TOTAL CONTROL FROM EVERY PERSPECTIVE JULY/AUGUST 2023 ISSUE 85 PROMOTING ON-SITE POWER & COGENERATION www.wipmagazines.com www.powermediagroup.co.uk

ISSUE 85

Publishing & Events Director Richard Teasdale richard@wipmagazines.com

Publisher/Sales DIrector Neb Saric neb@wipmagazines.com

Managing Editor Aidan Turnbull aidan@wipmagazines.com

Accounts Manager Alison Williams accounts@wipmagazines.com

Sales & Marketing Manager Sarah Hallows sarah@wipmagazines.com

Far East Sales Bob Liu Shanghai, China bob.liu@ronco.com.cn

US Sales & Subscriptions

Jelena Milojevic power@wipmagazines.com

Austrian & German Agent Mario Dobresko power@wipmagazines.com

Power Media International Group, The Courtyard, 30 Worthing Road, Horsham, West Sussex, RH12 1SL, UK

Tel: +44 (0) 1403 888019

www.powermediagroup.co.uk

© Africa Power News (ISSN 1468 7100)

POWER CUTS & GRID INSTABILITY - THE FACE OF SOUTH AFRICA TODAY?

South Africa is faced with the prospect of the country’s worst-ever power cuts - up to 16-hours a day. There are issues with the coal supply - powerful criminal cartels are allegedly stealing a billion rand ($52m; £42m) every month from Eskom and its coal-fired power stations. Today, more than 80% of South Africa’s electricity is generated by coal-fired power stations - an astonishing figure. As a result, the country is ranked as the world’s 14th largest emitter of carbon-dioxide, despite having only the 33rd biggest economy.

Recently, former Eskom CEO Andre de Ruyter publicly highlighted that one of the biggest challenges the power utility is facing is combating internal crime syndicates which he says are contributing to the country’s power crisis.

South Africa’s electricity utility, insists a national grid collapse is ‘unlikely’ despite public warnings in the media and from government sources - and that it would take an ‘unforeseen and sudden sequence of events’ to lead to a countrywide loss of supply. Nevertheless, public and private sector organisations have been preparing for the worst by running scenarios and diverting scarce funds to source backup solutions.

Grid collapse is the total or partial interruption or suspension of electrical power supply, resulting in widespread outages. It could range from a province being without electricity to a country-wide blackout.

South Africa has already adopted a strategy of load shedding’ or power cuts for the past 15 years, as ageing power stations are taken offline for urgent repairs or stop working altogether. As the duration and frequency of outages have steadily worsened, the prospect of a total grid collapse has grown.

The country’s transition to green fuels has been hampered by capacity issues and powerful vested interests. This is in sharp contrast to other African middle-income countries such as Kenya, which uses renewables for 80% of its energy supply. Rapacious corruption, sabotage of power plants, and cable theft by crime syndicates all contribute to a dismal picture.

South Africa is not alone when it comes to the threat of grid collapse. Botswana too has experienced a temporary shutdown in May 2023.

Within South Africa’s economy organisations and residents are looking to reduce their dependence on grid power by investing in alternatives such as solar panels and wind & water turbines and BESS systems. Unfortunately there are examples where operations which have been installing backup batteries and generators have discovered them stolen not long afterwards. Diesel fuel is also becoming expensive - making this another lucrative target for criminals - and so the situation escalates.

AIDAN TURNBULL Managing Editor

JULY - AUGUST 2023 3 AFRICA POWER NEWS

www.powermediagroup.co.uk

www.wipmagazines.com

EDITOR’S NOTES

“ TOTAL CONTROL FROM EVERY PERSPECTIVE JULY/AUGUST 2023 www.wipmagazines.com www.powermediagroup.co.uk

“SOUTH AFRICA FACES A SERIOUS RISK OF TOTAL GRID COLLAPSE IN 2023, SUGGEST SOME INDUSTRY OBSERVERS.”

LEADER AND NEWS

19

22MW POWER PLANT FOR THE EXTENSION OF THE MARAMPA MINES, SIERRA LEONE

The Anglo Belgian Corporation has supplied a 22MW power plant.

FOUR DIESEL GENSETS FOR THE KEY PORT OF ALEXANDRIA, EGYPT

A KOHLER partner company has delivered, installed and commissioned four 3000 KVA diesel- powered PRP 11KV gensets (3,000kVA), one unit KD1100F 400V and a V550 400V genset to a multipurpose terminal based in the port of Alexandria.

EKO ATLANTIC CITY, LAGOS, NIGERIA

Gensets for Eko Atlantic City development in Victoria Island, Lagos.

13

Comments and International News 14

POWER AFRICA IN MADAGSACAR

US Aid is transforming the lives of 26.26 million people.

A 406KW CHP SOLUTION AT AN AFRICAN SOAP PLANT

A well-known South African detergent manufacturer approached SustainPower to reduce its overall carbon footprint.

15

LAKE KIVU, RWANDA: 19 GAS-ENGINED GENSETS

Gas gensets at Lake Kivu have an output of 76 MW, reports MWM.

16

NEW GENSET FOR THE MOROCCO PAPER INDUSTRY

A DP222LBF DOOSAN engine is the key power provider for a HDW-675 T5 three-phase soundproof generator set

18

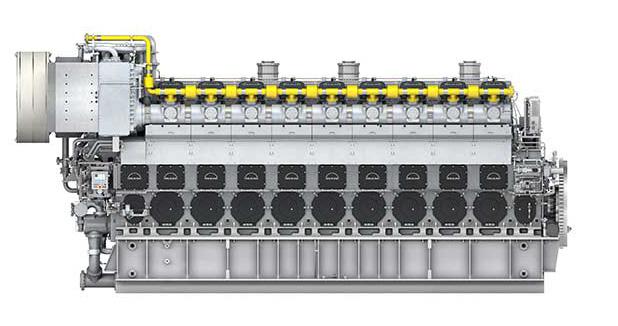

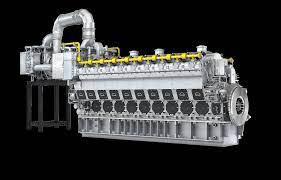

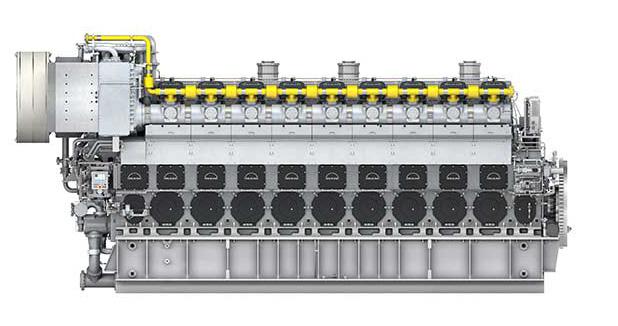

50MW DUAL-FUEL ENGINES FOR NAMPOWER’S ANIXAS POWER STATION IN NAMIBIA

Three MAN 18V51/60DF dual-fuel engines with alternators and auxiliary equipment were delivered to Walvis Bay, Namibia.

1,000 KVA GENSET FOR THE SUEZ TECHNOLOGICAL CENTRE

ONIS VISA has installed an Onis Visa 1000 kVA diesel genset for the “Suez Technological Centre for Citizen Services” recently opened in Suez by the prime minister of Egypt.

4 X 1.5MW GENSETS FOR A REAL ESTATE PROJECT IN NIGERIA

Four 4 x 1.5MW generators with MTU engines have been supplied to a residential retail project in Nigeria. The four units of MTU gensets offer 1.5 MW each and a lifetime of up to 84,000 hours.

JULY - AUGUST 2023 4 AFRICA POWER NEWS www.wipmagazines.com www.powermediagroup.co.uk

12 14

03-12

12

CONTENTS

21 20

Like and follow us on Facebook @powermediainternationalgroup

@PMI_WIP

our activity on LinkedIn Power Media International Group Ltd Visit us online at www.powermediagroup.co.uk Subcription to 27 power publications: 1 Year - £120 UK, £180 ROW | 2 Years - £192 UK, £280 ROW. Payment in full or credit/debit card information is required to process your order. Subscription request must include subscriber name and email. For new subscriptions or renewal, call +44 (0) 1403 888019. Single copy price: £23.50 (including postage and packaging). In addition to your subscription you will also recieve a FREE GIFT worth £100 (Worldwide Gen-Set & Cogeneration Directory), plus our Year Planner which includes all relevant global power industry events. For customer service and

Content Licensing: For all content licensing, permissions, reprints / e-prints, please contact

| Subject Line: Content Licensing Copyright: © 2021 Power Media International Group Ltd. All rights reserved. 24

Follow us on Twitter

Follow

address changes, call +44 (0) 1403 888019 or email power@wipmagazines.uk.com

power@wipmagazines.com

IN BRIEF

950 KVA DIESEL GENSET FOR A FURNITURE GIANT OPERATING IN MOROCCO

Two diesel gensets - 1 x HDW-750 T5 (Doosan engine) + 1 x HFW-125 T5 of (Iveco engine) have been supplied to IKEA TETOUAN - a major furniture retailing chain in Morocco.

The retail giant has installed a HDW750 T5 with a Doosan engine with a backup power of up to 823 KVA and an HFW-125 T5 Iveco engine. Both sets will now supply emergency power in case of grid power failure.

BACKUP POWER GENSET PROVIDED TO THE MINING SECTOR IN CONAKRY, GUINEA

GRUPEL has provided a PKGR 600kVA diesel genset with Perkins engine and Leroy Somer alternator to provide prime power and backup power to help with the mining support industry in Conakry, Guinea. Conakry is the capital and largest city of Guinea. A port city, it serves as the economic, financial and cultural centre of Guinea. The new power generator in question has 660kVA of power and comprises a Perkins engine, a Leroy Somer alternator, and a DeepSea controller.

The genset offers a number of advanced features for the industry users:

- Temperature, oil level and fuel sensors - they will ensure the easy monitoring of the equipment and its safe and efficient operation

- Water and air filters, crucial in environments prone to dust, dirt and other particles, exactly like those found in the mining industry.

- Manual oil pumping system, ideal for safe storage and distribution.

The genset uses the PERKINS 2000 Series engine - this is a family of well-proven 6-cylinder in-line engines, for electric power generation and stationery industrial applications.

Designed well in advance of today’s uncompromising demands within the power generation and industrial sectors, the range has a deserved reputation for providing reliable power and outstanding economy. For increased versatility, gas-fuelled, sparkignited variants for 50 or 60Hz constant speed operation are also available. The engine features a gear train, forged from steel and hardened for improved wear resistance - plus a there is a Fuel Injection Pump, gear-driven from the engine timing case.

HOW THE AZITO THERMAL POWER PLANT HAS HELPED COTE D’IVOIRE BECOME AN ENERGY EXPORTER

Built in 1998, the Azito Thermal Power Plant generates two thirds of the energy produced in Côte d’Ivoire.

With the help of this power plant the country has managed to develop the third largest electricity generation system on the continent and recently became one of the leading electricity exporters in West Africa. Boasting an installed power capacity of almost 2,230 megawatts (MW), Côte d’Ivoire fully meets its domestic demand and exports the roughly 10% generation surplus to the subregion.

Whereas only 34% of Ivorians had access to electricity back in 2013 when the post-electoral crisis triggered a 40% decline, close to 94% of Ivorians are now connected to the grid and the most destitute customers benefit from a subsidised rate.

“The plant generated 140 MW at the outset, and we expanded over the past 20 years to triple our capacity to the current 480 MW,” states Jacques Kouassi, Technical Director of the Azito plant.

The ongoing Phase IV Azito expansion project has now taken generation capacity to around 700 MW.

Power cente is the ultimate tool when planning your project, enabling you to instantly size a generator that will meet your power needs, find inventory near you in stock and configure a generator set to meet your project specifications.

5 AFRICA POWER NEWS NEWS JULY - AUGUST 2023 www.wipmagazines.com www.powermediagroup.co.uk

Start today at power.fgwilson.com

SIZE, FIND AND CONFIGURE YOUR GENERATOR INSTANTLY WITH POWER CENTRE FROM FG WILSON

Noise control experts Keeping your world clean, quiet, and safe. Dürr Universal is a global leader in the design and manufacture of inlet and exhaust systems for gas turbines and reciprocating engines in the OEM and retrofit markets. www.durr-universal.com Dürr Limited United Kingdom Phone +44 1455 8944 88 Email solutions@universalaet.com

IN BRIEF

EQUITY FUNDING FOR THE DRC

Nuru, one of Africa’s pioneering renewable energy-powered metrogrid companies, has announced the successful close of over US$40m in Series B equity funding and anticipates the close of an additional $28m in project finance by the end of July 2023.

The funds will enable Nuru to begin construction on 13.7 MWp of projects, designed to significantly expand its existing operating assets in eastern Democratic Republic of the Congo (DRC) and help bridge the enormous energy gap in the country.

Less than 20% of the DRC’s population has access to energy, and with a rising energy demand projected for the future, Nuru’s approach to renewable energy access unlocks the immense market potential across the country with its utility-scale solar metrogrids.

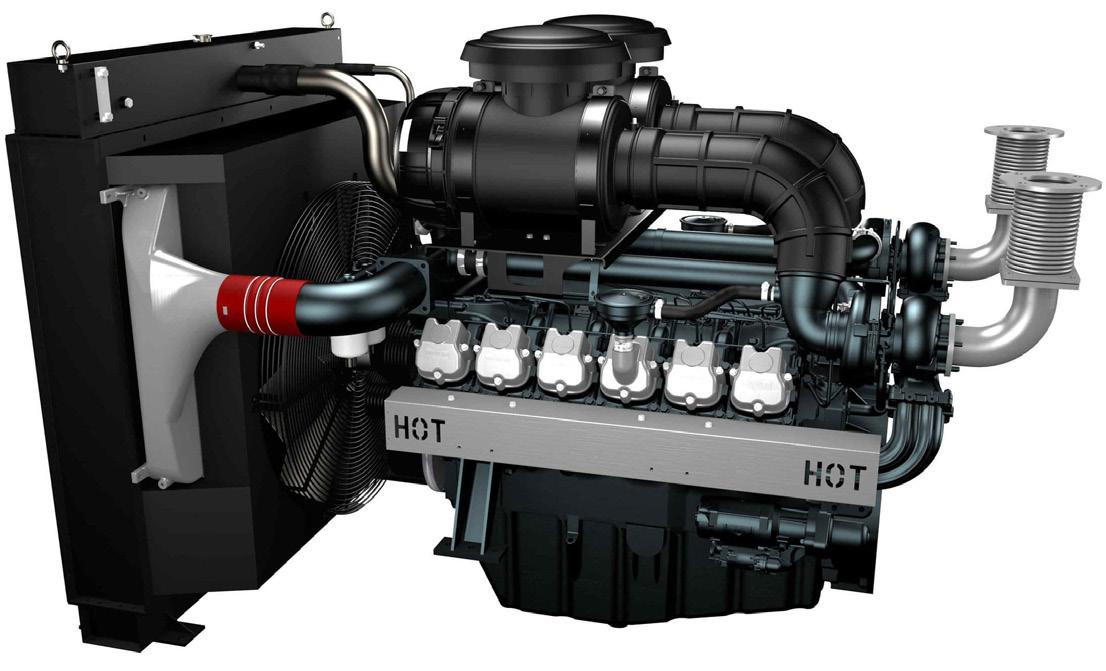

1MW GAS POWERPLANT ESTABLISHED FOR A LARGE PAINT MANUFACTURER BASED IN WEST AFRICA

Nicen Industries Limited, one of the largest paint manufacturers in Aba Nigeria, is establishing a gas power plant to improve operations amid unreliable grid supply. Chris Eze, Managing Director at Nicen Industries explains: “The decision to install the energy resilient power plant is one of the most rewarding decisions the company has taken since it was founded in 1990.”

According to Eze, when the power supply became unsustainable in Aba, and the cost of diesel increased, the company began inquiring about a sustainable solution. They subsequently contacted Clarke Energy, a multinational specialist in engineering, installation, and maintenance of sustainable power generation solutions, to install a gas power plant.

Clarke Energy supplied and commissioned a 1MW gas power plant solution which included the complete front end engineering design, installation and project management and continues to provide maintenance support to the plant.

Ioannis (Yiannis) Tsantilas Managing Director of Clarke Energy Nigeria commented: “The 1MW power plant solution delivery describes the Clarke Energy commitment towards improving the manufacturing and processing value chain in Aba and the south-eastern part of Nigeria. Clarke Energy partnered with NICEN in its vision to improve its costs of manufacturing durable plastics and high-quality decorative paints that are affordable and competitive in the local market.”

The plant is powered by natural gas supplied by Shell Nigeria through gas pipelines belonging to the Nigerian National Petroleum Corporation (NNPC).

“The engine is one of the best that we have seen,” said Eze, “Even before we got in contact with them, we made enquiries and found that Clarke Energy engines are good, and many companies in Aba are already using the company’s products. So we signed up,” he said.

NEW GENSETS ARE NOW POWERING NIGERIA’S TELECOMS SECTOR

JMG, an official FG Wilson dealer in Nigeria and one of FG Wilson’s key worldwide network of 370 dealers, has been appointed by the largest mobile operator in West Africa to help power a multi-million pound modernisation of Nigeria’s mobile communications network.

The £6m project will see JMG deliver power solutions for MTN Nigeria’s network upgrade. With nearly 50 years’ experience of delivering world-class power solutions throughout Africa, JMG has been a partner of FG Wilson for 15 years.

Telecoms giant MTN Nigeria Communications Ltd. offers mobile network services and business solutions to more than 45 million subscribers and currently provides network coverage to almost 90% of Nigeria’s land mass.

The power solution to be delivered for MTN by JMG will involve the installation of 12 high-capacity FG Wilson generator sets at MTN Switch Locations in Asaba, Lagos, Kano and Ibadan. The installation will provide Nigeria with enhanced network coverage to meet the growing population’s increasing requirement for an enhanced mobile communications capacity. The initial three-month installation project will encompass the supply and installation of six 2,000 kVA, three 1,500 kVA and three 1,250 kVA generator sets.

Commenting on the project, Mazen Jubaili, JMG Managing Director, said:“We have a proven pedigree of delivering world-class power solutions for some of the most significant projects in Nigeria and it is a strong endorsement of our work that MTN Communications has chosen us.”

Power cente is the ultimate tool when planning your project, enabling you to instantly size a generator that will meet your power needs, find inventory near you in stock and configure a generator set to meet your project specifications.

JULY - AUGUST 2023 7 AFRICA POWER NEWS www.wipmagazines.com www.powermediagroup.co.uk

NEWS

Start today at power.fgwilson.com

SIZE, FIND AND CONFIGURE YOUR GENERATOR INSTANTLY WITH POWER CENTRE FROM FG WILSON

POWER BUILT TO

THE POWERKIT M SERIES

COMPACT AND MORE POWERFUL, THE M SERIES ENGINES DELIVER RELIABLE HIGH POWER FOR PRIME AND CRITICAL APPLICATIONS.

The newest, most comprehensive powergen range on the market.

DURABLE. ROBUST. BUILT TO LAST. BAUDOUIN.COM

IN BRIEF

14MW IN GENSETS FOR THE MINISTRY OF ENERGY - SIERRA LEONE

Ghaddar Machinery has supplied the Ministry of Energy in Sierra Leone with diesel generators consisting of Cummins KTA50-G3 & KTA19-G4 engines and Leroy Somer LSA50.2M6 & TAL0473C alternators.

Through its dealer in Sierra Leone Ghaddar Machinery Co. has delivered the first batch of a project with a total capacity of 14 MW, consisting of multiple units synchronised together. The gensets will be distributed across seven power stations across the country.

Thanks to its position and climate

Sierra Leone is endowed with abundant renewable energy potential, but however it faces severe energy scarcity at grid level.

The energy supply infrastructure is limited to mainly oil-fired thermal plants and hydropower plants, with a small share of solar and biomass. Electrification is at 14% and only 17.8% of Sierra Leone’s total population of 7 million people has access to electricity.

DELIVERING A ROBUST SOLUTION TO MARKETS IN AFRICA WITH THE NEW V-TYPE ALTERNATOR RANGE

Mecc Alte works hard with its clients to continually develop a high-level of insight into the challenges which the power generator market faces with their generator sets and where/how they are operated.

The company’s latest heavy-duty alternator range - The V-Type - meets a demand from the markets for a product that offers increased resilience for use in gensets where environment or operation affects performances and could reduce performance.

Through continually speaking with Original Equipment Manufacturers (OEMs) and end-users and gathering intelligence, Mecc Alte says it has been evolving its range with technical expertise and aftersales experience to bring customers its most resilient product.

The V-Type is built for optimum performance and reliability in tough environments. Having undergone rigorous testing, the V-Type is designed to operate in ‘harsh’ environments, so you can be sure of reliable power generation, regardless of the operational conditions.

Mecc Alte has incorporated several durability features to deliver maximum uptime for power requirements needed in severe environments:

•V-Type TOTAL+ is an exclusive winding treatment designed specifically to be more resilient, this insulation system upgrade further enhances the VPI impregnation which is standard on the range.

•Reinforced tape around the lower radius of the stator, plus an additional internal and external covering adds further durability to the NDE stator winding head

•Upgraded excitor stator, which are taped and given the VTP treatment

•30,000 premium bearing hours, for increased reliability

•Lower lamination slats reinforced with TOTAL+ insulation protection

•MxK digital regulators for safe setting/interrogation and offering integration to genset controllers

•Premium paint with anti-rust treatment

•Extended warranty

Mecc Alte’s Group Marketing Director, Jonathan Stokes, told AFRICA POWER NEWS: .“Power generation has become much more about complete solutions rather than individual products, we’re now supplying OEMs with alternators, controllers, battery chargers and governors that are required for their power generation applications. The result: is an integrated solution that very closely matches the unique demands of each and every power requirement. Understanding the full product lifecycle enables us to further evolve products from new perspectives.”

He concludes: “We pride ourselves on being the Power from Within the systems and generator sets that our customers produce; the V-Type is built for optimal uptime across the whole product lifecycle. Choose wisely. Choose the V-Type.”

Mecc Alte is a high-volume manufacturer producing in Italy, the UK, China, and India. Its diverse range includes small 2-pole and large 4-pole alternators, as well as medium and high voltage machines, DC units, custom builds and multi-pole units, spanning 1 – 5000kVA.

9 AFRICA POWER NEWS NEWS JULY - AUGUST 2023 www.wipmagazines.com www.powermediagroup.co.uk

IN BRIEF

SOUTH AFRICA WILL NOT MEET DECARBONISATION TARGET FOR 2030

Research by Rystad Energy suggests that South Africa’s decarbonisation efforts have not been wholly successful as renewable power capacity is expected to fall short of the 2030 target

The independent research and business intelligence company has indicated that renewable energy will account for just 20% of the country’s power mix by the end of the decade - very much short of the 41% target.

120MW COMBINED HEAT & POWER PROJECT FOR THE CALABAR REGION IN NIGERIA

Marelli Motori will be supplying alternators to ten 12MW Bergen B36:45V20 gas engines for a landmark 120MW Combined Heat & Power (CHP) project in Nigeria. Each generator set will have a weight of over 175 tonnes.

The contract was formally signed this year by Bergen Engines AS in the presence of Sir Benedict Ayad, Executive Governor of Cross River State.

The project will provide heat and power to a major new industrial complex and its surrounding area in the Calabar region of Nigeria’s Cross River State.

The gas-fired combined cycle heat & power (CHP) plant is designed with high overall energy efficiency, reduced emissions and the flexibility to support renewables as they become available.

The complex being powered by Bergen engines will be home to many new developments for the Calabar region. Plans include a biotechnology research laboratory, a nano-water plant for production of hydrogenated drinking water, and a waste transformation recycling centre which features biofertilizers and the ability to process used tyres and plastics. The development will be undertaken between Bergen Engines AS and Nigeria’s Alternative Petroleum & Power Ltd (APPL), supported by Lagos consulting engineers Kelm Engineering Ltd and Diesel Electric Services (PTY) Ltd of South Africa.

EnSmart Power has been selected to provide uninterruptible power supplies for the IT systems at the operational branches of Algeria Director General of National Security. This keeps the security systems running and enhance power availability for Algeria’s civil police force. It polices Algeria’s larger cities and urban areas.

The Sûreté is part of the Ministry of Interior and is charged with maintaining law and order, protecting life and property, investigating crimes, and apprehending offenders. It also performs other routine police functions, including traffic control.

To provide uninterruptible

power and increase power availability of critical IT systems , DGSN identified a need to find an uninterruptible power supply (UPS) partner capable of supporting the entire process. The partner also has to have the technical knowledge and advanced technology required to meet the UPS power protection chosen as the UPS supplier for DGSN.

EnSmart recommended the Compact 3L Series UPS 10kVA - 40kVA for the branches which need 3phase power protection and SmartPack UPS 3-6-10kVA models for single phase UPS for this project. The EnSmart Compact 3L Series has so far proved the right choice for the police forces.

NEWS 10 AFRICA POWER NEWS JULY - AUGUST 2023 www.wipmagazines.com www.powermediagroup.co.uk

UPS SYSTEMS PROVE THE RIGHT CHOICE FOR ALGERIA’S POLICE

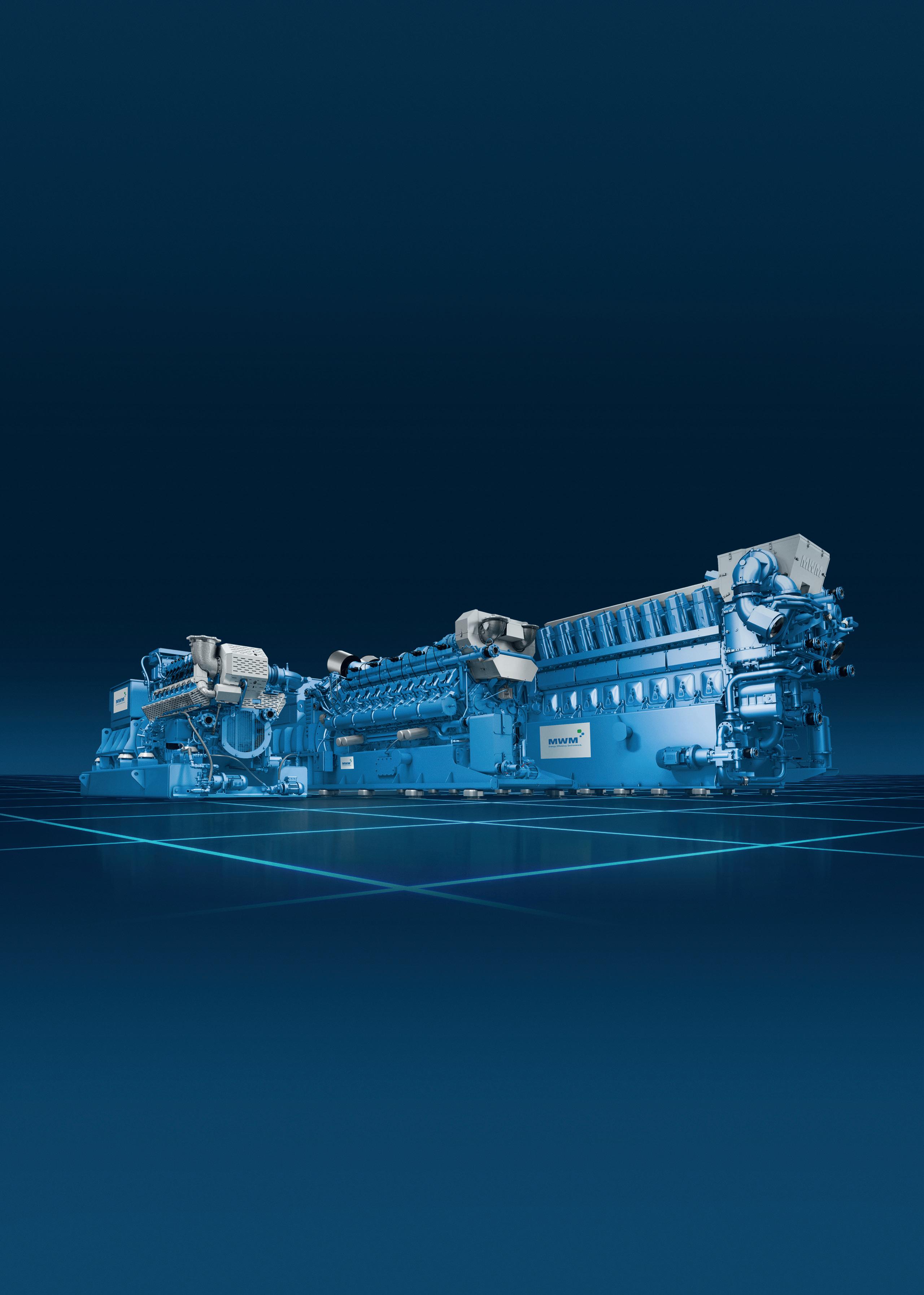

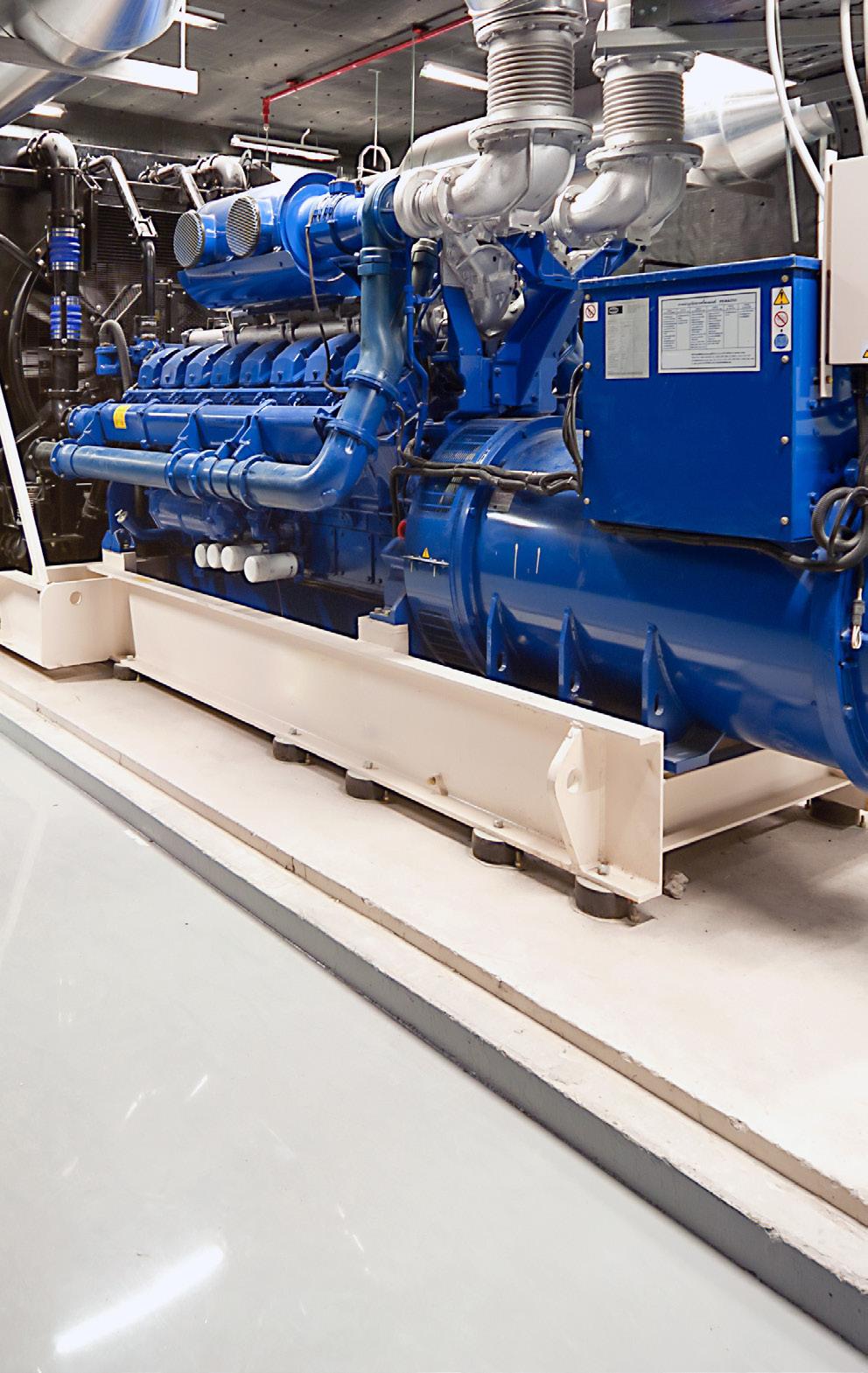

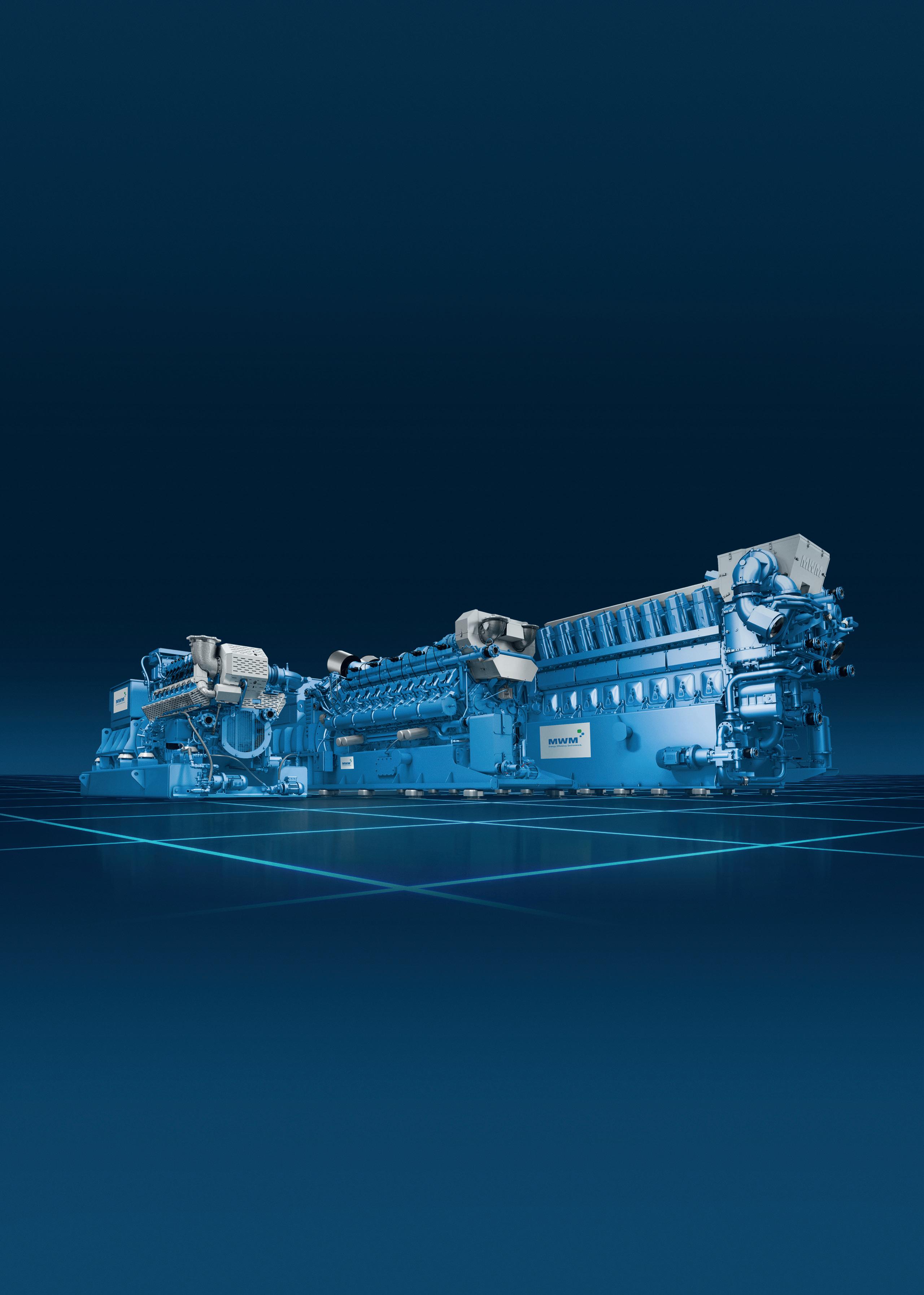

MWM gensets. Efficient, low-maintenance and highly available.

The MWM product portfolio comprises gas engines and gensets in the output range from 400 kWel to 4,500 kWel . Power plants with an output of 100,000 kWel and more are technically feasible. The units are designed for maximum electrical and thermal efficiency, low operating and service costs, and high reliability and availability. Thus, they reach efficiency levels of more than 90 percent.

www.mwm.net/en

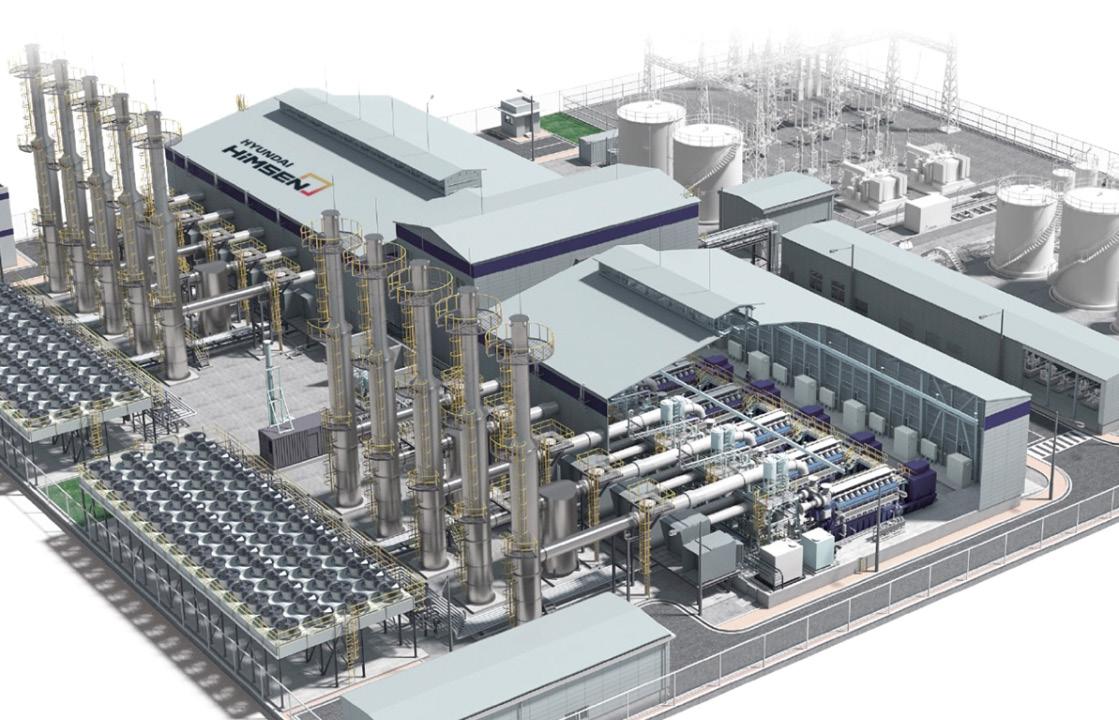

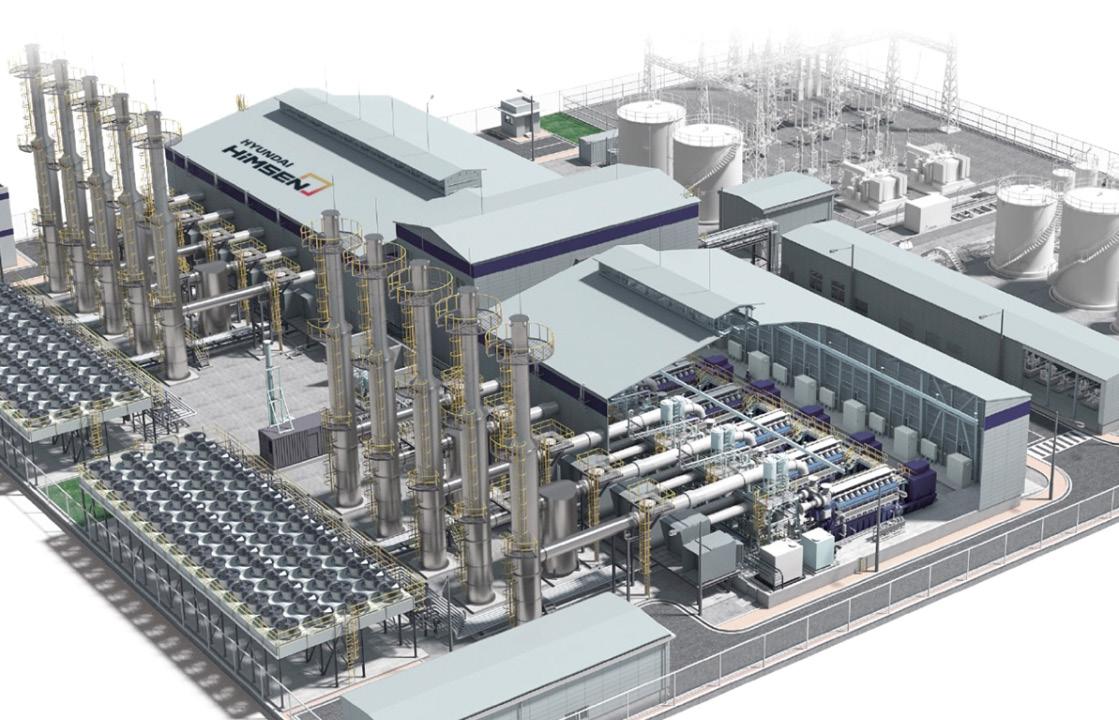

56.4MW GAS POWER PLANT FOR THE EKO ATLANTIC CITY, LAGOS, NIGERIA

The distributor MIKANO has officially entered into an agreement with HHI-EMD for the supply of six gas engine generator sets (HYUNDAI HiMSEN 20H35GV) to deliver a total of 56.4MW in the first phase of this partnership with a plan to extend to a total of 500MW.

This project will establish a primary power plant for the Eko Atlantic City development in Victoria Island , Lagos, with the supply of the of first batch of generators being delivered in early 2024.

The genset manufacturer HHI-EMD has become the forerunner in the sector of engine power generation as well. A great number of its domestic and overseas engine power plants have given superb performance, contributing to the HYUNDAI’s high reputation.

Specifications on the HYUNDAI gas engine genset are as follows: H35/40G(V) Rated Power of Genset at 100% load Heat Rate & Electrical Efficiency 720 rpm / 60 Hz

Rated Output (kW) Engine Type Heat rate In-line type Electrical In-line type Efficiency Vee type, It conforms to ISO 3046/1 reference conditions and is optimised to TA luft legislation at the reference condition.

The heat rate & electrical efficiency at generator terminals, without engine driven pumps and with +5% tolerance, are within normal parameters.

Fuel gas L.H.V. is 35 MJ/Nm³ with M.N. 80. The set is arranted at 100% load only.

The engine block is made of monoblock cast iron with a combustion air chamber.

The camshaft is of a split type for each cylinder and each camshaft is jointed by screws. Each piece of camshaft has an intake cam and an exhaust cam. Surface hardening has been provided for the each cam profile. The gear wheel for driving the camshaft, as well as the gear wheel for connection of governor drive, are mounted on the flywheel side. The front end block is located on the free end of the engine.

The extreme miller timing for intake cam has been applied to reduce NOx emission and prevent knock combustion. Variable Cam Timing (VCT) has been proven to be a very effective method in PFI (Port Fuel Injection) engines for improved fuel economy and combustion stability, and reduced emissions. In DISI (Direct Injection Spark Ignition) engines, VCT is applied in both stratified-charge and homogeneous charge operating modes.

Studies conducted in the past conceptualised Miller cycle by early inlet valve closure (EIVC) using also high values of boosted air pressure through two-stage

turbocharging. These studies showed that extreme values of EIVC in conjunction with increased boost pressure resulted in a remarkable reduction of engine-emitted NOx up to 50% without deterioration of brake specific fuel consumption (BSFC) compared to conventional diesel engine operation.

Though various methods have been proposed in studies to materialise Miller cycle in diesel engines, it has not been clarified which is the best combination of methods for simultaneous reduction of diesel-emitted specific CO2 and NOx emissions.

More about the gas genset H35/40G(V) gensets provide an automation system for engine safety, control and indicating based on programmable logic controller. The system is independently installed in each engine and also can be connected to the remote system, for example main switch board of engine control room via hard-wired communication cables.

Gas engines like these are able to operate with more stability than other gas turbine under different ambient temperatures. The HYUNDAI

gas engines have a shorter start time compared with gas turbines. Gas engines only take 7 minutes.

HYUNDAI gas engines have higher efficiency and lower emission rates in energy production, reports the company.

Engine specifications

Specifications are as follows:

*Number of cylinders: multi-cylinder

*Product applications: for generator sets, power generation

* Other characteristics- highefficiency

*Power:

Min.: 5,558 kW (7,556.774 hp)

Max.: 9,600 kW (13,052.363 hp)

*Rotational speed

720 rpm, 750 rpm (4,523.89 rad. min-1)

*Weight

Min.: 56 t (61.73 us ton)

Max.: 153.9 t (169.65 us ton)

*Length 10,810 mm, 11,435 mm, 12,384 mm, 12,437 mm, 13,062 mm (425.6 in)

*Width

1,460 mm (57.5 in)

*Height 4,753 mm, 5,325 mm (187.1 in)

www.hyundai-ec.com

JULY - AUGUST 2023 12 AFRICA POWER NEWS www.wipmagazines.com www.powermediagroup.co.uk

POWER PLANTS

POWER AFRICA BRINGS ELECTRICITY TO MADAGASCARS’ ENERGY-HUNGRY CONSUMERS

Madagascar has substantial natural resources, including hydro, wind and solar.

Diesel powered electricity generation is a prominent form of energy generation, resulting in localized costs which can run as high as $0.70-0.80/kWh.

High tariff rates result in low collection rates, and subsequent power plant failures have been the result of a lack of funding for maintenance.

Access rates to electricity for the 26.26 million inhabitants are low countrywide, and are described as ‘very low’ in rural areas. There are seafood processing areas in the south which would economically benefit from cold chain storage, if only reliable power sources were made available.

The United States Agency for International Development (USAID) offers a program called Power Africa. It has awarded grants totaling US$1.2 million to mini-grid developers lighting up more than 5,200 households and businesses in rural Madagascar.

Although rich with renewable energy resources like solar and wind, only 5% of rural Madagascar has access to electricity, resulting in dependency on candles, batteries, and firewood to meet daily energy needs. Off-grid electrification solutions, such as mini-grids, can play a vital role in electrifying Madagascar’s rural areas. However, private developers and operators capable of installing and operating mini-grid systems often struggle to enter and expand the mini-grid market because they lack access to project financing.

Power Africa launched the “Power Africa Madagascar Mini-Grid Development Grant” to bridge the financing gap and support implementation of new mini-grid projects as well as expansion of existing mini-grids to new customers.

What the grant awards have achieved

Following a request for applications in May 2020, 17 companies applied for grant funding. After evaluation, shortlisting and negotiation phases, Power Africa awarded grants to three companies: Autarsys Madagascar, Henri Fraise Fils & Cie, and Hydro Ingénierie Etudes et Réalisations (HIER).

Collectively, the three companies project that this grant funding will help them bring electricity to approximately 14,000 people.

Autarsys is involved in electrifying three settlements located in the Atsimo Andrefana region with new hybrid solar PV-powered mini-grids with integrated battery storage technology.

“These facilities, in particular the storage systems, are in line with ‘state of the art’ international technology,” says Matthias Ross, Autarsys Chief Executive Officer.

Henri Fraise Fils & Cie is responsible for building a new solar mini-grid with battery storage, a backup generator, and a 4-kilometre low-voltage line at Manaratsandry village in Boeny region.

“This grant will allow us to not only reduce the initial investment cost but also to drastically reduce the cost of energy for the beneficiary village, Manaratsandry,” explains Charles van der Straeten, Henry Fraise Fils & Cie General Manager.

HIER’s role is to extend the distribution network of an existing hydro-powered mini-grid in the town of Tsarazaza, which is a part of Amoron’i Mania region.

“This grant will allow us to extend the areas served by our existing hydroelectric production plant while allowing, in a short time, the connection of more than 1,500 households,” says H.I.E.R. General Manager, Raolijaona Dieudonné.

Solar PV mini-grids can power carpentry tools such as saws and drills, larger-scale agricultural processing such as milling and grinding,

as well as irrigation pumps and cold storage.

This productive use of electricity provides a foundation for sustainable economic development by increasing incomes and improving the welfare of communities.

The grant winners will incorporate community outreach programs into their projects to promote the use of clean, affordable and sustainable energy, and to ensure that communities have the knowledge to get the most out of the productive use potential that the mini-grids introduce.

The award of these mini-grid development grants advances Power Africa’s goal to connect 60 million new homes and businesses to electricity by 2030.

Mark Carrato, Power Africa

Co-ordinator comments: “Mini-grid developers and operators play a critical role in expanding access to electricity in Madagascar, especially to rural and hard-to-reach areas. He concludes: “Through these grants we hope they can continue to significantly improve the lives of the Malagasy people.”

powerafrica.medium.com

JULY - AUGUST 2023 13 AFRICA POWER NEWS www.wipmagazines.com www.powermediagroup.co.uk

MINI-GRIDS

A 406KW CHP SOLUTION AT A SOAP PLANT, SOUTH AFRICA

SustainPower designs and supplies clean energy solutions for domestic & industrial markets. For industry, the company offers biogas, natural gas, & other gas-to-power solutions for continuous, prime, or emergency standby power supply.

With a special focus on energy efficiency, SustainPower’s systems save clients money through power outage protection, peak shaving, & waste heat recovery, displacing environmentally harmful sources of energy such as coal and diesel.

In the domestic and light commercial space SustainPower offer solutions in the form of gas genset and battery technology, providing a clean & quiet back-up alternative to the traditional petrol and diesel options.

One of its clients is a well-known South African detergent manufacturer with international standards of excellence. With a capacity of 8,000 tons per month, and state-of-the-art packaging facilities, this industry leader in environmentally sustainable operations continuously strives to improve the highest level of environmental values. The company even asked Solar Africa Energy to install and operate a Solar PV system in 2022.

SustainPower was keen to reduce the overall carbon footprint of the client’s plant, while providing the company with additional savings on electricity and heat costs.

SustainPower was tasked with building a 406 kW/507 kVA gas-topower unit and to integrate it with the existing solar PV system on the client’s roof.

The client reported a continuous electrical load of approximately 480 kW and a current thermal requirement of 2.3 t/h of hot water, at temperatures varying between 40 and 60°C, depending on the product being made.

Condensate from steam is combined with make-up water from the municipality and is kept at 50°C inside the boiler room hot well. A secondary hot well of 4000 litres is kept at 40°C inside the plant for production processes.

The controller of the new system gives preference to the solar energy due to the driving factor being energy savings. The hybrid controller

allows both the CHP unit and the PV system to run.

The power shortfall between them comes from grid power which becomes a top-up when the PV and the generator cannot meet the entire site power requirements.

The CHP system generates 272.9 kW of heat from the water jacket - the client only needs 30% of this for the current facilities, while the remaining 70% of the water jacket heat will be supplied for the plant’s future expansion.

An ultrasonic sensor and a temperature sensor will be installed at the hot well to detect and monitor the water level and provide make-up water from the CHP and ensure that the water inside the boiler room’s well remains at 80°C.

For additional savings, 273.2 kW of heat from exhaust gas will be introduced to the client’s spray dryer.

A temperature sensor controlled by a hybrid controller allows the SCADA system to detect whether exhaust gas is too hot for the product being dried, and a stream of fresh air will be introduced to cool the exhaust before it reaches the product inside the spray dryer.

The hybrid controller ensures the smooth harmonious syncing of the individual hybrid components. The controls will regulate the engine running parameters to ensure that KT Wash receives the desired hot air required for their processes.

Future value to the client from this CHP system includes electricity savings, heat savings, gas usage savings, overall carbon footprint reduction. The client will definitely benefit from the implementation of a sustainable strategic energy management plan, says the company. sustainpower.com

JULY - AUGUST 2023 14 AFRICA POWER NEWS www.wipmagazines.com www.powermediagroup.co.uk

“ CHP

SUSTAINPOWER WAS TASKED WITH BUILDING A 406 KW/507 KVA GASTO-POWER UNIT & TO INTEGRATE IT WITH THE EXISTING SOLAR PV SYSTEM ON THE CLIENT’S ROOF. THE SITE ALSO HAD TO MAINTAIN A CONTINUOUS ELECTRICAL LOAD OF 480 KW.

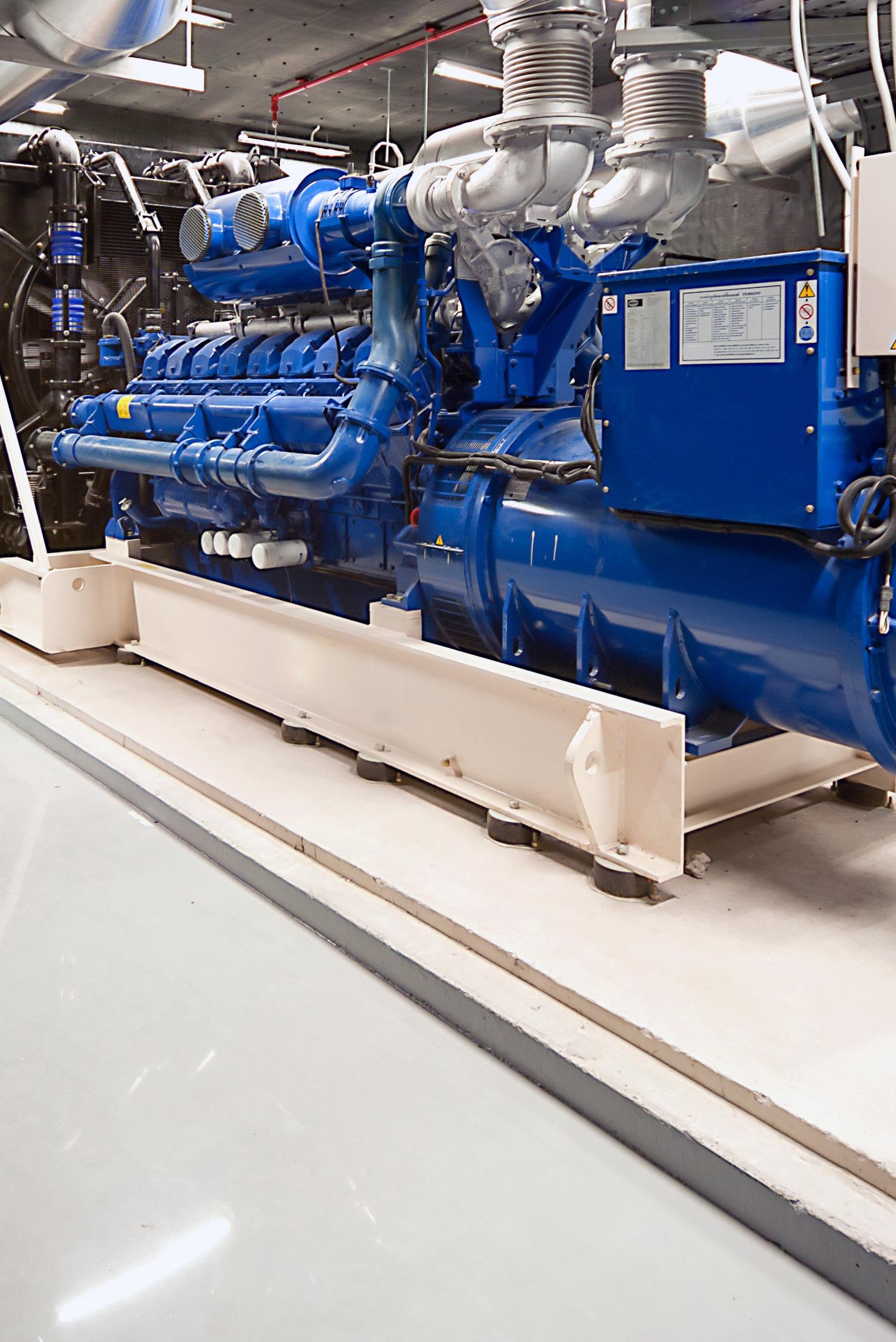

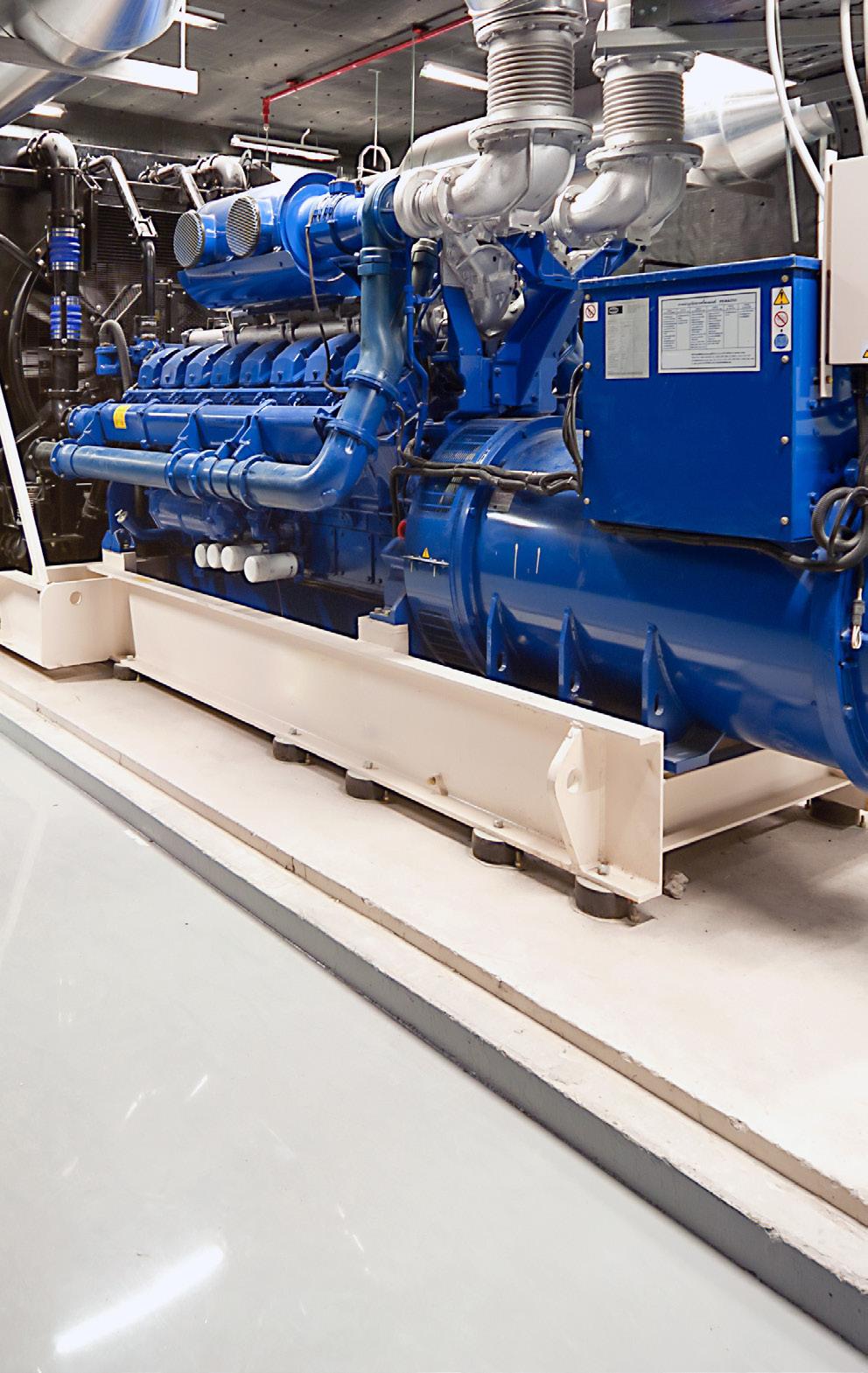

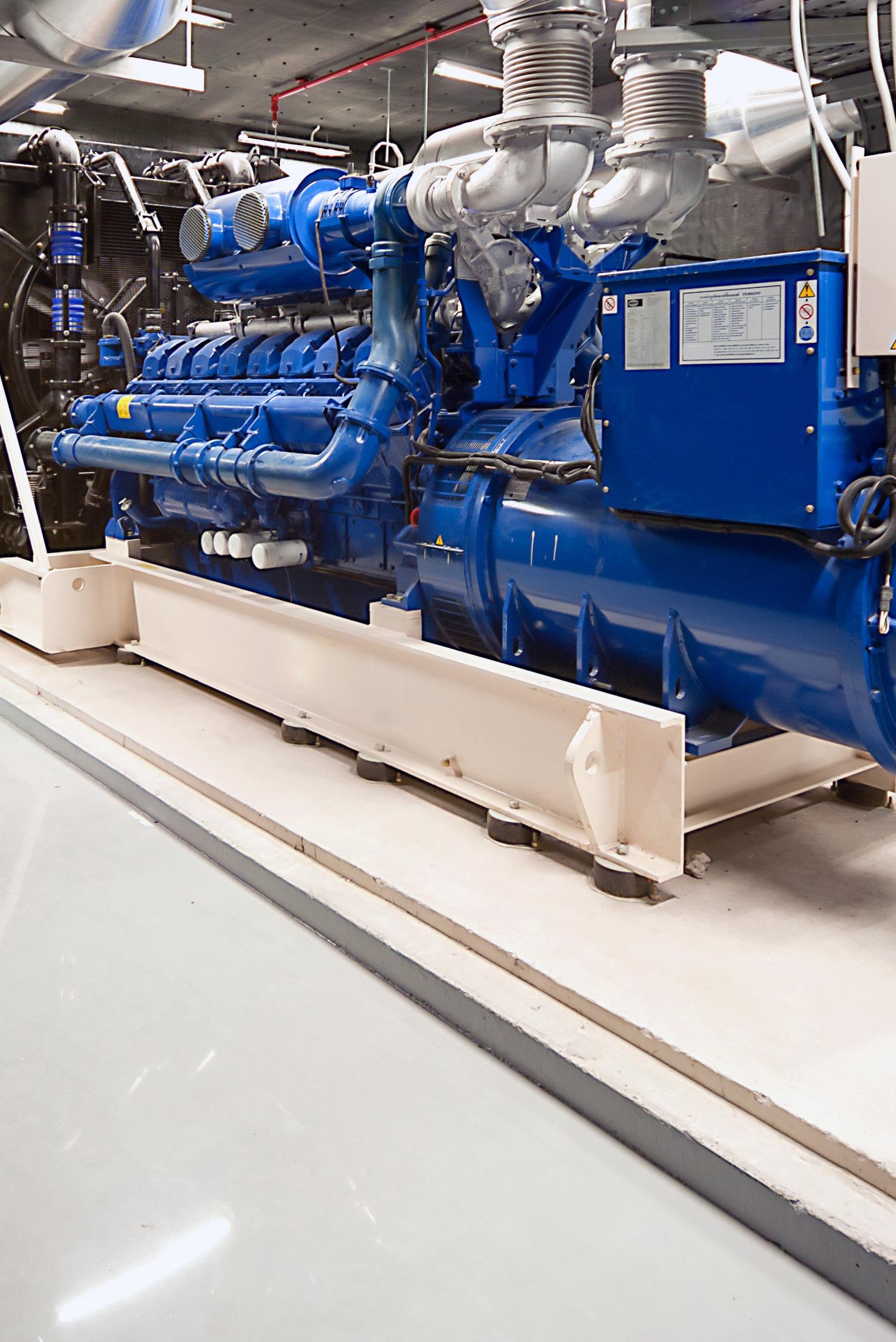

ENERGY PROJECT ON LAKE KIVU, RWANDA: POWER PLANT WITH 19 GAS-ENGINED GENSETS

Lake Kivu in Rwanda is the scene of an unusual energy project. The Rwandan lake of 2,400 km2 and a depth of 490 m has methane deposits which are used for eco-friendly energy generation.

The construction of a power plant, comprising 19 MWM TCG 2032B V16 gas gensets began in 2019. Now, the go-live phase of the MWM gas engines is imminent.

These gas gensets form the core of the power plant on the shores of Lake Kivu, which has an output of 76 MW.

Methane is extracted from the depths of the lake by means of a suction system and transported to the shore through pipelines of a length of up to 17 km. At the surface, the methane is processed and ‘sweetened’ in scrubbing towers in order to improve the quality of the gas.

From July 2023, methane extracted from the lake will be used to produce energy for Rwanda. The MWM commissioning engineers are preparing the power plant for its go-live debut onsite.

The first step is a mechanical preliminary go-live, which takes five days per MWM gas genset. Among other things, this includes an endoscopy of the cylinder combustion chambers, the filling of oil, and the review of the cooling water modules and peripheral parts such as pumps and valves.

The MWM gas gensets have made a long journey from Hamburg to Rwanda. The ship voyage was followed by a trip of 1,600 km on both desert and savanna tracks from Mombasa to Rwanda.

“By means of extensive controls, we make sure that the MWM gas gensets will run perfectly when the power plant is ramped up,” explains Thomas Mattil, the project manager responsible for the plant.

In the next step, the electric switchboard will be checked and commissioned. A total of 19 MWM TCG 2032B V16 gas gensets form the core of the power plant, which has an output of 76 MW.

The central plant switchboard of the highly complex power plant is the largest ever set up at a customer by Caterpillar Energy Solutions for the MWM brand.

The plant switchboard is used for the central control of the MWM gas gensets, cooling water modules, and other components on land. By July 2023, all 19 MWM TCG 2032B V16 gas gensets will be ready to produce sustainable energy for Rwanda.

“If everything proceeds smoothly, the energy project on the shores of Lake Kivu will be one of the world’s most exciting and innovative projects for the energy supply with MWM gas gensets”, says Mattil.

An ambitious energy project Lake Kivu in Rwanda - a body of water about five times the size of Lake Constance - forms the basis for this nationwide energy supply project. The lake hosts major methane deposits which can be used for eco-friendly energy generation purposes. The methane will fuel one of Rwanda’s largest power plants, which, in turn, will supply the landlocked country with energy.

According to estimates of the Swiss Federal Institute of Aquatic Science and Technology (Eawag), some 300 km³ of carbon dioxide and 50 to 70 km³ of methane are dissolved in Lake Kivu.

Methane - the main component of natural gas - is a key fossil energy source.

The colourless and odourless gas in the lake can escape to the surface in an uncontrolled manner, which not only harms the environment and contributes to global warming. It also represents an acute danger for humans. Scientists and businesses want to harness the gas hazard from Lake Kivu before disaster strikesand produce power from the gas.

The MWM TCG 2032B V16 gas gensets transform the methane gas, which is harmful to the environment,

into useful electrical energy.

“In this way, our gas gensets greatly contribute to the reduction of climate-damaging methane gas, while at the same time producing clean energy,” explains Tim Scott, Director for MWM.

The gas-water mixture is transported up to the surface of the lake through pipes. At the surface, the methane is processed in scrubbing towers. In this way, the gas is upgraded for the energy generation, enabling the extraction of even more electrical energy. The carbon-dioxide is sent back down to the depths of the lake.

The Lake Kivu project will supply Rwanda with energy for several decades. According to the Swiss Federal Institute of Aquatic Science and Technology (Eawag) of the ETH, the 55 km³ of methane present can be transformed into power worth some US$20 billion, based on today’s energy prices.

“We are pleased to be able to deliver a significant contribution to this sustainable, extraordinary energy project with our MWM gas engines, thereby supporting Rwanda’s economic growth”, says Scott.

www.mwm.net

JULY - AUGUST 2023 15 AFRICA POWER NEWS www.wipmagazines.com www.powermediagroup.co.uk CHP

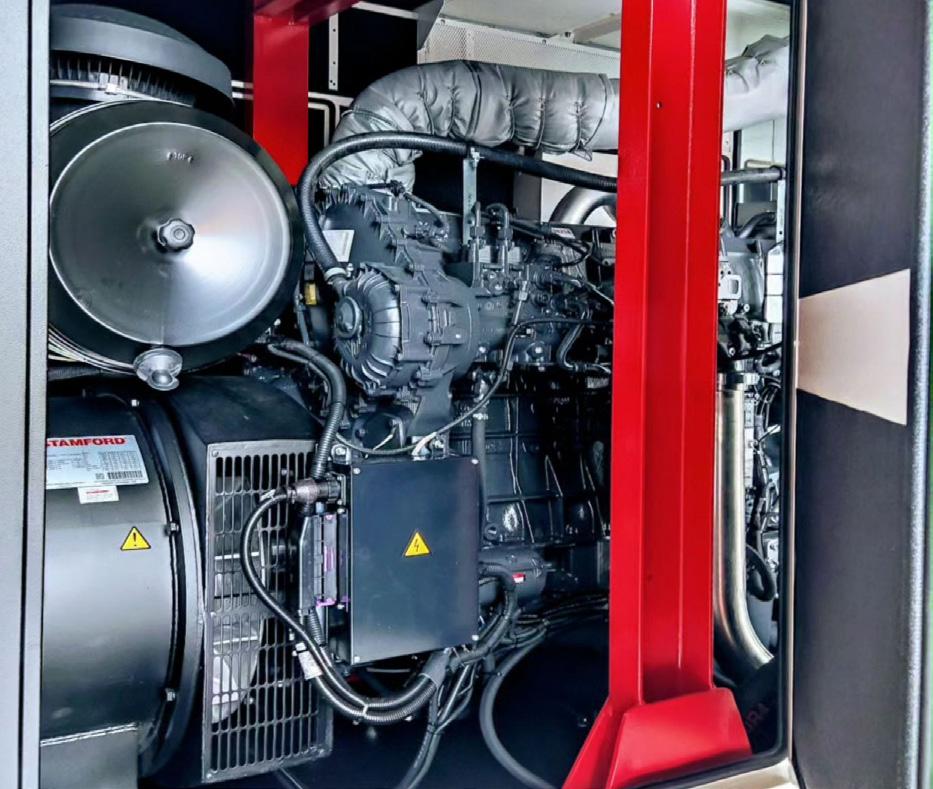

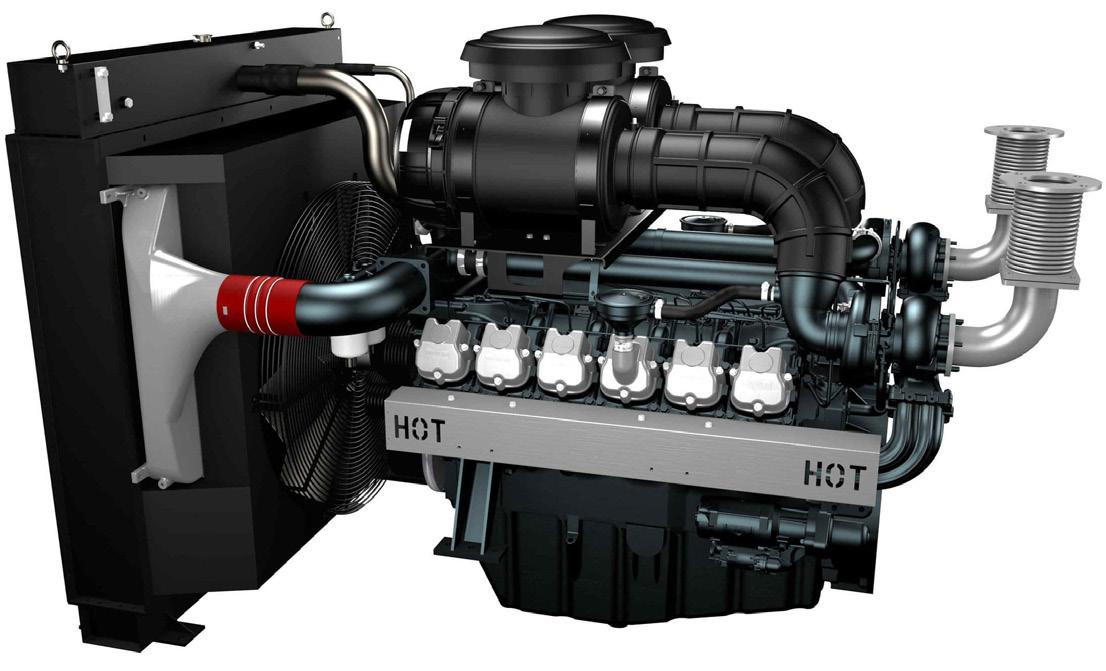

MOROCCO PAPER INDUSTRY BUYS NEW GENSET TO ENERGISE ITS NORTH AFRICA OPERATIONS

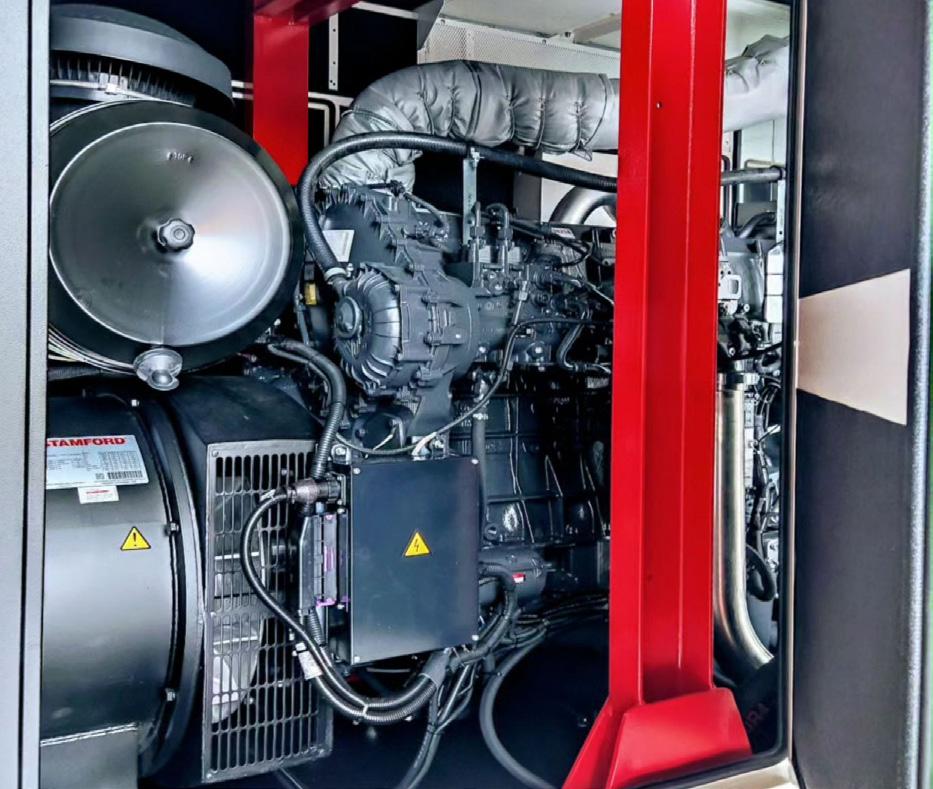

Amodel DP222LBF DOOSAN engine is the key power provider for a HDW-675 T5 three-phase soundproof generator set now at CMCPInternational Paper - one of the largest paper and cardboard production plants in Morocco.

The newly-installed genset with its STAMFORD alternator currently ensures a stable and reliable backup power supply in case of power failure.

CMCP-International Paper is Morocco’s largest integrated supplier of corrugated boxes, serving customers across multiple sectors, including fruit & vegetable, food & beverage, automotive, electronics, ceramics, chemicals, and textiles.

A spokesman for the company comments: “ CMCPInternational Paper is a single point of contact for all your packaging needs. We offer complete, superiorvalue packaging solutions with best-in-class services and logistics. Choose from all types of corrugated packaging, including sustainable punnets in many forms and shapes, or triple-wall for heavy duty applications.

“If you are in the fruit & vegetable sector, you can benefit from our unique network of erecting centres for assembly and storage.”

The CMCP site has bought and installed an HDW-675 T5 three-phase soundproof generator. This has been produced in factory facilities which have received leading certifications such as environmental (FSC™, PEFC, ISO 14001), quality (ISO 9001), occupational health and safety (ISO 45001), and food safety (BRC), among others.

It meets the following regulations: 2006/42/CE Machinery safety; 2014/30/UE Electromagnetic compatibility; 2014/35/UE electrical equipment designed for use within certain voltage limits; 2000/14/ EC Sound Power level. Noise emissions outdoor equipment. (amended by 2005/88/EC); and EN 12100, EN 13857, EN 60204.

At the heart of the genset is a 4-Cycle, V-type, 12cylinder, turbocharged & intercooled (air to air) engine which is both rugged and reliable.

The engine’s dry weight is 1,420 kg (with Fan). Its bore x stroke measures 128 x 142 mm. The engine dimensions (LxWxH) are 1,738 x 1,389 x 1,258 mm and it has a displacement of 21.927 litres.

The compression ratio is 15:1 while the rotation is counter-clockwise viewed from Flywheel. There are 160 teeth on the Flywheel.

Other features include: * Injection timing 21˚±1˚ BTDC @ 1800 rpm, 19˚±1˚ BTDC @ 1500 rpm.

It is a tough model: Maximum Bending Moment at Rear Face to Block is 1,325 N.m..

The DP222LBF DOOSAN engine has a Maximum Back Pressure of 5.9 kPa. The Air Induction System is as follows: Maximum Intake Air Restriction with Clean Filter Element is 2.16 kPa. With Dirty Filter Element it is 6.23 kPa. Max. static pressure after Radiator is 0.125 kPa. The Cooling Systems on the enghine depends on water circulation by centrifugal pump on engine (fresh water forced circulation).

Keeping the engine cool in Morrocco’s hot climate is a challenge but the coolant capacity of the engine is as follows: approx. 23 litres, with Radiator(Air On 43°C) : Approx 114 litres.

*Coolant flow rate: 660 litres / min @ 1800 rpm, 550 liters / min @ 1500 rpm.

*Pressure Cap Max. 49 kPa

* Water Temperature - maximum for Standby and Prime Power: 103 °C. Before start of full load 40 °C. The water pump is a centrifugal type driven by belt

* Thermostat Type and Range Wax –pellet type, Opening temp. 71°C , Full open temp. 85°C.

* Cooling fan Blower type, plastic , 915 mm diameter, 9 blades. Two radiator options are provided, based on allowable maximum Air temperature On radiator inlet (Air

On) : Air On 43°C / Air On 52°C - ATB (Ambient Temperature before Boiling) of generator set varies depending on the engine room ventilation design, even if the same radiator applied, explainsd Doosan. The company advises that ‘adequate selection of radiator options by means of the cooling test is highly recommended, and generator set makers are responsible for the selection’.

The engine’s fuel system is based around a Bosch type in-line pump with integrated, electromagnetic actuator. The diesel fuel feed pump has capacity of 630 litres/hr.

Battery Charging depends on a 27.5V x 45A STAMFORD alternator with a built-in type IC regulator. www.doosan.com

JULY - AUGUST 2023 16 AFRICA POWER NEWS www.wipmagazines.com www.powermediagroup.co.uk GENSETS

LOADBANKS for GENERATORS THE TRUSTED NAME FOR LOAD TESTING LOADBANK PACKAGES ■ 20kW to 7000kW ■ Resistive Only Loadbanks ■ Resistive / Reactive Loadbanks ■ DC Loadbanks SALES | SERVICE | RENTAL Call today: +44(0) 1283 531 645 www.crestchicloadbanks.com Sales & Rental Offices in : UK, North America, Singapore, Germany, Brazil, Netherlands, France, China and UAE Crestchic Limited, Second Avenue, Centrum 100, Burton upon Trent, Staffordshire DE14 2WF, UK T: +44 (0)1283 531645 F: +44 (0)1283 510103 E: sales@crestchic.co.uk

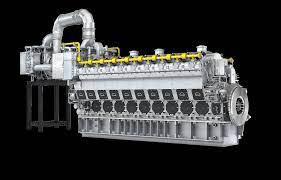

50MW DUAL-FUEL ENGINES FOR NAMPOWER’S ANIXAS POWER STATION IN NAMIBIA

Three MAN 18V51/60DF dual-fuel engines with alternators and auxiliary equipment were delivered to Nampower’s Anixas Power Station in Walvis Bay, Namibia, as part of the site’s expansion programme late last year.

A new power station has been built directly next to the existing facility, expanding the current generation capacity of 22.5 MW by an additional 50 MW.

The project is a joint venture between FK Namibia –represented by FK Generators and Equipment (International) – and the two Namibian firms, PHIM and August Twenty Six Construction.

This new power plant has been designed to enhance the Namibian power grid’s security of supply by introducing 50 MW of dispatchable generation capacity.

Furthermore, the new plant provides grid support to compensate for sudden losses of energy caused by the intermittent nature of renewable energy sources on the grid.

The MAN 51/60DF engines will initially run on liquid fuel. As soon as an appropriate gas infrastructure becomes available regionally, the dual-fuel engines can seamlessly switch to operation on low-emission natural gas, while maintaining the flexibility to operate on liquid fuels should the gas supply be interrupted.

This dual fuel engine converts diesel or natural gas efficiently, and can switch from one fuel to another without any fluctuations in speed or output.

*Engine speed: 500/514 rpm

*Frequency: 50/60 Hz

*Up to 20,700 kWm

The main advantage of dual fuel technology is fuel flexibility. This makes it possible to take advantage of the low cost and superior environmental benefits offered by gas.

If the supply of gas fuel is interrupted, the engine can continue operating using liquid fuel. In addition to natural gas, the dual fuel engines can also run on liquid biofuel or distillates like marine diesel oil (MDO), marine gas oil (MGO), crude oil and heavy fuel oil (HFO).

A company spokesman commented: “Dual fuel engines from MAN Energy Solutions are known for their reliability, efficiency, performance and the ability to switch between fuel sources. And if you already have one of our liquid fuel engines, it’s easy to upgrade to dual fuel capability to meet changing needs.”

MAN gas and dual fuel engines offer a clear path toward net zero. By using natural gas in comparison to coal, they immediately reduce CO2 emissions.

The ability to run on SNG or biofuels offers users independence from the price and supply fluctuations of the natural gas market.

At the same time, they have the highest electrical efficiency, are very dynamic and allow modular plant design.

Reciprocating engines have the highest electrical efficiency, are very dynamic (fast ramp up, ramp down, part load), and allow modular plant design with multiple units to optimize operation and thermal management.

MAN Energy’s gas and dual fuel engines are a future-proof investment in a low-carbon future, reports the manufacturer.

The energy challenge

The challenge is to provide the highest possible grid stability while maintaining adaptability to future regulations and market conditions.

The answer is in gas engine technology. Its ability to run on 100% biogas ensures independence from natural gas supplies.

Gas and dual fuel engines can lower the CO2 emissions of utilities and industrial plants using smart thermal management.

To create additional revenue streams, gas power plants can be

operated as thermal balancing units in RES grids.

Future-proof gas and dual fuel engines offer a clear path toward net zero.

Even today, CO2 emissions can be further reduced by using 100% SNG or 100% biofuels or by blending up to 25% hydrogen.

Carbon-neutral fuels such as methanol and carbon-free fuels like ammonia and 100% green hydrogen will also be usable in the future.

The use of alternative fuels such as SNG and biogas is now made even more relevant by rising prices and the falling availability of natural gas threatening security of supply.

To ensure the growing availability of alternative fuels, MAN Energy Solutions reports that it is ‘driving forward the power-to-X technologies for their production’.

NIXAS, the 22.5MW power station, is situated adjacent to the existing Paratus Power Station in Walvis Bay, will provide an emergency standby electrical capacity of 22.5 MW to Namibia.

www.man-es.com

JULY - AUGUST 2023 18 AFRICA POWER NEWS www.wipmagazines.com www.powermediagroup.co.uk

POWER TURBINES

22MW POWER PLANT FOR MARAMPA, SIERRA LEONE

The Anglo Belgian Corporation has supplied a 22MW power plant composed of eight thermal power generators - full installation will be commissioned in Autumn 2023.

The Gerald Group, founded in the US and headquartered in the U.K., one of the world’s leading global metals trading houses for the trading of ferrous, non-ferrous, precious metals and related concentrates and raw materials, chose International Montage Maintenance (IMM) to provide an extension for the mine’s existing, onsite power plant at the Marampa Mines Limited site in Sierra Leone.

This extension consists of the Engineering, Procurement and Construction (EPC) site involving a 22MW power plant composed of eight thermal groups equipped with ABC motors, as well as all the auxiliaries and seamless integration with the existing power plant.

A spokesman commented: “This new mission reinforces IMM’s role as a trusted partner for mining stakeholders in Africa.”

For 100 years Anglo Belgian Corporation (ABC), with headquarters and production facility in Gent (Belgium), supplies power solutions for electricity production.

ABC’s reliable, medium speed engines, in combination with an alternator, ensure that we can offer powerful solutions to those looking for a reliable source of energy.

Generator sets based on ABC engines are widely- used in (hybrid) power plants, industrial groups and emergency gensets. As an independent power producer (IPP) or non-utility generator (NUG), you want to rely on solid and experienced partners to produce power for resale at the lowest cost per kWh.

Anglo Belgian Corporation (ABC) is an open-source manufacturer of medium speed engines with various energy outputs, operates a state-of-the-art production facility in Belgium. Our reliable engines, in combination with an alternator, offer powerful yet economical power generation solutions.

The characteristic medium speed engine (up to 1000 rpm) and cleverly-engineered distribution of loads ensure a low mechanical deterioration and therefore guarantees a long life of the engine and its components.

A spokesman comments: “Our engines are 100% mechanical, making them easier to maintain and more reliable. We call this “SMART”: Simple, Mechanical, Affordable, Reliable and Tailormade according to your requirements. The total cost of ownership and uptime of medium speed engines easily outperforms high speed

engines in the long run. This is due to the low fuel and lube oil consumption, the lower frequency of maintenance interventions and general robustness of the medium speed engine. Your benefit is a much lower operating and life-cycle cost.

“ABC also has extensive experience with containerised generating sets operating in the most difficult and harsh environments.”

ABC containerised solutions are designed according to the needs of each project, including the necessary scope of supply and tailored to the environmental requirements. ABC’s solutions include not only the power units but also fuel treatment systems and electric switchgear, all of which can be integrated in containers.

The Gerald Group-owned Marampa Mines Limited has commissioned a 3.25 million tonnes per annum expansion of the name iron ore mine in Sierra Leone.

The expansion follows a restart of mining on September 1, 2021, and ups output from 2 million tonnes per annum, producing the company’s trademarked Marampa Blue product.

Marampa Blue ore is a >65% iron content concentrate currently in high demand as the world’s iron smelters seek to reduce their carbon footprints.

Sierra Leone president Maada Bio has welcomed the restart of full-scale operations.

“Exports of high-value products such as Marampa Blue iron ore concentrate from Sierra Leone will increase year-on-year and deliver a long-awaited boost to our country’s economic growth and stability,” he said in a statement.

Gerald Group and Marampa Mines CEO Craig Dean said the expansion is part of a shared vision to optimise the 1.7 billion tonnes of compliant resources at Marampa, which combines Marampa North and South concessions.

“The venture brings additional revenues to the government of Sierra Leone and creates opportunities by developing a sustainable and resilient mining operation, so Sierra Leoneans significantly benefit from MML’s growth and success,” he said.

The 3.25 million tonnes per year expansion mainly includes the addition of a new feed point and a new product line to accommodate the additional feed and product volume, as well as the addition of a new set of spiral blocks to increase processing capacity, and an expansion of the mining fleet with large 90 million tonne capacity excavators to increase mining volume. Marampa Mines has laid out plans to expand the operation further. This will involve further options to access additional power and renewable or lower carbon-intensive energy sources.

Discussions about operational access to Pepel’s rail and port facilities are now underway and will contribute significantly to MML’s streamlining of export operations and reduction in carbon footprint, key components to ensure future competitiveness.

www.abc-engines.com

JULY - AUGUST 2023 19 AFRICA POWER NEWS www.wipmagazines.com www.powermediagroup.co.uk

GENSETS

FOUR DIESEL GENSETS FOR THE KEY PORT OF ALEXANDRIA, EGYPT, NORTH AFRICA

AKOHLER partner company has delivered, installed and commissioned four 3000 KVA diesel-powered PRP 11KV gensets (3,000kVA), one unit KD1100F 400V and a V550 400V genset to a multipurpose terminal based in the port of Alexandria port, Egypt, reports Elswedy, the site contractor.

A KOHLER spokesman comments: “From planning the design and choice of equipment to final testing and commissioning, we have one goal: to offer you reliable power systems, precisely designed to your specifications. “We provide great flexibility in manufacturing, extreme rigor during testing, meticulous precautions during commissioning. Everything is done to provide you with a solution adapted to your activity and your budget.”

The KOHLER X-SERIES range of generating sets equipped with Baudouin engines offers an optimized solution for emergency applications, and comes with all of the most popular functions.

The product is quick and easy to install, offering excellent value for money and reliability.The generating sets are powered by robust, traditional engines and offer short lead times and easy installation and maintenance.

The range comprises 6 output levels from 900 kVA to 1500 kVA, available in open or soundproofed versions to minimize sound levels and protect the product from the weather.

The KD1100F 400V now operating in Alexandria is part of the KOHLER KD Series (a G3) with a KD27V12-5DFS engine type and an M80-D Standard Control Panel. The generator set, its components and a wide range of options have been fully developed, prototype tested, factory built, and production-tested.

The generator sets are designed in accordance to ISO8528-5 performance class G3. The sets offers smooth running thanks to engine conception and integral vibration isolation mounts between components and skid. There is low fuel consumption thanks to a high technology common rail injection engine and a smaller footprint thanks to a high power density.

The set offers low temperature starting capability and long maintenance intervals. The genset alternator provides an industry-leading motor starting capability with an excitation system to permit sustained overcurrent > 300% In, during 10 sec.

It is built with a class H insulation and IP23. Cooling is provided by a compact and complete solution using a mechanically driven radiator fan. There is a high temperature and altitude product capacity, running without power derating.

The V550 400V is powered by a TAD1641GE-B1 VOLVO engine with a APM403 Standard Control Panel.

Key features of this genset include: electronic governor, a fully mechanically-welded chassis with antivibration suspension, a main line circuit breaker, a radiator for core temperature of 48/50°C max with mechanical fan and a Protective grille for fan and rotating parts (CE option).

The 9 dB(A) silencer is supplied separately and there is a Charger DC starting battery with electrolyte, 24V charge alternator and starter, and the genset is delivered with oil and coolant -30°C.

The TAD1641GE-engine is a powerful, reliable and economical generating set diesel engine built on the dependable in-line six design.

Designed for easiest, fastest and most economical installation, it is well-balanced to produce smooth and vibration-free operation with low noise level.

To maintain a controlled working temperature in cylinders and combustion chambers, the engine

is equipped with piston cooling. The engine is also fitted with replaceable cylinder liners and valve seats/guides to ensure maximum durability and service life of the engine.

The state of the art, high-tech injection and charging system with low internal losses also contributes to excellent combustion and low fuel consumption, reports the manufacturer.

www.kohlerpower.sg

JULY - AUGUST 2023 20 AFRICA POWER NEWS www.wipmagazines.com www.powermediagroup.co.uk GENSETS

1,000 KVA GENSET FOR THE SUEZ TECHNOLOGICAL CENTRE

ONIS VISA has installed an Onis Visa 1000 kVA diesel genset for the “Suez Technological Centre for Citizen Services” recently opened in Suez by the prime minister of Egypt

Mr. Mostafa

Mr. Mostafa

Madbouly.

The Onis Visa POWER FULL S range has been designed for particularly complex projects, and thanks to its sturdy structure it represents the right choice for heavyduty use, reports the company. The gensets housed in the Onis Visa soundproofed canopies incorporate an arrangement of additional accessories and systems. External and internal technical equipment can be customised - such features include a special filter to prevent water and dust from entering, high-capacity fuel tanks, customised control panels and special radiatorsand many more accessories. The range meets high levels of soundproofing.

A spokesman commented: “Our range of ONIS VISA Generating sets and stand-by power generators are manufactured in Italy and are used to ensure the functionality of critical systems, the running of production, or a controlled shut-down and electrifying the main services of facilities or buildings.”

ONIS VISA HAS INSTALLED AN ONIS VISA 1000 KVA DIESEL GENSET FOR THE “SUEZ TECHNOLOGICAL CENTRE FOR CITIZEN SERVICES” RECENTLY OPENED IN SUEZ BY THE PRIME MINISTER OF EGYPT MR. MOSTAFA MADBOULY. THE ONIS VISA POWER FULL S RANGE HAS BEEN DESIGNED FOR COMPLEX PROJECTS LIKE THIS.

The spokesman continued: “Our ONIS VISA generating sets can be used as prime power to produce electricity at remote areas where access to the electric grid is unfeasible or impossible.

“Our generating set range can be personalised and applied to in order to adapt to the various different industry sectors, are the ideal choice for demanding users.”

Egypt’s drive to upgrade its digital transformation through science and technology

In alignment with Egypt Vision 2030, and Egypt’s digital transformation strategy, the nation’s Ministry of Communications and Information Technology (MCIT) has embarked on building what it calls Digital Egypt.

A spokesman commented: “Digital Egypt is an all-encompassing vision and plan, laying the foundations for the complete transformation of Egypt into a digital society.

“To usher this transition to a digital society and build a strong digital economy, the government has established a facility - the “Suez Technological Centre for Citizen Services” which contains the most up-to-date electronics resources and data processing systems in the country.”

About the company

Onis Visa designs and manufactures generating sets, power stations, and dewatering motor pumps. It offers a range of generators for industrial uses, mobile purposes, data centres, DCP (Data Centre Power) ranges, lighting towers, and many others.

The company was founded in 1960 and is based in Fontanelle, Italy.

A VISA company spokesman said: “Visa SpA has a global

presence across nearly 100 countries, addressing the increasing need for customised gensets designed for specific applications and projects that go beyond standard products.

“Their engineering team is backed by a professional technical staff, enabling them to deliver appropriate solutions even for the most challenging projects.

He concludes: ““Onis Visa products are selected not only for their quality and reliability but also for the company’s expertise in executing specialised projects in different applications.

“Moreover, opting for Onis Visa products also ensures access to expert local support. “

www.visa.it

JULY - AUGUST 2023 21 AFRICA POWER NEWS www.wipmagazines.com www.powermediagroup.co.uk

“ GENSETS

GET ACCESS TO MEGSA... GET ACCESS TO MEGA CONNECTIONS. The Voice of the Middle East Generating Set Industry. Special Inaugural prices for joining in 2023! Be part of our Inaugural year and Join for the 1st year @ £2450.00 or 2 years @ £1950.00 each year. BECOME A MEMBER: Get In Touch: sales@megsa.org sales@megsa.org | www.megsa.org | Middle East Gen-Set Association | Copyright © 2023

4 X 1.5MW GENSETS FOR A REAL ESTATE PROJECT IN NIGERIA

Four 4 x 1.5MW generators with mtu engines from Rolls-Royce have been supplied to a residential retail project in Nigeria.

The Eko Atlantic real estate development project has just bought four units of mtu gensets with 1.5 MW each, totalling 6 MW and a longer lifetime of up to 84,000 hours, reducing maintenance time and boosting efficiency.

Each of the mtu 12V 4000L 64 FNER mobile and stationary power modules provide unique flexibility wherever power is needed.

From construction sites to factories to entire communities - the power modules are said to be the ideal solution to maintain power supplies.

mtu genset containers like these offer numerous features and benefits that speed deployment, facilitate installation, reduce environmental impact and cut operating costs.

The containerised unit includes a generator set, switchgear - including a control and monitoring system – together with all necessary connections and supply systems (such as ventilation, lubricant supply and heat recovery).

It is designed not only to provide operators with consistent power, but to enable customers to keep in control and ensure that any downtime is kept to a minimum. The containerised power supply modules use reliable diesel engines which can power a variety of applications, from entire communities to construction sites and factories.

Eko Atlantic is an entire new coastal city being built on Victoria Island adjacent to Lagos, Nigeria. It is a focal point for investors capitalising on rich development growth based on massive demand – and a gateway to emerging markets of the continent says its developers.

Standing on 10 million square metres of land reclaimed from the ocean and protected by an 8.5 kilometre-long sea wall, Eko Atlantic will be the size of Manhattan’s skyscraper district.

Self-sufficient and sustainable, it includes state-of-theart urban design, its own power generation, clean water, advanced telecommunications, spacious roads, and tree-lined streets.

mtu 4000 series generator sets perform at the highest level and cover the power range from 1125 to 3250 kWe (1550 to 3730 kVA).

With a robust design and optimal fuel consumption, mtu diesel generator sets are trusted by customers around the world.

Designed and manufactured in facilities certified to standards ISO 9001:2008 and ISO 14001:2004

Verified product design, quality and performance integrity Industry-leading average load factor

The sets feature cutting-edge emissions control and outstanding fuel economy. The gensets have superior onsite specific de-rating behavior thanks to to state-of-the-art engine controllers with engine site condition management systems.

Compliant with industry codes & standards the generator set fulfills performance per ISO 8528 and offers 100% load acceptance according to NFPA 110

A permanent magnet excitation system is provided with each generator as standard for improved transient response. It offers best-in-class reliability and availability along with optimised maintenance intervals, This development project in Nigeria

is being privately funded by South Energyx Nigeria Limited – the developers and city planners, a subsidiary of the Nigeria-based Chagoury Group of companies.

The companies are working in strategic partnership with the Lagos State Government and are being supported by the Federal Government of Nigeria.

Notable national and international banks have been quick to capitalise on the opportunities with some of Nigeria’s biggest – FCMB, First Bank, Access Bank and Guaranty Trust Bank – partnering with Eko Atlantic, with support from BNP Paribas Fortis and KBC.

A spokesman for the development commented: “ For savvy investors, Eko Atlantic City represents far more than just surging Lagos land value.

“As Nigeria continues its unstoppable trajectory to become the financial capital of Africa, investing in Eko Atlantic opens unprecedented opportunities for tapping into the wider potential of the continent as a whole – widely recognised as the world’s most promising growth horizon.”

mtu-solutions.com

www.rolls-royce.com

JULY - AUGUST 2023 24 AFRICA POWER NEWS www.wipmagazines.com www.powermediagroup.co.uk

GENSETS

Alternators Made in Italy Viale del Lavoro, 30 - 37040 Arcole (VR) Italy T. +39 045 7639201 - F.+39 045 7639202 info@linzelectric.com - www.linzelectric.com COGENERATION CYCLE CYCLE PLUS STORAGE STATIC GAS SOLAR THERMAL OIL & GAS SHORT BREAK POWER PLANT GEN SET ENERGY WHERE NEEDED INNOVATIVE SOLUTIONS +39 0536 94.36.15 www.margen.it info@margen.it Via Dino Ferrari, 50 - 41053 Maranello (MO) - Italy MARGEN s.p.a. Leaders in complete power solutions Hire, Sales, Service & Maintenance, Contingency Planning, including 24/7 Emergency Response WOODLANDSPOWER.COM UK: 0845 600 3335 | INTL: +44 138 644 2622 Winding. Rewinding. Supply. Service. Repair. Cabel UK Limited CMF Technology Park Maresfield Road Oakham LE15 7FW E: info@cabeluk.com T: +44 (0)1572 755 168 www.cabeluk.com Part of the Mecc Alte Group THE VOICE OF THE MIDDLE EAST GENERATING SET INDUSTRY WWW.MEGSA.ORG LAUNCH OF

ENGINE MANUFACTURERS GUIDE

INNIO Jenbacher gas engines

T +43 5244 600-0 F +43 5244 600-527 jenbacher.info@ge.com www.gejenbacher.com

Manufacturer of gas driven generator sets and cogeneration systems in a power range from 0.25 to 3 MW.

R Schmitt Enertec GmbH

56743 Mendig, Germany T +49 2652 9351810

F +49 2652 9351822 info@rschmitt-enertec.com

www.rschmitt-enertec.com

Manufacturer of gas driven engines,generator sets and cogeneration systems in the range from 100 - 500 kW.

RSE Engines for natural gas and biogas

Ratings natural gas standard, NOx ≤ 500 mg/ m3N. Dry exhaust gas; based on 5% O2. For engines with 1,200 rpm please contact GE Energy’s Jenbacher product team.

Perkins Engines Company Limited

Peterborough PE1 5FQ

Contact name:- Simon Gray

Tel: +44 (0) 1733 583000

Email: gray_simon_j@perkins.com

Perkins is one of the world’s leading suppliers of off-highway diesel and gas engines, offering dependable cost-effective power up to 2500 kVA in dieselor 1000 kWE prime in gas.

SCANIA ENGINES

SE-151 87 Sodertalje Sweden

Tel +468553 81000

Fax +468553 898 12

E-mail engines@scania.com

Web www.scania.com

UK Contact – Mark Swindell

Scania GB Ltd

Tel +44 1908 329386

E-mail mark.swindell@scania.com

Diesel & Gas engines for power generation

Prime power 250kVA to 700kVA Stand by power 250kVA to 770kVA

Engine range prime power 50hz & 60hz at (70% mean load factor)

Scania produce diesel and gas powered engines for various Industrial and Marine applications, superior quality and reliability, offering exceptionally low fuel consumption.

All models are available to meet current emissions requirements, Scania engines are now available to meet both Tier 4F and EU Stage V. Alternative fuels

Many of our engines can also operate on Bio-diesel conforming to EN14214 and HVO conforming to EN159540

Model fuel Freq. Electric output M06-G/B T0D41 g 50 140 kW M06-G/B TID41 g 50 200 kW M06-G/B T2D41 g 50 250 kW M08-G/B TID41 g 50 260 kW M08-G/B T2D41 g 50 333 kW M12-G/B TID41 g 50 400 kW M12-G/B T2D41 g 50 500 kW M06-G/B T0D41 g 60 150 kW M06-G/B TID41 g 60 210 kW M06-G/B T2D41 g 60 250 kW M08-G/B TID41 g 60 280 kW M08-G/B T2D41 g 60 333 kW M12-G/B TID41 g 60 420 kW M12-G/B T2D41 g 60 500 kW RSE engines for LPG M06-PT0D41 g 50 115 kW M06-PTID41 g 50 173 kW M06-PT2D41 g 50 205 kW M08-PTID41 g 50 233 kW M08-PT2D41 g 50 260 kW M12-PTID41 g 50 350 kW M12-PT2D41 g 50 450 kW M06-PT0D41 g 60 130 kW M06-PTID41 g 60 173 kW M06-PT2D41 g 60 205 kW M08-PTID41 g 60 233 kW M08-PT2D41 g 60 260 kW M12-PTID41 g 60 350kW M12-PT2D41 g 60 450 kW RSE engines for Woodgas M06-HT2D41 g 50 122 kW M08-HT2D41 g 50 166 kW M12-HT2D41 g 50 250 kW M06-HT2D41 g 60 140 kW M08-HT2D41 g 60 180 kW M12-HT2D41 g 60 275 kW Volvo Penta 405 08 Gothenburg, Sweden Tel +46 31 235460 Model Spec RPM kWm kVA TAD530GE Diesel 15002) 75 85 TAD531GE Diesel 15002) 88 100 TAD532GE Diesel 15002) 113 130 TAD550GE1) Diesel 15002) 76 86 TAD551GE1) Diesel 15002) 89 101 TAD730GE Diesel 15002) 113 130 TAD731GE Diesel 15002) 132 152 TAD732GE Diesel 15002) 162 186 TAD733GE Diesel 15002) 175 201 TAD734GE Diesel 15002) 213 245 TAD750GE1) Diesel 15002) 114 131 TAD751GE1) Diesel 15002) 13 152 TAD752GE1) Diesel 15002) 158 182 TAD753GE1) Diesel 15002) 173 199 TAD754GE1) Diesel 15002) 217 250 TAD940GE Diesel 15002) 241 277 TAD941GE Diesel 15002) 280 326 TAD1341GE Diesel 15002) 271 315 TAD1342GE Diesel 15002) 303 352 TAD1343GE Diesel 15002) 325 378 TAD1344GE Diesel 15002) 354 412 TAD1345GE Diesel 15002) 388 451 TAD1351GE1) Diesel 15002) 279 324 TAD1352GE1) Diesel 15002) 314 365 TAD1354GE1) Diesel 15002) 328 381 TAD1355GE1) Diesel 15002) 355 413 TAD1640GE Diesel 15002) 392 461 TAD1641GE Diesel 15002) 430 505 TAD1642GE Diesel 15002) 503 591 TWD1643GE Diesel 15002) 536 630 TAD1650GE1) Diesel 15002) 393 462 TAD1651GE1) Diesel 15002) 430 505 Engines are also available for1800rpm/60Hz

Headquarters: A-6200 Jenbach (Austria)

Model Fuel rpm Pel Pth JMS 208 GS g 1,500 330 358 JMS 208 GS g 1,800 335 406 JMS 312 GS g 1,500 625 731 JMS 312 GS g 1,800 633 808 JMS 316 GS g 1,500 834 988 JMS 316 GS g 1,800 848 1,079 JMS 320 GS g 1,500 1,063 1,190 JMS 320 GS g 1,800 1,060 1,313 JMS 412 GS g 1,500 844 892 JMS 416 GS g 1,500 1,131 1,194 JMS 420 GS g 1,500 1,415 1,492 JMS 612 GS g 1,500 1,820 1,792 JMS 616 GS g 1,500 2,433 2,399 JMS 620 GS g 1,500 3,041 3,020

TAD1242GE 352 409 TAD1640GE 393 462 TAD1641GE 433 509 TAD1642GE 485 570

NOTES

The latest V-Type alternator has been developed in response to changing market needs and has been built for optimum performance and reliability in harsh marine environments. Having undergone rigorous testing, the V-Type is designed to deliver optimal uptime, so you can be sure of reliable power generation, regardless of the operational conditions and compliant with all marine classifications. With over 75 years in the power generation market we pride ourselves on being the Power from Within the systems and generator sets that our customers produce.

Choose wisely… Choose the V-Type.

The world’s largest independent producer of alternators 1-5,000kVA

FOR FURTHER INFORMATIO N VISIT WWW.MECCALTE.COM

Mr. Mostafa

Mr. Mostafa