subscriptions@structuremag.org

EDITORIAL BOARD

Chair John A. Dal Pino, SE Claremont Engineers Inc., Oakland, CA chair@STRUCTUREmag.org

Marshall Carman, PE, SE Schaefer, Cincinnati, Ohio

Erin Conaway, PE AISC, Littleton, CO

Sarah Evans, PE Walter P Moore, Houston, TX

Linda M. Kaplan, PE Pennoni, Pittsburgh, PA

Nicholas Lang, PE

Vice President Engineering & Advocacy, Masonry Concrete Masonry and Hardscapes Association (CMHA)

Jessica Mandrick, PE, SE, LEED AP Gilsanz Murray Steficek, LLP, New York, NY

Jason McCool, PE

Cool Country Engineering PLLC,Cabot, AR

Brian W. Miller

Cast Connex Corporation, Davis, CA

Evans Mountzouris, PE Retired, Milford, CT

Kenneth Ogorzalek, PE, SE KPFF Consulting Engineers, San Francisco, CA (WI)

John “Buddy” Showalter, PE

International Code Council, Washington, DC

Eytan Solomon, PE, LEED AP Silman, New York, NY

Jeannette M. Torrents, PE, SE, LEED AP JVA, Inc., Boulder, CO

Executive Editor Alfred Spada aspada@ncsea.com

Managing Editor Shannon Wetzel swetzel@structuremag.org

Production production@structuremag.org

MARKETING & ADVERTISING SALES

Director for Sales, Marketing & Business Development

Monica Shripka Tel: 773-974-6561 monica.shripka@STRUCTUREmag.org

nucor.com/madeforgood

By Bryan Seamer, PE, SE

The award-winning project updated the structural systems of the University of California San Diego building while preserving its architectural heritage.

By Jason Armes, SE; Gina Carlson, SE; and Leo Panian, SE

For many existing buildings, a targeted and more cost effective solution can be found through the use of advanced nonlinear analysis procedures.

By Nik Blanchette, SE; Steve Heyne, SE; and Chris Warner, SE

A charter high school in Northern California planned to make a large commercial building its new permanent home, but first the structure needed to be given a seismic upgrade without disrupting the other tenants.

During the seismic rehab project, a new basement story was created along

Introducing the Simpson Strong-Tie ® Yield-Link ® brace connection ( YLBC).

Now you can add more resilience to structural steel projects. Ideal for new builds or retrofit work, the YLBC connects braced frames in structural steel buildings. It has bolted connections that simplify design. During extreme seismic or high-wind events, the YLBC isolates damage to the connection only — allowing the braced frame to remain intact. In addition, our Yield-Link technology tools make it easy to plan, model and document complete designs according to your unique specifications. Like other Simpson Strong-Tie products, the YLBC is widely available and backed by our industry-leading service and technical support.

Design your next project with all of our structural steel solutions. To learn more, visit go.strongtie.com/yieldlinkbraceconnection or call (800) 999-5099.

a Recruiting Tactic: Find a Purpose By Anthony LoCicero, PE

Considering the Potential Impact of Tsunamis on Structures By Steven Baldridge, PE, SE, LEED AP

Splices (Couplers) in Reinforced Concrete Constructions By Dr. N. Subramanian, Ph.D., FNAE

By Justin Moresco, PE, and David Mar, SE

Jennifer Goupil, PE

By John “Buddy” Showalter, PE, and Sandra Hyde, PE

By John A. Dal Pino, SE

19th Century Mississippi River Bridges: Prairie Du Chien Floating Bridge 1874

By Dr. Frank Griggs, Dist. M. ASCE

By Anthony LoCicero, PE, LEED AP

Recruiting and retaining top engineering talent has never been more challenging. Construction is booming across many markets, leading to strong demand for engineering services. Yet the pool of engineering candidates remains limited across disciplines, including structural.

Retirements are on the rise. Students are choosing among a growing number of technical career pathways. To counteract a potential workforce shortfall, traditional recruitment and retention strategies, such as compensation, advancement opportunities, and work-life flexibility, are important. But often, it’s not enough.

The American Society of Civil Engineers last year partnered with the National Governors Association to identify strategies for counteracting engineering workforce challenges across public and private sectors. I advise my structural colleagues to familiarize themselves with the report’s short-term as well as long-term strategies. While all are important, for this column, I want to highlight one in particular: “Praising and promoting the technical achievements of infrastructure.”

matter our area of focus, we should all find some way to draw connections between our structural designs and these important challenges.

The following examples are just a few of the topic areas where structural design innovations will have far-lasting implications for social, environmental, and economic change.

Resilience. Extreme weather is becoming more frequent and costly. Climate change is antici-

transition is cleaning up tailpipe emissions at a time when transportation is becoming the largest contributor to climate change. Structural engineers play a major role in EV enablement. Electric vehicle supply equipment (EVSE) and on-site power generation technologies are being attached to building roofs through canopy configurations. Roofs will need to be strengthened or new pantograph systems created from scratch. Charging systems may also require thoughtful cable management approaches such as trench-based cable reels, overhead conductors, or mounted cables installed on mobile equipment.

New generations of engineers want to be involved in bringing about solutions for society’s most complex challenges: how to adapt to a warmer world, transition to promising new technologies, overcome growing economic disparities, etc.

The ASCE and NGA report makes the correct point that, “too often in engineering and public infrastructure, workers are scorned for public failures and only rarely praised publicly for their success.” As any structural engineer knows well, a successful structural design goes largely unnoticed until something fails. To better recruit and retain talent, the structural engineering field must do better at celebrating individual and collective contributions toward high-profile projects, while drawing connections between structural designs and a project’s social, environmental, and economic benefits.

It is not uncommon for structural engineering recruits to hear how a building’s designs are critically important to occupant safety. Our industry’s high standards of engineering excellence will always be driven by the need to maintain public safety. But when telling the story of the structural profession, safety may no longer be sufficient. New generations of engineers want to be involved in bringing about solutions for society’s most complex challenges: how to adapt to a warmer world, transition to promising new technologies, overcome growing economic disparities, etc. No

pated to increase the intensity of heavy rain and hurricane events, while sea level rise is expected to amplify the impacts of storm surge. Flood risks are disproportionately expected to impact marginalized communities. In areas exposed to new risks, structural enhancements will become necessary to uphold the resilience of critical infrastructure. Tools may include new flood walls and other hardening measures. Depending on the application, these measures may be scaled to protect a single piece of equipment, a building, or for many city blocks.

Sustainability. A structure’s embodied carbon is an accounting of the greenhouse gas emissions associated with construction materials, including material production and installation. Embodied carbon is estimated to make up roughly 11 percent of energy-related carbon emissions worldwide. A growing number of jurisdictions now require life cycle assessments of a development’s embedded carbon, material-specific limits for carbonintensive building materials such as concrete and steel, or declarations of a design package’s carbon footprint. Structural design teams are being called upon to calculate—and lower—the Embodied Carbon Order of Magnitude (ECOM) for a project’s structural materials.

Electrification. The electric vehicle (EV)

Adaptive Conversions. With office vacancies reaching a 30-year high and land available for new construction often limited, developers are reimagining empty office buildings through adaptive reuse. Revitalizing these spaces can help revive downtown neighborhoods and alleviate housing shortages. Conversions have repurposed offices into apartments, hightech laboratories, and educational facilities. In the process, structural design teams are removing walls to access natural light, strengthening floors to hold heavy research equipment, reducing vibrations to accommodate hyper-sensitive lab equipment, and supporting new mechanical, electrical and plumbing systems.

If you ask ChatGPT, a structural engineer’s typical projects include the design of buildings, bridges, and utility structures. But what it means to be a structural engineer is changing. A broader definition is necessary to reflect the increasing complexity—and importance—of structural innovations. In doing so, we can elevate the profession and establish the field as one in which young professionals can pursue both their personal aspirations and technical interests. ■

Full references are included in the online version of the article at STRUCTUREmag.org

Conscientious design of buildings and infrastructure at risk of a tsunami impact can reduce the extent of the destruction. By

Steven Baldridge, PE, SE, LEED AP

With nearly one-third of recorded large tsunamis occurring in Japan, the phenomenon is reflected extensively in the region’s culture and history. Thus, the Japanese word “tsunami,” which means “harbor wave,” is recognized globally for an event that can occur along any coastline.

Tsunamis adjacent to harbors can be very destructive due to several factors, including the presence of ships and containers that can float inland, damaging nearby structures. Many harbors also have a shape both above ground (topography) and below the water’s surface (bathymetry), that can force the incoming tsunami wave to rise higher as it is squeezed into a smaller space.

The risk of the potential devastating effects from tsunamis is not limited to Japan or harbors for that matter. The Pacific coast states and provinces of the U.S. and Canada have both the risk and history of tsunamis. These include deadly tsunamis in Liuya Bay, Alaska, in 1958; Prince William Sound, Alaska, in 1964; and Hilo, Hawaii, in 1946. A deadly tsunami also occurred on the U.S. Atlantic coast in Cape Hatteras, North Carolina, in 1883.

The most common triggering events of tsunamis are earthquakes below or near the ocean floor, but a tsunami can be created by volcanic activity, landslides, undersea slumps, and even meteorite impacts. The Tohoku 9.0 earthquake in March 2011, which is considered one of the most powerful earthquakes ever recorded, occurred on the east coast of Japan and caused a massive tsunami that killed thousands and sent 30-foot waves of water across much of the countryside, destroying entire towns and leveling hundreds of low-rise buildings. The tsunami caused the Fukushima Daiichi nuclear disaster.

Tsunamis are rare but devastating events; as such, strategies to mitigate risk have usually involved horizontal evacuation to areas of naturally occurring high ground outside the tsunami inundation zone. This can be the most efficient and safest way to protect life when there is enough warning. For some coastal communities, additional options

can include a vertical evacuation strategy, utilizing buildings or manmade mounds or hills that have sufficient height to evacuate the level of tsunami inundation and the strength and resiliency needed to resist the effects of tsunami waves.

As coastal populations continue to grow in the U.S. , horizontal evacuation cannot be the only strategy, especially for Risk Category III and IV buildings. Lessons learned from Japan showed that consideration for hardening infrastructure can be critical to recovery. Essential services such as water supply, wastewater treatment, and power facilities, often located near the coasts, can be crippled by the effects of tsunami wave inundation. The Fukushima nuclear disaster, for example, was caused by tsunami damage to the backup generators that were needed for reactor cooling. Emergency facilities and hospitals are additional candidates for hardening.

Tsunamis are categorized by the location of the triggering event and the time it takes the waves to reach a site. A far-source-generated tsunami is one that originates from a source that is far away and takes two hours or longer after the triggering event to arrive. A near-source-generated tsunami originates from a source that is close and could have 30 minutes or less advanced warning. A mid-source-generated tsunami is one that originates from a source that is close to the site of interest but not close enough for the effects of the triggering event to be felt at the site and would be expected to arrive between 30 minutes and two hours after the triggering event.

Wave propagation times from near-source-generated tsunamis can strike suddenly with little to no warning while far-source-generated tsunamis can allow for advanced warning to distant coastal communities. The 2004 Indian Ocean Tsunami, for example, devastated coastal areas both near and far. Coastlines near the tsunami were inundated in as little as 15 minutes, while those far away waited seven hours for the tsunami to reach their shores. On average, 20 tsunamigenic earthquake events occur each year worldwide, with five large enough to generate tsunami waves capable of causing structural damage and loss of life. With the trend toward increased habitation in coastal areas, more populations will be exposed to tsunami hazard.

There is significant uncertainty in the prediction of hydrodynamic characteristics of tsunamis because they are influenced by tsunami waveform and surrounding topography and bathymetry. Although exceptions exist, field research and surveys indicate that tsunamis have the following characteristics:

• The magnitude of the triggering event determines the period of resulting waves, and generally—but not always—the tsunami magnitude and damage potential.

• A tsunami can propagate more than several thousand miles with little loss of energy. This is due to the large wavelengths of tsunamis, which can be more than 100 miles.

• Tsunami energy propagation has strong directivity—it tends to propagate in a direction normal to the major axis of the tsunami force. Direction of approach can affect tsunami characteristics at the shoreline because of the sheltering or amplification effects of other land masses and offshore bathymetry.

• For a locally generated tsunami, the first leading wave is often a receding water level followed by an advancing positive heave or elevation wave. This may not be the case if the coastal ground subsides by co-seismic displacement. For far-source-generated tsunamis, the leading wave is often an elevation wave. This trend may be related to the pattern of seafloor displacement resulting from a subduction-type earthquake.

Tsunami hazard is a measure of the potential for a tsunami to occur at a given site. It also is a measure of the potential magnitude of site-specific tsunami effects, including extent of inundation, height of runup, and velocity of tsunami flow. Tsunami risk is a measure of consequence given the occurrence of a tsunami, which can be characterized in terms of damage, loss of function, injury, and loss of life. Risk depends on many factors including vulnerability and population density.

Evaluation of tsunami risk will depend on several factors including the presence of a tsunami warning system, existence of a local emergency response plan, availability of various evacuation alternatives, the vul nerability of the existing building stock, and location of existing short and long-term shelter.

Evidence points to the ability for multi-story concrete and structural steel structural systems to survive tsunami inundation with little more than nonstructural damage in the lower levels and to continue to support the levels of a building above the inundation depth. This can be attributed in part to these buildings being designed for lateral wind and seismic forces that exceed the force of a tsunami rolling through the lower levels of those buildings. Recent data, including those from the 2004 Indian Ocean Tsunami, 2009 Samoa Tsunami, and 2011 Tohoku Japan Tsunami, where no six-story or higher concrete or steel buildings collapsed due to the tsunami, support these conclusions. Building survivability does, however, vary with construction type. For example, for a given tsunami height, wood or other light-framed construction can experience considerably more damage and frequently be destroyed. In Hawaii, the potential survivability of multi-story buildings is recognized in its tsunami evacuation messaging, informing the public that vertical evacuation in buildings taller than 10 stories is an option if horizontal evacuation is not feasible.

Despite a long history of tsunamis around the world, because they are relatively rare, there has not been good guidance on designing to mitigate their effects. For the U.S., this started to change in 2004 when the Applied Technology Council (ATC) was awarded a contract by the Federal Emergency Management Agency (FEMA) to help develop design guidance for special facilities for vertical evacuation from

tsunamis. That seminal document FEMA P-646 would become the forebearer of a new chapter to ASCE 7-16: Chapter 6 Tsunami Loads and Effects, which includes tsunami design requirements specific to Risk Category III and IV structures.

Several good resources now provide guidance for the design to resist the loads induced by tsunami as noted here:

FEMA P-646 Third Edition—“Guidelines for Design of Structures for Vertical Evacuation from Tsunamis,” 3rd Edition, provides guidance on planning for vertical evacuation from tsunami. This document includes determination of tsunami and earthquake loads along with the structural design criteria necessary to address them, and structural design concepts and other considerations including using existing structures. It provides additional guidance and commentary on the structural design criteria contained in ASCE 7.

ASCE/SEI Standard 7-22—The American Society of Civil Engineers/ Structural Engineering Institute (ASCE/SEI) Standard 7-22 Chapter 6 “Tsunami Loads and Effects” provides minimum requirements for tsunami-resistant design and construction of Risk Category III and IV structures located in a tsunami inundation zone.

ASCE Press—The book “Tsunami Loads and Effects: Guide to the Tsunami Design Provisions of ASCE 7-16” is a good companion document to ASCE 7 and includes detailed commentary and example problems.

While detailed modeling can be performed, the primary method referenced in ASCE 7-22 for determining tsunami flow depth and velocity at a location is Energy Grade Line Analysis (EGLA). This method is based on ASCE Tsunami Design Zone (TDZ) maps which can be found at asce7tsunami.online. The EGLA includes establishing topographic transects, a straight line that cuts through the topography to determine the impact of topography in a given direction of tsunami flow. The EGLA is based on looking at three transects where the center transect is perpendicular to the orientation of the shoreline with the other two located +/22.5 degrees from the principal inflow direction. This initial step is based solely on topography and does not consider the potential impact of adjacent structures on flow velocity. ASCE 7-22 allows the velocity increase that may occur due to adjacent structures to be considered by three possible approaches: two requiring detailed site-specific analysis and one simpler method approximating their impact utilizing a roughness coefficient applied to the EGLA. That coefficient is indicated in ASCE 7-22 Table 6.6-1.

ratio (6.8.7) and in the drag coefficients for individual members in the hydrodynamic calculations. Also included in this section is consideration of potential hydrodynamic forces, including surge uplift on elevated slabs in a structure.

Debris Impact Loads (ASCE 7-22 6.11)—

The force and extent of a tsunami wave not only causes damage to structures, the debris from that damage, along with other floatable objects, can cause additional debris impact forces as those elements continue to move with the wave. These include scenarios such as impact by floating vehicles, tumbling concrete debris, wood logs or utility poles, shipping containers and if near harbors, floating vessels.

Foundation Design (ASCE 7-22 6.12)—

This includes potential scour and slope/ foundation failure. The rushing water can undermine shallow foundations. Deep foundations that have positive connections to the structure they support have a reduced potential for catastrophic impact.

Once the tsunami inundation depth and flow velocity are established, the extensive task of determining structural load criteria can begin. The primary structural impacts that can result in damage to a structure and have specific design requirements include the following:

Hydrostatic Loads (ASCE 7-22 6.9)—These include determining potential loads that might occur from buoyancy, unbalanced lateral hydrostatic forces, residual water surcharge load on walls and floors and hydrostatic surcharge pressure on foundations.

Hydrodynamic Loads (ASCE 7-22 6.10)—These forces are due to moving water and include the global forces on the overall structure along with the local loads on structural components of the structure. Because water-borne debris could potentially accumulate against vertical elements of the structure, consideration is given in both the global forces and individual member loads. This is considered in a minimum closure

CCW Transect

While ASCE 7-22 Chapter 6 is intended specifically for Risk Category III and IV buildings, communities can consider encouraging incorporating tsunami design into conventional buildings in areas with fewer horizontal evacuation options. Unfortunately, this comes with added costs during design and construction. For communities with longer warning times for tsunami, it may not even be necessary to design some low-rise Risk Category III buildings if those buildings do not require design per the Tsunami Risk Category and can’t be used for shelter or there is a well-developed horizontal evacuation plan. That money may be better spent elsewhere.

With recent construction cost inflation conflicting with the growing needs for affordable housing, it is critical that communities look to partner with their builders and designers to offset the costs if additional resiliency measures such as tsunami design are considered for these types of buildings. As all developers of affordable housing will attest to, any increase in regulations or design requirements directly decreases the production of affordable housing units.

Runup Elevation (MWH) 16.75 feet

Include Sea Level Rise Runup Elevation (MWH) 17.02 feet Inundation Depth (MWH) 20.19 feet Flow Velocity 24.25 feet/second

When considering requiring conventional construction to meet design requirements intended for essential facilities, it is critical for those communities to consider ways of keeping added costs to a minimum. FEMA recommends several methods to assist in mitigating the additional costs of this type of construction. These include offering tax incentives, modifying zoning requirements to increase height restrictions and FAR, or applying for federal or state grants.

Since no six-story or higher concrete or steel buildings collapsed in the devastating Tohoku Japan tsunami, it begs the question, “Is it worth using elaborate and time extensive analysis and design for multi-story buildings unless they are essential buildings?” A more cost-effective approach may be to just include tsunami-resistant design concepts in the construction of these buildings.

In performing tsunami design on several projects, Baldridge & Associates Structural Engineering (BASE) found multi-story buildings designed to current codes can meet the intent of ASCE 7-22’s tsunami design requirements without the expense of extensive modeling and additional structural analysis by simply enhancing them with a few structural design concepts, including:

• Provide structural systems that have inherent redundancy and utilize structural integrity concepts. This can include seismically designed cast-in-place concrete systems or structural steel framing, especially those utilizing perimeter moment frames for lateral resistance.

• Incorporate deep foundation systems where possible. For many

coastal locations this may be required anyway.

• Consider making the ground floor as open as possible and detailing non-load bearing walls connections to the structure with little if any overstrength for wind and seismic requirements. The more open the ground floor is, the less load and damage that may occur. A great example of this is podium style construction with open parking at grade level and residential uses starting at the 2nd or 3rd floor levels. With podium construction, the elevated residential levels of a building may not need to consider tsunami requirements at all and can utilize conventional wood or other light framing methods.

• The wild card in tsunami design is the potential for water-borne debris impact loading that might happen on lower-level structural elements. This can be addressed with more robust construction for those structural elements only. This could include increasing column vertical and tie reinforcement at critical concrete columns, concrete encasement of lower-level steel wide flange columns or filling tube columns to make them composite columns.

• Detail slabs to be able to relieve potential buoyancy or uplift forces. This can include areas of slab that can pop out if pressures start to build. ■

Steven Baldridge, SE, PE, LEED AP, is President of BASE, a structural engineering consulting practice. He has participated in natural disaster reconnaissance missions including serving as the EERI team leader in Samoa following its 2009 earthquake and tsunami. He was Project Technical Director for FEMA P646 “Guidelines for Design of Structures for Vertical Evacuation from Tsunamis”, the first U.S. design guide on tsunami loads from which some of this article is based.

Minimize steel tonnage

Minimize seismic detailing

Simplify fabrication

Increase erection speed

Complimentary design assist Resilience through repairability

Complimentary design assist

These best practices will ensure walls are properly reinforced and mechanical splices are staggered in a way to reduce the risk of failure. By

Dr. N. Subramanian, Ph.D., FNAE

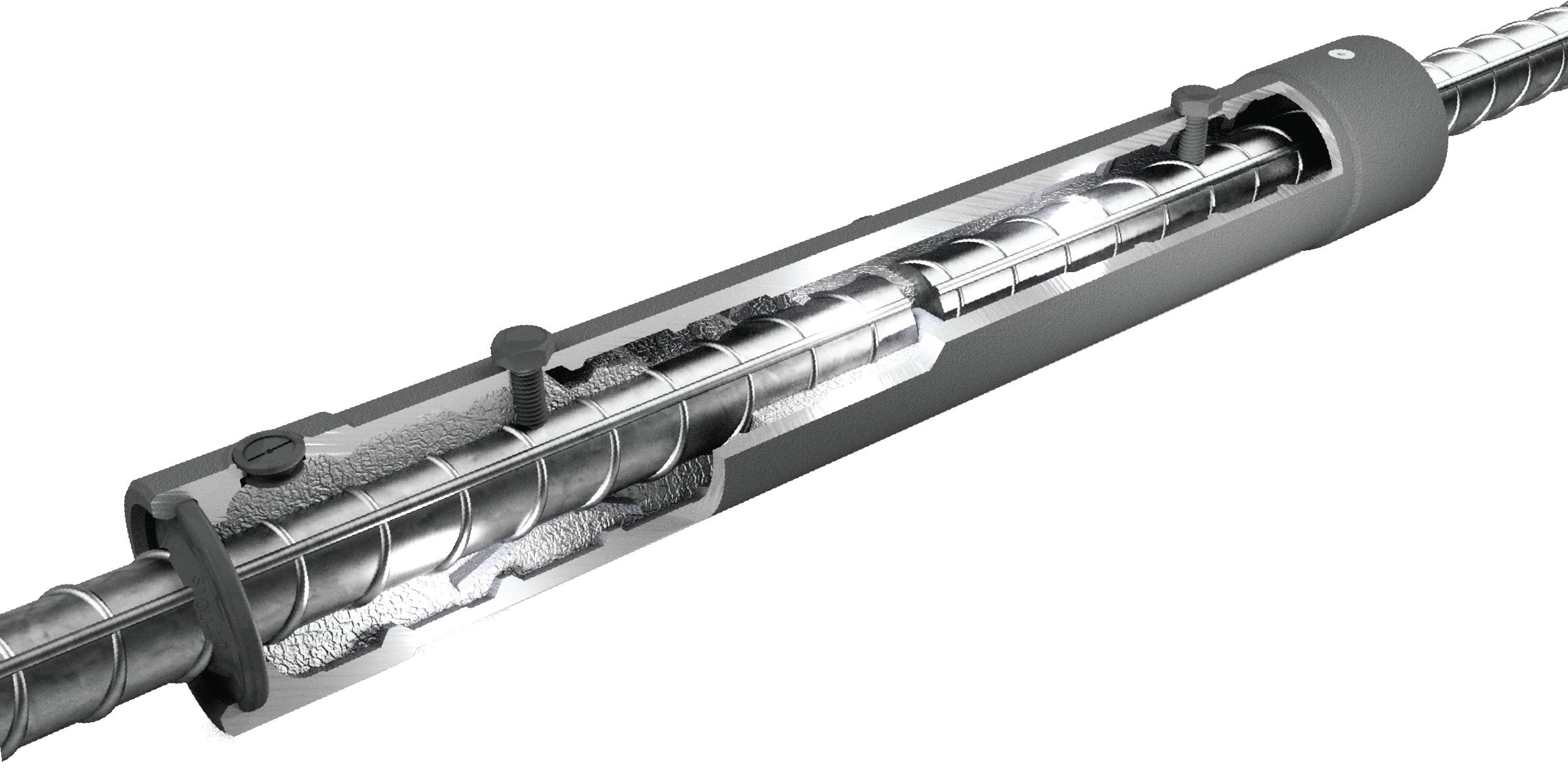

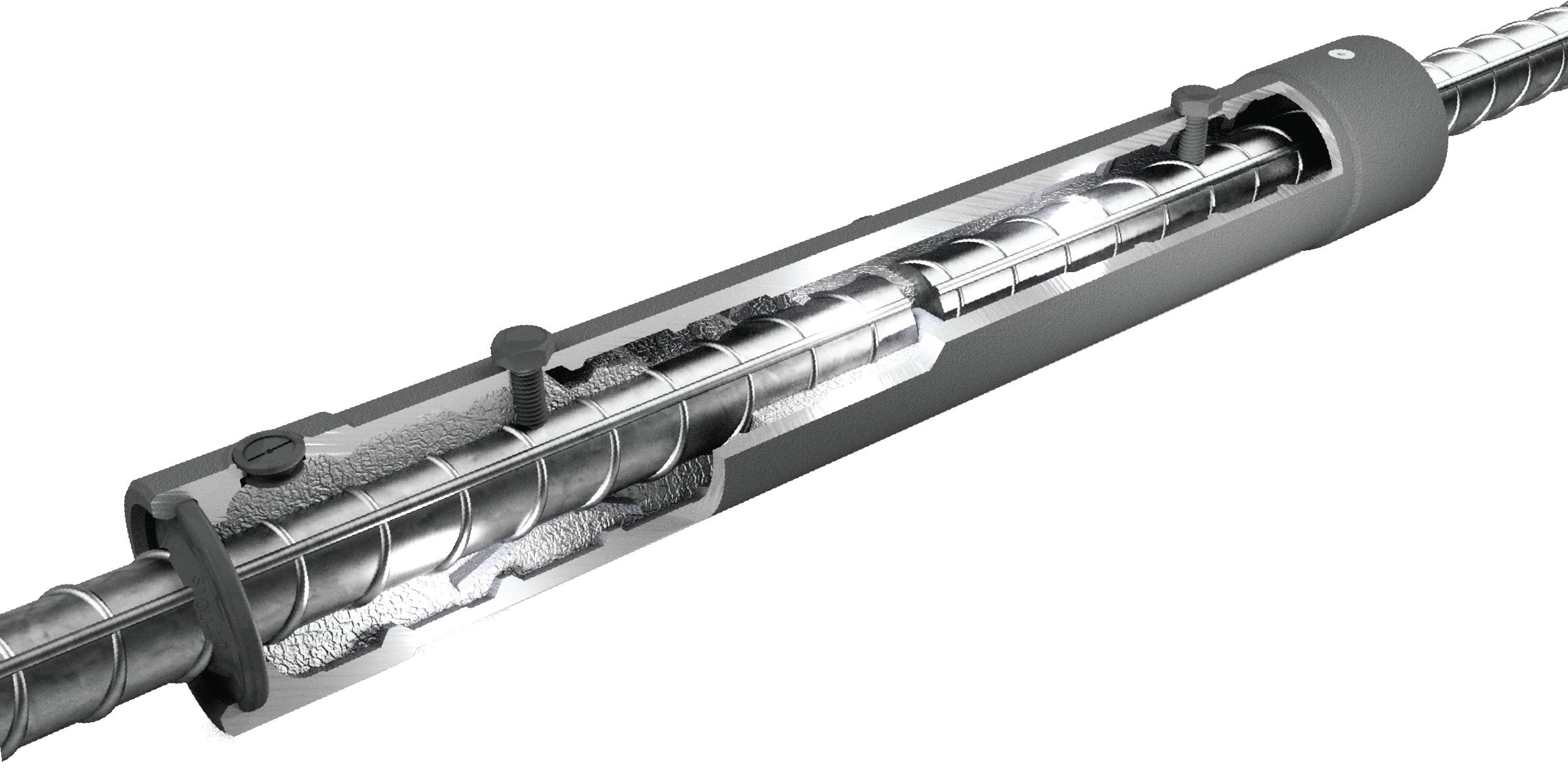

Mechanical splicing products (often called couplers) are widely used in the construction industry as an alternative to lap splices when joining two reinforcement bars, especially when there is no room for lap splices, when larger diameter of bars (larger than #11)are used, and in tension members. In addition, the use of mechanical couplers is useful where the reinforcement is congested or space does not allow for the full development length that a splice would require.

Couplers have the following advantages: 1) improved structural integrity thus offering strength and toughness even during seismic events, 2) no reliance on concrete for load transfer, 3) elimination of lap-splice calculations, and 4) reduced material costs. This cost savings can be significant when expensive epoxy coated bars are used, since building codes require up to 50% longer splice laps for these bars than for standard rebars (Hurd, 1998). A few other hidden costs associated with providing lap splices, such as the time spent preparing lap splices and the necessity for additional transverse reinforcement, are also eliminated. (Jacinto, et al., 2023). Additionally, codes such as ACI 318:19, Building Code Requirements for Structural Concrete and Commentary on Building Code Requirements for Structural Concrete(clause 25.5.7.1) require that

Enlarged bar end

Threaded bar area the same as unthreaded bar area

Internally threaded coupler

Internally threaded tapered coupler

Matching tapered bars

Steel sleeve half ontoswaged bars half threaded onto stud

Threaded stud

mechanical splices deliver higher performance than lap splices (typically 125% greater capacity). The use of mechanical couplers results in savings on rebar material and associated costs, including fabrication of lapping rebars. However, this cost advantage may be offset by the cost of couplers.

Several types of mechanical couplers are available-on the market (Table 1). Couplers may be categorized as tension couplers or compression couplers. Unless specified otherwise, tension couplers should always be used. Couplers may also be categorized as in-line couplers, in which the centerline of each spliced bar coincides and offset couplers, where the centerlines have an eccentricity.

Reducer insert-used when bars are of different size

Lock nut

Bar with helical deformations

Internally threaded coupler

Lock nut

Mechanical splices, shown in Figure 1, generally use a threaded annular sleeve, slightly larger than the diameter of the bars, that is placed around the bars at the joint. The sleeves are normally cold pressed against the bars, forcing the ribs of the deformed bars to become embedded into the wall of the sleeve. A sleeve embedment length of only two bar diameters (2db) for each of the two bars may be sufficient to transfer the load of the bar in tension. The connection can also be formed by filling the annular space between the bars and the sleeve with molten metal. Direct threading of bars is avoided to prevent reduction in bar size, and consequently its strength. One solution to this is to increase the size of the ends over a small length by tapering the bars, as shown in Figure 1a. A new type of coupler called a set screw coupler is not threaded, swaged, or metal-filled. Instead, they consist of a steel tube with a series of lock-shear bolts—generally six to eight—and two serrated strips that run the inside length of the coupler, as shown in Figure 1g. The installation of this coupler is carried out as follows: 1) after sliding one length of rebar halfway into the coupler, the bolts are tightened to fit snugly; 2) the second bar is then inserted into the coupler until it butts against the other bar end; and 3) the remaining bolts are tightened to a snug fit. A ratchet or an impact wrench is used to tighten the bolts until their heads shear off, implanting the bolt ends into the rebar and embedding the serrated strips into both the rebar and the interior coupler wall. This type of splicing system does not require any special bar-end preparation and can be used in projects where bars are in place or access is limited. More details about mechanical couplers may be found in ACI 439.3R-2007 Types of Mechanical Splices for Reinforcing Bars, BS 8597:2015 Steels for the reinforcement of concrete - reinforcement couplers

Steel sleeve hydraulically swaged into bars

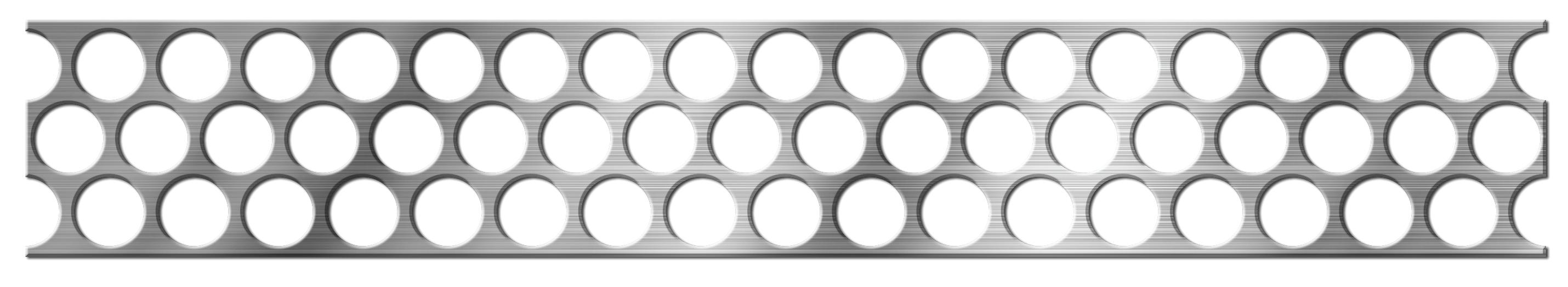

If seismic or high-wind challenges are important considerations for your next project, Vulcraft and Verco’s steel roof deck and PunchLok II® System is a valuable option to consider. Our team of experts can help you evaluate the variety of value-added sustainable solutions that Vulcraft and Verco offer to ensure that you have the right system in place.

Contact an expert today.

- requirements and test methods, IS 16172:2023

Reinforcement Couplers for Mechanical Splices of Steel Bars in Concrete—Specification, SP 34:1987 Handbook on Concrete Reinforcement and Detailing, and Prakash Rao, 1991. The use of couplers in column reinforcement is shown in Figure 2.

Mechanical butt splices provide superior strength during load transfer. Other advantages include superior cyclic performance and greater structural integrity during seismic events. From the structural standpoint, the most important benefit of mechanical splices is that they ensure load path continuity of the structural reinforcement. Using mechanical butt splices allows the use of larger diameter rebar in a smaller column thereby minimizing congestion. Unlike lapsplices which often extend into the plastic hinge regions (thus violating code requirements), mechanical splices can be easily located outside these high stress regions. In addition, the use of mechanical splicing eliminates the tedious calculations needed to determine proper lap lengths and the possible errors associated with the calculations. Also, mechanical splices are fast to install. However, mechanical splices also have a disadvantage compared to lap splices because of their complex process of installation. That is, rebars need to be prepared before installation by cutting the threads into the rebar so that these threads match the threads of the coupler. This process may need skilled labor, and two additional machines: the forging machine and the thread cutting machine (Damsara and Kulathunga, 2018). The installation must be carefully performed to ensure that the threads are well fitted. Also, the threaded ends of the rebars should be protected from corrosion before installation in order to obtain good fixity with the coupler.

Based on experimental results of testing of offset mechanical splices, shown in Figure 3, Coogler et al, 2008,the following was found:

• Offset splices are not recommended for use with bar sizes greater than #5(16 mm), unless tests indicate to satisfy the performance criteria.

• Offset splices should not be used in applications subject to seismic load reversals.

• Offset splices should be considered as a different category of mechanical splices (having a fatigue limit of 80 MPa).

During 1998, Cagley and Apple made a cost comparison between lap splices and mechanical splices and found that the additional cost of using mechanical butt splices was about 0.2 percent of the total cost of the structure. However, since then the cost of mechanical splices have reduced and the cost advantage of using a coupler instead of lapping may increase with the increase in size of rebar (approximately 11% for #5 bars to 140% for #10 bars) (Damsara and Kulathunga, 2018 and Singh, et al., 2013).

Clause 18.2.7.1 of ACI 318-19 Building Code Requirements for Structural Concrete and Commentary on Building Code Requirements for Structural Concrete (ACI 318R-19), defines two types of mechanical bar couplers, Type 1 and Type 2. According to clause 25.5.7.1 of this code, Type 1 coupler is a mechanical or welded splice that can develop 125%

Coldswaged steel coupling sleeve

Coldswaged steel coupler with threaded ends

Extruded steel coupling sleeve

Hot-forged steel coupling sleeve Grout-filled coupling sleeve Coupler for threaddeformed reinforcing Bars*

coupler

Couplers with standard NC threads Bar size range (mm) 3-18 (10-57) 3-18 (10-57) 4-18 (13-57) 5-18 (16-57) 3-18 (10-57) 6-18 (19-57) 4-18 (13-57)

(10-57) 4-11 (13-36)

of the yield strength of the bars (i.e., 1.25Abf y , where Ab is the area of bar and f y is the yield strength of bar) in tension or compression. Type 2 couplers are those that both conform to the requirement of Type 1 couplers and can develop the specified tensile strength of the spliced bars (clause 18.2.7.1). Thus, the requirements for Type 2 mechanical splices are intended to avoid a splice failure when the reinforcement is subjected to expected stress levels in yielding regions. ACI 318-19 requires using Type 1 only in the locations in which the couplers shall not experience yielding. This is because (per commentary R18.2.7, Mechanical splices in special moment frames and special structural walls), in a structure undergoing inelastic deformations during an earthquake, the tensile stresses in reinforcement may approach the tensile strength of the reinforcement. Thus, this requirement ensures that premature failure, bar pullout, or coupler fracture will not impact the ductility of the structural system.

Clause 18.2.7.2 of the code stipulates that except for Type 2 mechanical splices on Grade 420 reinforcement, mechanical splices shall not be located within a distance equal to twice the member depth from the column or beam face for special moment frames or from critical sections, where yielding of the reinforcement is likely to occur as a result of lateral displacements beyond the linear range of behavior. Type 2 mechanical splices on Grade 420 reinforcement shall be permitted at any location, except that clause 18.9.2.1(c) stipulates that they shall be located not closer than h/2(h is the depth of beam) from the joint face of beams. This is because Type 1 mechanical splices on any grade of reinforcement and Type 2 mechanical splices on Grade 550 and Grade 690 reinforcement may not be capable of resisting the stress levels expected in yielding regions. The locations of these mechanical splices are restricted because tensile stresses in reinforcement in yielding regions can exceed the strength requirements of clause 18.2.7.1. These restrictions on all Type 1 mechanical splices and on Type 2 mechanical splices on Grade 550 and Grade 690 reinforcement apply to all reinforcement-resisting earthquake effects, including transverse reinforcement. Although the ACI 318-19 requires mechanical splices should have at least 25% higher design strength than lap splices, clause 26.2.5.2 of IS 456:2000, Plain and Reinforced Concrete - Code of Practice, suggests 100% design strength be assumed for mechanical connections. Note that couplers should be provided with a cover similar to that specified for the reinforcement since there will be a reduction of cover at the splice due to the larger coupler size.

Staggering of mechanical splices in walls is generally recommended, but not required by most codes, except in seismic zones. There are several reasons for this:

• Reduces stress concentration. When mechanical splices are concentrated in one area, it can create a weak point. Staggering the splices helps to distribute the stress evenly.

• Improve concrete placement. Mechanical splices can make it difficult to place concrete properly, especially in congested areas. Staggering the splices gives the concrete more room to flow and helps to prevent voids.

• Reduce the risk of cracking. Cracks are more likely to form at the location of mechanical splices. Staggering the splices helps to reduce the risk of cracking by spreading out the stress concentration.

In seismic zones, ACI 318 Code requires that mechanical splices in special moment frames and special structural walls be staggered at least 30 inches (750 mm) to help improve the performance of these walls during an earthquake.

According to clause 25.5.7.3 of ACI 31819, mechanical or welded splices need not be staggered except as required by clause 25.5.7.4. Clause 25.5.7.4 stipulated that splices in tension tie members shall be made with a mechanical or welded splice provided that the splice develops in tension or compression at least 1.25f y of the bar. It also suggests that splices in adjacent bars shall be staggered at least 30 inches (750 mm). The commentary to clause 25.5.7.3 explains that although mechanical and welded splices need not be staggered, staggering is encouraged and may be necessary for constructability to provide enough space around the splice for installation or to meet the clear spacing requirements.

Mechanical splicing products are widely used in the construction industry to join two reinforcement bars as an alternative to lapping bars. Careful planning will ensure walls are properly reinforced and mechanical splices are properly staggered to reduce the risk of failure. ■

Dr. N. Subramanian, Ph.D., FNAE, FASCE, FIE, is an award-winning author, consultant, Alexander von Humboldt Fellow, and mentor. As a former chief executive of Computer Design Consultants, he has designed 800 projects over a span of 26 years. He has authored 26 books and more than 320 technical papers. He is the recipient of several awards and served as the past National Vice-President of ICI and ACCE(I).

A report published this January provides guidance to advance the understanding of the behavior of SWOF buildings and encourage improved practice in the design of retrofits. By Justin Moresco, PE, and David Mar, SE

Older, multi-unit wood-frame buildings with brittle, weak, and torsionally irregular stories have collapsed in past earthquakes. Often designated as soft, weak, or open-front (SWOF) buildings, many were constructed in the 1950s through 1970s and can be found across the United States, most notably along the West Coast. The lateral systems consist of non-engineered sheathing and architectural finish materials, such as diagonal and 1x lumber sheathing, cement stucco, plaster, and gypsum wallboard. SWOF buildings often house significant numbers of people.

The Federal Emergency Management Agency (FEMA) originally addressed the risk from SWOF buildings by developing and, in May 2012, publishing "FEMA P-807, Seismic Evaluation and Retrofit of Multi-Unit Wood-Frame Buildings With Weak First Stories." This guideline introduced a methodology to focus the retrofit on the first story to protect the building from collapse without transmitting excessive additional seismic forces into the upper stories. This approach accounted for the strength provided by the nonstructural walls and resulted in retrofits that balance performance with economics. Since that time, California municipalities increasingly have enacted mandatory or voluntary seismic retrofit ordinances for SWOF buildings. The ordinances reflect regional differences in their approaches, including the engineering design requirements for retrofits. These ordinances have increased retrofit experience and highlighted regionally based information regarding the configuration and construction materials used in these types of buildings. Many cities in Northern California require that the entire first story be considered and addressed, whereas many cities in Southern California allow retrofits to directly mitigate the open-front (or open-line) vulnerability without considering or strengthening the entire first story.

In 2020, FEMA NEHRP launched a project managed by the Applied Technology Council (ATC) that led to the publication of FEMA P-807-1, Guidance and Recommendations for the Seismic Evaluation and Retrofit of Multi-Unit Wood-Frame Buildings With Weak First Stories. The purpose of this report, which was published this January, is to advance the understanding of the behavior of SWOF buildings and to encourage improved practice in the design of retrofits. The report provides technical information about the expected seismic collapse performance of common

SWOF building configurations, both in their unretrofitted (or original) and retrofitted conditions. It also presents retrofit design examples. The report is intended to be used by jurisdictions and their consultants to inform decisions regarding ordinance scope and retrofit methods. Throughout FEMA P-807-1, both prevalent methods—full story and open-front retrofits—are analyzed and discussed, and much of the content, in particular the retrofit recommendations, is relevant to all types of SWOF building retrofits.

Two basic forms of archetype buildings were studied. They are rectangular in plan, two and three stories tall above ground, and with an open front on either a long or short elevation, designated as LO (long-side-open) and SO (short-side-open), respectively (Figures 1 and 2). The wall materials are cement stucco exterior siding and either gypsum wallboard or lath-and-plaster interior finishes. The diaphragms are either straight or diagonal sheathing. The selection of these materials was informed by an evaluation of common SWOF characteristics using Northern and Southern California datasets. The archetype buildings have two material combinations for the walls— strong wall (SW) and weak wall (WW). The strong wall set, which is representative of buildings constructed from the 1920s through early 1960s, has cement stucco exterior finishes and gypsum plaster interior finishes. The weak wall set, which is representative of buildings constructed from the 1950s through 1970s, has cement stucco exterior finishes and gypsum wallboard interior finishes. Two types of diaphragms were investigated—a strong diaphragm (SD) representing diagonal-lumber sheathing and a weak diaphragm (WD) representing straight-lumber sheathing. These different materials were combined with one another to create the “primary study” archetype building options (Table 1). They consist of long-side-open and short-side-open forms of two and three stories, with both the strong wall/ weak diaphragm (SW-WD) and weak wall/strong diaphragm (WW-SD) material configurations.

Besides the “primary study” archetypes, “variant study” archetypes were developed in FEMA P-807-1 to investigate the impact of wing walls, no open-front vulnerability, and relatively weaker and more brittle diaphragm properties. This article focuses on the “primary study” archetype results due to space limitations.

The buildings were modeled in three dimensions with OpenSees using an assemblage of non-linear

shear springs to represent the walls, diaphragms, and retrofit frames when present. The non-linear springs are placed along a single line in each principal building direction (e.g., Grid Line 3 in Figure 1b or Grid Line C in Figure 2b), and tributary masses are assigned at grid points. The springs were calibrated to physical tests of the representative wall and diaphragm materials. The springs have appropriate non-linear behavior for in-plane shear, high elastic stiffness for in-plane flexural and axial modes, and negligible stiffness for out-of-plane modes. The retrofit frames were modeled as point springs at the second-floor elevation, centered in the open line. The X direction is parallel to the open side and the Y direction is perpendicular.

The archetype buildings were subjected to seismic shaking per the FEMA P-695 protocol. The seismic input for the incremental dynamic analysis (IDA) was 22 bi-directional, far-field records. Each set of records was rotated 90 degrees to expand the set to 44 inputs. The records were scaled with increasing intensities until the models were identified to have collapsed. The peak inputs usually corresponded to walls reaching between 5%-10% drift, while collapse typically resembled an explicitly modeled P-delta collapse, primarily driven by the P-delta effects in the hysteretic wall spring models along with P-delta columns at the open front. Within the IDA results, collapse is seen as an infinite increase in drift without increase in spectral acceleration (Figure 3). As shown in Figure 3, spectral acceleration (Sa) values at each increment of the analysis are taken at a period, T = 0.25 seconds, consistent with the FEMA P-695 protocol.

The seismic resistance of the archetype buildings is limited by multiple vulnerabilities. These are the lateral strengths in each direction, the diaphragm strength, and the torsional imbalance of the structure. A useful analogy is that of a chain with several potential weak links, where the resistance to collapse is controlled by the weakest link. The buildings were found to have multiple vulnerabilities with similar capacities. As such, mitigating one vulnerability without improving the rest often resulted in little improvement to building collapse risk. A seismic retrofit of SWOF buildings usually needs to address several or all the vulnerabilities in the weak story to substantially improve safety.

WW-SD SW-WD

Long Side Open 2-Story LO2-WW-SD LO2-SW-WD

3-Story LO3-WW-SD LO3-SW-WD

Short Side Open 2-Story SO2-WW-SD SO2-SW-WD

3-Story SO3-WW-SD SO3-SW-WD

The most direct way to assess the building’s lateral capacity is to examine the first-story strength-to-weight ratio (V/W). Pushover studies were made of the “primary study” archetypes (Figure 5), and key results are:

• Archetype buildings with weak walls have slightly higher controlling strength-to-weight ratios than buildings with strong walls . This is because the buildings with strong walls are heavier.

• The archetypes are brittle, with very limited ductility. Most pushover curves have a steep strength loss after reaching the peak strength.

• The LO archetypes have similar strength-to-weight ratios in the X and Y directions for both the strong and weak wall conditions. The presence of an open side does not lead to appreciable weakness in the open direction. This is because the walls adjacent to the tuck-under parking are solid, without windows, unlike the typical exterior elevations.

• The SO archetypes are weaker parallel to the open front (X direction) for both wall types. The strength-to-weight ratio difference is greater with the strong walls.

• The controlling strength-to-weight ratios of the two-story buildings (not shown in Figure 5) are typically more than 40%, which is significantly greater than their three-story counterparts. This is because the first-story wall layout is the same, but the two-story building carries significantly less mass because there is one fewer floor.

Three types of retrofits were designed for each archetype: line, optimized line, and FEMA P-807. The line retrofits follow the requirements of the Los Angeles SWOF ordinance and associated city guidelines. The optimized line retrofits also conform to the Los Angeles SWOF ordinance except that the prescribed deflection limits on frames at the open front are ignored, making the frames controlled by strength requirements. The FEMA P-807 retrofits are in accordance with the FEMA P-807 report and are based on output of the Weak Story-Tool assuming default material property values. The Weak-Story Tool is a freely available electronic resource that was developed to help users apply the rules and perform the calculations described in FEMA P-807.

A site in downtown Los Angeles was selected for determining seismic demands, corresponding to a horizontal spectral acceleration of 1.0g for all three retrofits. This seismic demand reflects use of 75% of new building design spectral acceleration, which is permitted by the Los Angeles SWOF ordinance. The ordinance also specifies that acceptable performance for FEMA P-807 retrofits is based on drifts corresponding to onset of strength loss

and that the maximum drift limit probability of exceedance is 20% at the specific hazard. These FEMA P-807 design criteria were input into the Weak Story-Tool.

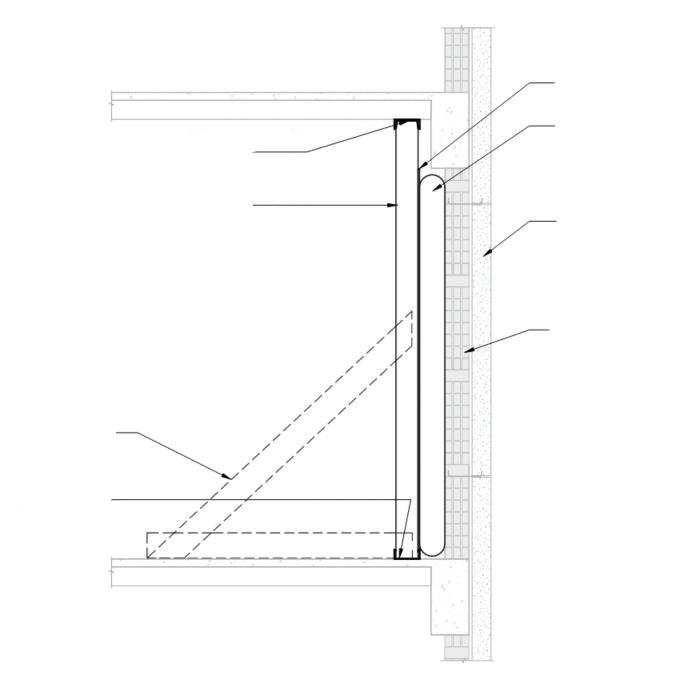

The line retrofits consist of cantilever columns cast into reinforced concrete grade beams along the open front. This system acts as an inverted moment frame, where the grade beam is strong and stiff enough to develop the capacities of the columns in flexure. The optimized line retrofits are similar to the line retrofits except that the removal of the deflection limits results in lighter and more flexible frames. The FEMA P-807 retrofits also use cantilever columns along the open front, as well as new plywood shear walls in both orthogonal directions applied to the inside of existing wood-frame walls. Table 2 provides selected seismic retrofit parameters for the three-story LO archetype building with weak walls and strong diaphragms, where “L”, “OL”, and “P807” corresponds to line retrofit, optimized line retrofit, and FEMA P-807 retrofit, respectively.

Figure 6 presents results of the IDAs for the “primary study” archetype buildings in terms of probability of collapse (POC) at spectral acceleration of 1.0g. The following trends are noted:

• FEMA P-807 retrofits are effective with results better than 20% POC.

• Line and optimized line retrofits do not consistently improve safety. Three-story LO archetypes show moderate improvements. SO archetypes show limited improvements.

• Line and optimized line retrofits provided similar results for a given archetype.

• Three-story archetypes are more vulnerable than their two-story counterparts.

• SO archetypes are usually more vulnerable than their LO counterparts.

FEMA P-807-1 presents a series of recommendations related to seismic retrofit ordinances that are based on the results of the aforementioned analytical studies. These recommendations include: Importance of Retrofit: In high-seismic-hazard regions, it is recommended that seismic retrofit ordinances be considered for SWOF buildings as part of a program to identify and address seismically vulnerable buildings. Based on the archetypes studied, high POCs were identified for unretrofitted SWOF buildings. This is consistent with observed collapses and near collapses of SWOF buildings in the 1989 Loma Prieta

and 1994 Northridge earthquakes. The POCs can be reduced through seismic retrofits. In moderate and low seismic regions, the need for seismic retrofit ordinances for SWOF buildings is less clear because unretrofitted POCs can be significantly lower.

Type of Retrofit, Part 1: It is recommended that full first-story retrofits be required, where practicable. For the archetypes studied, FEMA P-807 retrofits consistency provided notably better performance than line or optimized line retrofits, with POCs averaging about 10%. Published studies by others suggest that, in general, full-story retrofits in accordance with IEBC Chapter A4 or ASCE/SEI 41 will provide similar or improved performance of the first story relative to the requirements of FEMA P-807 (Buckalew et al., 2015; Burton et al., 2019).

Type of Retrofit, Part 2: Where it is not possible to require a FEMA P-807 or other full-story retrofit, it is recommended that screening occur for open-front wall lines on all exterior walls of the building, including those perpendicular to the evident open-front wall. Where suggested by screening criteria, retrofits should be provided for all applicable exterior walls, including those perpendicular to the evident open front.

Building Prioritization: Where prioritization of SWOF building retrofits is desired, it is recommended that SWOF buildings three stories or more be given higher priority than two-story SWOF buildings. The three-story archetypes generally have higher unretrofitted POCs and greater benefit of retrofit reduction in POC than two-story archetypes.

Local Seismic Hazard: When considering adoption of a seismic retrofit

ordinance, it is recommended that local seismic hazard levels be taken into consideration. Unretrofitted collapse potential of SWOF buildings varies significantly with seismic hazard, thereby varying the need for and benefit of retrofit. For example, the unretrofitted POC is less than 10% at a spectral acceleration of 0.5g for all primary study archetypes and is less than 20% at a spectral acceleration of 0.75g for all but one of the primary study archetypes.

FEMA P-807-1 includes a series of recommendations related to design and construction of SWOF retrofits. The objective of these recommendations is to assist engineering designers and building officials in avoiding common pitfalls and applying proven strategies for strengthening SWOF buildings. The recommendations address the following categories:

New Seismic-Force-Resisting Systems: Common retrofit options include adding new steel moment frames, steel cantilevered columns, wood-structuralpanel shear walls, proprietary systems or, in some cases, a combination of these systems. FEMA P-807-1 discusses each of these options and provides recommendations related to more general topics including redundancy, compatibility, and optimal location of new systems.

Protection of Existing Structural Systems: SWOF buildings do not have engineered lateral systems and are constructed using nonductile materials, making it essential that engineers pay special attention to the impact of their designs on the existing building. For example, local demolition of stucco at the second floor is often necessary to install new retrofit elements, such as collectors, that tie the existing structure directly to new vertical seismic-force-resisting elements. But exterior stucco walls in SWOF buildings often are a major contributor to lateral strength. Several examples are provided in FEMA P-807-1 for how to protect the existing lateral and gravity systems.

Foundations: It is recommended that the foundation system of a new seismic-force-resisting system be tied to the existing foundation system to minimize the possible negative effects of sliding, uplift, and overturning. Other topics covered in FEMA P-807-1 include recommended detailing for fixed-base retrofits, weak-axis implications for fixed-base retrofits, and protecting existing foundations.

Besides the categories noted above, FEMA P-807-1 also provides recommendations related to load paths to new retrofit elements; collectors, moment frame beams, and columns; and quality assurance. Two design examples are presented—an optimized line and a FEMA P-807 retrofit.

The design examples include conceptual construction details and illustrate implementation of the design recommendations.

SWOF buildings can be found across the U.S., and their structural vulnerabilities make them prone to collapse during earthquakes. Municipalities in California increasingly have enacted seismic retrofit ordinances for SWOF buildings, with the ordinances reflecting regional differences in their approaches. The purpose of FEMA P-807-1 is to advance the understanding of the behavior of SWOF buildings and to encourage improved practice in retrofit designs. The report is also intended to be used by jurisdictions and their consultants to inform decisions regarding ordinance scope and retrofit methods.

FEMA P-807 was shown to generate full-story retrofit designs that provide significant benefits in terms of reducing probabilities of collapse for SWOF buildings. A few suggestions for future FEMA P-807 enhancements are given, but no major shortcomings with the method were identified. Both line and optimized line retrofits were shown to provide mixed benefits in terms of reducing probabilities of collapse. For some archetypes, the reductions were moderate, whereas for other archetypes the reductions were negligible. ■

Similar to other ATC-managed projects, the project team included a Project Technical Committee and Working Groups who collectively conducted the technical work and authored FEMA P-807-1. In addition, a Project Review Panel provided technical review at key milestones in the development of the report. The work forming the basis for this publication was conducted pursuant to a contract with FEMA. The substance of such work is dedicated to the public. The authors are solely responsible for the accuracy of statements or interpretations contained in this publication. No warranty is offered with regard to the results, findings and recommendations contained herein, either by FEMA, ATC, its directors, members, or employees. These organizations and individuals do not assume any legal liability or responsibility for the accuracy, completeness, or usefulness of any of the information, products, or processed included in this publication.

Full references are included in the online version of the article at STRUCTUREmag.org

Justin Moresco, PE, is a Director of Projects at the Applied Technology Council in Redwood City, California. He manages multi-disciplinary teams on projects that develop technologies for structural engineering and natural hazards-related applications. (jmoresco@atcouncil.org)

David Mar, PE, SE, is Founder and Principal of Mar Structural Design in Berkeley, California. He was the technical director for the original FEMA P-807 SWOF Retrofit Guidelines, as well as the current follow-up study. (david.mar@marstructuraldesign.com)

By Leslie Jo Hurwitz, PE, Brian Fisher, PE, and Carl Schneeman, PE

Recent events, public perception, and the fact that electric vehicles (EVs) are heavier than gas powered (ICE) vehicles have caused many to question whether the current building code minimum design requirements are adequate to accommodate increasing EV sales. How this will affect minimum required design live loads depends on factors such as electric vehicle sales trends, the weights of the vehicles themselves, and the different loading scenarios.

Today, approximately 260 million vehicles are on the road and roughly 15.6 million passenger vehicles were sold in 2023. Roughly half of 2023 sales were crossover and SUV type vehicles, with the balance largely split between traditional cars and pickups. Trends show that car and van sales are steadily declining while the proportion

of pickup sales have been relatively stable over the past decade. So, how do EVs fit in the mix?

The auto industry is undoubtedly going electric; however, it will take quite a while for EVs to become the typical, much less dominant, passenger vehicle on the road. For comparison, in 2023 approximately 1.2 million electric passenger vehicles were sold, representing 7.9% of annual sales, per Argonne Laboratories data. Please note that the term EV herein includes only fully electric vehicles. Table 1 indicates Walker Consultant’s projections of BASE case (expected trend) and HIGH case (accelerated adoption) for electric vehicle sales and the corresponding percentage of such vehicles on the road. Both projections are based on a consensus of auto industry consultant projections. The on-the-road projections are based on a model developed by Walker that considers industry projections of total passenger vehicle sales through 2030, population growth, as well as historic vehicle scrappage rates to determine total vehicles and EVs on the road.

Sales projections of EVs as a percentage of all vehicles sold is expected to increase as more vehicle choices are offered, prices decrease, and technology improves; however, the actual EVs on the road as a percent of all cars on the road is increasing at a much slower rate. In 2040, the estimated sales range from 55% - 85% but the percentage of EVs on the road is only projected to be 23% - 42%.

Vehicle Weight

Walker has been tabulating vehicle size data since 1983 for cars, with light trucks (crossovers, SUVs, pickups and vans) added in 1996. Adjustments were made in 2016 to account for the percentage of pickups and vans that are classified as heavy duty and used for commercial purposes rather than personal transportation. This annual analysis uses sales data reported by Automotive News for individual makes and models, which is correlated to size, height, and weight data per the manufacturer websites. Historically, the primary focus of this analysis has been to study the footprint of vehicles to determine parking dimensions; however, the weight and height of vehicles have become

items of interest while crossovers and SUVs have become more prevalent on the road. Overall, vehicles today have gotten wider by 3 inches, generally stayed less than 6 feet tall, and still have lengths appropriate (or slightly less) for 18-foot-long stalls as compared to vehicles of the 1980s.

When it comes to the weight of passenger vehicles, 70% to 75% of all cars sold each year in the U.S. since 2001 including EVs, have curb weights between 3,000 pounds and 5,000 pounds. Overall, we have observed a reduction in vehicles of less than 3,000 and 4,000 pounds (predominantly cars), and an increase in vehicles that are 4,000 to 5,000 pounds, reflecting the increase in crossover sales. But, as demonstrated in Figure 1, the percentage of all passenger vehicles that are over 6,000 pounds has remained less than 5% since 1996.

The “Design Vehicle” is commonly used in traffic engineering to design roadways and intersections throughout the world. The concept has been applied to parking to define the composite vehicle on which parking geometrics are based. It is assumed that all cars using a parking structure will be the Design Vehicle and it is defined as the 85th percentile vehicle on the road from smallest (0%) to largest (100%).

By assuming all cars parking in a structure are the Design Vehicle for parking layout purposes, 84% of the vehicles actually parked in the structure will likely be smaller and have a more comfortable experience parking than the 14% of the vehicles that are larger than the design vehicle. In fact, the probability of having a parking space occupied by a vehicle larger than the Design Vehicle parked on both sides of it and across the aisle is 15% multiplied by 15% multiplied by 15%, or 0.33%. Very unlikely!

The percentage of all passenger vehicles that are over 6,000 pounds has remained less than 5% since 1996.

By studying annual sales, not the specific number of vehicles on the road, we are able to annually monitor vehicle size trends. Therefore, the Design Vehicle is not changed each year, but rather the analysis enables identification as to when a trend has been repeated for several years. We can then be reasonably confident that a lasting change has occurred. Since the average age of vehicles on the road is 12 years, the Design Vehicle on the road will not reach revised dimensions for 5 to 7 years. While some may argue that the average vehicle has gotten

larger, the sales data definitively identifies that the 85th percentile vehicle footprint has not changed more than a few inches in length or width in the last decade. This same sales data suggests that the footprint of EVs and conventional vehicles is also similar.

But what about weight? Are EVs heavier? Based on Walker’s tracking of vehicle sales and properties, yes, generally they are. Typical electric vehicles do appear to have a curb weight greater than their traditional counterpart. Over the last decade, the 50th percentile electric vehicle has a weight of approximately 4,400 pounds whereas the same percentile conventional vehicle has a

weight of approximately 3,700 pounds. As an example, the 2023 Volvo XC40 EV has an approximate curb weight of 4,780 pounds compared to 3,970 pounds for its conventionally-powered all-wheel drive variant. But as we look at larger vehicles a different trend emerges from the data.

When considering a design vehicle curb weight, the 85th percentile weight vehicle in 2022 had a curb weight of just over 5,000 pounds. The 85th percentile weight between 1996 and 2018 varied between 4,400 to 4,900 pounds, but since then has been slightly increasing on an annual basis. The 85th percentile curb weight of vehicles over the past five years is roughly 5,000 pounds, whereas over the last 10 years was 4,900 pounds. Therefore, it is reasonable to identify the Design Vehicle curb weight of passenger vehicles is currently 5,000 pounds.

Considering electric vehicles, study of sales data from 2011 through 2023 yields information relative to their specific design vehicle weight. Over the prior 11 years, the 85th percentile electric vehicle weight is 4,861 pounds, represented by the Audi Q4 e-tron. Over the prior 5 years, the 85th percentile electric vehicle weight is 4,877 pounds represented by the VW ID4. Note that these figures are very near that of the Design Vehicle curb weight for all vehicles.

Yes, a small number of EV models with curb weights of 7,000 pounds and up to the 9,063 pound Hummer EV have been introduced, but they sell in small numbers, or exist above the 85th percentile point. In fact, the Hummer is not a “light duty passenger vehicle,” but rather a “heavy duty” truck. In its earlier 1992 to 2006 ICE form, Hummers were never more than a fraction of 1% of cars on the road.

Figure 2 shows the trends in the 85th percentile weight of EVs as well as the total passenger vehicle sales since the first EVs were sold in 2011.

Before the International Building Code (IBC) was first published in 2000, three general building codes were used throughout the U.S. that are considered ‘model’ or ‘legacy’ codes. Those codes were: The BOCA National Building Code primarily used in the northeast, the Standard Building Code (SBC) generally used in

the southeast, and the Uniform Building Code (UBC) that was used in the rest of the of the U.S. Over time, the IBC has been adopted in most, if not all, areas of the country. Much of the design load criteria contained in IBC and in ASCE 7, Minimum Design Loads and Associated Criteria for Buildings and Other Structures, are applicable to the determination of parking garage live loads.

A paper by Y.K. Wen and G.L. Yeo, “Design Live Loads for Passenger Cars Parking Garages” in Journal of Structural Engineering,” published

in March of 2001,provided a better understanding of live loads in parking structures and recommended an appropriate value for design. Looking at the maximum load effects on beams and columns due to vehicle loads over the anticipated life expectancy of a parking structure, Wen and Yeo determined the axial loads and beam midspan moments using the design live load of 50 pounds per square foot (psf) would be two to three times greater than floor members would actually experience. They also concluded that dynamic

amplification resulting from moving vehicles would not increase the prescribed design load unless it is a speed ramp with slope greater than 10-degrees. Their final conclusion recommended a design live load of 40 psf with no allowance for area-based reductions. This recommendation did not apply to special purpose or densely parked structures especially when there would be no variety in the vehicle type parked.

About a year later, the March 2002 Concrete International magazine included an article by Javed Malik who was concerned with the increase in SUVs on the road and argued for point and uniform live loads in parking structure design to be significantly increased suggesting the wheel point loads be increased by 50% and the uniform live loads doubled.

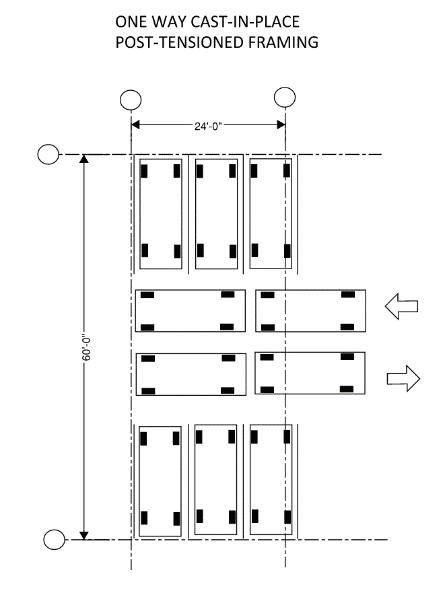

His analysis was subject to an extremely conservative and rare building framing system for parking structure construction. The typical construction materials and framing systems for parking structures at the time was, and still is, precast concrete or cast-inplace post-tensioned concrete systems.

A rebuttal white paper by Mary Smith, PE, and Tony Chrest, PE, of Walker Consultants, reviewed the vehicle trends at the time and analyzed the assumptions made by Malik for maximum wheel loads, axle distribution, vehicle curb weights, and gross vehicle weight ranges (GVWR). The use of the 85th percentile vehicle in the range of lightest to heaviest curb weight was proposed for the first time to be used as the Design Vehicle in the determination of uniform loads since at the time, the practice of using the 85th percentile vehicle was the standard for parking geometrics and commonly used in traffic engineering.

Using the Design Vehicle, Smith and Chrest analyzed loading

Design Vehicle: Volkswagen ID4 Weight

Curb Weight (lbs.)

4877

Passengers (max): 6 adults @ 175 lbs. 1050

Cargo (lbs.) 981

Total Weight when driving (= gross vehicles weight rating) 6908

Total Weight when parked (curb weight + cargo) 5858

conditions for various parking structure concrete and steel framing systems as shown in Figures 3-5.

Next, they considered heavier vehicle density stacked parking such as rental car storage or valet parking.

Consistent with Wen and Yeo, Smith and Chrest’s analysis found that in spans greater than fifteen feet, uniform loads were all less than 40 psf. Shorter span conditions and some uncommon high vehicle density conditions were slightly greater than 40 psf.

Today, the IBC/ASCE 7 still specifies a 40 psf design live load for parking structures.

Walker intentionally checked for the live load when an entire area is parked with EVs due to the local requirements to design 20% or more of the parking spaces to be EV Ready. This is increasingly leading to EVs comprising all the parking stalls in one area. Using the theories of analysis used by Wen and Yo and Smith and Chrest, the uniform load is evaluated over typical bay sizes that are based on framing systems commonly utilized in parking structures in the U.S. today as shown in Figures 4 through 5.

To start, Wen and Yeo’s study found that while dynamic effects from moving vehicles can increase the anticipated load, “It would be reasonable to conclude that dynamic amplification due to moving vehicles would not cause the equivalent uniformly distributed load (EUDL) to be more than the case of fully parked two-way traffic bays with vehicles waiting in the aisles.” In short, it was determined that with moving vehicles in a parking structure, the suggested dynamic amplification factor is independent of vehicle weight since the shallow slopes in which vehicles interact with floors does not transmit appreciable vertical load to the structure. As is consistent with generally accepted practice, when closely spaced concentrated wheel loads are distributed at a 45-degree angle from the direction of span they quickly overlap other wheel loads, allowing the load to be judged as a uniformly distributed load.

Following the Smith and Chrest philosophy of using the Design Vehicle for the determination of uniform loads, Walker used the 85th percentile electric Design Vehicle to establish the anticipated loading on structural members. Following this approach, all parking spaces in a structural bay were assumed to be occupied by electric Design Vehicles at curb weight plus cargo and that a string of electric Design Vehicles loaded to their gross vehicle weight rating (GVWR) are simultaneously placed each way along the drive aisle. This approach is a conservative estimation of uniform live load in a bay since the likelihood that all the vehicles in an area are all an 85th percentile Design Vehicle simultaneously

traversing the drive aisles is extremely small. Additionally, for most public parking facilities serving visitors, commuters, or shoppers the odds of all the vehicles in the drive aisle being loaded to the full GVWR are even less likely.

Let’s now check the uniform load for the electric Design Vehicle created by the scenario in Table 2.

Assumptions:

• Parking Geometrics: 8 ft. 6 in. stalls @ 90 degrees on 60 ft. modules

• Assume Electric DV at 6908 lbs. are driving both ways down the aisle

• Assume Electric DV at 5858 lbs. are parked in every stall

The authors then considered what the equivalent uniform distributed load would be for the framing systems commonly employed in parking structures in the U.S. today:

• Precast Garage.

• Post-tensioned, cast-in-place concrete with one way slabs and beams.

• Conventionally reinforced concrete with 30” x 30” column grid.

• Steel beams and column with P/C double tees.

• Steel beams and columns with a cast-in-place post-tensioned slab.

The calculated equivalent uniform loading with an electric Design Vehicle for each system is shown in Table 3.

As can be seen, none of the typical parking structure framing systems have an equivalent uniform load exceeding 40 psf when considering the electric Design Vehicle. This should be no surprise as the design vehicles weights between conventional and electric vehicles are quite similar.

Despite all the discussion surrounding electric vehicle weights exceeding the weight of their internal combustion engine counterparts, Walker’s data base of vehicle sales and weight indicates that the electric Design Vehicle is of similar curb weight than the overall passenger vehicle mix sold in recent years. As such, the overall 85th percentile weight vehicle is most appropriate for live load calculations. Combined with Wen and Yeo’s finding that maximum load effects on beams and columns using a uniform load of 50 psf would be two to three times greater than what they expected the members to actually experience, the current IBC and

ASCE 7 prescribed live load of 40 psf for passenger vehicle garages is viewed as an accurate representation of expected conditions for the current information available on EV’s and their presence on the road.

Structures that have experienced deterioration represent a very different structural concern, one that is not specific to electric vehicles or internal combustion vehicles. Aged or neglected parking structures that have experienced deterioration may need to be assessed structurally to ensure that they have a sufficient strength for the loads in which they are intended to support. If the available strength is determined to be inadequate, then it is only prudent to repair, strengthen, or restrict loads to such a deteriorated structure. However, this is not due to electric vehicles, but rather the overall shift to SUVs and pickups, as compared to 20 years ago.

How vehicle weight will change remains to be seen as battery technology is still in its infancy and could change to be lighter yet more efficient and achieve longer ranges; but it is viewed by the authors as unlikely that trends of ever-heavier cars, crossovers, and pickups that meet consumers vehicle range expectations will continue. Further, is it premature to consider an increase in design loads on the speculative basis of vehicle weights 25 years in the future if/ when EVs are finally approaching 50% of the vehicles on the road? As engineers, it is important to consider that realistic, rational, and safe loads for the design of facilities that are to be used by the public. However, finding a prudent balance for reasonable design is also necessary so that designs may not be viewed as unreasonably conservative and undermine public trust. Further, judicious designs are needed more than ever to foster sustainable designs and reduction of costly construction materials. Continual monitoring of data will help ensure that the evolution of code load standards reflects actual load scenarios combined with rational safety factors rather than on public perception. ■

Full references are included in the online version of the article at STRUCTUREmag.org .

Leslie Jo Hurwitz, PE, is the Managing Principal of Walker Consultants’ Charlotte, NC office and have worked with Walker for over 20 years in the design and restoration of parking structures.

Brian Fisher, PE is Director of Design in Walker Consultants’ Charlotte, NC office. He has 18 years at Walker and 23 years in the industry designing parking structures.