FLEXIBLE POWER GENERATION

GENSET FOR BAHÍA BLANCA AIRPORT, ARGENTINA

OTTO FUCHS KG provides an excellent example for US industry to follow, reports MWM.

Gensets which exceed 1200kVA standby power were recently provided by a distributor, the Elecsen Group.

2MW ORDER FOR GENSETS IN THE CARIBBEAN

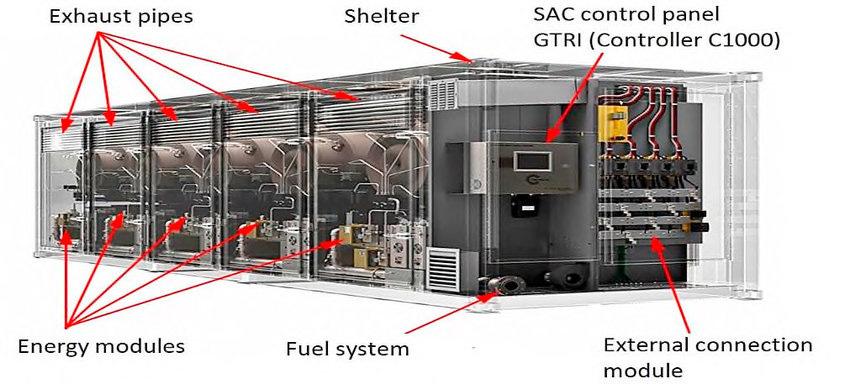

Two Capstone C1000S microturbine systems have been bought by a government water authority to provide power.

GENSET FOR THE TERMOCANDELARIA POWER PLANT IN COLOMBIA

We look at a a 1,470 kVA diesel genset with MTU engine & NIDEC alternator.

DISTRIBUTED poultry industry.

NEW MODULAR & INTEGRATED BATTERY STORAGE SYSTEM

Hitachi Energy has launched improved and new versions of its e-meshTM PowerStore BESS for its customers

Under the terms of a contract signed with the USN, Rolls-Royce’s Power Systems division will supply four of its MTU naval generator sets for the US Navy’s second newgeneration guided missile frigate in the Constellation class.

Mitsubishi Power and Georgia Power, along with the Electric Power Research Institute (EPRI), have validated fuel blending of hydrogen and natural gas at both partial and full load on an M501G natural gas turbine at Georgia Power ’s Plant McDonough-Atkinson in Smyrna, Georgia.

The demonstration project is said to be the first to validate 20% hydrogen fuel blending on an advanced class gas turbine in North America, according to an announcement issued by the organizations It is the largest test of its kind to date

Newly upgraded production facilities in Aiken, South Carolina and Mankato, Minnesota will support the manufacture of these generators, which are based on the MTU 20V 4000 M53B engine.

energy research and development organization which supported development of the project

The four generator sets, each rated at 3000 kWe, will provide a total power output of 12 MW for propulsion and onboard power supply.

The 20% blend was shown to provide a roughly 7% reduction in carbon emissions compared to natural gas

“EPRI’s future-focused collaboration with Georgia Power and Mitsubishi Power Americas is helping bring net-zero goals within reach ”

executed through Mitsubishi Heavy Industries America, Inc (MHIA), which joins a consortium of investors including Breakthrough Energy Ventures, Equinor, Amazon, Honeywell and Rio Tinto

Constellation-class frigates have a combined diesel-electric and gas (CODLAG) propulsion plant, which combines a single gas turbine, two electric propulsion motors, four ship service diesel generators and one auxiliary propulsion unit.

“Accelerating low-carbon technology development is essential to achieve net-zero targets by mid-century This successful hydrogen demonstration test reinforces the significant, gamechanging role that this and other low-carbon technologies can play to help reach economy-wide decarbonization,” said Neva Espinoza, vice president of Energy Supply and LowCarbon Resources, at EPRI, an independent, non-profit

The MTU diesel generators will provide electrical power for onboard electronics and cruising speed. The gas turbine is used when the frigate is travelling at high speeds.

Commenting on the contract, Rolls-Royce Solutions America director,

NEW US NAVY FRIGATES TO RECEIVE 4 SPECIAL GENSETS TO POWER THEM

Mitsubishi Heavy Industries, Ltd (MHI) has also invested in Electric Hydrogen (EH2), a clean hydrogen startup, to support its efforts in developing cost-competitive, fossil-free hydrogen

Adam Wood, said RollsRoyce is “thrilled to bring the manufacturing of our MTU naval gensets to the US.”

According to EH2, the company received US$198 million financing to support its efforts in making costcompetitive fossil-free hydrogen

gensets for the lead ship in the Constellation-class programme, the frigate USS Constellation (FFG-62).

Through this investment, MHI said it aims to strengthen and diversify its hydrogen value chain, advance its energy transition business, and act on its commitment toward global carbon neutrality goals The investment has been

He comments: “The seamless transfer of technology from Germany to our Aiken and Mankato facilities has strengthened our ability to meet the high expectations of this project and better position us to compete for future government programmes.”

This contract follows RollsRoyce’s supply of four MTU

“No single company can provide needed technology to achieve global decarbonization, which is why we recognize the importance of investing in and enabling companies like Electric Hydrogen to develop new solutions,” Takajiro Ishikawa, president and CEO of MHIA, told APN

The US-manufactured gensets installed in USS Congress (FFG63), the second ship in the Constellation-class programme (formerly known as the FFG(X) programme).

The engines will be delivered to Fincantieri Marinette Marine in Marinette, Wisconsin in late 2023.

1 AMERICAN POWER NEWS JULY/AUGUST 2023 July/August 2023 Issue Issue 83

Page 13

Page 16

J U N E - J U LY 2 0 2 2 A M E R I C A N P O W E R N E W S

Page 13 Pages 14 Page 20

H 2 TU R B I N E T E S T S U C C E S S F U L AT M CD O N O U G HAT K I N S O N P L AN T I N G E O R G I A June - July 2021 Issue Issue number 81 PROMOTING STANDBY POWER & COGENERATION TECHNOLOGY THROUGHOUT THE AMERICAS If you are reading this advert, so are over 62,000+ others Digitally. Special summer rate @ £525.00

take ADVANTAGE of this special offer and book this advert please email: power@wipmagazines.com or call Tel. +44 (0) 1403 888019

To

Publisher/Sales Director:

Neb Saric neb@wipmagazines.com

Publishing & Events Director: Richard Teasdale richard@wipmagazines.com

Managing Editor:

Aidan Turnbull aidan@wipmagazines.com

Accounts Manager:

Alison Williams accounts@wipmagazines.com

Sales & Marketing Manager

Sarah Hallows sarah@wipmagazines.com

Far East Sales:

Bob Liu

Room 926, No.1 Building, Phase II No.100 Jinyu Road, Pudong Shanghai, China Mobile:+86-013817410089

Email: bob.liu@ronco.com.cn

Austria & Germany agent Mario Dobresko power@wipmagazines.com

Contributors

Rolls-Royce, mtu, Basin Electric Power, Gruppo AB, FG Wilson, Durr, MWM, Hyundai, Cpastone Energy, Scania, Paramount Power, Grupel, Siemens, Energy, Honda North America, Nixon Power Services, ABB, NIDEC, L&M Radiators, Blair Energy, AGCO Power, Hotstart, Geo-Thermal, FMD, Flexgen Power Systems, Precision Controls, Ameresco, Genesal Energy, CSU, Portland General Electric, FPT Industrial, Cummins Inc, Xcel Energy,

AMERICAN POWER NEWS

Published by: Power Media International Group Ltd, The Courtyard, 30 Worthing Road, Horsham, West Sussex, RH12 1SL, UK Tel: +44 (0)1403 888019 Fax: +44 (0)1403 220751 powermediagroup.co.uk © Worldwide Independent Power (ISSN 1468-7100).

Subscription price £70 (UK), £140 (overseas) per year. Please send address changes to UK Power News, Power Media International Group Ltd 30 Worthing Road, Horsham, West Sussex RH12 1SL, UK.

NEW BALANCING POWER PLANTPIONEER PHASE IV - FOR NORTH DAKOTA

The technology group Wärtsilä will supply the generating capacity for a new balancing power plant being built in the U.S.A.

The Pioneer Generation Station Phase IV power plant project is located in North Dakota. It will provide Basin Electric Power Co-operative with the flexible gas generation needed to balance the inherent variability of energy from renewable sources, notably wind and solar.

This balancing capability will enable Basin Electric to expand its generation to ensure reliable, affordable and responsible power to its membership.

The plant will operate with six Wärtsilä 50SG gas engines having a combined net output of 108 MW.

The fast-starting and stopping ability of Wärtsilä’s engine technology allows full output to be reached in just minutes, thus ensuring a stable and reliable electricity supply regardless of the weather conditions.

The Wärtsilä equipment is scheduled for delivery in the beginning of 2024, and the plant is expected to become fully operational by the summer of 2025.

The Pioneer Generation Station Phase IV power plant project will serve the growing needs of the co-operative’s members with reliable, affordable, and responsible electricity.

BIOGAS GENERATORS FOR SANTA CATARINA LANDFILL SITE, BRAZIL

At a landfill site in the city of Itajaí, Santa Catarina, Brazil, AB COGENERATION (part of GRUPO AB) has installed two ECOMAX® 12 units, providing more than 2MW of power.

The powerplant is fuelled by biogas harvested from the landfill, which goes through a process of dehumidification and compression first. The biogas also passes through a SILEX system - the AB solution which removes not only siloxanes, but also other harmful components of biogas.

The operation and maintenance of the biogas plant for power generation is achieved thanks to the efforts of a highly qualified technical team of AB.

The ECOMAX LANDFILL line has been specially developed as the solution for transforming waste into a renewable energy source. Termocandelaria is a key power-generating company, providing Colombia and the Caribbean region with a highly-reliable electricity supply, creating opportunities for diverse communities.

With the ECOMAX® Landfill Gas line, AB offers a series of solutions to transform the controlled storage of waste into electrical and thermal energy, to be used directly on site or to be transferred to the network.

A renewable energy source is created from the waste stored in landfills, which feeds the cogeneration plants. Thanks to a calorific value that averages between 3.5 and 5.0 kWh / Nm³, landfill gas is in fact a good fuel for internal combustion engines. The resulting energy efficiency represents a significant competitive advantage for the company that decides to use this technology.

In fact, in the average life of a landfill, one million tons of waste can produce 1.7 to 2.5 million m³ of methane.

AB’s multidisciplinary teams have designed ECOMAX NEXT® Landfill Gas based on the combination of specialist know-how and the industrial development of the product: a compact, versatile and modular landfill gas cogeneration solution, at the forefront of energy efficiency. It offers the following:

-Easy configuration, which meets the needs of all markets

-Ease of transport and installation

-Time and risk optimization in the installation and commissioning phase

-Interconnection with existing plant systems

-Availability of service assistance even in difficult situations

The biogas produced in landfills contains pollutants, such as siloxanes and volatile organic compounds (VOCs), which, as a result of combustion inside the engine, cause oil contamination and the deterioration of pistons and cylinder heads, forcing continuous maintenance work to the plant.

SILEX removes the harmful components from the biogas before it reaches the engine, thus minimizing maintenance operations, improving operation and reducing downtime. The plant thus works longer, producing more electricity, consuming less oil and optimizing the availability of biogas.

With the ECOMAX® Special Gas line, AB also provides a means for cogeneration plants to handle special gases - gas recovered during oil extraction and in coal processing processes.

In oil wells, ECOMAX® Special Gas allows the safe treatment of associated petroleum gas or APG, mainly composed of methane, which escapes under pressure during mining activities and which is often flared in order to avoid explosion hazards.

With cogeneration it is possible to control and manage it, transforming it into an opportunity: it is exploited as a fuel for cogeneration plants powered by gases generated by oil production, which in turn produce electricity and heat and allow a reduction in energy costs.

Coke oven gas, an abundant by-product of converting coal to coke for steelmaking, is also suitable as a fuel for ECOMAX® Special Gas.

In coal mines, ECOMAX® Special Gas makes it possible to exploit methane, present both as a free gas and as a gas absorbed on the internal surface of the carboniferous rock and surrounding rocks. With the ECOMAX® Special Gas solutions, both the heat and the electricity produced can be used for the needs of the mining sites. Excess electricity, on the other hand, can be sold to the network.

POWEREX LIVE 2023 - THURSDAY 7TH DECEMBER, LONDON, UK

PowerEx Live 2023 at London’s Park Plaza Hotel, will be held on Thursday 7th December, 2023.

PowerEx Live 2023 aims to offer the perfect networking opportunities for international professionals across the Genset, CHP, Data Centre and Consultancy industry sectors.

With conference speakers at the top of their respective fields alongside premier display space in a world class venue, this event becomes a priority for all those in the power and energy markets. Exhibit with us at this prestigious venue in December 2023.

The ‘GEN-SET LIVE’, ‘CHP LIVE’ and ‘CHP & Renewables LIVE’ conferences will run parallel with prime exhibitor space available in adjoining rooms. Take your products to your customers with the opportunity for networking with experts in all fields of CHP, Data Centres, Consultancy and Gensets.

New - The Training & Equipment Zone PowerEx Live 2023 will also feature a special Training & Equipment zone. This will cover four subjects presented by different companies. The object is to teach students, young people and other industry professionals about familiarisation with new equipment and key aspects of training on the job within the industry. The choice of stands is allocated on a ‘first-comefirst-serve’ basis, so please contact us today and prepare for the highlight of the UK’s Power & Energy calendar for 2023. The venue is situated on London’s iconic South Bank, Park Plaza Westminster Bridge.

2 JULY/AUGUST 2023 AMERICAN POWER NEWS NEWS NEWS www.powermediagroup.co.uk

****************

FUEL CELLS FOR MINING

Everyelement which is important to sustaining life in the modern world – from a mobile phone to a refrigerator to a wedding ring – is made from minerals which are extracted from mining sites across the globe. In the coming years, as the world transitions from gas and diesel-powered equipment to power sources involving batteries and hydrogen, the need to mine minerals to support this technology will become even more critical.

It is also true that 1.5%to 2 % of carbon-dioxide (CO2) emissions worldwide are generated from the mining industry. In the face of these realities, an important question being raised is: considering the importance of mining to obtaining the minerals we need for all of the things we need, how do we go about mining in an innovative, sustainable way, without significant increases in production costs?

The answer to meeting this challenge may be in new technology being developed for heavy-duty equipment by L&M Radiators.

Electric motors which source energy from hydrogen fuel cells (often called a stack), as opposed to the traditional choice, diesel fuel, is making its way into the mining industry and leading the charge for increased sustainability and efficiency, safer operations, and the possibility of cost savings for mining operations across the globe. Hydrogen fuel cells operate by transforming hydrogen into clean energy, whose only output is electricity, water, and heat.

Though the environmental advantages of hydrogen fuel cell technology are clear, the use of fuel cells and batteries in heavy-duty mining equipment is so new that few companies are prepared to take on the challenge. But not L&M Radiator.

The Hibbing, Minnesota-based heat exchanger manufacturer has proven itself instrumental to the implementation of this new, green technology for the mining industry with its recent projects developing coolers for fuel cell-powered mining equipment.

“It’s an exciting time for greener applications in the oil and gas and mining industries,” said Tim Cass, L&M Radiator Applications Engineer for Truck and Underground. “L&M is ready and we are poised to be at the forefront of developing cooling solutions for our customers which provide the best green alternatives that not only help our planet but maintain and maximize our customers’ operating efficiencies - just as our customers have come to expect from L&M Radiator and our Mesabi-brand products for more than 60 years.”

Approximately 8,950 miles across the globe and just north of Pretoria and Johannesburg in South Africa, an open-pit platinum mine called Mogalakwena is making history with the testing of hydrogen fuel cell based equipment. L&M Radiator was called upon by the mine’s owner, AngloAmerican, to develop a first-of-its-kind radiator solution for a vehicle test project.

AngloAmerican operates a number of haul trucks at Mogalakwena. As a test to develop a long-term green energy solution for its mining operations worldwide, the company converted the diesel engine powertrain on a 930E into a powertrain driven by a hydrogen fuel cell stack.

“After the ‘proof of concept’ was finished in Seattle,” said Laura Ekholm, Executive Vice President of L&M Radiator, “AngloAmerican shipped the power train - eight hydrogen fuel cells, a battery pack and our cooling package - off to the mine in South Africa. It is amazing to see new technology our team was a huge part of coming to fruition.”

“The primary goal of this test was to determine if hydrogen will be able to provide the necessary power for the mine’s operation and to determine the overall efficiency of the hydrogen fuel conversion,” said Cass.

This singular converted 930E is only the beginning of what will become structural change for the industry at large. AngloAmerican intends to transform its entire fleet of converted 930Es at Mogalakwena (and at its other mines worldwide) into hydrogen fuel cell-powered electric equipment.

“The data from this successful test will be used to implement future applications for the Mogalakwena fleet as well as additional green initiatives for haul trucks and other mining equipment,” added Cass.

“For this initial 930E conversion, it was necessary to take the whole engine module out and replace it with fuel cells and batteries,” Cass explained. “Space constraints were definitely a challenge for our engineers. Designing the fans and motor mounts and getting the air flow to work in that limited space took some engineering ingenuity.”

“Another challenge was the very strict set of guidelines for limiting contamination, including materials that fuel cell manufacturers have in place,” added Josh Mitchell, an Applications Engineer with L&M Radiator. “That’s where the Mesabi All-Aluminum M-Tube came in.”

L&M Radiator engineered an All-Aluminum M-tube cooler for fuel cell cooling compatibility with the existing coolant on the 930E as brass and copper were not viable options.

According to Chris Domogalla, an L&M Design and Applications Engineer, hydrogen fuel cells operate at a lower maximum temperature than diesel engines, and they have a narrower coolant operating range. When outside of that operating range, the output of the fuel cell stack decreases.

In addition, approximately 40% of the energy produced by hydrogen fuel cells is heat, which must be removed. This posed a unique challenge for engineers at L&M Radiator. Hydrogen fuel cells emit a lot of heat, especially towards the end of their operating life.

ROBUST GENSET SOLUTIONS WITH THE NEW V-TYPE ALTERNATOR RANGE

Mecc Alte works hard with its clients to continually develop a high-level of insight into what challenges the power generator market faces with their generator sets and where/how they are operated.

The company’s latest heavy-duty alternator range ‘The V-Type”’meets a demand from the markets for a product that offers increased resilience for use in gensets where environment or operation affects performances and could reduce performance.

Through continually speaking with Original Equipment Manufacturers (OEMs) and end-users and gathering intelligence, Mecc Alte says it has been evolving its range with technical expertise and aftersales experience to bring you our most resilient product ever. The V-Type is built for optimum performance and reliability in tough environments. Having undergone rigorous testing, the V-Type is designed to operate in ‘harsh’ environments, so you can be sure of reliable power generation, regardless of the operational conditions.

Mecc Alte has incorporated several durability features to deliver maximum uptime for power requirements needed in severe environments:

•V-Type TOTAL+ is an exclusive winding treatment designed specifically to be more resilient, this insulation system upgrade further enhances the VPI impregnation which is standard on the range.

•Reinforced tape around the lower radius of the stator, plus an additional internal and external covering adds further durability to the NDE stator winding head

•Upgraded excitor stator, which are taped and given the VTP treatment

•30,000 premium bearing hours, for increased reliability

•Lower lamination slats reinforced with TOTAL+ insulation protection

•MxK digital regulators for safe setting/interrogation and offering integration to genset controllers

•Premium paint with anti-rust treatment

•Extended warranty

Mecc Alte UK’s Group Marketing Director, Jonathan Stokes, comments:

“Power generation has become much more about complete solutions rather than individual products, we’re now supplying OEMs with alternators, controllers, battery chargers and governors that are required for their power generation applications.

“The result is an integrated solution that very closely matches the unique demands of each and every power requirement. Understanding the full product lifecycle enables us to further evolve products from new perspectives.”

He concludes: “We pride ourselves on being the Power from Within the systems and generator sets that our customers produce; the V-Type is built for optimal uptime across the whole product lifecycle. Choose wisely … Choose the V-Type.”

Mecc Alte is a high-volume manufacturer producing in Italy, the UK, China, and India. The diverse range includes small 2-pole and large 4-pole alternators, as well as medium and high voltage machines, DC units, custom builds and multipole units, spanning 1 – 5000kVA.

GREEN HYDROGEN FACILITY IN TEXAS HELPS ENERGY NETWORK

ABB has been selected to join the Bair Energy Green Hydrogen and Technology Alliance to provide expertise on turnkey automation, electrification and digitalization solutions that support the optimization of low-cost green hydrogen production at the 1 GW Clear Fork Texas facility.

Phase one of the project will utilize renewable power to produce up to 33,000 kg of green hydrogen per day initially, with daily capacity designed to increase to 132,000 kg by 2028. The green hydrogen, which emits zero carbon when used

as an energy source, will be liquefied on site, stored and transported to customers to help establish hydrogen networks in the mobility and transportation industry.

ABB Adaptive Execution™, a project methodology from design through to operations, will be employed.

AMERICAN POWER NEWS JULY/AUGUST 2023 3 NEWS NEWS

COMPANY CELEBRATES ITS 30TH ANNIVERSARY IN BRAZIL

MARKET ENHANCEMENTS AT HOME AND ABROAD FOR THERMAL MANAGEMENT CORPORATION

In 1993 AGCO Power expanded operations to Mogi das Cruzes, Brazil. and the company recently celebrated its 30th anniversary in Brazil and also the production of 300,000 engines at its factory in Mogi das Cruzes.

A spokesman comments: “This makes us even more proud and fills us with desire to produce another 300,000 engines. We certainly don’t need to wait another 30 years to reach this number, because considering the rapid growth of AGCO in the world, and consequently in Brazil, we will certainly reach the mark of 600,000 engines in little more than a decade – and we are getting ready for it.”

AGCO Power engines are recognized in the agricultural market for their fuel economy, superior performance, easy maintenance and quick access to spare parts due to its strong network of dealerships throughout Brazil and South America. Its after-sales team is always attentive and close to its customer base to provide fast technical support and assistance to farmers, reports the company.

The spokesman continues: “AGCO Power is investing heavily in technology and bringing the best in terms of machinery and equipment to its factory in Mogi das Cruzes. This ensures that the products we manufacture are high quality, robust and reliable. The same applies to our engine plant in General Rodriguez, Argentina. In addition to implementing new technologies, these investments will allow us to increase our volume of machined parts and engine production.”

AGCO Power has been manufacturing diesel generators since 1952. It has been in business for decades with applications for hospitals, industry, data centers, military and agricultural customers to name a few. This expertise and know-how means the company is able to manage even complex projects according to customer requirements.

AGCO Power’s product program features a power range from 60 to 2400 kVA consists of the AGseries up to 250 kVA PRP with our own AGCO Power engines and AG-series above that with 3rd party engines. When used as a stand-by power system, the automatic generating sets start providing electricity in less than 10 seconds from power grid failure and stop automatically once the electricity in the main grid is reliable again. Generating sets are typically used for prime power generation in locations where the main grid is not available. In a remote location, generating sets may even be a more cost-effective solution than a power grid connection, reports AGCO Power.

US$100 MILLION SERIES INVESTMENT ROUND FOR ENERGY STORAGE

FlexGen Power Systems, Inc. a leading integration services and software technology provider for energy storage solutions in the U.S. and globally, has announced the close of a $100 million Series C Investment round.

The investment is anchored by Vitol, the largest independent energy trading company globally, in partnership with existing investors. This latest investment further solidifies FlexGen as a leader in energy storage integration, and will support the execution of its large pipeline of projects across multiple regions.

“We are excited to have Vitol join our existing investors to help power our continued growth. It is clearer than ever that the future of energy relies on energy storage that is cost-effective, safe, and easy to manage. This latest round of investment expands the advantaged position that FlexGen has with our customers across the utility, IPP, and co-op markets,” said Kelcy Pegler, CEO of FlexGen. “We are laser-focused on delivering the industry’s best software and integration services to our valued clients.”

In late 2022 Hotstart acquired GEO-THERMAL SYSTEMS, INC. (GTS) - and the acquisition brought high efficiency heating systems using proven heat pump technology to maintain standby generators installed in the Americas.

The company acquisition further enhances Hotstart’s thermal management product portfolio. The heating systems provide up to 75% energy savings while adding a level of backup redundancy with the existing engine heaters which are often Hotstart systems.

GTS was founded in 1991 by Jim Whittlesey, a former Caterpillar employee, who saw an opportunity to improve the traditional engine heating process for standby generators. By adding a modified air-source heat pump to the existing block heater installation, a more energy efficient solution was possible. GTS supplied this solution to customers during 30 years of operation.

Thousands of heating systems have been installed on generators in facilities including commercial, industrial, government, military,

universities, airports, hospitals, and data centers, saving end users significant energy and money.

Patrick Whittlesey, former GTS VP of Operations, joins Hotstart as Market Manager – High Efficiency Generator Heating - Americas. Patrick is responsible for sales of heating systems throughout North, Central, and South America. Jim Whittlesey serves as advisor to Hotstart in a consultant role.

“I’m was excited to have the GTS team join Hotstart,” said Terry Judge, CEO of Hotstart. “Their generator experience and strong customer relationships aligns well with our 80 years of engine heating expertise. We are already providing this technology to customers that seek energy savings and lower carbon footprints.”

“We have been thrilled to be part of the Hotstart team,” said Patrick Whittlesey. “Over the years, we’ve seen Hotstart products on numerous emergency generators in the field. It’s apparent they are the leader in the industry, which made joining them an easy decision to make.

“The GTS product line is now be offered as Hotstart High Efficiency (HE) Heating Systems. “

NFORCER ENGINE TESTED FOR AN ‘ALL-ELECTRIC SHIP’

Fairbanks Morse Defense (FMD), a portfolio company of Arcline Investment Management, has been contracted to provide and test one nForcer high-speed engine to qualify for the US Navy’s large unmanned surface vessel (LUSV) platform.

To qualify, the engine must perform for a minimum of 720 hours in a land-based test environment without human intervention. Testing on the new engine has already begun.

“The LUSV platform has unprecedented power and propulsion requirements, which means that the Navy needs a powerdense engine with a reliable track record,” said FMD CEO George Whittier. “While the nForcer is the

most power-dense, high-speed engine on the market, this award will drive incremental design improvements to support extended unmanned operations in a marine environment. It’s an extraordinary example of the numerous technological solutions offered by FMD that align with the distinctive needs of the LUSV program.”

4 JULY/AUGUST 2023 AMERICAN POWER NEWS NEWS NEWS

LOADBANKS for GENERATORS THE TRUSTED NAME FOR LOAD TESTING LOADBANK PACKAGES ■ 20kW to 7000kW ■ Resistive Only Loadbanks ■ Resistive / Reactive Loadbanks ■ DC Loadbanks SALES | SERVICE | RENTAL Call today: +44(0) 1283 531 645 www.crestchicloadbanks.com Sales & Rental Offices in : UK, North America, Singapore, Germany, Brazil, Netherlands, France, China and UAE Crestchic Limited, Second Avenue, Centrum 100, Burton upon Trent, Staffordshire DE14 2WF, UK T: +44 (0)1283 531645 F: +44 (0)1283 510103 E: sales@crestchic.co.uk

The latest V-Type alternator has been developed in response to changing market needs and has been built for optimum performance and reliability in harsh marine environments. Having undergone rigorous testing, the V-Type is designed to deliver optimal uptime, so you can be sure of reliable power generation, regardless of the operational conditions and compliant with all marine classifications. With over 75 years in the power generation market we pride ourselves on being the Power from Within the systems and generator sets that our customers produce.

Choose wisely… Choose the V-Type.

The world’s largest independent producer of alternators 1-5,000kVA

FOR FURTHER INFORMATIO N VISIT WWW.MECCALTE.COM

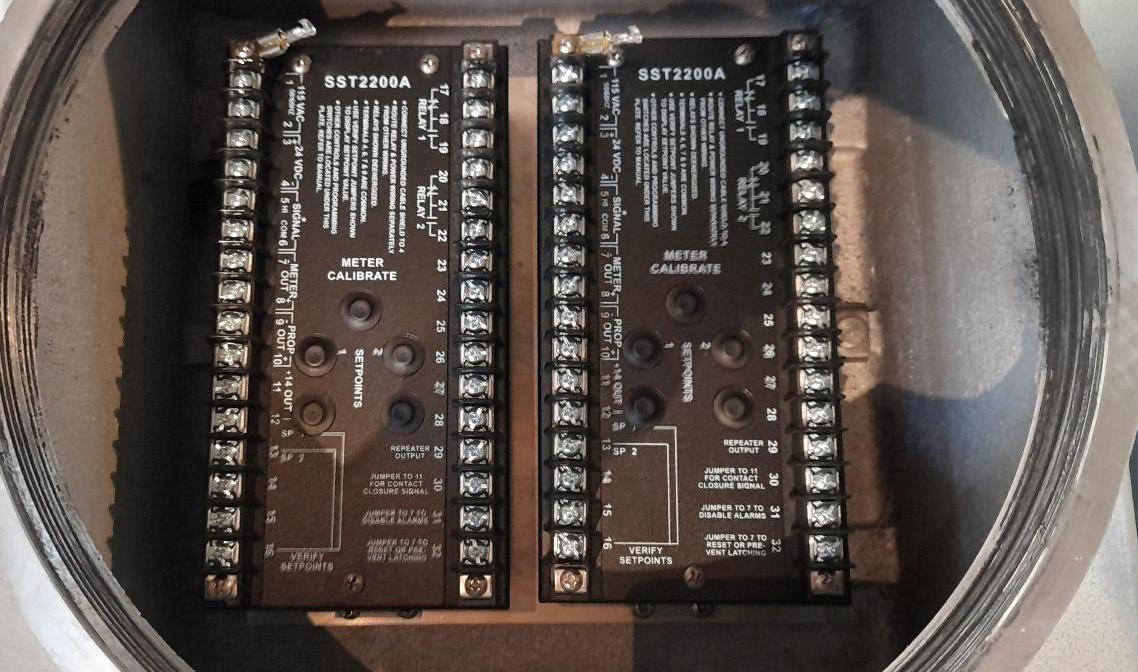

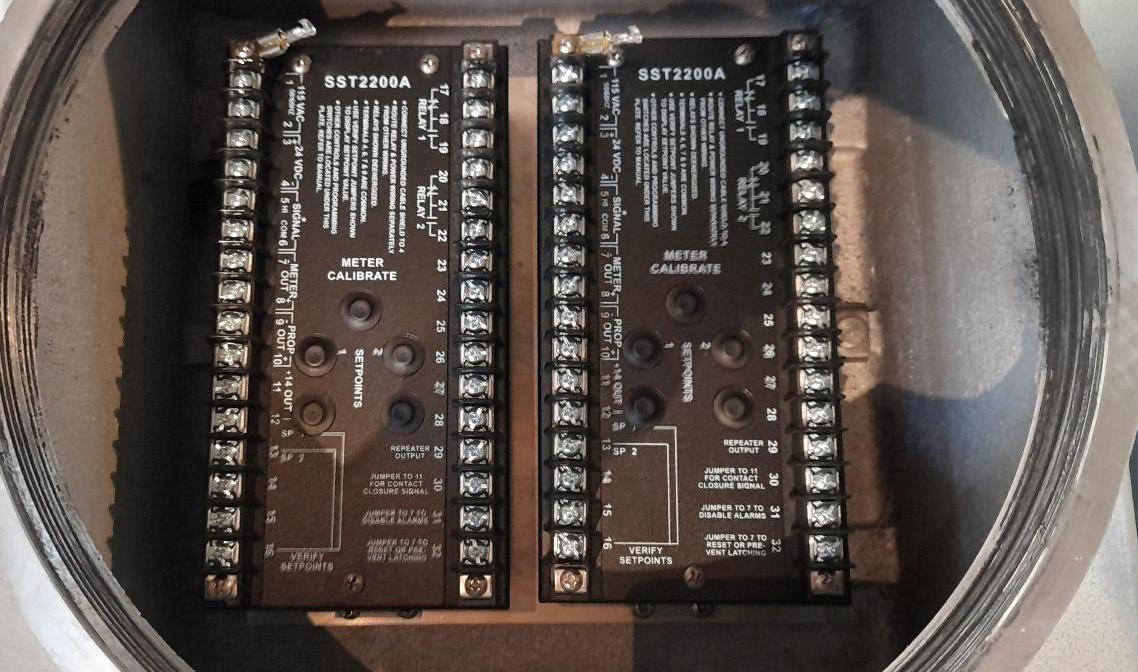

Precision Controls Ltd (PCL) announces a newly formed subsidiary, PCL USA, in Henderson, Nevada, US. Company Director, Kurlin Wilson, notes: ’’ This expansion is an important step for PCL to offer our line of Ex-d hazardous area RPM display and Alarm systems to USA customers. We will now be able to offer the same services and quality systems to customers with the additional options for shipping and delivery convenience and cost savings of not requiring import from PCL in the UK.’’

PCL has an established 30 years’ experience in the distribution of quality products in the engine/ generator control and accessory markets in the UK and Europe including products from such stalwart suppliers as Dynaclo, TDI, Woodward and Basler.

This new presence in the United States was the next logical step in ensuring the consistent and efficient service customers around the globe have come to know and expect after three decades in business.

PCL has brought quality components together for control systems for diesel and gas engines in the Industrial power generation industry. Applications in the industrial engine market include accessory products as magnetic pickup sensors and speed switches (overspeed/crank disconnect switches).

Microprocessor speed switches are now available for Engine / Generator Set Manufacturers that allow ‘base’ units held in inventory and to be calibrated easily with a software file for any engine model and generator set in production.

Specially designed EX-d magnetic pickups are supplied in the oil and hazardous area pipeline systems including off shore oil rigs, oilfield pumps and gas compressor stations. Application engineering for air starters applications in the marine industry along with parts and full service/overhaul support of air starters has been a mainstay of PCL.

System design and drawing services are provided in support of customer special applications or modifications of PCL products. Quotations are provided in accordance with a customer’s application outlining the best and most cost effective solutions considering the option of local delivery in either the US or UK.

PCL USA utilizes the decades of PCL experience to provide customer application assistance and products in the US markets.

PCL USA can offer customized Ex-d systems like the Dual Turbocharger RPM display and Alarm system which utilizes high quality Dynalco components. The central control system has two remote RPM displays that are conveniently mounted for easy RPM reference by the operating engineer. Customized solutions for hazardous area assemblies are supplied to either ATEX, IECEx, UL or c/UL certification.

Along with the Ex-d systems, PCL USA offers the established range of Goetze valves, including the Goetze 812 Safety Valve as an option for the no longer manufactured Honeywell S245 Safety Valve. Additionally, OEM low cost, high quality magnetic pickup sensors and engine thermocouples can be supplied to customer specifications.

All OEM products are offered with quantity pricing and scheduled deliveries to best economically optimize OEM costs and on time production.

313.34 MWH BATTERY STORAGE SYSTEM DEPLOYED

Ameresco has signed a deal with United Power for a multiple site, 78.3 MW, 313.34 MWh battery storage system to be deployed in three Colorado counties.

The deal includes a 20-year agreement between Ameresco and United Power. Locating battery arrays across United Power’s service territory is expected to help the cooperative balance its load and integrate renewable resources into its operations.

Ameresco is expected to provide four 11.75 MW and four 7.84 MW battery arrays across eight different substation sites owned by United Power in Adams, Broomfield, and Weld counties, north and northeast of Denver.

In June 2023 , a joint venture between Atura Power, a unit of Ontario Power Venture, and Ameresco was selected to build a 250 MW / 1,000 MWh battery energy storage system (BESS) by the Independent Electricity System Operator (IESO) in Canada.

Under terms of that award, the JV was expected to enter into a 20-year capacity agreement with the IESO.

Ameresco is a 10.1% minority partner in the JV and will provide engineering and construction services under a separate contract.

Ameresco, Inc. is a leading cleantech integrator and renewable energy asset developer & operator.

The company’s comprehensive portfolio includes energy efficiency, infrastructure upgrades, asset sustainability and renewable energy solutions delivered to clients throughout North America and Europe.

A company spokesman commented: “Our solutions range from upgrades to facility’s energy infrastructure to the development, construction and operation of renewable energy plants combined with tailored financial solutions.

“We work with customers on both sides of the meter to reduce operating expenses, upgrade and maintain facilities, stabilize energy costs, improve occupancy comfort levels, increase energy reliability and enhance the environment.”

Today, Ameresco leverages budget neutral solutions - including energy savings performance contracts (ESPCs), power purchase agreements (PPAs) and off-balance sheet Energy as a Service (EaaS) contracts. It seeks to eliminate the financial barriers which traditionally hamper energy efficiency and renewable energy projects.

Ameresco has successfully

SILENT AND ANTI-HURRICANE GENERATOR SETS FOR HOSPITAL

Providing emergency backup power to hospitals is one of Genesal Energy’s key achievements in both international and domestic projects such as the refurbishment of the 12 de Octubre Hospital in Madrid.

On the international market, one of Genesal’s latest projects has taken it to the island of Trinidad and Tobago where they have reinforced the safety of a hospital complex.

Two 1.500 kVA generators capable of overcoming power failures in just seconds.

Genesal has supervised the design, manufacturing, commissioning and maintenance of the GEN1500TC gensets which work effectively in a fail-safe environment. Two 1500 kVA gensets

with a low noise level soundmitigation features have already been installed in a hospital complex. Besides, Trinidad and Tobago, represented a greater challenge for their engineering department as it is a Caribbean hurricane zone where power cuts occur annually.

The two 1.500 kVA generator sets are rugged, powerful and welladapted to withstand severe adverse weather conditions. Furthermore, the generator sets were fitted with - 40 decibel baffles to ensure a low noise level.

AMERICAN POWER NEWS JULY/AUGUST 2023 7 NEWS NEWS

COMPANY EXPANSION IS AN IMPORTANT STEP IN NEW U.S. DISTRIBUTION PLAN INVOLVING QUALITY PRODUCTS & SERVICES

PORTLAND WILL ESTABLISH A NEW 400MW BESS INSTALLATION

UTILITY COMPANY NEEDS 1,250MW OF RENEWABLE ENERGY BY 2030

Portland General Electric, the utility serving Portland, Oregon, has announced it is putting in the second-largest battery storage installation in the United States, at 400 MW of power. The significance of such projects is they diminish the need for power plants that burn fossil fuels that warm the planet.

The only larger standalone project in the country is Vistra Moss Landing in California, currently at 400 MW, but it will soon add an additional 350.

The Portland project will generate enough electricity for around 260,000 homes, roughly the size of the city, for four hours at full power.

“Although we are a small utility, I like to think we punch above our weight,” said Brett Greene, PGE’s senior director, calling it an important step towards reducing carbon emissions 80% by 2030.

Batteries are playing a critical role in the clean energy transition because they supply electricity during times of low sunlight and wind, and can also prevent blackouts when demand for electricity surges, such as heat waves. The battery power during peak periods also helps avoid the need to buy “extremely expensive” energy from other utility providers, Greene explained.

“Batteries are like a huge refrigerator for electrons,” said Shirley Meng, a professor at the University of Chicago’s Pritzker School of Molecular Engineering.

“Batteries let us capture electrons created when sunlight strikes solar panels or the wind spins a turbine, which is how we can use solar power at night after the sun has set, for example,” Meng explained.

Jiangbiao He, an assistant professor of engineering at the University of Kentucky, said: “Batteries also help the grid cope with “rush hour,” when energy usage spikes around 5 p.m. as people come home from work and turn on lights, start cooking and run their air conditioning,.”

ZERO-EMISSIONS BRAND EMERGES FROM COMPANY BUYOUT

Cummins Inc. announced the buyout of Air Liquide’s 19% interest in Hydrogenics Corp. Cummins acquired Hydrogenics in 2019, adding key fuel cell and electrolyzer technologies to its portfolio. It is now housed under Cummins’ zero-emissions brand, Accelera by Cummins. Terms were not disclosed.

Cummins said the buyout reinforces its commitment to these technologies and the increasing importance they will play in creating value for all stakeholders and decarbonizing the globe. The move is expected to enable continued investment and growth in hydrogen technologies to meet rapidly growing demand.

Air Liquide said that under Cummins’ ownership, Hydrogenics will remain one of its suppliers for its own electrolyzer projects. Electrolyzers are considered an ideal way to balance the growing share of renewable energy in power grids. They allow more renewable power to enter into the energy system for power production, injection in gas grids, industrial use, ammonia production, renewable fuels, or use in mobility, such as in fuel cell electric vehicles. Hydrogenics is a developer and manufacturer of hydrogen generation and fuel cell products based on water electrolysis and proton-exchange membrane (PEM) technology. Hydrogenics is divided into two business units: OnSite Generation and Power Systems. Onsite Generation is headquartered in Oevel, Belgium. Power Systems is based in Mississauga, Ontario, Canada, with a satellite facility in Gladbeck, Germany. Hydrogenics maintains operations in Belgium, Canada and Germany, with offices in the Indonesia, Malaysia and the USA.

Colorado Springs Utilities intends to release a request for proposals to secure 1,250 MW of new renewable energy and energy storage capacity by 2030.

The utility is seeking approximately 525 MW of solar, 100 MW of energy storage, and 625 MW of wind capacity, in addition to 350 MW of natural gas.

The solicitation is part of Colorado Springs Utilities’ effort to reduce its carbon emissions by 80% by the end of the decade. The target date for new resources to be integrated is May 2028.

While the procurement targets are based on a preliminary analysis, Colorado Springs Utilities said it is open to exploring alternative technology types and a combination of resources that align with its reliability and sustainability goals.

The RFPs will provide potential bidders with an opportunity to propose various resource types and commercial structures such as power purchase agreements, build-operate-transfer arrangements and Colorado Springs Utilities

ownership models.

GEP, a global procurement and supply chain consulting firm, will serve as the procurement advisor for the RFPs.

Colorado Springs Utilities and three other utility companies operating in Colorado are currently seeking new sources of renewable natural gas as part of ongoing statewide efforts to reduce greenhouse gas emissions.

Colorado Springs Utilities, Atmos Energy Corporation, Black Hills Energy and Xcel Energy-Colorado have issued a joint request for information seeking future developers of renewable natural gas.

“This is the beginning of what’s going to be a long-term project for all utilities in the state ... to provide renewable natural gas for our systems,” comments Tom Henley, senior community program manager at Black Hills Energy. The request will help each of the four utilities meet new Colorado laws passed in 2021 for clean heat sources, utilities officials said on their respective websites.

NEW DISTRIBUTOR FOR CANADA’S BRITISH COLUMBIA

FPT Industrial announced a strategic partnership which allows Klassen Diesel, a distributor of diesel engines for marine and industrial applications, to represent FPT Industrial in Canada’s British Columbia and Yukon provinces.

“FPT Industrial is pleased to welcome Klassen Diesel to our distribution network in North America,” said Braden Cammauf, vice president of FPT Industrial Brand North America. “Klassen Diesel’s strength and reputation in diesel engine sales and supporting their customers makes them a great fit for the brand family. They will be able to offer their customers a wider range of engines from 42 to 1000 hp

to fulfill their needs.”

Founded in 1965 and based in Delta, B.C., Canada, Klassen Diesel has grown through the sale of marine engines and generator sets to construction companies, fisheries, forestry, mining and other endusers. The company’s marine engines power a range of vessels, from water taxis on Vancouver, B.C.’s inner harbor to salmon seiners and

8 JULY/AUGUST 2023 AMERICAN POWER NEWS NEWS NEWS

Linden

Cogeneration has completed the commissioning of its hydrogen blending initiative, which aims to reduce carbon emissions from power and steam generation.

Linden Cogen is a 972 MW natural gas-fired cogeneration plant located in Linden, New Jersey. The facility, which began operating in 1992, has six gas turbines and three steam turbines. With modifications that include PSM’s FlameSheet system, Linden Cogen is now taking refinery off gas containing hydrogen produced by the Phillips 66 Bayway Refinery and blending it with natural gas to fuel the unit 6 gas turbine.

“Actual reductions will be based on how much hydrogen is used at any given time of plant operation, but the joint project is expected to reduce overall CO2 emissions by approximately 10% of annual CO2 emissions from the unit 6, while staying within the gas turbine’s stringent NOx emission requirements,” said Todd Kerschbaum, Chief Technical Officer for JERA Americas.

Linden Cogen is owned by JERA Americas (50%), EGCO (28%), DBJ (12%), GS-Platform Partners (10%).

Power and steam produced from the plant is supplied for industrial use under long-term contracts, while most of the electricity is sold into the New York Independent System Operator and PJM power markets.

Linden Cogen is a CCGT with Cogen power plant. The power plant run on dual-fuel. The primary fuel being used to power the plant is natural gas. In case of shortage of natural gas the plant can also run on Waste Oil. The fuel is procured from PSE&G Pipeline. The project has generated 5,088,263MWh of electricity.

Hydrogen has an important role to play in decarbonising emissions across a variety of different sectors including heating, transport, industry and power generation, according to a new report from the Climate Change Committee (CCC). If used in conjunction with energy-efficiency heat pumps and expanded reliance on renewable energy sources, hydrogen could eventually displace fossil fuels as a major energy source of tomorrow.

However, in order to be both cost-effective and environmentally-friendly, low-carbon hydrogen would have to be produced on a mass scale and accompanied with carbon capture and storage (CCS) technology. This would most likely be created using natural gas (including shale and potentially biomethane) and would still entail a significant outlay.

Industrial heat generation is one of the biggest contributors of carbon to our atmosphere, so a lowcarbon hydrogen solution could have a huge impact on the sector’s emissions. It would also be wellsuited to reducing emissions in specialised sectors such as the food and drink industry. Power generation. As long as natural gas power plants are made “hydrogen-ready”, it could replace the fossil fuel as a primary energy source and work in tandem with the electricity generated by renewable sources.

Challenges facing the industry include:

*CCS. Without adequate CCS technology, it will be impossible to achieve low-carbon hydrogen production, which makes the use of the substance more damaging than helpful. At the moment, hydrogen production methods emit huge amounts of carbon and it’s unfeasible to consider using renewables to create hydrogen on a large scale.

*Awareness. At present, the public has little idea about the existence of alternatives to traditional forms of energy generation and home heating (i.e. gas) and even less grasp of why transitioning to those alternatives is important. As such, educational and awareness-raising campaigns must be enacted. Strategy. As yet, there is no coherent strategy on transitioning away from fossil fuels in the long-term. Creating a bespoke hydrogen plan within the next three years will be imperative in ensuring that the source can act as a viable alternative for gas going forwards.

Linden

Cogen’s onsite turbines

GE Power was selected as the turbine supplier for the gas-fired project mentioned above. The company provided 5 units of 7E.03 gas turbines, each with 95.2MW nameplate capacity. GE Power was also selected as the turbine supplier for the gas fired project. The company provided 3 units of D11 steam turbines, each with 95.2MW nameplate capacity. The common GE® D11 steam turbine, a single-casing HP/IP design used extensively in combined cycle applications, is demanding increased focus during normal outages, and ongoing attention for reliability, efficiency, and plant safety. Units modified for higher efficiencies and compatibility with 7FA Gas Turbine exhaust temperatures are subject to the even higher rotor to casing differential thermal expansions in the more tightly-packed seal areas of this single-casing design.

SUPPORTING BRAZIL’S NATIONAL GRID POWER GENERATION PROGRAM\

An FG Wilson dealer has installed 576 x P675P5 generating sets at two power plants in Brazil.

Aruanã Energia SA was instrumental is supplying one of the world’s largest generating set installations.

The plant is powered by over 500 FG Wilson units. Aruanã Energia, one of the company’s key dealers in Brazil, installed and commissioned an impressive 576 x P675P5 generating sets over a nine month period at a site in the town of Igarassu, Pernambuco.

When combined, these generating sets have the capacity to supply a total output of 236 MW of standby power to the national grid in Brazil.

The power plant is expected to operate between 1000 - 2000 hours every year during times of peak demand and to provide additional power during the winter months. Aruanã Energia, successfully won the contract to supply two power plants, Pau Ferro (94 MW) and Termomanaus (142 MW), which were later merged on to the same site.

As part of this contract Aruanã Energia, were appointed to supply power via this installation for the next 15 years.

Aruanã Energia, were contracted to supply and install the following:

• 576 x P675P5 (baseload rated at 450 kW, 60 Hz, 440v)

•EasYgen 3200 syncronising panels

•Industrial silencers

•Battery chargers

•Motorized circuit breakers

•Ř Fuel transfer solenoids.

The installation was a difficult challenge due to the extreme weather conditions at the time and the rugged terrain. Pau Ferro and Termomanaus power plants

were designed to be the most cost effective solution for standby/peak shaving applications for the Brazilian power market.

These costs savings are gained through the innovative use of highly efficient diesel engines as the main source of power.

Traditionally, larger more expensive industrial, locomotive or ship engines would be used in Brazil for standby/peak shaving applications.

This unique design was the most cost-effective solution available and was based on a 15% annual plant utilisation factor.

Some of its most impressive features include very low acquisition and installation costs, optimised fuel economy at all dispatch levels and low operations and maintenance costs.

The generating sets operate at 440v and step up to 34.5 kV transformers, which again step up to the 230 kV transmission grid line. A single plant operator remotely controls each plant, via a state-ofthe-art SCADA system which was developed specifically for this project by Aruanã and FG Wilson.

This advanced control system dispatches and regulates power from the generating sets as required, with a user-friendy interface. This provides tremendous savings in operating and maintenance costs over the lifetime of the power plant.

DOE GIVES AN AWARD OF US$32.6M FOR CARBON HUB

Colorado School of Mines, Carbon America and Los Alamos National Laboratory (LANL) were awarded $32.6 million from the U.S. Department of Energy (DOE) to advance the development of a carbon storage hub for the Pueblo, Colorado area.

The DOE’s Carbon Storage Assurance Facility Enterprise (CarbonSAFE) initiative aims to develop large-scale, commercial carbon storage projects with capacities to store 50 or more million metric tons of carbon-dioxide underground.

CarbonSAFE Eos was one of

nine projects selected by DOE as part of a $242 million nationwide investment. It intends to reduce emissions from industrial and power plant emitters in the region and at the same time, create a communitycentric model for carbon capture and storage (CCS) from the ground up.

“The DOE partnership really allows us to add more capital into a project opportunity and do all the screening that we need to do to be able to see if this is actually going to be a viable carbon capture and sequestration project,” comments Brent Lewis, CEO and Co-Founder of Carbon America.

AMERICAN POWER NEWS JULY/AUGUST 2023 9

NEWS

HYDROGEN BLENDING INITIATIVE TO REDUCE CARBON EMISSIONS

THERE IS ROOM FOR FURTHER CHP DEVELOPMENT ACROSS THE USA

US$20M FOR NEW ENERGY PROJECT IN MINNESOTA & COLORADO

CHP is installed at more than 4,700 facilities across America, representing over 81 gigawatts - or almost 8 percent of the nation’s total electricity capacity. There are CHP systems in every state in the United States and Washington D.C., Puerto Rico, and the U.S. Virgin Islands. Despite CHP’s use for more than 100 years in the US, there is still much opportunity for growth. A number of market drivers make it an attractive energy option, reports the US EPA in a recent report: * Lower energy costs. CHP has lower operating costs than traditional, separate heat and power generation technologies due to its enhanced efficiency.

* Role in decarbonization. Because CHP produces fewer emissions than grid power generation, it can play a role in decarbonizing energy production, especially with the use of renewable and zero-carbon fuels. This can be important for hard-to-decarbonize sectors, such as industrial facilities with high thermal demands.

* Focus on resiliency. CHP systems can be designed to keep critical infrastructure (e.g., hospitals, military bases, wastewater treatment facilities) as well as other facilities operational in the event of a power outage or grid disruption.

* Availability of packaged CHP systems. Increasingly, standardized, factory-built, ready-to-install CHP systems are available for purchase and installation. These systems can make CHP procurement and installation simpler and quicker.

* Policy Support. A number of state and federal policies and financial incentives are available that encourage the market for CHP. In 2016, DOE estimated the remaining technical potential for new CHP systems across the country (technical potential is an estimation of market size constrained only by technological limits; it does not account for economic or market factors). Room for further CHP growth still exists across all sectors.

ARIZONA’S LATEST 250 MW/1000 MW ENERGY STORAGE PROJECT WILL GO ONLINE IN 2024

Construction has begun on a 250 MW/1000 MWh battery storage project based in Tolleson, Arizona. The partners from Salt River Project (SRP), Plus Power and the City of Avondale, say the Sierra Estrella Energy Storage facility will be the largest standalone battery facility in Arizona once it comes online in 2024.

Storage from the project will serve SRP customers during times of peak electricity demand and facilitate more renewable integration. The project will use Tesla lithium-ion batteries.

Sierra Estrella was one of two battery storage projects SRP announced with Plus Power in the Fall of 2022. The other, a 90 MW/360 MWh project called Superstition Energy Storage, is expected to be built in Gilbert, Arizona. SRP has reported its corporate goal of surpassing a total of 1,100 MW in battery storage by 2024.

The utility aims to reduce emissions (from 2005 levels) by more than 65 percent by 2035 and 90 percent by 2050. As a part of that plan, SRP will have retired approximately 2,600 MW of coal-fired generation by 2032. Salt River Project is a community-based, not-for-profit organization which provides affordable water and power to more than 2 million people in central Arizona.

Breakthrough Energy Catalyst has agreed to commit US$20 million in funding for two multiday energy storage projects under Xcel Energy.

$10 million would each support the two 10 MW/1,000 MWh ironair battery systems Xcel Energy is constructing at the sites of retiring coal plants.

Xcel’s development would allow for the long-duration energy storage to be built at the Sherburne County Generating Station in Becker, Minnesota, and the Comanche Generating Station in Pueblo, Colorado.

Both projects are expected to come online as early as 2025 and are subject to regulatory approvals.

The batteries will allow Xcel Energy to store renewable energy such as solar and wind when it is being produced and then later distribute the energy during periods of lower production.

This month (July, 2023) Xcel Energy signed an agreement with Ambri, a provider of Liquid Metal battery system.

This collaboration marks the field deployment of Ambri’s Liquid Metal batteries, showcasing their potential in a real-world setting. The 300kWh system will be jointly tested with Xcel Energy at SolarTAC in Aurora, Colorado, for a year to assess its capabilities and performance.

Xcel Energy and Ambri are set to embark on a 12-month test of the 300kWh Liquid Metal battery system at SolarTAC.

The installation is scheduled to begin in early 2024, with full operation expected later that year. The system will utilize the GridNXT Microgrid Platform at SolarTAC to integrate multiple energy sources, including solar and wind, inverters, load banks, and 3-phase distribution connections and communications.

This is Ambri’s first opportunity to showcase its Liquid Metal batteries in a utility pilot system deployed in the field. Additionally, it is the first evaluation and demonstration of these advanced batteries by a major U.S. utility. Xcel Energy and Ambri will explore various use cases, such as solar and wind integration.

BH-ESS PROVIDES POWER FOR CALISTOGA, NORTHERN CALIFORNIA

The California Public Utilities Commission has approved a key project between Pacific Gas & Electric, the state’s largest utility, and energy storage provider Energy Vault.

PG&E and Energy Vault want to use a battery plus green hydrogen long-duration energy storage system (BH-ESS) to power the downtown and surrounding area of Calistoga, a city in Northern California, for situations such as planned outages and shutoffs during high wildfire risks. Calistoga is a city in Napa County, California, located near the head of Napa Valley. It is located about 75 miles north of

San Francisco and 27 miles north of the town of Napa. The city had a population of 5,228 as of the 2020 census.

10 JULY/AUGUST 2023 AMERICAN POWER NEWS NEWS

CLOUD-BASED ANALYTICS TO BENEFIT ENERGY HARVESTING

Kraken Technologies, part of the Al Gore-backed Octopus Energy Group, has signed a deal with energy manager Tenaska Power Services (TPS).

Through a cloud-based platform, Kraken uses advanced data analytics, AI and optimization to maximize usage, revenues and environmental benefit at wind and solar farms or batteries.

Kraken will initially manage certain TPS customer battery sites in Texas but could grow across the company’s U.S. portfolio.

The collaboration will give TPS “greater operational flexibility, enhance grid stability, and optimize its customers’ revenue streams in an increasingly dynamic energy landscape.”

Kraken is active in 14 countries and manages over 6 GW across more than 45,000 green energy assets. It is targeting the management of 200,000 assets and 10 GW of energy capacity by the end of 2023.

It is also under contract to serve 30 million energy customer accounts globally, targeting management of 100 million by 2027.

TPS is part of Tenaska, one of the largest natural gas and electric power marketing companies in North America. Its portfolio includes more than 23 GW of solar, wind, energy storage and 10 carbon sequestration projects.

Tenaska is a private, independent energy company based in the United States. The employee-owned company was founded in 1987 and is headquartered in Omaha, Nebraska, with regional offices in Dallas, Denver, Philadelphia, Boston, Houston, and Calgary and Vancouver in Canada. The company employs approximately 700 people. Tenaska is involved in all aspects of power generation, as well as natural gas and electric power marketing. The company has developed approximately 16,400 megawatts (MW) of natural gas-fueled and renewable power projects (solar, wind and hydroelectric). Tenaska and its affiliates have managed the acquisition of approximately 10,750 MW of energy assets. Forbes magazine consistently ranks Tenaska among the largest private U.S. companies.

UFR1001E G99/98 compliant Loss of Mains Relay

The UFR1001E system-disconnection relay monitors voltage and frequency in single or three-phase networks.

• Presetting per G99/98, values as per the standard pre programmed

• Under and overvoltage monitoring 40…520 V

Under and over frequency monitoring 45…65 Hz

• Monitoring of Rate of Change of Frequency (ROCOF, df/dt)

• Monitoring the voltage quality (10 minute average value)

Response time adjustable 0.05 … 130.0 s, individual setting for each limit

• Fail-safe, with monitoring of the connected section switch (can be switched off) 2 automatic restarts on error

• Supports the mains synchronisation when using generators

• Measurement 3 phase 3 or 4 wire systems or single phase

Self-test

• Third Part Independently tested Compliant to G99/98 by Bureau Veritas

PUMPED STORAGE HYDRO ENERGY PLANT PLAN FOR TENNESSEE

Tennessee Valley Authority is asking for public input on the scopes of environmental reviews for three generation projects, including a pumped storage hydro plant. These environmental reviews are the first steps in considering potential environmental impacts of projects that would support a cleaner energy future, while maintaining affordability, reliability and resiliency.

First, TVA said it is studying various technologies to store energy, including pumped storage hydroelectricity. TVA will need longduration energy storage to meet energy demand as more intermittent renewable energy sources are added to the grid.

TVA is developing a Programmatic Environmental Impact Statement (PEIS) to increase pumped storage hydropower capacity within its power service area.

The PEIS will evaluate the potential environmental and economic impacts of several options, which include expanding the existing 1,652 MW pumped storage facility at Raccoon Mountain or constructing a new pumped storage

facility at one of two locations in Jackson County, Ala.

Public comment is invited about the scope of the PEIS, alternatives being considered, and environmental issues which should be addressed.

The other two projects for which TVA is seeking input are a solar and battery storage project and a natural gas combustion turbine and battery energy storage system.

TVA has a strategic goal to add 10,000 MW of solar by 2035. To facilitate this goal TVA is developing new guidance to help review solar energy and battery storage projects that could be built on private and TVA-owned land in its service area. TVA is now preparing a PEIS to help develop new guidance and a bounding analysis.

AMERICAN POWER NEWS JULY/AUGUST 2023 11 NEWS NEWS

TVR Instruments Limited 143 Butt Road, Colchester CO3 3DP Essex, United Kingdom Tel: +44 (0) 1206 575755 Email: sales@tvri.co.uk www.tvri.co.uk

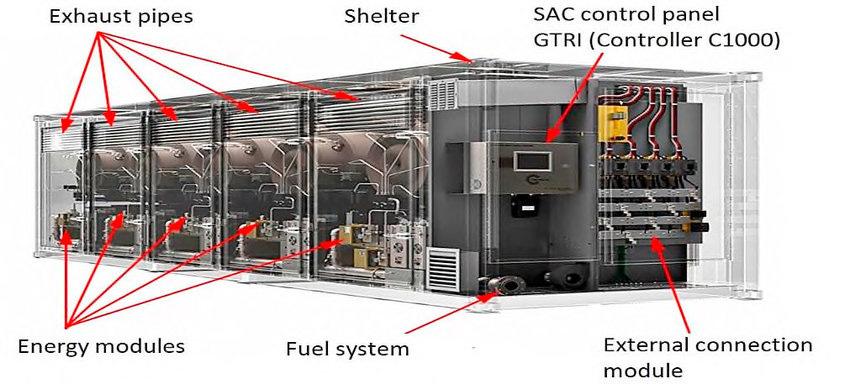

MICROTURBINES

DAIRY IN COLUMBIA ORDERS C1000 SIGNATURE SERIES MICROTURBINE

Supernova Energy Services SAS, Capstone Energy’s authorized distributor in Colombia, has secured an order for a C1000 Signature Series microturbine. The system will be operated at an industrial dairy alongside an Alfa Laval steam boiler evaporator, producing 6,200 lbs. of steam per hour.

An industrial dairy based in Columbia, South America, has ordered a C1000 Signature Series microturbine from Capstone Green Energy.

The contract was secured by Supernova Energy Services SAS, Capstone Energy’s authorized distributor in Colombia. The system will be operated at an industrial dairy alongside an Alfa Laval steam boiler evaporator, producing 6,200 lbs. of steam per hour.

Alfa Laval AB is a Swedish company founded in 1883, providing specialised heat recovery products, and is a Capstone Green Energy approved Network Partner for heat recovery systems. It is expected to be commissioned in October 2023.

Capstone Green Energy President and Chief Executive Officer, Darren Jamison, comments: “For operations like a dairy where any loss of power can result in product waste, the reliability of a Capstone microturbine makes it a natural choice.

.“This is particularly true in locations where electricity from the grid is relatively unreliable. Confidence in Capstone’s reliability combined with the turbine’s low maintenance requirements and compatibility with other technologies, like the steam boiler being used here, continue to prove the value of Capstone’s modular design and engineering as well as its versatility for use

in multiple industries.”

The Capstone powered energy system will run on high-pressure natural gas (HPNG) to provide power for the dairy’s pasteurisation operations.

The Alfa Laval boiler will provide steam for the entire plant. Reliability was the top reason the customer selected Capstone, but they indicated that minimal maintenance needs and low emissions were also factors in their decision.

The microturbine and steam boiler combination will replace the grid-sourced electricity and a natural gas boiler that the dairy is currently using to run its operations.

This is the first dairy that Supernova has worked with in Colombia and the first to use steam rather than absorption chillers in its processes.

Nestor Moseres, President of Supernova Energy Services SAS, comments: “Working with a customer who is willing to take a different approach to powering their operations is exciting.

“Once we knew that reliability was their top priority, the Capstone microturbine was the obvious choice. By combining the Capstone turbine with the Alfa Laval steam boiler, this customer has found an innovative solution which will give them more operational predictability and reduce product waste.”

The C1000S is part of the Capstone range of clean and green turbines, which are scalable

from 30kW to 30MW and can operate on a variety of gaseous or liquid fuels. Capstone turbines are said to be ‘the ideal solution for today’s distributed generation needs’.

According to the U.S. Energy Information Administration’s (EIA) International Energy Energy Outlook for 2016, natural gas and electricity are amongst the fastest-growing forms of industrial energy use in terms of industrial fuel use.

Each energy source has been increasing by about 0.7% per year since 2012, providing significant growth opportunity for Capstone microturbines.

Capstone Turbine Corporation (Nasdaq:CPST) is the world’s leading producer of low-emission microturbine systems and was the first to market commercially viable microturbine energy products.

Capstone has shipped approximately 8,800 Capstone Microturbine systems to customers worldwide.

These award-winning systems have logged millions of documented runtime operating hours.

Capstone is a member of the U.S. Environmental Protection Agency’s Combined Heat and Power Partnership, which is committed to improving the efficiency of the nation’s energy infrastructure and reducing emissions of pollutants and greenhouse gases.

A UL-Certified ISO 9001:2008 and ISO 14001:2004 certified company, Capstone is headquartered in the Los Angeles area with sales and/or service centers in the United States, Latin America, Europe, Middle East, China and Singapore.

www.capstoneturbine.com

12 JULY/AUGUST 2023 AMERICAN POWER NEWS

“The reliability of a Capstone microturbine makes it a natural choice. This is particularly true in locations where the grid is relatively unreliable. The C1000 Series turbine’s low maintenance requirements and compatibility with other technologies, continue to prove the value of Capstone’s modular design and engineering.”

1,200 KVA DIESEL GENSET FOR BAHÍA BLANCA AIRPORT, ARGENTINA

Bahía Blanca Airport, Argentina, has now installed two backup power gensets - the HIMOINSA HSW 500 and HSW 705 generator sets. Each has been fitted with Scania engine and CRAMACO alternator. Combined, the gensets exceed a standby power of 1200 kVA and were provided by the regional distributor, the Elecsen Group.

Comandante Espora Airport, also known as Bahía Blanca Airport, is a domestic airport in Bahía Blanca, Argentina, which is served by Aerolíneas Argentinas and LADE. Espora is also the main base of the Argentine Naval Aviation, and was given the identifier BACE by the Argentine Navy.

The site need a rugged and reliable backup power system to replace the ageing generators it had previously relied on. The airport authorities turned to a reliable regional distributor, the Elecsen Group, for a solution.

The equipment specified was two backup power gensets in the form of HIMOINSA HSW 500 and HSW 705 generator sets. Each was fitted with Scania engine and CRAMACO alternator. Combined, the gensets exceed a standby power of 1200 kVA.

The SCANIA model DC13-72A (02-14) diesel engine 4 strokes-cycle is based on a robust design with a strength-optimised cylinder block containing wet cylinder liners, which can easily be exchanged. Individual cylinder heads with 4 valves per cylinder promotes reparability and fuel economy.

The engine is fully-equipped with a Scaniadeveloped Engine Management System (EMS) to ensure the control of all aspects related to

engine performance. The injection system is based on electronically controlled unit injectors, which provides good fuel economy and a high torque.

The engine can be fitted with many accessories such as air cleaners, PTOs and cooling package, to suit a variety of installations. The HSW 705 generator set is powered by a 4-stroke diesel DC16, 16-litre V8 engine also from SCANIA, with a STAMFORD alternator. This is direct injection, turbocharged and aftercooled engine, a 90º V8 with a coolant-based cooling system (collant capacity 68-litres).

Details of the engine are as follows:

*Compression Ratio: 16,7:1

*Fuel Consumption ESP: 154,98 l/h

*Fuel Consumption 100% PRP: 137,92 l/h

*Fuel Consumption 75 % PRP: 102,36 l/h

*Fuel Consumption 50 % PRP: 68,24 l/h

*Lube oil consumption with full load: 0,2 g/kWh

*Lube Oil Specifications: ACEA E5 or E7. The engine is supplied with 24V electrical system, a water separator filter (visible level), a dry air filter, radiator with pusher fan, radiator water level sensor, an HTW sender, an LOP sender, an electronic governor, hot parts protection and moving parts protection.

“Bahía Blanca Airport, Argentina, now has two backup power gensets in the form of HIMOINSA HSW 500 and HSW 705 generator sets. Each is fitted with Scania engine and CRAMACO alternator. Combined, the gensets exceed a standby power of 1200 kVA.”

The HSW 705 generator set comes with a 4-pole CRAMACO alternator. This has a Star-seriesconnection type and S-1 14”mounting type with Class H insulation. The IP23 alternator enclosure (according IEC-34-5), the exciter system is selfexcited, brushless. The Voltage regulator: is A.V.R. (Electronic) with a Single bearing bracket type and flexible disc coupling system. The Coating type is standard (vacuum impregnation)

The industrial alternators meet the requirements of the relevant parts of the IEC EN 60034 and the relevant section of other international standards such as BS5000, VDE 0530, NEMA MG1-32, IEC34, CSA C22.2-100 and AS1359. These alternators quality assurance to BS EN ISO 9001.

The HSW 705 generator (Open Set version) is built on a a steel chassis and features an emergency stop button, an oil sump extraction kit, with anti-vibration shock absorbers.

The chassis itself has an integrated fuel tank, a fuel level gauge, a fuel tank drain plug, a steel industrial silencer -15db(A) attenuation system. The genset can be delivered with a fuel transfer pump (optional) and a steel residential silencer -35db(A) attenuation (optional).

This set runs on diesel fuel and is fed by a 740-litre fuel tank.

Electric control is provided via a power panel with measurement devices and control unit (according to necessity and configuration).

There is a 4-pole thermal magnetic circuit breaker, a Battery Switch and Adjustable earth leakage protection (time & sensitivity) standard in M5 and AS5, with thermal magnetic protection.

The set is provided with a battery charger (standard on gensets with automatic control panels) and heating resistor (standard on sets with automatic control panels).

There is a battery charger alternator with ground connection and a starter battery/ies installed (cables and bracket included). The system is fitted with a ground connection electrical installation with connection ready for ground spike.

Maximum exhaust temperature: 578 ºC

Maximum allowed back pressure: 100 mbar.

www.elec-sen.com

www.scania.com

www.himoinsa.com

AMERICAN POWER NEWS JULY/AUGUST 2023 13

GENERATORS

GENSETS

THREE 1000 KW DIESEL GENERATORS FOR A LARGE LONG TERM CARE FACILITY

PARAMOUNT POWER SYSTEMS has supplied three diesel-powered genset to provide backup power for a long-term care facility (LCTF) based in Mississauga, Ontario. Mississauga, historically known as Toronto Township, is a city in the Canadian province of Ontario. It is situated on the shores of Lake Ontario in the Regional Municipality of Peel, adjoining the western border of Toronto.

Mississauga, historically known as Toronto Township, a city in the Canadian province of Ontario, has a population of 717,961 with a significant portion being seniors over 65 years of age.

Mississauga is the seventh-most populous municipality in Canada, third-most in Ontario, and second-most in the Greater Toronto Area (GTA) after Toronto itself.

The area has a significant number of care facilities and one of these centers, a long-term care facility (LCTF) based in Mississauga itself, has just bought three diesel-powered genset to provide backup power.

PARAMOUNT POWER reports that it has completed the commissioning for these three 1000kW T4-compliant paralleled generators for this large LTCF facility. All the the generators designed, built and tested by PARAMOUNT POWER SYSTEMS.

How do paralleled generators work?

Three generators with same frequency, voltage and phase difference can be connected to the bus-bar; such that it increase their overall capacity, ease of maintenance, and active load management. When gensets are connected in parallel the process used in this method to assist is known as synchronising. It is an effective way to increase the overall power output of a plant with much better control and ease of maintenance.

This helps do the job without spending money on buying high-capacity generators. The process is used where the demand for power is variable with extreme points; too low and too high power demand. For two generators to be synchronized; the waveform of their output must match with one another. This can be achieved by using a synchroscope or dark and bright lamp methods. To ensure further safety; it is required to keep the

the incoming generator at slightly higher frequency.

A generator already connected to the bus bar is called a running generator; while the one which need to be synchronized to connect is called incoming generator.

A generator’s frequency reduce slightly once it is applied to active load; and thus an increased frequency help it avoid running as a synchronous motor. Moreover a generator is not connected to the bus bar under stationary condition as; it will cause high induced emf in stator winding causing it to short circuit.

Heavy industries with high power demand can install two or more threephase generators to effectively share the load and provide increased output when needed.

For two generators to be synchronized they must have equal number of phase; same phase angle, same voltage, frequency and identical voltage sine curve ( waveform ). This means the RYB connection point of bus bar should be connected to RYB terminals of incoming generator and not RBY.

A three-phase incoming generator can be synchronized to the one connected to the bus bar; using bright lamp, dark lamp or synchroscope method. For generators to be properly synchronized they must be locked finally to the system frequency; irrespective of their initial speed or frequencies. Once synchronized they must share the total load according to their individual capacity and not equally. For generators to share equal loads they must be identical in most aspects.

Paramount Power Systems is an authorised Kohler Titanium Dealer with stock readily available to look after all generator needs.

Paramount Power Systems also supplies generator accessories, including:

* Paralleling switchgear: This system helps multiple generators work together to provide electricity. It helps to distribute the electricity evenly among the generators so that they work efficiently and don’t get overloaded. Paralleling switchgear is used in the facilities that need a lot of power to keep running.

*Transfer switches: This device helps keep the electricity running in case there’s a problem with the primary source of electricity. It switches the power supply from the primary source to a backup source so that power is supplied at places like hospitals, data centers, and factories without interruption.

www.paramountpower.com

14 JULY/AUGUST 2023 AMERICAN POWER NEWS