UNIQUE AESTHE WORDS: SAM DAVIES

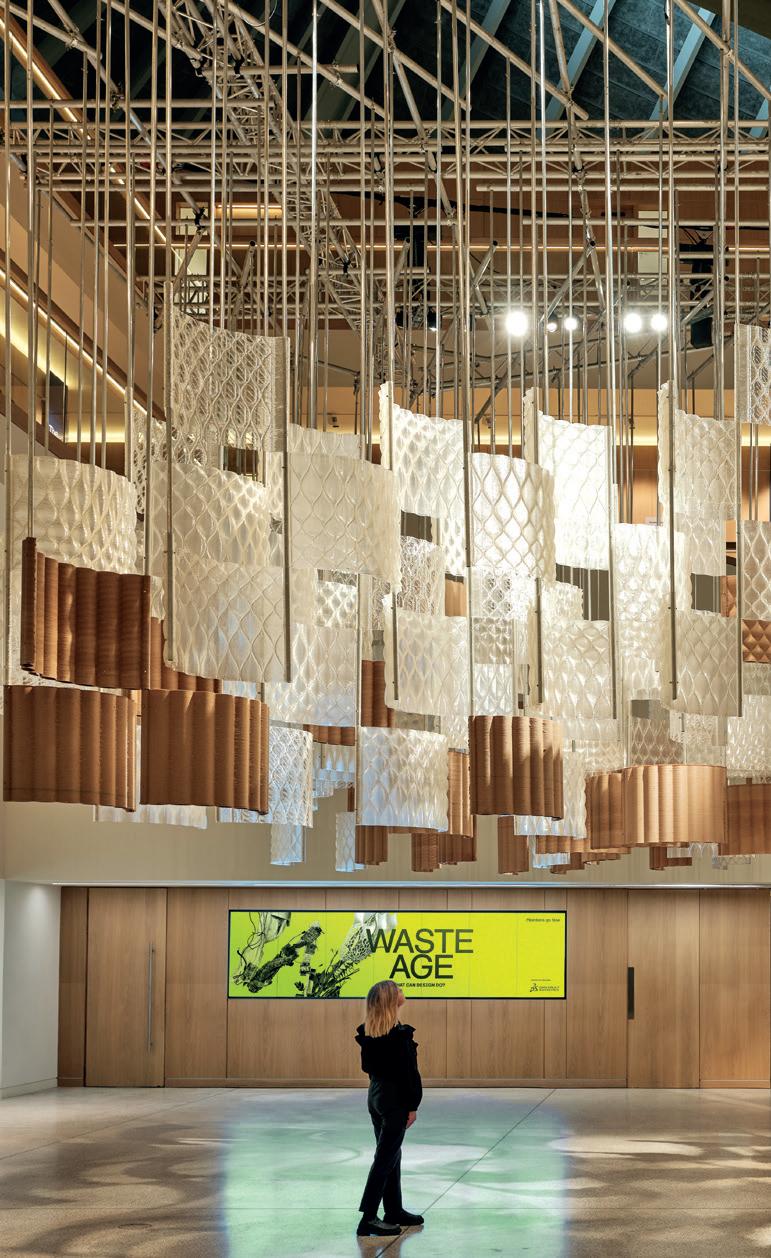

SHOWN: CRYSTAL GLACIERS

T

o me, the most important thing is that I achieve something which looks unique, so it has a unique aesthetic embedded in it, something innovative and novel, which sets itself apart from anything that we have seen before.” The standards were set more than six years ago. Julia Koerner founded JK Design in 2015 in Austria, with a new brand, JK 3D, being established last year with her partner Kais Al-Rawi. In that time, Koerner has found success in architecture, fashion design and product design, leaning on her specialities that span 3D printing, robotic technologies and computational design. Her name has appeared in this very magazine before, after she produced 3D printed garments and accessories for Marvel’s 2018 Black Panther movie, while a fashion collaboration with Stratasys and Ganit Goldstein also filled the column inches of many a 3D printing publication in 2021. Last spring, Koerner was reaching another professional landmark. Commissioned to develop two art sculptures measuring up to six feet tall, that would be put on public display in Santa Monica, California later that year, she was embarking on her very first public art endeavour. But due to unforeseen circumstances (a global pandemic; you may have heard about

022 / www.tctmagazine.com / 30.1

SHOWN: 3D STELAE SCULPTURE

it), things didn’t go exactly according to plan on her '3D Stelae' project. The plan at one time was to hand the production of the 3D Stelae sculptures to a service provider that operated large-format 3D printing systems. With the costs deemed prohibitive, Koerner then explored CNC milling, which was a little more affordable. But by the time she was ready to place her orders with a digital fabrication shop suited to her needs, they were all either closing down because of COVID-19 restrictions or swamped by the demand for faceshields and other Covid-related applications. At this point, the deadline was just months away, with the first 3D Stelae installation slated for July 2020. The only way forward was to turn to JK Design’s in-house Fused Deposition Modelling (FDM) platforms, 3D printing the two sculptures in four-to-six sections measuring around one metre tall and 30 x 30 cm in diameter. “We started printing it and it worked without adapting the geometry largely,” Koerner tells TCT. “It was so fascinating because all of a sudden we were able to print these large sections at 1.5 millimetres thick without any support material, so it’s super lightweight and the material can withstand outside environmental forces, such as sun and heat. “We started to produce this in our studio, and it was revolutionary because I realised what we can do in-house and how we can make our own products with very limited resources.”

SHOWN: HY CLUTCH