for transportation and on-site power.

• Conceive of novel structural solutions for resilience in the face of natural disasters increasingly driven by climate change.

The Structural Engineering Institute as a Leader in Sustainability and Resilience

The Structural Engineering Institute (SEI) is especially well positioned to take broad leadership in addressing sustainability and resilience in the built environment. We are always looking for leaders, partners, and innovators to help drive forward new solutions. Throughout SEI and the American Society of Civil Engineers (ASCE), there are numerous efforts to address climate change and its impact on the built environment, including Resilience and Sustainability Committee efforts, and the publication of the new ASCE/COS 73-23: Standard Practice for Sustainable Infrastructure

Within SEI, the Technical Committee on Sustainability is leading several outstanding initiatives, including producing major reports on Whole Building Life Cycle Assessment: Reference Building Structure and Strategies, and Structural Materials and Global Climate: A Primer on Carbon Emissions for Structural Engineers; as well as spawning the SE2050 initiative. As the lead organization for the SE2050 initiative, SEI members are working with companies to foster commitments to incorporating sustainable design into their practice and providing technical information and education forums to foster sustainable design.

In addition, a Future Conditions Subcommittee has been formed within the standards committee that produces ASCE/SEI 7 Minimum Design Loads and Associated Criteria for Buildings and Other Structures. The subcommittee is developing a plan to address climate change within the ASCE 7 standard, a crucial step forward within our profession.

A New Paradigm in Structural Engineering Education

In addition to the evolutions required in our practice, it is important to consider

integration of sustainability and resilience in our higher education programs. There is increasing recognition that our emphasis in structural engineering education is starting to shift, as programs adopt new courses and degree programs related to repair, retrofit, and rehabilitation of structures; addressing embodied carbon as a key design objective; and considering resilient design strategies for structures. Industry is seeking new talent trained to meet climate-related engineering challenges, and today’s students are vocal in their desire to study and address these issues.

New Framework for Structural Design

It is my hope that sustainability and resilience become premier design objectives within our profession, underpinned by our current design objectives that address safety, serviceability, constructability, aesthetics, and economy. Achieving ubiquitous sustainable and resilient structural designs will take more than technical innovation. It will require an evolving mindset within the profession and the public. We can each take steps to accelerate this transformation through continuing to learn about and adopt structural systems and practices that are more sustainable and resilient, and advocating for these designs within the profession and to the public.

Representing one of the largest structural engineering organizations and publishers of structural engineering information in the world, the Structural Engineering Institute continues to take the lead in partnering with other organizations worldwide to address global opportunities for fostering sustainable and resilient structural design. For those interested in participating in such activities, I encourage you to join the SEI efforts underway, initiate new SEI efforts, and attend forums and conferences in which SEI is a host or partner organization—www.asce.org/SEI . Together we can develop the vital solutions required to address sustainability and resilience in structural engineering.■

STRUCTURE magazine MARCH 2024 9

EDITORIAL

Jerry Hajjar is CDM Smith Professor and Chair of the Northeastern University Department of Civil and Environmental Engineering, and President of SEI.

high-strength steel is enabling sustainable design. nucor.com/madeforgood

See how

structural DESIGN

Residual Drift—The Ignored Outcome

Mitigating residual drift following an earthquake can help maintain the vitality of affected buildings and avoid demolition.

By John Worley, S.E. and Pierre Quenneville, Ph.D

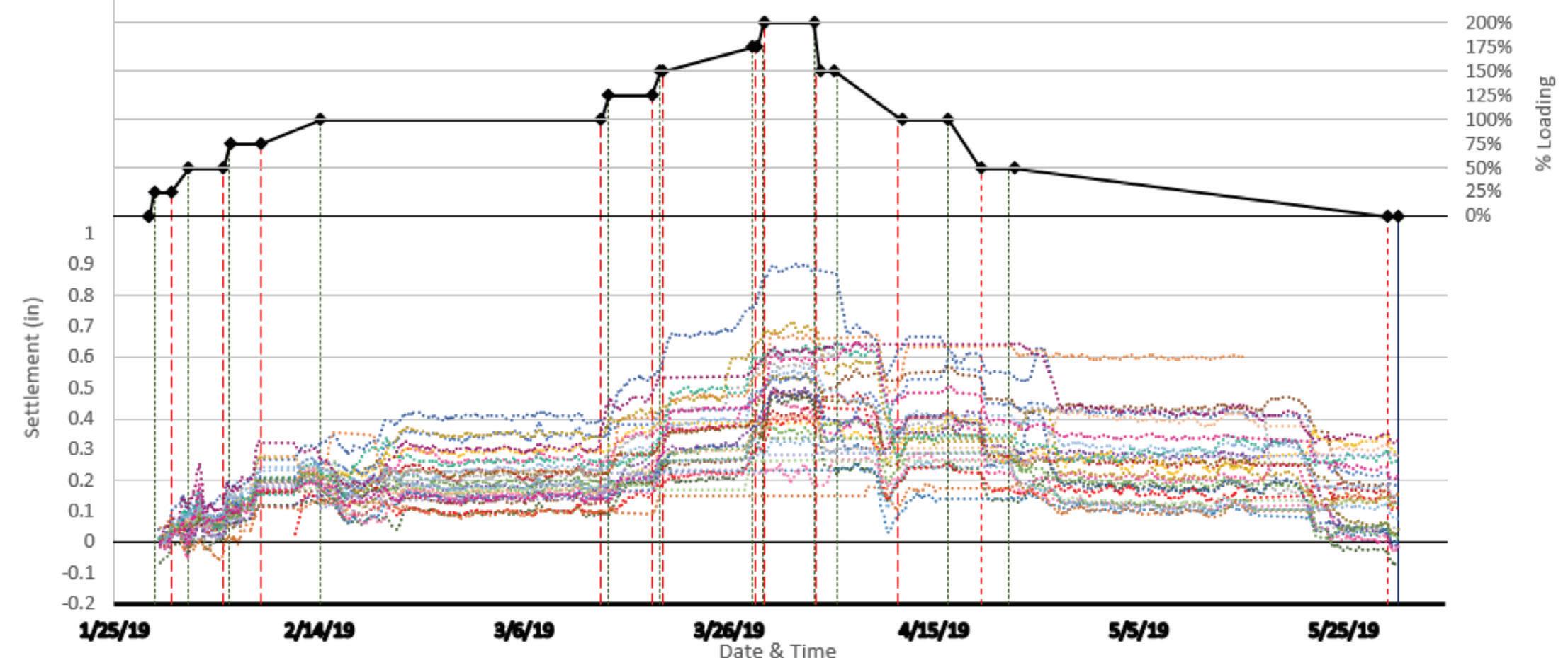

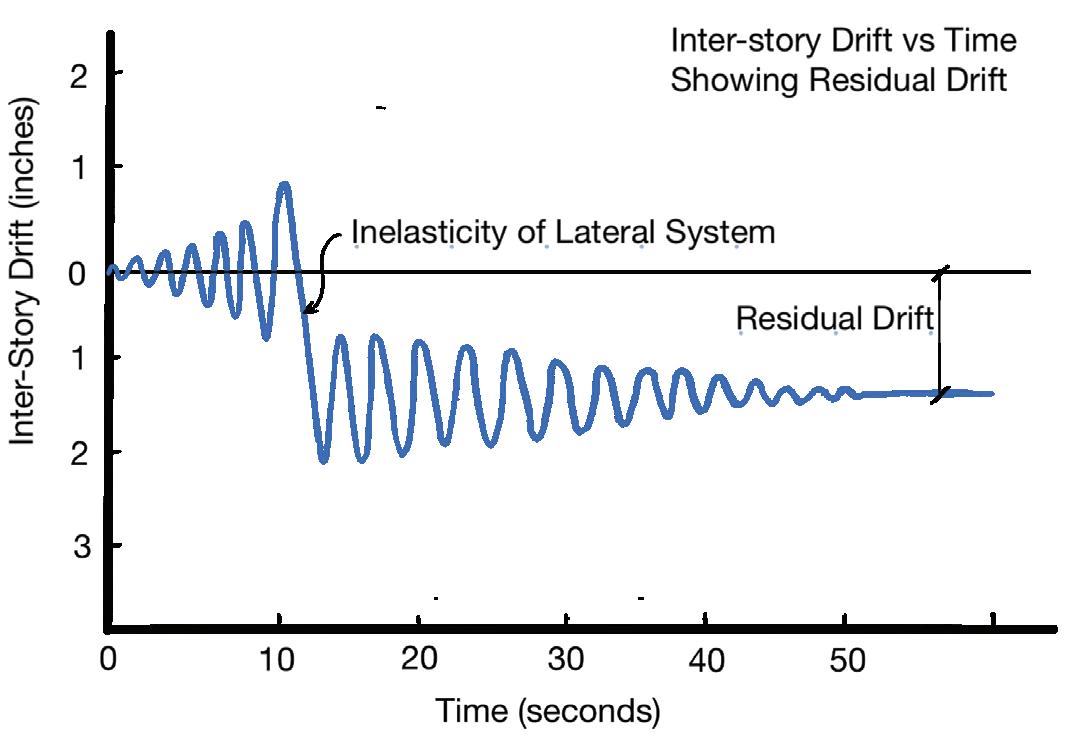

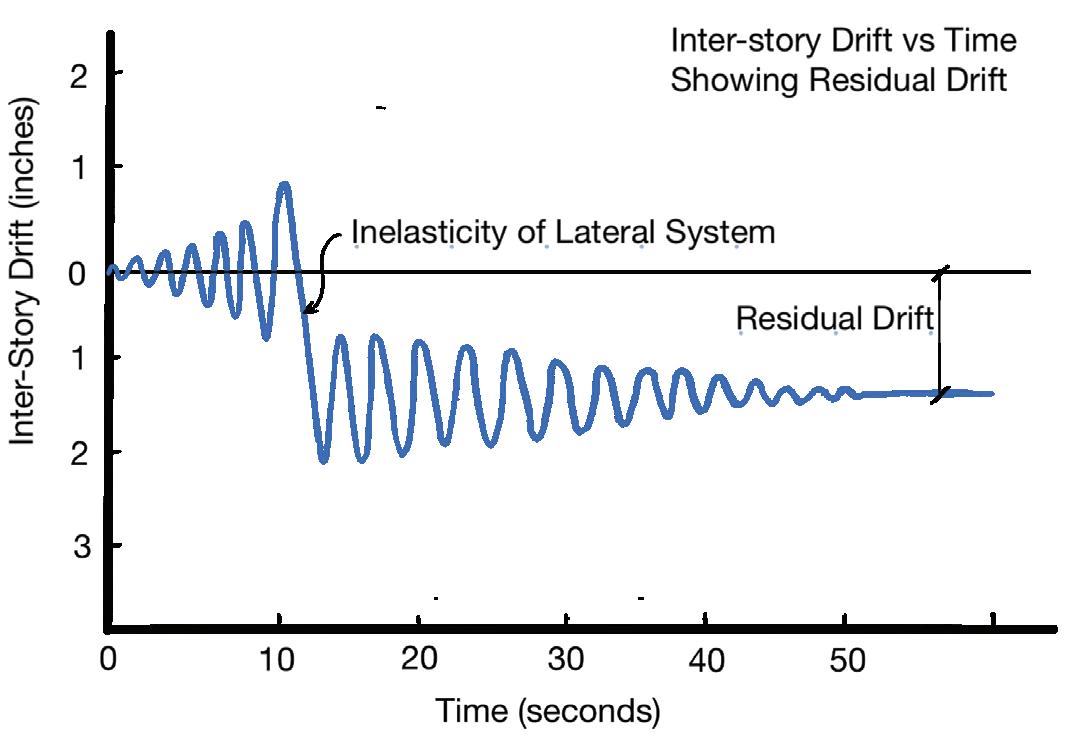

“Residual drift” is the permanent lateral deformation of a building following an earthquake (Figure 1). In high seismic regions, buildings designed per code utilizing ductile seismic force resisting systems defined in ASCE 7 could experience excessive residual drifts in a major earthquake that may result in a damage level deemed to be uneconomical to retrofit and therefore be demolished. Most ductile lateral systems rely on yielding fuse elements to protect other elements of the structure, but the inelasticity of these elements can lead to significant residual drifts in a major earthquake as shown in Figure 2. The building’s lateral force resisting system may have performed exactly as intended by code design (to not collapse and to preserve life safety), but the residual drift can have a huge negative impact on the building owner and occupants. During design, building owners are often unaware of the potential residual drift that could occur with a code-designed structure and the resulting ramifications. It is important for structural engineers to understand residual drift and to inform building owners of the potential residual drift that could occur with a basic code-designed lateral system and offer design enhancements that can help mitigate residual drifts.

U.S. building codes do little to limit residual drift. For new building design per ASCE 7-22 there are no residual drift limits for buildings less than 240 ft. in height, and a large 1% residual drift limit is imposed for buildings taller than 240 ft. if a non-linear response history analysis is utilized. For seismic retrofit of existing buildings per ASCE 41 there are no residual drift limits. Residual drift limits are not prescribed in the building code for two main reasons. First, the focus of the code is on life safety and collapse prevention in a major earthquake. Residual drift is not seen as a threat to these if other code requirements are satisfied, including the transient drift limits. Second, a more complex non-linear time history analysis is required to calculate the residual drift that often is not used in design and even then, it is difficult to accurately calculate. FEMA P-58-1 (Seismic Performance Assessment of Buildings) acknowledges the difficulty of calculating residual drifts with standard non-linear analyses and provides a method

of estimating residual drift based on the transient story drift. Although the code does not put limits on residual drift, it is important for engineers to understand the level of residual drifts that could occur for a given lateral system and to convey to building owners the potential for these residual drifts in a major earthquake and the corresponding ramifications. Building owners that value the useability of their building following a major earthquake may choose a higher level of performance that limits residual drift. Designing to mitigate residual drift not only provides value to building owners, it is also one of the most effective things a structural engineer can do to contribute to the sustainable design of a project. A building that must be demolished following an earthquake is extremely unsustainable. For example, after the New Zealand Christchurch earthquake, buildings with residual drifts greater than 0.5% were deemed to be uneconomical to retrofit leading to the demolition of over 2,700 buildings in the central business district. This was not only a huge impact on building owners and occupants but on the entire community of Christchurch. Studies by Erochko et al. 2011 and McCormick et al. 2008 found that residual drifts over 0.5% can lead to damage that is uneconomical to retrofit, leading to building demolition. Unfortunately, new building designs that adhere to all the requirements of the code can exhibit residual drifts of more than 0.5% in a major earthquake and therefore may be rendered uneconomical to retrofit and demolished following a major seismic event.

Listed below are a few design enhancements that can help mitigate residual drift with some of these being more effective than others.

• Utilize steel or concrete moment frames along with viscous dampers to reduce a structure’s earthquake response and therefore reduce residual drift. Figure 3 shows viscous dampers in braces. This system can be effective in mitigating residual drift if the moment frames stay within their elastic range while being stiff enough to provide the restoring force to recenter the structure. Depending on the analysis method and jurisdiction, this enhancement may require a design peer review.

• Utilize braced frames or shearwalls along with backup moment frames to provide a post yield

STRUCTURE magazine 12

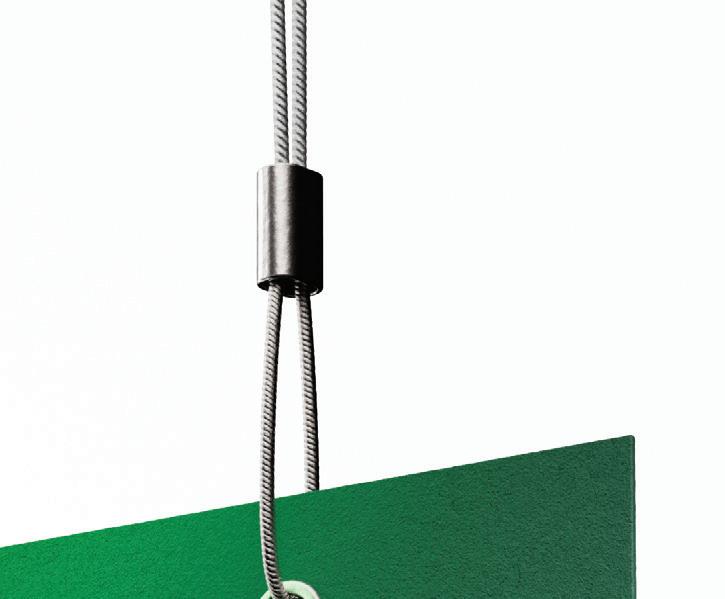

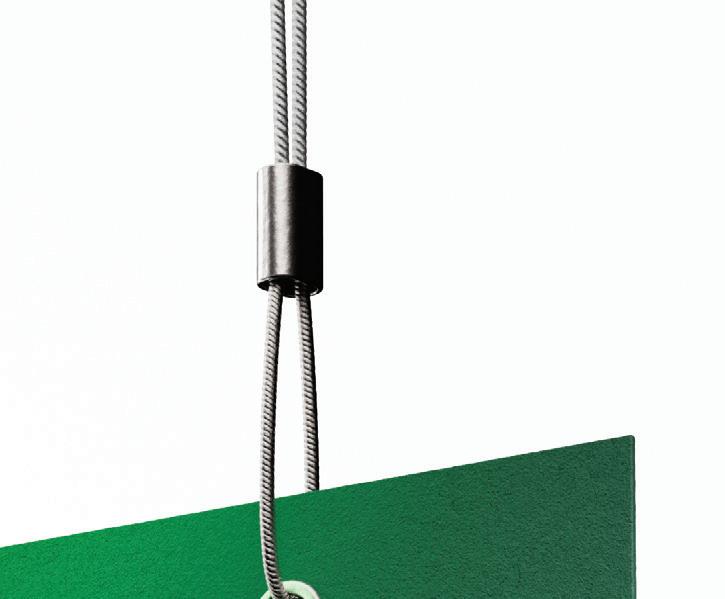

Figure 2. A plot of inter-story drift versus time shows the residual drift.

Figure 1. This figure illustrates residual drift on a structural frame.

stiffness and to provide a restoring force that reduces the amount of residual drift. This system can be effective in mitigating residual if the moment frames are kept in their elastic range while being stiff enough to provide a restoring force necessary to recenter the structure. The brace frames or shearwalls rely on element yielding and these elements may need to be repaired following a major earthquake.

• Utilize a rocking lateral force resisting system that employs gravity and/or post-tensioning to provide a restoring force that helps recenter the structure. Figure 4 shows a simple diagram of rocking shearwall. This system can be effective in reducing residual drifts. Rocking systems typically have ductile yielding elements which may require repair following a major earthquake. Depending on the analysis method and jurisdiction, this enhancement may require a design peer review.

• Utilize self-centering technology such as resilient slip friction joints (RSFJs) by Tectonus that provide both damping and a restoring force to recenter a structure so that there is zero residual drift. RSFJs can be used in-line with any lateral force resisting element including braces and ends of shear walls (Figures 5-6). This system is extremely effective and has been tested to show that it essentially produces zero residual drift. In addition, since this system does not rely on material yielding, there will be no structural elements to repair following a major earthquake. Most likely, this enhancement will require a design peer review.

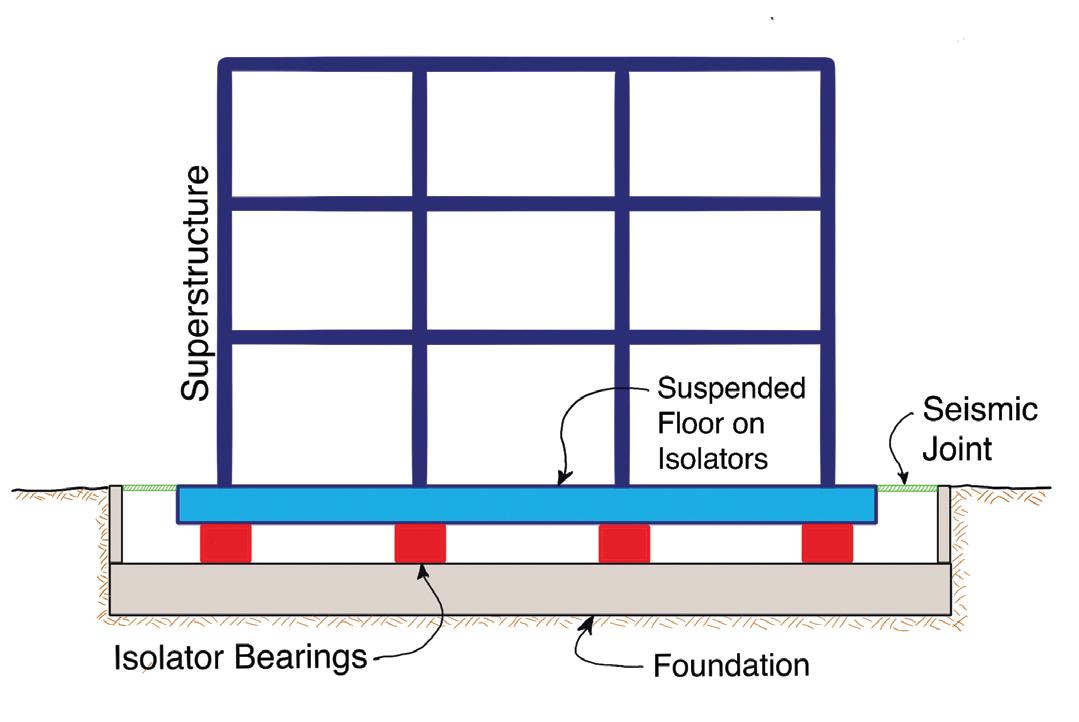

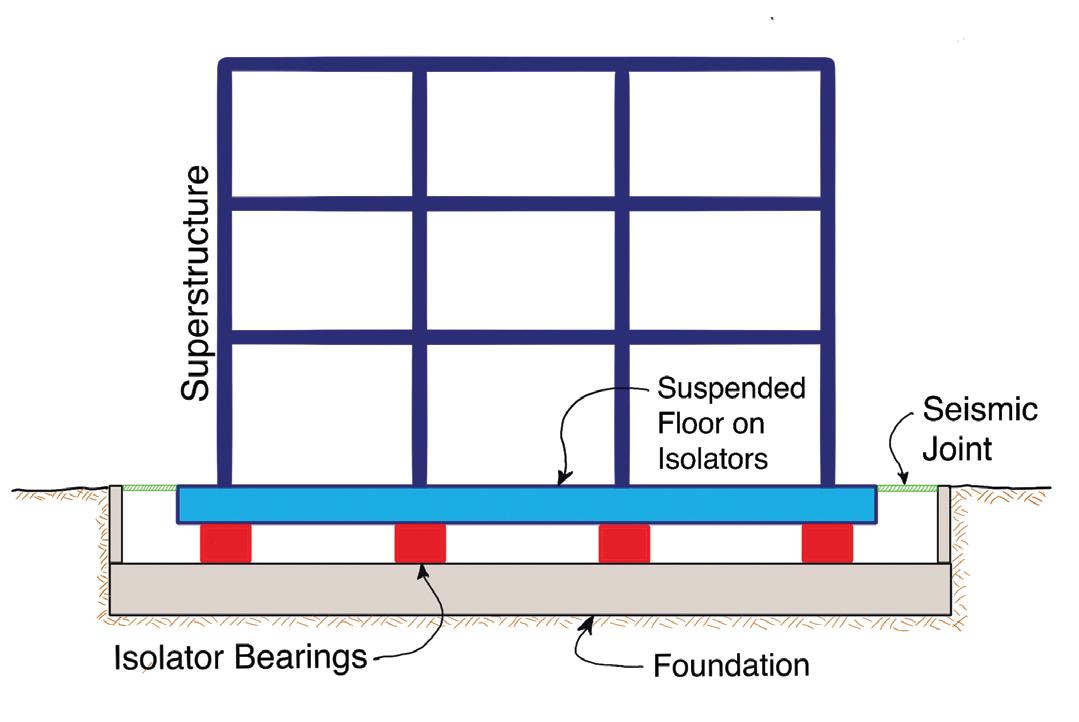

• Utilize base isolation system (Figure 7) that does not rely on steel yielding and inherently provides a restoring force that helps mitigate the effect of residual drift. This is an effective system to mitigate residual drift as well as minimize damage to the building. To implement base isolation, a significant construction cost increase will be incurred, and a design peer review will be required.

• Design a much stiffer and stronger lateral system that stays elastic

at higher force levels and does not rely on a high level of ductility. Doing this can have adverse effects by causing much higher lateral accelerations within the building, causing more damage to the building contents. In addition, a stiffer and stronger lateral system will require much more structural material and will be expensive. This can be effective for unusual structures with many irregularities but is not recommended for conventional structures.

In summary, minimizing residual drift in buildings following an earthquake is vital for maintaining functionality and the usability of buildings. It facilitates faster recovery, reduces repair costs, preserves structural elements, and enhances public confidence in the resilience of buildings. By striving for minimal residual drift, communities can mitigate the potential consequences of seismic events and build a safer and more resilient built environment. To achieve minimal residual drift engineers should inform their clients of the potential seismic residual drift that could occur with a standard code design based on ASCE 7 & ASCE 41 and then propose design enhancements that mitigate the amount of residual drift that could occur. To implement these enhancements, a performance-base-design approach utilizing a non-linear analysis may be needed which could require a design peer review. ■

Full references are included in the online version of the article at STRUCTUREmag.org

John Worley, S.E, retired Principal at Arup, has practiced Structural Engineering in California for over 35 years and has designed many significant structures including Apple Park in Cupertino, currently is the US Advisor for Tectonus (john.worley61@gmail.com)

Pierre Quenneville, Ph.D, Professor at University of Aukland, New Zealand, Founder & Chief Technical Officer of Tectonus. (pierre.quenneville@tectonus.com)

MARCH 2024 13

Figure 3. Moment frame with viscous dampers. Figure 4. Rocking shearwall system.

Figure 5. Self-centering resilient slip friction joints in concrete and CLT shearwalls.

Figure 7. Illustration of base isolated building.

Figure 6. Self-centering resilient slip friction joints in steel and timber braces.

structural DESIGN

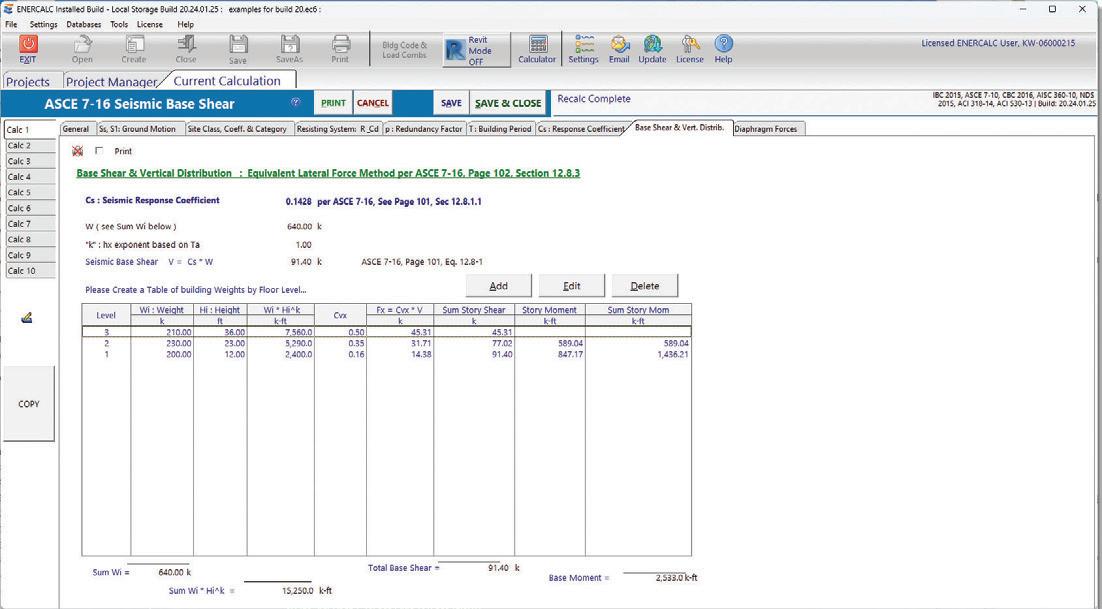

Seismic Response Factor in Cold-Formed Steel Flat Strapped Lateral Systems

Two seismic designs are compared in a hypothetical 10-story building.

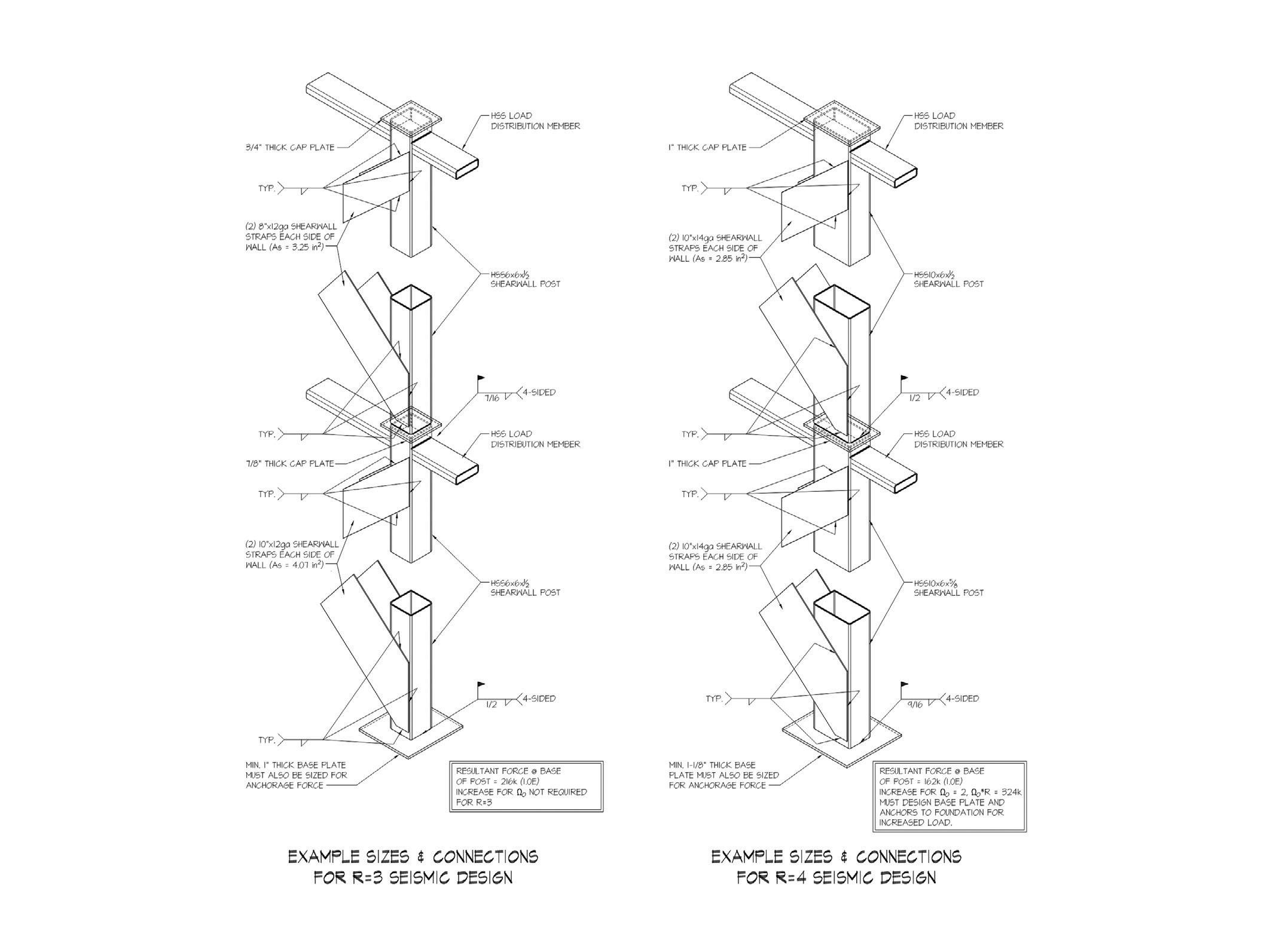

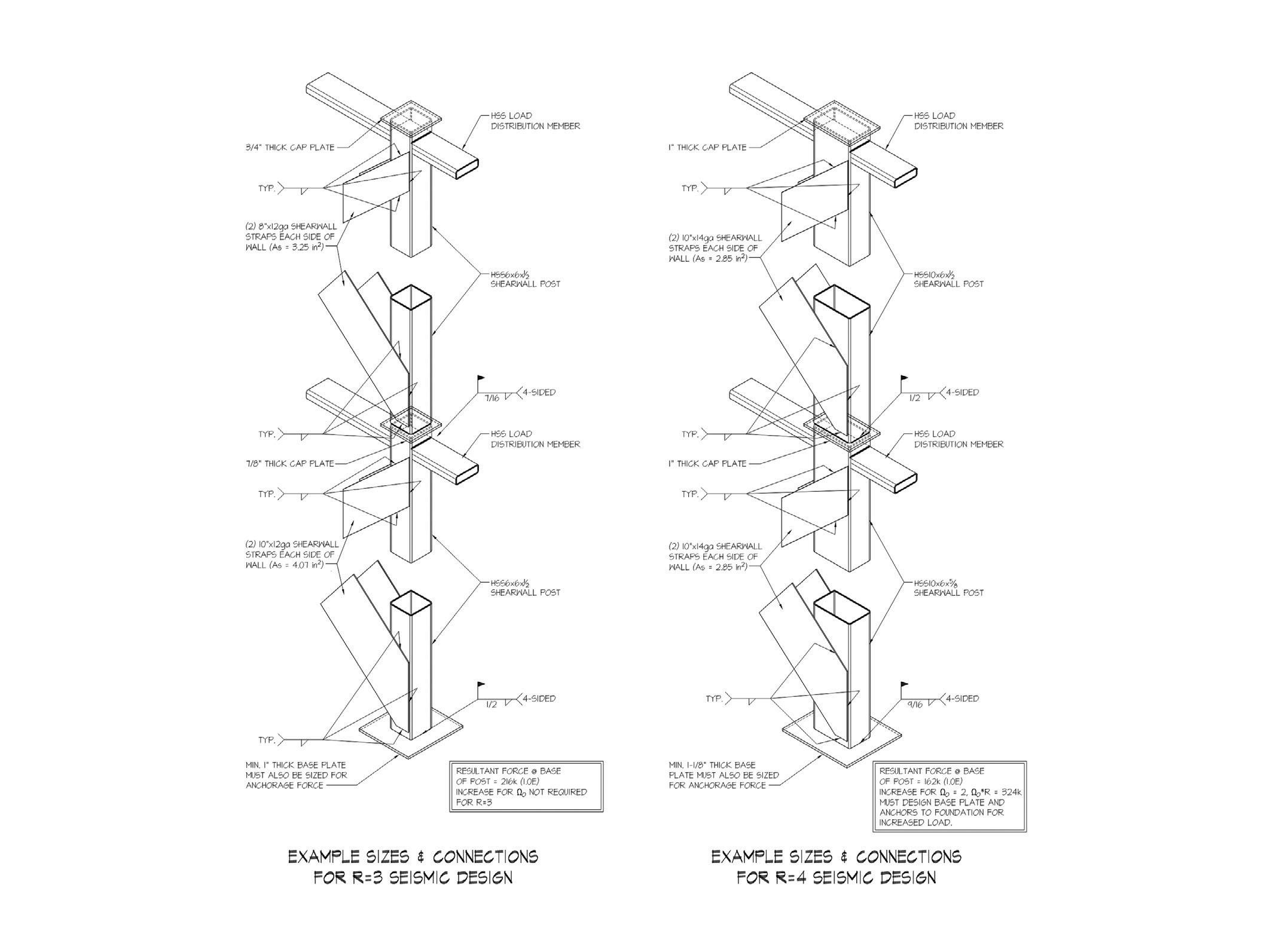

By Timothy R. Donahue, P.E.

Generally speaking, for a given structure, the higher the seismic response factor (R) value is, the more ductile the structure is and the lower the total seismic load acting on the building. With this concept in mind, one might conclude that reducing the seismic load acting on a building by selecting a more ductile seismic force restraint system (SFRS) with a higher R value would ultimately lower the material cost; however, when evaluating the overall cost implications for what it takes to achieve the increased ductility, the cost savings may not always be realized. This is primarily due to the requirements of overstrength factors in the design and detailing of the straps and other protected components of the SFRS with an R greater than 3.

For cold-formed steel framed buildings utilizing flat strap bracing in Seismic Design Categories (SDC) B or C, the structural engineer can design for either an R of 3 by clas sifying the SFRS as “Steel Systems Not Specifically Detailed For Seismic Resistance”, or for an R of 4 by classifying the SFRS as “Light-frame (cold-formed steel) wall systems using flat strap bracing” (per AISI Section A1.2.3 and Table 12.2-1 of ASCE 7-16). Due to increased ductility, buildings designed with an R of 4 have story forces that are 25% less compared to a building designed using an R of 3. To achieve the higher ductility however, more in depth design of the protected components is required in accordance with AISI-400, Section E3.2. These protected components include collectors, connections of strap brac ing, chord studs, vertical boundary elements, and floor to floor connections of the boundary elements (see figure 1). This is to ensure that the energy dissipating elements (the straps) yield while the boundary members and connections remain elastic.

To better understand the potential cost implications of the two different designs, let’s look at a typical end post connection of a hypothetical ten story building, in SDC B, that uses a light gauge strapped wall bracing SFRS. Figure 1 shows the connection design for the R=3 case, while Figure 2 shows the connection design for R=4.

As expected, the strap sizes are slightly smaller (or lighter) for the design utilizing an R of 4, as the lower base shear values result in lower strap forces. However, the end post sizes are larger for the R=4 design in order to provide enough weld length for the end post tensile and shear forces. While there are other potential solutions to resolving the increased connection forces beyond increasing the post size, such as adding angles or gussets, each solution ultimately adds cost to the assembly which offsets or negates the savings found in the straps.

Another element of the SFRS that is impacted by the overstrength requirements is the anchorage of the assembly to the concrete foundation. For the aforementioned building, the embed plate with welded studs used to transfer the loads into the foundation would need to accommodate

324 kips of total load for the R=4 design once overstrength is applied but would only need to account for 215 kips in total for the R=3 design. The larger forces, once the overstrength factor is applied, for the R=4 condition results in a more expensive base connection.

In this specific test case, the lower base shear obtained by using the higher R factor did not correlate to a more economical structure. The more ductile design (with R = 4) is in fact quite a bit more costly than the simplified design (with R = 3) despite having to resist lower seismic loads. While this result will not always be the case and there often is potential to economize a building’s lateral design by taking advantage of the reduced story shears resulting from an R of 4, the cost impact of overstrength requirements needs to be considered when selecting the SFRS. ■

Timothy R. Donahue, P.E. is Project Manager at Mulhern + Kulp. He can be reached at tdonahue@mulhernkulp.com.

STRUCTURE magazine 14

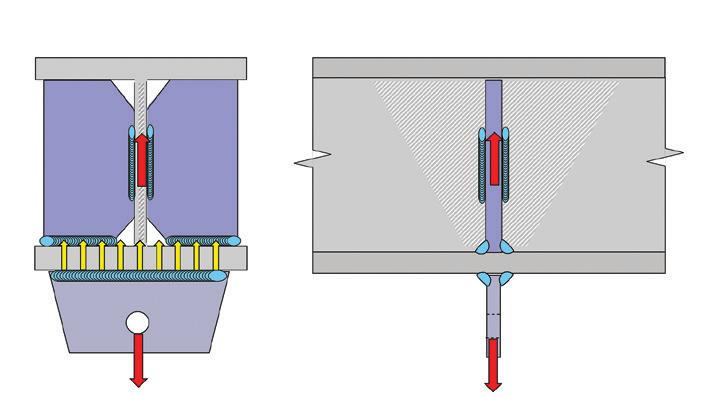

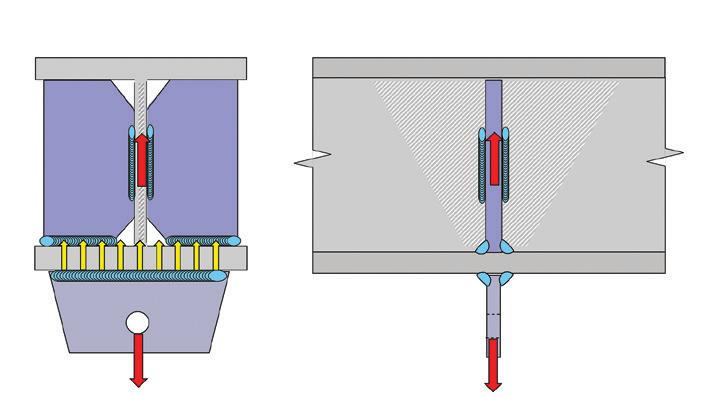

Figure 1 (left). Connection design for the R=3 case. Figure 2 (right). Connection design for R=4.

RISA NEW RELEASE

PRODUCT RELEASES FOR 2024 NOW AVAILABLE

Trusted leader in 3D analysis and multi-material design.

VERSION 22.0 UPDATES

Tapered Member Area Load

Columns in Walls

Customizable Hot Keys

Move Nodes Graphically with Mouse

Model, Load, Analyze and Design Multi-Storybuildings with ease.

VERSION 18.0 UPDATES

Enhanced Wall Panel Opening

Quick Add & Edit Tool

Columns in Walls

COME VISIT US

NASCC: THE STEEL CONFERENCE BOOTH #911

Your One-Stop Shop for Foundation Design.

VERSION 16.0 UPDATES

Modernized Ribbon User Interface

Improved and Better Organized

Drawing Tools

Improved Graphics and Report

Printing

Fully Integrated Design for Concrete Buildings

VERSION 23.0 UPDATES

Torsion Design of One-Way

Slabs and Beams

New Tendon and Rebar Display

Managers

Column Code Check Improvements

RISA o ers a comprehensive suite of design software that work together to simplify even the most complex projects. As a result, engineers can work e ciently on a variety of structures in a mix of materials including steel, concrete, wood, masonry and aluminum. risa.com

structural DESIGN

Declaring Independence

Structural design considerations for independent equipment frames in existing buildings

By Kyle A. Karschner P.E., S.E., Jacob Sun, P.E., and Michael F. Hughes, P.E., S.E.

Building owners are turning to adaptive reuse of existing buildings to meet the market demand for alternative uses, such as life science, data, robotics, and other tech-related industries. These uses typically require upgrading the building’s mechanical, electrical, plumbing, and fire protection (MEP-FP) systems that use larger and heavier equipment than the building’s original structural design. As a result, this work can trigger costly structural upgrades for strength, serviceability, or both to comply with building code requirements.

When an alteration increases design gravity and lateral loads (wind or seismic) on structural elements beyond certain thresholds, the International Existing Building Code (IEBC) requires evaluating those elements. In general, if the demand-to-capacity ratio for gravity load resisting or lateral load resisting elements increases by more than 5% and 10%, respectively, the designer must show that those elements satisfy the gravity and wind load provisions of the International Building Code (IBC), and the reduced seismic provisions of the IEBC.

Many older and historic buildings do not have well-defined lateral load resisting systems (LLRS) or lack the gravity and/ or lateral capacity to accommodate the additional loads, which makes reinforcing the existing structure per IEBC requirements challenging and sometimes cost-prohibitive. To address this issue, the authors have designed new independent equipment frames within the existing building footprint to carry most, if not all, of the new equipment. This strategy can meet the project goals without whole building strengthening or a detached horizontal addition. Avoiding the latter might save the project from additional zoning reviews and approvals processes by the Authorities Having Jurisdiction (AHJs). This article discusses the design considerations for these independent frames.

Example Frame Types

Several approaches exist to designing independent frames within existing buildings, depending on the building geometry, story height, overhead clearance, aesthetics, and other constraints. The authors have used the three types shown in Figure 1 for various design applications.

Type 1 is an interior mezzanine, the simplest version of a structurally independent frame. The columns typically go through any interior building floor(s) but do not penetrate the roof. Columns installed through floors require floor openings. A 3-foot by 3-foot opening is typically adequate for most columns and tolerances. After installing the columns, infill the openings with matching floor construction, but provide proper separation joints for fire separation between floors and relative movement between the original and new structure. Ideal candidates for this system type are tall warehouse structures with lightly framed roofs, buildings with shallow purlins with widely-spaced deep roof trusses allowing equipment and access between the trusses, or buildings requiring intermediate floor space for mechanical or other occupancy uses.

Type 2 can be used if the existing building has limited overhead clearance for a mezzanine or a lightly framed roof structure that cannot support the new equipment. In this system, the independent platform frame extends through the roof. Sometimes, designers add screens to conceal the rooftop equipment; however, the screens can add significant wind load to the building. The engineer and the architect must pay close attention to the details of columns penetrating the roof to provide adequate movement, maintain fire separation, prevent leakage, and minimize thermal bridging. The size of the roof openings is similar to the floor openings of Type 1. The Type 2 system typically works well with existing 1-2 story buildings. For taller buildings, the column sizes

STRUCTURE magazine 16

Figure. 1. Independent frame types are depicted.

can be large and uneconomical due to long unbraced lengths and lateral load stiffness demands, and larger columns increase the likelihood of interferences with intermediate existing structures and MEP-FP service lines at lower floors.

Type 3 is an independent exterior penthouse. This system is similar to Type 1, except exterior, and Type 2, except enclosed. The authors consider this system when the renovation requires additional indoor mechanical units, but there is insufficient interior space or height clearance.

Design Considerations

Common to All Types

Common design considerations exist for all independent equipment frame types described in the previous section.

Lateral Load Resting System (LLRS)

Like buildings, independent equipment frames require their own LLRS and close coordination with the project team and stakeholders to select the best system and layout. The authors have used braced frame and moment frame systems. The authors found that architects and owners typically opt for moment frames because they introduce less structure into the interior spaces where the owner or end-users are accustomed to only the existing structure. Although moment frames have less interior structure than braced frames, moment frames usually require deeper beams.

For seismic loads, the designer must determine whether the independent equipment frame is a “building structure,” “nonbuilding structure,” or “nonbuilding structure similar to a building,” as defined by ASCE 7, to select the appropriate design method. The authors believe that most independent frames should comply with the seismic design requirements for a “building structure” (ASCE 7-16 Ch. 12) so that the frame has performance and reliability similar to or exceeding those of the surrounding building.

For wind loads, the authors consider shielding provided by the surrounding building; therefore, the Type 1 system is not subject to wind loading. The Type 2 system is subject to the loads defined by ASCE 7-16, Chapter 29 (Building Appurtenances). Depending on the footprint of the Type 3 system, ASCE 7-16 Chapter 29 applies for penthouses with a small footprint relative to the building, or Chapter 27 or 28 (Building Structures) applies for penthouses with large footprints compared to the main building. The design wind pressures will be higher for penthouses with a small relative footprint.

The independent equipment frames often require intermediate beams below the floor and roof levels. These beams serve two primary purposes: 1) brace multi-story columns and 2) being part of the LLRS. These beams should be set sufficiently below the existing floor or roof structure to accommodate deflection and construction tolerances of the new and existing structures. The engineer must coordinate these beams with the project team because they reduce overhead clearance and may clash with existing or proposed MEP-FP service lines.

Column Layout and Foundations

Locating new columns and footings within the existing structure is a multivariable challenge. The column layout must avoid existing roof and floor framing and provide sufficient clearance for the relative movement of the two structures and construction tolerances.

Foundation exploration via selective demolition or test pits should be performed early in design to locate and understand all below-grade

elements. For the equipment frame foundations, designers should consider proximity to existing foundations and other below-grade obstructions, like under-slab utilities.

Separation joints between existing and new foundations are unnecessary since the relative horizontal movements at the foundation level are generally negligible. However, where the new and existing foundations abut, provide a bond breaker between the foundations to reduce unintended gravity load transfer.

Designers should avoid retrofitting the existing foundation for the new frame column with large gravity loads to create a combined foundation because there could be differential settlement when loading the new column.

For buildings supported on shallow foundations, the authors consult with the geotechnical engineer and typically design the new foundations for an allowable bearing pressure less than the original design bearing pressure to reduce the risk of excessive differential settlement.

The equipment frames require new piles and pile caps for buildings supported on deep foundations. Drilled-in piles are typically used to control vibration and noise transmission. The existing structural slab must be locally removed and replaced for the new deep foundation installation. The slab replacement must be isolated from the new columns.

Installing new foundations in buildings where the base slab resists sustained hydrostatic uplift pressures (i.e., pressure slabs) is likely technically infeasible or not economically practical.

It is usually preferable to place the new frame columns as close to the existing building columns and exterior walls as possible to maximize program flexibility. These schemes often result in foundations with eccentric loadings. The authors regularly use strap beams to resist eccentric foundation loads.

Separation Joints

The interfaces between the new frame and the existing structure require separation joints to isolate the new frame properly. Figure 2 shows a Type 2 structure with columns penetrating the existing roof deck with separation joints. The joints must accommodate the relative lateral movement between the new and existing structures (i.e., the two structures moving towards or away from each other) and incorporate

MARCH 2024 17

Figure 2. Type 2 frame columns are shown isolated through the roof deck

fire protection requirements.

To estimate the existing building’s horizontal movement, designers commonly use the IBC and ASCE 7 maximum drift limits to estimate the wind and seismic movements of the existing building instead of analyzing the entire building.

The structural engineer must provide the selected joint size to the architect and other project team members. Designers must detail the architectural and MEP-FP elements that cross the joints to accommodate the relative movement. The design team must clearly indicate these requirements in the contract documents. During construction, the structural engineer should inspect the as-built separation joint to ensure the new and existing structures are not inadvertently tied together.

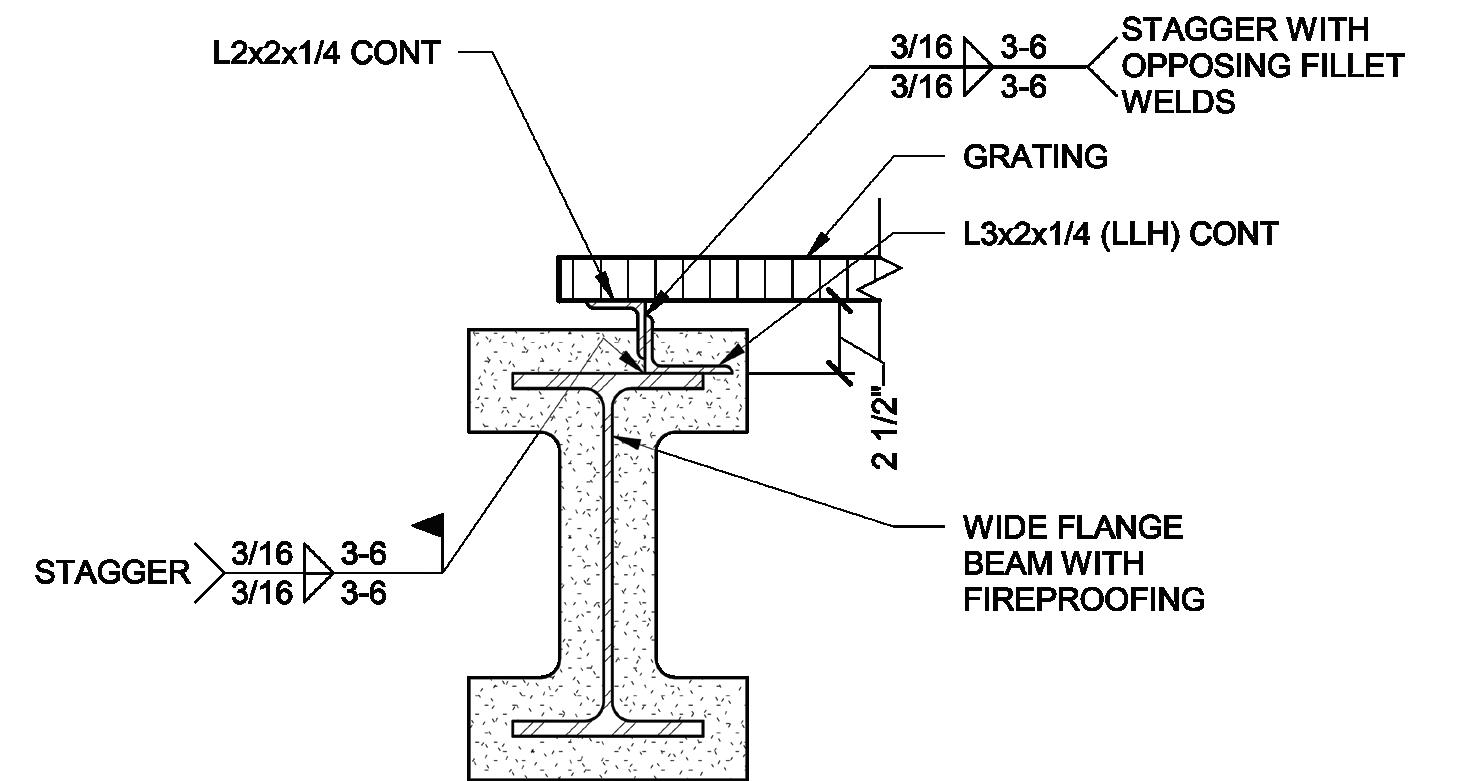

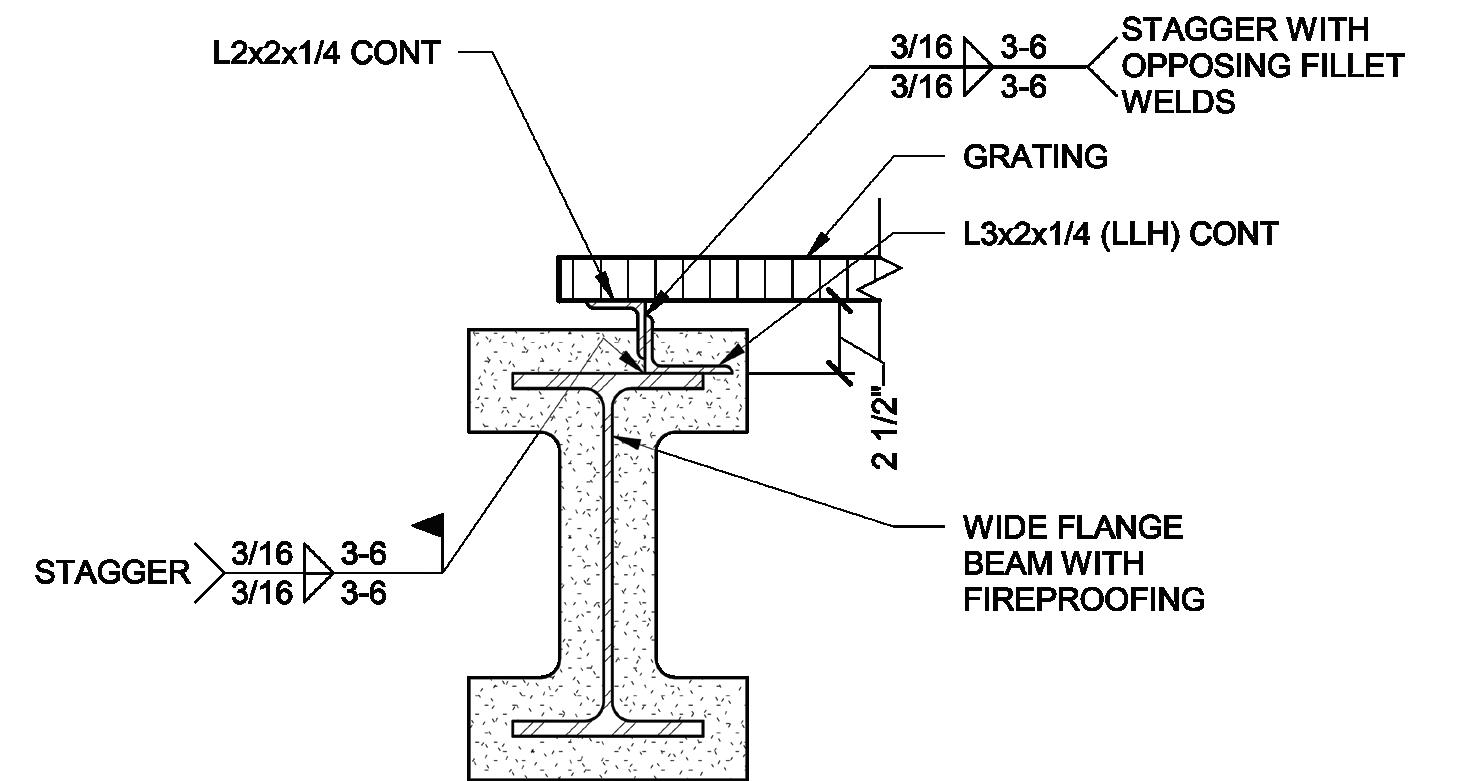

Fire Protection

Fire protection requirements can impact the structural and separation joint detailing and must be coordinated with the project’s architect and code consultant.

In one instance, there was a need for continuous fireproofing around beams that support grating for equipment access. The grating would have conflicted with the fireproofing. The authors raised the grating above the fireproofing using continuous angle bolsters like those in Figure 3 to allow for continuous fireproofing.

The architectural or code drawings should clearly delineate the extent of fire protection to avoid unnecessary fireproofing. Depending on the project, the new frame may not require fire protection compared to the adjacent existing construction.

Type 2 and 3 Specific Design Considerations

Type 2 structures have interior and exterior structural elements. Since the columns pass through the roofing, they can create a thermal bridge. Designers can provide a thermal break at the roof’s insulation plane, consisting of a thermal isolation pad, module, or coating. The architect, envelope consultant, and mechanical engineer should review the impacts of this bridge and determine whether they should provide a thermal break.

Where the frames are located in buildings with considerable floorto-floor heights, such as warehouses, it is possible to infill with intermediate framing, similar to the Type 1 system, to create an interior mezzanine space. Depending on the project, the owner may want flexibility to add the infill floors in the future; therefore, designers should discuss the current and future conditions with project stakeholders to determine design requirements.

A significant design consideration for Type 3 structures is the penthouse height. Avoid setting the penthouse floor at or below the roof elevation to improve waterproofing and reduce leakage potential. To minimize the penthouse height, the designers can set the floor slightly above the adjacent roof elevation, approximately 6 inches. If a higher penthouse elevation is acceptable, the designers can locate the mechanical level above the existing roof, creating an interstitial space. In that case, most of the roof structure can remain, except for small roof openings to install the columns like Type 2.

Depending on the project, the interstitial space may present some challenges if it requires conditioning, fireproofing, and accessibility for maintenance.

Since the Type 3 system may create a large opening in the roof diaphragm, the diaphragm stresses near the opening can be significant and may require local diaphragm strengthening. Also, the penthouse may change the wind uplift zones on the existing roof; therefore, the engineer should check the deck fasteners for combined in-plane shear and uplift loading.

Snow drifts could accumulate next to the new frame depending on the proximity of the Type 2 and 3 systems to the roofing. Starting with ASCE 7-16, Section 7.8 specifies that drift loads may be ignored when the bottom of the platform or other projection is at least 2 feet above the balanced snow load height. The engineer must evaluate the existing structure, including the roof deck, beams, columns, and their connections, to confirm adequacy for any added snow loads. In addition to snow drifts, designers should consider potential reroofing when establishing the clear height under the platform in a Type 2 structure. The National Roofing Contractors Association (NRCA) Roofing Manual for Membrane Roof Systems contains recommendations for clearances under the platform to allow for roofing.

Conclusion

For projects that add significant gravity and lateral loads to existing buildings, new independent frames within an existing building can reduce the impacts on the existing building’s structure. A successful design of these independent frames relies on proper detailing and close coordination with the project team during design and construction. ■

Kyle A. Karschner, P.E., S.E., is a Senior Consulting Engineer at Simpson Gumpertz & Heger’s office located in Waltham, MA (kakarschner@sgh.com)

Jacob Sun, P.E., is a Consulting Engineer at Simpson Gumpertz & Heger’s office located in Waltham, MA (jsun@sgh.com)

Michael F. Hughes, P.E., S.E., is an Associate Principal at Simpson Gumpertz & Heger’s office located in Waltham, MA (mfhughes@sgh.com)

STRUCTURE magazine 18

Figure 3. Bolster for grating support above fireproofing

LOCATIONS

St. Louis: 866.421.2460

Great Lakes: 314.568.3827

N. Central: 612.280.8940

Northeast: 410.568.5261

structural DESIGN

Watch Out for Unevenly Loaded Welds Part 2

Welds with nonuniform loading require special design attention.

By Duane K. Miller

Many welds are evenly loaded: the applied loads are uniformly transferred through the throat and length of the welds. Such welds are easily designed and routinely perform as expected. Other welds, however, are unevenly loaded. One end of the length of the weld may be more severely loaded than the other, or the loading along the weld throat may be non-uniform. The design of these welded connections is more complicated.

Fortunately, design codes dealing with welded connections, such as the American Institute of Steel Construction’s AISC 360, Specification for Structural Steel Buildings, and the American Welding Society’s AWS D1.1, Structural Welding – Steel provide design rules to accommodate unevenly loaded welds. The unfortunate situation is that engineers and detailers involved with the design of welded connections may be unaware of the need to treat such connections in a special manner. When unevenly loaded welds are treated incorrectly, the performance of the welded connection will likely be compromised.

This article summarizes five of the ten most frequently encountered conditions involving unevenly loaded welds. See Part 1 of this article from the February issue of STRUCTURE for Conditions 1 through 5.

Condition 6: Unevenly Loaded Because the Weld Group is Unevenly Loaded

In many situations, a weld group resists the applied loads. A beamto-column connection, for example, may consist of groove welds to the flanges and fillet welds to the web. In this case, the weld group consists of horizontal groove welds and vertical fillet welds. Collectively, this weld group resists the moment and shear applied to the connection. However, the various components of the weld group are not evenly loaded. Bending loads the top flange weld in tension and the bottom flange weld in compression. The vertical fillet welds to the beam web resist tension at the top and compression at the bottom, resulting in an unevenly loaded weld group. There are several ways to deal with unloaded weld groups. One of the easiest ways is to use the AISC Steel Manual approach, as shown in Tables 8-4 through 8-11. The Steel Manual discusses how to use the tables, as well as alternative methods to the tabular approach,

such as the instantaneous center of rotation method.

Condition 7: Unevenly Loaded Because the Weld Attaches a Rigid Member to a Flexible Member

The late Omer W. Blodgett, a pioneer in the design of welded connections and the author’s mentor, famously said, “One of the common oversights is failure to provide a path so a transverse force can enter that part of the member (section) that lies parallel to the force.” A parallel member is stiff, and forces preferentially are attracted to the stiff part. Accordingly, Blodgett encouraged designers and detailers to “provide a path” so the force could be transferred to the stiffer member.

When such a path is not provided, the welded connection is unevenly loaded; more load is transferred through the weld that is connected to the stiffer portion of the member or section, and correspondingly, less is transferred through the weld connected to the flexible part.

As shown in Figure 1, Part A contains an example where the lug is parallel to the beam web. In this case, the transfer of load through the weld is direct and uniform. In Part B, the same lug is welded to the same beam, but the lug is rotated 90 degrees. The loading is no longer uniform as the flange is flexible. Part C provides a possible solution: stiffeners have been added in order to “provide a path” for the force to enter into the parallel member, i.e., into the web.

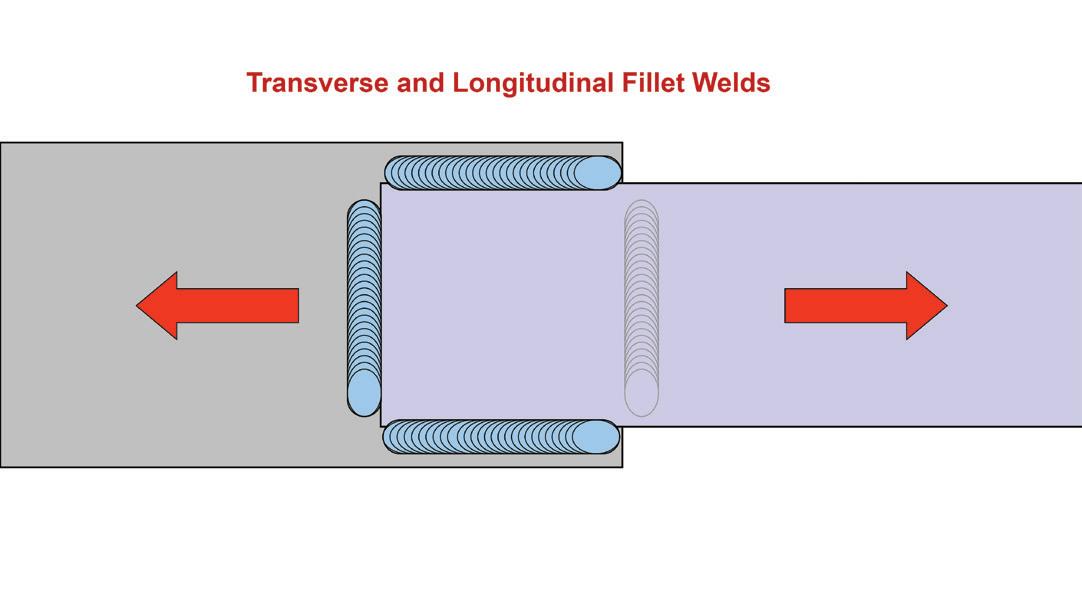

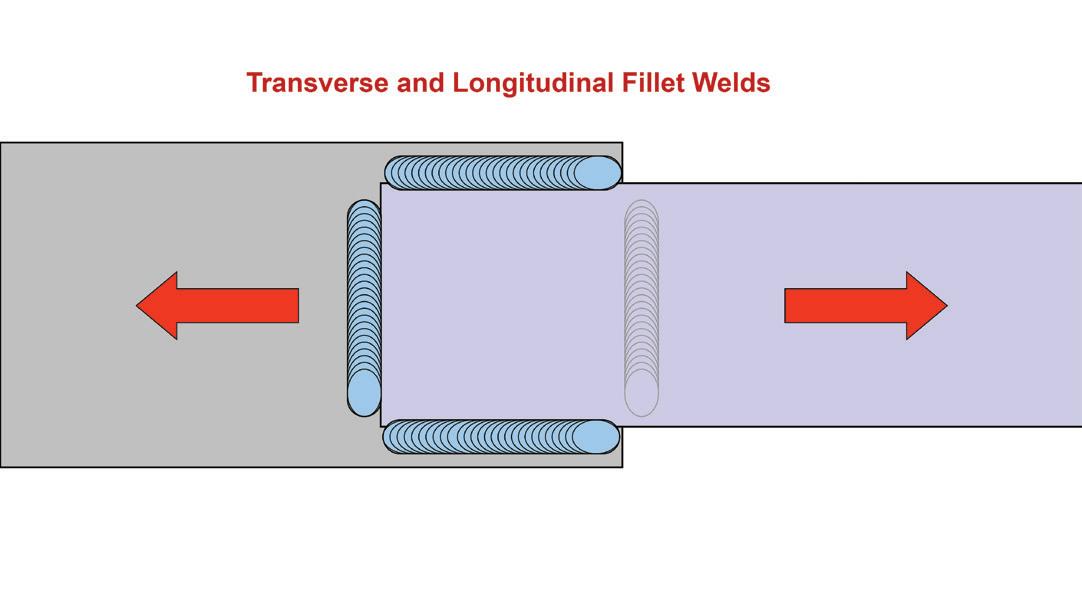

Condition 8: Unevenly Loaded Because Transverse Welds are Combined with Longitudinal Welds

Some welded connections involve combinations of longitudinal and transverse welds, as shown in Figure 2. Testing has demonstrated that transverse welds are stronger than longitudinal welds. AISC 360 equation J2-5 addresses this directional strength increase. Transverse fillet welds are generally permitted to be loaded to a 50% higher level than longitudinal fillet welds of the same size and length, made with the

STRUCTURE magazine 20

A B C

Figure 1. Even and uneven welded connections, adapted from Blodgett.

Flush frame

Design composite joist end connections more quickly and efficiently

Improved flush-frame connections by New Millennium feature a more efficient design that eliminates beam torsion concerns. Our new standardized connections simplify design and specification. Now you can more quickly realize the added benefits of flush-frame connections in multi-story applications. Together, let’s build it better.

LEARN MORE

Standardized connections reduce design time Joist reaction point occurs at beam centerline

Flush-frame connection designed for efficiency

SEE US AT NASCC BOOTH 1117 newmill.com

same filler metal. The directional strength increase factor (kds) is 1.0 for longitudinal fillets and 1.5 for transverse fillets.

The unevenly loaded condition occurs when transverse and longitudinal welds are combined in one connection. Because of the differential deformation capacity, the transverse weld will assume more load than the longitudinal weld. Therefore, it is not acceptable to directly add the capacity of the longitudinal weld with kds = 1.0 and transverse fillet weld with kds = 1.5. Instead, two conditions should be considered when this unevenly loaded condition exists. First, the capacity of the transverse weld and the longitudinal weld are directly added, assuming kds = 1.0 for both welds (i.e., with no directional increase for the transverse weld). Then, the capacity of the two welds is evaluated using this relationship as shown in equation J2.6 in AISC 360:

R n = 0.85 F nwAwel + 1.5F nw A wet where

Awel = effective area of longitudinally loaded fillet welds, in.2 (mm2)

A wet = effective area of transversely loaded fillet welds, in.2 (mm2)

The capacity of the two welds may be taken as the greater of the two calculations. Depending on the relative capacity of the two different weld orientations, either the normal strength calculation (i.e., with kds = 1.0 for both welds) or the strength calculated in accordance with equation J2.6 may provide the greater capacity.

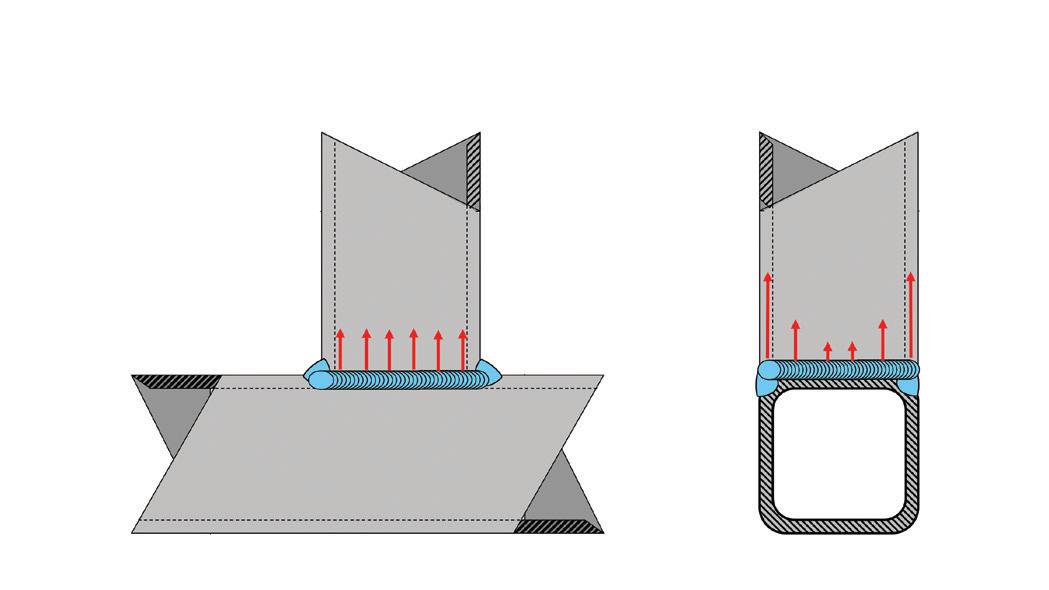

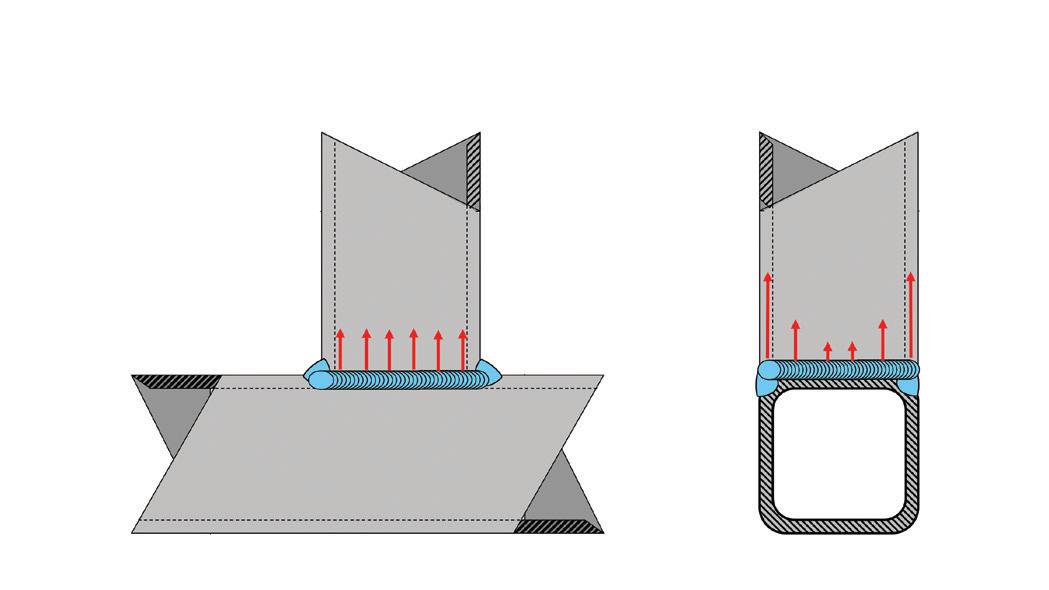

Condition 9: Unevenly Loaded Because the Weld is Part of a Tubular Connection

When tube-to-tube connections are made, the welds around the tube may be unevenly loaded due to the variable stiffness of the tube. Condition 9 is a specialized example that is related to the previously discussed Condition 7. Consider a square-tube to square-tube connection in a tee configuration, as shown in Figure 3, where the tubes are of the same size. The flare groove weld (i.e., the longitudinal weld) that connects the branch tube to the main tube is evenly loaded along its length. The side wall of the main member is stiff. The fillet weld across the face of the main member (i.e., the transverse weld) is unevenly loaded since the face of the tube is flexible. This flexibility forces an additional load to be transferred into the longitudinal weld.

AISC 360 provides “effective length” factors that account for this uneven loading.

Returning to the longitudinal flare groove weld, it was previously stated that the weld was uniformly loaded along its length. However, due to the flexibility of the tube face, the longitudinal weld is not uniformly loaded along its throat; strains are concentrated at the weld root when the tube face deflects. Therefore, the directional strength increases (discussed under Condition 8) cannot be applied to welds on the ends of square HSS members. This is a new restriction incorporated into the 2022 edition of AISC 360.

Condition 10: Unevenly Loaded Because Welds are Combined with Bolts or Rivets

The final condition examined is when welds and mechanical fasteners are expected to share loads in a single connection. This is not a typical situation for new construction where it is common to use welded or bolted connections, but not both in a single connection. The typical application of this condition involves the retrofit of existing mechanically joined connections where welds are specified to add new capacity. Occasionally, for new construction, changes made to the structure late in the construction process may necessitate the addition of welds to bolted connections for additional capacity for conditions that were unexpected during the original design process.

Condition 10 deals with uneven loading between the welds and mechanical fasteners, not uneven loading on the weld itself. As was discussed in Condition 8, transverse welds are stiffer than longitudinal welds. Welds, regardless of their orientation, are stiffer than bolted connections. Thus, the relative deformation capacity of all the elements in a single connection needs to be considered when the strength of the connection is determined. There are several factors that must be considered: longitudinal versus transverse welds, the type of bolted connection (e.g., snug-tight versus pretensioned), whether rivets or bolts are involved, and whether slip has likely occurred in the bolted connection.

AISC 360 states: “Bolts shall not be considered as sharing the load in combination with welds, except in the design of shear connections on a common faying surface where strain compatibility between the bolts and welds is considered.” After the prohibition on sharing loads between bolts and welds, an exception is listed: sharing of loads is permitted when strain compatibility between bolts and welds is considered. AISC 360 provides details of how longitudinal welds and pretensioned high-strength bolts can be considered to share load.

Conclusion

There may be, and probably are, situations where welds are unevenly loaded other than the ten commonly encountered conditions discussed in Parts 1 and 2 of this article. Engineers should watch out for uneven loading on welds and take action to mitigate it. More detailed information on how to mitigate these conditions can be found in AISC 360, the AISC Steel Construction Manual, and AWS D1.1. ■

Full references are included in the online version of the article at STRUCTUREmag.org .

Duane K. Miller, PE, ScD, is a recognized authority on the design and performance of welded connections. He retired after 44 years of service with The Lincoln Electric Company who retains his services as a consultant.

MARCH 2024 21

Figure 2. Transverse and longitudinal fillet welds in a single connection.

Figure 3. Uneven loading on a square HSS tube-to-tube tee connection

structural ANALYSIS

Special Wind Zones in Washington and Oregon

Site-specific wind studies have indicated special wind regions on the east side of the Cascades in Oregon and along the Columbia River Gorge could be eliminated.

By Seth Thomas

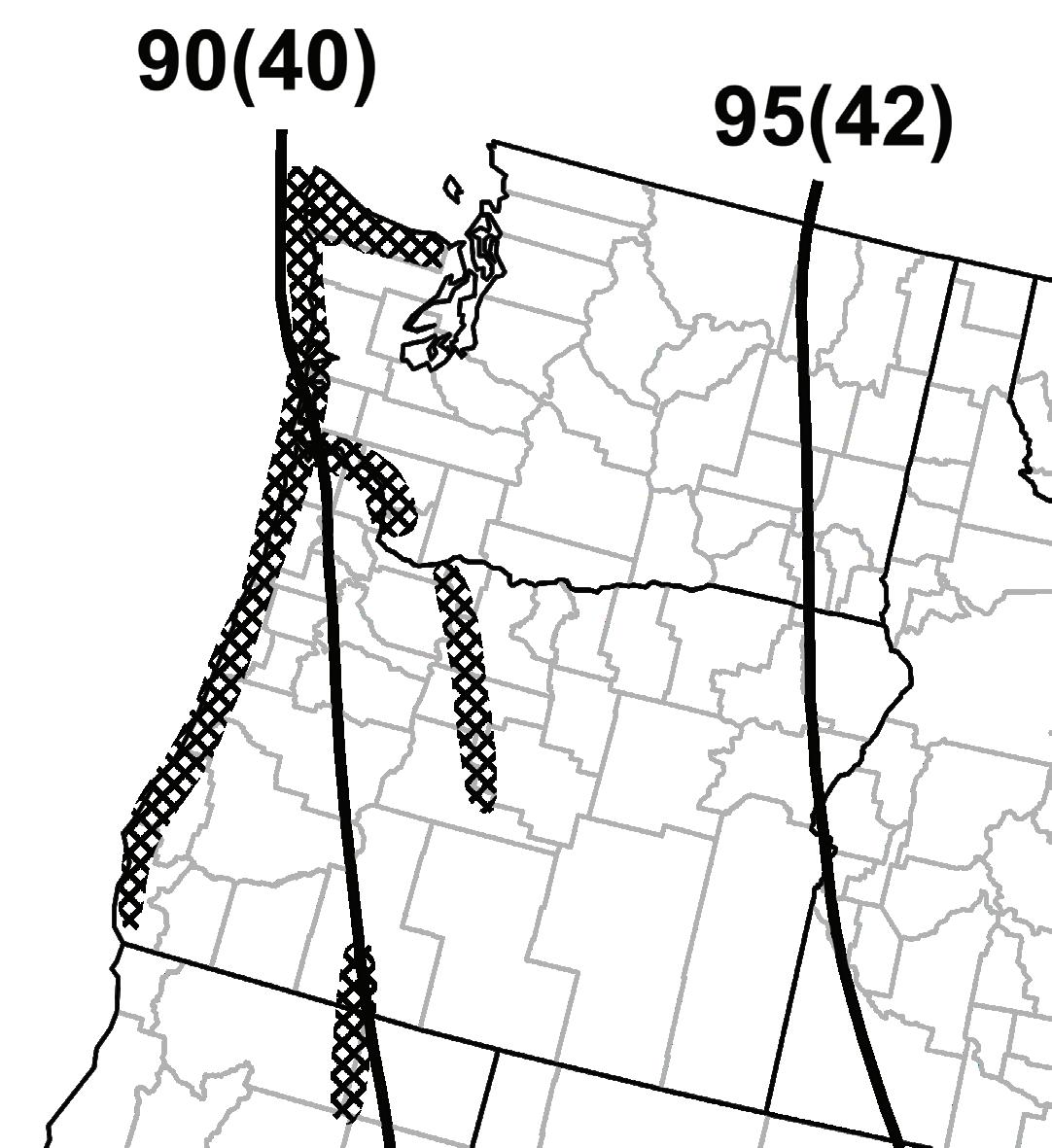

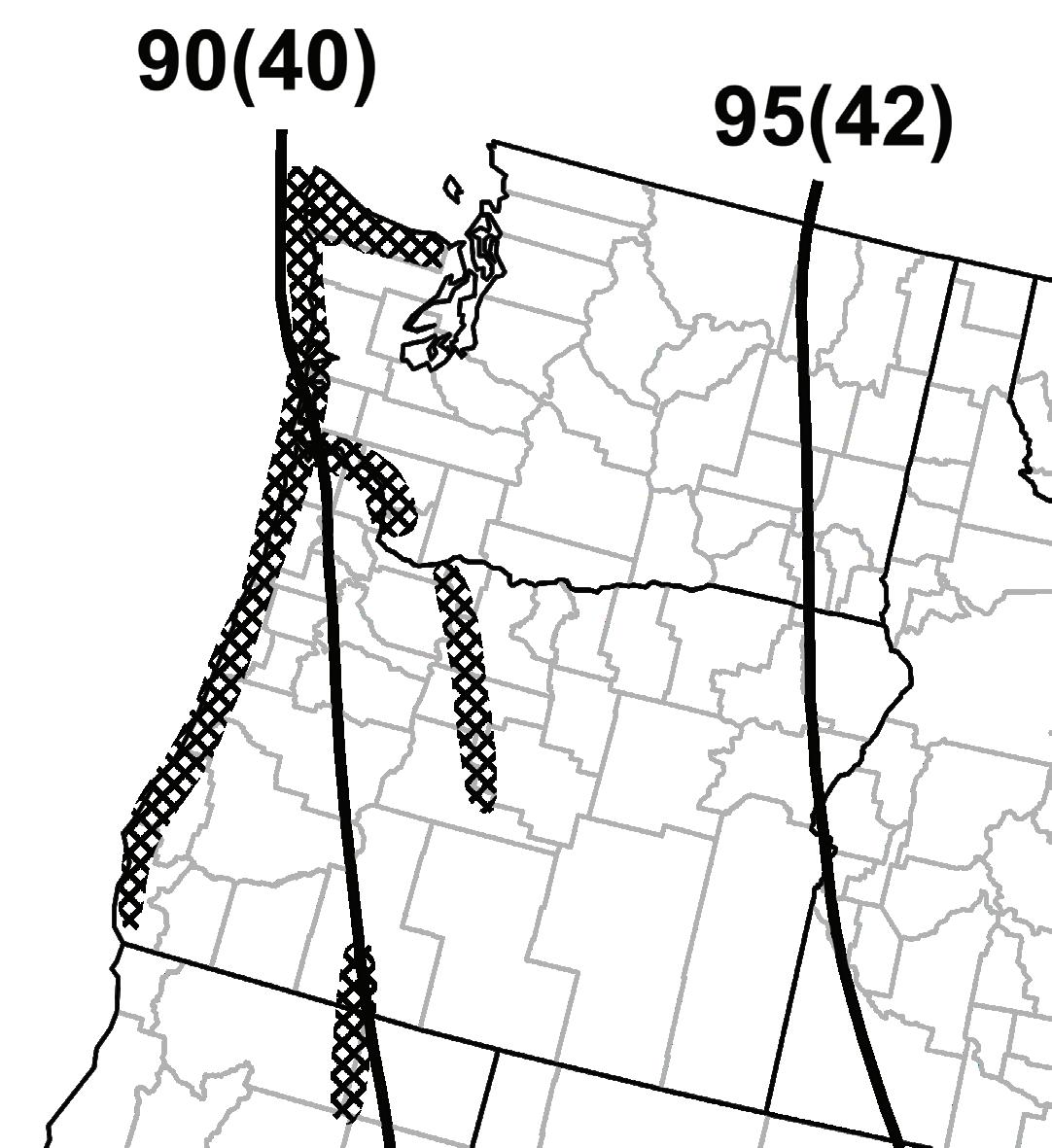

Special Wind Regions (SWR) are defined in ASCE 7-22 Section 26.5.2.

as “Mountainous terrain, gorges, and special wind regions shown in Figure 26.5-1.” These regions are identified in ASCE 7 to highlight the lack of data or the high variability of wind speeds in localized areas where the wind data from the surrounding areas may not be adequate to properly capture the hazard.

The origin of special wind regions by name is from ANSI A58.1-1982 (predecessor to ASCE 7-88). The initial special wind regions were established without detailed analysis but were based on the expertise of climate/ wind experts on the ANSI A58.1-1982 committee. While the extents and locations of these regions have changed somewhat, they are very similar in ASCE 7-22 to what they were in ANSI A58.1-1982.

Before ANSI A58.1-1982, the 1978 Oregon Structural Specialty Code (OSSC) specified higher wind speeds along the Oregon coast and the Columbia River Gorge, the 80-mile-long portion of the Columbia River east of Portland. It should be noted that the special wind region in the OSSC along the Columbia River Gorge never existed in ASCE 7 or the building codes on the Washington side of the river.

The commentary in ASCE 7-22 notes that the lack of climatic data along

the Washington/Oregon coast as the reason for that special wind region. The Commentary further states that winds blowing over mountain ranges or through gorges or river valleys have the potential to develop speeds that are substantially higher than the maps of ASCE 7 Figure 26.5-1.

ASCE 7 Section 26.5.2 and the ASCE 7 Commentary note that the design wind speed for the special wind regions specified in ASCE 7 are to be determined by the Authority Having Jurisdiction (AHJ), based on regional knowledge and experience. In Oregon, design wind speeds are established by the state Building Codes Division and have remained static for several code cycles (same for 2007/2010/2014/2019, except for the conversion to strength level in 2014). In Washington, basic wind speeds are determined by each of the nine county AHJs with SWRs. After the significant reduction in wind speeds in ASCE 7-16 (adopted in the 2019 OSSC) wind speeds in the special wind regions for Oregon and Washington typically became 25 to 35 mph higher than those in the adjacent nonspecial wind region areas. This results in wind pressures that can be 50 to 90% higher. This difference comes before any exposure and topographic factors have been applied. Some of the edges of the special wind regions do occur in populated areas, thus a large step function can occur leading to significant changes in design loads at the border of these zones.

Footnote 6 of ASCE 7 Figure 26.5-1A states that site-specific values for selected special wind regions noted on the maps shall be permitted to be determined using the ASCE Wind Design Geodatabase in the ASCE Hazard tool https://asce7hazardtool.online. Site specific analyses have been performed in accordance with ASCE 7 Section 26.5.3 for northern Colorado and Kern County, California, with the results adopted in ASCE 7-22 and incorporated in the Hazard tool.

In 2018, as part of the 2019 OSSC adoption process, the Structural Engineers of Oregon (SEAO) Code Committee submitted a code change proposal to the State for the adoption of ASCE 7-16, which included the recommendation that a site-specific study be performed for the Oregon

STRUCTURE magazine 22

Excerpt from ASCE 7-22 Figure 26.5-1A. Special Wind Regions (SWR) are defined in ASCE 7-22 Section 26.5.2. as “Mountainous terrain, gorges, and special wind regions" shown here. Figure 1609.3 from 2022 OSSC: Special wind regions in Oregon are noted.

BUILD TALL WITH POWER COLUMN ®

STRONG, EFFICIENT, SUSTAINABLE

POWER COLUMN® FEATURES

• Complement to Mass Timber wood framing systems

• Sustainable Forestry Initiative (SFI®) Certified

• Manufactured with superior strength southern yellow pine MSR Lumber

• Available in range of appearance grades for structural and architectural applications

• Superior alternative for Tall Wall applications

• Load path solution for Engineered Beam and Header Products

• Framing members such as Power Beam® can easily be attached to Power Column® with simple connection detailing

©Anthony Forest Products Company, LLC WWW.CANFOR.COM | 800.221.BEAM | WWW.ANTHONYFOREST.COM Anthony Forest Products is part of the Canfor Group of Companies

special wind regions as part of the change proposal. While Oregon agreed it was a worthwhile effort, there was no funding available, so this was dropped as part of the 2019 OSSC adoption process. SEAO’s code committee reached out to the SEA Wind committee to establish a partnership with SEAW, and a budget was established based on the estimate to complete the work in both states. This partnership was prudent from a funding standpoint, as study costs along the Columbia River, the border between Washington and Oregon, could be shared by both SEAW and SEAO. Each SEA set out to fundraise their portion of the study with the intent to finish in time for adoption in the ASCE 7-22 cycle. This goal was not met and revised to target the ASCE 7-28 cycle.

In 2022, SEAW was able to complete funding and commissioned a site-specific study for all the SWRs in Washington State, including both the Washington and Oregon sides of the Columbia River. Funding was achieved with an NCSEA grant, significant contributions from the Structural Engineers Foundation of Washington, and numerous engineering consultants and individuals. The SWR study for Washington State and the Columbia River was completed in the summer of 2022.

In the summer of 2023, SEAO finished the process of raising money, commissioning, and completing the study for the remaining SWRs in Oregon. The special wind region studies for both Washington and Oregon (performed by CPP Wind Engineering Consultants) looked at climatic data from a number of local reporting stations near existing special wind regions (typically from regional airports) and used the same methodology to establish the design wind speeds based on Risk Category as established in ASCE 7-16. Using this process, the design wind speeds were established statistically and compared to the wind speeds shown in ASCE 7 outside the special wind region.

As a result of these two studies, there are significant reductions or eliminations of the special wind regions across both states. The studies showed that the special wind regions on the east side of the Cascades in Oregon and along the Columbia River Gorge could be eliminated. The extents of the special wind regions along the north coast of the Olympic peninsula and from the mouth of the Columbia River were significantly reduced. Additionally, while the special wind region on the Pacific Coast remained, the wind speeds established by the local AHJs along the Washington and Oregon coast could be reduced. The study did show one area where the existing special wind regions did not extend far enough. In the Southwest corner of Oregon in Curry County, the study showed the special wind region should extend to the Oregon/California border (and beyond).

After a review period by SEAO, Oregon’s study was finalized. The information from both studies is currently being used by SEAW and SEAO to pursue a change proposal for ASCE 7-28 to eliminate the unnecessary SWR, while mapping the wind speeds and updating the extents of the SWR that remain.

Since ASCE 7-28 will not be adopted until the 2030 IBC (2031 OSSC), the SEAO Code Committee has been working with the Oregon Building Codes Division to allow for a path of early adoption of these reduced wind speeds. On August 9th, 2023, the Oregon Building Codes Structures Board approved an interim amendment to the 2022 OSSC for the reduction in wind speeds the special wind regions shown in ASCE 7-16 matching the results of the study. The interim amendment went into effect on October 1st, 2023 (https://www.oregon.gov/bcd/codes-stand/Documents/22osscdesignwindspeed-amendments.pdf). The special wind regions in the Columbia River Gorge, Redmond/Bend area and Klamath falls area are all essentially eliminated by defaulting the special wind region speeds in these areas to match the adjacent area per ASCE 7-16. The special wind region at the coast will remain but most counties will see a reduction in wind speed. SEAW has authored a white paper, approved by SEAW’s State Board of Directors, and published in February 2023, recommending a similar reduction matching their study (https://static1.squarespace. com/static/5c3faa364eddecdc367bedc5/t/63f3db7af61577050df48 30e/1676925822712/White+Paper+WEC+%233+-2023.pdf). These recommendations are being submitted by SEAW for consideration as a 2024 amendment to the Washington State Building Code.

In summary, the partnership of two-member organization to spearhead a study has led to improvements in design wind maps which will benefit the structural engineering profession. The changes would not have been possible without the outstanding efforts of the SEAO and SEAW committees, along with the generous donations by many to support their studies. SEAOC, and possibly SEAC will be joining SEAO and SEAW in submitting the results of their respective SWR site-specific study recommendations for adoption in ASCE 7-28. Much of this cooperation between these SEA Member Organizations was facilitated the NCSEA Code Advisory Wind Engineering Subcommittee. ■

Seth Thomas is an Associate at KPFF in Portland Oregon and a member of ASCE 7 Main, Flood, Tsunami, and Seismic, standard subcommittees. He can be reached at seth.thomas@kpff.com.

STRUCTURE magazine 24

Left: Recommended special wind regions in Washington (SEAW White paper). Above: Changes to wind speeds in 2022 OSSC based on October 1, 2023 interim amendment (Risk Category II)

STRONG. SECURE.

If seismic or high-wind challenges are important considerations for your next project, Vulcraft and Verco’s steel roof deck and PunchLok II® System is a valuable option to consider. Working with our team of experts early in your design process can help you evaluate the variety of value-added solutions that Vulcraft and Verco offer to ensure that you have the right system in place.

Contact an expert today.

VULCRAFT VERCO

VULCRAFT VERCO

PUNCHLO K® II SYSTEM P NEUMATICALLY-OP ERATEDCONNECTO R

Seismic Rehab of the Oregon State Capitol

STRUCTURE magazine 26

The Oregon State Capitol Renovation project seismically retrofits and renovates multiple structures utilizing ASCE 41.

By John McDonald, S.E., Stefanie Chamorro, P.E., and Geoff Bomba, S.E.

Driven by the importance of the Oregon State Capitol and disproportionate seismic damage from the 1993 Scotts Mills seismic event, the Oregon Legislature moved forward with measures to protect and preserve the historic building. The project includes a seismically base-isolated retrofit of the 1938 Capitol building, which is a non-ductile brick infilled concrete frame structure with marble cladding. The Capitol is flanked by a pair of five-story 1977 reinforced concrete buildings retrofitted using a fiberreinforced polymer (FRP) strengthening system, which remain fixed base structures. The seismic isolation system of the Capitol utilizes a triple friction pendulum system tuned to reduce the acceleration of the building during a Cascadia Subduction Zone (CSZ) seismic event. Once complete, a new occupied level will be constructed below the existing building footprint to increase program space and meet the changing needs of the Oregon State Capitol.

History, Seismology, & Existing Buildings

The Oregon Capitol Building has been rebuilt three times in Salem, Oregon. The first two capitol buildings were destroyed by fires in 1855 and 1935, and the citizens of Oregon have a keen interest in preserving this third building, completed in 1938 with an adjacent expansion in 1977 to expand the Capitol complex (Figure 1). The State of Oregon performed multiple studies over the past decades to determine the optimal remedy to the seismic vulnerability of the Oregon State Capitol complex. A Master Plan, completed in 2009, recommended seismic rehabilitation, life-safety improvements, and renovations to improve the operational efficiency of the Legislature. The Capitol Master Plan Review Committee recommended that the seismic and other life-safety concerns be addressed as top priorities. Initial discussions focused on traditional methods such as adding concrete shear walls or applying fiber reinforced polymers to existing concrete walls. With the desire to preserve historic murals

Design Team

• Architects: SRG + CannonDesign and Architectural Resources Group

• Structural Engineers: Forell Elsesser Engineers and Catena Consulting Engineers

• General Contractor: Hoffman Construction Company

• Site Hazard Analysis Engineers: Geotechnical Resources, Inc. (GRI)

MARCH 2024 27

Fig. 1: (Left) An aerial photo of project site looking from the north (Photo Courtesy of SRG+CannonDesign). (Right) Plan view map of project site showing the interconnected building segments.

and fabric within the Capitol, the Design Team investigated a less structurally intrusive approach. The Review Committee prioritized seismic isolation as the preferred retrofit strategy and recommended that the 1938 portion of the Capitol be seismically isolated together with portions of the 1977 Capitol Connector building. There are distinct stakeholders who have influence and control of the project. The ownership decision authorities for the capitol complex is … complex: The Legislature owns and manages the buildings, while the Parks Services owns and manages the grounds. Finally, the Department of Administrative Services maintains responsibility and control for all utilities, monuments, and dedications. These entities, of course, are separate from the permitting authority.

Seismology & Ground Motions

There is significant geologic evidence indicating a tectonic plate boundary off the Western US coast—extending from northern California to Canada. The project site is approximately 40 miles from the eastern edge of the Cascadia Subduction Zone (CSZ) which is the active convergent plate boundary between the subducting Explorer, Juan de Fuca, and Gorda Plates and the overriding North American Plate. According to the Oregon Resiliency Plan, there is a 10-37% chance of occurrence of a Magnitude 8.0 or larger earthquake in the next 50 years. Based on the tectonic setting and historical seismicity, the Oregon State Capitol project site is subject to earthquakes from major sources such as megathrust earthquakes along the interpolate CSZ, interslab earthquakes on the subducted portion of the CSZ, and shallow crustal faults.

While there is a limited database of historical earthquakes for Oregon, two events have occurred within 50 miles of the site, including a

magnitude 4.6 in 1963 and a magnitude 5.6 event in Scotts Mills in 1993. The 1993 Scotts Mills earthquake caused damage to the Capitol, which prompted the initial phases of retrofitting the 1938 structure. This initial phase of seismic renovation strengthened areas with new concrete shear walls. These walls were strategically placed so as not to disrupt the historic murals and finishes within. While helpful, the available areas were limited. Additionally, these initial steps relied upon future completion—the new shear walls did not extend down to the foundation.

Given the significant variability in magnitude and types of earthquakes that could impact the site, GRI, the geotechnical consultant, completed a site-specific seismic hazard analysis for the project that included site response modeling from the underlying bedrock through the soil layers of interest. For the structural time history modeling, both amplitude scaling and spectral matching were initially considered while spectral matching was selected for final design of the seismically isolated portions of the retrofit following ASCE 41. To accommodate the range of potential earthquake sources and magnitudes, the number of time histories for each type of earthquake were selected based on review of the deaggregation, overall contribution at each hazard level, and period range of interest for the proposed base isolated solution. All the selected ground motions for non-linear response history analyses were subduction zone motions and deemed appropriate given the seismicity of the site.

Existing Buildings: 1938 Capitol Building

The 1938 main Capitol building is a four-story structure plus a basement with a central drum and rotunda and Senate and House chambers symmetrically placed to the east and west of the rotunda. The structure consists of a cast-in-place reinforced concrete frame with clay brick infill and some limited areas of unreinforced masonry (URM) bearing wall. Floors consist of reinforced concrete pan joist slabs spanning to concrete beams supported by concrete columns. The central drum has a cylindrical shape with a concrete roof slab spanning to steel beams supported on a circular URM bearing wall. This bearing wall is supported by a ring of concrete beams at the main roof level transferring the load to concrete columns that continue down the building. All concrete columns are supported on shallow footings that are constructed with a concrete plinth on a larger concrete base. At the exterior, the structure is clad with marble panels varying from 10 in. thick at the base and narrowing to a mere 6 in. at the

STRUCTURE magazine 28

Fig 2. Historic Drawings of Floor & Turret Plans.

Figure 3. This vintage out-of-plane anchor was deemed insufficient for modern loading.

upper levels. This cladding contributes to the already considerable weight of the building. The marble panels stack vertically from the base and are braced to the building with metal anchors into URM infill installed within the perimeter framing (Figure 3). At the drum, the marble is anchored to the URM bearing wall.

After the 1993 Scotts Mills earthquake, the rotunda of the building was strengthened with reinforced concrete shear walls. This retrofit was designed to a force level that assumed a subsequent project would seismically isolate the entire 1938 building. The entire dome and turret received an added layer of reinforced concrete shear wall cast on the interior. Below the transfer beams of the drum at the roof, a square layout of shear walls was constructed down to the foundation level.

Existing Buildings: 1977 Legislative Wings & Connector Building

The east and west Legislative Wing building structures are mirror images of each other and flank each end of the Connector Building. The Legislative Wings are separated from the Connector Building by an existing seismic joint. All three buildings consist of conventionally reinforced concrete pan-joist construction at the roof and floor slabs supported by reinforced concrete columns founded atop shallow spread footings.

Reinforced concrete shear walls founded atop shallow strip footings provide lateral resistance against wind and seismic forces. Exposed sides of the buildings are clad with marble veneer panels.

The Wing Building retrofits, which added strength using FRP (Figures 4-5), proved an effectively elegant solution – preserving floor space and most finishes. During exploratory investigations, the Design Team confirmed foundation sizes and depths and discovered an unusually high-water presence (Figure 6). During the design of the isolated building, the need for construction and permanent dewatering wells became apparent as the excavation would dig approximately 15 ft. below existing basement floor level.

Project Goals & Constraints

A master plan in the early 2000s identified the owner's desire to rehabilitate the Capitol complex to improve seismic safety and resiliency. The Oregon Constitution allows the governor funding authority without legislative approval for 30 days following an emergency. For this reason, the performance goal for the seismic renovation is to have the capitol building operational within 30 days following a seismic event so that the legislature can convene and continue its system of checks and balances throughout the response and recovery.

The construction of the Oregon State Capitol Renovation is being conducted in phases, with the final phase currently ongoing. The phased construction maximizes the efficiency of the legislature to continue meeting within the building – Oregon Legislature convenes annually: in odd years, “long sessions” lasting 160 days occur, while in even years, a "short session" lasting a maximum of 35 days is held.

This article is the first of three articles presented in STRUCTURE magazine that showcases the new retrofit of the Oregon State Capitol buildings. The next article will discuss the retaining walls creating the moat of isolation and those supporting existing permanently undermined buildings. It will also cover the foundation selection and design for performance and to work with the high water-table and other onsite problem solving. The final article will focus on the details of the seismic base isolated retrofit design, and construction. ■

MARCH 2024 29

Figure. 4. Analytical model rendering of the 1977 Wing with concrete shear walls (yellow) + FRP strengthened sections (red) at the vertical LFRS.

Figure 5. Reinforced concrete column strengthened with FRP. (Left) Full FRP wrap fabric around column. (Right) FRP anchors to actively terminate ends of the FRP wrap fabric.

John

McDonald, S.E. (john@catenaengineers.com) is a Principal with catena consulting engineers in Portland, Oregon

Figure 6. A high water-table combined with perched water visible was observed by Maya Foty, Historic Architect Extraordinaire and Mark Fitterer, Vintage Building Investigator.

Preserving a Landmark

Using performance-based seismic design, the structural engineering team retrofitted the existing venue while maintaining the original 1960s feel.

By Brian MacRae, P.E., S.E.,Kerem Gulec, Ph.D., P.E., S.E.

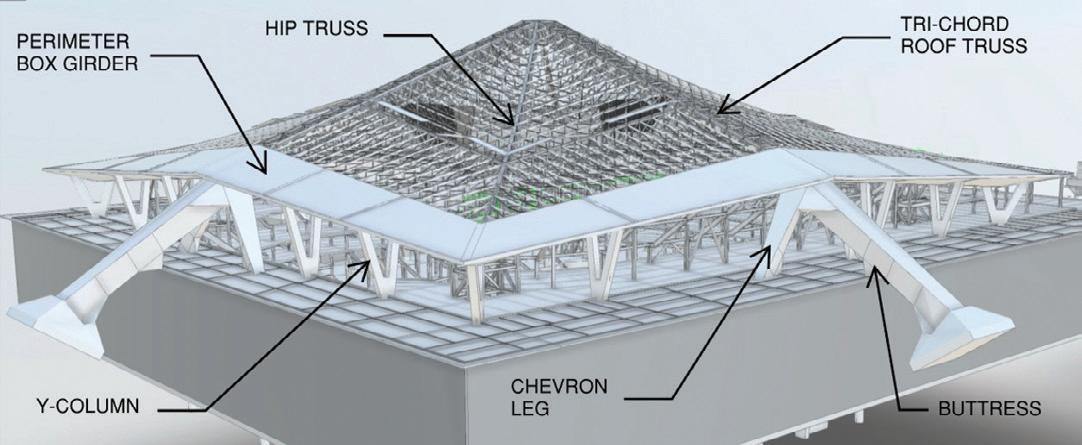

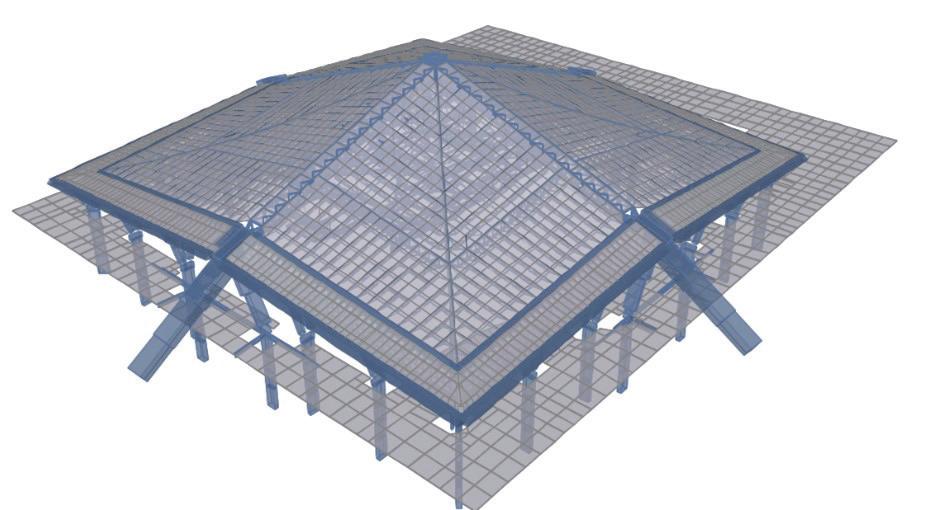

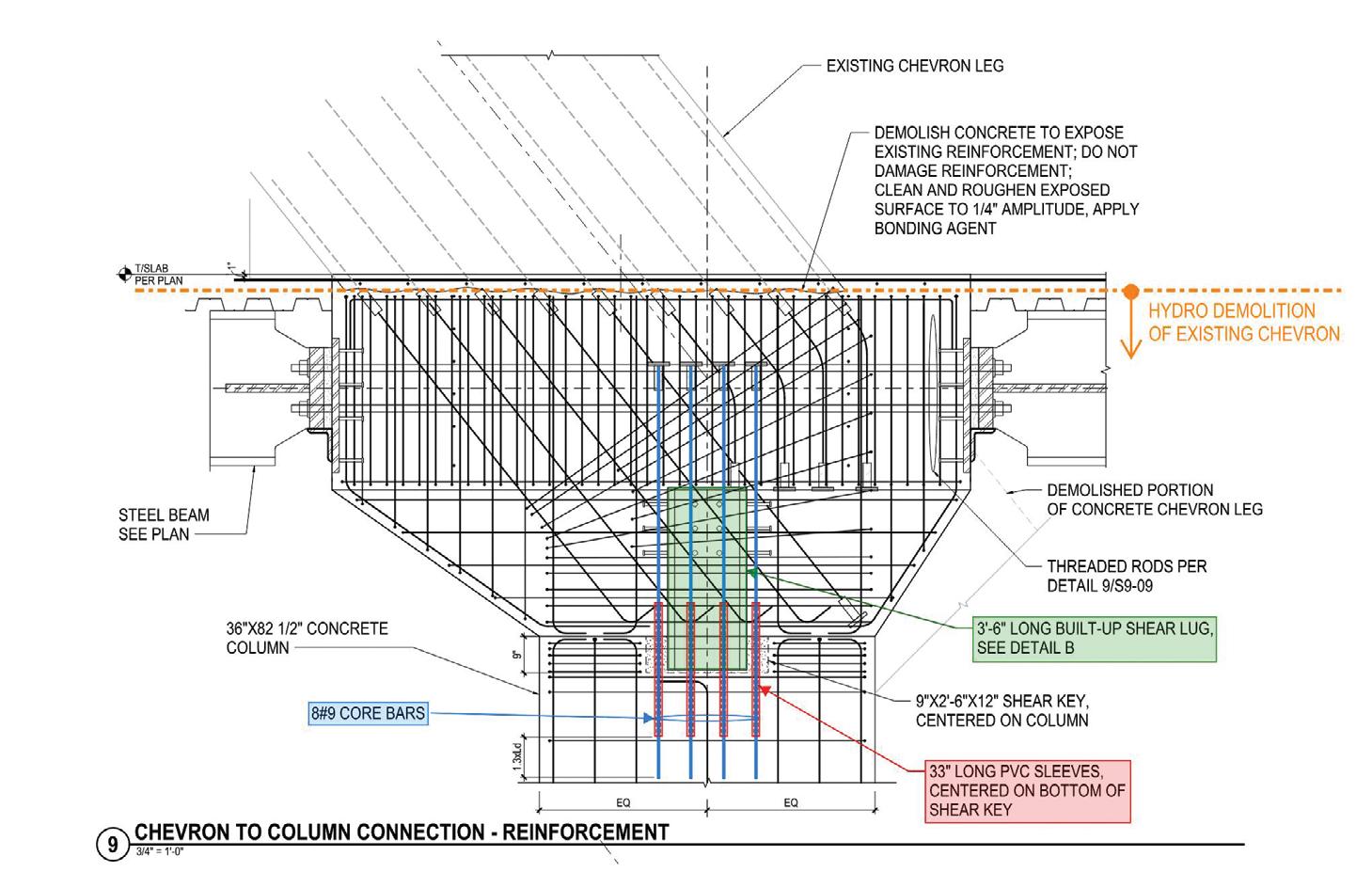

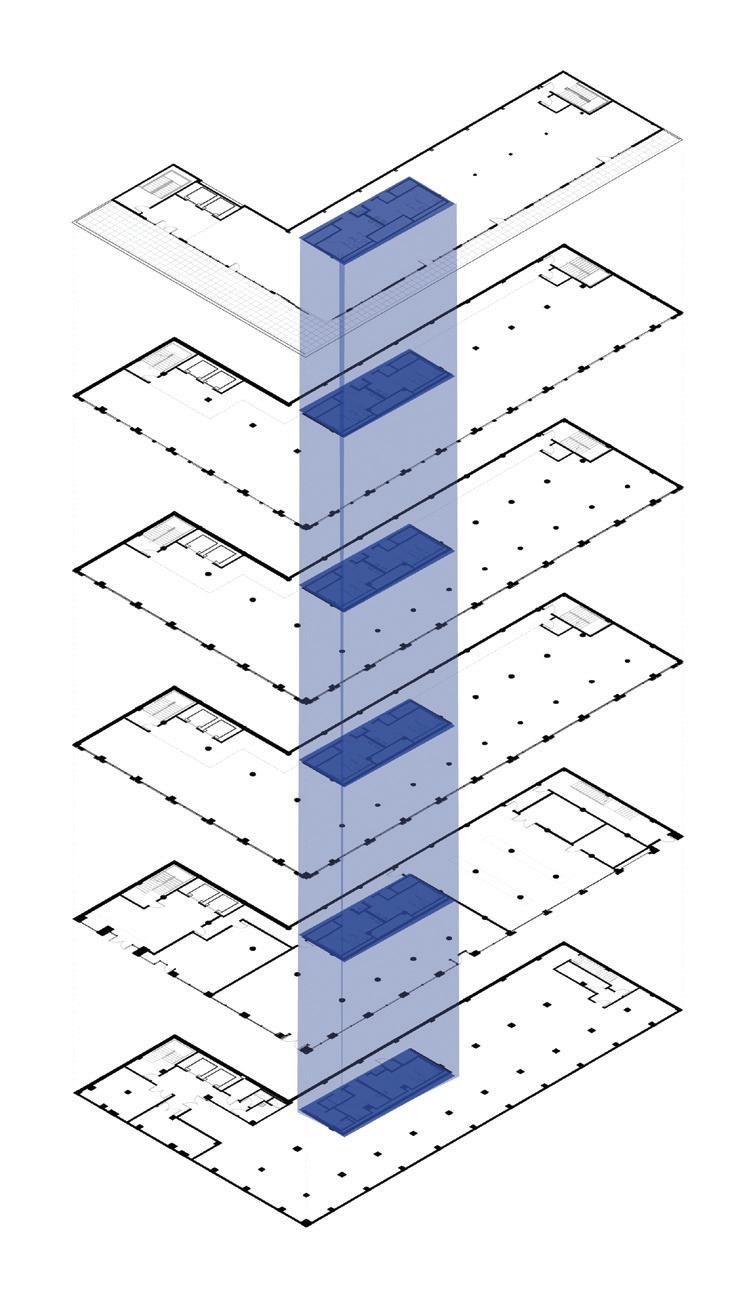

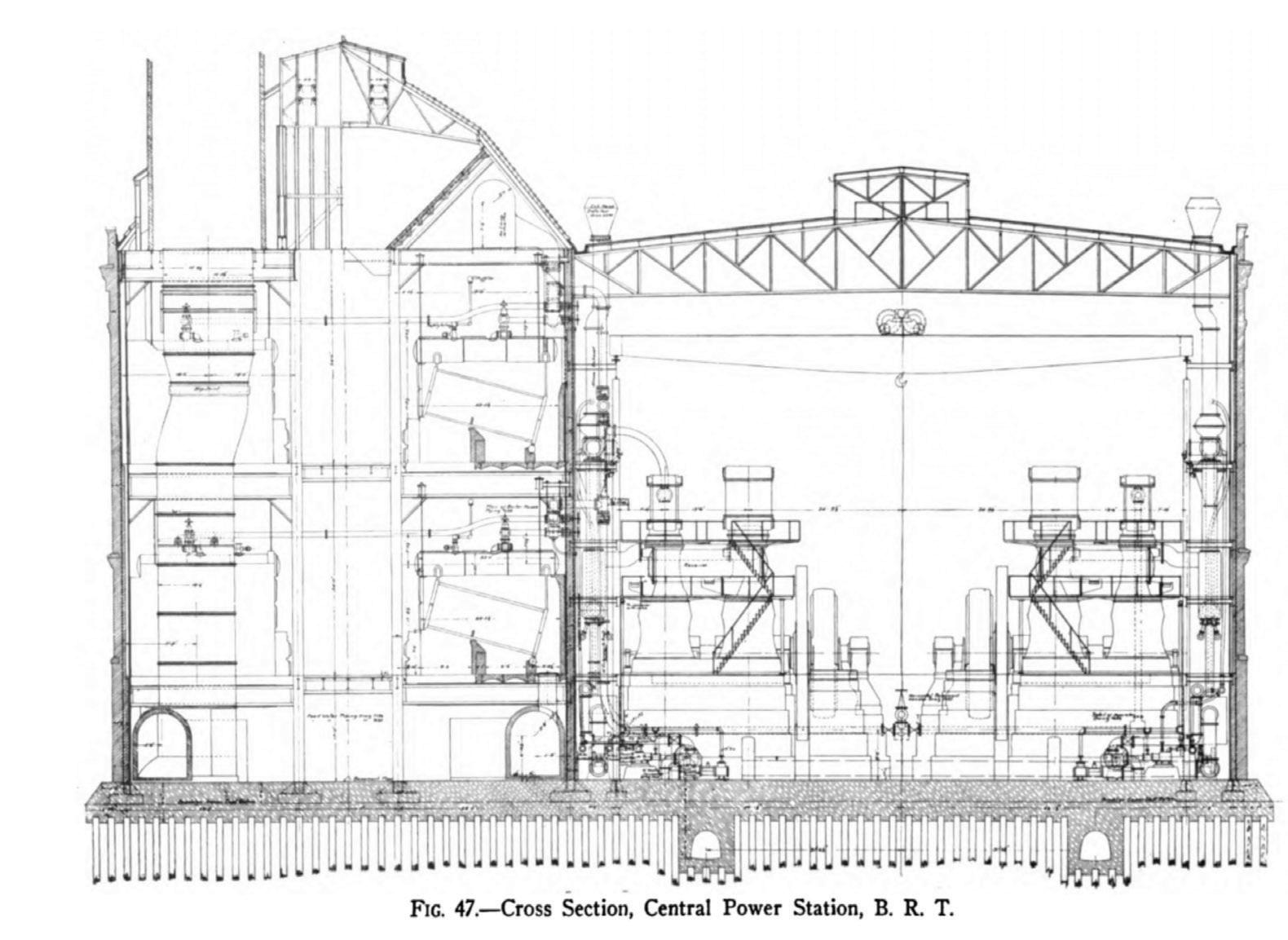

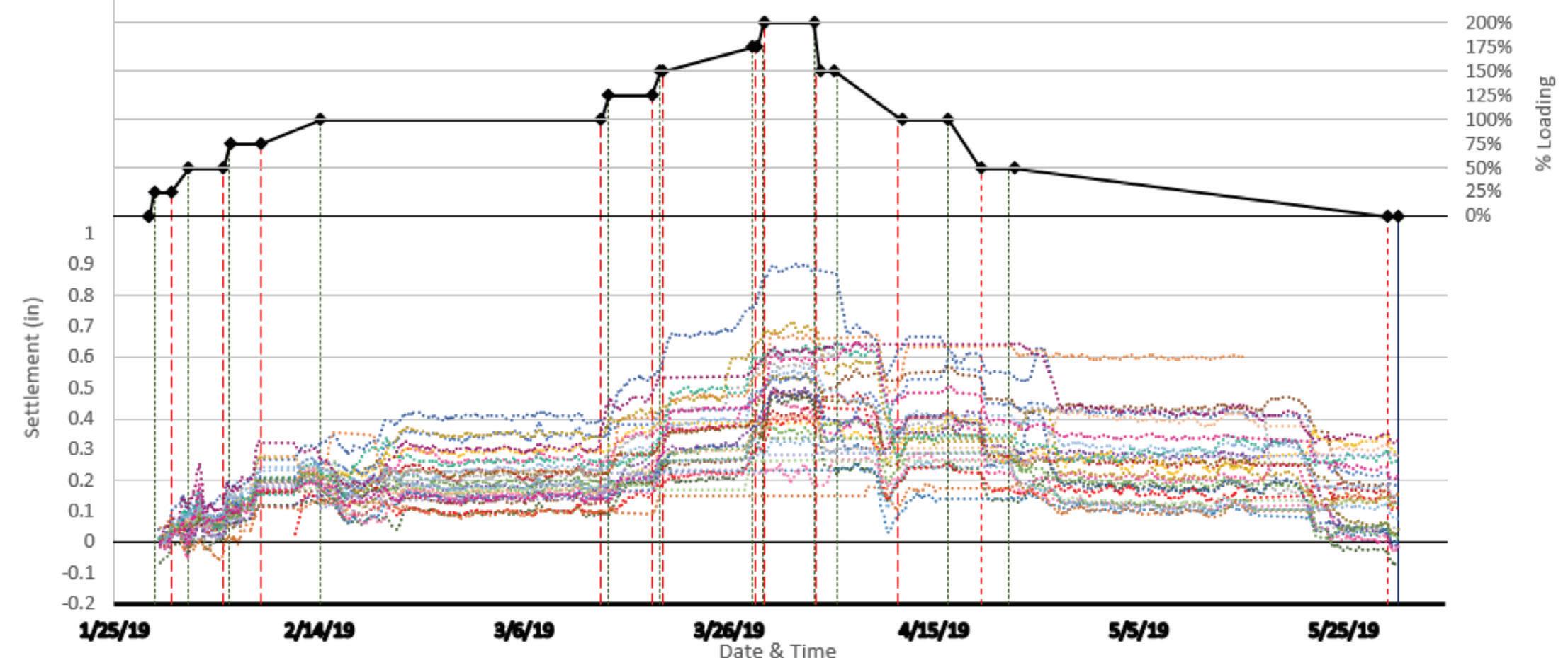

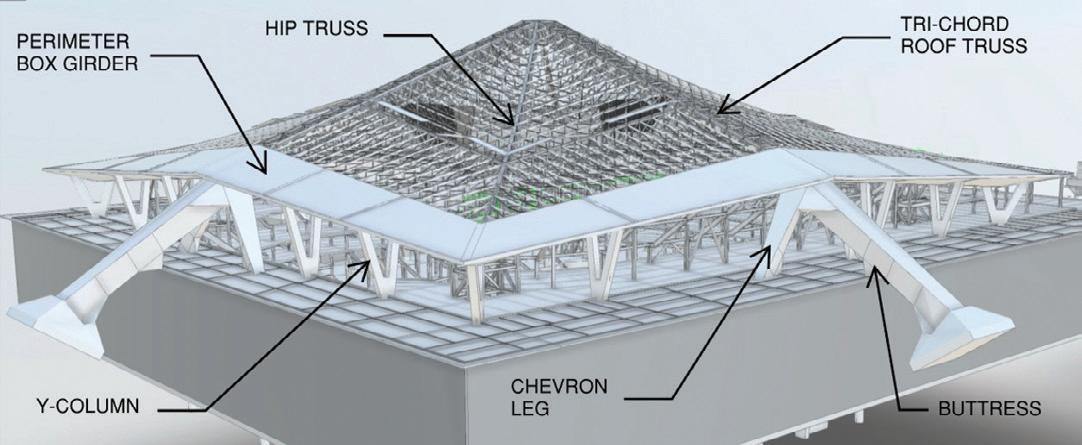

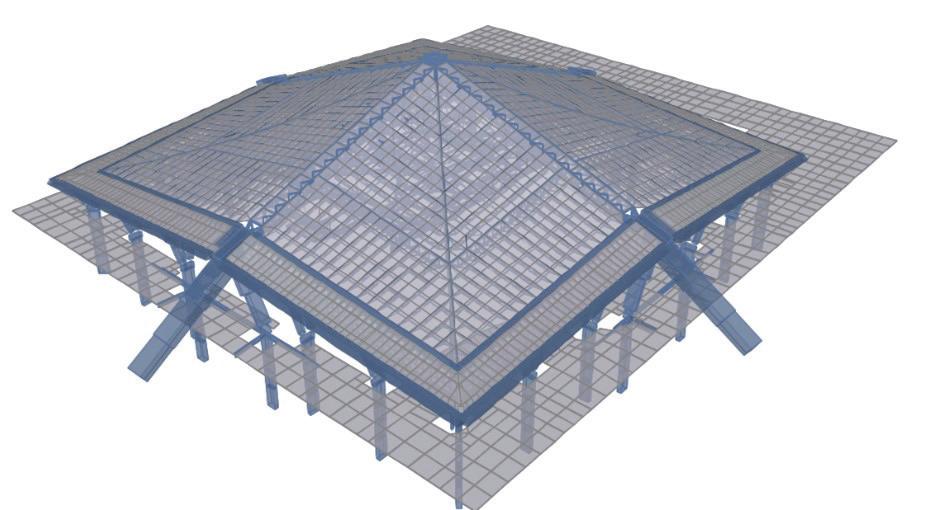

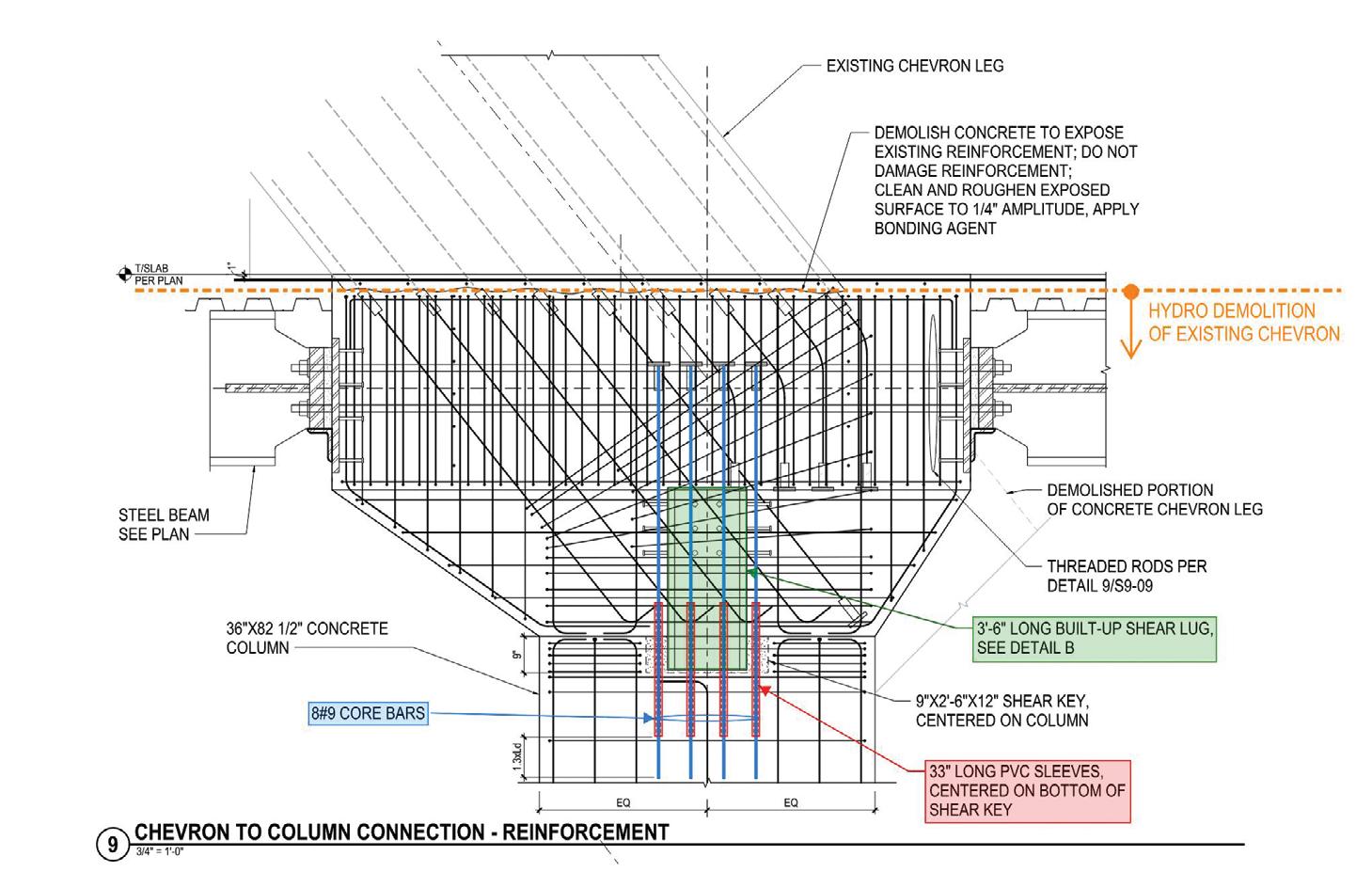

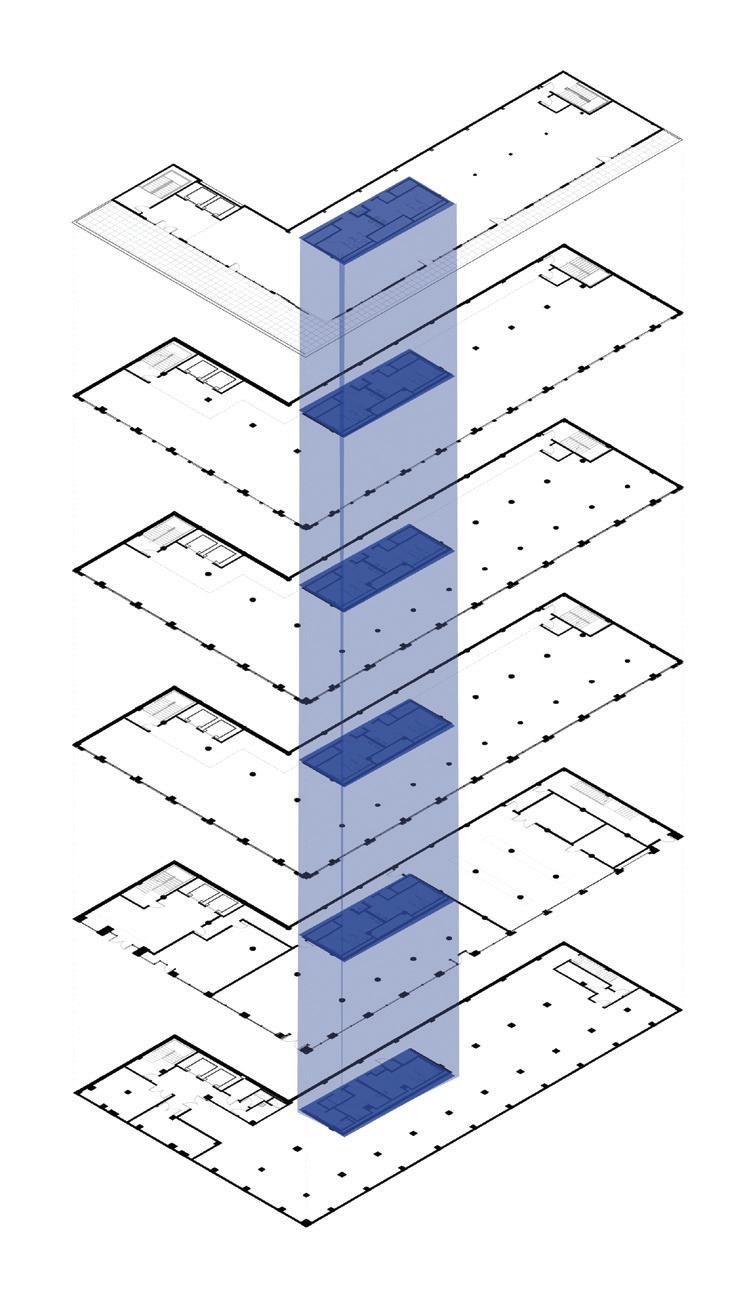

STRUCTURE magazine 30