RESEARCH TOPIC

MATERIAL DISTRIBUTION

1

The Strategic Usage Of Material Distribution In Historic Timber Ship Construction

BACKSTAY MAINSAIL LEECH

MAIN CLEW BOOM

TILLER

REVERSE TRANSOM

RUDDER

2

MAST TACK FORESTAY BOW WATERLINE HULL KEEL

The Nordic Folkboat is a wooden 25 ft Swedish sailboat that was designed as a racer-cruiser and first built in 1942. In nautical history it has spawned various guises and several derivatives.

MAIN HEAD HEADSAIL/JIB

DECKING

BILGE STINGER

FUTTOCKS

FLOOR

WATERLINE

KEELSON

WOOD GRAIN DIRECTIONS / NORDIC FOLKBOAT 1942

The hull has a spooned, raked stem, a sharply angled transom, a keel-mounted rudder controlled by a tiller and a fixed modified long keel, with a cut-away forefoot.

GRAIN DIRECTION

PARALLEL LONGITUDINAL TANGENTIAL

3

MAST GUNWHALE LAPSTRAKES

IRON BALLAST KEEL

MAIN HEAD

BACKSTAY

MAINSAIL

TIMBER BATTENS

LEECH

MAIN CLEW

BOOM

TILLER

RUDDER

Yngling is a Norwegian sailing boat of 21 feet for regatta and day sailings. Jan Herman Linge designed Yngling in 1967 as a little sister to Soling and the idea was that it would be a recruitment boat for Soling.

TIMBER BATTENS FORESTAY

HEADSAIL/JIB

TACK

SPREADER PATCH HULL WATERLINE KEEL

4

MAST

FUTTOCKS

WATERLINE

FLANGED FLOOR

KEEL

WOOD GRAIN DIRECTIONS / YNGLING 1967

Yngling is a racing keelboat, built predominantly of fibreglass.. It has a fractional sloop rig with aluminum spars. The keelboat has flexible wood battens inserted into a sail, parallel to the direction of wind flow, that helps shape its qualities as an airfoil.

GRAIN DIRECTION

PARALLEL LONGITUDINAL TANGENTIAL

5

ALUMINIUM MAST

TIMBER BATTENS

FIBREGLASS

FORESTAYKSTAY

HEADSAIL/JIB

AIRFOILS

MAIN CLEW

DOUBLE HEADSAIL

HULL

Cheveyo steps away from the current norm of modern J’s aluminium fabrication process and returns to the historically accurate construction method, though with the use of modern epoxies and laminating techniques to maintain a constant grain direction for maximum performance yield.

TIMBER BATTENS

MAINSAIL

BACKSTAY

SPREADER PATCH

TACK

HULL

INTEGRATED RUDDER

WATERLINE

6

MAIN HEAD

LONGITUDINAL BOLTS LONG ARM

THROUGH-BOLTS

SHORT ARM

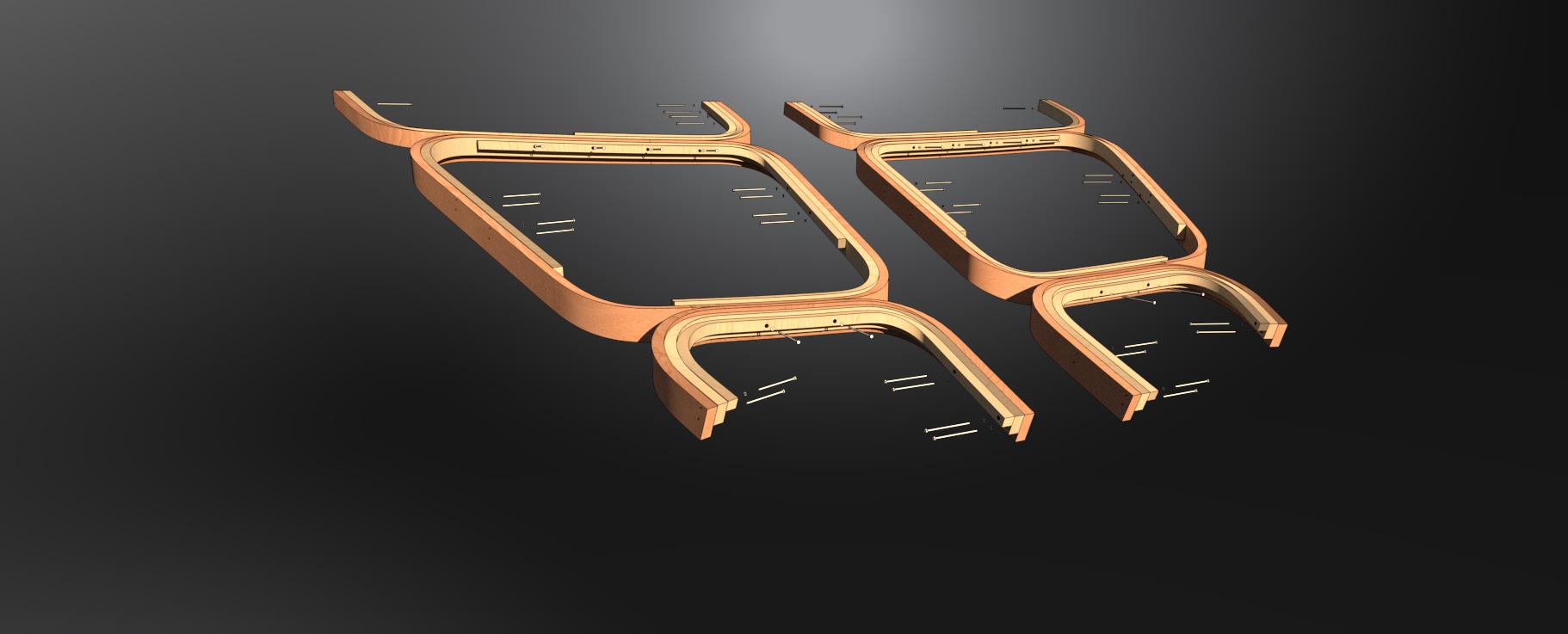

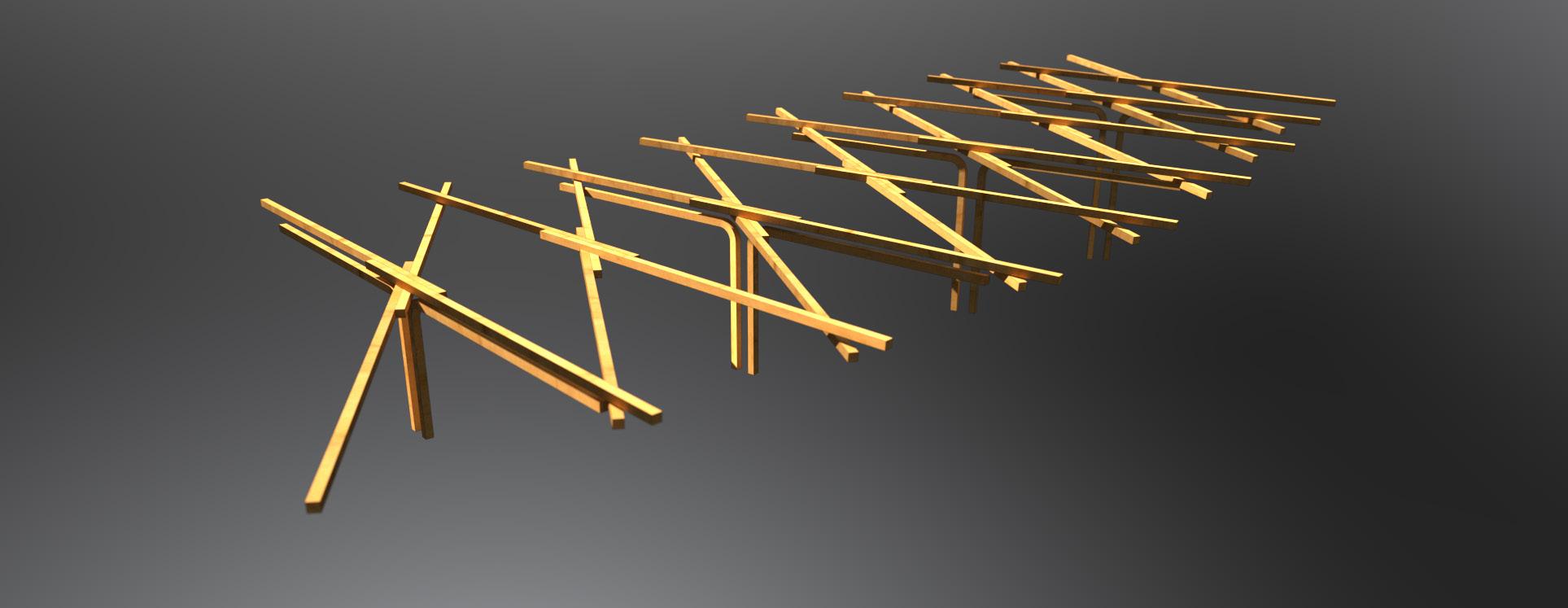

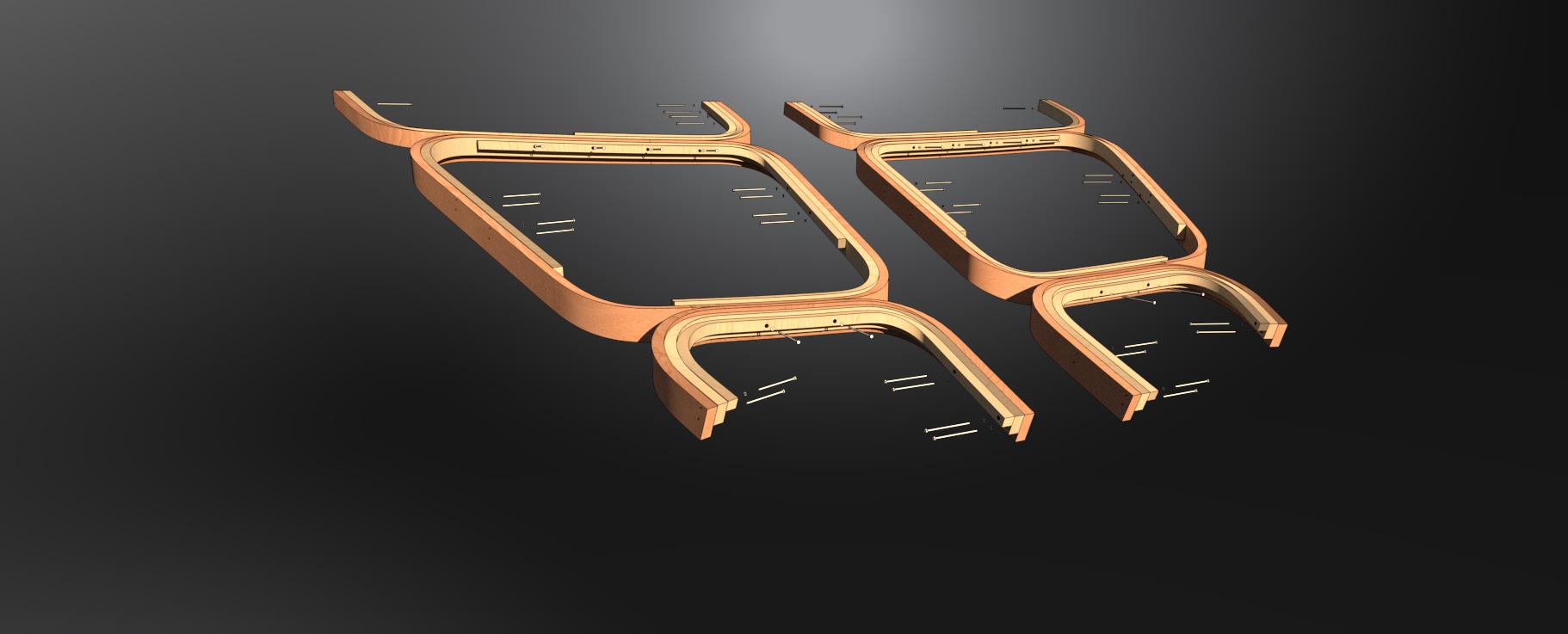

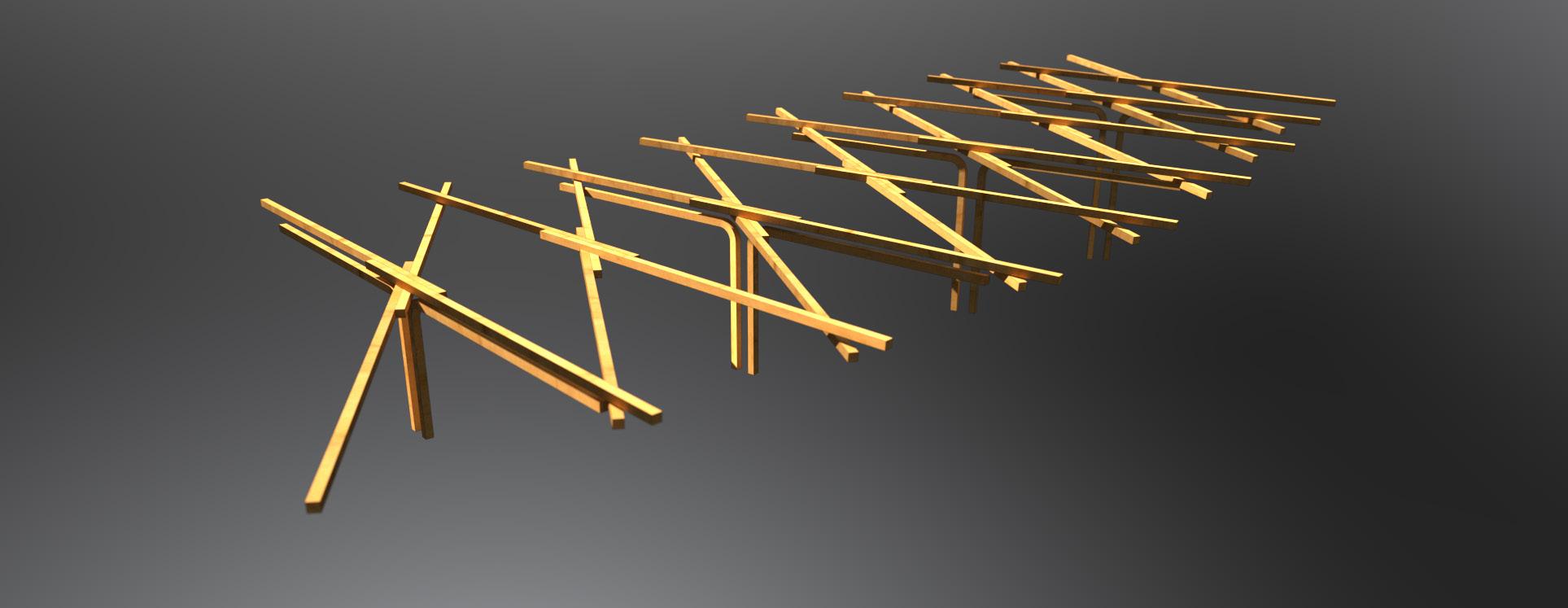

CHEVEYO FRAMES AND INTEGRAL JOINERY

Principal strengths of the frame is to keep the grain of the wood running parallel to the direction of the frame edge. The futtocks use integral joints, where forces between the parts are transferred through geometrical features rather than on the joints themselves.

7

3RD FUTTOCK

2ND FUTTOCK

4TH FUTTOCK

CILL

KEELSON

1ST FUTTOCK

TOP TIMBER

FLAT SCARF JOINT DOWEL-JOINT INTEGRAL JOINT

3RD FUTTOCK

2ND FUTTOCK

1ST FUTTOCK

KEEL

4TH FUTTOCK CILL

KEELSON

CONSTRUCTION OF FUTTOCK FRAMES

Joints between two futtocks are not located at adjacent heights primarily because splicing connections act as a weak point in the hull. Therefore the futtocks have different lengths to allow consistent shear connections between the scarf joints.

8

STAGGERING FRAMES

THINNEST MEMBERS

SHORT ARM

LONG ARM

SHEAR JOINT

KEEL FLAT SCARF JOINT

THICKEST MEMBERS

PARALELL GRAIN

PERPENDICULAR CUT

KEELSON

ONRUST 1614 / DOUBLE-SIDED FRAME

Onrust was constructed in less than four months in 1614. Due to its speedy completion, it is assumed the ship was built with the leftover parts from its successor, together with new building materials soruced locally,.

9

3RD FUTTOCK

3RD FUTTOCK

2ND FUTTOCK

2ND FUTTOCK

FIRST SHELL

1ST FUTTOCK

STERN LAPSTRAKE (CLINKER)

KEEL THROUGH BOLTS

BILGE FUTTOCK

TRANSOM

KEELSON

KEEL

LUMBER AS FRAMES AND FUTTOCKS

Lumber hero chart of typical framing dimensions and first futtocks sourced from solid wood. The bottom row illustrates the same scantling cut from timber of different curvature with direct application and use.

10

2x6 2x6

4x6 4x4

2x8 2x6

6x6 4x4 140

140

140mm flat-sawn bow crook twist cupping longitudinal rift-sawn diamonding curved quarter-sawn bulge edge straight

2x4 2x6 38 x 89mm 38 x 140mm 4x4 4x4 89 x 89mm 89 x 89mm

38 x 140mm 38 x 140mm

89 x 140mm 89 x 140mm

38 x 184mm 38 x 140mm

x 140mm

x

Sawn timber: SS-EN 1313-1 and SS-EN 336

CATEGORIES

NORWAY

11

/ CROSS-SECTIONAL SAWN TIMBER CHART

100mm 47mm 75mm 44mm 63mm 38mm 50mm 32mm 25mm 22mm 19mm 250mm 225mm 200mm 175mm 150mm 125mm 100mm 75mm 50mm 38mm 25mm 16mm 12mm

Chart of cross-sectional dimensions commonly occurring in sawn timber in Sweden and Norway. Sawn timber chart is sorted hierachial in dimensions of width and thickness.

JOIST PLANK

BEAM-AND-POST BATTEN BOARD

Planed timber: SS-EN 1313-1 and SS-EN 336

CATEGORIES

NORWAY / CROSS-SECTIONAL PLANED TIMBER CHART

12

33mm 28mm 70mm 18mm 45mm 15mm 12mm 9mm 21mm 220mm 195mm 170mm 145mm 120mm 95mm 70mm 45mm 33mm 21mm

Chart of cross-sectional dimensions commonly occurring in planed timber in Sweden and Norway. Planed timber chart is sorted hierachial in dimensions of width and thickness.

JOIST PLANK

BEAM-AND-POST

BATTEN BOARD

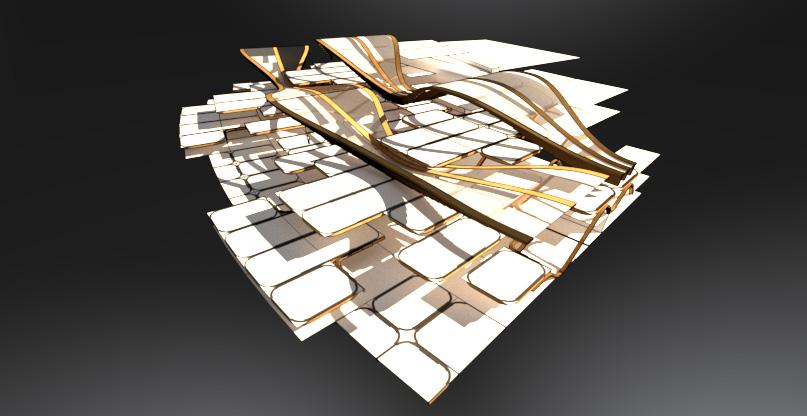

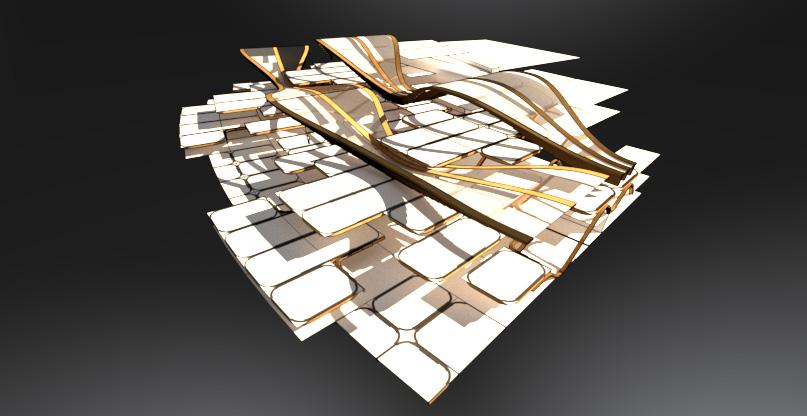

MATERIAL DISTRIBUTION

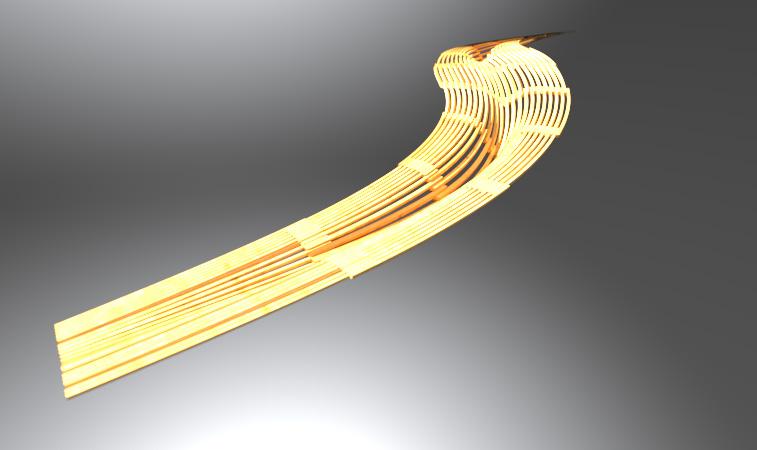

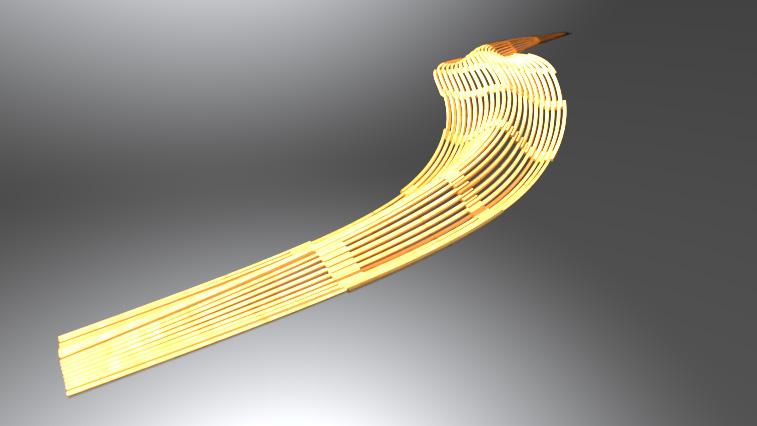

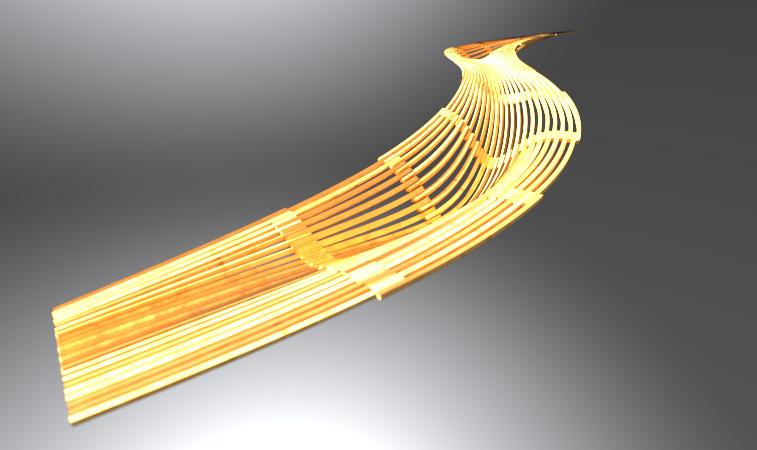

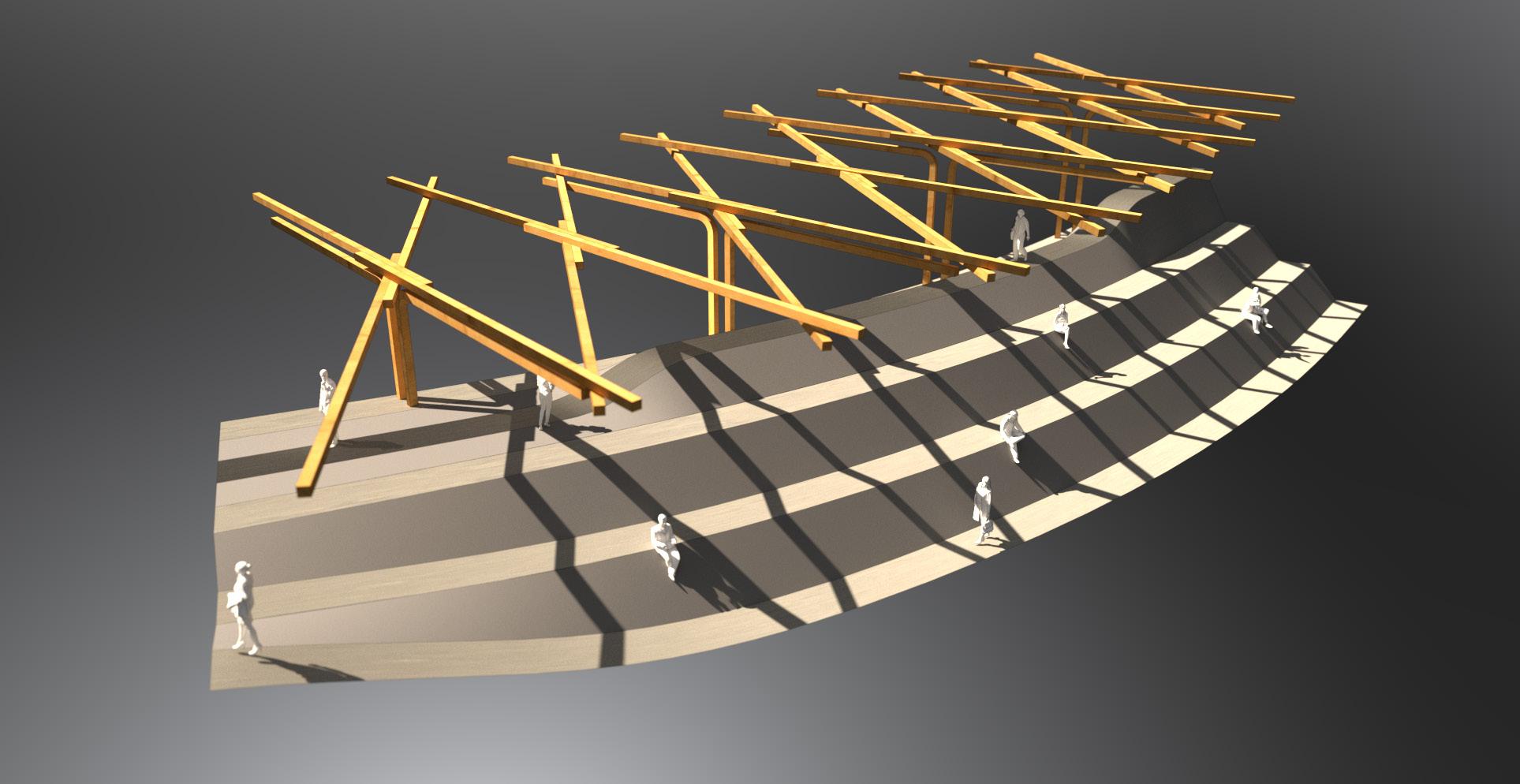

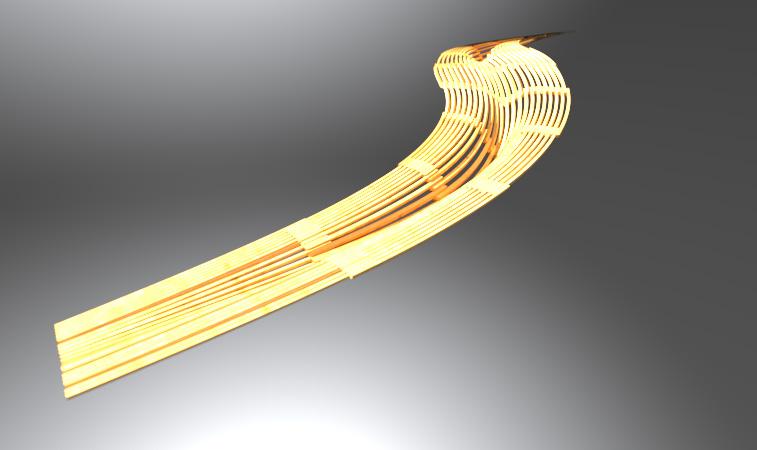

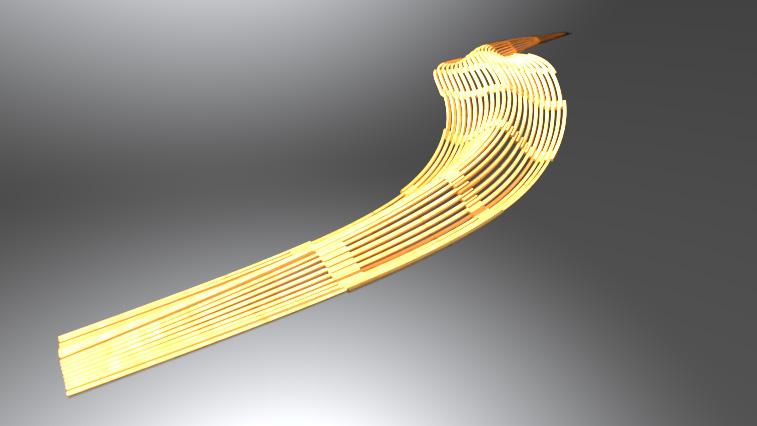

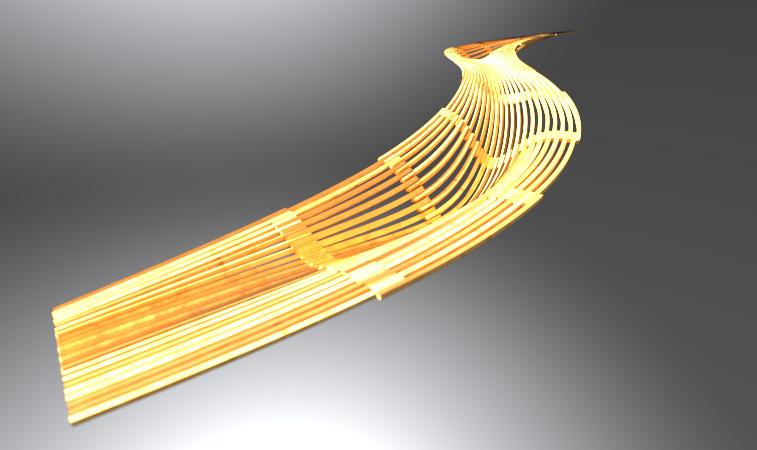

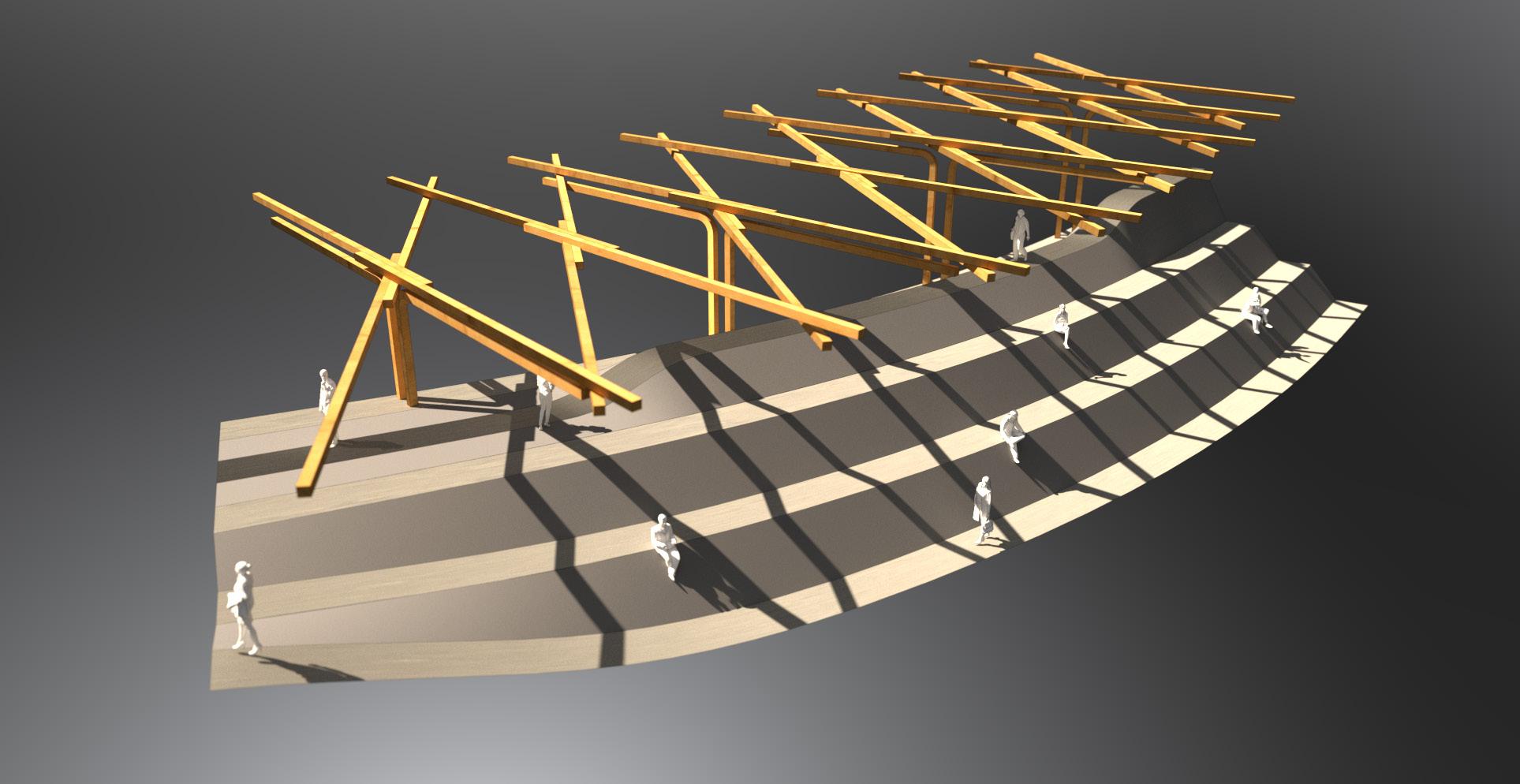

SCANTLING TECTONICS

Systems of Scantling Timber with Distinct Hierarchy for Performance and Program

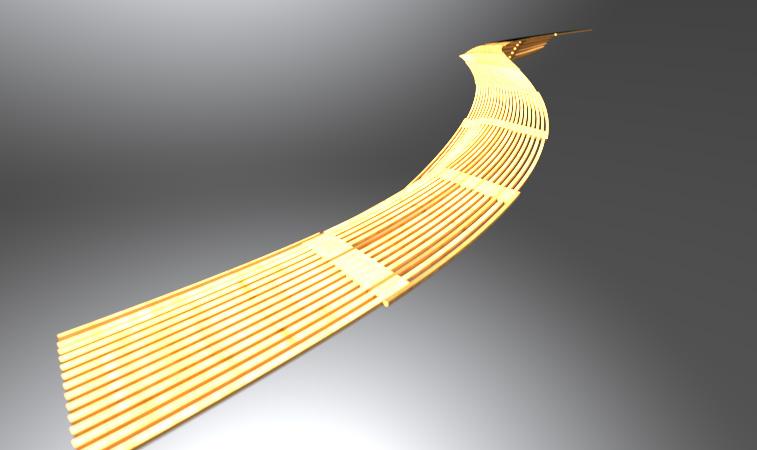

13

surface shell

Area: 231m²

THICKEST BEAMS 20cm

THINNEST BEAMS 5cm

individual members

Total members: 220

SIMPLE MEMBERS-TO-SURFACE

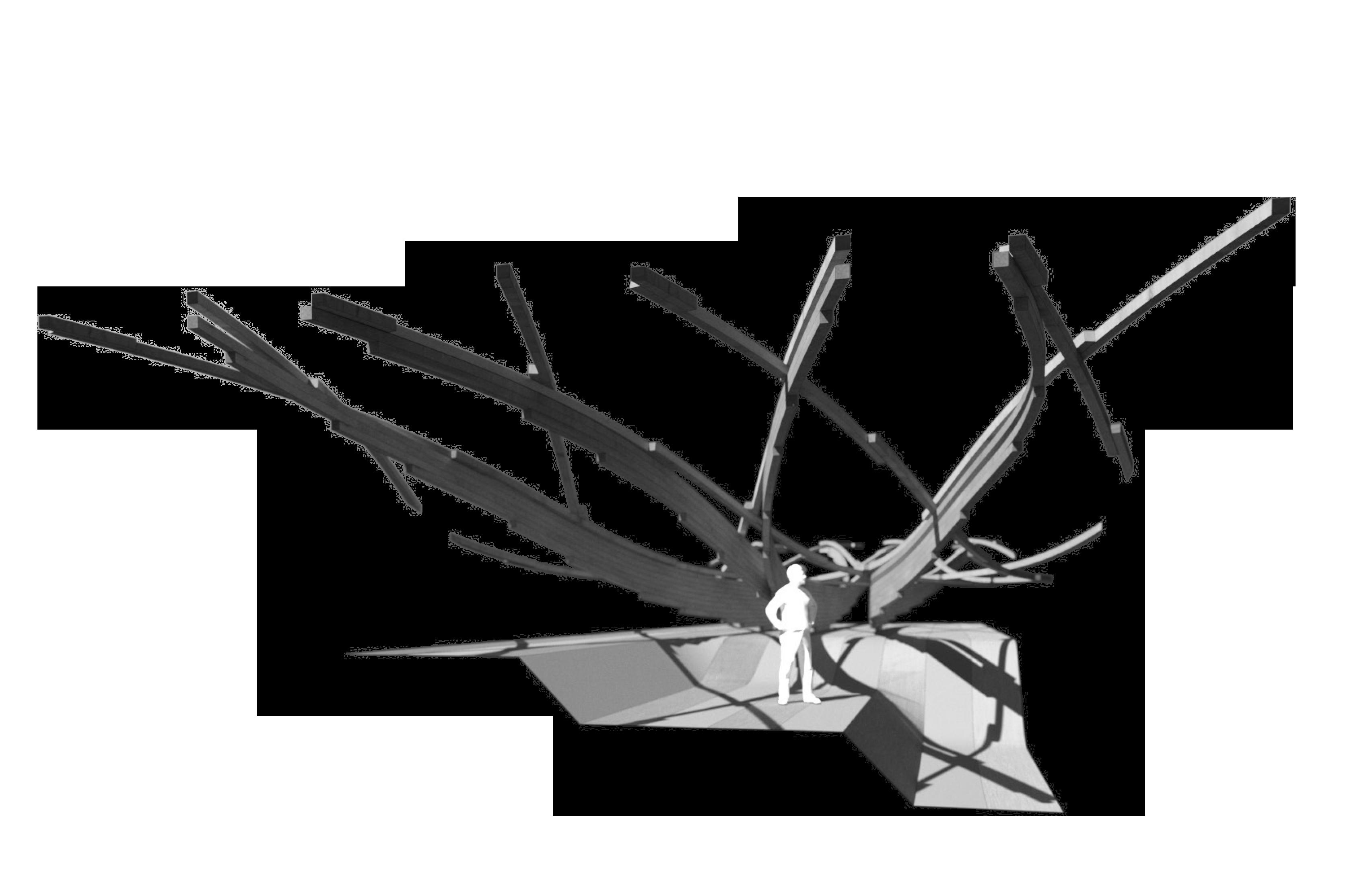

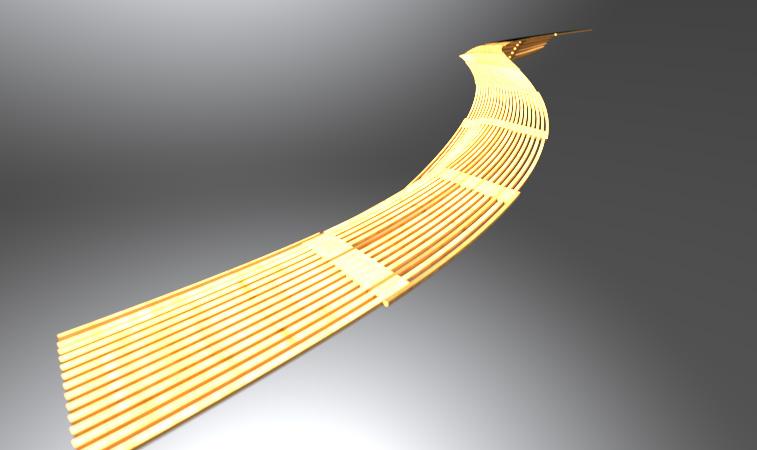

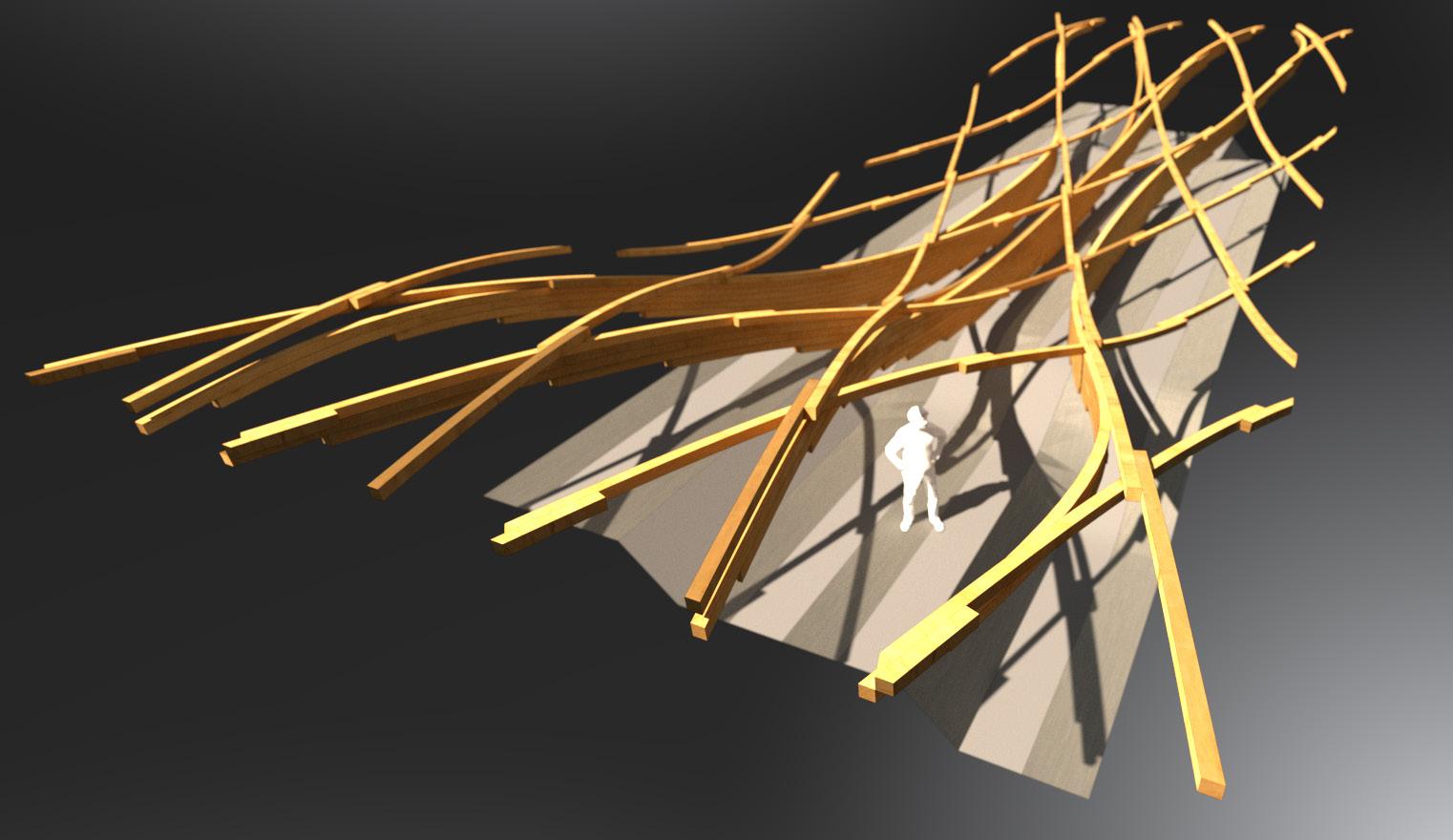

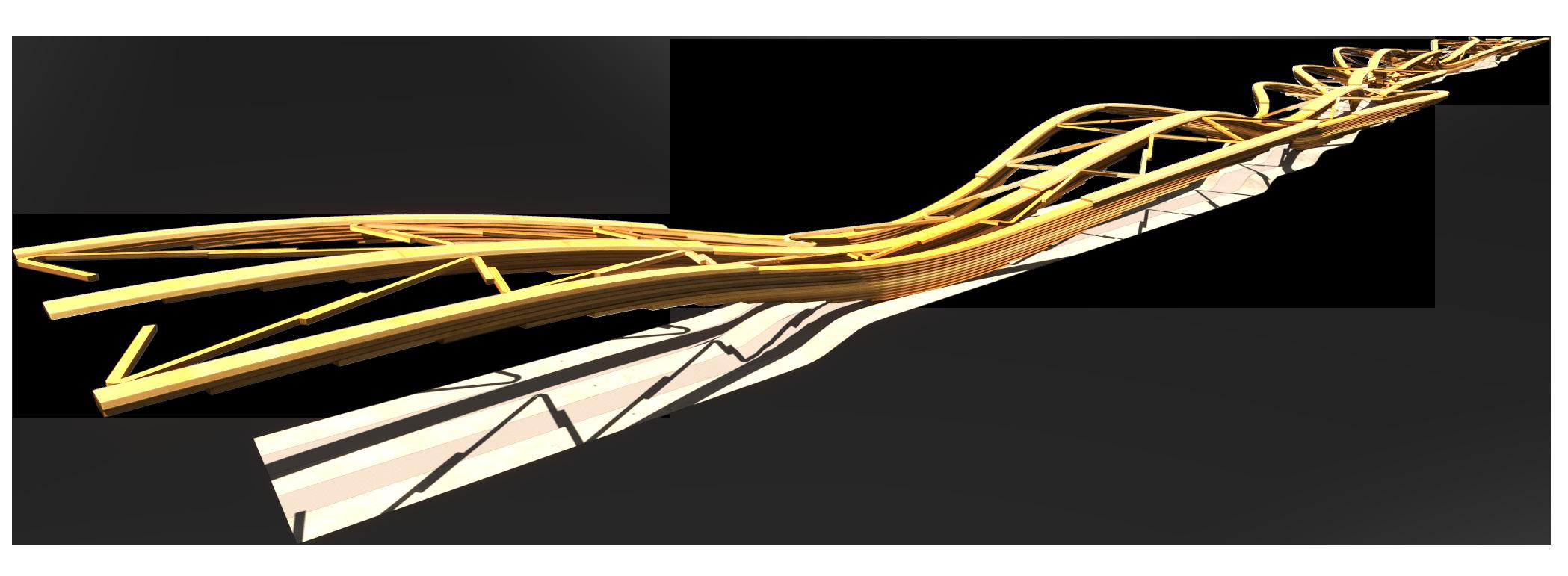

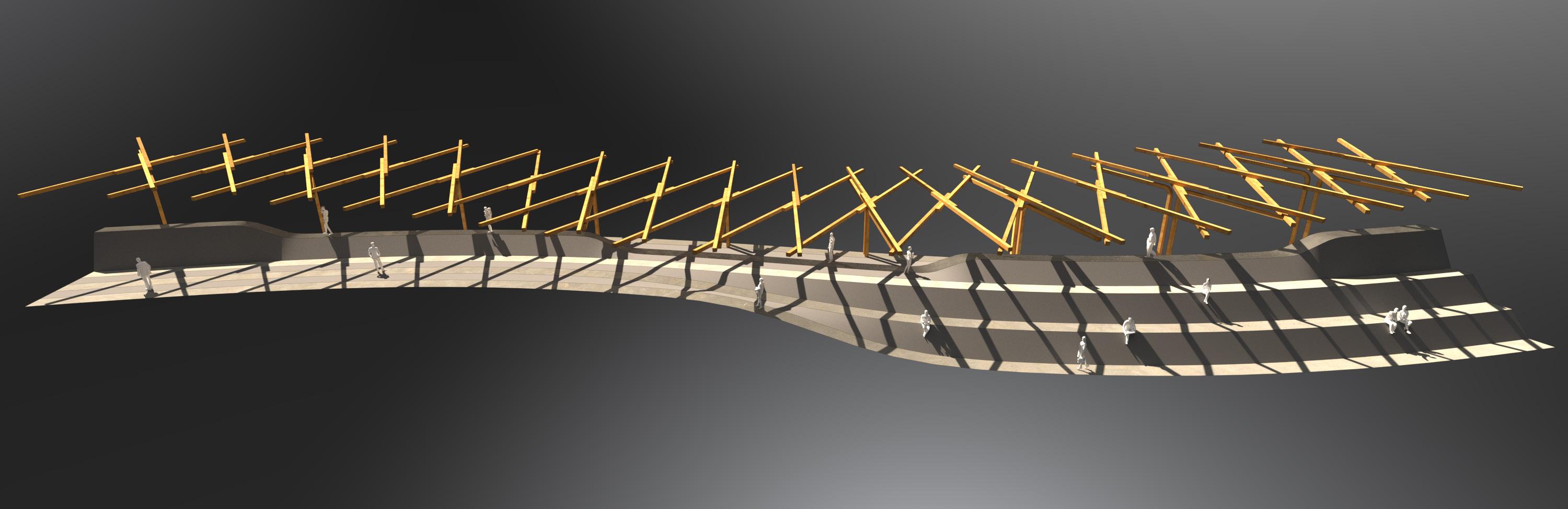

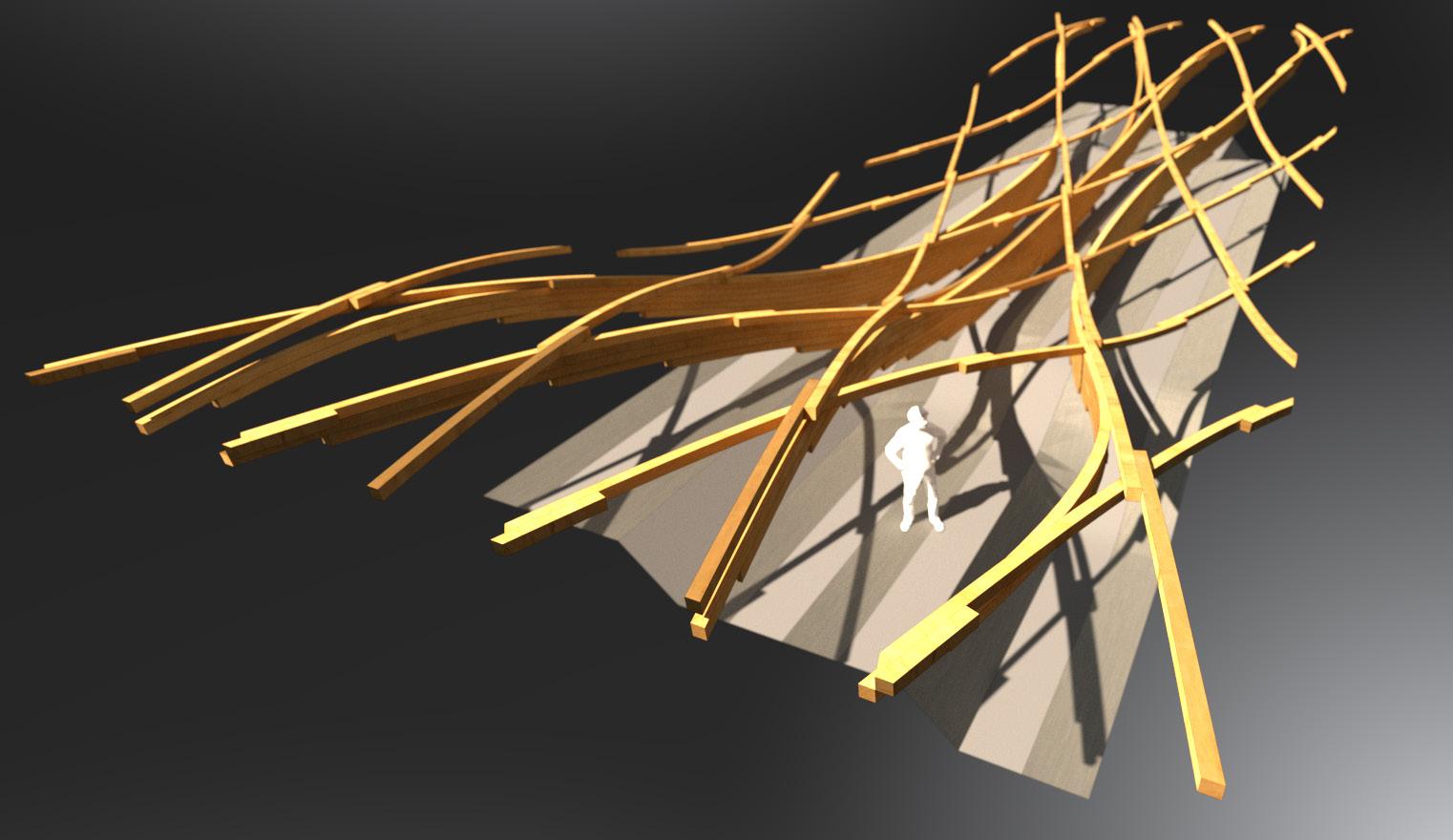

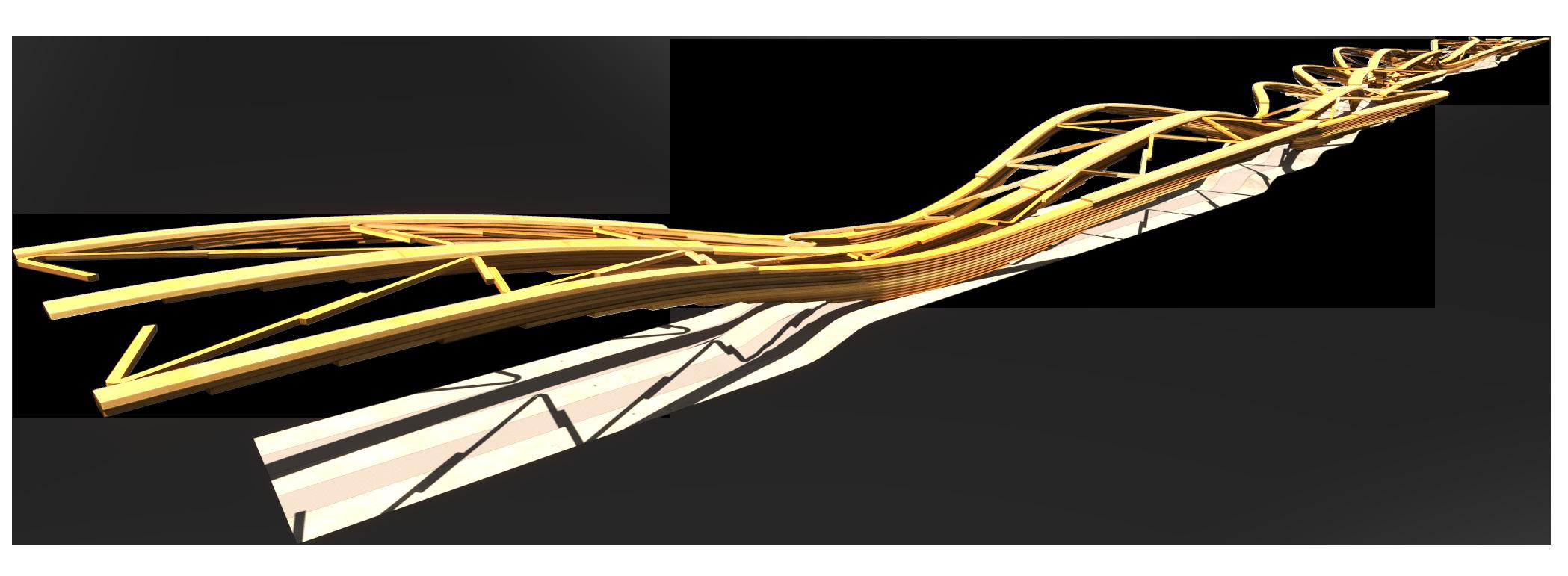

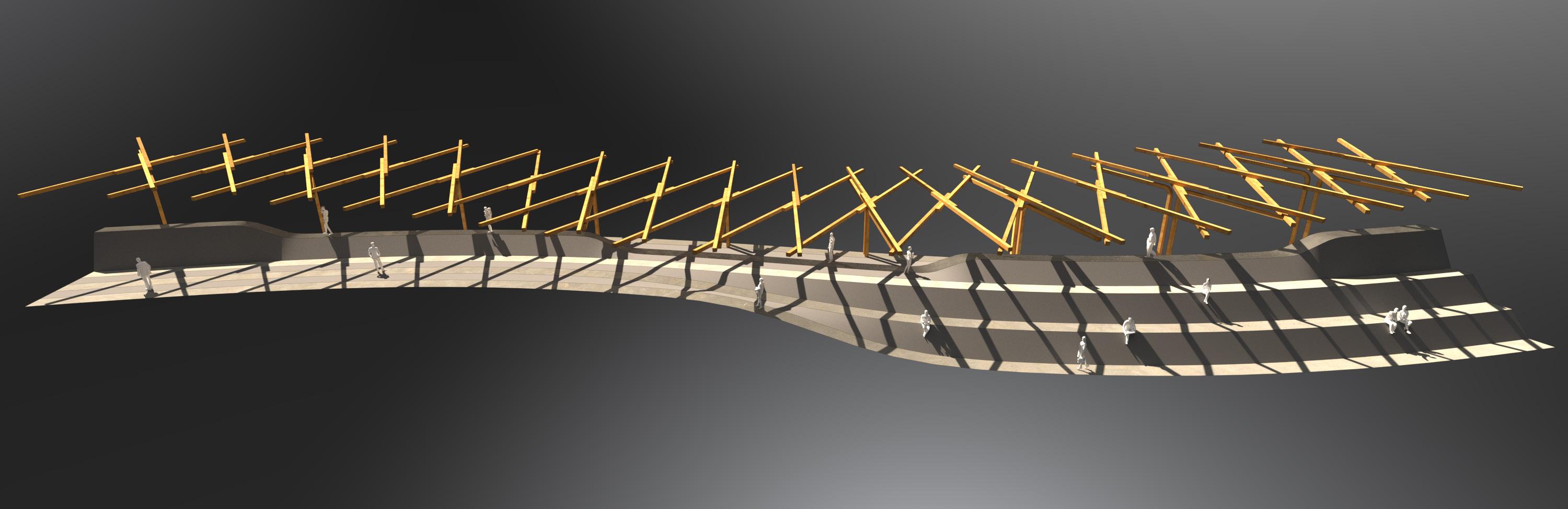

Rationalizing the main principals of the ship hull’s futtocks and applying its intrinsic logic of staggering timber battens. The simple members can be viewed as a series of interlapping beams spanning across various ranges to form a rigid surface.

14

FIRST FUTTOCK

COLUMN 40x115cm

STAGGER

1B FUTTOCK

2A FUTTOCK

2B FUTTOCK

1A FUTTOCK

right view left view

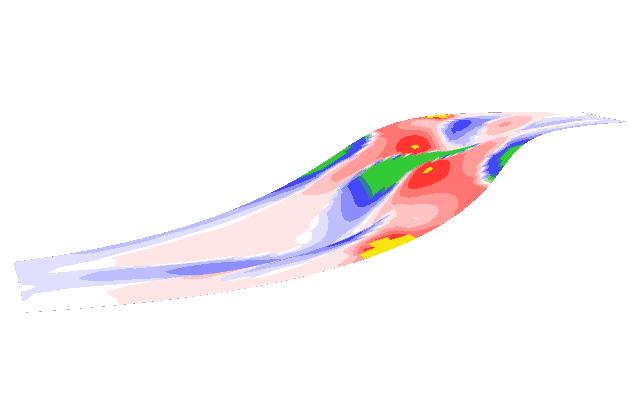

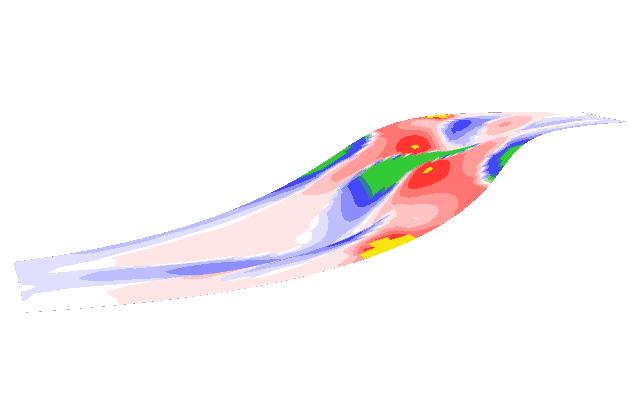

utilization

Upper threshold: 55

Lower threshold: 38

High compression

High tension

surface as shell

Upper threshold: 77

Lower threshold: 13

High displacement

Low displacement

surface as individual beams

grain direction

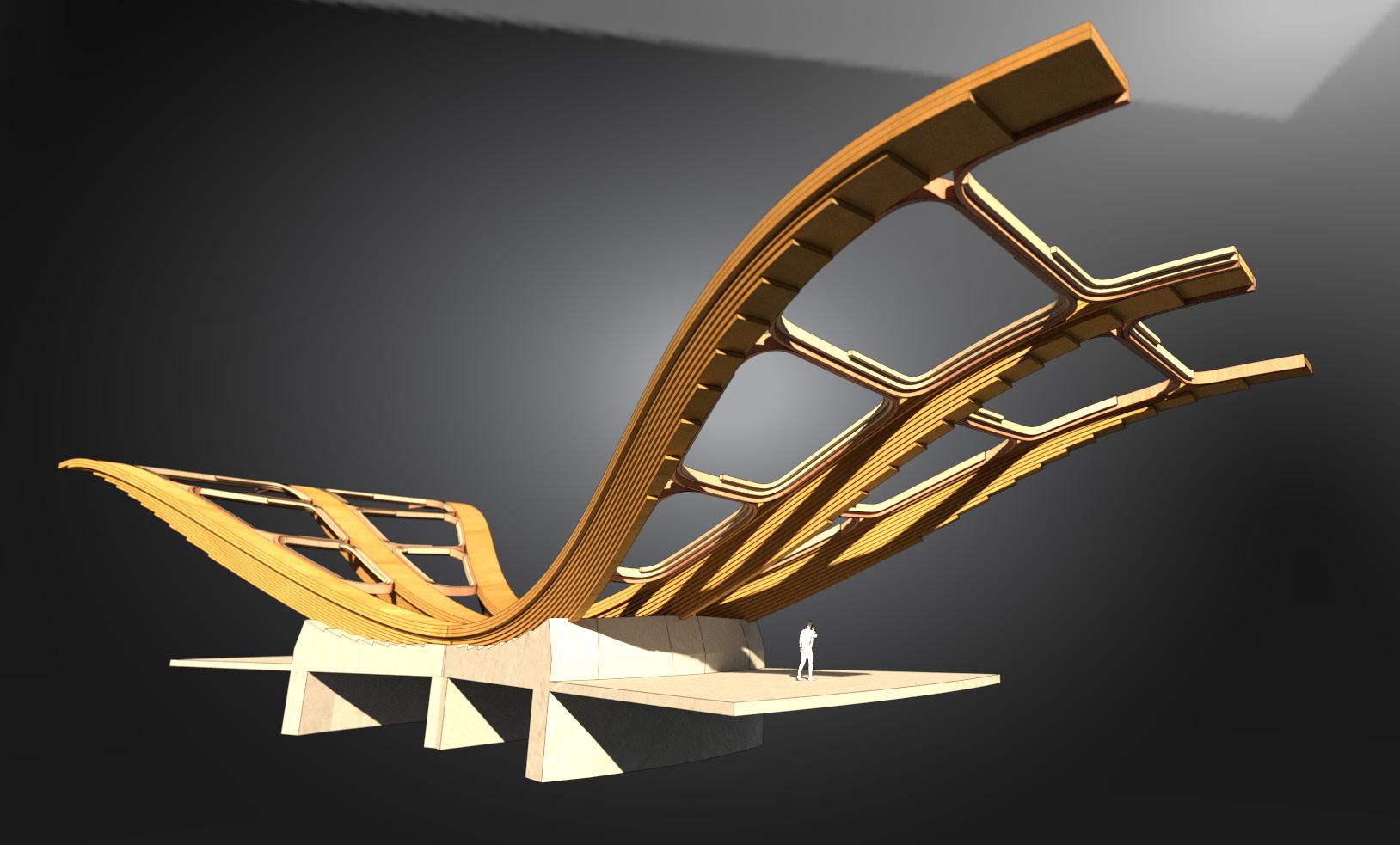

SURFACE AS INDIVIDUAL BEAMS

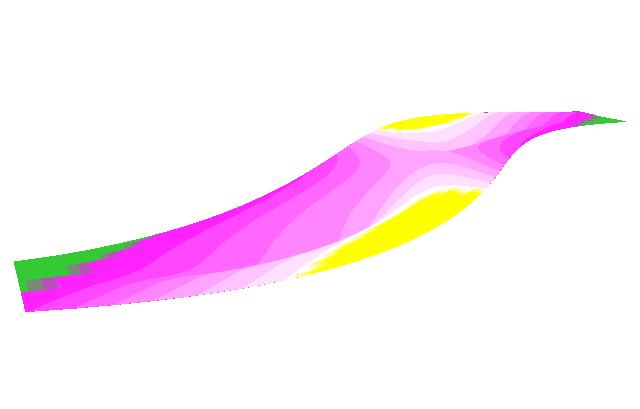

Surface geometry is understood and then created in order to inform the gently curved timber battens to form a series of simple beams that are interlocked in a staggered system with naturally increasing cross-sections at high stress areas.

15

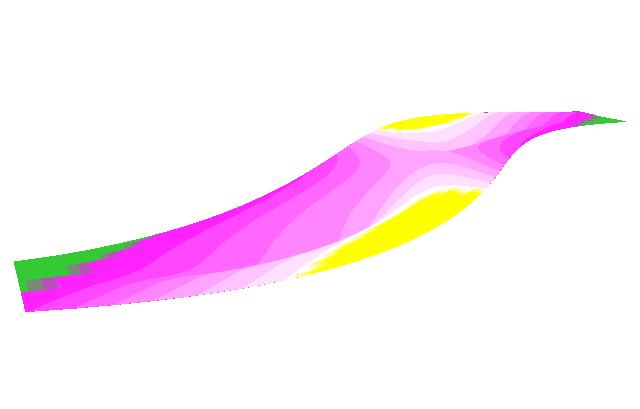

displacement

4.79m to 4.80m 41.99m to 42.06m 4.80m to 4.82m 42.09m to 42.75m 4.79m to 4.79m 41.95m to 41.99m LENGTHS LENGTHS 4.82m to 4.87m 42.20m to 42.75m

timber battens

PARALLEL

Members: 220

Lengths: 4.78m to 4.80m

Members: 220

Lengths: 4.79m to 4.85m

Members: 220

Lengths: 4.78m to 4.81m

Members: 220

Lengths: 4.79m to 4.87m

Members: 220

Lengths: 4.78m to 4.83m

Members: 220 Lengths: 4.79m to 4.80m

Members: 220

Lengths: 4.78m to 4.85m

Members: 220

Lengths: 4.78m to 4.81m

MEMBER DIFFERENTIATION ANALYSIS

Simple iterative study of beam members in surface driven design used to influence the choice of how geometry and curvature informs differentiation in beam length range.

16

2cm 6cm 3cm 8cm 5cm 1cm 7cm 3cm

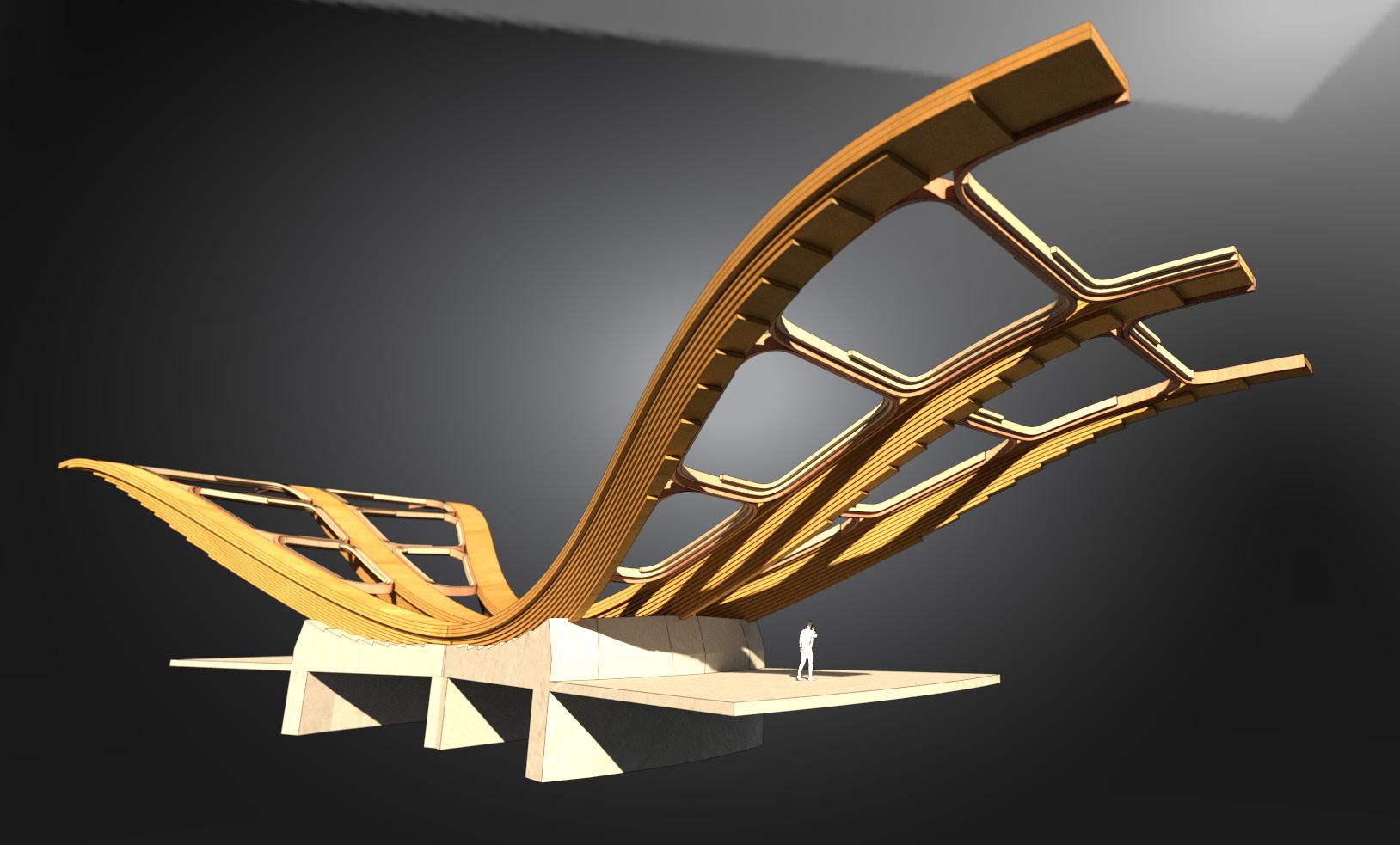

structural shell

Area: 380m²

timber battens

Total members: 300

SHORT SPAN 6.6m

LONGER SPAN 17.0m

STAGGERING TIMBER BATTENS

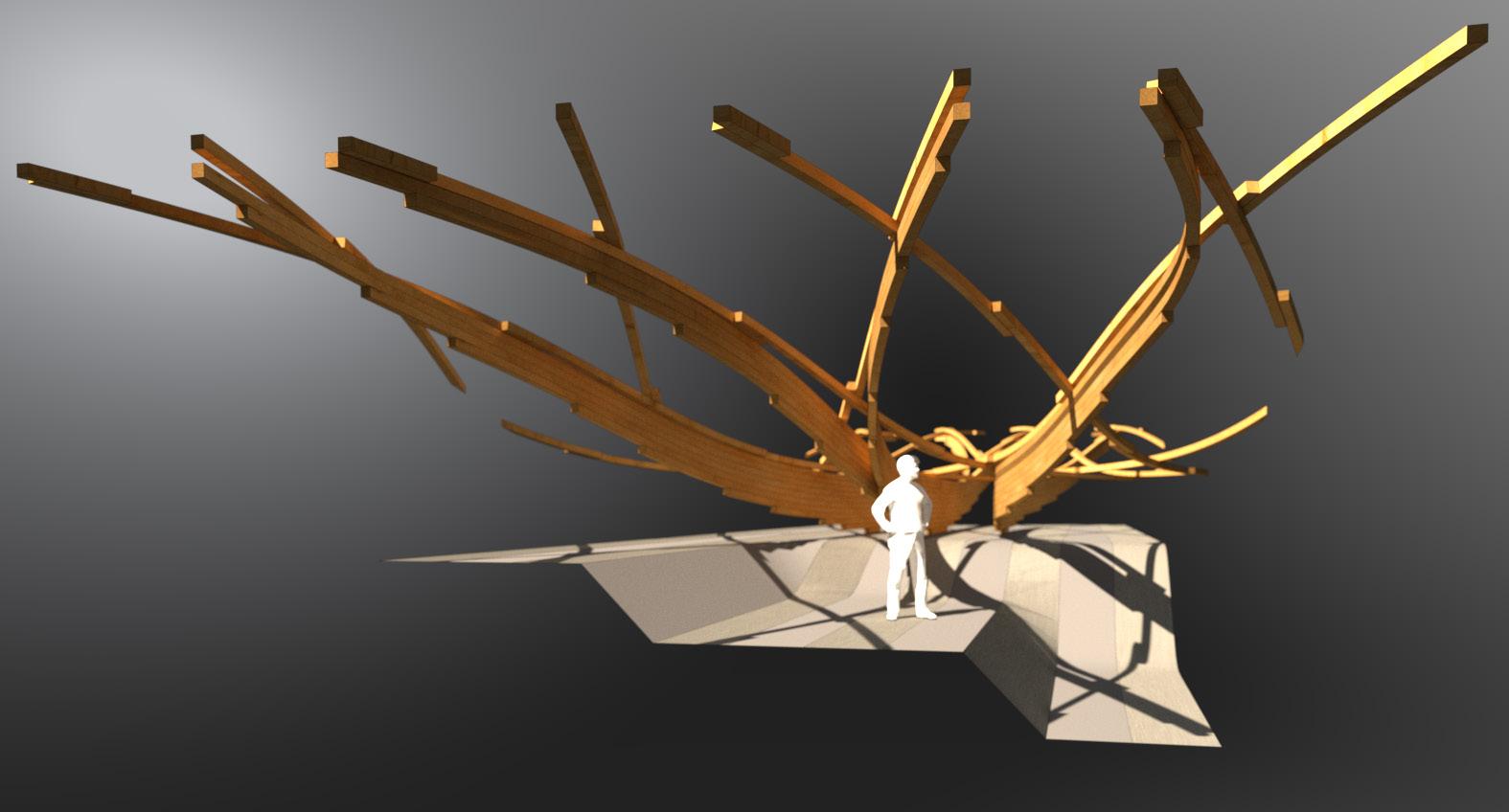

Using the staggering logic of interlocking each members by alternating each group of curves allows the continuity of a complex surface to be generated from simple members.

THINNEST BEAMS 13cm

THICKEST BEAMS 17cm

PLYWOOD SHEET 18mm

THROUGH BOLTS

LONGITUDINAL BOLTS

right view left view

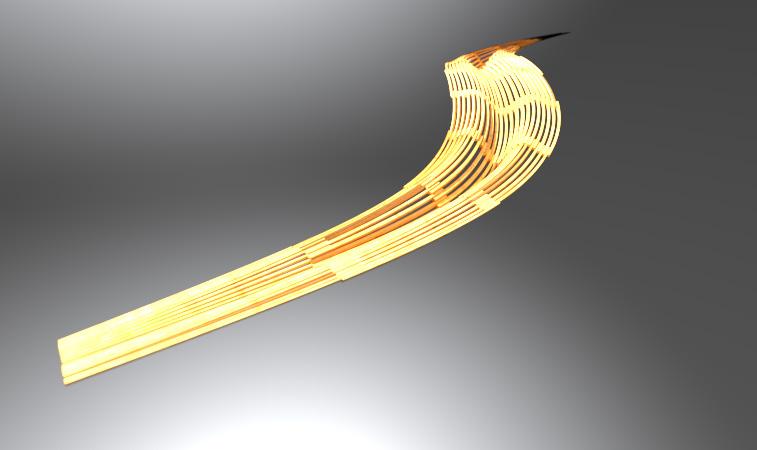

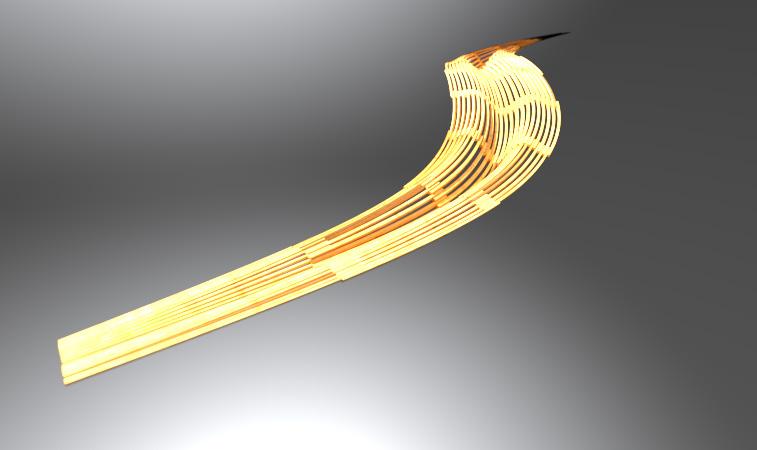

17

SHELL HEIGHT 2.6m

exploded staggering

Total members: 98

CILL BEAM

DOWEL-JOINT

assembled staggering

Lengths: 3.54m to 5.44m

LONG ARM

SHORT ARM

DOOR OPENING

FUTTOCK SHELL ASSEMBLY

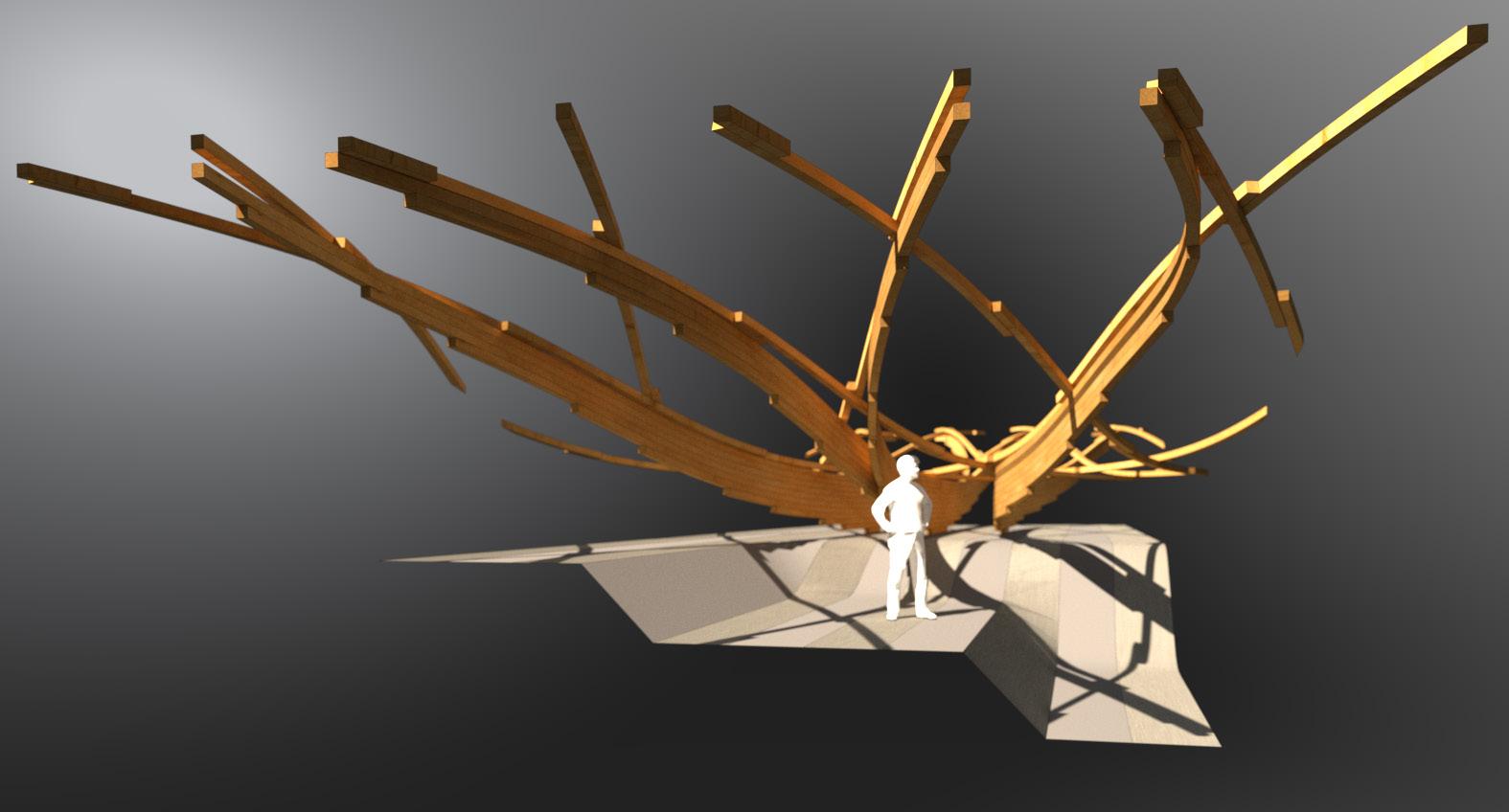

Fragment showcases the simple logic of staggering inter-stepping members to generate stiffness in a shell structure. The fragment showcases a spatial investigation of continuity for circulation inside.

PARALELL GRAIN

STAGGERING FRAMES

THINNEST BEAMS 13cm THICKEST BEAMS 17cm

STAGGER

2B FUTTOCK

1B FUTTOCK

2A FUTTOCK

1A FUTTOCK

18

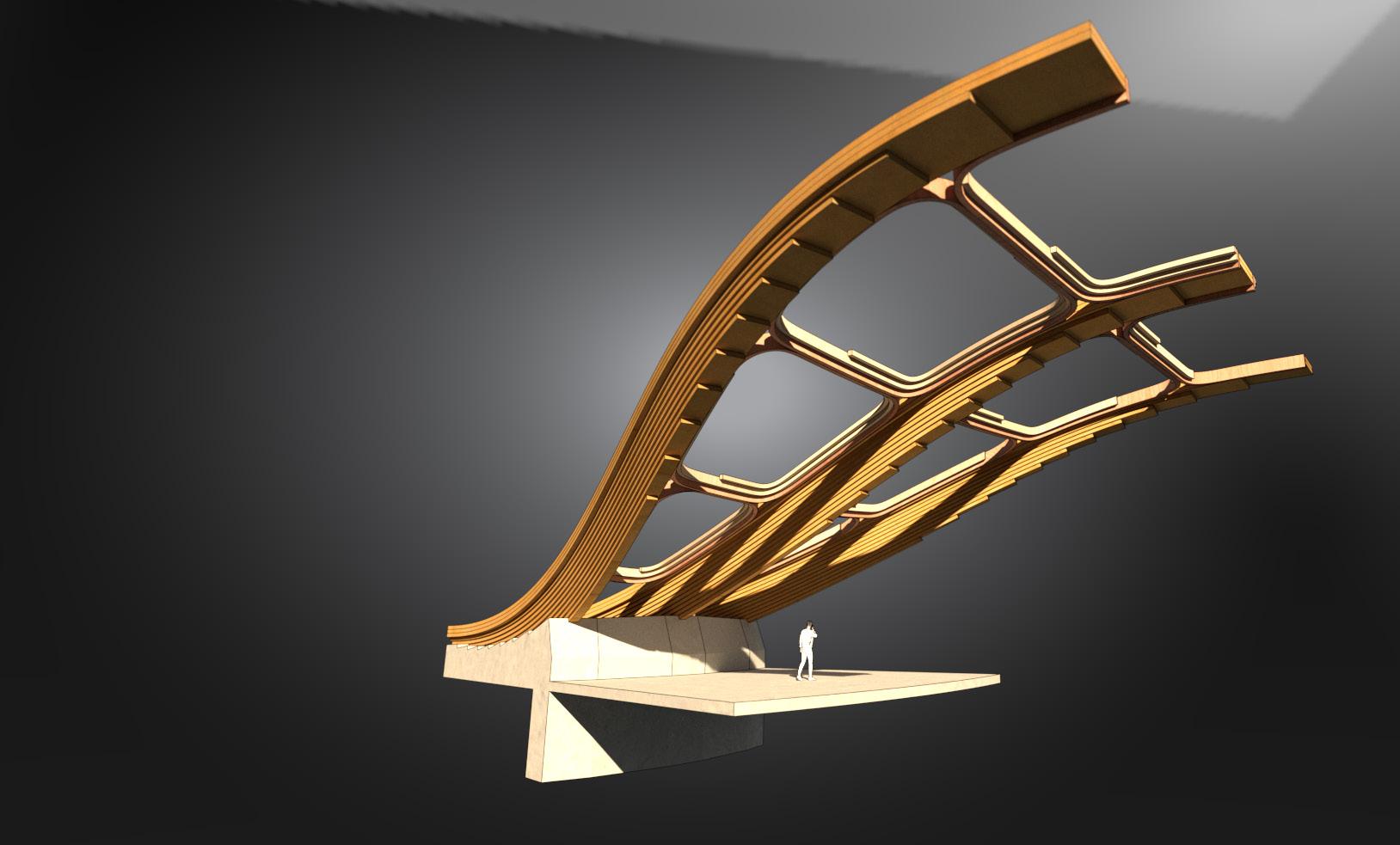

staggered truss

Battens: 40

BEAMS 10x10cm

BEAM SPACING 30cm

TRUSS DEPTH 43cm

total length

Length: 74.3m

LONGITUDINAL BOLTS

SPACED SLATS

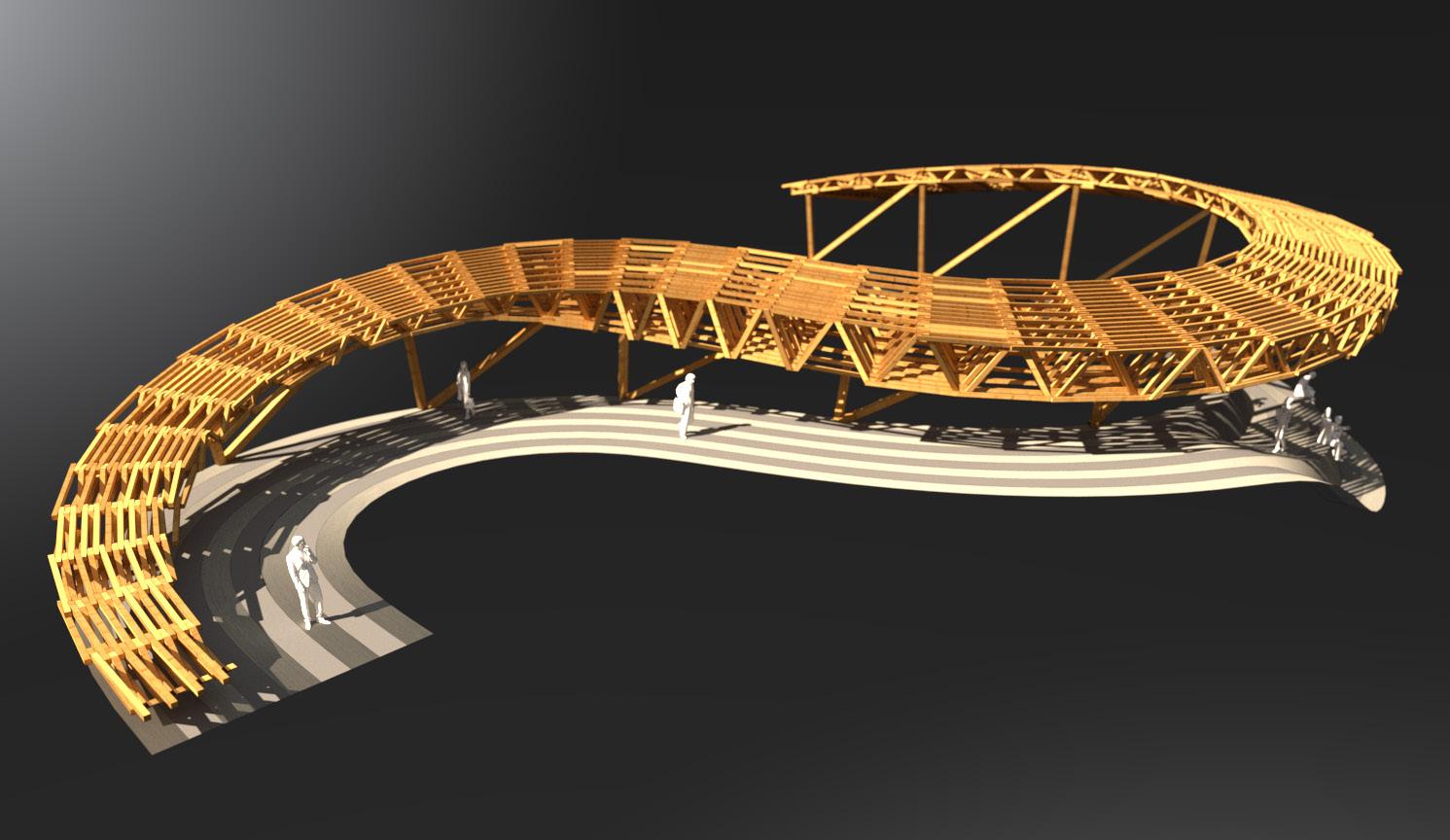

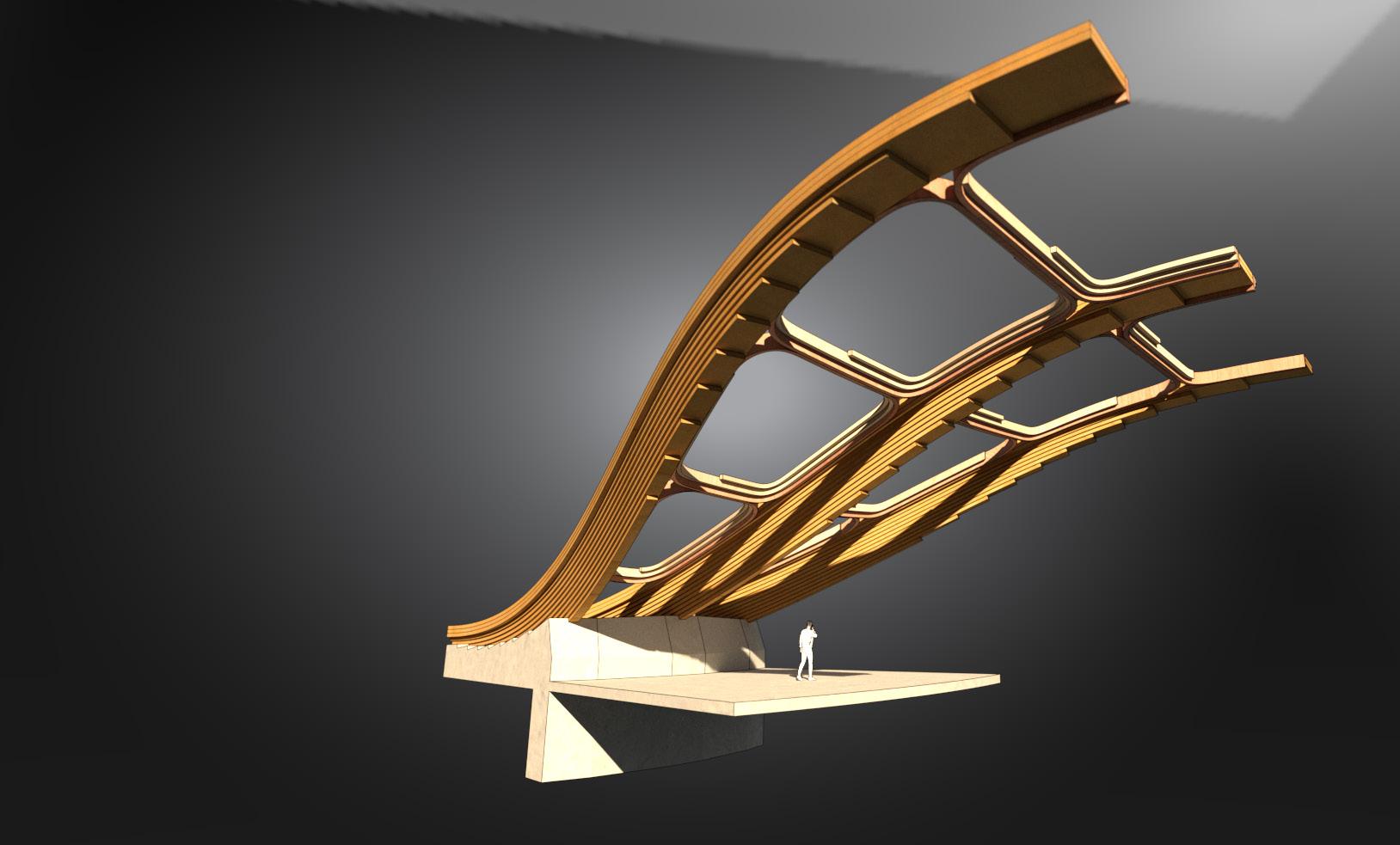

SEQUENTIAL STAGGERED DISTRIBUTION

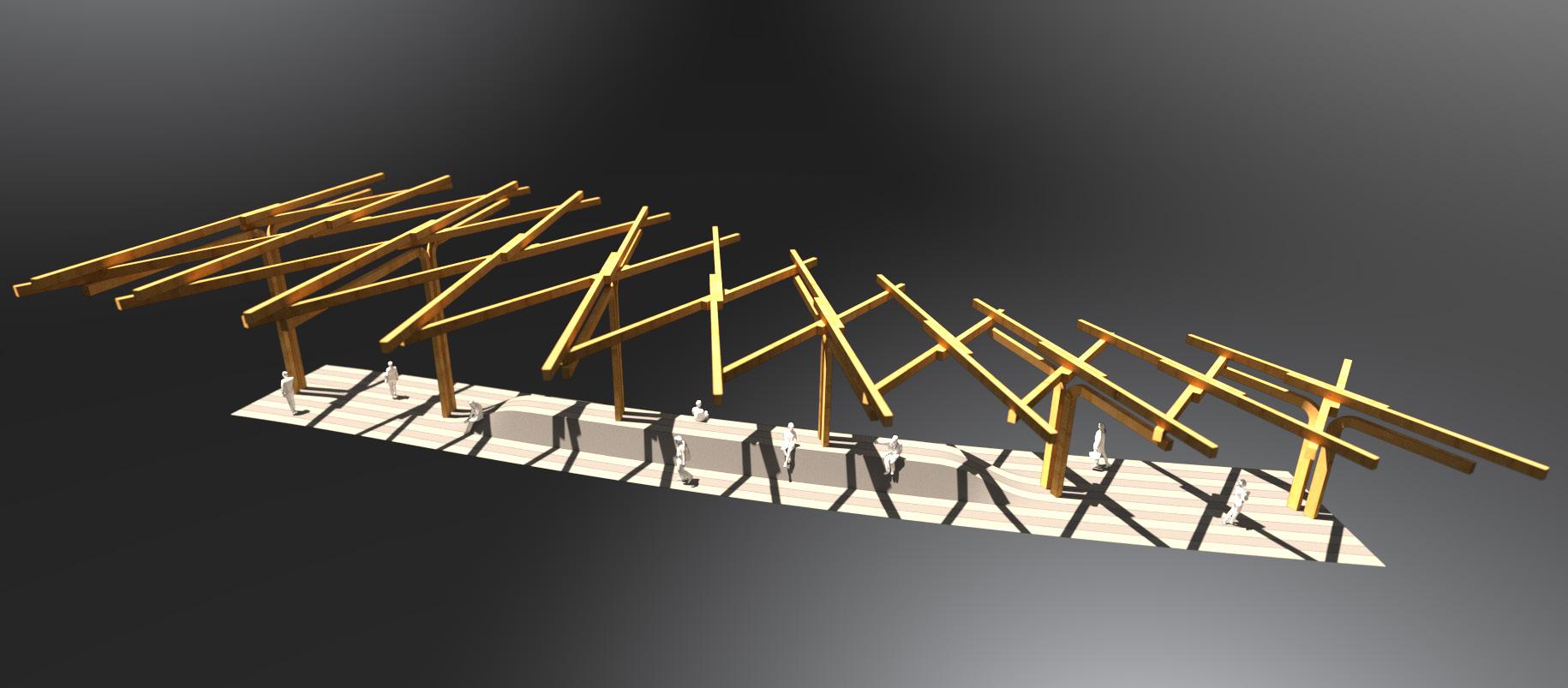

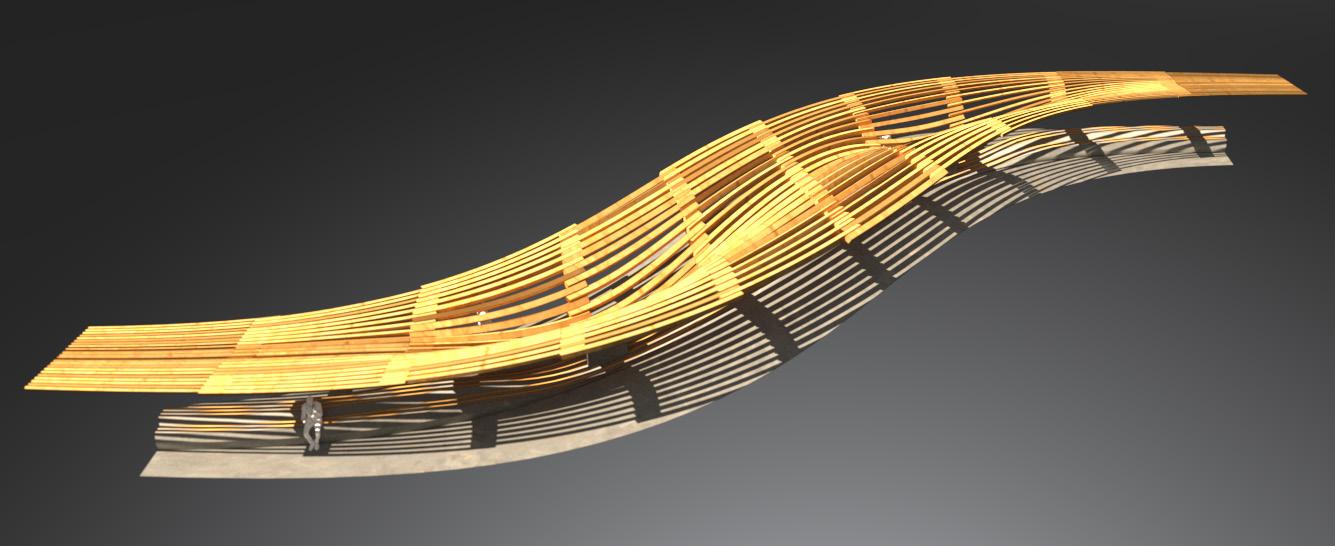

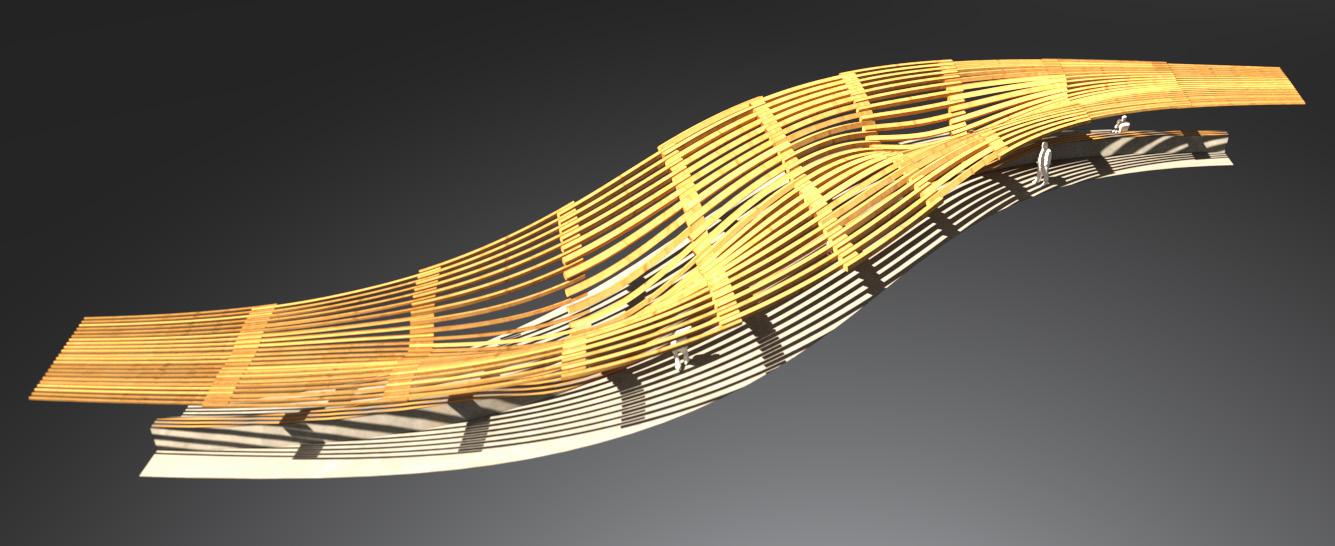

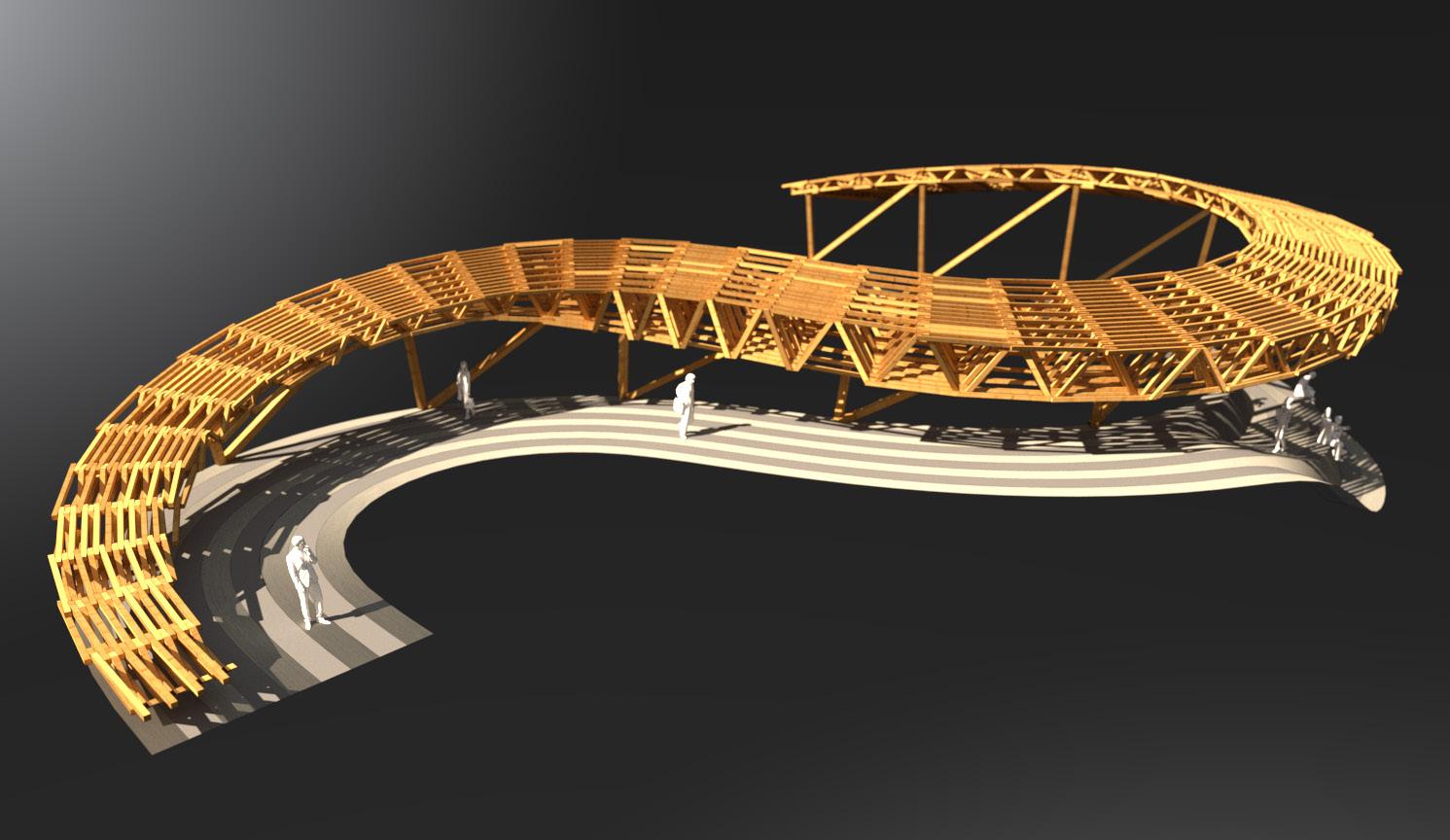

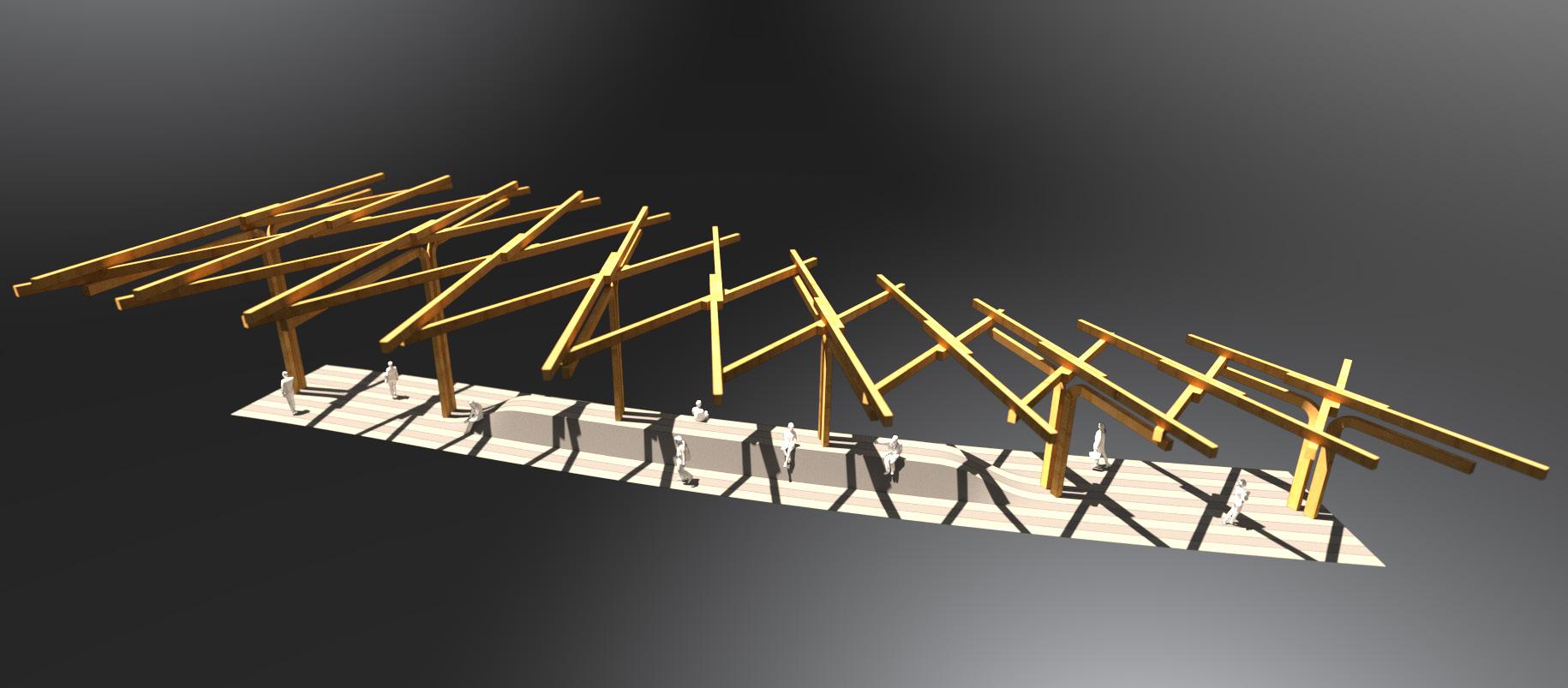

A complex assembly with simple straight members that increases its depth and width by stepping the members. Timber slats are staggered in a sequential pattern to cater for a truss system alongside the timber slats.

FLAT LAP JOINT

LONGITUDINAL BOLTS

TRUSS

SEQUENCE

SLAT 2

SLAT 1B

SLAT 3 SLAT 1A

19

STAGGERED SLAT

STAGGERED TRUSS

INCREASING TIMBER SLAT TRUSS

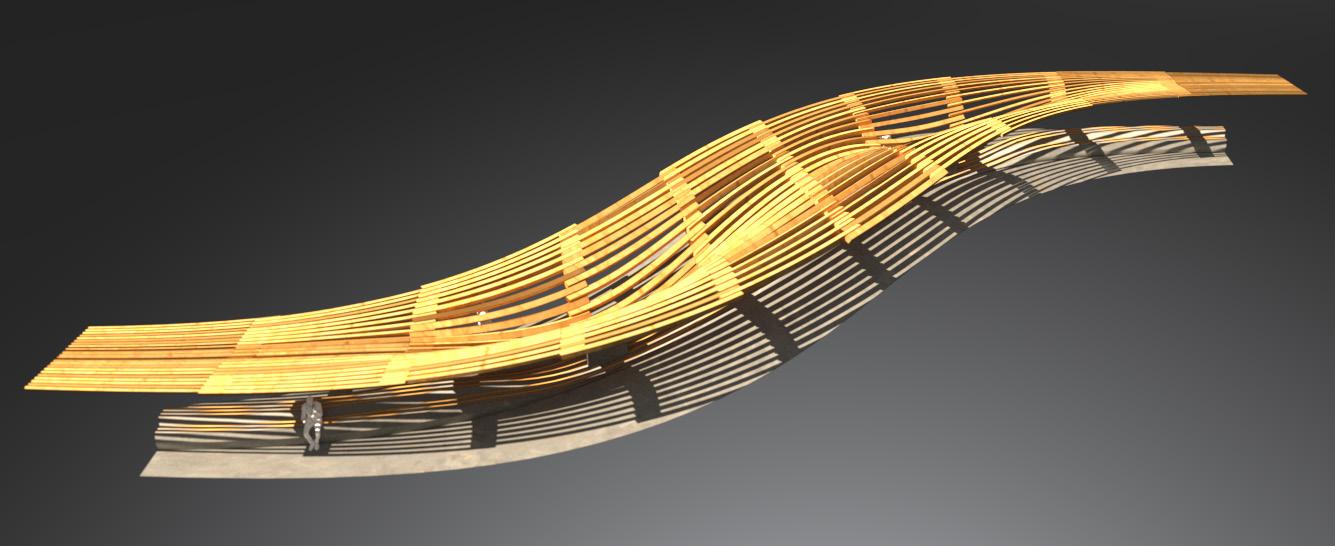

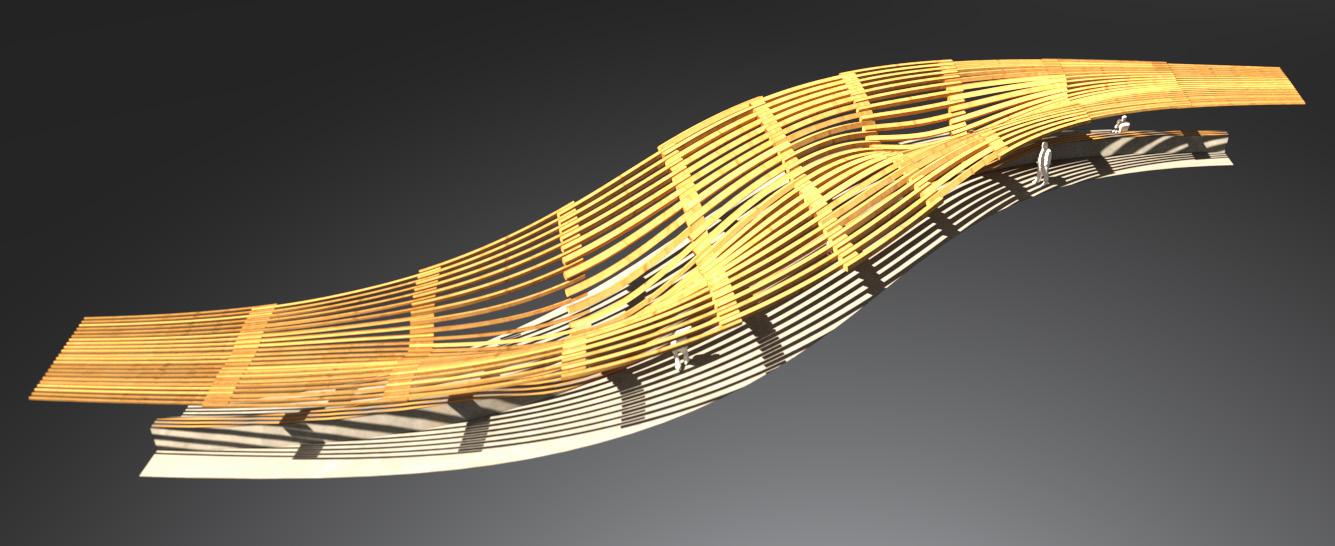

Timber slats in large scale complex roof with integrated trusses. The abstract roof fragment is made up of 1955 individual timber slats that primarily differ in the dimensions of the increasing length of the trusses at the wider cantilevers.

20

1.4m to 2.4m 2.4m to 2.8m 0.9m to 1.4m

LENGTHS

SHALLOW TRUSS 64cm

DEEP TRUSS 132cm

Members: 1955

timber slats

SHORTEST SLATS 1.8m

TRUSS WIDTH 260cm

TRUSS WIDTH 300cm

INCREASING TRUSS

DECREASING TRUSS perspective

LONGEST SLATS 2.6m

cross-sections

Battens: 10cm

Dowels: 1cm

kite dimensions

Length: 15.5m

Depths: 0.10 to 1.10m

PARALELL TRANSFER

THROUGH BOLTS

LONGITUDINAL BOLTS

NORWEGIAN GIRDER TECTONIC

In Norwegian heritage, traditional girders are more commonly understood as load bearing kites (i.e., “drager” norw.). Kites are often used in recipricol support to other beams. Kites transfers the load to adjacent structures such as columns, foundations, and walls.

DIAGRID

BATTEN 2B

BATTEN 2A

BATTEN 1B

BATTEN 1A

21

KITES (DRAGER)

NORW. TERM

RECIPRICOL JOINT

GIRDER DEPTH 10cm

DIAGRID 5.0x5.0m

exploded diagrid

Longituidnal: 71

Through bolts: 35

DIAGRID

BATTEN 2B

BATTEN 2A

BATTEN 1B

BATTEN 1A

diagrid-to-girder

GIRDER DEPTH 10cm

GIRDER SUPPORT 10cm

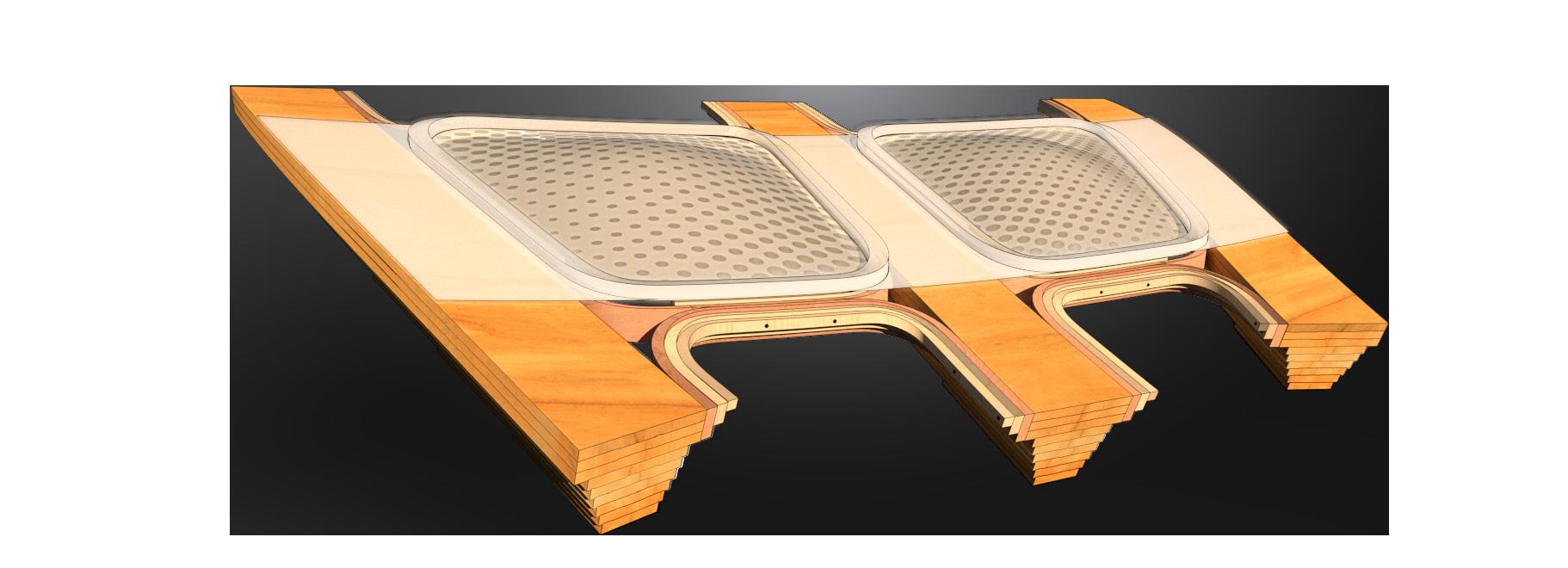

DIAGRID BATTEN ASSEMBLY

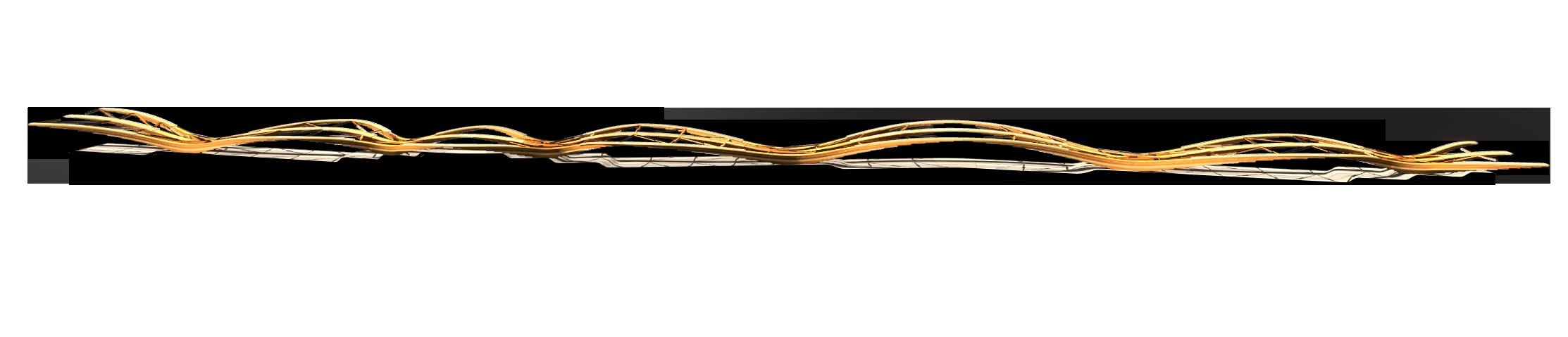

The girders allow the diagrid members to be segmented in a consistent length range throughout the member network. At the apex of the span, the depth of the diagrid battens require support from the girder, elsewhere they remain freeform.

22

timber batten diagrid

Lengths: 5.0x5.0m

diagrid members

Total members: 71

STANDARD BEAM 10cm

RECIPRICOL JOINT

BATTEN DIAGRID

DIAGRID-TO-GIRDER SYSTEM

Longer spans and a different matrix acquires rethinking of the batten inter-stepping playfulness from the futtock construction. The long span kites withdraw from the rigid diagrid structure but returns at the apex of the span to join in to its polynomial points and support the staggering battens.

DIAGRID

KITES (DRAGER)

BATTEN 2B

BATTEN 2A

BATTEN 1B

BATTEN 1A

23

PARALELL TRANSFER

SHEAR SUPPORT LAP JOINT

left view

exploded lattice

Total members: 55

assembled lattice

Heights: 3.30 to 6.86m

LONGEST BEAM 10.8m

lattice dimensions

Lengths: 4.85 to 10.85m

Depths: 0.10 to 0.30m

TRAVERSAL LANE 1.40m

FORMAL SEATING 1.40m

INCREASING LAP-TO-SPAN

In this fragment a formal language is developed in order to test the flexibility of straight timber battens. As the height increases the member span and lap joint increases in length. Members are made straight and simple to allow flexibility for elements to rotate, extend and move within the diagrid.

LATTICE

COLUMN

LATTICE 2B

LATTICE 2A

LATTICE 1B

LATTICE 1A

24

LONG LAP JOINT 1.40m

SHORT LAP JOINT 2.60m

SHORTEST BEAM 6.0m

INCREMENTAL STEPPING MEMBERS

Tectonic study that looks in to the utilization of member lengths and the result of less curvature, in which ultimately allows the spawning of level differentiation. Material distribution thins out as the span increases, likewise the depth of each member thins out proportionally.

25

41.9m

40.8m stepping lamellae ≥2.2m ≥2.1m ≤38.8m 18.9m 18.4m ≤37.8m 13.6m to 16.9m 13.9m to 17.4m 19.9m to 28.8m 20.4m to 29.5m 2.1m to 11.0m 2.2m to 11.3m LENGTHS 31.8m to 37.8m 32.6m to 38.8m Total members: 14 Total members: 14 beam lengths LEVELS (+2.50m) LEVELS (+0.00m) HEIGHTS

Length:

Length:

26

1:100 prototype aeroply

ceiling heights

Heighest: 7.40m

Lowest: 3.65m

BOARD 22x103cm

BEAM 22x62cm

BATTEN 22x21cm

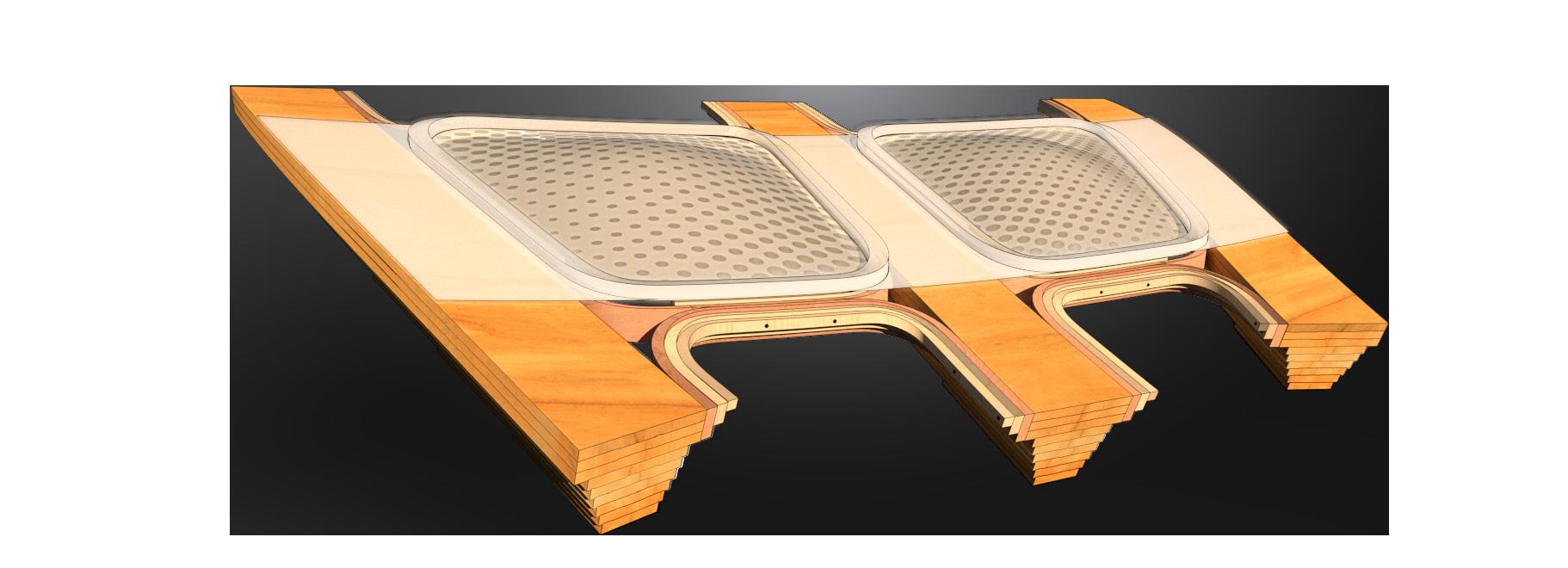

LAMELLA MATERIAL DISTRIBUTION

SHEAR SUPPORTS

Early fragment of stepped and curved lamellae scaled according to a material distribution principal. The different lengths of the lamellae yield different curvature resulting in staggered span arches. The girders are equally braced by diagonals staggered but gluelaminated this time.

DECREASING DEPTH

INCREASING WIDTH

LENGTHS

2.1m to 11.0m

13.6m to 16.9m

19.9m to 28.8m

31.8m to 37.8m

27

GIRDER 22x103cm GIRDER 22x160cm

worm’s-eye view

girders

Length: 356m

Width: 20.4m

Shortest: 40.8m

STAGGERED SPAN ARCHES

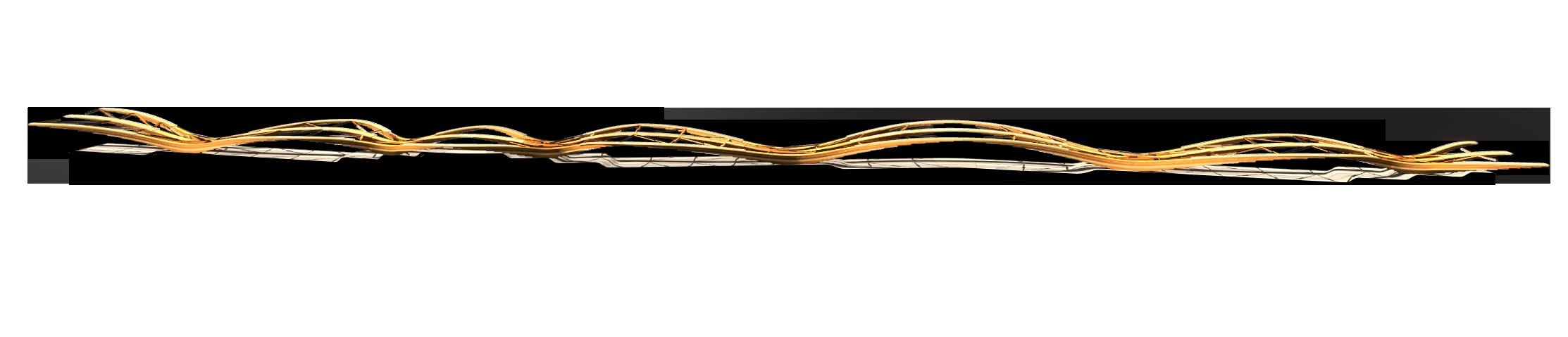

Large scale infrastructural fragment with staggered long span arches braced by staggered lamella diagonals. Spaces are generated from two components that were differentiated from the initial level study by discarding extreme curvatures in the lamellae.

29

front view

Longest: 61.2m span arcs

LOWER

END CONDITION 6 12

7 1 8 2 9 3 10 4 12 11 5 6

TRUSS BRACING TRI-SPAN 1 7 UPPER ARC STEPPED LANDING 5 11 LAP JOINT GROUND PLANE 3 9 KITES (GIRDER) SHORT SPAN 2 8

ARC

ABUTMENT LANDING LONG SPAN 4 10 LEGENDS

Member range

≥82.7m ≥82.7m

≤1.4m 26.9m

LAMELLA NETWORK MODULES

Modules: 6pc

Modules: 9pc

swing parallel hybrid 34.9m 28.3m

HEIGHTS

CENTER GIRDER (+0.40)

GROUND (+0.00m) GROUND (+0.00m)

Set of standardized parts or independent units that can be used to construct a more complex structures that subsequently can faciliate spaces in two directions. The staggered arches can be further sharpened and optimized through form-finding processes.

30

Modules: 8pc ≥82.7m ≤2.3m ≤1.4m

SYSTEM DIFFERENTIATION

Members are diversified by the usage of three-to-four modules to allow flexibility in multiple directions. The lamellae are free to join in at specific node connections to bifuricate or yield recipricol support to the connection.

31

swing parallel varied height SHEAR PLATE (+0.40m) L 00 (+0.00m) L 00 (+0.00m) L 00 (+0.00m) L -01 (-4.50m) HEIGHTS PLANK 22x295cm BOARD 22x216cm BEAM 22x115cm JOISTS 22x144cm BEAM 22x108cm 15.5m to 28.3m 28.4m to 47.7m 1.4m to 15.3m 47.7m to 83.1m

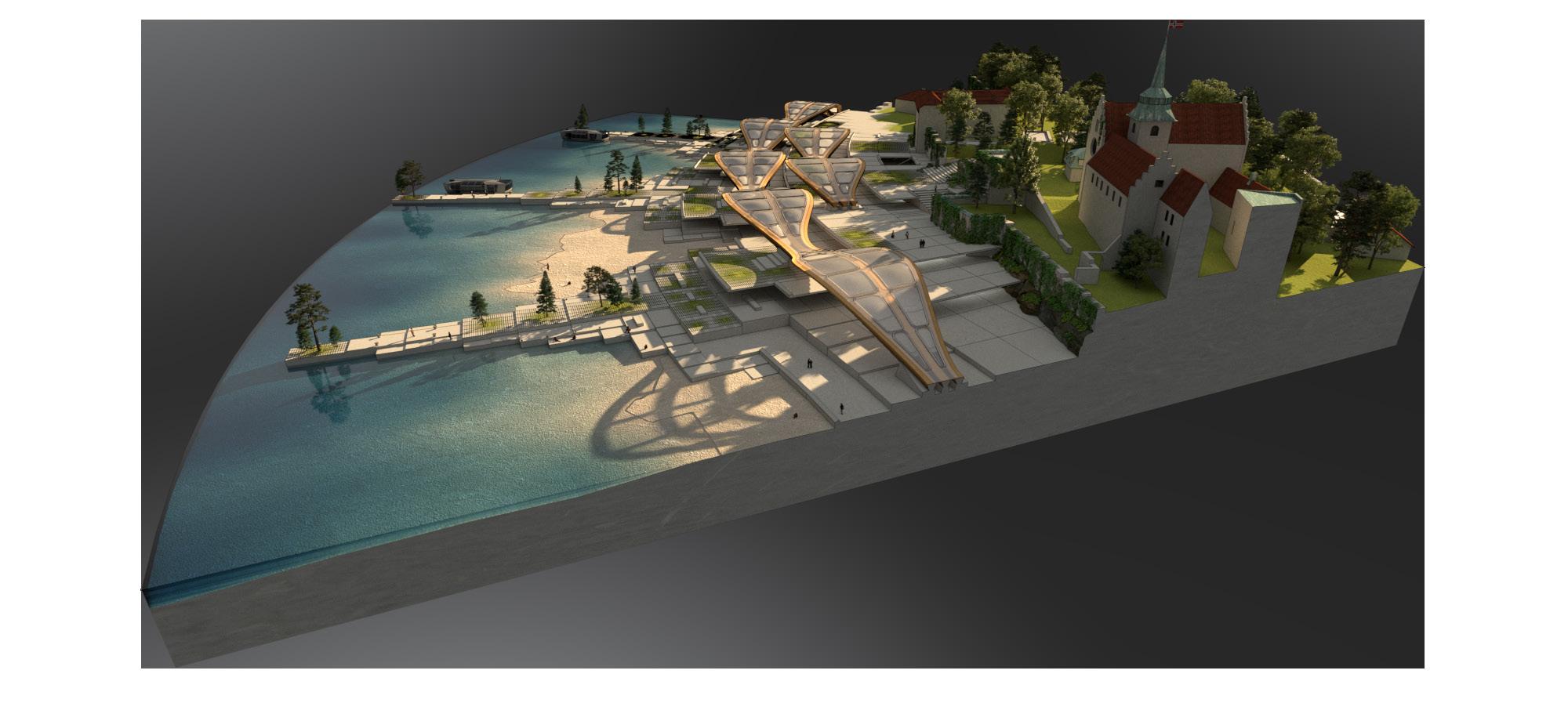

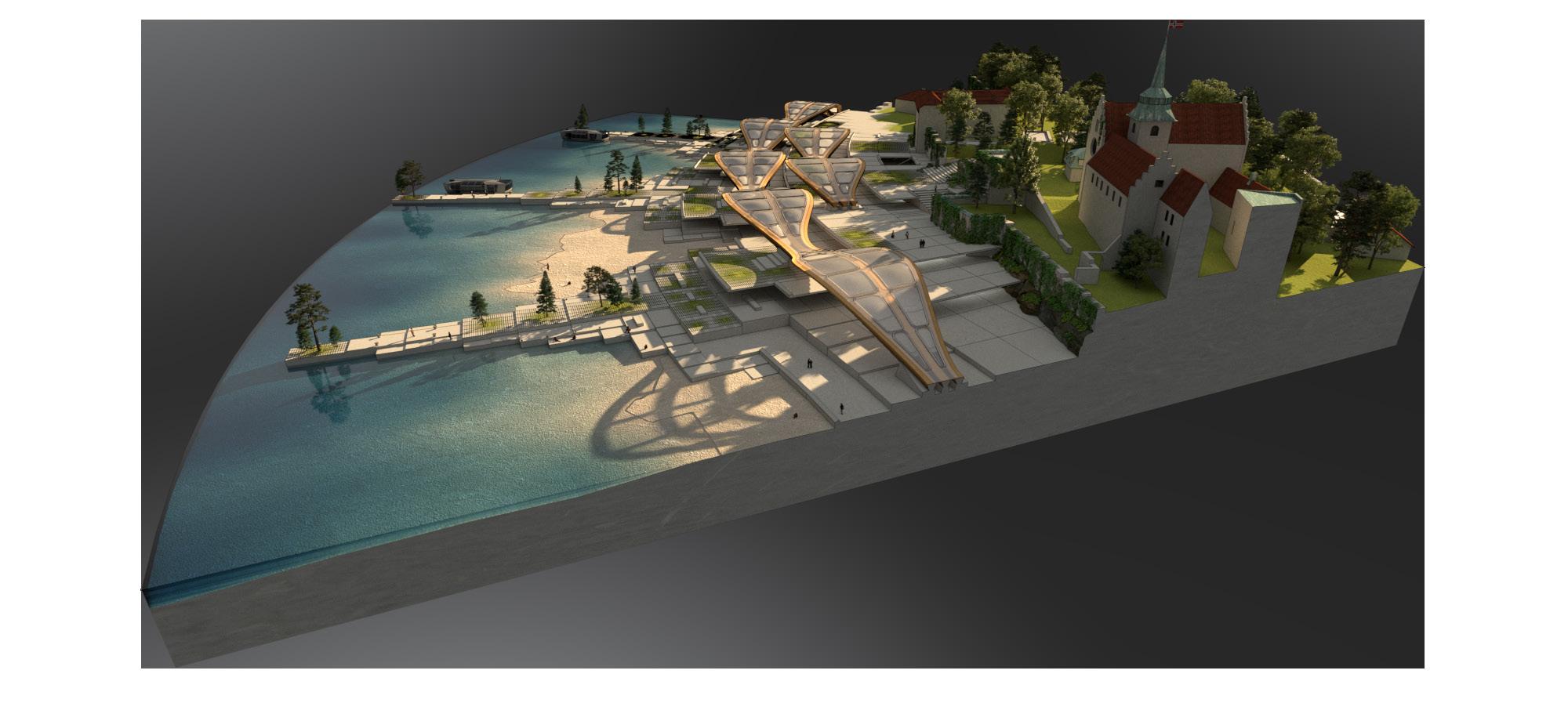

AKERSHUS FORTRESS

A NEW MARINA FOR

32

Ferry Terminal At The Waterfront Of Oslo Block-Laminated Beams In A Composite Material System

OSLO

H

TRAM LINES OSLO

LINE 19

LINE 18

LINE 17

LINE 13

LINE 12

LINE 11

MAP INFOGRAPHIC

LARGE INTERCHANGE

SMALL INTERCHANGE

HIGH FREQUENCY CITY BUS LINE INTERCHANGE

STOP IN DIRECTION OF ARROW ONLY

OSLO TRAM LINE NETWORK

Oslo Tram is a 39,6 km tram network, with 6 lines and 99 stops. Oslo Tram was formed in 2003 and is responsible for the management of tramway operation in Oslo. The map shows the the most densified tram lines by line thickness.

33

TRAM REPORTS 2011

TRAM PROJECTS DONE 2000-2010

PLANNED TRAM PROJECTS 2011-2014

CURRENT TRAM LINE

REGISTERED RAIL UPGRADES

RAIL WEAR, RESULTS WEAR MEASUREMENT 2010

TRACK GAUGE ERROR, RESULTS AUTUMN 2010

RAIL DAMAGE, AUG-OCT 2010

FJORD-LINE INTERCHANGE

H HIGH FREQUENCY INTERCHANGE

OSLO PORT LINE

Analysis of Oslo’s tram line network development and the urge to ease the commute intensity from west-to-east Oslo. The proposed fjord city shifts the center of gravity toward the seafront. Former transport and port areas will be replaced by city, park and important destinations.

35

OSLO PORT LINE CLOSED IN 1983

FJORD CITY

PROMENADE

ATTRACTION

RECREATIONAL

AKERSHUS FORTRESS

FJORD INTERFACE

POINT OF INTEREST

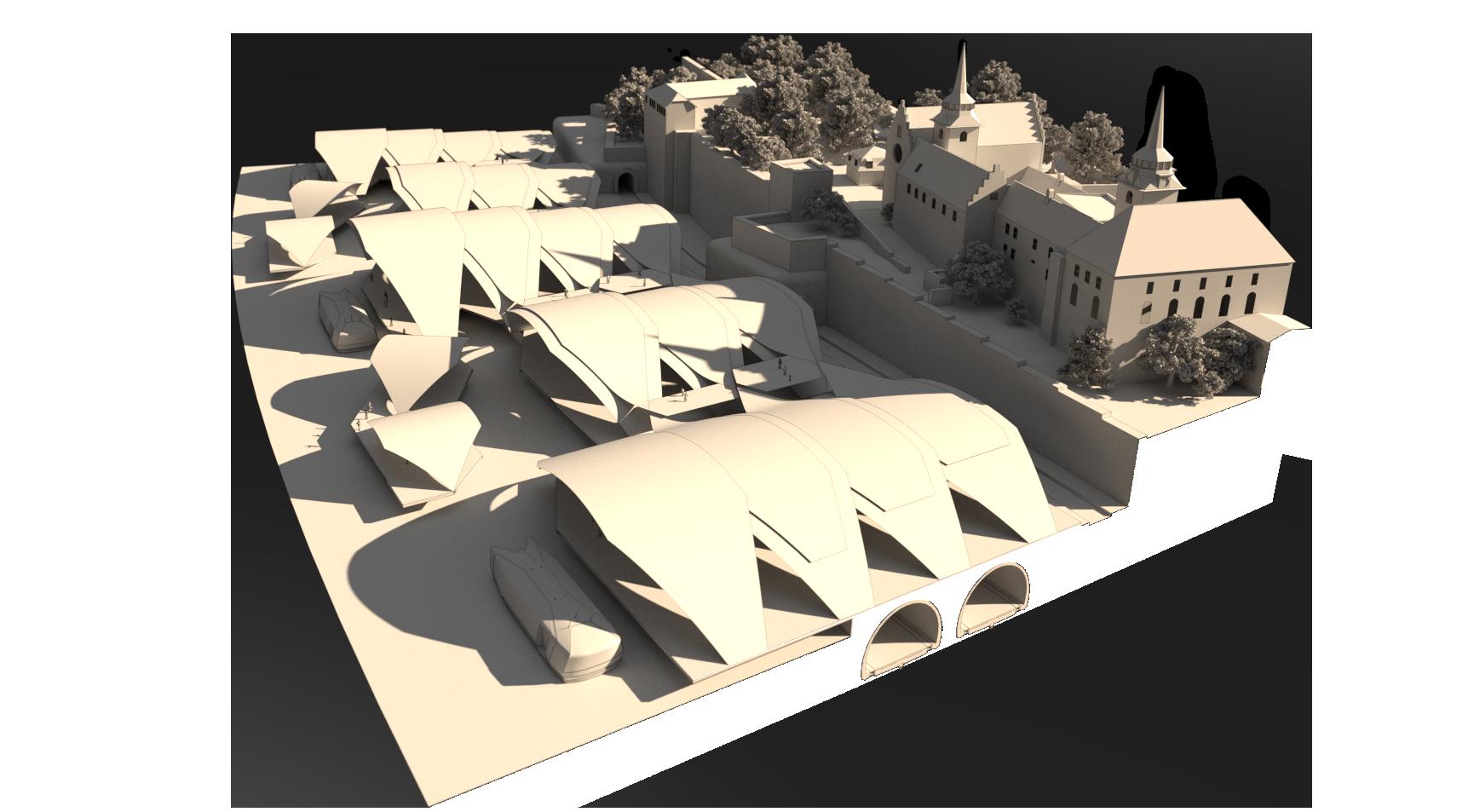

FJORD CITY OSLO

Fjord City is a project issued by the muncipality of Oslo that aims to free up the current inactive areas towards the sea and use these for future-oriented urban development with housing, recreation and public amenities in such a way that the city opens up towards the fjord.

37

PIPERVIKA

AKERSHUS PIER

PIPERVIKA

TYPOLOGIES

WHOLE SALE MARKET

MIXED USE

FOOD SERVICES

FERRY TERMINAL

PIER

WHARF

BUILDING CODE

BUILDING PROTECTED UNDER CULTURAL HERITAGE ACT - § 22A

PROTECTED THROUGH OWN REGULATIONS

AREA PROTECTED UNDER CULTURAL HERITAGE ACT - § 22A

AREA PROTECTED UNDER CULTURAL HERITAGE ACT - § 6

AFFECTED PROPERTY OF THE NATIONAL PROPERTY BOARD

AFFECTED PROPERTIES

AKERSHUS

VIPPETANGEN PIER 3

OSLO FERRY TERMINAL

FORTRESS / VIPPETANGEN PENINSULA

The peninsula was previously the location of a military facility and of a stone quarry, as well as military and civilian baths. Vippetangen has always been an important transport hub, and remains the main port for passenger ferries in Oslo.

38

AL OSLO FISHING HALL

AKERSHUS PIER

vippetangen

AKERSHUS PIER

TYPOLOGIES

WHOLE SALE MARKET

MIXED USE PIER

FOOD SERVICES WHARF

SHED 32

SHED 31 SHED 34

SHED 33

scale and dimension

OSLO CRUISE TERMINAL

AKERSHUS FORTRESS / VIPPETANGEN PENINSULA

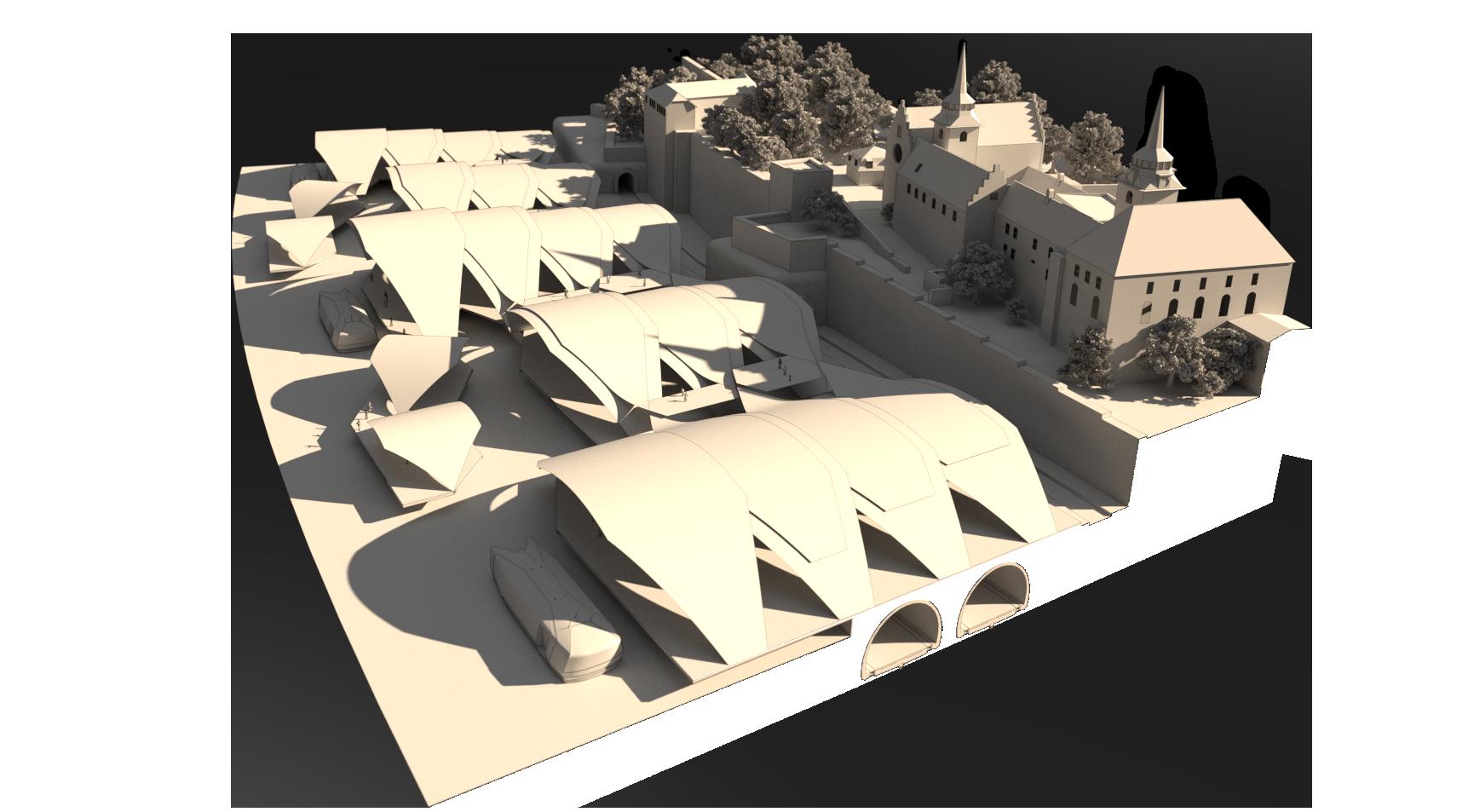

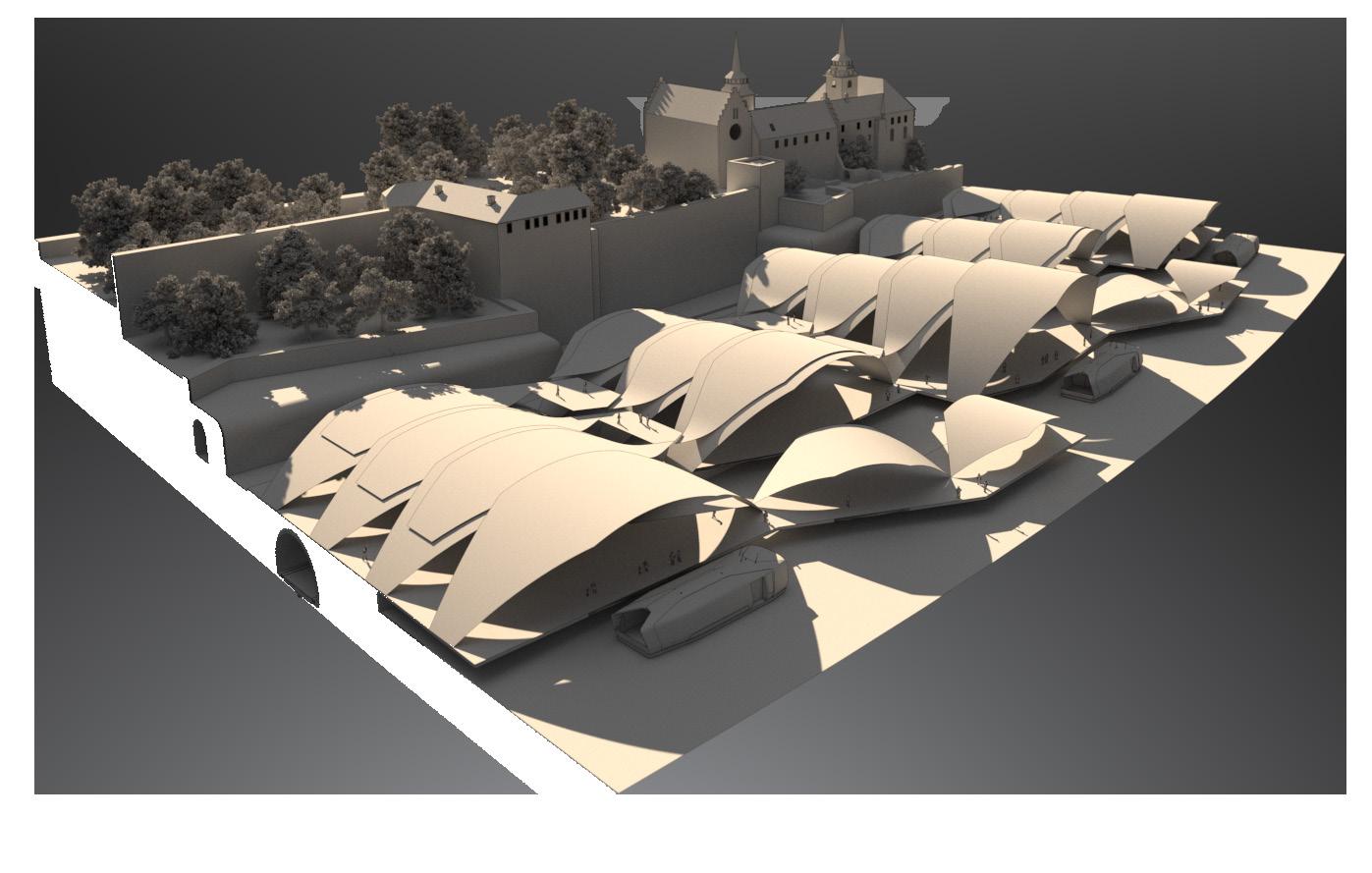

Vippetangen is the southern tip of the Akersnes peninsula in central Oslo, Norway, located southeast of Akershus Fortress looking out in to the Oslofjord. It has in the past served as an important part of the port of Oslo. The area is currently undergoing urban renewal as part of the Fjord City development.

39

AKERSHUS FORTRESS

AKERSHUS FORTRESS

PIPERVIKA

AL OSLO FISHING HALL

OSLO GRAIN SILO

OSLO FERRY TERMINAL

TUNNEL

parallel arcs 1

Surfaces: 54

varied arcs 2

Surfaces: 42

docks

quay arcs

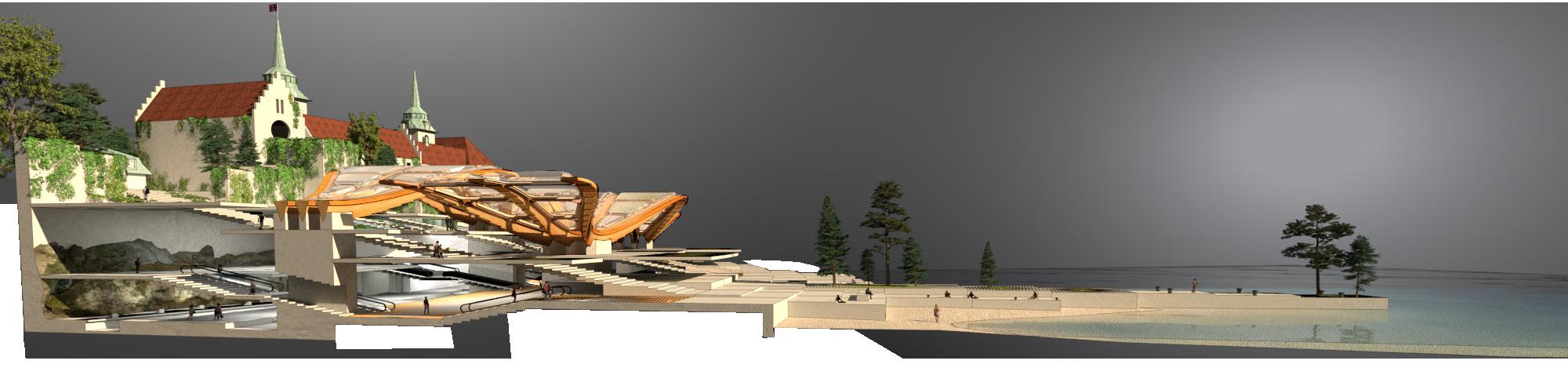

GLOBAL MASSING ITERATION 1

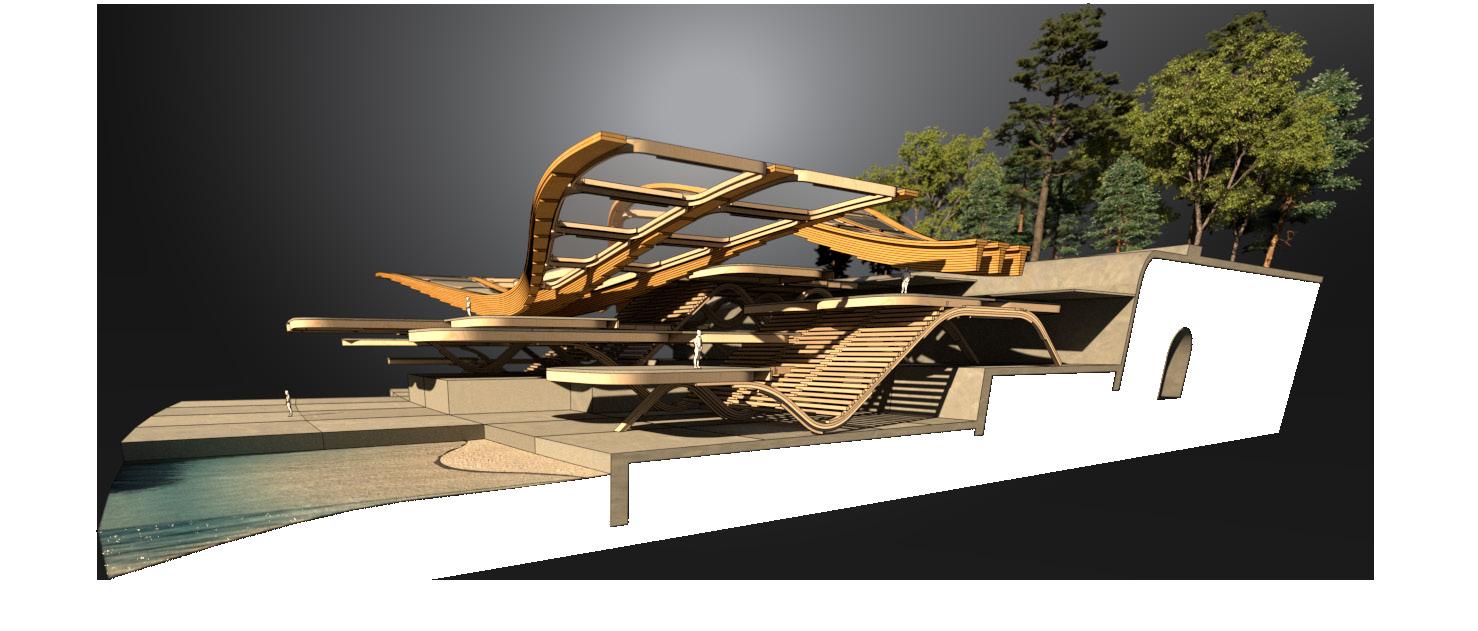

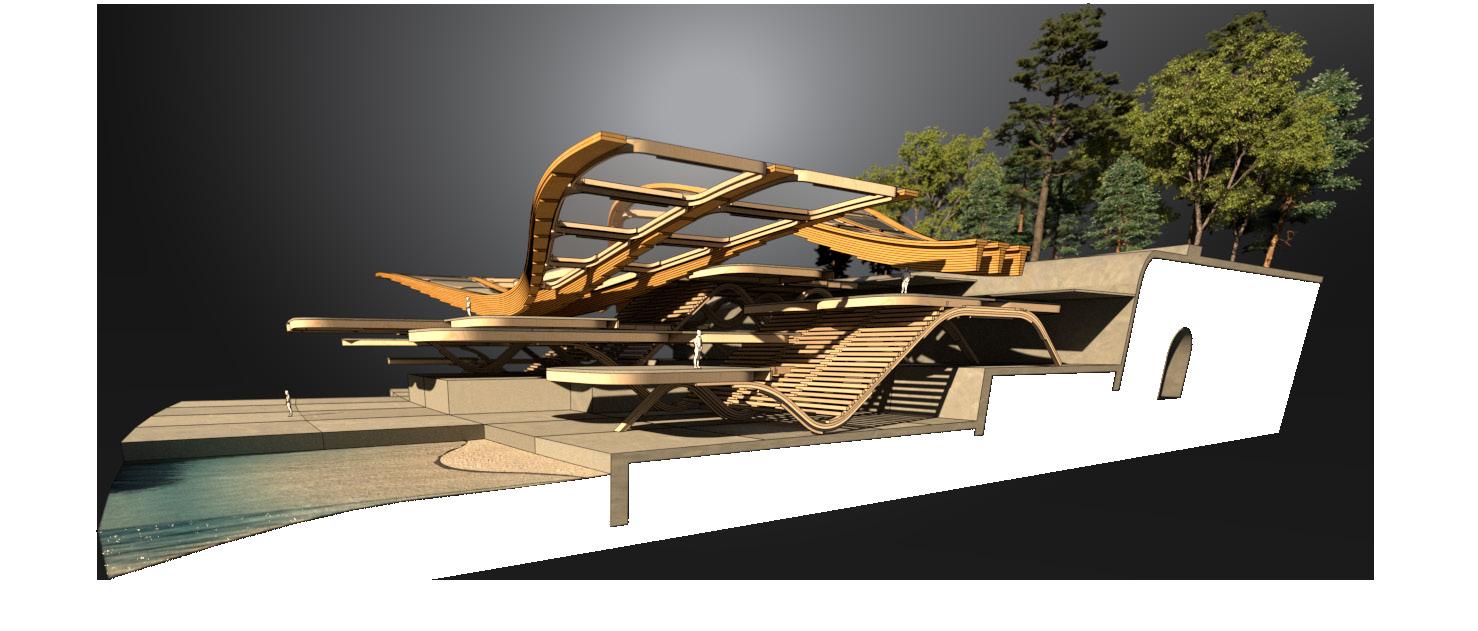

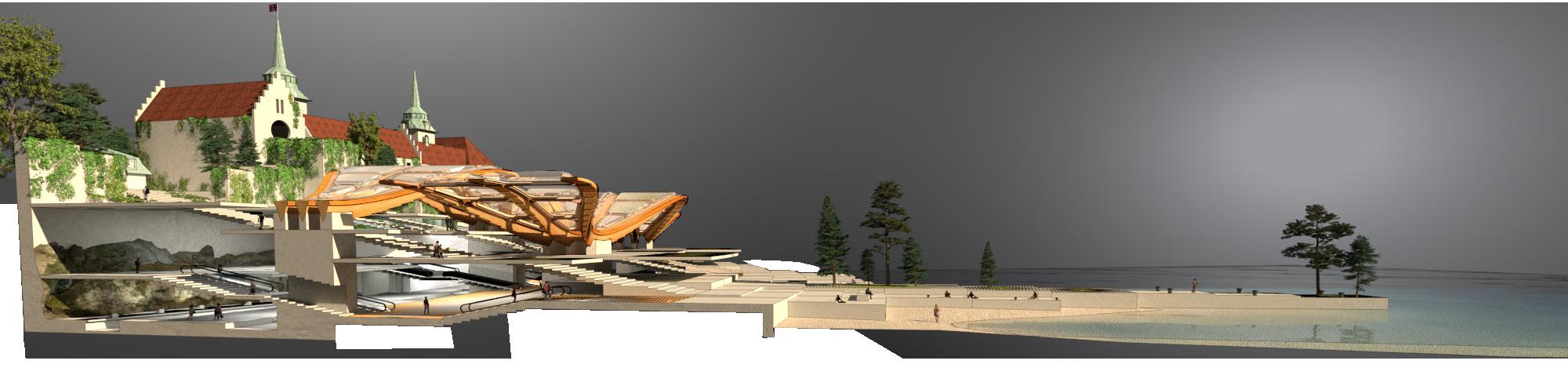

Simple shells are generated in Karamba3d iexploring the ideal arc massing for the site. Various attempts are made to address current access points and new quays for the transport hub.

40

OSLO PORT LINE NEW TRAM LINE

GLOBAL MASSING ITERATION 2

The massing models are designed around the arc height and span limitations from Karamba3d and also the integration of the Oslo Port Line and the Akershus Fortress context.

41

Area: 21 221m2 total area ≤155m2 458m2 ≥641m2 Area: 18 947m2 total area ≤163m2 511m2 ≥818m2

FERRY TERMINAL DEVELOPMENT

Formalizing the geometries to surfaces and planes allows the flexibility of changing and adjusting relationships happening in the array of shell-like-structures. Additionally, generating a system from key control points of a set of parallel running NURBS curves from structural software plugin Karamba3D.

42

PORT LINE (+0.00m)

FERRY DOCK (-1.00m)

OSLO FJORD

PLATEAUS (+6.25m)

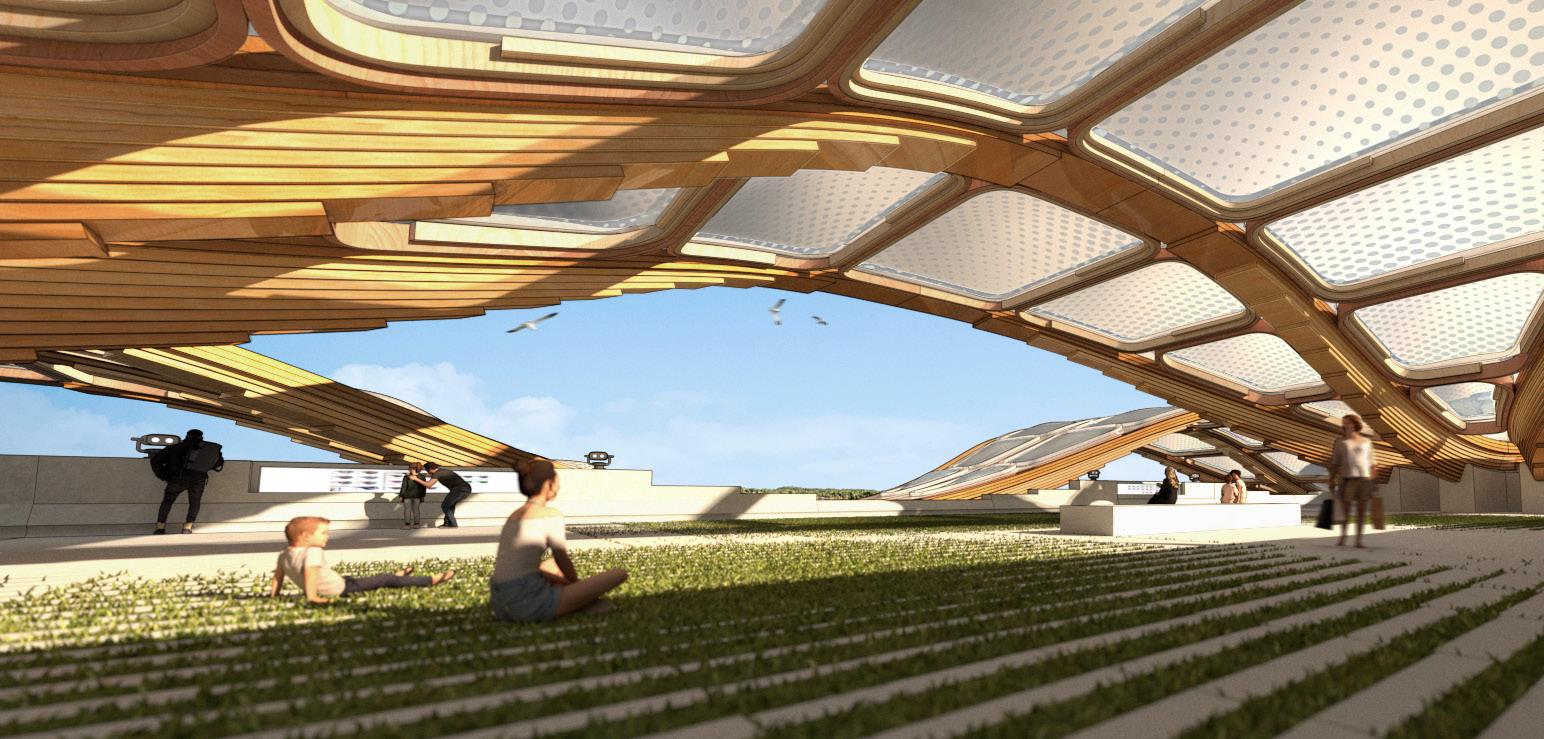

ROOF OVERHANG SHELL GRID LANDING

SHELL STEPPING

AKERSHUS FORTRESS

simple beam analysis

inverse bending moment

cross-sections generated

parallel lamellae

grain continuity

SIMPLE BEAM ANALYSIS

A simple structural analysis of the glue-laminated beam as a stick model is generated in order to optimize the arc shape further. Cross-sections are equally generated to develop a more efficient changing cross-section throughout the individual beam spanning across.

43

≤3.7m 15.9m ≥30.2m

VIENNA NASCHMARKT

Vienna Naschmarkt has been around since the 16th century and offeres a wide range both Viennese and foreign products. The marketplace is an array of three rows of various stall columns over a 1.5 kilometres long stretch.

44

vienna naschmarkt

MARKETPLACE (+1.20m)

TYPOLOGIES

STALLS

DOCKING STORAGE

WHOLESALE

RETAIL

SERVICES

clipping plane

+1.75 meters

TO: PARKING LEVEL

TO: AKERSHUS F.

ACCESSIBILITY

FERRY TERMINAL

MARINA

MARKETPLACE

PROMENADE

TRAM-LINE

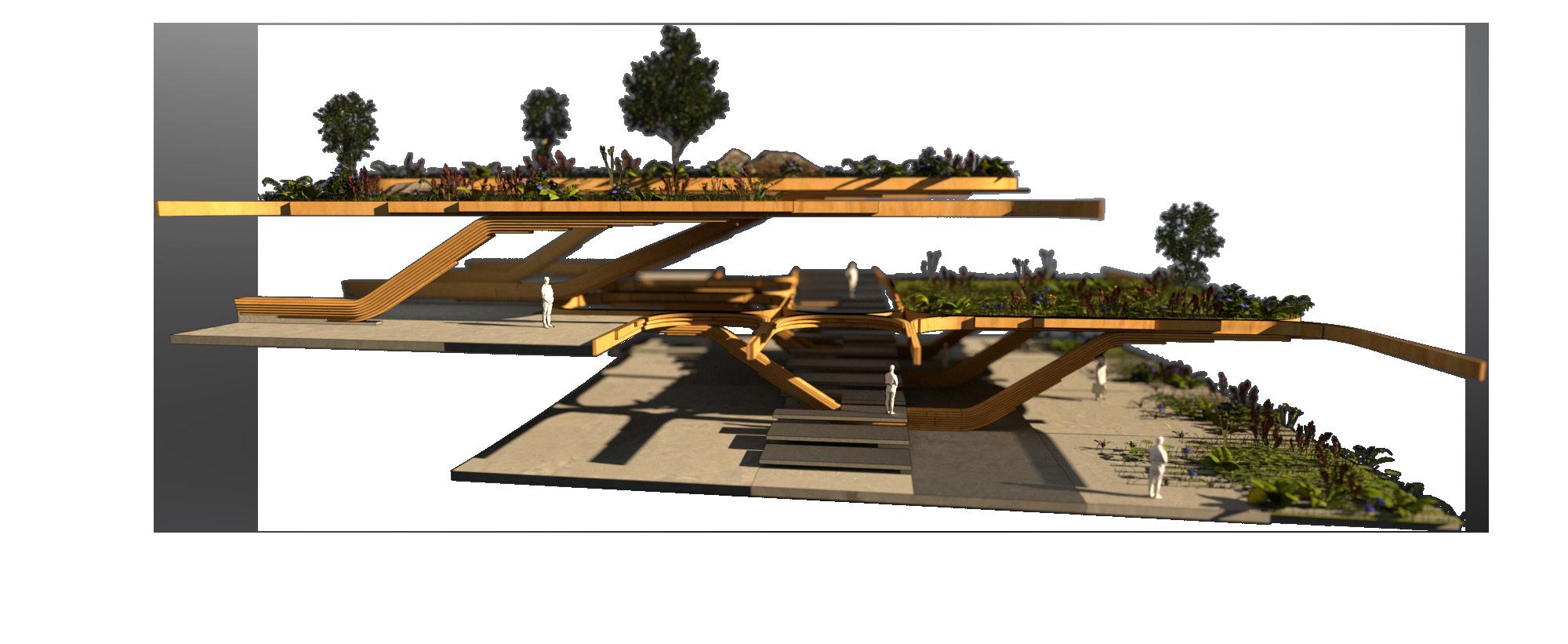

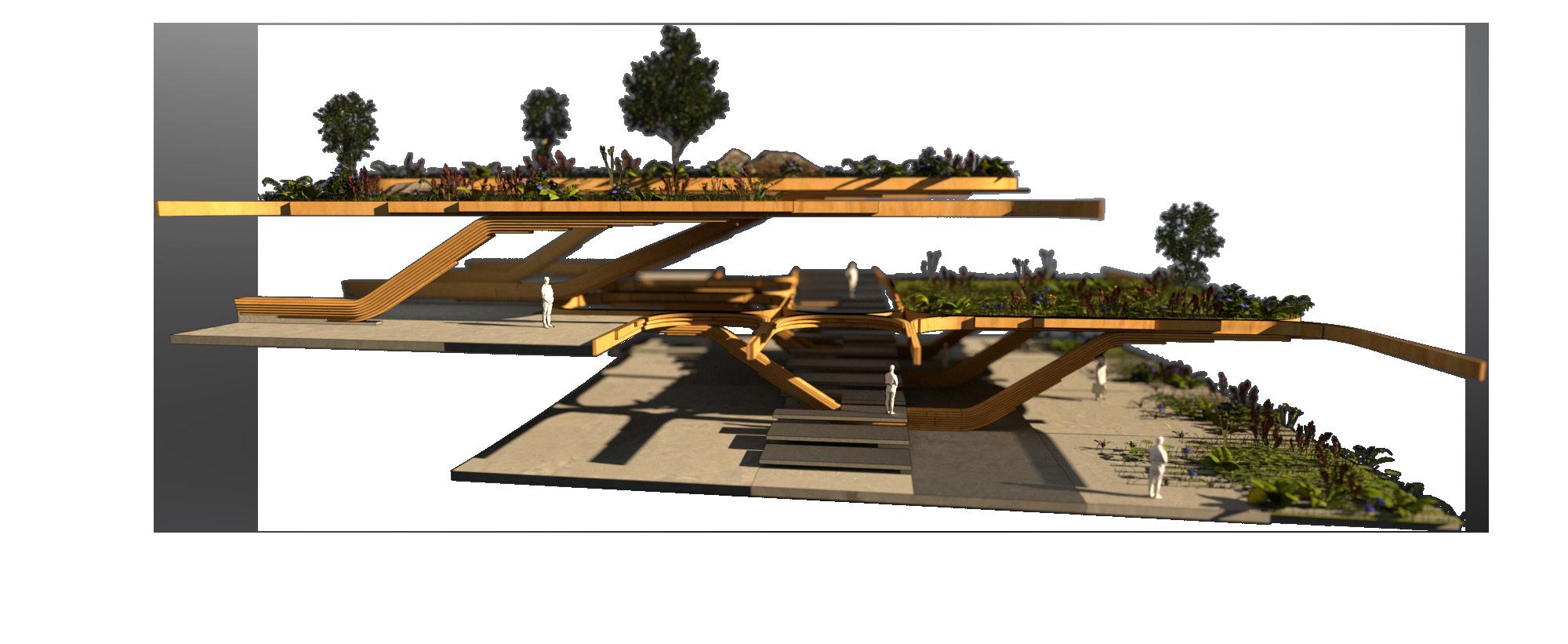

MARINA MARKETPLACE DEVELOPMENT 1

The urban landscape was informed by both the current Viennese Naschmarkt’s row and column layout and the traditional marked’s temporary parasol stalls that allowed for flexibility. The scheme is a combination of a set of modules that array, mirror and flatten to cater toward different access points.

45

wholesale market

perspective view

PLATEAUS (+3.00m)

PIER (+3.00m)

MAIN ENTRY TO: VIKING MUSEUM

TYPOLOGIES ACCESSIBILITY

FOOD SERVICES RETAIL MARINA FERRY TERMINAL PUBLIC AMENITY MARKETPLACE WHOLESALE LEISURE PROMENADE

MARINA MARKETPLACE DEVELOPMENT 2

46

wholesale market +1.80 meters perspective view clipping plane LOADING DOCK (+0.00m) LOUNGE BAR (+0.20m) PLATEAUS

The marketplace is defined a by a central radial reference point that divides the scheme into plots, however the grid is arranged orthogonal. Staircases and swept landscape is repeated and processed with planar flat slabs that are made for multi-purpose use in the new harbour side. UPPER LEVEL

(+3.60m)

(+4.00m) MAIN ENTRY FERRY TICKET BOOTH SEATING TRAM-LINE STOP TRAM-LINE

LOADING DOCK (-0.20m)

PIER ROOF (+5.00m)

FERRY PIER WATERFRONT

WHOLESALE (+6.00m)

MARINA MARKETPLACE DEVELOPMENT 3

The marketplace is defined a by a central radial reference point that divides the scheme into plots, however the grid is arranged orthogonal. Staircases and swept landscape is repeated and processed with planar flat slabs that are made for multi-purpose use in the new harbour side.

TYPOLOGIES

FOOD SERVICES

RETAIL

PUBLIC AMENITY

ACCESSIBILITY

DROP-OFF

MARINA

LEISURE PROMENADE perspective view clipping plane

MARKETPLACE

47

WHOLESALE wholesale market +4.00 meters

LAMELLA (+14.00m)

VISTA PLATAEUS (+4.00m)

TRAM-LINE STOP

TRAM-LINE

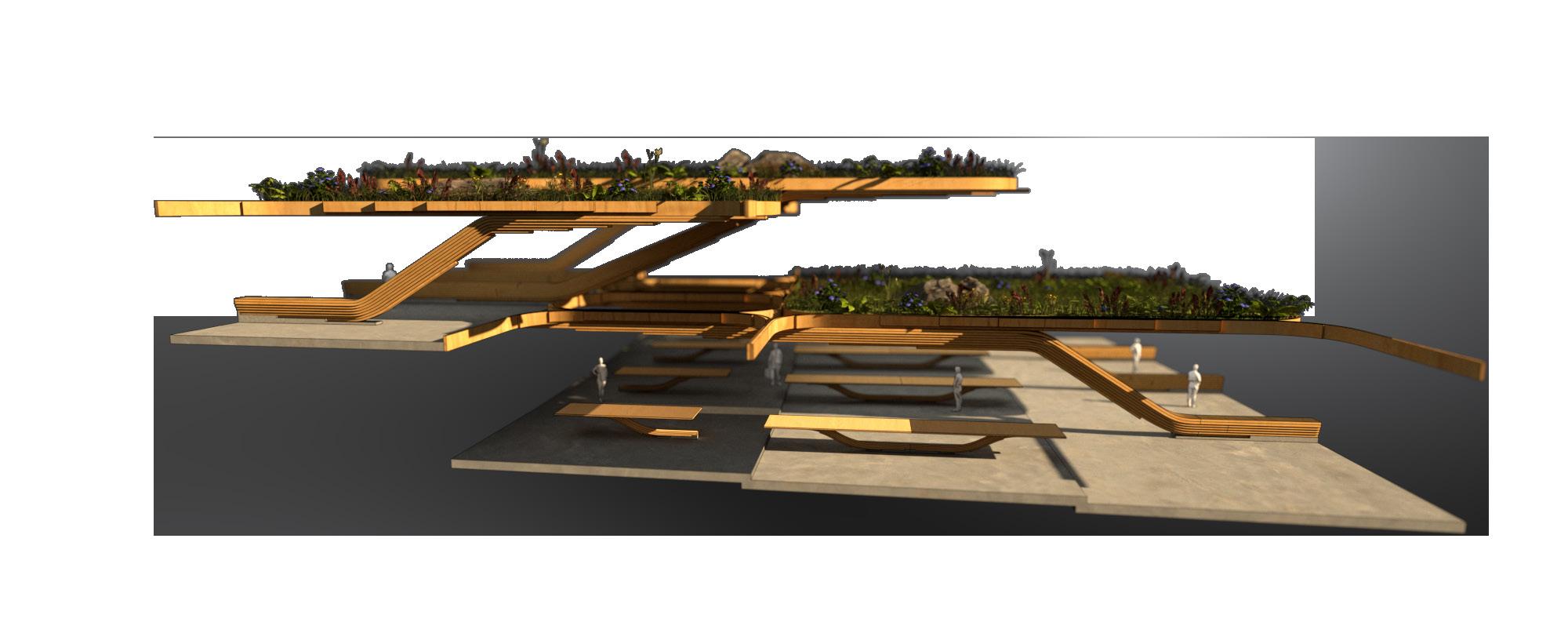

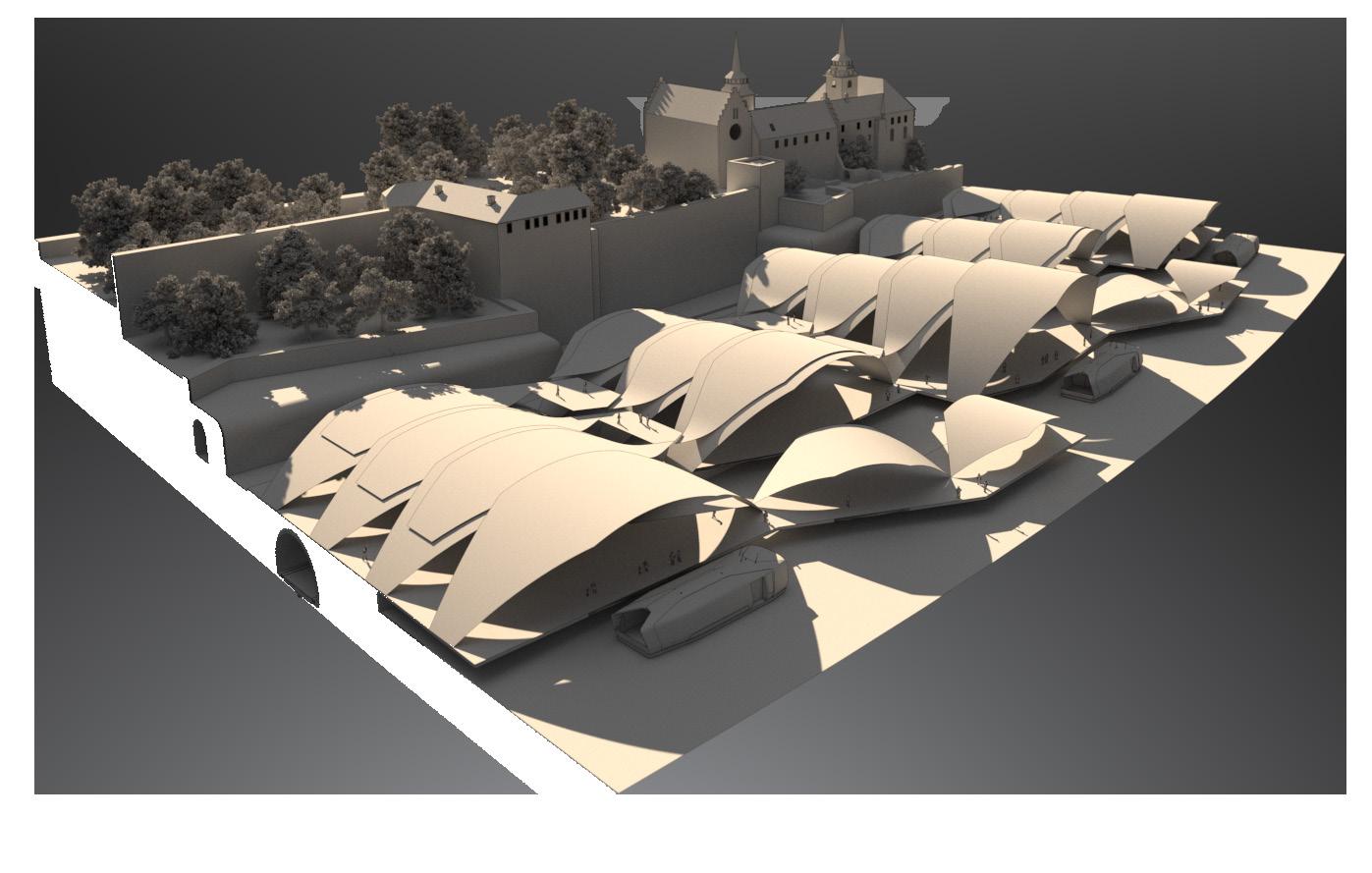

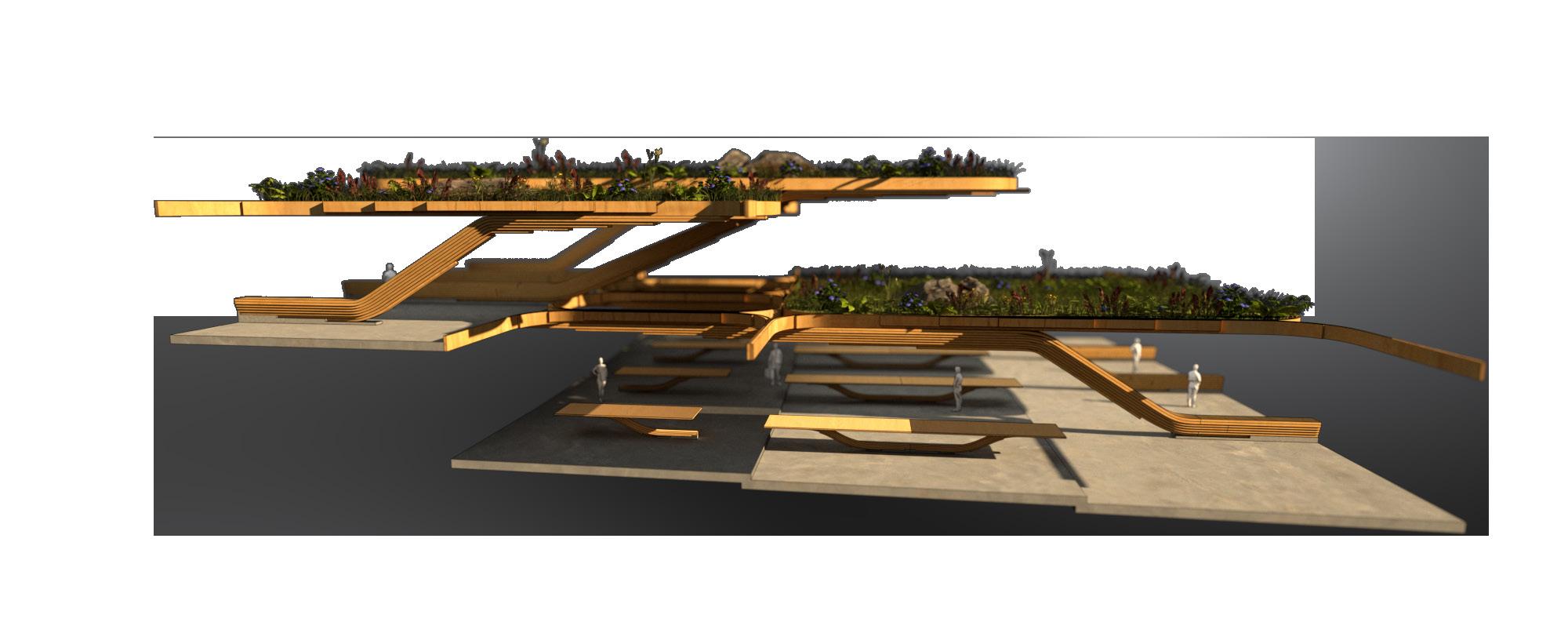

FJORD CITY MASSING

Overall strategy for Fjord City with two fjords or coves where the program is split between transport and leisure. The stepping plateaus activate the site with new access points of interest to the Akershus Fortress.

49 TYPOLOGIES RECREATIONAL RETAIL LEISURE PUBLIC AMENITY EVENT SPACE RESTURANTS OSLO TOWN HALL 1 LEISURE HUB 5 A.F. ACCESS 3 A.F. LOWER ACCESS 2 WHARF ACCESS 6 TRANSPORT HUB 4 LEGENDS 1 6 5 4 3 2

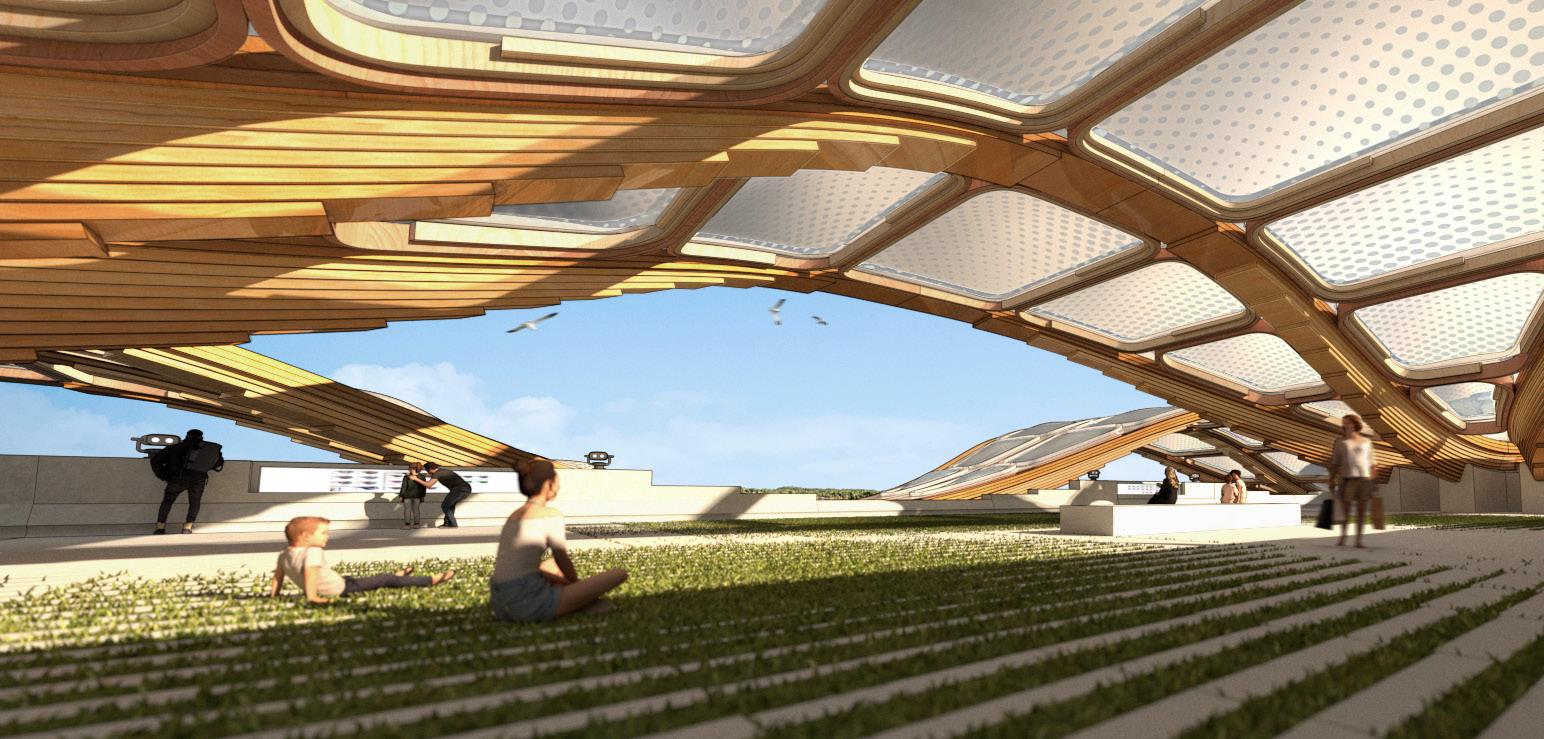

DEVELOPING SINGLE-CURVED TYPOLOGIES

Different spatial typologies are developed for mixed-use purposes. All space are designed planarly and avoids any double curvature and can be flexibly configured to cater different programs.

50

workshop auction hall offices

mezzaine akvavit bar norw. saeter

retail promenade recreational space open air space

mezzaine space staircase integrated

staircase integrated

retail promenade recreational space

TYPOLOGY MIXED USE

staircase integrated

retail promenade recreational space

51

Single-curved typologies are configured around a radial plan that steps creating terraces. Timber is used in a single curvature using the block lamination technique in response to formalize the terracing of project.

Sorting tapered profile by rounding of widths to specified factors

Sorting hierarchy tool

DOMAIN START DOMAIN END

SPECIFIED CROSS SECTIONS

NUMERIC SORTING TOOL

Cross sections are informed by specifying the top and bottom dimensions to generate a consistent tapering profile. Number of profiles is also specified, by which dictates the stepping consistency. The intermediate dimensions that are generated within the domain, can easily be adjusted to standard widths. This method can be combined with rounding the numbers to specify predictable dimensions.

52

Sorting in C24 timber strength grade application

C24 75mm

6x3” 75 x 150mm

7x3” 75 x 175mm

8x3” 75 x 200mm

4x3” 75 x 100mm 9x3” 75 x 225mm

Rounding off amount of profiles involved in matrix

5x2” 47 x 125mm

6x2” 47 x 150mm

7x2” 47 x 175mm

8x2” 47 x 200mm

9x2” 47 x 225mm

Generating outputs from tables of different timber stock dimensions

C24 47mm C24 47mm

2x2” 47 x 50mm

3x2” 47 x 75mm

47 x 100mm

5x2” 47 x 125mm

6x2” 47 x 150mm

7x2” 47 x 175mm

8x2” 47 x 200mm

BLOCK LAMINATION SORTING TOOL

Cross sections are measured in domains that are representative of industry standard categories. From the created pool of dimensions, cross sections can also be manually adjusted and controlled in the list structure.

53

4x2”

Sorting in C24 timber strength grade application

Rounding off amount of profiles involved in matrix

Generating outputs from tables of different timber stock dimensions

AUTOMATED SORTING PROCESS

Material information on available dimensions within the Norwegian C24 grade timber table is sorted using stock dimensions in two different ranges: 47mm and 75mm. The block groups stacks are created by plotting the available dimensions from the chart and specifying the profile quantity. In this way, dimensions remain consistent within a referenced chart.

54

8x3” 75 x 200mm 4x3” 75 x 100mm 4x3” 75 x 100mm 9x3” 75 x 225mm 7x3” 75 x 175mm 7x3” 75 x 175mm 6x3” 75 x 150mm 6x3” 75 x 150mm C24 75mm C24 75mm 5x2” 47 x 125mm 2x2” 47 x 50mm 6x2” 47 x 150mm 7x2” 47 x 175mm 8x2” 47 x 200mm 9x2” 47 x 225mm 4x2” 47 x 100mm 3x2” 47 x 75mm C24 47mm

stepping plateaus

INFORMAL TERRACES

MARINA PROMENADE INTERNAL PROMENADE

BEACH CONDITION

TRANSPORT ZONE

WATER TAXI ACCESS

RECREATIONAL ZONE

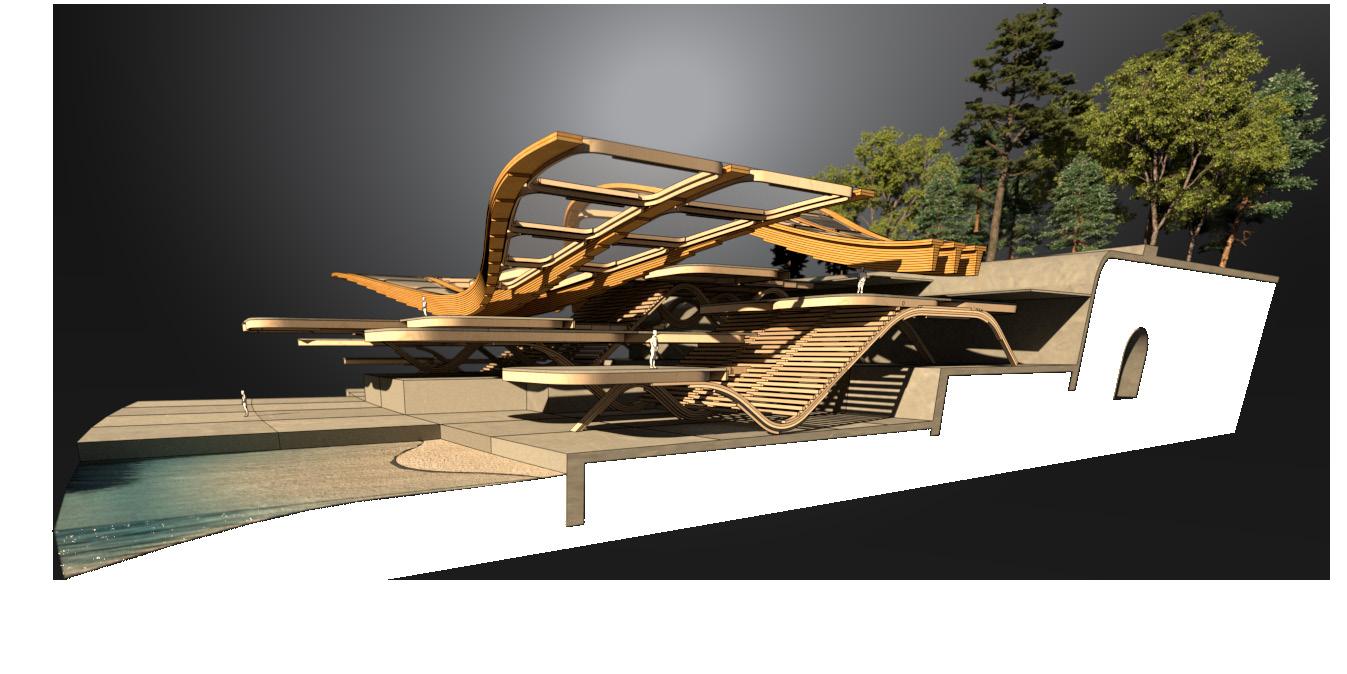

SITE DEVELOPMENT 1

Project re-investigates the potential to step and interact with the boundary conditions of the Akershus Fortress retaining wall. Terraces are stepping down, creating programmatic and level differentiation.

STEPPING LANDSCAPE

TYPOLOGIES

RESTURANTS

RECREATIONAL

EVENT SPACE

RETAIL

55

OSLO PORT LINE

FORMAL TERRACES

TRANSPORT ZONE

WATER TAXI ACCESS

RECREATIONAL ZONE

FJORD CONDITION

WHOLESALE MARKET

RETAIL PROMENADE

SITE DEVELOPMENT 2

Further development highlights the contraints of the timber terraces, shifting the attention to formalize the terraces stepping down to the fjord and rethinking material options.

FORTRESS ACCESS

TYPOLOGIES

RESTURANTS

EVENT SPACE stepping plateaus

56

RECREATIONAL RETAIL

spatial fragment

ROOF OVERHANG

TRANSPARENT FILM

ABUTMENT CONDITION

roof girders

EVENT SPACE

RESTURANT TERRACE

RECREATIONAL

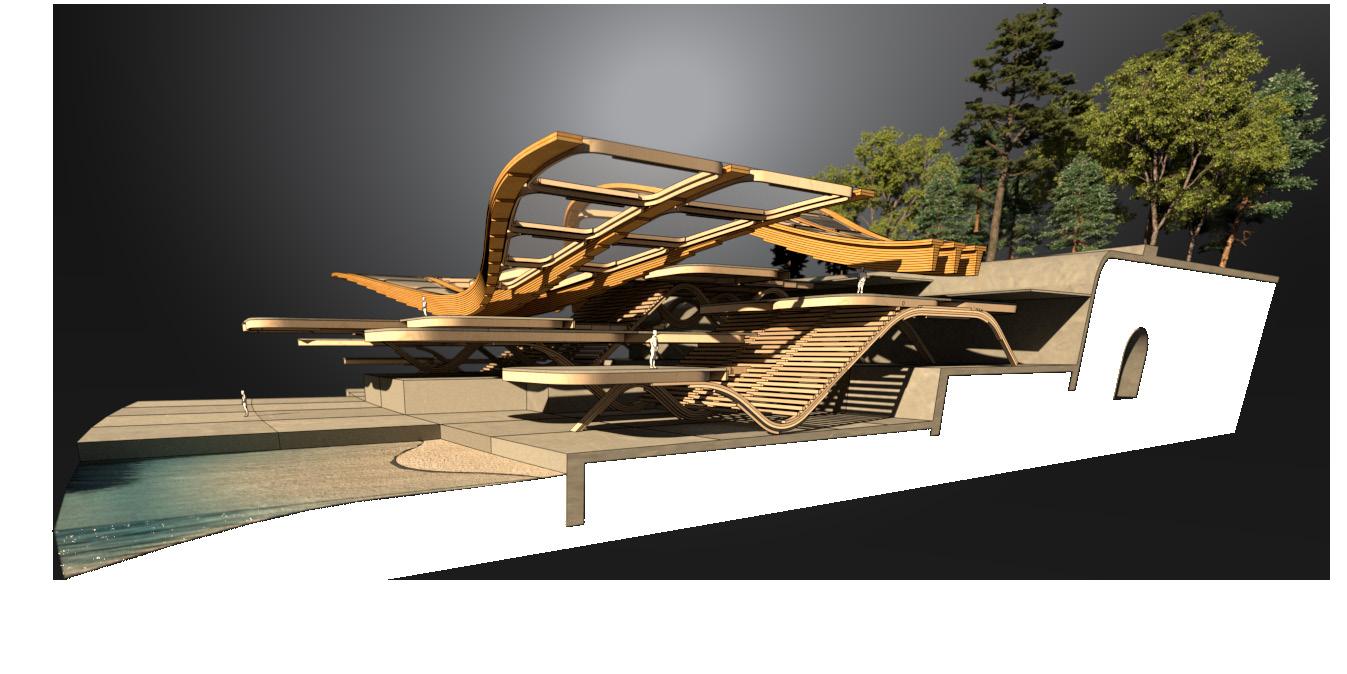

TERRACE DEVELOPMENT

Development of timber terraces integrated with roof structure. Fragment explains the relationship of the two different modules to the girders acting inversely, and also connecting the wharf to the Akershus Fortress.

57

ROOF BRACING

ROOF DOME LIGHT

double tri-span

PROFILE THINNING

PROFILE THICKENING

STEPPED LAP JOINT

GROUND LEVEL

single tri-span

SECONDARY STRUCTURE

FLAT FLANGE EDGE

ABUTMENT LOAD TRANSFER

ABUTMENT DESIGN

58

Principal design of the arch springing from foundation and delaminating the material layers. The horizontal thrust is taken directly by the abutment and a tie rod in the slab.

RECESSED HOLES

THREADED RODS

WASHER & NUT

SINGLE STEPPED LAP

DOUBLE STEPPED LAP

ASSEMBLY LENGTHS

The girders may be conveniently transported in segments on pull-out trailers, with the parent struCtures being installed first, followed by the patch girders at the construction site. For ease of transportation, the facility is also accessible by sea, where larger shipments may be made.

LANDING GIRDER

SECOND GIRDER

59

REINFORCEMENT LAYER

PATCH

FIBER ORIENTATION

STEPPED LAP JOINT

STEPPED LAP WIDTH

DOUBLE STEPPED LAP

JOINT LOCATED AT MOMENT ZEROLINE

RECESSED WEATHER PROTECTION HOLES

STEPPED LAP JOINT

THREADED RODS

WASHER & NUT

PATCH GIRDER

PARENT STRUCTURE

STEPPED LAP-JOINT

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Duis at volutpat ex. Morbi quis egestas elit. Morbi sit amet imperdiet turpis. Etiam pulvinar, sem at vehicula pellentesque, justo nisl aliquam erat, id gravida massa felis vitae sem. Nullam commodo velit vitae tortor scelerisque, nec malesuada odio aliquam.

60

PROGRAMME AND TERRACES

Abutment design and terraces are designed together to inform and address the programme and structural logic of the loads needed to transfer as the scheme increases in levels.

61

TIE ROD PLATE PILLAR TRANSFER WINDOW SUPPORT clipping

PROGRAM

SPACE +1.75 meters clipping

plane RESTURANTS/RETAIL PROMENADE/LEISURE

EVENT

plane

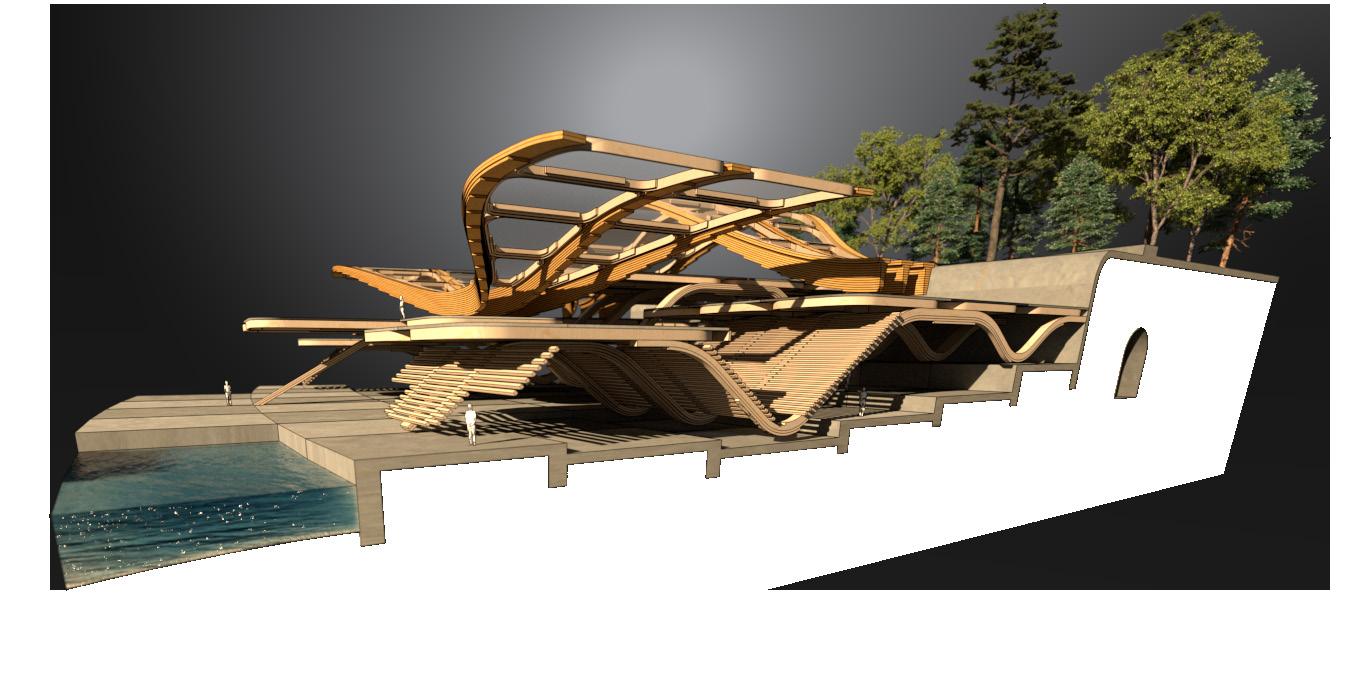

WEATHER PROTECTION PROFILE

The wicking angle for the glulam girders was tested and controlled with the addition of a water shedding angle control. The top flange of the glulam girder profile, by which is used as a perpendicular landing for the curved batten bearings to be dowelled to, achieves the passive water protection angle.

62

EXPOSED SURFACE EXPOSED SURFACE 26.7° - 23.0° 38.8° - 30.0° WICKING ANGLES FLANGE

1 WICKING

3 GIRDER

2 LEGENDS 2 1 3

DETAIL

ANGLE

RIDGE

RECESSED HOLES

THREADED RODS

WASHER & NUT

GIRDER

T-PROFILE FLANGE

ETFE FILM

ETFE FOIL CUSHIONS

ROOF BUILD-OUT COMPOSITE

The girders are braced with single curved stepped profiles to address the lateral stiffness in the arcs. An ETFE (Ethylene tetrafluoroethylene) membrane is laid on top of the roof alongside ETFE foil cushions that is inflated to create dome skylights for spaces below.

TIMBER BRACING

STEPPED LAMELLAE

63

AKERSHUS FORTRESS DEVELOPMENT

Programmatic cross section development of the Akerhus Fortress, where the terraces are of the same material and consistency as the current retaining wall. The access point from the quay to the fortress is enabled by opening up the fortress wall.

65

FORTRESS ACCESS

TYPOLOGIES RECREATIONAL RETAIL LEISURE EVENT SPACE RESTURANTS WHOLESALE MARKET 1 LEISURE ACTIVITIES 5 INTERNAL STREET 3 TRAM-LINE STOP 2 FJORD QUAY 6 AKVAVIT BAR 4 LEGENDS 5 6 4 1 2 3

LEISURE ACTIVITIES MARINA PROMENADE RESTURANTS MEZZAINE AKVAVIT BAR RETAIL PROMENADE INTERNAL STREET TRAM-TRAIN PLATFORM

QUAYS TRANSPORT HUB WATER TAXI

SITE PLAN

66

OSLO PORT LINE TRAM-LINE STOP 1 7 A.F. ENTRANCE EVENT SPACES 5 11 TRANSPORT HUB A.F. MAIN GATE 3 9 WATER TAXI URBAN FJORD 2 8 PARK CAR LANE 6 12 MARKET ENTRANCE AKVAVIT BAR 4 10 LEGENDS 1 2 3 6 7 5 9 4 8 10 12 11

Closer view of Fjord City integrated with the Akershus Fortress and Oslo Fjord.

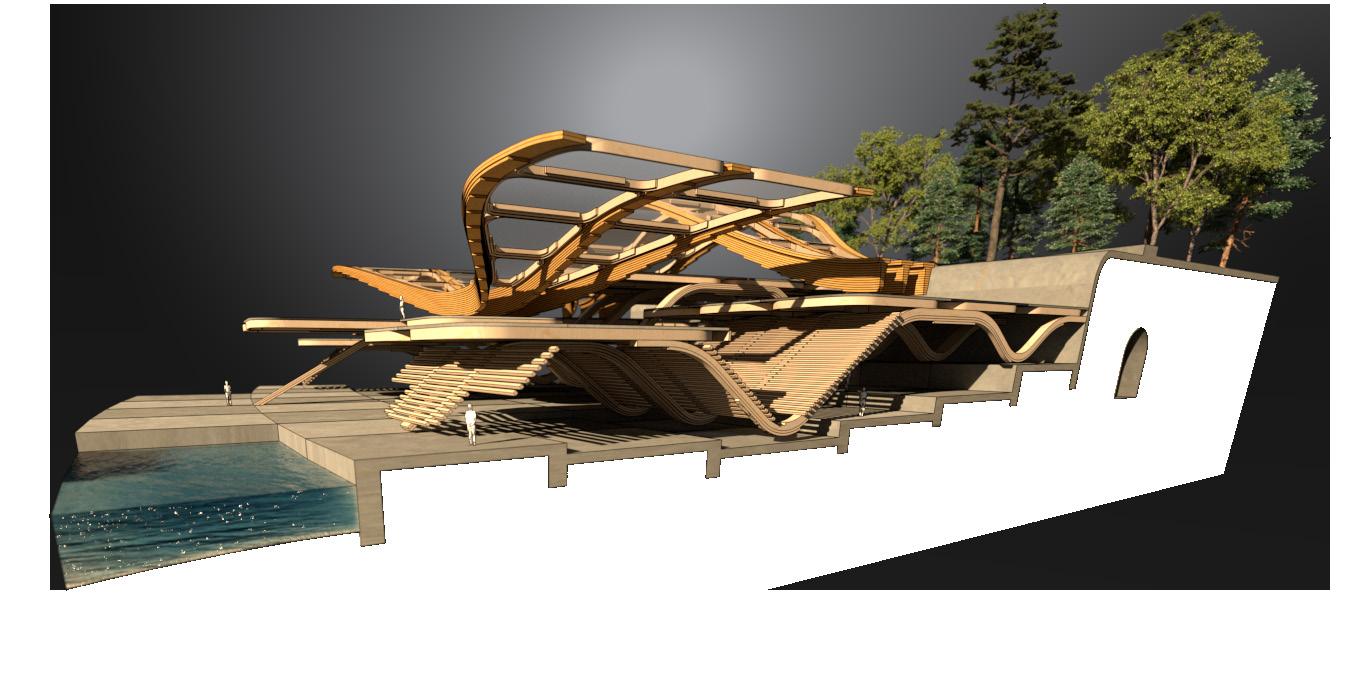

SECTIONAL FORTRESS OVERVIEW

The diagram shows the new connectivity to the city and the previous access points. Program and layout overview of Fjord City and its layering. The inaugrated spaces are embedded in the plinth allowing the double-durved glulam to be free of curtain walls and insulation.

68 3 4 5 2 1 7 6 CITY ACCESS 1 7 OSLO PORT LINE FOYER 5 11 AKERSHUS BEACH OFFICES ATRIUM 3 9 AKVAVIT BAR FORTRESS ACCESS 2 8 TRAM-LINE STOP AKERSHUS FESTNING 6 12 FJORD QUAY CAR PARKING 4 10 WATER TAXI 8 12 10 11 9 LEGENDS

ROOF CANOPY DEVELOPMENT

Exploring varied spans for differentiating program under the roof canopy. The fjord with more sand is centered around leisure activities and public use, whilst the adjacent is the transport hub for the water taxis.

69

3 3 4 4 5 5 2 2 1 1 7 6 6 TRANSPORT HUB URBAN FJORD 1 1 7 OFFICE ATRIUM AKVAVIT BAR TRAM CONNECTION 5 5 11 CITY ACCESS OSLO FJORD PARK 3 3 9 WHOLESALE MARKET RECREATIONAL BOAT DOCKING 2 2 8 FORTRESS ACCESS NORTH ENTRANCE LARGE SPAN 6 6 12 AKERSHUS FESTNING RESTURANT MARINA LOUNGE 4 4 10 WHARF 8 12 10 11 9 LEGENDS LEGENDS long span roof short span roof symmetrical unsymmtrical sides

APPENDIX FJORD CITY

lattice lengths

Columns: 9.64 to 11.84m

Diagrid: 7.93 to 12.37m

individual members

Total members: 48

LAP JOINT SUPPORT

LATTICE ROTATED

LATTICE STAGGERED SYSTEM

LATTICE

COLUMN

LATTICE 2B

LATTICE 2A

LATTICE 1B

LATTICE 1A

Early stage experiment with a staggered rectilinear lattice canopy that allows for subtle twisting of the roof.

LATTICE LEVEL

CROSS-SECTION EXPLORATIONS

A series of simple cross-sections were developed to investigate a Norwegian cultural re-distribution of scale and program at Akershus Fortress.

PLAN ITERATION 01

Radial configuration of multiple quays centered around one reference point. Wholesale market and ferry terminal are developed with the clash of two languages by which informed the pixelation landscape further on.

All work produced by Unit 14

Unit book design by Charlie Harriswww.bartlett.ucl.ac.uk/architecture

Copyright 2021

The Bartlett School of Architecture, UCL All rights reserved.

No part of this publication may be reproduced or transmited in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage and retreival system without permission in writing from the publisher.

-

@unit14_ucl UNIT

Cover design by Charlie Harris

Cover design by Charlie Harris