For the first time since Construction Leadership Council’s Product Availability working group began meeting at the height of the pandemic, there is good availability of the vast majority of building materials across the UK, with increasing reports that availability is back to pre-Covid levels. Some issues continue around products reliant on semiconductors, but the general feeling is that this is slowly improving.

While there has been a slight decline in construction activity, the industry overall is performing better than forecasted six months ago,” said the statement from John Newcomb, CEO of the Builders Merchants Federation and Peter Caplehorn, CEO of the Construction Products Association, co-chairs of the group.

“With demand lower than at this time last year, there is also less pressure on prices. As a result, early indications suggest prices for many products appear to be stabilising and in isolated cases even declining from recent highs, though volatility persists.

“This does, however, vary by sector and sub-sector. For example, RMI work in both the public and private sector housing to support decarbonisation and improve energy efficiency is driving sales of insulation products Manufacturers in this area are seeing volumes ahead of expectations but are managing supply.

“As reported last month, brick stocks have increased due to a slowdown in the housing market and increased production. There are approximately 8 weeks of bricks in stock and, with new plants in the UK coming on stream over the next 6-12 months, the UK’s reliance on more expensive imports to top up stocks will fall rapidly.”

However, the encouraging news was somewhat tempered by the CPA’s latest forecast. Construction output is forecast to fall from a record-high level and contract by 6.4% in 2023 according to the association’s Spring Forecasts.

This is a downgrade from a fall of 4.7% expected in the Winter, driven primarily by sharp falls in the two largest construction sectors – private new housing and private housing repair, maintenance and improvement (rm&i) – together with recent government announcements of delays to major infrastructure projects.

Paul Groves || Group Editor

Paul Groves || Group Editor

The A. Proctor Group has been in the Gas Protection market for the past 20 years promoting a range of gas membranes and venting components for use on contaminated land sites. Adequate protection against the ingress of ground gas and vapours is crucial and the A. Proctor Group can provide safe, cost effective and value engineered solutions.

See pages 20-21 for their article about protecting buildings on radon affected land.

The government has announced its commitment to rebuild five major hospitals by 2030, as part of the New Hospital Programme.

These hospitals all have significant amounts of reinforced autoclaved aerated concrete (RAAC), a lightweight type of concrete used to construct parts of the NHS estate in the past but has a limited lifespan, after which it deteriorates significantly.

The five hospitals are Airedale in West Yorkshire, Queen Elizabeth King’s Lynn in Norfolk, Hinchingbrooke in Cambridgeshire, Mid Cheshire Leighton in Cheshire and Frimley Park in Surrey.

The NHS has asked the government to prioritise the rebuilding of these hospitals given the risks they pose to patients and staff - the full extent of which has come to light since the New Hospital Programme was first announced in 2020.

Two of the worst affected hospitals - West Suffolk Hospital in Bury St Edmunds and James Paget Hospital in Norfolk - have already been announced as of the New Hospital Programme and the construction of these major new hospitals will be prioritised to ensure patient and staff safety.

As a result of this reprioritisation, as well as the rising cost of construction materials, up

to eight schemes that were originally due to be constructed towards the end of the decade will now be completed past 2030.

The government remains committed to delivering all hospitals within the programme as soon as possible – the biggest in a generation - and will ensure all schemes have adequate funding.

Health and Social Care Secretary Steve Barclay said: “These five hospitals are in pressing need of repair and are being prioritised so patients and staff can benefit from major new hospital buildings, equipped with the latest technology.

“On top of this I’m strengthening our New Hospital Programme by today confirming that it is expected to represent more than £20 billion of new investment in hospital infrastructure.

“As we approach the 75th anniversary of our fantastic NHS, this extra investment will ensure it can care for patients for decades to come and help cut waiting lists so they get the treatment they need quicker.”

Going forward, new schemes will be considered through a rolling programme of capital investment in hospital infrastructure to secure the building of new hospitals beyond 2030.

A groundbreaking initiative to rebuild Ukraine has commenced in Lviv, Ukraine.

This remarkable project is led by the humanitarian foundation Team4UA and carried out by the Danish 3DCP Group using COBOD’s BOD2 printer and aims to address the pressing need for educational infrastructure in the country.

Ukraine has faced severe challenges due to the full-scale invasion of Russia, resulting in the destruction or damage of over 2,000

schools, with 277 schools completely demolished, as reported by the Ministry of Education and Science of Ukraine. In light of this crisis, the primary goal of this project is to swiftly respond to the dire shortage of educational infrastructure in the country.

By introducing 3D printing technology into the construction process, the project initiators aim to expedite the creation of educational facilities and lay the foundation for the reconstruction of housing and vital infrastructure throughout Ukraine.

Hundreds of high-rise buildings are being registered with the new building safety regulator as the stricter regime to protect residents begins.

Around 750 applications have been opened with the new Building Safety Regulator (BSR) since its registration process for high-rise buildings opened last month.

All high-rise residential buildings must be registered with BSR by law. Those responsible for the safety of buildings have until the end of September to register or face prosecution.

BSR is pleased with the early response from the building industry but is urging all owners and managers to act now. Up to 12,500 buildings in England are covered by the new regulator, set up in response to the Grenfell Fire tragedy and officially launched earlier this year.

BSR is an independent body set-up by the Building Safety Act 2022 and part of the Health and Safety Executive (HSE). Its launch is the biggest change in building safety for a generation.

HSE’s Director of Building Safety, Philip White, said: “We’re pleased with the early response from industry but I urge owners and managers to act now and register their buildings if they haven’t already done so.

“This is a legal requirement they will have to meet by the end of September. Registration is a crucial part of the new regime and our efforts to ensure residents of high-rise buildings feel protected and safe in their homes.”

High-rise residential buildings that are at least 18 metres in height or have seven or more floors containing at least two residential units must be registered with BSR.

How confident are you that your proposed fire resistant glazing solution is backed up with detailed, accurate information on all aspects of its design, manufacture and installation?

With Promat SYSTEMGLAS® you can specify with confidence when designing and specifying fire resistant glazing. It has ‘golden thread’ thinking at its core, with full traceability in raw material sourcing, manufacture and installation.

Promat UK Ltd 0800 588 4444

promatglass@etexgroup.com

We go the extra mile for you and your clients.

The Construction Leadership Council has welcomed the publication of Our Shared Understanding: a circular economy in the built environment, which unites the industry for a sustainable future, where we live within our planet’s capacity to provide resources and handle waste.

Our Shared Understanding sets out the core concepts that guide the transition to a circular economy. It will ensure we get the maximum benefits for people and planet, not only from managing resources and products more effectively, but also by getting more value from the use of assets and systems that last for years.

The Green Construction Board has for a long time promoted the need for more circular approaches through the work of its Resources, Waste and Circular Economy Group. It has developed significant outputs like the Interpretation of Zero Avoidable Waste and the Zero Avoidable Waste Routemap, which sets key recommendations for industry and government on reducing waste in construction.

Ongoing projects include the waste to landfill study, identifying waste streams by type and understanding the impacts of composite and the cost of waste.

ConstructZero is the CLC’s net zero carbon industry change programme, accelerating

the sector’s transition to net zero. Its Performance Framework is underpinned by nine priorities and a set of 31 metrics, including retrofitting, waste reduction and reuse. Its public quarterly progress update reports have illustrated that by setting benchmarks and measuring progress, we are motivating and encouraging businesses to action, whilst helping those outside the sector understand our progress.

Commenting on this call for us to pull together to make a circular economy in the built environment go mainstream, David Pinder, Chair Green Construction Board, said: “At this time when we are all trying hard to understand how we can achieve our Net Zero targets in a challenging environment, it is encouraging to see the industry come together to agree how embracing circular principles can accelerate our progress. Through holding core concepts in common, we can make real progress.”

Micheala Chan, Net Zero & Biodiversity Young Ambassador, said: “The engineering and construction industry is one of the largest consumers of resources in the world. Embracing circular economy principles will enable us to reap multiple benefits (such as minimising our environmental impact, creating new jobs, and reducing costs), while also ensuring a sustainable and liveable future for all.”

Morgan Sindall Construction’s Northern Home Counties business has held a topping out ceremony at the Buntingford First School, marking an exciting milestone for Hertfordshire County Council (HCC) and Scholars Education Trust in delivering the region and country’s first carbon neutral school.

The event included speeches from Councillor Caroline Clapper and Councillor Duncan Wallace from Hertfordshire County Council before a guided site tour for all attendees and a reception at The Bury Clubhouse. Other guests on the day included Morgan Sindall Construction’s Northern Home Counties area director David Rowsell and Deputy CEO of Scholars’ Education Trust, Matt Gauthier.

Scheduled to open in 2023, Buntingford First School was procured through the Pagabo framework and will be one of the first net zero school’s – in both embodied and operational carbon – in the UK. In line with Hertfordshire County Council’s sustainability strategy and ambition to be carbon neutral by 2030, it is set to achieve Passivhaus Plus, meaning it will improve the school’s air quality, reduce carbon emissions and lower its energy running costs.

The Building Engineering Services Association (BESA) has announced that Mitsubishi Electric will once again be the headline sponsor for its Industry Awards and Annual Conference.

The Association has revamped and expanded its awards scheme for 2023 introducing a new qualifying format and extending the categories. They are free to enter and are designed to reward individuals, teams, and companies responsible for delivering projects, products, innovations, and initiatives that demonstrate excellence in building services engineering.

Although some awards are exclusively for BESA members, many are now open to the whole sector and entries are encouraged from across the whole industry supply chain to ensure the programme reflects the full breadth of building services expertise. Mitsubishi Electric has sponsored the Awards for the last three years and said it had “not hesitated” when given the opportunity to support this year’s expanded programme.

Our range of roof access and safety products enable easy and secure access onto and around the roof.

Solutions for roof access via a hatch or smoke vent, fall protection, security and step over or up and over units for access over ducting, parapet walls or any other obstructions.

Manufactured to the highest standard, they comply with National Building Regulations ensuring the safety of maintenance personnel at all times.

So the next time you need safe roof access, make sure it’s a Bilco.

Adual-screen film installation will reveal how people use the spaces created by architecture, left to their own devices.

Buildings are often documented at their point of completion but this exhibition will explore what happens once the architect has returned to their studio and inhabitation has begun.

It will draw together the moments of humanity that so often capture Stephenson’s imagination and present them as a series of vignettes examining the multitude of ways that people naturally occupy both the interiors and exteriors of buildings.

The show has been created in response to the theme of this year’s London Festival of Architecture, which is ‘In Common’. Displayed as a dual-screen installation, the exhibition will work on different scales to explore the idea and impact of a ‘shared place’ and the contextual detailing that makes them successful.

In this form, The Architect Has Left The Building will ask its audience to pause for a moment, and imagine the stories that are unfolding on the screen, while offering an opportunity to reflect and immerse themselves in the vision of the filmmaker, a vision that creates a space for the viewer to

engage with a subtle visual connectivity that spans fifteen years of Stephenson’s career. The work, edited and sequenced with photographic artist Sofia Kathryn Smith, features a soundscape composed by long-time collaborator Simon James.

A wide range of projects and people are featured in the installation, ranging from schools in Hackney, east London and Berkshire, to galleries and museums stretching from Cornwall to the Lake District. Stirling Prize-winning universities are used to show how the very best architecture in the country can frame daily life, while a community centre in West London reveals the small moments created when different groups use a single building.

The presentation aims to quietly disrupt the traditionally neat visions of these perhaps familiar buildings often presented to the public, and instead offers a textural, atmospheric experience - a theme that runs throughout much of Stephenson’s work.

Jim Stephenson said: “During the making of this new film for the exhibition, we took the opportunity to slow down and reflect on the way our work forms part of a narrative that the buildings go through after completion and now we’re asking the audience to do the same.

We hope that they’ll enjoy the chance to pause as well, and observe how these spaces are used, misused, what they have in common and what makes them different.”

Featured in The Architect Has Left The Building:

• National Youth Theatre by DSDHA

• Cambridge Mosque, Marks Barfield

• Airdraft, Benedetta Rogers and Thomas Randall Page

• Kingston, Grafton

• Magdalene Library, Niall McLaughlin

• Windermere Jetty Museum, Carmody Groarke

• Horris Hill, Jonathan Tuckey

• Yorkshire Sculpture Park, Feilden Fowles

• Tate St Ives, Jamie Fobert

• Tintagel Bridge, William Matthews

• London Bridge, Grimshaw

• Sands End, Mae

• Brittania Leisure Centre, Faulkner Brown

• Hackney New School, HenleyHalebrown

The NEW Aquaboost iBolt and iMatic range of high flow, high head, cold water pressure and flow boosting solutions. Designed to optimise space and provide a very quiet, simple to install solution for domestic and commercial applications.

Situated alongside The Grand Union Canal in West London, the Gramophone Works comprises a mix of refurbished, extended and new-build contemporary office spaces.

Retaining the existing concrete elements to the two-storey record factory allowed the project team to integrate the striking property into the historic and social fabric of the surrounding neighbourhood; while at the same time adopting advanced timber technology to help deliver a sustainable and healthy phased development.

Situated in the Kensal Rise district of NorthWest London, The Gramophone’s heritage as a record factory has strong resonance with the local community’s tradition of diverse music genres. The vision for the developer, Resolution Property, was to respect both the location and the history of the building by reusing as much of the original structure as possible, while creating a vibrant new set of different sized studios or offices.

Resolution assembled an experienced team of consultants led by N1 based Studio RHE with Heyne Tillett Steel (HTS) as structural and civil engineers. Graham Construction was appointed as the main contractor, while structural timber specialist B&K Structures was awarded the contract to supply and install an integrated package of engineered timber and structural steel elements which would enable the reconfiguration and extension of the usable spaces.

Working with established supply chain partners Binderholz and Derix for the just-in-time delivery of the Cross Laminated Timber (CLT) and glulam elements respectively, BKS liaised closely with both Graham Construction and HTS on refining the design of the structure and the sequencing of its erection programme. In particular, the concept of having much of the building’s M&E services on view across the soffits, rather than concealed by suspended ceilings, required many of the CLT panels to be routed in the factory ready to take pipework and cabling.

The landmark commercial property comprises two distinct parts: The Studio contains 19,892 sq ft of industrial-style work spaces with resin floors, Crittall style metal framed fenestration and a timber canopy, along with feature staircases.

The Dock’s 64,132 sq ft is an expressed timber structure, with contemporary engineering solutions employed throughout to optimise the building’s functionality as an attractive, healthy and sustainable workplace. >>

With a vast choice of finishes available for any Design scheme, including larger formats and co-ordinating internal tiling, Levato Mono porcelain paver system is perfect for balconies, roof terraces, garden decks and piazzas. Key benefits include; high slip resistance & load bearing, fade & wear resistance – so low cost ongoing maintenance. Both of our self-levelling support pedestals promote a fast cost-effective installation process for use on delicate waterproofing or covering tired slabs. The tilting head adjustment compensates slopes up to 5% even with multiple falls. If a Fire rated pedestal is specified then the FRSL range has Class A1 classification or the SL polypropylene type which have their own key features; secure height locking, non- slip acoustic dampening pads and large height range (28 to 550mm).

Enquiry 8

WWW.SURFACE360.CO.UK

0118 391 4120 | INFO@SURFACE360.CO.UK

New brick and glazed façades have been added to all elevations; while other improvements include louvres for solar shading, planted green roofs and photovoltaic solar panels, as well as LED lighting controlled by sensors. Both zones offer outdoor spaces in the form of terraces or canal-side dining areas, as well as cycle hubs for 130 bicycles.

The use of glulam frames and CLT panels - as well as steelwork - employed in a variety of applications, work along with the retained reinforced concrete and other elements of the original building, combining to create a property which optimises outcomes for the client, end users and the environment.

The case for specification

Studio RHE Director, Tom Foster said: “The ambition from the outset was to reuse the existing industrial structure so the client team was seeking a quick and accurate construction method which could be procured and manufactured while the existing reinforced frame was stripped back”. The accuracy and speed of prefabricated timber was therefore ideal.

In common with every commercial conversion, the repurposing of the semiderelict canal-side factory posed unique challenges. The ambition to create additional workspace, including adding more floors above the existing roof level, inspired the design team to use a hybrid timber solution very early on.

A fundamental desire was to not only retain large parts of the building’s concrete walls, but also to avoid sinking new foundations which meant minimising loadings imposed by new additions where possible. Engineered timber was therefore ideal, being lightweight and strong while offering a natural aesthetic to merge with the existing, industrial structure.

The decision by Studio RHE and HTS, in consultation with BKS, was to construct a steel transfer deck above the existing roof slab, carrying four new floors, where a glulam frame supports CLT units spanning between secondary beams. CLT elements were also used to create the new lift core rising up through the building. Additionally, the choice of mass timber, needing just a small, highly

The adoption of an offsite solution, including extensive engineered timber elements offering an attractive selffinish, helped allow the main contractor to programme in the remedial work required to the retained sections of The Gramophone Works, effectively providing time and space for complex reconstruction operations.

Overall significant programme savings were achieved compared with a traditional redevelopment, the upper floors taking only 15 weeks to complete, while the ability of BKS to progress separate elements of the installation work simultaneously in different areas of the property was a key benefit.

There are far fewer deliveries involved in the construction of a CLT and glulam structure: just one against every seven HGV turnarounds compared to reinforced concrete, with less crane time required and an average lower lift weight. The ability to affix edge protection to CLT floor panels at ground level, prior to them being installed, avoids the need for alternative fall protection measures.

Significantly less on-site labour is required and less waste generated, resulting in a cleaner, safer site. Not only do follow-on trades such as MEP find it much easier to fix to timber than concrete, all of the CLT panels can be precision routed in the factory ready to take pipes and cables. Dry construction subsequently increases potential for future adaptability and ultimately simplifies disassembly, moving towards a truly circular economy.

skilled team, proved a major benefit under the pandemic’s limitations.

The design of the structural timber package has helped create a healthy and sustainable building which sequesters biogenic carbon throughout its working life, and helps mitigate the worst consequences of climate change in advance of the 2030 targets, while the self-finished, visually expressed material will reduce continuing maintenance.

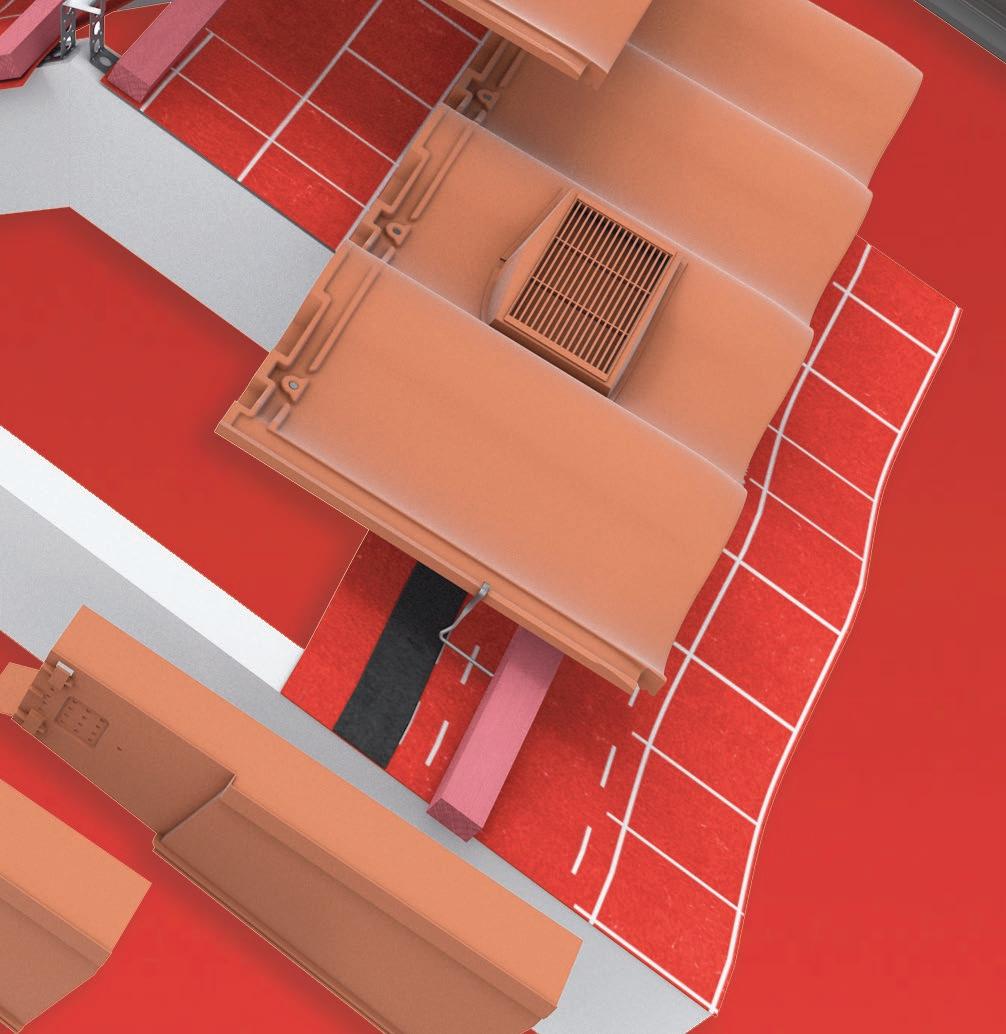

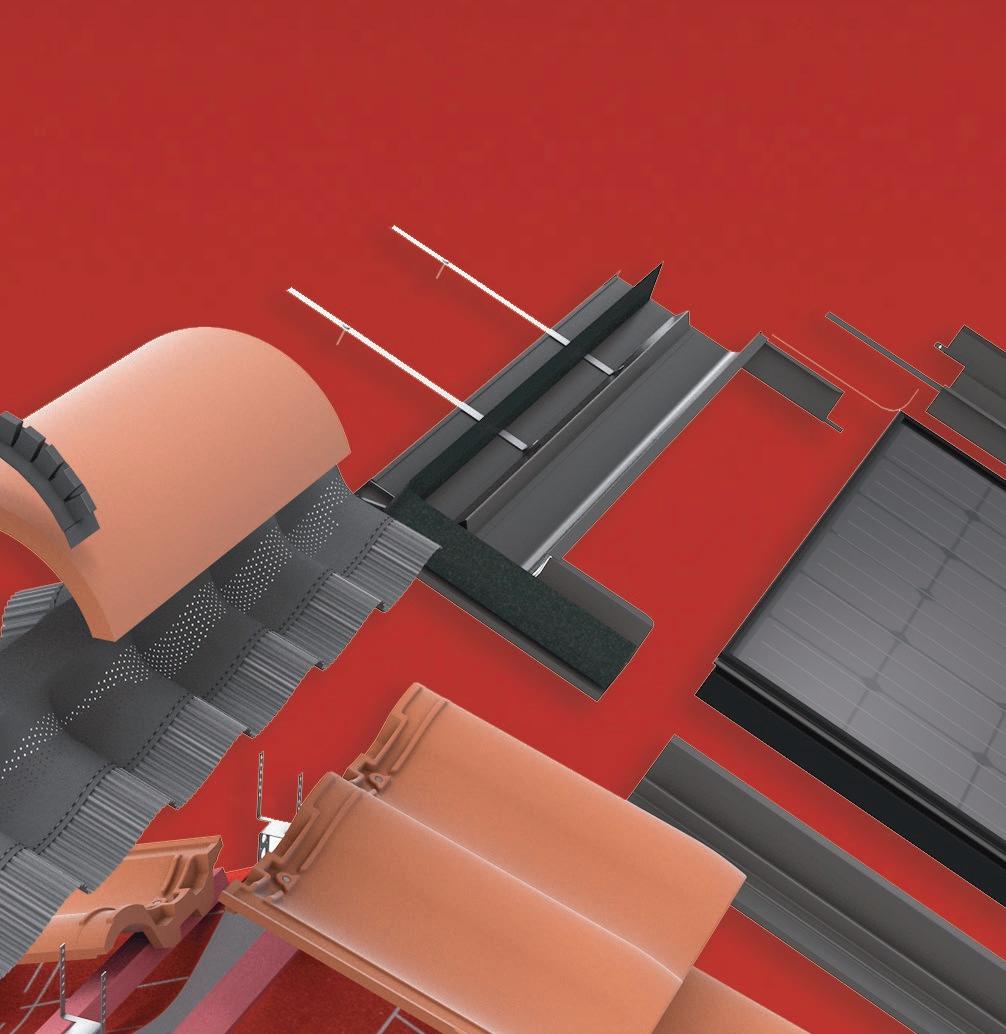

With a dedicated product range that has been specifically developed to improve the operational energy efficiency of buildings, leading manufacturer Glidevale Protect has launched a number of in-house initiatives that places importance on the area of sustainability and helps further reduce the environmental impact of its business operations.

Glidevale Protect is at the forefront of designing and developing ‘hidden protectors’ such as specialist roofing and construction membranes and ventilation solutions that help build healthy solutions, improving a building’s overall thermal efficiency and airtightness, whilst reducing the risk of condensation and heat loss. The manufacturer is working on ways to improve the sustainability and operational efficiency of its business, with key projects underway including the creation of Environmental Product Declarations (EPDs) for key products, progressing towards accreditation to the ISO 50001 energy management standard and putting new systems in place to track recycling levels and energy consumption across its UK based manufacturing facilities.

The business has also invested in closed loop recycling of its product waste as well as looking at how it can improve the environmental footprint of its packaging.

The company’s investment in this area has been supported by a dedicated Group Sustainability Board which meets monthly as well as the business having currently achieved its silver accreditation from the Supply Chain Sustainability School, serving to highlight its commitment to employee engagement and training.

The company’s Sustainability Board is executing a bespoke sustainability action plan and one of its initiatives is the use of an inhouse conveyor to deliver closed loop recycling. This involves granulating waste ABS offcuts from its tile ventilation production line which are compounded, moulded, and recycled back into products by local suppliers based within five miles of the factory.

The recyclate is then used within Glidevale Protect’s tile ventilation hoods. For rolled goods, the company is also collaborating with a recycling partner who is collecting reflective membrane waste from Glidevale Protect’s UK factories and recycling the material. A partnership is also underway with a local company who is collecting all used pallets and waste timber from the factory site for recycling.

Glidevale Protect is also working with both its suppliers and customers to reduce the plastic content in its product packaging. Currently 100% of the company’s plastic bag and shrink wrap suppliers are delivering products that contain a minimum of 30% recycled material and overall, 93% of total plastics used contain at least 30% recycled content. 95% of all cardboard boxes, roll cores and corrugated material used are FSC compliant or verified by the Forestry Commission, with suppliers confirming that all of the cardboard boxes used in the company’s packaging contain a minimum of 70% recycled material. Glidevale Protect is working alongside its suppliers to identify new ways to improve their own sustainability credentials.

Where appropriate, Glidevale Protect has already been able to remove some plastic from its product packaging for customers who have accepted reduced packaging on their deliveries. In addition, the manufacturer is also currently collaborating with selected customers on a take-back service on roll cores and stabilising cradles which are used when membranes are delivered on pallets, which will allow materials to be reused and put back into its production process.

As part of this commitment to improving its environmental impact, the company has installed EV chargers at both its UK factories and all new company cars will be either electric or hybrid vehicles.

Further updates will be announced throughout the year as Glidevale Protect identifies new opportunities to improve efficiency and reduce its carbon footprint.

More information can be found at www.glidevaleprotect.com or follow Glidevale Protect on LinkedIn.

Glidevale Protect – Enquiry 11

67 Vertical Sliding sash windows by Epwin Window Systems have been installed as part of a refurbishment programme of several Merseyside properties owned by North West Housing Services, a member of the Lark Lane Housing Cooperative. The properties, which fall within a conservation area, needed to be sympathetically upgraded to improve their aesthetics and provide more thermally efficient and sound-insulated windows for the occupants.

The project was awarded to experienced installer Countrywide UPVC of Ormskirk, Lancashire, who has over 20 years of experience in commercial installations. The team at Countrywide worked closely with all parties to plan an efficient installation programme which was completed over a sixmonth period.

The authentic heritage appearance of the Vertical Sliders met all the aesthetic considerations required on such a sensitive project and delivered the exacting standards needed to meet the thermal efficiency requirements.

The Epwin Window Systems Vertical Sliding windows were manufactured in white with run-through sash horns and chrome hardware for traditional styling.

The popular Epwin Window Systems Vertical Slider is a design classic that sympathetically captures many of the key features of the traditional window design combined with all the benefits of a modernday window. This includes superb energy efficiency and smooth operating balance mechanisms that ensure ease of use for occupants.

An efficient installation

With 67 Vertical Sliding windows needing to be installed across the various properties, the installation programme needed to be meticulously planned to minimise disruption of the occupants.

Heritage aesthetics and modern practicality

The finished result has transformed the properties and improved the homes’ thermal efficiency and noticeably reduced noise penetration. Paul Campbell, Director at Countrywide UPVC, said: “We were delighted to be invited to work on this refurbishment project. It’s a great example of how our team can deliver energy efficient and sympathetic window solutions for exacting refurbishment projects. We are looking forward to working with Lark Lane Housing Cooperative in the future.”

Epwin Window Systems – Enquiry 12

Howells Patent Glazing, experts since 1973 in manufacturing, supply and installation of unique roof glazing systems for the private, public and commercial sectors.

• Northlights, double and single pitch rooflights, patent glazing, canopies, vents & guttering

• Auto CAD drawings

• U values of 0.4w/m2 (under specialist conditions)

• Weather tightness tested to current British standards

• Quality assurance to ISO 9001:2015

• Members of council for aluminium in building

• Railway stations, shopping centres, schools, heritage buildings, industrial & commercial buildings, together with domestic applications, swimming pools and conservatories

• Prebuilt range rooflights, 14 day turnaround

Hörmann UK have announced the addition of ThermoSafe Decoral to their range of aluminium entrance doors, developed to provide discerning specifiers and consumers with a high quality, secure aluminium door in a selection of five beautiful and modern décor finishes.

The company are also making five new Duragrain colours available in their range of LPU 42 L-ribbed sectional garage doors which have been designed to provide the perfect match to the ThermoSafe Decoral doors. Five eye-catching colour finishes are available –Cement, Rusty Pantina, Wild Oak, Barnwood and Barnwood Grey.

The Hörmann ThermoSafe range of aluminium doors are manufactured to the highest quality standards and feature a solid 73mm door leaf installed within an aluminium frame. The door is robust yet elegant with the door being flush fitting to the frame on the inside, giving it a particularly spacious and modern look. It also provides high levels of security, long life, good acoustic insulation, and excellent thermal properties with a U-value of 0.87 W/M2K being achievable.

The Decoral finish is applied to the powder coated surfaces of the ThermoSafe door using a patented coating method resulting in a beautiful, colour fast and detailed appearance.

The five new Decoral colour finishes are available in eighteen exclusive door styles. Supplied with a standard frame in Jet Black, the ThermoSafe Decoral door is also offered with the exterior handles and embellishments in Jet black or in one of the Decoral colour options to match or contrast. The addition of the Decoral colour options further enhances the ThermoSafe range of doors and adds to an already extensive selection of styles, finishes and colour options.

Hörmann’s market leading sectional doors offer a winning combination of high-quality materials, safe operation, and good thermal insulation properties. The five new Décor colours are applied using the company’s Duragrain finish which is extremely hard-wearing and scratch resistant.

The surface finish is created using an innovative, UV-resistant digital print that’s applied to the primed sections of the door with the Duragrain protective coating added to safeguard against environmental effects and keep the door looking beautiful for years to come.

All sectional doors can be fully automated with Hörmann operators providing homeowners with safe, quick, and easy opening of their garage doors from the comfort of their car. Operation can be by either a handheld transmitter or a Smartphone using the Hörmann BluSecur app. For added peace of mind all automated Hörmann sectional doors are supplied with Secured by Design as standard (subject to fitting criteria and door style selection).

The Hörmann Group have also recently announced that due to their long-term commitment to sustainable manufacturing and green initiatives they are the first and only construction component manufacturer to offer CO2 neutral garage doors, entrance doors and residential internal doors - another good reason to choose Hörmann to make a difference.

For further information on Hörmann UK Hörmann innovations 2023 | Hörmann (hoermann.de) or call 01530 516868.

Hörmann UK– Enquiry 14

Long term protection for flat roofs, buildings and critical structures

Warm roofs, inverted roofs, green roofs, podium Whatever your requirements, we have a certified and proven solution to meet your needs.

With over 60 years’ experience, there’s not many challenges we haven’t faced, confronted and overcome.

Contact us to discuss

Whether it’s a school, hospital, hotel, car park, balcony, the list is endless, KEMPEROL® has a range of cold applied products to suit every application.

visit www.kemperol.co.uk

To find out more about the KEMPEROL® range of products

Tel: 01925 445532

Email: enquiries@kempersystem.co.uk

Enquiry

As part of its objective of constructing 300,000 new homes per year, in late 2020, the UK government issued reforms to fast-track planning for brownfield land regeneration.

The A. Proctor Group has over twenty years of experience in providing solutions for the safe development of brownfield land and an extensive range of products and solutions that will cater for most scenarios from typical ground gases, including Radon.

Radon is a naturally occurring, colourless and odourless radioactive gas. It was discovered in 1900 by the German physicist Friedrich Ernst Dorn, who was studying the radioactive decay of Radium, itself only discovered by Marie Curie two years earlier. This work was expanded by the Nobel prize-winning Scottish chemist Sir William Ramsey, who identified Radon as the heaviest gaseous element, 9 times heavier than air.

In Ground Gas terms, Radon is produced by the radioactive decay of trace amounts of uranium found in specific soil and rock types. Therefore, the site geology determines the level of Radon present as opposed to historical usage or pollution. This type of geology is most common in areas with granite bedrock, such as Devon, Cornwall, the Peak District, Northamptonshire, south Wales and northeast Scotland.

Radon is harmful to humans as the radioactive elements formed by its decay can be inhaled into the lungs, where they continue to emit harmful alpha particles. These alpha particles cause localised damage to the lung tissue, leading to the development of lung cancer. The British Medical Journal estimates around 1100 deaths per year are directly linked to in-home Radon poisoning, making Radon the second most significant contributor to lung cancer rates behind smoking. Legislation requiring action against Radon in UK buildings has been in place since 1985, initially for workplaces, but since expanded to include housing.

The average UK household radon level is 20 Bq/m³. The current “action level” for residential buildings is 200Bq/m³, and for commercial buildings, it is 300Bq/m³. If the Radon level is at or above the action level, protective measures must be taken to reduce the ingress of the Radon.

Some sources suggest at least 1200 new build homes per year will be above the safe level of exposure and should have remedial action taken. In addition, the risk of potential exposure to Radon has led to suggestions that building regulations should be updated to include more widespread Radon protection.

The first step to ensuring unsafe concentrations of Radon is not present is understanding how the gas enters buildings. There are several main routes of ingress for Radon or any other ground gas. These include cracked or porous solid floors, junctions and joints between components,

cracked or porous below-ground walls such as in basements, gaps in suspended floors, porous walls and foundations, gaps at service penetrations and pipes and through cavity walls.

Due to the geological origins of Radon gas, there is generally no scope to remove or neutralise the source of the gas, so barrier and venting solutions are most commonly employed. However, limiting the extent of the ingress paths here can help by reducing the long-term reliance on a barrier and providing additional protection.

The principal source of Radon guidance in the UK is the BRE document “BR211 Radon: Guidance on protective measures for new buildings”. This document is referenced in Approved Document C for England and Wales, Section 3 in Scotland and Technical Booklet C in Northern Ireland. There is also extensive guidance available from the UK Health Security Agency’s website, www.ukradon.org. The website offers help and advice for householders, employers, professionals, local authorities and housing associations.

The distribution of Radon producing geology is illustrated in Radon maps distributed by the UK Health Security Agency for the UK and the Irish Environmental Protection Agency. These maps indicate the Radon risks associated with a specific location.

The basic mapping will typically provide Radon levels based on a 1km by 1km grid. For most areas of the UK and Ireland more detailed geographic guidance is available on request. In the UK, the lead agency responsible for this is the UK Health Security Agency, which also provides this information for Scotland, Wales and Northern Ireland. In addition, the Irish Environmental Protection Agency can provide guidance specific to the Republic of Ireland.

Low-risk areas with less than a 1% chance of exceeding action levels do not require any special measures to be taken. Sites between 3 and 10% are classed as medium risk and require a basic level of protection, with sites over 10% being high risk and requiring full protective measures. Basic protection typically comprises a Radon barrier membrane within the floor or solum of the building, linked to a damp proof course in the wall. This barrier system should extend across the entire footprint of the building, including the cavity, and all overlaps and service penetrations should be fully sealed. Full protection requires a Radon barrier membrane but supplements this with additional ventilation to increase the rate of gas exfiltration. The ventilation can be a ventilated void. If there is no void, then a Radon sump should be installed. Ventilation systems are usually passive, with the option to convert to active by adding mechanical extraction fans. Active ventilation is only necessary if Radon levels are above the action level, even with a barrier membrane and passive ventilation.

Ensuring a barrier membrane system works effectively requires the material used to be suitably robust and the system to be well installed. Like other ground gas protection measures, the system is only as good as its installation, and if joints are not properly sealed or the membrane is punctured, then adequate performance cannot be guaranteed. However, a properly designed and fitted barrier will also function as a dampproofing membrane. The first point to consider here is the specification of the membrane itself. The BBA requires Radon barrier membranes to be at least 0.4mm, or 400 microns in thickness. It’s important to remember, though, that membranes, if stretched, will become thinner, so ensuring that the material has good tensile strength and elongation characteristics will ensure that the membrane retains its properties.

When installed under a slab, for example, concrete poured on top can exert forces on the material, causing it to stretch, and become thinner, creating a zone where the permeation of gas becomes more likely, even if the membrane is still intact and unbroken. This is the risk of using unreinforced DPM-style membranes for Radon protection. Reinforced membranes made from virgin material typically have the best mechanical strength properties thickness for thickness. The A. Proctor Group’s Protech Radon 400 membrane is manufactured from 100% virgin polymer with a polyester reinforcing scrim to provide excellent robustness and minimal elongation under load.

Once the membrane is installed, it should be thoroughly inspected prior to covering, as fixing any issues after the membrane is covered is often effectively impossible. This inspection should look for continuity issues such as unsealed joints, unsealed penetrations such as waste pipes, and punctures. Finally, although it may seem obvious, it’s also essential that the protective membrane and any associated accessories, such as DPCs, extend across the entire footprint of the building, from external to external, closing off any potential gas ingress points. This includes closing off any cavity walls with a suitably sealed and gas-resistant DPC.

Where it’s necessary to move beyond a basic level of protection, ventilation should be introduced below the barrier membrane. Where there is a ventilated void, a block and beam system, for example, the void depth should be a minimum of 150mm. The void can be ventilated with periscopic vents and airbricks, ground-level gully vents or several other options depending on the requirements of the occupiers or developers.

Where there is no void, a ground bearing slab, for example, Radon sumps, should be installed to provide subfloor depressurisation. The sumps and pipework are installed under the slab. A single, centrally located sump will provide extraction over a radius of 9m from the sump, around 250m2. If

the area under the slab is subdivided, for example, with foundation beams or other compartmentalisation, a separate sump may be required for each compartment. As a minimum, pipes or air bricks in the subdivisions should be provided to ensure the sumps can provide adequate extraction. If multiple sumps are used, they can be connected with pipework to form a manifold system and ducted to a single extraction system.

The A. Proctor Group has a comprehensive range of venting accessories, from simple periscopic vents and airbricks to ground-level gully vents.

As well the above-ground living space, it’s crucial that any basements or occupied underground spaces are protected, particularly as these areas are at greater risk as Radon can permeate not only through the floor but also through the retaining walls. For a typical domestic house, the areas in contact with the ground could be several times higher than for a similar house without a basement. This risk is further compounded by the lack of natural ventilation in spaces below ground level. Alongside this, it’s also important to consider waterproofing when creating a new basement or converting an existing cellar. Guidance and recommendations for basement waterproofing are given in BS8102, which also advises on the importance of considering Radon mitigation when designing basements. In these situations, it’s usually best to appoint a specialist to design and install the combined system, as Radon and waterproofing requirements can sometimes conflict.

While providing protection to an extension when there’s none in the existing building may seem pointless, a subfloor depressurisation system can help provide some degree of protection to the existing structure. Space for a sump under the existing structure can be created by locating the new sump and extraction pipework adjacent to the existing structure and knocking through the existing wall. The new depressurisation system can therefore extract from the fully protected extension and the existing unprotected structure via the two linked sumps.

The A. Proctor Group’s experienced technical support team can assist with the specification of Radon protection systems, reviewing drawings and site investigations to ensure a suitable and safe solution optimised to fit the individual project circumstances.

WRAS (Water Regulations Advisory Scheme) is a vital part of any commercial building's water system, ensuring that all water systems are kept safe and clean. Our pressurisation unit, Mikrofill 3 is the best on the market for commercial applications and it carries the WRAS Cat 4 certification.

WRAS Cat 4 certification carries with it some important benefits. It ensures that all products meet strict quality and performance standards, which helps to reduce costs associated with maintenance and repair.

It also provides an assurance to customers that their systems will be kept safe from contamination or damage due to poor installation or use.

Finally, it gives businesses and other organisations peace of mind when selecting water-related products, as they can be confident that all WRAS-certified products meet the highest standards set by the Water Regulations Advisory Scheme.

Our pressurisation unit Mikrofill 3 has been designed with WRAS Category 4 compliance in mind, meaning that it meets the very highest standards for quality and performance.

This product is ideal for commercial buildings due to its robustness, low maintenance requirements, energy efficiency, and flexibility – making it suitable for a wide range of commercial applications.

Additionally, our pressurisation unit has been designed with safety in mind; providing additional protection against cross-contamination.

Remember that in order to install a pressurisation unit into your commercial application you have to have WRAS Cat 4 certification. At Mikrofill we want you to have peace of mind that you have the right product for your project.

Contact us today to discover how we can help and support you right from the commencement of your project and remember we manufacture right here in the UK.

Stuart Turner – Enquiry16

It also provides an assurance to customers that their systems will be kept safe from contamination or damage due to poor installation or use

the

standards, well so do we.

Pendock Linea building linings provide a comprehensive range of decorative architectural casings and finishing solutions for interior and exterior applications.

Bespoke manufactured and formed to meet individual project requirements, the Linea range can also be installed by our experienced teams to ensure the perfect fit and finish are achieved.

The Linea range includes:

Pendock Linea is part of our extensive casings, enclosures and decorative architectural products range, which combines aesthetics with practicality and design flexibility.

01952 580590

Over 1,000 school building improvement projects have received the green light as part of plans to boost the condition of the school estate.

Atotal of 859 academies, sixth-form colleges and voluntary-aided schools in every region of the country will receive a share of a £456 million pot created to help refurbish and repair school buildings.

The condition improvement funding will ensure that pupils can learn in safe, warm and energy efficient classrooms.

Overall, the government has committed £1.8 billion of capital funding for the financial year 2023 to 2024 to improve the condition of school buildings – including £1.1 billion for local authorities, large multiacademy trusts and voluntary aided bodies announced in March.

Minister for the School System, Baroness

Diana Barran MBE said: “Our Condition Improvement Fund has already completed over 11,000 projects, making a difference to pupils and teachers across the country. These projects help to create safer learning environments that make a difference to the quality of education for pupils.

“It’s hugely important that every school has access to high-quality learning facilities and these funding allocations will make sure that responsible bodies can start to plan ahead and get projects started to replace roofs, boilers and windows – so pupils and teachers can learn and work in a comfortable space.”

The department has allocated over £15 billion since 2015 to support the government’s priority for schools to have safe, well-maintained facilities that support a high-quality education for pupils.

The announcement follows on from 239 new school buildings confirmed in December as part of the Schools Rebuilding Programme, with 400 out of 500 schools and sixth-form colleges now been selected for rebuilds through the 10-year programme.

RIBA have previously warned of the dangerous condition of England’s school estate.

RIBA President Simon Allford said: “England’s school estate remains in serious disrepair, so I am pleased to see this

funding to make much-needed upgrades. However, after many years of funding falling in real terms, this only represents a small proportion of the amount needed.

“Safety must be at the top of the agenda, but it is vital that investment also ensures that school buildings foster positive student engagement and support their communities.

“Whether retrofit or new build, we must deliver well-designed, energy efficient schools – architecture that guarantees that our schools are fit for future generations.

“We would urge the Government to publish the Buildings Conditions Survey – so we can better understand the scale of the problem we face.” >>

Granada Glazing has helped to reduce external noise at Manchester Metropolitan University’s All Saints Building, located next to the city’s busy ring road.

The units installed within the All Saints Building were horizontal sliders, which were selected to blend seamlessly with the stylings of the existing window. Sleek aluminium frames were used to construct the horizontal sliding units, which were glazed with 6.4mm acoustic laminate glass for maximum performance. As with all of Granada’s products, the frames were specifically designed to feature the slimmest sightlines available.

Granada’s horizontal sliding secondary glazing system works to enhance the thermal and acoustic performance of the primary window without restricting cleaning access or ventilation.

A central push button release mechanism ensures that all panels remain fully locked off until they are operated, providing an extra layer of security. Horizontal Sliders are suitable for all property types and styles, delivering up to 65% reduction in heat loss and up to 80% reduction in noise levels.

The frames are designed to be virtually invisible, seamlessly blending in with any interior décor. The Granada Glazing product range includes a variety of options such as hinged, sliding, and vertical sliders, as well as tilt-back and lift-out options.

In addition, Granada Glazing collaborates with architects and specifiers to design, manufacture, and supply high-quality commercial secondary glazing solutions to various sectors and building types throughout the UK.

Alumno, a specialist student accommodation developer, conceived and delivered a sophisticated and welcoming space for Element Bermondsey, a new student accommodation overlooking Bermondsey Spa Gardens.

To do this, Forbo Flooring Systems’ Sarlon and Safestep floor coverings were specified, for their technical and aesthetic qualities.

Operated by CRM Students, the UK’s leading independent student accommodation management brand, Element Bermondsey provides 143 students living in Southwark with high-quality, fully serviced and sustainable accommodation.

Greenaway Architecture and Tatham Studios worked with Alumno, to create contemporary spaces for the increasing number of students coming into London to study.

Forbo’s Sarlon 19 dB was specified in two different colours for this project.

Not only this, but the XtremePUR finish ensures Sarlon delivers improved scratch resistance, which is important for student accommodation as it endures heavy use across an academic year. Additionally, Sarlon is phthalate free, minimising the impact it has on the residents’ wellbeing.

Furthermore, Forbo’s Safestep product was used in the ensuite bathrooms, offering a good level of slip resistance.

They fit within square apertures punched through soffits in the glulam timber roof grid and bring additional light into the atrium designed by Tate+Co Architects as an exhibition, teaching and theatre space, as well as somewhere for students to mix and relax.

The Whitesales rooflights were designed and specified complete with preformed 300mm PVC splayed upstands, which enabled them to be fitted directly into the glulam grid. These are estimated to have saved the roofing team at least two weeks on site because they didn’t have to construct the upstands themselves and the integrated splay made waterproofing the roof a lot easier.

Tate+Co chose Whitesales’ em.glaze rooflights for the contract because of their sleek, minimalistic aesthetic, and because they offered flexible options like the upstands and matching concealed actuator smoke vents via Whitesales’ affiliate business Sertus.

Tate+Co Director Andy Baker-Falkner explained: “The internal look of the rooflights was important for the overall design intent

of the atrium, which is lean and crisp with services hidden wherever possible. We liked the design of the Whitesales em.glaze units, particularly with the clean white reveal and option for fully concealed vent actuators.”

The Whitesales em.glaze rooflight is a flush-glazed glass-to-edge design with flat sealed glass units fitted within a fully welded, thermally broken aluminium frame. There are 14 stocked square and rectangular sizes, from 600mm to 2500mm, but bespoke options can be up to 3200mm. em.glaze is double glazed and Part L compliant as standard, but rooflights can be specified with triple glazing if preferred and in any RAL colour as required.

The Creative Centre was designed from the outset as a low energy building and has achieved a BREEAM Excellent rating, based upon the use of low embodied carbon materials including glulam and CLT, as well as triple glazing in places and mixed mode ventilation. In the atrium, there was a requirement for a degree of solar gain to minimise the requirement for heating, so

the em.glaze rooflights were specified with bespoke glass to allow for that.

Glenn Knight, Business Development Manager at Whitesales, commented: “The design of the atrium was intended to frame the views of the city and the timber columns reference the detailing in the nearby York Minster. It was key to the architects’ vision for the whole building, so it was a privilege to be able to play our part in helping to realise that.

"Our technical team advised on the design modifications we could make to the rooflights and upstands to fit into the glulam grid without adding significantly to the cost and we also recommended the splayed upstands which delivered many times over in terms of time saved on site.”

The main contractors on the building were Kier Construction and the architects were Tate+Co. More details at:

https://www.whitesales.co.uk/products/ product-category/rooflights/

Whitesales – Enquiry 20

When two top-performing Wakefield schools needed to source high quality flooring for their sports halls they turned to international flooring specialist Gerflor to supply 1300m2 of their world class Taraflex® Performance vinyl sports flooring, together with 1350m2 of Isolsport isolating membrane to complete the refurbishment project.

Queen Elizabeth Grammar School for boys (QEGS) and Wakefield Girl’s School are both something of academic legends. At QEGS, “sport for all” is a principle they live and breathe every day.

Kent Oliver, Estates Manager at Queen Elizabeth Grammar said, “We had an urgent need to refurbish our Boys’ and Girls’ tired granwood main sports hall flooring. We engaged with a number of Gerflor’s previous clients, who could not speak highly enough of the quality products installed and the fantastic levels of service provided by the Specification and Technical teams.”

On making the decision to specify Gerflor flooring, Kent Oliver went on to say, “We were in search of a surface that was ideal for a variety of sports. Offering a good level of shock absorption, minimising the force of impact on the body, and reducing long term injury risk. We are delighted with the final results. The surfaces are better performing than the granwood and offer a lot more protection than the previous flooring. Both floors installed are of the highest quality with a superior finish to them.”

On specification, Wayne Andrews also commented, “We proposed an Isolsport overlay with Taraflex® Performance onto the existing granwood floor, this provided a robust solution avoiding high labour costs that would be incurred from the uplifting of the existing granwood floor and also any sub floor preparation costs. The boys and girls sports halls are used by professional players for a wide variety of sports.”

The fitting of the new Gerflor sports floor would be undertaken by one of the country’s leading installers of sports floors. Stockport-based Recreational Coatings Limited has over 30 years’ experience of installing sports surfaces in various prestigious events some of which include the Olympics, Commonwealth Games, World and European events throughout the UK and beyond.

Jed Hill, its Managing Director said, “with a strong reputation to uphold, the school entrusted our team here at Recreational Coatings Limited to overlay the existing granwood floor with a new, high-performance, cushioned surface.”

Jed Hill added, “The school had taken the time to find out more about other local Taraflex® installations in other eeducation establishments. Gerflor’s Taraflex® Performance vinyl sports flooring ticked all the boxes for its sport and multi-use requirements. Taraflex® Performance vinyl sports flooring can be specified for a wide range of sporting applications and leisure activities. It has excellent safety, comfort and performance qualities, as well as being available in vibrant colours and realistic wood designs, thus it’s an ideal solution for a vast array of areas.”

Wayne Andrews concluded by saying, “The client is extremely pleased with the final installation. A number of Gerflor people were involved, right from the Specification Team through to high level management who all agreed how important and unique this project was. Kent Oliver, the Estates Manager at the school was very impressed with the service received from Gerflor. In addition to this the impact protection and playability of Taraflex® was a big talking point for him.”

Kent Oliver ended by saying, “We would definitely specify Gerflor again. The performance and appearance has surpassed our expectations and we have received nothing but positive feedback from the schools, and other sports hall users. I would also like to add that Wayne Andrews from Gerflor was very knowledgeable and professional during our initial meetings and throughout the entire project.”

Gerflor – Enquiry 21

Working with architects, BDP Glasgow Studio and main contractor, Balfour Beatty, Style was specified to create flexible space in both the auditorium and one of the main classrooms in Strathclyde University’s £60 million new Learning & Teaching Building.

In the tiered auditorium, a Skyfold Zenith stepped moveable wall was the ideal solution. Offering an outstanding 59dB acoustic rating and descending from the ceiling at the push of a button, the vertically rising moveable wall offers a unique ‘thin path of travel’ which means it can descend into tight spaces, in this case the narrow gap between the seating.

In the main classroom, a Dorma Hüppe Variflex moveable wall offers a 56dB acoustic rating

and its semi-automatic operation means the acoustic seals are applied to the correct pressure to maximise the effectiveness of this operable wall.

David Louden, Style’s director for Scotland, said: “The Skyfold looks fabulous in situ, with clean, white panels and is a real showcase for the University, and the classic laminate white finish on the Variflex complements the styling of the main classroom perfectly."

Built with a sharp focus on sustainability, the Learning & Teaching Building was created through the refurbishment and integration of two existing buildings.

VORTICE supplies HR unit for school gymnasium

VORTICE has supplied a commercial roof mounted MVHR unit to St Paul’s School in Barnes for a gymnasium, on time and on budget, providing an effective solution that was managed by KPS Southern Ltd. VORTICE consulted with KPS and agreed that the VORTICE NRG Mega would be the best possible solution. The unit included 50mm insulated panels, an onboard CO2 sensor, defrost module complete with dampers and sound attenuation. Because of its size, it was delivered in three sections and lifted by crane onto the school roof along with other plant equipment, where it was assembled and commissioned. The VORTICE NRG Mega heat recovery unit uses the plate heat exchanger to control the internal thermohygrometric conditions through the recovery of energy from the air extracted from the room.

Alumno, a specialist student accommodation developer, conceived and delivered a sophisticated and welcoming space for Element Bermondsey student accommodation, with Forbo Flooring Systems’ Sarlon and Safestep floor coverings specified for their technical and aesthetic qualities. Sarlon 19 dB was specified in two different colours for this project. The XtremePUR finish ensures Sarlon delivers improved scratch resistance, which is important for student accommodation as it endures heavy use across an academic year. Additionally, Sarlon is phthalate free, minimising the impact it has on the residents’ wellbeing. Forbo’s Safestep product was used in the ensuite bathrooms, offering a good level of slip resistance.

Forbo Flooring Systems – Enquiry 24

A Mapei system has been used by Titan Flooring to promote a fast and safe floor installation at Sunningdale SEN School in Sunderland.

The project, which included installation of vinyl and carpet tiles throughout the £12.5 million new-build school, was completed for Kier, a leading UK infrastructure services, construction and property group.

Sunningdale SEN School is the city’s only specialist school for children with severe, profound and multiple learning difficulties, aged 2-11.

During the installation, Titan Flooring installed Mapeproof One Coat – a single application damp proof membrane - to protect the new floor coverings from residual moisture. All-purpose primer, ECO Prim T Plus, was then applied to bond the damp proof membrane to the levelling and smoothing compound - Latexplan Trade. ECO Prim T Plus features a solvent-free, low odour formulation, with EMICODE EC1 Plus for very low emissions of VOC.

Following installation of the Latexplan Trade – which benefits from a low odour and protein-free formulation - Titan used two Mapei adhesives for the floor installation: solvent-free Ultrabond ECO Tack TX+ carpet tile tackifier and Ultrabond ECO V4 Evolution all-in-one adhesive for the vinyl. Both adhesives also feature a very low VOC formulation, with EMICODE EC1 Plus certification.

Mapei – Enquiry 25

Luke Davies, Product Manager - Rock Mineral Wool at Knauf Insulation explains the launch of its first cavity barrier product, Rocksilk Rainscreen FFCB and how the company is designing products for the real world.

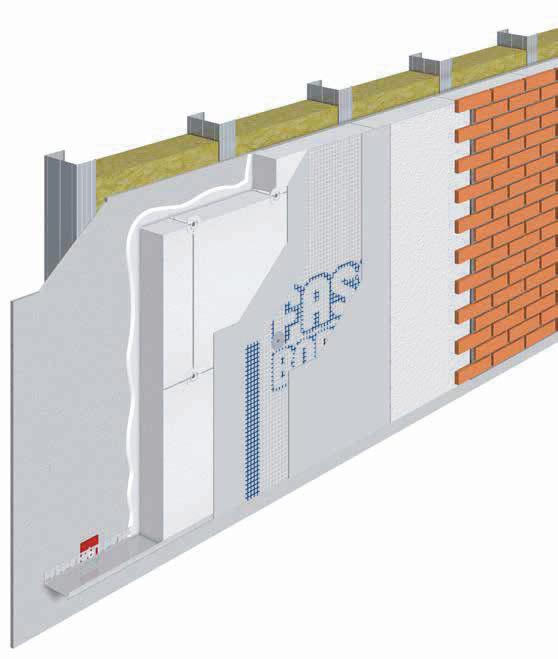

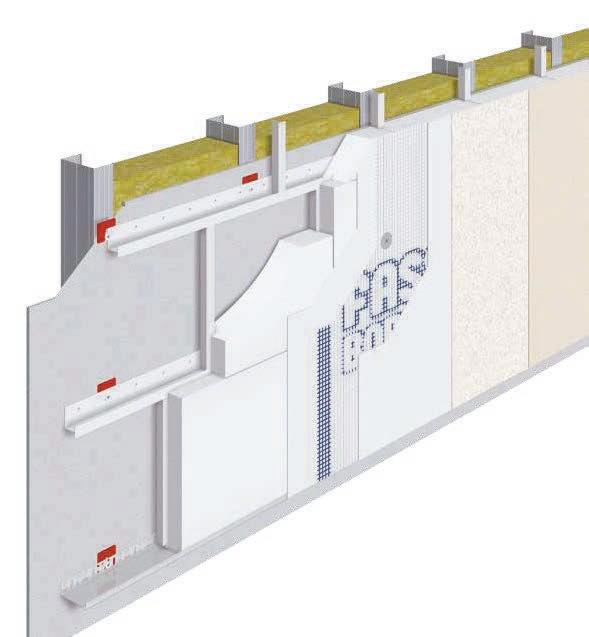

Rocksilk RainScreen FFCB is a completely new concept in cavity barriers. It is the first cavity barrier that is fixed to the face of the insulation and built in to masonry façades during construction.

The patented non-combustible solution is part of a system that comprises Rocksilk RainScreen Slab sheathing insulation for behind masonry façades and the fixings. The system has been certified to provide fire resistance for up to 90 minutes insulation and integrity (EI90) in the residual cavities of buildings with masonry façades.

We believe it’ll be a real game-changer –by making installation easier, it will give architects and specifiers the reassurance that it can deliver the ‘as built’ performance required by stricter legislation.

How did the idea come about?

Knauf Insulation is acutely aware of the performance gap. So, we’ve been taking steps to help ensure the systems specified by our customers can deliver their intended performance in the ‘real world’.

As part of this, we’ve been looking at how products are actually installed on site. One brickwork contractor expressed frustration over the installation method for cavity barriers for use behind masonry façades.

Typically, bricklayers cut recesses into the insulation post installation, install the fixings then the cavity barrier. It’s an arduous, timeconsuming process that can potentially have wider implications on performance.

As well as being inefficient, it was clear that ‘breaking’ the sheathing insulation to insert the cavity barriers could result in unintentional air gaps which could compromise the thermal, fire safety and acoustic performance of the system as a whole.

How did you identify a solution? When we looked at the issues, the solution – fixing the cavity barrier to the face of the insulation – seemed obvious. It would prevent breaks in the insulation that could affect performance and would be easier to install. It would reduce costs and make product selection easier because just three sizes of

cavity barrier are required for all cavity depths. And it would also reduce waste.

Before developing the product, we undertook due diligence to confirm there was a viable market and consulted trusted partners for feedback about every aspect from fire safety testing to installation.

Then we refined the product. The rock mineral wool ‘recipe’ needed to complement our Rocksilk® RainScreen Slab. It had to be non-combustible with a Euroclass A1 reaction to fire classification. And we wanted to achieve 90 minutes insulation and integrity (EI90) for fire resistance – three times the requirement of the building regulations. All of which we achieved.

In terms of fixings, reducing metal penetration into the insulation was important because it affects thermal performance.

Mineral ceiling tiles by leading UK manufacturer Zentia have played an instrumental part in the redevelopment of Glasgow's historic Grade A listed Custom House.

Some 3,500m2 of Zentia's Ultima+ range features in the public circulation and corridor areas of both the Clayton hotel and the Adagio aparthotel built by main contractor McAleer Rushe as part of the £52 million landmark restoration scheme which opened in November 2022.

It was the first time architects Leach Rhodes Walker had worked with Zentia products.

Steven Allcock, senior project leader at LRW, said: "The scheme was challenging in several ways. Firstly, we had to deal with the existing listed building and incorporate it within the overall scheme. Then there were the acoustics.

So, we replaced traditional brackets with slimline ‘pegs’ that are installed from the outer leaf and mortared into the cavity.

It’s fair to say that today’s construction industry is defined by stricter legislation and that the high standards set by building designs must translate into real, as-built performance. That’s not possible if installation methods can undermine a product’s performance.

That’s why manufacturers, such as ourselves, need to focus on what’s actually happening on site when we’re developing products that address the needs of architects and specifiers, as well as other stakeholders across the supply chain.

"With it being located next to a railway line, the building had to be designed to be isolated to avoid sound transference throughout the structure.

"And then there was movement tolerance of +/- 50mm in two directions and +/25mm in the opposite two directions."

Ultima+ tegular-edged mineral ceiling tiles were fixed on a Prelude 24 TLS grid by specialist subcontractors CCL Interiors.

The Association of Noise Consultants (ANC) has partnered with the Institute of Acoustics (IOA) and the Chartered Institute of Environmental Health (CIEH) to create new guidance on acoustics in gym environments.

The ProPG Acoustic Guidance has been developed for practitioners, developers, operators and Local Authorities involved in the construction of gyms. The document is the culmination of two years of hard work, involving cross-industry consultation with multiple experts from different fields.

Gym owners and developers will naturally want to create a pleasant acoustic environment for people exercising in their

Manufactured with up to 64% recycled content and up to 100% recyclable, the Ultima+ range is available in three core densities that allow specifiers to engineer sound absorption and attenuation for optimum and balanced acoustic performance.

premises and avoiding creating noise complaints from people living or working nearby. However, gym equipment is often a major cause of vibration and noise, so appropriate preventative and mitigative strategies need to be considered at the earliest possible stage. This is a growing problem as many gyms belong in dual use buildings or are located in close proximity to residential buildings, where tolerance of noise is understandably lower.

The key aim was to help standardise the approach for acoustics for gym operators, developers and local authorities for the first time. The guidance represents the latest science and thinking on this topic, but will need to be updated frequently in light of changing regulations, research findings and evolving best practice.

Acoustic issues from gym activity can be separated broadly into three sub-groups: high impact response, synchronised repetitive excitation and airborne noise. High impact response (HIR) typically includes things like weight drops, while synchronised repetitive excitation (SRE) includes equipment like a treadmill. Airborne noise, in contrast, would be something like amplified music.

The ProPG guidance sets out appropriate methodologies for dealing with HIR and SRE. For testing, the aim of a testing methodology should be to simulate the source activity in the proposed gym area, whether impact or repetitive excitation, and measure the resulting noise levels in the nearest sensitive receptors. The results can then be assessed against defined criteria, which the guidance also sets out.

All apartments at the Triptych Bankside development, next to the Thames in Southwark, benefit from spacious balconies, with an emphasis on the quality of the finishes. However, their highly unconventional and dramatic semicircular profiling meant Schöck had to demonstrate its design expertise in meeting the structural load-bearing thermal break requirements.

Triptych Bankside is at 185 Park Street, in Southwark. It comprises three elegant building forms within a landscaped park setting and is a close neighbour of the Tate Modern, the Millennium Bridge and the Globe Theatre.

The mixed-use development provides two residential blocks – fifteen and nineteen storeys respectively – along with office accommodation and creative workspace in a ten storey building.

There are also retail and cultural amenities at ground level. A subtle twisting form, combined with undulating curved terraces wrapping around the exterior, affords the buildings a considered architectural elegance – but central to the residential buildings design is also its ability to be adaptive and maximise both amenity space and local views.

The development has a commitment to the local community too and Triptych Bankside is facilitating the delivery of 57 new, purposebuilt almshouses, to be operated by the United St Saviour’s Charity, which has been working in Southwark since 1541.

In addition the design reinstates the lost historic street, Emerson Place, which creates new pedestrian connections through the site to the River Thames and which features a continuous flow of green spaces including a central public square.

Special demands need a special solution

The special demands of the Triptych Bankside semicircular balcony profiling required bespoke Isokorb T type SK units to be designed with specific postional load capacities, using built-in steel reinforcement.

The T type SK is a complete system structural thermal break for minimising thermal bridges between cantilevered steel constructions on reinforced concrete components. Since it can be prefabricated to a large degree, installation time on the building site is reduced.

Also, due to its superb load-bearing capacity, the engineering and structural design is ideal, even for heavy modern balconies.

It is capable of absorbing large bending moments and shear forces; and is certified as a safe and verifiable solution through independent third party evaluations from the BBA and Oxford Brookes University.

At present, no other UK product for concrete-to-steel applications meets these load-bearing requirements, or meets the current and future thermal performance required by building standards (Part L).

Minimising thermal bridging is critical

The entire project is built very much with sustainability in mind and minimising any risk of thermal bridging at the balcony detailing is critical for a number of reasons.

Namely, local heat loss will result in more energy being required to maintain the internal temperature of the building.

Also, low internal surface temperatures in the area of any thermal bridge can cause condensation and this in turn is likely to result in structural integrity problems.

Mould growth too is a possible risk, which in a residential situation can cause asthma and allergies.

The Schöck Isokorb range of structural thermal break solutions is the largest in Europe and in the UK helps projects meet full compliance with the necessary Building Regulations (and the impending Future Homes Standard criteria where relevant).

In addition to the Isokorb type used on this project, there are also solutions for concrete-to-concrete, steel-to-steel, renovation projects, Passive House – and even a maintenance free alternative to wrapped parapets.

All products have the security of independent BBA Certification, which provides NHBC approval.

The temperature factor requirement (fRSI) used to indicate condensation risk, which must be equal to, or greater than 0.75 for residential buildings, is also easily met by incorporating the Isokorb.

At present, no other UK product for concrete-to-steel applications meets these load-bearing requirements, or meets the current and future thermal performance required by building standards (Part L)

High performance spray foam insulation has been used in an innovative shipping container repurposing project in central Manchester.

The project – The OGS Container Scheme - has been built at the Old Granada TV Studios site and uses an array of 20 foot-long metal shipping containers to create low cost office space for start-up’s and other small businesses.

The £3m development uses 42 containers to form a four-story integrated block comprising three rows of 14 containers over a ground floor podium of steelwork. A blockwork core houses lifts to all floors and each level has WC and kitchen facilities and a floating walkway with staircases at both ends.

Main contractors for the project were Artez Interiors LTD of Bolton. Artez QS, Jeff Greenwood explains. “Overall construction was straightforward with each container being craned into position and locked in place. We used brand new containers rather than recycled so we knew everything would fit together perfectly,” said Greenwood.

He continued “One of our biggest challenges however, was thermal insulation. Metal boxes are notoriously difficult to insulate effectively and reaching the required thermal values meant we had to think out of the box.”

To solve this issue, Artez brought in Stockport based insulation specialists Green Horizon Energy Solutions Ltd, who recommended a highperformance closed cell insulation system from Huntsman Building Solutions (HBS).

Matt Lawford of Green Horizon specified HBS Heatlok HFO, a polyurethane-based product which is spray applied directly to the internal walls of each container.

Heatlok HFO is a premium closedcell foam that expands 100-fold on application, completely filling difficult to reach construction voids and creating a continuous, uninterrupted thermal barrier.

Before spraying, each container was lined with 75mm deep galvanised steel studwork to the walls and ceiling and electrical and related services installed. After application, a vapour barrier and conventional plasterboard were applied creating an effective self-contained fire compartment and at the same time, providing a decorative internal finish.

The spray foam insulation completely encapsulates the studwork and adheres to the contours of the metal container shell, eliminating the risk of condensation.

According to Huntsman, Heatlok HFO uses recycled plastic materials and renewable soy oils in its composition. Its hydroflouroolefin [HFO] blowing agent is the most environmentally conscious blowing agent produced to date, with zero ozone depleting potential [ODP] and a global warming potential [GWP] of 1, making Heatlok HFO one of the most durable and environmentally friendly insulation.