FOR YOUR LARGEST PROJECTS, CHOOSE JUMBO HSS.

For industrial projects like manufacturing facilities, using structural steel with wider spans and high axial load capacities is essential. Jumbo HSS from Atlas Tube have the highest strength-to-weight ratios in the industry, so you can build bigger with less steel and lower embodied carbon.

Go big with Jumbo HSS at atlastube.com/jumbo

BOLT THE IMPOSSIBLE.

With Shuriken,™ you can use HSS in more designs, more ways, more a�ordably by field bolting columns that used to require welding. Using Shuriken to bolt HSS results in fewer field welds, easier installation, faster visual inspections, and lower costs, which means you get all the benefits of HSS.

Applications include HSS columns, beams and trusses; SpeedCore; connections in tight spaces; retrofits; and more.

BOLT HSS IN THREE SIMPLE STEPS. Watch how it works at atlastube.com/shuriken

STRUCTURE

WIND/SEISMIC

INSIDE: Seismic Repair in Alaska

Seismic Design of CLT Walls

FRP Collector Strengthening Wind Retrofit Resources

STRUCTURES CONGRESS | MAY 3 6

NCSEA | CASE | SEI MARCH 2023

INNOVATE FREELY

Creative. Integrated. Transformative. Accommodating over 50 million travelers each year, Charlotte Douglas International Airport is the world’s seventh busiest aviation travel hub. The airport’s newly expanded and state-ofthe-art Concourse A features Cast Connex ® Custom Steel Castings, each working to brace the structure against wind, seismic, and blast loading while providing a 2-hour fire-resistance rating without the need for intumescent coating.

Design

Photography

CAST CONNEX ® custom steel castingsallow for projects previously unachievable by conventional fabrication methods. Custom Cast Solutions simplify complex and repetitive connections and are ideal for architecturally exposed applications.

allow for flexible building and bridge geometry, enabling architects and engineers to realize their design ambitions.

Innovative steel castings reduce construction time and costs, and provide enhanced connection strength, ductility, and fatigue resistance.

Structural

Charlotte Douglas International Airport, NC Designed by Perkins+Will and C

Engineers- Stewart Photography by Studio 66

Charlotte

D e s i g n e d b y P e r k i n s + W i l l a n d C D e s i g n S t r u c t u r a l E n g i n e e r s - S t e w a r t P h o t o g r a p h y b y S t u d i o 6 6 P h o t o g r a p h y

International NC

Freeform

castings

CUSTOM CASTING www.castconnex.com info@castconnex.com | 1-888-681-8786

ADVERTISER index

All Weather Insulated Panels

AllPlan

ASDIP Structural Engineering Software

Atlas Tube 1|2

Cast Connex

CSI - Computers & Structures, Inc

DuraFuse Frames

ENERCALC

Explore

Please support these advertisers

ICC - Evaluation Service

Keller - North America

NCEES

MAX USA Corp Quick Tie Products

RISA

Simpson Strong-Tie Savage Brands Champion Fiberglass

March

Digital

STRUCTURE

CIRCULATION

subscriptions@structuremag.org

EDITORIAL BOARD

Chair John A. Dal Pino, S.E. FTF Engineering, Inc., San Francisco, CA chair@STRUCTUREmag.org

Jeremy L. Achter, S.E., LEED AP ARW Engineers, Ogden, UT

Erin Conaway, P.E. AISC, Littleton, CO

Linda M. Kaplan, P.E. Pennoni, Pittsburgh, PA

Charles “Chuck” F. King, P.E. Urban Engineers of New York, New York, NY

Nicholas Lang, P.E. Vice President Engineering & Advocacy, Masonry Concrete Masonry and Hardscapes Association (CMHA)

Jessica Mandrick, P.E., S.E., LEED AP

Gilsanz Murray Ste�cek, LLP, New York, NY

Jason McCool, P.E. Robbins Engineering Consultants, Little Rock, AR

Brian W. Miller Davis, CA

Evans Mountzouris, P.E. Retired, Milford, CT

John “Buddy” Showalter, P.E. International Code Council, Washington, DC

Eytan Solomon, P.E., LEED AP Silman, New York, NY

Jeannette M. Torrents, P.E., S.E., LEED AP JVA, Inc., Boulder, CO

EDITORIAL STAFF

Executive Editor Alfred Spada aspada@ncsea.com

Production production@structuremag.org

MARKETING & ADVERTISING SALES

Director for Sales, Marketing & Business Development

Monica Shripka Tel: 773-974-6561 monica.shripka@STRUCTUREmag.org

STRUCTURE ® magazine (ISSN 1536 4283) is published monthly by The National Council of Structural Engineers Associations (a nonpro�t Association), 20 N. Wacker Drive, Suite 750, Chicago, IL 60606 312.649.4600. Periodical postage paid at Chicago, Il, and at additional mailing of�ces. STRUCTURE magazine, Volume 30, Number 2, © 2023 by The National Council of Structural Engineers Associations, all rights reserved. Subscription services, back issues and subscription information tel: 312-649-4600, or write to STRUCTURE magazine Circulation, 20 N. Wacker Drive, Suite 750, Chicago, IL 60606.The publication is distributed to members of The National Council of Structural Engineers Associations through a resolution to its bylaws, and to members of CASE and SEI paid by each organization as nominal price subscription for its members as a bene�t of their membership. Yearly Subscription in USA $75; $40 For Students; Canada $90; $60 for Canadian Students; Foreign $135, $90 for foreign students. Editorial Of�ce: Send editorial mail to: STRUCTURE magazine, Attn: Editorial, 20 N. Wacker Drive, Suite 750, Chicago, IL 60606. POSTMASTER: Send Address changes to STRUCTURE magazine, 20 N. Wacker Drive, Suite 750, Chicago, IL 60606.

STRUCTURE is a registered trademark of the National Council of Structural Engineers Associations (NCSEA). Articles may not be reproduced in whole or in part without the written permission of the publisher.

MARCH 2023

ADVERTISEMENT–For Advertiser Information, visit STRUCTUREmag.org

®

Issue

at STRUCTUREmag.org

Available Only

2023 S Em g 2 3 M T + e STRUCTURAL ENGINEERS 30,000 via PRINT 25,000 via EMAIL 75,000 via WEBSITE Reach Practicing S E Available Online

MEDIA KIT Including the 2023 Editorial Calendar STRUCTUREmag.org/2023mediakit/file.pdf

2023

STRUCTURE’s print, digital, and webinar marketing opportunities to reach the structural engineering audience.

Your market. Your schedule. Your needs. Your vision. Our purpose. A Customer First approach. A purpose-built team. Three world-class manufacturing facilities in California, Arkansas, and now, Pennsylvania. All Weather Insulated Panels is distinctly positioned to support your design intent, performance requirements, and sustainability goals with our industry-leading lineup of insulated metal walls, roofs and roof deck solutions. Visit awipanels.com/you Great Park Ice & FivePoint Arena | Irvine, CA

Features

SEISMIC REPAIR AND

RETROFIT

IN ALASKA

By Ellen Hamel P.E., S.E.

Gruening Middle School, located in Eagle River, Alaska, was signi�cantly damaged during a magnitude 7.1 earthquake on November 30, 2018. The epicenter of the earthquake was only 11 miles from the school.

FRP COLLECTOR STRENGTHENING IN A CALIFORNIA HOSPITAL

By Erik Moore, S.E., Aniket Borwankar, Sarah Outzen, P.E., Jay Love, S.E.I

The Seton City Medical Center is located south of San Francisco in Daly City. The hospital, originally named Mary’s Help Hospital, was built in 1965 for the Daughters of Charity to support an underserved community in northern San Mateo County.

Columns and Departments

Editorial

Collaborating for Safer, More Reliable Temporary Structures

By Jennifer Goupil, P.E., F.SEI, M. ASCE

Structural Influencers

A Golden Era: Walter P Moore’s Larry Grif�s re�ects on 50 years as a structural engineer.

Engineers Notebook

Afghan Earthquake Response –July 2022

By Dr. Kit Miyamoto

Guest Column

The Forensic Engineering Process for Structural Failures

By Kevin Goudarzi, P.E.

Codes and Standards

Underlying Causes of Exterior Sign Accidents

By Dan Eschenasy, PE F.SEI

Structural Adhesives

Adhesive Bonding Ef�ciency of Concrete Interfaces

By Dr. Martin Brandtner-Hafner

Mass Timber

Seismic Design of CLT Shear Walls Using ASCE 7-22 and SDPWS 2021

By M. Omar Amini, Philip Line

Structural Resilience

A Call to Action

By SEI Board of Governors Resilience Committee

Structural Connections

Collaborative Fall Protection Design

By Travis Nelson, P.E., CSP, and John Noriega, P.E.

In Focus

Dif�cult Conversations

By John A. Dal Pino – FTF Engineering

Structural Retrofit

Wind Retro�t Resources for Structural Engineers

By William L. Coulbourne, P.E., F.SEI, F.ASCE

Code Changes

Structural Changes in the 2020 Edition of ICC 500 – Standard for the Design and Construction of Storm Shelters

By Jeffrey D. Viano, P.E., S.E. and Connor J. Bruns, S.E.

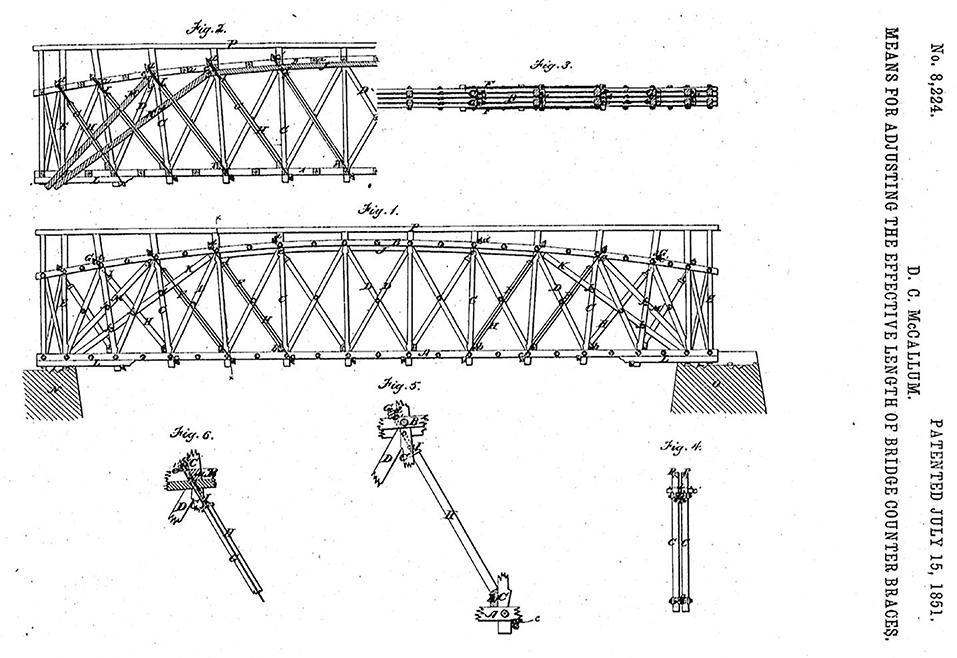

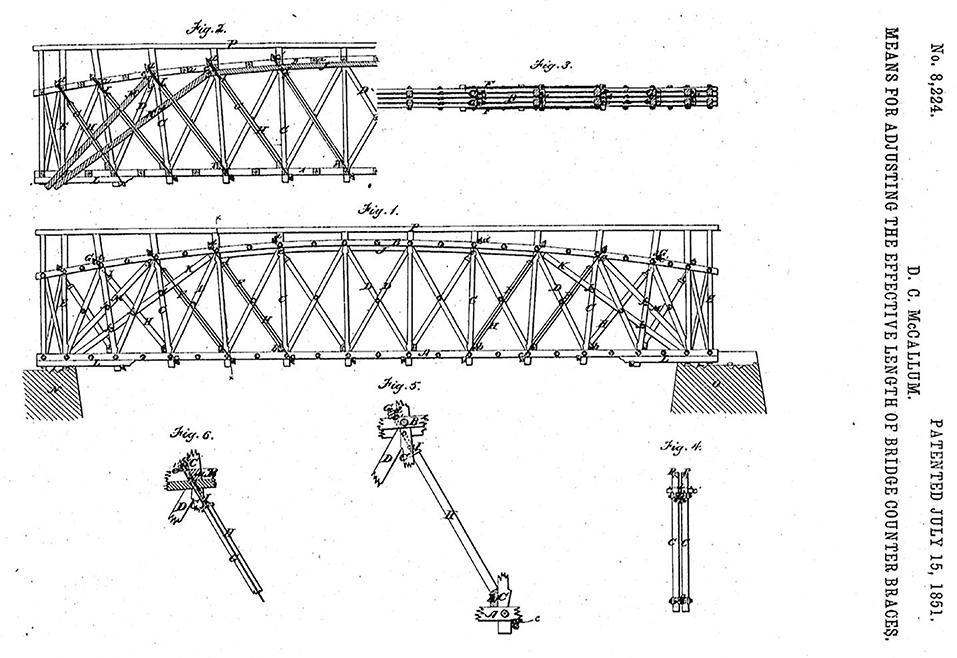

58 Historic Structures

Clinton, Iowa Bridge 1860 and 1865

By

Frank Griggs,

Jr., Dist. M.ASCE, D.Eng, P.E., P.L.S.

66 Business Practices

Managing the Engineer’s Risk in Design-Build Contracts

By Bruce Burt, P.E., P.Eng.

In Focus

What Would Jane Jacobs Say?

By John A. Dal Pino – FTF Engineering

In Every Issue

Advertiser Index

Software Guide

NCSEA News

SEI Update CASE in Point

MARCH 2023 Publication of any article, image, or advertisement in STRUCTURE® magazine does not constitute endorsement by NCSEA, CASE, SEI, the Publisher, or the Editorial Board. Authors, contributors, and advertisers retain sole responsibility for the content of their submissions. STRUCTURE magazine is not a peer-reviewed publication. Readers are encouraged to do their due diligence through personal research on topics.

MARCH 2023 Cover Feature

Contents

Collaborating for Safer, More Reliable Temporary Structures

By Jennifer Goupil, P.E., F.SEI, M. ASCE

Starting

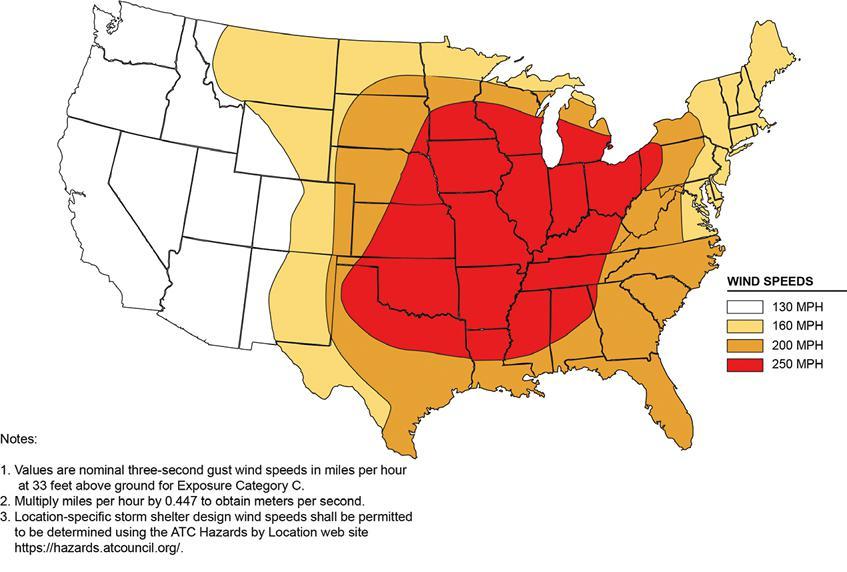

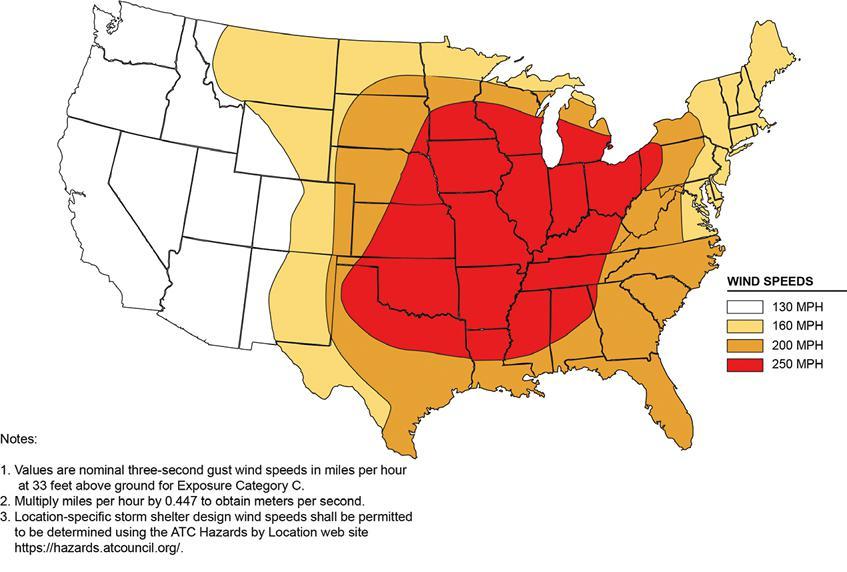

in mid-2020, following the outcome from the 2019 International Code Council’s (ICC) Group B Hearings, an ad hoc committee of dedicated experts from the ASCE/SEI 7 Minimum Design Loads and Associated Criteria for Buildings and Other Structures committee began a two-year process to develop a code change proposal for the next cycle of the ICC Hearings in 2022. �is happens all of the time, but this e�ort was the epitome of collaboration.

� e catalyst for this dedicated committee e � ort was to deliver on a promise made on the � oor of the hearings: to work together to � nd an appropriate solution for needed code provisions for minimum structural loads for temporary structures. Unfortunately, in past code cycles, inappropriate references were attempted to be introduced to the International Building Code (IBC) as a design basis and requirement for temporary structures but failed due to lack of consensus within the industry and direct objection from ASCE/SEI 7 committee leadership. Following the failed attempt in 2019, and the fact that ASCE led the objection, ASCE/SEI 7-22 wind loads subcommittee chair Don Scott led the e � orts of a diverse group of experts from the committee, building o � cials from many jurisdictions from across the country that have experience with large events and temporary structures, and industry representatives from the U.S. entertainment industry. � e group developed provisions that align with the design basis for IBC Chapter 16 and ASCE/SEI 7, as well as provide the appropriate level of risk and structural reliability to the public. As a result of this collaboration, a new section 3103 Temporary Structures has been approved for adoption into the 2024 IBC, which addresses wind, seismic, snow, � ood, and ice loads with direct pointers from those sections of IBC Chapter 16.

NEW SECTION 3103 TEMPORARY STRUCTURES

�e ICC’s I-Codes regulate the construction of new buildings and temporary structures through IBC Chapter 31. Since Temporary Special Event Structures are regulated by the International Fire Code, but also are a type of temporary structure, those structures also need to meet the requirements of this new section.

In addition to the new Section 3103, four new de � nitions are added to Section 202 De � nitions for public-occupancy temporary structures, service life, temporary event, and temporary structure Public-occupancy temporary structures are new buildings or structures that are used by the general public, or that support public events, where the public expects similar levels of reliability and safety as o � ered by permanent construction. Public-occupancy temporary structures are often assembled with re-useable components and designed for a particular purpose and de � ned period of time, which is de � ned as a temporary event when the period of time is less than one year. Public-occupancy temporary structures in service for a period that exceeds 1-year are required to comply with

the IBC for new buildings. Temporary structures should not pose more risk to occupants than permanent structures, but because the code's design-level environmental loads are far less likely during a temporary event, this proposal makes adjustments to reduce the requirements for a consistent level of risk. � e code change addresses the hazards in the built environment in IBC Chapter 16 for public-occupancy temporary structures. � e code change includes the ability to mitigate some hazards through Emergency Action Plans and controlled occupancy to address cases where an environmental loading hazard cannot be reasonably mitigated. � is allows a Building O � cial to use a preapproved action plan to permit installations that cannot resist code prescribed loads. For example, in mapped areas such as � ood hazard areas and tsunami inundation zones evacuation plans can be adopted and temporary structures subject to high wind loads may be evacuated and have sections removed to reduce the wind load. � e code change proposal recognizes that it may be desirable for a temporary structure to remain in service for more than 180 days, whether continuously occupied or not, and provides a process that the Building O � cial can follow to facilitate such an extended service period. However, after 1-year has passed, the structure is required to comply with requirements for new buildings or is removed from service by being disassembled.

NEXT STEPS

Due to the staggered nature of the ICC and ASCE 7 Standard code development processes, this IBC proposal is the �rst of two e�orts to address the need for provisions for loads on temporary structures. �e second e�ort includes development of a new chapter to ASCE/SEI 7 to address temporary structures. Additionally, the Fire Code will be updated to re�ect the new IBC de�nitions and section in Chapter 31. As the work continues in the 2028 cycle of ASCE/SEI 7, the goal is to bring the design requirements into the standard, remove them from the code, and then update the code to point back to ASCE/SEI 7.

In summary, this is an amazing example of how the leadership of members of the ASCE/SEI 7 ad hoc committee worked across the industry to �ll a gap in the code and ful�l its promise to the industry. Two years later, in partnership with industry and many key stakeholders, new provisions have been developed that will lead to safer more reliable temporary structures.

�e ad hoc committee included the following members: Chair Don Scott; Jennifer Goupil; �erese McAllister, Ph.D.; John Hooper; John Duntemann; Andrew Stam; Bryan Lanier; Chris Cerino; James (Greg) Soules, Ph.D.; Ali Fattah; and Constadino (Gus) Sirakis.■

MARCH 2023

Jennifer Goupil, P.E., F.SEI, M.ASCE is the SEI Director of Codes, Standards, and Technical Initiatives.

EDITORIAL

structural INFLUENCERS

A Golden Era

Walter P Moore’s Larry Grif�s re�ects on 50 years as a structural engineer.

Larry Gri�s, P.E., senior consultant in the Structures Group at Walter P Moore, is the �rm’s longest current employee, recently celebrating 50 years with the �rm. Larry is a nationally renowned structural engineer with extensive experience contributing to more than 80 major buildings throughout the U.S. and internationally. His vast expertise involves the design of long-span roof structures, high-rise buildings, composite steel and concrete systems, analyzing large structures under wind and seismic forces, and designing retractable roof stadiums and ballparks. Many projects under his direction have received numerous awards, including the American Council of Engineering Companies Texas Chapter’s Eminent Conceptor Award, representing the top engineering projects in Texas.

He has also received the Kimbrough Award, which is the American Institute of Steel Construction’s (AISC) most prestigious honor recognizing engineers who are universally acclaimed as the pre-eminent steel designers of their era and have made outstanding contributions to the steel industry through their work. In addition, Larry received AISC’s TR Higgins Lectureship Award, which recognizes an outstanding lecturer and author whose technical paper or papers published during the eligibility period are considered an outstanding contribution to the engineering literature on fabricated structural steel, and AISC’s Lifetime Achievement Award. Larry has also been named to the National Academy of Engineering and is a Fellow in both the Structural Engineering Institute and the American Concrete Institute.

What has been your favorite engineering project and why?

�is is a tough question because there are many iconic and exciting projects to choose from. One thing that was very fortuitous in my career was being around when movable roof stadiums came on the scene. Bank One Ballpark (now known as Chase Field) in Phoenix, Arizona, was the �rst retractable roof in the U.S., and it was fraught with design and construction challenges. I was hired as a consultant with Schu� Steel. I spent six months wading through all the vast information on that project and learned a lot about moveable roof stadiums—how to design them and what can go wrong—it was a great lesson for me. So when we got our �rst opportunity to work on a movable roof for Minute Maid Park in Houston, I was pretty well versed in the challenges and solutions I knew were coming. Working through all those challenges for the �rm’s �rst moveable roof stadium project, and developing a relationship with Uni-Systems Engineering, who has been a partner in almost all of our moveable roof stadiums as the mechanization consultant, helped solve a lot. I was fortunate to have a talented team behind me for Minute Maid Park; I was just the team’s leader, but it was certainly a very satisfying project.

What best advice can you give a new engineer joining the firm?

My advice would be, “being a structural engineer is not an easy profession,” particularly when you work on large complex projects. We have to take our responsibility very seriously. We live in an era

STRUCTURE magazine

Remember, you may be the only person checking your work in this fast-paced environment. Take responsibility very seriously, and reach out when you need help.

DESIGNED TO SAVE YOU TIME

REQUEST A DEMO TODAY �e images above were created from real customer projects. courtesy of Steel Detailing, Inc. (right and left) and Lincoln Engineering Group (center) sds2.com

STEEL DETAILING SOFTWARE

- STRUCTURAL STEEL - CONNECTION DESIGN - STAIRS & RAILS - MISCELLANEOUS STEEL - MATERIAL HANDLING

when owners, architects, and clients want projects done faster, better, and cheaper. Many do not understand the challenges we face when engineering large structures. It takes patience and a sense of responsibility that the work being done impacts public safety because we are dealing with heavy loads, long spans, and tall structures in many cases. Furthermore, young engineers should seek advice when they think it is needed. Remember, you may be the only person checking your work in this fast-paced environment. Take responsibility very seriously, and reach out when you need help.

What is the most challenging project you have worked on and why?

Early in my career, during the 1970s, 80s, and 90s, I had a chance to work on many tall buildings. One that I am proud of is the �ree Houston Center building, where our corporate headquarters is located. I was actually the engineer of record for the building. It is a 52-story composite-framed building, and I learned a lot of the things an engineer needs to know about how to design and build such a tall building.

Based on your past experiences as a structural engineer, is there anything you would have done di �erently?

I was fortunate enough to know and work with Bill LeMessurier, one of the great tall building designers responsible for the Citicorp Center (now known as the Citigroup Center) in New York. I met Alan Davenport and Jack Cermak and learned about wind tunnel testing. I felt fortunate to work on some iconic structures and manage our enormous talent at Walter P Moore. People threw challenging projects at me, and I worked hard to be sure I was up to the task. If I did not know something, I �gured out how to do it. I was fortunate to have so many people I met in professional circles and at the �rm who helped me get these projects engineered and built.

What key changes have you seen in the industry over the last 50 years?

Two things come to mind. �e Boundary Layer Wind Tunnel is one of the most critical achievements in structural engineering. For many of the structures being built, whether they are long-span bridges or super high-rise buildings, none would be possible without the Boundary

Layer Wind Tunnel. Second are the advances in steel, concrete, and composite structures. We have seen concrete go from 7,000 or 8,000 psi compressive strength to 18,000 or 20,000 psi. �e admixtures have made concrete stronger and easier to work with in the various new forming systems that have been developed. We used to say you could work a lot faster using steel, but now you can build a concrete building almost as fast as you can build a steel building. �e advances in reinforced concrete, particularly in tall buildings, have been a signi�cant achievement over the years. And we now have higher strength and more specialized steels to use in our building and bridge designs.

What accomplishment are you most proud of outside of a structural engineering project?

Early in my career, I was mentored by Walter P. Moore, Jr., who pushed me to get involved in professional activities and meet people in the industry. I am grateful for that because I luckily met many people in many areas of our practice, including wind tunnel and other consultants, researchers, and professors. I could rely on these contacts to help me throughout my career. Being involved in professional activities is enormously rewarding, and I encourage young engineers to get involved professionally, such as by publishing or contributing their time to a professional committee. You will meet many people and make lifelong friends that will help you throughout your career.■

STRUCTURE magazine

"We used to say you could work a lot faster using steel, but now you can build a concrete building almost as fast," said Larry Grif�s, P.E

Being involved in professional activities is enormously rewarding, and I encourage young engineers to get involved professionally, such as by publishing or contributing their time to a professional committee.

The brace connection with a breakthrough design.

I nt r od u c i ng t h e S i m p so n S t r o ng-Ti e ® Y i e l d - Li nk ® b r ac e c o n n e c t io n ( Y LBC).

Now you can add more re silie nce to str uctural ste el proje cts Ide al for new builds or retrofi t wor k, th e Y LBC c o nn e c ts brac e d f ra m e s in str u c tu ra l ste e l buildings It ha s bolted connections that simplif y design During ex treme seismic or high-wind events, th e Y LBC iso late s d a m ag e to th e c o nn e c tio n o nl y a llow ing th e brac e d f ra m e to r e m a i n i n t a c t I n a d d i t i o n, o u r Y i e l d - L i n k te c h n o l o g y to o l s m a ke i t e a s y to p l a n, m o d e l a n d d o c u m e nt c o m p l ete d e s i g n s a c c o rd i n g to yo u r u n i q u e s p e c i fi c ati o n s L ike oth e r S im pso n S tro ng-T i e produ c ts, th e Y LBC is w id e l y ava ila bl e a nd bac ke d by our industr y-le ading se r vice and te chnical suppor t

De sign your nex t proje ct with all of our str uctural ste el solutions. To le ar n more, visit go.st rongt ie.com/yieldlinkbraceconnect ion or call (800) 999-5099.

©2023 Simpson Strong-Tie Company Inc. YLBC23-E

Structural Steel Solutions | Products, Software and Service for Smarter Building

Seismic Repair and Retrofit in Alaska

By Ellen Hamel P.E., S.E. By E l le n H a m e l P E , S E

Gruening Middle School, located in Eagle River, Alaska, was signi�cantly damaged during a magnitude 7.1 earthquake on November 30, 2018. �e epicenter of the earthquake was only 11 miles from the school. Due to the damage, Gruening was shut down for almost three years for earthquake repair, seismic upgrades, and programming upgrades. �e Gruening Middle School Earthquake Recovery Project was an important e�ort by the Anchorage School District (ASD) to repair and upgrade the almost 40-year-old school (Figure 1). �e project was a success thanks to committed team members and the �rst use of Simpson Strong-Tie (Simpson) FabricReinforced Cementitious Matrix (FRCM) in Alaska.

Background

Gruening was originally designed in 1981 as a two-story, approximately 124,000-square-foot building that is X-shaped in plan. �e gym and multipurpose room (MPR) are both 2-story spaces that in�ll the arms of the X. �e building is wood framed with both wood shear walls (interior and exterior) and stack bond Concrete Masonry Unit (CMU) shear walls (interior only). �e exterior wood shear walls were covered in 5-inch masonry veneer that is identical in appearance to the interior

CMU walls (Figure 1). Foundations are concrete spread footings. A lateral redesign was completed in 1984; these Corrective Actions addressed signi�cant �aws in the original seismic design. �e 200 added details in the Corrective Actions included new shear walls and upgraded many of the lateral connections. Reid Middleton reviewed the 1981 drawings and the 1984 Corrective Actions drawings as part of the repair and upgrades project. In addition, selective demolition was done to con�rm material types (wood versus masonry) in select locations.

Seismic Screening

As part of ASD’s commitment to evaluate and upgrade all the 91 facilities in its inventory to current seismic standards, engineers performed an ASCE 41-13 Seismic Evaluation and Retrofit of Existing Buildings (ASCE 41) Tier 1 screening on Gruening Middle School in 2013. The Tier 1 screening indicated the following noncompliant items:

Checklist for Building Type W2 – Wood Frames

1. SHEAR STRESS CHECK

2. DIAPHRAGM REINFORCEMENT AT OPENINGS

STRUCTURE magazine

3.DIAGONALLY SHEATHED AND UNBLOCKED DIAPHRAGMS

Checklist for Building Type RM1 – Reinforced Masonry Walls

1.OPENINGS AT SHEAR WALLS

Based on this evaluation and ASD’s commitment to evaluating and upgrading all their facilities, ASD created a Seismic Evaluation and Retro�t Guide (ASD Seismic Guide) for all their existing schools in 2014. �is guide was updated in 2021 to the ASCE 41-17 standard, and as of this writing, ASD has used this guide to complete Tier 1 evaluations of every facility in the district.

2018 Earthquake and School Closure

On Friday, November 30, 2018, a magnitude 7.1 earthquake occurred at 8:29 am, Alaska Standard Time. At the time of the earthquake, there were no accelerometer recording stations in Eagle River; a station in nearby Chugiak recorded a maximum spectral acceleration of 0.47g for short periods (0.2 seconds), and in Anchorage, the maximum recorded short-period acceleration was 1.49g (Dutta et al., 2019). For perspective, the mapped MCER , 5 percent damped, spectral response acceleration parameter for short periods at this site is 1.5g. Gruening Middle School is located on Site Class D soils and within Seismic Design Category D. Beginning the day of the earthquake, engineers walked through and evaluated all the buildings in the district. Engineers �rst evaluated Gruening on Sunday, December 2, 2018, and then visited three more times in the next three weeks. As a result, the building was red-tagged per ATC-20-1 Field Manual – Postearthquake Safety Evaluation of Buildings (ATC-20). Damage observations included cracked masonry, leaning of the two-story CMU gym wall, stairway to column connection damage, bent gym curtain support beam, cracked drywall, acoustic ceiling tile failures, and gypsum-board

ceiling failures. Repairs of minor masonry cracking and ceiling tiles began immediately; the leaning two-story CMU gym wall was shored along with similar two-story CMU walls at the MPR.

Students at Gruening Middle School did not return to school after the one-week shutdown of all schools in the district. Instead, Gruening students and sta� temporarily relocated to the nearby high school for the next two and a half years.

Repair, Retrofit, and Redesign

In spring 2019, design began on the Gruening Middle School Earthquake Recovery Project. ASD separated the project into three parts to accommodate multiple sources of funding: earthquake repair, seismic mitigation, and programming upgrades. Engineers referenced ASCE 41 and ASCE 7-10 Minimum Design Loads for Buildings and Other Structures (ASCE 7) for structural design.

Engineers used the following ASCE 41 Performance Objectives in evaluating the existing structure and the design of repairs and upgrades, per a Risk Category III building and the ASD Seismic Guide (Table 1).

Earthquake Repair

�e most urgent structural earthquake damage at Gruening was the leaning of the two-story CMU wall in the gym. Upon further observation, engineers determined that the top of the CMU wall had detached from the roof diaphragm via splintering of the wood top plate (Figure 2). Detachment occurred along 110 linear feet of wall, and a similar connection existed along 700 linear feet of wall throughout the building.

To repair the damaged top of CMU wall connections, and reduce the risk of failure in future earthquakes, a new connection for the top of the wall had to be developed. �e new top-of-wall connection was designed to resist out-of-plane seismic forces per ASCE 7. Engineers designed two di�erent top-of-wall connections to remediate the existing condition: (1) a two-sided connection using steel bent plates on both sides of the wall, and (2) a single-sided connection using a single steel plate on one side of the wall, anchored to the CMU wall using a through-bolt. �e engineer, architect, and contractor coordinated throughout the design and construction process to determine which of the two connections would be best suited at each location. Once all

MARCH 2023

Figure 1. Gruening Entry Before and After

Table 1. ASCE 41 Performance Objectives

700 feet of new connections were installed, the contractor removed the temporary shoring of the tall gym and MPR walls.

Top of interior CMU wall to diaphragm connection is not an ASCE 41 Tier 1 screening item; the Checklist for Building Type RM1 includes a wall anchorage check, but only for exterior concrete or CMU walls. However, Gruening does not have any exterior concrete or CMU walls. �erefore, a Tier 2 de�ciency-based evaluation would not have detected the de�cient top of interior CMU wall connection, but a Tier 3 systematic evaluation may have.

During the post-earthquake evaluations, extensive damage was observed to the CMU walls and the masonry veneer. Of particular concern was the damage at CMU wall intersections. At approximately 120 corner T-intersections, engineers detailed a connection to rigidly attach the intersecting walls. Face shells were demolished as required, and L-shaped (bent) reinforcement was post-installed into the existing CMU. At 15 of these intersections, the existing CMU walls had tube steel columns embedded. At these locations, engineers detailed a connection to rigidly attach the intersecting CMU walls to the steel columns.

Immediately following the earthquake, ASD’s contractors

temporarily repaired the damaged stairway to column connection. �e permanent solution to this damage was to rigidly connect the stairs to the adjacent wood stud wall. �is was done using horizontal tension ties with lag screws. In the gym, 40 feet of the curtain support beam was bent during the earthquake (Figure 3). After coordination with Gruening’s architect and sta�, the contractor removed the damaged portion. As part of the reprogramming of the school, the damaged length of curtain wall support was no longer needed. However, the remaining beam length lacked lateral bracing in the longitudinal direction. Engineers designed an open-channel strut bracing the beam in the longitudinal direction.

Seismic Retrofit

ASD elected to incorporate voluntary seismic upgrades per ASCE 41 in addition to repairing the earthquake damage. Before beginning ASCE 41 upgrades, engineers, in coordination with the architect, decided to remove the existing masonry veneer from the exterior of the building. �is decision was signi�cant because it removed substantial seismic weight from the building, reducing seismic design loads. �e existing veneer weight was 63 pounds per square foot; the new siding weight is less than �ve pounds per square foot; removing the veneer removed 1,200 tons of seismic weight (Figure 4). In addition to reducing weight, removing the masonry veneer and replacing it with a new, lightweight, blue-insulated metal panel siding gave the school a refreshed look. �e new look helps to give the public a visual di�erentiation between the old and new Gruening Middle School.

During the Tier 1 screening, engineers �agged the wood shear walls at Gruening as Non-Compliant per the SHEAR STRESS CHECK of the Tier 1 Type W2 Checklist. As part of the seismic retro�t of Gruening, engineers evaluated the existing shear walls for ASCE 41 Tier 2 compliance. Linear static procedures (LSP) were used. Since all the �oor and roof diaphragms in the building are �exible and limited drag struts were observed in the existing building, loads were distributed to the wood and masonry shear walls based on total length. All wood shear walls that were non-compliant per an ASCE 41 Tier 2 de�ciency-based evaluation were upgraded to meet Damage Control at the BSE-1N Seismic Hazard Level and Limited Safety at the BSE-2N Seismic Hazard Level; this included approximately 300 linear feet of wall.

Existing single-sided wood shear walls were upgraded to double-sided wood shear walls, with nailing/staples on the new sheathing equal to that of the existing. One of the challenges of this upgrade was determining the existing nailing patterns. Original drawings called for nailing, but in some cases, engineers discovered that staples were used in place of nails. �is was not documented in the original or corrective drawings. Per the National Design Speci�cations (NDS) for Wood Construction, “for shear walls sheathed with the same construction and materials on opposite sides of the same wall, the combined

STRUCTURE magazine

Figure 2. Top of CMU Wall Damage

nominal shear capacity shall be permitted to be taken as twice the nominal unit shear capacity for an equivalent shear wall sheathed on one side.” �erefore, engineers needed to know the existing capacity of the shear walls to determine the new, doublesided wall capacity. Using selective demolition of �nishes, Reid Middleton was able to determine a representative sample of the size, spacing, and pattern for the shear wall nailing/stapling throughout the building.

Gruening’s second level is open to the ground �oor below in many locations. �is provides an open concept and allows natural light throughout the hallways. However, during the Tier 1 screening, engineers noted that the �exible wood diaphragm openings on the second level had re-entrant corners that were not reinforced/strapped horizontally and did not align with the existing lateral-force resisting elements. In addition, the wood ledgers adjacent to these diaphragm openings were not adequately attached to the existing CMU walls. To alleviate these issues at diaphragm openings, Simpson holdowns were installed in horizontal pairs at 49 locations.

As a follow-up to the Tier 1 screening non-compliant checklist item, DIAGONALLY SHEATHED AND UNBLOCKED DIAPHRAGMS, all �exible wood diaphragms were evaluated for ASCE 41 Tier 2 compliance. Over 21,000 square feet of diaphragms were strengthened as part of this project. �e diaphragms were strengthened by adding blocking (where not present) or adding a new layer of wood sheathing atop existing sheathing. Floor diaphragm

strengthening was done from below (due to existing concrete topping over the wood sheathing), whereas roof diaphragm strengthening was done from above in conjunction with the reroo�ng. All roo�ng was removed and replaced down to the sheathing, which provided convenient timing to upgrade the roof diaphragms.

As part of this project, engineers reviewed the existing CMU walls compared to current design and detailing standards. Although the ASCE 41 Tier 1 screening compares CMU wall reinforcing to a maximum spacing of 48 inches on-center, current Masonry Standards Joint Committee (MSJC) Building Code requirements do not allow 48-inch spacing for stack bond masonry, or for Special Reinforced Masonry Shear Walls, which are required in Seismic Design Category D. Current MSJC code requires a minimum spacing of 24-inch spacing for both vertical and horizontal reinforcement. �e spacing of the existing masonry reinforcing at Gruening was 32-inches vertical and 48-inches horizontal; the existing CMU walls at Gruening did not meet the minimum spacing requirements of MSJC. In addition, existing unbraced CMU walls greater than 17 feet high were determined to have insu�cient out-of-plane bending capacity.

Reid Middleton evaluated multiple solutions to address the CMU wall deficiencies: inserting traditional reinforcing steel (rebar) into the walls, overlaying the CMU with Simpson FRCM, or overlaying bi-directional fabric-reinforced polymer (FRP). In collaboration with Simpson engineers, Reid Middleton and ASD elected to use FRCM on all existing CMU walls in the building. The use of FRCM accomplished two objectives: upgrading existing stack bound CMU walls to meet current MSJC reinforcing requirements and strengthening tall walls to meet out-of-plane bending capacity requirements.

FRCM combines a high-performance sprayable mortar with a carbon-fiber grid to create a thin structural layer that does not add significant weight or volume to the project. FRCM had never been used in Alaska prior to this project. Reid Middleton and the Simpson team worked closely during the design and construction phases to ensure the installation went smoothly. In addition, Simpson engineers aided in detail development, including end-of-wall anchorage, as well as specifications.

The FRCM application process was as follows ( Figure 5 ):

MARCH 2023

Figure 3. Damaged Curtain Support Beam

Figure 4. Removal of Masonry Veneer

1. Remove finishes from single (or both) sides of masonry shear walls as noted on plans.

2. Remove paint from the surface.

3. Fill the existing CMU flutes and place the fabric matrix. The anticipated added thickness to the CMU wall is a maximum of � inch.

4. Trowel finish and paint as shown on Architectural Drawings.

With close collaboration between the contractor, Simpson, and the engineer, the FRCM installers could place the FRCM ahead of schedule. The installers covered approximately 36,000 square feet of wall with FRCM per the structural drawings. Most of the FRCM was single-sided, except at the tall walls of the MPR, where FRCM was required on both faces of the wall to address deficient out-of-plane bending reinforcing.

Returning to School

Students returned to Gruening Middle School on August 17, 2021. On October 14, 2021, the principal of Gruening Middle School, Mr. Bobby Jefts, the ASD superintendent, Dr. Deena Bishop, Alaska’s governor, Governor Mike Dunleavy, along

with students, parents, and the design and construction team celebrated the ribbon cutting at Gruening. Students proudly gave tours of their revitalized school, which has been upgraded to receive excellent marks during the next earthquake pop quiz. ■

Full references are included in the online version of the article at STRUCTUREmag.org

Ellen Hamel is a Senior Engineer with Reid Middleton, Inc., located in Anchorage, Alaska. (ehamel@reidmiddleton.com)

Project Team

Owner: Anchorage School District

Structural Engineer: Reid Middleton, Inc.

Architect: MCG Explore Design

Fabric-Reinforced Cementitious Matrix Supplier: Simpson

Strong-Tie

Contractor: Cornerstone General Contractors

Demolition Contractor: Alaska Demolition

STRUCTURE magazine

Figure 5. Fabric-Reinforced Cementitious Matrix (FRCM)

on the GROUND

Afghan Earthquake Response – July 2022

By Dr. Kit Miyamoto

By Dr. Kit Miyamoto

A6.2 magnitude (Mw) earthquake struck southeastern Afghanistan on June 22, 2022. It was felt over a wide area, most strongly a�ecting the Paktika and Khost provinces and parts of neighboring Pakistan. According to the USGS, the earthquake had a maximum Modi�ed Mercalli Intensity of VIII (Severe). Over 1,100 people died, and over 6,000 others were injured, making it the country’s deadliest earthquake in over 20 years.

For several generations, structural engineers have traveled to the sites of damaging earthquake to learn what worked and what did not, with the primary goal of improving design practices and building codes in their home country. In recent times, except perhaps for the 2010 Haiti earthquake, most engineers have focused on earthquakes where the local construction is similar to what they design themselves. We do not often get a �rsthand account from a place like Afghanistan where the goal is improving local construction practices and getting the a�ected population into safe housing as quickly as possible. In this regard, the e�orts of Dr. Kit Miyamoto of Miyamoto International stand out. We hope you read his report from Ukraine in the December 2022 issue of STRUCTURE. Last summer, he and his team traveled to Afghanistan to provide technical guidance for reconstruction to the United Nations’ International Organization of Migration (IOM/UN).

Observations

We arrived in Afghanistan on July 18th. Our team is sitting outside around a conference table under the shade, but the hot summer sun is simmering the concrete in our vicinity.

�e team consists of David, a veteran and famous humanitarian response personality; Mark, a trusted earthquake structural engineer who worked on many disaster response projects, from the Haiti earthquake to the Palu, Indonesia, earthquake; and Shahzar, a local, respected program manager who used to work for many U.N. agencies. It is critical to have a trusted local partner when entering this country. �ey can really show you the way.

�e Afghanistan people are struggling economically, and even this medium-sized earthquake can cause major issues for people living in the a�ected area. �e earthquake site is in the southeast of the country, an area used by Al Qaeda. If you recall, Osama Bin Laden hid in a cave in this area during the U.S. bombings following 9/11. �is will be a challenging mission.

Two days after our arrival, we board a 1970s-era Soviet-made cargo helicopter provided by the U.N. Besides us, Fiona and Jago from the IOM/UN have joined us for this mission. Also, Zadran, our Afghanistan program manager, to whom we were introduced a couple of days ago through our contact in the U.S., is with us.

�e last few days have been hectic at the U.N. base where we live inside steel containers. We met engineers who had just come back from the �eld. We have met decision-makers of the U.N. system, and based on their inputs, we have developed a housing reconstruction and repairability assessment app. Miyamoto International’s India o�ce team (seismic R&D experts) was a great help.

We plan to sample a few hundred houses in the next four days. �en we will use the data to interpolate the total housing reconstruction needs. �is is a critical relief e�ort for people in the disaster zone. We must identify and repair as many houses as possible before winter comes in this mountainous area.

Inside the helicopter, it is hot and humid. �e roar of the blades is deafening. We are heading to the Pakistan border district of Barmal. Once in Barmal, we entered a devastated village on the top of a steep hill in a heavy thunderstorm. I �rst notice that the mud-made walls and roofs are now �attened on the ground like pancakes. Some walls still stand, but these are rare. Villages are typically large-walled compounds for housing extended families.

We are greeted by six of this settlement’s elders. Among them is their spokesperson, a young intelligent-looking fellow with sharp brown eyes, a dark complexion, and a skinny nose. He wears his hair long and the same traditional hat I saw earlier. He speaks softly. “I lost 18 of my family members to this earthquake. I lost everything, and I have nothing. We live in small U.N. tents and have no idea what tomorrow holds.”

STRUCTURE magazine

The Team in Afghanistan

A 6.2 magnitude earthquake struck southeastern Afghanistan.

I scan through the area and see broken villages and a city of white tents next to them. I notice there are not many international NGOs here. International sanctions and governing uncertainty make it dif�cult for private nonpro�ts to show up.

Our team and the elders walk over the rubble, followed by many children. �ey are cheerful and friendly, even in such adverse conditions. Specks of light-colored hair and blue eyes catch my eye. Over millennia of migration, people here now have Asian, Caucasian, and Arab looks.

In the next village, we enter a large compound that is intact. �e style of the structures reminds me of European fortresses from the Middle Ages but made of clay mud. �e boundary mud walls are about 15 feet high and 20 inches thick, and the dimensions in-plan are roughly 300 feet (100m) by 1000 feet (300m), an impressive, imposing structure. Individual families have small rooms inside made of thick clay mud walls and layered mud roofs. �ese rooms are attached to the inside face of the boundary walls. �e thick walls and roofs function as thermal insulation for occupants.

I see distinctive characteristics in the construction methods used on these structures. First, the clay mud roofs are much thinner in this location, about 12 inches. �e collapsed structures had roofs that were around three times thicker. �ese walls are also made of clay mud, but they speci�cally use plaster-like materials on the surface to protect the wall interior from rain. Furthermore, I noticed a fair amount of small sharp aggregate in the mud bricks. �e collapse ratio of this village is probably one-tenth of the others. I see some hope here. We must dig up this evidence of good local practices over the next few days and transfer that knowledge to other villages to ensure the re-constructed structures fare better in the next earthquake.

As the red sun sets beyond the horizon and the rain dries out, we hop onto our o�-road vehicle and drive o� to the U.N. tent city to rest up for the next busy day.■

Dr. Kit Miyamoto is a world-leading disaster resiliency, response, andreconstruction expert. He provides expert engineering and policy consultation to the World Bank, USAID, U.N. agencies, governments, and the private sector. He is a California Seismic Safety Commissioner and Global CEO of Miyamoto International.

MARCH 2022

ICC Evaluation Service • Testing, Inspection and Certification • Acceptance Criteria Development • Over 90 Years of Industry Experience www.icc-es.org Code officials trust and approve ICC-ES evaluated products with confidence. A Mark of Confidence™ ICC ADVERTISEMENT–For Advertiser Information, visit STRUCTUREmag.org

The structures are made of clay mud.

The Forensic Engineering Process for Structural Failures

By Kevin Goudarzi, P.E.

Forensic structural engineering involves the investigation and determination of the causes of a failure of structures such as bridges, buildings, industrial structures, and metro stations. (Figure 1). Along with understanding the legal procedures and giving testimony, forensic structural engineers use their knowledge and experiences in these investigations to act as a detective, investigator, and expert witness when confronted by attorneys and other opposing experts during the litigation process.

First Steps A�er a Structural Failure

1) Safety and Structural Stability Assessment

Safety is the �rst priority after a structural failure. Safe routes through the debris should be identi�ed for the investigation. �ere may be areas to avoid until stabilized and components and elements that are in danger of further collapse. �e structure should be investigated for stabilization and any protection required for public access should be implemented to provide safe public tra�c. In addition, alternatives for demolition phasing should be examined and evaluated (Figure 2).

2) Preserve Destructible and Perishable Evidence

Forensic engineers know that after a collapse, any condition and circumstances of the site could be potential evidence; therefore, they document the evidence that could possibly change. Durable evidence may remain unchanged for a period of time, and perishable evidence must be documented immediately after collapse. An example of perishable evidence is the weight of the snow accumulation on the roof or other horizontal areas of the structure such as balconies. �is is very important as it may indicate whether the failure was due to a design or construction error, or any unforeseen overload (Figure 3).

3) Reserving Samples

In large size structural failures, it's not practical to reserve the entire structure; therefore, the forensic engineer needs to take samples of both failed and non-failed elements and key components of the structure.

4) Documentation of Conditions

�e documentation of the failure can be in the form of �eld notes, photographs, video, or other methods of recording.

5) Interviews

Interviews with witnesses and other persons on site can provide valuable information for the forensic engineer. �e interviews should be performed as soon as possible after the collapse as they help to identify and locate the witnesses, receive fresh information, and assist in formulating the scenarios for investigation.

6) Cooperation with Other Forensic Engineers

When multiple specialties are involved in the investigation, establishing a common system or program so all parties can use the resources can avoid and minimize misidenti�cation and debates. Pooling resources can avoid duplication of e�orts and establish a common knowledge base. For instance, di�erent parties could agree at the beginning that destructive testing should be performed on certain components of the structure and all parties use the same testing protocol during the investigation process.

7) Initial Document Gathering

Forensic engineers need to collect and review the project documentation such as design drawings, speci�cations, boring logs, engineering calculations, shop drawings, submittals, inspection reports, daily and weekly reports, test results, correspondence, and any other pertinent information related to the structure.

STRUCTURE magazine guest COLUMN

Figure 2. Collapsed concrete slabs in a steel structure. Photo courtesy of BJEtC

Figure 1. Structural failure of a concrete structure. Photo courtesy of TEEX,

8) Preliminary Evaluation

After the initial information is collected during the above steps, the forensic engineers may be able to provide a preliminary evaluation and develop failure scenarios, a testing program, and perform the preliminary structural analysis. �e engineers may also identify the missing documents, additional required expertise, and more individuals to interview after the �rst steps are completed.

Legal Process A�er a Structural Failure

�e legal process may simply consist of assembling the investigative and legal response team, developing an action plan, establishing a plan to protect con�dentiality, cooperation and dealing with public agencies such as the Occupational Safety and Health Administration (OSHA) and Federal Emergency Management Agency (FEMA), dealing with media, and providing for special consideration of interested parties.

Engineering Investigation of a Structural Failure

Project Initiation and Assembling the Investigation Team

�e project objective, scope of work, and the investigative plan will be established by all parties to start the investigation process. To avoid con�icts of interest, the investigative team should not have any relation with the parties involved on the loss such as contractors, designers, or other initial project interests.

Investigative Process

�e structural analysis of a new design is di�erent than the analysis in a structural failure investigation. Passing the yield point, nonlinear behavior, reaching out to ultimate capacity point, and load redistribution should be taken into account by the forensic engineer. A common mistake by the forensic engineer may be not examining and considering all failure scenarios due to their experience with similar investigations in the past. �ey may jump to the conclusion that the failure is the same as a previous investigation and may ignore other hypotheses and scenarios for the failure. �e loads and capacity of the structure should be evaluated and calculated through the structural analysis with hand calculations or computer software.

Document Review

Forensic structural engineers may need to review the following documents throughout the investigation process:

•Contracts and Revisions

•Contract and As-built Drawings

•Material Strength Reports or Certi�cation

•Project Correspondence

•Consultant Reports

•Engineering Calculations

•Contract Speci�cations

•Shop Drawings and Other Submissions

•Maintenance and Modi�cation Records and Other Documents

Field Investigation and Laboratory Analysis

Further �eld investigations, sampling of the materials and components, �eld tests, interviews, and laboratory tests may be needed in the investigation process and may be performed per the forensic engineer's request (Figure 4).

Structural Analysis

From a simple hand calculation to the complicated �nite element calculations using computer software, various computations are used by the engineers to investigate a failure. Determining the loads and strength of the structure is the main task in this stage. In many cases, there may be parameters regarding the strength of the structure that are not precisely known. In these cases, sensitivity analysis may be performed, and the engineer may use the probable low and high values as the input for the unknown parameters to evaluate the sensitivity of the calculation result.

Determining Structural Failure Causes and Report

As the investigation moves forward and the results, facts, and calculations advance, the failure scenarios and hypotheses are dropped and rejected or approved. New scenarios may emerge through the investigation process. In some cases, all failure scenarios may be eliminated except one and in other cases, the results are not straightforward. Multiple causes may lead to a critical combination of the load and capacity that �nally cause the failure. After narrowing down the potential causes of failure to one or a few, all evidence should be examined to determine whether it does or does not support the �nding cause(s). Finally, the investigation team provides a report including an introduction and background, description of the structure, �eld investigation, laboratory tests, calculation results, discussion, conclusion, and recommendations.■

�is article, all or in part, was previously published in the Concrete Repair Bulletin, March 2022. It is reprinted with permission.

MARCH 2023

Kevin Goudarzi, PE, is a Forensic Structural Engineer at EFI Global in Chantilly, Virginia. Kevin has been serving for three years on the Board of Directors of the ICRI Baltimore/Washington Chapter and chairs the chapter's Industry and Community Outreach Committee and is a member of ASCE.

Figure 3. Structural failure due to the heavy snow. Photo courtesy of www.twincities.com.

Figure 4. Insuf�cient welding on the gusset plate observed on site.

CODES and STANDARDS Underlying Causes of Exterior Sign Accidents

By Dan Eschenasy, PE F.SEI

Since 1980, when a periodic façade inspection and repair program (Local Law 11) was legislated in New York City (NYC), � ve fatalities have been caused by facades of buildings whose inspection is mandated by the program. Over the same period, there were � ve fatalities due to the collapses of parapets to which business signs were a � xed. However, when a similar fatal accident involving a business sign occurred in the neighboring Westchester County, the New York Times reported that the Yonkers Fire Chief quali � ed it as a freak accident. Questioning this assertion, this article provides an overview of sign-related incidents in NYC and o � ers explanations of the most likely causes of fatal accidents.

Standards and Regulations

Appendix H of the International Building Code provides several requirements for sign design, installation, and acceptable materials. While the technical literature mentions façade accidents and abounds with articles regarding façade inspection, it is di�cult to �nd texts discussing accidents related to signs a�xed to buildings. �is article tries to make a start in this direction and re�ects observations on data collected in NYC.

Local jurisdictions (Chicago, Philadelphia, etc.) permit signs according to their zoning statutes. NYC regulations use sign as a zoning term de�ned as “any writing—words, pictures, or symbols—that is on or attached to a building or other structure.” �e city’s zoning resolution provides speci�c de�nitions for accessory signs, which “directs attention to a business, profession, commodity, service or entertainment conducted, sold, or o�ered upon the same zoning lot,” and advertising signs, which “directs attention to a business, profession, commodity,

service or entertainment conducted, sold, or o�ered on a di�erent zoning lot.” Outdoor advertising has a long history that started in the 1800s. It involves serious amounts of money. Ordinances trying to prohibit billboards in cities were litigated to the US Supreme Court. Engineering standards pay special attention to the e�ect of wind on signs. Speci�c instructions for design can be found in ASCE 7-22 Minimum Design Loads and Associated Criteria for Buildings and Other Structures, Section 29.3 Design Wind Loads: Solid Freestanding Walls and Solid Signs, and in 29.3.2 Solid Attached Signs, as well as in 4.8.2 Ordinary Roofs, Awnings, and Canopies. However, the accidents discussed here did not result from signi�cant environmental loads. �ere is probably no need to discuss the ASCE 7 provisions since an article on wind design of canopies was published in STRUCTURE in July 2020. �e article referenced ASCE 7-16, but its speci�c provisions have been kept in the current ASCE 7-22. An engineer can also �nd useful criteria for design in the AASHTO LRFD Speci�cations for Structural Supports for Highway Signs, Luminaires, and Tra�c Signals. �e NYC Building Code, Appendix H, contains requirements beyond those in IBC. It also makes owners responsible for the yearly inspection of outdoor signs.

Wind Incidents in NYC

A search of NYC wind incidents of the past 25 years noted few incidents that identify a notable collapse of a sign or billboard in high winds. However, in

STRUCTURE magazine MARCH 2023

REASON ALL STRUCTURES ONLY STORES Nos Pct. Nos Pct. VARIOUS 1670 9% 391 2% Installed Without Licensed Hanger /Electrician 1414 7% 62 0% Not Registered/False 3865 20% 39 0% Without Permit 6447 33%1414 7% Illegal Zoning 5454 28% 52 0% Physical Condition 468 2% 122 1% Grand Total 19318100%208011% Table 1 Scope sign related ECB Violations 2009-2021

Figure 1 Example of taxpayer building with signs competing for attention, site of 2020 fatality due to sign panel collapse at corner store of building.

1999, a large vinyl billboard was ripped by 40 mph gusts injuring 3 people in the Times Square area. More recently, a billboard was involved in a serious accident when the blades of a collapsing wind turbine hit it.

In January 2012, during moderate winds, a monopole collapsed, damaging three buildings. A large billboard was attached to the arm of the monopole. � e collapse was due to the fracture of rusted bolts attaching the monopole to its foundation. � e rust resulted from ponding water around the top of the foundation, surrounded by dirt. � e fatigue from intermittent wind actions over the years might have also weakened the bolts. In the aftermath, the relatively few monopoles existing in NYC were inspected, and regulation for annual inspection was issued. In the � rst decade of the 2000s, there were several failures of sidewalk sheds with large signs attached to their parapets. In some cases, owners kept sidewalk sheds only to collect fees for advertising signs. � e sidewalk sheds were permitted according to an antiquated design that had not accounted for wind loads. � e standard required only a 4-foot parapet, but the installed advertising signs far exceeded this height, and it was no surprise that the failures occurred under modest wind loads. Again, more stringent enforcement eliminated advertising signs on sheds and allowed only accessory signs that met the 4-foot height of the parapet.

Some Data

Over the past 20 years in NYC, there were accidents related to failures of monopoles, signs a�xed to temporary installations, and signs a�xed to facades. Table 1 lists the number of violations issued for accidents or de�cient sign conditions for the period 2009-2021. �e statistics presented in this section were obtained from NYC Open Data lists of applications and violations that were searched for texts that included the words: sign, awning, or billboard.

Some simple statistics are listed to provide some context to the cases of fatality and sign deterioration. It is dif�cult to approximate how many signs exist in the city. Considering only store accessory signs, a segment of the total sign population, one can �rst approximate about 30,600 buildings containing stores. Since many buildings contain several stores, the number of accessory store signs might be over 50,000.

Since only window signs or very small signs are exempt from permitting, one can estimate the total number of signs by considering there have been 22,521 applications submitted since 2000. However, this approach may be unreliable as the applications might include replacing previously permitted signs.

Applications for sign installations can be signed by Licensed Sign Hangers when they are less than 150 square feet and up to 300 pounds. Out of the total of 22,521 sign applications submitted since 2000, licensed engineers (PEs) signed 9,303 (41%) and registered architects (RAs) 6.085 (27%). Of the 2,486 applications that mentioned a structure, RAs signed 638 and PEs 1,837. �e pool of licensed applicants is diverse and consists of about 400 di�erent PEs and close to 600 RAs.

In NYC, regulation of individual signs in terms of size, surface area, type of illumination, and height is pegged on the zoning district category. �e number of non-compliant sign installations, especially with zoning resolutions, reached such high numbers that in 2019 a moratorium on penalties was issued. A listing of the type of violations can be seen in Table 1. Note that the “ONLY STORES” column contains only violations related to accessory signs. Over 90% of violations result from installations without a permit or not permitted in the respective zoning district.

MARCH 2023

REASON ALL STORIESONE STORY No Pct No Pct INJURY 3 2% 1 1% BROKE/ DETACHED/FELL 30 25% 9 7% DISREPAIR 19 16% 3 2% FALLING/ COLLAPSING/ HANGING 39 32% 11 9% LEAN/LOOSE 30 25% 10 8% FATAL 1 1% 0 0% Grand Total 122100%35 28%

Table 2 Violations indicating deterioration (2009-2021)

Figure 2 Section parapet prior to 2007 collapse. Note – Parapet stability against overturning was provided by its own gravity and by the roo�ng inserted in the mortar joint.

�e 19,318 violations were issued to 5,300 addresses over 13 years (2009-2021). Aside from miscellaneous violations, the “VARIOUS“ category includes mostly noncompliance with �re regulations (e.g., installations blocking exits or containing �ammable materials). Only 2% of violations describe a deteriorating condition or an actual partial or total collapse. �e addresses of buildings with stores account for 1,316 violations; the balance represents 4,000 addresses, probably with advertising signs.

Like in the case of façades, the most common sign accidents are due to material deterioration and occur in the absence of major environmental events. Table 2 lists the de�ciencies described in violations for the period 2009-2021. �e entries are self-explanatory.

Fatalities

In 1973, the NYC Buildings Department enacted a rule requiring a competent person’s yearly inspection of masonry parapets. Only one- or two-family residences were excused. �is regulation, later known as §32-04 Masonry Parapet Walls, was incorporated into the Administrative Code. It was triggered by the death of three people crushed by the collapse of a parapet holding store signs. �e text in §32-04 speci�ed, “Structural members supporting parapet walls shall be designed to resist torsional stresses.”

It is not clear if this regulation was complied with over the years. It does not seem to have been enforced as it is not mentioned in any violation. But one should consider that store signs are placed in areas of maximum visibility on purpose. �eir condition is in plain sight. A

neglected sign would not draw customers into the store. Because most signs are set above the �rst �oor of a building, any major de�ciency (loose, lean, detached, etc.) is more likely to be noticed than a façade de�ciency occurring high above the curb. �e number of violations in Table 1 is evidence of the systematic attention given by building inspectors. A building inspector �eldinspecting the legality of a sign installation in a certain zoning district is also likely to notice conditions that might lead to collapse.

Fatalities caused by parapets with a�xed signs occurred in December 1990, May 1998, April 1994, August 2002, and December 2021. In 2003, the parapet of a store collapsed, injuring a person. In 2007, the author performed a forensic analysis when a parapet and business sign collapsed, injuring three people, including a young boy that had a foot amputated. All these accidents, including the fatal 1973 case, occurred on taxpayer buildings. In real estate, a taxpayer building refers to a one- or two-story commercial building built along a commercial artery. In NYC, these types of buildings started to be erected during the Depression to cover the property taxes on the lot. �e expectation was that the lot would increase in value and be redeveloped. Usually, the building is divided into smaller stores, each with its own sign attached along the common parapet (this was the case in four collapse cases). �e poor construction and especially the inadequate �rewall separating the stores are known to cause serious �re hazards. In the vast majority of cases, glass windows and doors cover the entire frontage to serve the commercial purpose of the establishment (Figure 1). �e parapet supporting the sign is set directly over a steel lintel beam. In NYC, about 5,600 taxpayer buildings were built between 1920 and 1960, containing over 14,600 commercial units.

�e accident shown in Figures 2 and 3 occurred in 2007. �e collapsed sign was one of a series of signs attached to a building built in 1950. �e building is classi�ed as a Multi-Story Retail Building, but a onestory taxpayer structure occupies the frontage. �e building contained �ve stores along its 125-foot frontage. Over the years, there have been about 20 submittals related to this building’s electrical sign inspections or sign changes. In 1998 the façade was repaired, and a continuous cavity wall parapet was installed over the entire frontage.

�e signage included an awning with a 3.5-foot �at sign installed above that exceeded the coping stone’s level. �e backup CMU was grouted and reinforced but was not attached to the beam below. As observed

STRUCTURE magazine

Grand Total Collapsed Danger Collapse Falling Partial Colapse

Over Six Families with Stores (16056) 8 19 14 1 42 Fireproof with Stores (1389) 2 4 6 Semi-Fireproof with Stores (5275) 5 7 3 15 One-Story Retail Building (7760) 7 7 1 15 Multi-Story Retail Building (3482) 5 2 2 9 Predominant Retail with Other Uses (6375) 8 1 9 Stand Alone Food Locales (564) 1 1 Shopping Centers (255) 1 1 Miscellaneous (166) 1 1 All Other buildings 99 137 101 5 342 Grand Total Parapet Incidents 128 185 122 6 441 Stores No of Incident 29 48 21 1 99 Pct of Parapet Incidents 23% 26% 17% 17% 22% One-Story Retail Building 5% 4% 1% 0% 3% Table

BUILDING CLASS (NYC TOTAL) DEFICIENCY

STORES

3 Parapet Incidents 2009-2021

in Figure 2, the masonry was placed on top of plastic sheet �ashing that protected the steel lintel. �e roof waterproo�ng, partially placed in the CMU joints, was the only lateral attachment. �e stability of the parapet was practically provided by self-weight and the resulting friction between CMU and �ashing. It can be inferred that, over time, under intermittent moderate winds that had acted horizontally on the sign and that also induced a downward rotation of the awning, the parapet started to slightly “walk.” �is particular accident occurred on a reconstructed parapet, but it illustrates a weakness that most likely led to fatalities in other cases – large signs attached to masonry parapets not anchored to the supporting steel beams. Except for their weight, these parapets do not have any system to prevent overturning. �e return (perpendicular) parapet may help provide stability on shorter facades, but these returns are as far apart as taxpayer buildings have long frontages. � e subdivision of the taxpayers into smaller stores creates conditions where tenants may use large signs and awnings as they compete for pedestrians’ attention.

Should these accidents be considered parapet collapses or sign collapses? �e parapet is one of the most vulnerable components of a façade, especially because of its exposure to elements on both sides. Table 3 provides statistics obtained by searching NYC Open Data texts of violations that indicated some de�cient parapet condition but did not include the word sign. �e buildings containing retail stores seem to have de�cient parapets at a higher ratio than most other buildings. �e statistics in Table 3 are not all entirely relevant as signs at multi-story buildings are usually attached at the spandrel over the �rst �oor and would not a�ect the condition of the parapet. Also, many NYC multi-story buildings have cornices that hide the condition of parapets, and violations would not mention parapets. However, the data for one-story retail buildings is pertinent to the discussion as signs are highly likely to be attached to the parapets of these buildings. �e ampli�ed risk is signi�cant for these 7760 buildings that represent about 1% of the NYC building stock and 5% percent of collapsed parapets incidents. �is table does not include the violations/collapses shown in Table 2.

Discussion

In the case of fatal accidents, the signs and the parapets of taxpayer buildings were at relatively low heights, and a fall from a lower height develops limited energy. Still, descriptions of these accidents mention a rain of bricks as large segments of masonry fell. �e fatalities belong to a particular typology of store signs and should not be considered an indication of particularly hazardous conditions posed by most signs. Because these taxpayer signs are placed along busy arteries, the dense presence of pedestrians increases the possibility of injury. As evidenced by the high ratio of occurrence of parapet collapses, the failures are most likely due to �aws in the installation of the parapet. �e number of collapsed parapets (Table 3) strongly indicates their fragility. About 15,000 facades are being periodically inspected in NYC. Despite repeated repair campaigns, over the period from 2006 -2019, there were 29 parapet-related incidents (some included in Table 3). Facades and weather-exposed accessories deteriorate, but timely observations should prevent accidents. As demonstrated by the number of violations, signs are under serious scrutiny through inspection protocols. Statutes also require owners to inspect every year. Although the data collected here could not be adequately normalized, the ratio of violations indicating physical de�ciencies versus an actual collapse needs to be given some consideration: out of 35 violations of signs on one-story buildings, 10 were related to a condition of broken, detached, or had fallen (Table 2). From Table 3, out of 15 violations related to parapets of one-story retail buildings, seven registered an actual collapse. No large-scale statistics provide criteria for acceptable ratios, but those listed here seem worrisome.

�e fatalities discussed were caused by collapses of masonry parapets. �e attached signs or awnings might have masked the condition of the supporting masonry parapet, and thus contributed to the accidents.

�e NY Times article describing the Yonkers accident also quoted a building engineer for the city’s Bureau of Housing and Buildings; the engineer stated that signs along the building front could obscure cracks that might signal damage from the elements. �is was a much more accurate assessment.■

MARCH 2023

Dan Eschenasy, PE F.SEI is a Principal Forensic Engineer with Gilsanz Murray Ste�cek LLP. He can be reached at 212.254.0030

Figure 3 View of 2007 collapse, Photo Courtesy of Daily News.

structural ADHESIVES

Adhesive Bonding E�ciency of Concrete Interfaces

Why pull-off tests and tensile strengths do not allow statements about adhesive bonding ef�ciency.

By Dr. Martin Brandtner-Hafner

Aliterature review regarding concrete bonding reveals a limited number of publications specifically addressing bonding safety assessment. Some are dealing with pure concrete-toconcrete bonding, whereas others are focusing on the bonding of �ber composite components for structural external reinforcement of concrete buildings. Technically, this takes the form of wraps joined by epoxy resin bonding. Traditional mechanical test methods, such as the shear test and pull-o� test, are used to characterize the adhesion properties of bonded concrete interfaces. As illustrated graphically in Figure 1, the latter is standardized by ASTM D7234 (Standard test method for pull-o� adhesion strength of coatings on concrete using portable pull-o� adhesion testers) and ASTM C1583 (Standard test method for tensile strength of concrete surfaces and the bond strength or tensile strength of the concrete repair and overlay materials by direct tension). �ere, a concrete slab is refurbished and adhesively bonded with carbon �ber reinforced plastic (CFRP) wraps. Adhesively bonded dollies are utilized to carry out pull-o� adhesion tests by measuring the peak strength until the specimen ruptures. �is simple and inexpensive procedure leads to quick results indicated by mechanical stress values. However, the main constraint is the complete omission of fracture-energetical parameters. Hence, a holistic multi-level principle is introduced to overcome such limitations. In this context, the term "fracture analysis" means an evaluation of the structural safety of bonded concrete joints under pre-damage, also called "pre-cracking". In doing so, a small initial crack is initiated in the interface and propagated in a controlled manner to measure softening parameters. It is a great advantage over the above-mentioned pull-o� tests, which are technically and methodologically incapable of achieving this because of their technology and design.

Materials and Methods

Basic Considerations

Today, mechanical standard procedures are used to evaluate adhesively bonded concrete interfaces with tensile strength as a stress-based single-failure criterion. As indicated above, their major limitation is the ignoring of bonding quality, failure modes, and damage shielding e�ects from fracture analytics.

Reverse Failure Engineering

To overcome such limitations stated above, a three-stage evaluation principle called reverse failure engineering (RFE 3D) is introduced and applied on adhesively bonded concrete interfaces. It is composed of three di�erent assessment dimensions:

1) adhesion bonding quality,

2) failure modes, and

3) damage shielding.

Adhesion Bonding Quality

�e �rst evaluation methodology is called the Adhesion Bonding Quality (ABQ). It describes the ex-post wetting of adhesive surfaces after the complete separation of bonded joint specimens by measuring the adhesive wetting in percent of the fractured surface. Already standardized, there are three classi�cations:

• poor quality,

• moderate quality, and,

• high quality (Figure 2, No. 1).

Failure Modes

�e next dimension of evaluation concerns so-called Failure Modes (FM) of adhesive interfaces. �ey are classi�ed into four types starting with cohesive, adhesive, mixed, and substrate failure (Figure 2, No. 2). �e occurrence of one type of defect has a direct e�ect on the bonding reliability of the entire composite.

Damage Shielding E�ects

�ese are phenomena responsible for crack propagation delay (Figure 2, No. 3). �ere are two basic types of Damage Shielding E�ects (DSE):

STRUCTURE magazine