Y5 SB

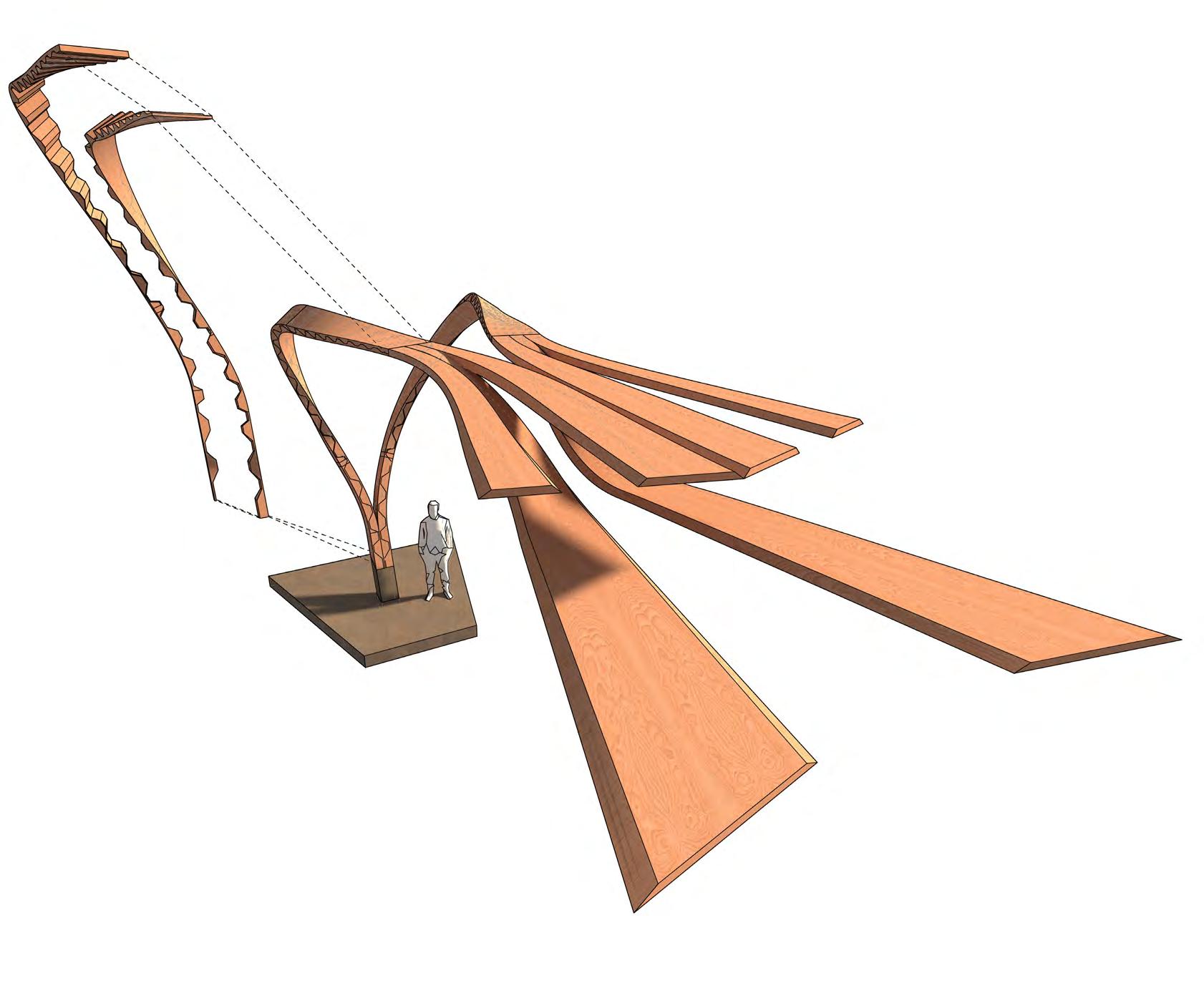

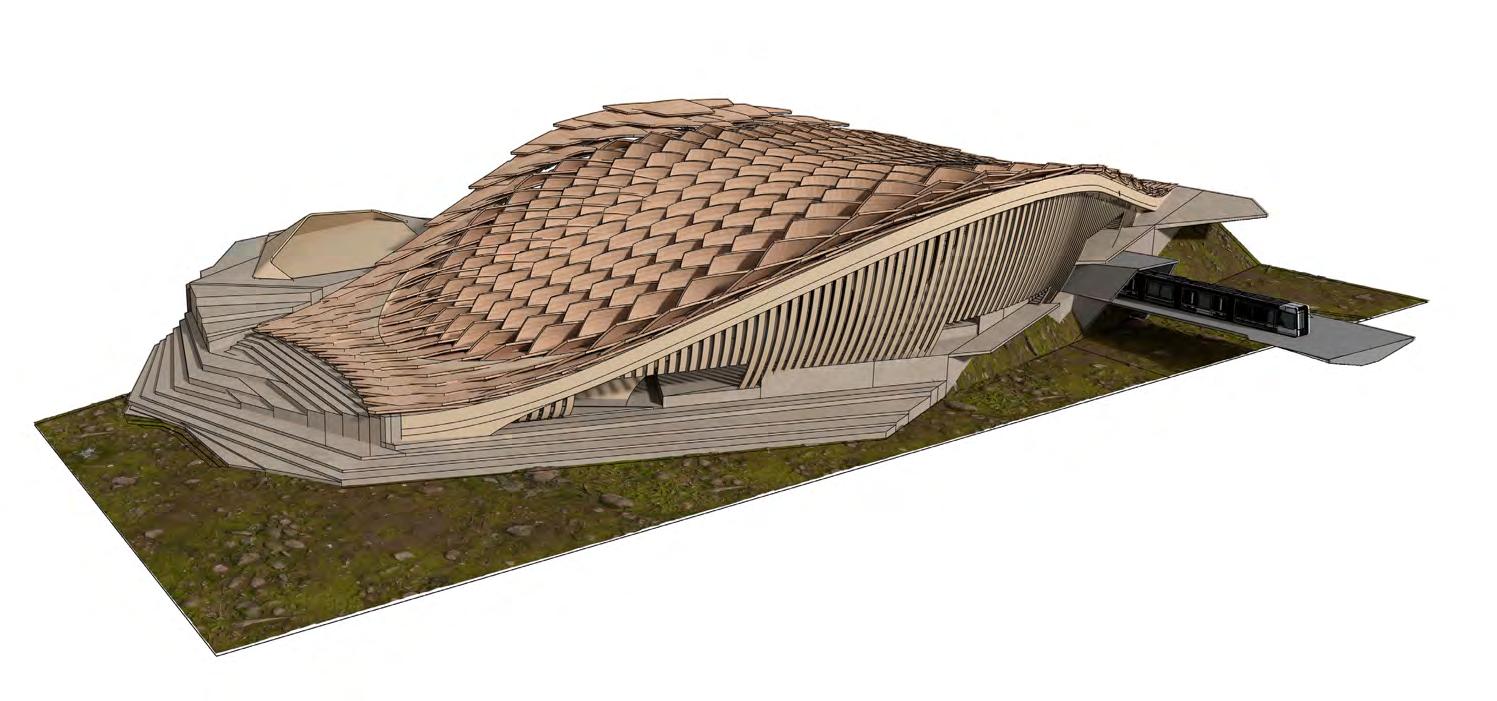

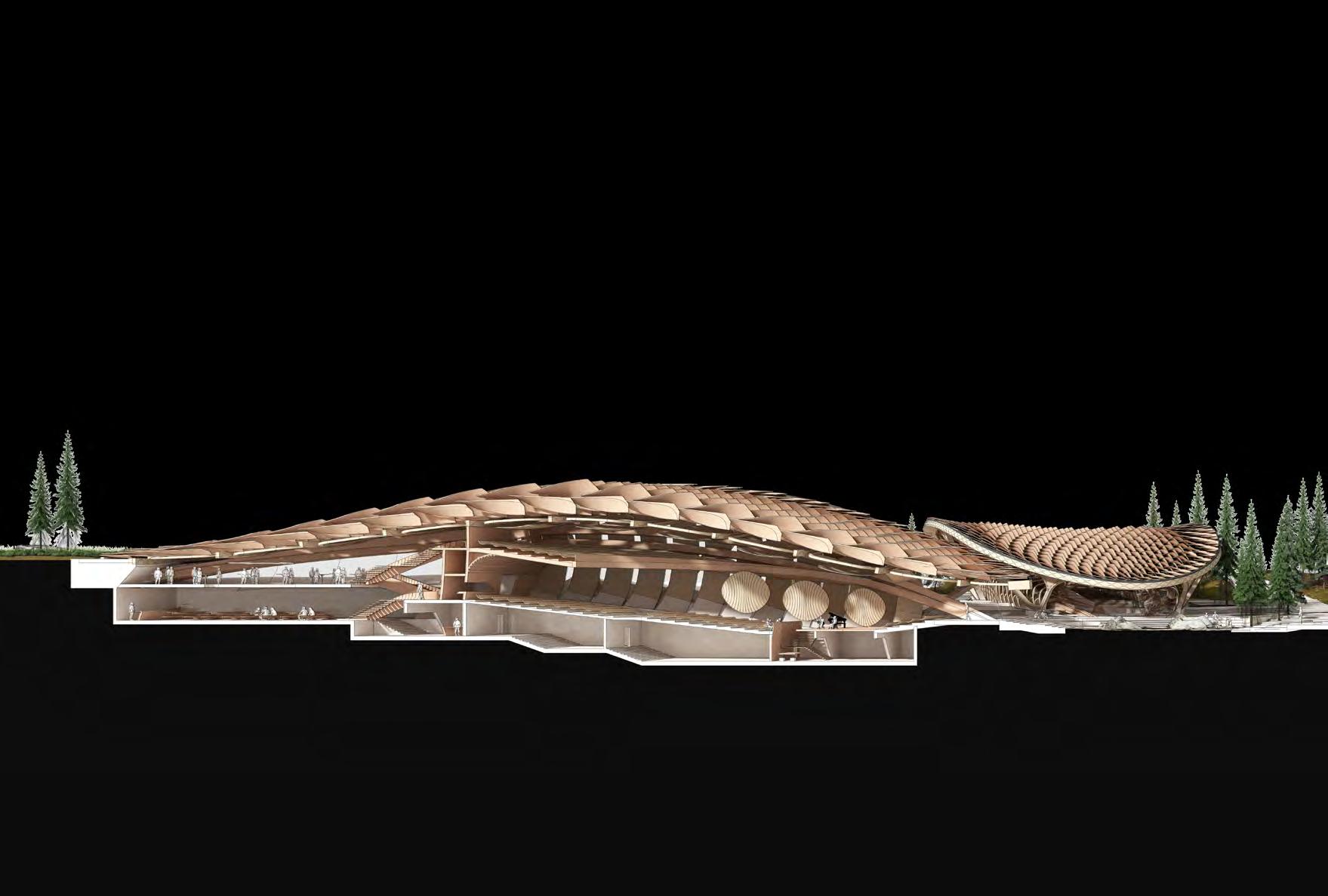

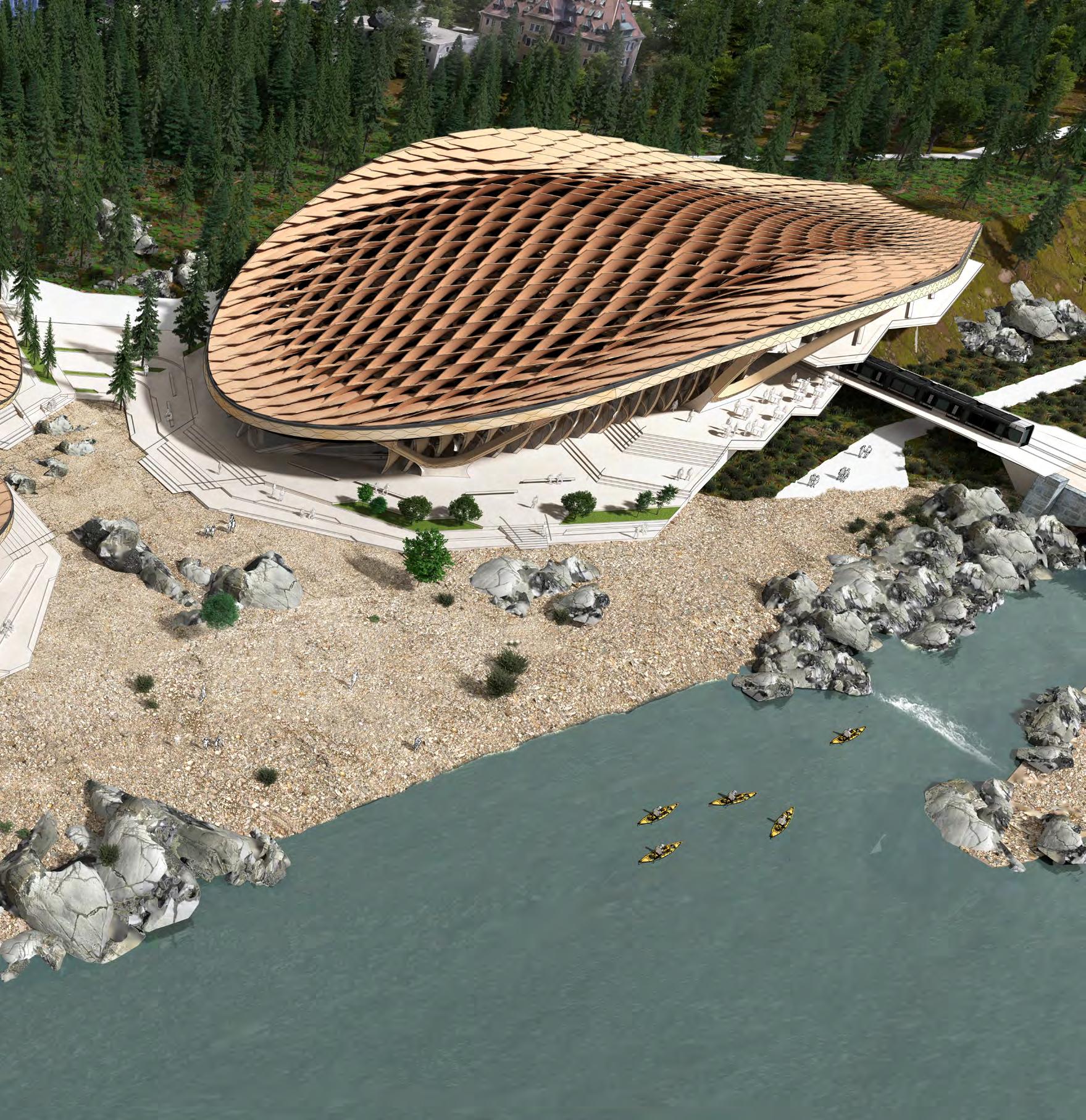

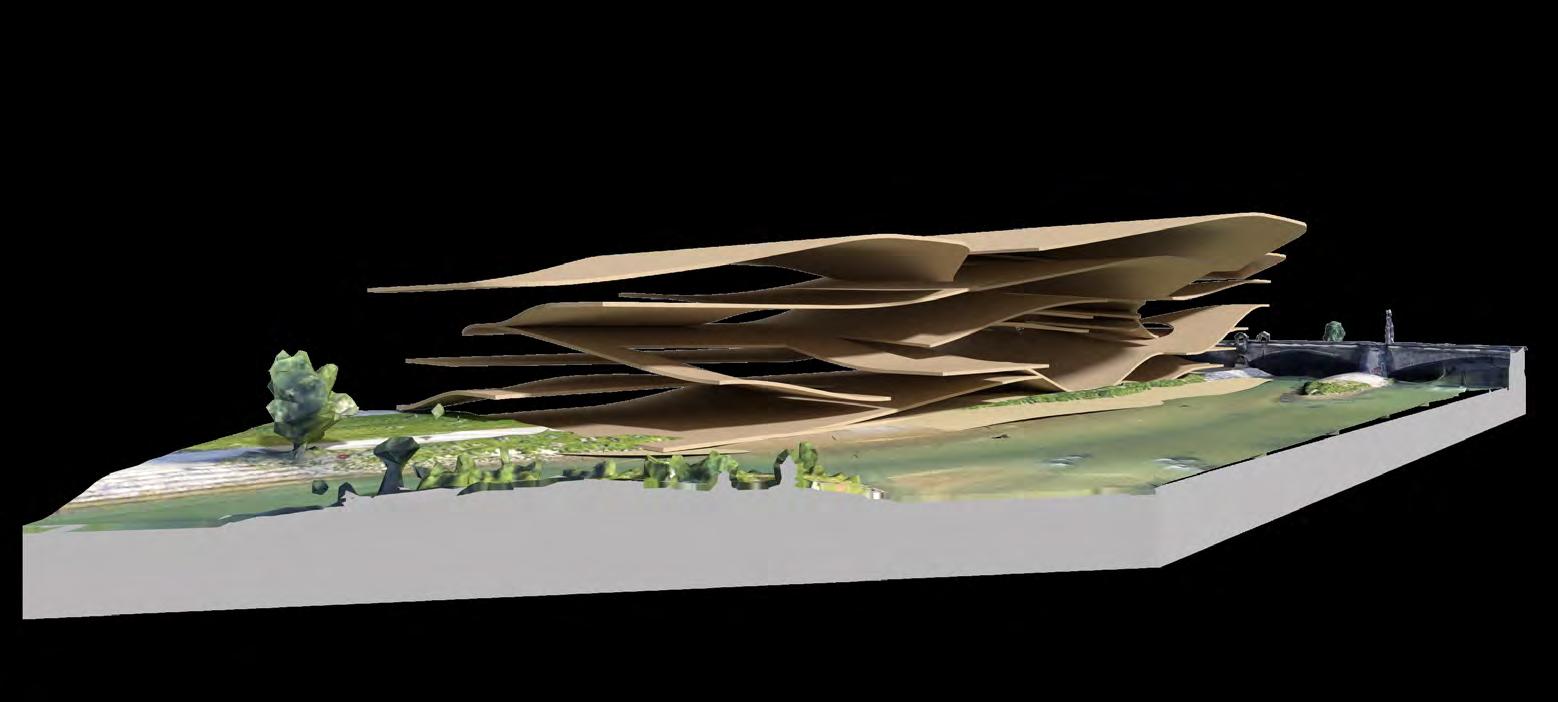

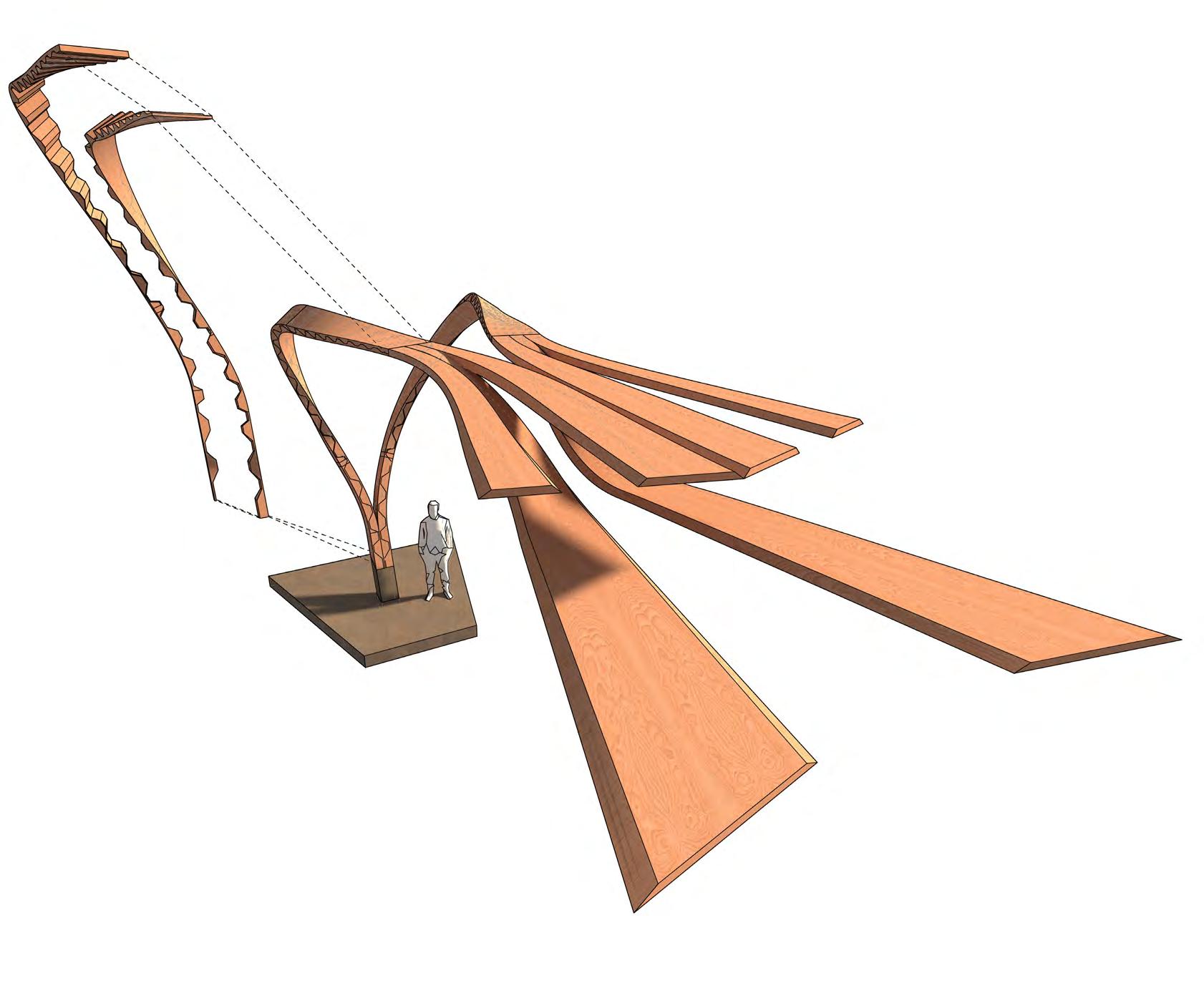

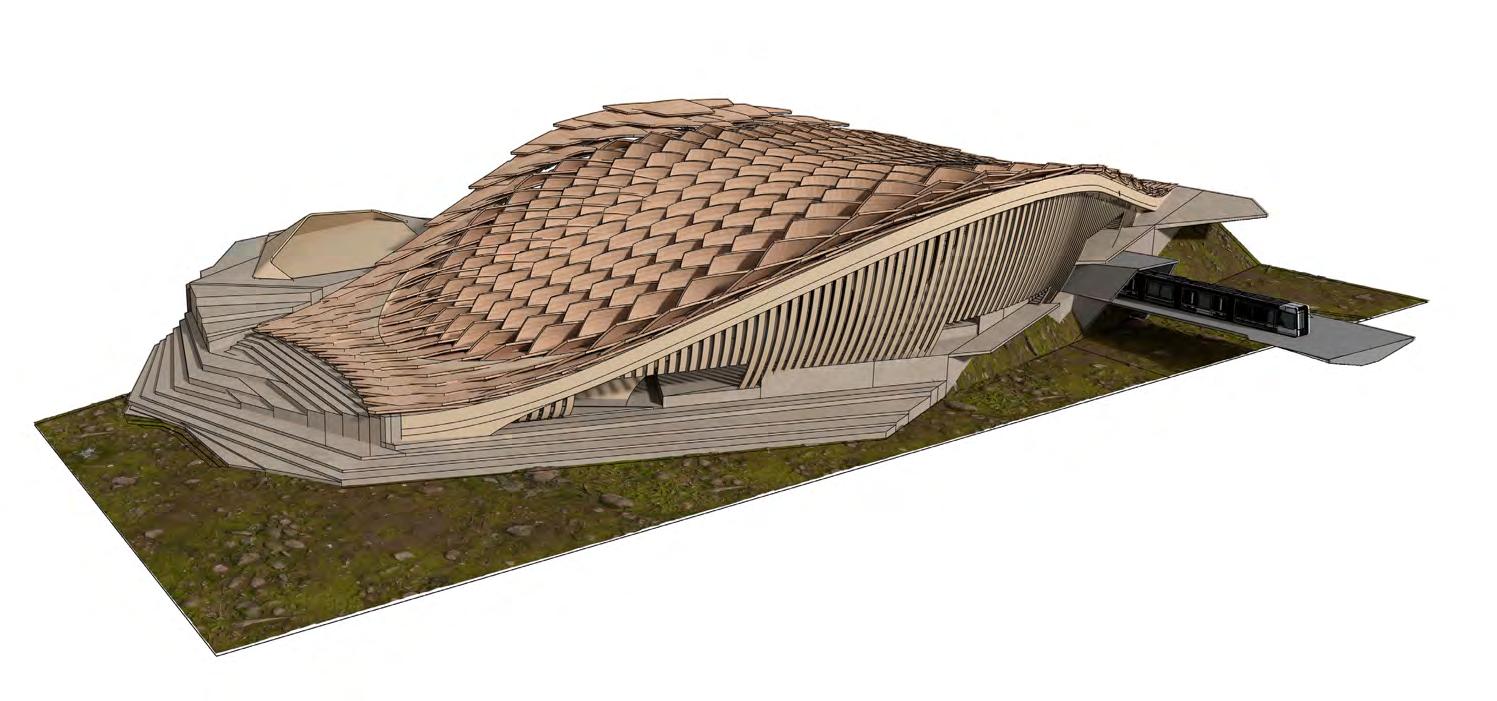

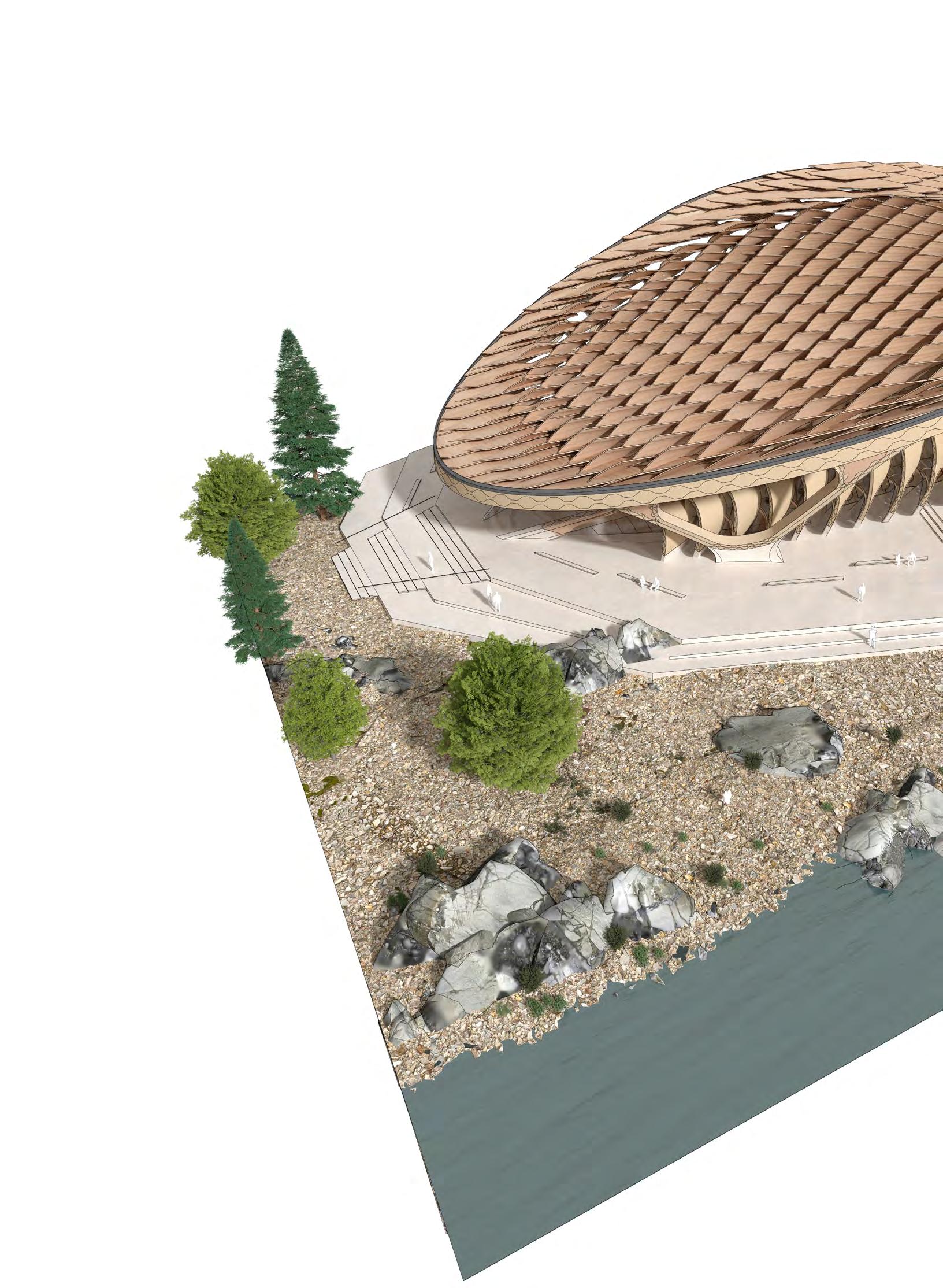

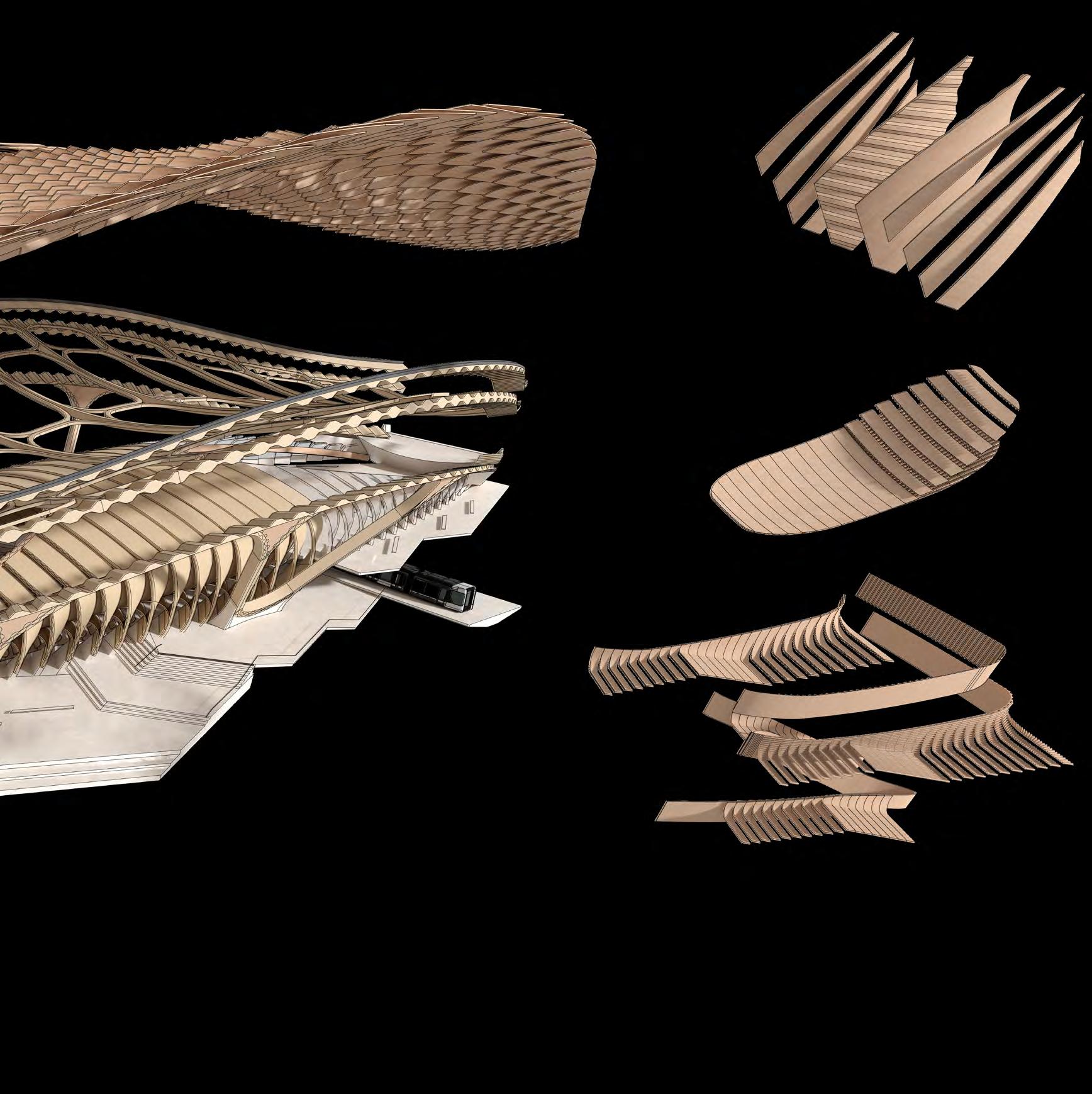

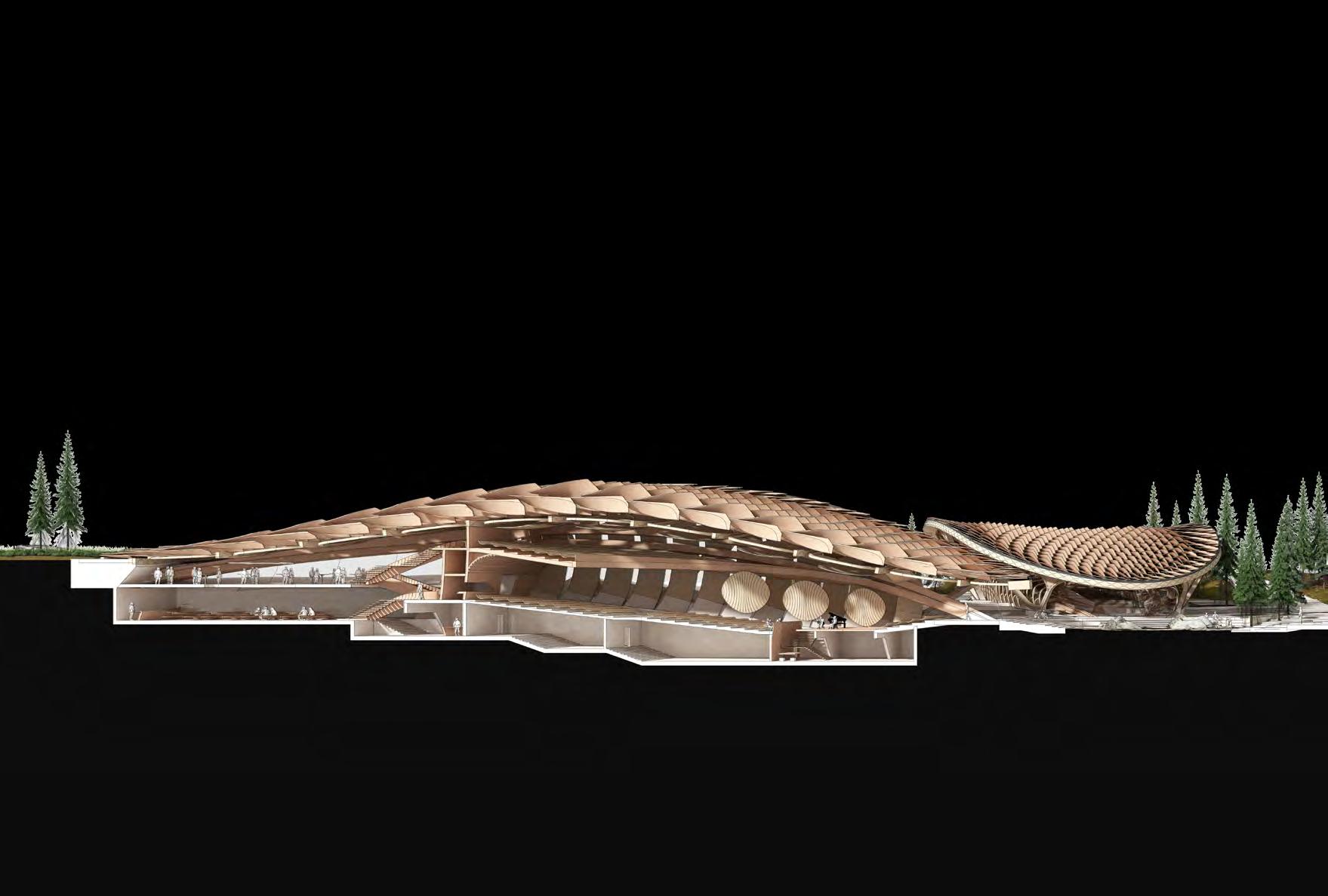

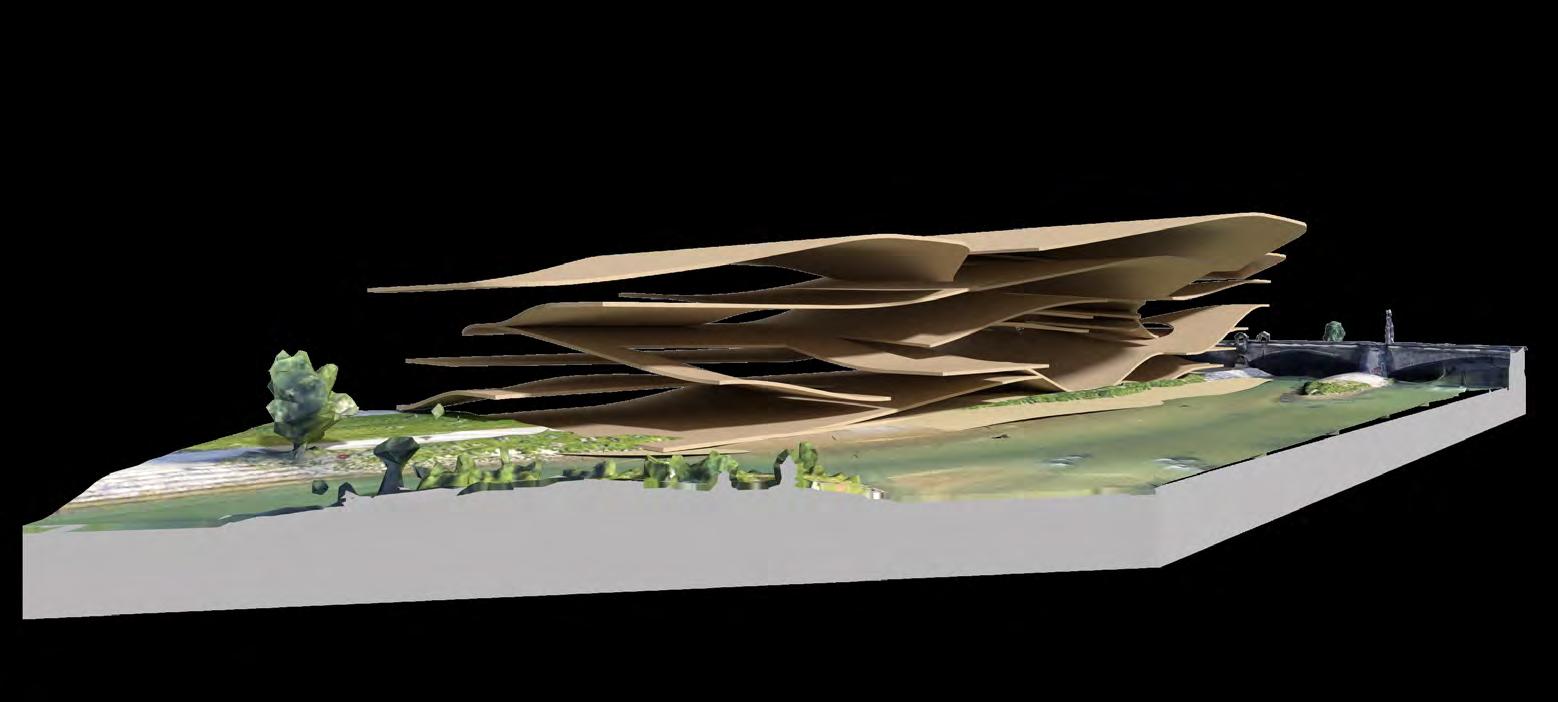

The project begins with a research phase investigating the architectural possibilities of the self-forming zip bending method in wood with an aim to refine and develop new and tailored fabrication approaches. This first-hand knowledge of material behaviour is used to inform the application of the system at the architectural scale, in the design of a new philharmonic hall, sited in Munich, Germany. The proposal utilises the full possibility of the zippered system and speculates on its scaled up implementation as a novel construction approach. Zippering is therefore presented as a potential alternative to freeform glulam but with the potential for greater fabrication efficiency and expression suited to timber’s inherent qualities.

Alongside innovation at the tectonic level, the project speculates on the future development of the concert hall as an entertainment typology. Given the decline of the formal concert hall as a mainstream entertainment venue - replaced by a rise in more informal types – the building’s performance halls are designed as public facing arenas. The building integrates itself closely

SEBASTIAN BIRCH YEAR 5

with the surrounding landscape, which becomes formalised into architecture through an activated plinth condition, drawing both the city and nature into the performance spaces. Fabrication approaches developed through testing are applied at the building scale in the generation and design of components composed of developable ruled surfaces, generating high spatial complexity underpinned by fabrication logic. The possibilities of the twisting zippered timber surface – allowing roof, wall and façade to open up – is made use of to activate a series of interstitial conditions which engage the surrounding urban realm at this site of cultural celebration. @unit14_ucl

MUNICH PHILHARMONIC MUNICH, GERMANY

section 1 design research

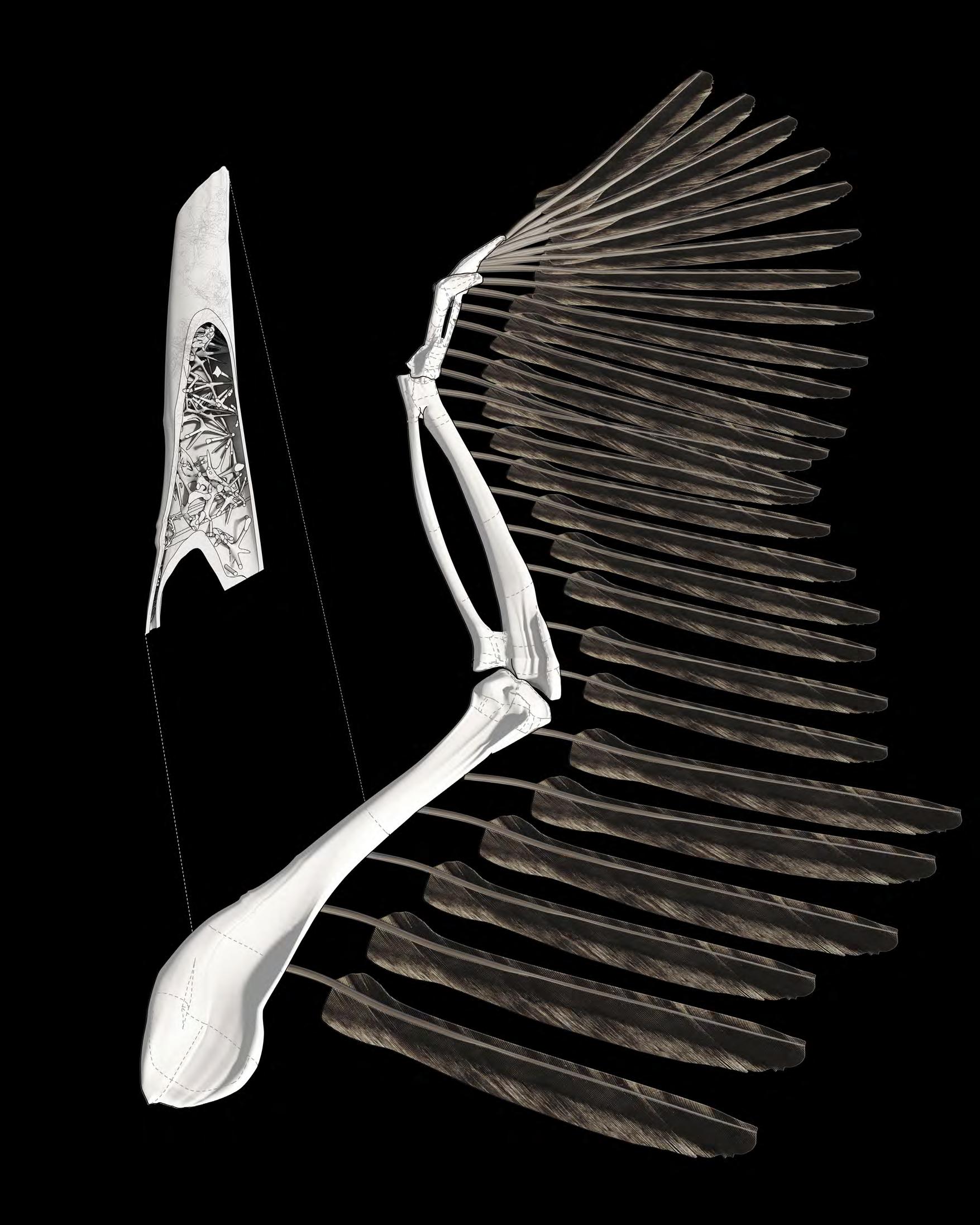

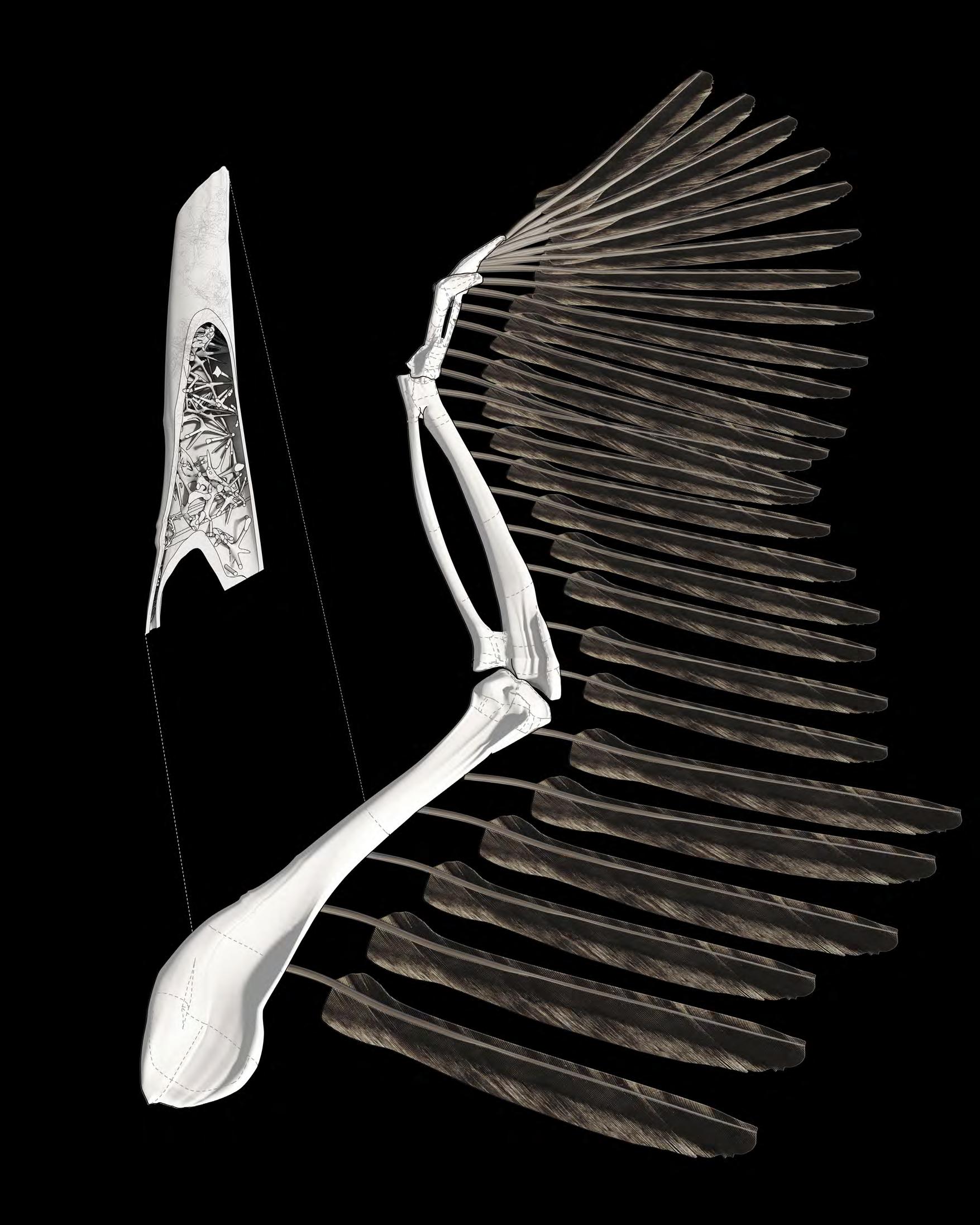

Structural Performance in Vulture’s Wing Bone Diagrams explain the targeted densification of reinforcement within the wing bone to cope with extreme loading conditions (Sullivan et al, 2017)

Structural Performance in Vulture’s Wing Bone Diagrams explain the targeted densification of reinforcement within the wing bone to cope with extreme loading conditions (Sullivan et al, 2017)

1.0 Extreme loading requires designed response to resist torsion and bending with lightest possible construction

2.0 Components with varying Cross Sections and densification in areas of highest loading

3.0 Intelligent design down to micro scale for efficiency of flight

3.1 Cross section variation in wingbone

3.2 Cross section variation in feather

1.1 Extreme forces of bending and torsion develop during flight

Ulna

Carpometacarpus

Structural Performance in Vulture’s Wing Bone Bird skeleltons are some of the most advanced structures in nature. Adapted for flight, they are both highly lightweight and can cope with extreme loading. Intelligent structural form and optimal material distribution can be observed in these structures

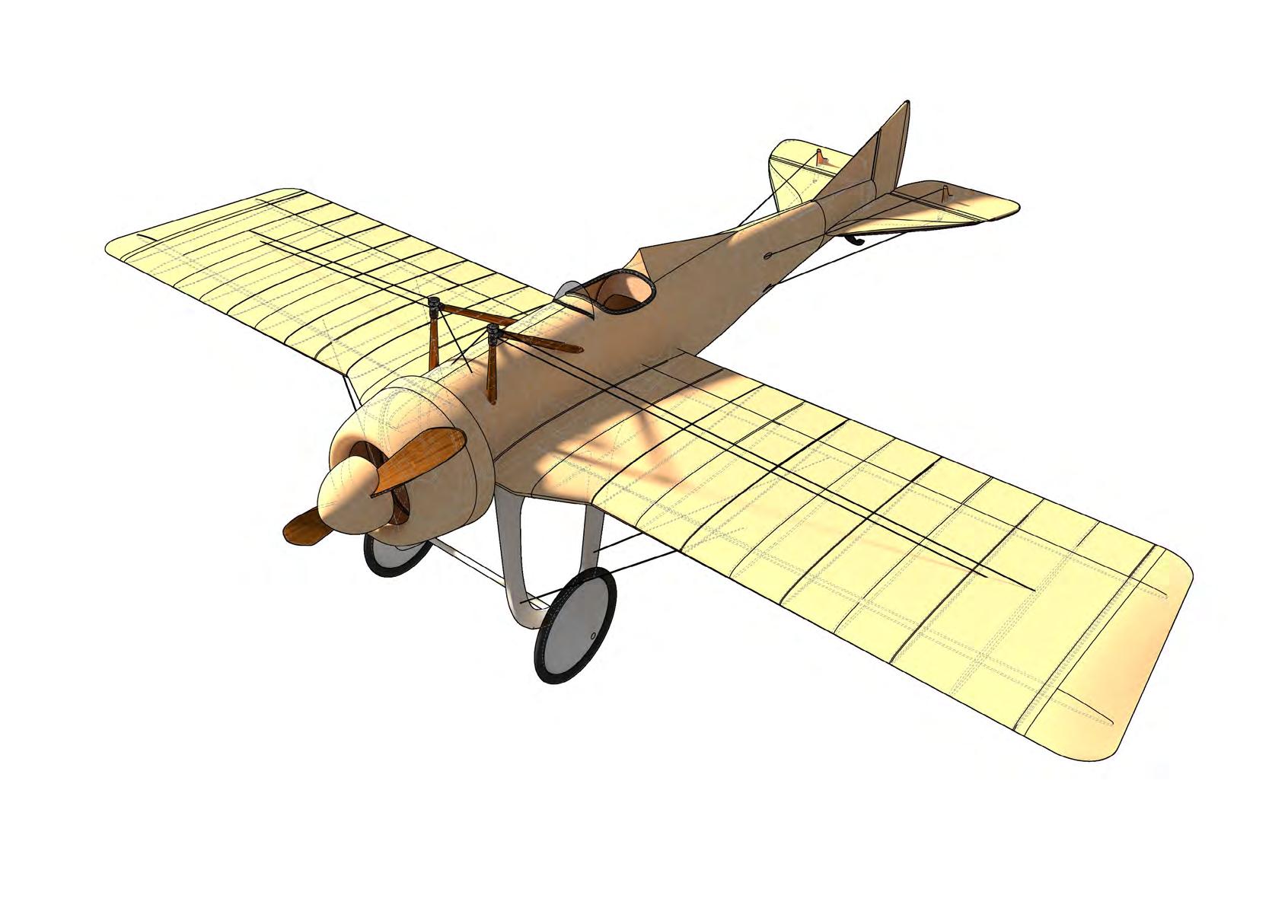

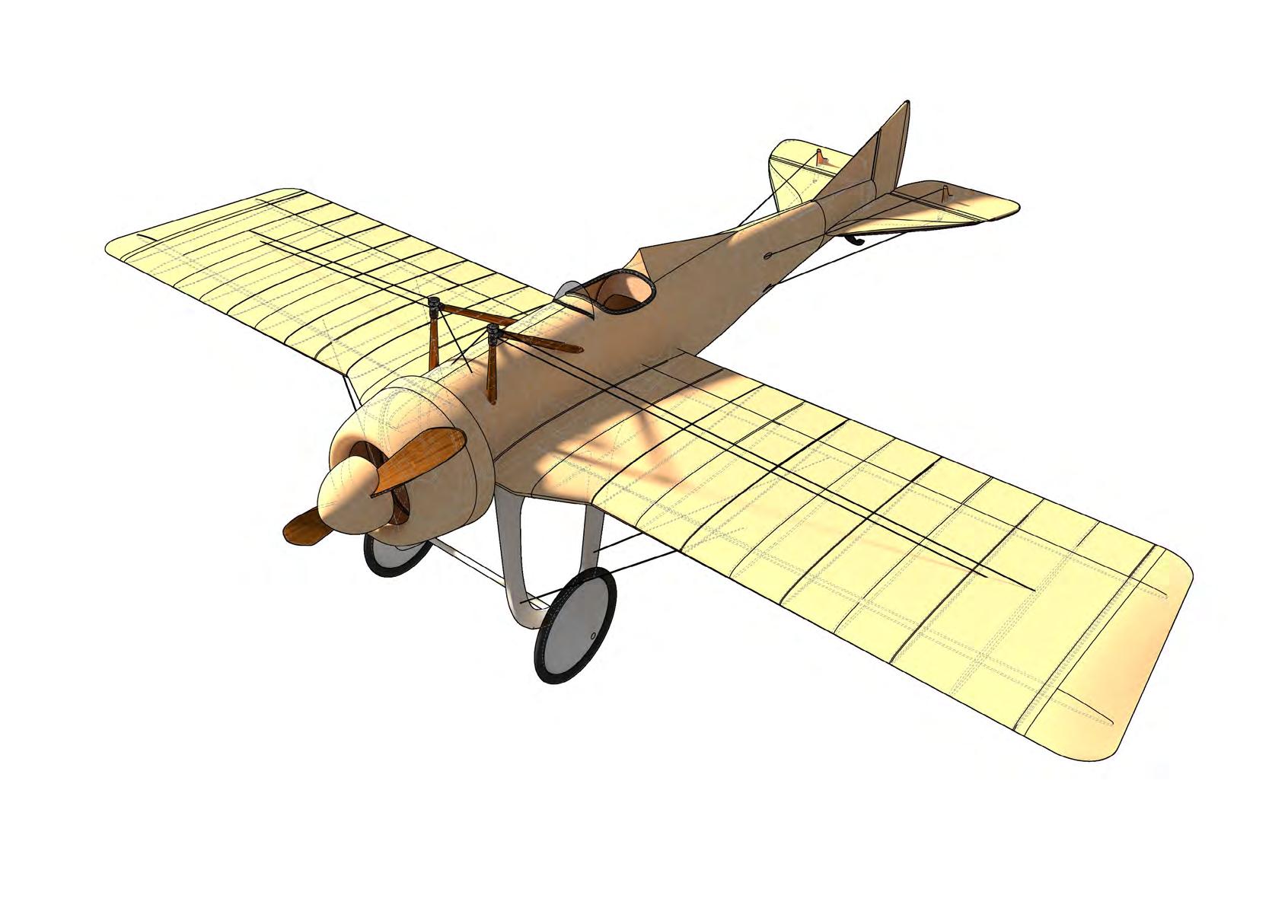

Deperdussin’s workshop produced numerous timber racing planes in this early period with their development of the stressed timber skin ‘monocoque’ construction. This allowed planes to become lighter and faster, making use of a multi-layered thin veneer construction as well as a secondary component based framing. Perhaps their is something to be learned in utilising the full breadth of timber’s potential as a lightweight, high performance material.

6

Deperdussin Monocoque GB 1913

Stucture/Skin Relationship in early plane manufacture

The high point of timber plane manufacture relied on a symbiosis of both component based frame and a continuous, stressed skin

7

1.

4.

4.

3.

2.

5.

6.

7.

8.

1. Fabric outer layer to fuselage and wings

2. Crosslaminated tulipwood formed around mould in 2 halves, glued in 3 layers, 3mm thick overall

3. Hickory and ash spars

4. Ribbing to wings and internal frame from pine

5. Elevator and rudder tulip wood due to high strenght to weight ratio, handshaped

6. Propellor, 2 bladed Chauviere, 2,31m diameter fitted with spinner

7. Tension wires support monowing

8. Plywood U-shaped wheel-chassis

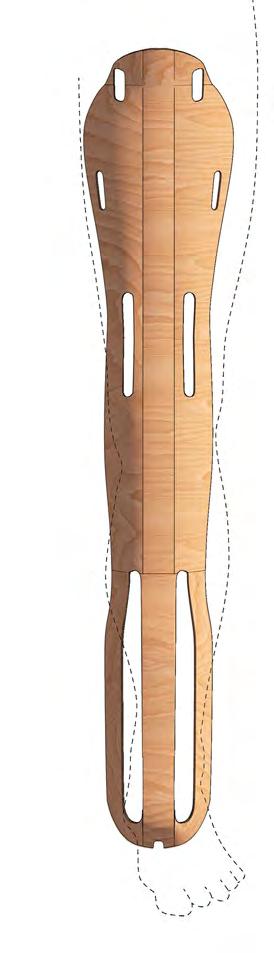

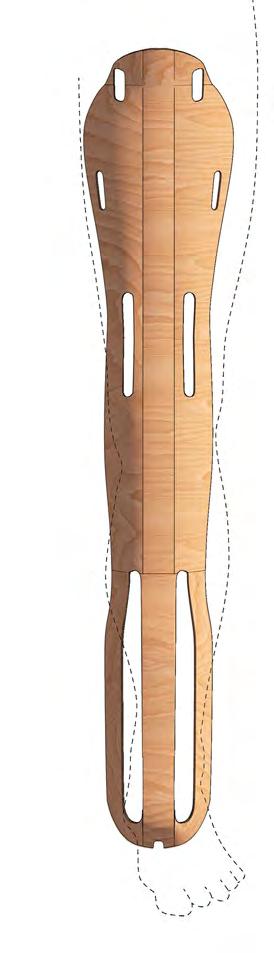

Vertebrae Table (1951) - Shell-like, highly continuous

1.3 Deviation from structural shell form within continuous assembly allows for

1.2 Post -lamination machining to fit brass connection details

Reale Table (1948) - Volumetric Frame, Component Based

1.4 Cold bending of lamellae over reuseable mould to form highly strong arched shell

2.3 Components are also shaped in cross section for structural performance and expression

Carlo Mollino Tables: Master Surface vs Component Based Frame Mollino (1905-1973) pioneered the development of timber construction with his experimental furniture. This included the development of a patented form of cold plywood lamination which enabled the creation on highly thin, shell-like furniture. He also pioneered component based systems. This dichotomy of component-based frame vs highly continuous thin-shell construction continues to be observed in timber construction today.

2.2 Material is optimally placed, creating a thin, elegant form while still performing well

2.4 Bolted shear connections are the weak points of the structure

8

3.

3.

2.

2.

3.

3.

1.

1.

2.1 Table constructed from series of different components shaped to fit together at bearing points.

1.1 Shell constructed from layered timber veneer sheets.

1. Lapjoint integrated to veneer glue up

2. Void spaces are designed into veneers to enable shell folding

1. More complexity to seams enables more complex shell folding

2. Variation in void form for different joint types

spline joint method ties

1. Splits in veneer enable 3-Dimensional lamination from same surface

2. Precision machining takes place after lamination as clean up operation

Eames’ Moulded Plywood: Surface Logic through targetted incisions Charles and Ray Eames’ experiments in veneer lamination in the interwar years led to unprecedented advances in plywood production. Three dimensionally-molded wood shells were created by gluing and pressing wood veneers over plastercast molds. Mapping of seampoints to enable a 2d veneer to match a precise curvature was necessary. Curvature is achieved through targetted removal of material

9

Plywood seat (1942) - initial prototype for single-shelled chair

Pilots seat (1943) - organic form achieved through overlapping seams

Plaster mould with inflated pressing within plywood splint

1.

2.

1.

2.

1.

2.

1. Splits in veneers allow for structural folding and apertures in structure

2. Laminated sheets becomes expressivethrough series of raised seam-edges

3. Roofing integration to component

1. Structural depth created through stepping / layering of timber lammellae

2. Member o surface transition as element tapers

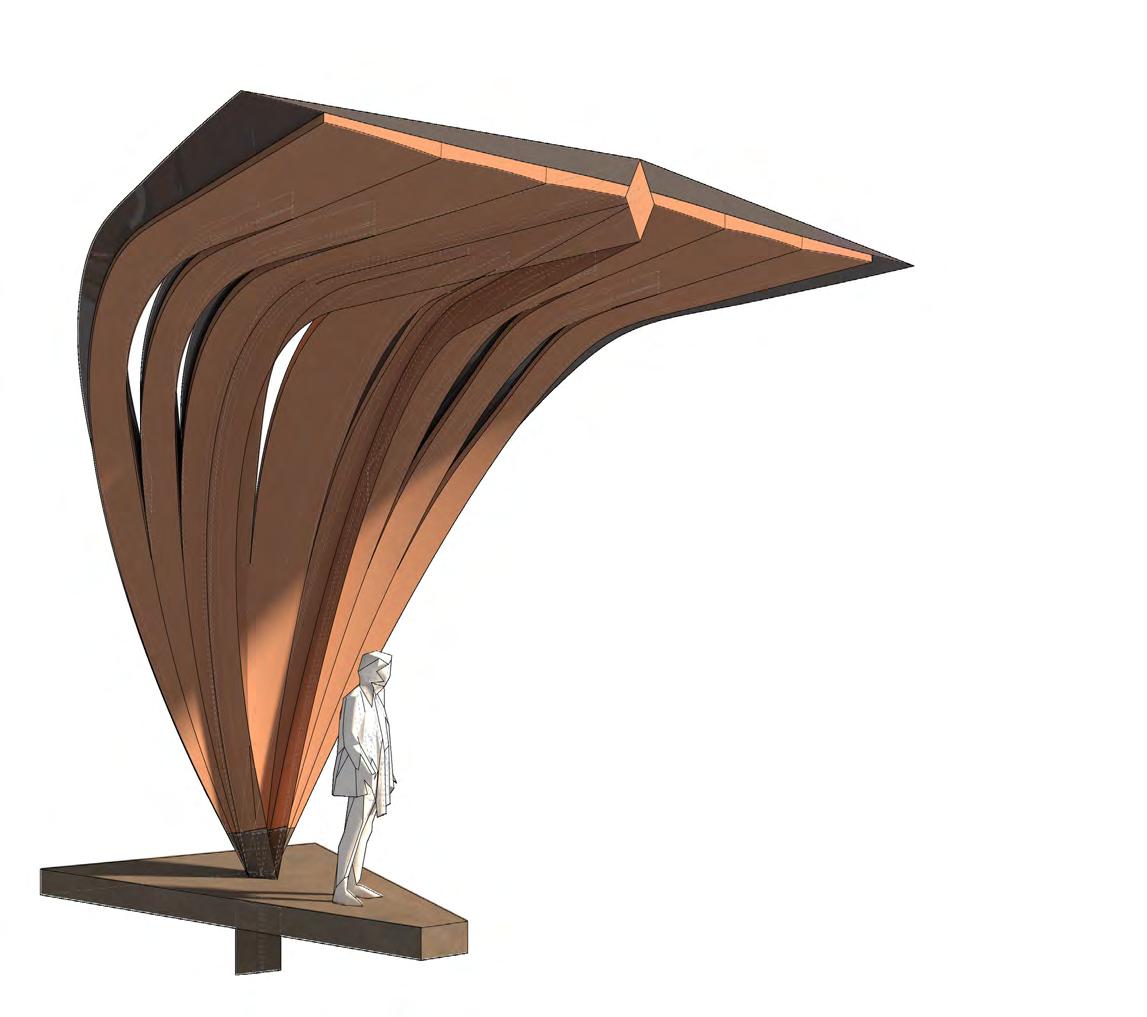

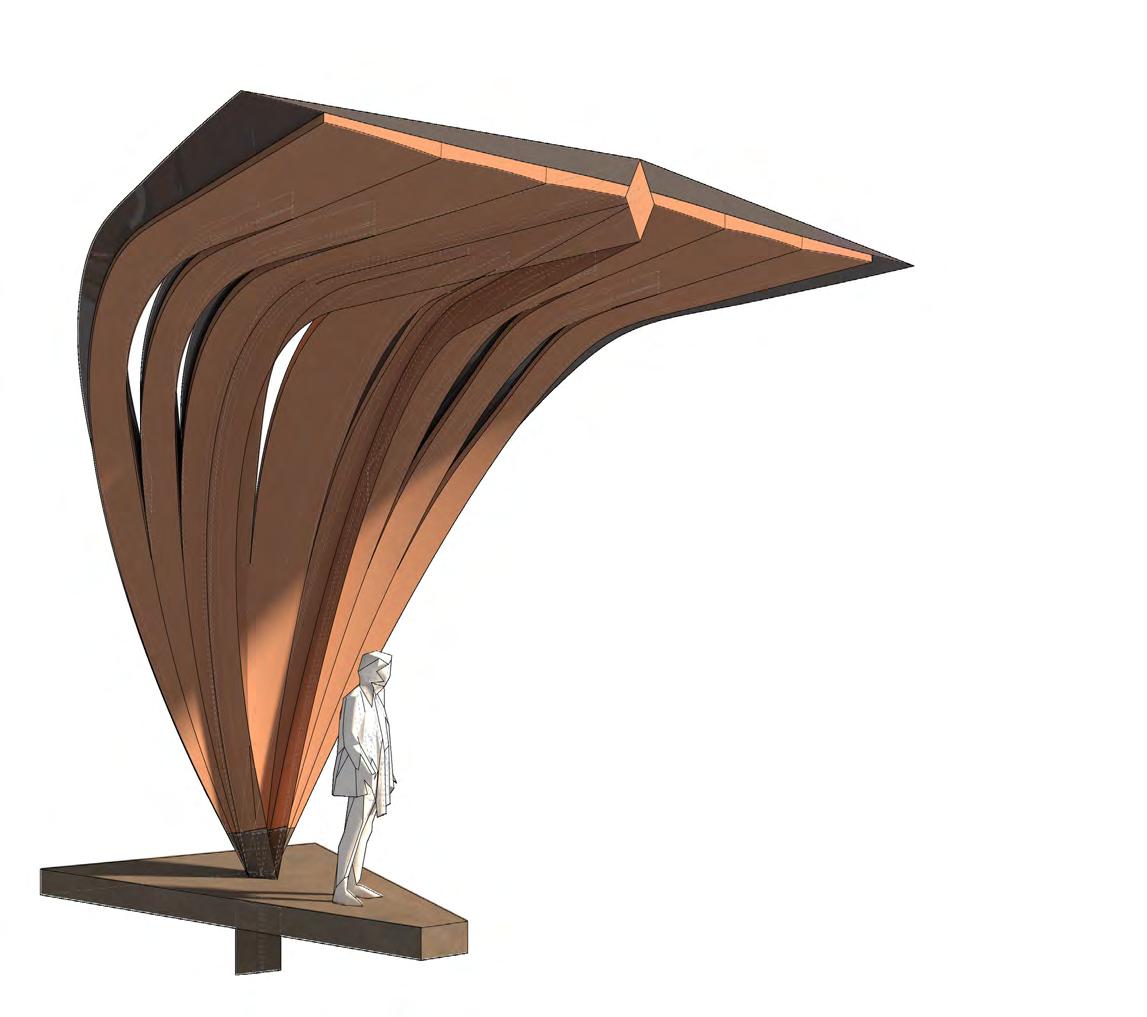

Variation 04 - Surface pleating to create structural depth, targetted incisions allow for surfaces to move apart offering spatial opportunities

1. Members develop from surface to strengthen at strategic points

2. Pleated surface made up of laminated boards

1. Incisions in surface lamination create architectural opportunity for stair

2. Varying cross section through targetted placement of more material onto master surface

Surface / Member Studies 01: Column to Surface Transitions from column to surface are imagined in different degrees of surface logic dominance vs member dominance. A continuous logic in the timber structure is present in all.

10 11

Variation 03 - Stepped variation in surface lamination

1.

1.

2.

2.

Variation 01 - Collumn to surface - Folding at apertures

Variation 02 - Member fins strengthen pleated surface at strategic points

1.

1.

2.

2.

3.

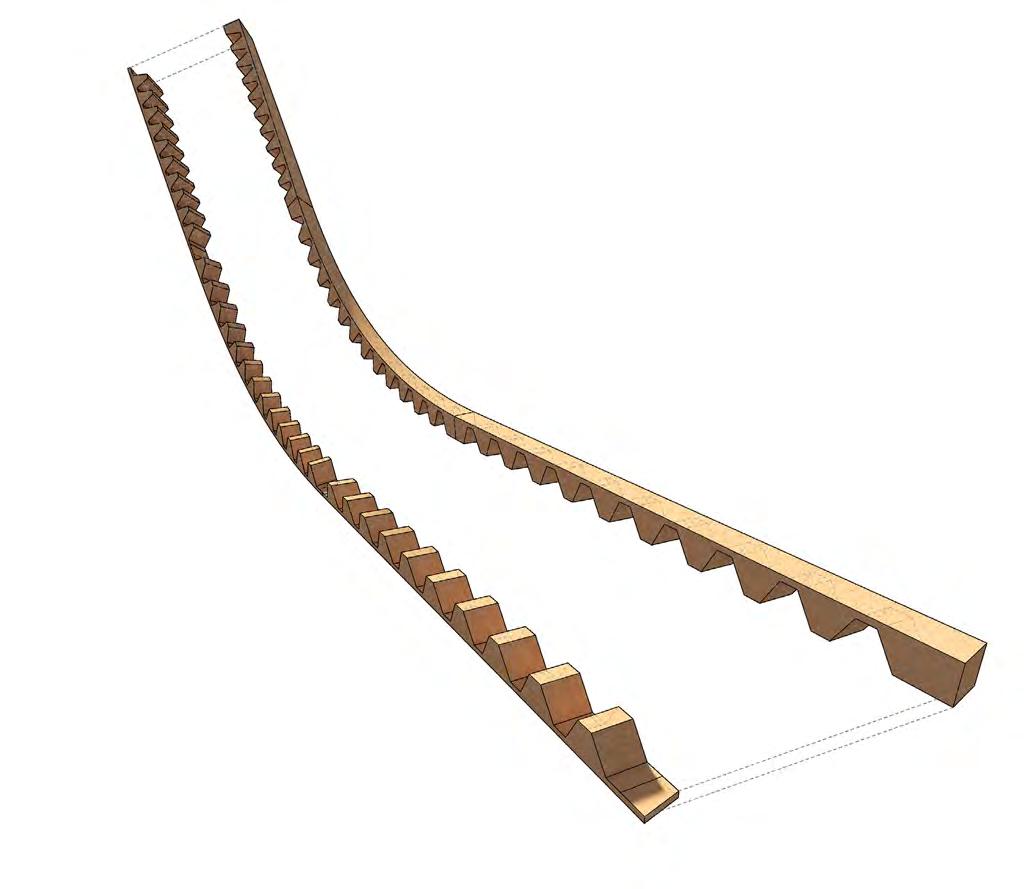

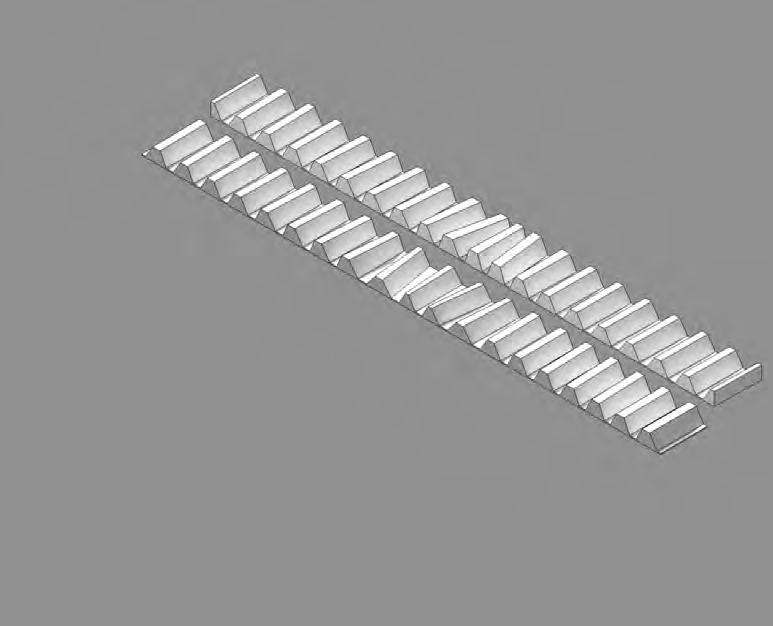

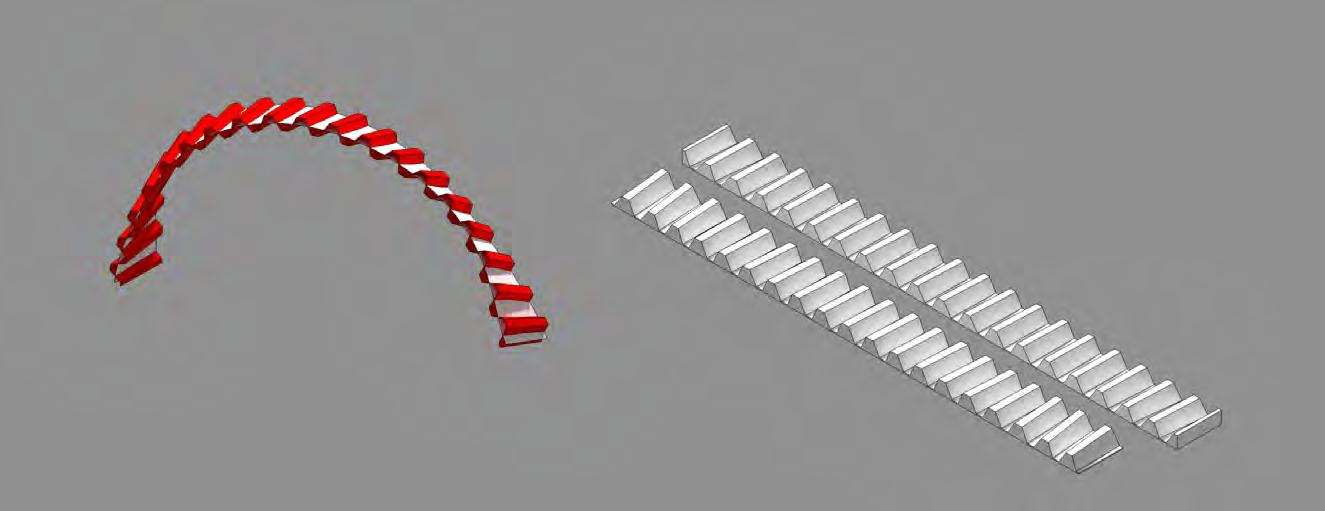

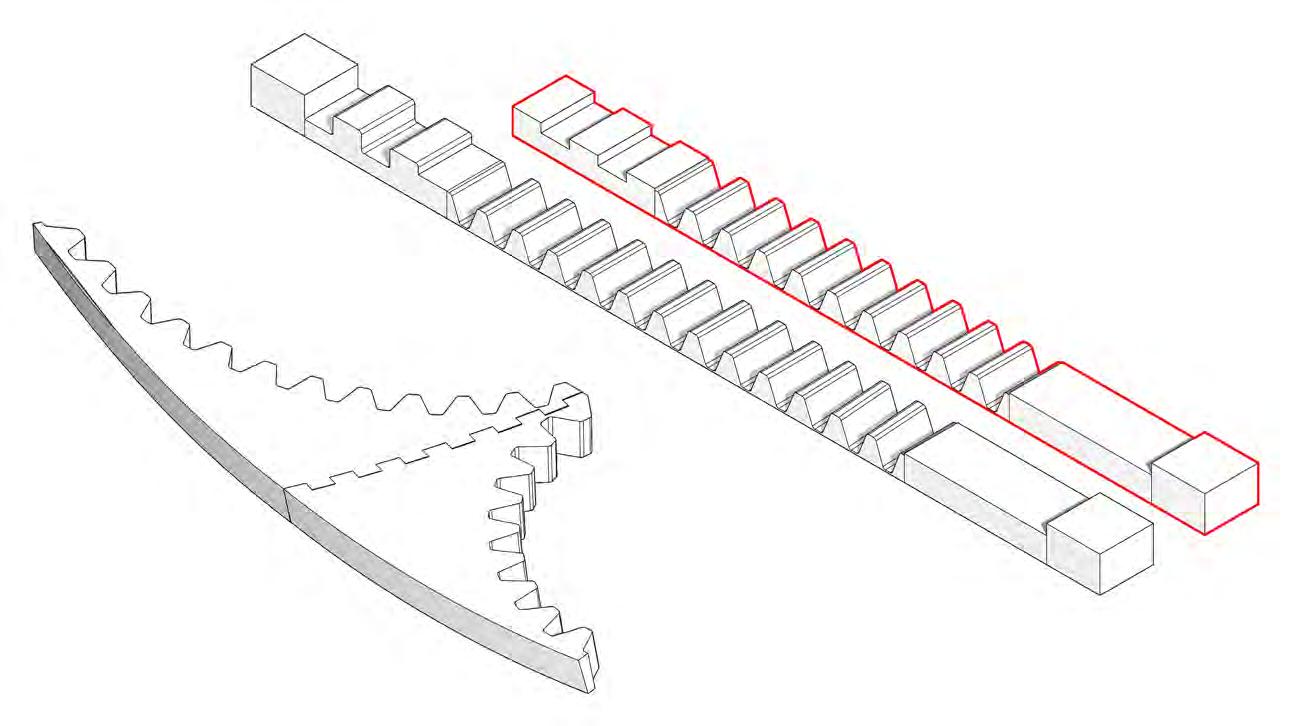

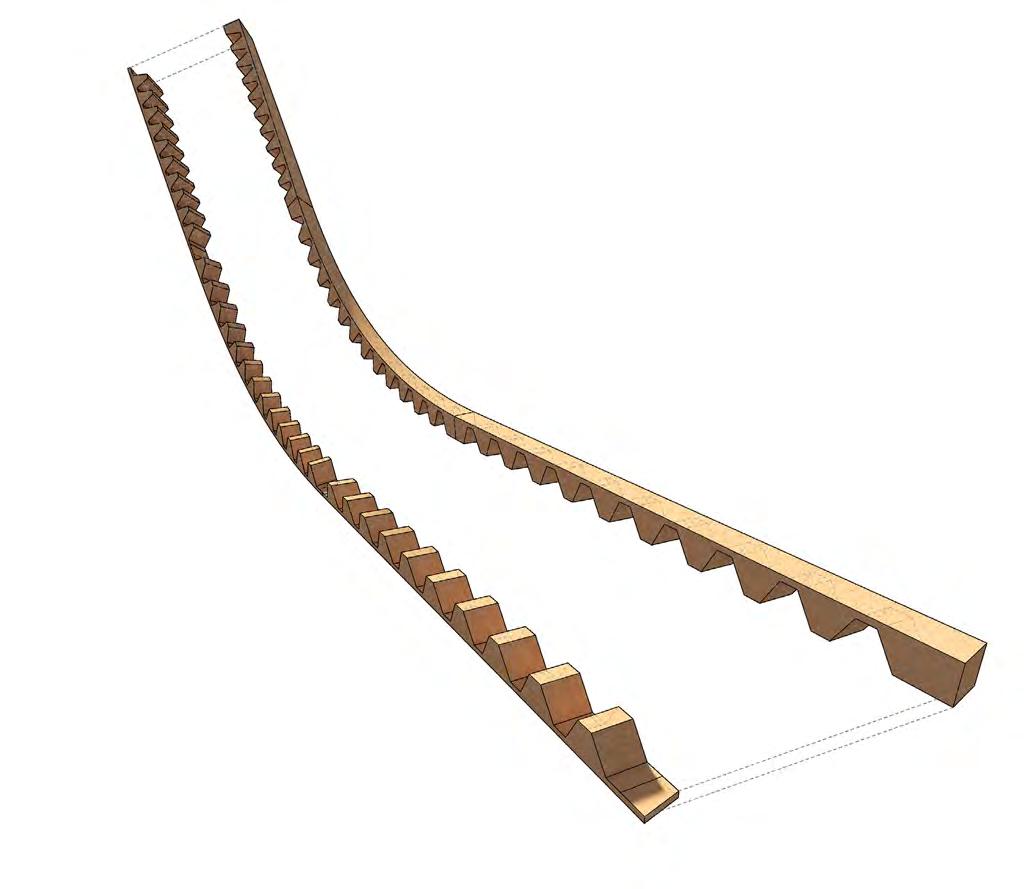

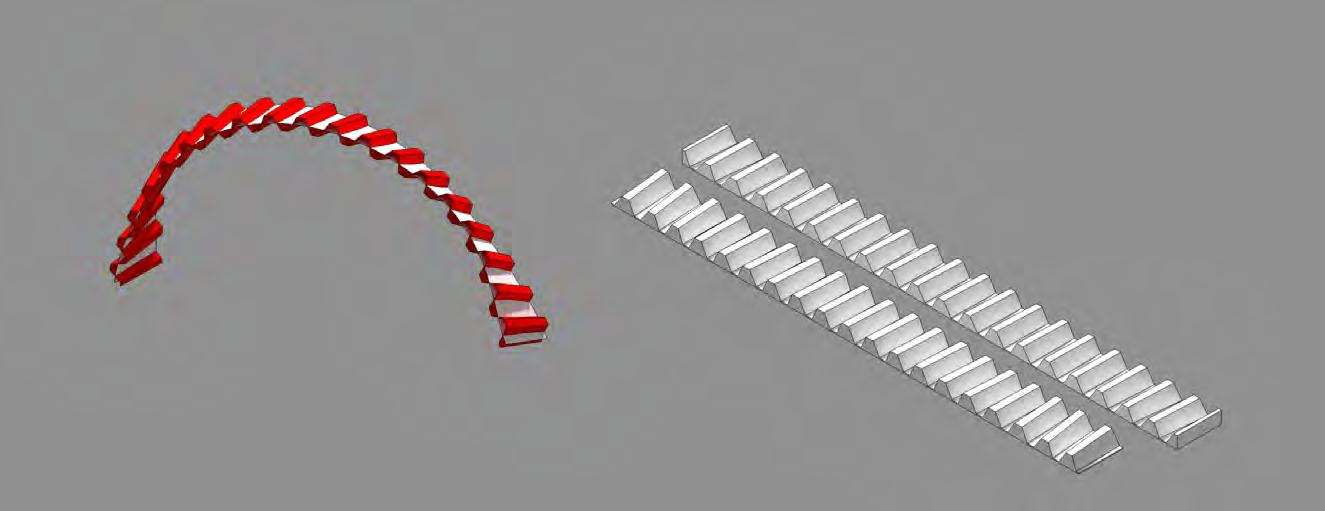

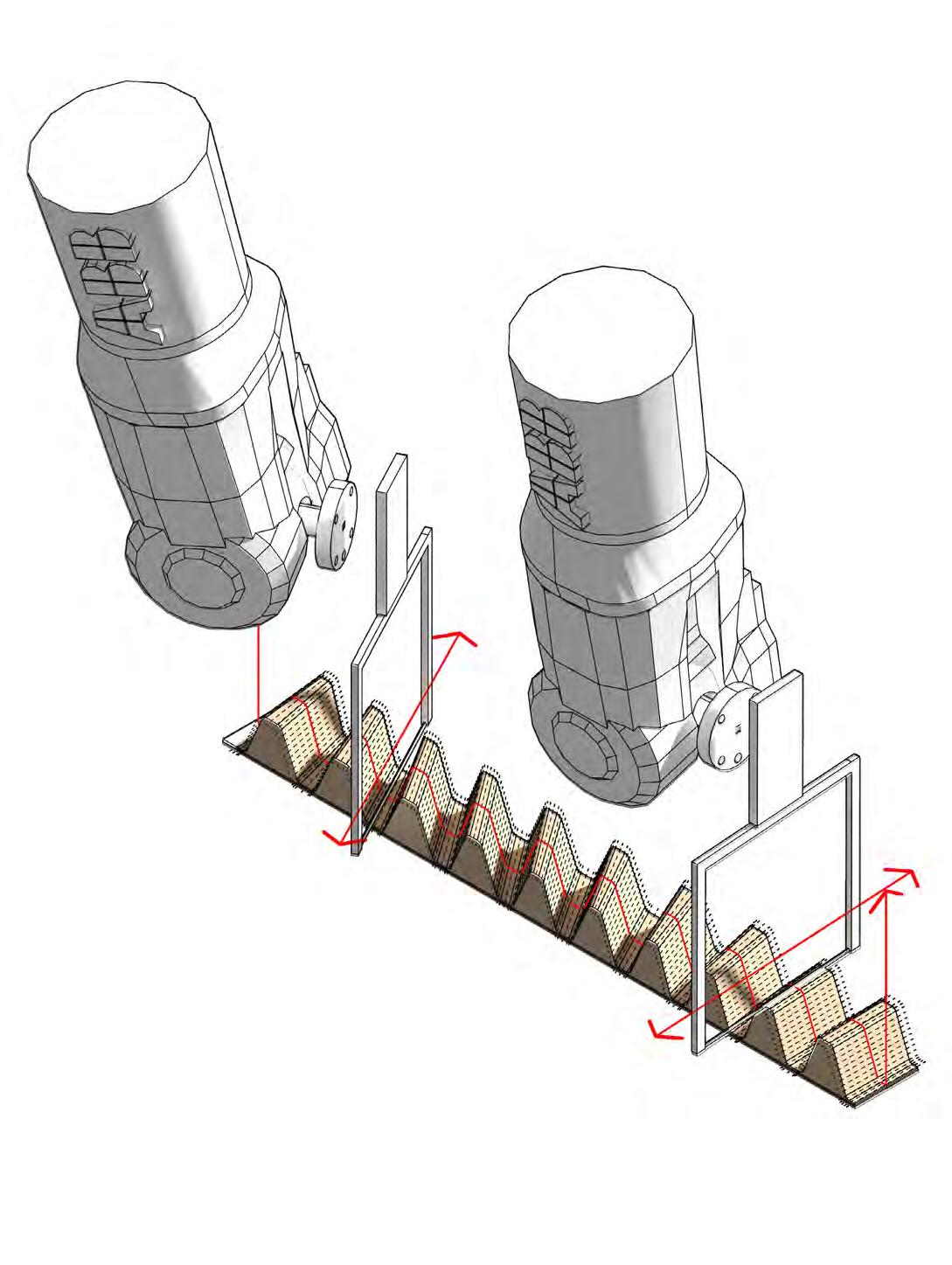

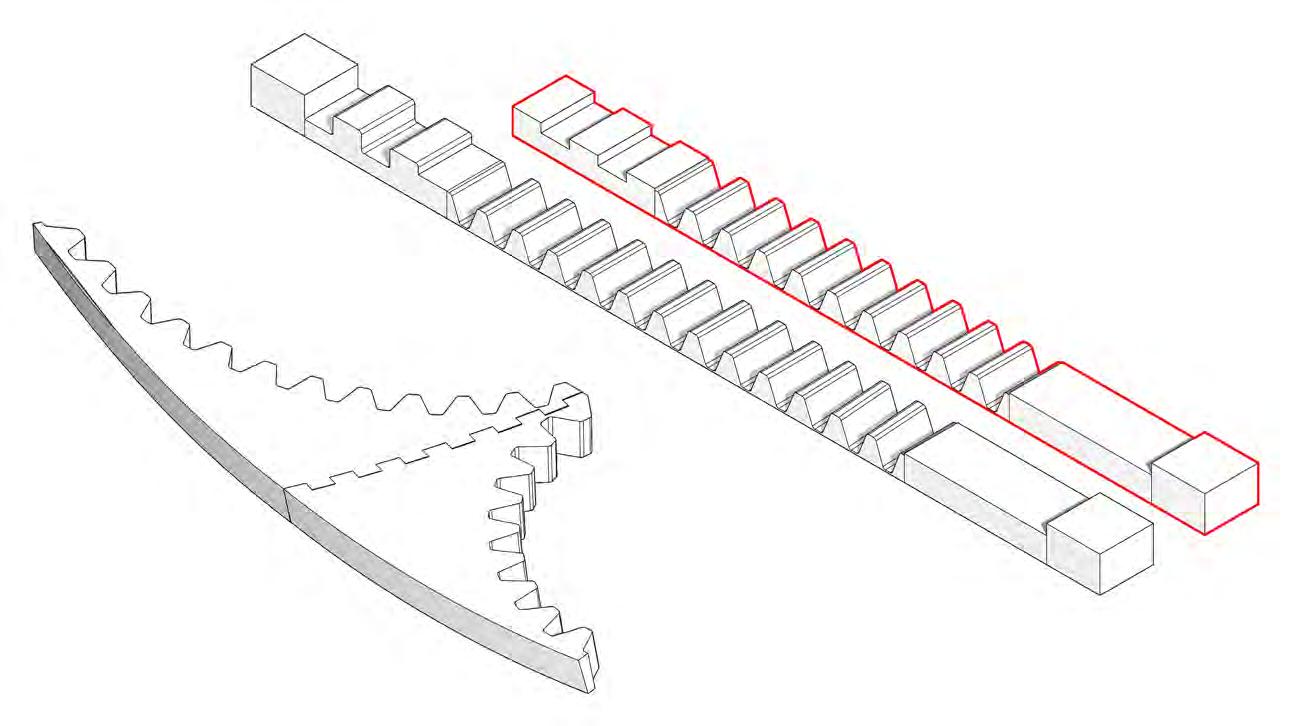

Kerfing Systemics - Kerfing can enable the forming of complex curvature and tortion, defined through cut spacing and angle.

Zippering Systemics - Zippering marries an opposite kerfed member to another creating form stability for structural applicaitons

Kerfing and Zippering: Targetted Material Weakening Targetted incisions at the member scale can enable tight bends, allowing for the production of high curvature without the need for veneer lamination. Processes by which targetted weakening can be achieved are called kerfing and zippering. Zippering allows for form stabilising while maintaining bends. Introducing this process at key moments could be a good contrast to moments in the structure where high continuity is required.

12

Complex kerfing (A Menges, 2010)

13

Fragment 01: Zippered Beam to Surface: grain continuity vs splitting The anisotropic qualities of timber can be harnessed through highly targetted moments of grain splitting (kerfing and zippering) vs grain continuity (formed lamination)

Curved Glulam Fabrication Procedure

Lamellae machined from raw timber

Twisted Lamination: Adding tortion to a glulam blank adds some fabrication complexity but could also be employed on single curved elements to add complexity with reduced steps

Existing optimisation approach for generic beam

compression

neutral axis

High grade timber in areas of higher stress/ strain

Hooke Park Training Centre by ABK, Buro Happold, Frei Otto in Dorset, England

Glulam Systemics 01: Fabrication Procedure

The project speculates on the application of singly and doubly-curved laminated timber elements, forming the nodal conditions within a volumetric frame structure. It looks to intersect and develop the existing procedures for curved glulam fabrication outlined above.

14

Existing Glulam Typologies

INVCREASED FABRICATION COMPLEXITY

tension Straight

Glulam Blank

Single Curvature Double Curvature

Finished component machined within blank

Lower grade timber (juvenile timber or greater knot density) in areas of lower stress/strain toward neutral axis

2 or 3 axis gluing on reconfigurable press Robotic mill shaping

Lamellae machined from raw timber

Typical Blank Types

A1. Straight blank for straight component

Glulam Blank Finished component machined within blank

A2. Finger jointed blanks for single curvature component

A3. Finger jointed blanks for double curvature component

Non-curved / Jointed Blanks

Single Curvature Blanks

B1. Single curvature blank for single curvature component

B2. Single curvature blank with integrated tortion

B3. Single curvature blank for double curvature component

Double Curvature Blanks

C1. Double curvature blank for double curvature component

C2. Double curvature blank with integrated twist

Hooke Park Training Centre

Glulam Systemics: Glulam Blank Types

Lower Grain allignment/continuity but faster fabrication time

Good grain allignment but limited formal complexity to single curvature

Good grain allignment but very limited formal complexity

Good grain allignment/continuity but complex fabrication procedure

Forming blanks can be a multi-stage procedure: when forming blanks with integrated tortion, for example (Svilans, 2020). Most industry standard methods sacrifice grain continuity and create a greater amount of waste. My project proposes a targeted application of high curvature limited to connection points, with the majority of the building being composed of straight, easily fabricated parts. Grain continuity is prioritised due to its structural benefits.

15

by ABK, Buro Happold, Frei Otto in Dorset, England

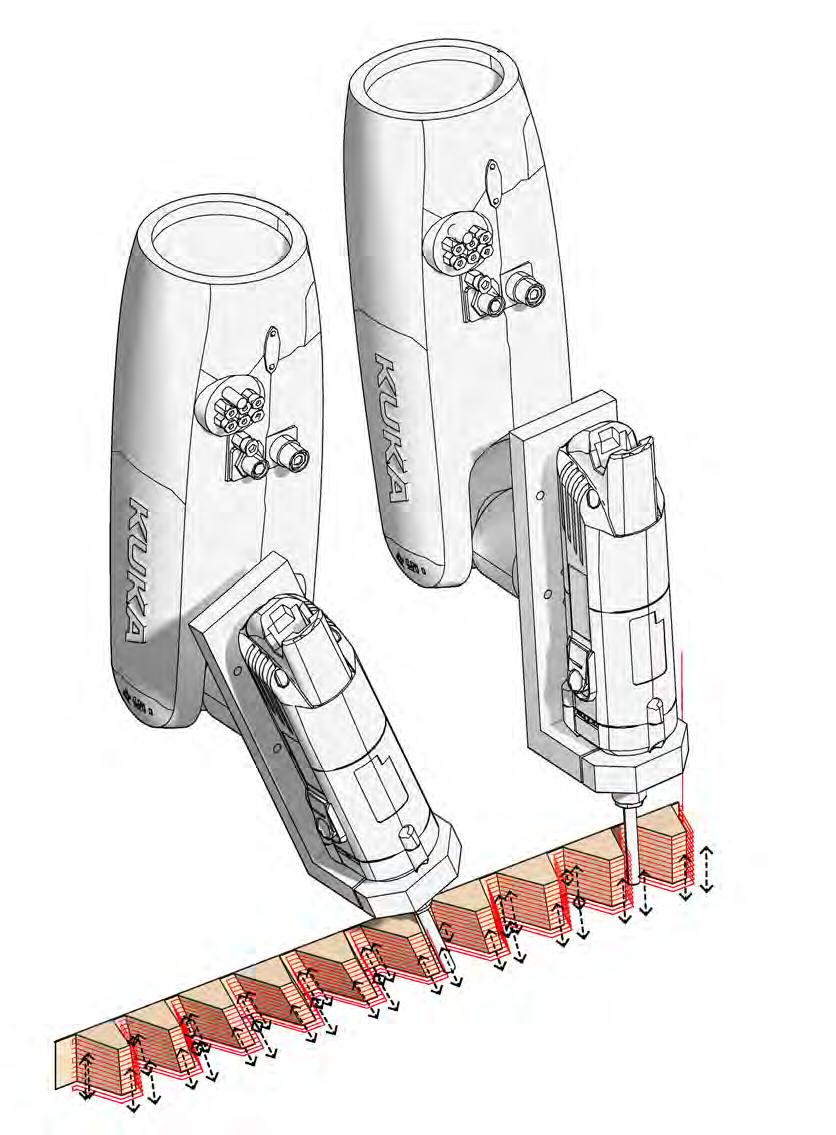

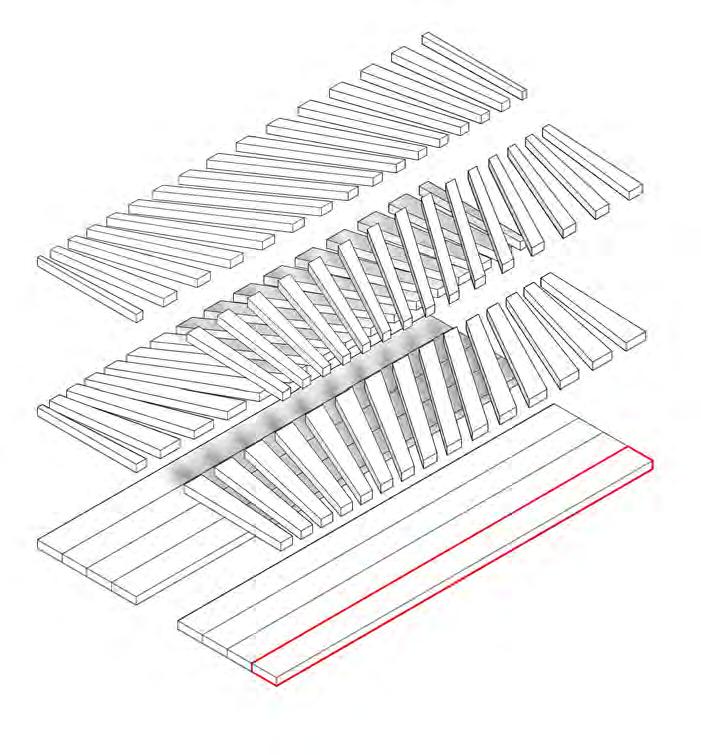

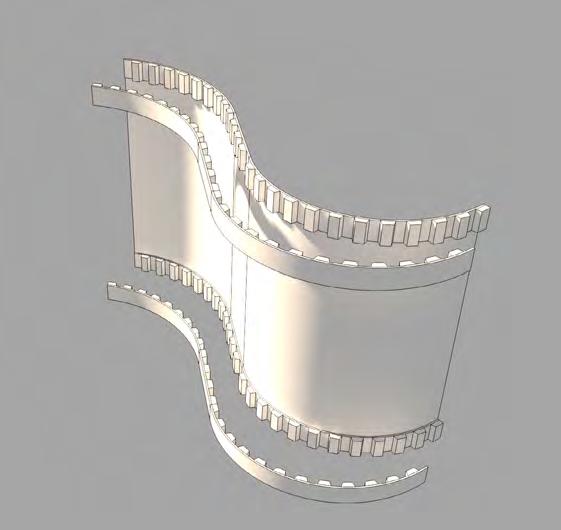

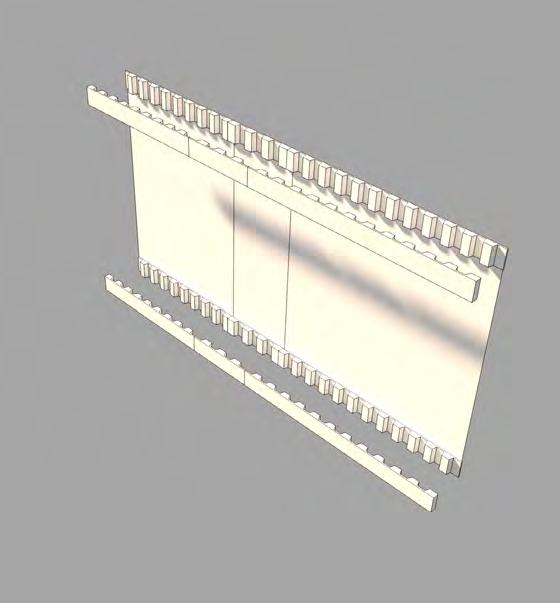

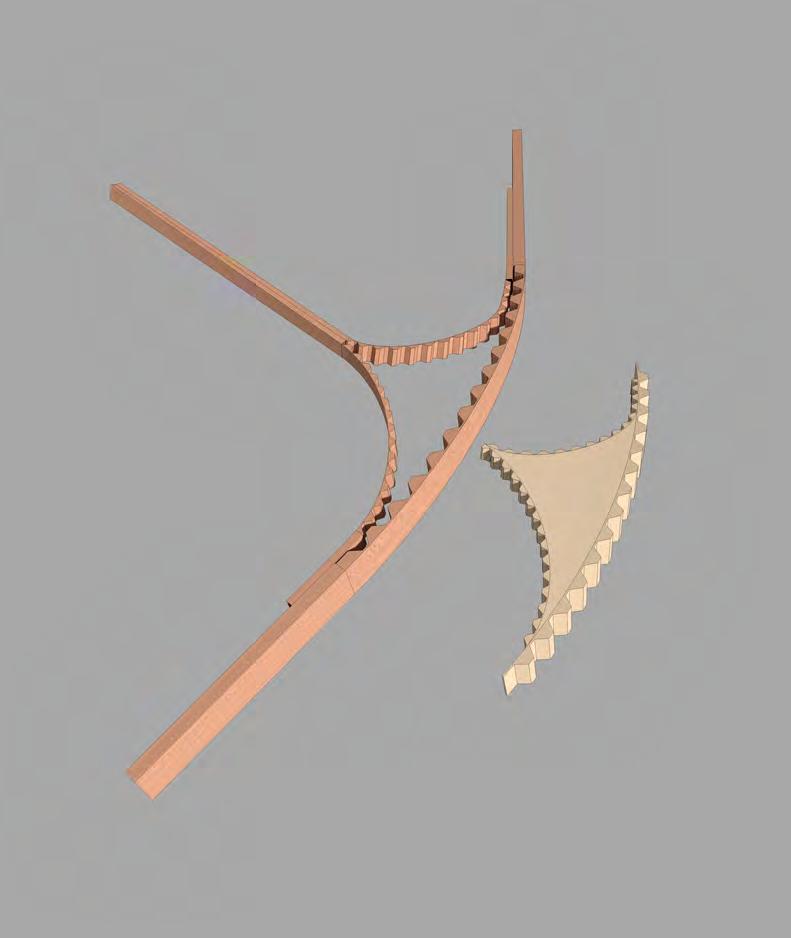

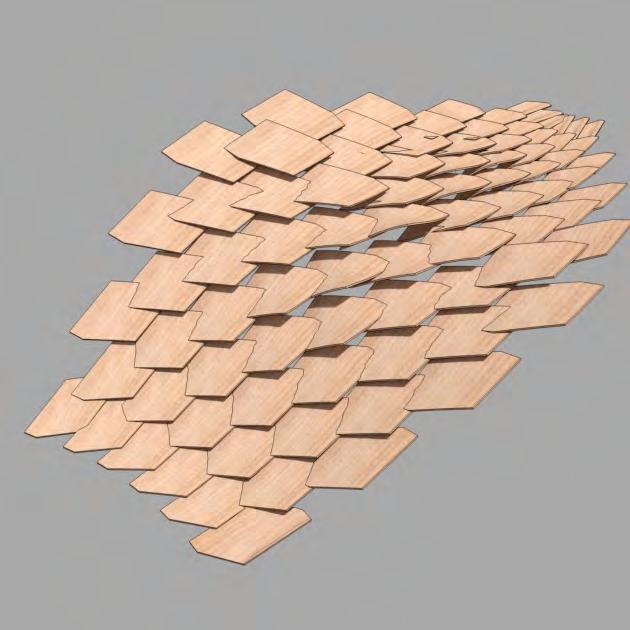

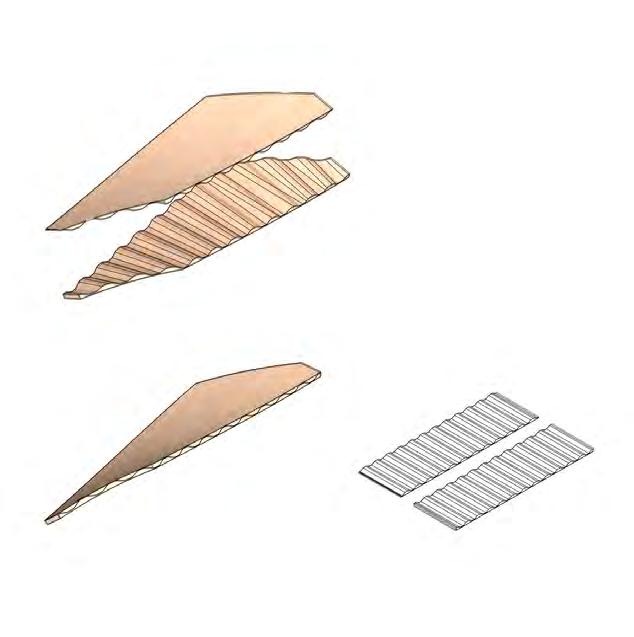

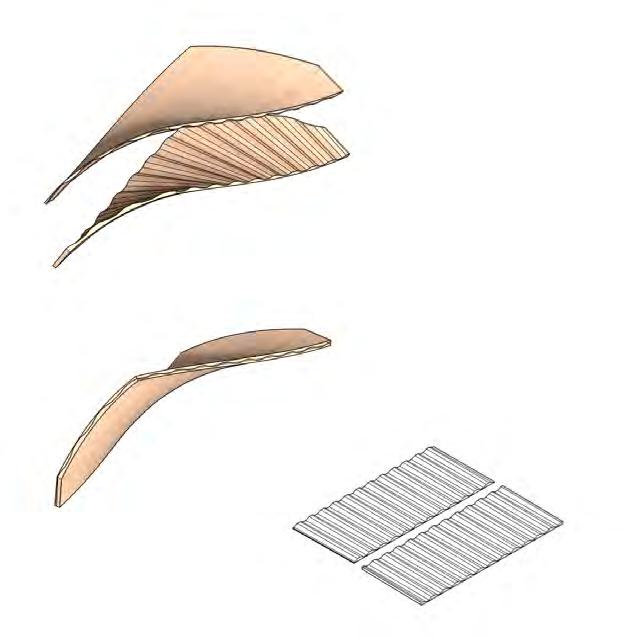

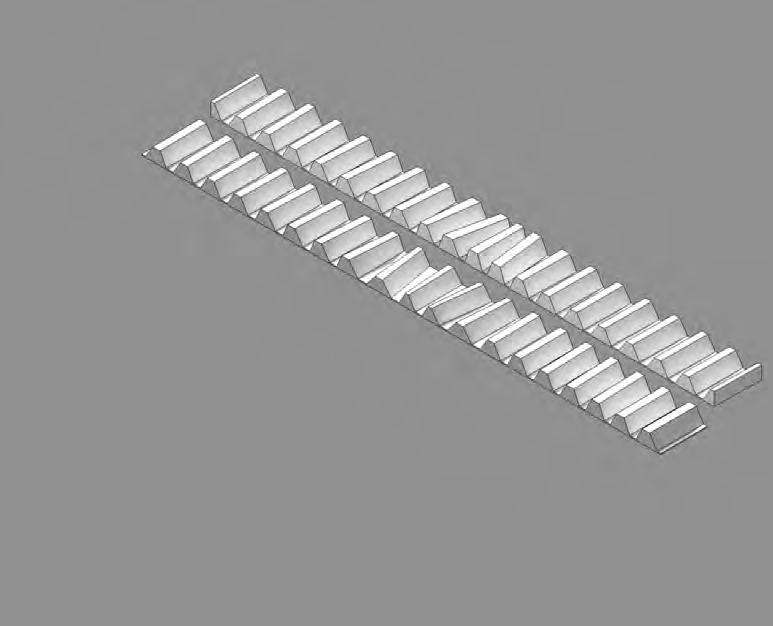

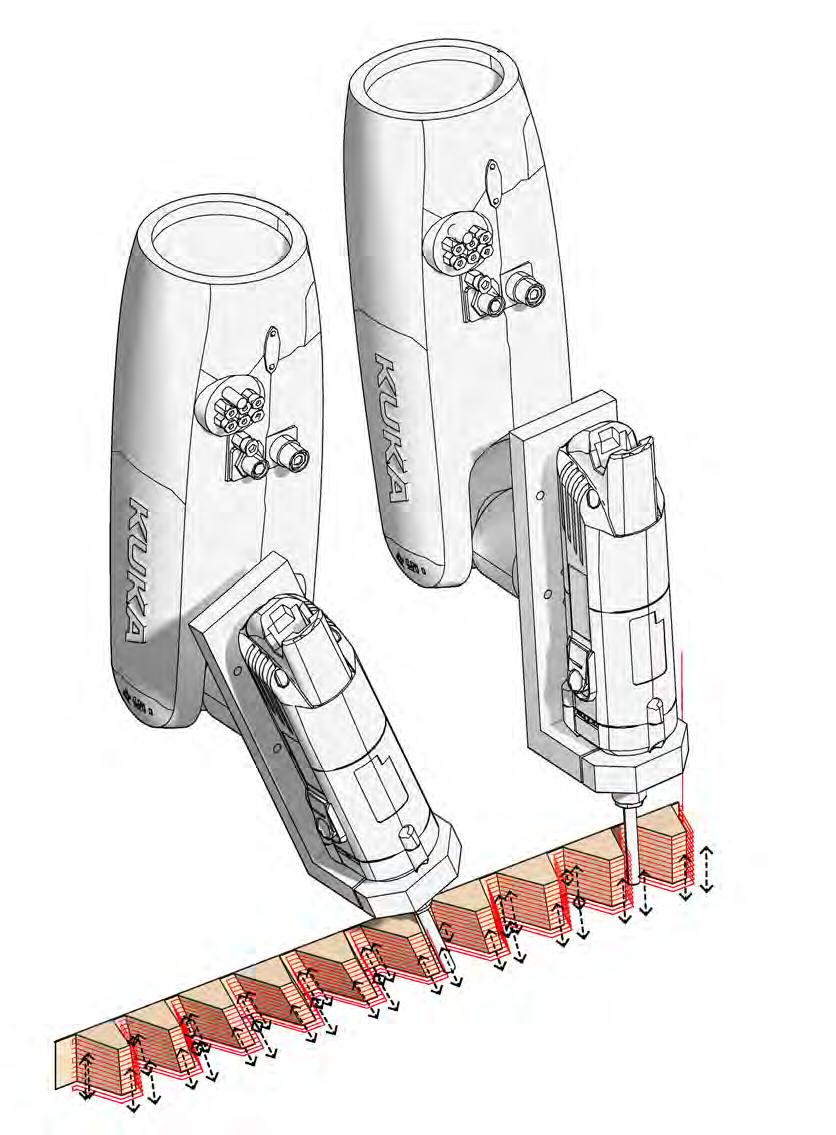

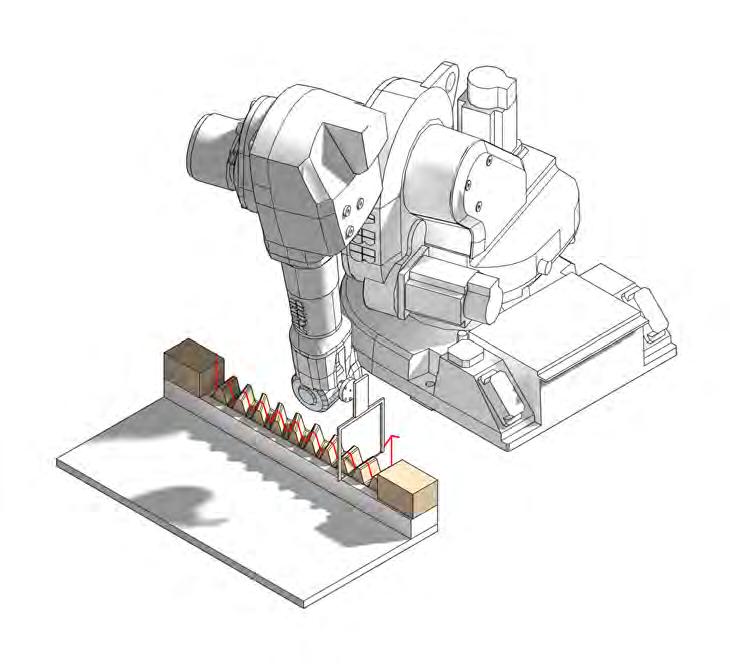

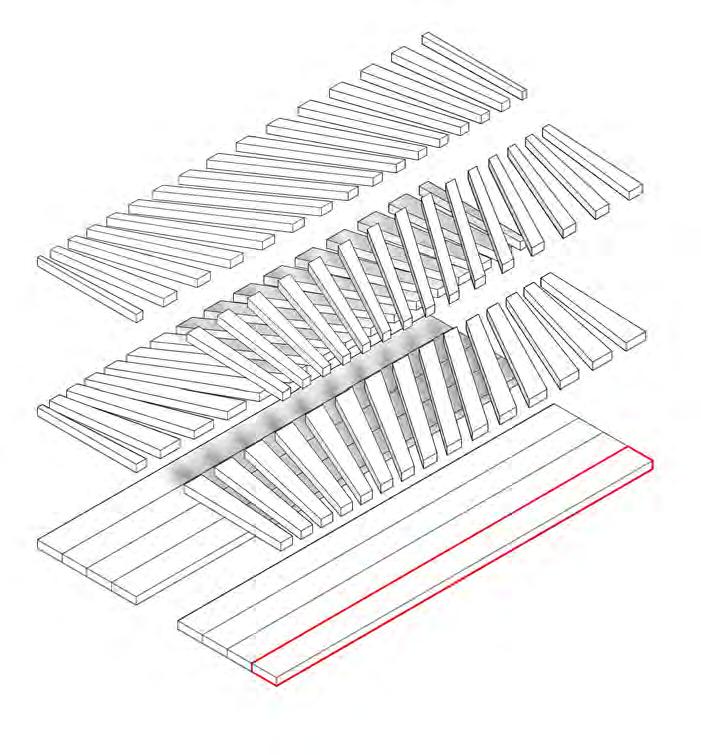

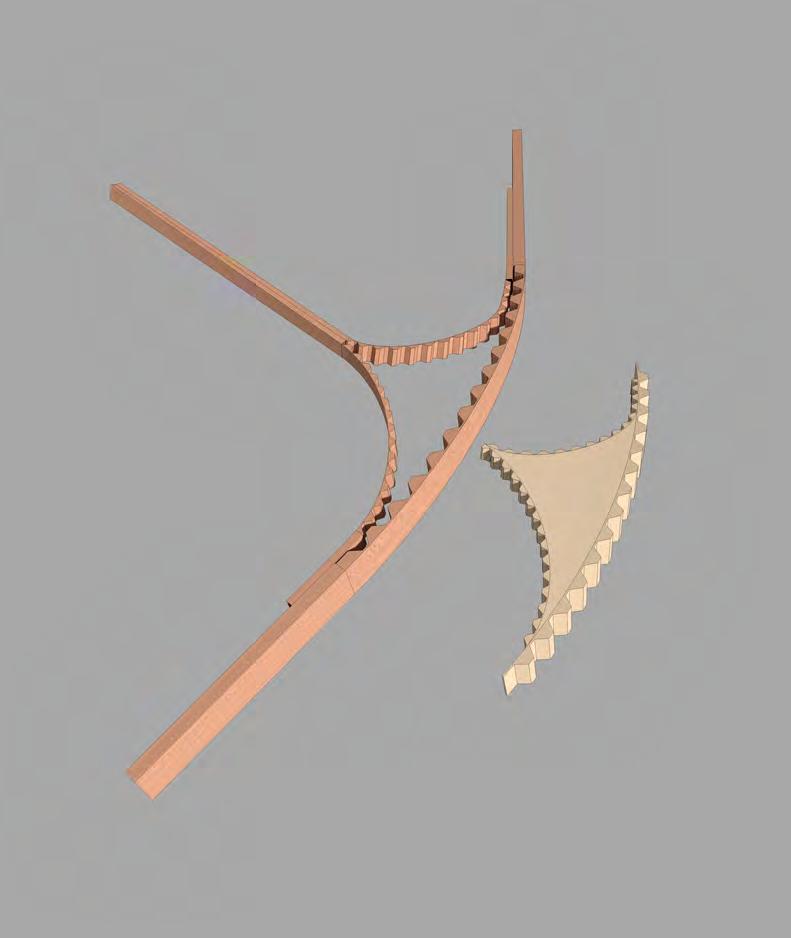

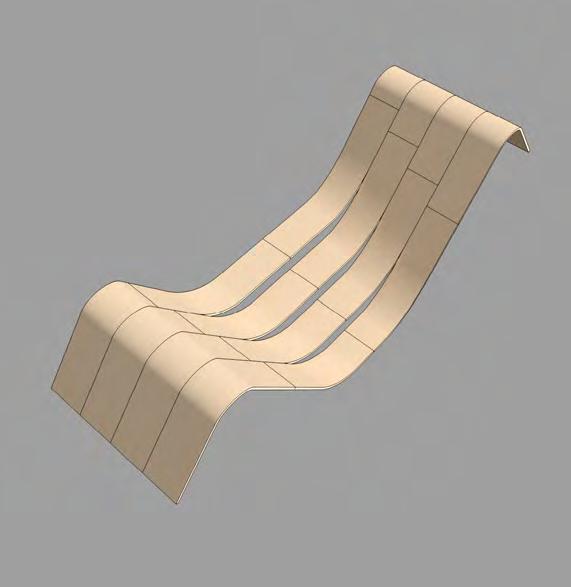

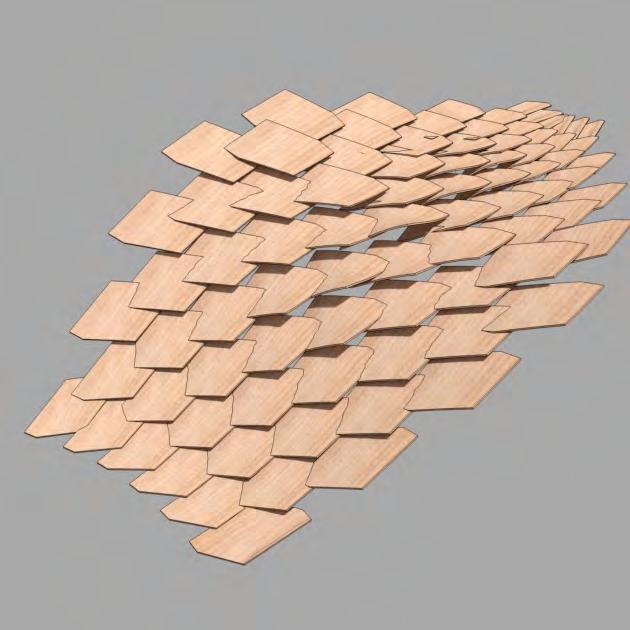

Prototyping Driven Research: Zippered Taxonomy

Initial prototyping tests allow me to explore the potentials of the zippering procedure to create curvature. These were developed through the use of different CNC technologies and scripting approaches, allowing for the creation of a number of different forms and assemblies using the zippering method.

16

1. 2. 3. 4.

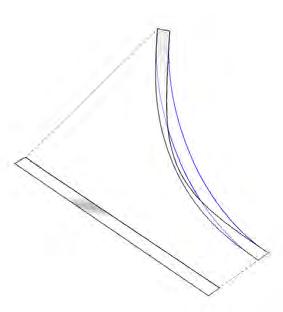

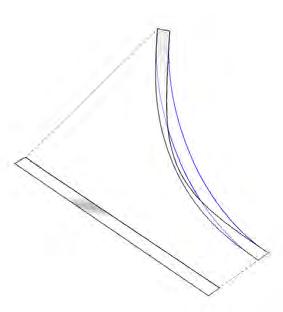

Generation of desired ruled surface, developable to a flat, straight strip (Kangaroo)

Generation of zippered teeth in curved form

Unrolling of zippered teeth to planar surface for fabrication

CNC tool path generated to machine self forming geometry

Form Generation through Scripting

A tailored method for generating the zipper forms was developed, enabling prototype testing and informing an architectural language appropriate to the possibilities and limits of zippering.

17

input curves define shape and torsion

unrolled geometry

zipper in curved form

zipper in curved form

input curves define shape and torsion

input curves define shape and torsion

unrolled geometry

shifting of rulings enables good twisting of component

zipper in curved form

Scripting Approaches

These tailored methods were developed into a two part approach: the first employing Kangaroo to generate a developable ruled surface, the second

unrolled geometry

18

Ruled surface Zipper generation: script developed

1. input member/ surface with overbending depending on material elasticity

2. kangaroo relaxation applied to generate closest straight developable surface

3. surface ruling generated through kangaroo

4. generate zippered toothing from surface ruling

5. zippered toothing plane measurement

6. zippered teeth are remapped onto planar surface using lengths

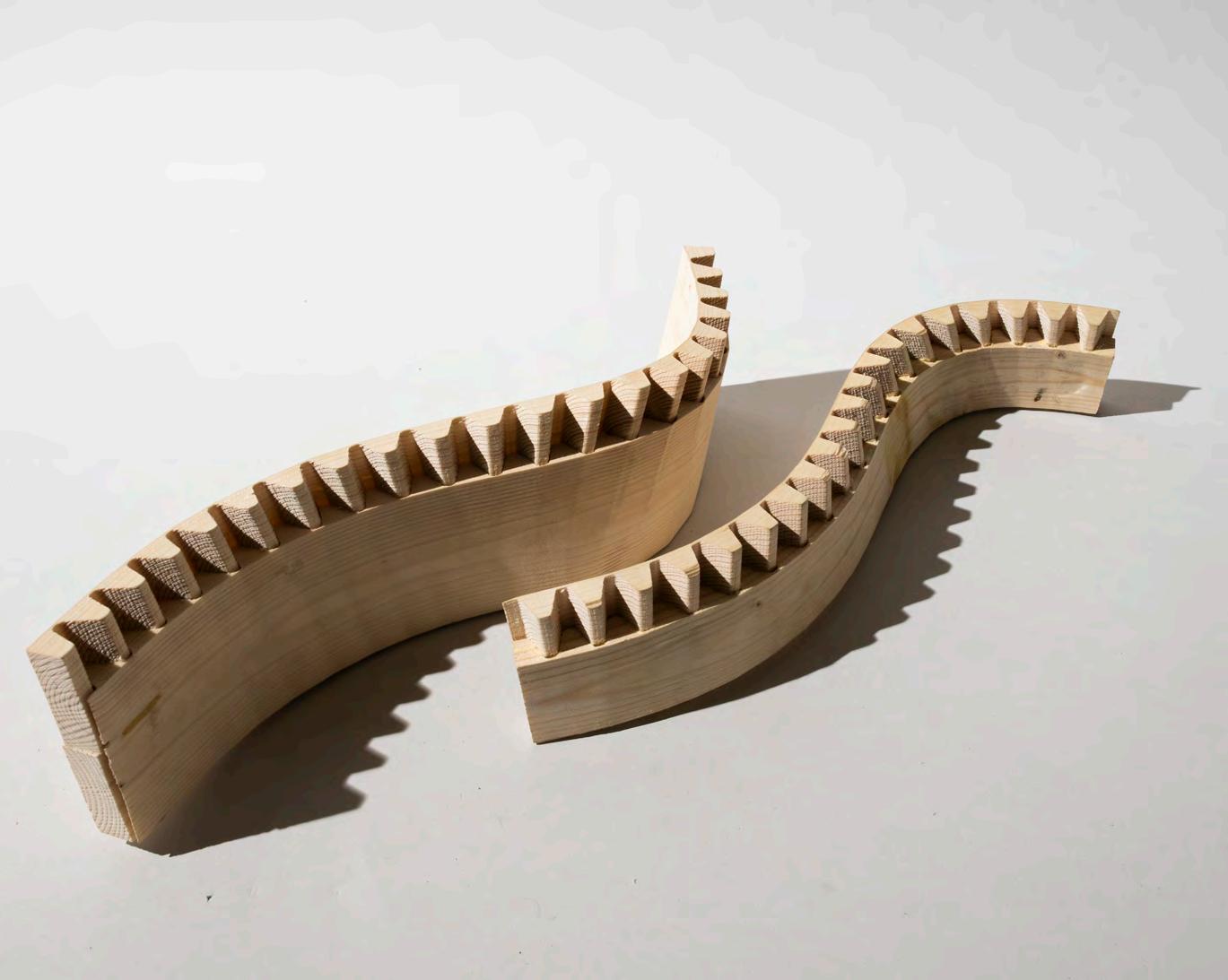

Physical Testing: Ruled Surface Zippers

Physical testing was used to refine and develop the results: here an initial test investigates the extent to which torsion can be achieved in the components.

19

Ruled surface Zipper generation: digital simulation

3. High twist, High bend

2. Minimal twist, medium bend

20

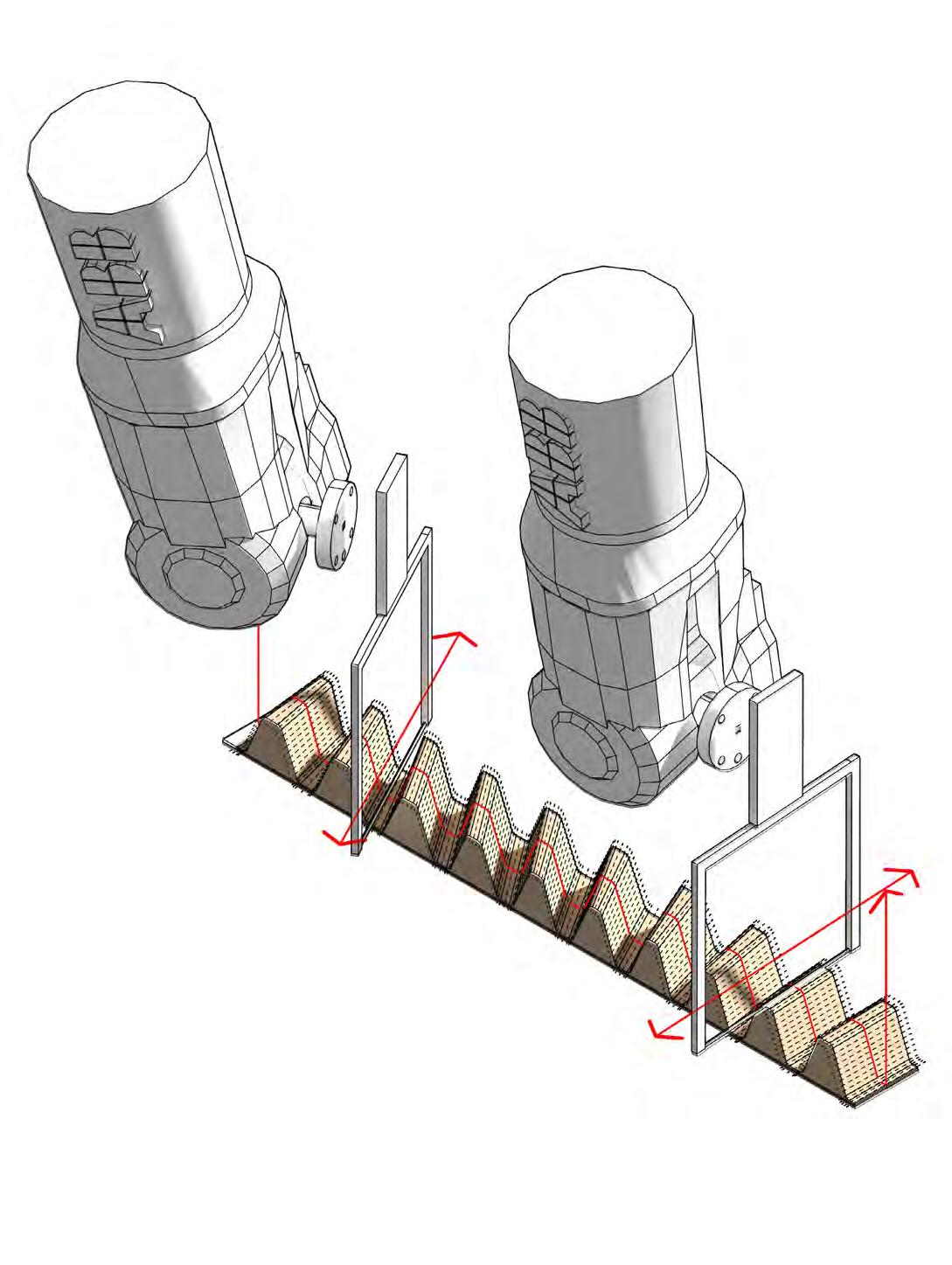

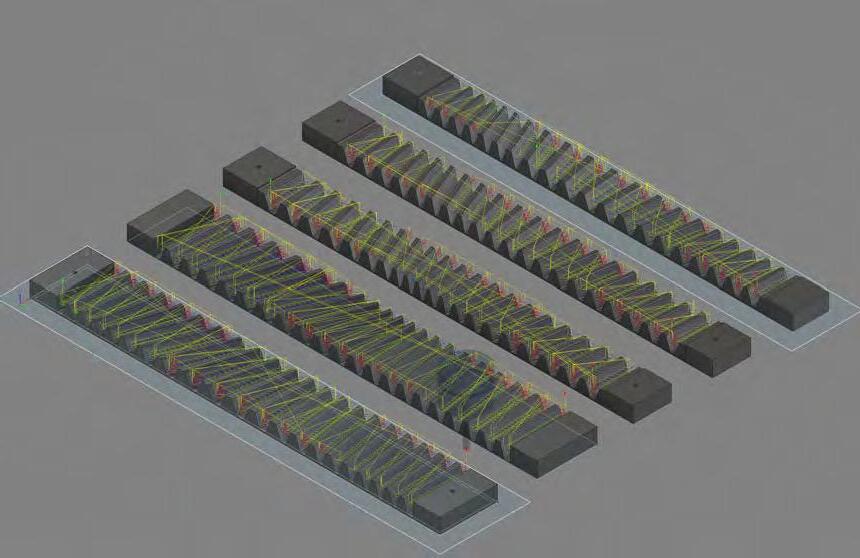

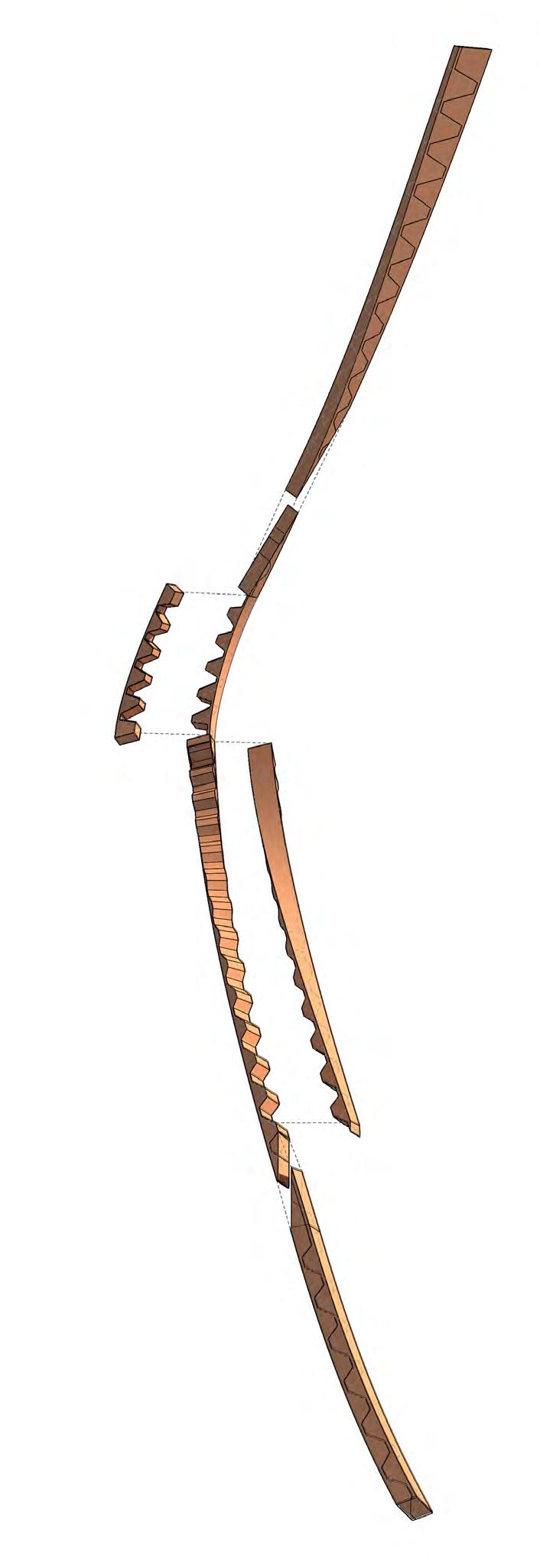

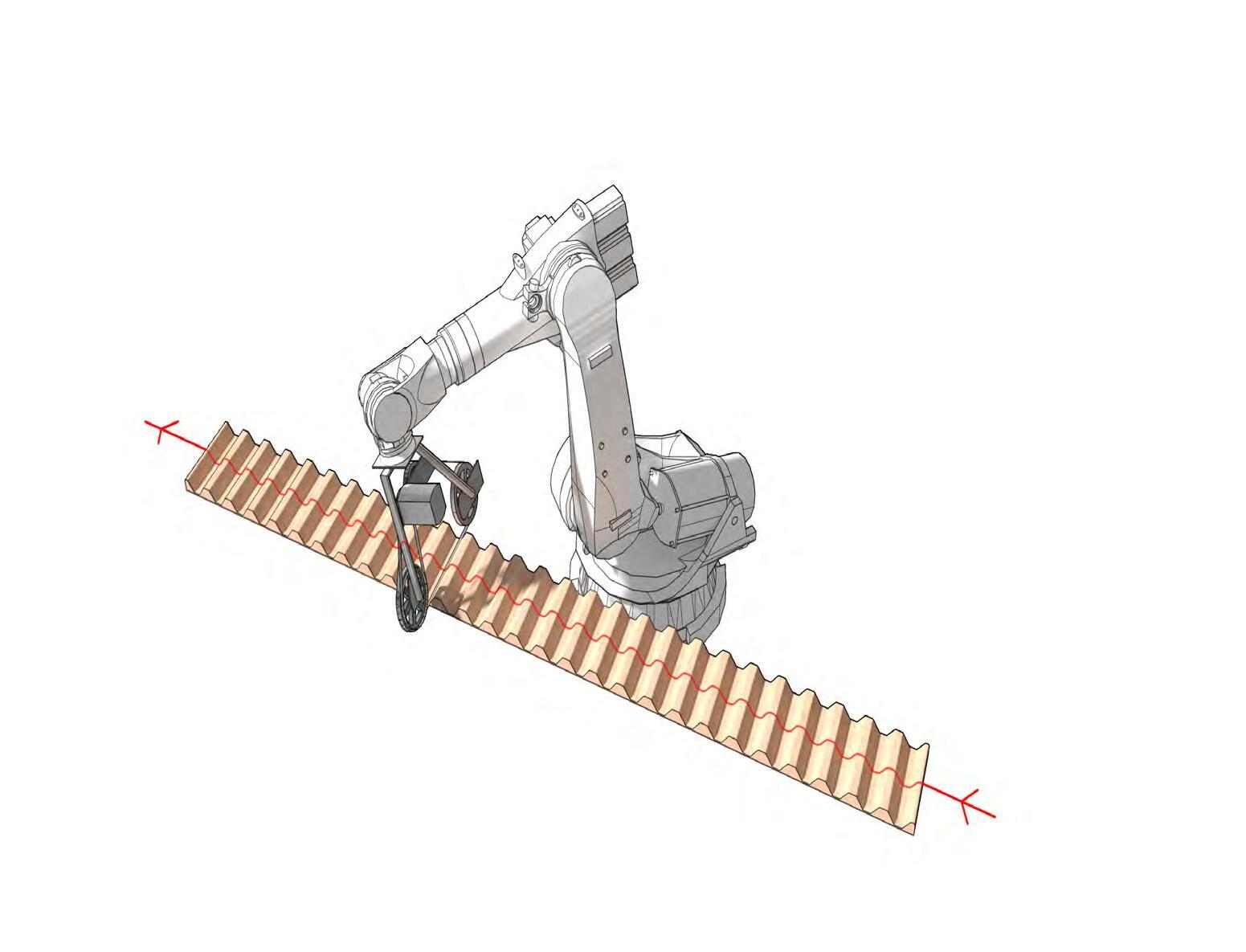

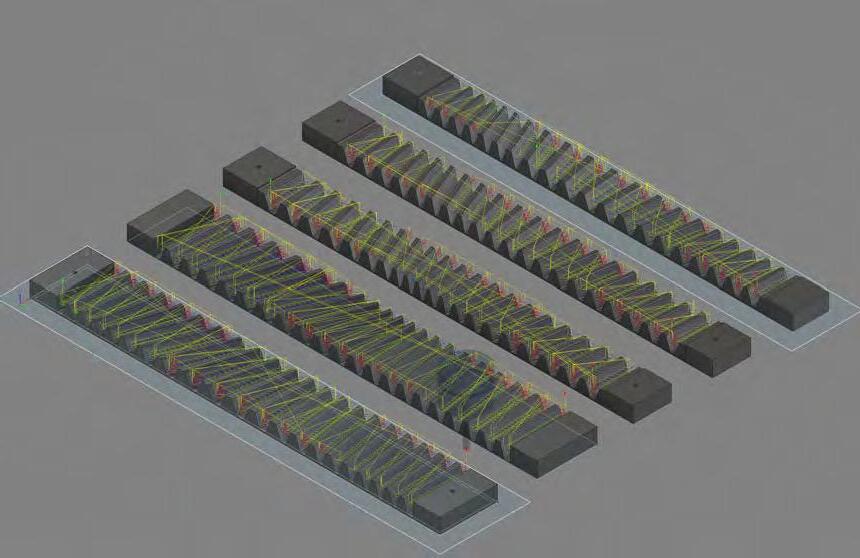

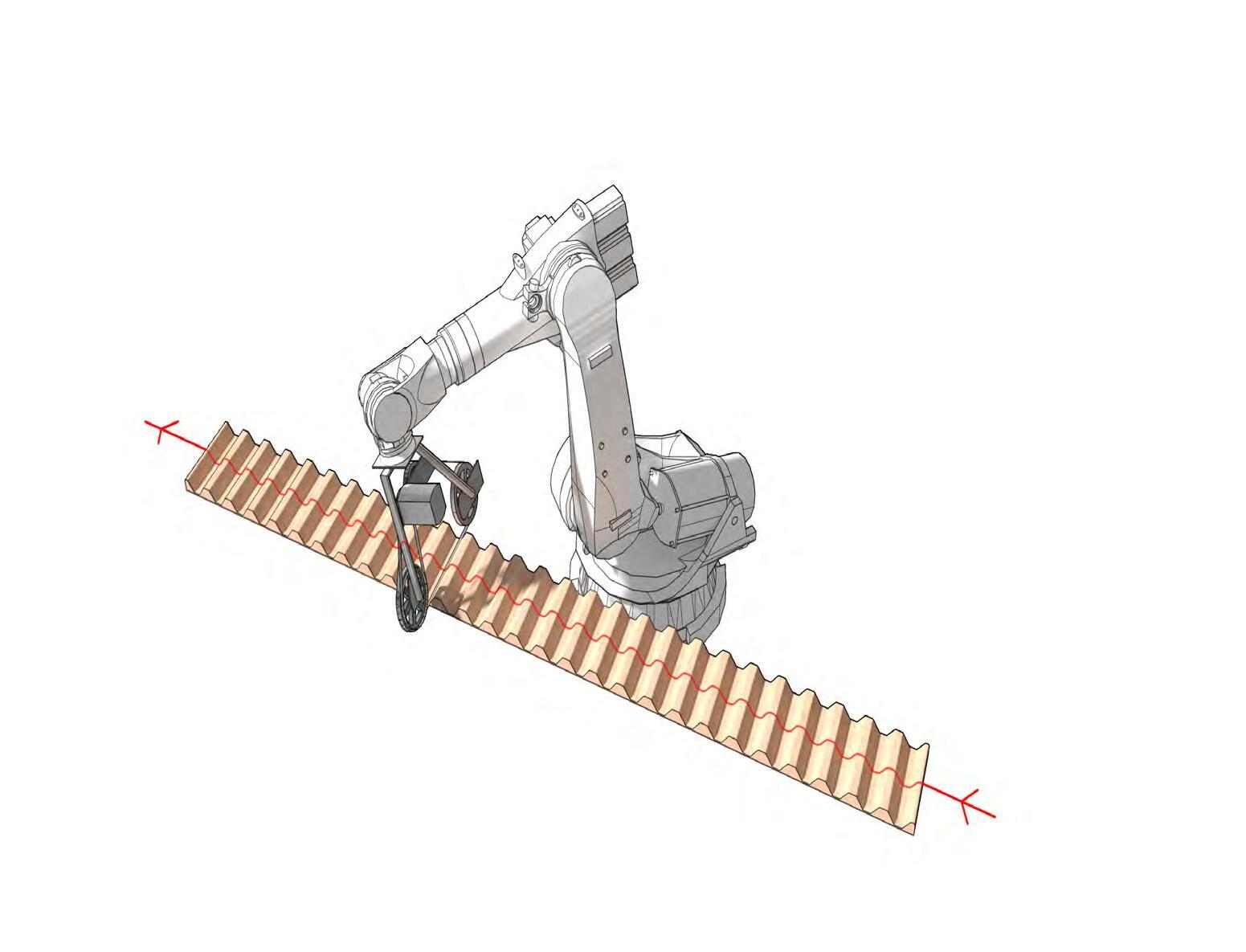

Milling with Reduced Waste 01: Side Milling

A 6-axis milling approach for producing the is tested where cutting from the side of the piece results in a far lower waste level than conventional milling from the top.

Toolpath makes good use of 6 axis movement of the industrial robot for efficient cutting Robotic milling approach result

Tool directionality is defined by zip teeth edges

2. Toolpath 2

1. Toolpath 1

Parts must be offset from oneanother to allow for the router diameter.

Sacrifical boards fixed to outer faces prevent tear out (can be reused)

21 Conventional (milling from the top) vs reduced waste method (milling from the side or with wirecutter or similar) waste comparison

Milling with Reduced Waste 01

≈50% waste ≈3% waste

The miling sequence is tested at 1:5 scale, producing two parts from a single piece.

Coping saw attachment is simply modelled and would need to be developed further to facilitate this research outside of this thesis

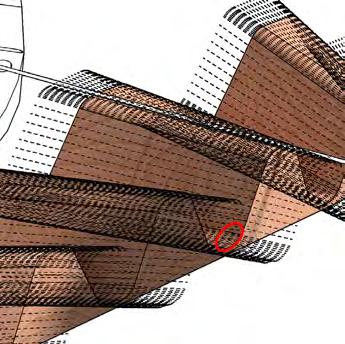

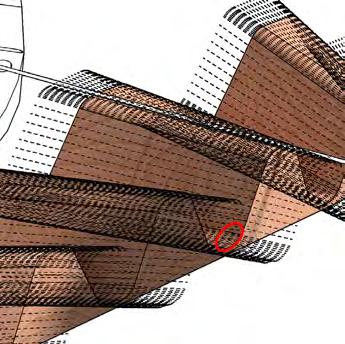

Milling with Reduced Waste 02: Wiresaw Cutting

A method for cutting with close to zero waste could be to use a wiresaw attachment, a preliminary test for which is simulated digitally here.

22

Toolpath plane alligment in accordance with rulings of zippered surface

Robot moves saw back and forth multiple times per a defined length to facilitate cutting

Toolpath plane alligment in accordance with rulings of zippered surface

Fillet radius at corners needs to be above minimum cutting radius

Only a small section of central to the member has good reach for the robot, allowing for extreme movement without collisions.

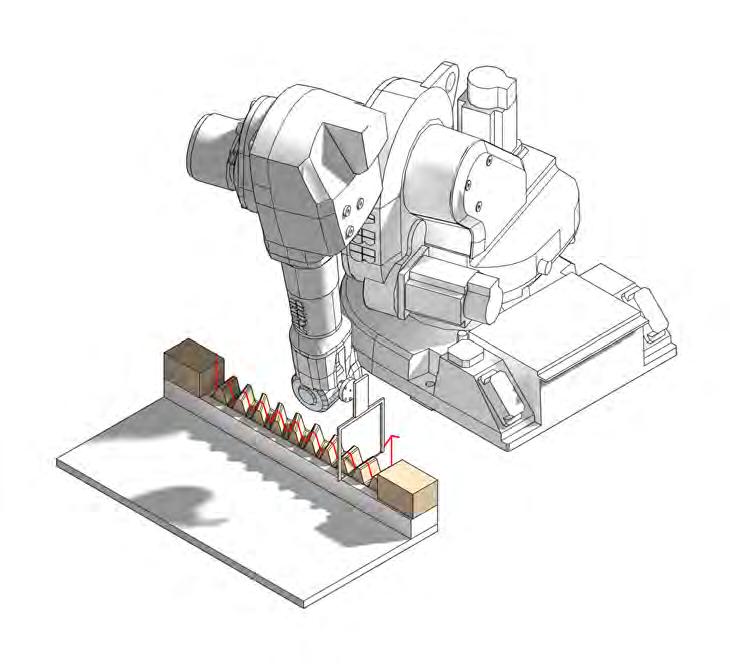

Fabrication Speculation: Bandsaw Cutting Operations for cutting zippered parts with reduced waste are speculated upon, driven by an approach to use 6-axis machining to produce two parts out one piece of stock. Utilising a bandsaw end effector would be a fast way to produce zippers at the larger scale, but the tightness of fillet radius must be sufficiently reduced for this method.

23

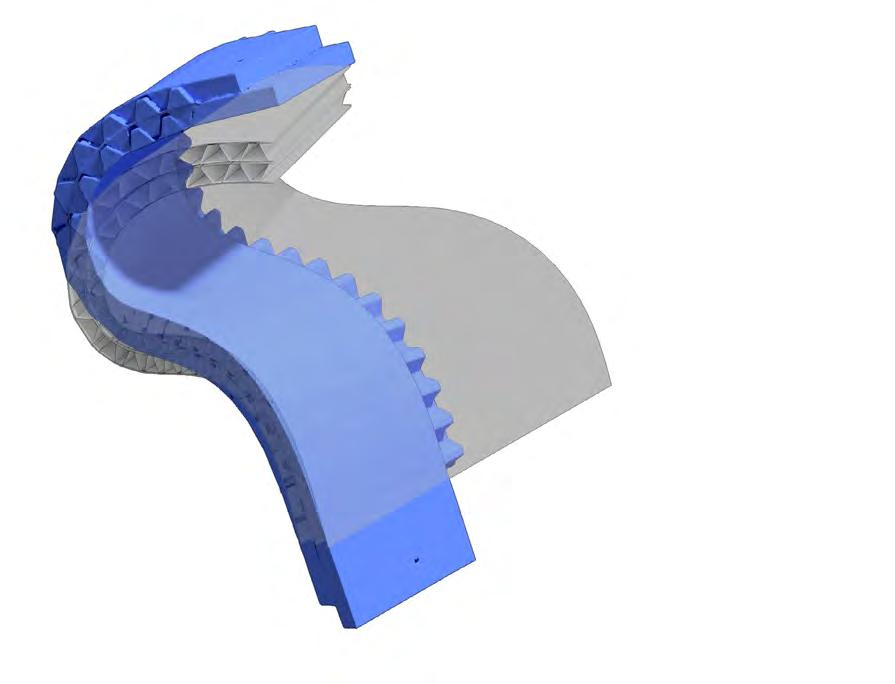

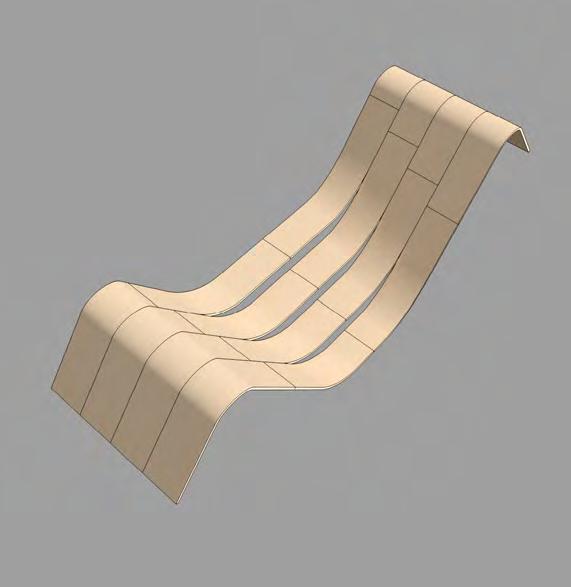

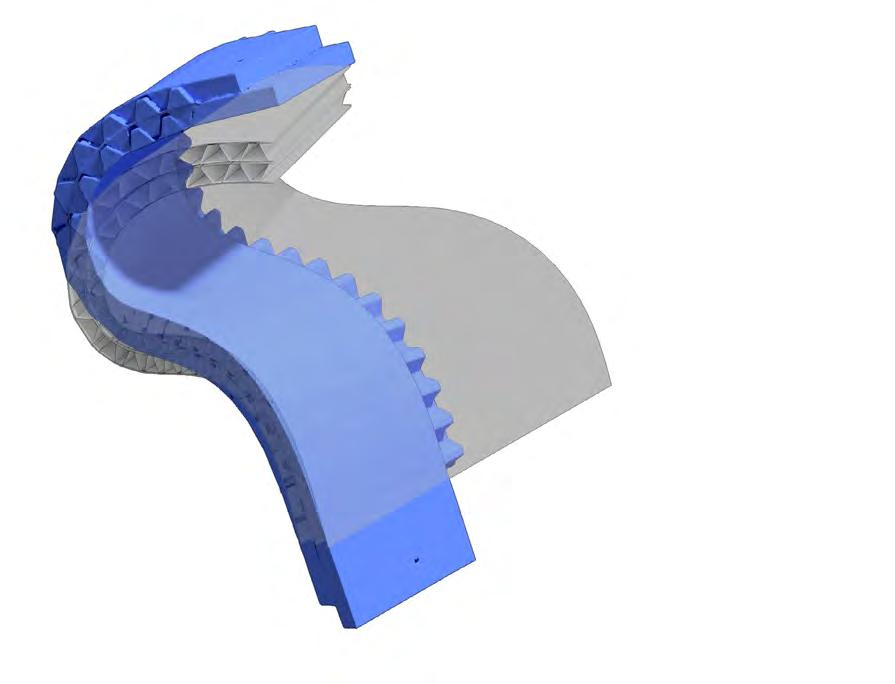

Enabling Scalability

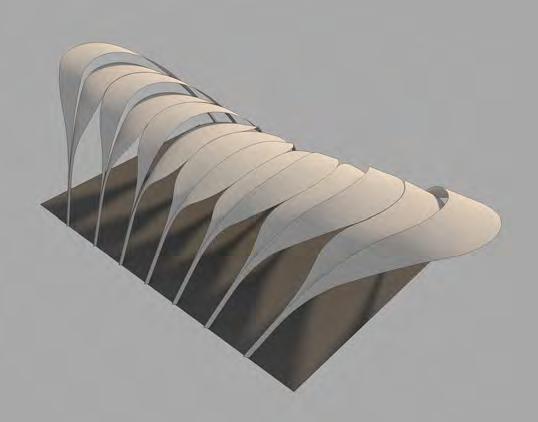

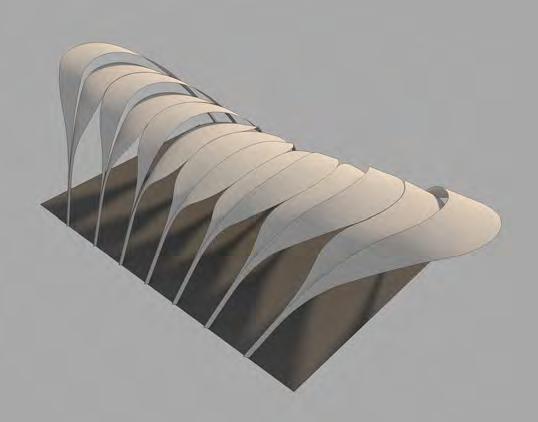

Approaches for generating forms for laminating zippers together as well as discretisation were explored for scaling the system up - a particular departure from previous research into this method is the creation of large surfaces as single architectural elements.

24

1. Glued up blank prior to machining

2. CNC machining creates zippered parts with cross-lamination3. Original laminations are visible in the final assembly

01. Possibility to create larger laminations

Continuous grain maintained in outer skin by orienting lower lamination layer

02. Discretisation of the blank lamination approach for creating large surfaces

Developmental Workshop Testing

Initial prototype tests were carried out in the workshop by hand to get to grips with the zippering method and to assess it’s potential. A key outcome here was the realisation that a very low tolerance would be needed to achieve the desired bend and to enable good gluing of the surfaces, necessitating the use of CNC manufacture.

25

Developmental prototypes were made with analogue machinery and hand tools in the workshop. A key outcome here was the realisation that the low tolerance of digital fabrication would be necessary to facilitate accurate allignment of the zippered halves.

27

Hand Tool Prototyping

01. Torsionalmember cut and bent to test workflow

01. Component logic explored 02. System logic explored 1. Torsional surface 1.

1. Torsional S-curve surface 2.

2:

3. Discretisation of larger surface created using smaller stock pieces 3.

4. variation of tooth orientation 4.Tri-part

Initial Prototype Testing from Component to System A 3D printer is employed as a quick protoyping tool for developing the scripting appraoches as well as exploring the possibilities of a zippered system by investigating how components might connect or bifurcate.

Bifurcation approach1: solid infill

Bifurcation approach

infill defines form

Lap joint integration

no infill (may require reinforcement)

generated

2. CNC milling ot define bending form in unrolled state

3. Soaking of timbers for 4 hours to ensure pliancy

4. Drying while parts are clamped to oneanother

Prototyping test 01: Tortional Zipper: fabrication procedure Methods are refined for producing the zippered component with thought given to scalability and architectural component creation.

30

1. CNC toolpath

5. Glue application

6. Vacuum forming generates final shape

31

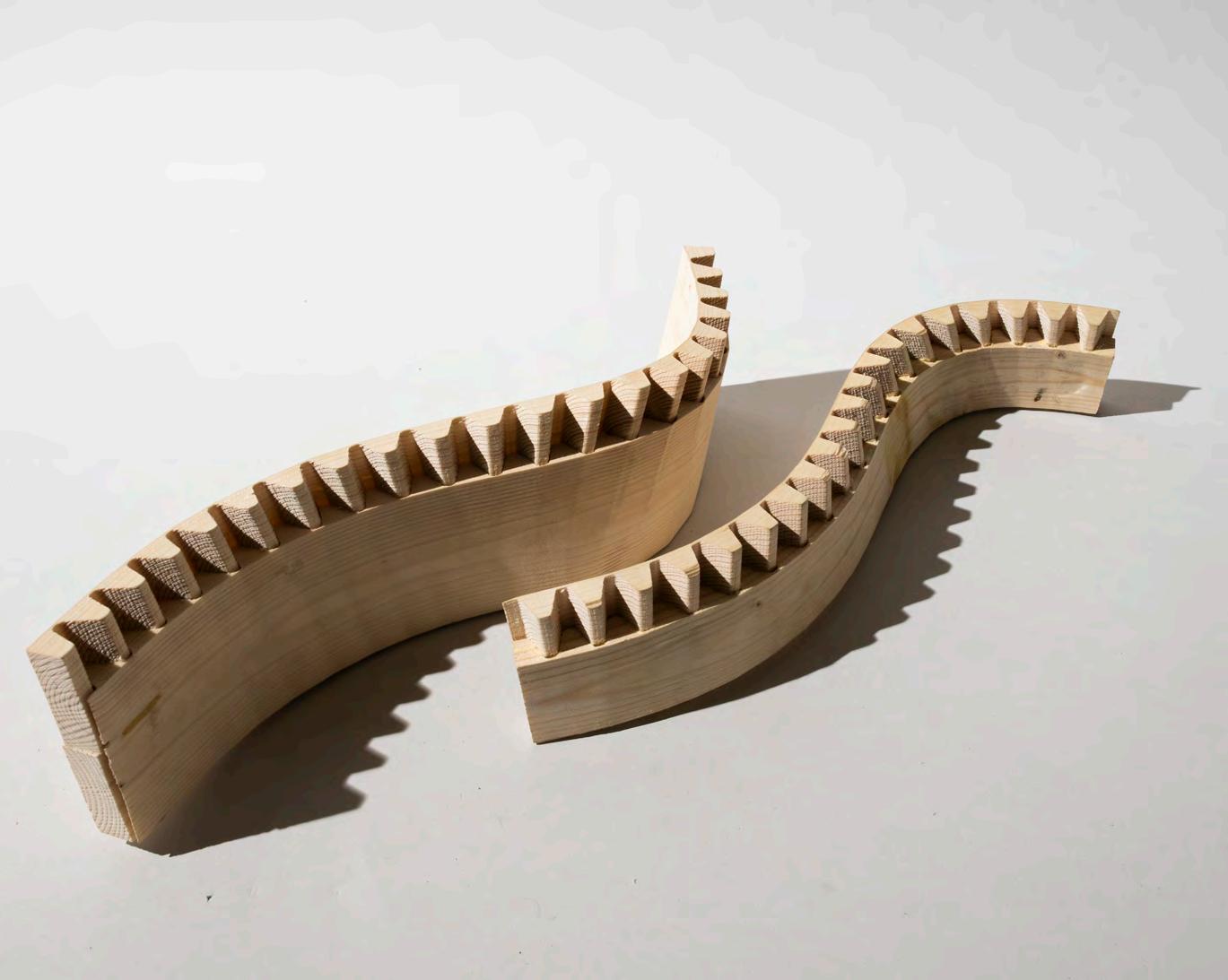

Prototyping test 01: Tortional Zipper: result CNC milling the zippers gives a good result, confirming fabrication possibility of the method.

32

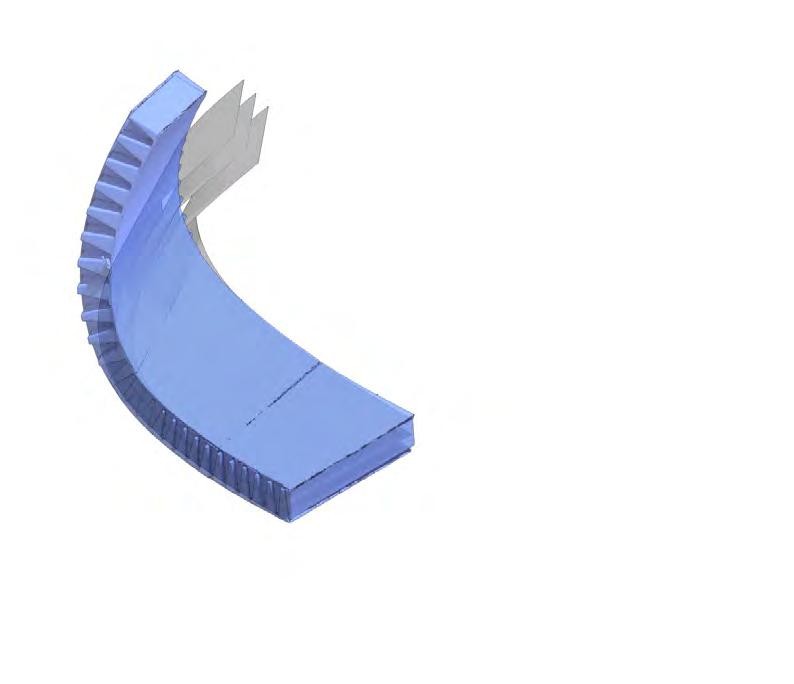

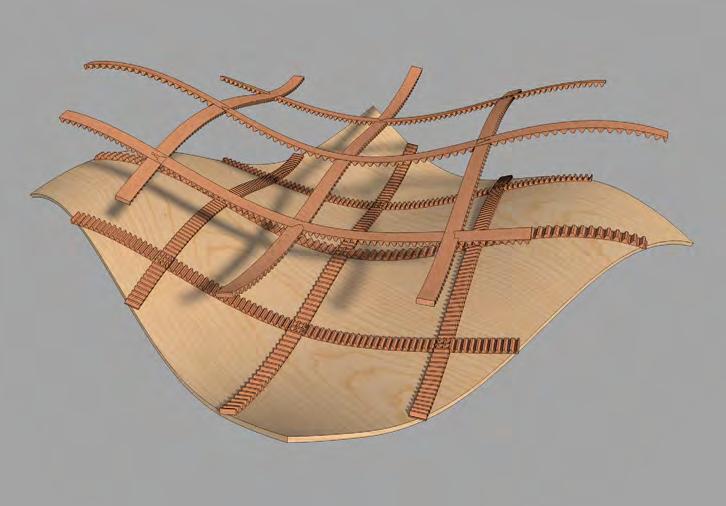

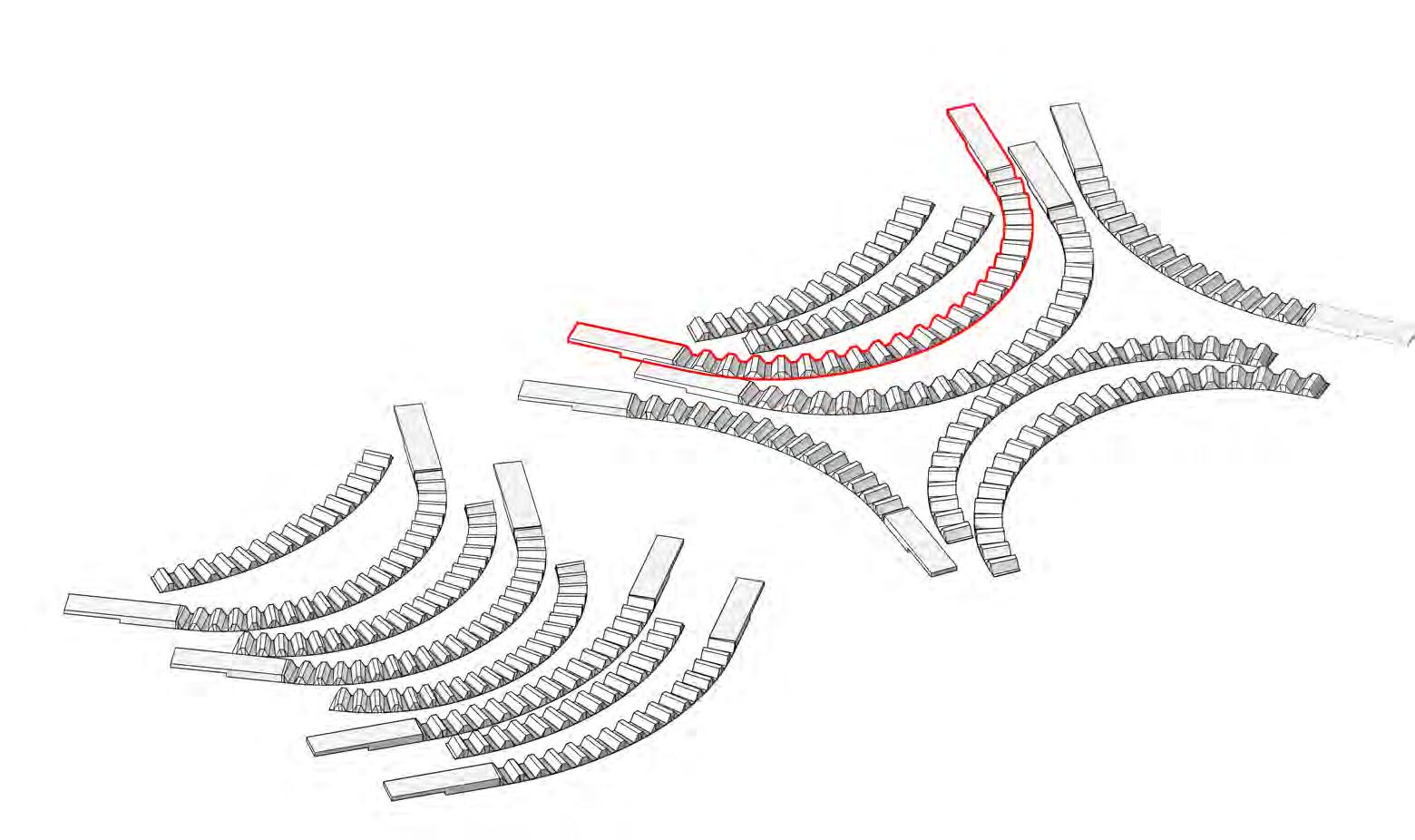

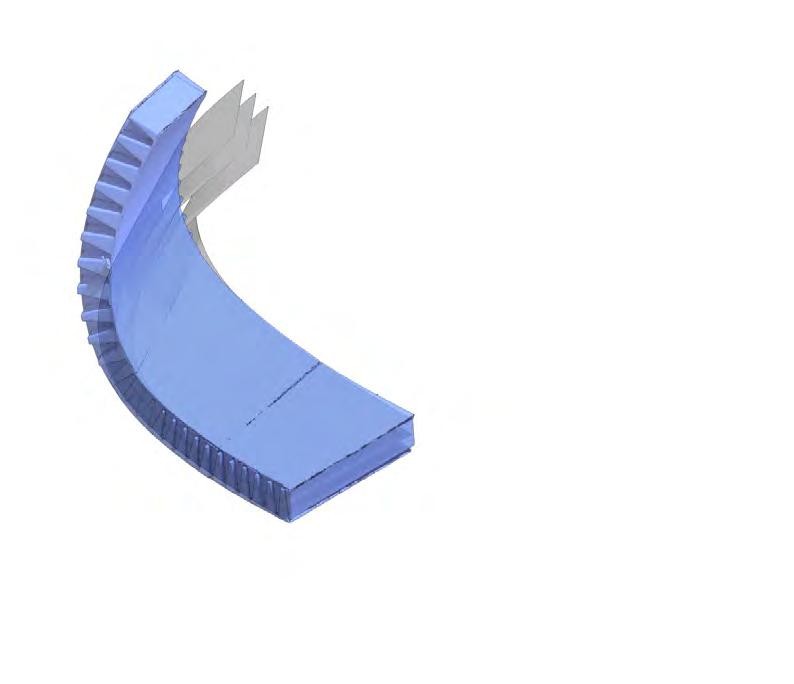

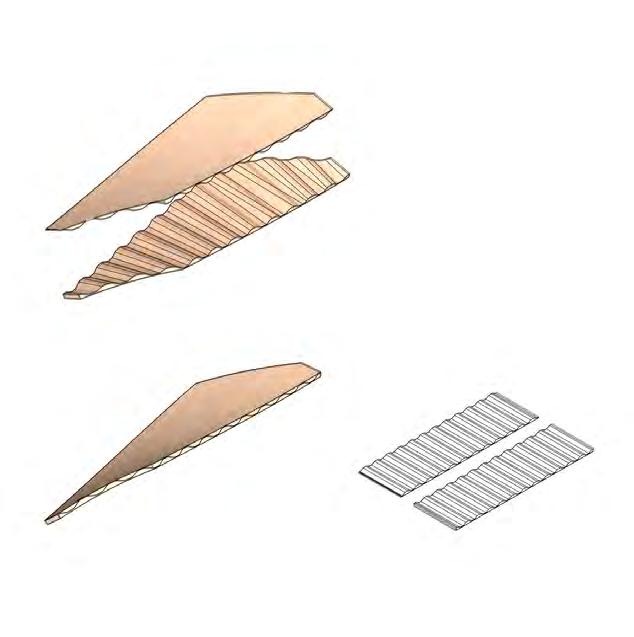

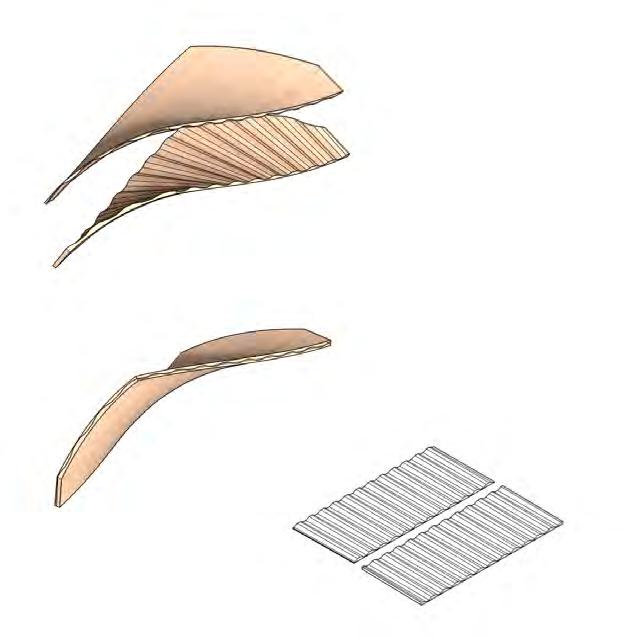

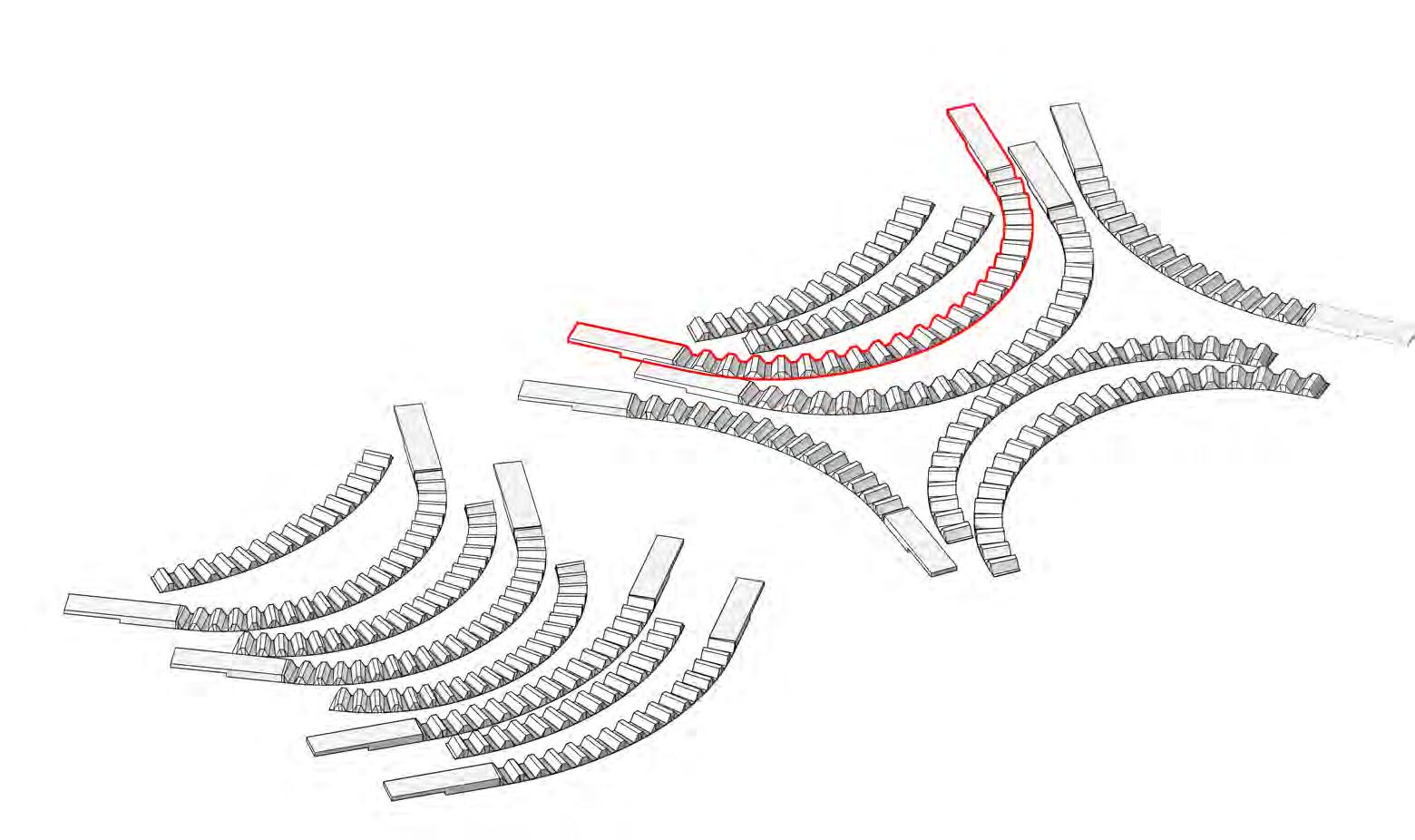

Prototype Test 02: Discretisation to Smaller Strips

The creation of larger scale surfaces could be enabled through a discretisation of a zippered surface into smaller strips. The offsetting of seams on either side of the component can allow for the surface to extend across a wide area, along its rulings.

Prototyping Test 03: Additive Approach

An approach where the zip-teeth are glued to a veneer skin is tested as a method for producing the zippers with less waste, since material does not need to be milled away. Each tooth being unique however means that some unresolved complexity remains. Since each will have to be CNC manufactured.

34

36

Prototyping Test 04: Laminated Zipper

The issue of scaling the zippered system could be addressed by laminating zippered surfaces together. Laminated elements can be extended by varying splices to create large surfaces.

38

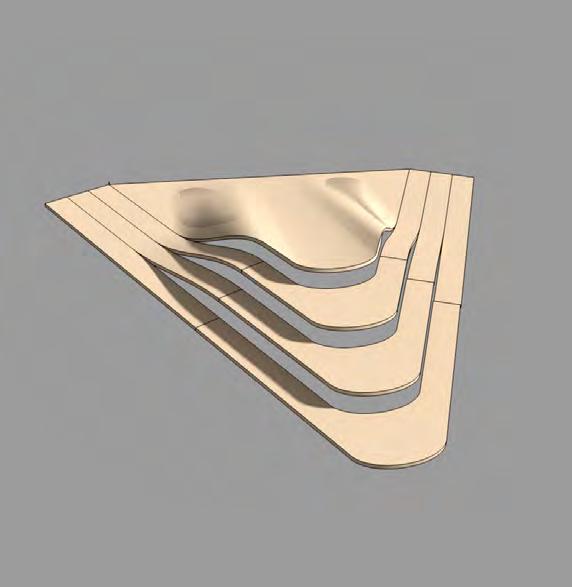

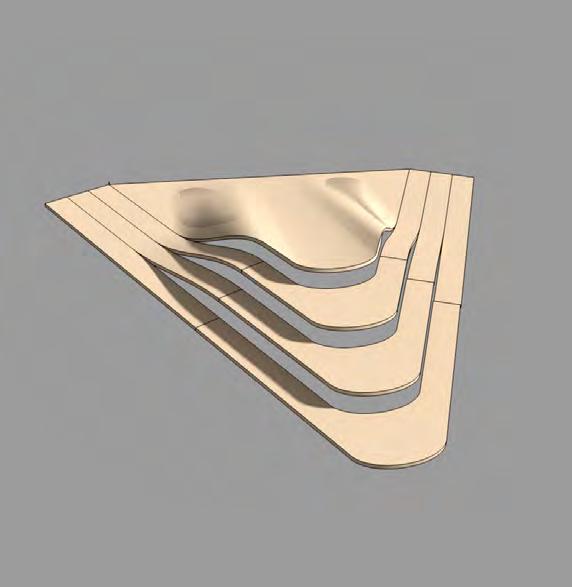

Prototyping Test 05: Double Curved/Conal Zipper

By changing the shape of the unrolled zipper to unroll curved rather than straight, double curved zippers can be fabricated, greatly increasing design possibility.

40

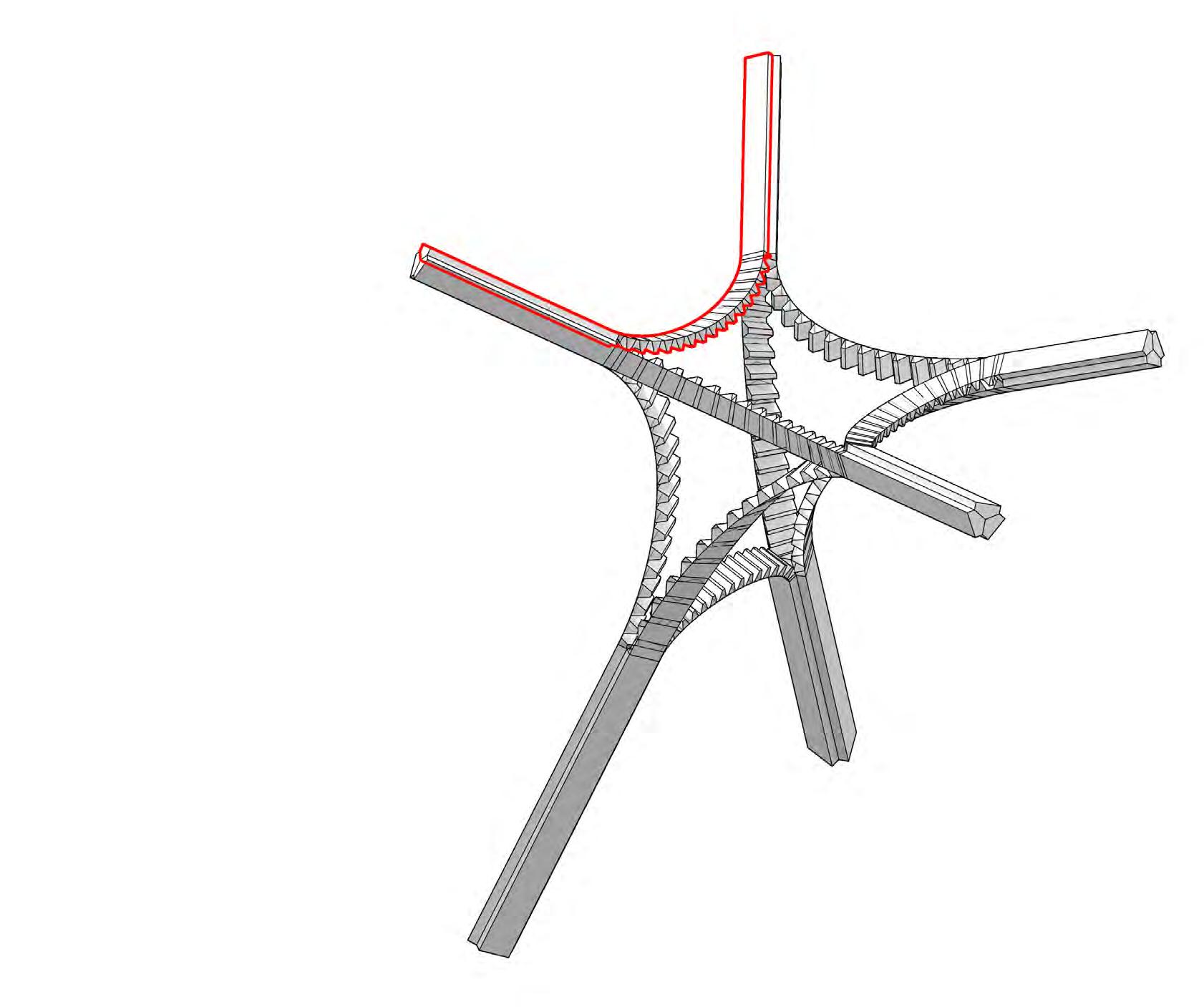

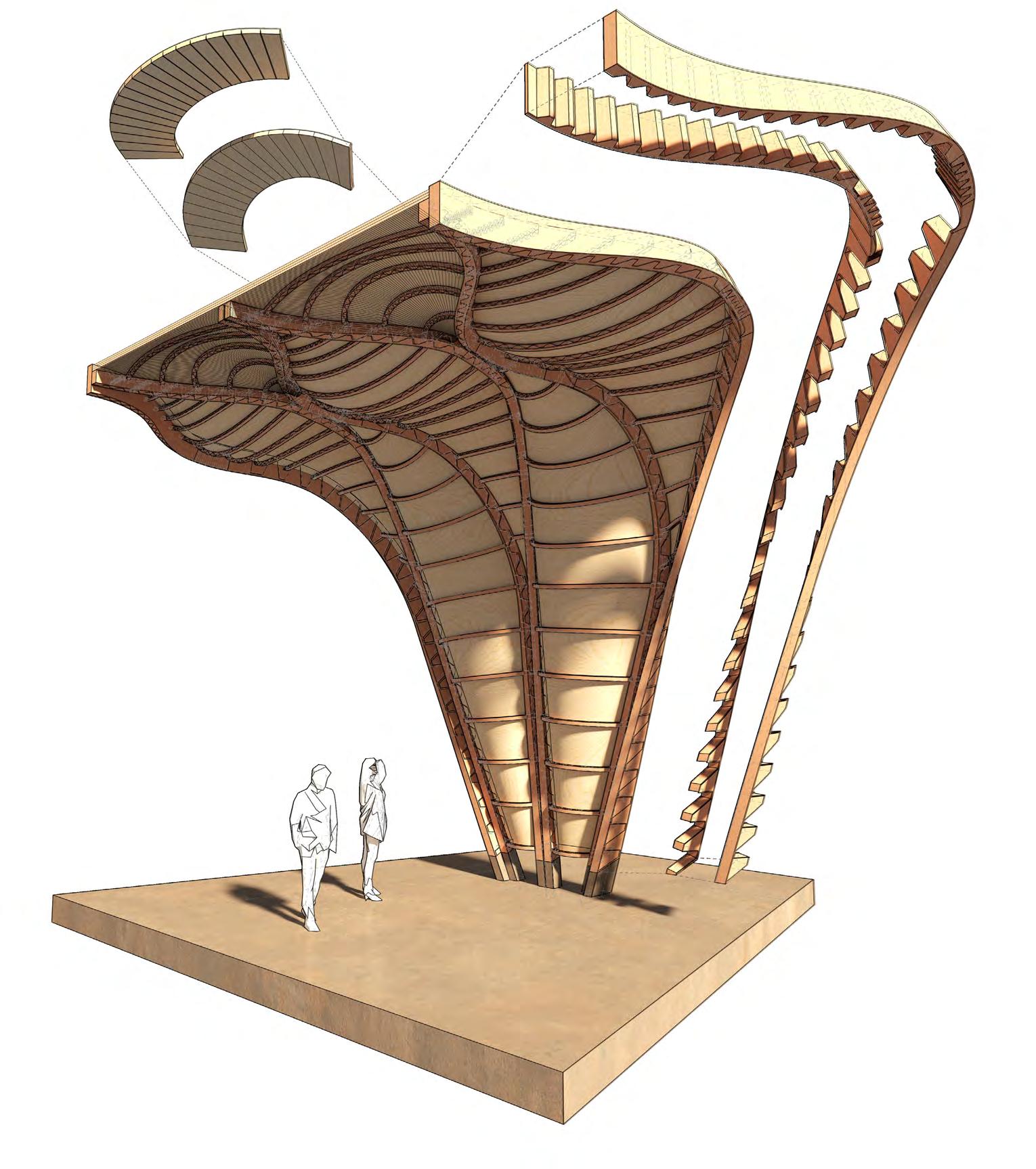

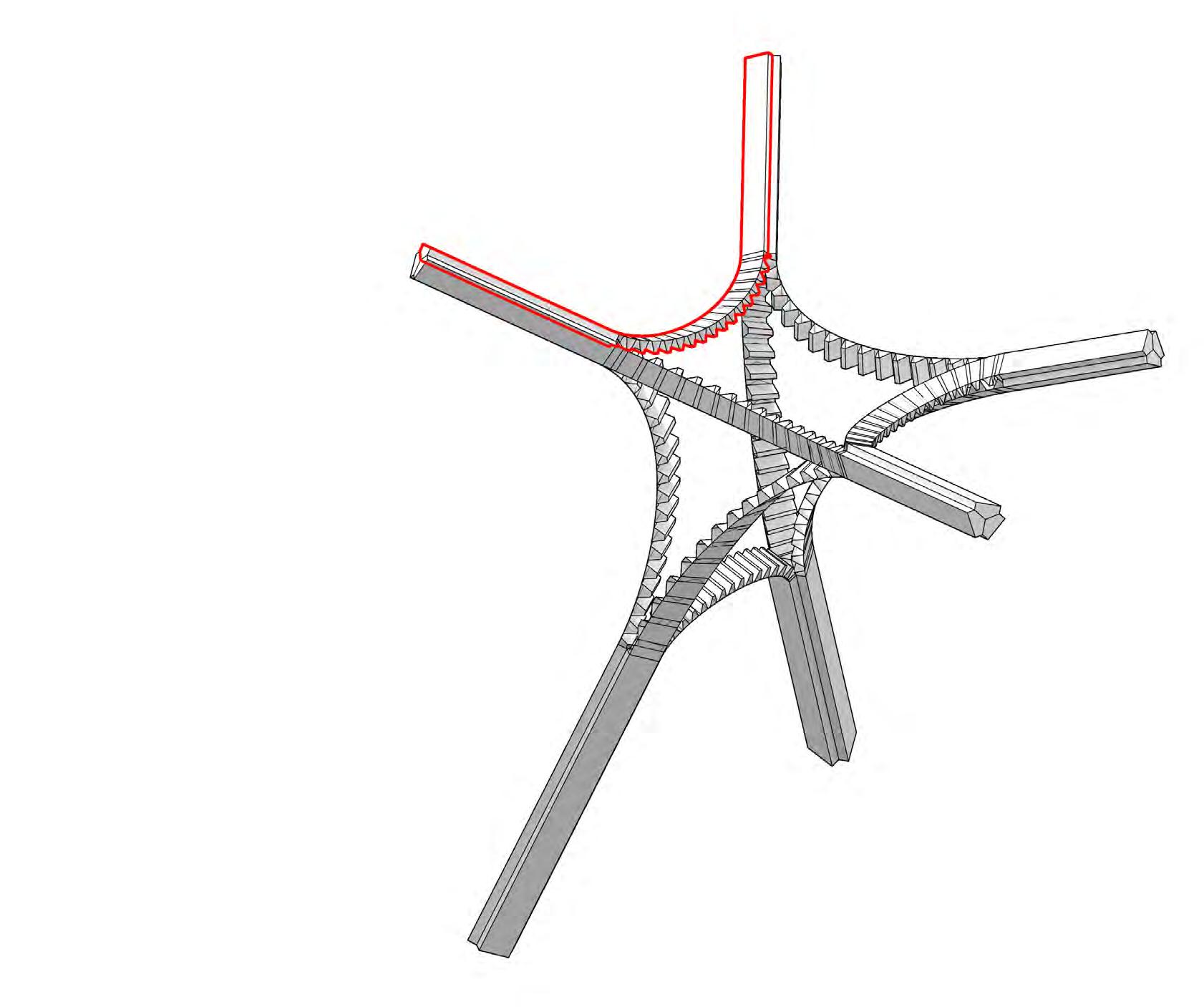

Prototyping Test 07: Nodal Assembly

A nodal assembly of a series of double curved zipper parts is fabricated as an example of a possible architectural assembly.

Torsional and overall underbending

Underbending is not as extreme

Torsional movement is also lower than digital model

Underbending in both areas of high and low curvature

Torsional and overall underbending

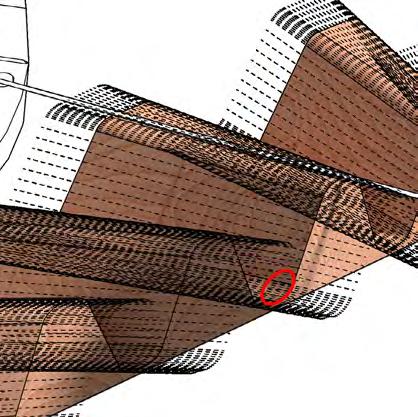

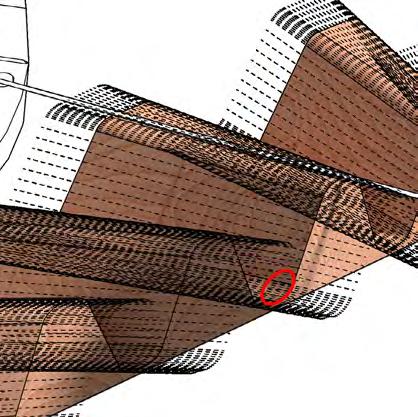

Future development: 3D Scanning Results

High resolution 3D scanning reveals a degree of underbending present in all the results, compared with digital models. Future developments outside of this research will look to account for this level of underbending in the form generation.

42

Fig 2.111 Laminated zipper digital/physical comparison (Author)

Digital model

physical

Fig 2.109 Low grade pine S-curve zipper digital/physical comparison (Author)

Scanned

protoype

Overall good allignment in terms of double curvature

section 2

abstraction: Architectural form

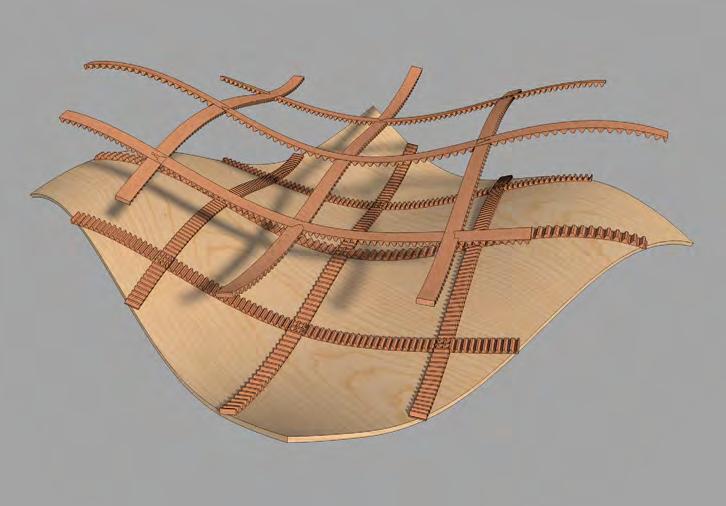

A zipper-based fabrication approach could be best utilised where zipper members are glued to a surface, therefore defining an envelope and structural geometry simultaneously

6. Surface kerfing can produce more complex geometries where bending of surface too can be predefined

5. Double curvature surfaces can be formed with zippering going in multiple directions. To make these surfaces developable, careful splitting of the surface into developable strips is required. An intial layout of structure can be adapted in accordance with stress analysis

Zippered Expression // Kerfed Surface Expression

Zippering and kerfed surface approaches could be hybridised to produce a significant architectural output. Zippered members can be tectonically expressed through different approaches to member branching.

44

1. Cylindrical

2. Conal

45

Physical testing: Surface/Zipper Integration

The fabrication of an integrated zipper member/moulded skin assembly was tested in simple form at the model scale.

Prototyping exercises testing: Zipper systems

Zipper members can be combined to form systems, where members are rolled into form simulataneously forming a building component. Different system approaches are outlined digitally in preparation for physical testing.

46

1. Zippered lattice

4. 3-way Branching with infill

2. Mortice/Tenon Branching

Fragment 03: Developable surface studies

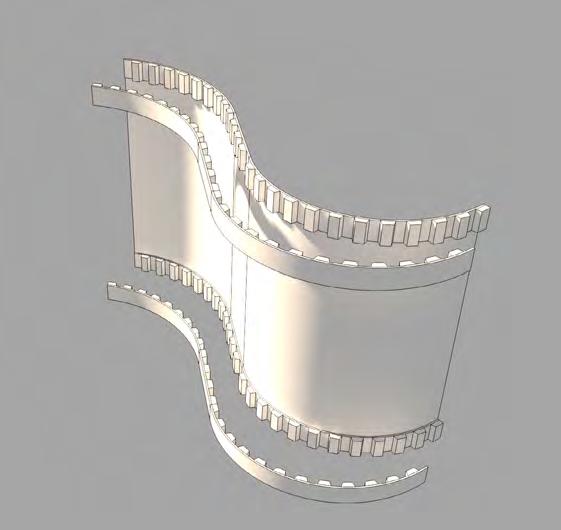

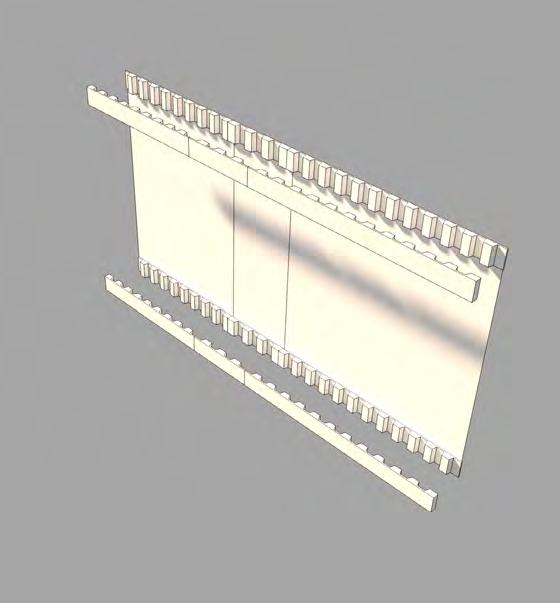

Developable surfaces can be applied to zippered elements in various ways. Zippering allows for single curvature and torsion defining edge curves and tangents. The developable surface types can be combined to create a high level of complexity

47

Fragment 02: Zippered

and continuous

material homogeneity in master surface adherence in timber building. Could the volumetric frame/component based whole be a valuable challenge?

48 49

member

skin Ultimate

Skin // Structure relationship: as the members zip together a continuous plywood skin is also applied

Possible arrangement studies 1

Possible arrangement studies 2

Zippered surfaces Glue up to form surface developable, ruled surface

Zippered timber members

Fragment 04: Branching for highly complex zippering with structural skin

Zippering can be employed to create more complex members by applying cuts in different 3D axes around the member. These members can branch and rejoin one another with a developable skin, descretized into strips, reinforcing the splits.

50

1. Structural heirarchy through larger zippered members

2. Twisted connections allow for member continuity despite changing curvature

1. Veneer lamination creates continuous surface from developable strips

2. Rafters also utilise zippered curvature

Fragment 05: Twisting intersections and roof relation At times, surface logic is containted to roof elements. This can blend into the member structure and support it.

51

1. Member branching with opposing zippers

2. Plywood lamellae are pressed into roof form

1.

1.

1.

2.

1.

2.

required geometry

Fragment 6: Developable panels composed from kerfed strips Surfaces of complex curvature can be fabricated from developable elements, employed in a faceted fashion, as seen above. Scaling up the developable elements to define whole surface infills can greatly benefit buildability and cost. Curvature can be predefined through secondary zippered elements which reinforce the panels. Complex curvature of the panels is enabled through kerfing of the surface itself.

52

3. Complex double curvature panel can be approximated with propOsed system

Abstract studies: applications for bending, folding and twisting for envelope creation all utilising planar curves

Surface splitting member/srf transition

Surface bending, folding for apertures

Surface bending and folding for shape/strength

Surface splitting and twisting for roof logic

Surface folding roof logic

Surface cut and twist for apertures

Surface splitting and twisting from single piece

Surface bending from single piece

Surface transition studies: More spatial applications for bending, folding and twisting are explored in relationship between 2 surfaces

Facade application

Transition 01

Transition 02

Surface studies in folding, bending and twisting

Transition 03

Abstract studies investigate potential applications for surface folding, bending and twisting as methods for surface generation. These simpler methods for surface generation would enable the use of larger developable elements as opposed to smaller slatting, greatly benefitting buildability.

53

1.0 Investigations into surface driven expression

Optimised distribution of zipper elements on surface Zippered elements could be distributed accoring to surface stress analysis

2.0 Surface input can be rationalised to produce beam layout through stress analysis

3.0 Fabrication approach

1. stress lines through uniform top loading of shell

1. Zippered beams glued to developable strips

2. Shell formed through member bending and reinforced following shell formation

2. rationalisation

3. beam layout produced accordlingly

Abstract studies: applications for bending, folding and twisting for envelope creation all utilising planar curves

Surface splitting variation1

Surface splitting pitched roof

Surface splitting corner detail

Surface splitting and twisting for roof logic

Surface twisting for aperture creation

Surface cut and twist for apertures/ venting

Surface splitting and twisting structural application

Surface splitting and twisting for apertures/venting 2

Potential floorplate application

Continuous fins act as wall and floor

Abstract facade tectonics: timber plate folds and twists

Basic tectonic ideas for facade expression using the continuous zip bent logic.

55

Fragment 7: Roof surface as zippered element

Surfaces of complex curvature can be fabricated from developable elements, employed in a faceted fashion, as seen above. Scaling up the developable elements to define whole surface infills can greatly benefit buildability and cost. Curvature can be predefined through secondary zippered elements which reinforce the panels. Complex curvature of the panels is enabled through kerfing of the surface itself.

56 57

1. Surface is fabricated as a flat sheet rolled up to final geometry as the zipping element bends elements

58 59

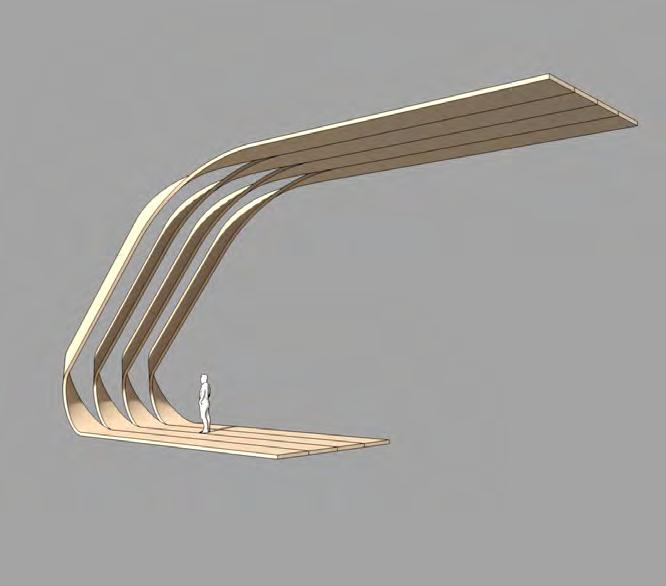

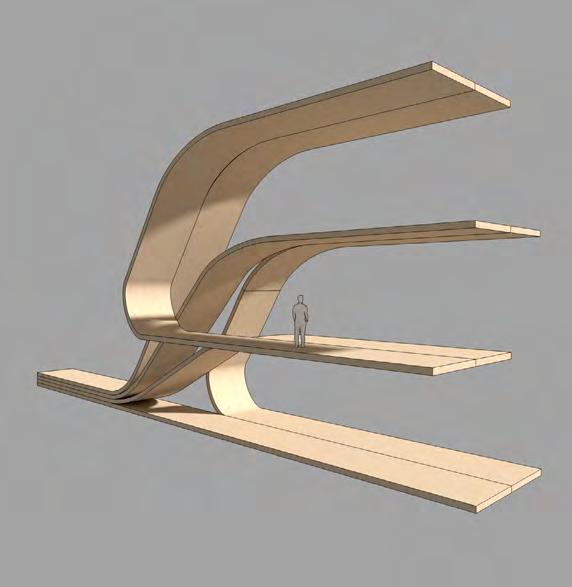

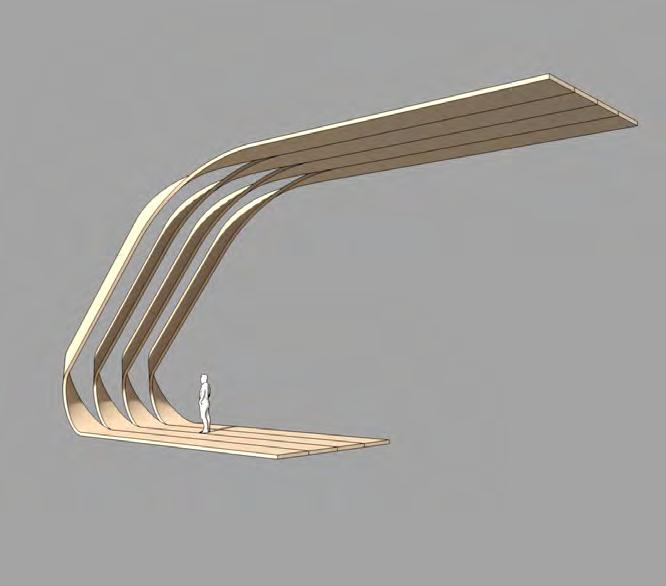

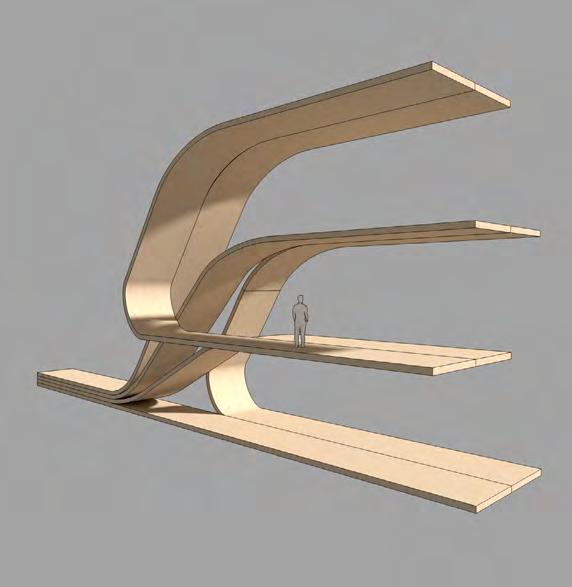

Fragment 8: Stacked arrangements

A larger scale application of the zippered system is tested for achieving a larger span space.. Height and variation in facade can be achieved by stacking and offsetting spaces at the building’s edge.

section 3

synthesis: Munich Philharmonic

61

Die Neue Münchner Philharmonie Ein kulturelles leuchtumprojekt des freistaats bayern

Constructed

Futures: Munich Philharmonic A promotional poster for the new Munich Philharmonic

43% Physical

36% Digital

1% Synchronisation

20% Performance rights

DüsselDorf 610,000

-Tonhalle (2,500) orchestral hall

– Mitsubishi electric hall (7500)

– Robert Schumann Saal (800)

-Significant punk and electronic music scene

Hamburg 1.79 million

- Elbphilharmonie great hall (2,000), recital hall (550), Kaistudio (170) as site for Hamburg’s music landscape

- Heritage of baroque and church music, top level performers and ensembles of all genres

- Active band and DIY scene in small venues

IFPI

frankfurt 733,000

- Festhalle (15,000)

- Alte Oper (2500)

- Mozart Saal (700)

- Leading cultural locations assosciated with economic activity

Concentration of electronic music produc-

Germany: established cultural centres

Germany has many cultural centres with similar provision of cultural infrastructure. While the cities in the north are generally considered hubs of contemporary arts, those in the south tend to lack this cultural impetus. Rather they are known for more established cultural production.

A new concert hall in Munich would should allign with the shift toward mixed programming and more a inclusive cultural offering.

berlin 3.52 million

- Berlin Philharmonic (2440)

- Chamber Music hall (1180)

- Konzerthaus Berlin(1700)

- Kantine (200) and Kulturbrauerei (500)

- Mercedez Benz Area (17,000)

- Music industry € 1.9 billion sales volume

- 250 + venues and 77 concert organisations, large club and festival scene, high density/number of small venues

leipzig 560,000

- Gewandhaus Orchestra (1900)

- Leipzig Opera (1267)

- Arena Leipzig (12,000)

- Strong history of classical music production and presentation

stuttgart 625,000

- Liederhalle (2100)

– LKA Longhorn (1500)

- Laboratorium (500)

- Hans-Martin-Schleyer Halle (15,500)

- Known for classical/traditional programming

municH 1.45 million

- Isar Philahrmonic (2000) temporary measure

- Hercules Hall (1270)

- Konzerthaus Munich - pending completion (1800) smaller auditoirum (600)

- Gasteig concert hall (3500)

- Olympiahalle (14,000)

- Known for traditional cultural offering. New efforts in contemporary programming look to rival other cultural centres

62

Germany 3rd largest music industry 2017,

tion in germany

Opera Houses

Concert Halls

Theatres

Arena/Stadia/Large gig venues

Outdoor Stages

Music Studio/recording spaces

Music schools

Bars and gig venues

Club

Munich: a concert hall for the city: current arrangements

Proposed new Konzerthaus funded by Bavarian State Original Concert hall at Gastein (1985) unfit for purpose

Temporary concert hall Isar Philharmonie discussed to be kept

Temporary measures: Isar Philharmonic acts as temporary building on former industrial site - new efforts in alternative programming

Cultural history/prevalence of performance culture in the city - ongoing discussion of concert hall. Concert hall as city symbol. Existing cultural offering is traditional in nature.

Existing proposal approved 2021 Konzerthaus Munich Behind East Central Station

63

Munich: City Context

Munich’s existing cultural centres

Gasteig Concert Hall (3500 seats)

Bavarian State Opera (2101 seats) Feierwerk, Kranhalle (1,500 seats)Olympic Stadium (14,000 seats)Outdoor stages

The future concert hall as engine for civic life?

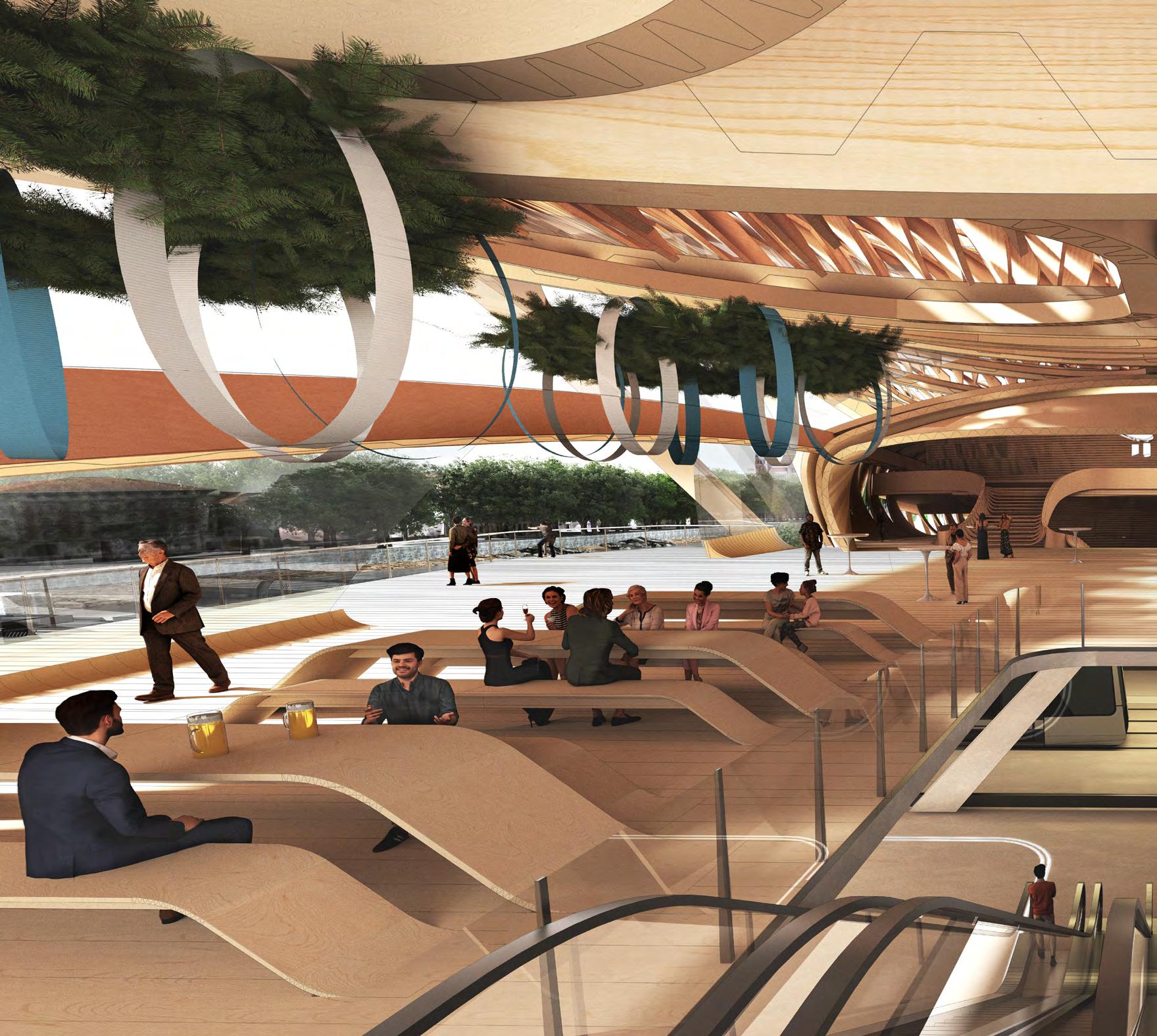

The concert hall as a typology is frequently employed as a celebratory urban gesture but often lacks a relationship to surroundings/ an inclusive environment. A future concert hall typology could look to celebrate the interaction between performance and the city environment, activating a surrounding interstitial condition itself as a piece of civic infrastructure.

64

? 30.4% 28.4% 17.9% 11% 7% Session Music school Landscape integration Interstitial occupied Activation of fringes internal/external relation Scale variation Hiding and revealing / environmental variation Concert hall as city symbol 1600-1750 baroque: beginings of music in a secular context is played in palace chambers. Private spaces with shoebox volumes provide acoustic conditions 1750-1850 classical era: concert halls open to the public. Larger spaces which can hold an audience. First oganisation of civic symphony orchestras 1820 - 1900 Romantic period: Music becomes connected to other forms of art. Size of concert hall increases. Generally halls still show influence of the court chamber 1900 present Modern era: the age of freestanding object buildings surrounded by open space: largely this typology lacks integration into the cityscape Contemporary/non-classical: Amplified music allows for more architectural expression. Arenas lack the prestige and urban presence of the concert hall typology but remain inward looking urban objects. Future concert halls could be a hub for cultural production/civic life, enabling exchange and production as well as cultural presentation, engaging the city surrounding it. Concert hall as engine for civic life Live music consumption Germany 2022 (statistica) vs. rise in music production The contemporary civic Rock/Pop/other Ticket Sales 2500 Million 0 2015 2025 Classical Musical FestivalFolkJazz AuditoriumPublic squaresStudio/workshopNightclubBar/cafeInstrument making Consumption/exchange Communal gathering Digital relation organisation/debate work/production Performance Idea exchange education recreation placemaking Networking Innovation Theatre Library/archiveOffices

Concert Festival Club SoundsystemRadio Streaming

Gig

Street performance

flaneuring as a basis for ciVic life

The ‘flaneuring’ and inhabitation of civic spaces as a pasttime was an idealised vision of public city life, made possible through the rise in the middle classes in the modern era.

timber proDuction/craft

Timber production is a histroic industry in the area. oriented culture with emphasis on craft.

walDfest/seefest

Folkloric celebrations still carried out are key moments for the gathering of the city’s inhabitants

‘sommerfriscHe’

19th century nobility would leave the city during the summer months to participate in rural pasttimes.

folk garDens (Volksgarten)

19th century initiatives to bring the natural world into the city.. These sites were to act as the infrastructure for civic life and recreation, by making aspects of rural life available to all.

Civic life tied to alpine cultural traditions

Bavarian cultural traditions of dress, consumption and production are still present in the contemporary culture and strongly tied to the surrounding mountainous landscape. The project draws on the significance of these cultural elements in reference to the flaneur/ bourgeois culture which grew out of the integration of these ideas into urban life. We question what a future entertainment typology tied to these local tradtions could look like.

Folkloric styles of dress and entertainment remain contemporary

beerHouse/brewery as ciVic engine

The beerhouse and garden can be considered a locus for cultural exchange and consumption in this region

65

alpine culture anD Dress

?

5.

6.

2.

4.

3.

1.

37%

Glulam manufacture CLT manufacture

Automotive industry, Hyrdogen Power and synthetic fuels (Munich, Nuremburg, Straubing)

Artificial Intelligence and SuperTech programme (Munich)

Robotics and Machine Learning (Schweinfurt)

Geriatronics, Prosethetics and Digital Care (Garmisch, Krempten, Aschaffenburg)

High-tech Construction, specifically timber (Kleinheubach, Augsburg, Munich)

WinterCarneval / Fasching (5 days)

SpringSpring Festival / Frühlingsdult (13 days)

SummerMay Celebration / Maidult (10 days)

Forest and Lake Festivals / Wald und See Feste (Summer months)

AutumnAutumn festival / Herbstfest (16 days)

Alpine folklore has continued cultural significance

Mythical creatures of the mountains hold significance in folkloric tales

‘Tracht’ styles of dress celebrated culturally are a remnant of alpine peasantry styles of dress

Festivals with pagan routes mark key dates in calender

Traditional crafts for the making of objects and food are celebrated

Bavaria: High-Tech/Folk Intersection

The building acts as an intersection point for culturally resonant folkloric traditions with the evolving high tech production industry which characterises the Bavarian economy. The cultural/entertainment building type is imagined as a key overlap point for celebrating technology and tradition in the city.

Music and entertainment: traditional instruments

66 Bavaria’s high tech agenda

Bavarian folk festival calender

1. Munich (captial)

2. Augsburg (Holzbau digital Hochtenkirchen (medical and

6. Kleinheubach (Hess Timber)

7. Schweinfurt (Robotics centre)

1.

7.

2.

3.

4.

6.

5.

Arena as contemporary replacement for concert hall type as more informal entertainment takes precedence

Population spending on forms of live music entertainment Statista, 2022

Popularity of different music genres Statista, 2022

Folk garden

Music/performance

Alpine culture

Communal gathering/ Beerhall culture

Advanced fabrication and manufacturing industries of the area

interstitial performance spaces

Park/Landscape zone

Arena zones

Re-imagining the concert hall type

beerhall zones celebrate traditonal crafts and their products

The ‘giant form’ concert hall caters to a limited form of entertainment culture which is becoming obsolete. A future model for entertainment infrastructure could look to integrate itself more fully into the surrounding urban condition and civic life, becoming outward looking arena as well as inward looking performance space.

Tram station as key urban interface

67

32% Rock/Pop Arena / Gig 25% Rock/Pop 26% Opera / Classical 21% Classic hits 19% Musicals 14% Schlager/folk music 8% Hip hop/ rap 7% hardrock/metal 12% Festivals 6% Electronic 7% Schlager 5% Country/Blues/ Jazz/other 4% Jazz/Blues/Folk 13% Classical + Opera

Programmatic diagram

68 69

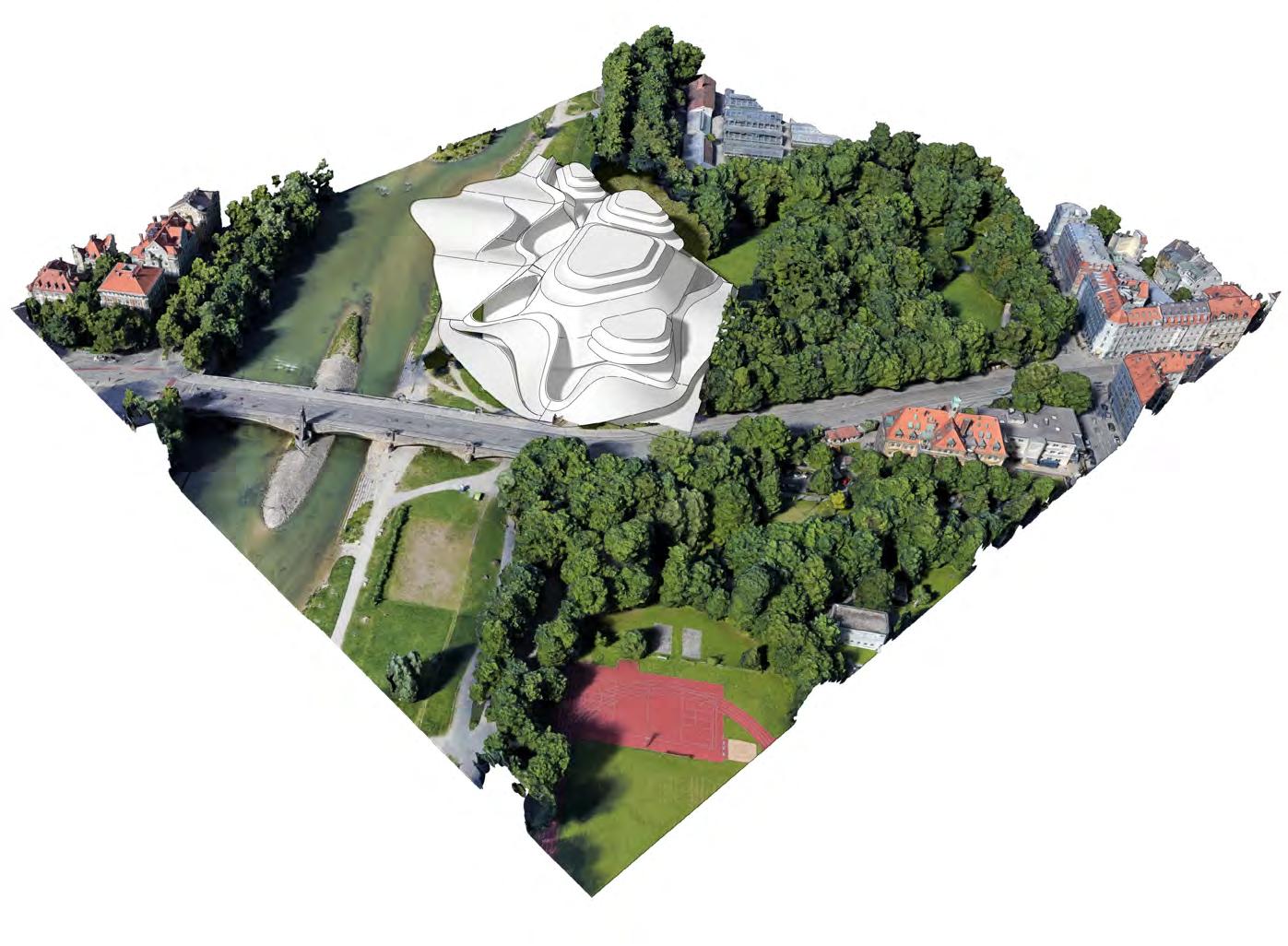

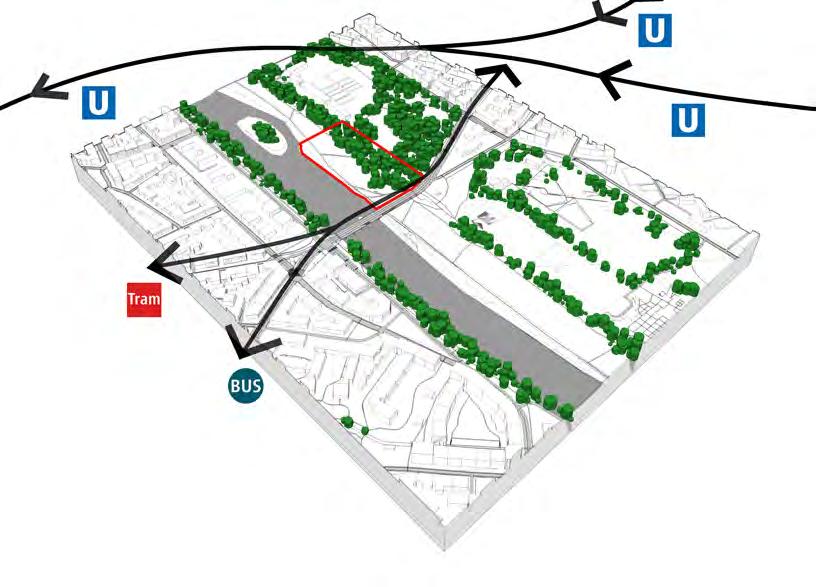

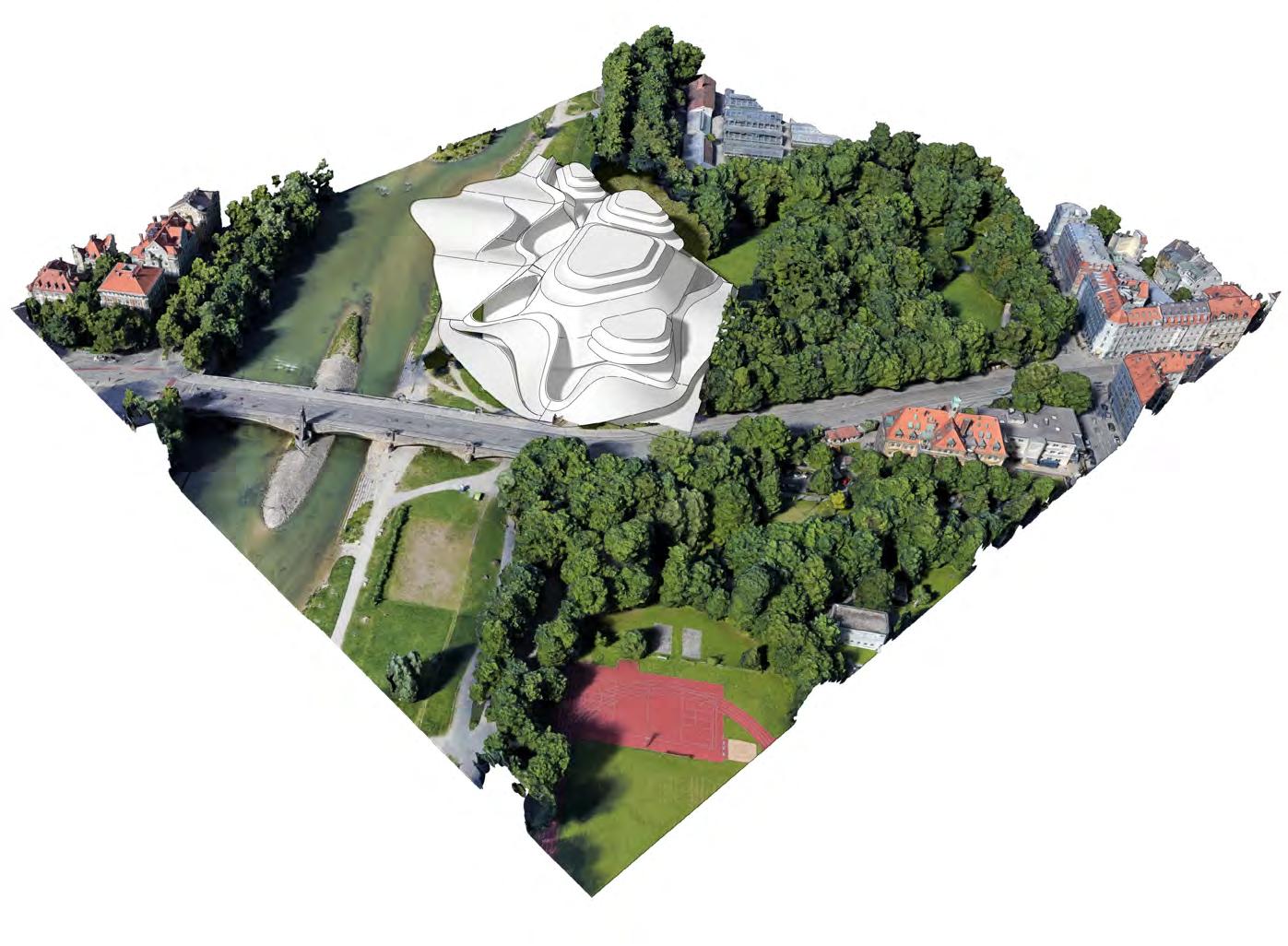

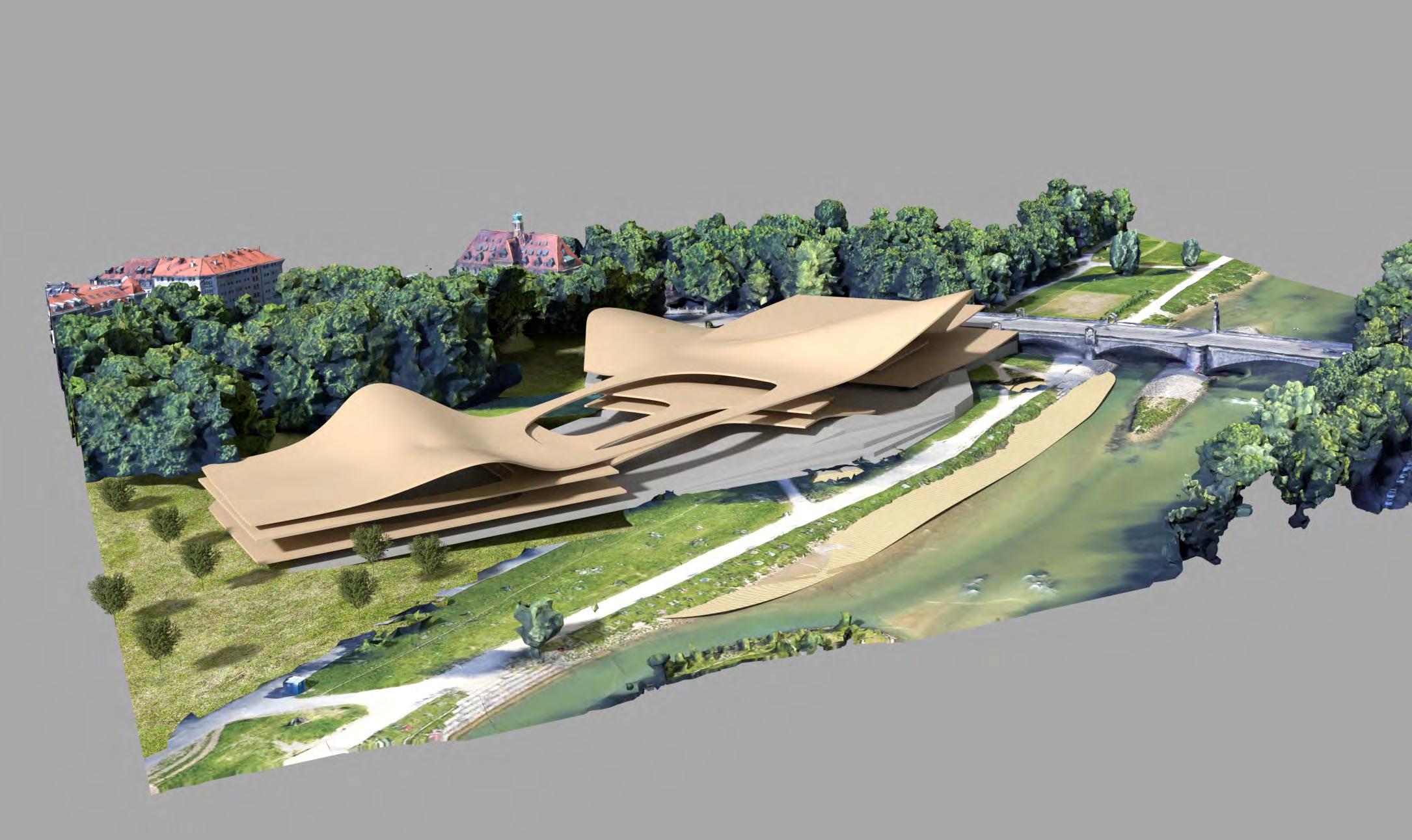

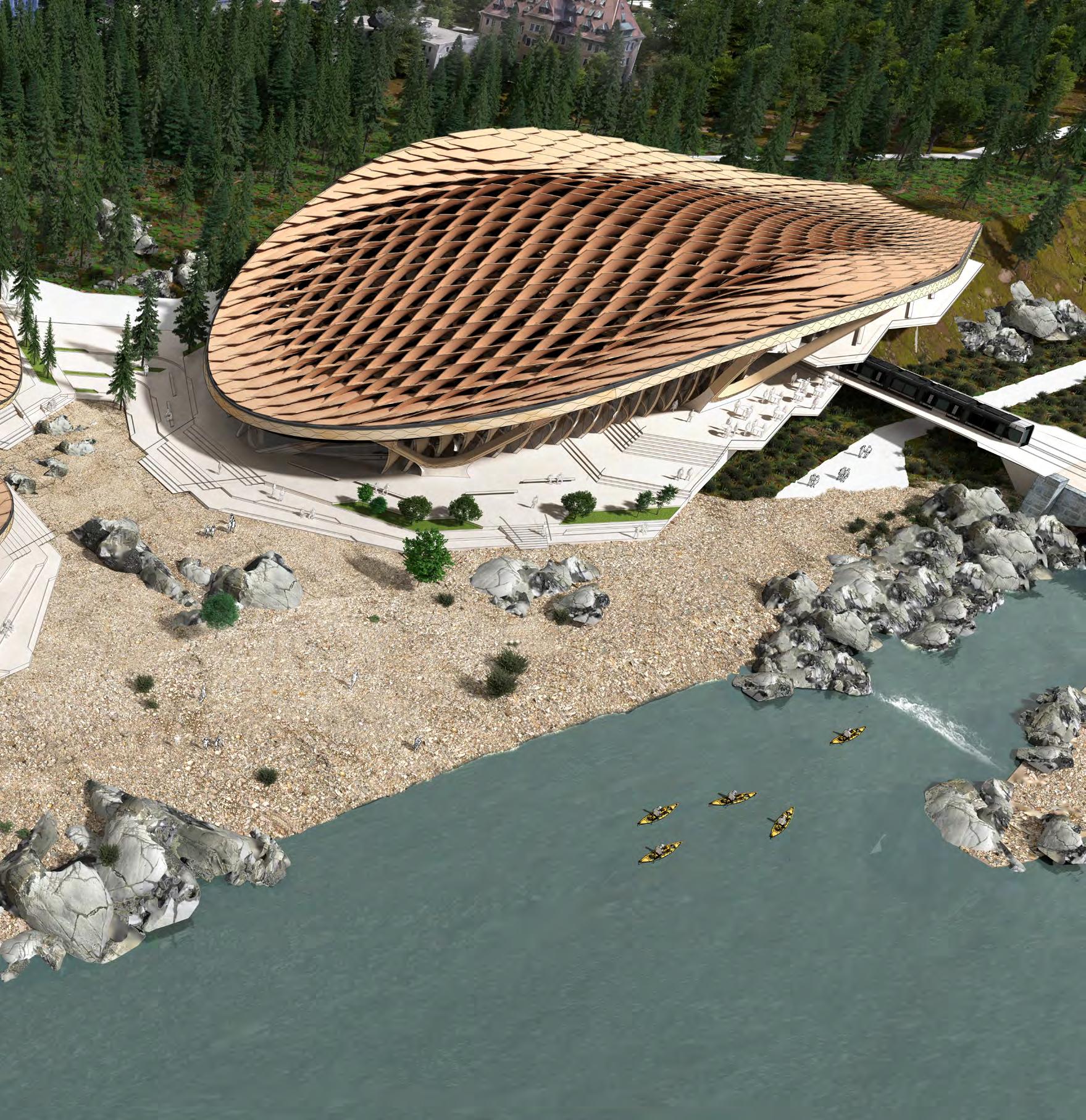

Site Analysis: Old city gateway The project is sited to the south east of the city centre. Space by the river allows for close integration of public life of the building into significant urban fabric with impinging on historically protected zones

Site Location Greenery/ameneties

Transport/Infrastructure

Topography (slope %)

Bavarian ‘Bundwerk’: Plinth condition with oversailing balconies and roof enables inhabitation at building’s edges and a more outward looking spatial condition

The bavarian timber frame and the wider German timber vernacular presents a specific relationship between internal and external. Overhanging eaves, balconies and gable ends create buildings with outward looking/public features and inhabitation at their edges. The expressive facade further acts as a celebration of the region’s prowess in the timber crafts.

70 71

Edge condition of the Bavarian timber frame vernacular

Bundwerk lap joint variations facade panel assembly

Facade study shows ornamental expression resulting from the variation of a single jointing method

Doweled timber connections allow facade to act as exoskelton

Site Plan: Immediate Conditions Scale 1:2000

Site to the south east of the city centre. Space by the river allows for close integration of public life of the building into significant urban fabric with impinging on hisorically protected zones. Series of different urban conditions surround the site. The proposal will look to bridge together these conditions.

72

73

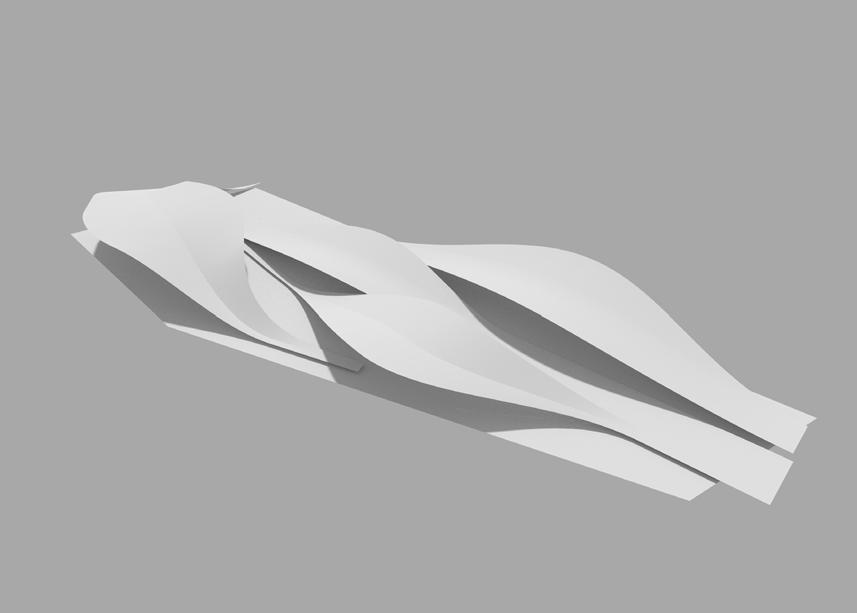

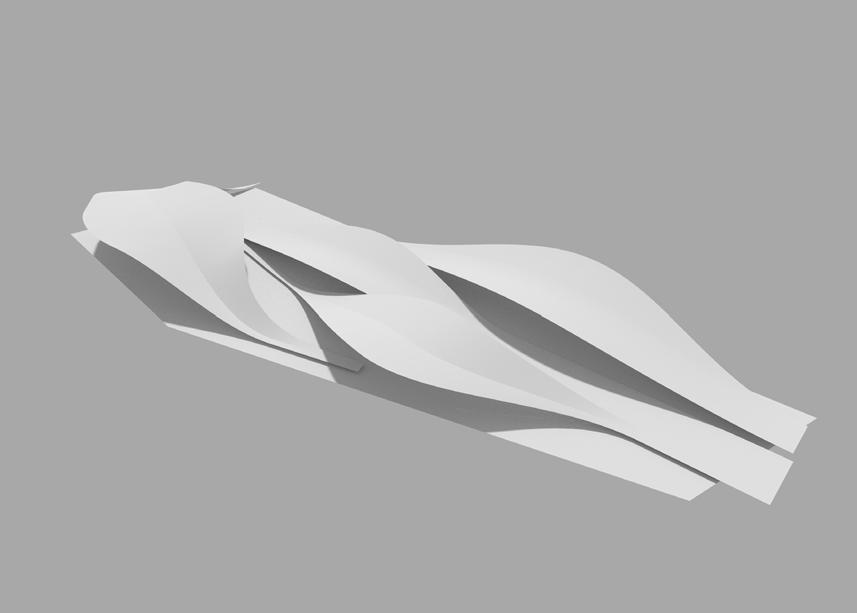

01: Global Form Massing Intial steps for investigating global arrangement of building elements

Massing Option 02: Plinth and raised stages

The building challenges the typical inward looking notion of a concert hall, instead imagining the cultural type as an engine for civic life, a part of the public city fabric. A plinth building with visible towers hosting the main performance spaces are highly visible from the city. Ancillary and other public facing functions are held in the plinth.

Recital space 440m2

Main auditorium 3000m2

Music school stage 440m2

Plinth contains informal performance spaces and ancillary functions

74

Breaks in the plinth roof create informal public spaces

Arrangment diagram

75

Massing Option 03: Linear arrangement

The building challenges the typical inward looking notion of a concert hall, instead imagining the cultural type as an engine for civic life, a part of the public city fabric.

Arrangment diagram

Sectional Study 1

Sectional studies investigate the potentials of the continuous surface organisation of the building

76

Main auditorium

Main auditorium upper balconies

Public ground foyer with bars/ restaurants

Music school Studio auditorium

Recital auditorium

Studios

Library/archive

Public riverfront and beach

and workshop

Offices

Studios and workshop

Public foyer with bars/restaurants

Music school

Library/archive

Offices Public riverfront and beach

Sectional Study 2

Sectional studies investigate the potentials of the continuous surface organisation of the building

77

Main auditorium

Studio auditorium Recital auditorium

Park integration: the building seeks to act as an inhabitable extension of the landscape, bridging park, beach and city

Urban integration: Engagment with surounding urban routes

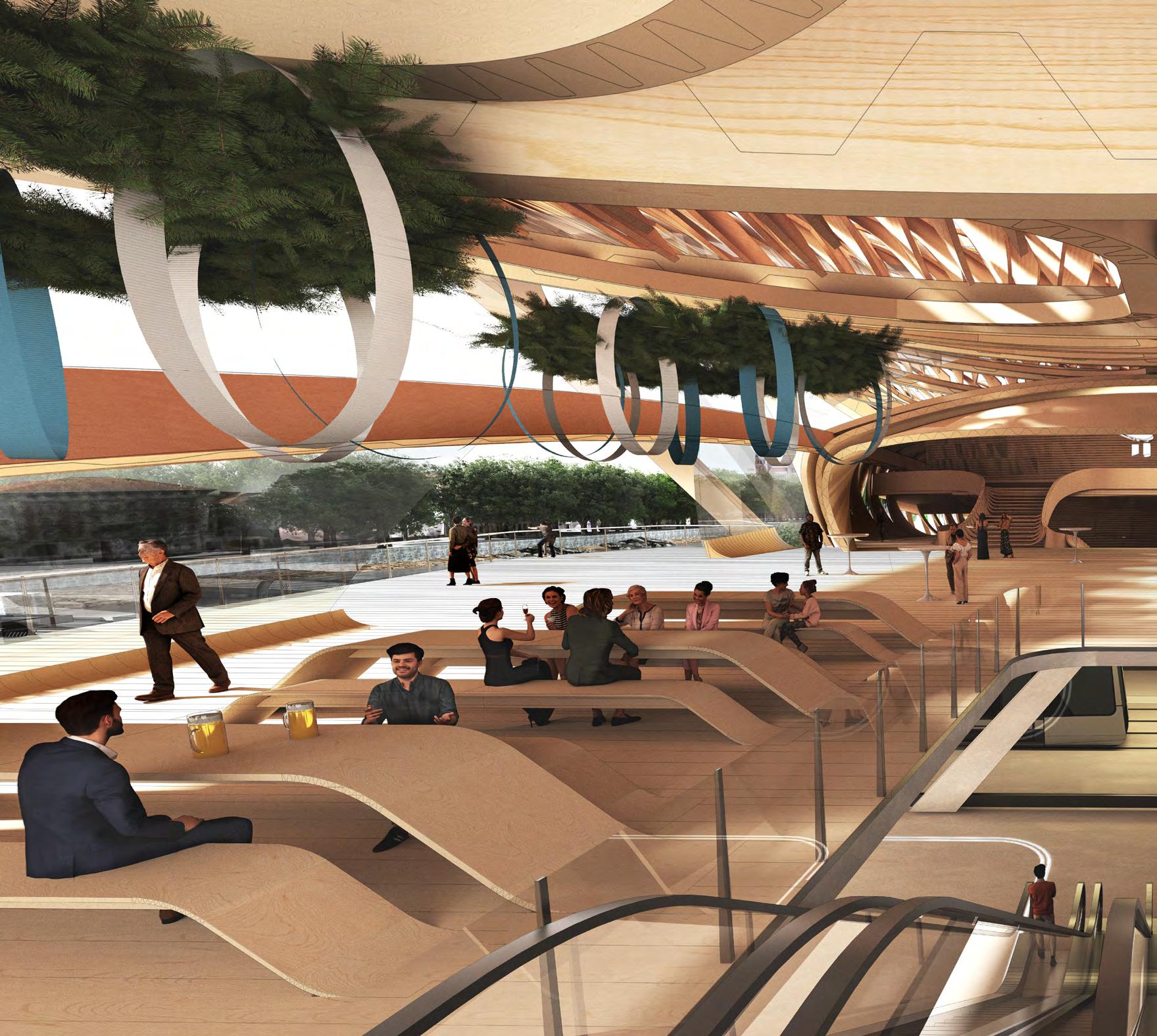

In order to challenge the concert hall as an introverted, exclusive institution, the project proposes a mixed-use programing approach where elements of civic and public infrastructure are integrated into the building. This merging of different programmes creates a series of intersections between public city life and the concert hall institution which can become architectural opportunities.

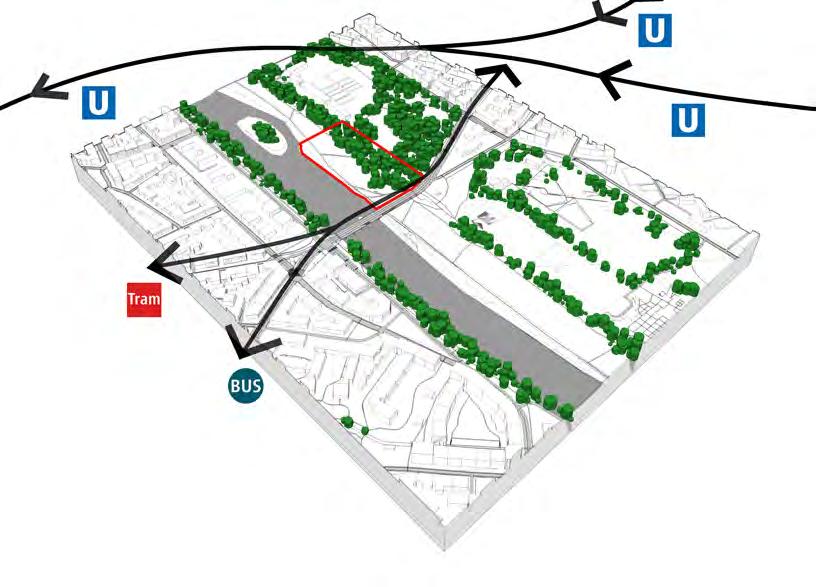

78

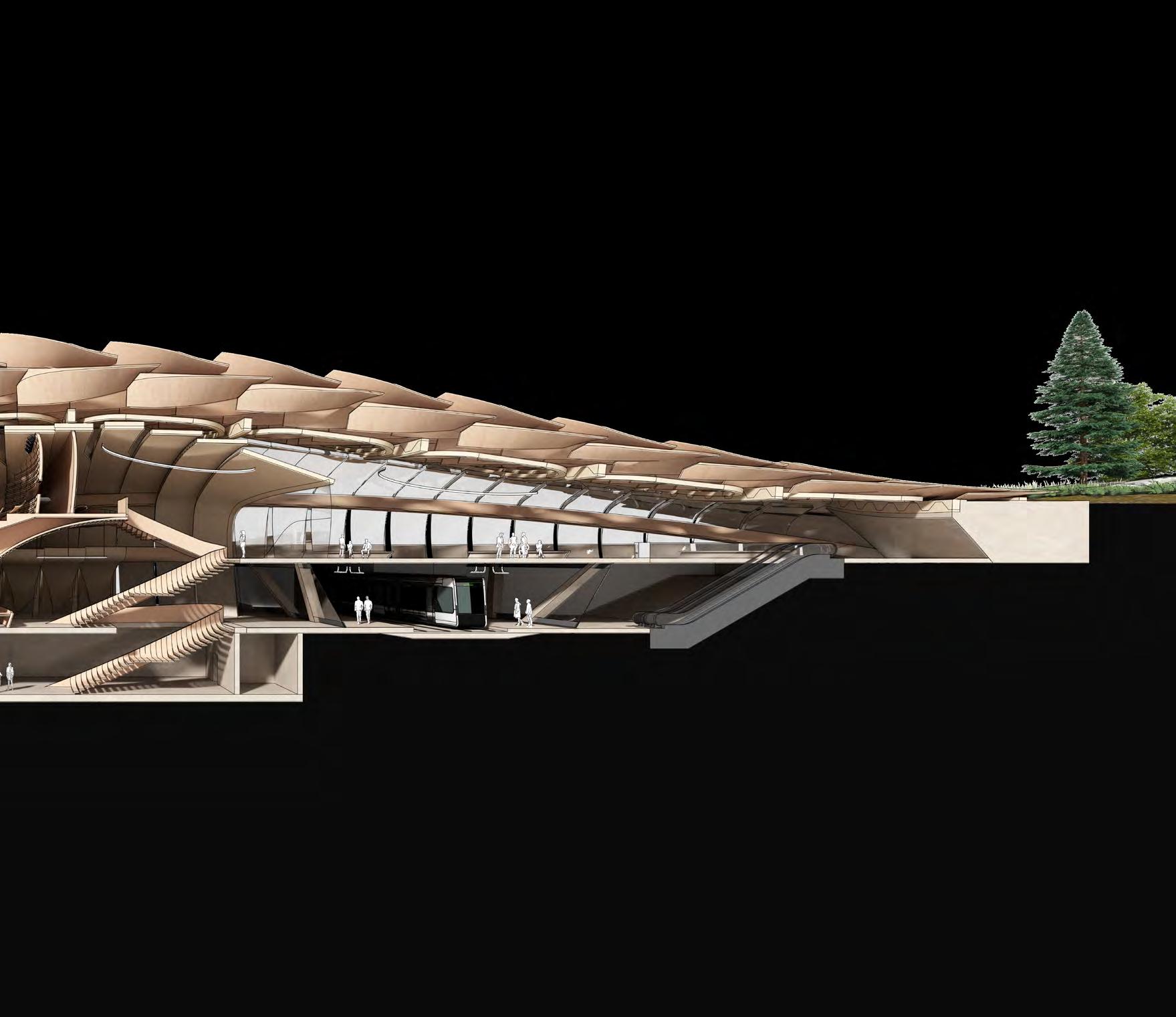

Existing underground trainline

Proposed extension to connect underground train network to site Pedestrian and tram route to city centre

Pedestrian route along river’s edge key for bathing in summer months

Site at interchange of different transport modes

Site location between different districts

Site at river’s edge Glockenbach district Frühlingsanlagen public parkAuhaidhausen district

Axial public ground Diagonal public ground Hybrid public ground

Rosengarten public park and sportsfields

Isarvorstadt district

79

Global form study 2

Sectional studies investigate the potentials of the continuous surface organisation of the building

Plinth imprinted with lower seating

Industry fair zones bleed into performance spaces

Undulating roof

80 building

Plinth imprinted with lower seating

Industry fair zones bleed into performance spaces

Undulating roof

Centralcourtyard

The building is imagined as a series of different large scale halls with more informal programme inserted between all under one roof. Zippered acoustic panels serve to create appropriate acoustic environments within the open plan arrangement. A series of routes are created through the building through a continuous floor condition

81

Site Plan Iteration 3 Scale 1:2000

Beerhall

Forestplaza

MainLobby Tradingfairzones

Trading fair zones

Beachplaza

Mainhall

Recitalhall

theatreStudio

82 83

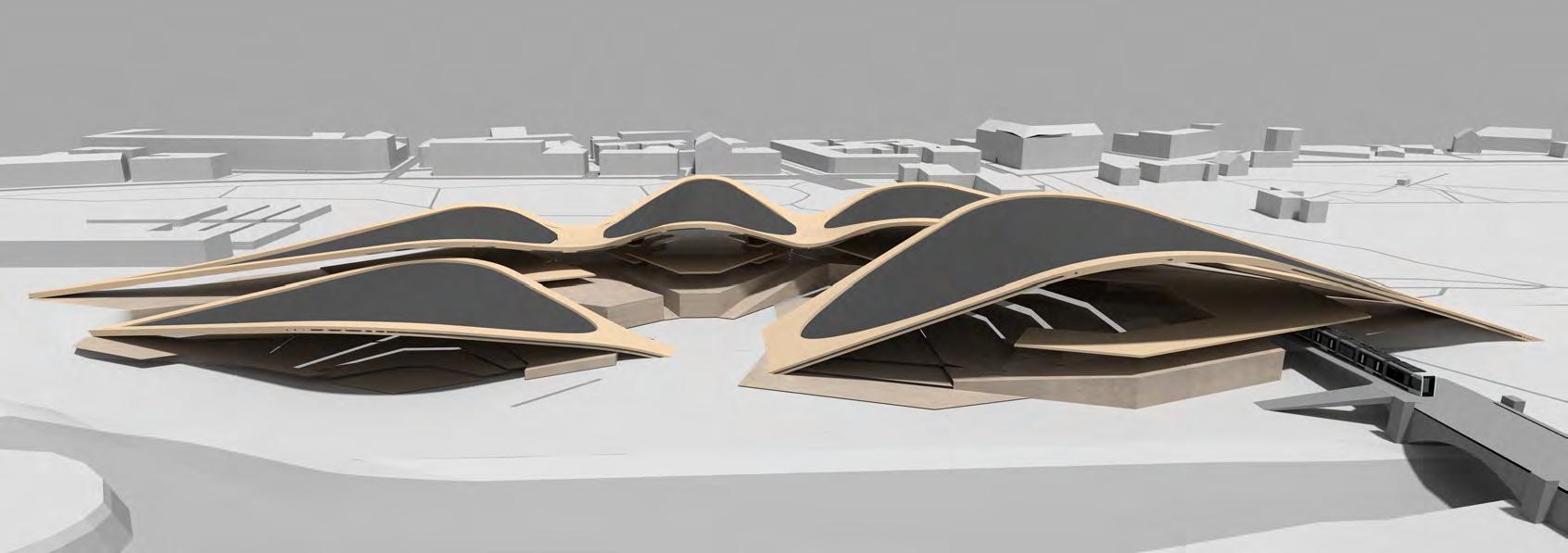

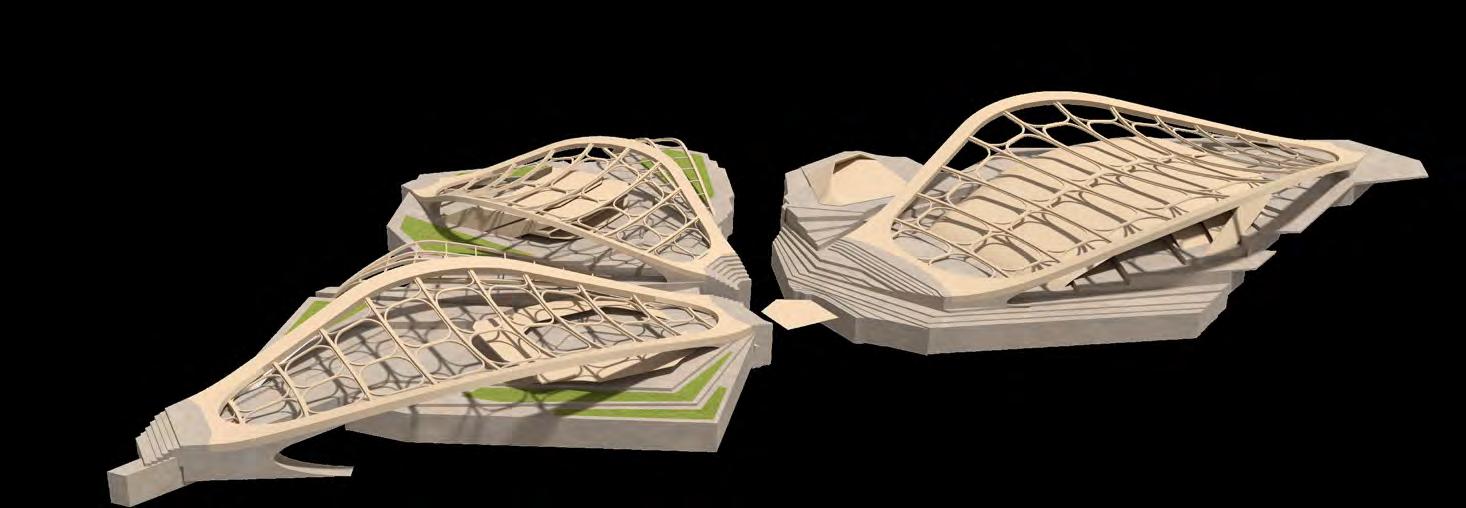

Global form study 4

Plinth condition/Programmatic arrangement

Arena floors and services imprinted within plinth

The building is imagined as a series of different large scale halls with more informal programme inserted between all under one roof. Zippered acoustic panels serve to create appropriate acoustic environments within the open plan arrangement. Tectonic articulation of the roof is reminiscnet of the highly precise tectoncis of an instrument. A series of routes are created through the building through a continuous floor condition

Landscape plinth condition

Undulating roofscape

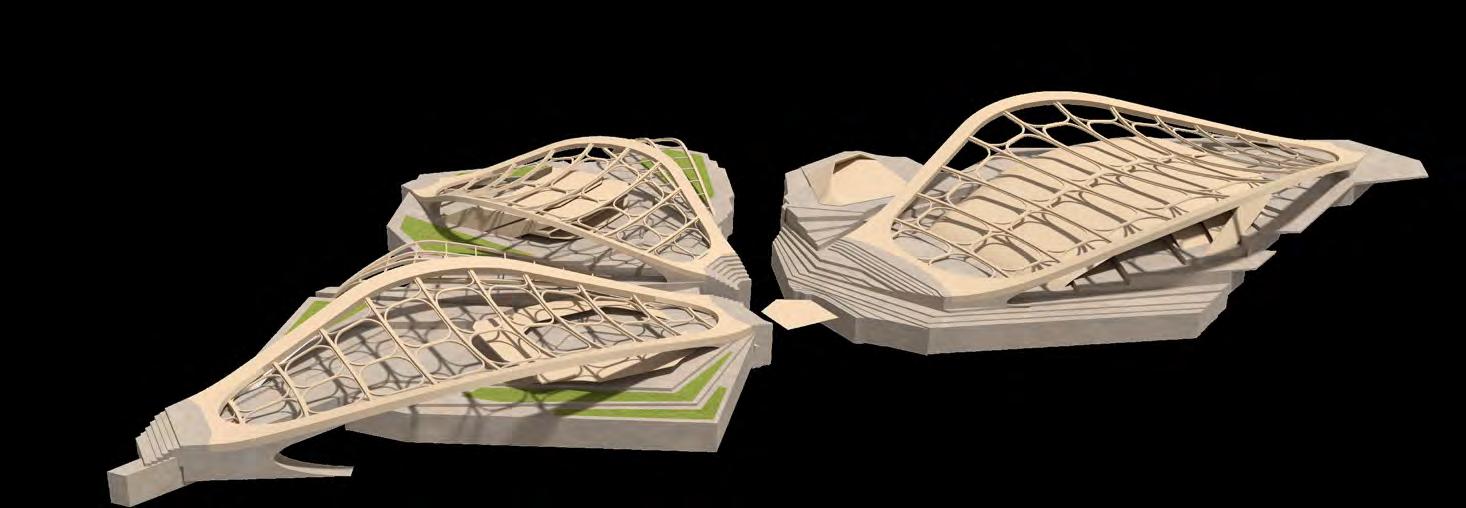

Plan studies 1

Plan studies 2

84 85

The building seeks to integrate with the site through a formalisation of landscape and a distinct relation to the external within each of the halls. Arrangements are tested in plan.

The building seeks to integrate with the site through a formalisation of landscape and a distinct relation to the external within each of the halls. Arrangements are tested in plan.

Global form study 6b: Condensed

86

Plinth condition/Programmatic arrangement

The building is imagined as a series of different large scale halls with more informal programme inserted between all under one roof. The tectonic articulation of the roof is reminiscnet of the highly precise tectoncis of an instrument. A series of routes are created through the building through a continuous floor condition

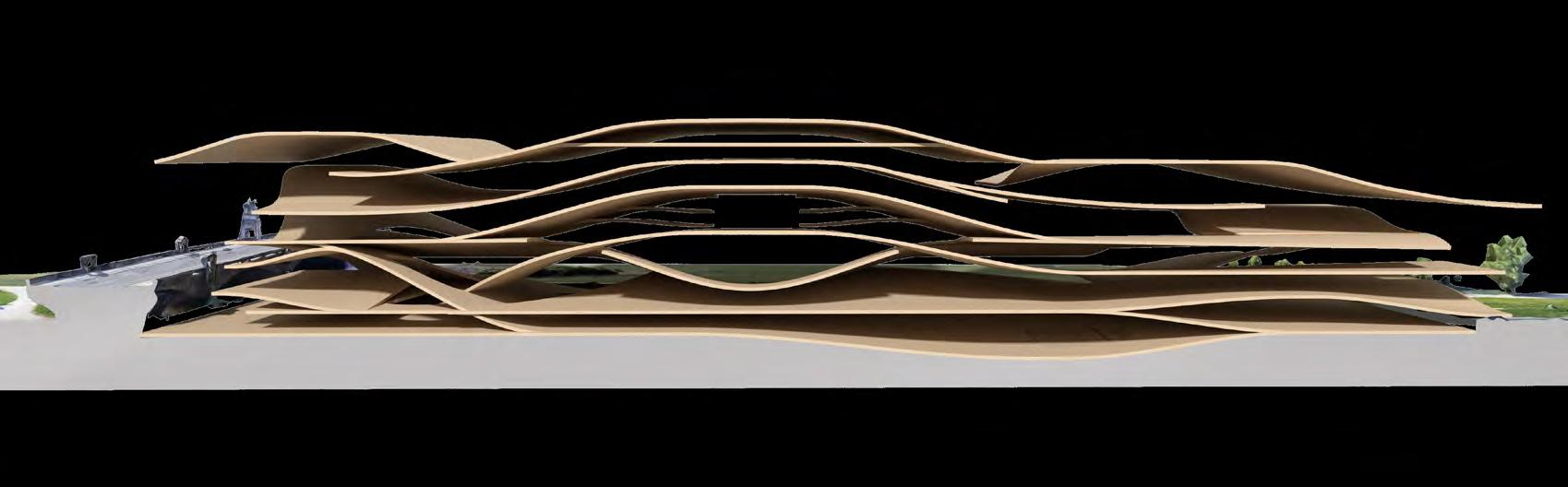

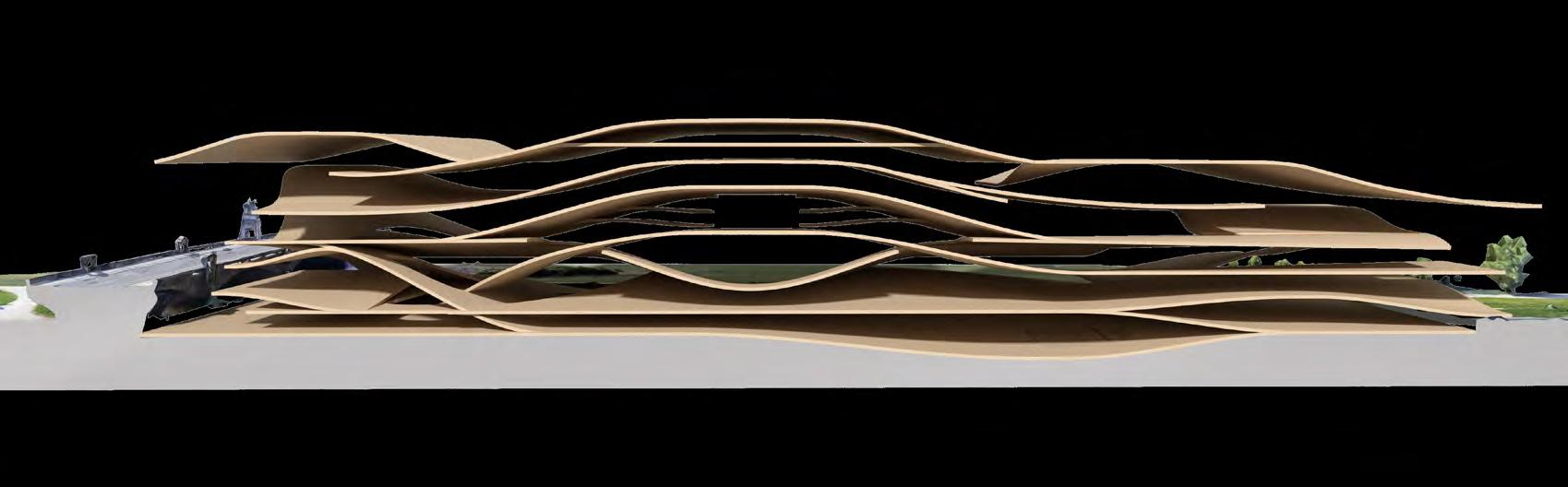

Simple section (long)

Simple section (short)

Global form study 5: radial/axial

87

Plinth condition/Programmatic arrangement

The building is imagined as a series of different large scale halls with more informal programme inserted between all under one roof. The tectonic articulation of the roof is reminiscnet of the highly precise tectoncis of an instrument. A series of routes are created through the building as the plinth reforms the surrounding landscape.

Simple section (long)

Simple section (short)

Global form study 6: Route through The building is imagined as a series of different large scale halls with more informal programme inserted between all under one roof. Zippered acoustic panels serve to create appropriate acoustic environments within the open plan arrangement. The tectonic articulation of the roof is reminiscnet of the highly precise tectoncis of an instrument.

88

Plinth condition/Programmatic arrangement

Simple section (long)

Simple section (short)

89

Plinth/Superstructure Fragment

The main hall is set up as a fragment to test different tectonic approaches for enclosing the halls.

90

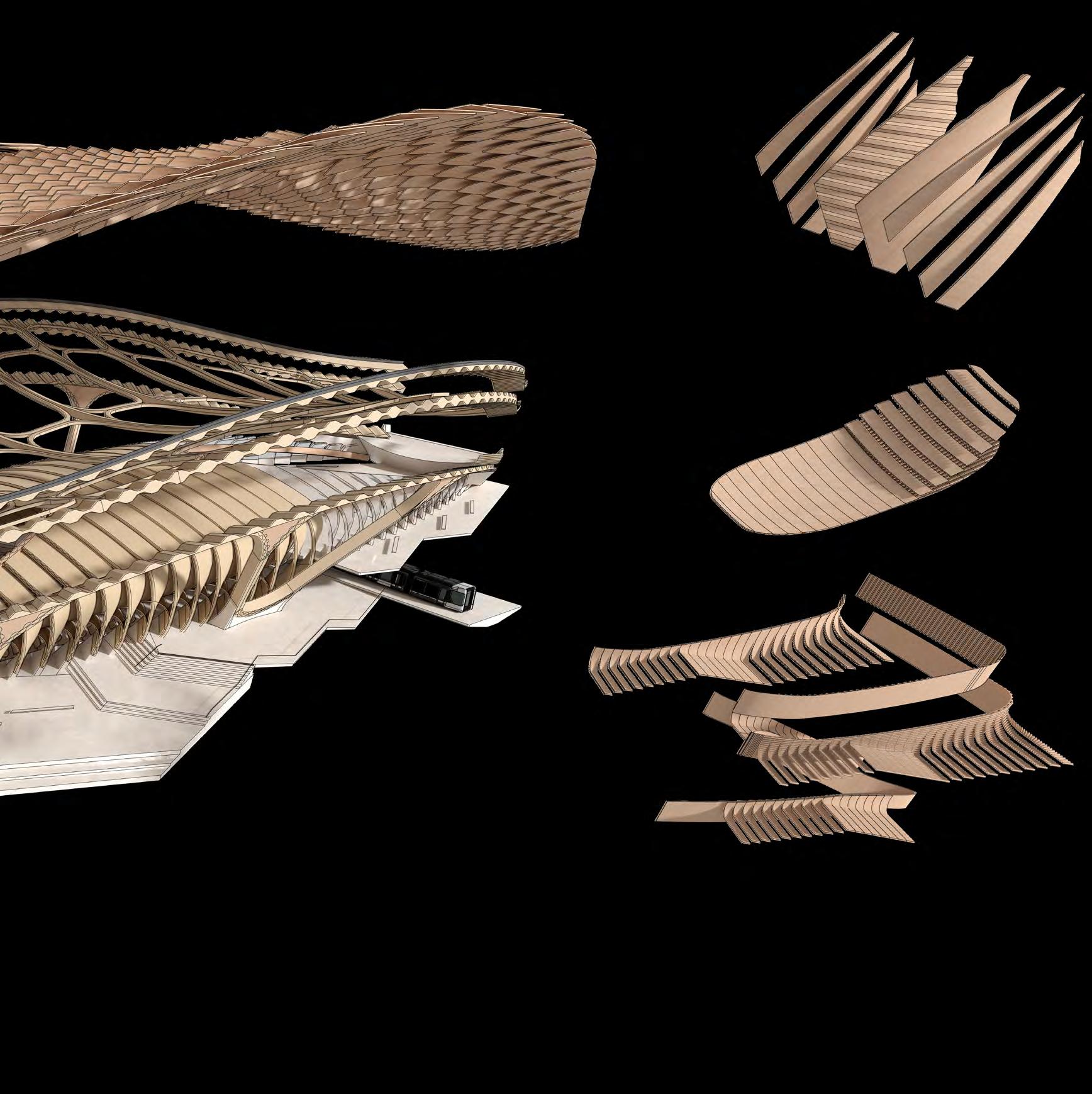

Zippered shingles

The shingled roof construction allows for toplighting through the twisting of covering shingles. These are constructed as zippered panels, allowing for their discrete distortion.

Line attractor - scaled down

Line attractor - large scale shingle

Surface attractor

Surface attractor

Zippered shingle variation

Flat shingle: cross laminated

Low twist, low curvature: zippered

Low twist, medium curvature: zippered

Shingle tectonics

High twist, high curvature: zippered

91

A rainscreen membrane is placed below the shingles while their zippered twisting enables a top lighting of the spaces below.

Shingle roof assembly logic

Highly durable modified timbers as outer face to zipper.

92 93 Facade Options 02 Facade options utilising the zip-formed bending system are tested at higher resolution. Wall option1 Wall option 2 Wall option 3 Facade Options 02 Facade options utilising the zip-formed bending system are tested at higher resolution. Wall option4 Wall option 5 Wall option 6

94 95

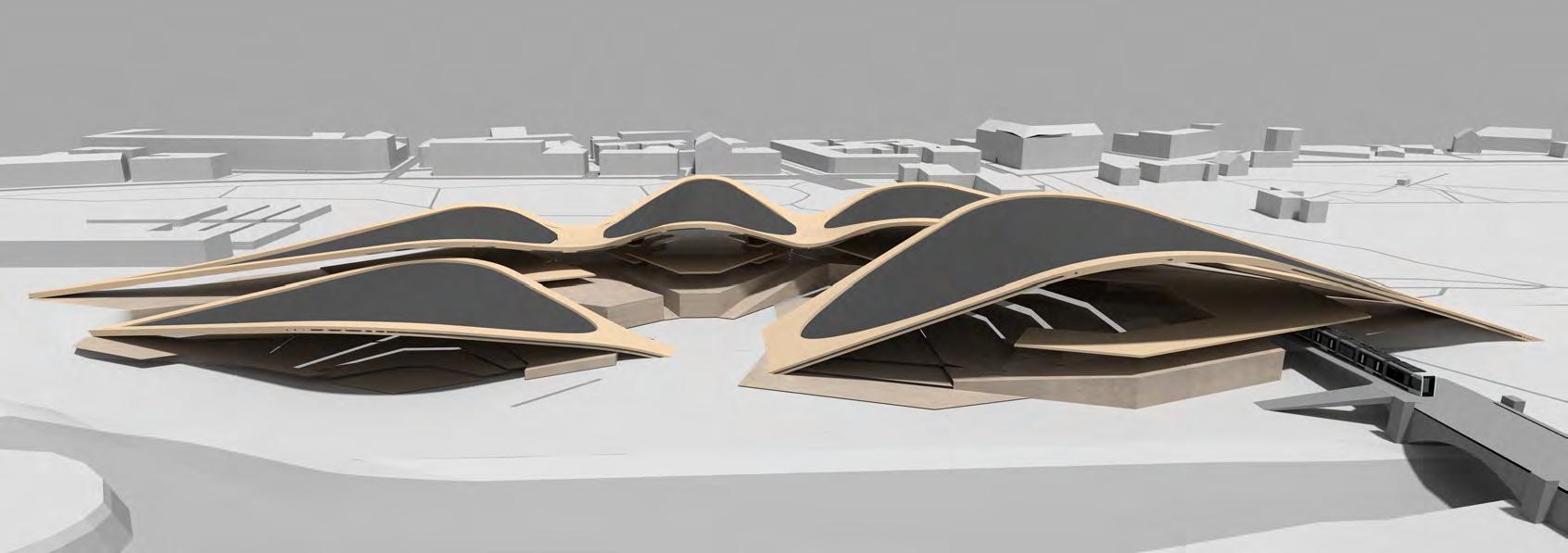

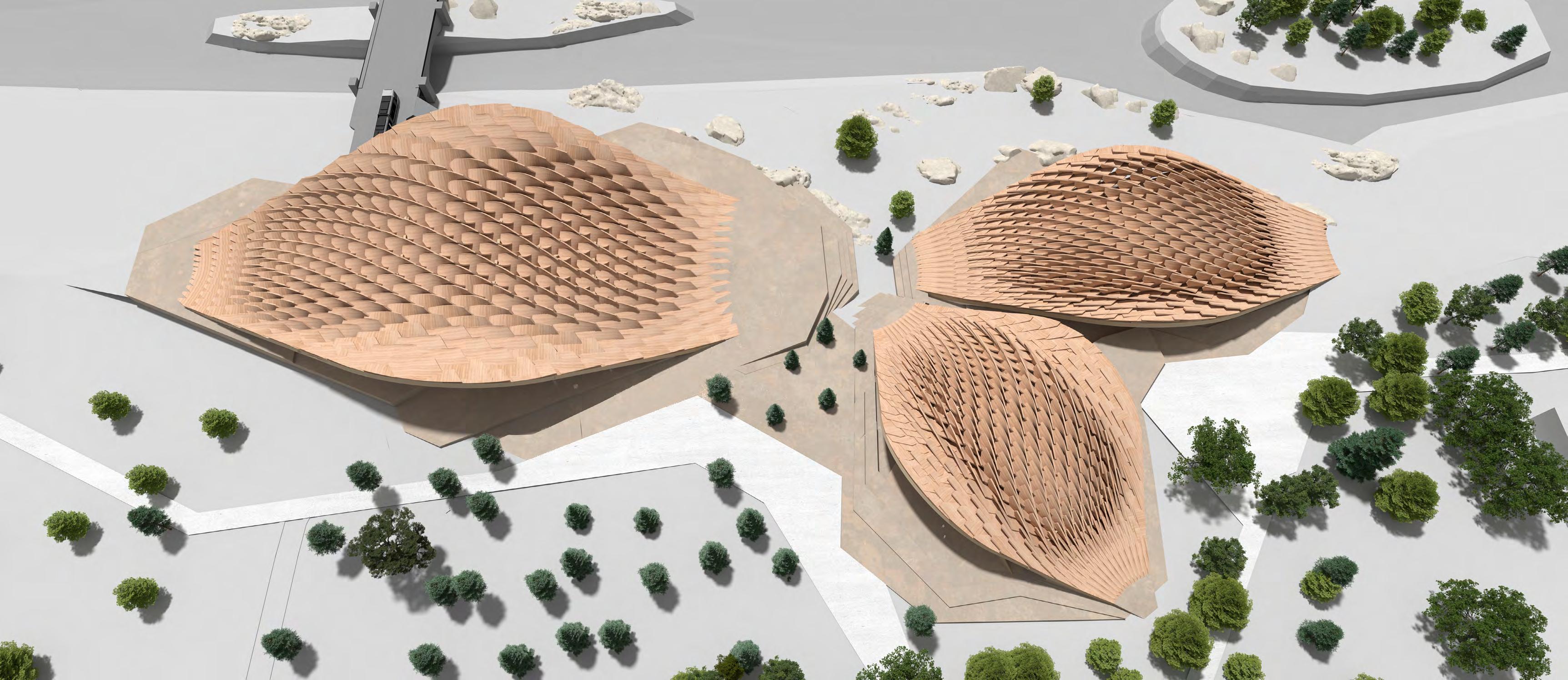

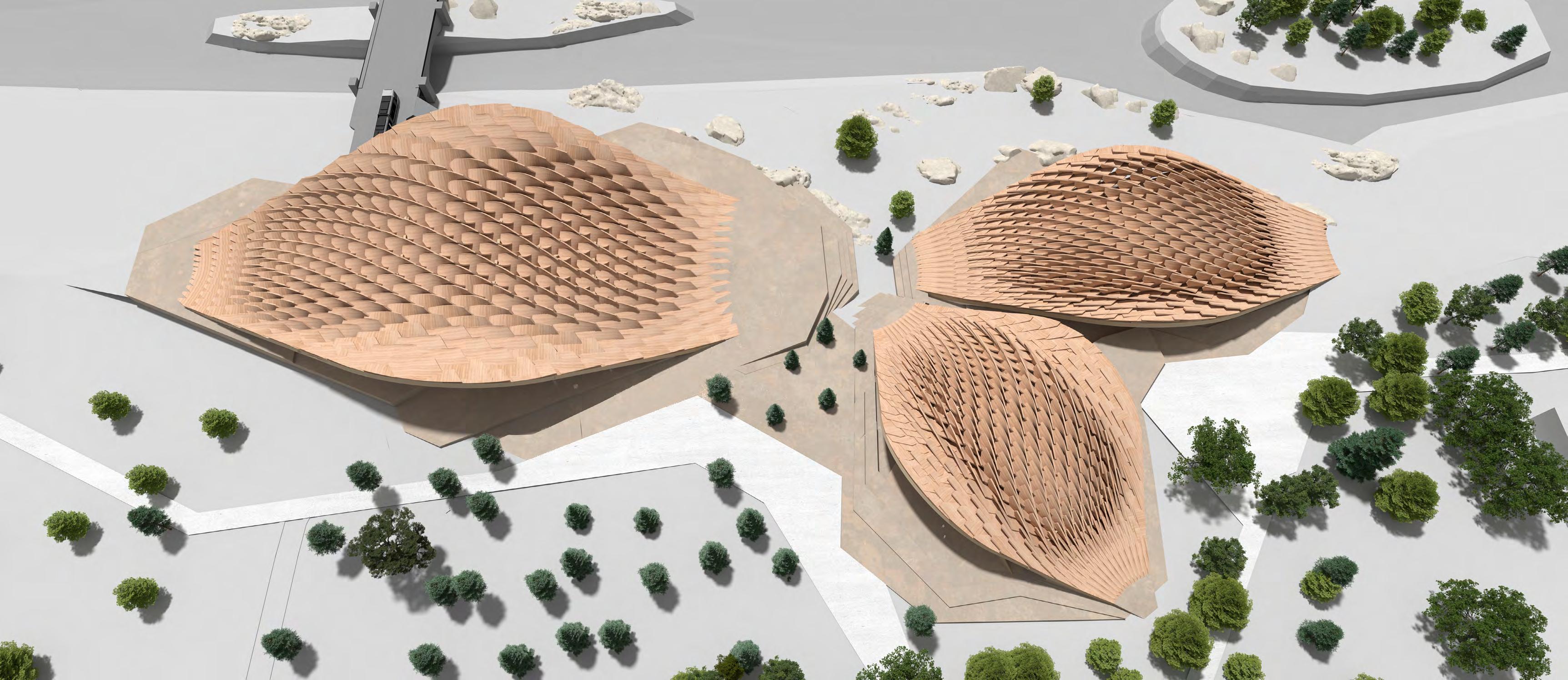

Global form study: 3 Hall Arrangement

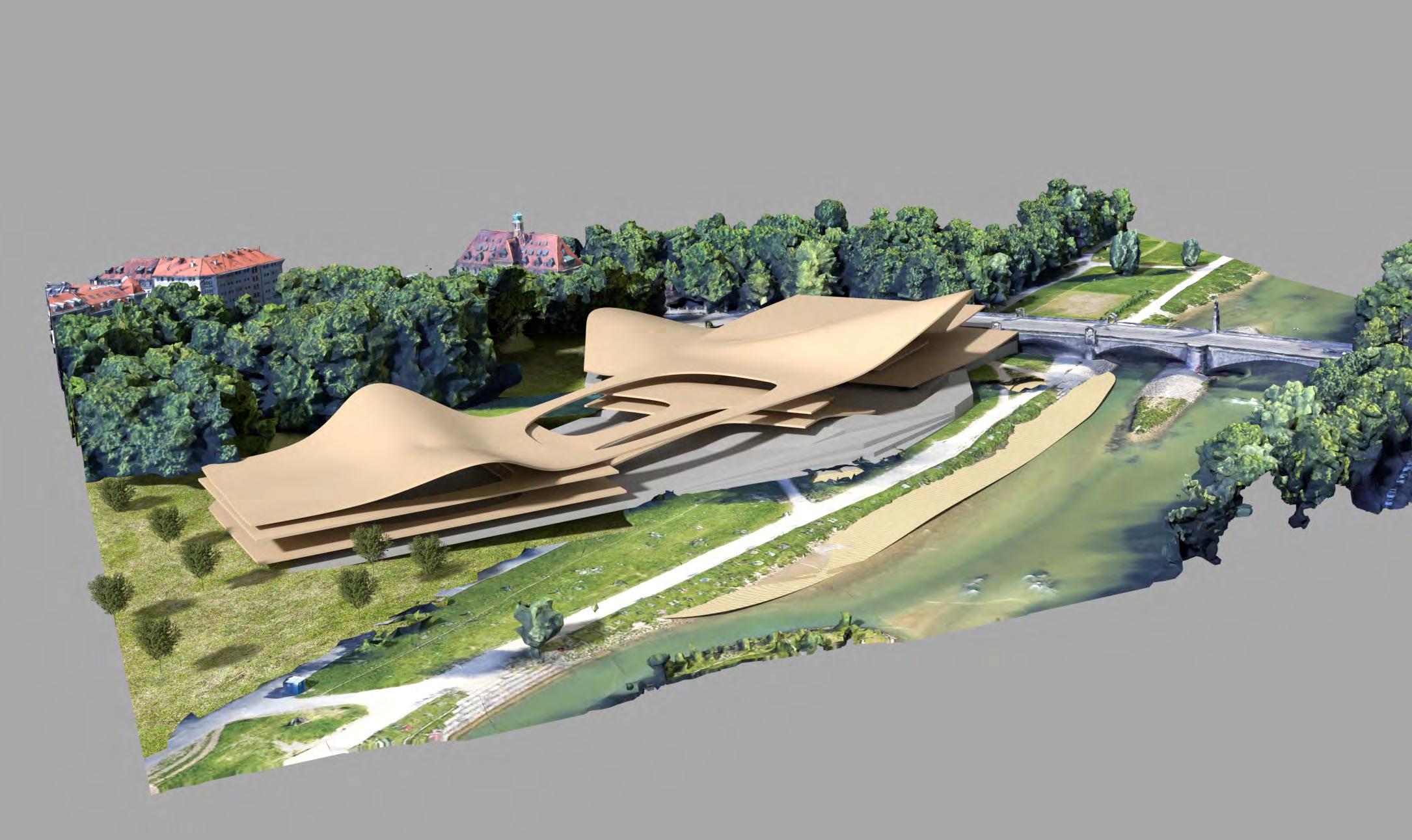

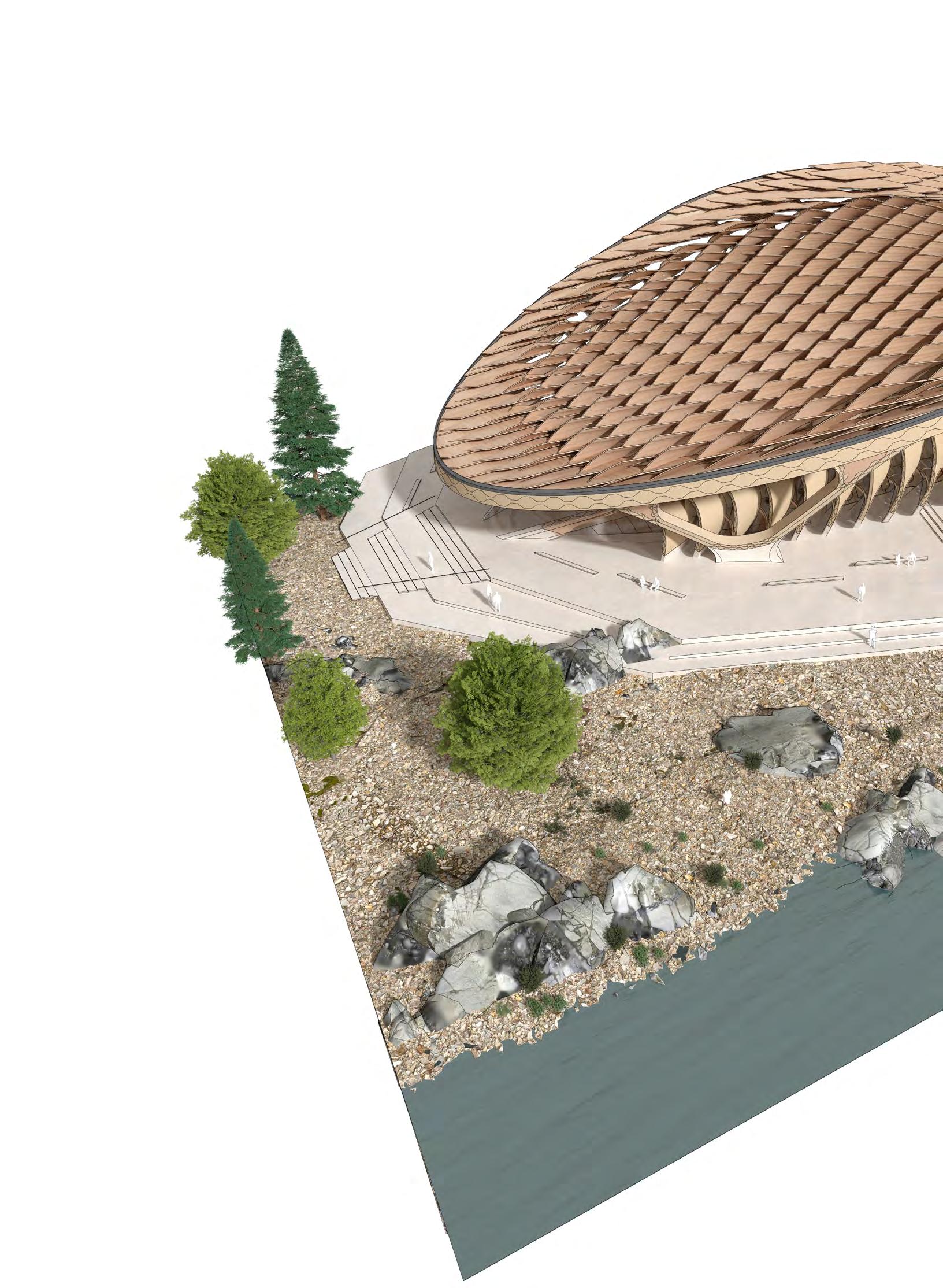

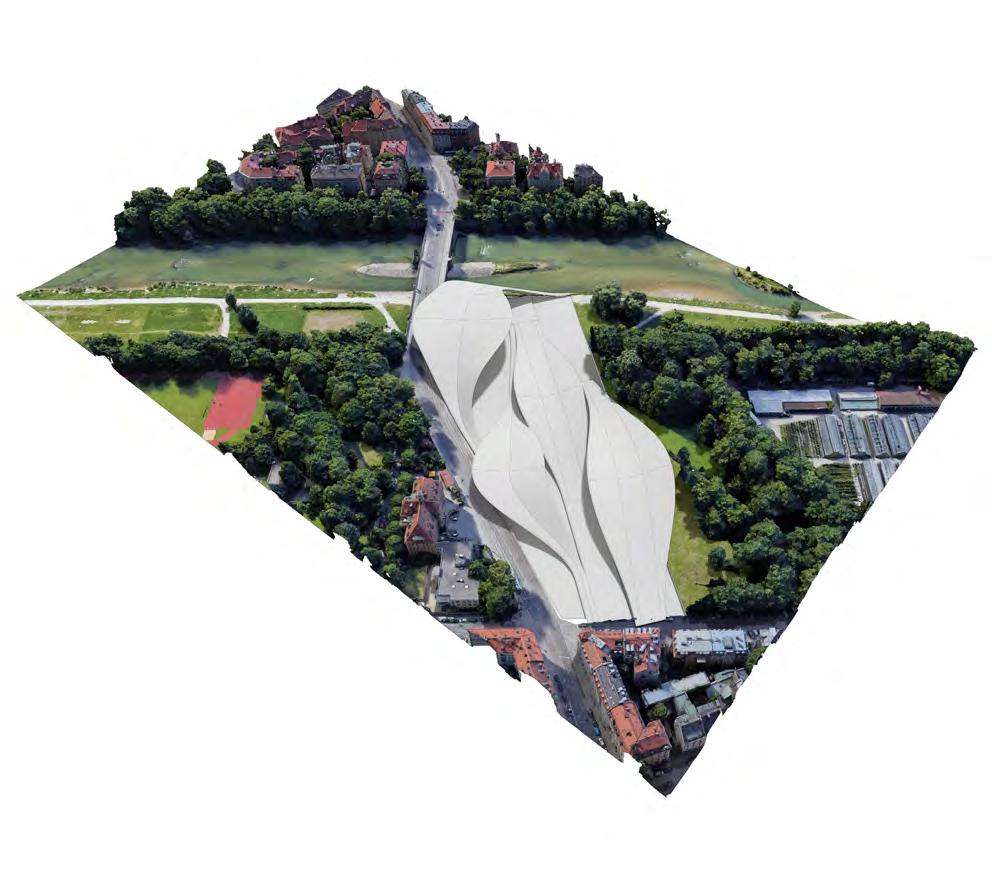

An arrangment of 3 halls is developed which integrates the landscapes of park and beach, bridging accross the road to create a continuous walkable area.

Plinth

condition/Programmatic arrangement

Landscape

plinth condition Arena floors and services imprinted within plinth

Undulating roofscape

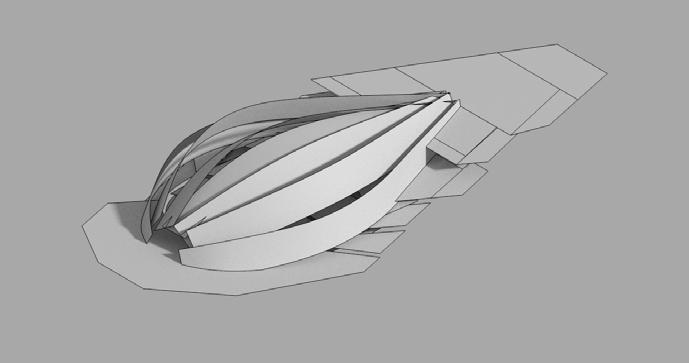

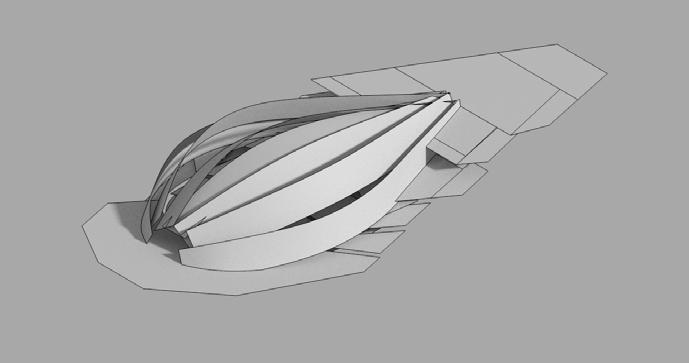

Roof Form Iterations

Different iterations for the roof form are tested in order to define the final form, driven by the formal possibilities of the zippered system. The final anticlastic form sees the topography change of the site as an architectural opportunity, rising from the ground at one end, while being lifted on supports to allow access to the central courtyard.

96 97

Iteration 1: Arch meeting ground

Iteration 3: Roof raised on V-supports version 2

Iteration 2: Roof raised on V-supports

Iteration 4: Form elongated and rising from the ground to one side

Form finding through developable ruled surface generation (Kangaroo)

Performance Hall Overall Enclosure

The surface generation tools used in the original prototyping experiments are employed in a form finding exercise for the overall building. The possibilities of the zippered surface to twist and open up are employed to create a public facing concert hall.

98

Longitudinal

Lateral

Lateral with torsion

1. Surface modelled as planar quad mesh

2. Mesh pulled onto guide curve

3. Anchor point force increased and mesh pulled strongly

4. Twist can be applied to surface

99

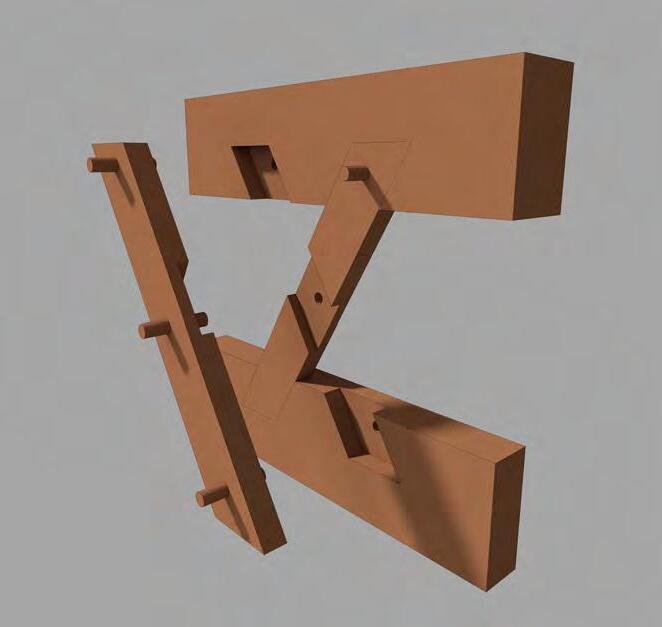

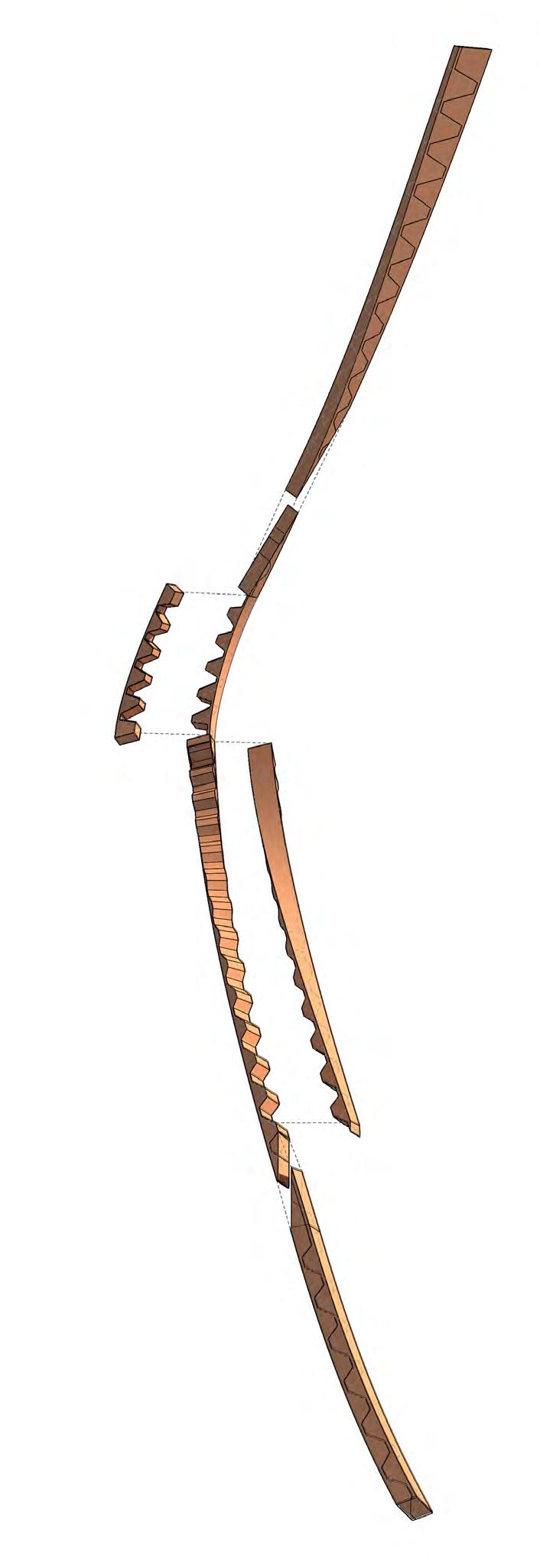

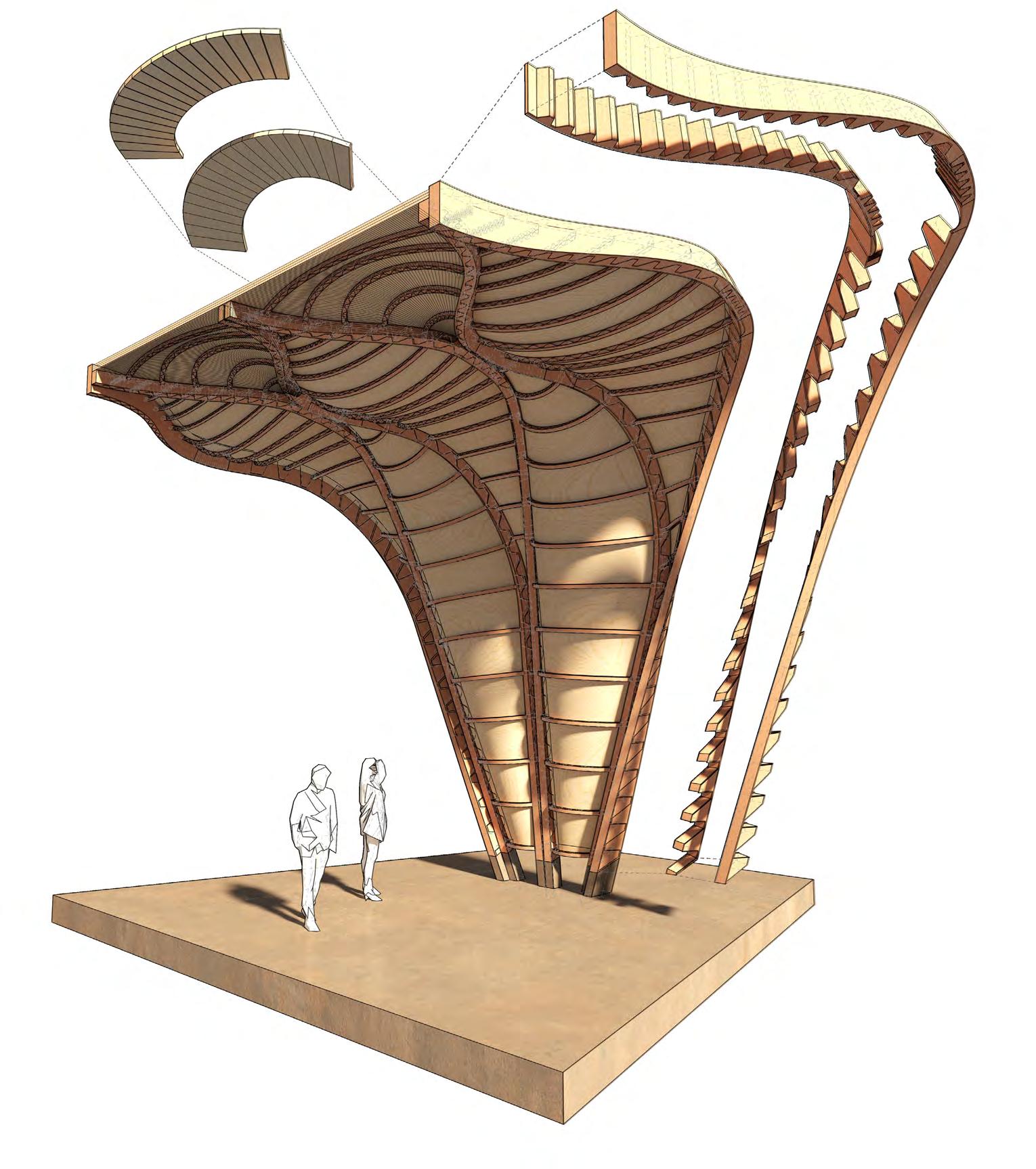

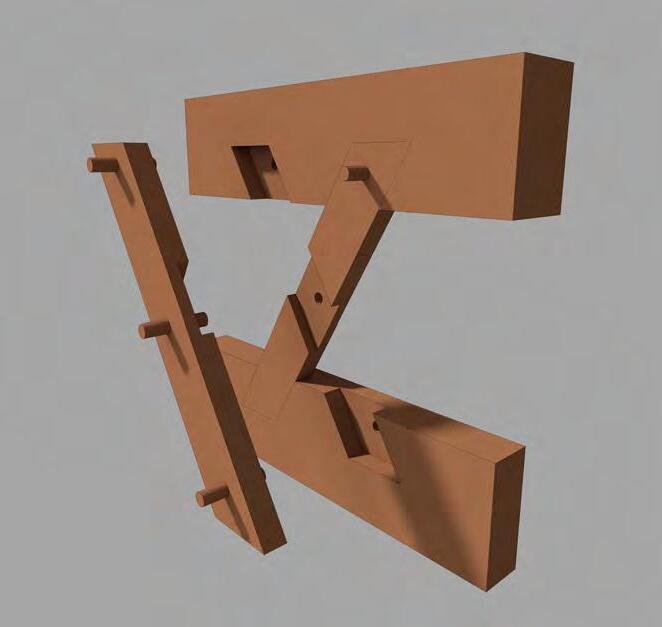

Ringbeam Component Discretisation

A series of different double curved blanks are fabricated to create an assembly of 8 individually self-formed zippered elements.

Building part protoype 1: Ringbeam fabrication Methods are refined for producing the zippered component with thought given to scalability and architectural component creation.

100

1. Large blank glued up at 10mm thickness

2. Parts nested

3. Parts cut on CNC

4. Self-forming procedure with vacuum bag

5. Dry fit

299.10 580.90 38.78 60.00 60.00 75.00 173.00 64.50 173.00 75.00 75.00 42.82 35.74 75.00

6. Glueup procedure

101

Building part protoype 1: Ringbeam Fragment Different blanks are created in double curved form. In absence of finger jointing machinery, a lapping method usign two layers of material is developed to preserve grain continuity in the component.

Fig 3.36 Curved blanks with good grain aligment could be made through finger jointing straight sections of timber together (Author)

Finger jointing between sections for creation of curved blank

102

Building part protoype 1: Ringbeam Prototype

The ringbeam prototype demonstrates the assembly possibilities of the tools developed, composed of 8 individually formed parts.

Surface generation of the building’s parts using tools developed to ensured developability.

Straight unrolling Conical unrolling Hybrid straight and conical

Form finding zip system: Balcony fragment

Component 2: Conal and straight unrolling hybrid

Component 3: Conal unrolling element

A part of the building is shown at higher resolution, composed of a combination of double curvature and straight zippered parts.

103

104

Building part protoype 2: Bifurcating Node

The bifurcating joint at the top of the V-brace columns is developed through fabrication testing. By integrating an infill element with a zip-tooth pattern cut to it, a mouldless formation of the joint is possible. A development of the creation of these infill pieces could be as a panel rather than mass timber element. The node can be reinforced by laminating further zippers externally.

105

Building part protoype 2: Bifurcating Node

A preliminary prototype for future development: the bifurcating node could be reinforced with further zippers externally.

106

to create a convex doubly curved surface, as suited to the reflection of sound.

employed

Robotic bandsaw cutting principle can be applied at the larger scale

Raytracing shows principle of reflector layout

Unrolled geometry

Overlapping of splices allows for the creation of larger scale surfaces

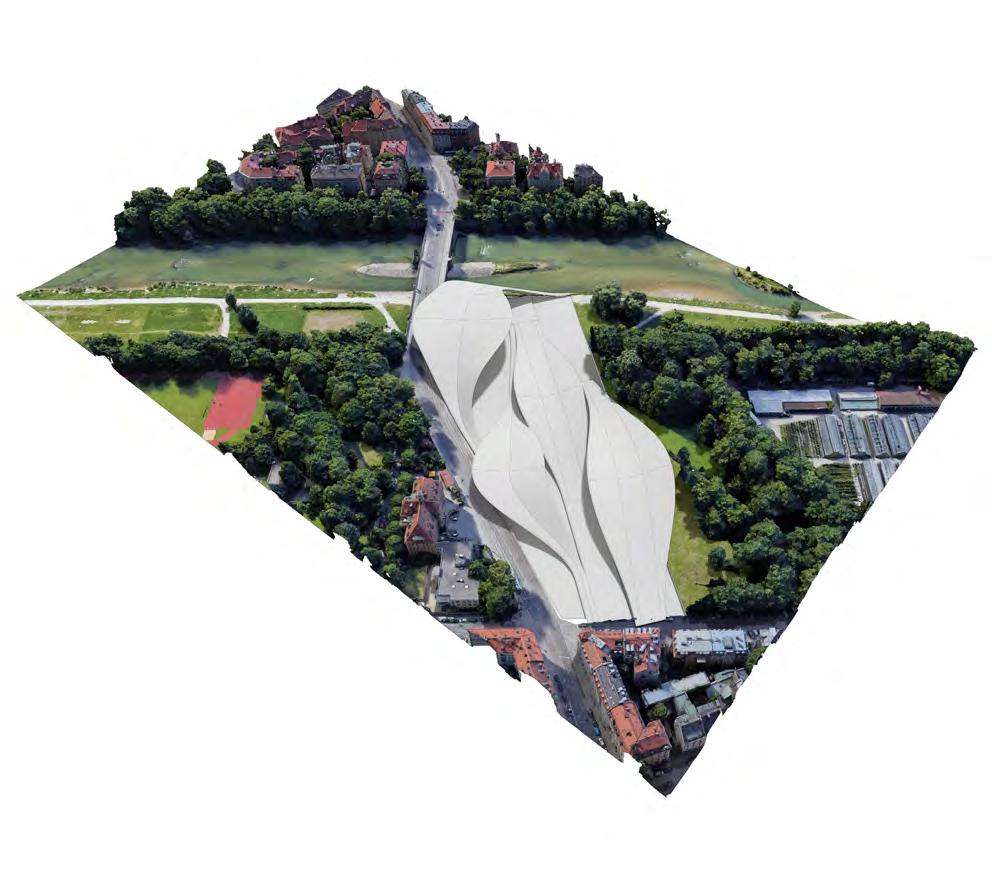

Final Site Plan: An Urban Park Scale 1:2000

The final building arrangement is composed of 3 halls which negotiate and bring together the different conditions of city, park and beach at this site. A thoroughfare through the centre of the complex curates the transition between the environments, leading to the central plaza and breakout zone, from which the halls can be accessed.

107

108

Final Site Plan Iteration 7 Scale 1:2000 - radial 01

The building is imagined as a series of different large scale halls with more informal programme inserted between all under one roof. Zippered acoustic panels serve to create appropriate acoustic environments within the open plan arrangement. A series of routes are created through the building through a layered plinth condition.

109

1234567891011121314151718

FFL+19.55m-RoofShingleTopEdge

FFL+11.70m-RoofShingleTopEdge

FFL+3.45m-BalconyLevel

FFL+/-0.00m-GroundLevel

FFL-3.15m-Lobby

FFL-8.75m-MainStageLevel

FFL-7.65m-BeerHall

FFL-12.65m-Basement/BackofHouse

AE BCD

FFL+27.80m-RoofShingleTopEdge

FFL+13.00m-RoofUnderside

FFL+7.60m-ViewingBalconyLevelI

FFL+/-0.00m-MainStage

FFL-4.25m-BeerHall

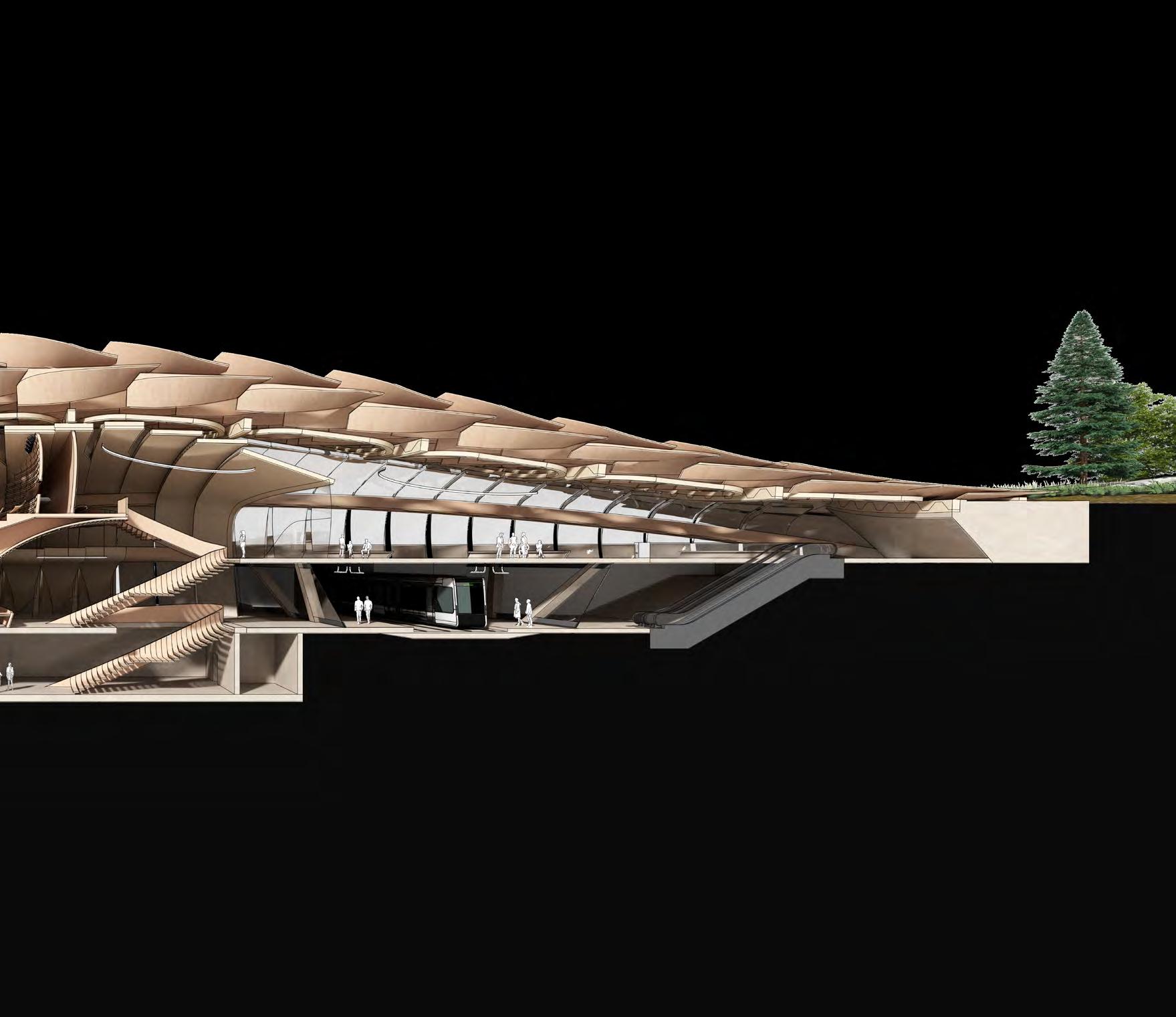

Final sections: Linear The section reveals the architecture’s opportunistic a series of different conditions in the building. orchestrating a clear transition between urban service spaces for the halls are situated underground, above column-free

110

16

Linear organisation

opportunistic use of the site’s level change to create building. Spaces are arranged in a linear fashion, urban interface, lobby, hall and landscape. The underground, allowing for the full inhabitation of the column-free space.

111

1920212223242526272829303132333435363738394041424344454647484950 F

r= 2968mm zip skin =14mm

r= 8962mm zip skin =45mm

r= 68453mm zip skin =50mm

Single hall fragment: A meeting The building negotiates the collision of different curated and brought together around the performance are underpinned by the fabrication logic of the zippered on the scalability of the methods developed to

112

meeting point of landscapes

different forms of landscape: park, beach and city are performance spaces. The building’s complex forms zippered experiments. The building speculates to create architecture driven by material logic.

113

Zippered roofsubstructure

Zippered V-supports

Zippered hall enclosure and balconies

Single hall fragment: Form The building’s complex forms are underpinned experiments. The building speculates on the scalability architecture driven

114

115

Form driven by tectonics underpinned by the fabrication logic of the zippered scalability of the methods developed to create driven by material logic.

Zippered shingle

Zippered reflectors

Zippered staircases

116

Long section: Landscape The central courtyard acts as key urban interface key breakout space for the halls which

Landscape Plaza

interface where different landscapes collide. This is a negotiate and heighten this condition.

117

118

Long section: A concert The hall has both an urban and park interface The performance space is embedded between opening to the city at the point where the master

concert in the city allowing for different streams of entry and exit. between these two conditions, with a large glazed master surfaces of roof and hall envelope peel apart.

119

120

Park Integration

The performance enclosure opens onto the surrounding zones can become spaces for informal performance between the

Integration surrounding park. These interstitial landscape performance as well as acting as the circulation space different halls

121

122

Interior view: entrance Glass walls replace the timber fins in the entrae can be felt as views can be seen through to the

123

entrance lobby

entrae space. the linearity of the barn-like building performance enclosure, drawing the visitor in.

124

Main Hall View: Form The possibilities of the zippered system to open are leveraged to create a performance space with the building type are achieved

125

Form Driven by Tectonics open up and create a porous envelope condition with a view. The reflective surfaces required by achieved through the zippered logic.

126

A Meeting Point of Landscapes: The building leverages the collision of different curated and brought together around the performance architecture.

Landscapes: Celebrating Alpine City Life different forms of landscape: park, beach and city are performance spaces through a carefully crafted architecture.

127

section 4

Appendix: design development

Lobby enclosed by separate structure allowing for insetting of facade

Balconies integrated to zippered fins

Access to back of house beneath stage

Structure tying zippered fins together celebrated as primary element

Performance Hall Stair and balcony integration

Different options for integrating circulation and balcony seating are tested using the zippered logic. The integration of continuous, expressive forms is pursued for this central space.

129 Stair/Balcony integration study iteration 01 Stair/Balcony integration study iteration 02

130

Sectional Study 3 - parallel to river

Sectional studies investigate the potentials of the continuous surface organisation of the building

Main auditorium Main auditorium upper balconies

Public ground foyer with bars/ restaurants

Music school

Studio auditorium

Recital auditorium

Recital auditorium

Studios and

Library/archive Offices

Access to U-bahn station

workshop

131

Global Form Study 1

The building’s stacked organisation allows for the targetted interaction of the building’s different cultural and infrastructural functions. Spaces interlock and are experienced through views and sounds.

Landscape/service plinth

Commercial/circulation

Arena zones

Building arrangement study 02

132

The organisation of the building is stripped back into 3 components: landscape plinth (containing key services and imprinting down to create arena seating), commercial zone (brewhouses and industry fair as distilled elements of the alpine civic) and arena stages.

Arrangement study 01: Cluster

Arrangement study 02: Linear

Arrangement study 03: Radial

Building arrangement study 1

Sectional studies investigate the potentials of the continuous surface organisation of the building in simple form

133

134

Global form study: 3 halls, lower The building is imagined as a series of different gramme inserted between all under one roof. propriate acoustic environments within the open created through the building through

Undulating roofscape

Landscape plinth condition

lower elements, reduced plinth different large scale halls with more informal proZippered acoustic panels serve to create apopen plan arrangement. A series of routes are through a layered plinth condition.

135

Plinth condition/Programmatic arrangement

Arena floors and services imprinted within plinth

All work produced by Unit 14

Unit book design by Charlie Harriswww.bartlett.ucl.ac.uk/architecture

Copyright 2021

The Bartlett School of Architecture, UCL All rights reserved.

No part of this publication may be reproduced or transmited in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage and retreival system without permission in writing from the publisher.

-

@unit14_ucl UNIT

Cover design by Charlie Harris

Cover design by Charlie Harris

Structural Performance in Vulture’s Wing Bone Diagrams explain the targeted densification of reinforcement within the wing bone to cope with extreme loading conditions (Sullivan et al, 2017)

Structural Performance in Vulture’s Wing Bone Diagrams explain the targeted densification of reinforcement within the wing bone to cope with extreme loading conditions (Sullivan et al, 2017)