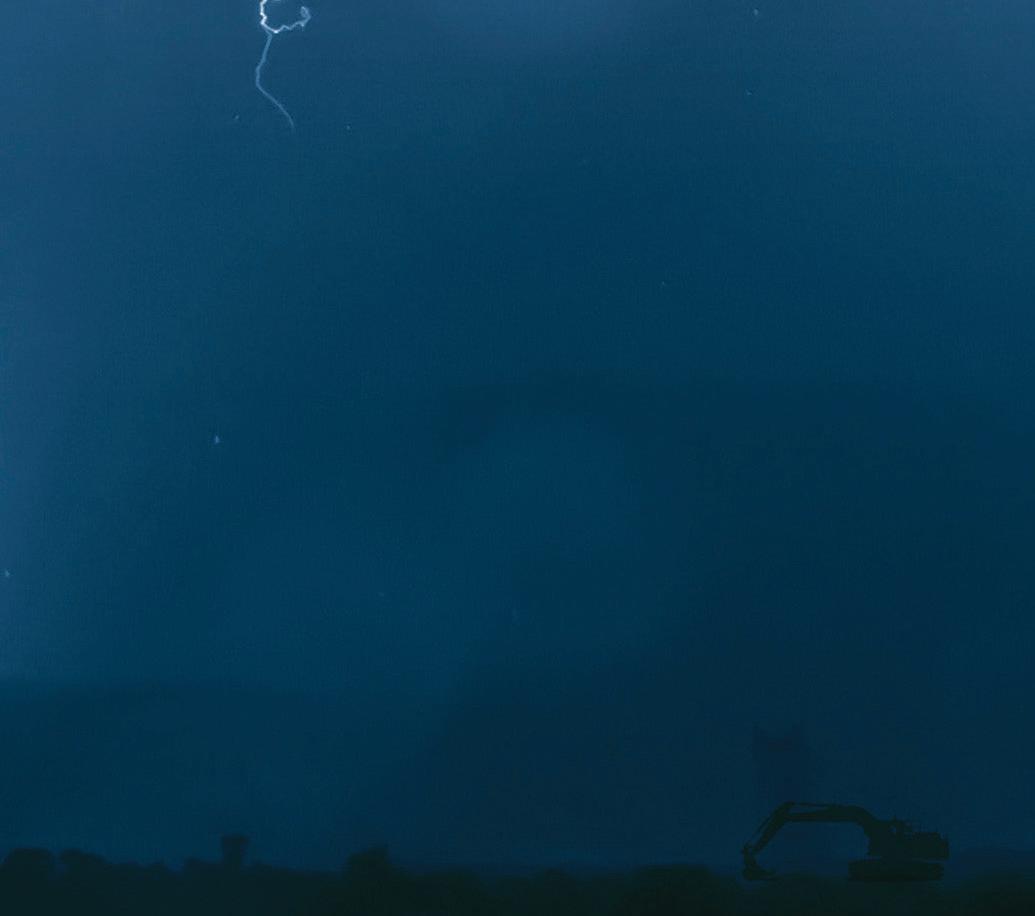

During John Deere’s CES 2023 keynote address, the company revealed two new technologies, ExactShot™ and an electric excavator, that will help Deere’s customers be more productive, profitable, and sustainable.

“Everything we do at John Deere is focused on real purpose and real impact,” said Jahmy Hindman, CTO at John Deere. “This means we’re developing technology that enables our customers to provide the food, fuel, fiber and infrastructure that our growing global population needs.”

ing planting by more than 60%. The technology uses sensors and robotics to place starter fertilizer precisely onto seeds as they are planted in the soil, rather than applying a continuous flow of fertilizer to the entire row of seeds.

The electric excavator, powered by a Kreisel battery, will provide construction workers and road builders with lower daily operating costs, reduced jobsite noise, enhanced machine reliability, and zero emissions, without sacrificing the power and performance they need in a machine.

ExactShot allows farmers to reduce the amount of starter fertilizer needed dur-

• ExactShot will help farmers be economically and environmentally sustainable as they work tirelessly to grow the food, fuel and fiber that we all rely on.

With the global population expected to grow from 8 billion to nearly 10 billion by 2050, farmers need to increase production by 60% to 70% on today’s arable land.

• ExactShot uses a sensor to register when each individual seed is in the process of going into the soil. As this occurs, a robot will spray only the amount of fertilizer needed, about 0.2 ML, directly onto the seed at the exact moment as it goes into the ground.

• Across the U.S. corn crop, ExactShot could save over 93 million gallons of starter fertilizer annually and prevent wasted fertilizer from encouraging weed growth or increasing the risk of running off the field into a waterway.

• Deere’s new electric excavator, powered by a Kreisel battery, will improve reliability, performance and safety in construction. Its use on construction sites will result in fewer moving parts, less noise pollution, and few-

er emissions.

• Deere acquired a majority stake in Kreisel Electric, which created state-of-the-art battery technology for a wide range of mobile and stationary applications.

Kreisel’s patented immersion cooling architecture provides unsur-

passed lifetime, enhanced safety, and improved performance for batterypowered equipment.

• Kreisel’s charging technology results in faster and lower-cost connections to the electrical grid. SP

2000

2008 CATERPILLAR 160M

MOTOR GRADER, STK #6823 JF, CAT C9 Eng., 248 HP, 35,000 lbs. Op. Weight, 17.5R25 Tires in Good Shape, 16’ MB w/ Carbide Tips, A/C & Heat, 4WD, EPA Label Present, 12,891 Hrs., Very nice shape & ready to work!

2017 MANITOU MLT 737130 PS+ TELEHANDLER, STK#6827 BP, Deutz TCD3.6L4 Diesel, 127 HP, 16,854 lbs. Op. Weight, 460/70R24 Pneumatic Tire, 3,700 kg. Max Lift Cap., 6.9m Max Lift Hgt., Torque Converter with P/S, 6-Fwd & 3 Rev., 40 km/h Max Spd., A/C & Heat, 1-Owner, 8,495 Hrs.

2017 BOBCAT E35 ZTS

EXCAVATOR W/ 12” DIG BUCKET, STK #6833 BP, Bobcat 1.8L Diesel, 33.5 HP, 7,744 lbs. Op. Weight, 12” Rubber Pads, 69” Dozer Blade, Pin Q/C, 4’6” Stick, EPA Label Present, Zero-swing, A/C & Heat, 2,644 Hrs., 1-Owner, Fully Serviced.

2015 MACK PINNACLE CXU614 TRI DRIVE WINCH STK #6820 BP, Mack MP8 Diesel, 505 HP, Frt. Tires: 315/80R22.5, Rr. Tires: 11R24.5, Meritor RZ-XX166P Diff., 4.10 Ratio, Mack T318 Trans., 18-Spd. Man., 45,000 lbs. Winch, Webasto, EPA Label, 145,484 Kms., CVIP 2024, 267 WB, Lockers, Air Ride, 2,788 Hrs.

2015

Q/C, 16.5”W Coupler, Aux. Hyd., RV Cam., Webasto, A/C & Heat, 9’7” Stick, 31” Pads, 9,685 Hrs., 1-Owner, Service records avail.

2011 HYUNDAI 760-9 WHEEL LOADER, STK #6825 JPH, Cummins QSB6.7, 215 HP, 39,460 lbs. Op. Weight, 23.5x25 Tires, 4.3 cu yds Bkt Cap. Heaped, Hook Q/C, EPA Label, A/C & Heat, 3’5” Dig Depth, 9’9” Dumping Clearance at Max Height., 16,479 Hrs.

2012 FL CORONADO, STK #6843 JP, Detroit DD15 (rebuilt at 795,648km), 530 HP, Tandem, Sleeper, PTO & Roper 3” Pump (Rebuilt 2021), High Cap. Dbl. Lung Air Comp. w/ Trailer Hookup, 3-Way Lockers, 12,000 lbs. frt. Susp., 46,000 lbs. Rr. Susp., 4.30 Rr. Ratio, 18-Spd. Eaton Fuller, DEF Deleted, 988,225 kms.

2010 NEW HOLLAND T7040 TRACTOR W/ 860TL LOADER, STK #6812 BP, FPT NEF Intercooled Turbo Diesel Eng., 180 HP, 17,595 lbs. Op. Weight, 420/85R30 Frt., 520/85R42 Rr., 3 Rr. Remotes, NH IntelliView III Monitor, Block Heater, A/C & Heat, PTO 540/1000, 8,341 Hrs., Grapple Bkt. Avail. For Extra Cost.

2015 KENWORTH C500 W/ EFFER 2055H/8S CRANE + JIB 6S LIGHT, STK #6834 BP, Cummins ISX15, 525 HP, 425/65R22.5 Frt., 11R24.5 Rr., 18-Spd. Eaton Fuller, EPA Label, A/C & Heat, CVIP Nov 2023, 311 WB, Rebuilt Eng., Lockers, Spring Susp., 6,636 Hrs., 184,700 Kms.

2009 CASE IH 485HD STEIGER TRACTOR W/ TRIPLES, STK #6811 BP, Iveco Turbocharged Diesel, 485 HP, 54,000 lbs. Op. Weight, 520/85R Tires, AFS Pro 600 GPS, Full Power Shift Trans., 16 Fwd. & 2 Rev., 4 Rr. Remotes, Webasto, EPA Label, A/C & Heat, 8” Tire Space, 4WD, 4,502 Hrs.

DIG BKT CALL

2022 YANMAR VIO25-6A CANOPY, RUBBER, HYD THUMB, 2 BKTS, 83 HRS $46,900

2022 YANMAR VIO35-6A CANOPY, RUBBER, 2 BKTS, HYD THUMB CALL

2022 YANMAR VIO35-6A CAB AIR, RUBBER, HYD THUMB, 2 BKTS, 431 HRS CALL

2022 YANMAR VIO35-6A CAB AIR, RUBBER, 2 BKTS, HYD THUMB, 201 HRS CALL

2022 YANMAR VIO35-6A CAB AIR, STEELBOR, HYD THUMB, 2 BKTS, 308 HRS CALL

2021 YANMAR SV40 CAB AIR, RUBBER, 2 BKTS, HYD THUMB, 158 HRS CALL

2022 YANMAR SV40 CANOPY, RUBBER HYD Q/C, 2 BKTS HYD THUMB CALL

2013 YANMAR VIO45-6 RUBBER, BLADE, AUX PIPING, 4,785 HRS $36,900

2021 YANMAR VIO50-6A CAB AIR, RUBBER, 2 BKTS, HYD THUMB, 320 HRS CALL

2021 YANMAR VIO55-6A CAB AIR, RUBBER, HYD THUMB, 2 BKTS, 992 HRS CALL

2014 YANMAR VIO80-1 BOR, BLADE, AIR COND, ONLY 3,673 HRS $59,900

2021 YANMAR VIO80-1A STEEL W/BOLT ON RUBBER, 2 BKTS, HYD THUMB, 450 HRS CALL

2021 YANMAR VIO80-1A RUBBER, CAB AIR, 2 BKTS, HYDRAULIC THUMB, 362 HRS CALL

2016 HITACHI ZX75US-5B 18" PADS, BOLT ON RUBBER, BLADE, AIR, 1,334 HRS CALL

2018 HITACHI ZX75US-5B 18" PADS, BOLT ON RUBBER, BLADE, ONLY 1,099 HRS CALL

2019 HITACHI ZX75US-5B 18" PADS, BOR, BLADE, PIPING, ONLY 907 HRS SOON

2017 YANMAR SV100-2 18" PADS, CAB AIR, BLADE, ONLY 3,113 HRS SOON

2021 YANMAR SV100-2A RUBBER, CAB AIR, HYD Q/C, 2 BKTS, HYD THUMB CALL

2011 HITACHI ZX135USBL-3 20" PADS, BOR, AIR, BLADE, 7,053 HRS CALL

2011 HITACHI ZX135USBL-3 20" PADS, AIR, BLADE, 7,611 HRS, NEW RAILS/SPROCKETS CALL

2013 HITACHI ZX135USBL-3 20" PADS, BOR, BLADE, DIG BKT, 4,759 HRS CALL

2013 HITACHI ZX135USBL-3 20" PADS, BOR, BLADE, DIG BKT, 4,866 HRS CALL

2014

ZX135USBL-5B

2015

2019 HITACHI ZX135USBL-6 20" PADS, AIR, BLADE, 2 BKTS, HYD THUMB, ONLY 863 HRS CALL

2019 KOBELCO SK135SRD-5 20" BOR, BLADE, Q/C HYD THUMB, DIG BKT ONLY 1,411 HRS $174,900

2021 HITACHI ZX135US-6 20" BOR, SLIDE ARM, 2 BKTS Q/C, EXTRA CWT, ONLY 982 HRS $199,900

2021 KATO HD514MR-7 20" PADS, BLADE, AUX HYD PIPNG, ONLY 20 HRS AS NEW SOON

2018 HITACHI ZX200LC-6 32" PADS, AIR COND, ONLY 4,387 HRS CALL

2018 HITACHI ZX200LC-6 32" PADS, AIR COND, ONLY 4,166 HRS CALL

2018 HITACHI ZX200LC-6 32" PADS, AIR COND, ONLY 3,528 HRS SOON

2018 HITACHI ZX200-6 24" PADS, AIR ONLY 2,800 HRS CALL

2019 HITACHI ZX200-6 24" PADS, AIR, ONLY 1,185 HRS CALL

2019 HITACHI ZX200LC-6 32" PADS, AIR, ONLY 4,865 HRS CALL

2019 HITACHI ZX200LC-6 32" PADS, AIR, ONLY 1,960 HRS CALL

2008 HITACHI ZX225USLC-3 24" PADS, AIR, Q/C, DIG BKT, HYD THUMB, 7,829 HRS $94,900

2010 HITACHI ZX225USRLCK-3 24" PADS, AIR, AUX HYD PIPING, 5,212 HRS SOON

2017 DEERE 245G LC 32" PADS, 2 BKTS Q/C, HYDRAULIC THUMB, 2,762 HRS CALL

2018 DEERE 245G LC 32" PADS, Q/C, PRO LINK THUMB, CABGUARD, 2,564 HRS $259,900

2018 DEERE 245G LC 32" PADS, 2 BKTS, Q/C, HYD THUMB, CABGUARD, 2,893 HRS $259,900

2019 CAT 336 24" PADS, AIR, 2 BKTS, Q/C, HYD THUMB, ONLY 2,625 HRS CALL

2018 CAT D3K2 LGP 6 WAY DOZER, CAB AIR, ONLY 12 HOURS, 80HP, 20K LBS CALL

2015 CAT D6K2 XL 6 WAY, CAB AIR, MS RIPPER, ONLY 3,453 HRS, GPS READY CALL

2009 BOBCAT S70 CAB, Q/C BKT, ONLY 1,541 HRS CALL

2008 VOLVO SD25D 41" DRUM DRIVE, CANOPY, 1,473 HRS, NEW BEARINGS/SEALS IN DRUM

APRIL 2022 CALL

CORNIVER CT48S 48" SMOOTH DRUM, CANOPY, KUBOTA ENG, 1,958 HRS CALL

2005 ING RAND SD45D 54" SMOOTH DRUM, CANOPY $49,900

2006 ING RAND SD70D TF AT 1,600, VERY CLEAN, SHELL KIT, NEW HYD PUMP $35,000

2005 ING RAND SD77F TF 66" PADFOOT COMPACTOR, CANOPY, 3,327 HRS CALL

2016 SAKAI SW354 47" TANDEM DRUM ROLLER, WATER SYS, 1,395 HRS $26,500

2021 CANYCOM SC75PDH PIVOT DUMP CARRIER W/2,200LB PAYLOAD, 236 HRS CALL

2021 YANMAR C50R-5AR CAB AIR, SWIVEL DUMP, 8,379LB + PAYLOAD, 288 HRS $111,900

2021 YANMAR C50R-5AR CAB AIR SWIVEL DUMP, 8,379LB PAYLOAD, 272 HRS $111,900

1998 KOMATSU CD110R-1 CAB AIR, SWING DUMPER, NEW U/C, 7,429 HRS $124,900

2011 CAT 730 23.5X25 TIRES, ONLY 5,652 HRS CALL

2022 SOUTHLAND SL714-14K

DUMP TRAILER, 15,432 GVWR, CAP 10,875 LBS, WT 3,125 LBS, LIFT CAP 9 TONNES, BOX DIMS 14' (L) X 7' (W) X 16" (H), 2-7,000 LB AXLES, CHARGING KIT, SIR, TARP, REMOTE CALL

2022 SOUTHLAND SL714-16K 14' DUMP TRAILER, 16,032 GVWR, CAP 12,300 LBS, WT 3,700 LBS, LIFT CAP 9 TONNES, BOX DIMS 14' (L) X 81" (W) X 20" (H), 2-8,000 LB AXLES, CHARGING KIT, SIR, TARP, REMOTE CALL

2022 SOUTHLAND SL714-16K HD 14' DUMP TRAILER, 17,461 GVWR, CAP 13,210 LBS, WT 3,792 LBS, LIFT CAP 9 TONNES, BOX DIMS 14' (L) X 6.5' (W) X 18" (H), PWR JACK, 2-8,000 LB AXLES, CHARGING KIT, SIR, TARP CALL

2020 VAN ED VUC202-PJ CRUSHER WITH PULVERIZER JAW (CWS200) $30,000 2004 TOYOTA 7FGU30 LP, CANOPY, 3 STAGE MAST, 6,000LB CAP $27,900

2020 TRAILTECH L270-20 TILT 4' STATIONARY, 16' TILT DECK, 82.5" BETWEEN FENDERS, HYD CUSHION, 16,100 GVWR, WT 3,200LBS, TOOLBOX CALL

2018 TORO TRX20 WALK BEHIND CRAWLER TRENCHER 36" BAR, GAS PWR CALL

The Brandt Group of Companies is proud to announce its support for local and national charities with total funding commitments of $500,000.

For the third consecutive year, Brandt hosted an online holiday celebration with their more than 6,000 employees around the world. The event concluded with the announcement of a $500,000 fund that saw employees voting for charitable organizations that matter to them. The results of this vote then drove the distribution of funds to 14 world-class nonprofit organizations across Canada, the USA, Australia, and New Zealand.

“We are very grateful for the faithful support of our customers, our employees, and the communities in which they live and work,” says Brandt Senior Vice President of Marketing, Matt Semple. “Brandt’s Thanks A Billion Holiday Fund is our way of saying ‘Thank You’

and no time of the year could be better-suited for that than the holiday season.”

As the company has grown significantly in the past few years, so too has the total size of the Thanks A Billion Holiday Fund, which has doubled since the program’s first year in 2020. This year’s recipients, by country, include:

Canada ($275,000 CAD)

• Canadian Cancer Society: $127,000

• Ronald McDonald House

Charities: $74,000

• Red Cross: Ukraine Humanitarian Support in Canada Appeal: $37,000

• MS Society of Canada: $27,000

• Canadian National Institute for the Blind: $10,000

US ($75,000 USD)

• St. Jude Children’s Research Hospital: $37,500

• Illinois Cancer Care: $19,500

• Wounded Warrior Project: $18,000

Australia ($75,000 AUD)

• The Royal Flying Doctor

E2S Warning Signals, the world’s leading independent manufacturer of life safety notification signals for industrial, marine and hazardous areas, are pleased to announce their next generation of SIL1 and SIL2 compliant warning devices.

The D1x, GNEx, STEx, AlertAlarm and AlertAlight ranges of alarm horn sounders, LED and Xenon Strobe beacons, plus combination sounders with beacons, are now available with SIL1 and SIL2 compliance as standard. This globally approved range of signals provide the ultimate in life safety notification in both hazardous area and safe area applications.

Expert third party PFD analysis of the extensive product reliability data available for these product ranges confirms SIL1 and SIL2 compliance. Assessed to IEC 61508 (2010) Random Hardware Failures and Systematic Failures – Route 2H. As compliance is achieved in a 1oo1 architecture no duplication or redundancy of devices is required.

In addition to the standard SIL1 and SIL2 compliance described above, the unique E2S SIL2 diagnostic module can be specified, providing an industry leading solution for safety systems requiring warning signals with active diagnostics and SIL2 compliance via Route 1H in a 1oo1 configuration. The module is factory integrated with the signal electronics allowing the diagnostic circuitry to assess the audible or visual output of the sounder or beacon. Any detected power supply failure or failure-to-activate event is reported back to the controlling system via the diagnostic relay output. The SIL2 diagnostic module product version is now available across the D1x, BEx, GNEx and STEx ranges of explosion proof audible and visual signals in marine grade aluminum, GRP or stainless-steel enclosures.

For safety system initiation the E2S ranges of break glass manual call points and push buttons with tool reset, momentary and dual action, are also SIL1 and SIL2 compliant as standard. SP

Source: E2S Warning Signals

Service: $37,000

• Ronald McDonald House Charities: $23,000

• Rural Aid: $15,000

New Zealand ($75,000 NZD)

• Cancer Society New Zealand: $41,000

• New Zealand Rural Support Charitable Trust: $25,500

• Heart Foundation New Zealand: $8,500

“It is exciting to see our employees get involved in how the holiday fund is distributed,” concludes Semple. “The charities they’ve chosen to support this year are having a huge positive impact on the lives of people, both on a lo -

cal level and around the world.”

2022 marks the 11th anniversary of Brandt’s Thanks A Billion program. Since its inception, over $22 million has been invested in local communities and community partners across the company’s footprint. SP

Source: BrandtThe province of British Columbia has convened a new advisory council in support of forestry workers and communities.

“As someone who has worked in forestry and lives in a forestry community, I know personally how vital the sector is for our province,” said Katrine Conroy, Minister of Forests. “It is a foundation of the B.C. economy, providing good, well-paying jobs for over 55,000 people. As the major employer in many communities, it is the lifeblood of rural economies. Our vision is to build stronger, more resilient forestry communities and create new economic opportunities

through innovative, valueadded manufacturing. The council will help ensure we get this right.”

The Forestry Worker Supports and Community Resiliency Council will advise the Province on improvements to existing programs and the development of new, forwardlooking initiatives aimed at supporting forestry workers and the economic resiliency of rural communities. The council will assist government in ensuring programs are targeted, effective and re-

sponsive to community needs and priorities.

Chaired by Doug Routley, Parliamentary Secretary for Forests, the council includes 18 members from broad sectors of B.C., including local government, Indigenous communities, forest industry and labour representatives, academics, and non-governmental organizations.

“I am thrilled to be leading a diverse group of council members from across the province that bring a range of skills, expertise and back-

grounds to the table,” Routley said. “We need to move past the boom-and-bust cycles of the past that left workers and communities behind. Now is the time for us to work together to build a more sustainable, diverse and innovative forest sector.”

The B.C. forest sector is facing a declining mid-term supply of timber. Set by the independent chief forester, reductions in the annual allowable cut are primarily the result of the end of the beetle kill harvest and the impact of wildfires on the land base. Government’s vision includes shifting the sector from a focus on high volume to highvalue production, with more innovative wood products manufactured locally and more jobs created for every tree harvested.

“People in rural communities have built the B.C. we know and love today in large part through their work in our forests,” said Roly Russell, Parliamentary Secretary for Rural and Regional Development. “As global economies and demands change, we know that we need to be better prepared across the province to navigate this shift. As a government, we’re working

with rural communities to develop pathways to truly resilient economies, mitigating the impacts of sector downturns and helping people

ties as they adapt to changes resulting from the shift to new approach for managing B.C.’s old-growth forests. Budget 2022 included $185 million over three years to provide co-ordinated and comprehensive supports for forestry workers, industry, communities and First Nations who may be affected by new restrictions on old growth logging. This funding is helping expand and enhance existing programs:

thrive in the communities they call home. This council will help ensure that we’re doing the best job we can of supporting rural communities through that transition.”

The Old Growth Strategic Review also recommended that the Province support forestry workers and communi-

• Forest Employment Program – creating shortterm employment for forestry contractors and their employees

• Skills Training for Job Pathways – connecting workers and communities with skills training and educational opportunities

• Rural Business and Com-

New tour kicks off January 17, 2023 in St. Louis and travels all throughout the midwestern, western, southern and mid-Atlantic U.S. through March

CASE Construction Equipment is launching the second leg of its Groundbreaker Roadshow celebrating the launch of the CASE Minotaur™ DL550 compact dozer loader — a first-ofits-kind machine and an all-new equipment category launched in 2022. The tour attracted crowds last Fall and put a huge exclamation point on one of the largest and most dynamic product launches of the year. The allnew machine was named to all major year-end awards lists, including Construction Equipment magazine’s Top 100 New Products; Compact Equipment’s Innovative Iron awards; and Heavy Equipment Guide’s Top Introductions for 2022.

Attendees of The Groundbreaker Roadshow will experience the Minotaur firsthand while enjoying a day on the lot with chances for prizes and giveaways. The second leg

of the Groundbreaker Roadshow kicked off on Tuesday, January 17 with Luby Equipment. For the full roadshow schedule, visit http://casece. com/Roadshow.

versatility, power and precision — all culminating in an entirely new product category created by CASE: the compact dozer loader.

Weighing in at more than 18,000 pounds and working with 114 horsepower, the new first-of-its-kind machine delivers true dozing and grading performance, as well as powerful site loading capabilities and compatibility with hundreds of attachments. A single platform has never delivered this level of

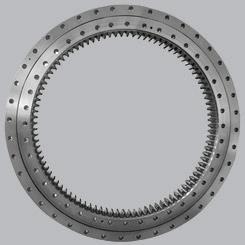

The hallmark advancement of the CASE Minotaur DL550 is the chassisintegrated C-frame with six-way dozer blade. The C-frame hydraulically couples into both the chassis of the machine, as well as the attachment coupler. This design provides the stability and smooth operating plane of a small dozer while ensuring that all operating power is channeled through the whole body of the machine. This establishes greater performance and long-term reliability than the simple combination of a dozer blade attachment to a traditional compact track loader.

It also comes standard with CASE Universal Machine Control, which makes

the machine ready for any of the major three providers of machine control technology, which are sold separately. It’s also available with an optional, industry-exclusive fully integrated ripper for tearing up tough terrain to simplify dozing and earthmoving operations.

The C-frame is then detached to allow the operator to use it as a loader with a heavy-duty 1.25-cubic-yard bucket, or with hundreds of common loader attachments many equipment owners already have in their fleet. SP

Source:

munity Recovery Initiative – funding to hire advisers to support rural businesses and communities with strategic decision-making

• Community Transition Rapid Response Team –delivering on-the-ground economic development and community support services

• Bridging to Retirement – providing as much as $75,000 to eligible forestry workers and contractors

55 or older to transition to retirement, helping to open up jobs for younger workers

New programs are also being developed focused on long-term economic development opportunities, including:

• Industry Innovation Program

• Rural Economic Diversification and Infrastructure Program. SP

Source: Gov.bc.ca

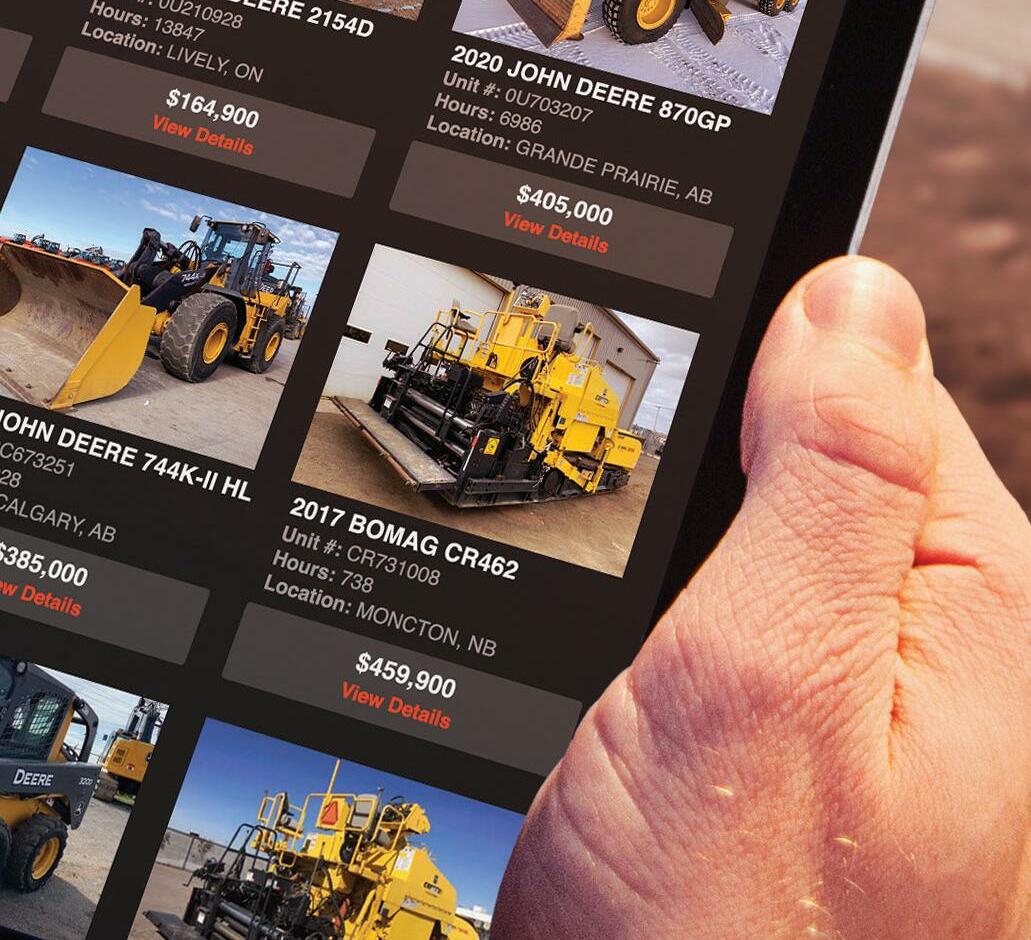

CASE CEbrandtused.ca

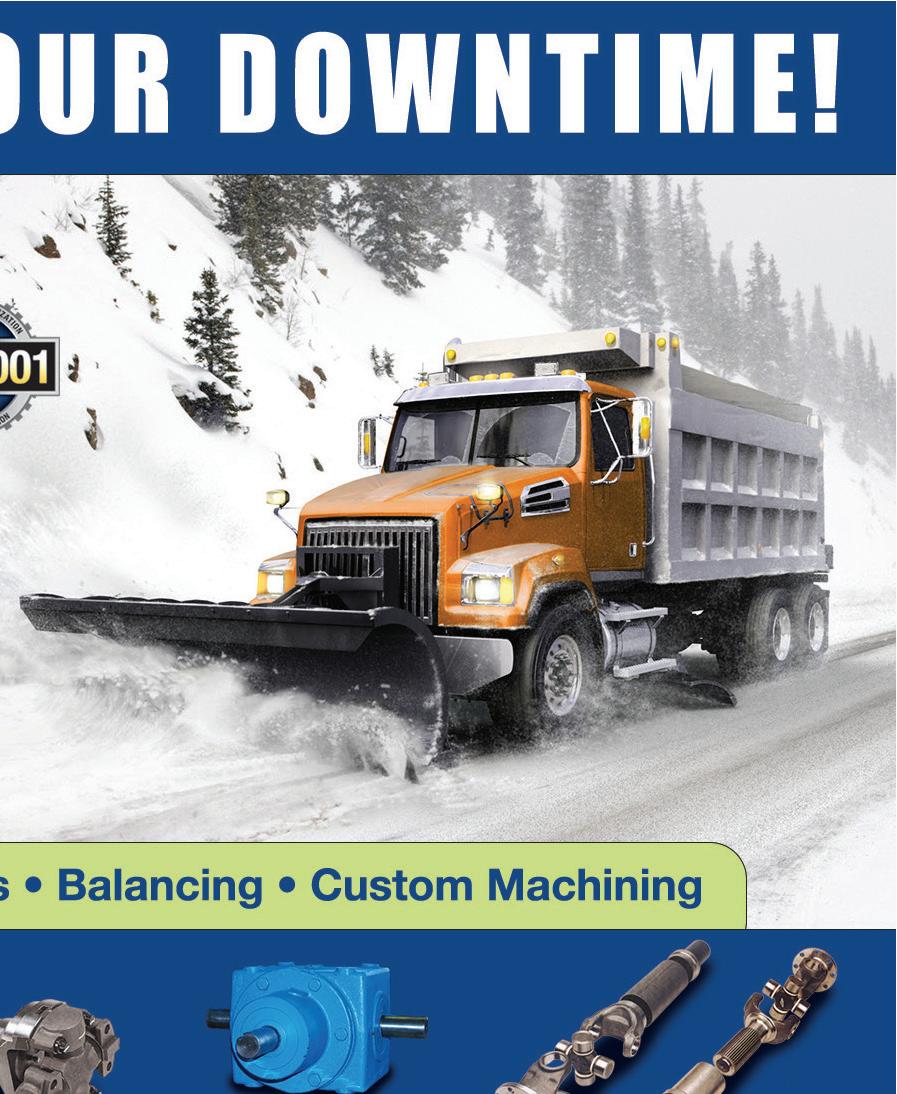

Searching for used equipment just got a whole lot easier with advanced searches, currency conversion and monthly payment calculations. And every machine is backed by Brandt –the best-trained and committed after sales support team in the business.

Tractor Bob’s, a dealer of Yanmar America Corporation has designed and fabricated a tractor conversion for a handicapped customer in a wheelchair.

The Yanmar YT3 chair lift is the first chair lift on a compact Yanmar tractor and allows a person in a wheelchair to access the tractor and operate it by hand. The further addition of a Jiffy Hitch allows the user to easily change tractor implements.

According to USDA figures, approximately 19% of US farmers suffer from a disability. This can add challenges to an already demanding profession. Technology can help disabled farmers access vital information and services, but assistive technologies which include modified tractors and farm equipment are an important way to keep disabled farmers working on their land.

Located in Oklahoma City, OK, Tractor Bob’s is an authorized Yanmar dealership serving the Oklahoma City area. The Tractor Bob’s team’s outstanding customer focus and deep experience in tractor maintenance and customization have long made

them a favorite with rural lifestyle customers in Oklahoma. Tractor Bob’s was approached with a request to retrofit a Yanmar YT3 tractor for easy access for a customer in a wheelchair.

The team fabricated a custom seat lift transfer system

and a hand-operated braking mechanism enables the user to operate the Yanmar YT3 tractor entirely by hand.

“The Yanmar tractor, by design, is capable of being hand controlled relatively easily,” Neil Snow, owner of Tractor Bob’s explains of the Yanmar YT3. “Most of the other tractors in that size category just wouldn’t be suitable.”

Neil also praised the ergonomics of the tractor, the positioning of the joystick and the spaciousness of the cab as being particularly suitable for the conversion. He also highlighted the smoothness of Yanmar’s iHMT transmission which has none of the “jerky” response that can sometimes happen with tractors under joystick control.

and fitted it to the Yanmar YT3 tractor. The system allows the user to transfer from their wheelchair to the lift, be raised to the tractor cabin and easily transfer across to the tractor seat. The seat lift comes with a wireless remote that controls the lifting operations of the chair. Once in the cabin, a hand throttle

The final element in the conversion was the addition of a Jiffy Hitch implement attachment system which allows the user to easily change out an implement without leaving the seat.

“The system operates really well,” said Neil. “It makes the customer happy and gives you that sense of pride that you were able to take care of the customer.” SP

You voted for your favourites in ten categories, and here are the winners!

The Supply Post newspaper was pleased to host our 2nd annual Readers’ Choice Awards, where readers voted for their favourite businesses who advertised in Supply Post in 2022, in these ten categories: Best Construction Equipment Dealer; Best Forestry Equipment Dealer; Best Commercial Truck Dealer; Best Commercial Trailer Dealer; Best Aggregate Equipment Dealer; Best Agriculture Equipment Dealer; Best Attachment Dealer; Best Parts Dealer; Best Financing Company; and Best Auction Company. Congratulations to all the winners!

Winning 4 out of 10 categories, JPH Equipment is this years’ winningest advertiser!

sells heavy equipment in partnership with their customers. “Every day, we have the privilege of helping people sell equipment,” said JP Tone. “Matching buyers with equipment that suits their needs is what we do best.”

time wasters. Once they find a qualified buyer, they then involve their seller in the final stages or complete the entire process for them.

They always say, “all inclusive to the door delivery” and often do customs documentation and transport arrangements/scheduling for their customers.

The Supply Post newspaper was pleased to host our 2nd annual Readers’ Choice Awards, where readers voted for their favourite businesses who advertised in Supply Post in 2022. This year’s winningest advertiser is JPH Equipment, headquartered in Lethbridge, Alberta.

JPH Equipment was

founded five years ago by JP Tone and his wife Danni. JP came from Manitoba and has farmed, tree planted, worked rigs, and sold equipment for the last sixteen years.

Danni and JP love doing business in Lethbridge, because of family, friends, and supporting businesses.

JPH Equipment buys and

JPH Equipment’s process is simple: they gather all the necessary information on the equipment, properly representing the equipment while freeing up the seller to do what they do best — manage their business.

JPH Equipment’s business model makes the sales process easy: they eliminate tire kickers, fraudsters, and general

“Receiving Top dealer awards from Supply Post for 2021 and 2022 has allowed us to show our consignors and buyers that we are a company that ‘makes selling simple’,” said Mrs. Tone. “We simplify the buying process.”

We at The Supply Post congratulate JP, Danni, and the entire JPH Equipment family on this accomplishment. Check out JPH Equipment at JPHequip.com SP

JPH Equipment won in the following categories: Best Construction Equipment Dealer, Best Commercial Truck Dealer, Best Commercial Trailer Dealer, and Best Agriculture Equipment Dealer.

Brandt

Chieftain

Equipment was recently purchased by Frontline Machinery. frontline-machinery.com

For over 40+ years, Arrow-West Equipment Ltd. has been offering a wide selection of heavy equipment and attachments for sale and for rent, as well as parts. They also offer big savings on parts for all makes and models of construction equipment. arrowwest.com

Brandt Value Parts delivers new, refurbished, aftermarket and used parts, backed by our comprehensive Value Parts warranty to give you peace of mind and help keep you productive and profitable, every single day. brandt.ca/ValueParts

Since 1977, CWB National Leasing is Canada’s largest and longest-standing equipment financing company. CWB is Canada’s equipment financing experts, providing over $11 Billion in financing. They’ve helped more than 324,000 business customers secure equipment with a full range of financing services in agriculture, construction, transportation, forestry, health care, commercial, and golf and turf equipment industries. cwbnationalleasing.com

Team Auctions, formerly-known as Sekura Auctions, has been operating for over 50 years. They are a fast-growing auction company, servicing On-Site, Real-Estate, Industrial, and Farm Auctions, with units capable of doing auction sales anywhere, with internet bidding, cash advances, appraisals, and custom auction proposals to meet your specific challenges, throughout Western Canada, BC, Alberta, and Saskatchewan. teamauctions.com

Industry Experience of 30+ Years; Weaver Auctions are your Auction Advantage. They strive to make your selling experience hassle free! That’s why they offer an all-inclusive auction service, including Advertising & Marketing, Shipping Recommendations, Equipment Storage, Lien Search Pay out, Buyer Inquires & Inspections, Collecting Sale Revenue on your behalf and Handling any post-sale issues. weaverauctions.com

More than 2,000 tons of CO2 will be saved in a partnership to transform a 100-year-old meatpacking district in the center of Stockholm, Sweden, setting a new benchmark for almost entirely fossil-free construction sites.

The 100-year-old ‘Slakthusområdet’ area of Stockholm city center in Sweden, also known as the meatpacking district, will become a testbed for innovation and emission-free construction equipment as work begins on its urban transformation. Construction is set to finish in 2033 and when open to the public, it will provide 3,000 new homes and 14,000 workplaces.

Sustainability has been built in from the project’s inception with a stipulation for fossil-free contracts, including transport to and from the construction site. With a particular requirement that at least one of the larger excavators working on site should be electric, there was only one partner for the job: Volvo CE and its industry-leading range of electric construction equipment.

The new 23-ton EC230 Electric excavator, offered in selected markets, has already been proving its potential across a range of applications and is one of only a few midsize electric machines commercially available. Early next year it will be put to work in

the first stages of the project, for an estimated 2,700 working hours.

“Partnership is how we can accelerate our journey towards emission-free jobsites. We have powerful and reliable solutions like our EC230 Electric providing all the benefits of electric equipment: zero exhaust emissions, near silence and more comfortable operation. But it is by collaborating with partners like Skanska and the City of Stockholm, who are aligned with our mission to build a better world, that we can really drive the transformation of our industry in a much more holistic way.”

ing standards and find new innovations, and we do this in collaboration with, among others, Volvo CE.”

work.

Stockholm, together with a mobile peak-shaving power unit supplied by Volvo CE, to help excavate 75,000 tons of rock and 96,000 tons of soil in

Lisa Kroon, project manager at Skanska, says: “It is Sweden’s largest testbed in an urban environment for fossil-free contracting, where we will convert almost 35,000 machine hours to fossil-free. We want to challenge build-

Insights from the EC230 Electric’s use will not only be instrumental in helping Volvo CE build the world we want to live in through our electric solutions – providing data on factors such as productivity, cost and scalability – but will also prove useful for other partners in their ongoing ambitions to reduce climate impact through their

Anders Österberg, deputy financial councillor and chairman of the exploitation committee in the City of Stockholm, says: “We want to drive the development of fossil-free contracts, and we can do that by setting tender requirements in our procurements. In the contract, where large amounts of rock and soil are to be excavated, one of the requirements is that at least 10% of the machine hours must be powered by electricity.”

Fredrik adds: “The type of procurement that the City of Stockholm has required for fossil-free contracts will contribute to a breakthrough in the transition to electric machines. The EC230 Electric will contribute to 2,700 fossilfree hours in the project.”

Richard Sjöblom, Excavator Operator for Skanska, has

had overwhelmingly positive feedback after operating the EC230 Electric, particularly in terms of the ease of charging and the performance of the machine when testing it across different applications. He says: “If I had the choice of an electric or diesel machine in this size class I would choose electric as there are so many advantages over a diesel machine. When the machine was delivered to site there were many sceptics who thought the machine didn’t have the capacity to last the whole day, but they have all been proved wrong!”

In addition to the EC230 Electric, it is required that all other machines be run on HVO (hydrogenated vegetable oil) – a biofuel which reduces greenhouse gas emissions by up to 90%. SP

2015 Caterpillar 246D 2 speed Skid Steer Loader, hyd Q/C, aux hyd, joystick controls, 72” bucket, ride control $41,500.

2015 Caterpillar 259D Compact Track Loader, Q/C, aux hyd, A/C cab, joystick steer, rearview camera, 78” bucket $58,900.

2015 Bobcat S510 Skid Steer Loader, solid tires, Q/C, aux hyd, cab, joystick controls, 61” bucket $41,000.

2005 Caterpillar 267B Multi Terrain, 71 HP, 2 speed, closed cab, heat $41,000.

2017 Caterpillar 246D Skid Steer, 74 HP, 7400lbs, closed cab, A/C, heat, 2 speed, 12x16.5 tires @ 90% $54,900.

2018 Bobcat S650 Skid Steer Loader, 12x16.5 aperture tires @ 95%, cab, A/C, Pos. air shut off, 7 pin elec. kit, hyd Q/C, 2 speed 72” bucket $51,900.

2012 Bobcat S770 Skid Steer Loader, new tires, cab, A/C, ride control, joystick steer, 7pin elec. kit, hyd Q/C, 68” bucket, 2 speed $47,900.

2013 John Deere 310 SK Extenda hoe, 4 in 1 bucket $63,000.

The new Cat 340 Hydraulic Excavator features a more powerful engine, wider track, and 7.5-ton counterweight to increase productivity by 10% over the 2020 model year Cat 336. Its increased power and stability, combined with Next Generation electrohydraulic system efficiency, make it the best choice in the 40-tonne (45-ton) class

for moving tons per hour.

“The 340 reaches a new level of performance,” said Brian Abbott, Caterpillar global product manager for large hydraulic excavators. “Our additions make the machine more productive and stable with larger work tools, giving contractors more flexibility to complete a wider range of projects.”

The new excavator’s reinforced structures ensure long-term durability in harsh digging, truck loading, and hammer applications. The Cat C9.3B engine’s 14 million hours of service attest to its long-term reliability. Three engine modes match excavator power to the demands of the job while sav-

ing fuel. Power mode delivers maximum power to meet the most demanding tasks; Smart mode automatically matches engine and hydraulic power to digging conditions to lower fuel consumption. Reducing engine speed to a constant 1500 rpm, Eco mode minimizes fuel consumption.

Synchronized 1,000-hour oil and fuel filter service intervals reduce downtime. The extended intervals also eliminate labor cost for nine oil and fuel filter changes and parts cost for 27 oil and fuel filters over 10,000 machine operating hours compared to many competitive 30 – 40-ton excavators.

High-ambient temperature capability of 52˚ C (125˚ F), cold-start capability at -18˚ C (0˚ F), and the ability to work at up to 4500 m (14,764 ft) above sea level make the 340 suitable for virtually any environment. Auto hydraulic warmup in cold temperatures gets the machine to work faster and prolongs the life of machine components. The air intake filter with pre-cleaner features high dust capacity, and a high-efficiency hydraulic fan offers optional automatic reverse to keep cores free from debris.

Product Link™ collects data automatically. View information like location, hours, fuel usage, idle time, maintenance alerts, diagnostic codes, and machine health online through web and mobile applications. Maximizing machine uptime, Remote Troubleshoot and Remote Flash allow dealers to remotely connect with the machine to diagnose fault codes and update operating software.

From Deluxe to Premium, Next Generation cab trim level options are avail-

able. Deluxe cabs come with a heated air-suspension seat, and Premium cabs come with a heated and ventilated airsuspension seat. Both have a tilt up left-hand console for easier access in and out of the machine.

tern preferences for individual operators.

A touchscreen monitor and jog dial offer quick navigation through machine controls and provide easy access to the machine’s digital operator’s manual. Keyless pushbutton start is standard, and Bluetooth® key fob is available. An Operator ID passcode allows for engine starting, and Operator ID can quickly save and restore joystick button, response, and pat-

Optional Cat Stick Steer makes travel and turning much easier. A host of standard technologies – Cat Payload on-board weighing, Grade Assist for maintaining grade, and 2D Grade with depth and slope indication – elevate operator efficiency and machine productivity. All Cat Grade systems are compatible with radios and base stations from top third-party technology suppliers. Operators can store up to four depth and slope offsets to quickly cut to grade without a grade checker. Auto Hammer Stop warns operators after 15 seconds of continuous firing and then shuts off the hammer after 30 seconds to prevent wear and tear. Auto Dig Boost and Auto Heavy Lift increase bucket penetration and lift capacity by 8%, and Lift Assist helps operators avoid tipping the machine. SP

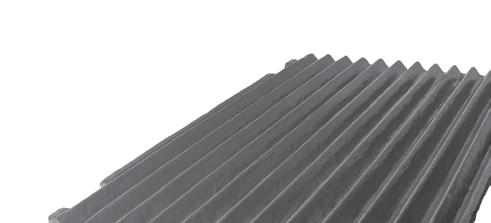

To meet the compaction demands of numerous industries and jobsite requirements, Bobcat has launched nine light compaction machines in North America.

This latest expansion of product offerings provides customers with the added versatility and productivity they have come to expect from Bobcat in an innovative product lineup fit for construction, roadwork and landscaping.

“By adding light compaction machines to our current product offering, customers have a greater array of equipment options to help them

accomplish more,” said Mike Ballweber, president, Bobcat Company North America.

“We know our customers work hard each and every day, and these machines give them even more versatility to do their best work.”

The full range of Bobcat light compaction products includes rammers, forward

plates compactors, reversible plates compactors and trench rollers. The light compaction line can be used in a variety of settings and is designed to meet compaction requirements on nearly all jobsites.

Includes: Bobcat rammers (models R60P and R68P) are highperformance machines that are user-friendly and engi-

neered to last. Highly efficient in confined work areas, Bobcat rammers reach places other equipment can’t. Directing all compaction power onto any target surface while maintaining optimal balance, Bobcat rammers are agile, precise and built to last.

Three Bobcat forward plate compactors (models FP10.33, FP15.40, and FP15.50) are equipped with industry-leading forward movement capabilities for great compaction results and less operator fatigue. While working with Bobcat’s forward plate compactors, operators will get quality performance with low fuel consumption.

Three Bobcat reversible plate compactors (models RP22.40, RP30.50 and RP49.20D) are ideal for compacting granular material such as sand, gravel and asphalt. These walk-behind machines are as nimble as they are durable. These machines enable operators to experience quick directional changes with minimal effort in tight spaces.

The Bobcat TR75 trench roller, operated by remote control, delivers high-compaction performance on

a variety of soil types. The TR75 trench roller can take on a variety of jobsites with its oscillating articulated joint that allows the trench roller’s drums to maintain contact on uneven ground.

Bobcat’s light compaction range of products contain many state-of-the-art features to increase productivity. Each machine within the line possesses different strengths, including maneuverability, power, fuel-efficiency and much more. The versatility of this line was thoughtfully designed with operators in

mind, crowning maneuverability and efficiency as the utmost priority.

“Bobcat’s light compaction equipment was created for jobs in small spaces, requiring efficient compaction with an emphasis on operator comfort,” said Travis Kidder, senior product specialist for Bobcat Company. “Whatever your compaction needs are, look no further; Bobcat’s light compaction range provides the necessary capabilities to meet your needs.” SP

Source: BobcatTwo renewed forest management agreements will support Alberta’s Recovery Plan with hundreds of secure, stable jobs and long-term wood fibre access for harvesting operations.

The Government of Alberta has renewed two Grande Prairie and Pembina Timberlands forest management agreements (FMAs) held by Weyerhaeuser Company Limited for the next 20 years in exchange for important stewardship responsibilities. These agreements establish the company’s right to grow and harvest Crown timber from forest management units near Grande Prairie and Drayton Valley.

Over their lifespans, the renewed Grande Prairie and Pembina FMAs are expected to maintain more than 1,250 full-time, contract and seasonal positions, and will potentially contribute:

• $12.2m and $14.7m in annual holding and protection charge payments

• $313 million and $277 million in timber dues

• $3.2 billion and $3.5 billion to Alberta’s gross domestic product

“The decision to renew Weyerhaeuser’s forest management agreements is a great example of how we can provide industry partners with the security needed for longterm investment, maintain hundreds of well-paying jobs for Albertans and ensure sustainable management practices for Alberta’s forests,” stated Nate Horner, Minister of Agriculture, Forestry and Rural Economic Development. “A competitive for-

estry sector drives growth by ensuring that our wood fibre products remain sought-after in a globalized economy.”

“We’re very pleased with the decision to renew these tenure agreements,” said David Graham, president, Weyerhaeuser Company Limited. “This support reinforces confidence in our long-standing investments, providing continued security for employees and partners across both regions. Weyerhaeuser is proud of the strong local working relationships, including Indigenous communities, which are foundational to our activities in these areas. Our focus on sustainability and responsible resource management reflects our deep commitment to accountable stewardship practices that benefits our Indigenous and community neighbours.”

An FMA is the most secure type of forest tenure, providing a company with rights to establish, grow and harvest timber on Crown land consistent with sustainable forest management principles and practices. FMAs also establish nu-

merous legal obligations for companies, including developing forest management plans that help protect biodiversity, increase forest

Approval of Weyerhaeuser’s FMAs supports the Forest Jobs Action Plan initiative to provide forest companies with long-term fibre access, ensuring that Alberta’s forests continue to provide ecological, economic, social and cultural benefits for future generations.

resilience and reduce the risk of catastrophic wildfires and mountain pine beetle outbreaks.

Weyerhaeuser Grande Prairie’s FMA for operations in forest management unit (FMU) G16 was first established in 1969 and applies to an area of 1,117,146 hectares located mostly south of

Grande Prairie.

Weyerhaeuser’s Grande Prairie sawmill and associated activities in the area employ 277 full-time staff and about 380 contract staff in logging, transportation

and other forestry support services.

Weyerhaeuser’s Pembina Timberlands FMA, for operations in FMU R15, was first established in 2005 and applies to an area of 953,917 hectares located in five piec-

es north and south of Edson and west of Drayton Valley.

Weyerhaeuser’s Drayton Valley sawmill employs 160 full-time employees. In Edson, the oriented strand board facility employs 300 full-time equivalents and

150 seasonal employees.

FMA holders are subject to strict requirements to reforest harvested areas within two years. On average, forest companies plant two trees for every tree harvested, establishing young,

healthy forests that provide for wildlife habitat. Over the lives of the current FMAs, Weyerhaeuser has planted more than 373 million seedlings.

About 286 million seedlings have been planted un-

The Association for Mineral Exploration (“AME”) is pleased to announce its 2022 Celebration of Excellence Award recipients.

The recipients are recognized for their remarkable contributions, achievements, innovation and leadership in the mineral exploration and development industry. They will be celebrated at the prestigious AME Awards Gala to be held at the Vancouver Convention Centre West on Wednesday, January 25, 2023. Tickets are available through AME Roundup 2023 registration at www.roundup.amebc. ca/register.

This year’s award recipients are:

Maggie Layman is the recipient of the 2022 AME H.H. “Spud” Huestis Award for her significant contribution to developing the geological model which allowed Barkerville Gold Mines (BGM) to define 4.3 million ounces of gold in new underground resources at the Cariboo Gold Project near Wells, BC. In addition

to helping to revive a historic mining district, Maggie is committed to fostering the development of young geologists.

John Robins is recognized as the 2022 AME Murray Pezim Award recipient for his significant contribution to advancing the financing of numerous mineral exploration and development projects, generating over $500 million in direct and indirect mineral expenditures throughout Canada, Latin America and Australia and over $1 billion in merger and acquisition activity.

Craig Parry, Steve Blower, Andy Carmichael, and Justin Rodko are recognized with the 2022 AME Colin Spence Award for their discovery of the Hurricane Zone on the Larocque East property in 2018, arguably the most significant recent uranium discovery in the historically productive eastern part of the Athabasca Basin, Saskatchewan.

Clement (Clem) Pelletier is the recipient of the 2022 AME Robert R. Hedley Award for Excellence in Social and Environmental Responsibility, sponsored by ERM. Clem is recognized for his leadership and contributions over more than 50 years, particularly in directing large environmental and social impact studies, providing training opportunities for Indigenous groups and permitting major projects in BC and throughout the world.

The VRIFY Product & Development Team receives the 2022 AME Innovation Award for its groundbreaking work developing an interactive 3D and 360-degree presentation platform for exploration and mining companies to communicate with investors.

Larry Jones is acknowledged with a Special Tribute

der Weyerhaeuser’s Grande Prairie FMA.

More than 88 million seedlings have been planted under Weyerhaeuser’s Pembina Timberlands FMA. SP

Source: Gov.ab.ca

from AME for his leadership in assembling and distributing the British Columbia Geological Survey databases and geospatial datasets and for leading his team in the design, development and marketing of MapPlace, an internet-based geographic information system providing access to BC geospatial data to diverse client groups.

Ed Beswick is awarded the 2022 AME David Barr Award for his leadership as Inspector of Mines in Prince George: Ed was instrumental in promoting safety on every visit he made to exploration sites throughout the Cariboo and Prince George areas over many years.

Lana Eagle is recognized with the AME Frank Woodside Gold Pan Award for her distinguished service to AME. A natural relationship builder with the ability to strategically connect Indigenous groups with industry, her legacy includes The Gathering Place at AME Roundup, which celebrated its 10th year in January 2022, along with more than a decade of guidance and direction in how the industry approaches Indigenous relations and reconciliation.

Britannia Mine Museum is the recipient of AME’s Outreach Education Fund to support the ongoing development and growth of the Museum’s programming to enhance the Earth Materials content to appeal to a wide range of visitors, educators and professionals.

Jill Tsolinas, Chair of the AME Board of Directors, commented, “Today, on behalf of the AME Board of Directors, I congratulate the diverse group of industry leaders recognized with AME Awards in 2022. Each recipient has gone above and beyond to achieve, contribute and innovate in their mineral exploration and development specialty. I look forward to celebrating their distinguished service, leadership and contributions at the Awards Gala at AME Roundup 2023.” SP Source: AME

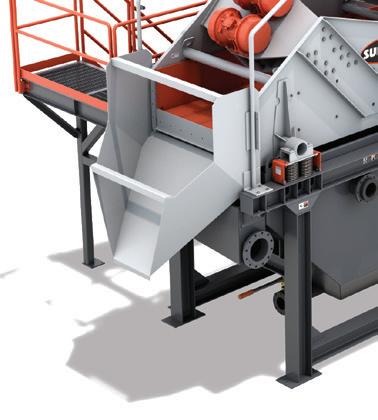

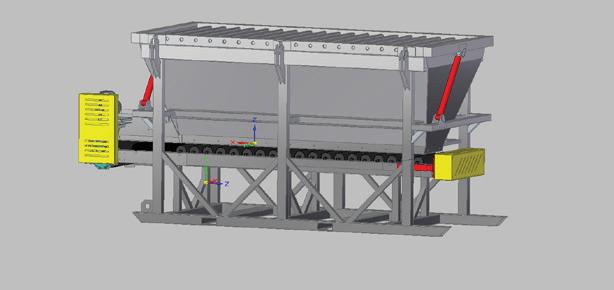

Terex MPS has announced the launch of the Cedarapids CRC1350 Portable Cone Plant featuring the new TC1300X cone crusher.

increase thru put, and an improved quality product shape. Other key features include automated cone controls and larger closed side settings.

The portable plant includes an oversize quickrelease cone feed hopper extension with overflow chute, a 42” (1070mm) rugged straight-line product conveyor, a metal detector for off-plant feed conveyor, and service platforms with elevated deck, guard rails and access ladder.

Maintenance & safety features include conveniently located grease banks, ground access cone lubrication module, emergency stop stations on both sides of the frame, and manual crank-style landing jacks.

Cedarapids leads the industry with the most advanced portable plants designed for high productivity and easy portability. The complete CRC1350 solution delivers peak productivity at an economical price point and easy access maintenance.

The implementation of the enhanced TC1300X cone

crusher features 400 hp, a significant increase in power over the previous version.

The TC1300X use of high efficiency roller bearings, boasts several notable advancements that enhance performance and functionality overall. This complete configuration increases stroke from 45mm to 70mm that results in an

Astec has joined the Department of Energy (DOE) Better Plants program that works with leading U.S. manufacturers to achieve voluntary energy performance improvement goals.

The Cedarapids CRC1350 was engineered to meet the growing industry trend toward larger, mobile, electric powered, low-maintenance plants, that provide an increased production capacity. Contact your local Cedarapids dealer for more information pertaining to the CRC1350. SP

Source: Terex MPS

ergy savings goals, develop energy management plans, and track and report annual progress. In return, the DOE offers support in the form of technical advice, energy efficiency training, data analyzation, and training sessions to help reduce energy consumption across facilities.

“Astec’s initiative to improve its energy productivity establishes the company as a leader in efficiency and helps strengthen the nation’s manufacturing competitiveness,” said Becca Jones-Albertus, Acting Director, Advanced Manufacturing Office, U.S. Department of Energy.

The Better Plants program has more than 250 partners with more than 3,600 facilities across the United States. From auto and transportation to food and consumer products, Better Plant partners account for 14% of the U.S. manufacturing footprint.

“We are focused on making a positive impact in our industry and the communities in which we have operations, and that includes doing our part to promote

a healthy environment for generations to come,” said Barry Ruffalo, Chief Executive Officer for Astec. “Our participation in the Better Plants program, along with NAPA’s The Road Forward, reaffirms our commitment to manufacture sustainable solutions for the road building, aggregates and mining industries in plants that are energy efficient.”

Through the Better Plants program, partners create en-

Astec has taken steps recently to improve the energy efficiency and safety of its plants around the world by installing LED lighting. The company also installed a solar farm at its Johannesburg site and is exploring additional opportunities to use solar in other locations.

“Our partnership with the DOE is yet another step in the right direction to reach the goal of more sustainable manufacturing and improve value for our stakeholders,” Ruffalo said. SP

Source: Astec

Manitou Group, a world reference in the handling, aerial work platform and earth moving sectors, presents its roadmap for research and development on hydrogen-powered machines.

Its opportunity to present the first innovative prototype telehandler running on green hydrogen.

With a target of reducing greenhouse gas emissions by 34% per hour of use of its machines in 2030, Manitou Group has set off on an ambitious course, in line with the commitments of its low-carbon trajectory communicated in January 2022 and validated by the SBTi in July. Following on from the recent electrification of its all-terrain platform and telehandler ranges, the Group is also looking to hydrogen as a medium-term alternative for its users. Manitou Group wants to see its electric and hydrogen ranges side by side depending on each user’s applications, with a target of 43% low-emissions products marketed in 2030.

Manitou Group has presented its new facilities for making its hydrogen development plan a success to journalists and elected representatives. By kitting its test center out with a green hydrogen station, the Group now has the means for testing

its brand-new prototype telehandler.

The first step of this plan involves guaranteeing range and reliability in real-life conditions, while testing the durability of components. The Group based this first prototype on an existing model from its range of construction machines, capable of lifting loads up to 14 m. This ma-

ers. Michel Denis, Managing Director of the Group, explains: “We are studying all the hydrogen-related technologies based on what users need. This prototype is only the first step. A second rotating telehandler prototype will be developed in the coming months. There are many benefits of green hydrogen with production possible using wind power that has no greenhouse gas emissions at all. This fits in perfectly with our low-carbon trajectory”.

chine will be tested and sent out to construction sites by the end of 2023 with a view to collecting valuable feedback from users to improve on this prototype. Two types of hydrogen technology are currently being evaluated by the market, namely the combustion engine and the fuel cell. The Group’s first prototype is built around a fuel cell, but the Group will choose the hydrogen solutions that best meet the needs of its custom-

With this first prototype, the Group is showcasing its ability to innovate in order to measure the autonomy of this new energy while offering its customers the hydrogen solution that best meets their needs, but without compromising on performance. Almost 50 engineers and technicians are dedicated to this approach, which was launched in 2021. To come up with an innovative solution that can be fully industrialized, the Group hopes to rely on the support of the public authorities to develop an emerging ecosystem. Julien Waechter, VP R&D Manitou Group, explains: “The green hydrogen sector is gradually becoming more established with the entry onto this market of a number of players. All of the aid mechanisms pro-

posed by the different governments will encourage the transition to hydrogen, and will speed up the development of the distribution network and ultimately the reduction in the usage costs of our machines using this energy”.

With these new facilities, Manitou Group hopes to offer its customers new innovative prospects, with a 100% hydrogen-powered telehandler available on the market by 2026.

With over 350 engineers on its workforce, Manitou Group is constantly innovating by offering its users highadded-value solutions. To succeed, the Group invests almost €60 million a year in all of its 10 R&D centers around the world. The modernization of its production units is also essential to ensure this abil-

ity to innovate. This is demonstrated by the recent €150 million investment plan announced for the production sites in the US and France.

The most recent aerial work platform factory opened in 2022 clearly illustrates this willingness. Whether it concerns the choice of components, user comfort, or the attachment on the machine, innovation is everywhere.

An autonomous order-picking robot, electric all-terrain platforms, and 100% electric telehandlers are all examples of innovation. To support this development, the Group incorporates engaging CSR criteria from the design stage to develop machines that are increasingly durable and responsible.

As a world reference in the handling, aerial work platforms and earth moving sectors, Manitou Group’s mis-

sion is to improve working conditions, safety and performance around the world, while protecting people and their environment. Through its flagship brands – Manitou and Gehl – the group designs, produces, distributes and services equipment for construction, agriculture and industry. By placing innovation at the heart of its development, Manitou Group constantly seeks to bring value to all its stakeholders. Through the expertise of its network of 1,050 dealers, the group works more closely with its customers every day. Staying true to its roots, with its headquarters located in France, Manitou Group turned over €1.9 billion in 2021. It unites 4,500 talents worldwide with passion as their common driver. SP

Source: Manitou

When Bloomfield Composting needed to invest in a new waste shredder and trommel screen for their 18 acre waste and recycling facility at Cannock in Staffordshire they turned to EDGE Innovate, and not without good reason.

Bloomfield Composting was established about 15 years ago and takes in green waste and wood and forestry waste from a number of sources to produce not only PAS 100 compost and BS3882 multipurpose topsoil, but also biofuel and pellets used in power stations and for other applications. Nigel Gill became Managing Director of Bloomfield Composting just over a year ago, having a wealth of experience in the waste recycling and demolition sectors,

working for some 30 years alongside David Humphries of the Humphries Holding Group of companies. Today, as an independent, privately owned and managed company, Bloomfield Composting’s facilities are considered to be among the best in the country, taking in general green waste from local authority civic amenity sites, wood waste from demolition sites and forestry waste from tree surgeons and arboriculturalists.

EDGE Innovate supplied the UK company with an EDGE VS420 slow speed shredder and an EDGE TRT620R tracked trommel which have been earning their keep for some months now without any hitches.

Featuring an intelligent operating system which incorporates tramp metal protection that provides the ultimate protection from contaminants and prevents asset damage, the fuel efficient EDGE VS420 is a high

capacity, high torque, twin shaft waste shredder that is ideal for the processing of a large array of materials including green waste, MSW, C&D waste, biomass and end of life tyres. Its versatility can be attributed to the fact that a number of shredding programmes and chamber configurations are available. At its heart are twin synchronised, high torque shredder shafts which can be customised to suit a customer’s exact application and desired product piece size. EDGE’s twin shaft design provides exceptional material intake, ensures less wear, promotes self-cleaning and prevents material wrapping even in the toughest of applications, as Bloomfield Composting quickly discovered.

“After discussing our specific requirements with the team at EDGE Innovate, we took delivery of the VS420 waste shredder early last year and added the TRT620R track trommel screen several months later,” says Nigel Gill. “We needed a shredder that was robust, operator friendly, versatile and efficient to process a variety of wood waste, a lot of which contained metal such as nails, hinges and door handles. It also needed to break down other difficult waste like tree stumps and roots before putting the material through the high speed shredder, and the VS420 fits the bill perfectly with its different programme options and settings.”

“The operator likes the VS420 because its design is not overly complicated, and it can be controlled remotely

from the cab of his excavator, so it is essentially a one man operation,” Nigel continued.

“He actually runs two shredders and a screener all from the remote. by putting the shredder into reverse after so many turns, it helps keep the rotors clean and if they are

we had changes to the system to compensate and it is performing brilliantly.”

The EDGE TRT620R has a unique feature of a remote operated, 180° radial fines conveyor which has been combined with the ability to track, screen and stack material simultaneously. This functionality allows for enhanced production capacities, reduced material handling and the ability to create large radial or windrow stockpiles.

kept clean, you will be cutting back on power and using less fuel, so it is very efficient.”

He added that with easy access to the engine compartment and ground level access to all the filters, routine daily maintenance checks can be carried out quickly, resulting in minimal downtime.

Complementing the VS420 high torque shredder is the EDGE TRT620R track trommel. With its heavy-duty construction design and high manoeuvrability, it has proven to be perfect for Bloomfield Composting as it is well suited to handling biomass, soil and compost, as well as construction and demolition waste.

“EDGE Innovate were very accommodating when we asked for some modifications to the trommel,” says Nigel. “We don’t tend to shred the kerbside collected green waste when it comes into our facility, it goes straight into windrows, but there tends to be quite a lot of oversize now and again and it was catching on the chute, so

The positioning of the radial fines conveyor whether at 0° or 180° allows the TRT620R to have the same small footprint of a side conveyor trommel format but with a much superior product separation and reduced material contamination.

Another notable bonus is that it can accept several other trommel manufacturers’ drums, enabling operators to take full advantage of their existing drum stock. A quick and simple drum exchange procedure is facilitated via an innovative sliding feeder design and double sided 180° swinging drum doors allowing the screening drum to be exchanged in a matter of minutes.

“We hadn’t dealt with EDGE Innovate before acquiring these two machines, but they’ve been very supportive, although to be honest we haven’t had any issues since putting the shredder and trommel to work; they’ve been reliable and have been performing very well,” says Nigel. SP Source:

Sandvik Mining and Rock Solutions has launched a highlyautomated, compact, twin-boom drill for underground development and small-scale tunneling.

drilling to make underground operations safer and more productive.

Sandvik DD322i provides flexibility for operations, starting from small size drifts up to 58 square meter coverage area, reaching up to 6.8 meters high and 9.5 meters wide. The new SB55i booms provide 19.3 square meters side coverage, which is over 48 percent more than its predecessor, Sandvik DD321.

Sandvik DD322i is a versatile drill that can be utilized in mining or tunneling applications, and provides a high level of performance, accuracy and reliability. Sandvik DD322i has a new carrier and design, and can tram in small headings, tight corners and intersections thanks to its compact size, low profile cabin and Boom Control While Tramming option.

“Sandvik DD322i was very successful and well-received by our customer during the field testing in Finland earlier this year,” said Jari Talasniemi, product manager for development drills. “The site reported that almost 60 percent of their development drilling during the trial period

was completed using Sandvik DD322i. It performed extremely well from day one and the Boom Control While Tramming feature was useful for their operation.”

The Boom Control While Tramming option allows the operator to simultaneously control the two booms while tramming, ensuring improved control when moving the drill and reducing potential risk of boom damage. The new SB55i booms with two roll-overs ensure improved drilling performance and accuracy, as well as high flexibility to drill crosscut and bolt holes. Sandvik DD322i can also be equipped with features such as semi automatic drill bit changer and tele-remote

Adecco’s program upskills and elevates talent into certified, high-demand forklift operators, amid industry shortage; aims to fill 200 open positions.

Adecco Canada, part of the world’s leading provider of workforce solutions, today announced the launch of its Forklift Upskilling Program, as part of its goal to fill over 200 currently available forklift operator positions amid an ongoing talent shortage for skilled roles.

Supported by the Adecco Group US Foundation and offered in partnership with Raymond Johnston Equipment, this eight-hour training transforms the general labour workforce into a pipeline for skilled positions. The Forklift Upskilling Program offers candidates the unique

opportunity to obtain official certification in the operation of powered industrial trucks at no cost and position themselves to transition into higher paying skilled roles. Many participants are eligible to receive hourly compensation for their training.

Bieler added, “With the completion of this program, and all of our upskilling offerings, we strive to equip participants with the skills they need to increase their employability, while also enhancing productivity, engagement and retention for employers. We’re thrilled to have the opportunity

The low profile cabin has been redesigned and the new larger glass doors offer 55 percent more visibility, maximizing safety and improving operator comfort while creating a modern, spacious and ergonomic working environment. Larger displays provide an improved user interface and Sandvik DD322i is compatible with Sandvik’s digital offering, including Sandvik DrillConnect, iSURE®, AutoMine®, OptiMine® and My Sandvik.

Scalable automation packages and tele-remote drilling are available as options for Sandvik DD322i, enabling better drill utilization and continuous working hours over shift changes and during blasting and ventilation hours.

“Sandvik DD322i offers versatility and flexibility, and sets a new standard for automated features in Sandvik’s underground drilling portfolio,” Talasmiemi said. SP

Source: Sandvik

to place upskilled candidates into these difficult-to-fill roles in a way that also pays dividends to their long-term success and professional goals.”

Participants will utilize Raymond Johnston Equipment’s tools to combine hands-on practical training with virtual reality (VR) simulations. The program is compliant with Canadian Standard Association’s Lift Truck Standards, and those who successfully complete the training will be certified as forklift operators by Raymond Johnston Equipment.

Adecco Canada is seeing high demand for forklift operators. These positions feature a variety of unique benefits and perks, including referral bonuses, flexible shift schedules, pay flexibility and career advancement opportunities. SP

Source: Adecco Canada

The award-winning hybrid S-60 FE and electric S-60 DC booms offer increased versatility, productivity and a reduced environmental footprint.

Responding to increasing jobsite regulations and environmental needs, Genie is expanding the availability of its electric S®-60 DC and hybrid S-60 FE boom lifts — the industry’s first lightweight, four-wheel drive electrified telescopic boom lifts in the 60 ft (18 m) height class. Made available in May for customers in Europe, the booms are now also available in North America, Latin America and the Asia Pacific region.

With a working height of 65.1 ft (20 m) and a 61 ft 2 in (18.60 m) platform height, the S-60 FE and S-60 DC rough-terrain electric boom lifts build on the success of Genie’s FE hybrid and DC electric technology to deliver clean, quiet jobsite performance in two versatile models that require less maintenance and have a lower total cost of ownership.

“Genie’s newest electrified boom lifts — the hybrid S-60 FE and electric S-60 DC boom lifts — deliver the reduced emissions and rugged performance modern jobsites need, along with the quality, durability and reliability equipment owners expect from Genie,” says Sean Larin, Genie Global Product Director. “With a best-in-class jib length and a low total cost of ownership, these booms have been well received by the industry.”

Although these booms have only been in the market since May, the S-60 FE and S-60 DC have already garnered industry accolades for their ability to offer performance, versatility and a reduce environmental footprint. In June, the booms were awarded the “Access Equipment of the Year” award at Premios Potencia in Spain. And, in October,

the booms received an Editor’s Choice Award from Rental magazine.

There is an increasing demand on large jobsites for versatile equipment that can work indoors and outdoors, including on rough terrain. The FE and DC versions of Genie’s tried-and-true S-60 telescopic boom solve this problem with machines that can operate in rough terrain and have clean emissions.

With Genie’s “no compromises” hybrid technology, the S-60 FE offers all the performance benefits of a 4x4 diesel machine but also delivers the benefits of a clean, quiet electric boom. The S-60 FE can be used indoors and outdoors and work more than one week on a single tank of fuel. Both the S-60 DC and

the S-60 FE – when run in full electric mode – deliver a full day’s performance on a single battery charge. Additionally, the FE model’s intelligent control system keeps the batteries charged and the machine ready to work by using both regenerative braking technology and automatic engine start and stop. By charging the batteries while the boom works, jobsites can almost entirely eliminate downtime usually caused by plug-in charging.

“These booms can work outdoors in rugged terrain at the beginning of a project, and then move indoors for finish work, meeting multiple end user needs with a single machine. This saves the time, money and hassle of transporting new machines to a jobsite in the middle of a project,” Larin says. “For that reason, rental companies can expect a high utilization rate

and strong returns on their investment.”

Like the S-60 FE, the S-60 DC delivers true four-wheel drive capabilities with four efficient AC electric drive mo-

tors. Additionally, the S-60 DC model offers a low weight of 17,600 lb (7,983 kg) and quiet operation for end users looking for a powerful, all-

Market demand in North America fuels addition of new dealers, new products

One year after launching the brand, McCloskey Environmental’s growth globally is driving its expansion into fast-developing markets, including North America.

The world is facing some major challenges, and North America is no exception. The USA is one of the most developed and technologically advanced countries of the 21st century. However, there is a ways to go to reach the potential of an advanced program of organic and waste recycling. Initiatives like the National Recycling Strategy and the recent announcement of funding for major compost infrastructure development included in a federal funding bill are driving the development of long term solutions and the resulting need for efficient, highly productive equipment to achieve them.

McCloskey Environmental partners with companies that have the expertise to

deliver comprehensive and cost-effective solutions for their customers. Recent appointments for distributors across North America will ensure there is appropriate expertise and support for the full range of products including shredders, trommels, and stackers. Products introduced in 2022, including the ES-250 and ESS-300 shredders, are already assisting in diverting millions of tonnes of waste from landfill, building on McCloskey’s 35+ years of designing and manufacturing industry leading trommels, crushers, screeners and stackers working in a variety of applications.

“Our customer-driven approach to product development has led us to invest significantly in the establishment of this new business unit, focused on the design and manufacture of high-quality recycling equipment,” said Niko Lamminmäki, Head of McCloskey

Environmental. “The products produced by McCloskey Environmental will deliver significant advantages to customers, including lower cost of ownership, lower cost of production, and ease of operation and maintenance.”

It is estimated that more than 12 billion tons of waste is generated each year in the United States. McCloskey Environmental’s commitment to contributing to solutions for this sector is clear as they highlighted new and upcoming products at the USCC Compost Council’s annual event and Demo Day January 24-27, 2023 in Ontario California.

“Municipalities and producers are seeking modern, flexible and cost-effective waste processing solutions. The products developed by McCloskey Environmental will deliver significant advantages to their operations, including lower cost of ownership, lower cost of production, and ease of operation and maintenance.”

All of the above advantages are paired with the need to meet the increasingly stringent regulations being introduced worldwide. McCloskey Environmental is in

the perfect position to provide recycling products and solutions to assist customers in meeting these standards.

Over the past twelve months a team of highly skilled and experienced Design Engineers have developed an impressive

range of smart solutions that achieve higher levels of efficiency than required.

Lamminmäki concludes: “Looking ahead, we are very optimistic about the future of this division and the strong position that we are entering

electric boom.

The FE version weighs 17,750 lb (8,051 kg), just slightly more than the DC version, making either boom ideal for applications where floor loading must be managed.

At the same time, highefficiency AC drive motors on all four wheels provide similar torque as hydraulic drive motors while using 3040% less energy. Four-wheel drive plus electronic traction management and active oscillating axles enable outstanding performance on uneven terrain with 45% gradeability in rough terrain.

A 24.8 hp DPF-free Stage V engine eliminates the need for after-treatment or lowsulphur fuel, reducing the

time and expense of maintenance and repairs while offering instant performance — it takes just seconds to start the engine, delivering instant power and torque when needed. Additionally, maintenance needs are further reduced by a design that has 70% fewer hydraulic components and moving parts.

Key specifications of the S-60 FE/DC include maximum platform height of 61 ft 2 in (18.6 m) and a maximum outreach of 40 ft 6 in (12.3 m), as well as an unrestricted platform capacity of 660 lb (300 kg) on a 6 ft (1.83 m) jib that delivers a 130-degree working range.

A wide range of options and accessories increase the versatility of the S-60 FE or DC for rental applications. The boom lift can be configured with either of two plat-

2023 with. We have an exciting list of products introductions and strong partnership announcements in the coming months for the North American marketplace SP

Source: McCloskeyform configurations. An 8 ft (2.44 m) three-entry with side swing gate is standard, while a 6 ft (1.83 m) dual entry with side swing gate is optional.

Genie Lift Guard™ half and full mesh platform panels, air line and power to platform, work lights, and other accessories are available. In addition, hostile environment kits or cold weather packages are useful for specific applications.

The new S-60 FE and S-60 DC models join Genie’s full boom lift product line offering, which includes the S-60 J for essential performance in a simple machine and the S-65 XC™ (Xtra Capacity™) range for heavy lifting applications with dual-envelope capacities.

With these choices, rental companies can offer their customers the right boom lift option for any jobsite SP

Major players in the compact wheel loaders market are Caterpillar Inc, Deere, Hitachi Construction Machinery Co Ltd, Komatsu Ltd, Volvo AB, CNH Industrial N. V. , Yanmar Holdings Co Ltd, JCB Inc, Kubota Corporation, Case Construction, Larsen & Toubro Limited, Holland Construction, Wacker Neuson Group, Sany Heavy Industry Co. Ltd., and Liugong Machinery Co Ltd.

Reportlinker.com announces the release of the report Compact Wheel Loaders Global Market Report 2022: Ukraine-Russia War Impact

The global compact wheel loaders market is expected to grow from $4.83 billion in 2021 to $5.13 billion in 2022 at a compound annual growth rate (CAGR) of 6.3%.

The Russia-Ukraine war disrupted the chances of global economic recovery from the COVID-19 pandemic, at least in the short term. The war between these two countries has led to economic sanctions on multiple countries, surge in commodity prices, and supply chain disruptions, effecting many markets across the globe. The compact wheel loader market is expected to reach $5.89 billion in 2026 at a CAGR of 3.5%.

The compact wheel load-