TURNER INDUSTRIES

EDITORS

Jason Broha, Marie Crespo, Corinne Bergeron, Terry Kenney, and Andrew White

WRITERS & CONTRIBUTORS

Ryan Beeson, Corinne Bergeron, Chad Bradley, Mark Brittain, Jason Broha, Carson Chaisson, Marie Crespo, Kent Dartez, Ricky Diggs, Dylan Frederick, Wesley Freeburgh, Eric Fruchtnicht, Lori Garza, Trey Glascock, Dustin Gordon, Carlos Guidry, Eddie Hymel, Joey Keller, Terry Kenney, Kevin B. Landry, Chris Lossett, Raul Luna, Ben Martinez, Kash McMahon, Bryan McMillan, Gerry Meyers, Ed Newman, Colby Plaia, Karen Smith, and Eric Stampley

CREATIVE DIRECTOR

Jason Broha

GRAPHIC DESIGN

Scott Greci

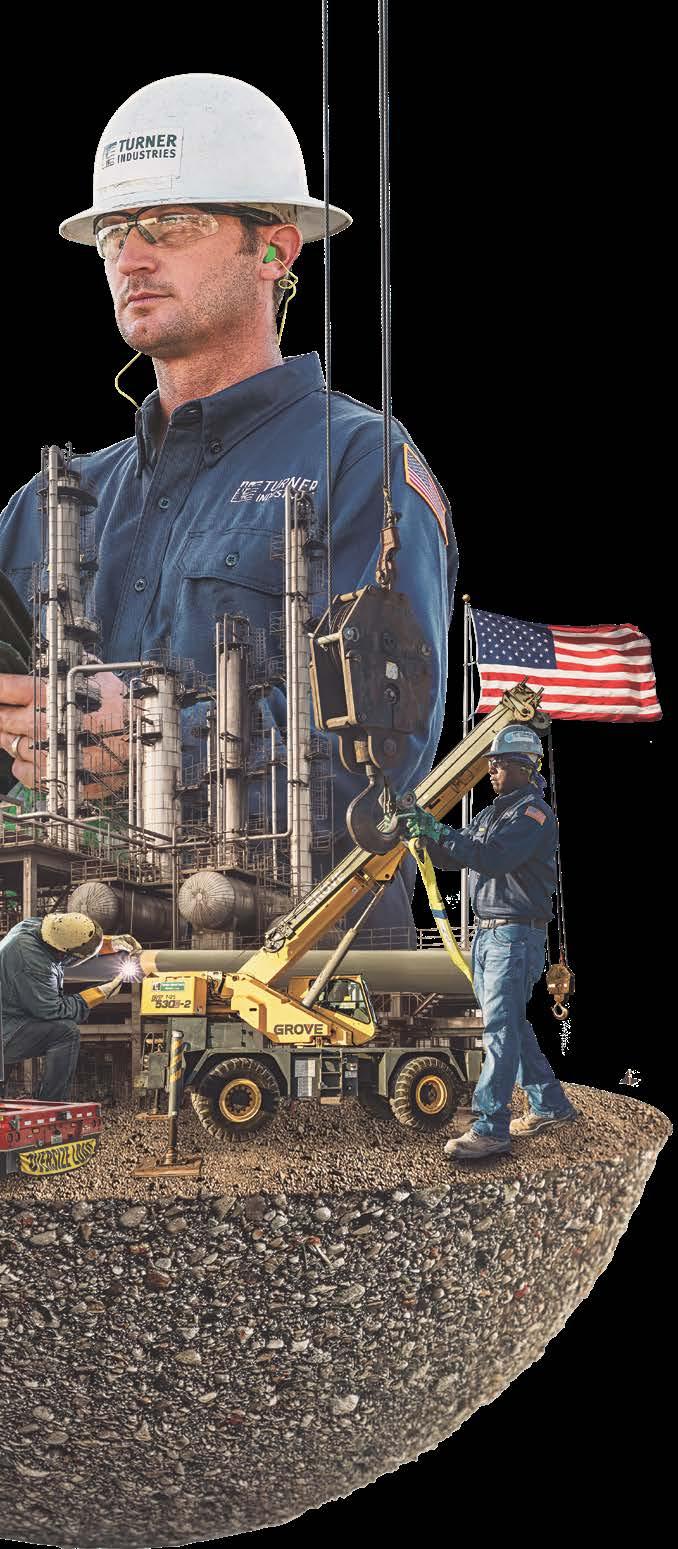

In this issue, we’re spotlighting the Construction Division of Turner Industries, a group with a rich history dating back to the late Bert Turner. Over six decades ago, Bert bought the assets of the bankrupt Nichols Construction, and with steadfast determination, he transformed a small, local company into the national industry leader that Turner is recognized as today.

In the heyday of the post-World War II industrial boom, Nichols played an instrumental role in the construction of a significant number of the nation’s critical refining and petrochemical facilities. As decades passed, Turner’s range of services broadened, yet our spirit stayed rooted in building and construction.

We invite you to dive deeper into the world of Turner’s Construction Division — where solid foundations meet bold innovations, and excellence is built into every project. Enjoy the rest of your summer and stay safe!

© 2023 Turner Industries Group, LLC. All Rights Reserved. Except for any owned by others, all trademarks, trade names, copyrights, and other intellectual property rights referenced herein are exclusively the property of or licensed by Turner Industries Group, LLC.

Freeport, Texas — As a proven tool in helping achieve Goal Zero, the Stop Work Authority (SWA) program is one of the most successful approaches in establishing an effective safety culture. The use of SWA has become a fundamental safety initiative for Turner at the Olin Freeport, Texas site. The use of the SWA program is not only a core value to Turner employees, but it has also been fully embraced by Olin Freeport’s site leadership. Olin Freeport Site Maintenance Director Al Cagle showed appreciation for several Turner work groups by treating them to lunch for their involvement and contributions to the SWA program.

“The Stop Work Authority program creates a culture where every employee feels empowered to intervene when necessary. It has become an integral part of our daily operations, and thanks to Turner for continuing to foster a culture where safety takes precedence,” said Olin Freeport Health, Safety, and Security Leader Tim Garza.

“In my mind, there is nothing more courageous than when a person looks at a situation and says ‘ No.’ It takes confidence in yourself, confidence in the leadership supporting you , and confidence in your teammates to pull that trigger and stop work when you suspect something is not right. I continue to be impressed at the quality of Turner’s team on stopping work and bringing to attention places that need further review and understanding before proceeding. It saves everyone from injury and I truly am appreciative,” said Olin Freeport Site Maintenance Director Al Cagle.

Deer Park, Texas — Turner Industries employees at Shell Chemicals in Deer Park, Texas recently celebrated 1,129,434 workhours without an OSHA recordable incident. Management from Turner and Shell attended the celebration, which included a well-deserved lunch for all employees.

“As a site that prioritizes safety above all else, we are incredibly proud of our employees for reaching this extraordinary milestone,” said Turner Site Manager Donny Greer.

Baton Rouge, La. — Turner Industries employees at NovelAire Technologies recently celebrated 10 years OSHA recordable free. This milestone was achieved with the support of NovelAire and the commitment from all Turner employees to work safely every single day.

Hahnville, La. — Turner Specialty Services’ inspection and NDE groups at Dow’s St. Charles Operations recently celebrated 20 years OSHA recordable free with a crawfish boil.

Sulphur, La. — Turner Industries employees at Venator recently celebrated 23 years and over 350,000 workhours OSHA recordable free.

Alvin, Texas — Turner Industries recently participated in Ascend Chocolate Bayou’s Safety Day, which featured vendor demos, unit sponsored booths, and a fork truck rodeo. During the event, Turner Specialty Services highlighted some of its latest innovations and services, including its hydro blasting, drones, and inspection services.

Geismar, La. — Congratulations to Methanex Geismar ’s HSE Crews of the Week and the Beaumont Crews of the Month for their outstanding dedication to health, safety, and environmental excellence. Well done to all these deserving Turner employees who have made a significant impact to safety throughout the months of March, April, and May.

The Beaumont Crew of the Month award is named after Jeremy “Beaumont” Moore, who sadly passed away in 2021. He was a highly cherished and respected superintendent who consistently prioritized the safety and well-being of his work family above all else.

Pictured here are a few of Methanex Geismar ’s HSE Crews of the Week and the Beaumont Crews of the Month .

Deer Park, Texas — The Turner Industries team at Westlake Epoxy in Deer Park, Texas has worked 16 years OSHA recordable free. This milestone was recognized with a celebratory lunch, with Westlake and Turner leadership congratulating the team on this remarkable milestone.

“It takes everyone on site to be able to achieve our goal each day. With the support from both our Turner and Westlake families, we would not have been able to achieve the milestone of 1.3 million workhours and 16 years OSHA recordable free here at the Westlake Epoxy site,” said Turner Site Manager Brian Hamilton.

H ouston, Texas — At the recent 36th Annual Houston Safety Excellence Awards, Turner Industries’ Equipment, Rigging, and Specialized Transportation Division was honored with the Newcomer of the Year and Best in Class awards for the Crane & Rigging category. Turner Industries also received the Gold award in the General Contractor Large category.

The Houston Safety Excellence Awards, a prestigious recognition program sponsored by the Houston Business Roundtable and the Health and Safety Council, are designed to acknowledge and honor outstanding safety performance among contract companies and their partners operating in the Greater Houston Area.

N EWCOMER OF THE Y EAR CRANE & RIGGING CATEGORY

B EST IN C LASS AWARD CRANE & RIGGING CATEGORY

G OLD AWARD GENERAL CONTRACTOR LARGE CATEGORY

Kenner, La. — The Gulf Coast Safety Council’s (GCSC’s) 21st Annual Contractors Safety Excellence Awards recognized and celebrated outstanding achievements in safety within the contracting industry along the Gulf Coast region. The GCSC awards ceremony highlights and rewards the best practices, innovation, and dedication exhibited by contractors in their pursuit of excellence in safety.

Several Turner Industries groups and divisions received multiple GCSC awards in recognition of their exemplary commitment to safety.

Maintenance Division

• Dow St. Charles Operations

• Oxy Taft

• Shell Norco

SIPA Division

• Oxy Taft

• Shell Norco

Environmental

SWS/Turnaround

• Dow St. Charles Operations

• Shell Norco

TSS Mechanical

• Oxy Taft

• Shell Norco

TSS Non-Destructive

• Dow St. Charles Operations

TSS SIPA (Abatement)

• Oxy Taft

Mechanical

• TSS Mechanical at Shell Norco (25,000-50,000)

Specialty

• SIPA at Oxy Taft (25,000-50,000)

• Turner Industries Group at Dow St. Charles Operations (100,000 to less than 250,000)

• Turner Industries Group at Shell Norco (250,000 to less than 500,000)

The Corporate Safety Excellence program represents the top safety awards presented by our company. Site performance is reviewed by an evaluation team and submitted to the Executive Safety Committee for final approval. Awards are based on the following criteria: Incident Performance Statistics, Safety Process Implementation, Metrics/Leading Edge Indicators, Employee Involvement and Engagement, and Employee Development Processes.

Overall Top Corporate Performers

Ascend Performance Materials

Decatur, Alabama

Westlake

Plaquemine, Louisiana (Maintenance)

Westlake

Plaquemine, Louisiana (Turnaround)

Methanex G3 Construction

Geismar, Louisiana

Baton Rouge Equipment Operations

Baton Rouge, Louisiana

Port Allen Pipe Fabrication

Port Allen, Louisiana

Turner Specialty Services NDE Corporate

Regional and Business

Unit Top Performers

Shell Norco

Norco, Louisiana

Total Petrochemicals

Carville, Louisiana

Sasol

Westlake, Louisiana

Indorama

Port Neches, Texas

Marathon Petroleum

El Paso, Texas

GCGV

Corpus Christi, Texas

Westlake–Hexion

Deer Park, Texas

SIPA Operations

Decatur, Alabama

TSS Mechanical at Honeywell

Metropolis, Illinois

TSS Environmental at Graphics Packaging

Augusta, Georgia

Raul Luna joined Turner Industries almost five years ago because h e wanted to be part of a company that was founded on strong family values and takes care of its people.

Raul ’s journey with Turner began as a soft craft superintendent at Shell Deer Park Chemicals, where he was also able to show his expertise on furnace rebuilds. Recognizing his potential, Raul was then called on to manage SIPA (scaffolding, insulation, painting, and abatement) services, as well as refractory services, at the refinery. At the end of 2022, he took on the role of his current position as the maintenance manager at Shell Chemicals in Deer Park, Texas.

Outside of work, Raul is passionate about and heavily involved with Habitat for Humanity Pasadena. Collaborating with fellow Turner and Shell Deer Park employees, he actively participates in constructing small homes from the ground up in the local community.

“On the weekends, we volunteer our time and craftsmanship to help those in need throughout Pasadena,” Raul said. “Working with Habitat for Humanity Pasadena has been such a wonderful opportunity and experience. I know everyone at Turner who’s been involved with this organization is excited to continue our work. There are still tasks ahead, including installing siding and drywall, paving concrete driveways, and completing the final touches with painting. Together, we will leave a lasting impact on the lives of those we serve.”

What do you find most satisfying about your job? The most rewarding aspect of my job is the opportunity to lead, encourage, listen, coach, motivate, influence, and, most importantly, help empower my fellow coworkers.

Do you have a favorite quote? “Many are the plans in a person ’s heart, but it is the Lord’s purpose that prevails.”

— Proverbs 19:21 .

What’s the best advice you’ve ever received? Embrace change, and don't hesitate to give yourself the credit you truly deserve.

What are your top three life highlights so far? My first and most important life highlight is my marriage, which has blessed me with being a father to two beautiful girls. The second highlight is my family has not only changed my life, but also my family history. My two daughters became our family ’s first generation of college graduates. The third, most recent highlight was jumping out of a perfectly good airplane and skydiving with my wife and two daughters.

Turner Industries successfully executed a challenging project at its Decatur, Alabama facility, involving the design and fabrication of a custom heater for a gas company. Turner delivered a high-quality product within tight deadlines, while also demonstrating exceptional craftsmanship and an innovative approach.

Construction Material: Type 321 S tainless S teel

Fabrication Method: Automatic O rbital Welding for O ver 2 M iles of T hin Wall 1-inch OD Tubes

Test Pressure: 735 PSIG

Shipping Weight: 40,000 P ounds

Selling Price: $ 650,000

Delivery: Expedited D elivery S uccessfully M et

Design Challenges: L ack of Complete Drawings Required Reliance on 3D Scans for Fabrication Plans

Turner Industries has signed a master service agreement with Harvest Midstream for maintenance services at the Belle Chasse Terminal, formerly the Alliance Refinery located in Plaquemines Parish, Louisiana.

Turner has had a nested presence at the facility since 2010 and has consistently demonstrated its expertise, providing critical maintenance solutions. Turner’s personnel have also shown an exceptional work ethic, strict safety measures, and a strong attention to detail—all main reasons why the contract was retained under the new ownership.

“Our ability to execute complex maintenance tasks efficiently and effectively has earned the trust and confidence from Harvest Midstream,” said Turner Project Manager Eddie Hymel III. “We look forward to continuing this successful partnership with Harvest.”

In November 2022, Turner Industries received a request from DuPont in Parlin, New Jersey to assist in performing critical activities during an unplanned outage. During the outage, Turner performed an extruder change out. Originally planned as a repair job, the extruder ended up needing to be pulled and replaced once the magnitude of repairs w as determined.

Leading from the front, Turner Superintendent Edgardo Zavala and his team executed the work flawlessly. Shortly after the first of the year, Turner was then requested to mobilize a nested team of four employees to perform mechanical maintenance services.

Turner Industries has signed a maintenance contract extension with Phillips 66 for the refinery in Lake Charles, Louisiana. This extension solidifies Turner ’s position as the provider of general mechanical maintenance services at the refinery. On average, Turner has approximately 225 personnel working on site.

“With our industry - leading expertise and a dedicated workforce, we look forward to this continued partnership with Phillips 66, helping to ensure the refinery ’s long-term efficiency and reliability,” said Ben Bourgeois, project manager for Turner Industries.

“Remote markets require reliance on digital reporting and Turner Tablet Applications™ alongside the monthly maintenance KPI dashboard . This has allowed us to provide detailed data and visibility,” said Turner Project Manager Adam Brittain.

“Turner Industries is committed to helping Phillips 66 maintain the refinery’s operational excellence while also providing value and quality services,” said Jimmy LeBouef, site manager for Turner Industries.

Turner Industries recently worked on the construction of an expanded PVC unit and a cooling tower for Formosa Plastics Corp. in Baton Rouge, Louisiana. The project, which lasted nine months, involved the collaboration of multiple Turner groups and divisions, and Turner self-performed 98% of the work.

Turner’s S mall C aps G roup : G eneral C ontractor

Turner’s Decatur, Alabama F acility : S teel, M aterial P rocurement S pecifications, a nd P ipe S upport S hop F abrication

Turner’s Port Allen, Louisiana S hop : P ipe F abrication a nd P aint

Turner’s S IPA G roup : S caffolding, I nsulation, a nd Touchup P aint S ervices O n S ite

Turner Specialty Services : F ield Testing S ervices S uch a s R adiographic Testing a nd P ositive M aterial I dentification

Turner’s C rane a nd R igging G roup : 30- Ton a nd 60- Ton C ranes, Trucks, Trailers, a nd R igging E quipment

Site Preparation/Excavation: Minimal, Closure Welds to Underground Pipe

Civil: Elevated Concrete Floor, Pump P edestal Prepping, Etc.

Structural Steel: More Than 50 Tons of Steel Erected on E xpanded PVC Unit

Equipment: More Than 15 Pumps, 2 Skids, 4 Vessels, 1 Tank, and M iscellaneous Screens, Filters, and Hoopers

Hydro Testing: More Than 6,000 Feet of Pipe Tested

Painting: 4,500 Feet of Paint Touchup

Insulation: 4,000 Feet of Piping I nsulation Plus Several Equipment Units

Scaffolding: Erected and Dismantled Two Truckloads of Materials for Five Months in Various Areas

Piping: More Than 6,000 F eet of Carbon, Stainless 304 and 316, Low-Temp Carbon, and Jacketed Pipe

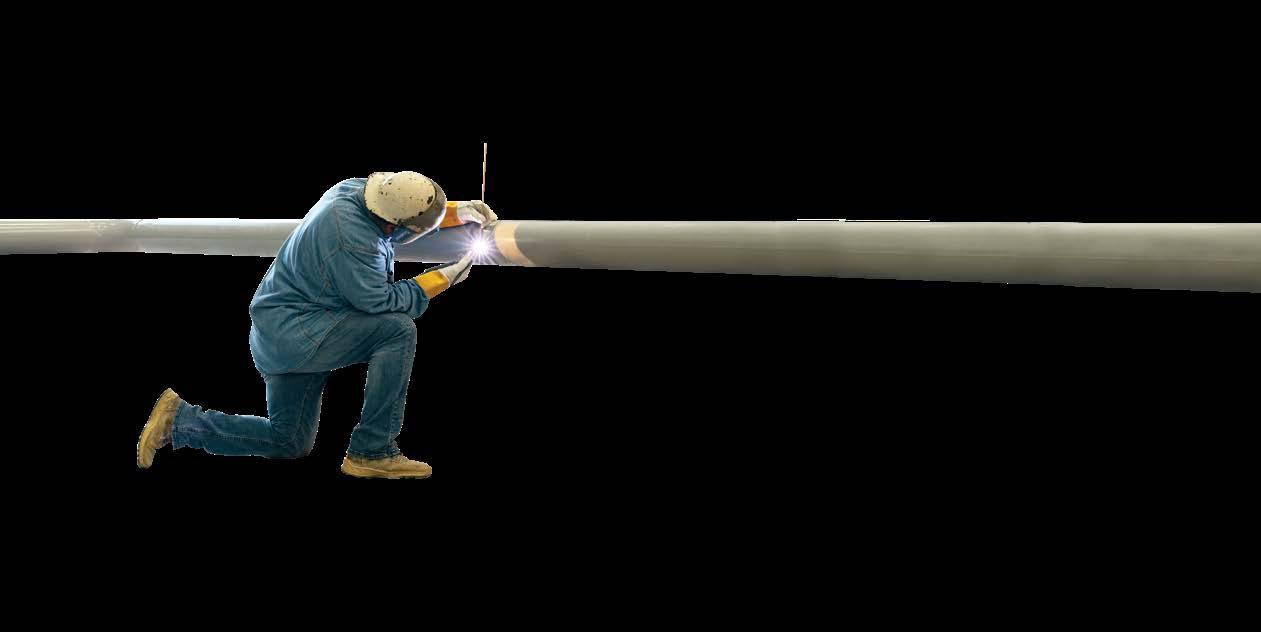

Turner Industries’ pipe fabrication team in Paris, Texas recently partnered with AMERICAN SpiralWeld Pipe to complete grout port installations for a raw water delivery infrastructure project. Each spiral welded pipe, measuring 80.25 " OD by 0.574 " wall thickness and weighing 15,500 pounds, spanned 25 feet in length. The pipes were lined with a 0.500" thick mortar and featured a polyurethane coating.

All 110 pipe sections were safely transported to the Turner fabrication plant and staged for fabrication. Meticulous attention was given to the removal of mortar and polyurethane to ensure the successful installation of grout ports, allowing the final product to facilitate water transportation in the Austin, Texas area for many decades to come.

Turner ’s fabrication shop in Paris boasts exceptional capabilities for handling diverse projects. With 375 acres and 450,000 square feet of combined manufacturing space under one roof, as well as a 100-ton crane capacity, seven fabrication bays, and induction bending capabilities of up to 54" OD, Turner’s Paris shop is fully equipped to respond to our clients’ needs.

Turner Industries’ modular fabrication group, in collaboration with Agilyx and Toyo Styrene, has successfully completed the construction of a module that will play a pivotal role in the transformation of post-use polystyrene by converting waste polystyrene into purified styrene monomer, ultimately producing high-value polystyrene products with a significantly reduced carbon footprint compared to those made with virgin monomer.

Under contract from Toyo Styrene, Agilyx designed the module, while Turner’s modular fabrication group took charge of its construction. The module was assembled at Turner’s modular yard in Port Allen, Louisiana. Comprised of six main skids, a cooling screw, a sophisticated reactor, and a char bin system for efficient product movement, this module aids to revolutionize the polystyrene recycling industry, paving the way for a more sustainable and ecofriendly approach to polystyrene production.

With a tight deadline of only nine weeks to receive materials, install the steel, pipe, electrical and instrumentation, perform required testing, and devise an efficient plan for disassembly and shipment using eight shipping containers, the modular fabrication group went to work. Turner Construction Supervisor Eric Fruchtnicht commended the modular facility crews led by Red Fogleman stating, “The crews at our modular facility did what they do best — providing top-notch services and solutions, even under the most demanding schedule.”

This summer, Eric will travel to Chiba, Japan to lend his expertise and guide the reassembly process for the module. This crucial step ensures that the module seamlessly integrates into the recycling plant.

As we navigate through the 21st century, heavy industrial construction is undergoing a rapid transformation, shaped by technological advancements, sustainability breakthroughs, and innovative practices. In this pivotal era, Turner Industries’ Construction Division is at the forefront of these changes, setting new industry standards and pushing the boundaries of what's possible. With the continue d importance of fossil fuels, liquefied natural gas, renewable energy sources, and the chemical industry—coupled with the increasing demand for infrastructure upgrades—heavy industrial construction projects must be at the forefront of innovation, resilience, and environmental stewardship.

Off-site modular fabrication has emerged as a transformative solution to on-site construction work, offering increased efficiency, shorter construction timelines, improved quality control, but most importantly, better safety results. As the industry embraces this development and heavy industrial construction projects are gaining post-COVID momentum, Turner—with over 200 acres of world-class modular fabrication space—is well positioned to help clients realize the projects of tomorrow.

Our vast array of services—from planning to execution and everything in between—gives clients an efficient and cost-effective ONE Solution option when it comes to construction projects.

Turner’s Construction Division is successful today because of its exceptional people. Our employees are committed to working safely above all else, while also following the highest industry standards in terms of quality and efficiency. Our middle management team has an average tenure of over 20 years with Turner, our senior management team has an average tenure of more than 30 years with Turner, and our skilled crafts average over a decade of industry experience.

Turner Industries’ ONE Solution approach provides clients with the ability to effectively manage and execute projects. By consolidating services under one contractor, redundancies are avoided, resulting in cost reductions and increased efficiencies. Having a contractor involved in the early planning stages of a project ensures productive communication and can lead to less change orders. Turner integrates our comprehensive range of services, covering eve ry aspect of a construction project. This approach guarantees seamless coordination, enhanced accountability, and a unified experience for our clients, establishing Turner as the top choice for streamlined and successful construction projects.

Turner’s Construction Division leverages technology to transform work processes effectively. With Turner Tablet Applications™, paper-based forms and tasks become automated—significantly reducing the burden of paperwork. Our DECIDE WITH DATA™ suite of technologies allows our clients to make data-driven decisions.

The Job Safety Analysis (JSA) tool generates real-time digital forms for identification and resolution of jobsite risks, and it intuitively guides employees through the workflow, ensuring each potential hazard is considered. The JSA tool

also enables employees and supervisors to remain in the field, where their presence is essential, rather than being tied to a desk handling tedious paperwork.

Another valuable tool is the Request for Information (RFI) application, serving as a comprehensive project correspondence tracker. It captures critical information, such as site logistics, responsible parties, original and change order work, and cost totals. Equipped with an advanced customizable dashboard featuring filtering, sorting, and audit history, the RFI application delivers instant visibility and control over project communications.

CONSTRUCTABILITY We offer constructability services to support clients throughout the design, planning, construction, and commissioning phases. Our knowledgeable team ensures quality, safety, and efficiency.

SIPA

Turner ’s SIPA group specializes in scaffolding, insulation, painting, and abatement services, with over 3,000 highly trained professionals in the Gulf South region.

TECHNOLOGY We develop constructionbased technologies such as Turner Tablet Applications™ to enhance productivity and efficiency on our projects.

C ONSTRUCTION COORDINATION Turner ’ s

Construction Division manages and hires personnel for various specialties to transform raw land (fields) into operating facilities. We collaborate closely with engineers and owners for successful project outcomes.

MODULAR FABRICATION Turner has over two decades of experience in modular fabrication and is the industry ’s most capable contractor with our Gulf of Mexico Operations facility in New Iberia, Louisiana.

ROPE ACCESS Turner’s Rope

Access group is the largest and most experienced on the Gulf Coast, performing skilled crafts on ropes with certified technicians.

QA/QC Our certified quality managers and technicians maintain high-quality standards using our in-house software WeldTracker.

Turner sets the standard for excellence in crane and rigging services, planning with precision and care to ensure safety and efficiency. Our specialized transportation group offers engineering, logistics, and transportation services for any size or weight of commodities.

SAFETY At Turner Industries, our safety programs and initiatives are designed so that everyone has the right knowledge, tools, and guidance to perform at the highest level and make it home safely at the end of each day. Last year, we achieved a record-breaking low TRIR of 0.20 across over 400 jobsites and more than 40 million workhours.

S PECIALTY S ERVICES Our specialty services group offers best practices and state-of-the-art technology (drones are one example) for any project size. Our Specialized Welding Services has skilled craftspeople who are the best in the business.

We use state-of-the-art robotics for pressure vessels, structural steel, process piping, and metal forming, delivering on time and within budget.

Our project controls team utilizes our award-winning in-house software and scheduling tools to plan and report detailed job progress.

P IPE FABRICATION AND B ENDING With multiple pipe fabrication facilities and extensive shop space, we have the capacity to produce thousands of spools per month and deliver worldwide.

Constructability

Maintenance & Turnarounds

Decommissioning

Recommissioning

Facility Management

Turner’s ONE Solution™ approach also supports clients throughout the lifecycle of a facility.

• Site Preparation/Excavation: Excavated roughly 55,300 cubic yards of dirt

• Civil Work: 14,740 cubic yards of concrete and 1,210 tons of rebar

• Structural Steel: 3,430 tons split between new structures and additions to existing ones

• Equipment: Setting 366 total pieces of process equipment

• Hydro Testing: 631 hydro test packages

• Painting: 34,180 square feet of paint touchup

• Insulation: 29,600 linear feet of piping insulation

• Scaffolding: Erected over 592,000 leg feet of scaffold

• Piping: 166,396 linear feet of piping

450 Turner employees on site (peak personnel)

W ORKHOURS: 450,000

PERCENTAGE OF LABOR SELF-PERFORMED: 95%

W ORK SELF-PERFORMED BY TURNER

• Civil Work: 900 cubic yards of concrete

• Structural Steel: 130 tons

• Equipment: Setting 37 pieces of process equipment

• Piping: 16,467 linear feet of piping (1,302 pipe spools fabricated)

• Hydro Testing: 232 pipe packages and 826 mechanical test packages

• Insulation: 4,585 linear feet

• Welding: 7,075 shop welds and 714 field butt welds (0% weld repair rate)

• Scaffolding: 175,833 leg feet of scaffold erected

Winner of four ABC Excellence in Construction Awards – Pelican and Bayou Chapters

W ORKHOURS: 5.6 MM

PERCENTAGE OF LABOR SELF-PERFORMED: 75%

SUBCONTRACTORS: 58

W ORK SELF-PERFORMED BY TURNER

• Site Preparation/Excavation: Roughly 50,000 cubic yards of dirt excavated

• Civil Work: 19,051 cubic yards of concrete and 1,532 tons of rebar

• Structural Steel: 4,738 tons split between 68 modules, 24 structures and 5 pipe racks

• Equipment: Setting of 611 total pieces of process equipment including 160 pumps and 101 columns/vessels

• Piping: 365,037 linear feet of piping, with roughly 1/3 routed through existing pipe rack

• Hydro Testing: 1,844 test packages

• Painting: 179,000 square feet of paint touch up

• Insulation: 265,951 linear feet of piping insulation

• Modules: 68 modules built on site and set

• Scaffolding: Over 750,000 leg feet of scaffold erected

“The true strength of Turner’s construction services lies in the caliber of our people. Their efficient workflows and exceptional problem-solving abilities ensure projects are completed within the set timeframe and budget. Our employees’ skills, dedication, and expertise serve as the driving forces behind the success of our projects.” — Turner Industries President of

Senior Construction Manager; 24 Years with Turner Industries

How has technology improved your ability to effectively manage a construction job?

“With Turner Tablet Applications™ deployed on-site, we empower our team to effortlessly access project models, record progress updates, and complete timesheets—all without the need to make frequent trips back to the office. These technological advancements not only enhance the efficiency of our work but also contribute to a safer working environment, improving the overall quality of our operations.”

Combo Welder; 15 Years with Turner Industries

Why is Turner the right fit for you? “Turner is an ideal fit for me as they have cultivated an environment that enables me to thrive in my role. I have consistently experienced a sense of ease and assurance in carrying out my job responsibilities. With an open mind, a positive attitude, and a strong appreciation for teamwork, Turner continues to support me in being a reliable coworker, a trusted mentor, and a supportive friend.”

Site Manager; 32 Years with Turner Industries

What is the most rewarding project you have been a part of during your time with Turner? “Working on the Shell AO4 project has been the most rewarding project I’ve been a part of. We assembled an extraordinary team, and as the project manager, I had the privilege of leading this $375 million endeavor. Almost every division of Turner played a key role in making that project a success. It was truly a team effort.”

Expeditor; 6 Years with Turner Industries

What advice would you give to a new Turner employee? “At Turner, there’s plenty of room to grow and learn different crafts. I started as a fire watch and gradually transitioned to different roles, including an insulation helper and pipefitter helper. I’m now an expeditor on the G3 project at Methanex in Geismar. Maintaining a can-do attitude is crucial, and you should never hesitate to ask for additional responsibilities. It’s important to communicate your enthusiasm to learn more and make the most of those valuable insights shared by your colleagues. Remember, no one achieves success alone.”

With a rich history spanning decades, o ur ONE Solution approach in the petrochemical, refining, energy, pulp and paper, and related industries has made Turner one of the nation’s top industrial contractors and earned us the No. 1 spot on ABC’s 2022 Top Performers list. We are continuing to help the world move forward by providing turnkey industrial services and solutions to the companies that produce fuel, energy, and the materials essential to modern life.

As the renewable energy market also continues to expand, Turner’s Construction Division has broadened its project portfolio, building a reputation as a trusted partner in this rapidly evolving industry. Examples of these projects include the completion of the Diamond Green Diesel facility in 2013, a greenfield construction project for one of the largest biodiesel facilities in the U.S., and the ongoing Vertex Energy renewable diesel conversion project in Alabama.

Corpus Christi, Texas — Four talented welding students from Veterans Memorial High School in Corpus Christi, Texas have recently signed on to begin their careers with Turner.

Turner Industries is proud to provide the next generation of industrial professionals with the opportunity of a rewarding career right out of high school.

“On behalf of Veterans Memorial High School, thank you to Turner Industries for recognizing the talents of our amazing welding students,” said Veterans Memorial High School Principal Scott Walker. “We could not be more excited about the future of this partnership and the opportunities it presents our students.”

La Marque, Texas — Turner Industries recently held a signing day ceremony at La Marque High School where Dylan Holly was offered the position as a mechanic at the Marathon Galveston Bay Refinery. Dylan’s exceptional performance during an interview event held at the Industrial Safety Training Council led to Turner offering him the position.

From left to right are Turner Industries Site Manager Dustin Gordon, Dylan Holly, Turner Maintenance Superintendent Daniel Bauer, and Marathon Maintenance Superintendent Mark Reisenweaver.

Corpus Christi, Texas — Turner Industries Coordinator of Public Affairs and Community Relation s Lori Garza was invited to speak for career day at Banquete ISD to three third grade classes. Lori shared with students her current roles and responsibilities with Turner.

Singer, La. — Turner Industries supports the Beauregard Parish Jump Start Summer Welding Program, which offers students the opportunity to earn a Carnegie Credit and a statewide industry-based credential for the Jump Start pathway. With 140 hours of dedicated welding booth time, students receive hands-on training that hones their skills and instills confidence.

Students create résumés and participate in interviews to secure their place in the program. While in the program, students also receive a stipend for various achievements. Turner supports the class by meeting with the students and tracking their progress, supplying PPE, and attending the graduation ceremony.

Turner Industries is proud to graduate another set of Voice of Leadership (VOL) classes from Baton Rouge and Lake Charles, Louisiana and Pasadena, Texas.

This 12-week program, started by Dwight Braud almost 20 years ago, continues Turner’s commitment to increase leadership excellence and maintain a culture of leadership development. As a symbolic thank you for all his hard work during this year’s VOL class, Dwight was presented with a Turner hard hat signed by all at the Baton Rouge leadership class.

Year after year, the VOL program continues to evolve because of the input and contributi ons of everyone involved. It’s an exciting opportunity for participants, and the future looks bright for this remarkable program.

Catlettsburg, Ky. — Turner Industries recently participated in the 2023 Marathon Petroleum Corp. United Way Golf Classic in Catlettsburg, Kentucky. This two-day annual golf tournament supports the United Way of Northeast Kentucky. Thanks to these Turner employees who helped make the event a success: Gary Truxillo, Karen Smith, Clarissa Fuller, Rick Francis, BJ Lott, and Ray Derrickson.

Baton Rouge, La. — TEAM Turner collected gently used and new shoes to benefit families in need around the world. The collected shoes were donated to Funds20rgs, which works with individuals and families to create small businesses in developing nations.

Houston, Texas — Turner Industries recently attended and helped to sponsor the United Way of Greater Houston’s Centennial Celebration. The United Way of Greater Houston (UWGH) traces its roots back to 1922 when a group of community leaders established the Houston Community Chest. Over the years, the organization underwent several name changes before becoming the United Way of Greater Houston in 1972.

Dur ing the celebration, UWGH honored those whose outstanding contributions have played a pivotal role in United Way’s ability to provide help and hope to millions of neighbors. With a 70-year history as the leading supporter and partner of UWGH, ExxonMobil topped UWGH’s honoree list as Company of the Century.

Baton Rouge, La. — TEAM Turner members in Baton Rouge volunteered at the Miracle League at Cypress Mounds, a registered nonprofit organization that gives children with any type of disability or special needs the opportunity to play baseball as part of a team and an organized league. The league depends on volunteers to assist and keep players safe during the games.

Corpus Christi, Texas — Turner Industries representatives participated in Junior Achievement’s Groovy Bowlathon presented by Marathon Petroleum Corp Attendees gathered for some bowling fun in costume in support of their local Junior Achievement chapter.

Beaumont, Texas — Turner employees in Beaumont, Texas generously participated in a blood drive to support LifeShare Blood Centers.

Pasadena, Texas — The Armand Bayou Nature Center (ABNC) is a natural treasure in the greater Houston area, offering visitors an opportunity to reconnect with nature across its 2,500 acres of wetlands forest that’s home to more than 370 species of birds, mammals, reptiles and amphibians. It depends on community support to preserve the preserve. That’s why volunteers spent a day at ABNC, making repairs to fencing, gates, ramps, buildings, and trim vegetation.

In the days leading up to the volunteer day, Shell Deer Park teamed up with Turner Industries to erect scaffolding and prepare the site for the day’s activities. Here’s what Shell had to say about Turner’s volunteers:

“I would like to personally thank each and every one of you for sponsoring our Shell event to help Armand Bayou Nature Center with repairs. I am very proud to know you all had my back from the beginning to end to make sure we had everything we needed,” said Shell Deer Park Turnaround Logistics Coordinator Jimmy Soliz.

Turner Industries employees participated in a company-wide effort to help restock local food banks for spring and summer.

Houston, Texas — Turner employees in the Houston area collectively donated over 12,000 pounds to several food bank organizations across the region including Pasadena Community Ministries Food Pantry, Brazoria County Dream Center Food Pantry, and Liverpool Food Bank. In addition to the food drive, Houston sites participated in a food barrel decoration competition.

1st Place: Olin – Freeport (3,274 Pounds)

2nd Place: Shell Chemicals – Deer Park (2,041 Pounds)

3rd Place: Pemex – Deer Park (1,799 Pounds)

Lake Charles, La. — Turner Industries operations in Lake Charles, Louisiana partnered with Second Harvest Food Bank, donating over 1,400 pounds of food to Catholic Charities of Southwest Louisiana.

Decatur, Ala. — In partnership with area clients (Ascend, IVXP, Toray, 3M, Daikin, Hexcel, Nucor, INEOS, and IP), Turner employees collected 20,000 pounds of food for the Barrels of Love food drive, filling the gap during spring break for the school backpack feeding program.

Corpus Christi, Texas — Turner employees in the Corpus Christi region collected 575 pounds of food for the Coastal Bend Food Bank. Turner jobsites, the pipe fabrication shop, along with administrative and personnel offices participated in the food drive.

Baton Rouge, La. — The annual Race to Restock the Food Bank yielded 8,544 pounds of food for the Greater Baton Rouge Food Bank, which equals over 7,000 meals. There was also a food barrel decorating contest.

1st Place Small Site (less than 100): Olin Chlor Alkali

1st Place Medium Site (100-300): Westlake – Plaquemine

1st Place Large Site (300+): ExxonMobil Baton Rouge – Refining & Chemical Plant Barrel Decoration Winner: (Pictured) Westlake – Plaquemine

Beaumont, Texas — Turner operations in Beaumont, Texas came together to help the Southeast Texas Food Bank. This region collectively donated over 700 pounds of food to help serve the community.

Turner Specialty Services recently held demo days in both Louisiana and Texas.

Plaquemine, La. — Turner Industries SIPA Project Manager Judy Mendoza recently sat on a panel as part of the Manufacturing Institute’s Women MAKE Mentorship Event. Judy was joined by Carolyn Lee, president and executive director of the Manufacturing Institute (moderator); Stacey Gautreau, director of public affairs (U.S. South) for Dow; and Johnneisha Tillman, analytical technician for Dow Plaquemine. The panelists shared their experiences and insights about their careers in modern manufacturing.

The Manufacturing Institute’s Women MAKE Mentorship Program helps female mentors connect to younger women in the industry. This program is an opportunity for women in the manufacturing industry to form a relationship that can provide professional guidance on how to navigate challenges and career advancement.

Lake Jackson, Texas — For the fourth year in a row, Turner Industries supported the Junior Achievement of Brazoria County’s Who’s Who Golf Classic. The event raises funds to help provide financial literacy, entrepreneurial, and work readiness programming for over 6,000 youths annually.

Pasadena, Texas — Turner Industries recently attended the Pasadena Chamber of Commerce Industrial Appreciation Membership Luncheon, which honored Kaneka with the 2023 Industry of the Year award.

Deer Park, Texas — Turner Industries would like to acknowledge Billy Lee, a fuel truck driver and dispatcher, who worked 47 years at the Shell Deer Park site. Billy, who recently retired, joined Turner in 2006. Working at the same jobsite for almost five decades certainly calls for celebration. Congratulations, Billy.

Orange, Texas The Turner Industries’ operations team at Dow Sabine participated in a contractor-led BBQ Cook-Off in support of their local United Way chapter. Contractors currently working at Dow facilities in the area were invited to participate in support of their community

Galveston, Texas — Turner Industries attended the 2023 Texas Chemical Council (TCC)/Association of Chemical Industry of Texas (ACIT) Awards Banquet at the Moody Gardens Hotel. The event recognizes and celebrates TCC/ACIT members and member facilities who, during the previous calendar year, achieved exemplary results and demonstrated a commitment to safe operations through implementation and continuous improvement of safety-related programs.

El Dorado, Ark. — Turner Industries has opened a new office for the SIPA group in El Dorado, Arkansas. The office is located at 3324 North West Ave. Stay tuned for further updates and information regarding this new facility, as it will bring additional opportunities for Turner in the southern Arkansas area.

Billy Lee, center, who recently retired from Turner Industries, worked at the same jobsite (Shell Deer Park) for 47 years.

Billy Lee, center, who recently retired from Turner Industries, worked at the same jobsite (Shell Deer Park) for 47 years.

Turner Industries is always searching for ways to improve collaboration and innovation for our clients and employees. With this in mind, we’re excited to announce that by the end of the summer, we’ll be shifting gears from Microsoft Office to the Google Workspace platform for messaging, productivity, and collaboration.

The move toward cloud-based technology will streamline our processes, open the door to future innovations, and provide numerous benefits:

• Google’s cutting-edge solutions and real-time collaboration features will enhance teamwork and simplify connections across projects and initiatives.

• Enhanced message retrieval, easy calendar and file sharing, and access to services from anywhere will boost collaboration.

• Google Workspace is more cost-effective, efficient, and secure than our current solutions.

To prepare for this switch, we’ll be migrating work email, calendar, and OneDrive data from Office 365 to Gmail and Google Calendar, as well as adopting Google Workspace’s suite of productivity tools, including Docs, Sheets, and Slides.

For more information or if you have questions, email

.

“Google offers Turner an opportunity to continue leading the industry with a potential for increased innovations and long-term cost savings,” said Turner Industries CIO Amy Kling. “The transition will occur in three phases, with completion targeted for the end of August.”

Turner Industries provides a single solution in heavy industrial construction, maintenance, turnaround, pipe and module fabrication, equipment, rigging and specialized transportation, and associated specialty services. With $2.35B in 2022 revenue, Engineering

News-Record Sourcebook ranks Turner as the nation's top maintenance contractor in petroleum, and one of the top contractors in Texas and Louisiana. The company, headquartered in Baton Rouge, L ouisiana , employs 18,000+ and works across the United States.