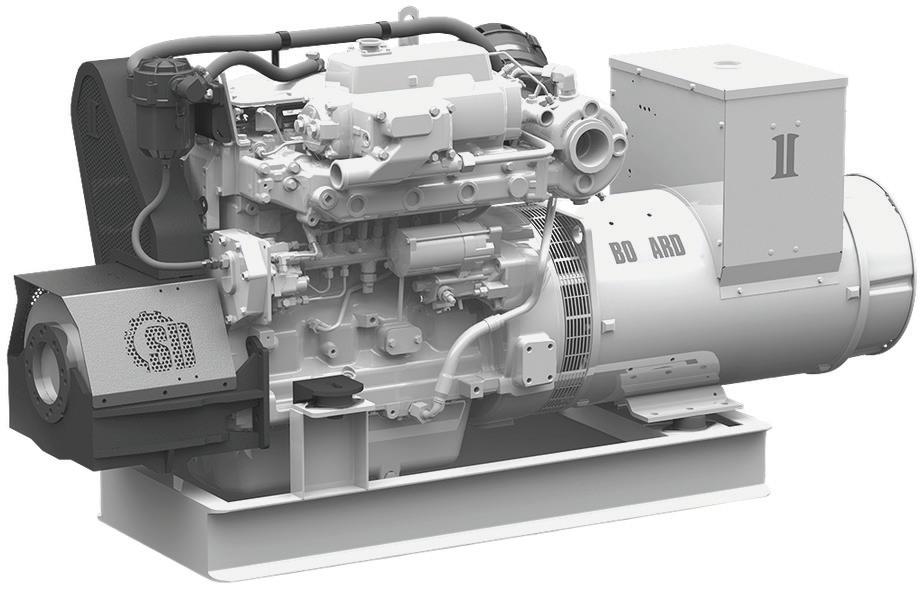

Over 120,000 units sold. Over 320 million operating hours. For over 25 years.

Providing ever cleaner, safer and more competitive solutions is always on our mind – even when we’re not at work.

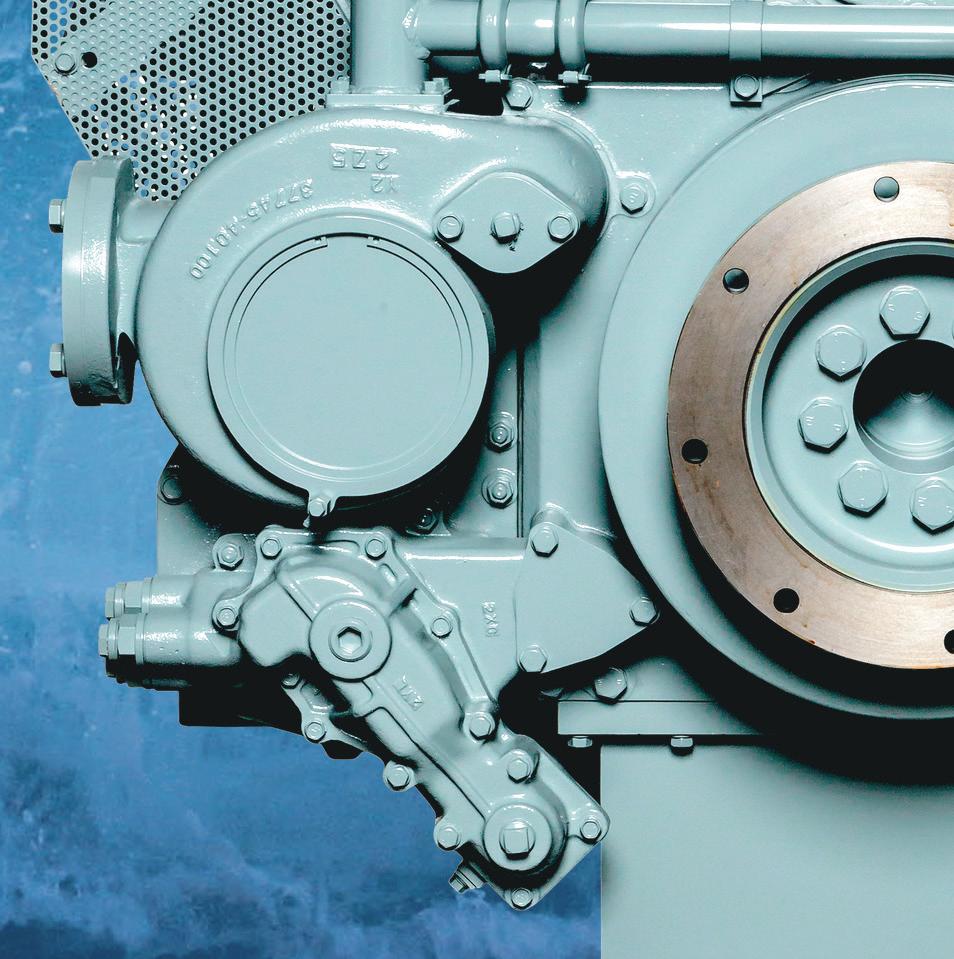

Talk to Andi about mtu Series 2000 and 4000 engines.

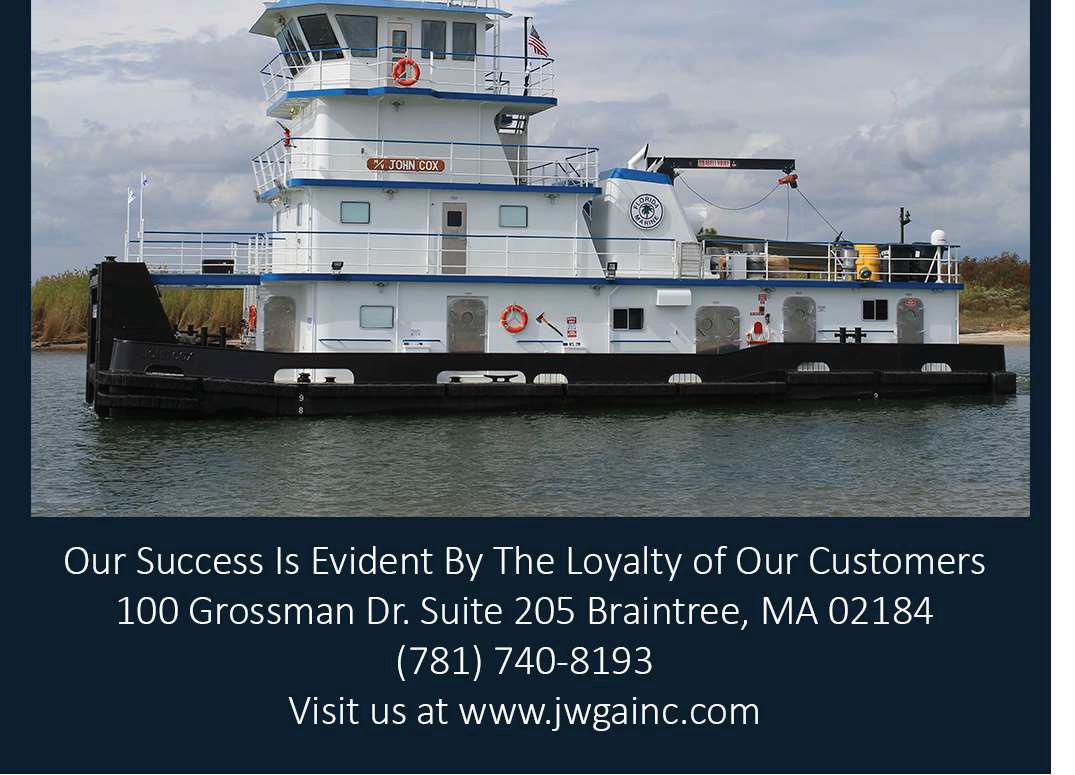

Last year, after a two-year Covid-induced pause, the International WorkBoat Show returned to New Orleans. This year, the 42nd edition of the show, which opens Nov. 30, promises to be even stronger. More exhibitors are signed up and a bump in attendance is expected.

Last year, most of the talk at the show revolved around the pandemic and how it has affected workboat businesses. While Covid is still around, businesses are more positive this year. We anticipate that there will be more scuttlebutt about contracts and other business deals.

The improved business climate is most evident in the passenger vessel industry, the workboat sector that many would argue was hit hardest by the pandemic.

Passenger vessels rebounded, with operators reporting improved numbers. Dan Yates of Portland Spirit said the company had not only a solid year in 2022 but “the most successful income year in our 28 years.”

In our annual top news stories of the year report (see page 36), the passenger vessel rebound was one of the positive stories. Another was that things are nally looking up for the U.S. offshore oil and gas sector as it moves to capitalize on an increase in energy prices.

Headwinds persist, however, namely a shortage of suitable vessels and, more notably, the crews to man them. In fact, labor problems continue to plague most workboat sectors.

Another big news story this year was the milestone reached by the towing

industry in July when Subchapter M, the long-awaited federal towing vessel inspection program, ended its four-year phase-in period with about 5,000 U.S.ag towing vessels certi ed as compliant with new safety rules.

Among other top stories in 2022 were the increased interest in offshore wind, zero emissions, and autonomous technology. And of course, Adm. Linda Fagan was sworn in as the 27th commandant of the U.S. Coast Guard on June 1. Adm. Fagan became the rst woman, and rst mother, to lead any branch of the U.S. Armed Forces.

Have a great WorkBoat Show. I hope to see you there.

ai16389015345_editwatch_BPA_2021.pdf 1 12/7/21 1:25 PM

671 0444 22

Portland, ME 04112. POSTMASTER: Send address changes to WORKBOAT, P O Box 1792, Lowell, MA 01853. Copyright 20 A S U in Printed Communications Diversified by

EDITOR IN CHIEF David Krapf / dkrapf@divcom.com

SENIOR EDITOR Ken Hocke / khocke@divcom.com

CONTRIBUTING EDITOR Kirk Moore / kmoore@divcom.com

CONTRIBUTING WRITERS Capt. Alan Bernstein • Bruce Buls • Michael Crowley • Jerry Fraser • Pamela Glass • Betsy Frawley Haggerty • Max Hardberger • Joel Milton • Jim Redden • Kathy Bergren Smith

ART DIRECTOR Doug Stewart / dstewart@divcom.com

EDITORIAL DIRECTOR Jeremiah Karpowicz / jkarpowicz@divcom.com

Chapel Steel distributes and processes the highest quality, most reliable steel products in the industry. Even for the most demanding projects, Chapel Steel offers dynamic solutions to meet every need.

ADVERTISING ACCOUNT EXECUTIVE S

Kim Burnham 207-842-5540 / kburnham@divcom.com

Mike Cohen 207-842-5438 / mcohen@divcom.com

• Structural, Carbon, & HSLA

• Alloy & Abrasion Resistant

• Marine & Offshore

• PVQ

Chapel Steel distributes and processes the highest quality, most reliable steel products in the industry. Even for the most demanding projects, Chapel Steel offers dynamic solutions to meet every need.

Kristin Luke 207-842-5635 / kluke@divcom.com

Krista Randall 207-842-5657 / krandall@divcom.com

Danielle Walters 207-842-5634 / dwalters@divcom.com

• Structural, Carbon, & HSLA

• Alloy & Abrasion Resistant

• Marine & Offshore

• PVQ

Chapel Steel distributes and processes the highest quality, most reliable steel products in the industry. Even for the most demanding projects, Chapel Steel offers dynamic solutions to meet every need.

• Armor & Ballistic Advanced Manufacturing & Processing

ADVERTISING COORDINATOR

Wendy Jalbert 207-842-5616 / wjalbert@divcom.com

Booth 3555

• Structural, Carbon, & HSLA

• Plasma & Oxy-Fuel Cutting

• Plasma Etching / Plate Marking

• Alloy & Abrasion Resistant

• Marine & Offshore

• Beveling

• Armor & Ballistic Advanced Manufacturing & Processing

• PVQ

• Plasma & Oxy-Fuel Cutting

• Press Break (Up to 60’)

• Plasma Etching / Plate Marking

• Drilling / Tapping

• Counter Boring

• Beveling

• Press Break (Up to 60’)

• Shot Blasting

• Drilling / Tapping

• Counter Boring

• Armor & Ballistic Advanced Manufacturing & Processing

Producers of The International WorkBoat Show and Pacific Marine Expo www.workboatshow.com • www.pacificmarineexpo.com EXPOSITION SALES DIRECTOR Christine Salmon 207-842-5530 / c salmon@divcom.com PRESIDENT & CEO Theodore Wirth / twirth@divcom.com GROUP VICE PRESIDENT Bob Callahan / bcallahan@divcom.com

• Shot Blasting

• Plasma & Oxy-Fuel Cutting

• Plasma Etching / Plate Marking

• Beveling

For more information, please contact a sales representative at 800-570-7674, or visit us online at www.chapelsteel.com.

For more information, please contact a sales representative at 800-570-7674, or visit us online at www.chapelsteel.com

• Press Break (Up to 60’)

• Drilling / Tapping

For more information, please contact a sales representative at

www.workboat.com

22’ Fire-Rescue, Sherman, Connecticut

22’ Fire-Rescue, Sherman, Connecticut

Iamwriting this in response to the story “Shored Up” in the August issue of WorkBoat by Bruce Buls.

It seems like I cannot pick up a newspaper, boating or marine trade magazine today without hearing about rising seawater or “SLR.” They all talk about the ice melting in the Polar regions. Now don’t get me wrong, I do agree with that problem. But we have another one and no one has addressed.

A few years ago, I attended an environment protection meeting on this matter. The meeting was organized by the state of New Jersey and the Army Corps of Engineers. Their answer to stop the ooding in my area, Barnegat Bay (Ocean County, N.J.), was to build a 10' seawall around the bay and put sea doors on the inlets. My question was if they were going to try this, how would they expect the people

on waterfront properties to react? At that time people were ghting the raised dune regulations. I also pointed out that the sea doors would block the ow of storm water in the rivers and the water would back up into the towns.

The other thing the state did was to dredge channels and place the spoils into natural holes that were sh habitats. Sometimes I wonder about the engineers they hire.

Recently a local marina built in the 1960s dredged its basin back to a ve-to-six-foot depth. I was amazed at the amount of spoils/sand that was removed from this small marina. This got me to think what about other areas that were lled in by runoff from the land and wave action washing away the shoreline. I can say without a doubt that much of the land has washed away in my 40 years, lling in channels and creating sandbars on the bay. Let us not forget how much

sand from inland was dumped on our beaches to be washed away by nor’easter storms.

Dredging channels to seaports are being done all along our coast. The spoils are generally loaded into hopper dredges or barges and dumped somewhere at sea. Basic math tells me that you are moving the problem from point A to B. We see the ooding in the Midwest and the brown oodwater carrying yards of soil into the rivers lling in our waterways. Test it yourself. Take a glass of water and ll it half way, then place some marbles in and the water rises with no additional water being added to the glass

Wouldn’t it make more sense to dredge the waterways and put the spoils back on higher land or create islands that once existed?

Capt. R.M. Silva Toms River, N.J.

Capt. R.M. Silva Toms River, N.J.

Actisense and Gemeco — it’s what legends are made of.

Whether installing an entirely new electronics system or modernizing an existing installation, Actisense is fluent in NMEA. We offer innovative solutions for rock-solid performance and reliability using intelligent marine sensors, interfaces, and technology designed to enhance your customers’ experience.

Joel Milton works on towing vessels. He can be reached at joelmilton@ yahoo.com.

I

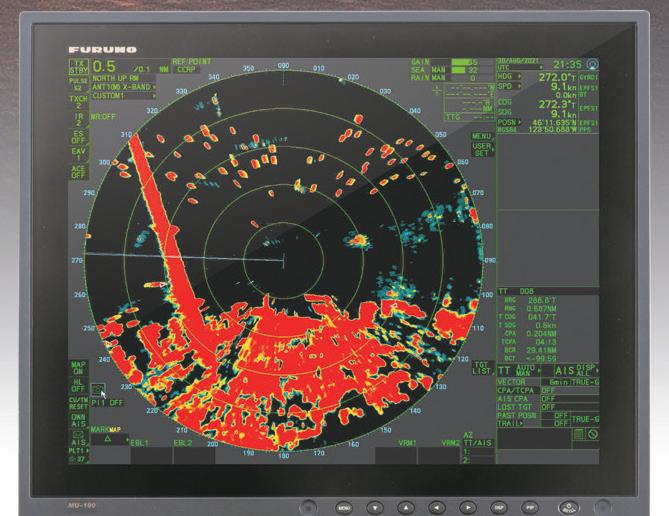

It’s slow. Very, very slow. Painfully slow. Like pouring blackstrap molasses on a cold morning. But sometimes it does work. It refers to education and the subject in question is something that is extremely simple: proper radio watchkeeping, primarily on recreational vessels.

Specifically, I’m referring to the dangerous, age-old habit of those who operate recreational vessels of all kinds in and around channels and waterways used by commercial traffic of not properly monitoring their VHF marine radios.

We are all too familiar with this problem. And when recreational vessels are in close proximity to commercial traffic without knowing how to communicate quickly, it puts everyone at elevated risk for something to go wrong. If we can’t communicate verbally via radio then we’re left with, depending on visibility and distance, hand signals or other body gestures (sometimes vulgar) and sound signals. It’s debatable which is better understood by the recipients, or more

Asa professional mariner and business owner, I am committed to safety. The safety of my passengers and crew are at the forefront of how I approach my job each day.

Crew training and drills are particularly important. These two items are a given and what we do as professionals. Those of us who work on the water witness a variety of unsafe activities from recreational boat operators. Most of the unsafe actions are the result of inexperience and a lack of knowledge of the rules of the road. There are many instances in which professional mariners compensate for or avoid boaters’ dangerous behavior to prevent problems and injuries.

Similar to commercial vessels, recreational boats are required to have life vests on board. This is a smart requirement. Life vests have been proven to save lives in emergencies.

But there is one group of boaters who ply

effective in ensuring safe passage.

Most annoying are the legendary “deep-draft” 40’ sailboats that insist on navigating in the middle of the channel for no apparent reason. If they could be hailed at all it would typically be on Channel 16, but there are no guarantees of success. Then comes the familiar five short-blasts of frustration and frantic maneuvering. But on most of the occasions that I’ve heard about where contact was made on Channel 16, captains and mates on tugs and pilots on the ships would try to engage the operator of the recreational boat and explain the importance of monitoring and communicating with commercial traffic on Channel 13.

It’s become increasingly noticeable over the last decade that a significant percentage of recreational boat operators, particularly sailboats, have absorbed this information and actually practice it far more than I ever would have imagined possible. It’s by no means universal, but the improvements are real.

Mariners should know that their efforts haven’t all been in vain and continued efforts may bear even more fruit.

most U.S. waters who are not required to have life vests on board — racing sculls. Recently, there was an accident involving a racing scull in which one of the student athletes was killed. Would he have survived if a life vest was required on the scull?

Racing sculls are currently exempt from life jacket requirements in waters considered navigable by the Coast Guard.

All racing sculls should be required to carry life jackets on board or on their person. With current technology and innovation in life jacket technology, the Coast Guard should review racing sculls and life jackets and take some positive action. I have heard from many individuals that because rowers are athletes, they do not need life jacket protection. The idea that a life jacket gets in the way of competitive rowing is negated by the fact that both teams would have the same advantage or disadvantage. To think that a small uninflated ring around someone’s neck and chest would be in the way is shortsighted. All sports can adapt as situations require.

Serious discussions about adding a life jacket requirement for racing sculls should be held.

Despite a contentious production cut, it remains to be seen if the drop in oil prices over the past few months will prove to be temporary or if prices will return to earlier 2022 levels.

Prices on the Brent benchmark are expected to return to more than $100/ bbl by Christmas, said Norwegian consultancy Rystad Energy, while others predict fears of a recession, accompanied by a drop in demand and increased supply, may keep a handle on prices.

The West Texas Intermediate (WTI) benchmark price consistently lags behind Brent, which stood at $94.65/ bbl on Nov. 1, with WTI coming in at $88.37/bbl.

Saudi Arabia-led OPEC and allied producers decided to cut global oil production beginning in November, effectively spurning President Biden’s plea in July to raise production.

The announced 2 million bbl/d reduction will likely amount to around 1.2 million bbl/d, when adjusted for some producers’ unmet quota levels, said Rystad and others.

Regardless, the global oil cut has

AUG '22 SEPT '22 OCT '22

WTI Crude Oil 97.40 77.17 86.54 84.64

Baker Hughes Rig Count 18 16 14 13 U.S. Oil Production (millions bpd) 12.1 12.0* 11.9* 11.3

Sources: Baker-Hughes; U.S. EIA *Estimated

dampened the already prickly relationship between the U.S. and the desert kingdom.

The production curb comes amid “weaker-than-expected demand as recession weighs and as supply ticks up in the U.S.,” said Rystad Senior Vice President Jorge Leon. “The announced OPEC+ cuts, even if executed at a 60% level, would push inventory draws into bullish territory.”

In a counter-forecast, the U.S. Energy Information Administration (EIA) predicts WTI will average just

over $88/bbl and Brent $95/bbl into next year, staying fairly close to current levels.

“We lowered our price forecast for 2023 by $2/bbl compared with last month’s forecast, which largely re ected a 0.5 million bbl/d reduction in our forecast for global oil consumption in response to a lower forecast for global GDP (gross domestic product) from Oxford Economics,” the EIA concluded in its Oct. 12 Short Term Energy Outlook.

• Acoustic and Thermal solutions suitable for all marine projects

• Superior vibration damping and marine barrier products

• Compliant to IMO and US Military standards

• Maintained stock for key marine products

• Lightweight structural fire protection

• Prompt response to quote requests

address noise, vibration & heat For any inquiries contact: 504-416-3238 sales@marine-acoustics.com

In October, the WorkBoat Stock Index gained 530 points, almost 19%. For the month, gainers topped losers by an 11-1 ratio.

The PHLX Oil Service Sector Index gained a whopping 37%. Predictably, energy issues were among the top percentage gainers in October.

Leading the way was Helix En-

ergy Solutions Group, Oceaneering International, Nabors Industries, Tidewater and Transocean. Roderick Larson, president and CEO of Oceaneering International, said the “offshore recovery is clearly underway. And with increasing emphasis on both energy security and development of the cleanest, safest and most reliable en-

Source: FinancialContent Inc. www. nancialcontent.com

INDEX NET PERCENT

COMPARISONS

8/31/22 9/30/22 CHANGE CHANGE

Operators 346.08 417.95 71.87 20.77%

Suppliers 4,067.77 4,822.46 754.69 18.55%

Shipyards 4,132.51 4,837.04 704.53 17.05%

WorkBoat Composite 2,821.18 3,351.70 530.52 18.80%

PHLX Oil Service Index 59.93 82.31 22.38 37.34%

Dow Jones Industrials 28,725.50 32,732.95 4,007.45 13.95%

Standard & Poors 500 3,585.62 3,871.98 286.36 7.99%

For the complete up-to-date WorkBoat Stock Index, go to: www.workboat.com/resources/workboat-composite-index

ergy sources, I expect positive market fundamentals to support our energy-focused businesses for years to come,” he said during the company’s third-quarter earnings call in October.

“In addition, with increasing competition for, and scarcity of, available labor, our mobile and subsea robotics businesses are experiencing heightened levels of interest as automation lowers on-site personnel requirements and enables remote supervisory control.”

Looking forward to 2023, Larson said, “supportive commodity prices and the increasing importance of energy security underpin our expectations for a strong ve-year outlook in our offshore energy businesses. With energy transition expected to require an all-of-theabove solution across energy sources, we are well positioned to support our customers in enabling the production of cleaner, safer and more reliable energy from traditional sources.”

— David Krapf

BY KEN HOCKE, SENIOR EDITOR

BY KEN HOCKE, SENIOR EDITOR

There’s low water on the Mississippi River. What will barge companies do? What they always do — they deal with it.

It seems like the only years there

isn’t a low-water problem on the Mississippi River are years when there is a high-water problem on the river. If neither of those exist, then there’s total mechanical collapse of the gates at a lock and dam or two.

aren’t bad. They are. The low water level at Memphis, Tenn., in mid-October set a new record at 10.77’. The water level in Greenville, Miss., was a dismal 7.74’.

“The ‘normal’ river stage at Greenville for this time of year is 17.70’. To make matters worse, the National Weather Service (NWS) sees no relief in the immediate future and is forecasting continued declines in river levels,” according to River Transport News.

In late October, there were blockages attributed to drought along the Lower Mississippi at Memphis; Little Rock, Ark.; Lake Providence, Miss.; Baton Rouge, La.; Tunica, Miss.; Greenville; Vicksburg, Miss.; and New Orleans, according to the Agriculture Transportation Coalition (ATC).

“The delivery costs are skyrocketing because you can’t get the product down the river,” said ATC’s executive director Peter Friedman.

Earlier in October the Lower Mississippi River was closed for days near Lake Providence to clear the grounded barges.

How bad is it? According to the U.S. Department of Agriculture, to ship a ton of grain southbound on Oct. 13, 2020, it cost $21.43. That same ton of grain cost $21.91 on Oct. 12, 2021, and $105.85 on Oct. 11, 2022.

As always, one solution is to lightload the barges, so the drafts decrease and it takes less water to move the steel boxes. But that means more barges to move the same amount of grain, which drives up transportation costs.

The Army Corps of Engineers has been scrambling to dredge areas that are most affected by the drought, but the agency is constantly playing catch-up.

“Even though the major river blockages have been resolved, at least for now, barge groundings and periodic closings continue to plague the industry on the Mississippi and lower Ohio Rivers,” according to RTN

The law isn’t what you rst think of when you hear the word “innovation.” But the law does change with the times, sort of.

That dry-rotted concept called the “Walker Doctrine” (breach of employment duty barring recovery) is barely ever applied these days. And when it comes to calculating an injured seaman’s daily stipend (maintenance), the law has moved to appreciate the expenses of modern life.

BY JOHN K. FULWEILER

BY JOHN K. FULWEILER

Maintenance is structured so that money should ow to the injured seaman. For instance, the obligation to pay maintenance doesn’t relate to whether there’s a showing of negligence or unseaworthiness. And it doesn’t matter whether the injury was suffered onboard or ashore as long as the seaman was in the service of the vessel. That said, while maintenance payments are calculated based on a seaman’s expenses, they’re never enough, and maintenance seems largely ineffective at providing meaningful assistance. It’s for this reason that it’s important to include as many expenses as possible in undertaking the calculus.

Lodging expenses can arguably include all expenses “necessary to the provision of habitable housing” such as heat, electricity, home insurance, trash service and real-estate taxes.

In negotiating a maintenance payment, I have successfully included the rental cost of a hot-water heater and loan payments on new windows, making it reasonable to believe loan payments for rental furniture and appliances would also be considered. There is relatively new law rightly stating that cellphone and internet service are “common utilities in the life of most people” and are properly included in the maintenance calculation.

And while transportation costs are sometimes considered part of cure, seaman shouldn’t hesitate to shoehorn them (car payments, insurance, fuel, etc.) into the maintenance sum because cure isn’t paid regularly and those transit expenses being paid as maintenance go to “palliating the disadvantages of seafaring life.”

The maintenance system doesn’t help drive outcomes that ultimately improve the working conditions of seafarers. Still, so long as it’s in place, those who need what bene t it offers should appreciate that, despite what they’re told, the maintenance calculation covers many of the expenses of modern-day life.

you lose your insurance), which can often feel hard to digest.

BY DAN BOOKHAM

BY DAN BOOKHAM

Dan Bookham is a vice president with Allen Insurance & Financial. He specializes in longshore, offshore and shipyard risk. He can be reached at 1-800-236-4311 or dbookham@ allenif.com.

It doesn’t have to be that way, however. By taking a proactive approach to risk management and drawing on the resources of your insurance company (resources your premiums fund), those loss-control visits can feel less like a visit by a drill instructor looking for an unmade bed and more like a collaboration with safety specialists. These specialists can save you money and ensure your people head home each day injury free.

In preparing for a loss-control visit, work with your insurance agent and take a preliminary walk-through to see if you both can spot any easy xes or potential trouble spots (a frayed cord on a tool for example, or sloppy housekeeping in a workshop). Having your own punch list of planned corrections and improvements will minimize any surprises and make it easier to budget for the xes. When the loss-control team visits, rather than just relying on the written report, be sure to ask them to ag issues in a post walk-through meeting so you can discuss them while memories are fresh.

When the report comes in, be prepared to respond with a timeline to address the recommendations. I’ve often found that draconian demands to make immediate xes soften if you demonstrate a willingness to work on trouble spots at a reasonable (and often more affordable) pace.

Use the tools insurers provide, both online and in person, to make the most of your premium dollars and improve the safety and risk pro le of your business.

New moves to reconcile offshore wind and fishing

The expanding drive to establish wind energy areas off the Paci c and Gulf of Mexico coasts is attracting tentative new efforts to head off con icts with the commercial shing industry and compensate for wind development impacts.

The Bureau of Offshore Energy Management published a nal-sale notice Oct. 18 offering five California OCS lease areas that total approximatel y 373,268 acres.

This will be the rst-ever offshore wind lease sale on the U.S. West Coast and the rst-ever U.S. sale to support potential commercial-scale oating offshore wind energy development, BOEM said

The notice drew a measured response from the Responsible Offshore Development Alliance, a coalition of shing groups that appears aiming to nudge BOEM rather than confront the agency.

“At present, there are no large-scale such facilities anywhere in the world,” according to a RODA statement “A thoughtful and measured approach to design, construction and operation should be ensured given the lack of veri able scienti c data on potential impacts to the environment and ecological function of the California Current Large Marine Ecosystem.”

The shermen gave credit to BOEM for acknowledging that the lease areas have historically been used for shing, for increasing bidding credit incentives for wind developers to provide community bene ts, and for requiring them to develop communication plans and strategies to reduce shing con icts.

However, BOEM should still require speci c nancial commitments from wind companies to qualify for community bene t credits, said RODA. Those should incorporate “sliding-scale bid credits so that more robust mitiga-

tion agreements are afforded greater weighting,” the group said.

“Fishing community members are hopeful that winning bidders will make nancial commitments to impacted communities commensurate with their full, cumulative impacts and induced risk,” said Mike Conroy, RODA’s lead for West Coast activities.

Two lease areas are in the Humboldt region off northern California, and three are northwest of Morro Bay. A day after BOEM’s sale notice, central California coast shing associations and wind companies announced forma-

tion of a new effort to foster coordination and cooperation between the industries.

The Morro Bay Commercial Fishermen’s Organization and the Port San Luis Commercial Fisherman’s Association are working with Castle Wind LLC, a joint venture between Trident Winds Inc. and TotalEnergies Renewables USA, to establish the Morro Bay Lease Areas Mutual Bene ts Corp. (MBC).

“The purpose of the Morro Bay MBC is to facilitate communication, coordination, and cooperation between

the Central Coast commercial shing industry and offshore wind project developers, as well as to provide nancial resources in furtherance of California Coastal Act policies,” the shermen and developers said in a joint statement.

“Morro Bay MBC creates a pathway for the industry to demonstrate to the shermen, to BOEM, and to the California Coastal Commission, the commitment of project developers to responsible offshore wind development that protects and supports a sustainable commercial shing industry.”

The

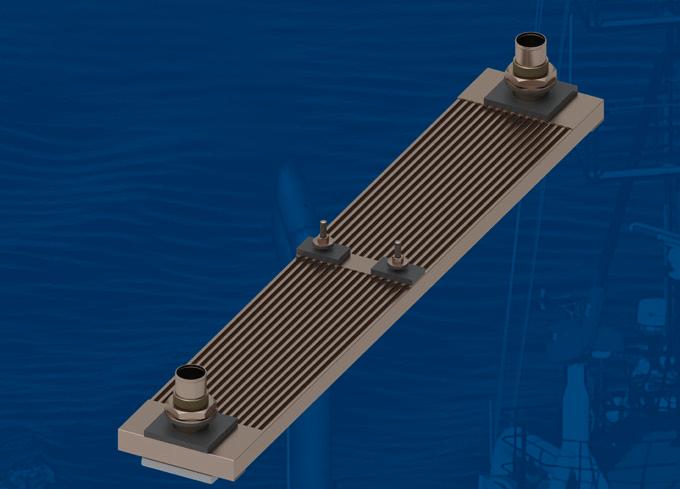

“It’s a source of comfort for the families,” said Maine artist and sculptor Jay “J-Bone” Sawyer, who created the monument dedicated Sept. 24 in Rockland, Maine. “A symbol to increase awareness for the maritime industry, and those that make the sacri ces daily.”

Prior to the ceremony family and friends gathered in front of the memorial hugging people with familiar faces. Others looked for their loved ones name etched in the at steel, then rubbed an impression with paper and crayon.

Patricia Quammie of Jacksonville, Fla., lost her husband, Theodore Quammie. He was a merchant mariner for 37 years, the El Faro’s chief steward, and the oldest person on the ship.

“Everyone has my deepest sympathy and condolences,” said Quammie. “I pray that we stay united forever, like our 33 precious loved ones who will stay together forever. For those going out on the ships now and their families, if you see something is wrong, don’t be afraid to speak up. Don’t be afraid to challenge the system. Make sure if you’re supposed to have your safety equipment, you know the location, you know where it’s at. Make sure you just take all the necessary safety precautions.”

Sawyer welcomed the more than 300 family members and guests.

“Public art is powerful,” said Sawyer. “And putting it here in Rockland for the dedication of the El Faro Salute proves that. It now belongs to both Rockland and the maritime community.”

El Faro translates as “the lighthouse.” If you look through the port holes, you’ll see Rockland Breakwater Lighthouse in Penobscot Bay. Beyond that, merchant mariners will continue to sail by.

A week before the dedication the sculpture was still white metal. Tim Matheson, a Maine Maritime Academy graduate, sandblasted it with salt water to start the rusting process. Since then, the color has transformed, and it’s not nished changing. The bottom is core 10 steel.

Shipmate Ray Moody, who now teaches at Maine Maritime, modeled the male uniform. Classmate Maggie Letarte modeled the woman’s jacket. — Robin Coles

The grounding of the high-speed passenger ferry Commodore in New York’s East River that resulted in $2.5 million in damage to the Seastreak-owned and -operated vessel was largely a result of a software flaw that saw the catamaran’s operators lose primary speed and steering control of both port waterjets, the National Transportation Safety Board said in October. However, NTSB investigators also found that better training for loss of propulsion or steering would have enhanced the captain’s response to the emergency, either using back-up controls or by shutting the engines down. One minor injury was reported among the seven crewmembers and 107 passengers.

The Department of the Interior announced in October that the Bureau of Ocean Energy Management (BOEM) will hold an offshore wind energy lease sale on Dec. 6 for areas on the Outer Continental Shelf (OCS) off central and northern California. This will be the firstever offshore wind lease sale on the U.S. West Coast and the first-ever U.S. sale to support potential commercial-scale floating offshore wind energy development.

Federal agencies have released a new plan to protect endangered North Atlantic right whales, as the government promotes aggressive development of offshore wind energy projects. The Bureau of Ocean Energy Management and the National Marine Fisheries Service released their joint strategy Oct. 21 “to protect and promote the recovery of North Atlantic right whales while responsibly developing offshore wind energy.” Comments on the plan can be submitted through Dec. 4.

Download our NEW mobile app. Search WorkBoat in your app store on your mobile device.

The inland barge industry is getting hip and cool, taking its message about top pay, great bene ts and cool jobs onto social media networks where they know the next generation of potential mariners hangs out.

Faced with a competitive and persistently tight job market, the industry is trying to reinvent its image as it attempts to attract more young job seekers to the ranks of tugboats and towboats, seeking to capture their attention with snappy slogans, fast-moving videos and promises of great pay, quick advancement, work that makes a difference, comfortable boats

and a work environment that treats employees like family.

At Moran Towing, “we connect the world.” At Foss they ask: “Are you a salty dog or a landlubber?” At Crowley Marine they call it “a workplace like no other.” Ingram Barge promises careers that are “exciting and unique.” At Vane Brothers, applicants are reminded that vessels are built “with CREW COMFORT in mind” and that an “even-time work schedule” means that “you are working six months out of the year but receiving a full year’s salary!” And a video from Parker Towing invites job seekers “on our journey into the

future as we deliver the cargo that fuels the American dream.”

This is all part of both a short-term and long-term effort by inland tug and barge companies to recruit workers for current openings but also prepare the ground for the future. As more and more senior mariners retire, the maritime industry is expecting a job shortage of

150,000 mariners by 2025, at a time when the industry has been growing at an average rate of 6.4% a year.

Companies that once turned away applicants, rarely advertised and didn’t have hiring managers now have fulltime recruiters. They spend thousands of dollars traveling to job fairs, advertising openings, offering hiring bonuses

and investing in modern boats that offer fancy galleys, comfortable living spaces and the most sophisticated navigation and propulsion systems.

“We need to be especially creative with our eet recruiting practices to not only encourage maritime academy students and military veterans to consider tugboating as an option, but

also to attract young men and women who perhaps had not even thought about a career on the water,” said Capt. Rick Iuliucci, vice president of operations at Baltimore-based Vane Brothers. “We continue to actively partner with groups such as the American Waterways Operators to get the word out: You can make a very good living in this industry, with terri c pay and bene ts while working in a safe and comfortable environment. The schedule is also favorable, if you consider that most Vane Brothers crews generally work two weeks on the vessel and then get two weeks off. It is just as important that we work to retain quality mariners and help them advance their careers.”

In mid-August, AWO launched a new social media initiative on Facebook, Instagram and Twitter to highlight the unusual things that tugboats push or pull

and barges carry. Called the “Coolness Factor,” the campaign pro les unique things that the industry has done that evoke “oh wow” reactions and show that jobs that can be tedious, physical, dirty and dangerous can also be exciting and cool.

“The tugboat, towboat and barge industry is a huge contributor to our

nation’s economy, security, supply chain and quality of life, and beyond that, it’s a unique industry that does fascinating things every day,” said Jennifer Carpenter, president and CEO of AWO. “Many Americans, including potential employees, have no idea what barges and towing vessels do that affects their everyday lives for the better, or what a great place

Whether you’re powering an offshore service vessel, a passenger vessel, or an inland pushboat, Louisiana Cat has the right engine for your hard working fleet. We focus on you, the customer, and the reliability, safety and profitability of your business. Let us help you navigate every waterway. Visit us online to request an engine quote for your next project: www.LouisianaCat.com/Marine.

to make a career this industry can be. The ‘coolness factor’ campaign aims to catch people’s attention and entice them to take a deeper look at an industry that does amazing things every day.”

In addition to hauling coal, steel and soybeans, commercial barges have

transported NASA’s Space Shuttle, Army tanks, and for the past 46 years have provided the platform for the 4th of July reworks on the East River in New York City.

“Cool” examples highlighted in the campaign include:

• The movement this summer by Canal Barge of a restored PT-305 World War II patrol torpedo boat to the National WW II Museum in New Orleans, where it will be permanently displayed to the public. Canal Barge donated time and resources.

• The donation by Vane Brothers of a retired 120-foot VB-1 water barge to the Ocean City Reef Foundation, which sunk the barge for use as an arti cial reef off the coast of Maryland.

• A barge supplied by Hughes Marine Firms that was used to stage a concert by Colombian reggaeton musician J Blavin on the East River in New York.

• A Hughes Marine barge that served as a construction site to build the West Thames Street Pedestrian Bridge at the company’s yard in Brooklyn, N.Y. It was then towed to Lower Manhattan where Weeks Marine Inc. lifted the bridge and placed it over the West Side Highway as a replacement to bridges that were damaged or destroyed on 9/11.

The MSV(L) is scheduled to undergo builder’s trials through November, followed by extended acceptance trials. The prototype isn’t slated for delivery to the Army until early 2024.

— Ken Hocke

Bellingham, Wash.-based All American Marine (AAM) was recently awarded a contract to build a research vessel for the University of Hawaii at Manoa and the University of Hawaii Foundation (UHF).

The 68'6"×25' semi-displacement, aluminum-catamaran hull was developed by Teknicraft Design, Auckland, New Zealand. The vessel will contain proven design elements found in the recently commissioned research vessels Blue Manta and Shearwater, which were built for BlueTide Puerto Rico and Duke University, respectively.

Vigor was awarded a 10-year contract from the Army in 2017 to design and build up to 36 new-generation landing craft. The shipyard partnered with BMT to design the Army’s new 117'×28'2" aluminum, tri-bow monohull maneuver support vessel light, or MSV(L). A prototype was launched Oct. 10 at Vigor’s marine fabrication facility, Vancouver, Wash.

Currently, the Army’s objective is to build 13 vessels to replace the landing craft mechanized-8 (LCM-8), a Vietnam-era watercraft that is unable to transport some of today’s equipment due to the weight of modern combat vehicles.

“Not only does this prototype represent the rst of its kind for the Army as a digital vessel, but also, the overall team has surmounted several hurdles having to do with Covid-19-related workforce and supply-chain issues,” said Col. Beth Behn, the Army’s chief of transportation. “I couldn’t be more proud of this partnership to become one step closer to providing Army mariners the world over a truly modernized

capability.”

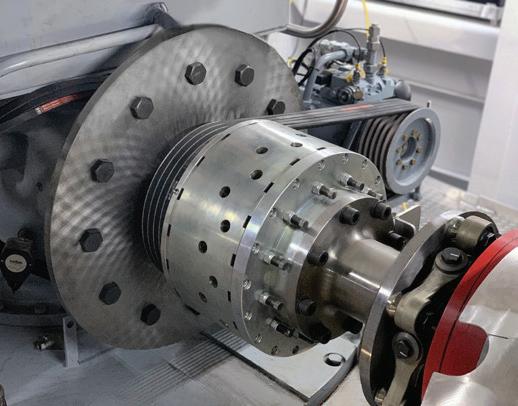

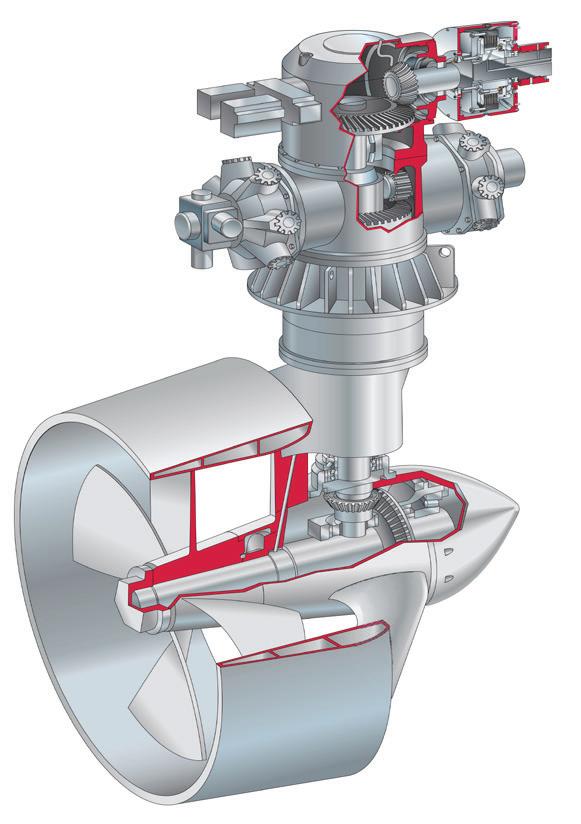

Main propulsion comes from three MTU 2,600-hp diesel engines, matched to three waterjets. (WorkBoat requested more information, but the Army said it would probably not have any more speci cations to announce.) The prototype has a running speed of 21 knots (laden) and more than 30 knots (unladen), a range of 360 nautical miles, and a 4' draft (laden).

The MSV(L) is designed to be faster and more maneuverable than its predecessor and to have the ability to operate in intercoastal areas, inland waterways, and in anti-access and area-denial environments.

The prototype has a payload of 82 short tons, meaning it can haul one combat con gured M1 Abrams tank, or two Stryker combat vehicles, or four joint light tactical vehicles, as well as multiple other payload con gurations.

MSV(L)s feature a 1,697-sq.-ft. deck area with drive-through capability, bifold bow ramp and kedge anchor system. The boats will carry an eightperson crew.

The vessel for Hawaii is being constructed to Coast Guard standards for service in waters where the range to refuge is 150 nautical miles or less. It will operate as a multipurpose research vessel in Hawaiian waters and offshore on ocean routes for a crew of up to 12.

The propulsion package will include two xed-pitch propellers powered by twin Scania DI16 082M Tier 3 engines, each rated at 800 hp at 2,100 rpm. The twin-engine speed and fuel-ef ciency of the vessel will allow University of Hawaii researchers to access and study marine environments in the Hawaiian Islands.

Onboard the vessel, scientists and crew will have comfortable live-aboard quarters, large wet and dry lab spaces, as well as a range of the latest oceanographic equipment in which to conduct a variety of missions.

The vessel has been custom designed to support a diverse portfolio of science and outreach missions.

“We are incredibly excited to be able to have a custom-built vessel for our environmentally driven research

missions in and around the Hawaiian Islands,” Carl Meyer, a University of Hawaii researcher, said in a statement. “All American Marine understood our mission and provided a new design to meet our mission-speci c needs. We are excited about the positive impacts this vessel will have for us including a substantial increase in the abilities of our programs.”

The new research vessel integrates the signature Teknicraft Design symmetrical and asymmetrical combined hull shape, bow-wave piercer, and a hydrofoil-assisted hull design. The hull and hull components are designed to break up wave action and ensure reduced drag while enhancing passenger comfort. Teknicraft’s hydrofoil-assisted hull design features low-wake wash energy and fuel economy. The main foil action reduces the power needed to maintain service speed.

The vessel is designed to offer passengers and crew a smooth ride and com-

fort, as the hull provides a cushioned effect when encountering waves.

Shipyard of cials said the boat will be able to maintain an estimated fully loaded cruise speed of 22-24 knots and with a fuel-ef cient minimum survey speed of three knots. With a large fuel capacity of 1,800 gals., the design will support a science team of eight on offshore missions and 22 students/crew on shorter day excursions.

“This vessel will expand U of H’s environmentally focused research activities and will aid them with their conservation efforts in the Paci c,” said Ron Wille, All American’s president and COO.

AAM was also awarded a contract in October to build a high-speed, longrange, eco-tour vessel for Phillips

Research vessel for Hawaii is being built for service in waters where the range to refuge is 150 nautical miles or less.

Cruises and Tours. The vessel will operate in Whittier, Alaska.

The Teknicraft-designed 84'6"×30'7" semi-displacement aluminum catamaran hull will be built in AAM’s facility on Bellingham Bay. It is scheduled for delivery by May 1, 2024. The new passenger vessel will be added to the Phillips Cruises eet that operates in Prince Wil-

liam Sound on daily sightseeing tours.

The new tour boat will be Coast Guard-certi ed Subchapter T. With a fuel capacity of 1,200 gals., the fuelef cient design will be assisted by a xed aluminum hydrofoil, designed to enhance its speed and stability at high speeds.

The propulsion package includes four MJP 350X waterjets powered by four Scania DI16 082 engines rated at 800 hp each. Cruise speed is 32 knots fully loaded.

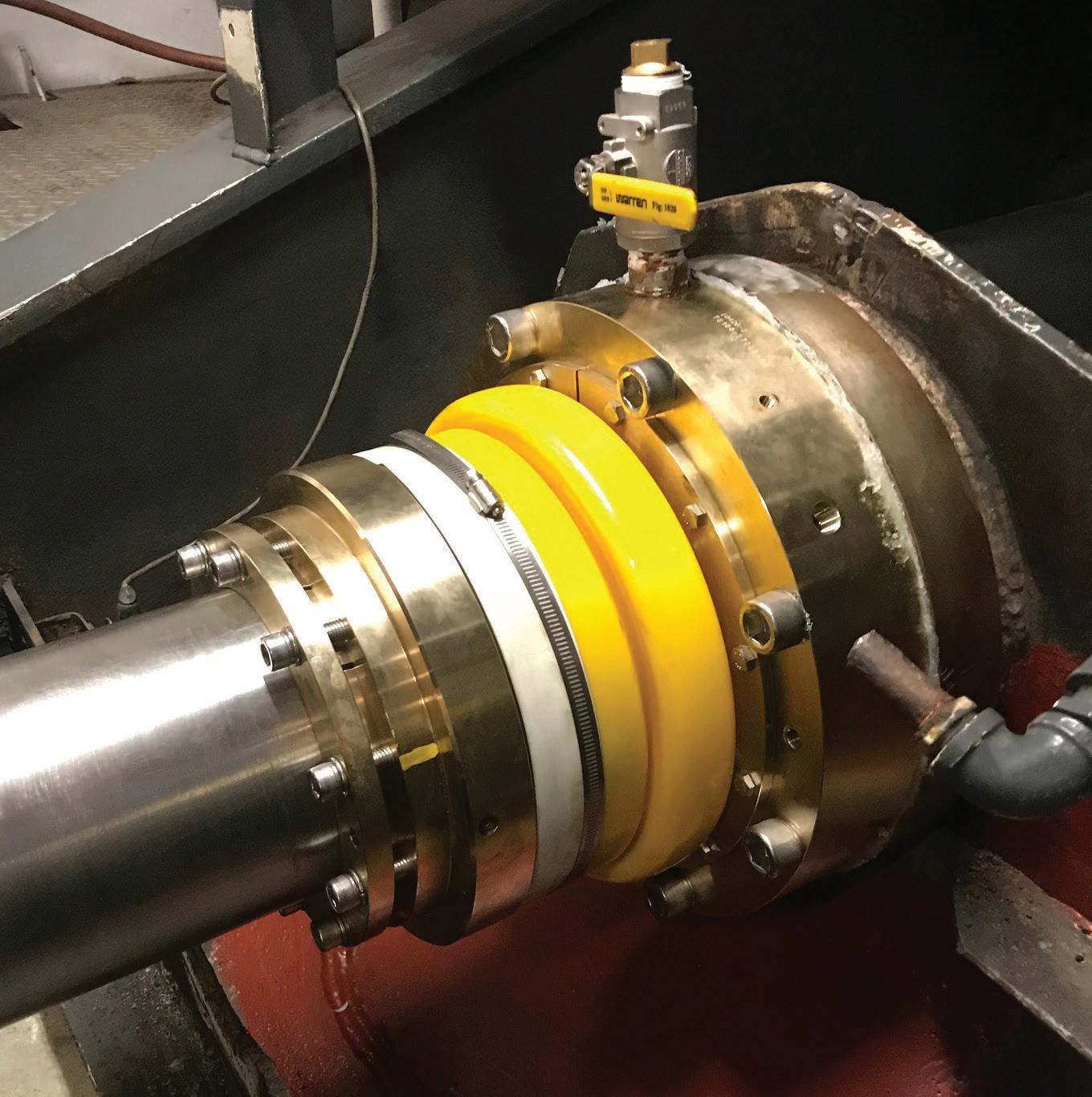

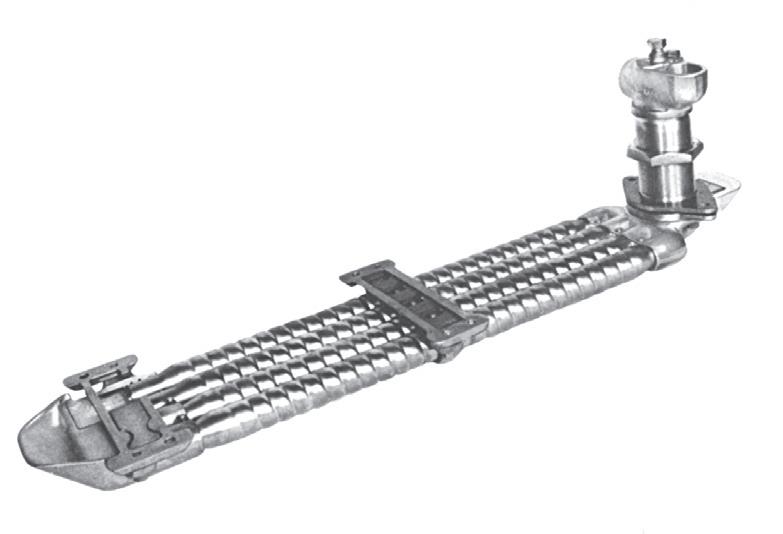

The Tampa Bay Pilots Association will have one of its Chesapeake-class pilot boats repowered and repaired at GladdingHearn Shipbuilding

The 53' was built in 2003

when the Somerset, Mass., shipyard introduced the Chesapeake-class of midsize, high-speed launches.

In 2015, the Tampa pilots took delivery of the shipyard’s rst Chesapeakeclass MKII, which incorporates Volvo Penta’s IPS 2 pod system.

With more than 50,000 operating hours, the all-aluminum pilot boat will

be repowered and undergo repairs.

“After 19 years of hard work, the vessel is showing some wear and tear but she still has a lot of life left so it’s de nitely worth reinvesting in,” said Peter Duclos, Gladding-Hearn’s copresident and director of sales.

Along with modifying the engine beds, hull frames, exhaust systems,

cooling- and fuel-system piping to accommodate the new engines, the yard will replace the twin 600-hp Caterpillar 3406E engines with a pair of Cat C18, EPA Tier 3 diesel engines, each delivering 670 hp at 2,100 rpm.

The repowered boat will have a top speed greater than 25 knots.

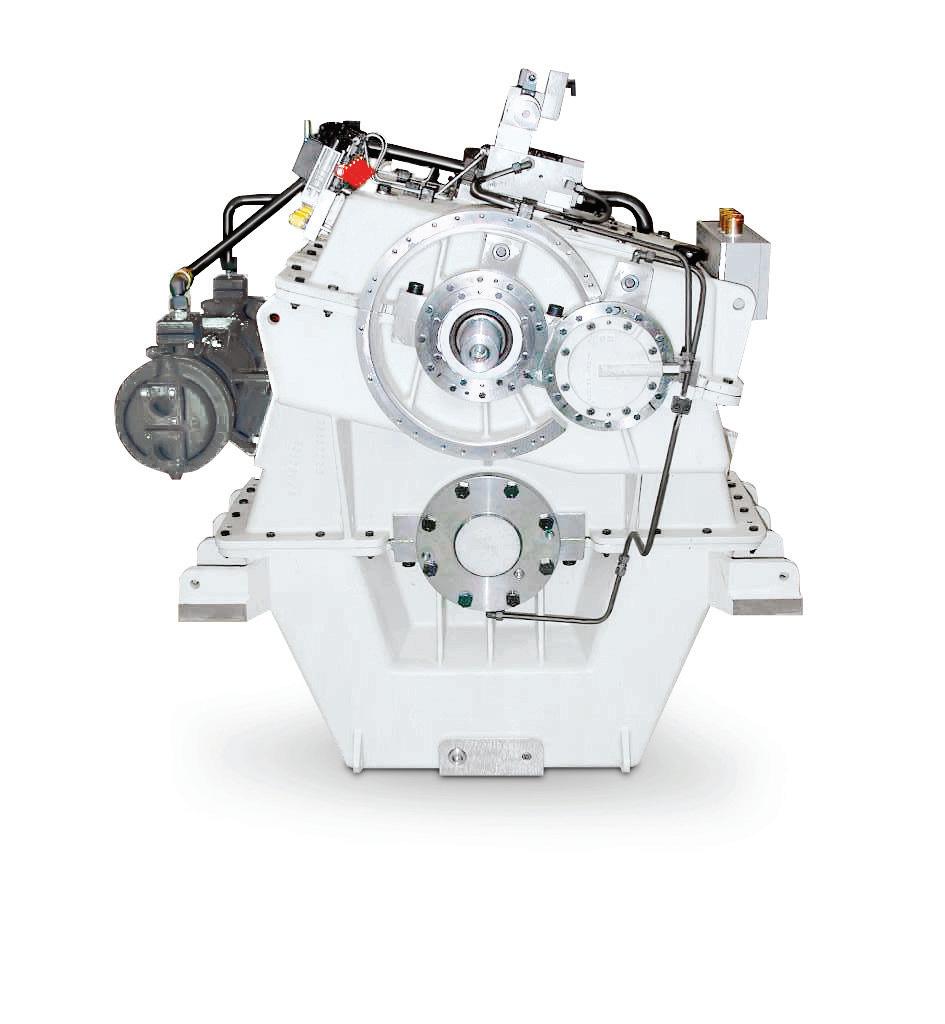

After installing new shafts, bearings, seals and couplings, the engines will turn new 5-bladed Bruntons propellers through Twin Disc MGX-5136A Quickshift gears.

In addition, the pilot boat will receive a new SeaStar Optimus steering system and a new Northern Lights 12kW generator.

Other upgrades include new Norsap 1500 pilot seats, new windows, three new doors to the pilothouse and four new hatch covers.

The boat’s bottom, topsides and pilothouse will be stripped to bare metal and receive a fresh coating

system.

In other Gladding-Hearn news, the Pilots’ Association for the Bay and River Delaware have ordered a 54' pilot boat from the shipyard.

It’s the Lewes, Del.-based association’s fourth Chesapeake-class launch and 11th pilot boat built for the pilots by the Somerset, Mass., shipyard since 1957.

Delivery of the new pilot boat is scheduled for 2024.

The deep-V hull was designed by Ray Hunt Design. The new, allaluminum 53.6'×17.8' launch has a 4.9' draft.

The boat will be powered by twin Volvo Penta D16 diesel engines, each rated at 651 hp at 1,800 rpm. Top speed will exceed 25 knots.

The engines will turn 5-bladed Bruntons propellers through ZF 500-1-A gear boxes.

A Humphree interceptor trim

control system, with its automatic trim optimization, will be installed at the transom.

Compmillennia LLC, Washington, N.C., has designed, built, and delivered a 41'×13' Lightspeed 1188 catamaran compositecored pilot boat to the Biscayne Bay Pilots Association

Designed with a 2' draft, the shipyard calls the Miami a fast, reliable, economical offshore pilot boat.

“Compmillennia’s mission is to produce a small catamaran to compete with larger V-bottom center consoles in open water, but with a much friendlier fuel consumption,” said Compmillennia’s Stephanie Tenney. “Larger V-bottoms need a lot of engine horsepower to push

Today’s modern vessels are highly sophisticated and represent a much higher risk profile for a ship owner when it comes to selecting the right shipyard. Eastern’s proven track record of successfully engineering and building these large and complex ships on time and on budget dramatically reduces that risk. As one of the top tier-two shipyards in the United States, Eastern Shipbuilding Group is the reliable partner you can trust to deliver your next vessel on time, every time.

their 22-foot to 39-foot length along the waterline, and more horsepower equals more weight, more cost, larger vehicles to tow and more fuel.”

Built for pilot boat associations seeking economical acquisition and operations, the Lightspeed pilot boat is designed to deliver ef ciency,

low-maintenance and exibility in high-speed transit, safe pilot boarding, and search and rescue missions, Compmillennia said.

The boat’s all-composite construction features selective use of berglass, carbon and aramid ber, impact- and vibration-absorbing core

and high-elongation vacuum-resininfused vinyl ester resin.

It is designed to increase durability and lower weight by 35% versus other composites and by 50% versus typical metal construction, according to Compmillennia of cials.

The Miami has room for a captain who can haul up to six pilots at a time.

Main propulsion comes from twin Mercury 300-hp Sea Pro outboards with Mercury’s Enert ECO 16"×20" stainless steel props, giving the boat a running speed of 45 knots. The boat is also tted with Mercury controls and an Optimus 360 steering system.

The outboards are fed from a 424gal. fuel tank.

“Our mission is achieved with the Lightspeed catamaran,” said Tenney. “Less horsepower is required, less weight, greater fuel economy and our trademark smoother ride.”

— K. Hocke

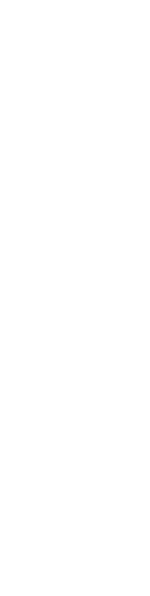

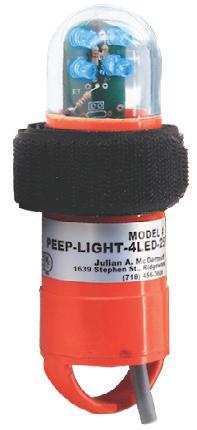

It took 200 years to evolve from wooden boats to steel boats. Like any industry with heavy equipment as a primary asset, global maritime operators don’t just move quickly toward big shifts in technology. Yet, today, change they must as worldwide mandates for reduced emissions are pushing the industry down a new path. Because of this reality, the transition to cleaner fuels is about more than just the fuel itself. Solutions must provide strategic value to shipbuilders and maritime professionals, allowing them a workable path to longterm mandated decarbonization. Methanol, common to the marine industry in portside and on-vessel applications, provides an example and an opportunity. By tapping into existing fuel availability infrastructure, methanol as a hydrogen carrier feedstock removes risk and increases comfort with change – two key factors as the industry navigates toward environmental mandates. Methanol’s global port availability is powering Methanolto-Hydrogen (M2H2) systems, solving the inherent complexities, cost, and logistics of on-board hydrogen as a clean source of ship energy.

When methanol is used as a high-density hydrogen carrier feedstock, self-contained reformer systems can now create hydrogen on-demand – as needed and on-vessel – via a safe and efficient chemical process. Reforming methanol into high purity, fuel cell grade hydrogen eliminates the need for high pressure gaseous or cryogenically cooled liquid hydrogen storage tanks, saving precious vessel space, and significantly reducing safety risk. When combined with Polymer Electrolyte Membrane (PEM) fuel cells, these selfcontained M2H2 reformer units support power demands ranging from 30kW to 200kW; multiple sets of M2H2 reformers and PEM fuel cells can be combined to handle MW applications.Workboat vessels fit the bill for methanol-to-hydrogen’s optimal power levels, with ferries, tug and tow boats, fishing boats, and crew transfer ships demonstrating the potential.

While Hydrogen One, the world’s first methanolpowered tow boat, has a relatively high price tag for the M2H2 reformer/PEM fuel cell systems, costs for future vessels is expected to decrease significantly as the technology is adopted and commercialized over time. The Hydrogen One operators are not facing the hundreds of millions it could cost to place other alternative fuel fueling stations all along the Mississippi. The vessel can readily capitalize on an existing and proven support infrastructure for immediate value. Methanol – and so, methanol-to-hydrogen – is available all over the network of US waterways and global shipping ports. This first-of-its-kind workboat generates hydrogen ondemand via methanol-to-hydrogen systems, combining the fuel with PEM fuel cells to deliver primary power for the vessel.

Naval architects take note, as on-board hydrogen generation has positive impact on ship designs. Systems are highly efficient and eliminate the costly and complex requirements of pure hydrogen storage, reducing safety risk and increasing usable cargo space. Hydrogen ondemand is just better, to the point of making hydrogenpowered shipping a reality.

Infrastructure matters as much as – or more than – the fuel itself. Methanol-to-hydrogen is available now, can be instantly implemented on existing vessels with minimal retrofit, and offers immediate and significant reduction in emissions. At the same time, it puts shipbuilders on a path to full decarbonization, even as maritime pros are familiar with methanol and its requirements for safe handling and transport.

Fairbanks Morse Defense (FMD) announced in October that it has been awarded a contract by Huntington Ingalls Industries to build and deliver four main propulsion diesel engines featuring common-rail technology to power the Navy’s newest landing platform/dock (LPD) ship, LPD 32. The vessel will be the third San Antonio-class Flight II amphibious ship. The 684’x105’ ships are

used to embark and land Marines, their equipment and supplies ashore via air cushion or conventional landing craft and amphibious assault vehicles.

Colorado-based Birdon America Inc. has been awarded a $1.2 billion contract to design and build 27 waterways commerce cutters (WCC) for the Coast Guard. The WCC contract comprises two separate but related vessel designs: the river buoy tender (WLR) and the inland construction tender (WLIC).

Both variants are complex, modern, and designed to military standards. The new cutter design is expected to provide up to 11 days of accommodation and habitability for up to 19 crewmembers. The 27 WCCs will be constructed within a 10-year period beginning with an 18-month design finalization period. Bollinger Shipyards, Lockport, La., will

The river buoy tender (WLR) and the inland construction tender (WLIC).

subcontract to Birdon for production of the bare hulls.

TOTE Services LLC and Philly Shipyard Inc. held a keel-laying ceremony in October for the second of five new purpose-built, state-of-the-art training vessels for state maritime academies. Marad’s new vessel program — known as national security multimission vessels (NSMVs) — was designed to provide

First of five maritime academy training vessels.

Academy, Maine Maritime Academy, Texas A&M Maritime Academy and California State University Maritime

Silver Ships Inc., Theodore, Ala., recently delivered a multimission Explorer 40 landing craft vessel to the Suffolk County (N.Y.) Public Works Department. The custom-built 40’x14’ workboat’s primary purpose is transporting heavy machinery and equipment to further support the efforts of the Suffolk County Public Works Department. The vessel is powered by triple 250-hp Honda outboard motors and includes a Vetus 8-hp bowthruster to facilitate maneuvering and docking in close quarters. The Explorer 40 operates with a 12-volt direct current electrically actuated bow door that is connected to a stainless-steel braided cable routed through a series of pulleys.

When it comes to vessel repair, many boat owners discover that most shipyards are still stuck in the 20th Century. Simply because they have forgotten that in the 21st Century, the customer is king. For years, the focus of Bay Ship & Yacht has been to transform our shipyard to the one that provides Absolute Customer Satisfaction to every customer, every time. At Bay Ship & Yacht, good enough is never good enough, and because of our commitment to continuous improvement and innovation, we have become a knowledge-based shipyard where ideas are shared freely, and where the best ideas get adopted. Whether it’s installing advanced technol-

A keel-laying ceremony was held at St. Johns Ship Building (SJSB) for the second Incat Crowther 30 crew transfer

40' landing craft for New York. Silver Ships

vessel (CTV) to be built to comply with the Jones Act. Officials from Windea CTV LLC, a partnership between Hornblower Wind LLC and MidOcean Wind who will operate multiple vessels in support of U.S. offshore wind development, were in attendance. The first series of vessels underway at St. Johns will go directly into service in support of the Vineyard Wind I construction project.

ogy, like our Synchrolift transportation the HMB-1, the only covered drydock Coast, to providing dedicated Project each customer – it’s all done with our absolute satisfaction in mind.

The U.S. offshore wind industry began 2022 with a bang when the Bureau of Offshore Energy Management (BOEM) scored $4.37 billion from bidders for six wind-energy leases in the New York Bight.

It was the highest-grossing competitive offshore energy lease sale in history, including oil and gas sales, according to the U.S Department of Interior.

“This week’s offshore wind sale makes one thing clear: the enthusiasm for the clean energy economy is undeniable and it’s here to stay,” said Interior Secretary Deb Haaland in announcing the Feb. 23 auction results.

Some 480,000 acres of ocean leases between New Jersey and Long Island were pared down, a 72% reduction “to

avoid con icts with ocean users and minimize environmental impacts,” according to the BOEM.

The agency says it is evolving that planning methodology as a result of the political battering BOEM took for years from the commercial shing industry over wind-energy sites off southern New England.

The Biden administration’s march

to establish East Coast wind leases moved south when an auction in the Carolina Long Bay region drew bids from TotalEnergies Renewables USA LLC and Duke Energy Renewables Wind LLC totaling $315 million. Lower prices paid there eased some concern from industry leaders that the New York Bight auction in ated expectations and could hurt the still nascent U.S. industry.

Coastal Virginia Offshore Wind pilot project has been fully operational since fall 2020.

Dominion Energy’s Coastal Virginia Offshore Wind project, the biggest planned in U.S. waters at $9.8 billion to build out a 2.6-gigawatt turbine array, faced new political challenges. The Virginia State Corporation Commission demanded a performance guarantee for CVOW to protect consumers from footing the bill for higher costs if the turbines don’t perform as well as expected, if energy output falls short of shortfalls a “net capacity factor” of 42% as calculated over a three-year average.

Meanwhile vessel designers and

shipyards pushed forward. Damen Shipyards said it is developing a new class of vessel that will be capable of supporting large-scale, oating offshore wind turbines and their anchoring requirements in deepwater sites off the U.S. West Coast and the Gulf of Maine.

Atlantic Wind Transfers, the rst U.S. offshore wind farm support company, has its eye on six 82’ Chartwell Ambitious-class crew transfer vessels (CTVs) designed by UK-based Chartwell Marine. To be built by St. Johns Ship Building Inc., Palatka, Fla., the rst two vessels are to be delivered in summer 2023 and January 2024 with the others to follow.

Big boats on the way include a service operations vessel (SOV) contracted by Empire Offshore Wind, a joint venture between Equinor and BP, with Edison Chouest Offshore.

The “plug-in” hybrid SOV will be the rst in the U.S. offshore wind sector capable of sailing partly on battery power, operating out of New York.

During construction the Empire Wind projects will depend on a new wind turbine installation vessel to be built in Singapore, teamed with U.S.-built tugs and barges, according to wind developers Equinor and BP, and Maersk Supply Service.

Maersk said it’s been developing a design concept since 2019 with “unique feeder capabilities” to make its wind turbine installation vessel (WTIV) 30% more ef cient than using other jackup vessels.

Until U.S.- ag WTIVs are built, wind developers are expected to rely on the so-called feeder model – using Jones Act-compliant tugs and barges to carry wind turbine components out to foreignag installation vessels at sea.

With its improved handling design, the Maersk WTIV may address some of the shortcomings of those tricky transfers at sea of heavy turbine tower parts.

SembCorp Marine, Singapore, will begin construction in the fourth quarter, according to Maersk. The vessel’s jacking units, load transfer system and crane will be provided by offshore crane manufacturer NOV, while ABS is

supporting the design work.

Maersk expects it will deliver the vessel into U.S. waters in 2025.

Kirk Moore—

taf ng shortages across the U.S. over the past year have exacerbated an already dif cult labor market in the maritime sector as operators struggle to ll vacant positions on boats and in of ces.

In September, federal gures showed that there were more than 11 million job openings and only six million unemployed workers, a national mismatch that has found maritime employers ercely competing against each other to recruit, hire and retain their workforce, and having to pay a lot more to do it. The shortage has hit all maritime segments, from inland barging to shipbuilding to passenger vessels.

Knowing that without manpower they can’t run their boats or build them, maritime companies have gone into new territory both geographically and in hiring practices, moving far from their river or coastal bases to reach recruits, employing hiring managers, launching social media campaigns, increasing salaries and bene ts, and adding training programs to bring new people onboard quickly and create new career advancement opportunities. Many are also offering signing and retainer bonuses, relaxing pre-employment requirements, reaching out to veterans and offering jobs on the spot at job fairs.

Help is coming too from the outside, as maritime academies encourage their students to look at other maritime careers beyond big blue-water shipping, and vocational schools, high schools and community colleges are teaching maritime classes and promoting the industry as a viable and valuable career option.

Hiring challenges have been around for years but worsened during the pandemic, when people received generous government bene ts and stayed home, having little incentive to go back to work. In fact, the unemployment rate in the maritime sector throughout the pandemic has been higher than the national unemployment rate, according to the U.S. Bureau of Labor Statistics.

The inland industry lost many workers at this time, especially experienced, senior mariners who decided to retire. Meanwhile, there are fewer younger people wanting to take their place in the industry. The average age of mariners is currently about 55 years old, which will present continued staf ng challenges in the years ahead as these workers retire.

Jennifer Carpenter, president and CEO of the American Waterways Operators, calls it both a shortand long-term challenge for inland companies. They face the immediate need to hire workers and keep their boats moving, but also the long-term need to attract a generation of younger people to the profession and train them to take jobs into the future.

“It will require a multifaceted approach in the short term and the long term too,” she said, adding that inland companies are concerned not just with hiring workers but with the current high cost of attracting and retaining them and whether this is sustainable for their business.

The biggest challenge industry experts say is communicating the advantages and good salaries of a

waterways job to young people who have little knowledge of the work and little interest in the maritime lifestyle of living in close quarters with others, being away from home for up to a month and working in conditions that can be dangerous, include long days, bad weather, heavy physical demands, and intermittent internet connection. In short, the younger generation seems to value quality of life more than the big bucks when considering a maritime career — especially if they can have both elsewhere.

Another factor affecting hiring and retention are the increasing bureaucratic burdens on mariners that have made obtaining and retaining their licenses more costly and time consuming.

Observers suggest that the industry emphasize career pathways more than a single job, look at ways to team up with environmental organizations to

show their green stripes to younger recruits, and emphasize how mariner jobs are part of bigger national economic and security goals, according to Ken Ericksen, a senior vice president at IHS Markit (now part of S&P Global) who follows the maritime industry. Additionally, those workboat companies involved in the emerging wind power industry, he said, should emphasize how young people would be entering an exciting new renewable energy sector that is on the verge of explosive growth. — Pamela Glass

Things are looking up in the U.S. offshore oil and gas sector as it moves to capitalize on an

increase in energy prices.

Headwinds persist, however, namely a shortage of suitable vessels and, more notably, the crews to man them, as well as a four-decade-high in ation rate and nagging supply chain issues.

“There’s stiff competition for Jones Act-quali ed mariners right now and I don’t think it’s going to abate,” Richard Sanchez, senior marine analyst for S&P Global, said in October. “We’ve seen a big reshuf ing where people with high skills can pick whatever they want from a range of jobs.”

The problem is particularly glaring in the deepwater Gulf of Mexico, where three new oil and gas elds came online this year. The Energy Information Administration (EIA) had earlier predicted nine new elds would deliver rst production between 2022 and early 2023. Oil prices, in the meantime, were forecast to return to triple-digits before year end, driven largely by Saudi

Arabia-led OPEC and allied producers’ controversial decision to reduce production beginning in November by roughly two million bbl/d.

The Bureau of Ocean Energy Management (BOEM) predicts Gulf of Mexico oil production will increase to 1.892 million bbl/d this year, from 1.693 million bbl/d in 2021, but still 88,000 bbl/d less than pre-COVID 2019. Earlier this year, Wood Mackenzie estimated that 2022 would see record Gulf production of 2.3 million bbl/d. Gas production, likewise, is projected to increase to just over 2.34 bcfd and rise steadily to 2031, according to BOEM.

While generally shunning exploration drilling, operators have kept an average of 19 higher-priced deepwater rigs active for most of the year, mainly engaged in development drilling, as companies opt to squeeze more production from existing production assets. Production support has created signi cant demand

for 4,000-6,000-dwt platform support vessels (PSVs), commanding day rates ranging from $35,000 to $45,000/day for charters of six months to a year, said Sanchez. He noted that the spot market for large PSVs is as high as $50,000 to $55,000/day.

Much of the higher charter rates, however, are being offset by recordhigh costs, primarily in wages and

bene ts, as vessel owners are forced to boost compensation to attract and retain quali ed mariners. “When you’re talking about the operating costs on a deepwater supply boat, your crew accounts for about 70% of OpEx, so while costs have gone up for maintenance, repair, parts and support labor, it’s not as signi cant a dollar amount increase, as it’s a small percentage of the operating costs on a deepwater vessel,” said Matthew Rigdon, vice president and COO of Jackson Offshore Operators LLC, Houston.

He added that labor problems go beyond PSVs and other support vessels. “Our major vendors are having a hard time getting labor as well,” he said. “So, if you can get the parts you need, then it’s a matter of having quali ed labor from the vendor to do the work. That’s driving some serious delays in repair work, as well as any more reactivations that may or may not happen in the

future.”

However, few PSVs over 4,000 dwt remain stacked and ready for a return to the Gulf market. A number of large, U.S.-flag vessels also have mobilized overseas, while still others are being incorporated into entirely different industries, most notably the offshore wind sector on the U.S. East Coast.

Offshore wind developers, likewise, face a dearth of both qualified labor

and vessels, especially Jones Act-compliant wind turbine installation vessels (WTIVs). Rising inflation and supply chain challenges are causing would-be WTIV owners to hesitate, according to a Sept. 22 Reuters report. “We’ve had real conversations, people who were almost signing on the dotted line, but when the tide goes down, people wait to sign the contracts until a later date,” Alberto Morandi, general manager of GustoMSC,

Houston, told Reuters. “There’s been a lot of postponement of WTIV projects due to these disruptions.”

Regardless, a combined 943 MW of incremental offshore wind is on target to begin powering homes and businesses in Massachusetts, New York, and Maine next year, according to the Department of Energy. Vineyard Wind 1 off Massachusetts highlights the three projects expected to come online in 2023. At 800 MW, Vineyard will be the nation’s first commercial grade offshore wind farm.

Also scheduled for 2023 start-up are the Ørsted and Eversource South Ford Wind farm (132 MW) off New York and the 11-MW Aqua Ventus pilot project in Maine. Project participants include Cianbro Corp. and the University of Maine. — Jim Redden

Adm. Linda Fagan was sworn in as the 27th commandant of the U.S. Coast Guard on June 1. Adm. Fagan became the first woman, and first mother, to lead any branch of the U.S. Armed Forces.

Adm. Fagan began her 36-year career as a deck watch officer on the Seattlebased heavy icebreaker Polar Star U.S. Sen. Maria Cantwell, D-Wash., chair of the Committee on Commerce, Science, and Transportation, led Adm. Fagan’s nomination hearing in April. “This is a historic moment for our country and for women in the Armed Services,” Cantwell said in her opening statement. “It will be the first time that a woman will lead one of the six branches of the Armed Forces. I am hoping that your leadership will also lead to more progress on getting women recruited and retained in the Coast Guard.”

Adm. Fagan “will inspire generations of American women to strive to serve at the highest level in the Armed Forces,” Cantwell said.

As commandant, Fagan oversees all global Coast Guard operations and

42,000 active-duty, 7,000 reserve, and 8,700 civilian personnel, as well as the support of 21,000 Coast Guard Auxiliary volunteers.

She previously served as the 32nd vice commandant. Prior ag assignments include commander, Paci c Area; commander, Coast Guard Defense Force West; deputy commandant for Operations, Policy, and Capability; commander, First Coast Guard District; and a joint assignment as deputy director of Operations for Headquarters, U.S. Northern Command.

Adm. Fagan has served on all seven continents. Operational tours include commander, Sector New York, more than 15 years as a marine inspector, and sea duty on the cutter Polar Star, a 399' heavy polar icebreaker.

Adm. Fagan has worked with the International Maritime Organization and International Labor Organization on ag state and port state issues. This work

includes the development of the International Ship and Port Security Code (ISPS) and the Consolidated Maritime Labor Convention.

“Today, the Coast Guard faces both new challenges and new opportunities. My vision for the service is responsive to this changing world and includes three tenets: transform our total workforce, sharpen our competitive edge, and advance our mission excellence,” Fagan said

in a July hearing before the House Homeland Security Subcommittee on Transportation & Maritime Security. “The Coast Guard workforce is my highest priority and requires innovative tools, inclusive policies, trustworthy technology, modernized training, and exceptional support to meet demand today and tomorrow.”

Fagan continued: “Moving forward, we will continue to pursue policies and practices that enable us to recruit, train, and retain a workforce representative of the American public we serve. We will build an inclusive culture that enables a sense of belonging, empowering all to deliver their personal best while serving as part of the world’s best Coast Guard.

“We will seek improved opportunities for our workforce and their families to access high quality healthcare, housing, and childcare. We will remain relentless in our effort to eradicate harmful behaviors, such as sexual assault and sexual harassment, from our service,

and continue our work to implement the military justice reforms from the 2022 National Defense Authorization Act. We will continue to revisit policies that deter otherwise quali ed members from continuing their careers, and instead we will actively encourage our brightest talent to stay.”

Adm. Fagan has earned numerous personal and team awards during her 37 years of Coast Guard service. She holds the distinction of being the Coast Guard’s rst Gold Ancient Trident recipient. Established in 2016, the award honors the of cer with the longest time in the marine safety program.

After her con rmation by the Senate as commandant in May, President Joe Biden congratulated Fagan. “My administration is committed to seeing more quali ed women in senior leadership and command roles, making sure women can succeed and thrive throughout their military careers,” Biden said.

— David Krapf

2019 was a banner year for passenger vessel operators. Then Covid hit. Since then, it’s been a struggle for many companies.

Before Covid, Seastreak, a New York City-based passenger vessel operator with six vessels, had been transporting 2,500 to 3,000 commuters to work every day from New Jersey to Manhattan. But early in the Covid epidemic the number fell “to about 50 people,” said James Barker, the company’s president, mostly doctors, nurses and rst responders. Because they had to go to New York to treat people, “we decided to offer our service for free” for the rst three months of Covid.

Seastreak, like many passenger vessel operators, has compared the passengers

carried for a particular day or week to that same day or week in 2019. In 2020 and 2021 during good times “we were getting back to 30%, 40%, then it would drop with another wave of Covid,” said Barker.

Fuel has been Seastreak’s No. 1 expense. “If it goes up by any amount it hurts our bottom line.” The price paid is about 70% higher than 2019, which has

meant using the company’s smaller but equally fast boats to try and reduce fuel expenses.

Covid also forced Seastreak to look for other ways to use its boats. So, Seastreak launched whale watching tours. “We had over a 90% rate spotting whales from Manhattan,” said Barker. “It’s been a big hit and it’s here to stay.”

In October Barker described the situation as “slow but de nitely moving in the right direction. De nitely experienced a surge after Labor Day.” Most of that was probably due to what Barker said was a “surge back in the of ce for our area,” with of ce occupancy in New York at 40% to 45% capacity in early October. “Now we are carrying about 70% of what we were carrying in 2019.”

Going forward, Barker is optimistic. “We are clawing our way back, but the future is bright. Looking forward to 2023 as a more normal season.”

Portland Spirit operates ve dining

and sightseeing boats out of Portland, Ore., as well as cruises along the Columbia River Gorge. Its eet consists of two 499-passenger vessels, one 144 passenger, and a 120 and 35 passenger.

Some effects of the Covid epidemic lingered through 2022. A reduced labor force was one holdover. In 2019 Portland Spirit had “about 225 employees at our peak,” said Dan Yates, Portland Spirit president, but “couldn’t get above 170 this year. We really struggled to hire.” Thus, the number of cruises was reduced as was the number of passengers on many of the cruises. Vessels often left the dock with only a 40% to 50% passenger load because of the crew shortage. That resulted in focusing only on high-value cruises “and walking away from a lot of low-value events,” such as music cruises and dance cruises. Even so, Yates said Portland Spirit had not only a solid year in 2022 but “the most successful income year in

our 28 years.” Mainly that was because Portland Spirit anticipated higher costs for 2022 and thus “did an aggressive price increase and aggressive demand pricing.”

That pricing practice will continue in 2023, since Yates “really doesn’t see things improving nancially next year.”

One area that is nally improving is the labor market. “Twenty- ve-yearolds can’t retire at 25, normally,” noted Yates, “so they are starting to come back and look at working.”

In fact, in late August Portland Spirit was able to do something it hasn’t done in a couple of years: let someone go. “We had been so desperate for employees we wouldn’t re them, no matter how poorly they performed.”

Looking ahead to 2023, Yates feels there will be “a better ability to man up our boats.” Maybe not adding more cruises, but with more crew available he thinks they will be able to carry

more passengers on cruises. Currently, vessels leaving the dock this October are capped at 60% capacity. That’s why Portland Spirit has demand pricing “so we can get more revenue out of people to make up for the shortfall of seats.”

Savannah Riverboat Cruises, Savannah, Ga., operates two dinner vessels: a 1,000 passenger and 600 passenger. “2021 and 2022 have been strong for us,” said Capt. Jonathan Claughton, owner of the company. His company is “at or above our 2019 numbers. Pretty much all the market segments are coming back.”

Claughton said individual leisure travel has done very well the past 18 months. — Michael Crowley

5,000 U.S.- ag towing vessels certi ed as compliant with new safety rules.

Known as Subchapter M, the inspection program sets new requirements for the design, construction, onboard equipment, and operation of U.S- ag towing vessels. It also requires that towing vessels carry valid certi cates of inspection (COI) in order to operate. Vessel crews must undergo scheduled training and there’s now a paper trail required for just about everything they do.

This is a major change for this workboat sector, as unlike other commercial vessels, tugs and towboats have operated in U.S. coastal and inland waters

Senesco Marine is the premier ship building and repair facility in the Northeast.

with the uninspected tag for decades.

As of July 19, the Coast Guard reported that 96% of the domestic towing eet that is subject to inspection had received COIs (including temporary ones) since the program’s phase-in period began on July 20, 2018. The Coast Guard issued 774 de ciencies for noncompliance and, as of July 27, 749 towing vessels were in the laid-up

status.

With the goal of improving vessel safety, the industry approached Congress and the Coast Guard in 2003 requesting development of a federal inspection program. Over the next two decades, the industry and the Coast Guard worked closely to develop regulations that would enhance safety and environmental stewardship and also be

practical on a variety of vessels that operate in different geographic locations and with different cargo requirements.

“Vessel owners have invested millions of dollars and countless hours in equipment, maintenance and crew training,” Jennifer Carpenter, president and CEO of the American Waterways Operators (AWO), said in a video marking the end of the phase-in period. “Marine and shoreside personnel have worked tirelessly to implement and upgrade procedures, and the Coast Guard has nearly doubled the number of vessels that its marine inspection workforce oversees.”

The new rules will now “raise the regulatory oor for the entire industry to better protect the environment and property,” according to the AWO.

Subchapter M gives vessel owners two options to become compliant: an annual safety inspection by the service itself, or through the Coast-Guardapproved Towing Safety Management System (TSMS). Under a TSMS, routine audits and surveys of vessels can be done by Coast Guard-approved third-party organizations that certify that a company’s eet is in compliance with regulations. This would be done every ve years by a certi ed inspector.

Of vessels inspected during the phase-in period, the Coast Guard said that 67% were certi ed under the TSMS option, and 33% under the Coast Guard option.