PIM METALS

NEWS BEARINGS WELDING EVENTS 2 11 12 19 INCORPORATING IMT VOLUME 2 l ISSUE 8 l APRIL/MAY 2023

Welcome to the April issue of PIM Metals, as both producers and processors of metal struggle with the cost of energy there is also the added pressure of trying to meet environmental legislation.

As an example, processors of metal tube, pipe, sheet, strip, bar, and wire are adopting technology to ensure as near a net waste process, this can start with precise measuring and product optimisation technology. When looking at primary metals production there is a growing but costly move away from using coal/coke to alternate fuels, switching to electricity, gas, hydrogen or even nuclear are all on the table.

There are however some good points when looking at replacing coke with gas or even hydrogen for our industry, namely new pipelines to supply the plant with the gas or hydrogen will need to be commissioned.

In our next issue June, we will be looking at Welding technology, Stainless steel and Roll forming.

News should be sent to imtmagazine@virginmedia.com no later than June 19th, a word document and supporting print ready images would be preferred.

And finally, may I wish the entire team at Unison Ltd a happy 50th Birthday and Combilift a happy 25th.

Email: imtmagazine@virginmedia.com

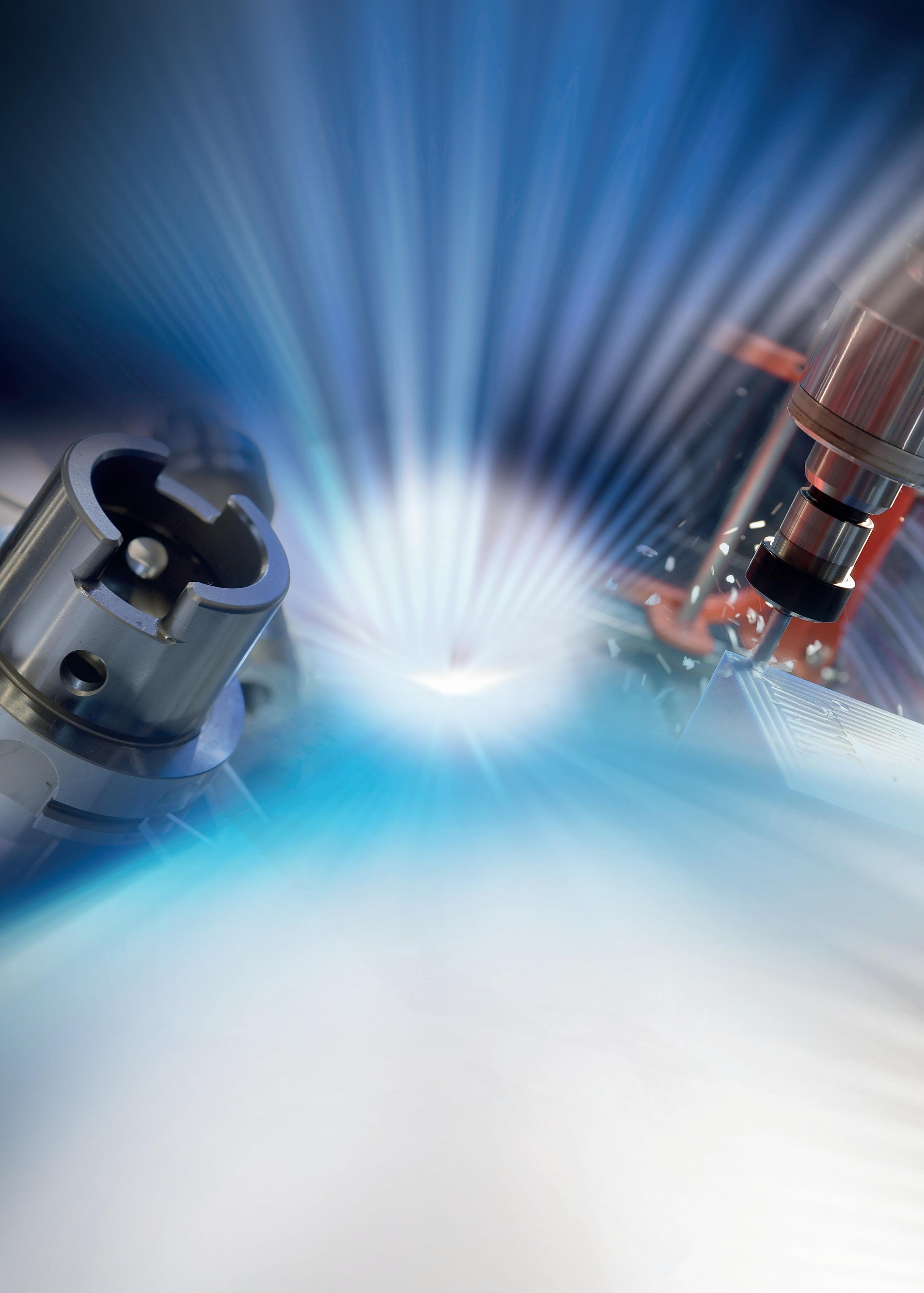

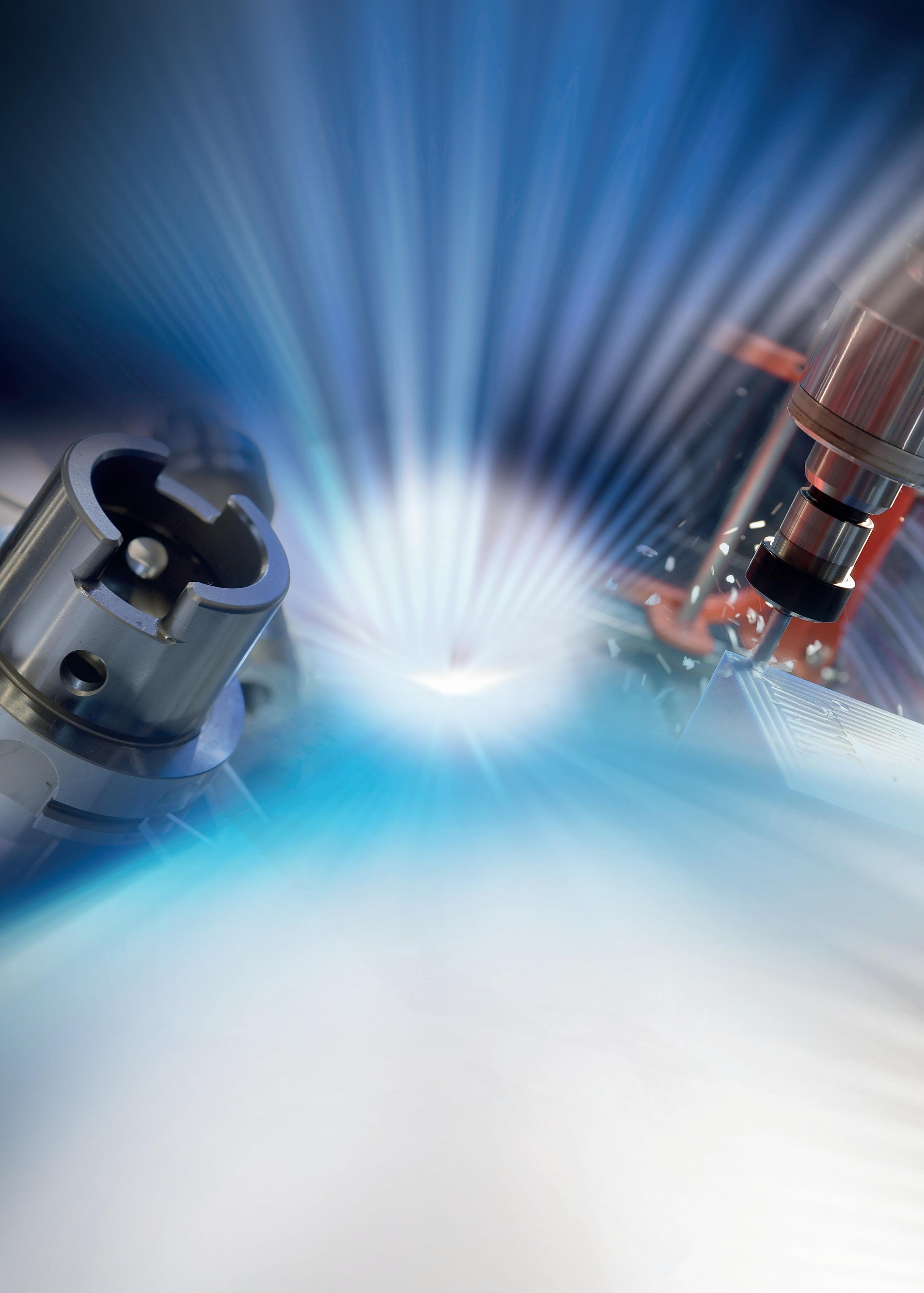

Cover picture: Fein, Welding page 14

Tel: +44 (0) 1732 505724

Mobile: +44 (0) 7747 002286

Email: processindustrymatch@virginmedia.com

PRODUCTION

Anthony Wiffen

ASTAC Business Publishing

Tel: +44 (0) 1460 261011

Mobile: 0785 161 2799

Email: anton_print_1@mac.com

PRINTING

Brown Knight and Truscott

Tunbridge Wells, Kent, TN2 3BW, UK

Tel: +44 (0)1892 511678

©2022 KVJ Enterprises

NEWS 1 PIM Metals April/May 2023 IN THIS ISSUE COMMENT NEWS WELDING BEARINGS UNISON 19 EVENTS NEW PRODUCTS Combilift premieres new product at LogiMAT 18 16 12 11 2 New Trumpf Trulaser Tube at Lasercell eliminates outsourcing Unison Ltd, the inventors of all-electric tube manipulation, celebrate 50 years Plasma instead of chemicals

bearings save steel wire plant over €1.2m a year

new Zero4 program to receive €70m from Business Finland to unlock industrial productivity

NSK

Konecranes’

COMMENT/IN THIS

and advertising deadline for the June/July issue of PIM is: June 18th

Editorial

–

VOLUME 2, NUMBER 8

APRIL/MAY 2023 Contact information

Konecranes’ new Zero4 program to receive EUR 70 million from Business Finland to unlock industrial productivity

Konecranes today launched its new Zero4 research and innovation program to improve the industrial productivity and competitiveness of Finnish companies. Business Finland has granted EUR 70 million to Zero4, part of its broader “Veturi” program that aims to significantly boost research, development and innovation activities in Finland and create hundreds of new jobs in the coming years.

During the past years in Finland, increases in industrial productivity have tended to be the result of investments in more efficient equipment, automation, and enterprise resource planning systems. However, this growth potential has now largely been

tapped, and new innovations are needed to ensure the continued competitiveness of Finland’s exports and economy.

Zero4 will be a Konecranesled ecosystem of partners, universities, research institutes and customers working towards the vision of a unified material flow platform. The program will focus on reducing four major deficiencies in material flows: information barriers, greenhouse gas emissions, energy consumption and accidents. The ecosystem is expected to consist of more than 70 partners by 2027, with Konecranes to develop selected production plants into material flow flagship sites and model factories to boost research and innovation efforts.

“This is a result of long and

hard work that we have done together with an extended team, and of course we are very proud and excited about it. It is strong recognition from Business Finland of the innovativeness and the technology leadership at Konecranes, and our ability to boost the Finnish economy. With the developed material flow solutions, Finland will become a technological pioneer in the subject area and a significant exporter of related solutions,” says Konecranes’ Executive Vice President of Technologies Juha Pankakoski.

In addition to the grant from Business Finland, Konecranes plans to invest EUR 40 million into Zero4 during the next five years to continue executing on its technology vision and

sustainability ambitions, and to generate productivity growth. Funding from Business Finland will enable Konecranes and its ecosystem partners to significantly grow their broader research and innovation activities during the next five years.

Konecranes expects the program to boost its own exports from Finland, and further strengthen its efforts to decarbonize its own operations and value chain as well as to accelerate circularity. Konecranes is committed to reducing emissions in alignment with the Paris Climate Agreement’s goal of limiting global warming to 1.5C. Further information:

Emmi Vähäsarja, E: emmi. vahasarja@konecranes.com or

T: +358 40 508 8166

NEWS 2 PIM Metals April/May 2023

MACH 2024 Headline Sponsor Announced

MACH 2024, the UK’s national event for inspiring, innovating and connecting manufacturing, has reached the landmark of just one year to go before the doors of the NEC, Birmingham open to start the show.

In recognition of the landmark, and reaffirming its commitment to UK manufacturing, Lloyds Bank has confirmed its headline sponsorship of MACH for the sixth time.

MACH is the destination of choice for companies looking to adopt and invest in the digital revolution.

James Selka, CEO at the MTA, said: “We are delighted to again be working with Lloyds Bank –this time on the promotion of MACH 2024. Being owned by the industry, for the benefit of the industry, the MTA’s primary aim is to help and support the sector we represent to do business, boosting the UK’s manufacturing performance and enabling UK PLC to compete at a global level.

Manufacturing is the heartbeat of the UK economy and growing a resilient manufacturing industry has never been more important. Lloyds Bank is an ideal partner for MACH as we share common goals and commitments.”

A key theme of MACH 2024, which takes place between 15-19 April, will be around sustainability, supporting UK manufacturers transition to a low-carbon, sustainable business model.

Dave Atkinson, UK head of manufacturing at Lloyds Bank commented: “Making the transition to Net Zero represents a significant growth opportunity for the UK economy, particularly for the manufacturing sector. However, we must invest in technology and skills to support such an ambitious change. Lloyds Bank are delighted to again sponsor MACH – the UK’s national showcase for the best in next-generation manufacturing technologies.”

As a full working week event, MACH exhibitors power their equipment and technology on

display, demonstrating latest techniques and trends to improve productivity, reducing material resource and energy used in the process – helping to ensure a sustainable future, contributing to the drive towards Net Zero. Attracting new talent into the engineering-based manufacturing sector is another key driver for growth and a shared focus for both the MTA and Lloyds Bank. Mr Selka continued: “The MTA invests in a dedicated Education and Development Zone at MACH, successfully attracting over 3,000 students in the key age range of 11-18. The zone is designed to inspire a future generation into engineering as an exciting

career, helping to close the skills gap by investing in people.”

With 12 months to go before the doors open at MACH 2024, the show is already well on the way to being a sell-out. Attracting an audience of more than 26,000 people to meet and network with around 500 exhibitors, business attributed to the event in 2022 amounted to more than £180m.

Lloyds Bank’s sponsorship deal also extends to the Engineering Supply Chain Show. This three-day event, co-located alongside MACH in 2024, is where engineering and manufacturing buyers go to find world-class suppliers, exclusively in the UK engineering and manufacturing supply chain.

bars in-house, an important ability for the positioning and growth in medical as well as aerospace applications.

Alleima has signed an agreement to acquire the Swedish company Söderfors Steel Operations AB (“Söderfors Steel”). The acquisition will add capabilities in hot rolling of small diameter bars and profiles to expand the offering of advanced materials for the Medical and Aerospace segments. The company will be reported within the Tube division.

“Important drivers of our profitable growth strategy

include winning business and market shares within the fastgrowing Medical and Aerospace segments. The acquisition of Söderfors Steel allows us to further widen our offering in these segments by adding complementing capabilities, enabling expansion to many new product applications within attractive niches. I welcome Söderfors Steel to our Group”, says Göran Björkman, President

and CEO of Alleima.

The acquisition will provide Alleima with capabilities to manufacture bars with a diameter less than 80 millimeters in high performance materials as nickel base alloys and remelted stainless steel. Currently, Söderfors Steel is a subcontractor to Alleima and other customers. By adding these capabilities, Alleima will be able to manufacture small diameter

The production facility and head office of Söderfors Steel is located in Söderfors, Sweden, with approximately 50 employees. In 2022 Söderfors Steel had revenues of approximately SEK 145 million and an EBIT margin neutral to the Tube division. Impact on earnings per share will be accretive from the start. The parties have agreed not to disclose the purchase price. The transaction is expected to close during the first half of 2023.

NEWS 3 PIM Metals April/May 2023

Alleima acquires production facility for small diameter bars

Precision Inline Profile Measurement • Full profile measurement • Surface fault detection • 3D image analysis Family owned since 1957, Zumbach is a global leader in the industry. Driven by innovation and experience. We are here for you and ready to build the future together. www.zumbach.com • sales@zumbach.ch

Unison’s Steve Haddrell becomes sales director of Nukon Lasers UK

Steve Haddrell, Key Account Manager at Unison Ltdthe inventors of all-electric tube manipulation - has been appointed as Sales Director of sister company, Nukon Lasers UK. In addition to fulfilling his new role, Steve will continue to support Unison’s tube bending machinery customers in the Midlands and South. Nukon Lasers UK became the exclusive UK and Ireland distributor for Nukon’s European-made fibre laser flat sheet metal and tube cutting machines in autumn 2021.

Beginning his career in laser as Supervisor with Nuneaton-based Subcon Laser Cutting Ltd in the late 1980s, Steve moved to 600 Group’s laser division in 1998, where he worked in machine tool sales & applications. He joined

Yamazaki Mazak UK’s optonics division as General Manager in 2004 and moved to Unison Ltd as Key Account Manager in 2009.

“It’s probably fair to say that I’ve accrued more than my fair share of laser-cutting expertise over the years,” he says. “I remember seeing laser-cut parts from some of the first commercial fibre laser machines in the late 1980s, when I was a foremanfabricator in Birmingham. I was awestruck by what those machines could achieve. Obviously, since then, laser cutting has advanced in leaps and bounds, with developments such as highpower fibre laser technology – like the 20 kW nLIGHT model we showcased at EuroBLECH 2022.”

Talking about Unison’s desire to expand into laser cutting technologies, Steve Haddrell adds: “For quite some time we

had been looking to extend the Unison product range to include high quality fibre lasers, as we believed they would be a natural fit with our all-electric Unison Breeze tube bending machines. Short of building our own fibre laser machines in-house, however, the challenge was to find an established fibre laser product range that matched the uncompromising levels of reliability and build quality that Unison tube benders are renowned for.

“That wasn’t easy,” he continues. “But after considerable research and frequent reservations about machine quality or support, we finally met with European fibre laser manufacturer, Nukon. Quite apart from offering exceptionally wellmade and price-accessible fibre laser machines - and having a

Corinth Pipeworks is awarded contract for the N05-A pipeline

Corinth Pipeworks has been awarded a contract by ONE-Dyas

B.V. to provide High Frequency

Welded (HFW) steel pipes for the N05-A platform.

The N05-A platform is located in the North Sea, about 20 kilometers north of the Ems estuary.

This offshore gas production project will run entirely on renewable energy from the nearby Riffgat wind farm, which makes for an active contribution to the energy transition and to achieving the goals of the Climate Agreement.

The contract covers

approximately 16km of 20” diameter & 20.6mm wall thickness, High Frequency Welded (HFW) linepipe, including external 3-layer polypropylene coating and concrete weight coating applied at the same location as pipe manufacturing. The HFW pipes will be manufactured in Corinth’s facility in Greece and delivered within 2023.

Furthermore, the pipeline will be certified according to the ASME B31.12 Option B code for hydrogen pipelines, supporting the plans for future transportation of up to 100% hydrogen.

This project is important in the effort to reduce the environmental footprint of natural gas production with the assistance of electricity from renewable sources, such as

Steve Haddrell

fantastic manufacturing facilitythe thing that impressed us most about the people at Nukon was their attitude to business. Just like Unison, they’re committed to building superb machines that exceed customer expectations, and to providing outstanding levels of service and support. Since partnering with Nukon, we’ve sold their fibre laser machines to manufacturing companies across the UK. The quality of the Nukon product is exceptional and customers have the added reassurance of support from our own Nukontrained service teams. What more can I say? Apart from: if you’re one of my Unison tube bending customers, don’t worry – I’m still here to support you.”

NEWS 5 PIM Metals April/May 2023

offshore wind farms. Electricity from the wind farm will be able to be converted into green hydrogen and transported via pipelines to the onshore grid.

MZ and AMADA WELD TECH sign €11Million Deal

BMajor

MADA WELD TECH, innovator of creative joining and metal processing solutions and BMZ Group, a global specialist in lithiumion battery manufacturing, are pleased to announce their latest deal. BMZ signed to invest over €11 million, acquiring welding systems from AMADA WELD TECH, for its battery production. This major investment in BMZ’s German production capacity is dedicated to serve growing demand in the booming energy storage solutions market.

Welding is one of the key processes within battery production and at the same time a potential bottle neck of the whole production process. With over 100 years of experience in resistance welding, AMADA WELD TECH is well aware of the challenges of joining appliciations in battery pack production. By combining the knowledge from its in-house design department with the expertise of its application and research labs, resistance welding systems can be created to make daily operation as efficient as possible.

As a key player (white lable as well as BMZ-branded products) on the energy storage solutions market, BMZ extends its market position by investing early in enlarging production capacity, in order to continue to meet the exponential rise in customer demands. As a leading manufacturer of welding equipment AMADA WELD TECH will contribute to BMZ’s future growth, by providing maximum process stability and excellent repeatability, by supplying proven, reliable welding systems.

The energy storage market is

estimated to almost quadruple its worldwide volume by 2027. The rising demand is a result of increased responsibility amongst industry and homeowners, as part of the energy transition for climate development. Additionally, the world market shows a growing desire for energy storage, which AMADA WELD TECH fully supports. As a welding specialist, AMADA WELD TECH will continue to offer design expertise, technical knowledge and optimum solutions, by providing fully automated production machines.

About AMADA WELD TECH:

With this latest major investment in German production capacity, BMZ not only commands its own market position and strenghthens the ‘made in Germany’ share of the global energy market, it also protects existing and creates numerous new jobs in the industrial competence area, at the Bavarian lower Main.

Dave Fawcett – CEO of AMADA WELD TECH’s European and American Operations commented: “After being able to already supply our valued client, BMZ, with many of our AWS-3 Jupiter

RW Resistance Welding Systems in the past, this latest major order is to date, our biggest deal with BMZ. We look forward to fullfilling this latest order and to continue our successful business partnership into the future.”

BMZ CEO and Founder Sven Bauer comments: “BMZ and AMADA WELD TECH are linked by a business relationship full of trust and understanding, lasting already for many years.We are glad to have such a strong and experienced partner at our side when it comes to such a major investment in our future viability.”

AMADA WELD TECH is a leading manufacturer of equipment and systems for Laser Welding, Laser Marking, Laser Cutting, Resistance Welding, Hermetic Sealing and Hot Bar Reflow Soldering & Bonding. We design and manufacture industry-leading product families for the global market and customize our products around specific micro-joining applications for all our customers. AMADA WELD TECH product markets include medical devices, battery, automotive, solar industry, electronic components and aerospace. AMADA WELD TECH Europe is headquartered in Germany and has additional production facilities in The Netherlands and UK, as well as sales offices in France, Hungary and Italy. And is part of the worldwide AMADA Group, with about 8500 employees worldwide. www.amadaweldtech.eu

NEWS 6 PIM Metals April/May 2023

Ainvestment strengthens partnership Sven Bauer, BMZ CEO & Founder (on the left) and Dave Fawcett, CEO of AMADA WELD TECH’s European and American Operations, shaking hands on their latest deal.

Combilift donates its 75,000th truck to International Charity

As part of Combilift’s celebrations for its 25th anniversary, the Irish materials handling specialist has announced that it is donating its 75,000th truck - an Aisle Master articulated forklift - to Convoy of Hope, a non-profit humanitarian and disaster relief organization.

Convoy of Hope works alongside communities and its wide network of volunteers aim to alleviate poverty and hunger and to bring help and hope wherever they are most needed in the world. As this type of aid is sadly always in demand, operational expansion has also seen a corresponding increase in the requirement for warehousing capacity to accommodate the vast volume of supplies that are stored and ready for delivery to areas in need.

The World Distribution Center is based in Springfield, Missouri, and from this location at the “crossroads of America” truckloads of relief supplies and food are sent on their way across the USA and further afield around the globe. Combilift supplied its first Aisle Master for this site four years ago,

and a further three units were delivered last year. Convoy of Hope’s Senior DirectorDistribution Jeff Smethers: “A lot of our exponential growth has been down to the Aisle Masters as they enable us to get more loads in and out faster. And thanks to Combilift’s free warehouse layout service and the Aisle Master’s narrow aisle capability we have achieved the best possible storage density

and very efficient operation.”

The announcement was made at a gala dinner in Chicago during the ProMat trade fair, and Combilift’s CEO and Co-Founder Martin McVicar said: “The work that Convoy of Hope does is invaluable to relieve suffering around the world and we wanted to make our own contribution by donating our 75,000th truck to this very worthwhile charity.”

Erick Meier, Senior Vice

President - Supply Chain at Convoy of Hope said ”We are so grateful that Combilift and Martin and the whole team have actually given us one of these trucks for our operations. This is going to help people for years – and ensure that every day someone in the world will receive aid - and that brings hope.”

www.combilift.com

https://convoyofhope.org/

NEWS 7 PIM Metals April/May 2023

Ohmi Press Works and Forging in Japan orders an energy-efficient, latest-generation ring rolling machine from SMS group

Japanese forging company Ohmi Press Works and Forging has placed an order with SMS group for a RAW 500/400-4500/800 EH radial-axial ring rolling machine. This is Ohmi’s sixth ring rolling machine from SMS group.

By expanding capacity at its Shigaraki plant, Ohmi can supply larger and heavier rings for a wide range of applications in the automotive, shipbuilding, aerospace, mechanical engineering, oil & gas, and wind power industries. The new RAW is capable of rolling seamless rings with diameters of up to 4,500 millimeters and a maximum height of 800 millimeters. The ring rolling machine is scheduled to go into operation in May 2024.

We chose SMS group because we are convinced that it’s the best technology on the market. We rely on SMS as a system supplier who not only delivers the plant and equipment but has also been supporting us with expert technical service for many years”, says Hiroyuki Sakamoto, President of Ohmi Press Works and Forging.

Ohmi benefits from the innovative electrohydraulic direct drive concept featured in the RAW EH: Depending on the application, energy consumption is reduced by up to 25 to 50 percent compared with conventional ring rolling machines. This drive concept developed and patented by SMS provides even more precise and energy-efficient control of the ring rolling machine. Instead of a large central hydraulic system, several small electrohydraulic

drives are used for all rolling axes, which supply the necessary power on demand. In contrast to conventional fully hydraulic ring rolling machines, the electrohydraulic drive concept reduces the need for machine and foundation pipework, resulting in significantly lower investment costs.

Ohmi’s trust in our machines and technologies is encouraging us to boost our commitment to long-term and productive collaboration. We are confident that our wealth of experience and our dedication to the development of advanced technologies will help to consolidate Ohmi’s position as a leading manufacturer of ring rolling products”, says Martin Gellhaus, Head of Technical Sales Ring & Wheel Rolling at SMS group.

The ring rolling machine ordered by Ohmi Press Works &

Forging has a radial rolling force of 5,000 kN and an axial rolling force of 4,000 kN. SMS group’s scope of supply covers all machine components including the rolling tools and an extensive software and technology package.

The RAW comes with CARWIN (Computer Aided Rolling under Windows) control software and the ROLLTECH Rings and ROLLTECH Profiles technology software. CARWIN checks the target data for the ring to be produced and controls the automatic rolling process together with the ring rolling machine’s CNC system. The ROLLTECH technology package enables the ring rolling process to be simulated and certain process parameters to be generated. To this end, the finished ring geometry and the material are entered into the

system. The technologies used enable reproducible rolling results and can be relied on to ensure close manufacturing tolerances. The quick tool changes and remote-controlled tool settings also contribute to this and guarantee a high level of machine availability.

The Ring Monitoring System (RMS) can be used to continually optimize product quality during the rolling process: Working in conjunction with the line laser, it delivers real-time measurements that are displayed in graphical mode as the ring geometry and form deviations. The stateof-the-art plant technology is rounded off by digital solutions developed at SMS for intelligent monitoring (Smart Alarm) and a comprehensive overview of the status of production and the condition of the machine (SMSMetrics).

NEWS 8 PIM Metals April/May 2023

Ohmi Press Works and Forging in Japan orders an energy-efficient, latest-generation ring rolling machine from SMS group

Rhodes Interform wins major contract to refurbish metalforming press

Rhodes Interform, the UK manufacturer of hot and cold forming equipment for metals and composites, has won a major new order with Braime Pressings in Leeds, to fully refurbish one of its existing metalforming presses.

Braime Pressings is a specialist in deep drawing, multistage progression and transfer presswork with over 130 years of manufacturing experience.

The project, which is due to be completed in Summer 2023, will involve Rhodes Interform fitting the press, which Braime Pressings bought from a Swedish manufacturer, with brand new electrics throughout, including control panel, operator station, human machine interface (HMI) and software.

The press will also be updated with several safety features, such as new light curtains, linear transducers, mechanical safety hold up devices and newly designed guarding to ensure the machine is brought up to the latest CE/ UKCA marking standards.

Rhodes Interform will also install a new hydraulic power pack featuring the highest energy efficiency motors available on the market (IE4) which will offer significant

savings in energy costs.

Senior engineer at Rhodes Interform, Ben Jennings said: “This project allows us to both enhance and extend the life of a machine that is already nearly 40 years old. The investment by Braime Pressings remains a major saving against a new

machine, and yet operationally the press will be significantly more efficient by incorporating the IE4 motors. Rhodes Interform is proud to be involved in such a project that has efficiency and sustainability at its core”.

Braime Pressings’ Operations Director Alistair Barr said:

“Braime Pressings and Rhodes Interform have a long-standing relationship and we are pleased to be working together on this project.

The major investment we have made demonstrates our commitment to significantly improving our offer to our stakeholders in terms of capacity, flexibility and competitiveness.”

Rhodes Interform offers fully certified refurbishment services on any make and model of metalforming and composite presses.

If you are interested in investigating similar opportunities on any existing machine, please contact the service department for more details on 01924 371161.

NEWS 9 PIM Metals April/May 2023

North American Aluminium demand up 4.8% in 2022

As part of its monthly Aluminum Situation statistical report, the Aluminum Association released preliminary estimates showing 4.8% year-over-year demand growth for the aluminum industry in North America (U.S. and Canada) in 2022. This outpaced overall estimated 2.7% Gross Domestic Product (GDP) growth in the United States in 2022. While estimates show yearover-year growth, the report indicates a slowdown in demand for the second half of 2022.

“Despite some headwinds and softer demand in the second half of the year, this latest data shows an industry built to last,” said Charles Johnson, president & CEO of the Aluminum Association. “Geopolitical

disruptions, supply chain issues and inflationary pressures could continue to pose some challenges in 2023. However, with historic investment in U.S. aluminum manufacturing last year and continued market growth opportunities, the midand long-term trendlines for aluminum in America remain incredibly strong.”

Among key takeaways from the report:

l Aluminum demand in the United States and Canada (shipments by domestic producers plus imports) totaled an estimated 27.5 billion pounds in 2022, advancing 4.8% over 2021. Overall demand in 2022 approached record levels seen in 2018 and 2019.

l Compared to December 2021,

aluminum demand contracted 3.7% in December 2022 following a similar contraction in November.

l Most major semi-fabricated –or “mill” – product categories saw increased year-over-year demand growth, led by sheet and plate products (6.1%) and foil (5.1%). In total, mill product demand grew 4.1% year-overyear in 2022.

l Aluminum exports (excluding scrap) to foreign countries increased 3.8% from the yearago level

Last year, the U.S. aluminum industry announced more investment in domestic manufacturing than in the past several decades combined. Firms announced billions to build new aluminum rolling and recycling

capacity, including greenfield plants slated to come online in the coming years. It has been more than 40 years since a similar, new U.S.-based mill was built.

The Aluminum Situation report is one of more than two-dozen ongoing industry statistical reports developed exclusively by the Aluminum Association through surveys of aluminum producers, fabricators and recyclers. Subscribers to the Aluminum Association statistical reports have access to an online portal with data users can manipulate directly to produce interactive, presentation-ready charts and graphs.

To learn more about the Aluminum Association’s statistical offerings or to subscribe, visit www.aluminum.org/statistics

NEWS 10 PIM Metals April/May 2023

Industry approached record demand levels driven by packaging, other segments despite slower second half of year

NSK bearings save steel wire plant over €1.2m a year

NSK’s assistance proved vital to a company experiencing repeat failures of bearings fitted to the roller assemblies of its steel wire drawing machinery. Thanks to the intervention of NSK, which identified the problem and recommended the optimal solution, the customer is witnessing costs savings in excess of €1.2 million a year.

The bearing failures were leading to excessive downtime of around 75 stoppages a month, along with high maintenance costs, causing critical concern for the company’s management team. An urgent and robustly engineered resolution became a clear priority, which is why the steel wire manufacturer turned to NSK and its team of highly trained bearing experts.

As part of a thorough failed bearing analysis and application review, NSK engineers identified a problem with the lubrication and sealing of the company’s incumbent bearings. In particular, a lubrication analysis showed that the existing grease was graphitebased, which was not suitable for

the application. Compounding the issue was a continuous steel wiredrawing process with high loads and arduous operating conditions.

Relief arrived in the form of a new bearing and lubrication package recommended by NSK. As part of a value proposition, the solution consisted of an NSK sealed double row cylindrical roller bearing together with specially selected lithium grease.

NSK’s full complement cylindrical roller bearings feature high-performance contact seals that prevent the ingress of contaminants or water. Further features include inner and outer ring re-lubrication holes for ease of maintenance, and a highly corrosion-resistant phosphate coating for use in external

environments (if required). Prelubricated with lithium grease, the sealed units offer a high load

rating for increased radial and axial capability.

With the potential solution identified, the next task was to put the new bearing/grease combination through its paces via a comprehensive trial process. The result was highly positive, showing a 40% improvement in bearing life, which in turn led to large improvements in productivity and reduced maintenance costs. In fact, the reductions in lost production time and man hours, alongside the elimination of previously required technical support and engineering time, are delivering substantial annual savings calculated at €1,202,455.

The customer has since converted all of the roll assemblies on its wire-drawing machinery over to NSK’s proposed bearing/grease combination.

EVENTS 11 PIM Metals April/May 2023

TUBE BENDING BEARINGS

The steel wire manufacturer was enduring around 75 stoppages a month on average.

Photo: Copyright (c) 2022 Photography Germany/Shutterstock

NSK’s full complement cylindrical roller bearings are prelubricated with lithium grease. Photo: NSK

Plasma instead of chemicals

Fronius uses hot active plasma for surface cleaning

The cleanliness of part surfaces is essential in production. To be able to carry out process steps such as welding, adhesion, sealing, painting, printing, and brazing to a high standard, contamination must be removed prior.

Industrial surface cleaning with Acerios, the hot active plasma technology from Fronius, is particularly environmentally friendly and cost effective.

To be able to join individual aluminum parts to a side wall using spot welding when constructing an automotive body, the surface of the sheets must be freed from foreign

When the hot active plasma comes into contact with a surface, the gas flow mechanically cleans while the plasma and resulting heat trigger a chemical cleaning process. This combination reliably removes organic residues and film impurities.

Chemical cleaning: expensive and bad for the environment

Up until now, the automotive industry has relied on chemical cleaning processes in which the component is immersed in chemicals. The use, storage, and disposal of the required chemicals is not only time-consuming and expensive, but also problematic in terms of their impact on the environment. Such cleaning processes are also subject to strict safety requirements.

Plasma: the sustainable and efficient alternative

effectively. It is suitable for metals such as aluminum and steel as well as plastic, glass, and ceramic. The Acerios system generates a plasma flame on the welding torch with a temperature of up to 1,000 degrees Celsius, which a robot guides precisely over the surface at speeds of roughly 6 meters per minute.

particles or film impurities, otherwise a serious lack of fusion could arise.

A technology developed by Fronius can help: hot active plasma removes residues precisely, quickly, and

Depending on the requirements, entire surfaces or specific areas can be treated. This significantly increases efficiency, as instead of cleaning as much of the surface as possible, Acerios cleans only those areas that actually need cleaning. This technology comes without harmful

WELDING 12 PIM Metals April/May 2023

Hot active plasma removes organic residues from metal, plastic, glass, and ceramic surfaces precisely, quickly, and without harming the environment.

cleaning additives, meaning it is environmentally friendly and saves resources.

Fronius develops atmospheric pressure plasma

By using plasma in its welding technology, Fronius has extensive expertise in this area. The company has also been researching possible applications for plasma in surface treatment for ten years, the key to this eventually being found in the generation of atmospheric pressure plasma. This is a hot, gaseous, and energy-intensive mixture of atoms, molecules, ions, and free electrons.

When the hot active plasma comes into contact with a surface, the gas flow mechanically cleans while the plasma and resulting heat trigger a chemical cleaning process. This combination reliably removes organic residues and film impurities.

Easy integration and simple system design

The Acerios system consists of just a few components:

l Plasma torch with active cooling

l Power source with a power range from 35 to 200 amperes

l Industrial robot which guides the welding torch

l Active process gas control

l Cooling system with varying performance depending on the operating mode (from spot to continuous operation)

The system is compact and can be easily integrated into automated systems and production lines thanks to different interface variants. Pre-defined job settings shorten the training phase and make the device intuitive to use. Acerios is therefore a simple, affordable, and environmentally friendly technology for component cleaning.

WELDING 13 PIM Metals April/May 2023

(Top and above) The Acerios system is compact and can be easily integrated into automated systems and production lines.

FEIN announces new grinding range to elevate industry safety and performance

FEIN, the leading power tools and accessories manufacturer, has announced a new grinding product range, revealing new safety and performance features to meet the latest user needs.

Following the launch, power tool operators working across disciplines will be able to choose from the extended range of over 40 grinding tools, with corded and cordless options available. The range has been developed as a result of first-hand industry feedback, to provide a product suitable for every application, for example, angle grinding, die grinding and stainless-steel processing.

The portfolio includes the launch of the CG 15 compact angle grinder - the first of its class to feature a fully encapsulated, brushless FEIN PowerDrive motor. The tool’s powerful, yet efficient, 1500W motor and superior powerto-weight ratio allow user to

operate with superior efficiency and endurance. Furthermore, the angle grinder has been designed with cost and longevity considerations in mind, it requires fewer wearing parts, has longer service intervals and incurs lower

maintenance costs throughout its life.

The CG 15 grinder also offers users extensive protection through a variety of safety features which were driven by user feedback, including restart

protection, kick back check, jam monitoring and an efficient brake which brings the tool to a stop in less than 2 seconds.

Safety remains an important topic in the industry, with grinding tools classified by RoSPA (The Royal Society for the Prevention of Accidents) as one of the most dangerous tools, with 5,400 injuries recorded annually. FEIN’s Protago high-safety angle grinder, featured in the grinding tool range, was created in collaboration to set new safety standards in the industry. Bouygues, the construction giant, had previously banned the use of compact angle grinders following a serious accident, however, together with FEIN, the teams developed the Protago with safety features that almost fully eliminate the serious risks associated with improper operation.

The Protago, in addition to 9

WELDING 14 PIM Metals April/May 2023

other tools in this launch, is now available on the 18v AMPShare battery platform, powered by Bosch. The multi-brand shared system allows users to power over 200 different tools from over 30 brands with just one AMPShare battery, eliminating the costly requirement to purchase a specific battery type per tool.

Speaking on the grinder range extension, Andy Mills, managing director at FEIN UK shared: “Our grinder portfolio was developed as a result of our application-based approach at FEIN, which means that we are out in the industry meeting users to gain a detailed understanding of their working environments and the challenges they are facing to ensure that our products are meeting their needs. By continuing this approach with our grinding tools and this development, we are really proud to be offering users the right product for every application.”

“This grinding tool launch will also see an additional 10 FEIN products becoming available on AMPShare. We are really excited to see our customers responses to this development because we know how the shared battery system makes their lives easier and enables them the freedom to pick the best tool for the job – and we will be continuing to make our products available on AMPShare throughout the year.”

FEIN has a rich history in providing application-based solutions for end-users across metalworking sectors. With over 150 years’ experience in manufacturing power tools, FEIN is research and innovation-led, continuing to meet the industry’s needs with new product features year after year.

To find out more about the FEIN’s range of grinding tools, visit fein.com/en_uk/.

Xiris unveils SeamMonitor™ system for precise TIG tube welding

Xiris Automation introduces the new SeamMonitor™, a real-time measurement tool that monitors torch tip to weld seam alignment and weld seam size on TIG welded tube mills. With this, fabricators can achieve highquality welds and minimize production losses. Written by Cameron

Xiris Automation, a leading provider of innovative camerabased solutions for quality control in the metal fabrication industry, has announced the launch of SeamMonitor™, a camera-based measurement tool that provides real-time monitoring of the the torch tip-to-weld seam alignment and weld seam size on Tungsten Inert Gas (TIG) welded tube mills.

Metal tube fabricators who use TIG welding know that precise alignment of the welding torch to the welding seam is critical to achieving high-quality welds with clean edges and minimal weld bead. Occasionally, the seam to torch tip alignment can move over time due to various tensions in the tube, causing it to twist as it is pulled through the weld head. As a result, the weld seam can rotate in and out of position with respect to the welding torch, which may result in defects and production losses.

To solve this problem, Xiris has enhanced its SeamMonitor™ system, which provides a robust solution to monitor ttip-to-weld seam alignment on TIG Tube mills. The SeamMonitor™ combines a High Dynamic Range (HDR) weld camera that can clearly capture the torch, weld arc, and surrounding environment with powerful machine vision measurement software that enables real-time

monitoring of the weld seam size, torch tip location, and relative offset between the torch tip and its seam.

The SeamMonitor™ provides a system solution for use on TIG Tube mills providing warning and error alerts on key

Serles

measurements to operators or external equipment for process control. The system includes data analysis tools and onscreen graphing of key measurements that can be sent to external equipment using OPC, analog or digital interfaces.

WELDING 15 PIM Metals April/May 2023

Figure 2: Seam Out of Alignment with TIG Torch

Figure 1: Seam in Alignment with TIG Torch

Unison Ltd, the inventors of all-electric tube manipulation, celebrate 50 years

Unison Ltd, the UKbased inventors of all-electric tube manipulation, celebrate their 50th anniversary on 3rd April 2023. To mark reaching a half century, the business is planning a special birthday party at its Scarborough HQ on 24th May 2023, when several of its latest tube bending technologies will be on display, alongside fibre laser metal cutting machines from its sister company, Nukon Lasers UK.

Customers, colleagues, friends and neighbours of Unison Ltd will all be invited to the event, as will members of Made in Yorkshire, a trade group of which Unison Ltd is a council member. For an invitation to the 50th party, email: sales@unisonltd.com.

Unison Ltd was established in 1973 as a control systems specialist and provided its expertise to a number of tube

bending machinery firms, including Addison Machine Tools. Convinced there was a better way

of bending tube than by noisy, messy hydraulic operation, where accuracy and repeatability were

often affected by fluctuating oil temperature, Unison Ltd set out to create the world’s first allelectric tube bending machine. Prototypes were built, a patent was taken out and, in 1994, the company unveiled the world’s first all-electric 3-axis tube bender.

Operated by electronic linear actuators and, therefore, unaffected by changing hydraulic oil temperature, this pioneering machine redefined the world of tube manipulation. By 1998, Unison Ltd had launched the first all-electric robot benders. Twin-head, multi-stack and 5-axis machines followed, along with the world’s largest all-electric tube bender for the shipbuilding industry.

Bringing a crazy idea to life

Reflecting on those early days when the world’s first all-electric

NEW PRODUCTS 16 PIM Metals April/May 2023

From left: Alan Pickering and Julian Kidger – Unison Ltd’s joint managing directors.

UNISON

From left: Alan Pickering, Joint Managing Director; Jamie Dobson, Automation Manager; Steve Chambers, Sales Project Manager; Chris Bond, Manufacturing Project Manager; Elliot Lumsden, Yorkshire CNC Manager; Chris Helm, Operations Manager; Nick Bullamore, Shop Floor Manager; Julian Kidger, Joint Managing Director.

tube bending machine was in development, Unison’s joint managing director, Alan Pickering says: “I remember my dad giving me the challenge of bringing his crazy idea to life! We were pushing the servo technology of the day to the limits. But we succeeded, and right-first-time tube bending was born.

“It took a number of forwardthinking customers to put their faith in our technology,” adds Alan Pickering. “However, the big breakthrough came when Airbus ordered their first allelectric tube bender from us. The machine paid for itself in 16 weeks, in reduced scrap alone. Competition from the bigger players was inevitable, but we kept our heads down and kept on pushing forward.”

Today, Unison Ltd is the UK’s leading manufacturer of tube bending machines, has facilities in the UK and USA, and offers

the world’s largest range of ultra-precise, all-electric tube and pipe bending technologies for diameters ranging from 4 mm to 275 mm. Available in singlestack, multi-stack and right/ left versions, Unison ‘Breeze’ machines are delivered to more than 20 countries globally, and to sectors as wide-ranging as motorsport, marine, oil & gas, aerospace and architecture.

The Unison family of companies includes automation specialists, Ingenium Integration Ltd and Nukon Lasers UK.

Precise, repeatable and robust

“From the outset, our goal was clear: to make achieving accurate, repeatable tube bending simple and straightforward, all supported by outstanding levels of customer care,” continues Alan Pickering. “That’s why every

Unison Breeze machine offers fast, intuitive setup, rapid tooling changes, exceptional power, rigid mechanical design, and all-electric control for right-firsttime results, or immediately after bending a trial part – and why we are renowned for the quality of our aftersales support.”

That same ethos is also why all Unison Breeze machines are equipped with the company’s own dedicated Unibend CNC control, and why Unison continually invests in developing leading-edge support software – such as its Opt2Sim tube bending simulation suite and its recently updated, free-touse tube bending application app. Available for desktop, tablet or mobile, the app is so sophisticated it will even show users the tooling type, mandrel style, size and material, as well as bend torque and machine size

required for a particular bend or a series of bends.

“All in all, it’s been an incredible journey,” adds Alan Pickering. “One made possible by having fantastic people on our team, and amazing customers around the world who, every day, put their trust in our uncompromising technologies. Moreover, having invented all-electric tube bending, we intend to stay at the top of our game. This is why, each year, we recruit and nurture a number of technical apprentices, and why we offer extensive development opportunities for our employees – all to ensure they’re the best they can be. Here’s to the next 50 years!”

For more product information, please contact:

Alan Pickering – Unison Ltd

T: +44(0) 1723 582 868

E: sales@unisonltd.com

www.unisonltd.com

NEW PRODUCTS 17 PIM Metals April/May 2023 TUBE BENDING

Gain

cutting edge. nukonlasers.co.uk • 2D, 3D and tube fibre laser cutting machines from Europe • Accessible high power and high performance • American-made nLIGHT fibre lasers • Advanced Lantek CAD/CAM nesting software • From the exclusive Nukon distributors for the UK and Ireland Contact us now to discuss your needs: +44 (0) 1723 582 868 I sales@nukonlasers.co.uk UK UNISON

the

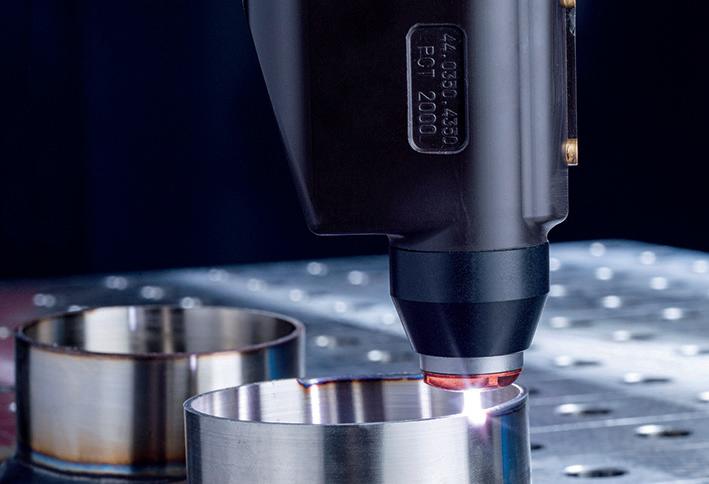

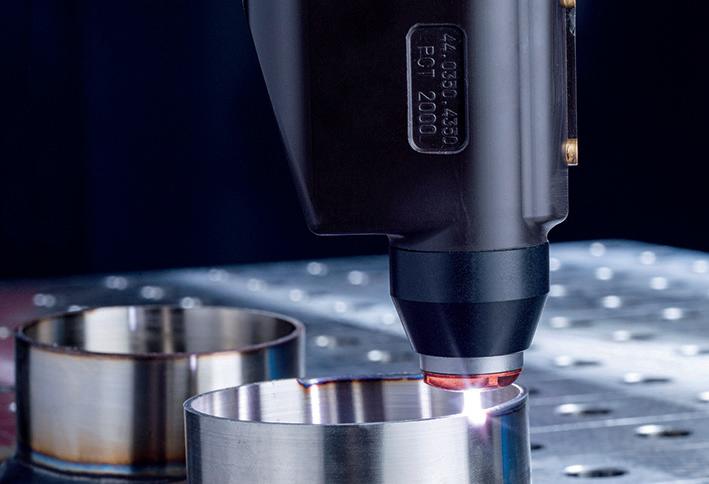

New Trumpf Trulaser Tube at Lasercell eliminates outsourcing

The arrival of a new TRUMPF TruLaser Tube 3000 fiber at Salisbury-based LASERCELL has allowed the company to eliminate the cost of previously outsourcing its tube laser cutting requirements. Alongside the associated reduction in lead time, LASERCELL’s new inhouse capability also means the company can now design many parts more efficiently.

LASERCELL commenced operations in 2012 and has already grown into a 25-employee business. Initially, the company focused on architectural sheet metalwork, installing a flat-bed laser to facilitate this work. However, LASERCELL soon became a notable subcontractor in the region, supplying sectors such as shop fitting, marine and general engineering.

“Primarily we are a laser profiling subcontractor, both sheet and now tube laser,” confirms one of three company directors Kieran Bernstein. “It provides a good balance – a fairly even split – with the other side of our business, architectural metalwork. From a subcontract perspective we take on almost anything, although we tend to pick up a lot of thinner gauge laser work in attractive metals such as brass, copper and stainless steel.”

Impressive growth over the past decade prompted LASERCELL to investigate the potential for an in-house tube laser facility.

“Not only would a tube laser eliminate the cost of outsourcing, it would allow us to design some of our architectural metalwork differently,” explains Mr Bernstein.

“Previously, if we had an urgent job, we would have to design folded profiles for features that would normally lend themselves to box section, just so we could produce it quickly in-house using our flat-bed laser and press brakes. By investing in a tube laser we can make it a lot easier and more efficient for ourselves in terms of design and how we join parts together.”

LASERCELL looked at a few major manufacturers of tube laser machines before drawing up a shortlist of two. After a comprehensive assessment, the company opted for the TRUMPF TruLaser Tube 3000 fiber, a machine that can accommodate tube diameters up to 152mm and process mild steel up to 8mm thick, stainless steel and aluminium up to 6mm, and copper and brass up to 4mm. The 3kW machine installed by LASERCELL, which is the first of its type in the UK, includes a 3D cutting head and LoadMaster Tube automation with bundle space for up to 4 tonnes of unprocessed material.

TRUMPF has seen enormous growth in the tube laser demand over the past few years, prompting the company to expand its machine portfolio and associated software offer.

“Perhaps the most influential reason behind our choice was TRUMPF’s Programming Tube 3D software, which was superior to that of the other potential supplier,” says Mr Bernstein. “With Programming Tube, we quickly and intuitively create NC programs. The software offers flexible data import procedures and efficient design, with step-bystep support.”

The TRUMPF TruLaser Tube 3000 fiber laser arrived in August 2022 and is busy serving both sides of LASERCELL’s business: architectural metalwork and general subcontracting. On a day-to-day basis, the machine processes mild and stainless steel box, angle and tube, as well as brass and aluminium, typically in thin gauge and small diameter material. Occasionally, however, the company will process material

up to 5 or 6mm thick.

“Although we’ve been really busy, the machine is so quick that keeping it fed can sometimes be a challenge,” says Mr Bernstein, alluding to the exceptionally fast processing speed of the TruLaser Tube 3000 fiber. “As well as eliminating the need to outsource our tube laser work, reducing lead times and designing parts more efficiently, the new machine gives us a unique selling point when promoting our services.”

Along with laser cutting and bending, LASERCELL offers welding, assembly, polishing, powder coating and galvanising, as well as specialist services such as 3D CAD design, rapid prototyping and even site installation.

“Quality, speed and understanding are what set us apart from our competitors,” concludes Mr Bernstein. “We have a lot of engineering knowledge: it’s not simply about taking what the customer gives us, it’s what we can offer them in return. Our aptitude in problem solving is what brings our customers back.”

With business currently flourishing, LASERCELL will continue investing in both technology and people. The company’s recent recruitment of an additional five employees ably demonstrates this strategy.

NEW PRODUCTS 18 PIM Metals April/May 2023

Combilift premieres new product at LogiMAT

Combi-CUBE launched in Stuttgart

As Combilift celebrates 25 years of innovation, the company plans to ensure that 2023 will be a year to remember, by launching multiple products across various exhibitions on a global scale!

To kick off, the newest product – the COMBi-CUBE was launched at the LogiMAT International Intralogistics show in Stuttgart.

This new electric model incorporates a host of technological and design features that not only enhance handling procedures but also offer a high level of driver comfort.

Immediately noticeable is the new vibrant colour - this bold fresh Combi-green shade will contribute to improved safety as the trucks will be easily visible in their operational environment. Aside from optics however, a focus is on a number of ergonomic features.

The driver’s position in the centre of the cab offers generous room and excellent all-round visibility. The angle of the telescopic steering column can be adjusted and the Grammer MSG65 seat, combined with hydraulic cabin mounts guarantees a comfortable ride. An adjustable arm rest is mounted to the seat suspension which incorporates a

multi-function joystick and an LCD colour touch screen.

Combilift’s unique dynamic 360 steering that enables seamless directional change while on the move can be integrated into the Combi-CUBE as an optional extra, making it the most manoeuvrable counterbalance forklift on the market.

Further notable features are the large rear wheel and rubber tyres on all three wheels. This means that, unlike certain other brands of electric multidirectional trucks, this model is not restricted to super flat floors and is eminently suitable for working indoors and out, ensuring that semi-rough terrain is no impediment to reliable operation. And for quicker battery changeover during heavy shifts, two new easy-change roll-out batteries are provided (Overall Design Copyright 015019216-0001)

Combilift CEO and Co-Founder Martin McVicar said: “Our engineers and R&D department have been tirelessly preparing for a year of new launches, and the Combi-CUBE is proof of our continued commitment to provide the best and most innovative handling solutions for our worldwide customers.”

www.combilift.com

EVENTS 19 PIM Metals April/May 2023

Fast approaching: Manufacturing and Engineering Week 2023, June 7-8 at the NEC

Manufacturing and Engineering

Week celebrates the best in UK manufacturing and engineering excellence and innovation. It features a series of co-located events which cover the entire product lifecycle from design, engineering, manufacturing and maintenance and seeks to share successes, raises critical discussion and is a destination for professionals

to source products and services in order to keep them competitive. The live events take place on the 7-8 June at the NEC, Birmingham showcasing end-to-end manufacturing and engineering solutions,

to encourage business and knowledge sharing across a range of sectors. This show will include, Design and Engineering Expo, Drives and Controls Zone, Smart Factory Expo and Maintec – all of which will cover the full

SCHWEISSEN & SCHNEIDEN 2023

The programme for the world’s leading trade fair for joining, cutting and coating is becoming more concrete. Numerous events at SCHWEISSEN & SCHNEIDEN 2023 will offer visitors real added value for their own business at Messe Essen. Christina Kleinpaß, Head of Project, reveals: “Above all, we will be focusing on the topic of digitalisation from 11 to 15 September. We are very pleased that, together with DVS –Deutscher Verband für Schweißen und verwandte Verfahren e. V. (German Welding Society), we are cooperating with the Industry Fusion Foundation IFF for the first time.”

The focus of the foundation is the development of a crossmanufacturer open-source networking solution for the manufacturing industry. The IFF, the DVS and Messe Essen will organise a digital rally at SCHWEISSEN & SCHNEIDEN in which trade visitors will learn more about concrete applications and their advantages in an entertaining way.

Know-how and the transfer of knowledge are also the focus of the DVS CONGRESS, which will take place during the world’s leading trade fair in the nearby Congress Center West of Messe Essen. Here, the participants can inform themselves in lectures from operational practice and about the latest findings from current research projects.

Another highlight of the trade fair participation of DVS –Deutscher Verband für Schweißen und verwandte Verfahren e. V. (German Welding Society) is the

final of the national competition “Jugend schweißt” (Young Welders). Germany’s best welders aged between 16 and 23 will show their skills here.

Informative theme areas: underwater technology and national stands

In addition, several special areas await the trade visitors. The field of underwater technology is becoming increasingly important - there is a separate information area in Hall 7. The focus will be on a diving container in which

product life cycle from design, engineering, manufacturing and maintenance. This event will showcase end-to-end manufacturing and engineering solutions, to encourage conversation, business, knowledge sharing and action, flying the flag for manufacturing and engineering in the UK. See the full press release here. Secure your FREE pass here > https://me-week-2023.reg. buzz/pim-metals

experts will demonstrate this sophisticated welding technique and the appropriate equipment.

Trade visitors who want to find out about the products and services of a particular country have an ideal place to start with the international joint stands. There, companies present their products and services together with other exhibitors from their country. This year there will be such national stands from China, France, Japan, Korea, Taiwan and the USA.

Another joint stand at SCHWEISSEN & SCHNEIDEN is sponsored by the German Federal Ministry of Economics and Technology: with the Young Innovative Companies programme, it gives German start-ups the opportunity to present themselves at the fair at low cost. Trade visitors interested in new ideas should make a note of Hall 3. This is where the young companies will be located and show their forwardlooking solutions.

Further information at: www. schweissen-schneiden.com

EVENTS 20 PIM Metals April/May 2023 20 PIMM Metals June/July 2022 20

Special show on digitalisation, DVS CONGRESS and theme areas

What to expect

• World-class two-day conference agenda

• Solution Theatres

• Guitar Legends competition (win a 3D guitar)

• Masterclasses

• STEM features (next-gen talent)

• Sustainability initiatives (plant a tree in our forest)

• Future of Manufacturing

• 400+ exhibitors providing the latest innovations/ industry solutions

• Expert-Led sessions

• Post-event drinks and networking TWO

Wednesday 7 & Thursday 8 June 2023

NEC Birmingham

Join 1000’s of like-minded peers at Manufacturing & Engineering Week Secure your FREE pass: www.mandeweek.co.uk

LIVE EVENT DAYS

INCORPORATING Find out more at www.mandeweek.co.uk @mandeweek2023