HOT-HOLD OR GRAB & GO HOT FOOD CHILLED FOOD TO-GO FOOD ProAmpac’s Food To-Go Packaging is designed for sustainability and built for performance ProAmpac’s Food To-Go Packaging enhances product and shelf presence while helping customers meet their sustainability goals. Our fibre-based packaging is widely recyclable in paper streams when film barrier is removed, and increases operating efficiencies for our customers. Visit www.proampac.com/food-to-go/ to view our extensive collection of specialist chilled and hot products SALES freshfoodtogo@proampac.com HOTLINE +44 (0) 20 8069 0700 PROAMPAC.COM FOOD SERVICE PACKAGING ISSN: 20568355 Volume 24 • Issue 04 • FOOD AND DRINK NETWORK UK SOLUTIONS FOR YOUR FOOD WASTE ‘PROBLEMS’ The end goal is simple but the process is far from it... Turn to Page 23

www.markem-imaje.com Printer Intelligence. Packaging Intelligence. Brand Intelligence.

EDITORIAL:

ADVERTISEMENT SALES:

KIMBERLEY

AMANDA

STUART TURNBULL -

WALTONS PUBLICATIONS LTD

46 HENEAGE ROAD, GRIMSBY N.E. LINCOLNSHIRE DN32 9ES

Kimberley Read at: kimberley@ foodanddrinknetwork-uk.co.uk or Gina Maddison at: gina@foodanddrinknetwork-uk.co.uk

foodanddrinknetwork.co.uk

HOT-HOLD OR GRAB & GO HOT FOOD CHILLED FOOD TO-GO FOOD ProAmpac’s Food To-Go Packaging is designed for sustainability and built for performance ProAmpac’s Food To-Go Packaging enhances product and shelf presence while helping customers meet their sustainability goals. Our fibre-based packaging is widely recyclable in paper streams when film barrier is removed, and increases operating efficiencies for our customers. Visit www.proampac.com/food-to-go/ extensive collection of specialist chilled and hot products freshfoodtogo@proampac.com FOOD SERVICE PACKAGING Astell Air Products Eriez Biopak Harford Control Multimodal Curious Heads Media PPMA William Reed Exhibitions Yakult UK Limited

READ (Advertisement Sales Manager) GINA MADDISON

WALMSLEY

WOOLSTON

EVELYN

Manager

Designer

Studio

RACHEL RILEY -

02 04 NEWS NETWORK Q&A WITH YAKULT All rights reserved. No part of Food and Drink Network UK Magazine may be reproduced or stored in a retrieval system or transmitted in any form, electronic, mechanical or photocopying, without prior written permission of the publishers. The publishers do not accept responsibility for views expressed, or statements made, or in those reproduced from any other source. No responsibility is borne by the publishers for any errors made in any advertisement, or for claims made by any advertiser which are incorrect. The publishers cannot be held responsible for any breach of copyright arising from any material supplied. This includes copy, design and/or images. Find us on LinkedIn Copyright © 2024 All Rights Reserved. 01472 359036 ProAmpac and Sammi join forces for sustainable fiber-based packaging innovation The cream of the crop: Supporting the resilence of the UK dairy industry Solutions for your food waste ‘problems’ As the issue of food waste rises to the forefront of the sustainability agenda within our industry, producers are striving to show they are part of the solution rather than the problem. Cross and Morse: Makes conveying easy! VOLUME 24 • ISSUE 04 Produced in Europe’s Food Town SUBSCRIPTION: 12 issues - £84.00 (inc. postage) A guide to the exhibitions and events supporting the Food & Drink Industry ACCOUNTS & ADMINISTRATION: GRAPHICS DEPT: PUBLISHED BY: TELEPHONE: EMAIL: WEBSITE: TWITTER: @fdnetworkuk FOOD AND DRINK NETWORK UK 08 EXHIBITIONS & EVENTS PACKAGING DAIRY SUSTAINABILITY & DECARBONISATION POWER TRANSMISSION SOLUTIONS 19 Navigating the Future: The critical role of Cold Chain Logistics Solutions in the food industry 13. Machine Vision Conference Machine Vision Conference will host an impressive range of exhibitors and seminars 14. Automation UK Discover cutting-edge automation and robotics technologies at Automation UK 16. Food & Drink Expo Reasons to visit... the UK Food and Drink Shows 2024 20. Exhibition News Biopak has been awarded the coveted title of Innovation Award at the 2024 Manufacture Excellence Awards Introducing THE food and drink machinery auction experts... Industrial Auctions 32 FOOD MACHINERY AUCTIONS 21 Streamlining Food Production: The Role of Processing Equipment in the Modern Food Industry How to ensure you process is free from metal contamination PROCESSING EQUIPMENT METAL CONTAMINENT REMOVAL 25 28 31 23 26 Transform manufacturing with Connected Worker An article suppled by Roy Green of Harford Control Ecofill Autoclaves - Revolutionising sustainability in the food & drink industry 06 30 SPECIALIST VIEW ECOFILL AUTOCLAVES 11. Multimodal 2024 The Future of Logistics Unfolds LOGISTICS 09. Sustainable Food Factory First speakers announced for Sustainable Food Factory 2024 24. Revolutionising Food Preservation: How Modified Atmosphere Packaging is tackling food waste 29. Ensuring food safety and equipment longevity: The role of Metal Detectors in the food industry

H-Pack celebrates Great British Chippy with launch of ‘Great Taste’ range of products

Europe’s packaging one-stop shop, H-Pack Packaging has launched a line of products exclusive to fish and chip shops which it expects to appeal to high-end UK chippies that want packaging that stands out, while reflecting the quality of the food it holds.

The new ‘Great Taste’ fish ‘n’ chips packaging range includes a series of small, medium, and large, eye-catching paper boxes and small and large paper bags, with handles. The bags carry the same design as the boxes and are intended to complement those boxes, with the complete range offering an opportunity for sellers to provide a more considered, identifiable offering that appears unique to the individual food retail outlet.

Head of merchant sales for H-Pack, David Martin explains: “Higher ingredients costs and facilities charges have impacted on the price of takeaway meals. The ‘Great Taste’ range enables chip shop owners, who may not have the means to market their products or to create a brand, to maximise their food offering with packaging that stands out and elevates the

Enabled by the Recycling Alliance: ALDI rolls out innovative TANDIL bottle and top made almost entirely from PCR

• Interseroh+ supports the ALDI Packaging Mission

• Optimised packaging for TANDIL washing machine cleaner on sale now

• Bottle and top made almost entirely from postconsumer recyclate (PCR)

Interseroh+ is once again helping ALDI to close the material loop for plastic packaging from the ‘yellow bag’ or ‘yellow bin’ in Germany. In mid-February, ALDI SÜD introduced new packaging for its own-brand TANDIL washing machine cleaner made out of almost 100% post-consumer recycled plastics (PCR). The product will be available on the special offer shelves at ALDI Nord in early summer.

This is ALDI’s second packaging innovation in conjunction with strategic partner Interseroh+ after its packaging for TANDIL 3-in-1 Caps, which was recognised in the Sustainability category of the German Packaging Awards as well as in the Household category of the WorldStar Awards. “Using recyclates results in considerable savings when it comes to greenhouse gas emissions and primary energy. We’re glad to be able to help ALDI optimise its packaging and work together to take another important step towards sustainability,” said Frank Kurrat, CSO at Interseroh+.

The packaging for TANDIL washing machine cleaner is a genuine innovation, as for the first time its bottle and top are made from at least 95% PCR derived from recycled lightweight packaging. The body of the bottle is made from HDPE (high-density polyethylene) using blow moulding, while injection moulding is used to manufacture the top from PP (polypropylene). “We optimised the characteristics of the recycled materials for both packaging elements and adapted them to the customer’s specific requirements,” explained Dr. Manica Ulcnik Krump, Managing Director Interzero Plastics Innovations.

These customised formulations developed at the company’s own competence centre for recycled plastics ensure that the materials perform as desired, irrespective of the consistency and composition of the raw material. This product innovation results in significant savings on raw materials, energy and carbon emissions compared to using new plastics.

ALDI has been part of the Recycling Alliance since 2022. This strategic partnership encompasses Interseroh+’s entire spectrum of packaging recycling services – from packaging licensing and optimising the recyclability of packaging to developing new formulations for plastic applications.

overall appearance of the meal provided. There’s no great price difference between ‘Great Taste’ bags and boxes and those of the plain brown or white variety but the range makes any offering look higher value. Given that, we’d say to any chippy owner, the ‘Great Taste’ range must be one to try.”

H-Pack is the UK arm of leading, global food packaging brand, Hotpack and, as such, can offer bespoke custom products, working with pioneering new materials and state of the art machinery and technology, along with its internationally recognised, premium lines.

For further information visit h-packglobal.com

Zippy Edibles Chooses Coperion as Partner for the Advanced Production of Plant-Based Meat Analogues

To significantly advance its production, Zippy Edible Products Pvt Ltd, Rudrapur/India, decided on a Coperion ZSK 54 Mv PLUS twin screw extruder with a cooling die and a highaccurate Coperion K-Tron K2-ML-D5-T35 feeder to manufacture High Moisture Meat Analogues (HMMA).

With this state-of-the-art extrusion system, the company is not only able to produce various types of meat analogues that are tailored to the dynamic needs of the Indian market but also enters a new era of food processing using extrusion technology.

Zippy Edibles produces various plant-based dishes such as Soya Chaap, a popular North Indian delicacy known for its meat-like texture, on the Coperion system. This versatile food extruder is ideally suited for this task as it offers high operational reliability as well as a flexible and economical production set-up. The ZSK 54 Mv PLUS twin screw extruder features a specific torque of 11.3 Nm/ cm3 and screw speed up to 1500 min-1 ensuring a constantly high quality level. With the high throughput of the machine the Indian food specialist is able to produce up to 500 kg per hour of HMMA and can thus meet the high demand for vegetarian products. Thanks to the deeply cut screw flights with a diameter ratio Do/Di of 1.8 the system ensures a very large free screw volume that improves the feed intake of plant-based ingredients that are often poorly flowing. Furthermore, the modular process section of the extruder can flexibly be adapted to changing requirements, giving Zippy the possibility to expand their range of protein products over time. The versatility of the Coperion extruder allows for extensive control over various parameters to create different types of extrudates which can be formed, coated and marinated to target the individual market needs.

For more information visit www.coperion.com/plantbasedproteins

News Network 02 | foodanddrinknetwork-uk.co.uk General

Further information can be found at www.interzero.com

SGS delivers Qatar’s conformity assessment program for food

SGS, the world’s leading testing, inspection and certification company, is an approved body for Qatar’s conformity assessment program for food.

Implemented and monitored by the Food Safety Department of Qatar’s Ministry of Public Health (MoPH-FSD), this program requires food consignments to the country to be assessed and achieve a certificate of conformity (CoC). As a MoPH-FSD approved assessment body, SGS assesses restricted products, including meat and meat products, honey, seafood and genetically modified products, against Qatari technical standards and regional requirements.

Comprehensive expert advice is given to exporters throughout the certification process. This includes support with registration for the electronic safety system WATEQ, quality management systems, labeling, inspection reports and required product sample analysis documentation.

Made Smarter and tech institutes join forces to demystify digital transformation

New white paper aims to inspire and inform SME manufacturers in food and drink sector about technology adoption

Made Smarter and leading technology demonstrators have joined forces to demystify digital transformation with a new white paper. ‘Made Smarter technologies: powering the digital transformation of SME manufacturers’ is a practical guide from the government-backed and industryled technology adoption programme in the North West.

The free-to-download document aims to inform and inspire manufacturers exploring existing technologies such as software, industrial IoT, automation and robotics, 3D printing, and cyber security, while showcasing emerging digital tools like artificial intelligence (AI) and digital twins.

The white paper is backed by industry-leading institutions who work with Made Smarter to demonstrate technology in action to SME manufacturers, including:

• the North of England Robotics Innovation Centre (NERIC), the University of Salford’s state-of-the-art for automation and robotics;

• PrintCity, Manchester Metropolitan University’s 3D printing facility;

• The Manufacturing Technology Centre (MTC) in Liverpool, part of the High Value Manufacturing Catapult;

• the Advanced Manufacturing Research Centre (AMRC) North West, based in Samlesbury, Lancashire;

• The Hartree Centre at Sci-Tech Daresbury, Cheshire.

The white paper also showcases Made Smarter-supported manufacturers already reaping the rewards of technology adoption, including: Fylde Fresh and Fabulous and First Play Dietary Foods.

For more information about Made Smarter and to download the white paper visit: https://www.madesmarter.uk/resources/made-smartertechnologies-how-made-smarter-inspires-digital-transformation

With decades of experience in managing conformity assessment programs around the world, SGS’s global network provides costeffective and tailored solutions for businesses to ensure the regulatory conformity of shipments and boost product quality.

Learn more about SGS and Exporting Food Products to Qatar visit https://www.sgs.com/en/news/2024/03/pca-2024-q1-exportingfood-to-qatar

Nation’s favourite pickle brand launches trio of fermented Kimchi

Mrs Elswood, the nation’s number #1 pickle brand which forms part of the Empire Bespoke Foods portfolio, is launching its first ever range of fermented Kimchi.

Utilising Mrs Elswood’s 75 year experience of preserving vegetables, the range of Kimchi has been carefully developed to retain the crunch of the vegetables with a chilli heat and a distinctive lactic tang from the fermentation.

The British appetite for Korean cuisine has been growing in popularity in recent years with Kimchi being the most iconic and recognisable dishes.

Kimchi has a complex flavour and texture profile which goes exceptionally well with fried or BBQ-style food like burgers and grilled fish, but it also boosts the flavour of classic dishes like toasties and omelettes.

Mrs Elswood follows an authentic method where the vegetables are slowly fermented in small batches for two weeks resulting in a product with crunchy vegetables, a distinctive lactic tang, and warming chilli kick. They feature 70% Napa cabbage and at least three different vegetables including kohlrabi, beetroot and white cabbage.

All three varieties are suitable for vegetarians and contain at least 3 different vegetable types.

1. Classic – Slowly fermented napa cabbage with kohlrabi and gochugaru chilli - giving a classic, traditional Kimchi.

2. Beetroot - Napa cabbage, beetroot and white radish combine to give a deep purple colour with a crunchy bite.

3. Turmeric - Napa cabbage, white radish, ginger and turmeric give a perfectly balanced, naturally yellow Kimchi

The trio of Mrs Elswood Kimchi will be available in Ocado from April 2024 for £3.79 per 300g jar.

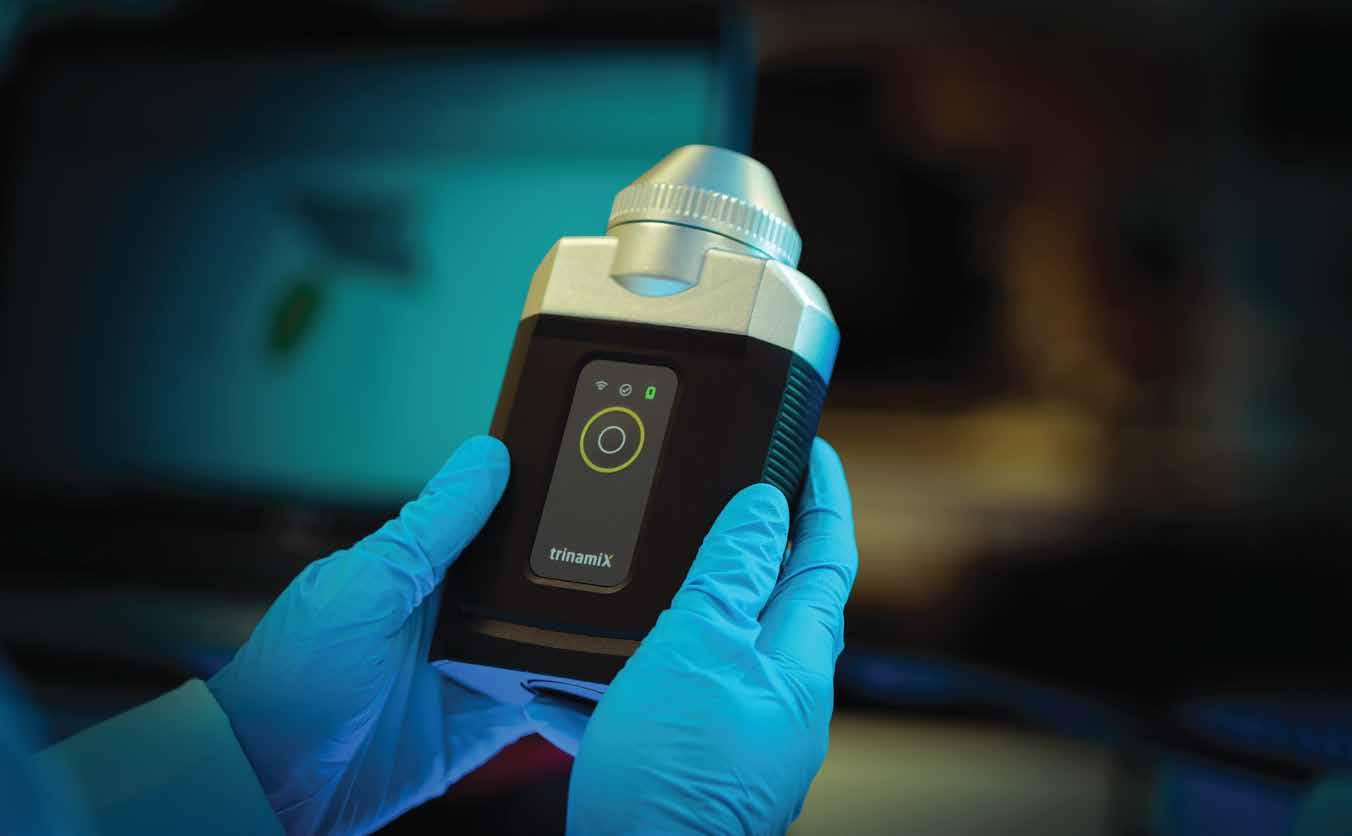

Belfast based Bia Analytical Ltd. announce release of a Portable Testing Service

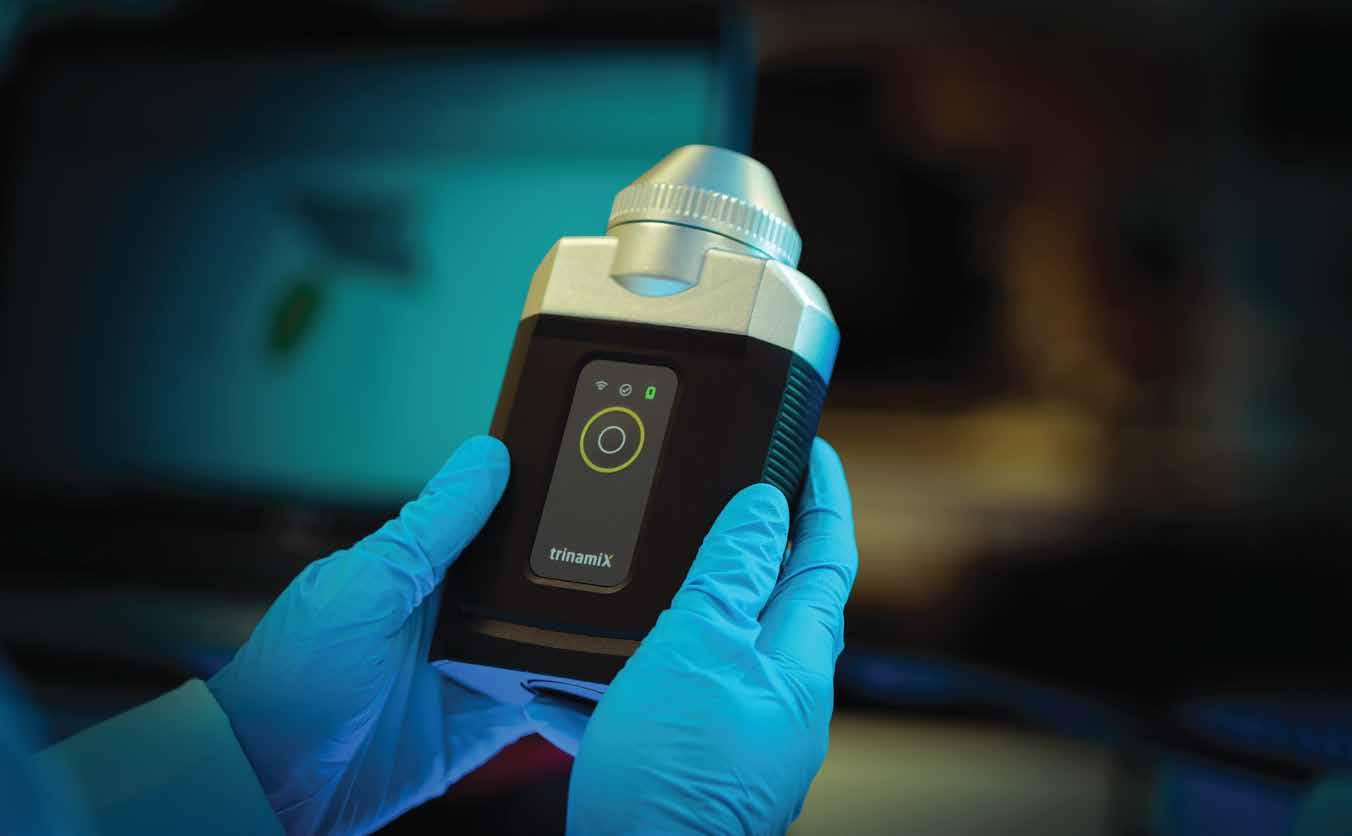

Initially focused on the Herbs and Spices market this ultra-fast portable service as recently featured on BBC Radio 4’s The Food Programme - utilises Bia Analytical’s robust scientific models to provide an indication of authenticity within seconds.

Delivering rapid results at the press of a button, enabling real-time decisionmaking and significant cost saving. It allows anyone in the supply chain, whether producer, distributor, supplier, retailer or auditor to instantly test the authenticity of their goods anytime, anywhere. This is the quickest, most effortless, and portable solution on the market utilising technology from trinamiX.

Backed by the trusted and accredited Bia Analytical lab it provides a robust and trusted indication of authenticity in seconds. This ground-breaking portable solution delivers cutting-edge science via exclusive access to Bia

Analytical’s rigorously validated authenticity solutions, enhancing quality control process with rapid on-the-spot authentication at the point of sampling. Results are delivered within seconds through a handheld device powered by cloud-hosted unique tests. This service is a game-changer within the food industry, enabling unlimited testing anywhere across the supply chain, giving end-to-end authenticity confidence across products.

For more information visit www.bia-analytical.com

News Network General foodanddrinknetwork-uk.co.uk | 03

Q&A

Getting to the core of the dairy probiotics sector, we had the pleasure of chatting with Reshma Patel, the Marketing Manager at Yakult UK. In this interview, we explore the current trends in gut health and Yakult’s plans for growth in this dynamic industry.

1. What are some of the biggest trends in the dairy probiotics sector right now?

The emerging trend we’ve seen is the expansion of probiotics and gut health claims beyond the non-dairy sector, in products such as juices, pet food and other areas. The growing recognition of the importance of the gut presents an opportunity for brands to enhance the value of their products. However, consumers should be aware that if a product claims to be probiotic they should check labelling for bacteria strain name, quantity and storage instructions - not all bacteria are probiotic bacteria, and a probiotic should be produced under strict conditions and backed by a large catalogue of research.

Within the dairy sector, which is home to probiotics with decades of research behind them like Yakult, the formats have been fairly static, typically in easily consumable shots or pots. In this categor y consumers can anticipate new flavours and more added value to cover multi-health solutions.

2. Yakult was among the first brand voices to actively promote gut health, what do you attribute the recent explosion in the gut health sector to?

Consumer understanding of gut health has grown significantly in recent years, and we attribute it to three main factors.

1) While probiotics have been recognised globally for some time, recent scientific advancements have highlighted their broader impact on- gut health beyond digestion.

2) The cultural shift towards preventive health measures rather than just focusing on treatment or cure.

3) Coverage through trusted voices, media coverage, and influencers who have mainstreamed the concept and impact of gut health, helping reach a wider audience more frequently.

As the first probiotic brand with over 85 years of research into gut health, Yakult has played a major role in educating people about the importance of gut health. We’re pleased to see this growing awareness as it ultimately helps us deliver our philosophy to contribute to health and happiness for all. We remain committed to upholding our scientific credentials and continue to invest in this growing area.

3. Figures show that the gut health sector is set to continue growing. How does Yakult plan to capitalise on that growth, and will we see any product development? We expect growth in the category at a local and global level as awareness of the link between the gut and its impact on the various organs and systems of the body continues to grow. In the UK, our current offerings include Yakult Balance, Yakult Plus and Yakult Original. However, there are exciting plans in the pipeline so watch this space!

4. How is Yakult different from the new entrants to the market?

Yakult proudly stands as the unparalleled choice for discerning consumers, thanks to the inclusion of our unique L.casei Shirota bacteria or `friendly bacteria’, which is scientifically proven to reach the gut alive and increases the lactobacilli and bifidobacteria in the gut. Is there another brand which can say that its unique bacteria has been part of a study to research the impact on the immune system and intestinal microbiota of astronauts at the International space station, been sold for 85 years, and is easily available at your local supermarket? Our investment, unwavering dedication in this field, alongside our bacteria and its unique heritage, speaks for itself versus new entrants.

For more information about Yakult, visit www.Yakult.co.uk

Yakult Q&A with... 04 | foodanddrinknetwork-uk.co.uk

Explore Harford Connected Worker Call +44 (0)1225 764461 www.harfordcontrol.com

end-to-end MIS/MES provide real-time insights into factory performance, process quality, and OEE on tablets and mobile devices anytime and anywhere.

Harford Connected Worker, manufacturers could benefit from: Actionable information

employee engagement

cross-functional collaboration Performance improvement Empower Frontline Operations and Optimise Data-Driven Manufacturing with Connected Worker

Harford

Using

Higher

Seamless

Transform Manufacturing with Connected Worker

A Proven Solution for Efficiency, Collaboration and Operational Excellence

An article By Roy Green, Harford Control Ltd. April 2024

2023 was the worst year on record for company insolvencies with 26,595 failures. Manufacturing accounted for 8% of the insolvencies in 2023 (R3 Association of Business Recovery Professionals). While the media and factories may blame the pandemic and the cost-of-living crisis, many potential problems have long been entrenched internally within manufacturing.

On the one hand, manufacturers have paid high prices for inefficiency with old machines and processes. On the other hand, the lack of employee engagement has led to low productivity. According to a Deloitte report, an estimated 49% of factory workers lose 10 minutes of productivity per hour due to technological and process inefficiencies.

To survive in this increasingly competitive commercial world, manufacturers must not only invest in digital systems but also engage employees in the performance improvement process. Connected Worker is the technology that can encourage digital transformation in factories and improve the synergy between technology and people.

What is a connected worker?

Connected Worker is the modern technology application that unifies operators, leaders, maintenance teams, and other workers with real-time actionable information, enabling them to stay connected and perform their jobs more efficiently and productively.

Tablets, mobile apps, wearable devices, IoT devices and digital work procedures are all

examples of connected worker technologies.

Why do Manufacturers Need Connected Workers?

A real-time view of operations and production line performance is available at their fingertips, keeping operators and leaders updated and connected. Connected Worker technologies have already proven beneficial for 80% of leaders who have implemented ‘Connected Worker’, according to LNS Research. Let’s take a closer look at the advantages that manufacturers are experiencing.

Empower Frontline Workers

Connected Worker empowers frontline workers to take ownership of the process and resolve problems independently. During quality checks or barcode scanning, operators receive real-time feedback. In the event of an issue, automated error-proofing allows operators to report and address the problem immediately, preventing production defects, batch rejections and product recalls. This approach allows frontline workers to actively engage in the process and improve productivity, fostering a culture of Right First Time.

Make Data-Driven Decisions

Connected Worker also enables factory managers to access and monitor real-time information. In the event of a downtime alert, factory managers can conduct ‘5 Whys’ and root cause analyses to identify areas for improvement and make datadriven decisions to reduce defects and enhance product quality. Factory managers can access the performance data (i.e. OEE, quality, downtime, etc.) conveniently on their mobile devices, anytime and anywhere.

“To survive in this increasingly competitive commercial world, manufacturers must not only invest in digital systems but also engage employees in the performance improvement process. Connected Worker is the technology that can encourage digital transformation in factories and improve the synergy between technology and people.

” 06 | foodanddrinknetwork-uk.co.uk Specialist View

“Despite an increasing awareness of the benefits of Connected Worker, we still find that ‘disconnected workers’ are more common in many factories. Departments such as production, technical and quality function within their own silos, like pieces of a jigsaw puzzle, lacking comprehensive insights into the entirety of the factory.

”

Improve Productivity and Drive Continuous Improvement

Imagine a factory using Connected Worker: A continuous improvement manager, using his computer tablet, identifies the bottlenecks causing downtime. An operation manager records short interval control hourly stats at their fingertips, preparing for an in-depth line performance analysis. A supervisor reviews the incident reports and health and safety reports on his mobile device while he’s on a business trip.

By replacing old devices and inefficient processes with Connected Worker and engaging their employees with smart devices, manufacturers can access realtime information and see what ‘actions’ have been taken. This enables operators to complete tasks more effectively and empowers the whole team to drive continuous improvement.

What Happens When There Are Disconnected Workers?

Despite an increasing awareness of the benefits of Connected Worker, we still find that ‘disconnected workers’ are more common in many factories. Departments

communication and collaboration, but also hinders the ability to identify overarching issues that may impact the entire production process. Even worse, the dysconnectivity might lead to a blame culture among departments, further impeding the factory’s improvement objectives.

By choosing a reliable and trusted technology partner, manufacturers can fully understand the use of Connected Worker and integrate the technology into their daily operations, bringing sustainable benefits to performance improvement.

Harford Connected Worker

Harford Connected Worker encompasses the platform, interface and smart sensors that factories need to access real-time actionable information. All our devices, machines, and applications are connected seamlessly. Leaders and operators can have access to

Empower Drive

real-time insights into factory performance, process quality, and OEE on tablets and mobile devices. This comprehensive snapshot of performance enables the identification of production issues and the evaluation of performance, driving improvements towards operational excellence.

There is clearly a high cost associated with inefficiency, coupled with the real challenge posed by the lack of operator engagement. It’s time to make a change and adapt to technological advances. After all, no manufacturer wants to find their business on the list of insolvencies.

If you are ready to explore the possibility of improving your manufacturing performance, please reach out to us at info@harfordcontrol.com or give us a call on +44 (0)1225 764461.

foodanddrinknetwork-uk.co.uk | 07

Explore Call +44 www.harfordcontrol.com Harford end-to-end insights into factory and OEE on tablets and anywhere. Using Harford Connected could benefit from: Actionable information Higher employee Seamless cross-functional Performance improvement

Data-Driven with

Sustainable Food Factory 2024 REGISTER NOW TO ATTEND DECARBON ISATI ON Sponsors correct at time of print. Attendance is free for food and drink manufacturers – delegate passes are allocated at the discretion of the organiser. HEADLINE SPONSORS EVENT SPONSORS A NEW one-day event for senior-level UK food and beverage manufacturers FOR FULL DETAILS VISIT sustainablefoodfactory.live #SFFE24

First Speakers Announced for Sustainable Food Factory 2024

The organisers of June’s event announce the first set of speakers who will be presenting at the conference

The speakers are part of a day-long program that will educate delegates about the latest strategies for reducing carbon emissions in food and beverage manufacturing and supply chain operations through engaging presentations and interactive panel debates.

Tom Maidment, Group Product Sustainability Senior Manager at Hilton Foods, who is leading the development of the company’s decarbonisation strategy and providing life cycle assessment (LCA) expertise across the business, will present in the morning session.

Tom’s presentation, entitled ‘Decarbonising the Factory: A Whole Business Approach,’ will outline the importance of addressing emissions and resource use both within the business operation and throughout the supply chain to reach net zero.

This approach will help food and beverage manufacturers create a list of priority actions and plans that allow them to enhance resilience and profitability while reducing their impact on the environment.

David Moore, Group Head of ESG at The Compleat Food Group, will also join Tom in the morning with a presentation titled, ‘How to Reduce Scope 3 Emissions using Product Level LCA’.

David’s presentation will concentrate on Scope 3 emissions in the value chain, which constitute the majority, and how conducting a comprehensive LCA analysis can help the business develop a focused action plan to reduce their impact.

The conference also recognises the unique challenges SMEs can face in creating sustainable manufacturing operations.

Alain Dilworth, Programme Manager of Made Smarter UK’s Northwest Adoption Programme, has overseen the programme’s roll-out in the region, which has helped hundreds of SME manufacturers – including food and beverage manufacturers – adopt new technology.

These funded projects have helped businesses increase productivity, upskill their workforce, create new jobs and become more sustainable.

Alain will present in the afternoon session with a presentation entitled, ‘Technology Transformation and Its Impact: An Overview of the Made Smarter Adoption Northwest Programme. How it Impacts on Productivity, People and Sustainability in SMEs’.

The case for decarbonisation

As the largest manufacturing sector in the UK, the food and beverage sector must prioritise sustainability and decarbonisation, with manufacturers playing a crucial role in reducing their environmental impact.

Decarbonisation is not merely an unnecessary expense; rather, it represents an opportunity to improve operations, drive innovation and enhance brand reputation.

Consumers and other stakeholders increasingly demand sustainable practices, compelling the industry to continue rising to the challenge of achieving a greener, more sustainable world.

Collaboration and networking

Collaboration across the supply chain holds immense importance and the Sustainable Food Factory event offers ample opportunities for attendees to network with peers and speakers and gain a deeper understanding of this crucial topic.

The event will also feature 15 exhibitors who are uniquely positioned to assist delegates in their low-carbon journey.

Sustainable Food Factory 2024 takes place on 12 June at Clifton Campus, Nottingham Trent University and is FREE to attend for UK food and beverage manufacturers.

Sustainable Food Factory Exhibitions foodanddrinknetwork-uk.co.uk | 09

More information is available at www.sustainablefoodfactory.live

Supported by Free to Visit Including the Conference Sessions Free to attend SUSTAINABLE TRANSPORT, LOGISTICS & SUPPLY CHAIN MANAGEMENT EVENT FOR CARGO OWNERS Multimodal 2024 celebrates 17 years of bringing together shippers and cargo owners with exhibitors and sponsors who can offer products and services to help them make their supply chains more efficient and more cost effective. Visitors attend to meet new suppliers, compare new routes and modes, source new products and ideas to improve their efficiency and to network with the industry. 11-13 June 2024 NEC Birmingham UK 300 Exhibitors 60+ Conferences Digital sessions from Google Networking Drinks Party Established since 2008 REGISTER IN ADVANCE AT www.multimodal.org.uk

THE FUTURE OF LOGISTICS UNFOLDS

Bigger and better than ever, Multimodal 2024 is already smashing records with over 230 exhibitors already signed up, including industry giants such as Amazon, CEVA Logistics, DP World, Hapag-Lloyd, Kuehne+Nagel, Maersk, Maritime Transport, Malcolm Logistics and Samskip Services. With expectations to exceed 300 exhibitors, this year’s event will offer unparalleled networking and business opportunities for the 12,000+ visitors over the three days of the show.

Multimodal is the one-stop shop for shippers and cargo owners to discover ways to improve their move their goods more sustainably, efficiently and more cost effectively. The three-day show between 11-13 June 2024 at the Birmingham NEC, offers unique opportunities to make valuable face-to-face contact with new prospects and existing companies.

It’s free to visit Multimodal 2024, registering in advance is recommended, to save time on arrival, at www.multimodal.org. uk All the conference sessions are free to attend too and with 4 theatres there is something of interest to everyone.

You’ll be in great company as already registered are representatives from Sainsbury’s, Aldi, Whitworths, Nestle UK&I, Diageo, Lovering Foods, Rowan International, Bunzl Catering, Glanbia Nutrition, Crops UK, Kingsland Drinks, AB World Foods and Poundland to name just a few.

Multimodal works in partnership with the leading trade associations ensuring all aspects of the industry are served, also ensuring that relevant topics are covered in the free to attend conference sessions. Partner associations include Logistics UK, the Cold Chain Federation, the Rail Freight Group, The Chartered Institute of Transport and Logistics, the British International Freight Association, Institute of Export and International Trade, the United Kingdom Warehousing Association, and the Road Haulage Association.

A special highlight of the three days is the Multimodal Awards, which recognise outstanding industry-leading supply chain businesses and individuals. With seats for the awards always selling out, and just 200 places currently remaining, attendees are now being urged to secure their seats for the 11 June evening ceremony as soon as possible.

The 2024 Awards include some new judged Awards to continue the development and evolution of the event. The evening will be hosted by Kevin Keegan, an incredible host who brings enormous professionalism and fantastic humour. Places at the Awards can be booked at www.multimodal.org.uk/awards

The networking event you won’t want to miss! Be there for the Multimodal Mixer on 12 June. It’s a fun relaxed drinks reception open to all visitors and exhibitors, hosted by DP World on their stand in the Hall from 5pm, giving everyone a chance to mingle in a relaxed and fun atmosphere.

To find out more about attending, entering the awards, exhibiting, or sponsoring, visit www.multimodal.org.uk, or contact Robert Jervis, Director on +44 (0) 20 7384 7760 or robert.jervis@clarionevents.com

Multimodal 2024 Exhibitions foodanddrinknetwork-uk.co.uk | 11

Machine Vision Conference will host an impressive range of exhibitors and seminars

The two-day Machine Vision Conference opens in just over three months’ time on 18th June at the CBS Arena in Coventry.

MVC is recognised as the leading event for the latest cutting-edge industrial vision in the UK and features a vast array of the latest machine vision technology as well as an outstanding seminar programme. This provides a perfect platform for visitors to discover the innovative industrial vision and imaging technologies, learn from the industry experts at the excellent seminars, and network with over thousand visitors expected in June.

The MVC’s engaging seminar programme is a perfect place to be captivated with all machine vision industry future developments, learn about latest trends, and soak in the knowledge shared by the experts delivering a bumper selection of inspiring presentations. Some of the key topics to be discussed within the content rich seminar programme, includes deep learning and embedded vision, vision in robotics, understanding vision technology, systems and applications, 3D vision, camera technology, optics and illumination, and vision innovation.

These sessions will provide visitors with a wealth of knowledge and inspiration to take away and explore how this knowledge can be used to deliver benefits to their business. The MVC exhibitors have a brilliant opportunity to present on the above topics whilst at the same time capture the attention of potential buyers and visitors with their expertise. Those exhibitors interested in this opportunity should contact the organisers via the MVC website.

MVC is renowned for bringing the whole vision industry together, so in between fascinating seminar sessions there will be plenty to explore and experience. Over 50 well-known companies will be showcasing their most innovative products and services, including fascinating demonstrations and exciting product launches. They will be eager to discuss how they can help businesses deliver improvements through adopting machine vision solutions.

Here are some of the companies that will be exhibiting: Acrovision, Advanced Illumination, Allied Vision, Alrad Imaging, Balluff, Basler, Bytronic Vision Automation, Chromasens, Clearview Imaging, Computar, Emergent Vision Technologies, Flir (Thermal), Flir IIS, Get Cameras, IDS Image Development Systems, IFM Electronic, Lambda Photometrics, Lincode, LMI Technologies, Lucid, Micro-Epsilon, Navitar, Neousys, OEM Automatic, Opto Engineering, Pro-Lite Technology, Scorpion Vision, SICK, Smart Vision Lights, Specim/Spectral Imaging, SVS Vistek, Teledyne Dalsa, The Imaging Source Europe, TPL Vision, Wenglor Sensoric, and Zebra Technologies Europe.

The exhibition hall at the CBS Arena will be buzzing with visitors, exhibitors and industry experts that will provide significant opportunities to network, collaborate and connect with existing and new contacts. This creates an ideal environment to establish and develop business relationships that can be very beneficial for knowledge sharing, problem solving, catching up and gaining new customers.

One of last year’s MVC visitors, John Grace, Euro Head of Quality at Product Safety and R&D at Loop said: “Very good selection of companies and an opportunity to learn about new developments and find potential suppliers.”

MVC is once again co-located alongside Automation UK, organised by British Automation and Robot Association (BARA), providing visitors to MVC 2024 an additional benefit of being able to visit Automation UK to find out the latest developments in the world of automation and robotics, all under one roof.

The Machine Vision Conference visitor registration is open, to reserve your free ticket, please visit: https://www. machinevisionconference.co.uk/

Machine Vision Conference Exhibitions

foodanddrinknetwork-uk.co.uk | 13

Discover cutting-edge automation and robotics technologies at Automation UK

In less than three months’ time Automation UK will return to the CBS Arena in Coventry on 18-19 June. This renowned event is recognised for bringing industrial automation and robotics to life. The wide spectrum of features in the show ensures it delivers something for everyone. This includes showcasing the very latest innovative technologies and solutions, to providing an abundance of thought-provoking seminars where visitors can soak up the knowledge and be inspired to improve their own businesses. The show also provides many great networking opportunities where visitors can both develop new contacts and build on existing contacts.

According to the World Robotics 2023 report by the International Federation of Robotics, the robotics industry is predicted to continue its year-on-year growth, with a 7% increase forecasted for 2024. This provides an excellent opportunity for UK manufacturers to take advantage of the numerous business benefits that innovative automation and robotics solutions can deliver. Integrating these remarkable technologies offer many benefits including enhanced productivity through accelerating production, increased operational flexibility, a safer work environment, an ability to manage routine tasks efficiently, an attractive return on investment, and innovative solutions to address labour shortages. When can combined, all of these benefits will deliver significant business improvements and enable the business to thrive in the future.

Automation UK provides a perfect platform for automation and robotics technologies to be demonstrated throughout the hall, giving visitors a vast array of opportunities to see for themselves what can be achieved. An impressive list of

well-known companies will be showcasing their cutting-edge products and services including robots, robotics systems, systems integration, automation control parts and systems, and sensor and machine safety. The leading experts from the exhibiting companies will be eager to answer questions, provide technical guidance and recommendations on the most suitable solutions for specific needs as well as highlight the advantages their solutions can bring to businesses.

Here are some of the companies that will be exhibiting: ABB, AMP Automation, Apex Dynamics (Midlands), AP Technologies, Beckhoff Automation, Bowe Systec, British Encoder Products, Epson, Fanuc UK, Festo, Gudel Lineartec, Heidenhain, HepcoMotion, HowToRobot, IDEC (Apem Components), Idem Safety Switches, IFM Electronic, IKO Nippon Thompson Europe, KUKA Robotics, Lamonde Automation, Mikata Technology, Mitsubishi Electric, Mobile Industrial Robots, MRK Engineering Solutions, MTA, MTC, Olsen Actuators & Drives, Olympus Technologies, Omron Electronics, Piab, RARUK Automation, Reeco Automation, Rollon, Safety Systems Technology,

Automation UK 2024 14 | foodanddrinknetwork-uk.co.uk

One of last year’s Automation UK visitors, Tea Chalidze, Manufacturing Excellence Manager at Marks & Spencer said:

“I’m here to look at new equipment, and to see what’s on the market especially regarding robotics and automation which is our future, so attending this show and exploring and seeing new ideas is very useful.”

Throughout the two-day show, visitors will be treated to a broad range of inspiring seminar sessions delivered by the industry leading speakers. These captivating sessions will provide visitors with a wealth of knowledge and inspiration to take away and digest how it can be used to deliver benefits to their business.

In between fascinating presentations, visiting numerous interesting companies showcasing their products and services, experiencing live demos, and hearing about new product launches, there are many opportunities to meet new contacts and develop existing business relationships. These can be mutually beneficial for sharing knowledge, industry insights and problem solving.

Automation UK is co-located alongside Machine Vision Conference (MVC), which is organised by the UK Industrial Vision Association (UKIVA), providing visitors to Automation UK an additional benefit of being able to visit MVC to discover the latest innovative industrial machine vision and imaging technologies, all under one roof.

For more information, please visit: https://www.automation-uk.co.uk/

Exhibitions foodanddrinknetwork-uk.co.uk | 15

Schmalz, Schubert, Schunk Intec, Shibaura Machine, Simmatic Automation Specialists, SMC Corporation, Troax, Universal Robots, Vex Robotics, Wieland Electric, and Zimmer Group.

Reasons to Visit…

the UK Food & Drink Shows 2024

The UK Food & Drink Shows return to the NEC, Birmingham next month (29th April – 1st May) bringing together the very best of the grocery, specialist retail, wholesale, foodservice and hospitality sectors. Promising a festival of talent, advice, innovation and networking across three days, we whittle down the top reasons to make a trip to the midlands.

One free ticket, five jam-packed shows

The UK Food & Drink Shows comprise five individual events under one roof all of which can be accessed with just one visitor badge. Across Food & Drink Expo, Farm Shop & Deli Show, The Restaurant Show, National Convenience Show and The Forecourt Show, there are countless opportunities to witness innovation and get networking, meaning valuable time spent offsite can have even more of an impact for visitors whose interests go beyond any individual show.

Exhibitor Excellence

Over 1200 exhibitors are set to come together across the five shows, giving visitors an abundance of choice whilst also providing brands with the most up-to-date look at innovation in their respective sectors. The breadth of exhibitors offers visitors solutions across all aspects of their business, from the latest trending products to drive footfall, to the essential services required to keep operations running more smoothly than ever.

Food & Drink Expo 16 | foodanddrinknetwork-uk.co.uk

Specialist zones

After their inaugural success in 2023, two exclusive zones are set to return to Food & Drink Expo for 2024. Healthy & Natural Zone will include a range of healthy, wellness and natural products encompassing free-from, vegetarian, low-calorie and organic items to name a few. Meanwhile, Plant-Based Zone will also be making a comeback with everyone’s favourite vegan and plant-based exhibitors showcasing the future of this evergrowing sector.

Business advice

Five stages – The Grocer Stage, Farm Shop & Deli Stage, Chefs’ Stage, Restaurant Stage, Convenience Store and Forecourt Trader Stage – present a standout programme of seminars with industry experts offering their takes on the most pressing issues and thought-provoking topics.

Whether it’s questions around sustainability, the impact of the cost-of-living crisis, the future of plant-based eating, improving diversity and inclusion, harnessing technology making the most of your manufacturer relationships or trends for 2024 and beyond, sessions are designed to tackle the problems that the industry professionals continue to come up against, whilst also giving visitors an opportunity to ask their burning questions.

Industry heavyweights out in force

Five separate stages, set up across the different shows, include a panellist line up that reads like a who’s who of industry specialists. Just some of the names signed up to speak are:

• Heather Mills, Founder of VBites

• Suzy McClintock, VP of Grocery and Retail at Deliveroo

• George Wright, CEO of FareShare

• Sam Akinluyi, UK&I Managing Director of Innocent Drinks

• Karen Betts OBE, Chief Executive of Food & Drink Federation

• Hugh Fearnley-Whittingstall

• James Cosmo, Company Director/Actor at Annandale Distilleries – Storyman Whisky

Innovation at every turn

Whether you’re looking to expand your retail offering, get hold of a new energy drink range, find a financial solution, smarten up your forecourt storage set up or discover the latest back-ofhouse formats, hundreds of innovative products are set to grace the show floor at the NEC.

Favourites return and evolve Dragons’ Pantry, the ultimate retail test, is back after popular success last year, with a new batch of brave entrepreneurs facing big characters and big questions as they aim to secure a new listing. In 2024, it’s joined by the all-new Retailers’ Den, a similar concept that drills down into the convenience landscape. See which brands make a splash and try the products for yourself on Tuesday 29th April and Wednesday 1st May at 2.15pm on The Convenience Store Stage.

Don’t just take our word for it…

Of course we think you should attend our shows. To show some impartiality, here’s what previous visitors had to say…

Karen Betts OBE, CEO, Food & Drink Federation

“There’s a great range of companies across the diversity of the industry. There’s a real sense of optimism here at the show, it’s a great event to be part of.”

Caroline Cooper, Director, Sunnyside Gifts LTD

“We’re a new company and didn’t know what to expect as we haven’t been here before – we were looking for new suppliers and ideas and it’s just been brilliant. The vendor choices are amazing and the event is in the calendar for next year already!”

John Gill, Head of Marketing and Trading, Booths

“It’s a one stop shop. I think it’s absolutely invaluable to spend time at this show.”

Covering the entire industry, the UK Food & Drink Shows are unparalleled in their ability to bring people together, build and foster better relationships, discover business building insight and celebrate innovation, all with the support of the multi-award-winning William Reed brand.

Register for your free pass today at: foodanddrinkexpo.co.uk

Exhibitions foodanddrinknetwork-uk.co.uk | 17

18 | foodanddrinknetwork-uk.co.uk Logistics Qualifying Criteria Apply *T&C’s available on request from enquiries@transportservicesuk.com Logistics, Warehousing & B2B Fulfilment Scan the QR code to register for your FREE audit transportservicesuk.com Sign up today for a FREE logistics audit worth £1,200! SPECIAL OFFER 0208 124 1274

Navigating the Future:

The critical role of COLD CHAIN LOGISTICS solutions in the food industry

The food and beverage industry is a dynamic and vital sector, contributing significantly to the economy and ensuring the nation’s food security.

At the heart of this industry’s success is the cold chain logistics network, a sophisticated system designed to transport perishable goods under controlled temperatures. In recent years, businesses have been investing heavily in this sector, aiming to create a more effective, efficient, and reliable cold chain process. This investment is not just about enhancing operational efficiency; it’s a critical measure to prevent catastrophic losses of products and capital due to breakdowns in the cold chain logistics.

Technological Advancements in Cold Chain Logistics

The evolution of cold chain logistics has been marked by significant technological advancements, particularly in the development and deployment of modern refrigerated trailers, known as reefers. These trailers are now equipped with an array of sensors that continuously monitor the temperature inside, ensuring that it remains within the optimal range for the goods being transported. These sensors can automatically adjust the cooling system’s operation, reducing the risk of spoilage due to temperature fluctuations and shutting down the system when necessary to save energy. Moreover, the introduction of remote monitoring systems has revolutionized the way shipping lines manage their refrigerated cargo. These systems enable realtime monitoring of not only the temperature but also the humidity levels and the precise location of the refrigerated trailers. Such capabilities are crucial for maintaining the integrity of perishable goods throughout their journey, from producer to consumer. They also provide logistics operators with the data needed to optimize routes, improve efficiency, and respond swiftly to any issues that may arise during transport.

The Impact of Investment in Cold Chain Logistics

The substantial investments pouring into the UK’s cold chain logistics industry underscore the critical importance of this sector. By adopting advanced technologies and improving infrastructure, businesses aim to mitigate the risks associated with transporting perishable goods. A breakdown in the cold chain, whether due to equipment failure,

logistical errors, or external factors like traffic delays, can lead to significant losses. Spoiled goods not only represent a financial loss but can also damage a company’s reputation and lead to regulatory penalties. However, the benefits of these investments extend beyond risk mitigation. Enhanced cold chain logistics contribute to sustainability efforts by reducing waste and improving energy efficiency. They also play a vital role in expanding market access for UK food and beverage producers, enabling them to reach distant markets with their products still in perfect condition, thus increasing competitiveness on a global scale.

Looking Ahead

As the food and beverage industry continues to grow and evolve, the demands on cold chain logistics will only increase. The ongoing investments in technology and infrastructure are laying the foundation for a more resilient, efficient, and sustainable cold chain network. However, the industry must continue to innovate and adapt to emerging challenges, including the impacts of climate change, evolving consumer preferences, and the complexities of international trade.

foodanddrinknetwork-uk.co.uk | 19 Cold Storage and Temperature-Controlled Transportation Logistics

BioPak has been awarded the coveted title of Innovation Award at the 2024 Food Manufacture Excellence Awards.

Global sustainable packaging brand BioPak has won the coveted title of Innovation Award at this year’s Food Manufacture Excellence Awards at London Hilton Bankside.

Fourteen accolades were up for grabs at the 2024 ceremony, which took place on Thursday 8th February and included more than 60 finalists, recognising the very best in British food and drink operating standards and processes.

The Innovation Award featured a range of BioPak’s world-class packaging solutions that cater to a wide variety of cuisines, including:

Aqueous BioCups

Christmas BioCups

Hot Cup Plant Fibre Lids

Wahaca Plant Fibre Taco Box

Plant Fibre Sushi Trays

Chinese Plant Fibre Soup Spoon

Included in these innovations was BioPak’s first custommade plant fibre home compostable (NF T51-800) taco packaging in the UK market for Wahaca, helping MasterChef winner, Tommi Miers, and her team deliver their tacos fresh and piping hot to customers.

BioPak’s home compostable (NF-T51-800) Aqueous BioCups were also a stand-out, utilising a ground-breaking technology that creates a unique water-based dispersion coating that significantly reduces the amount of material needed while still providing the same leak and grease-proof benefits as other coatings like traditional PE plastic. When paired with certified home compostable (NF-T51-800) Plant Fibre Lids, they provide a groundbreaking alternative for consumers.

BioPak UK Managing Director Leanne Osborne commented on the significance of this award for BioPak. “Innovation is at the core of BioPak, and we are incredibly proud to be recognised by the industry for a number of our unique designs,” said Osborne.

“Our goal is to create world-class products that disrupt the market and champion circular solutions. We pride ourselves on cultivating a dedicated team who work tirelessly to provide the very best product designs, staying at the forefront of technology to provide leading compostable solutions that are functional, scalable and put the planet first.”

Bethan Grylls, Food Manufacture’s editor, added: “The calibre of both the paper entries and interviews were exceptional, and it goes to show how incredible our food and drink sector is as the world continues to grapple with numerous challenges.”

“If you’re seeking business excellence, then look no further than the winners of the Food Manufacture Excellence Awards. Established in 2000, this annual night has become one of the most prestigious award programs in the industry. Each winner has been recognised by an incredible team of industry experts as a powerhouse of dedication, innovation, business acumen and skill.”

“On behalf of Food Manufacture and everyone behind the scenes of the awards, I’d like to extend a huge congratulations to all the finalists and, of course, the winners. I look forward to seeing next year’s entries in due course and celebrating with the industry once again in 2025!”

The full list of winners for the FMEAs 2024 is here: https://foodmanawards.co.uk/live/en/page/winners-2024

BioPak Exhibition News 20 | foodanddrinknetwork-uk.co.uk

ProAmpac and Sammi Join Forces for Sustainable Fiber-Based Packaging Innovation

ProAmpac introduces a groundbreaking fiberbased, modified atmosphere sandwich pack (MAP) for grab and go sandwiches with SAMMI. This partnership makes a significant step towards improving product freshness, enhancing sustainability by replacing rigid plastic, and reducing food spoilage in the food-to-go market.

Sammi’s commitment to sustainability is reflected in its selection of innovative packaging solutions, prioritizing sustainable impact and extended shelf-life, thus significantly minimizing packaging and food waste. Using fiber-based packaging from well-managed forests, Sammi is a pioneer in grab-and-go sandwiches by replacing rigid plastic clam shells, thereby reducing its packaging footprint.

ProAmpac is introducing its fiber-based MAP RAP Sandwich Wedge to the North American market in a joint effort to innovate the food–to–go packaging landscape. Designed for sandwiches and wraps, this patented technology combines the benefits of modified atmosphere packaging with mainly fiber materials.

“Sustainability lies at the heart of ProAmpac’s business strategy,” says Chad Murdock, president of ProAmpac’s fiber business.

“Our collaboration with Sammi underscores ProAmpac’s commitment to helping customers meet their sustainability objectives with high-performance packaging.”

The ProAmpac RAP Sandwich Wedge incorporates a carton board structure with a thin transparent film liner to optimize product preservation and visibility. Engineered for hermeticity, this innovative solution utilizes high-barrier technology to improve freshness, extend product shelf-life, and minimize food spoilage costs.

Customer satisfaction further underscores the success of this collaboration.

“We’re getting very positive feedback. Customers love that Sammi Sandwiches are not just healthy and delicious, but the fiber-based packaging is what truly sets Sammi apart. The packaging also provides us with design and branding options that simply weren’t available before, like devoting an entire panel to why sustainability is important. This sentiment is also resonating with consumers and they’re contacting us regularly to say so. Sammi Sandwiches and our sustainable packaging is the future of grab-and-go in the U.S.,” states Joel Simpler, founder of Sammi.

The pioneering sandwich brand offers six different kinds of sandwiches including Classic Chicken Salad, The Club, Honey Gold Ham & Cheddar, The Italian, Smokehouse Turkey & White Cheddar, with the Vegan Chick’n Salad option coming soon. Each Sammi is packed fresh using fresh, high-quality, ethically sourced ingredients, sealed in a modified atmosphere environment, and will keep refrigerated products fresh longer.

Sammi’s can be found at one of their retail locations, including Dollar General stores across the U.S., or consumers can contact Sammi directly to buy wholesale in any quantity or configuration.

ProAmpac remains at the forefront of sustainability and innovation, empowering brands to achieve their circular economy goals. For inquiries and orders, please contact Marketing@ ProAmpac.com or visit ProAmpac.com.

FOOD SERVICE PACKAGING

ProAmpac Packaging foodanddrinknetwork-uk.co.uk | 21

Freshline® Modified Atmosphere Packaging (MAP) helps you seal in freshness, wherever you are. Air Products offer high-purity gases and equipment which provide the results you need, come rain or shine. So for a taste of something better, put our unrivalled supply capability, unmatched experience, and outstanding technical support to the test.

Air Products 22 | foodanddrinknetwork-uk.co.uk

As the issue of food waste rises to the forefront of the sustainability agenda within our industry, producers are striving to show they are part of the solution rather than the problem.

Solutions for your food waste ‘problems’.

The end goal is simple but the process is far from it, and across the food sector, companies are seeking out solutions to minimise food waste. At Air Products we know just how pressing an issue this is for our customers – and is one in which they, with our help, are looking to make continual improvements. To this end, recent innovations we have brought forward seek to tackle the problem head on.

First was our Freshline® Aroma MAP launch, the first advance in modified atmosphere packaging (MAP) technology in decades. While from a brand standpoint the innovation allows producers to give their products their own recognisable scent – crucially, it also plays two key roles in the war on food waste.

Consumers regularly throw away food before a sell by date for the simple reason that it no longer smells appetising – a waste which they see as a sensible precaution despite the food being perfectly edible. Aroma MAP ensures that consumers retain confidence in these products – cutting down on the number of product returns and therefore the amount of edible food being wasted.

At Air Products we know just how pressing an issue this is for our customers – and is one in which they, with our help, are looking to make continual improvements.

Secondly, in some cases some essential oils used in Aroma MAP have antimicrobial qualities, further extending shelf life beyond previous MAP solutions and creating longer lasting products.

More recently we have launched an online tool to help draw attention to the issue of sustainability in food packaging.

The food waste calculator, which can be accessed for free on the Air Products website, assesses which packaging solution provides the best answer to minimising food waste and the carbon footprint of any given product. It helps producers make the right choice between products packaged with MAP gases, products packaged with air and those presented in no packaging at all. It looks holistically at the best bespoke approach for producers trying to cut down on plastic usage while preventing food waste.

These are just two examples of the vital work being done to tackle what remains such a crucial issue.

We will never stop trying to improve our practices, nor to use our expertise to generate a cleaner future

Sustainablility & Decarbonisation foodanddrinknetwork-uk.co.uk | 23

In an age where sustainability and environmental responsibility are more than just buzzwords, the food industry is under increasing pressure to find innovative solutions to reduce waste and improve the efficiency of food distribution

Revolutionising Food Preservation: How Modified Atmosphere Packaging is Tackling Food Waste

One such technological advancement that has shown significant promise in extending the shelf life of perishable goods is Modified Atmosphere Packaging (MAP). Companies like Air Products are leading the charge with their Freshline® MAP solutions, offering an eco-friendly and effective method to keep food fresher for longer, thus significantly reducing food waste.

The Role of MAP in Reducing Food Waste

Modified Atmosphere Packaging is a technology that involves altering the atmosphere inside a food package to slow down the product’s deterioration and extend its freshness. By adjusting the levels of oxygen, carbon dioxide, and nitrogen within the packaging, the growth of aerobic organisms and the speed of oxidation are reduced. This not only helps in preserving the quality and texture of the food but also significantly extends its shelf life. MAP is especially beneficial for perishable goods such as fruits, vegetables, meats, and dairy products.

The implications of this technology for food waste are profound.

According to the United Nations Food and Agriculture Organisation, approximately one-third of the food produced globally for human consumption is lost or wasted. By extending the shelf life of food products, MAP allows for longer storage and transport times, reducing the amount of food that spoils before it can be consumed. This not only benefits the environment by reducing waste but also supports food security by improving the distribution of food resources to areas where they are needed most.

Air Products and the Freshline Solution

Air Products, a leading industrial gases company, has positioned itself at the forefront of this technology with its Freshline® MAP solutions. Understanding the critical balance between sustainability and the need to reduce food waste, Air Products has developed an array of

MAP applications that cater to different food products, ensuring optimal freshness and quality. Their approach is not just about extending shelf life; it’s also about maintaining the taste, texture, and nutritional value of the food, which are crucial factors for consumers.

The Freshline® MAP solutions by Air Products are a testament to the company’s commitment to sustainability. By improving the efficiency of food packaging and distribution, they are helping to reduce the environmental impact of food waste. This is particularly important in a world where the demand for sustainable and environmentally friendly packaging solutions is growing.

The Environmental Impact

The environmental benefits of MAP and solutions like Freshline® extend beyond just reducing food waste. By increasing the efficiency of food distribution and storage, MAP also helps in lowering the carbon footprint associated with the food supply chain. Less food waste means fewer resources spent on production, transportation, and disposal. Moreover, the use of environmentally friendly packaging materials in conjunction with MAP technologies further enhances the sustainability of this approach.

Looking Forward

As the world continues to grapple with the challenges of food waste and environmental sustainability, technologies like Modified Atmosphere Packaging offer a beacon of hope. Companies like Air Products, with their Freshline solutions, are leading by example, demonstrating that it is possible to marry quality and sustainability in the fight against food waste. As this technology continues to evolve and become more widespread, its role in shaping a more sustainable future for food preservation cannot be understated.

Sustainability & Decarbonisation 24 | foodanddrinknetwork-uk.co.uk

Images courtesy of Air Products | https://www.airproducts.expert/uk/MAPgas/

Streamlining Food Production:

The Role of Processing Equipment in the Modern Food Industry

In the bustling world of food production, efficiency, reliability, and quality are paramount. Behind every delicious meal, snack, or beverage lies a sophisticated network of processing equipment meticulously designed to transform raw ingredients into finished products. From steam boilers to water treatment systems, each component plays a crucial role in ensuring the smooth operation of food processing facilities.

From steam boilers to water treatment systems, each component plays a crucial role in ensuring the smooth operation of food processing facilities. We delve into the significance of processing equipment in the food industry, exploring key technologies such as fuel-fired and electric steam boilers, ancillary plant systems, and engineered solutions for water treatment.

FUEL-FIRED AND ELECTRIC STEAM BOILERS:

Powering the Heart of Food Production

Steam boilers serve as the beating heart of many food processing operations, providing the energy necessary for cooking, sterilization, and heating processes. Fuel-fired steam boilers utilise natural gas, propane, or diesel to generate steam, offering robust performance and high efficiency. These boilers are prized for their versatility, capable of delivering precise temperature control essential for cooking, pasteurisation, and other thermal processes in food production.

On the other hand, electric steam boilers have gained traction due to their cleanliness, ease of installation, and minimal environmental impact. By harnessing electricity as a power source, electric boilers eliminate the need for on-site fuel storage and combustion, reducing emissions and ensuring compliance with stringent environmental regulations. Moreover, electric steam boilers excel in applications requiring rapid start-up times and precise temperature modulation, making them ideal for small-scale food processing operations and niche production lines.

ANCILLARY PLANT SYSTEMS:

Enhancing Efficiency and Productivity

Beyond steam generation, ancillary plant systems play a pivotal role in optimising the efficiency and productivity of food processing facilities. These systems encompass a wide range of equipment, including heat exchangers, pumps, valves, and piping networks, designed to transport fluids, regulate temperatures, and facilitate material handling throughout the production process.

Heat exchangers, for instance, play a critical role in energy recovery and process optimisation by transferring heat between different fluid streams. By harnessing the heat generated during pasteurization or cooking processes, heat exchangers can preheat incoming product streams, reducing energy consumption and enhancing overall efficiency. Similarly, pumps and valves regulate the flow of liquids and gases, ensuring precise control over process variables and minimizing product waste.

ENGINEERED SYSTEMS FOR WATER TREATMENT:

Safeguarding Quality and Compliance

Water serves as a ubiquitous ingredient and processing medium in the food industry, necessitating stringent quality standards and regulatory compliance. Engineered systems for water treatment play a pivotal role in safeguarding product quality, mitigating contamination risks, and ensuring compliance with food safety regulations.

Our class-leading range of fuel-fired and electric steam boilers and portfolio of aftercare solutions can help with your decarbonisation strategy and put your company on the Road to Net Zero.

As a complete solutions provider, Fulton can provide your food processing facility with:

· fuel-fired and electric steam boilers

· off-grid and point-of-use solutions

· ancillary plant / engineered systems

· steam surveys

· project management

· water treatment contracts

· accredited / certified training

· installation / commissioning / upgrades

· repair / service / maintenance programmes

For further information scan the QR code, visit www.fulton.co.uk, email sales@fulton.co.uk or call the office on +44 (0)117 972 3322.

Efficient & Reliable Processing Machinery Processing Equipment foodanddrinknetwork-uk.co.uk | 25

ON THE ROAD TO NET ZERO FBW253 - Net Zero Advertisement - FDN.indd 1 21/03/2024 11:28

HELPING YOUR FACILITY

At Cross+Morse we aim to fulfil all industry demands, from the simplest to the highest level of precision required. Our objective is to offer a complete solution - not just products - to your power transmission challenges.

Cross+Morse are known in the industry as pioneers in quality standards, which is why we take our quality control processes very seriously. Quality assurance is central to our organisation with controls encompassing all aspects of design, manufacture, logistics and customer service. We are ISO 9001:2015 accredited and have been for over 30 years.

26 | foodanddrinknetwork-uk.co.uk

Cross & Morse

At Cross+Morse we have continuously invested in top of the range measuring equipment: Co-ordinate Measuring Machine (CMM), digital tri-bore gauges and micrometers which are constantly calibrated to comply with ISO standards. Our stringent inspection process guarantees that when manufacturing each operation is thoroughly inspected by either a highly trained shop-floor staff supervisor or an inspector, ensuring that manufacturing is only allowed to continue when each phase has been approved. Our hardening treatment is checked using either our Rockwell or Vickers hardness testing machines.

We review our quality procedures continuously to provide up-to-date mechanisms for ensuring conformity to the quality system; different audits are carried out on all activities in the company throughout each year.

freewheels, roller ramp clutches, combined sprag and bearing units and many more.

Cross+Morse is the largest authorised distributor and stockist for American transmission products manufactured by RegalRexnord (formerly EPT) in the United Kingdom. The range includes Sealmaster®, Browning®, Jaure®, Kop-Flex®, McGill® and Morse®.

Inverted tooth chain: including the standard SC type from 3/16” to 2” pitch and HV type from 3/8” to 2” pitch; as well as conveyor chains up to 12” width in centre or outside guide construction. We manufacture standard and special sprockets in-house for a complete drive solution.

We pride ourselves in offering a complete range of overload protection devices ranging from the simplest to the most accurate and precise overload clutch: Sheargard range of overload clutches, wedge pin type, available as a chain coupling and the option of low inertia rubber elastic couplings for higher speed drives. The Crossgard range, ball detent type, comes in 3 versions and also available with roller chain and low inertia rubber coupling option. The Safegard CS series, ball/roller detent type, comes in 2 two basic types (standard or mini) and also available as shaft couplings. Series CZ and CN zero backlash Safegard clutches for responsive overload protection, available in both basic and shaft coupling types.

We offer a wide stock range of flexible shaft couplings to accommodate different types of misalignment: Jaw couplings, elastomeric couplings, roller and Delrin® chain couplings, gear couplings GFA & GFAS, polymer gear couplings, Morflex elastomeric disc couplings and Crossflex disc couplings.

Our Crossbore® rework service includes reboring, keywaying and setscrewing of standard sprockets, pulleys and gears in a dedicated production area with specialised CNC machines for a rapid response. Induction hardening of teeth is also offered in-house.

For further information contact:

Shaft clamping elements for precision transmission of torque with no backlash: a complete range from stock.

Our range of Freewheel clutches for overrunning, indexing and backstopping applications; including sprag clutches, industrial ratchet

Telephone: +44 (0) 121 360 0155

Email: sales@crossmorse.com or visit www.crossmorse.com

Power Transmission Solutions

Due to the pandemic we’ve seen increased attention to cleanliness, washdown procedures and prevention of foreign contaminants from getting into the manufacturing process within fish, food and beverage processing companies. Recently there has been concern over a rise in contamination in meat processing and fruits and vegetables; which has changed procedures in food manufacturing across the board. In an environment of increased operational requirements regulatory guidelines, today’s bearings and power transmission are exposed to a host of demanding conditions. Such include corrosive cleaning agents, high pressure washdown array of environmental factors that can negatively impact Overall, a balance of material strength, corrosion resistance, and lubrication are required for all products used where paramount importance. Cross & Morse CORROSION

foodanddrinknetwork-uk.co.uk | 27

SOLUTIONS

How to ensure your process is free of metal contamination

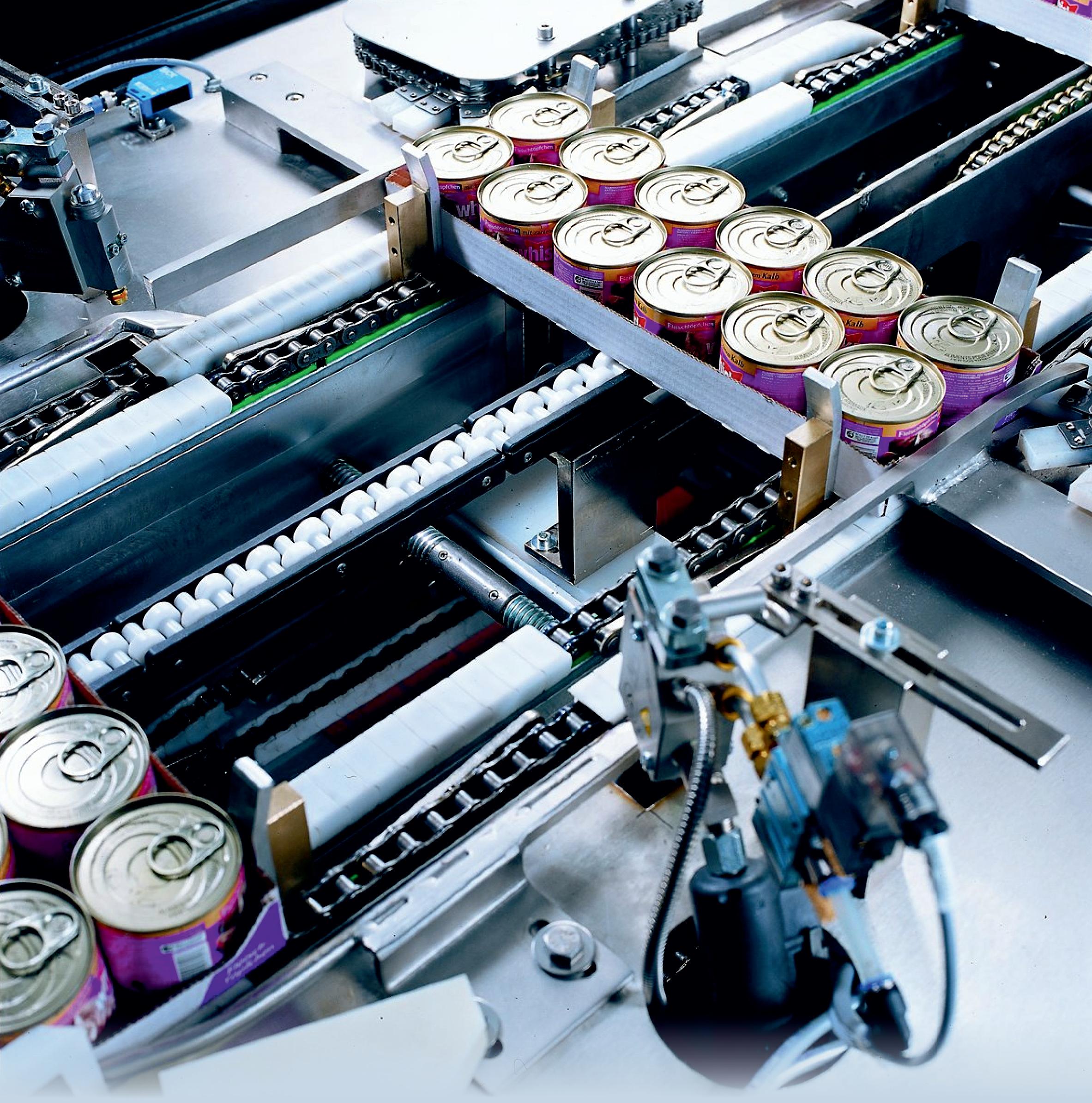

Employing Eriez powerful magnetic separators for ferrous contaminants and metal detectors for both ferrous and non-ferrous metals ensures your product is free of dangerous tramp metals. Regardless of your process and material, Eriez offers a solution for gravity, conveyed, pneumatic or liquid line flows. Below are several factors to consider when choosing a magnetic separator for your food application.

Temperature: Permanent magnetic materials lose strength when exposed to elevated temperatures. Some losses are reversible, so that when the temperature is returned to normal, the magnetic strength returns. Depending on the specific material, permanent magnets heated beyond certain temperatures may also suffer irreversible loss—a reduction in strength that cannot be recovered by cooling. When specifying a magnet application, it is important to note the ambient as well as any clean-in-place (CIP) temperatures to ensure a proper magnet design suitable for long-term separation performance.

Flow rate: Magnetic separators perform best when the contamination is presented to the surface of the separator. It is best to select a magnetic separator configuration that provides for a thin “burden depth” or thickness of the material layer over or under the magnet to ensure the magnet will havethe best opportunity to capture the ferrous contamination.

Flow characteristics: Many products exhibit different flow characteristics when damp or moist. Are there large chunks that may plug an opening or gap in the separator? Will the product flow freely through the selected magnetic separator? For example, brown sugar with any significant moisture content will not flow between the tubes in a grate magnet assembly, although they may be positioned only 1 inch apart.