The on-going pandemic and the new post-Brexit landscape are both ensuring we head into the new year with a large degree of uncertainty.

However, research suggests a growing number of companies believe the opportunities outweigh the risks for their businesses given significant investments in boosting productivity and agility, while manufacturers are also more confident about the prospects for their own companies than they are for either the global or UK economies.

The 2021 Make UK/PwC Executive survey shows a number of significant concerns for companies moving forward. Yet the research also shows that firms are beginning to focus on new products, building resilience and agility to counter risks.

“The transition to new trading arrangements with the EU was always going to be the biggest challenge facing manufacturers this year and the fact we have an agreement in place doesn’t alter that,” commented Stephen Phipson, Chief Executive iof Make UK, “However, just as the sector rose to the challenge of aiding the national effort at the start of the pandemic, it is clearly set to do so again as we re-build the economy and take advantage of the opportunities from digital technologies.

“To ensure we cement the role of industry in the future economy we need to see a strategic vision from Government for the whole economy across the UK. This must go way beyond short term tinkering and involve an industrial strategy that takes at least a decade long horizon with the whole of Government putting its shoulder to the wheel to deliver it.”

Cara Haffey PwC UK’s Manufacturing and Automotive Leader, believes the EU trade deal, taken alongside the positive progress with both COVID-19 vaccines, will give business leaders the confidence to start planning for the future with greater clarity.

“UK manufacturers are resilient by nature and, with the right investor and government support, their agility and drive will enable them to build new trade networks and embrace the clean, green digital revolution, ensuring the UK remains a go-to destination for many more years to come,” she added.

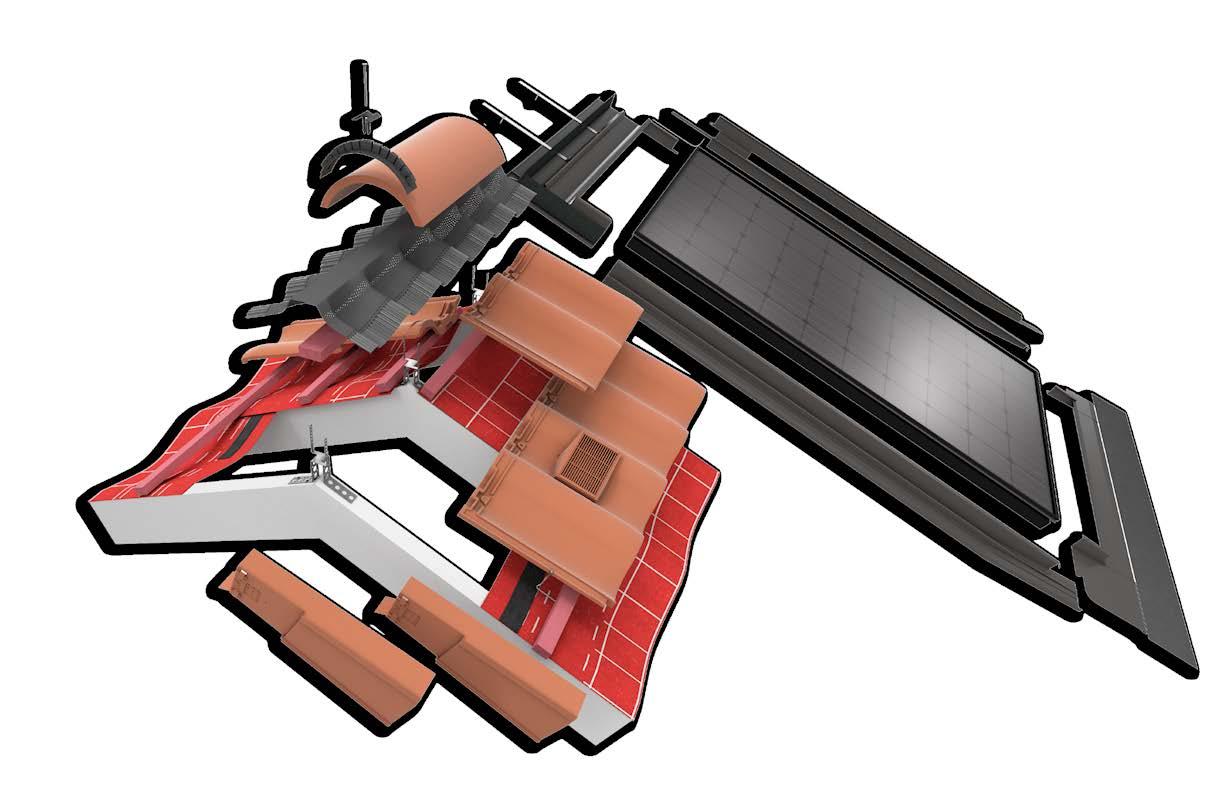

Howells Patent Glazing, experts since 1973 in manufacturing, supply and installation of unique roof glazing systems for the private, public and commercial sectors.

• Northlights, double and single pitch rooflights, patent glazing, canopies, vents & guttering

• Auto CAD drawings

• U values of 0.4w/m2 (under specialist conditions)

• Weather tightness tested to current British standards

• Quality assurance to ISO 9001:2015

• Members of council for aluminium in building

• Railway stations, shopping centres, schools, heritage buildings, industrial & commercial buildings, together with domestic applications, swimming pools and conservatories

• Prebuilt range rooflights, 14 day turnaround

Howells Patent Glazing Ltd - Triton Works, Woods Lane, Cradley Heath, Warley, West Midlands B64 7AN

As we enter 2021 the challenges facing the wider industry remain significant.

Our tree pit covers are designed to your exact size and configuration, accurately and cost-effectively providing easy tree root ball access for on-going maintenance. Manufactured in rust and corrosion resistant stainless steel or aluminium, tree pit covers eliminate tripping hazards, allow the integration of your choice of stone paving for a high quality finish and provide landscapers with hidden access for uplighters and water features to enhance the aesthetics of any urban area.

Given the choice, why would you specify anything less?

Construction membranes may be hidden after the project is complete, but their role in ensuring proper heat, air and moisture movement through the building envelope and safeguarding the health of the building and occupants is essential.

Roofshield has been the trusted industry standard air- and vapourpermeable underlay for pitched roofs for over 20 years. Certified by the BBA, LABC and LABSS, Roofshield provides a fully ventilated roof without the need for any ventilation accessories. See page 18-19 “Pitched Roof Design Considerations”.

The Government has committed to establish a national regulator for construction products as part of wider reforms to address systemic failings identified by the Hackitt Review.

The regulator for construction products will have the power to remove any product from the market that presents a significant safety risk and prosecute any companies who flout the rules on product safety.

The regulator will have strong enforcement powers including the ability to conduct its own product-testing when investigating concerns. Businesses must ensure that their products are safe before being sold in addition to testing products against safety standards.

Chair of the Independent Review of Building Regulations and Fire Safety Dame Judith Hackitt described it is another really important step in delivering the new regulatory system for building safety. “The evidence of poor practice and lack of enforcement in the past has been laid bare,” she continued. “As the industry itself starts to address its shortcomings I see a real opportunity to make great progress in

conjunction with the national regulator.”

The Construction Products Association’s Chief Executive, Peter Caplehorn, welcomed the announcement. “We have worked closely with the Ministry of Housing, Communities, & Local Government to progress the reforms to culture and practices outlined in the Dame Judith Hackitt Review,” he said.

“This marks an important milestone in those reforms, and we look forward to supporting the work of the regulator and Office for Product Safety and Standards to develop how this will be put in place in the coming months.”

The regulator will operate within the Office for Product Safety and Standards (OPSS) which will be expanded and given up to £10 million in funding to establish the new function. It will work with the Building Safety Regulator and Trading Standards to encourage and enforce compliance. The government has also commissioned an independent review to examine weaknesses in previous testing regimes for construction products, and to recommend how abuse of the testing system can be prevented.

All homes and businesses will have to meet rigorous new energy efficiency standards to lower energy consumption and bills, helping to protect the environment, the Housing Minister Chris Pincher has announced.

Responding to a consultation on the Future Homes Standard, the government has set out plans to radically improve the energy performance of new homes, with all homes to be highly energy efficient, with low carbon heating and be zero carbon ready by 2025.

These homes are expected to produce 7580% lower carbon emissions compared to current levels. To ensure industry is ready to meet the new standards by 2025, new homes will be expected to produce 31% lower carbon emissions from 2021.

Existing homes will also be subject to higher standards – with a significant improvement on the standard for extensions, making homes warmer and reducing bills.

RIBA President, Alan Jones, said: “Several measures outlined in the government’s

response show some endeavour to tackle the climate crisis. Regulation to ensure no new home will be reliant on fossil fuels; decisions to close the loopholes in the transitional arrangements; and powers to allow local authorities to continue to set their own energy targets are all welcome.

“However, I am concerned to see no requirement to calculate the operational

Diamond Build PLC has begun work on a new £28m development in Tottenham, it will be transformed into a 51,000 sq ft scheme offering 13,000 sq ft of office space and 48 new homes.

Located on the ground floor, 50 per cent of the office accommodation will be used as Diamond Build Group’s new head office with the other half available to local businesses at affordable rent.

A mix of one and two-bedroom apartments as well as three-bedroom duplex houses will be built above the office space and available for sale. Each home has been designed with an open-plan layout and private balcony with access to a communal courtyard.

Externally, the architecture will reflect the site’s industrial surroundings featuring exposed brickwork and metal cladding.

energy or embodied carbon of new homes. The proposed ‘performance gap’ measures are not sufficient to determine how well new buildings actually perform.

“Both the Future Homes Standard and new Future Buildings Standard – which the RIBA and its members looks forward to helping shape – must provide the changes needed to meet net zero.”

Timber frames and biodiversity are the key features of Brent Cross West’s new eastern entrance, which has received planning consent from Barnet Council and will provide an essential link between two major schemes as part of the ambitious Brent Cross Cricklewood regeneration programme.

The new station eastern entrance, which has sustainability and environmental innovations

at the heart of its design, will provide a stunning first impression of London’s new £40 million state-of-the-art train station, which is due to be completed at the end of 2022.

Designed by architects Studio Egret West, the eastern entrance will also provide the link between the new station and Barnet’s new park town, Brent Cross Town, which incorporates 50 acres of parks and playing fields.

An application for planning permission for the development of high-quality student accommodation on London Road has been approved by City of Edinburgh Council.

The 76-bed development is being undertaken by developer HG Developments and is situated opposite Meadowbank Stadium.

The contemporary state of the art development will replace the existing car wash and will see the delivery of a six-storey block, predominantly in brick, bringing a strong architectural element to the corner site.

The planning application was progressed after the site was re-marketed when a previous residential development consent for the scheme could not be progressed due it not being possible to build over a sewer present on the site.

On completion, Edinburgh based charity People Know How will locate their headquarters on the ground floor of 61-63 London Road, closer to the communities in which they operate.

The Chartered Institute of Building (CIOB) is launching a Certificate in Fire Safety for Construction, due to begin on 17 February 2021.

The course provides an overview of fire safety and the knowledge to enable the learner to manage fire safety in buildings. The course follows the recommendations in Dame Judith Hackitt’s Independent Review of Building Regulations and Fire Safety, which outlined the improvements that the sector should make to prevent incidents such as the Grenfell Tower fire from reoccurring in the future.

This course is aimed at improving the fire safety awareness for managers in the construction industry and for those who are faced with managing fire safety in the workplace. It looks at current and future legislation, building design and building construction, fire risk assessments, fire

science and human behaviour, and how to manage and implement fire safety systems.

Brad Walker, Eng Tech, AIFireE, course leader, said: “We are pleased to be able to offer this Certificate in Fire Safety. A crucial aspect of building safety, it has been designed for those who are looking to gain an improved understanding of how fire safety principles are applied in the built environment. It will also provide the delegates with a stepping stone to competency for those who have fire safety management responsibilities.”

Meanwhile, the Grenfell Tower Inquiry has decided to temporarily suspend oral hearings.

“This was a difficult decision, but the increase in transmissibility of the new variant of Coronavirus means that there is a significant increase in the risk of infection

facing anyone who travels to and works at the Inquiry’s premises, notwithstanding the robustness of the arrangements in place,” said a spokesperson for the inquiry. “In the current circumstances it is unreasonable to ask witnesses and Inquiry team staff to travel into a particularly high-risk area to attend the Inquiry.”

The Inquiry is working with its supplier to make urgent preparations for remote hearings, including safely distributing equipment to witnesses and testing it to ensure that hearings proceed smoothly.

It is hoped remote hearings will start as early as possible in February, and the Inquiry team will write to core participants to confirm the resumption date and any other details, including how bereaved, survivor and resident core participants will be able to follow the proceedings remotely.

To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

DLA Architecture has completed and handed over a significant new collection of buildings comprising community space and housing in Hackney.

The £21 million project was an enabling development between developer, Thornsett, The London Diocesan Fund (LDF) and The Parochial Church Council (PCC) of St John at Hackney.

The scheme is designed around the existing Grade I listed St Augustine Tower and the Grade II* listed St John at Hackney

Church. Chris Levett, Director at DLA Architecture, said: “We carefully designed a scheme to respond to the direct urban fabric of the locality, with hard and soft landscaped squares, open views of the Church and Tower and new passageways connecting to the high street.”

The new housing offers a mix of residentials types, including one and two bedroom apartments as well as family house size duplexes with gardens, responding to the Local Authority housing needs.

An in-depth new NHBC Foundation report on how the role of Modern Methods of Construction (MMC) has evolved within the house-building industry has just been released.

Prefabricated homes have been longheralded as the future of house building; but if the arguments for homes to be manufactured like cars are so compelling, why is factory-built housing not more common?

That’s the question ‘Modern methods of construction: building on experience’ examines, by scrutinising notable periods of transformation in the industry and exploring the elements of design, as well as the social and economic influences, that fuel change.

The report also looks at the history of non-traditional housing through a range of different technologies and advancements since the 19th century and how builders and developers can harness technological advances to respond to the increasing demand for new homes.

In summary, NHBC’s Head of Standards, Innovation and Research, Richard Smith, said: “As we navigate the COVID-19 pandemic and come out of the EU, there is an opportunity to innovate. This new report looks at the best features of homes from the past to inform the homes of the future.

“We really hope that ‘Modern methods of construction: building on experience’ will ultimately be an enabler of change for the industry.”

Utilising light steel frame as the principle structural component in a building creates many design opportunities.

Engaging the manufacturer’s design team early ensures that their knowledge and expertise in the use of the system permeates through the design process.

There are some crucial factors that can transform design, engineering and specification decisions which not only streamline the construction process but can also save a vast amount of time and money.

Established to support the overall objectives and growth of the sector - the

Light Steel Frame Association (LSFA) have formed a working group with some of its members including EOS, DACS, Evolusion Innovation, Fusion Building Systems, Sigmat, Siderise, Ayrshire Metals, Cogent Consulting and SCI, to develop a Specification and Engineering Guide to ensure that construction professionals gain maximum benefits from specifying light steel framing systems.

Freely available to download, this guide outlines design opportunities, fire safety, performance in construction and in use together with the different types of systems, applications, and interfaces of light steel frame.

To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

NHBC Foundation reveals new report on the history and future of MMC

Leading manufacturer of water pumps and pump systems, Wilo Group, has been announced as one of the top 50 Sustainability & Climate Leaders.

With a target of providing 100 million people with access to drinking water by 2025, Wilo is heavily incorporating sustainability into its approach and working to provide intelligent, efficient and climate-friendly solutions.

To find out more about Wilo’s energy efficient products, visit: wilo.com/gb/en

The new broadcast centre and HQ for BBC Cymru Wales lies at the heart of the Capital Square redevelopment in the centre of Cardiff and is an exemplar, BREEAM outstanding building, setting new standards for innovative, flexible and cost-effective workplaces.

Project: HQ for BBC Cymry Wales

Architect: Foster+Partners Suppliers: Kawneer, SAS International

Designed by Foster+Partners, the new headquarters brings together a wide variety of studio, administration and support spaces in a single building, which is open to the city, highly flexible, energy efficient and provides a creative, collaborative and inspiring workplace for BBC staff.

Located opposite Cardiff Central Station, the project is situated on the site of the former bus station to create a dynamic media quarter around Capital Square, which is planned as a major new public space for the city.

“The building is designed to be open and welcoming – visitors can access the ground floor and look up through a fullheight atrium into the working spaces above, as well as into a new café facing the square,” explained a spokesperson for the architectural team, which was led by Toby Blunt and Adam Newburn.

“The design also establishes a sense of openness and transparency between different departments to create new opportunities for collaboration

The building is designed to be open and welcoming – visitors can access the ground floor and look up through a full-height atrium into the working spaces above.

and interaction. The heart of the headquarters is a 4,000-square-metre ‘hub’, which extends across three linked levels and incorporates studios, offices and production facilities. The scheme includes a sheltered garden on the roof of the hub, which is connected to a restaurant and provides a unique venue for filming, as well as a valuable social amenity for staff.

“The project targets BREEAM ‘outstanding’ environmental accreditation with strategies such as chilled beams, locally sourced and recycled materials and an efficient

envelope. Mechanical systems have been carefully integrated to create a highly flexible interior, which can anticipate and respond to changing technologies.”

Foster+Partners was appointed to the project in 2010 by the Rightacres Property Company and the 30-metre high, 25,600m² building was completed in 2019. Last year it won both the Innovation in Design category in the RICS Awards and was winner of the Building Project of the Year title in the Constructing Excellence Awards, Wales. >>

The high-performance ceiling system for BBC Wales’ new facility was designed by SAS International in partnership with Sheppard Robson.

Over 5000m2 of SAS International’s acoustic metal hybrid raft ceiling systems provide a distinctive aesthetic suited

to a 21st century digital broadcast environment.

Hybrid metal acoustic rafts, made up of varying sized panels supported on a concealed grid with bespoke upstands, are suspended between the rows of chilled beams that supply cooling to the

>> Two types of curtain walling, and entrance doors, by Kawneer, including the first use in the UK of a new severe duty welded door, feature on the award-winning building.

Kawneer’s AA®100 capped and zonedrained aluminium curtain wall, complemented by its SSG (Structurally Silicone Glazed) and mullion-drained sister product, have been used throughout the glittering façade of the striking new headquarters building for BBC Cymru at Three Central Square.

They in turn are complemented by thermally-superior AA®720 doors and the new dual colour AA®190 TB severe duty welded doors with class-leading thermal performance that is so robust they are offered with a lifetime guarantee.

office floors. Light fittings in a distinctive cruciform arrangement are suspended beneath the ceiling.

The TV studios, with exceptional acoustic requirements, are lined with SAS International’s WP10 metal acoustic wall panel system.

Collaboration and innovation are central themes at the new, £30 million Barbara Hepworth Building at the University of Huddersfield. The faculty comprises flowing spaces set around an internal atrium, which is easily adapted to meet the varied needs of the multi-disciplinary faculty.

Polyflor collaborated closely with AHR, Morgan Sindall and Phoenix Flooring using a variety of vinyl flooring products to create a flooring specification which properly reflects the building’s artistic and practical aspirations.

The multi-floor central atrium is set around a feature staircase and the design team were eager for this space to be attractive and easily navigable whilst also encouraging interaction between the different disciplines housed in the building. To help support these goals, Polyflor worked with the project team to create a bespoke flooring design using Expona Flow PUR.

The vinyl sheets beautifully recreate the aesthetic of wood and concrete floors and provide excellent durability in this high traffic area. AHR and Polyflor’s technical team designed and developed a bespoke pattern for each atrium area, combining Warm Limed Ash, Steel Blue and Light Industrial Concrete colours. These patterns are both attractive and help students to intuit and navigate the surrounding open-plan spaces and adjoining rooms.

As well as Expona Flow, several other Polyflor products were also utilised to provide a high-quality flooring finish throughout the new building. Polyflor Finesse SD was chosen for the communication and infrastructure rooms where static build-up needs to be carefully controlled and Polysafe Stone FX PUR and Wood FX PUR were also specified in areas where there was potential for water spillage. The specification was completed with the use of hardwearing Bloc PUR in Classic Black and Urban Chic. By specifying Polyflor products across the building, flooring maintenance is streamlined.

The sheets achieve a BRE A+ rating and are certified as ‘Excellent’ under the BES 6001 responsible sourcing standard. In addition, the products feature recycled content and are 100% recyclable at end of life through the Recofloor scheme – supporting the circular economy.

Designed and manufactured in the UK, Powermatic controlled, concealed door closers deliver exceptional performance as well as a host of benefits that surface-mounted closers cannot match:-

• Genuine independent third-party certification

• Closing speed and latching action adjustable without removing closer from door

• Certified for use on one-hour and half-hour fire doors

• Contributes towards the achievement of accessibility requirements (AD M)

• The only CERTIFIRE jamb-mounted door closer

• Improves aesthetics and reduces risk of damage from vandalism or tampering

• Perfect for social housing, hotels, health, care homes, secure accommodation, commercial and many other situations.

• Suitable for anti-ligature applications

• Completely concealed when the door is closed

www.concealeddoorclosers.com

Tel 0121 766 4200 info@samuel-heath.com

ONLEVEL are proud to announce the introduction of DEKTEK, a fully non-combustible aluminium decking system, perfect for residential and mixed-use developments.

The product development team at ONLEVEL have been busy again, DEKTEK is the fourth new product launched in 2020. The innovative A2 fire rated aluminium decking system features non-combustible deck boards, subframe and adjustable cradles. DEKTEK has been designed to replace frequently used non-fire rated products to provide peace of mind, better performance, and easier installation.

Made in the EU from structural grade 6063 T6 aluminium DEKTEK is ideal for high rise concrete balconies, terraces walkways, roof terraces, pubs, gardens and numerous other decking applications and public areas. It is simple to install with an adjustable cradle and deck support system, the cradle spacing extends up to 1800 mm in width to aid installation. The system is lightweight for efficient transportation and ease of installation. Furthermore, DEKTEK is a low maintenance system offering a cost saving up to 50%, when compared to other systems.

Gary Dean Director, ONLEVEL comments: “I’m so pleased to be talking about another fantastic addition to the ONLEVEL range of products. DEKTEK is a system that provides

both peace of mind and cost savings. It’s a system that provides great benefits and dovetails nicely with the range of solutions we already offer, such as our balustrading and railing systems”

DEKTEK provides peace of mind, the system has been manufactured to last and withstand the inclement British weather, so throw away your paint brush! It has a 100 micron Qualicoat™ premium powder coating with a 10 year warranty. The premium coating is slip resistant and provides low surface temperatures underfoot, especially when compared to composite materials.

DEKTEK outdoor aluminium decking boards are available in three colours; Anthracite, Black and Serengeti Sand. The Qualicoat™ premium powder coat finish provides an extremely strong and UV stable surface finish.

In addition to the numerous glass hardware solutions ONLEVEL provide, four new product ranges have been introduced in 2020, DEKTEK, Banana Slide, a simple, sleek, and easy to install internal glass sliding door system, plus LAZORTRACK and

SPARTAN LED SPIGOT, two innovative LED lighting solutions to suit a range of glass railing solutions. Furthermore, ONLEVEL has developed a fantastic online resource this year, with their new website www.onlevel.com, featuring the full range of product, technical information, news, and downloadable documents.

ONLEVEL recently created their new allencompassing product catalogue featuring ONLEVEL’s full range of glass hardware solutions. With over 290 pages of products, available to download or in hard copy format, it’s the ‘go to’ glass hardware brochure for designers and installers alike!

ONLEVEL – Enquiry 11

DEKTEK is a system that provides both peace of mind and cost savings. It’s a system that provides great benefits and dovetails nicely with the range of solutions we already offer

Pitched roofing design has evolved over recent years, and strategies have been adopted to manage the movement of air and moisture to ensure our roofs are both energy efficient and free from condensation.

Roofshield® air and vapour permeable underlay membrane was introduced back in 1996, and since this time, the A. Proctor Group have been involved in all aspects of pitched roof design, from working to build acceptance on non-ventilated cold pitched roofs to contributing to technical standards addressing wind uplift.

The approach taken has been based on testing and experience gained across all types of roof in the most challenging conditions around the world, building both the knowledge and the technology to meet whatever problems a site may pose.

The building regulations across the UK and Ireland all base their moisture control guidance for roofing on BS5250. The BS5250 standard, formerly the code of practice for the control of condensation, but now in its draft 2020 edition for “management of moisture” covers all aspects of keeping buildings dry. The 2020 draft is currently open for consultation, so bear in mind there might be some changes to the details after the consultation is complete.

There are two main types of moisture that roofs of all types must control, moisture from internal sources, vapour and condensation, and moisture from external sources, rain and snow.

External moisture is assumed to be primarily dealt with by the external weatherproofing once the building is complete, but in order to provide a secondary layer of weather protection, roofs are fitted with an underlay membrane beneath this outer layer.

These underlay membranes contribute to the performance of the roof systems in a variety of ways – they provide; a degree of resistance to wind uplift forces, protection from wind driven moisture penetrating the structure of the roof and a temporary weather protection until the outer covering can be completed.

BS5250 defines two primary types of roofing underlay:

1. HR Underlay: membrane with water vapour resistance, Sd, greater than 0.05 m (0.25 MNs/g) i.e. traditional bitumen roofing felts

2. LR Underlay; membrane with water vapour resistance, Sd, not exceeding 0.05 m (0.25 MNs/g) i.e. typically composed of polyethylene or polypropylene.

BS5250 defines four classes of pitched roof constructions, two of which are: Cold Pitched Roofs - In this type of roof the insulation is placed horizontally across the ceiling ties, with the loft space and the structure of the roof being outwith the buildings heated envelope, hence cold.

Warm Pitched Roofs - In this roof type the insulation follows the pitch of the roof, either between the structural members, over the top of the structure or a combination of both. This leaves the enclosed space under the pitch as part of the heated envelope.

The BS5250 standard gives detailed guidance specific to each combination of roof type and underlay type, to ensure the response of the roof system to moisture is within acceptable limits. A roof that cannot adequately deal with moisture is susceptible to a variety of negative effects, from mould growth to structural damage and weakness.

The air permeability of the outer covering must be considered as roofs with continuous coverings such metal sheets will have significantly different hygrothermal performance from discontinuous roof covering like tile or slates.

There can be substantial differences in the performance of apparently similar materials. While CE marking and the construction products directive have gone some way to clarifying and standardising testing and the presentation of information, 3rd party certification specific to the proposed application remains the most effective way to ensure design criteria are met.

Whether or not roofs and lofts require ventilation has been the subject of a long running but now largely settled debate across the industry since vapour permeable underlays first gained mainstream acceptance in the late 1990s.

Traditionally roofs of all kinds required ventilation to ensure moisture could escape as bitumen felt underlays did not allow moisture transfer to any significant extent. While there’s nothing wrong with this approach and it has been used successfully for a very long time, as building become increasing well sealed and moisture loadings increase, it’s not always the optimal solution.

The BS5250 document offers various solutions dependent on the roof configuration, underlay type and permeability of the outer roofcovering.

The first factor to consider is the air permeability of the outer covering, as if this is not permeable, then some degree of ventilation will be required. In most cases, this requirement to ventilate will apply to coverings such as metal sheeting, and slates and tiles usually offer sufficient air permeability.

Cold Roof (Ventilated) - this is the traditional form of pitched roofing used all over the UK, and is historically the standard against which more modern alternatives are judged in terms of condensation risk and timber moisture contents. Given the various categories and differing guidance for ventilation, and the lack of clear specification advice for more complex roof types and shapes, a simpler option is often to omit the ventilation altogether and rely instead on the vapour permeability of the underlay to remove moisture.

Cold Roof (Non-Ventilated) - Where an airtight LR underlay is specified on the roof, the BS5250 standard does not directly address situations where ventilation is reduced below the levels given in L5.5, however if the underlay membrane is covered by appropriate third-par ty certification it may be permissible. There’s a also good number of airtight LR membranes on the market and uncertainty can be avoided by using an air permeable membrane.

The inclusion of the newly defined APLR membranes as a specific construction type is one of the principle additions in the 2020 BS5250, and this type of roof requires no additional ventilation. The particular advantage of this type of underlay, referred to as Air Permeable Low Resistance or APLR underlays, is that in additional to allowing vapour to escape by diffusion, they also allow a degree of airflow to boost the transfer of moisture vapour.

Membranes that are used in this type of construction must meet specific criteria however to ensure no problems arise.

They must have an air permeability of not less that 6m3/m2/hr at 10 pascals when tested as required by BS EN 13859 parts 1 and 2, and also a vapour resistance not greater than 0.07 MNs/g, or Sd-0.014m when tested to BS EN ISO 12572 Method C.

Membranes meeting this specification can however be used in all circumstances with no ventilation, regardless of the size and shape of the roof. They also do not require a well-sealed ceiling, making this type of underlay a good choice in refurbishment applications where the precise ceiling specification may be unknown.

Taken together, these factors make APLR underlays which meet the performance criteria the simplest solution to address condensation in cold pitched roof application, and the only solution that can be specified across multiple projects with no changes.

Warm Roof Constructions - In warm roof construction, the lack of a large cold void in which moisture can collect makes the moisture control a little simpler, but care must still be to ensure the correct specifications are followed. Warm roof constructions are those where the insulation follows the line of the roof from eaves to ridge, the spaces within the roof and structure itself are within the heated envelope of the building.

HR Underlays - As with cold roof constructions, warm roofs with impermeable HR-type underlays will always require ventilation below the underlay to ensure the escape of moisture vapour is facilitated. This is in addition to a vapour control layer at ceiling level. The depth of the ventilated void between the insulation and the underlay should be a minimum of 25mm deep, plus the maximum allowable underlay drape of 15mm, if applicable. Ventilation openings must be provided at high and low levels, with 25000mm2/m at low level and 5000mm2/m at high level. Openings should also be provided at any features like dormers or roof lights, so the ventilation is unobstructed across the entire roof.

LR Underlays - As with cold roofs, this can be simplified by using an LR underlay. In the case of warm roofs this allows the ventilation to be removed provided the internal layers are convection tight. If this can’t be guaranteed, or if the outer covering is not air permeable, then ventilation would be needed.

In a purely warm roof situation, where the insulation follows the pitch of the roof from the eaves all the way to the ridge, the lack of large voids in the roof means there is less benefit to the use of an air permeable underlay. This correspondingly makes this type of roof a good choice for buildings where low air leakage rates are a priority. This allows the airtightness of the roof assembly to be maximised, in turn lowering the air leakage rate of the building as a whole.

If we extend this principle out to the building as a whole, and air tight warm roof construction can be easily integrated into a wall assembly with an external air barrier membrane. Wraptite®, in a roofing application can simplify achieving a good airtight interface at the wall and roof junctions.

In summary, the simplified answer is to consider that for very airtight buildings, a warm pitched roof with an external air barrier layer presents a far more optimal solution.

Roofshield® - Carnoustie Golf Club Refurbishment

Column casings are an important and widely used feature of contemporary building design. In addition to providing a practical method of concealing interior and exterior structural steelwork, concrete columns and building services, they also contribute to a building’s aesthetics and style.

The combination of aesthetics, practicality and decorative design are common features within the wide range of projects undertaken by Peterborough based casing solutions specialist, Encasement Ltd.

Encasement’s column casings range includes ‘Circa’ and ‘Quadra’, manufactured from pre-formed plywood, together with the metal ‘Forma’ range, as well as the ‘Polyma’ and ‘Gypra’ casings, which are moulded from glass reinforced plastic (GRP) and glass reinforced gypsum (GRG) respectively. The range is completed by ‘Metza’, a specialised solution for mezzanine support columns that can provide up to 2 hours fire protection.

Although all Encasement’s column casings are suitable for interior use, its ‘Forma’ and ‘Polyma’ ranges are also widely used for exterior applications due to their inherent weather resistance and durability. Both ranges can also be stacked to reach extended heights.

Available in aluminium or stainless steel, ‘Forma’ offers a diverse range of options and can be specified as circles from 250mm to 1000mm diameter, or in square, rectangular or hexagonal forms, as well as unique bespoke manufactured profiles. The choice of finishes is also wide and includes PPC coatings in any RAL colour, as well as brushed, anodised, embossed and textured options, including Rimex.

Strength, durability and colour choice are also features of the moulded ‘Polyma’ GRP range. This manufacturing method allows a high degree of design flexibility with the shape; size and colour all open to specification to meet both standard profile options or bespoke project requirements.

Projects, such as Winchester College, Tetrosyl’s head office and Cardiff Bay’s Premier Inn, perfectly illustrate the versatility of Forma and Polyma casings.

However, where casings are needed for interior use only, Encasement’s pre-formed plywood ‘Circa’ and ‘Quadra’ casings allow circular, square and rectangular profiles to be specified while also providing a wide range of finish options with the most popular being decorative laminated finishes.

In addition to resisting damage, scuffs and scratches, they also provide the specifier with a diverse palette of finishes including plain colours, wood grains and metallics, as well as textured and real

wood veneers. As a result of this versatility, Circa and Quadra are used in almost every building type, including retail, offices, hotel, sports and leisure, as well as the health and education, sectors.

The Dame Kelly Holmes Sports Centre and Farnborough’s Sixth Form College are ideal examples of Quadra projects, whilst among the many Circa installations, Gateshead International Stadium, Liverpool University and Gatwick Airport’s South Terminal are major installations

Encasement’s Managing Director, Martin Taylor, commented: “Our entire range is configured to provide the widest possible choice and versatility. This allows specifiers to source different specialised casing solutions from a single company, backed by our high levels of expertise and experience. We also have our own contracting arm, which enables us to offer a full supply and install service to support contractors.”

Encasement – Enquiry 16

This winter’s flooding is a timely reminder of the importance of sustainable drainage systems – or SuDS – in reducing the damaging impacts of rainwater runoff. The latest developments in SuDS and concrete block permeable paving are featured in a new webinar and guidance from the trade association Interpave.

Over 25 years use, concrete block permeable paving has demonstrated unique capabilities as a multifunctional SuDS technology. It combines a structural pavement with an inherent drainage system and needs no additional land take for water conveyance, attenuation and storage. This technology also eliminates pipework, gulleys and manholes, and therefore costs less to install or maintain than conventional drainage and paving.

Permeable paving is specifically designed for a dual role, acting as the drainage system

as well as supporting people and vehicles. At the same time, many pollutants are substantially removed and treated within the paving layers before the water leaves it. As a result of this unique capability, permeable paving offers a gradual supply of treated water that can be integrated within landscape design, promoting biodiversity and green infrastructure. It also provides clean water at the head of the ‘SuDS management train’ enabling safe open SuDS features on the surface, downstream.

Concrete block permeable paving can be laid level and still avoids puddles without the need for drainage gulleys. It provides a safe, firm surface for everyone – including wheelchair users and people pushing prams – unlike gravel and other loose materials. It is therefore the preferred option around trees, rather than tree grilles, according to BS8300-1 (2018).

National and local planning policies call for SuDS, encouraging techniques such as permeable paving. For example, the Draft London Plan says that: ‘Development proposals for impermeable paving should be refused where appropriate, including on small surfaces such as front gardens and driveways’.

This stance is supported by the 2019 National Planning Policy Framework.

There is a growing choice of concrete products available from Interpave manufacturers, designed specifically for permeable paving. Essentially, they have the same impressive performance as conventional modular concrete paving products, being slip resistant, durable, strong and sustainable. And today there are more shapes, styles, finishes and colours than ever to give real freedom of choice. The difference with permeable paving is enlarged joints, filled with a permeable aggregate, and the materials used below the blocks, which are specifically selected to accommodate water.

A new CPD webinar – presented by Bob Bray of Robert Bray Associates, with over 20-years’ experience in SuDS and landscape design – explores how straightforward flow controls can optimise permeable paving and SuDS. It covers techniques including water storage in paving compartments deployed around a site, to integrate SuDS within development and avoid land-take.

The webinar is supported by the latest edition of ‘Understanding Permeable Paving and SuDS’, an essential introductory guide to all aspects of concrete block permeable paving for SuDS – and much more. Its benefits include potential for ‘cool pavements’ helping to reduce the urban heat island effect, making our cities more comfortable in summer. Another important innovation – set to play a major role in the post-pandemic public realm – is the retrofitting of concrete block permeable paving as an overlay to existing streets. This low-intervention technique enables transformation of the public realm in response to the raft of recent active travel and open space initiatives.

www.paving.org.uk/home/permeable-paving/

With the government setting a net zero carbon target for 2050, the drive in the building products sector is towards sustainably sourced or recycled building products.

Leading from the front is Newton Waterproofing, the UK’s leading independent designers and suppliers of guaranteed structural waterproofing systems for everything from large-scale commercial developments to new-build and existing domestic properties.

Having launched its award-winning Recycling Service in 2017, the family-run company has had sustainability as its focus ever since.

The closed-loop recycling scheme works in collaboration with the company’s nationwide network of Newton Specialist Basement Contractors (NSBC), who store offcuts of Newton’s plastic membranes, which are then collected by Newton when they arrive at the site to deliver new products.

The HDPE membrane is then processed and chipped into small granules at Newton’s headquarters in Tonbridge, Kent, before being collected by a national reprocessor who recycles the granules ready to be made into new products for the construction industry. Newton then donate all profits made by the scheme to the marine conservation charity Surfers Against Sewage.

Newton Waterproofing’s Managing Director and creator of the scheme, Warren Muschialli, said: “Despite the unprecedented coronavirus outbreak, our dedicated team worked hard to ensure our clients have continued to be fully supported throughout and it’s fantastic to see our recycling service has continued to thrive.

“Before this service there was a complete lack of any such scheme in the UK, which resulted in the waterproofing industry sending hundreds of tonnes of plastic membrane to landfill every year. To be able to have recycled more than 18 tonnes since 2017 is an excellent achievement from everyone involved so far.

“We’re not stopping there though, and we will continue our partnership with Surfers Against Sewage as part of their 250 Club of top donors.”

Newton Waterproofing recently became the first UK waterproofing supplier to have an entire waterproofing solution, the Newton CDM System for below-ground cavity drain waterproofing, certified to BES 6001 by BRE Global.

BES 6001 is the framework standard for the responsible sourcing of construction products and is an increasingly important and valuable standard for customers looking to procure building products. Certification is a voluntary process and demonstrates a supplier’s commitment to reducing the environmental and societal impacts of their construction products, through sound environmental credentials, social awareness, and ethical practices.

The certification can be added to Newton’s long list of environmental/sustainability memberships and accreditations already held, including ISO 14001, Constructionline Gold, the Supply Chain Sustainability School, the UK Green Building Council (UKGBC), and the Fleet Operator Recognition Scheme (FORS).

“The BES 6001 certification was a long audit process, so we are delighted to achieve it,” said Warren. “We are also the first company in the UK waterproofing industry to have achieved it. As part of this certification, we will now be listed on Green Book Live alongside other products and services that can help reduce environmental impact.”

The company will soon be putting together guidance on how specifying Newton will help to maximise BREEAM (Building Research Establishment Environmental Assessment Method) points on construction projects.

Customers can also improve their eco credentials with Newton’s 100% recycled waterproofing product range and their recycling service expansion to include plastic tubs and containers.

Waterproofing

Since the first lockdown of March 2020, a huge percentage of us have chosen to stay closer to home rather than venture further afield. Industry analysts Glenigan ask if the hotel & leisure construction pipeline is ready to meet demand?

The development pipeline suggests that the sector has been expectant of growth for some time, and has even remained strong throughout lockdown and the COVID-19 emergency.

According to Glenigan data, the total value of hotel & leisure approvals during the three months to July 2020 was 27% higher than the previous year with a total value of £1.75 billion.

Underlying approvals (under £100 million) performed best with YoY growth of 28%, and 47% growth on the preceding three months (seasonally adjusted). Underlying approvals added up to £1.41 billion during the period.

Underlying approvals were 29% up on the preceding twelve months, and major projects (over £100 million), were 20% up

during the three months to July. The total value of hotel projects receiving detailed approval has been climbing ever since the Brexit referendum, with a particularly strong end to 2019 and beginning of 2020.

The value of approvals during the seven months to July 2020 has already surpassed the value of approvals in the entirety of 2017, and each of the years between 2013-2015.

The budget hotel chains are certainly taking advantage of the staycation boom. Premier Inn has numerous projects in the pipeline, with 20 new hotels being granted detailed planning approval yet to start on-site. Away from the budget hotels, many major hotel developments are ready to move to site in the near future. The 30 Grosvenor Square Rosewood hotel in London is one of the most exciting. The £1 billion hotel is at the site of the former US embassy.

Besides hotels, the development pipeline is also healthy among the rest of the sector, with many major projects being granted detailed planning approval, yet to commence on-site.

Of huge interest is the £500 million SnOasis Resort in Ipswich. The scheme is designed to create a world class winter sports resort, featuring 14 different year-round sports including ski slopes, an ice rink and rock climbing.

Therme Manchester is another resort in the pipeline. The 28-acre resort is the UK’s first city-based wellbeing resort, which will create a tropical environment with warmwater lagoons. The £250 million scheme is due to commence on-site in 2021.

Looking further into the development pipeline, there are some very exciting projects that could encourage more domestic tourism in years to come.

The £3.5 billion London Resort (pictured) is quite possibly the most exciting project within the sector. Currently at the preplanning stage, the scheme includes a new theme park, a 3,550-room hotel, and a conference centre.

With Brexit, COVID-19 and recession all likely to boost staycations over the coming years, it’s crucial that the Hotel & Leisure sector is ready to take advantage. With the development pipeline particularly strong, it’s clear that with the amount of work ready to move to site, that the construction industry is ready to play its part. >>

>> Other schemes are already well advanced or completed. Part of a regeneration project in Edinburgh’s New Fountainbridge district, the 262-room Moxy Hotel from Marriott International is situated on the former Scottish & Newcastle Fountain Brewery site, alongside offices, cafés, co-working spaces and a restaurant.

For any hotel, the visible furnishings and decoration be of the highest calibre for the guests’ comfort. However, all aspects under the surface must also match these standards and offer best possible performance. To keep quality high and installation time to a minimum, Emtec chose polymer specialist REHAU to provide soil and waste pipework for the project.

Faced with the challenge of finding a solution that could meet these demands, Emtec used REHAU’s acoustic soil and waste system, RAUPIANO.

Ideal for multiple occupancy buildings like hotels, it combines sound-absorbing multilayer technology, elbow joints with thicker walls, and patented acoustic brackets in a system with 17 dB sound rating, meaning vibrations or system noise do not disturb occupants. Not only did it match up to the building’s acoustic requirements, but also helped tackle challenges posed by the offsite-manufactured rooms.

“RAUPIANO was not only a good choice because of its performance, but also because of how compatible it is with other pipework,” said Andrew Currie, Project Manager at Emtec. “Sometimes with prefabricated units like these there can be lots of adaptations required, which uses more components and takes lots of time. The REHAU solution, by contrast, was able to be installed easily without giving us more work to make it fit.”

The

BRL Architects were appointed by the local council to design a state-of-the-art leisure centre that embraces the beauty of the surrounding tree-lined park, with established sports and walking facilities, to provide sports, art and a social hub for the users. Sustainability improvements and the local community were at the heart of this project.

“We wanted to achieve the feeling of an outdoor path or street within the enclosed building that could become a market, a foyer to the theatre, or simply a space for people to gather,” explains Stephen Rickhards, the Architectural Director at BRL Architects.

“We used timber in the large double-height central gallery to knit into the beautiful surrounding trees and the idea was to flood

the area with natural light. The hope is that the community will own the space and shape its future use.”

The eco-friendly Braywick Leisure Centre is a result of close cooperation of the community, the architects, and contractors. Despite the bespoke nature of the rooflight system design, VELUX Commercial delivered the frame, the roof glazing, and the ventilation elements largely pre-manufactured to reduce material waste and maximise the efficiency of the on-site installation. This meant some of the structural systems used for the glazing had to be adjusted to reflect the custom nature of the design. A schedule was devised to deliver the complete solution in readiness for the electrical connections and to prevent water ingress and subsequent damage to the building envelope.

The roof glazing system is designed to work in harmony with the building envelope and to support the comprehensive energy strategy for the leisure centre.

Projects involving water begin with a visit to SPATEX Virtual, the UK’s ONLY dedicated international water leisure show that is moving online for 2021 from Tuesday 2nd to Thursday February 4th. It’s a show aimed at hoteliers, architects, building contractors, quantity and building surveyors, interior designers, and property developers.

SPATEX Virtual is the most accessible water leisure showcase and shop window in the world and FREE to everyone with internet from the comfort of office or home. Featuring the virtual booths of the world’s top water leisure manufacturers, suppliers and installers, you can source 2021’s latest models and innovations of water features, swimming pools, spas, hot tubs, enclosures, saunas and steam rooms, all their associated equipment, such as plant room equipment, and much more. Energy saving was a big feature of SPATEX 2020 and this theme will be further explored in 2021.

SPATEX Virtual will be accessible from all laptops, desktops and tablets and does not require a webcam or Zoom.

• Interact with international water leisure professionals from the comfort of your desk. Time Saving — at a real-life event it

can be difficult to see everything on offer and there is usually something you miss because you simply run out of time.

• Chat with exhibitors via audio, video and text message and network in chatrooms.

• Use a virtual shopping bag to collect product manuals, demos, brochures, videos on your computer which you can then email to yourself or others.

• Hold one to one real time meetings with exhibitors

• Gain inspiration - There’s few projects that can’t be enhanced with the addition of water. Whether for artistic effect or leisure, water adds another dimension, both in sound and vision.

• Attend free workshops - delivered by industry experts, on the latest design techniques. Pose questions in live Q and A about your own projects or dip in and out of the talks, whilst also popping into the expo area for meetings with exhibitors or leaving the event for a while

to carry on with your own tasks. Access to all sessions that are streamed live are available on-demand for 30 days after the event concludes along with all the show’s content.

• Tap into a unique pool of free expertise for your projects - SPATEX Virtual is fortunate to count the Industry’s many esteemed associations amongst its supporting partners such as SPATA (Swimming Pool and Allied Trades Association) and BISHTA (British and Irish Hot Tub and Swim Spa Industry Association). There’s no better place to seek free, impartial advice from experts throughout the three day live event.

SPATEX Virtual Tuesday 2nd to Thursday 4th February 9.30 – 17.00.

Registration is free and takes seconds. Visit www.spatex.co.uk

SPATEX – Enquiry 23

To make an enquiry – Go online: www.enquire2.com or post our: Free Reader Enquiry Card

When Leeds Teaching Hospitals NHS Trust earlier this year approved capital funding to convert a disused area of Chapel Allerton Hospital into a new dental facility, they engaged with Yeoman Shield wall & door protection specialists to provide durable yet attractive wall protection that would achieve the interior fit-out brief.

The project was managed by The Leeds Teaching Hospitals NHS Trust, Bridger Carr Architects and main contractor Bermar Building Co. Ltd., with Yeoman Shield supplying and installing the wall protection elements.

The unit will have amenities to accommodate a 13 - chair dental facility for the provision of dental treatment for adults and children with the flexibility to be used for student training as part of the link with Leeds University School of Dentistry.

Due to the mixed use of the new unit the project team were keen to provide an environment that would be suitable for all users and uses. The project required an attractive yet durable interior design that contributed to the wellbeing of both service users and staff members alike.

In the waiting and corridor areas, which would experience heavy footfall and require wall protection, it was important to create

a décor that was not sterile and cold but one that would create a calm soothing environment for clients who may become nervous before their dental treatment.

Yeoman Shield, along with providing standard FalmouthEx wall protection panels in mid- grey and contrasting Guardian Handrails, supplied and installed Imagery panels that had specifically chosen designs reverse printed on to clear protection panels.

The artwork was chosen with both adults and children in mind and, with collaboration between all involved, Yeoman Shield were able to deliver a finished product that showed the artwork in perfect colours, definition and quality. Designs included playful birds, cheerful flora and fauna along with calming green hues of forestry and foliage.

The reverse method of printing for the protection panels served to shield the

decorative design from any impact damage with the smooth surface being conducive to thorough cleaning, maintaining high hygiene standards without detriment to the colourful images.

The overall effect of the décor was welcoming, fresh and bright offering break out areas that were inviting for colleagues of the dental unit and other hospital departments to use for meetings, breaks and study time.

For more information on Yeoman Shield Imagery panels or any other of the wall & door protection products available go to www.yeomanshield.com or call 0113 279 5854.

Yeoman Shield – Enquiry 25

Specifiers can rely on the unique qualities of Nullifire SC902 intumescent coating to achieve fire protection for their steel frame projects in winter application projects.

Weather resistant in less than an hour, the unique, high-build nature of SC902 delivers 120 minute fire protection in just one coat, enabling work to be completed on the fast track, while still achieving building fire strategy.

Its high technology formulation is also more tolerant of ambient conditions than thin film systems, and capable of curing in high humidity and low temperatures.

SC902 is backed-up with the support of Nullifire’s renowned technical department, who understand the Building Regulations for steel frame structures and work closely with architects and specifiers to ensure safety and performance comes as standard.

Nullifire’s Sales Director, Gary Pullinger, said: “Optimised for on-site application, Nullifire SC902 comes into its own in colder months.

“It can achieve up to 6mm in one application and 120 minute fire protection is achieved in 24 hours – in comparison to more traditional base coats where full fire protection takes 7 days.”

Part of the Construction Products Group portfolio of brands, and previously available in the UK under the Firetherm name, Nullifire products are used extensively across built environments. SC902 also features Optifire+ technology to provide traceability as standard across this and other products in Nullifire’s renowned intumescent steel coatings range.

A unique pigment, which is impossible to manipulate, Optifire+ offers a guaranteed source of quality to deliver new levels of assurance to architects, main contractors and specifiers.

Nullifire – Enquiry 27

The refurbishment of a community leisure centre in Wiltshire has been given a paint finish that is more than fit or purpose, thanks to leading paint manufacturer Crown Paints.

With cleanliness a top priority, Crown Trade’s Clean Extreme Scrubbable Matt was the ideal choice for use throughout the centre, and has been applied in the fitness suite, sports hall and servery, as well as high-traffic areas such as corridors and

reception. The advanced formulation of Clean Extreme enables the painted surface to be repeated and rigorously cleaned without diminishing its flat matt appearance, helping the centre keep its facilities looking freshly decorated and hygienically clean.

For extra protection in areas where moisture and condensation could otherwise prove problematic, Crown Trade’s Clean Extreme Mould Inhibiting Acrylic Eggshell was specified for use in the changing rooms, toilet facilities and around the swimming pool.

Combining a high opacity matt formulation with a built-in fungicide that can’t be washed or wiped away, Clean Extreme Mould Inhibiting Acrylic Eggshell can help prevent the growth of mould and mildew and is also highly resistant to other stains appearing on the paint surface. Here, it has been used in conjunction with Crown Trade’s Fastflow Quick Dry Satin, which has been applied to the centre’s woodwork and trim areas.

The project team opted to use Sandtex Trade’s 365 All Weather Smooth Masonry paint on the main facades and Sandtex Eggshell X-Tra for the exterior woodwork. Both products offer excellent and longlasting protection against weathering, with the 365 All Weather Smooth Masonry paint benefitting from a Pliolite ® resin formula which creates a microporous film to effectively block any wind-driven rain.

Crown Trade – Enquiry 28

Harris Manchester College is one of the main Colleges at Oxford University and with a new construction site opposite the main building, Selectaglaze treated four rooms that were affected by noise and dust ingress in the Grade II Listed building.

In the two meeting rooms: Series 20 slimline vertical sliding units were installed; colour matched in a wood grain finish to complement the wood panelling and reveals. They were glazed with 6.8mm acoustic glass and placed to optimise the cavity.

The primary windows in the Tate Library are tall gothic arched windows, with three stained glass windows forming a main bay. To complement the interior décor and leaded casings, the timber sub frames and secondary glazing profiles were colour coated in 9005 Jet Black Matt.

The tall gothic arches measured around 4.5m tall and had a mezzanine cutting them part way, which made the design and installation tricky. The portion of the

window below the mezzanine was a Series 10 horizontal sliding unit. Stacked above, in an area not requiring access, were two series 42 fixed lights. Above these up to the spring point, was another Series 10, followed by three Series 42 curved fixed lights including reverse curving to follow the lines and details of the tracery at the head. Installed with 6.8 laminate glass and a generous cavity.

The student Common Room needed a resolution to prevent noise entering from the neighbouring construction site, and also to stop noise escaping from it and troubling locals. Series 20 slimline vertical sliders were installed in white to match the interior design.

Selectaglaze – Enquiry 29

Future-proofing their facilities, Hirwaun Primary School included space flexibility as a key feature of a new £10.5m building, that opened in Autumn 2020.

Allowing teachers to quickly adapt one of the main classrooms, Style worked with contractor Morgan Sindall and architects, Boyesrees, to install a Dorma Hüppe Variflex moveable wall system.

Style’s operable wall was selected by Morgan Sindall following their tender process – the final solution giving teaching staff the freedom to separate the room into two with ease or open it up into one large teaching space.

An advanced and lightweight prefabricated brick slip soffit system from market leader IG Masonry Support, manufactured to meet A1 fire rating regulations and suitable for applications over 18 metres, is now available. It is the B.O.S.S. A1, a prefabricated brick slip soffit system, designed to be quickly and easily bolted to IG’s Welded Masonry Support (WMS) and meets a growing market need for improved fire safety on tall buildings. The prefabricated components are delivered to site complete with brick slips adhesively bonded and mechanically secured to the brick carrier unit using only A1 Fire-Rated materials making it Document B:Fire Safety compliant–suitable for all building heights.

IG Masonry Support – Enquiry 30

With an impressive 55dB Rw acoustic rating, once the wall is in place, separate classes can run undisturbed on either side, making this an ideal solution for isolating pupil bubbles, as well as being intensely practical in accommodating a wide variety of ongoing daily activities.

The wall’s pearl grey melamine finish perfectly complements the classroom décor and, with social distancing measures being a priority for all educational establishments, it gives Hirwaun Primary the ability to subdivide space to rapidly reduce class sizes. The Variflex system is suitable for any school, college or university seeking to add flexibility into their teaching areas.

Style – Enquiry 31

Work has drawn to a close on the two-year refurbishment of the roof of a historic arts college that required 26,000 new welsh slates for 39 separate roof areas.

The £4.8 million project has won specialist contractor Clarke Roofing Southern Ltd a place in the history books, for the fact it required one of the largest, free-standing scaffolds in the UK at the time, as well as a shortlisting in the 2020 Pitched Roofing Awards.

West Dean College of Arts and Conservation in Chichester, West Sussex, has an international reputation for excellence in arts and conservation education, from short course to degree level, including professional development courses in building conservation.

The work to repair numerous leaks and failed masonry at high level to provide a fully-ventilated contemporary cold roof had to be carried out in two stages – Phase 1 starting at the west end of the house, moving towards the centre, and Phase 2 working from the centre to the east end, stopping at the workshops.

Each of the 39 areas varied in pitch and condition but Clarke Roofing Southern managed to salvage a limited number of the existing Penrhyn Heather Blues from Welsh Slate which had been re-fixed many times, limiting their re-use due to the angle of creep.

The 26,000 new 500mm by 300mm Penrhyn Heather Blues used to make up the difference were fixed at 110-125mm headlap with copper nails. Prior to installing, all the slates were sorted and graded to ensure correct fixing in accordance with BS 5534 and BS 8000 – the codes of practice for slating and tiling.

The team from Clarke Roofing Southern worked closely with the architect, engineers and college, each of whom had significant input into the design and finishes. The college managed the progress by moving students and guests to varying locations and bedrooms to avoid being under a significant work area.

The building’s Grade II listing and Wyatt flint façade meant Clarke Roofing Southern Ltd could not fix scaffold ties to the fabric. At 100m long and with a roof spanning 50m, it was one of the largest free-standing scaffolds in the UK at the time.

Rooflight tolerance was 2mm, measured with lasers, to ensure the ornate ceiling in the stairwell was not damaged. The vast number of structural repairs required necessitated more than 1,000 architects’ instructions.

“As

we are aware of our responsibility in choosing the correct materials and known provenance for all heritage projects.

“We discussed with Welsh Slate and our suppliers, Chandlers merchants, the pitch, angle of creep and headlap on each of the individual roofs on the project, and our slaters were able to use the chart on site showing everything they needed on each roof. The new Penrhyn slate matched perfectly.”

All the materials used were chosen to provide long-term durability (with Welsh Slate guaranteed for 100 years) and not compromise the heritage building or listed building consent as well as to enhance ventilation.

Fixfast, the leading supplier and manufacturer of quality building envelope fasteners, has added a cutting-edge manufacturing and R&D cell to its UK operations. The new facility in Rolvenden, Kent, allows Fixfast to design and produce its range of fasteners with industryleading quality, accuracy and speed.

The expanded, rapid-response production capacity is an investment in Fixfast’s ‘Maximum Reliability, Minimum Fuss’ customer promise, making the company an even more reliable and responsive supplier of quality fasteners to the UK construction industry.

“We believed adding to our local manufacturing capacity was important and necessary, after seeing shortages from other suppliers during the coronavirus crisis. Now, more than ever, customers need a fastener partner they can depend on. That’s why we’ve invested heavily in new UK manufacturing capability to ensure we’re always here for customers when they need us,” said Ken Lynes, Managing Director of Fixfast.

“Everyone at Fixfast is focused on improving the way fasteners are made and used in the construction of better, safer buildings. We’re doing that through three programmes; service excellence, technical leadership, and raising standards in our industry. Our new facility in Kent enables big steps forward in each of these areas,” added Lynes

“We’ve brought together best-in-class machines from around the world for each step of the manufacturing process. This, coupled with the kind of techniques normally only seen in highly advanced

industries like aerospace and automotive, means we’ve created one of the most cutting-edge manufacturing and engineering environments in the UK construction industry” said Michael Edwards, Head of Engineering at Fixfast.

The new manufacturing cell uses data to link Internet-of-Things enabled machines in one of the sector’s first Industry 4.0 grade facilities. This data allows close monitoring of each stage of the manufacturing process and deep insight into the performance of

the cell. This ultimately gives unprecedented control, so fasteners can be produced with greater speed and accuracy than ever before.

“Our new cell also has exciting implications for product innovation and testing. Timescales for prototyping have been slashed, so we’re able to explore and develop new fastener solutions with our OEM partners in a matter of days,” added Michael Edwards.

Fixfast – Enquiry 34

Innovation continues to advance the composition and thermal performance of insulation products, helping to create better-performing buildings. It’s also proving influential in relation to building elements such as flat roof terraces, which require different design considerations. Chris Knowles, Business Manager (Vacuum Insulation Panels) at Recticel Insulation, one of the world’s leading PIR manufacturers, looks at the challenges involved with roof terrace insulation and how to overcome such issues.

With suitable plots at a premium, an increasing number of property developments are being built with outdoor space in order to optimise available land. As such, keeping thresholds low through innovation of ultra-thin insulation and waterproofing design is a growing challenge.

The following guide provides some useful tips on dealing with issues relating to roof terrace design, which can be overcome with vacuum insulation panels: a super-slim, VIP solution which provides maximum performance but at a much reduced product thickness, thus helping to overcome threshold issues.

1. Prevention is better than cure, a saying that is particularly pertinent to house building and renovation. In the case of roof terrace insulation, it means providing answers for some initial key questions, such as how can specified U-values be achieved whilst working within insulation height restrictions? This is where standard PIR products fall short in terms of terrace installation performance, as it generally means either compromising on U-value outcomes or compromising on drainage by installing channels or raising the low thresholds. VIP solutions are ideal for terraces and flat roofs as they deliver

a high thermal performance without the need for structural alterations. Working with a specialist roofing design team such as Gradient -- Recticel’s tapered insulation division – will ensure the specified VIP solution will meet a project’s design, optimising performance, materials and cost.

2. Conduct a site survey. In many instances, the initial take-off drawing/ specification of a project will differ from what is the ‘reality’ on-site. Therefore, it is always recommended to have a site survey carried out prior to ordering a VIP solution. Given that VIPs cannot be cut or altered on site, it is vital that dimensions are correct prior to order. This should also take into account potential obstructions or openings such as rooflight and drainage outlets, which would affect the layout of a vacuum insulation panel scheme.

3. Use a protected VIP, as vacuum insulation panels are vulnerable to puncture. If this happens the VIP’s insulation value will degrade to that of a conventional PIR material. A construction site could therefore pose problems for VIPs during their handling and installation. The best solution is to utilise a product such as Recticel’s Deck-VQ, as the VIP is fullyencapsulated within a high density PIR protective shell. This provides reassurance that the VIP can be easily installed by the contractor, with the knowledge that the VIP’s excellent insulation value will be maintained.

Ensure the contractor is aware of the insulation technology being used in a roof terrace scheme, particularly in relation to VIPs. They need to be aware that VIPs cannot be cut or modified on-site, which is a complete shift of mind-set from when they use conventional insulation products.

5. Always use the design layout supplied. By working with Gradient, a full project design package is provided. This will provide a scheme layout in conjunction with the product delivery and ensure the quantity of material delivered is optimised to eliminate or reduce site waste. It is therefore vital that the design scheme is followed exactly, in order to avoid installation difficulties and product shortfall.

The aforementioned VIP solution Deck-VQ® has been specifically developed by Recticel to deliver high thermal performance for applications such as terraces where insulation build-up thickness is an issue. Its superior thermal credentials – it has a lambda value of the core of 0.006 W/mK –come to the fore in enabling even the most complex terrace projects to be carried out without the need for structural changes, thus reducing on-site working times and onsite working times and materials. Therefore, with building space an ever more precious commodity, Deck-VQ® is the ideal insulation solution because however small the stage, it delivers a big performance.

Recticel – Enquiry 36

• Proudly manufactured in the UK

• Eliminates the need for hot rolled steel or a concrete primary frame

• Protects the existing flat roof with a durable, cost-effective roof covering

• Our systems are guaranteed for 40 years, designed with an expected lifetime of 60 years

• Enhances the thermal performance of the existing building, reducing heating costs and saving energy

• Extends the life of a flat roof by double

Full audited design and installation service, supported with a full independent insurancebacked warranty Britmet is committed to supplying the marketplace with a bespoke refurbishment/new build system package, incorporating a lightweight steel framing system that is primarily designed to create a roof pitch. Their Britframe system offers a permanent solution to failed flat roofs and can be used to construct a variety of pitched or curved roof structures.

All projects are individually designed and tailored to suit the specific structural design requirements of the existing roof, offering a permanent solution to failed flat roofs. This lightweight structural metal frame system has an excellent strength to weight ratio, as Britframe over-roof conversion systems are constructed using a bespoke lightweight steel framing system, primarily designed to create a roof pitch but can support both modern and traditional over-cladding systems to achieve the required aesthetics.

Britmet’s Britframe system has been recommended and specified on a fundamental number of projects including schools, MOD, social housing and many more.

The Biotope building, located in the French city of Lille, is an iconic 30,000m² seven-story architectural complex that transforms conventional office accomodation into a self-sustaining ecological community. Although originally designed to accommodate the European Medicines Agency (EMA), the building now houses ‘The European Metropolis of Lille’, an intercommunal public authority responsible for transport and infrastructure across 85 cities in the North of France.