UNITING MATERIALS, TECHNOLOGY AND DESIGN

Spotlight on Closets — a Conversation with Industry Giant Eric Marshall

Elevating Spaces — Designer Pulls Double-Duty with Personal Project

Unlocking Plywood’s Potential

UNITING MATERIALS, TECHNOLOGY AND DESIGN

Spotlight on Closets — a Conversation with Industry Giant Eric Marshall

Elevating Spaces — Designer Pulls Double-Duty with Personal Project

Unlocking Plywood’s Potential

richelieu.com

Tel. : 1 800 619-5446 US

AGT’s MDF panels are covered with a superior polymer sheet and offered in a wide variety of rich colors in Glossy Supramat or Soft Touch. Make room for these timeless colors to have aesthetics and elegance in your living spaces! Find the product that suits the design and function your space requires.

Cabinet pulls and knobs come in a variety of styles and finishes that enhance your cabinetry by either standing out or blending in. They also play a key role in showing off your sense of style and personality.

Richelieu makes it easy to create lighting plans that add beauty and value. Brighten kitchens, baths, book shelves, closets and beyond. No one else lights up a room like Richelieu.

04 /

and out of sight

Discover how our innovative solutions can help you maximize space, increase functionality, and keep things organized… without sacrificing comfort or elegance.

From

8 From the President Patrick Adams on how to “make the most of the dash.”

10 From the Editor Jennifer Williams on quantity versus quality.

12 Happenings

Industry news and announcements.

42 Sales & Marketing Are you significant?

44 Human Resources Using AI in HR

68 Ad Index

70 Three Questions with Matthias Bulla, executive vice-president of GRASS USA

• Registration

• AWFS

• NeoCon

An affordable, sleek, modern surface, MIRLUX Premium Panel is available in high gloss and super matte finishes in twelve on-trend colors.

MIRLUX is sustainable, easy-to-clean, durable, scratch-resistant, and manufactured in the United States with short lead times.

Order panels, edgebanding, and doors through a distributor near you.

PRESIDENT/PUBLISHER

Patrick Adams

PH: 714-486-2735

padams@526mediagroup.com

VICE PRESIDENT

Shelly Adams

PUBLISHER EMERITUS

John Aufderhaar

PH: 920-206-1766

john@bedfordfallsmedia.com

MANAGING EDITOR

Jennifer Williams

PH: 714-486-2735

jwilliams@526mediagroup.com

David Koenig, DIRECTOR OF EDITORIAL

Sara Graves, SENIOR EDITOR

GUEST COLUMNISTS

Kevin Gammonley, Amy Gath, David Kahle, Susan Palé

CONTRIBUTORS

Jaime Alvarez

SALES

Nick Kosan

PH: 714-486-2735

nkosan@526mediagroup.com

Chuck Casey

PH: 714-486-2735

ccasey@526mediagroup.com

John Haugh

PH: 714-486-2735

jhaugh@526mediagroup.com

GRAPHIC DESIGN

Dara Fowler

DIGITAL SUPPORT

Alekxandr Olson

aolson@526mediagroup.com

CIRCULATION/SUPPORT

PH: 714-486-2735

info@526mediagroup.com

526 MEDIA GROUP 151 Kalmus Drive, Ste. E200 Costa Mesa, CA 92626

PH: 714-486-2735

Surface & Panel is published quarterly by 526 Media Group, 151 Kalmus Drive, Ste. E200, Costa Mesa, CA 92626,

High quality finishes on MONARC composite wall panels for interior design solutions such as feature walls, backsplashes, shower surrounds, lobbies & entryways, retail spaces and more. Premium properties of MONARC ensure an extremely flat, light weight, waterproof panel that offers easy installation & delivers a striking visual appearance inspired by natural elements such as marble, wood, tile, and other variations of stone & metal.

For more information or to order samples, scan QR code with mobile camera or email us: info.usa@3acomposites.com

I’VE HAD MANY calls in the middle of the night, and none of them were good. When the phone rang this evening, I knew it wasn’t good news, I just didn’t know how bad. A good friend’s youngest daughter had been killed.

She was just 17 years old, driving with her boyfriend returning from his high school graduation party. There was no alcohol, or drugs. There was no distracted driving while texting on a phone. In fact, he was driving, she was a passenger, and his younger sister was in the back seat while his parents followed in another car. A red light was run by another vehicle and in a second, many lives changed forever. I’ve always taken a weird comfort in bad situations in being able to assess, learn and tell myself, “This is what could have been done differently to change the outcome.” This was not one of those situations because it was a reminder of the stark reality that sometimes, horrible things just happen that are outside of our control.

It shouldn’t matter, but when I say this family is special, it’s an understatement. The parents are amazing in every way … the type of people that make everyone around them better, and happier simply because they are around. All three of their kids are amazing, strong, competitive, kind and funny. But their youngest was truly something amazing.

She was smart and kind, funny and beautiful, competitive and strong. She wore her heart on her sleeve and was never afraid to speak her mind. She was ferociously loyal, stuck up for her friends and the “little guy,” and loved her family.

As I heard the words that she was gone, a million thoughts raced through my mind and yet, there wasn’t a word that seemed appropriate to say, so I sat speechless. Finally, I just said, “I love you, brother.” With that, the call was over and the flood of thoughts began. About me, about my family and friends, and about whether I’m still living with the knowledge that every day is a gift and we’re not assured another chance to say what needs to be said.

I learned as a child, and throughout my adult life, that our time is not a guarantee. Each day is a gift and frankly, I never expected to be around this long. I give thanks every morning I wake up, and every evening before I go to sleep. I give thanks that my family is safe and healthy for another day. But, I think it’s human nature to take our lives for granted.

How many times have we left the house either mad or in a rush? Maybe not taken the time for that extra hug or to sincerely share how much people mean to you before you depart? Maybe put off that call, or visit to a longtime friend or family member? If I told you that today was the last day of your life, what would you say, and to whom?

As we attended her Celebration of Life, I was not surprised that it was being held at her high school gymnasium, as she was a talented athlete who was ferociously competitive and cared about her team.

As I looked around, I can almost promise that this gym had never held so many people. It was standing room only. As person after person stood and shared stories of her, it felt more like this day belonged to someone in their senior years. Funny stories, mixed with testimony of how much she impacted lives filled the room over and over again. Each person had their own, amazing experience with her that was somehow all packed into her short 17 years.

While I sat there filled with emotions of heartbreak for my friends having to go on without their amazing daughter, something that was shared with me in my youth came to mind. I was about to start a career and someone who became a mentor said, “Your life is made up of two dates, and a dash. Make the most of the dash.” That was it. On someone in their twenties, it wasn’t as meaningful as it is now. In just 17 short years, she filled that dash with a LOT! She impacted countless people and created a legacy that will live on for far more years than the short few that she was with us.

I could go on, but I hope by now you are thinking not just of your own life, but of those you care most about and questioning, “Do they know how I feel about them? Have I left anything unsaid? Have I done everything I’ve wanted and if my time came, would I pass without regret?” This is what I’ve thought about almost non-stop since that phone call; that our time is short and tomorrow is not a promise. Imagine if you could wake up reminded of this every day, and live your life knowing that not only are you living your fullest life, but also saying and doing everything in your heart with those who mean the most to you?

As I’ve shared in other stories, it’s simple, but not easy. However, some things are worth it and it took my friend’s heartbreaking tragedy to remind me that we should not take the gift of tomorrow for granted. Take an extra minute and give them a hug, or a call, or send an email.

Thank you for the honor of serving you and this great industry. I am humbled by your dedication and support of what we do, as well as allowing me to share my thoughts with you each month. I hope you all have a wonderful summer, building on the legacy of your “dash.”

Patrick Adams, President 526 Media Group, Inc.

�I learned as a child, and throughout my adult life, that our time is not a guarantee.�

It’s a common question in the building industry and many others — should you go for quantity or quality? It also can apply to many different things in life.

When I was younger, I loved shopping — especially for clothes. The more clothes I had to choose from, the better. I would shop sales and collect things I loved. But at some point, I ran out of room for all these amazing deals and needed to start editing my stuff…and figuring out the best way to store it.

In the weeding-out process I found that I gravitated not towards my (vast) collection of trendy and dated items, but preferred instead my “good” items — well-made classics I can mix and match for work and other occasions.

But inevitably, I would collect more of the “good stuff” and still needed places to put it. Cue my woodworking husband, who was tasked with creating closet systems to help keep me organized.

The past few decades have seen the explosive growth of closet and organizing systems, and I was fortunate enough to speak with one of the closet industry’s pioneers at the recent AWFS Fair in Las Vegas.

Closet Guru Eric Marshall held an education session on the Live stage on the AWFS show floor. I attended several of these sessions, but one thing was for sure — his was the bestattended that I saw. This guy knows what he’s talking about.

We sat down the next day and talked at length about all things closets — I even shared a few accessory ideas my husband fabricated for me in my current closet. You can read more from our conversation on page 16.

While talking, Marshall would greet friends and fellow closet connoisseurs. One gentleman remarked how he thought there

wasn’t as much foot traffic at this year’s show, but Marshall was quick to respond.

“When I see people like you here, I know that the right people — owners of companies — are walking through, and that's all they need,” said Marshall. “There’s not as many large companies but there are way more small booths and vendors, which is great!”

He gets it. Sometimes, it’s more about the quality than the quantity.

Jennifer Williams, Managing EditorBut inevitably, I would collect more of the “good stuff” and still needed places to put it.

Don’t make things complicated; simplify your operations with ZBOX. ZBOX drawers assemble in two minutes or less with the same quality and durability as traditional methods but in a fraction of the time. ZBOX steel sides and integrated ball-bearing slides meet the architectural specs required of industrial case goods. It’s the perfect balance of engineering, performance, and economy. Save time. Save money. Reduce complexity. Life just got easier with ZBOX

CAN BE COMPLICATED CABINETRY SHOULDN’T BE

Independent showrooms play a critically important role in the kitchen and bath industry’s supply chain, according to NKBA’s 2023 Independent Kitchen and Bath Showrooms Report.

Representing multiple K&B product brands, showrooms serve as a conduit between manufacturers and those who purchase their products — whether they are designers, remodelers, builders or consumers.

Recognizing their importance to the industry, NKBA conducted a thorough research study to provide insights into the role of showrooms in the K&B industry today. And they are going strong, according to the research.

In fact, this sector of the kitchen and bath industry has seen steady sales over the last two years, with most showrooms surveyed predicting strong and steady growth for the immediate future as

well. The report surveyed a broad base of the NKBA membership community, including independent showroom dealers and designers and homeowners who had completed a full-scale kitchen or bath remodel in the past two years.

The top concerns of dealers and designers are issues outside their control. They reported high levels of concern regarding supply chain/ product availability, recession, inflation and labor shortages. Among showrooms, the top internal challenges they faced were keeping their products current and attracting visitors.

While the NKBA Research Team expected that "competition from e-commerce" would have ranked higher, they learned from this research that consumers who are remodeling their kitchens or baths place a high value on seeing and touching products before they purchase them.

Showrooms seem to recognize that they need to continually evolve to service the needs of their customers and stand out among their competition. Many showrooms have been making big changes. In the past two years, 65% have carried new or additional brands, 53% have significantly remodeled their showroom, and 40% have added product categories. Within the next two years, four in 10 showrooms will be carrying new brands or remodeling their space.

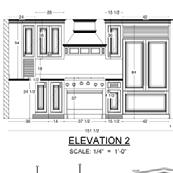

Showrooms are also turning to technology to improve their customers’ shopping experience as well as their own operating efficiencies. It is particularly noteworthy that 50% of dealers have added new technology to their showrooms in the past two years, and 35% are planning to either continue or follow suit in the next two years. Enhanced monitors and displays are the most frequently mentioned enhancement in terms of customer-facing technology, and updated design software and hardware tops the list in terms of operational technology. n

While the NKBA Research Team expected that �competition from e-commerce” would have ranked higher, they learned from this research that consumers who are remodeling their kitchens or baths place a high value on seeing and touching products before they purchase them.

With strong industry partnerships, a commitment to sustainability, and an eye for biophilic design, we aim to enhance your business and the health of the planet. As North America's leading distributor and importer of hardwood lumber, specialty softwoods, and panel products, we are proud to partner with you to build unique solutions for the market.

What you need. When you need it. By people that know and care.

www.ucfp.com www.sierrafp.com

SURTECO North America has recently announced important changes to its North American leadership structure. These changes come as the company continues to move forward with its recent acquisition of the operating assets of the OMNOVA Solutions, Inc’s., films and laminates business and its coated fabrics business.

SURTECO is pleased to name Lawrence (Larry) Schorr as Co-Chair of SURTECO North America, who together with Wolfgang Moyses, Group CEO of SURTECO, will guide the company forward. Previously NonExecutive Chairman of the SURTECO North American Board of Directors, Mr. Schorr provides critical strategic leadership and extensive knowledge and direction to the management group.

Terry Hemmelgarn will become CEO of SURTECO North America, including the OMNOVA films and laminates division, effective January 1, 2024. Mr. Hemmelgarn joined the organization post-acquisition as CEO of OMNOVA and has played a key leadership role in the successful integration of the two companies.

As part of this leadership transition, Mike Phillips will be retiring as CEO from SURTECO North America at the end of this year. Mr. Phillips has been with the organization for over 35 years and is credited with developing SURTECO’s professional and team-focused culture which continues to drive both business success and lasting industry relationships.

Rodney Cuevas will continue to be CEO of OMNOVA Engineered

Construction of Accoya USA’s new 100,000-square-foot U.S manufacturing facility continues to progress and is on track to start operations in mid-2024. Progress to date includes completing ground works, ongoing steelwork, main warehouse construction, placement of multiple large sub-contracts, and procurement of more than 80 percent of major equipment.

The reactors, essential for the wood acetylation process, arrived in May and were successfully installed at the new Kingsport, TN, facility. Accoya, the ultra-high performance sustainable wood, broke ground on its first U.S. manufacturing facility in June 2022. The plant is a joint venture between Accsys, the only acetylated wood producer in the world, and Eastman, a global specialty materials company. As part of the joint venture, Accsys leverages Eastman’s world-class acetyl production capabilities to produce its Accoya wood products.

Services (Thailand), Inc and the global coated fabrics business of SURTECO.

Wolfgang Moyses, Group CEO, stated, “I would first like to thank Mike Phillips for his many years of dedicated, loyal, and successful leadership of our business in North America. His broad and deep relationships in the industry are unmatched and we hope that he will continue to provide guidance and advice to our new team in the years ahead as special advisor to the office of chairman and a board member of SURTECO North America.”

Moyses further commented, “Terry Hemmelgarn brings a long history of success in managing larger organizational entities and has also developed a strong and successful relationship with customers, suppliers and associates in the films and laminates business. In these difficult and unpredictable macroeconomic times, we will rely on his leadership to both weather the storm and grow the business.”

Lastly, Moyses said, “I have had many years of successfully working with Larry Schorr and as a Co-Chair of SURTECO North America, he will allow me to focus more attention on the many challenging issues we face in Europe and Asia.”

As the company perfects and grows the leadership structure of SURTECO North America, the company believes it is well-positioned to lead the industry forward in terms of design, customer service, best-in-class manufacturing, and team dynamics. With an experienced and enthusiastic leadership team in place, we are confident that our customers will continue to receive excellent service and innovative products throughout the coming years. n

“The reactors represent a major milestone in our construction process here in the U.S.,” said Rod Graf, general manager of Accoya USA. “The arrival of the reactors was significant for the community, closing roads—due to the size—to make way to the facility’s location.”

North America represents the largest potential regional market for Accoya, and the new plant will ensure a ready supply of Accoya to the U.S. market. Once operational, the Kingsport facility will only supply the North American market, representing an additional 67 percent increase in capacity compared to 2022 volumes worldwide.

The company combines chemistry, technology, and ingenuity to make high performance wood products that are extremely durable and stable, opening new opportunities for the built environment and giving the world a choice to build sustainably. n

Visit

ANCA is proud to announce the appointment of Edmund Boland as the new General Manager of ANCA CNC Machines. Edmund is the son of ANCA co-founder Pat Boland and brings an impressive 15-year tenure at ANCA.

“When Pat McCluskey and I founded ANCA, our primary goal was to design the best technology that solves real customer problems,” says Pat Boland. “I am proud that my son has joined this mission and has accepted this important leadership role in the business to continue fostering a culture of innovation.”

ANCA is a privately owned business and proud of its reputation for being first to market with technology that has proven time and again to revolutionize the cutting tool industry. Celebrating its 50th anniversary next year, Pat McCluskey, ANCA co-founder comments that “being privately owned brings great benefits as it means that we can focus on investing and developing new innovations while maintaining our long-term view of the market to design products with longevity and customer focus.”

Edmund Boland says he is honored and thrilled to be a part of ANCA CNC Machines. “[It is] such an exciting company in the cutting tool industry,” he says. “Every day, I am amazed by the skill and prowess of our customers, who continue to push the entire industry forward. ANCA is in my blood, and our commitment to innovation is unparalleled. Throughout our extensive history, we have consistently been the first to market with new technology, investing over 15% of our revenue every year into research and development.

“Technology is truly in our DNA. For example, ANCA’s Integrated Manufacturing System (AIMS) is one of our latest products [that] could be considered akin to the impact of a printing press, and is set to revolutionize the cutting tool industry. I am excited to lead ANCA into a future of continued innovation, growth, and success, while educating the market about the transformative power of our new nanometer control system and ensuring the success of our internal investments such as in our machine shop or our sub-micron metrology equipment.

“We take pride in hosting the only customer competition in our field, the ANCA Tool of the Year, and I am particularly excited that this year we will have a new category of Female Machinist of the Year. Together, these, and many other initiatives will contribute to the continuous growth and prosperity of our esteemed company."

Edmund's journey at ANCA began in February 2008, and throughout his career with the company, he has held key positions in the finance, operations, strategy, regional management and applications teams. This diverse experience has afforded him a deep understanding of ANCA's operations and a comprehensive perspective on the company's strategic goals.

Prior to assuming his new role as General Manager, Boland led ANCA's European Branch with remarkable success during the unparalleled challenges presented by the COVID-19 pandemic. His exceptional leadership and strategic vision enabled ANCA to

navigate through this disruptive period while ensuring uninterrupted supply of high-quality CNC machines to customers worldwide.

As General Manager, Boland eagerly looks forward to collaborating with the talented team at ANCA to address the challenges and seize the opportunities presented by the current global environment.

Boland's exceptional expertise and leadership make ANCA CNC Machines wellpositioned to further solidify its position as a global leader in CNC machines. His strategic direction and unwavering commitment to excellence will drive innovation, enhance customer satisfaction, and foster overall company growth.

ANCA CNC Machines extends its warmest congratulations to Edmund Boland on his new role as General Manager, marking 15 years of dedicated service and expertise. The company looks forward to a bright future under his guidance and leadership. n

Eric Marshall knows a thing or two about closets.

As a junior in high school, he became the first employee of Neil Balter, founder of California Closets and Organizers Direct in 1979. Despite a saw accident his very first day on the job, Marshall persevered and learned all about closets—and has continued to evolve with the closet industry over the past 44 years.

BY JENNIFER WILLIAMS“Just in the past five years, the closet industry has gone crazy,” says the cancer survivor who has served as President and/or board member for the Association of Closet and Storage Professionals (ACSP). “California

CLOSETS ARE BOOMING WHILE OTHER HOME RENOVATION PROJECTS ARE STAGNANT OR IN DECLINE.

Closet guru Eric Marshall tells us why — and why more companies should get into the closet business.

LEFT: STORE, HANG, PROTECT, CONTAIN, PULL OUT. CLOSETS HAVE BECOME A POPULAR DESIGN ELEMENT IN THE HOME. HERE, SALICE’S EXCESSORIES COLLECTION OFFERS A VARIETY OF SOLUTIONS DESIGNED TO OPTIMIZE SPACE AND TO FACILITATE THE PERFECT ARRANGEMENT OF WARDROBE INTERIOR FITTINGS, OFFERING INFINITE POSSIBILITIES OF EXQUISITE STYLE AND CONVENIENCE. PHOTO FROM SALICE BELOW: ERIC MARSHALL HAS BEEN DESIGNING AND INSTALLING CLOSETS FOR MORE THAN 40 YEARS. HE MAINTAINS THAT EVERYTHING HAVING A PLACE MAKES FOR MORE EFFICIENT USAGE OF SPACE. PHOTO COURTESY OF ERIC MARSHALL

Closets in Philadelphia recently had me out and told me that two years ago, they were doing about $15 million a year in business. This year, they’re on track to do $30 million.”

“So, if you're not in the closet industry…this is probably a good reason you should get in it — the growth chart is unheard of in an industry,” says Marshall. “And we haven't scratched the surface of what's going on in closets today…growth opportunities are still available.”

The Global Pandemic that stifled many industries actually benefitted the closet industry, he says. “People started working from home — we all remember that — the longer they stayed home,

they more they realized, ‘I need a home office;’ the longer they stayed the more they realized, ‘Oh my kids are moving back in I need more beds… more office… more garage cabinets…’ the longer they stayed in the home the more they discovered that maybe they need a Murphy bed because maybe their kids were moving in and out.”

And there’s not just room for the large companies in this multibillion-dollar industry, says Marshall. “You've heard the saying, ‘a rising tide rises all ships’…welcome to the closet industry,” he says. “That's what's going on right now — we're rising and the more people that start doing this, the more will rise with it.”

To learn the business, Marshall says you can attend trade shows and talk to people, but franchises are not going to teach you unless you buy one. “You can also start your own business, and this is where I can come in to help,” he says.

After venturing on his own in 1997, Marshall founded Modern Closets and Garage and later opened DEA Kitchen Remodeling in 2015. Today, Marshall runs the Closet Training Institute out of Scottsdale, Arizona, where he hosts training and consulting sessions on how to grow your closet business. He also travels around the country, speaking and helping companies get their closet systems on track.

• Hamper

• Valet

• Belt Rack

• Scarf Rack

• Jewelry Tray

‹ CONTINUED FROM PAGE 17

“You can come for 2-5 days and get educated on how to do a closet organizer, from installation, which is different, to design — toes out, pants on top and never put anything folded in a drawer — those are my three rules,” says Marshall.

“My whole goal is to help people be more successful in life,” he adds. “I am now 100 percent about building the closet industry.”

And while home remodels have leveled off over the past year or so, closet remodels have continued their upward trajectory, he says. “Why do you think closet remodels are on the rise?” he asks. “Because they're affordable. They're easy.”

“What is happening now with the higher interest rates…people don’t want to take out a $100,000 loan to redo their kitchen,” says Marshall, who says that’s the average cost of a kitchen remodel today. “Instead, people are more interested in remodeling smaller spaces. What's that mean? Closet companies right? Kitchen cabinet companies don't benefit from this, but somebody who could make a mud room with TFL cut on their CNC machine… you're benefiting.”

The average cost of a closet remodel is about $7,500, says Marshall. “That’s more doable for a majority of consumers,” he says. “Plus, a kitchen or other large remodel can take months, even years to finish, while some closet companies can be in and out in a day — instant gratification.”

Marshall says that closet companies, most of which use TFL

for their systems, get their materials from right here in America, alleviating the lingering supply chain worries. And from a business side, the closet companies can charge more per board foot than other industries.

“When you sell a shelf, there’s value in it,” he says. “Board square foot in closets is valued way more than any other board in your home — and there’s a lot of them! This is an 'I want that' purchase, so we can ask more money — closet people are making more than carpenters these days. Most of us in the closet industry are selling each board foot at 4-5 times cost… people ask why are they charging that much — and I say, why aren’t you charging more? Cause it’s adding value — it goes back to ‘she wants it, she gets it.’ There’s a huge value in that.”

“So the real question is, why are builders not doing this?” asks Marshall. “Why are we not in the builder market? I mean, It’s really interesting…until some builders start putting good, functional closets in every single house they sell, we haven't done our job.”

“Doesn’t every house get a toilet paper holder?” he asks. “Do you use your closet more than you use the toilet paper holder? I mean, every house gets a kitchen…they all get doors and then you get a crap closet that’s not useful. Do they make dysfunctional kitchens? No!”

“But just let them keep doing it wrong so we can keep tearing it out and making that space more usable,” he adds. “But going forward, we need to get in the door — we need to knock on that door and break it down and tell them they need new closets.”

CONTINUED ON PAGE 20 ›

At Daubert, our belief in lasting bonds begins with our commitment to your success. Whether that means developing a custom formulation that'll keep your product together, or traveling cross-country to learn about your challenges in depth, you are our only focus. We've thrived since 1935, not because we're the biggest adhesives company (we're not), but because we make your success the focus of everything we do, and the results speak for themselves.

‹ CONTINUED FROM PAGE 18

“We’re selling a lifestyle. We’re selling a change in what happens through the process of organizing your stuff,” he says. “Organizing your clothing makes time savers happen. I can put all my stuff away and can see what I have. That’s huge!”

“Movies, television shows, social media…people see cool closets and they want one,” he says. “It’s helping to drive the industry, along with the fashion industry. People have been stuck inside for too many years and they now are out there, looking for what’s new.”

Marshall says new options in closet design are changing the game and making redesigns more attractive. “The new lighting we’re using is flexible, and they make a switch for it you can have right on your nightstand. In some sense, you can be looking at your closet considering what you’re going to wear while you’re lying in bed in the morning, waking up.”

And while TFL remains the most popular material used in closet designs today, there are a “crazy” number of colors and designs available, he says. “Because this industry is so competitive, people jump in and try to come up with these new ideas,” explains Marshall. “But TFL is one of those things that just works…and while the offerings of colors, textures, edgebanding are out of control, 80 percent of new closet designs are white. It’s the most reflective color and does show your clothes really well. Browns are also big these days. We are also seeing a lot of warmer colors, like rojo, reds, yellows that are being used as accents.”

“A lot of the materials we have today — you have to look really closely and a lot of times, you still cannot tell if it’s ‘real’ wood or not,” he says. “And these materials are incredibly durable and sustainable, so it’s a win-win.

But closets encompass so much more these days, says Marshall. “We’re no longer just talking about the closets in your bedroom,” he says. “It’s mudrooms, pantries, garage cabinets, home offices, wall beds — can make all these spaces function better for my lifestyle. Closet companies can actually come to your house, measure for you and custom design for your particular space. What’s easier than that?”

“Closet Maid does a study every year — it's all about home sales, since Closet Maid is big into new

“... if you're not in the closet industry … this is probably a good reason you should get in it — the growth chart is unheard of in an industry.”

— ERIC MARSHALLABOVE: ERIC MARSHALL SAYS THAT WHEN YOU CAN SEE WHAT YOU HAVE IN A CLOSET, IT MAKES FOR NOT ONLY A BEAUTIFUL SPACE, BUT SAVES TIME AS WELL. PHOTO COURTESY OF ERIC MARSHALL

construction with the bulk of their business being wire shelving — that's what they do,” says Marshall. “For the past 20 years, they have asked what consumers look for in a new home. For 19 years, the study found that a women looks first at the kitchen and then at the closets. This past year, the study found that the woman looked at storage (closets) first, and then goes to the kitchen. We’ve finally come of age — we're finally playing!”

The internet and social media are full of organization tips and tricks and hacks, he says. “The market, the opportunity for further growth…it’s there. It’s ripe for the picking,” he says. “For example, Modular Closets are all over the Internet. If you're not following them and you're a competitive company not already following them, find Modular Closets on your Instagram and start following them because they're doing crazy stuff right now. They’re doing full high rises. They’re shipping closets in the box that people that are installing themselves and their influencers are pretty good.”

And while Marshall has seen many changes in closets over the past four decades, he says one thing has remained constant. “I can

Versatile: Whether you work with plastic sheets, custom cabinets, furniture, MDF doors/drawer fronts, or non-ferrous metals, the Model 43 can handle it all.

High-quality: Made from fully stress-relieved structured steel, the Model 43 boasts topof-the-line features such as Siemens drives, THK rails, and three-dimensional volumetric position compensation.

Expandable: Designed for ease of use and expandability, the Model 43 can grow with your business and adapt to your changing needs.

Three varieties: The Model 43 comes in three varieties - the Multi-Purpose 43, Cut Ready 43, and the CabinetShop 43 - so you can choose the perfect fit for your needs and budget.

still remember the dimensions of the closets we did 40 years ago,” he says. “By the way, we didn’t have drawers…no belt racks no tie racks no adjustability. Walk-in closets weren’t even really around yet. We used raw particle board and sanded the edges… the only thing that's still true today about the original closet that we did is the standard panel is still 14 inches deep today.”

“And while it's kind of the same closet — it does the same thing — but the features are different,” he says. “We still have long hangers and double hangers women are still gonna wear dresses; we still have drawers we still use all those things… but it's different in the choices available. Tiebacks have gone from chrome to gold, handles have gone from really small to quite large. There are so many choices for everything these days.”

The closet industry actually puts people who wouldn’t normally be in the woodworking industry in the woodworking industry,”

he says. “It doesn’t take a crazy amount of time to train and learn the business, and once you train people to design and create closets, within 4-5 years, they can be making six digits. We also are seeing more women get involved, which is important to me because there is such a gap in the industry. Closets provide a huge opportunity for women to jump into this place and start making money.”

Another key selling point for closet renovations are that closets are American made, says Marshall. “I don't know anybody that's importing closets at all. They might be importing Italian melamine, or they might have components that come from Germany, but guess what — they cut it and make it here in America.”

“So, people ask me all the time...why closets?” he says. “Because organization is really big right now; working from home remains popular; full remodeling costs can be prohibitive… that's why closets are gold.” s p

Ultrapan is a U.S. manufacturer of superior, customizable Ultra-HighGloss and Ultra-Matte laminated panels. Our radiant finishes are perfectly suited for the contemporary lifestyle that embodies clean yet stylish looks for kitchens, furniture, displays, and myriad other residential, commercial and institutional applications.

Ultrapan PET and acrylic laminates feature highly durable decorative surfaces with excellent resistance to stains, scratches and harmful UV rays. These eco-friendly products are also easy to clean and maintain.

• The Ultrapan collection features more than 60 surface options including solid and woodgrain designs; pearlescent and metallic finishes; and deep emboss textures.

• Our wide selection of in-stock panel options includes cores made from particleboard, standard MDF, lite MDF, fire-retardant MDF, moisture-resistant NAF MDF, exteriorgrade MDF, and hardwood plywood. We offer panels from ¼" to 1½" thick in 4x8 or 4x10 sizes.

• Matching edge-banding, including 15/16" and 1-3/4" widths, are available in stock for most of our designs. Custom widths can be produced by special order in gloss or super matte.

• Anti-fingerprint (AFP) coatings are standard on all Ultra-Matte surfaces.

• Our expanded metallics collection is available on 4x10 as well as 4x8 panels.

• Our quick-ship program features the same color laminated on both sides of ¾" 4x8 MDF panels.

• We inventory a variety of substrate types and sizes to support our ready-for-production program.

• Special orders don’t upset us. Contact us to discuss your requirements.

Check out our website—ultrapan.net—to learn how Ultrapan modern finishes can add a superior elegance to your home, office or storefront.

Contact us about our Distributor Network at up@glosspanels.com

fter spending more than half of the pandemic living and working in a 940-square foot condo with his family, John McClain realized he needed more space to do it all.

So the creative director and CEO of John McClain Design began looking for a space with multifunctional potential that checked important boxes: more space, more design potential, and a home where he could incorporate his eponymous design office.

“I took it as my opportunity to design, feature, and showcase my love of lux materials and undiluted design vision,” he says. “It was a place where I could really bring my vision to life.”

After months of searching, McClain found a series of new homes that were being built by a Los Angeles builder in the San Fernando Valley suburb of North Hollywood. The all-too-common cookie cutter interiors did not faze McClain, who looked past the sameness and saw the opportunity to put his design stamp on a larger home that checked all the boxes. “It was too good to pass up,” he says.

McClain loved the first level of the four-level home, with its separate entrance that easily could be converted

into his new Los Angeles office. And while the home was full of plainness — buildergrade white walls, cabinetry and light fixtures — McClain was not deterred. “I saw it as a blank canvas for me to really create exactly what I wanted.”

He recalls the walkthrough before the final closing, when the builder was showing the various fixtures and finishes throughout. “I stopped him and said, ‘Let me spare you the sales pitch, this entire kitchen will be gutted shortly after we move in.’”

True to his word, soon after he closed on the house, McClain went about removing the things he did not like and replacing them with what he loves.

Fast forward to the home today. All new wood flooring was added throughout the entire four levels of this “Modern Loft Bungalow,” with every wall, stair rail, and ceiling sanded and repainted, and loads of design details were added to truly make this home the couples’ cup of tea.

McClain knew he needed something to add a dramatic focal point to the living room while also bridging the wall space from the living room to the loft above, and this custom porcelain slab and leather fireplace was the key. McClain’s love of simplistic but impactful shapes is evident in the fireplace design while also an ode to his love of Mid-Century and Art Deco genres.

The fireplace insert itself is actually water vapor mist; and McClain added selenite logs to create a one-of-a-kind fireplace. The fireplace ledge is cantilevered on the left and extends across to the adjacent wall on the right for additional living room seating.

In the center of the room is a bespoke Industrial glam chandelier that also is easily seen from both the living room and the loft.

As you make your way into the kitchen, McClain’s take on a waterfall edge is the angular countertop material backed by brass on the end of the peninsula. “This detail really emphasizes my love of geometry, mixed metals and drama,” he says.

The countertops themselves are actually large-scale porcelain slabs that very realistically resemble real marble through the manufacturing process. In fact, the countertop was the very first selected for the house, says McClain. “It was love at first sight when I spotted these slabs across the stone yard. I knew I had to have them. When I learned the slabs were porcelain, I was doubly pleased. Not only are they overwhelmingly beautiful but also the pinnacle of practicality. I don’t have to worry about placing a hot pan on the counter or surface stains.”

In fact, McClain says he likes to scare his guests by placing a hot pan directly from the oven onto the countertop, only to demonstrate how truly durable it is.

“We have witnessed the full evolution of countertop materials in my lifetime,” he says. “We have seen butcher block or tile turn to laminate, Corian, granite, quartz and now porcelain slab. Each evolutionary step has improved upon the last and as technology and availability advance, so too does the selection and number of brands to choose from.”

“Over the last several years we have seen the large format tile trend explode,” explains McClain. “At this year’s Coverings convention, it seemed a veritable contest as to who could manufacture the largest possible slab. The variety of vendors and designs has also increased exponentially. We saw traditional marble patterns, floral designs, metal inlays and lots of texture. Clients have been very accepting and excited towards this trend as it offers both stunning aesthetics and incredible durability.”

“The lack of grout lines is also an added plus,” he continues. “Our greatest challenge with this trend has been finding fabricators and installers willing to work with this material. Many fabricators do not have the proper equipment, procedures, or knowledge to work with large-format porcelain. Many installers are reluctant to work with any tile larger than 48x48 due to its weight and the requirement for extra workers on the job. We hope as the products gain in popularity and momentum additional companies will adapt and educate their trades to work with this material.”

“We find the type of material selected for the kitchen counter tops often dictates the quality of finishes elsewhere in the home. While granite countertops may have been a high-end selling feature 20 years ago, today we are tearing them out due to preference towards quartz or porcelain slab. While there is still a faction of our clientele who prefer the beauty and uniqueness of natural stone, we do our best to educate our clients on the benefits and challenges of each material type. Marble can be soft and susceptible to pitting and stains. Quartz is highly stain-resistant but cannot be used in high heat situations. Porcelain is both stain- and heatresistant, but there are fewer fabricators familiar working with this product.”

The home’s cabinetry is a fresh take on the Shaker style with smaller-scale door fronts. The refrigerator wall is clad with a charcoal-stained veneer wood

CONTINUED ON PAGE 28 ›

“I took it as my opportunity to design, feature, and showcase my love of lux materials and undiluted design vision. It was a place where I could really bring my vision to life.”

that also extends around the corner of the kitchen to create an architecturally pleasing design and balance. It is also a trick to the eye to make the kitchen feel larger. The upper and lower cabinets each received different hardware with brass pulls on the bottom and black knobs on the top.

McClain says that paneled walls and surfaces have come a long way, and are being sought out in higher-end projects today for their luxurious and state-of-the-art materials and finishes. “This almost always includes paneling the appliances and creating practically seamless counter tops and back splashes,” he explains. “Very often, in lieu of selecting a contrasting backsplash tile, we create a selfsplash, continuing the countertop material up the walls to produce a unified and dramatic effect.”

“Wood paneling walls have also increased in popularity,” adds McClain. “This is not your grandpa’s den paneling from the 1970s but rather a modern and sleek interpretation, adding texture and interest to your space. The “shiplap” trend of a few years ago may have kick started the creation of new ideas when it comes to paneling. This was quickly followed by wallcoverings made of paper-thin wood veneers in precise patterns, a variety of applied moldings, and the current tambour wood craze we are currently seeing. We predict this trend will advance via large format veneers either book matched much like marble or paneling applied to the walls in Mondrian-like geometric patterns.”

Making our way up to the loft, McClain explains that he designed this space to be a throwback to the swanky lounges of the past. Reds, oranges, golds, and even blues play together to

FAR LEFT: MCCLAIN’S DESIGN DOESN’T STOP ON THE INTERIOR OF HIS HOME. THE PATIO OFF OF THE LOFT PROVIDES A PANELED PRIVACY SCREEN AND TOUCHES THAT REFLECT HIS STYLE WHILE EMBRACING THE OUTDOORS.

LEFT: PANELED WALLS AND SURFACES HAVE COME A LONG WAY, SAYS MCCLAIN, AND ARE BEING SOUGHT OUT IN HIGHEREND PROJECTS TODAY FOR THEIR LUXURIOUS AND STATE-OF-THE-ART MATERIALS AND FINISHES.

make this color-filled, patterned space unique. Custom cabinetry brings the kitchen design upstairs (both spaces are visible from the living room) while also housing a refrigerator and icemaker for easy cocktails.

The play on pattern starts at the fully draped wall that not only adds softness and drama, but also camouflages the slider that leads to a patio just off of the loft. The custom hide area rug is a cousin to the drapery panels in color, but instead features small squares and rectangles, overlapping circles made of sustainably sourced cowhides are used. A classic dark red leather chesterfield sofa brings the throwback feel home.

McClain took the opportunity to purposefully combine his home and office in California, using materials and ideas he loves. “In the end, I wanted to create a stunning and cohesive collection throughout the space,” he says. “One that my family and guests find thoroughly comforting and pleasant.” s p

John McClain is the creative director and CEO of John McClain Design, a residential and commercial design firm with offices in California and Florida. He is an associate with ASID and a member of NKBA. He is the author of the book The Designer Within, available on his website and Amazon. McClain also hosts The Designer Within podcast and blogs about design issues on his website: johnmmclaindesign.com

uniboard.com

COLLECTION

As the world becomes increasingly aware of the need for sustainable practices, many architects and designers are taking steps to reduce their environmental impact. However, one of the major challenges they face is finding a solution that is both sustainably produced and suitable for each unique project. While traditional building materials like hardwood and concrete have their merits, an often overlooked but increasingly popular choice among designers, architects and suppliers is plywood. Offering a remarkable blend of versatility and adaptability, plywood offers limitless possibilities beyond the realm of conventional applications.

Plywood has earned a reputation for its reliability in industrial applications, especially with regards to fire safety. Traditional hardwood, if not treated, can be dangerous in industrial settings

ABOVE: WITH GROWING TECHNOLOGICAL INNOVATIONS COUPLED WITH AN INCREASING WORLDWIDE COMMITMENT TO SUSTAINABILITY, E-BIKES ARE NOW BECOMING AN INTEGRAL MODE OF TRANSPORTATION AROUND THE WORLD. THIS INNOVATIVE E-BIKE FEATURES A PLYWOOD BASE WHICH IS BOTH LIGHTWEIGHT AND DURABLE.

as it is highly flammable, but plywood veneers can be individually soaked in a fire-retardant solution and then glued and compressed making them uniquely fire-resistant and effectively safeguarding a variety of applications, including elevator interiors. High-rise buildings are becoming commonplace in urban settings which means the demand for elevators is growing in tandem. The risk of electrical and mechanical malfunctions cannot be overstated, and it is essential to take every precaution to avoid potential hazards including fires. Architects, builders and suppliers are increasingly relying on fire-rated plywood panels to ensure the safest possible elevator designs.

In addition to its durability and strength, plywood is extremely lightweight, meaning it can be used in the transportation sector to significantly reduce the overall weight of vehicles, leading to improved fuel efficiency. RVs and model homes in particular can drastically reduce their overall emissions and costs by using lightweight plywood paneling in their kitchen cabinetry, bed frames and overhead storage compartments. Plywood is also an increasingly popular choice for boat hulls and bows as it is flexible and helps reduce the overall weight of vessels so they can move through water more efficiently. Companies such as Evie Bee Designs have gone even further in their mission to explore plywood’s potential creating ElectraPly, an environmentally friendly plywood e-bike.

CONTINUED ON PAGE 32 ›

Using digital print technology, companies have further managed to revolutionize plywood’s potential. Garnica, a leading manufacturer in the industry has developed a product line called Infinity which recreates highly sought-after veneer designs on a premium poplar plywood platform. This innovative solution not only produces stunning and realistic designs but also aligns with the industry's growing demand for sustainability. Although their current primary focus is on printing various wood grains and patterns, it is technically possible to print solid colors or even photographs and logos, opening up a world of possibilities for creative minds. By incorporating digital print technology into their plywood shelving, display units, and fixtures, retailers can effectively re-create the look of hardwood in their spaces without breaking the bank or compromising strength and durability.

As the demand for sustainable and versatile building materials continues to grow, responsiblysourced plywood is positioned to play a central role in shaping the future of the industry. The architect and design community is always looking for ways to obtain LEED certifications for their projects and using sustainably sourced plywood can be a key component in that process. A widely available alternative to rare and exotic hardwoods which need to be protected, plywood is the ultimate cost-effective and endlessly adaptable solution that suppliers and their clients can count on for everything from interior design to transportation. S P

JAIME ALVAREZ

is the Head of Marketing at Garnica and has been with the company for almost 10 years. Fluent in Spanish and English, Jaime lives and works in La Rioja, Spain, overseeing marketing initiatives for both the European and North American divisions. He studied Economics at the University of Zaragoza and also obtained a master’s degree in marketing Management from the ESIC Business & Marketing school.

Offering a remarkable blend of versatility and adaptability, plywood offers limitless possibilities beyond the realm of conventional applications.ABOVE: PLYWOOD PANELING, ESPECIALLY WHEN FIRE RESISTANT, IS IDEAL FOR ELEVATOR INTERIORS AS IT’S LIGHTWEIGHT, DURABLE AND DESIGNED TO BEAR EXTREME LOAD CAPACITIES.

BY AMY GATH

BY AMY GATH

The dominance of home design content on social media has sparked even greater interest in interior design and changing aesthetics among younger ages. As surfacing professionals, of course it’s wonderful to have more interest in our industry, especially when it can spark lifelong passions for young people.

However, the volume of home design content has allowed the market to constantly evolve microtrends that move at the speed of its surrounding culture. The summer of 2022 saw the Nancy Meyers-inspired “coastal grandmother” trend in both fashion and decor, and this summer, pink took over as “Barbiecore” dominated news and social media, with countless other increasingly specific microtrends springing up in between.

While we would love to be able to cater to every passing trend, the changing landscape of pop culture can make it difficult to truly address each one, especially in a field with a long production timeline and a longer life cycle in consumers’ homes. However, as these new microtrends have become the norm, it’s become clear that there are still ways to keep a pulse on ever-changing consumer preferences while also developing portfolios for the long haul.

In honor of Formica’s 110th anniversary, our team recently created a new book that gives a decade-by-decade look at the brand’s patterns over the years. While diving into our archive

during this process, I would pull a pattern from the ‘50s, and with the right context and complementary elements, it felt refreshingly modern and new.

Similarly, putting your collection or specific pattern in the context of the trend helps consumers envision the possibilities. Whether it’s through social media or individual customer engagements, concretely show these microtrends in action and how current offerings can cater to their ever-evolving needs.

To effectively address these trends that seem to turn on a dime, it does require a diverse and versatile collection. Microtrends aside, with the wide range of design information available to consumers, we’ve never seen more personalization and unique senses of style driving residential interiors. To cater to these diverse tastes, a wide-ranging portfolio is already critical to addressing modern design needs and it makes it possible to address these microtrends with the designs already in your repertoire.

While catering to microtrends, it’s not just possible but also critical to keep in mind the larger design movements driving consumer preference. These evolving influences can offer a window into the consumer mindset, but they’re not always representative of the long-term arc.

From material design to marketing, these microtrends should only affect business decisions to the extent of their true value. Don’t let one microtrend overinfluence how you work, but given their overall force in pop culture, being mindful of them as an aggregate can help keep a finger on the pulse of how consumers are changing.

Catering to these microtrends, however fleeting, can both drive sales and prove relevance to consumers. By getting creative with your current collection and keeping your eyes on the bigger picture, it’s possible to both jump on these social media-driven trends while also driving design for the long haul s p

MÜNZINGFENTAK® ADDITIVE SOLUTIONS FOR THE WOOD INDUSTRY

A wide range of additives featuring…

Decorative and Industrial Paper Impregnation

Release Agents for Improved Processing

Catalysts for MDF and Particle Board Resins

Aqueous Organic Dye Solutions and Pigment Dispersions

MÜNZING’s worldwide production network of manufacturing plants in Germany, USA, Australia and Malaysia, facilitate supply and prompt delivery wherever our customers do business

www.munzing.com

info@munzing.us

It’s no secret that supply chain issues over the past few years have greatly affected manufacturers and distributors in nearly all industries across the country.

Experts say that while the situation may not be as critical as it was a few years ago, there are still challenges related to the supply chain, including delays in raw materials and shipping and labor shortages.

Manufacturers say they are evolving to be more flexible to accommodate these challenges and to better serve their customers. One discussion at AWFS focused on these issues.

“Just-in-time (JIT) inventory just doesn’t work anymore,” says Paul Wilmes, president and CEO of Mereen-Johnson, which has been expanding its manufacturing operations over the past decade. “It’s really interesting how ordering and vendor relationships have evolved.”

“At one point, shipping times from overseas became VERY extensive,” he adds. “We were ordering a lot more than we thought we needed, but we found that you need to be prepared to select alternative components … you may have machinery that is 99.9 percent complete and be missing one key component. It’s not usable, so you may need to pivot and figure out something else

you can use instead. You do have to be careful, though, and know what you’re getting.”

Identifying alternatives and maintaining a good relationship with vendors is key, agrees Jonathan Thompson, sales manager for E.B. Bradley Co & West Coast Laminating.

“Product knowledge is really important,” he says. “A few years back, we found we were under promising and trying to overdeliver when demand exceeded what we realistically could provide.”

Being transparent with their team, vendors and customers helped bridge the gap, says Thompson. “Just-in-time can still work,” he adds. “But it needs to be more flexible. We learned a tough lesson that we’re not in control of certain variables.”

And fabricators need to also be more flexible in what they offer over the next few years, says Thompson. “Supply chain issues will not affect the market as much as the lack of highly skilled workers will — especially as it relates to JIT.”

Wilmes agrees that the labor issues are here to stay “for a very, very, very long time,” but says they are key to helping alleviate that shortage can be found in automation and robotic machinery. “There’s no question that the only way American industries can compete to be leaders is through robotic integration in our

manufacturing facilities,” he says. “Our industry usually lags, but we have to be looking at making these changes…things like sorting, stacking, palletizing, robotic forklifts…these things that we can’t hire for anymore.”

Finding people who want to work has been our biggest challenge, says Bob Brown, who serves as executive vice president of Royal Plywood Co. and is on the AWFS board of directors. “We need more education for our workforce…getting wood shops back in schools.”

As for retaining current employees, he says, the key is engagement and being generous with not only wages but things including time off and flexibility as needed.

“It’s so important to take care of your people,” Brown says. “They are what make us.”

And while onshore manufacturing has captured recent headlines, Thompson says it’s impossible to onshore everything, especially with labor shortages. “I do foresee China imploding soon, though, and we will have more opportunities for onshoring,” he says.

Shipping and distribution also remains an issue for many manufacturers, adds Thompson. “We import most of our products from Europe and have had different issues at different times,” he

says. “But the bigger challenge has been getting the containers out of Europe — the war in Ukraine has really affected that aspect of our business.”

“Fifty percent of the cost of goods has to do with shipping and import costs,” he says. “Amazon has pretty much taken over small parcel shipments, so there are additional challenges and opportunities for small businesses to step up.”

Brown says that the trucking industry today is a nightmare that affects every level of manufacturing. “Today it can take 12-18 months to get a new truck — and then it may be missing parts. And on the West Coast — California, Oregon, Washington — the electric vehicle agenda doesn’t work. Electric trucks are VERY expensive and they just don’t work…not to mention that we just don’t have the power grid to handle these mandates. And all of these significant costs would have to be passed down to the consumer.”

But it’s not all bad, says Thompson. “Stop watching the news — it’s never as good or bad as they say,” he stresses. “Focus on your people. The businesses that are growing are the ones who are willing to change and try new things.” s p

“Supply chain issues will not affect the market as much as the lack of highly skilled workers will — especially as it relates to JIT.”

Iam just back from the AWFS Fair in Las Vegas where I met with many distributor and manufacturer executives in the woodworking/ decorative surfacing industry. They were at the event primarily for one reason – to establish and/or deepen relationships that will help them grow sales. Now that the 2023 AWFS Fair is behind us, many distribution executives have shifted their focus to the upcoming 2023 Annual Convention of the North American Building Material Distribution Association (NBMDA) scheduled for November 14-16 in Colorado Springs. The NBMDA event is focused exclusively on strengthening the distributor-manufacturer relationship. Early registration for the NBMDA event is pacing well ahead of our historical trends clearly indicating that savvy distribution executives understand the value of such a relationship-building opportunity.

Simultaneously, I came across an extremely interesting article by Mark Mitchell who is a respected building material sales and marketing consultant titled How to Use Associations to Grow Your Building Material Sales. This article outlines a unique strategy for industry executives to increase their sales which has not been

widely covered. The premise is to remind us that strong relationships have been and always will be the cornerstone of sales but many firms have drifted away from this thanks to impersonal technologybased platforms and strategies. An incredibly powerful sales tool that many do not take advantage of is the basic idea of using your customer’s associations to help you grow your business. Why do many firms miss this easy growth opportunity?

Mitchell goes on to explain that simply joining your customers association is not going to cut it. Paying your dues, slapping the association’s logo on your website and showing up at events to network won’t move the needle. To see actual growth, one needs to be more involved, take proactive steps and not shy away from leadership opportunities.

He goes on to outline five keys to succeeding with associations:

1 | Find the right person. Not everyone in your company will be suited for this kind of approach. Remember, it’s all about relationships, so the person taking the lead on this should be a people-person who knows how to make a great impression.

2 | Be patient. Joining an association isn’t going to grow your sales overnight. If you have start trying to sell your product right away, you’ll leave a sour taste in the other members’ mouths. Don’t even think of it as a sales strategy. Stay focused on helping the association and let the sales come organically.

3 | Find out what the real problems are. Every association has a few challenges they really struggle with, like difficulty moving initiatives forward or trouble with outreach. Find out what those problems are and do what you can to help solve them

4 | Bring new ideas to the table. As an outsider, you can bring a fresh perspective and push members out of their rut. So, don’t waste your time on a committee waiting for someone to give you a task. Propose ideas and volunteer to move things along.

5 | Don’t be afraid to shake things up. Focus on the elected leaders of the association. They want to earn their title by making a difference. You might just have the big idea they need to achieve that.

Sales not coming as easily as they had been over the past 2-3 years? Do you like relationship selling? Do you need to revive your relationship-building skills?

Selling through associations is only one of the many ways you can sell to various types of customers and become more successful. But it’s one that should definitely be in your arsenal. It may be time to refresh your approach to industry associations to ensure that your firm is getting the maximum return on your involvement. Following the five steps outline by Mark Mitchell is a great place to start. s p

KEVIN GAMMONLEY has served as the Executive Vice President of the North American Building Material Distribution Association (NBMDA) for more than 30 years. www.nbmda.org

To see actual growth, one needs to be more involved, take proactive steps and not shy away from leadership opportunities.

My whole life, I was told that we were one of the richest nations on earth, but now I see that we are one of the poorest. It’s like my whole life has been wasted.”

That comment marked one of the saddest and most poignant moments of my life. Here’s the story:

At one point in our life together, my wife, Coleen, and I were foster parents. Over the years we had 19 foster children of various sexes, races, and physical and emotional disabilities. One of those was Michael, who arrived in our home as a 17-year-old refugee from Albania, which was then the most closed and repressive socialist country in the world. Michael had escaped the regime by swimming across a portion of the Adriatic Sea and eventually landing in a U.N. refugee camp in what was then Yugoslavia.

During the time that Michael was in our home, the regime fell. Albania and the country opened up. Michael was able to speak with his parents via a phone in the village where his family lived.

One thing led to another, and a couple of years later, Coleen and I visited his parents in their village in the remote foothills in Albania. We eventually hosted John, Michael’s 80ish father, for a couple of weeks in our home.

Culture shock is too mild a term to describe John’s experiences. For example, Albania at that time did not have a single stoplight in the country because there was no need for one. There were no cars; people walked or traveled in oxcarts. Bringing John to America was like time travel — fast-forwarding him a couple of hundred years. He was overwhelmed and awestruck. The treadmill, for example, was a source of amusement. “Why would somebody walk on it when they could just walk outside? Silly Americans.” Expressways provided a terrifying experience; air conditioning was a wonder.

As we escorted him to the airplane that would take him back to Albania, he thanked us, said goodbye to his son, and then said, “My whole life, I was told that we were one of the richest nations on earth, but now I see that we are one of the poorest. It’s like my whole life has been wasted.”

For years that moment stuck with me like a weight on my heart — every time I thought of it, I felt sad.

But, in recent years I’ve seen it differently. John was wrong. His life wasn’t wasted, unless of course you judge your life solely by the amount of material possessions you’ve accumulated. It is true that the socialist government lied to him for a lifetime, and that those lies narrowed his world and prevented him from seeing opportunities he never had.

But John made the most of the situation in which he found himself. He was the village elder, and helped his villagers survive in a difficult

time. He and his wife raised two children and instilled a sound character in them, embedding one with the self-confidence and courage necessary to escape. There was something in John that sought for more, and he instilled that hunger to do more, see more, be more, and accomplish more into his prodigy. He made an impact. He had influence. In John’s world, he was significant.

According to Meriam-Webster, significance is defined this way: “the quality of being important: the quality of having notable worth or influence.” Wiktionary sheds this light on it: “extent to which something matters.”

While there is a degree of significance to be achieved though one’s family — John had influence on his family, for example — my focus in this article is on a higher level of significance. Having “notable worth or influence” implies that significance on that level is relatively rare. People take note of it.

Suppose you could lay a foundation of significance with your family, and then reached out to “matter” to a larger world. Suppose you could seek significance in your career and your business.

Just that idea alone would put you in as special category. The sad truth is that very few people seek to be significant to anyone over and above their core family. Most people are content to just get by.

In my work of helping sales forces sell better, for example, I’ve often observed that if you randomly select 20 salespeople and survey them, you’ll find that only one of those 20 have spent $25 of their own money on their own improvement over the course of the year. While salespeople happen to be the professional group with whom I am most familiar, I suspect that salespeople are not unique in their indifference to personal improvement. Probably the same thing could be said about product managers, customer service representatives, social workers, and every other job title.

Gaining significance means, among other things, performing in such a way as to be notable. Notable implies performance above and beyond the average. And that means striving for excellence in your work or business. Striving for excellence means continually improving yourself. You can’t become excellent unless you do better — forever. And doing better means sharpening the saw and continually improving. So, being indifferent to personal improvement is to deny an attraction to significance.

There are compelling reasons to strive for significance in your career and your business. One is the exceptional positive impact on people. As we noted in the definition, significance is defined by its impact on others. To be “notable” requires people to notice. To be “important”

With a ShopBot CNC, you can increase production throughput while minimizing material handling. For example, you can drill shelf pin holes, cut rabbets and dados, and profile-cut the completed panel. The operator only needs to handle the full sheet once to load the machine, and then remove the perfectly cut parts that are ready for assembly.

Thanks to the affordability of ShopBot’s professional grade CNC tools, the technology of manufacturing cabinet boxes, doors, drawer fronts, shelves, and even countertops, is now well within the reach of smaller shops, not just large cabinet manufacturing facilities.

See our full line of tools at ShopBotTools.com. Then give us a call at 888-680-4466. We’ll find the tool that works best for your needs.

requires someone else to deem it so. So, significance is achieved through positive impact on other people.

There is something in the soul of human beings that compels us to help others. So many of these ideas rise out of the Judeo-Christian mindset and scriptures. We only have one life, the Bible tells us, and we should live it with an eye toward eternity. “Love your neighbor as yourself” Jesus commanded. Significance is one manifestation of that command. It informs the way you do your job and live your life, encouraging you to make the most of every minute by positively impacting others.

But significance also reaches inward and prompts us to attain more of our potential, to be more, and to achieve more. Insignificant people are content to utilize a fraction of their potential. Those who strive for significance stretch themselves, put themselves in challenging situations so that they stretch and build the abilities and competencies they were born with.

Show me a person who continually challenges himself/herself, who pushes the boundaries of latent potential to exercise more of that potential, I’ll show you someone who is growing in significance.

Significance then, can be much more than just a handy phrase. It can be an organizing principle in one’s life, ordering priorities and organizing actions in pursuit of a higher calling.

Maybe that’s why so few people seek it. Its not easy, it doesn’t come quickly and there are prices to pay as you seek it.

Significance in your job or business requires several things: motivation, focus, sacrifice and discipline, to begin with.

Motivation speaks to that desire that wells up from inside a person to be significant. It probably won’t happen by chance. You’ll need to want it. As a lifetime student of motivation (I’m forever asked how to motivate a sales force, for example) I’ve observed that motivation is rarely injected from outside, but instead is often instilled during our formative years — typically very intentionally by parents or circumstances. Motivation is often kept in check by our beliefs and our thinking habits. Once we have the idea that we can be significant in our careers and our businesses, that concept can free us to unleash motivation that has lain dormant.

Focus speaks to our ability to prioritize and harness our resources to the highest priority tasks. Once we have decided to seek significance, we need to focus on those things that will bring us closer to that goal.

Sacrifice is that dragon that guards the path to significance and discourages most people from taking the next step. The idea of giving some things up now in exchange for greater influence later just doesn’t resonate with many of our colleagues. For many, the choice between buying tickets to a ball game, or paying for a seminar is a no-brainer. Taking a cut in pay for a promotion that brings greater influence is, for those uninterested in significance, an unreasonable choice.

Discipline is, like sacrifice, a word that scares many people. It this context, discipline means that you exert your will to invest time and energy into things that move you closer to significance, even if they are difficult and uncomfortable.

Sounds like a challenge, and it is. That’s why few people really choose to seek significance in their careers and businesses. But for those who believe there is more to life than just this, that they can be more, achieve more, and impact more, it can provide an overarching way of life and a lifetime of fulfillment.

The first step is to recognize that it is available to you, and to decide you want it. S P

DAVE KAHLE is a leading sales authority, having presented in 47 states and 11 countries, and written 12 books, including the best-selling How to Sell Anything to Anyone and his latest, The Good Book on Business. For more information, visit davekahle.com.

For every type of movement… the answer is Salice. A comprehensive range of products that combines excellence in research-based design and technical expertise to provide solutions for every cabinetry application.

-Hinges & mounting plates

-Lift systems

-Sliding systems

-Runners & drawers

-Kitchen & Closet Accessories

onversations about artificial intelligence (AI) have been everywhere recently. Congress held hearings about it. News outlets have written articles about it, including that content providers have sampled AI’s abilities by having it draft something for them. But how does it affect companies and Human Resources?

According to the Pew Research Center, 62 percent of Americans believe AI will have a major impact on workers, but only 28 percent believe it will impact them directly. Unfortunately, AI is already affecting employees, as 4,000 jobs were lost in May 2023 due to AI — the first time AI was listed as a reason for a layoff.

While most of the recent conversation involves AI-generated content, other AI formats have been used in the workplace for a while.

AI tools used in the hiring process have been praised for saving hiring managers valuable time and creating a diverse pool of applicants by removing bias from the initial review process.

Concerns have been raised that there is unintentional bias built into these tools.

Resume-review tools can use predictive analysis to determine what candidate profile would be the best fit for an open position and then compare received electronic resumes to find the “best available” candidates. However, if a candidate uses certain words or phrases which may not fit the AI tool’s expectations, the candidate will receive a lower evaluation for no real reason.

More concerning are tools which analyze an applicant’s personality, knowledge, and communication skills using recorded responses to interview questions and facial expressions. These tools assess a candidate’s fit for a job by matching them to a profile of the company’s “ideal employee” using appearance, communication skills, speech patterns, body language, personality, etc. However, some of these tools have been found to be biased, eliminating people of certain genders, races, ethnicities, and disabilities by giving lower scores for factors (such as facial structure, accents, hair style, or wearing glasses or head scarves) that do not match the “ideal” parameters in the programming.