subscriptions@structuremag.org

Chair John A. Dal Pino, SE Claremont Engineers Inc., Oakland, CA chair@STRUCTUREmag.org

Marshall Carman, PE, SE Schaefer, Cincinnati, Ohio

Erin Conaway, PE AISC, Littleton, CO

Sarah Evans, PE Walter P Moore, Houston, TX

Linda M. Kaplan, PE Pennoni, Pittsburgh, PA

Nicholas Lang, PE Vice President Engineering & Advocacy, Masonry Concrete Masonry and Hardscapes Association (CMHA)

Jessica Mandrick, PE, SE, LEED AP Gilsanz Murray Steficek, LLP, New York, NY

Brian W. Miller

Cast Connex Corporation, Davis, CA

Evans Mountzouris, PE Retired, Milford, CT

Kenneth Ogorzalek, PE, SE KPFF Consulting Engineers, San Francisco, CA (WI)

John “Buddy” Showalter, PE

International Code Council, Washington, DC

Eytan Solomon, PE, LEED AP Silman, New York, NY

Jeannette M. Torrents, PE, SE, LEED AP JVA, Inc., Boulder, CO

Executive Editor Alfred Spada aspada@ncsea.com

Managing Editor Shannon Wetzel swetzel@structuremag.org

Production production@structuremag.org

Director for Sales, Marketing & Business Development

Monica Shripka Tel: 773-974-6561 monica.shripka@STRUCTUREmag.org

• Concrete Repair Mortars

• Corrosion Protection

• Construction Grouts

• Waterproofing

• Sealants and Joint Fillers

• Coatings and Sealers

• Epoxy Adhesives

• Cementitious Flooring Systems

• Cure and Seals

• Densifiers

• Structural Strengthening Products

• Precast

• Epoxy Adhesives

Visit www.mapei.com/us for details on all MAPEI products. Your single-source provider for construction

MAPEI offers a full range of products for concrete restoration, waterproofing and structural strengthening. Globally, MAPEI’s system solutions have been utilized for such structures as bridges, dams, tunnels, highways, parking garages, stadiums and high-rises.

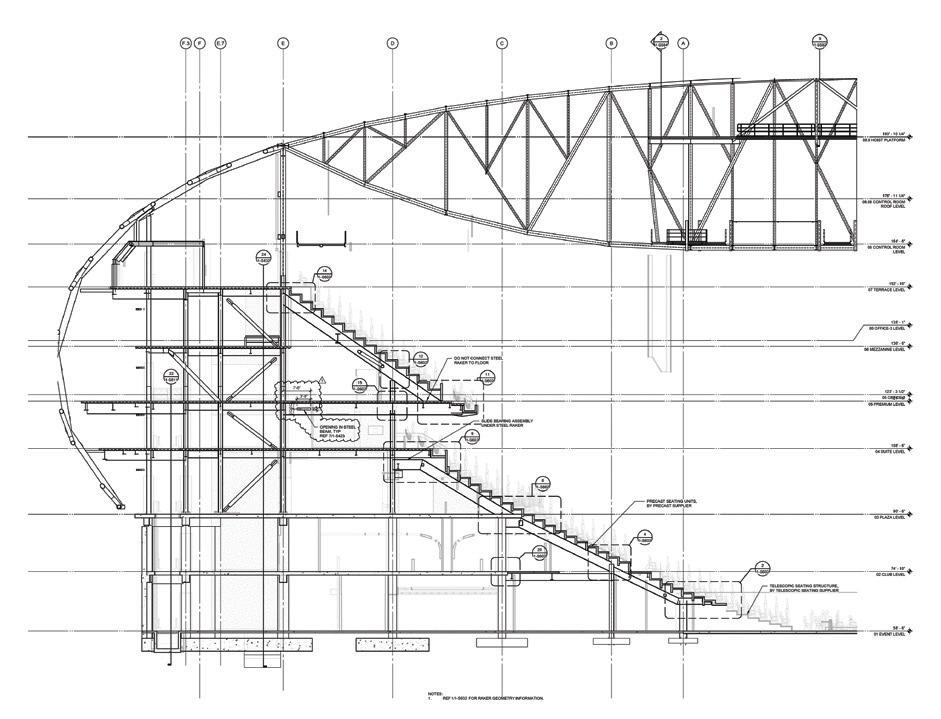

By Austin Reese, PE

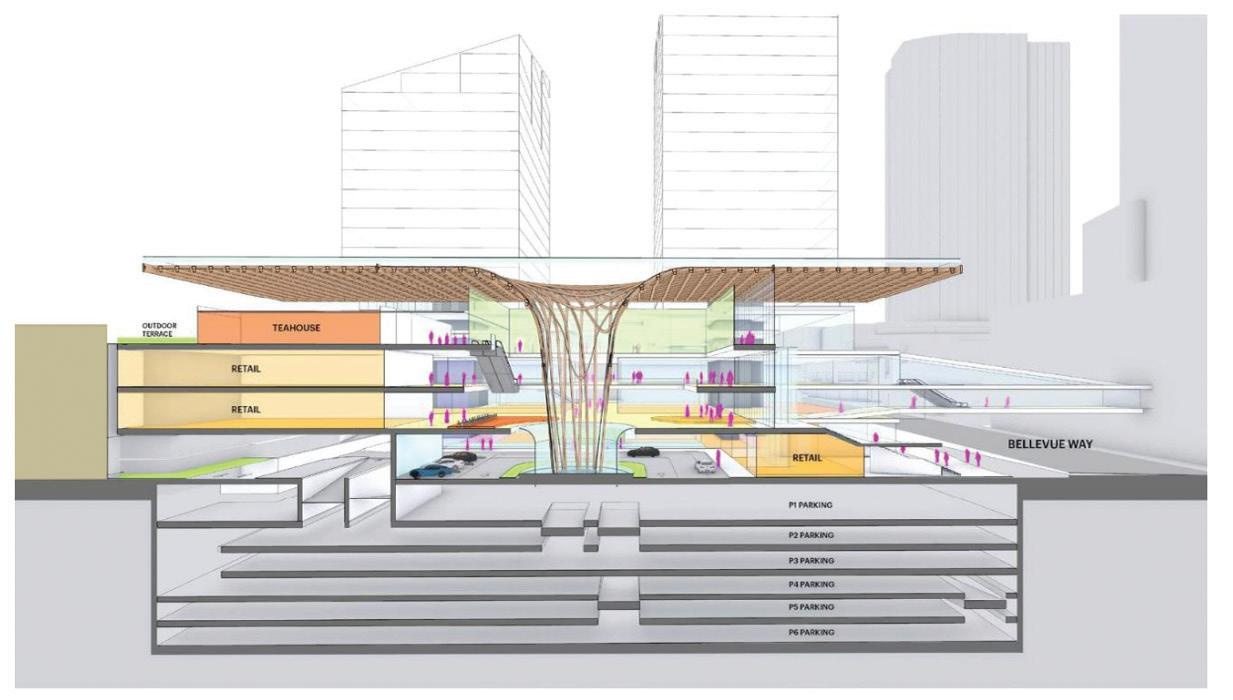

Coordination, collaboration, and creativity were required to meet the structural engineering challenges created by the building's unique canyon feature.

Geology, hydrology, hydraulics, and more go into the structural engineering puzzle of each dam project.

By Bryan Seamer, SE, and John Wilson, SE

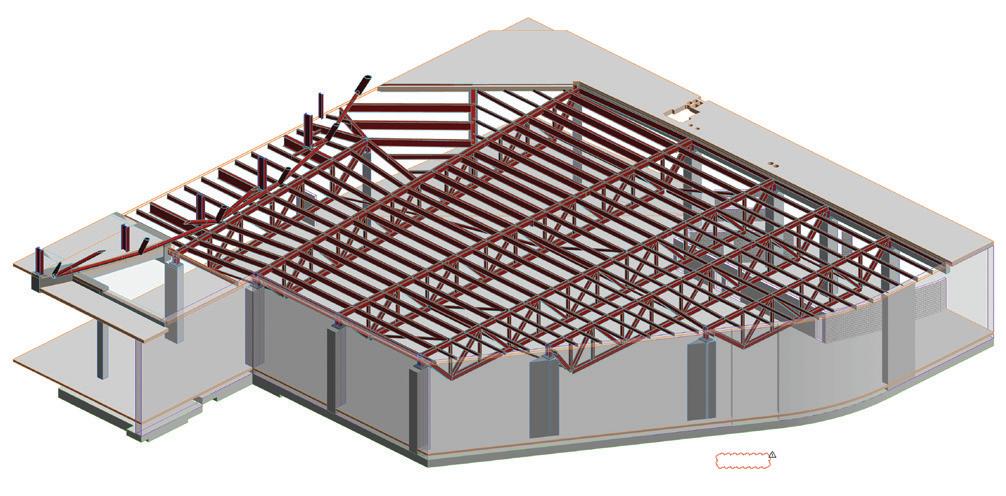

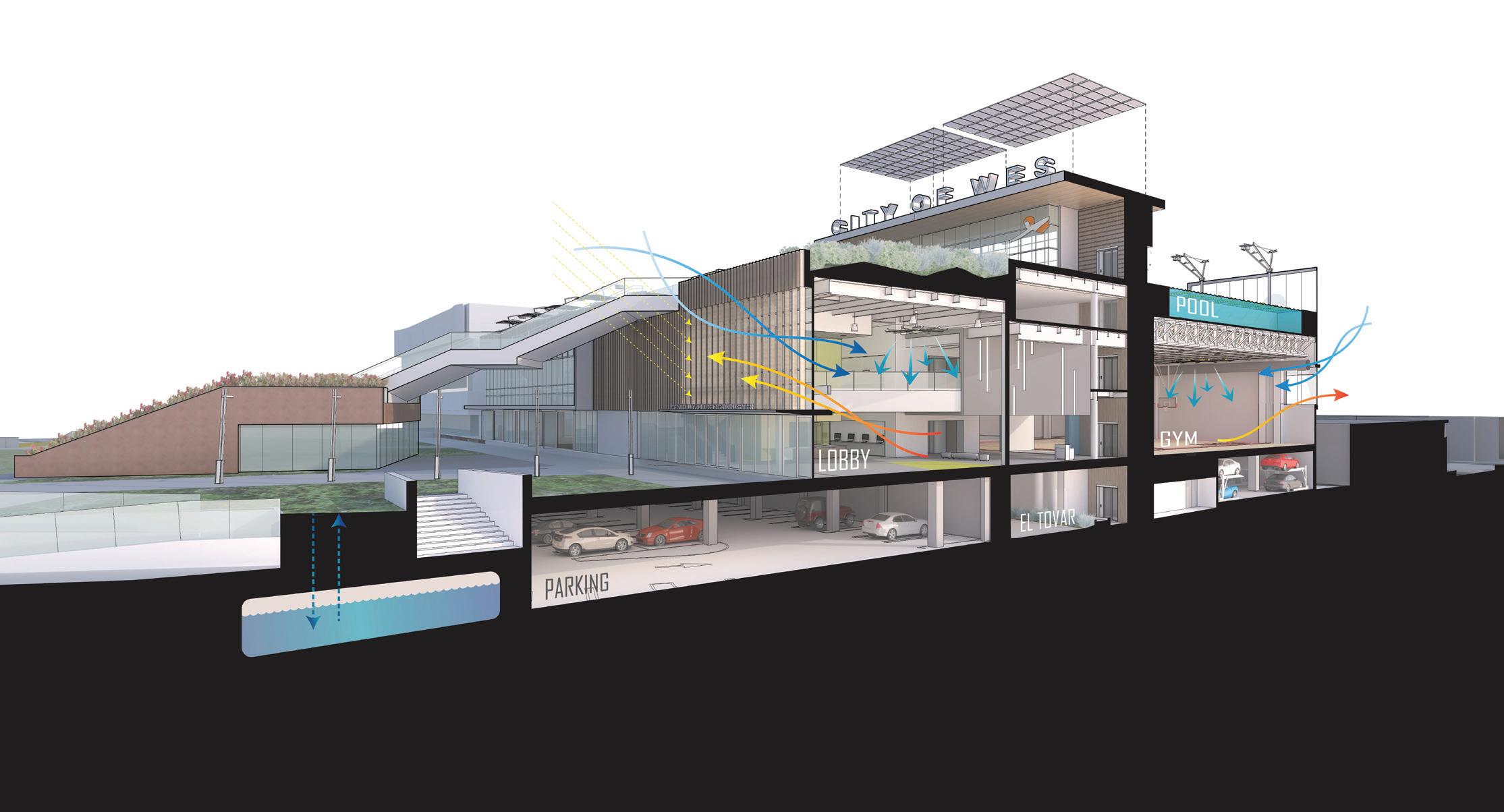

On a tight, urban site, LPA’s West Hollywood Aquatics and Recreation Center (ARC) uses inventive structural engineering to create space for community and well-being.

Simpson Strong-Tie provides comprehensive product solutions for commercial institutional construction. Whether you’re building an educational facility, healthcare center or public office, you can rely on a full array of products that are assembly-tested and proven for strength and versatility. From cold-formed steel and structural steel to adhesive and mechanical anchors, code-listed connectors and fastening systems, we have what you need to build safer, stronger structures. Our nationwide distribution network ensures product availability and timely jobsite delivery. Along the way, our expert field, technical and sales support teams are always ready to assist you. With Simpson Strong-Tie as your partner, you have a total solution designed to elevate performance. To learn more about our complete solutions for institutional construction, visit strongtie.com/institutional or call (800) 999-5099.

Carl Josephson, PE,

Terrence Paret, Hayley Proctor, PE, Gwenyth Searer, PE, SE, and Prateek Shah, PhD

By Tim Lane and Cris Moen, Ph.D, PE

Dr. Ibrahim M. Metwally, Ph.D,

By Carl Josephson, PE, SE

There are eleven member boards in NCEES (National Council of Examiners for Engineering and Surveying) that require an engineer to have a Structural Engineer license to design some or all the buildings or bridges in their jurisdictions. There are four other states in which use of the title Structural Engineer is restricted to engineers licensed as a Structural Engineer. It has become increasingly clear that engineers who practice structural engineering across state lines or who design buildings that are commonly called “significant structures,” need to become licensed as a Structural Engineer. As with all engineering licensing, the minimum requirements involve the “three-legged stool” of education, experience, and examination. The examination for would-be Structural Engineers is now the NCEES PE Structural Exam that is used by all jurisdictions that license SEs.

To improve the exam, make it relevant and more in keeping with typical office practice, NCEES needs licensed practicing structural engineers (including newly licensed engineers) to participate in the process.

The exam went from being a two-part (16hour) exam that tested vertical design one day and lateral design the next, to a four-part (21-hour) exam that takes at least four days to complete. The previous exams had the breadth portion (vertical or lateral) in the morning and the depth portion of the respective section in the afternoon. Previously, the exam was graded with a “hybrid compensatory grading system” which meant that one could not get an acceptable result in either vertical or lateral if they did especially well in the multiple choice portion and bombed the “paper and pencil” portion. Now the four sections (vertical breadth, lateral breadth, vertical depth, and lateral depth) are all graded separately, reported separately, and acceptable results are required for each. The first administration of the new computer-based NCEES PE Structural exam took place this year, with the depth portion of the exam in April. For the first administration of the new SE exam, the pass rates for the breadth (multiple choice) portions of the exam were in the 50% range, while the pass rates for the depth (alternate item type) portions were in the 15% range. The pass rates for the breadth sections were slightly higher than what has been seen in the past for the combined score, and the pass rates for the depth sections were lower.

That said, common concerns that have been raised by examinees who recently took the exam were that the use of the computer-based references were clunky and slow, only one window could be open at a time, some references did not have bookmarks, it was reported that one couldn’t go back to a problem later, and time seemed too short for the exam.

The licensing committees of SEI, NCSEA, and CASE have been monitoring the exam, and fielding concerns and complaints. The committees or their members have discussed these issues with NCEES, who has been open and receptive, and is looking to continually improve the exam. Here is some of the feedback that we received:

For exam security, we will never see personal reference material come into or out of the exam rooms again. The solution is providing all references that the examinee needs in a searchable digital format. Unfortunately, the proprietary software used by Pearson VUE test centers does not allow more than one window open at a time. For the foreseeable future, one will not be able to have two references open simultaneously, and there are no plans by Pearson VUE to rewrite their software or to provide multiple monitors for any of their exams.

It is true that after the break, for security reasons, one is not allowed to go back to work on uncompleted problems. This was true with the “paper and pencil” exams as well and it does not reflect a change in policy. Before or after the break, one can “flag” questions to go back to later.

The depth portions of the structural exam are indeed difficult. With the “Alternate Item Type” questions, which may require fill-in-the-blank, multiple correct responses, drag and drop, etc., there is no partial credit. The answers are either right or wrong. The previous method of grading did not report the relative difficulty of the breadth and depth sections of the exam and it is hard to know if the depth portions of the new exam are truly more difficult.

All would-be examinees should take advantage of reviewing NCEES videos that explain how the new Structural Exam works by watching “P.E. Structural Computer-Based Exams” by NCEES Media on YouTube.com. NCEES has the reference text materials available prior to taking the exam, but the code materials are not available in the same digital format as will be provided at the exam due to copyright protections. The exam writers and standard setters for all the NCEES exams including the PE Structural Exam are volunteers who, after they apply to help on the exam, are vetted and invited to participate. NCEES pays for travel, lodging, and incidentals for the volunteers, who can also receive continuing education credit for the time spent working on the exam. Participants have found the experience of working on the exam to be extremely rewarding, both personally and professionally, and many of us have developed close friendships with colleagues across the country that have served as resources and helped us in our practice. To improve the exam, make it relevant and more in keeping with typical office practice, NCEES needs licensed practicing structural engineers (including newly licensed engineers) to participate in the process. Learn more and get involved at ncees.org/volunteer/. ■

The comments and statements in this article are the author’s alone and do not necessarily reflect the positions or policies of NCEES.

Carl Josephson, PE, SE, is a Senior Principal at JosephsonWerdowatz & Associates, Inc. in San Diego, and Chair of the Structural Engineering Licensure Coalitionwww.selicensure.org.

Janiele Maffei is the California Earthquake Authority's Chief Mitigation Officer and Director of Research. Among several responsibilities at CEA, she manages an incentive program that has helped more than 23,000 California residents com plete code-compliant seismic retrofits. She earned an AB in architecture and an MS in structural engineering at the University of California Berkeley. She is also a past president of the Structural Engineers Association of Northern California.

STRUCTURE: What or who encouraged you to seek a career in structural engineering?

Maffei: My grandfather was a carpenter, and he had a magical workshop in his basement with a box of scrap wood specifically saved for his granddaughters’ special projects. Each of us had our own little tool box and we loved spending time with him building objects with maximum nails and minimal usefulness. My grandfather built a playhouse in our back yard and filled it with creative homemade toys. My Barbie dream house and dream car were made of wood. I loved designing and building things and was the only girl I knew who had a Mattel power shop. I was the only girl in my 8th Grade mechanical drafting class and one of three girls in my high school drafting class. I majored in architecture at the University of California (Cal) but took all the math, science, and undergraduate electives necessary to be accepted into the Structural Engineering Structural Mechanics (SESM) graduate program. While the ratio of men to women was close in architecture, I was one of only six women in the graduate program. While being a female certainly made me stand out I shared the same desire to build great things.

STRUCTURE: If you had to give advice to young people considering a career in structural engineering, what would that be?

Maffei: The typical advice to someone interested in engineering is to take all the math and science you can. However, the people who gravitate towards engineering already tend to already be interested in math. I would encourage them to make sure that they focus on being a well-rounded person. Study music, art, and literature, and be an effective communicator too.

STRUCTURE: Any pitfalls to be avoided?

Maffei: Structural engineers play a hugely important role in society, not only in their contributions to the built environment, but also in providing solutions to the challenges and problems of our world. I read an article once about how many of the significant improvements in health and safety in our communities were advancements in civil engineering: improved sanitation; access to clean drinking water; protection from inclement weather; and building fire protection to name a few. It may feel comfortable to be behind the desk on a computer, but real problems are solved through creativity, collaboration, and communication.

STRUCTURE: Your working career started out in a traditional engineering office. What did you learn there or who did you meet then that proved useful later?

Maffei: To answer your question about who I met as a young(er) engineer that proved useful today, I have a one-word answer: everyone. My current job is to take the best and brightest structural engineering ideas and put them to use to create earthquake resilience in residential

buildings. I really enjoy the notion that everyone in structural engineering, and in the broader earthquake engineering community, has a little piece of the puzzle and I am the puzzle master. The modern term for this is networking but it feels more like making friends to me.

STRUCTURE: Of all of the projects you have worked on, would you describe the one or two that you are most proud of and why?

Maffei: The work I am now doing in research and mitigation for the California Earthquake Authority (CEA) will most definitely be at the top of the list but there are a few projects from my consulting days that I am very proud of too. As a Bay Area native, after I graduated from Cal I remained in the area working in the East Bay and in San Francisco. I still live about 5 miles from the Berkeley campus and I drive by the historic Claremont hotel and numerous campus buildings that I worked on. Being a part of preserving those gorgeous buildings still brings me joy. I remember walking through Le Conte Hall and being told by the architect I was working with on the seismic retrofit of that structure that “Oppenheimer touched these doorknobs.”

STRUCTURE: What lessons did you learn that were valuable for later?

Maffei: The grass is not greener on the other side of the fence. It might taste a bit different, but it is still pretty much grass. When I first started Janiele Maffei SE after my son was born, I had the pleasure of working with a number of structural engineering firms around the Bay Area. I found similar issues at all of them with middle managers, less so with the older guys. I found giant egos and gentle souls. I also discovered the depth and breadth of talent in our industry was enormous.

STRUCTURE: After several years in the industry, you shifted focus and went to the California Earthquake Authority. Why?

Maffei: I was in a semi-retirement state, traveling a lot with my husband. We visited 12 countries in 12 months one year and I was pretty much able to work anywhere with a laptop. Then the job description for the Chief Mitigation Officer with the CEA flashed across my screen. I realized that I wasn’t finished yet, I had more to give. The notion of working on residential earthquake resilience directly through mitigation could be described as being my sweet spot. I also had that collection of friends, otherwise known as my network, who teemed with solutions ready to be put into action.

sexual harassment, and there was barely any maternity leave let alone parental leave. I can honestly say that it was very difficult to compete with my male colleagues who had a wife at home. I took a leap and started my own company and that forced me to take a lot of responsibility and also allowed me to work with so many different engineering firms. From lemons—lemonade.

STRUCTURE: You have demonstrated a long and dedicated commitment to professional activities. What is the most rewarding aspect of your service?

STRUCTURE: Most engineers don’t want to speak, let alone be the voice of an industry. What can we learn from your experience?

Maffei: The common notion is that public speaking is number one on the list of human fears. Seinfeld had a great bit about people preferring to be the guy in the casket rather than the one giving the eulogy. A quick internet search suggests that the fear of heights is actually number one, and contractors I have worked with can attest that I definitely have acrophobia. However, I somehow found my voice somewhere around the time I stepped into that middle school drafting class as the only girl. I stood up at a school assembly and said something into the mic and realized that the world didn’t come to an end. It didn’t rise to the level of “Ich bin ein Berliner” but I think it encouraged me to speak up. In my current job I have on average one public speaking event a week, sometimes more. However, I don’t consider myself to be a fully formed orator. I am continually watching and listening to other speakers, at conferences, on TV, and in movies, noting how they succeed, and fail.

STRUCTURE: There is a lot of talk these days about community resilience. But more than talk about that, you actually did something. Would you tell us a little more about your motivations and goals?

Maffei: My success started with the important decision in 1996 to include continual funding for mitigation in the CEA’s operating budget. While the contributions are small ($5 million maximum per year) we are able to leverage that funding with State and FEMA funding to provide $3,000 grants for what is, on average, a $5,200 retrofit. We also just received news that we have Building Resilient Infrastructure and Communities (BRIC) funding for multi-family soft-story retrofit grants. The decision to ask the California legislature to create the Chief Mitigation Officer position was also an important step towards success. My motivation was to step up and accept the challenge to put that funding to good use.

STRUCTURE: Can you say a little more about what it was like entering an industry where women are few and far between?

Maffei: With a nod to Ruth Gordon, the first woman to become a structural engineer in California, there were definitely challenges to being one of very few female engineers in the profession in the 1970s and 1980s. While there were supposedly around 20 women who got their California SE before me, I knew of only a handful of women who were older than me who were still working in the profession. It was a time when construction calendars and marketing materials featured scantily clad women on their covers. The Anita Hill testimony hadn’t yet socialized the notion of

Maffei: We asked the very first homeowner who retrofitted with one of our grants how he felt about the program and about the retrofit. He said, without prompting, that he slept better at night. I honestly feel that my team is “fighting the good fight.” Our residences are typically the single largest investment we will make, they are where our family sleeps at night, they are our home. Knowing that we are assisting homeowners increase the resilience of their homes is so worth it.

STRUCTURE: What is your approach to mentorship?

Maffei: It still surprises me when I am the oldest person in the room. I laugh at myself because I have become that older person who always has a related story to tell, on any subject. Being around longer does afford one the opportunity to share lessons and wisdom. But it is also an opportunity to assist a mentee find the value in themselves, regardless of what stage they are in their career. The most important part of being a good speaker is being a good listener because everyone learns more from a dialogue than from a monologue.

STRUCTURE: Many people think the structural industry broadly, including risk mitigation and insurance, has changed during the last few decades. Do you agree? Is it for the good or bad?

Maffei: Mitigation and insurance has definitely changed. Mitigation has become enormously important because we have so many buildings that are becoming un-insurable. The confluence of older buildings designed and built before building codes with seismic provisions, the upward financial pressures of inflation and the cost of global capital make catastrophe insurance unaffordable to most people. Many cities in California are moving in the right direction by retrofitting their vulnerable structures. However, life-safety retrofits don’t necessarily improve the insurability of the building. It is safe to say that there is more work to be done.

STRUCTURE: We all have mentors and people who helped us be successful. Who would you like to thank and why?

Maffei: I would like to thank my husband who taught me what torque was when I was an architectural student and he was in civil engineering at Cal. I think my forming a study group with two other female graduate students was absolutely the right thing for me to do for our relationship at the time. However, he has been a sounding board and incredible engineering confidant and mentor. He is, and I believe I am qualified to say this, one of the best structural engineers I know.

STRUCTURE: In terms of your personal legacy, what would you like to be remembered for?

Maffei: Just to prove I can make up a story about anything: a few friends and I pondered the question of whether we would like to be known for our intellect, our beauty, or our kindness. I don’t think anyone is truly intelligent or beautiful if they are not kind. I will go with kindness. ■

This article explores the subject of radial and spiderweb cracking in reinforced concrete two-way flat plates and flat slabs (herein referred to as “two-way slabs”) and the underlying reasons for it. Proper investigation of radial and spiderweb cracking will be addressed in a following issue of STRUCTURE.

By Terrence Paret, Hayley Proctor, PE, and Gwenyth Searer, PE, SE, and Prateek Shah, PhD

Over the years, the writers have observed radial (sometimes called “starburst” or “sunburst”) and spiderweb cracking in dozens of two-way slab structures. These slabs were constructed in different regions of the country, were designed by different engineers in different decades using different editions of ACI-318, support different occupancy types, and were constructed by different contractors. Many of these slabs were found to exhibit radial and spiderweb cracking during construction, i.e., before the addition of finishes and before being put into service, but others were only reported to have radial and spiderweb cracking after years of continuous occupancy, sometimes only discovered after the removal of floor finishes during routine maintenance or remodeling. The relatively common occurrence of such cracking across a breadth of circumstances warrants a technically accurate understanding of its causes and structural significance. While radial and spiderweb cracking sometimes are interpreted to be symptoms of elevated punching shear stress, and therefore are mistakenly interpreted to signify high risk conditions, analysis and research both demonstrate that these crack patterns are actually characteristic of flexural behavior that typically manifests at loads significantly below ultimate punching shear capacity, as documented by Elstner and Hognestad as well as Paret et al. This cracking largely results from a fundamental disparity between the explicit averaging of flexural demands across column strip widths in the ACI 318 strip method of design and the quantifiable distribution of bending moment in real slabs. Before delving into supporting analyses, it is helpful to

explore the conceptual behavior of two-way slabs.

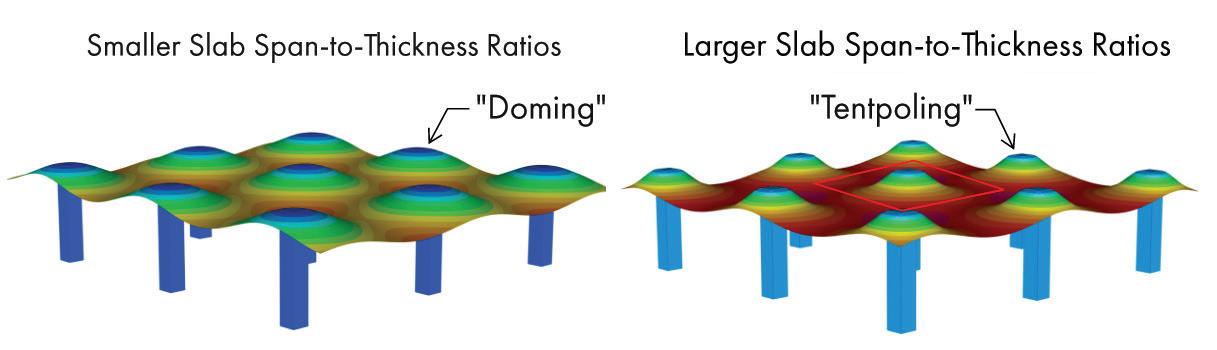

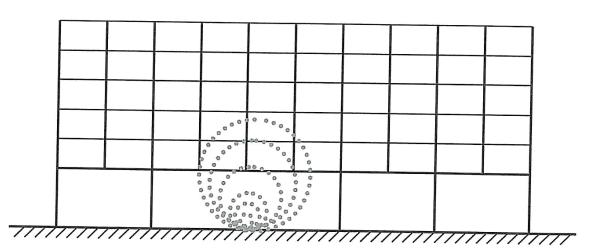

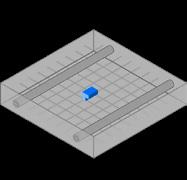

When subjected to service-level gravity load, multi-span, two-way slabs with larger span-to-thickness ratios are generally expected to experience larger midspan deflections, and therefore larger curvatures near the columns, than slabs with smaller span-to-thickness ratios, all other things being equal. These differences can be idealized in three dimensions by thinking of the relatively flatter deformed shape in slabs with smaller span-to-thickness ratios as “doming” and the amplified curvatures in slabs with larger span-to-thickness ratios as “tentpoling” (Fig. 1). Both behaviors are flexural as they are associated with curvature. The larger curvatures associated with larger span-to-thickness ratio slabs necessarily increase the propensity for cracking and local yielding of negative flexural reinforcement close to the columns, both of which would further amplify deflection and tentpoling.

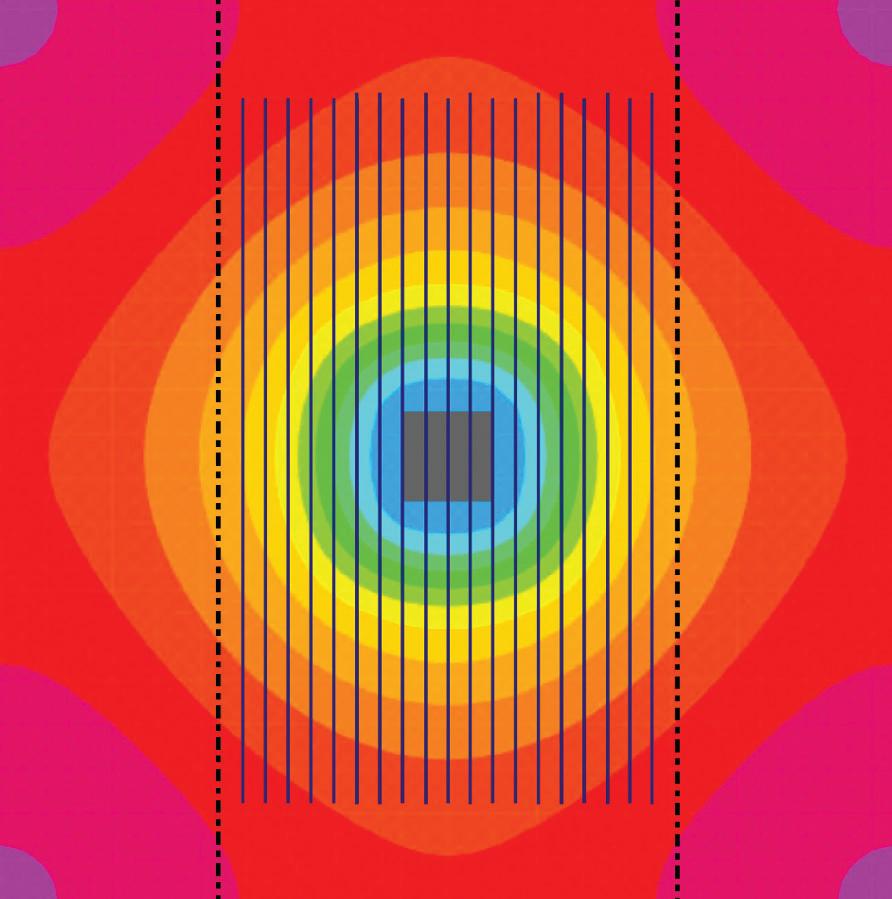

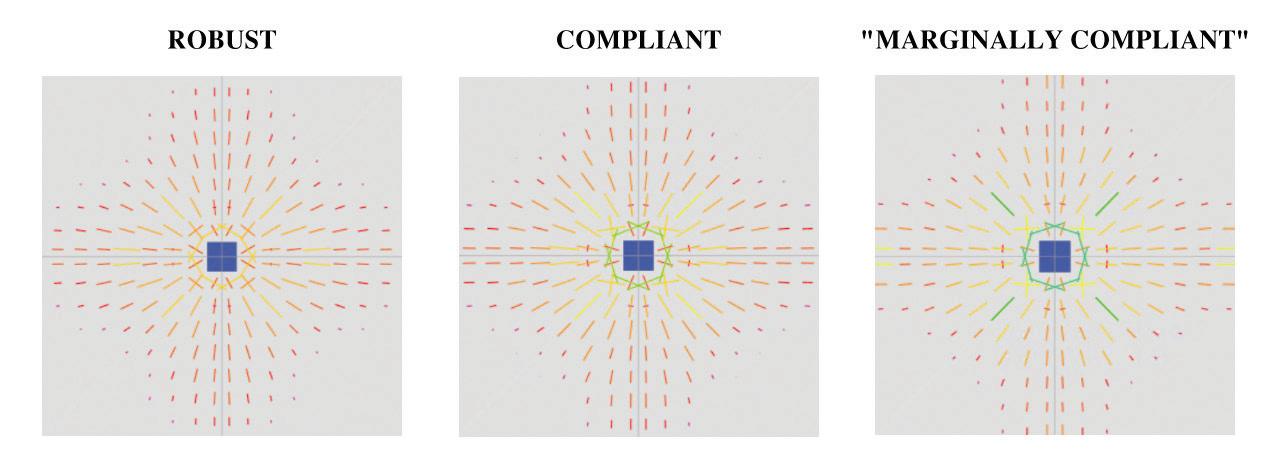

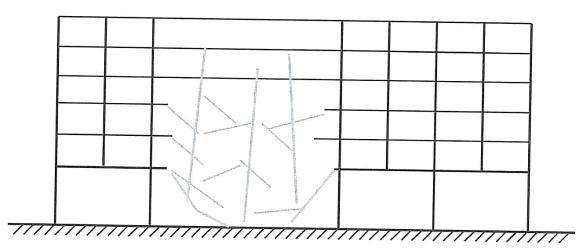

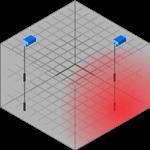

Figure 2 overlays a typical layout of column strip reinforcement onto a plan view of the deformed shape for a typical bay extracted from the tentpoling illustration in Figure 1. Because curvatures vary across the width of the column strip, the distribution of negative moment across the width of the column strips also must vary, with the highest negative moment located near the centerline of the column strip (close to the columns) and significantly diminished negative moment near

Fig. 1. (Above) Notional deformed shape comparison of slabs with varying span-to-thickness ratios. The area outlined in red is shown in plan view in Figure 2.

Fig. 2. (Right) Plan view of overlay of distribution of negative moment reinforcing steel (solid blue lines) and deformed shape (see Figure 1). The edges of the column strip are shown with black, dashed lines. The corners of the plan coincide with the centers of the surrounding bays.

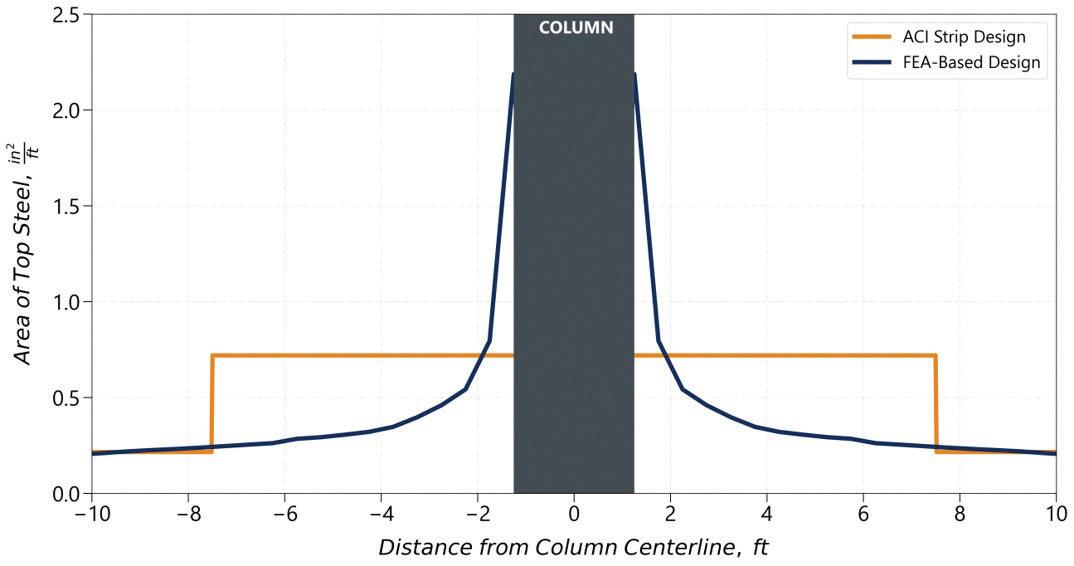

the edges of the column strip. This distribution, whether for the larger or smaller span-to-thickness ratio slabs, is at odds with the ACI 318 strip method of design which assumes an averaged, uniform distribution of moment across the column strip width, thereby leading to designs in which negative moment reinforcement is uniformly distributed across the column strip width.

For typical span-to-thickness ratio slabs, even when the total quantity of column strip reinforcement is adequate to carry the total column strip moment, the concentration of negative bending stresses very close to the column results in a mismatch when compared to the more uniform distribution of steel in the column strip. This mismatch is indicative of what the writers refer to as a “nonuniform utilization” of the negative moment reinforcement: closer to the column, the stresses in the column strip reinforcement are necessarily higher than they are farther away from the column. Intuitively, the greater the degree of nonuniform utilization of the reinforcing steel, the greater the likelihood of developing relatively wide concrete cracking and yielding of reinforcing steel. However, this mismatch must be quantified to objectively assess the consequences of the mismatch.

with the letter of the code – to distinguish it from the “Compliant” model, which met the minimum slab thickness requirements, while the marginally compliant model did not. The flexural reinforcement in all three models was “designed” by ETABS to comply with the ACI 318 strip method.

Finite element software packages commonly used in structural design can readily quantify the severity of any nonuniform utilization, provide insight as to whether this nonuniformity is sufficient to lead to radial and spiderweb cracking and yielding of reinforcement, and predict the midspan deflection and crack pattern that results. Using ETABS, the writers developed three models of an idealized multi-span parking garage slab to isolate and study the influence of span-to-thickness ratio on performance (Table 1). The analyses, described below, demonstrate that characteristic tentpoling behavior due to nonuniform utilization of negative moment reinforcement, including radial and spiderweb cracking and yielding of reinforcement close to columns, predictably occurs even in code-compliant slabs under service loading.

The three models were identical in every respect (e.g., span length, column size, and loading) except for slab thickness, which was used to alter the span-to-thickness ratio. As tabulated, the slabs in all models were compliant in two-way shear (i.e., punching shear), though to different degrees since the slab thickness varied. Models characterized as “Robust” and “Compliant” had 12-inch-thick and 10-inch-thick slabs, respectively; each satisfied the minimum thickness requirements and the deflection limits set forth in ACI 318-19 Table 8.3.1.1 and Table 24.2.2. The third model, which had a 9-inch-thick slab, did not meet ACI 318’s minimum slab thickness requirements but was also ACI-318-compliant because it satisfied the calculated deflection limits. The 9-inch-thick slab model was characterized as “Marginally Compliant” – despite being compliant

For parking garages, which typically have few, if any, deflectionsensitive finishes, the controlling criterion for immediate live load midspan deflection per ACI 318 Table 24.2.2 is ℓ/360, or 1 inch in the case of a 30-foot span. Table 1 shows the predicted immediate live load deflections; all are less than 1 inch, indicating that the designs are code compliant, though notably, the predicted midspan deflection of the “Compliant” and Marginally Compliant” slabs are roughly five and eight times, respectively, the predicted deflection of the “Robust” slab. These values represent the deflection increment due to short-term live load on a slab that may have already experienced some cracking due to dead load.

The dominant slab cracking patterns predicted by ETABS for the three slabs are distinctly radial and concentrated close to the columns (Fig. 3), which is consistent with expectations for the flexural doming and tentpoling behavior illustrated in Figure 1. Although the meshsize dependency of these predictions makes them more reliable as qualitative points of comparison than as explicit predictions of in-field performance, the ETABS prediction that even the “Robust” slab will crack radially suggests that this behavior is inherent to two-way slabs regardless of level of safety and that engineers should not be surprised to see such cracking in buildings they design, even when the slabs are code-compliant in all ways, including punching shear.

The ETABS analyses also illustrate that the underlying mechanics of the radial cracking issue derive from nonuniform utilization of the uniformly distributed negative moment slab reinforcement. Figure 4 graphically depicts the nonuniform utilization from the ETABS analysis for the “Compliant”/10-inch-thick slab. Since the negative moment demand across the width of the column strip is not uniformly distributed while the negative moment reinforcement is, the local moment demand close to either side of the column significantly exceeds the reinforcement provided per the ACI 318 strip method. At the same time, near the outer margins of the column strip width, the reinforcement is more than adequate to resist the local moment

demand. Said another way, while the ACI 318 strip method provides adequate capacity to resist the total column strip moment, the demand significantly exceeds the slab capacity over the portion of the column strip width nearest the column, which leads to radial and spiderweb cracking and yielding within that portion of the column strip. In a true nonlinear analysis package that explicitly accounts for yielding and redistribution, the lateral extent of the overstress would spread farther from the column.

Radial and spiderweb cracking and yielding of reinforcement that results from the described nonuniform utilization may not negatively impact the ability of the slab to support design loads, but it can impact how the slab performance is perceived, and – if exposed to water and chlorides – the slab’s long-term performance. In addition to the possibility that some owners and occupants may consider the cracking to be objectionable and may express alarm due to the presence of radial cracking, tentpoling behavior can lead to a potentially significant increment of deflection that might not always be considered during design especially if it is not relevant to the ACI deflection criteria for that structure; that increment can also impact owner and occupant perception of performance even if it does not impact safety. For example, for the design of parking garage slabs for which immediate live load deflection is the only relevant codified calculated deflection criterion, dead load deflection and incremental dead load deflection due to tentpoling would normally be ignored, even though those together may be several times greater than the immediate live load deflection. In the writers’ experience, when tentpoling and out-oflevelness of two-way slabs become readily visible, the users’ experience and owner satisfaction regarding those slabs may be reported as being diminished (Fig. 5).

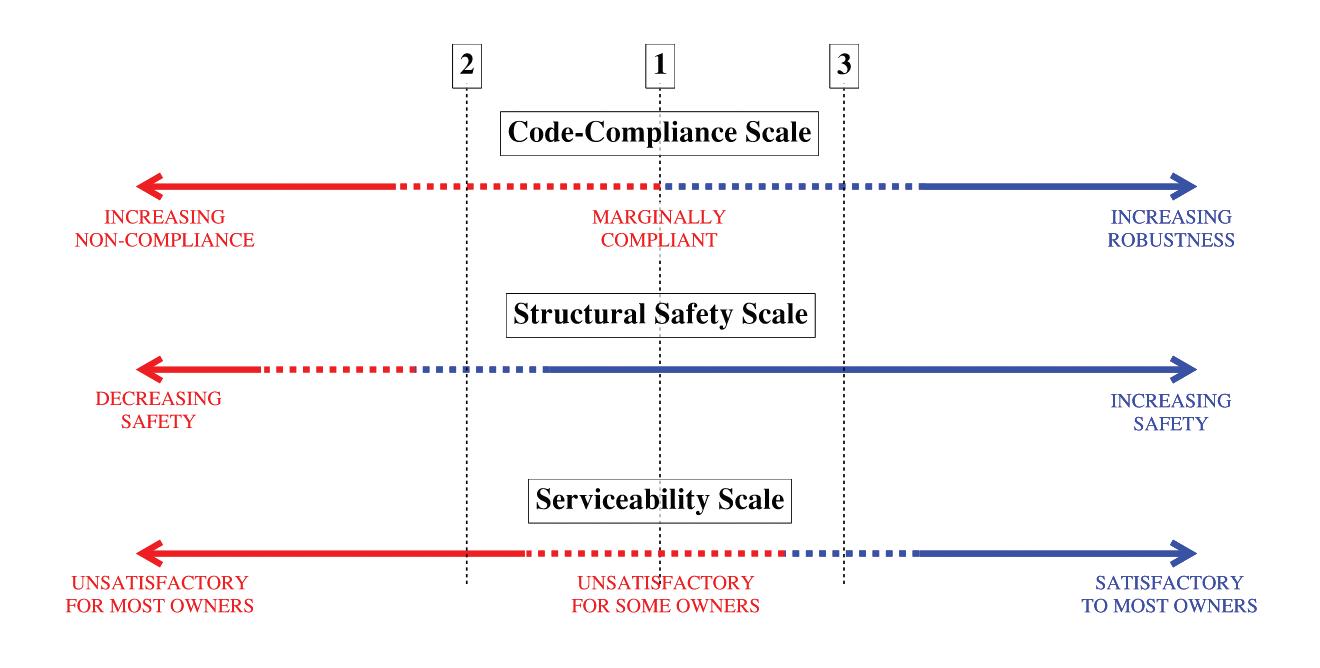

Three of the primary considerations often involved in structural design of two-way slabs are code-compliance, structural safety, and serviceability. In part due to the nonuniform utilization of negative reinforcement, all code-compliant two-way slab designs do not attain comparable degrees of safety and serviceability. Given that ACI 318 provides no guidance on this subject, it might be assumed that a design that exactly satisfies minimum code requirements would attain comparable degrees of safety and serviceability. This

assumption, however, does not withstand scrutiny. Not only will common design software predict tentpoling behavior, including cracking and amplified deflections, in code-compliant designs, but slabs that are code-compliant also commonly exhibit such behavior in the field. This phenomenon has sometimes resulted in design engineers, third-party engineers, developers, owners, and occupants characterizing normal predictable radial cracking and measured elevation differences in slabs that exceed code design limits as objectionable or even as safety risks. As such, an objective understanding of two-way slab behavior is urgently needed by the profession.

To assist in developing the needed understanding and perspective, Figure 6 sets forth conceptual “scales” of code compliance, structural safety, and serviceability notionally achieved by any given slab design. The scales depict ranges of possible design outcomes from “increasing non-compliance” (solid red) to “marginally compliant” (dashed red to dashed blue) to “increasing robustness” (solid blue) relative to code-compliance; from “decreasing safety” (solid red) to “increasing safety” (solid blue) with intermediate degrees of safety (dashed red to dashed blue); and from “unsatisfactory for most owners” (solid red) to “unsatisfactory for some owners” (dashed red to dashed blue) to “satisfactory to most owners” (solid blue) relative to serviceability. The scales are intended to be read in accordance with their vertical alignment, e.g., reading vertically along Line 1, the dashed red and blue “marginally compliant” portion of the code-compliance scale aligns with the solid blue of the structural safety scale because “marginally compliant” designs are likely to still be structurally safe, but may well perform unsatisfactorily for some owners; this may represent a design that meets only the minimum strength and deflection requirements of ACI 318. At the lower end of “marginal compliance” (i.e., Line 2), structural safety is still likely but is less assured while serviceability tends toward “unsatisfactory for most owners.” At the higher end of “marginal compliance” (Line 3), structural safety becomes more assured while serviceability tends toward “satisfactory for most owners.”

While the ACI 318 strip method of design has proven to be a reliable method for achieving safe two-way slab designs, the mechanics of two-way slab behavior result in nonuniform curvature—and therefore nonuniform utilization of the negative reinforcement— across the width of the column strip in slabs designed by the strip

method. These nonuniformities are underlying causes of commonly observed radial cracking and spiderweb cracking, which are characteristic flexural behaviors of two-way slabs and are often exhibited by code-compliant slabs. Commonly used design software can be used to demonstrate that radial and spiderweb cracking are predicted to occur in slabs that are proportioned and reinforced to just satisfy all code requirements, including for punching shear, as well as in slabs that are substantially more robust than required by code. Localized slab softening that develops in the vicinity of the supports as a result of nonuniform utilization of the negative moment reinforcement will result in greater curvature close to column supports (i.e., tentpoling), which is sometimes noticeable and necessarily amplifies midspan deflection beyond what would otherwise occur.

Engineers designing and assessing twoway slabs should anticipate this behavior, take steps to mitigate it by relying on more robust proportioning and reinforcement than is set forth by code minimum requirements, and be aware that radial and spiderweb cracking and tentpoling behavior are sometimes incorrectly construed as ramifications of punching shear or as otherwise detracting from the safety of the slabs that exhibit them. The performance of highly optimized designs will not be comparable to more robust designs with regard to these behaviors. More robust designs generally tend to experience less noticeable radial and spiderweb cracking and less noticeable tentpoling even if these behaviors will not be completely eliminated. Expectations of behaviors that may be unsatisfactory to some owners (i.e., cracking and out-of-levelness) should be clearly discussed with clients before completion of new designs to ensure that design decisions regarding slab span-tothickness ratios are not driven entirely by code minimum requirements and cost.

“Then and now” structural differences for the purlin lines of an existing metal building roof in Ohio highlight the need for engineering care during a retrofit.

By Tim Lane and Cris Moen, Ph.D, PE

Metal building roof system design has evolved since the 1980s. Design wind and snow loads for buildings with gable roofs are updated every few years. Also, consistent research investment by the Metal Building Manufacturer Association (MBMA) and the American Iron and Steel Institute (AISI) has led to improvements in the strength prediction of thin-walled cold-formed steel purlins with partial bracing from the roof panels. But what about the purlins?

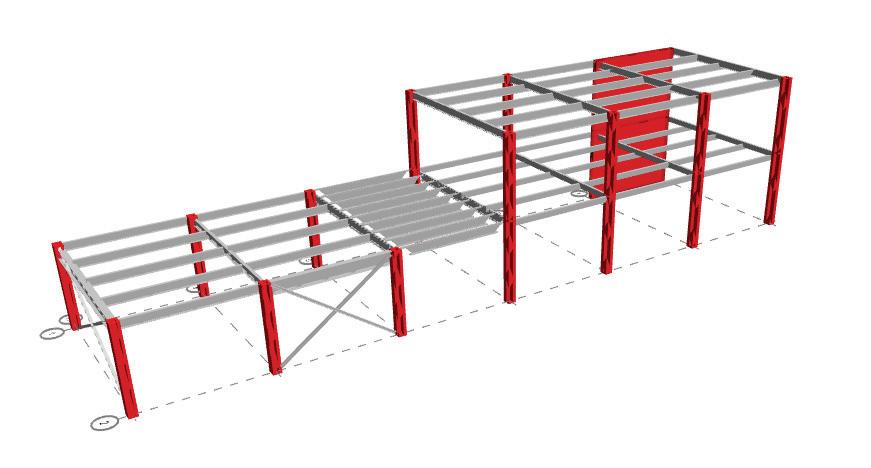

Many existing metal building roofs show significant strength deficits when evaluated with modern building standards which makes it challenging when a roof is slated for a retrofit. And industry practice allows additional dead load without engineering and calculation that can lead to more roof performance uncertainty, e.g. the International Existing Building Code (IEBC) Section 502.4 “5 % rule” which states:

Any existing gravity load-carrying structural element for which an addition and its related alterations cause an increase in design dead, live or snow load, including snow drift effects, of more than 5 percent shall be replaced or altered as needed to carry the gravity loads required by the International Building Code for new structures.

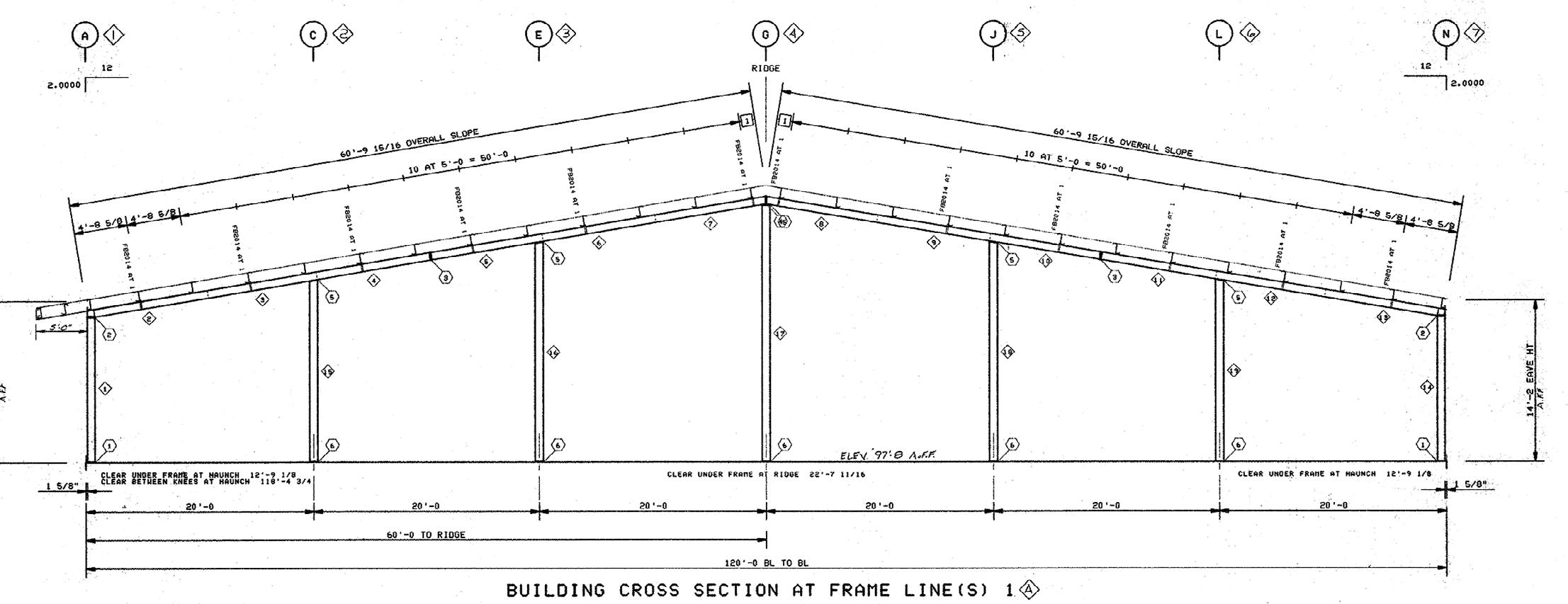

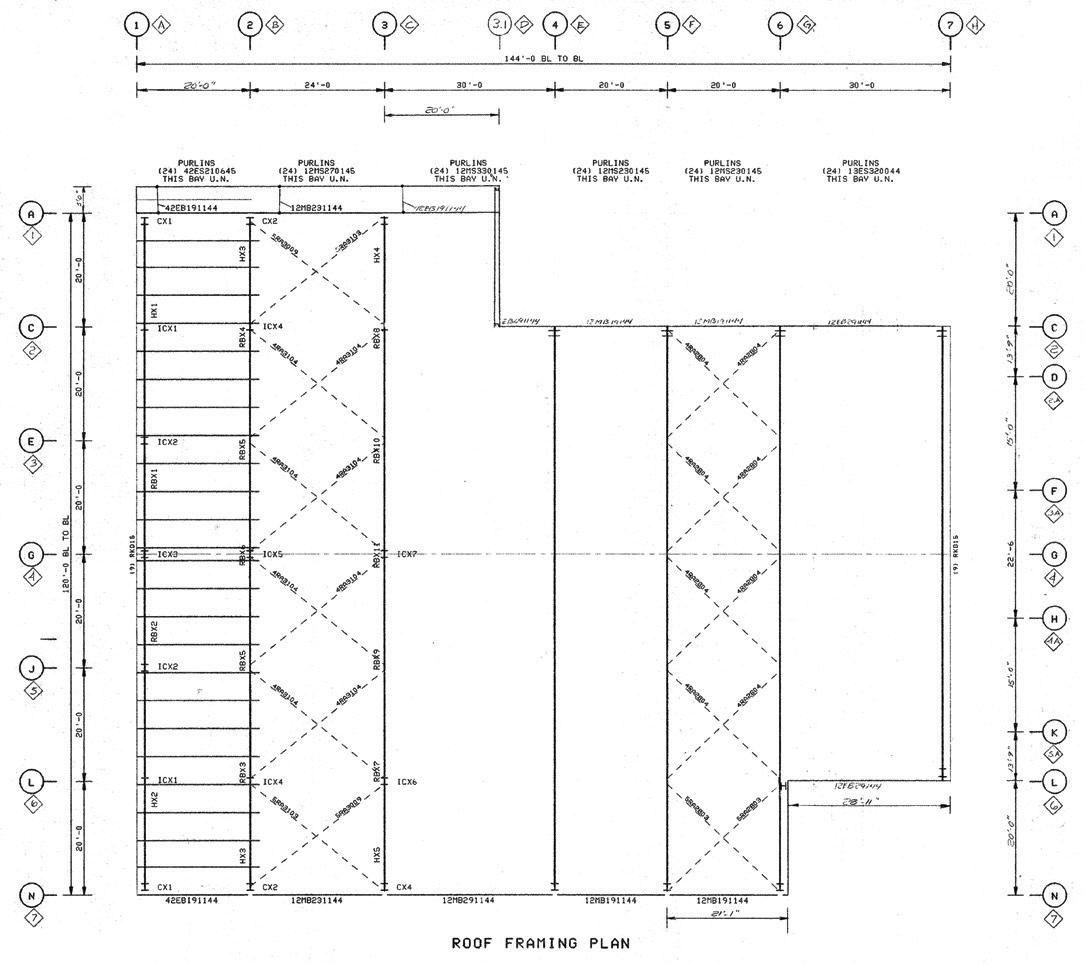

A pre-engineered metal building built in 1989 in Delaware, Ohio, is shown in Figure 1. The overall building dimensions are 144 feet long by 120 feet wide, with varying frame spacings. The roof slope is 2 on 12. The building was designed according to the 1987 Ohio Basic Building Code which references the 1984 Building Officials and Code Administrators National Building Code.

The purlins are 12 inches deep with 2.5 inch wide flanges and 1-inch stiffening lips oriented 45 degrees from the horizontal flange. There are two purlin base metal thicknesses, 0.067 inch (interior spans) and 0.075 inch (end spans). The purlins are spaced at 5 feet on center and they are assumed to lap 1.5 feet on either side of a frame. (Fig. 2). The roof deck is assumed to be a 24 gauge R panel. The purlins are rolled from ASTM A570 steel with a nominal yield stress of 55 ksi. It is assumed that the building was designed for 25 psf live load plus 5 psf defined in the general notes, and this load is applied everywhere on the roof.

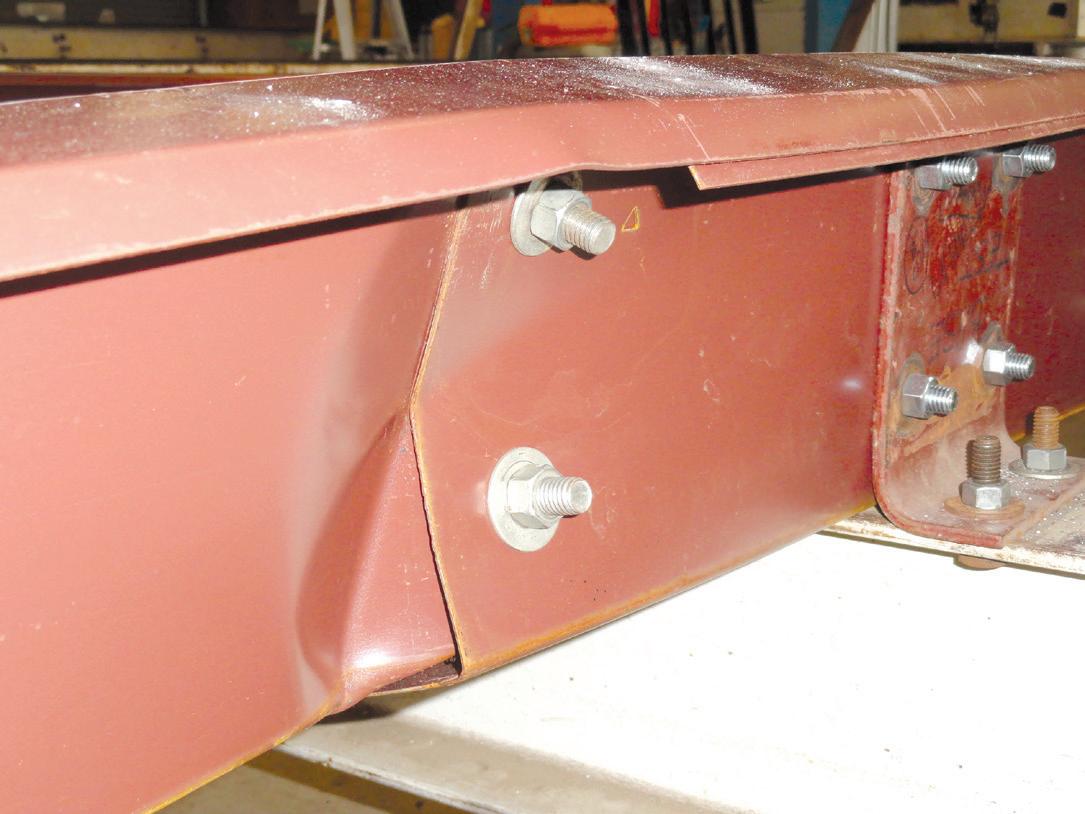

It is challenging to know exactly how purlin line strength was determined for the original building. Distortional buckling, i.e., partially restrained flexural-torsional buckling of the purlin compressed flange, had not been incorporated into the AISI standard in 1989, and combined action checks considering flexure, torsion, and shear were also not fully developed yet. Metal building manufacturers typically relied on simply-supported single span pressure box tests (base tests) and extrapolated these results to continuous spans which could miss strength limit states near the frame line purlin laps--for example the common failure mode of bottom flange purlin buckling near a lap (Fig. 3). Now, the AISI S100-16 North American Specification for the Design of Cold-Formed Steel Structural Members provides approaches for considering all the potential strength limit states including combined actions and even partial bracing from attached roof panels, see AISI S100-16 Section I6.1.

In this study the building purlin strength for gravity loads is calculated

with the open-source software PurlinLine.jl (https://www.runtosolve. com/purlinline) utilizing AISI S100-16 Allowable Stress Design (ASD) and structural analysis (https://github.com/runtosolve/ThinWalledBeam. jl) to predict the roof pressure where the first strength limit state develops. This software considers the continuous spans, varying purlin sizes (end spans versus interior spans), and the partial lateral bracing provided by the R panel roof deck.

For gravity loads on this building’s roof, the typical 6 span purlin line allowable pressure is 19.6 psf. (A detailed structural report is available [https://runtosolve.com/purlinline/structures_magazine]).

The failure develops at the end of the lap in the 30 feet end span, consistent with Figure 3. The strength limit state is predicted by AISI S100-16 to be shear + flexure interaction, which makes sense for this 12-inch-deep purlin.

The original demand design load for the roof is 30.0 psf, and the predicted ASD purlin line strength is 19.6 psf, resulting in a demand-to-allowable strength ratio of 1.5 which means the purlins are probably overstressed at ultimate loads (Table 1). This is an example where industry practice of applying the IEBC “5% rule” should be questioned.

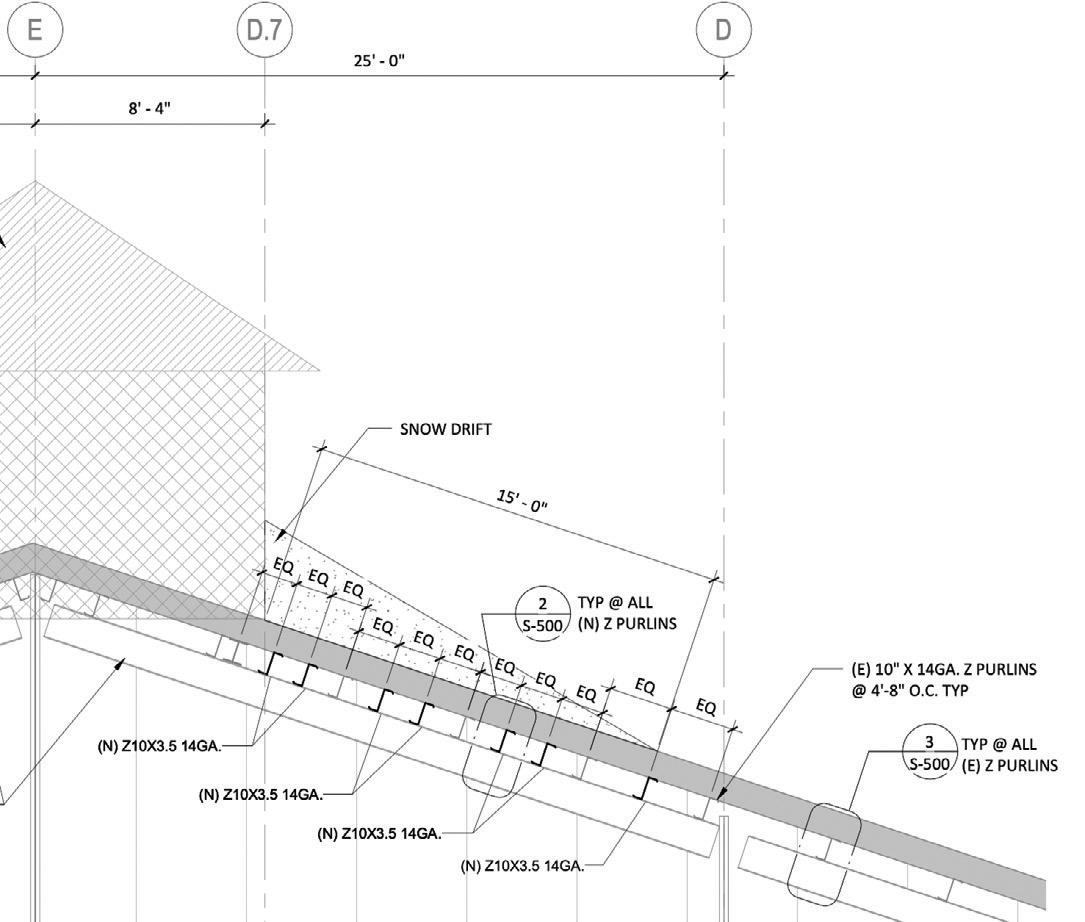

What would happen if this building was designed with modern building codes? Consider the unbalanced snow load described in ASCE 7-22 Section 7.6.1 since it will create the most severe conditions for the purlins near the ridge. The ground snow load in Delaware, Ohio, for Risk Category II is 32.0 psf, see ASCE 7-22 Figure 7.2-1B. The unbalanced snow depth is calculated as 2.7 ft., resulting in an

ultimate-level unbalanced snow load on the leeward side of the roof of 42.0 psf extending 18 ft. down from the ridge. The ASD snow load factor is 0.7, resulting in a demand pressure of 29.4 psf and a demand-to-capacity ratio of 1.5. Both the original design and a design check following modern codes shows that the roof purlins are overloaded by about 10 psf.

When a metal building roof system like this one in Ohio is found to be overstressed, common engineered roof retrofit solutions considered are: adding additional purlin lines or reinforcing the existing purlins.

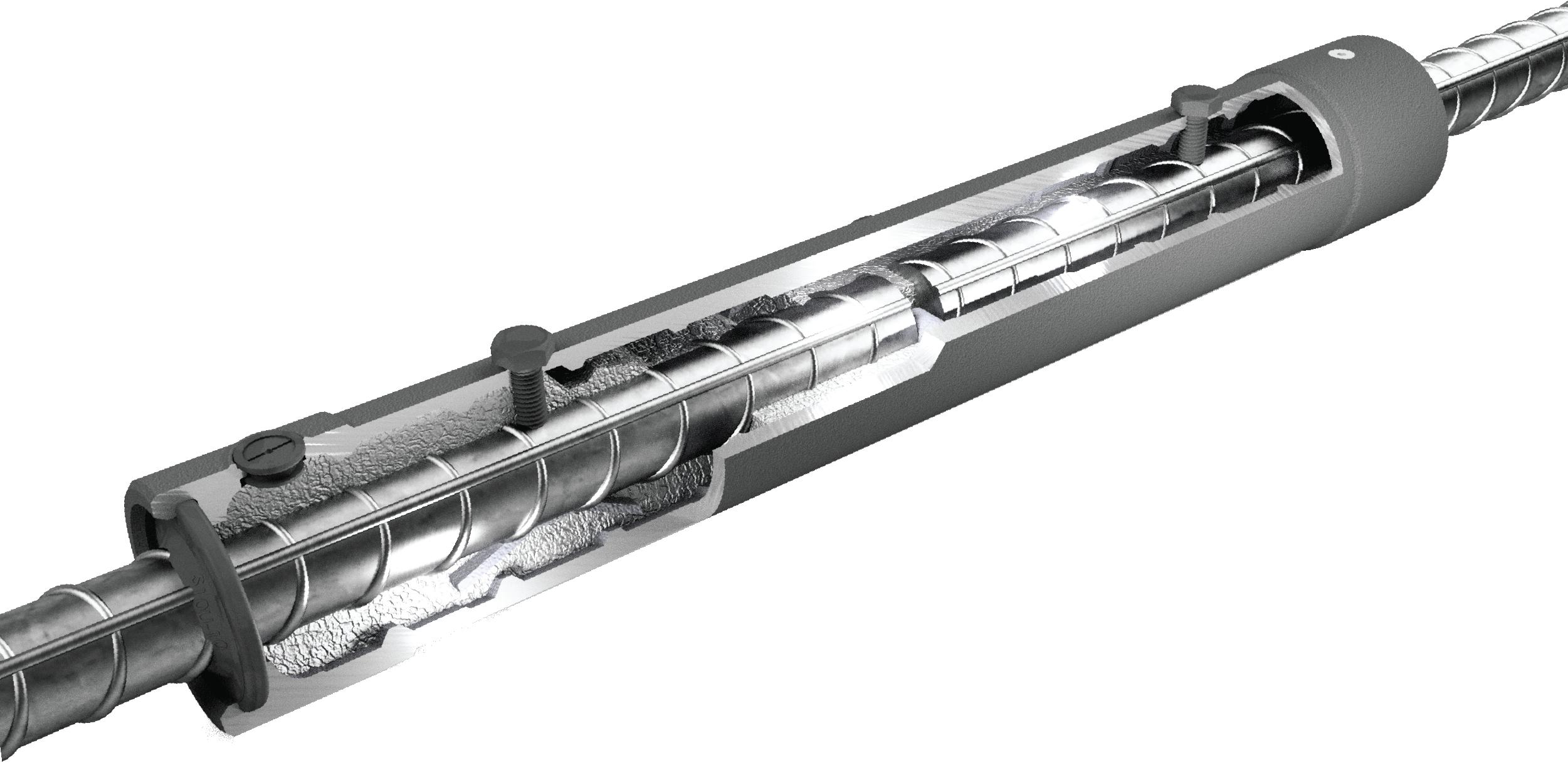

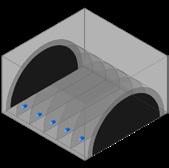

Roof retrofits where additional purlin lines are placed between the existing lines (Fig. 4) are effective and can bring a roof up to

either of which can be time-consuming and costly. An exterior purlin line reinforcement solution like that shown in Figure 5 can be implemented while the building is still in service. A roll-formed pre-punched hat subframe is fastened to the existing purlin lines, adding 10 psf or more capacity to the roof system. A new roof (typically a standing-seam roof) is then attached to the hat subframe top flanges.

The roof purlins in this Ohio metal building were originally designed at or beyond their calculated structural limits. This does not mean that all metal building roofs are about to fail in a snowstorm. The conclusions herein are intended to highlight that: (1) there can be concerning mismatches between existing metal building roof strength and code-specified demand loads; (2) use of the IBEC “5 % rule” should be supported by engineering calculation; and (3) roof retrofit solutions are available to mitigate existing metal building roof system failure risk . ■

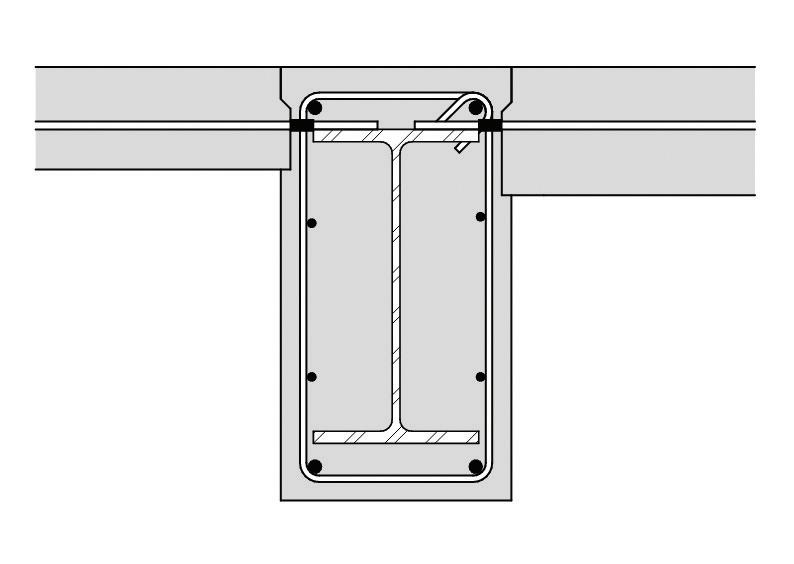

Fig. 5. In this purlin line exterior retrofit solution, a roll-formed pre-punched hat subframe is fastened to the existing purlin can provide 10 psf or more additional purlin line roof strength.

With over 45 years of experience in the metal construction industry, Tim Lane is the owner and president of TopHat Framing Systems. TopHat offers patented subframe systems as solutions for metal roof retrofit projects.

Cristopher D. Moen, Ph.D., PE, F.SEI is an engineer, software developer, researcher, and educator. His company RunToSolve LLC creates fast open-source computational tools for predicting structural system performance.

Reducing blast demands is an important aim achieved through reducing deformations.

By Dr. Ibrahim M. Metwally, Ph.D, PE

The main strategy for blast-resistance structures design is to reduce blast demands, which inherently is achieved by reducing the deformations in structural and non-structural building components. This is accomplished through various techniques:

Providing sufficient protection by increasing protected standoff distances against external attacks. The most cost-effective solution for mitigating explosive effects to a building is to ensure the explosions occur as far away from the building as possible (increased standoff). Therefore, the site selection for new construction and site protection in existing structures is important in mitigation blast risk.

Many types of barriers are designed to resist the impact of a vehicle explosive. Among them are massive concrete barriers (Kontek 2008), concrete enclosed with steel plates (Crawford and Lan 2006), and soil filled corrugated metal (Crawford and Lan 2006). Each barrier is designed to absorb the large amounts of energy from an impact or blast with minimal effect on the facilities it is protecting.

effects of blast loading. Re-entrant corners and overhangs are likely to trap shockwaves and amplify blast effects. The reflected pressure on the surface of a circular building is less intense than on a flat building. When curved surfaces are used, convex shapes are preferred over con cave shapes. Figures 1-2 present desirable and undesirable structural

shapes and layouts of buildings when designing for blast loading.

Not many code resources are available when designing for blast loading. However, FEMA 427 does provide guidelines. The general design recommendations are not that different from what has been discussed here, in that blast resistant building designs should use simple geometries without sharp re-entrant corners and be placed on a project site as far from the lot perimeter as practical. The following discusses FEMA 427 recommendations for different types of framing systems:

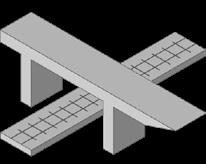

In frame structures, column spacing should be limited. Large column spacing decreases the likelihood that the structure will be able to redistribute load in the event of column failure (Figure 3).

In frame structures, the exterior columns should be designed to resist the direct effects of the specified blast.

The frame structures system should be designed to resist the likely progressive collapse. In case of occurrence any localized failure must be considered.

The primary loading on the roof is the downward air-blast pressure. The preferred system is cast-in place reinforced concrete with beams in two directions. If this system is used, beams should have continuous top and bottom reinforcement with tension lap splices. Stirrups to develop the bending capacity of the beams closely spaced along the entire span are recommended. Finally, use two-way floor and roof systems.

Cast-in-place reinforced concrete is the structural system preferred for blast-resistant construction. This is the material and structural type used for military bunkers. The military has performed extensive research and testing of its performance. Concrete has significant mass, which improves response to explosions.

Generally, simple geometries and minimal ornamentation (which may become flying debris during an explosion) are recommended. If ornamentation is used, it is preferable to use lightweight materials such as timber or plastic, which are less likely than brick, stone, or metal to become lethal projectiles in the event of an explosion.

Ultra high performance concrete (UHPC) is known for its superior mechanical properties; compressive strength can reach up to 200 MPa (29,000 psi) and tensile strength up to 40 MPa (5800 psi). Also, the crack propagation can be well controlled due to inclusion of steel fibers in its cement matrix, leading to a higher ductility and energy absorbing capacity so as to make it an ideal material for structural members that are exposed to the constant threat of blast attacks. Previous experimental work conducted by Mao et al. and Wu et al., Barnett et al., Ibrahim Metwally, Schleyer et al., and Melançon confirmed the superior blast resistance of UHPC structures under high loading rate conditions such as explosion and impact compared to traditional normal and highstrength concrete.

Concrete-filled steel columns have high ductility and very good blast resistance [Peyman, et al., Ibrahim Metwally and Zhang, et al.). Concrete systems have significant inertia but are susceptible to

Fig. 2. Less than desirable building features for blast loading are multiple levels of stories, complex designs, projecting roofs or floors, and U-shaped buildings.

shear failures. Steel systems have inherent ductility but are locally vulnerable open sections and connections. A combination of steel

Blast-resistant design philosophy allows structural elements to undergo large inelastic (plastic) deformations under blast loading. A ductile structure that undergoes large deformations without failure can absorb much more energy than a brittle structure of the same strength. Tensile reinforcement between 0.5% and 2% of the crosssectional area of the concrete element will usually ensure ductile behavior while providing the required strength.

Compression steel in flexural members serves two purposes. After a structural member is deflected by blast loads, it attempts to spring back or rebound. Dynamic rebound causes load reversal and, under certain conditions, can result in catastrophic failure.

Minor: Non-structural failure of building elements such as windows, doors, and cladding.

Moderate: Structural damage is confined to a localized area and is usually repairable. Structural failure is limited to secondary structural elements, such as beams, slabs, and non-loading bearing walls. However, if the building has been designed for loss of primary members, localized loss of columns may occur without initiating progressive collapse.

Major: Loss of primary structural components such as columns or transfer girders leads to loss of additional elements that are adjacent to or above/below the lost member. In this case, the building is usually not repairable.

Full references are included in the online version of the article at STRUCTUREmag.org

Ibrahim M. Metwally, PhD, PE, is a professor of concrete structures at the Concrete Structures Research Institute at the Housing and Building National Research Center, Giza, Egypt. He is licensed by the Wyoming Board of Professional Engineers in the U.S. and registered as a senior structural consultant at DRSO of the Ministry of Housing of Egypt.

These frequently asked questions (FAQs) about tall mass timber are reprinted with permission of WoodWorks—Wood Products Council. The website address is: www.woodworks.org/learn/mass-timber-clt/tall-mass-timber/.

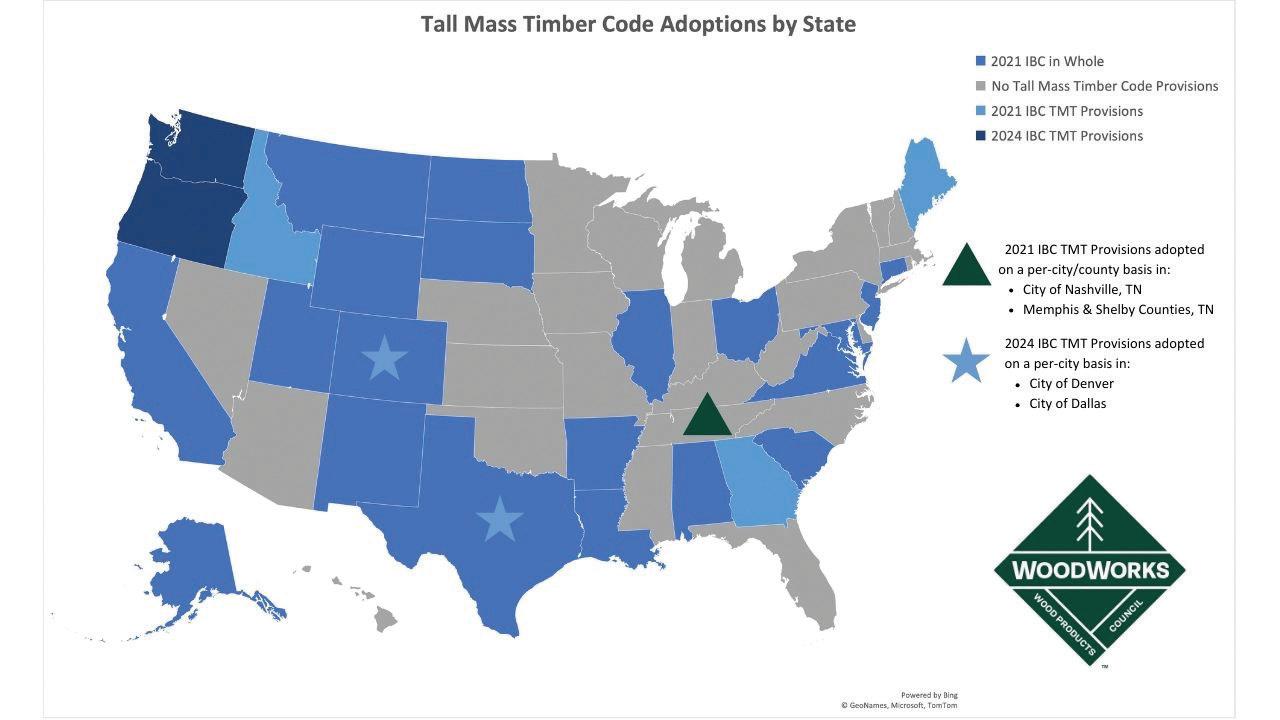

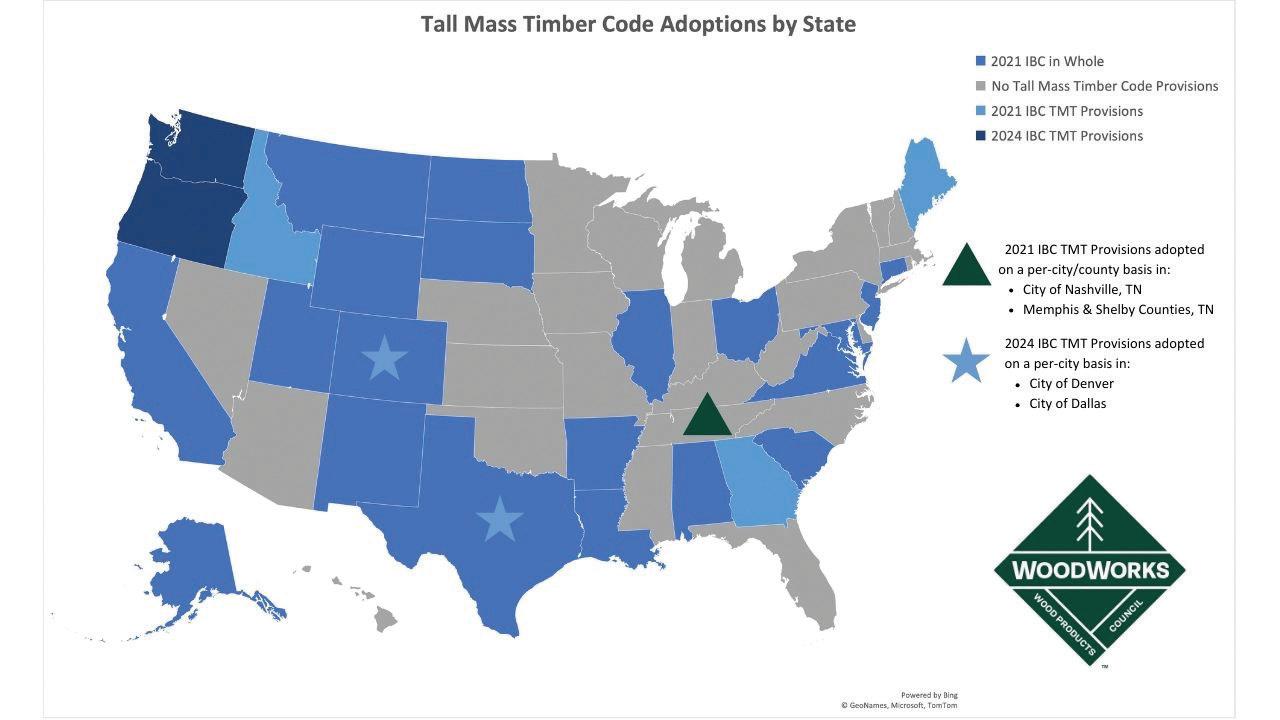

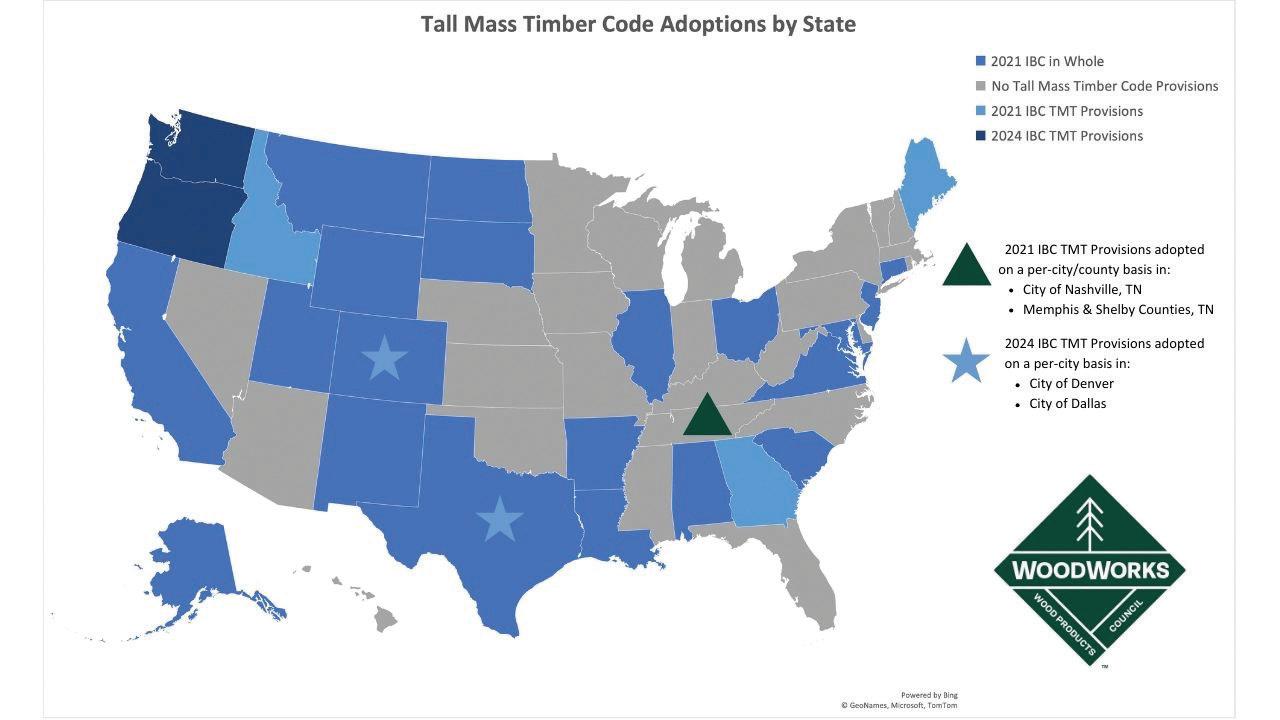

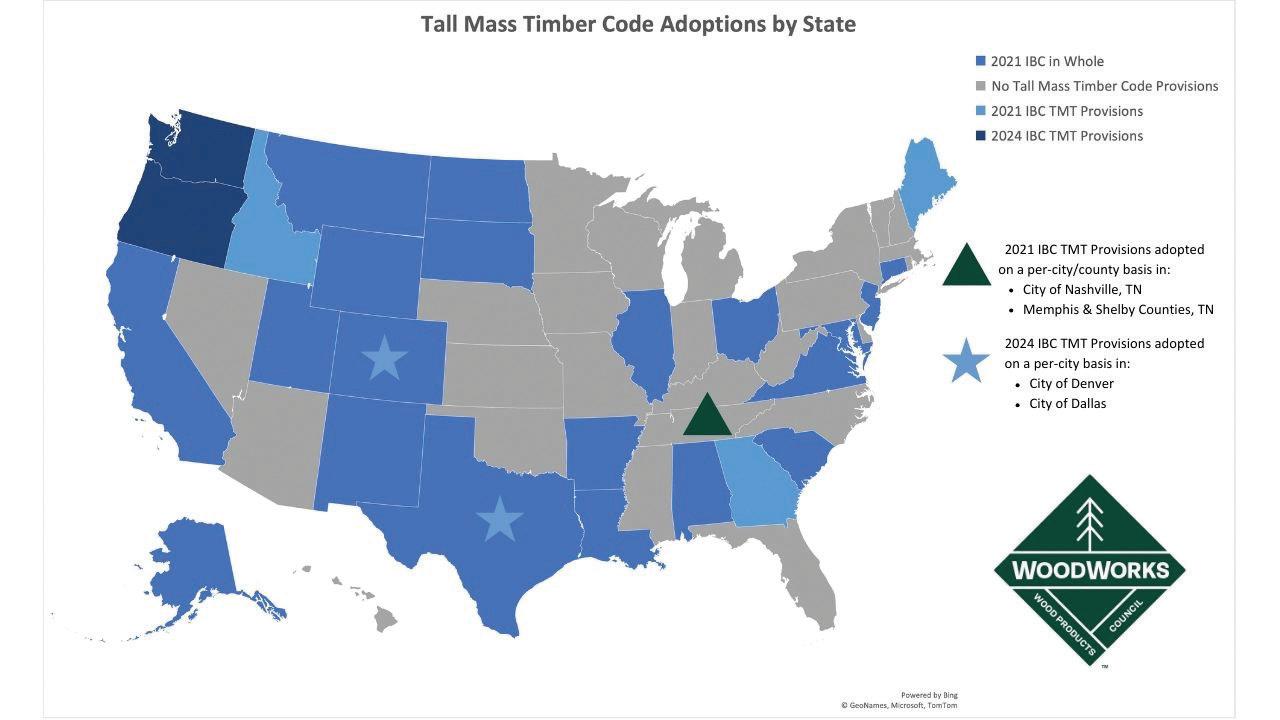

What is the current status of tall mass timber buildings in the building code?

Follow this link for the status of the 2021 IBC and jurisdictions that have adopted the tall wood code provisions: www.woodworks.org/resources/ status-of-building-code-allowances-for-tall-mass-timber-in-the-ibc/.

Tall Mass Timber Code Adoptions by State No Tall Mass Timber Code Provisions

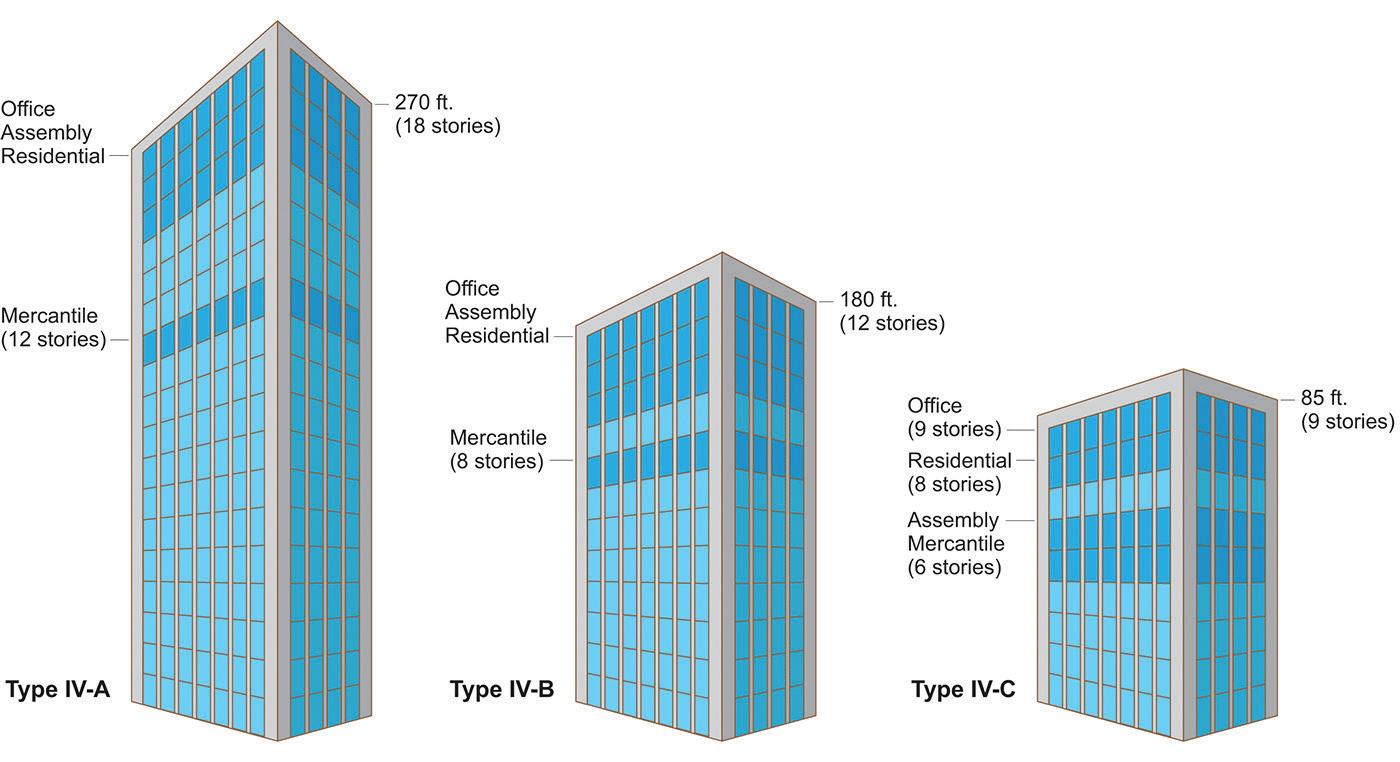

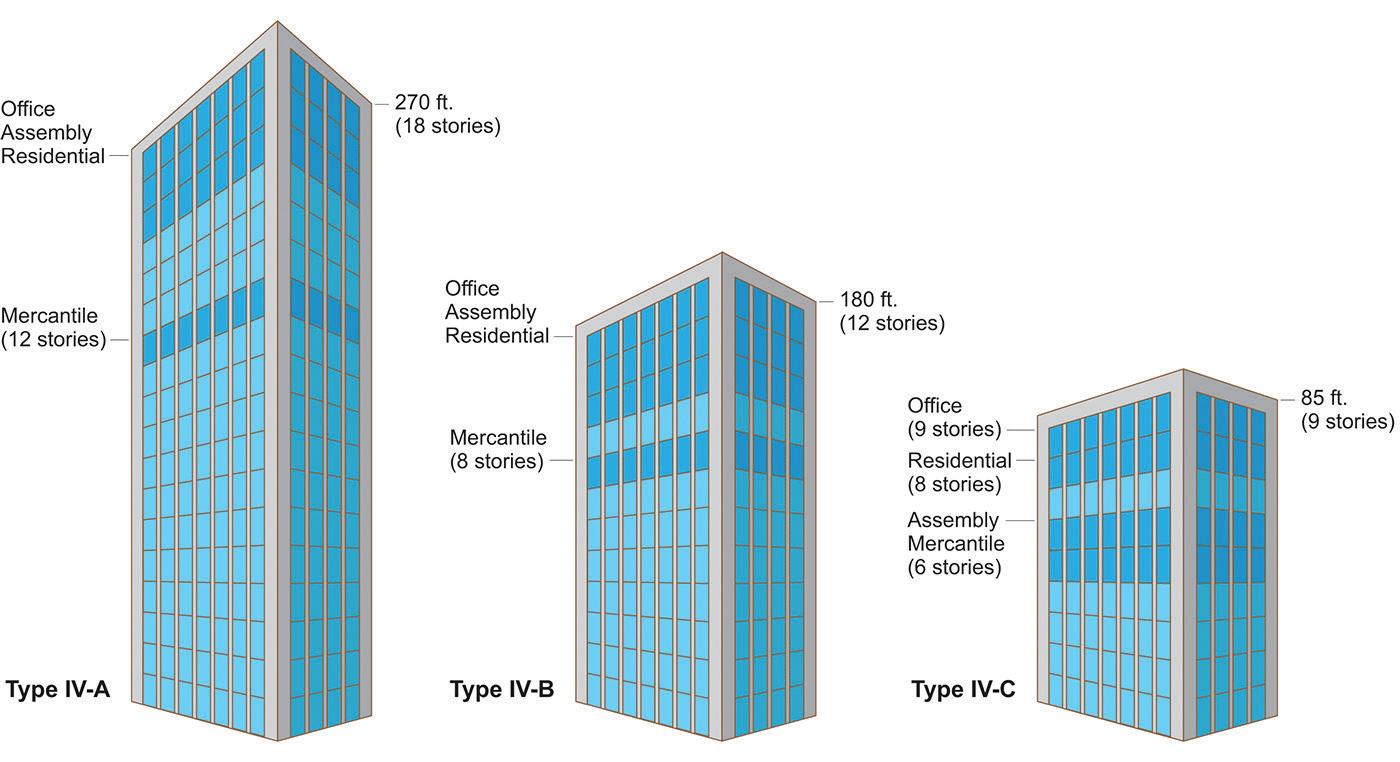

What are the height limits for the new construction types?

2021 IBC TMT Provisions

2024 IBC TMT Provisions

2021 IBC TMT Provisions adopted on a per-city/county basis: City of Nashville, Tennessess, and Memphis & Shelby Counties, Tennessee

2024 IBC TMT Provisions adopted on a per-city basis in: City of Denver and City of Dallas

What are the timber exposure limits for Types IV-A, IV-B, IV-C and IV-HT construction?

Timber Exposure Allowances

exposed timber permitted Ceilings and integral beams up to an area equaling 20% (per 2021 IBC) or 100% (per 2024 IBC) of fire area or dwelling unit area or Walls and integral columns up to an area equaling 40% of fire area or dwelling unit area or A combination of each, with the sum of ratios (actual exposed divided by allowable exposed) not to exceed 1.0

FRT sheathing or 1/2″ gypsum board or noncombustible material

of Floor (above Mass Timber)

What are the fire-resistance rating requirements for tall mass timber?

Requirements for Tall Mass Timber Structures (hours) *Not required by construction type. Other code requirements may apply. 5/8″ Type X gypsum = 40 minutes

I’ve heard that the 2024 IBC allows 100% timber ceiling exposure in Type IV-B construction, up to 12 stories tall. Is that correct?

Yes, the 2024 IBC includes new code provisions which allow timber ceiling exposure in Type IV-B construction up to 100%. The new code language in the 2024 IBC is available at codes.iccsafe.org. Several jurisdictions such as the City of Denver, City of Dallas, State of Oregon and State of Washington have incorporated these new timber exposure limits in their building codes, and several design teams are looking to utilize the new limits in project-specific discussions with their local building officials.

For more information, contact WoodWorks: info@woodworks.org

Type K shrinkage-compensating concrete optimizes performance and value and minimizes carbon intensity impact.

By Susan Foster

Improving overall structural behavior and long-term performance of critical concrete infrastructure is paramount to supporting today’s carbon neutral initiatives and ensuring good stewardship of both public and private owner investments. More stringent performance requirements combined with the challenging dynamics of change in type, quality, and availability of concreting materials is inspiring innovation, creativity, and collaboration. It is also renewing interest in materials with established, proven performance that offer solutions to today’s challenges. One of those experiencing an inspiring renaissance is Type K cement.

Developed in the late 1950s and brought to market in the early 1960s, Type K cement has proven to be a valuable innovation in cement technology for over 60 years. It is specifically engineered to eliminate negative volume change and improve durability by lower ing permeability, increasing density, improving sulfate and abrasion resistance, and eliminating drying shrinkage cracking. It effectively addresses the fundamental shortcomings of Portland cements by improving the quality of the cement paste and inherently improving long-term performance and structural behavior of vital structures.

From its earliest use in prestressed pipes and pavements to its use in shrinkage-compensated designs for post-tensioned structures, containment structures, dams, spillways, mat slab foundations, bridge decks, pavements, and slabs-on-ground, Type K cement has proven to be a reliable solution for all types of critical structures. Its performance continues to aid designers in simplifying designs and influencing more efficient constructability while minimizing in-service costs and operational downtime for repairs.

Type K cement (American Society of Testing and Materials’ ASTM C845 – Standard Specification for Expansive Hydraulic Cement) is a hydraulic blended cement that combines an expansive calcium sulfoaluminate (CSA) cement-based additive with a Portland cement source (ASTM C150, C595, and C1157). It is proportioned to achieve sufficient expansion to overcome the shrinkage characteristics of concrete and grout mixes. The advanced hydration mechanism of the expansive CSA cement-based additive (marketed primarily as Komponent in the U.S. ) drives the performance of Type K cement-based mixes. During hydration, primary ettringite (the mineral name for calcium

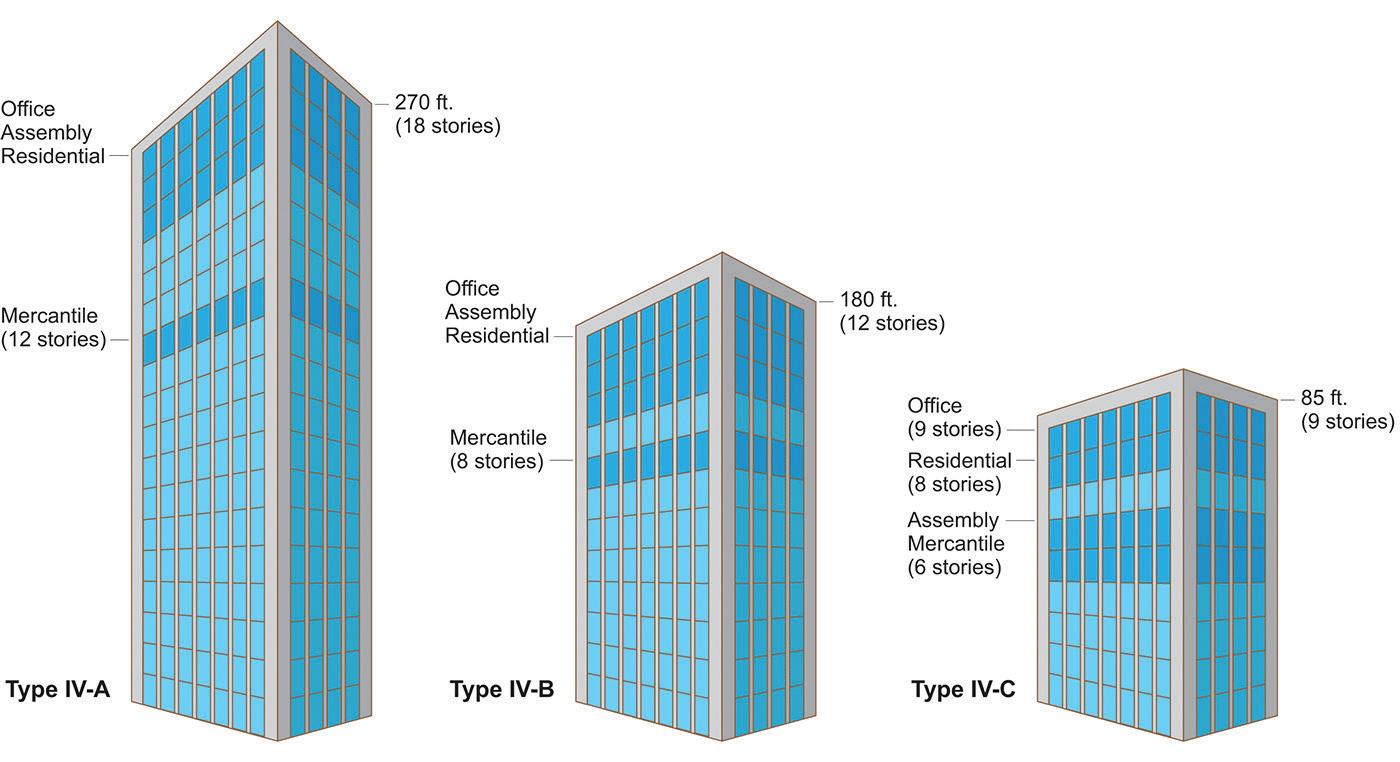

sulfoaluminate) is formed that contributes to design strength, controlled set, and early expansion. The qualified dosage of the expansive cement additive needed to create adequate expansion is determined by ASTM standards designed for use with expansive cements (i.e., ASTM C806 - Standard Test Method for Restrained Expansion of Expansive Cement Mortar and ASTM C878 - Standard Test Method for Restrained Expansion of Shrinkage-Compensating Concrete). The goal is to create sufficient designed expansion to compensate for the shrinkage characteristics of the mix and ensure the concrete is kept in compression for the life of the placement (Figure 1).

By efficiently consuming the excess mix water that is not used by Portland cement during hydration and minimizing bleed water, Type K shrinkage-compensating cement mixes result in dense, low permeability concrete with substantially improved abrasion resistance without the use of admixtures or surface hardeners. The consumption of excess mix water prevents voids and capillaries that allow room for drying shrinkage and results in a more dimensionally stable concrete placement. By eliminating curling and shrinkage stresses, the load capacity of the placement is increased, allowing thinner sections to be placed and reducing the overall volume of concrete required. In addition, its 0% tricalcium aluminate (C3A) content means sulfate resistance is improved proportionately to the percentage replacement used with all Portland cements, making it ideal for containment, marine, and other environmentally exposed structures.

When designing with shrinkage-compensating concrete, industry standards, guidelines, specifications, and other published resources are available to aid in design and constructability. The “Key Resources” sidebar provides a brief overview of commonly referenced standards, methods, codes and resources, from the American Concrete Institute (ACI) and ASTM, when designing with shrinkage-compensating concrete.

As engineers, owners, and project budgets are now more heavily influenced by supply chain dynamics, project and maintenance budgets, global warming potential (GWP) impacts, and commitments to sustainability, shrinkage-compensating concrete maximizes versatility. When designing with Type K shrinkagecompensating concrete, reinforcement options are no different than with other cement types required for concrete design—from traditional steel rebar and steel fibers to FRP, synthetic fibers and hybrids. Whichever is most suitable, available, and cost effective for the project can be used.

Type K cement was originally brought to market regionally as a finished cement. By the 1980s, effective ASTM standards and ACI guidelines had been developed to support consistent quality as a locally blended cement and made the use of the expansive cement additive economical and readily available nationwide. Type K cement is now prequalified per ASTM C878 and added at the local batch plant using normal bulk batching and mixing operations. This is a more practical and cost-effective way to deliver high-performance Type K shrinkage-compensating concrete (K-SCC) and grout (K-SCG), and it paved the way for use in a wide range of applications. Key

critical structures like concrete containment, post-tensioned designs, bridges, and mass elements have been constructed optimizing design, durability, constructability, and sustainability.

For critical concrete containment structures, preventing contamination from external impurities and preventing seepage and leakage of contents into the environment is crucial. Since the early 1970s, K-SCC has been used successfully to create well designed, reliable concrete containment structures with extended joint wall panels, foundations and slabs that help prevent leakage, unscheduled downtime, and costly repairs.

The Bustamante Wastewater Treatment Plant in El Paso, TX, and the J.W. Rogers Water Treatment Plant demonstrate the design possibilities. With tanks including 110 feet (33.5 meters) diameter by 30 feet (9.1 meters) high digesters, 120 feet (36.6 meters) diameter by 20 feet (6 meters) high primary clarifiers, and 140 feet (42.7 meters) diameter by 16 feet (4.9 meters) high secondary clarifiers, all were constructed without joints by using K-SCC. More than ten years later they are still crack free and leak free.

The $255 million 69th Street Complex Wastewater and Sludge Treatment Plant in Houston, TX, used K-SCC for the construction of foundation slabs for the reactors, clarifiers, pump stations, thickener and digester complex, roof slabs, and reactor train beams. Key drivers for use on this project were eliminating drying shrinkage cracking and preventing leakage in critical areas, reducing shrinkage reinforcement, and placing large sections that minimized construction joints and waterstops. Other advantages included low permeability, higher abrasion and sulfate resistance, and its inherent cohesiveness that allowed for ease of placement of smooth, dense surfaces.

The reduction in steel reinforcement and waterstops combined with the reduction in formwork, mobilizations, man hours and pump days resulted in an overall savings to the project. As reported by the joint venture design team of Environmental Management Consultants (EMC) and the City of Houston, “The use of Type K concrete on the 69th Street Complex was certainly a valuable learning experience for both the consultants and the contractors and has demonstrated that the economies of shrinkage-compensating concrete construction and the resulting long-term, crack-free performance of those structures is worth the extra effort and care.”

The City of New York’s project for eight underground, four-milliongallon combined sewer overflow (CSO) tanks is another example of K-SCC delivering innovation, constructability and value. Hazen and Sawyer were selected to design these critical structures with a focus on minimizing the number of construction joints. With conventional concrete, ACI 350 – Environmental Engineering Concrete Structures recommends a maximum construction joint spacing of 30 feet to control shrinkage cracking. When using shrinkage-compensating concrete, ACI 223 – Shrinkage Compensating Concrete recommends spacing up to 150 feet (45.7m).

By using K-SCC a reduction in construction joints minimized points of water leakage and reduced total construction time. In a comparative analysis between the use of conventional concrete and shrinkage-compensating concrete, the net savings for the project was over two months of construction time saved on the slabs, four months on the walls, and approximately $900,000 in materials and labor. Additional value was realized in-service by minimizing maintenance costs and operational downtime.

In post-tensioned structures, the dimensional stability of K-SCC offers significant advantages. Post-tensioning provides control over flexural cracking while K-SCC eliminates other key challenges related to negative volume change, like drying shrinkage cracking and restraintto-shortening (RTS). It also significantly reduces the effects of long-term creep and shrinkage helping to overcome the effects of differential displacement of supports and minimizing long-term relaxation of steel tendons. This improved dimensional stability eliminates labor intensive and time-consuming details like pour strips, slip joints, wrapped dowels and additional reinforcement for crack control.

Economic studies have shown that in properly designed structures, the savings in design element costs, traditional reinforcement and posttensioned steel more than offset the moderate material cost impact of the cement additive. Of the three key influencers of prestress losses (i.e., prestressing steel relaxation, creep shortening, and shrinkage), shrinkage constitutes approximately 42% of the long-term losses and reduces the initial prestress force by ~7%. When shrinkage is eliminated, this reduction translates into a reduction in the quantity of prestressing steel required. Additionally, a K-SCC structure has less dimensional change resulting in substantial reduction in column moments and affects a reduction in total column steel. Expansion joints can realistically be increased to approximately 500 feet (152.4 meters) without sacrificing performance.

The University of Alabama’s Ridgecrest Community Residence, an eight-story dormitory and parking structure, illustrates the advantages of using K-SCC in post-tensioned structures. Structural Design Group (SDG) of Birmingham, Alabama, used K-SCC to optimize design and improve structural behavior, meet budget requirements, and reduce time to completion. During onsite inspection two years

after placement, critical areas where RTS cracking could be expected revealed the K-SCC placements to be crack-free. The structural designer stated: “The real proof is in the slab itself—there are virtually no cracks in more than 420,000 square feet (39,019 square meters ) of slab. Further, the concrete frame was bid and completed 42 days ahead of a very aggressive schedule.” Net savings by elimination of pour strips were estimated at $250,000 with a total realized savings of the redesign using K-SCC of ~$3 million.

The Dallas Municipal Center is another iconic structure that optimized design and performance of K-SCC. It exemplifies what can be achieved when innovation is combined with collaboration and communication. This structure is a monolith of 60,000 cubic yards (45,873 cubic meters) of buff-colored K-SCC integrated into a unique post-tensioned structure consisting of underground parking and office spaces. The use of K-SCC allowed structural engineers to address cracking concerns related to temperature and shrinkage and reduced the amount of reinforcement needed to address RTS. It also allowed the contractor to cast large individual sections of exposed concrete (up to 70 feet long by 14 feet high (21 meters long by 4 meters high)). This improved project efficiencies and time to completion. Final reports noted that the shrinkage-compensating concrete performed “very satisfactorily,” the contractor “did a commendable job in obtaining the designed architectural finish.”

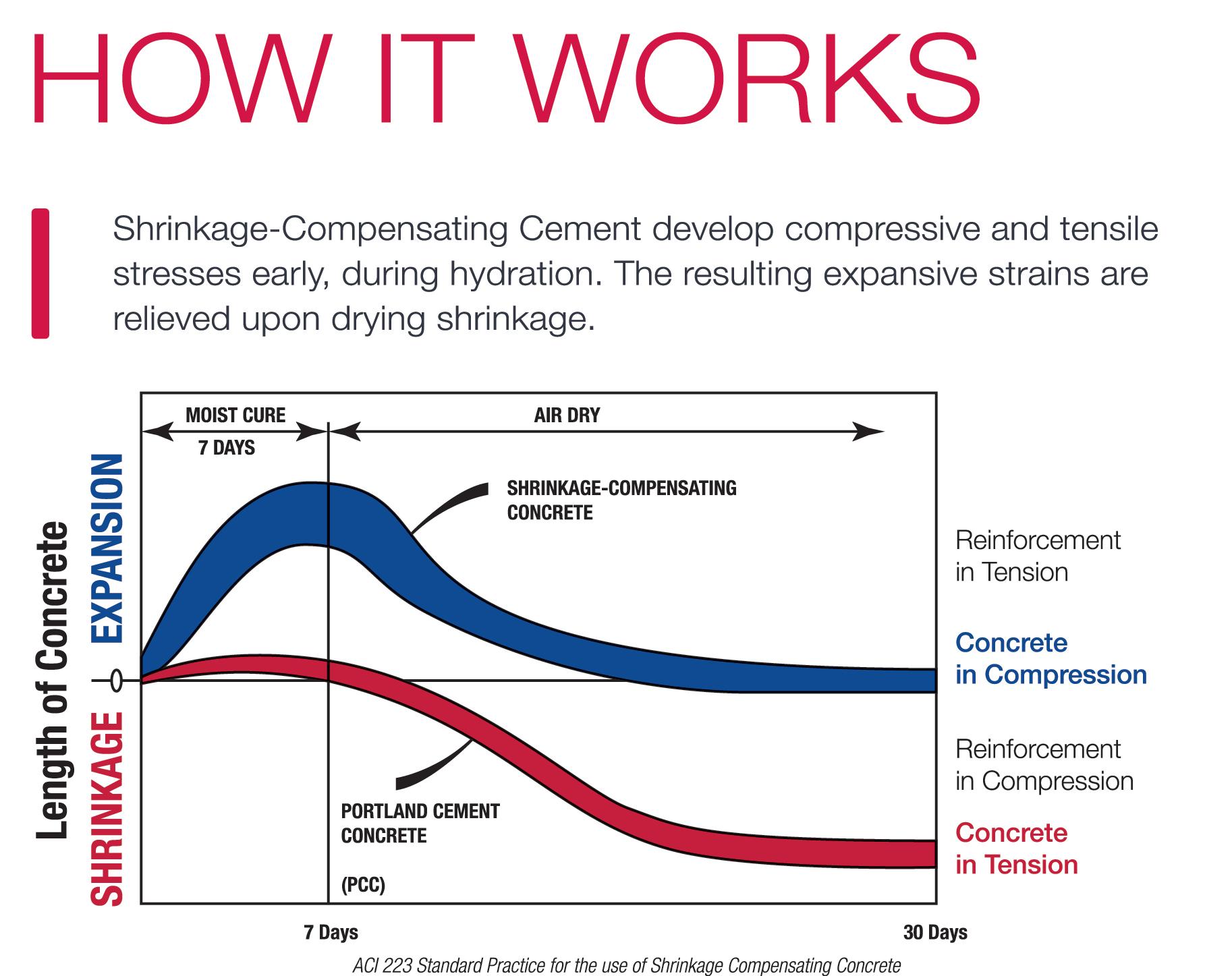

The use of K-SCC in bridge decks has also been well documented through the years. The Ohio Turnpike Authority has been using it on their bridge decks since the 1980s with great success (Figure 2). In a comparative study conducted from 1983 to 1990, results showed substantial improvement in bridge deck performance, resulting in

ACI 223 – Shrinkage Compensating Concrete is the primary resource for the design and construction of shrinkage-compensating concrete structures. It offers the most comprehensive insight into design considerations like durability, permeability, sulfate resistance, elimination of curling, warping, and drying shrinkage cracking, increased load capacity, prevention of calculated shortening in conventionally reinforced and post-tensioned structures, along with recommended constructability practices.

ACI 301 – Specifications for Structural Concrete includes a section reviewing the use of shrinkage-compensating concrete that addresses requirements and qualifications designers and specifiers should consider.

ACI 302 – Guide to Concrete Floor and Slab Construction, Chapter 5 reviews specifics related to design and construction of joints when using shrinkage-compensating concrete.

ACI 360 – Design of Slabs on Ground, Chapter 9 reviews design of shrinkage-compensating concrete slabs with design examples in Appendix 5 and Chapter 14 highlighting the elimination of saw cut joints when using shrinkage-compensating concrete.

ACI 350 – Environmental Engineering Concrete Structures references performance characteristics like minimizing drying shrinkage and improving both sulfate and abrasion resistance using Type K shrinkage-compensating concrete. It discusses the elimination of bleed water and ultimate lower permeability and reviews key advantages and related engineering regarding thinner walls, elimination of contraction joints, and reduction in reinforcement (maximum 0.3 percent shrinkage steel is common with joint spacing up to 150 ft (45.7m).

ACI Special Publications and the Post-Tensioning Institute’s PTI Journal have published numerous research reports on the use of shrinkage-compensating concrete for innovation and advancement in post-tensioned buildings, bridges, slabs-on-ground, soil anchoring and other infrastructure.

ASTM C150 – Standard Specification for Portland Cement

ASTM C595 – Standard Specification for Blended Hydraulic Cements

ASTM C806 – Standard Test Method for Restrained Expansion of Expansive Cement Mortar

ASTM C845 – Standard Specification for Expansive Hydraulic Cement

ASTM C878 – Standard Test Method for Restrained Expansion of Shrinkage-Compensating Concrete

ASTM C1157 – Standard Performance Specification for Hydraulic Cements

zero instances of drying shrinkage cracking. When asked about maintenance cost impacts, Chief Engineer, Doug Hedrick noted “The answer is quite simple, it is very low cost to maintain the shrinkagecompensating concrete decks – no deck delamination's, spalls, or steel corrosion. We don’t even think about cracks, crack maintenance or spalls on our shrinkage-compensating concrete decks.”

In cooperation with various states throughout the U.S., other studies

of the use of K-SCC in bridge designs have been published demonstrating the performance advantages that can be achieved. The durability attributes that contribute to their extended service life include abrasion resistance, significantly reduced shrinkage cracking, reduced surface capillaries and porosity; superior compressive and splitting tensile strengths ease of placement, consolidation, and finishing, ultra-low permeability, and excellent freeze/thaw results with air entrainment. Grouting is another common application of K-SCG. The Bob Kerrey Pedestrian Bridge in Omaha, Nebraska, is 3,000 linear feet. K-SCG was used for this cable-stayed superstructure to protect the posttensioned (PT) tendons which are essential to the bridge’s long-term durability. Its low permeability, increased density and dimensional stability ensured the PT tendons were effectively protected from moisture, salts, air, and other elements that promote corrosion and deterioration. Adding the Type K expansive cement additive to a bulk shrinkage-compensating grout mix improved production efficiencies at the plant and during pumping operations on-site. It also achieved cost savings over the pre-blended bag material typically used. Success stories continue as many transportation departments across the country embrace a proven solution to building safer, more sustainable infrastructure.

In reinforced pavement designs, eliminating joints in runways

and taxiways is essential. Joints are the location of curling, spalling, and cracking that result in foreign object debris (FOD), creating safety hazards and costly maintenance and repair projects. To identify the most durable pavement solution that would reduce the number of joints required on airport runways and taxiways and significantly reduce the costs associated with maintenance and repair, K-SCC was chosen for use on one of the most innovative concrete slabs ever constructed. In 1993, this post-tensioned, steel fiber reinforced pavement was placed at Rockford International Airport’s Runway Extension project in Rockford, Illinois.

In a side-by-side comparison of two K-SCC designs using steel fiber reinforcement the contractor was able to place two contiguous “Innovative Pavement Slabs” (IP1 and IP2, respectively) of taxiways paralleling a new runway extension. IP1 and IP2 were placed in 75-foot (23 meter) wide pavement sections. The additional flexural strength provided by using steel fibers allowed a reduction in pavement thickness from 15 inches (38.1 centimeters) to 10 inches (25.4 centimeters). Transverse joints were cut in the steel fiber reinforced IP1slab at varying span lengths from 85 feet to 200 feet (26 meters to 61 meters) to test how far apart natural cracking of the material would be with increased joint spacing. IP2 used steel fiber reinforced K-SCC for a 1,200-foot (365.8 meter) long placement with longitudinal post-tensioning and no control joints. The increased flexural strength provided by post-tensioning allowed further reduction in slab thickness to only 7 inches (0.18 meters). The pavement was inspected quarterly for five years. After 10 years of heavy use, the slabs were performing exceptionally well with minimal cracking and virtually no spalling. The FAA’s Pavement Condition Index (PCI) reported the steel fiber reinforced K-SCC (IP1) in Very Good condition (PCI 82), and the post-tensioned K-SCC slab (IP2) in Excellent condition (PCI 98).

Dams and spillways are other critical structures where K-SCC and K-SCG are used. The U.S. Army Corps of Engineers approved the use of K-SCC for their first full-size prototype at the Ririe Dam located about 25 miles (40 kilometers) from Idaho Falls, ID. The goal was to place larger, uniform surface slabs of concrete and minimize cracking. Using K-SCC, the spillway chute invert slab allowed the contractor to increase panel sizes to either 91 feet x 75 feet (27.7 meters x 22.9 meters) or 45.5 feet x 75 feet (13.9 meters x 22.9 meters) in area (vs. the conventional panel size of 22 feet x 25 feet (6.7 meters x 7.6 meters)). This allowed a reduction in total number of invert panels from 104 to either 18 or 9, depending upon the option selected. Minimum thickness was 12 inches (0.3 meters). Total spillway invert slab contained 5,584 cubic yards (4,269 cubic meters) of concrete. The reduction in linear feet of joints, percentage of steel reinforcement, linear f ootage of foundation anchors and foundation drain holes provided economic incentive for this project. Evaluations following the placement noted limited cracking at abrupt foundation irregularities and overbreak in the rock excavation, none deemed detrimental to the slabs, and many slabs that did not exhibit any signs of cracking.

In 2014, the U.S. Army Corps of Engineers, U.S. Department of the Interior, and US Bureau of Reclamation Cooperative used K-SCG for the $900M Folsom Dam Auxiliary Spillway Control Structure project (Folsom, CA). This bulk shrinkage-compensating

grout project was batched on this remote site to achieve 7,000 pounds per square inch (psi) strength. Six submerged steel gate supports were successfully secured and protected using K-SCG with the two-year inspection indicating the grout was meeting dimensional stability design expectations.

With a GWP of 461, K-SCC provides a GWP 56% lower than Portland cements and 37% lower than Type 1L Portland-limestone cements (Fig. 3). The use of K-SCC not only lowers the overall carbon impact of any mix design, it also significantly reduces overall carbon impact throughout the concrete’s service life. By reducing materials and labor requirements during construction, improving durability, and minimizing repair and maintenance, owners, designers and patrons benefit from an asset life two to three times that of a similar Portland cement concrete structure.

With ever increasing demands to build more durable critical infrastructure efficiently, and with more sustainably and added value, Type K shrinkage-compensating cement will continue to deliver. Embracing innovative approaches to design, integration of new products, and the collaborative efforts of professionals throughout the industry in its use will make a difference in the race to carbon neutrality while improving performance.

Full references are included in the online version of the article at STRUCTUREmag.org

Susan Foster is Director – Strategic Initiatives & Komponent for CTS Cement.

The new ACI Center of Excellence is focusing on ways to advance construction productivity.

By Phil Diekemper, Cary Kopczynski, and Michael L. Tholen

In 2017, the McKinsey Global Institute (MGI) published a sobering study showing that construction industry productivity gains have lagged significantly behind those of other industries for many years. In fact, MGI concluded that very little progress has been made in construction productivity for several decades.

In a 2023 report, the National Bureau of Economic Research (NBER) found much the same thing. Their work was published in the paper, “The Strange and Awful Path of Productivity in the U.S. Construction Sector.” The report showed that inflation-adjusted productivity, defined as “value creation per worker,” has made no net progress since the 1950s. It further concluded that the construction sector’s deteriorating efficiency in transforming intermediate construction goods—essentially the raw materials of construction—into finished products is largely responsible.

In the wake of these and other critical reports on construction productivity, many individuals and organizations have scoured the data to try to better understand it. And the news is not uniformly bad. Innovative processes and technology have improved many segments of the industry and will continue to do so. Building information modeling (BIM), for example, is revolutionizing design. Modular assembly is doing the same for construction. However, the aggregated data for the industry at large shows that productivity has been in a neutral to negative trend for many years.

MGI and others disagree on the cause of the problem. Many theories have been proposed, including aversion to innovation due to disproportionate risk sharing, contractual roadblocks that discourage teamwork, the fractured nature of the industry that “silos” its players, and deterioration of

construction document quality. One thing all agreed on, however, was that structural engineers and other designers have enormous power in setting the stage for productivity improvement. By improving the constructability of design, they can change construction.