TURNER INDUSTRIES

Jason Broha, Marie Crespo, Corinne Bergeron, Terry Kenney, and Andrew White

Tony Ditta, Ryan Beeson, Corinne Bergeron, Jason Broha, Robert Callaghan Marie Crespo, David Ducote, Derryl Gaspard, Phil Gauthreaux, Bryan Gerace, Jonathan Guidry, Carlos Guidry, Michelle Hardy, Terry Kenney, Kevin B. Landry, Rodney Landry, Andy Lofton, Raul Luna, Colby Plaia, John Richard, Amy Rouse, Chelsea Smith, Sean Stanford, Carla Thompson, Jimmy Watkins, and Andrew White

This issue’s cover story features the industrial cleaning group, one of the fastest-growing areas of Turner Specialty Services (TSS). Whether it’s providing hydro blasting, vacuum, tank cleaning or chemical cleaning services, TSS can handle the pressure (pun intended) and complete the job safely and efficiently. In this issue, we also highlight some of the women who make up Turner’s workforce on the ExxonMobil PPG project, how Turner is “Fueling the Future” at Cheniere’s Sabine Pass LNG Facility, our work with Vertex Energy on its renewable diesel project, and more.

© 2022 Turner Industries Group, LLC. All Rights Reserved. Except for any owned by others, all trademarks, trade names, copyrights, and other intellectual property rights referenced herein are exclusively the property of or licensed by Turner Industries Group, LLC.

Jason Broha

Scott Greci

Jason Broha

Scott Greci

Sulphur, La. – Turner Specialty Services’ inspection and NDE groups at Westlake Chemical South have worked six years OSHA recordable free. At this plant, more than 35 TSS employees provide maintenance and inspection, turnaround planning, QA/QC , and NDE support.

Garyville, La. – Turner Industries employees at Marathon Petroleum’s Garyville Refinery recently celebrated one year OSHA recordable free.

Hahnville, La. – Turner Industries employees were acknowledged for participating in the “Stop Work, Good Catch” program at Dow’s St. Charles Operations. In July, they submitted “Stop Works,” which have played a part in Turner achieving over 100,000 safe workhours since transitioning to the site in March of this year. The “Stop Works” that were submitted involved lockout/ tagouts, line equipment openings, rigging, scaffolding, etc. These Turner employees have fully embraced the “I’ve Got Your Six” initiative.

Carville, La. – Turner Industries employees at the TotalEnergies site in Carville, Louisiana, have completed 1.6 million workhours OSHA recordable free.

Port Neches, Texas – Congratulations to James Vallery, who received the Stop Work Authority of the Month award for July 2022. Vallery and his crew were performing a pre-job walk down when he smelled an odor, so he stopped the work and communicated it to operations.

The area was cleared, and a sniff test was performed, determining a small liquid propane leak. Operations then repaired the leak, sniffed the area again, and work was able to commence under normal work authorization.

Vallery joined Turner Industries in May 2022 and works under the leadership at Cheniere.

Great job, James!

– Turner Industries at Oxy Vinyl’s Houston Division recently received its OSHA Voluntary Protection

Port Arthur, Texas – At the Golden Triangle Business Roundtable’s 31st Annual Contractor Safety Awards, Turner

Turner is proud to be a part of the Golden Triangle Business Roundtable and grateful for the organization to recognize our commitment to safety. We also want to thank Indorama and ExxonMobil and all the hard-working

Port Allen, La. – Turner employees at Placid Refining have worked six years OSHA recordable free.

Turner Industries sites across the country participated in OSHA’s Safe and Sound Week — a nationwide event held each August that recognizes the successes of workplace health and safety programs and offers information and ideas on how to keep America’s workers safe.

During Safe + Sound Week 2022, Turner dedicated each day of the week to a topic related to hand safety. Here are a few photos from the week.

Medical ID helps first responders access your critical medical information from the Lock screen, without needing your passcode. They can see information like allergies and medical conditions as well as who to contact in case of an emergency.

“This is a huge help to us in Safety when an employee has a medical crisis on-site. It is also very valuable to share with our families, particularly older folks,” said Construction Safety and Health Director Derryl Gaspard. “We are finding that most of our employees are not aware of this important feature on their phones.”

Employees typically spend more time at work than they do with their families. Therefore, personal medical conditions and resulting emergency situations are more likely to occur during work hours. In a medical crisis, response time is critical, so quick access to medications and conditions saves time and lives.

Earlier this year, Turner Industries was awarded its first nested contract in the liqu e fied natural gas (LNG) marketplace by the largest producer of LNG in the U.S. and the second largest LNG operator in the world. Cheniere Energy’s Sabine Pass LNG facility, located in Cameron Parish in Southwest Louisiana, is a major six-train liquefaction facility capable of exporting 30 million metric tons of LNG per year.

The site team, led by Project Manager Alan King, Site Manager

Joey Ward, and Superintendents

George Spell and Chad Yellott, has provided an all-inclusive portfolio of services and disciplines to provide a “One Solution” approach for Cheniere’s capital project needs. These services include civil, structural, electrical, mechanical, crane and rigging, scaffolding, insulation, paint, and NDT/inspection.

“ We are looking forward to expanding our services with Cheniere,” said Turner Operations Manager Colby Plaia. “As unconventional oil and gas production expands within the U.S., Turner will continue to have the expertise necessary to support customers’ needs in processing, storing, and transmitting key transitional energy products for both domestic use and export to growing world markets.”

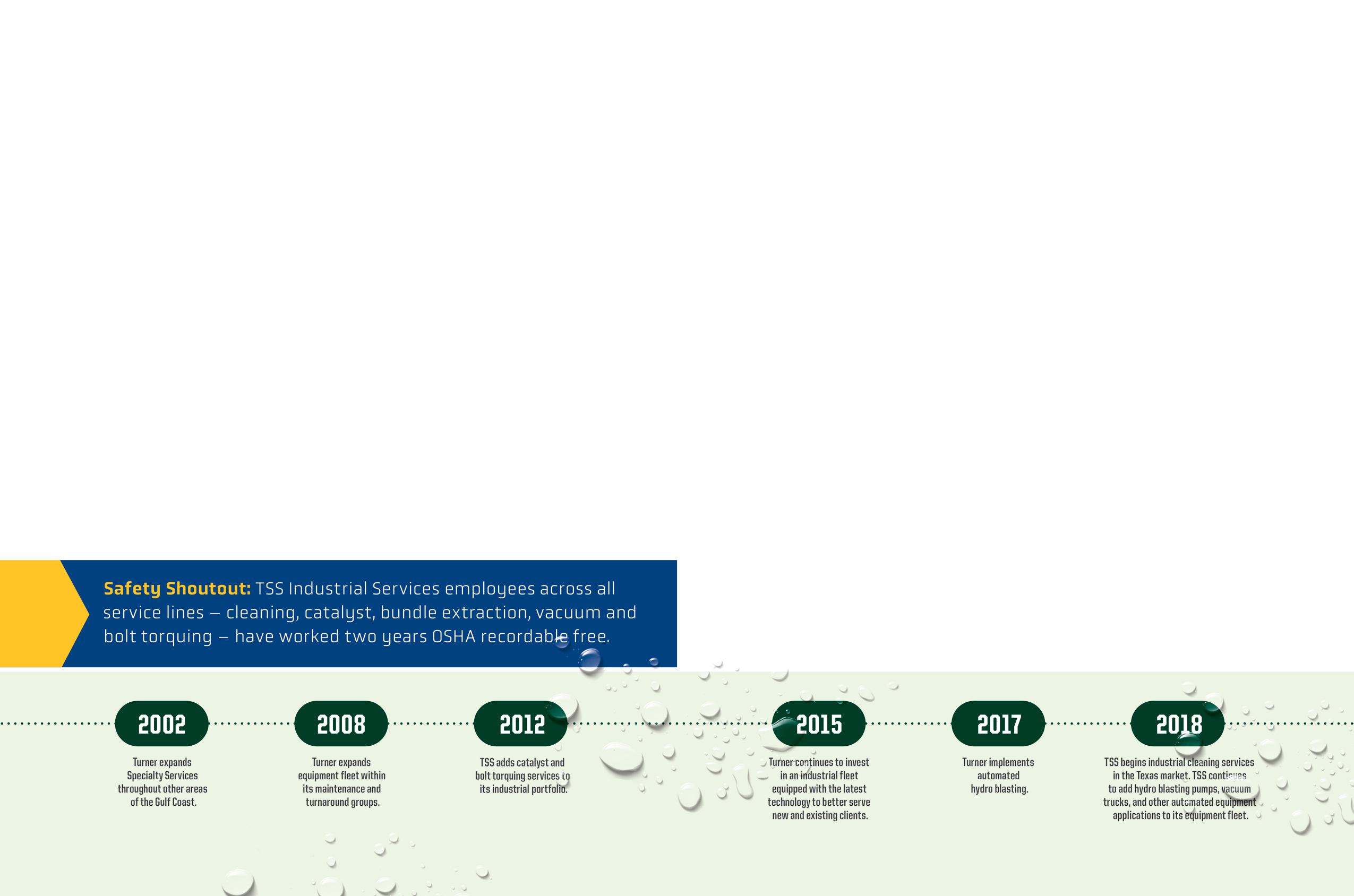

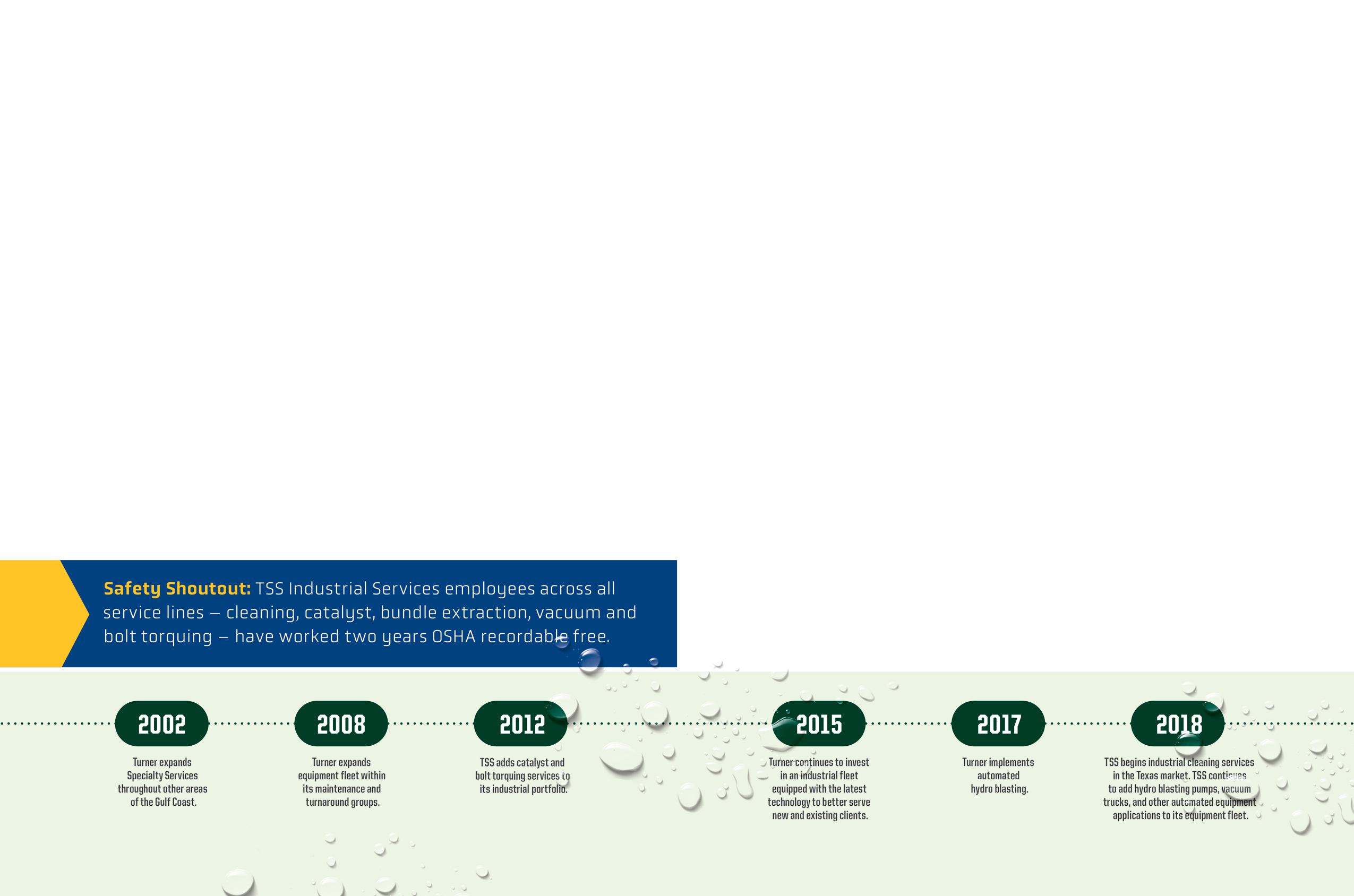

Turner Specialty Services’ (TSS) Industrial Group offers best practices and state-of-the-art technology, equipment and experience to the refining, chemical, petrochemical and pulp and paper industries in the service lines of bolt torquing/tensioning, bundle extraction, catalyst, hydroblasting and vacuum truck. We maintain a large fleet of equipment to service our clients on an on-demand need. TSS has the capability to offer our services on a maintenance, project, and turnaround basis.

For more information about this service please contact us at: turnerbusdev@turner-industries.com

Turner Industries has been selected by Vertex Energy as the mechanical general contractor for their renewable diesel conversion project in Mobile, Alabama. This project is designed to modify an existing hydrocracker to produce renewable diesel fuel and is expected to conclude by the first quarter of 2023. Upon completion, the refinery expects to commence production of approximately 8,000 - 10,000 barrels per day (bpd) of renewable diesel, with production volumes anticipated to subsequently ramp up to approximately 14,000 bpd.

Renewable diesel is produced from organic waste and vegetable oils and is a sustainable, fungible replacement for petroleum-based diesel fuel.

While California remains the primary market for domestically produced renewable diesel, given the economic benefits of its use under the state’s Low Carbon Fuel Standard, other states are expected to follow suit, creating significant, incremental demand during the next decade. Once operable, the converted hydrocracking unit will be capable of processing a wide range of feedstocks.

Turner Industries will provide fabrication, mechanical, scaffold, paint, insulation, specialty services, and heavy haul and lifting. Pipe and structural steel fabrication will be done at Turner’s Port Allen and Decatur shops. Turner’s construction group will work alongside the nested maintenance and turnaround groups during the pre-turnaround and turnaround phases. There are currently 50 employees on site performing civil work. At its peak, Turner expects to have approximately 200 personnel on site.

“As the world looks for low carbon solutions, Vertex Energy is leading the way in energy transition with its Renewable Diesel Conversion Project. We are excited to be part of such a great team made up by Vertex, Worley, Hargrove, and Turner Industries,” said Turner Senior Vice President of Construction Carlos Guidry.

Freeport, Texas – Turner employees at Olin ChlorAlkali ’s site in Freeport, Texas, recently celebrated three years and three million hours OSHA recordable free.

This milestone was celebrated in style with the king himself, Elvis Presley, to go along with the site's motto: “ Taking Care of Business.”

“We have some very strong leaders within this group who take the safety of our employees to heart. Our employees have bought into the ‘Safety First’ work culture and it definitely shows,” said Turner Site Manager Ryan Beeson.

“I truly appreciate how each and every one of the Turner team has taken the idea of safety and claimed it to be their own right and responsibility. It is because of that attitude that you each continue to go home the way you came to work,” said Olin Freeport Site Maintenance Director Al Cagle.

Turner Industries currently has 475 employees on site who perform maintenance, capital projects, and specialty services.

Turner Industries recently completed a furnace rebuild at Shell Deer Park. All nested refractory; scaffolding, insulation, painting, and abatement (SIPA); mechanical; heavy equipment; soft craft; safety; and rope access services — plus additional Specialized Welding Services (SWS) work — w ere consolidated under one management team at the site. Turner was able to communicate effectively across all disciplines to ensure a “One Solution” approach, working efficiently and providing cost savings for the client. The work was also completed on time with zero motor vehicle accidents, zero first-aid incidents, and zero OSHA recordable injuries.

Turner provided refractory repairs and specialized welding, mechanical, crane and rigging, scaffold, insulation, and soft craft services.

“Turner employees turned any challenges into opportunities, building trust and accountability. There is no greater accomplishment than going home safely to your loved ones every day. On behalf of our site leadership, we would like to thank everyone for your high level of care, concern, and courage. I’ve never been prouder to be part of the Turner family,” said Turner Industries Superintendent Raul Luna.

“I cannot say enough good things about Rolando Alvarez, but nothing could’ve happened without his team and fellow co-workers. His confidence in the team and their abilities is hard to match. Turner has done a fantastic job and I cannot be any happier. Thank you for everything you and the team do; it doesn’t go unnoticed,” said Shell’s William Turney.

“SWS’ Quinton Vaughn and his QC team were able to deliver near-perfect execution, finished ahead of schedule, and maintained a zero-incident event. We handed him and his team curve balls and scope deviations from day one , and he handled them like a true professional and never got rattled,” said Shell’s Brett Hendon.

Pictured are Zachary Tullier, Donald Greer, Placido Galvan, Lesly Cadena, Mario Sanchez, Rolando Alvarez, John Velasquez, Quinten Vaughn, Guadalupe Munoz, William Turney (Shell), Lindsey Leeper, Brett Hendon (Shell), James A. Haynes (Shell), Lorenzo Rendon (Shell Agent), Andrea Salazar, Elva Galvan, Roberto Trevino, Kris Veillon, Abril Ramirez, Trent Smith (Shell Agent), and Eddie Almendarez.

450,000 metric tons per year to meet growing demand in North America and the Asia Pacific for high-performance, lightweight durable plastics. C onstruction is nearing completion with start-up expected in the fourth quarter of 2022. T he project will give the plant the capability to manufacture lightweight, durable plastics that can be used for car parts to achieve better fuel efficiency; products that provide strength, flexibility and insulation for appliances like washers and dryers; and plastics used in packaging to help preserve food for longer. The project is providing the local area 650 construction jobs, of which Turner Industries employees hold almost 600.

“As I have recently joined the Polypropylene Growth team, I have been impressed with the diversity and strength of our construction workforce ,” said PPG Venture Executive Pamela Rafferty. “ One area that I am particularly proud of is how we are empowering

business results follow.

“The construction industry like many others is defined by its people. Diversity is not just a buzz word; it is the reality of how to be more successful. PPG is proud to be an industry leader, and we challenge other ventures to go further. I am thrilled to see many women joining our team at all levels of experience from helpers or flaggers to highly skilled craftspeople. These hard-working women are building up their families by mastering a trade. They are proud to be part of the PPG team, and we are pleased to provide well-paying jobs in a safe work environment .”

“On a sunny morning in September, we had the opportunity to get together for a group photo. Thank you to all—we are proud to have you be part of our Turner family—and thank you ExxonMobil for letting us be a part of this exciting project,” said Turner Project Manager Kevin B. Landry.

Years with Turner Industries: 8

Years in the industry: 16

Why did you choose to work in heavy construction? At first it was just a job, but then I realized how much I like being part of building something from the ground up.

What has been your favorite moment during this project? Watching crews come together and building friendships and families outside of your own. And celebrating each other on jobs well done.

What advice would you give women considering entering heavy industry? Don’t let anyone tell you that construction is not for women.

Years with Turner Industries: 3 months

Years in the industry: 3 months

Why did you choose to work in heavy industry? This line of work runs in the family.

What is your favorite part of your job? Getting paid and knowing I worked hard for it.

What has been your favorite moment during this project? Meeting my co-workers and joining the safety committee.

Time with Turner: 10 months

Years in the industry: 5 years

Why did you choose to work in heavy industry? It is a new learning experience and a well-paying job.

What has been the most rewarding aspect of being a part of this project? Being able to be a part of the safety committee.

What was your favorite moment during this project? My favorite part is being able to say that I have more than one favorite moment.

Years with Turner Industries: 7

Years in the industry: 8

Why did you choose to work in heavy construction? I needed a change, and I wanted a higher paying career.

What has been the most rewarding aspect of being part of this project? Building relationships and the work-life balance this job affords me.

What has been your favorite moment during this project? That employees are continuously rewarded for working safely and meeting quotas. It means a lot to be appreciated.

Today, TSS is using robotics, automated tools, and drones and has assembled a large rope access team capable of performing both NDE and mechanical rope access services.

In this issue of Turner Industries Company Magazine, we will explore the services of TSS’ Industrial Services, specifically industrial cleaning.

Industrial cleaning is the process and act of cleaning for both hazardous and non-hazardous industrial areas, equipment, and materials in locations such as refineries, chemical plants, paper mills, power plants, and other types of facilities. There are many different applications/services to utilize when it comes to industrial cleaning.

Hydro blasting uses a high volume of water at a high pressure to clean surfaces or equipment. Based on the jobsite’s conditions and the needs of the client, TSS tailors its hydro blasting response to the most effective and efficient solutions. The company performs hydro blasting on exchangers; pipes and drains; concrete surfaces; tanks, vessels, and drums; boilers and furnaces; towers and silos; and trays, valves, and other components.

Hydro blasting is accomplished using various types of equipment with different combinations of volume and pressure. Dieselpowered pumps, lances, tips, surface cleaners, and other accessories all factor into what equipment is needed for the assigned job.

Vacuum services involve the use of specialized trucks or trailers to remove hazardous and non-hazardous materials from equipment or property. Examples of vacuum services include wet/dry solid removal, liquid removal, material with hydrocarbons, units with scrubber capabilities, hydro excavation, and sewer cleaning applications.

Tank cleaning services can span the project’s complete lifecycle. TSS’ tank cleaning capabilities are extensive — from complete project planning and centrifuge setup to robotic sludge removal, solid waste management, de-gassing, and vapor recovery. TSS handles small routine jobs as well as complex, highvolume projects, and its experience encompasses every tank design and type of material: crude, finished products, petrochemical feedstock, black oil, asphalt, wastewater, sour water, and more.

Chemical cleaning services use the form of vapor-phasing cascading, foam, or circulation with the proper chemistry to eliminate deposits and scaling and maintain the integrity of the system being cleaned. Chemical cleaning services include acid treatment for scale removal, de-gassing services, neutralization services, pre-operational cleaning services, and organic deposit removal.

Turner’s commitment to continually adapt and utilize the latest in industrial cleaning technologies allows its clients to benefit from a safe, efficient, and dependable solution. Automation has led to all sorts of innovation throughout the industrial cleaning sector, and TSS owns automated equipment from leading manufacturers and partners with them regularly.

Using automated cleaning equipment is much more efficient, consistent, and thorough than manual methods. There is less likelihood for the work to fail inspection due to human error, and this eliminates re-work that has plagued jobs with downtime in the past. In most cases, automated equipment exceeds the inspection benchmark upon the first inspection. When the laborer/field technician is operating a machine instead of manual manipulation, that person is less prone to fatigue, and an alert technician is

The benefits of automated equipment are also seen in extended run times and greater heat transfer of process equipment cleaned by automated means. The more complete the fouling is removed from a surface, the longer it takes new fouling to accumulate. In many scenarios, an application-specific machine can deliver high-pressure water to locations not ergonomically or physically possible by humans. Better stated, machines can manipulate hardware in ways that people cannot. Machines can handle high-pressure water at larger volumes than humans, so a single tool can outperform a person. Examples of these machines include rotating hose devices, flex lance/hose feeders, and 3-D tank cleaning heads.

TSS is continuing to invest in its two most valuable resources: people and equipment. The company is training its technicians and supervisors to operate the latest, innovative technology and stay safe while doing so. TSS is also consistently investing in equipment that will bring the most value to its clients.

TSS has invested an average of $3 million each year for the past five years to upgrade and replace its current equipment inventory. This investment has allowed the company to expand its automation capabilities and ensure the equipment is adequate and reliable for everyday use.

TSS is also continuing to integrate with Turner’s Maintenance and Turnaround Division to capture efficiencies and reduce downtime for clients.

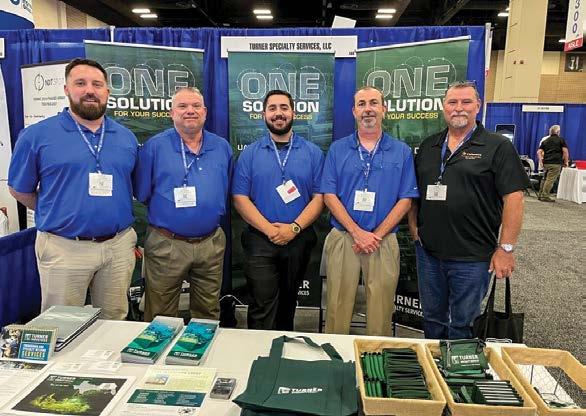

Turner Specialty Services is part of Turner Industries Group’s “One Solution” service offering which also includes: Construction; Equipment, Rigging & Specialized Transportation; Pipe Fabrication; Modular Fabrication and Maintenance & Turnarounds.

Because of COVID-19, TSS adds disinfecting and sanitation to its service line to meet clients’ demands.

TSS starts up operations in the eastern part of the Gulf Coast.

With a substantial presence in the Gulf Coast and the northeastern U.S., TSS is meeting future client challenges and seizing additional opportunities with plans to increase its presence in Corpus Christi and Decatur soon.

“With our best practices and state-of-the-art technology, equipment, and experience, TSS is set for future success. Whether it’s on a maintenance, project, or turnaround basis, we can meet our clients’ needs,” said Turner Specialty Services – Industrial Vice President Jimmy Watkins.

Established in 1998, Turner Industries’ Paris, Texas, pipe fabrication facility sits on 300-plus acres and has an 8,000-spoolper-month capacity with six fabrication bays, which total 350,000 square feet. Turner’s Fabrication Division was recently awarded a $2.2 million order to supply bends for an Alaskan pipeline project, and the Paris facility is set to take on the work. The project consists of 1,000 bends ranging from 6 inches to 24 inches in size with an extra heavy wall thickness in grade API5LX65 ERW of high-yield carbon steel. The bends will be performed by two Cojafex PB 16 machines and the PB 1400 machine.

The production bending is expected to start in November 2022 and be completed in the third quarter of 2023. The projected output of the pipeline is 80,000 barrels per day with the first oil to be produced in 2026.

Turner Specialty Services’ (TSS) NDE and Inspection Group has grown into one of the largest service groups of its kind on the Gulf Coast. Working at more than fifty nested maintenance accounts, TSS is uncompromisingly committed to integrity and safety, having zero recordable injuries since inception at many of our job sites and client relationships spanning decades. A recognized leader in digital transformation, TSS brings innovative robotics and drones, and uses the most advanced NDE inspection technology in the market. Using these advancements, TSS can lower the cost of ownership to our partners by reducing unnecessary inspections.

Mechanical Integrity

Technicians

Advanced Ultrasonics - Automated UT

Array, TOFD, TFM, and Bulk Wave

Computed and Direct Radiography

Testing-EDDY Current

Field

Inspection - Internal and External Drones with Thermography and OGI

20-Hydrocarbon Gases

For more information about this service please contact us at: turnerbusdev@turner-industries.com

Guided Wave Short- and LongRange Ultrasonic Testing

Rope Access NDE and Mechanical

Pulsed Array Eddy Current

MFL Tank Floor Inspection Equipment

LFET and SLFET Tank Floor and Pipe Inspection Equipment

3D Laser Imaging

GE BIKE Robot with UT Thickness Capability

Inuktun Modular Robot

Zenith Automated Visual Robotic System

Gonzales, La. – Turner Industries’ 2022-2023 United Way campaign kicked off in August at Turner’s safety meeting in Gonzales, Louisiana. Capital Area United Way (CAUW)

President and CEO George Bell attended the kickoff along with several members of his staff. Turner Public Affairs and Community Relations Director Michelle Hardy has been elected CAUW board chair for the 2022-2023 fiscal year, and during the kickoff meeting , Bell presented her with the official gavel.

United Way has always been Turner’s major philanthropic focus

because it serves the largest number of people in the most areas where our employees live and work. During Turner’s 2021-2022 campaign, employee pledges and corporate donations totaled $1,736,278.

If you have any questions regarding Turner’s current United Way campaign, or if you need help running a campaign at your site, contact Karen Smith at ksmith1@turner-industries.com.

Lake Charles, La. – Turner representatives attended the United Way of Southwest Louisiana’s campaign kickoff breakfast. United Way of Southwest Louisiana also selected Turner Business Development Director Gregory P. Thibodeaux as its new campaign chair. He will lead the community workplace giving campaigns with the 2022 theme of “Catch the Feeling.”

Baton Rouge, La. – At the 2022 Capital Area United Way’s annual meeting and awards luncheon, Turner Industries was recognized for its outstanding financial and volunteer support with the Achievement Award. Turner also ranked No. 2 in the category of “Top 25 Workplace Campaigns” and No. 3 in the “Top 25 Current Year Financial Support” category.

Annie Scheumack believes when you do something in life, you should go all in at 100 percent. She joined Turner Industries in 2019, working in the accounts payable department in vendor relations. In the summer of 2020, she became a vendor relations representative and then last summer, was promoted to her current position of accounts payable assistant supervisor. When Annie isn’t at work, she enjoys spending time with her family and is an avid reader. She is also passionate about her alma mater, Texas A&M University.

“My husband and I both graduated from Texas A&M University,” Scheumack said. “Our love for Texas A&M and desire to positively impact other Aggies runs deep. About six years ago, we decided it was our turn to give back to the university. We had a scholarship set up to assist Aggies interested in joining the Corps of Cadets. The scholarship started this fall and benefits a freshman cadet. My husband and I are proud and humbled to be able to help incoming Aggies get their start in Aggieland.”

Why was Turner a great fit for you? Before I joined Turner, I actually had no experience in this industry. My background is in education, but the people here saw potential in me. Turner gave me a chance to change my career path and do something different. I’m so grateful for that opportunity and to be at Turner.

What’s the best advice you’ve ever received? If you’re wrong, admit it. If you’re not, then don’t.

Do you have a favorite quote? “Whether you think you can or think you can’t, you’re right.” — Henry Ford

What are the top three highlights of your life so far? My marriage to my husband, Chris, of 23 years and the birth of our two boys, Henry (7) and Sid (17). I love the trips we have been able to take with our older son and look forward to continuing the tradition with our younger one. I also treasure the times that all four of us are able to sit down and share a meal together. Our older son is a high school senior, so those times are already few and far between and about to be even more rare.

La Porte, Texas – In August, the Construction & Maintenance Education Foundation (CMEF) held its 2022 graduation celebration for craft and construction site safety technician graduates from the NCCER-accredited programs. Turner Industries had 10 graduates from the boilermaker and electrical programs.

The 30 company-sponsored graduates completed all levels of the NCCER training courses in La Porte, Texas. NCCER Workforce Development Manager Matt Clark attended the graduation along with members of the ABC of Greater Houston. CMEF is the education affiliate of the ABC Greater Houston, and all courses are taught using the nationally standardized NCCER curriculum.

members of Turner’s workforce development team, Turner Site Managers Doug Taylor and Jose Gutierrez attended the graduation ceremony.

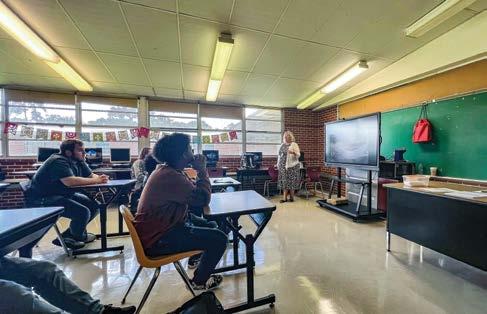

Beaumont, Texas – Turner Industries Workforce Development Manager Carla Thompson recently spoke to students at Beaumont’s Early College High School (ECHS). Thompson presented “Build Your Future,” providing an overview of the industry. The goal of her presentation was to show students how to find entry-level job opportunities.

Houston, Texas – The Houston Workforce Development team recently offered a Career and Technical Education (CTE) Teacher Externship, in partnership with the ABC Construction Career Youth Committee, to eight Goose Creek Independent School District (ISD) Career and Technical Education instructors from five high schools in the district. The externship’s goal was for the CTE instructors to see a variety of departments and functions within Turner, and to obtain a full view of opportunities available for high school graduates. The entire Workforce Development team was excited to show its appreciation for the Goose Creek ISD “Business Partner of the Year” award it recently received and to provide guests with a wonderful experience.

“This job shadowing was the best field experience I’ve had in 34 years. [Turner’s] staff was highly informative and supportive. Thank you for inviting us to tour the facility and having the staff explain how they can help our high school students in their future careers. It was an awesome experience,” said Goose Creek CTE Coordinator Michael Riojas.

Deer Park, Texas – Turner Industries employees at Shell Deer Park recently participated in NCCER Fundamentals of Crew Leadership training. This training teaches the skills needed to be an effective leader, including the ability to communicate effectively, provide direction to a crew, and effectively plan and schedule the crew's work.

“Any time we have a chance to upskill our employees and magnify the importance of various subjects such as safety and motivation, we jump at the chance,” said Turner Industries Superintendent Raul Luna. “It is a way for the jobsite and work areas to be managed at the highest possible level. With this training, the crew leaders become great ambassadors for our company, and in return, our workers become better as well. This makes Turner better as a whole.”

Baton Rouge, La. – Turner Industries recently attended the 15th Annual Greater Baton Rouge Industry Alliance (GBRIA) Craft Workforce Development Awards Banquet. These awards recognize high schools, post-secondary institutions and contractors for their craft training and workforce development efforts.

Turner Industries Group won the Award of Excellence in Division III for General Construction & Maintenance. Turner Specialty Services also won the Award of Excellence in Division II for Technical Support.

Pasadena, Texas – Turner Industries’ Maintenance and Turnaround Division and the Rope Access Group hosted Dragon Industrial Wrap for a training session for their teams. Dragon Industrial Wrap offers a professional engineering designed carbon fiber wrap, with a two-part epoxy resin. Their carbon fiber kits reinforce piping and vessels to their designed strength, to prevent unplanned outages and prolong the lifespan of equipment. Employees were able to experience these processes hands on and acquire certification in this technique.

Request for Information (RFI) and Field Change Order (FCO) documents are commonly utilized throughout the industry. However, the nature of the documents and related processes var ies greatly among sites, customers, and other disciplines. The supporting documentation may be paper forms or editable PDFs. While at other times, a job task or status update may be strictly communicated via email.

To help streamline communication, share information, and keep reportable data in a central location, Turner Industries has developed a custom-built RFI-FCO application. This application is standardizing the RFI and FCO processes both within the company and with our clients.

“This application allows the applicable levels of management to get the information we need to make informed decisions in a timely manner,” said Internal Audit Director

Michael Schoen. “From an internal auditing perspective, we will be able to monitor the status of pending RFIs/FCOs in ‘real-time.’ The timely nature of this information will provide our senior management the opportunity to proactively discuss any open items with the client(s) that are awaiting approval and/or clarification.”

The RFI-FCO application offers a customizable dashboard with filtering, sorting, and audit history. The application also captures site logistics, responsible parties, change orders, and cost totals.

“It assists with on-the-job organization and facilitates efficient communication both internally among our employees and externally with customers,” said Project Controls Vice President Andrew McCracken. “Customers that do not have their own solution are able to access data at a central location and communicate during the course of a job more efficiently.”

Internal and external users can approve, send messages, and add their own attachments. There’s even a smartphone option for both internal and external users as well.

Turner Specialty Services’ (TSS) Environmental Group’s experience, diversity, and resource capabilities are proven to reduce client risk while achieving cost-effective solutions in the petrochemical, chemical, energy, power generation, pulp and paper and related industries. TSS provides an innovative, consolidated approach as a fullservice waste management contractor.

more information about this

please contact

at:

This summer, Turner Industries participated in several school supply drives providing much-needed materials for underserved students and families.

We hope these donations served as a source of excitement for students as they geared up to succeed this school year! Pasadena; Texas City; and Freeport, Texas – Turner Industries employees collected and donated school supplies to the Pasadena Independent School District, Brazosport Independent School District, and Texas City Independent School District. The cost of school supplies continues to rise, so this year it was even more important to collect the items needed for those school districts.

Baton Rouge, La. – TEAM Turner members also dropped off supplies for The Emerge Center. The center aims to empower children with autism and individuals with communication challenges to achieve independence through innovative education and family-centered therapies.

Alvin, Texas – Turner Industries was a proud sponsor of Ascend Chocolate Bayou’s Officer Appreciation Day. The event invited Ascend officers, off duty that day, to partake in a day of fellowship, food, and fun along with two target shooting competitions at Ascend’s shooting range.

Destrehan, La. – Turner Industries representatives attended the opening of Rainbow Rehabilitation Park at Ochsner Health Center – Destrehan. Rainbow Rehabilitation Park provides an alternative therapeutic setting for Ochsner Therapy and Wellness pediatric patients to aid in improving their functional skills.

Geismar, La. – TEAM Turner members at Shell Geismar competed in this year’s Jambalaya Cookoff—a yearly event where the winners go on to compete in the Capital Area United Way’s Jambalaya Jam in Baton Rouge. One of Turner’s cooking teams, consisting of Percy Brown and Michael Newman, finished second in the contractor lineup and will represent Turner

Baton Rouge, La. – More than 25 Turner Industries project managers recently met to discuss safety, quality, productivity, technology, and other topics. They were also given company updates from members of Turner’s leadership team including CEO Stephen Toups, COO David Franks, Executive Vice President of Maintenance and Turnarounds and TSS Dwight Braud, and more.

Employment Relations Supervisor Leanne Maples also spoke about Turner’s anti-harassment, anti-discrimination, and antiretaliation policy; the proper methods to document employee issues; and the company’s ethics and compliance hotline.

CIO Amy Kling highlighted how Turner Tablet Applications™ — Scaffold Tracking, Job Safety Analysis, Force Report, Timesheets, Foreman’s Progress ™ , etc. — are reducing the burden of administrative work by digitizing and automating paper-based forms and tasks. The project managers also offered feedback regarding the use of Turner Tablets on jobsites.

Baton Rouge, La. – Turner Industries participated in the Baton Rouge Area Chamber’s Economic Inclusion Symposium, presented by D ow. The half-day event experience featured a keynote speaker, panel, and fireside chat sessions as well as the BR-POP Vendor Connect Showcase.

Studies show that diversity and economic inclusion are correlated with economic vitality. Regions that are more inclusive have greater levels of entrepreneurship, innovation and overall economic growth and prosperity. The ability of the Baton Rouge a rea to accelerate economic opportunity across the region hinges on its commitment to economic inclusivity and ensuring that the economy works for everyone, not just the few.

Baton Rouge, La. – The Baton Rouge office graduated its “Voice of Leadership” class for 2022. The 11-week “Voice of Leadership” class is designed to enhance leadership excellence and maintain a culture of leadership development. In addition to enhancing leadership capabilities, course-led objectives include improving communication and problem-solving skills. These 2022 graduates help ensure continued growth and success within the Turner organization.

– Turner Industries recently hosted the Economic Alliance Houston Port Region’s Task Force Committee Meeting. The committee held its monthly meeting at Turner’s Houston Personnel and Training Center. The task force’s mission is to attract new projects and businesses, promote capital investment, and create jobs in the Houston Port Region. Turner Industries Public Affairs Coordinator Lori Garza welcomed the group to our facility. At the conclusion of the meeting, Workforce Development Manager Carla Thompson and Training Manager Jay Roberson also provided a tour of the personnel office and training center, discussing the facility’s capabilities and Turner’s hiring process.

Baton Rouge, La. – Turner Industries recently attended the North Baton Rouge Industrial Training Initiative’s (NBRITI’s) advisory council meeting at Baton Rouge Community College’s Acadian location. Turner has been with NBRITI since the initiative started in 2012. Spearheaded by ExxonMobil, NBRITI is a collaborative effort comprised of diverse community, industrial, and educational partners throughout the Greater Baton Rouge area, all committed to one goal: to provide a sustainable process to recruit, train, and develop North Baton Rouge residents for successful careers with local industrial employers. The program trains millwrights, welders, pipefitters, and electricians.

Turner participates in the recruitment and placement of graduates, and the NBRITI training program is underway with its eight h cohort.

Pictured to the right: Bryan Gerace, Taylor Watts, Frank Canella, and Ray Neck attended the NBRITI advisory council meeting.

Turner Industries provides a single solution in heavy industrial construction, maintenance, turnaround, pipe and module fabrication, equipment, rigging and specialized transportation, and associated specialty services. With $2.36B in 2021 revenue, Engineering News-Record Sourcebook ranks Turner as the nation's top maintenance contractor in petroleum, and one of the top contractors in Texas and Louisiana. The company, headquartered in Baton Rouge, L ouisiana , employs 20,000+ and works across the United States.