EXCLUSIVE! ATTACHMENTS OWNER-OPERATOR TMK TREE SHEAR SHOWS OFF PRODUCTS AND DEVELOPMENTS PROSILVA HARVESTER PLUS FACTORY WALK-AROUND AUTUMN 2022 • ISSUE 9 • £4.40 TIMBER HARVESTING TOP JOHN DEERE MACHINES OF G&G TIMBER HARVESTING MARKET REVIEW - FIXED TOOTH MULCHERS HIGH WALKER! APF EXHIBITION PREVIEW PLUS! FORESTRYSPEC HYUNDAI HX145A IN ACTION

WWW.ROTTNE.COM FORESTRY MACHINERY FOR ALL NEEDS FROM LIGHT THINNING TO HEAVY FINAL FELLING UNIQUE FORWARDER FOR BOTH THINNING AND FINAL FELLING STEERABLE WAGON WITH 54° STEERING ANGLE & ACCURATE TRACKING TIGHT TURNING RADIUS | POWERFUL CHASSIS SPACIOUS CAB WITH COMFORT LINE + www.rottne.com/en/steerablewagon ROTTNE F13D WITH STEERABLE WAGON ROTTNE F13FILM

EDITOR Kyle Molyneux kyle@sundialmagazines.co.uk

ART DIRECTOR David ‘Spike’ McCormack

ADVERTISEMENT SALES

Alex Cronin 020 8639 4405 Tom Pickford 020 8639 4417

ADMINISTRATOR Martin Attis 020 8639 4409

PUBLISHING DIRECTOR Paul Cosgrove 020 8639 4401

CONTRIBUTING WRITERS AND PHOTOGRAPHERS Paul Argent, Eoghan Daly, Nick Drew, Ken Topham and David Wylie

Forestry Machinery is published by Sundial Magazines Ltd, Sundial House, 17 Wickham Road, Beckenham, Kent, BR3 5JS

TEL 020 8639 4400 FAX 020 8639 4411

EMAIL info@forestrymachinerymagazine.co.uk

WEB www.forestrymachinerymagazine.co.uk

SUBSCRIPTIONS

Earthmovers subscriptions, Trinity House, Sculpins Lane, Wethersfield, Essex, CM7 4AY

TEL +44 (0)1371 853632

EMAIL earthmovers@escosubs.co.uk

Farm Machinery Journal subscriptions, Trinity House, Sculpins Lane, Wethersfield, Essex, CM7 4AY TEL +44 (0)1371 853634

EMAIL farmmachineryjournal@escosubs.co.uk

NEWSTRADE

Seymour Distribution, 2 East Poultry Avenue London, EC1A 9PT TEL 020 7429 4000

REPRO Design & Printing Solutions Ltd, The Coach House 101 Northwood Road, Whitstable, Kent CT5 2HE TEL 01227 770034

PRINTING

Walstead Southernprint, 17-21 Factory Road, Upton Industial Estate, Poole, Dorset, BH16 5SN

Kent, BR3

Wylie

WELCOME

to Forestry Machinery, the magazine dedicated to modern forestry equipment.

Approximately 70% of Scandinavia is covered in forest, so it’s no wonder there is an abundance of forestry machinery manufacturers in the region, particularly in the likes of Finland and Sweden. For this issue, Eoghan Daly headed over to the former nation in search of interesting kit and came back with plenty material. So much, in fact, I’ve had to hold back some of it for issue 10! There’s a great feature on long-time ProSilva user Heikki Heino (page 36), plus a look behind the scenes at ProSilva itself (page 30). Eoghan also met the ambitious minds behind TMK Tree Shear (page 54) and learned more about the company’s latest products including new MultiGrab.

This issue’s cover story is another cracker – and a big exclusive! David Wylie tracked down the world’s rst Hyundai HX145A LCR in High Walker forestry speci cation (page 18), working in Scotland and getting stuck into thick gorse with its ail attachment. Not done yet, owner MAM Contracting has made a few worthwhile upgrades to create its ultimate forestry excavator. Elsewhere in this edition of Forestry Machinery, Ken Topham is back with another handy Market Review, this time covering xed tooth mulchers from a host of manufacturers. We’ve also added a new Used Machinery section at the back of the magazine, which provides a useful snapshot of the market and covers some interesting metal. By issue 10, I hope to have further input from traders in this area, who will no doubt share advice worth listening to. Until next time!

Kyle Molyneux, Editor

FORESTRY MACHINERY AUTUMN 2022 3 ED’S LETTER

COPYRIGHT Sundial Magazines Ltd 2022. All rights reserved. Reproduction in whole or in part is forbidden without the express permission of the publishers. Sundial Magazines Ltd. Registered in England no. 4134490. CONDITIONS FOR ADVERTISING All advertisements are accepted subject to the publisher’s standard conditions of insertion. For a copy of advertising terms & conditions, please write to Paul Cosgrove at Sundial Magazines Ltd, Sundial House, 17 Wickham Road, Beckenham,

5JS

Satisfy your appetite for off-road machines with Earthmovers and Farm Machinery Journal –the magazines for owners, operators and contractors NEED MORE MACHINERY? Autumn 2022 Issue 9 COVER IMAGE David

ATTACHMENTS OWNER-OPERATOR TMK TREE SHEAR SHOWS OFF PRODUCTS AND DEVELOPMENTS PROSILVA HARVESTER PLUS FACTORY WALK-AROUND AUTUMN 2022 ISSUE 9 TIMBER HARVESTING TOP JOHN DEERE MACHINES OF G&G TIMBER HARVESTING MARKET REVIEW - FIXED TOOTH MULCHERS HIGH WALKER! APF EXHIBITION PREVIEW PLUS! FORESTRYSPEC HYUNDAI HX145A IN ACTION FROM ALL GOOD BOOKSTALLS & ON SUBSCRIPTION AVAILABLE NOW Shi ing gearsWhy Deutz-Fahr’s new RV Shiftis a transmission revelation FREE!!! CONTRACTOR HANDBOOK WITH THIS ISSUE* September 2022 // www.farmmachineryjournal.co.uk MOBILE DAIRY PARLOURS & THEBENEFIT OF WATER BORE HOLES KUHN FEEDER PLUS VICON,ROC & PÖTTINGER GRASS KIT FIRST IMPRESSIONS FARM UPGRADES FMJ VERDICT GENESIS REVIEWED CLAAS ON TRACKS PLUS6C DRIVEN! £4.30 LEXION 8700 & 35 YEARS OF TERRA TRACS NEW HOLLAND T8.410 IN ACTION NORTHERN JCB 245XR at workKobelco demo rig Short swing Sany ● Show reports Hillhead and Maxpo ● Classic electric haulers EARTHMOVERS NUMBER ONE FOR ALL THE LATEST PLANT & MACHINERY NEWS CATERPILLAR’S UK-BUILT COMPACT LOADER RANGE BOBCAT GOES ALL ELECTRIC DRIVE CATERPILLAR’SUK PRODUCT LAUNCH Owneroperator feedback EXCLUSIVE! ALL NEW DUCK FROM DOOSAN PLUS Cover_v8.indd

FORESTRY MACHINERY AUTUMN 2022 5 REGULARS FEATURES 3 WELCOME What’s in store for readers of issue 9 7 NEWS The latest updates and developments AUTUMN 2022 CONTENTS 10 SHOW PREVIEW 2022 APF EXHIBITION The APF and Arb shows join forces 18 NEW MACHINE HYUNDAI HX145A LCR HW World’s rst High Walker model in Scotland 24 TIMBER HARVESTING G&G TIMBER HARVESTING Brand new machines from John Deere 30 COMPANY PROFILE PROSILVA Finnish rm stands out from the crowd 36 OWNER-OPERATOR PROSILVA S4 HARVESTER Heikki Heino is on his third ProSilva unit 42 TRACKED SKID-STEER JCB 325T Tracked JCB Forestmaster skid-steer 48 TREE CLEARANCE MAPLE TREE CARE Kobelcos clear poplars in Derbyshire 54 FACTORY VISIT TMK TREE SHEAR Behind the scenes at the company 60 BOGLAND REVIVAL ENVIRONMENTAL FORESTRY SERVICES Returning sites to nature the right way 64 MARKET REVIEW MULCHERS A close look at xed tooth machines 72 USED MACHINERY FORESTRY VETERANS Second-hand kit that caught our eye CONTENTS

FORESTRY MACHINERY NEWS

TIGERCAT 6900 GRINDER

The 6900 is the rst production grinder designed and built by Tigercat. The 6900 is a heavy-duty upswing grinder made for high throughput material reduction and mulch production.

The upswing rotor and large infeed opening with outward wing walls are said to maximise processing capacity, while the grinder’s upper frame pivots on the undercarriage, allowing the operator to adjust the infeed angle or discharge height for different material lengths. Meanwhile, the adjustable angle eliminates the need for outriggers,

and the pivoting upper frame allows transport on a 460mm lowboy trailer without the need to fold the discharge conveyor.

The machine has remote control functions, along with a 10-inch display for machine monitoring and function adjustment. Maintenance promises to be straightforward, and an optional large diameter magnetic head pulley is available to effectively remove metal from the end product. The machine is also prepared to accept over-band magnet systems.

KRONOS SMART BOOM CONTROL

Smart Boom Control is a crane tip control from Kronos and is a part of the xCrane system. Available for new cranes or as a retrofit for used cranes, Kronos says SBC means the operator only needs to think about controlling the crane tip instead of controlling each movement separately.

This latest 2.0 version of SBC now includes a sensor on the turn axis, making it possible for SBC to automatically lower the movement speed of the crane, while the crane tip is inside the loading area. This gives the operator a more precise control of trailer loading. The system will also switch to regular operating mode while the crane is being moved to parking position, which makes the parking of the crane easier.

NEWS 6 AUTUMN 2022 FORESTRY MACHINERY

MULAG MOWER

Wildflowers are set to bloom on roadside verges across the north of England after specialist contractor GVA became the first UK customer for a new, environmentally-friendly mowing head designed to protect insects and other creatures.

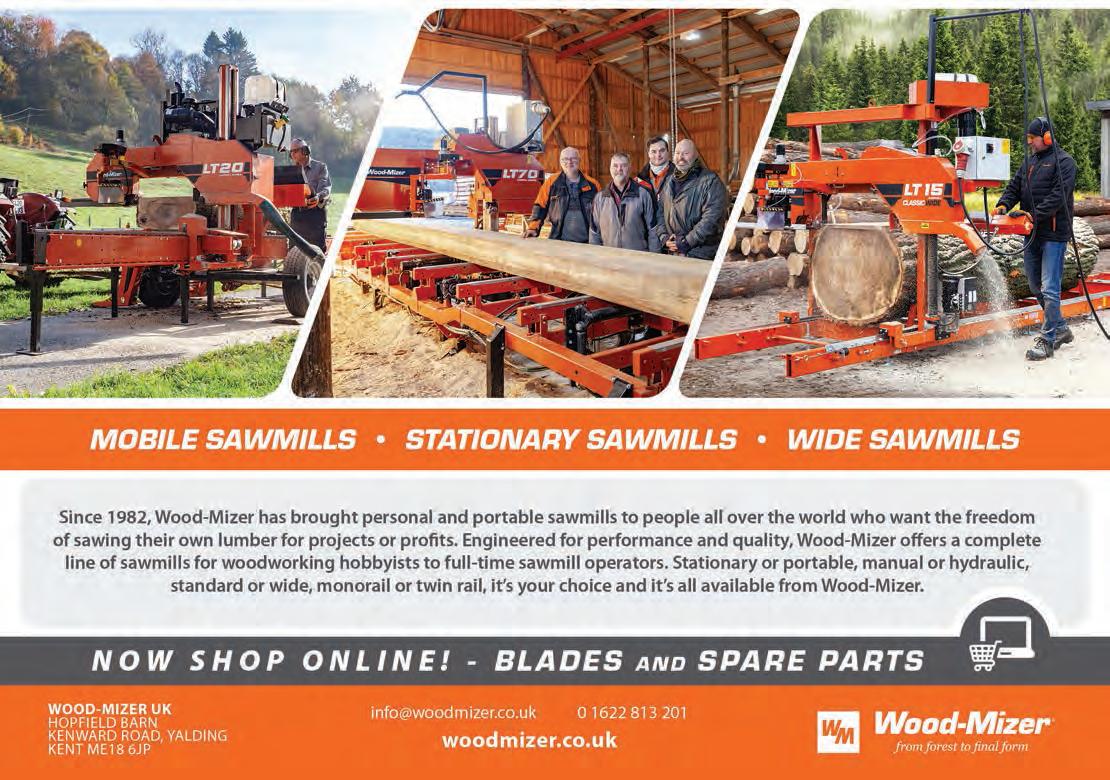

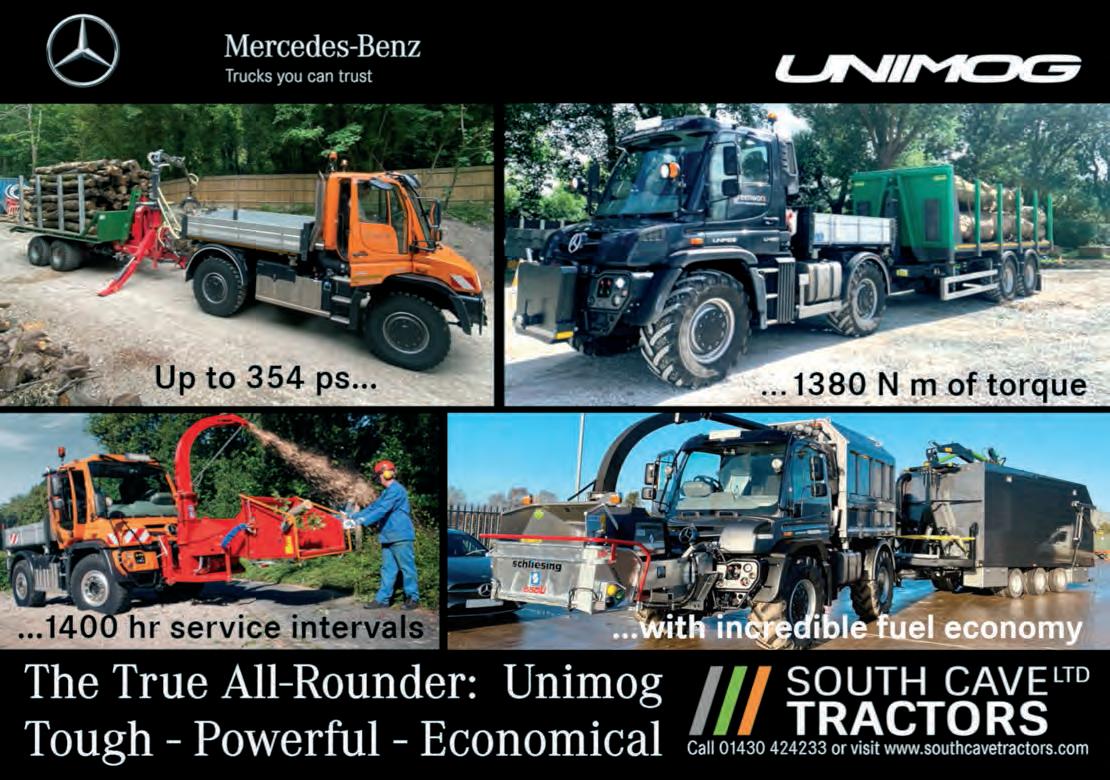

The Eco 1200 plus head was developed by Mulag and delivered by South Cave Tractors, the German manufacturer’s sole agent in the UK. It has now been fitted to the PTO-operated Mulag SB600 suction mower that Halifax-based GVA has been using since 2019. This was also supplied by South Cave Tractors, of Brough, East Yorkshire, as was the Mercedes-Benz Unimog on which it is mounted. The 4x4 vehicle pulls a Harsh drawbar trailer with grass collection box.

BRACKE FOREST SOLD TO KOMATSU

Komatsu Forest AB, fully owned subsidiary of Komatsu Ltd, has acquired Swedish equipment manufacturer Bracke Forest AB from Cranab AB (part of Fassi Group). Bracke Forest had been part of Cranab Group since 2013, and its sale will open up new funds for Cranab AB to divert into its own operation.

Bracke Forest will continue as before under the current company name, and the management of the company will be the same with Klas-Håkan Ljungberg as CEO. The sale will allow Bracke Forest to take advantage of Komatsu’s sales and service network.

The Eco 1200 plus head features a disc mower, ahead of which a mechanical scourer is fitted. The scourer ‘chases up’ insects sitting in the grass before the cut material is sucked up from above. The mower has a 1.2m cutting width and also employs ‘sensor rollers’ that offer reduced ground contact and thereby provide more protection than a conventional pressing roller.

GVA will be deploying its impressive looking Mulag mowing and collection system on motorway and major A-roads throughout northern England, as it becomes a direct supplier of ecology and landscaping works services to National Highways, formerly known as Highways England.

PONSSE MILESTONE

The 18,000th Ponsse forest machine was recently completed at Ponsse’s factory in Vieremä, Finland. After its handover, the Ponsse Elk will be operated by VMC Bois in France. Entered in serial production in 2005, more than 1,000 PONSSE Elk forwarders have been completed, delivered to over 20 countries and tested in real-life conditions across the globe.

Starting as the dream of Einari Vidgrén, Ponsse is a familyowned business that now operates in the harvesting markets of over 40 countries. All Ponsse forest machines are still manufactured in the company’s birthplace in Northern Savonia, Finland.

Forestry England, the country’s largest land manager, has recorded the highest ever number of visits to the nation’s forests across England over the last year. Some 363 million visits were estimated to have taken place – an

increase of 67 million (over 20% per cent) compared to the previous year’s estimate. This is the second consecutive year Forestry England has seen a substantial increase, and memberships are also up 38% on the previous year.

FORESTRY MACHINERY AUTUMN 2022 7

RECORD VISITOR NUMBERS

Seeking machine operators to deliver peatland restoration

Peatland

ACTION - with funding from Scottish Government’s pathway to net zero by 2045 - are improving the condition of degraded peatlands across Scotland.

Peat is the largest and most efficient land-based store of carbon, capable of storing on average 10 times more carbon per hectare than any other land-based ecosystem. However, Scotland’s peatlands are in such poor condition that they are emitting carbon rather than storing it. The best available evidence suggests damaged peatlands are responsible for 20% of Scotland’s total carbon emissions.

carbon to one that is actively capturing it. Restoration will ensure that Scotland’s peatland landscape is more climate-ready - better able to cope with the anticipated effects of climate change - and to continue to provide essential ecosystem services. This includes alleviating the challenges associated with both flood events and drought conditions.

The restoration of peatlands can also address the biodiversity crisis. It does this by restoring valuable habitats which support higher plant diversity, and in turn, higher numbers of invertebrates - a food source for birds such as grouse and other upland species.

The main objective of peatland restoration is to create conditions that reduce the loss of organic and atmospheric carbon, and encourage the growth of active, peat-forming plant species.

This is done using techniques that raise the water table and stabilise the peat, such as ditch blocking, re-profiling peat hags and revegetating bare peat areas. This kick-starts the process of changing a peatland from one that is releasing

In 2020, the Scottish Government made a commitment to a £250 million ten-year funding package to support peatland restoration, with a target of restoring 250,000 hectares of degraded peatlands by 2030. This investment, and target, means that peatland restoration will continue to be one of the most important nature-based mechanism available to help deliver Scotland’s ambitions to reach net zero by 2045.

However, peatlands can be restored to nearnatural conditions.

ADVERTISMENT FEATURE

Forest-to-bog restoration

Peatland restoration is one part of managing forestry sustainably within the wider landscape.

MAKEDOYOUTHECUT

Historically, plantations on deep peat were established before the environmental sensitivities and impacts of doing so were not appreciated. In addition, the potential for tree growth on deep peat is compromised by the combination of waterlogged, low nutrient, acidic conditions of a typical peatland habitat. Today, carbon calculations inform whether to restock existing afforested peatland areas or “restore” the peatland.

The shears harvesting phase

Forestry and Land Scotland (FLS), a Peatland ACTION partner, is helping to restore Scotland’s peatlands.

First, a specially adapted excavator with wide tracks and a shears harvesting head snips the trees just above the roots. The whole tree is then passed several times through a second machine, a conventional harvester, which removes the brash (branches) from the main trunk. The brash is used to create a mat so that a third machine, a conventional forwarder, can follow on behind, collect the logs and take them to the forest road for collection to the mill.

Peatland restoration phase

The main objective of peatland restoration is to twofold: stabilise the peat to secure the existing carbon store “now”, and encourage the growth of active peat-forming, carbon-sequestering vegetation for “the future”.

To achieve successful restoration of previously afforested peatland habitats, the ridges and furrows - created when the trees were originally plantedneed to be levelled or smoothed.

Ground smoothing covers a range of operations, including for example, stump flipping. Stump flipping involves lifting the remaining tree stumps and shallow root system left by the shears harvester, flipping them over and squashing them down into the furrows with the back of the bucket.

The benefits of forest-to-bog restoration

The benefits of peatland restoration are far reaching. It not only helps to keep existing carbon stores in the ground: a healthy peatland is also better able to support a range of species, many of which are unique to peatland habitats. Some of these habitats expand existing areas, often within designated protected sites, making the landscape as a whole more robust and resilient to the anticipated effects of climate change.

For example, peatlands with a water table near the surface are better able to cope with the effects of wildfires. As the climate warms, we are seeing an increase in wildfires not just in Scotland but also across Europe. A high water table keeps the surface vegetation wet, helping to reduce the impact of drought, reduce the risk of wildfires and slowing their spread when they do occur. A good example of this was the wildfire event at Golticlay Forest in Caithness in 2019 where peatland restoration helped prevent the fire spreading.

Peatland ACTION are ramping up efforts to meet this ambition and we are actively seeking contractors to get involved in peatland restoration. Contact us today to be added to our contractor list to receive job alerts, training dates and latest project news peatlandaction@nature.scot

or this year, APF 2022 has joined forces with The Arb Show, effectively giving exhibitors and visitors two shows for the price of one. Taking place on September 22 to 24 at Ragley Estate in Alcester, Warkwickshire, around 300 exhibitors and around 25,000 visitors are expected over the three days. One big draw of this year’s exhibition is that much of the machinery is shown working under realistic conditions. Many of the large machinery dealers will be in attendance including Ponsse, R J Fukes, Kingswell Holdings, W M Clark, Clark

Komatsu. If you want to nd out the full line-up, a complete exhibitor list can be found at www.apfexhibition.co.uk.

Event organisers want APF 2022 to be not just the place to buy machines and meet colleagues, but where you can learn new skills, keep up to date with the latest news, see the latest technology in action and be able to talk to industry experts about every aspect of forestry machinery and equipment.

The list of high class competitions is longer than ever. There is the Husqvarna world 25m pole climbing championship,

Tracks, Case IH, Jas Wilson and many more. However, we are not expecting to see the likes of Tigercat, Rottne, John Deere and

Tracks, Case IH, Jas Wilson and many more. However, we are not expecting to see the likes of Tigercat, Rottne, John Deere and

10 AUTUMN 2022 FORESTRY MACHINERY

After a four-year break, the APF show is back with a bang as organisers join forces with The Arb Show for an exhibition like no other, as David Wylie explains

TWO FOR ONE

F

“AROUND 300 EXHIBITORS AND AROUND 25,000 VISITORS ARE EXPECTED”

IMAGES DAVID WYLIE

British Horse Loggers.

RJ Fukes just one of many large dealers in attendance at APF.

COMBINEDSHOW

PREVIEW

APF EXHIBITION

In the Forest Worker Zone, there will be a Komatsu harvester simulator, chainsaw maintenance workshops, information on chainsaw competency and the new guides for using tree shears. Advice on the new rules for producing and selling rewood, the new FC funded project for mapping the UK’s coppice resource, winching safety demos and discussions on the training needs for forest workers, as well as the infamous chainsaw holdout competition!

FISA has managed to get a Komatsu simulator which is believed to have been donated to Barony

equipment and techniques, a technical demo area will see workshops by all the main manufacturers on the latest hand tool technology and maintenance and the arborists workshop will see short seminars by industry experts on the latest topical issues such as plant health, safety and training.

In the new tree climbing area, in addition to the premier UK Open competition, there will be a competition for the novice climber as well as an exciting team rigging challenge. There will also be the opportunity to try out and use new Harkie equipment under expert guidance. Training features strongly with Lantra and City and Guilds on hand to give details of the latest courses and assessment. The British Horse Loggers will be offering a fantastic opportunity to have a go at horse logging, too.

This year’s exhibition also includes a truly remarkable range of traditional woodland craft demonstrations.

the A W Jenkinson and Tilhill European chainsaw carving championship, the Harkie UK Open tree climbing championship, and the McVeigh Parker UK Open fencing championship.

college for training purposes, to help attract new blood into the industry and help train the next generation of operators.

The new Arb Worker Zone will see demos of the latest new climbing and rigging

the A W Jenkinson and Tilhill European chainsaw carving championship, the Harkie UK Open tree climbing championship, and the McVeigh Parker UK Open fencing championship.

college for training purposes, to help attract new blood into the industry and help train the next generation of operators.

The new Arb Worker Zone will see demos of the latest new climbing and rigging

SHOW

|

FORESTRY MACHINERY AUTUMN 2022 11

Tilhill European chainsaw carving championship.

Buy tickets in advance to ensure swift entry.

Ian Millward has been the APF Exhibition secretary since 1994.

Training for real machines on the Komatsu simulator.

Simulators should help to attract new blood to the industry.

Husqvarna world 25m pole climbing championship.

EXHIBITORDETAILS

Robustrack

Oldbury-based Robustrack is a family-run business and exclusive distributor of Italian hydraulic attachments and Eurocomach machines, with nationwide links. This is Robustrack’s rst time at APF and the company is said to be incredibly excited to exhibit. On display will be the Agriforest range of log grabs and tree shears plus stump grinders, grapple saw and of course, Robustrack’s ail and mulcher range. The company will be debuting its xed-tooth skid-steer mulcher and the incredible Eurocomach 90ZT excavator. Merchandise, such as Robustrack hoodies and hats will be available to purchase. Visitors are welcome to pop by the demo circuit and say hello to Davide and the Robustrack team.

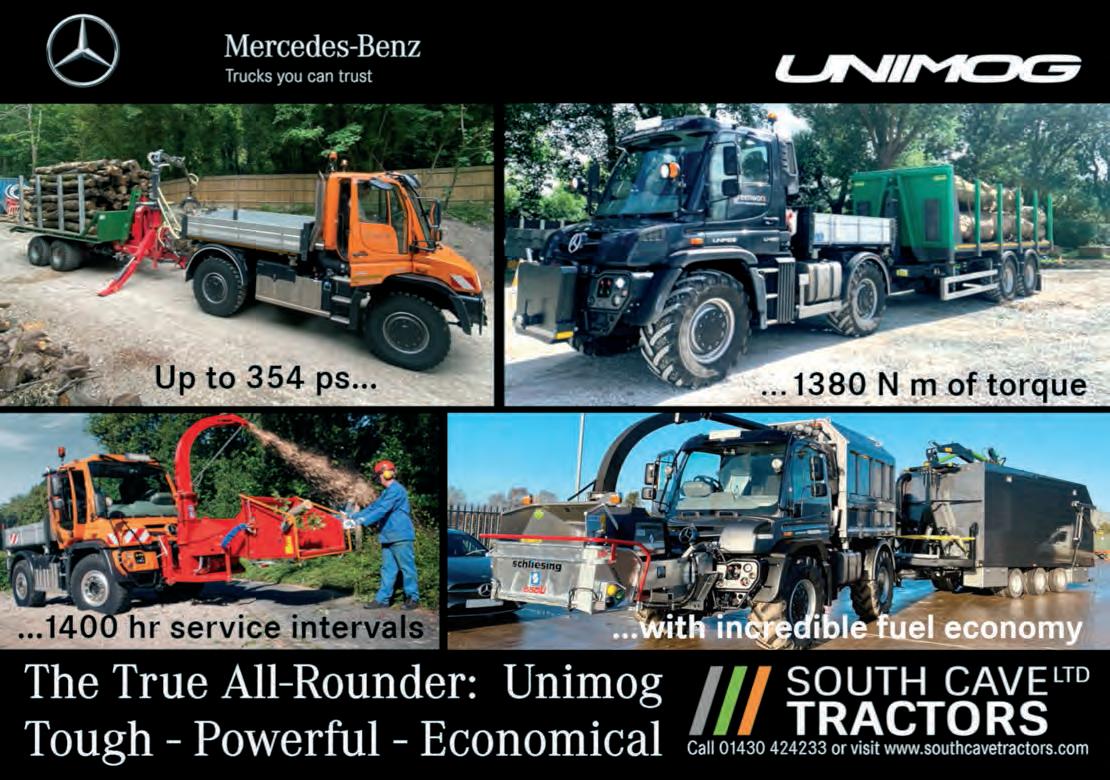

South Cave Tractors

East Yorkshirebased South Cave Tractors Ltd is the regional main dealer for Mercedes-Benz Unimog vehicles, which has been involved in the Forestry and Arboriculture industries almost since its creation 75 years ago, and for more than 50 of those years South Cave Tractors Ltd has been synonymous with the name Unimog here in the UK. The rm be showing a good selection of the very latest range of Unimog models available, including new U535 UGE model with the latest 350hp engine producing 1,380Nm of torque, and you can see why the Unimog continues to enjoy a unique place in the forestry sector.

Case IH

Case IH will be exhibiting at APF for the rst time this year and will feature a Puma 175 CVX tractor complete with full forestry kit, kindly lent from Forestry England. This specially adapted tractor with roll cage is fully reversible, with swivel seat and rear controls. A multipurpose vehicle, it can undertake various tasks associated with forestry such as mulching brush cut from trees, creating routes that provide accessibility for other machinery and transporting logs. It can be ordered fully tted from the factory on any tractor from Luxxum to Magnum, with optional dual wheels for extra stability. For more

Specially adapted tractor with roll cage and swivel seat/controls.

South Cave has dealt in Mercedes Unimogs for over 50 years.

Robustrack debuts at APF and will have lots on display.

Specially adapted tractor with roll cage and swivel seat/controls.

South Cave has dealt in Mercedes Unimogs for over 50 years.

Robustrack debuts at APF and will have lots on display.

SHOW PREVIEW | APF EXHIBITION FORESTRY MACHINERY AUTUMN 2022 13

“YOU CAN LEARN NEW SKILLS, KEEP UP TO DATE WITH THE LATEST NEWS, AND SEE THE LATEST TECHNOLOGY IN ACTION”

EXPERTS IN MODERN FOREST TECHNOLOGY THE PERFECT SOLUTION THAT ADAPTS TO YOUR EXACT REQUIREMENTS For more information contact: Simon Rudyard: 07585 118136 simon.rudyard@chandlersfe.co.uk THE APF SHOW 2022 22ND - 24TH SEPT VISIT US AT www.chandlers.co.uk SALES | PARTS | SERVICE

information on the machine, call Anton Stander on 07725 069237, or contact your local Case IH dealer.

UK Power Networks

UK Power Networks will be at APF raising awareness on working safely around the electricity network. Tree trimmers and the arboriculture industry are being reminded of the risks associated with overhead electricity wires by the UK’s biggest electricity distribution company, UK Power Networks said, “We’ll be highlighting the need to ‘Look Out, Look Up’ and where to obtain safety guidance.” Visitors to the interactive stand can pick up free safety giveaways, too!

Chandlers Forestry Equipment

Chandlers Forestry Equipment will be displaying and demonstrating its range of Kelsa Forestry Equipment in conjunction

SHOW PREVIEW

with the very well matched Valtra Forestry Tractors. Supporting its UK-wide sales, parts and service dealer network for Kesla, there will be a range of Timber cranes and grabs, both tractor- and trailer-mounted including the popular 326T model, as well as the Kesla C645T Tandem Axle Heavy Duty Chipper in action, which is ideally suited to the Valtra T254 tractor.

ATVTrac

The team behind ATVTrac makes their debut at APF 2022, showcasing their anti-theft tracking technology that is increasingly being adopted by the industry. Initially specialising in the agriculture market, the system’s small, discreet and lightweight attributes have been quickly adopted by many kinds of businesses looking to protect their machines. The team will demonstrate how the system can protect all manner of equipment, from ATVs to woodchippers, showing how it can not only be used to protect against theft, but can safeguard lone workers too in certain situations with ATVTrac multi-tier technology.

APF EXHIBITION |

14 AUTUMN 2022 FORESTRY MACHINERY

Chandlers Forestry Equipment stand is one to look out for.

ATVTrac will showcase anti-theft kit for various machines.

An important message from UK Power Networks.

“THE TEAM BEHIND ATVTRAC MAKES THEIR DEBUT AT

APF 2022”

SHOW PREVIEW

Spaldings Forestry

Spaldings Forestry is a division of Spaldings Ltd and is the UK and Ireland exclusive supplier of TMC Cancela, a manufacturer of agricultural, forestry and hydraulic machinery specialising in the process of mulching and ground clearance. At APF, Spaldings will have a range of TMC Cancela machines, which are said to be earning a positive reputation thanks to heavy-duty build, innovative features and the userfocused philosophy of the manufacturer. These high performance mulchers will be complemented with a wide selection of forestry hand tools, including chainsaws, brushcutters, hand tools and climbing equipment.

Reeds Construction and Engineering

Reeds Construction and Engineering will be displaying a wide range of state-of-the-art plant and equipment from the likes of Stehr, MeriCrusher, Fransgard and Wacker Neuson machinery, for whom they are UK sales representatives. Reeds also specialises in track recycling, forestry, crushing and a

wide range of attachments for Wacker Neuson machinery, and their experts will be on hand to share their knowledge of the equipment and to answer any questions from show visitors.

Close Brothers Asset Finance

Over the last 30 years, Close Brothers Asset Finance has grown to become a top asset nance company, providing nance for

businesses wanting to buy new or used equipment. Working closely with individual businesses, its team of experts offer tailor-made, practical solutions that help enable success and growth. This will be the rst time Close Brothers’ newly formed Agriculture team has attended APF and the team will be on site ready to help with any nance requirements for forestry machinery.

Organisers revealed to Forestry Machinery magazine that advance tickets sales are at record levels.

Buying tickets in advance at £21 will ensure swift entry to the show and visitors will save £4 on the gate price. A 2-day ticket is just £37 and a 3-day only £53. If you can get a

EXHIBITION INFO

group together, the cost of buying 10 or more tickets is just £19 per ticket.

On-site camping is only 200m from the entrance, and camping can be booked online for £18 per person per day. However, bookings are already very high, and places

cannot be guaranteed on the day. Please pre-book to ensure a pitch. Local hotels and B&Bs can be found around Stratford upon Avon – located just 10 miles away – and there should be a wide range of accommodation to suit all pockets. Note though, that there

are no organised transfers from local railway stations or airports.

Organisers have, however, made sure their 5,000-capacity car park is more than fit for purpose.

For full details about this year’s APF Exhibition, head over to www.apfexhibition.co.uk.

APF EXHIBITION |

16 AUTUMN 2022 FORESTRY MACHINERY

“AT APF, SPALDINGS WILL HAVE A RANGE OF TMC CANCELA MACHINES”

High performance mulchers from Spaldings Forestry.

Forestry hand tools including chainsaws, brushcutters and climbing gear.

ALLTHELATEST EQUIPMENTFOR ESTATESAND SMALL WOODLANDS ● THE WORLD POLECLIMBING CHAMPIONSHIPS ● EUROPEAN CHAINSAW CARVING CHAMPIONSHIP ● UK OPEN TREE CLIMBING COMPETITION ● WOODLAND CRAFTS ● HORSE LOGGING ● WORLD LOG TO LEG CHAMPIONSHIP ● BRITISH OPEN FENCING CHAMPIONSHIPS ● FOREST WORKER ZONE ● FENCING VILLAGE ● ARB WORKER ZONE ● TREE HEALTH SEMINARS ● FIREWOOD PROCESSING ● BIOMASS PRODUCTION FEATURING... LLTHELATESTIPMENTFOR ATESANDALLANDS #APF2022 & THE ARB SHOW CONFOR PRESENTS THE UK’S LARGEST & MOST EXCITING TREES & TIMBER SHOW... www.apfexhibition.co.uk | info@apfexhibition.co.uk 22nd, 23rd and 24th September, 2022 | Ragley Estate, Alcester, Warwickshire B49 5PS OVER 300 EXHIBITORS! OFFICIAL SPONSORS

IMAGES DAVID WYLIE

Headquartered in Crieff, Scotland, MAM Contracting (MAM) was established in 2004 by Mike Melville. Mike started out as an agricultural apprentice mechanic, then moved on to becoming a machine operator, cutting his teeth on a JCB 812 power-slide excavator. After 15 years’ experience and gaining an HNC quali cation in construction management, Mike’s plan was to start a new business and live halfway around the world in Australia, however that plan suddenly changed when his father fell ill and passed away at an early age, leaving Mike to return to the UK to look after his dad’s small farm contracting business, consisting of two Ford agricultural tractors.

Mike then rapidly developed and expanded the business and, along with his experienced and skilled team, has built a portfolio of projects including green energy run-of-river hydropower schemes, which he and the team are incredibly proud of. Today, MAM is one

18 AUTUMN 2022 FORESTRY MACHINERY

BIG FOOT David Wylie visits the world’s first Hyundai HX145A LCR High Walker forestry-spec excavator, travelling to Perthshire in Scotland to see MAM Contracting’s modified machine in action

WORLD EXCLUSIVE!

of the leading privately-owned civil engineering companies in Scotland. A registered member of CITB Construction Skills, the company’s services range from the construction of high-quality hydro schemes, new access roads and forestry bridges, to smaller projects such as new-build groundworks, landscaping, and monoblocking. It also offers rents out a modern eet of machines through its plant hire operation.

MAM Contracting has a team of over 30 people and more than 20 individual subcontractors. The company is the main contractor of bridge maintenance and building (subject to certain tender values) for Forestry and Land Scotland (FLS), which is the Scottish Government agency responsible for managing our national forests and land. A recent project undertaken by MAM involved constructing a new spur road and upgrading a forest road at FLS’s Loch Nant site, complete with surface water drainage and ditches.

TREADING LIGHTLY

MAM owns the world’s rst Hyundai HX145A LCR HW (High Walker) forestryspec excavator, and the impressive standard undercarriage frame has been further modi ed by John Craig at JCC Group based in the nearby Stirling area. I met up with Mike Melville to nd out more.

Mike explained that he has a great working relationship with the Hyundai dealer through Leigh Dalgleish Sales Manager (Central Region) H.R.N. He commented, “Leigh Dalgleish is great to deal with as he is very honest and straightforward, and over the years we feel he’s always had the customers best interest at heart, and we

NEW MACHINE | HYUNDAI HX145A LCR HW FORESTRY MACHINERY AUTUMN 2022 19

“TODAY, MAM IS ONE OF THE LEADING PRIVATELY-OWNED CIVIL ENGINEERING COMPANIES IN SCOTLAND”

The standard machine weighs in at 18,120kg, but MAM’s is around 20 tonnes with its larger footprint.

The slew turret can also accommodate 1,200mmwide track pads.

Lengthened undercarriage with 11 extra track pads significantly reduces ground pressure.

Shaun Stewart is the lucky operator of the new HX145A LCR HW, and has just under a year on a conventional counterbalanced HX140 L with a modified and lengthened undercarriage. “The high undercarriage is ideal for straddling tree stumps when we undertake stump mounding work. The 145’s lengthened undercarriage helps a lot, as it’s so firmly planted on the ground, even when swinging the heavy mulcher. It very rarely lifts a track when swinging over the side at full reach. I presumed the High Walker design would have had a bit of a nod to it, but that’s not the case with this machine and certainly not with this lengthened undercarriage modification,” Shaun continued.

The HX145A LCR comes with a set of variable displacement tandem axis piston pumps that produce 2x 127L/min and a fixed displacement gear pump single stage pilot pump at 29.3L/min. Both Mike and Shaun report that the combined hydraulic pump capacity helps to deliver great hydraulic flow to the hydraulic attachments, such as this powered flail mower seen during our visit.

Shaun commented, “The HX145A has plenty of hydraulic flow and power which makes a massive difference to the hydraulic performance of the hydraulic powered attachments, such as this powerful fixed-tooth mulcher drum.”

Shaun explained that he does

all the regular servicing himself and welcomes the ground level access to filters, lube fittings and master switches make servicing more convenient. The machine has two longer lasting filters (1,000-hour), and service intervals for the pre-filter, engine oil filter and fuel filter have increased from 500 hours to 1,000 hours thanks to the CK-4 engine oil.

Shaun mentioned the cab of the HX145A LCR reduced tail-swing is very comfortable and quiet, and also likes the smooth and responsive hydraulic control levers and the thumb-mounted proportional controls to work the front end attachments.

HYUNDAI HX145A LCR HW | NEW MACHINE 20 AUTUMN 2022 FORESTRY MACHINERY

VIEW FROM THE CAB

also feel we’re really looked after by Leigh and the rest of the Agritrac team at HRN and the Hyundai product is excellent.

“The regular minor services at 500 hours we do ourselves, as we buy a 4-year service plan from Agritrac for the lters etc, with the main servicing carried out by the dealer,” Mike continued. “And the machines are so reliable we’ve not really needed their backup service. That said, in general we have always found them to be responsive to our calls for assistance.

“We looked at High Walker excavators from other manufacturers, but to my mind there is simply nothing else out there that can touch the Hyundai for build quality, robust undercarriage, price, performance, ease of maintenance, low running cost and dealer backup,” Mike af rmed.

MADE TO MEASURE

As seen at the recent ScotPlant show on the HRN stand, in standard trim on 800mm-wide pads, the HX145A LCR HW weighs in at a very respectable 18,120kg to produce a low ground pressure of just 0.34kgf/cm2.

However, Mike asked John Craig at JCC Group to lengthen the undercarriage, which increases the machine weight to around 20 tonnes, while boosting stability; extra track pads support the machine’s weight and signi cantly reduce ground pressure.

Mike explained that the undercarriage was lengthened by 1.04m for 11 extra track pads on each track frame, which gives 5.5 pads on the ground. Three extra bottom rollers were added, and a bottom roller used as an additional top roller to support the tracks/chain and it’s currently sitting on 800mm-wide track pads and Mike has a set of wider 1,200mm track pads – aimed at peat restoration jobs where extreme LGP equipment is required.

Above: 3.8-litre Cummins 4-pot is Stage 5-compliant.

TECH SPEC

HYUNDAI HX145A LCR HW

ENGINE CUMMINS 3.8L

4-CYLINDER TURBOCHARGED (STAGE 5)

GROSS POWER 100KW (134HP) @2,200RPM

NET POWER 98 KW (131HP) @2,200RPM

MAXIMUM DRAWBAR PULL 16,717KGF FOR HIGH WALKER MODE VERSUS 12,672KGF FOR STANDARD HX145A LCR

TRAVEL SPEEDS HIGH WALKER: 2.5KM/H (LOW), 4.4KM/H (HIGH); STANDARD 3.3KM/H (LOW), 5.6KM/H (HIGH)

GRADEABILITY 35 DEGREES (70%)

SWING SPEED 11.4RPM

FUEL TANK 210L

DEF/ADBLUE TANK 27L

Below: One of four cameras tted to the Hyundai as standard.

Below right: Display for high-tech AAVM camera system.

OPERATING WEIGHT 18 TONNES

BUCKET CAPACITY 0.50-0.77MÐ

FORESTRY MACHINERY AUTUMN 2022 21

“TO MY MIND THERE IS SIMPLY NOTHING ELSE OUT THERE THAT CAN TOUCH THE HYUNDAI FOR BUILD QUALITY”

Above: The cab is said to be very comfortable and quiet.

Clearing thick gorse around young trees with a rigid drum flail attachment.

This latest undercarriage modi cations take the total to ve machines JCC Group has carried out for MAM in recent years. As Mike has taken all reasonable steps to help ensure his machines do not become bogged in very soft ground conditions in either very wet forestry applications, or in peat restoration jobs which is becoming more regular work. In his experience, simply putting on extra wide tracks won’t cut it on peatland, as you need the extra long undercarriage too, as Mike feels it simply 100% safer for the operator.

As a Perthshire St Johnston football team sponsor, MAM has a very nice company livery. “We sat down with Leigh and picked different colours for the rams, cab panels and handrails and so on,” explained Mike. “It’s a fantastic service given the work that is involved and very cost effective.” MAM also has plans to make the HX145A LCR HW even more versatile and safer as a tilt-rotator from Rototilt will be tted. Until then, the machine will mainly be working with an existing tilting hitch from Geith. IDig will also be tted for simple machine guidance for drainage work. The front cab guards and powerful LED light bar were sourced and tted by the Agritrac team.

Mike sees many applications for his new HX145A LCR HW near zero-tailswing machine, where it could sit on a lane closure or narrow well-establish tree-lined lanes, for example, and tackle felling trees with stage 3 and 4 ash dieback disease as more enquiries are being received for this type of work. And quick deployment of bog mats or bolt on rubber city pads will protect the road surface from any possible damage from the existing steel track pads.

ON THE JOB

At the time of our visit, Shaun and the new HX145A LCR High Walker were busy tackling a large amount of thick gorse plants on an estate for Scottish Woodlands near the town of Comrie in Perthshire. The thick gorse, some 40mm in diameter, was becoming a problem for a young crop of recently planted trees as they were sti ing growth. However, they were proving no match for the xed teeth on the high-speed drum of the powerful ail head attachment. At just 2,840mm wide (with 800mm wide track pads tted), the High Walker was also able to easily slip through a standard forestry or farm gate to reach the steeper

FLAIL HEAD

Right: Compact enough to slip through gates without issue.

ground in the adjacent eld.

The High Walker model has very powerful track motors, with a maximum drawbar pull of 16,717kgf versus 12,672kgf for the standard HX145A LCR excavator model, to power the extra long undercarriage up the hill to start mulching the extensive coverage of gorse, which will take at least three days to clear.

At the steepest part of the hill, the long undercarriage provided excellent grip and lowdown stability and the machine’s powerful swing motor has suf cient grunt to rotate the upper structure through a 180-degree arc for fast cycle times.

The HX A-Series has a state-of-the-art AAVM video camera system to provide 360-degree vision for operators. There’s also a very useful Intelligent Moving Object Detection system to inform the operator when people or moving objects are detected within the range of operation (5m).

With the world’s rst Hyundai HX145A LCR High Walker forestry spec excavator now out earning its keep, MAM will be putting this machine – and its skilled operator – to good use across its varied applications, from simple mulching to more complex forestry road and bridge building and small hydro schemes for many years to come.

MAM Contracting’s Mike Melville has also adapted the powerful flail with a fabricated heavy duty post that is used to help lift the long undercarriage off the ground to quickly change direction, rather than put high load forces through the endplate drum of the flail attachment itself. The post is also used to assist with climbing steeper ground in much the same way as a bucket is.

HYUNDAI HX145A LCR HW | NEW MACHINE 22 AUTUMN 2022 FORESTRY MACHINERY

“THE UNDERCARRIAGE WAS LENGTHENED BY 1.04M FOR 11 EXTRA TRACK PADS”

Above: Mike envisages many applications for his new Hyundai.

KETO NEW RELEASE! Dealer: Jas P Wilson Forest Machines info@jaspwilson.co.uk tel 01556 612 233 KETO150 Karate Multi KETOFORST Xtreme V2

&G Timber Harvesting Ltd of County Laois recently acquired a new John Deere 1270G 8-wheeled harvester with new-generation H425 harvesting head, paired with a new John Deere 1010G forwarder.

Arguably two of the highest speci cation machines to enter service with an Irish contractor in recent times, much of G&G’s future prosperity rested on the choices of Greg and Garrett Cuddy, so it’s understandable why they’ve gone to town here.

Running a Komatsu 901XC 8-wheeled harvester with a C123 harvesting head since it arrived new as a successor to a 6-wheeled Komatsu 911 in 2018, three and a half years of successful harvesting had been achieved with 3,600 largely incident-free hours recorded. Deciding the time was right to upgrade before the onset of fading reliability, the same thinking applied to a John Deere 1010E forwarder, which had served the operation since 2017 with over 11,000 hours service contributed.

“Even though the Komatsu 901XC was an excellent harvester and worked very well in some challenging sites in thinning and clearfell, we still looked at all the options before deciding on our next machine,” Greg explains. “We ran a Ponsse Scorpion King on demonstration and even though it was a strong contender, we decided to look more closely at what John Deere could offer us.”

While an 1170G from John Deere would be the most likely successor, Greg and Garrett believed such a machine would be slightly out of its depth when faced with completing all stages of

Garrett and Greg Cuddy with saw operator Leo Brophy.

GREEN DREAMS

G

24 AUTUMN 2022 FORESTRY MACHINERY

Regular machine replacement and upgrading is the key to consistent performance and reliability. Eoghan Daly reports on the high-specification John Deere machine choices of G&G Timber Harvesting in Ireland

“A 1270G FOR HARVESTING ACTIVITIES COMPRISING A HIGH CONCENTRATION OF THINNINGS MAY SEEM AMBITIOUS TO SOME”

IMAGES EOGHAN DALY

thinnings as well as clearfell harvesting on dif cult terrain in the Slieve Bloom Mountains region where they hold a long term contract harvesting for Coillte.

Therefore, an 8-wheel-drive 1270G seemed the best solution provided it could be tted with wider tyres and remain narrow enough for effective stand penetration in thinnings. With John Deere having taken all G&G’s requirements on board, the manufacturer returned with a proposal.

CUSTOMER FOCUS

“Garrett and myself sat down with Ed Power at John Deere Forestry and we could see straight away that he was serious about getting us the machine we wanted,” Greg recalled. “The 1270G was always going to be in a different league to machines like the 1170G, which would struggle long term harvesting in the areas we work. Many of the sites are second and third rotation on very challenging ground,

so they call for more than just any harvester to get through the work productively and still be kind to the ground and remaining trees when thinning.”

Even though machines like their new 1010G forwarder may be a common sight in thinnings, the choice of a 1270G for harvesting activities comprising a high concentration of thinnings may seem ambitious to some. However, potential is found in the machine’s dimensions, which reveal it’s more compact than many other machines engaged in long term thinning operations; far from a standard 1270G, G&G’s machine measures 2.99m wide on 800mmwide tyres, which is the secret to its success.

“By tting the 800mm-wide tyres, we have been able to increase oatation by 30%, which is a massive plus for the machine,” Greg explained. “Even though the machine’s width has been kept narrow, this extra tyre width means it is also really stable.”

Going to work in a thinning at Glenafelly, close to Kinnitty,

New John Deere 1270G with H425 head in thinnings.

TIMBER HARVESTING | G&G TIMBER HARVESTING FORESTRY MACHINERY AUTUMN 2022 25

JOHN DEERE H425 HARVESTING HEAD

As the largest model in John Deere’s H400 range, the H425 is ideally suited for mounting on G&G’s 1270G harvester. Launched in 2021, the H425’s design advancements have clearly taken forward the John Deere harvesting head concept by a number of important steps.

Updates include re-routing of hoses to the outer feed motors through the frame, for a more streamlined look and improved damage protection. Elsewhere, head services access to the head has been improved, with all grease points reachable when the head attains the single upright position, eliminating the need for time consuming repositioning through the greasing process. In addition, access to the head’s valve chest assembly is eased considerably through a hinged rear cover, which opens clear by releasing two bolts.

The head features the latest SuperCut 100S saw-motor for a fast and precise cutting action. Other benefits of this set-up include reliable automatic chain tensioning and an ability to facilitate chain replacement without the need for tools.

As a four-roller head, the angular position of the outer rollers help cup the stem in the head, while the two embedded rollers in the frame of the head create a feeding ring around the stem as it passed through the unit. Further enhancing performance, the outer rollers were specified as TP feed wheels for enhanced grip during the feeding action without being overly aggressive thanks to their spike profile.

Variable speed feed motors units were turned down in favour of a 500 and 780cc motor combination, which balances speed and feed force. The delimbing action is boosted by four movable and two fixed knives. “Even in coarse timber, the H425 cleans the log very well and keeps log lengths very accurate, which is the real test of what it can do,” Greg said. “This head is a massive improvement over previous John Deere designs – it has been changed in so many ways for the better.”

County Offaly, the machine’s manoeuvrability in the stand was extremely impressive and it had no dif culty in passing through the thinned racks, nor any issues dealing with steeper terrain. On completion of this assignment, the 1270G moved to the ecologically sensitive Glenregan valley for completion of a clearfell with an average tree size of 0.62 cubic metres. The machine’s light footprint and excellent stability with the crane in use allowed it to rapidly progress through the site.

Speaking of the crane – utilising the proven parallel design for decades on the 1270 concept, the CH7 offers a reach of 10m in G&G’s con guration and is speci ed with the optional IBC system. “The IBC [Intelligent Boom Control] really is a brilliant feature and makes operating the machine so much easier,” said Greg. “It is amazing how well the crane follows the ground at a precise level and on steep sites. It’s just a case of selecting up or downhill mode. In both the thinning and clearfell, where many trees were well beyond the 0.62 cubic metre average tree size, it worked perfectly well and still gave me full control at all times.”

IBC was not the only design feature requiring a degree of adjustment. Having the crane in front of the cabin again after using Komatsu harvesters may be a different format, but it does not

Hoses to motors sent through frame.

Maintenance access on the H425 is about as good as it gets; SuperCut 100S motor.

Aimed at 250-500mm diameter trees.

Hoses to motors sent through frame.

Maintenance access on the H425 is about as good as it gets; SuperCut 100S motor.

Aimed at 250-500mm diameter trees.

26 AUTUMN 2022 FORESTRY MACHINERY

TIMBER

present any big disadvantage from a machine operation perspective, as Greg continued. “The visibility from the John Deere’s cab really is excellent. The only time the crane set-up affects visibility is when felling a tree directly in front of the machine, but it’s not an issue.”

LINE OF SIGHT

Obviously, the crane and head performance are only as good as the combined performance of the engine and hydraulics, coupled with the governing systems tted to the machine. In this regard, the 1270G has proven itself very capable. “Even though the 1270G is a higher output machine with greater ability in bigger tree sizes, I have seen no difference in fuel consumption over the levels of the 901XC we were using before now,” Greg revealed.

“The 1270G is consuming 15 litres per hour, which is impressive. It was working in mode 3 in the clearfell and mode 2 in thinning. It is very easy to match the machine to the demands of the work at hand.”

G&G Timber Harvesting has clearly set a new benchmark in all-round harvester speci cation based on the level of oatation and harvesting head capacity offered by the company’s new John Deere 1270G. “So far, the 1270G has been excellent. It’s a really

Above left: Working on a sensitive clearfell site.

Above: The view from the 1270G’s operator seat.

Top: Easy travel through stand with 800mm tyres.

Above left: Working on a sensitive clearfell site.

Above: The view from the 1270G’s operator seat.

Top: Easy travel through stand with 800mm tyres.

“THE CH7 CRANE OFFERS A REACH OF 10 METRES”

HARVESTING | G&G TIMBER HARVESTING FORESTRY MACHINERY AUTUMN 2022 27

comfortable machine to operate and is achieving very impressive performance in all the sites we have harvested. It really is the machine for the type of work we are doing and the terrain we face on an daily basis,” Greg af rmed.

JOHN DEERE 1010G FORWARDER

Already familiar with the 1010 concept through the long-term operation of a 1010E, G&G’s new 1010G forwarder takes performance and productivity to another level. Stability has improved dramatically, as has climbing ability, while

the tment of 710/45-26.5 tyres with the traditional forest rubber encased in Olofsfors band tracks ensure a terrain-friendly footprint.

“Our 1010E never missed a beat and worked over 11,000 hours, wearing out three sets of band tracks in the process, which proves it didn’t have an easy life with the type of ground we are working on,” Garrett con rmed. “Even though we were happy with the 1010E, we knew the 1010G was going to be of a much higher standard with lots of new features to make it even more productive.”

Working in thinnings extraction initially and most recently a demanding clearfell assignment, the 1010G has met Garrett’s high expectations, with him praising the machine’s sheer working ability and user-friendly design. Speci ed with the rotating and levelling operator’s cabin, Garrett considers this feature a must-have. Meanwhile, the addition of IBC control of the crane has improved things further still. “Having used the 1010G in thinnings and clearfell so far, it is easy to see it’s the ultimate all-round forwarder,” Garrett reckoned. “The stability it provides with the long rear bogie, and the exibility it offers with the bunk mean it’s equally at home in thinnings and clearfell, and with the unbalanced bogies it’s very easy on the ground too.”

Plenty of sawlog lengths to handle at Glenregan Wood.

G&G TIMBER HARVESTING | TIMBER HARVESTING 28 AUTUMN 2022 FORESTRY MACHINERY

“IT IS EASY TO SEE THE 1010G IS THE ULTIMATE ALL-ROUND FORWARDER”

A flexible bunk only boosts this forwarder’s appeal to G&G...

The 1010G delivers excellent stability and low ground pressure.

Useful crane with John Deere’s Intelligent Boom Control (IBC).

www.johndeere.ie/forestry For Sales & Service please contact John Deere Forestry Ltd. Ballyknocken, Glenealy, Co. Wicklow, Ireland Tel: +353 (0)404 44969 (Sales) Contact Ed Power Mob: +353 (0)87 2542570

VERSATILE PERFORMERS

To succeed as a smaller scale forest machine manufacturer, offering something different to larger mainstream competitors is the only sure way of attaining market recognition. This approach is working very well for Finland-based ProSilva, as Eoghan Daly reports

IMAGES EOGHAN DALY

IMAGES EOGHAN DALY

30 AUTUMN 2022 FORESTRY MACHINERY

t a time when most forest machines follow a distinct design template, it is refreshing to see that a degree of individual thinking still prevails, with some manufacturers not afraid to go out on a limb with their own design features.

Never one shy away from embracing the unconventional, ProSilva has maintained a respected position in the market over the decades, which con rms the company’s belief in the offering of simplistic machines with a high level of durability and an ability to succeed in harvesting conditions where other designs prove less effective.

Initially offering a relatively limited range, this position has changed in recent years with the harvester line-up now re ecting a high degree of comprehensiveness.

However, of even greater note is the ability to specify machines with a high degree of options, which goes much further than the normal choices for head and crane type, but also wheel base con guration and the option of tting wheels on pendulum levelling arms and even an interchangeable triangular pro le steel track drive system.

From these choices alone, it is apparent ProSilva is determined to offer machine solutions to suit every end user requirement, with a particular focus on catering for contractors who work on the most challenging terrain.

BACK IN THE 1980S...

Even though the ProSilva name may not be one that is familiar to everyone in the industry, the company is clearly by no means

a novice when it comes to forest machine design and manufacture. With the ProSilva company itself established in 1998 by Lasse Karilainen, the engagement of the founder can be traced back to the 1980s when he and his brother Markku produced their rst tracked carrier to haul forest fertiliser to satisfy their own in-house requirements.

Following on from the success of their endeavours, Lasse recognised the potential of terrain- sensitive compact machines and followed up this observation with the development of the Joker forwarder, with the rst prototype developed in 1985. The design rights for this unit were subsequently sold in 1986 to Nokka, who many UK and Irish users will be familiar with, for the production of a range of forwarders and harvesters for thinning applications.

Moving on from his Joker forwarder design endeavours, Lasse Karilainen went on to build his rst harvester in 1995. Name inspiration for the machine continued to be drawn from the playing card deck, with the result of his efforts designated Ässä 810 or ‘Ace’ 810 when translated from Finnish. From this starting point ProSilva was established a few years later in 1998 to focus on the production of machines based on the concept initiated on Ässä 810, which was a low-impact, four-wheeled harvester base with a range of distinctive features, not least of which was its focus on simplicity and an alternative driveline arrangement coupled with an extremely low centre of gravity based on its distinctive formation.

Despite constant evolution, these initial design features continue to be the basis for the ProSilva formula. Based on these values, much has been achieved over the years in successfully penetrating new markets, with the scale of the operation being central to offering bespoke harvesting solutions. Nevertheless, a new chapter in the company’s history is currently being written as ProSilva steps up its efforts in increasing its product offering in response to the requirement to become a full-line forest machine supplier.

BUILDING FOR THE FUTURE

While this move requires a high level of con dence, senior management believe the time is right for this advancement. Indeed, the company has enjoyed a much greater level of stability since it became part of the Tampereen Konepajat Group in 2019. Even though the original structure of a small and intimate manufacturing unit worked well, the determination to further the company’s position without overstretching to an unrealistic level is now ProSilva’s strategy for growth.

Being part of the Tampereen Konepajat Group has brought numerous bene ts, not least of which is the group’s

“PROSILVA IS DETERMINED TO OFFER MACHINE SOLUTIONS TO SUIT EVERY END USER REQUIREMENT”

A

Above: ProSilva factory and HQ in Ruovesi, Finland.

Below: Frame section with hydrostatically driven bogies.

COMPANY PROFILE | PROSILVA FORESTRY MACHINERY AUTUMN 2022 31

PROSILVA MILESTONES

1981 Lasse and Markku Karilainen design and build their first tracked forest carrier for fertiliser

1985 Joker forwarder prototype introduced

1986 Joker rights sold to Nokka

1995 First Ässä (Ace) 810 harvester exported to Estonia

1998 ProSilva founded by Lasse Karilainen and Ässä 810 harvester renamed ProSilva 810

2002 ProSilva 910 harvester model introduced

2004 New factory Teollisuustie, Ruovesi, Finland

2007 The 100th ProSilva harvester produced and exports of forest machines to Chile begin

2008 Steel track type variant of the 910 harvester introduced

2010 Tracked 15-4ST forwarder introduced

2011 First harvester exported to Japan

2012 World’s first hybrid harvester, the ProSilva 910 EH makes its debut

2015 First new S4 harvester model produced

2016 Range expanded to include S5 and S6 harvesters as well as the F2/2 forwarder model

2017 ProSilva F4 forwarder exported to France

2018 Founder Lasse Karilainen retires and the process of transferring ownership of ProSilva to a new owner begins

2019 ProSilva officially becomes part of the Tampereen Konepajat Group

2022 ProSilva poised to introduce new harvester cabin design together with new wheeled forwarder model, as well as launching new brand identity

manufacturing capacity at its Ylöjärvi, Finland headquarters, which can be used to positive effect in supplementing the production capability of the main ProSilva operation at Ruovesi. Furthermore, since Tampereen Konepajat Group has many interests within its business units, the sharing of knowledge and support across the group will be an important asset to the ProSilva growth model.

The extent of Tampereen Konepajat Group interests is demonstrated by its ownership of companies that specialise in dedicated equipment manufacturing elds, which include MPH who produces a range of agricultural and peat harvesting equipment, and the Rikonen Group which is the largest unit within Tampereen Konepajat and is responsible for delivering turnkey specialist engineering elements to a wide range of clients in the construction, mining and transportation sectors.

Other activities embraced by the business units within the group include PeatMax,

who produce a comprehensive range of peat equipment totalling an impressive 30 different models.

Another important aspect to the group is NTcab, which was acquired just last year on the retirement of the original owner, as chairman and chief executive Juhani Lehti explained. “The ProSilva company is a very important addition for us and complements our existing product ranges particularly well. Being part of Tampereen Konepajat Group will give ProSilva greater stability for the future and a shared knowledge and manufacturing base to expand based on the resources we offer.”

SHARING THE KNOWLEDGE

Even though the ProSilva operation may be part of a larger group of companies, the high level of experience in forest machine design and manufacturing held by the original founder and his original workforce prevails. The legacy of Lasse Karilainen lives on especially in the continuing involvement

of his nephew Jukka-Pekka Syvälahti, who serves as research and development manager.

Working with ProSilva all his professional working life, Jukka-Pekka clearly knows the product intimately and remains as passionate now as at the outset to achieve furtherance of the ProSilva concept. Based on this long term engagement with the company, he and other members of the dedicated ProSilva team are ideally placed to serve production, design and product support for customers over a wide area.

Currently there are a number of important markets where ProSilva has been particularly successful. When it comes to thinning operations and peat-based site harvesting, Finland, Sweden and Baltic States have many ProSilva, users while short rotation Eucalyptus and pine in countries such as Chile and Uruguay are important markets. Steep slope harvesting has also proven receptive to the concept, with intrepid users in the nations of Japan and

“WE ARE NOT AFRAID TO CHALLENGE CONVENTIONAL THINKING”

Above: Wheels easily swapped for tracked units.

Left: Norbert Schalkx, Juhani Lehti and JukkaPekka Syvälahti.

32 AUTUMN 2022 FORESTRY MACHINERY

Chile being the most prominent. In the interests of expanding its market position even further, experienced forest machine specialist Norbert Schalkx was brought on board to serve as International Sales Director. Moves such as this are considered pivotal in capturing a greater share of the market, with the current range – soon to be boosted by a new wave of product launches – offering an attractive alternative to that of larger and arguably better known manufacturers.

FLEXIBLE BY DESIGN

Based on the machine’s design features and the wide range of options available, it is possible to commission a machine that meets the demands of a contractor’s typical application range precisely. “ProSilva offers the highest level of exibility when it comes to building a machine to suit a customer’s needs, to help them perform at a peak level in their application,” said Norbert. “We hope to become the preferred choice for

PROSILVA HARVESTER RANGE

ProSilva’s current harvester line-up comprises four models, with each of these available in a range of configurations. Occupying the position of the range’s smallest harvester is the S3 model. Delivering an impressive power-to-weight ratio thanks to its 6-cylinder engine, this unit can be specified in 4- or 6-wheeled versions and is aimed mainly at thinning applications where it is particularly appealing based on its light weight and tight turning radius.

The next model in the range is the S4, which is an enhanced and heavy-duty version of the

S3, and as a consequence can run larger cranes and harvesting heads. It can also be specified with rear pendulum wheel arms.

Moving to the mid-range offering from ProSilva, the S5 is classed as an all-round harvester with equal aptitude in thinning and clearfell. As a 6-wheeled harvester it comes with a rotating cabin as standard which can also have a tilt facility as an option and with its reinforced crane bed accepts larger crane and head options.

Catering for the needs of the most demanding

harvesting operations are the range’s largest models – the S6 and S6HD (pictured above), which retain the same principal features but benefit from enhanced durability. This is especially true of the S6HD, which can accept the largest cranes and harvesting heads available for wheeled harvester base machines to cater for large volume clear fell harvesting.

The S6 and S6HD utilise a more powerful 240kW Cummins Stage 5 engine, while its oil flow from the dual pump system reaches 448 plus 336L/min hydraulic oil flow.

Left: Low-set engine and hydraulic pumps.

Below left: Crane base levelling cyls.

Right: 15-4 ST once the firm’s most popular forwarder.

Left: Low-set engine and hydraulic pumps.

Below left: Crane base levelling cyls.

Right: 15-4 ST once the firm’s most popular forwarder.

COMPANY PROFILE | PROSILVA FORESTRY MACHINERY AUTUMN 2022 33

continuous cover forestry harvesting, which is a hot topic in Finland and Sweden at present, and in addition to that continue to serve the diverse needs of customers worldwide on existing and new markets which will be explored step by step.

“We believe the ProSilva machines are most economical over the life cycle of the machine and are completely customer focused,” Norbert continued. “Most of all, we are not afraid to challenge conventional thinking and in the process have developed a range of machines which are productive, economical and cause minimal impact.”

SIMPLE AND EFFECTIVE

Even though the company is pressing on with plans to broaden its global presence, the importance of maintaining a manageable scale and retaining a personal approach run rich through the company’s future strategy.

While the Tampereen Konepajat Group facilities offer capacity for preassembly of certain elements, the Ruovesi factory will remain at the core of the operation. Offering the capacity to assemble three machines simultaneously, the production

UNIQUE FEATURES

Among the design features of the ProSilva harvester that set it apart from the competition are the extremely low centre of gravity, which is achieved by the low-set

facilities also incorporate preassembly areas which focus on the t out of cabins. As mentioned earlier, the cabin structure is obtained from NTcab, which is also part of the Tampereen Konepajat Group. In addition to the production area, the facility also incorporates a large capacity dedicated service workshop and a comprehensive parts storage warehouse which feeds production as well as the service

needs of machines working in the forest with customers worldwide.

All administration, as well as research and development are conducted at the Ruovesi facility, which also includes machine testing facilities for both production machines and machine prototypes as the company presses on with a number of new projects in this regard. Nevertheless, despite the continuing focus on future development, the core principals at ProSilva remain the same. There is a distinct focus on simplicity and creating practical alternative design features, which have delivered for users over the decades.

Going forward, the importance of continuing to give customers what they command will remain central, as Juhani Lehti concluded. “The machines offered by ProSilva have always been focused around what the customer wants. Going forward, if we believe there is a requirement for an 8-wheeled machine in our range then that is what we must deliver. Based on the core design features of the ProSilva harvesters incorporating rear bogies does present some challenges, which we must overcome if our customers require such a machine.”

position of the engine and hydraulics between the two main chassis rails that double up as diesel and hydraulic oil tanks.

In addition, the machines

incorporate wheel-specific torque and speed management, offer extremely high tractive forces, and a short turning radius. The threesection frame also represents an

alternative design formation, while the tilt lock for the front section is achieved by common hydraulic cylinders for the crane base levelling functions.

“THE RUOVESI FACTORY WILL REMAIN AT THE CORE OF THE OPERATION”

Above: S3 conducting first thinnings at nearby demo site.

PROSILVA | COMPANY PROFILE 34 AUTUMN 2022 FORESTRY MACHINERY

ProSilva S5 harvester with Kesla parallel crane and Waratah H425 head undergoing final assembly.

Quality Machinery speaks for itself Visit our website for all our product information Tel: 01892 770 788 Mobile: 07836 274 164 www.marshalllogging.co.uk sales@marshalllogging.co.uk MADEIN SWEDEN wood chippers by eschlboeck.at Eschlböck BIBER Maschinenbau GmbH Made in Austria

THIRD TIME PLUCKY

orking as a seasonal harvesting contractor in privately-owned forests, Orivesi-based Heikki Heino has built a reputation for delivering a professional service when it comes to forest thinning, and much of this

is down to his choice of harvesting equipment. Working with a single ProSilva S4 4x4 harvester, extraction is subcontracted to a fellow contractor, leaving Heikki to concentrate on harvester operation. Despite being in service since 2019, several features

incorporated into this S4’s design have delivered performance superior to that of its predecessors, even in the most adverse winter harvesting situations.

On starting his own timber harvesting business, Heikki took the affordable option

IMAGES EOGHAN DALY

IMAGES EOGHAN DALY

Long-term service gives a true impression of any harvesting machine as reliability and productivity in real-life working situations become apparent. Eoghan Daly reports on the experiences of one Finnish contractor who is now running his third ProSilva harvester

W 36 AUTUMN 2022 FORESTRY MACHINERY

Finnish operator Heikki Heino is now on his third ProSilva harvester.

of focusing on a Valtra forest tractor as his rst machine. But soon his attention turned to a purpose-built harvester. “Other contractors using ProSilva harvesters were seeing very high levels of reliability over long-term service, which meant the machines were worthy of a closer look,” he explained. “As simple, robust machines, they are ideal for an operation like mine and allow me to keep costs low. After getting my rst ProSilva machine, I haven’t had any reason to look at other options and I am now running the third my third harvester from ProSilva.”

Each new machine that has turned in a shift with Heikki has sported a different speci cation, with the current S4 4x4 being the rst unit employing the pendulum arm concept to the machine’s wheels. In addition, the choice of crane and harvesting head differs from that of previous machines.

Even though many UK and Irish contractors have a distinct preference towards 6- and 8-wheeled machines, the long-term use of 4-wheeled variants of the ProSilva units has been a positive move for this operator and has not proved in any way limiting in the harvesting assignments being undertaken.

WITHOUT COMPROMISE

Harvesting a delayed rst thinning of a 30-year old Scotts Pine stand near Ruovesi in Finland during May 2022, the abilities of the machine in this stand were impressive, with no impact on the terrain whose surface carried the nal remnants of winter snow. As the machine worked its way through the stand, little trace of its passage was evident.

“I have never had any reason to doubt the effectiveness of a 4-wheel harvester and it has in no way limited the kind of work I can

do,” Heikki explained. “It copes very well with dif cult working conditions, especially through the most severe Finnish winters. I have worked in 1m-deep snow and the big wheels have no problem in these type of conditions.”

Affording the clearance necessary to overcome this extreme snow depth, the pendulum arm concept comes into its own while bringing other advantages when working on cross slopes, or negotiating obstacles such as larger rocks on the forest oor. The pendulum arms have increased machine width to 3.10m, but this has not seen inhibited stand penetration in Finnish thinning environments. “Machine width on these 710mm wide tyres makes it very stable and there is no need for water ballast in the tyres, which helps to cut down on unnecessary weight too,” said Heikki. “It

“OTHER CONTRACTORS USING PROSILVA HARVESTERS WERE SEEING VERY HIGH LEVELS OF RELIABILITY OVER LONG-TERM SERVICE”

OWNER-OPERATOR | PROSILVA S4 HARVESTER FORESTRY MACHINERY AUTUMN 2022 37

Joystick and keypad designs, plus TimberRite control system all deemed very user-friendly.

Almost 3.1m wide with 710mm tyres –the ProSilva S4 has no issues navigating this first thinning stand.

OWNER-OPERATOR

also helps me get the most from the 11m-reach crane with the machine being very well balanced.”

In addition to the favourable footprint afforded by the machine’s stance, its overall structure and drivetrain composition are also noted as being particularly bene cial. Using wheel speci c hydraulic hub drive, the machine yields excellent performance in a full range of terrain types, while its turning circle remains extremely tight, making it especially manoeuvrable even when tted with these wide oatation tyres. However, there is much more to the S4 than just low ground impact positive mobility and highly rated stability, as it also has the power and oil ow to deliver impressive harvesting performance.

The S4 draws power from a 186kW Cummins engine and Heikki considers it a very costeffective harvester to run. “Fuel consumption is 14 litres per hour, which I am very happy with. Even better is the production it can get from this low fuel burn, with this double hydraulic pump machine being very fast and productive.”

Typically harvesting 600 to 700 trees per day in this type of thinning stand (three log classi cations are harvested including sawlog, mini logs and pulpwood; no slash for wood energy was being harvested in this application), the combination of impressive oil ow with a tactfully chosen crane and harvesting head has formed the ideal harvesting solution for this discerning operator.

Periods of simultaneous operation of the crane and harvesting head are easily facilitated, which con rms the positive contribution of the machine hydraulics that are based around a dual-pump system, with the pumps delivering ow ratings of 448 and 336L/min.

Another highlight of the S4 is its cabin. Featuring levelling and slewing motions, the cab is mounted independently of the crane and offers good visibility in all directions. The upward view is particularly good and eases tree selection and felling in thinnings, while the low set crane base design means the forward view is also very good, even though it’s slightly affected by the larger front tyres.

SUITED AND BOOTED

ProSilva offers a wide variety of options for its harvesters. Heikki’s latest spec includes a Logmer 14-11 US parallel crane with

| PROSILVA S4 HARVESTER FORESTRY MACHINERY AUTUMN 2022 39

“FEATURING LEVELLING AND SLEWING MOTIONS, THE CAB IS MOUNTED INDEPENDENTLY OF THE CRANE”

Access to the high-set cabin is made easier by these fold-out steps.

Dual-pump hydraulic system delivers flow ratings of 448 and 336L/min.

11m reach and dual slewing motors. “When I used Kesla cranes, I could not fault their performance. The parallel movement of Kesla and Logmer cranes is very different and both bring their own advantages, but on this occasion I decided Logmer was the best option for my latest machine.”

Originally using a Kesla head on his rst harvester, Heikki made a change to Waratah on his second harvester and has remained loyal to the marque on the current machine. Based on his engagement in early thinnings, the H413 head has been favoured and, to add to its working compatibility with smaller diameter material, this unit has been speci ed with multi-stem capability. This multiple stem handling system incorporates a gripping facility for multiple stems below the rotator, leaving the head’s knives and rollers free to cut and fell an additional stem and then process both simultaneously in the interests of boosting productivity in smaller diameter material.

KEEPING IT SIMPLE

Equipped with angular pro le outer rollers two further rollers embedded in the rear frame of the head, an impressive grip on the

stem during all stages of the felling and feeding processes is ensured. In addition, the head incorporates four wrap-around delimbing knives, which further enhance the gripping characteristics and, based on the level of contact attained, result in thorough delimbing even where lower limbs are present through the double lower knife design, despite the head’s short chassis length.

Another bene t of utilising Waratah harvesting heads with Heikki’s S4 is the unit’s user-friendly control and measurement system. All other heads offer dedicated systems, but Heikki appreciates Waratah’s TimberRite system, which bears many similarities to John Deere’s Timbermatic measurement and control computer, while also using ‘D’ model joysticks and control keypads that are renowned for their ease of use.

In addition, the harvester run by Heikki offers full data transfer capability with the John Deere forwarder used on extraction. This ensures a full record of harvested material, and its location in the stand is shared with the forwarder operator (important for these seasonal operators) to ensure all logs are retrieved during even the peak of the Finnish winter.

PROSILVA S4 HARVESTER | OWNER-OPERATOR 40 AUTUMN 2022 FORESTRY MACHINERY

At first, Heikki Heino used a Kesla crane, but now runs a Logmer on his latest S4 harvester.

“AS SIMPLE, ROBUST MACHINES, THEY ARE IDEAL FOR AN OPERATION LIKE MINE”

Waratah H413 head with multi-stem handling equipment.

NEWS – FARMA , larger cranes that reach longer