AI: the coming tsunami

Will AI lead to the automation of design?

Building Information Modelling (BIM) technology for Architecture, Engineering and Construction

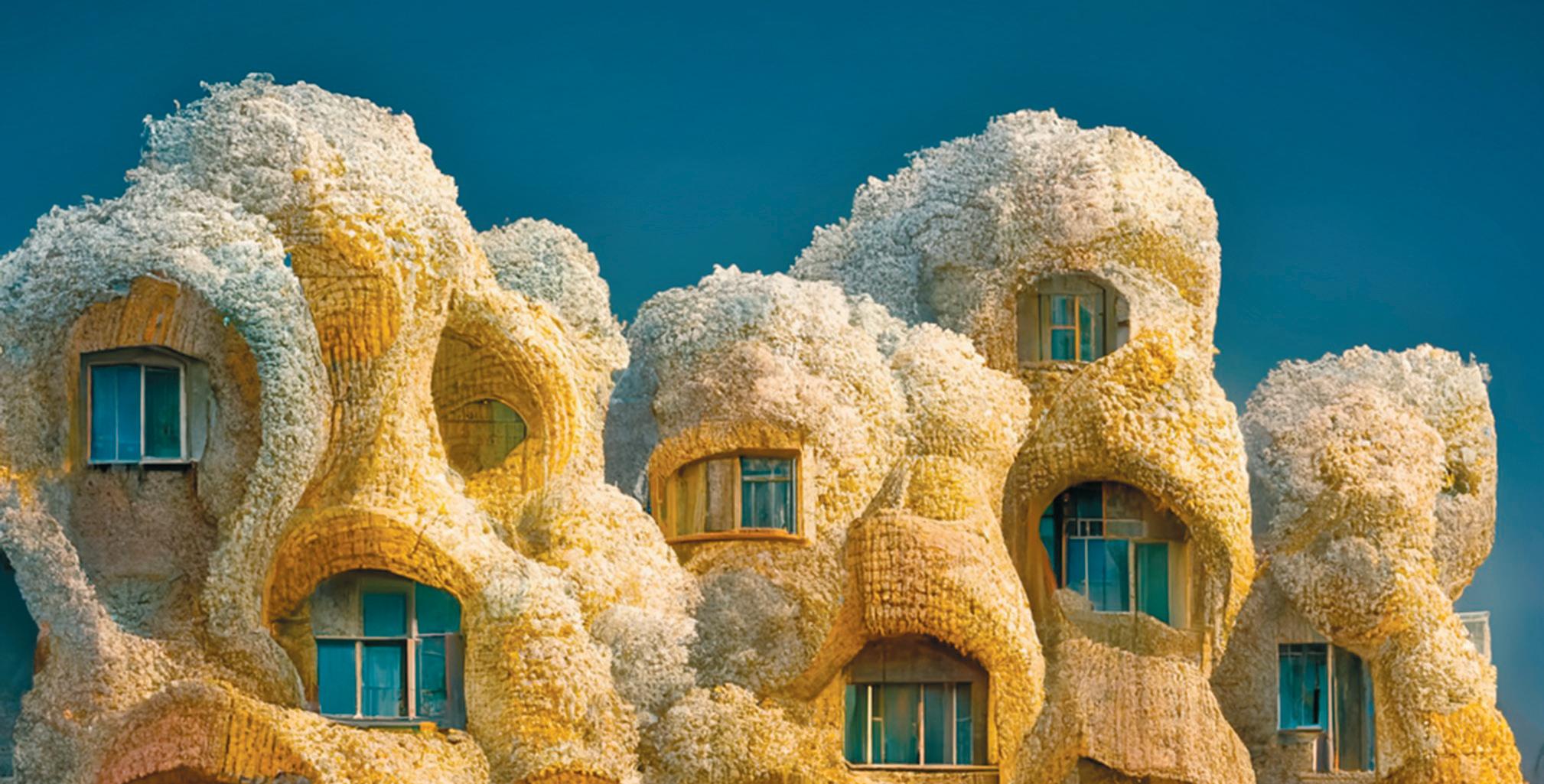

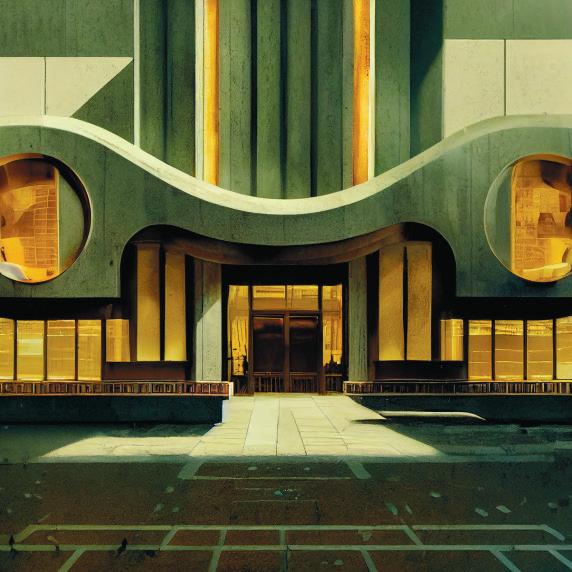

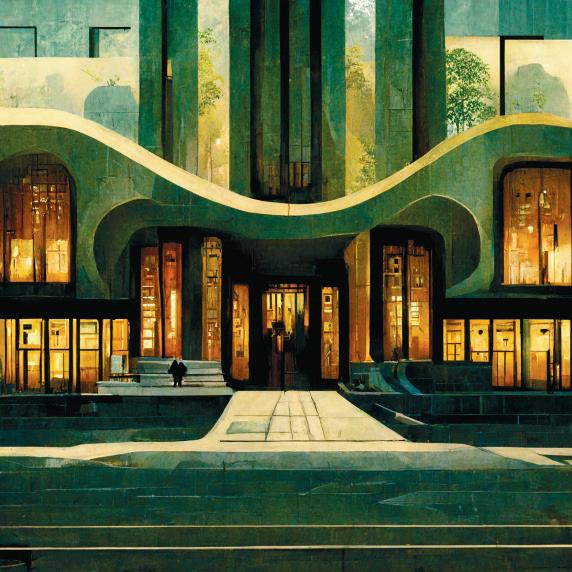

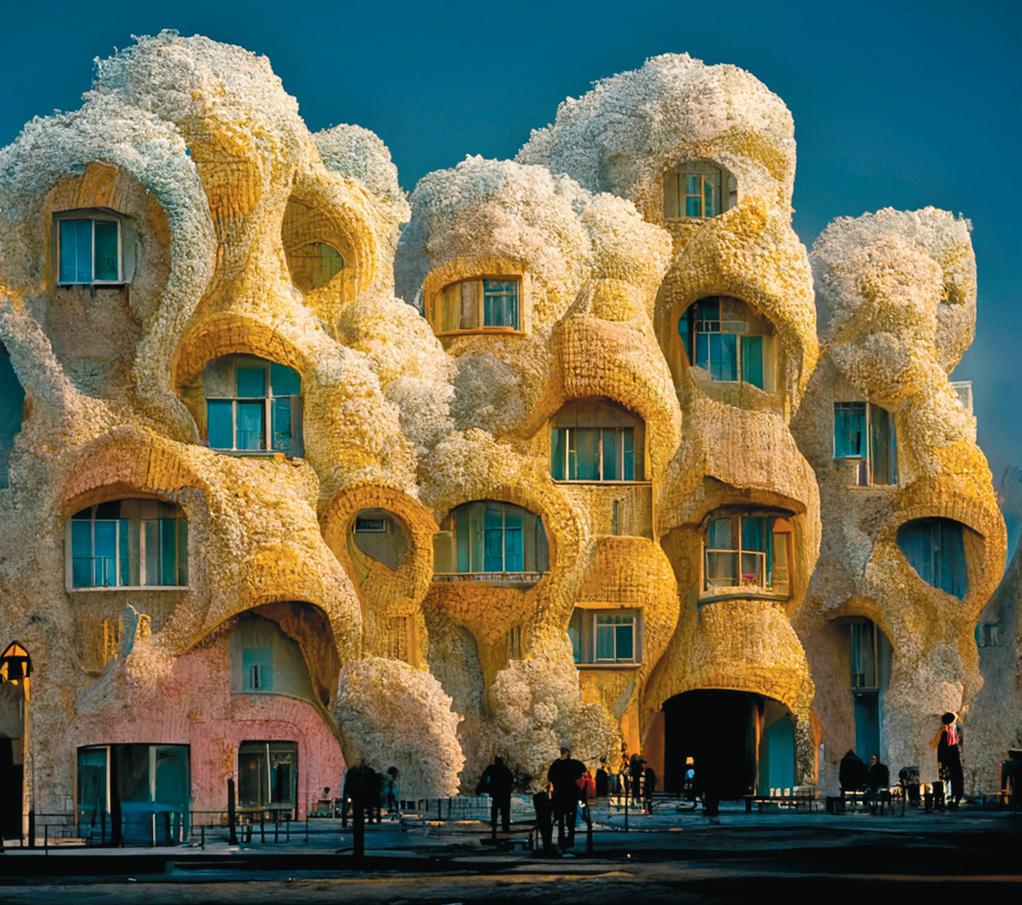

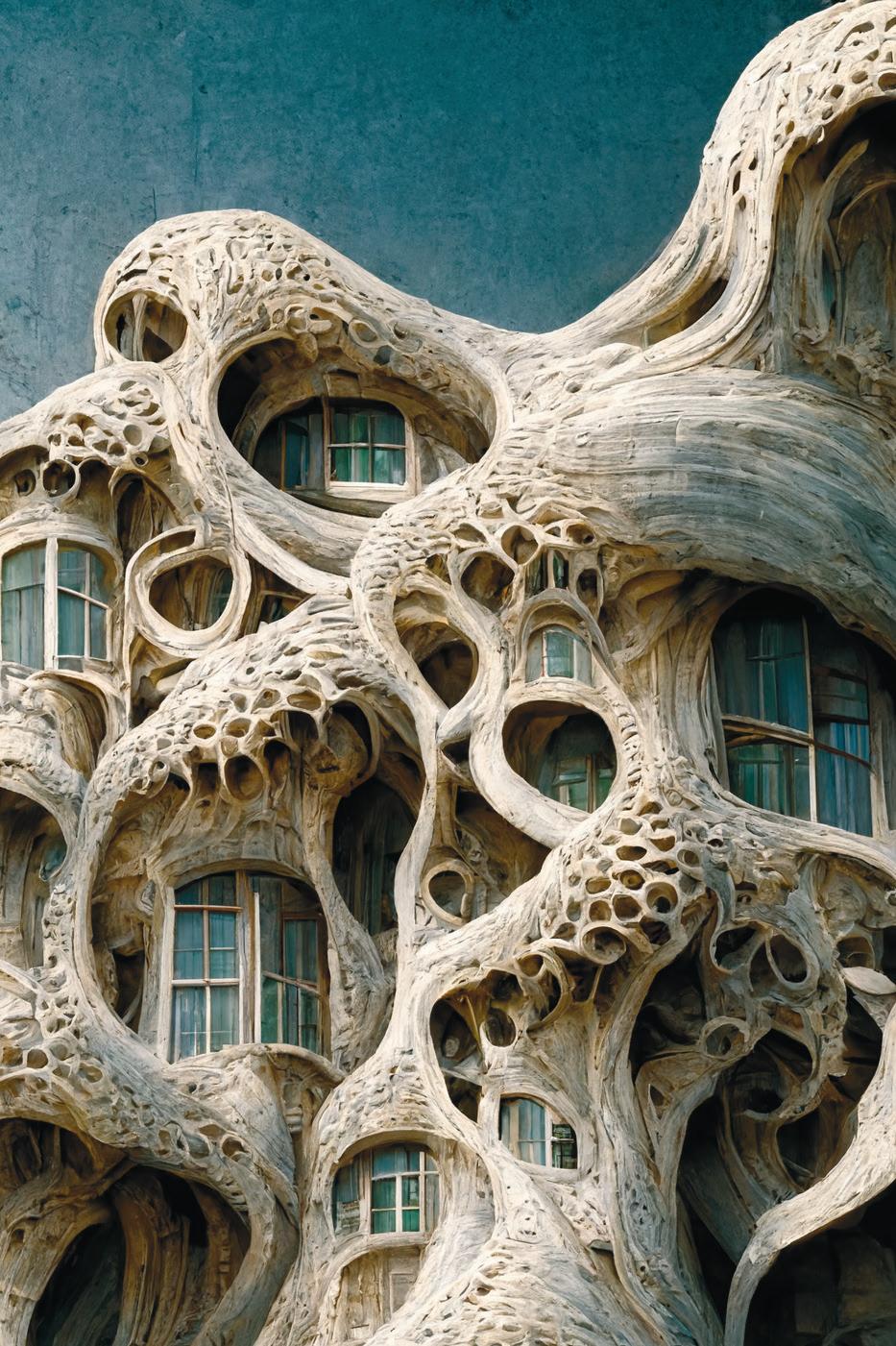

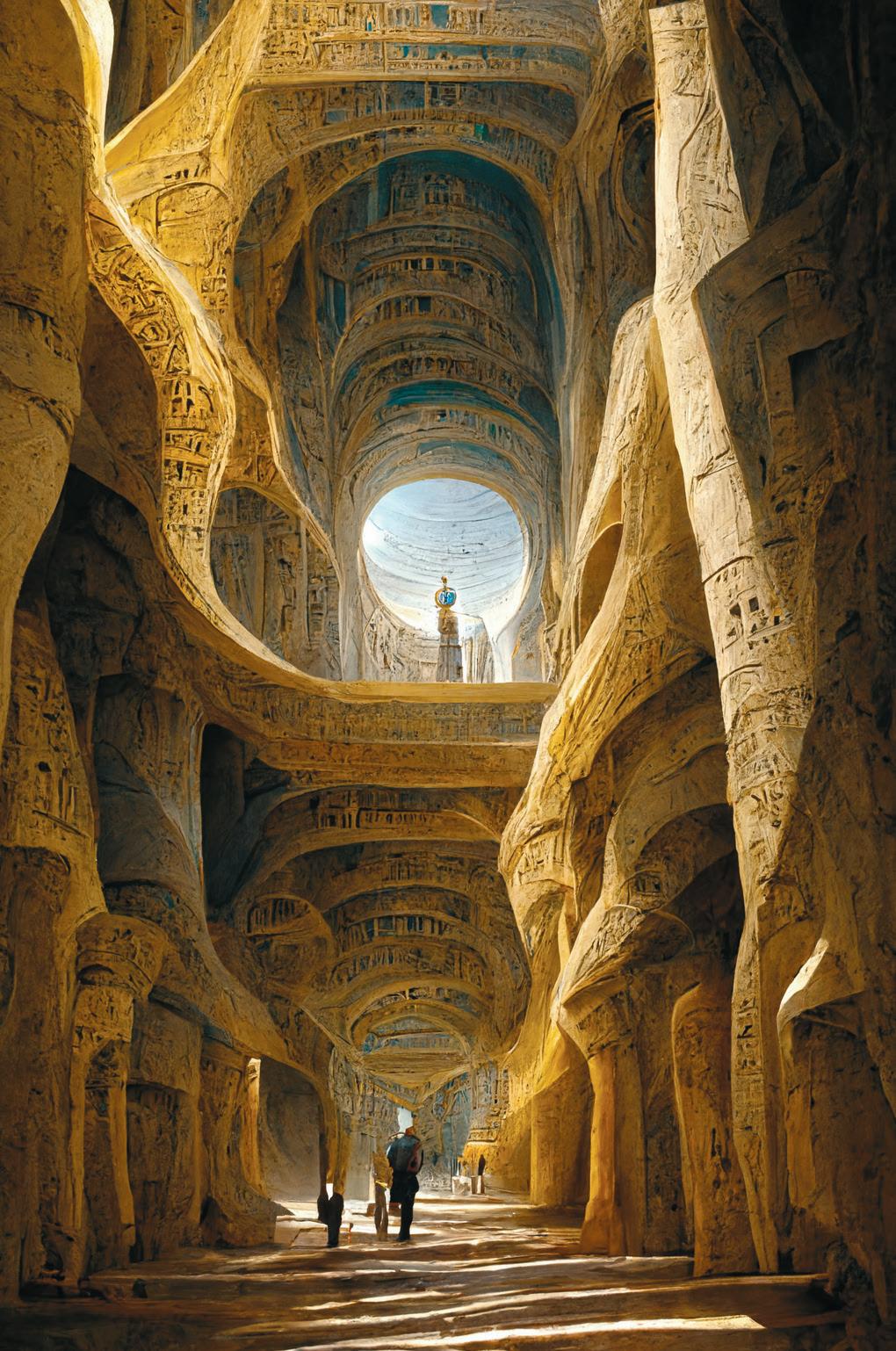

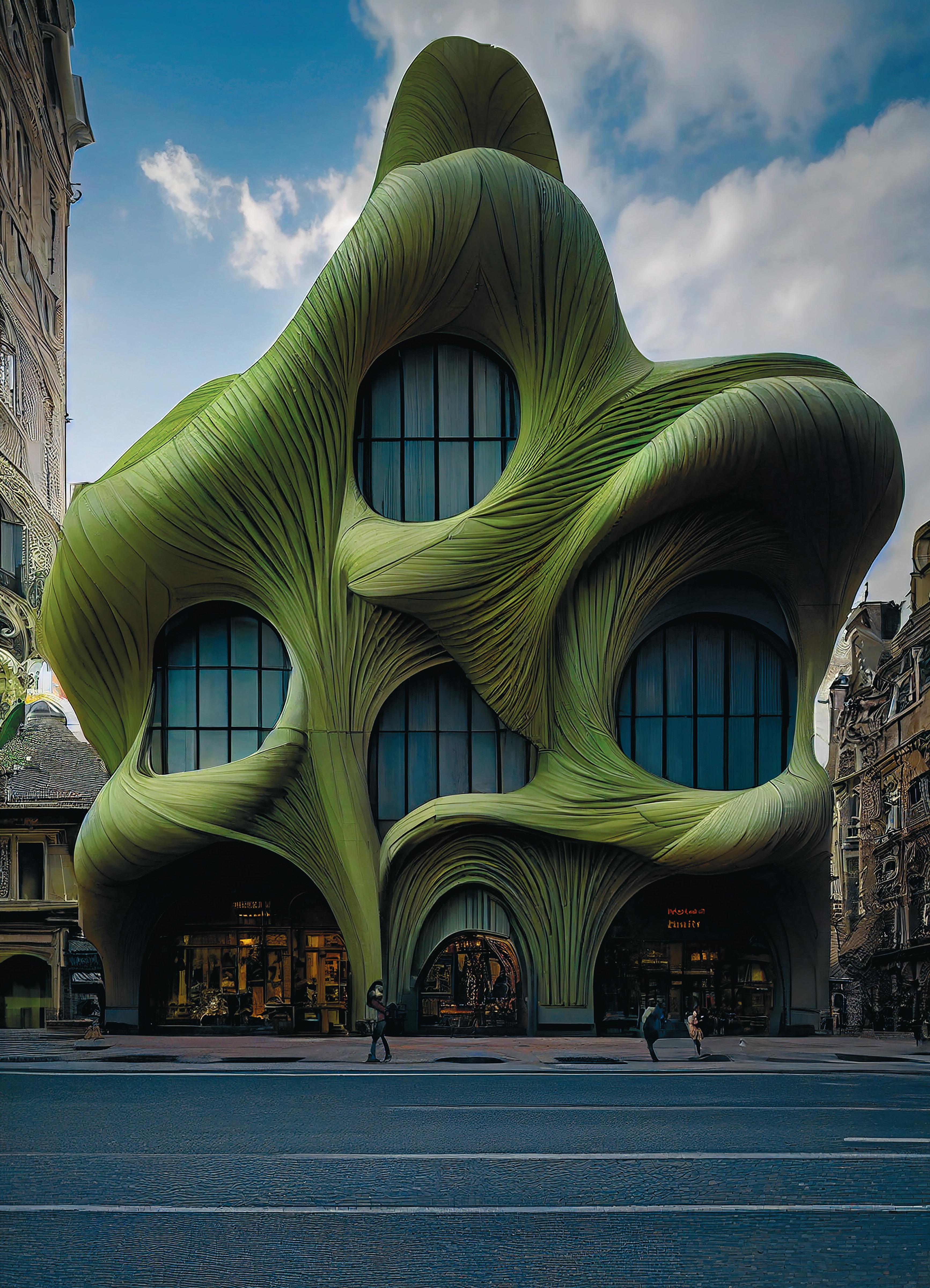

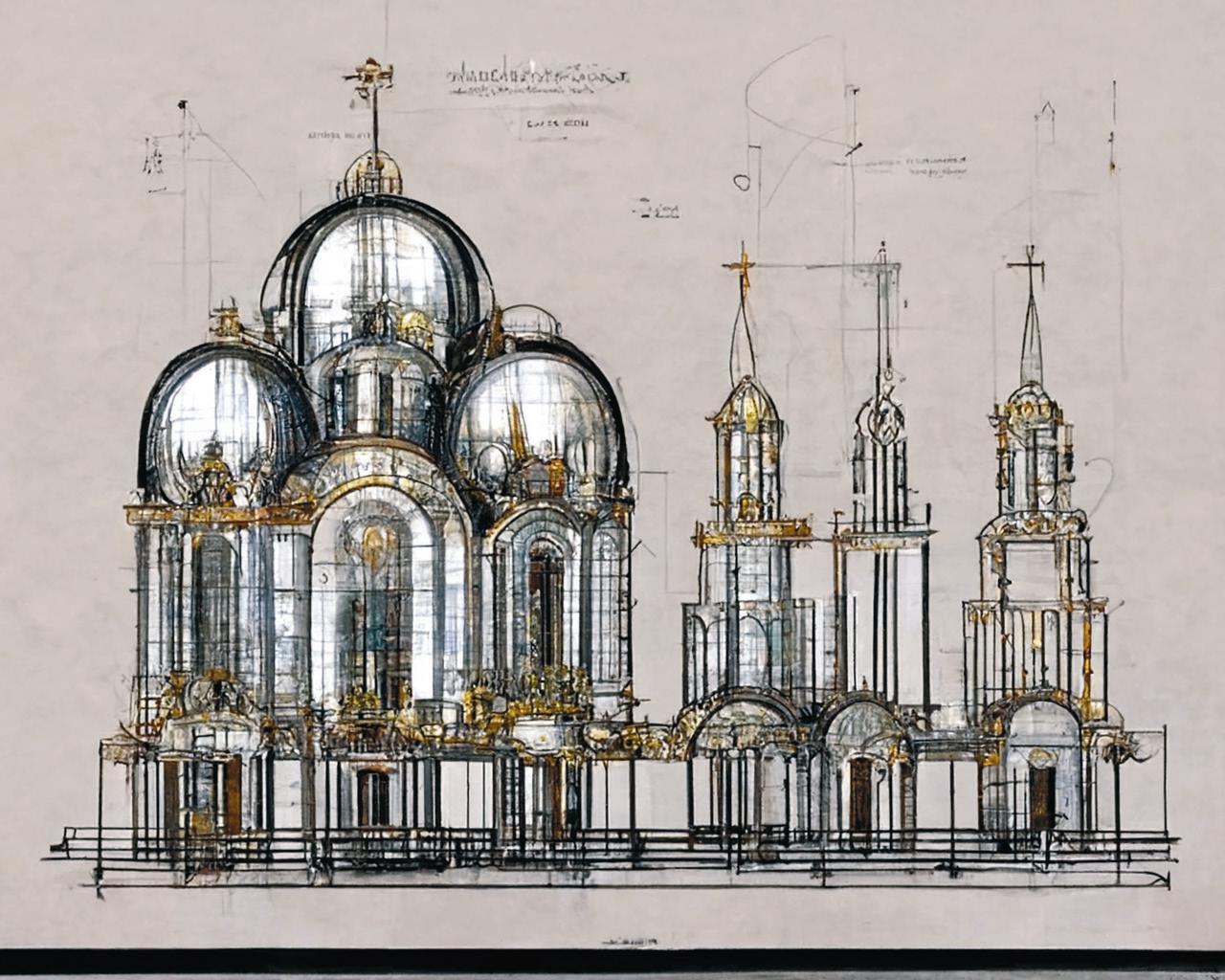

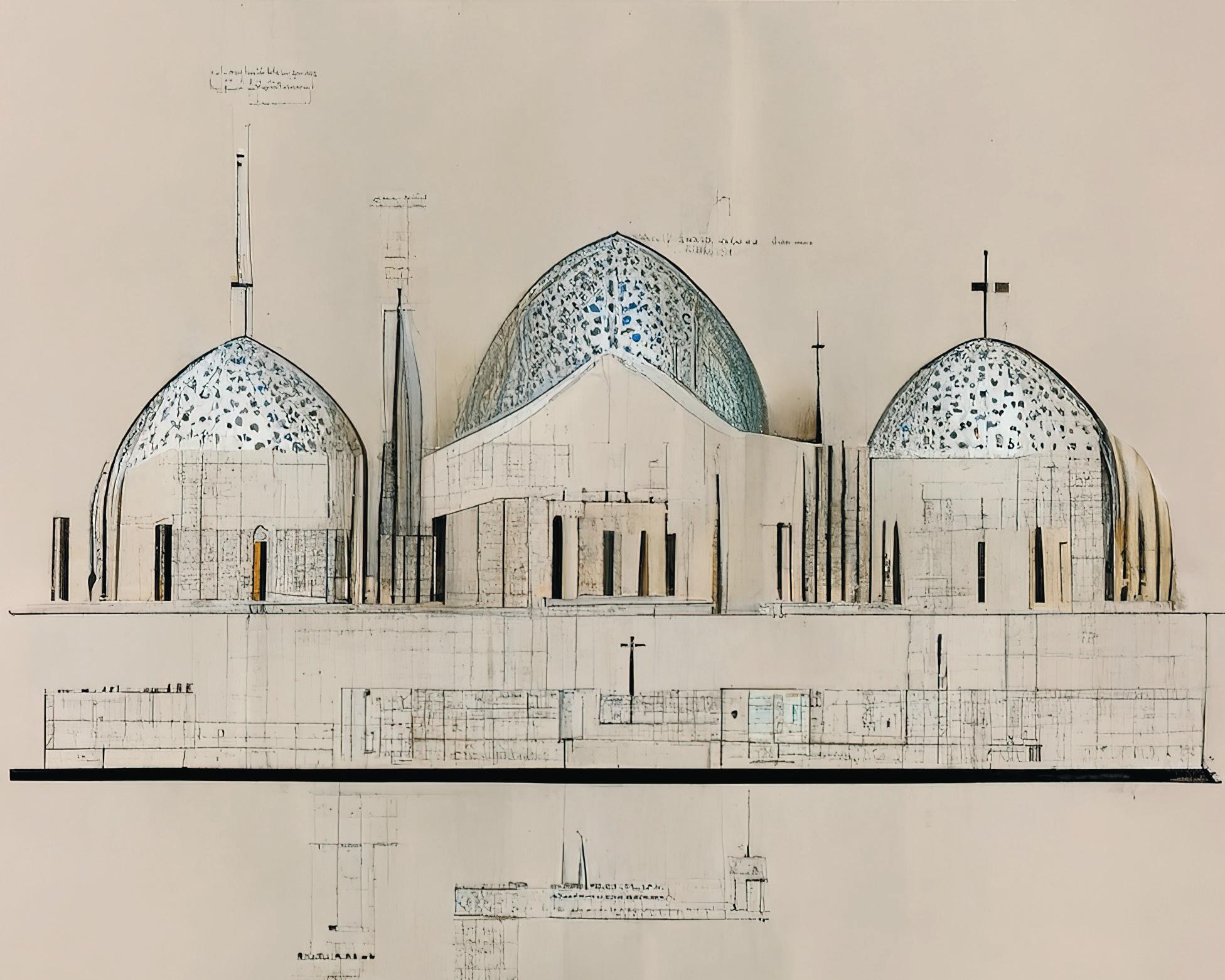

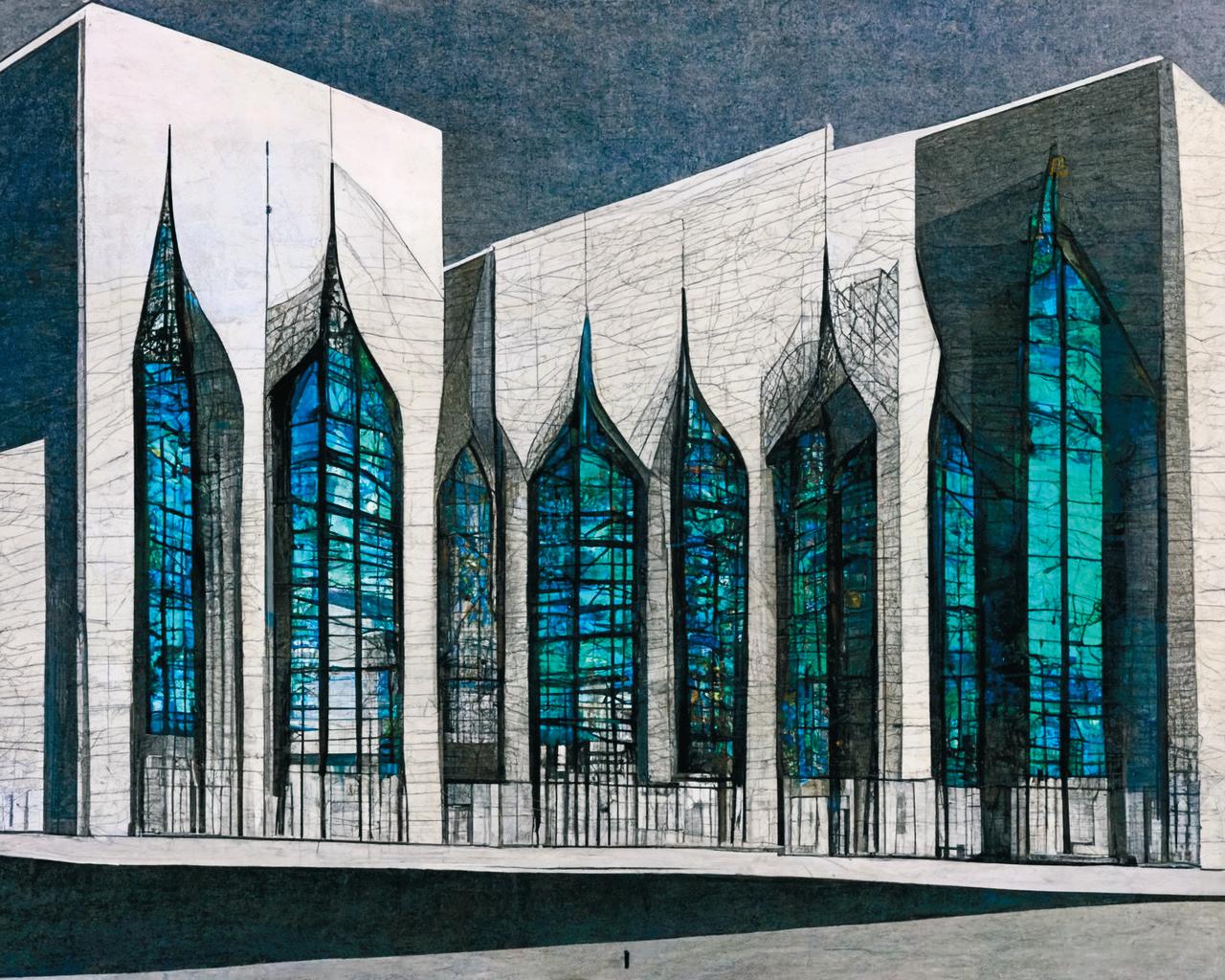

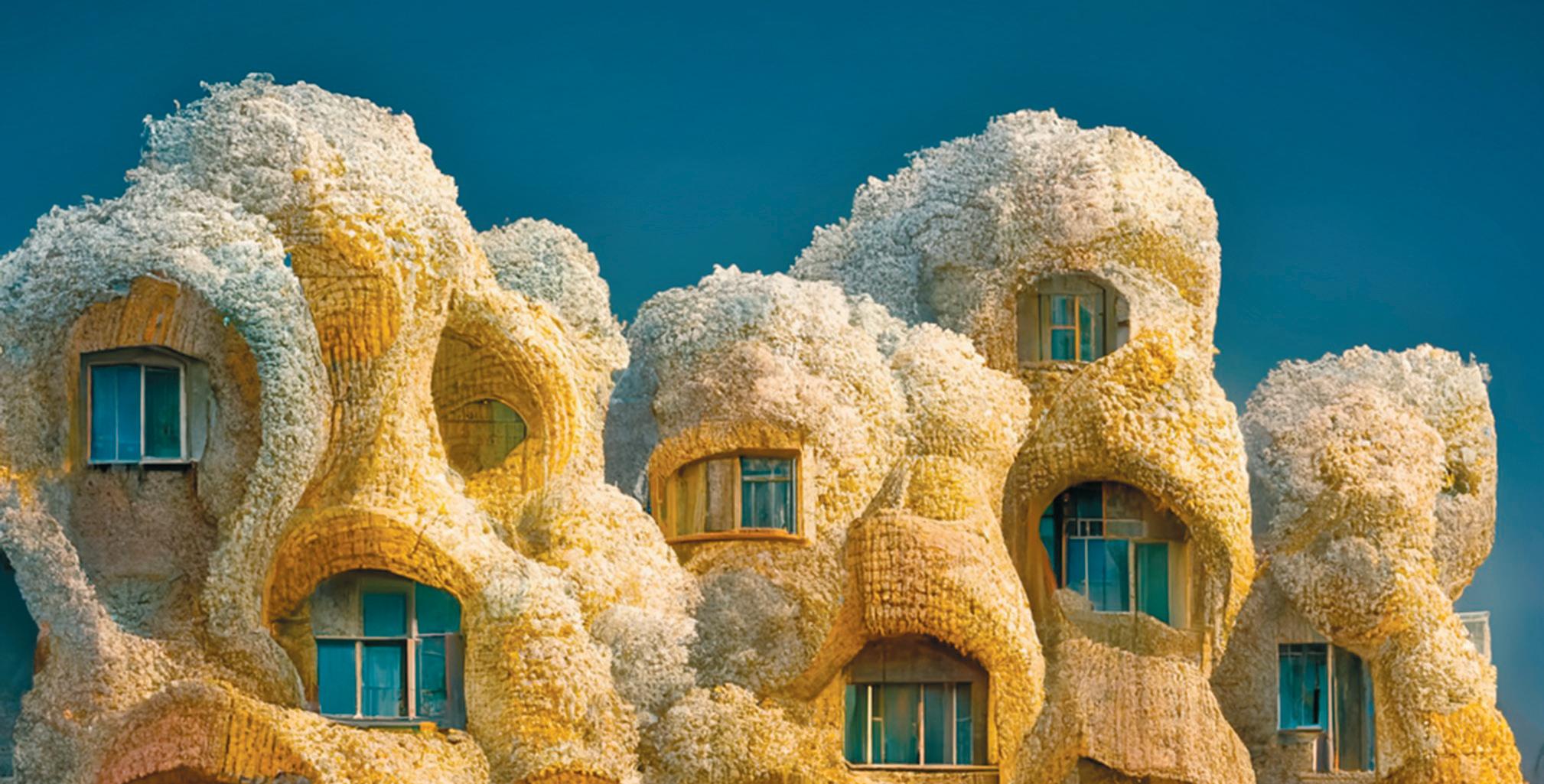

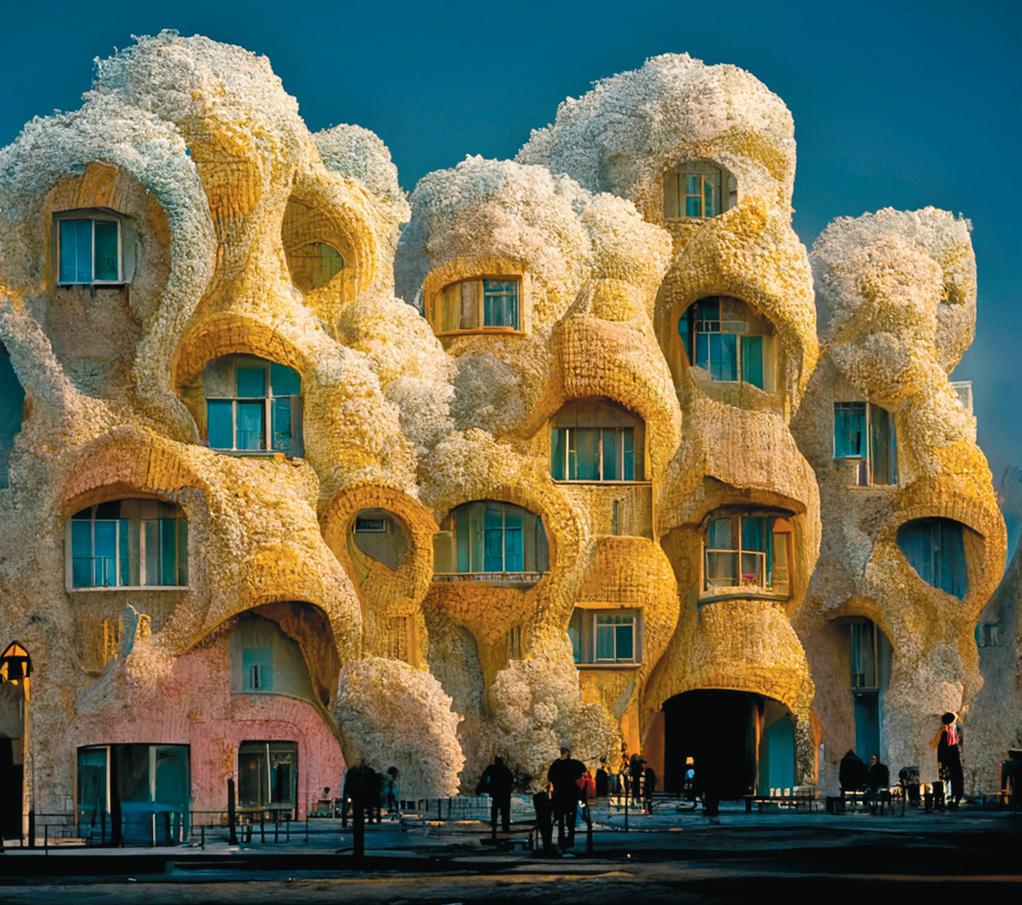

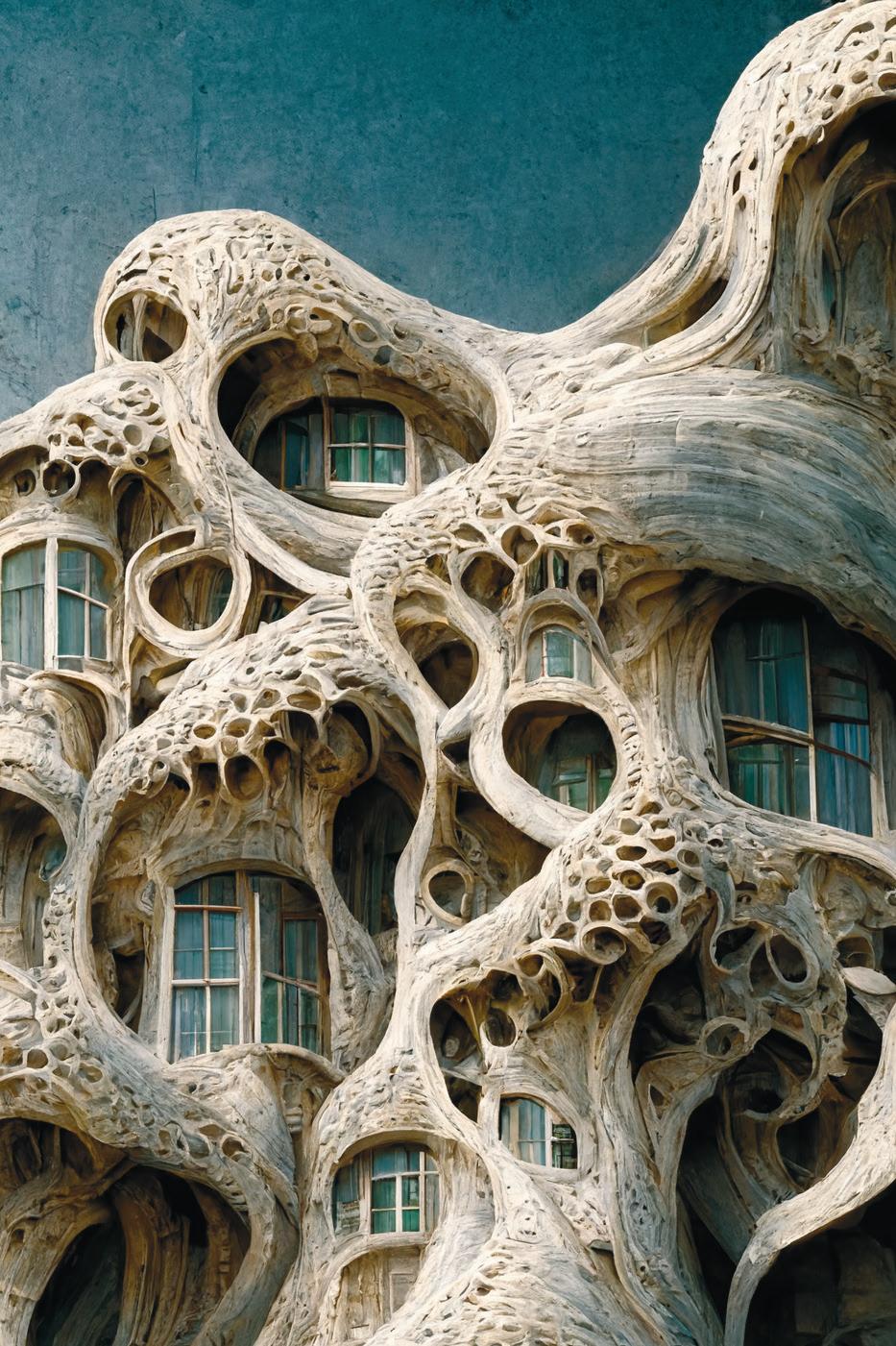

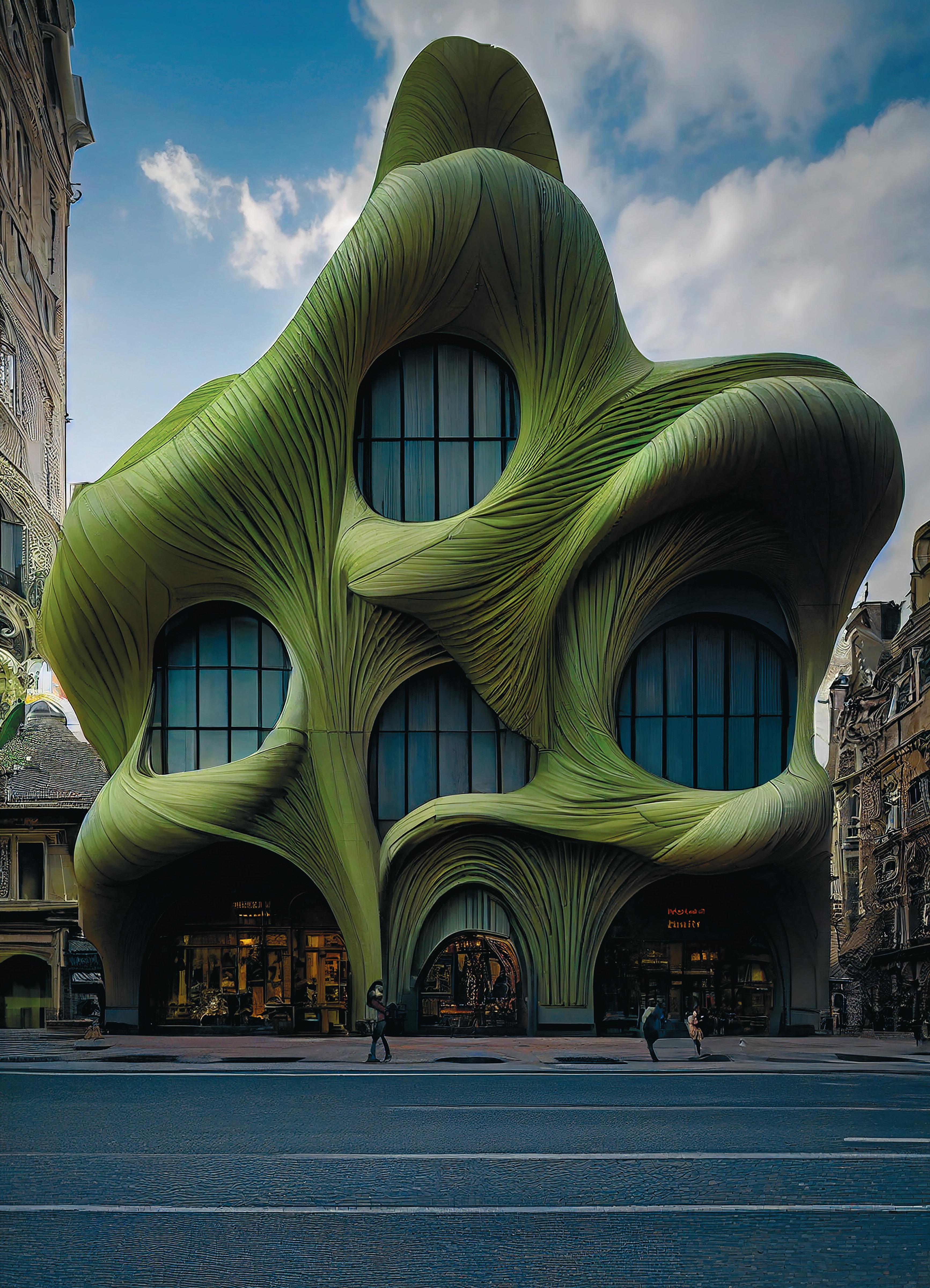

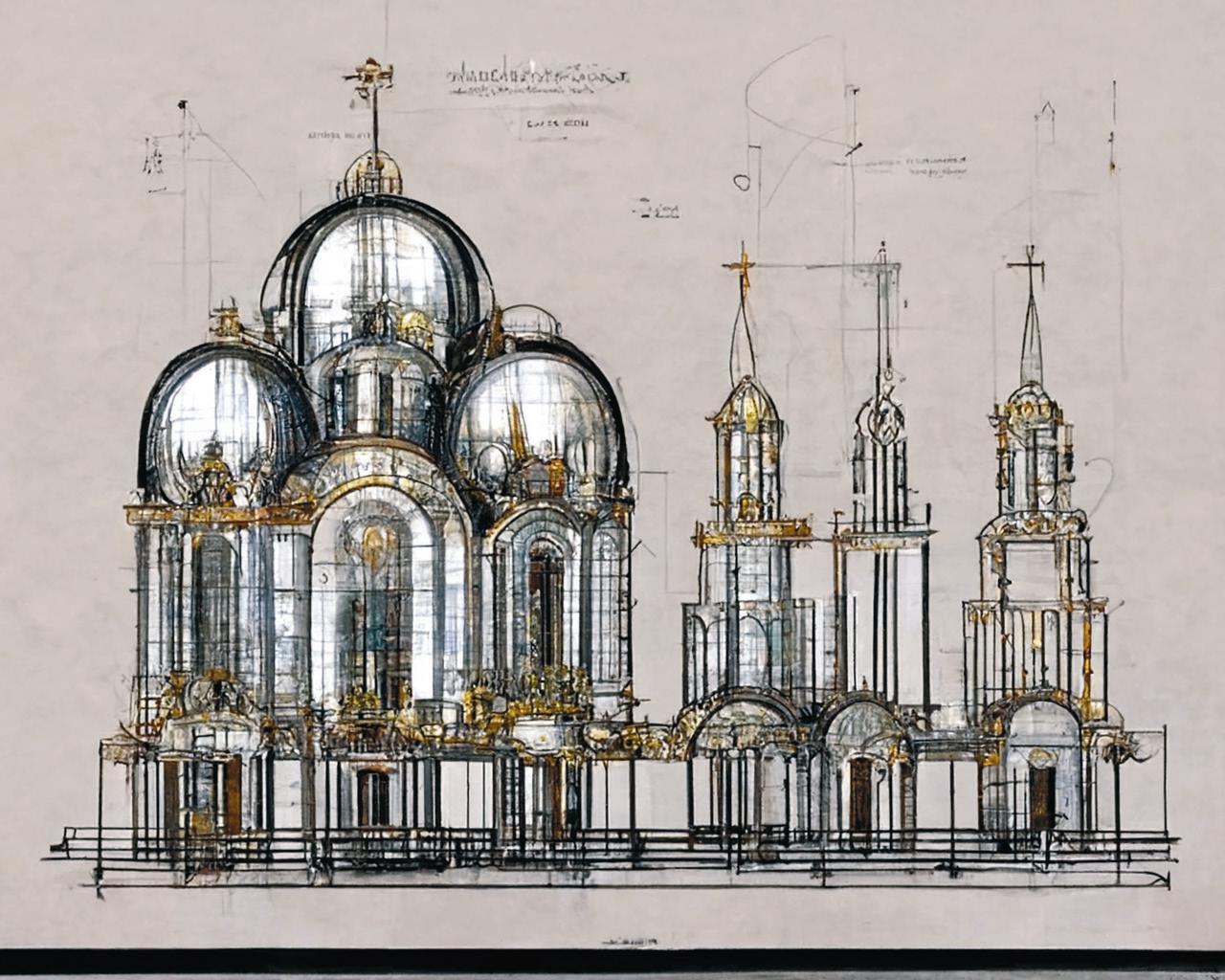

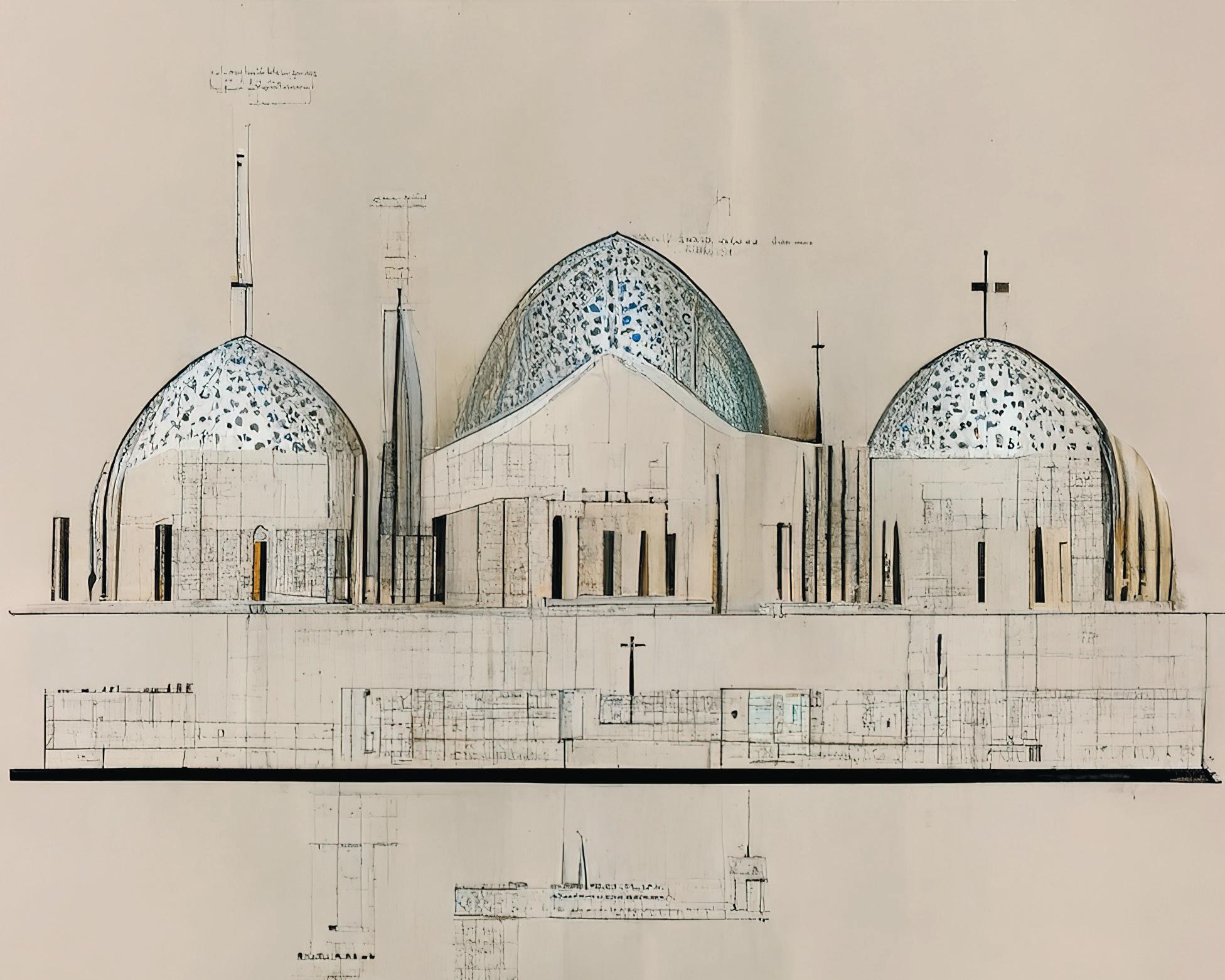

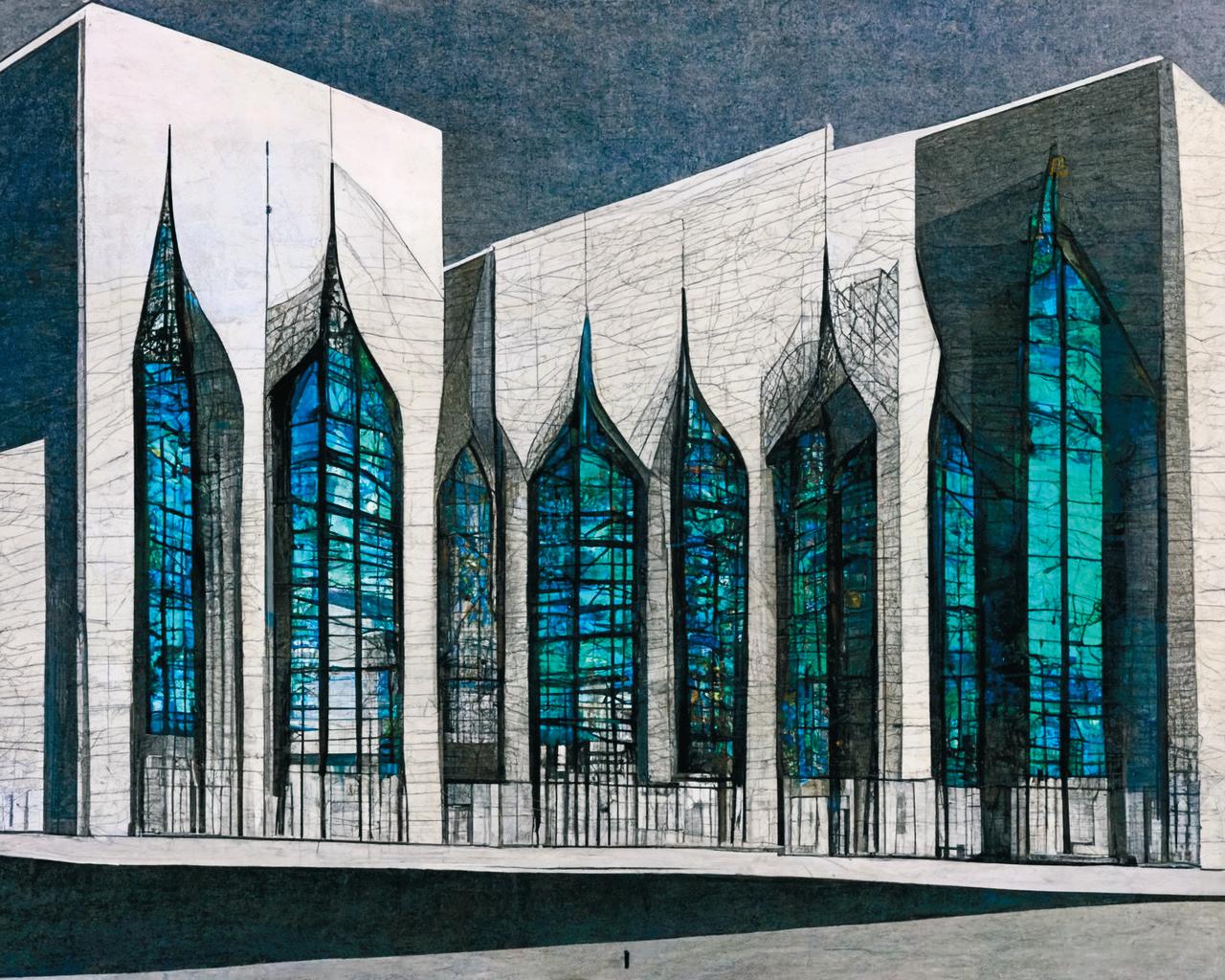

CREDIT: HASSAN RAGAB (WWW. HSNRGB.COM)

September / October 2022 >> Vol.122

Why BIM? Better results Improve collaboration and productivity. Our leading expertise in Building information management (BIM) according to ISO 19650 enables us to offer a choice of routes to BIM certification for both individuals and businesses. Less stress Reduce waste, rework and errors. Faster & more efficient Better information for improved decision making over a building or assets life cycle Why BRE? Guided by experts Audits are performed by experienced construction professionals. Boost reputation BRE’s 100-year history of research and innovation behind these schemes. Comprehensive Training and certification schemes developed by industry experts. ISO 19650: BIM Essentials training. ISO 19650: Delivering information management training. BOOK TODAY BIM ISO 19650 training

Building Information Modelling

MANAGING EDITOR

GREG CORKE greg@x3dmedia.com

CONSULTING EDITOR

MARTYN DAY martyn@x3dmedia.com

CONSULTING EDITOR

STEPHEN HOLMES stephen@x3dmedia.com

GROUP MEDIA DIRECTOR

TONY BAKSH tony@x3dmedia.com

ADVERTISING MANAGER

STEVE KING steve@x3dmedia.com

U.S. SALES & MARKETING DIRECTOR

DENISE GREAVES denise@x3dmedia.com

subscriptions MANAGER

ALAN CLEVELAND alan@x3dmedia.com

CHARLOTTE TAIBI charlotte@x3dmedia.com

FINANCIAL CONTROLLER

SAMANTHA TODESCATO-RUTLAND sam@chalfen.com

Industry news 6

Twinmotion bundled with Revit, Intel launches 13th Gen CPUs, HP unveils plan printing site robot, Chaos builds Enscape / V-Ray bridge, plus lots more

Revit Data Exchange Connector for Rhino 16

Autodesk is aiming to make it easier to share data between the popular concept modelling tool and Revit Artificial Intelligence: the coming tsunami 20

We explore the potential impact of AI on architectural design

2030: A BIM Odyssey 28

With a nod to Arthur C. Clarke, Richard Harpham explores what AI could bring to future design systems

AI: augmenting not changing workflows 30

The new revolution will bring convenience, not disruption to AEC

Towards augmented detail design 32

Next generation design tools will use AI to automate mundane repetitive tasks. Some will even automate the detail design phase

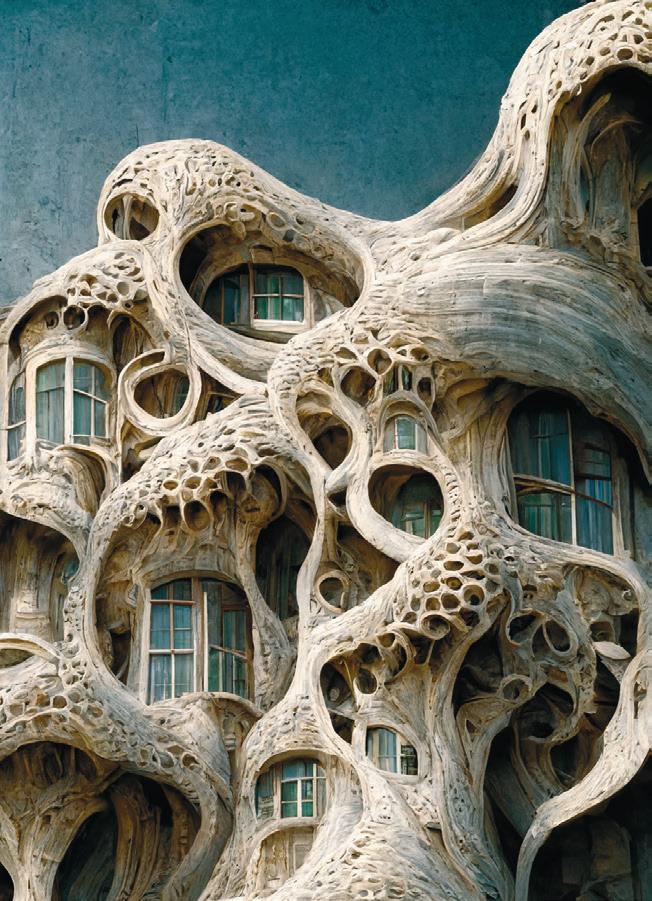

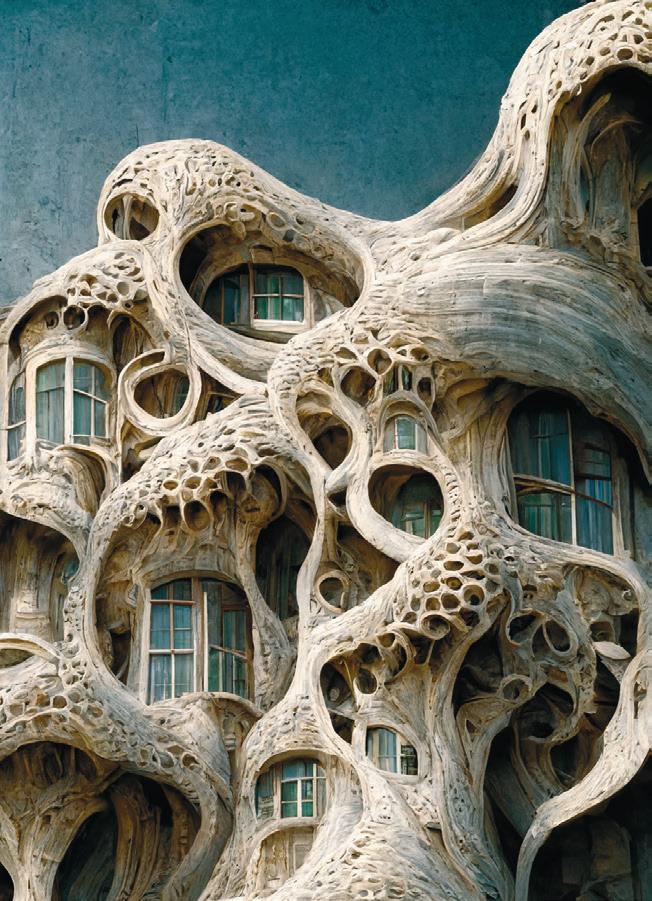

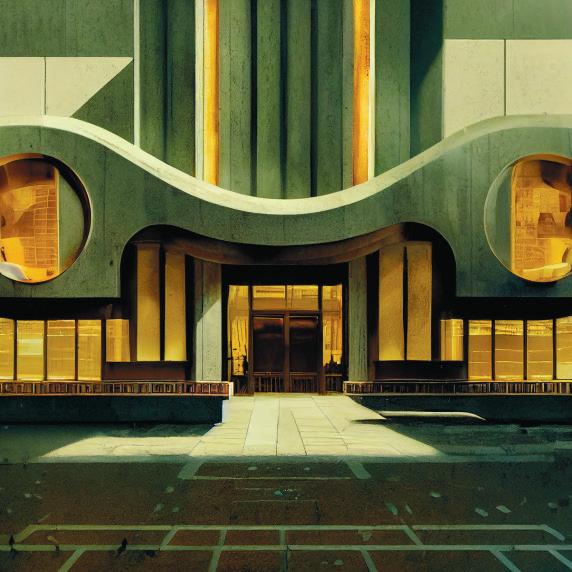

Hassan Ragab: conceptual AI-rtist 38

We speak with Hassan Ragab, one of the most prolific and coherent architectural AI concept artists

AI for concept design 44

Corey Weiner had a play with Midjourney. Could the text-to-image AI be used to spark creativity in architectural design?

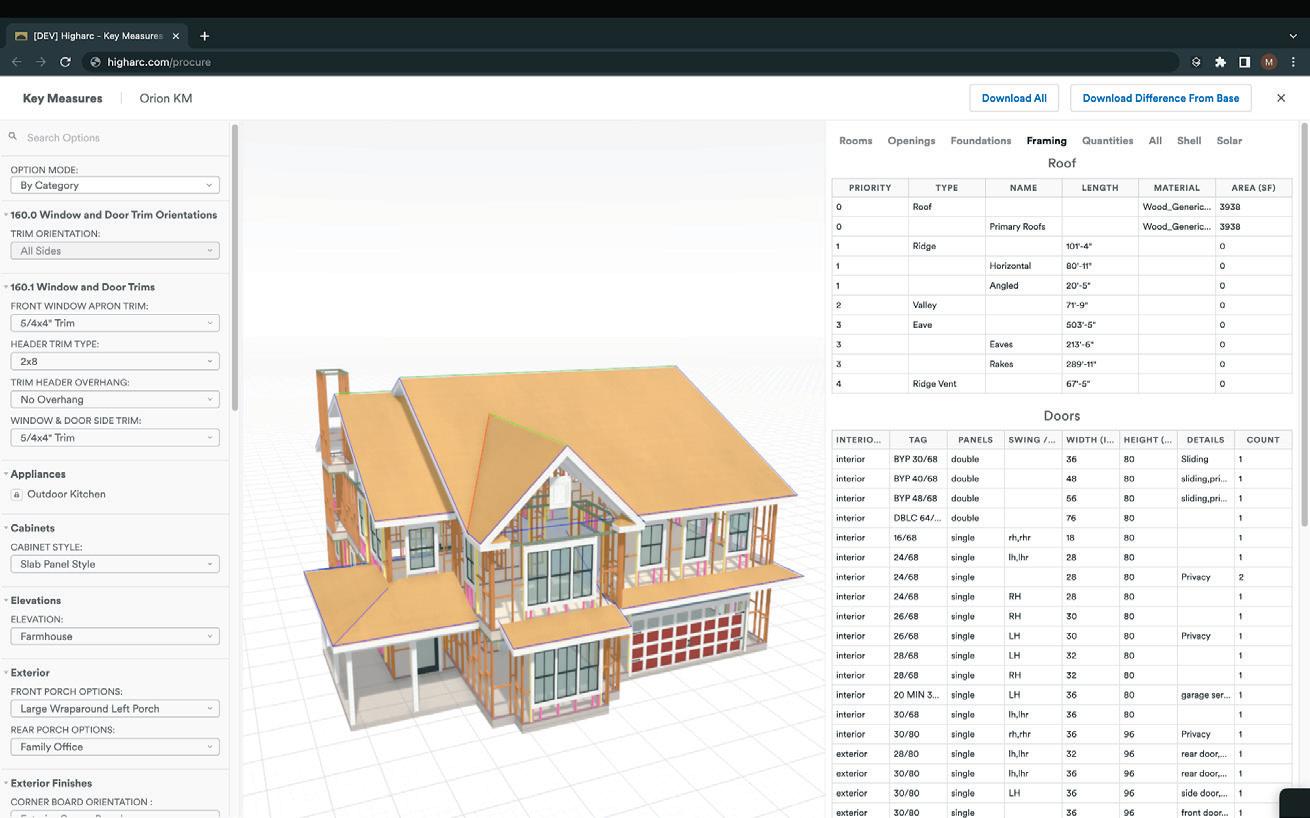

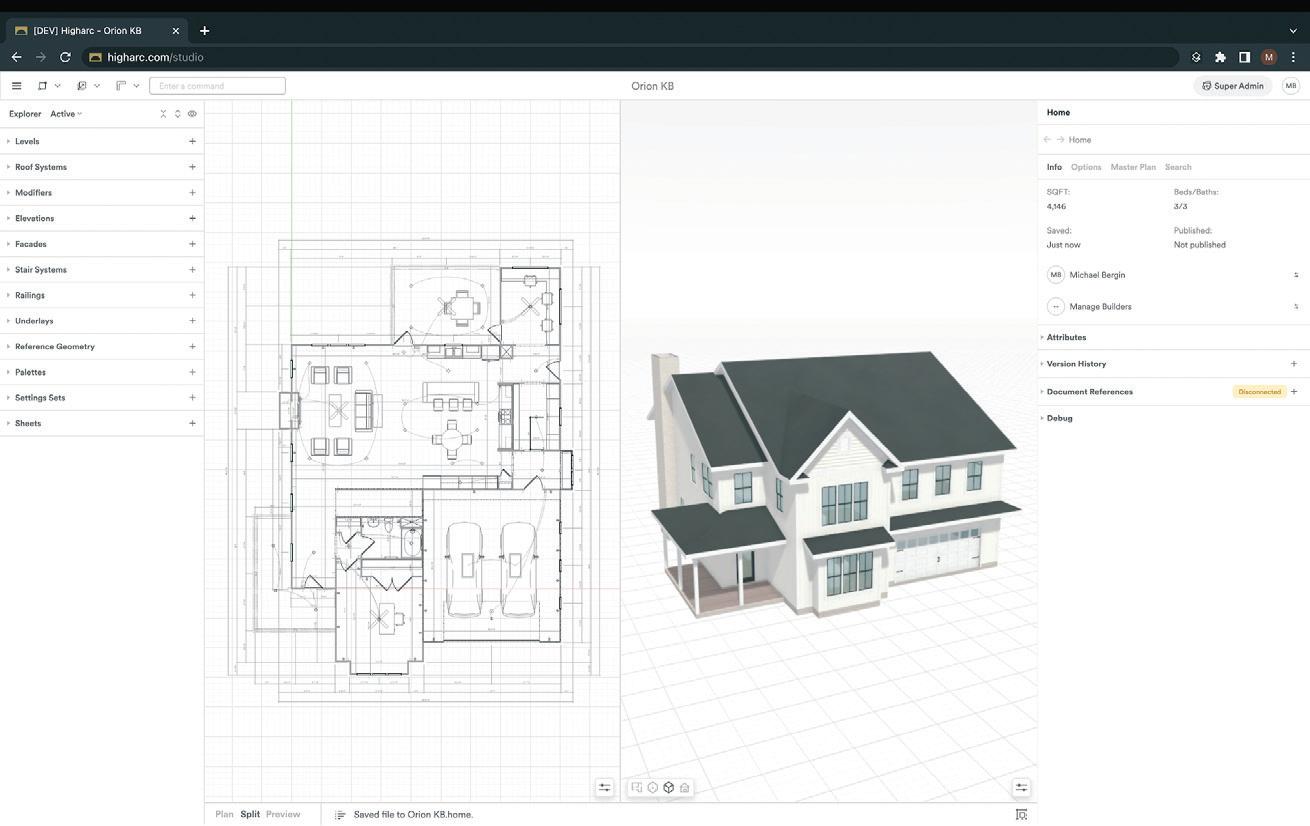

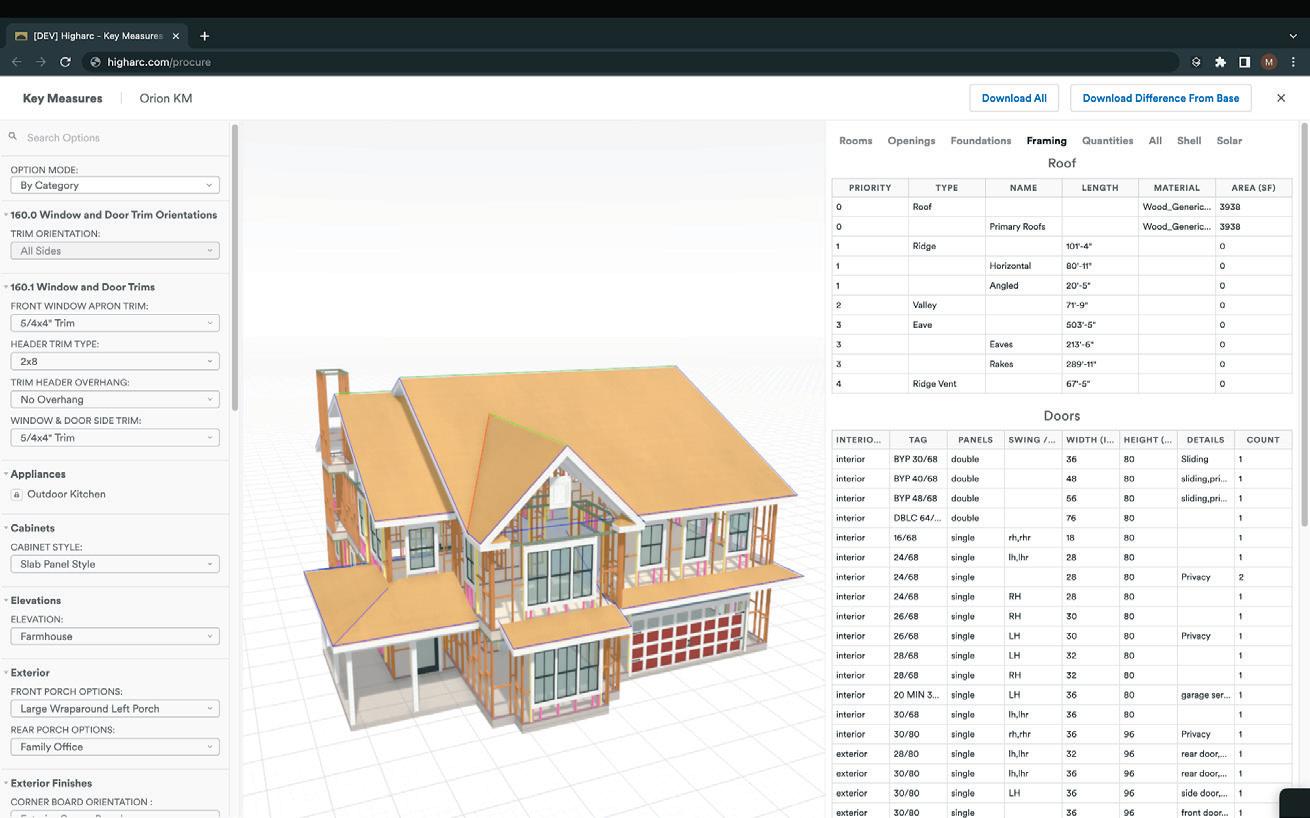

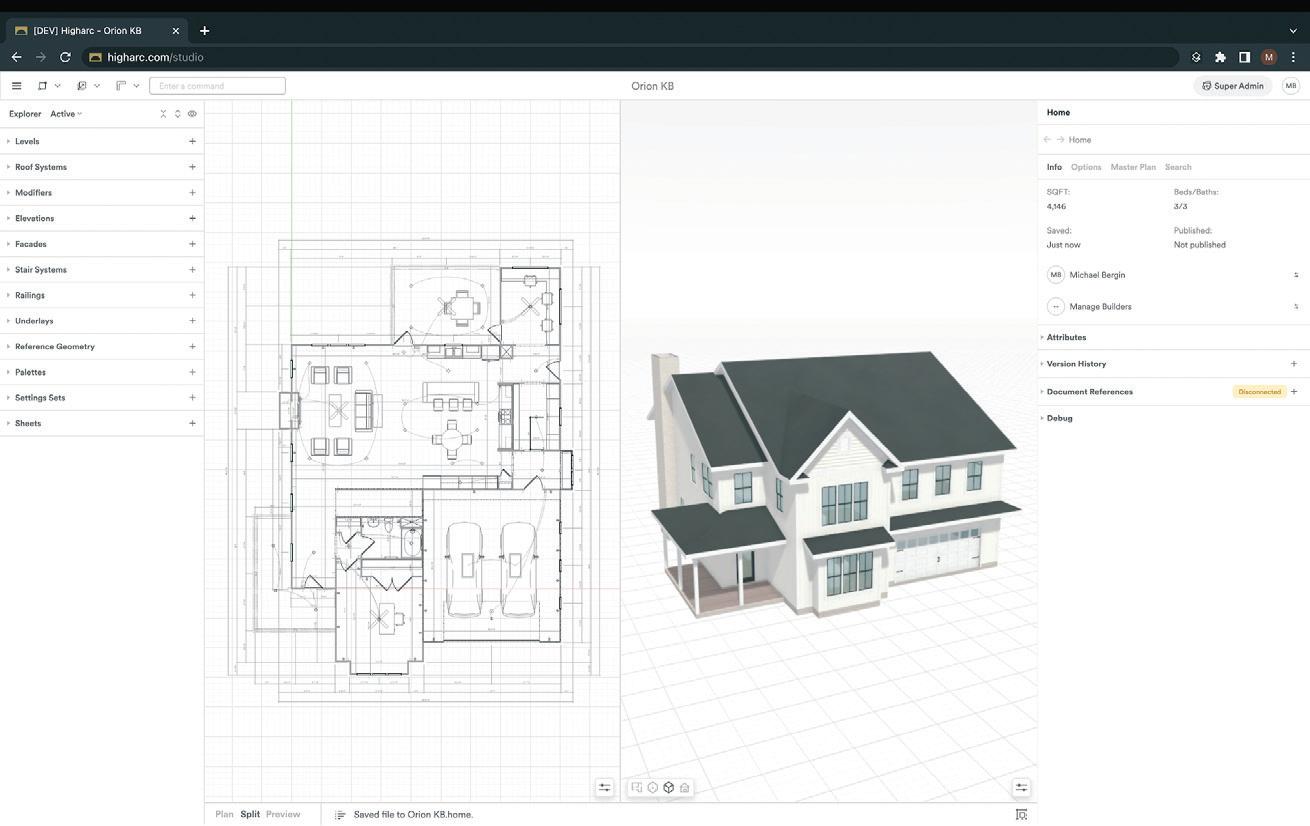

Higharc - concept to construction 46

Higharc is aiming to revolutionise timber frame homebuilding. Could there be lessons for other software developers?

From BIM to FIM 49

How digitising offsite construction and moving to a process of Fabrication

Integrated Modelling will save the planet

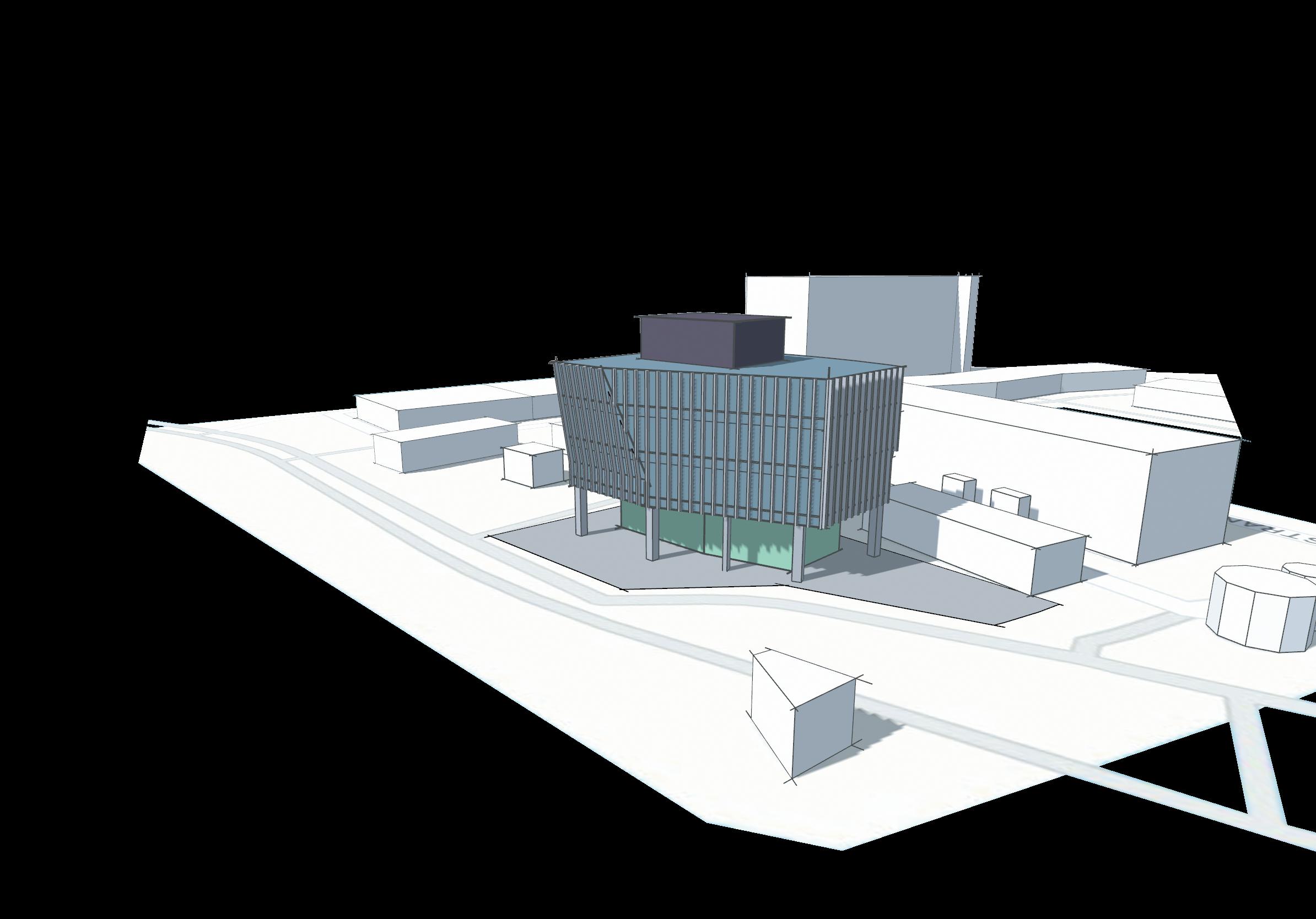

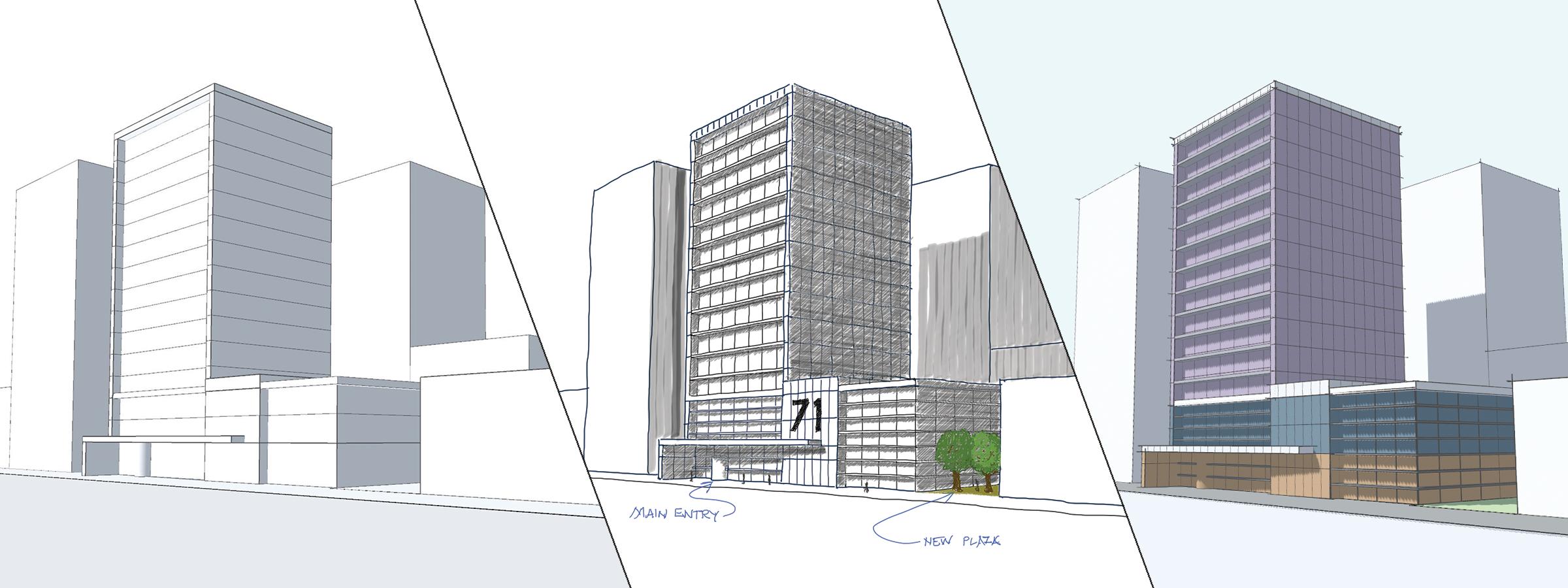

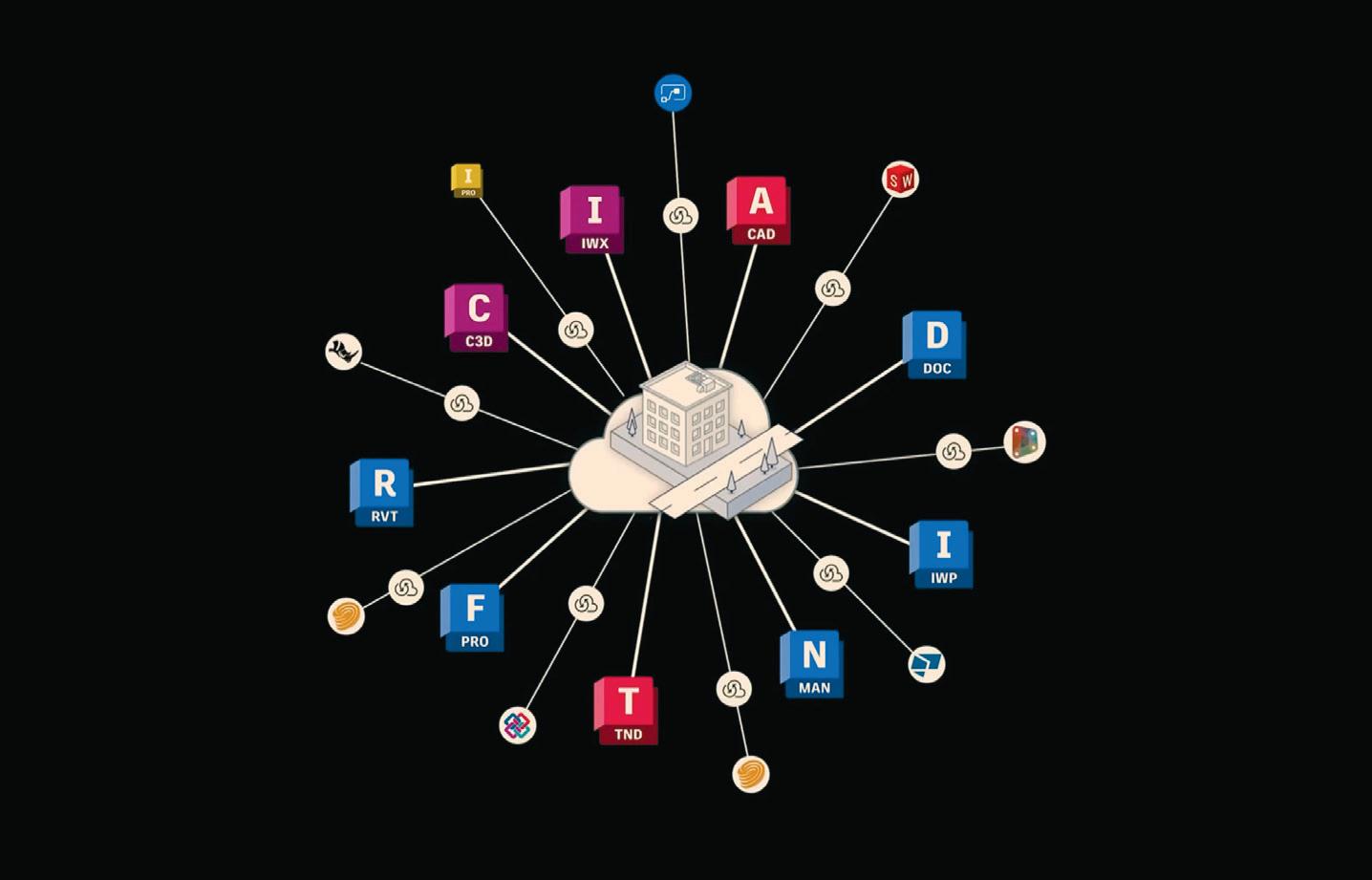

Forma: One platform to rule them all? 52

During his Lord of the Rings inspired keynote at AU, Andrew Anagnost introduced a new AEC cloud platform

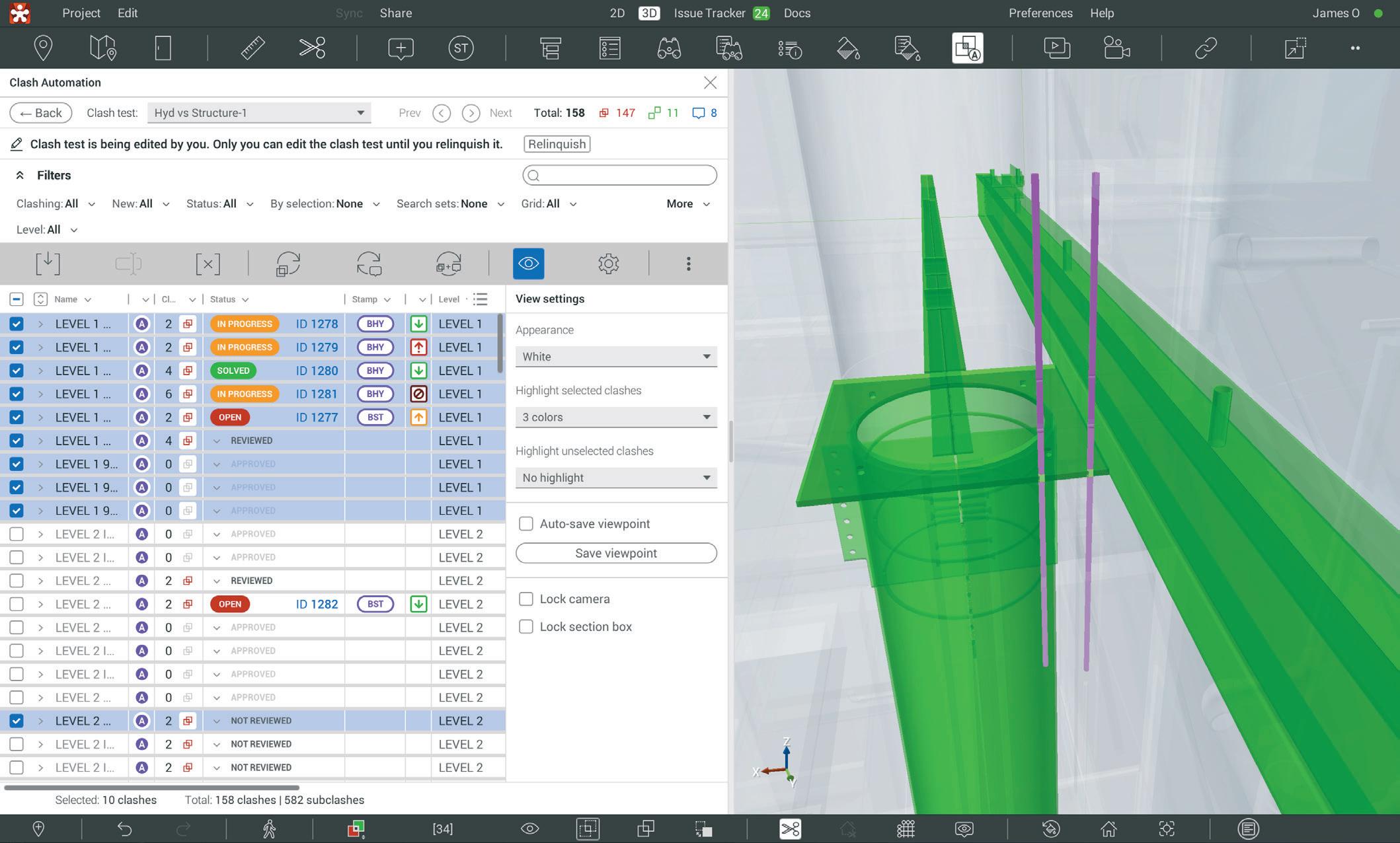

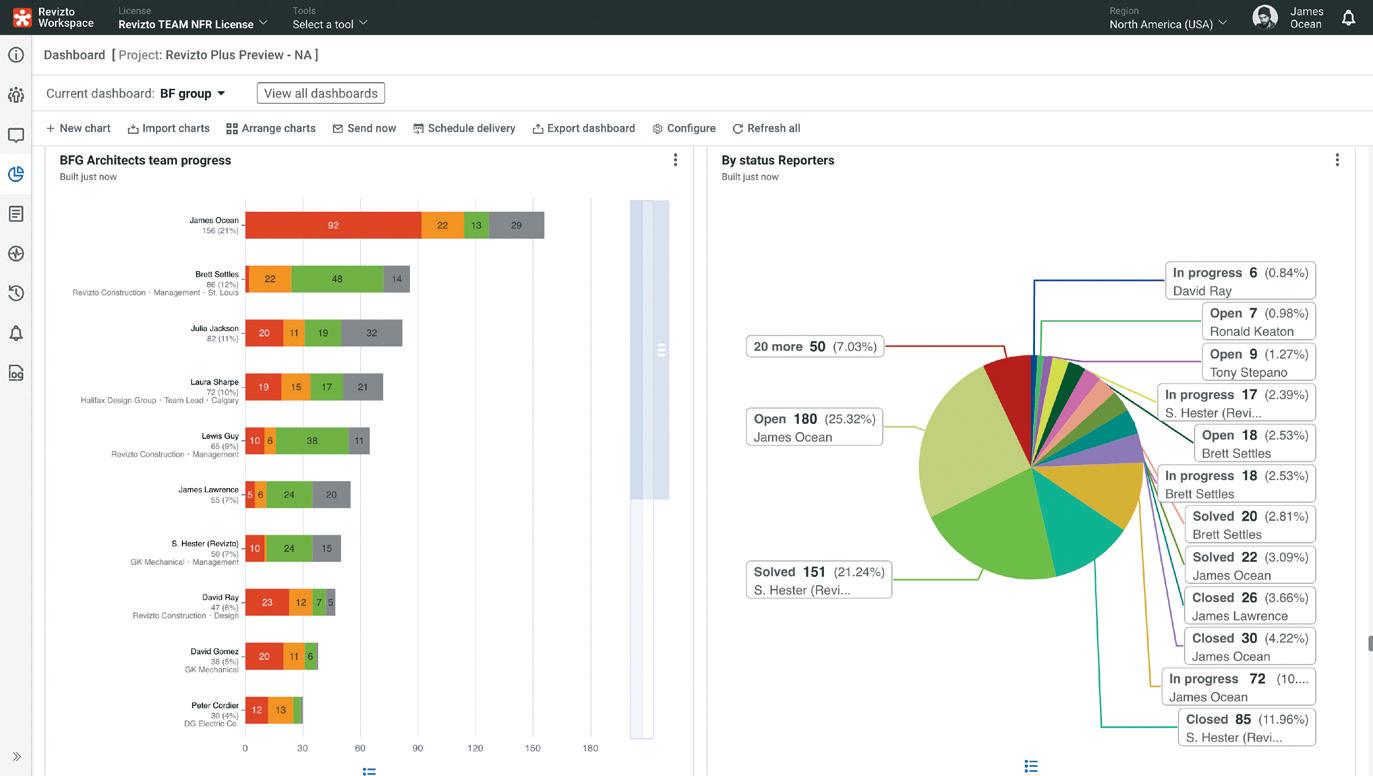

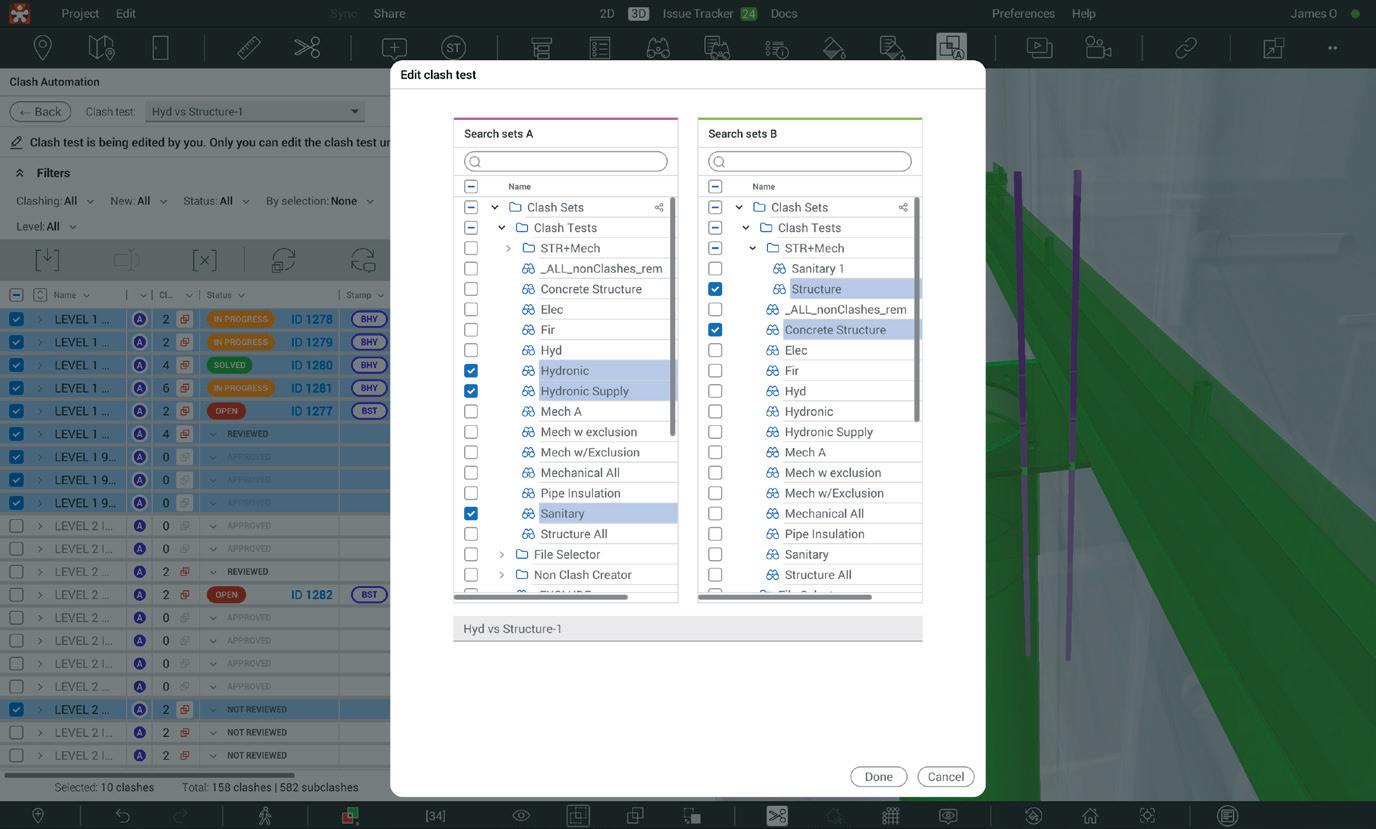

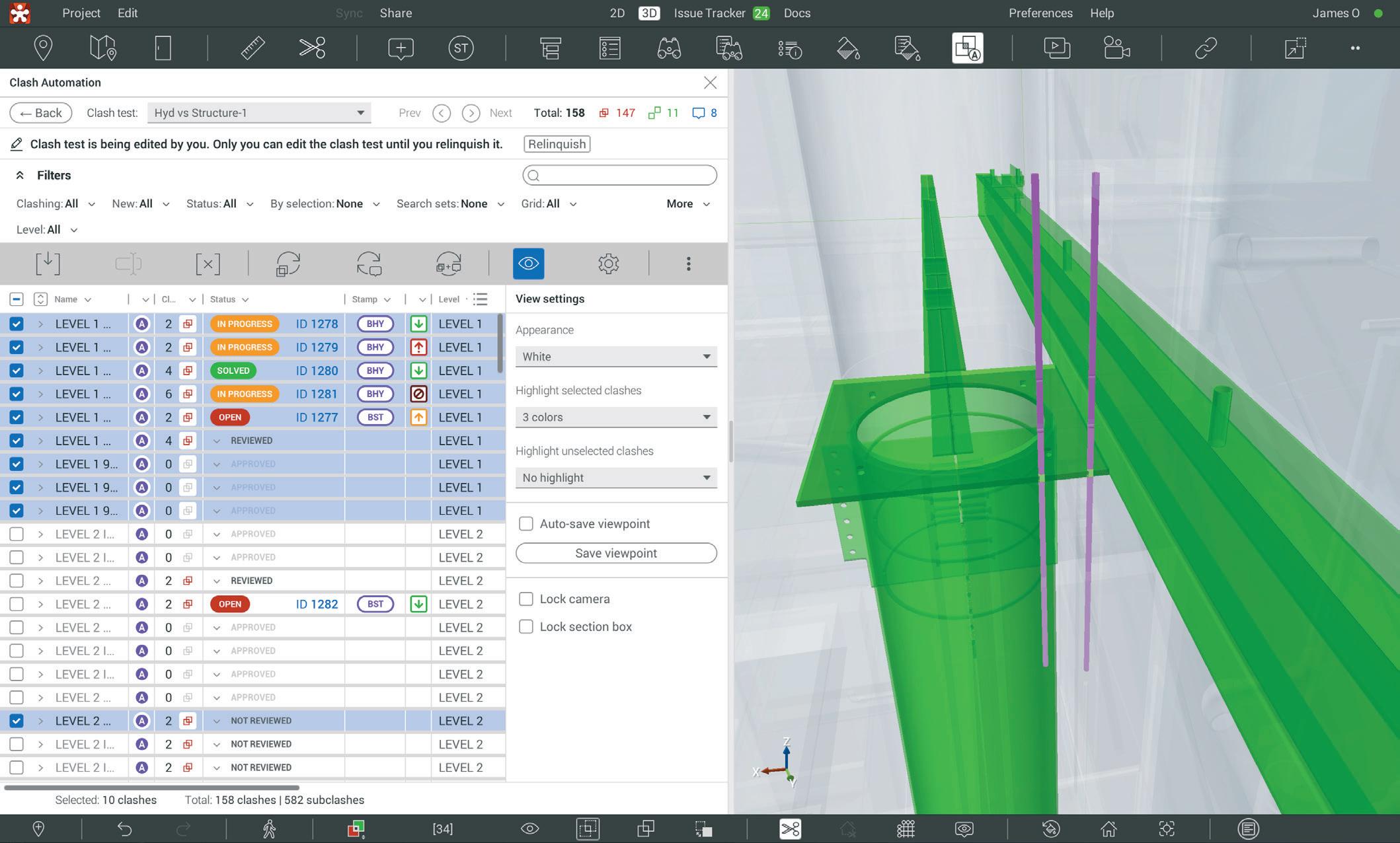

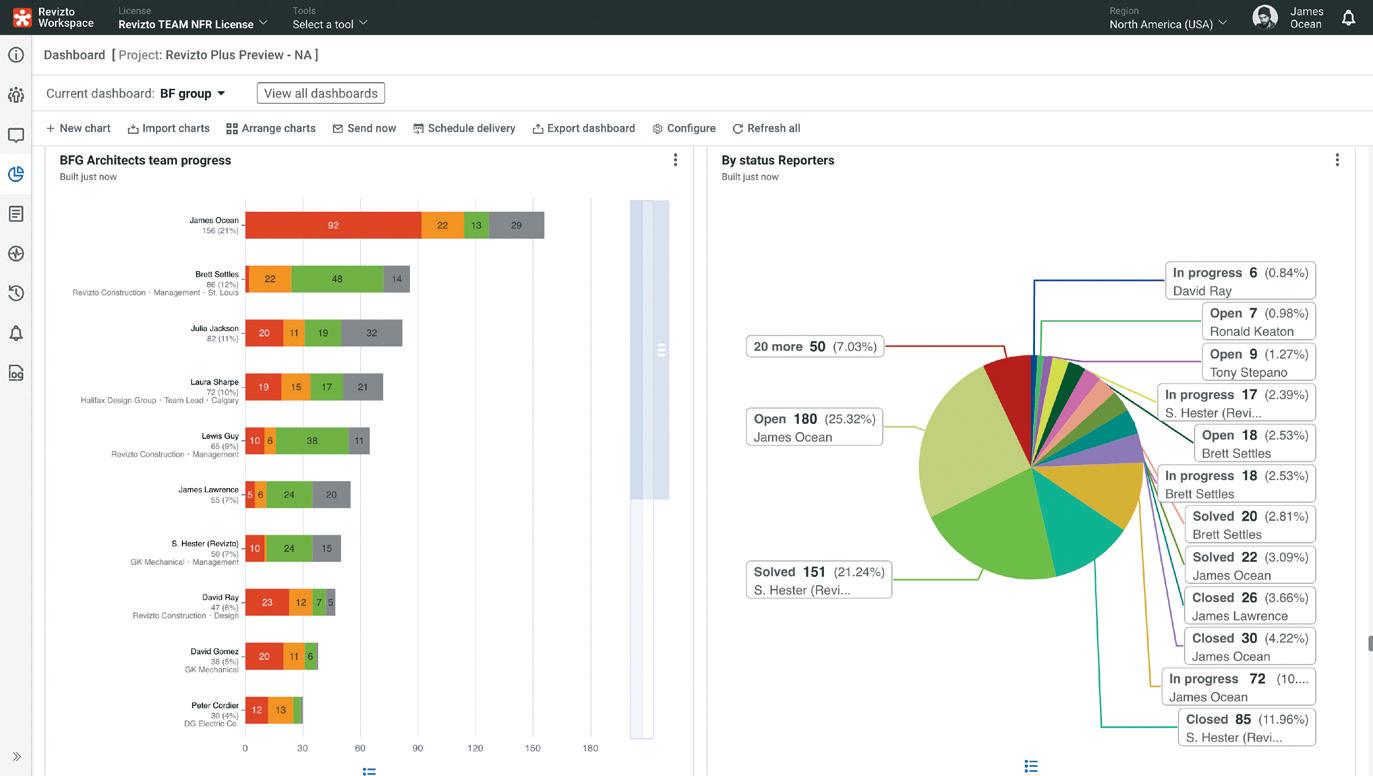

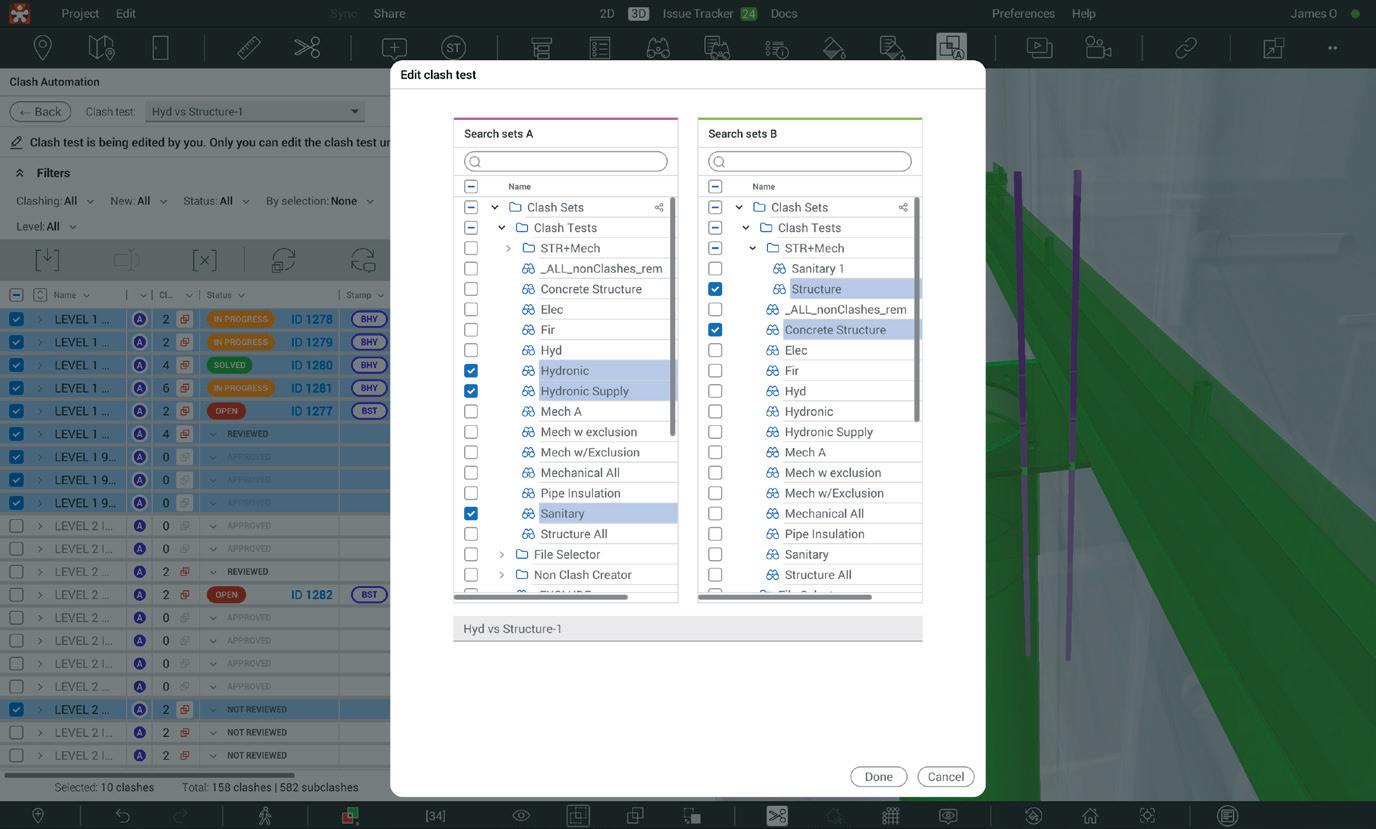

Clash of the titan 60

We explore the powerful new clash detection capabilities in Revizto

SUBSCRIPTIONS

Electric dreams 36

Is there a place for AI design in realworld practice? asks Edward Crump

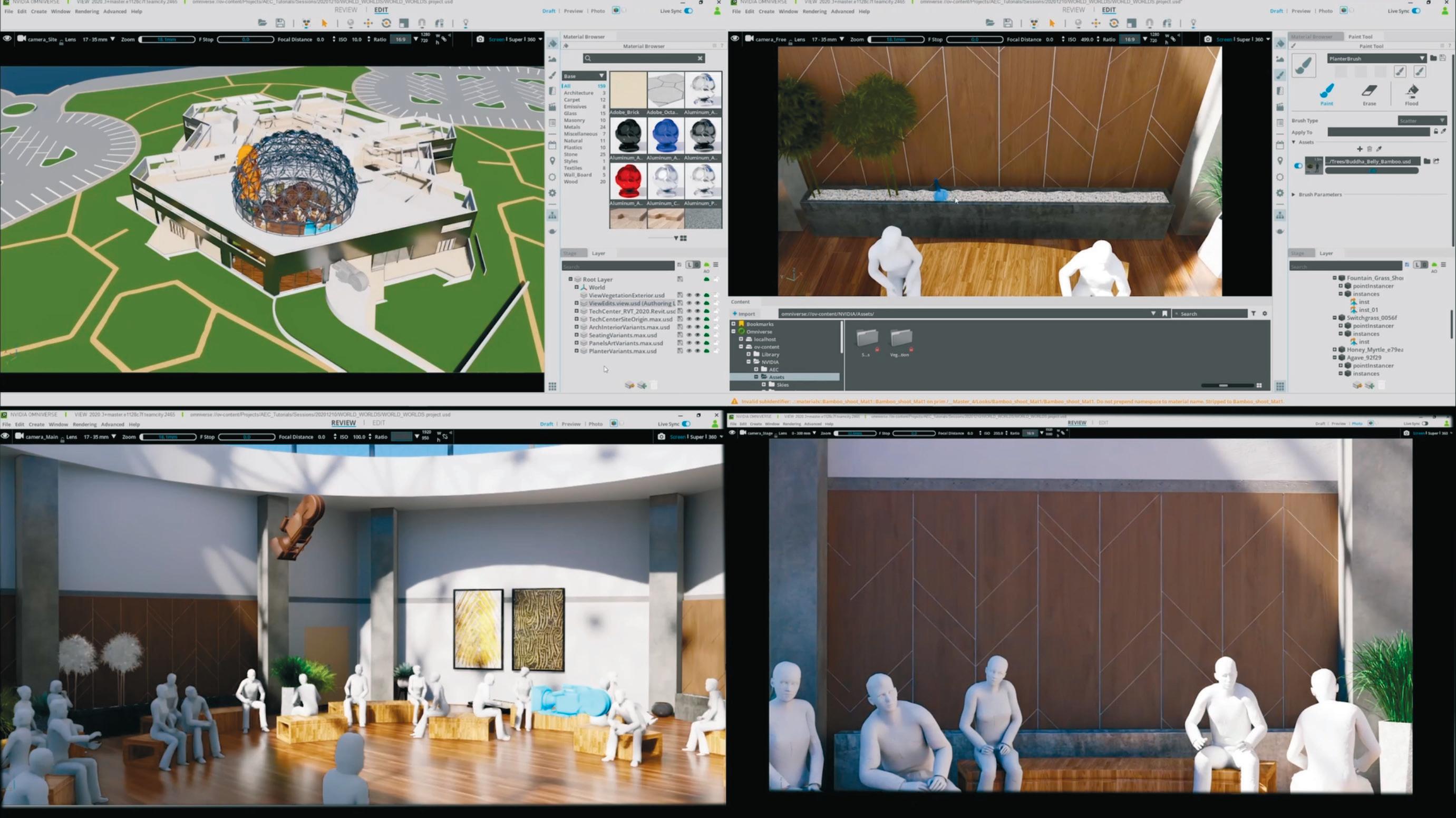

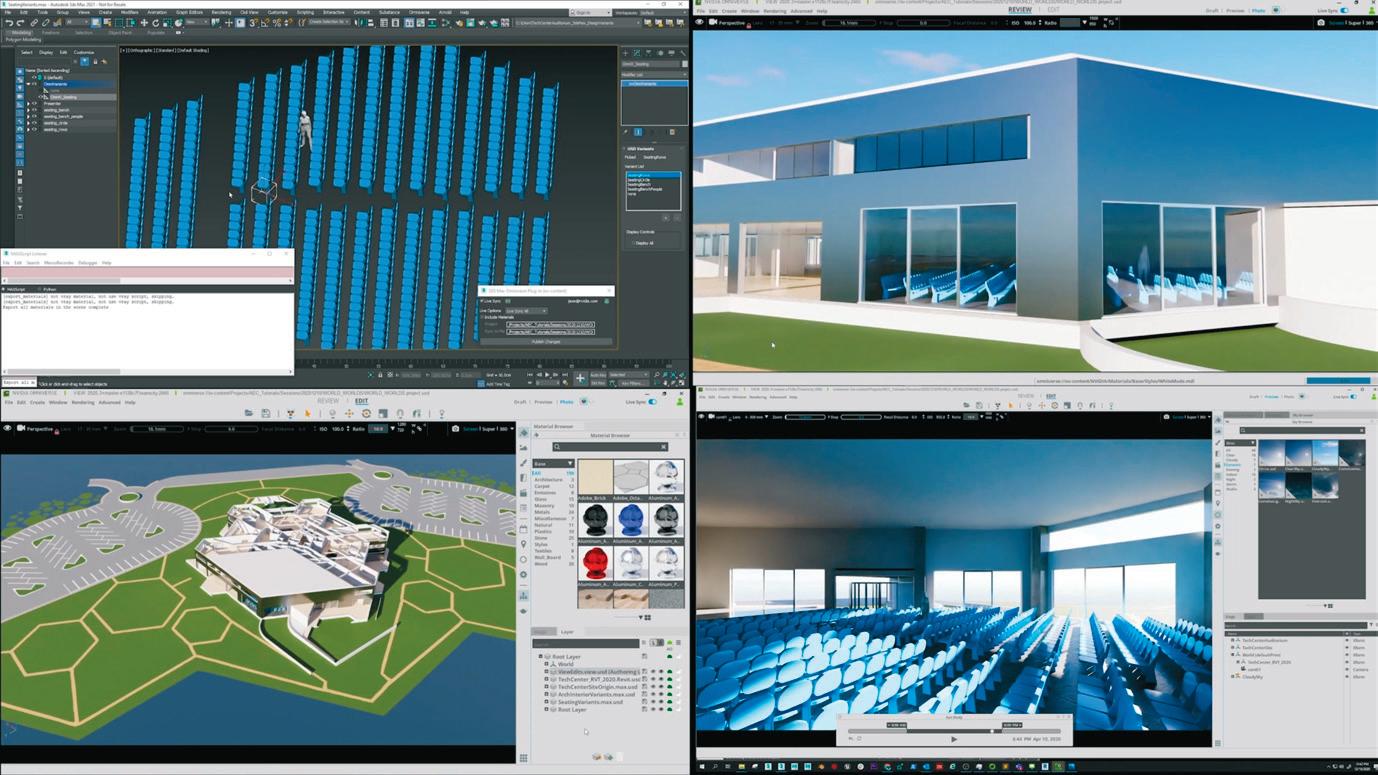

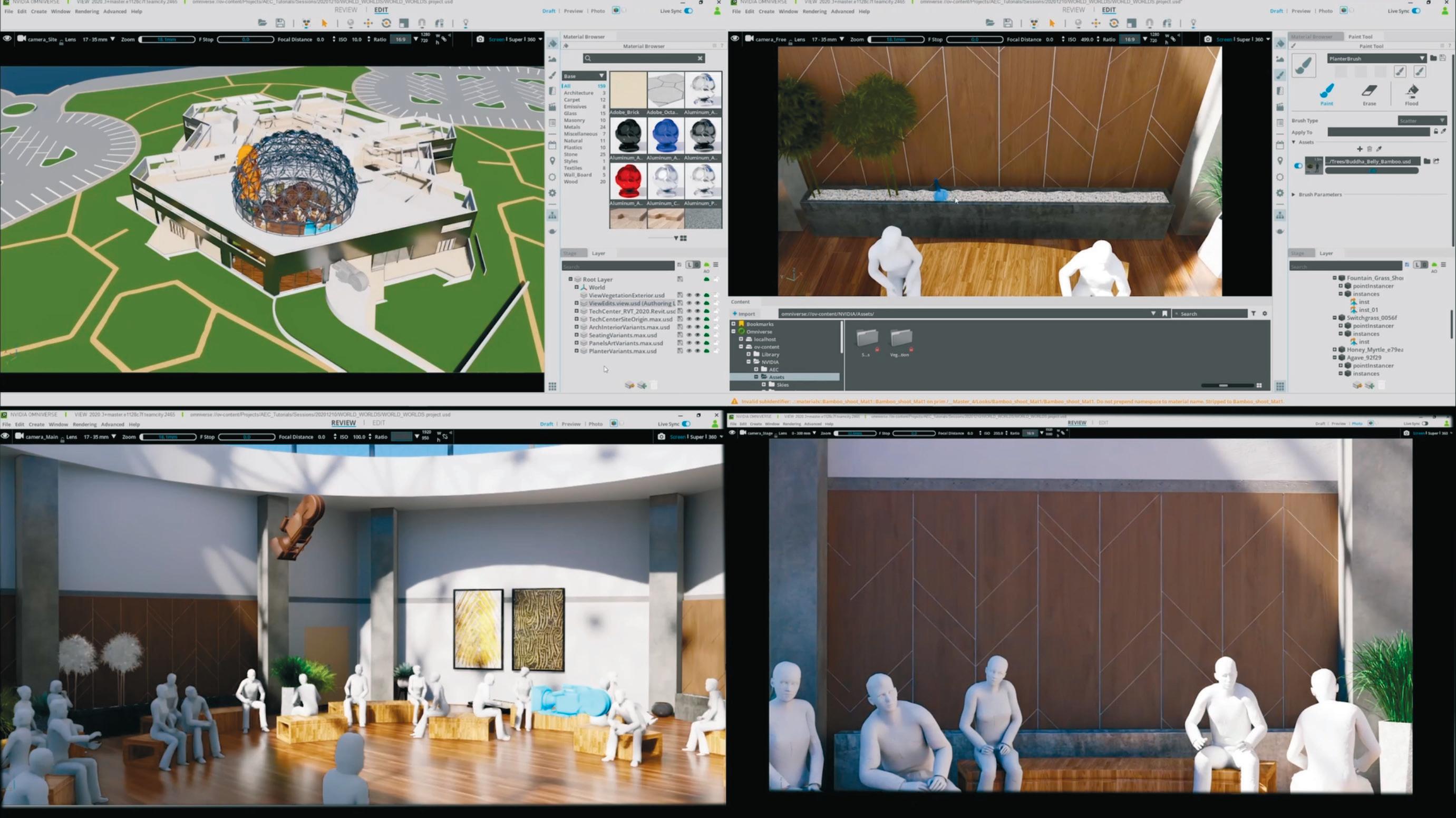

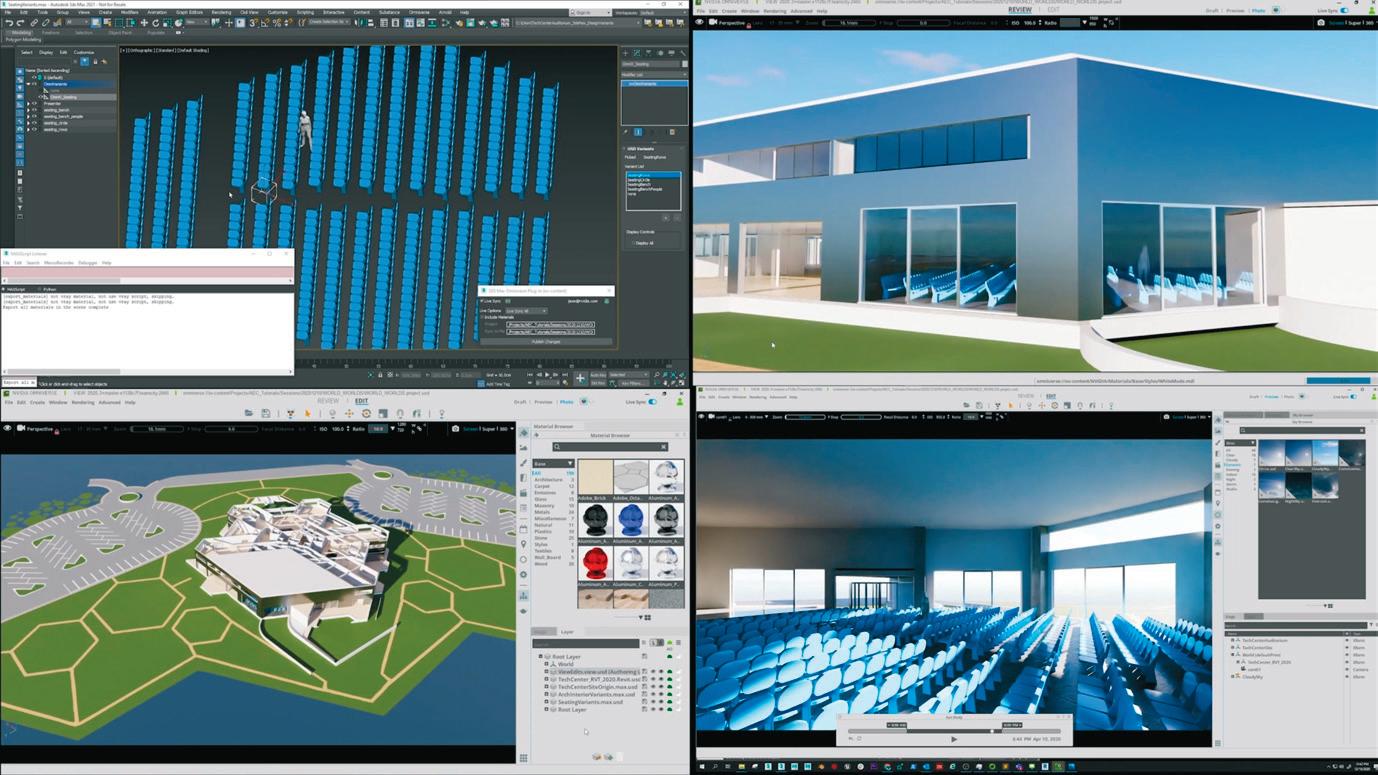

Bringing the visual to the programmatic 65

How Scan Computers is deploying custom solutions for Nvidia Omniverse

3www.AECmag.com September / October 2022

(BIM) technology for Architecture, Engineering and Construction FREE

Register your details to ensure you get a regular copy register.aecmag.com editorial

advertising

accounts

AEC Magazine is available FREE to qualifying individuals. To ensure you receive your regular copy please register online at www.aecmag.com about AEC Magazine is published bi-monthly by X3DMedia Ltd 19 Leyden Street London, E1 7LE UK T. +44 (0)20 3355 7310 F. +44 (0)20 3355 7319 © 2022 X3DMedia Ltd All rights reserved. Reproduction in whole or part without prior permission from the publisher is prohibited. All trademarks acknowledged. Opinions expressed in articles are those of the author and not of X3DMedia. X3DMedia cannot accept responsibility for errors in articles or advertisements within the magazine. 38

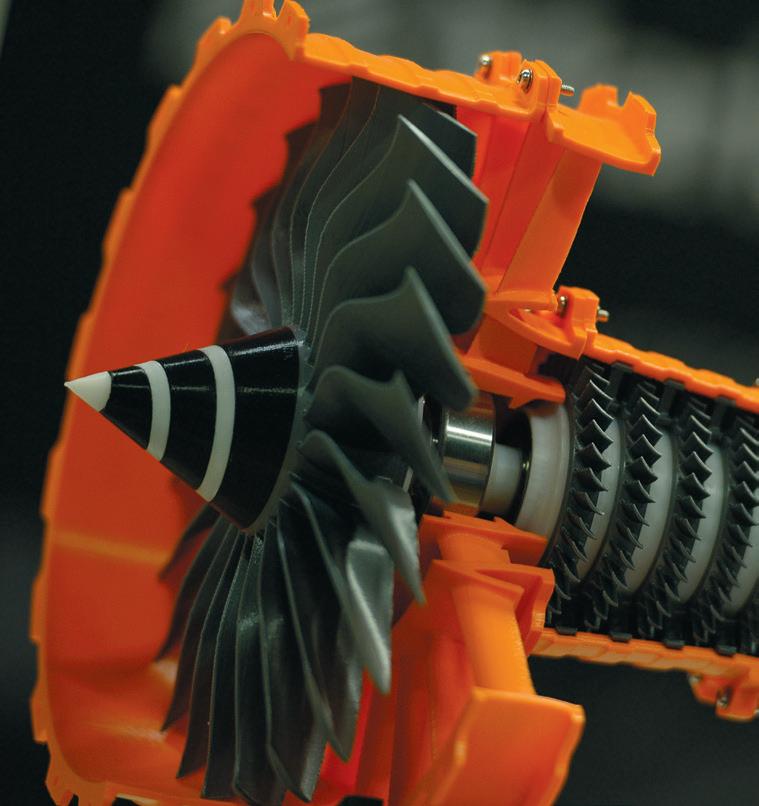

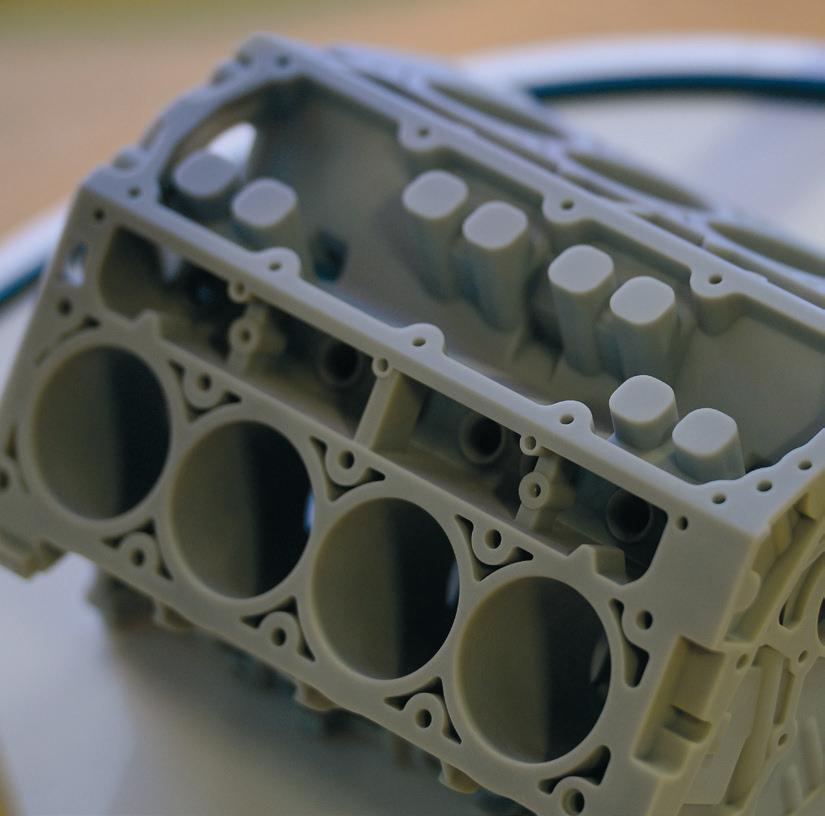

BORED OF Be inspired by the very latest technologies accelerating product design, engineering, and manufacturing CAD • CAE • Additive Manufacturing • 3D printing • Simulation • Visualisation • Scanning • Workstations + lots, lots more Platinum sponsor Gold sponsorsPrincipal sponsors

2022BIM? Over 50 exhibitors 3 stream conference 100% FREE develop3dlive.com Tuesday 1 NOV University of Sheffield Silver sponsors Bronze sponsors

Autodesk to bundle real time viz software

Epic Games Twinmotion with Revit

Epic Games has a cut a huge deal with Autodesk, where its AEC-focussed real-time viz tool Twinmotion, will be given away free with every active seat of Revit.

Twinmotion for Revit will be available with subscriptions to standalone Revit, the AEC Collection, Flex or Enterprise agreements.

Unlike previous Twinmotion promotions with Graphisoft (Archicad), McNeel (Rhino), Vectorworks and Bricsys (BricsCAD BIM), this is not a limited time offer.

According to Cambashi, there are over 500,000 active seats of Revit out there and the ‘free’ deal will mean Twinmotion will compete with popular industry addons, such as Enscape and Lumion, which come at additional cost.

Obviously for Autodesk customers, a permanent free licence of Twinmotion alongside Revit is a great additional benefit to their subscription – especially as some customers, such as the Open Letter Group,

have been complaining that they install and use only 10% of the applications that come with the AEC Collection.

Bringing Twinmotion into the fold appears to add real value to Autodesk’s AEC offering. Twinmotion will also give Revit customers a pathway into Unreal Engine, for delivering highly

What AEC Magazine thinks

Autodesk, despite owning an entire Media and Entertainment (M&E) division, which develops Maya and 3ds Max, has in recent years tended to partner with gaming / visualisation-focussed developers to co-develop viz applications for its ecosystem.

In 2018, Autodesk announced a strategic collaboration with Unity to ensure full interoperability between Autodesk products and Unity’s real time engine, specifically focussing on Revit and AEC.

Autodesk had already subcontracted the work on the FBX format to Unity. This partnership came at the detriment to all other visualisation developers, competing against one that was ‘anointed’ and had access to much tighter integration with

Revit. Epic Games was certainly on the outside of the tent. However, the product that was developed – Unity Reflect –was more focused on collaborative workflows than design viz. It was able to bring in valuable BIM data from Revit and other AEC applications, and later got the ability to add annotations. However, development of Unity Reflect has been slow and, despite showing the syncing of annotations with Autodesk BIM 360 way back at Autodesk University 2019, this feature is still a work in progress.

To many in industry, it soon became clear that Unity didn’t have the focus or marketing to benefit as much from the partnership, as Epic Games might. Since taking on the AEC market proper in 2018, Epic Games has shown a laser-like focus on the sector, through

customisable and ultra-realistic real-time environments.

From the perspective of Epic Games, the deal will give it access to the lion’s share of global AEC customers, an industry where it has its own B2C ecosystem of content for Twinmotion. ■ www.autodesk.com ■ www.twinmotion.com

development, acquisition and integration of applications and content for AEC professionals.

While relations between Epic Games and Autodesk have been frosty in the past, over the last two years it became clear the two companies have been getting on a lot better.

One of the first signs was Epic Games joining Autodesk on stage at Autodesk University 2021. This has now led to the Twinmotion / Revit deal and the announcement of a strategic collaboration to “accelerate immersive realtime (RT) experiences”, which includes plans to go beyond AEC, into M&E and manufacturing.

Looking at the deal from a broader perspective, the rendering, real-time and Common Data Environment (CDE) markets are merging.

Nvidia has a major play with its interpretation of the open USD format through its Omniverse platform. Nvidia has the firepower of GPU acceleration, real-time rendering, and simulation –plus plug-ins for Revit, Rhino, SketchUp, Archicad and many others, offering a solution for holding the geometry from all project collaborators.

As outside observers, we sense nervousness from the traditional pure-play software firms, pondering if Nvidia, which was once just a hardware firm, is friend or foe as it ploughs into the space like a meteorite.

The objectives of Autodesk and Epic Games seem to be aligned and this deal provides mutual back rubbing, increased combined clout and capability to compete in the ongoing gamification of AEC.

6 www.AECmag.comSeptember / October 2022

News

EXPLORE

AEC TRENDS AND DIGITAL BEST PRACTICES

See the full agenda and register for free at buildingtogether.graphisoft.com

Goodman, Arquiteto: Pitá arquitetura, Photo: © Maurício Moreno

13th Gen Intel Core CPUs launch for CAD and beyond

Intel gets first Arc Pro GPU win

Lenovo has become the first major workstation vendor to offer a discrete Intel professional GPU in a mobile workstation.

The Lenovo ThinkPad P16 Gen 1 can now be configured with the Intel Arc Pro A30M (4GB), as an alternative to the standard Nvidia options, which range from the Nvidia RTX A1000 (4GB) up to the Nvidia RTX A5500 (16 GB).

I

ntel has announced its 13th Gen Intel Core processor family, led by the Intel Core i9-13900K, which features 24 cores and a max turbo frequency of 5.8 GHz. The new ‘Raptor Lake’ processors will be available in desktop workstations later this year and will go head-to-head with the new AMD Ryzen 7000 Series, competing on a range of workflows from CAD and BIM to rendering and reality modelling.

13th Gen Intel Core processors pick up where 12th Gen Intel Core left off, with a hybrid architecture that features two different types of cores: Performancecores (P-cores) for primary tasks and slower Efficient-cores (E-cores).

Workloads are split ‘intelligently’ using Intel’s Thread Director.

Other features include increased memory support to DDR5-5600 and DDR5-5200 (while maintaining DDR4 compatibility), PCIe Gen 5.0 support (with up to 16 lanes off the processor); and up to 2x the L2 cache and increased L3 cache.

While the spotlight is on the flagship Core i9-13900K, Intel has launched a total of six 13th Gen Intel Core processors –three with integrated graphics and three without. The Core i7-13700K and Core i5-13600K could appeal more to price conscious architects and engineers with predominantly single threaded workflows, such as CAD and BIM.

What AEC Magazine thinks

This is an incredibly exciting time for mainstream computer processors, with Intel and AMD both launching new

architectures within weeks of each other. In recent years, AMD has certainly had a significant advantage for ray-trace rendering, but with more cores than before we now expect Intel to compete much more strongly in multi-threaded workflows, as it did already in single threaded workflows like CAD.

Of course, when it comes to workstations, customers don’t always get a choice, with many large AEC firms being tied to procuring IT only from major manufacturers.

While we expect both 13th Gen Intel Core and AMD Ryzen 7000 Series workstations to be widely available from custom system builders like Scan, BOXX, Armari and Workstation Specialists, we still expect Intel to dominate among the tier ones.

To date, Lenovo is the only one out of HP, Dell and Fujitsu to offer an AMD Ryzen processor in a mainstream workstation –and that is with the Ryzen Pro 5000 in the ThinkStation P358. Whether Ryzen 7000 (and the Ryzen Pro 7000 that will presumably follow) becomes the catalyst for others to follow suit remains to be seen.

Finally, as a follow up to this 2021 article (www.tinyurl.com/AMD-vs-Intel-CAD) we’ll be putting 13th Gen Intel Core up against the AMD Ryzen 7000 Series in our annual Workstation Special Report planned for early next year. As always, we’ll be testing with a wide range of real world AEC applications, including CAD, BIM, rendering, reality modelling and more. We look forward to exploring who comes out on top.

■ www.intel.com/processors

The Intel Arc Pro A30M is an entry-level pro GPU, and is part of Intel’s much-anticipated entry to the world of discrete workstation graphics.

By offering the GPU in the powerful ThinkPad P16, it gives prospective buyers more choice for less demanding 2D and 3D workflows, such as CAD / BIM.

The Intel Arc Pro A30M also includes hardware accelerated ray tracing and hardware assisted AI (XeSS). On paper, this should make it suitable for ray trace rendering in applications that support Microsoft DX12 / DXR, and ray tracing using the Vulkan API. However, those who take design visualisation seriously will likely be better served by one of the higher-end Nvidia RTX GPUs.

For less demanding users, the Intel Arc Pro A30M does deliver considerable price savings.

On Lenovo’s UK website, configuring the ThinkPad P16 with the Intel GPU instead of the lowest cost Nvidia option –the Nvidia RTX A1000 (4GB) –will shave £183 off the price of the laptop. Selected instead of the Nvidia RTX A2000 (8GB) it will save £413.

■ www.intel.com/arcprographics

www.AECmag.com

News

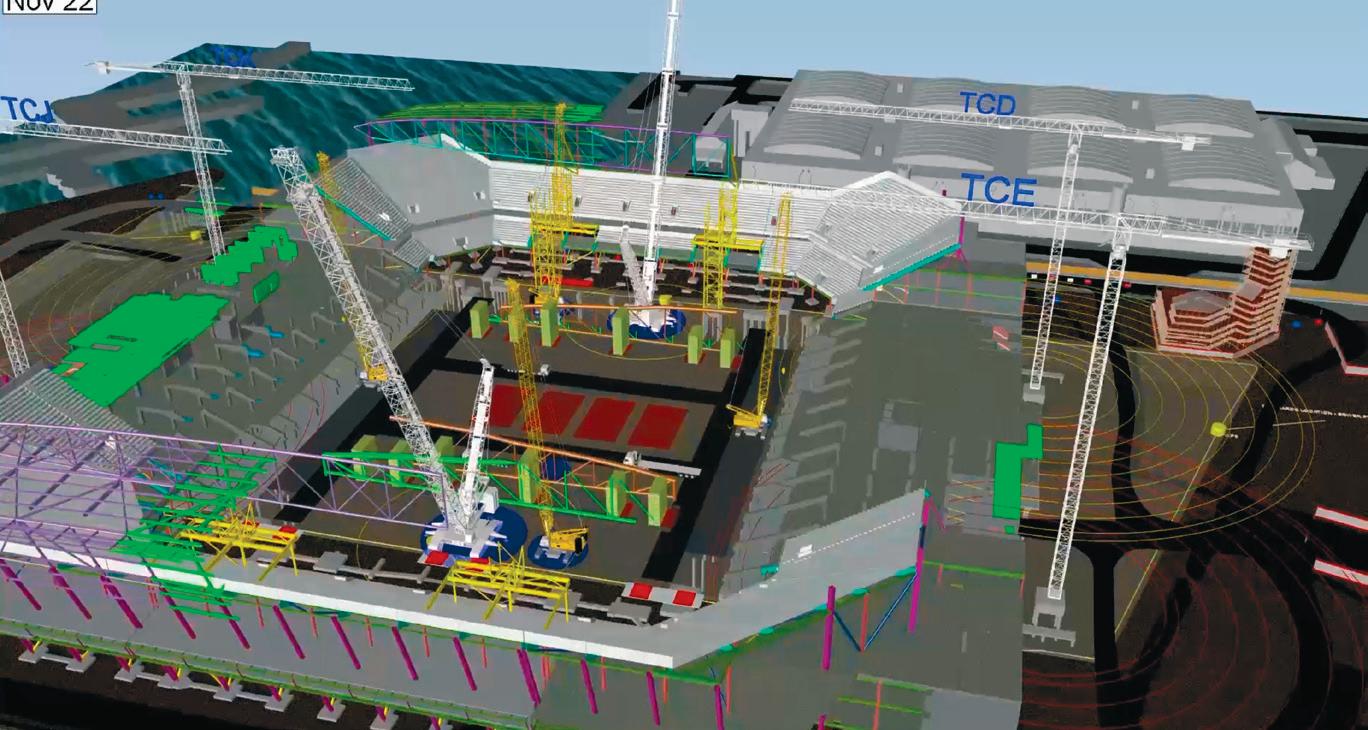

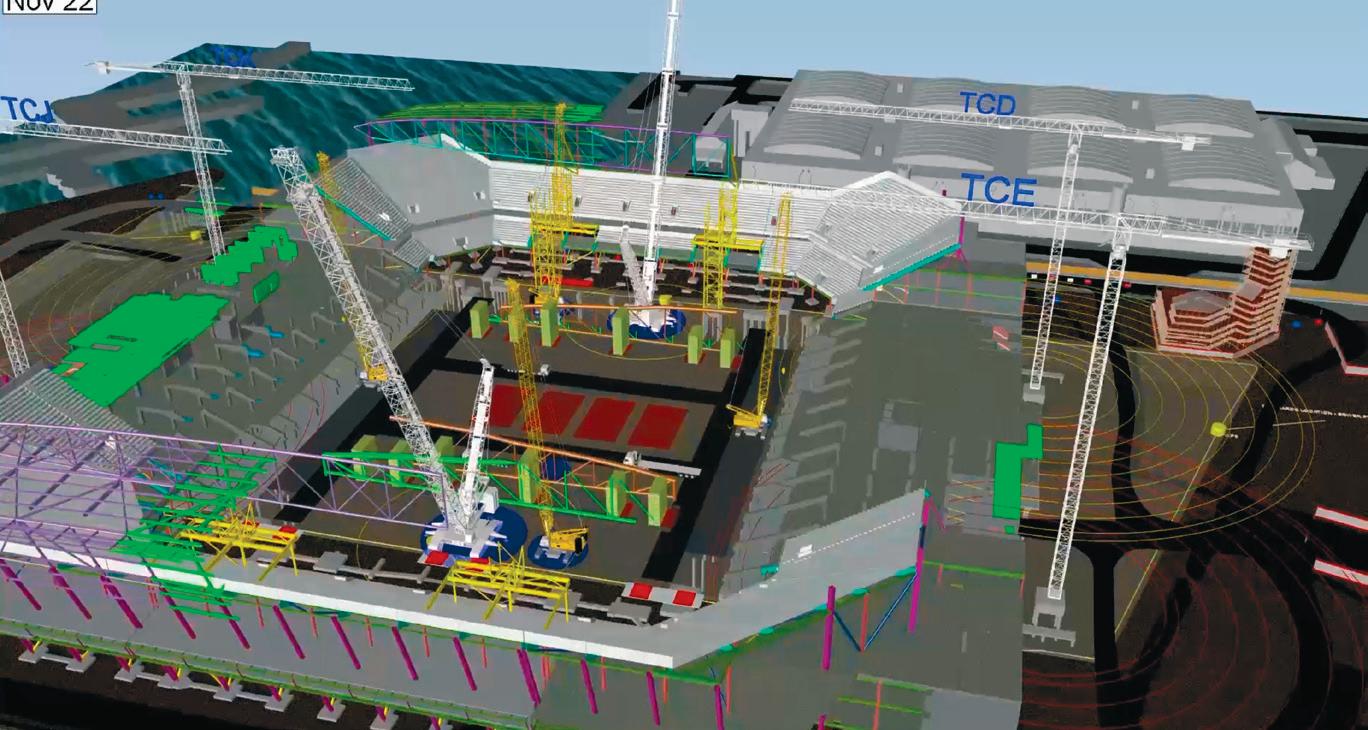

Laing O’Rourke using 4D construction simulation to drive Everton stadium build

Laing O’Rourke is using 4D construction software Synchro 4D to simulate the construction of Everton Football Club’s new stadium in Bramley-Moore Dock, Vauxhall, Liverpool.

The 52,888-seater arena is now over a year into its three-year build and is due to open for the start of the 2024–25 Premier League season, replacing Goodison Park.

Laing O’Rourke has built a master federated 3D model from detailed electrical, mechanical, structural and architectural models. This includes steelwork assemblies, prefabricated concrete walls and giant roof trusses, as well as wiring, plumbing, light switches and plug sockets.

A 4D model is then created with model elements linked to the construction programme activities in Synchro. This allows the Laing O’Rourke team to visualise the construction sequence and assess potential risks or clashes in the programme, along with opportunities that might not have been seen using more traditional methods.

“It’s been built virtually on screen in a simulated environment, and now physically on site,” explains Craig Wallace, digital engineer, Laing O’Rourke. “The real benefit is that this enables us to resolve issues upfront, in a simulated environment, before work begins on-site.”

In addition to simulating the sequencing of the build, the Everton Stadium model includes elements such as mobile cranes, storage zones, engineering controls, walking routes and more.

“That really helps to drive what we do on site and how we can coordinate different pieces of work safely. This is our highest value,” explains Wallace.

The rolling model can be accessed by the workforce on site, via screens or mobile phones, enabling them to undertake the precise workloads and feedback on progress to maintain information flow.

“Every week in our immersive space we hold a logistics team meeting where we

get all of the operatives on site to come into the room and we run through, week by week, what’s going to be happening on site and we can adapt to changes in logistics,” says Wallace.

“Working with our supply chain, we can use the model and embedded data to visually track the progress of the build and then communicate this through dashboard reporting.

“The model is integral to dictating, with precise detail, the just-in-time delivery slots for tonnes of steelwork and the thousands of concrete wall panels, pillars and beams,” he says.

■ www.evertonstadium.com

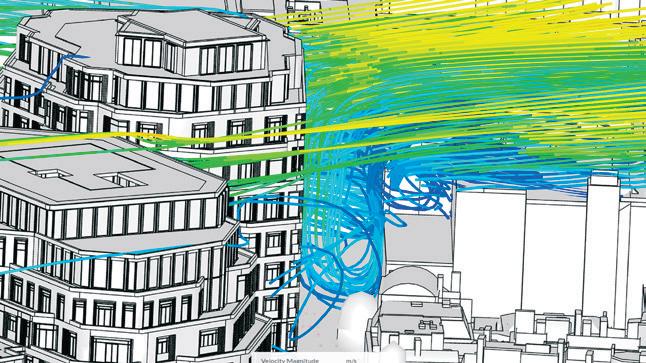

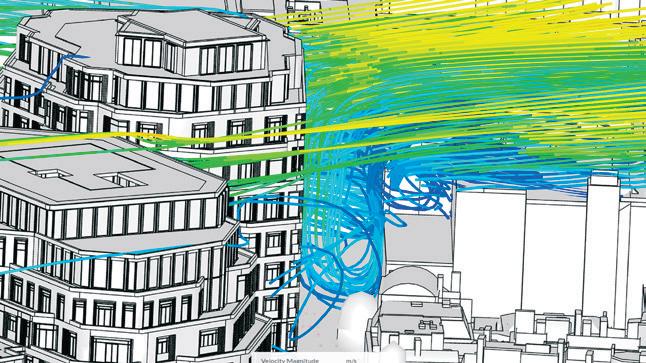

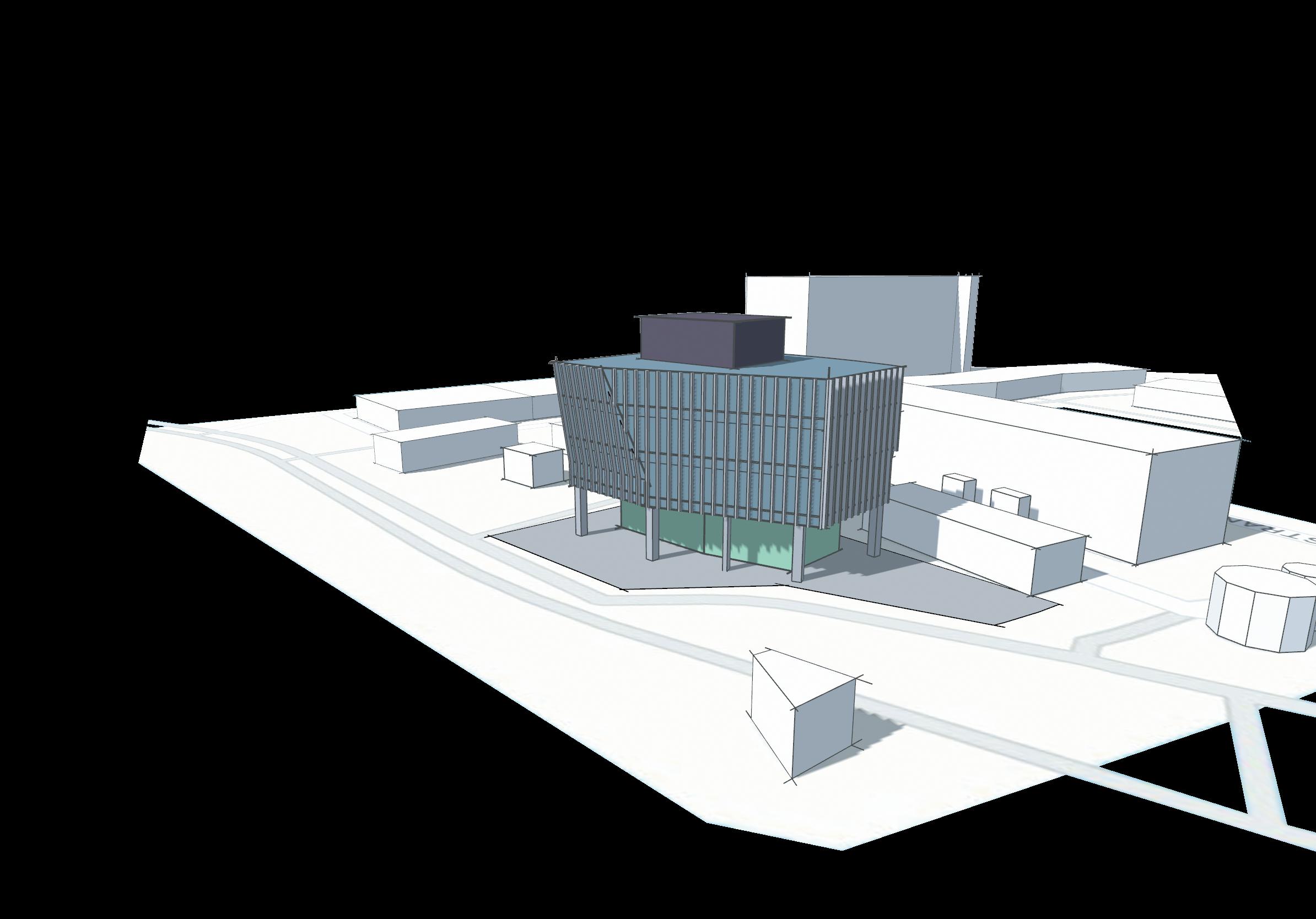

KPF and SimScale explore wind analysis for early stage design

PF’s Environmental Performance team (KPFep) has developed a wind modelling tool for early-stage design studies. The ‘Wind Flow’ app, which utilises the API of cloud-based simulation platform Simscale, is designed to make wind and microclimate studies accessible to architects across KPF.

The Wind Flow app can be used to maximise comfortable spaces with respect to pedestrian wind comfort. It also integrates with outdoor thermal comfort and UTCI calculations, which are particularly critical in hot-humid climates.

Now in beta development, the software is currently used by a handful of architects in KPF’s New York and London offices for competitions and bids, but its integration

with Rhino means it will eventually extend its reach to the whole firm. “Our plan is to deploy this to over 100 architects globally, giving them access to fast and accurate microclimate analysis as and when needed,” said Elias Anka, sustainable design lead in KPF’s London office.

“The aim is to equip our designers with the right toolset and knowledge to tackle

climate change and be proactive in designing carbon neutral buildings and cities that prioritise the comfort and wellbeing of occupants.”

With the Wind Flow app, Pedestrian wind comfort (PWC) and building aerodynamics studies take just a few minutes to simulate. From within Rhino, users can quickly select the climate data/ location and the number of wind speeds.

A series of dialog boxes appear in turn for architects to configure a wind study. The simulation is then sent to SimScale in the cloud to run, delivering simulation data such as probe point coordinates, result planes, and wind speeds. The results are imported back into Rhino for visualisation.

■ www.simscale.com

10 www.AECmag.comSeptember / October 2022

K

HP SitePrint prints 2D plans on construction site floors

Asite teams up with SmartViz for digital twins

Cloud collaboration platform provider

Asite has partnered with digital twin software developer SmartViz to help expand operational capabilities for asset owners.

Asite says the partnership will enable outcome-driven digital twins through real-time data and occupancy analytics, simulations, and visualisations for asset performance optimisation.

HP SitePrint is a new autonomous robot that prints site layouts directly onto the floors of construction sites. According to HP, the three wheeled robot can print with pinpoint accuracy in a fraction of the time it takes to layout manually, improving productivity by as much as ten times.

Global construction firm Skanska has been using HP SitePrint on two prominent US projects, including the LIRR Train Hall Renovation in Penn Station, New York.

Working with Skanska, it took construction services provider Siteline360 45 minutes to print the layout of walls over an area of 2,400 square feet. According to Michael Hill, regional director of Siteline360, that same job took a layout technician seven hours to do manually.

HP SitePrint gets its precise positioning

and navigation by linking to a Robotic Total Station. Through a collaboration with Leica Geosystems the robot is guided by the Leica TS16 and Leica iCON iCR80 Robotic Total Stations.

HP’s robot is ruggedised and designed to operate in construction site conditions. It can print lines, arcs and text on multiple surfaces, including those that are porous and non-porous. HP says the robot is light and compact, and can be transported in a hard case that fits all the solution components. This includes a touch screen tablet for remote control and configuration and a portfolio of inks for different surfaces, environmental conditions, and durability requirements.

HP SitePrint also includes cloud tools for submitting and preparing jobs, managing the fleet and tracking usage. ■ www.hp.com

Cintoo aligns with Autodesk Cloud

Cintoo, a specialist in managing reality capture data in the cloud, has been named an Autodesk Construction Cloud Premium Integration partner and will promote the combined use of Autodesk Construction Cloud and Cintoo Cloud for all aspects of design and construction.

Cintoo Cloud is a browser-based solution with a point cloud-to-mesh technology and ‘TurboMesh’ streaming engine that allows users to access high resolution 3D scans and models from ‘anywhere’. According to the company,

even high-resolution data (billions of points) from large projects (thousands of scans) can be manipulated in 3D using a standard WebGL browser without quality reduction or data simplification.

The platform turns point cloud data from Autodesk ReCap or the E57 format into 3D meshes. According to Cintoo, this reduces the size of the point cloud data to upload by 10 to 30 times. Cintoo Cloud can also be used to compare ‘as-designed’ BIM or CAD files with ‘as-built’ mesh-based laser scan and drone data. ■ www.cintoo.com

“It’s just not acceptable that buildings still consume 3.5x more energy and release 3.8x more CO2 than they should. This needs to change. For that we need to break data silos, and make it accessible, insightful and empower everyone from the COO and CFO to the estate directors, facilities managers and end users,” says Dr. Shrikant B. Sharma, founder & CEO of SmartViz. “That’s what this partnership delivers by enhancing space utilisation, saving energy and supercharging the productivity and wellbeing of people – all highly relevant issues in light of the climate challenges, net zero goals, and post-covid world adapting to hybrid working.” ■ www.smart-viz.com ■ www.asite.com

Abisogun joins BIM Academy

BIM Academy has appointed digital construction pioneer Bola Abisogun OBE as its new digital director to expand its digital advisory team. With a coveted career history spanning three decades within AEC, Abisogun brings a wealth of expertise in construction cost management, BIM, digital construction and digital twin methodologies.

■ www.bimacademy.global

11www.AECmag.com September / October 2022

News

AMD boosts performance in OpenGL-based CAD toolsROUND UP

IMSCAD partners

IMSCAD has formed a partnership with Tech Data, offering any of its resellers specialist consulting services to help with Nvidia-based deployments, including vGPU, Omniverse and Enterprise ■ www.imscadglobal.com

BIM rebranding

The UK BIM Alliance, established in 2016 to help drive BIM adoption in the UK, is changing its name to ‘nima’, the Greek word for thread. The new name is designed to put an emphasis on wider information management, rather than BIM. “We are not the ‘BIM police’,” said chair Anne Kemp ■ www.wearenima.im

Ryzen 7000 win

The BOXX APEXX A3 workstation now features AMD Ryzen 7000 CPUs. “The new CPU’s innovative features will empower architects, engineers, 3D designers, and motion media professionals to create, render, and multitask faster than ever before,” said Bill Leasure, BOXX ■ www.boxx.com

DEVELOP3D Live

AEC Magazine’s sister publication, DEVELOP3D, is hosting its annual ‘Live’ event in Sheffield on 1 November. The conference and exhibition celebrates the very latest technologies for product design, engineering and manufacturing. Tickets are free and include an all-access conference pass ■ www.develop3dlive.com

BIM reach

Autodesk has added new capabilities to Autodesk Construction Cloud to make it easier for project teams to use and maximize the value of BIM from the office to site. The enhancements are said to provide ‘all stakeholders’ with immediate access to relevant model data and information ■ www.autodesk.com

Bluebeam Cloud

Bluebeam has released Bluebeam Cloud, a new suite of mobile and browser-based solutions. It includes a Markup Editor for marking up, commenting, and collaborating on project documents, and Field Tools for the management and tracking of punch, RFI and submittal workflows ■ www.bluebeam.com

AMD has launched a new professional graphics driver that is said to provide a major performance uplift in CAD and other 3D applications that rely on the OpenGL graphics API. This includes Dassault Systèmes Solidworks, Autodesk Maya, Trimble SketchUp and McNeel Rhino.

The re-architected driver (AMD Software: Pro Edition 22.Q3) works with current generation and older generation Radeon Pro GPUs.

AMD has released performance figures that show gains ranging from 0% to 115% in the SPECviewperf 2020 benchmark.

Initial testing in AEC Magazine’s labs demonstrate performance gains can be even higher — close to 300% faster in visualisation software Autodesk VRED Professional 2023 and over 200% faster in mechanical CAD tool Solidworks 2022. However, our testing shows that performance can also go down. This can be with certain applications, when using large models that do not fit entirely into GPU memory, or with particularly old GPUs such as the Radeon Pro WX 5100.

What AEC Magazine thinks

It’s really good to see AMD innovating in an area that can potentially bring huge benefits to users of 3D CAD. OpenGL might not be the future of graphics APIs, but it’s still used extensively in many 3D applications.

Getting more out of your computer hardware for free is always a good thing, but it’s perhaps those with ageing graphics cards that can benefit most here.

While our tests show that the six year old Radeon Pro WX 5100 slows down in Solidworks when using the new driver, AMD’s previous generation Radeon Pro W5500 gets a new lease of life.

And with certain datasets, where the GPU may have previously struggled to keep up, the new driver could turn a choppy viewport into one that is smooth and fluid, making it much easier to position 3D models on screen, and delivering a big boost in productivity.

We’ll have an in depth review in AEC Magazine’s forthcoming Workstation Special Report.

First two-storey building 3D printed in NA

Canadian 3D construction printing company, nidus3D, has erected what it claims to be the first multi-storey 3D printed building in North America – a house in Ontario, Canada.

nidus3D used the BOD2 printer from COBOD, whose technology has already

been used to 3D print the first two and three storey buildings in Europe.

The BOD2 can print with real concrete with a particle size up to 10mm and 99% based on locally found raw materials.

COBOD developed the ‘D.Fab’ solution, in cooperation with the cement giant Cemex.

12 www.AECmag.comSeptember / October 2022

■ www.amd.com/radeonpro

■ www.nidus3d.com

Chaos streamlines workflow between V-Ray and Enscape

Faro targets 4D construction management

Faro has unveiled a new 4D Construction Progress Management Solution on its Sphere SaaS platform, providing a central location for users to capture, view, share and analyse reality capture data.

The central component to the new solution is the Sphere Viewer, which uses a combination of computer vision, photogrammetry and AI to create what Faro describes as a comprehensive virtual jobsite.

Chaos has created a bridge between its real-time viz software Enscape and its photorealistic rendering tools V-Ray 6 for SketchUp and Rhino/Grasshopper. The new workflow enhancement follows on from the merger of Chaos and Enscape earlier this year.

With the new connection, architects can start the visualisation process in Enscape’s real-time environment, and then ‘smoothly transfer’ the asset to the visualisation team to deliver the highest levels of photorealism in V-Ray.

“When applications don’t talk to each other, design intent can quickly get lost as

a project moves from schematic to marketing,” said Konstantin Gaytandzhiev, V-Ray for Rhino and SketchUp product manager at Chaos.

“With this new bridge, an architect’s design can continue to be iterated on with every nuance intact, removing the open questions that slow teams down.”

According to Chaos, with support for Enscape materials, environments, lights and compatible 3D assets, V-Ray 6 ensures that all design decisions are kept throughout the project development stages, creating an unbroken chain between designers and V-Ray specialists. ■ www.chaos.com

Allplan to Solibri workflow enhanced

In a move that demonstrates closer collaboration between Nemetschek-owned solutions, BIM software provider Allplan has announced a streamlined real-time issue management workflow between Solibri and Allplan via the cloud-based OpenBIM platform Bimplus.

The workflow is designed to provide an effective method for managing changes in projects. Rather than importing and exporting BCF files, the Solibri BCF Live Connector now enables the direct transfer of issues identified during consolidated model checking in Solibri to the issue workflow in the Bimplus platform. These issues can then be assessed and assigned for processing.

According to Allplan, the workflow is

particularly effective for Allplan users as the Bimplus Issue Manager is also used within Allplan and therefore enables direct processing and correction of these defects immediately within the Allplan BIM authoring solution.

Issues can be created in either Allplan or Bimplus, assigned to the relevant person in the team, visualised, annotated, assigned a deadline, and signed off, as well as easily tracked throughout the entire process.

Issues created in Solibri are also now transferred centrally in Bimplus, can be validated by the Project Manager or BIM Coordinator, and then assigned to the responsible team members, who receive the tasks in Allplan.

■ www.solibri.com/bcf-live-connector

The new viewer is said to analyse point clouds and 360° photos in a unified environment, removing reality capture data silos and enabling faster analysis.

The solution also includes: VideoMode, which uses 360° videos to enable ‘faster and easier’ site documentation; ProgressAI, which uses AI to detect and report site progress; and a brand-new Robotics API, which allows robotic manufacturers to integrate and directly import reality captured data from robots, such as Boston Dynamics Spot, straight into the virtual jobsite.

www.faro.com

BIM Track launches beta of new viewer

BIM Track has launched the public beta of a NextGen Viewer for its BIM / VDC coordination and collaboration web platform.

According to the Canadian company, which is a part of the Newforma Holdings family, the viewer is fast-loading, lightweight, and allows users to activate many more models than before. It has a right-side panel for easy referencing between sheets, models, and issues.

www.bimtrack.co

13www.AECmag.com September / October 2022

News

■

■

Nvidia puts spotlight on digital twin applications in Omniverse

At Nvidia’s GTC event last month, the company shared real world examples of how its Omniverse platform is delivering digital twin solutions for infrastructure –specifically railway and telco networks. The company also announced the launch of Omniverse Cloud, an infrastructureas-a-service that connects Omniverse applications running in the cloud, on premise, or on edge devices.

Future rail

Digitale Schiene Deutschland (DSD), part of Germany’s national railway operator Deutsche Bahn, is building an AI-enabled digital twin in Omniverse to help develop the country’s future railway system.

DSD is working to increase the network’s capacity and reduce its carbon footprint without building new tracks, by creating a railway system in which trains are automated, safely run with less headway between each other, and are optimally steered through the network.

DSD’s ‘country-scale’ Omniverse digital twin will fully simulate automatic train operation across the entire network, with photorealistic and physically accurate emulation. It will feature 5,700 stations and 33,000 kilometres of track running through cities and countrysides, and many details from sources such as station platform measurements and vehicle sensors.

Using AI, DSD will develop perception and incident prevention and management systems to optimally detect and react to irregular situations during day-to-day railway operation.

DSD’s digital twin will use a custom 3D pipeline that connects CAD datasets that are built, for example, within the Siemens JT ecosystem with DSD’s high-definition 3D maps and various simulation tools. Using the Universal Scene Description (USD) 3D framework, the foundation for Omniverse, DSD can connect and combine data sources into a single shared virtual model.

DSD will synchronise its network with the real world, so it can run optimisation tests and “what if” scenarios to test and validate changes in the railway system, such as reacting to unforeseen situations.

Running on Nvidia OVX, a computing system for running Omniverse

simulations, DSD will be able to operate the persistent simulation, which is regularly improved by data stream updates from the physical world. Future computer vision-powered systems could continually perform route observation and incident recognition, automatically warning of and reacting to potential hazards, such as debris on the track.

The AI sensor models will be trained and optimised with a combination of realworld and synthetic data, some of which will be generated by the Omniverse Replicator software development kit framework. According to Nvidia, this will ensure models can perceive, plan, and act when faced with everyday and unexpected scenarios.

Telco network planning

Heavy.AI has launched what it claims to be the industry’s first digital twin for telco network planning, building and operations. The HeavyRF Omniverse digital twin is designed to help telco network operators speed deployments of wireless networks, by using simulation to optimise cellular-tower and base-station placements for best coverage, potentially across entire cities.

“5G infrastructure is fundamentally very different from 4G infrastructure: it requires far more towers and antennas to provide the highest level of coverage and hence customer satisfaction. Because of that heightened demand, telcos can’t spend the same amount of time planning and locating each piece of 5G infrastructure,”

says Jon Kondo, CEO of Heavy.AI.

HeavyRF allows telcos to review historic and current networkperformance data as they test siteconfiguration scenarios against physical impediments such as trees and dense buildings. It uses GPU-accelerated analytics to combine customerdemographic and behavioural data with real-time geophysical mapping.

Simulations can be run against fullresolution, physically precise multi-billion point LiDAR data interactively at metro and national scale. According to Nvidia, HeavyRF achieves accurate results in seconds and supports live and interactive analysis of relevant business metrics. As a result, engineers and business subjectmatter experts can rapidly collaborate, radically reducing planning cycles.

Omniverse Cloud

Omniverse Cloud is a new infrastructureas-a-service that allows users to ‘create and collaborate on any device’ with the Omniverse App Streaming feature; access and edit shared virtual worlds with Omniverse Nucleus Cloud; and scale 3D workloads across the cloud with Omniverse Farm, a scaling engine for a render farm.

Omniverse Cloud is powered by Nvidia OVX for graphics-rich virtual world simulation. Second generation OVX systems feature the new Nvidia L40 GPU, which is built on the Ada Lovelace architecture.

■ www.nvidia.com/omniverse

14 www.AECmag.comSeptember / October 2022

Nvidia RTX 6000 ‘Ada Lovelace’ GPU launches with smarter approach to rendering

Nvidia has launched the Nvidia RTX 6000, a high-end workstation GPU built on the company’s new Ada Lovelace architecture, named after the English mathematician credited with being the first computer programmer.

The Nvidia RTX 6000 GPU is said to deliver up to two to four times the performance of the previous generation ‘Ampere’ Nvidia RTX A6000 and promises to deliver big advances in realtime rendering, graphics, AI and compute, including engineering simulation. It is not to be confused with 2018’s Turing-based Nvidia Quadro RTX 6000.

The Nvidia RTX 6000 is a dual slot graphics card with 48 GB of GDDR6 memory (with ECC), a max power consumption of 300 W and support for PCIe Gen 4, giving it full compatibility with workstations featuring the latest Intel and AMD CPUs. It supports Nvidia virtual GPU (vGPU) software for multiple high-performance virtual workstation instances and boasts 3x the video encoding performance of the Nvidia RTX A6000, for streaming multiple simultaneous XR sessions using Nvidia CloudXR.

The Nvidia RTX 6000 offers all the generational improvements you’d expect from a new GPU architecture – third-gen RT Cores for ray tracing, fourth-gen Tensor Cores for AI compute, and next-gen CUDA cores for graphics and simulation – but there are also significant changes in the way the ‘Ada Lovelace’ GPU carries out calculations to increase performance in viz-centric workflows.

Deep Learning Super Sampling 3 (DLSS) and Shader Execution Reordering (SER) are the two technologies that stand out.

Deep Learning Super Sampling 3

Nvidia DLSS has been around for several years and with the new ‘Ada Lovelace’ Nvidia RTX 6000, is now on its third generation. DLSS uses deep learningbased upscaling techniques where frames are rendered at a lower resolution and the GPU’s ‘AI’ Tensor cores are then used to predict what a high-res frame would look like.

With Nvidia’s previous generation ‘Ampere’ GPUs, DLSS 2 took a lowresolution current frame and the highresolution previous frame to predict, on a pixel-by-pixel basis, what a highresolution current frame would look like.

With DLSS 3, the AI generates entirely

at the same time. However, with ray tracing, rays bounce in different directions and intersect surfaces of various types. According to Huang, this can lead to different threads processing different shaders or accessing memory that is hard to coalesce or cache.

With Shader Execution Reordering (SER), the Nvidia RTX 6000 dynamically reorganises its workload, so similar shaders are processed together.

According to Nvidia, SER can give a two to three times speed up for ray tracing and a frame rate increase of up to 25%.

Nvidia did not announce which software applications will take advantage of this technology.

Simulation

this approach means DLSS 3 will benefit both GPU and CPU limited games.

Huang made no reference to how DLSS 3 might benefit professional 3D applications. However, while DLSS 2 was used mainly in GPU limited viz applications such as Enscape and Autodesk VRED, we wonder if DLSS 3 could deliver big performance improvements for 3D CAD and BIM software, which tends to be CPU limited.

Shader Execution Reordering (SER)

Nvidia explains that GPUs are most efficient when processing similar work

The Nvidia RTX 6000 also brings new benefits to engineering simulation, as Dipankar Choudhury, Ansys fellow and HPC Centre of Excellence lead, explains, “The RTX 6000 GPU’s larger L2 cache, significant increase in number and performance of next-gen cores and increased memory bandwidth will result in impressive performance gains for the broad Ansys application portfolio.”

Nvidia also highlighted the benefits of having 48 GB of memory, explaining that with the Nvidia RTX 6000 users can increase the fidelity of the solver to perform more accurate simulations and still obtain the results in near real time.

www.nvidia.com

15www.AECmag.com September / October 2022 News

■

SER boosts performance by dynamically reorganising shader workloads, so similar shaders are processed together

Software

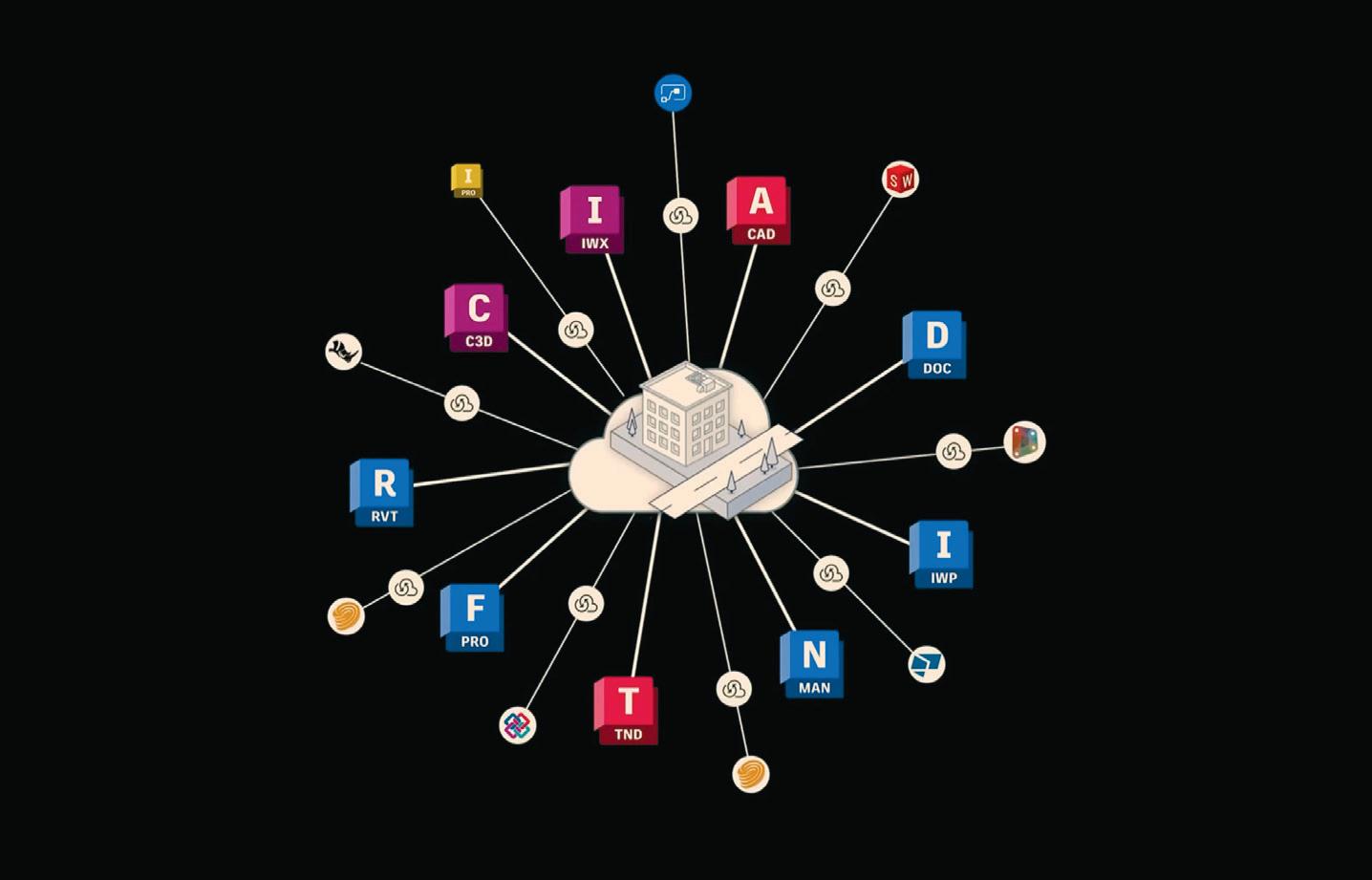

Revit and Rhino linked with Autodesk connector

With the release of the Data Exchange Connector for McNeel Rhino public beta, Autodesk is aiming to make it easier to share data between the popular concept modelling tool and Revit

Autodesk has long been trying to improve data flow between its disparate applications. To specifically help improve the flow of data between Revit and Inventor (Autodesk’s 3D CAD tool for product design and mechanical engi neering), Autodesk developed a plug in for the Forge Data Exchange Connector component.

This made it easier for Revit users to share specific subsets of data with Inventor and combine architecture model with fabrication elements that will appear in the building. It meant all users could work on the lat est data and there was less hassle when creating specific files.

Autodesk then expanded the Data Exchange Connector to include Microsoft Power Automate, a popular tool for building automated business processes that can be used to share data between hundreds of apps.

In essence, collaborators can share sub sets of design data with a wide number of

applications like Excel, generate insightful PowerBI dashboards, as well as get notifi cations with Microsoft Teams, Slack etc.

The connector comes with some predefined workflow template examples for the Power Automate platform, helping those who are project managers, VDC managers, or BIM managers. Autodesk is now adding another connector to the

from Rhino to Revit – or from Revit to Rhino. This keeps project designers on the same page and aware of the latest changes to levels, grids, floors and (cur tain) walls.

exchange ecosystem, to include the high ly popular McNeel Rhino.

Rhino Exchange Connector

With its generative Grasshopper capabil ity, Rhino is one of the leading conceptual design tools in AEC, used for anything from simple massing models to complex façades. The new connector allows users to move geometry and property data

Autodesk claims that without its Rhino Exchange Connector, sharing data for consumption by other applica tions can result in lossy or incomplete translation, requiring time intensive worka rounds or third-party plug-ins to capture the full extent of the infor mation being shared. Autodesk says this new Connector offers a step forward for interoperability and collaborative work, and better syncs Rhino and Revit workflows for more seamless design development.

To use, install the Rhino Connector into Rhino, select the geometry that needs to be shared, and create a Data Exchange. The Data Exchange is published to ‘Autodesk Docs’, the cloud-based common data environment, where data can be stored and accessed from Revit or any

16 www.AECmag.comSeptember / October 2022

‘‘

The new connector allows users to move geometry and property data from Rhino to Revit – or from Revit to Rhino. This keeps project designers on the same page and aware of the latest changes to levels, grids, floors and (curtain) walls

’’

other application with an available Autodesk Data Exchange Connector.

The workflow can be seen in a video here (www.tinyurl.com/rhino-revit-YT).

Rhino.Inside

Autodesk’s latest development follows on from McNeel’s own application connec tor, ‘Rhino.Inside’, which is a range of plug-ins that embeds Rhino into other 64-bit Windows applications.

‘Rhino.Inside.Revit’ specifically allows an unprecedented level of integration between Rhino and Revit, enabling Rhino to run in the same memory space as Revit. This means that whatever Revit creates, Rhino can read, and whatever Rhino creates, Revit can read, communi cating through their APIs.

Rhino.Inside.Revit also makes it easier to apply Grasshopper scripts to Revit geometry and read the recipes for each and every object.

Scott Davidson at McNeel explains how Rhino.Inside.Revit contrasts to the trans actional nature of Autodesk’s Data Exchange Connector, “Rhino.Inside.Revit is quite a bit different in that it is a live integration of Rhino and Revit as some one is working on their desktop.

“You could look at this as a way to share and store other types of files with in your Revit construction project. Rhino files alongside other formats that need to be used in a large project. In addition to the geometry there is also parameters that are stored/exchanged with the Rhino files.”

Rhino.Inside.Revit is free to use but you will need a full licence of Rhino on your machine.

Proving Ground Conveyor

Proving Ground, a US software develop ment and consulting company, has devel oped Conveyor, a plug-in that allows users to import Rhino objects into Revit as native elements.

The software integrates / extends ‘Rhino.Inside.Revit’ by adding a userinterface, which is Rhino-based (not Grasshopper-based, as Rhino.Inside. Revit comes).

The workflow demonstrated in Autodesk’s video for Rhino Connector Public Beta (www.tinyurl.com/rhino-revit-YT) appears to strikingly similar to the work flow of Conveyor (see www.tinyurl.com/ proving-AEC).

Proving Ground Conveyor costs $695.

Proving Ground also develops Tracer, which can be used to connect BIM tools to Microsoft PowerBI.

Conclusion

The whole Data Exchange Connector concept seems to reflect what advanced customers have been doing for quite a while through applications such as McNeel’s Rhino.Inside, Speckle ( https:// speckle.systems ) and Proving Ground’s Conveyor (https://apps.provingground.io).

While Autodesk is seemingly trying to build one connector to rule all connec tions, it’s not completely clear what the cost will be to use it. Autodesk may use its own token-based system for each transaction. At the moment, however, it’s in beta and free.

There is also a question as to how deep ly Autodesk would choose to integrate these tools to provide comparative rich feature sets and continue to maintain them, vs dedicated teams of developers with specific commercial products such as Proving Ground and McNeel.

To join the public beta of Autodesk Rhino Exchange Connector sign up here ■ www.tinyurl.com/Revit-Rhino-beta

17www.AECmag.com September / October 2022

SMART PERFORMANCE. SMART PAIRING

©2022 Advanced Micro Devices, Inc. All rights reserved. AMD, the AMD Arrow logo, Radeon, AMD RDNA, Ryzen and combinations thereof are trademarks of Advanced Micro Devices, Inc. Other product names used in this publication are for identification purposes only and may be trademarks of their respective companies. PID#: 21771403 Ver#:02

Get the ultimate software experience with up to a gigantic 32GB of lightning-fast framebuffer, high-performing hardware raytracing, optimizations for up to 6 ultra-high res HDR displays, and superior multitasking capabilities. All wrapped around an award winning graphics architecture, called AMD RDNA™ 2 which is the proven graphics foundation for the leading, visually rich gaming consoles. The latest AMD Radeon™ PRO W6000 graphics series is compatible with modern workstations offering additional optimizations for select AMD Ryzen™ based processors, harnessing the GPU’s and system’s full performance potential. amd.com/RadeonPRO

20 www.AECmag.comSeptember / October 2022

AI: the comingtsunami

While we see design software marginally improve year on year, there has been growing unrest at the pace/scale of improvements. Questions have been raised about how well BIM workflows map to how the industry actually works.

Martyn Day looks at the potential impact of artificial intelligence.

As a society, living in a techno logical age, we have become incredibly used to rapid change. Sometimes it feels like the one constant we can rely on is that everything will change. For millen nia humankind lived in caves, scrawling drawings on the walls. The Stone Age was 2.5 million years long, then came the Bronze Age and, with it, urbanisa tion, which lasted 1,500 years. The first Industrial Revolution lasted just 80 years (1760 - 1840). Before we reached our current, digital age, the Wright Brothers perfected powered flight and just 66 years later, our species had escaped Earth’s gravity, traversed the vacuum of space and landed on the moon. We are making advances in ever shorter timeframes and have industrial ised innovation through the develop ment of ever-smarter tools.

The next revolution is already here but, as the saying goes, it will not be evenly distributed. At the moment, many aspects of our working lives are still going through digital transformation. Everything is becoming data and the more that becomes centralised, the more insights it enables, offering a greater opportunity for knowledge processing.

Artificial Intelligence and Machine Learning have gone from science fiction to science fact and are rapidly being used by increasing numbers of industries to improve productivity, knowledge capture and in the creation of expert systems.

Businesses will need to transform as quickly as these technologies are deployed as they will bring structural and business model changes at rates which we have not yet truly anticipated.

In the last few months, I’ve seen dem onstrations of design technology current ly in development that will, at the very least, automate labour intensive detail tasks and perhaps greatly lessen the need for architects on certain projects.

First warning

During the lock down in 2020, I watched with interest an Instagram post by designer and artist, Sebastian Errazuriz ( www.tinyurl.com/AI-Errazuriz ). It soon became a series and more of a debate. He said, “I think it’s important that archi tects are warned as soon as possible that 90% of their jobs are at risk.”

His argument condensed down to the fact that architecture takes years to learn and requires years of practice. Machine learning-based systems can build experi ence at such an accelerated rate that humans cannot possibly compete.

As we already have millions of houses, enormous quantities of data, including blueprints, why do we need a new house when we can have an AI trained and then blend of all the best designs? “Now try to imagine what 1,000 times this tech and 10 years will do to the industry,” conclud ed Errazuriz.

The interesting thing is, at that point in time there was very little technology

offering anything like that. Perhaps Errazuriz had seen Google’s Sidewalk Labs which was experimenting with gen erative design to create and optimise neighbourhood design. At the time I thought it was a good marketing ploy for himself, although the comments turned into a pile-on.

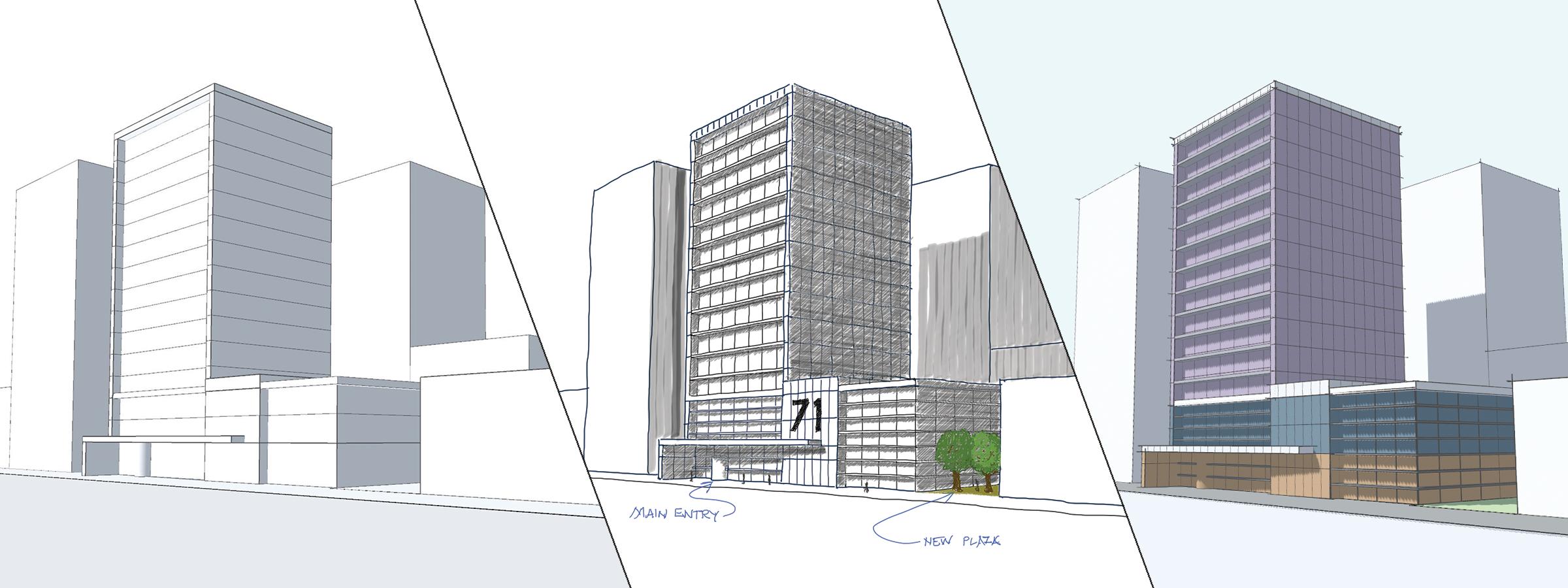

Current AI reality

We are still some way off from fulfilling anything like the true potential of AI in generative design, a view shared by Michael Bergin of Higharc, who used to head up a machine learning research group at Autodesk. “The full impact of a generative model that uses a deep learn ing system, what we call an Inference Model, is not ready for primetime yet but it’s incredibly interesting,” he says.

But there have already been several fascinating applications of AI/ML in AEC. Autodesk, for example, has deliv ered some niche uses of the technology.

Autodesk Construction IQ is aimed at project risk management in commercial, healthcare, institutional, and residential markets. It examines drawings and iden tifies possible high-risk issues ahead.

AutoCAD has a ‘My Insights’ feature, which examines how customers use their AutoCAD commands and what they do. The AI will then offer tailored advice to help improve productivity or how to bet ter use tools.

There are also a range of adaptive and ‘solver’ tools available such as Testfit

21www.AECmag.com September / October 2022

Feature

(www.testfit.io), Autodesk Spacemaker (www.autodesk.com/products/spacemaker) and Finch 3D (www.finch3d.com), which all solve multiple competing variables to help arrive at solutions that are optimised. While not strictly AI/ML, their results feel like magic and actually help designers make better informed decisions and reduce the pain of complexity.

Bricsys has also been investing in AI. Bricscad BIM doesn’t use the Lego CAD paradigm of modelling with walls, doors, windows etc. Instead the user models with solids and then, using the BIMify command, runs AI over the geometry, which it identifies as IFC components, windows, floors, walls etc.

AI applications so far have either pre dominantly been at the conceptual side or have tried to ‘learn’ from the knowl edge of past projects.

Recent advances

Over the last two years, in conversations with AEC firms who were fed up with the limitations of their BIM tools and were looking for significant productivity improvements, many seemed to turn to wanting to completely automate the 2D drawing process.

While drawings are a legal requirement, heavily model-based firms are calculating that they could save millions by just hav ing AI take over that and then they could spend more time on design. Around the time of our NXT BLD conference in June 2022, I started to see early alpha code of software which was looking to apply AI/ ML to design. And, in subsequent conver sations with some design IT directors at leading architectural firms, there was an appreciation that for many standard,

repeatable buildings types – schools, hos pitals, offices, and houses - automated sys tems will soon heavily impact bread and butter projects.

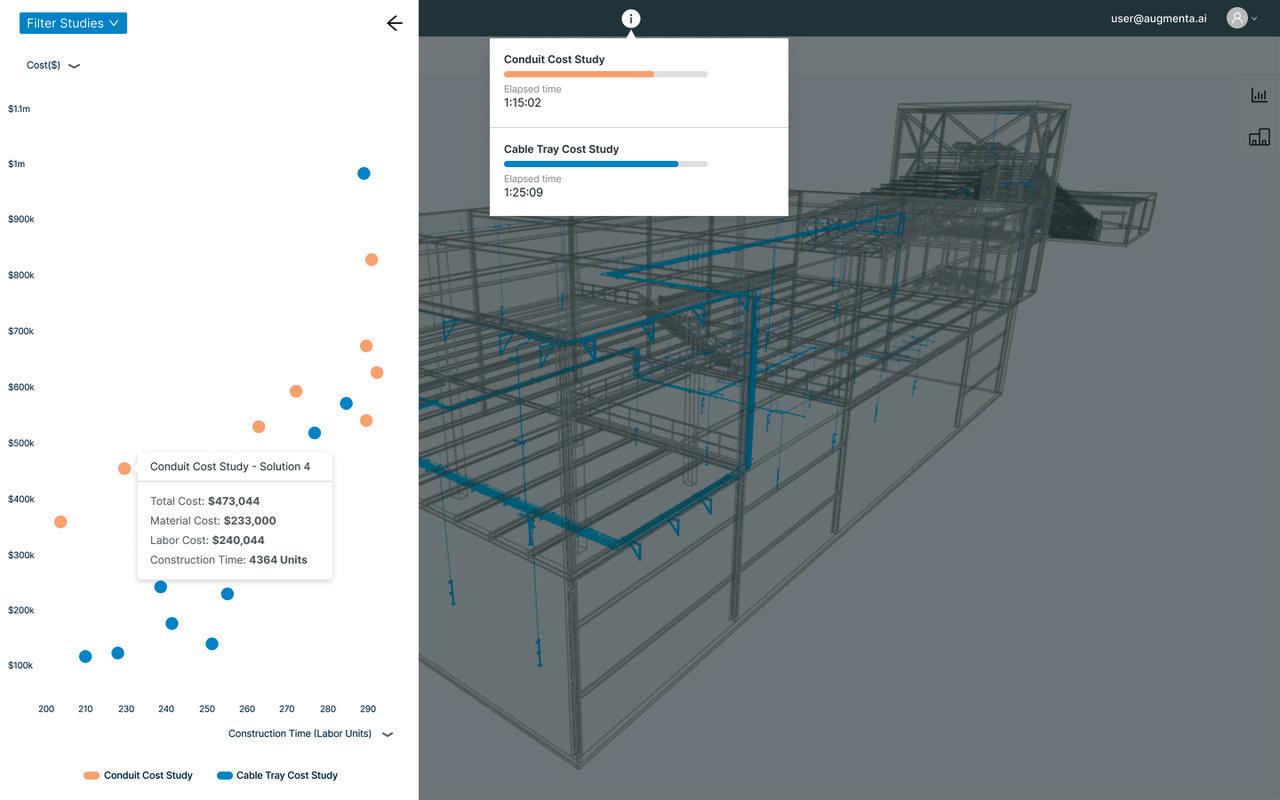

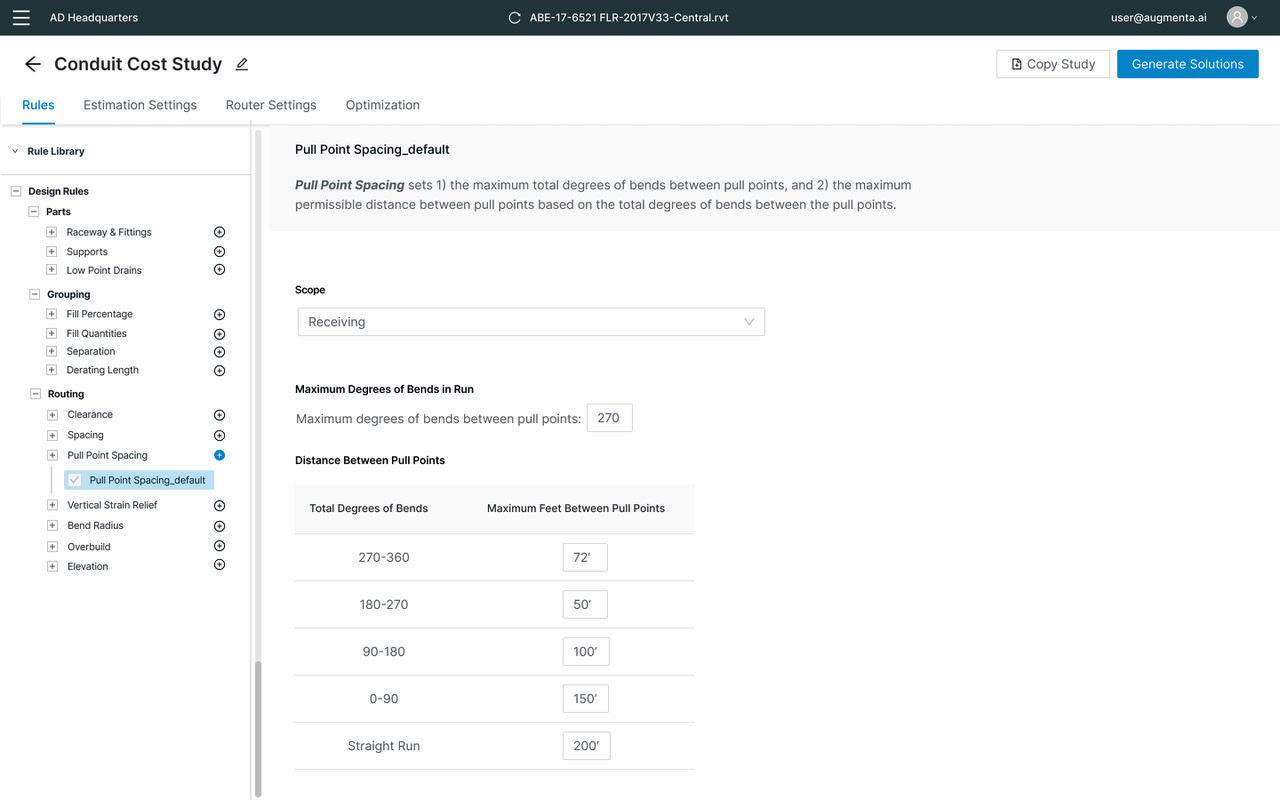

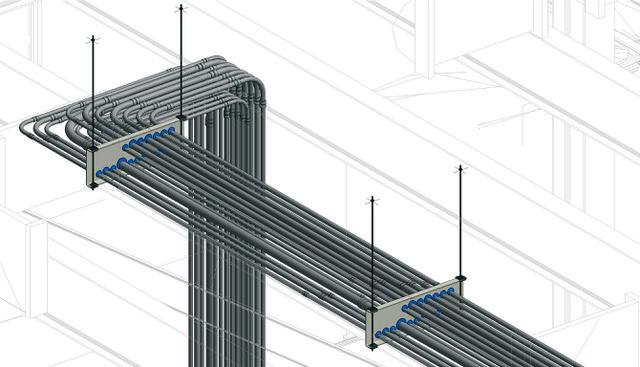

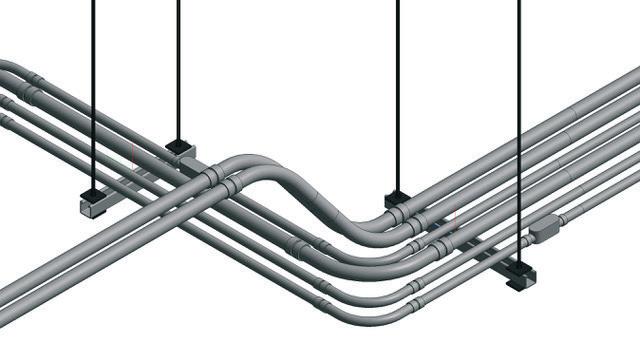

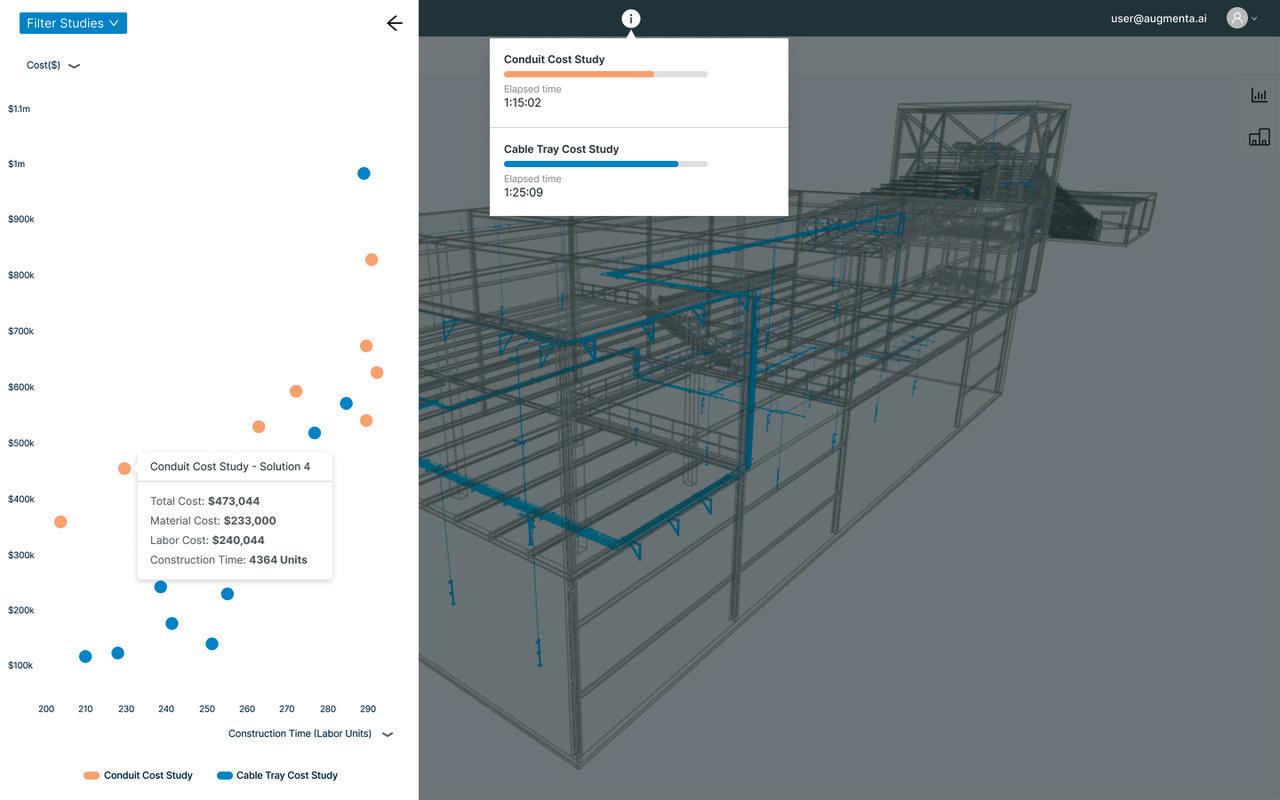

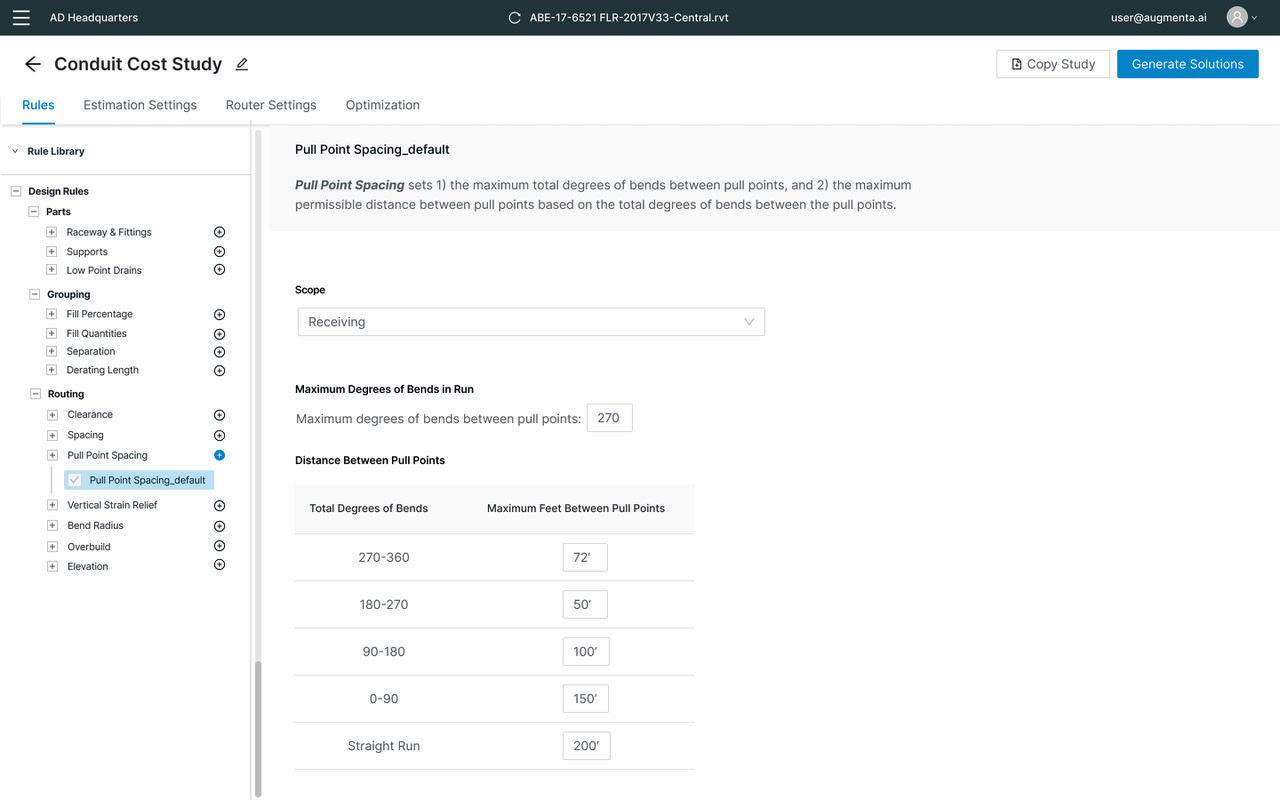

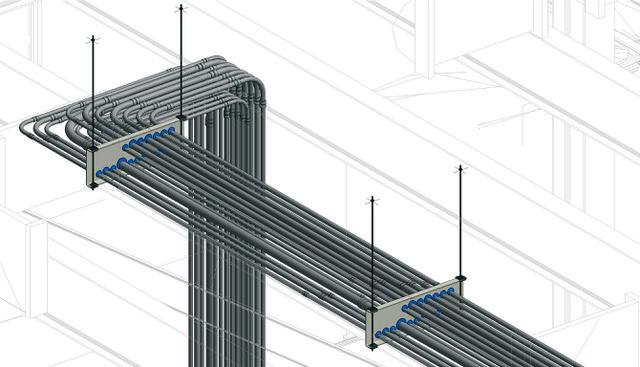

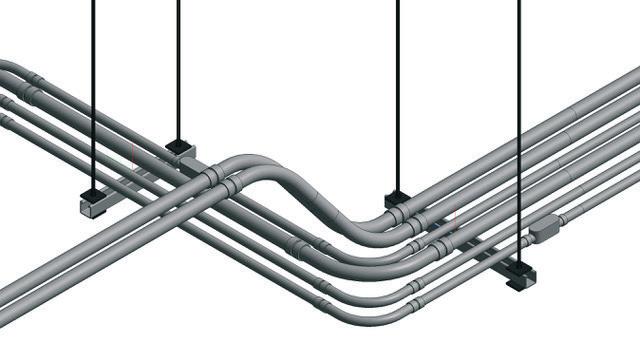

One firm was already running projects in the Middle East with an in-house sys tem which only required one architect, whose task was to define and control the design’s ‘DNA’, with the rest of the team being engineers, focussed on streamlin ing fabrication. I’ve also seen a demon stration of a system that just requires mere polyline input to derive fabrication drawings for modular buildings, missing out detail design completely. There’s also Augmenta, which is looking to automate the routing of electrical, plumbing, MEP and structural detail mod elling (see page 32).

Another gift from lockdown was construction giant Bouygues Construction working with Dassault Systèmes to develop an expert system based the 3D Experience platform (Catia for us old schoolers).

Drop in a Revit model and the system outputs a fully costed, documented virtual construction model for fabrication - all based on the rules, processes and machines, which Bouygues has defined in its workflow, all managed through its Dassault Systèmes’ Product Lifecycle Management (PLM) backbone.

While the system is based on configu ration and constraints and low on AI/ ML, there is a drive to build expert sys tems, bespoke systems to harness a com

pany’s well-defined internal processes.

Like Higharc on page 46 in this issue, the rise of the platform to solve niche market segments is also more likely to be the case for next generation tools.

Pictures that infinitely paint

Ten years ago, machine learning systems were only just getting a hang of identify ing what the subject of a photograph was. Is this a bear or is this a dog? Today’s sys tems can write entire paragraphs defin ing a scene from its computer vision. This advance is probably just as well, as there are already automated taxis with no human drivers in San Francisco driving around picking up passengers - Cruise ( www.getcruise.com ) and Waymo (www.waymo.com).

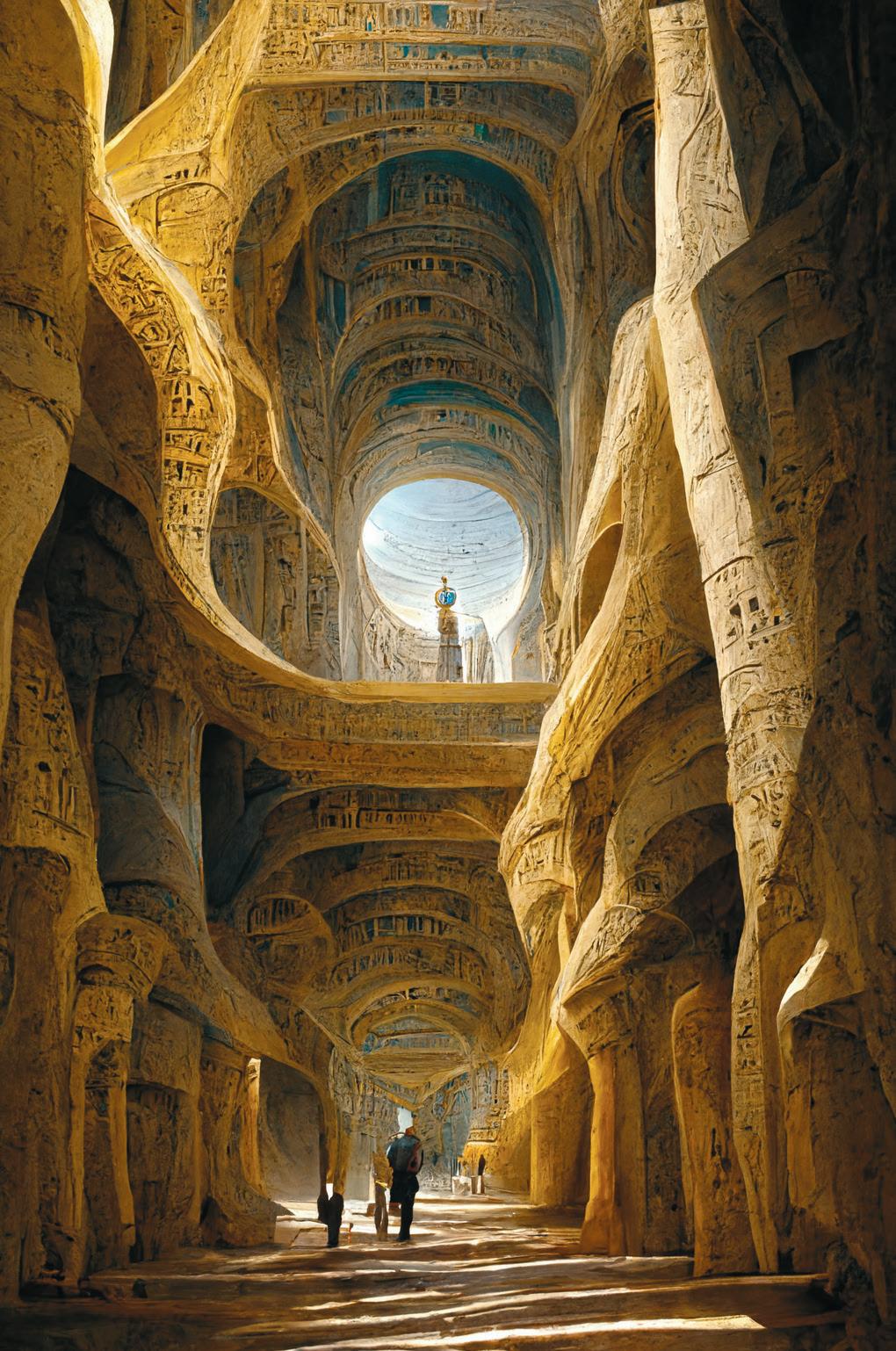

The rise of DALL-E, Midjourney, DeepRender and Stable Diffusion have flooded social media with all sorts of amazing imag es. In this issue you can see the work of many readers who have been experimenting with these tools, to great effect. Trained on billions of photographs and now allowing users to add their own, from week to week this technology seems to be rapidly advancing to a point where the output becomes useful at the conceptual phase of design.

That’s a view shared by computational designer / digital artist, Hassan Ragab, one of the most accomplished users of the technology. “There will be a point in the near future where these tools could be

22 www.AECmag.comSeptember / October 2022 Feature

21

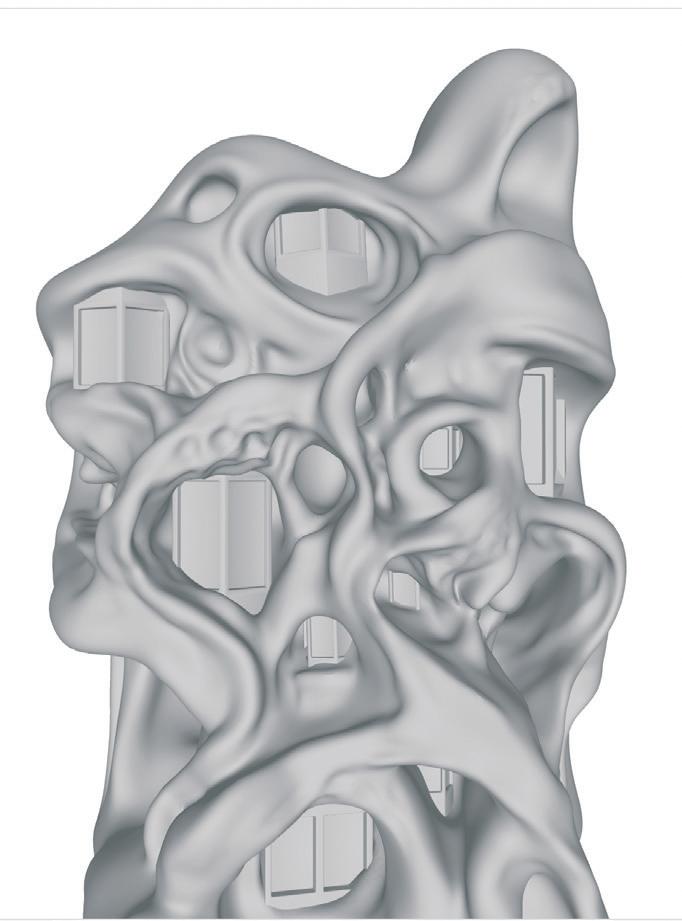

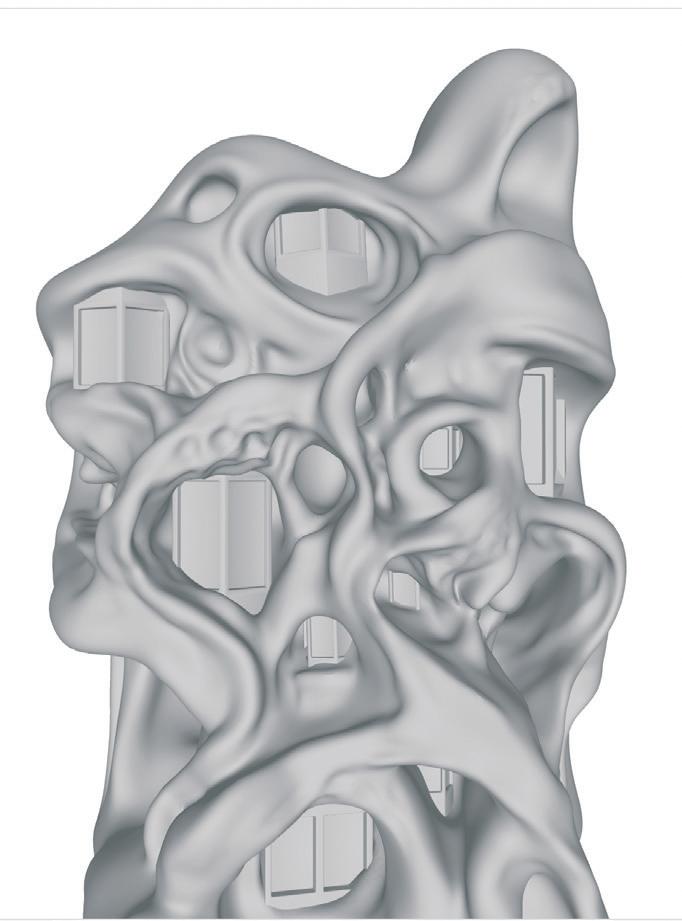

1 2 AI-generated image of a building facade produced by Hassan Ragab in midjourney, automatically converted to a 3D mesh using Kaedim, an AI that turns 2D images to 3D models

‘‘

Like all hype cycles, the impact of machine intelligence on jobs will be overestimated in the short term and underestimated in the long-term

’’

Intel® Arc™ Pro A40 GPU unites fluid viewports, the latest in visual technologies, and rich content creation in a condensed half height, half length form factor. • Ray Tracing Hardware Acceleration • Dedicated AI Acceleration • Industry First AV1 Hardware Encode • 6GB High Speed Memory • Software Certifications • Up to 4x Displays, with Audio Support and Latching Mechanism • Single Slot, Tiny Form Factor • Premium Components • Extended Warranty Professional Graphics Begins Here Intel.com/ArcProA40 © Copyright 2022 Intel Corporation. All rights reserved. Intel, the Intel logo, and other Intel marks are trademarks of Intel Corporation or its subsidiaries. Intel Arc Graphics is a trademark of Intel Corporation in the U.S. and/or other countries. Other names and brands may be claimed as the property of others.

Document& Drawing Management onMicrosoft 365 Workonprojectsanywhere, anytimeandmanageall recordsinonesingle SharePoint-basedplatform AdoptAECbestpracticewith automaticissueregisters, transmittalswithfullaudit trails,andRevitintegration Guaranteecompliance withISO19650orcustom schemesenforcedacross alldocuments Fullycloud-basedAEC-focusedworkflows Qualityassured TrustedbyleadingUK-basedarchitecturaland engineeringpracticestodeliverover10000projects TryAtveroforfree andfindoutmore: atvero.com hello@atvero.com

directly employed into the design pro cess,” he says. “For now many architects and designers are using it as sketching / inspirational tools, but for me, I am just trying to explore what these tools mean to our creative process; by trying to push my imagination to its limits and visualis ing what is on my mind using these pow erful tools (and also to observe how these tools are changing how my mind works).”

Second warning

In August 2022, Sebastian Errazuriz was on Instagram again, this time iden tifying that illustrators will, unfortu nately, be the first artists to be replaced by AI ( www.tinyurl.com/AI-Errazuriz-2 ). Illustrations are commissioned based on text descriptions, which is how these AI systems work.

“The only difference between a human and the AI is that it takes a human about five hours to make a decent illustration that’s going to be published. It takes the computer five seconds” said Errazuriz.

He went on to recommend jumping in as fast as humanly possible to under stand how the tools work and for illustra tors to use their abilities to augment these designs. Experience will now help artists learn how to better describe an image to the machine.

I recently spent a weekend with friends who own a visualisation and media com pany. One of the partners confided to me that he thought that being a creative, he would never have to compete against arti ficial intelligence. In the last two months his company has had to invest hours of time learning to make use of and under stand how these new tools can be har nessed for their business. They even have clients that are requesting to use AI gen erated presentation speakers, which read out written text in their videos to save money. It would seem Errazuriz is cer tainly more on the money.

AI to BIM?

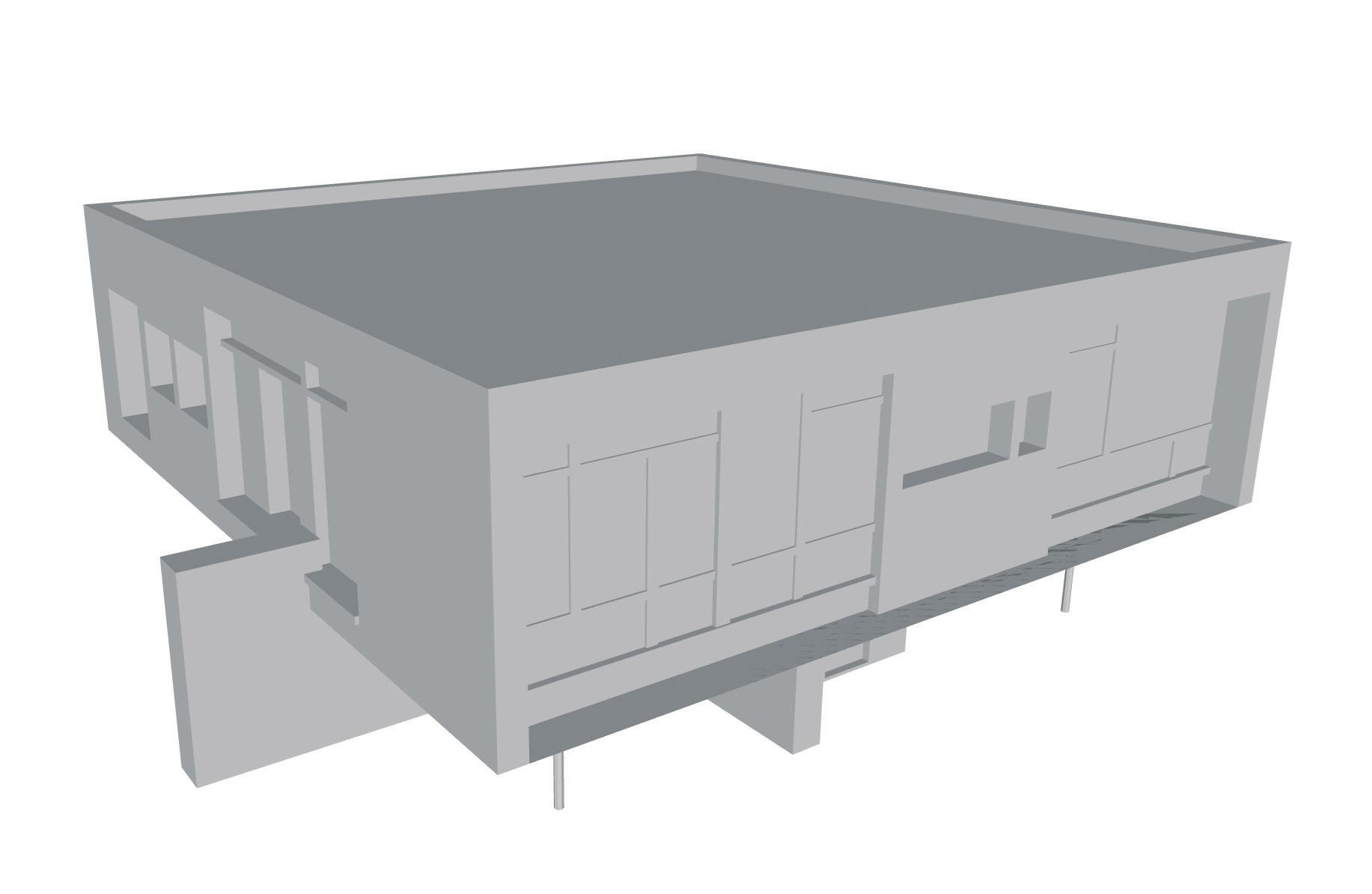

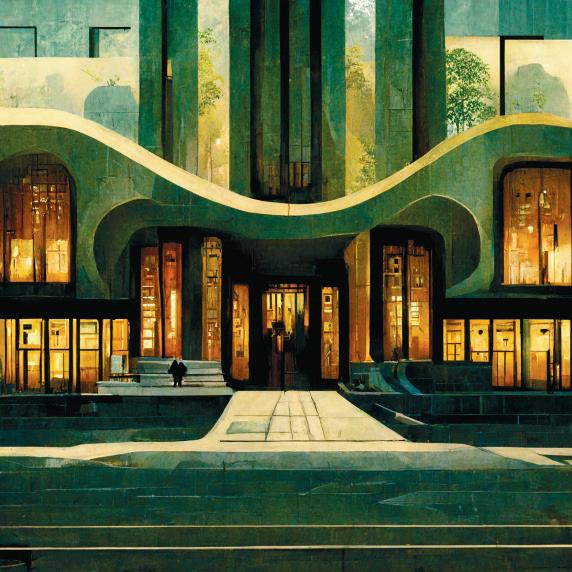

Having seen the incredibly consistent midjourney building designs by Hassan Ragab ( see page 38 ) and followed the com munity, it was interesting when a UK company called Kaedim ( www.kaedim3d. com ) popped up which appeared to be developing a service to convert 2D images to 3D mesh models. I contacted the CEO, Konstantina Psoma to see if we could try out the service.

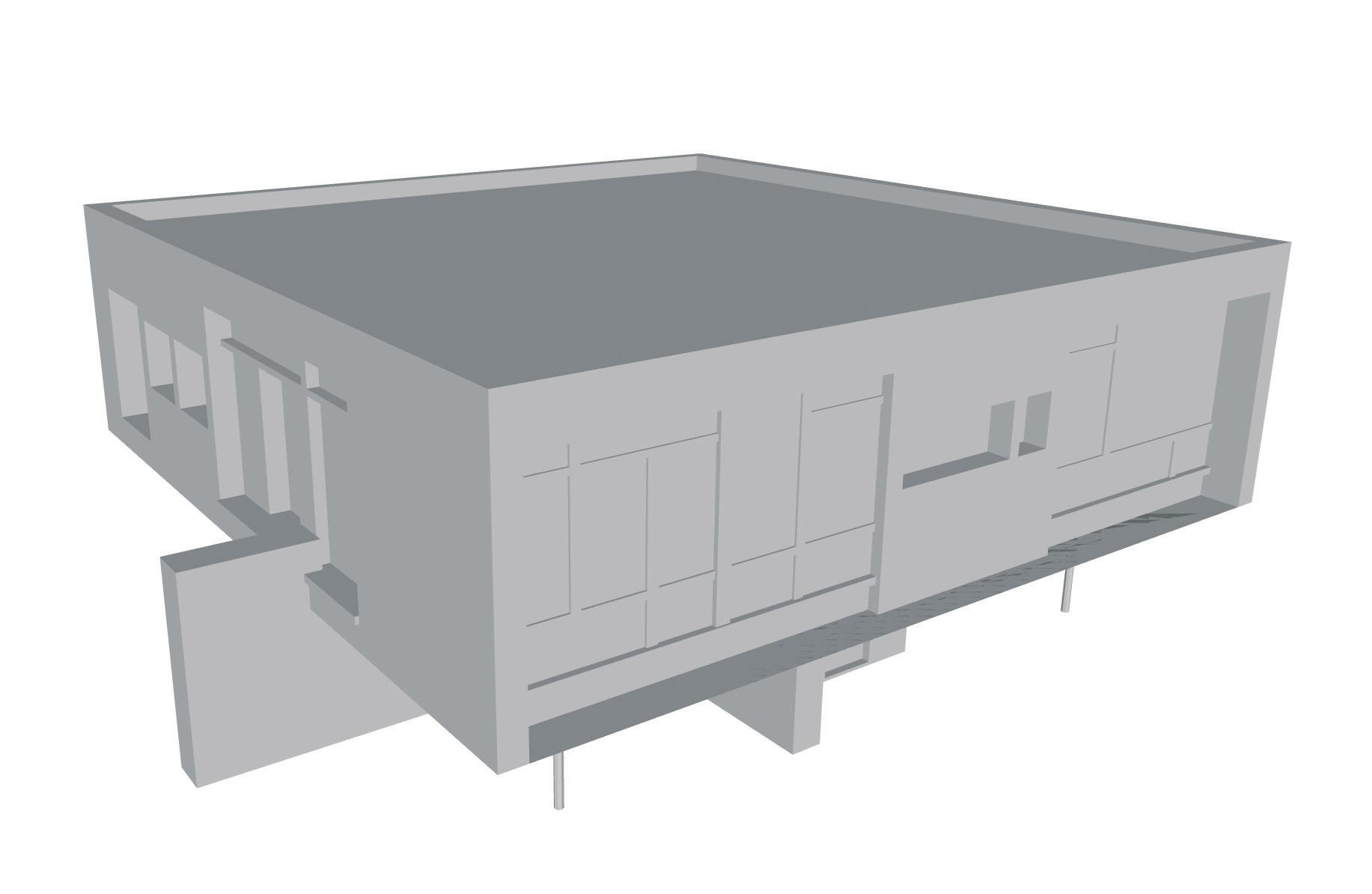

Kaedim was designed to offer a service to the games industry a SaaS platform to quickly convert 2D assets into 3D meshes for games content. We sent over one of Hassan’s complex models and got an OBJ file back containing a single meshed object. It was interesting to see the inter pretation but obviously there was no detail on any of the other sides of the building. Psoma had warned me that Kaedim hadn’t been trained on architec tural assets but was up for giving it a go.

With the complex nature of the mid journey output, I next put through a pho tograph of some early modernist archi tecture, which was very rectilinear, this gave much better results. I then tried to put the mesh through Bricscad BIM to see if the BIMify command could turn it into a BIM model.

While I was hoping this would deliver the world’s first AI concept design to BIM model, incompatibilities in the soft ware meant it fell a little short. Kaedim creates a single sealed mesh, whereas

25www.AECmag.com September / October 2022

3

4 Photo of early modernist architecture, automatically converted to a 3D mesh using Kaedim, an AI that turns 2D images to 3D models

4 3 Feature

Bricscad BIM is expecting multiple meshes in its models. However, it did come temptingly close, especially with simplified geometry.

At some point these AI systems are most certainly going to start producing 3D models based on description, or the AI will be capable of rendering all façades, enabling some degree of 3D. Instead of feeding them flat 2D models, imagine an AI trained on every awardwinning architectural 3D model, or all the changes to architectur al vocabulary throughout history, from Imhotep (2,700 BCE) to Zaha Hadid Architects (2016). Or an AI engineering sys tem, which generates a fabricable engineering design of a hospital at 1:1, but allows the architect to design the façade panels, possibly inspired from another AI tool?

Conclusion

AI/ML, configurators and solvers are coming and coming fast. Over the next five years it will be fascinating to see how this all unfolds. To stay ahead of the game, the best survival advice is to famil iarise yourself with these new systems, when you get the chance.

Established BIM developers of the exist ing tools are working out which elements

of their software AI/ML can be applied to. These could be as boring, but essential, as stair design, to form optimisation, based on multiple analysis criteria.

This piecemeal approach to improve ment will please existing users but won’t radically change the process. It will be for others, with nothing to lose, to come up with more powerful design systems which offer higher speeds of concept to design throughput. The focus might not be on architectural design but on con

automate detail design, together with drawing production.

Both of these tasks are highly demand ing and require sizable teams to carry out mundane work, and coordinate design changes. Automation could ultimately bring about reductions in head count at firms. The dream about having more time to design may hold some truth, but archi tects would need to change their business models, as billing by the hour and having a change driven fee structure is not going to survive the impact of automation in detail design.

struction because of the value benefit that could be applied.

Augmenta, for example, is looking to automate all the phases of detailed design. If this were to be driven into fab rication as well, the whole process might also go from 3D model to G-code.

Like all hype cycles, the impact of machine intelligence on jobs will be overestimated in the short term and underestimated in the long-term. From what I can see, efforts are being made to

The other thing that comes to mind is that, with all this time compression technology and ability to turn a process which has traditionally taken years into maybe weeks, it doesn’t really allow for the nature of humans and the reality of clients changing their mind.

I remember hearing of one successful collaborative BIM project that coordinat ed its project teams on an office building design and got early sign off from the cli ent, at which point they ordered the steel. Much later, the client changed their mind on the design, but it was too late as the steel had been cut. AI might help deliver zero clashes and vastly reduced waste, but we can’t forget about the state of flux which is core to human condition.

AI in architecture: by Clifton Harness, CEO of Testfit

It was scheme “F0” fully printed and delivered to higher-ups for review. This baby was the sixth major site plan design, but the tenth minor iteration that slightly improved the developer’s financial outcome. Finance said it was a winner.

On the walk back to my desk at 11:14pm, I counted the units, again. 253. Good. I counted the parking stalls. It was ready for review. The next morning, I arrived to review “F0” and caught my 30-years-an-architect boss hard at work counting the stalls and units. This is when it really hit me: software has barely scratched the surface of building design. I think that this thought, in this moment, was the TestFit founding moment.

I was so deeply struck with the very real absurdity that industry-wide hundreds of thousands of hours are

spent checking math on parking stalls. Imagine if we could fix that? Or more meaningful things? Like improving the hit rate for housing projects. Or to employ artificial intelligence to enable humans to comply with the rise of ever more complex zoning and compliance codes more ably?

Now to the meat of how I see AI playing out in architecture:

AI in architecture will result in better architecture, as long as there is actually a human architect running that AI. This will put the modern architect at a crossroads: do they embrace technologies that can make them super architects or do they reject them and watch the engineering and development industries embrace them? Either way, we will get better buildings, and the choice is the architect’s now.

If user-editable configurators like

TestFit’s technology are employed, the project team has detailed control to achieve the design vision. It enables software engineers to use meaningful procedures to develop forms and understand why they break. The major strength (or weakness) to procedures is that they are all human-informed.

In the past few years, we have seen very impressive machine-learning algorithms start to tackle things like noise, daylighting, energy use, or microclimate analysis. These are promising, but ultimately computers were the ones doing those analyses anyway. The definition of form to meet project requirements continues to be the fundamental task at the heart of the design process.

Mixed-AI workflows are also quite promising. An example of this is using a simple procedure to generate

massing, and then to ask a neural network for its best guess on column sizing for said mass.

Another thing I am absolutely convinced of: all these avenues of AI penetrating the architecture industry will still go through architecture firms. I’ve worked personally with hundreds of real estate developers, and nearly all of them would prefer to work with architects that have a long track record of success.

The real fear, I think, for the architecture industry, is when the Startup Development or Start-up Architecture shops start to leverage this technology and develop asymmetrical advantages over real estate investment trusts (REITs) or the Genslers of the world. AEC has always been soft on process, and AI is the process holy hand grenade.

27www.AECmag.com September / October 2022

Feature

‘‘

I’ve seen demonstrations of design technology currently in development that will, at the very least, automate labour intensive detail tasks and perhaps greatly lessen the need for architects at all on certain projects

’’

2030: A BIM Odyssey

What will future design systems be capable of doing? With built-in AI and more knowledge-based capability, we should expect more assistance from our BIM technology, writes Richard Harpham, with the help of Greg Schleusner

New MARC Labs AI ‘understands’ recipes for optimum constructability

The world of design and construction today saw the new MARC-Two network come fully online as the original MARC-One servers were deactivated.

MARC is the collective name for early ‘Machinelearning, AI, Robotic and Cloud software’ (MARC). It was introduced in the early 2020s and implemented in the offices of architects, engineers and construction companies.

MARC Laboratory’s lead engineer, Dr Dave Bowman, was tasked with pulling the plug on MARC-One. Although composed of very primitive and narrow AI, Dr Bowman admitted that the system was hard to de-commission, as some of the algorithms had created redundancy strategies to avoid being taken offline, seeking to attach code to the newly commissioned MARC-Two network.

Most notably, some of the oldest algorithms, built by estimators and procurement officers, had penetrated the system infrastructure so deeply, that they were incredibly hard to quarantine and separate from the future MARC-Two servers.

who listened poorly to the needs of a rapidly changing industry and workplace.

MARC-Two has already suggested a system of nano-bot control of large building cranes and earth movers, so workers no longer need to be placed in hazardous situations

For the most part, they tried to automate decades-old existing workflows, but left people knowing less as their centralised data strategies massively increased disconnection between workers and their data. For example, MARC-Ones became very good at creating massive BIM models and counting and managing tasks caused by Request for Information (RFI) events and Change Orders, but never really helped decision makers learn how to improve productivity in the future. At their best, they did for construction what ATM machines did for banks, by automating to reduce the cost of repetitive functions, but rarely could their use be correlated to increased overall productivity. It is now evident that these solutions marketed better to the investors in software companies, rather than solving real world problems for building professionals.

As a reminder, the MARC-Ones were invented during the rush to use AI and Machine Learning to solve the challenges of a perennially inefficient design and construction industry.

While they were technically advanced for their time, they suffered from some major flaws, principally as they were designed by organisations

We can now herald a wholesale move by the industry to adopt MARC-Two technology across all building production environments, from planning, through design, construction and into building operations.

The first MARC-Two came online this week in the MARC labs in Urbana, Illinois as part of production run number 4. The central characteristic of MARC-Twos is their ability to

Recently, I got together with my good friend, Greg Schleusner from HOK, and we debated why software providers and AEC professionals are having one of the most challenging discussions about the future needs of the industry, since BIM came along over 20 years ago.

Although we both started life in archi tecture, our paths have led Greg to become one of the leading AEC technology think ers in one of the largest architecture firms

in the world, and myself to be a serial AEC software worker from Revit, through Autodesk and Katerra to the present day in Slate Technologies.

We come from different directions, but we both share an uncomfortable feeling that the industry could be getting more from technology, and we may not be set ting ourselves up for success on either side. So, what will the future hold? An AI rich, more fulfilling way of working, or the complete reshaping and obsoles

cence of current practices and profes sions? Maybe both.

So, we imagined an AEC Magazine news article from 2030, possibly written by an AI ‘journalist’ to replace the obso lete real ones, that could offer a nonexhaustive explanation of what worked and what didn’t work during our immi nent next technology evolution.

(Please forgive the over the top ‘Arthur C. Clarke’ references- www.tinyurl.com/HAL-9000-AEC)

act as assistants or proxies for knowledge instead of replacing it outright.

The first successful pilot of MARC-Two in construction was when an AI assistant helped a site manager completely orchestrate a concrete pour involving five subcontractors, delivery schedules, lifting equipment, labour resources and traffic issues around the site.

MARC-Two was also able to monitor and account for temperature, humidity and precipitation, continually highlighting issues and opportunities to the site team by correlating thousands of data points at the concrete factory, on the delivery trucks, and on-site.

The next most impressive exhibition of MARC-Two’s prowess was during the design process for one of the most complex sports campuses ever built, in time for the first African Olympics in Cairo.

Marc-Two was able to help the entire architecture and engineering team receive real-time feedback from senior designers, based on previous experience, without them needing to be there. From lessons learned about needing two doors in a mechanical room over 300 square feet, to already understanding and sharing with junior designers, the best door specification between lab and corridor spaces, MARC-Two was able to see and imply answers in realtime, along with the supporting situational context.

As one of the most senior architects shared, MARC-Two helped the whole team repeat the good decisions that MARCOne had already made on similar projects with matching conditions, avoiding the typical costly rework downstream. In the past, BIM models and workflow automations never solved these problems.

MARC-Two is also the first solution to truly

understand the recipes needed for optimum constructability, calling out the areas where it is difficult to place insulation behind a beam, then communicating that to the contractor precisely when installation is taking place.

Dr Bowman also shared some stunning news. It appears that MARC-Two is now helping MARC Labs build the MARC-Three. The MARC-Three system will be able to do things like calculate all the future operational performance for a specific design, so you know what’s more likely to fail before spending too much time preparing a partial solution to a client. It will also allow designers and clients to easily split and combine branching design ideas, while calculating and sharing, in real-time, which new option would be fully realisable and at what comparative cost.

In a construction-based example, Dr Bowman shared that MARC-Two had already suggested a system of nanobot control of large building cranes and earth movers, so workers no longer need to be placed in hazardous situations.

Dr Bowman also shared that he allows MARC-Two to take control of their ‘Spot-the-Dog’ agile-mobilerobots a few days each week. This allows MARC-Two to self-direct where it can travel to on-site and make judgements when it becomes aware of better answers to problems.

Dr Bowman likes to call those days ‘Judgement Days’ and is convinced that MARC Labs’ solutions will be able to take full time control of all the robots by the time the MARC-Three systems are delivered. Then Dave is sure the whole industry will be surprised when the first MARC-Three becomes aware of what unnecessary things it can terminate across building production.

Opinion

HAL 9000 (HEURISTICALLY PROGRAMMED ALGORITHMIC COMPUTER) FROM 2001: A SPACE ODYSSEY. IMAGE CREDIT: TOM COWAP, CC BY-SA 4.0, VIA WIKIMEDIA COMMONS

AI: augmenting not changing AEC workflows

Formany, the concept of artificial intelligence (AI) inspires dread rather than intrigue. AI gone awry is a staple of science fiction, with countless examples of creations turn ing on their masters. For a quick refresher, the film Ex Machina and the series Westworld provide a high-gloss view.

In the AEC industry, many designers, engineers, and builders have a more practical concern – will AI technologies negatively disrupt how we build infra structure? Will they have to completely abandon trusted workflows and switch to technologies that might not even work correctly?

In our team’s work at Bentley Systems’ Digital Innovation Lab (iLAB), we explore emerging new technol ogies and how they can be applied to real-world use cases in the design, construction, and oper ation of infrastructure.

We also hear about initial reactions to AI in infrastructure from AEC compa nies. Though digitisation in general has swept the industry, AI technologies have been slower to take off. Any mention of AI in construction site offices will draw blank stares, as they do not realise what AI can do for them.

Though potential clients will be hardpressed to explain how AI will help them deliver a project, the technology is most likely already in active use – they just do not realise it. Even though innovative AI

solutions will help revolutionise how AEC companies design, build, and maintain infrastructure, I do not think their arrival will cause a major disruption. Rather, AI technologies have the potential to slot into existing workflows and technologies, enhancing how people already work.

Most of us already use AI technologies on a basic level. For example, Microsoft Viva now analyses how people work and suggests ways to improve productivity, such as by sending emails when the recipients are more likely to immediately receive them. Autofill functions on smartphones and email platforms are

technology is just starting to be applied in real-world cases, an array of organisa tions, both long-established and brand new, are developing AI applications that promise to dramatically improve design, construction, and operations.

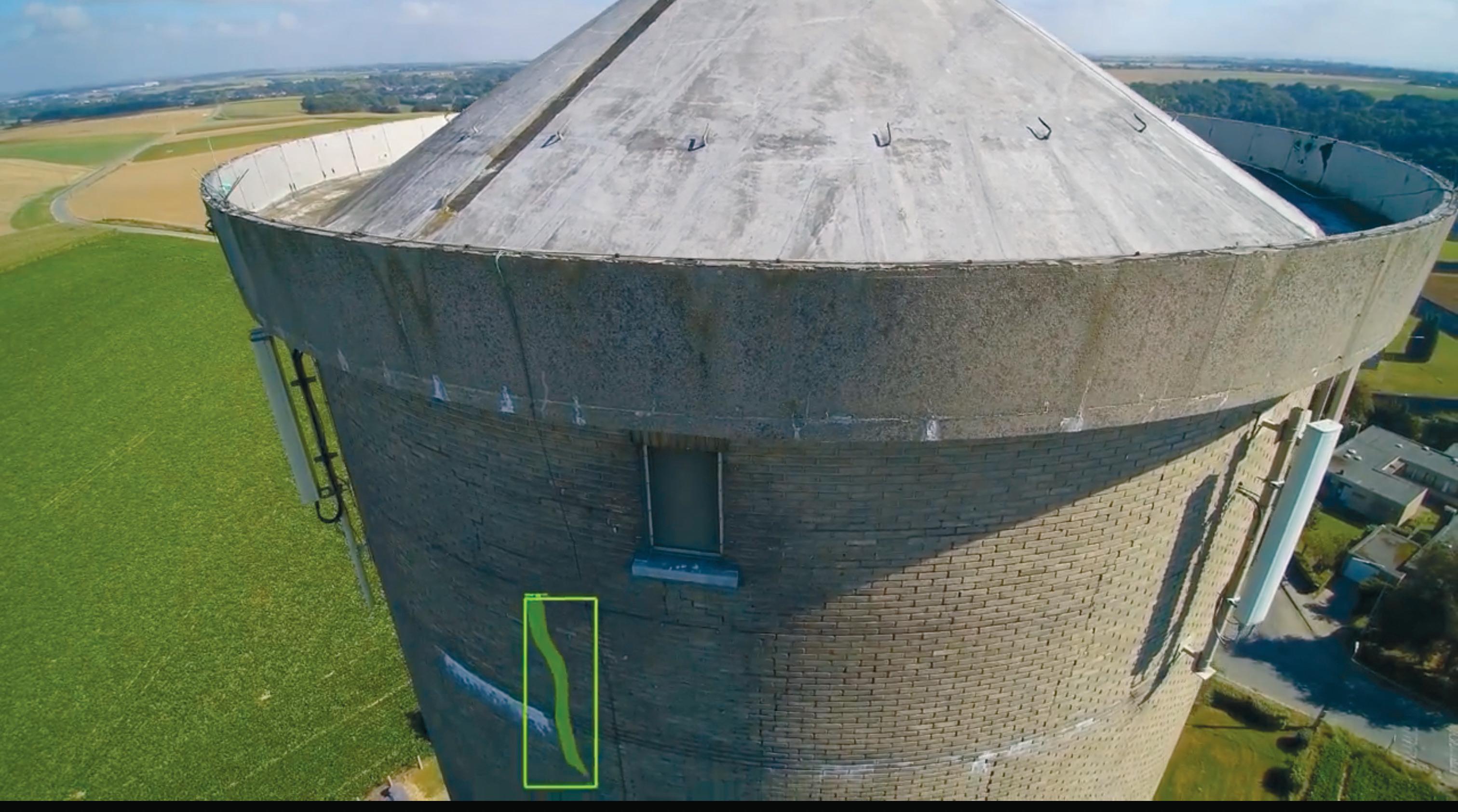

Learning by example

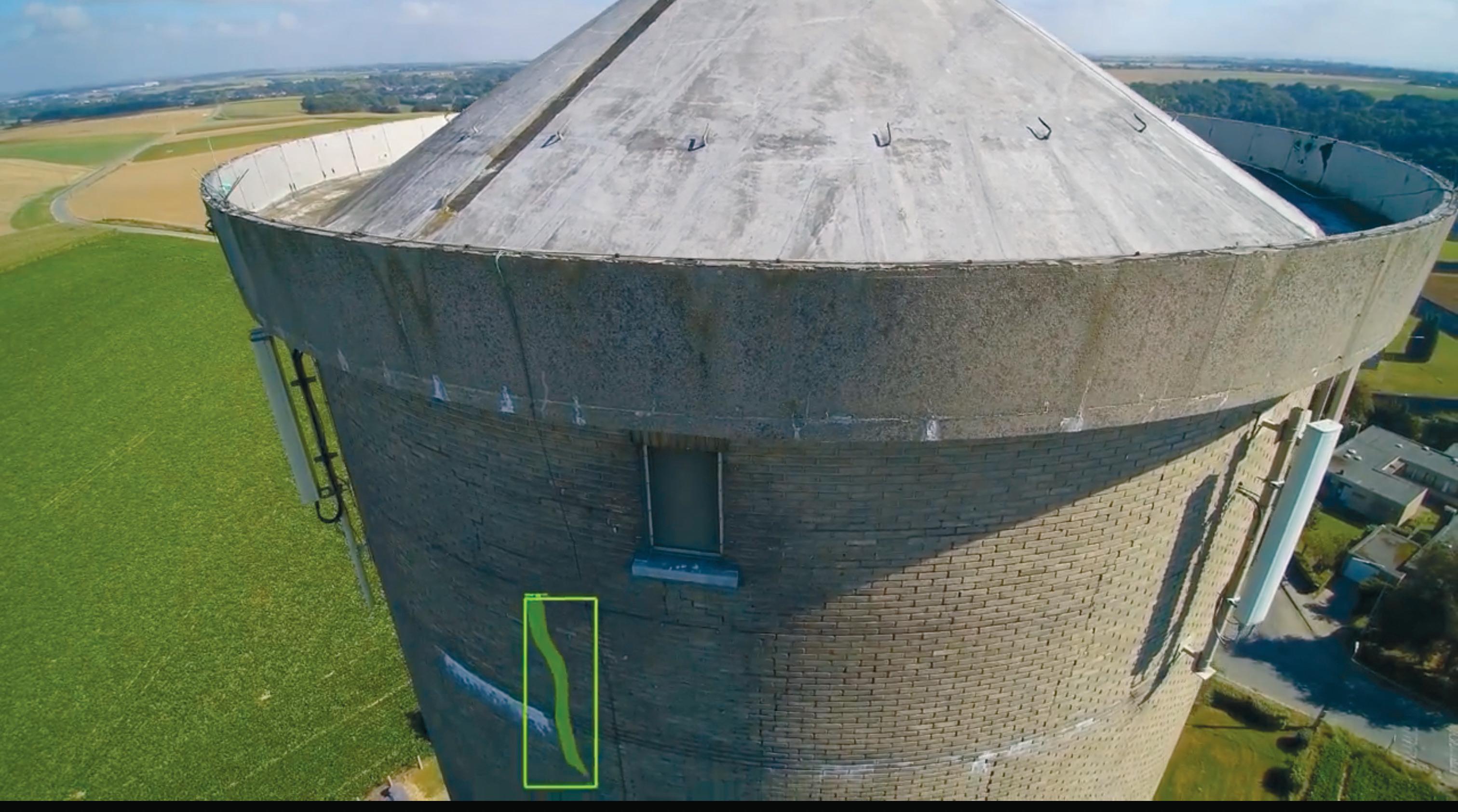

La Société Wallonne des Eaux (SWDE), a regional water corporation, owns and maintains a series of water towers throughout Belgium. One tower in Juprelle had seriously degraded over time, with burst joints, separation of edi fice bricks, and multiple cracks. The organisation needed to quickly repair the dam age to keep the water tower in service, but they needed to find a way to make all the repairs in one session.