LHUENTSE SCHOOL OF CRAFTS -

MULJI -

4

UNIT Y4 KM

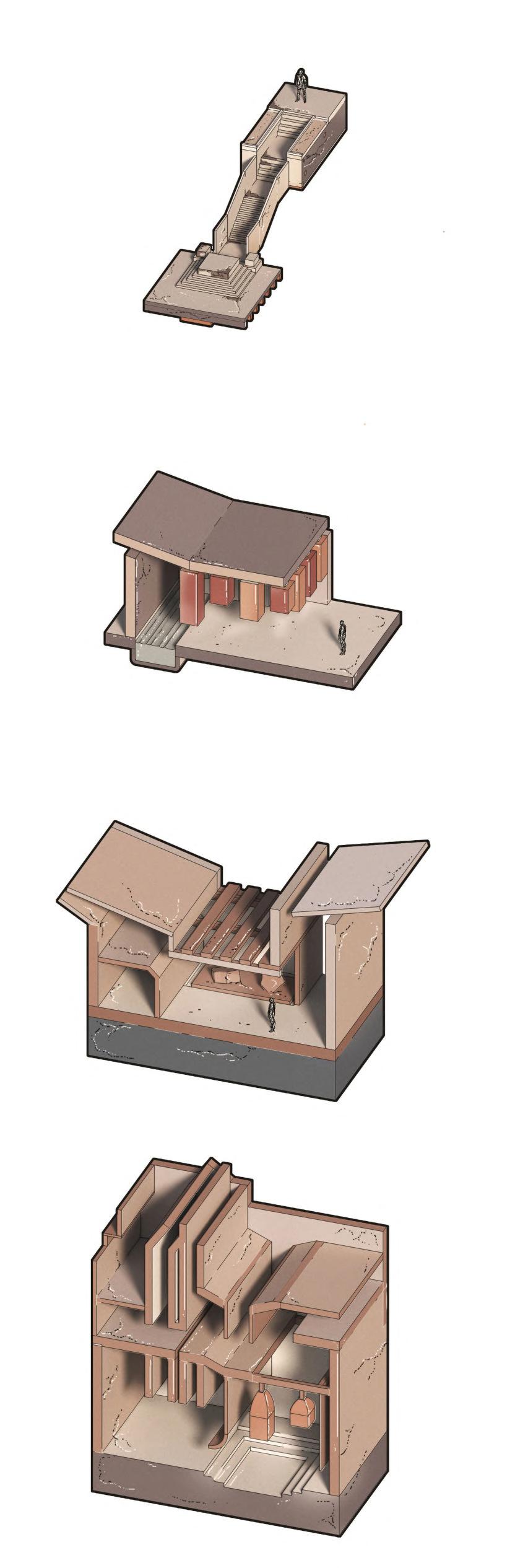

KISHAN

YEAR

@unit14_ucl

All work produced by Unit 14

-

www.bartlett.ucl.ac.uk/architecture

Copyright 2021

The Bartlett School of Architecture, UCL All rights reserved.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage and retrieval system without permission in writing from the publisher.

@unit14_ucl

Cover design by Charlie Harris

Cover design by Charlie Harris

LHUENTSE SCHOOL OF CRAFTS

BHUTAN

BHUTAN

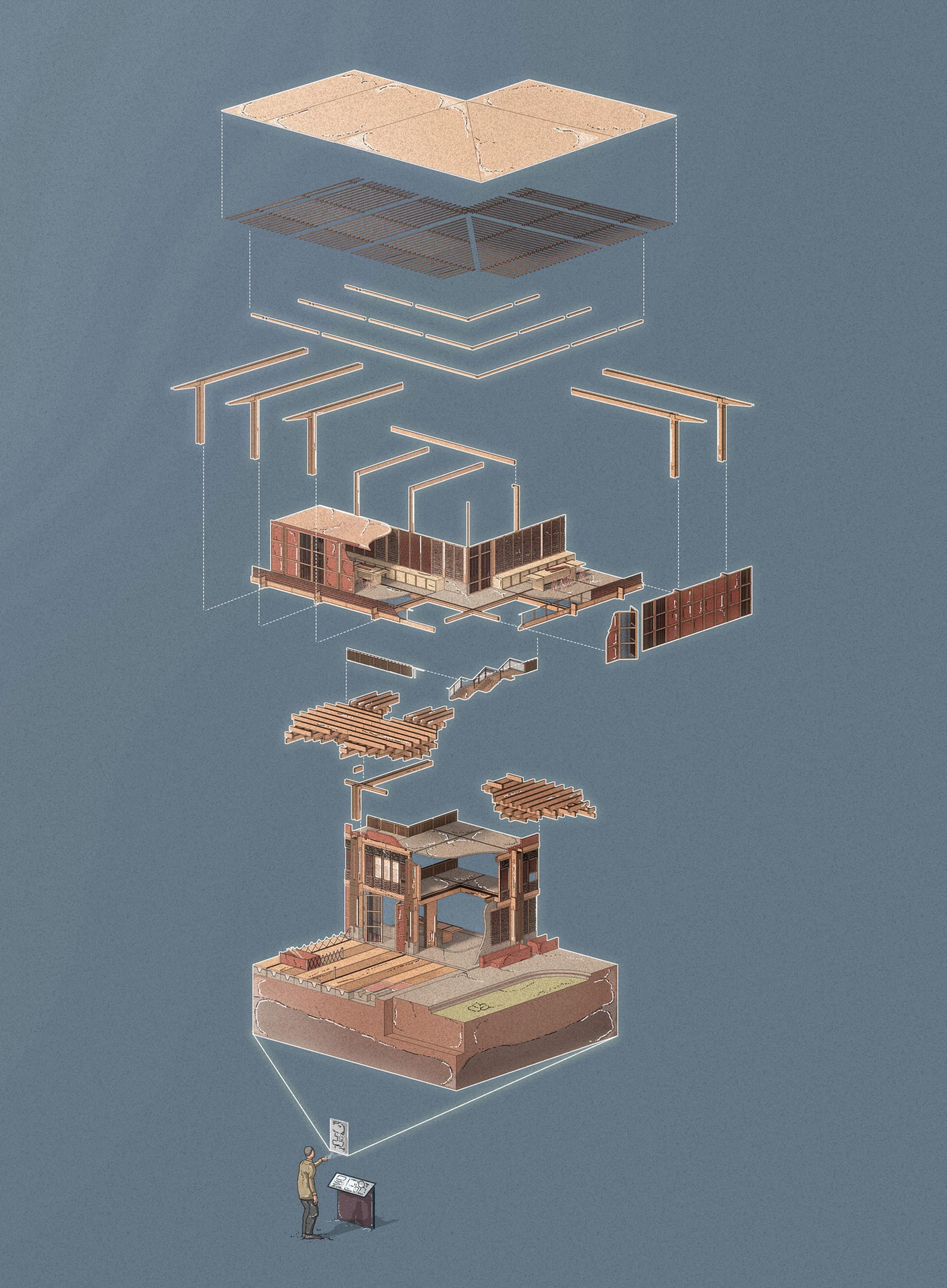

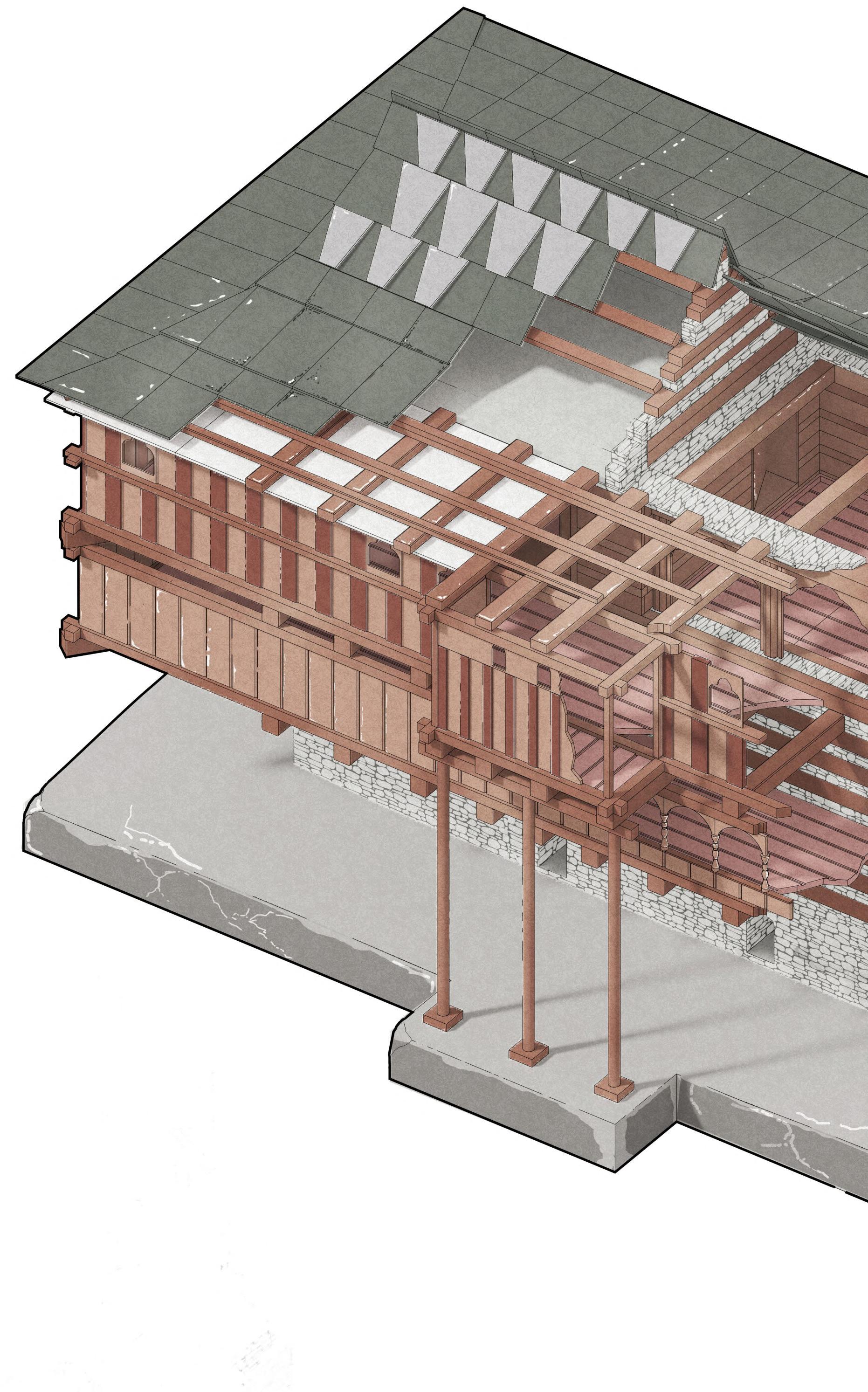

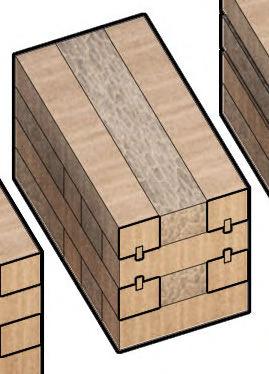

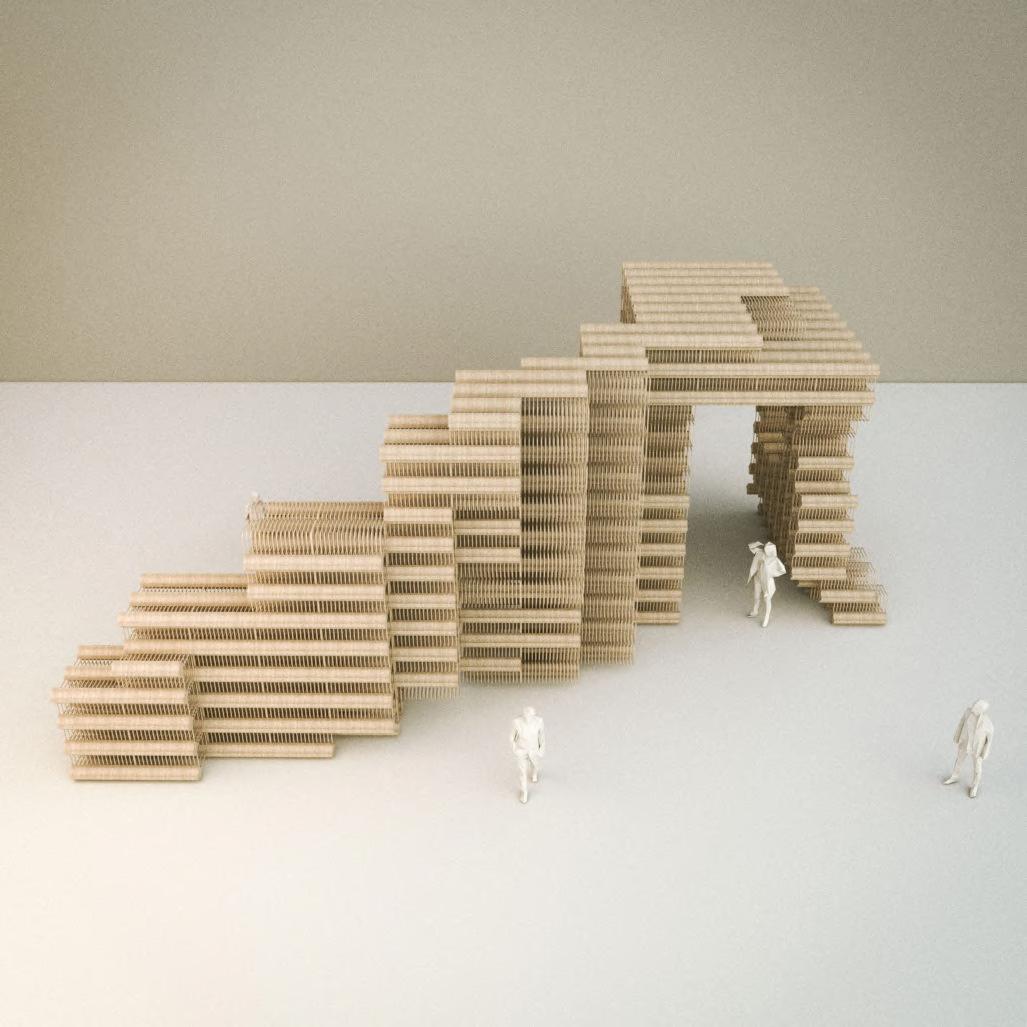

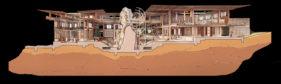

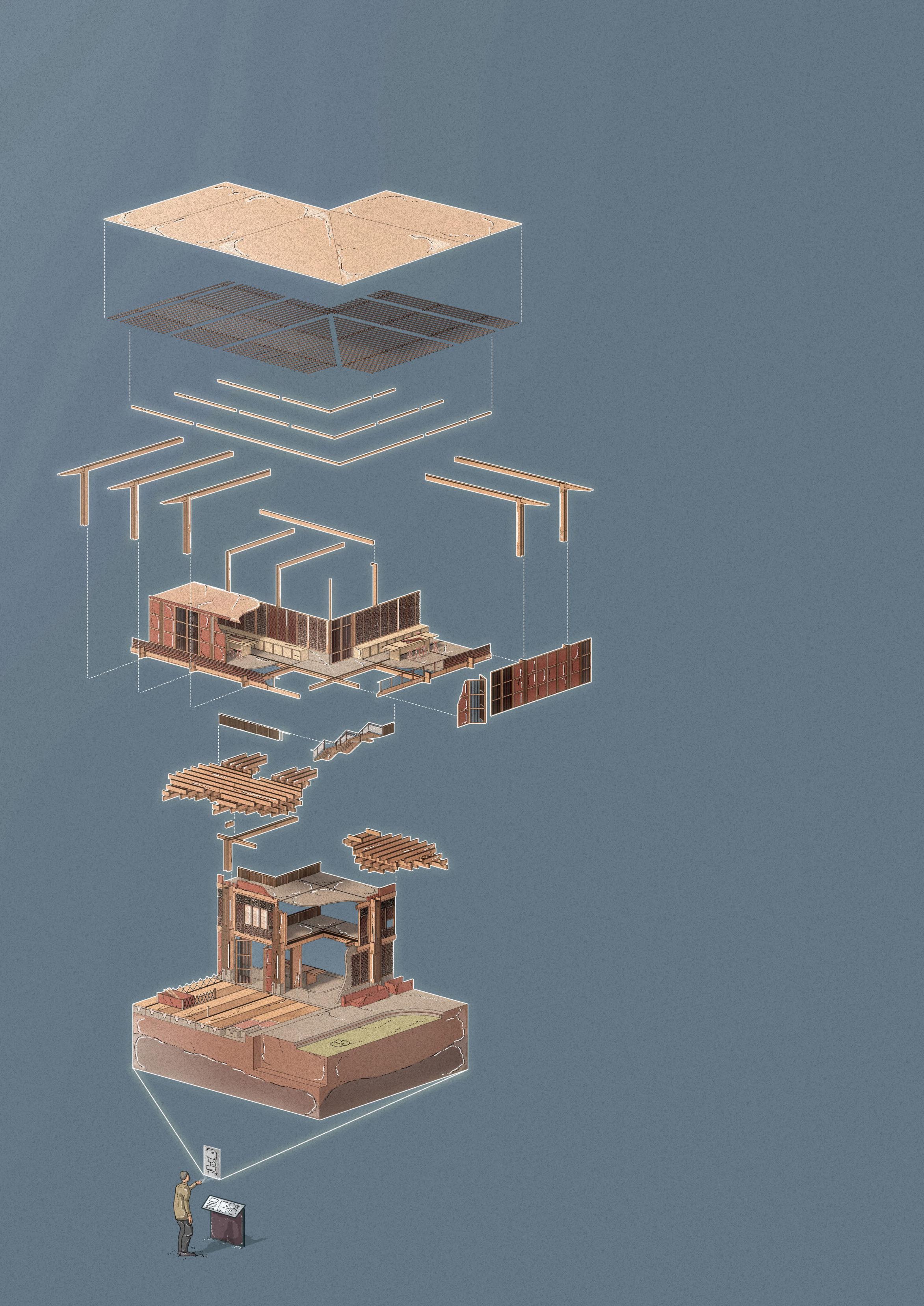

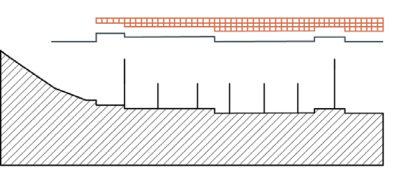

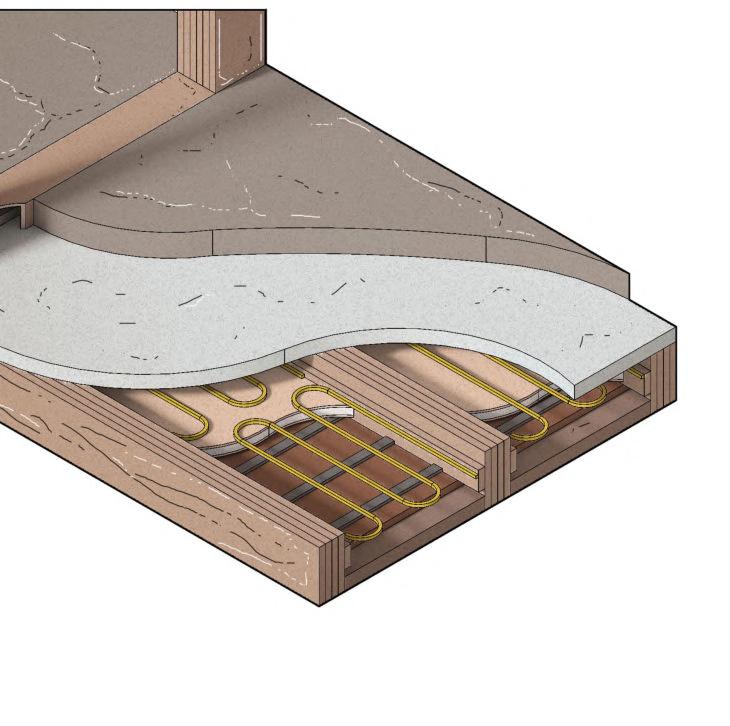

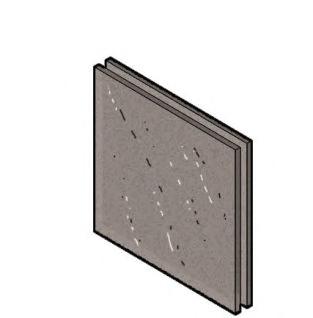

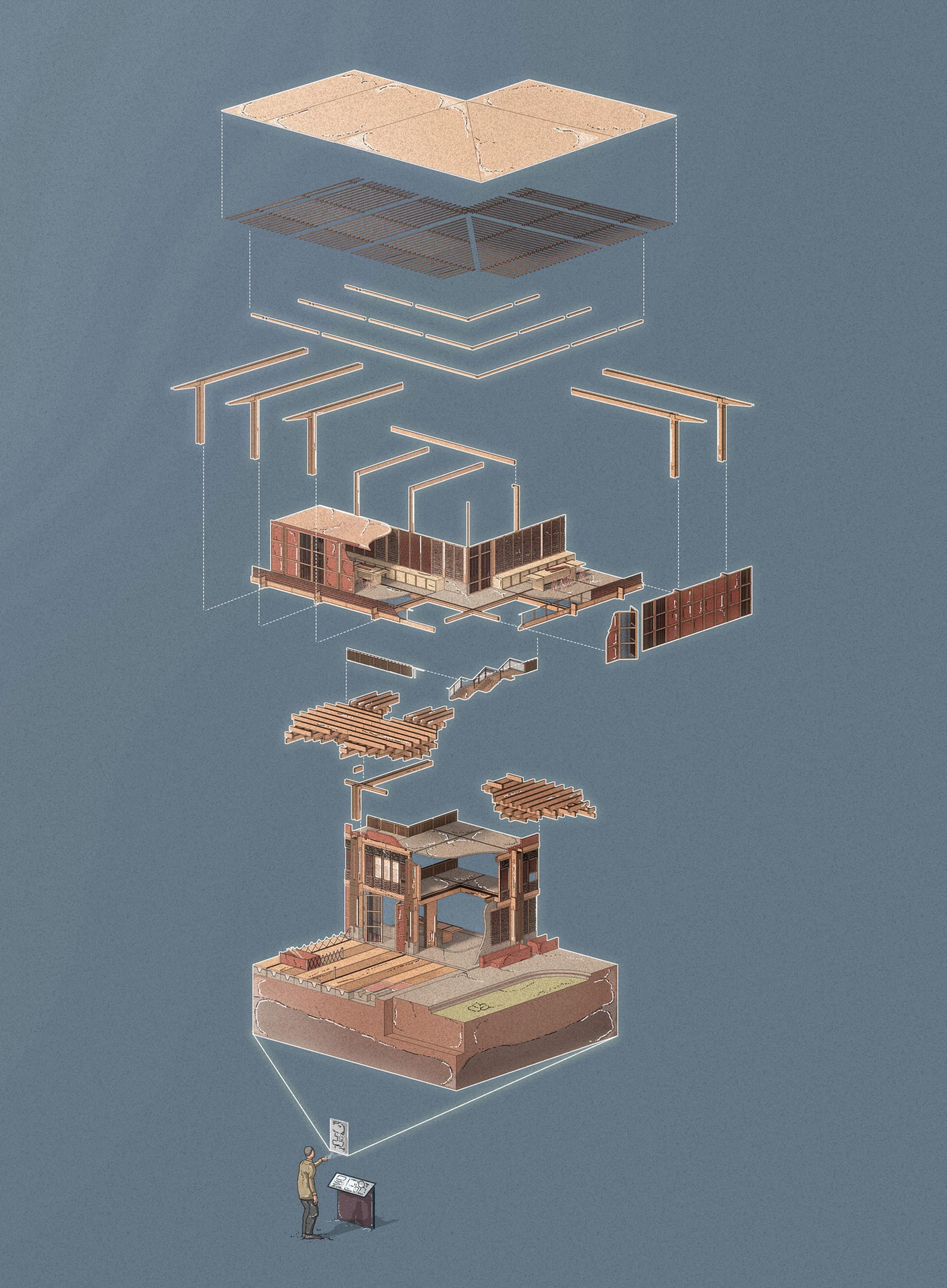

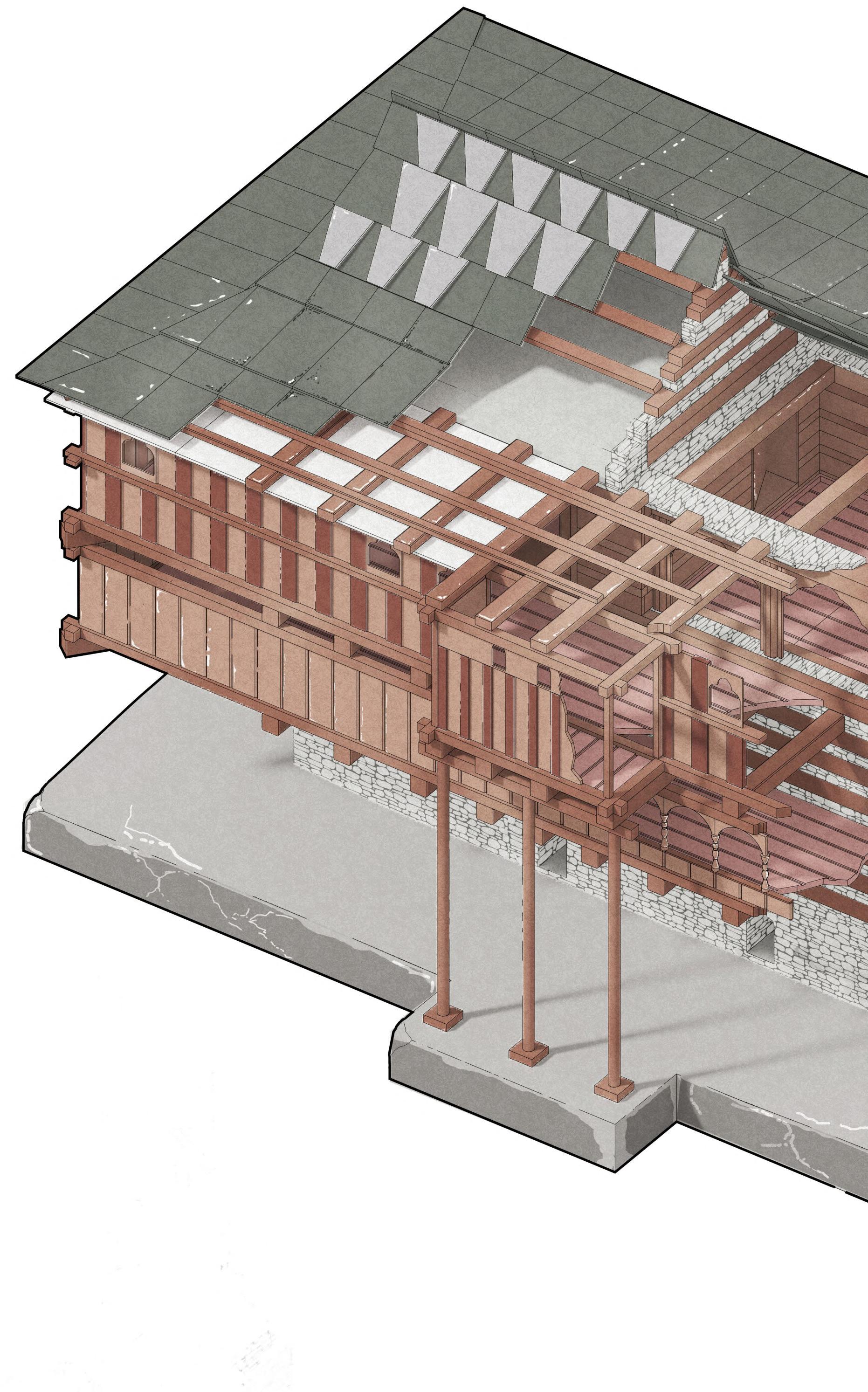

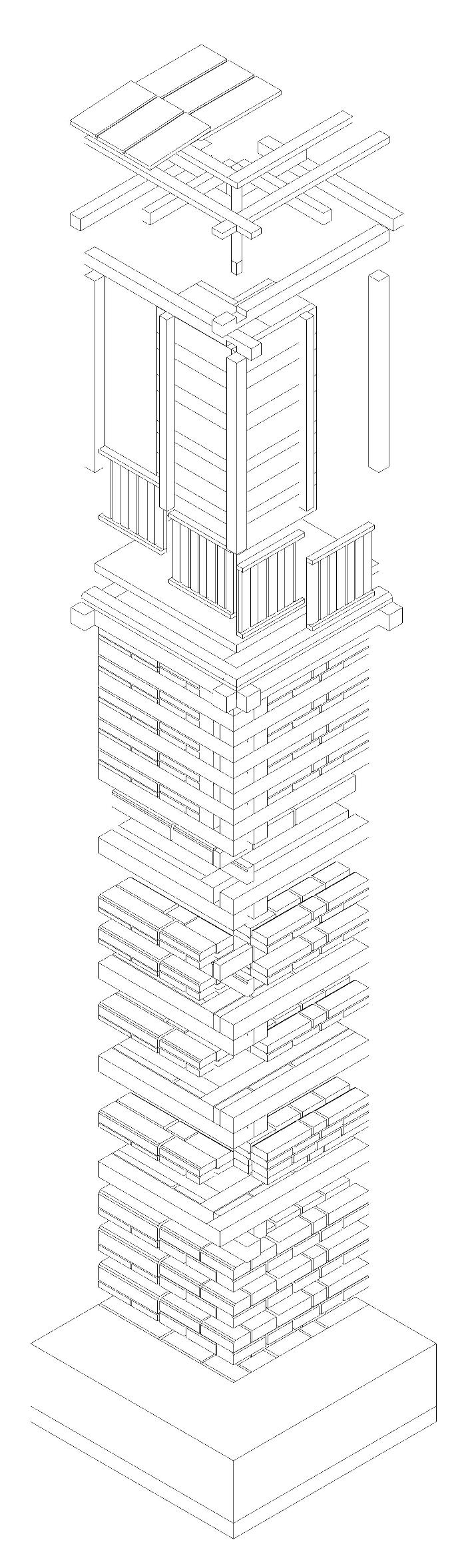

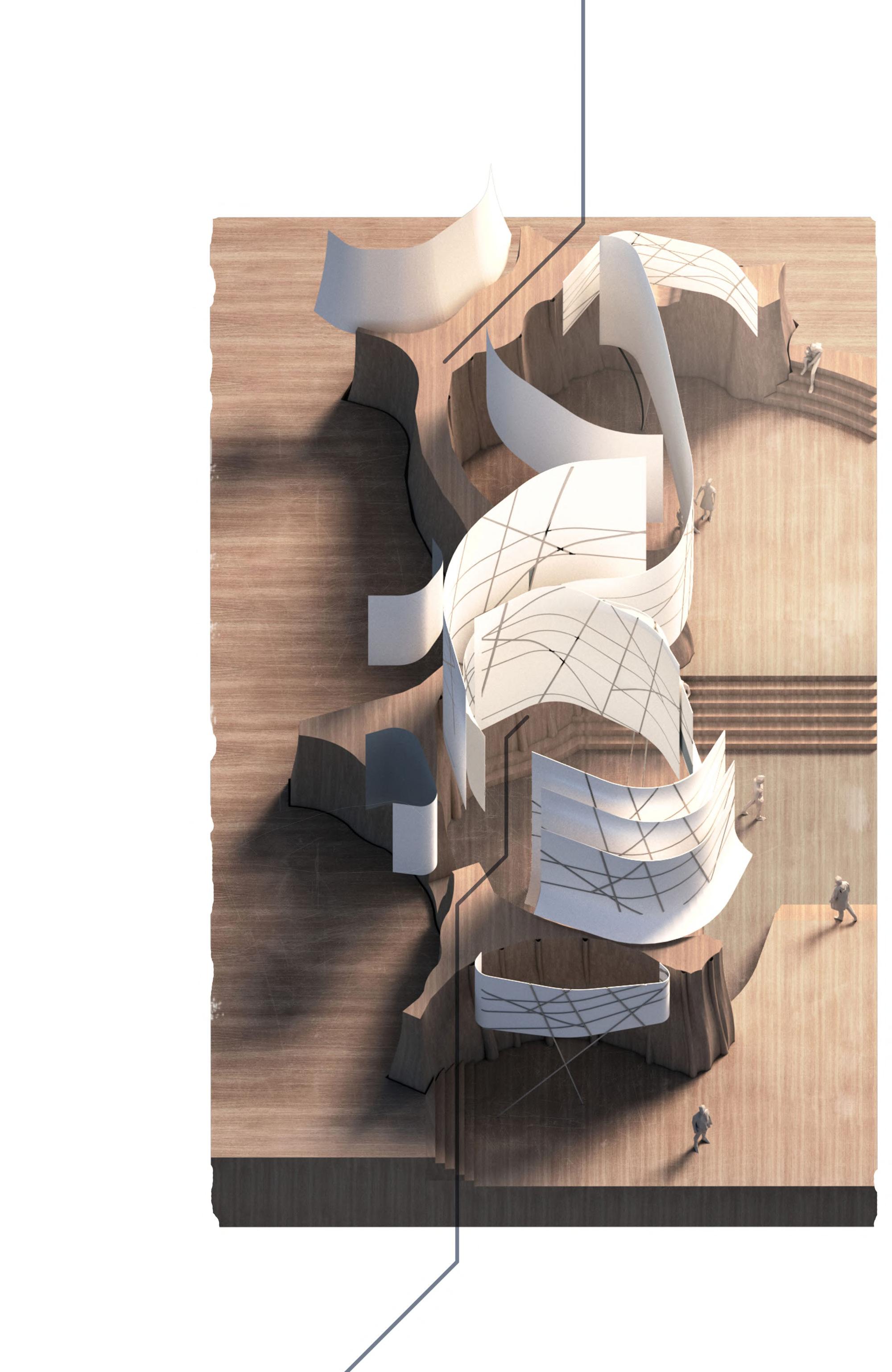

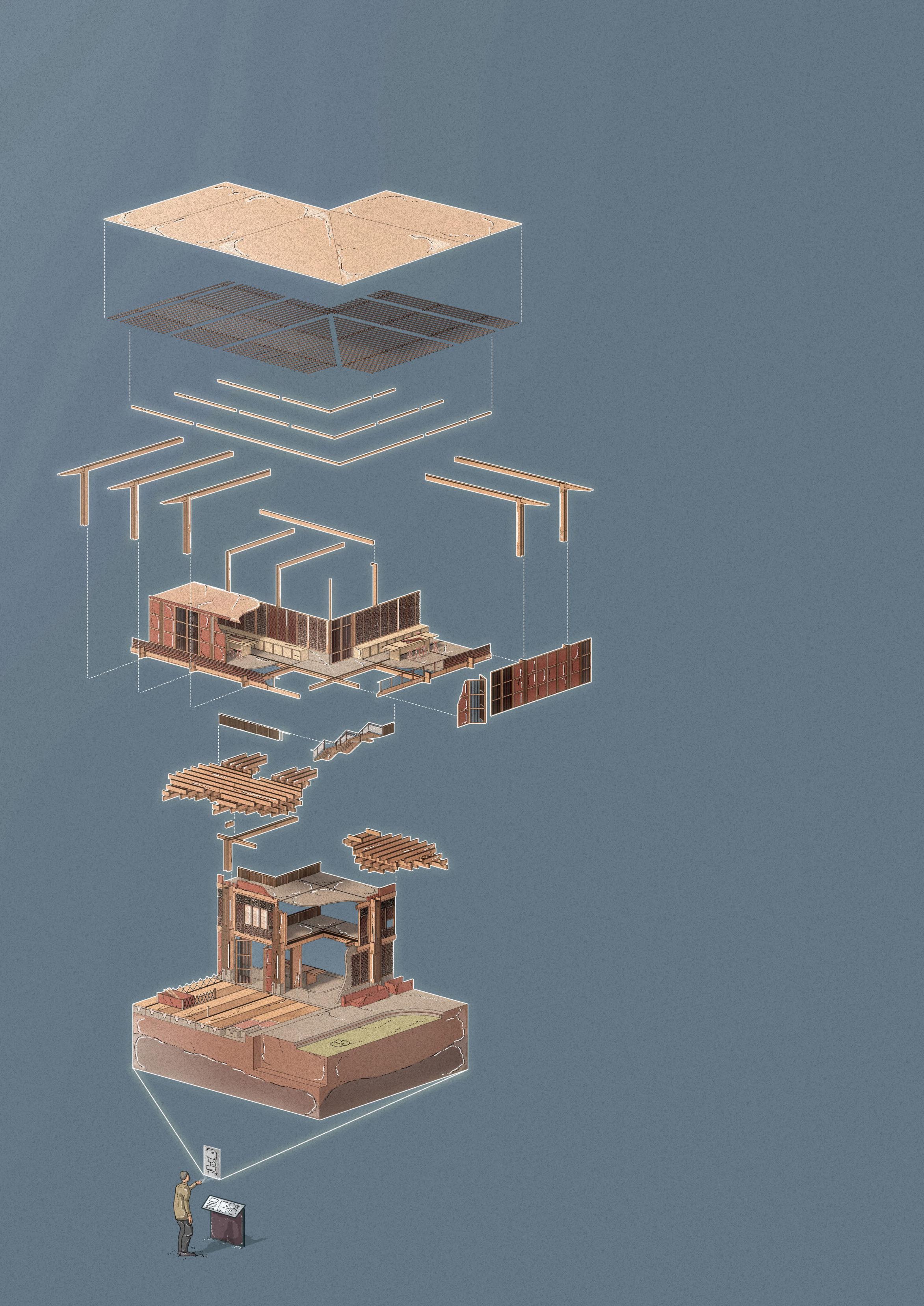

Characterised by the systematic layering of bands of timber and dry stone, ‘Lhuentse School of Crafts’ speculates on the potential of the Himalayan construction technique of Kath Khuni, and the possibilities of this novel material hybrid. While using a double skin of timber to maintain rigidity, the technique uses rubble infill to dissipate the energy from earthquakes through friction, creating a low-tech solution for the region’s extreme environment.

The proposal adopts a similar approach while speculating on its application in the remote context of Lhuentse in eastern Bhutan, a nation caught between the push of modernisation and the conservation of its unique cultural heritage.

Through the introduction of a crafts based educational programme, the scheme seeks to consolidate Lhuentse’s textiles industry with a hybrid user group of foreign exchange students and native craftspeople, diversifying the nation’s overreliance on tourism revenue and generating more capital for the nation. Consequently, the proposal aims to celebrate the region’s resourceful nature and existing infrastructure, reframing the heavily spiritualised lens through which the Himalayas is normally viewed.

KISHAN MULJI YEAR 4

@unit14_ucl Y4 KM

LHUENTSE,

kishanmulji@hotmail.co.uk

KISHAN MULJI UNIT 14

Design Tutors: Dirk Krolikowski & Jakub Klaska

Project Statement

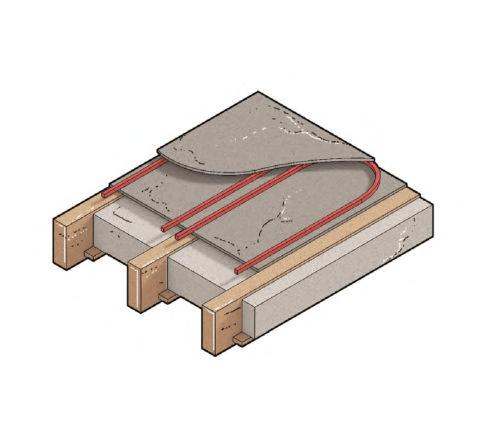

Characterised by the systematic layering of bands of timber and dry stone, ‘Lhuentse School of Crafts’ speculates on the potential of the Himalayan construction technique of Kath Khuni, and the possibilities of this novel material hybrid. While using a double skin of timber to maintain rigidity, the technique uses rubble infill to dissipate the energy from earthquakes through friction, creating a lowtech solution for the region’s extreme environment.

The proposal adopts a similar approach while speculating on its application in the remote context of Lhuentse in eastern Bhutan, a nation caught between the push of modernisation and the conservation of its unique cultural heritage.

Through the introduction of a crafts based educational programme, the scheme seeks to consolidate Lhuentse’s textiles industry with a hybrid user group of foreign exchange students and native craftspeople, diversifying the nation’s overreliance on tourism revenue and generating more capital for the nation. Consequently, the proposal aims to celebrate the region’s resourceful nature and existing infrastructure, reframing the heavily spiritualised lens through which the Himalayas is normally viewed.

With credit to the following used as precedents throughout the project:

Graphic Reference:

Doug John Miller

Report Template Reference:

Thomas Band - Fondazione Gucci, 2020

Please refer to:

Appendix: Bibliography & Figures for all text and image references

NB. Figure 1.01A

Referenced Figure for Respective Page

Section Number

Contents HIMALAYAS, ABODE OF SNOW DESIGN DEVELOPMENTDESIGN LHUENTSE SCHOOL OF CRAFTS ENVIRONMENTAL STRATEGY 01. 02. 03. 04. 05. NB.Allworkproducedbyauthorunlessotherwisestated 01A. HimalayanSystems 1.01 HimalayanSystemsResearch- Kath Khuni Variations 1.02 AuktaHouseAnalysis- Kath Khuni: Key Elements 1.03 HybridSystemsResearch- Kath Khuni Variations 1.04 DhajjiDewari- Key Joinery 1.05 ConsolidatedJoinery 1.06 SystemsResearch- Modern Response to Extremity 01B. InitialDesignResponse- Stone/Timber Hybrid Studies 1.07 AbstractFragment- Systemising Kath Khuni 1.08 AbstractFragment- Half Lafting/Half Dry Stone Hybrid 1.09 DevelopedAbstractStudy- Half Lafting/Dry Stone Interface 1.10 AbstractFragment- Aggregation with Reinforcement 1.11 DesignResearch- Typical Retaining Wall Construction 1.12 GabionCage- Timber Reinforced Gabion Cage Skeleton 1.13 AbstractFragment- Vertical Stack 1.14 AbstractFragment- Horizontal Stack 1.15 AbstractFragment- Fluid Plinth/Light Superstructure 1.16 SpatialFragmentStudy- Stone/Timber Prototype 01 1.17 FragmentStudies- Stone/Timber Prototypes 02 1.18 SpatialFragmentStudy- Stone/Timber Prototype 03 07-08 09-10 11-12 13-14 15 16 17-18 19-20 21 22 23 24 25 26 27 28 29-30 31 32 33-34 35-36 37-38 39 40 41 42 43-44 45-46 47-48 49-50 51-52 53 54 02A. WiderSiteContext 2.01 WiderSiteContext- Himalayas Overview 2.02 WiderGeographicalContext- Himalayan Border Nations 2.03 WiderPoliticalContext- Disputed Himalayan Borders 2.04 WiderTopography- Himalayan Passes 2.05 HimalayanInhabitation- Expanding Urbanism 2.06 HimalayanInfrastructure 02B. SiteandBrief 2.07 Site- Lhuentse, Bhutan 2.08 Brief&Programme- Lhuentse School of Crafts 2.09 PlanningStrategy- Deliveries & Sourcing 2.10 Contracts&Procurement 2.11 Roles&Responsibilites 57-58 59-60 61-62 63-64 65-66 67 68 69-70 3.01 InitialZoningStudies- Global Form Development 01 3.02 InitialMassingStudies- Global Form Development 02 3.03 DevelopedMassingStudy- Design Iteration 01 3.04 PlanDevelopment- Design Iteration 02: Volumetric Study 3.05 DesignDrivers 3.06 DesignConcept01- Carved Earth 3.07 DesignConcept02- Cascading Ground 3.08 ConsolidatedDesignResponse- Carpentry Workshop 73 75 76 77-78 79 80 81 82 83-84 85-86 87-88 89 90 91-92 93-94 4.01 BuildingGenesis 4.02 MassingStrategy 4.03 Programme&Organisation- Access & Circulation 4.04 OverallStructuralStrategy 4.05 Excavation&FoundationConstruction 4.06 DryStone/TimberComposite 4.07 ToolAgetoMachineAgeTimber 4.08 MaterialSourcing- Glulam Manufacture 4.09 PrimaryGlulamStructure 4.10 HybridConstructionalHierarchy 4.11 RoofConstruction 4.12 ConstructionSequence 4.13 DormDetailStudy 4.14 CentralCourtyardDetailStudy 4.15 MechanismsoftheCarpentryWorkshop 97-98 99 100 101 102 103 104 5.01 OverallEnvironmentalStrategy- Carpentry Workshop 5.02 EnergyUse 5.03 Ventilation&Cooling 5.04 SolarGainStrategy 5.05 Acoustics 5.06 Health&Safety 5.07 FireStrategy

DESIGN RESEARCH 01A. Himalayan Systems 01B. Initial Design Response 01 Chapter BARC0174 _ AAD1LHUENTSE SCHOOL OF CRAFTS 06 SHIMLA FINAL DRAWINGS BIBLIOGRAPHY 06. 07. 107-108 109-110 111-112 113-114 115-116 117-118 119-120 121-122 123-124 6.01 AerialView 6.02 AerialEntranceView 6.03 CentralCourtyard 6.04 CarpentryWorkshopFragment 6.05 CarpentryWorkshop 6.06 1:5000SitePlan 6.07 1:500GroundFloorPlan 6.08 1:500RoofPlan 6.09 1:125LongSectionAA 127-130 131-134 7.01 Bibliography 7.02 Figures

CHAPTER 1 _ DESIGN RESEARCH 08 BARC0174 _ AAD1

DESIGN RESEARCH Himalayan Systems 01A

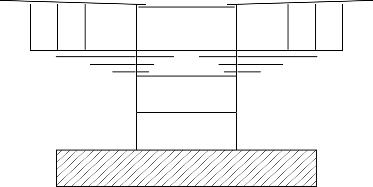

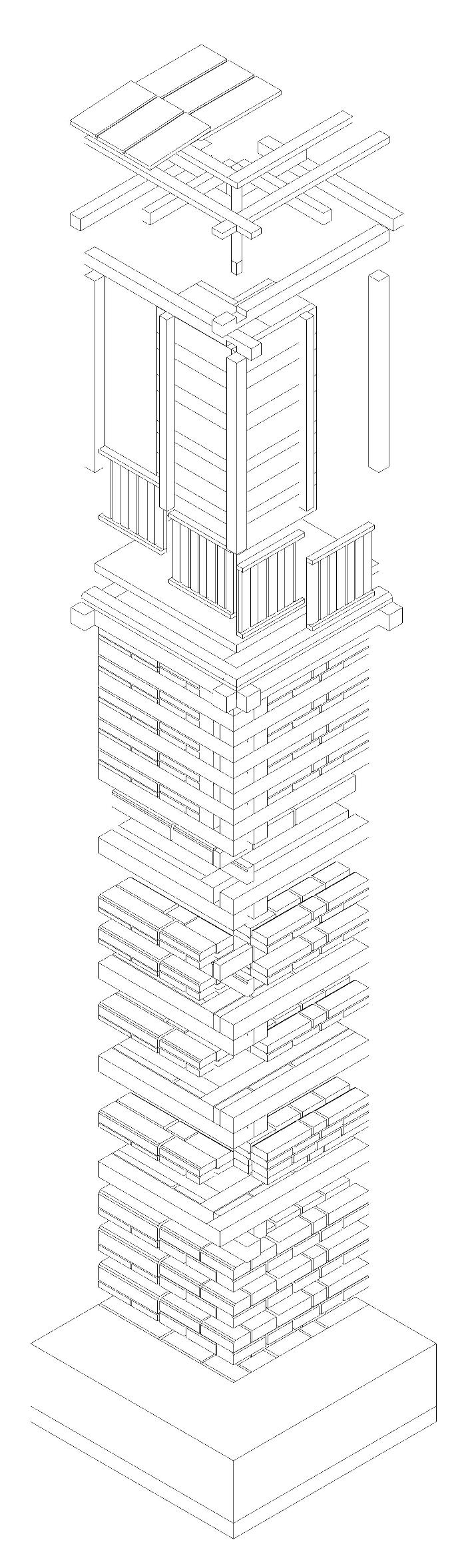

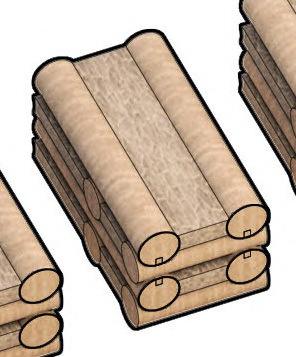

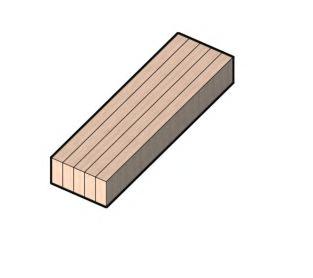

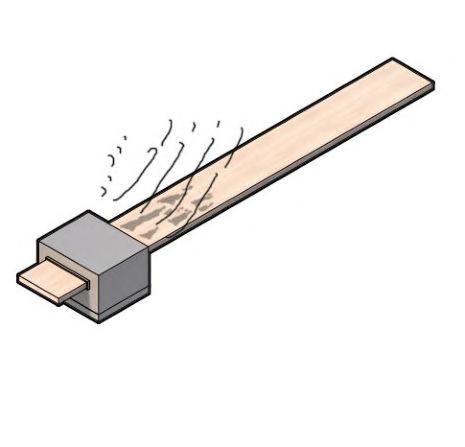

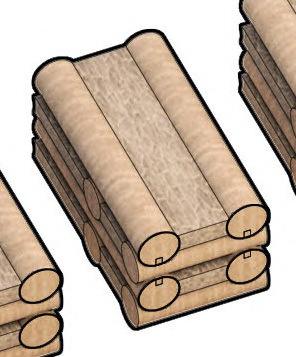

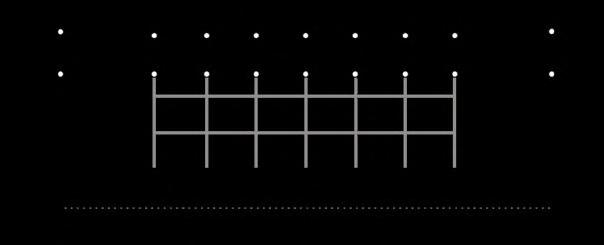

Kath Khuni Construction

OLD JUBBAL

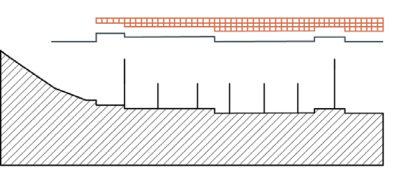

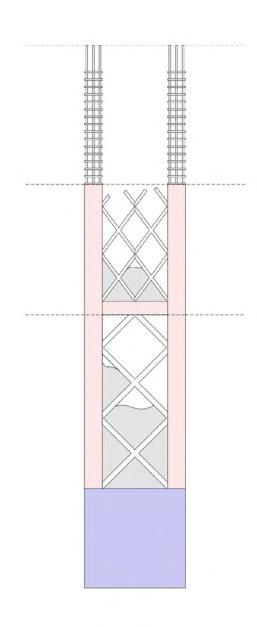

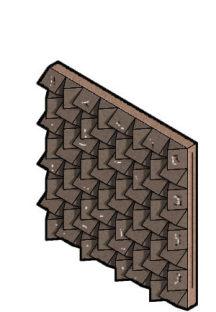

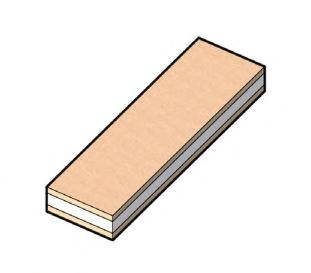

The drawing explores my initial interest in Kath Khuni (cator and cribbage) construction, a technique used in all built forms in Sutlej valley of Himachal Pradesh. Using a systematic process of layering, the technique uses wood and dry stone to create stable, flexible, and strong buildings, appropriate to the region’s mountainous terrain, prone to earthquakes.

KATH KHUNI CONSTRUCTION

Characterised by layered bands of wood and stone topped off by slate roofs, Kath (wood) Khuni (corner) is used across large darbargadhs and kots (forts), intricate temples, to smaller dwellings, and is distinctive in silhouette.

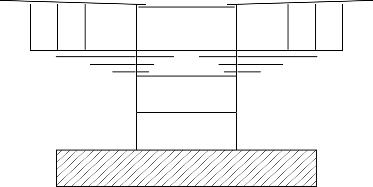

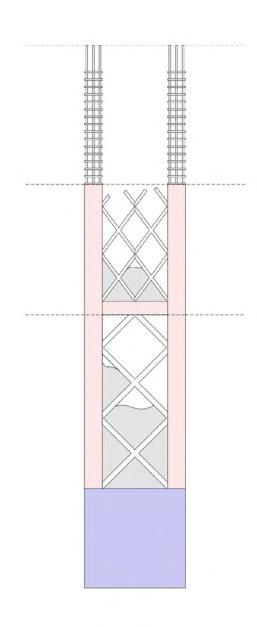

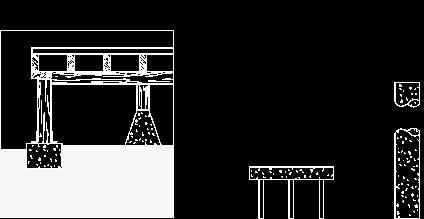

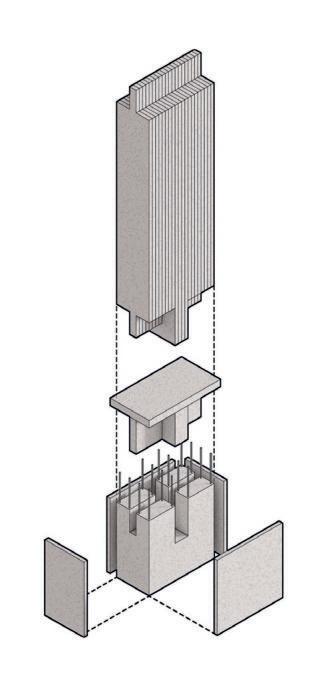

The building plinths are constructed entirely of stone. Layers of stone and wood are then constructed with a double skin and its internal cavity is filled with rubble. External and internal skins are held together by cross-braces.

The heavy stone base carries the lighter wooden structure at upper levels. No mortar is used between the courses and the shear weight of dry masonry holds it down in place.

SEISMIC PERFORMANCE

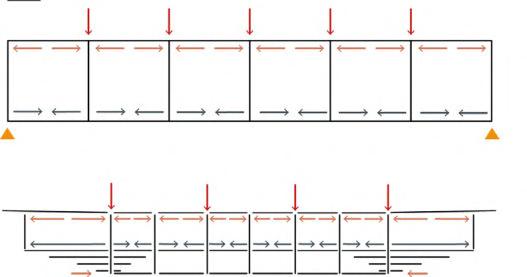

The non-rigid Kath Khuni allows the building to flex with seismic waves and to efficiently dissipate the energy generated by earthquakes.

The technique caters to the social, aesthetic and environmental sensibilities of the site. The buildings in the region have survived years of tremors, weathering and earthquakes, proving the sustainability and durability of the construction.

5 MAIN

COMPONENTS 01_ Foundation and Plinth 02_ Walls and fenestrations 03_ Walls and stairs 04_ Projecting wooden balconies 05_ Roof CASE STUDY: AUKTA

BUILDING

HOUSE,

01 11 02 03 04 05 06 04 05 06 01 02 03 Roof wall beam Stone slate tile Roof joist Filler wooden pieces Balcony roof purlin Roof cantilevered beam ROOF

1.01 _ Himalayan Systems Research

Figure 1.01A

OLD JUBBAL

Old Jubbal is a small hill town located east of Shimla in the Indian state of Himachal Pradesh.

The village has been resided by Indo-Mongolian kiratas, who settled in the remote northern Himalayas, practicing Lamanistic Buddhism, alongside IndoAryans who found residence between the 12th and 16th century.

Second floor door

First floor planks

First floor beam

Stone slabs

Wall beam

07 07

08 08

12 09 09

13 10 10

14

15

11

12

13

14

15

Stone rubble infill

Stone slabs

Wall

beam

Wall

niche

WALL INTERNAL

10 BARC0174 _ AAD1CHAPTER 1A _ HIMALAYAN SYSTEMS

SHIMLA

Kath Khuni: Key Elements

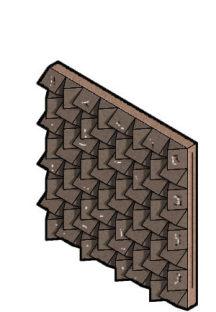

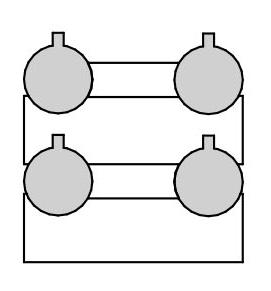

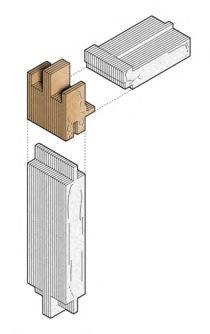

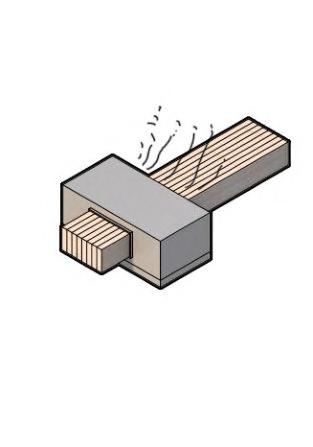

01 _ INTERLOCKING STONE/TIMBER

Using a composite application of timber bands and stone works with alternating, staggered timber beams integrated at right angles, the structure is both durable and flexible, resistant to earthquakes.

WIDER ROOF TYPOLOGY

Local roof variations include pent and gable roofs, with pitch and geometry changing in higher altitudes in response to changing patterns and intensity of precipitation in these areas.

ROOF

internal and external environments, and a wooden frame which acts as a flexible diaphragm. Two layers of slate shingles nailed to a single point to allow a degree moisture and adjust to any movement during

WIND RESISTANCE

02 _ EXTREME ENVIRONMENTS

The site’s key conditions of extremity include the mountainous terrain, the variable climate, and tectonic plate movement, which provide grounds for further exploration.

The balcony behaves as a wind blocker, protecting internal spaces from chilly winds at the valley side, with accompanying larger openings on the mountainside.

WALLLOADEDIN-PLANE OUT-OF-PLANE LOADEDWALL

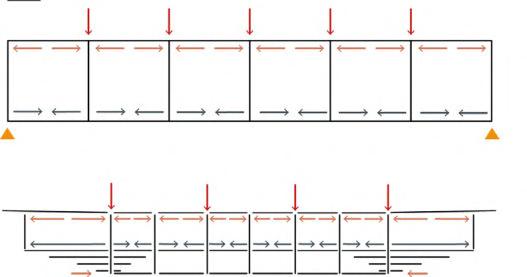

03 _ SEISMIC RESISTANCE

Stiff long span timber beams, dovetail and dowel connections keeps the structure rigid, generating box-action, and transfers the lateral force from out-of-plane loaded walls directly to in-plane loaded walls.

LOCAL CULTURE & WOODCRAFT

Woodcarving is integrated into local architecture through tools including nehori (chisel), hathodi (hammer), punch tools and basoki (adze), creating ornament through the expression of classical and local motifs.

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC

MONSOON

KEY ELEMENT 01KEY DEODAR WOODWOODCARVING TOOLS

SUMMER +20C<

WINTER -10C< WINTER -10C<

AS FLEXIBLE DIAPHRAGM

BALCONY BALCONYGAUSHALA

LIVING

STORAGE

1.02 _ Aukta House Analysis

Figure 1.02A

Figure 1.02D

Figure 1.02C

Figure 1.02B

STRUCTURAL DURABILITY

Using timber under tension and stone under compression, the walls are configured to resist the sliding or overturning during land movement. Wood frames the stone that anchors the structure to gravitational forces, allowing higher damping and the quick dissipation of energy from earthquakes.

The use of a heavy stone plinth base and a lighter wooden frame construction at upper levels allows stronger distribution of mass, making it harder for the building to rock during movement.

The box shaped volume is also more effective at resisting sideways movement, distributing load transfers and shear forces during earthquake tremors.

THERMAL COMFORT

The air lock between the habitable core and balconies presents an example of passive heat containment, whereby heat is distributed evenly across the building. The stone also behaves as insulation.

DIAPHRAGM uses flexible are degree during

GF & Mezzanine Guashala (Cowshed)

First Floor Storage for grains, apples & other life support Second Floor Habitation - Bedroom, Kitchen, Living Room

PROGRAMMATIC DISTRIBUTION

Aukta House provides shelter for a family of five and three cattle. The guashala at ground level is supported by first floor storage and second floor inhabitation, alongside a second floor 1.8m cantilevered balcony supported by deodar beams.

PASSIVE HEAT GENERATION

The guashala (cowshed) located at ground level provides a base for cattle in summer, and allows the heat produced by the cattle to be directly radiated to the habitable spaces above.

Stone rubble walls also maintain internal temperature when outside temperatures reach below freezing point.

1.5M 2.8M OO O1 O2 ROOF 1.8M 1.8M 2.6M GAUSHALA STORAGE BEDROOM WC WC BEDROOM 12 BARC0174 _ AAD1CHAPTER 1A _ HIMALAYAN SYSTEMS

Kath Khuni Variations

DHAJJI DEWARI

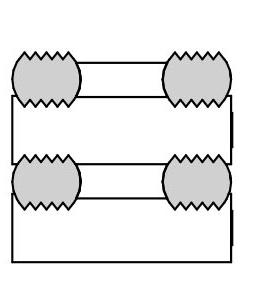

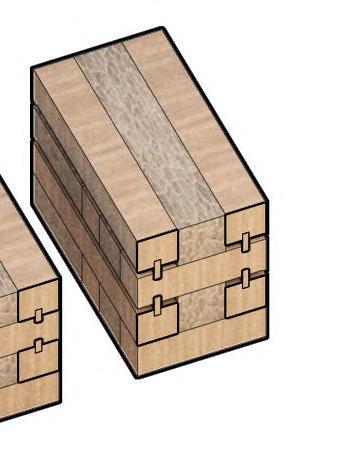

Deriving from the Persian word “patchwork quilt wall”, Dhajji Dewari is a traditional construction method found in the Western Himalayas, and behaves as an extension of Kath Khuni. It uses a simple method of half-timbering, in which timber is infilled with masonry and sometimes mud mortar.

INFILL & BRACING VARIATIONS

Jackpads

Base Beam

Timber Cross Bracing

Main Post

Horizontal Beam

Wall Beam

Jackpads

Base Beam

Timber Cross Bracing

Main Post

Horizontal Beam

Wall Beam

TYPICAL DWELLING _ KEY PLAN

Intermediate Post

Braced with increasingly random subdivisions Regular cross

Intermediate columns with regular

1.03 _ Hybrid Systems Research

HIERARCHY OF ELEMENTS

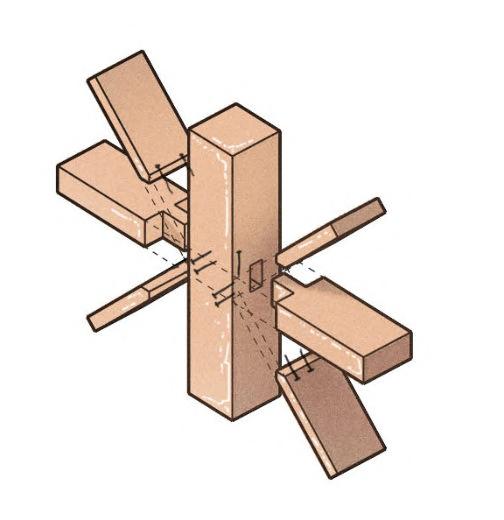

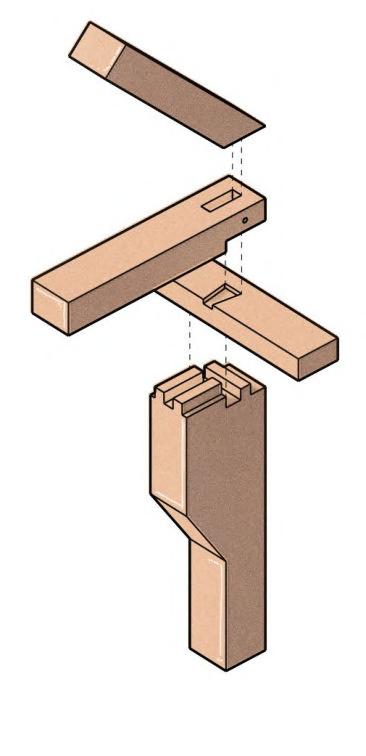

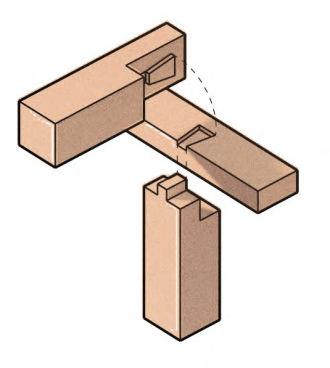

Various components of varying thicknesses allow better load distribution. Intermediate posts and horizontal beam ends are nailed, while main posts have mortise and tenon joints.

Wall Beam and Base

Main Post

Intermediate Post

MOISTURE RESPONSE

Horizontal Beam

Cross Bracing

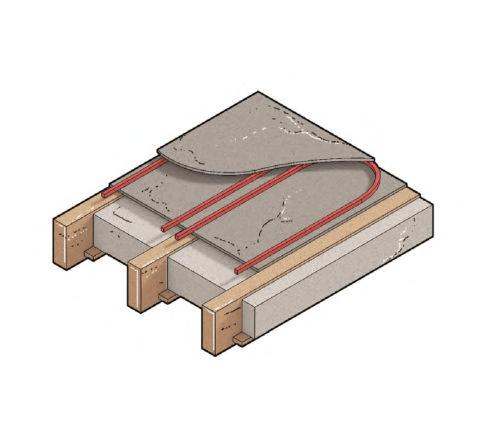

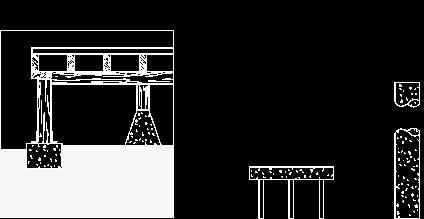

Although bricks are not traditionally used in foundations, the diagram below the roof diagram shows how a Dhajji Dewari dwelling could control moisture through the use of a damp proof course and by raising the ground floor from the ground to allow more air to circulate below. Due to the use of sand and cement mortar, timber is more susceptible to moisture build up, hence controlling the foundation is a way of easing this.

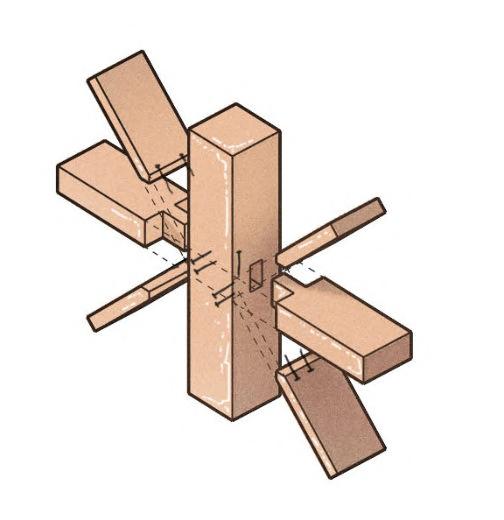

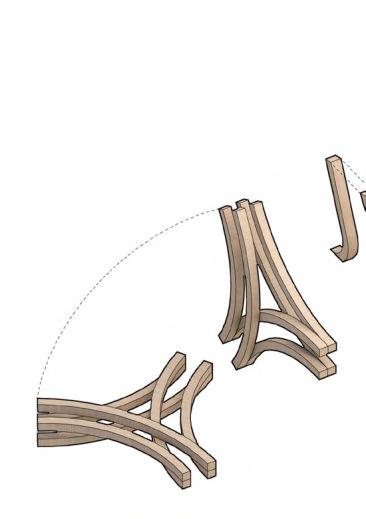

TIMBER JOINERY

Simple mortise and tenon joints and lap joints are common mechanisms used to strengthen and brace diagonal elements in Dhajji Dewari dwellings. Masonry infill offers increased friction when compression is applied to the walls. Nails allow more energy to be absorbed, and enable the timber frame to be held together, allowing the infill to be more closely confined, ensuring structural stability.

Masonry Infill

Vertical Secondary Horizontal Damp Proof Course cross bracing cross bracing Air Space Perforated Brick

Tie Beam (centre)

Rafter

Tie Beam (end) 14

Rafter (lower end)

ROOF

Figure 1.03A

Figure 1.03B

Figure 1.03C

BARC0174 _ AAD1CHAPTER 1A _ HIMALAYAN SYSTEMS

Figure 1.03D

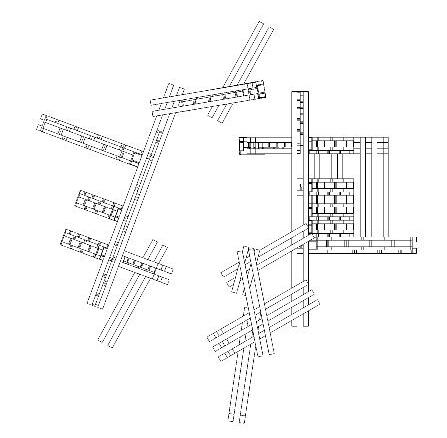

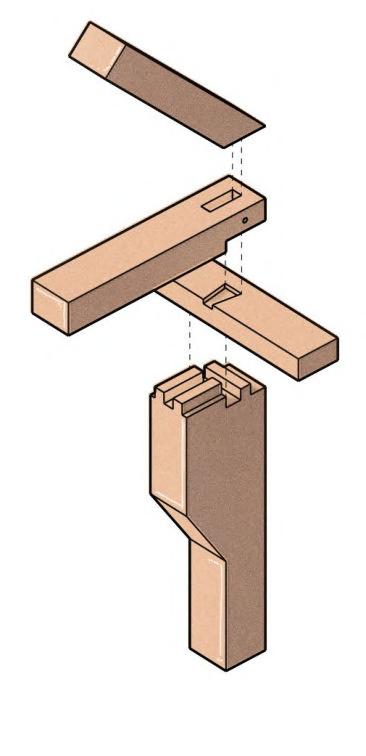

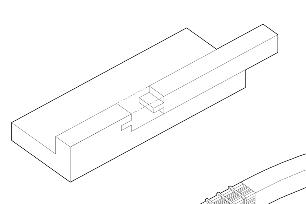

Key Joinery

BASE PLATE - CORNER POST

The corner junction is typically made from high quality timber due to its proximity to the ground, and the perpendicular connection ensures the building acts like a box during an earthquake. The corners are locations for strategic strengthening.

WALL FRAMING

The principle members of walls are timber posts and ring beams that help to create robust frames. If connections are poorly prepared, it can result in the premature failure of the timber frame.

SPLICE JOINTS

The use of wooden pegs is important to prestress the connection, as well as the use of metal strapping or nailing which can improve the strength of these connections. Plane joints do not work well in tension when cross-halved, hence blocking pieces are sometimes used if the joint is not cross-halved, helping to add more interface to prevent the joint from opening.

BEAM TO BEAM - COLUMNS

C displays the least amount of cut in the column; D introduces a ledge to the beam to mobilise full beam shear capacity and E shows the best housing of the beam, but the highest reduction in the column section capacity. Pegs allow the columns to have reduced tension capacity.

ROOF & COLUMN TO FLOOR BEAM

Roof Trusses typically use nailed connections, as well as the column to timber floor beams connection, shown below, which can be nailed to achieve larger spans, and strengthen the connection.

DHAJJI DEWARI

Construction Details

Timber frames of typical Dhajji dwellings are sometimes constructed with blunt tools, sometimes making it hard for the joints to function properly. The index of joints here are a study of typical dwellings as well as some adaptations to ensure increased strengthening of connections.

Peg gives junction limited tension capacity

Dovetail gives tensile capacity, helping to reverse load

A A B B CDE

1.04 _ Dhajji Dewari 15 Figure 1.04A

NO MORTAR JOINT

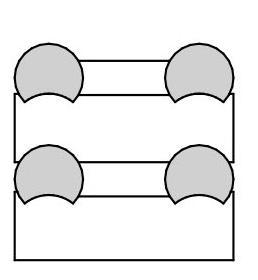

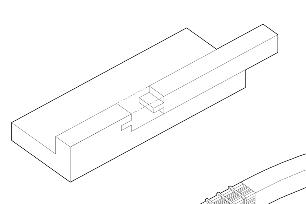

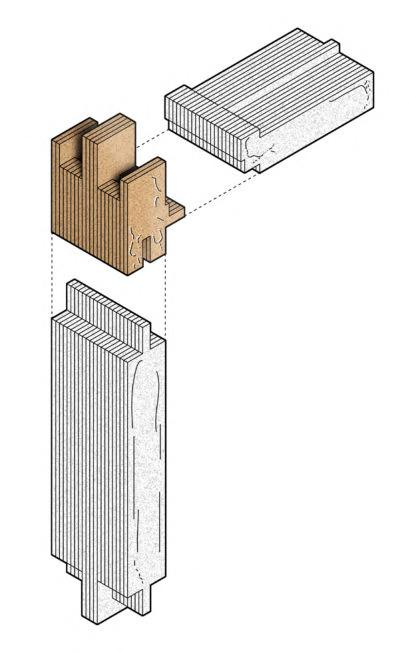

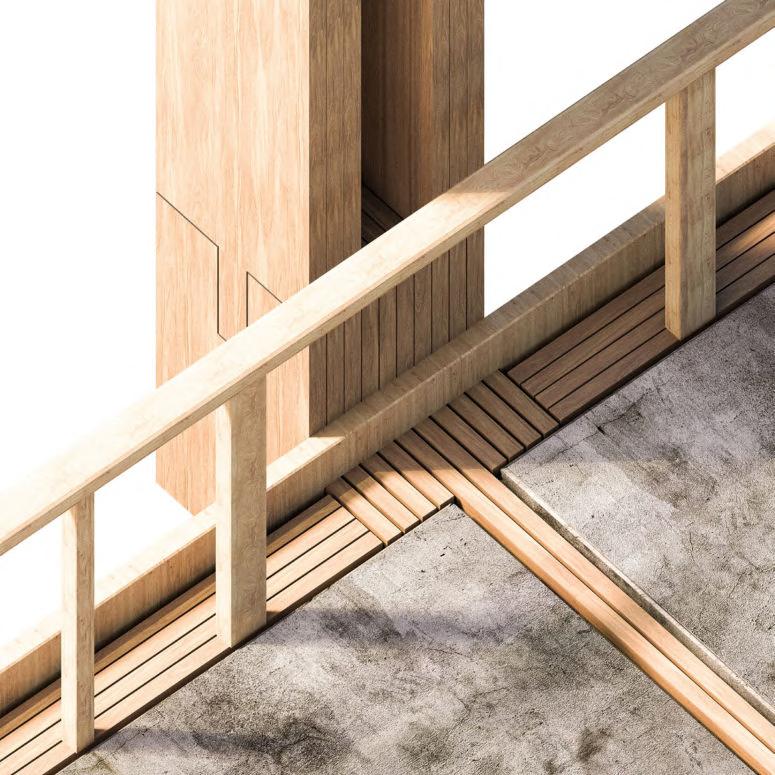

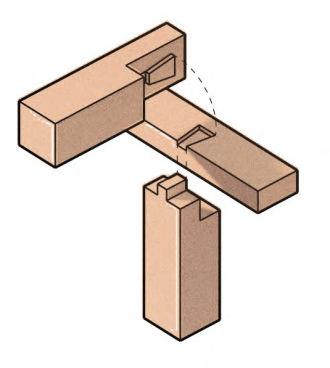

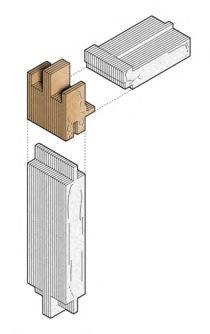

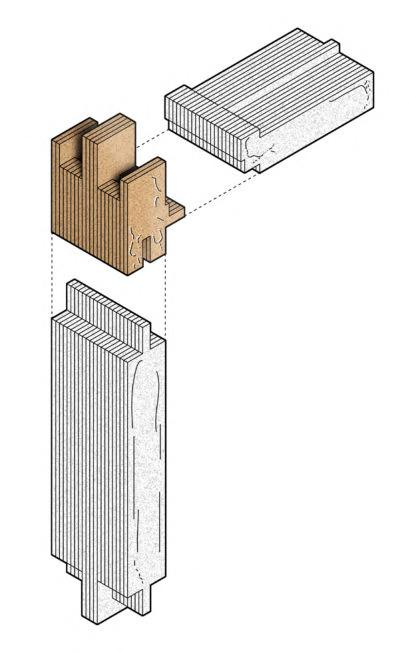

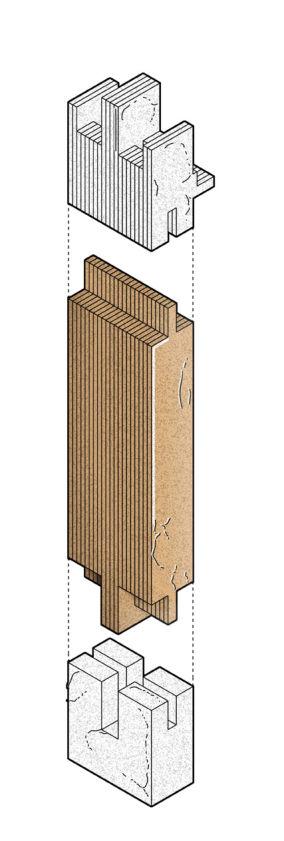

Similar to the catalogue of Dhajji Dewari joinery shown opposite, this junction looks at a precedent corner detail for a typical dwelling that uses Kath Khuni construction, demonstrating a consolidated approach to both Dhajji Dewari and Kath Khuni. The detail explores the timber stone hybrid with a changing gradient on upper levels. The plinth is comprised of dry stone and rubble infill with a cantilevered floor plate introduced on the upper storey supported by overhanging timber members. The horizontal stack displays an absence of vertical members as well as differentiated members of reduced scale on the upper storey to create less weight for the timber superstructure.

Consolidated

Section 1.05 16

Joinery

Figure 1.05A

Modern Response to Extremity

CONDITIONS OF EXTREMITY IN THE HIMALAYAS:

Extreme Cold - Heavy Snowfall

Mountainous Terrain within High Altitude

Monsoon Season - Heavy Rainfall

Dry/Arid Climate - Extreme Heat

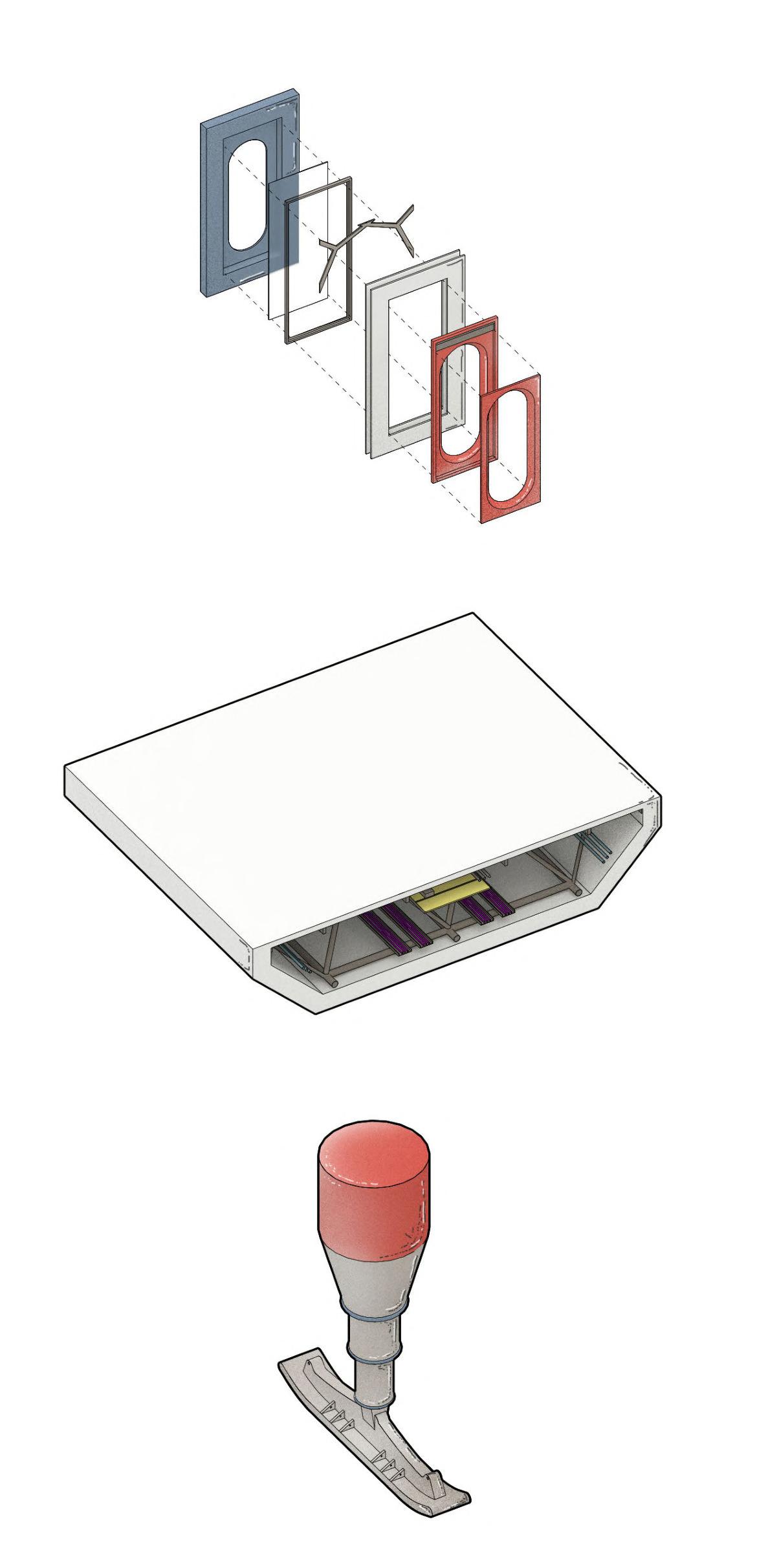

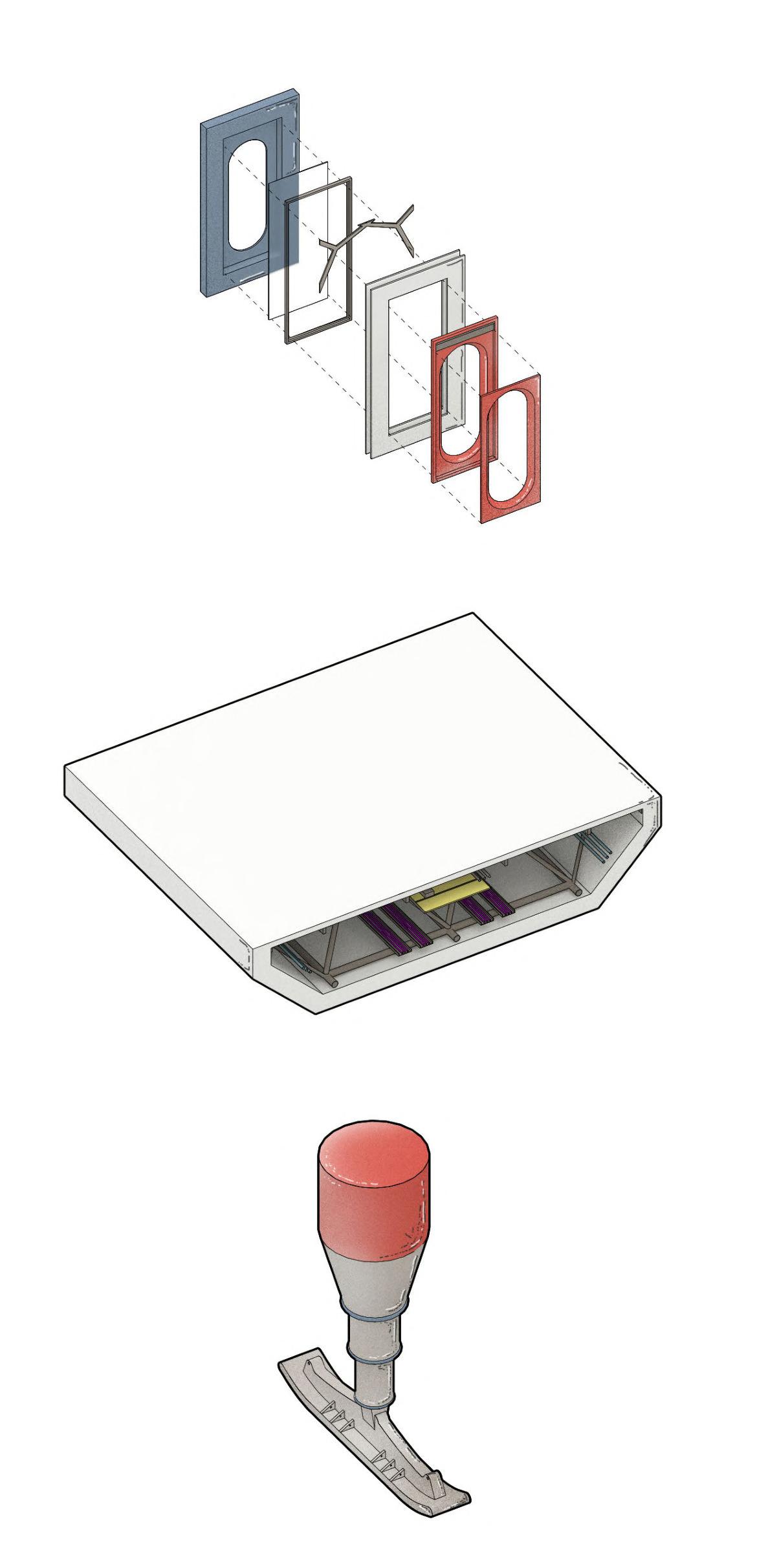

HALLEY VI RESEARCH STATION, HUGH BROUGHTON ARCHITECTS, ANTARCTICA, 75°S, 26°W

In contrast to Aukta House, the Halley VI Research Station based in Antarctica is a 21st century response to extreme cold, a condition also experienced in the Himalayas, hence I chose to explore the building as a foil to Aukta House, and compare the different methods employed within their geographically disparate, but shared climates.

Located on a 150m thick floating Burnt Ice Shelf, the building is mounted on skis, in direct response to the shelf which moves 400m per year towards the sea.

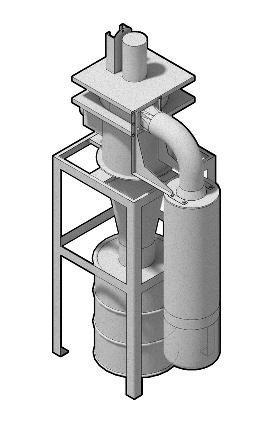

The research station’s eight self-contained modules are divided into sleep, leisure, work and living, and are self-supported by its own supply of power, water and waste disposal.

KEY COMPONENTS

Porthole window comprises steel structure clad in highly insulated composite Glass Reinforced Plastic panels

Intumescent (swells under heat exposure) coated steel space frame substructure

Hydraulic (related to liquid moving in a confined space under pressure) operated cassette within paired steel Rectangular Hollow Section structure

Pre-fabricated service cassette within space frame void

Double glazed curved oval cockpit rooflight allowing full views of auroral displays in winter

Hydraulic operated leg wrapped in high performance insulation and mandrel wrapped with GRP skin

EPDM (synthetic rubber) thermal break between ski and leg

Extendable steel skis - allows station to mechanically climb up

01 02 03 03 GRP WINDOWS INTEGRATED SERVICING EXTENDABLE SKI LEGS E B A A C C D D F F G G H H

1.06 _ Systems Research

Figure 1.06A

KEY PLAN BRIDGE LINK Sharing of power, drainage and water E 18 BARC0174 _ AAD1CHAPTER 1A _ HIMALAYAN SYSTEMS

Abstr 01. Systemising 02. Half 03. Aggr 04. Timber 05. Vertical 06. Horizontal 01 04 02 05 03 06

Abstract Fragments

SystemisingKathKhuni

HalfLafting/HalfDryStoneHybrid

AggregationwithReinforcement

TimberReinforcedGabionCageSkeleton

erticalStack

HorizontalStack

INITIAL DESIGN RESPONSE

20

Stone/Timber

01B CHAPTER 1 _ DESIGN RESEARCH BARC0174 _ AAD1

Hybrid Studies

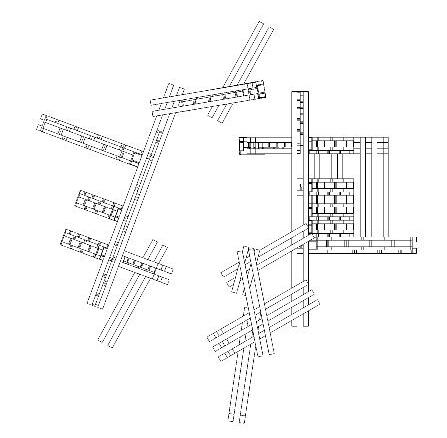

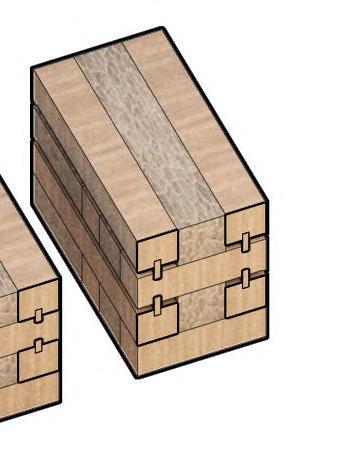

Systemising Kath Khuni

Robust corners in Aukta House

Creating a negative for stone

infill to dissipate seismic load

Bending members creates stack

Double member interlock mimics Kath Khuni in section and increases strength in interlock

Robust corners to achieve box action

Extended Corner

Bending members to create stackSingle to Double member interlock

SYSTEMISING KATH KHUNI

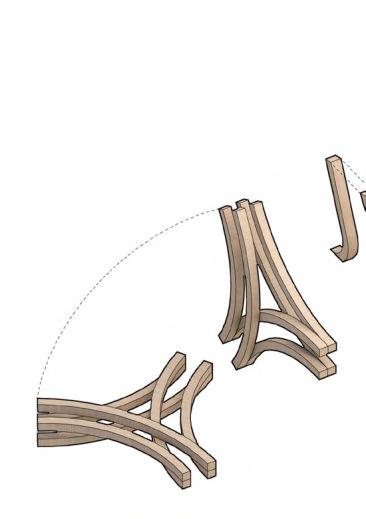

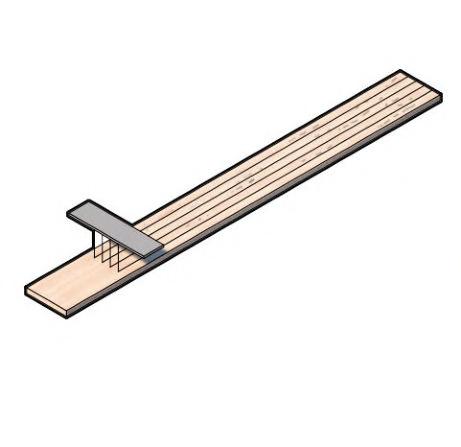

The fragment aims to translate the efficiency and seismic resistance of Kath Khuni to a larger scale by mimicking the system in section, and through the development of a system that combines adjacent members, dowel joints, single member splitting and splice joints.

Using the corners of Aukta House as reference where robust connections achieve box action, the timber members are extended, bent, stacked and infilled to create varied levels of permeability, and offer spatial opportunities.

Creating negative

Three member dowel jointTri-axial, tri-planar joint

1.07 _ Abstract Fragment 21

A A B B C CD D AXONOMETRIC PERSPECTIVE VIEW

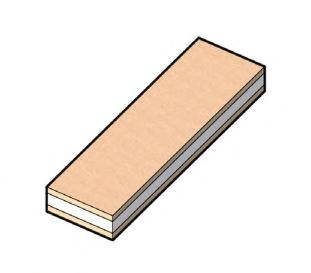

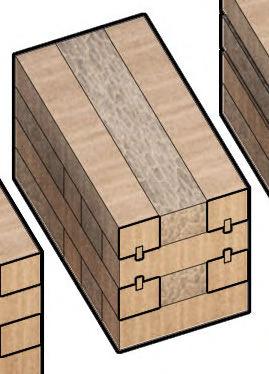

HALF LAFTING/HALF DRY STONE HYBRID

By exploring the transition from one material interface to another, the half timber lafting, half dry stone hybrid use the compressive strength of stone and the tensile strength of timber to introduce novel joinery in between material interfaces, through the exploration of variable timber profiles. Timber members are split and extended across separate axes to create differentiated aggregation, and the possibility to create scaled up spatial fragments.

The fragment translates the plinth superstructure of Aukta House into a differentiated inhabitable space, with timber members intervening with stone to create permeable counterpoints to the solid walls, and reciprocating with the base to create different points of entry when the members are splayed.

Half Lafting/Half Dry Stone Hybrid

1.08 _ Abstract Fragment

22

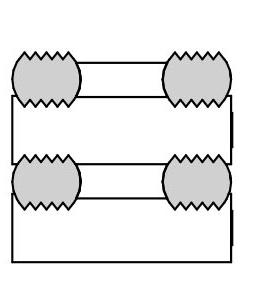

Traditional Circular Profile Traditional Circular Profile (Canadian) TriangularTriangular inwardTriangular chopped ABCDE KEY PLAN Triangular angled Triangular angled Triangular chopped dual vertical angled Triangular chopped dual angled Triangular chopped vertical angled Triangular angled extendedTriangular angled dual extended F I KL J GH Figure 1.08A

Half Lafting/Half Dry Stone Interface

FLAT SURFACE

Square profile

SPLINE SUPPORT

Square profile

CORNER SUPPORT

Square profile

ROUNDED STACK

Circular profile

SPLINE SUPPORT

Circular profile

CORNER SUPPORT

Circular profile

SINGLE INTERFACE

Tongue and Groove

DOUBLE INTERFACE

Tongue and Groove

CHAMFER INTERFACE

Tongue and Groove

SINGLE INTERFACE

Square Tongue and Groove

DOUBLE INTERFACE

Square Tongue and Groove

CONCAVE INTERFACE

Circular profile

LOG PROFILES

Full Round Swedish Cope Flat and Round Round and Flat Bevelled Edge Square Chamfered Edge Triangular ABCDEFGH AE BF CG DH

1.09 _ Developed Abstract Study 23 Figure 1.09A

AGGREGATION WITH REINFORCEMENT

Combining Fragments 1 and 2, the use of timber reinforcement introduces a continuity between both materials, strengthening the hybrid and increasing durability, whilst reducing the construction’s weight at higher levels. Differentiated members create stronger ground and wall-to-wall interface.

A AB B

Splice joint between timber member and stone

1.10 _ Abstract Fragment 24 KEY PLAN

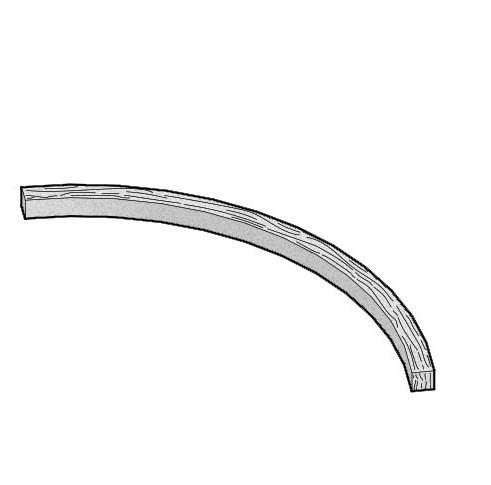

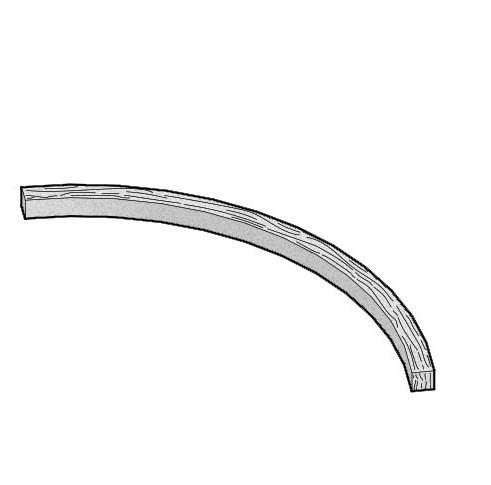

Curved timber member exploring continuity between timber reinforcement and thicker interface

Aggregation with Reinforcement

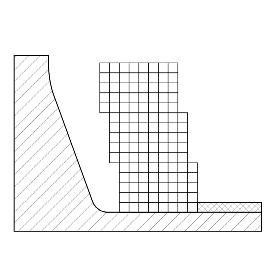

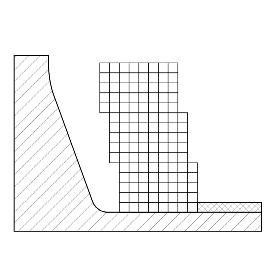

Typical Retaining Wall Construction

VARIATIONS

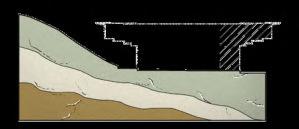

The extreme mountainside terrain of the Himalayas opens the possibility to retain soil through separate solutions including retaining walls, in particular gabion cages, which can later be adapted for varied programmatic functions. As a mechanism that contains and bleeds into the landscape, typical variations of the retaining wall allow soil retention whilst engaging different forms and uses.

REINFORCED BLOCK

INCLINED

GRAVITY RETAINING WALL

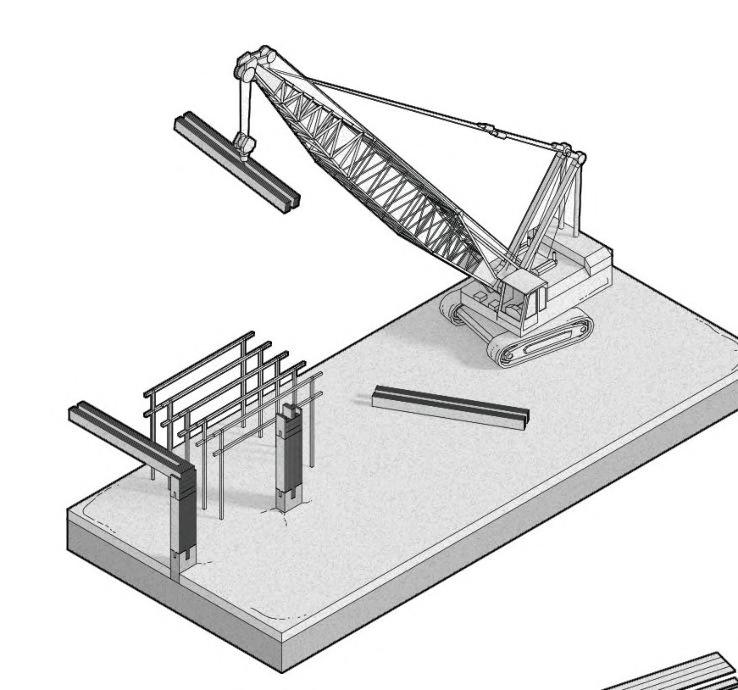

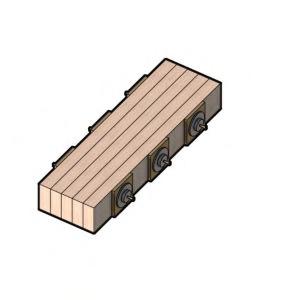

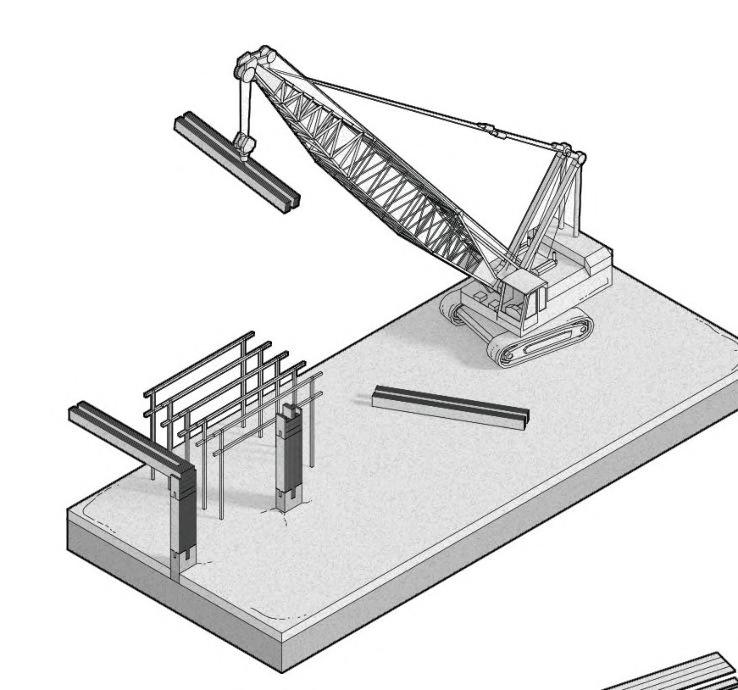

GABION WALL CONSTRUCTION PROCESS

Assembly Wire baskets/cages assembled

ADAPTATION WITH TIMBER REINFORCEMENT

Employing a similar pre-stressed logic to that of gabion cage assembly, the concept images on the right display a mechanism in which timber reinforcement supports timber wire baskets which are later infilled with random rubble and dry stone, creating the possibility of an inhabited condition between the reinforced cage walls. Using a geotextile membrane would prevent clay and thicker earth from clogging the gabion cages.

Infill Cages infilled with random rubble/dry stones

Drainage Drainage pipe inserted at rear of wire baskets

Geotextile Geotextile membrane conceals drainage and rear of baskets

Backfill

0102030405

Rear of baskets backfilled with soil and topsoil inserted on roof of cages

Reinforce Ground dug out and timber reinforcements laid for timber mesh baskets insertion

Infill Stone and rubble infilled into baskets for added stability

Stack Baskets stacked to create an expansive wall with varied permeabilities

CRIBLOCK WALL GABION BASKET L-SHAPE REINFORCED EARTH 01 01.02.03. 02 03

1.11 _ Design Research 25

Figure 1.11B

Figure 1.11A

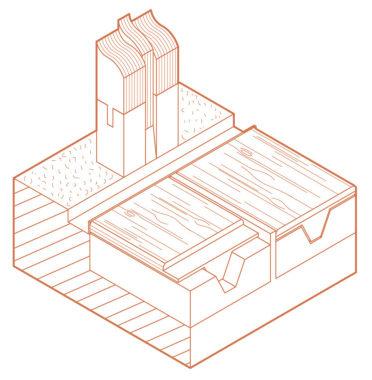

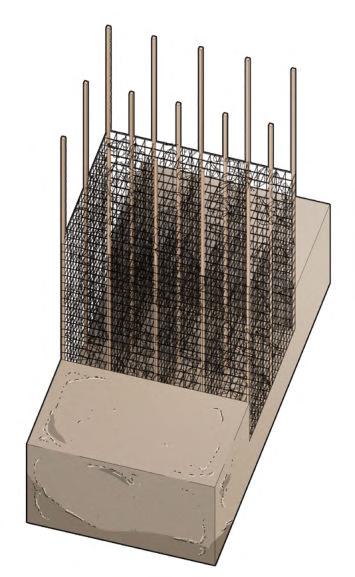

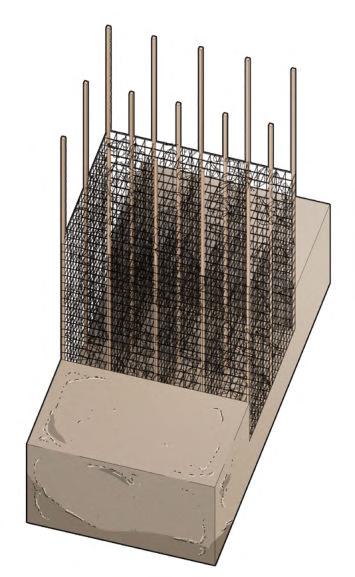

Timber Reinforced Gabion Cage Skeleton

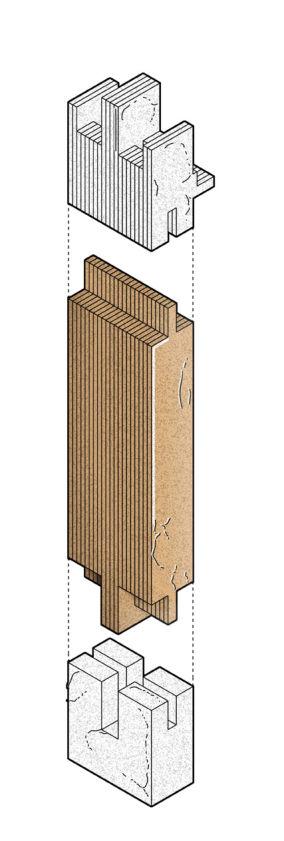

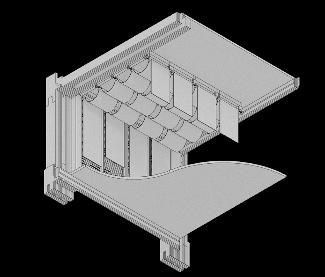

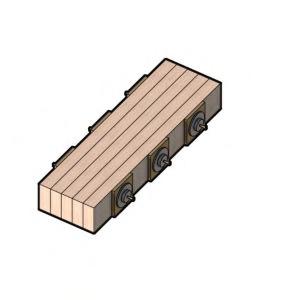

TIMBER REINFORCED GABION CAGE SKELETON

Using Aukta House as a framework to tap into the concept of an unzipped inhabitable wall to draw attention to the interstice, the fragment mediates a permeable layer of enclosure through the use of timber reinforced gabion cages. Timber members with filleted corners create slots for rounded timber cages that extend and collapse, blurring thresholds between internal and external spaces.

The cages can later be used as temporary storage devices for demolition rubble or dry stone aggregate, creating a further layer of permeability and enclosure for users.

COMBINING TIMBER REINFORCEMENT WITH BRACING & INFILL

Through the introduction of nodal points in the timber reinforced gabion cage, member sizes can be increased and diverted with varying subdivisions to reinforce areas of increased tension.

CONSTRUCTION PROCESS CONCEPT Timber members assembled Timber reinforcement creates cage Dry stone plinth Timber member Timber reinforcement Regular hybrid Cross-braced hybrid Random subdivisions hybrid Infill Stone infilled in extended wall 01 02 03

A.

A.

B.

B.

C.

C.

Dhajji Dewari inspired bracing hybrids

1.12 _ Reinterpreted Gabion Cage 26

Vertical Stack

VERTICAL STACK

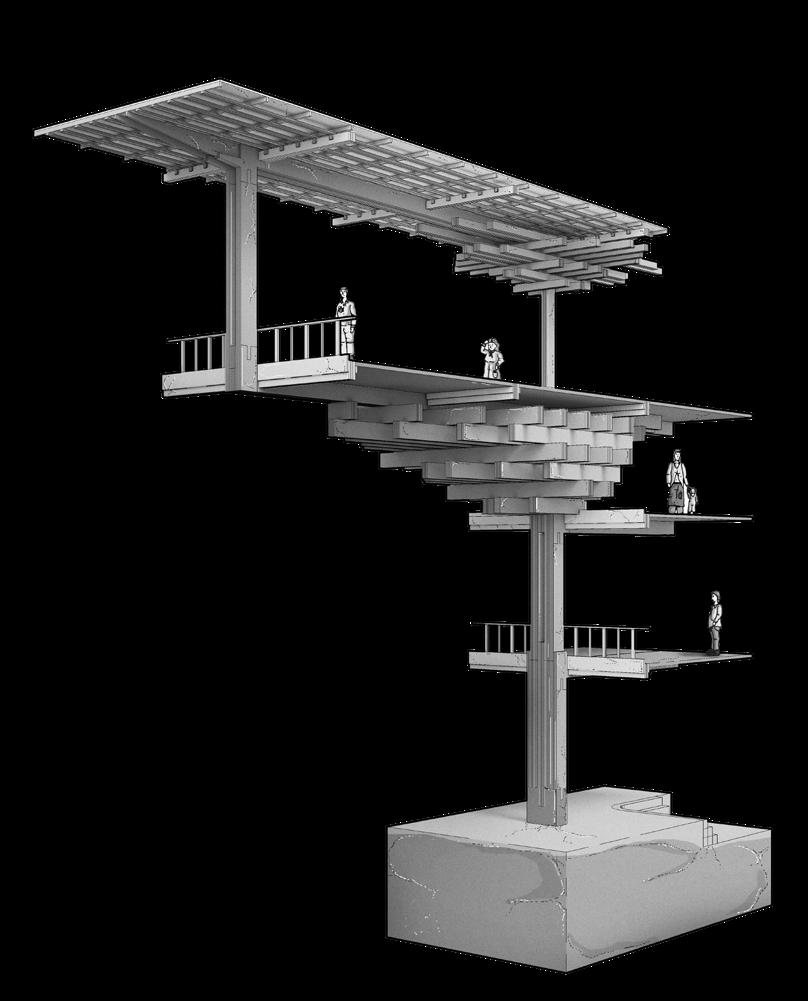

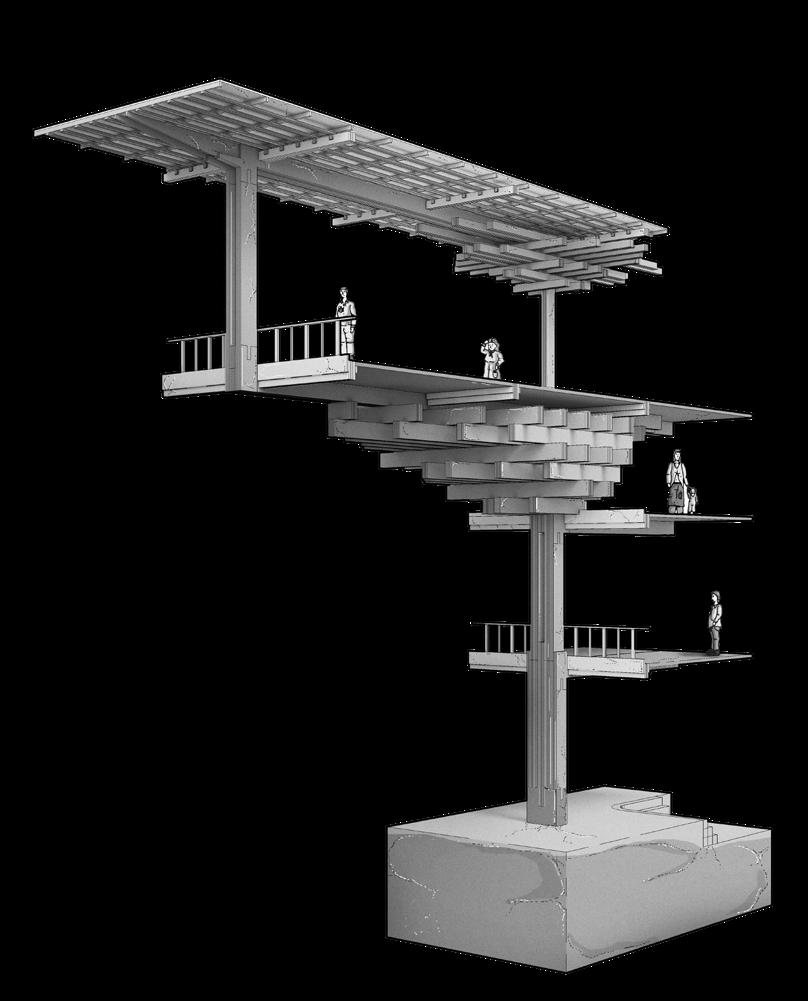

Using the differentiated interlocking timber members of Kengo Kuma’s Yusuhara Wooden Bridge as reference (shown in different shades of grey below), the fragment develops an orthogonal cantilevered form (as referenced in Aukta House) with a hybrid of timber members and dry stone, including a deeper base of dry stone, and stacked timber members above, creating a plinth superstructure in elevation.

ELEVATION Plinth Superstructure

YUSUHARA WOODEN BRIDGE MUSEUM Kengo Kuma Architects Short Section

AUKTA HOUSE _ SHORT SECTION

1.13 _ Abstract Fragment 27

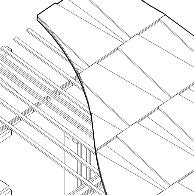

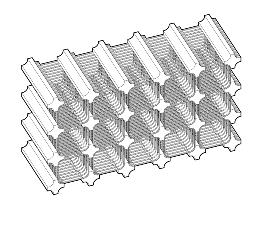

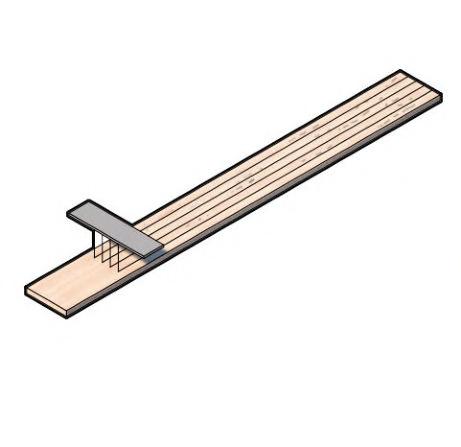

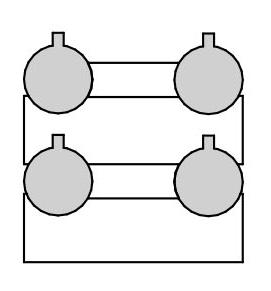

HORIZONTAL STACK

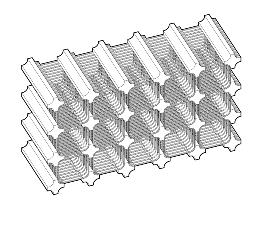

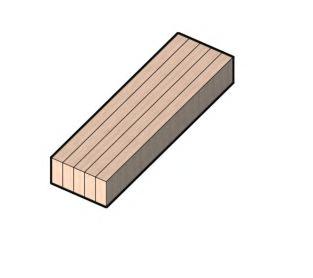

As an adaptation of Kengo Kuma’s Yusuhara Wooden Bridge Museum plan, which employs an interlock effect, the fragment explores the spatial potential of a horizontal hybrid stacking system using glulaminated timber and stone infill, within branching legs and columns. The use of tiers introduces interdependence between the members, while creating equilibrium within the overall structure.

Horizontal Stack

MEMBER DIFFERENTIATION

ELEVATION AUKTA HOUSE ROOF PROFILE Using Aukta House’s overlapping slate shingle roof tiles as reference, the fragment mimics the roof profile in section at an enlarged scale.

Rotated double member creates horizontal stack Dry stone infilled between glulam members creates wedge to increase compression outwards while tapered timber members retain tension

1.14 _ Abstract Fragment 28

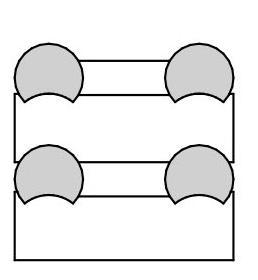

Fluid Plinth/Light Superstructure

STRUCTURAL CONCEPT

Made of a heavy plinth combining aggregate with timber, a single member is repeated into a splaying volume.

CONCEPT

In contrast to the previous fragments exploring the stone/ timber hybrid, this fragment takes on an alternative approach, expanding on the importance of the wall in Kath Khuni. The fragment explores a more fluid form, conceptually displayed as a continuous splaying volume. Fabrics that behave as translucent shading devices dapper light into spaces below.

PROGRAMMECOMMON ROOM

Taking reference from Aukta House’s central gathering space, the fragment is divided with fluid breaks and thresholds between levels, creating a taller central space.

KEY ELEMENTS

SHORT ELEVATION Parallel Projection

Geometry

Scaled

Translucent Skins Fluting A.

1.15 _ Abstract Fragment

Fluted members create slotting mechanism for small scale timber members supporting skins

PERSPECTIVE VIEW

Low resolution logging transitions to high resolution milling, creating openings within wall

LONG ELEVATION A

Small scale timber members bleed into translucent skins

Layered hemp fabric offsets heavy plinth with sculptural skins

Layered fabrics dapper light

30 BARC0174 _ AAD1CHAPTER 1B _ INITIAL DESIGN RESPONSE

Stone/Timber Prototype 01

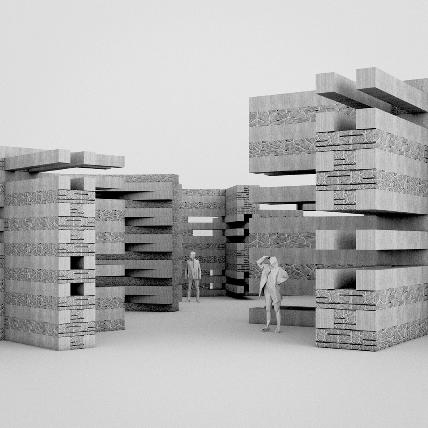

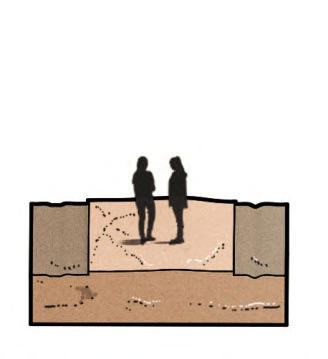

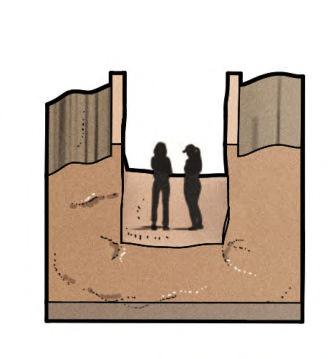

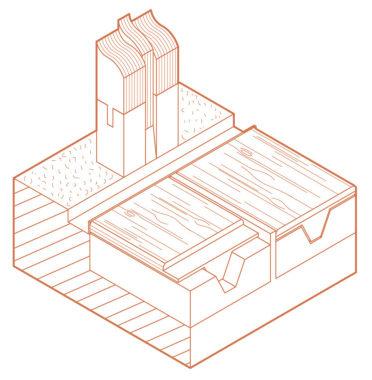

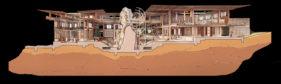

LARGE SCALE PLINTH SUPERSTRUCTURE

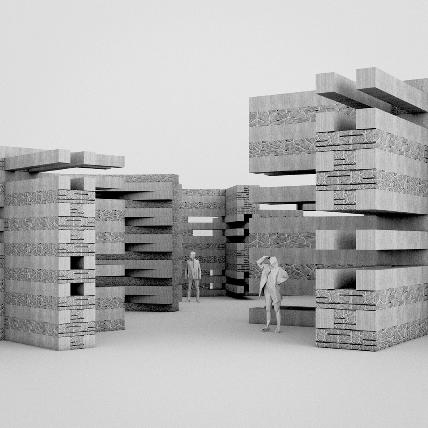

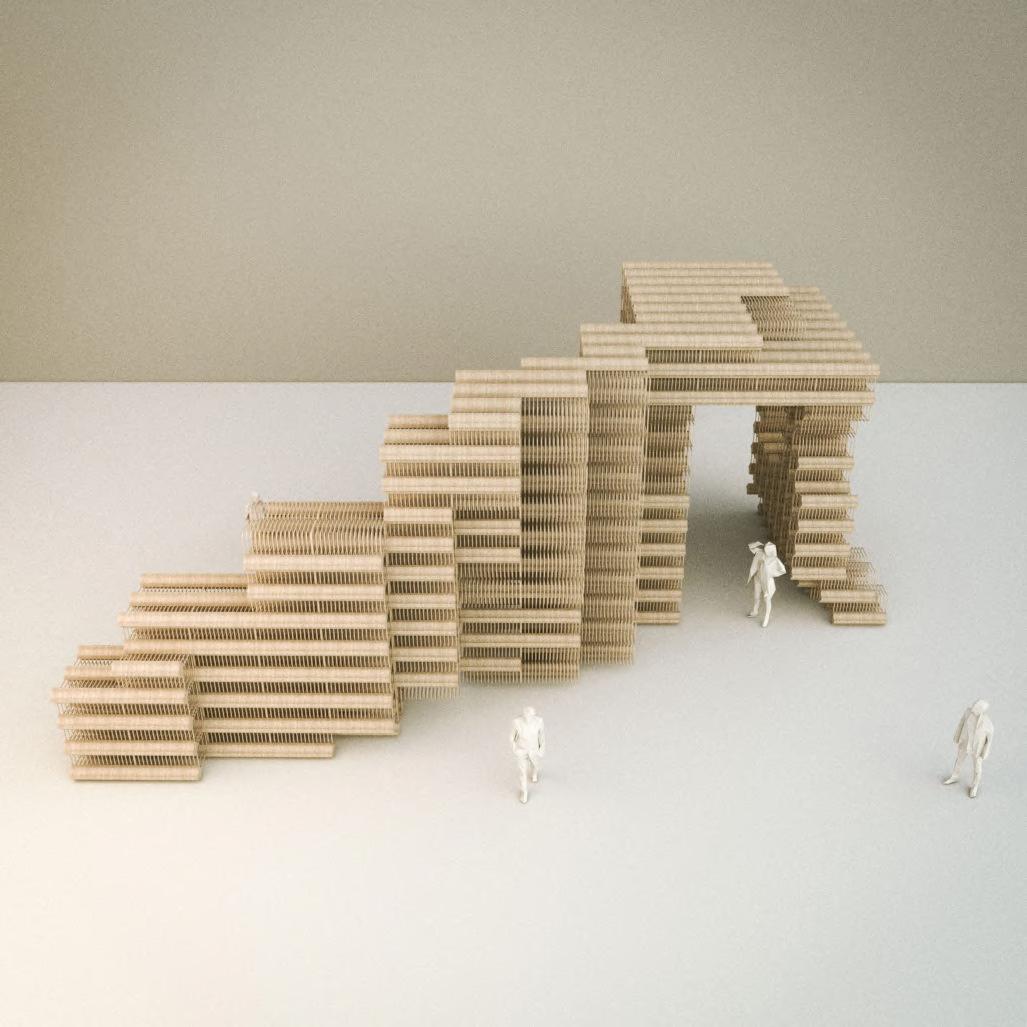

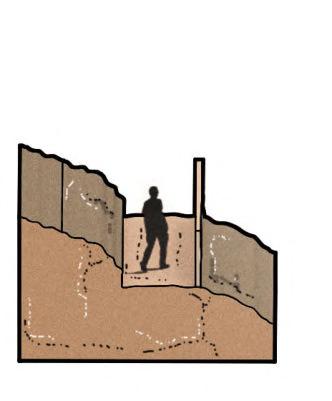

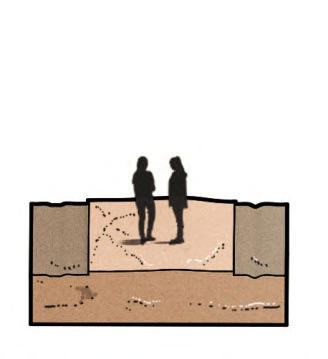

As a development of an earlier fragment titled ‘Vertical Stack’ which explored a vertical stacking system combining timber members with stone infill, this fragment speculates on the same idea at a larger scale, introducing a rock interface to present compact and expansive spatial opportunities. Using a large scale timber superstructure, sitting on top of a stone/concrete plinth, the fragment denotes a hierarchy of material, which extends to the programme through the use of a double height gathering space on the upper storeys.

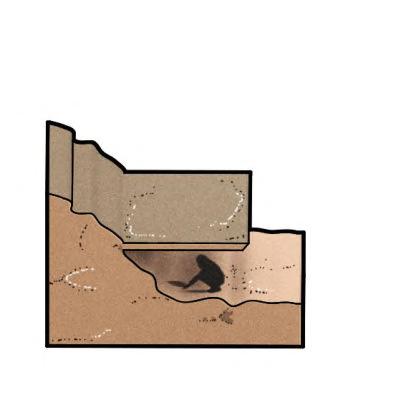

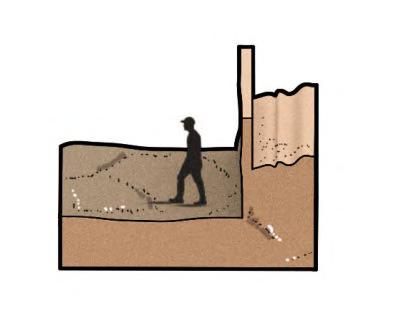

Submerged condition

Figure 1.16A

Trench condition

Figure 1.16B

Hemp fabric, native to the Himalayas, creates semi-enclosures

PLAN

Central roof opening creates untempered interior

ROOF

A.

A.

B.

C.

B.

C.

1.16 _ Spatial Fragment Study 31

Stone/Timber Prototypes 02

ESTABLISHING A HYBRIDISED SYSTEM

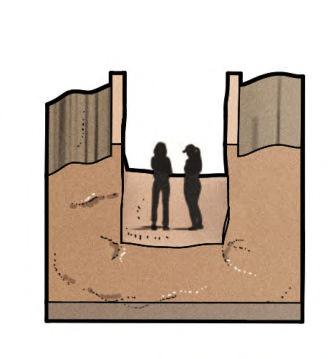

Fragments 01 and 02 explore a hybridised architecture which pairs a glue laminated framework with dry stone of various sizes. Fragment 01 uses a gradient of stone sizes to create a hierarchy within the frame, while Fragment 02 uses the logic of retaining walls to bleed glue laminated members into the landscape, which then splay into differentiated sizes, creating a stronger curvilinear form and entrance.

FRAGMENT 01

Rockface to Wall Interface

A standard orthogonal grid is differentiated for permeable rubble infill.

FRAGMENT 02

Curvilinear Timber/Rubble Infill

Mesh Basket Steps Study

Combining the fragments on pages 26, 28 and 31 developed into a series of splaying glue laminated members that merge into a landscape integrated retaining wall, supported by rubble infilled mesh basket steps, the elevations of which are reinforced with timber, behaving as a non-intrusive continuation of the landscape.

1.17 _ Fragment Studies 32

1.18 _ Spatial Fragment Study

Stone/Timber Prototype 03

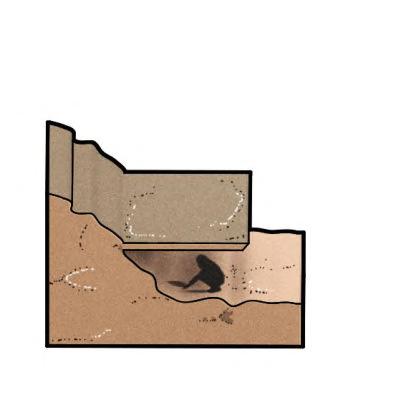

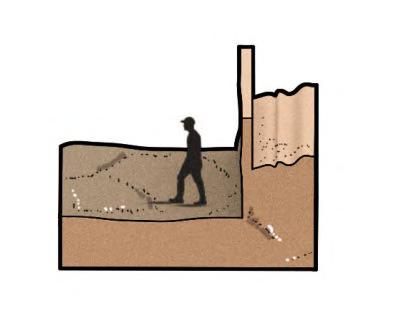

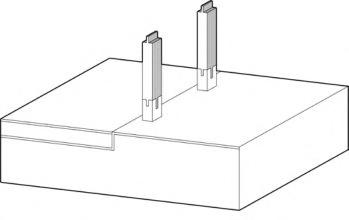

TIMBER REINFORCED PLINTH SUPERSTRUCTURE

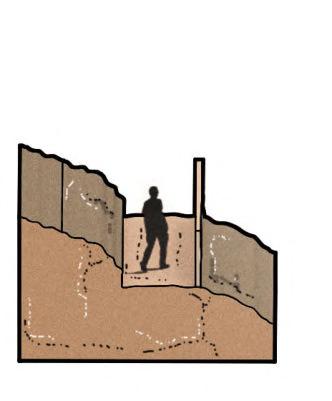

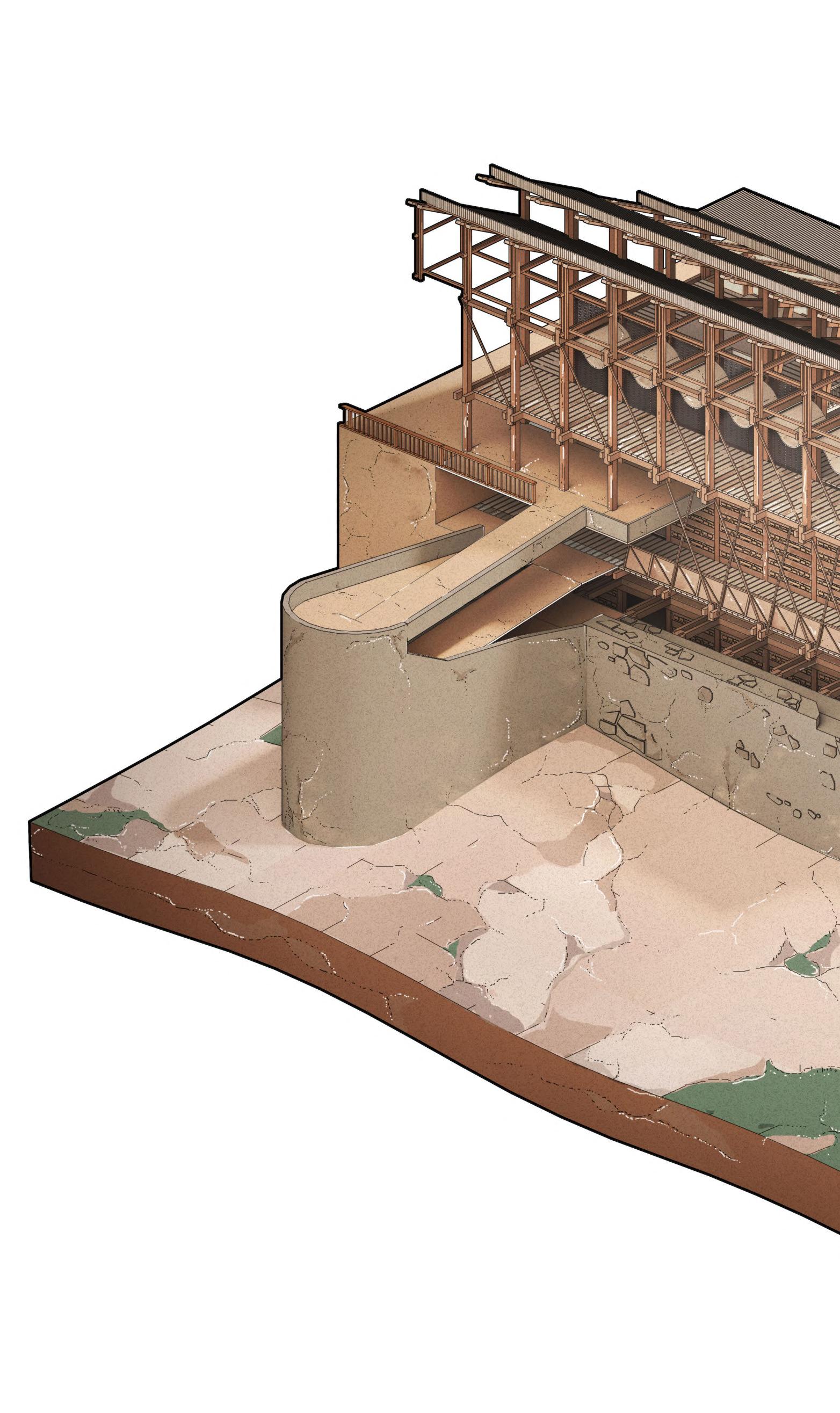

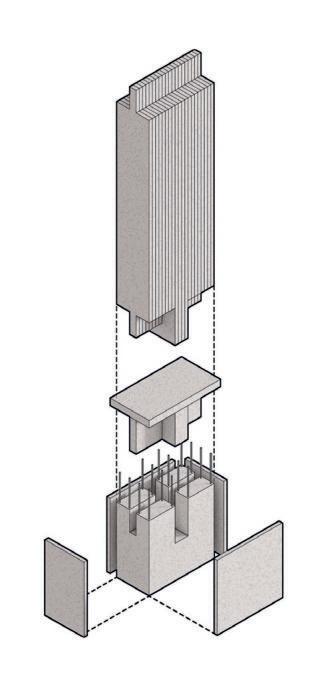

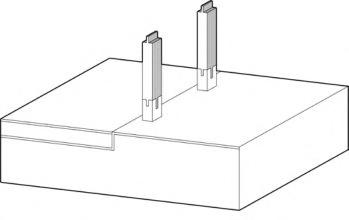

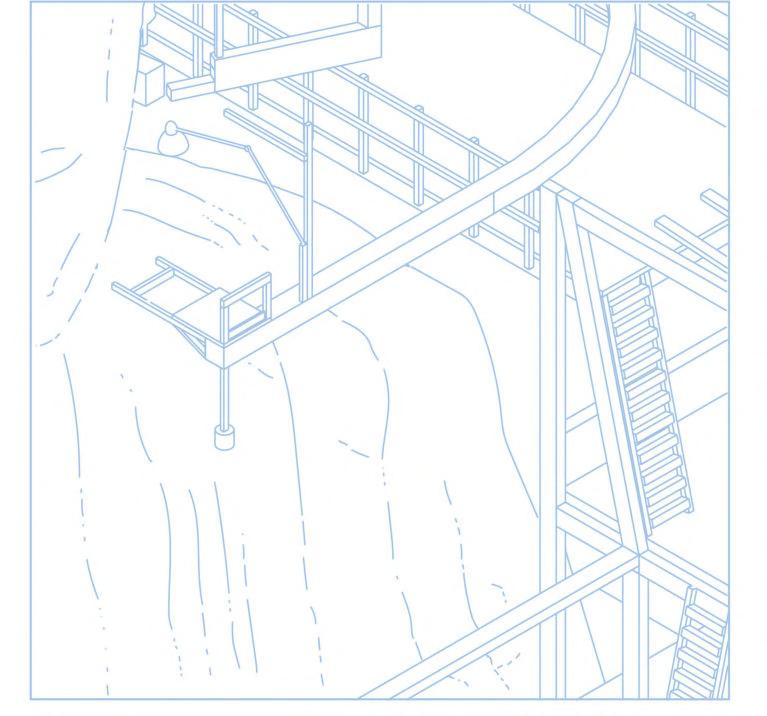

Employing a similar prestressed logic to that of gabion cage assembly, the concept images here display a system for the plinth in which timber reinforcement supports timber wire baskets which are later infilled with random rubble and dry stone, sustaining an inhabited ground condition with a constructional hierarchy that uses varied timber members that are reduced at higher levels.

Stone Infill Gradient

Integrated Landscape

A. INHABITED GROUND CONDITION

SPATIAL OPPORTUNITY - INHABITED GROUND CONDITION

C. EXTENDED WALKWAY INTERFACE

I. Carved Plinth - Retaining Gabion W II. Inhabited Timber Superstructur III. Suspended Walkway

III.

B. COMBINED LANDSCAPE ARCHITECTURE

ENTRANCE/ SUSPENDED WALKWAY CONDITION

Suspended Walkway

D.

ISOMETRIC

B.

D.

A.

D.

ISOMETRIC

B.

D.

A.

CONDITION Wall Superstructure

C. FRONT

alkway

GABION BASKET

Figure 1.18B

GABION BASKET I.

Figure 1.18A

34 BARC0174 _ AAD1CHAPTER 1B _ INITIAL DESIGN RESPONSE

II.

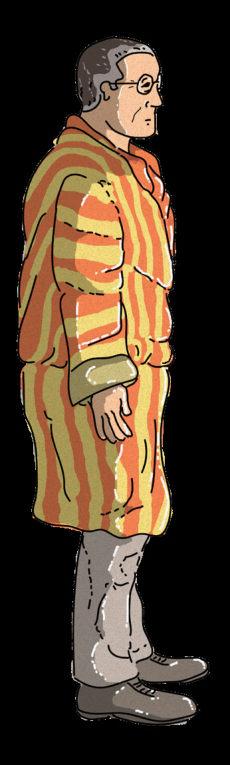

IN THE HIMALAYAS GOLDEN TEMPLEBUDDHIST SYMBOLS SADHUS A RECORD OF TRAVELS THROUGH THE HIMALAYASDEATH CEREMONY STEPS IN LADAKHFLOATING SHIMLA KHYBER PASSKALASH PEOPLEICE STUPAS BHUTANESE CLOTHING AND GEOMETRICAL PATTERNS

CULTURAL EXPRESSION

LHUENTSE SCHOOL OF CRAFTS 36 02 Chapter

OF

WIDER SITE CONTEXT 02A 02A. Wider Site Context 02B. Site and Brief BARC0174 _ AAD1

HIMALAYAS, ABODE

SNOW

Himalayas Overview

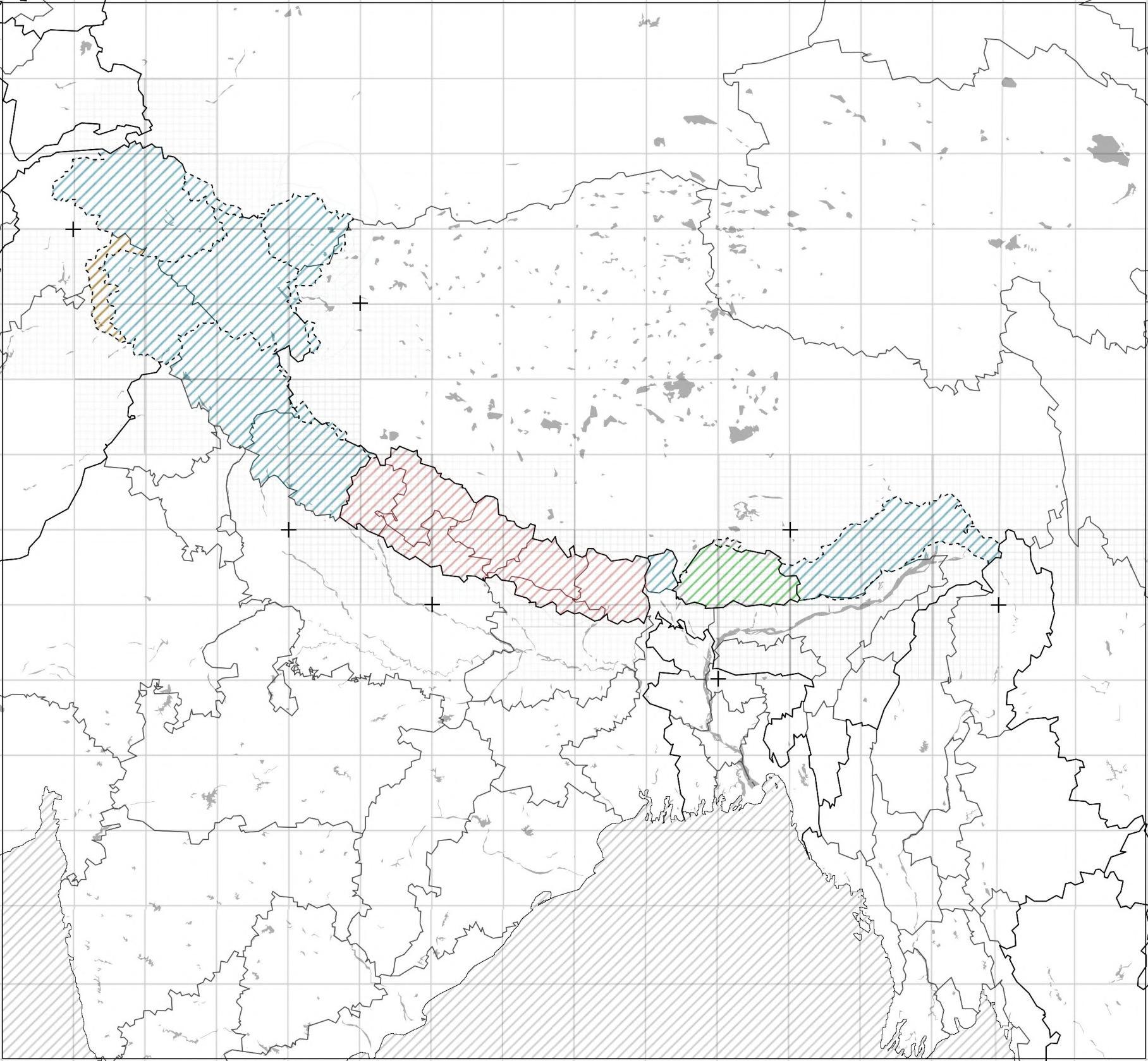

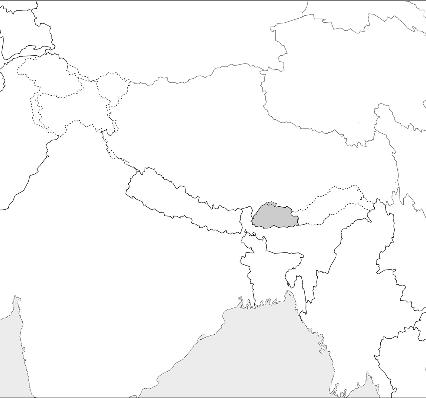

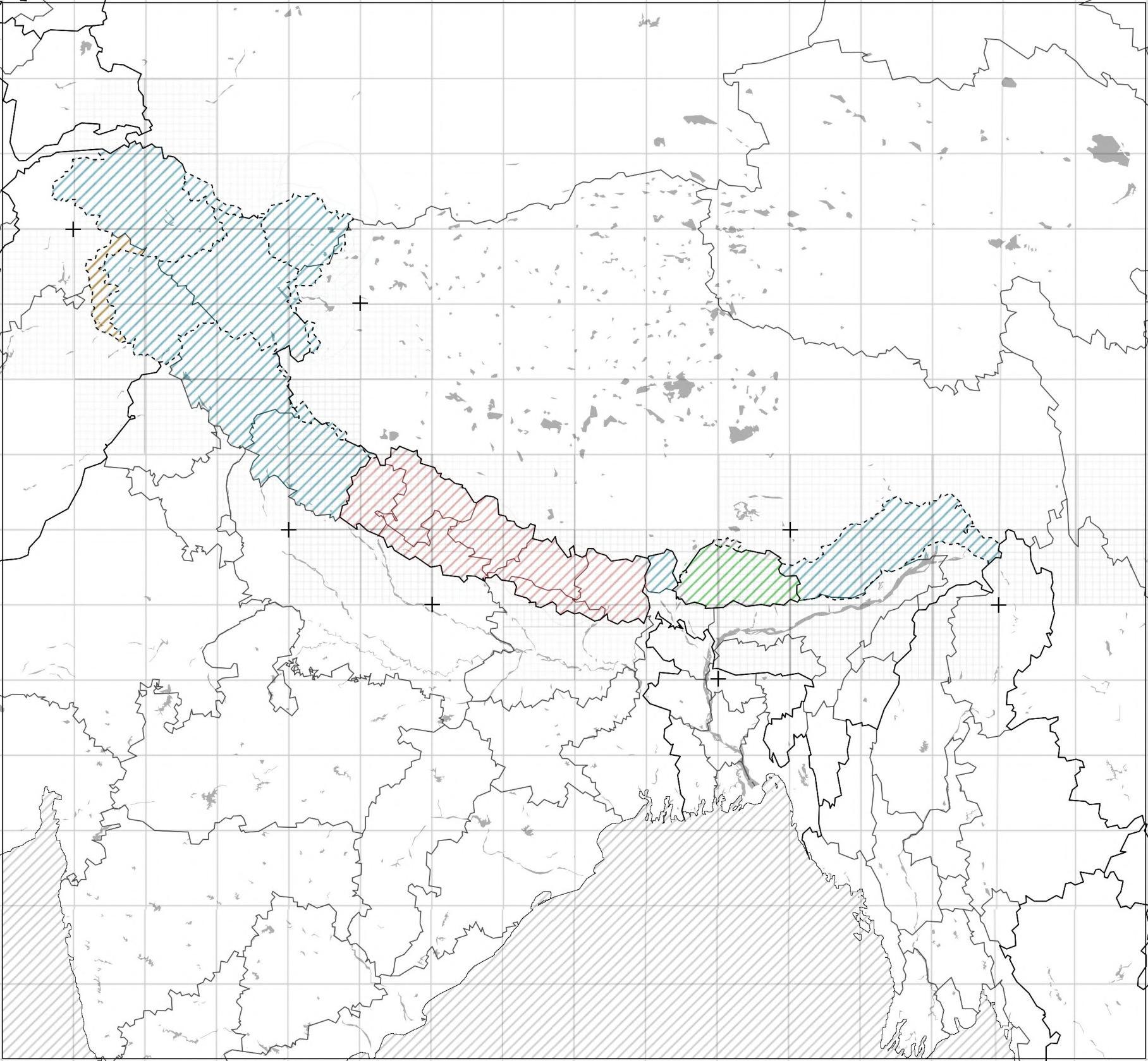

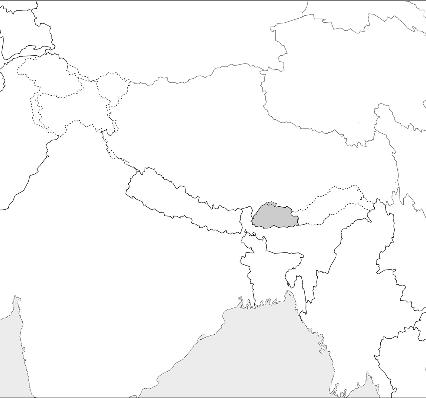

HIMALAYAN BORDER NATIONS

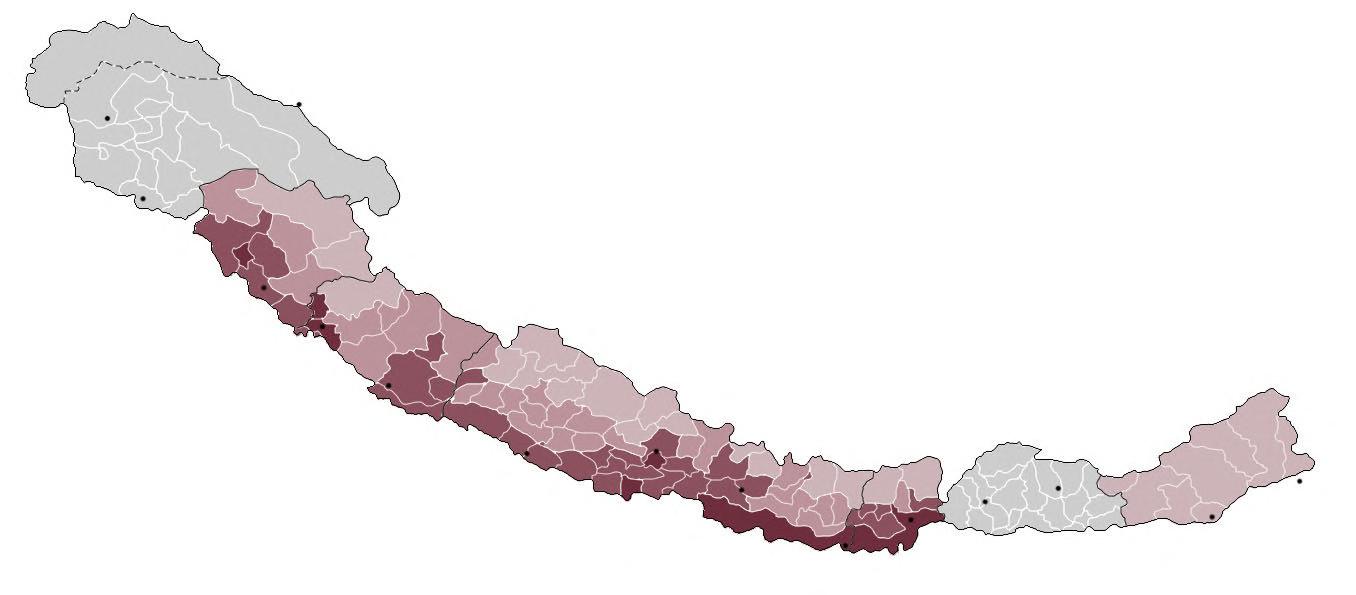

The Himalayas extend for over 2400 km from the North southward from the Tibetan Plateau to the Indus-Gangetic Plain and contain 11 peaks above 8000m, with an average height across the Himalayas of 6000m. Several border conditions are disputed between India, Nepal, Tibet, Pakistan and Bhutan, alongside several glacial sites that converge into lakes in the west. The scheme aims to re-frame the expedition, natural beauty and heavily spiritualised lens through which the Himalayas is viewed, instead drawing upon the region’s urban features to consider a new civic programme with hybrid functions and users.

Following increased population growth in the Himalayas since the 1960s, increased strain has been placed on local resources, triggering a rise in urban dwelling on mountainous slopes, despite the majority of Himalayan inhabitants remaining rural.

The opposite mapping of major passes is a study into the man-made interventions used to navigate the foothold nature holds over the Himalayas, as well as the extreme altitude, major peaks and ultras distributed across the mountain range. Much of the passes serve as interventions for trade, vehicles and people, and respond directly to the high footfall from tourists, largely in Nepal due to trekking and mountaineering expeditions.

The urban fabric of many high altitude towns has changed due to the flow of migration from countryside to the city.

Dehra Dun, Shimla, Darjeeling and Gangtok are recent examples of Himalayan towns that have been urbanised, some of which were prominent leisure locations for colonial British military officers during the summers. Although several nations have experienced modernisation trends, Bhutan stands out as relatively insular, having never been colonised, and invites further speculation for an architecture caught between the push of modernisation and the protection of its unique cultural heritage.

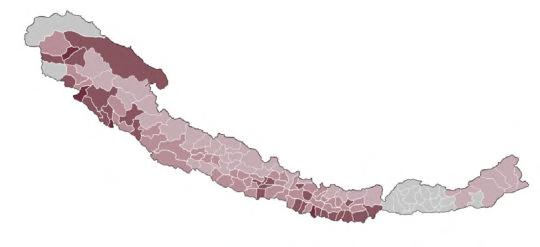

EXPANDING URBANISM HIMALAYAN PASSESHIMALAYAN ALTITUDE (M) 8300m 5641m 3062m 1411m 240m 13m Passes Locations Major Peaks Pakistan Nepal India Bhutan

2.01 _ Wider

KEY (PERSONS PER HECTARE) Very High (>3) High (1.5-3) Medium (0.5-1.49) Low (0-0.49) Insufficient Data 1 810 000 1 003 000 569 578 502 197 264 991 169 578 154 019 138 951 17 820 30 870 41 377 59 490 114 551 120 414 India Nepal Bhutan Srinagar Kathmandu Dehra Dun Jammu Pokhara Shimla Dibrugarh Nepalgunj Darjeeling Thimpu Itanagar Nainital Leh Bumthang POPULATION BY RANK HIMALAYAN NATIONS DISTRIBUTION TIBETAN PLATEAU BANGLADESH MYANMAR BHUTAN INDIA N NEPAL PAKISTAN CHINA TIBET Leh Population (2011): 30 870 Pokhara Population (2011): 264 991 Bumthang Population (2017): 17 820 THIMPHU Population (2011): 114 551 Jammu Population (2011): 502 197 Dehra Dun Population: 569 578 Nainital Population (2011): 41 377 Nepalgunj Population (2017): 138 951 KATHMANDU Population (2011): 003 000 Birlanagar Itanagar Population (2011): 59 490 Shimla Population (2011): 169 578 Srinagar Population (2011): 810 000 Figure 2.01B Zoji La Elevation: 11575 ft K2 Khardung La Elevation: 18373 ft Changla Pass Elevation: 16522 ft Bara-lacha La Elevation: 14600 ft Kunzum Pass Elevation: 15060 ft Sela Pass Elevation: 13862 ft Jelep La Elevation: 13950 ft Banihal Pass Elevation: 9291 ft Rohtang Pass Elevation: 13035 ft Mohan Pass Elevation: 5900 ft Umling La Elevation: 19301 ft Shipki La Elevation: 14764 ft Mana Pass Elevation: 18478 ft Lipulekh Pass Elevation: 14436 ft Kora La Elevation: 15072 ft Thorong La Elevation: 17769 ft Arniko Rajmarg Elevation: 17260 ft Nathu La Elevation: 14140 ft NANGA PARBAT DHAULAGIRI ANNAPURNA MAKALU KANGCHENJUNGA MANASLU MT EVEREST GASHERBRUM Figure 2.01A Figure 2.01C 2.04 2.05 Jharkot VillageNakho VillageBhutanNepalNepalDoon 2.02

Site Context

The infographic looks at the highest 38 peaks across the Himalayan mountain range, gauging the altitude range,

potential footfall for tourism, and the peak distribution and borders by nation. First ascents range between

the years of 1931 and 1992, with the highest peaks having been summited in the 1950s.

Peak Distribution by Country 8% Bhutan 4% Pakistan 21% India 31% China 36% Nepal Himalayan Peaks: Commodifying Nature Nepal India 5000 Mount Everest K2 KanchenjungaLhotseMakaluChoOyuDhaulagiriIManasluNangaParbatAnnapurnaIShishapangmaGyachungKangNuptseNandaDevi Namcha BarwaKametGurlaMandhata Gangkhar PuensumKulaKangriYangraLabucheKangJomolhariGyalaPeriLangtangLirungTongshanjiabuNoijinKangsang NunKangto MachapuchareDorjeLakpaKedarnathKedarnathIIAmaDablamKangtega Mount KailashManaPeakBandarpunch 5000 00 1000010000 1500015000 2000020000 2500025000 3000030000 3500035000 32500 19301930 19401940 19501950 19601960 19701970 19801980 19901990 20002000 32500 2750027500 2250022500 1750017500 1250012500 75007500 25002500 Pakistan China Bhutan Altitude (ft) Country Name First Ascent Unclimbed 38

BARC0174 _ AAD1CHAPTER 2A _ WIDER SITE CONTEXT

Himalayan Border Nations

WIDER GEOGRAPHICAL PARAMETERS

Containing 11 peaks above 8000m, with an average height across the Himalayas of 6000m, the Himalayas extend for over 2400 km from the North southward from the Tibetan Plateau to the Indus-Gangetic Plain. Covering the territories of India, Nepal, Tibetan Autonomous Region, Pakistan and Bhutan, several border conditions are disputed. The width of the mountain system varies from 180 to 350km, with a total area of 650 000 sq km.

The Himalayas are also home to the source of the Indus, Ganges, and Brahmaputra rivers, some of which converge into lakes, predominantly in the Western Himalayas, containing tectonic and glacial origins.

BANGLADESH MYANMAR BHUTAN INDIA N NEPAL PAKISTAN

TIBET

TIBETAN PLATEAU

CHINA

HIMALAYAN NATIONS DISTRIBUTION HIMALAYAN STATES 01 0105 04 0207 08 03 02 03 05 04 08 07 Pakistan Nepal IndiaBhutan Jammu and Kashmir Himachal Pradesh Uttarakhand Sikkim Nepal Arunachal Pradesh Bhutan

2.02 _ Wider Geographical Context 39

Kashmir is the site of multiple disputed areas, having seen multiple skirmishes between Indian and Chinese troops. Both India and China are competing to build infrastructure along the border, known as the Line of Actual Control. India’s proposal for a new road to high-altitude air base is considered the cause of a 2020 clash. The diagram explores sites of contention within the wider Himalayas, alongside accompanying transport infrastructure interventions.

2.03 _ Wider Political Context

Disputed Himalayan Borders

N AFGHANISTANTAJIKISTAN KYRGYSTAN TIBET MYANMAR LAOSTHAILAND XINJIANG QINGHAI SICHUAN YUNNAN GANSU PAKISTAN DISPUTED BORDERS TRANSPORT INFRASTRUCTURE INDIA NEPAL BHUTAN BAY OF BENGAL BANGLADESH Area ceded by Pakistan to China Claimed by: India DURAND LINE DISPUTED BORDER LINES OF ACTUAL CONTROL Shigatse Yadong Railway Bilaspur Leh Railway China National Highway G219 DELHI KATHMANDU DHAKA ISLAMABAD Lahore Amritsar Shimla Dehra Dun Jaipur Kanpur Varanasi Patna Lhasa Pasighat Kolkata Darjeeling Lucknow Jammu Srinagar Kargil Leh Lhasa Nyingchi Railway Medog Zayu Road INDUS RIVER GANGES RIVER BRAHMAPUTRA RIVER “MCMAHON LINE” DISPUTED BORDER Siachen Glacier Claimed by: India and Pakistan Area held by China Claimed by: India Disputed Areas KEY Durand Line DisputedRoadsRoads Borders RailwaysRailways Airfields/Airbases Hotan AirportDaulat Beg LhasaOldi Gonggar AirportTuting Ngari Gunsa AirportFukche Nyingchi Mainling AirportPasighat Shigatse Peace AirportDharasu Airfields/Airbases Lines of Control India Pakistan Disputed Areas Siachen Glacier Himalayas Range JAMMU & KASHMIR Administered by India LADAKH KASHMIR Administered by Pakistan ARUNACHAL PRADESH Largely claimed by China 01 02 04 03 02 01 03 04 05 05 Ghatibagar Lipulekh Road TIBET/CHINAINDIA KEY 01 01 01 01 04 04 02 02 05 05 03 03

40

Figure 2.03A

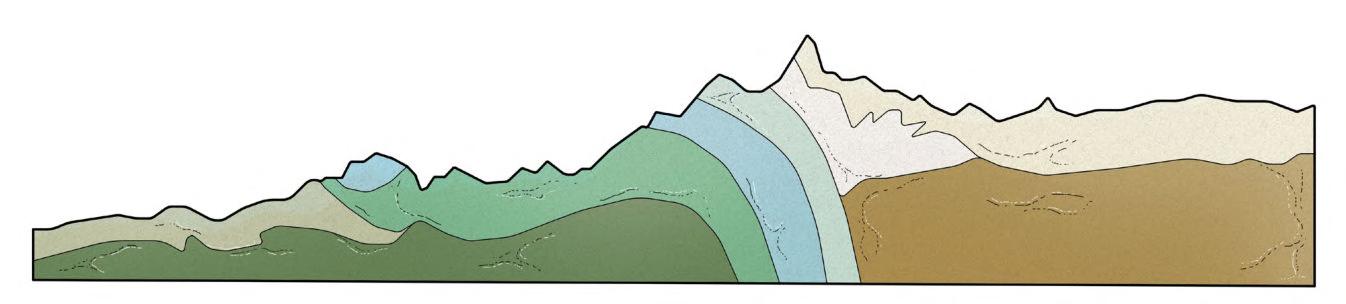

As an extension of the study into the major peaks and ultras (with topographic prominence greater than 1500m/4921ft) distributed across the Himalayan mountain range, formed by the movement of tectonic plates, the mapping of major passes is a study into the man-made interventions used to navigate the foothold nature holds over the Himalayas.

Although the terrain is extreme, some passes have been constructed as interventions for trade, vehicles and people.

Much of the passes are a direct response to the high footfall from tourists, largely in Nepal due to trekking and mountaineering expeditions.

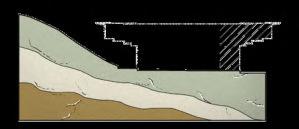

In addition to the large mountainous coverage, glaciers occupy over 33000 sqkm of the Himalayas. The longest glaciers lie in Everest (Chomolungma) (up to 19km) and Kanchendzhanga (26 and 16km), in the Kumaon Himalayas. The glacier border ranges from 2500m in the lower region to 4000m in the central Himalayas.

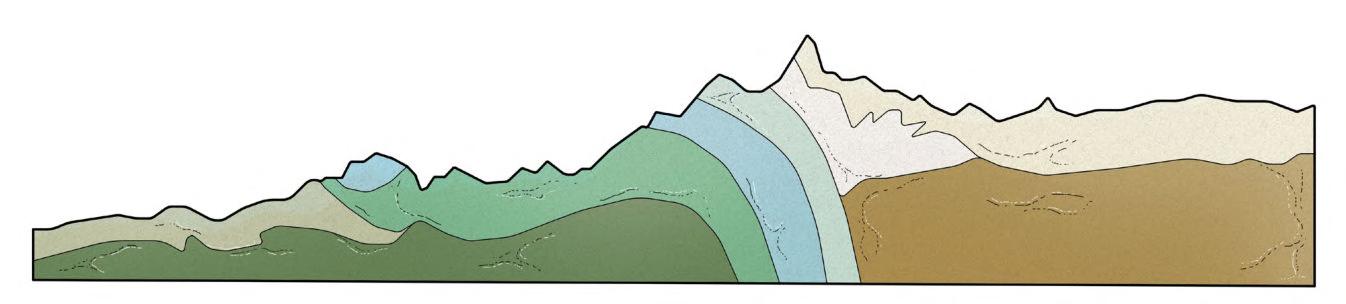

The main feature of the Himalayan geological structure are a series of flatlying overthrust plates (a reverse fault in which rocks on the upper surface move over the rocks on the lower surface) which moved from the north to the south, creating superposed folds, causing complex layered geometry, also called interference patterns. The cross section above through Mount Everest (Chomolungma) displays the onset of the tectonic processes of uplift, which create contrasting rock layers and mineral content, which are separated by faults and thrust boundaries. Zoji La Elevation: 11575 ft K2 Khardung La Elevation: 18373 ft Changla Pass Elevation: 16522 ft Bara-lacha La Elevation: 14600 ft Kunzum Pass Elevation: 15060 ft Sela Pass Elevation: 13862 ft Jelep La Elevation: 13950 ft Banihal Pass Elevation: 9291 ft Rohtang Pass Elevation: 13035 ft Mohan Pass Elevation: 5900 ft Umling La Elevation: 19301 ft Shipki La Elevation: 14764 ft Mana Pass Elevation: 18478 ft Lipulekh Pass Elevation: 14436 ft Kora La Elevation: 15072 ft Thorong La Elevation: 17769 ft ALTITUDE (M) GEOLOGICAL CROSS SECTION ACROSS 87° LONGITUDE HIMALAYAS IN CONTEXT 8300m Mount Everest 5641m 3062m 1411m 240m 13m Passes Locations Major Peaks Arniko Rajmarg Elevation: 17260 ft Nathu La Elevation: 14140 ft Kilometers 150 0 300 N NANGA PARBAT DHAULAGIRI ANNAPURNA MAKALU KANGCHENJUNGA MANASLU MT EVEREST GASHERBRUM Kantega Midlands Mahabharat Lekh Ganges Plain Siwaliks Indian Basement Nawakot Thrust Sheet Kathmandu Thrust Sheet Khumbu Thrust Sheet Tibetan Granites Tibetan Plateau Tibetan Basement Tibetan Sediments MAN-MADE INTERVENTIONS India Tibet China Pakistan Nepal Bhutan Bangladesh Myanmar

2.04 _ Wider Topography 41

Himalayan Passes

Figure 2.04A

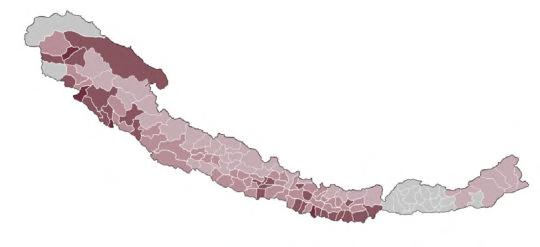

Following increased population growth in the Himalayas since the 1960s, the large volume of persons per hectare has created increased strain on the landscape, putting pressure on farm land, forests and water resources. Within mountainous districts, the densities have caused more occupation on slopes, much of which is located on the hills and Terai region of Nepal, where annual population change exceeds 4% per year. Although the majority of dwelling in the Himalayas is rural, the percentage of urban dwellers has continued to increase.

The flow of migration from countryside to the city has changed the urban fabric of many high-altitude towns. Dehra Dun, Shimla, Darjeeling and Gangtok are recent examples of Himalayan towns that have been urbanised, some of which were prominent locations of leisure for colonial British military officers during the summers, due to their cool climate in high altitude. Kashmir Valley contains one of the most populated towns in the Himalayas, Srinagar which has experienced modernisation trends - the onset of roads built for military use and hill stations during colonialism.

DENSITYMIGRATION

URBANISATION India Tibet China Pakistan Nepal Bhutan Bangladesh Myanmar Leh Population (2011): 30 870 Pokhara Population (2011): 264 991 Bumthang Population (2017): 17 820 THIMPHU Population (2011): 114 551 Jammu Population (2011): 502 197 Dehra Dun Population: 569 578 Nainital Population (2011): 41 377 Nepalgunj Population (2017): 138 951 KATHMANDU Population (2011): 1 003 000 1 810 000 1 003 000 569 578 502 197 264 991 169 578 154 019 138 951 17 820 30 870 41 377 59 490 114 551 120 414 Birlanagar Itanagar Population (2011): 59 490 Dibrugarh Population (2011): 154 019 Darjeeling Population (2011): 120 414 India Nepal Bhutan Srinagar Kathmandu Dehra Dun Jammu Pokhara Shimla Dibrugarh Nepalgunj Darjeeling Thimpu Itanagar Nainital Leh Bumthang Shimla Population (2011): 169 578 Srinagar Population (2011): 1 810 000

HIMALAYAS IN CONTEXT POPULATION

AND

NEPAL UTTARAKHANDSIKKIM BHUTAN ARUNACHAL PRADESH HIMACHAL 02PRADESH04 0107 01 02 03 04 0506 07 0305 06 JAMMU AND KASHMIR The modernisation trends in the Himalayas has created increased demand for tourist amenity, cannibalising the landscape to a commercialised extension of modern day activities. The expeditions that culminate in the Himalayas as the ultimate destination, have provided an economical footboard for the region, ranging from the colonial landscape of Shimla to the signage dominated lodges in the urban areas of Nepal (location of Mt. Everest).

CANNIBALISED LANDSCAPE POPULATION BY RANK Very High (>3) High (1.5-3) Medium (0.5-1.49) Low (0-0.49) Insufficient Data LeisureReligiousCivicCommunityOffices Raj Bhatwan (Peterhoff) Kilometers 150 0 300 N 19611981 2001 Shimla Expanding Urbanism 2.05 _ Himalayan Inhabitation 42

KEY(PERSONSPERHECTARE)

Figure 2.05A

2.06 _ Expanding Urbanism & Wider Economy Summary

Himalayan Infrastructure

MINERAL DEPOSITS

LOCATIONMINERAL

ZASKAR

MOUNTAIN RANGE

INDUS RIVER

BALISTAN

KASHMIR

LADAKH

JAMMU HILLS

NEPAL

BHUTAN SIKKIM, INDIA

FORESTRY

Sapphires

Alluvial Gold

Copper Ore

Iron Ore and Bauxite

Borax and Sulfur

Coal Seams

Coal, Mica, Gypsum, Graphite, Iron, Copper, Lead, Zinc

FOOD EXPORT

Fruits from Kashmir and Himachal Pradesh are exported to cities in India, as well as grapes used for wine and brandy. Bhutan also exports oranges to India.

Tea is grown in Darjeeling, and spice cardamon is found in Sikkim & Bhutan.

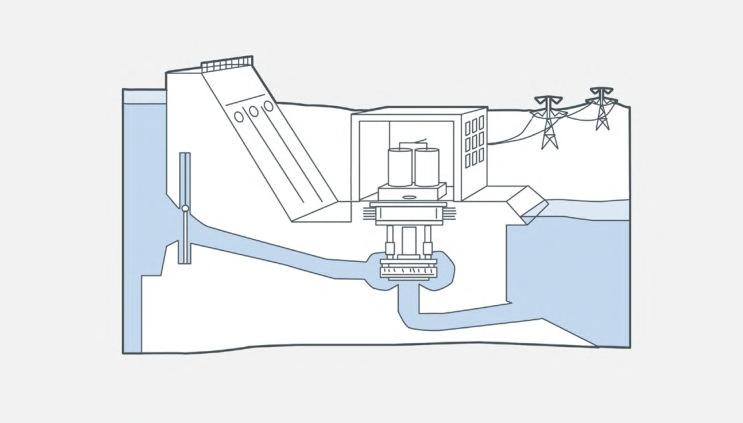

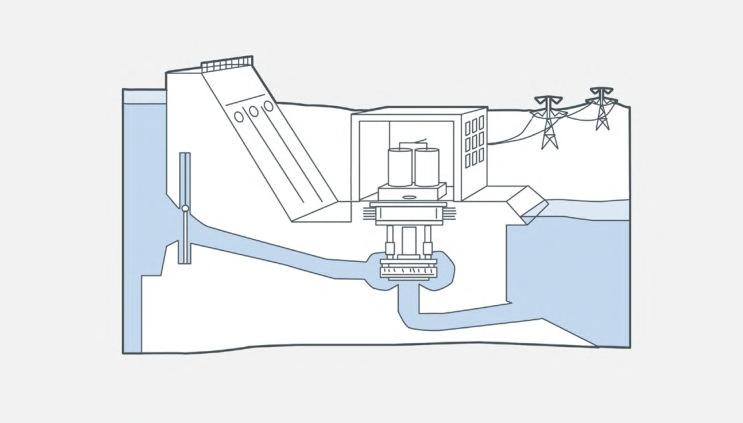

HYDRO-POWER

Capacity for Hydro-power first harnessed in India

Reservoir at Bhakra-Nangal on Sutlej River completed in 1963 with storage capacity of 10 billion cubic metres of water and generating capacity of 1050 megawatts

Nathpa Jhakri Dam on Sutlej Valley, Himachal Pradesh and Rampur Station operational Nepal and China have constructed hydropower projects in the Himalayas, with the Zangmu Station on Yarlung Zangbo (Brahmaputra) River completed in Tibet in 2015

FARMING

Sheeps, goats and yaks are grazed at higher elevations and migrate to lower levels during cold weather.

Arable lands in the western Himalayas are in the vale of Kashmir, Kangra valley, the Sutlej Valley Basin, and the periphery of the Ganges and Yamuna Rivers in Uttarakhand, producing rice, corn (maize), wheat, and millet.

The central Himalayas produces corn, wheat, potatoes, and sugarcane.

TOURISM

Nepal largely relies on tourism as a sourc of income, including from mountaineers looking to climb Everest. However, this caused increased traffic and tourists’ consumption of the region’s limited resourc causing further stress on the environment.

Sikkim and Bhutan are large regions heavily forested, with land used for planting to supply firewood, paper and construction materials.

RAILROADS

One major railroad connects Kalka and Shimla in the western Himalayas, while the second connects Siliguri to Darjeeling in the eastern Himalayas.

A narrow gauge line in Nepal runs 30 miles from Raxaul, Bihar State, India to Amlekhganj.

Two shorter railroads run to the outer Himalayas, one from Pathankot to Jogindarnagar in Kullu Valley and the other from Hardiwar to Dehra Dun.

CARAVAN TRADE ROUTES

The Sikkim Himalayas use the historic Kalimpang-to-Lhasa trade route which passes through Gangtok. Several roads passable via four wheel drives have been built in southern Sikkim, with the highway from Siliguri having been extended through Lachung in northern Sikkim to Tibet.

The Kosi, Gandak and Jaldhaka Rivers were harnessed by India to supply electric power to Nepal and Bhutan.

AIRPORTS

Two major airstrips in the Himalayas are located in Kathmandu and Srinagar, with Kathmandu’s airport servicing international and regional flights. Increased road and transport infrastructure has expanded the growth of tourism in the Himalayas.

ROAD CONNECTIONS

Many new roads have been built since 1950, connecting several territories across the Himalayas.

KATHMANDU

NEPAL PAKISTAN

HIMACHAL PRADESH

MANALI PUNJAB

Low Himalayan Highway

via Kodari Pass

Karakoram Highway

Hindustan-Tibet Road

POKHARA, TIBET

BIHAR STATE INDIA

CHINA

TIBET

Srinagar, Kashmir via 5404m Khardung Pass

Highway Connection

Highway Connection

480km via Shimla and Shipki Pass via Jalandhar to Srinagar

LEH

KASHMIR

01 02 03 06

INFRASTRUCTURE

INFRASTRUCTURE

INFRASTRUCTURE

TRANSPORT

TRANSPORT

TRANSPORT

TRANSPORT INFRASTRUCTURE

1950S 1963 2014 2015 05 07 08 10 09

source mountaineers has heavy resources, environment. 04 09 07 10 08 06 05 04 03 02 01 44 BARC0174 _ AAD1CHAPTER 2A _ WIDER SITE CONTEXT

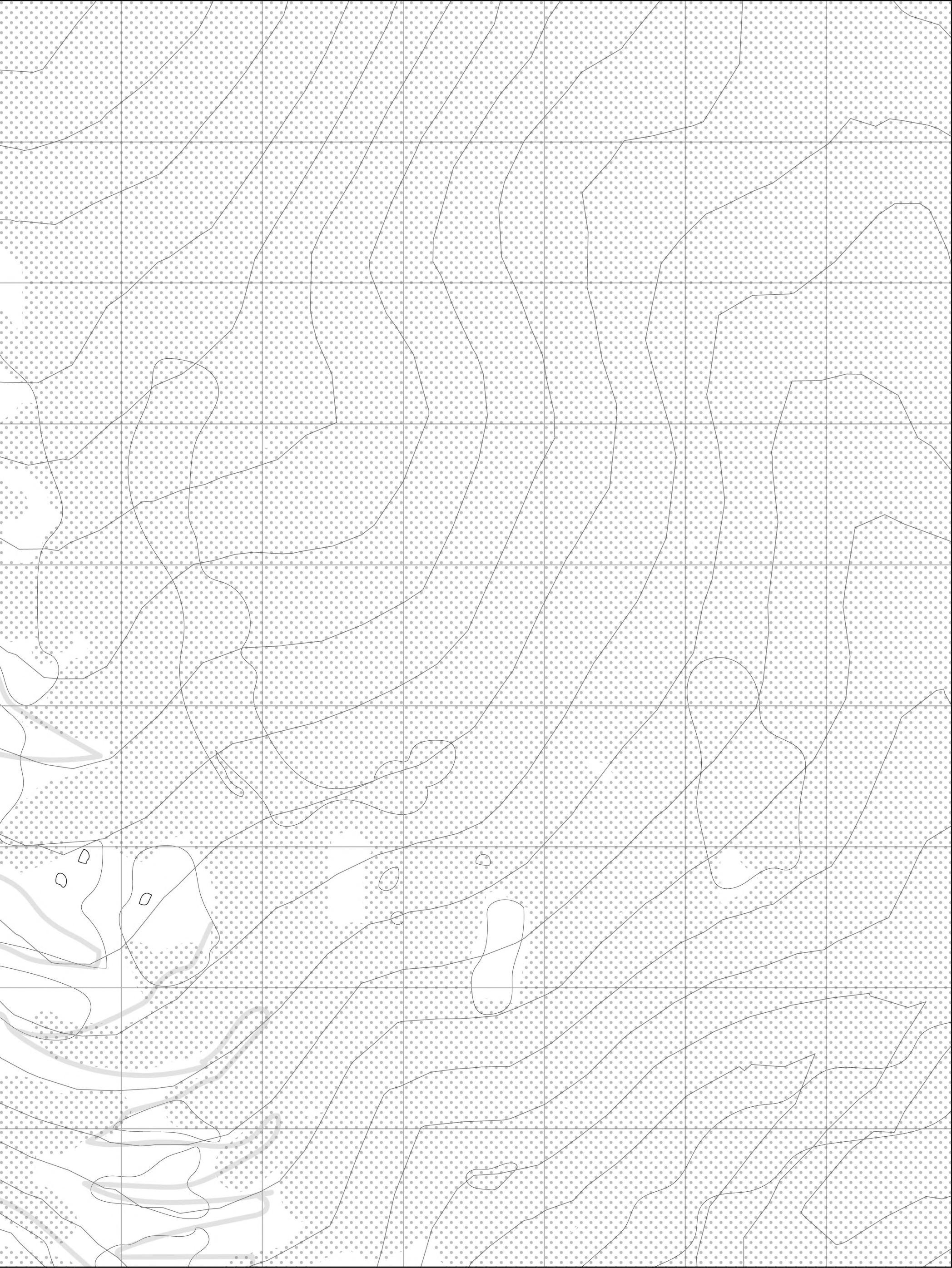

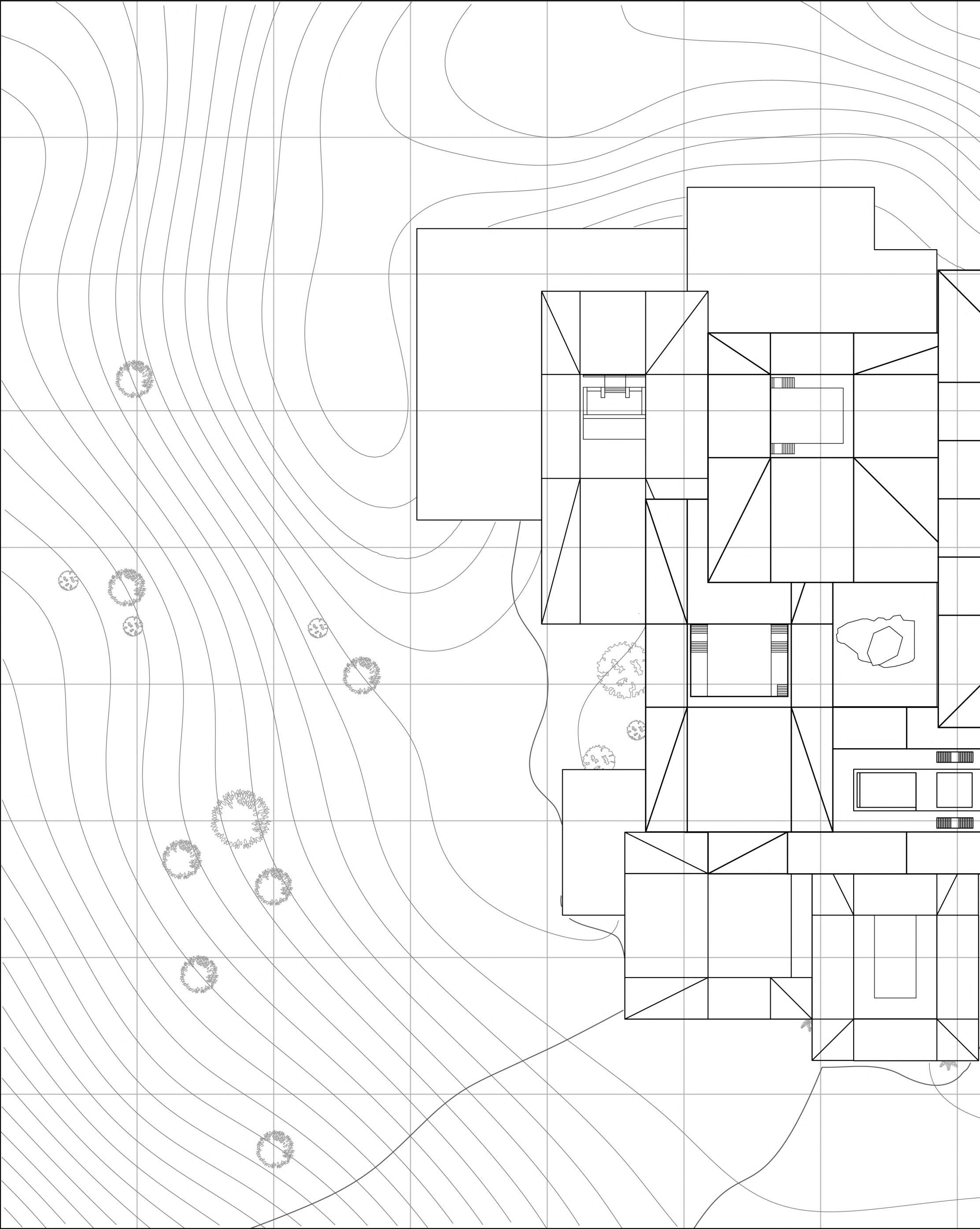

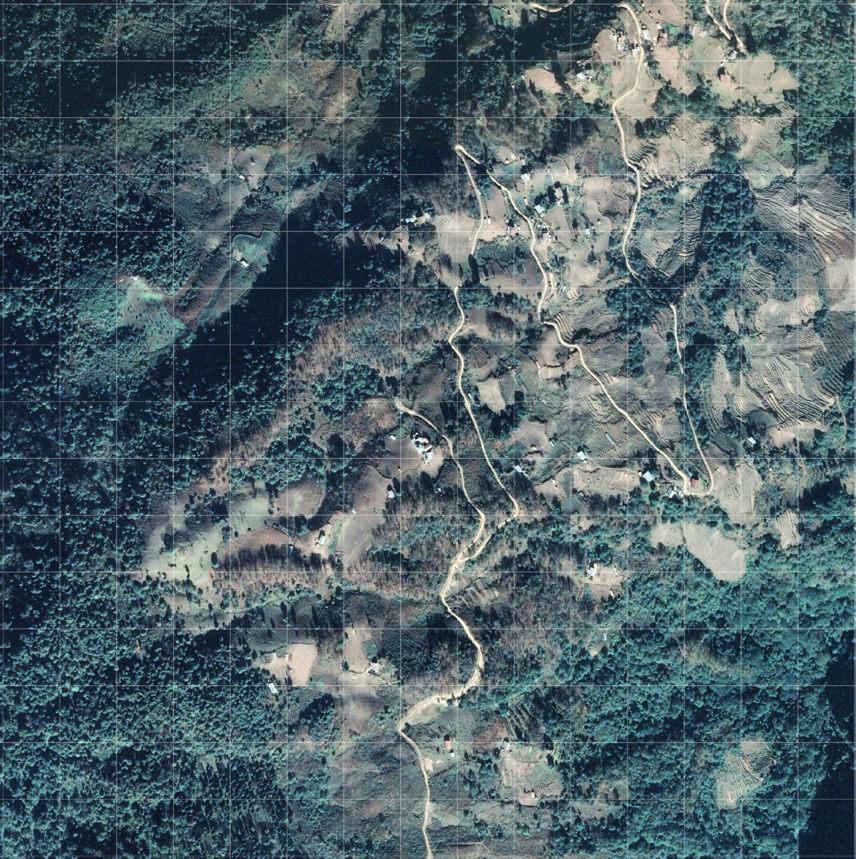

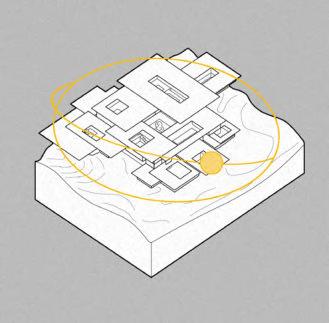

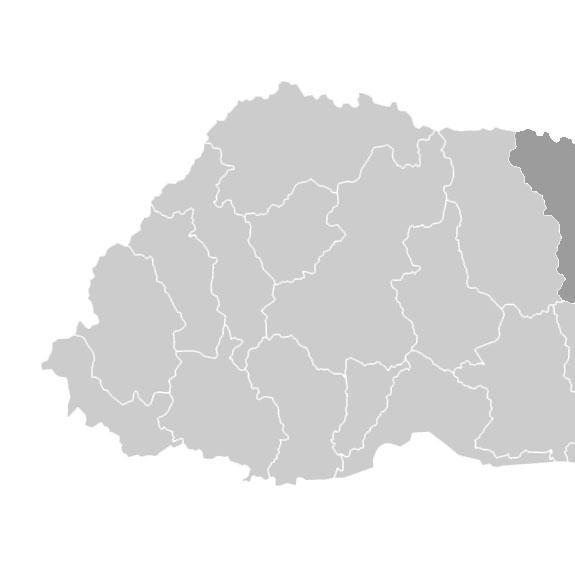

N 0m100m GANGZUR KURTOED KHOMA MINJEY TSAENKHAR JAREY MAEDTSHO MAENBI KEY Main Highway Feeder Road Kuri Chhu River Rivers Foot Path Lhuentse Dzong & Site Location Bridge Gewog Centre Village Historical Sites SITE TIBET TASHI YANGTSE MONGAR BUMTHANG

Lhuentse DistrictBhutan

Site Overview:

LHUENTSE TOWN, LHUENTSE DISTRICT, BHUTAN

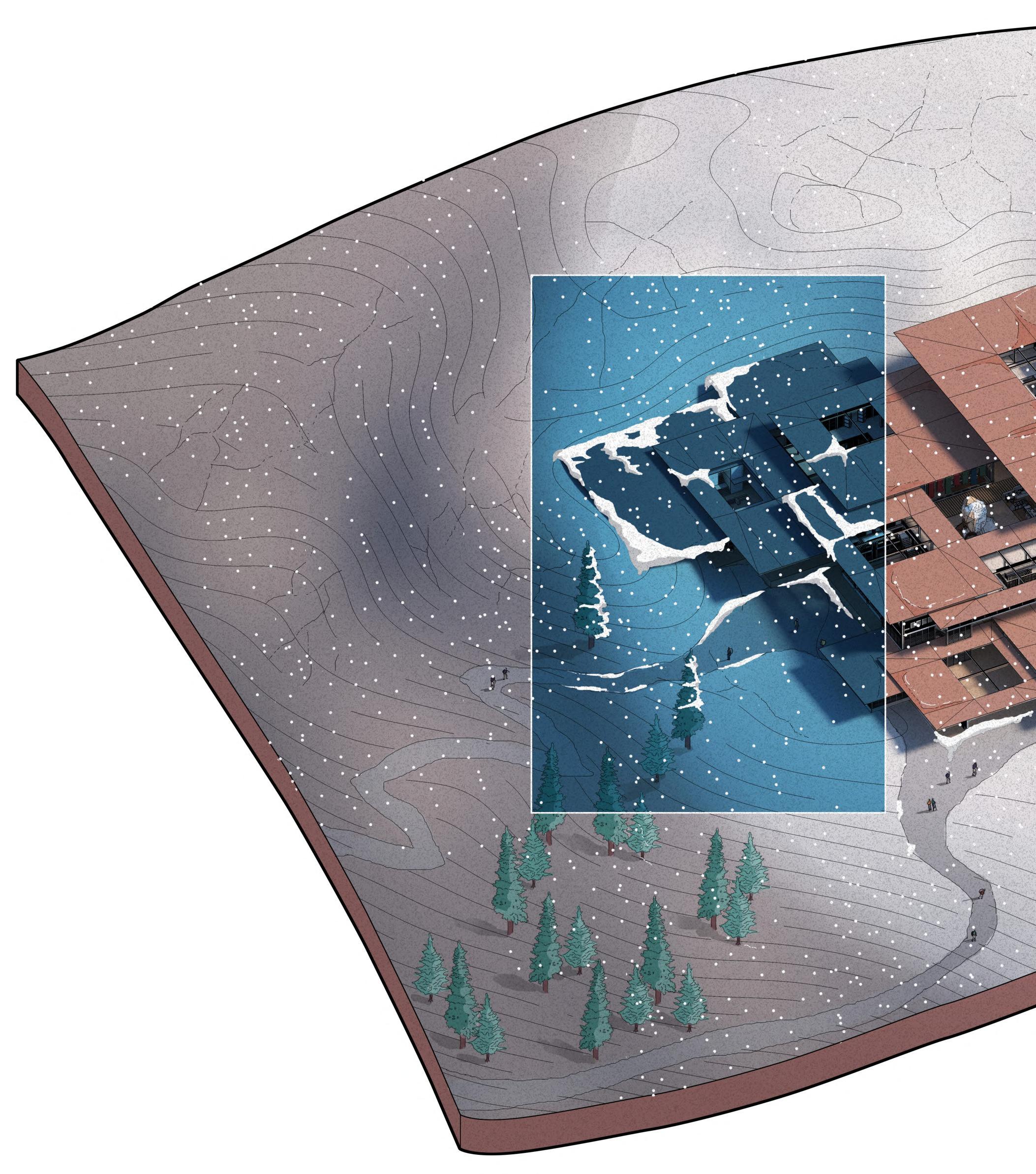

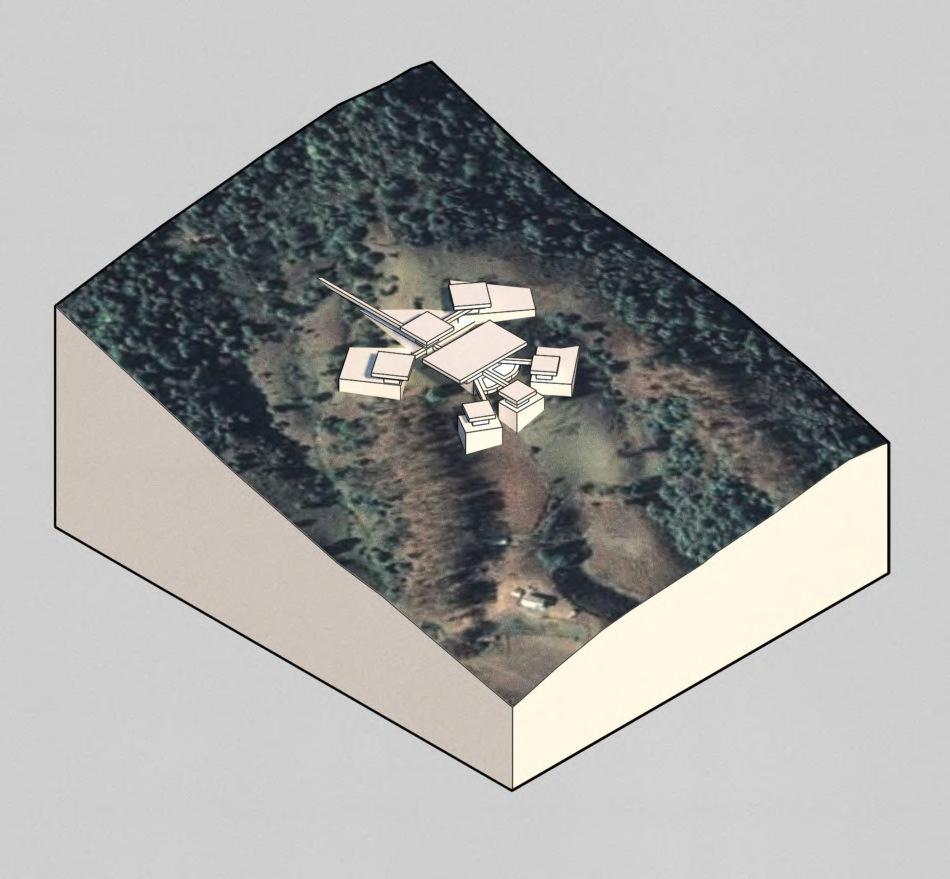

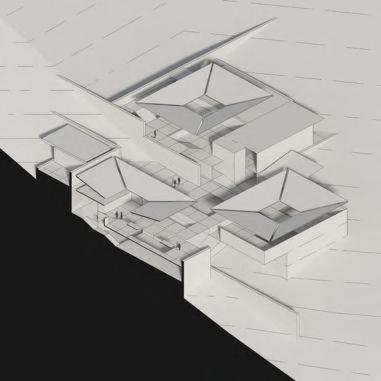

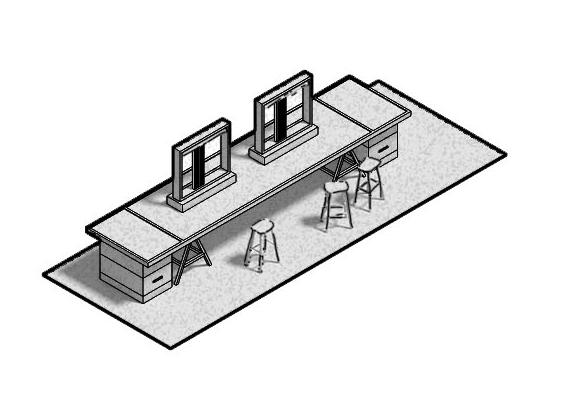

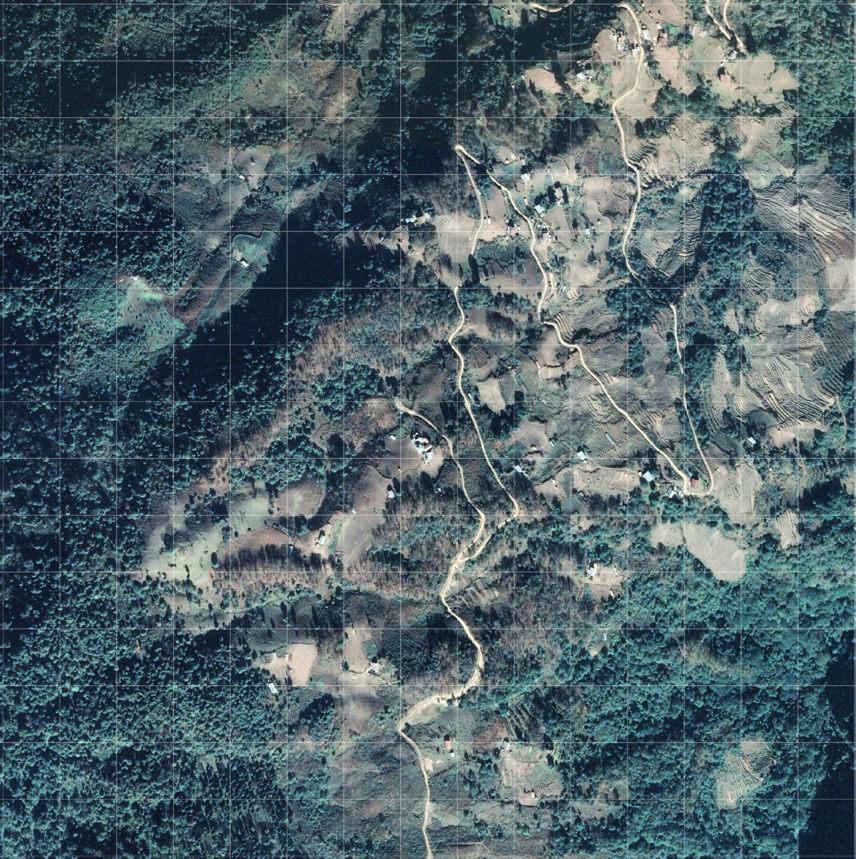

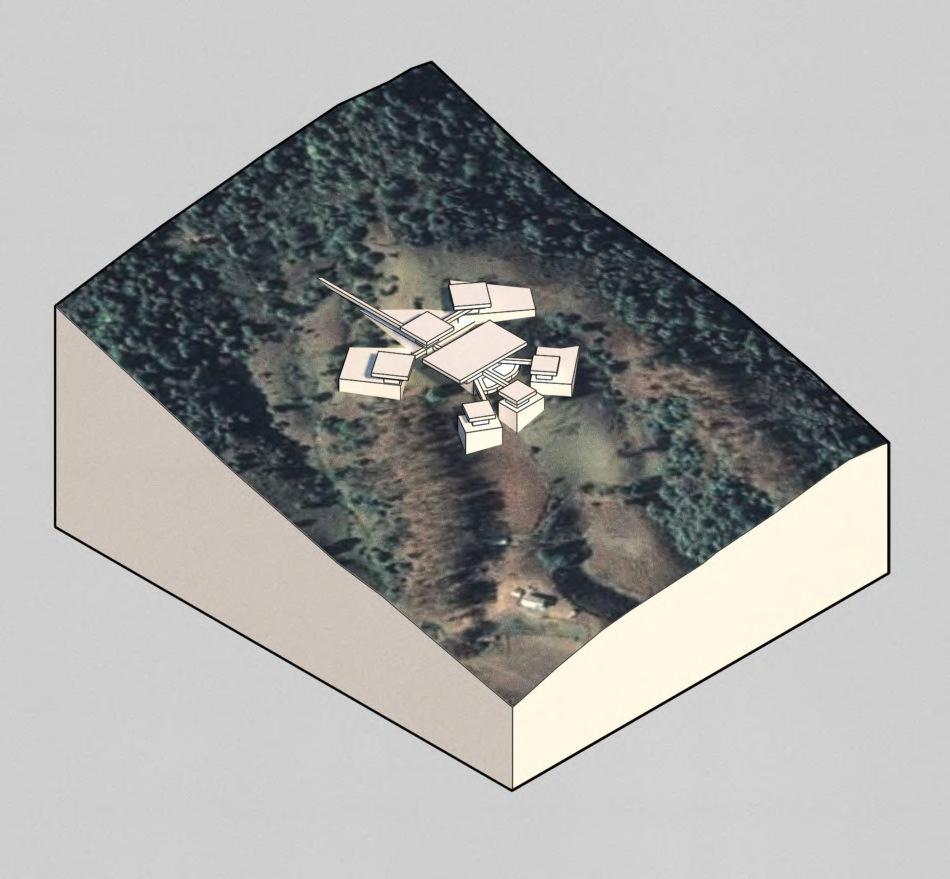

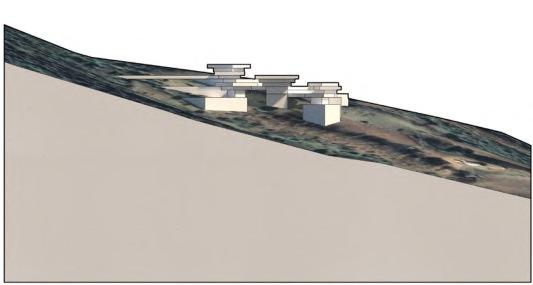

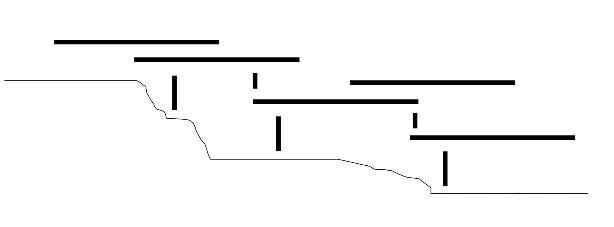

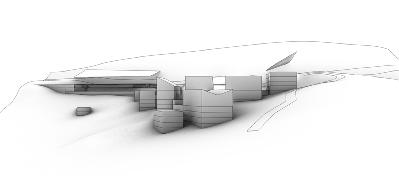

Having identified Bhutan as an insular and never before colonised nation in the Himalayas, the chosen site in eastern Bhutan presents an opportunity to preserve the nation’s cultural heritage and identity whilst engaging both locals and tourists within a rural, but moderately urban context. The remote site is located nearby a cluster of historical spots in the ancestral homeland of the Bhutanese royal family in Lhuentse Town, the headquarter of Lhuentse District, whilst providing vast views across the high altitude town.

Brief Ambition: CRAFTS: A CIVIC & EDUCATIONAL OPPORTUNITY

The scheme seeks to consolidate Lhuentse Town’s reputation for textile/crafts production and its existing exposure to tourists/campers, aiming to introduce an educational programme for both local/ foreign users, creating a civic presence with a hybrid structural expression, materialising a novel cultural exchange.

02B BARC0174 _ AAD1CHAPTER 2 _ HIMALAYAS, ABODE OF SNOW

SITE AND BRIEF

Lhuentse Town, Bhutan 46

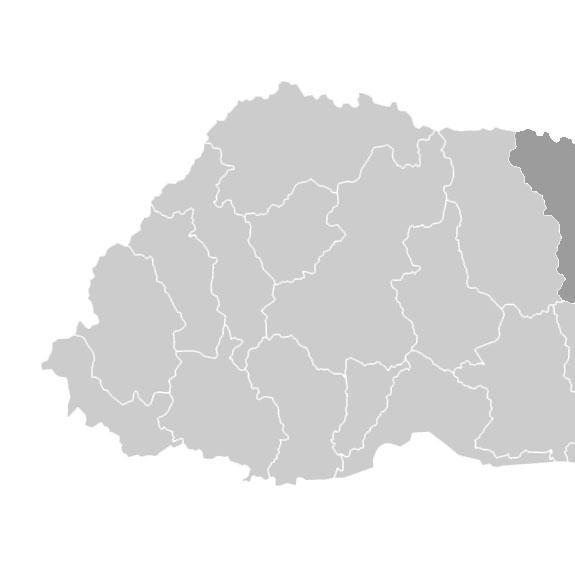

Lhuentse, Bhutan

LHUENTSE TOWN

The site is located at high altitude with a vantage point over the town of Lhuentse in Lhuentse District, the headquarter of the district. Located 450km east of Bhutan’s capital Thimpu, the site is in the gewog (county) of Gangzur. The proposal for a citadel of culture/craft seeks to propel footfall in the remote district, and consolidate the existing infrastructure problems including poor electricity distribution, and the difficult terrain, which makes social welfare access a challenge.

Chorten

Views 2 & 3 - Looking towards site View 1 - Looking out of site INHABITED CONDITIONS SITE CONTEXTWIDER VIEW 1 VIEW 1 VIEW 2 VIEW 3 VIEW 2 SITE CONTEXT VIEW 3 KEY

300m100m 100m0m200m500m1000m

Lhuentse Town Boundary

Gangzur Village Kuru Chhu River

Gadongla Tshongkang

Lhuentse Dzong

Bhutan SITE SITE N N

LHUENTSE DZONG Dzongs monasterie Bhutan Lhuents a a offices, ac specifically Tibetan as of also focussing sky the will this main N N

Lhuentse Court Bank of

SITESITE LHUENTSE DZONG LHUENTSE COURT

2.07 _ Site

Figure 2.07A

Dzongs are fortified monasteries, of which Bhutan contains many.

Lhuentse Dzong wraps central courtyard with temple, administration offices, and monks’ accommodation. It is a specifically Bhutanese/ Tibetan typology, behaving as the main civic centre the district. Large walls also obstruct lateral views, focussing attention to the sky (and the symbolism of the heavens). The scheme will seek to consolidate this landmark as well as its main conditions.

LHUENTSE COURT (CIVIC)

BANK OF BHUTAN (CIVIC)

LHUENTSE BACKGROUND

The site is moderately urban, yet still remote, as well as the ancestral homeland of the Bhutanese royal family. The site’s terrain and characteristics attract campers, making the site a potential mediator of such activity, creating an opportunity for cultural exchange.

This creates the possibility for structural expression referencing Kath Khuni, materialising a hybrid cultural architecture.

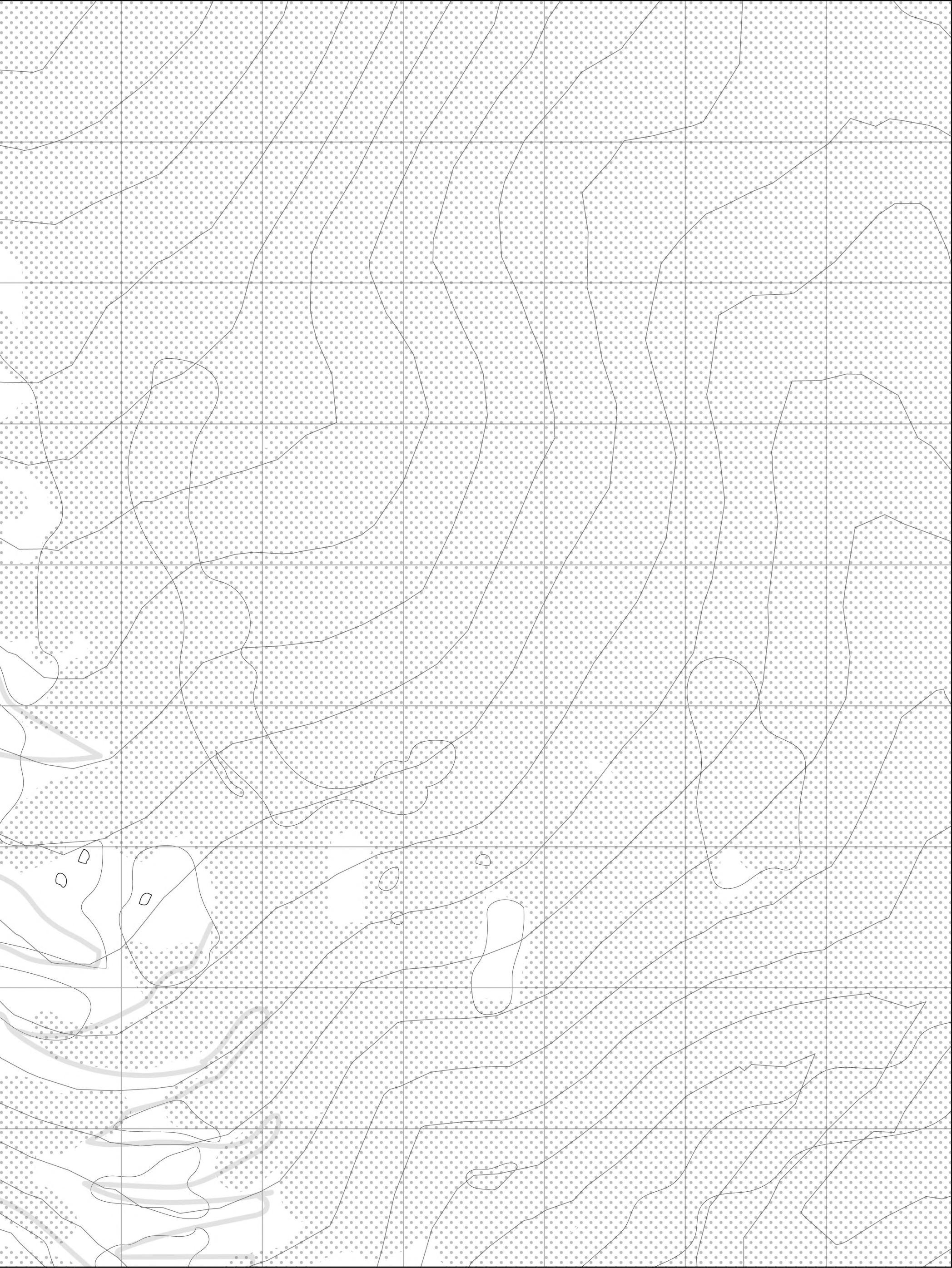

DZONG CONTOUR MAP

The scheme also seeks to mediate the environmentally protected areas and capture expansive views of the landscape steeped in myths and historical sites dotted across the terrain.

Lhuentse Town is well known for textile production, a significant aspect of Bhutanese culture. Weavers use looms to craft garments of clothing distributed across Bhutan. The scheme seeks to preserve the tradition of Bhutanese textile production, and create more visibility outside the nation.

WINDING ROAD CREATES ACCESS POINT

GANGZUR VILLAGE

CHORTEN

LHUENTSE DZONG (CIVIC)

KURU CHHU RIVER

Meters 1005001000 0 N SITE SITE

The site sits at a high altitude of approximately 2190m (7185ft). An existing road creates an access point, and an overlooking position across the town.

48 Bhutan Nepal Tibet India BARC0174 _ AAD1CHAPTER 2B _ SITE AND BRIEF

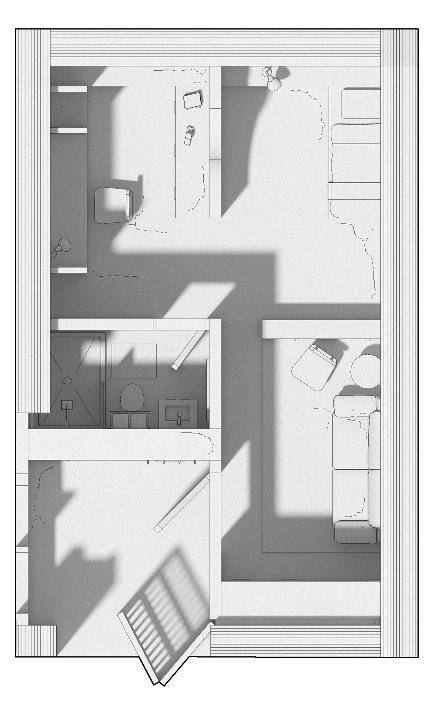

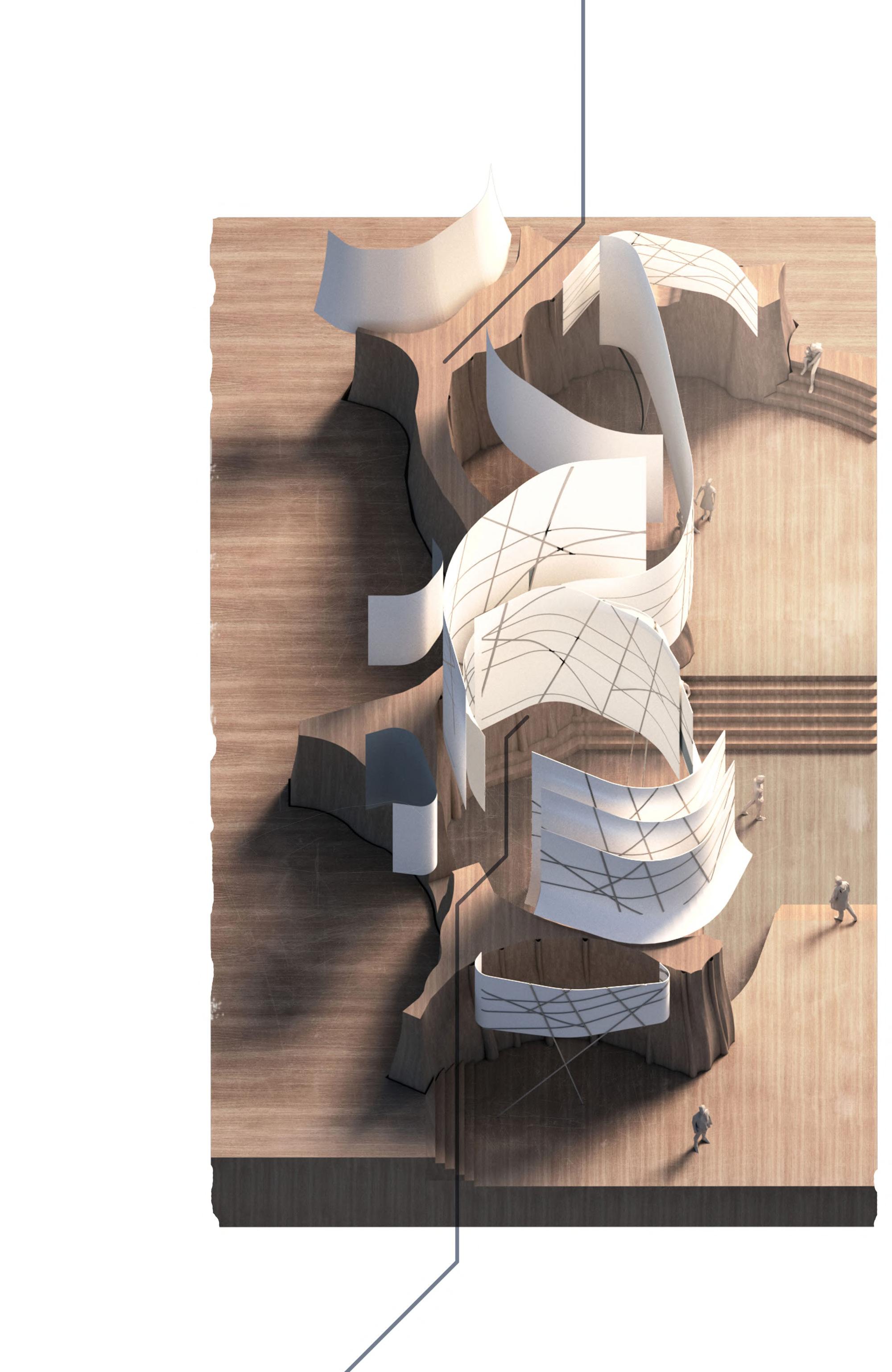

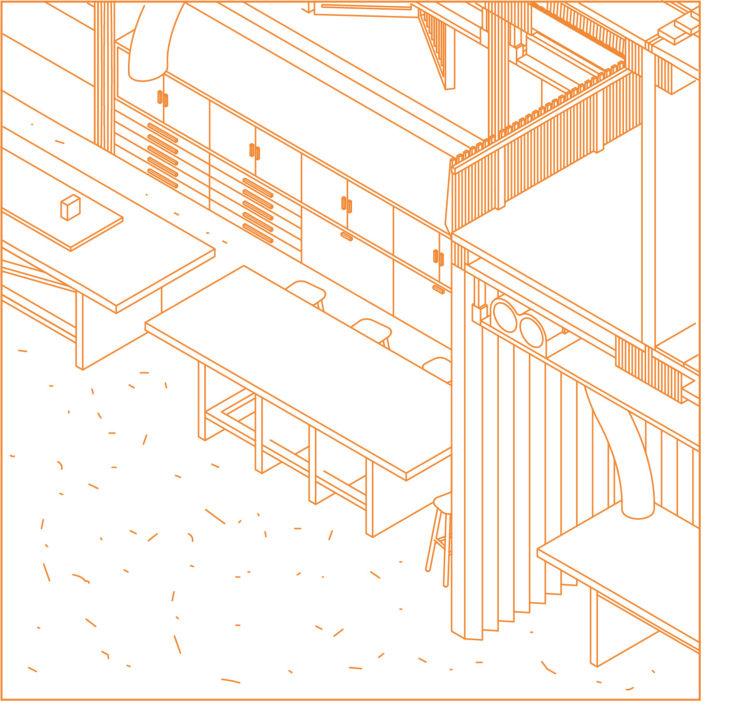

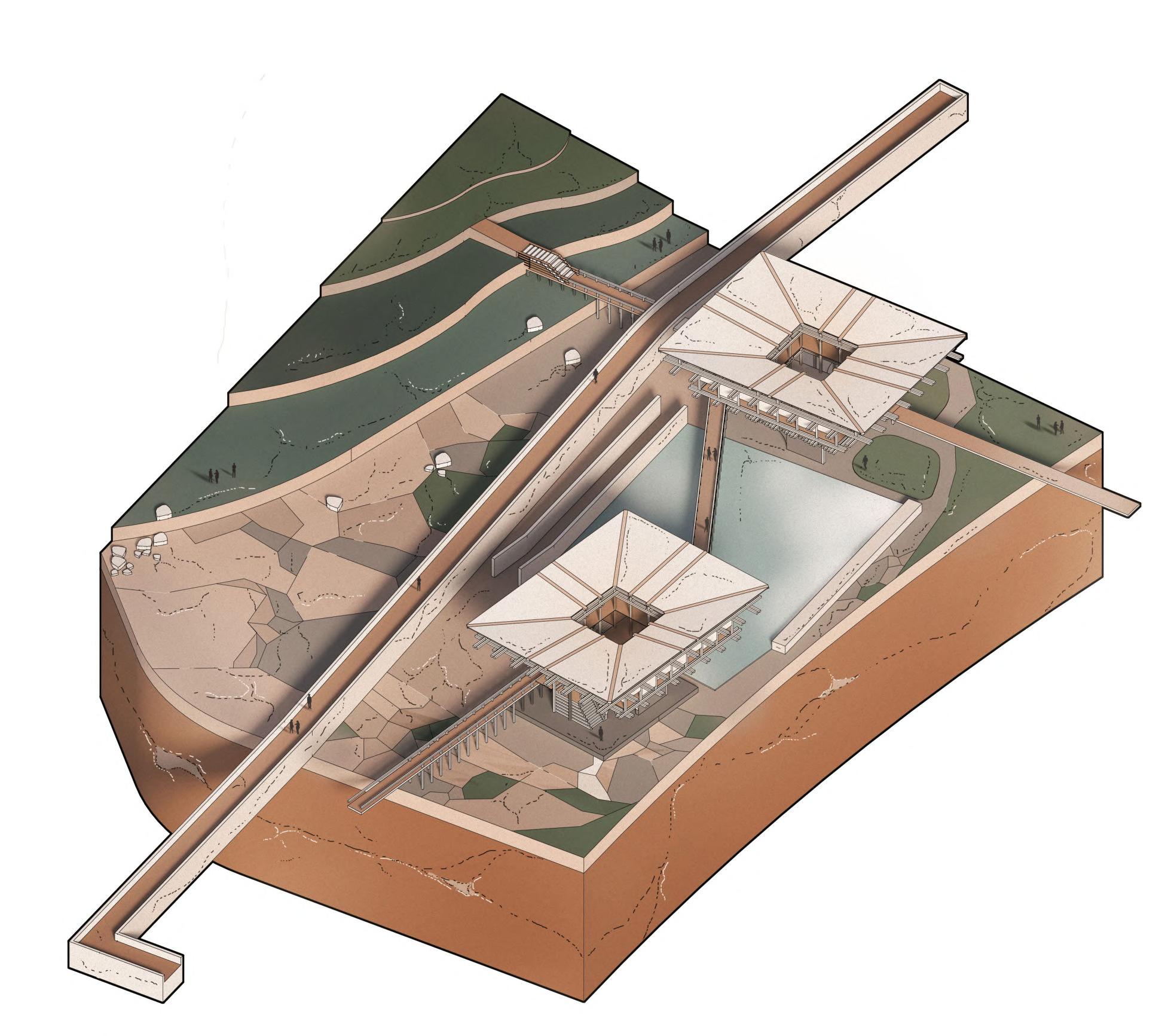

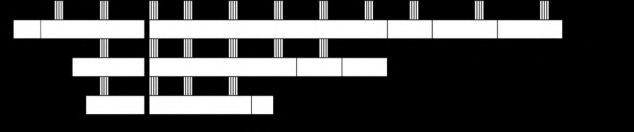

Lhuentse School of Crafts

DESIGN PROPOSAL

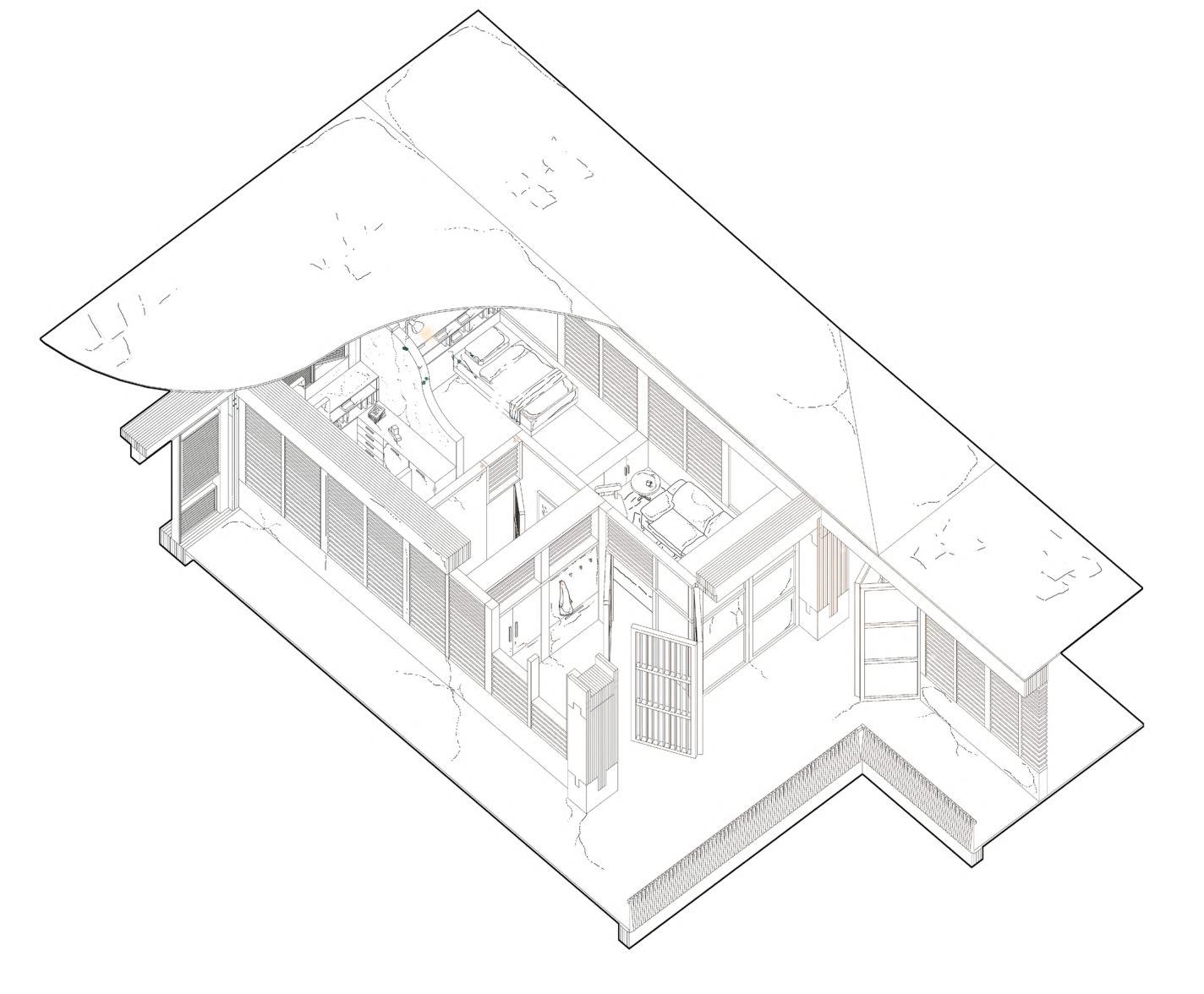

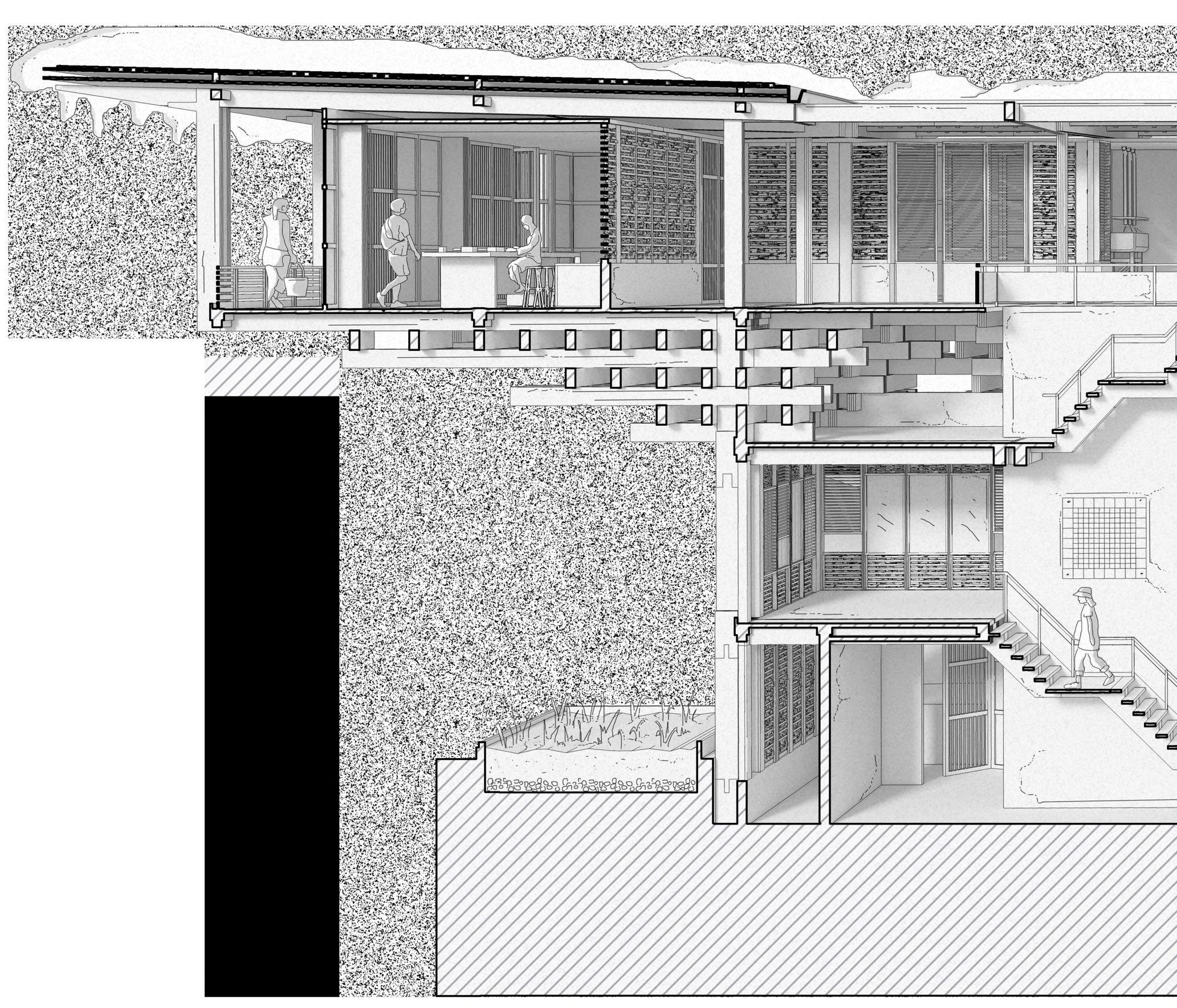

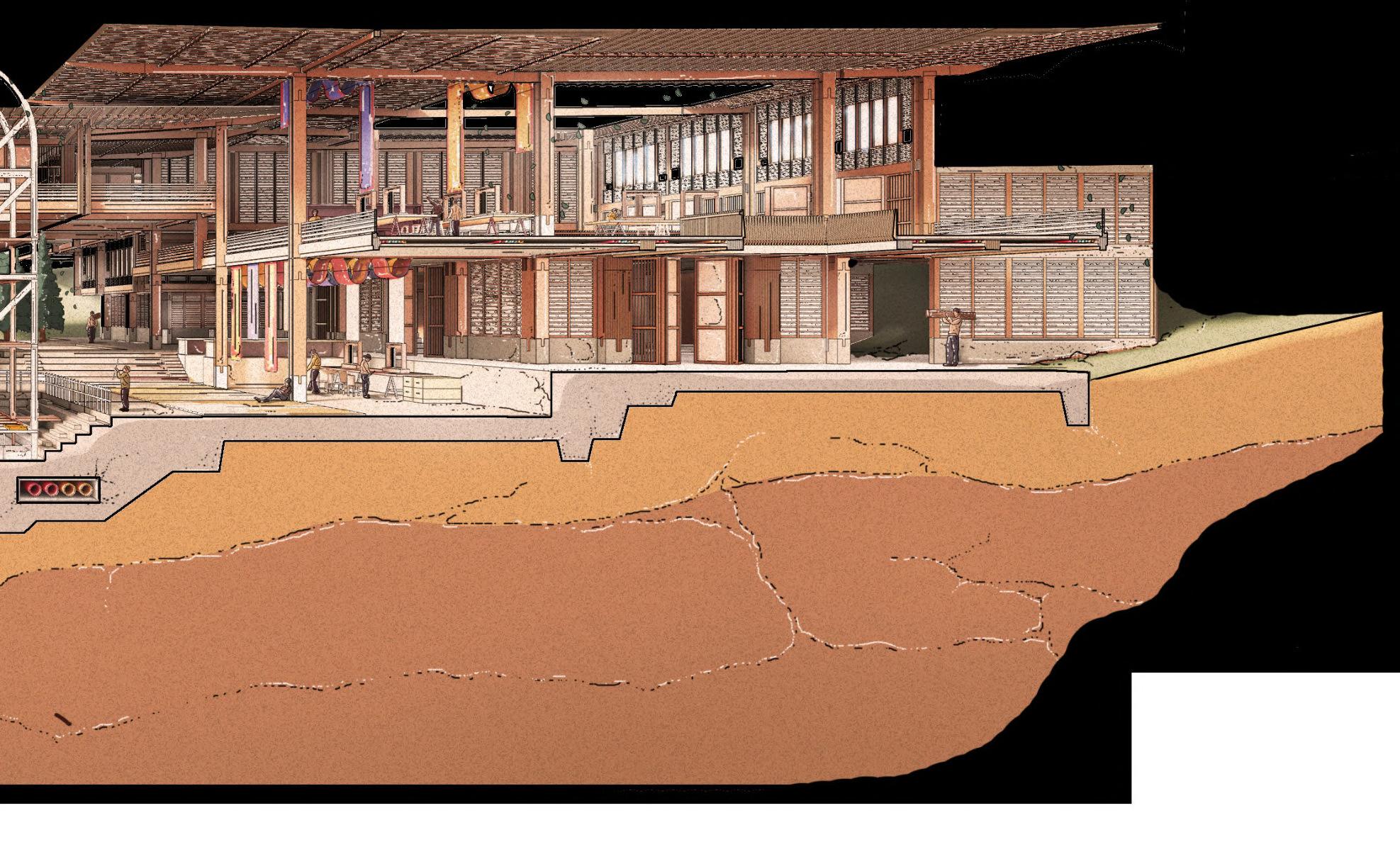

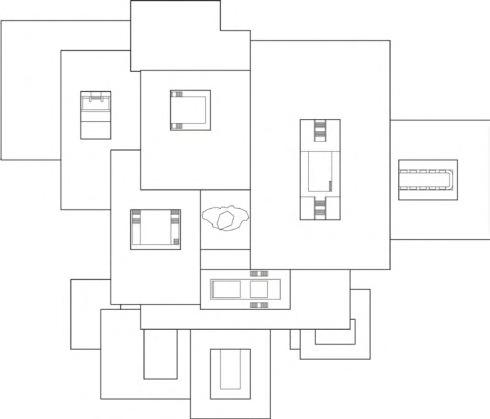

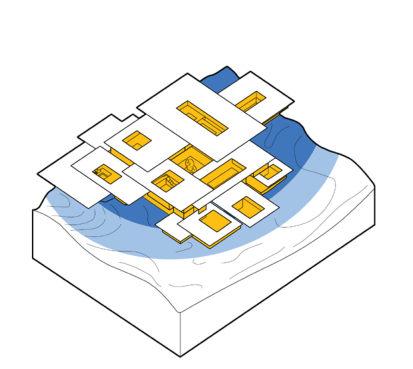

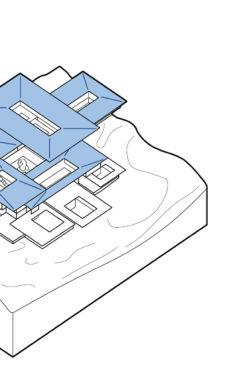

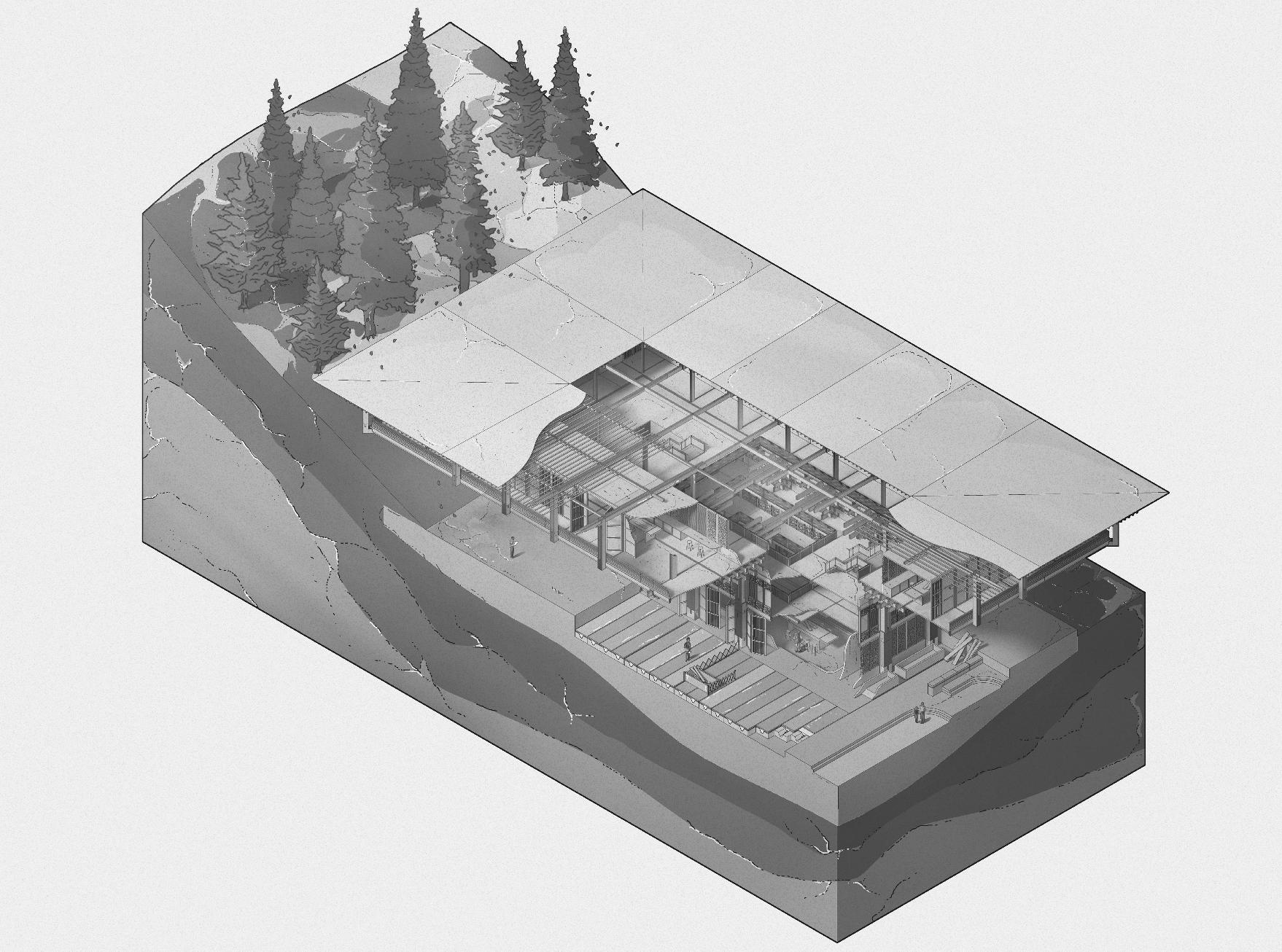

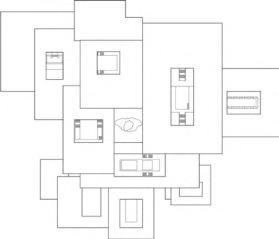

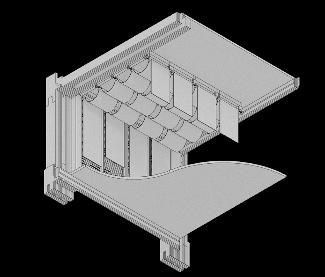

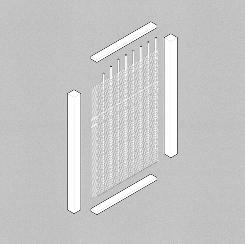

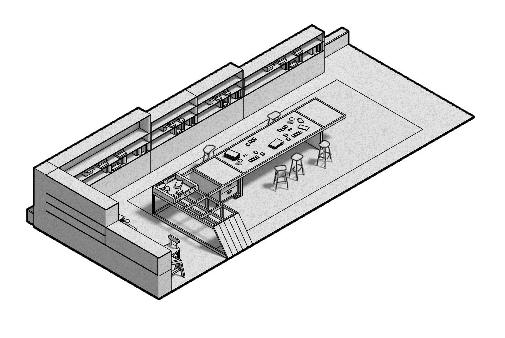

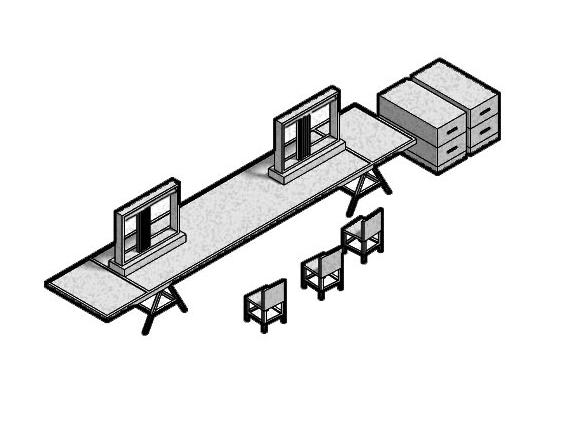

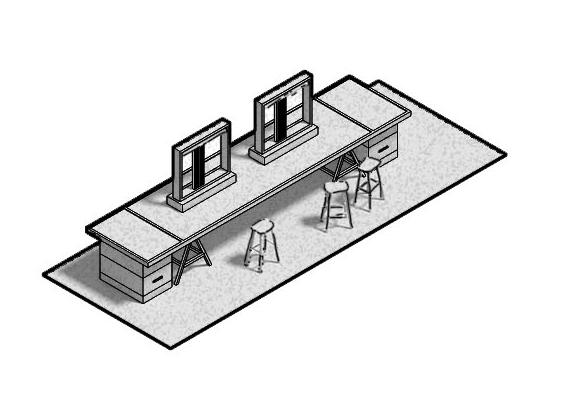

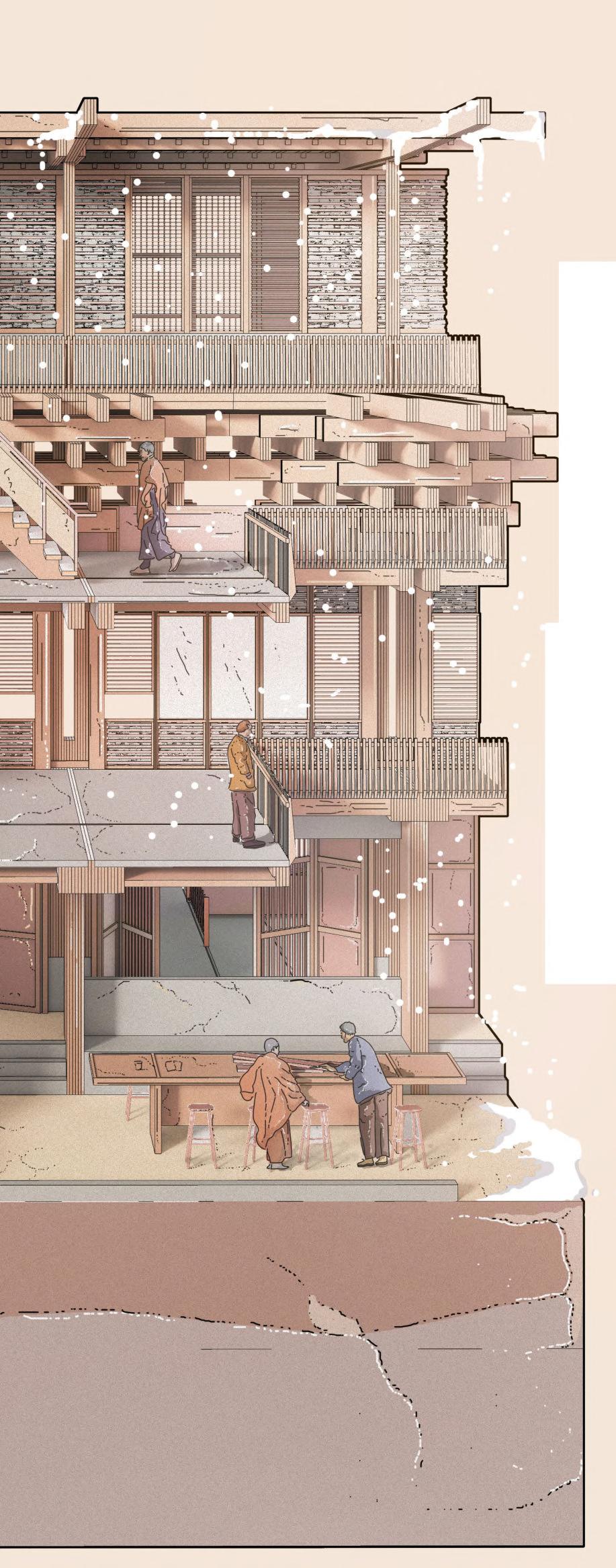

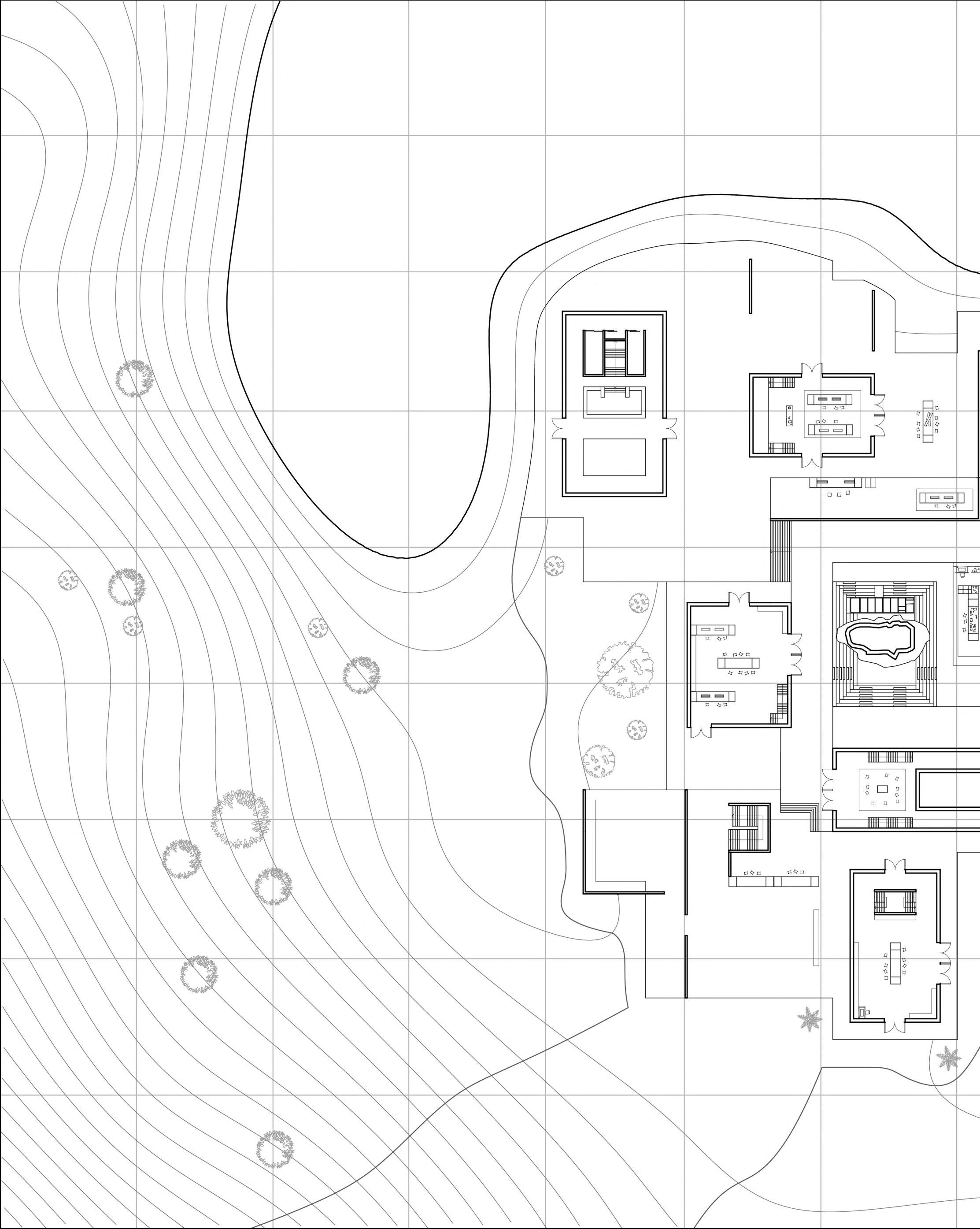

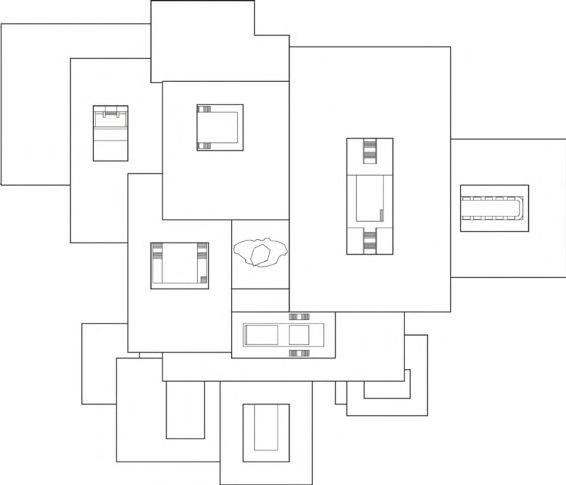

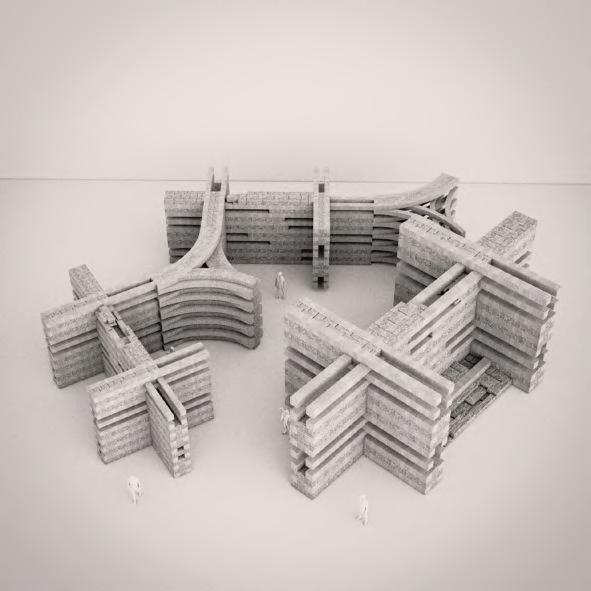

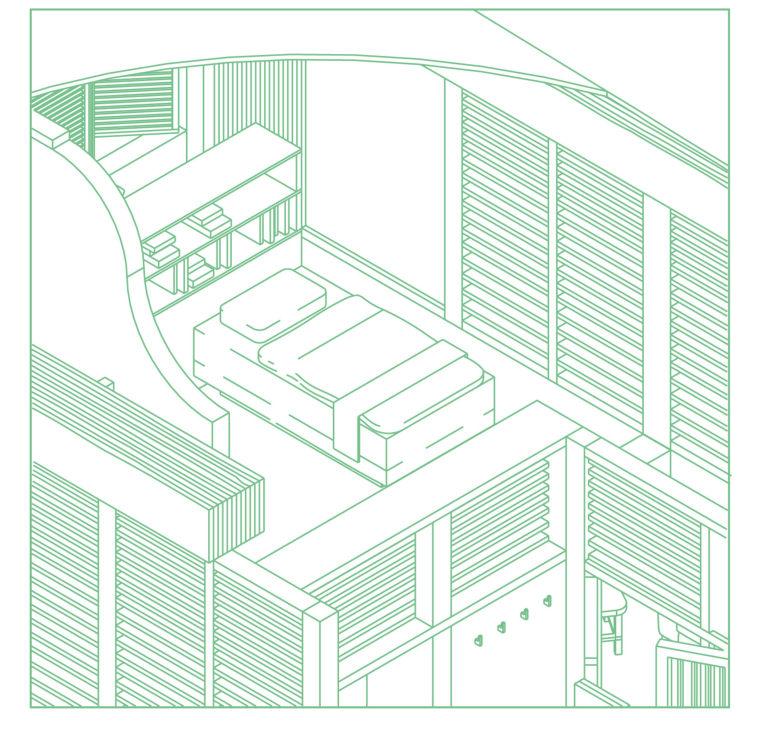

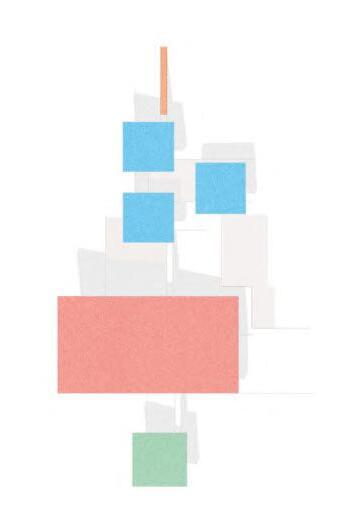

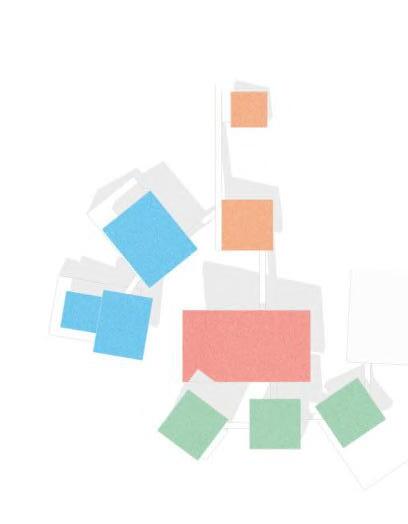

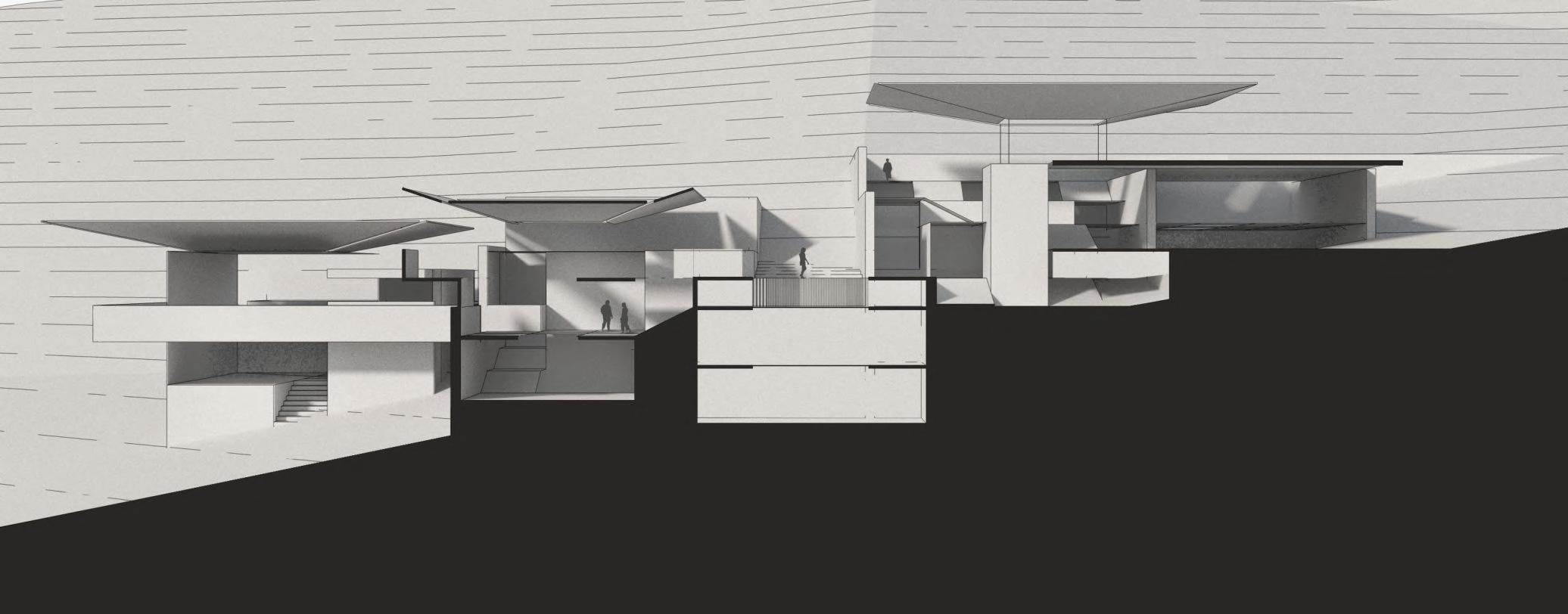

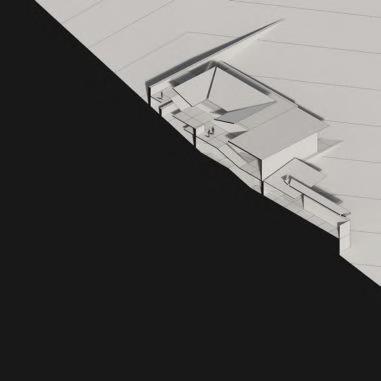

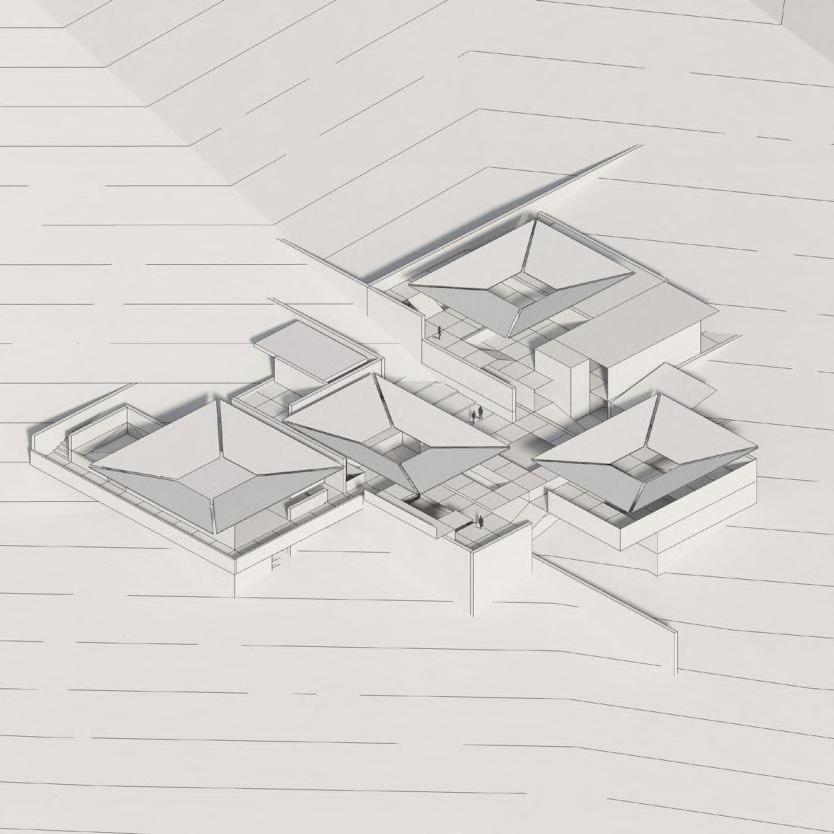

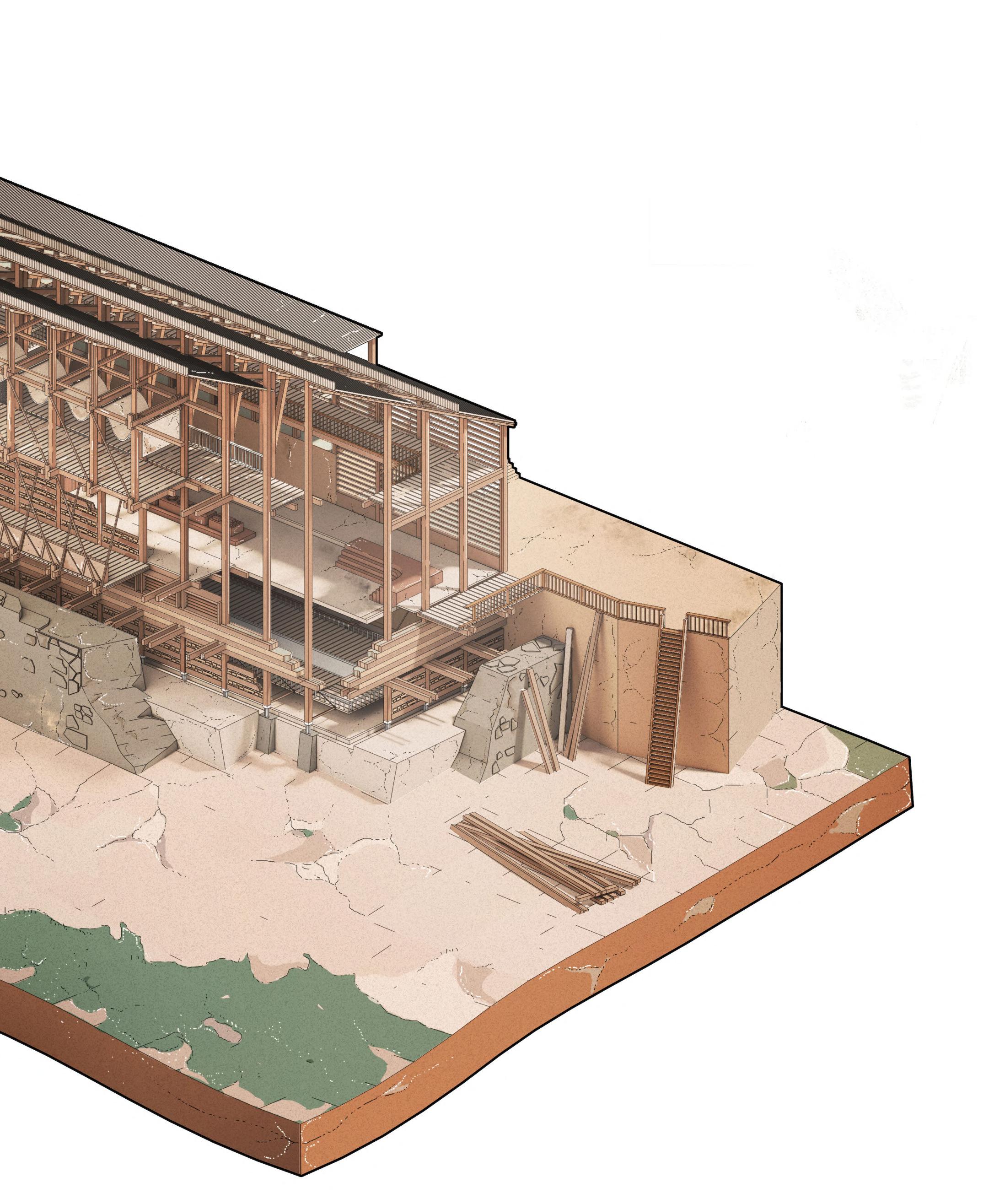

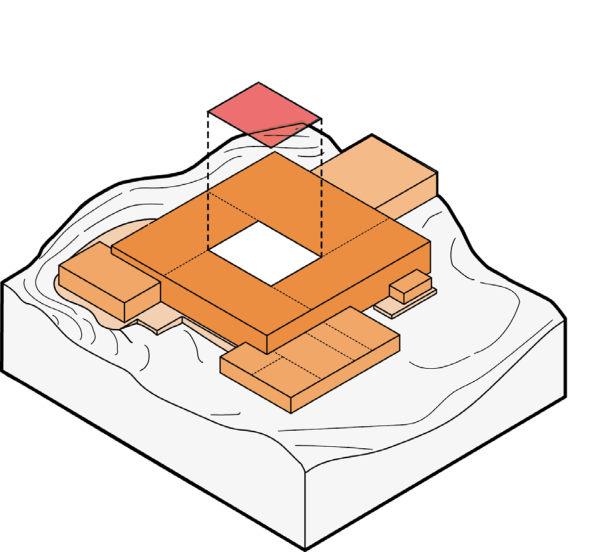

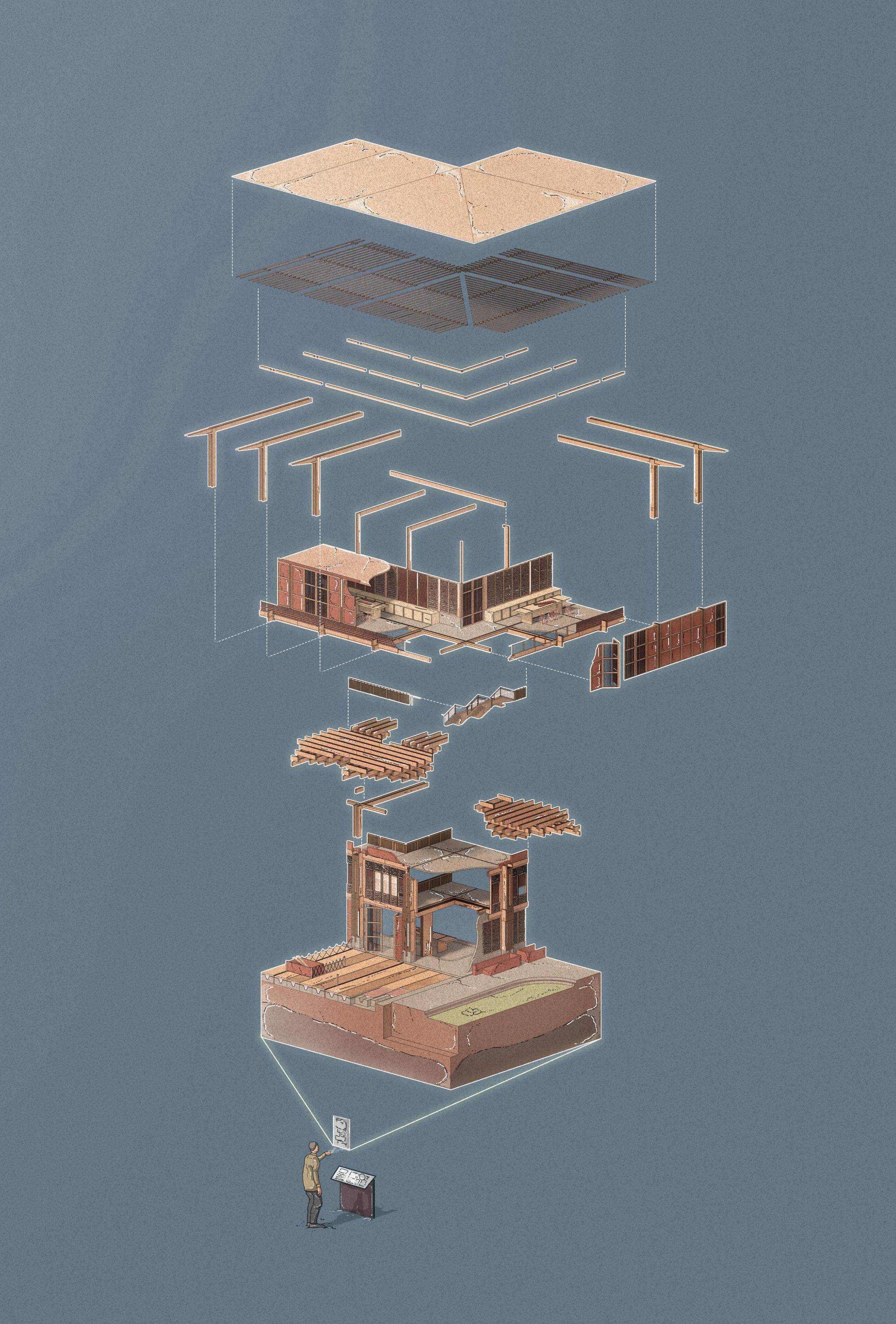

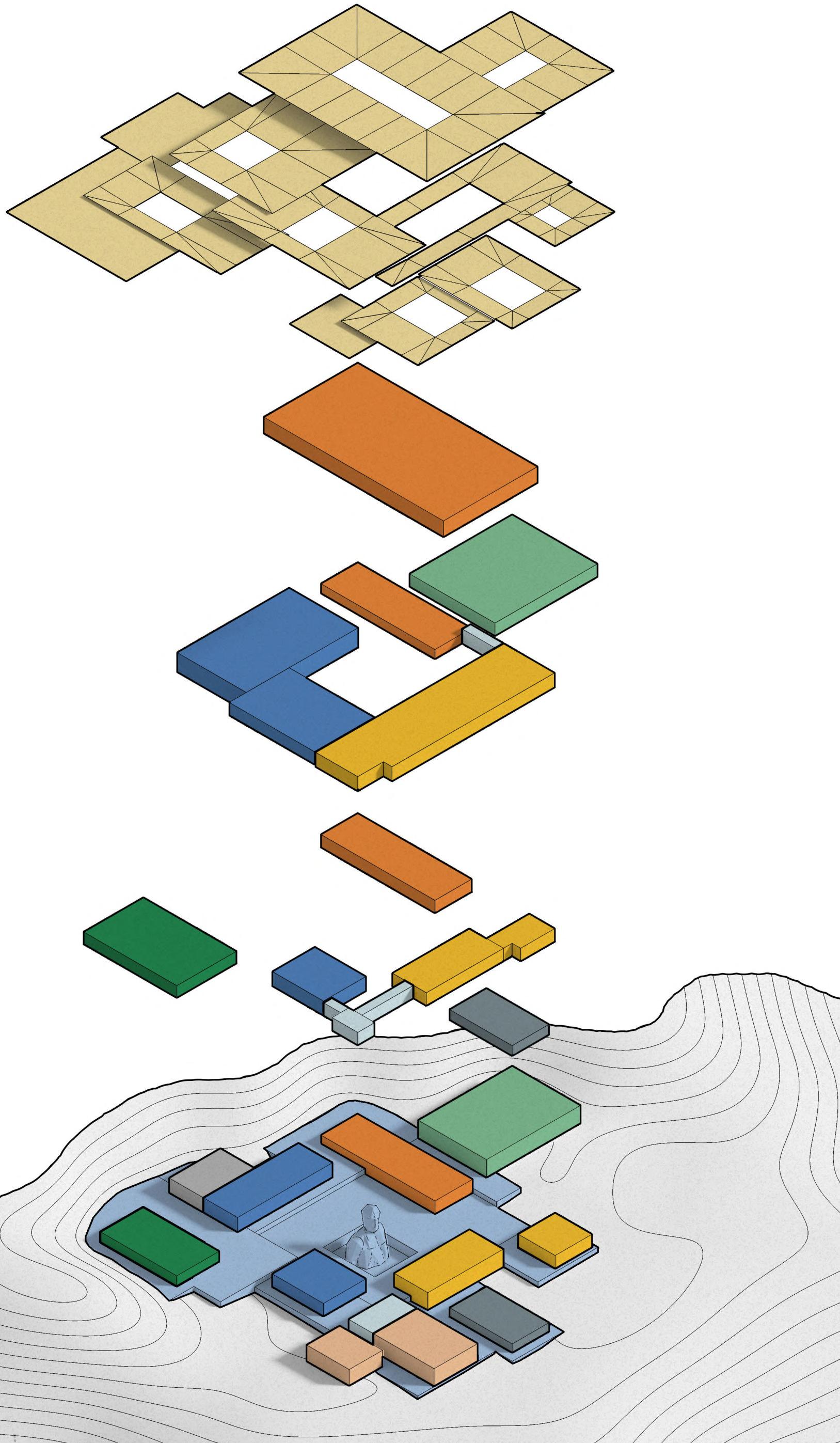

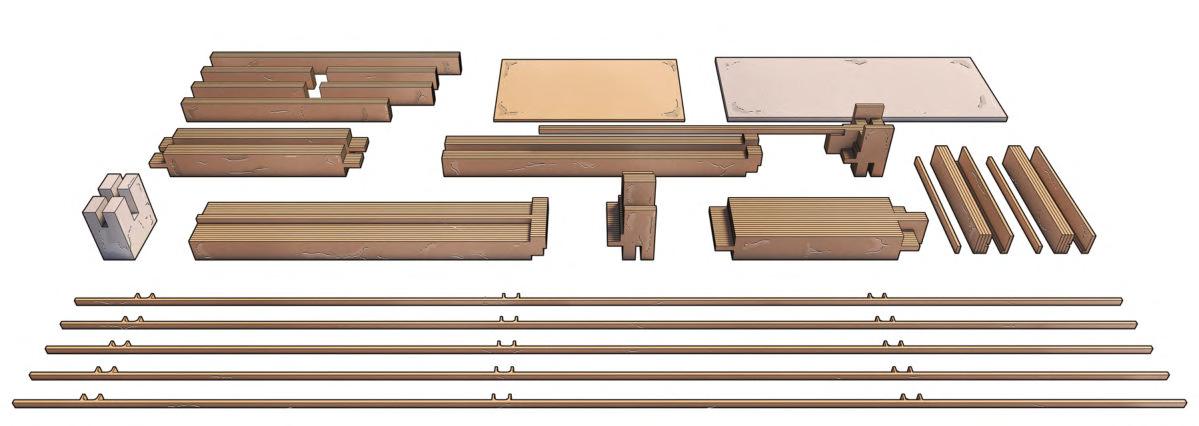

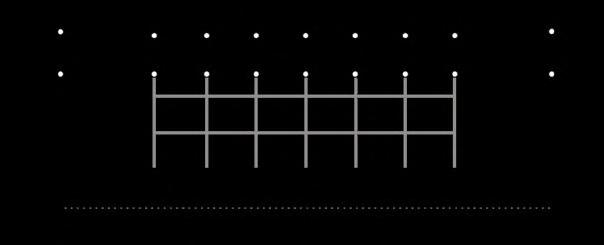

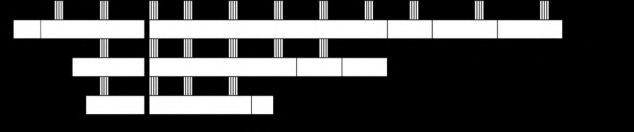

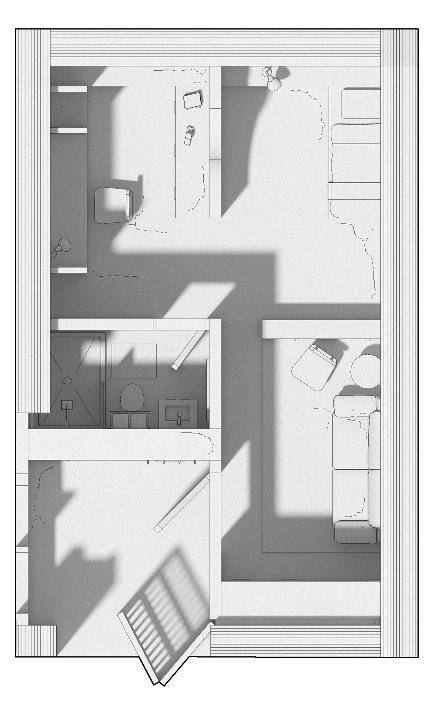

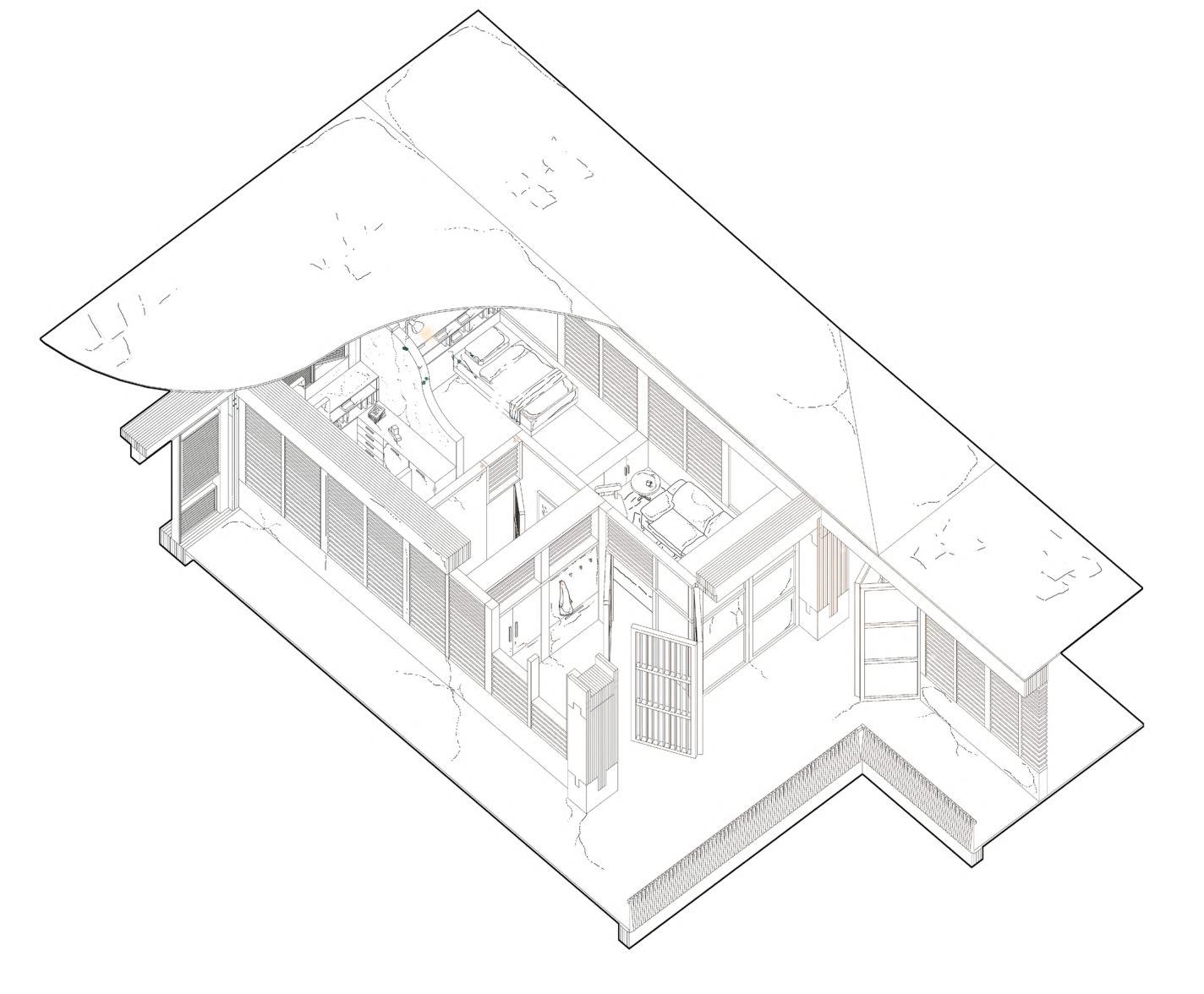

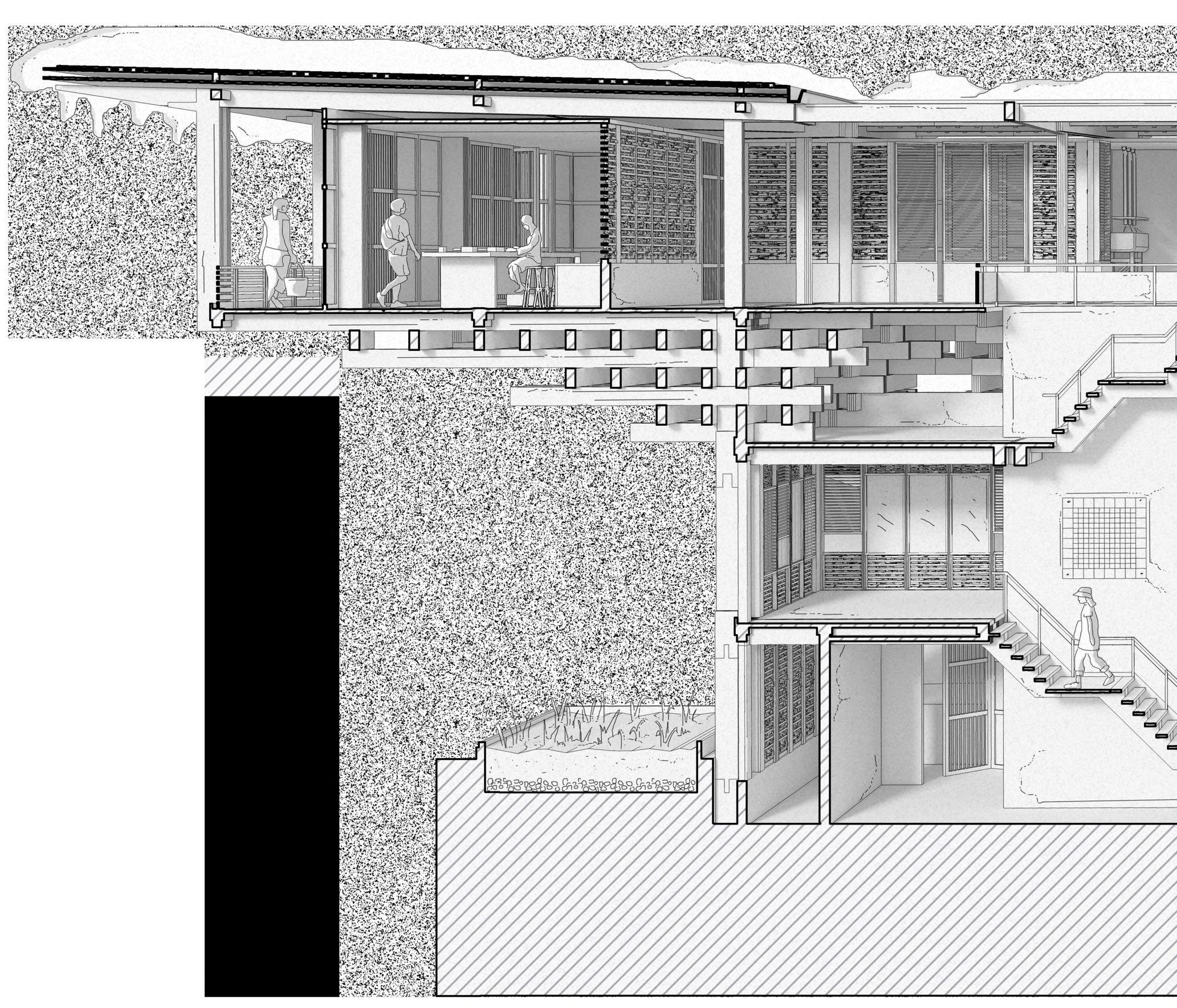

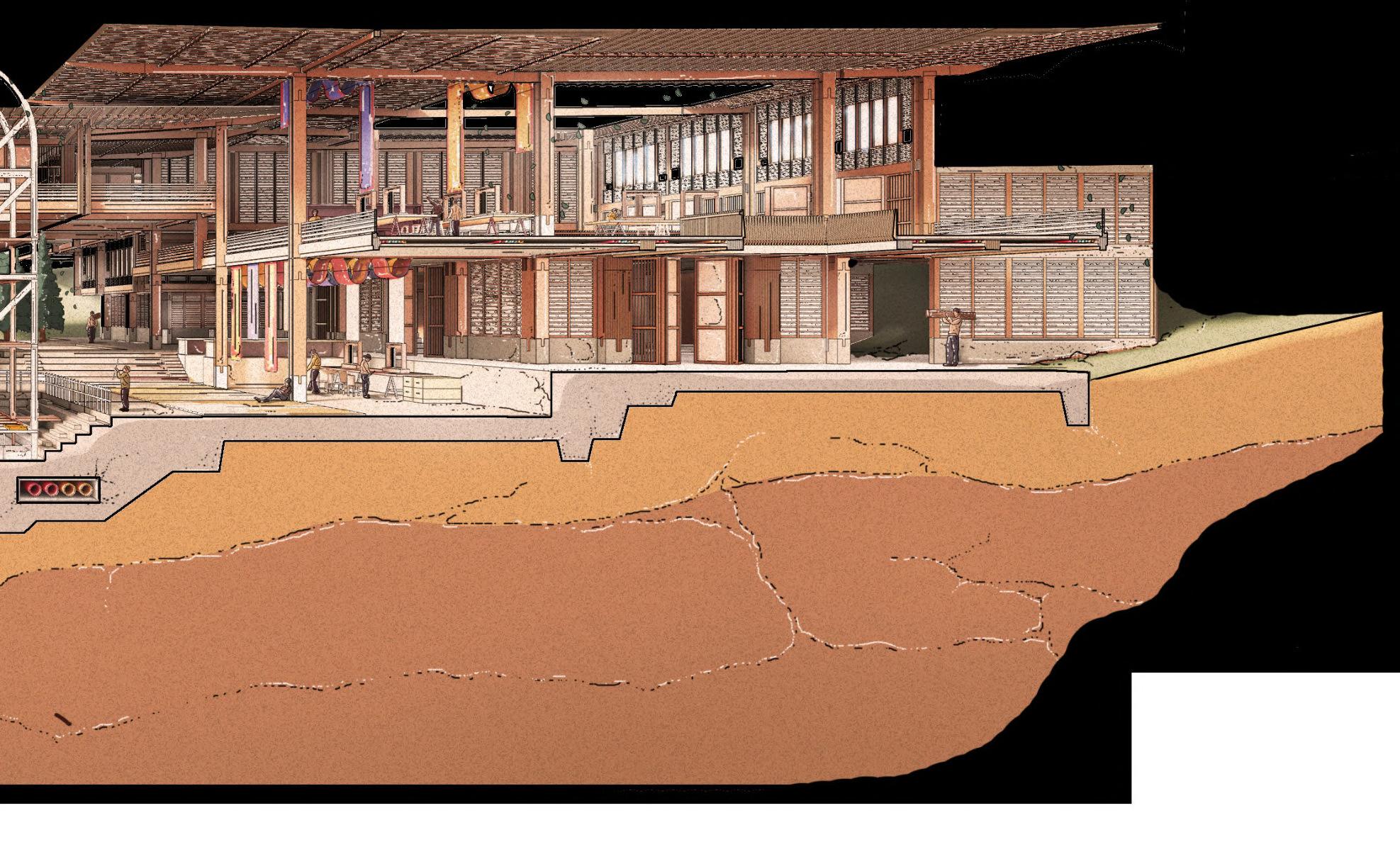

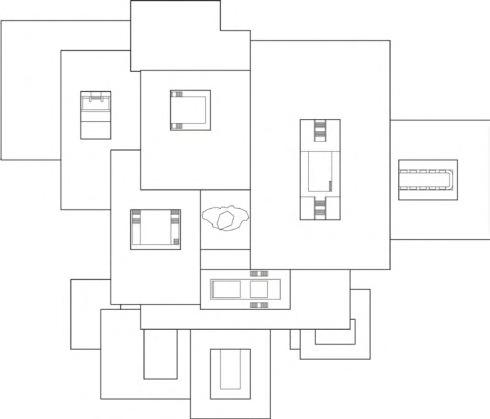

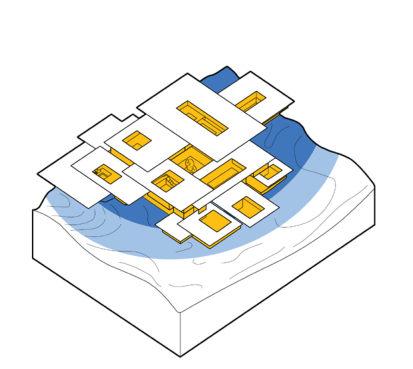

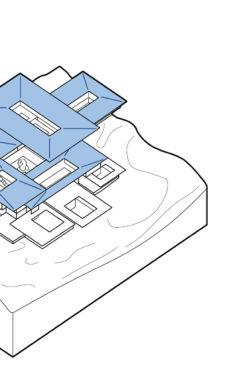

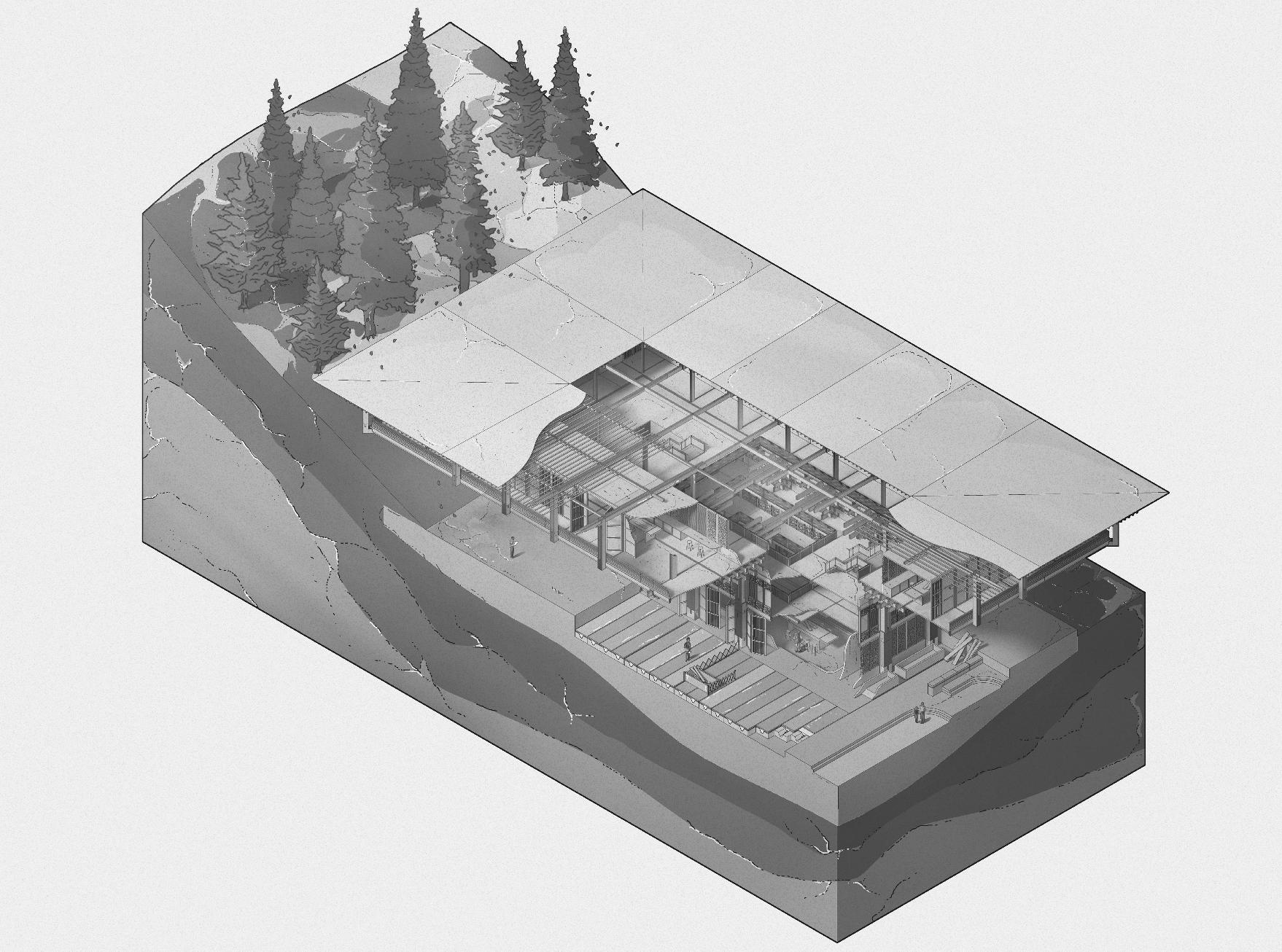

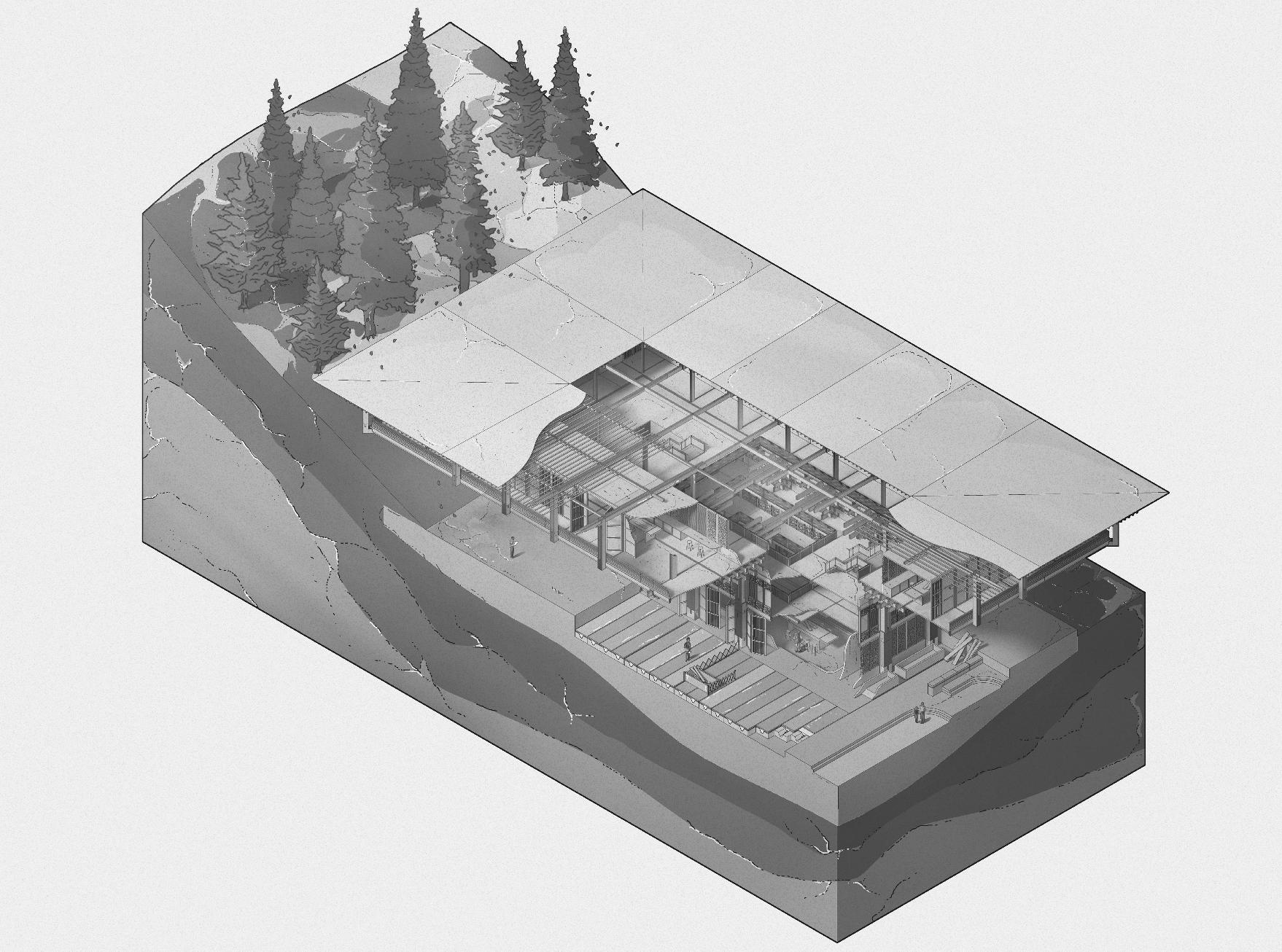

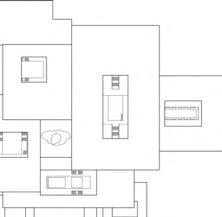

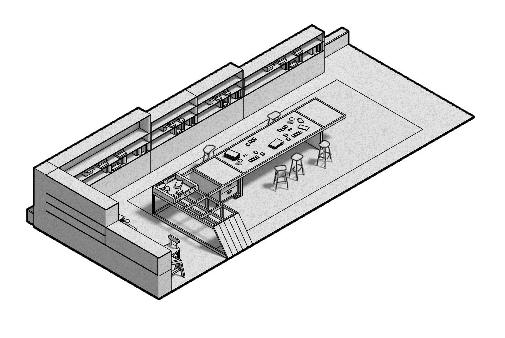

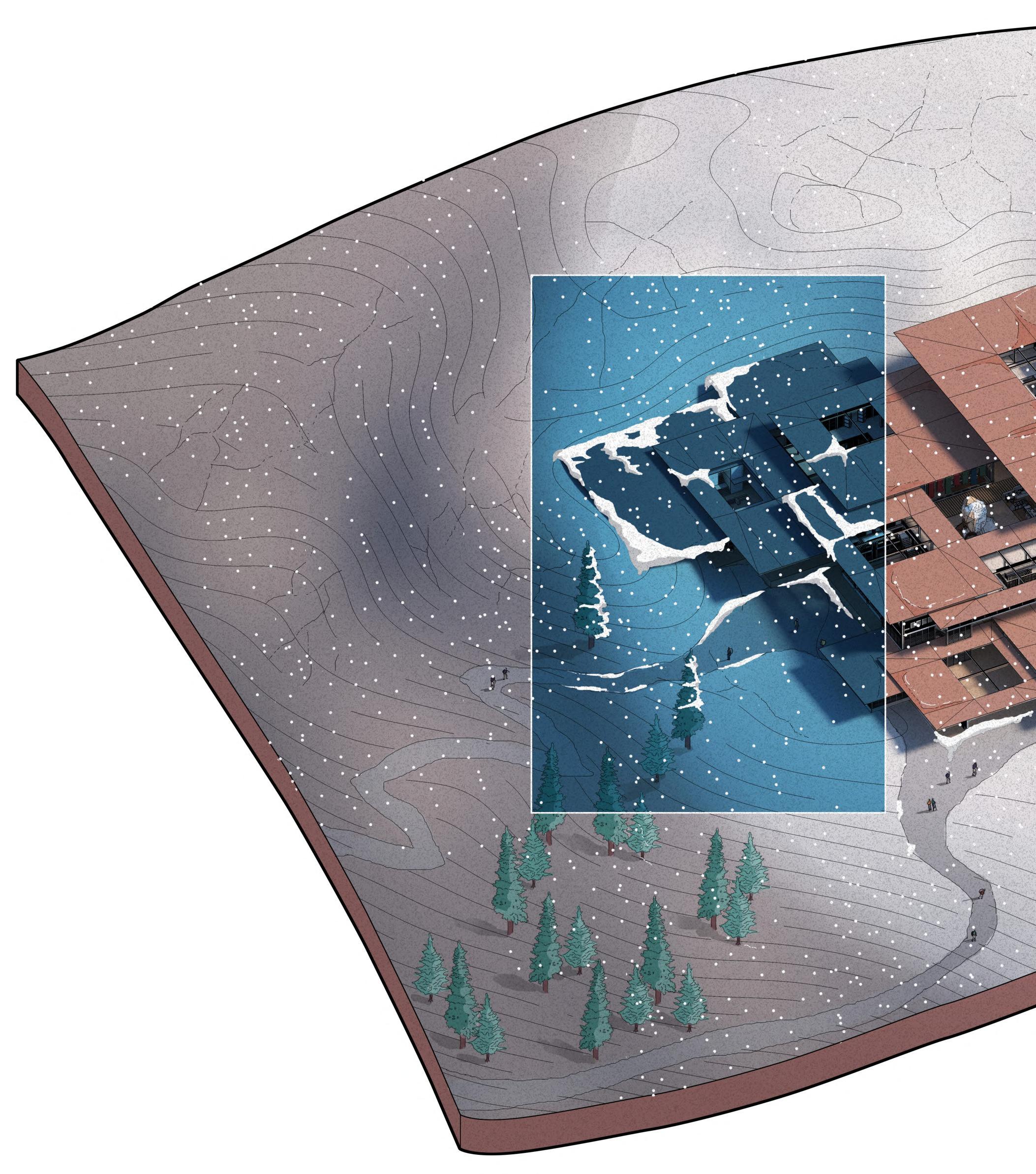

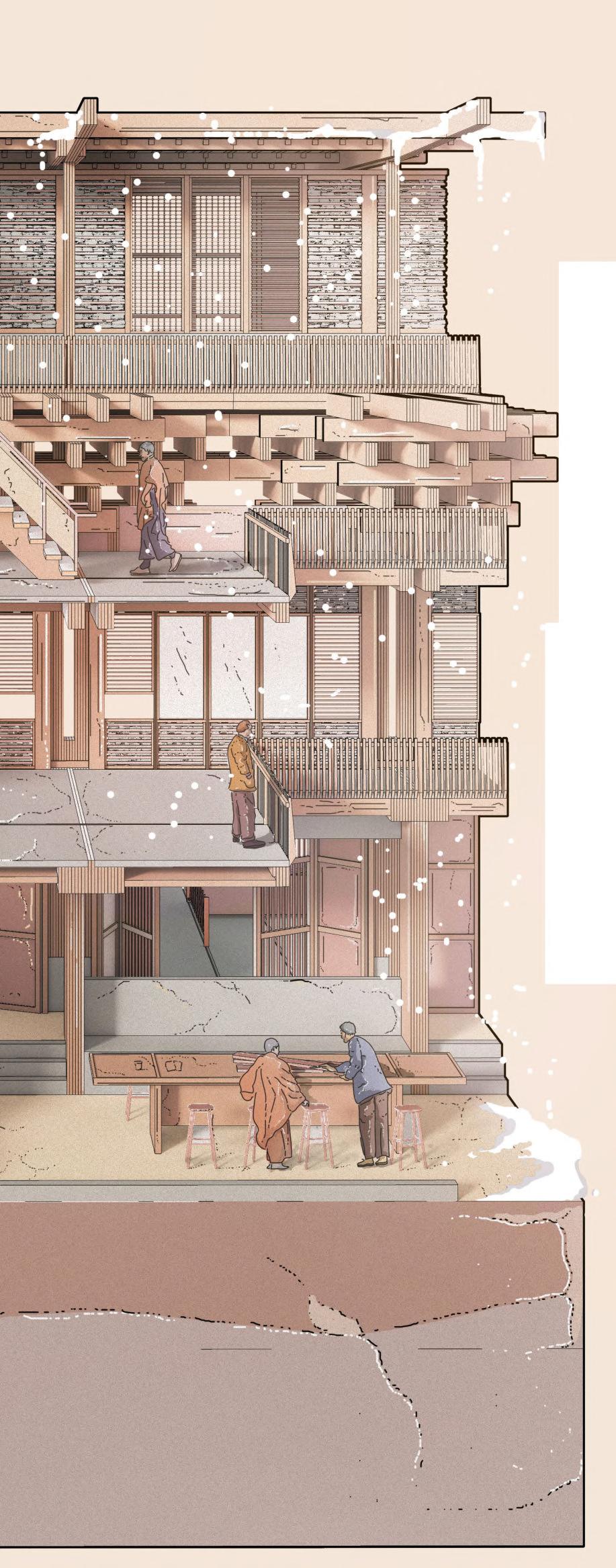

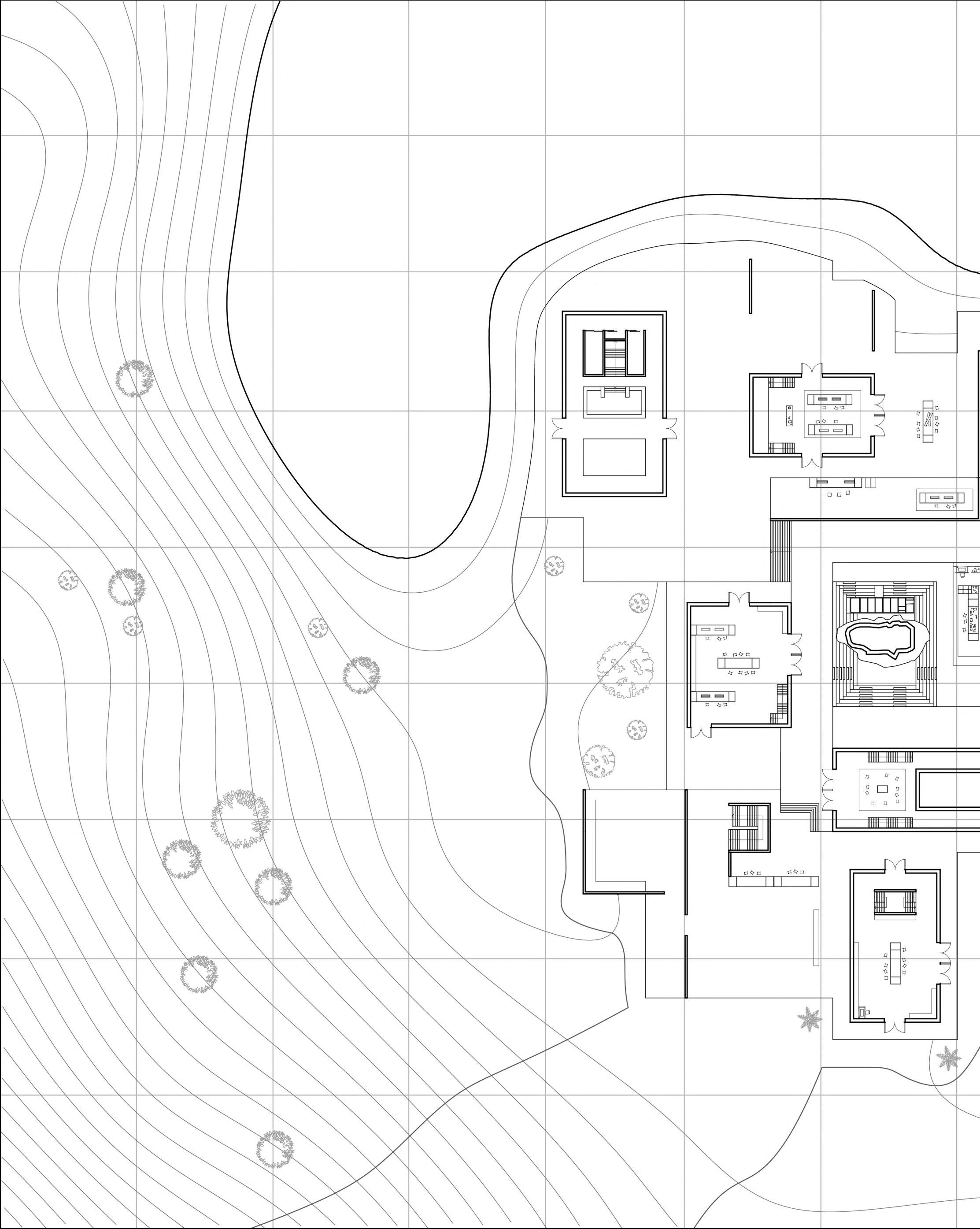

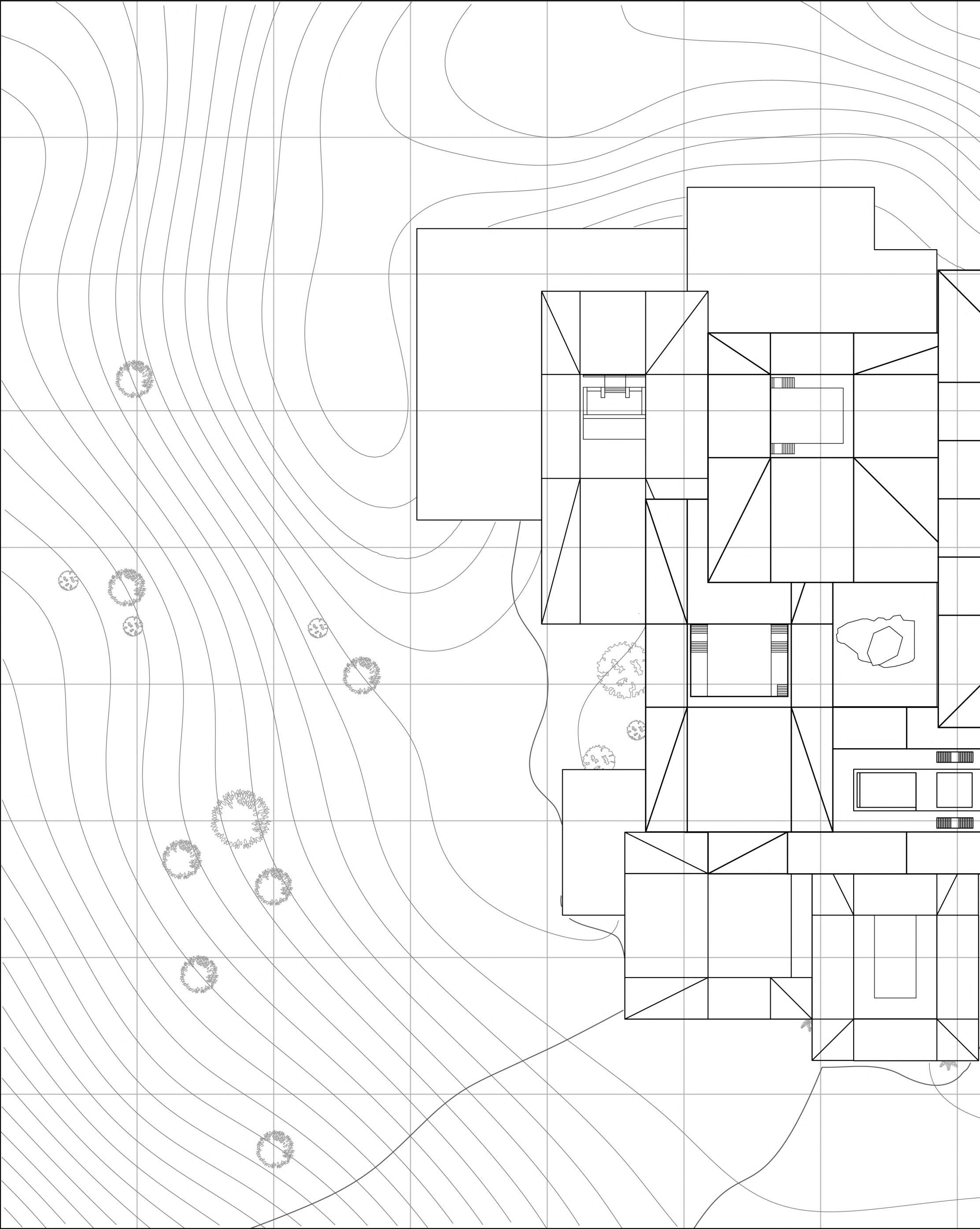

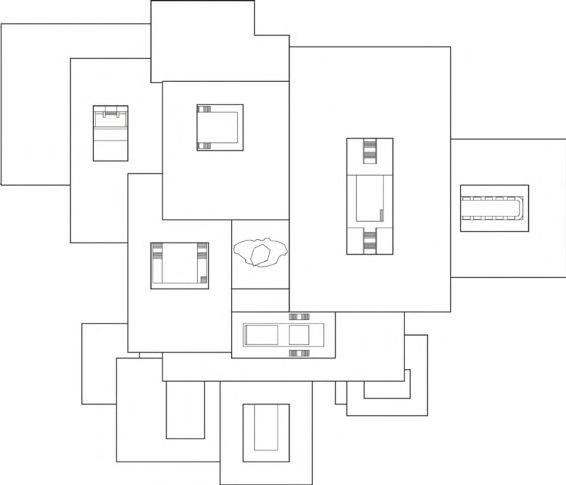

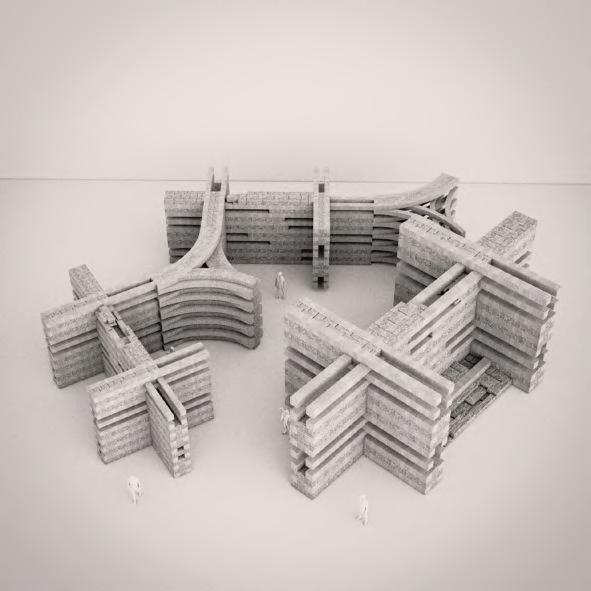

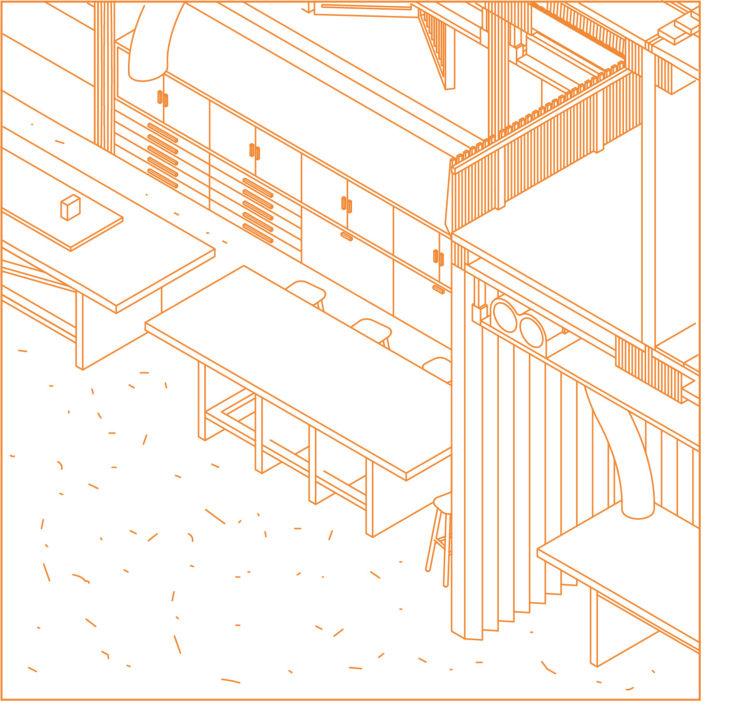

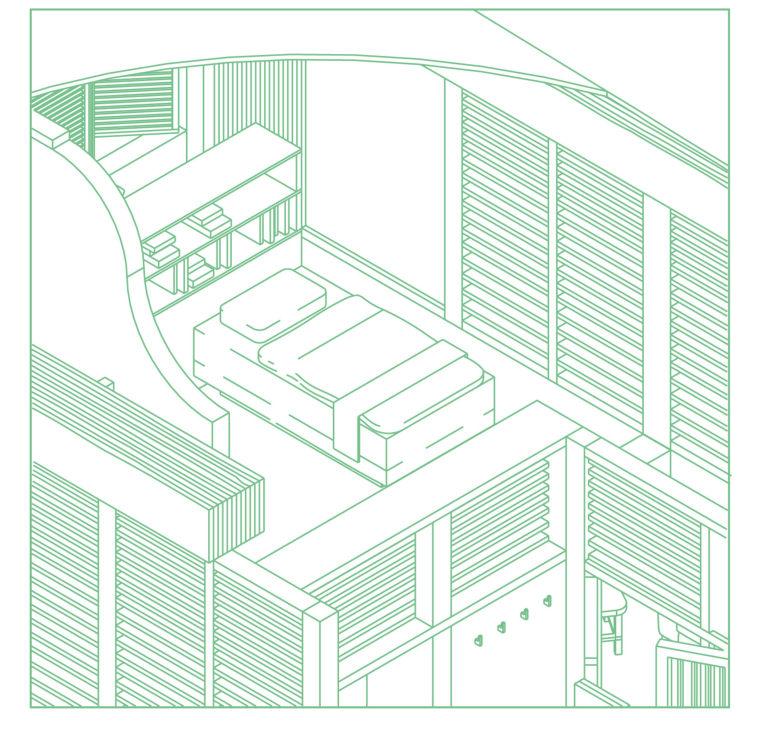

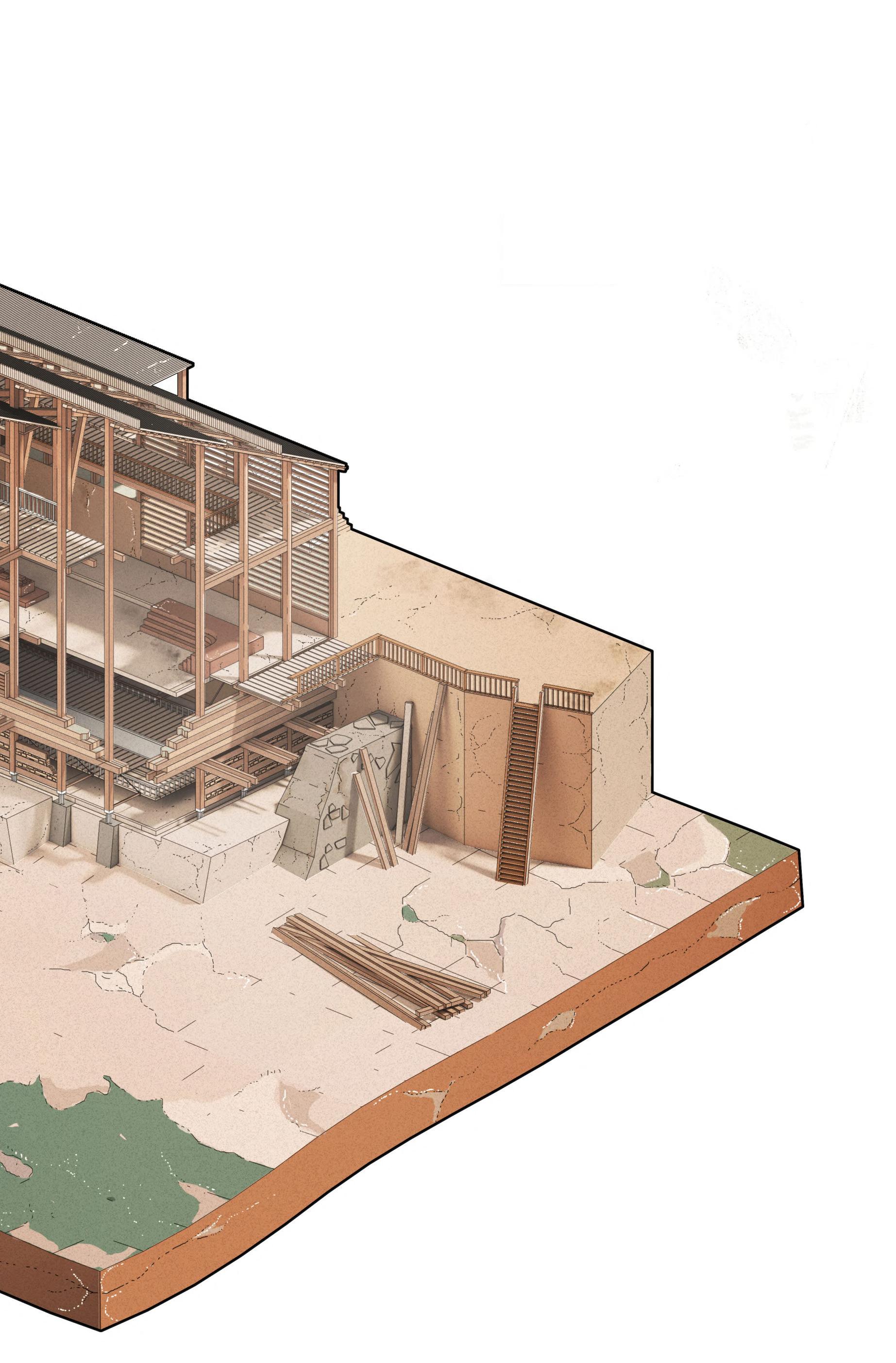

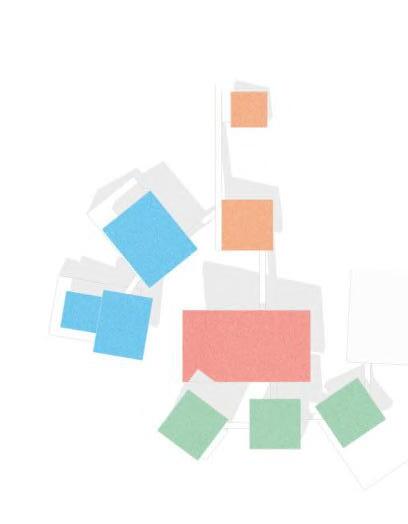

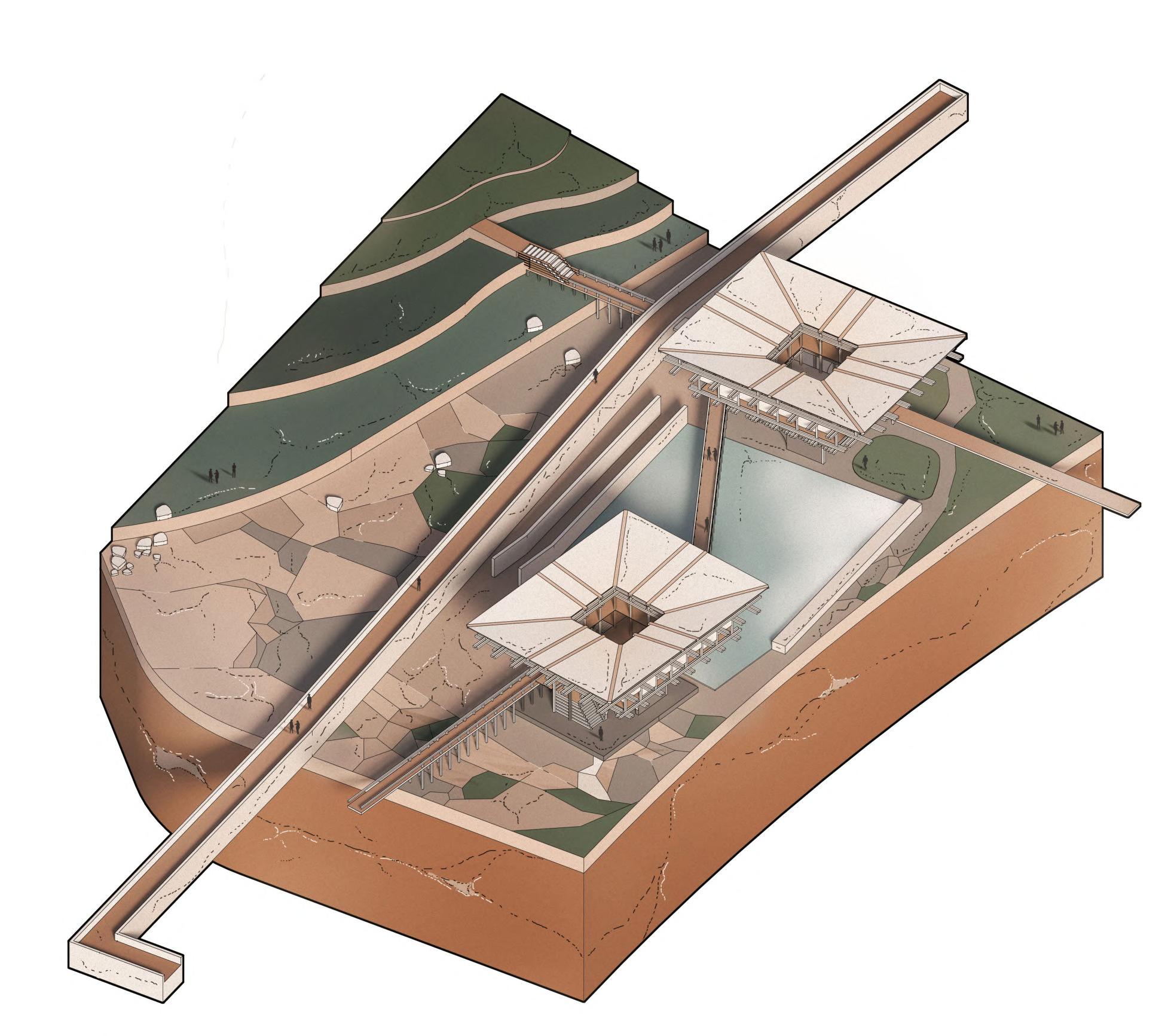

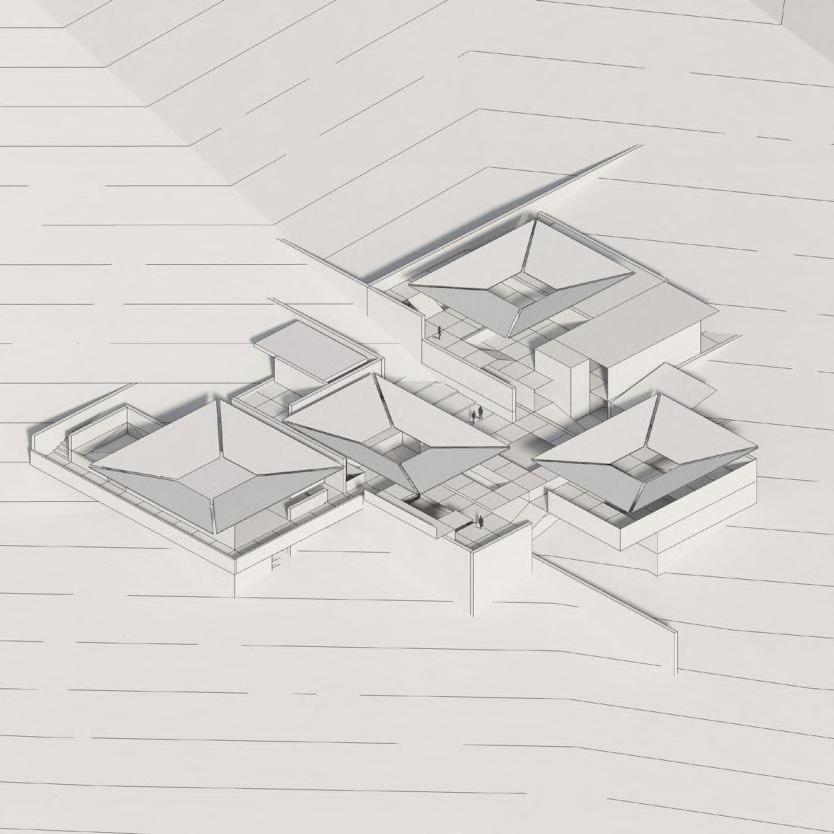

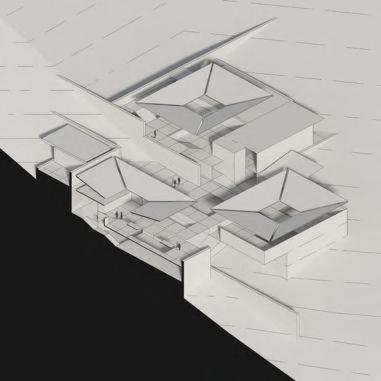

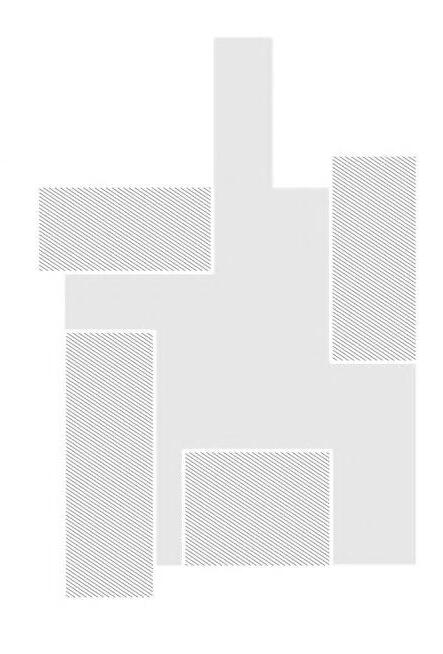

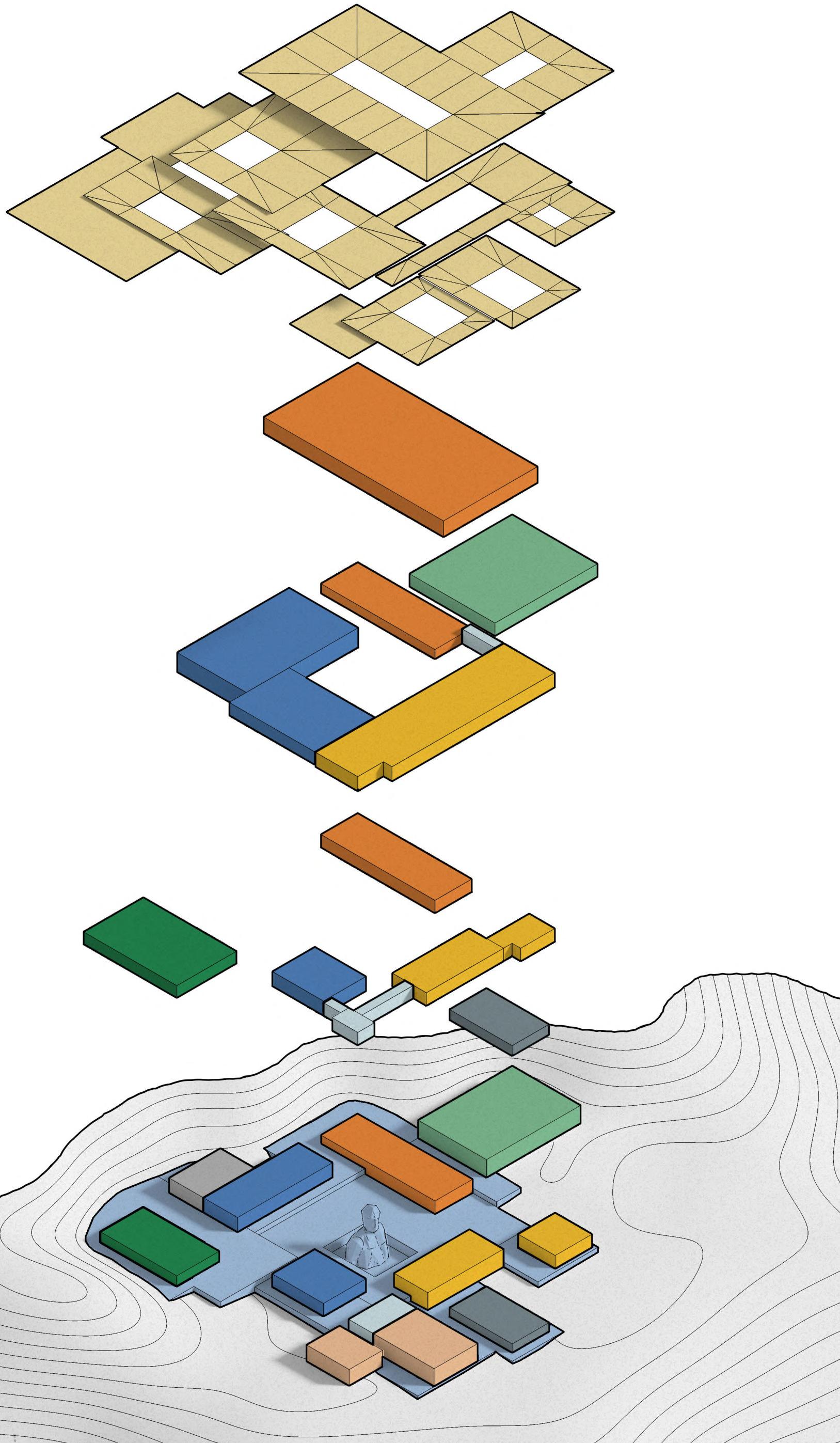

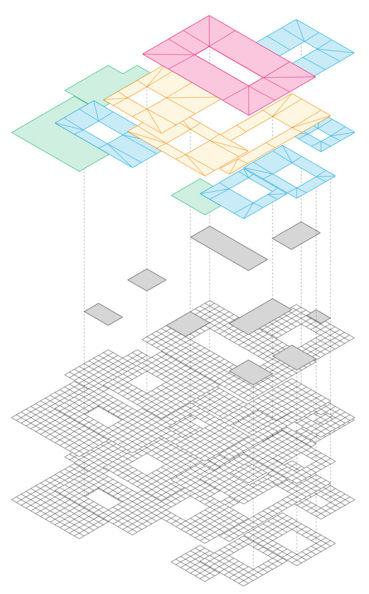

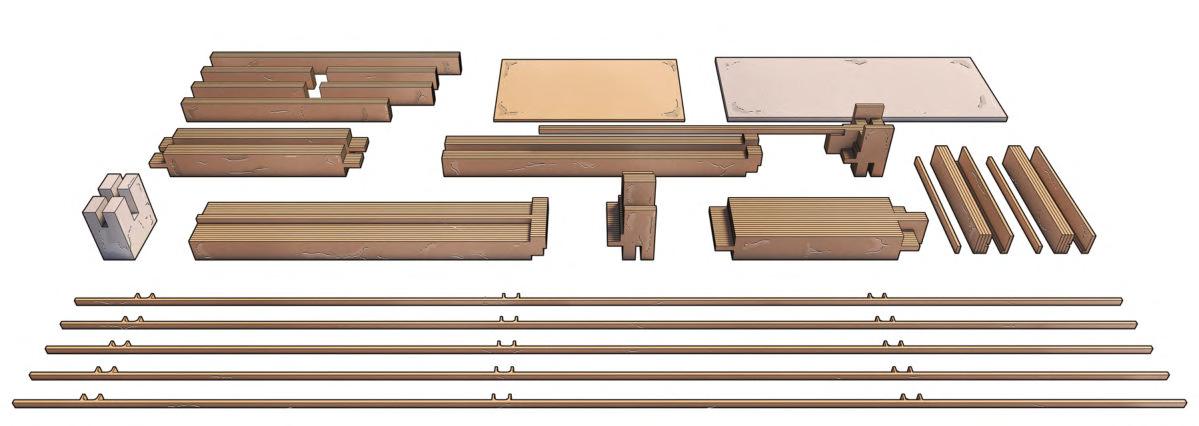

Using the research into Kath Khuni construction as a schematic basis, the proposal speculates on the possibilities of this material hybrid in the remote context of Lhuentse in eastern Bhutan, a nation caught between the push of modernisation and the maintenance of its unique cultural heritage. Through the introduction of a crafts based, higher educational programme, the scheme seeks to consolidate Lhuentse’s textiles industry with a hybrid user group of foreign exchange students and native craftspeople. Programmatically, the campus explores three primary Bhutanese crafts including carpentry, textiles and painting, and reconsiders traditional modes of sleeping and dining, outside of a central courtyard.

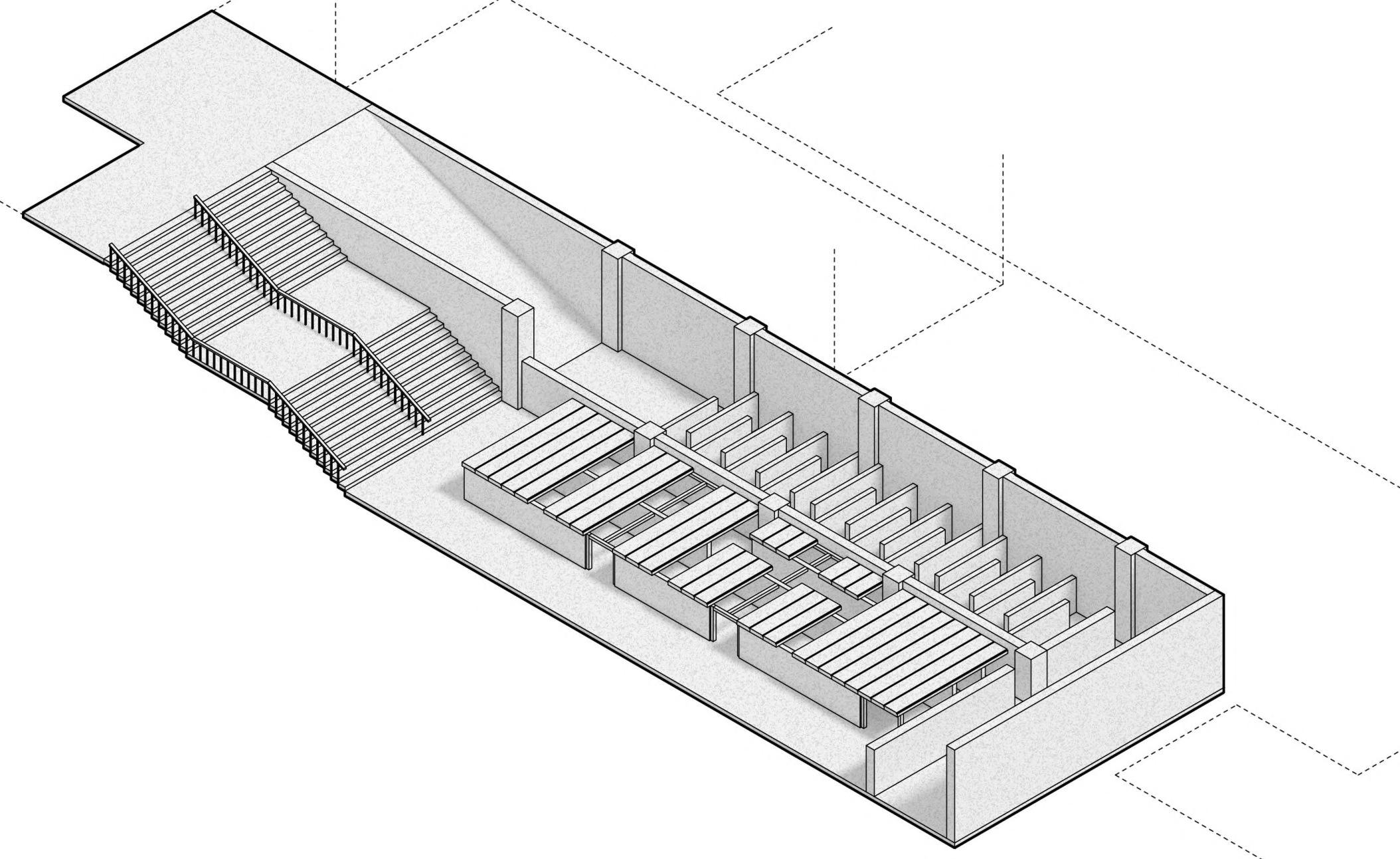

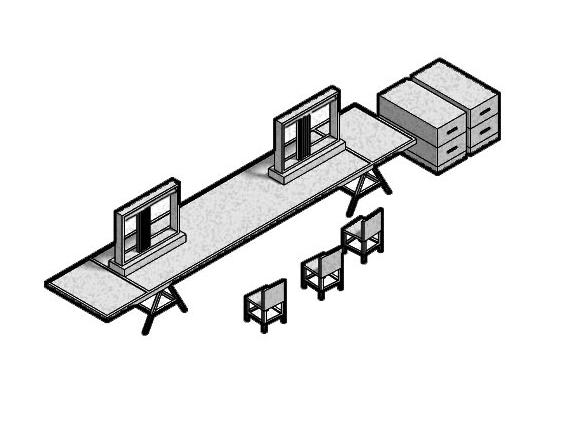

Carpentry Workshop Painting WorkshopDormitories

Textiles WorkshopDining/AuditoriumCentral Courtyard

Grey shows the main entrance and security zones, behaving as a public information point to the campus. hierarchy.

Carpentry Workshop

01.02.

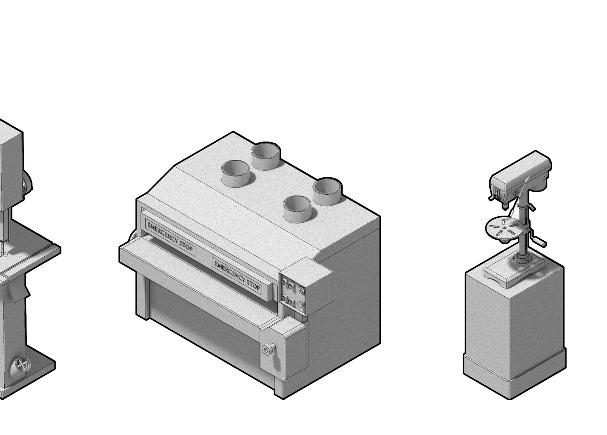

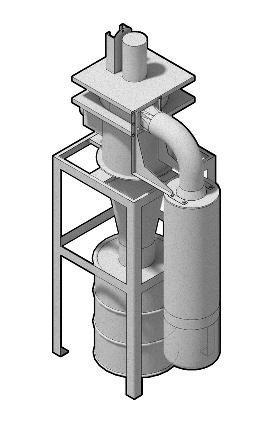

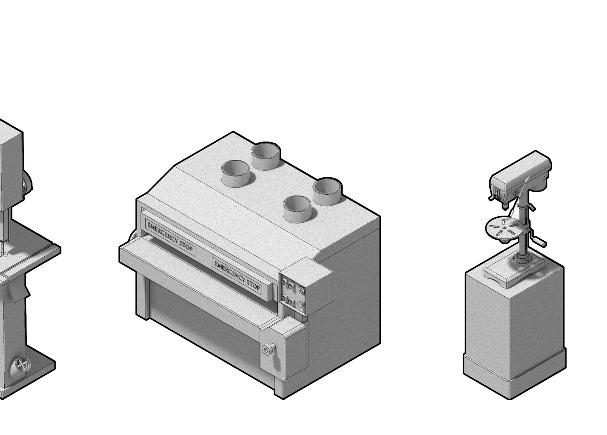

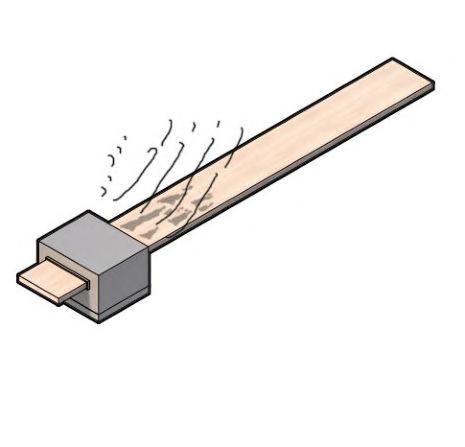

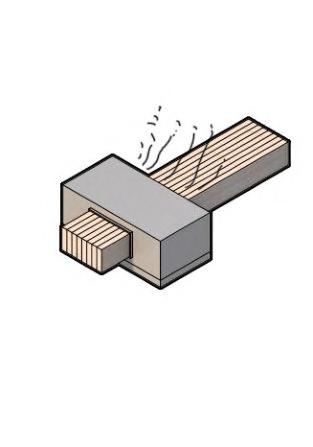

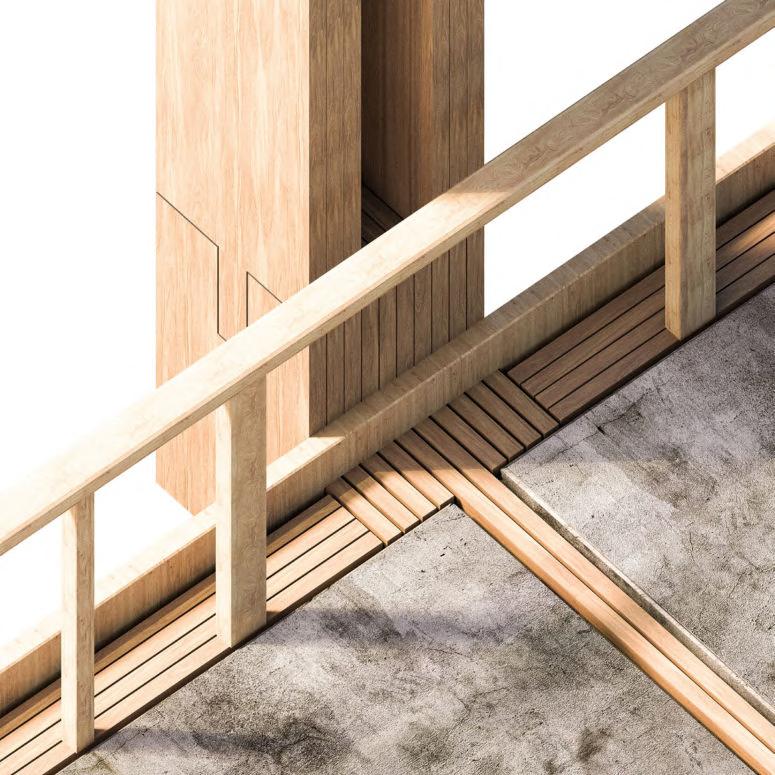

Taught by Bhutanese master craftsmen known as Zo Chen/ Zo Wo, students learn the intricate and ornate techniques of Bhutanese Shingzo (carpentry), using a mix of both traditional and contemporary machines including lathes, chisels, hammers and bandsaws.

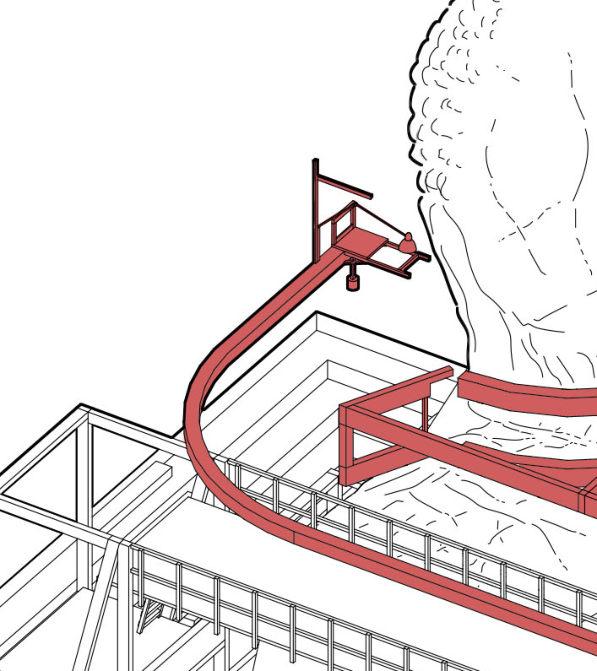

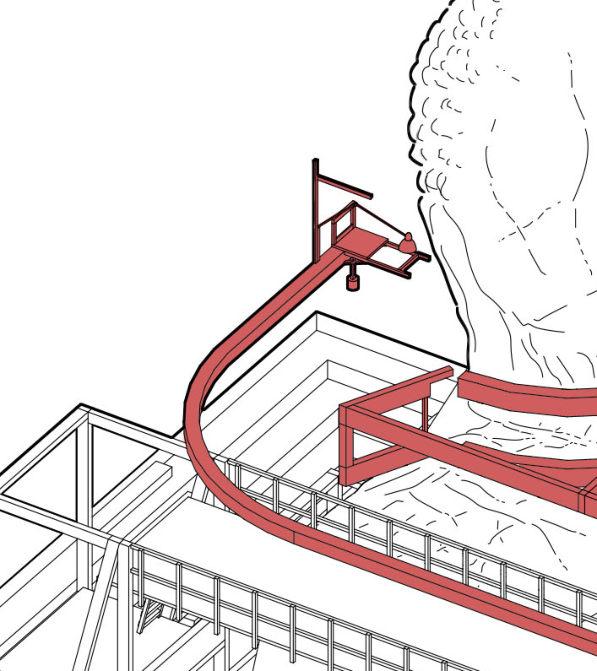

Central Courtyard

Behaving as the main point of contact between students and staff, the central courtyard acts as a combined outdoor workspace/exhibition space. A large central Buddha sculpture consolidates the nation’s Buddhist symbolism whilst exhibiting its real time construction process onlookers.

Dining/Auditorium

A multipurpose large dining room/ auditorium creates a communal gathering space for Bhutanese people and foreign students. Locally sourced foods, sitting and eating practices engages existing and historic local practices.

Painting Workshop

03.04. 05.06.

Master painters known as Lharips teach students to paint murals and frescoes using traditional religious symbols, deities and icons, using a restricted palette of mainly blacks, reds and yellows.

Dormitories

Sixteen rooms with 1, 2, 4 and 8-bed provisions for staff and students across two stories provide 86 beds for relaxation and socialising, creating the same sense of enclosure and domesticity as Bhutanese dwellings.

Textiles Workshop

Using rich vibrant colours, intricate dyeing, and manual weaving techniques, traditional looms are used to craft textiles, acting as a continuation of one Bhutan’s oldest crafts.

2.08 _ Brief & Programme

Figure 2.08A

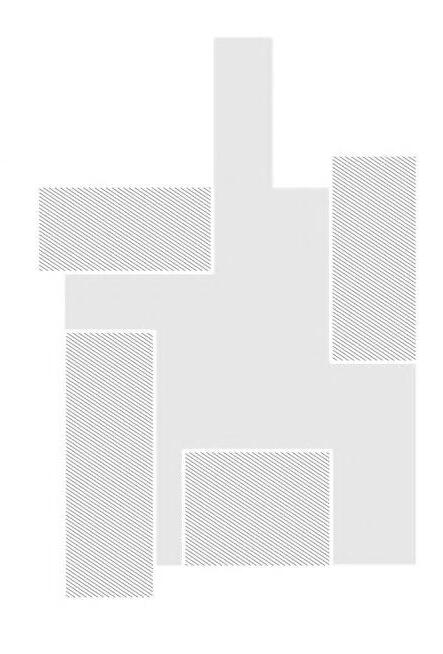

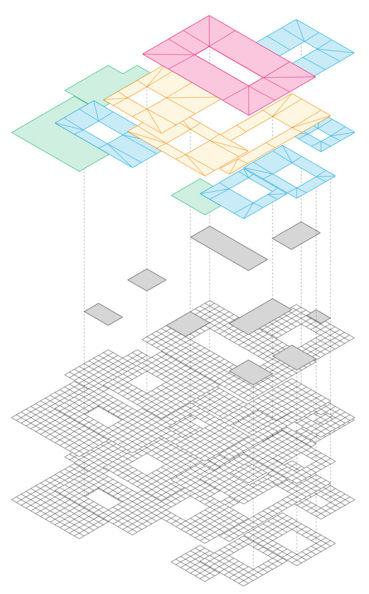

Using three of Bhutan’s thirteen traditional arts and crafts as a programmatic framework (shown above) - carpentry, painting and weaving create the most global reach, creating a strong transferable skillset for foreign students to practice following completion of their respective courses. The building’s campus typology creates a series of courtyards that interweave between workshop spaces, engaging the local context, and morphologically, create a visual hierarchy of rectilinear, outwardly pixelating volumes. Each of these conditions contribute to a hybrid cultural exchange between Bhutan and the rest of the world.

Using foreign student fees as a source of income for the campus and Bhutan, the scheme speculates on Bhutan becoming a less insular nation through education, rather than tourism, to prevent their fear of becoming over-commercialised. This invites foreign students to engage more closely and strongly with the culture.

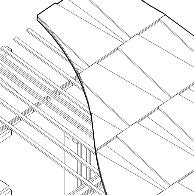

An adaptation of Kath Khuni construction creates a cross-cultural structural strategy for the building, engaging influences from both the western and eastern Himalayas.

50

A HYBRID CIVIC IDENTITY

Programme - Consolidating Three of Bhutan’s

Traditional Arts and Crafts

Chusum) Typology & Morphology Shingzo Carpentry Dozo Masonry Parzo Carving Lhazo Painting Jinzo Sculpting Lugzo Bronze Casting Garzo Blacksmithing Troeko Ornament Making Tsharzo Cane & Bamboo Weaving Thagzo Weaving Tshemzo Tailoring Shagzo Woodturning Dezo Paper-making

Thirteen

(Zorig

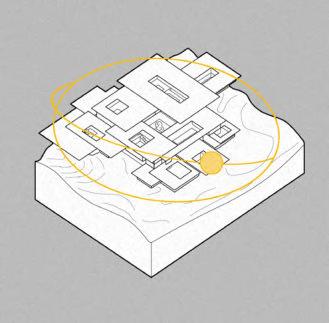

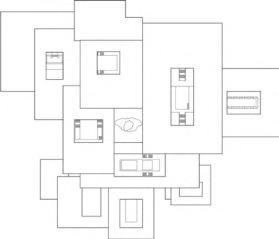

Cultural Exchange Buddhist for SCHEMATIC PLAN same domesticity textiles, of Hybrid Construction Local Religious Symbolism Increasing capital for Bhutan Traditional/Contemporary Exchange Stairs/Lift Access 03 01 02 05 09 07 08 04 06 DINING / AUDITORIUM 687 m2 TEXTILES 01 638 m2 TEXTILES 02 1077 m2 SECURITY 286 m2 PAINTING 01 169 m2 PAINTING 02 761 m2 DORMITORIES 1080 m2 ENTRANCE 610 m2 CARPENTRY 1710 m2 Roof Plan Indicative Upper Storey (approximate surface area indicated) Proposed Circulation Route 2.08A

BARC0174 _ AAD1CHAPTER 2B _ SITE AND BRIEF

Figure 2.08B

Deliveries & Sourcing

PLANNING STRATEGY

The building’s main premise relies on an initial startup meeting between foreign and local architect planners and the Bhutanese government. Bhutan’s Ministry of Home and Cultural Affairs oversees 20 dzongkhags (local governments) across Bhutan, of which the campus sits in the dzongkhag of Lhuentse. This local government will behave as the review board and will appoint the project team, alongside the foreign architect/planners. They will also fund the project. Following the building’s completion, fees will be charged to foreign students to attend courses at the school, allowing the project to pay itself off and increase returns for Lhuentse’s dzongkhag. This aims to generate increased capital for the town and district, to stimulate improved social and economic welfare whilst speculating on the impact of foreign capital for the relatively insular nation of Bhutan.

Project Delivery Overview

Approval of government fund by Bhutan’s Ministry of Education to develop infrastructure to benefit the community & economy.

Government Funding

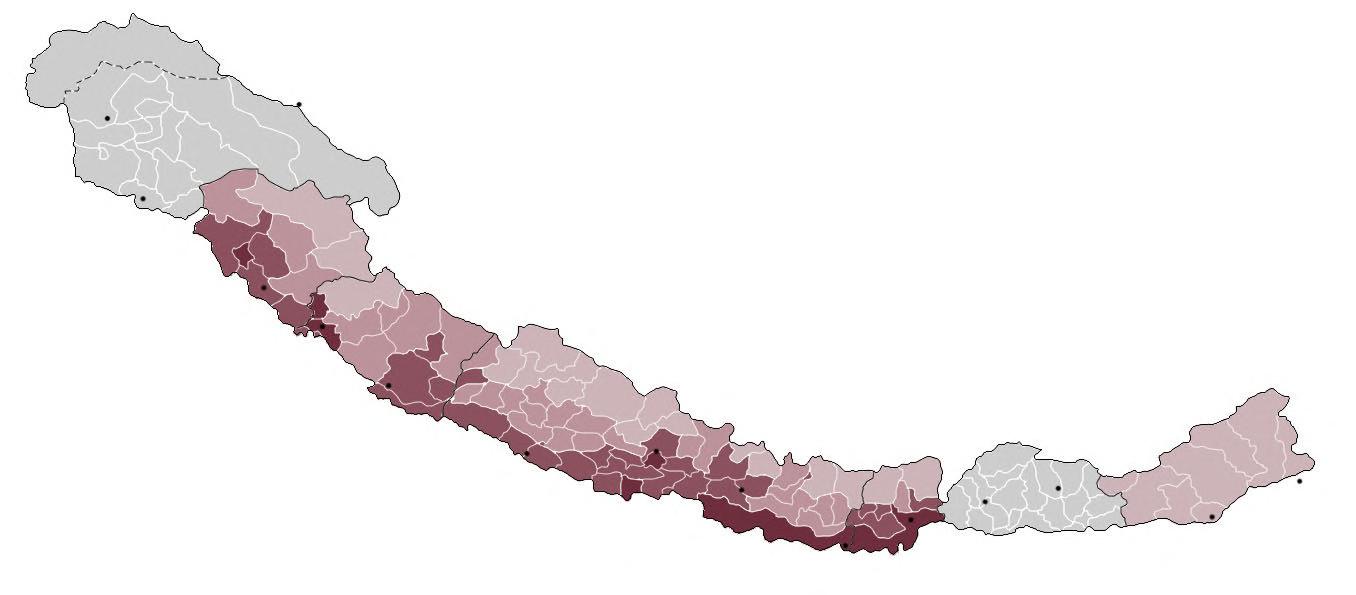

The Kingdom of Bhutan is divided into 20 districts, known as Dzongkhags (borders shown below). The campus sits in the Dzongkhag of Lhuentse (or Lhuentse District). As one of the least developed districts in Bhutan, the scheme seeks local funding from the Dzongkhag to create increased footfall, and propel infrastructure including electricity, roads and gas stations, for the benefit of over 2000 households in the district.

Building Compliance

Bhutan Building Rules

Bhutan Five Year Plan

Bhutan’s Department of Urban Development & Housing sets out a series of requirements during the planning and submission stages for construction projects in Bhutan. This document is known as Bhutan Building Rules (an earlier version dated to 2002 is shown above). The campus aims to follow the document’s guidance on planning permission, change of building use, providing coverage for parking areas, and a suitable architectural design.

Phase 1 - Preparation & Briefing

- Establish project team & define brief

- Start up meeting & design team appointed

- Costs estimated

- Project coordination

- Client review

Phase 2 - Concept Design

- Concept design delivery & production

- Concept design deliverables issued

- Material selection & sourcing identified

- Site survey

- Lhuentse Dzongkhag consultation

- Scale prototyping

- Finalise brief

- Consultants & architect appointed

Phase 3 - Design Development

- Construction Manager appointed

- Planning application submitted

- Initial costing

- Quantity surveyor

Phase 4 - Technical Design

- Tender packages submitted

- BIM Model

- Facade Mock-up

Phase 5 - Final Project Approval

- Planning submission to Dzongkhag administration

- Planning Approval

Phase 6 - Manufacturing & Construction

- Material quantity determined

- Liaison with local parks and supply routes created

- Materials procured and delivered

- Pre-fabricated elements delivered

- On-site fabrication and assembly

- Internal fit-out

Phase 7 - Handover & Use

- Building construction complete

- Building opened to staff and students

- Building use and maintenance begins

Planning Approval following building compliance with Bhutan Building Rules set by Department of Urban Development & Housing.

Liaison with Department of Forest and Park Services for safe logging and delivery of materials, outside of conservation areas.

Temporary accommodation provides housing for local labour force and foreign students during initial construction phase.

2.09 _ Planning Strategy

DESIGN TIMELINE

S 202220232024 JMJMSNMJMJNOFJFJODAAAAD On-site pre-fabrication & testing 01 02 Figure 2.09A

Beginning in 1961, Bhutan’s 12th Five-Year Plan (2018-2023) aims to free the nation from social and economic disruption through an emphasis on Gross National Happiness (GNH), which the scheme considers.

Timber Sourcing

Bhutan’s Department of Forests and Park Services conserve and manage Bhutan’s forestry resources. The department has used several pieces of policy and legislation to control the use of forest land for construction. Planting trees whenever one is cut down ensures that a minimum of 60% of the nation remains covered by forest, contributing to Bhutan’s carbon negativity. Lhuentse District contains a rich resource of forests, which also ensures a renewable source of energy for future generations.

Protected Areas of Lhuentse District

Protected Biological Corridors

Protected ParksNational Parks

Site Location

Bhutan’s Department of Forests and Park Services

Following completion of building construction, the campus is opened to staff and students. Building use and maintenance begins. 2025 SJNMOFDAA

User Group

Initially funded by the Bhutanese government to realise the project, the campus becomes a civic destination for incoming students, who are taught by expert local craftspeople. This reframes the overly spiritualised lens of the Himalayas, and creates a productive educational programme for the benefit of both the local people and foreign students.

On the right diagram, shown in light grey are parks in Lhuentse District including Wangchuk Centennial Park (1) in the north and Thrumshingla National Park (2) in the south. Each of these parks are connected by protected parks and protected biological corridors which allow the opportunity to locally source wood for the campus. This may then be transferred to a local factory prior to delivery to site (illustrated right). This would follow government guidance.

Widened Higher Education

The campus consolidates Bhutan’s position in a constantly modernising world, by introducing a crafts based educational programme that combines contemporary and traditional methods of carpentry, textiles and weaving:

The scheme relies on income from foreign exchange students to break even and make profit for the scheme’s construction, opening Bhutan to foreign relations for the relatively insular nation, whilst expressing the nation’s Buddhist religion and values.

A consortium of existing institutions of higher education in Bhutan, many of which fall under the umbrella of the Royal University of Bhutan (founded by Royal Decree) are largely used by Bhutanese students. Most offer courses based in engineering, sciences, law and business. This invites the opportunity for the study of a creative discipline.

Falling under Royal Decree, LSC (Lhuentse School of Crafts) sits in eastern Bhutan (the majority of institutions are currently based in the west), opening up both social and economic benefits for the local community and government.

52

Buddhist ReligionBhutan’s Global Reach Income through Foreign Exchange LSC A A B B C C

01. 02.

01. User 1 Bhutanese Craftspeople as Teachers

02. Client Bhutanese Government

0102

03. User 2 Local & Foreign Exchange Students

Figure 2.09B

Figure 2.09C

Figure 2.09D

BARC0174 _ AAD1CHAPTER 2B _ SITE AND BRIEF

Figure 2.09E

Using the local government of Lhuentse (Dzongkhag) as guarantors for the project’s funding, the Royal University of Bhutan behaves as an umbrella organisation that funds the delivery of Lhuentse School of Crafts (which is later incorporated as an affiliate college of the university). The state acts as a guarantor for loan agreements (through its national bank) between the Royal University of Bhutan & India (Bhutan’s largest creditor) where the state borrows capital for the building’s construction, expecting the profits made to be greater than the interest payable. Loans are repaid via student fees paid to the Royal University of Bhutan and the contractor.

A design and build contract also offers more agency to local craftspeople, allowing them to be brought into the project at an earlier stage. A project manager is responsible for the coordination of foreign architect planners, consultants and local contractors (and craftspeople), assisting with drawings, site visits, surveys, budgeting and feasibility studies. This procurement method also allows construction to begin without a finalised design via mockups and material testing.

Fulfilling Bhutan’s Five-Year Plan

By sustaining public finance on an even level, and using a lean bureaucracy, the contract aims to use traditional social institutions to engage local people in the project’s planning and implementation.

Sustaining Carbon Negativity

As the only carbon negative nation in the world, the building’s use of local resources ensures the continued management of the nation’s forests and the renewable hydro-electric power sources.

Gross National Happiness

The building’s culture-specific programme fulfils Bhutan’s emphasis on the concept of Gross National Happiness (as opposed to Gross Domestic Product), giving equal importance to non-monetary aspects of personal well-being.

DESIGN & BUILD CONTRACT

A design and build contract provides both architect and contractor services. It ensures clear organisation, planning, communication and control at every stage of the delivery process. This aims to create a more efficient relationship between client and contractor, and use local contractors’ expertise during construction.

Economic & Social Benefits Contracts & Procurement Section 2.10 53

Lhuentse Dzongkhag (District) State Owned Consortium Overall Contractor Contractor Performance of Client Role Design & Build Contract ArchitectsSub-Contractors Client Project Manager Consultants Cost Consultant Contractor Sub-Contractors Architect Engineers Consultants Operations & Maintenance CreditorsCreditors Royal University of Bhutan Royal University of Bhutan Public, decentralized university Public, decentralized university India (Bhutan’s largest creditor) India (Bhutan’s largest creditor) Lhuentse School of Crafts Fees Absorbed as affiliate college of the Royal University of Bhutan A combination of foreign and local architects are appointed throughout the contract. Appointed during the contract, sub-contractors are responsible for certain on-site works. Appointed throughout the contract, engineers are involved throughout the design process. A team of consultants are appointed throughout the contract. RepaymentsRepayments Construction Contract Services Contract Works Contract Operations & Maintenance Contract Bhutan Department of Higher Education

ClientClient

CONTRACTS & PROCUREMENTS

LSC

LoansLoans

State Guaranteed CapitalState Guaranteed Capital

CLIENT & FUNDING

As shown on the previous page, a state owned consortium performs the client role on behalf of both Lhuentse Dzongkhag (local government) and the Bhutan Department of Higher Education. The completed building will be incorporated into the Royal University of Bhutan as an affiliate college, hence they also behave as a client. The project will be funded primarily by the Bhutanese government, with India’s banks behaving as creditors. The project aims to make a profit for Bhutan and its local government through student fees, charged at $2 800 per year for Bhutanese students (approximate based on existing fees for Bhutanese universities). Foreign students from nearby nations will be charged twice this figure, and those from further afield, based on a tier system, three times this figure. In comparison to UK universities, the fees will be considerably lower, whilst still aiming to generate a significant long-term profit. This intends to help boost Lhuentse and Bhutan’s social and economic welfare.

Local Government & Education

State financial backing throughout the project will ensure GNH is considered.

Local & Foreign Students

Public consultations will ensure local and foreign students can contribute to the building’s social and economic welfare.

Local Residents & General Public

Nearby residents and the Bhutanese public should be consulted throughout, with public consultations, contributing to the building’s civic identity.

PROJECT DELIVERY TEAM

To help coordinate information between different teams and consultants, Building Information Modelling (BIM) can be used throughout the design process, from the initial concept design phase through to construction and operation. Using a software like Revit, different simulations can be explored and tested, for the benefit of every team, to ensure the quick and efficient transfer of information.

Overall Contractor

Project Manager

Central BIM Model

Coordination of Information

Section 2.11 54 State Owned Consortium Responsible for Client Role Main Board Advisory Board

Key Stakeholders Roles & Responsibilities

Local Craftspeople Local Architect Lead Architect Delivery AnalysisStructural Simulations Environmental Simulations Landscape AnalysisFacade Simulations MEP Engineer Delivery Contractor Interior Architect Structural Engineer Landscape Architect Civil Engineer Technical Designer Timber Engineer Quantity Surveyor Fire Engineer Environmental Engineer Detail Design Consultant Software Engineer 01. Skeleton Facade02. Ornate Facade Completed building facade prior to opening behaves as skeleton/canvas for crafting by students. Students use crafts skills learnt at school to dress facade with ornate details typical of Bhutanese architecture.

Early

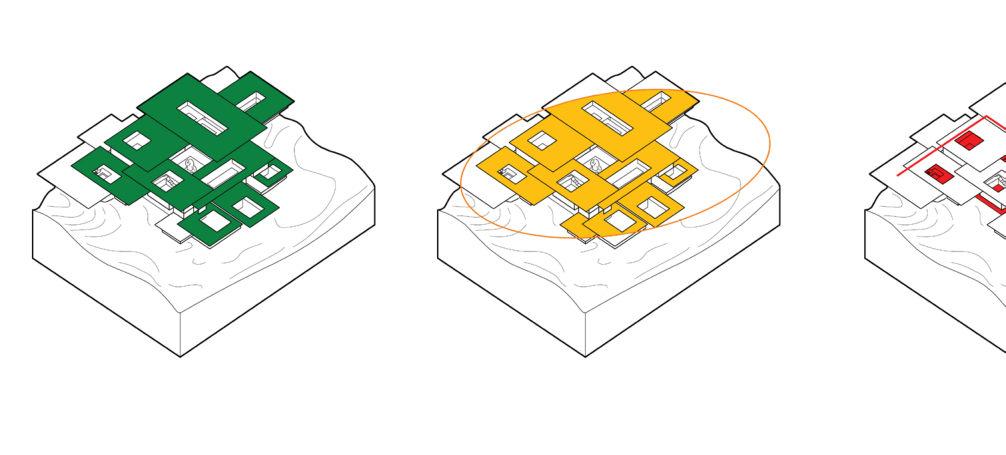

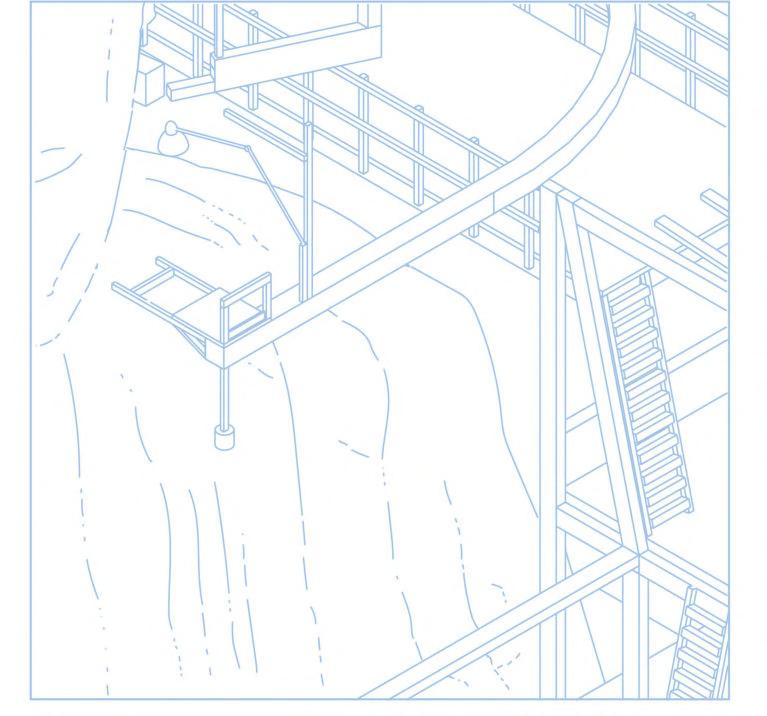

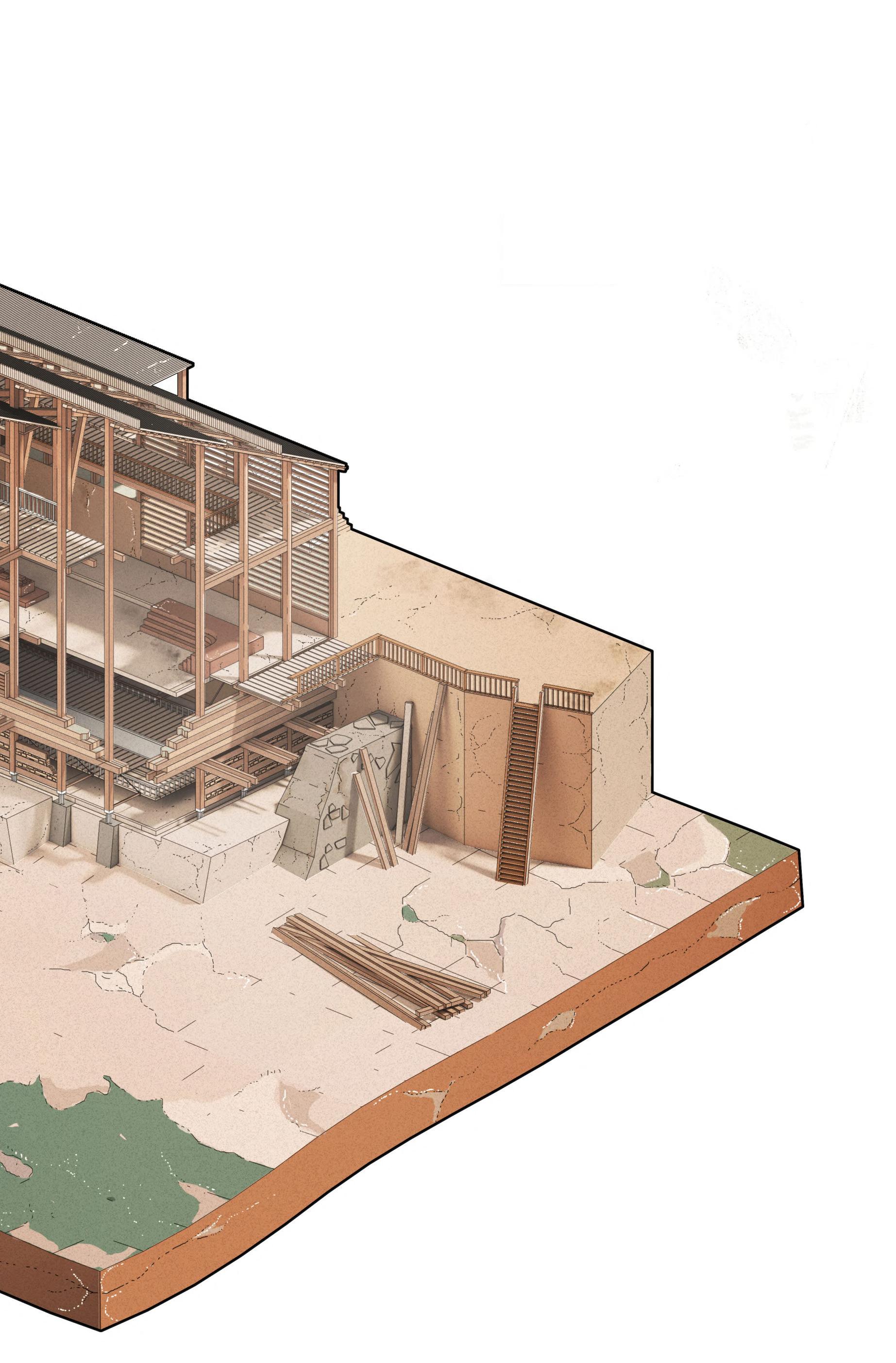

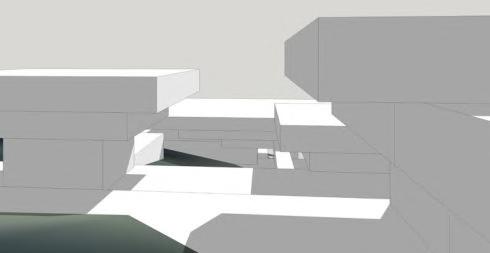

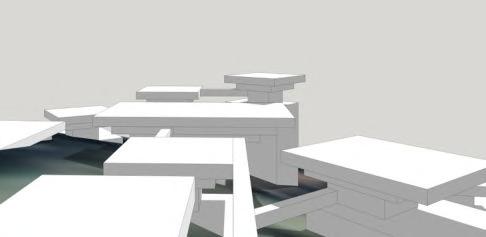

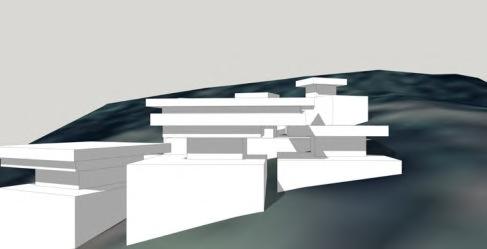

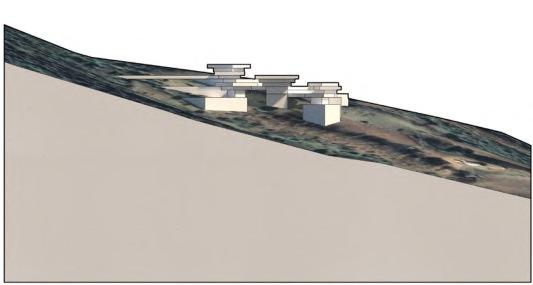

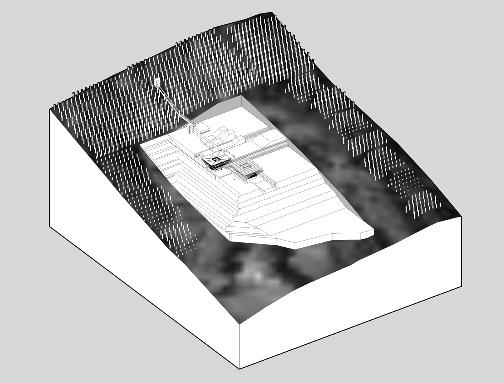

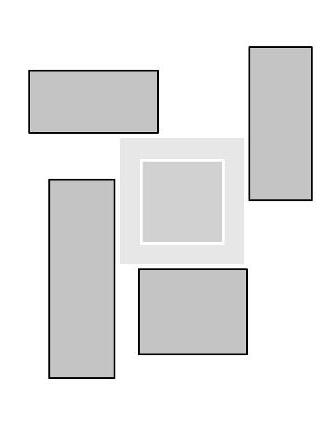

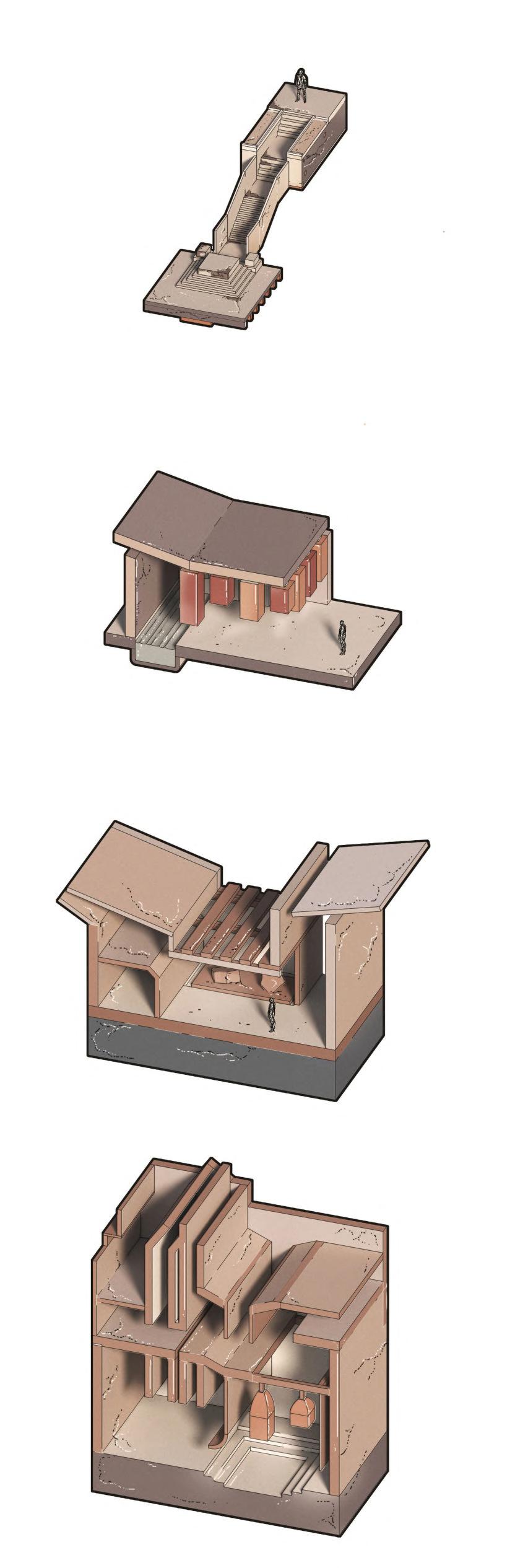

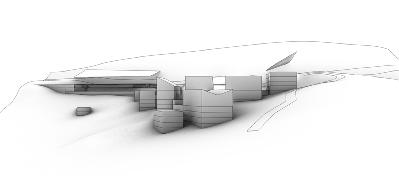

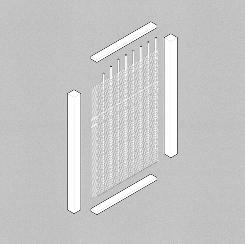

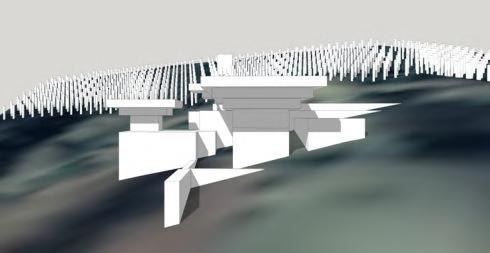

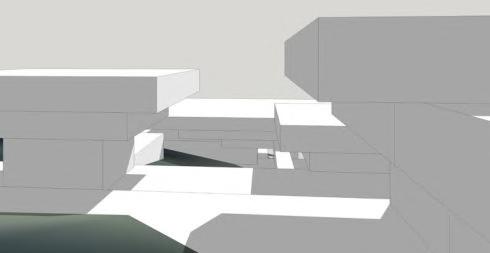

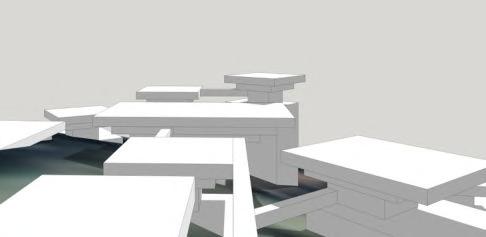

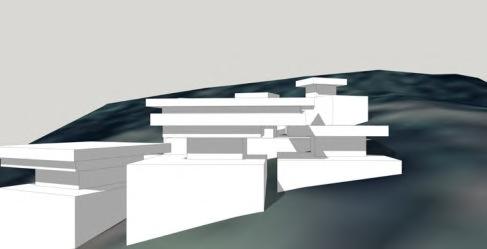

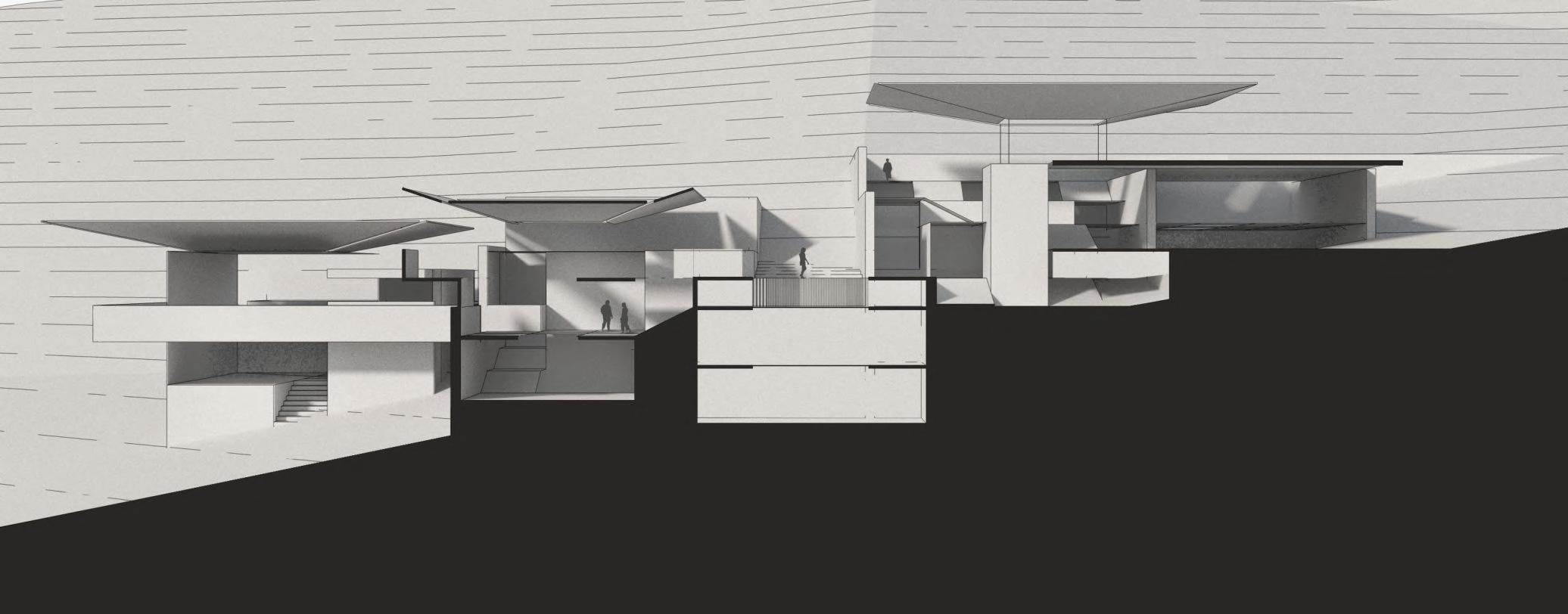

Iteration: CARPENTRY WORKSHOP

The carpentry workshop behaved as a key space to explore the development of structural and spatial strategies across the campus, as the design developed from low resolution massing studies to a higher resolution with increased detail.

03 Chapter 56 BARC0174 _ AAD1LHUENTSE SCHOOL OF CRAFTS

DESIGN DEVELOPMENT

Global Form Development 01

Linear arrangement with cascading levels.

Linear plan with main volumes surrounding central courtyard, with dining volume reoriented to create expansive views.

Dining space reoriented parallel to central circulation spine.

Main volumes contained in square space on perimeter of central courtyard with staggered exit extending from central spine.

As Option 4, except sleeping volume rotated 90 degrees to create staggered transition to dining space.

All volumes (excluding entrance) concentrated to square plan with circulation on perimeter of central courtyard, transitioning between submerged and above ground interstitial circulation.

As Option 6, except main volumes overhang at edges to create shaded reflection spaces below.

Secondary courtyard introduced between sleeping and dining volume, with diagonal staggering from top right to bottom left of image.

1OPTION 5

OPTION

OPTION 3OPTION 7 OPTION 2OPTION 6 OPTION 4OPTION 8

15 3 7 26 48

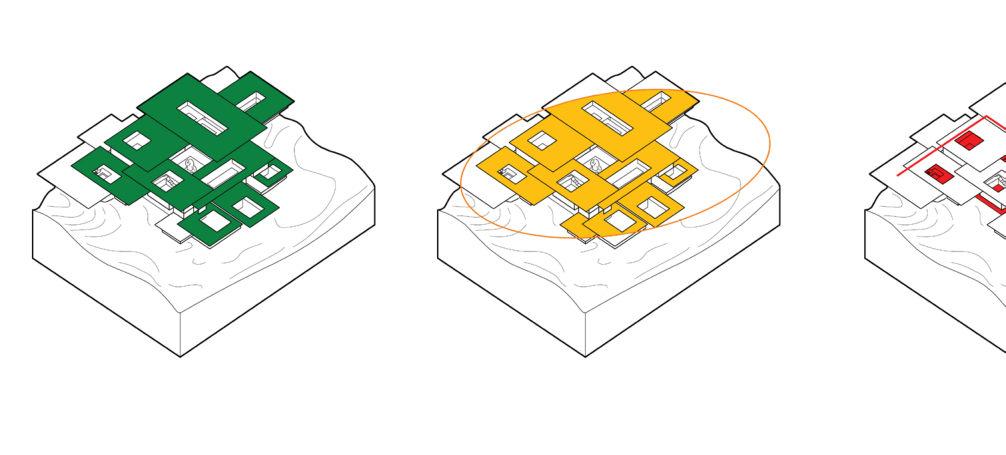

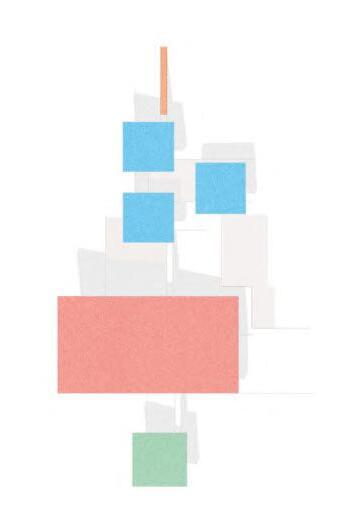

3.01 _ Initial Zoning Studies

Fanning arrangement with courtyard spaces at corners and next to central courtyard.

Angled roofs with fanning arrangement, and scale of campus enlarged.

OPTION 10OPTION 14

Fanning arrangement with each volume rotated except for craft volume which remains parallel to original central axis. Introduction of staggered, rotated entrance lobby.

As Option 13, except staggered exit rotated and courtyard space introduced at corner of dining space and crafts volume.

OPTION 11OPTION 15

Linear arrangement with walls introduced to create enclosures and demarcate guided circulation routes.

Each volume arranged in cluster on perimeter of central courtyard at slight angle with double planar roofs, to create hidden interstitial spaces on approach.

OPTION 12OPTION 16

Linear/square arrangement with roofs angled from top right to bottom left of image to maximise views.

As Option 15, except extended entrance volume introduced and three planes for paving on perimeter of each volume.

OPTION 9OPTION 13

9 13

1216 KEY Multipurpose Auditorium & Dining Crafts & Education Meditation Spaces & Courtyards Interstitial Circulation Options of Interest Sleeping 58 BARC0174 _ AAD1CHAPTER 3 _ DESIGN DEVELOPMENT

1115 1014

LINEAR LINEAR CLUSTER AXIAL 01 02 03 Meditation space in forest Tall meditation space in forest Slender walkway intensifies scale of meditation volume Central walkway Overlapping roof planes Central meditation room Global Form Development 02 3.02 _ Initial Massing Studies

Multipurpose Auditorium & Dining

Sleeping

Crafts & Education

RADIAL 1

Meditation & Spiritual Provision

Courtyards

Options of Interest

Crafts in rear with restricted light, creating introspective workspaces

RADIAL 2

Sleeping in rear creating dappered light from forest

Meditation space in forest

RADIAL

Public Information/ Entrance Lobby

Interstitial courtyards

Sleeping provision faces north for naturally low lux lighting

Meditation space in forest

Radially expanding craft spaces

Meditation space in forest

Volume height increases clockwise, drawing attention to central space

KEY

60 BARC0174 _ AAD1CHAPTER 3 _ DESIGN DEVELOPMENT

3 04 05 06

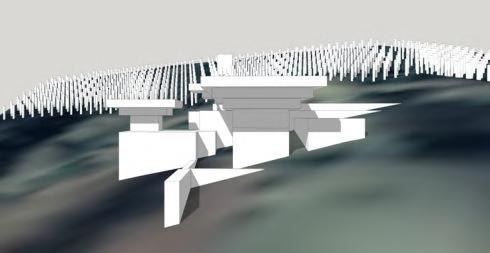

Design Iteration 01: Linear Cluster

Rear landscape creates facility for extracting resources.

ROCK CARVING/WOODWORKING

ENTRANCE PERSPECTIVE 1 2 3 4 5 6 7 MEDITATION ROOM SLEEPING AUDITORIUM/ DINING CRAFTS

3.03 _ Developed Massing Study

DESIGN ITERATION 01

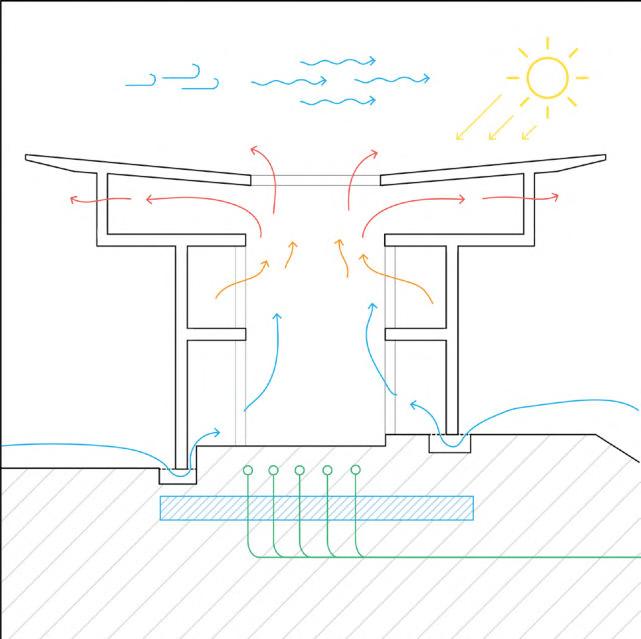

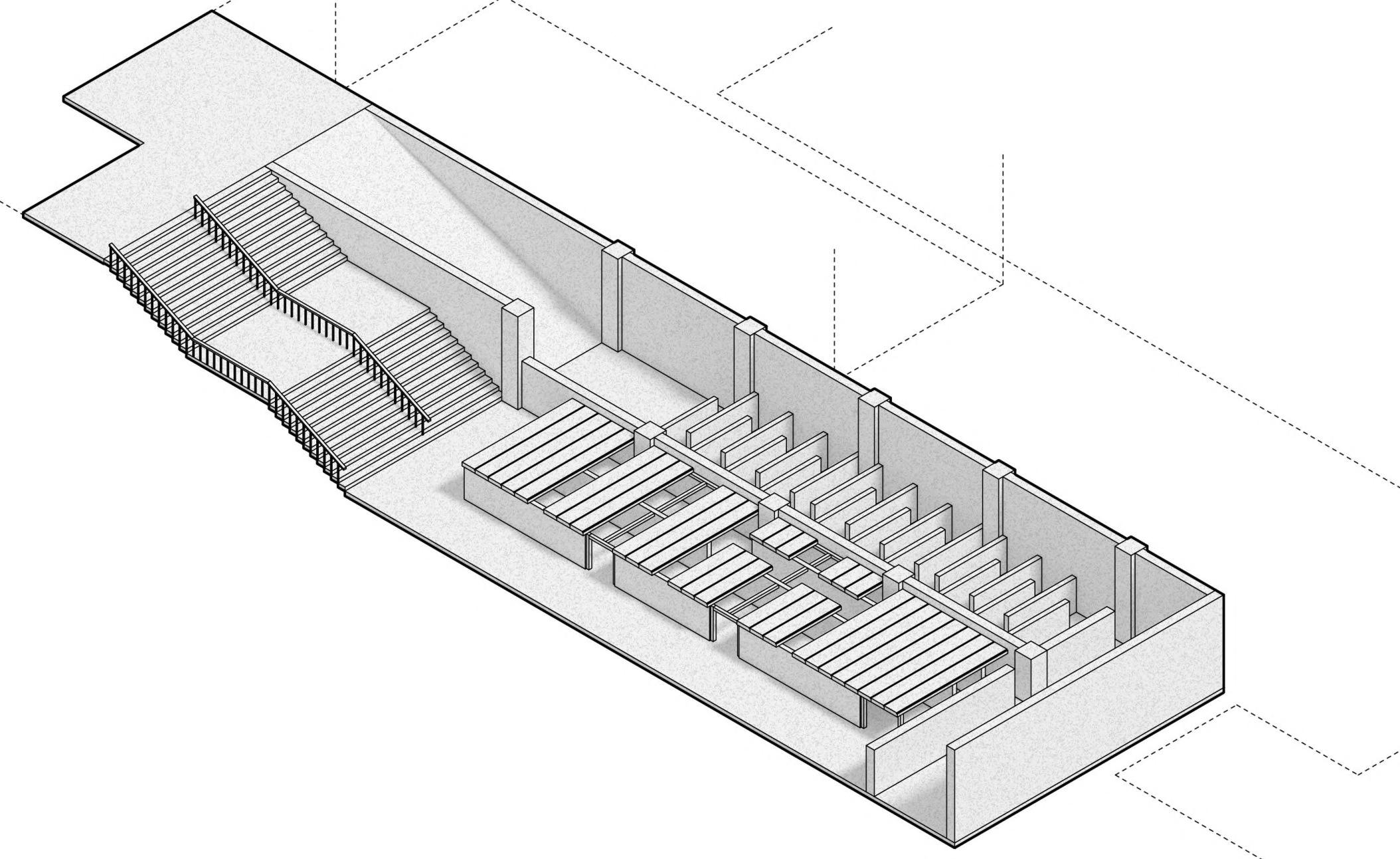

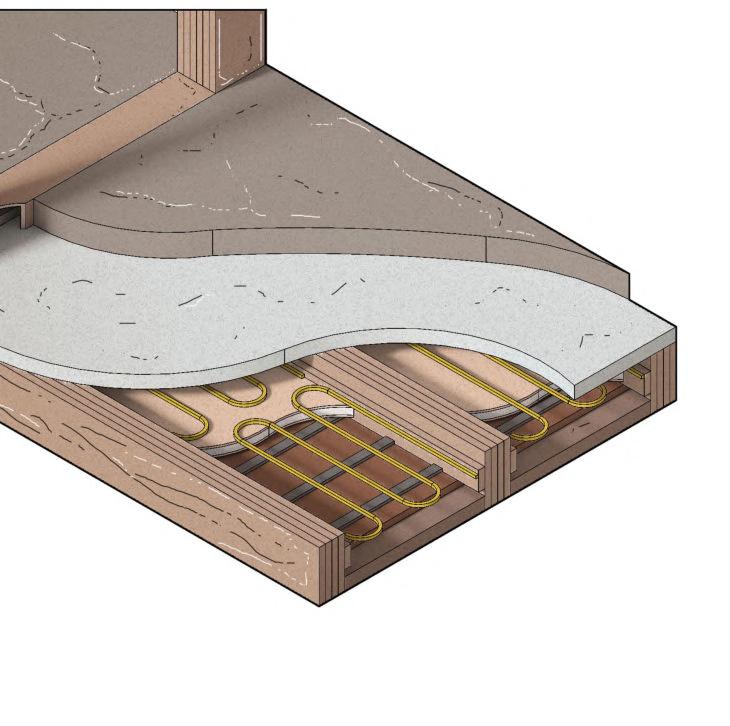

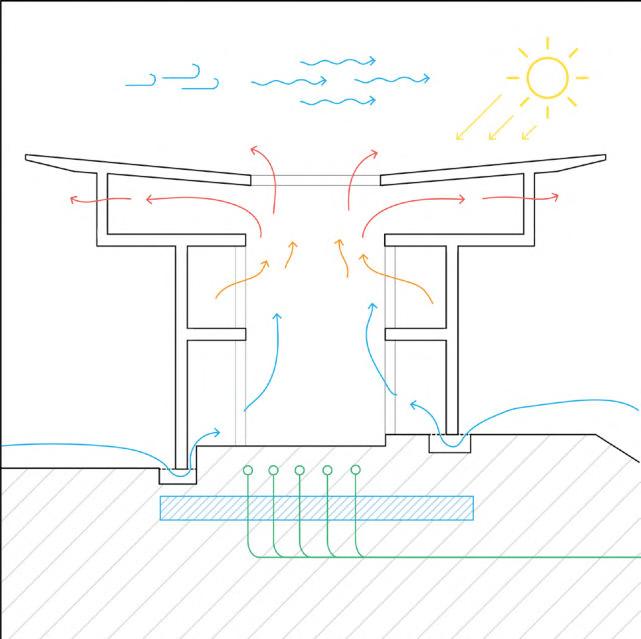

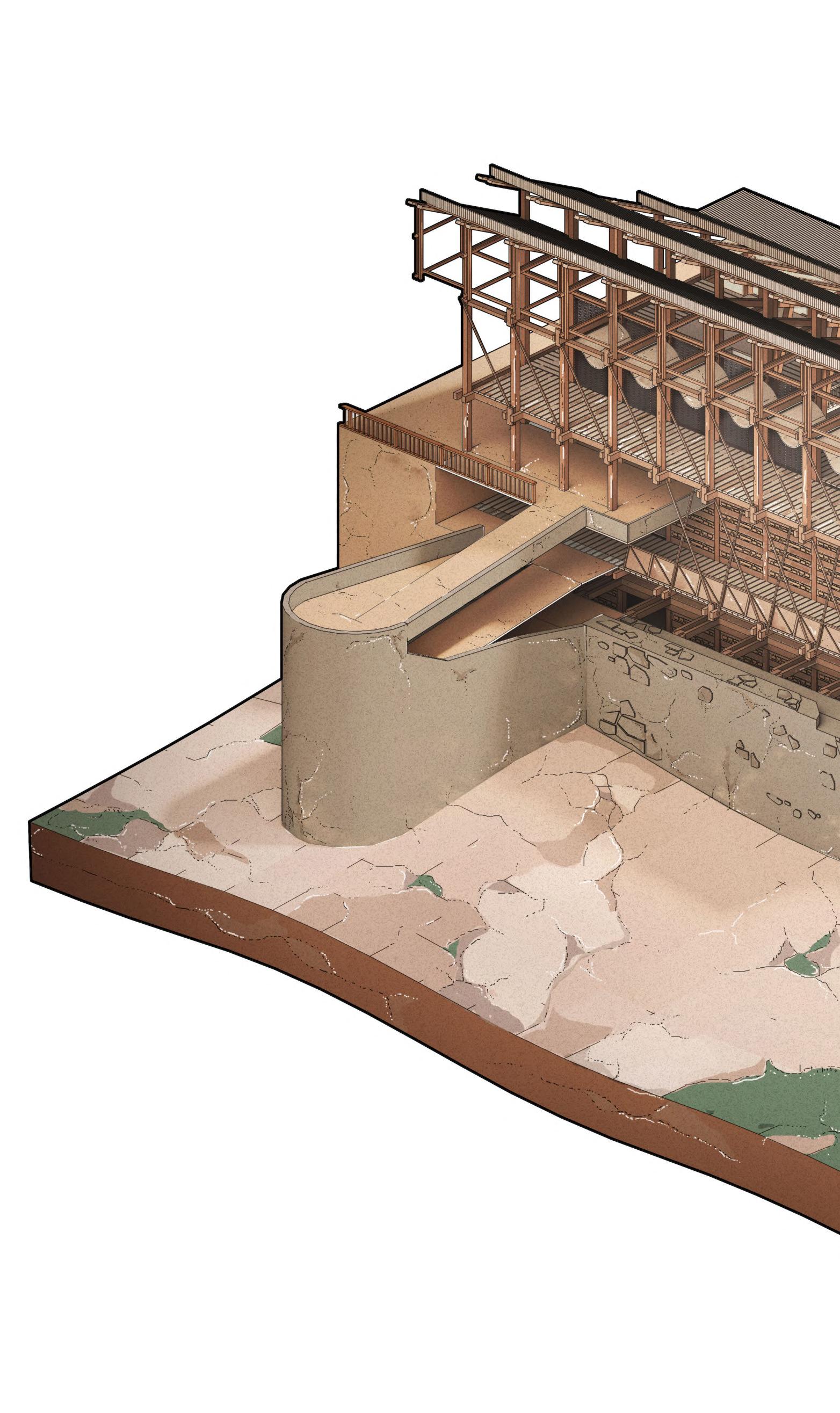

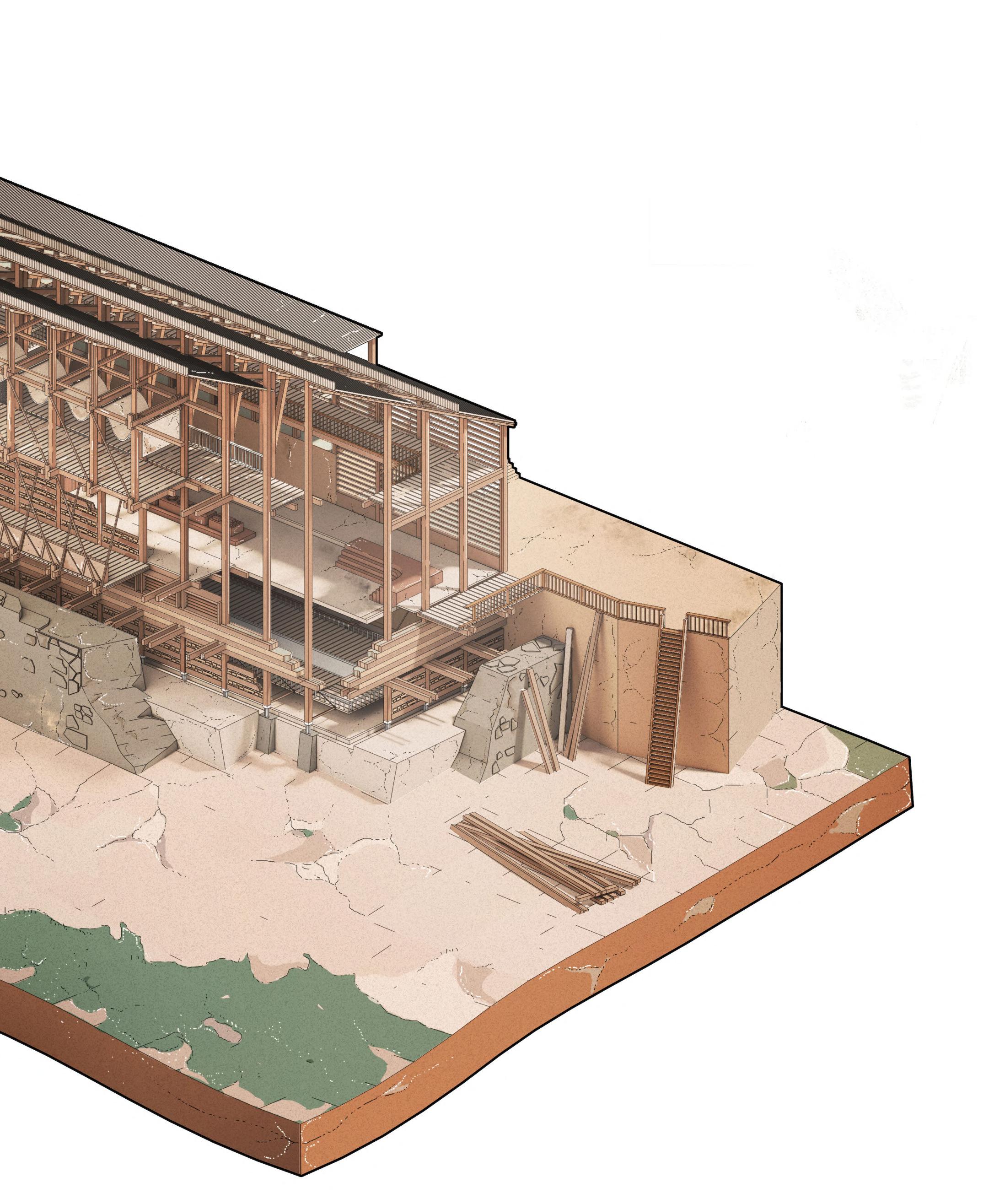

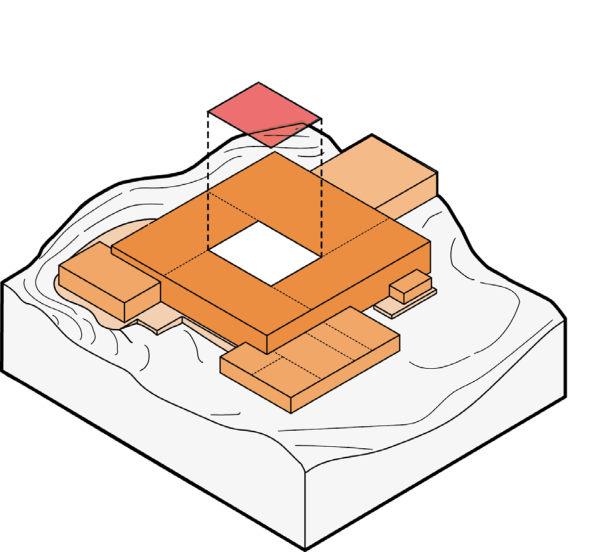

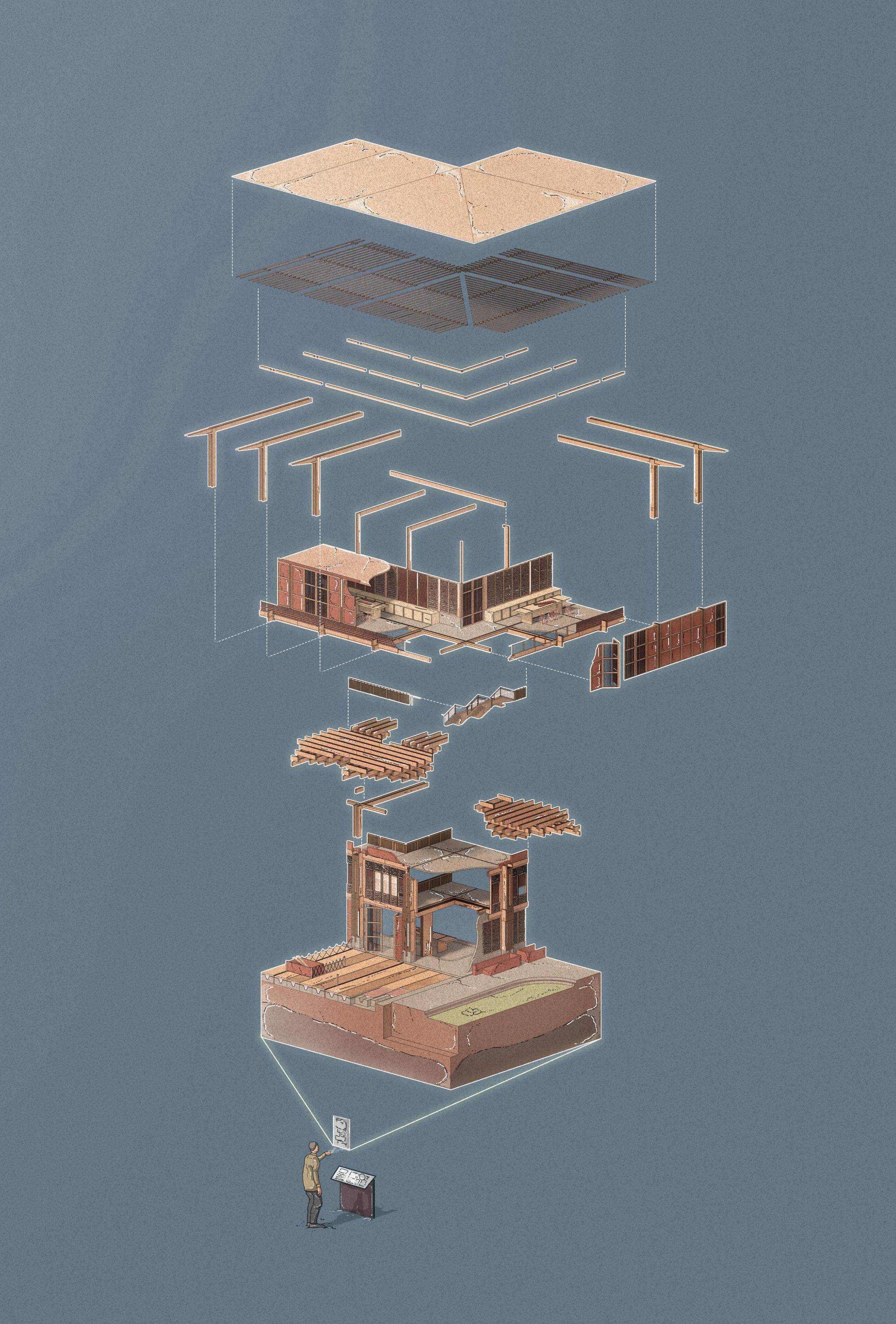

Early global form development studies suggested that linear and linear cluster arrangements were most successful in achieving efficient circulation, and a visually clear form, alongside the introduction of a central courtyard. Design Iteration 01 (shown opposite) develops the linear cluster massing on the previous page at a higher resolution with storeys and carved/ above ground interstitial circulation. It also tests the