DIESEL

GENSET

FOR GERMANY

A new 1650 kVA AKSA genset has been installed in a German retail centre. It has a PERKINS 401246TAG2A engine with an vital ECO 46-1S/4 A.

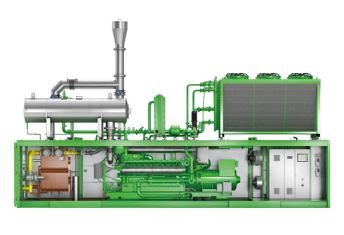

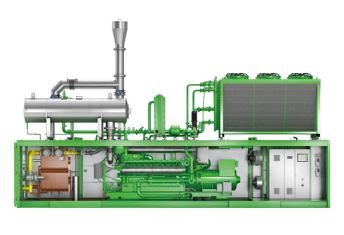

PAN-LEDI d.o.o. has chosen a Jenbacher J420 engine for the project in Nova Pazova, Serbia.

The contract calls for the delivery of a containerised CHP unit to generate about 1 MWe.

The power will be used by PAN-LEDI for its electric vehicle (EV) charging station, with any excess energy fed into the grid and the engine waste heat sold to a commercial customer nearby.

The CHP unit consists of a Jenbacher container and a complete heat recovery system. The Jenbacher CHP plant is expected to be delivered and commissioned ater this year.

The Jenbacher CHP plant will be fuelled with hydrogen produced by an electrolyzer which is powered by a solar photovoltaic plant based at Cuprija.

The electrolyzer is used to produce green hydrogen for interim storage before the hydrogen is transported from Cuprija to Nova Pazova.

Most of the hydrogen will be produced during the Summer when the output produced by solar plants is high. In times of low hydrogen supply, the CHP plant will run on natural gas, to ensure the continuous provision of energy. The Jenbacher team

Serbia installs a new hydrogen-powered CHP plant

will work with its distributor, STI d.o.o., to implement, install and service the hydrogen CHP unit..

Dr. Olaf Berlien, president and CEO of INNIO, commented: “Our H2engines provide the flexibility and sustainability to meet PAN-LEDI’s pioneering requirements. INNIO’s technology will deliver carbon-free electricity when hydrogen is available, while maintaining continuity of power

generation when hydrogen is scarce.”

INNIO’s Jenbacher CHP solution will provide the whole operation with the flexibility required for a sustainable EV mobility & employ hydrogen at high CHP use rates.

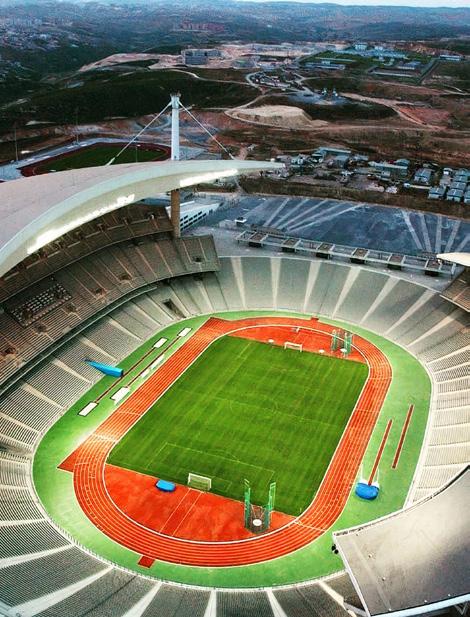

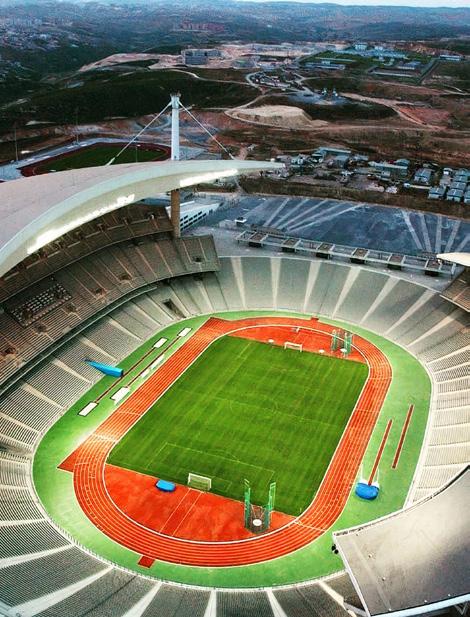

We look at the energy tech in the Atatürk Olympic Stadium during the Cup Final.

PremiumTowerTM offers an on-line operating efficiency of 96.6% in double conversion mode minimizes running costs and reduces the Total Cost of Ownership.

Don’t Compromise on Performance PremiumTower™ Standalone Three-phase UPS From 10kW - 250kW SWISS MADE Phone: 01420

Email: sales@centiel.co.uk Web: centiel.co.uk

82031

NURTURED BY CHP IN POLAND An MWM TCG 2020 V16 gas genset was supplied to the Hajduk Group to help with

energy needs.

MUSHROOMS

key

Page 14

Page 18

SUPPLY

Page 24 POWER

FOR THE THE JUNE 2023 EURO CUP FINAL

SUMMER 2023 1 EURO POWER NEWS SUMMER EDITION 2023 If you are reading this advert, so are over 62,000+ others Digitally. Special summer rate @ £525.00

take ADVANTAGE of this special offer and book this advert please email: power@wipmagazines.com or call Tel. +44 (0) 1403 888019

To

Publisher/Sales Director: Neb Saric neb@wipmagazines.com

Publishing & Events Director: Richard Teasdale richard@wipmagazines.com

Managing Editor:

Aidan Turnbull aidan@wipmagazines.com

Accounts Manager: Alison Williams accounts@wipmagazines.com

Sales & Marketing Manager

Sarah Hallows sarah@wipmagazines.com

Far East Sales:

Bob Liu Room 926, No.1 Building, Phase II No.100 Jinyu Road, Pudong Shanghai, China

Mobile:+86-013817410089

Email: bob.liu@ronco.com.cn

Austria & Germany agent

Mario Dobresko power@wipmagazines.com

Contributors

Kohler, MOTEURS Boudouin, MWM, AKSA, EUROPGEN, Ansaldo Energia, Doosan Skoda, ABB, MEGSA, Volvo Penta, INNIO, Green Biofuels, Dagartech, Eurogen, Koc Holdings, Ford Motor, LC Energy Solutions, Margen, Siemens Energy, FATA, GE, DAMCO, KOHLER Power, De Watergroep, AKSA Energy, Zwart Techniek, DTEK, Anglo Belgian Corp., VM Motori, EMSA Generators, Van Twist, Coelmo

Green Biofuels launches Ireland’s first low-carbon fuel terminal

EPN DIARY

EURO POWER NEWS

Published by:

Power Media International Group Ltd, The Courtyard, 30 Worthing Road, Horsham, West Sussex, RH12 1SL, UK

Tel: +44 (0)1403 888019

Fax: +44 (0)1403 220751

powermediagroup.co.uk

© Worldwide Independent Power (ISSN 1468-7100).

Subscription price £70 (UK), £140 (overseas) per year. Please send address changes to Euro Power News, Power Media International Group Ltd 30 Worthing Road, Horsham, West Sussex RH12 1SL, UK.

Leading biofuel supplier Green Biofuels Limited (GBF) has announced the launch of Ireland’s first renewable biofuel terminal in a built facility in Cork Harbour. The facility has already taken its first cargo delivery. Through its Irish business Green D Project Limited, the new terminal is a major commitment by GBF to Ireland’s cleaner energy infrastructure for transport and generator power, further accelerating the transition to Net Zero. The terminal will act as both an import facility to service the accelerating demand for HVO renewable fuel in Ireland, and a blending/export facility to enable the collection and use of renewable fuels overseas. The terminal investment is the next stage in the GBF’s rapid growth and increased distribution of its flagship product, Gd+ HVO. GBF has supplied in excess of 200 million litres of Gd+ HVO to the UK over the past year covering different sectors, including construction, logistics and marine industries. Ireland’s Climate Action Plan follows the Climate Act 2021 and commits Ireland to a legally binding target of net-zero greenhouse gas emissions no later than 2050, with a reduction of 51% by 2030. The brownfield site identified for investment by GBF repurposes a previous development which has sat idle for over 10 years and serves as a springboard for Ireland’s ambitions to decarbonise, cut emissions and create a cleaner economy. This investment also provides the Cork Harbour economic area with a much-welcomed boost to job opportunities and trade activities. Magnus Hammick, COO, GBF, said: “We are really excited about this project and constructing the first low-carbon fuel terminal in Ireland in support of its Climate Action plan. We are committed to making a difference in every possible situation, and the low-carbon fuel terminal will allow us to expand our supply.”

825 KVA DIESEL GENSET FOR A KEY WINERY IN SPAIN

DAGARTECH has supplied a 825 kVA diesel generator to Pago de Carraovejas, a Valladolid winery, founded in 1988.

A company spokesman comments: “To guarantee the energy supply to the failure of the network, we have designed and manufactured a generator set of 825kVA of power, providing an uninterrupted and automatic power supply in the event of falis or interruptions in the network. In addition, it allows complete event monitoring and comprehensive visualization of engine information to facilitate maintenance and repair of the machine.”

DAGARTECH has modern manufacturing facilities located near Zaragoza, Spain. These facilities have been equipped with stateof-the-art technical means for the design, production and testing of gensets as part of the company´s commitment to the quality of its processes and products.

The company has reputation for providing installations which can guarantee the electrical energy supply needed, and designs robust and reliable equipment which guarantees an uninterrupted energy delivery of energy.

Its gensets offer an optimal level of fuel consumption, designing an efficient installation. The company designs the generator sets taking into account their application context, so that the noise levels and adaptation to environmental regulations for this type of installation are respected. DAGARTECH’s technical expertise both reduces and optimize the maintenance and replacement tasks as much as possible.

Pago de Carraovejas, a Valladolid winery, has production facilities which occupy more than 26,000 m2 of a vanguard-built space around beautiful plazas. These flank the ‘incomparable views’ on the vineyard from the southeast to the Botijas valley and the Peñafiel Castle. The facilities are constantly being renewed in order to improve product quality in the superior grade wines. The site has been ; designed and built to always respect both the gravity vinification process and the grapes’ natural characteristics.

The winery operators are currently building a new waste management point outside the winery and plan to construct new agricultural warehouses next to the vineyard, as well as new spaces for the public to learn more about the wine making process.

POWEREX LIVE 2023 - THURSDAY 7TH DECEMBER, LONDON, UK

PowerEx Live 2023 at London’s Park Plaza Hotel, will be held on Thursday 7th December, 2023.

PowerEx Live 2023 aims to offer the perfect networking opportunities for professionals across the Genset, CHP, Data Centre and Consultancy industry sectors.

With conference speakers at the top of their respective fields alongside premier display space in a world class venue, this event becomes a priority for all those in the power and energy markets. Exhibit with us at this prestigious venue in December 2023.

The ‘GEN-SET LIVE’, ‘CHP LIVE’ and ‘CHP & Renewables LIVE’ conferences will run parallel with prime exhibitor space available in adjoining rooms. Take your products to your customers with the opportunity for networking with experts in all fields of CHP, Data Centres, Consultancy and Gensets.

The choice of stands are allocated on a ‘first-come-firstserve’ basis, so please contact us today and prepare for the highlight of the UK’s Power & Energy calendar for 2023. The venue is situated on London’s iconic South Bank, Park Plaza Westminster Bridge London is just a short walk from Westminster and Waterloo.

2 SUMMER EDITION 2023 EURO POWER NEWS NEWS NEWS www.powermediagroup.co.uk

****************

POWER FOR ITALY’S TELECOMMS TOWERS

Anew emergency diesel generator has been installed by EUROGEN in one of the most important telecommunications nodes of North East Italy. EUROGEN is a member of the Italian DataCenter Association.

The genset is a Model GS2000BAD/CF nominal power 1600 kWe PRP ISO8528 with a Baudouin engine 20M33 SERIES. The engine features a cast-iron cylinder block with an inspection door per cylinder, cast iron cylinder liners, wet type and replaceable valves guides and seats and separate cast iron cylinder heads with 4 valves.

Other points of interest include a hardened steel forged crankshaft with induction-hardened journals, crankpins and radius, lube oil-cooled light alloy pistons with high performance piston rings and an advanced cooling system.

Radiator and hoses are supplied separately. There are two separate circuits and the high temperature circuit is equipped with a thermostatically-controlled system with two gear-driven coolant pumps.

The Baudouin engine has 20-cylinders, Bore & Stroke 150 X 185 mm, a total displacement of 65.4 litres and a counter-clockwise engine rotation. The Rated Speed is 1500/ 1800 RPM.

The engine’s lubrication system includes full-flow screwable oil filters, a lube oil purifier with replaceable cartridge and a water-cooled lube oil cooler.

The engine’s fuel elements include a high pressure common rail system with one high pressure pump gear driven in the V-angle of the cylinder block. Two rails are mounted on the sides of the engine, double wall, under inlet manifold. There is a duplex fine filter and water separation filter assembly with transparent cup for better efficiency. An electric fuel priming pump ihas been ntegrated into the filter support. There is also a special rear mounted air filter with restriction indicator, plus an exhaust manifold shield for heat isolation.

In the Air Intake and Exhaust System 4 compressors are feeding a single water-air intercooler, mounted over the exhaust system flywheel housing, with vertical flow. There is a special rear-mounted air filter with restriction indicator.

The engine’s electrical system has a 24V DC electric starter motor and battery charging alternator, with low oil pressure & high water temperature sensors. There is also an SAE 00 flywheel housing and 21” flywheel.

Typical operational hours of the engine are projected at 200 hours per year, with a maximum usage of 500 hours per year. This includes an annual maximum of 25 hours per year at the ESP power rating, according to the manufacturer specifications.

North East Italy is famous for its rugged terrain and mountainous landscapes. In areas like this telecommunications providers rely on backup power to maintain a constant power supply, to prevent power outages, and to ensure the operability of cell towers, equipment, and networks. The backup power supply must be reliable and rugged to cope with local conditions.

The telecommunications industry relies on an elaborate network of cell phone towers and field facilities to transmit phone calls and provide services. To operate effectively, each of these towers and field facilities requires a constant and highly reliable electrical power supply.

The industry transmits voice and electronic data through wired and wireless networks. To provide these services, facilities require substantial electrical power, which usually comes from the electrical grid but may also be converted to direct current (DC) power at -48 volts for wired networks and +24 volts (and its European equivalents) for wireless networks.

Adequate, effective backup power is essential because the electrical grid is subject to disruption by natural and man-made causes like extreme weather and power shortages.

As the telecommunications industry continues to expand rapidly in Italy, the increased use of cell phones, computers, and highspeed Internet requires a corresponding increase in the number of cell phone towers and field facilities needed to support these services.

This expansion introduces new challenges, and service reliability through backup power sources remains at the forefront for industry providers. To prevent power outages, providers must rely on redundancy and backup power sources. Generators provide alternating current (AC) power and can be automatically or manually activated. In remote, off-grid locations, generators are even used as general power sources (Prime Power).

SPAIN’S HEALTH SERVICES BUY 715 KVA DIESEL GENSET

A DE715GC genset (715 kVA, 50 Hz, 400 V, Standby rating) has been installed at a medical building in Madrid, Spain - this building and it s power systems will be completed by a target date of December 2023.

The GC range has been designed primarily for standby power plants offering simplicity and reliability.

Producing reliable power 715 kVA at 50 Hz, the DE715 GC generator set is powered by C15 diesel engine designed to ISO 8528-5 transient response requirements.

The diesel engine is said to be a reliable, rugged, durable design which has been field-proven in thousands of applications worldwide, reports the company.

A spokesman comments: “A four-stroke-cycle diesel engine combines consistent performance and excellent fuel economy with minimum weight.

“The genset has been optimised for 5% Lower Fuel Consumption with longer run times between fuel fills; reduced operating costs.”

The generator set package for Madrid has been fully prototypetested and accepts 100% block load in one step and meets NFPA 110 loading requirements.

It conforms to ISO 8528-5 steady state and transient response requirements.

Special features to look out for on this set include: superior motor starting capability which minimises need for oversizing the alternator. It is designed to match performance and output characteristics of typical

diesel engines and also offers robust Class H insulation, with a control panel offering user-friendly interface and navigation.

To cope with Madrid’s high summer temperatures the cooling system has been designed to operate in standard ambient temperatures up to a blistering 55°C (131°F).

Madrid is considered the largest European data centre location. Its geographic location, robust infrastructure and tech-savvy workforce are all reasons companies find the area attractive for infrastructure requirements. Reserach suggests that Spain’s data centre market will see investments of US$ 2.67 billion by 2028, growing at a CAGR of 8.73% between then and now.

The “Digital Spain 2025” agenda launched by the government outlines the country’s digital transformation strategy, which is naturally expected to boost the growth of the data centre industry in the country. Growing demand for managed cloud services has largely driven investments in hyperscale data centres.

FORD BACKS NEW BATTERY PLANT IN TURKEY - ONE OF THE LARGEST IN EUROPE

Koç Holding, Ford Motor Co. and LG Energy Solution (LGES) and have signed a non-binding memorandum of understanding to form a new joint venture company. This will support a new venture involving the building of one of Europe’s largest commercial battery cell production facilities. Based in Baskent, Turkey, near the capital city of Ankara, construction will begin at the new facility in last 2023 with production beginning in 2026. The

new project will deliver a capacity of at least 25 GWh, with potential to reach 45 GWh.

Lisa Drake, vice president, Ford EV Industrialization, comments: “Ford continues to ramp up our electrical power plans as we scale to be a leader in the electric vehicle revolution. Establishing the new joint venture with LGES and Koç Holding will lay a solid foundation that is certainly fundamental to building a thriving electric future for Ford in Europe.”

EURO POWER NEWS SUMMER EDITION 2023 3 NEWS NEWS

NEW POWER INTERCONNECTOR TO LINK ITALY, SARDINIA & SICILY

DATA CENTRE GETS FIVE NEW GENSETS FOR BACKUP

MARGEN S.p.A. is supplying five 2,250 KVA diesel gensets to a data centre in Lombard, Italy. The sets provided are containerised parallel generator sets: 5 x 2250kVA SB POWER.

Margen power plants are said to be easy to install and manage, and also provide the user with a completely reliable service, reports the company.

MPS Power Plant production systems are made with diesel or natural gas endothermic engines and can be integrated with heat energy recovery units to improve plant efficiency.

The MPS systems are equipped with remote control solutions to allow management of the entire plant from a remote location with the possibility of having automatic regulation of the power requested by the user and scheduled maintenance.

Margen’s team of technicians provide the necessary support for installation and activation of the plant and training courses are periodically organised for the customer’s personnel.

the supply of 2.5 MVA units certified Tier for data centres - each power unit offered a very low noise levels of LPS 55 dBA.

The stations were both low and medium voltage types.

To ensure electricity for a massive construction site of the MilanGenoa high-speed railway section under construction, Margen built a substantial electrical power system consisting of both transformer substations and a series of emergency generator sets providing a total of 3MW in power.

For Italy to benefit from renewable energy in the future, the islands of Sardinia, Sicily and the Italian mainland must be able to flexibly exchange electricity. Siemens Energy will make this possible by providing the high-voltage direct current (HVDC) transmission technology to a 970 km long power link. Italian transmission system operator Terna has awarded the consortium of Siemens Energy and Italy’s FATA (part of Danieli group) a contract to supply four converter stations for the “Tyrrhenian Link” project.

The HVDC link will enable more efficient use of renewable energy, increase stability of the power grids, and enable the close down of coal-fired power plants on the two islands to reduce CO2 emissions. The order volume for Siemens Energy amounts to just under one billion euros.

“The expansion of power grids must receive the same attention as the expansion of renewable energies,” says Tim Holt, member of the Managing Board of Siemens Energy. “Italy has excellent conditions for renewable power generation. The project will ensure that the regions involved can also derive the best possible economic benefits from this and help Italy achieve a more sustainable and secure power supply.”

To meet the EU’s Fit-for-55 targets by 2030, it will be necessary to install 70 gigawatts of new renewable energy capacity in Italy to reach at least 65% share in gross electricity consumption. Interconnecting Italy’s largest islands and the mainland will make it possible to flexibly transport green energy to where it is needed.

Tyrrhenian Link is Siemens Energy’s first HVDC project in Italy. The energy technology company will build four converter stations at the respective end points of the two sections of the link: The East Section of the link connects Campania on the Italian mainland with Sicily, while the West Section connects Sicily with Sardinia.

The stations convert alternating current fed from the respective local grid into direct current for transport via undersea cables. The station at the other end of the line converts the electricity back into alternating current so that it can be fed back into the regional grid. In this way, a total of up to one gigawatt of green power for each interconnection can be efficiently transported over the long distances at a DC voltage of 500 kilovolts.

Siemens Energy will manufacture the main components of the four stations, such as the converter technology, transformers, and switchgear, in Europe.

Consortium partner FATA, in sub-consortium with Italian construction companies

Impresa Manca Costruzioni Generali S.p.A. and Pizzulo Costruzioni s.r.l., will be responsible for the civil works, electromechanical installation & ancillary facilities.

In 2022 MARGEN supplied important data centres in northern Italy with 12 MW of installed power. The construction of these systems, installed in Northern Italy, involved

840MW GAS POWER PLANT TO BE BUILT IN GREECE

A new 840 MW natural gas-fired power plant will support the energy transition in Greece and the development of the Alexandroupolis region.

The project is the brainchild of the Copelouzos Group’s Damco Energy S.A. (DAMCO) and the facility will be built in Alexandroupolis, Greece. The Alexandroupolis plant will be powered by an equipment package which includes a GE 9HA.02 gas turbine, an STF-D650 steam turbine, a W88 generator, a triple pressure with reheat Heat Recovery Steam Generator (HRSG) and the Mark VIe Distributed Control System (DCS) software solution. The plant is expected to start operation in 2026. Public Power Corp. S.A. and

DEPA S.A. will each participate in the share capital of Alexandroupolis Electricity Production SA. DAMCO is the nominated EPC contractor by Alexandroupolis Electricity Production SA.

Andreas Diamandopoulosof DAMCO, tells EPN: “This power plant is in the crossroads of the natural gas network of the Balkan region. It was crucial for us to select the most advanced technology.”

4 SUMMER EDITION 2023 EURO POWER NEWS NEWS NEWS

The proposed Alexandroupolis power plant, Greece.

The power of independence

Volvo Penta is one of the world’s biggest independent suppliers of engines for power generation. It is our business to build and support engines that make the most of any OEM’s genset design – a range of reliable, fuel-efficient diesel engines that meet a wide span of specific demands. Mobile or stationary. 24/7 or standby. In any climate: freezing or scorching, dry or wet, in deep shafts or at high altitudes. Tell us your needs and we’ll show you the engine. www.volvopenta.com/industrial

85-800 kVA WELCOME TO VISIT US AT MIDDLE EAST ELECTRICITY, DUBAI WORLD TRADE CENTRE STAND S2.E39, 3–5 MARCH 2020

The Power of 10

Modular Power Solution

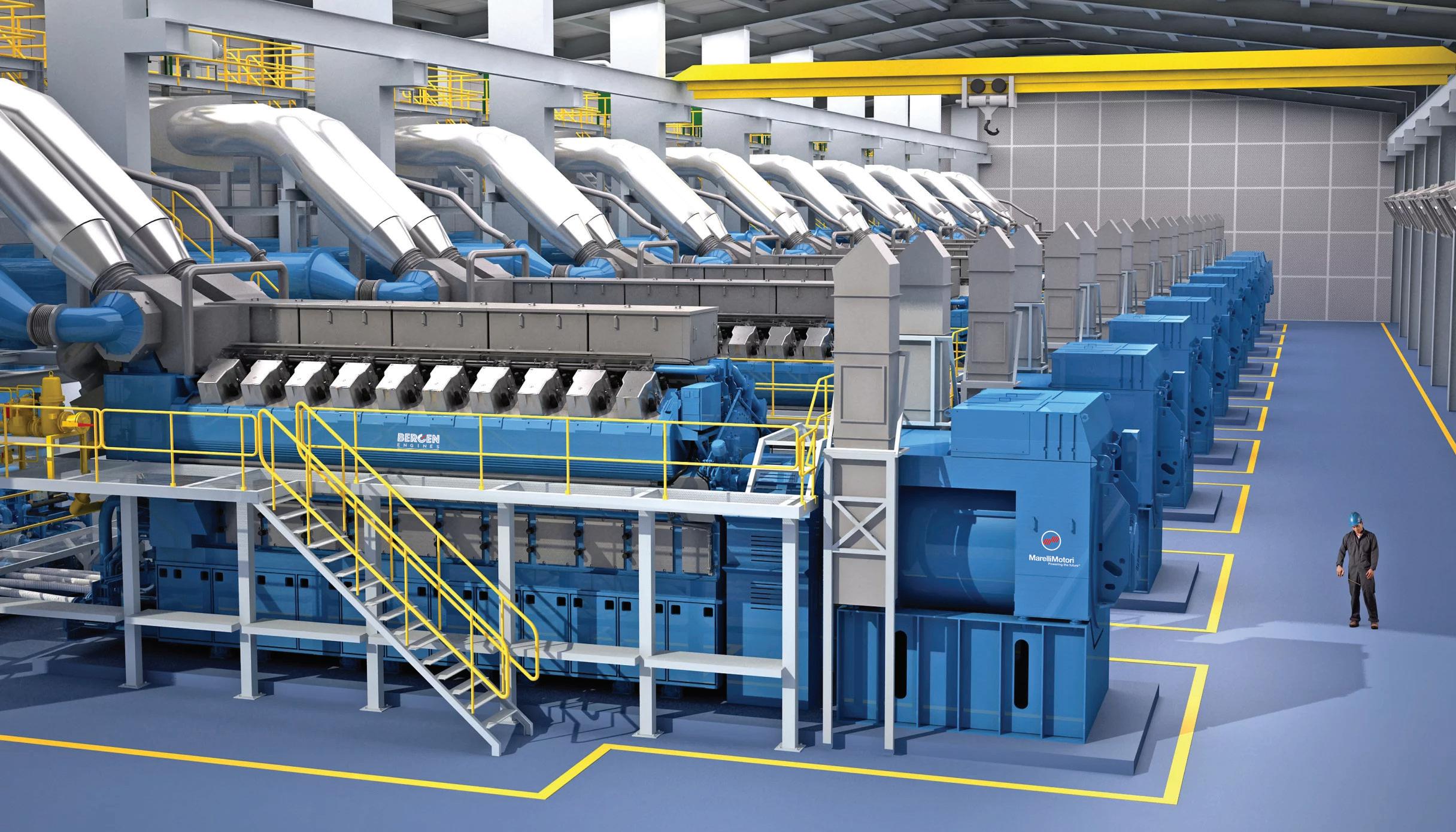

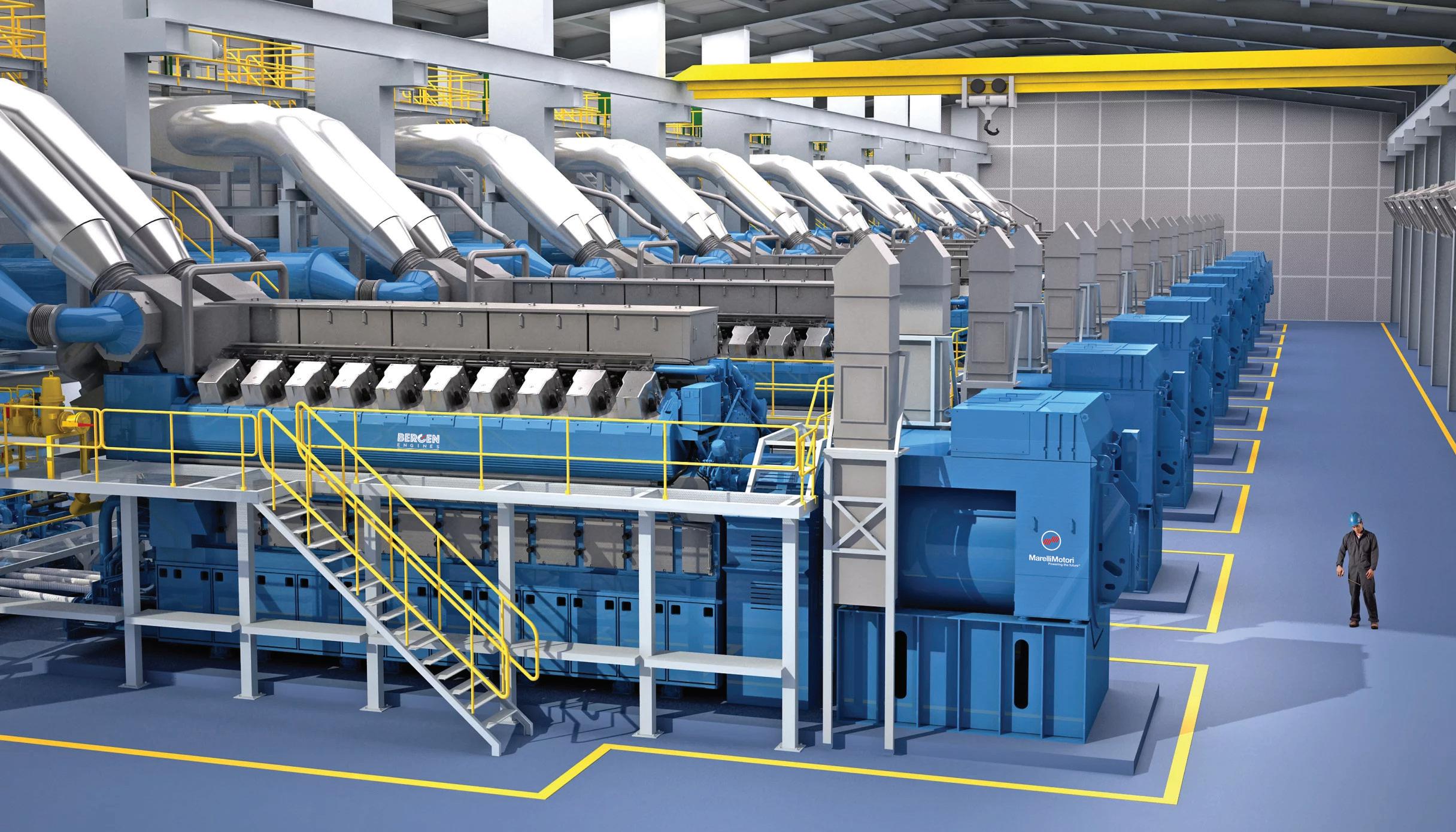

Bergen Engines, together with Piller Power Systems and Marelli Motori, present The Power of 10.

A scaleable microgrid power solution featuring optional Integrated Power Conditioning Technology (IPCT).

n 10MW multiples to 100MW+

n No standby generators

n Waste heat recovery to cooling

n Totally flexible in conjunction with renewables

So, if you are thinking partial or total grid-independence, think The Power of 10.

We have the power.

POWER SOLUTIONS A

of

bergenengines.com/power-solutions/

Division

Langley Holdings plc

Example of 100MW installation

GE POWER PLANT SHIPPED TO UKRAINE TO HELP RESTORE THE NATIONAL POWER GRID

CANCER HOSPITAL IN SPAIN BUYS NEW 2,500KVA GENSET

AGE TM2500 aeroderivative gas turbine has been shipped to Ukraine from Arizona, USA, on a Ukrainian Antonov cargo plane to help support emergency power needs in the country. The portable turbine was purchased by USAID, the United States government’s humanitarian and foreign aid agency, to help Ukraine restore power where it is needed most.

“GE is uniquely positioned to be able to support Ukraine in their infrastructure rebuilding efforts, and our mobile aero technology has a proven track record for emergency power response situations due to its mobility, reliability, and flexibility,” says Aman Joshi, the general manager of GE’s aeroderivatives business at GE Gas Power, which is part of GE Vernova. The arrangement with USAID, he adds, “is really symbolic of the kind of support GE can provide to countries that are in need of urgent power infrastructure.”

In simple terms, the TM2500 is a giant, mobile gas generator - a power plant on wheels, Joshi says. The TM basge stands for “trailer-mounted.” Whereas building a new plant takes one to four years, the approximately 28-megawatt machine, capable of powering the equivalent of more than 100,000 homes in Ukraine, can be trucked to a location and attached to a damaged power plant, or hooked directly into the electrical grid, within a few weeks.

Based on the technology behind GE’s CF6 jet engine - which powers the Boeing 747 and the Airbus A310, among others - the aeroderivative turbine delivers with the speed and efficiency of an airplane.

Once in place, it can power up and shut down in just five minutes, providing emergency responsiveness and reducing fuel waste. And where fuel is limited, the TM2500 offers a range of possibilities: It can run on natural gas or diesel, as well as sustainable aviation fuel blends. In addition, the TM2500 is hydrogen capable, with the ability to burn up to an 85% H2 blend, ensuring a pathway to help utilities and other stakeholders to reduce their carbon emissions.

“In 20-plus years on the marketplace, more than 300 units have been put to use in about 30 countries worldwide, totalling over 6 million hours of operating experience,” says Midhat Mirabi, GE Gas Power’s aeroderivatives CEO for Europe, the Middle East, and Africa. “In Europe, GE’s TM2500 and other aeroderivative units were the ideal solution for energy security at this time of crisis. The units have been deployed to provide fast emergency power in Ireland and Switzerland and powered local communities on remote Greek islands, and will now help Ukraine increase the supply of electricity where it is needed, which may include homes, hospitals, schools, critical infrastructure providers, and other institutions.”

GE worked closely with USAID’s Energy Security Project (implemented by Tetra Tech) to be sensitive to the security and urgency of the power emergency in Ukraine. “The situation is pretty severe,” Joshi says. “The Ukrainians know they need a lot of power, but it’s like a moving chessboard, because every week something new is happening and something new is getting damaged.”

Once in place, the turbine could help keep Ukraine’s lights on and drinking water flowing into taps. “It might be very difficult, because it’s a war zone,” Joshi says, “but GE will be involved and will co-ordinate with contractors and local crews to get the TM2500 up and running as soon as possible.”

IRELANDS’S DUAL-FUEL ENGINES

MAN Energy Solutions will supply 16 dual-fuel engines with a total generating capacity of 311 MW to three new power plants in the Republic of Ireland. These plants will act as back-up facilities to stabilise the power grid and support the integration of renewable energy.

“Our dual-fuel engines are an optimal partner for renewable energies because they can reach full power in a short time and thus respond quickly to any fluctuations in the power grid. Their dual-fuel capability also offers maximum fuel flexibility and reliability,” says Martin Höhler, Head of Sales Power Plants, Europe, MAN Energy Solutions

The plant operated by Sustainable Development Capital LLP in Dublin’s Grange Castle Business Park will be powered by 6 MAN 18V51/60DF engines to generate 111 MW of energy to support the Irish grid and reduce peak loads. A joint venture between Mountside Partners Limited and Bord Gáis Energy is building two new power plants, each using five of our MAN 18V51/60DF to generate 100 MW of energy and act as back-up for the grid. One will be located in Profile Park in Dublin, and the other near Athlone, Co. Roscommon.

Electra Molins was recently involved in the installation of a 2,500 kVA genset in a Cancer Hospital in Spain.

This new genset comes with a Baudouin 20M33 engine and a Mecc Alte alternator is equipped with an MP15 synchronisation and closed loop transfer control panel, the same type which Electra Molins technicians installed in the existing genset (from another manufacturer) for parallel operation between the two gensets.

The Baudouin 20M33 engine (pictured top) features a common rail system with one high pressure pump gear driven in the V angle of cylinder block.

There are two rails mounted on the sides of the engine, double wall, under inlet manifold. It features a Duplex fine filter and water separation filter assembly with

transparent cup for better efficiency. Electric fuel priming pump integrated in the filters support. Special rear mounted air filter with restriction indicator.

Exhaust manifold shield for heat isolating The 4 compressors are feeding a single water-air intercooler, mounted over the exhaust system flywheel housing, with vertical flow Special rear mounted air filter with restriction indicator. Exhaust manifold and turbocharger.

NATURAL GAS CYCLE POWER PLANT NOW HAS BACKUP

ARKEN Generators has supplied and commissioned a backup power system for a natural gas cycle power plant in Turkey. Involving two ARKEN 100 kVA diesel gensets, the power system has been installed in air-conditioned special containers with IP-55 insulation class, 80dbA acoustic feature at 1 mt, fire detection and dry fire extinguishing system.

Double-walled flame arrester fuel tanks in the generator sets are supported by an automatic, motorized valve filling system. The system features a test

synchronisation system with each 2 mains coupled return and forward mains of both generators - it has the ability to communicate with the customer SCADA.

The SCADA Supervisory control and data acquisition is a control system architecture comprising computers, networked data communications and graphical user interfaces for high-level supervision of gensets and power processes. It also covers sensors and other devices, such as programmable logic controllers, which interface with process plant and machinery.

EURO POWER NEWS SUMMER EDITION 2023 7 NEWS NEWS

TWO KD 3500-E 3,500 KVA DIESEL GENSETS FOR A PHARMACEUTICAL PROJECT IN BELGIUM

SIX 1MW H2-ENGINES FOR A NEW DATA CENTRE

TwoKohler KD 3500-E diesel gensets have undergone FAT testing at Kohler France. They have been designed and built to provide emergency power for a revolutionary pharmaceutical project in Belgium.

The sets are powered by the Kohler KD83V16, 3800HP strong with a displacement of 83470cc and 16 cylinders in V. KOHLER G-Drive diesel engines produce industry-leading kW displacement in a package which produces a smaller generator set footprint while delivering best fuel consumption at more nodes than any competitor between 800 and 3250 kW. That means higher performance at reduced operating cost.

The engine architecture, injection system and engine management of G-Drive engines have been designed to achieve optimal generator set performance while meeting all worldwide emission requirements.

The generator set, its components and a wide range of options have been fully developed, prototype tested, factory built, and production-tested. The sets are designed in accordance to ISO8528-5 performance class G3 and are smooth running thanks to engine conception and integral vibration isolation mounts between components and skid. There is a low fuel consumption thanks to a high technology common rail injection engine and a smaller footprint thanks to a high power density. Special features include a low temperature starting capability and long maintenance intervals. The alternators have been designed to provide an industry-leading motor starting capability, with an excitation system to permit sustained overcurrent > 300% In, during 10 sec.

This has been built with a class H insulation and IP23 and cooling is achieved thanks to a flexible solution using an electrical driven radiator fan. There is a high temperature and altitude product capacity, running without power derating Turbochargers have been designed for maximum power and optimal combustion. They are specifically matched to each engine and engineered to provide the required amount of air at all times, which reduces fuel consumption and enables operation at high altitudes. The common rail fuel system also generates up to 2200-bar injection pressures for maximum efficiency, optimising the combustion pressure curve through multiple injections.

TURKEY SUPPLIES CHP TECHNOLOGY TO NEAR NEIGHBOUR

AKSA ENERGY has won a contract to build a combined heat and power plant to supply the Kyzylorda region as part of modernisation of the Kazakhstan power infrastructure.

The new 240 MW plant, expected to be commissioned in 2025, will be powered by two GE’s 6F.03 gas turbines. GE will also provide maintenance services to help ensure long-term availability and reliable operation for the equipment. The project represents a step in the country’s energy system transformation aimed at reducing coal baseload generation, supporting renewable energy balancing and eventually reaching net-zero carbon emissions by 2060.

Kazakhstan is making progress to improve grid stability and is committed to modernise its power infrastructure as part of its long term objectives. The country’s power infrastructure has been operating for an average of 40 years, and it is heavily reliant on elderly coal-fired power generation. The new CHP plant will help address the growing demand for reliable and flexible power, while balancing renewable energy and supporting coal phase out.

INNIO’s Jenbacher Ready for Hydrogen engine technology has been selected by NorthC Datacenters (NorthC) to deliver an emergency backup power solution for its newest data centre which will be constructed in Eindhoven, Netherlands.

Six Jenbacher hydrogen engines will provide carbon-free emergency backup power in cases of electricity grid outages.

The Jenbacher Type 4 hydrogen engines generate a total power output of six megawatt and will be delivered as a containerized package.

The Eindhoven data centre including the hydrogen emergency backup power solution and the onsite hydrogen storage solution is a greenfield project, that is expected to be operational in the second half of 2023.

Dr. Olaf Berlien, president and CEO of INNIO commented:“We are excited and proud to build the first 100% green hydrogen emergency backup power solution with engines for data centres globally together with NorthC.

“As a carbon-free energy source, hydrogen is an important pillar of the energy transition,”

NorthC has implemented a strategy to be fully carbon neutral by 2030. This will be accomplished through four sustainability pillars: 100% green energy, modular construction,

making efficient use of residual heat, and green hydrogen. The Eindhoven data center will be powered with solar and wind energy from the grid.

To provide additional flexibility and security to NorthC the six Jenbacher Type 4 engines are configured as dual-gas engines. In case of an electricity grid outage the engines are operated with the on-site stored hydrogen.

For longer duration grid outages, NorthC has the option to switch to natural gas as an energy source during operation of the engines, in case of shortage in the H2 supply infrastructure. I

INNIO’s myPlant Performance cloud-based digital platform solution will provide NorthC secure, real-time monitoring of the emergency backup solution. The project supports the Netherlands strategy to achieve carbon neutrality by 2050.

Jarno Bloem, COO of NorthC Datacenters explains:

“We selected INNIO’s Jenbacher technology to support our green hydrogen powered electricity generation because of their longterm experience and proven track record with special gases, like hydrogen. With INNIO’s Jenbacher hydrogen emergency backup power solution coupled with the renewable power sources from the electricity grid, we are able to decarbonize our complete energy supply infrastructure.”

FLEMISH COMPANY IS BEHIND KEY GENSET PROJECT

La Liberté is a key water & waste treatment centre in Suriname in which has been designed, developed and built by De Watergroep.

The project will provide safe drinking water for around 30,000 people. Vandaele Power has just delivered an H1750 KVA diesel genset mounted in a 40ft steel container to provide backup power for the site’s pumping systems.

De Watergroep is the first Flemish water company to develop an installation of this size in the region.

A spokesman for Vandaele Power comments: “We supply generator

sets for fixed installations stand out for their reliability and fast response. These are generators capable of establishing communication with the grid or with other generators, being able to work in parallel, if the application requires it. They can supply continuous or backup power with immediate response time to guarantee continuous power supply.”

8 SUMMER EDITION 2023 EURO POWER NEWS NEWS NEWS

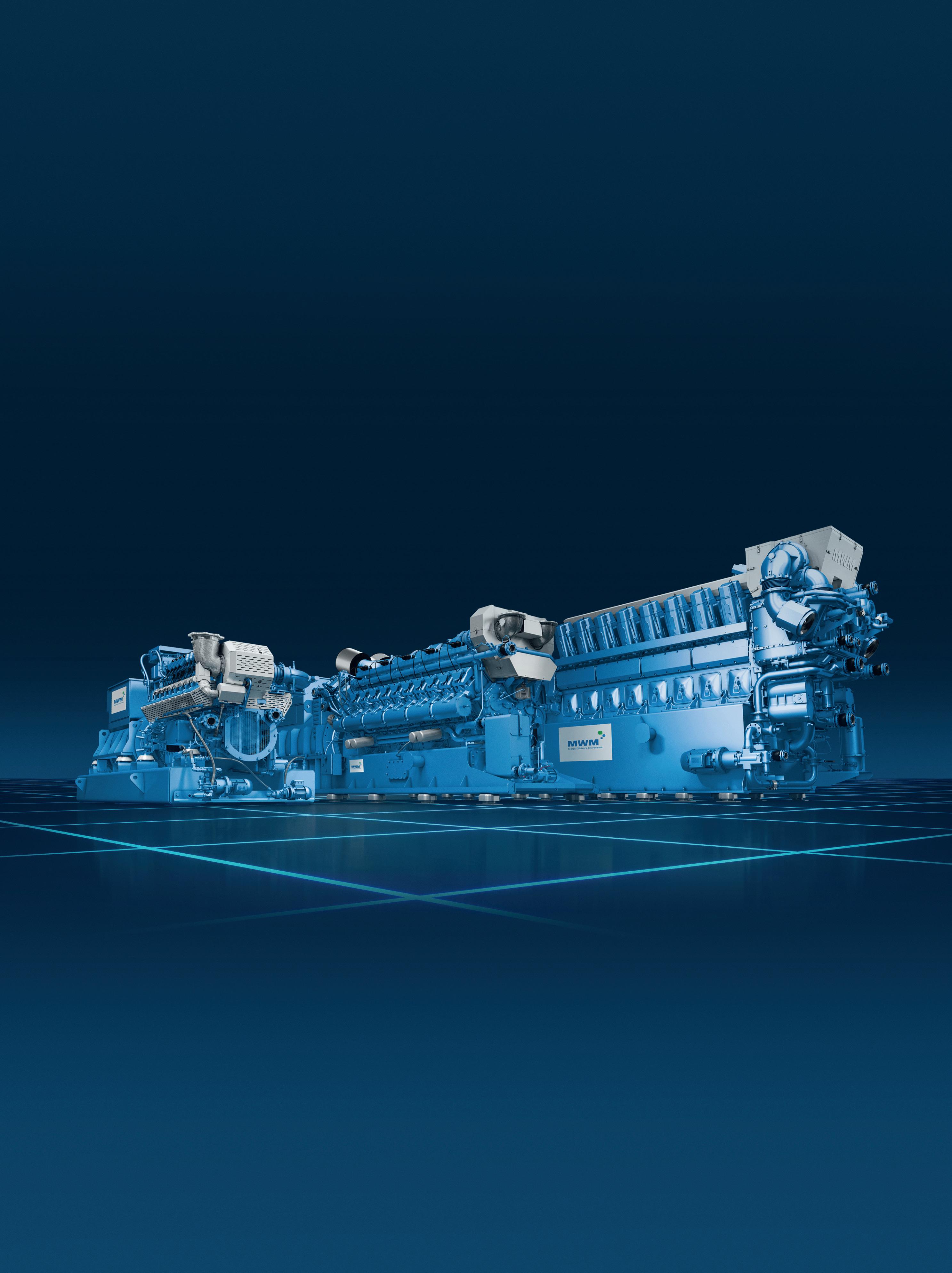

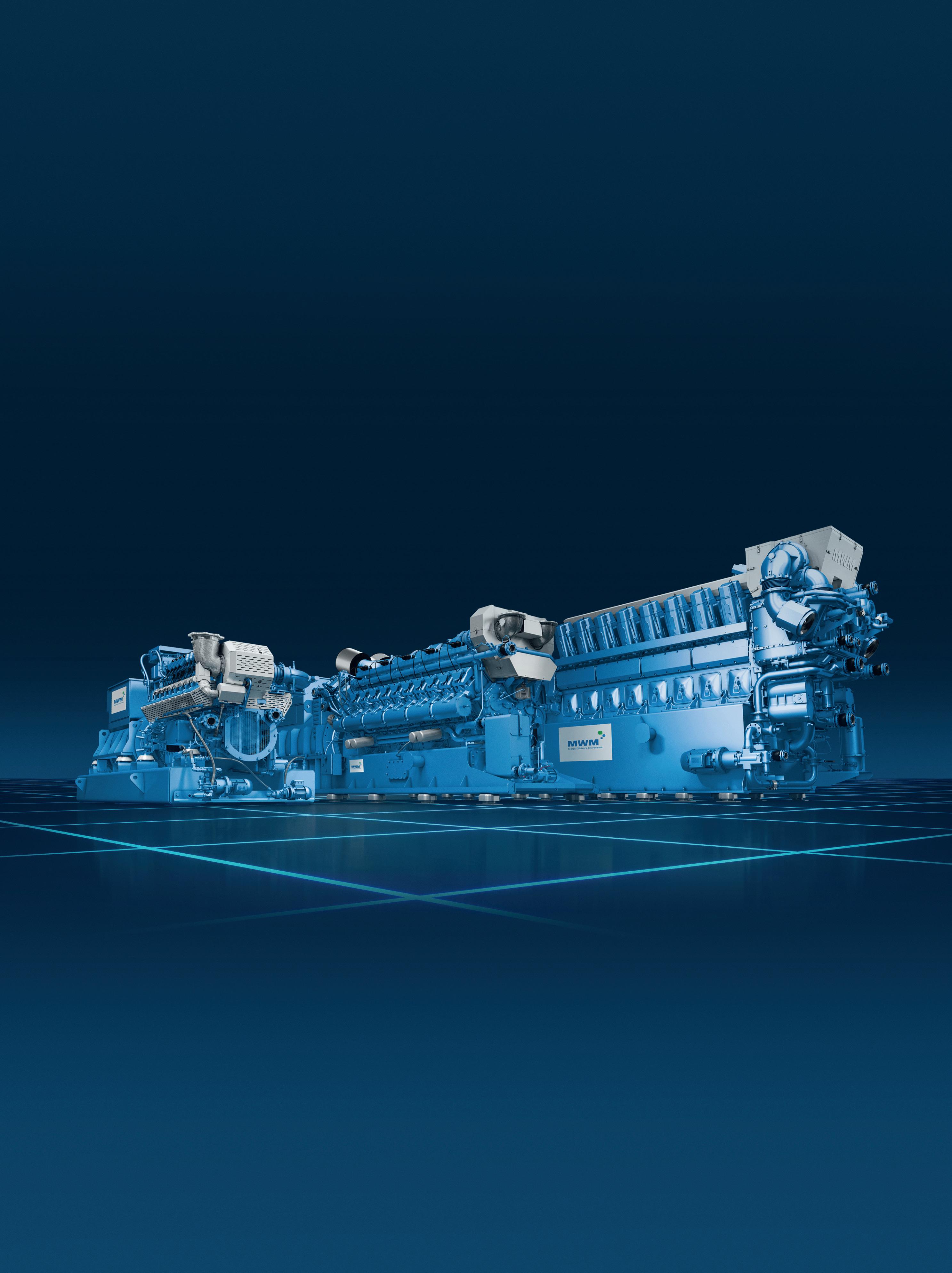

MWM gensets. Efficient, low-maintenance and highly available.

The MWM product portfolio comprises gas engines and gensets in the output range from 400 kWel to 4,500 kWel . Power plants with an output of 100,000 kWel and more are technically feasible. The units are designed for maximum electrical and thermal efficiency, low operating and service costs, and high reliability and availability. Thus, they reach efficiency levels of more than 90 percent.

www.mwm.net/en

BATTERY ENERGY STORAGE SYSTEM

SUPPLIED TO THE NETHERLANDS INCORPORATES PV AND ENERGY MANAGEMENT TECHNOLOGY

UKRAINE COMPLETES FIRST STAGE OF 500MW PROJECT

Ukraine’s biggest private energy company, DTEK, has launched the first stage of a 500-megawatt wind power plant in a boost to the country’s energy sector following Russian air strikes.

Phase I of the Tyligulska Wind Power Plant (WPP), which lies just 60 miles (100 km) from the frontline in the Southern region of Mykolaiv is already generating green power. The plant’s 19 turbines have an installed capacity of 114 MW, generating up to 390,000 kWh – enough to power 200,000 households a year.

Once completed, the Tyligul wind farm will be the largest in Ukraine. For now, 19 wind turbines will generate electricity to support Ukraine’s energy balance.

DTEK began building the plant in 2021 but construction halted after Russia invaded Ukraine on February 24th, 2022.

An energy Storage Solution (BESS) is being supplied to BE Fresh Produce BV of the Netherlands by Zwart Techniek Battery.

BE Fresh is a full-service supplier of top-quality fruit and vegetables to chefs, importers, wholesalers and food & beverage managers in hotels and restaurants all over the world.

Zwart is committed to supplying, installing and commissioning a 1 MW/2 MWh BESS next to the office and warehouse of Be Fresh in De Lier.

A company spokesman comments: “Our Power Management System (PMS) integrates all the assets, including 500 kWp solar PV and energy management system of Samax B.V., who will provide the energy management on the different energy flex markets.”

“Our hybrid off-grid plants power communities and businesses in developing countries. A combination of solar power and diesel generators (sometimes combined with battery storage) ensures that electricity is generated in the most energy-efficient and economical way.

“This can be done for an Angolan village of 200 homes, a power station in Kenya or a region in Burundi that needs electricity to keep the local fruit and vegetable harvest cool and prepare it for sale. We have already installed over 100 power systems in Africa, driving local businesses and connecting these communities to the world. With over 7,000 projects in more than 50 countries in the field of emergency power and off-grid solutions, Zwart has an outstanding track record, throughout Europe, Africa and the Middle East.”

According to Zwart, Europe’s the biggest data centres and financial institutions i- as well as major airports and mobile networks - rely on Zwart expertise and technology. Its 100 in-house trained professionals are qualified to design, engineer, realise and maintain integrated and complete systems for emergency power supply and have been doing so for over 90 years, reports the company.

“We set the bar high for ourselves and demand the same from our partners and suppliers; we work exclusively with premium quality products and service providers, we assemble the systems at our own 6,000-square metre site in Ijmuiden.”

DTEK has already invested US$24.34 million to repair thermal power plants in the first four months 2023. It expects to spend seven times this amount to restore all the equipment damaged and destroyed at thermal power plants in the country.

The Russian attacks on Ukraine’s energy infrastructure has caused widespread damage and left millions without electricity and heating.

Maxim Timchenko, chief executive officer of DTEK, commented: “We celebrate the completion of the first stage of the 500-megawatt wind project. We’ve managed to build 114-megawatt capacity during wartime.”

Phase II of the project in Ukraine will involve adding up to 64 turbines to raise potential output to 500 MW. The 500MW capacity at that point, will make it Eastern Europe’s largest WPP and provide secure energy for homes and businesses in the south of Ukraine.

DTEK’s plans to expand Tyligulska - part of the company’s broader strategy to achieve net zero emissions by 2040 and help Ukraine become a clean energy exporter to the European Union –remain dependent on it securing an additional 450 million euro in funding – mostly from foreign investors.

DUAL FUEL METHANOL ENGINES NOW AVAILABLE

Anglo Belgian Corp. is marketing an extended range of dual fuel methanol engines into Europe.

The medium-speed DZD MeOH engines, based on the DZ engine family, develop up to 3536 kW (4810 HP) and are designed for heavy-duty applications such as gensets.

An important alternative fuel for decarbonisation in heavyduty applications such as power generation, methanol is largely CO2 neutral and offers customers a method of significantly reducing their CO2 emissions, reports ABC.

ABC reports that methanol also matches the “Fit for 55” package, presented in 2021 and is designed to realize the European Climate Law objectives: climate neutrality

by 2050 and a 55 % reduction of net greenhouse gas (GHG) emissions by 2030, compared with 1990 levels.

The DZD MeOH engine range is a new range of medium-speed dual fuel methanol engines for ABC. The range consists of 6- and 8-cylinder inline engines and 12- and 16-cylinder V-engines covering a power range between 955 kW (1300 hp) and 3.5 MW (4810 hp).

10 SUMMER EDITION 2023 EURO POWER NEWS NEWS NEWS

NEW HYDROGEN-POWERED ENGINE RANGE CAN BE USED FOR POWER GENERATION SAY ITS ITALIAN DEVELOPERS

2,250 KVA DIESEL GENSET FOR A HIGHWAY TUNNEL

VMMotori announced it is developing a hydrogen combustion version of its 2.2 L, threecylinder inline engine. Based on the R753 diesel model, the company has indicated that the H2-ICE version ‘marks a new chapter in the company’s history, which was previously dedicated specifically to the design and production of diesel engines’. The performance of the hydrogen combustion engine will be around 10% higher than that of the R753 diesel, reports the company.

VM Motori believes hydrogen is destined to become one of the main energy carriers of the future, contributing to the global drive for CO2 neutrality. As such, a team of engineers has worked to update the technical specifications of the engine to include state-of-the-art injectors, common rail, pistons, spark plugs, ignition coil and pressure regulator – all necessary for hydrogen fuel – while maximizing component standardization with its diesel predecessor.

The performance of the hydrogen internal combustion engine will be around 10% higher than that of the diesel engine from which it was created, offering a62 kW output and 270 Nm peak torque, VM Motori has said. The engine will meet EURO VI E and STAGE V emissions regulations. hydrogen is destined to become one of the main energy carriers of the future, contributing to the global drive for CO2 neutrality, M Motori believes. Company sources indicate that its team of engineers has worked to update the technical specifications of the engine to include state-of-the-art injectors, common rail, pistons, spark plugs, ignition coil and pressure regulator - all necessary for hydrogen fuel - while maximizing component standardization with its diesel predecessor.

Hydrogen is an increasingly popular energy carrier. It can be readily produced from water using renewable electricity, and it burns without any greenhouse gas emissions. It is colourless, odourless, and does not spill. Four-stroke hydrogen internal combustion engines (Hydrogen ICE) operate on the same cycle as regular natural gas engines and have almost the same components- engine block, crank, cylinder heads, ignition system, installation parts etc.

Hydrogen is a useful, clean and zero-emission fuel which can be used in fuel cells or internal combustion engines. Hydrogen fuel produces only water when burned with oxygen. Hydrogen can be produced relatively easily from various domestic resources, such as natural gas, nuclear power, biomass, and - of course - renewable power.

1,300 KVA GENERATING SET FOR THE PIOMBINO REGASIFIER, ITALY

COELMO recently supplied a BDT12M1500 generating set for the Piombino Regasifier located in Italy. In April 2023 Coelmo completed the design, production and testing of the 1,300 kVA generating set which was also equipped with parallel control panel and a 2,500-litre external fuel tank.

The set is based in in a 40-foot container. This has been treated with an anticorrosive paint suitable for particularly aggressive environments. Powered by an MTU 12V4000G14RF engine, the generator package features a single bearing alternator IP23, insulation class H/H, plus a dry type air filter, fuel filter & oil filter. There is a Permanent Magnet Generator PMG, a standard control panel, four 12V batteries, rack and cable, a ripple flex exhaust pipe, exhaust siphon, flange and muffler.

COELMO generating sets are designed and produced for professional applications covering a range from 3 to 4000 kVA. These robust and reliable gensets can be personalised and have accessories designed to adapt to the various different industry sectors, making them the ideal choice for demanding users.

The Italian government recently approved plans for the rapid construction of a regasification terminal at Piombino to make up for a shortfall of Russian gas imports.

EMSA Generators has supplied its its 2250 kVA diesel generator set Baudouin Engine Generator Set to the Czech Republic Highways Tunnel Project.

The 2,250 kVA diesel generator with Baudouin engine was manufactured in compliance with 2000/14/ EC European noise emission directive and certified from Ente Certificazione Macchine.

EMSA products also have TS ISO 8528-4, TS ISO 8528-5, TS EN 13501-1+A1:2013 flame retardancy and TTS EN ISO 9227 certificates against anti-corrosion together with CE Declaration.

Features of the 16M33G2250/5 model include a BAUDOUIN heavy duty diesel engine; 4-cycle, water cooling system, turbochargedaftercooler induction, ECU governor system,12/24 volt self-starter and charger alternator, Changeable air,

fuel and oil filter and a flexible fuel pipe.

The genset was also supplied with an oil discharge valve and extention pipe, an industrial-type silencer, exhaust spiral/compensator, a maintenance-free battery and an e ngine block water heater (supplied with automatic models).

Included with the packge is an EMSA EG450-1600N brushless, single bearing, flexible disc 4-pole alternator for harmonic failure.

This meets H -type isolation class standards, and P 21-23 protection class, with a self exciter. An electronic automatic voltage regulator is provided, plus a Stator 2/3 step for harmonic failure.

The genset comes with a DATAKOM SMART 500-MK2. This is a cost-effective genset controller ready for BMS integration and internet monitoring.

EMERGENCY POWER FOR NETHERLANDS HOSPITAL

Last month KONINKLIJKE VAN TWIST of Dordrecht, NL, supplied a 3,130 KVA diesel genset to a key Netherlands hospital. The generator now provides emergency power in case of a potential grid outage.

A company spokesman commented: “The NSA entered the site in parts. First, load spreaders were placed to reinforce the floor and the old emergency power generator was taken out.

“Then the new NSA, without a generator, was hoisted in. This is

was to prevent the team exceeding the maximum floor load. Finally, then the generator was also brought in and placed on the frame behind the engine.”

In 2021 a new era began at VAN TWIST when the company partnered with Kohler to become a distributor in the Netherlands and Belgium.

A new building dedicated to Kohler is opening in Summer 2023. It will house stock generators, spare parts and more than two dozen technicians as part of generator operations.

12 SUMMER EDITION 2023 EURO POWER NEWS NEWS NEWS

www.megsa.org MEGSA FOUNDER MEMBERS: MEGA CONNECTIONS Get In Touch: sales@megsa.org sales@megsa.org | www.megsa.org | Middle East Gen-Set Association | Copyright © 2023 MIDDLE EAST GEN-SET ASSOCIATION

GENSETS

DIESEL ENGINE GENSET FOR A SUPERMARKET

Germany’s second largest supermarket chain has chosen AKSA as its supplier of emergency backup power equipment.

A new 1650 kVA AKSA genset has been installed by AKSA’s local partner in Germany.

The AP 1650 genset comes with a PERKINS 4012-46TAG2A engine, and an Mecc Alte ECO 46-1S/4 A alternator, plus a DSE 7320 control system.

The powerful Perkins 4012-46TAG2A diesel engine is a part of the reliable family of Perkins 4000 series engines. The 4012-46TAG2A is a V12, 46 litre turbocharged diesel engine.

The Perkins 4012 range packs a real performance punch, with 12 cylinders and 46-litre displacement providing all the power you need.

The range’s diesel ElectropaK engines are supplied complete with radiator and air cleaner, or as engine only.

They provide 1000-1880 kVA generator output, with exceptional power-to-weight ratios. The compact design of the engines makes them easy to transport and install.

This diesel engine is currently manufactured in Stafford, UK. The Perkins build list for this engine model begins DGDM.

The 4012-46TAG2A can only run at the 50Hz configuration however it is still a very capable and versatile engine. It also has the option of either a temperate or tropical radiator.

The turbocharged and air to air cooled engine requires 177-litres of oil for lubrication, 207-litres

of coolant for the water cooling system and has a total displacement of 45.842 litres. The power output of the Perkins 4012-46TAG2A is 2203 horsepower (1643 kWm) at 1500 RPM. This engine will cover most generator power requirements as it can run at Prime (PRP), Standby (ESP) and Continuous (COP) ratings. This Perkins Diesel Engine has dimensions of 3915mm (154”) Long, 2198mm (87”) Wide and 2259mm (89”) high. The cylinders have dimensions of 160mm for the bore and 190mm for the stroke. The (dry) mass of the engine is 4400kg. (Note these are the measurements with a temperate radiator).

This powerful engine can be used for a variety of high power industries around the world. If a larger output is required, this engine could also be placed in parallel with other engines to increase output.

The ECO46 alternator range from Mecc Alte has many product features designed into the alternator. Self-regulation is obtained through a digital electronic regulator that is fed by an auxiliary winding.

The manufacturer guarantees an almostconstant supply from the generator – under any possible operating condition. A rotating inductor is fitted with a damper cage.

The windings have a 2/3 pitch in order to reduce the harmonic content of voltage. The entire series is manufactured according to, and complies with, the most common specifications.

“ A new 1650 kVA AKSA genset has been installed in a supermarket by AKSA’s local partner in Germany. The AP 1650 genset comes with a PERKINS 401246TAG2A engine, and an Mecc Alte ECO 46-1S/4 A alternator, plus a DSE 7320 control system. The Perkins 4012 range packs a real performance punch, with 12 cylinders and 46litre displacement providing all the power

Of particular interest in the genset package is the DSE7320 MKII.

This is a powerful, new generation Auto Mains (Utility) Failure Genset Control Module with a highly sophisticated level of new features and functions, presented in the usual DSE user-friendly format. This is said to be suitable for a wide variety of single, diesel or gas genset applications.

About AKSA Power Generation

Established in 1968, AKSA Power Generation is one of the leading power generator manufacturers worldwide and belongs to Kazanci Holding (https://www. kazanciholding.com.tr/DefaultEN.aspx).

This is a global energy conglomerate operating in the production and distribution of power worldwide with a combined revenues around US$ 6 billion in 2022.

AKSA Power Generation is the largest independent power generator producer globally, with manufacturing bases in Turkey, China and the USA producing around 25.000 units per year.

With their large sales & after-sales channels, AKSA provides products & services to 178 countries via 25 global offices and their reputable partners worldwide. Highlights of company achievements can be seen in the corporate video available on: https://www. youtube.com/watch?v=LKHZGoGT7P8

More information: www.aksaeurope.com

14 SUMMER EDITION 2023 EURO POWER NEWS

AP 1650KVA

A supermarket located in Germany required a reliable generator to provide backup power for its equipment.

It turned to AKSA’s AP 1650 genset which is powered by the Perkins 4012-46TAG2A diesel engine.

you need.”

- AKSA

The Electromechanical Specialists CERTIFIED QUALITY SYSTEM Call: 01572 755 168 Email: info@cabeluk.com www.cabeluk.com We go further Essential electromechanical repair and rewind for alternators, pumps, motors and so much more. Designed to assist your business and extend the life of your equipment. WINDING REWINDING SERVICE &REPAIR SUPPLY 24/7 ALL BRANDS

NEW MACHINERY REGULATION PROPOSAL - COUNCIL

On 22nd May, 2023, the Council adopted the new regulation on machinery. The proposed legislation updates the 2006 machinery directive and transforms it into a regulation. The new text harmonises the essential health and safety requirements for machinery in the EU, promotes the free movement of machinery and ensures a high level of safety for workers and citizens, reports Europgen.

NEW MACHINERY REGULATION PROPOSAL (MR) – COUNCIL ADOPTION

On 22 May, 2023, the Council adopted the new regulation on machinery.

The proposed legislation updates the 2006 machinery directive and transforms it into a regulation. The new text harmonises the essential health and safety requirements for machinery in the EU, promotes the free movement of machinery and ensures a high level of safety for workers and citizens.

Conformity and documentation requirements

The regulation adopted today makes mandatory a third-party conformity assessment for six categories of ‘high risk’ machinery.

Safety information will have to be provided with every product, but in line with the digital transition, the regulation establishes that digital instructions will be the default option. Paper instructions will remain an option for customers who request them.

Background

The 2006 machinery directive was one of the main pieces of legislation governing the harmonisation of essential health and safety requirements for machinery at EU level.

The new regulation adopted today will establish a legal framework for the placing on the Union market of safe machinery, and cover new risks

linked to emerging technologies. The regulation also guarantees legal certainty by clarifying the regulation’s scope.

For instance, it includes small vehicles used for personal transport and light electric vehicles such as scooters or bikes, since these are widely used and could potentially be dangerous to their users.

Next steps

Following the Council’s approval today of the European Parliament’s position, this legislative act has now been adopted.

After being signed by the President of the European Parliament and the President of the Council, the regulation will be published in the Official Journal of the European Union and will enter into force on the twentieth day following its publication.

Member states and economic operators will have 42 months before the rules of the new regulation are applied. EUROPGEN representatives in the Commission experts group participated actively in this revision. The approved Regulation is available from the website.

EUROPEAN STANDARDS: CONSEQUENCES OF THE APPROVAL OF THE NEW MACHINERY REGULATION

The content of the future “Machinery” Regulation

all the issues to be addressed are now known: integration of new technologies (artificial intelligence, cybersecurity, autonomous machines, etc.), content of the future standardization request from the European Commission and annexes Z establishing the link between the standard and the regulation.

Integration of new technologies

Cross-cutting standards in the field of machine safety will have to be developed. Even if standards or projects exist on artificial intelligence or cybersecurity, none integrate the principles of machine security.

Content of the future standardisation request

The commission wants the standards to be drafted to be identified in the standardization request. The first draft of the Standardisation Request is expected to be received in June 2023. However, the particularly large volume of drafting machine standards (850) will complicate the task. CEN has therefore thought of a solution: to indicate the list of types of machines to be covered by standards. In order to organize discussions with the European Commission, a “standardization request ad ’hoc Group” (SRAHG) will soon be set up at CEN/ CENELEC. This group will bring together member bodies and representatives of all relevant technical committees.

Content of Annexes Z

The fleet of machine standards covers the period 2009-2023 and some old standards do not have appendix Z in the correct format. We now need a precise link between the essential requirements of the regulations and the requirements of the standard. It is therefore necessary for the technical committees to finalize these new annexes. In addition, the

16 SUMMER EDITION 2023 EURO POWER NEWS EUROPGEN

“Machinery” Regulation will apply 42 months after its publication without a transitional period: until this date, only the “Machinery” Directive 2006/42/EC will apply. The standards that will be published in the coming months must therefore cover both texts. Conclusion: the technical committees will be encouraged to develop two annexes Z.

OUTDOOR NOISE DIRECTIVE (OND) REVISION – 2000/14/EC. EUROPGEN PROVIDES FEEDBACK ON OUTDOOR NOISE REGULATION

On 5th May, the European Commission launched a 4-week feedback process to collect input on the draft delegated act, which aims to update the measurement methods outlined in Annex III of the Outdoor Noise Directive (Directive 2000/14/EC). EUROPGEN, will participate to this public consultation (available here) with the aim of providing expert input that represents the interests of the generating sets industry and EUROPGEN members and contributes to the achievement of the final delegated act.

JOINT BUSINESS STATEMENT : ACCESS TO DATA BY PUBLIC BODIES

As the Data Act Trilogues continue, the Swedish presidency and Parliament and Commission negotiators aim to reach an early agreement on business-to-government data sharing rules (“B2G”, chapter 5).

Given the broad and unrestricted scope of the B2G – Government Access provisions of the Data Act, the signatories of the joint statement expressed their concerns due to lack of proportionality, safeguards and risk

to fundamental rights and the rule of law (especially if the personal data remains in scope).

This publication is available online from the website.

MEETINGS & EVENTS

Next meetings

•EUROPGEN Special Event, Brussels, 6th June 2023

•EUROPGEN General Assembly, Brussels, 7th June 2023

•EUROPGEN Executive and Technical Committees meetings, Brussels, 7th June 2023

How did the European Genset Market Fare?

Imports of diesel generators have never been so important in the UK, reaching more than $30M in the first two months of 2023. This increase is very significant for generators of more than 2.000 kVA, which have reached levels records over the last 12 months, mainly from the United States and Germany. The still very strong growth of the data centre sector in the UK is driving this product segment.

The European diesel generator market hit a record level in Q4 2022

The diesel generator market reached record levels at the end of 2022, and remains very strong in most European countries in 2023, even if the market seems to have peaked and growth is slowing down (especially for small powers that had boomed in 2022).

Increase of generators below 375 kVA

The market for generators below 375 kVA reached a historic level at the end of 2022, boosted by Ukrainian imports but also the energy crisis in Europe as well as the significant delays on the largest powers. This hyper-growth seems to be over and the market should return to a pre-energy crisis level from the second half of 2023.

The boom in Ukrainian imports due to the conflict situation

Ukrainian imports peaked in Q4 2022 ($245M) with a record month in December ($155M).

It is generators of less than 375kVA which represent the vast majority of imports, mainly supplied from Turkey and Poland (+50% of generators come from these two countries). Imports, however, decreased slightly at the start of 2023, but still represent more than US$130M over the first two months of the year.

The United Kingdom Data Centre Market is projected to register a CAGR of 11.83%

The IT load capacity of the UK data centre market may grow steadily and reach 3609.68 MW by 2029, suggest media reports.

The country’s total raised floor area is expected to reach 17.79 million sq. ft by 2029.

The country’s total number of installed racks is expected to reach 889,896 units By 2029. London is expected to house the maximum number of racks by 2029. The United Kingdom has superior cybersecurity, and London is one of Europe’s largest data centre markets. The country remains a critical interchange and communications hub between North America and Europe, with over 50 undersea cables. Overall, there is a huge potential for growing data and government investment in fibre connectivity.

In the UK Tier 3 data centres are the most preferred due to features such as onsite assistance, power, and cooling redundancy. The Tier 3 DC market was operating at 1540.98 MW in 2022. The expected capacity during the forecast period is expected to grow from 1813.19 MW in 2023 to 3369.24 MW in 2029 at a CAGR of 10.88%.

EURO POWER NEWS SUMMER EDITION 2023 17 EUROPGEN

****

“ As the Data Act Trilogues continue, the Swedish presidency and Parliament and Commission negotiators aim to reach an early agreement on business-togovernment data sharing rules (“B2G”, chapter 5).

Given the broad and unrestricted scope of the B2G – Government Access provisions of the Data Act, the signatories of the joint statement expressed their concerns due to lack of proportionality, safeguards and risk to fundamental rights and the rule of law (especially if the personal data remains in scope).

Ursula von der Leyen is president of the European Commission

OPTIMAL MUSHROOM GROWTH THANKS TO CHP

Poland is the world’s leading exporter of mushrooms & truffles and the market leader in European mushroom production

ACHP plant with an MWM gas genset ensures high mushroom yields all year round at moderate energy costs for the mushroom producer, the Hajduk Group Sp.z o.o. in Poland. Polygeneration makes it possible.

Poland is the world’s leading exporter of mushrooms and truffles, ahead of China (Statista 2022), and the market leader in European mushroom production.

One of Poland’s leading mushroom and mushroom substrate producers is the Hajduk Group Sp.z o.o. The Hajduk Group produces around 160 tonnes of mushrooms per week in four cultivation plants.

As mushrooms are energy-intensive in production, the company already invested in a CHP plant in 2018. The cogeneration plant with an MWM TCG 2020 V16 gas genset was supplied by the official MWM distributor in Poland, Centrum Elektroniki Stosowanej CES Sp. z o.o..

Using polygeneration, the plant produces electricity and heat but also cooling and steam for mushroom cultivation.

Best conditions for mushroom cultivation

For a year-round harvest, mushrooms need stable growing conditions with the proper humidity and temperature.

Typically, this means cooling in summer and heating in winter with the help of air conditioning. Mushrooms are energy-intensive to produce.

The energy costs of the production facilities, therefore, significantly affect the mushrooms’ final price.

To keep these costs as low as possible, the polygeneration plant supplied by Centrum Elektroniki Stosowanej CES Sp. z o.o. is based on CHP. Liquefied natural gas is used as fuel.

Agricultural production plants far from conurbations and large cities often have limited connection options to the natural gas grid. To operate a CHP plant, Hajduk Group relies on LNG for its CHP plant with a capacity of over 1.5 MWe. With this solution, polygeneration plants can be installed almost anywhere.

Engine exhaust heat for cooling

Thanks to the additional equipment, the CHP plant generates steam and cooling, electrical energy, and heat. The plant is powered by an MWM TCG 2020 V16 gas genset with an electrical output of 1,560 kW and a thermal output of 1,580 kW.

In the cooling halls where the mushroom substrate is produced, an absorption chiller uses the exhaust heat from the MWM gas genset to generate cooling for the halls.

The absorption chiller has a capacity of 720 kW. Steam is used to sterilise the refrigeration halls between production cycles.

For this purpose, the high-temperature heat of the exhaust gases is used in the steam generator, which supplies 1,060 kg/h of steam at nine bar

equipment,

generates steam and cooling, electrical energy, and heat. The plant is powered by an MWM TCG 2020 V16 gas genset with an electrical output of 1,560 kW and a thermal output of 1,580 kW.

pressure. The hot water is also used for washing and other technical purposes. CHP plant enables independent and flexible energy supply

In typical operation, the CHP plant with the MWM gas genset covers the entire demand for heating, cooling, steam, and electricity of the production facility at Hajduk Group.

Part of the electrical energy is used on hot summer days for additional cooling. In winter, the halls can, in turn, be heated with heat from the CHP plant.

The polygeneration system offers flexibly controllable energy generation with a heat and cooling supply. This allows Hajduk Group to maintain optimal production conditions for the popular edible mushrooms all year round while saving energy costs through the combined production of the different media.

The MWM TCG 2020 V16 gas gensets offer the highest ratings in ecology and economy:

- Output range from 1,000 to 1,560 kWel

- Best electrical and thermal efficiency in its output class

- Runs on all gas types: natural gas, biogas, landfill gas, sewage gas, mine gas, etc.

- Low operating costs.

The TCG 2020 is mainly used for CHP plants in Europe and for biogas worldwide.

The MWM gas gensets of the TCG 2020 series are perfectly geared to the challenges of a dynamic market environment.

The models in the output range of 1,000 – 1,560 kWel are said to meet the high requirements of a broad range of applications and offer efficiency, reliability, flexibility and environmental sustainability, together with low lifecycle costs and high profitability. www.mwm.net

18 SUMMER EDITION 2023 EURO POWER NEWS CHP

One of its major growers is relying on energy from MWM gas gensets & CHP.

“Thanks to the additional

the CHP plant

In the cooling halls where the mushroom substrate is produced, an absorption chiller uses the exhaust heat from the MWM gas genset.”

LOADBANKS for GENERATORS THE TRUSTED NAME FOR LOAD TESTING LOADBANK PACKAGES ■ 20kW to 7000kW ■ Resistive Only Loadbanks ■ Resistive / Reactive Loadbanks ■ DC Loadbanks SALES | SERVICE | RENTAL Call today: +44(0) 1283 531 645 www.crestchicloadbanks.com Sales & Rental Offices in : UK, North America, Singapore, Germany, Brazil, Netherlands, France, China and UAE Crestchic Limited, Second Avenue, Centrum 100, Burton upon Trent, Staffordshire DE14 2WF, UK T: +44 (0)1283 531645 F: +44 (0)1283 510103 E: sales@crestchic.co.uk

POWER PLANT UPGRADING THE LEINI POWER PLANT - A NEW POWER

enhanced performance while maintaining and even improving the level of reliability (> 99.5%). Its balanced thermal distribution throughout the entire engine combined with its extreme operating simplicity enables high cycling capability.

It can be started and stopped without any time limitation and reach base load in approx. 20 minutes, a key factor for grid stability and peak plants.

A wide selection of fuels can be used, ranging from natural gas with hydrocarbons in several proportion or with hydrogen content up to 40% vol, up to liquid fuels such as Diesel Oil, High Speed Diesel and Naphtha.

Environmentally sustainable

The AE 94.3A gas turbine has a NOx level down to 15 ppm in dry gas mode and 60 ppm in dry oil mode (with possibility of reaching 25 ppm with small amount of water).

Ansaldo Energia offers what it calls ‘a Smart Maintenance approach’:

Ansaldo Energia will supply the plant – already built on turnkey basis in 2007 - with a new AE 94.3A gas turbine and related WY23Z generator.

The AE94.3A gas turbine - which will be installed in the Leinì project - has been improved through a process of continuous evolution, This model accounts for more than 4 million hours of operation with ever-increasing performance. According to the company it will incorporate the latest evolutionary updates which will lead to an increase in the efficiency of the whole combined cycle unit.

“The fact that ENGIE has again chosen us for the upgrade of the Leinì plant is a matter of great pride and confirms an ever more fruitful collaboration,” says Marco Lovisolo, Ansaldo Energia Senior Vice President Sales & Marketing.

“Ansaldo Energia built this plant in 2007 and continued to maintain the plant with a timely service, aimed at ensuring the maximum efficiency. With this project we will install a renewed and upgraded machine, backed by a proven experience”.

For ENGIE, Ansaldo Energia built the three plants at Voghera, Rosignano and Leinì in Italy, where they followed up with upgrade and maintenance activities. This has involved a collaboration spanning more than twenty years.

“The solid partnership with Ansaldo Energia is a concrete example of ENGIE’s willingness to invest in the research of technological innovations that make the plant a truly virtuous pole in terms of sustainability, flexibility and energy transition” comments Gelu Rapotan, Director of ENGIE Production.

“In 2022 the Leini plant produced iabout 2.1 TWh of electricity for the national electricity system and 55.5 GWh of thermal energy for the district heating network of the City of Settimo Torinese, also owned by ENGIE.”

Works on the plant will begin in February 2024 and will end with the delivery of the completely upgraded plant scheduled for October 2024. The simple and robust design of the AE94.3A has made it possible to progressively accommodate continuous upgrades over the years. This has

- Customised service agreements, including upgrading packages, allow

- Customers to choose the best solution to fit their needs.

- Extended time between major overhauls (up to 5 years, depending on operating conditions)

- High durability of hot gas path parts

- Quick onsite activities.

There are customised service agreements in place, including upgrading packages, to allow customers to choose the best solution to suit their needs. www.ansaldoenergia.com

Ansaldo Energia has been awarded a contract by ENGIE Produzione for the improvement of the combined cycle plant in Leinì (Turin). As part of the upgrades, Ansaldo Energia will contribute with the turnkey replacement of the entire gas power assembly, including the gas turbine and the generator with the related auxiliaries.

“ The solid partnership with Ansaldo Energia is a concrete example of ENGIE’s willingness to invest in the research of technological innovations that make the plant a truly virtuous pole in terms of sustainability, flexibility and energy transition.”

- Gelu Rapotan, Director of ENGIE

BESS

NEW BATTERY ENERGY STORAGE SYSTEMS

These battery systems are energy and poweroptimised to meet business and operational needs.

From just one, to as many units as are required for the OEM’s BESS applications, Volvo Penta’s solution is scalable up to hundreds of mega-watt hours.

Hannes Norrgren, President of Volvo Penta Industrial, comments: “Battery energy storage is increasingly in demand for a variety of applications including utilities, factories, decentralised microgrids and mobile charging stations.

“As our solution is application agnostic, we see huge potential for its adoption. Together with OEMs, our solution provides possibilities to store energy from and add resiliency to renewable solar or wind-powered sources, opening new business models that appeal to end customers on their road to net-zero emissions.

“BESS will enable highly flexible energy solutions, making low to no emissions a far more viable proposition for mobile and stationary use.”

He explains: “We’re starting by introducing the solution to customers in North America and Europe, followed by other markets, and are eager to begin collaborating with OEMs to kickstart new projects in BESS.”

Volvo Penta’s latest product is built on the Volvo Group’s electromobility platform which has seen success in applications such as trucks, buses and construction equipment.

In parallel, the Volvo Group is also investing in battery cell and pack manufacturing around the

world to secure capacity and large-scale series production.

Heléne Mellquist of Volvo Penta reports: “Volvo Penta’s engineering expertise, together with knowledge from the Volvo Group, will be key in guiding our OEMs in developing a battery energy storage solution to meet new segment and application needs as we jointly navigate this energy transition.

“The company has taken an exciting next step in its journey to visualising and realising an ecosystem of road-to-net-zero solutions which not only strengthens our power generation business but go well beyond into new segments.”

From just one to as many units as required, Volvo Penta’s solution is scalable up to hundreds of megawatts, and optimised to meet BESS business needs.

Packaged in a holistic, safe, and easy-tointegrate way, strengthened by our service network, parts availability, and longer-term battery cell production.

The new BESS system reflects the pairing of Volvo Penta’s dedication and experience in OEM applications with customers’ deep knowledge in power generation and grid operability.

Battery energy storage systems (BESS) are composed of one or more batteries which store energy from various sources. Volvo Penta will be supporting battery energy storage manufacturers with a compact, efficient, highpower density integrated solution that’s easy to install, control and maintain.

Hannes Norrgren concludes: “The battery pack is a high-energy-density, high-power battery pack derived from heavy-duty applications. It has a favourable C-rate, allowing for rapid and substantial charging and discharging. The battery systems are energy and power optimised to meet business and operational requirements, scalable from one to hundreds of megawatt hours in energy.”

Full system supplier

The Battery Management System contains control architecture which leverages the knowledge of the Volvo Group and built collaboratively with our customers for seamless integration with the battery energy storage control system.