Despite the major advances and continual improvements in today’s modern industrial processes, we have created a legacy of contamination within the soil and groundwater of the land on which we need to build. ‘Contaminated land contains substances which pose a risk to either human health, a body of water or an ecological receptor’ (Contaminated Land: Applications in Real Environments CLEAR). According to CLEAR in 2005 the Environment Agency estimated that whilst in England and Wales alone some 57,000 hectares of land were identified as contaminated, a total of 292,000 hectares were classified as potentially contaminated.

Read full article on page 24-25

www.enquire2.com - ENQUIRY 1

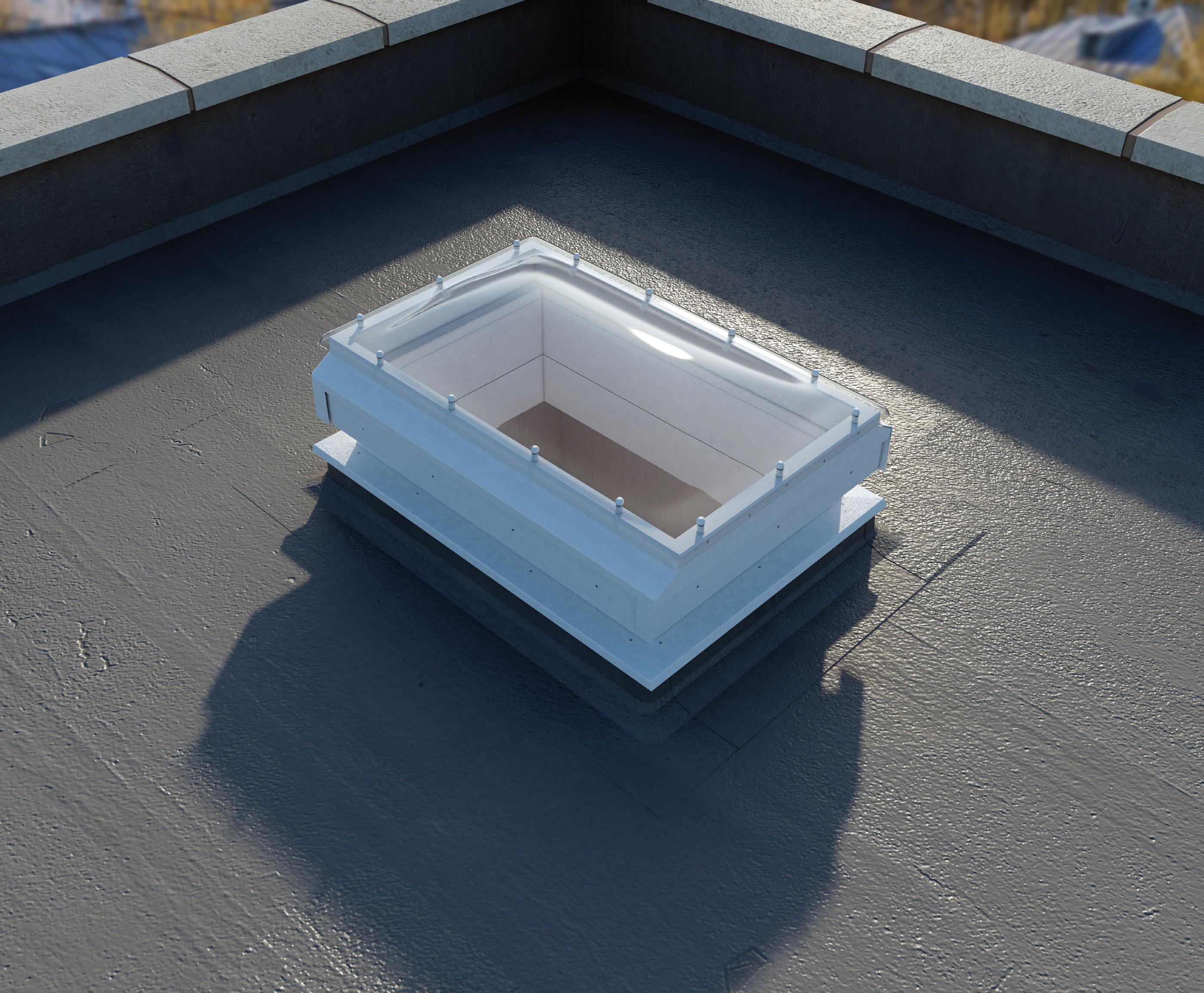

neo™ Rooflights,

With over 30 years’ experience in designing and specifying rooflights under his belt, architect Peter King knows it’s not just about maximising daylight; it’s optimising daylight that matters. Find out more about optimising top light and thermal efficiency. www.therooflightcompany.co.uk/daylight or call 01993 833108 to talk to an expert.

onstruction 2025 is the joint strategy from government and industry for the future of the UK construction sector.

Construction 2025 sets out challenging industry targets that include: 50% reduction in trade gap; 33% lower costs; 50% lower emissions; 50% faster delivery.

BRE, in collaboration with public and private industry partners, is calling for greater effort to meet the 2025 targets and improved co-operation within the industry to develop the right plan of action.

Simon Cross, BRE Construction Sector Business Lead and a Member of the Construction Leadership Council (CLC) and Chair of one of its Innovation in Buildings workstreams, points out that productivity increase has been negligible (1%) compared to many other comparable industries.

“The consequences for construction are shrinking contractor margins, a lack of investment in R&D and a skills deficit to other industries that have or are perceived to be more progressive or attractive,” he warns. “I’m calling for all of us in the sector to work collaboratively and at pace to meet our challenges and the Construction 2025 Strategy targets.”

Cross has outlined 10 factors that provide a provocation for us together to act upon our immediate and future needs, to meet the Construction 2025 Strategy targets and to create greater resilience in the sector.

The 10-point plan deserves to be reviewed by as wide an audience as possible in order to kick-start the type of open discussion the industry needs in order to meet the 2025 challenge.

As Simon Cross says: “Construction can no longer continue its business as usual approach. Together, we must adapt to offsite and advanced industrialised manufacturing, embrace digital technology and up-skill our workforce.

“We practically must work together at pace and with pragmatic ambition to meet our present challenges and future needs, and in doing so become a more resilient industry.”

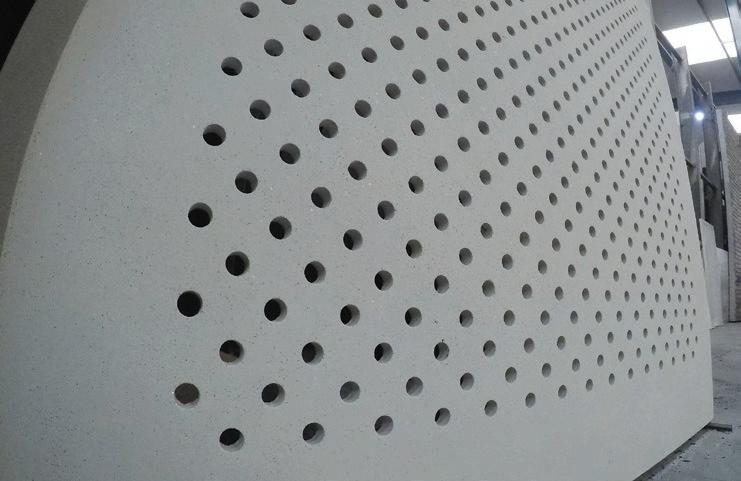

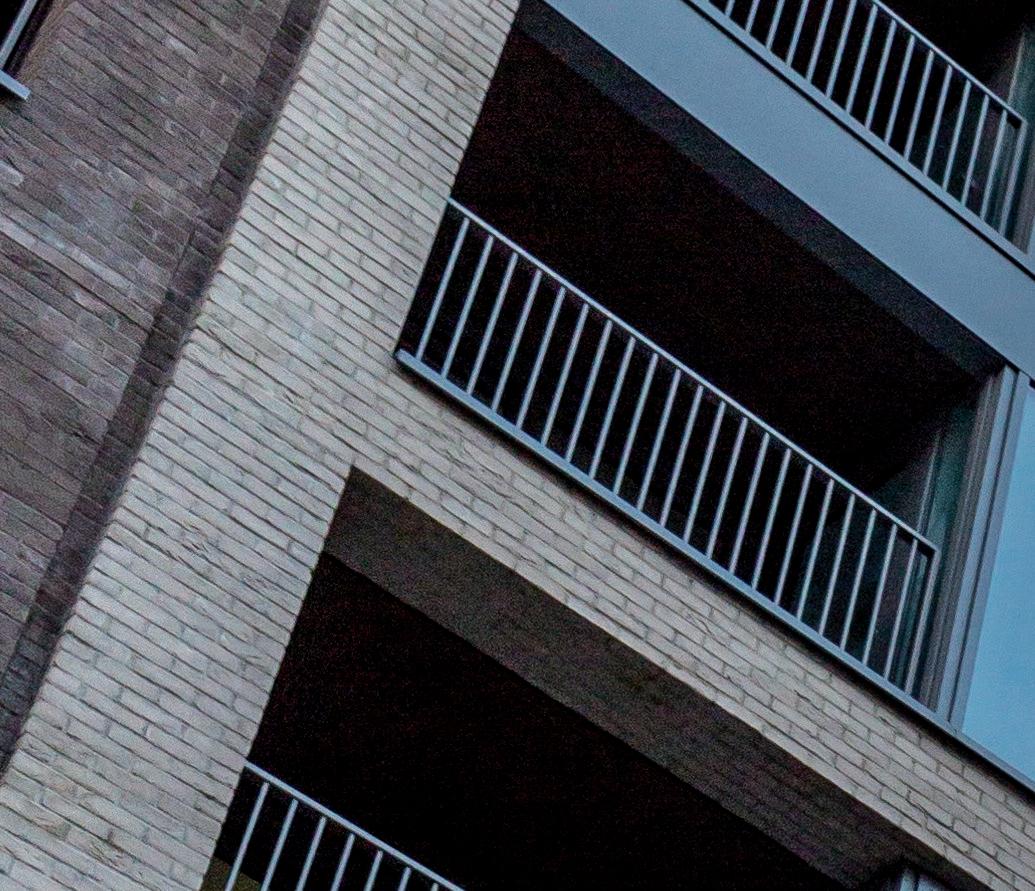

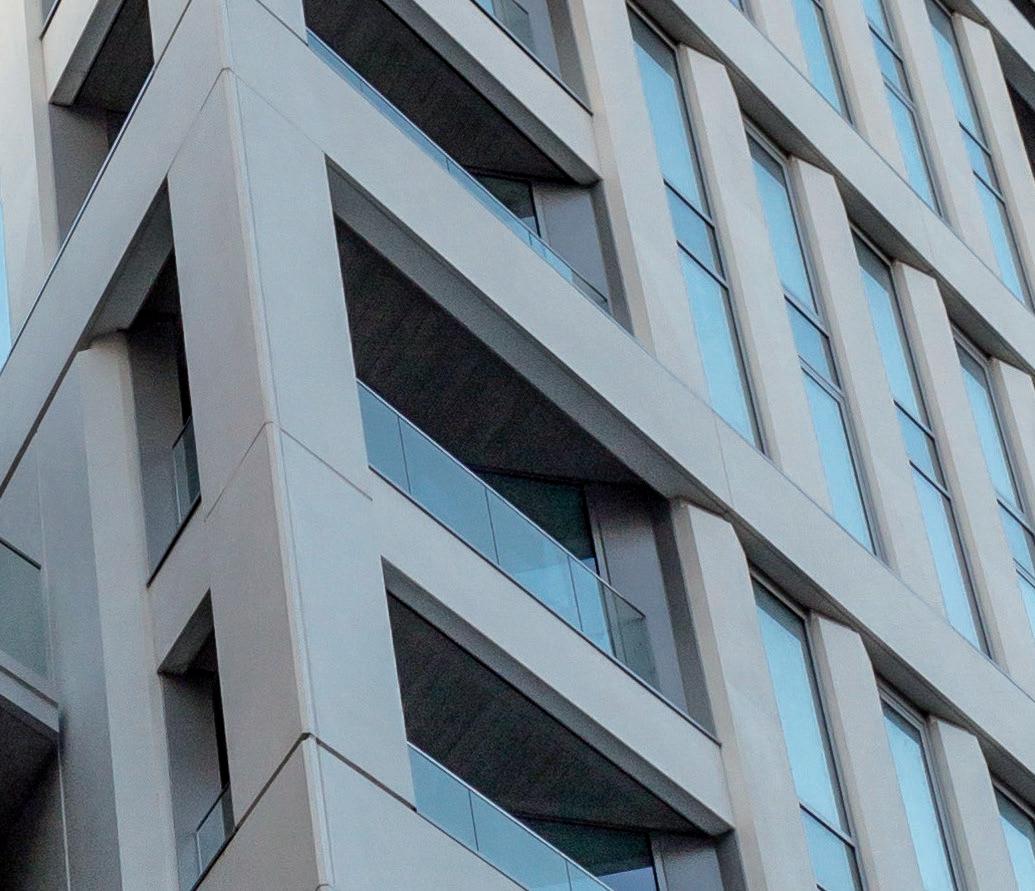

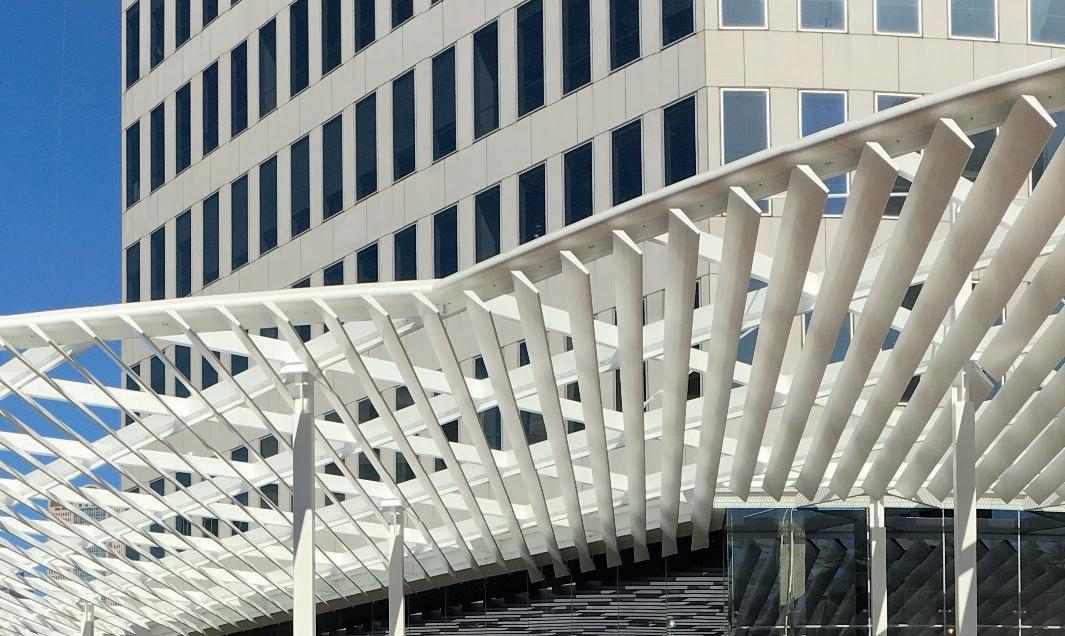

The front cover image features a project recently completed by Century Facades on the Apex House building in Wembley, London. Grade 18P Glass Reinforced Concrete (GRP) created monolithic 3D façade panels fixed back to a structure constructed from off site manufactured steel pods. The GRC contained three aggregates up to 8mm in diameter which were polished before sealing to enhance the weathering performance. Read more on pages 22-23.

One of the UK’s largest contractors, Willmott Dixon has launched its new All Safe Minds campaign, encouraging mental fitness across the UK construction sector. All Safe Minds makes it as easy as possible for vulnerable workers to tap into a variety of resources, and will instil the ‘3 Rs’ into its daily work culture:

• RECOGNISE - Be aware if you or someone you know is struggling to cope.

• REACH OUT - Start the conversation. If you are struggling, talk to someone you trust. Or if you know a colleague is struggling, offer your support –simply lending an ear can make all the difference.

• REBUILD - Use the resources available to you to start taking back control. For

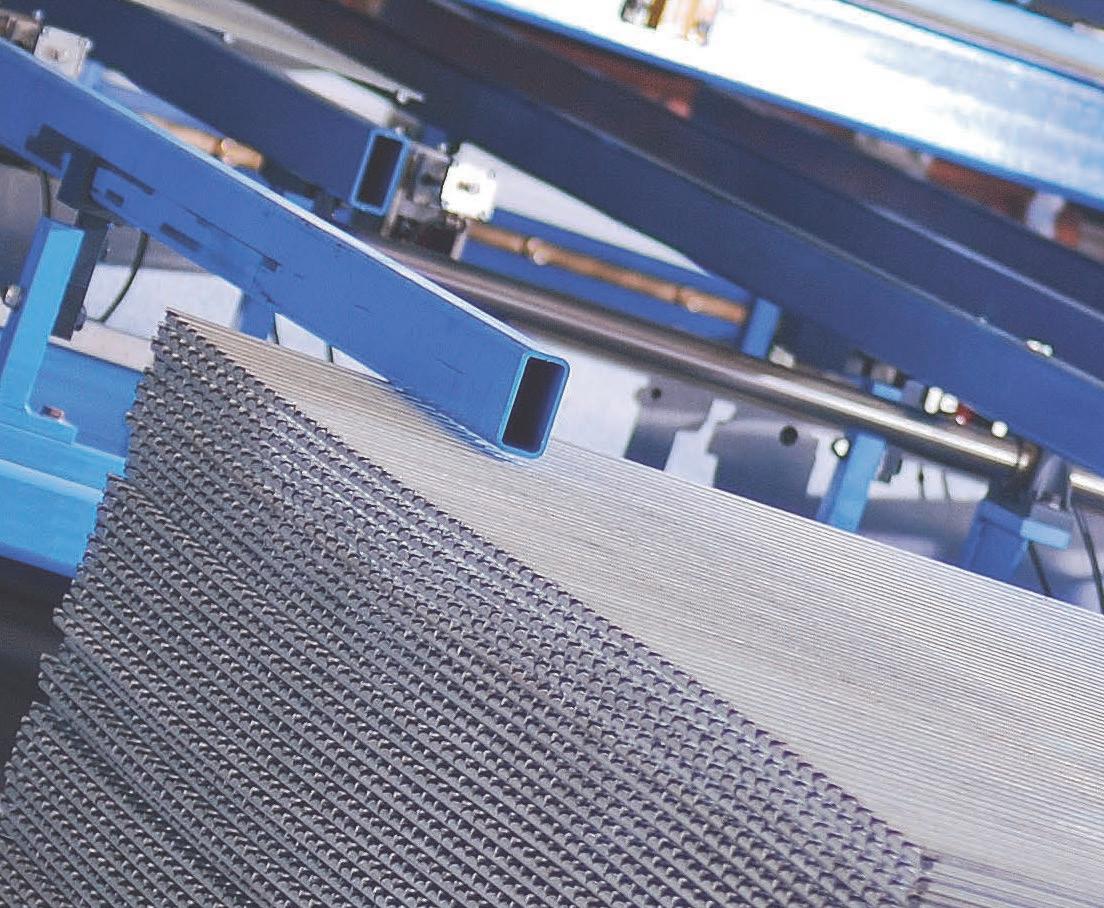

Following increasing demand indicated by visitors to the FIT Show, the organisers have announced the launch of Visit Glass, which will take place alongside the FIT Show in May 2019 at the NEC.

Responding to a massive 40% of the 10,000 visitors to the 2017 FIT Show who declared their interest in seeing glass products and glass-related processing equipment and technology at the event, Visit Glass will become the first UK exhibition and forum dedicated to the manufacture, processing and application of flat glass for almost 15 years.

The event is designed to appeal to glass industry professionals, together with specifiers and buyers of flat glass products and systems. These include insulated glass units, architectural glass, processed flat glass for all non-glazing applications including kitchens, bedrooms, bathrooms and the furniture industry; and glass for interiors including offices and decorative interior design schemes.

Visit Glass will take place in its own clearly designated space at the NEC alongside the FIT Show, in a space that combines key exhibitors representing leading brands alongside a powerful, thought provoking and informative seminar programme dedicated to the glass industry and markets in the UK. To ensure an appropriate format for Visit Glass was created the event was ‘soft launched’, during which time a number of powerful, key brands were quick to reserve exhibition space. These include Pilkington, SaintGobain, Edgetech, Lisec, National Glass Group and Sapphire Glass Merchants, with others joining the floorplan as word of the event spreads.

A dedicated seminar theatre within Visit Glass will offer a comprehensive programme of seminars addressing UK and general issues relating to the manufacture, processing and application of flat glass. Industry experts are being consulted to ensure content that is highly relevant and current for the UK flat glass industry when the event takes place in May 2019.

Organisers of UK Construction Week have released details of a Brexit survey from over 2,500 industry leaders.

The survey canvassed architects, contractors, SME builders, surveyors, engineers, local authorities and many more.

The survey clearly shows that the UK construction industry wants to discuss the positive impacts of BREXIT, with the majority of respondents believing it will force us to solve the skills shortage once and for all by investing in younger generations and encouraging them into the sector. This places extra emphasis on making sure the CITB is fit for purpose, and also supports the Farmer Report, Modernise or Die. Mark Farmer will present his view on what needs to be done following on from the report at UK Construction Week tomorrow.

It also points to resurgence in British building materials, as contractors and house builders protect themselves from any tariffs in future, but also to taking advantage of a blossoming UK manufacturing base.

Key survey findings:

• 64% believe BREXIT will force us to solve the skills crisis and invest in younger generations

• Over 50% said it will make us buy British Building Materials

• 43% believe building material costs will stabilise and 10% think materials prices may actually go down

• 53% said we will embrace offsite manufacturing as a solution to the challenges ahead

Whilst leaving the EU poses challenges, the construction industry is already looking ahead to the positives outcomes BREXIT could bring. The UKCW survey however has laid down a very clear mandate for the UK Government to invest more in apprenticeships and support British manufacturing.

A Hall for Hull with ‘Trois Points de Vue’ – a joint commission from The Royal Institute of British Architects (RIBA) and Hull UK City of Culture 2017 – has been unveiled to the public.

The monumental temporary installation has transformed Trinity Square with sixteen galvanized steel columns arranged in a grid formation in front of Hull Minster to form a new outdoor ‘room’ for the city.

Chile-based architects Pezo von Ellrichshausen have collaborated with Swiss artist Felice Varini to create the ambitious structure which responds to the historic heart of Hull and will remain in place until 11 November 2017.

It has been commissioned to encourage local people to see their city in new and memorable ways and to become a focal point for national and international tourists.

The installation will provide visitors with a range of different experiences as they enter each of the six-metre-high columns, open to the sky. Perforations across the columns’ frostedlike steel skin creates a delicate interplay of light and shadow across the interiors of each inhabited space.

Visual and physical contradictions merge as visitors first encounter a series of imposing, static steel columns from a distance but as they move closer the perforations create as feeling of lightness.

The UK Green Building Council (UKGBC) has launched a series of online infographics designed to profile ‘The State of Sustainability in the UK Built Environment’.

With input from wide-ranging stakeholders, including a significant number of UKGBC’s own members such as Arup, BRE and University of Leeds, the project has brought existing datasets together alongside some data that was previously unpublished.

UKGBC views the project outputs as an important step in clarifying the scale of the sustainability challenge facing the built environment industry. As the organisation embarks on its second decade, it calls for all built environment professionals to take responsibility for making positive and transformational change happen.

Stand out stats include:

• 22% of UK carbon emissions come from the operational and embodied carbon of the built environment

• 10% of UK carbon emissions come from heating buildings alone

• 3.2 million homes are in areas at risk of flooding from surface water

• Waste from construction, demolition and excavation represents 59% of the total UK waste

• Since 1970 56% of monitored species in the UK have declined

• The health effects of particulate air pollution cost the UK around £16 billion per year

• 11% of occupied homes in England are in serious disrepair

Julie Hirigoyen, Chief Executive at the UK Green Building Council, said: “This project was designed to bring the data that is available to life, and in collaboration with experts, to highlight where we urgently need to either measure new aspects or take different actions to address the magnitude of the challenges we face.

“Now more than ever, our industry must show leadership and galvanise around some of these issues. We need bold and decisive action to make sustainable development truly second nature in the built environment.”

A £2.5 million cash boost to speed up the delivery of over 155,000 new homes across England has been announced by the Communities Secretary Sajid Javid.

Nine locally-led garden town developments, from Bicester to Taunton, will each receive new funding to fast track the build out of these large housing projects.

The new funding will support local authorities and communities in delivering ambitious proposals, speeding up the progress of developments through additional dedicated resources and expertise.

Garden towns being supported by government are committed to delivering high quality, well-planed and well-designed new communities that will stand out as exemplars of good development in years to come.

The funding will support the development of 9 new locally-led garden towns at Bicester, Didcot, Basingstoke, Otterpool Park in Kent, Aylesbury, Taunton, Harlow-Gilston, North Northamptonshire and North Essex.

Communities Secretary Sajid Javid said: “Locally-led garden towns have enormous potential to deliver the homes that communities need. This new funding will help support the construction of more than 155,000 homes in 9 places across the country.

“New communities not only deliver homes, but also bring new jobs and facilities and a big boost to local economies.”

The government’s Housing White Paper sets out bold new plans to ensure the housing market works for everyone, so that more people can have the security of a decent place to live.

Across England, government is supporting the locally-led development of 10 garden towns and cities, as well as 14 garden villages – with the combined potential to deliver 220,000 new homes across England.

Interserve has been awarded a contract worth in excess of £70 million by Dandara Limited to design and build a residential development comprising 744 apartments in Leeds.

The four-building development, located in the south side of Leeds city centre, will offer one, two and three-bedroom apartments as well as a number of studio-style options. Landscaped areas, basement car parking, access control and a dedicated area for concierge and management services will also be provided.

Work has already commenced onsite, with the development due for completion in June 2019.

Sean O’Connor, Dandara’s Project Director said: “The Private Rental Sector (PRS) is already providing accommodation and can help deliver the homes needed by those who want to live and work in Leeds and other major UK cities.”

CREATING BESPOKE SPECIFICATIONS FOR A PROJECT IS PERCEIVED AS A LENGTHY TASK, LEADING MANY ARCHITECTS TO COPY OLD SPECIFICATIONS. TOM EVANS, NATIONAL SPECIFICATION MANAGER AT JOHNSTONE’S TRADE, DISCUSSES THE IMPORTANCE OF CREATING CLEAR, CORRECT AND BESPOKE COATINGS SPECIFICATIONS.

recent NBS report (2017) revealed that 94 per cent of built environment professionals have experienced difficulties when producing or using specifications. Two of the biggest challenges are the substitution of products, and the re-use of older specifications.

In fact, according to the report, 60 per cent of respondents stated they have reused specifications that have previously been written for other projects. While reusing specifications might initially save time, ultimately, no two projects are the same and this approach can mean newer products that

are most suitable for the job are not used, which can lead to application issues.

Making substitutions within a specification may lead to the end result of a project being compromised. In coatings specifications, this could mean a less durable paint coating is used that requires more frequent maintenance in the long term.

Being able to create these bespoke specifications, however, typically requires time, particularly when researching products and understanding new methods of construction and manufacturing. In reality, the time-pressures architects face often means that they have difficulty building bespoke specifications for every project. Working closely with manufacturers is one key way architects can make this process easier, quicker and more accurate.

According to the NBS (2017) report, 70 per cent of those surveyed agreed that specifications work best when manufacturers are involved early on. Manufacturers have the knowledge to support specifiers by providing the information they need in a digestible and functional format for each stage of the project. By engaging in an open dialogue, manufacturers can help architects quickly access technical product details and identify the solutions that will deliver the best performance.

As specifications become increasingly more demanding, relationships between architects and manufacturers can lead to new and more efficient ways of building these important project documents. Tools like Johnstone’s Trade’s .stdspec file download are helping to reduce the pressure architects face while making it much easier to create unique and precise specifications.

The downloadable office standard integrates into RIBA’s office standards location with

NBS Building software, helping architects to create comprehensive paint specifications quickly and easily.

It provides a list of pre-written clauses that can be selected or removed to tailor the coatings specifi cation to any project. This ensures there is no incorrect duplication of information and all products are referenced against the correct clause. With detailed guidance and comprehensive notes offering advice on the preparation and application of products too. In addition, the software ensures the latest products and technologies are specifi ed, so architects can be confi dent that they’re building robust specifi cations that do their designs justice.

Over the last decade, construction has become more digitalised to meet the demands of today’s built environment. As a result, specifications are more important than ever before.

They act as a detailed guide for contractors on the specific products that can achieve the added-value results the industry now expects as standard. But with time-pressures on the rise for architects and specifiers, creating these bespoke documents isn’t often achievable. Greater collaboration between architects and manufacturers is the key. By creating valued relationships that are based on knowledge-sharing and an understanding of what both sides need from one another, the process can become quicker, easier and more streamlined.

Johnstone’s Trade’s new M60 office standard is available to download in three different formats, including a.stdspec file that can be imported straight into RIBA’s NBS Building software.

Johnstone’s

CHRISTINE POUT, PRINCIPAL CONSULTANT, BREEAM, BRE GLOBAL, EXPLAINS HOW A BREEAM ENERGY PREDICTION AND VERIFICATION METHODOLOGY IS BEING PROPOSED WHICH AIMS TO ENCOURAGE ALL THOSE INVOLVED IN THE BUILDING DESIGN, CONSTRUCTION, COMMISSIONING, FACILITIES MANAGEMENT AND OPERATION TO TAKE STEPS TO CLOSE THE ENERGY PERFORMANCE GAP.

uilding owners, regulators and managers want buildings that behave as predicted and it’s in the designer’s best interest to ensure this actually happens.

Sadly, this is rarely the case. This is partly because UK buildings are designed to show compliance with Building Regulations and to produce EPCs which necessarily require standard operating conditions to permit comparison between buildings. This means that energy modelling is undertaken with standardised occupancy patterns and don’t include all equipment energy loads, often referred to as unregulated energy use.

Under actual operating conditions the energy use will generally be considerably higher than indicated by energy modelling software that is used to show compliance.

BRE is proposing to introduce additional criteria within BREEAM UK New Construction to actively encourage two things. The first is to improve the accuracy of predicted operational energy performance through more detailed and accurate modelling that takes account of the expected occupancy

and unregulated energy loads within the building and also the effect of management factors. The second is the setting of a realistic energy performance target range based on these predictions. Finally a post occupancy verification carried out as a separate assessment procedure once the building is fully operational, which may typically be two years later.

It is proposed that the prediction aspects of the methodology and commitment to verification will be rewarded within BREEAM UK New Construction, whilst the verification will be carried out under a separate post occupancy assessment scheme. The latter will also generate a preliminary BREEAM in Use operational energy score.

Developed to incentivise more detailed energy modelling and reward more accurate predictions of energy use throughout the design process to support better design and construction of new buildings, it incorporates practical steps to promote comparable measurement of energy use both in design and operation, by ensuring that energy predictions and sub metering strategies are consistent.

This will enable building operators to identify areas where measured energy consumption is higher than expected and to investigate, and where possible resolve, the discrepancy between predicted and actual consumption prior to verifying the energy performance.

A key element of the methodology is the setting of an overall energy performance target at the design stage and subsequent verification against measured energy consumption. The performance targets are not determined by internal scheme benchmarks but are based on the results of the detailed energy modelling.

It is envisaged that performance based credits will be awarded at the verification stage both how closely actual performance meets the target set and how stretching the performance target is.

The verifi cation stage is a key part of the process and involves collecting detailed energy consumption data for at least a year and comparing this to the predicted energy performance target adjusted to take account of the actual weather during the monitoring period.

By allowing design teams more time to spend on modelling and considering how the building will be used by its occupants, rather than using ‘default values’ and specification, we will go some of the way to eliminating this performance gap.

The consultation is open until November 3, 2017 and feedback from industry experts, clients, assessors and any other stakeholders involved in the BREEAM process is welcome.

Architectural detail delivered in 4 weeks. Specified by Architects, approved by Councils and chosen by House Builders for commercial projects and housing developments, SYTEX FoamStone has revolutionised the house building industry. FoamStone adds value and quality stone appeal to any project.

2400mm length of any shape profile. Any shape, any size, any length delivered in 4 weeks.

INSTALL during or after construction ROBUST any size, any shape, delivered in 4 weeks EASY to handle, quick to install QUALITY beautifully engineered FoamStone

Call:

DEMAND FOR PREMIUM NATURAL SLATE FOR ROOFING CONTINUES TO BE REMARKABLY ROBUST, ACCORDING TO AMANDA GREEN FROM SIGA NATURAL SLATE, BUT THE USE OF LOWER-GRADE SLATE PERSISTS, SO SHE OFFERS A GUIDE TO THE BENEFITS AND PITFALLS.

There’s no substitute for quality – but as the market leader in natural slate for roofing, we’re always going to say that! But it’s not just us: any organisation that has invested in first-class infrastructure, leading-edge manufacturing and the most-reliable processes and supply chains will say exactly the same – whether it’s roofing, cars, technology or retail.

When you set the benchmark for the rest of the industry, there’ll always be competitors that will try to go toe to toe with you and those that know they can’t match you, so they go low on quality and price, which has a knock-on effect on service and support.

That’s where we are with natural slate right now – and the current economic climate is only serving to shine a brighter light on the issue.

We’ve worked too hard for too long to be anything other than what we are, and the roofing market has responded in kind, which is why demand has remained strong.

However, demand for lower-grade slate persists – so in order to explain the pitfalls of it, we must single out the qualities of the good stuff.

The first and most important thing to say is that all our slate is T1; we were the first major distributor to discontinue the import of T2 slates back in January 2016. Slate tile quality is governed by British Standard EN 12326-1:2014, and one of the main tests is the ‘thermal cycle’ test, which assesses the levels of rust or oxidisation within the slate and involves repeatedly soaking pieces of slate in water and then drying them out over a period of up to three weeks. If there’s no apparent change or minimal surface rust/ changes to affect the structure or cause runs of discolouration, the slate is classed as T1.

Another vital benefit of our T1 slates is that they are fully compliant with CE and Construction Products Regulations and

come with warranties of up to 75 years that offer the assurance of consistent quality and full traceability, from the quarry to the roof. As well as compliance with any environmental and carbon footprint policies that architects, builders and roofers may have to satisfy, full traceability fulfils a much more fundamental requirement if identical slates are ever needed in the future for redevelopment, refurbishment or extensions of individual properties or developments.

It’s also worth noting at this point that in 2009, the National House Building Council (NHBC) took the decision to recommend only T1 slates and went so far as to prohibit the use of any other grade, such as T2, on new builds.

We certainly don’t condone it, however some roofers and contractors will cut corners to cut costs – we’ve seen the same issue rear its head in other roofing sectors, such as timber batten, where materials coming in from other parts of the world simply don’t meet the British Standard because of their sub-standard quality – and some suppliers trying to skirt around the rules!

And let’s not forget that natural slate is stunning – which is why it’s used on flagship projects such as the one by Haldane Construction Ltd. The company was presented with an award at the Federation of Master Builders’ (FMB) Scotland ceremony for a bespoke 1.5-storey house with a unique turret feature that was finished with a traditional slate roof.

SIGA 67 was specified by architects and conservation consultants Pollock Hammond Ltd. because it is an exceptional slate that conforms to the French standard, which means it has been tested over and above the European norm (BS EN 12326-1:2014).

And, finally, if we can blow our own trumpet for a moment, the level of technical support, datasheets, CPDs and even health and safety advice we provide as a company is second to none.

As previously mentioned, in respect of quality testing for compliance with BS EN 12326-1:2014, T2 slates may show signs of oxidation or appearance changes of the metallic inclusions that would cause staining, pitting and/or delamination and potential failure of the slate in as little as three weeks. It is this unpredictability which makes T2 slates a more risky option, because even to the trained eye, it’s difficult to notice the inconsistencies and imperfections that can affect durability and performance over time, resulting in increased costs to rectify the job.

The NHBC prohibits it, and the lifetime performance is unpredictable which means roofing contractors may incur additional costs, potentially at their own expense, if any problems or issues arise on installations in the future.

Whichever way you look at it, anything other than T1 natural slate for roofing is a false economy. The only way to be sure your slate is what it says it is, is to deal with a reputable supplier that can provide full traceability and back this up with a robust warranty and excellent customer service.

Amanda Green is the Marketing Manager of SIGA Slate.

More than ever, customers expect a stylish, reliable shower with minimal disruption to their lives... ...fortunately the Eden cubicle delivers just that.

SILICONE FREE CRISTAL PLUS GLASS

Silicone-free. Grout-free. Stress-free. NO LEAKS 2 YEAR GUARANTEE

2 YEAR www.enquire2.com - ENQUIRY 14

HECKMONDWIKE, THE UK’S LEADING FIBRE BONDED CARPET MANUFACTURER, IS ENTERING AN EXCITING NEW ERA WITH NEW BRANDING, NEW SHADE CARDS, A NEW BROCHURE AND A RE-DESIGNED WEBSITE.

With a powerful new strapline‘Heckmondwike – Makers of Fibre Bonded Carpets’ - the company is demonstrating its unique heritage, celebrating 50 years of fibre bonded carpet manufacture for the education, commercial and health sectors.

Heckmondwike’s refreshed contemporary image reflects a new design-led approach, which is reflected in its new shade card suite and corporate marketing literature and collateral.

The company’s shade cards are extremely popular with interior designers, architects, schools and flooring contractors. Recently released are shade cards for Heckmondwike’s Supacord,Broadrib, Hobnail, Wellington Velour, Iron Duke and Entrance ranges. All ranges have been used extensively across educational settings and other environments for over 50 years and their exciting new look will make it even easier for contractors, specifiers and endusers to select the correct carpet to suit their needs.

A new 20 page brochure presents the revitalised Fibre Bonded and Entrance ranges, clearly demonstrating the company’s comprehensive choice of colours and designs.

In addition to the new literature, there are a number of colours that have been added to Heckmondwike’s Hobnail, Iron Duke and Wellington ranges, to make them even more versatile for use in different environments and sectors.

The new website has been designed with a new contemporary and uncluttered look. The website features all Heckmondwike’s ranges,

Design is becoming increasingly important in the choice of carpet, rather than it being a purely functional purchase and this is reflected in our literature and in our extended choice of colours in certain ranges.

with high quality installation and product photography, plus NBS specifications, BIM models, downloadable literature, notable case studies and installation and maintenance advice.

Jeremy Broadhead, Commercial Manager at Heckmondwike, said: “We are really excited to be launching our new identity and support literature and website.

“Design is becoming increasingly important in the choice of carpet, rather than it being a purely functional purchase and this is reflected in our literature and in our extended choice of colours in certain ranges. With our new website, brochure and shade cards, we are making it even easier for the specifier or buyer to make the right choice for them.”

Heckmondwike’s Fibre Bonded carpets are renowned for their durability, but also for their low maintenance properties and the fact that they will not ravel or fray - great in high-traffic areas.

AN ICONIC AND POPULAR RESIDENTIAL DEVELOPMENT IN THE WEST MIDLANDS, THE LANDMARK AT BRIERLEY HILL, IS USING SMOKE CONTROL SYSTEMS FROM SE CONTROLS TO ENSURE ESCAPE ROUTES ARE KEPT FREE OF SMOKE IN THE EVENT OF A FIRE, ALLOWING RESIDENTS TO EXIT THE BUILDING SAFELY.

ocated at the Waterfront complex adjacent to the Merry Hill retail centre in Dudley, The Landmark was formerly the HQ for a financial services company before being acquired by investment property developer, Seven Capital, who converted it into 181 apartments with Colmore Tang Construction, all of which were sold off-plan within five months.

As the travel distance from some of the apartments to the building’s five existing escape stairs was more than the maximum 7.5 metres allowable for code compliant naturally ventilated smoke control system within Building Regulations Approved Document B, SE Controls designed and installed four individual smoke ventilation solutions. Each of these was based on the specific requirements of each floor within the building and combines both mechanical fan and natural smoke extraction.

The ground and first two levels have the largest floor areas and highest density of

apartments, so an SE Controls SHEVTEC Extended Travel Distance mechanical fan system was installed to protect the corridors and three of the stairwells where apartments are located more than 7.5 metres from the escape stairs.

On the second, third and fourth floors, supplementary automatic opening vents (AOV) are provided to ensure additional stairwells and corridors are kept free of smoke to aid escape from apartments located within 7.5 metres of the stairs.

A further naturally ventilated system is used on floors five and six. These have the smallest floor area, but additional dedicated escape stairs, which are protected by AOV louvres at the head of stairs. The main escape route in the seven-storey section of the building is also protected by a naturally ventilated smoke system, which covers all the floors.

SE Controls – Enquiry 17

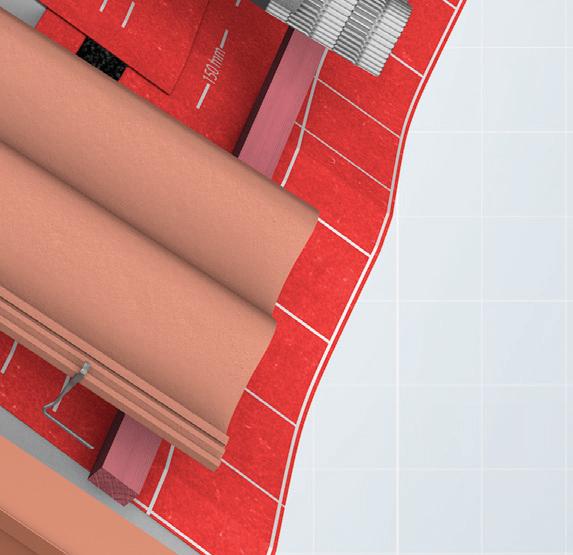

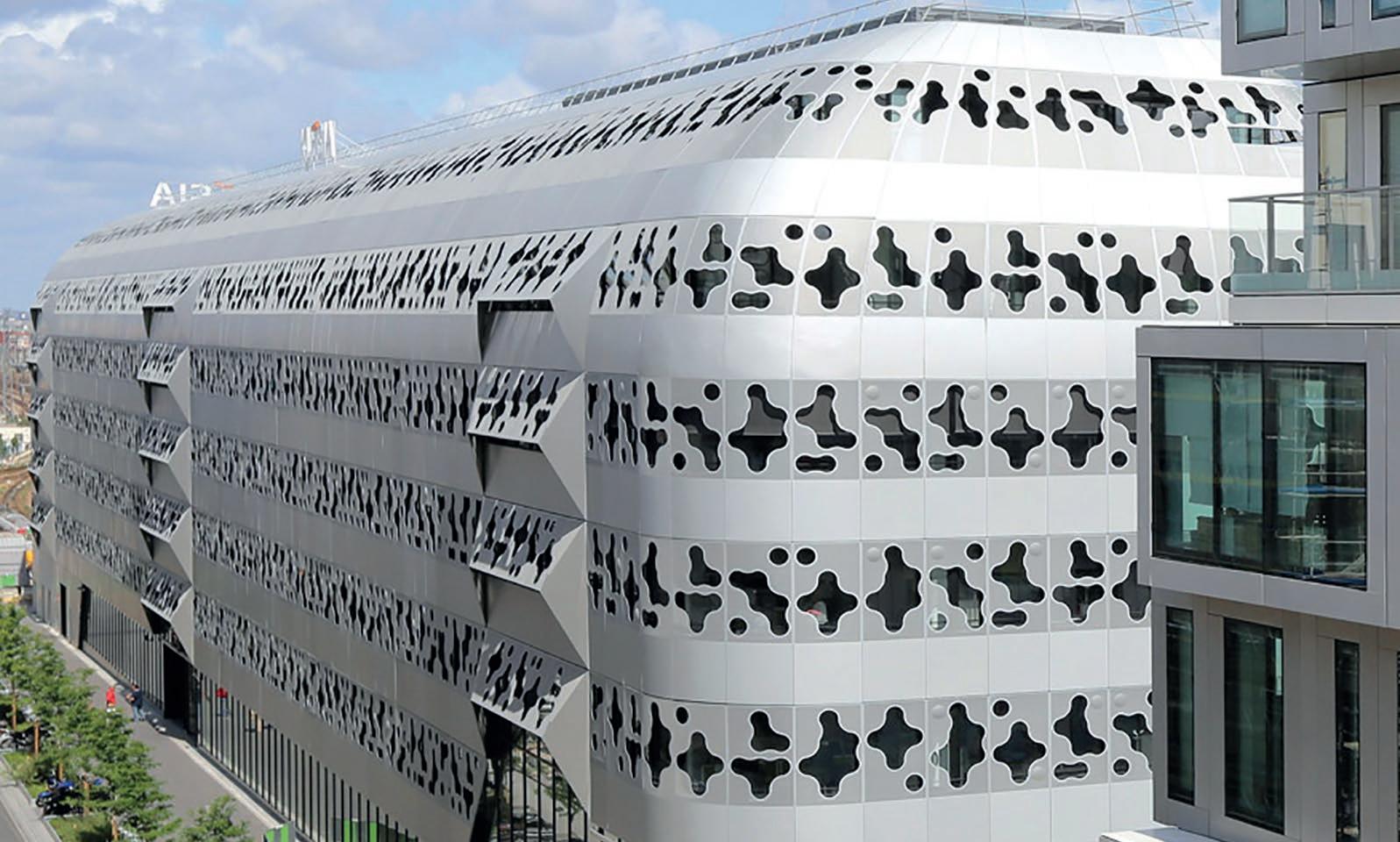

TELLING ARCHITECTURAL HAVE ESTABLISHED A MODERN FACILITY AT THEIR PLANT IN FOUR ASHES, WOLVERHAMPTON TO MANUFACTURE GLASS FIBRE REINFORCED

ur 60,000 sq ft modern facilities, handling equipment and methods enable us to offer off site manufactured GRC panel including pre-fabrication where required.

Our skilled operatives are capable of producing GRC ranging from the most basic flat panel forms, to complex 3D and curved forms, pre-fabricated and pre-finished with ceramic or brick

The majority of our façade projects require the specialised grade 18 GRC which is the highest technical performing of the GRC grades. This allows Telling to manufacture large format panel systems as standard or bespoke façade total solutions.

Telling have developed pre-fabricated brick columns and spandrel panels which at 100 kgs per m 2 will offer optimum savings to clients in weight, speed and installation.

The company can undertake specialised projects such as roof panels of GRC with ceramic tiles adhesively bonded and mechanically attached to GRC and artwork created in CNC cut rubber moulds from computer generated graphics.

GRC is a fibre reinforced pre-cast concrete with a 50-50 sand cement matrix in a typical wall thickness of 12 to 15mm thick. Hollow rib profiles created around the perimeter and across the rear face at designed centres provide the structural integrity of the components.

GRC is made in thin concrete sections created by a proprietary process of machine spraying an enriched OP cement and silica sand mix within which alkali resistant glass fibres and polymers combine to provide the engineered performance. Unlike steel, glass fibres will never rust and are consistent throughout the thickness of the profiles.

GRC is approximately 80% lighter than pre-cast reinforced concrete cladding and 70% per cent than traditional brick. It offers

greater accuracy in manufacturing and installation with excellent flexural strength. It is environmentally preferred with a lower carbon footprint by reducing the CO2 emissions created during manufacture and upon associated elements of the structure.

The GRC panels, range from basic storey height units, to more complex 3D and curved designs, in natural aggregate finishes, polished or faced with brick/ceramics. They are proving to be suitable for new construction and the refurbishment of existing buildings.

Telling GRC envelope solutions will fall into four categories;

• Bespoke GRC façade solutions including brick/ceramic facings

• M4 unitised GRC façade system

• NôRSKREEN™ GRC rainscreen façade system

• Unitised ‘I’ frame columns and panels

All GRC components are manufactured at a purpose built factory in Four Ashes, Nr Wolverhampton in England in all cases to the current guidelines laid down by the GRCA International specification for the manufacturing and curing of GRC components.

The thickness and weight of the systems will vary according to the system design:

• For bespoke and unitised solutions the weight per m2 will be project specific.

• M4 unitised solutions weigh approx. 50-70kg per m2

• NôRSKREEN™ solutions weigh approx. 40-50kg per m2

GRC is a versatile pre-cast concrete material creating façade elements from as small as 450X450mm up to storey height panels. Manufacturing seamless cast corners, returns to windows, integral window cill, coping and soffit details, all promote a widescale reduction in unsightly panel joints on the elevations.

Telling Architectural offer a range of façades ranging from spanning storey height units in their M4 range to thin section panels using the NôRSKREEN™ system. GRC cladding can be used in traditional construction, within unitised curtain walling or as a ventilated cavity rainscreen.

Whether a pigmented colour or natural in grey or white, textural or smooth faced, premixed GRC can be cast in moulds made from GRP, rubber or timber to produce the most consistent detail and quality available.

These formers allow GRC to closely replicate smooth natural stone or travertine, split face and ‘hammered’ effects. For refurbishment cornices, columns, parapet features and other mouldings can be replaced with excellent accuracy and consistency of profile. Decorative columns or other classical features can be added to existing or new buildings.

Telling Architectural manufacture their GRC in large format panels which are lightweight and can be mounted on aluminium or steel frames . They welcome NDA exclusive partnerships with specialised unitising fabricators. GRC can also be used in modular construction with brackets mounted prior to stacking of the pods.

Generally the performance of Grade

18 GRC (as with pre-cast concrete) is determined by engineered calculations although CWCT weather performance and impact testing has been undertaken upon a variety of schemes/applications.

Whilst GRC Grade 18P has a generic fire test evaluation indicating it to be Class O surface spread of flame, providing four hours integrity and A1 performance our systems are currently fire testing for our range of GRC systems including the brick facings.

Accellerated weather testing has been undertaken on polished aggregate, brick faced and standard GRC panels.

Brick and Ceramic Faced GRC Telling has developed the technology for brick faced GRC panels, columns and spandrels panels which at 100 kgs per m2 offer savings to clients in weight, speed and installation. Hand-made, extruded or standard brick slips, 16-24mm thick, are mechanically fixed to the grade 18 concrete with threaded stainless steel rods embedded in the rear face of the brick. Pull out values in excess of 2 kN per anchor are achieved. Special lime mortars ensure penetrating moisture is evacuated through the pointing joints. A recently completed scheme on 160 Aldersgate in London is testimony to the quality and benefits of lightweight offsite manufactured brickwork.

Manufactured in rubber moulds, brick faced GRC can use any brick of an appropriate

quality in stack, running and ‘Flemish’ bond with depth/style of pointing created from the in house manufactured mould design.

The development of offsite manufactured brick panels offers advantages in:

• weight to promote savings in the ground and the structural frame

• speed of installation removing the need for multiple trade contractors

• quality by obviating the skills shortages upon high rise structures

• logistics in material distribution and access strategy

• programme whereby the façade is wholly removed from the critical path and is supplied to site on a

• tower cranes – the reliance upon these for the external facade is removed with installation by mono rail

The weight of brick faced GRC is 40% of hand laid brick and 25% of precast.

Accellerated weather testing has been undertaken to determine the bond of the and performance of the brick, mortar and concrete in accordance with ETAG 034.

Impact and pull off testing were also undertaken with further detailed evaluation underway for review for a soffit application as well as general service as a cladding medium by the NHBC.

ver the years, the UK construction industry has experienced significant changes and advancements in part due to the need to service the demands of a growing population, with its impact on the places where we work, shop and live. Successive governments have sought to shape guidelines and legislation for the industry with numerous reports such as Constructing the Team (Latham 1994), Rethinking Construction (Egan 1997), Accelerating Change (2002), through to the Calcutt Review of Housebuilding in 2007 and the Strategy for Sustainable Construction in 2008.

The demand for housing and construction has always been a key component of the UK economy, and need continues to grow the recognition of the requirements for the sustainability, safety and health and wellbeing of present and future generations has become increasingly important.

The UK is not new to change having been a central player in the explosion and changes which arose out of the age of the industrial revolution. However, this era and its consequences has resulted in the exploitation and contamination of much of the very land which is now so urgently needed to satisfy the demands of the population.

Despite the major advances and continual improvements in today’s modern industrial processes, we have created a legacy of contamination within the soil and groundwater of the land on which we need to build. ‘Contaminated land contains substances which pose a risk to either human health, a body of water or an ecological receptor’ (Contaminated Land: Applications in Real Environments CLEAR). According to CLEAR in 2005 the Environment Agency estimated that whilst in England and Wales alone some 57,000 hectares of land were identified as

contaminated, a total of 292,000 hectares were classified as potentially contaminated.

Since 2008 the number of new households in the UK has continued to exceed the number of new homes built giving rise to the current shortage in housing supply, and creating the urgent need for a period of sustained development within new house building. The Government set two clear targets in relation to house building supply, to deliver 1 million new homes by 2020, and to provide 240,000 homes in 2016.

The Government has ambitions that it expects to see local development orders being used to get planning permissions on at least 90% on suitable brownfield sites by 2020. In order to do this, it has implemented a package of support that local authorities can use, with a total of £400 million of

government funding being invested to create housing zones on brownfield land. In the need to identify suitable land, the safe development of housing on brownfield sites will be fundamental in achieving the objectives set by government. The A. Proctor Group has over twenty years of experience in providing solutions for the safe development of brownfield land, and an extensive range of ground gas protection products to make the development of these sites safer and easier.

Aubrey Machin, Ground Protection National Technical Sales for the Group explains, “The Government is referring to the use of brownfield sites that are suitable for development, not sites which are too heavily contaminated and in need of expensive remediation. The sites that are to be identified are those which developers would consider viable, with either no special environmental protection measures or sites which would be considered viable within the guidance outlined in BS8485 2015 (Code of practice for the design of protective measures for methane and carbon dioxide ground gases for new buildings) or NHBC Guidance for the Safe Development of Housing on Land Affected by Contamination. Developers should also consult the guidance documents CIRIA 716 and 748 detailed below.”

The latest in ground gas protection “However, with the emphasis that is being placed on brownfield development, more is required from the systems that have traditionally been used for ground gas protection. We wanted to develop a new high performance membrane that is designed specifically to make the development of brownfield sites safer and easier. In order that designers and installers can have ultimate confidence in barrier membranes it is essential that they consider products which are able to provide accurate test data and not simply modelled data.”

A new high class performance VOC membrane Protech VOC Flex has been launched. Protech VOC Flex is a 6-layer flexible proprietary reinforced VOC gas barrier suitable for use on brownfield sites that require protection from dangerous contaminants such as hydrocarbons.

Key guidance, standards and codes of practice relating to protection and best practice when building on contaminated land is given in CIRIA C748 and BS8485:2015. The CIRIA C748 guidance stipulates that

a VOC membrane must be tested against a minimum of 9 challenge chemicals. The 9 chemicals included are: benzene, toluene, ethyl benzene, m.p xylene, hexane, vinyl chloride, tetrachloroethene (PCE), trichlorethene TCE, and naphthalene.

Protech VOC Flex has been extensively tested by an independent testing authority and fully complies with the requirements of BS8485:2015 where methane permeability must be >40ml/m2/day/atm. As a minimum VOC membranes must be tested against the 9 chemicals for vapour permeability (ISO 15105-1) and after immersion (EN14414). Protech VOC Flex was tested against several additional chemicals over and above the 9 listed.

“The reasons for developing Protech VOC Flex, and the benefits it provides are extensive. Previously the membranes which, were recommended to provide protection for buildings, were derived from landfill and industrial solutions, typically HDPEs of various thickness. “The main problem with these membranes is that they are incredibly difficult to work with and detail, particularly on housing schemes, where the house plots are small. So the main design objective was to produce a

membrane, which is highly resistant to Hydrocarbon and chemical attack, plus strong and robust enough to survive the build process (highlighted in BS8485 2015), more importantly flexible enough to detail and install quickly and easily. Our initial projections are that it should be four times faster to install against traditional HDPEs,” says Machin.

The A. Proctor Group works with developers and contractors to guide them on all aspects of designing gas protection systems. From recommending the ideal level of protection for a particular site, through to selection of suitable materials, and advice on detailing, highly trained specialists provide technical assistance to give developers the confidence to build on brownfield sites.

A. Proctor Group – Enquiry

To make an enquiry – Go online: www.enquire2.com Send a fax: 01952 234003 or post our: Free Reader

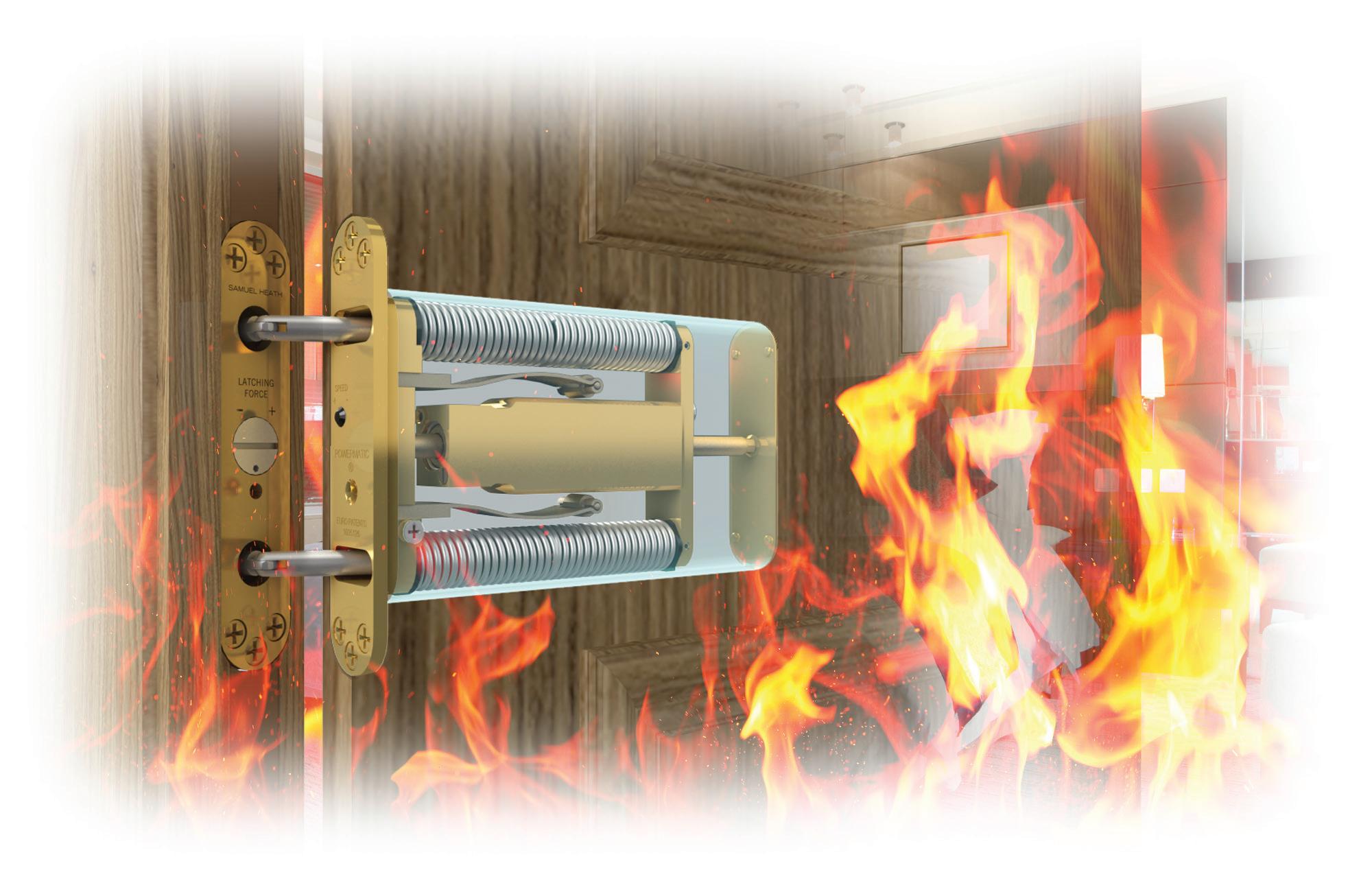

KNOWLEDGE AND UNDERSTANDING AROUND ACCESS CONTROL MEASURES IS STILL FAR FROM BEING AT THE IDEAL LEVEL IF WE ARE TO PROTECT OUR SCHOOLS BETTER AND PREVENT PUPILS COMING INTO HARM’S WAY, SAYS SIMON OSBORNE OF ALLEGION UK & IRELAND.

hen children and teachers go to school, they should feel safe and at ease. However, overall UK security levels are at their highest ever, while news around school security is alarmingly frequent across our newswires. It is becoming an unfortunate reality that our schools are not as protected as we would like them to be.

A quick recent timeline of events in the UK will ratify this:

• May 2017 – Theresa May raises UK threat level to ‘critical’, following terror attack at the Manchester Arena at a concert with predominantly teenagers and children attending.

• May 2017 - Metropolitan Police Chief Commissioner Cressida Dick told children as young as six years old are carrying knives by community members.

• November 2016 – Boy seriously hurt in City of Birmingham school stabbing.

• April 2014 – Teacher Ann Maguire stabbed and murdered during class by pupil carrying knife.

While education facilities should concentrate on educating, we cannot deny that these events could be negatively affecting pupil wellbeing and the ability to learn.

To better protect our schools, the concept of three levels of security vulnerability should be applied.

Perimeter security is all external gates and entry/exit doorways.

The simplest method of the perimeter is through mechanical padlocks or mortice locks. Ease of installation and maintenance makes this method highly practical. However, these locks require staff intervention, and a reliance on people to ensure the integrity of the perimeter is maintained.

For an electromechanical solution, consider electronic strikes. They are easy to install and are able to control access via various credentials such as keypads, cards and proximity readers.

For a complete electronic solution, schools can install maglocks which are centrally controlled and monitored.

The second level of security is the administration or reception area. Well designed schools will channel all visitors through this area.

A single point of entry allows better monitoring and restricts visitors from having free access to the rest of the school.

Access-controlled egress doors are permitted in all schools, and hardware can be pushbutton codes to proximity cards, biometric readers or any combination of entry control methods desired.

The third and most important level of vulnerability for a school are internal hallways,

corridors, stairwells, classrooms and restricted areas (e.g. laboratories, staff lounges).

When choosing access control solutions for classrooms, it is important to remember that there should be free egress from within at all times.

The most economical solutions are mechanical lockdowns, but electronic systems are highly recommended.

Networked systems are ideal for lockdown from a central command point, but remote lockdown options are best if the budgets are tighter - the locks are activated by remote control individually within proximity of the door in question.

BRIDLINGTON’S NEW LIFEBOAT STATION IS SET TO OPEN, REPLACING THE 114 YEAR OLD ORIGINAL STATION WHICH HAS BECOME OUTDATED, CRAMPED AND IMPRACTICAL.

The design of the charity’s new purpose built station not only considered the practicalities of a working station but also aesthetics as it stands in a prime location on the Spa Promenade adjacent to the beach - a convenient position saving precious minutes in the launch time of the lifeboat.

Echoing Art Deco lines, building materials for the new station were chosen for both design impact and durability, as the construction will have to withstand the Northeast coastal elements for many years to come.

With this in mind a stainless steel rainwater system from Yeoman Rainguard was chosen. Functional yet stylish, 145 x 165mm box gutters and 80mm dia. downpipes were fitted complementing the sleek linear appearance of the lifeboat house.

Stainless steel is a robust material which offers many years of maintenance free

service and is notable for being corrosion resistant, providing a cost effective and sustainable product. It is also eco-friendly with a stainless steel rainwater system being the perfect, non-contaminating, material choice for those wishing to collect run-off water.

The new two – storey RNLI lifeboat Station at Bridlington will not only look the part but will play the part too.

There is space to house a new Shannon class lifeboat alongside the inshore D class lifeboat.

The crew accommodation is more modern and the establishment will also include a workshop, changing and drying room, crew room, and a space for the charity’s lifeguards to store their lifesaving equipment.

All of which will result in improved efficiency and operating facilities for the volunteer lifeboat crew.

For information and news about the RNLI, please visit www.RNLI.org.uk

For information on Yeoman Rainguard’s full range of rainwater systems go to www.rainguard.co.uk

Yeoman Rainguard – Enquiry 27

Sheffield City Council has completed a programme to upgrade its fire safety throughout its 1,134 sheltered housing properties using Aico’s Multi-Sensor Fire Alarm for an enhanced level of safety. Aico’s Multi-Sensor Fire Alarm contains two sensor types, optical and heat, to constantly monitor smoke and heat levels, sending and receiving information via its intelligent detection software. This sensor information alters the alarm’s sensitivity and trigger points, automatically providing the best response to all fire types and reduces potential false alarms. A unique self-monitoring dust compensation mechanism reduces the number of false alarms and maintenance costs.

Aico – Enquiry 30

Myerscough College is a Higher and Further Education college dating back to the 19th century. The college itself sets extremely high standards when it comes to their curriculum and the results they expect from both staff and students alike. Therefore, it’s no surprise that when new flooring had to be installed they would turn to international flooring specialists Gerflor to supply the quality, design and durability they were seeking. It would be a task perfectly suited to Gerflor’s high-performing Taralay Impression Control and Tarasafe Ultra H2O safety flooring range.

Gerflor – Enquiry 34

Sto Ltd’s StoSilent Distance A2 110 system has been installed throughout the Marcus Garvey Centre in South Tottenham for Haringey Council, as part of a project which has seen the building’s interior undergo a series of major improvements. “Designers, the Frankham Consultancy Group, had used a Sto system on a very similar project, therefore StoSilent Distance was a natural choice for this library,” says Sto’s Technical Consultant for Acoustics, Mike Wallace. “It was able to achieve the desired acoustic performance and reduce reverberation times in the finished building to under 1 second.”

Sto – Enquiry 31

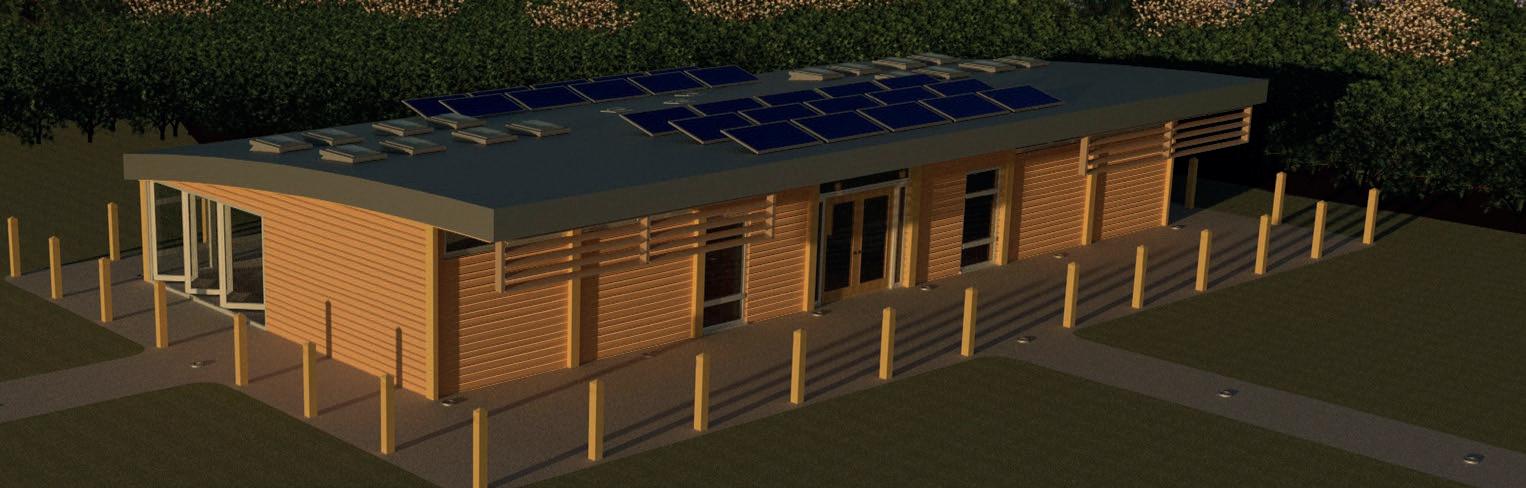

Designed in response to increasing demand for building solutions with a lower carbon footprint, Elite’s new eco concept features a built-in rainwater harvesting system, and solar PV panels. Elite has also specified more low VOC materials than typically used in modular or traditional construction, improving the overall health of the concept building.

The concept - which is suitable for use as a classroom, healthcare building, sports pavilion or office - also features solar shading and

Under updated design criteria for lifetime homes, bathrooms should be designed to be accessible, and provision should be made for the structure to be able to accommodate any future provision of a ceiling hoist, particularly between bedroom m and bathroom. To help architects, social housing providers and builders get it right from the outset, Closomat- Britain’s leader in the provision of disabled and elderly toilet solutions in and out of the home- has produced a new white paper- Design Guidance & Considerations for a Domestic Accessible Toilet/Wetroom. The white paper is available at www.clos-o-mat.com.

Clos-o-Mat – Enquiry 32

carefully-positioned triple-glazed windows to improve ventilation and reduce the need for air conditioning. As well as boasting the best eco credentials, the concept building is designed to be aesthetically impressive, with higher ceilings, an attractive curved roof, and sustainablysourced exterior timber cladding.

Elite Systems’ representatives were on hand on stand B641 at the Build Show to explain the benefits of bespoke design and the key features of the concept building. For more details on the concept, read Elite Systems’ blog at www. elitesystemsgb.co.uk

Elite Systems – Enquiry 33

Long Rake Spar was impressed with the new Resin Bound Gravel decorative walkway that was installed at the historic Sir Nicholas Winton Memorial Garden by Addagrip Approved installer Total Protection. The garden was built in the memory of Sir Nicholas Winton, who arranged the safety of many Jewish children in the Second World War. The family of Nicholas wanted to create a space for relaxation and contemplation to reflect on Nicholas’ heroic life. Total Protection were responsible for laying Addagrip’s BBA Approved Terrabound product in the colour Trent that requires specialist aggregates from Long Rake Spar.

Long Rake Spar – Enquiry 35

rooms, which are also not truly square.

Seventeen standard and bespoke Ultima Plus Radiator Guards were specified for the surgery: these Low Surface Temperature (LST) guards have been designed to provide the ultimate in protection against burns, while the ‘bullnose’ corners afford further safety in situations where patients might fall accidentally or be at risk from self-harm.

Pendock, the manufacturer of Pipe Boxing, Column Casings, Radiator Guards and specialist Perimeter Casings for heating, has supplied a range of products for work on a doctors’ practice, located in South-east London.

As it was a refurbishment project, Pendock was required to produce bespoke as well as standard radiator enclosures for some of the

Ultima and Ultima Plus guards, as with all items in Pendock’s radiator guard range, are finished with an anti-bacterial coating able to combat MRSA, Salmonella, E- coli and C-difficile. In addition a drop-down, lockable panel is fitted to the Plus models to allow for the regular routine cleaning and inspection.

The encasement specialist is able to pre-cut and pre-drill any extra holes for the covers and piping at its factory.

Pendock – Enquiry 36

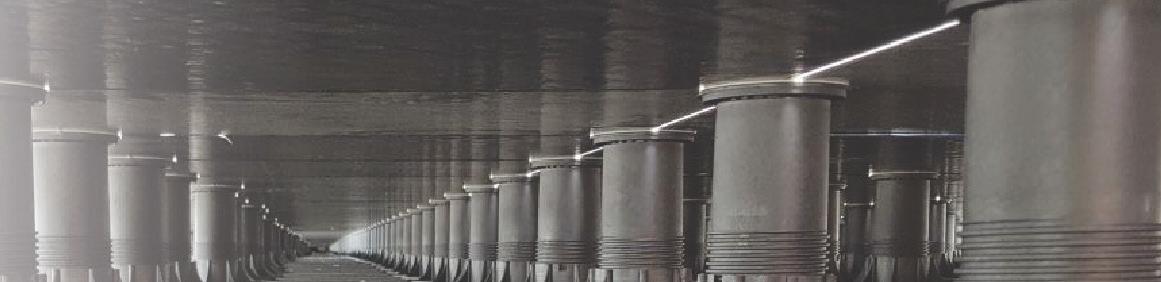

Aggregate Industries has provided the platform for the newly created National College for High Speed Rail, located in the centre of Birmingham.

The college, which welcomed students for the first time in September 2017, is a new three-storey building on Birmingham Science Park, and includes hundreds of metres of rail track and space to host a full size 25 tonne Eurostar power car.

Part of the £52bn HS2 investment, Aggregate Industries was awarded the contract to supply concrete for the landmark development by McDermotts, the Birmingham based groundwork and civil engineering company. The project saw Aggregate Industries deliver 1,500 cubic metres of ready-mixed concrete for the ground-works of the college, which will train the thousands of skilled workers required for the HS2 rail link.

The ready-mixed concrete used is EN 206 and BS 8500 compliant, providing reassurance to

architects and contractors that its concrete is produced to the highest standards and does not contain ingredients that could affect the durability of the concrete or corrode reinforcements.

Aggregate Industries also supplied readymixed concrete and concrete frameworks of Birmingham Conservatoire’s new £57m facility.

Aggregate Industries – Enquiry 38

Manufacturer of fittings and valves, Conex Bänninger is pursuing further growth by appointing two highly experienced Regional Technical Sales Managers in the South East.

Together boasting over 50 years of experience, John Curley and Stephen Norgate are primarily looking to get Conex Bänninger products in the hands of merchants, consultants and specifiers, important areas of focus for the brand. As Conex Bänninger make this push towards specification, supplying large commercial projects like hospitals, schools and office blocks, John and Stephen will bring a wealth of expertise and contacts to the company.

ConexBanninger – Enquiry 37

Following the launch of Aico’s Mobile Training & Demonstration Units earlier this year, the first visit to Scotland has proven highly successful.Aico’s Mobile Training & Demonstration Units enable the company to deliver detailed Smoke and Carbon Monoxide (CO) Alarm product and technology information, plus its CPD accredited Expert Installer training, right to customers’ doors. Information boards on all Aico technologies, such as RadioLINK+ and AudioLINK, and alarm ranges - with fully functional product attached - are installed within the units, along with a virtual video tour of the company’s manufacturing process in Shannon, Ireland.

Aico – Enquiry 39

Novus Property Solutions has transformed a former primary school building as part of a fast-track refurbishment to create the new, state-of-the-art JCB Academy, an apprentice training centre in Staffordshire.

During the fast-track 16-week project, which involved the careful co-ordination of specialist fit-out alongside traditional trades, the team completely transformed the former Dove First School building. Novus refurbished the existing single-storey school building and constructed a new extension to the front elevation to create the new state-of-the-art Dove Engineering Centre. In addition, the entire interior of the building was remodelled to create a new internal layout.

Novus – Enquiry 40

Conex Bänninger strengthens its UK team with two major appointmentsAico mobile unit brings training and support to Scotland

Get vital Industry training for free SPATEX offers a unique double programme of free educational seminars and training workshops on vital current topics. Hosted by water leisure experts and Industry trade organisations, such as the ISPE (Institute of Swimming Pool Engineers) and PWTAG (Pool Water Treatment Advisory Group), the seminars have particular reference to the specific demands of the commercial sector. Whether your interest is in construction or the operation, these expert-led Workshops will extend your skill set.

Attendees of the workshops receive CPD points and certificates of attendance. Click here for the full programme

FROM SWIMMING POOLS, SPAS, HOT TUBS TO SAUNAS, STEAM ROOMS, ENCLOSURES AND WATER FEATURES – ALL THE LATEST INNOVATIONS, DESIGNS AND PRODUCTS WILL BE REVEALED WHEN SPATEX 2018, THE UK’S LEADING POOL AND SPA EXHIBITION, OPENS ITS DOORS AT COVENTRY’S RICOH ARENA FROM TUESDAY JANUARY 30 - THURSDAY FEBRUARY 1.

If you’re a designer, builder, property developer, architect, hotelier, leisure operator, work for a leisure centre, health club, spa, school etc SPATEX 2018 is designed specifically for YOU. If your work involves anything to do with wet leisure, this is a must attend event.

See it at SPATEX 2018 first

With over a hundred exhibiting companies, comprising the biggest names in the Industry from both home and abroad, the Exhibition will showcase everything from beautiful spas, saunas, steam rooms, head-turning enclosures and stunning water features to the inner workings of water leisure equipment such as pumps, filters and heating and ventilation. Be the first to view the 2018 pool season new product lineup.

With organisations such as SPATA (Swimming Pool & Allied Trades), BISHTA (British & Irish Spa and Hot Tub Association), PWTAG (Pool Water Treatment Advisory Group) and STA (Swimming Teachers’ Association) out in force there is no shortage of expertise to draw on should you have a query on a project.

SPATEX 2018, Tuesday January 30th to Thursday February 1st, Ericsson Exhibition Hall, Ricoh Arena, Coventry CV6 6GE. Ricoh Arena is easy to get to - just 500 yards off the M6 and within two hours commuting time of 75 per cent of the population, it offers 2,000 free on-site car parking spaces.

HIGH-END BOUTIQUE GYMS FIRST STARTED TO DEVELOP AS A TREND IN THE US A FEW YEARS AGO BEFORE BEING ADOPTED BY THE UK LEISURE SECTOR. TREVOR BOWERS, DIRECTOR AT LEADING WASHROOM DESIGNER AND MANUFACTURER, WASHROOM WASHROOM, EXPLAINS HOW ITS BESPOKE APPROACH TO DESIGN HAS HELPED CREATE UNIQUE SHOWER AND CHANGING AREAS TO SUIT THE NEW BOUTIQUE GYM MARKET.

enerally smaller with a limited number of memberships available, boutique gyms often have a very focussed approach by offering a specific fitness class such as spin, dance or military fitness. They appeal to millennials who take fitness seriously but also want to have fun at the same time and feel like they belong to an exclusive club.

Carefully designed, on-trend interiors which reflect each gym’s individual personality or brand image is vital in the boutique gym market and the shower and changing areas are central to this. While some boutique gyms have expanded and opened up several gyms within the same group, often each will have its own individual design, rather than the same tried and tested design being rolled out each time.

involved the installation of glass shower and toilet cubicles which were manufactured in a range of bright oranges, reds and yellows. The bright colours reflect the high energy design scheme in the rest of the gym and were chosen to energise gym-users. Another recent project saw Washroom manufacture its full height toughened glass shower cubicles in a striking blue to complement the gym’s branding.

Elements such as exposed pipework, concrete vanities, monochrome colour schemes, stainless steel accessories and metro tiles with contrasting grouting can be used to create an on-trend industrial-inspired design. A recent boutique gym project which encapsulates this style saw Washroom design glass shower cubicles featuring a bespoke saloon-style door opening, created specifically and solely for the project. While for another luxury health club, its glass shower cubicles were manufactured with a bespoke diamond pattern design, again making the cubicles unique to that health club alone.

When it comes to boutique gyms, owners and members alike are looking for truly unique interior design and adopting a bespoke approach is the ideal way to achieve this in every area of the gym including the shower and changing areas.

Colour is an ideal way for gyms to make their mark and create their own sense of style and identity. It’s also something which can easily be incorporated into a gym’s shower and changing room areas thanks to advances in materials technology. Toughened, back-painted glass and digital screen-printing as well as solid surface materials, which can be manufactured in a wide range of patterns and colours, ensure that these areas tone in with any colour scheme used elsewhere in the gym.

Combining exciting, high impact classes with music is another feature of the boutique gym trend and some are even known to have their own resident DJs or world class sound systems to add to the experience. This high energy vibe can also be reflected in the interior design by using bright bold colour schemes. One recent project, for example,

Washroom Washroom – Enquiry 42

The vast 750m2 wrap-around terrace has been covered with the Timeless range of timber effect porcelain ‘planks’, a most complimentary finish blending in with the coastal location and it’s wonderful sea view.

The pre-installation support of the team at The Deck Tile Co. and the preparatory work involved was an essential part of this project and has resulted in an excellent finished result. With hurdles to overcome, such as multiple falls, facilitating the erection of signage struts and large static planters, the paver system has, due to it’s flexibility, meant that the terrace expanse was completed in under three weeks. The use of the unique slope correcting/height adjustable pedestals and retention system has enabled the creation of a stable, raised access ‘deck’ and when combined with the 20mm porcelain pavers - offers the user fine quality external flooring, with low level on-going maintenance costs and high slip resistance - to name just two of the key benefits of the Levato Mono Porcelain Paver System.

With all the benefits 20mm porcelain and the supports system has to offer, Levato Mono is the ideal product for exterior projects, both residential and commercial alike.

• 20mm Porcelain pavers; 40x80 45x90 60x60 75x75 30x120 40x120 60x120.

• ‘Floating floor’ – installation over single ply membranes.

• Eternal product - zero maintenance required, offering massive over-life savings.

• Highly abrasion and stain resistant.

• Highly slip resistant; R11 AB&C.

• Lightweight – 45kgs per m2

• High load bearing and impact resistance.

• Timber & stone effects; 40+ finishes available.

• Completely non-porous.

• Frost proof.

Available in 40+ colours in both ultra-realistic timber, stone and cementitious effects. Combining 3D printing (with up to 30 prints available) and mould making technology produces identical copies of the original materials, once laid the eye is unable to discern any replicated pattern allowing

for a completely natural looking surface. Recently specified for external dining areas at various JD Wetherspoon establishments, London Zoo, Jamie’s Italian Brighton, Bristol Airport East terminal extension, and the new Portico Terrace at Theatre Royal Drury Lane, where Levato Mono sandstone effect paver ranges were considered so similar to natural sandstone material that is was sanctioned for use on a Grade I listed building by English Heritage.

www.thedecktileco.co.uk info@thedecktileco.co.uk

The Deck Tile Co – Enquiry 44

Scandinavian design is known worldwide for its cool minimalist look. Now it makes wonders for the bathroom, giving you an almost invisible drain. The only thing giving the drain away is a narrow opening between the tiles where the water flows away. The rest of the drain is hidden beneath the tiles providing your bathroom with a unified look. The groundbreaking drain is called HighLine Custom and is designed and developed by the Scandinavian award winning brand Unidrain.

www.unidrain.com www.enquire2.com - ENQUIRY 45

Bright Goods announces its installation into Kingston’s brand new DoubleTree Hilton Hotel. The range of decorative, vintage-style LED filament lamps with a huge designer following is lighting up the ground floor public areas including the reception, lobby and restaurant. The project has been specified and managed by interior design architects, DesignLSM in conjunction with The Light Corporation. The Light Corporation was commissioned to design a lighting system that not only complemented the aviation theme but provided warm and elegant illumination throughout. An impressive range of Bright Goods LED filament lamps was specified to enhance distinct areas of the hotel. The lamps, all in 2.2K very warm colour temperatures highlight the various shaped LED filaments and create a welcoming, atmospheric ambience. The Florence 6W sepia tinted maxi globes, for example are hung bare and installed in clusters amongst the copper pipework that runs around the perimeter of the restaurant, giving a contemporary industrial feel. The Elizabeth 3W candles, Joseph 5W GLS’, Jane 6W sepia tinted classic pears and John 6W long tubes are installed throughout the reception area, lobby, lounge, kitchen, bar and restaurant area.

Bright Goods - Enquiry 48

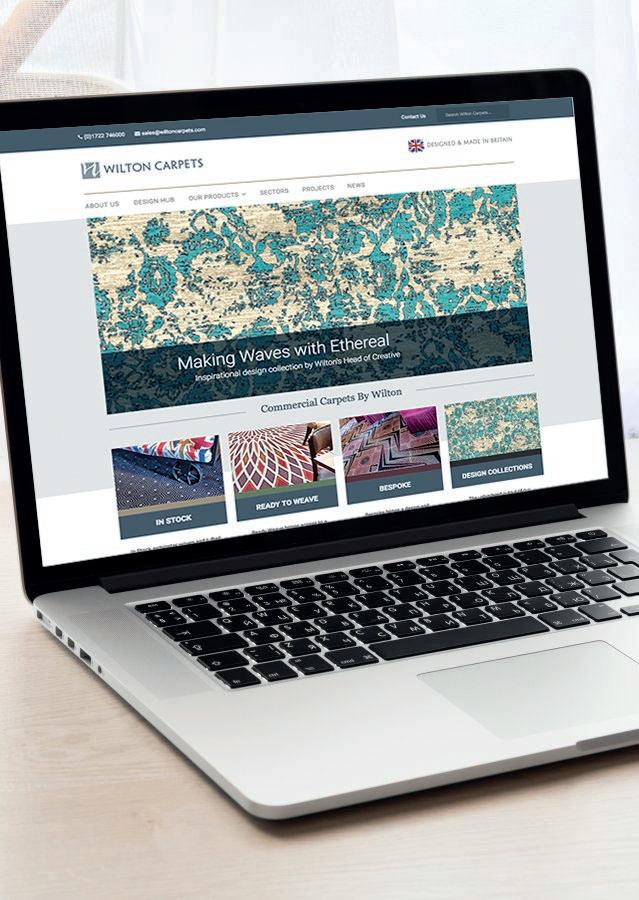

Wilton Carpets has redeveloped its website, providing more information and a fully-searchable catalogue through its Design Hub software. The new website, wiltoncarpets.com, has been developed from the ground-up to deliver improved content and navigation, with the ambition to inspire and inform a generation of designers and specifiers about good carpet craft. Andrea Evans, marketing manager, Wilton Carpets, comments: “With a history tracing back four centuries, the town of Wilton is cemented in carpet folklore, yet Wilton Carpets is regarded as one of the most forwardthinking wool carpet manufacturers still weaving solely in the UK. We wanted our website to reflect our unique blend of heritage and innovation, so it is full of content that designers and specifiers keen to learn about carpet will find genuinely useful.”

The site is centred around the Design Hub, a tool that allows designers to explore the potential of Wilton’s Ready to Weave concept, as well as browse the manufacturer’s In Stock collections of axminster and tufted carpets. The new website is live at wiltoncarpets.com.

Wilton Carpets - Enquiry 46

Howe Green’s Light Duty 5000 Series Floor Access Covers are playing their part in keeping a Victorian castle warm and cosy by providing safe and easy access to central heating valves.

Following a 25 year closure Lews Castle underwent a £19 million refurbishment and reopened last year. The Category A listed building is now a museum and cultural centre owned by the local council.The 5000 Series Aluminium Floor Access Covers were specified by GRAHAM Construction to provide access to the underfloor services, located in the corridors on the first floor of the Castle. Sixteen covers were supplied, in various standard sizes. The

covers were specified with the option of a brass show edge and were infilled with carpet or ceramic tiles, depending on their location.

The brass show edge with matching lifting points, which are anchored to the inner frame, give an even higher level of aesthetic appeal than the standard aluminium show edge. The brass finish fits perfectly with the historic surroundings of the Castle and the seamless fit with the floor finish reduces the risk of slips and trips.

Howe Green - Enquiry 47

Granorte is continuing to demonstrate the versatility of cork as a sustainable interior surface with a series of high-profile projects that use the material in novel ways. With ceiling panels at the Ace Hotel in Shoreditch, wall and ceiling tiles at Fleet Street’s Humble Grape, striking 3D geometric wall tiles and sinks at a leading restaurant chain and flooring at countless other locations; Granorte is headlining the cork revolution. Absorbing sound, insulating against heat loss, comfortable and warm to the touch, cork is a wonderful surface material.

Granorte - Enquiry 49

AN INNOVATIVE AND UNIQUE LINE, THE DFINE RANGE OF PANIC EXIT DEVICES FROM STRAND HARDWARE LTD IS CONSTRUCTED ENTIRELY OUT OF 316 STAINLESS STEEL, INCLUDING ALL INTERNAL AND EXTERNAL COMPONENTS.

he only panic device manufactured in stainless steel Grade 316.

This guarantees maximum functionality and a long lifetime even under the most extreme weather and atmospheric conditions. These devices are salt spray tested to 800 hours. The range represents versatility, style and functionality all in a single product. Stainless steel is well established as a corrosion resistant material for many items used in buildings and in particular equipment in swimming pools, Spas and Leisure centres. Grade 316 stainless steel has the highest corrosion resistance and is typically specified for equipment in pool areas, coastal locations and other corrosive environments.

Strand Hardware – Enquiry 50

SFS HAS PLAYED A KEY ROLE IN ENABLING ARTEZ, THE MAIN CONTRACTOR, AND LEADING ROOFING AND CLADDING CONTRACTOR LONGWORTH TO DELIVER AN ICONIC NEW BUILDING ON MANCHESTER’S VIBRANT MEDIACITY WATERFRONT FOR UPMARKET BAR AND RESTAURANT CHAIN THE ALCHEMIST.

The company’s powder-coated, high performance A4 (grade 316) stainless steel fasteners were key to creating a stunning gold building envelope for ‘The Bund’, a unique structure located on the land bridge crossing Dock 9 at Salford Quays, between The Lowry and the BBC.

Designed by Reid Architects, The Bund is an iconic new bar and restaurant on the waterfront next to the world famous Lowry Centre for Living Ventures and the company’s 11th Alchemist venue. The design brief provided scope for originality and creativity in meeting the key requirements to deliver a building that would be different and special, and draw together the diverse areas of Salford Quays in a single new building.

The Bund provides a revolutionary hybrid landscape in creating what is a unique and futuristic venue. The new building’s gold roof and walls, and stunning terrace that cantilevers out over the canal, are designed to match the aesthetic and style ambitions of Living Ventures and of the high class cocktail bar’s clientele.

Longworth, who are renowned for their expertise in metal roofing, were commissioned to construct the building envelope and to realise Reid Architects’ golden vision. The company’s Business Development Manager, Ben Parker, says, “We are immensely proud of our work on The Alchemist, an incredibly complex building envelope project that only a handful of companies in the UK could have successfully

implemented. To hear that the building has been shortlisted for a Building of the Year Award with Greater Manchester Chamber of Commerce this October makes it an especially memorable project for us. “Colour coordinating the gold zinc panels and the fasteners was critical, which is why we worked with SFS to ensure complete colour consistency on the fastener heads. We can rely on the excellent quality of SFS products, with their range of A4 (grade 316) fasteners enabling us to offer an extended life cycle on the building envelope, a requirement which is now generally specified by all the leading architects.”

To find out more about high performance fasteners for the building envelope visit www.sfsintec.co.uk.

SFS Intec – Enquiry 53

For designers, specifiers, contractors, consultants and building engineers looking to earn CPD hours, they can now book their place on Waterloo Air Products PLC’s ‘An Introduction to Air Distribution’.

On the course, attendees will hear from one of Waterloo’s air distribution experts. They include Andrew Wardle, Northern Sales Manager, Alex Macfarlane, Southern Sales Manager, Alan Smith, Commercial and Export Markets Manager, and Roy Nutley, Technical Advisor. The presentations will be followed by a Q & A and the course is free to attend. To book your place, visit www. waterloo.co.uk.

Gerflor is King of the West End

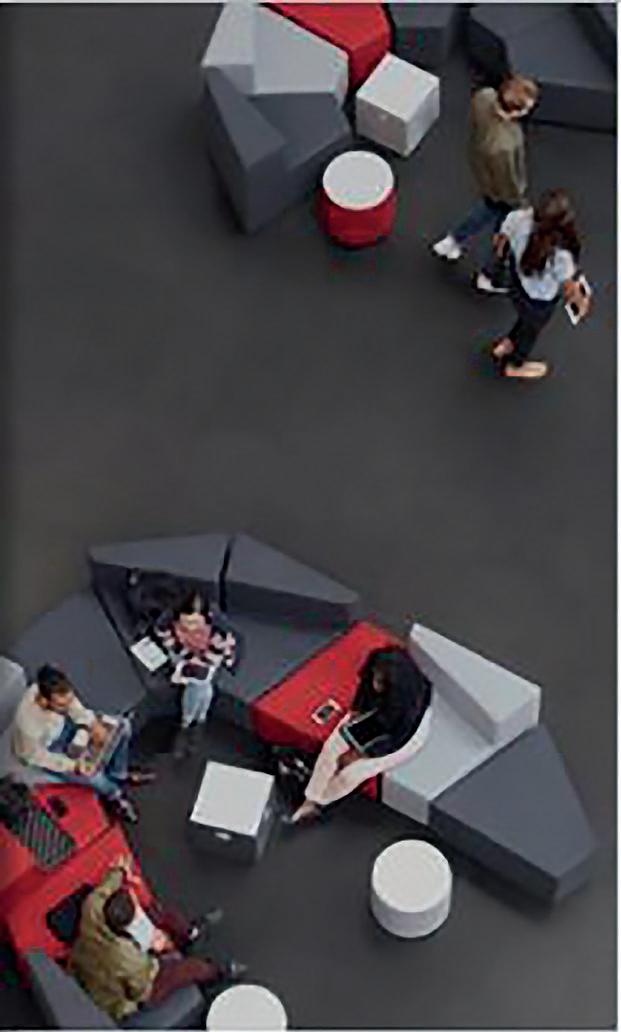

King is a leading interactive entertainment company for the mobile world, with people all around the world playing one or more of their games.

When the new King building in the heart of London’s West End was being conceived, it was always going to have a gym and fitness facility for the staff.

King, as in their previous building, would specify Gerflor products once again, this time choosing some 210m2 Gerflor’s Taraflex® Sport M Performance vinyl sports flooring in three pulsating colours; Pink, Silver Grey and London Light Blue. Taraflex® vinyl sports flooring has been used in many international

01952 234003 or post our: Free Reader Enquiry Card

and local sporting events and is available in 17 colours and three wood-effect designs.

The Sport M Performance product offers a P2 category shock absorbency 25% to 35% and meets the EN 14904 Standard for indoor sports surfaces. Taraflex® is recognised for providing durability, safety and comfort without impairing performance. The range also offers greater than 45% force reduction, making it unrivalled in the marketplace in terms of offering comfort for users.

Taraflex® meets the EN Standard of 22196 for antibacterial activity (E. coli - S. aureus - MRSA) (3) returning >99% levels of growth inhibition.

Gerflor – Enquiry 55

Project:

Exeter Science Park Product: Solid Wood, Linear Open System Architect: Stride Treglown

Horbury Facades, part of the Horbury Group, has secured a contract to design and install the innovative rainscreen cladding system for the new Digital Media Hub that forms part of the Confetti Institute of Creative Technologies on behalf of Nottingham Trent University.

The new building will feature the increasingly popular ‘Corten’ panel, which naturally weathers over time, producing a striking, oxide finish that protects the building. The natural patina, which mellows over time, creates a protective coating that provides a highly durable, low maintenance and aesthetically pleasing façade.