TECHNICKÁ UNIVERZITA VO ZVOLENE DREVÁRSKA FAKULTA ACTA FACULTATIS XYLOLOGIAE ZVOLEN 64 2/2022 VEDECKÝ ČASOPIS SCIENTIFIC JOURNAL

Vedecký časopis Acta Facultatis Xylologiae Zvolen uverejňuje pôvodné recenzované vedecké práce z oblastí: štruktúra a vlastnosti dreva, procesy spracovania, obrábania, sušenia, modifikácie a ochrany dreva, termickej stability, horenia a protipožiarnej ochrany lignocelu-lózových materiálov, konštrukcie a dizajnu nábytku, drevených stavebných konštrukcií, ekonomiky a manažmentu drevospracujúceho priemyslu. Poskytuje priestor aj na prezentáciu názorov formou správ a recenzií kníh domácich a zahraničných autorov.

Scientific journal Acta Facultatis Xylologiae Zvolen publishes peer-reviewed scientific papers covering the fields of wood: structure and properties, wood processing, machining and drying, wood modification and preservation, thermal stability, burning and fire protection of lignocellulosic materials, furniture design and construction, wooden constructions, economics and management in wood processing industry. The journal is a platform for presenting reports and reviews of books of domestic and foreign authors.

VEDECKÝ ČASOPIS DREVÁRSKEJ FAKULTY, TECHNICKEJ UNIVERZITY

VO ZVOLENE 64 1/2022

SCIENTIFIC JOURNAL OF THE FACULTY OF WOOD SCIENCES AND TECHNOLOGY, TECHNICAL UNIVERSITY IN ZVOLEN 64 1/2022

Redakcia (Publisher and Editor’s Office): Technická univerzity vo Zvolene (Technical university in Zvolen); TUZVO Drevárska fakulta (Faculty of Wood Sciences and Technology) T. G. Masaryka 2117/24, SK-960 01 Zvolen, Slovakia

Redakčná rada (Editorial Board): Predseda (Chairman): prof. Ing. Ján Sedliačik, PhD., TUZVO (SK) Vedecký redaktor (Editor-in-Chief): prof. Ing. Ladislav Dzurenda, PhD., TUZVO (SK) Členovia (Members): prof. RNDr. František Kačík, DrSc., TUZVO (SK) prof. RNDr. Danica Kačíková, MSc. PhD., TUZVO (SK) prof. Ing. Jozef Kúdela, CSc., TUZVO (SK) prof. Ing. Ladislav Reinprecht, CSc., TUZVO (SK) prof. Ing. Mariana Sedliačiková, PhD., TUZVO (SK) prof. Ing. Jozef Štefko. CSc., TUZVO (SK) doc. Ing. Hubert Paluš, PhD., TUZVO (SK) Jazykový editor (Proofreader): Mgr. Žaneta Balážová, PhD. Technický redaktor (Production Editor): Ing. Michal Dudiak, PhD.

Medzinárodný poradný zbor (International Advisory Editorial Board): Bekhta Pavlo (Ukrainian Natl Forestry Univ, Ukraine), Deliiski Nencho (University of Forestry, Bulgaria), Jelačić Denis (Univ Zagreb, Croatia), Kasal Bohumi (Tech Univ Carolo Wilhelmina Braunschweig, Germany), Marchal Remy (Arts & Metiers ParisTech, France), Németh Róbert (Univ Sopron, Hungary), Niemz Peter (Bern Univ Appl Sci, Architecture Wood & Civil Engn, Switzerland), Orlowski Kazimierz A. (Gdansk Univ Technol, Poland), Pohleven Franc (Univ Ljubljana, Slovenia), Potůček František † (Univ Pardubice, Czech Republic), Teischinger Alfréd (Univ Nat Resources & Life Sci, BOKU, Austria), Smardzewski Jerzy (Poznan Univ Life Sci, Poland), Šupín Mikuláš (Technical University Zvolen, Slovakia), Vlosky Richard P. (Louisiana State Univ, USA), Wimmer Rupert (Univ Nat Resources & Life Sci, Austria).

Vydala (Published by): Technická univerzita vo Zvolene, T. G. Masaryka 2117/24, 960 01 Zvolen, IČO 00397440, 2022

Náklad (Circulation) 150 výtlačkov, Rozsah (Pages) 146 strán, 12,12 AH, 12,25 VH Tlač (Printed by): Vydavateľstvo Technickej univerzity vo Zvolene

Vydanie I. – december 2022

Periodikum s periodicitou dvakrát ročne

Evidenčné číslo: 3860/09

Acta Facultatis Xylologiae Zvolen je registrovaný v databázach (Indexed in): Web of Science, SCOPUS, ProQuest, AGRICOLA, Scientific Electronic Library (Russian Federation), China National Knowledge Infrastructure (CNKI)

Za vedeckú úroveň tejto publikácie zodpovedajú autori a recenzenti. Rukopis neprešiel jazykovou úpravou

Všetky práva vyhradené. Nijaká časť textu ani ilustrácie nemôžu byť použité na ďalšie šírenie akoukoľvek formou bez predchádzajúceho súhlasu autorov alebo vydavateľa.

© Copyright by Technical University in Zvolen, Slovak Republic.

ISSN 1336–3824

CONTENTS

01. VIKTÓRIA SATINOVÁ – PAVOL HLAVÁČ – JÁN IŽDINSKÝ –LADISLAV REINPRECHT: ROT EVALUATION IN SPRUCE LOGS AND ROT REFLECTION INTO DIMENSIONS OF CHIPS FOR PARTICLEBOARDS 5

02. ZUZANA VIDHOLDOVÁ – GABRIELA SLABEJOVÁ: THE DECAY RESISTANCE OF FOUR HYDROTHERMALLY TREATED HARDWOOD SPECIES ................................................................................ 17

03. ELENA KMEŤOVÁ – MARTIN ZACHAR – DANICA KAČÍKOVÁ: THE PROGRESSIVE TEST METHOD FOR ASSESSING THE THERMAL RESISTANCE OF SPRUCE WOOD ........................................ 29

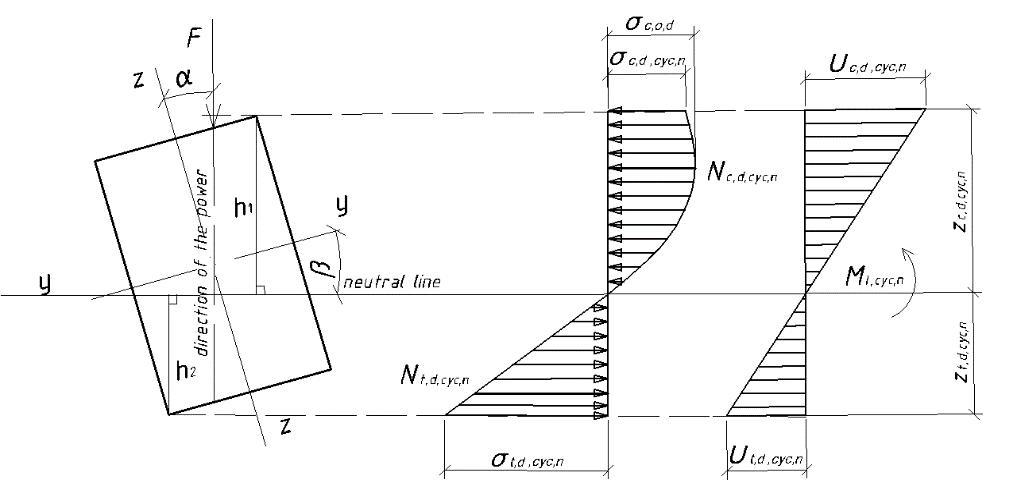

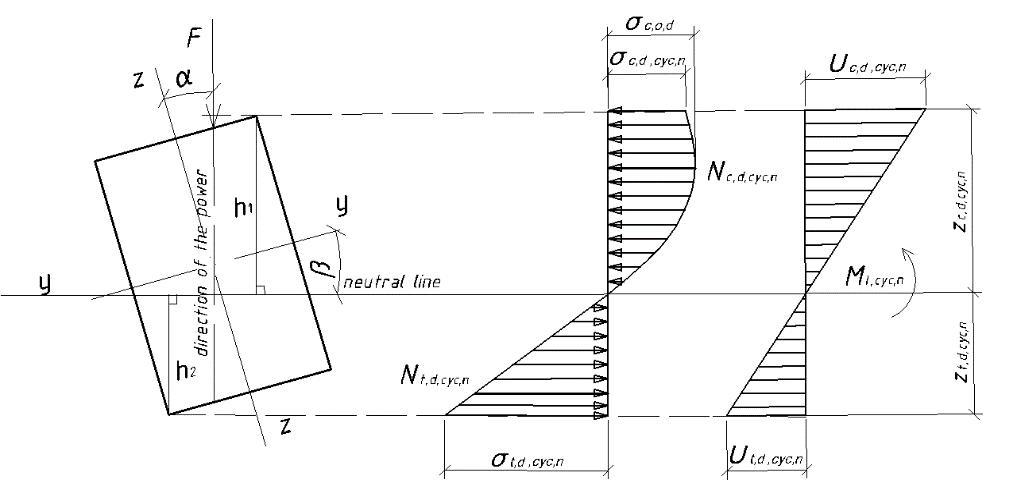

04. SVYATOSLAV GOMON – PETRO GOMON – OLEKSANDR KORNIYCHUCK – SVIATOSLAV HOMON – TETIANA DOVBENKO – LEONID KULAKOVSKYI – INNA BOYARSKA: FUNDAMENTALS OF CALCULATION OF ELEMENTS FROM SOLID AND GLUED TIMBER WITH REPEATED OBLIQUE TRANSVERSE BENDING, TAKING INTO ACCOUNT THE CRITERION OF DEFORMATION ........................................................................................... 37

05. ROMAN NÔTA: ANALYSIS OF THE THERMAL BRIDGE OF WOOD WINDOW INSTALLATION POSITION....................................................... 49

06. LUKÁŠ ADAMČÍK – RICHARD KMINIAK – ADRIÁN BANSKI: THE EFFECT OF THERMAL MODIFICATION OF BEECH WOOD ON THE QUALITY OF MILLED SURFACE ..................................................... 57

07. KAZIMIERZA.ORLOWSKI–DANIELCHUCHALA–DAWID STENKA–TOMASZPRZYBYLINSKI:ASSESSMENTOFWEAROF THEBANDSAWTEETHININDUSTRIALCONDITIONS 69 08. ZHIVKO GOCHEV – PAVLIN VITCHEV: COLOUR MODIFICATIONS IN PLYWOOD BY DIFFERENT MODES OF CO2 LASER ENGRAVING ................................................................................... 77 09. MIKHAIL CHERNYKH - MARIA ZYKOVA - VLADIMIR STOLLMANN - MAXIM GILFANOV: INFLUENCE EFFECT OF WOOD LASER ENGRAVING MODE ON AESTHETIC PERCEPTION OF IMAGES 87 10. ZUZANATONČÍKOVÁ–KATARÍNACSÚZOVÁ:THEEMULATION OFBIOMIMETICPROPERTIESOFWOODBYCREATINGA DATABASEOFABSTRACTEDDESIGNPRINCIPLES................................ 97 11. MIROSLAVA MELICHOVÁ – MARIANA SEDLIAČIKOVÁ –ANNA KOCIANOVÁ – JARMILA SCHMIDTOVÁ: WHAT IS THE APPLICATION OF SELECTED GREEN GROWTH INDICATORS IN WOOD-PROCESSING ENTERPRISES IN SLOVAKIA? 109

12. MÁRIA MORESOVÁ – MARIANA SEDLIAČIKOVÁ – JOSEF DRÁBEK – ANNA KOCIANOVÁ: SUCCESSION – A PREREQUISITE FOR SUSTAINABILITY AND DEVELOPMENT OF SLOVAK WOODPROCESSING FAMILY BUSINESSES 121

13. ANNA KOCIANOVÁ – MARIANA SEDLIAČIKOVÁ – JARMILA SCHMIDTOVÁ – MIROSLAVA MELICHOVÁ – LESIA HOGHOVÁ: PREREQUISITES FOR THE DEVELOPMENT OF THE WOOD-PROCESSING FAMILY ENTERPRISES 133

ACTA FACULTATIS XYLOLOGIAE ZVOLEN, 64(2): 5 16, 2022

Zvolen, Technická univerzita vo Zvolene DOI: 10.17423/afx.2022.64.2.01

ROT EVALUATION IN SPRUCE LOGS AND ROT REFLECTION INTO DIMENSIONS OF CHIPS FOR PARTICLEBOARDS

Viktória Satinová – Pavol Hlaváč – Ján Iždinský – Ladislav Reinprecht

ABSTRACT

Chips for particleboards (PBs) can be obtained from different tree species or other lignin-saccharide sources. In this work, the following factors are analysed: (1) the degree and type of fungal rot in the Norway spruce (Picea abies) logs using the drill-resistance device“Resistograph”andtheacousticdevices“Sylvatest-Duo”,“Fakopp”and“Arbotom”, and (2) following the reflection of wood-rot into dimensions of chips prepared for PBs. Using the devices, milder damage of logs caused by the white-rot Dark honey fungus (Armillaria ostoyae) was not detectable, but on the contrary, more serious damage of logs with the brown-rot Red banded polypore fungus (Fomitopsis pinicola) was clearly detectable. Wood chips prepared from the rotten logs had smaller dimensions compared to chips from the sound logs. By the sieve analysis, using the mesh diameters from 80 mm to 0.125 mm, the total percentage fractions marked as 7, 4, 2, 1, 0.5, 0.25, 0.125 and 0 were 31.1% for chips from the sound logs, 41.89% forchips from logs attacked by white rot, and 71.13% for chips from log attacked by brown rot.

Key words: spruce logs, rot, Resistograph, acoustic devices, chips, dimensions

INTRODUCTION

Particleboards(PB)areproducedfrom:(1)differentwoodsources–lowerqualitylogs and trunks of conifers and broadleaves; – recycled furniture, trusses and other aged wood materials;–wastecreatedattheproductionofnewwoodmaterials,e.g.,carpentryproducts, PBs, plywood or glulam, (2) agricultural lignin-saccharide bio-polymers, derived from straw,stalk,bagasse,seed/fruit,leaf,grass,andpalms;(3)textilesandpapersproducedfrom natural and synthetic fibers (ODOZI et al. 1986, ALWANI et al. 2014, IŽDINSKÝ et al. 2020, LEE et al. 2022).

The lower quality of logs is often given by their biological damage caused by wooddecaying fungi and wood-damaging insects. Chips prepared from bio-damaged wood sources may not have always acquire suitableyields, dimensions orother characteristics for the production technology of PBs and their properties required by valid standards, e.g., strength, elasticity, thickness swelling, fungal resistance, may not be achieved.

The rotten or otherwise bio-damaged wood logs most often come from accidental harvests (GÁPER 2003). For example, in 2020, the volume of accidental harvesting of tree wood material caused by the action of phytopathogenic organisms was 154 544 m3. Of the reported volume, trees attacked by the white-rot Dark honey fungus (Armillaria ostoyae

5

/Romang./ Herink) accounted for 81 854 m3 and by the brown-rot Red banded polypore fungus (Fomitopsis pinicola /Sw./ P. Karst.) for 754 m3 (LEONTOVYČ et al. 2021).

Armillaria ostoyae is one of the significant parasites of spruce and other coniferous plants.Itinfectsthematallstagesofgrowth,i.e.,fromseedlingstoadulttrees.Theinfection is caused by the mycelium, which penetrates the wood mainly with the vascular rays. The external symptom of spruce damage is resin discharge or bottle shaping of the basal part of the stem. The fungus causes intense and rapid spreading of white wood rot. The genus Armillaria representativesofmediumtolargefruitingbodies,usuallygrowninclumps.The fruitingbodyismadeupofapileusandastalk(GÁPER andPIŠÚT 2003).Duetothedrought, an increasein fungal pathogens is also foreseen for thefuture. The current drought has been identified as the main factor in the death of spruce in the lowlands of the Czech Republic. The trees thus weakened were subsequently attacked by the Dark honey fungus. For example, Holuša et al. (2018) indicate that up to 50% of the trees studied have long-term drought with inducing activity of this fungus.

Fomitopsis pinicola is a common species of the genus Fomitopsis. It is mainly a saprophyticfungus infecting living and healthytrees. It causes red rot prism likedecay with whitemyceliuminthecracks(ČERNÝ 1986).Thefruitingbodyishoof-shapedortriangular, and sometimes shelflike with orange-yellow margin. F. pinicola conks may grow for many years, each season adding a new layer of tubes. It is an important destroyer of conifer wood species, including the Norway spruce.

The type, degree and range of rot in the standing trees, harvested logs and wooden productscanbedeterminedvisuallyaswiththehelpofseveralinstrumentalmethods(WANG et al. 2007, RINN 2009, REINPRECHT and HRIVNÁK 2012, REINPRECHT and PÁNEK 2012, ROHANOVÁ andNUNEZ 2012, HRIVNÁK et al. 2013, REINPRECHT 2016, GERGEĽ et al. 2022, HOVDE et al. 2022).

The chips and particles prepared from chips must have suitable dimensions – for example, exactly determined dimensions for the core layer and the surface layers at the production of the tree-layer PBs.

It is ideal if the chips for the PBs production have the following dimensions: length 20-50 mm; width 20-40 mm and thickness 3-5 mm. For the following prepared fine surface particles is recommended a thickness of around 0.2 mm, at which this dimension is determined directly by the condition and preparation process of particles. The width of particles for the surface layer of PBs should not exceed 2 mm and the length should not exceed 5 mm. The thickness of large particles for the core layer of PBs is generally recommendedbetween0.4to0.7mm.Thelengthandwidthofparticlesinthecorelayer are allowed to be relatively variable, but with the largest slenderness ratio, i.e., the ratio of the length to the thickness of the particle (DEPPE andERNST 2000, IRLE andBARBU 2010).

The dimension of particle with the thickness under 0.125 mm or 0.08 mm, which was created either by processing (MARKOVÁ et al. 2016, OČKAJOVÁ et al. 2020, DEMBIŃSKI et al. 2022) or it was sorted, is regarded as dust not suitable to produce PB, due to a negative reduction in its properties, especially bending strength. In practice, there are these small particles – dust used for energy purposes, e.g., in the production of heat (KMINIAK et al. 2020).

The aim of this work was to analyse the influence of the white and brown rots in harvested Norway spruce logs on the dimensions of chips prepared for production of particleboards.

6

MATERIALS AND METHODS

Logs

From five Norway spruce (Picea abies Karst. L.) standing trees growing in the Central Slovakia, Forest region Budča, part No. 589 – two sound, two attacked by the white-rot fungus “Dark honey fungus” (Armillaria ostoyae /Romang./ Herink), and one attacked by the brown-rot fungus “Red banded polypore” (Fomitopsis pinicola /Sw./ P. Karst.) – were prepared 4 m long logs with diameters at the ends from 0.3 m to 0.45 m (Figures 1).

(a) (b)

Fig. 1. The Norway spruce standingtrees - attacked by the white-rot fungus Armillaria ostoyae with atypical pear-shaped trunk in the territorial part (a); - attacked by the brown-rot fungus Fomitopsis pinicola with presence of fruiting bodies andvisually detectable rot (b).

Rot evaluation in logs

Presence and degree of rot in the Norway spruce logs was evaluated by four instrumental methods (Figure. 2):

- drill-resistance measurement – performed in the radial direction of log; the device Resistograph IML-RESI F400 (Instrumenta Mechanik Labor GmbH, Wiesloch, Germany), equipped with 400 mm-long and 3 mm-thick steel drill, was used; log quality is presented in a form of graphical report, where on the y-axis the none or minimal resistance-peak indicates a significant damage of wood, e.g., due to rot or crack,whilethelocally-lowerresistance-peakinthedefinedannualcirclebelongsto the sap-wood and the locally-higher one belongs to the late-wood; a total of 25 boreholes were drilled into five logs (Figures 2a, 2b),

- 1-D ultrasonic measurement – performed in the longitudinal direction of log with a length of (LL) in /m/, with an accuracy of 0.01 m; the device Sylvatest-Duo (CBSCBT, Paris, France),equipped with 22 kHz conical transducers,which measures the transmission timeofan ultrasonicwave(TUW)(μs)through two conical transducers, one emitter and the other receiver located on the opposite sides of log, was used; a total of 20 TUW values were determined for five logs (Figures 2a, 2c); following the transmission velocity (vL) in /m.s-1/ was calculated, using the equation (1):

vL=LL/TUW (1)

7

- 1-D ultrasonic measurement – performed in the radial direction of log with a length in the defined diameter of (LD) in /m/, with an accuracy of 0.01 m; the device FAKOPPMicrosecondTimer(FakoppEnterpristeBt.,Ágfalva,Hungary),equipped with two 45 kHzultrasonictransducers US 2, which measures thetransmission time of an ultrasonic wave (TUW) in /μs/ between the transducers, was used; a total of 50 TUW values were determined for five logs (Figures 2a, 2d); following the transmission velocity (vR) in /m.s-1/ was calculated using the equation (2):

vR = LD/TUW (2)

- 2-D ultrasonic measurement – performed in the transversal area of log; the device Impulse Tomograph ARBOTOM Professional Pack 2D (Rinntech, Heidelberg, Germany), with a color graphical report of the sound zones and the less or more damaged zones in the log (RINN 2009), was used; a total of 15 measurements were performed for five logs (Figures 2a, 2e).

(a)

Fig. 2. Evaluation of rot in the Norway spruce logs in the defined places (a) – by the Resistograph /R/ (b), and by three acoustic devices, i.e., Sylvatest-Duo /S/ (c), Fakopp /FB and FA/ (d), and Arbotom /A/ (e).

Chips preparation and sieve analysis

The chips were prepared from the Norway spruce logs of three groups – sound, damaged by white rot, and damaged by brown rot. Firstly, from the logs were sawn boards with the thicknesses from 25 mm to 50 mm. The boards were then chipped on chips in the

8

230H drum mower (Klöckner KG, Hirtscheid Erbach, Westerwald, Germany). For the wooden chips – which in a practice are further milled to particles used for PBs preparation – their basic macrostructural characteristics, i.e., dimensions, were determined by the sieve analysis.

A representative sample with a weight of 750-1200 g was selected from chips of a given log-group. The sample of chips was divided into 5-8 homogeneous chip sets with a weight of 150 g and undergo to the sieve analysis. During sieving, individual fractions of chips were captured on sieves arranged one above the other from the largest mesh diameter to the smallest mesh diameter. The set of sieves is finished with a solid bottom, into which the finest dust fraction of chips falls. Individual chip fractions captured on sieves with the mesh diameters from 80 mm to 0.125 mm – chip fractions marked as 80, 50, 40, 25, 20, 15, 12, 11, 7, 4, 2, 1, 0.5, 0.25, 0.125 and 0 (a solid bottom) – were weighed with an accuracy of 0.01 g, with following calculation of their percentage amounts.

The sifting procedure was following: (1) the weighed chips were poured onto the top sieve; (2)theset ofsieves was closed with alid; (3)theactual sieving process in thesieving device lasted 10 minutes. The set of sieves was divided into two parts, i.e., first, the chips with a weight of 150 g were sieved through a set of sieves with the mesh diameters of 80, 50, 40, 25, 20.15, 12, 11 mm and bottom, and subsequently, the fraction of chips caught at the bottom was sieved in the second step through a system of sieves 7, 4, 2, 1, 0.5, 0.25, 0.125 mm and bottom.

RESULTS AND DISCUSSION

Rotpresenceinlogs

Drill-resistance analysis

The drill-resistance semi-destructive analysis of the Norway spruce logs with the IML RESI 400 Resistograph evidently documented the visually ascertained damage of wood caused by the brown-rot fungus F. pinicola (Figure 1b), when the rotten log No 1 gave in all five measurements 1/0 - 1/4 almost no resistance to the drill needle penetration – which indirectly showed the presence of extensive and intense rot (Figure3).

Onthecontrary,thevisuallytraceableattacksoflogsbythewhite-rotfungus A. ostoyae (Figure1a)werenot moreclearly detectableby theResistograph, becausedrill-resistances of these logs to the drill needle penetration were comparable with drill-resistances of the sound logs (Figure 3 – see results for logs No 1). Larger densities at the individual curves and the end of the measurement are result of the increased growth of the wood around the circumferenceofthetrunk.Theanalysisoflogsattackedbywhiterotcausedbytheparasitic wood-decaying fungus A. ostoyae detects the presence of the developing so-called mixedcombined rot (ORŁOŚ 1955). More pronounced physical changes in the output curves are noticeable at measurements 1/0 and 1/1 (Figure 3), which represent the lower (basal) parts ofthetrunk-log.Thiscanalsobeexplainedbythefactthatsprucerootrotismainlycaused by a root parasitic fungus and the infection in the tree gradually progresses from the roots upwards to the trunk. Even the external symptoms of the disease, i.e., the significant bottlelike thickening of the basal part of the trunk – log points to the reported process of rotting.

Generally,thedrill-resistanceofwoodsubstanceinlogswithamilderwhiterotdamage was comparable with the sound wood substance, while the wood substance having a higher damage by brown rot was evidently more accessible for the penetration of the drill. Similar results achievedREINPRECHT and HRIVNÁK (2012)for logs of five tree species.

9

Fig.3.Woodquality“rotpresence”oftheNorway spruce logsevaluatedbytheResistograph

10

Acoustic analyses

Thespeedofultrasonicwavesinthelongitudinaldirection(vL)andintheradialdirection (vR) were very similar in the sections of sound logs and logs attacked by white rot. It was confirmed by several different acoustic measurements – using Sylvatest-Duo, Fakopp, and Arbotom. In the longitudinal direction measurements performed with the Sylvatest-Duo, the average velocity of ultrasonic waves (vL) in the sound logs was 6271 m.s-1 and in the logs attackedbywhiterotevenhigher6383m.s-1.Inalogattackedbybrownrottheaveragevalue of ultrasonic waves (vL) was smaller only 5588 m.s-1. Similar values of vL for the Norway spruce logs having different stages of rot, in average namely 5076 m.s-1, determined REINPRECHTandHRIVNÁK (2012)usingtheacousticdevicePunditPlus. While the measured data in the longitudinal direction of individual logs did not show largerdifferences,thespeedsofultrasonicwavesmeasuredintheradialdirection(vR)differed more from each other. The individual values of ultrasonic waves (vR) determined by Fakopp Microsecond Timber showed in some cases the II. medium degree of damage characterized by values approaching to 920 m.s-1. However, the average values for two sound logs (1187 m.s-1)andtwologsattackedbywhiterot(1249m.s-1)wereverysimilar,withoutasignificance difference. The greatest IV. degree of spruce wood damage, which is characterized by vR ≤ 750m.s-1,wasdeterminedinalogattacked bybrownrot, with an averagevalueof622m.s-1 .

Tab. 1. Woodqualityofthe Norwayspruce logsevaluatedbytheacoustic devices Sylvatest and Fakopp. NORWAY SPRUCE LOG SYLVATEST

Longitudinal direction vL (m.s-1)

FAKOPP

Radial direction – A and B vR (m.s-1)

Place in log S1 S2 S3 S4 F1 0.2 m F2 1 m F3 2 m F4 3 m F5 3.8 m

Sound log No 1 6284 6145 6545 6601 A B 1192 1072 1263 1230 1308 1147 1228 1021 1250 1024

Sound log No 2 6128 5982 6261 6224 A B 1125 1250 1235 1272 1183 1242 1145 1213 1111 1226

White rot log No 1 6742 6567 6540 6540 A B 1085 1123 1269 1133 1137 1220 1264 1263 1366 1263

White rot log No 2 6164 6224 6224 6063 A B 1299 1240 1339 1330 1341 1328 1279 1100 1409 1235

Brown rot log No 1 5532 5423 5641 5754 A B 641 375 927 633 611 483 510 413 1032 590

Notes: 1) Places of the ultrasound measurements in the logs are schematically shown in Figure 1. 2) The averagemoisture contents(w)of spruce logsduringultrasound measurementswereas follows:18% for sound logs; 21.8% for logs with white rot; 29.3% for log with brown rot.

Results obtained by the Impulse Tomograph ARBOTOM Professional Pack 2D device, evaluatimg damages in the 2-D area of logs (Figure 2e), were in good agreement withresultsobtainedintheradialdirectionoflogsachievedbytheResistograph(Figures2b and 3) and the Fakopp (Figure 2d, Table 1, Figure 4). For example, from 15 measurements with the Tomograph, there in this work are visually presented the sound (green) and rotten (orange) zones in a one section of log attacked by white rot and in a one section of log attacked by brown rot (Figure 5). In the case of log-section damaged with white rot, the rot gradually developed in its central part, as it was confirmed by yellow-orange stains (Figure 5a). In thecaseofthesamples attacked with thebrown-rot fungus F. pinicola, an extensive rot on the entire cross-section of a log was confirmed (Figure 5b).

11

Fig. 4. Average speeds of ultrasonic waves in the longitudinal direction (vL) and the radial direction (vR) through the Norway spruce logs (see tab. 1).

(a) (b)

Fig. 5. The Norway spruce logs evaluated by the Arbotom – log-section with white rot (a), log-section with brown rot (b).

Effect of rot on the production of wood chips

The dimensional characteristics of wood chips prepared by the same standard technologydependonthewoodspecies,moisturecontentofwood,androtorotherdamages in thewood structure. Thetype and degreeofrot largely affects the size of woodchips. It is a consequence of the easer breakdown of the wood morphological elements, e.g., fibres, in which are depolymerized polysaccharides and overall is disturbed the lignin-saccharide matrix.

The sieve analysis showed that from logs attacked by white rot and mainly by brown rot were prepared chips with smaller dimensions (Table 2). Any chips affected by rot were caught on sieves with sizes 80 and 50. For chips from the sound-healthy logs, on the sieve of 80-size was 0.32% chips of their total amount, and on the sieve of 50-size was 0.57% chips. Chips from sound logs were in the largest amount chaptered on the sieves with sizes from20to4,atwhichtheirlargestpercentagewas onthe12-sizewhichrepresented21.93% of their total amount.

12

Thelargestamountofchipsfromlogsattackedby whiterotwascaughtonsieveswith sizes from 20 to 4 (84.10%), i.e., similarly to chips from sound logs (87.91%). The largest percentage amount of chips from white rot logs and sound logs was caught on the 12-size (19.93% vs. 21.93%). On the other hand, the largest percentage of chips attacked by brown rot was caught on the 4-size, which represented 23.92% of their total amount. The dust content of wood chips from sound logs was 0.03%, 0.06% from white rot logs, and even to 0.99% from brown rot log.

Tab. 2. Fractions of chips prepared from the Norway spruce logs. MESH SIZE [mm] CHIPS FRACTIONS [%] Sound log White rot in log Brown rot in log 80 0.32 0 0 50 0.57 0 0 40 0.58 0.38 0 25 4.30 4.10 1.20 20 9.92 9.45 3.90 15 21.71 17.12 7.26 12 21.93 19.52 9.02 11 8.59 7.37 7.33 7 15.53 17.18 13.24 4 9.93 13.46 23.92 2 3.92 7 14.01 1 1.19 2.62 9.28 0.5 0.40 0.90 5.08 0.25 0.14 0.35 2.98 0.125 0.15 0.32 1.63 0 [Bottom] 0.03 0.06 0.99 (a) (b) (c)

Figure 6. Fractions of the Norway spruce chips obtained at the sieve analysis – sound (a), white rot (b), brown rot (c).

CONCLUSION

• IntheNorwaysprucelogsthedrill-resistanceandacousticmethodsclearlyidentified the brown rot caused by the fungus Fomitopsis pinicola, however, the white rot causedbythefungus Armillaria ostoyae wasonlybarelyidentifiablebythem.These results came out from different type and degree of rotting in searched logs.

13

• The dimensions of wood chips, which have been prepared by the same technology fromtheindividualsprucelogs,dependedonthetypeanddegreeofrotinlogs–i.e., the fractions of chips having relatively smaller dimensions, intercepted between a mesh diameter of 7 mm and a bottom of 0 mm, were obtained in the lowest amount of31.1%fromsoundlogs,inahigheramountof41.89%fromlogsattackedbywhite rot, and in the highest amount of 71.13% from log attacked by brown rot.

• Theexperimentsshowed thattheprocessofwoodchippinginthetechnologyofPBs preparation should be appropriately adjusted – optimized with regard to the quality oftheinputwoodmaterial,specificallyinourcasewithregardtothetypeanddegree of wood rot in the logs in order to achieve high-quality PBs.

REFERENCES

ALWANI,M.S.,KHALIL,H.P.S.A.,ASNIZA,M.,SUHAILY,S.S.,AMIRANAJWA,A.S.N.,JAWAID, M. 2014. Agricultural Biomass Raw Materials: The Current State and Future Potentialities. In BiomassandBioenergy. (Hakeem,K.,Jawaid,M.,Rashid,U. -Eds),Springer,Cham.77-100.DOI: 10.1007/978-3-319-07641-6_5

ČERNÝ, A. 1986. Parasitic decay mushrooms. SZN, Praha, Czechoslovakia, pp. 32-33, ISBN 80209-0090-X.

DEMBIŃSKI,C.,POTOK,Z.,KUČERKA,M.,KMINIAK,R.,OČKAJOVÁ,A.,ROGOZIŃSKI,T.2022.The Dust Separation Efficiency of Filter Bags Used in the Wood-Based Panels Furniture Factory. In Materials 15(9), 3232. DOI: 10.3390/ma15093232

DEPPE, H.J., ERNST, K. 2000. Taschenbuch der Spanplattentechnik. 4th ed., DRW: LeinfeldenEchterdingen, Germany, p. 552. ISBN 3-87181-349-4.

GÁPER, J., PIŠÚT, I. 2003. Mycology - The mushroom taxonomy system, evolution and ecology. Matej Bel University, Banská Bystrica, Slovakia, 319 p., ISBN 80-8055-863-9.

GERGEĽ,T.,BUCHA,T.,GRACOVSKÝ,R.,CHAMULA,M.,GEJDOŠ,M.,VEVERKA,P.2022.Computed tomography as a tool for quantification and classification of roundwood - case study. In Forests 13, 1042, 17 p. DOI: 10.3390/f13071042

HOLUŠA, J., LUBOJACKÝ, J., ČURN, V., TONKA, T., LUKÁŠOVÁ, K., HORÁK, J. 2018. Combined effects of drought stress and Armillaria infection on tree mortality in Norway spruce plantations. In For. Ecol. Manage 427, 434-445. DOI: 10.1016/j.foreco.2018.01.031

HOVDE, T. J., FORSMAN, J., ROSS, R. J., RUDNICK, M., XIE, X., WANG, X., DICK-SON, Y. L. 2022. Sight versus sound: do visual assessments of dead standing trees reflect acoustic nondestructive evaluations of wood quality? In Forests 13, 1680, 13 p. DOI: 10.3390/f13101680

HRIVNÁK, J., KLOIBER, M., REINPRECHT, L., TIPPNER, J. 2013. Skúmanie kvality a poškodenia ihličnatého dreva akustickými a mechanicko-odporovými metodami. (Searching of quality and damageofconiferouswoodwithacousticandmechanical-resistancemethods).TechnicalUniversity in Zvolen, Slovakia, 78 p. ISBN 978-80-228-2552-8

IML RESI F300, F400, F500 - 2006. Mess- und Prüfgerät Bäume und Holzkonstruktionen (Bohrwiderstandsmessung). Bedienungsanleitung. Wiesloch: IML – Instrumenta Mechanik Labor GmbH, Stand 02/20026, 20 p.

IRLE, M.; BARBU, M.C. 2010. Wood-based panel technology. In Wood-Based Panels An Introduction for Specialists. (Thoemen, H., Irle, M., Sernek, M. – Eds), Brunel University Press: London, UK, Volume 1, pp. 1–90. ISBN 978-1-902316-82-6

IŽDINSKÝ,J.,VIDHOLDOVÁ,Z.,REINPRECHT,L.2020.Particleboardsfromrecycledwood.InForests 11(11), 1166. 16 p. DOI:10.3390/f11111166

KMINIAK,R.,ORLOWSKI,K.A.,DZURENDA,L.,CHUCHALA,D., BANSKI,A.2020.Effectofthermal treatmentofbirchwoodbysaturatedwatervaporongranulometriccompositionofchipsfromsawing and milling processes from the point of view of its processing to composites. In Applied Sciences 10(21), 7545. DOI: 10.3390/app10217545

LEE,S.H.,S.H.,LUM,W.CH.,BOON,J.G.,KRISTAK,L.,ANTOV,P.,PĘDZIK,M.,ROGOZIŃSKI,T., TAGHIYARI,H.R.,LUBIS,M.A.R.,FATRIASARI,W.,YADAV,S.M.,CHOTIKHUN,A.,PIZZI,A.2022.

14

Particleboard from agricultural biomass and recycled wood waste: a review. In Journal of Material Research and Technology 20, 4630-4658. DOI: 10.1016/j.jmrt.2022.08.166

LEONTOVYČ, R., KUNCA, A., LONGAUEROVÁ, V. 2021. Fytopatogénne organizmy v lesoch Slovenska v roku 2020. (Phytopathogenic organisms in the forests of Slovakia in 2020). In APOL –aktuálne problémy v ochrane lesa - Časopis lesníckej ochranárskej služby 2, 230-237. ISSN 26446308.

MARKOVÁ, I., MRAČKOVÁ, E., OČKAJOVÁ, A., LADOMERSKÝ, J. 2016. Granulometry of selected wood dust species of dust from orbital sanders. In Wood Research 61(6), 983-992.

OČKAJOVÁ, A., KUČERKA, M., KMINIAK, R., ROGOZIŃSKI, T. 2020. Granulometric composition of chips and dust produced from the process of working thermally modified wood. In Acta Facultatis Xylologiae Zvolen 62(1), 103–111. DOI: 10.17423/afx.2020.62.1.09

ODOZI, T. O., AKARANTA, O., EJIKE, P. N. 1986. Particle boards from agricultural wastes. In Agricultural Wastes 16, 237-240.

ORŁOŚ, H. 1955. Lesnícka fytopatológia. SVPL, Bratislava, Czechoslovakia, pp. 166-170, ISBN 301-04-40.

REINPRECHT, L., HRIVNÁK, J. 2012. Ultrazvuková a vŕtaniu odporová defektoskopia ihličnatej a listnatej guľatiny.(Ultrasonic and drillresistance defectoscopy of coniferous and broadleaved logs). In Acta Facultatis Xylologiae Zvolen 54(1), 43-54.

REINPRECHT,L.,PÁNEK,M. 2012. Ultrasonic technique for evaluationofbiodefectsin wood: Part 1 – Influence of the position, extent and degree of internal artificial rots. In International Wood Products Journal 3(2), 107-115.

REINPRECHT, L. 2016. Diagnosis, sterilization and restoration of damaged timber structures. Technical University in Zvolen, Slovakia, 69 p. ISBN978-80-228-2921-2.

RINN, F. 2009. Arbotom 3-D Tree Impulse Tomograph. User Manual. Heidelberg: Rinntech, 57 p. ROHANOVÁ, A., NUNEZ, E. 2012. Prediction models of structural timber. In Annals of Warsaw University of Life Sciences-SGGW, Forestry and Wood Technology (79), 210-213.

WANG,X.,CARTER,P.,ROSS,R.J.,BRASHAW,BK. 2007. Acoustic assessment of wood quality of raw forest materials - A path to increased profitability. In Forest Products Journal 57(5), 6-14.

ACKNOWLEDGMENTS

This work was supported by the Scientific Grant Agency of the Ministry of Education of Slovak Republic Grant No. VEGA 1/0665/22.

ADRESSES OF AUTHORS

Viktória Satinová (satinova@tuzvo.sk)

Technical University in Zvolen Faculty of Wood Sciences and Technology Department of Wood Technologies T. G. Masaryka 24 960 01 Zvolen Slovak Republic

Pavol Hlaváč (hlavac@tuzvo.sk)

Technical University in Zvolen Faculty of Forestry Department of Integrated Forest and Landscape Protection T. G. Masaryka 24 960 01 Zvolen Slovak Republic

15

Ján Iždinský (izdinsky@tuzvo.sk)

Technical University in Zvolen

Faculty of Wood Sciences and Technology Department of Wood Technologies

T. G. Masaryka 24 960 01 Zvolen Slovak Republic

Ladislav Reinprecht (reinprecht@tuzvo.sk)

Technical University in Zvolen

Faculty of Wood Sciences and Technology Department of Wood Technologies

T. G. Masaryka 24 960 01 Zvolen Slovak Republic

16

ACTA FACULTATIS XYLOLOGIAE ZVOLEN, 64(2): 17 27, 2022 Zvolen, Technická univerzita vo Zvolene DOI: 10.17423/afx.2022.64.2.02

THE DECAY RESISTANCE OF FOUR HYDROTHERMALLY TREATED HARDWOOD SPECIES

Zuzana Vidholdová – Gabriela Slabejová

ABSTRACT

StudiesonthedurabilityofEuropeanbeech(Fagus sylvatica),alder(Alnus glutinosa), paper birch (Betula papyrifera), and Norway maple wood (Acer pseudoplatanus) after hydrothermal treatment in saturated water were carried out. Treatment of hardwoods was performed at two temperatures of 105 and 135°C for 6 hours. Fungal resistance was tested in the laboratory conditions with brown rot fungi Serpula lacrymans, Gloeophyllum trabeum and white-rot fungus Trametes versicolor. Half-specimens from each species were leachedinaccordancewithSTNEN84priortothetest.Theresultsofdecayresistancetests showedstrongsusceptibilityofhydrothermallytreatedhardwoodspeciestobrownandwhite rotcausedbybasidiomycetefungi. Inallcases,themasslosswasgreaterthan20%,andthe moisture content significantly exceeded the fibre saturation point, above the level required forafungalattack.Leachinghadaninsignificant effecton fungal resistance.Allhardwoods were classified as non-durable species.

Keywords: alder, beech, birch, durability, Gloeophyllum trabeum, maple, saturated water steam, Serpula lacrymans, thermal treatment, Trametes versicolor

INTRODUCTION

Wood is an organic material that is sensitive to environmental conditions and microorganisms. In principle, wood with higher moisture content – usually more than 20% - may be damaged by biological degradation processes in the presence of wood-destroying fungi, staining fungi, moulds, or bacteria (REINPRECHT 2008). Wood-decaying fungi recognise wood cell polymers as a food source and have specific enzymatic systems capable of metabolisingthemintosimpledigestibleunits(SMIDTH 2006;GOODELL 2020).Somewooddestroying fungi can penetrate even masonry and can transfer water and nutrition over long distances to timber. However, when the wood is not adequately protected, wood degrading fungi such as the dry rot fungus (Serpula lacrymans), the cellar fungus (Coniophora puteana), Rhodonia spp. and other wood-destroying fungi can cause severe damage to buildings and the greatest structural changes in wood and potentially cause human injuries (HAAS et al. 2019)

S. lacrymans is a well-known fungus that causes dry decay of wood. It is regarded as themost damaging destroyerofinteriorwooden building materials also in Slovakia (GÁPER et al. 2018). It grows and spreads quickly. It has low wood moisture requirements. It can produce substantial quantities of water by breaking down the wood polysaccharide. The woodrapidlylosesitsstrengthafterbeingattackedbythisfungus(REINPRECHT et al. 2007)

17

Therefore,itisoneofthetestorganismsthatcomplywiththestandardSTNEN113-1(2021) used to test the resistance of softwoods and hardwoods.

Gloeophyllum trabeum is a representative of the brown rot fungus, which is characterized by a special pattern of brown cubic rot of hardwoods and softwoods during which they oxidatively break down the components of the wood cell wall, causing a rapid loss of wood strength (TIRALOVÁ and REINPRECHT 2000,DANIEL et al. 2007). It is common in poorly stored wood and in wood exposed to the weather. Especially wooden footbridges and bridges may be encountered by these rot fungi families attacking hardwoods in Central Europe (IRBE et al. 2012; FOJTÍK and DĚDKOVÁ 2016).

Trametes versicolor is a well-known white-rot fungal species. It produces decay in hardwoods with simultaneous reduced lignin and carbohydrate nearly at the same rate, with a slight preference for lignin (KARIM et al. 2017). Although white-rot is less frequent in wooden construction, as it occurs most often in standing and felled many deciduous trees and some conifers, white-rot fungus is selected to compare it with brown rot. The wood progressively loses its strength after being attacked by a fungus, and as WITOMSKI et al. (2016) stated, the flexural strength and compressive strength of Scots pine wood can decrease by up to 50% with 20% mass loss, respectively with 30 % mass loss.

At the present time, the selection of naturally resistant wood species or the improvement of the less durable by means of modification processes is a common solution to minimize fungal degradation of the wood in use (HILL 2011; STN EN 350: 2017; REINPRECHT andVIDHOLDOVÁ 2019). Woodmodificationprocesses areinterestingbecause theyareimplementedto improvetheproperties of wood including thefungal resistance and to producenewmaterials, and this is agood base for producing an environmentally friendly product (SANDBERG et al. 2021)

The hydrothermal modification of wood is one of the most important methods among methods of heat treatment. The notion of hydrothermal modification can be largely defined on the basis of a variety of temperatures and pressures. In addition, it can be performed in the presence of steam or liquid water under pressure or vacuum at different temperature levels,anditcan affectthedifferentcharacteristicsofwood(Aliet al.,2021).Thetreatment softens the wooden material, releases internal stress, chemically changes some components of the wood, changes can occur in the microstructure of the cell wall, as well as changes colour ofthewood(SOLÁR, 1997; TOLVAJ et al. 2009; TIMAR et al 2016; DZURENDA 2018; SHI et al. 2018; WANG et al. 2019; GEFFERT et al. 2020; SANDBERG et al. 2021). This treatmentistraditionallyusedinthewoodworkingindustry,forexample,inthemanufacture offurniturecomponentswithsolidwoodbending,fortheproductionoffloorsandpanelling for the interior.

The aim of this paper is to determine the decay resistance of four native and hydrothermally treated hardwood species (European beech (Fagus sylvatica), alder (Alnus glutinosa), Paper birch (Betula papyrifera) and Norway maple wood (Acer pseudoplatanus)) to brown or white rot fungi and to state the influence of pre-treatment of thespecimensbyleachingontheirdurability.Basedontheexperimentaldata,thedurability class will be assessed for the hydrothermally treated hardwood species.

MATERIALS AND METHODS

Wood specimens

Industrially hydrothermally treated heartwood planks of four hardwood species – European beech(F. sylvatica L.),alder(A. glutinosa L.Gaertn),Paperbirch(B. papyrifera Marsh)and Norway maple wood (A pseudoplatanus L.) were used There were 3 to 8 growth rings per

18

cm in each specimens and they were free from defects, The parameters of the treatment process were temperature of 105 and 135 ± 2.5 °C for 6 hours. The process is described in the works of DZURENDA (2018, 2019), DZURENDA and DUDIAK (2020) and DUDIAK and DZURENDA (2021) in more detail. Specimens were cut into 25 × 15 × 50 (axial) mm specimens. In total 32 specimens per wood species and hydrothermal treatments were used. Half of the specimens were leached, and the second half stayed without pre-treatment Further 6 specimens from Scots pine sapwood (Pinus sylvestris L.) and beech (F. sylvatica L.) were used as controls of virulence of the fungus strain.

Leaching test

Native and hydrothermally treated specimens were leached in demineralized water according to the procedure described in STN EN 84 (2021) by some modifications. After impregnation with water (30 min at 0.8 MPa), specimens were kept submerged at room temperature. Water (5 volumes of water for 1 volume of wood) was exchanged 9 times during 14 days of test duration

Durability test

The durability of wood was evaluated under laboratory conditions according to STN EN 113-1 (2021) and CEN/TS 15083-1 (2005)

Thefollowing fungal strains were used forthetests: thebrown-rot fungi S lacrymans (strain BAM 87), G. trabeum (Pers.) Murrill (strain BAM 115), and the white-rot fungus T. versicolor (Linnaeus ex Fries) Pilat (strain BAM 116).

After steam sterilization of specimens in an autoclave at 120°C for 30 min, they were soaked in demineralized water for 240 min to achieve a moisture content of 25 to 30%. Finally, sets of two (four in case fungus G. trabeum) specimens of the same species were deposited on stainless steel grids under which a fungal mycelium had already been grown on a sterilized 4.5 weight% malt agar medium (HiMedia, Ltd., Mumbai, India) with a thickness from 3 to 4 mm in Kolle flasks. All specimens were incubated for 16 weeks at 22 ± 2°C and 70 ± 5% RH in a culture chamber

After fungal exposure (Fig. 1), specimens were cleaned from adhering fungal mycelium. Their moisture content (MCF) and mass loss by fungal decay (MLF) were calculated in percentages using the following equations:

where: mw decayed is the moisture mass after fungal exposure [g], m0 is the initial oven-dry massbeforefungalexposure[g]and m0 decayed istheoven-drymassafterfungalexposure[g]. Specimens were oven-dried at 103°C until constant mass.

19

������ = ������������������ ��0�������������� ��

������ = ��

��

��

0�������������� 100 (1)

0

0��������������

0 ∙100 (2)

(a) (b) (c)

Fig. 1. The specimens with the mycelium grown on the end of decay resistance test (after 16 weeks) –brown-rot fungi Serpula lacrymans (a) and Gloeophyllum trabeum (b), and white-rot fungus Trametes versicolor (c).

(Note: left specimen - specimen without leaching, right specimen - specimen with leaching)

Classification of durability

Durability classes (DC) were derived from median MLF according to CEN/TS 15083-1 (2005) and STN EN 350 (2017), as shown in Tab 1.

Tab. 1. Durability classes (DC) based on median mass loss (MLF, med) (according to CEN/TS 15083-1: 2005 and STN EN 350:2017).

Durability class (DC) Description MLF, med [%] 1 Very durable <5 2 Durable 5 < MLF ≤ 10 3 Moderately durable 10 < MLF ≤15 4 Less durable 15 < MLF ≤30 5 Non-durable >30

Statistical evaluation

The data are presented as the median value and the standard deviation (SD). Statistical significance of the differences in the weight loss in the leached and u leached wood was tested by the nonparametric Kruskal-Wallis median ANOVA test at an 0.05 significance level was used.

RESULTS AND DISCUSSION

Durability against brown rot causing basidiomycetes

The mass loss (MLF) of tested specimens against brown-rot fungi S lacrymans and G. trabeum is given in Tab. 2. Following the SMITH and ORSLER (1994) and STIRLING et al. (2016) studies and with the standard STN EN 350 (2017) it is proposed, that the median (centraltrend)canbebetterdeterminedthantheaverage.Theimpactofcertainaberrantdata with extreme value deviations was eliminated by the use of the median value.

20

Tab. 2. Mass loss due to fungal decay (MLF) in durability tests against basidiomycetes.

Wood species Treatment Leaching S. lacrymans

G. trabeum T. versicolor Med. [%] Avg. [%] SD [%] DC Med. [%] Avg. [%] SD [%] DC Med. [%] Avg. [%] SD [%] DC

European beech

None No 30.22 d 30.85 3.25 5 42.85 d 42.03 3.07 5 29.95 d 29.16 5.82 4-5 Yes 24.30 24.24 4.18 4 38.16 38.39 7.14 5 28.65 28.74 3.90 4-5

HTT-105°C No 41.72 d 40.51 5.03 5 44.65 d 45.52 2.79 5 28.41 d 27.58 3.39 4-5 Yes 37.05 35.98 4.02 5 38.56 36.96 5.24 5 31.46 30.43 3.19 5

HTT-135°C No 41.94 d 41.21 5.56 5 48.85 d 47.02 4.92 5 31.48 d 31.88 2.04 5 Yes 39.36 36.63 8.15 5 42.23 42.60 4.39 5 29.65 29.50 1.95 4-5

Alder

None No 36.08 d 36.17 4.69 5 31.07 d 31.80 3.20 5 35.27 d 35.45 6.18 5

Yes 30.28 31.55 3.89 5 37.82 36.99 4.22 5 33.28 29.83 7.73 5

HTT-105°C No 36.20 d 37.15 5.37 5 32.74 d 33.16 5.56 5 35.87 d 37.03 3.99 5 Yes 34.58 34.02 2.41 5 31.52 32.40 4.33 5 32.66 33.25 3.15 5

HTT-135°C No 40.29 d 41.25 5.97 5 35.05 d 35.07 4.73 5 37.58 d 37.37 4.40 5 Yes 40.01 38.77 4.48 5 34.90 35.76 3.22 5 32.01 31.80 3.14 5

Paper birch

None No 32.12 d 32.77 5.51 5 30.96 d 31.07 1.93 5 35.54 d 34.29 3.46 5

Yes 32.50 32.59 0.83 5 30.85 31.17 3.31 5 32.68 33.35 2.81 5

HTT-105°C No 33.63 d 32.63 4.61 5 31.37 d 30.87 3.94 5 33.13 d 32.93 3.58 5

Yes 29.65 28.78 4.22 4-5 29.15 29.08 2.22 4-5 31.12 29.71 3.10 5

HTT-135°C No 34.61 d 35.40 7.52 5 34.09 d 33.92 8.21 5 36.58 d 37.47 5.16 5 Yes 24.57 24.25 2.98 5 33.07 34.10 6.06 5 31.36 32.01 4.34 5

Norway maple

None No 31.36 d 29.50 6.53 5 36.32 d 36.43 0.53 5 35.93 d 36.54 3.59 5 Yes 32.20 32.41 4.64 5 32.58 33.13 2.79 5 32.87 33.41 5.86 5

HTT-105°C No 36.16 d 35.65 1.83 5 35.35 d 35.53 2.86 5 30.87 d 31.28 2.47 5

Yes 30.22 29.09 4.99 5 30.52 30.84 2.10 5 35.06 34.84 5.53 5

HTT-135°C No 27.05 d 26.93 2.77 4-5 44.92 d 45.34 3.33 5 32.28 d 35.02 8.51 5 Yes 23.99 24.00 4.36 4 39.37 39.82 3.31 5 23.52 25.06 6.16 5

NOTE: Med. =Median, Avg.= Average, SD = Standard deviation, DC = Durability class d = No significant effect of theleaching procedure (Kruskal-Wallis test, p >0.05)

Thevalidityofthetestwasconfirmedbythesatisfactoryvirulenceofthefungusstrain, which in the specimens of P. sylvestris sapwood caused a mass loss of 23.28% by S. lacrymans and 26.90%, by G. trabeum – i.e.,morethanthelevel of20% required forthis reference wood species, according to STN EN 113-1 (2021), although it was very close to threshold (more than the level of 30%) according to CEN/TS 15083-1 (2005).

All native (untreated) hardwoods – European beech, alder, Paper birch, and Norway maple – showed a mass loss of over 30% against two brown-rot fungi tested. The highest mass lossvalue was obtained with G. trabeum on beech wood. Higher mean mass loss of birch wood with C. puteana was observed in a study by KLARSSON et al. (2011).

The durability of all hardwood species against brown rot causing basidiomycetes slightly decreased after hydrothermal modification at 105 °C and 125 °C. The difference between the median mass losses of the treatment varies is insignificant for almost every species. This result is in accordance with the work of OHNESORGE et al. (2009), by which theresistanceof hardwood species exposed to the brown-rot fungus S lacrymans wherethe medium treatment level (160 °C) showed higher weight losses thantheuntreated ones. This could be explained by the degradation of hemicelluloses due to dehydration reactions that took place during the hydrothermal process (GEFFERT et al. 2020; DUDIAK and DZURENDA, 2021). At low hydrothermal temperatures (60–80 °C), there are negligible chemical and structural changes in the basic wood components. Increasing the temperature of the hydrothermal reaction from 100 °C to 150 °C deepens the chemical and physicochemical changes of all components of the wood substance (SOLÁR 1997). The durability of wood against decaying fungi could be improved due to thermal modification methods, mainly at

21

temperatures higher than 180 °C depending on wood species, process conditions such as duration, oxygen or inert atmosphere, and others as was documented in many studies, for example, SAILER et al. 2000; SCHWARZE and SPYCHER 2005; METSÄ-KORTELAINEN and VIITANEN 2009; KLARSSON et al. 2011; WANG et al. 2019, BAAR et al. 2021; REINPRECHT and REPÁK 2019 and 2022; VIDHOLDOVÁ et al. 2022 and other.

On the other hand, pre-treatment with leaching has led to a slight decrease in mass loss. No significant effect of the leaching procedure on mass loss was confirmed by the medianKruskal-Wallistestwith p-valuewaslowerthan0.05(Tab.2).Similarresultsrelated to the effect of the leaching procedure on mass loss of native both hardwoods (European beech, English oak, Common juniper, Black cherry, Black locust, Rowan) and softwoods (Scots pine sapwood, English yew) were obtained in studies BRISCHKE et al. (2014, 2018) They observed no overall effect of leaching on the decay test results.

Durability against white rot causing basidiomycetes

The mass loss in the white-rot test with T. versicolor is presented in Tab. 2. The validity of the test was again confirmed by the satisfactory virulence of the fungus strain, which in the specimens of F. sylvatica sapwood caused a mass loss of 36.32% – i.e., more than the level of 20% required for this reference wood species according to STN EN 113-1 (2021) and CEN/TS 15083-1 (2005). Native alder, Paper birch, and Norway maple showed higher than 30% mass loss (MLF) against tested fungus. The durability of these hardwoods slightly changed after hydrothermal modification however it was still lower. It might be explained by the creation of easily accessible simple hemicelluloses due to the hydrothermal process (GEFFERT et al. 2020). In the case of beech wood, the mass loss closed to 30 % illustrates thevariationsintheirdecaycapabilities. T. versicolor wasassociatedwiththehighestweight losses, which tends to be more aggressive on hardwoods such as beech (BARI et al. 2021).

SALIMAN et al. (2017)studiedtheeffectsofhydrothermaltreatmentparametersonthedecay resistance of oil palm wood. They found that the weight loss of the treated wood caused by white-rot fungus reduced as the temperature and time increased. However, the influence of treatment time on decay resistance enhancement was less than treatment temperature. For example, specimens treated at 110 °C for 147 min showed higher weight loss compared to specimens treated at 160 °C for 80 min (18.24% versus 9.00%). The improvement in decay resistance could be attributed to the reduction of equilibrium moisture content in treated specimens. The reduction of equilibrium moisture content is directly proportional to the increase in temperature and time (ČERMÁK et al. 2022).

Similar results were obtained regarding the effect of pre-treatment by leaching on the loss of mass, as in the case of the action of brown-rot fungi. No significant effect of the leaching procedureon mass loss was confirmedby Kruskal-Wallis median test which the pvalue was lower than 0.05 (Tab. 2).

Moisture content after durability tests

After the decay resistance test, all native and hydrothermally treated hardwoods reached a moisturecontent considerably exceeding thefibre saturation point depending on thespecies of the tested fungus (Tab. 3)

The average wood moisture after the tests ranged from 49 to 103% for S. lacrymans. Itwashigherfor G. trabeum from102to169%.Aswasbeexpected,thesefungishowedthe ability to produce considerable amounts of free water by decomposing native and hydrothermally treated wood polysaccharide components The increased moisture content of degraded hydrothermally treated wood was also due to structural changes created during hydrothermal treatment, which increase a water absorption and migration. WANG et al. (2019) treated the Chinese sweetgum wood specimens in water bath with temperatures of

22

60, 80, and 100°C for 4 hours and investigated the increase in water absorption and the changes in microstructure, mainly pit membrane was ruptured after treatment. Also, in the study REZAYATI et al. (2007), a better anti-swelling efficiency value of beech wood was achieved at a higher temperature of 170°C

Tab. 3. Moisture content (MCF) after durability tests against basidiomycetes.

Wood species Treatment Leaching

European beech

Paper birch

Norway maple

S. lacrymans G. trabeum

T. versicolor Avg.[%] SD [%] Avg. [%] SD [%] Avg. [%] SD [%]

None No 79.12 27.71 151.06 9.75 65.87 17.17 Yes 79.06 16.34 138.92 30.23 55.17 9.71

HTT-105°C No 58.60 11.21 155.37 25.77 100.49 59.51 Yes 54.78 11.44 119.77 50.60 81.97 71.70

HTT-135°C No 74.00 19.77 164.66 15.72 58.99 18.31 Yes 81.94 19.55 148.44 19.31 80.48 13.71 Alder

None No 116.04 64.14 104.38 30.42 105.49 34.79 Yes 81.17 36.07 133.75 52.04 88.02 27.71

HTT-105°C No 84.13 35.94 133.48 23.99 138.67 28.67 Yes 75.56 23.15 119.41 10.70 113.97 23.68

HTT-135°C No 81.22 32.35 160.54 27.72 152.64 33.85 Yes 83.25 30.71 148.87 10.32 124.58 36.36

None No 58.61 24.38 104.54 44.88 97.76 58.37 Yes 82.14 60.91 123.14 14.89 68.76 10.36

HTT-105°C No 49.37 7.69 113.02 7.57 73.78 17.80 Yes 60.45 19.60 111.37 9.94 66.19 13.98

HTT-135°C No 59.28 17.91 126.29 24.68 91.18 23.90 Yes 60.29 11.71 136.80 17.68 103.46 8.28

None No 56.98 11.31 124.25 13.27 99.78 60.06 Yes 56.80 3.18 113.31 13.53 88.24 43.93

HTT-105°C No 52.28 5.89 127.97 11.54 49.86 3.53 Yes 58.04 12.83 106.83 10.68 60.51 17.38

HTT-135°C No 51.47 21.91 168.71 12.84 96.78 67.11 Yes 55.90 53.06 130.30 6.64 54.56 11.13

NOTE: Avg.= Average, SD =Standard deviation

The average moisture content of the wood (MCF) at the end of the white-rot fungus exposure period ranged from 50% to 153% and was above the levels required for fungal attack (Tab. 3). This fungus typically forms a compact mycelial film on the specimens in decay tests, which helps to increase the moisture level in the wood (BARI et al. 2021).

Some cell wall damage was observed for heat treated black alder at exposed to a temperature of 190 °C for 6 hours (SALCA and HIZIROGLU 2014). Slight deformations of scalariform perforation plates of the vessel such are axial cracks and the separation of S3 layer of the secondary wall were observed after processing at 100 °C and 4 MPa (BEKHTA et al. 2016).Cracksincreaseintheproportionofintercellularspacesofwoodcausedbyheat treatment, which may increase the capillary water flow along the longitudinal direction (ZAUER et al. 2014). LIN et al. (2016) found that the removals of extractives which was situated on the cell wall would block the pits of alder birch wood played an important roles in improving the permeability of wood after heat treatment. As noted above, the pit membrane, which was ruptured after treatment, can influence moisture migration and wood permeability (WANG et al. 2019).

Durability classification

The results from resistance tests against individual brown and white rot causing basidiomycetes were used to classify the four wood species according to their durability according to EN 350 (2016) as shown in Tab. 2.

23

As expected from the high mass loss determined for native alder (A. glutinosa), Paper birch (B. papyrifera) and Norway maple wood (A. pseudoplatanus) were classified as nondurable. In thecaseofnativebeechwood thepotentially high variation inthemass loss in T. versicolor on beech and its value which was very close to 30%, led to the determination of DC 5.

Inaddition,onthebaseofthehighmasslossdeterminedforallhydrothermallytreated hardwoodsattemperaturesof105and135 ±2.5°C,itwasclassifiedasnon-durablematerial (Durability class DC 5).

However,therewasnouniformleachingeffect,i.e.inonecaseimproving,intwocases decreasing the durability class. Consequently, in summary, no significant effect of the leaching procedureaccording toSTNEN84 (2021)on thedurability classification could be established. Similar findings were noted by BRISCHKE et al. (2014, 2018) and OHNESORGE et al. (2009).

CONCLUSION

The results of this laboratory study on decay resistance were as follows:

• Native and hydrothermally treated European beech (F. sylvatica), alder (A. glutinosa), Paper birch (B. papyrifera) and Norway maple wood (A. pseudoplatanus) were highly susceptible to brown and white rot causing basidiomycetes (S. lacrymans, G. trabeum and T. versicolor) – in all cases the mass loss was higher than the 20% and the moisture content considerably exceeded the fibre saturation point, so it was above the level required for a fungal attack;

• Leaching pre-treatment had a negligible impact on decay resistance;

• Native and hydrothermally treated hardwood species have been classified as nondurable species (Durability class DC 5).

REFERENCES

ALI, M.R., ABDULLAH, U.H., ASHAARI, Z., HAMID, N.H., HUA, L. S. 2021. Hydrothermal Modification of Wood: AReview. In Polymers 13(16), 2612. DOI: 10.3390/polym13162612

BAAR, J., BRABEC, M., SLÁVIK, R., ČERMÁK, P.2021.Effectofhemp oilimpregnation andthermal modificationonEuropeanbeechwoodproperties. InEuropeanJournalofWoodandWoodProducts 79(1), 161–175. DOI: 10.1007/s00107-020-01615-9

BARI,E.,OHNO,K.,YILGOR,N.,SINGH,A.P.,MORRELL,J.J.,PIZZI,A.,TAJICKGHANBARY,M.A., RIBERA, J. 2021. Characterizing fungal decay of beech wood: Potential for biotechnological applications. In Microorganisms 9(2), 247.DOI: 10.3390/microorganisms9020247

BEKHTA, P., MAMOŇOVÁ, M., SEDLIAČIK, J., NOVÁK, I. 2016. Anatomical study of short-term thermo-mechanically densified alder wood veneer with low moisture content. In European Journal of Wood and Wood Products, 74(5), 643-652. DOI: 10.1007/s00107-016-1033-2

BRISCHKE, C., WELZBACHER, C.R., GELLERICH, A., BOLLMUS, S., HUMAR, M., PLASCHKIES, K., SCHEIDING, W., ALFREDSEN, G., VAN ACKER, J., DE WINDT, I. 2014. Wood natural durability testing under laboratory conditions: results from a round-robin test. In European Journal of Wood and Wood Products 72(1), 129–133. DOI: 10.1007/s00107-013-0764-6

BRISCHKE,C.,HESSE,C.,MEYER-VELTRUP,L.,HUMAR,M.2018.Studiesonthematerialresistance and moisture dynamics of Common juniper, English yew, Black cherry, and Rowan. In Wood Material Science & Engineering 13(4), 222–230. DOI: 10.1080/17480272.2017.1356371

CEN/TS 15083-1 (2005). Durability of Wood and Wood-based Products – Determination of the Natural Durability of Solid Wood against Wood-destroying Fungi, Test Methods – Part 1: Basidiomycetes. EuropeanCommittee for Standardisation: Brussels, Belgium, 2005.

24

ČERMÁK, P., BAAR, J., DÖMÉNY, J., VÝBOHOVÁ, E., ROUSEK, R., PAŘIL, P., OBERLE, A., ČABALOVÁ, I., HESS, D., VODÁK, M., BRABEC, M. 2022. Wood-water interactions of thermally modified, acetylated and melamine formaldehyde resin impregnated beech wood. In Holzforschung 76(5), 437–450. DOI: 10.1515/hf-2021-0164

DANIEL,G.,VOLC,J.,FILONOVÁ,L.,PLÍHAL,O.,KUBÁTOVÁ,E.,HALADA,P.2007.Characteristics of Gloeophyllum trabeum alcohol oxidase, an extracellular source of H2O2 in brown rot decay of wood. In Applied and environmental microbiology 73(19), 6241–6253. DOI: 10.1128/AEM.00977-07

DUDIAK,M.,DZURENDA, L.2021.ChangesinthePhysicalandChemicalPropertiesofAlderWood in the Process of Thermal Treatment with Saturated Water Steam. In Coatings 11(898), pp. 1–12. DOI: 10.3390/coatings11080898

DZURENDA,L.2018.Huesof Acer platanoides L.resultingfromprocessesofthermaltreatmentwith saturated steam. In Drewno61(202), 165–176. DOI: 10.12841/wood.1644-3985.241.11

DZURENDA, L. 2019. Technical-technological characteristics of the thermal process of color modification of birch woodwith saturated water steam. In Acta Facultatis Technicae 2, 61–73.

DZURENDA, L., DUDIAK, M. 2020. Changes in wood tree species Fagus sylvatica L. and characteristicsofthethermalprocessofmodifyingitscolorwithsaturatedwatersteam. InAdvances in Ecological and Environmental Research 5(4), 142–156.

FOJTÍK, R., DĚDKOVÁ, K. 2016. Analysis of diagnostic methods for detecting the presence of Gloeophyllum spp. Wood research 61(4), 479–486.

GÁPER, J., GÁPEROVÁ, S., GAŠPARCOVÁ, T., KVASNOVÁ, S., PRISTAŠ, P., NÁPLAVOVÁ, K. 2018. Indoor fungal destroyers of wooden materials Their identification in present review. In Wood Research 63(2), 203–214. https://hdl.handle.net/1822/55192

GEFFERT, A., GEFFERTOVÁ, J., VÝBOHOVÁ, E., DUDIAK, M. 2020. Impact of Steaming Mode on Chemical Characteristics and Color of BirchWood. InForests 11(4),478. DOI: 10.3390/f11040478

GOODELL B. 2020. Fungi Involved in the Biodeterioration and Bioconversion of Lignocellulose Substrates. In Benz J.P., Schipper K. (eds) Genetics and Biotechnology. The Mycota 2. Springer. DOI: 10.1007/978-3-030-49924-2_15

HAAS, D., MAYRHOFER, H., HABIB, J., GALLER, H., REINTHALER, F.F., FUXJÄGER, M.L., BUZINA, W. 2019. Distribution of building-associated wood-destroying fungi in the federal state of Styria, Austria. In European Journal of Wood and Wood Products 77(4), 527–537. DOI: 10.1007/s00107-019-01407-w

HILL, C. 2011. An Introduction to Sustainable Resource Use (1st ed.). Routledge. DOI: 10.4324/9781849775304

IRBE, I., KARADELEV, M., ANDERSONE, I., ANDERSONS, B. 2012. Biodeterioration of external woodenstructuresoftheLatvianculturalheritage.InJournalofCulturalHeritage13(3),79–84.DOI: 10.1016/j.culher.2012.01.016

KARIM,M.,DARYAEI,M.G.,TORKAMAN,J.,OLADI,R.,GHANBARY,M.A.T.,BARI,E.,YILGOR,N. 2017. Natural decomposition of hornbeam wood decayed by the white rot fungus Trametes versicolor. In Anais da Academia Brasileira de Ciências 89 (4), 2647–2655. DOI: 10.1590/00013765201720160714

KARLSSON, O., SIDOROVA, E., MORÉN, T. 2011. Influence of heat transferring media on durability of thermally modified wood. In BioResources 6(1), 356–372. DOI: 10.15376/biores.6.1.356-372 LIN, L., YANG, Y., QIU, J., Luo, B., QIN, L., 2017. Effects of thermo-vacuum treatment on the anatomical structures of szemao pine wood and alder birch wood. In Wood research, 62(5), pp.673682.

METSÄ-KORTELAINEN, S., VIITANEN, H. 2009. Decay resistance of sapwood and heartwood of untreated and thermally modified Scots pine and Norway spruce compared with some other wood species. In Wood Material Science and Engineering 4(3-4), 105–114. DOI: 10.1080/17480270903326140

OHNESORGE,D.,TAUSCH,A.,KROWAS,I.,HUBER,C.,BECKER,G.,FINK,S.2009.Laboratorytests on the natural durability of six different wood species after hygrothermal treatment. Proceedings of the Fourth European Conference on Wood Modification, Stockholm, Sweden, April 27–29, 159–164.

REINPRECHT, L. 2008.Wood protection. Technical University. Zvolen, 453 p.

25

REINPRECHT, L., NOVOTNÁ, H., ŠTEFKA, V. 2007. Density profiles of spruce wood changed by brown-rot and white-rot fungi. In Wood Research 52(4), 17–28.

REINPRECHT, L., REPÁK, M. 2019. The impact of paraffin-thermal modification of beech wood on itsbiological,physicalandmechanicalproperties.InForests10(12),1102.DOI:10.3390/f10121102

REINPRECHT, L., REPÁK, M. 2022. Beech Wood Thermally Modified in the Melt of Polyethylene Glycol. In BioResources 17(1), 652–672. DOI: 10.15376/biores.17.1.652-672

REINPRECHT, L., VIDHOLDOVÁ, Z. 2019. Rot resistance of tropical wood species affected by water leaching. In BioResources 14(4), 8664–8677. DOI: 10.15376/biores.14.4.8664-8677

REZAYATI, C.P., MOHAMMADI, R.J., MOHEBI, B., RAMEZANI, O. 2007. Influence of hydrothermal treatmentonthedimensionalstabilityofbeechwood.InCaspianJournalofEnvironmentalSciences 5(2), 125–131.

SAILER, M., RAPP, A.O., LEITHOFF, H. PEEK, R.D. 2000. Vergütung von Holz durch Anwendung einer Öl-Hitzebehandlung. In Holz als Roh-und Werkstoff 58(1), 15–22. DOI: 10.1007/s001070050379

SALCA, E.A., HIZIROGLU, S. 2014. Evaluation of hardness and surface quality of different wood species as function of heat treatment. In Materials & Design (1980-2015), 62, 416-423. DOI: 10.1016/j.matdes.2014.05.029

SALIMAN,M.A.R.,ZAIDON,A.,BAKAR,E.S.,LEE,S.H.,TAHIR,P.M.,LEEMON,N.F.,KAIPIN,M.F., JULIANA, A.H. 2017. Response surface methodology model of hydrothermal treatment parameters on decay resistance of oil palm wood. In Journal of Tropical Forest Science 29(3), 318–324. DOI: 10.26525/jtfs2017.29.3.318324

SANDBERG, D., KUTNAR, A., KARLSSON, O., JONES, D. 2021. Wood Modification Technologies: Principles, Sustainability, and the Need for Innovation, 1st ed., CRC Press, Taylor and Francis Ltd.: Abingdon, 450p.

SHI, J., LU, Y., ZHANG, Y., CAI, L., SHI, S.Q. 2018. Effect of thermal treatment with water, H2SO4 and NaOH aqueous solution on color, cell wall and chemical structure of poplar wood. In Scientific Reports 8(1), 1–9.DOI: 10.1038/s41598-018-36086-9

SCHWARZE, F.W.M.R., SPYCHER, M. 2005. Resistance of thermo-hygro-mechanically densified wood to colonization and degradation by brown rot fungi. In Holzforschung 59, 358–363. DOI: 10.1515/HF.2005.059

SOLÁR, R. 1997. Lignin Changes in Hydrothermal Wood Treatment Processes, 1st ed., Technical University in Zvolen: Zvolen, Slovakia, 57 p.

SMITH, G.A., ORSLER, R.J. 1994. The biological natural durability of timber in ground contact. Document No. IRG/WP 94-20051. In 25th Annual Meeting of the International Research Group on Wood Protection (IRG25), May 29-June 3, Nusa Dua,Bali, Indonesia.

STIRLING, R., ALFREDSEN, G., BRISCHKE, C., DE WINDT, I., FRANCIS, L.P., FRÜHWALD HANSSON, E.,HUMAR,M.,JERMER,J.,KLAMER,M.,KUTNIK,M.LAKS,P.E.2016.Globalsurveyondurability variation–on the effect of the reference species. Document No. IRG/WP/16-20573. In 47th Annual Meeting of the International Research Group on Wood Protection (IRG47), May 15-19, Lisbon, Portugal.

STNEN 84(2021).Durabilityofwoodandwood-basedproducts-Acceleratedageingoftreatedwood priortobiologicaltesting-Leachingprocedure.SlovakOfficeofStandards,MetrologyandTesting: Bratislava, Slovakia, 2021.

STN EN 113-1 (2021). Durability of wood and wood-based products - Test method against wood destroying basidiomycetes - Part 1: Assessment of biocidal efficacy of wood preservatives. Slovak Office of Standards, Metrology and Testing, Bratislava, Slovakia, 2021.

STN EN 350 (2017). Durability of wood and wood-based products - Testing and classification of the durability to biological agents of wood and wood-based materials. Slovak Office of Standards, Metrology and Testing, Bratislava, Slovakia, 2017.

TOLVAJ, L.,NEMETH, R.,VARGA, D., MOLNAR, S.2009. Colour homogenisation of beech wood by steam treatment. In Drewno52, 5–17.

TIMAR,M.C.,VARODI,A.M.,HACIBEKTASOGLU,M.,CAMPEAN,M.2016.ColorandFT-IRanalysis of chemical changes in beech wood (Fagus sylvatica L.) after light steaming and heat treatment in two different environments. In BioResources 11(4), 8325–8343. DOI: 1010.15376/biores.11.4.8325-8343

26

TIRALOVÁ, Z., REINPRECHT, L. 2000. Beech wood decay due to individual and combined action of selected brown-rot fungi. In Acta Facultatis Xylologiae Zvolen res publica Slovaca 42(2), 139–146.

VIDHOLDOVÁ, Z., KAČÍK, F., REINPRECHT, L., KUČEROVÁ, V., LUPTÁKOVá, J. 2022. Changes in chemical structure of thermally modified spruce wood due to decaying fungi. In Journal of fungi 8(7), 739 DOI: 10.3390/jof8070739

WANG, C., LI, R., LIU, C., WANG, X. 2019. Effects of medium-low temperature hydrothermal treatmentonmicrostructureanddimensionalstabilityofChinesesweetgumwood.InWoodResearch 64, 97-104.

WITOMSKI, P., OLEK, W., BONARSKI, J.T. 2016. Changes in strength of Scots pine wood (Pinus silvestris L.) decayed by brown rot (Coniophora puteana) and white rot (Trametes versicolor). In Construction and Building Materials 102(1), 162–166. DOI: 10.1016/j.conbuildmat.2015.10.109

ZAUER, M., HEMPEL, S., PFRIEM, A., MECHTCHERINE,V., WAGENFÜHR, A. 2014. Investigations of the pore-size distribution of wood in the dry and wet state by means of mercury intrusion porosimetry. In Wood science and technology 48(6), 1229-1240. DOI: 10.1007/s00226-014-0671-y

ACKNOWLEDGMENTS

This work was supported by the Slovak Research and Development Agency under contract No. APVV-17-0456, the Scientific Grant Agency of the Ministry of Education SR Grant No. 1/0665/22 and Progressive research of performance properties of wood-based materials and products (LignoPro), ITMS 313011T720 supported by the Operational Programme Integrated Infrastructure (OPII) funded by the ERDF.

AUTHORS’ ADDRESSES

Zuzana Vidholdová (zuzana.vidholdova@tuzvo.sk)

Technical University in Zvolen Faculty of Wood Sciences and Technology Department of Wood Technology T.G. Masaryka 24 960 01 Zvolen Slovakia

Gabriela Slabejová (slabejova@tuzvo.sk)

Technical University in Zvolen Faculty of Wood Sciences and Technology Department of Furniture and Wood Products T.G. Masaryka 24 960 01 Zvolen Slovakia

27

28

ACTA FACULTATIS XYLOLOGIAE ZVOLEN, 64(2): 29 36, 2022

Zvolen, Technical University in Zvolen

DOI: 10.17423/afx.2022.64.2.03

MATERIAL AND METHODS

The selected type of lignocellulosic material was spruce wood (Picea abies L ), commonly used as a building material. For the experiment, carried out in laboratory conditions, we subjected samples of spruce originating from a 120-year-old stand at an altitude of 800 m above sea level. For the purposes of the test method 30 pieces of the test specimens were handled from logs with dimensions of 250 mm × 90 mm × 10 mm.

In creating the methodology, we also relied on standards that relate to the evaluation of materials in terms of reaction to fire. The standard test method for the flammability of construction products exposed to direct flame is the method according to STN EN ISO 11925-2 (2020), which evaluates the flammability of products when exposed to a small, directed flame with the placement of samples in a vertical orientation.

Whentestingsamplesoflignocellulosicmaterial, weused aprogressivetestmethod –modification of the flammability test, the procedure of which is specified in utility model application PUV 160-2021 (2021). This method assesses the flame spread over the surface ofthelignocellulosicmaterial undertheloadoftheflamesource, depending on theangleof inclinationofthesampleaswellasthemasslossofthesamples.Thedevicefordetermining the speed of flame propagation on the surface is shown in Figure 2

When providing the progressive test method, the samples are mounted in the device holder at three different angles. The required flame height is set with the propane burner valve and the flame is applied to the test sample for a specified time (10 min). The mass of the tested samples is also recorded at regular 10-s intervals using the KERN PES 6200-2M electronic scales and the KERN Balance Connection program. Subsequently, we calculated the relative mass loss from the measured values according to equation (1) for each sample (KAČÍKOVÁ et al. 2008).

����(��)= ��(��0) ��(��) ��(��0) ∙100 (%) (1)

Where: ����(��)–relativemasslossovertime(τ); ��(��0)–sampleoriginalweight(g);��(��) – sample weight at time (τ) (g).

The experiments were performed at three different angles of inclination of the sample (0°,45 °,90 °tothetestflame).Weperformed10 experimentsforeachangleofinclination of the sample, which represents 30 experiments at 3 angles of inclination of the sample.

2.

.

31

Fig.

Device for determining the speed of flame propagation on the surface

RESULTS AND DISCUSSIONS

Flame propagation is a fire property that affects the entire combustion process. Based on testing of different materials by other authors i.e., HUANG et al. (2015), who also investigated flame propagation over the sample surface, we selected a progressive test method.

Using the test method described in the material and methodology section, a series of experiments were performed to study the flame spread over the surface of spruce wood and the mass loss of the test samples after exposure to the test flame. The results of the studied evaluation criteria are shown in Figures 3 to 5.

Accordingtotheobtainedresults(Fig.3)wecansaythatthereisahigherriskofflame propagation with the test flame at 0 ° angle of inclination of the sample. When the samples werethermallyloadedat0°,theirburningwassignificantlymoreintense,theflamenotonly spread along the front side of the samples, but also spread to the back side of the sample. Also, depending on the angle of inclination of the sample, we see an observable difference (in terms of burn-in), the observable difference was also in the charred layer. While at 90 ° theflamepenetratedtheirinnerlayers,at45°itremainedonthesurfaceandspreadupwards. Fromtheresultingsampleswecanstatethatthesamplesat45°and90°angleofinclination showed more positive results compared to the samples at 0 ° angle of inclination compared totheactionoftheflame.Itfollowsthattheflamepropagatesoverthesurfaceofthematerial usually immediately after ignition, but the flame propagation is faster when there is an ascending flame propagation on the vertically oriented fuel surface. The cause is a change in the physical interaction between the flame and the unburned fuel when the orientation of thefuelchangesi.e.,achangeinthedirectionofpropagationofthereleasedflammablegases (ascending) with respect to the direction of flame propagation.

32

Fig. 3. Photo documentation of samples after the experiment.

Fig. 4. Relative mass loss of tested samples in 600 s (average ± SE).

0 ° 45 ° 90 °

0 1 2 3 4 5 6 7 8 9 relative mass loss (%) time (s)

Fig. 5. Relative mass loss of tested samples (average values).

The relative mass loss course (Fig. 5) was similar for the 45 °and 90 ° sample angles. We noticed a more significant difference at the 0 ° angle of inclination of the samples, in which a more significant mass loss occurred later, compared to the other two angles of inclinationofthesamples.Atthesametime,wecanstatethatallwoodyplantslostlessthan 9%oftheiroriginalweightin600seconds(Fig.4).Werecordedtheworstresultsforsamples at a 0 ° angle of inclination, which lost up to 8.18% of their weight, which we attribute to the faster spread of the flame. As we expected, even in the case of mass loss, the influence of the angle of inclination of the sample on the thermal degradation of wood was significantly manifested. This claim was confirmed as it was clear from the weight loss comparison that the samples at 90 ° tilt showed the lowest mass loss. If we compare the

33

samples based on their angle of inclination, we can rank them in the order from the best results to the worst as follows: 90 °, 45 °, 0 °.

KMEŤOVÁ et al. (2020b)inastudyaimedatcomparingthethermalresistanceofScotchpine andSessileoakforfireprotectionpurposes,usingthestandardtestmethodaccordingtoSTN EN ISO 11925-2 found that there is a higher risk of ignition when the test flame acts on the edge of the tested sample compared with the action of the flame on the main surface. When the samples were thermally loaded at the edge, their burning was a bit more intense, the flame spread in the samples not only in the vertical direction, but also along the edge of the sample.

ZACHAR et al. (2012) in a study aimed at determination of selected fire properties of spruce wood, also used the standard test method according to STN EN ISO 11925-2. Their results confirmed the higher ignitability of edges of samples.

MITTEROVÁ et al. (2021), using a flammability test, investigated the spread of flame over the surface of untreated and retardation-treated spruce wood and, assessed its contribution to the development of the fire to which it was exposed. The results of the tests of the investigated material indicate that after treatment with flame retarding substances, its resistancetotheflametowhichitwasexposedduringthetestincreased,itdidnotigniteand thus did not spread the flame.The effectiveness of flame retardants on wood samples, has also been demonstrated by KAČÍKOVÁ et al. (2021). In their research, they dealt with the influenceofnanoparticles TiO2, SiO2, ZnOand waterglass on thethermal resistance ofoak wood.

GAŠPERCOVÁ and MAKOVICKÁ-OSVALDOVÁ (2017) also studied and compared the flame length and mass loss of spruce and beech wood, which are often used in construction. The experiment was focus on testing the reaction to fire on two different types of surfaces, namely treated and untreated surfaces. The treated surface was sanded with sandpaper and the rough surface was only cut wood. The spruce wood was also studied on the cone calorimeter (MARTINKA et al. 2018; MARTINKA et al. 2016). With the help of this device, we can determine several characteristics, for example charring rate or heat release rate, which is a key parameter for the calculation of fire resistance of timber structures and for fire investigation. Many other authors are studying the flame spread of various materials. ZHANG et al. (2020) also investigated the effects of electric current and sample orientation on flame propagation over electric wires. GOLLNER et al. (2017), also addressed the effect of sample flow and inclination on flame propagation across solid fuels. Upward flame spreads are perhaps best studied,withvarioustheoriesavailabletodescribemanyaspectsoftheflamespreadprocess. But even in this well-studied configuration, work is still needed to refine these results.

CONCLUSION

The aim of the paper was an experimental comparison of the thermal resistance of a selectedlignocellulosic material – sprucewood, undertheloadofaflamesourcedepending on the angle of inclination of the sample. For this purpose, a progressive test method was used - modification of the flammability test. In the evaluation, we focused on the effect of theangleofinclinationofthesampleagainstthetestflameandthemasslossofthesamples. Fromtheresultswecanstatethatthebestresultsintermsofmasslosscomparedtotheangle ofinclination 0 ° and 45 °, recorded samples with anangle ofinclination of 90 °. Regarding the flame spread over the surface of the samples, it should be noted that the flame spread is fasterifthereisan ascendingflamespreadonthe verticallyorientedsurfaceofthefuel.The obtained original experimental results and their interpretation are a contribution to the

34

creation of adatabase of fire and material properties of wood forthe needs ofmodelling the spreadoffireintermsoffireprotection.Anewprogressivetestmethodhas alsobeentested for the benefit of this research.

REFERENCES

DIETENBERGER, M. 2002. Update for combustion properties of wood components. In Fire and Materials 26, 255-267. DOI: 10.1002/fam.807

DIETENBERGER,M.,HASBURGH,L.2016.Woodproductsthermaldegradationandfire.InReference module in materials science and materials engineering, 1-8. DOI: 10.1016/b978-0-12-803581-8.03338-5

DRYSDALE, D., 1999. An Introduction to Fire Dynamics, 2nd edn. John Wiley & Sons, UK.