anaheim: disneyland hotel| November 7-10, 2023 EARLY BIRD PRICING ENDS 9/30! 2023 STRUCTURAL ENGINEERING SUMMIT ncseasummit.com Join the best and brightest SE thought leaders this November! Engage in 14+ hours of high-quality education, reconnect with colleagues, have fun with friends, and network with suppliers showcasing the latest in technology and services to help you be the best you can be.

cONcRETE/ MASONRY INSIDE: Concrete Art Exhibit 10 Perforated Brickwork in Anchored Veneer 13 Ferndale Earthquake Observations 22 Two Approaches to Slender Masonry Walls 44 STRUCTURE SEPTEMBER 2023 NCSEA | CASE | SEI

ICC-ES provides total conformity assessment solutions for building products • Over 90 years of industry experience • Experts in building product testing, inspection and certification • Acceptance Criteria development for innovative products • Trusted by code officials for ease in approvals and installation 23-22862 www.icc-es.org | 1-800-423-6587 Look for the ICC-ES Mark of Confidence™ ICC

MAPEI offers a full range of products for concrete restoration, waterproofing and structural strengthening. Globally, MAPEI’s system solutions have been utilized for such structures as bridges, dams, tunnels, highways, parking garages, stadiums and high-rises. Visit www.mapei.com/us for details on all MAPEI products. Your single-source provider for construction projects, restoration, strengthening and corrosion protection MAPEI STRENGTHENS. MAPEI RESTORES. MAPEI PROTECTS. • Concrete Repair Mortars • Corrosion Protection • Construction Grouts • Waterproofing • Sealants and Joint Fillers • Coatings and Sealers • Epoxy Adhesives • Cementitious Flooring Systems • Cure and Seals • Densifiers • Structural Strengthening Products • Precast • Epoxy Adhesives

ADVERTISERindex

CSI - Computers & Structures, Inc.

CTS Cement

DEWALT

ENERCALC

ICC-ES

Holcim

MAPEI

Please support these advertisers

NCSEA Summit

PCA-Portland Cement Association

RISA Schaefer Simpson Strong-Tie Tech Sales, LLC

September

STRUCTURE

CIRCULATION

subscriptions@structuremag.org

EDITORIAL BOARD

Chair John A. Dal Pino, S.E. Claremont Engineers Inc., Oakland, CA chair@STRUCTUREmag.org

Jeremy L. Achter, S.E., LEED AP ARW Engineers, Ogden, UT

Erin Conaway, P.E. AISC, Littleton, CO

Linda M. Kaplan, P.E. Pennoni, Pittsburgh, PA

Charles “Chuck” F. King, P.E. Urban Engineers of New York, New York, NY

Nicholas Lang, P.E. Vice President Engineering & Advocacy, Masonry Concrete Masonry and Hardscapes Association (CMHA)

Jessica Mandrick, P.E., S.E., LEED AP Gilsanz Murray Steficek, LLP, New York, NY

Jason McCool, P.E. Robbins Engineering Consultants, Little Rock, AR

Brian W. Miller

Cast Connex Corporation, Davis, CA

Evans Mountzouris, P.E. Retired, Milford, CT

Kenneth Ogorzalek, P.E., S.E. KPFF Consulting Engineers, San Francisco, CA (WI)

John “Buddy” Showalter, P.E. International Code Council, Washington, DC

Eytan Solomon, P.E., LEED AP Silman, New York, NY

Jeannette M. Torrents, P.E., S.E., LEED AP JVA, Inc., Boulder, CO

EDITORIAL STAFF

Executive Editor Alfred Spada aspada@ncsea.com

Production production@structuremag.org

MARKETING & ADVERTISING SALES

Director for Sales, Marketing & Business Development

Monica Shripka Tel: 773-974-6561 monica.shripka@STRUCTUREmag.org

STRUCTURE ® magazine (ISSN 1536 4283) is published monthly by The National Council of Structural Engineers Associations (a nonprofit Association), 20 N. Wacker Drive, Suite 750, Chicago, IL 60606 312.649.4600. Periodical postage paid at Chicago, Il, and at additional mailing offices. STRUCTURE magazine, Volume 30, Number 9, © 2023 by The National Council of Structural Engineers Associations, all rights reserved. Subscription services, back issues and subscription information tel: 312-649-4600, or write to STRUCTURE magazine Circulation, 20 N. Wacker Drive, Suite 750, Chicago, IL 60606.The publication is distributed to members of The National Council of Structural Engineers Associations through a resolution to its bylaws, and to members of CASE and SEI paid by each organization as nominal price subscription for its members as a benefit of their membership. Yearly Subscription in USA $75; $40 For Students; Canada $90; $60 for Canadian Students; Foreign $135, $90 for foreign students. Editorial Office: Send editorial mail to: STRUCTURE magazine, Attn: Editorial, 20 N. Wacker Drive, Suite 750, Chicago, IL 60606. POSTMASTER: Send Address changes to STRUCTURE magazine, 20 N. Wacker Drive, Suite 750, Chicago, IL 60606.

STRUCTURE is a registered trademark of the National Council of Structural Engineers Associations (NCSEA). Articles may not be reproduced in whole or in part without the written permission of the publisher.

3 SEPTEMBER 2023

®

Issue Available Only at STRUCTUREmag.org

Digital

2023

MASONRY STRUCTURE

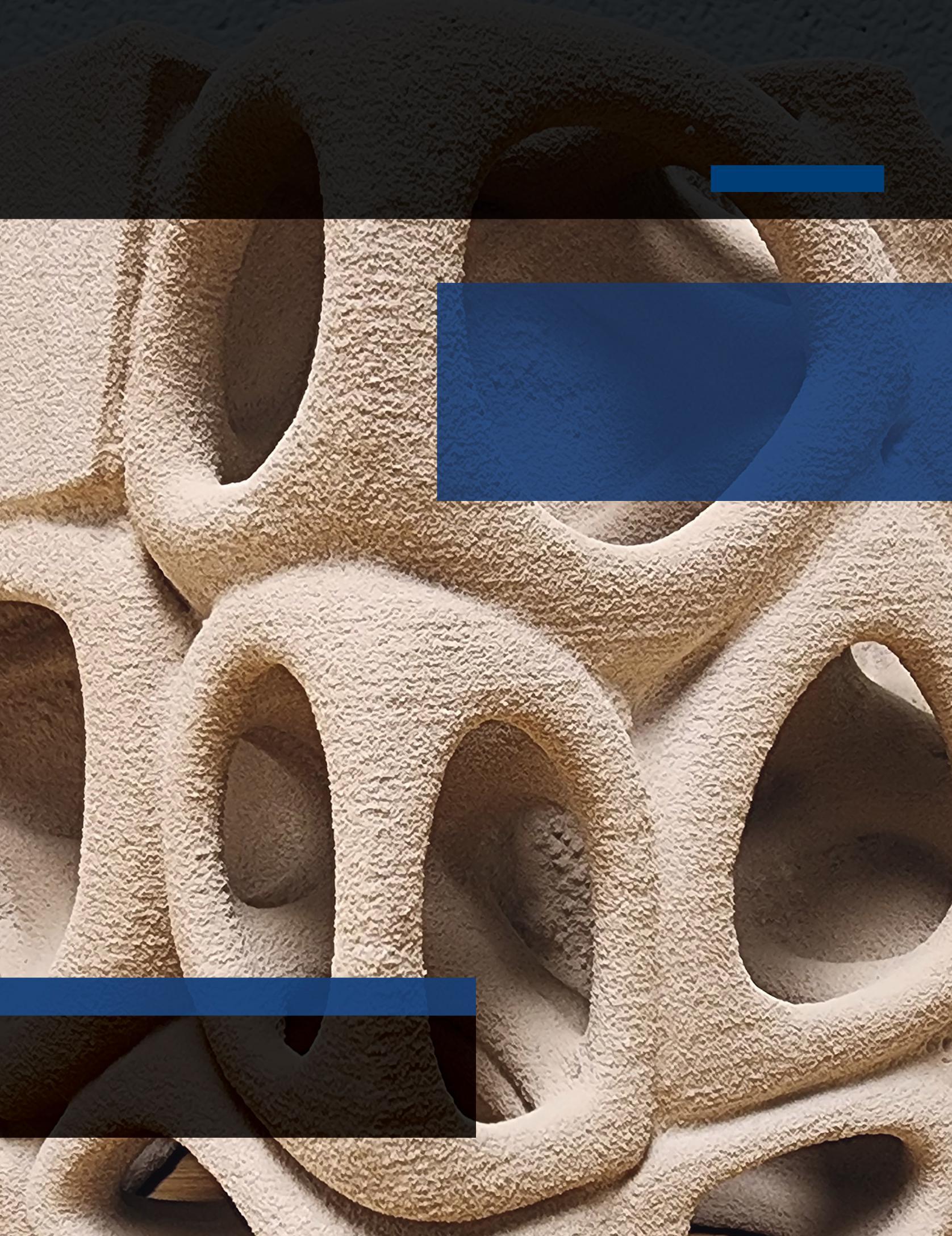

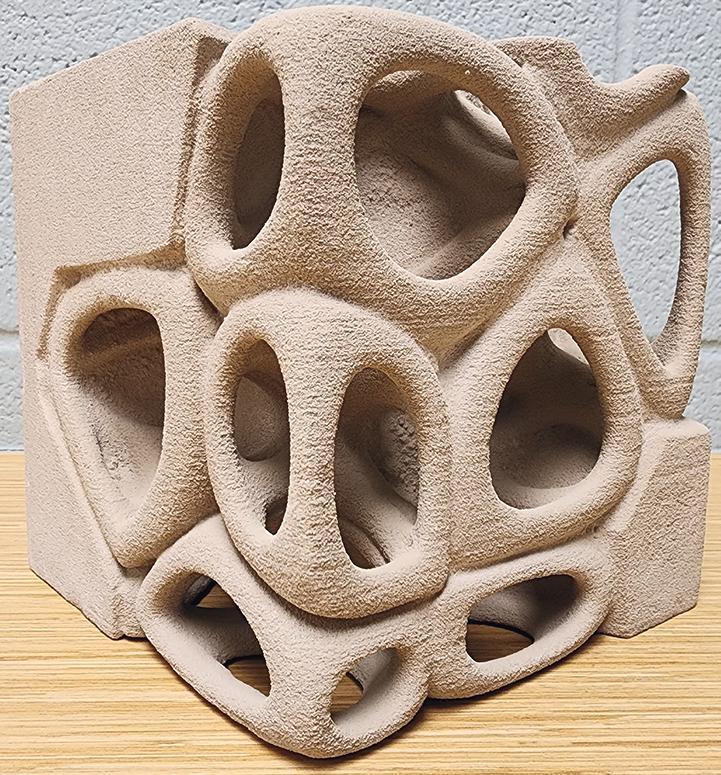

the Cover:

printed concrete sculpture from an exhibit at the National Museum of Industrial History, located in the former seat of Bethlehem Steel, Pennsylvania. Photo Courtesy of Xingjian Wang. ADVERTISEMENT–For Advertiser Information, visit STRUCTUREmag.org

cONcRETE/

On

A 3D

Specify more applications with one connector.

Now you can specify a single connector as a tension tie or holdown.

New from Simpson Strong-Tie, the code-listed LTTP2 light tension tie securely attaches wood joists, studs, or posts to concrete or masonry walls and foundations. With allowable loads 25% higher than previous models, it enables greater design flexibility. This versatile connector has two distinct nailing patterns for horizontal installation as a tension tie with I-joist purlins or 2x solid sawn purlins, plus an extruded anchor bolt hole that accommodates multiple bolt diameters. The LTTP2 also is suitable for vertical installation as a holdown, and can be fastened with nails or Strong-Drive® SD Connector screws. Select the LTTP2 and Simpson Strong-Tie® fasteners for your next project. To learn more, visit go.strongtie.com/lttp2 or call (800) 999-5099.

© 2023 Simpson Strong-Tie Company Inc. LTTP23-S Residential Solutions | Products, Software and Service for Smarter Building

SEPTEMBER 2023

Features

Columns and Departments

ABOUT THE FUTURE OF CONCRETE

By Xingjian Wang, John T. Fox, Ph.D, P.E., Clay J. Naito, Ph.D., P.E., F.PCI,

Nik Nikolov, Registered Architect (R.A.), AIA, NCARB, LEED AP, Urinrin Otite, Paolo Bocchini, Ph.D. F.SEI

Additive manufacturing is a rapidly developing technology that is already transforming many sectors and has the potential to usher in a new paradigm.

32 THE FUTURE IS LOOKING UP. LITERALLY. THE EVOLUTION OF PORTLAND INTERNATIONAL AIRPORT

By Christopher Pitt, P.E., S.E., LEED A.P., Associate, KPFF

By Christopher Pitt, P.E., S.E., LEED A.P., Associate, KPFF

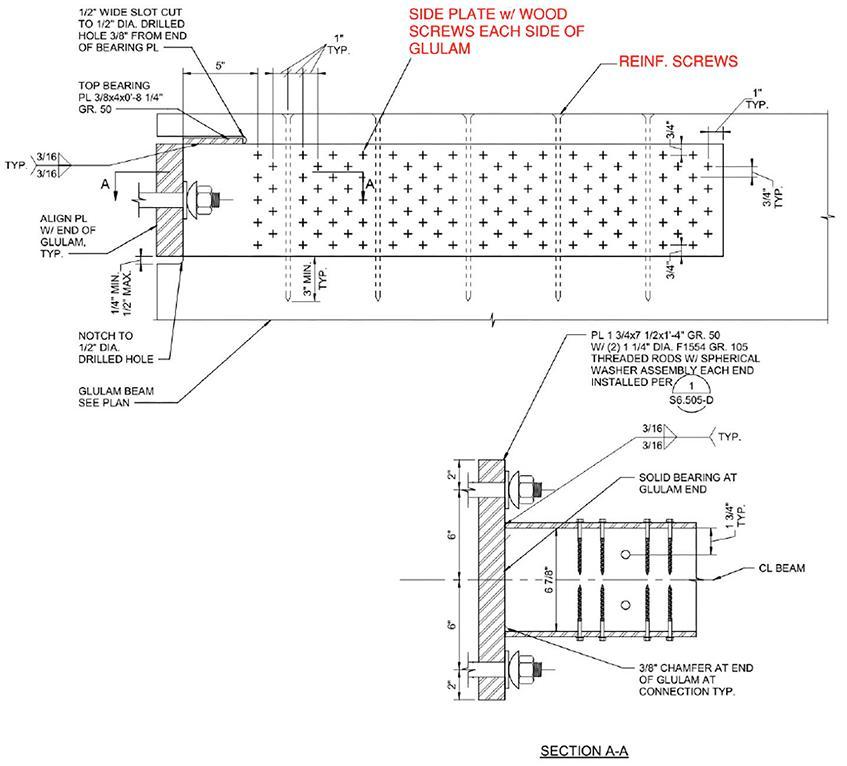

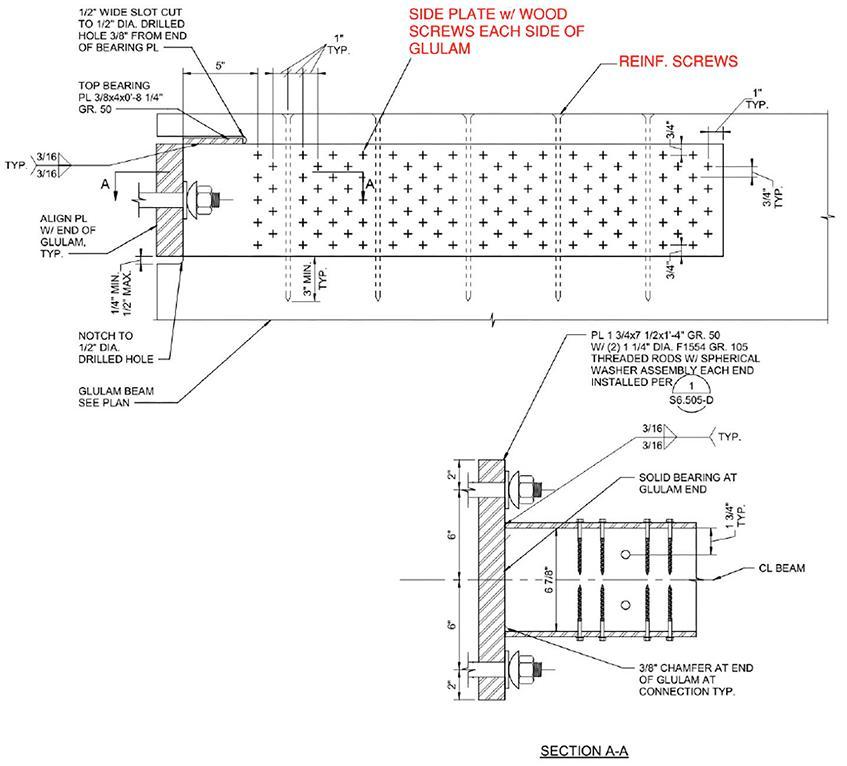

The approximately $2 Billion Portland International Airport Terminal Core Redevelopment Project, located in Portland, OR, is led by the Port of Portland as owner, with a design team featuring ZGF Architects and KPFF as Structural Engineer. It is currently being built by Hoffman-Skanska Joint Venture as CMGC. The project is summarized in Part One, published in the June 2023 Structure, and features many unique structural solutions.

44

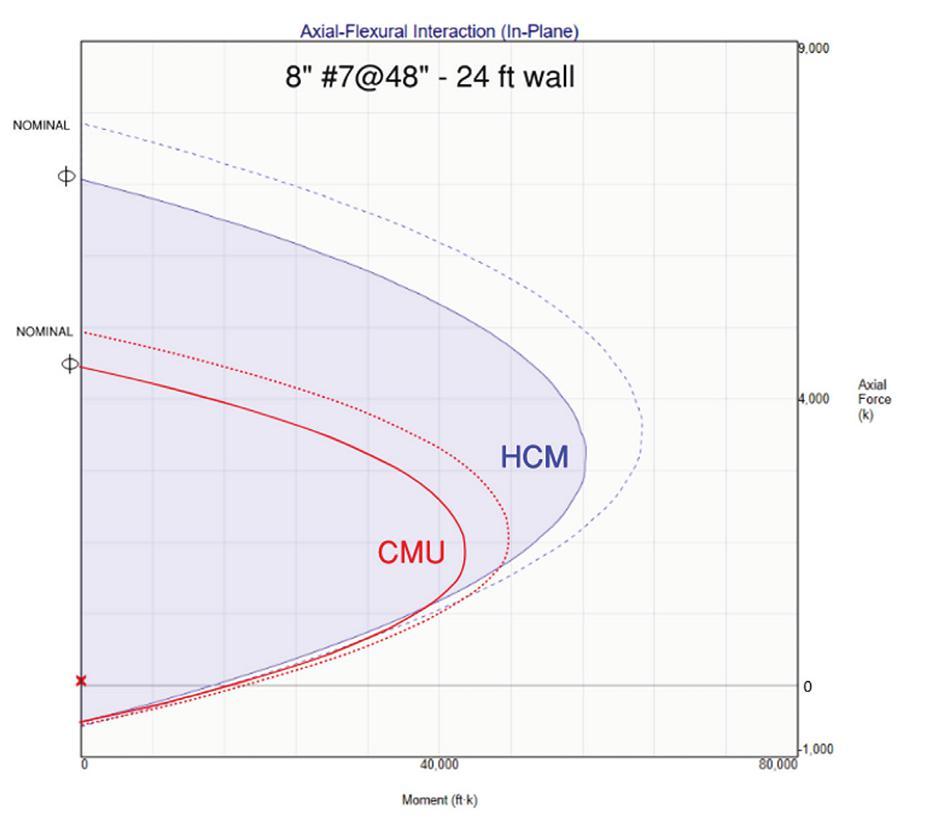

By Edwin Huston, P.E., S.E.

46

By Steven Judd, S.E.

The

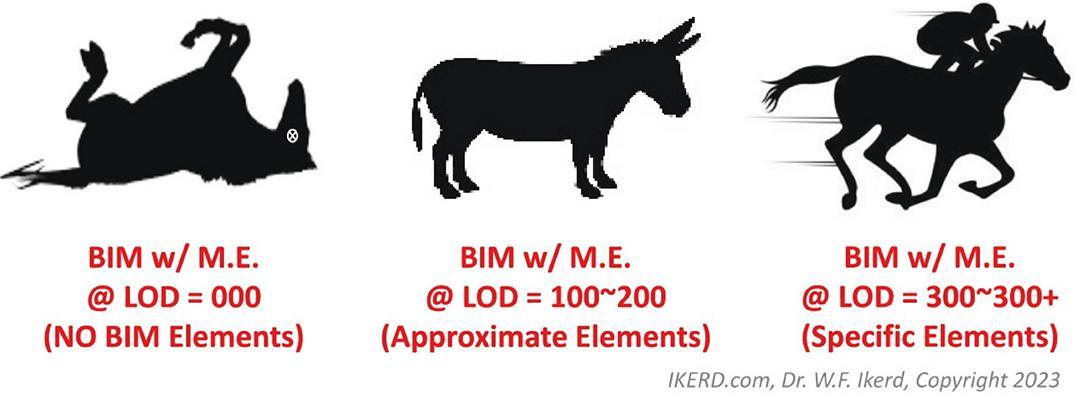

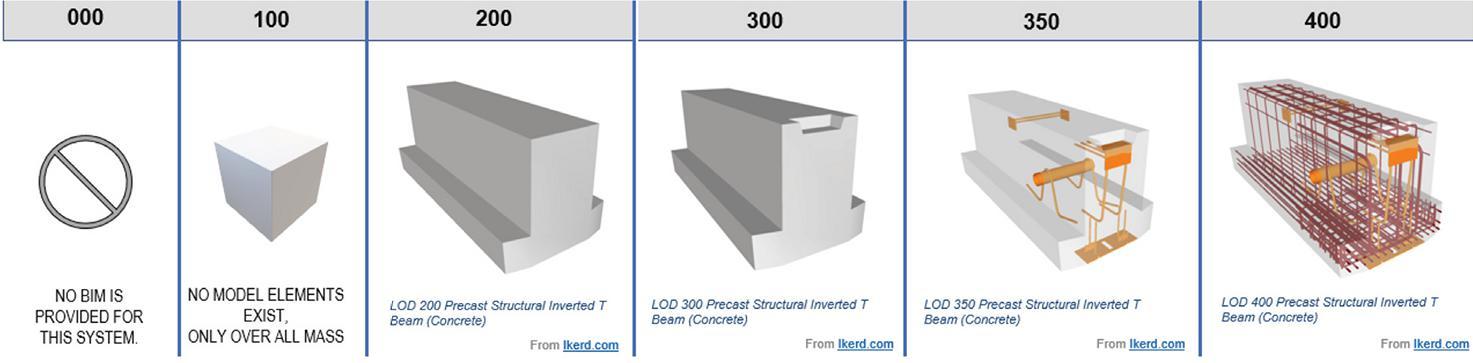

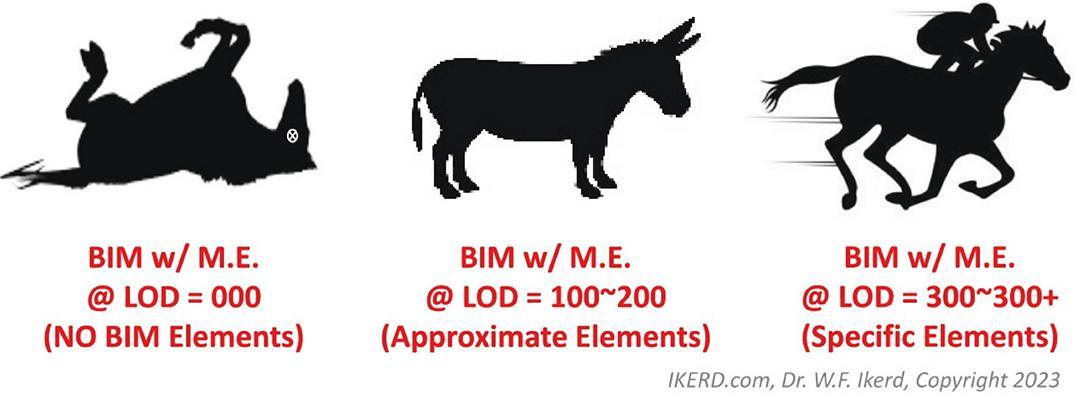

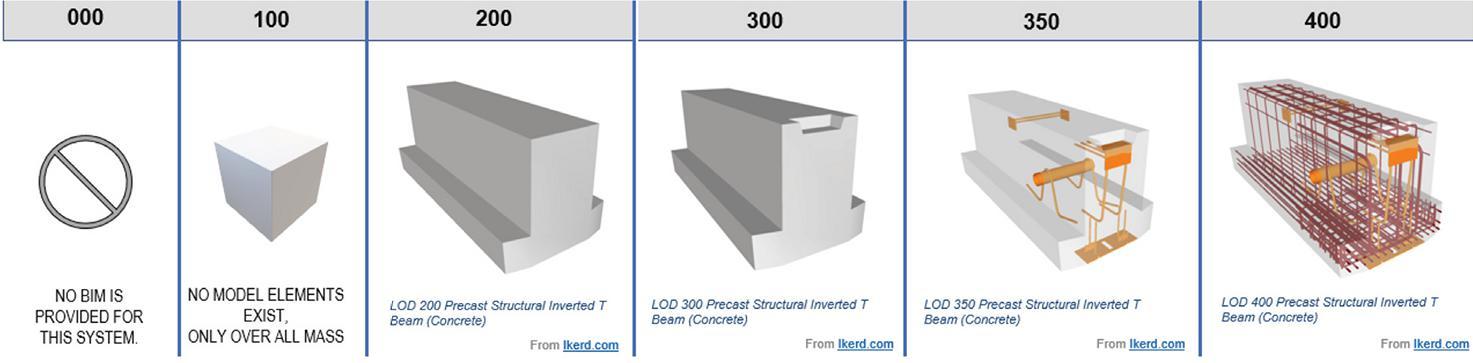

By Dr. Will F. Ikerd, P.E., Ph.D.

In

S.E.

5 SEPTEMBER 2023 Publication of any article, image, or advertisement in STRUCTURE® magazine does not constitute endorsement by NCSEA, CASE, SEI, the Publisher, or the Editorial Board. Authors, contributors, and advertisers retain sole responsibility for the content of their submissions. STRUCTURE magazine is not a peer-reviewed publication. Readers are encouraged to do their due diligence through personal research on topics. 7 Editorial A New Path for SEI By Stephanie Slocum, P.E. 8 Structural Influencers Kate Stillwell 13 Masonry Sunlight and Shade By Cortney Fried, P.E., 16 Structural Maintenance Concrete Defects and Preventive Maintenance By Ahmed Clayiff, P.E., CBSI 18 Structural Flexibility Deflections of Concrete Structures Using Bilinear Flexibility By Neil Wexler, Ph.D., P.E., Hoonhee Jeoung,

22 Infocus Observations from the December 20, 2022, Ferndale Earthquake

38 Structural Forum Understanding Developing Issues in Access to Design Data

Dispute Resolution,

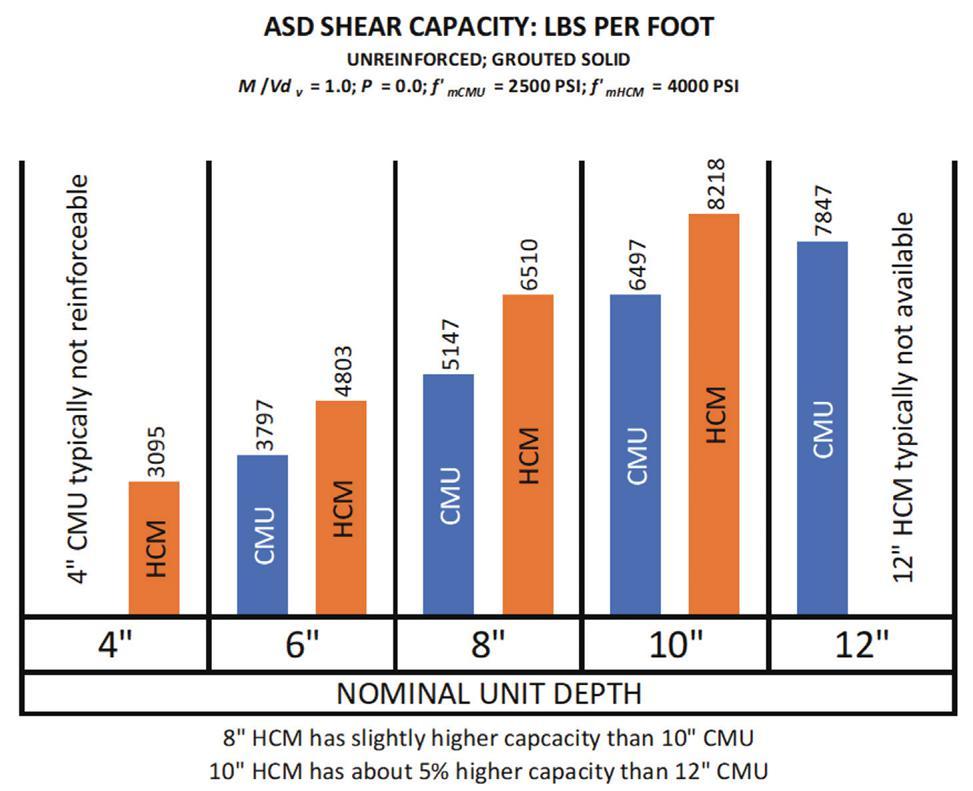

40 Structural Efficiency Maximizing Masonry’s Efficiency

P.E., Nissim Elmann, P.E.

By John A. Dal Pino, with assistance from Claire Hu, Elizabeth Bognar, and Hongxun Yang

By

Joan Malana Kennedy, BSc Architecture, MSc Building Science, MSc Construction Law

and

UAP, FCIArb, FPIArb, AMAE

By Philippe J. Ledent, P.E.,

Structural

Slender Masonry Walls

Methods Tall,

Masonry

Structural Resilience Hollow Reinforced Clay

Enhances Resiliency

56 Insights

Future of Concrete

BIM

Every Issue

Advertiser Index

Anchor Guide

NCSEA News

SEI Update

CASE in Point

3

21

50

52

54

A MUSEUM EXHIBIT

Cover Feature 10

Contents

A New Path for SEI

Building a bridge to a brighter future.

By Stephanie Slocum, P.E.

How will the structural engineering profession keep up in a rapidly evolving world?

This question has been on my mind for a long time and was brought to the forefront with my election to the SEI Board of Governors in the fall of 2020 as our profession grappled with the unknown long-term impacts of the pandemic. How structural engineers work has changed. Compared to when I started my career 20 years ago, the industry is more connected, more collaborative, and less hierarchical. It also requires professionals to lead themselves and their teams earlier in their careers.

Organizations that support our profession must also evolve. I’ve had the privilege of serving alongside structural engineering leaders on SEI’s BOG and experienced the dedication of volunteers serving our industry. That dedication has led the BOG to determine that an SEI Reorganization is needed to best serve members and the profession.

This article, written in collaboration with SEI Board Members, will explain why it’s happening and what it means to you.

Why SEI is Reorganizing

SEI was founded in 1996 under parent organization ASCE. In 2008, the SEI vision statement established four SEI priorities:

•A unique, fully engaged profession with a strong identity

•Recognized for the contribution the professional makes to public safety and risk management, economic and sustainable use of resources, the use of innovative technologies, and the creation of inspiring structures

•Stewards of the built environment

•Attractive to the best and brightest

In 2019, NCSEA, CASE, and SEI collaborated on the Vision for the Future of Structural Engineering, resulting in 10 key initiatives that also align with SEI’s original vision statement. This fundamental vision has not changed and will be unaffected by the SEI Reorganization. The challenge is that over time, how SEI contributes to this vision has morphed into a long list of activities that may or may not have evolved in direct connection to the original vision.

SEI’s original organizational structure has

remained mostly unchanged since its initial establishment 25+ years ago. As is typical with growing organizations, organizational structures must evolve to keep pace with members and industry needs or risk becoming stagnant.

SEI has experienced growing pains. They include excess bureaucracy, communication silos, struggles with resource allocation, slow and unequal pathways to leadership for rising stars depending on where you volunteered within the organization, and a lack of strategic focus due to an overwhelming list of “to-dos” to keep the outdated structure functional.

SEI’s Reorganization is in response to internal and external challenges and opportunities shaping the structural engineering profession.

What are SEI’S ReorganizationGoals?

SEI’s Reorganization started with internal conversations and a study completed before my time serving on the BOG. The process also included consultative forums with SEI leaders and gathering input and survey data from members.

SEI’s BOG voted to move forward with developing the transition plans for SEI’s Reorganization in Fall 2022 and is grateful for the leadership of countless volunteers in developing the plans for a brighter future.

Reorganization goals include:

• Increase collaboration and knowledgesharing throughout SEI by moving from the current five Division structure to a two Community structure.

• Reorganize the SEI BOG from a representative structure to a strategic board structure for long-term operation efficiency.

• Become a more nimble, responsive organization to meet industry and member needs as the pace of change accelerates.

•Focus the efforts and resources of SEI to establish and meet SEI priorities for the profession’s advancement.

• Increase leadership opportunities and pathways to leadership for rising stars.

The new SEI organizational structure will be implemented following new bylaws approval of parent organization ASCE, estimated in October 2023.

New SEI Structure Highlights

Highlights of the new organizational structure include:

• The size of SEI’s BOG is reduced. Studies show that large boards struggle with effective decision-making, and this shift is intended to refocus the BOG on being a strategic guiding hand in supporting the vision. A strategic board requires a more collaborative and communicative governance approach which empowers volunteers to execute the vision.

•The organizational structure shifts to a twocommunity structure instead of the current five-division structure. The new structure is intended to break down communication and collaboration silos and reduce the hierarchy and bureaucracy inherent in a more complicated organizational structure.

• A focus on collaboration, knowledge-sharing, and leadership pathways for young professionals and rising stars

SEI’s Reorganization comes down to this: better communication and collaboration so that SEI can best address priorities as an organization and better serve the structural engineering profession.

The SEI Reorganization Benefits The Industry

The overarching goal of SEI’s Reorganization is to better serve its members and the structural engineering profession.

The Reorganization allows SEI to be more streamlined and agile, better responding to industry trends and member needs. It enhances leadership opportunities for rising stars and young professionals, contributing to a more dynamic and inclusive profession. Leading organizations embrace the need to evolve so that they can best support the people that make up our profession. SEI’s Reorganization is how we prepare for a future in which knowledge-sharing, collaboration, strategy, and growth are all prioritized.

You can read more details about the reorganization structure on SEI’s website: https://go.asce. org/3P2wBF7 ■

STRUCTURE magazine SEPTEMBER 2023 7 EDITORIAL

Stephanie Slocum, P.E. is the Founder of Engineers Rising LLC, based in State College, PA, and SEI President-Elect FY24. (stephanie@engineersrising.com).

structural INFLUENCERS

Kate Stillwell

Kate Stillwell is a structural engineer and entrepreneur working at the intersection of physical and financial resilience. As a structural engineer, Kate has worked with Greg Luth & Associates, Degenkolb Engineers, and Holmes Consulting. In catastrophe modeling, she has worked at EQECAT (now CoreLogic) as the Product Manager of earthquake models worldwide, and she was the founding Executive Director of the Global Earthquake Model Foundation at the ROSE School in Pavia, Italy.

Kate founded and leads InsurTech startup Jumpstart, the first company to bring parametric insurance to consumers, starting with earthquake risk in California. Jumpstart was acquired in 2021 by Neptune Flood, where, as President of Parametric Insurance, Kate is now responsible for new product development and for continuing to lead sales of Jumpstart’s parametric insurance.

As a side project, Kate co-founded FireBreak, a consumer app for wildfire self-inspection, mitigation, and insurance eligibility.

Kate is a Past President and Fellow of SEAONC and a co-founder of the Building Ratings Committee (BRC), which later became the Resilience Committee. With other BRC members, Kate co-founded the US Resiliency Council. Kate is also a longtime member and Housner Fellow of EERI.

Kate holds an MS in Civil Engineering from Stanford University, an MBA from the Haas School of Business at UC Berkeley, and a Bachelor of Civil Engineering from the University of Minnesota.

Your working career started in a traditional engineering office. Before we move on to the present, what did you learn then, or better yet, who did you meet that proved useful later?

Mentors and muses come in all ages and experience levels. Some of my fondest co-workers are the most unorthodox - like Greg Luth, my first boss. Another person who influentially shaped my career was former Degenkolb CEO, Chris Poland. We didn’t always see eye to eye, but his involvement in real estate and public policy circles inspired me to see the bigger “pond” in which structural engineers work. Safe buildings are necessary for a resilient society, but they’re not sufficient without equitable governance, social ties, and economic stability. Another key player who shaped my journey is Laurie Johnson, particularly her post-Katrina research in New Orleans on social effects of mega-disasters.

After several years in the AEC industry, you shifted focus and went off to business school at Berkeley. May we ask why?

Precisely to learn about and participate in those “wider circles” that structural engineering touches – to apply the time and talents of engineers to the social and economic dimensions of disaster recovery. I’m pretty sure such a vague purpose statement would not earn admission to business school today, but lucky for me, that was the dark ages.

Were you planning on going back into structural engineering?

Yes! I was too proud to leave my credentials behind! Structural engineers have pivotal gravitas in policy making, which mere business people can only imitate. As it turns out, it has been many years since I have used my SE license in practice, but I keep a toe in the door by participating in SEAONC and staying in touch with my structural engineering friends.

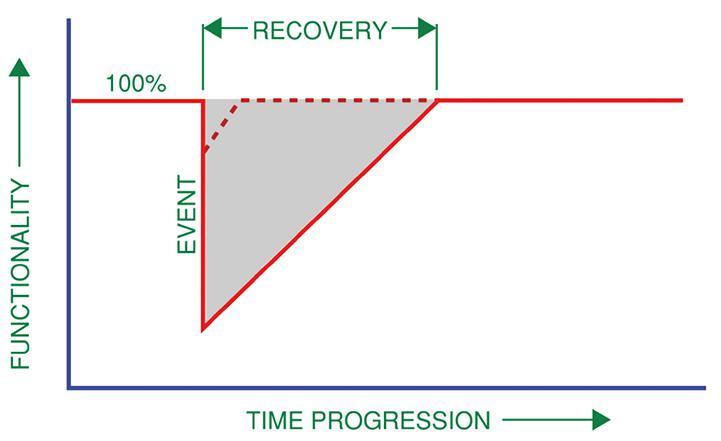

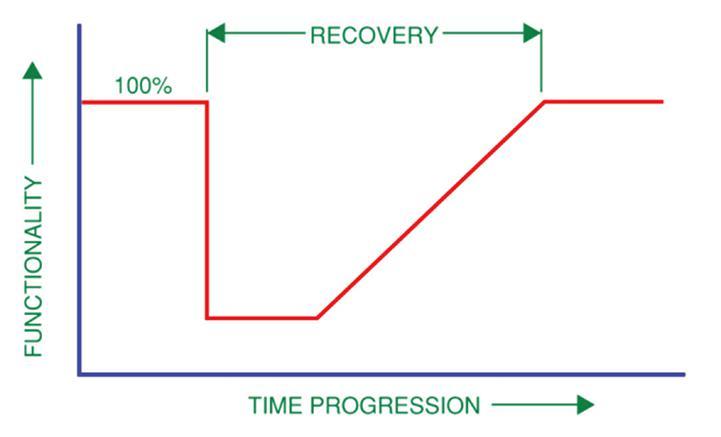

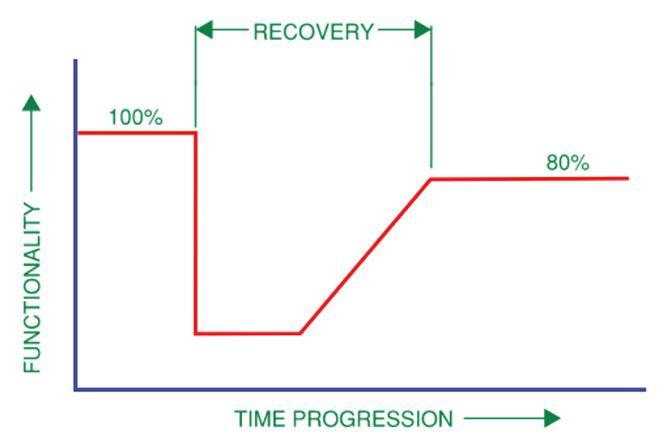

There is a lot of talk these days about community resilience. But more than talk about it, you actually did something. Would you tell us a little more about your motivations and goals?

It goes back to Katrina, a major galvanizing force not just for me, but for many resilience-minded professionals. As I watched real-time footage of the levees breaking, I felt a visceral pit in my stomach, seeing the social inequities and thinking, “after the next big earthquake, my hometown of Oakland will be the next New Orleans.”

I knew that the next big earthquake would be a triple-whammy to society and the economy: 1) FEMA is the first to admit that public aid is too little too late; 2) earthquakes are excluded from insurance; and worst of all, 3) a majority of Americans have less than $1000 in liquid savings – not just the poor, but people in all walks of life. Our personal finances have no buffer to face widespread disruption. Flash-forward to the COVID-19 pandemic, which made this truth all too evident.

When did you decide to start your own company? And what compelled you to do this?

As far back as 2006. When Katrina struck, I had just started business school. The following semester, in a real estate finance class by late professor Dwight Jaffee, I learned about catastrophe (“cat”) bonds, large-dollar-amount hedging instruments where companies swap their natural hazard risk for financial risk. In one of the first cat bonds, dating from 1997, Tokyo Disneyland arranged a deal where if a M7.3+ earthquake occurred in a specified geographical box in the next three years, they would receive $100M from the counterparty, which would make up for some of their lost operational revenue. Of course, they had to pay to offload their risk, by way of an “interest rate” on the $100M, but it was a way of protecting their cash flow

STRUCTURE magazine 8

and avoiding debt. A financial buffer!

That’s when I made the connection. We needed “micro” catastrophe bonds for earthquakes (and floods)! That’s how Jumpstart originated. But it was ten years before the technology and data were sufficiently mature to bring the idea to reality at scale.

How does Jumpstart work?

Jumpstart sells earthquake insurance that makes immediate $10,000 lump sum payments in areas that experience ground shaking greater than a pre-specified amount. The payout does not require physical damage but rather is intended to pay unexpected expenses and “jump-start” the recovery process.

Starting any business is challenging enough, but entering the capital-intensive and highly regulated insurance industry is an entirely different matter. What did you learn that our readers would benefit from?

The importance of intention cannot be understated. When your intention is clear, well-articulated, and authentically motivated to make good in the world, doors will open that would otherwise stay closed. As one example, we engaged with the insurance regulator early and often, whereas a conventional insurance incumbent might take the conservative view of not engaging - as a strategy to avoid the risk that regulators might scrutinize unrelated profitable operations. As a result, we were unblocked from proceeding with our unorthodox approach, whereas the incumbent, in an abundance of prudence, might conclude not to proceed at all.

Just as structural engineering attracts people whose intrinsic motivation is to “just build stuff,” people with an intrinsic motivation to “just make money” are drawn to insurance and finance. Unfortunately, this means the insurance industry is disproportionately populated by people with intentions that conflict with the common good, and this leads to widespread mistrust. More than once, I received feedback from partners – long after a deal was sealed – that the deciding factor to work with us was that our resilience motive was “a breath of fresh air.”

Can you say a bit more about what it was like entering an industry at a level where women are few and far between?

One of the best pieces of advice I’ve received in recent memory, and which I continue to lean on today, was an offhand remark in 2014 by my dear friend and EERI member Charlie Huyck, “go with your strengths.” Every person brings their uniqueness to a situation or negotiation. The trick is to be aware of it and learn how to leverage it. For example, I’m a believer that the advantage of sharing information to help “lift all boats” far outweighs the risks of a competitor stealing an idea. As a result, I’m not known as the most aggressive “winner” from a sales perspective, but the phone doesn’t stop ringing for potential partnerships and collaboration.

Getting Jumpstart up and running is memorable in itself. Would you share a few other achievements that would inspire others?

You’re asking me to stroke my own ego … so it’s hard to know how to respond. Make a joke to signal my humility? Pontificate on the virtue of gratitude? Take the bait and regurgitate my CV? Since the point of this question is to inspire readers, here’s what I’ll say: One of the hardest things in life is to act with courage. Even to know what the courageous response would be in a situation. Sometimes acting or speaking with courage causes pain, even if it’s the right thing to do. On a recent episode on the podcast Hidden Brain, guest Todd Kashdan described our current culture as “addicted to

comfort.” But pain is temporary and often a necessary part of the process leading to a just outcome. It’s natural to struggle when trying to discern between necessary pain vs. pain that tells us something is really wrong – and in either case, use that pain as a “helpful friend” who guides us toward courage.

Successful firms plan for ownership transition and firm longevity. But a start-up must be entirely different. What needs to be done every day to keep the ship afloat, so to speak?

A close friend, also a startup founder, asked me yesterday for a referral to a bookkeeper. The truth is, the founder of a startup is simultaneously both CEO and custodian. Yes, I enjoy the benefits of plum speaking engagements, but I also – quite literally – took out the trash and did other chores, including, to my friend’s disappointment (but not surprise), balancing the books. On the question of ownership transition, I liken the journey of a startup to a celebrity maintaining a social media account: it’s a continuous investment in perceived value. Startups are valued almost exclusively on intangibles. What is the value of your vision? Your customer feedback? The force of personality of the founders? The loyalty of the employees? You cannot abandon sales and operations, but there’s an additional responsibility (and privilege) of thinking long and hard about nonmonetary assets.

Concerning mentoring, we assume that you have had many, and that you mentor others yourself. What is your approach, and what have you found that works best?

Some of the most powerful questions, on either the giving or receiving end, are “What haven’t I asked that I should be asking?” and “How can I be most helpful?” The common thread is a lack of presumption. We’re trained to be experts – to KNOW the ANSWER to things, and I’m one of the worst offenders. But mentorship is all about relationships, and relationships work best when we meet people where they’re at, rather than presuming what they need, or what they want to hear. I sometimes have to force myself – and I don’t always succeed – to stop talking and ask the listener if they actually want advice before I just dish it out.

Work-life balance has been a hot topic for several years. Recently doing just enough to get by is a trend too. What advice would you give to young entrepreneurs?

A repeated theme in my responses so far is the power of awareness: knowing – authentically – your motivation. Your strengths. Your emotions and the signals they’re sending you. The limitations of your knowledge. So many of us, including myself, have poor awareness of our boundaries, and this can lead to resentment and the temptation to “quietly quit.” But there’s the flip side, too: knowing the full extent of our capabilities. Nelson Mandela captured this in his famous inaugural speech, “Our deepest fear is not that we are inadequate. Our deepest fear is that we are powerful beyond measure. It is our light, not our darkness, that most frightens us.” The challenge, then, is to become more aware – even if it brings (temporary) pain – of our capability to be the change we want to see in the world.

Regarding your personal legacy, what do you think you will be remembered for, and/or what are you most proud of?

Making something where nothing existed before. It’s what I love about cooking with leftovers. It’s what makes it so gratifying to start a venture. And it’s the fundamental pull of the engineering profession: the creative force made manifest.■

SEPTEMBER 2023 9

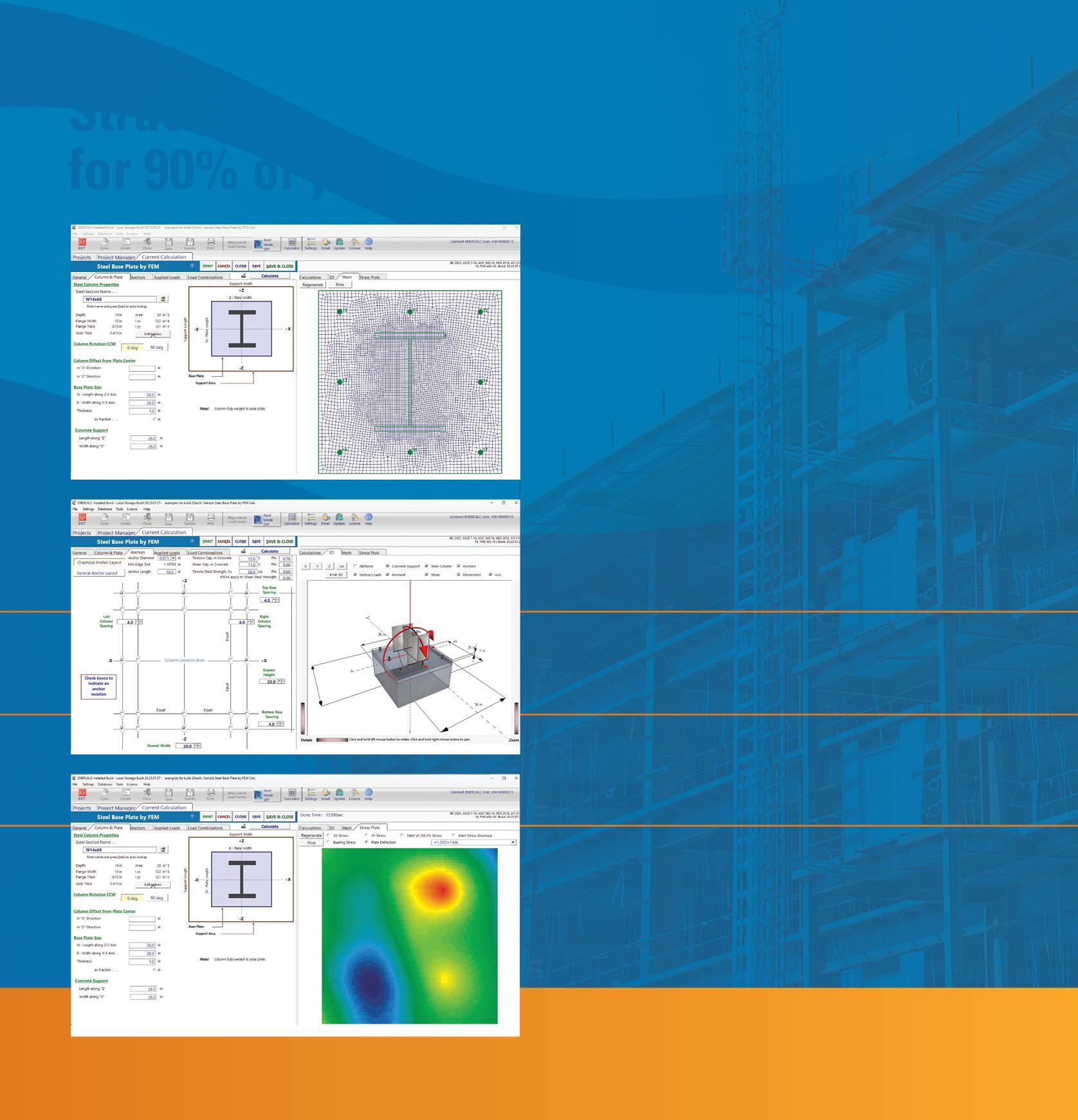

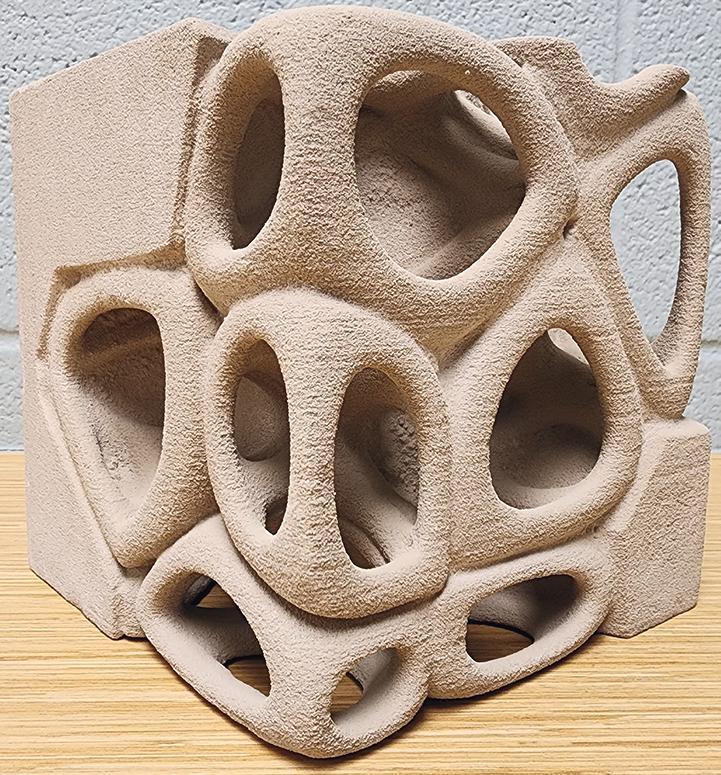

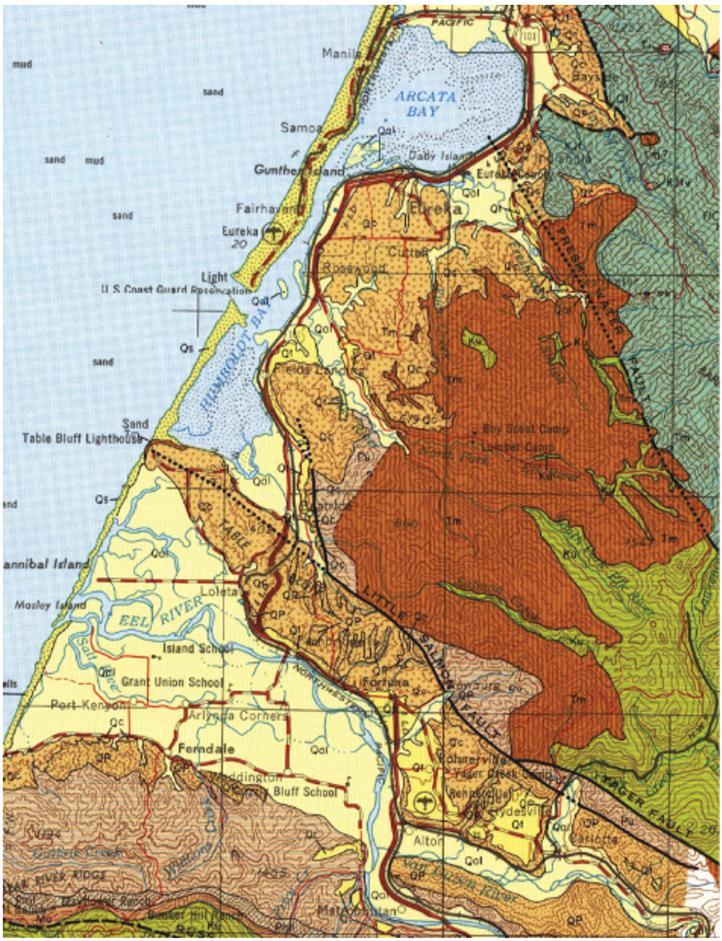

Additive manufacturing (AM) is a rapidly developing technology that is already transforming many sectors and has the potential to usher in a new paradigm. The automated production of structures is one of the potentially most impactful applications of AM, also called “3D printing.” A group of engineers and architects at Lehigh University investigated a technique called “Particle bed 3D printing by selective binder activation” to manufacture objects made of concrete. Their interests started with structural engineering and progressively expanded to include environmental impact, architecture, and topology optimization. The team also partnered with Buzzi Unicem USA Inc., an international cement producer headquartered in the Lehigh Valley (PA). Together, they are collaborating with the National Museum of Industrial History, located in the former seat of Bethlehem Steel, Pennsylvania, to showcase this technique and its potential through an exhibit. The exhibit is an opportunity to reflect on the past, present, and future of cement in Eastern Pennsylvania. This area historically has had a high density of companies in the cement sector. The PA Department of Community and Economic Development supported part of this research. Figure 1 shows a

A Museum Exhibit About The Future of Concrete

By Xingjian Wang, John T. Fox, Ph.D, P.E., Clay J. Naito, Ph.D., P.E., F.PCI, Nik Nikolov, Registered Architect (R.A.), AIA, NCARB, LEED AP, Urinrin Otite, Paolo Bocchini, Ph.D. F.SEI

3D printed totem, two freestanding columns and one portal frame, which are part of the exhibit.

Manufacturing Process

The first applications of additive manufacturing to concrete consisted of 3D printing disposable formwork made of polymers. This approach enables some interesting shapes that would be difficult to achieve with traditional formwork, but it does not 3D print concrete directly, nor does it fundamentally change the manufacturing process. Two types of 3D printing techniques exist for automated and direct concrete fabrication, with different technology readiness levels and market penetration. The first one is the material extrusion method which adopts the same 3D printing approach of household 3D printers for plastics. With this method, the operators mix cement, water, and aggregates to form plastic concrete which is then pumped and deposited through a nozzle connected to a computer- controlled

STRUCTURE magazine 10

Figure 1 3D printed products for the exhibit.

arm. This approach has been used for several demonstrations, including the construction of small houses and some military structures. The nozzle extrudes the plastic concrete to form layers of the structure, one on top of the other, which means that the structure can only grow vertically, with limited overhangs and challenges when windows or doors are installed. In contrast, with the particle bed printing technique developed at Lehigh, a machine uses a roller to distribute uniformly onto a platform a thin layer of a specifically engineered dry powder, including cement, fine sand, and in some cases, additives. Then, an aqueous liquid is jetted onto the layer at selected locations to activate cement hydration. The process is repeated, layer after layer, until the structure is complete. Notably, the powder that is not activated by the liquid stays in place and supports the subsequent layers, enabling the creation of cavities, overhangs, and any possible shape, even those that could never be created with formwork or with extrusion (see Figure 2). After printing, the object remains in the powder bed for 24 hours to have sufficient early strength to undergo postprocessing. After a day, the scientists at Lehigh take the printed structure out of the powder bed, clean and remove all the powder that was not activated, and perform heat treatment if needed. Then, they immerse the object in water to complete curing, usually for 14 to 28 days. This technique can reach a resolution of 300 × 450 dpi, so that precise details can be rendered in the manufactured objects.

Challenges and Solutions

A critical step of the process is cleaning the object after printing. With only 24 hours of curing in the powder bed, the structure is far from having its full strength. In these conditions, there is a risk of breaking the object and compromising its integrity, especially for designs with thin elements (Figure 2). Therefore, it is essential to design a powder mix that can achieve fast curing, and the Lehigh team accomplished that by using calcium sulfoaluminate cement (CSA), which leads to an early compressive strength of up to 0.9 MPa (130 psi) and can be safely manipulated after only 24 hours. Another benefit of having a dry powder based on CSA is its fast water absorption. Other mixes lead to very considerable “bleeding,” which means that water spreads far beyond the point where it is jetted, and the resulting object is just a blob. Instead, mixes based on CSA absorb water very quickly, almost entirely prevent bleeding, and enable very high accuracy and small details.

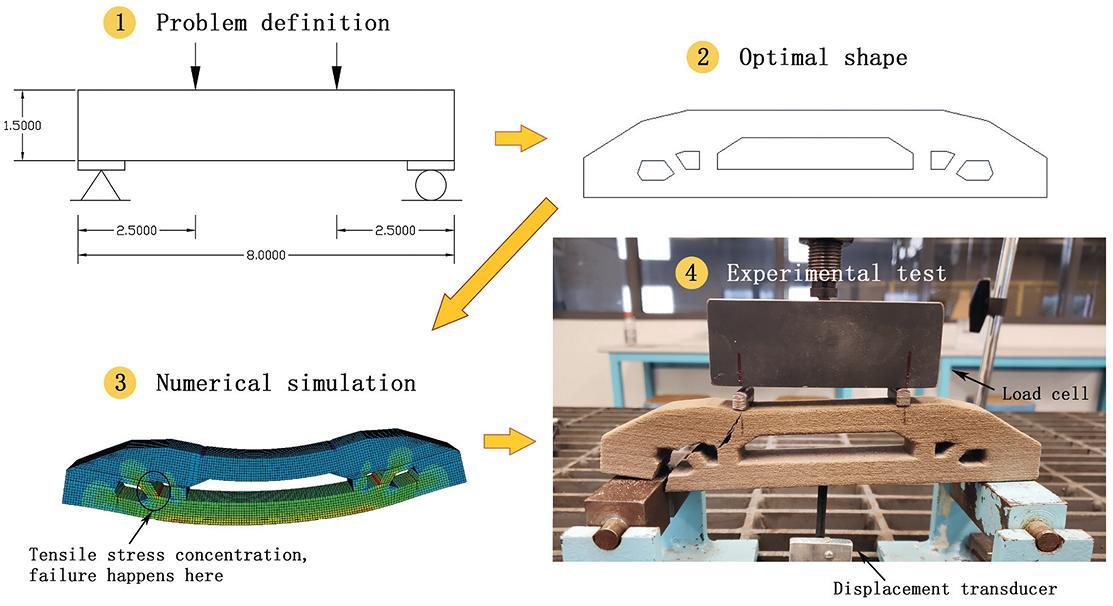

A New Design Approach Based on Topology Optimization

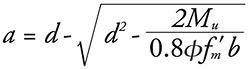

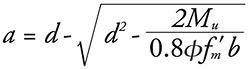

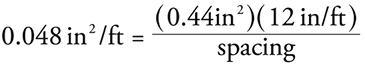

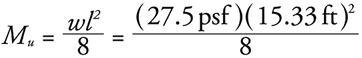

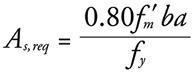

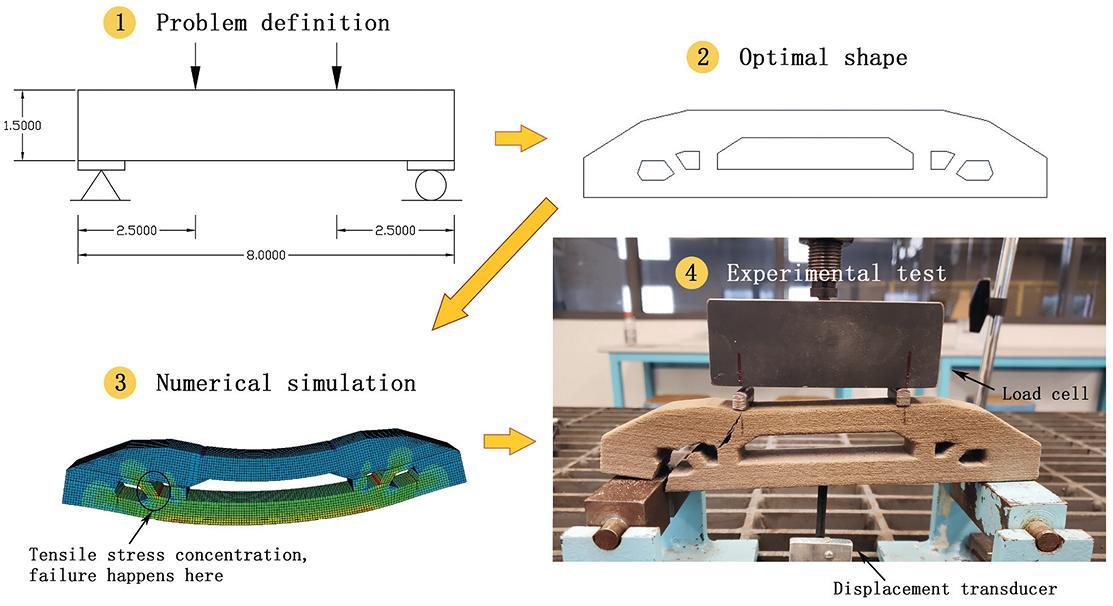

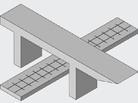

Traditional design approaches only leverage some of the freedom of shape offered by particle bed printing. For this reason, the team at Lehigh combines this new manufacturing technique with a design approach based on topology optimization (TO). This computational approach identifies an optimized shape for the structure in the design domain based on the desired objectives and constraints. Figure 3 shows a simple example application on a four-point bending beam. A conventional rectangular crosssection beam with unit width was

set as a design domain and studied as a reference. By applying topology optimization, an optimized design could be obtained with the objective of maximizing the stiffness of the beam and the constraint of reducing by 30% the material. A numerical simulation to predict the maximum capacity and breaking pattern of the optimized beam clearly shows that the failure occurs at the external diagonals of the structure, where the tensile stress is concentrated. The experimental results are in good agreement with the numerical simulation, especially in terms of determining the failure mechanism.

Figure 4 shows the test results for the conventional plain concrete beam (reference) and the optimized beams. The optimized beams have stiffness similar to the conventional beam (plain beam stiffness: 4.89 × 104 lb/in, optimized beam stiffness: 4.40 × 104 lb/in) while reducing the material

SEPTEMBER 2023 11

Figure 2 3D printed objects with many cavities and thin members.

Figure 3 Workflow of the case study.

by 30%, which leads to benefits in terms of weight, cost, and environmental impact.

Conclusions

All concrete 3D printing approaches endeavor to automate traditional concrete manufacturing. Particle bed 3D printing by selective binder activation

aims at going even beyond that by opening completely new horizons for concrete. The complete and unprecedented freedom of shape makes concrete behave like a new material requiring new structural and architectural design approaches. This technique is still in the early stages of its development, but the scientific results obtained so far and the interest of a national museum to create an exhibit on this as a form of art, technology, and creative expression are a testament to its potential. This approach enables innovative shapes, and even more importantly, it allows designers to use material only where it is most effective. The resulting reduction of the needed material can also have a considerable impact on carbon emissions. The current exhibit at the National Museum of Industrial History in Bethlehem (PA) is a wonderful opportunity for students, scientists, practitioners, and the general public to learn more about this revolutionary technique.■

Xingjian Wang is a doctoral student in Structural Engineering at Lehigh University (xiwa17@lehigh.edu).

John T. Fox, Ph.D., P.E., is Associate Professor of Environmental Engineering at Lehigh University (jtf211@lehigh.edu).

Clay J. Naito, Ph.D, P.E., F.PCI, is a Professor of Structural Engineering at Lehigh University (cjn3@lehigh.edu).

Nik Nikolov, Registered Architect (R.A.), AIA, NCARB, LEED AP, is an Associate Professor of Architecture at Lehigh University (nik@lehigh.edu).

Urinrin Otite is a doctoral student in Structural Engineering at Lehigh University (ubo221@lehigh.edu).

Paolo Bocchini, Ph.D., F.SEI, is a Professor of Civil Engineering, Director of Graduate Programs in Civil and Environmental Engineering, and Director of the Catastrophe Modeling Center at Lehigh University (paolo.bocchini@lehigh.edu).

We’re a nimble team with offices, projects + people across the country. We’re looking to partner with clients and hire individuals that bring their best every day. Our flexible work policy empowers our team members to both design cool structures + make it to that dance recital.

byald yyyy ayaay y fyllyw yyyy

STRUCTURE magazine 12

Figure 4 Experimental results of two types of beams: (a) conventional plain concrete beam (triangular markers) and (b) optimized concrete beams (circular markers).

aaaayaa

a lead the field

schaefer-inc.com/human-resources ADVERTISEMENT–For Advertiser Information, visit STRUCTUREmag.org

MASONRY

Sunlight and Shade

Incorporating Perforated Brickwork into Anchored Brick Veneer.

By Cortney Fried, P.E.

By Cortney Fried, P.E.

Perforated brickwork or brick masonry screen walls have a long history of use worldwide. The earliest known examples are found in Persia and the Middle East. More contemporary examples can be found in India. In hot climates like these, perforated brickwork helped screen the sun while allowing light and air to filter into the space beyond. Other names include pierced walls, lattice walls, hitand-miss brickwork, and jali. For consistency in this article, the term “perforated brickwork” will be used.

Perforated brickwork in the United States has typically been used in landscape applications such as garden walls or small utility enclosures, where their design and construction were empirical. More recently, the Brick Industry Association (BIA) has received inquiries requesting guidance for incorporating perforated brickwork into building facades at a larger scale. Inquiries generally include an inspirational photo without detailed information about the source project, which is typically located outside the United States.

The industry does not have a formal guide or comprehensive resource for the design and analysis of perforated brick walls/screen walls at this time. Still, it has compiled several resources and recommendations that are provided in response to the inquiries.

This article intends to present these resources to a broader audience while the industry is working to develop guides and references to catch up to the increased popularity and expanded use of perforated brick masonry.

Design

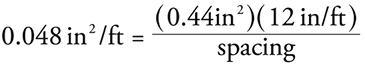

Methodology. The desired screen pattern dictates the design approach. Some screen patterns, such as that shown in Figure 1, utilize a clay solar screen tile, sometimes referred to as a “breeze block,” which is a hollow-fired clay unit with decorative perforations through the exposed face. These units typically maintain a solid rectangular or square perimeter. This solid perimeter and unit format allow them to be laid like traditional masonry, in accordance with the prescriptive code requirements for veneer, because there are full head joints between units and continuous bed joints. Per the prescriptive code requirements, if units are laid in a configuration other than running bond, such as that shown in Figure 1, veneer wire reinforcing with a minimum size of one W1.7 wire is required to be placed in the bed joint mortar at a maximum of 18 inches on center vertically. Other screen patterns incorporate solid clay brick units laid such that there are gaps in place of head joints to create the perforations (Figure 2). The lack of head joints change the veneer's behavior, so the masonry code's prescriptive provisions, TMS 402 - Building Code Requirements for Masonry Structures (TMS 402), no longer apply. In such a case, the alternative design provisions in the veneer chapter of TMS 402 are used as a substitute compliance path. These alternative design provisions consist of an engineered rational design method that applies the following four requirements or guidelines:

• Loads shall be distributed through the veneer to anchors (as applicable), and the backing through the principles of engineering mechanics

• Veneer stability must be maintained through limits to out-ofplane deflection

• The veneer need not be subject to the flexural tensile strength provisions of the Allowable Stress Design and Strength Design chapters in TMS 402.

• The general requirements for veneer must be met, along with the criteria for veneer not laid in running bond and the seismic prescriptive provisions.

Note that the 2022 version of TMS 402 includes a new engineered design method referred to as the “Tributary Area Method.” This method should not be applied to the design and analysis of perforated

SEPTEMBER 2023 13

Figure 1 Clay "Breeze Block"

brickwork, as the analyses performed to develop the method assumed masonry with head joints.

Wind Load. While calculating components and cladding wind loads is relatively straightforward, applying these loads to the perforated brickwork is less so. The presence of the perforations suggests that the loads should be reduced to reflect the proportion of the solid area. However, each unit within the screen pattern will have exposed top and side surfaces that experience drag and suction, resulting in a net wind load that is larger than expected by the proportion of solid area alone. Using unmodified components and cladding wind loads calculated for non-perforated claddings is recommended.

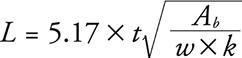

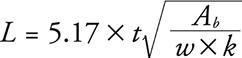

Existing Resources. The obsolete BIA Technical Notes on Brick and Tile Construction publication “Clay Masonry Shading Devices,” dated March 1957, includes some relevant information on the design of perforated masonry, including a formula to estimate the allowable unreinforced span length of a wall in feet.

and a larger specimen in shear to evaluate their load-bearing capacity. They found the compressive strength of a single wythe solid wall to be approximately 10 percent greater than a single wythe perforated wall. The perforated wall could only carry half of the in-plane lateral force compared to the solid wall. Finite element models demonstrated that the individual units are subjected to bending stresses due to the combination of compressive loading at adjacent units' bearing points and the unit's unloaded center. In-plane loads are managed by struts and ties formed through the unit intersections. Out-of-plane loads are managed through shear rotation within each segment of bed joint mortar.

Masia et al.conducted experimental testing of unreinforced perforated brick panels loaded outof-plane to evaluate both vertical and horizontal bending capacity and to compare with predicted capacities based on tested material strengths and current code equations per Australian Standard AS3700: Masonry Structures. Failures in both bending directions were non-ductile, but the specimens in horizontal bending exhibited larger capacities than predicted. Capacities in the horizontal bending direction were greater than the capacities in the vertical bending direction due to the differences in the loading of the mortar joints. In vertical bending, the out-of-plane load is resisted by the flexural strength of the mortar bed joints, whereas in horizontal bending, the out-of-plane load is resisted by the shear strength of the mortar bed joints and the flexural strength of the units.

Detailing

Reinforcing. Because the unreinforced capacity of perforated brickwork is limited, reinforcing must be integrated into the system. In some cases, this reinforcing is not readily apparent.

Where:

L = the allowable distance between lateral support in feet

t = the specified wall thickness in inches

Ab = ratio of actual bed joint length in a horizontal plane to the total wall length

k = ratio of solid wall area to total wall area in a vertical plane

w = design wind pressure in pounds per square foot

This formula is based on a standard allowable flexural stress equation (σ = M/S) with coefficients to reduce the section modulus of the wall. It includes an assumption for allowable flexural tension stress of 20psi. Note that the formula includes the old 1/3 stress increase that is no longer permitted. There has been limited research on the structural behavior and capacity of perforated brickwork, but two relatively recent studies provide insight. Ortlepp and Schmidt tested small-scale specimens in compression

Visible support framing is an obvious solution, typically used where the exposed framing would not be aesthetically objectionable. Where having visible support framing is objectionable, such as where the perforated brickwork spans across window openings, the support framing can be camouflaged. For instance, the London School of Economics Student Center used steel framing members fabricated to match both the size of the vertical window mullions and the overlap distance of the brick. Placed at each vertical mullion in the window system, this steel framing created intermediate locations to anchor veneer ties, reducing the unreinforced span length of the perforated brickwork while maintaining the desired appearance from the interior.

Internal reinforcement is necessary in cases where external support framing is not an option. If there are areas of solid brickwork directly adjacent to the perforated sections, these are ideal locations for placing reinforcement, which can consist of a bar or wire. Bed joint reinforcing may also be an option if the solid brickwork is oriented horizontally. Within the perforated brickwork, vertical reinforcing can only be placed within the overlap zones. For some designs, the geometry permits the brick cores to be used for reinforcing. Still, in others, the overlap zone needs to be narrower, and holes must be drilled into units without cores or frogs to incorporate reinforcing. Some of these configurations may not match the assumptions of the reinforced masonry requirements in TMS 402 and will need to be evaluated rationally. Load testing of a full-size mock-up panel would be prudent to help evaluate the design for structural performance.

STRUCTURE magazine 14

Figure 2 Screen pattern with solid clay units

Durability. Unlike traditional brick masonry veneer, the perforated brickwork openings expose the brick units' multiple sides to the environment and allow water to accumulate on horizontal surfaces. Because of this increased exposure inherent to the system, the performance of the perforated veneer walls will be different from that of traditional brick masonry veneers. The risk of general deterioration and freeze-thaw damage is higher.

It is recommended to use solid brick without cores or frogs. Standard solid brick units conforming to ASTM C216 – Standard Specification for Facing Brick (Solid Masonry Units Made from Clay or Shale) are permitted to have up to 25% cores, so units without cores or frogs must be explicitly specified. Use of cored units in perforated brickwork has been successful, but generally in more southern climates, where the risk of freeze-thaw is low.

ASTM C902 – Standard Specification for Pedestrian and Light Traffic Paving Brick has minimum requirements for strength and cold water absorption that exceed those required for units meeting ASTM C216 Grade SW due to their use in horizontal applications. Selecting bricks that meet these more stringent requirements can provide additional durability in the more severe exposure of perforated brickwork.

If special-shaped units are feasible on the project, consider units with sloped top surfaces and drip grooves at the underside to reduce the potential for ponding water on the horizontal surfaces. Some manufacturers sell special-shaped units with oversized cores at the unit ends for reinforcing but uncored in the center. Special-shaped units can also be used in the adjacent solid sections to create internal space for reinforcing and grout while maintaining the appearance of the exterior. With respect to other considerations to increase durability, polymer-modified mortar is an option to improve the durability of the mortar, but be aware that its use requires more care because of the difficulty of removing polymer-modified mortar smears from brick faces. Consider specifying stainless steel for veneer ties and horizontal joint reinforcement instead of galvanized steel. If desired, a postapplied breathable water repellent can be considered.

Closing

Perforated brickwork has a long history of successful use in many countries worldwide; however, the incorporation of perforated brickwork into anchored brick veneer is a relatively new variation of this concept.

As the masonry industry continues to develop formal guidance on the design of perforated brick veneer, the alternative design provisions in the code allow engineers the latitude to achieve the design intent. The information presented here can provide some guidance to engineers in the meantime.■

Full references are included in the online version of the article at STRUCTUREmag.org

PRODUCING LOW EMBODIED CARBON CEMENT SINCE THE 1960s

Reduce GWP of concrete mix designs using CSA cements

Lower CO2-eq per metric ton

Reduced emissions from raw materials

Fewer natural resources consumed

Reduce energy consumption

Meets GSA’s definition of top 20% of low embodied carbon (LEC) cement

EPDs available

SEPTEMBER 2023 15

Global Warming Potential (kg CO2e/mertric ton) 1000 Komponent® 50% Less Rapid Set® Cement Industry Average Portland Cement 461 673 922 900 800 700 600 500 400 300 200 0 100 27% Less

Cortney Fried is a Managing Senior Engineer at the Brick Industry Association (BIA) (cfried@bia.org)

Learn more about Rapid Set Cement’s role in lowembodied-carbon concrete. by

SUSTAINABLE SOLUTION PROVEN FOR REDUCED GLOBAL WARMING POTENTIAL CTScement.com 800.929.3030 ADVERTISEMENT–For Advertiser Information, visit STRUCTUREmag.org

CTS Cement Manufacturing Corp

structural MAINTENANCE

Concrete Defects and Preventive Maintenance

How preventative maintenance can prolong the concrete structure life, preserve integrity, and reduce repair cost.

By Ahmed Clayiff, P.E., CBSI

Concrete construction offers inherent benefits, such as resilience, durability, and strength. However, those benefits are dependent on the quality control of placing concrete during construction and the maintenance during its service life. During construction, concrete’s quality depends on the care taken during mixing the ingredients, handling, and curing the fresh concrete.

What is Concrete?

Concrete consists of a mixture of cement, sand, aggregate, and water; additional chemical substances, called admixtures, can be added to accommodate a specific need for a design application. The primary functionality of admixture is to change the properties of concrete to make it more workable, inhibit corrosion, and achieve higher strength or other improvements.

After all the ingredients are mixed, the concrete will be poured (placed) into forms with properly positioned conventional or prestressed steel reinforcement. Conventional reinforced concrete is constructed with non-prestressed steel reinforcement (i.e., reinforcing bars or welded wire fabric). Prestressed concrete contains high-strength reinforcement (i.e., bars, wires, or strands), which can be either pre-tensioned or post-tensioned. The pre-tensioning process consists of pre-tensioning the reinforcement to a desired stress level before pouring the fresh concrete. The post-tensioning process consists of placing the concrete before the reinforcement is tensioned. The reinforcement is placed inside a conduit or coated with a lubricant to prevent it from bonding with concrete. After the concrete is poured and reaches optimum strength, the reinforcement is post-tensioned to the desired stresses. During the process of concrete mixing, handling, and curing, the following precautions should be taken to achieve the desired concrete quality,

A- Mixing and Handling

• Accurate mix ingredients proportions.

• Adequate mixing.

• Appropriate delivery time to avoid segregation.

• Vibrating to reduce excess entrapped air to avoid poor consolidation.

• Sampling and testing

B- Reinforcement details.

• Maintain a proper clear cover of reinforcement.

• Maintain adequate reinforcement spacing.

• Adhere to design documents and specifications.

What Is Concrete Curing?

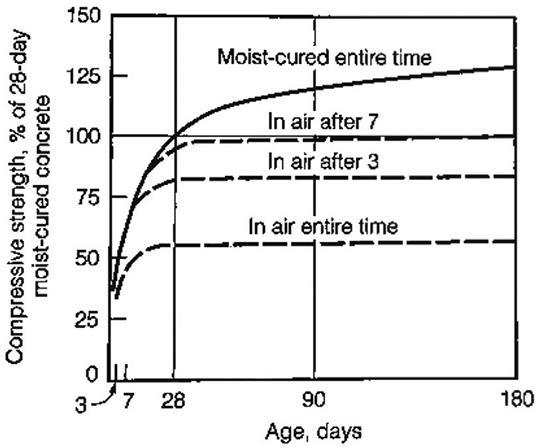

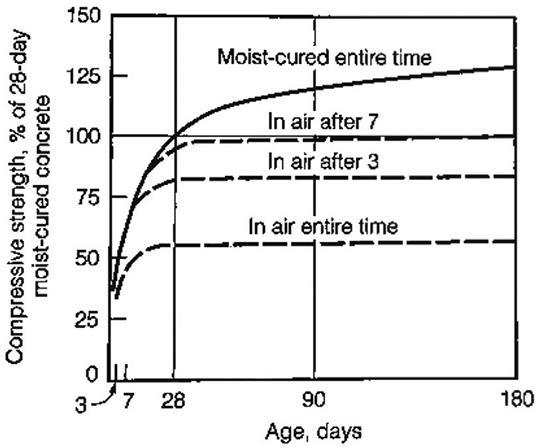

The process begins after the fresh concrete is placed into the forms and hydration begins at the appropriate temperature. The hydration process should be controlled to retain moisture within the concrete and avoid rapid temperature changes. As the hydration process continues, the concrete properties will change, and the concrete strength will increase over time (see Figure 1). Other improvements during the hydration process are the property changes (i.e., increase resistance to abrasion resistance, improved water tightness, etc.). A defective curing process may impair the concrete quality significantly. For

example, placing the concrete in an environment with high temperature and low humidity may cause rapid water loss or fast evaporation. The rapid water loss will result in quick concrete volume changes at an early age and may lead to cracks. Cracks are unfavorable results that can immediately be a significant issue for structures that store liquids and chemicals. Other problems that increase over the structure’s lifetime are discussed in the following concrete defects section.

The concrete quality depends on the concrete ingredients’ mix proportions and the means and methods of mixing and handling. Better quality can be achieved by implementing an effective plan for quality assurance and quality control (QA/QC), including workmanship, inspection, sampling, and laboratory testing.

Concrete Defects

During or after the concrete placement.

• Cracking: This may result during the curing process or at other times during the structure’s lifetime. During the structure’s lifetime, the gradient changes between low and high temperatures may result in cracking. For example, an expansion typically occurs during the summer, and a contraction typically occurs during the winter. These phenomena are the main causes of cracks in concrete. Other cracks may result from loading that exceeds the structural capacity, resulting in overstresses such as shear, flexure, or torsion.

• Honeycombs: This results from poor consolidation, such as a lack of vibration while placing the concrete. Proper vibration is needed to reduce excessive entrapped air. Excessive air leads to voids that increases permeability, exposes the reinforcement, and reduces the strength of the concrete.

• Spalling: This may result from excessive loading and poor bonding, resulting in a member separating a shell or a section. Other causes during the service life may include deterioration (weathering) and corrosion of reinforcing steel.

STRUCTURE magazine 16

Figure 1 Compressive strength of concrete at different ages and curing levels by Michaels Mamlouk – John P. Zaniewski

During the service life - deterioration.

• Efflorescence: Crystalline, white material that appears on the surface of the concrete (see Figure 2). It results from water penetrating the cracks over time, and a chemical reaction occurs with the cement paste leaching out to the surface.

• Freeze-thaw failure occurs when the water penetrates the voids, pores, or cracks and freezes at low temperatures. As water freezes within the concrete voids it increases in volume and induces forces inside the concrete, propagating the crack size, and may lead to spalling.

• Scaling occurs when a concrete surface breaks down, or erodes, exposing the aggregates.

• Delamination occurs where cracks and splits are generated parallel to the surface, caused by overloading and/or corrosion of steel reinforcement. These defects are aesthetically unpleasant and in many cases jeopardize the structural integrity of the reinforced concrete member. For example, corroded reinforcement can reduce the cross-sectional area of the member, expose the steel reinforcement to corrosive element and break off the concrete cover (see Figure 3). The cross-sectional area reduction of reinforcement can be visually seen when it expands or becomes smaller. Not all defects can be visually seen; in many cases, specific testing with a thorough inspection program is required to detect those defects. Other defects not discussed in this article that result from utilization include tears and chemical attacks such as chloride and sulfate. How do we avoid those defects and reduce their impact? Those can be avoided by implementing the program below.

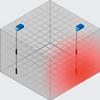

Preventative Maintenance

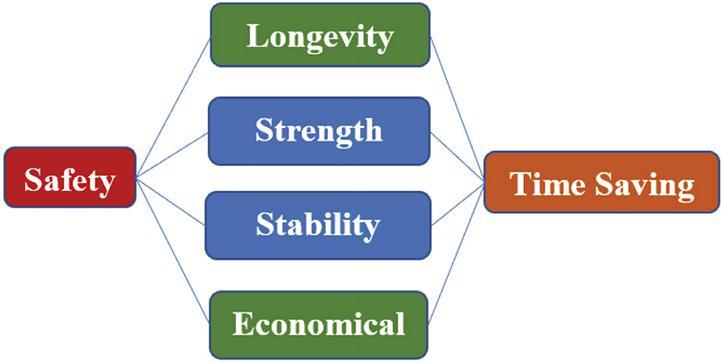

All those defects are structural and safety concerns, and it should be the priority of the structure’s owner to implement an effective process to ensure those are addressed and avoided. The process should consist of routine inspection and maintenance to prolong the structure’s life. The routine inspection is an evaluation process of the entire structure to identify potential and existing defects. Defect findings should be presented with a condition rating system such as (good, fair, and poor) and maintenance priority (immediate or routine). Preventive maintenance offers several critical benefits to the property owner, not limited to structures in poor condition; it also applies to structures in good condition (Figure 4).

The most crucial benefit is maintaining safety and structural integrity; this is achieved by preserving functionality, strength, and stability. An alternate advantage is that less effort is required to address an issue or

defects early in the process and prevent it from worsening its condition. For example, cracks are an issue but can be prevented by sealing them prior to the water penetrating and corroding the reinforcement that propagates to a spall. Other minor efforts that will help avoid a significant structural issue are cleaning and ensuring the drainage system is functional. This will also prevent water ponding (water accumulation). Ponding clearly leads to water intrusion; it may also induce loads that exceed the structural capacity and lead to structural instability and failure.

Major repairs are not only a structural concern and higher cost but also interrupt functionality and inconvenience the occupants. Interruption occurs when a portion of the structure needs to be vacant during the repair process, such as temporary shoring. Temporary shoring is a structural support or frame designed to support the structure (partial/entire) and prevent it from collapsing until the repair is finished.

Therefore, preventative maintenance substantially benefits the property owner by maintaining safety and the structure’s expected life cycle. It will also be cost-effective as significantly high-cost repairs will be avoided, as well as offers better budget planning, maintains the structure’s aesthetic, and provides a reliable environment for the occupants.■

SEPTEMBER 2023 17

Figure 2 Concrete surface with Efflorescence.

Figure 3 Concrete surface spalling with corroded reinforcement.

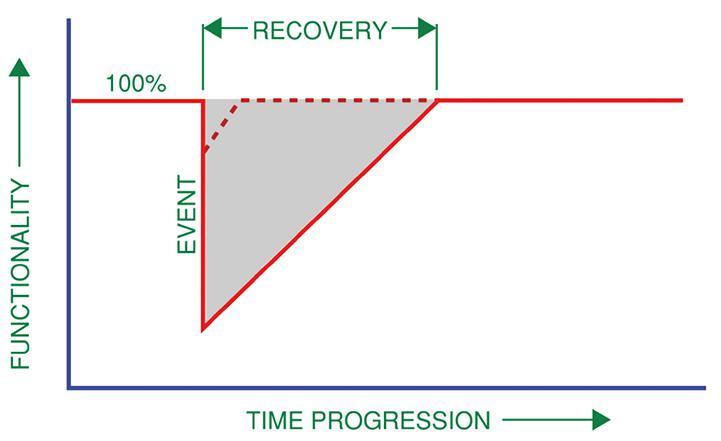

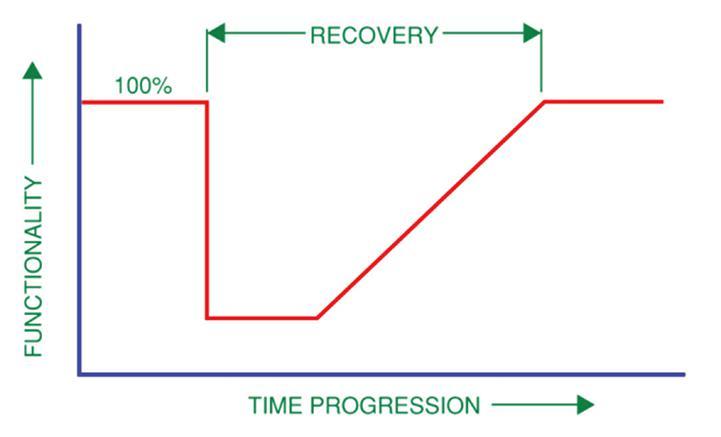

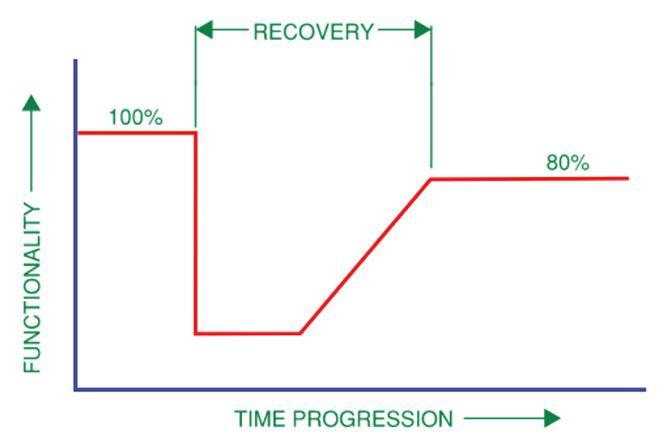

Figure 4 Preventative maintenance benefits.

Full references are included in the online version of the article at STRUCTUREmag.org.

Ahmed Clayiff, P.E., CBSI, owns Clayiff Engineering, LLC. He has experience in various structural engineering areas. Mr. Clayiff is also an adjunct faculty and has taught various engineering courses. He can be reached at (aclayiff@clayiff.com)

structural FLEXIBILITY Deflections of Concrete Structures Using Bilinear Flexibility

By Neil Wexler, Ph.D., P.E., Hoonhee Jeoung, P.E., Nissim Elmann, P.E.

Deflection of concrete members follows a bilinear curvature, and it can be affected by many different variables. Concrete members are often internally reinforced and/or tensioned, come in different shapes, and vary with regards to the ingredients and additives in the concrete. Despite these variations, engineers generalized concrete behavior and the ACI Code adopted these general procedures, though difficulties remain. Some research reported discrepancies between actual results and code predicted deflections. The Branson and Bischoff equations are currently in use for calculating Ie, but in reality, they also require calculations of y- and Icr, making the calculations of deflections lengthy and time consuming. In addition, the most recent ACI Code procedure is still dependent on curve fitting rather than a scientific basis.

A new proposed method for calculating concrete deflections is presented herein; this method is based on the general bilinear flexibility of concrete under flexural stress. An earlier paper related to the specific deflections of high-rise concrete shear walls and using the bilinear flexibility method was authored by the two senior authors. In this work, the method is extended in a general way to concrete beams, plates, and to other structural materials.

Ie = effective moment of inertia, in4

Icr = moment of inertia of cracked section transformed to concrete, in4 y- = distance from extreme compression fiber to neutral axis, in

Background

Concrete cracks when subjected to tensile stresses that exceed the modulus of rupture. Since stresses along the beam span are not uniform, the degree of cracking is also non-uniform; more and larger flexural cracks occur at locations of higher flexural stresses. Therefore, a concrete beam even if initially prismatic, becomes non-prismatic when cracked.

The stress magnitude relative to the modulus of rupture is one indicator of flexibility; the larger the ratio, the more cracks cause more flexibility. The amount of longitudinal steel reinforcement is another indicator of flexibility; less rebar causes more flexibility.

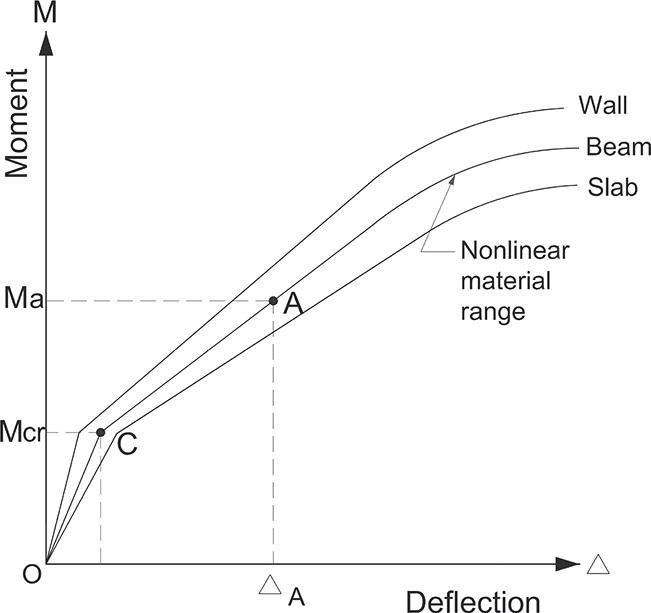

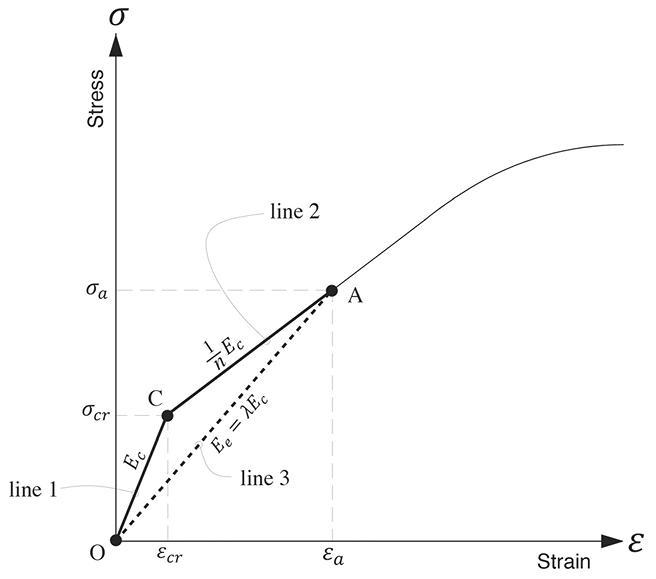

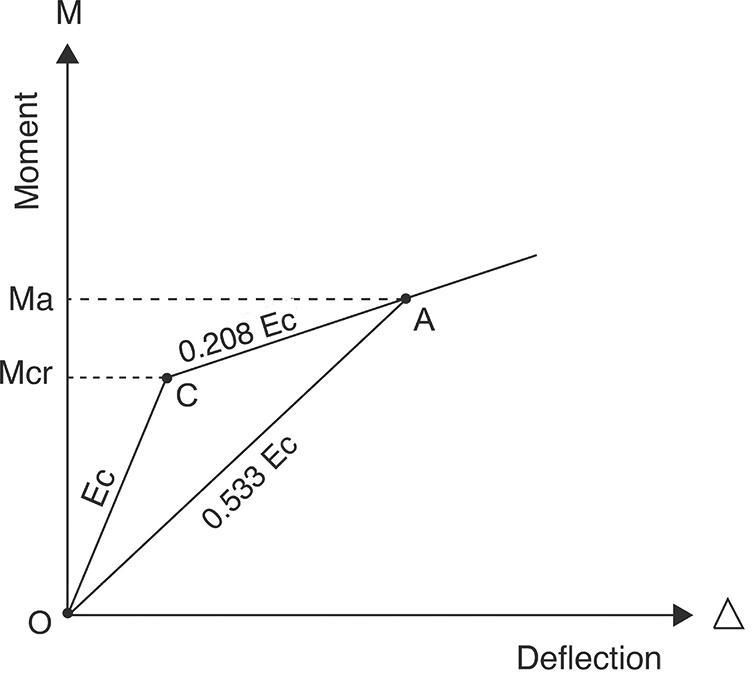

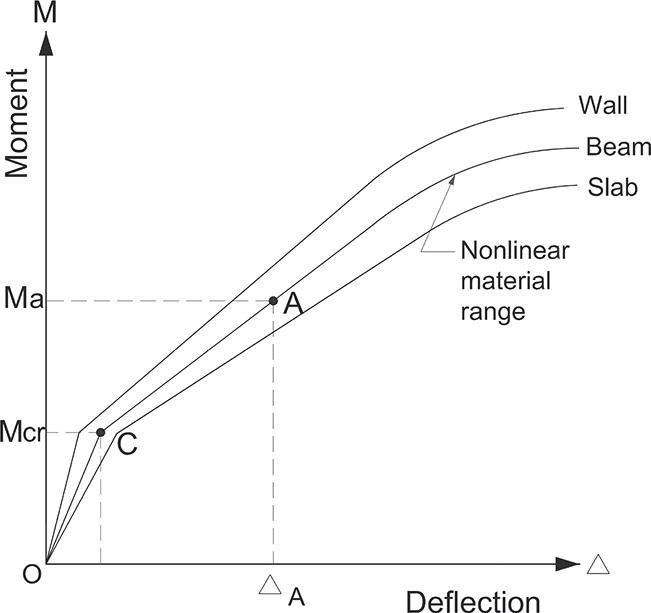

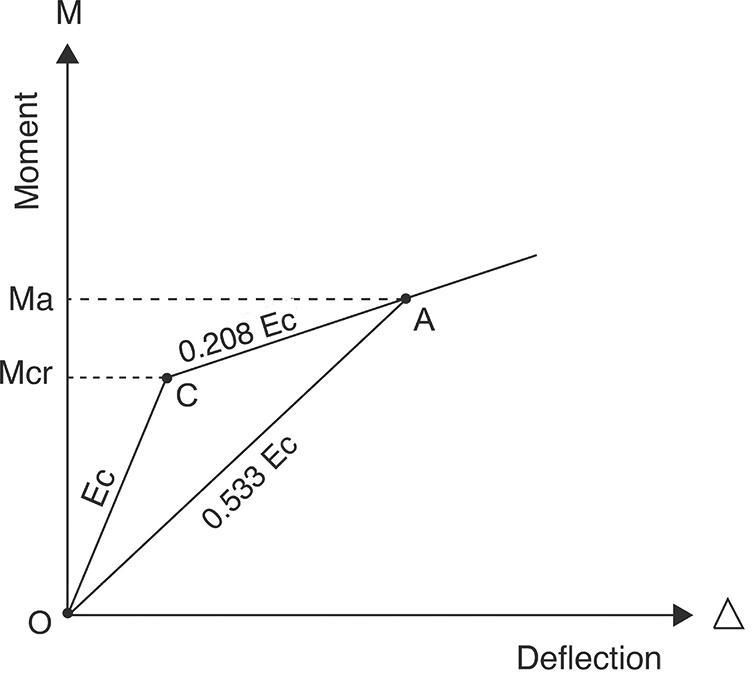

Figure 1 shows a typical load deflection curvature for concrete reproduced from Reference 7; the flexibility is bilinear. Below cracking (Point C), gross section properties predict deflections reasonably. However, above cracking, gross properties no longer predict deflections accurately. The larger the spread between the applied load and the load at which cracks initiate, the larger the error. Point A is arbitrary, where the moment Ma is larger than the cracking moment Mcr . Figure 1 also shows the general impact of section geometry on flexural flexibility. Thus, for a given section, the most significant variables affecting flexibility are:

1. The load ratio - Mcr/Ma

2. The area of longitudinal flexural reinforcement.

Concrete deflections follow general accepted formats, but walls are stiffer than beams and stiffer than slabs, as shown in Figure 1.

Flexibilities

Considering the modulus of elasticity E, the product EI is an indication of flexural flexibility. In a cracked beam the value of I varies along the span of the beam: it is Ig where un-cracked and Icr where cracked. For a simply supported beam we focus our analysis on the section at the center of the beam where flexural stresses are the largest. Ie from Branson and Bischoff are shown below; in which they depend on y- and Icr, also shown below.

As can be seen, to obtain Ie we must first calculate y- then Icr

E = modulus of elasticity, psi

E

c = modulus of elasticity of concrete, psi

STRUCTURE magazine 18

Branson II M M I M M 1 eg a cr cr a cr 3 3 =+aakk;E (1) Bischoff I M M I I I 11 e a cr g cr cr 3 2 2 = c ^ c h m m (2)

Figure 1 Flexural load/deflection curvature for different geometric sections

Ig = moment of inertia of gross concrete section, in4

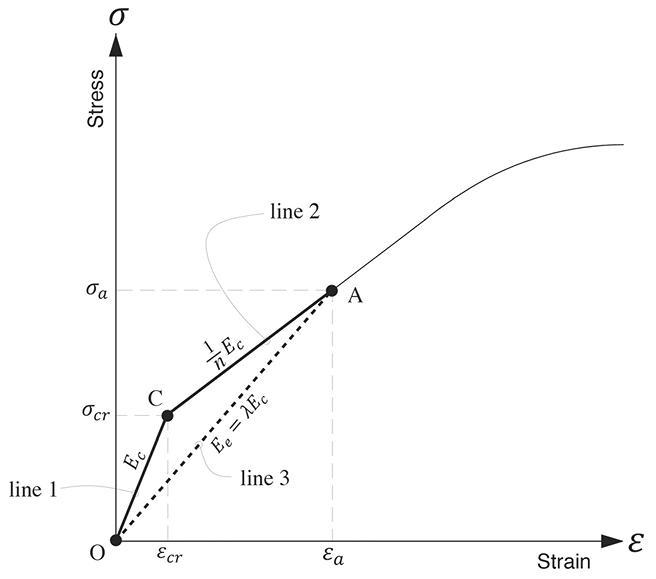

Figure 2 shows a bilinear stress-strain graph but includes a linear equivalent line as if the beam is prismatic, for both before and after cracking (in reality, a cracked beam is non-prismatic, as indicated earlier). The objective is to obtain the equivalent prismatic properties that can be used to predict accurate deflections. Note that concrete cracks at Point C, where stress is equal to v cr. But the goal is to obtain deflections at Point A and we do this directly by using Line 3.

In Figure 2, Line 1 shows the beam flexibility before cracking, Line 2 shows the beam flexibility after cracking, and Line 3 shows the equivalent prismatic flexibility.

Let’s define Ee = λEc, where λ is a coefficient to be calculated. va is the stress at Point A due to flexural loads and εa is the corresponding strain. The objective is to obtain λ as a function of other variables in triangle OAC.

Derivation

Working with triangle OAC in Figure 2, we obtain (see Ref. 3 for derivation):

simple and save time. They show the correct flexibility when loads exceed cracking without the need to evaluate three equations each time.

Determination of Flexibility Coefficient, n

Deflections of concrete structures are impacted by, among other things geometry, loads, and the quantity of reinforcement, as mentioned earlier. As a result, the value of n, is particular to each design case. This coefficient n may be determined using several possible methods, as follows:

1. Use an approximate n value.

2. Use an n value from tests and experiments.

Where 1/n represents the slope of the upper part of the bilinear graph as Line 2 in Figure 2; vcr is the cracking stress (for concrete); va represents flexural stress. Fy represents yield stress (for steel).

Equations (3), (4) and (5) are the Equations of Bilinear Flexibility and can be evaluated at any point along the beam span and the beam depth.

The ACI Code suggests specific values of n to calculate deflections but for lateral loads only. If Code values are to be used for gravity loads then n values need to be evaluated. ACI Code values at service loads are n = 3 for slabs, n = 2 for beams and cracked walls, but these values are to be used with lateral loads only.

It is instructional to note that λ =1 represents the case of uncracked concrete which occurs when n = 1 or, when va ≤ vcr or when Mcr/Ma > 1.0. When concrete is cracked Mcr /Ma < 1.0, n is greater than 1 and λ is less than 1.

Advantage of Bilinear Flexibility

The Equations of Bilinear Flexibility were developed herein using a method of substitution of bilinear properties with a single equivalent linear property. The variables needed are loads (moments or stresses) and the flexibility coefficient, n. These equations can be used for various concrete structures and materials. It is interesting to note that they are applicable not only for concrete but for all materials with dual flexibilities, including structural steel. They also have implications for seismic analyses, such as when demand exceeds the elastic strength of members and when structural loads get redistributed.

For an engineering office the new equations of bilinear flexibility are

3. Use n values from calibration with available tools, such as Branson or Bischoff.

SEPTEMBER 2023 19

λ nn 1 cr a a vv v = ^h (3) λ nn F F 1 1 a y = ^h (4) λ nn M M 1 1 a cr = ^h (5)

8” THICK SLAB Calculation of I cr for Different Reinforcement Configurations ρ nAs (in2) yˉ (in.) I cr (in4) .2% 1.3 1.1 48.2 .3% 2.0 1.3 68.7 .4% 2.6 1.5 87.7 .5% 3.3 1.7 105.6 .6% 3.9 1.8 122.4 .7% 4.6 1.9 138.5 .8% 5.3 2.0 153.8 .9% 5.9 2.1 168.4 1.0% 6.6 2.2 182.4 1.2% 7.9 2.4 208.9 1.4% 9.2 2.6 233.6 1.6% 10.5 2.7 256.6 1.8% 11.8 2.8 278.3 2.0% 13.2 2.9 298.8

Figure 2 Bilinear stress and strain diagram for beam deflection

Table 1 8” Slab – Coefficients to be used for determining

effective

moment of inertia (Ie)

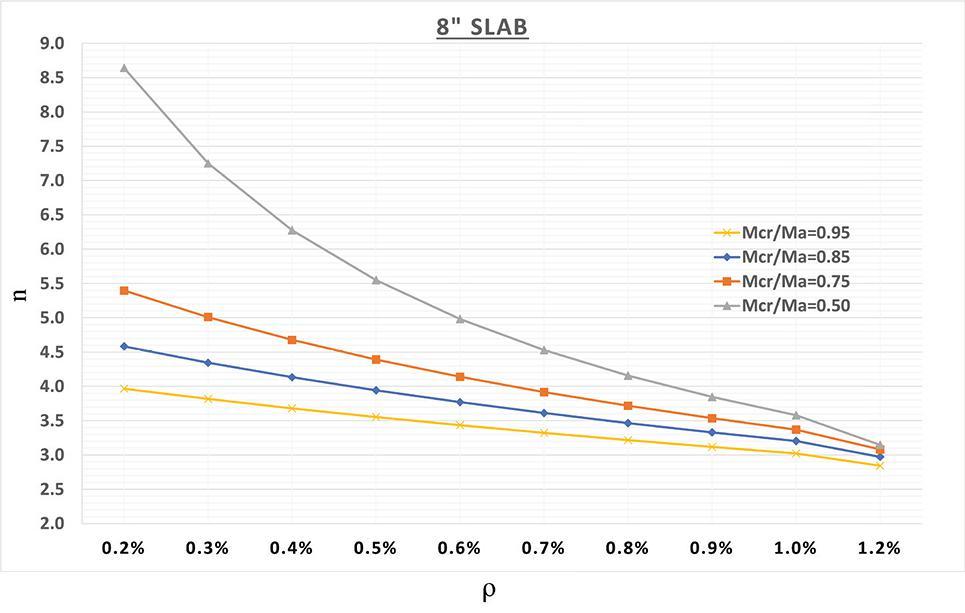

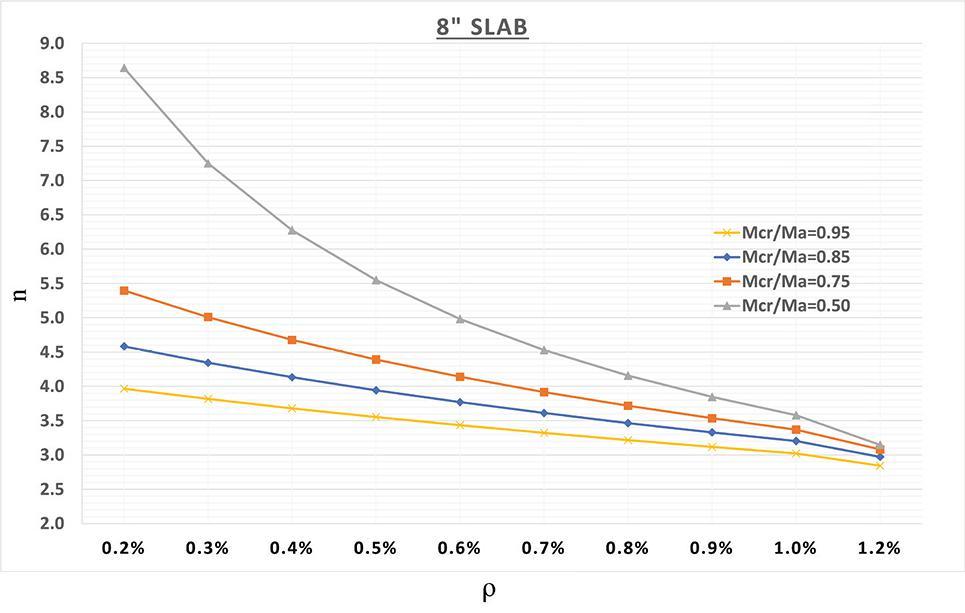

Table 1 and Table 2 are used to obtain Figure 3 for an 8-inch-thick one-way flat concrete slab (f’c = 4,000 psi), and calibrated to Bischoff. Mcr /Ma were selected arbitrarily and Ie was calculated for different reinforcement ratios, from Bischoff. The value of n is calculated as below:

Proposed Procedure

1. Design one-way concrete slab and select steel reinforcement ρ = As /bd

2. Enter Figure 3 graph and write down values of n for Mcr/ Ma equaling 0.50 thru 0.95. This will establish the slope for Line 2 in the bilinear graph (Figure 2).

3. Obtain values of λ and Ie using Equations 3 thru 5 or Figure 3 graph.

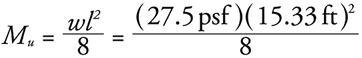

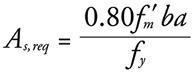

Example

Determine Ie for an 8-inch one-way concrete slab with bottom steel reinforcement of #5 bars at 12ʺ o.c. The slab spans 18 feet and support 160 psf of total residential loads.

STRUCTURE magazine 20

n M M M M 1 1 a a cr cr m =a a k k (6) I I g e m = (7)

Solution: Mcr = 5.0ft − k Ma = 160 × 18 8 2 = 6.48ft k M M cr a = . 648 5 = 0.77 From Figure 3: ρ = 812 31 # × 100 = 0.32% M M a cr = 0.77 n = 4.8 λ = nn M M 1 1 483877 1 a cr # = - ^h = 0.53 Ie = 0.53 × 512 = 271.4 in4

M cr/M a = .50 M cr/M a = .75 M cr/M a = .85 M cr/M a = .95 ρ I cr I e (in4) λ n I e (in4) λ n I e (in4) λ n I e (in4) λ n .2% 48.2 106.20.21 8.6243.90.48 5.4333.00.65 4.6445.90.87 4.0 .3% 68.7 124.10.24 7.3255.70.50 5.0340.90.67 4.3448.80.88 3.8 .4% 87.7 140.70.27 6.3266.70.52 4.7348.30.68 4.1451.50.88 3.7 .5% 105.6156.40.31 5.5277.00.54 4.4355.20.69 3.9454.00.89 3.6 .6% 122.4171.10.33 5.0286.80.56 4.1361.70.71 3.8456.40.89 3.4 .7% 138.5185.20.36 4.5296.00.58 3.9367.90.72 3.6458.70.90 3.3 .8% 153.8198.50.39 4.2304.90.60 3.7373.80.73 3.5460.90.90 3.2 .9% 168.4211.30.41 3.8313.30.61 3.5379.40.74 3.3463.00.90 3.1 1.0% 182.4223.60.44 3.6321.50.63 3.4384.80.75 3.2465.00.91 3.0 1.2% 208.9246.80.48 3.1336.80.66 3.1395.00.77 3.0468.80.92 2.8 1.4% 233.6268.40.52 2.8351.00.69 2.8404.60.79 2.8472.30.92 2.7 1.6% 256.6288.50.56 2.5364.40.71 2.6413.50.81 2.6475.60.93 2.5 1.8% 278.3307.50.60 2.3376.90.74 2.4421.80.82 2.4478.70.93 2.4 2.0% 298.8325.50.64 2.1388.70.76 2.3429.70.84 2.3481.60.94 2.3

Figure 3 8” Slab - n values as a function of reinforcement ratio

Table 2 8Ó Slab Ð Calculated n values to be used for bilinear flexibility in Equation 5.

Conclusions

The method of Bilinear Flexibility is presented herein. In this procedure, Bilinear Flexibility is replaced with an equivalent single flexibility. A calibration method was used to obtain flexibility coefficients n.

ASDIP Structural Software

Phone: 407-284-9202

Email: support@asdipsoft.com

Web: www.asdipsoft.com

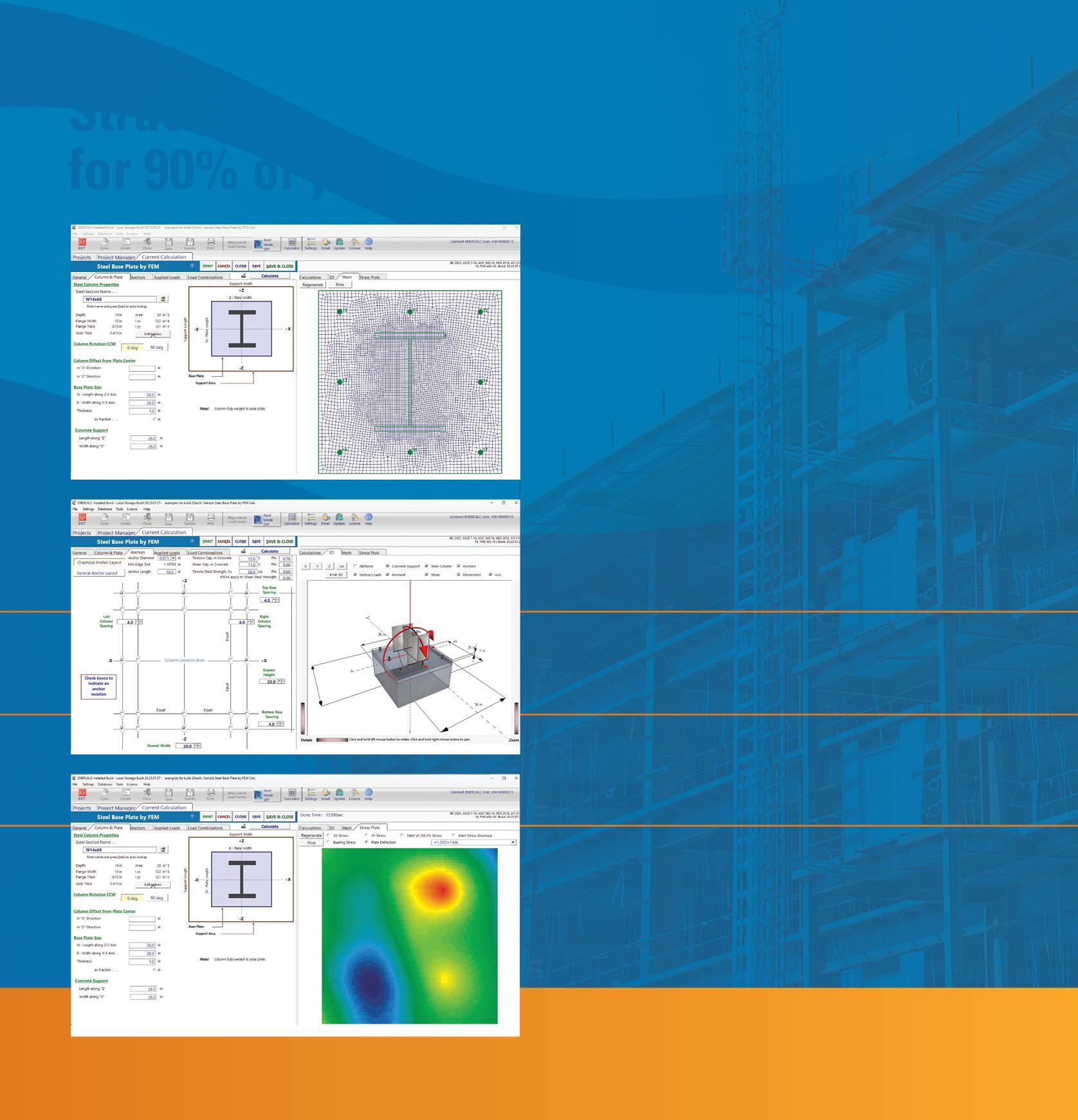

Product: ASDIP STEEL

Description: Intuitive software for the design of steel members and connections, such as composite/non-composite beams, steel columns, base plates, anchoring to concrete, shear connections, and moment connections, per the latest design codes. ASDIP STEEL includes 5 modules that substantially simplify the timeconsuming calculations of structural designs.

ENERCALC, LLC

Phone: 949-614-0689

Email: info@enercalc.com

Web: https://enercalc.com

Product: ENERCALC SEL / ENERCALC 3D

Description: Design of anchors and anchor bolts typically requires a thorough development of applied loads and possible analysis of full structures/ connected components. ENERCALC can help determine those loads & perform those analyses through its Loads & Forces module and its analysis and design modules. Clear, succinct reports represent your work well.

The equivalent single flexibility is obtained with the use of the equation of Bilinear Flexibility which converts n to λ. For accurate results, use appropriate n values, then calculate Ie using the general Equation of Bilinear Flexibility. This simple method is based on the first principles and, therefore, may be appropriate for adoption by building codes.

Future research may focus on the development of n-values considering different, concrete cross- sections, podiums, two-way slabs, etc. Additionally, this method can be used with other materials, and is applicable for post-elastic analyses.■

Full references are included in the online version of the article at STRUCTUREmag.org

Neil Wexler is the founder of Wexler Associates, a 39-year-old, New York City-based firm specializing in the design of high-rise concrete buildings. He received his BS from McGill University, Montreal, QC, Canada; his MS from City University of New York, NY; and his PhD from New York University, New York, NY, all in civil engineering.

Hoonhee Jeoung is a principal at Wexler Associates and a concrete design expert with more than 16 year of structural design experience in the fields of structural steel and concrete. He received his BS in civil engineering from the City University of New York and his MS also in civil engineering from New York University.

Nissim Elmann is an Associate at Wexler Associates and he has been with the firm for 8 years. Nissim currently lives in Miami where he manages Wexler’s Miami office. He received his Bachelor’s and Master’s degrees from NYU Tandon School of Engineering.

ANCHORguide

The Masonry Society

Phone: 303-939-9700

Email: info@masonrysociety.org

Web: masonrysociety.org

Product: TMS 402/602 - 2022

Description: Building Code Requirements and Specification for Masonry Structures. Contains TMS 402-22 (Building Code Requirements for Masonry Structures and TMS 602-22 Specification for Masonry Structures. Available in print, downloadable formats. Coming soon - subscription based convenience with additional enhanced features. Watch the TMS website for announcements.

RISA Technologies

Phone: 949-951-5815

Email: info@risa.com

Web: risa.com

Product: RISAConnection

Description: RISAConnection is at the cutting edge of next-generation connection design software and features full 3D visualization as well as expandable reports for every limit state. RISAConnection includes complete integration with RISA-3D and RISAFloor, as well as partner software packages such as Tekla Structures and Hilti Profis for anchorage design.

Trimble Inc

Phone: 770-426-5105

Email: tekla.us.marketing@gmail.com

Web: https://www.tekla.com/us

Product: Tekla Structural Designer

Description: Tekla Structural Designer allows you to seamlessly combine analysis and design into one easy and efficient single model-based process. For engineers working with concrete, the software offers unique interactive design capabilities for concrete beams, columns and walls, as well as reinforcement optimization for concrete slabs.

Williams Form Engineering Corp.

Phone: 616-866-0815

Email: williams@williamsform.com

Web: www.williamsform.com

Product: Anchor Systems

Description: Williams Form Engineering Corporation has been providing threaded steel bars and accessories for rock anchors, soil anchors, high capacity concrete anchors, micropiles, tie rods, tiebacks, strand anchors, hollow bar anchors, post tensioning systems, and concrete forming hardware systems in the construction industry for over 100 years.

Monthly 2023 Resource Guide forms are now available on our website. Not listed? STRUCTUREmag.org

SEPTEMBER 2023 21

Figure 4 Example flexural load/deflection curvature

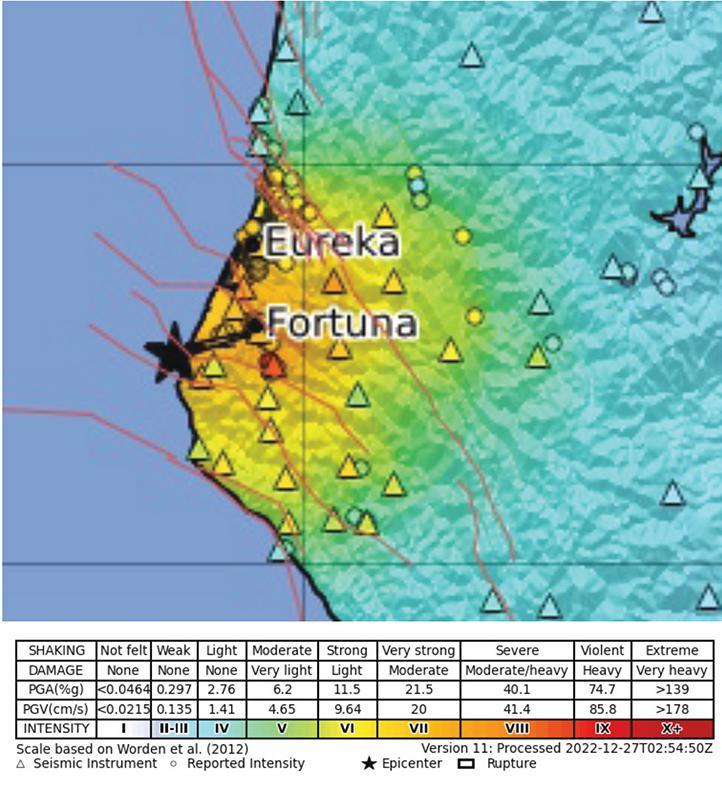

Observations from the December 20, 2022, Ferndale Earthquake

By John A. Dal Pino,

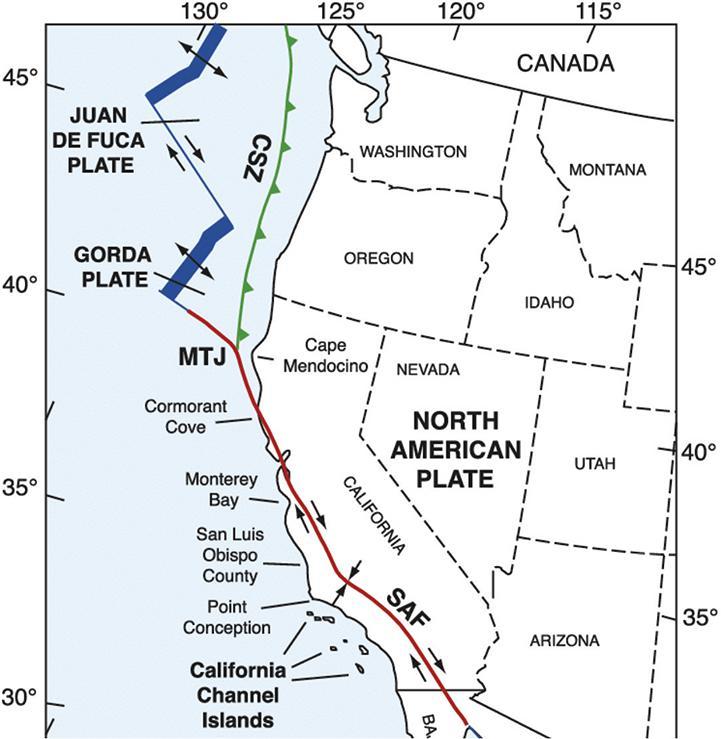

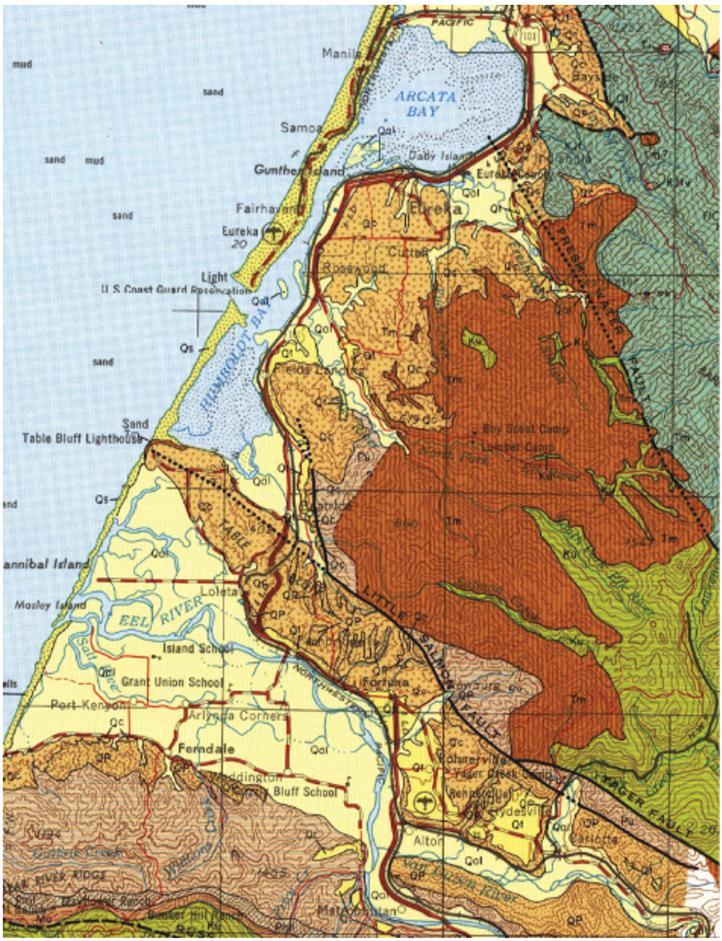

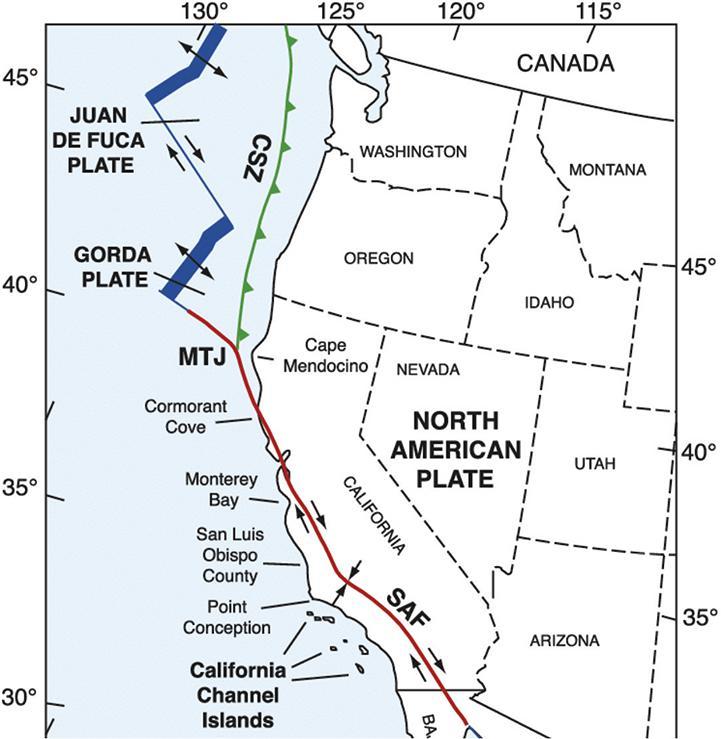

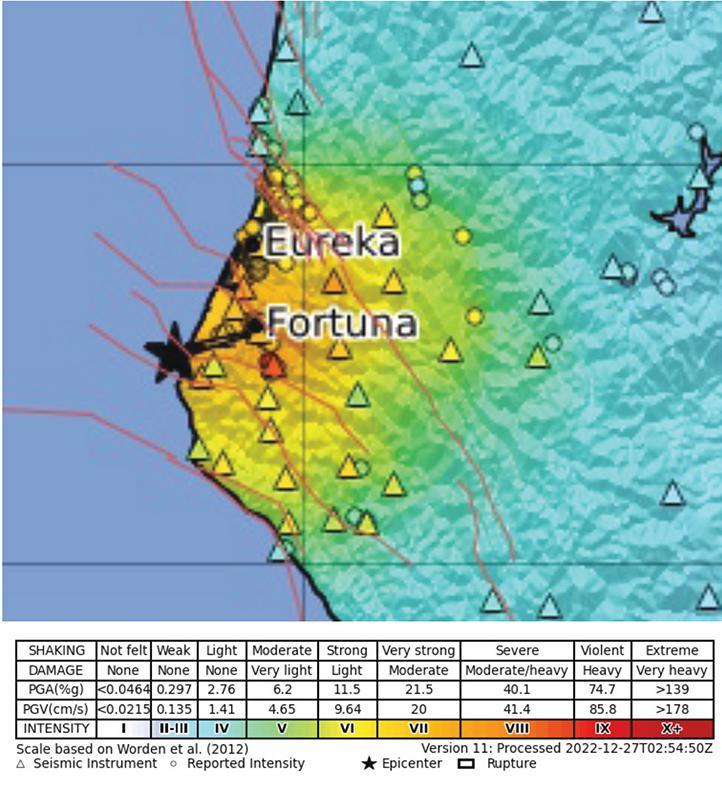

Between Christmas and New Year’s, I led a small group from FTF Engineering on a long day trip to the California North Coast to learn from the December 20, 2022, 6.4 magnitude (Modified Mercalli Intensity VIII, Severe) Ferndale earthquake. Our goal was to visit Scotia, Rio Dell, Ferndale, Eureka, and anything else that caught our eye. For me, the goal was three-fold: first, to take the opportunity to personally learn something new from a “local” earthquake; secondly, to provide the FTF staff who joined me with their first opportunity to go on what is commonly called an “earthquake chase,” and thirdly, to share our experiences with the broader community in the hope that seismic hazard mitigation will be once again placed in prominent view. Based on the first press reports, my expectations for learning about building types we design today were low. Still, I have come to understand that in any situation there are always a few nuggets to be found if you look or think hard enough. If you can do what we did after a future earthquake, or any similar natural hazard event, I strongly recommend it. Seeing something up close in the context of the local building inventory and how buildings are or have been generally constructed informs the observer in a way that photographs from recent or long past earthquakes cannot. I assume that engineers in other parts of the country do their own “chasing” after damaging windstorms, floods, fires, or snowfalls. Their experiences do not seem to be as well documented or widely published as for earthquakes, but I wish it were otherwise.

Background

First, I want to provide an overview description of the typical construction, the regional seismicity, and what our team observed. The North Coast is a large redwood forest stretching north-south from a few hours north of San Francisco to the California-Oregon border and east-west from the coast to the north-south center line of California (roughly Interstate 5). The primary industry has always been and will probably remain lumber. Most buildings are therefore constructed from wood. The local population is largely employed in some aspect of the lumber industry or commerce related to and sustained by the redwood forest, mainly tourism. Except for institutional buildings (hospitals, police stations, telephone exchanges, and so on) and a sprinkling of newer apartment buildings in Eureka (the largest city and main population center), most of the buildings are one and two-story stick-framed or heavy timber structures. Besides Eureka, the next largest city is Ferndale, followed by the smaller towns of Scotia, Rio Dell, Fortuna, and Petrolia. Some of the banking, commercial, and residential buildings in each city are in the grand Victorian style, particularly in Ferndale, dating to the late 1800s (considered old in California). The dairy industry is also significant in the local economy.